Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15910results about "Grinding beds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

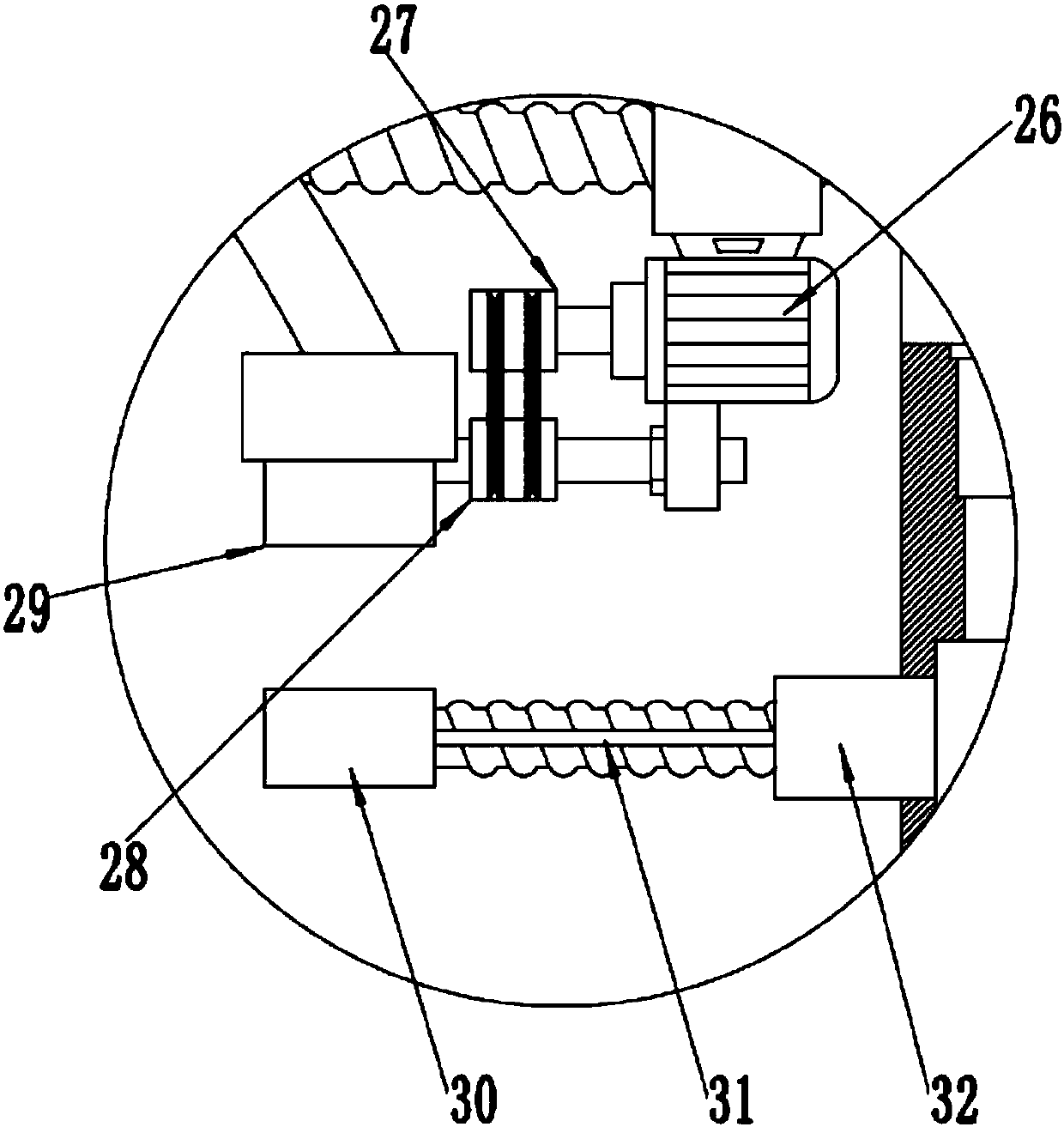

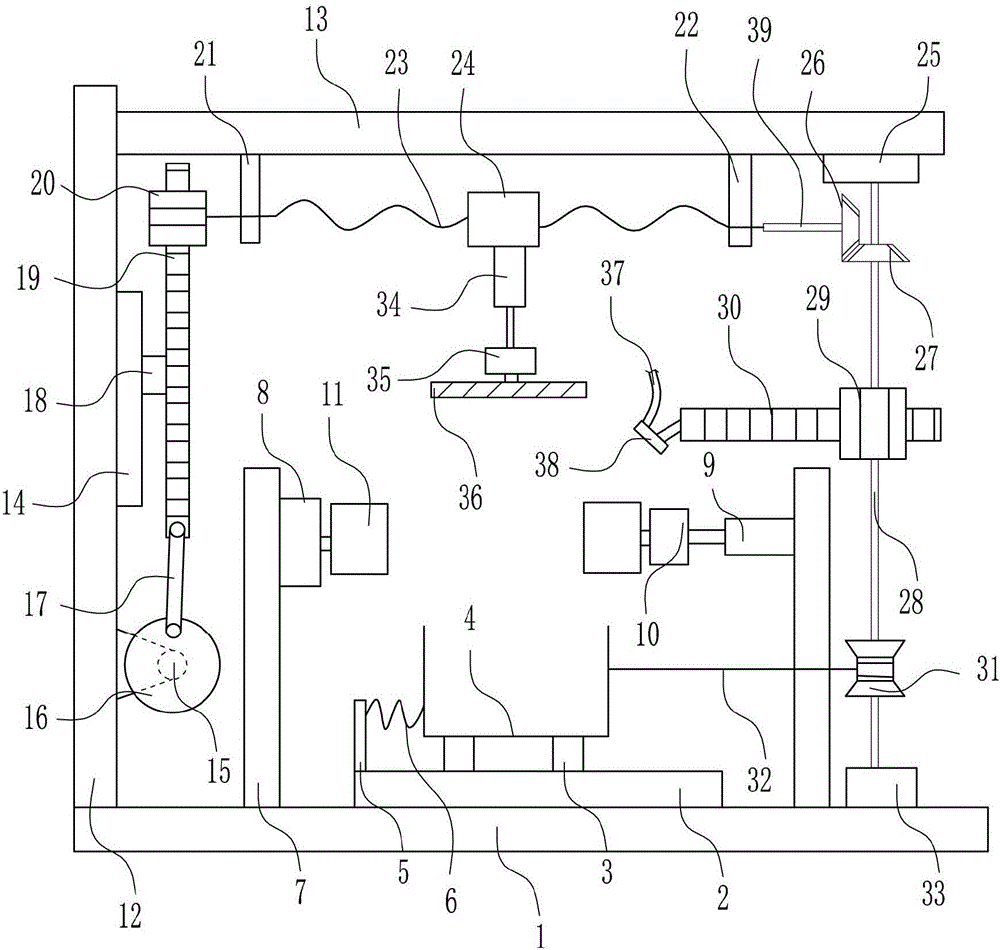

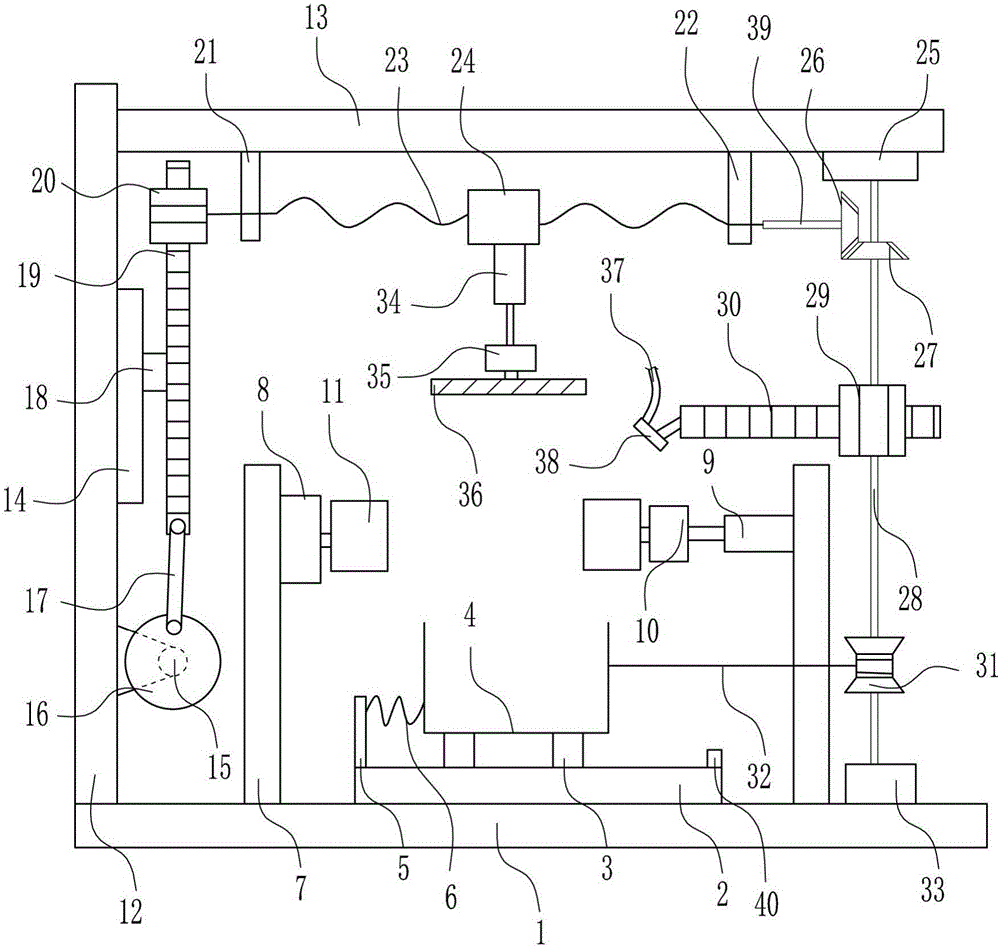

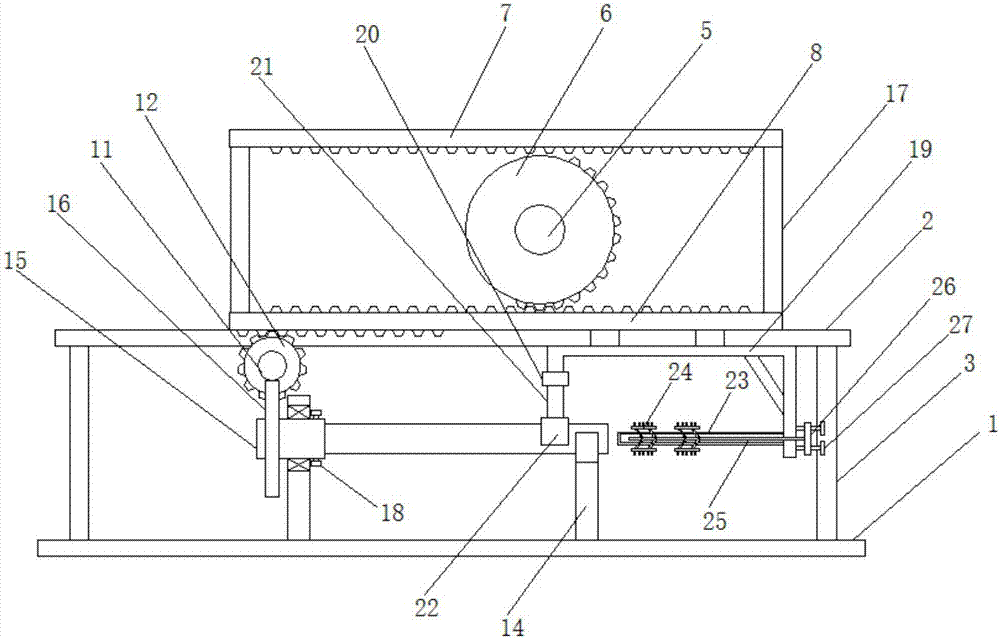

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

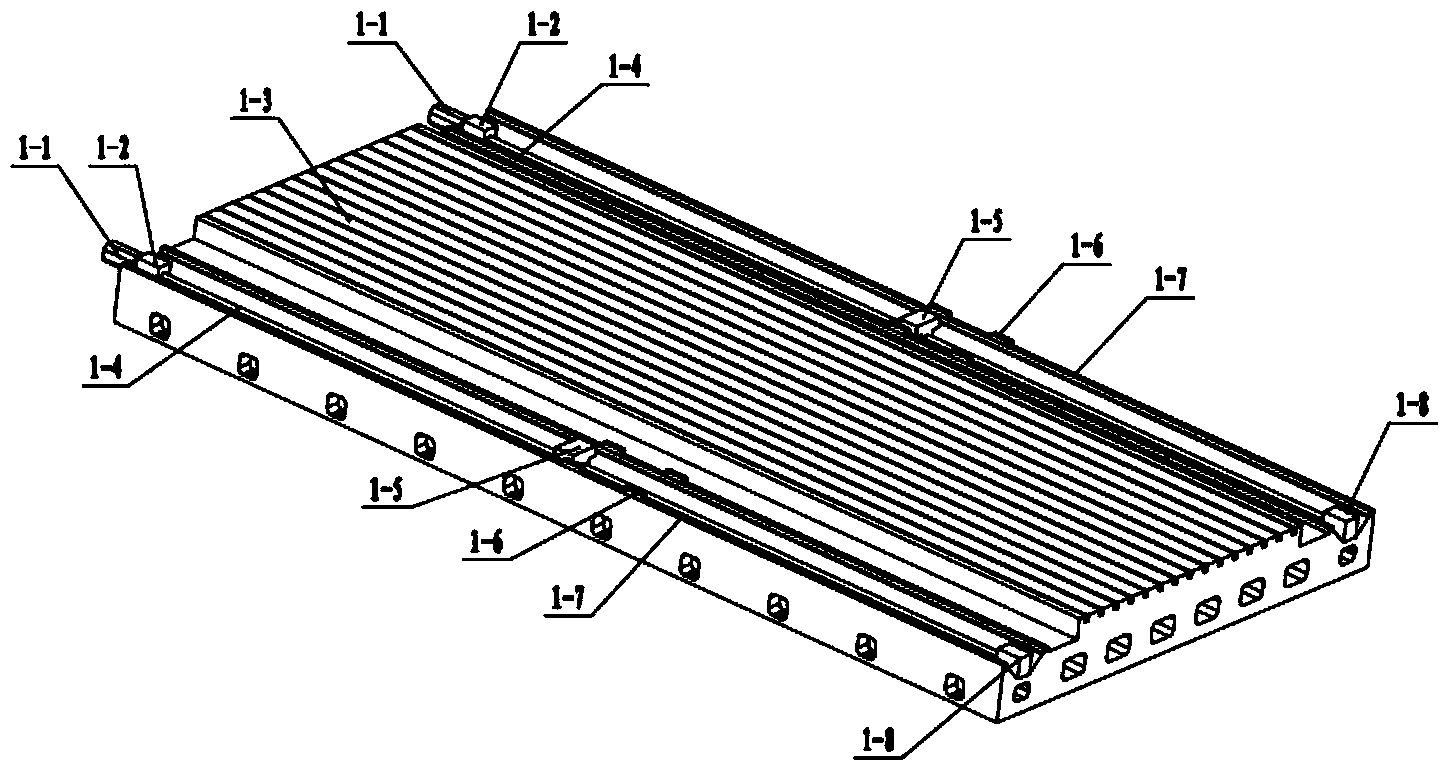

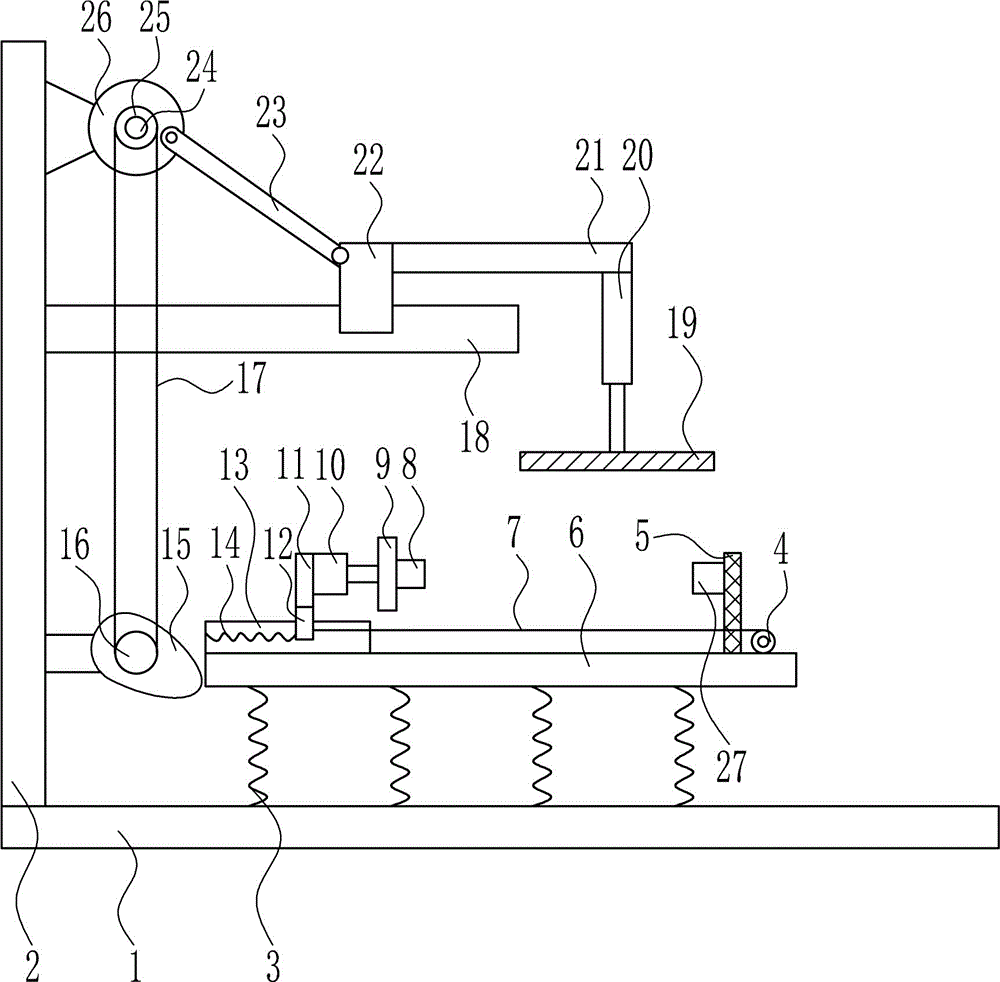

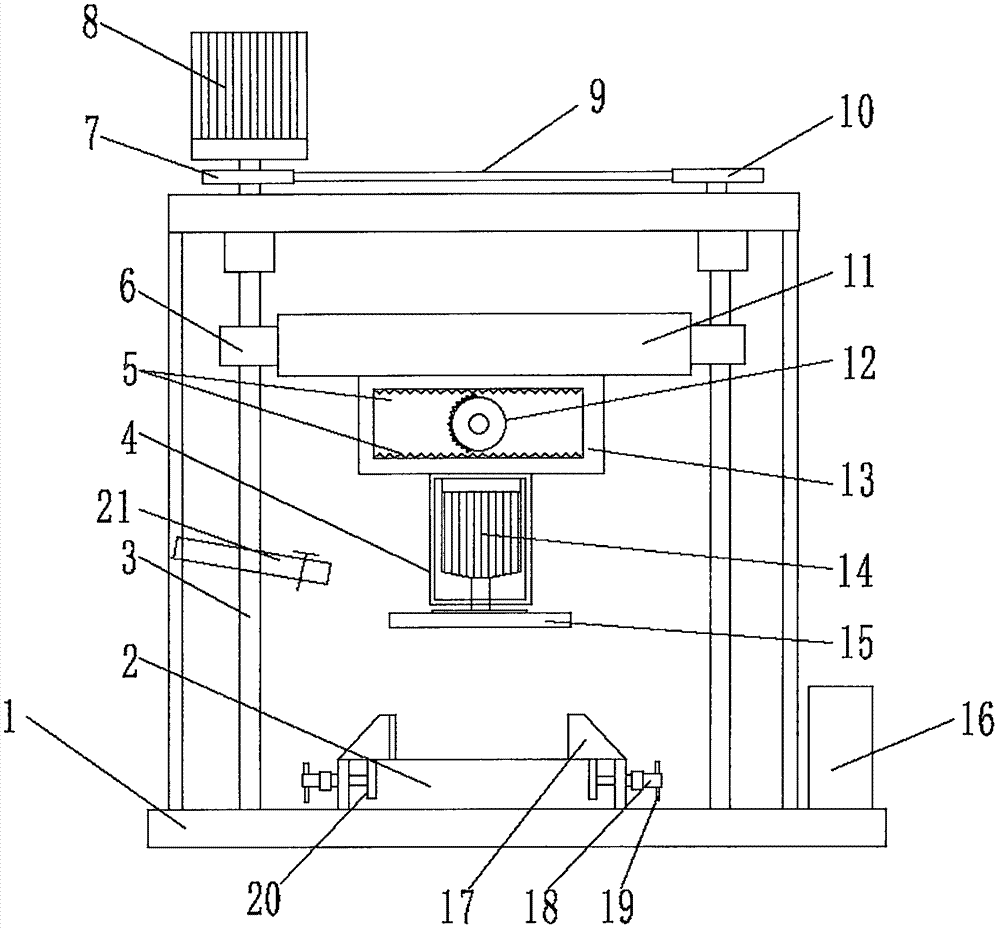

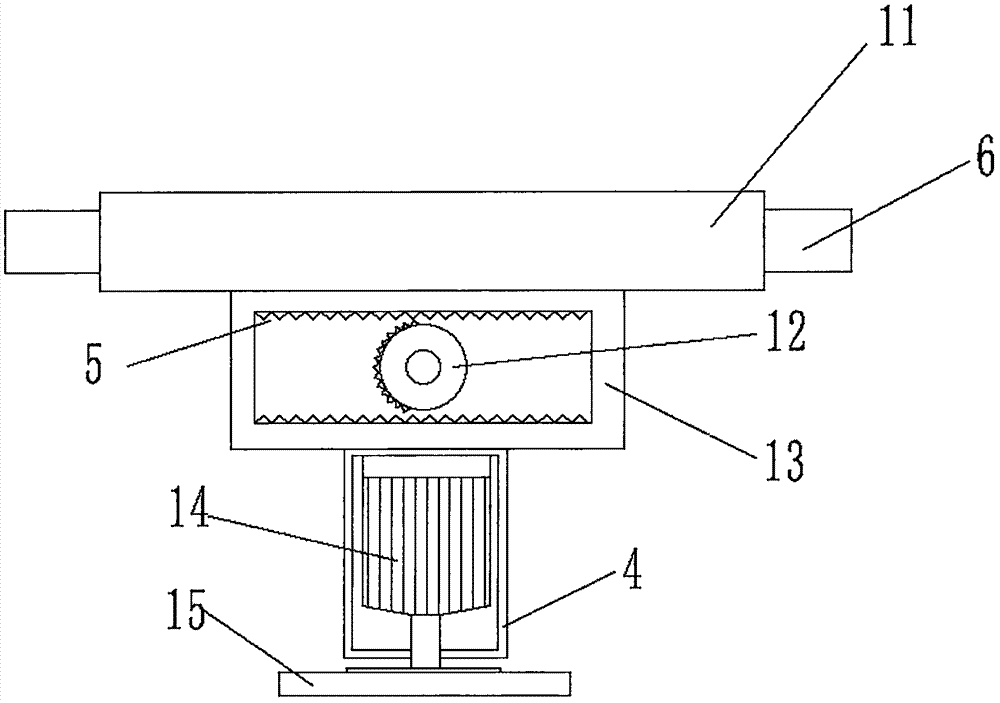

Steel plate surface polishing device for hardware machining

ActiveCN106141875AImprove corrosion resistanceHigh strengthGrinding carriagesPolishing machinesSheet steelMachining

The invention relates to a steel plate surface polishing device, in particular to a steel plate surface polishing device for hardware machining. The steel plate surface polishing device for hardware machining aims to achieve the technical purposes that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of operators is small. In order to achieve the technical purposes, the steel plate surface polishing device for hardware machining comprises a bottom plate, a first sliding rail, a first sliding block, a collection tank, a fixing stop block, a spring, a supporting rod, a first bearing pedestal, a first air cylinder, a disc and the like, wherein the first sliding rail is arranged in the middle of the top of the bottom plate. Through ingenious cooperation of the components, the effects that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of the operators is small are achieved.

Owner:如皋市通城冲压机械制造有限公司

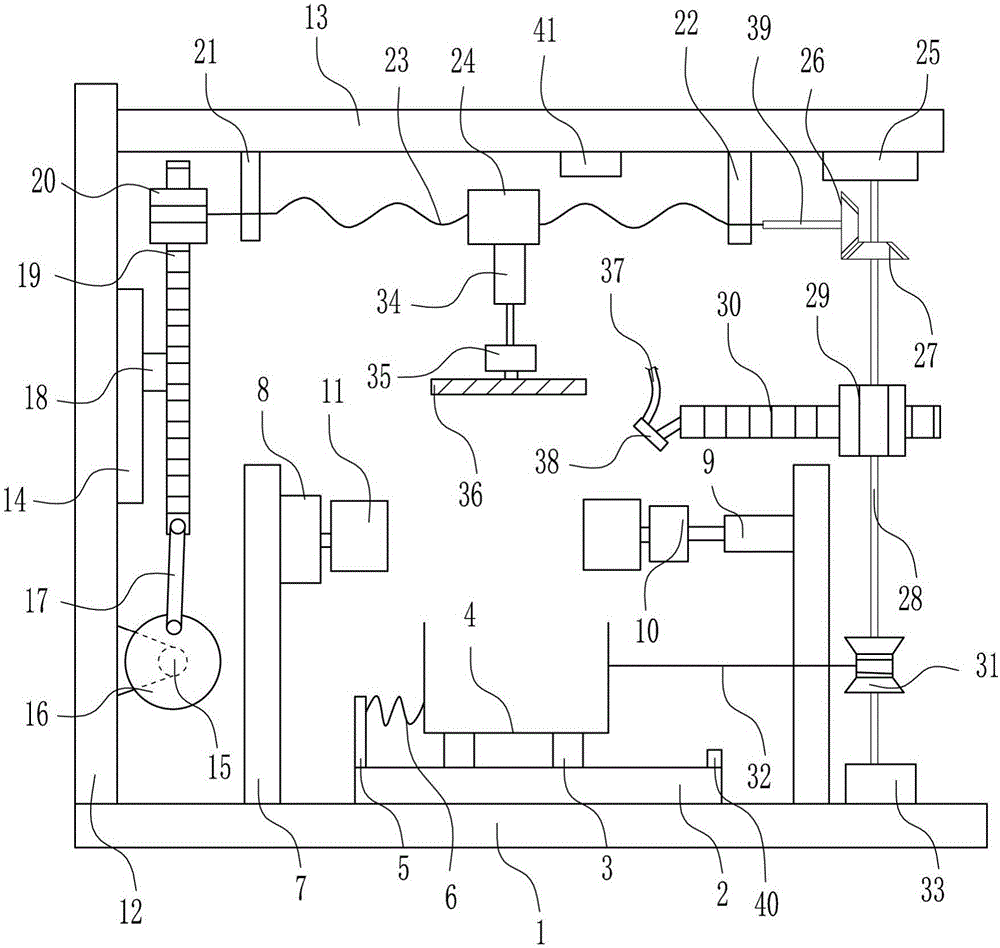

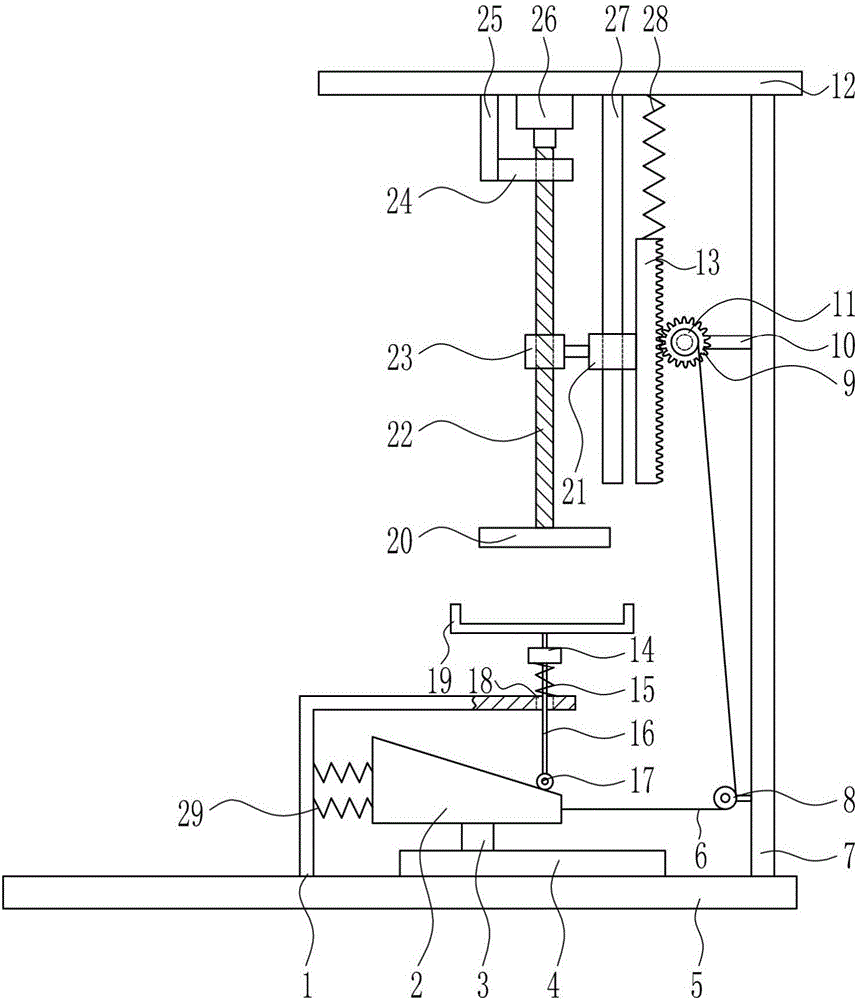

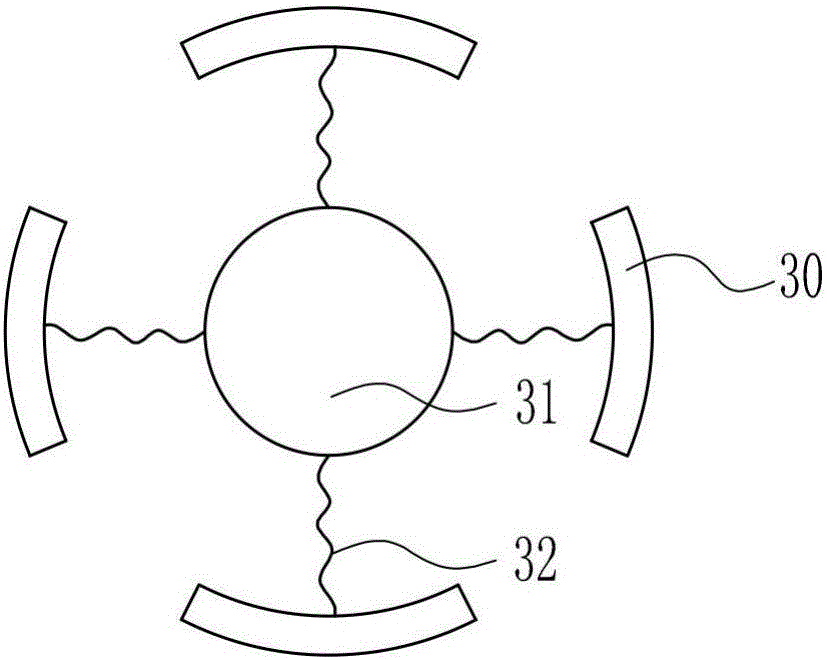

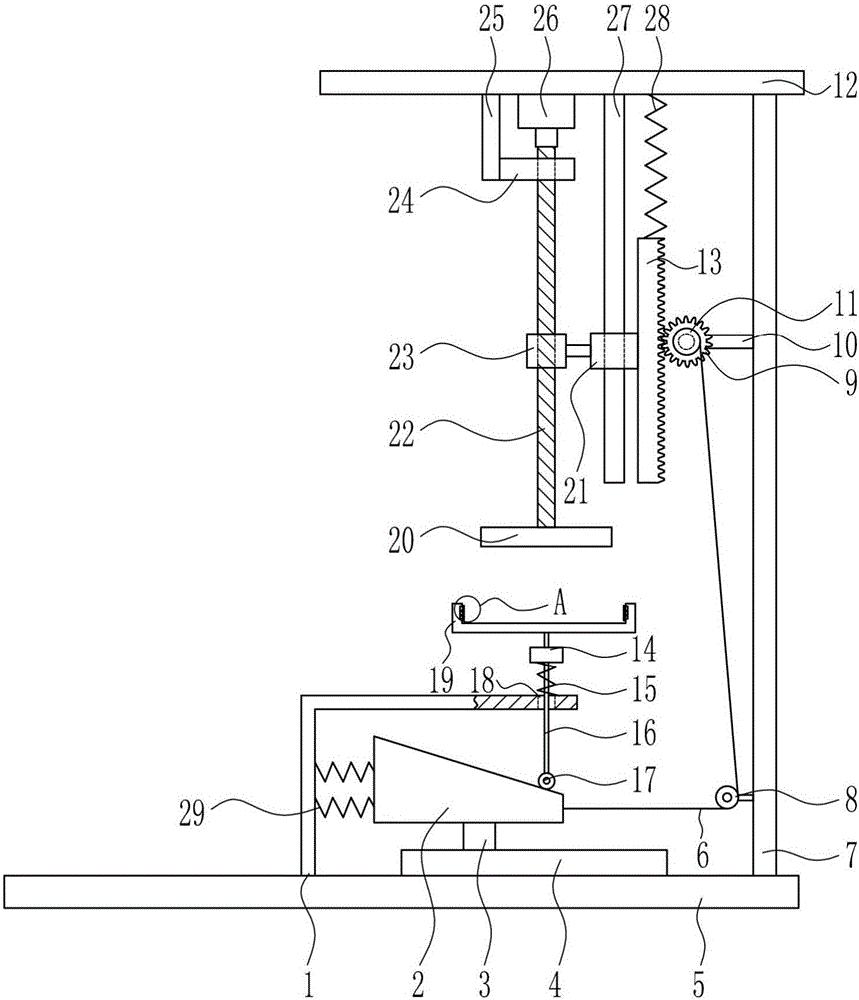

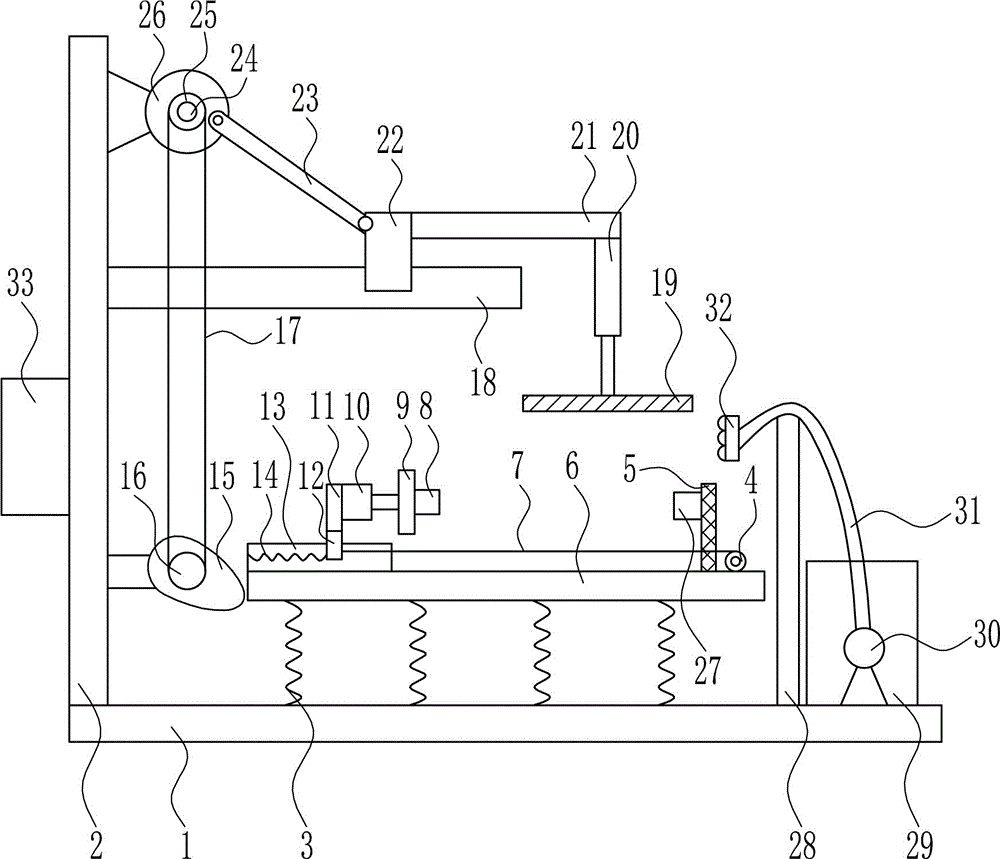

Efficient hardware kitchen ware grinding and polishing device for hardware manufacturing

ActiveCN106141877AEasy to grind and polishImprove grinding and polishing efficiencyGrinding carriagesPolishing machinesEngineeringConductor Coil

The invention relates to a grinding and polishing device, in particular to an efficient hardware kitchen ware grinding and polishing device for hardware manufacturing, and provides the high-working efficiency efficient hardware kitchen ware grinding and polishing device for hardware manufacturing which is aimed at solving the technical problem. The efficient hardware kitchen ware grinding and polishing device for hardware manufacturing provided to solve the technical problem comprises a fixing rack, a wedge block, a sliding block, a slide rail, a bottom plate, a pull wire, a first supporting rod, a fixed pulley, a gear, a second supporting rod, a wire winding wheel, a top plate, a rack, a first fixing block, a first spring, a lifting rod, a contact roller, a placing groove, a grinding device, a sliding sleeve, a screw rod, a nut, and the like, wherein the fixing rack, the slide rail and the first supporting rod are sequentially arranged at the top of the bottom plate from left to right. According to the efficient hardware kitchen ware grinding and polishing device, the grinding device is driven to grind and polish kitchen ware up and down through forward rotation and reverse rotation of a rotating motor, and the effect of high working efficiency is achieved.

