Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

306results about How to "Reduce fugitive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

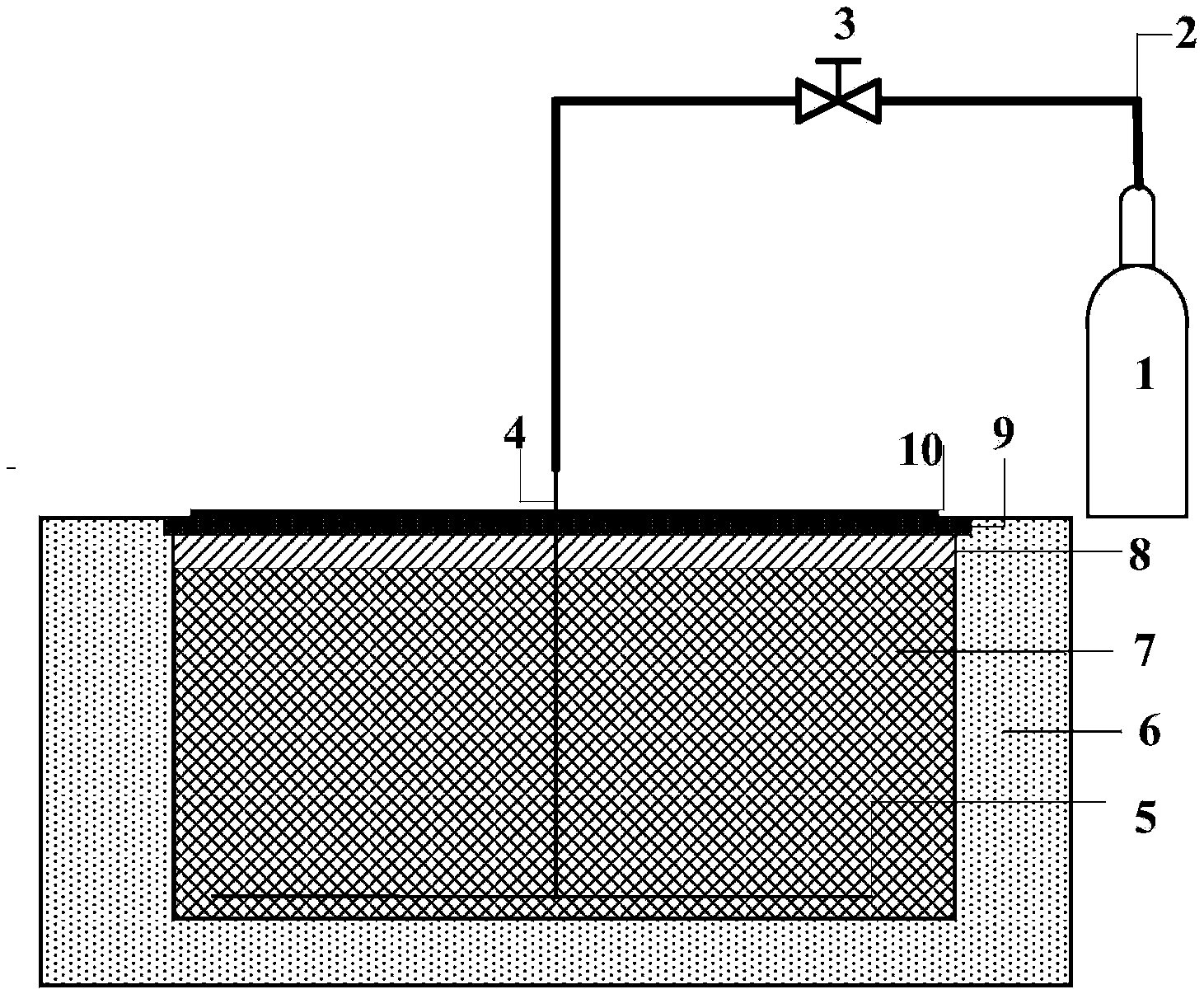

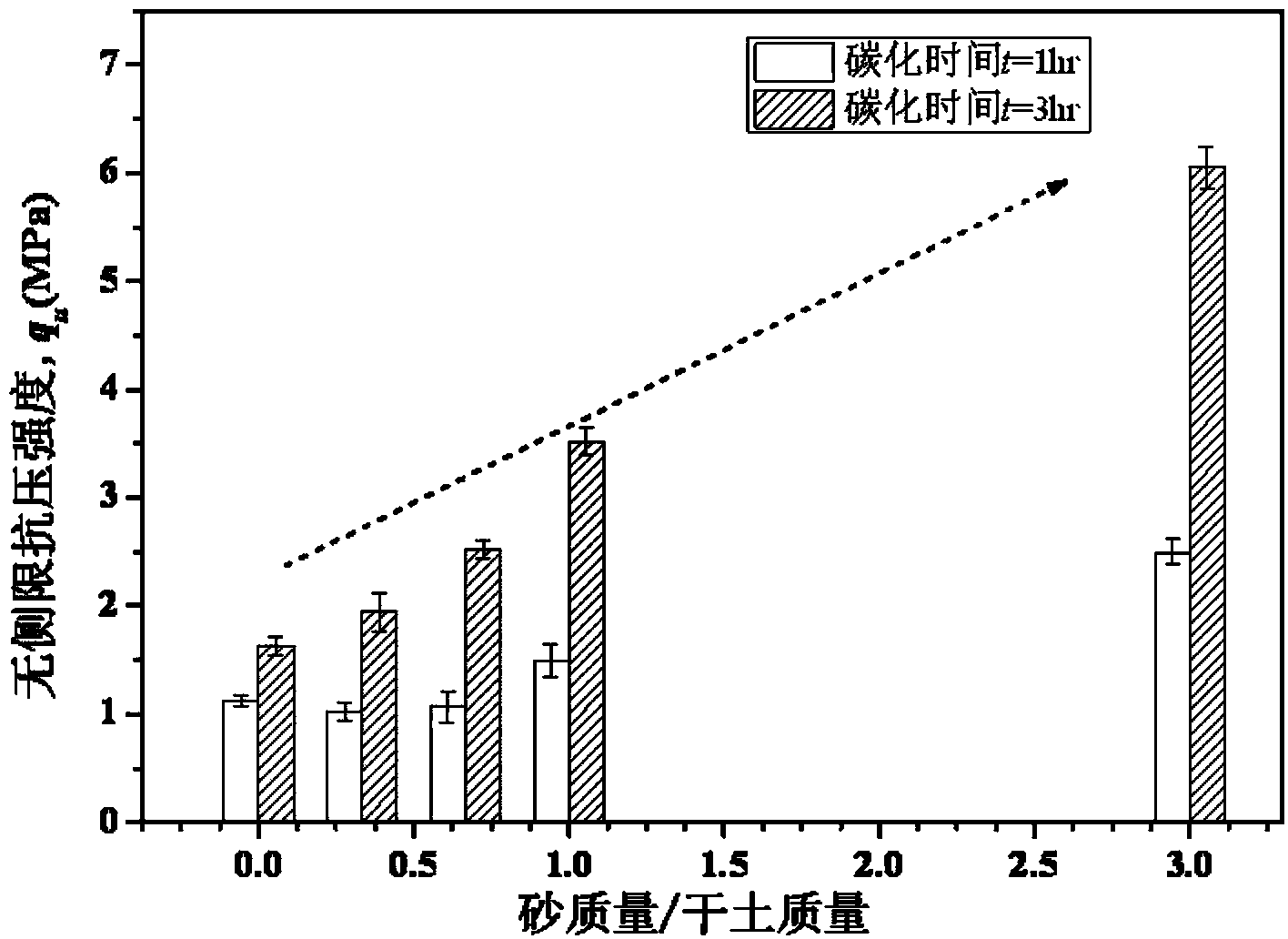

Bed course replacing and filling and carbonization reinforcing method of soft soil foundation

ActiveCN104018485AHigh strengthLow-carbon and high-efficiency constructionSoil preservationMaterials preparationSlag

The invention discloses a bed course replacing and filling and carbonization reinforcing method of a soft soil foundation and relates to a foundation handling method, in particular to a replacing and filling and carbonization reinforcing method of a large-area shallow soft uneven foundation. The method includes the steps of pit earth excavation, replacing and filling material preparation, pit bottom handling and initial pressurization, ventilating pipe network laying, replacing and filling material spreading and rolling compaction, arrangement of a sealing system, temporary ballasting and carbonization by introducing carbon dioxide gas. The replacing and filling material is prepared from original soil, fine aggregates, coarse aggregates and alkaline curing agent powder, and the fine aggregates and the coarse aggregates contain sand, coal ash, slag, gravel, construction waste and other cheap materials. Gas is introduced through a thin pipe, carbonization is performed through the greenhouse gas carbon dioxide and can be completed in several hours, high strength is achieved, and engineering requirements are met. Differential settlement of structures on the upper portion of the soft foundation can be avoided through bed course replacement and filling and carbonization reinforcement, and the bed course replacing and filling and carbonization reinforcing method of the soft soil foundation has the advantages that advantages that bearing capacity is high, manufacturing cost is low, construction is efficient, and low carbon and environment protection are achieved.

Owner:SOUTHEAST UNIV

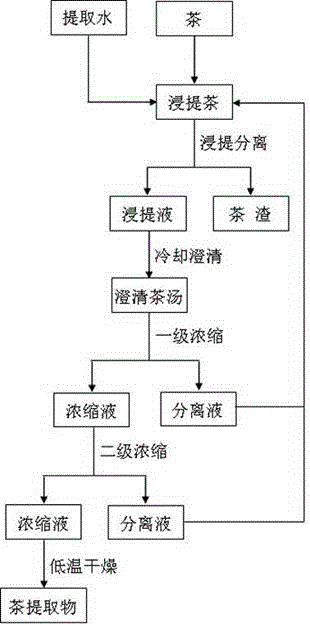

Tea extract for effectively retaining aroma and taste of original tea and preparation method and application thereof

ActiveCN102940074AImprove concentration efficiencyReduce oxidationTea extractionFood preparationInstant teaEffusion

The invention discloses a tea extract for effectively retaining aroma and taste of original tea and a preparation method and an application thereof. The tea extract comprises the following components in percentage by weight: 15-72% of tea polyphenol, 3-20% of caffeine, 10-45% of tea polysaccharide, 3-23% of amino acid and 0.01-0.25% of aroma volatile oil, and the total percentage by weight of the components is not larger than 100%. The preparation method comprises the steps of tea extraction, cooling clarification, primary concentration, secondary concentration and low-temperature drying. The tea extract for effectively retaining the aroma and the taste of the original tea is applied to instant tea drinks, tobacco or food. The technologies such as medium and low temperature extraction, normal temperature membrane concentration, and low temperature drying are adopted, and the oxidization and the effusion of main thermosensitive substances such as aroma and taste are reduced. The preparation method is simple, the production efficiency and the extraction rate are high, the extract has strong aroma after being brewed, and the tea water is green or orange, and is close to the original tea water in aroma, taste and color.

Owner:SPACE AQUA TECH

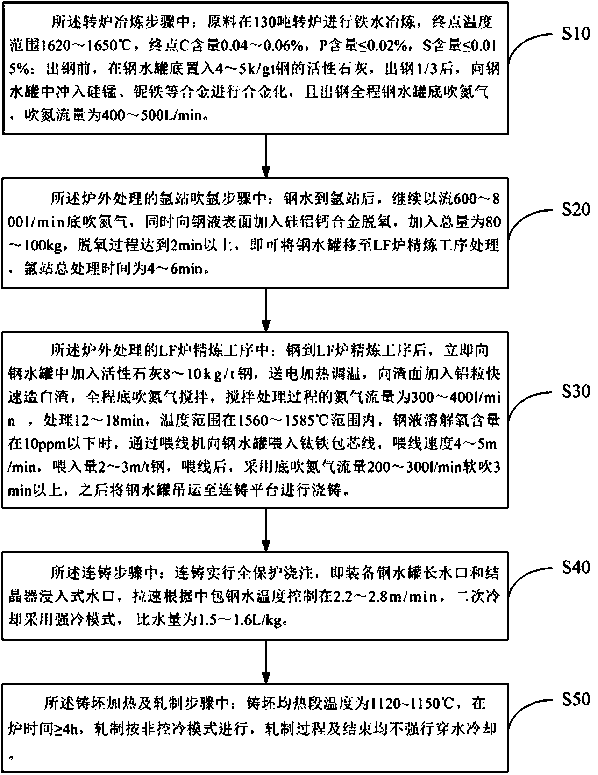

Niobium-titanium microalloying HRB400-scale screw-thread steel and manufacturing method thereof

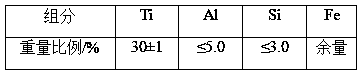

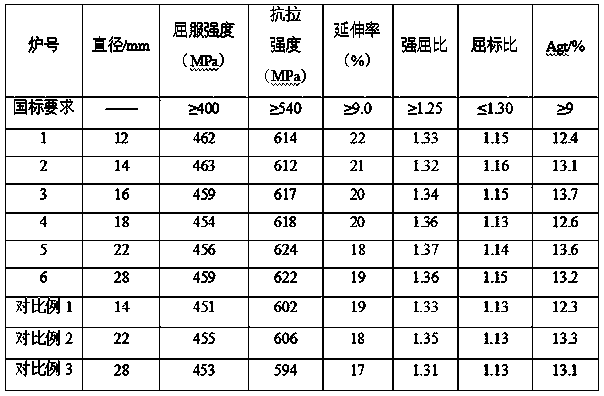

The invention discloses a kind of niobium-titanium microalloying HRB400-scale screw-thread steel and a manufacturing method thereof. The screw-thread steel comprises C, Si, Mn, P, S, Nb, Ti, N and the balance Fe and impurities. The manufacturing method of the niobium-titanium microalloying HRB400-scale screw-thread steel comprises the following steps of smelting in a revolving furnace, treatment outside the furnace, continuous casting, casting blank heating and rolling. During smelting in the revolving furnace, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment. During treatment outside the furnace, argon is blown in an argon station, and refining is conducted in an LF furnace. In the process of refining in the LF furnace, a ferrotitanium core-spun yarn is fed for titanium microalloying treatment. According to the technical scheme, before tapping, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment, the ferrotitanium core-spun yarn is fed in the process of refining in the LF furnace for titanium microalloying treatment, after titanium is fused into molten steel, proper niobium-titanium microalloying treatment is conducted, the yield of the niobium-titanium alloy is increased, and stable, sustainable and low-cost production of the screw-thread steel is achieved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

