Process for processing rubber

A processing technology and natural rubber technology, applied in the chemical industry, can solve problems such as inability to meet high-end rubber products, poor rubber quality consistency, insufficient rubber impurity removal ability, etc., to save equipment investment, enhance adaptability, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1. The entire rubber processing production line is composed of crushers, double-roll machines, crepe machines, granulators, and vibrating screens, which are connected by conveyor belts, followed by crusher No. 1, crusher No. 2, and double-roll machines. , No. 1 crepe machine, No. 2 crepe machine, No. 3 crepe machine, No. 1 granulator, No. 4 crepe machine, No. 5 crepe machine, No. 6 crepe machine, No. 2 granulator, pumping machine Rubber pump No. 1, vibrating screen No. 1, crepe machine No. 7, crepe machine No. 8, crepe machine No. 9, crepe machine No. 10, granulator No. 3, glue pump No. 2, vibrating screen No. 2 ;

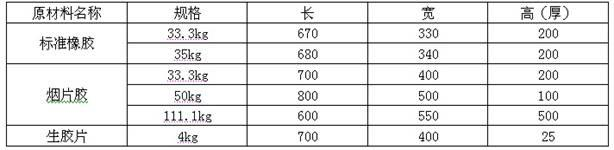

[0016] Optional raw materials include standard rubber, smoked rubber and raw film, raw material specifications and appearance dimensions:

[0017]

[0018] Device model set:

[0019]

[0020] Step 1. Put large pieces of rubber into two crushers one by one, spray water to wash at the same time, break the rubber pieces through the combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com