Owner:江门市赞兴不锈钢制品有限公司

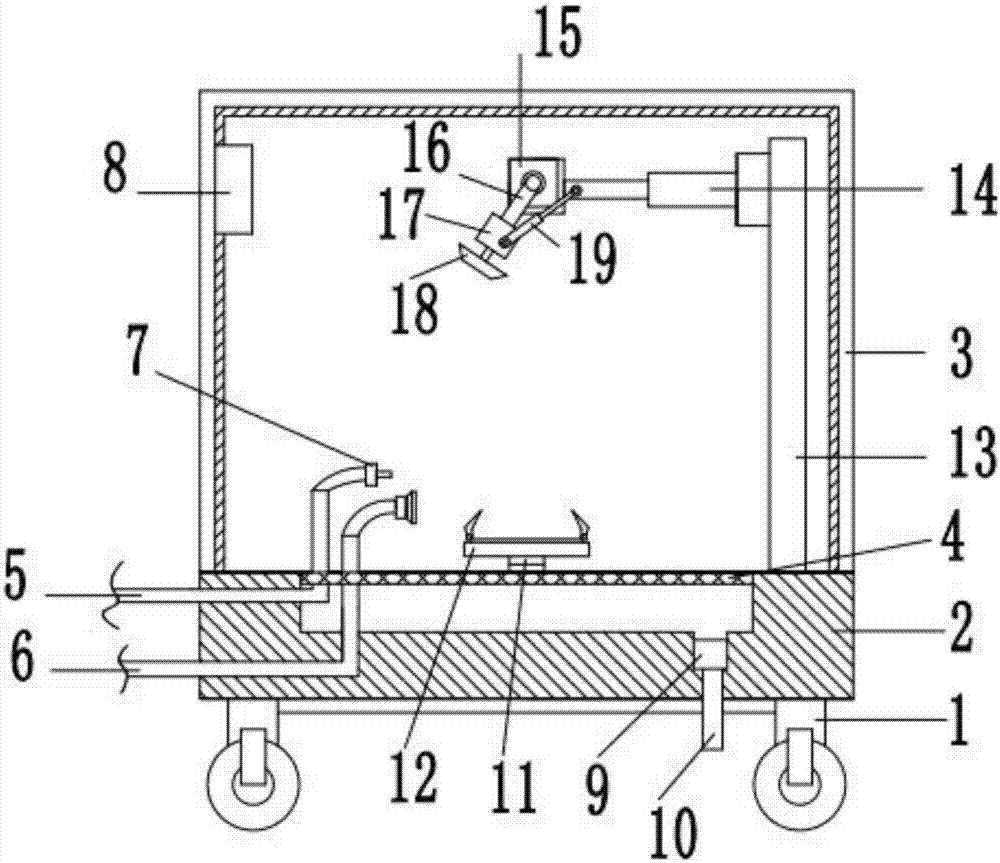

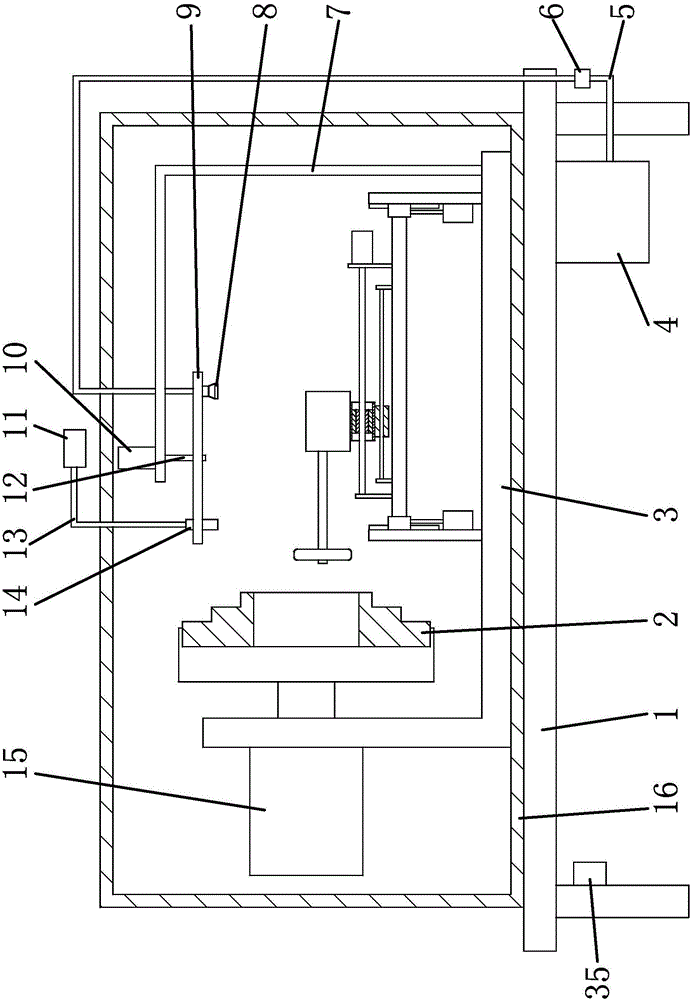

Die polishing washing equipment

InactiveCN106985025AReduce harmReduce pollutionEdge grinding machinesGrinding carriagesFiltrationEngineering

The invention discloses mold grinding and cleaning equipment in the technical field of mold processing equipment, comprising a movable support, a base is welded to the top of the movable support, a transparent cabinet is arranged on the top of the base, and the upper part of the inner wall of the transparent cabinet is There is a micro-vacuum cleaner, the top of the inner cavity of the base is fixed with a grid plate by screws, the side of the base is provided with an air inlet pipe and a liquid inlet pipe through a through hole, and through the rotating grinding wheel up and down, left and right, not only The flat surface can be polished, and the curved surface can be polished at the same time. The air inlet pipe and the liquid inlet pipe respectively use nozzles to eject air flow and liquid flow to clean the mold, and then filter out the grinding debris through the filter device to reduce pollution. The vacuum cleaner absorbs the dust generated during grinding and reduces the dust damage to the workers. The device has simple structure, convenient operation and strong practicability.

Owner:HEFEI DINGXIN MOLD

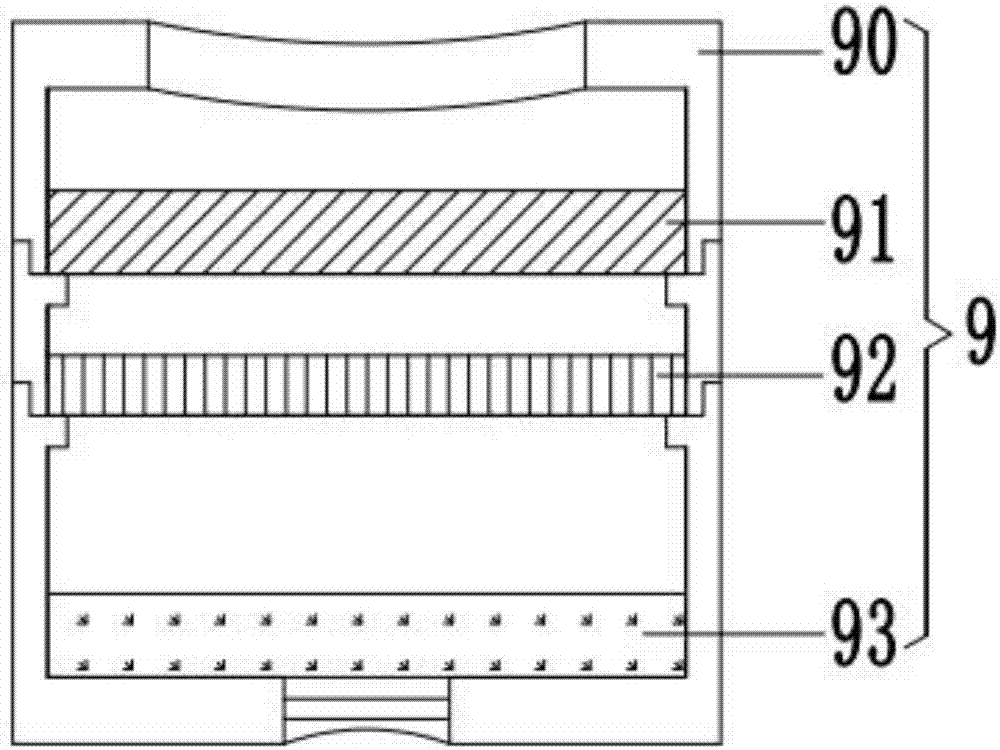

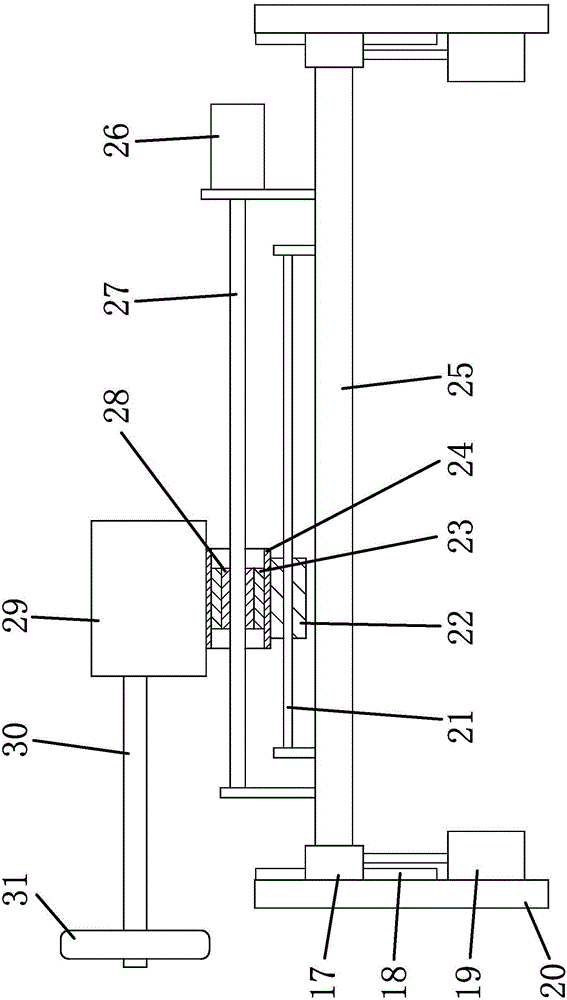

Synchronous dust extraction steel tube piece inner wall polishing device

InactiveCN106863040ASave sanding timeImprove quality and efficiencyGrinding carriagesRevolution surface grinding machinesWorking environmentDrive motor

The invention discloses a synchronous dust extraction steel tube piece inner wall polishing device which comprises an outer box and a base. A transverse support is arranged on the right side of the top of the base, a second stretchable cylinder is arranged on the left side of the transverse support, a rotary barrel is rotationally arranged on a vertical support, an eccentric gear is installed at the left end of the rotary barrel, a fixing rod is installed on the left side of the eccentric gear, and a polishing rod is installed at the left end of the fixing rod; and a driven belt wheel on the rotary barrel is connected with a driving belt wheel through a triangular belt, the driving belt wheel is fixedly installed on an output shaft of a driving motor, and the lower end of a piston rod of a first stretchable cylinder on the left side of the outer box and the upper end of a piston rod of a third stretchable cylinder are provided with an upper clamping plate and a lower clamping plate corresponding. By means of the synchronous dust extraction steel tube piece inner wall polishing device, the steel tube polishing time is greatly saved, steel tube polishing is more sufficient, the steel tube polishing quality and working efficiency are improved, synchronous dust extraction during polishing is achieved, the clean and tidy working environment is kept, and the health of workers is facilitated.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

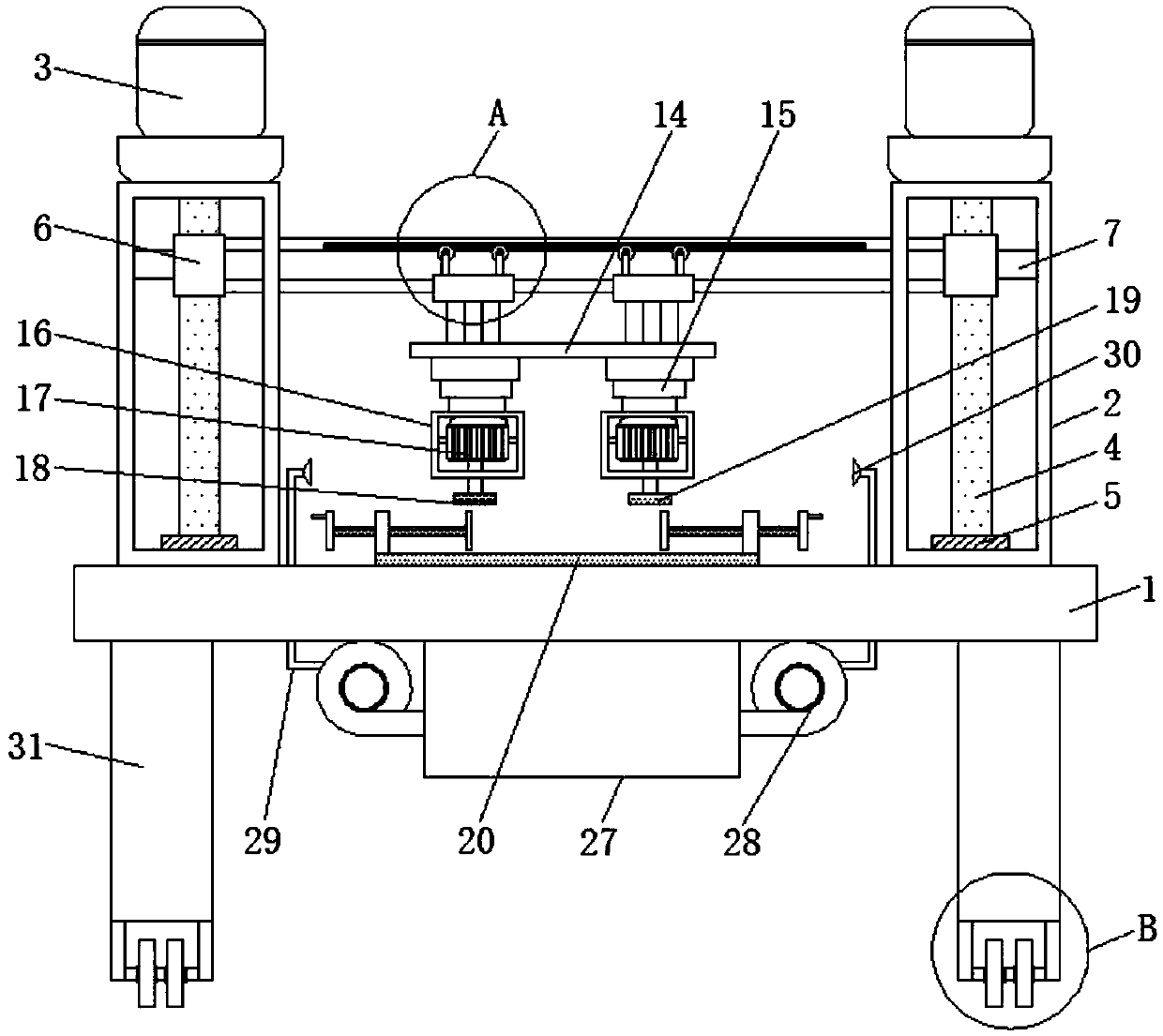

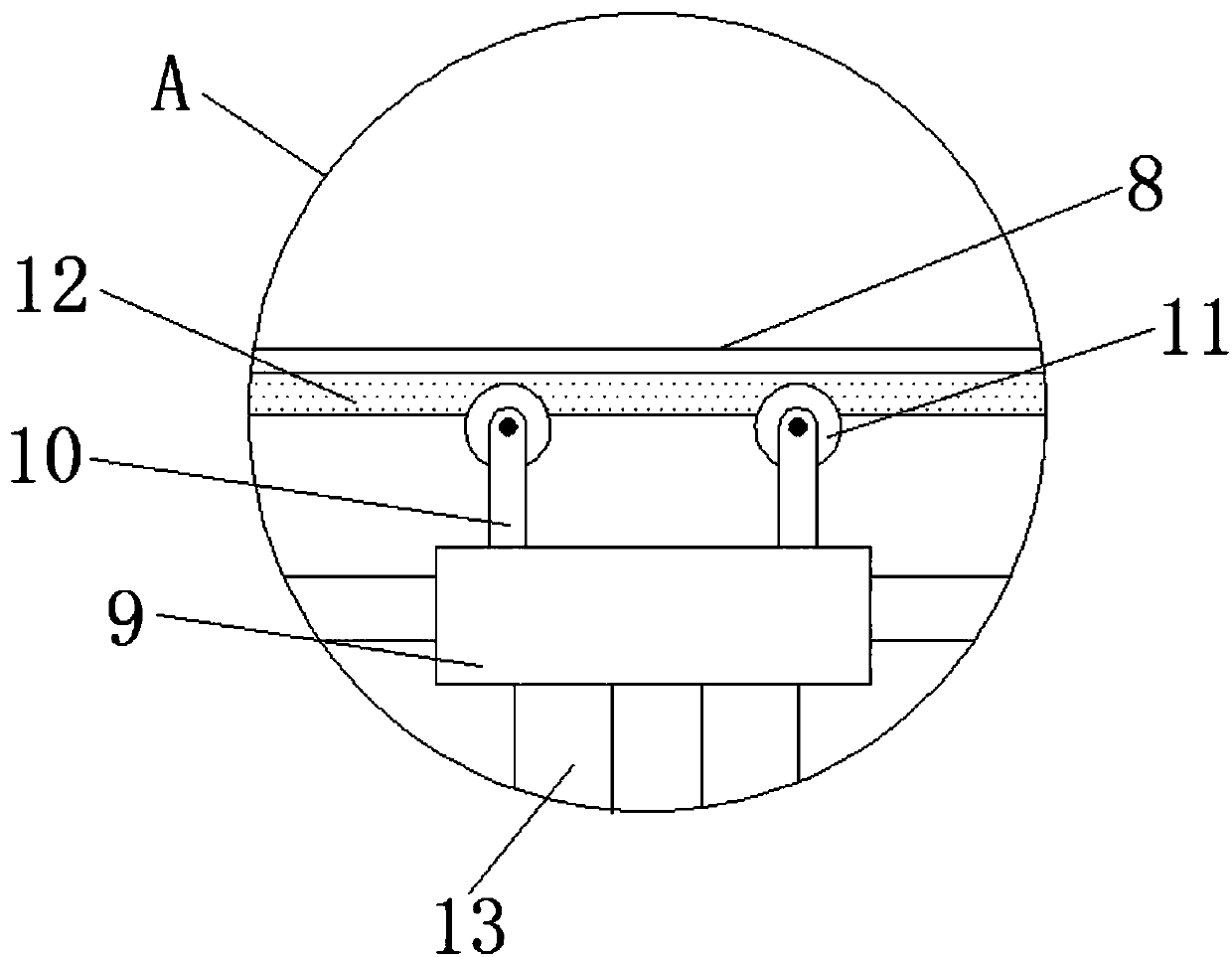

Polishing device for bearing machining

InactiveCN107695881AQuality improvementEasy to adjustGrinding carriagesGrinding machinesEngineeringMachining

The invention provides a grinding device for bearing processing, which relates to the technical field of bearing processing. The grinding device for bearing processing includes a processing table, a lifting box is fixedly installed on both sides of the top of the processing table, a lifting motor is fixedly installed on the top of the lifting box, and a screw rod is movably connected to the output end of the lifting motor. The grinding device for bearing processing is equipped with a processing table, a lifting box, a lifting motor, a screw, a bearing body, a telescopic block, a slider, a guide rod, a slip ring, a wheel shaft, a pulley, a wheel groove, a bracket, a horizontal plate, and a hydraulic telescopic rod. And the grinding motor, after the lifting motor is started, the grinding device including the grinding motor can be driven to move up and down on the top of the processing table through the rotation of the driving screw, and the grinding motor can be driven on the top of the processing table by sliding on the guide rod through the slip ring Moving left and right, in summary, the bearing processing and grinding device achieves the effect of easy adjustment, which is convenient for people to operate, saves time and effort, and is conducive to grinding out bearings with better quality.

Owner:郑艳峰

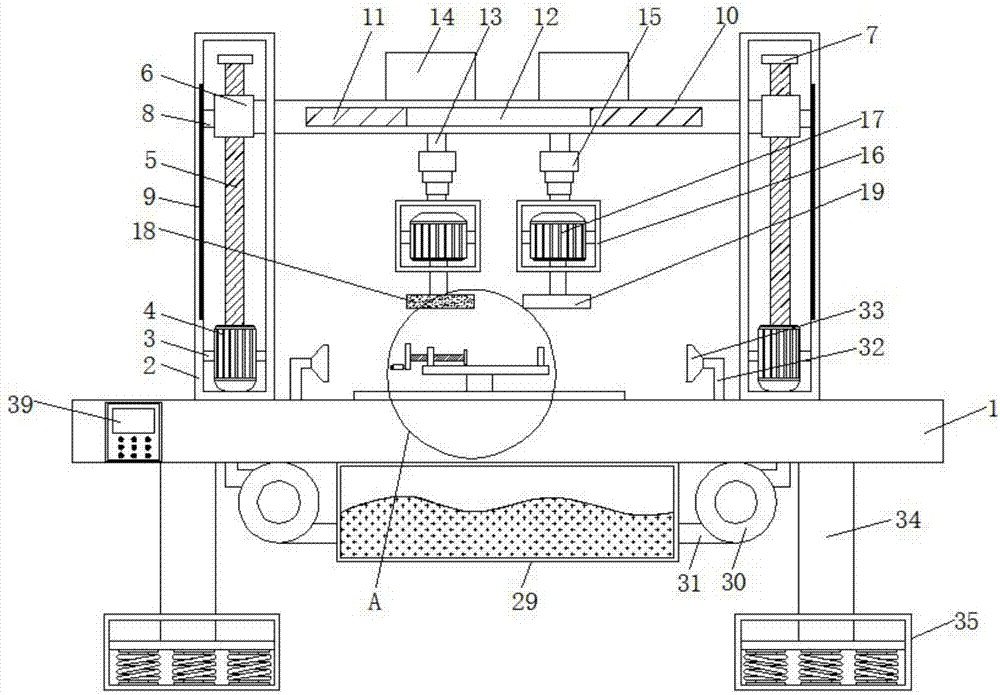

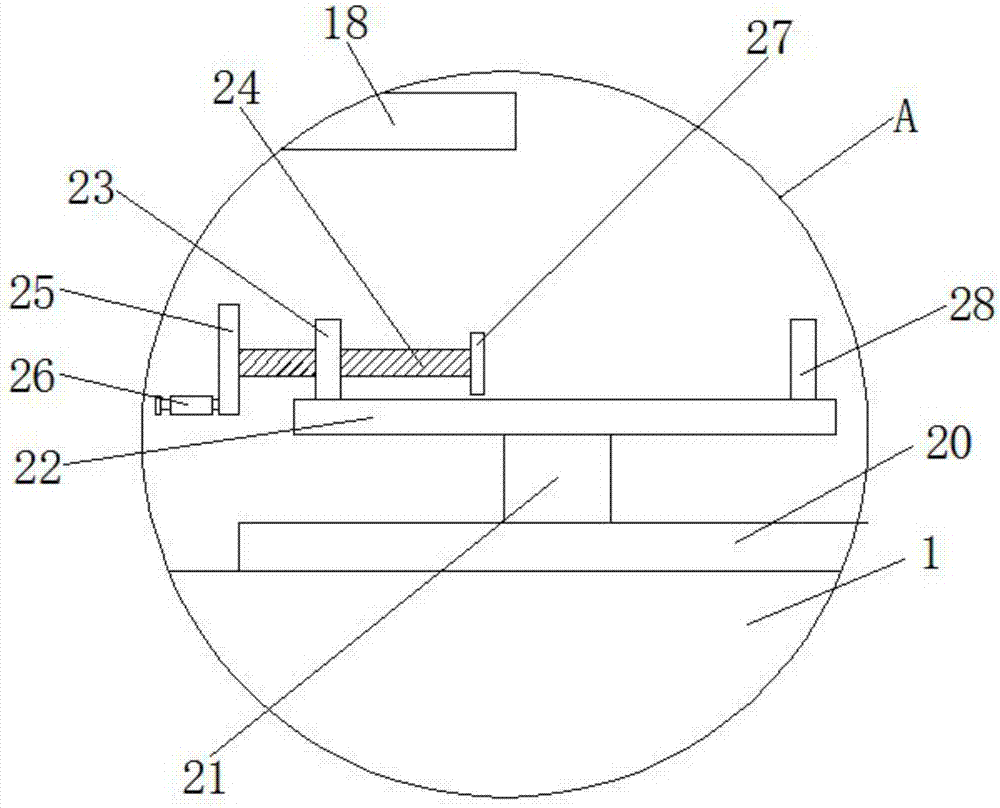

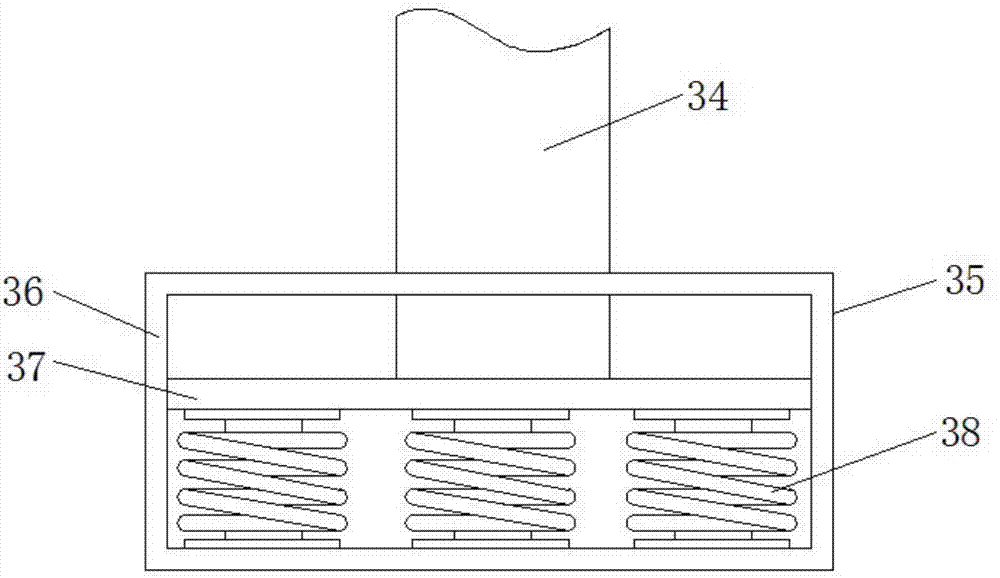

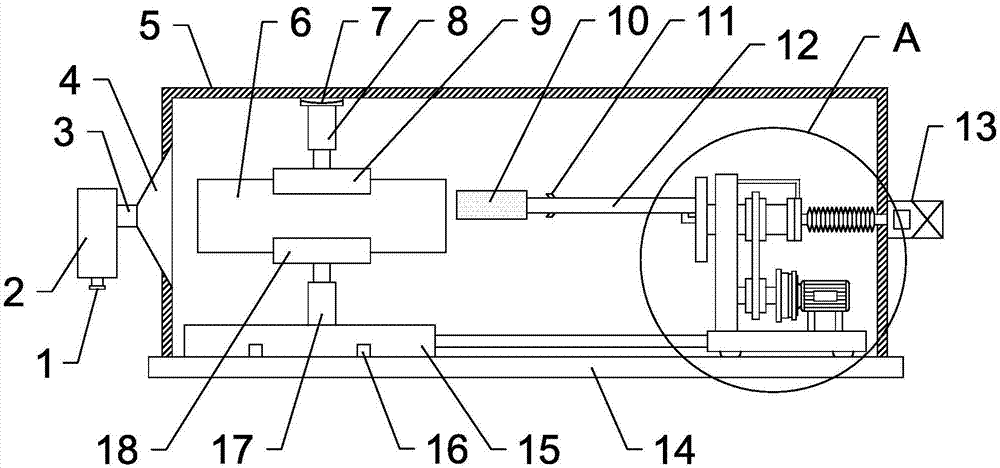

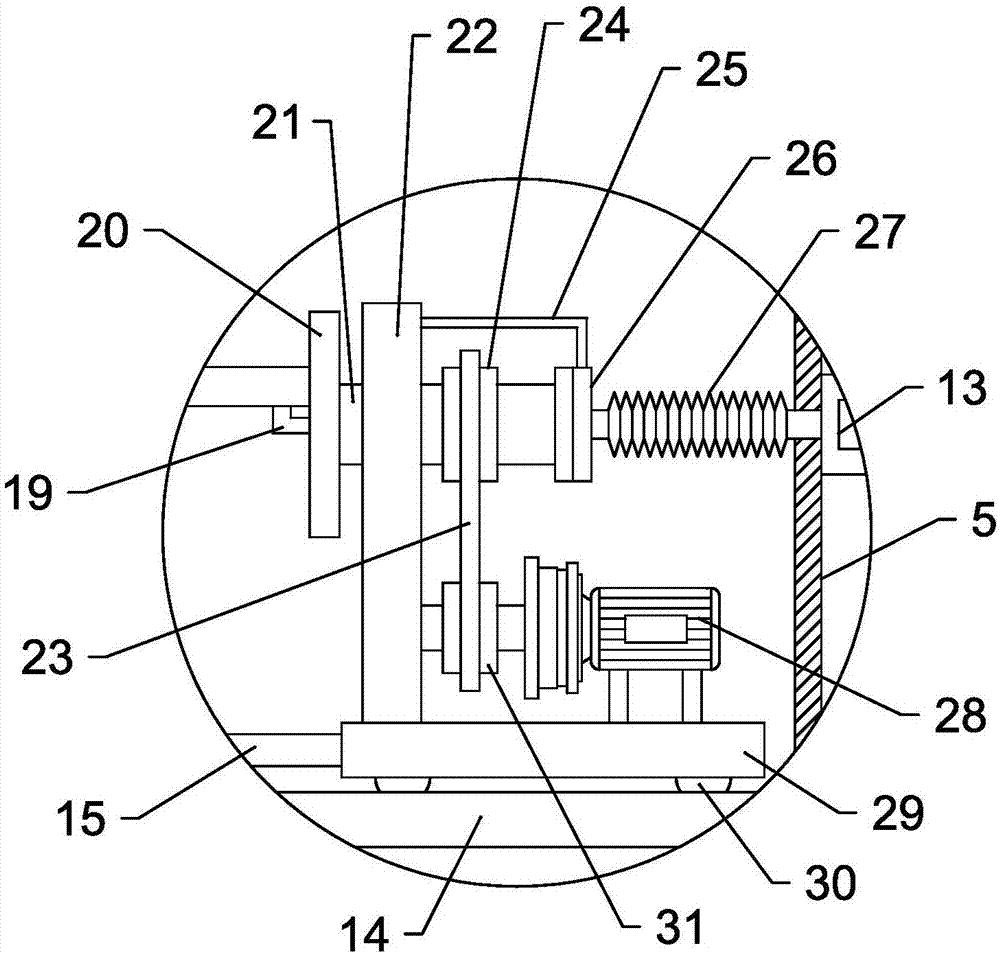

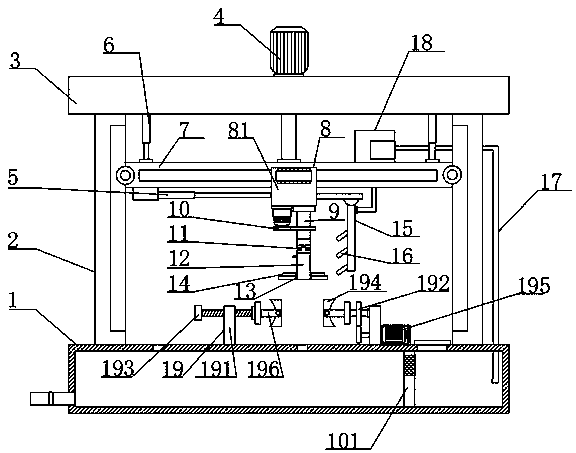

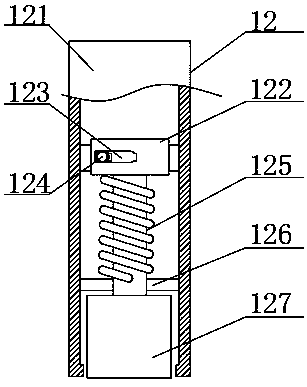

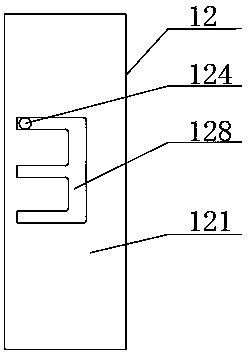

Automatic grinding machine for industrial machinery and grinding method

InactiveCN108789087AIncrease flexibilityImprove stabilityGrinding carriagesGrinding drivesHydraulic cylinderCoupling

The invention discloses an automatic grinding machine for industrial machinery and a grinding method. The automatic grinding machine comprises a base box body, wherein left and right sides of the topof the base box body are symmetrically equipped with stand columns; a top plate is arranged on the tops of the two groups of the stand columns; the outer wall of a bearing rod is movably equipped witha slide assembly; the bottom of the slide assembly is sequentially equipped with a grinding motor and a rotary rod from left to right; the bottom of the rotary rod is equipped with a universal shaftcoupler; the top of the base box body is equipped with a fixed clamp; and the right side of the top of the base bottom box is spliced with a water conveying hose I. The grinding machine for industrialmachinery is high in flexibility and is good in stability; a hydraulic cylinder drives the bearing rod to lift through a pushing rod, so that a grinding disc in grinding can lift; and an electric telescopic pole extends and shortens to drive the slide assembly to move left and right, so that the grinding disc in grinding can move left and right, and therefore, the automatic grinding machine has relatively high flexibility, and improves grinding working efficiency.