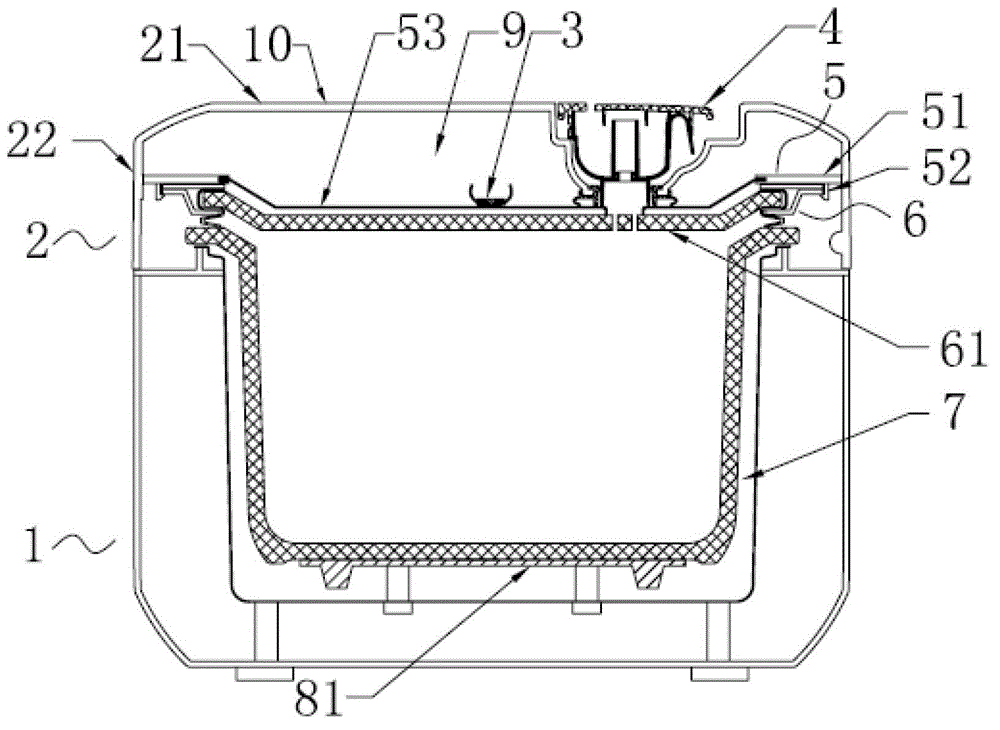

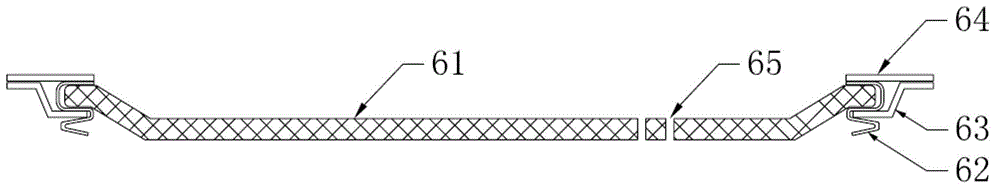

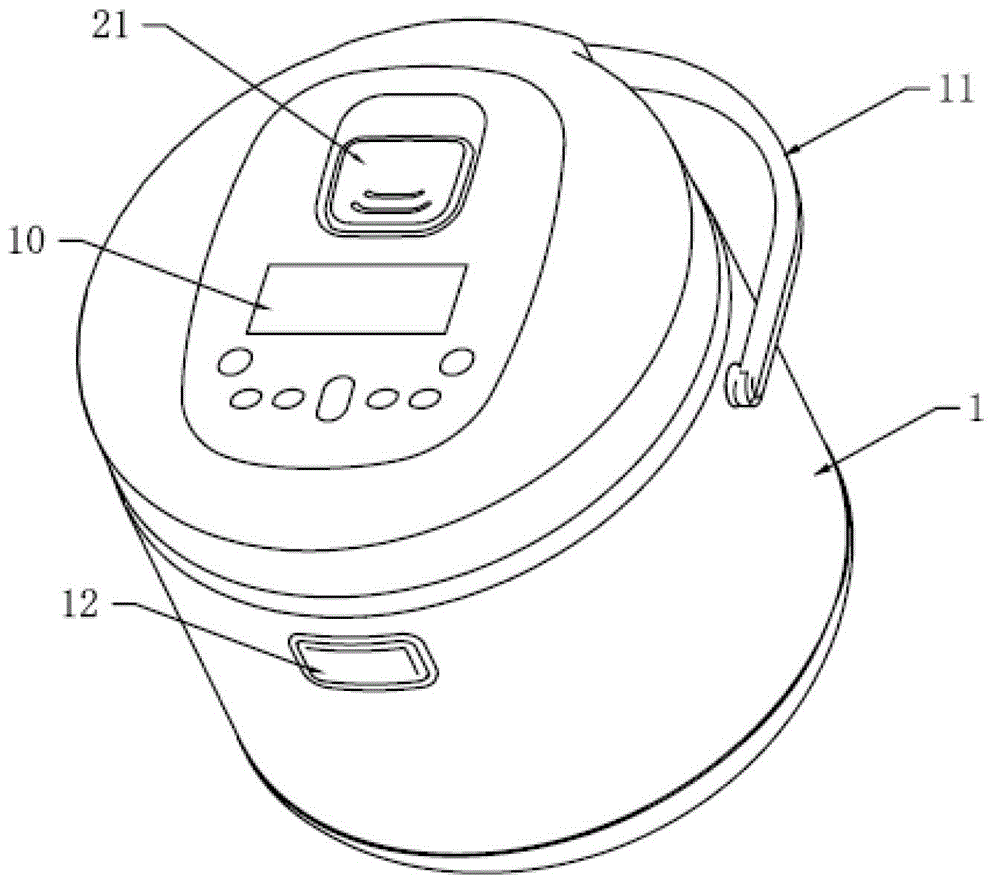

Cooking appliance

ActiveCN103142134AHigh control precisionAvoid safety hazardsCooking-vessel materialsCooking-vessel lids/coversDirect touchEngineering

The invention discloses a cooking appliance, which comprises a base body, a cover body and a container for holding food. A first heating device is arranged outside the container, the cover body comprises a plurality of cover layers, gaps are reserved between adjacent cover layers, a cover layer of one side of the cover body on the back side of the container is set to be a top cover, the cover layer close to the side of the container comprises an inner cover assembly which comprises an inner cover main body, wherein the inner cover main body covers the container, and the materials of the container and the inner cover main body are ceramics or red porcelain. By the adoption of the cooking appliance, the loss of cooking heat can be reduced to the largest extent, and the food processing is further enabled to be more silent; meanwhile, the occurrence of safety risks due to direct touch of a high-temperature inner cover which covers the container by a user can be prevented; and the materials of the inner cover main body and the container are red porcelain and ceramics, a relative sealing pure ceramic or red porcelain cavity is formed from a space used for processing food, and the characteristics of natural inadhesion, stainlessness, safety and hygiene of ceramics as well as stainlessness, safety and hygiene of red porcelain can be fully utilized.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

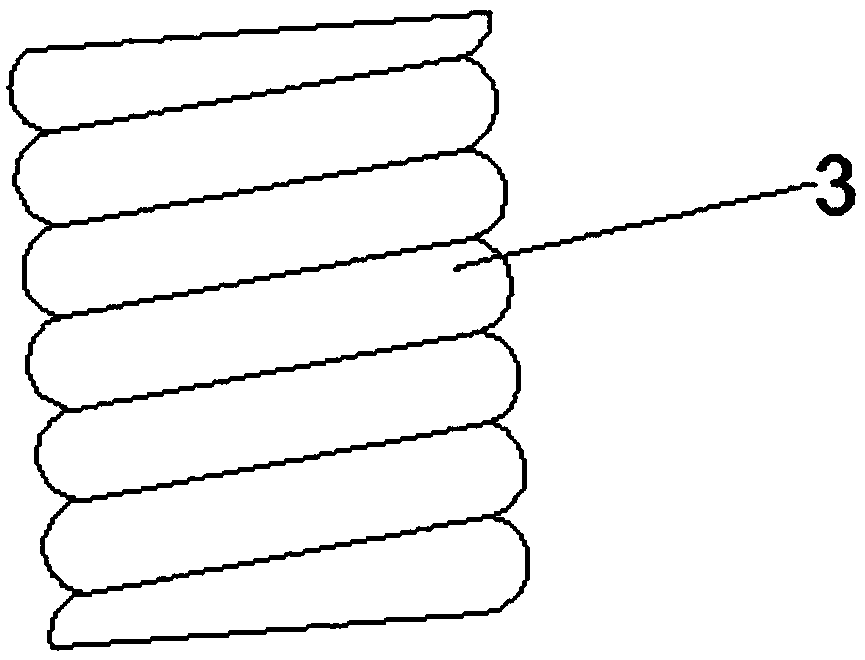

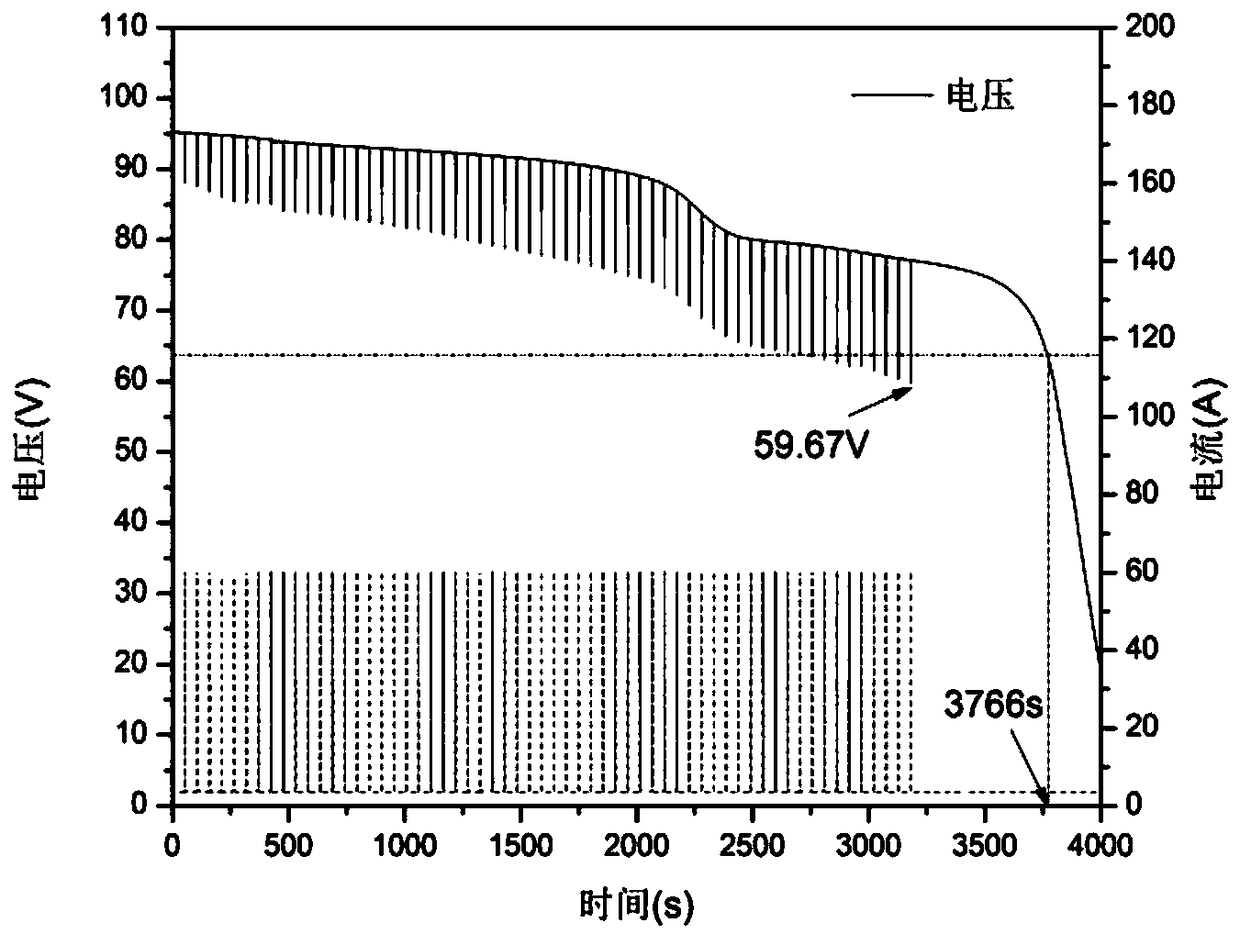

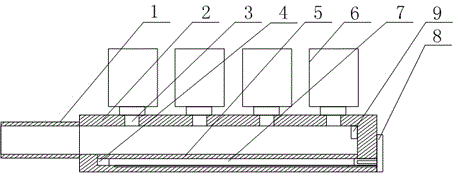

Slow-release heat supply device for heat battery

ActiveCN108878917AImprove utilization efficiencyStable jobDeferred-action cellsInsulation layerEngineering

The invention discloses a slow-release heat supply device for a heat battery, and belongs to the technical field of heat battery application. The slow-release heat supply device comprises a battery shell, wherein a battery pile is arranged in the battery shell; the outer part of the battery pile is coated with a composite insulation heat insulation layer; the composite insulation heat insulation layer is attached to the battery pile; a spiral winding heat pipe is wound on the outer surface of the composite insulation heat insulation layer; a heating material is filled in the spiral winding heat pipe; sealing tapes are arranged at the two ends of the spiral winding heat pipe; a heat preservation layer is further arranged in the battery shell; and the heat preservation layer is located between the spiral winding heat pipe and the battery shell. By the adoption of the scheme, the heat utilization efficiency can be greatly improved, the thermal shock degree at the moment of activation of the battery pile is reduced, and the device is suitable for a thermal battery which works for a long time.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Dedicated additive for hot fog machine and preparation method thereof

ActiveCN102165949AReduce flutterHigh densityBiocideAnimal repellantsVolumetric Mass DensitySURFACTANT BLEND

The invention discloses a dedicated additive for a hot fog machine and a preparation method thereof. The dedicated additive for a hot fog machine comprises the following raw material components in percentage by mass: 5-20% of surfactant, 1-25% of hot fog density modifier, 1-10% of antifreeze agent, 0.1-6% of antifoaming agent and the balance of water. When the dedicated additive is prepared, all raw material components which can be dissolved into water are mixed to obtain an aqueous phase; then the insoluble hot fog density modifier is introduced into the aqueous phase; the hot fog density modifier and the aqueous phase are stirred; and residues are removed by filtering to obtain a finished product. According to the dedicated additive, the prevention and treatment safety and effect of thehot fog machine can be effectively improved, the type range of the hot fog machine on preventing and treating crop pests is expanded, the compatibility problem of pesticides, smoke agents and water can be solved, and the problem that the hot fog machine is applicable to middle-stalked crops and short-stalked crops, such as corn, wheat and the like is solved.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

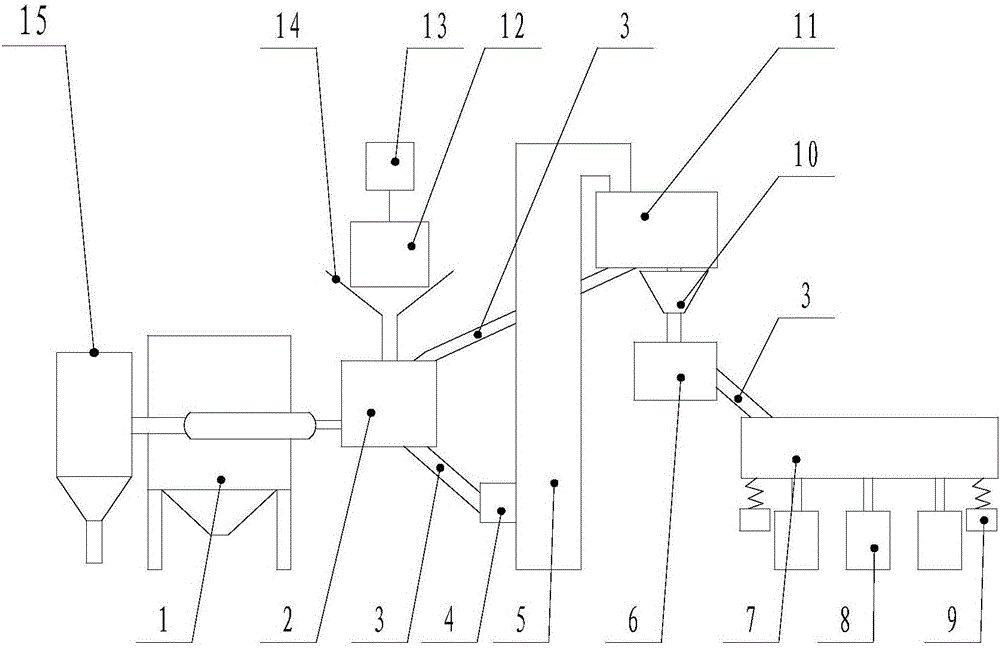

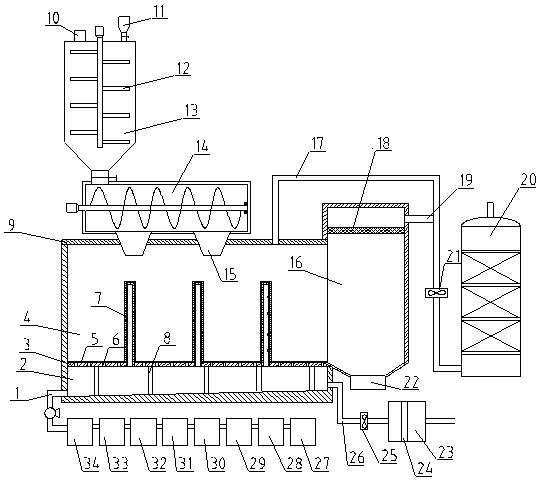

One-step nickel smelting system and one-step nickel smelting method

ActiveCN111101001ASolution conditionsSolve the problem of high nickel content in smelting slagProcess efficiency improvementSlagFlue gas

