Wandering star wheel

A technology of star wheel and sub-wheel, which is applied in the field of grinding vehicles after sapphire slicing, can solve the problems of high cost, easy broken pieces, and many defects, and achieve the effects of reducing grinding costs, uniform grinding operations, and ingenious and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

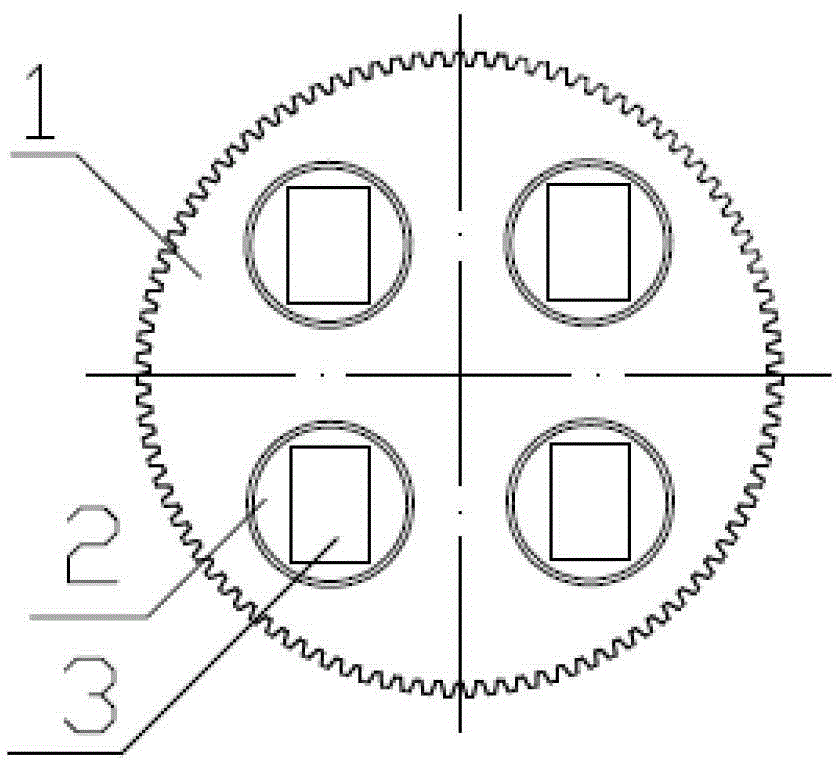

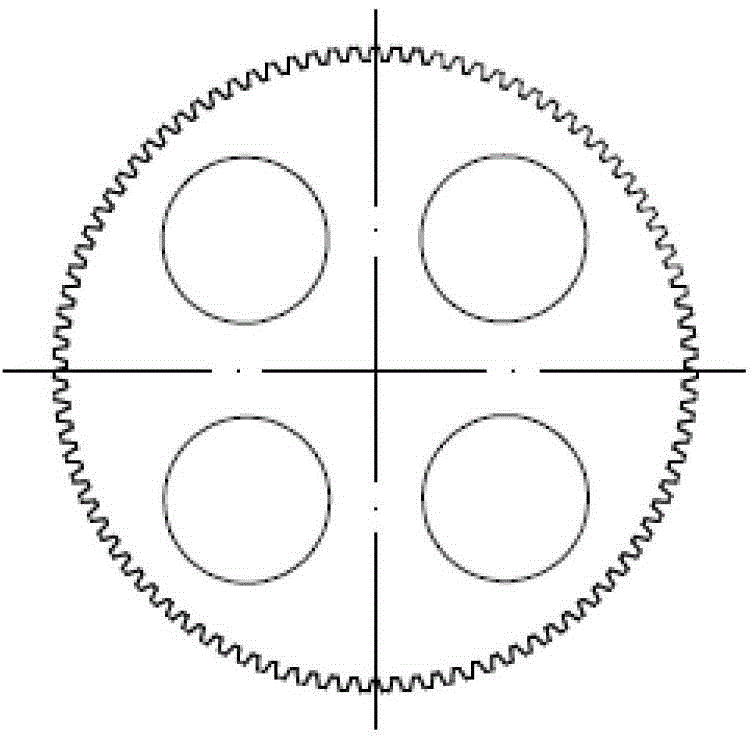

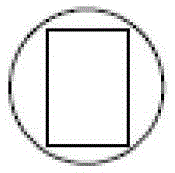

[0010] As shown in the figure, a planetary wheel of the present invention is suitable for grinding non-standard pieces of sapphire. The planetary wheel includes two parts, the main wheel 1 and the child wheel 2. The main wheel 1 rotates with the grinding equipment, and drives the sub-wheel 2 to rotate and revolve during the rotation. Preferably, the master wheel 1 is made of blue steel with good wear resistance, and the sub-wheel 2 is made of relatively cheap plastic fiber because there are many types of workpieces. During the grinding operation, first put the main wheel 1 into the grinding equipment as required, then put the sub-wheel 2 into the main wheel 1, and finally put the LED workpiece 3 to be processed into the sub-wheel 2. During the grinding process, the workpiece 3 will rotate and revolve correspondingly with the rotation and revolution of the sub-wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com