Owner:CHENGDU PUJIANG KEXIAN TECH

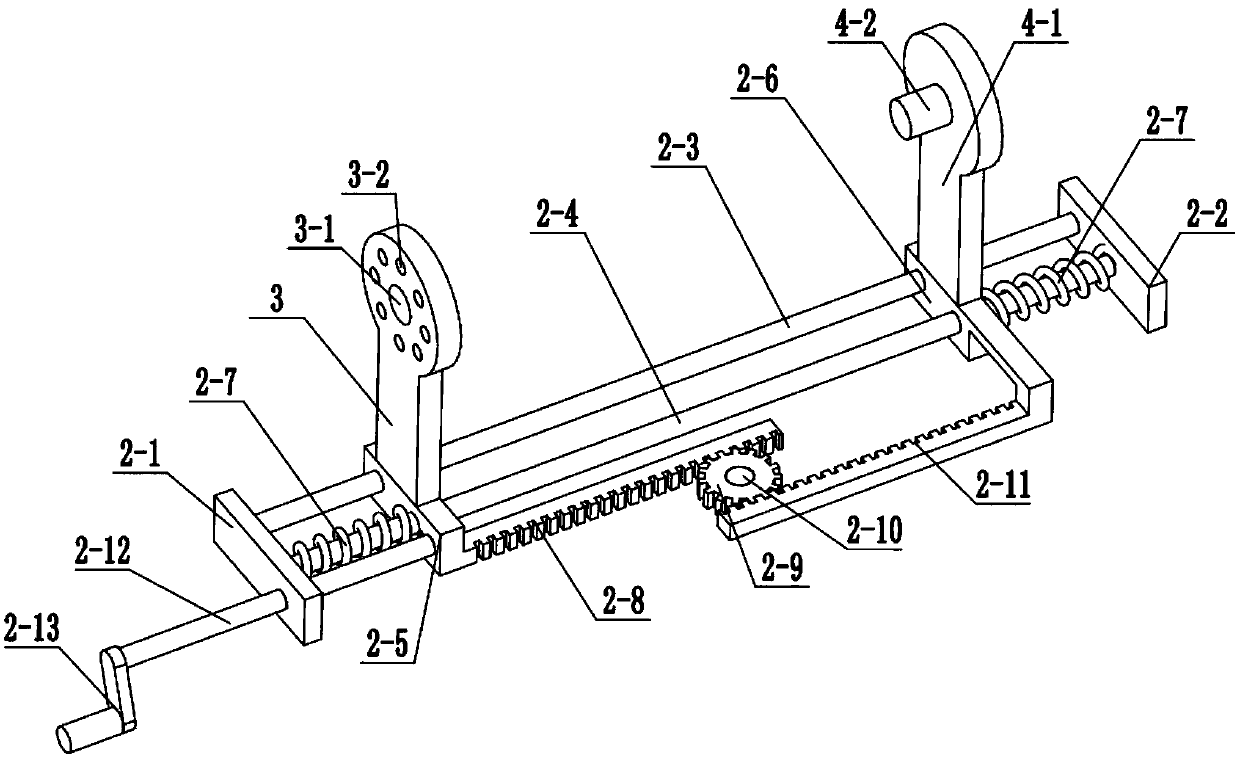

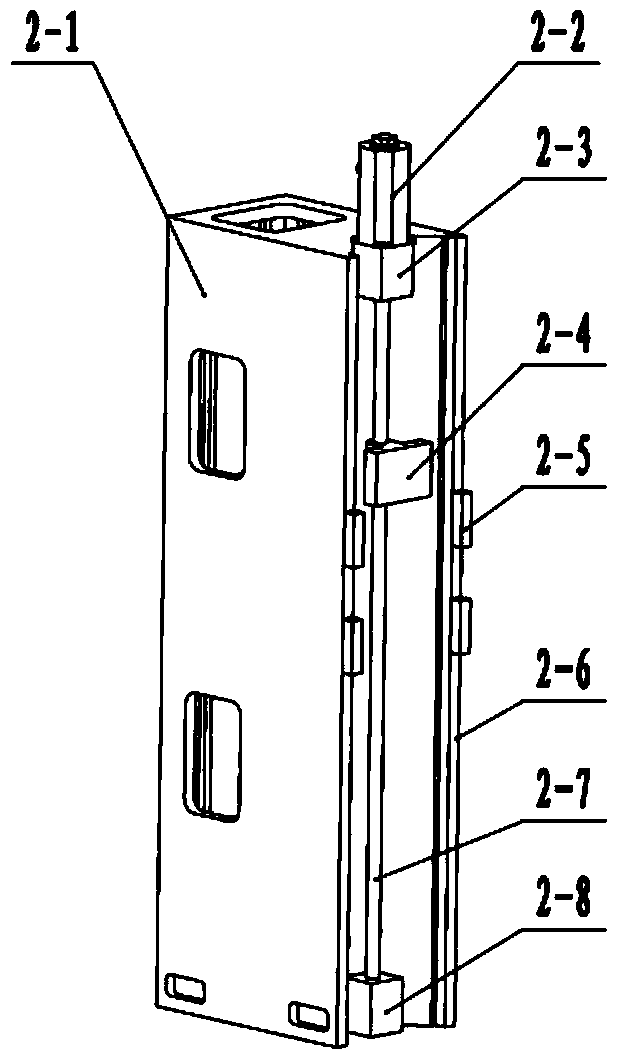

Multi-angle plate polishing device

InactiveCN109571180ARealize multi-degree-of-freedom grindingImprove grinding limitationsEdge grinding machinesGrinding carriagesMulti degree of freedomEngineering

The invention relates to the field of plate processing, in particular to a multi-angle plate polishing device. The multi-angle polishing device is characterized in that a length adjusting component isfixedly connected to the front end of a base; a left plate and a right plate are separately fixedly connected to the two ends of the length adjusting component; an angle adjusting component is connected to the upper end of the left plate; the number of plate clamping pieces is two; the two plate clamping pieces are separately fixedly connected to the inner sides of the angle adjusting component and the right plate; a grinding plate sliding seat component is fixedly connected to the rear end of the base; and a grinding component is connected onto the grinding plate sliding seat component in asliding manner. A plate can be polished from multiple angles and in multiple directions according to the self characteristics and the grinding requirements of a product, the multi-degree of freedom polishing of the plate is realized, or the omni-directional polishing and local polishing of the plate are realized, the polishing limitation of an existing automatic polishing machine is improved, andmanual operation is replaced with mechanical automatic processing, so that the production efficiency is improved, and the production quality of the product is ensured; and the multi-angle plate polishing device is applicable to plates of different sizes or shapes.

Owner:张馨文

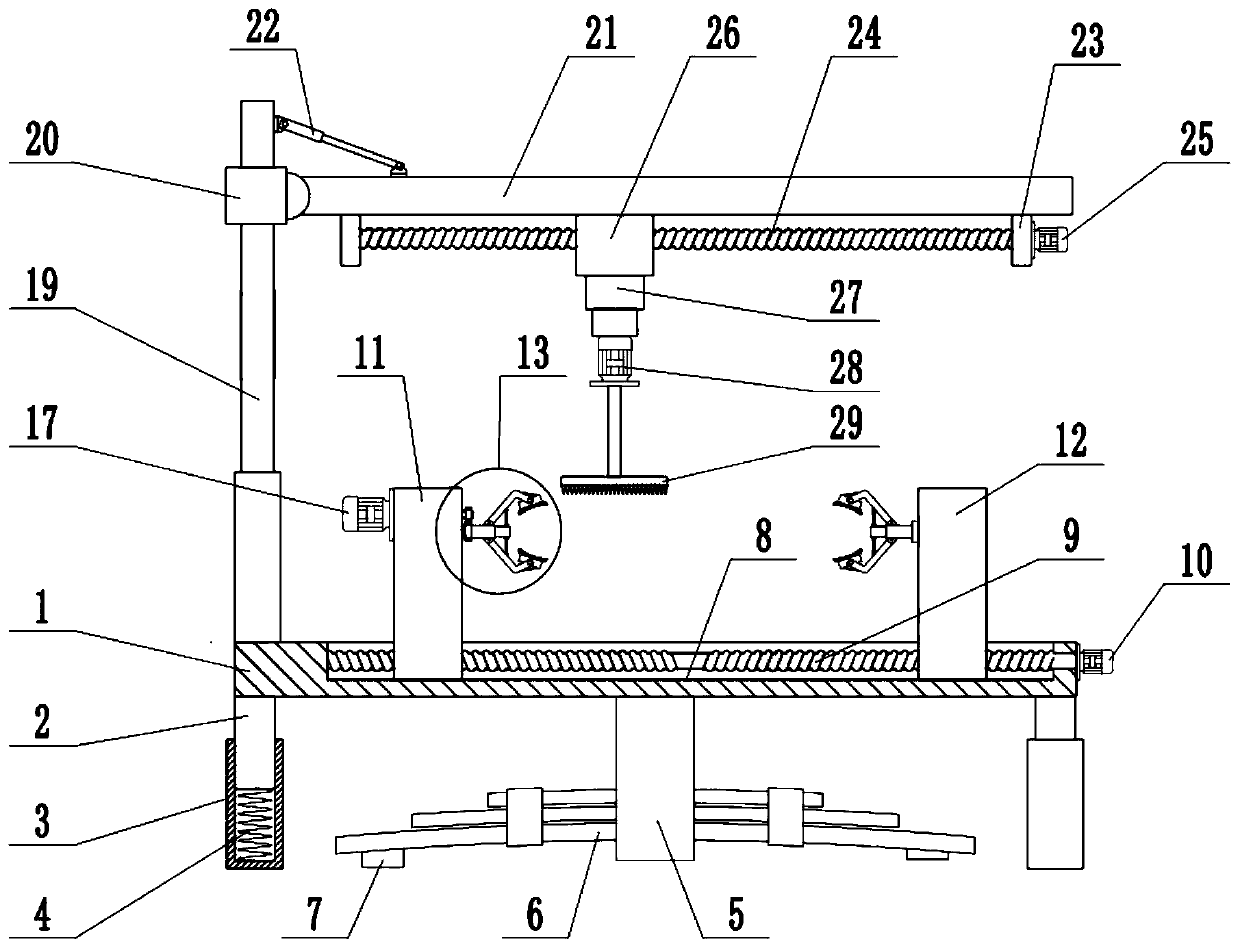

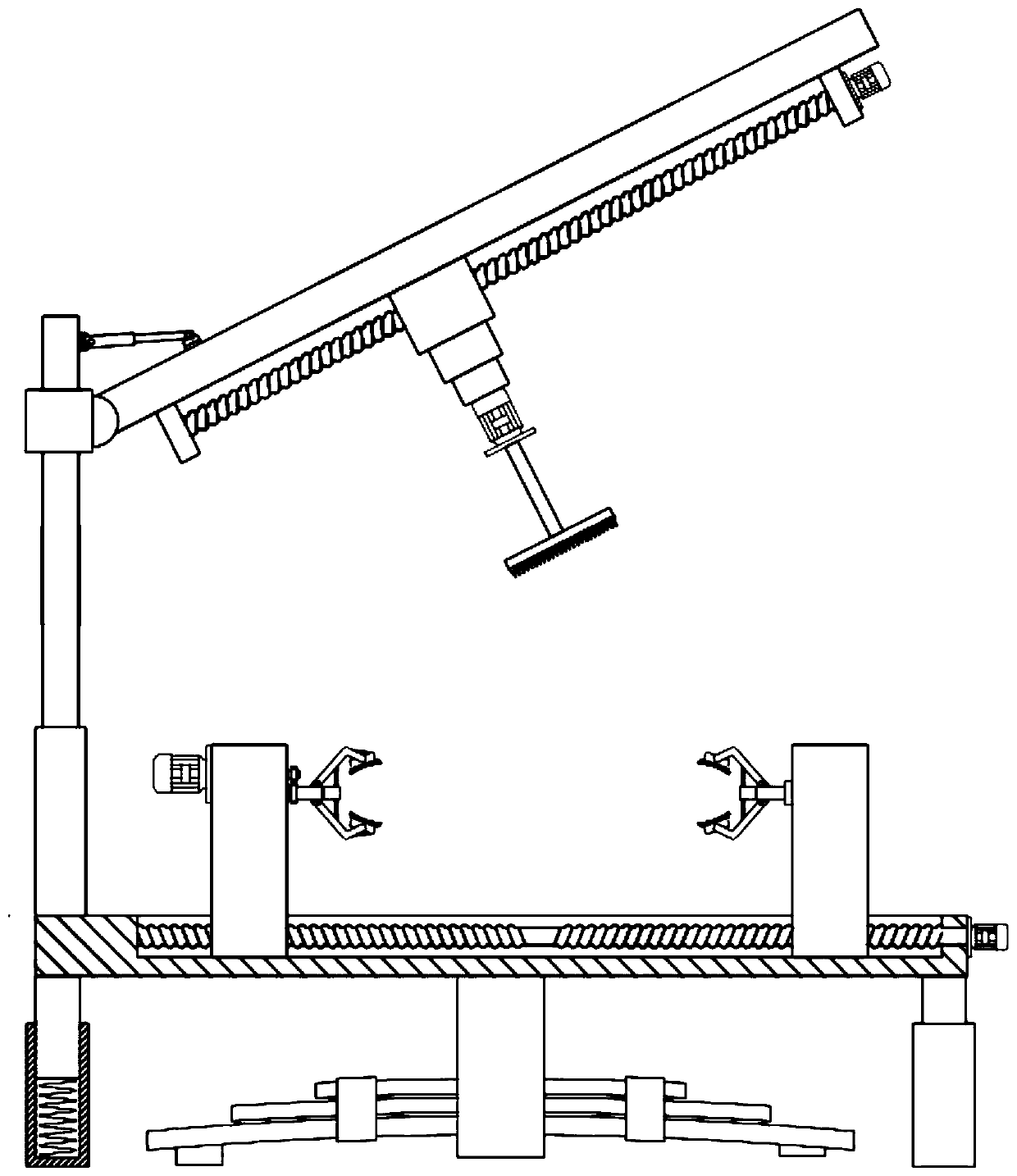

Overturning grinding rust removal device for metal plate

InactiveCN110142678AFast clamping speedEasy to remove rustGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to the field of metal processing equipment, and more specifically relates to an overturning grinding rust removal device for a metal plate. The overturning grinding rust removaldevice for the metal plate comprises a workbench, a left clamping block, a right clamping block and a rust removal brush plate, wherein a slide groove is formed in the upper surface of the workbench;a bidirectional screw rod is installed in the slide groove; the left clamping block and the right clamping block sleeve the bidirectional screw rod; a second telescoping mechanism is fixedly connectedto the upper surface of the workbench; a lifting block sleeves a stretching end of the second telescoping mechanism; an installation plate is hinged to the sidewall of the lifting block; a displacement screw rod is arranged below the installation plate; a movable block sleeves the middle part of the displacement screw rod; a fourth telescoping mechanism is fixedly connected to the lower surface of the movable block; and a rust removal motor is fixedly connected to the lower end of the fourth telescoping mechanism. The metal plate is clamped by virtue of the clamping plate to keep fixed, and high clamping speed is achieved; in a rust removal process, the rust removal brush plate moves to left and right, so that a rust removal range is expanded; and through arrangement for a rotary motor, rust removal can be conveniently carried out on the front surface and the back surface of the metal plate.