The invention provides a one-step nickel smelting system and a one-step nickel smelting method. The one-step nickel smelting system comprises a raw material conveying device, a one-step nickel smelting device and a flue gas treatment device; the one-step nickel smelting device is an integrated device and comprises a furnace body, and a molten pool smelting area and a reduction depletion area are sequentially arranged inside the furnace body; a first feeding inlet and a first blower nozzle are formed in the molten pool smelting area, the first feeding inlet is connected with the raw material conveying device, and the molten pool smelting area is used for performing molten pool smelting on nickel sulfide concentrates to produce high nickel matte containing 35-65 wt% nickel, smelting slag andflue gas; the reduction depletion area communicates with the molten pool smelting area, a second feeding inlet, a second blower nozzle and a flue gas outlet are formed in the reduction depletion area, and the reduction depletion area is used for enabling the smelting slag to be subjected to the depletion reaction to produce depleted slag and first metallized nickel matte; the flue gas treatment device is connected with the flue gas outlet. The problems such as high raw material feeding-into-furnace conditions of the DON process, high nickel content in the smelting slag, large load and high energy consumption when an electric furnace separately treats the smelting slag are effectively solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

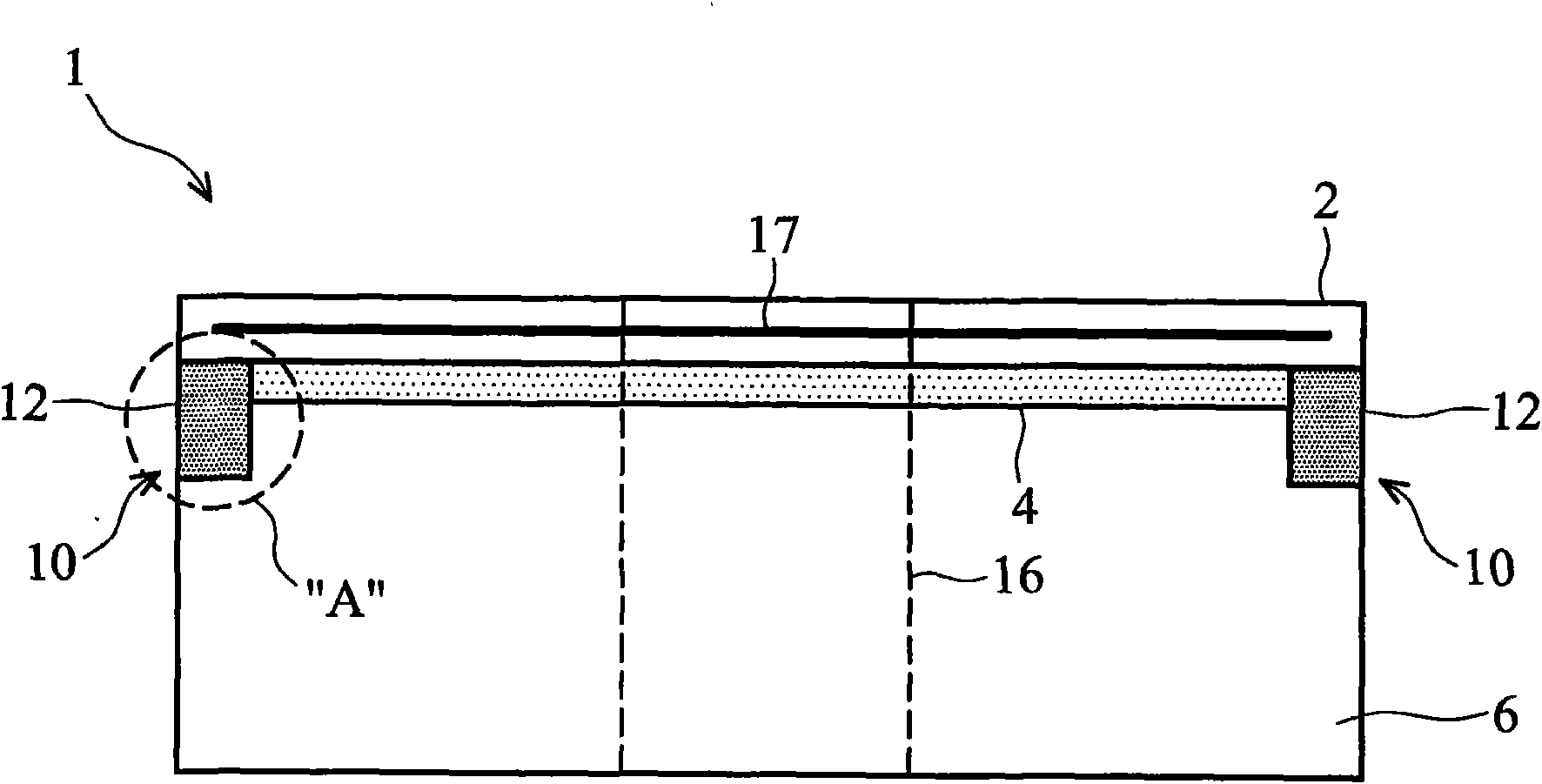

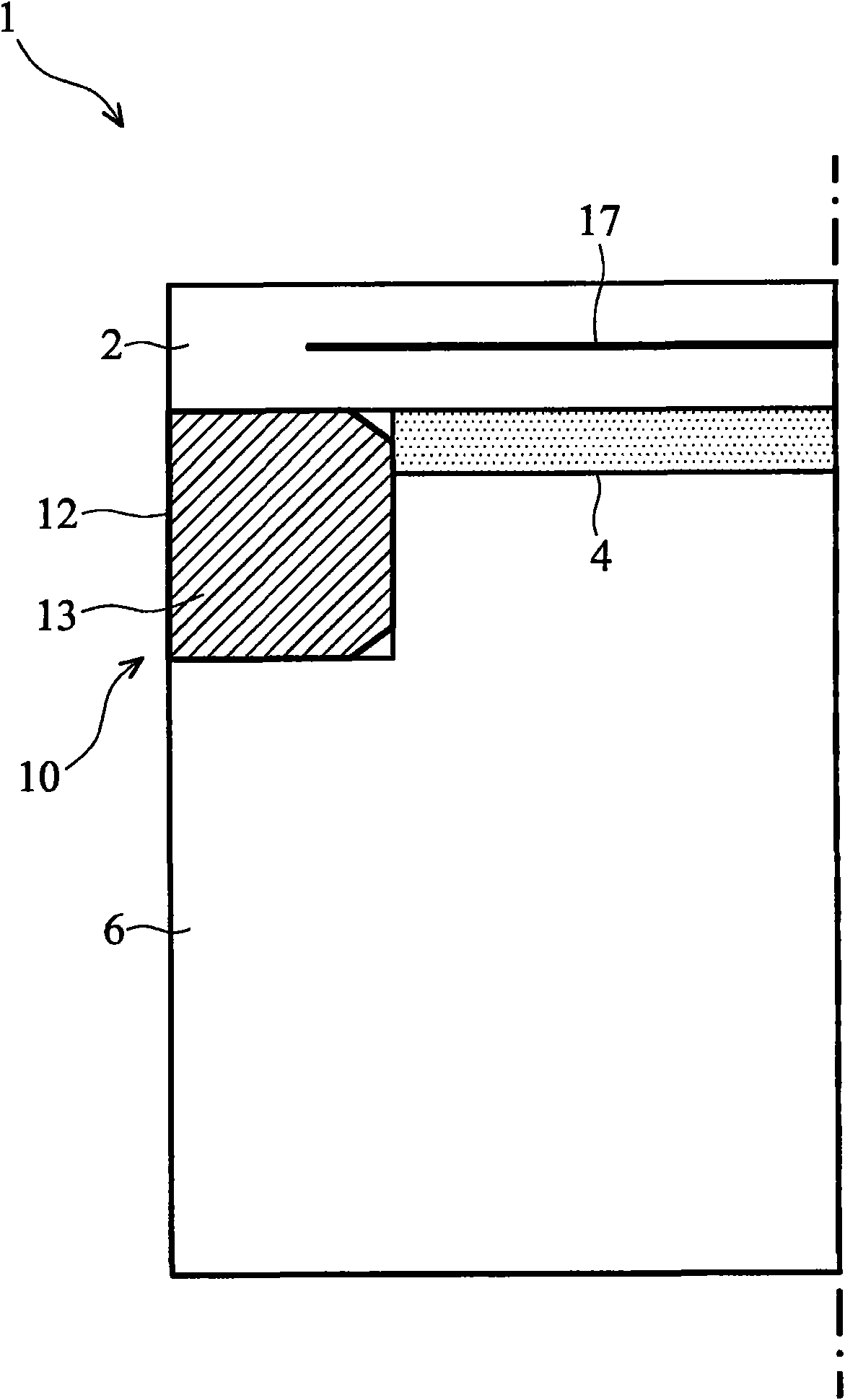

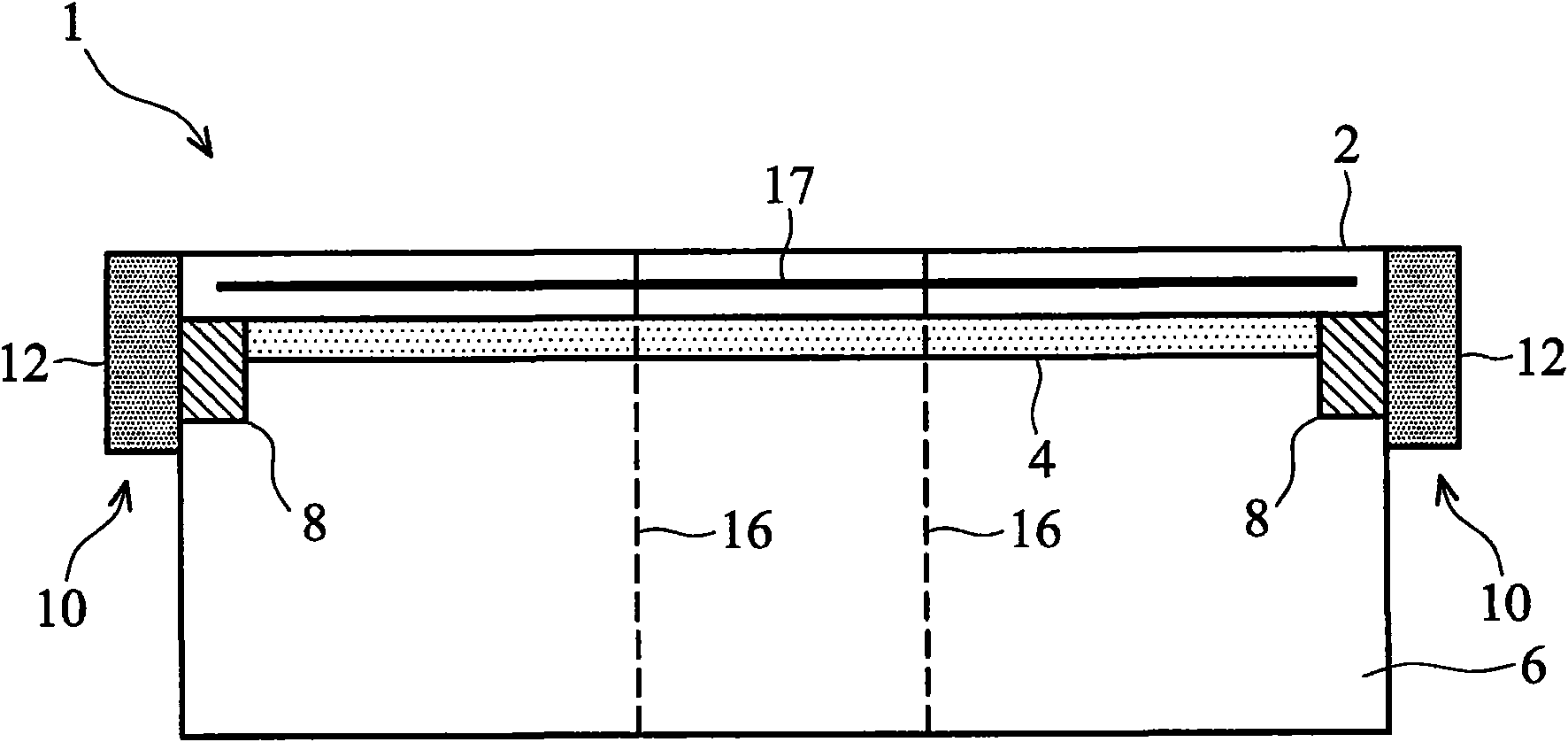

Electrostatic chuck and plasma device

InactiveCN101930892AExtend your lifeReduce fugitiveElectric discharge tubesSemiconductor/solid-state device manufacturingEpoxyElectrical and Electronics engineering

The invention provides an electrostatic chuck and a plasma device. The electrostatic chuck has a base member, a top member residing on a top surface of the base member, an indentation located at the interface of the base member and the top member, and a replaceable sidewall shield. The replaceable sidewall shield fills an indentation located between a base member and a top member of an electrostatic chuck, such that the replaceable electrostatic chuck sidewall shield may protect an epoxy in the indentation or may replace the epoxy within the indentation. The replaceable electrostatic chuck sidewall shield may be fully contained with the indentation. The replaceable electrostatic chuck sidewall shield may also cover an epoxy in the indentation such that the replaceable electrostatic chuck sidewall shield protrudes beyond the indentation. In an alternate embodiment, the replaceable electrostatic chuck sidewall shield substantially covers the area in which a conductive pole is embedded in a bipolar electrostatic chuck.

