Impurity removal cleaning machine for sesame

A washing machine and sesame technology, which is applied in the direction of solid separation, separating solids from solids with airflow, food processing, etc., can solve the problems of unstable cleaning quality, many processes, and low work efficiency of sesame cleaning, and achieve cleaning and removal Miscellaneous effects are good, the process is simple, and the design is reasonable and ingenious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

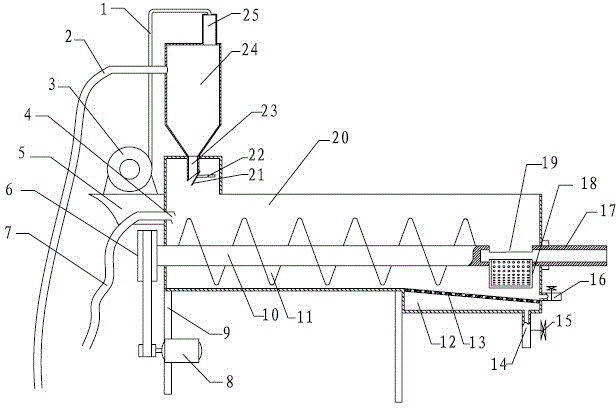

[0014] The specific structure and principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] As shown in the figure, a sesame cleaning machine for removing impurities of the present invention is characterized in that it has a cleaning tank, a storage bin is installed above the front end of the cleaning tank, and a cleaning bucket is installed on the top of the cleaning tank. There is also a support on which a fan is installed. The air inlet of the fan is connected to the top of the miscellaneous bucket through a pipe, and the feed pipe is connected to the upper part of the storage bin. The lower part of the storage bin is in an inverted cone shape. Discharge pipe, the angle between the plane where the discharge port of the discharge pipe is located and the axis of the discharge pipe is less than 90 degrees, the discharge port is equipped with a movable cover plate, and the cleaning tank is equipped with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com