Owner:蒋艳红

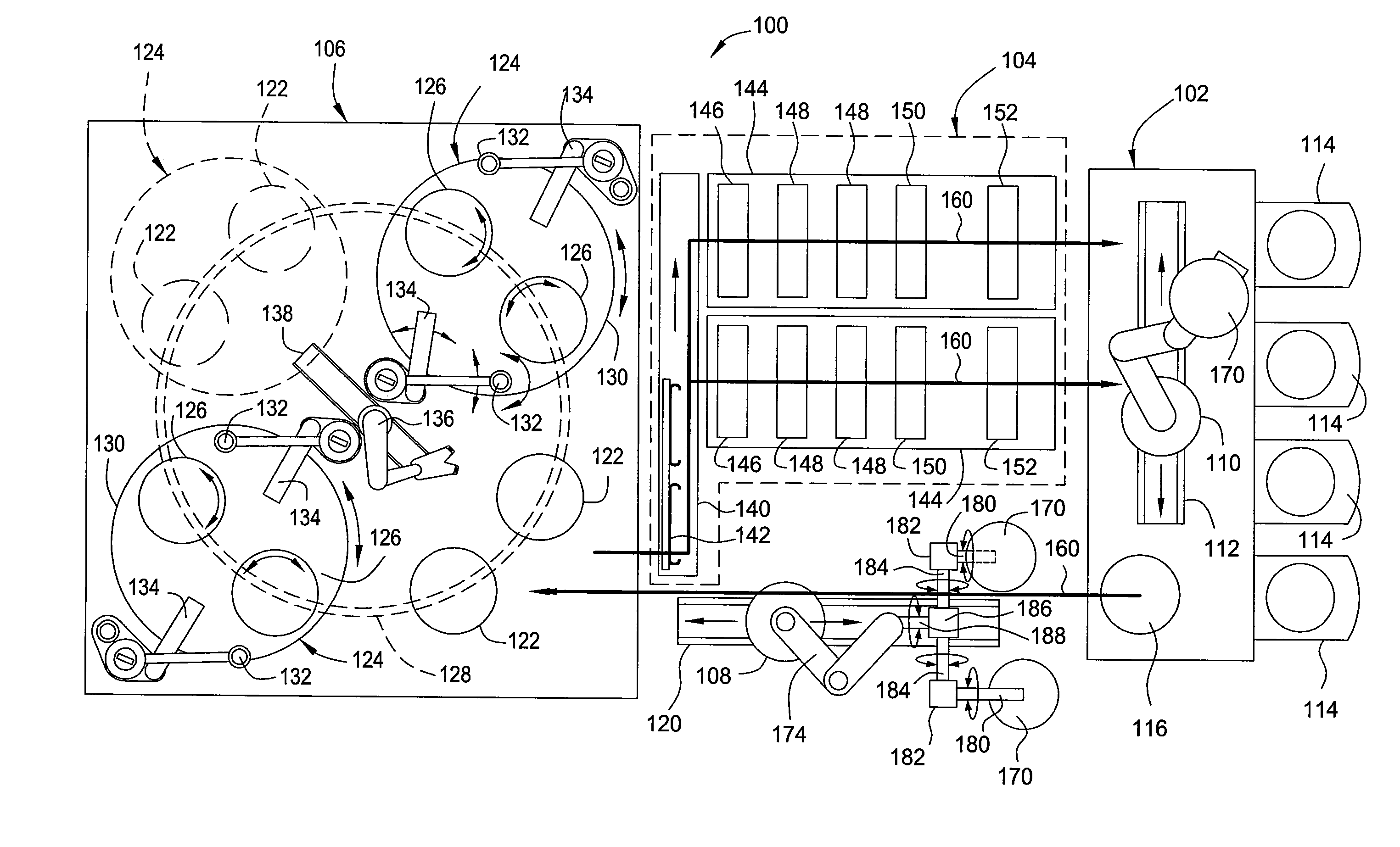

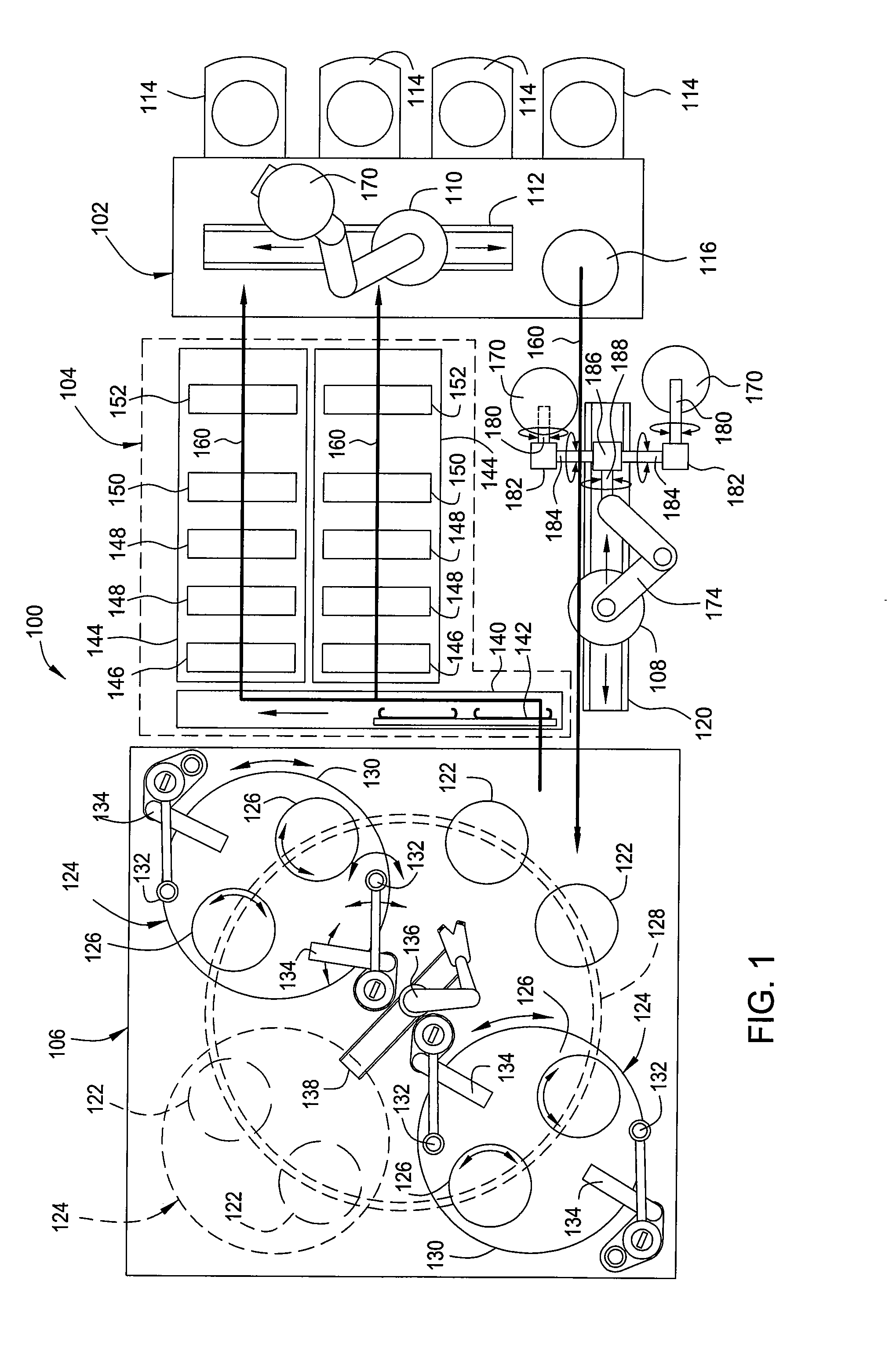

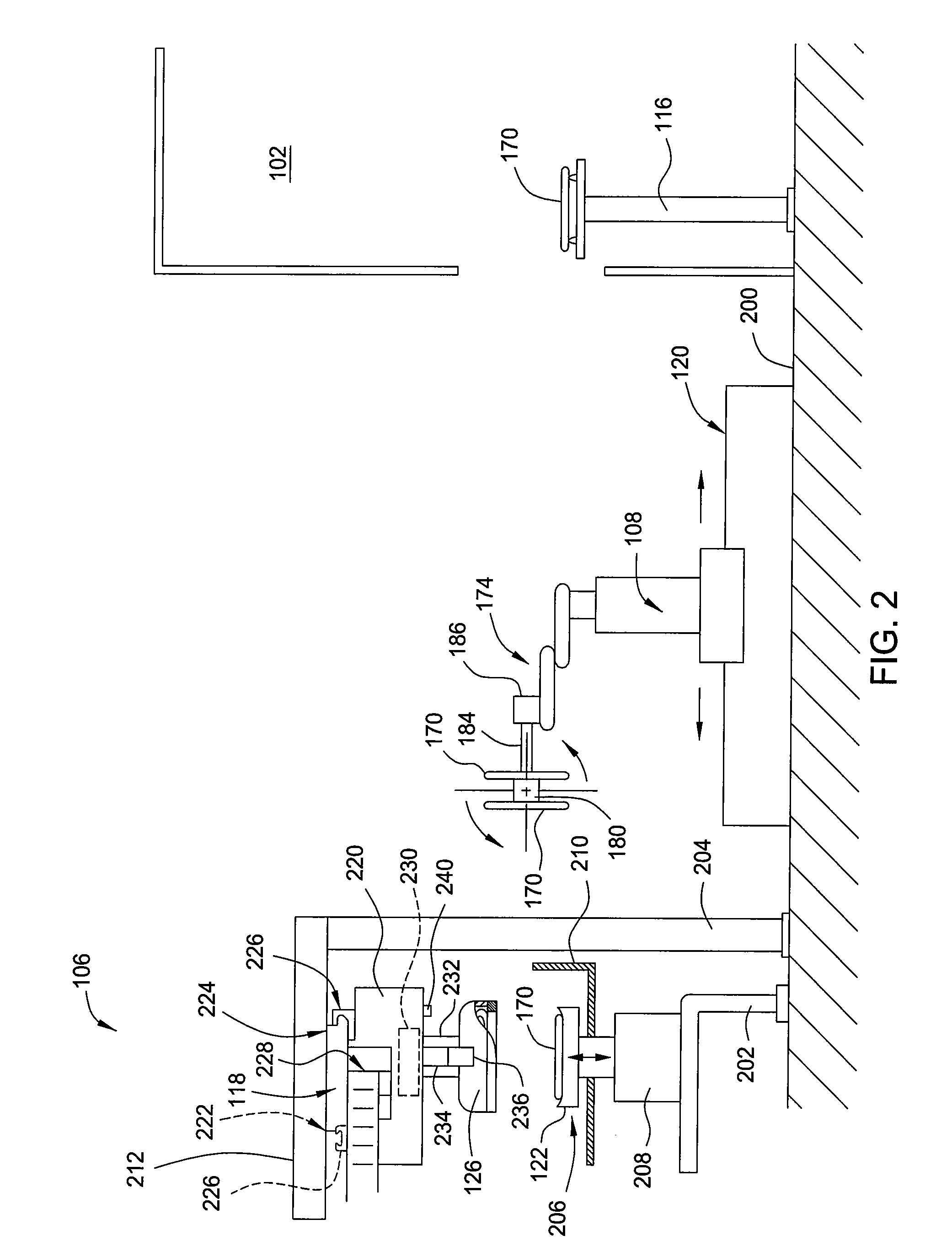

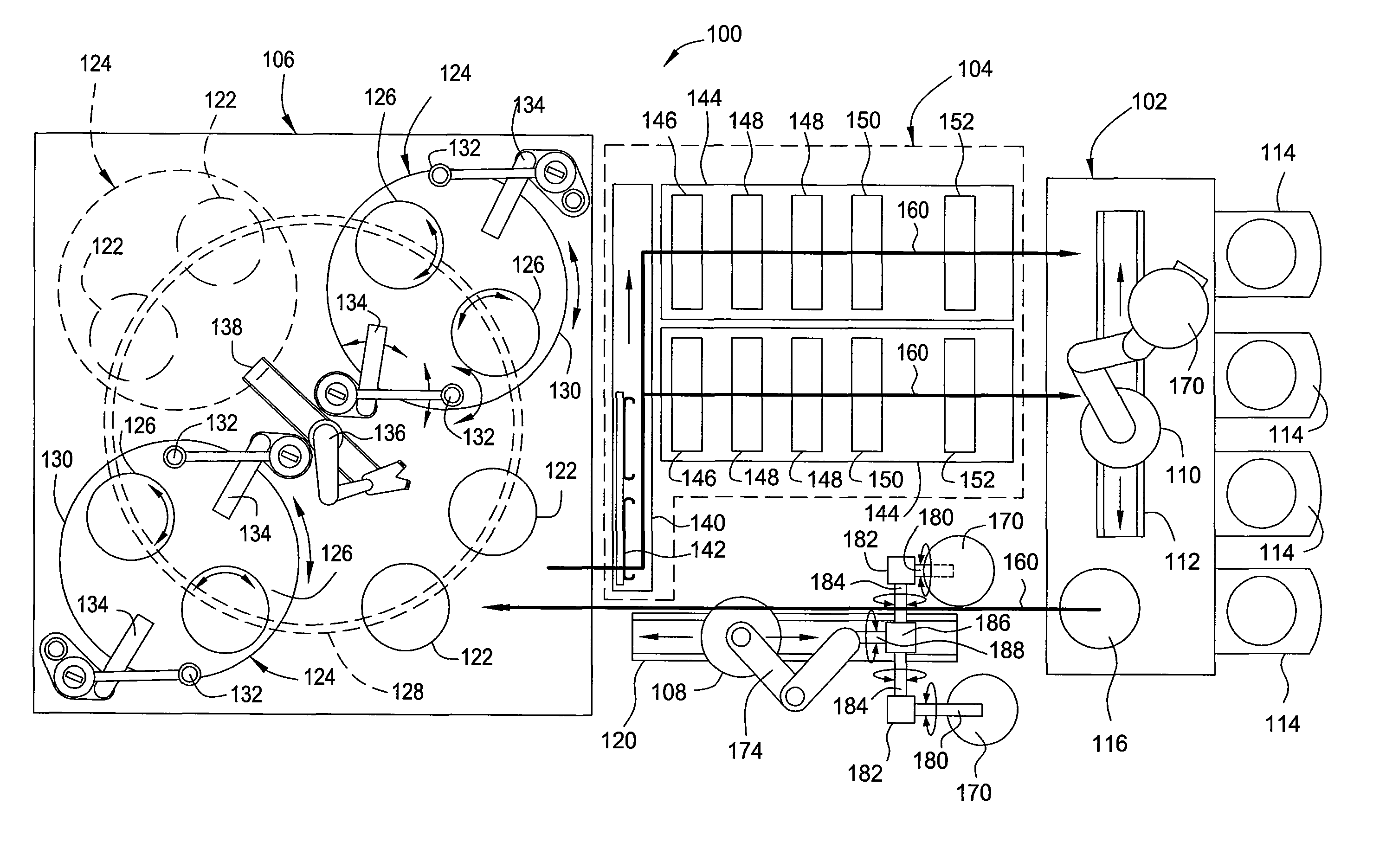

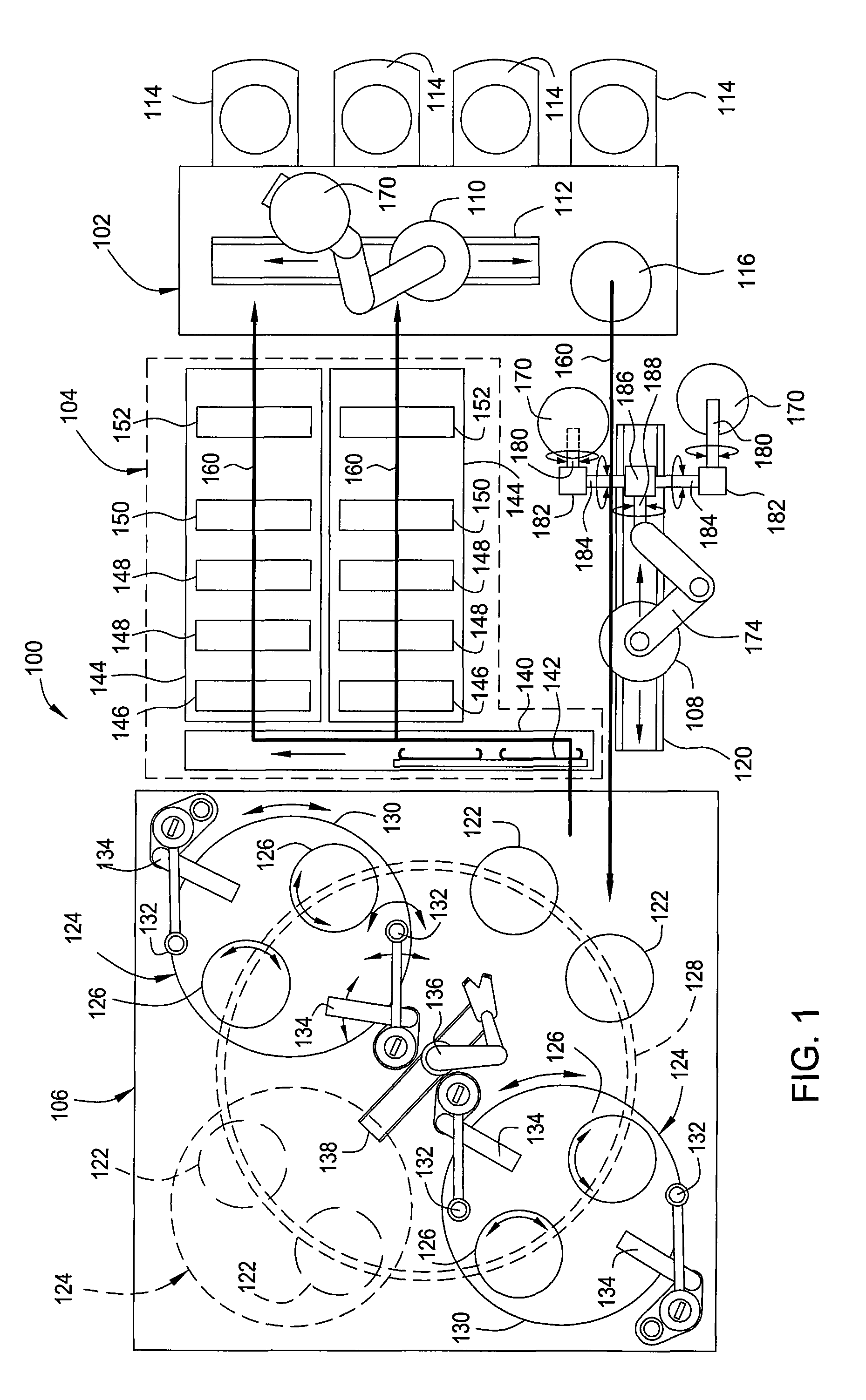

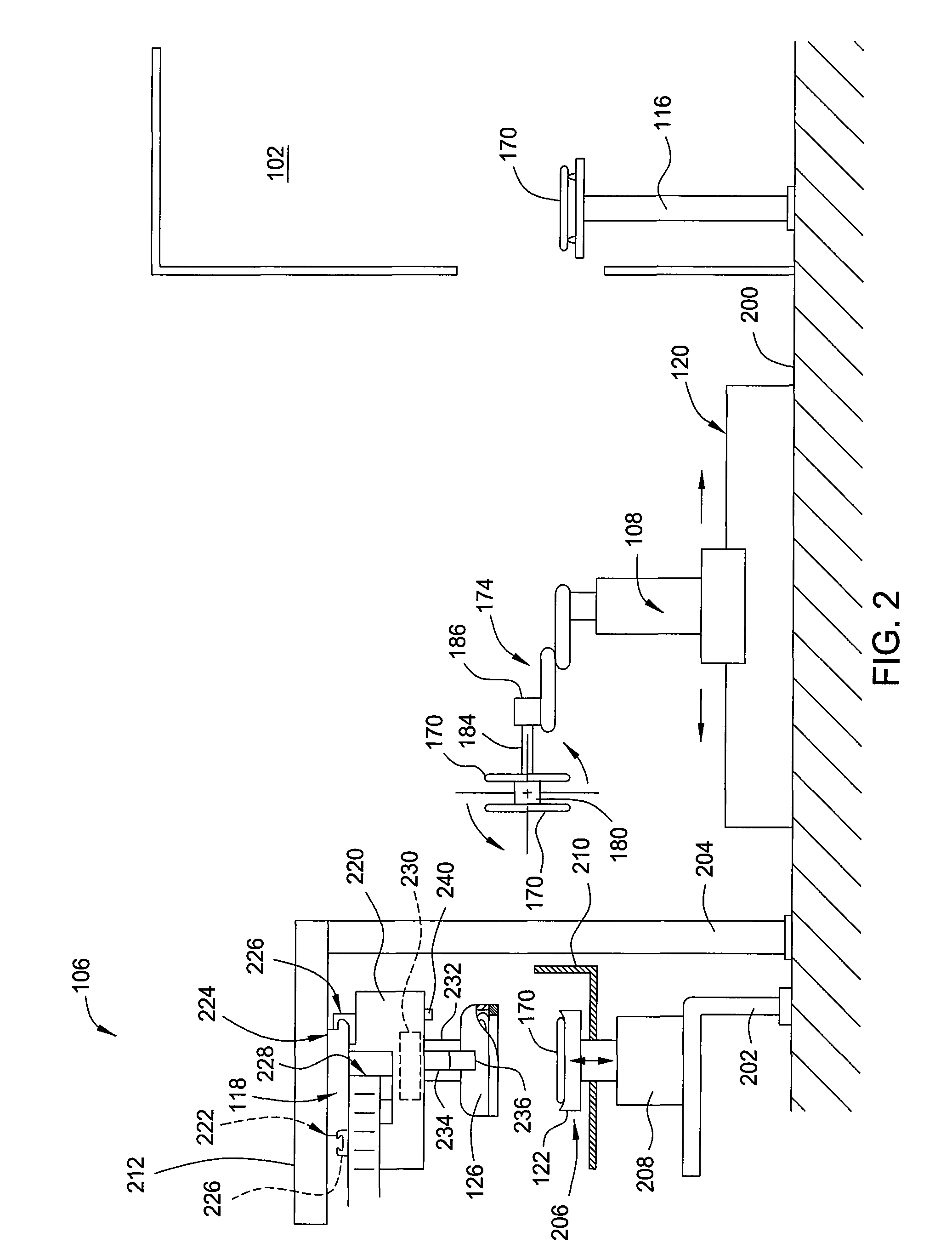

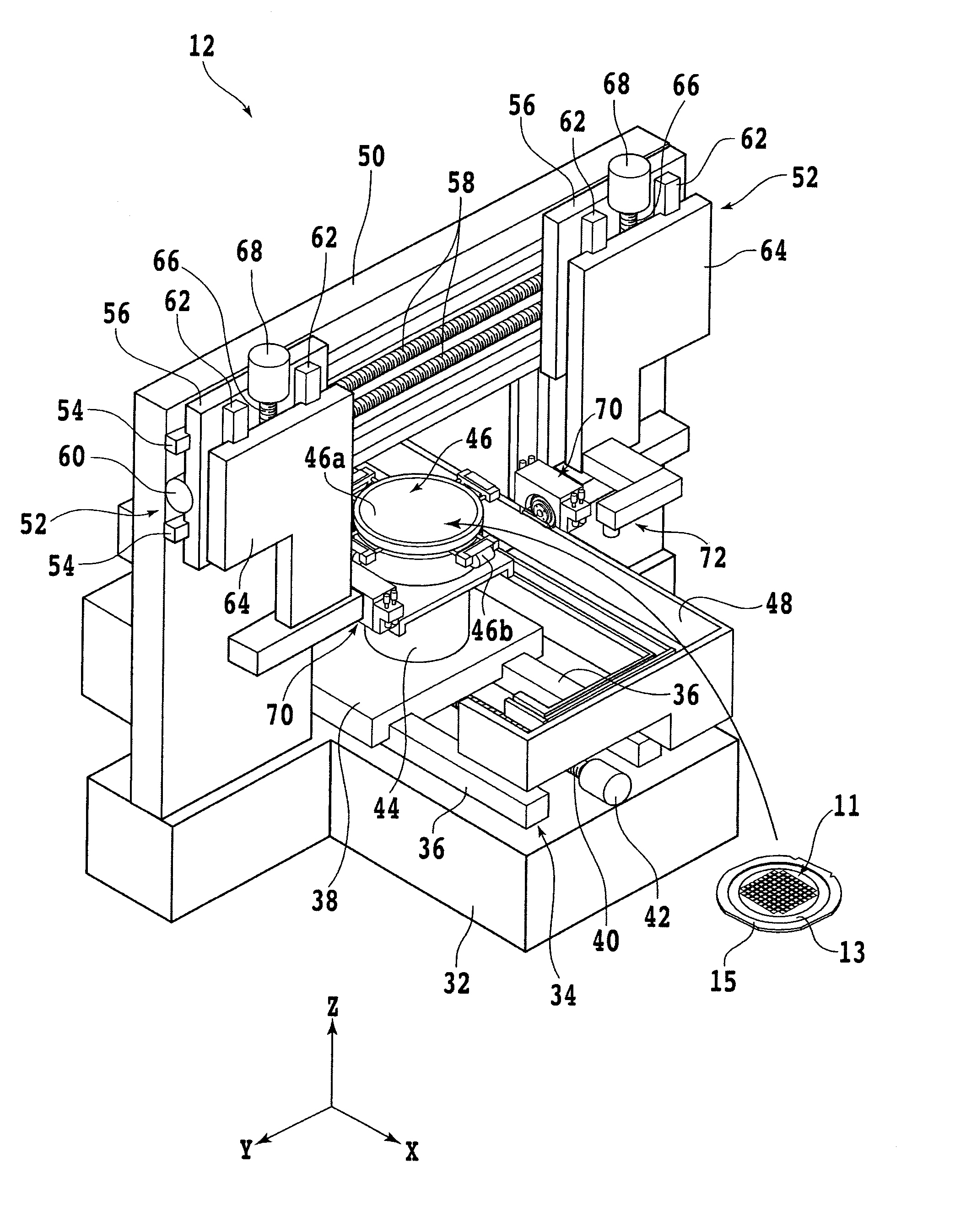

High throughput chemical mechanical polishing system

Embodiments of a system and method for polishing substrates are provided. In one embodiment, a polishing system is provided that includes a polishing module, a cleaner and a robot. The robot has a range of motion sufficient to transfer substrates between the polishing module and cleaner. The polishing module includes at least two polishing stations, at least one load cup and at least four polishing heads. The polishing heads are configured to move independently between the at least two polishing stations and the at least one load cup.

Owner:APPLIED MATERIALS INC

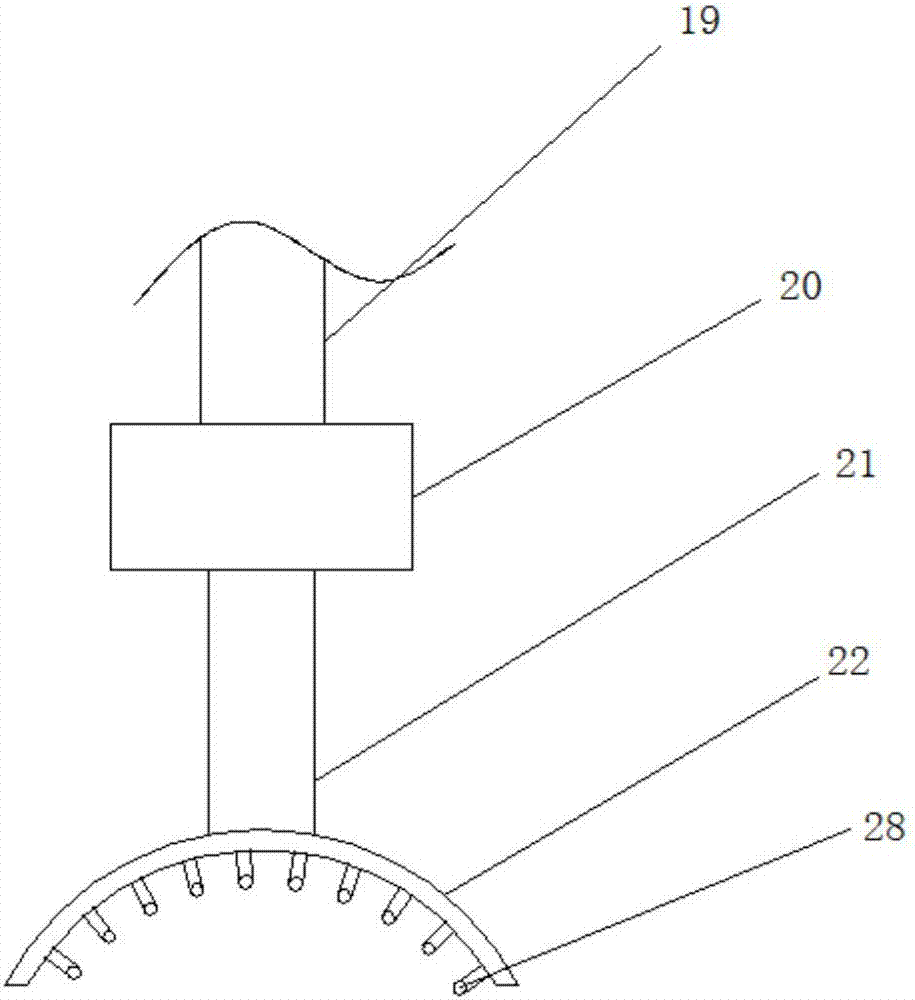

Building steel pipe inner wall and outer wall polishing and rust removing device

InactiveCN107414651AEasy to cleanSmooth transmissionGrinding carriagesGrinding drivesArchitectural engineeringRust

The invention discloses a building steel pipe inner wall and outer wall polishing and rust removing device which comprises a bottom plate, wherein a transverse plate in parallel with the bottom plate is arranged above the bottom plate; a transverse shaft is arranged on a bracket; a semi-circular teeth gear is further arranged on the transverse shaft; an upper rack and a two-sided rack are arranged at the upper end and the lower end of the semi-circular teeth gear; a fixed sleeve rotatably connected with a support frame is arranged at one end of the support frame; a fixed mount is arranged at the end, far away from a rotary sleeve, of the lower end face of the transverse plate; an air cylinder is arranged at the left end of the fixed mount; a pneumatic push rod is arranged at the lower end of the air cylinder; an arc-shaped clamping plate is fixedly connected with the bottom end of the pneumatic push rod; an outer wall cleaning brush is arranged on the inner side of the arc-shaped clamping plate; and a cleaning guide pipe coaxial with the rotary sleeve is arranged on the lower side of the right side of the fixed mount. The building steel pipe inner wall and outer wall polishing and rust removing device is simple in structure, can simultaneously clean the inner wall and the outer wall of a steel pipe, is sufficient in cleaning, high in cleaning efficiency, higher in cleaning effect, stable in transmission and higher in practicality.

Owner:湖北楚雄建筑工程有限公司

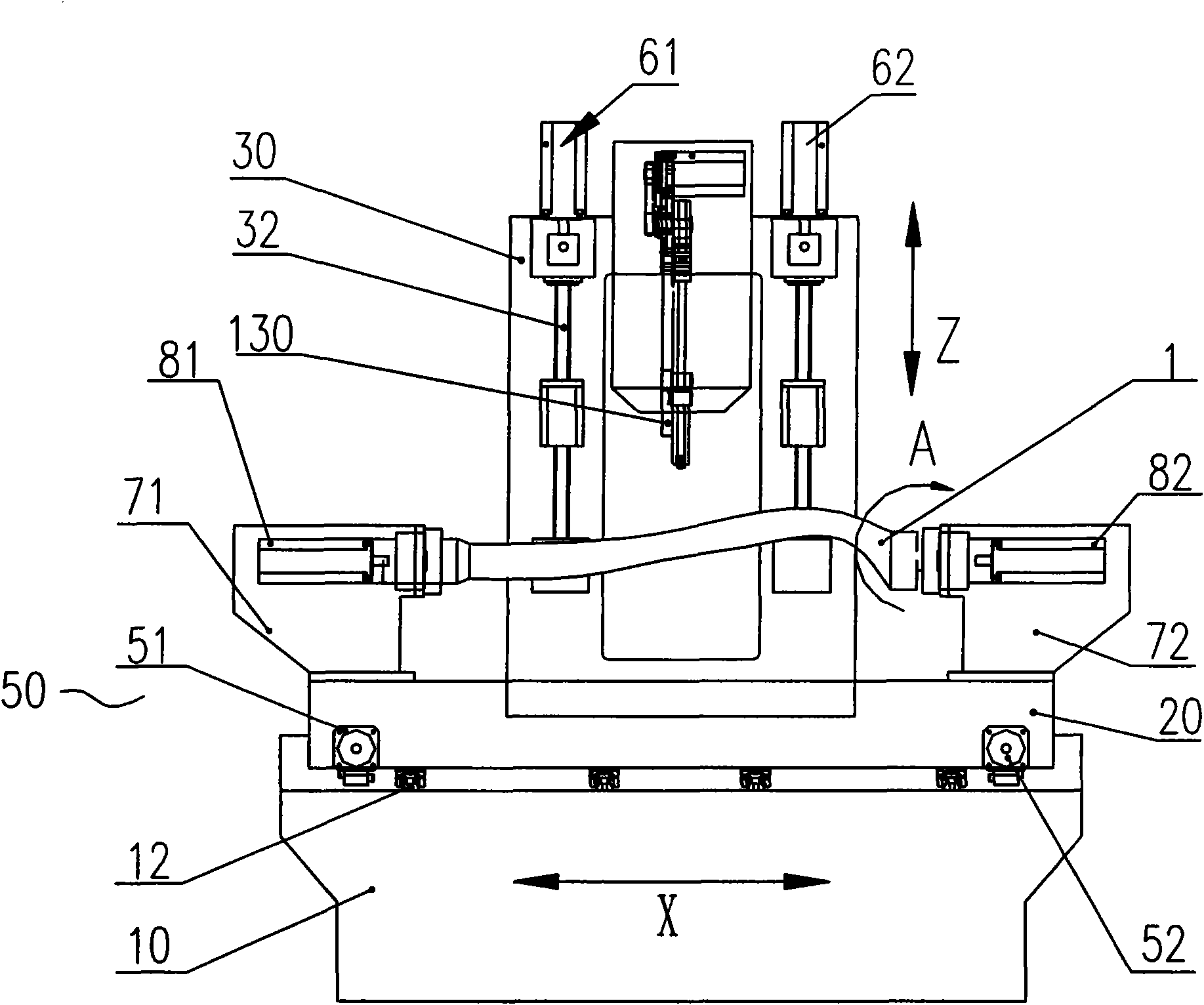

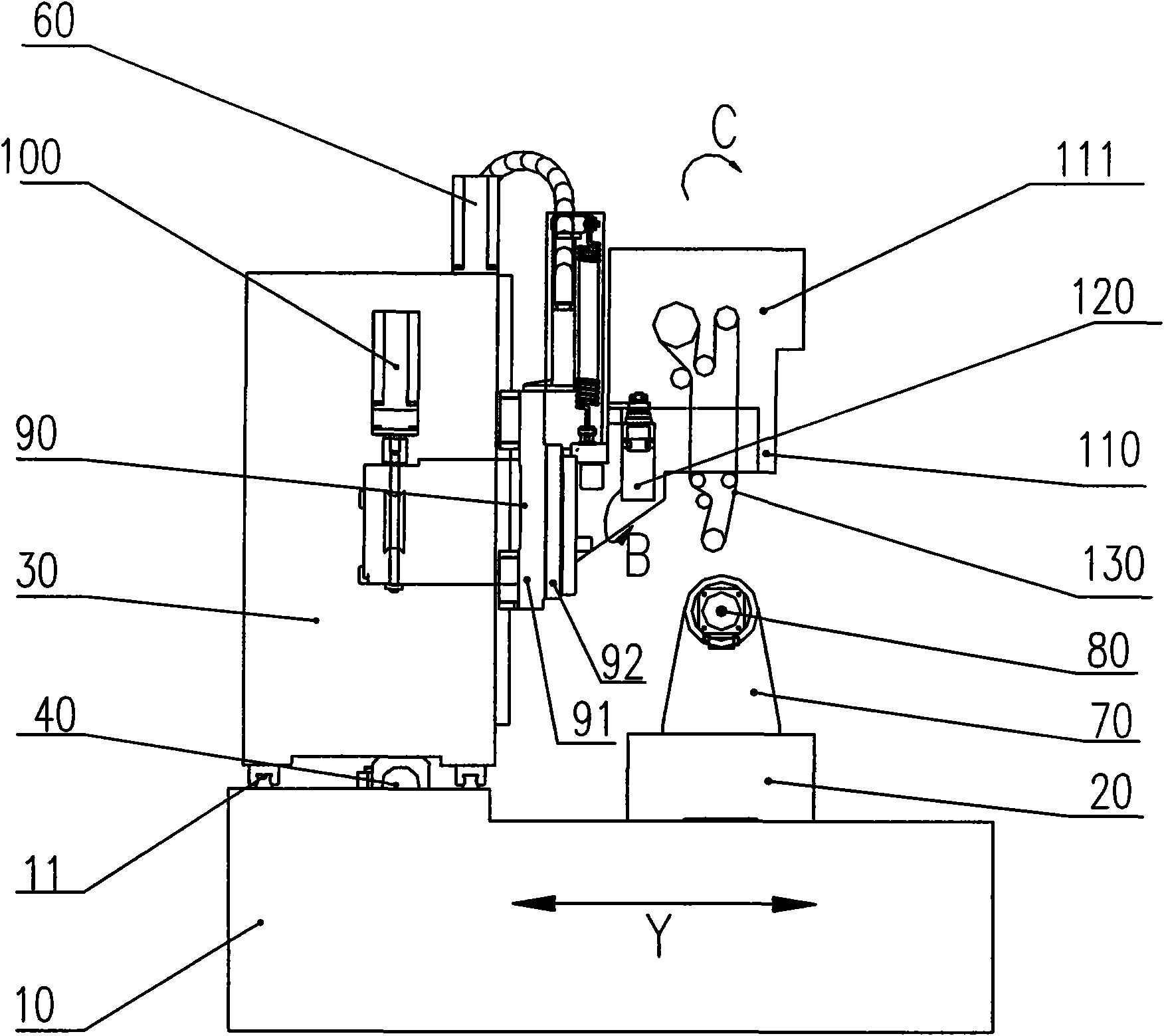

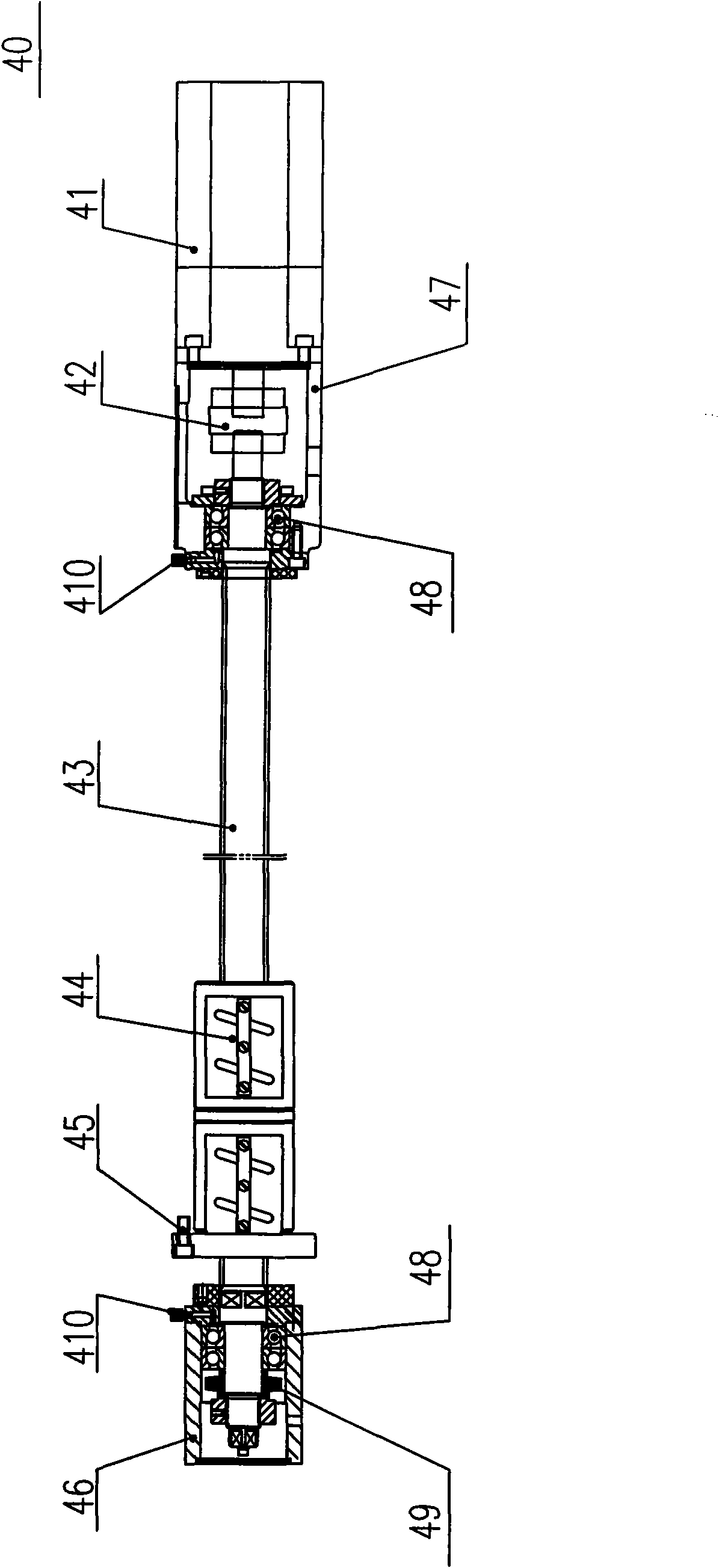

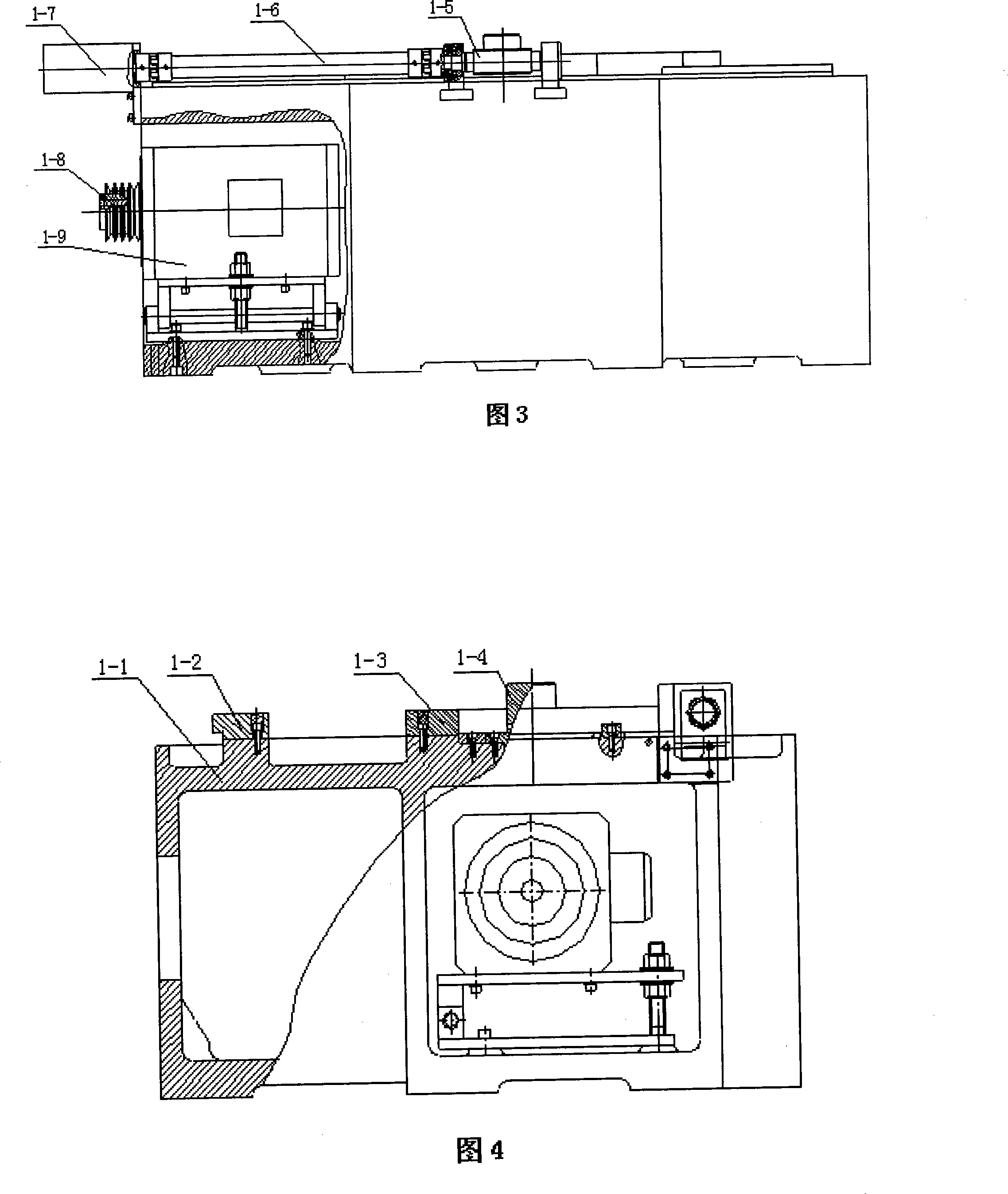

Numerical control abrasive belt grinding machine with six-axis linkage

ActiveCN101559574AImprove processing efficiencyHigh dimensional accuracyGrinding carriagesBelt grinding machinesMachine controlForm liner

The invention discloses a numerical control abrasive belt grinding machine with six-axis linkage. An upright post component and a worktable are arranged on the grinding machine body in a sliding way, and the relative sliding between the two of the upright post component and the worktable and the grinding machine body respectively forms liner motion of X-axis direction and Y-axis direction; an A-axis component is arranged above the worktable and used for clamping a workpiece to rotate around the axial line thereof so as to form rotary motion of the A-axis; a cantilever on the upright post component is provided with a grinding seat which is connected with the upright post component through a box body in a sliding way so as to form liner motion of Z-axis direction; a turntable is arranged on the box body in a rotating way, and the relative rotation between the turntable and the box body forms rotary motion of B-axis direction; an abrasive belt machine is arranged inside the grinding seat, and the relative rotation between the abrasive belt machine and the grinding seat forms swivel motion of C-axis direction; and the grinding machine controls the motion of each axis direction by a numerical control system. The numerical control abrasive belt grinding machine can greatly enhance grinding efficiency, and can effectively improve the grinding precision and surface quality of the workpiece.