Owner:TAIWAN SEMICON MFG CO LTD

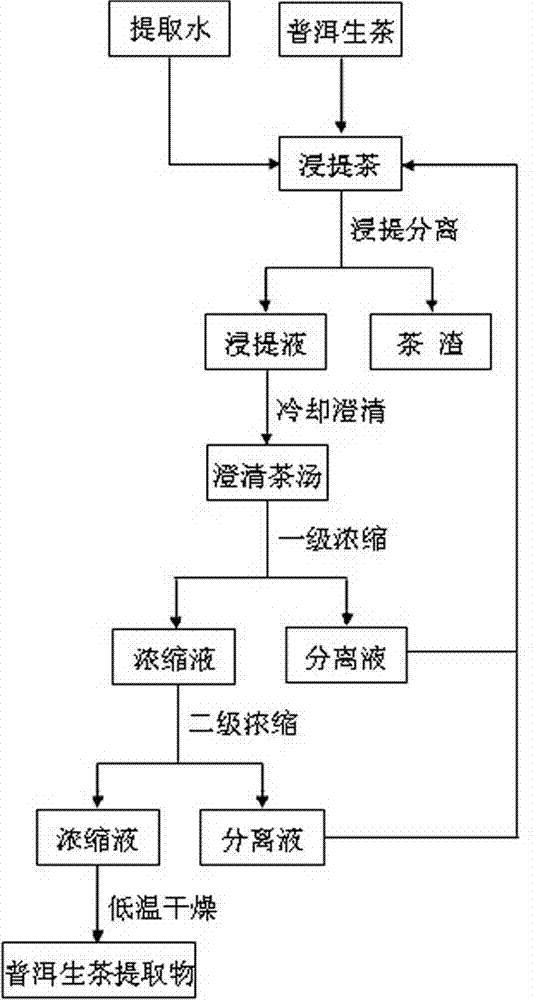

Pu'er raw tea extract for effectively retaining quality of original tea and preparation method and application of same

ActiveCN102919424AReduce oxidation and dissipationGuaranteed extraction efficiencyTea extractionFood preparationChemistryCaffeine

The invention discloses a pu'er raw tea extract for effectively retaining quality of original tea and a preparation method and an application of same. The pu'er raw tea extract comprises tea polyphenol, caffeine, tea polysaccharide, amino acids, and an aroma component. The mass percents of the components are respectively as follows: 25-69% of tea polyphenol, 8-20% of caffeine, 10-30% of tea polysaccharide, 5-23% of amino acids, and 0.01-0.1% of aroma component. The sum of mass percents of the component is not greater than 100%. The preparation method comprises the steps of: tea digestion, cooling and clarification, primary concentration, second concentration and low temperature drying. The pu'er tea extract is applied to instant tea beverages, tobacco or foods. Oxidation and loss of main thermosensitive substances such as aroma and taste are reduced by middle- and low-temperature digestion, constant temperature film concentration and low temperature drying technologies and the like. The preparation method is simple, and the aqueous solution of the extract has a scent and is strong in aroma, smooth to drink, sweet and liquid-engendering, and red and bright in liquor color. The pu'er raw tea extract is similar to the original pu'er tea in tea liquid scent, taste and liquor color.

