Rotational flow stopping block type pulverized coal concentrator

A concentrator and block-type technology, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems of large flow resistance, serious wear, and low concentration rate, achieve high-efficiency and low-pollution combustion, improve The effect of concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

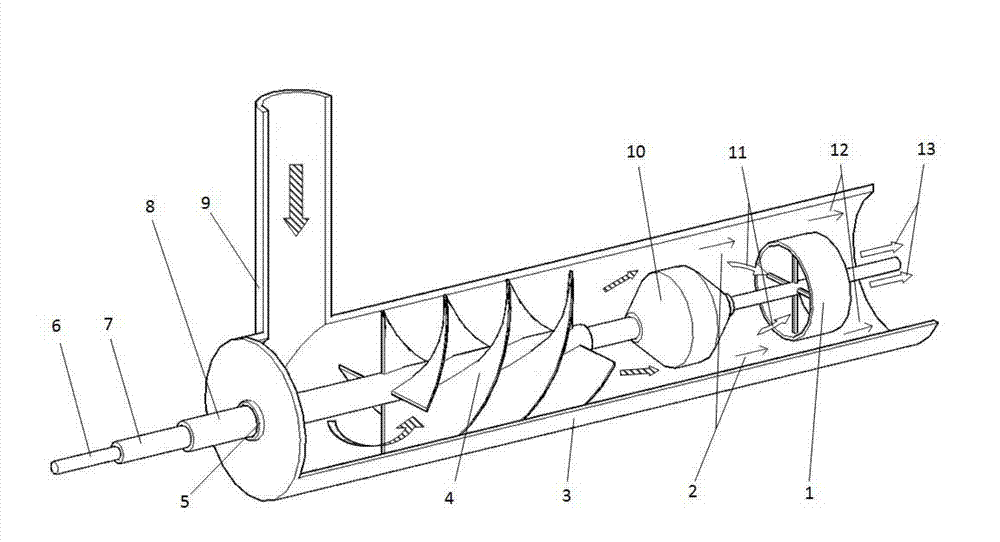

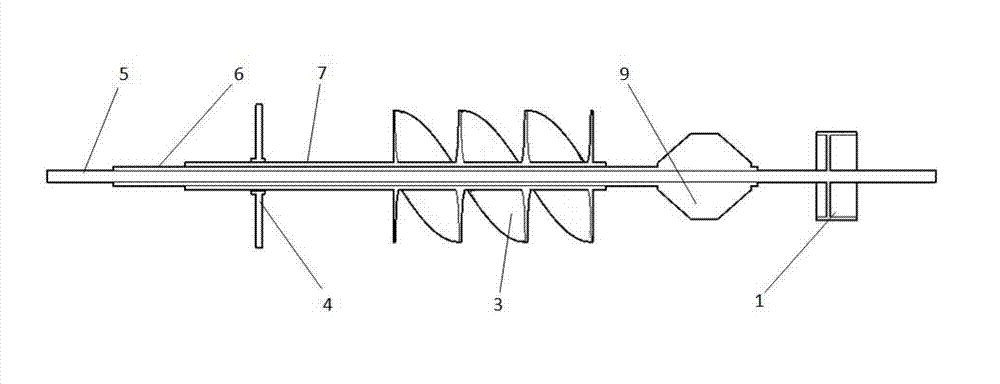

[0019] Such as figure 1 , figure 2 with image 3 As shown, a swirling block type pulverized coal concentrator includes a cylinder body 3, a tangential air intake channel 9, a swirling blade 4, a double cone block 10, a diversion block ring 1, a bearing 5, and an inner primary air channel 13. The outer primary air channel 12, the tangential air intake channel 9 is vertically connected to one end of the cylinder 3, the cylinder 3 is provided with a bearing 5 passing through the cylinder 3 in the axial direction, and the bearing 5 Along the flow direction of the pulverized coal airflow, there are rotating blades 4, double-cone stoppers 10, and diversion retaining rings 1 in sequence. The rotation occurs, and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com