Owner:北京胜为弘技数控装备有限公司

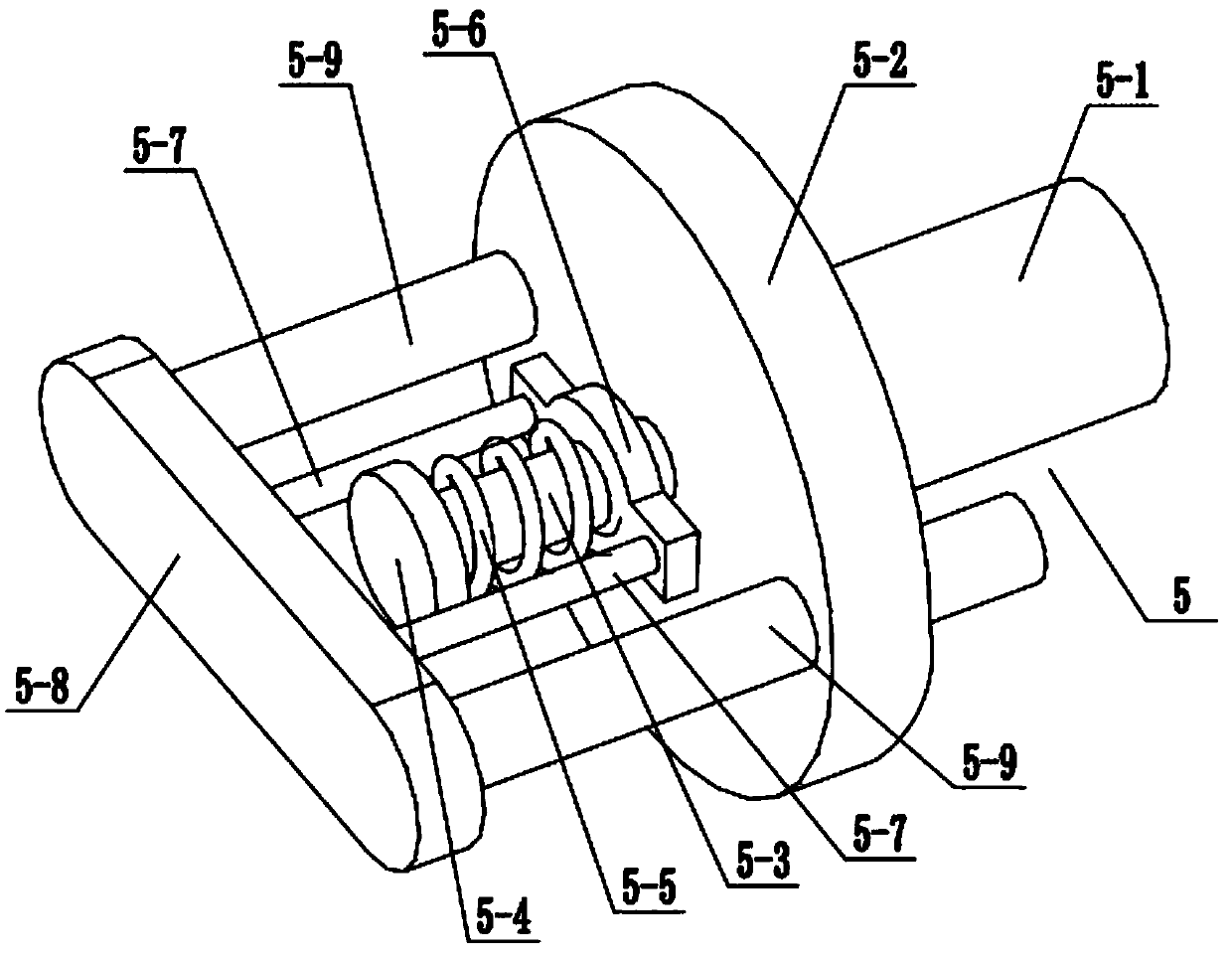

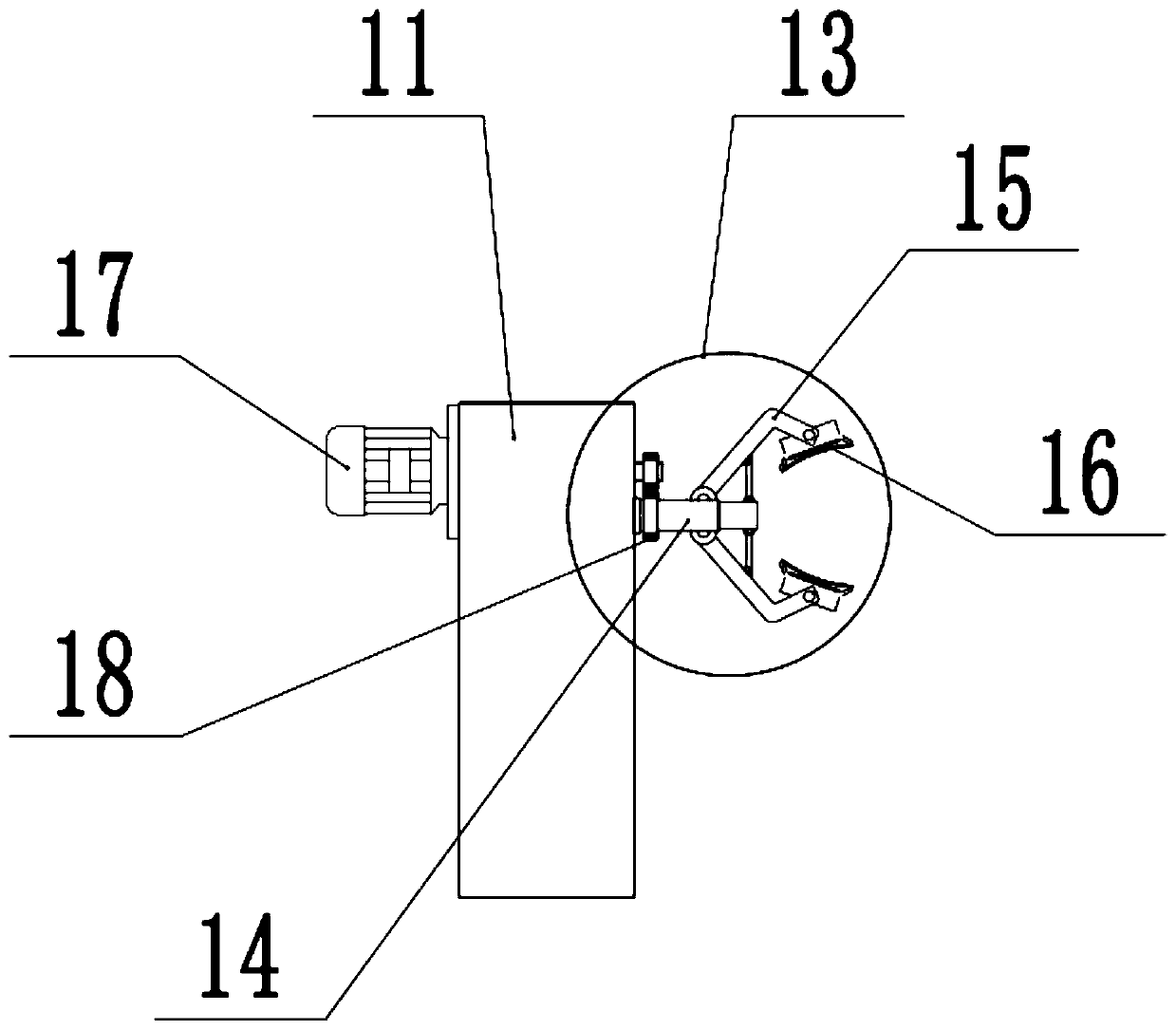

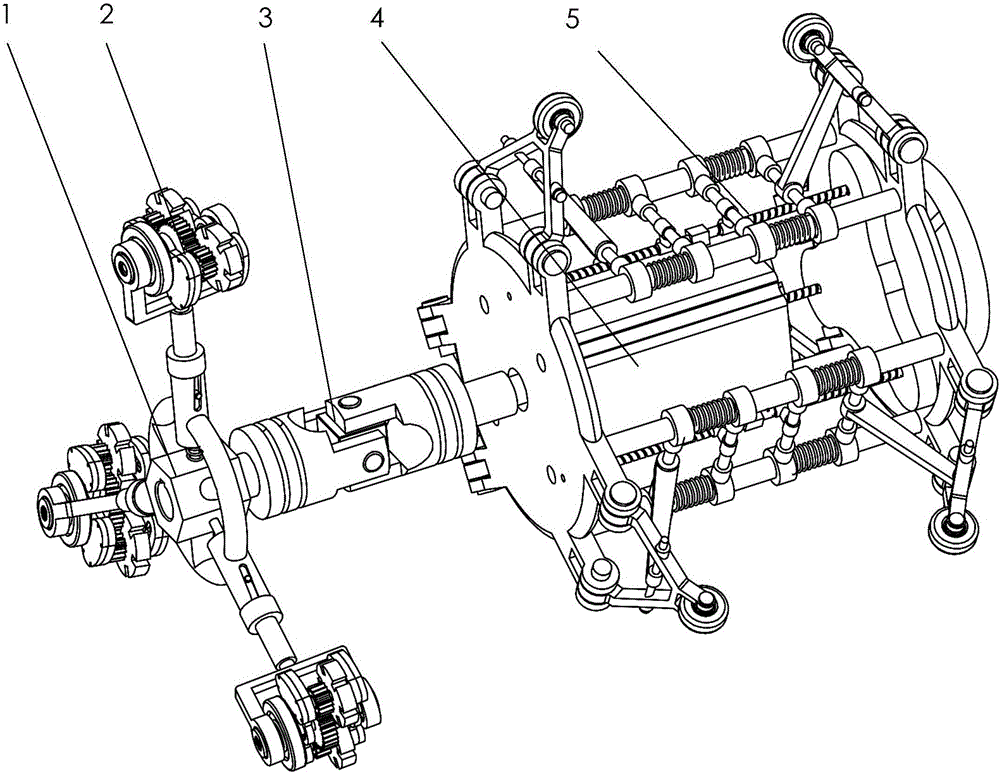

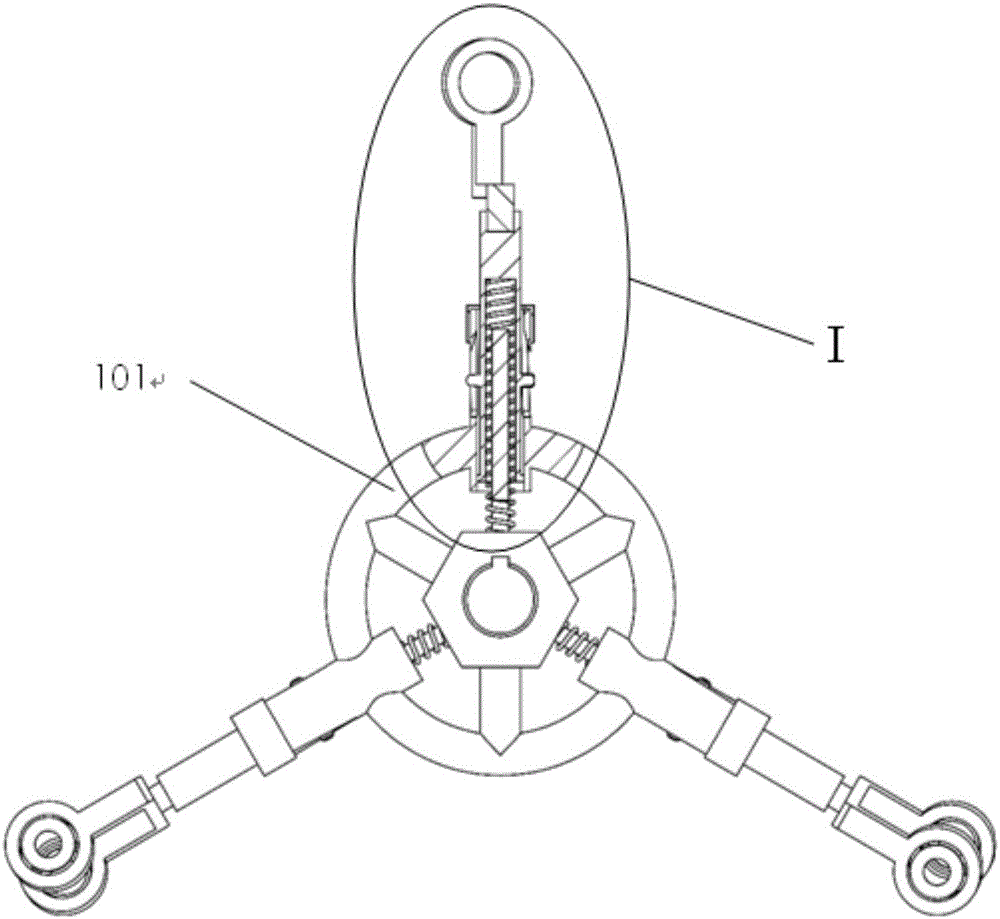

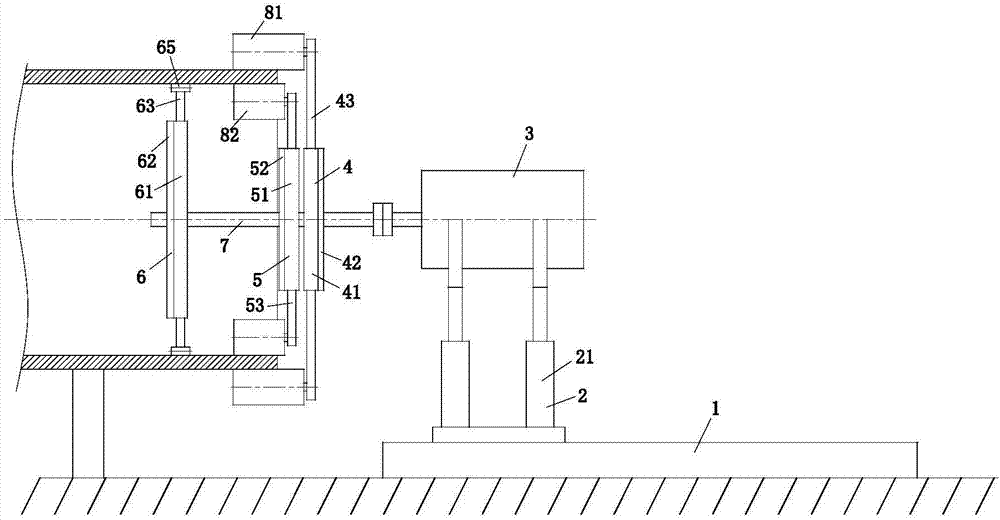

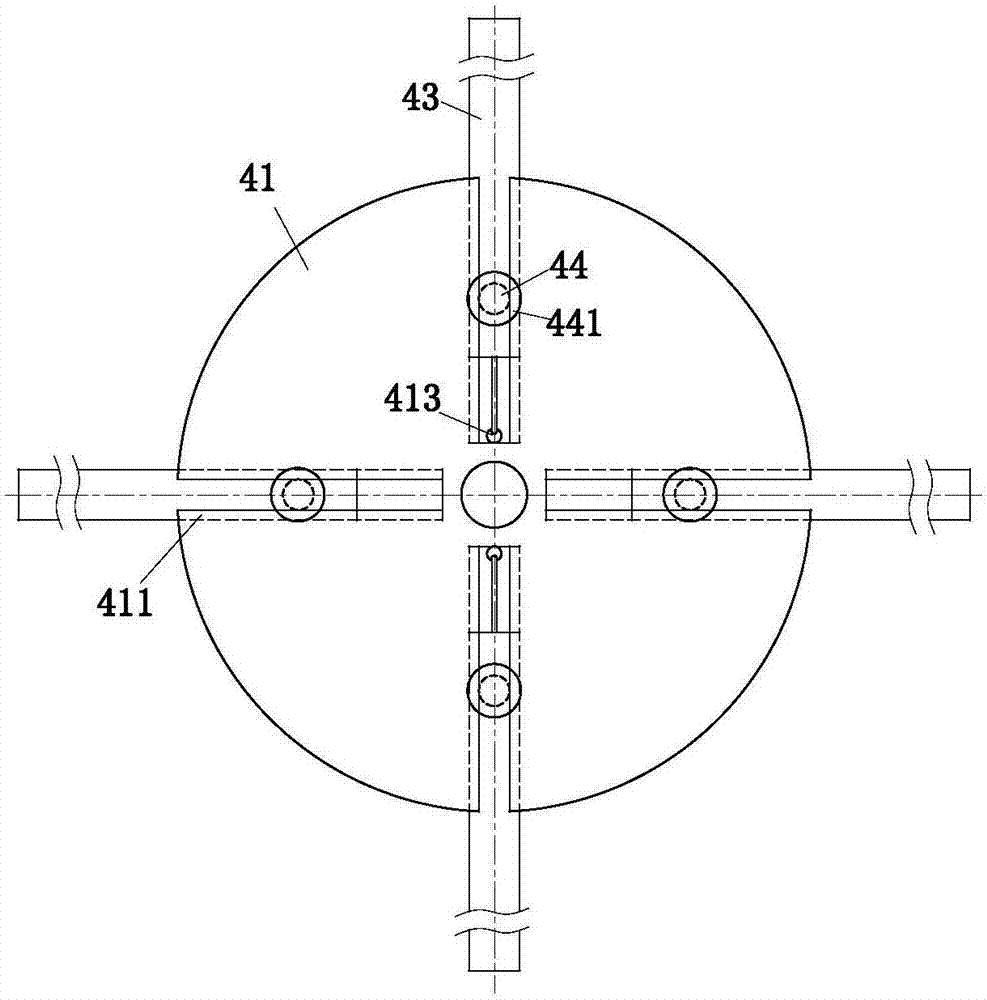

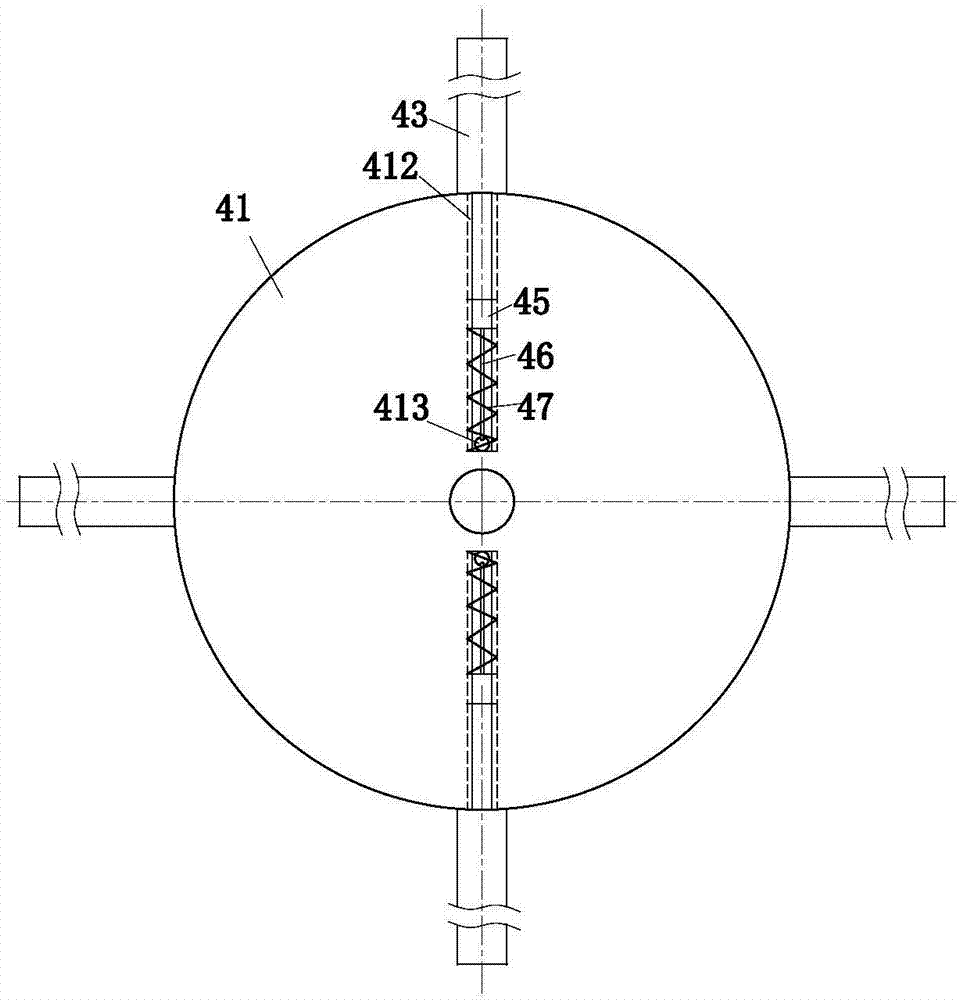

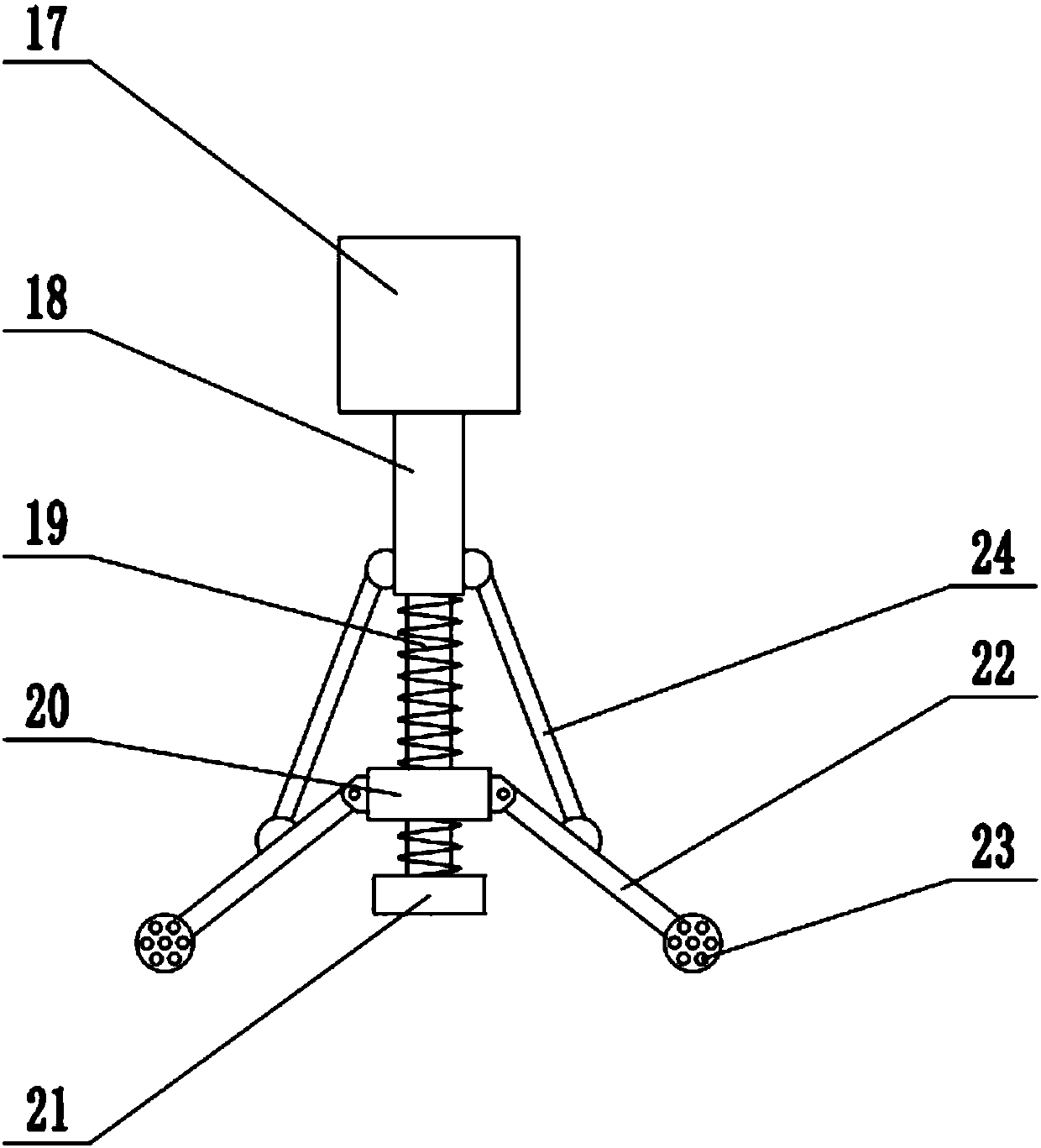

Spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters

ActiveCN106239284AGrinding muchLow costGrinding carriagesRevolution surface grinding machinesDrive wheelPipe fitting

The invention relates to a spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters, and belongs to the field of pipeline robots. A hub assembly and a cross-axis universal joint are mounted in a spline fit manner, three driving wheel grinding assemblies are arranged, two ends of drive shafts of the assemblies and a drive shaft support in the hub assembly are mounted in a matched manner through bearings, a motor and control and power assembly is mounted on a direction keeping mechanism, and a motor shaft of the assembly and the cross-axis universal joint are mounted in a spline fit manner. The spiral angles of the grinding assemblies relative to the cross section of a pipe fitting are adjusted in a self-adaptation manner, and therefore the aim that the position with the small pipe diameter and many impurities is ground much, and the position with the large pipe diameter and few impurities is ground little is achieved, the robot can be matched with multiple different-size grinding assemblies for use, the aim that one robot has multiple purposes is achieved, and the cost can be saved to a certain degree.

Owner:JILIN UNIV

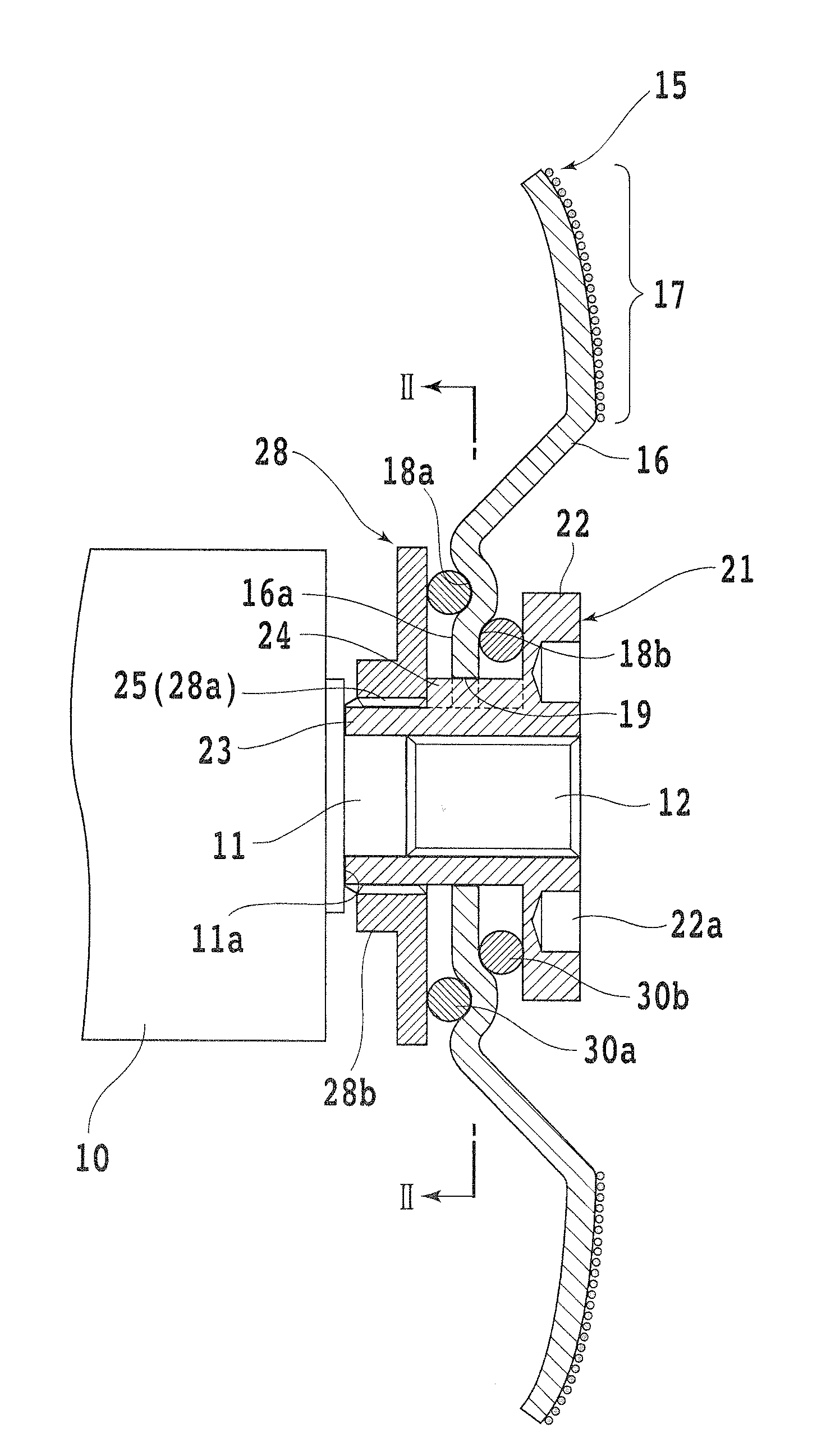

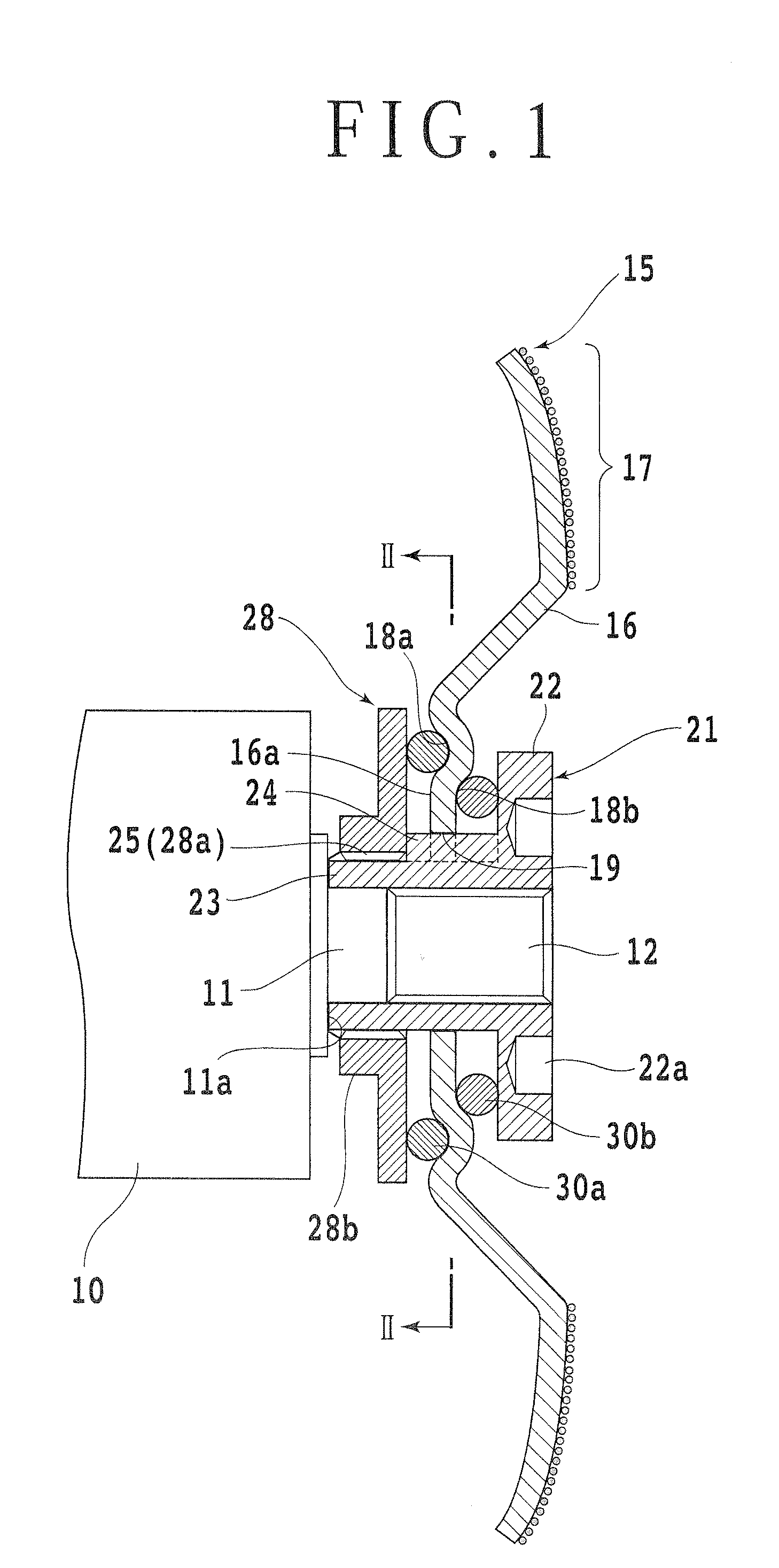

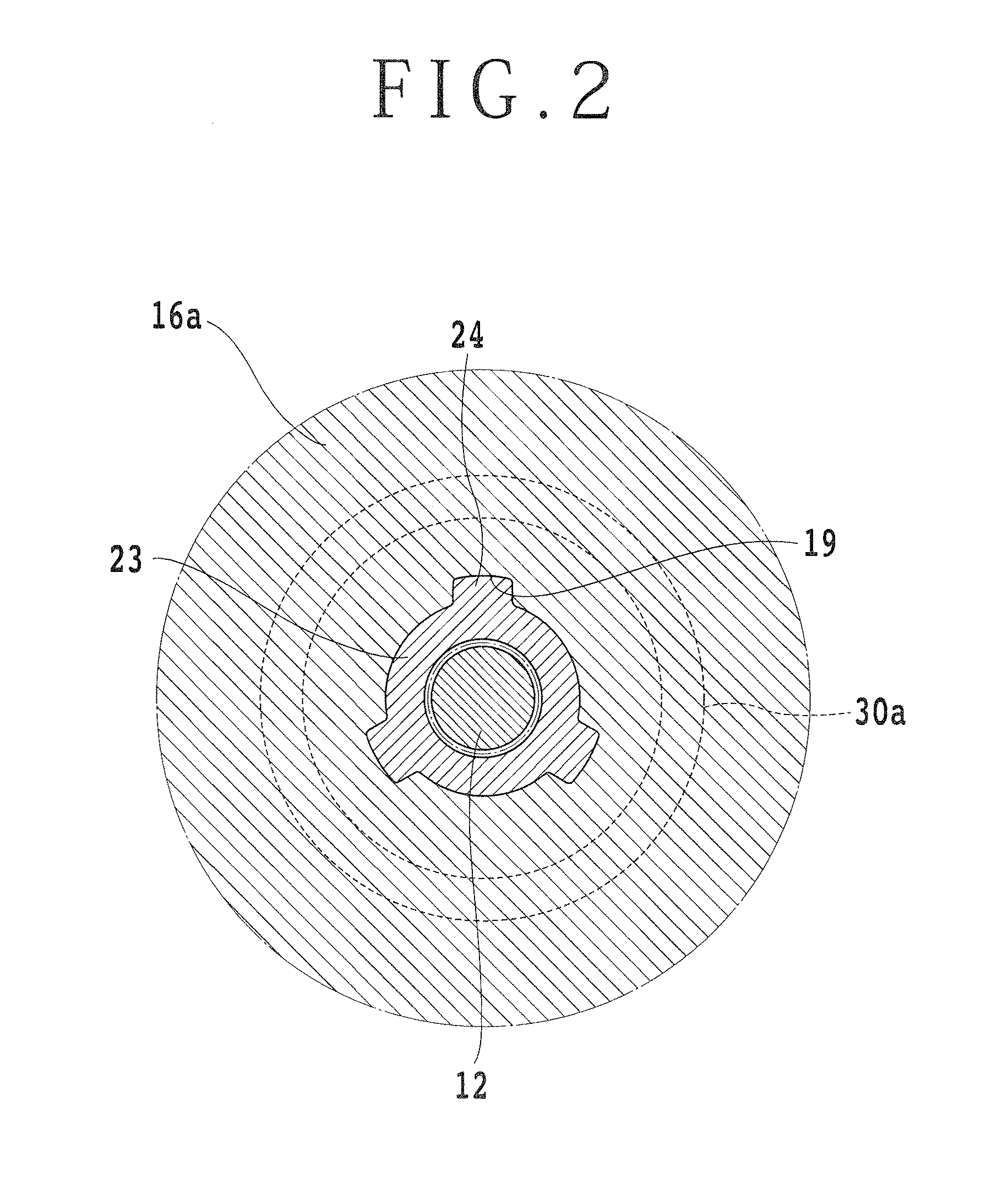

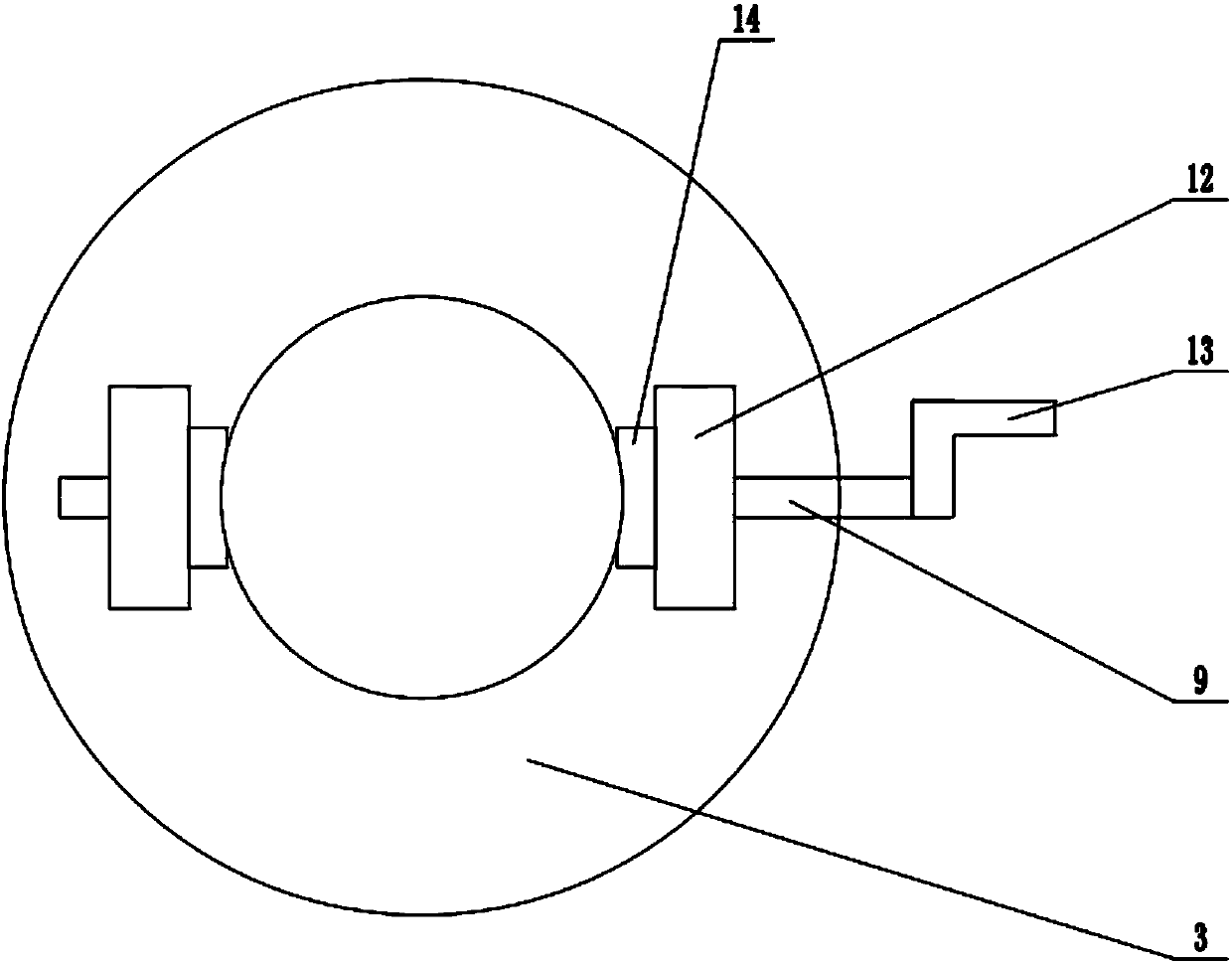

Mounting device for disk-shaped rotating tool

InactiveUS20110086582A1Reduce vibrationSimple structureGrinding wheel securing apparatusGrinding carriagesCushioningRotary machine

An annular retaining groove is formed on the inner circumferential portion of the disk-shaped rotating tool, and a ringlike cushioning member is fitted in this annular retaining groove so as to be partially exposed. Both sides of the inner circumferential portion of the disk-shaped rotating tool are held by first and second holding members through the annular cushioning member. An axial portion of the first holding member is engaged with an output shaft of an electric rotary machine so that the disk-shaped rotating tool is rotated through the first holding member by the output shaft.