Owner:SPACE AQUA TECH

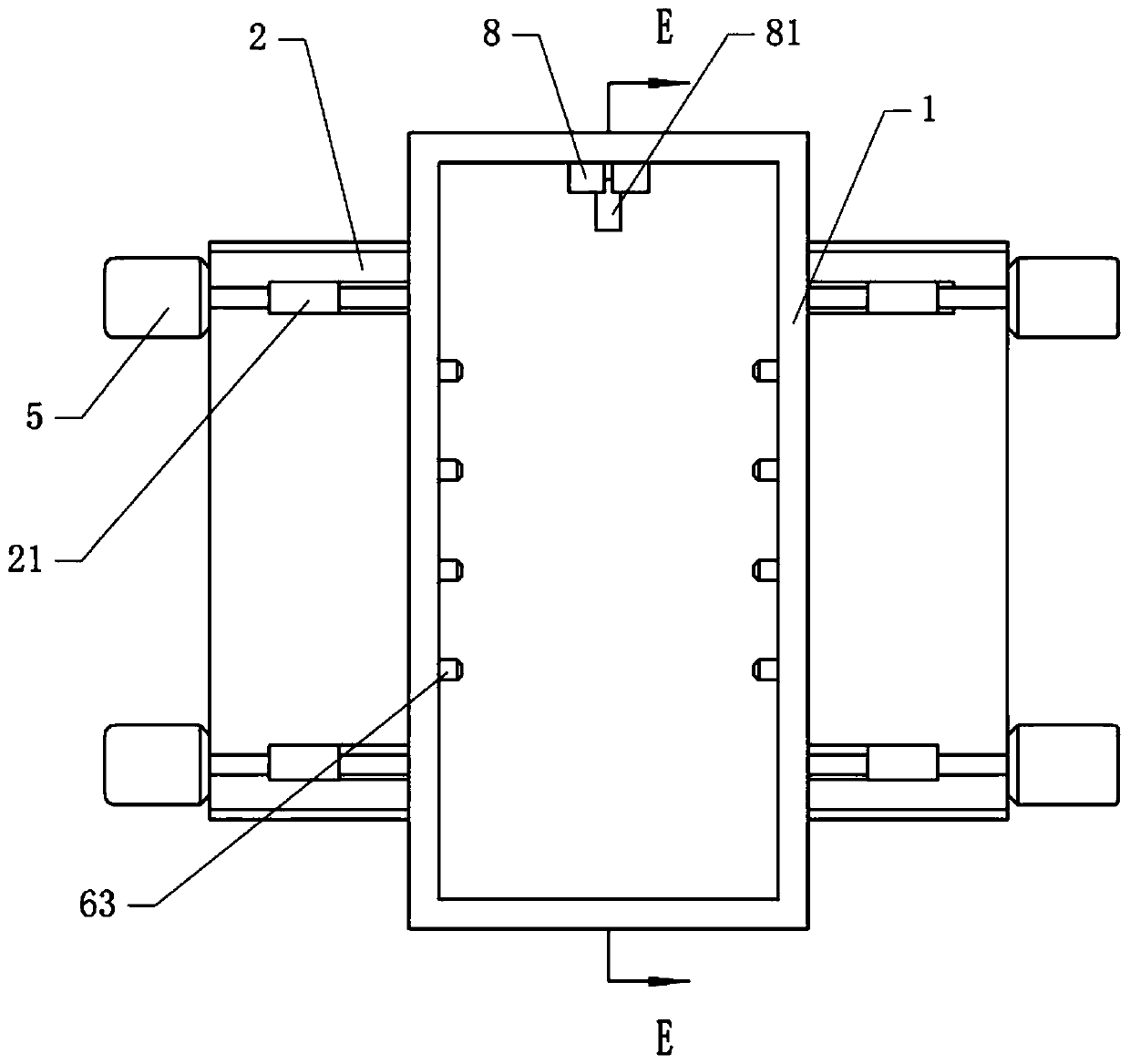

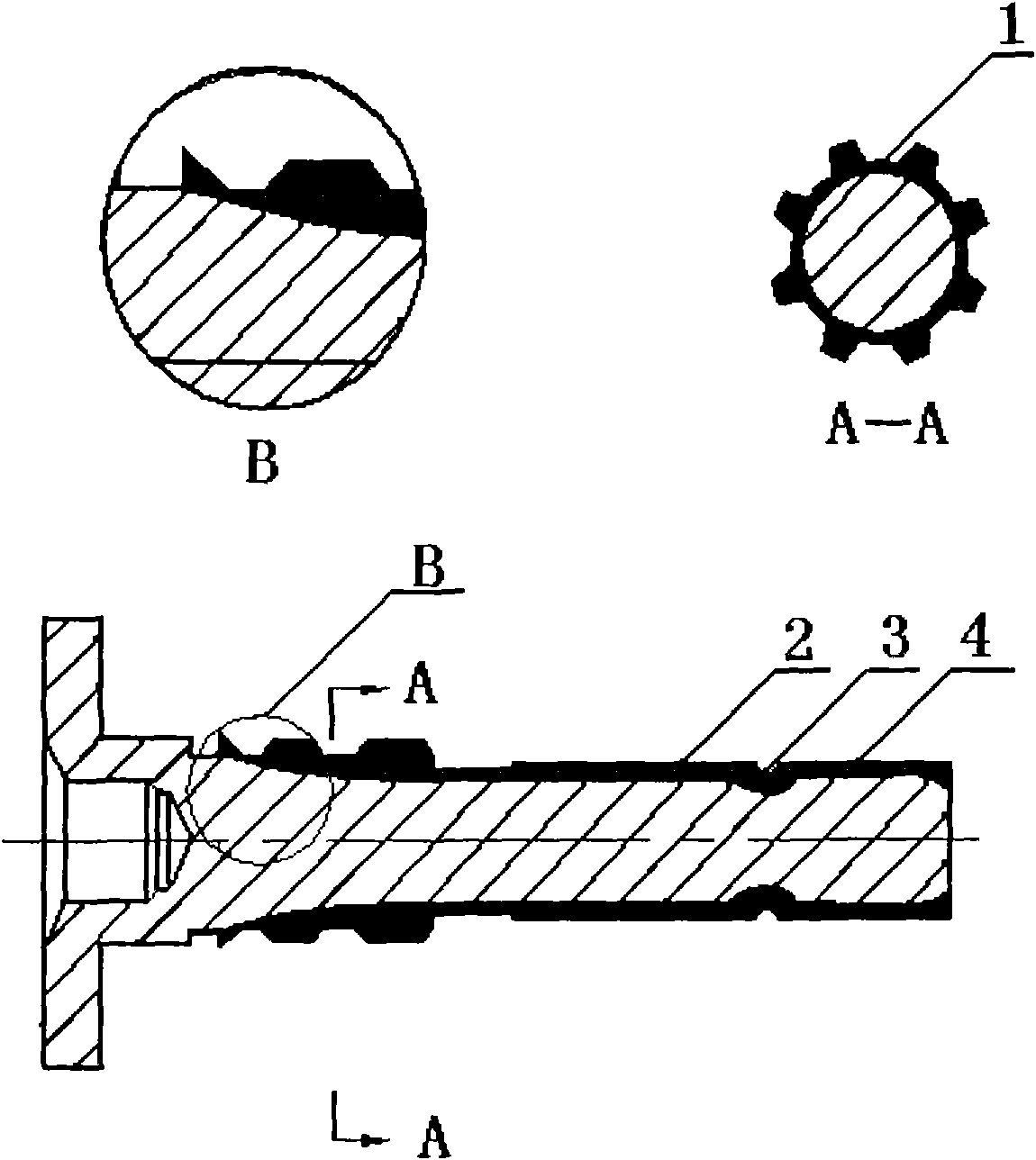

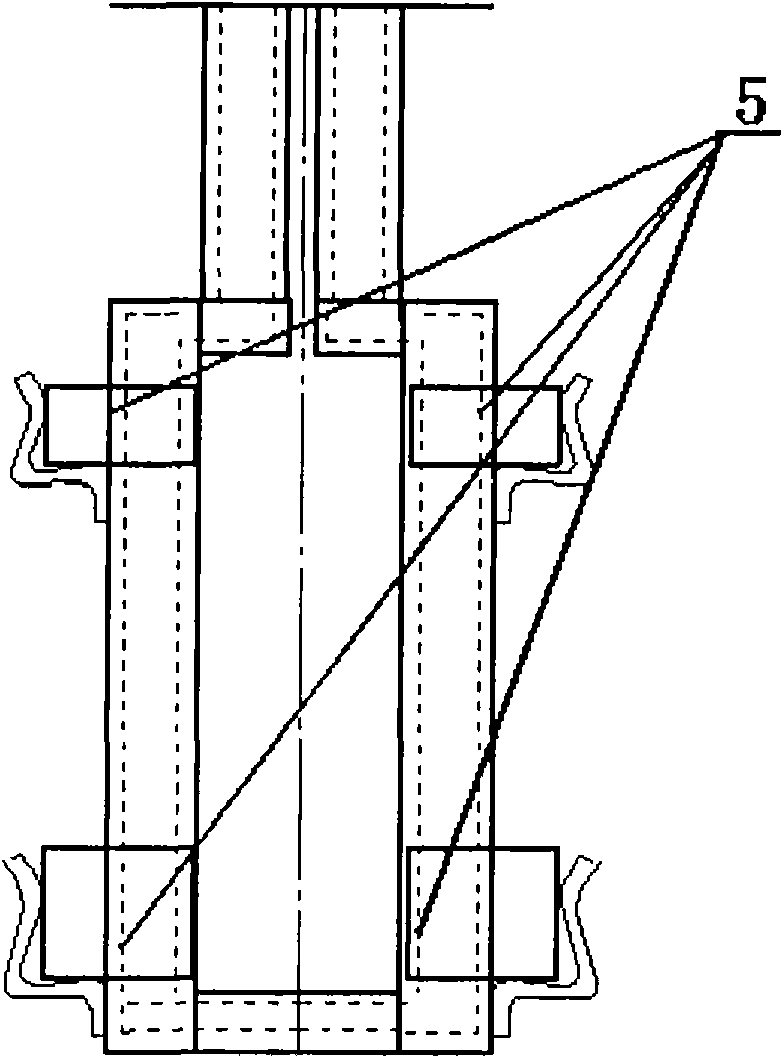

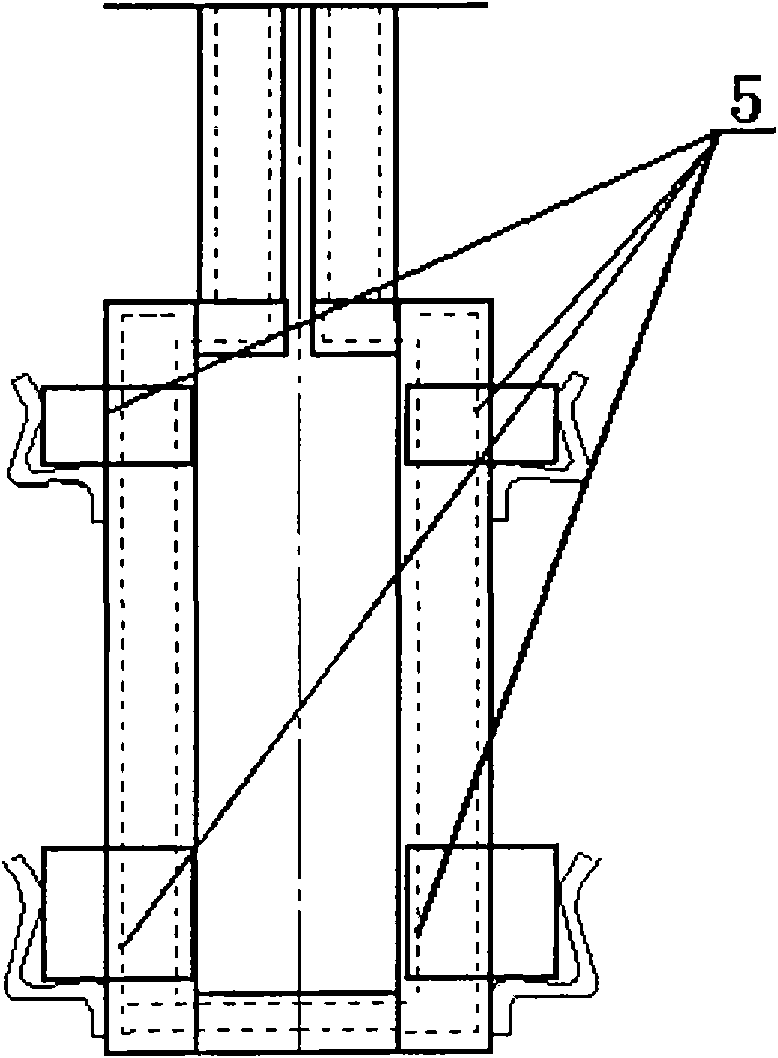

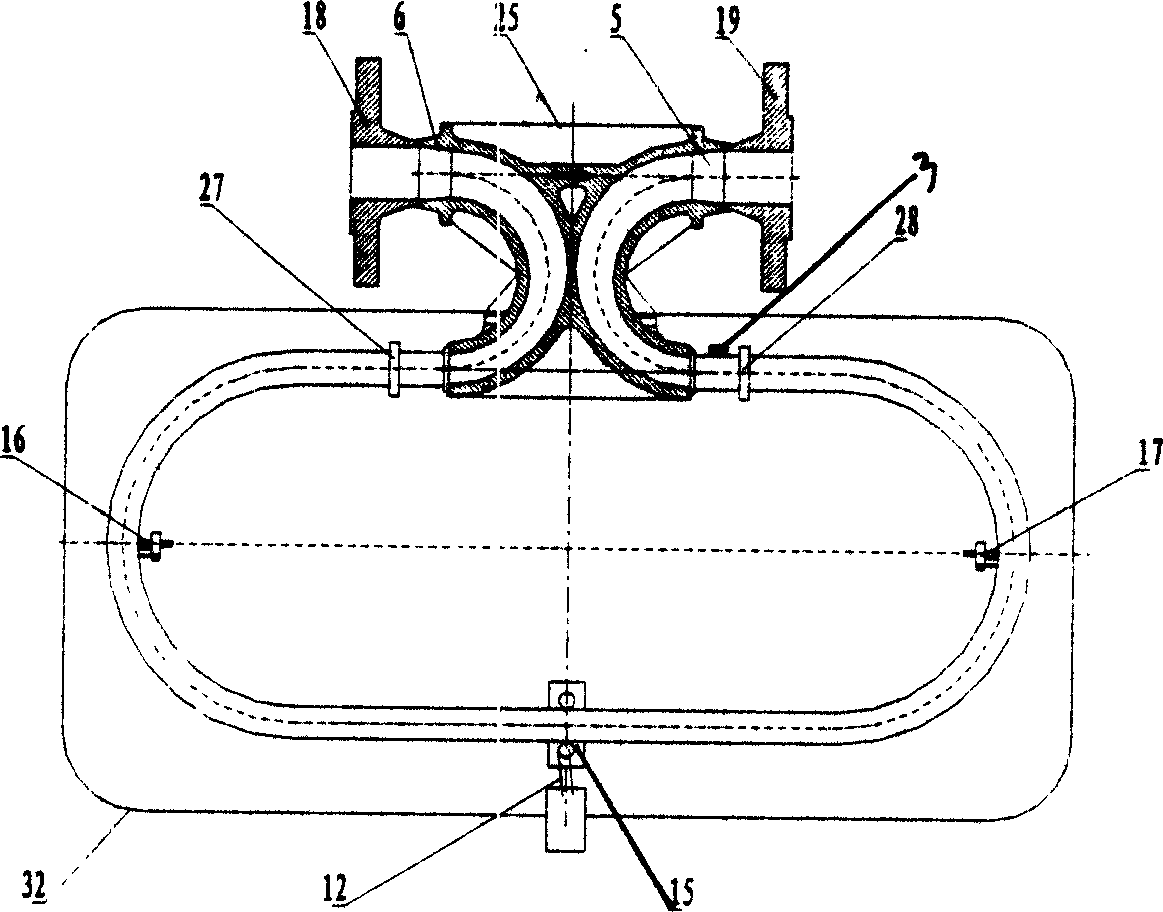

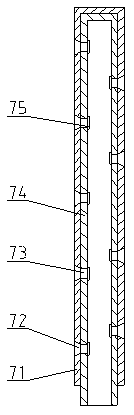

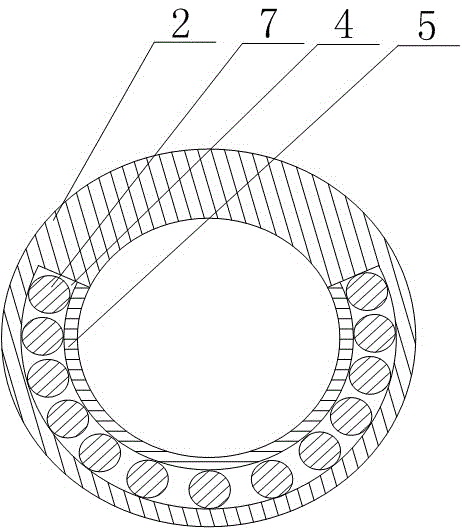

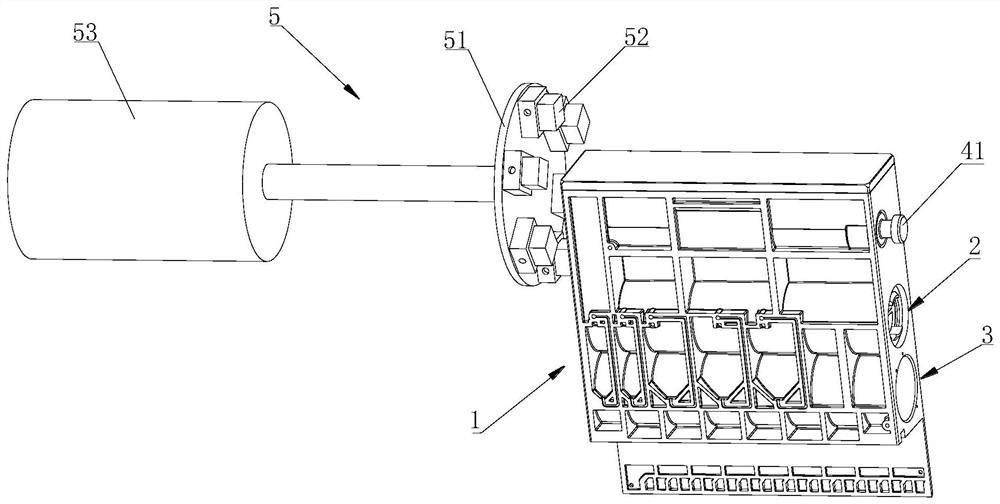

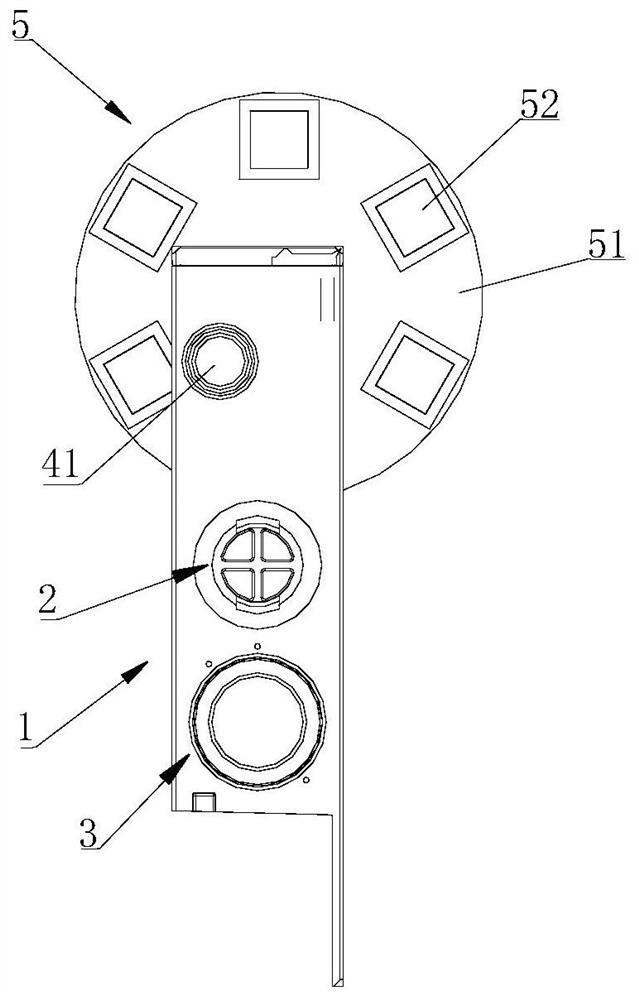

Core segmented sealing device and application method

ActiveCN104142258AReduce fugitivePreparing sample for investigationEarth material testingPilot holeEngineering

The invention provides a core segmented sealing device and its application method and belongs to the field of petroleum geology. The device comprises a core storage cylinder and inflation sealing rings. The core storage cylinder has a cylindrical structure, one end of which is a sealed end and the other end of which is an open end. The open end is provided with a top cover. At least two pilot holes are arranged on the wall of the core storage cylinder. Each pilot hole contains two through-holes which are apart from each other 180 degrees on a circle. Axes of all through-holes are vertical to the axis of the core storage cylinder 1. The inner wall of the core storage cylinder is provided with at least two annular seal grooves. Each annular seal groove is corresponding to a pilot hole. Each pilot hole enables its corresponding annular seal groove to be communicated with the outside world. One of the inflation sealing rings is installed in each annular seal groove. By the use of the device, rapid and segmented sealed storage of cores is realized, gas dissipation under the atmospheric condition is minimized, and a foundation is laid for the next steps of analytical tests and research work.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pu'er tea active paste for effectively retaining original tea aroma and taste and preparation method of same

The invention discloses a pu'er tea active paste for effectively retaining original tea aroma and taste and a preparation method of same. The pu'er tea active paste comprises tea polyphenol, caffeine, tea polysaccharide, amino acids, and an aroma volatile oil component. The mass percents of the components are respectively as follows: 10-67% of tea polyphenol, 2-20% of caffeine, 10-45% of tea polysaccharide, 3-23% of amino acids, and 0.01-0.1% of aroma volatile oil component. The sum of mass percents of the components is not greater than 100%. Oxidation and loss of main thermosensitive substances such as aroma and taste are reduced by middle- and low-temperature digestion, constant temperature film concentration and low temperature drying technologies and the like, and active enzymes in the original tea and active flora are prevented from being damaged. The preparation method is simple, and the chronic fermenting change of the original pu'er tea continues: the older, the better. The pu'er tea active paste has a scent and is strong in aroma, pure and mild in taste, red and bright in liquor color, and convenient to store. The pu'er tea active paste after being brewed is similar to the original pu'er tea in tea liquid scent, taste and liquor color.

Owner:云南活草堂生物科技有限公司

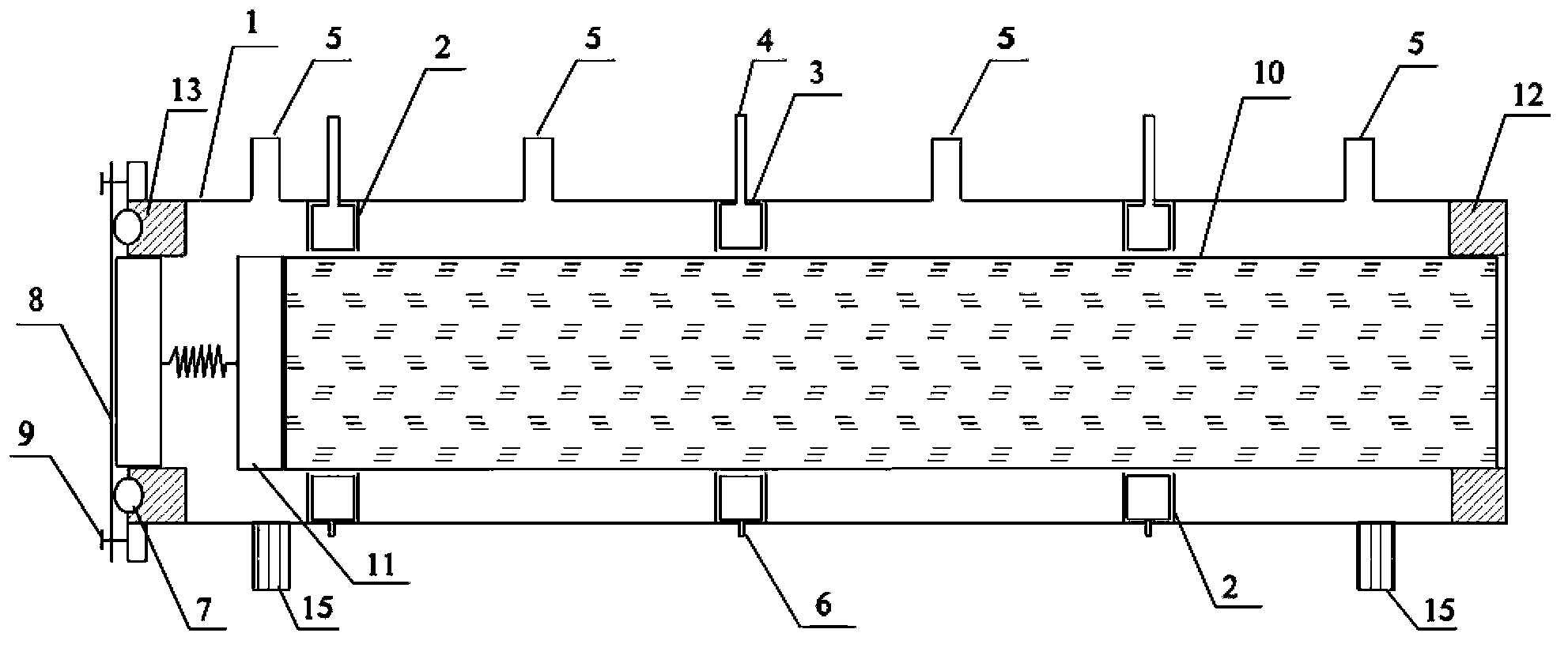

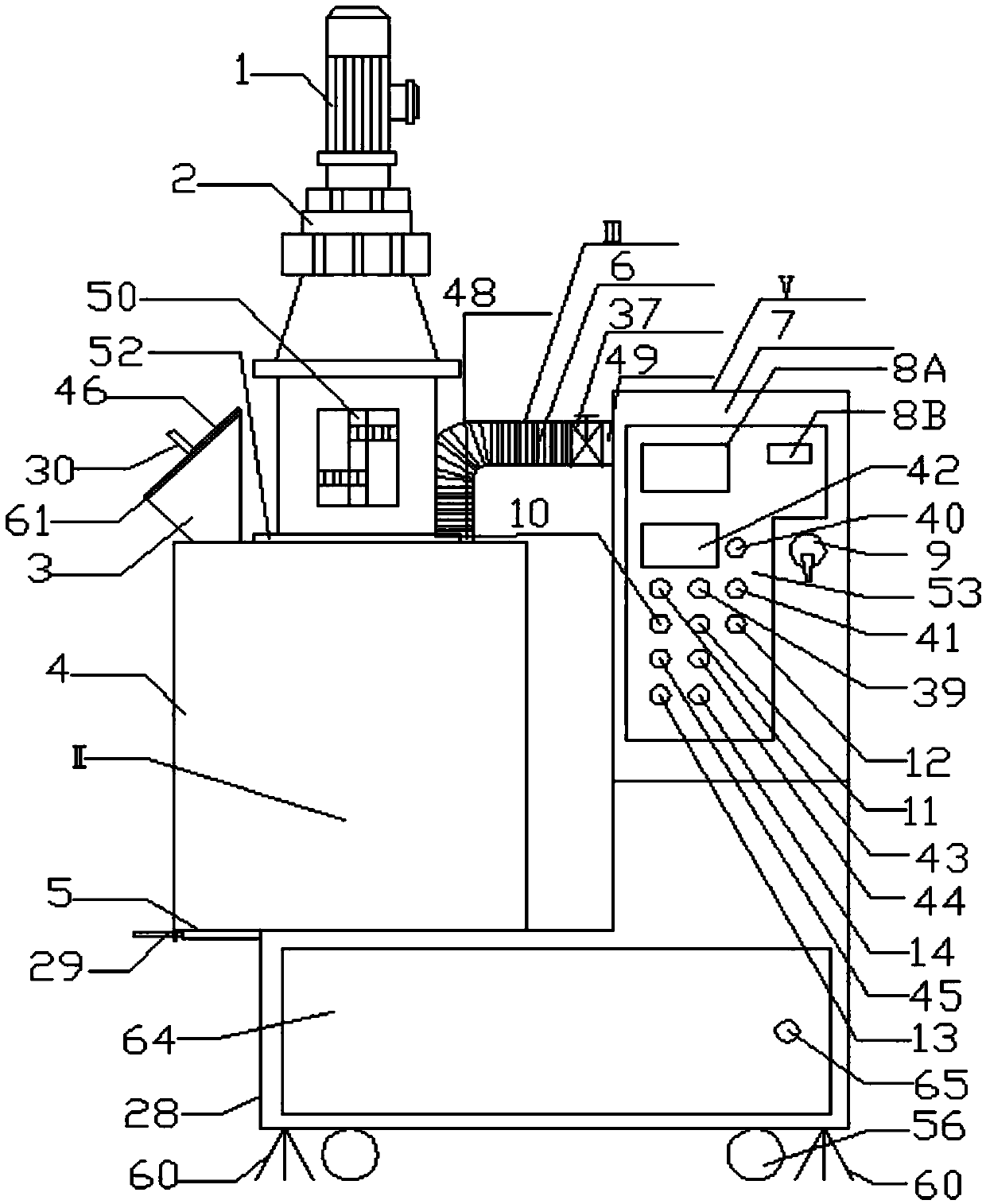

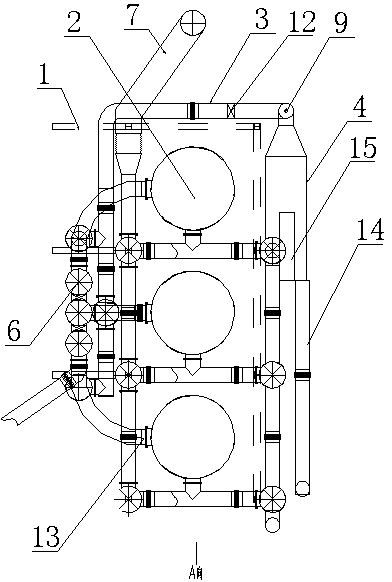

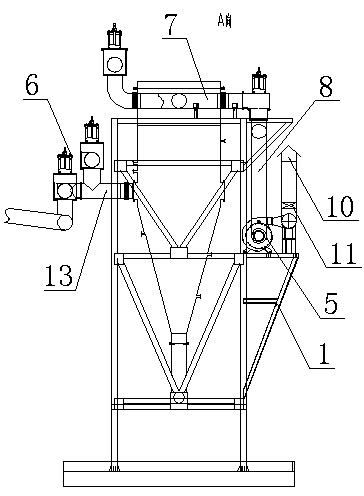

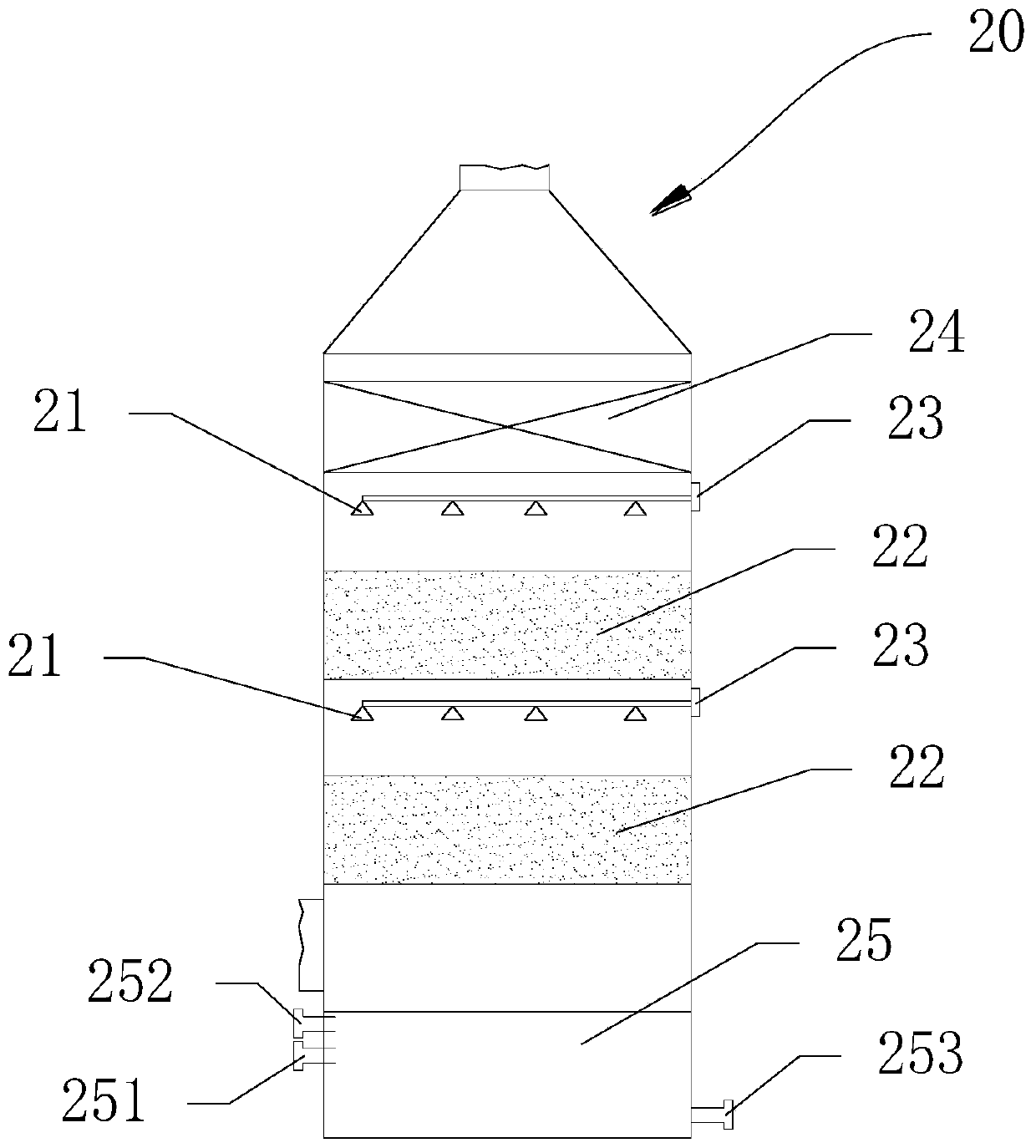

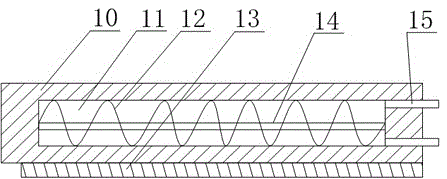

Integrated high-temperature aerobiotic organic waste processor

ActiveCN105503311ASmall footprintReduce energy consumptionBio-organic fraction processingOrganic fertiliser apparatusExhaust gasTransit time

An integrated high-temperature aerobiotic organic waste processor is an integrated device composed of a main fermentation system, a stirring system, a ventilation system, a waste gas processing system, a control system and a base. Wheels are arranged on the lower portion of the base so that the base can be conveniently moved. Combined work of the processor, a heating strip and an air compressor is controlled by the control system of the device, and therefore different temperatures of a fermentation tank can be regulated and controlled in real time. A middle heat preservation layer is arranged in the fermentation tank. Dead corners are not likely to appear when spiral stirring blades of the device conduct stirring. A filler chamber used for waste gas processing is layered. Filler can be partly replaced in good time. According to the integrated device, particularly through device integration of material fermentation and waste gas processing, the disadvantages that in existing processing links, the transit time between all devices is long, the production process is long, the number of devices is large, the occupied area is large, the utilization rate is low and the production cost is high are eliminated.

Owner:CHONGQING JIAOTONG UNIVERSITY

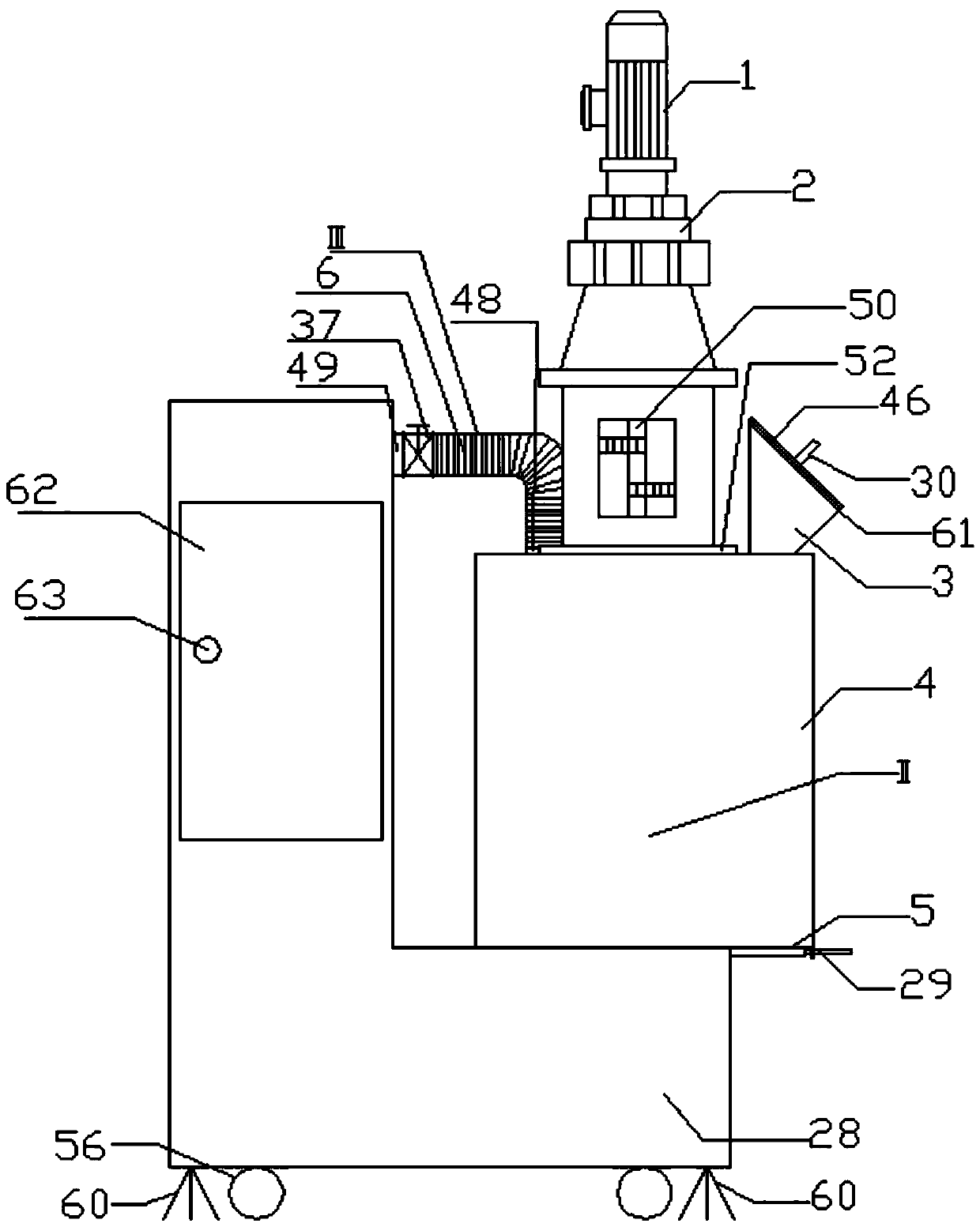

Melted quartz sand production line capable of recycling dust

InactiveCN106269152ASave the process of feedingPrevent escapeGrain treatmentsProduction lineMagnetic separator

The invention discloses a melted quartz sand production line capable of recycling dust, and belongs to the field of powder processing. The melted quartz sand production line comprises a dust remover, a crusher, an elevator, a magnetic separator, a graded screening system and a vibrating screen; the crushed is provided with a feeding hopper, an electric hoist is arranged over the feeding hopper, the crusher is connected with the bottom of the elevator through a pipeline, the top of the elevator is connected with the vibrating screen through a pipeline, the vibrating screen is connected with the crusher and the magnetic separator which are arranged below the vibrating screen through pipelines, the magnetic separator is connected with the graded screening system arranged below the magnetic separator through a pipeline, the elevator, the vibrating screen, the magnetic separator and the graded screening system are all of a sealed structure, the dust remover is connected with the elevator, the vibrating screen, the magnetic separator and the graded screening system through pipelines separately, and a cyclone dust removal machine is connected to the dust remover. According to the melted quartz sand production line, large-particle powder in powder sucked by the dust remover can be separated and collected through the cyclone dust removal machine, then the powder is recycled, and the utilization rate of the raw materials is increased.

Owner:东海县宏达石英材料有限公司

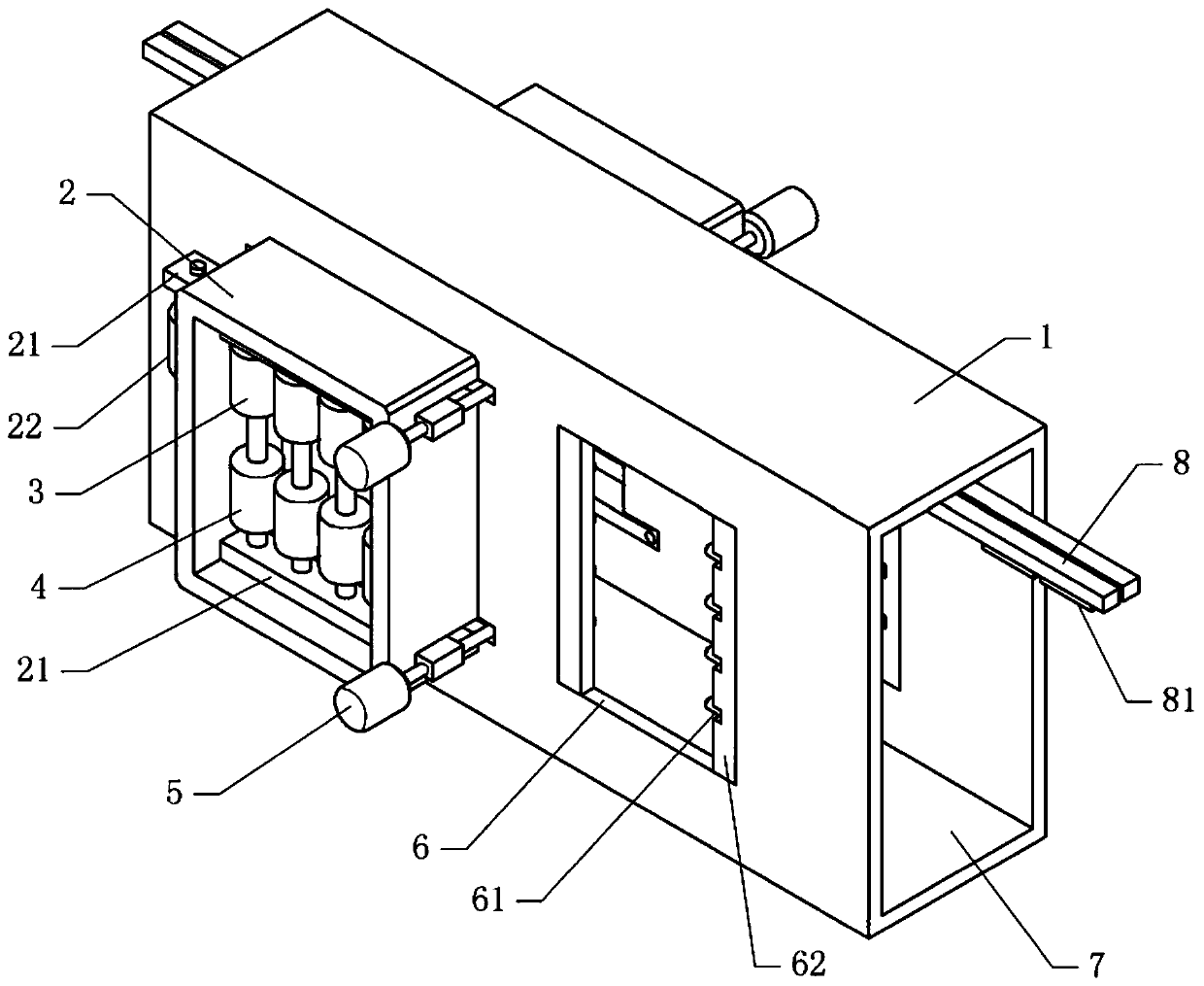

Steel structure painting process

ActiveCN111097630AImprove work efficiencyEasy to transportGrinding drivesPretreated surfacesRoller millManufacturing engineering

The invention relates to the technical field of steel structure painting, and discloses a steel structure painting process. The process comprises the following steps that S1, a steel structure is clamped through a clamp, and then the steel structure is conveyed into a painting box through a sliding rail; S2, the positions of roller grinding mechanisms on the two sides of the painting box are adjusted till the distance between the roller grinding mechanisms is equal to the thickness of the steel structure; S3, the roller grinding mechanisms are started, then the steel structure is conveyed to the position between the roller grinding mechanisms, and the steel structure is ground through the roller grinding mechanisms; S4, the steel structure is conveyed to a painting assembly through the roller grinding mechanisms, and the two sides of the steel structure are painted through the painting assembly until the surfaces of the two sides of the steel structure are covered with paint; and S5, the steel structure is conveyed to an air injection assembly, the air injection assembly is rotated to face the steel structure, and paint on the steel structure is blown to be dry through the air injection assembly. The process is simple in method, the steel structure can be rapidly painted, and the painting efficiency of the steel structure is improved.