Owner:TENRYU SAW MFG

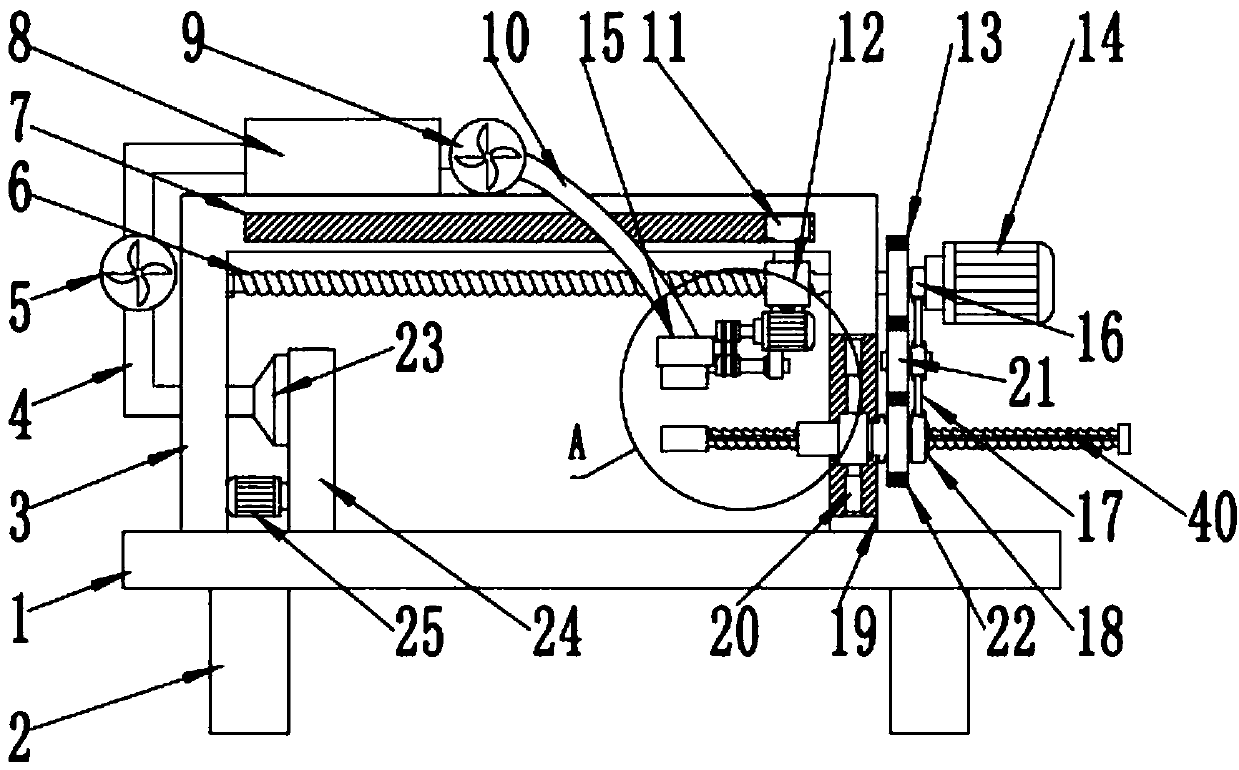

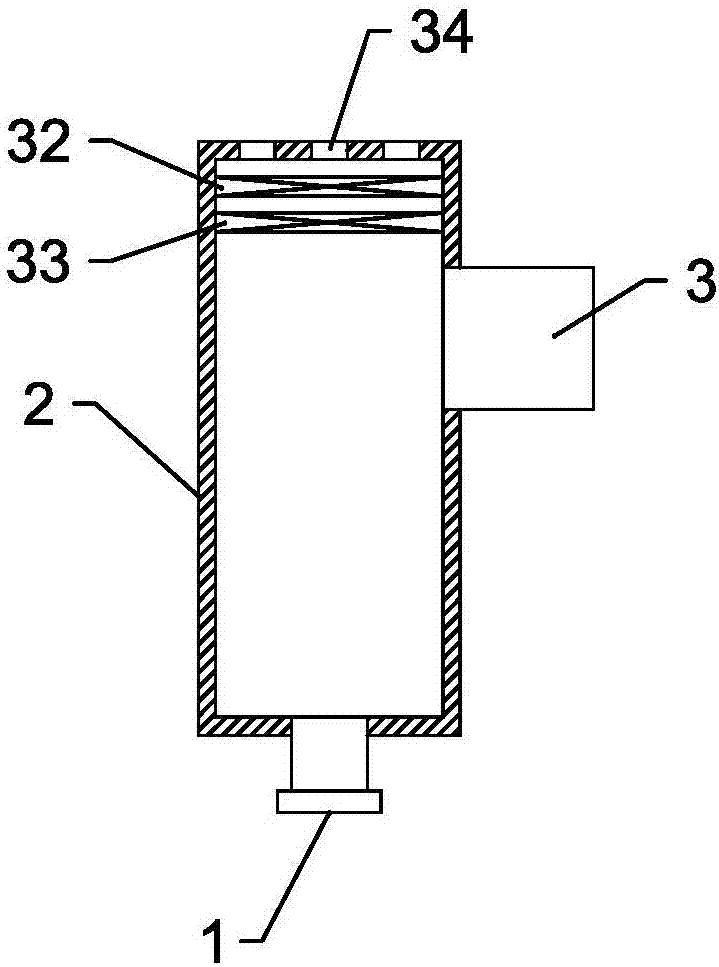

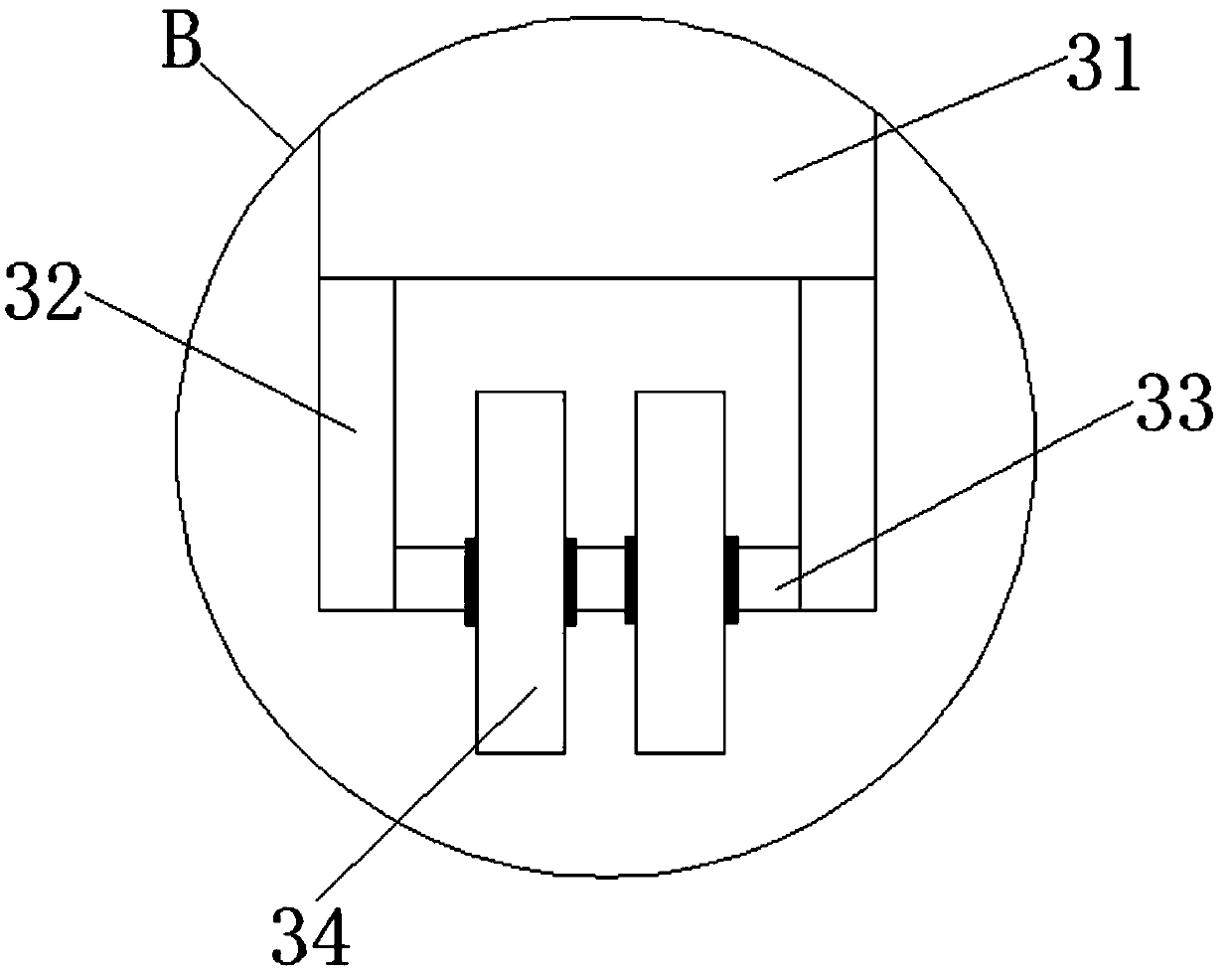

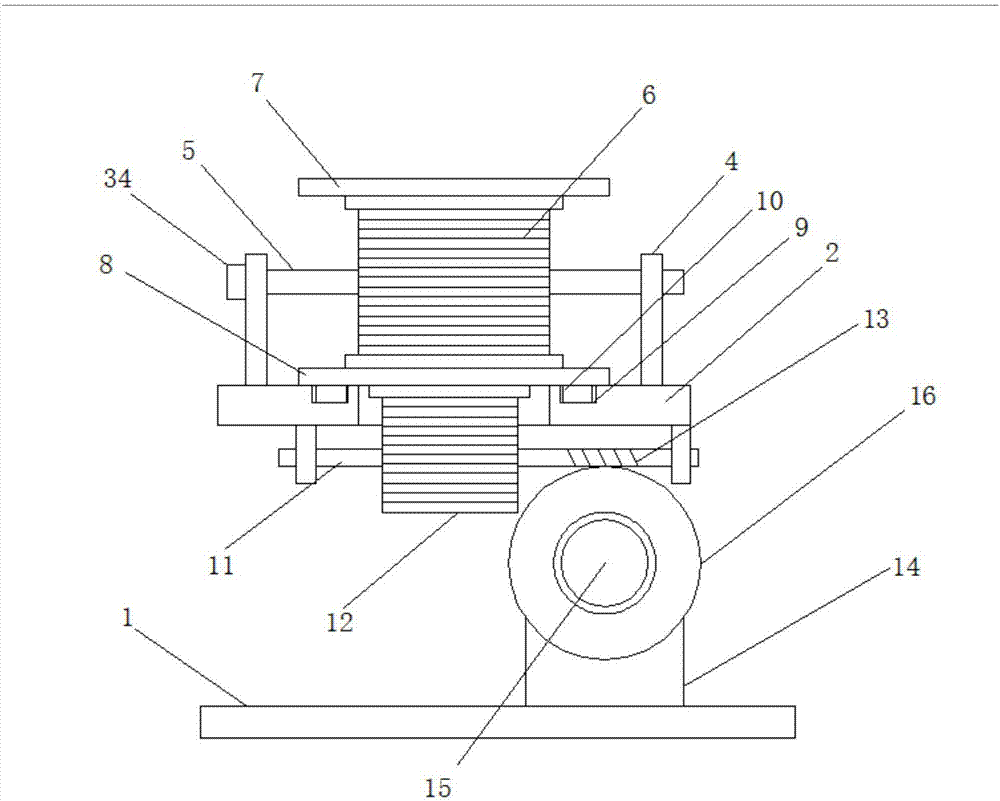

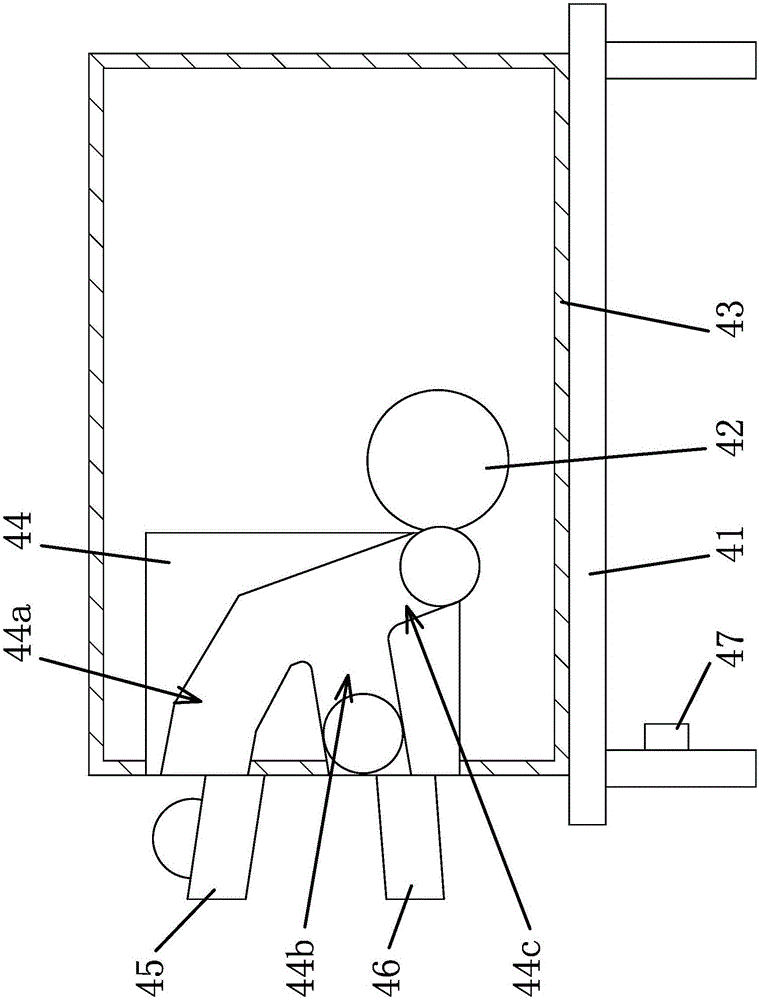

Stainless steel cylinder polishing wire-drawing treatment equipment

ActiveCN107363695ARealize automatic shrinkage adjustmentImprove production efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringDrive motor

The invention belongs to the field of mechanical processing equipment, and in particular discloses stainless steel cylinder polishing wire-drawing treatment equipment which comprises a bottom plate, an adjusting module, a driving motor, an outer cylinder grinding disc, an inner cylinder grinding disc, a centering support and a connecting rotating shaft, wherein the bottom plate is placed on the ground; an adjusting module is arranged on the upper surface of the bottom plate; the driving motor is mounted on the adjusting module; the inclination angle of an axis of the driving motor can be adjusted through the adjusting module; and the outer cylinder grinding disc, the inner cylinder grinding disc and the centering support are detachably mounted on the connecting rotating shaft coaxially. By adopting the equipment, automatic shrinkage adjustment on a polishing wire-drawing radius is achieved under the centrifugal action of the outer cylinder grinding disc and the inner cylinder grinding disc, then operation of polishing and wire-drawing is completed at one time, and the generation efficiency is improved.

Owner:南京拓创精密金属材料有限公司

Steel plate end face polishing device

InactiveCN105382649AEfficient grindingSimple structureEdge grinding machinesGrinding carriagesSheet steelEngineering

The invention aims at providing a steel plate end face polishing device. A conveying belt is arranged to convey a steel plate, a downwards-pressing air cylinder is arranged to downwards press and clamp the steel plate, and supporting bases are arranged on the two sides of a working table so as to be provided with polishing motors which are used for polishing the two ends of the steel plate; an ash suction machine is arranged for achieving ash sucking; and the transverse positions of the supporting bases can be adjusted on an adjusting rail, a pushing air cylinder is arranged for adjustment, and therefore the steel plate end face polishing device is quiet convenient. The steel plate end face polishing device is simple in structure, easy to operate and suitable for production, and steel plate end faces can be polished efficiently and rapidly.

Owner:WUHU BOKE ELECTROMECHANICAL

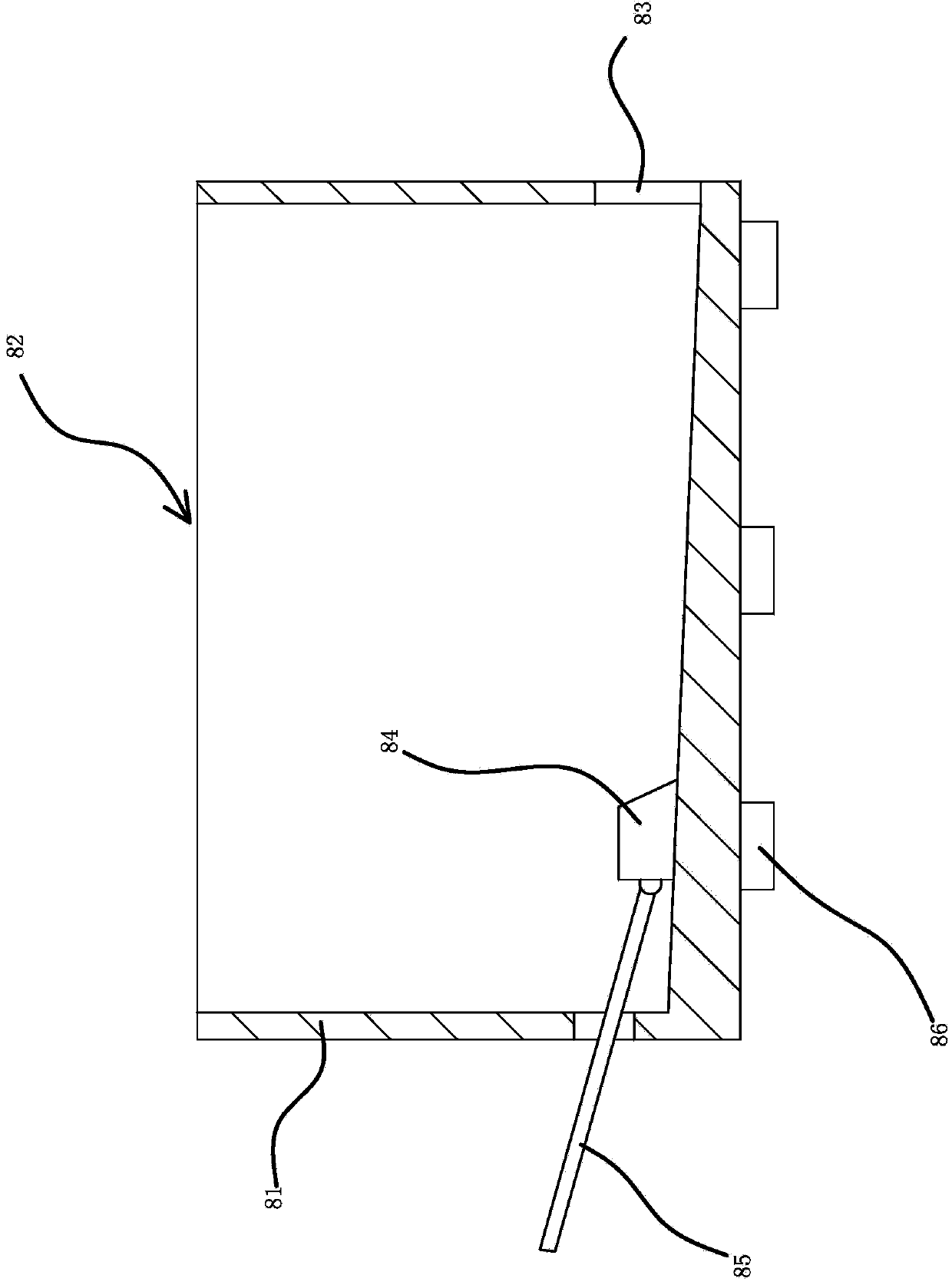

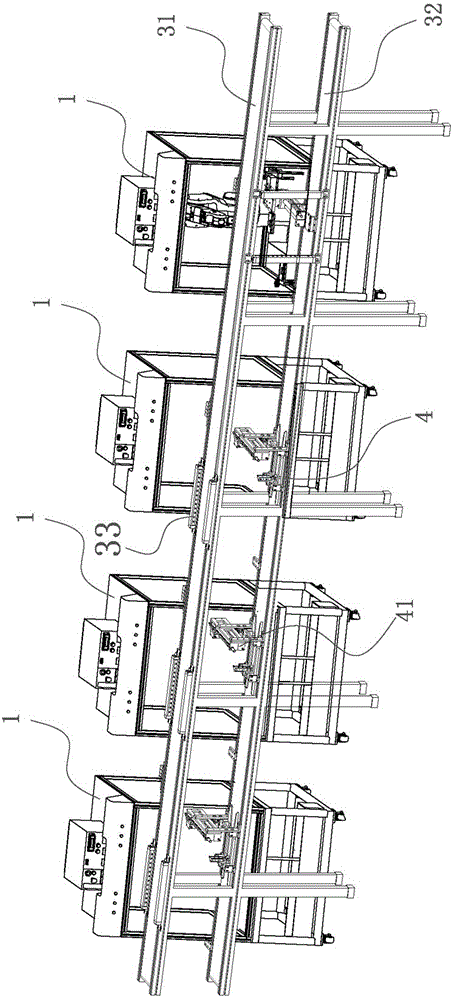

Production system of hub bearing

ActiveCN106050920ANo need for manual operationFast productionLiquid surface applicatorsGrinding carriagesThrust bearingEngineering

The invention provides a production system of a hub bearing, in order to solve the technical problems that the hub bearing is to be carried manually and the production speed is low because the structure of the conventional processing device is too simple. The production system of the hub bearing comprises a workbench, wherein an outer ring grinding device for grinding an outer ring of the hub bearing, an inner ring grinding device for grinding an inner ring of the hub bearing, a cleaning device for cleaning the hub bearing, a spraying device for spraying the hub bearing, and a detection device for detecting the hub bearing are sequentially arranged on the workbench. The production system has the advantage of high production speed.

Owner:嘉兴福可吉精密机械有限公司

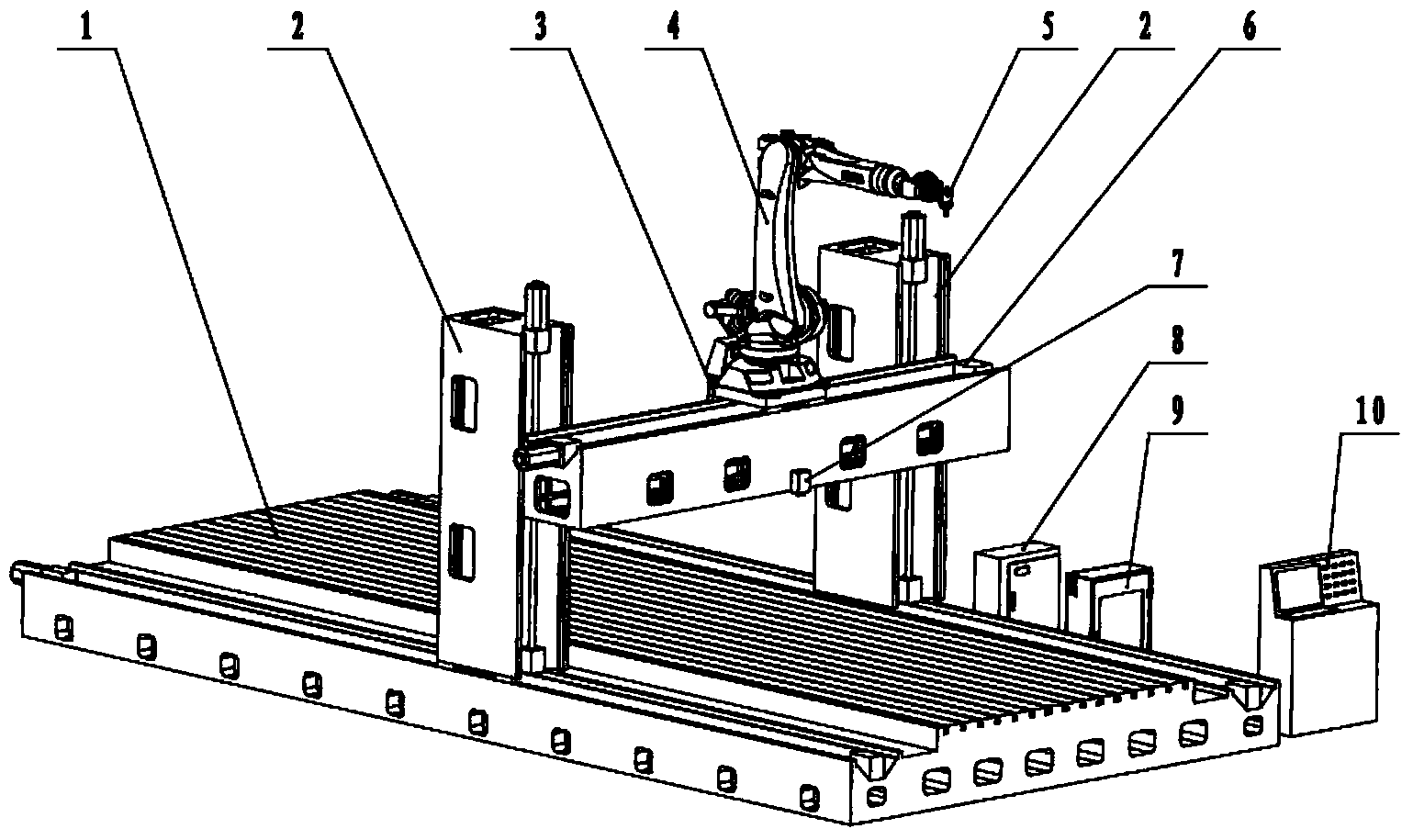

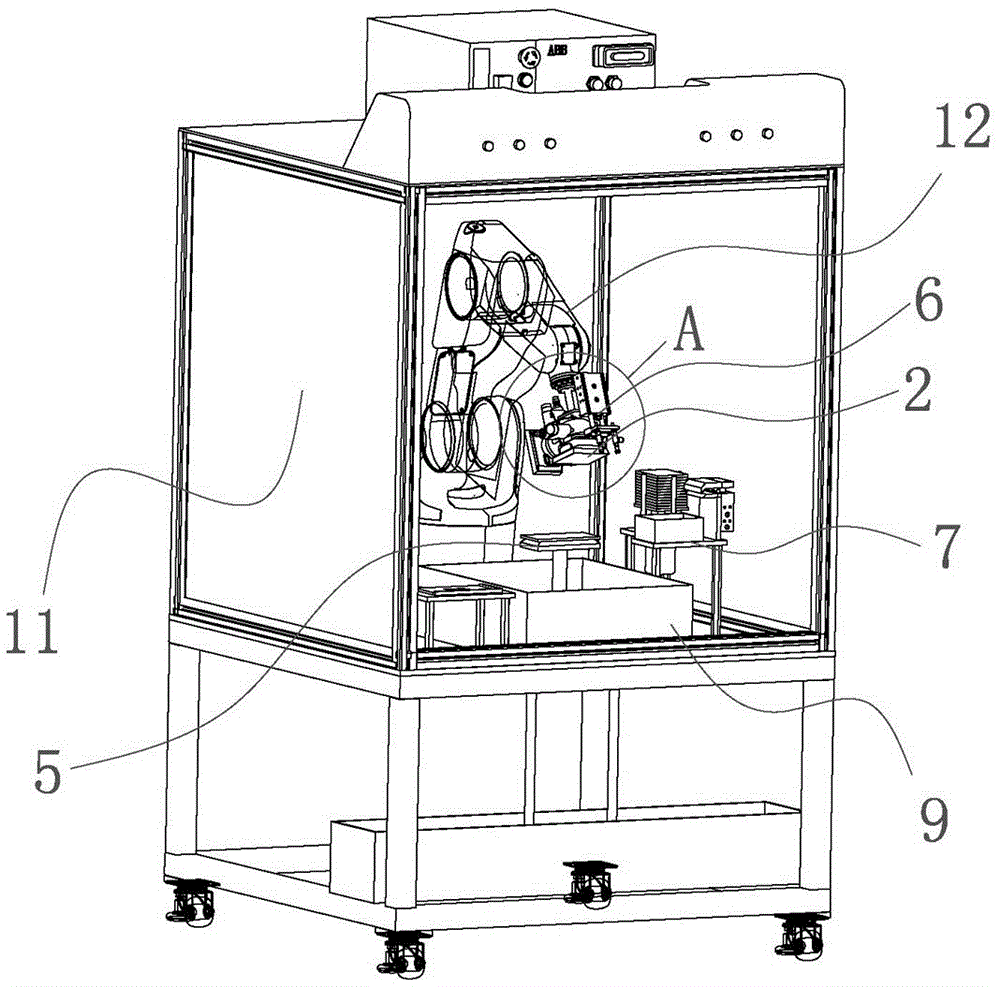

Large free-form surface robot polishing system

ActiveCN103831695AGrinding pressure is easy to controlGuaranteed grinding removalGrinding carriagesGrinding drivesFree formSimulation

The invention discloses a large free-form surface robot polishing system. The large free-form surface robot polishing system comprises a pneumatic polishing head, an industrial robot, a robot control cabinet, a traveler gantry, a visual system, a pneumatic control cabinet and a system control cabinet. When the polishing system works, a part standard is rapidly and accurately calibrated according to the standard accurate calibrating technique, the traveler gantry is used for driving the industrial robot to arrive at a target free-form surface, the pneumatic polishing head is driven by the industrial robot to polish the target free-form surface according to a planed path, the pneumatic smooth force control technique and the normal polishing force control technique are adopted in a polishing process, and consistency of polishing accuracy and polishing quality is effectively guaranteed; the industrial robot is driven by the traveler gantry to arrive at the next target free-form surface after the target free-form surface is polished, the industrial robot drives the pneumatic polishing head to conduct polishing according to the planed path again, and in this way, all free-form surfaces are polished step by step in sequence. The large free-form surface robot polishing system is simple in structure, wide in work range, and suitable for polishing the large free-form surfaces.

Owner:中科君胜(深圳)智能数据科技发展有限公司

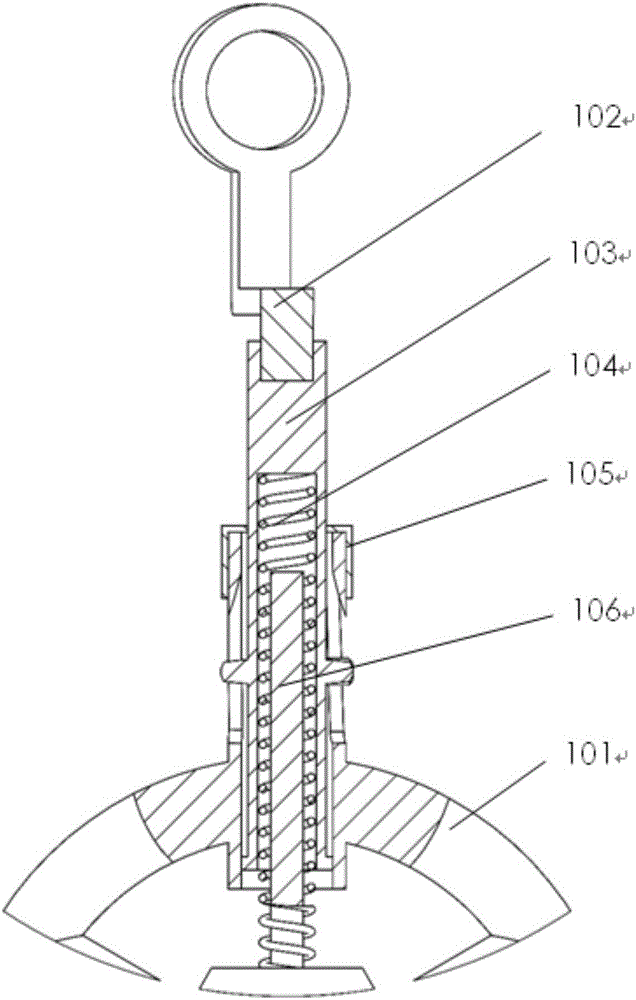

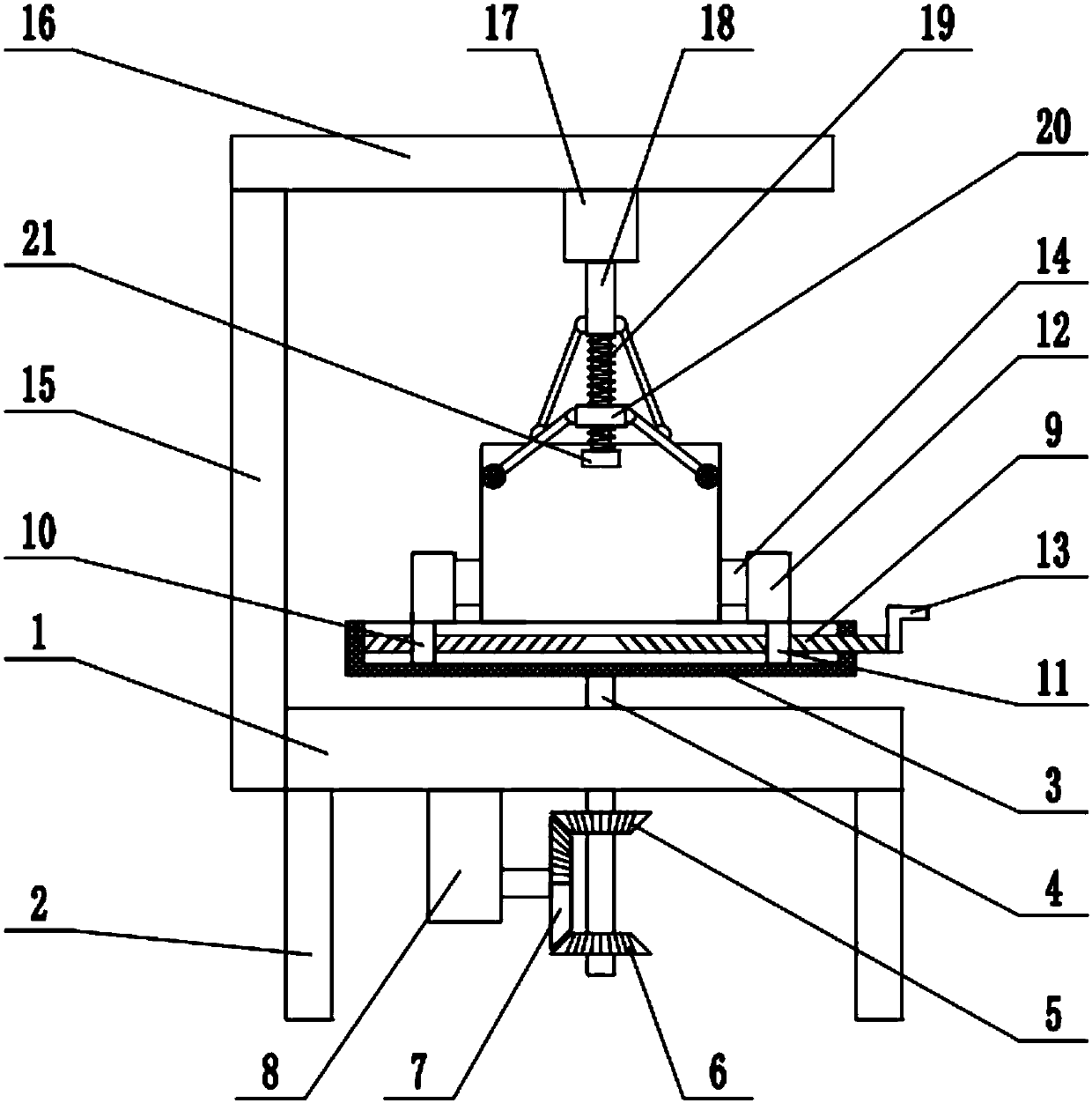

Oil drum rust removal device convenient to clamp

InactiveCN107855903AShorten the timeFast clamping speedGrinding carriagesGrinding machinesEngineeringThreaded rod

The invention discloses an oil drum rust removal device convenient to clamp. The device comprises a base, supporting legs, a rotary workbench, a clamping block, rust removal rods and rust removal balls. The rotary workbench is arranged above the base, the lower surface of the rotary workbench is fixedly connected with a rotary shaft, the lower surface of the base is fixedly connected with a motor,a supporting column is fixedly connected to the left end of the base, a top plate is fixedly connected to the top of the supporting column, a telescopic mechanism is fixedly connected to the lower surface of the top plate, a sleeve is fixedly connected to the lower end of the telescopic mechanism, a threaded rod is arranged in the sleeve and sleeved with a sleeve ring, and the rust removal rods are hinged to the left side and the right side of the sleeve ring. The clamping block is used for clamping an oil drum, the clamping speed is high, working efficiency is greatly improved, and time of workers is saved; the rust removal rods are adjusted to enable the rust removal balls to be in abutting connection with the inner wall of the oil drum so as to adapt to oil drums with different inner diameters, and the using range of the device is enlarged; and in the rust removal process, the rust removal balls are used for removing rust on the inner wall of the oil drum, and the rust removal efficiency is high.