Owner:重庆实创钢结构有限公司

Sludge composting method and organic fertilizer

InactiveCN109928791AImprove compost fermentation rateImprove fermentation rateBio-organic fraction processingOrganic fertiliser preparationSludge compostMicrobial enzymes

The invention relates to a sludge composting method and organic fertilizer. The sludge composting method comprises the steps that sludge, mushroom dregs and wood blocks serve as raw materials, and after the sludge, the mushroom dregs and the wood blocks are mixed, pile bodies are formed; the pile bodies are piled in a gore membrane, composite microbial enzyme fermented liquid is added, thus a stack is prepared, the surface of the stack is covered with the gore membrane, and the stack is placed in a ventilation oxygen-supplying environment to be subjected to aerobic fermentation; and after fermentation is conducted for 3-4 weeks, discharging and aging are conducted to obtain a coarse fertilizer product, sterilizing, dehydrating, air pumping for odor removing, drying and sieving are conducted sequentially, and thus the organic fertilizer with the uniform particle size is prepared. The sludge composting method is small in occupied space and easy to popularize, the problem that existing municipal sludge cannot be subjected to efficient harmless treatment and disposal is solved, the sludge composting fermentation rate is effectively increased, the pressure of treating the municipal sludge is effectively reduced, the production efficiency of converting organic solid waste into the organic fertilizer is improved, meanwhile, secondary pollution of traditional incineration or sludge landfill to the environment can be reduced, and good environmental protection significance is achieved.

Owner:XIAMEN UNIV OF TECH

Technique treatment method for induction heating of special-shaped piece

InactiveCN101962705AReduce energy consumptionGuaranteed compliance with technical requirementsIncreasing energy efficiencyFurnace typesConstant powerElectrical field strength

Owner:上海上大热处理有限公司

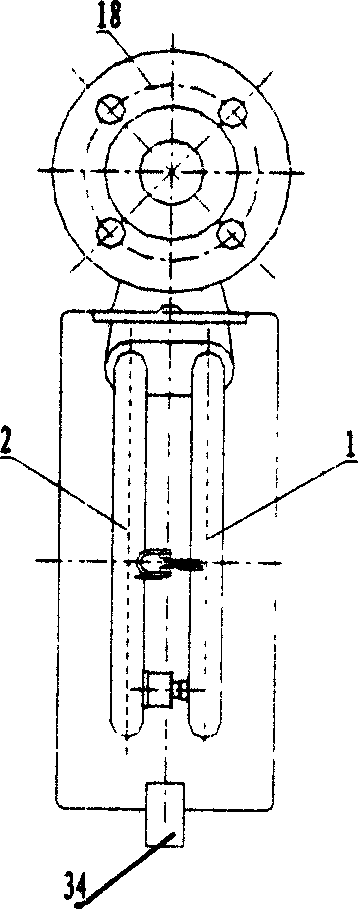

Double C-type tube coriodis mass flow meter

ActiveCN1587921AHigh measurement accuracyReduce overall form factorDirect mass flowmetersElectrical resistance and conductanceFree state

A double C type tube mass flow meter, with two 'C' type sensitiveness tubes fixed by fixed plate and welded to main tube is disclosed. Temperature sensor which is thermistor is installed on one end of sensitiveness tube or other pert not making influence for vibration characteristic; main tube is a reversal symmetric with completely input and output; between four ends of the two sensitiveness tube and the main tube the linking distance is small, nearly mechanical structure, making acting force of sensitiveness tube vibration in internal force condition so eliminating or decreasing vaporization of vibrational energy, and sensitiveness tube is in complete free state except its top linking to main tube so eliminating possibility of creating deformation stress and decreasing influence of exterior vibration and making convenience for installation of flow meter.

Owner:XIAN DONGFENG MACHINERY & ELECTRONICS

Deodorizing additive of compound plant extract for farm animal and its use

InactiveCN1672738AEmission reductionReduce fugitiveAnimal feeding stuffDeodrantsAnimal scienceFeed conversion ratio

The deodorizing additive is compounded with two or three kinds of volatile oil from pine needle, cassia and clove. It is added into feed for farm animal with the added amount being 0.05-2 wt%, and this can reduce bad smell the farm animal releases obviously, improve the raising environment, promote the growth of farm animal and raise feed converting rate. The deodorizing additive may be also added into animal excrement to reduce escaped bad smell and raise the nitrogen preserving rate in animal excrement. The deodorizing additive is safe, non-toxic and no residue.

Owner:ZHEJIANG UNIV

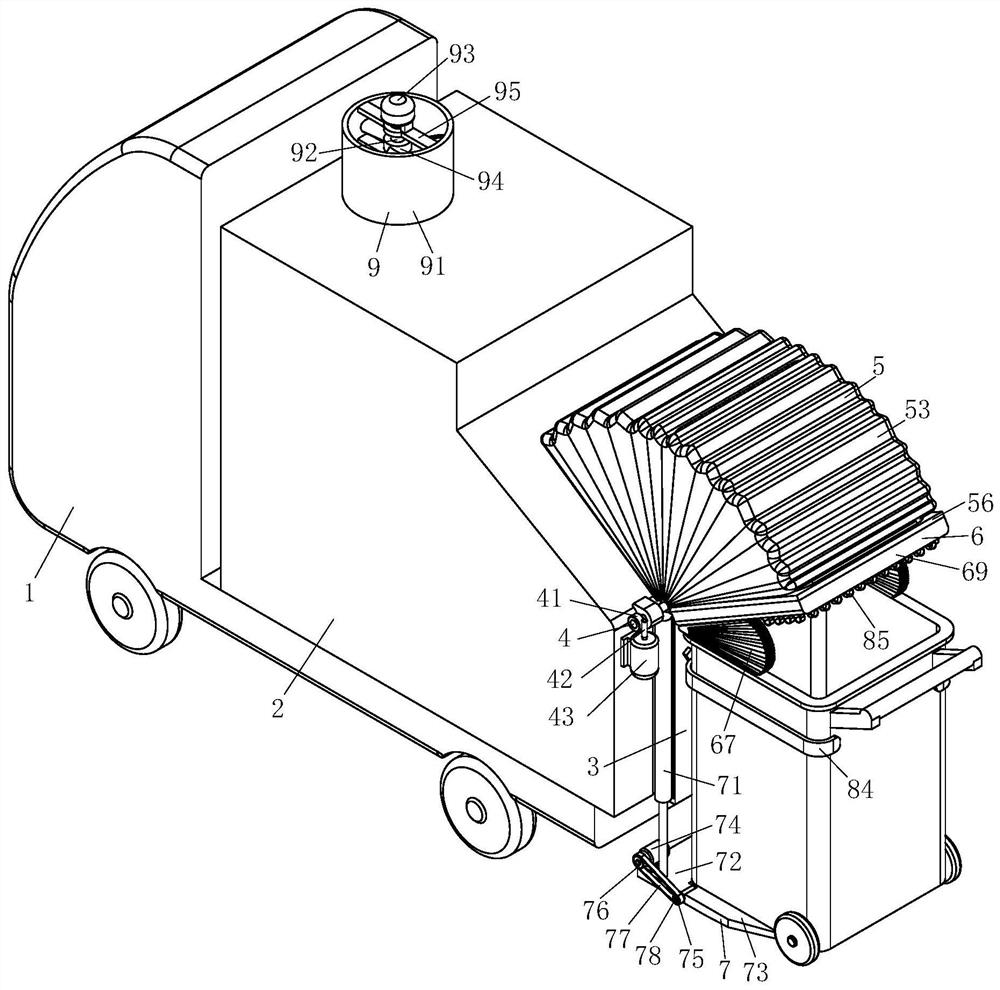

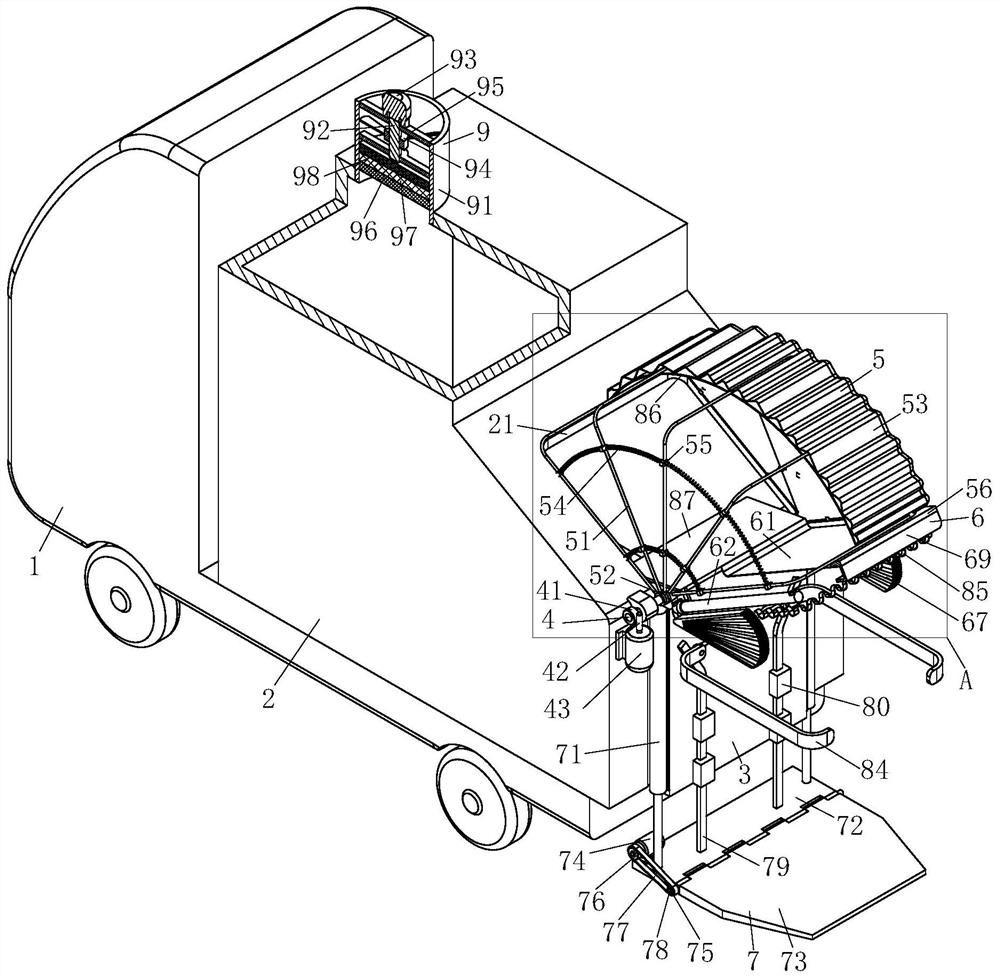

Garbage transfer trolley with deodorization function

InactiveCN112046974APrevent escapeAvoid pollutionRefuse vehiclesElectric machineryProcess engineering

The invention belongs to the technical field of garbage transportation, and particularly relates to a garbage transfer trolley with a deodorization function. The garbage transfer trolley with the deodorization function comprises a transport vehicle, a garbage storage box, a turning plate, a first rotating shaft, a worm gear, a worm, a first motor, a flexible sealing part, a lifting fixing part anda sealing part. According to the garbage transfer trolley with the deodorization function, a garbage can is clamped and fixed through the lifting fixing part in a garbage lifting process, a fixing lifting part rotates and drives the garbage can to rotate, then the sealing part is gradually opened, the garbage can extrudes the flexible sealing part, then garbage in the garbage can enters the garbage storage box through a garbage dumping opening, then odor is prevented from escaping when the garbage is dumped, then the air and environment are prevented from being polluted, when the garbage is dumped, a lifting fixing part drives the garbage can to gradually leave the flexible sealing part, then the sealing part is gradually closed, the odor is prevented from overflowing, and meanwhile, theodor is prevented from overflowing in the garbage transfer process.