Owner:邱杨舒

High throughput chemical mechanical polishing system

Owner:APPLIED MATERIALS INC

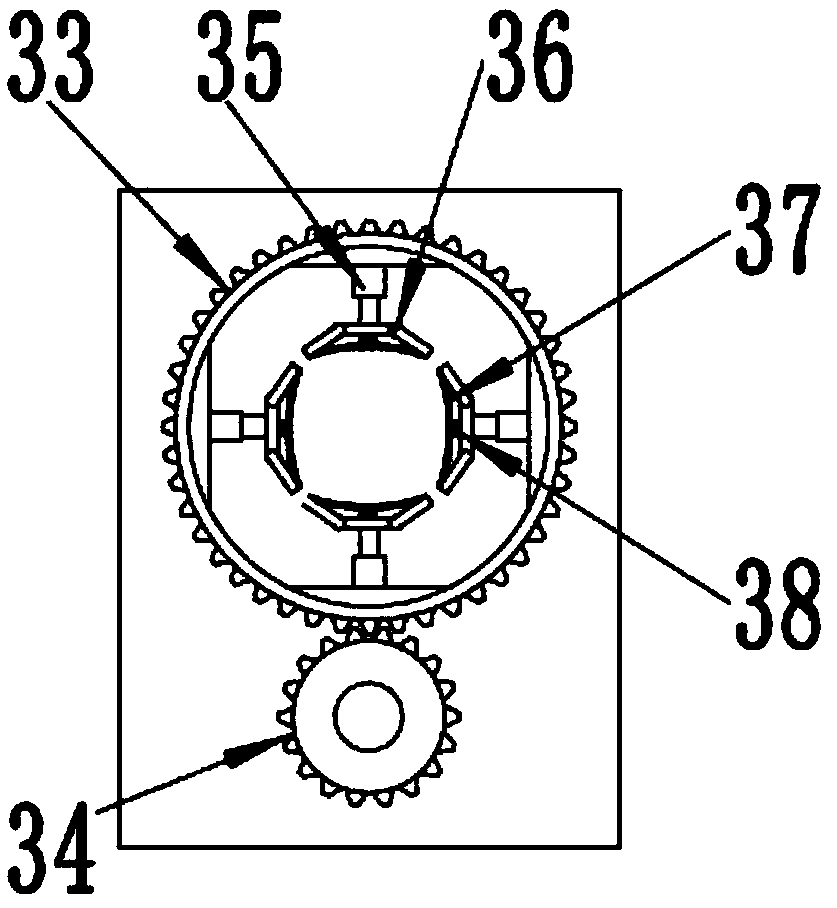

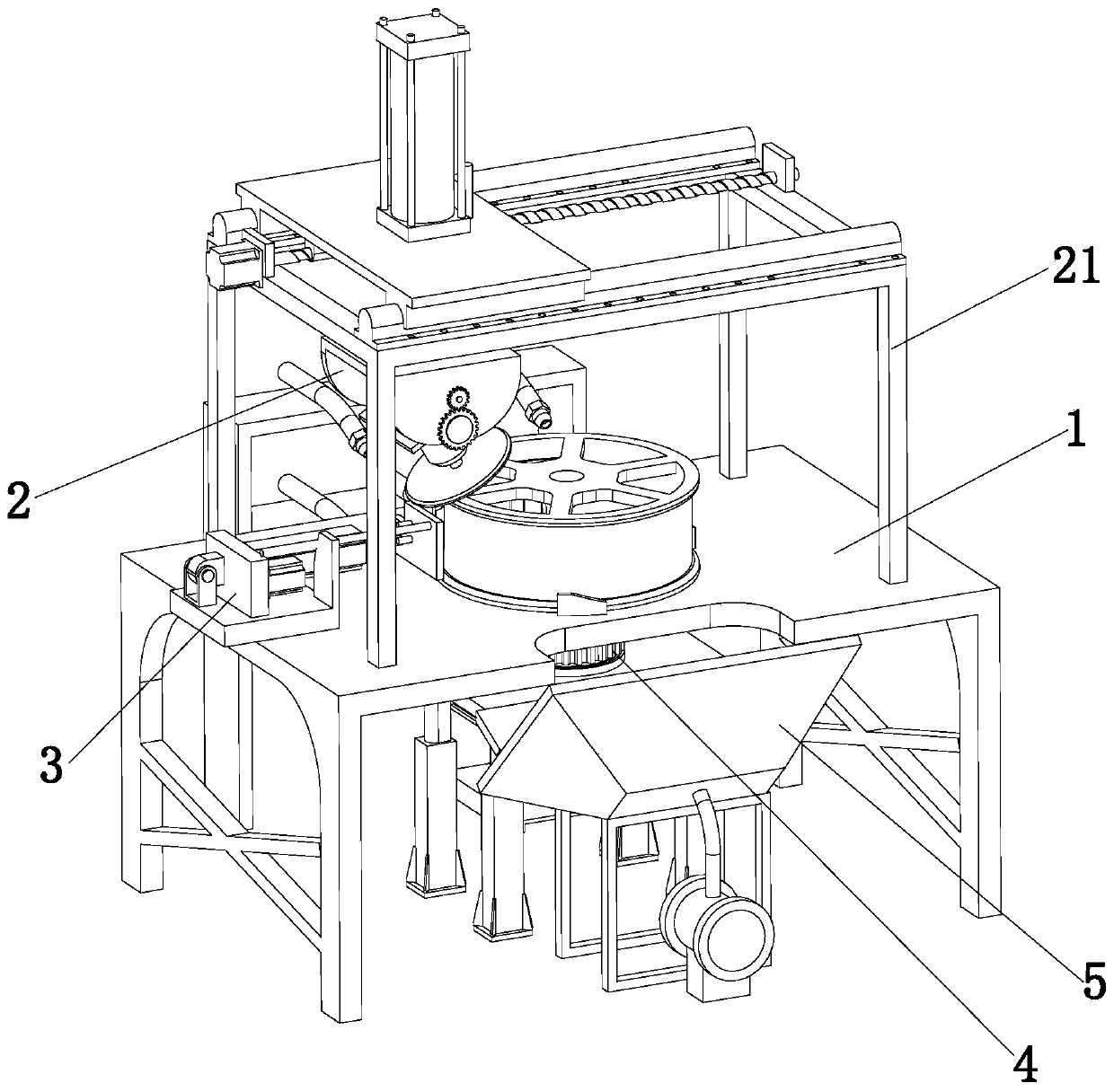

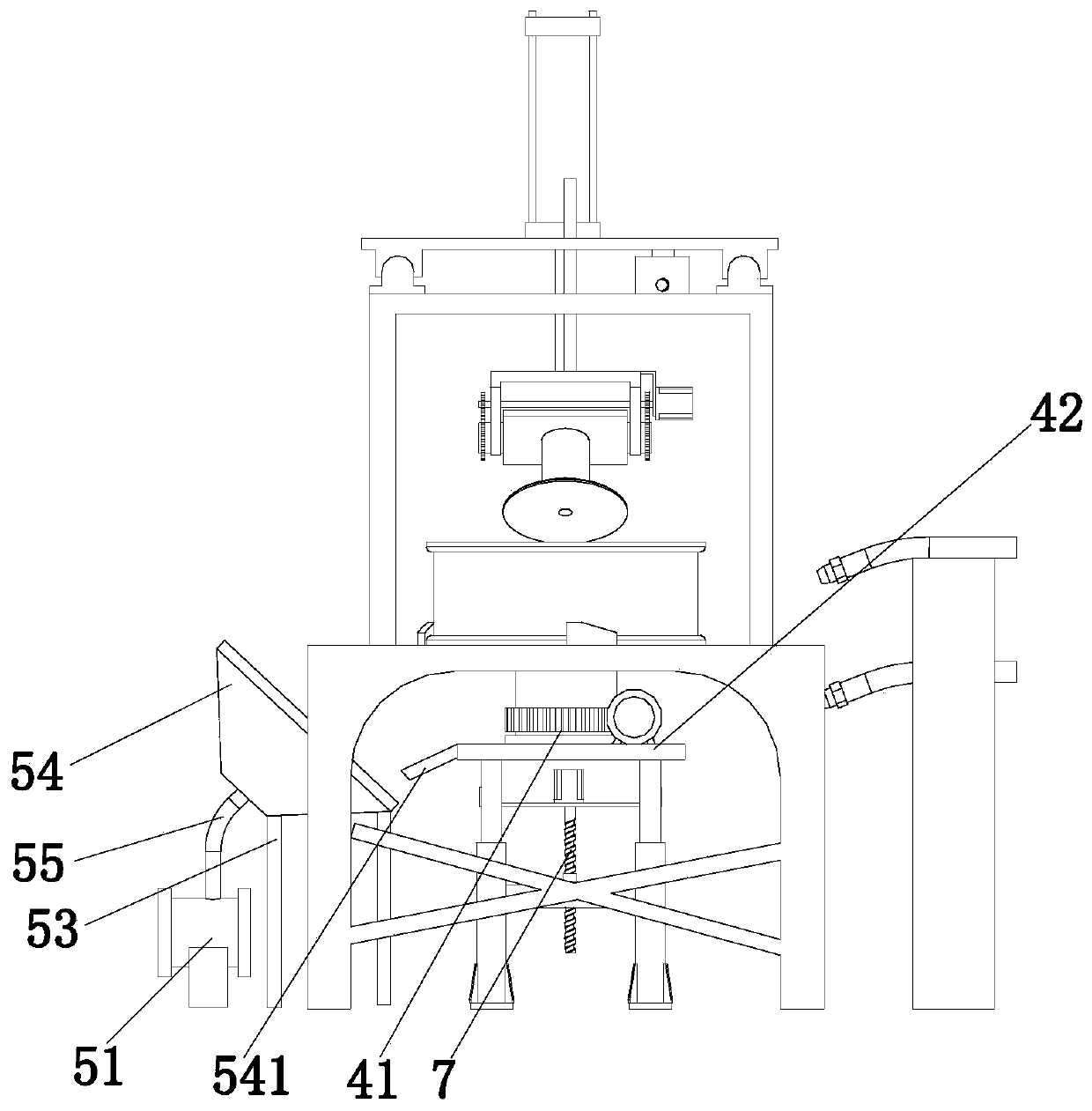

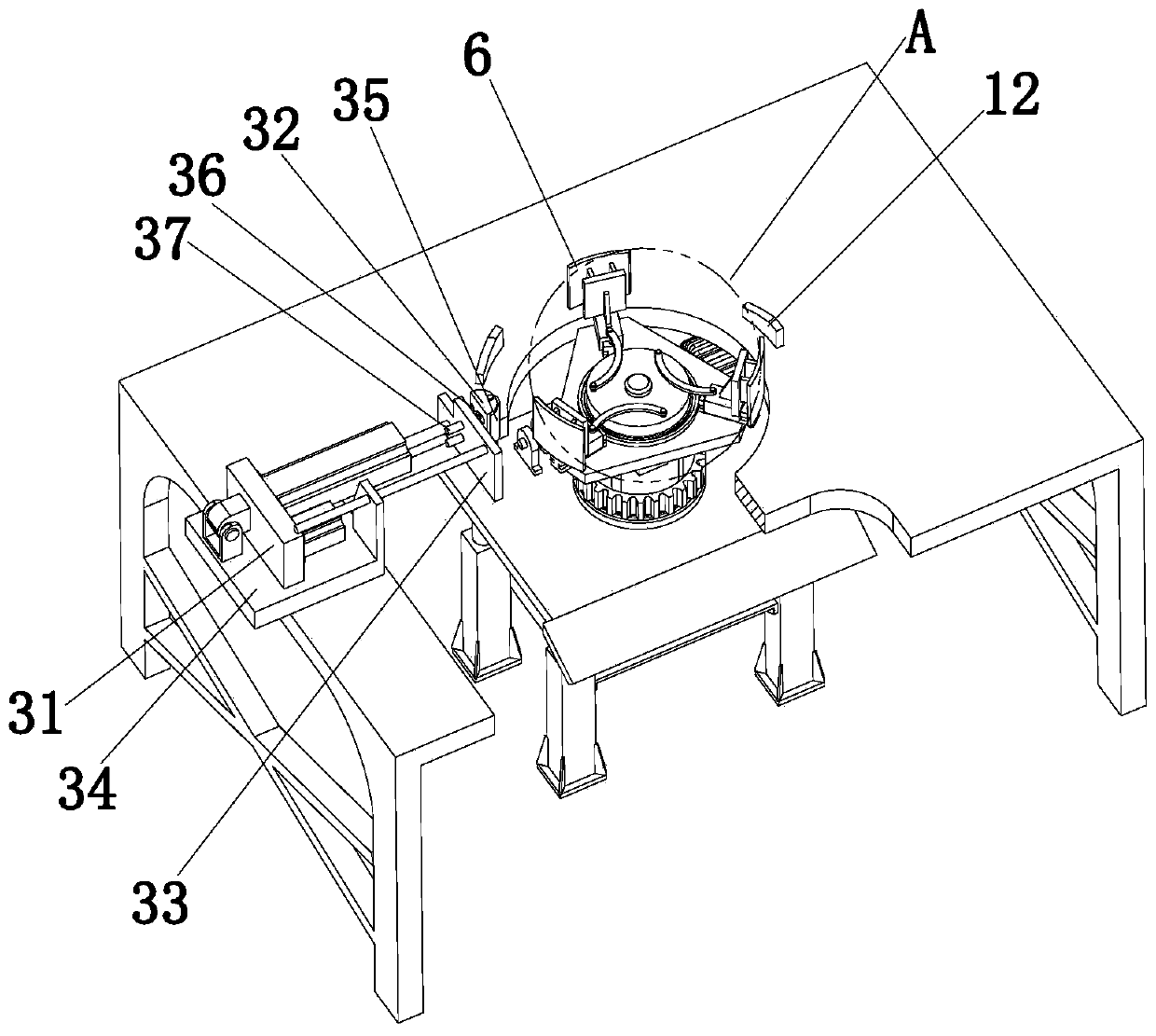

Polishing device for hub processing of new energy automobile

ActiveCN111230710ARealize polishing workRealize polishing and chamfering operationsEdge grinding machinesGrinding carriagesDrive wheelNew energy

The invention discloses a polishing device for hub processing of a new energy automobile, and relates to the technical field of automobile part processing. The polishing device comprises a worktable,a hub top polishing mechanism, a hub side polishing mechanism and a hub limiting rotation mechanism, wherein the hub top polishing mechanism is arranged above the worktable, the hub side polishing mechanism is arranged at the top of the worktable, and the hub limiting rotation mechanism is arranged below the worktable; the hub limiting rotation mechanism comprises a height adjustment assembly, a hub inner circle fixing assembly for clamping a hub inner circle and a rotating assembly for driving the hub to rotate, and a through hole is formed in the top of the worktable so that the hub inner circle fixing assembly can lift and pass through the through hole. According to the invention, the polishing device can clamp the hub inner circle and drive the hub to rotate under the action of the hublimiting rotation mechanism, the angle adjustment of a grinding wheel can be realized through the hub side polishing mechanism, and then polishing chamfering operation on the top surface of the hub is realized.

Owner:山东荣升重型机械股份有限公司

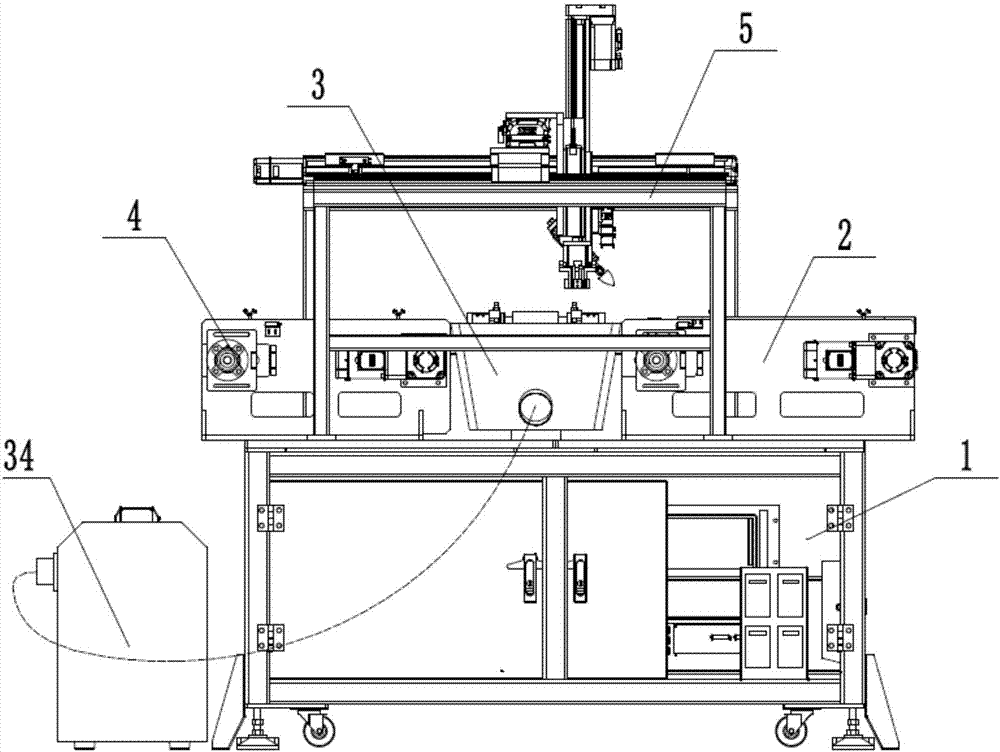

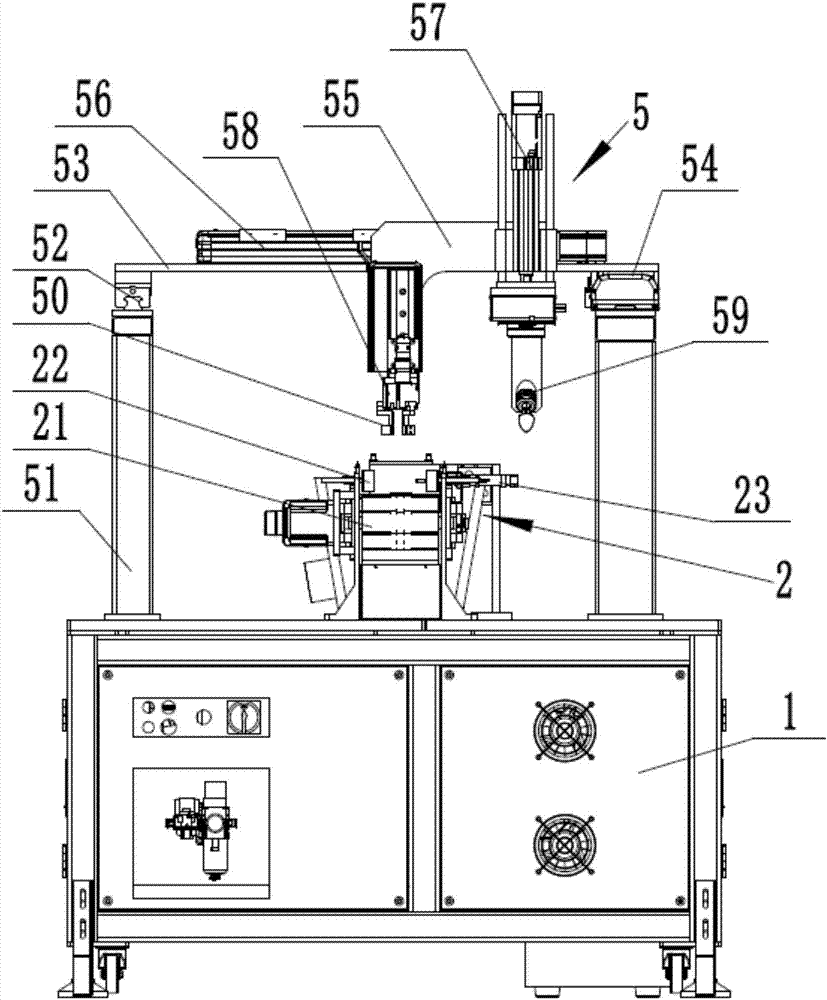

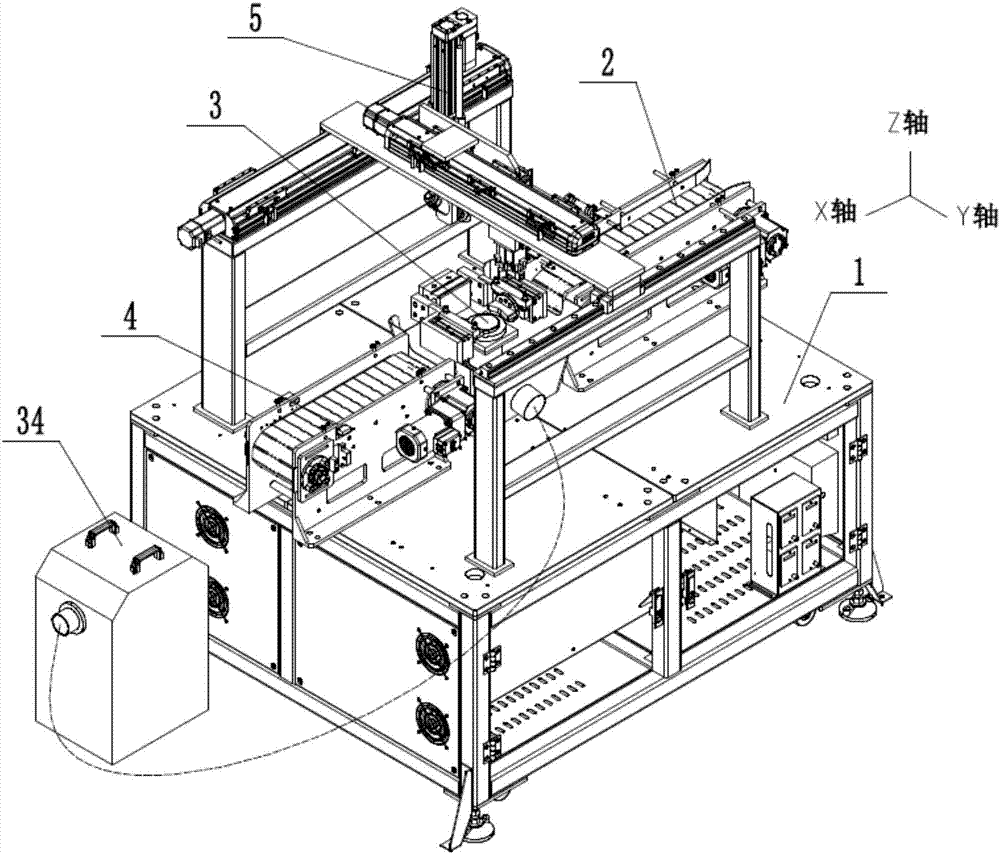

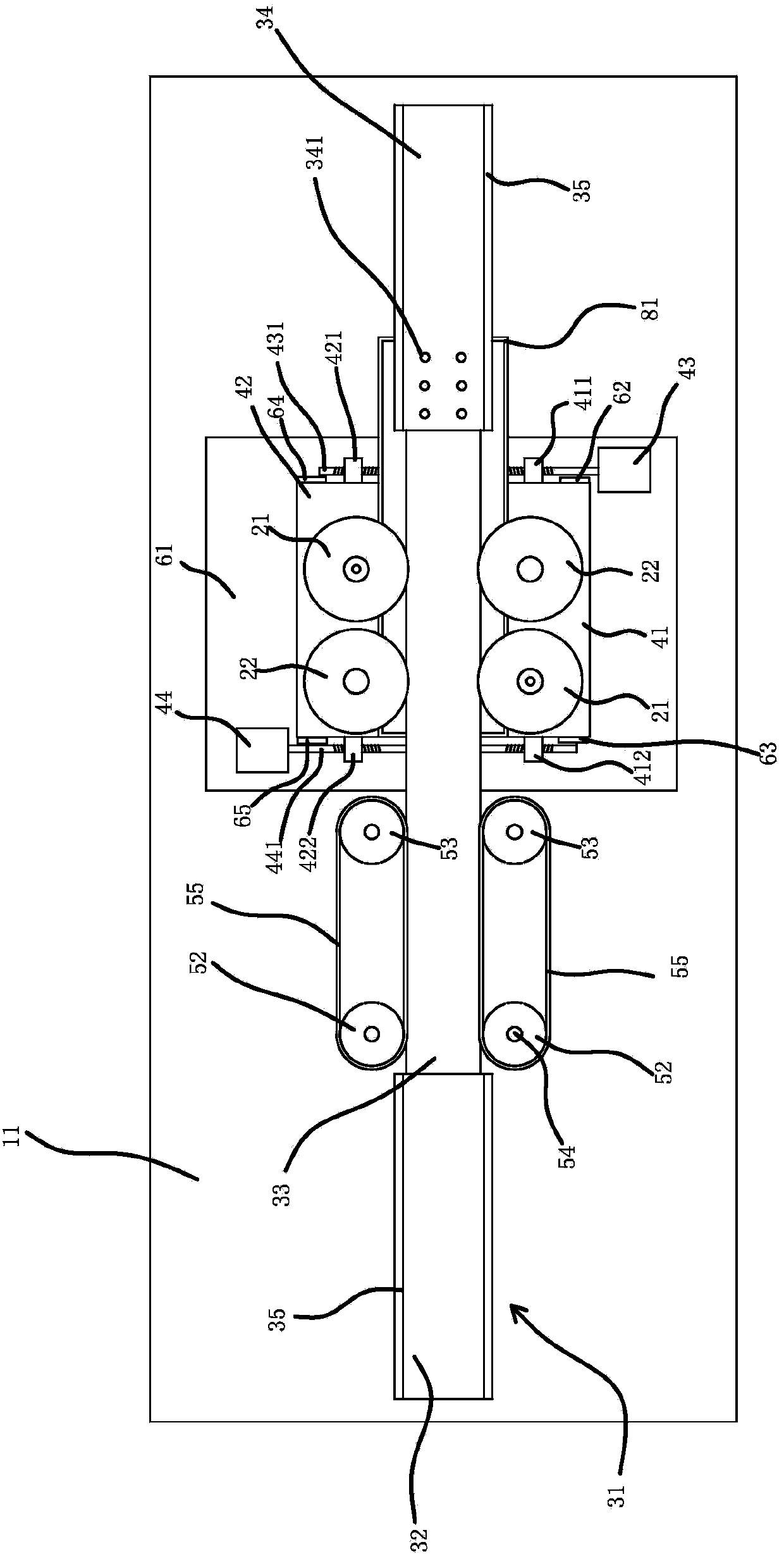

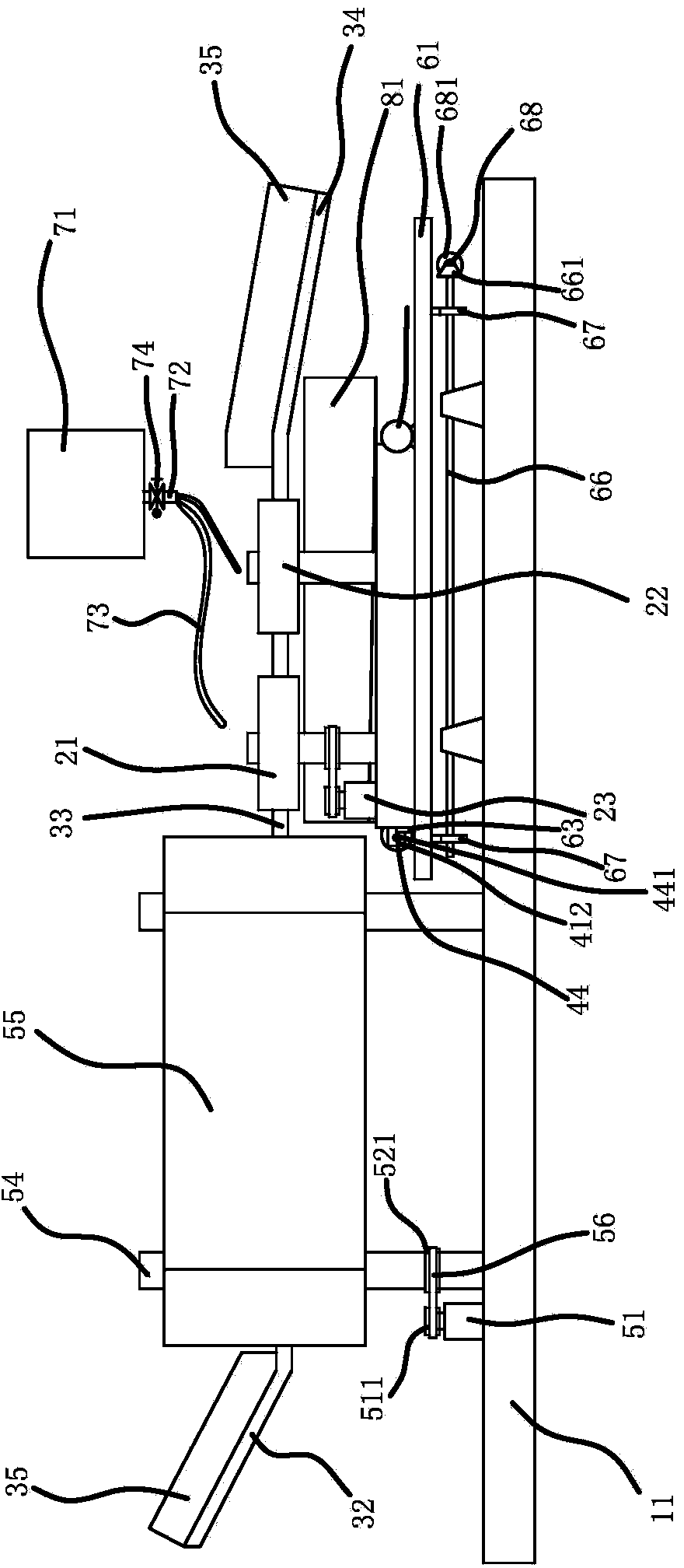

Automobile hub double-face full-automatic polishing production line

InactiveCN108000273AAccurate capturePrecise positioningEdge grinding machinesGrinding carriagesProduction lineManipulator

The invention discloses an automobile hub double-face full-automatic polishing production line which comprises a rack and a polishing mechanism. The rack is sequentially provided with a feeding mechanism, a hub polishing rotary table and a discharging mechanism, the polishing mechanism is located above the polishing mechanism, and the characteristics are that the feeding mechanism comprises a first chain plate conveyor, two guide plates and a stopping air cylinder; the hub polishing rotary table comprises a grinding collecting box, a hub polishing jacking table and an overturning tool; the overturning tool comprises a vertical plate, a wide type gas claw, two clamping connecting plates, two rotary air cylinders and two clamping blocks; the polishing mechanism comprises a support, an X-axisguide rail, an X-axis sliding base, a Y-axis sliding base, an X-axis electric cylinder, a Y-axis electric cylinder, a Z-axis electric cylinder, a Z-axis stretchable cylinder, an electric polishing head and a carrying mechanical arm; and the discharging mechanism at least comprises a second chain plate conveyor. The automobile hub double-face full-automatic polishing production line is used for automobile hub full-automatic polishing production, the front and back faces of a hub can be switched at will, and the reliability and the stability can be improved.

Owner:李茂菊

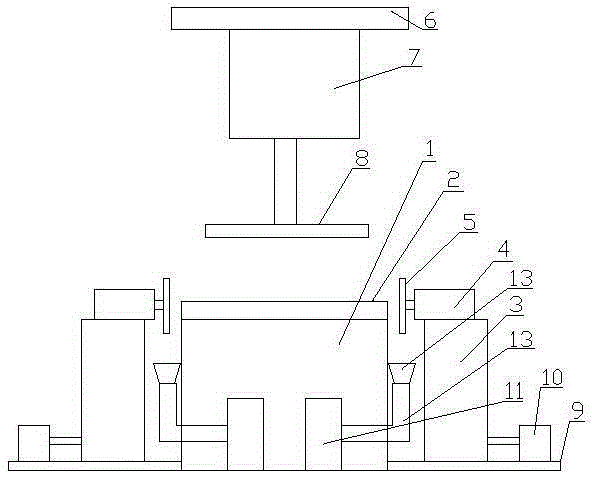

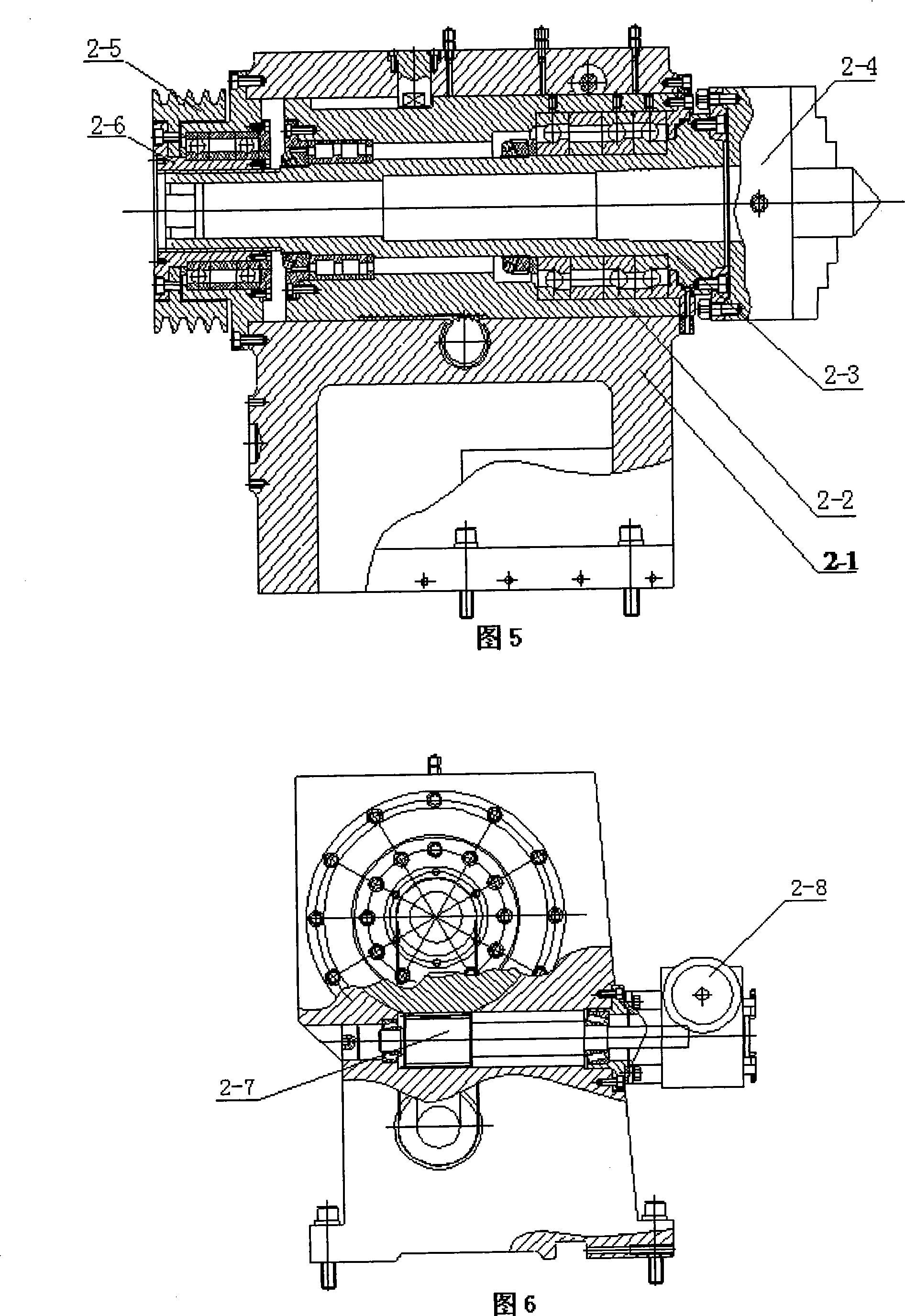

Polishing machine for outer ring end faces of bearings

ActiveCN103737439AAchieve grindingPrecise control of displacementEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention provides a polishing machine for the outer ring end faces of bearings, and belongs to the technical field of machines. The polishing machine solves the technical problems that an exiting polishing machine cannot meet the machining requirement of the bearings in different types, and the application scope is limited. The polishing machine for the outer ring end faces of the bearings comprises a machine frame, a polishing abrasion wheel and a guide rail, the guide rail is fixed on the machine frame, a first installation plate and a second installation plate are connected to the machine frame in a sliding mode, and the polishing abrasion wheel is respectively connected to the first installation plate and the second installation plate in a rotary mode. A first adjusting block and a second adjusting block are fixed on the first installation plate, a third adjusting block and a fourth adjusting block are fixed on the second installation plate, a first adjusting motor and a second adjusting motor are fixed on the machine frame, a first lead screw is fixed on the first adjusting motor and penetrates through the first adjusting block and the third adjusting block, a second lead screw is fixed on the second adjusting motor and penetrates through the second adjusting block and the fourth adjusting block, and a feeding device is further arranged between the polishing abrasion wheel and the feeding guide rail. The polishing machine has the advantages that the bearings in the different types can be polished.

Owner:HAINING QI SHENG BEARING

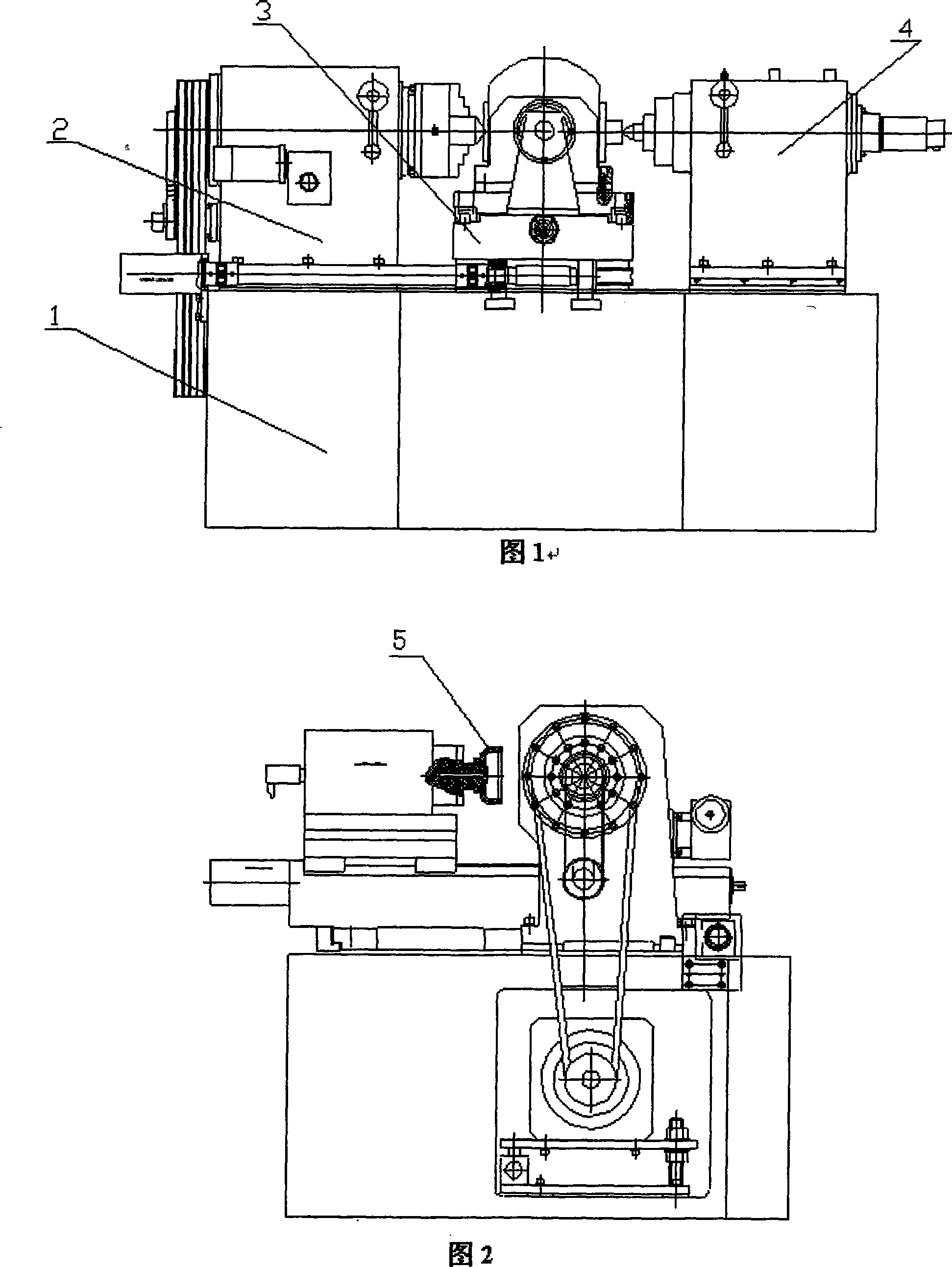

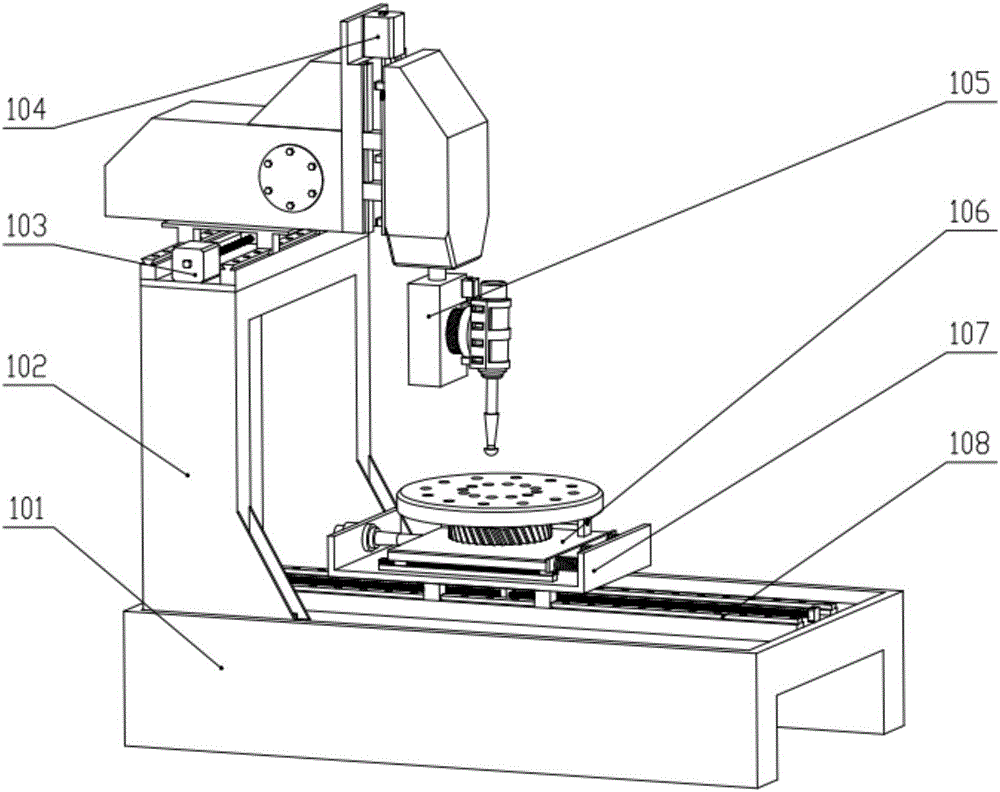

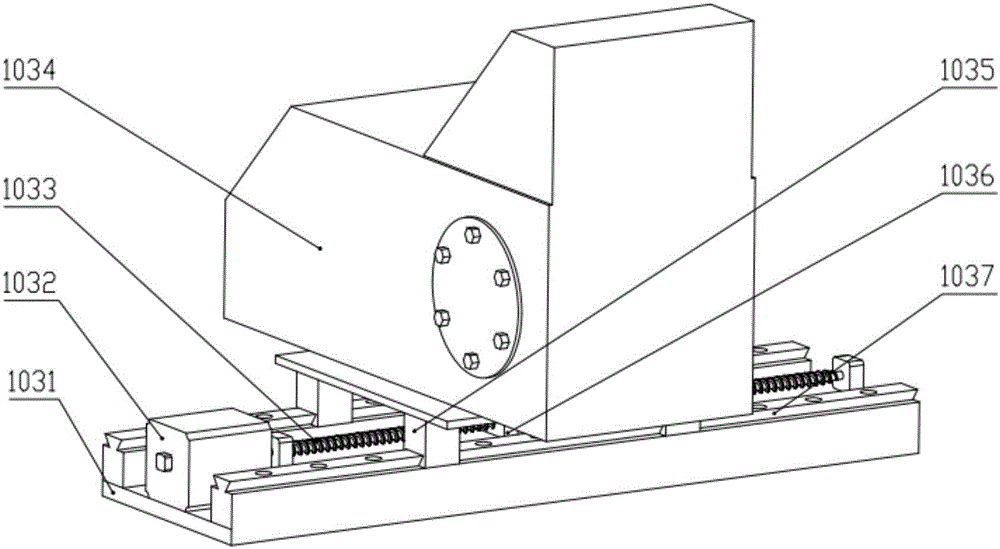

High-rigidity turning spherical surface numerical control accurate grinding equipment

InactiveCN101172330AFast precision grindingRapid grindingGrinding carriagesSpherical surface grinding machinesNumerical controlMotor drive

The invention relates to a rotating spherical surface numerically controlled accurate grinding equipment with high hardness. The equipment comprises a bed body part, a main spindle box part, a wheel stand rotating table part, a tail seat part and a grinding wheel. The main spindle box part and the tail seat part are fixed on the bed body through a bolt; the wheel stand rotating table part is supported on a circular arc guide rail and a circular ring guide rail, a winding and fixed axle moves to and fro through a worm rod and a sector worm wheel under the driving of an actuating motor; the actuating motor drives a wheel stand slide seat to do direct feed motion on the guide rail on the wheel stand rotating table through a feed screw nut pair; the grinding wheel composed of a grinding wheel disc and a grinding wheel block is directly connected with an electric principal axis through a connecting shaft, thereby the propose that the grinding wheel with diameter is used for grinding a rotating spherical surface work piece with high hardness and different diameters though the high speed rotation movement of the grinding wheel, the rotation movement of the rotating spherical surface work piece, the feed movement of the grinding wheel stand and the reciprocating motion of the grinding wheel stand.

Owner:SHANGHAI JIAO TONG UNIV

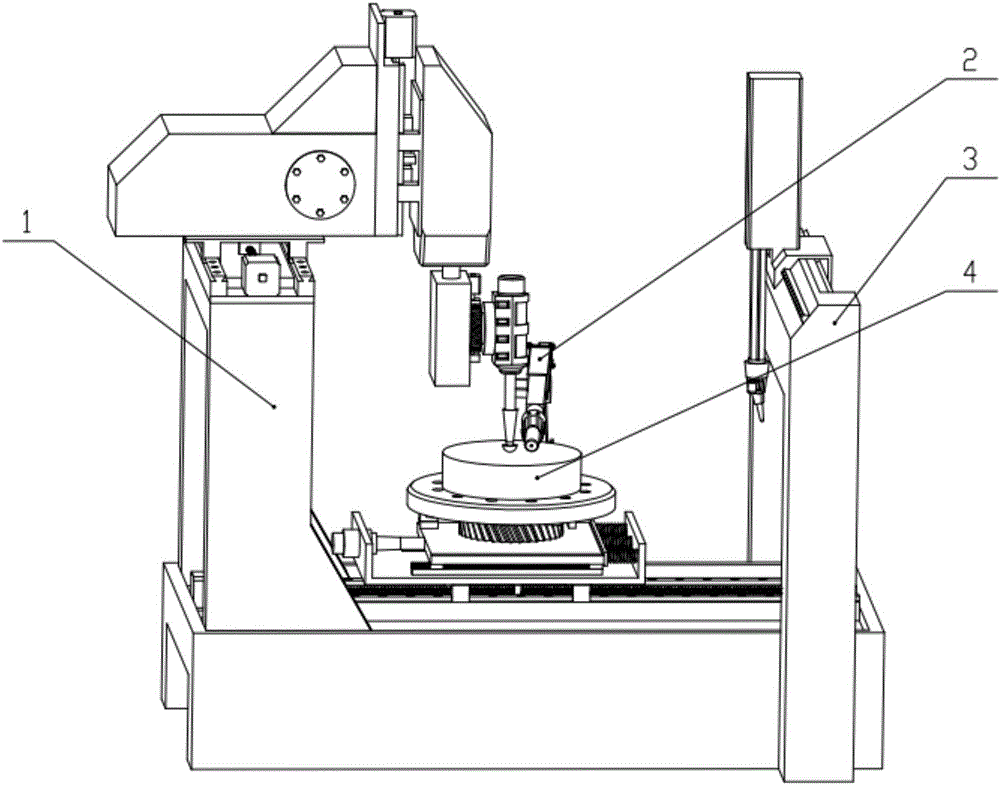

Five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining and use method of five-axis three-dimensional ultrasonic polishing machine tool

ActiveCN106736992AGood removal effectImprove efficiencyGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

The invention discloses a five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining. The five-axis three-dimensional ultrasonic polishing machine tool comprises a machine tool, an ultrasonic atomization device for applying polishing liquid and a workpiece on-line detection device. An X-direction travel mechanism, a Z-direction travel mechanism and a Y-direction travel mechanism are arranged on the machine tool; a spindle ultrasonic vibration polishing device is arranged on the Z-direction travel mechanism; a Y-direction ultrasonic vibration device is arranged on the Y-direction travel mechanism; a C-direction rotating work table is arranged on the Y-direction ultrasonic vibration device; the machine tool can enable the axis line direction of a polishing head parallel to the normal line of a polishing point of a workpiece through five-axis linkage; when the polishing head rotates, the ultrasonic wave of the Y-direction ultrasonic vibration device and the ultrasonic wave of the ultrasonic vibration polishing device which swings around the Z direction are vertically coupled in a plane; when the amplitude A1 of the Y-direction ultrasonic vibration device is greater than the amplitude A2 of the ultrasonic vibration polishing device, the polishing head and the workpiece can form an elliptic machining track where a long axis is in the Y-direction and a short axis is in the normal line position of the polishing point of the workpiece, so that the contact area between the polishing head and the workpiece is increased, and the curved surface removal rate and the polishing machining efficiency can be greatly improved.

Owner:NORTHEASTERN UNIV

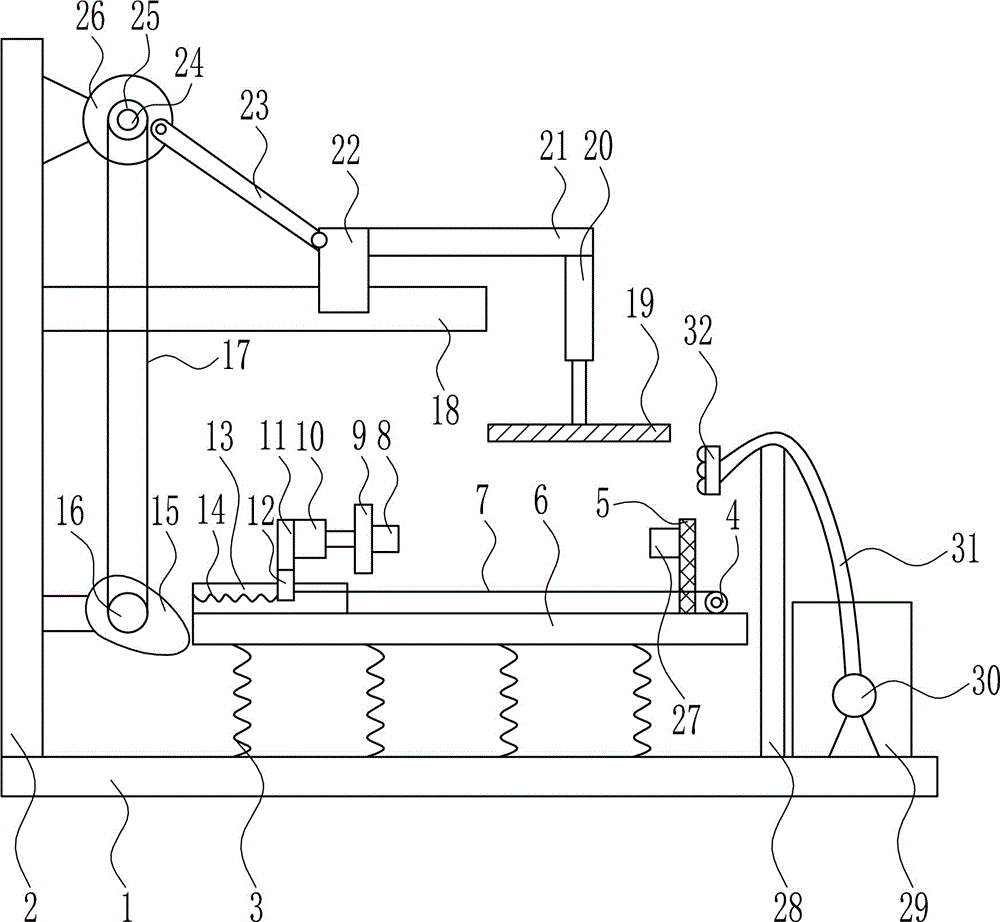

Rapid steel tube surface derusting device

ActiveCN106475881AReduce the temperatureReduce heat lossGrinding carriagesGrinding drivesMaterials scienceSteel tube

The invention relates to a steel tube surface derusting device, in particularly to a rapid steel tube surface derusting device, and aims at solving the technical problem of providing a steel tube surface derusting device which can remove rust thoroughly and is high in derusting efficiency and low in manufacturing cost. In order to solve the above-mentioned technical problem, the steel tube surface derusting device is provided and comprises a base plate, a left side plate, first springs, an electric winding wheel, a bearing base, an object placing plate, a pull wire, a first fixing block, a connecting plate, a first motor, a vertical plate, a first sliding block and the like, wherein the first springs are located on the right of the left side plate, the object placing plate is arranged on the tops of the first springs, a first sliding rail, the bearing base and the electric winding wheel are sequentially arranged on the object placing plate from left to right, the first sliding block is connected to the first sliding rail in a sliding mode, and a second spring is connected between the left side face of the bottom of the first sliding block and the inner left side of the first sliding rail. According to the rapid steel tube surface derusting device, the effects of being capable of removing the rust thoroughly, high in derusting efficiency and low in manufacturing cost are achieved.

Owner:扬州八方冷拉型钢有限公司

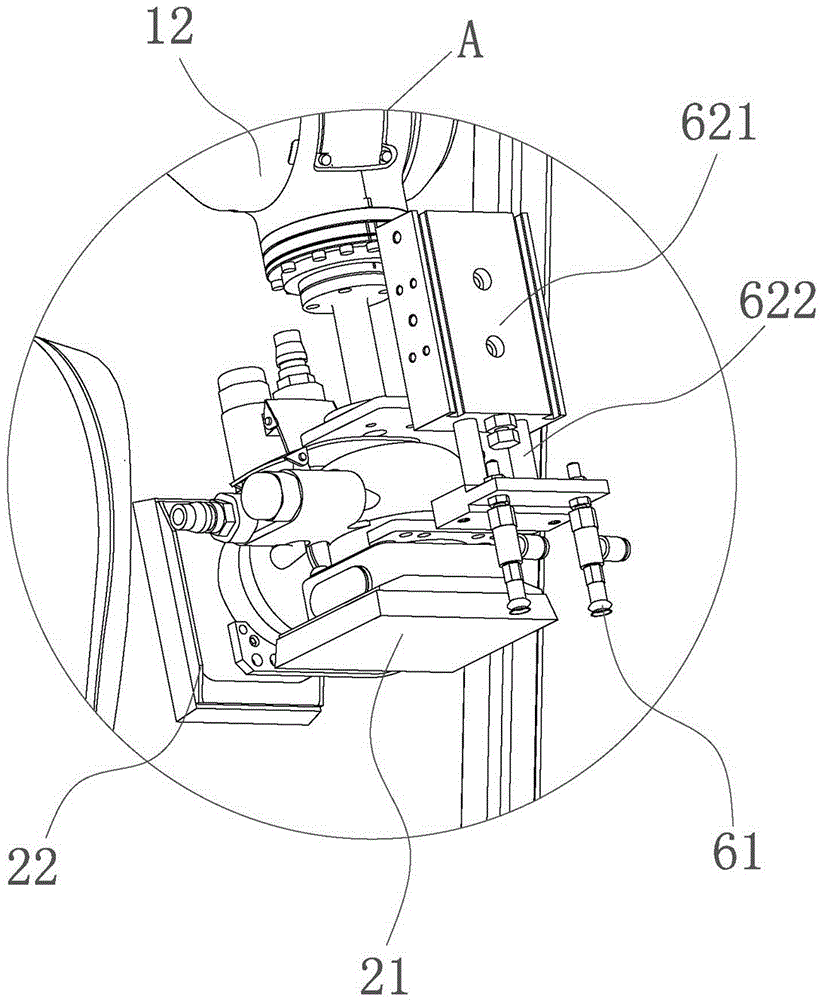

Manipulator grinding system

ActiveCN105666275AVersatileCompact structureEdge grinding machinesGrinding carriagesEngineeringManipulator

The invention relates to the technical field of grinding, and in particular relates to a manipulator grinding system. The manipulator grinding system comprises a grinding robot device and a conveying belt, wherein the grinding robot device comprises a mechanical arm, a grinding tool mounted at the tail end of the mechanical arm, and a grinding bench for fixing a product; the grinding tool comprises a first grinding tool and a second grinding tool; the mechanical arm is provided with a first mounting part and a second mounting part which are arranged in a certain angle; the first grinding tool is mounted at the first mounting part, and the second grinding tool is mounted at the second mounting part; the conveying belt comprises a first conveying belt and a second conveying belt which run oppositely and are arranged up and down; a stop mechanism for stopping the product is arranged on the second conveying belt; and a transplanting mechanism for catching the product from the second conveying belt to the grinding bench is arranged on the conveying belt. Compared with the prior art, the manipulator grinding system disclosed by the invention has complete functions and is compact in structure and higher in automation degree.

Owner:GUANGDONG TOPSTAR TECH

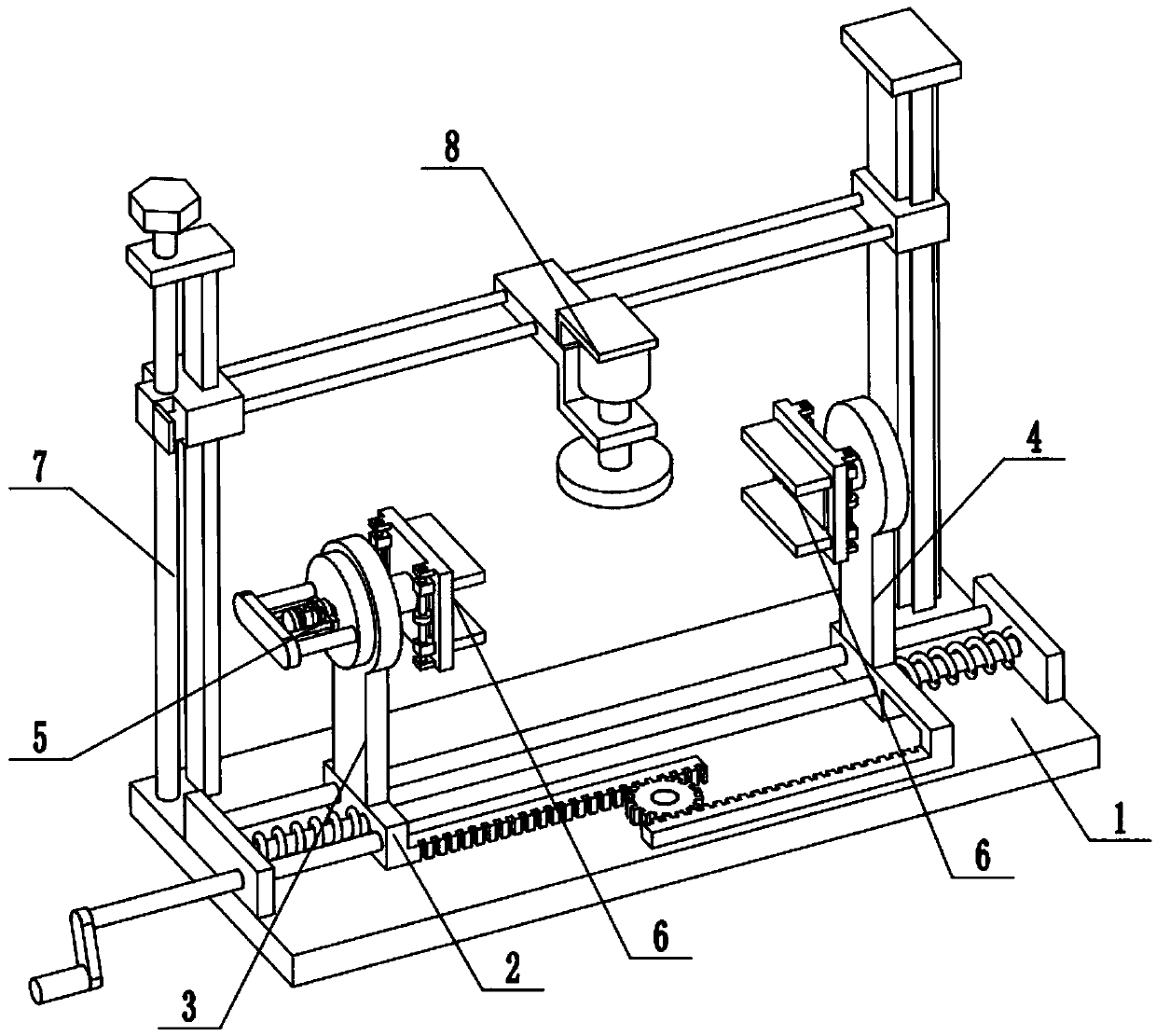

Multi-degree-of-freedom machining and grinding device

The invention discloses a multi-degree-of-freedom mechanical processing and grinding device, which includes a frame, a grinding motor and a grinding wheel. The frame is provided with a lifting outer frame for driving the grinding motor to move up and down, and the two sides of the lifting outer frame are fixedly installed. Sliding sleeve, the inside of the sliding sleeve is provided with a lead screw that forms a helical pair with it, and the tops of the two lead screws pass through the top plate of the frame, and one of the lead screws is connected with the lifting motor fixed on the top plate of the frame The output shaft of the lifting motor is connected through a coupling, and the output shaft of the lifting motor is also fixedly equipped with a driving pulley, and the driving pulley is connected to the fixed driven pulley on another lead screw through a belt. The beneficial effects of the present invention are: Due to the provided lifting motor, grinding motor and traverse motor, the grinding wheel has three degrees of freedom, that is, left and right movement, up and down movement and rotation, which can be adjusted conveniently so as to perform grinding operations on workpieces.

Owner:刘云海

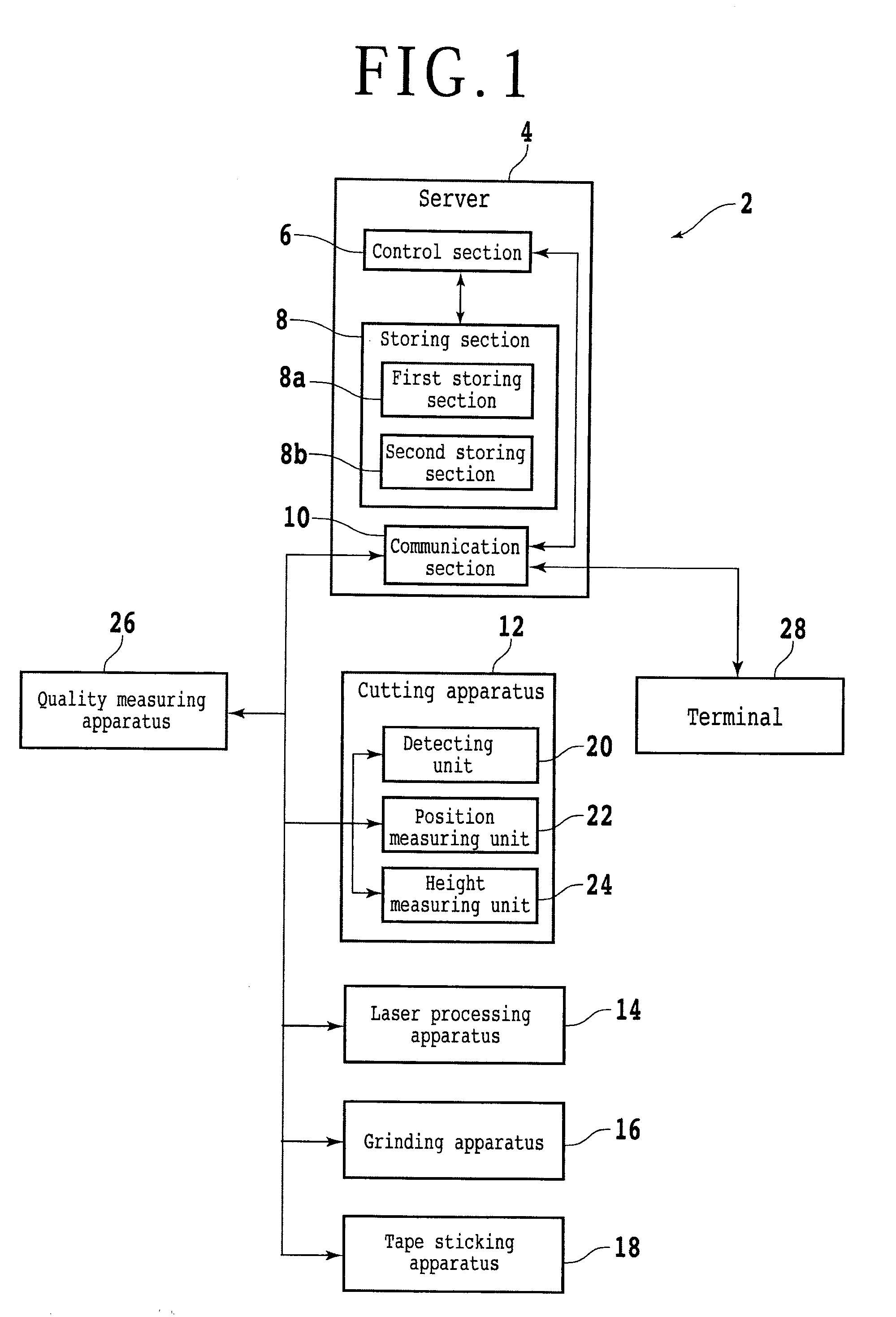

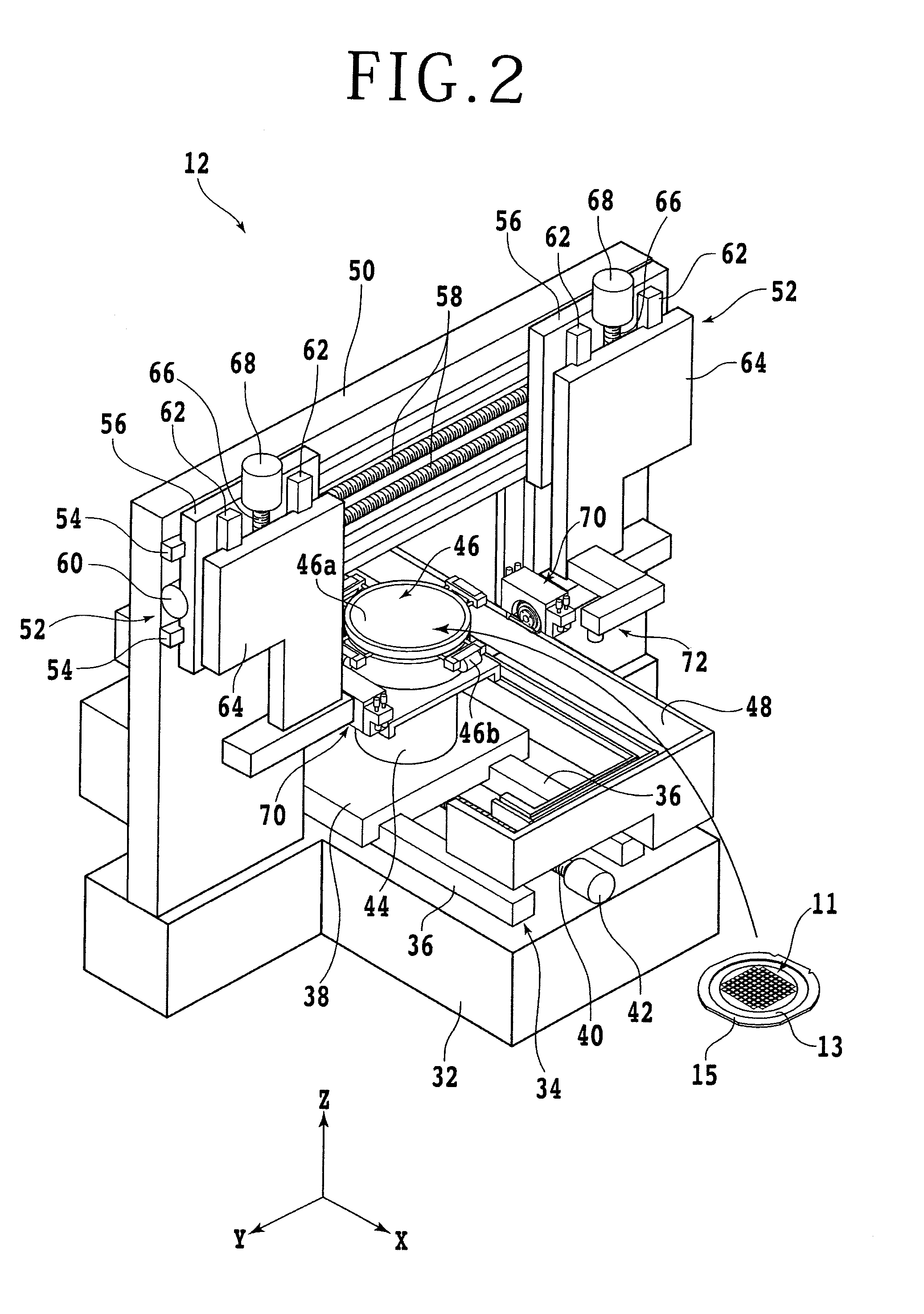

Processing system

ActiveUS20160346956A1Avoid it happening againGrinding carriagesSemiconductor/solid-state device testing/measurementEngineeringTreatment system

There is provided a processing system including a processing apparatus having functional units including a holding unit that holds a workpiece by a holding surface, a processing unit that processes the workpiece held by the holding unit, and a feed unit that moves the holding unit and the processing unit relatively. The processing system further includes a detecting unit that is provided for part or all of the functional units and detects any of vibration, current, voltage, load, speed, torque, pressure, temperature, flow rate, change in a taken image, and the thickness of the workpiece, and a data accumulating unit that accumulates information included in a signal output from the detecting unit as data.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com