Owner:合肥朗越信息科技服务有限公司

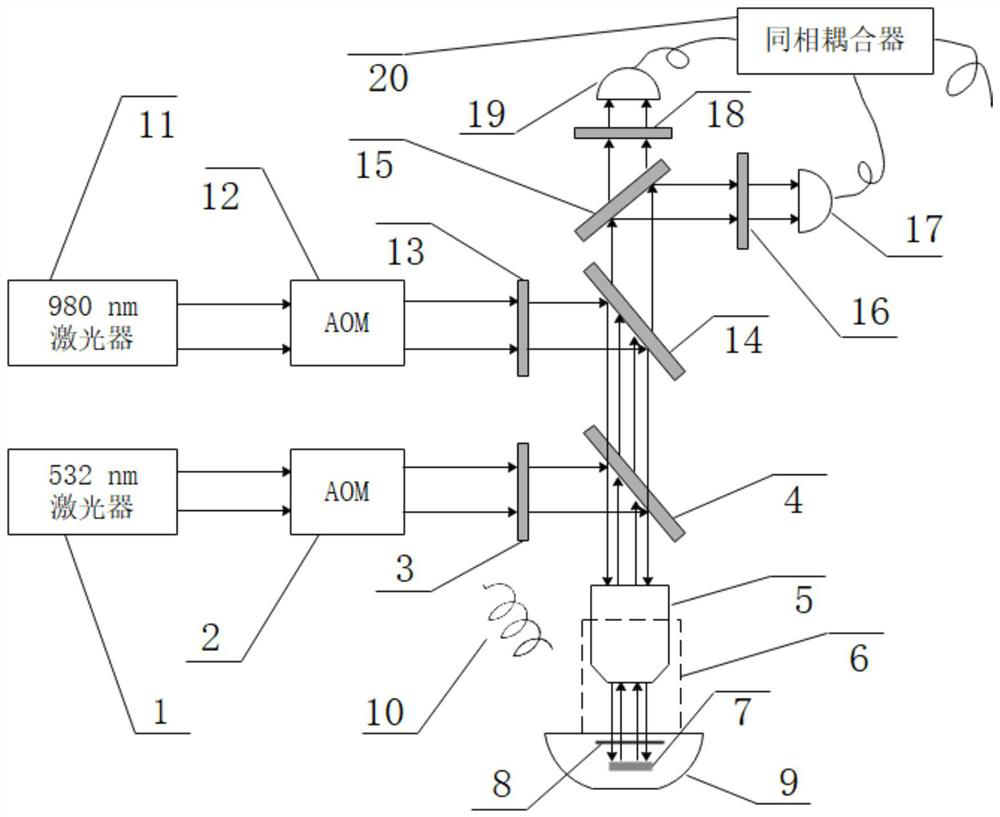

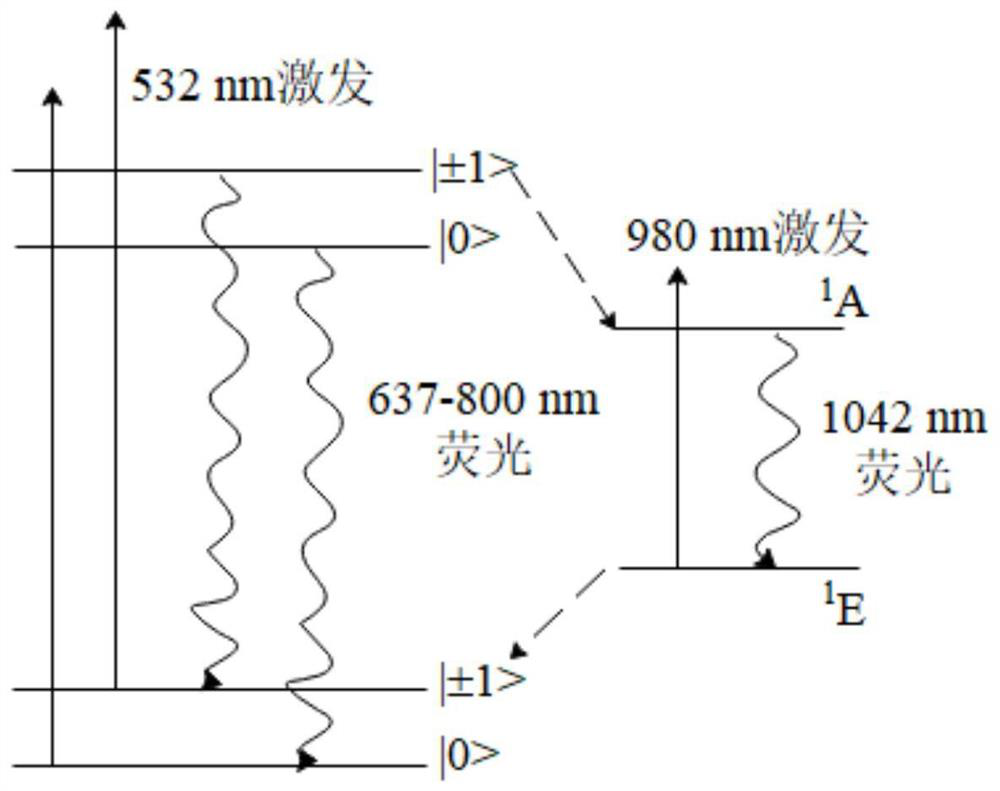

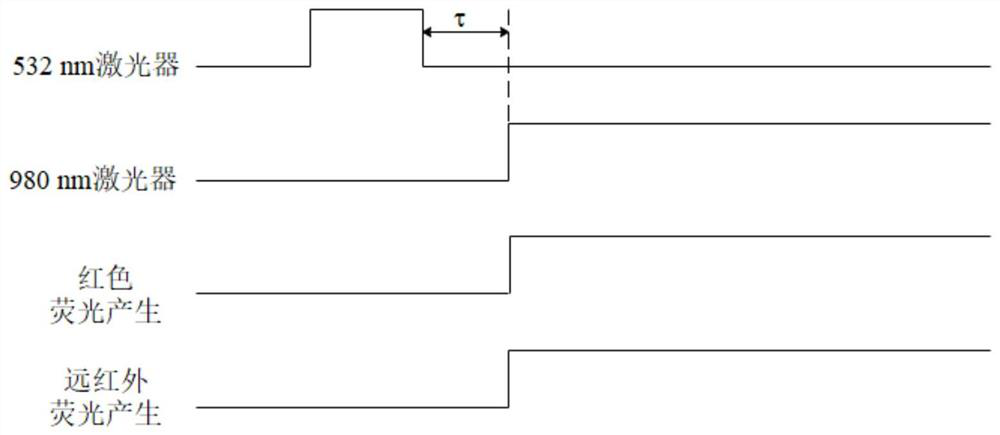

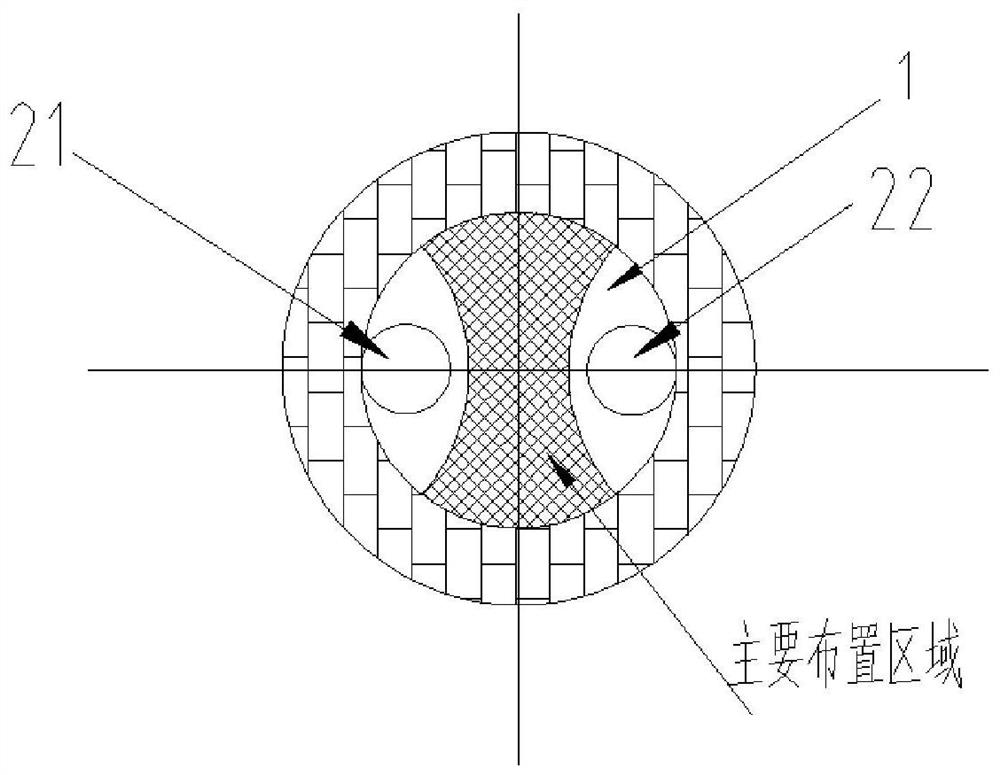

Diamond NV color center fluorescence high-efficiency collection device

ActiveCN111678896AIncrease collection rateRaise the ratioRadiation pyrometryRaman/scattering spectroscopyColour centreSingle photon imaging

The invention provides a diamond NV color center fluorescence high-efficiency collection device, belongs to the field of diamond NV color center fluorescence detection, and is expected to be applied to various quantum detection devices such as a diamond NV color center-based quantum computer, a gravity gradiometer, an accelerometer, a thermometer and a single-photon imager. According to the technical scheme, in-phase double collection of red fluorescence and far infrared fluorescence is adopted, and the fluorescence collection proportion is greatly increased; fluorescence excited by a diamondNV color center is reflected by a parabolic reflector, parallel focusing is performed by a Fresnel plane lens, and under the combined action of a shading cylinder, light dissipation is reduced to themaximum extent, and efficient gathering of the fluorescence is realized; the axial helical antenna with high directivity and high gain is adopted to provide high-efficiency microwave excitation, so that high-efficiency optomagnetic resonance is realized, and the intensity of red fluorescence generated by the diamond NV color center is increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

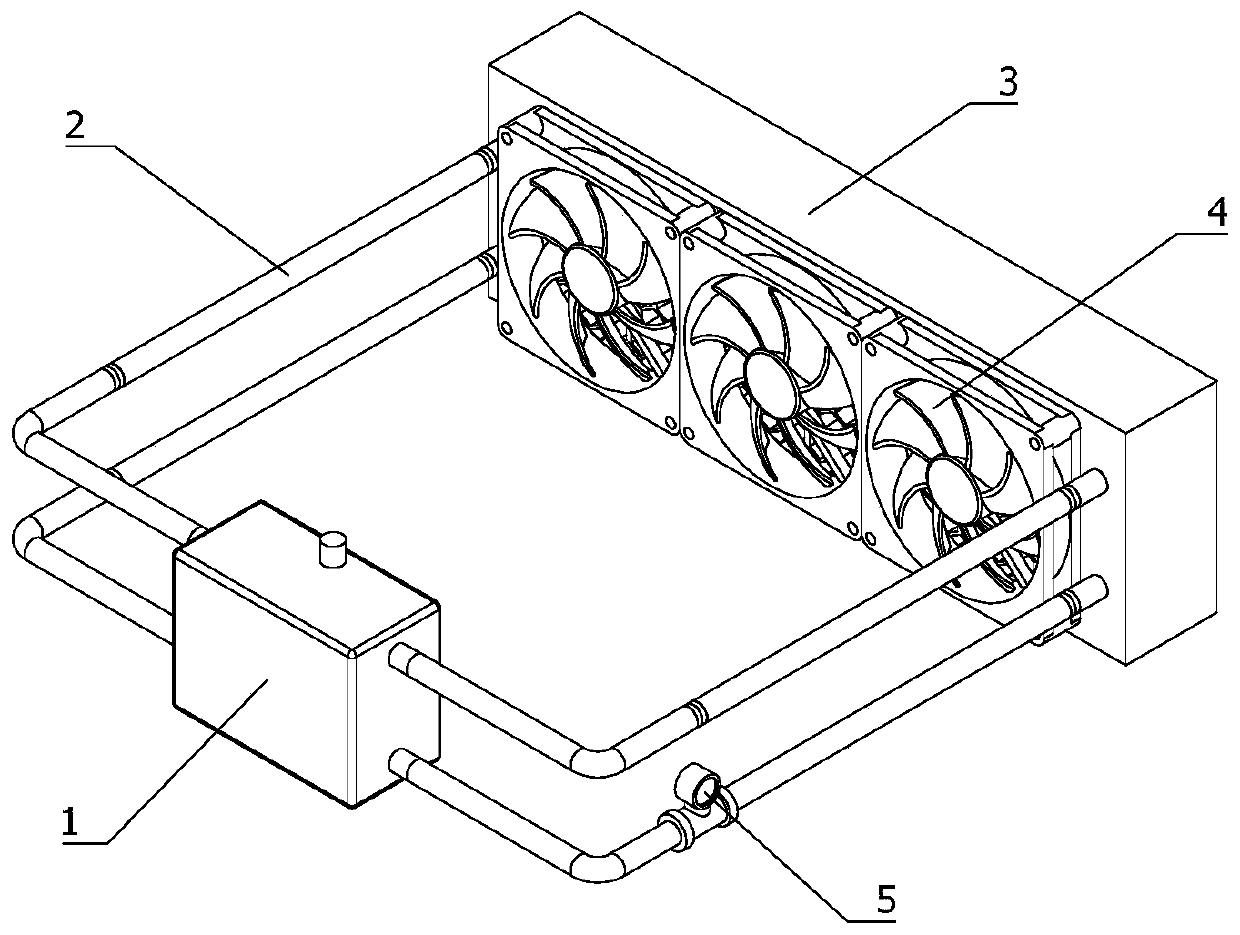

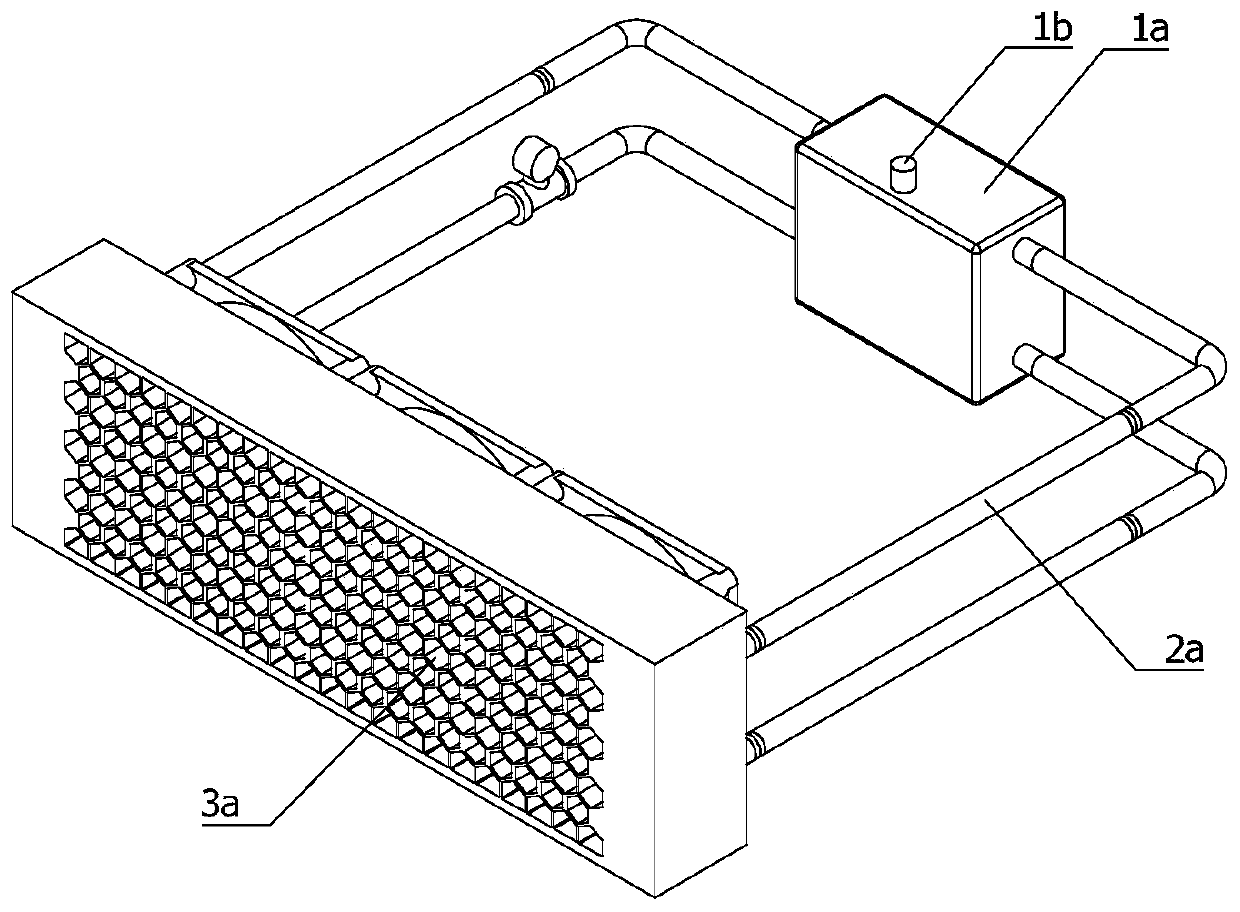

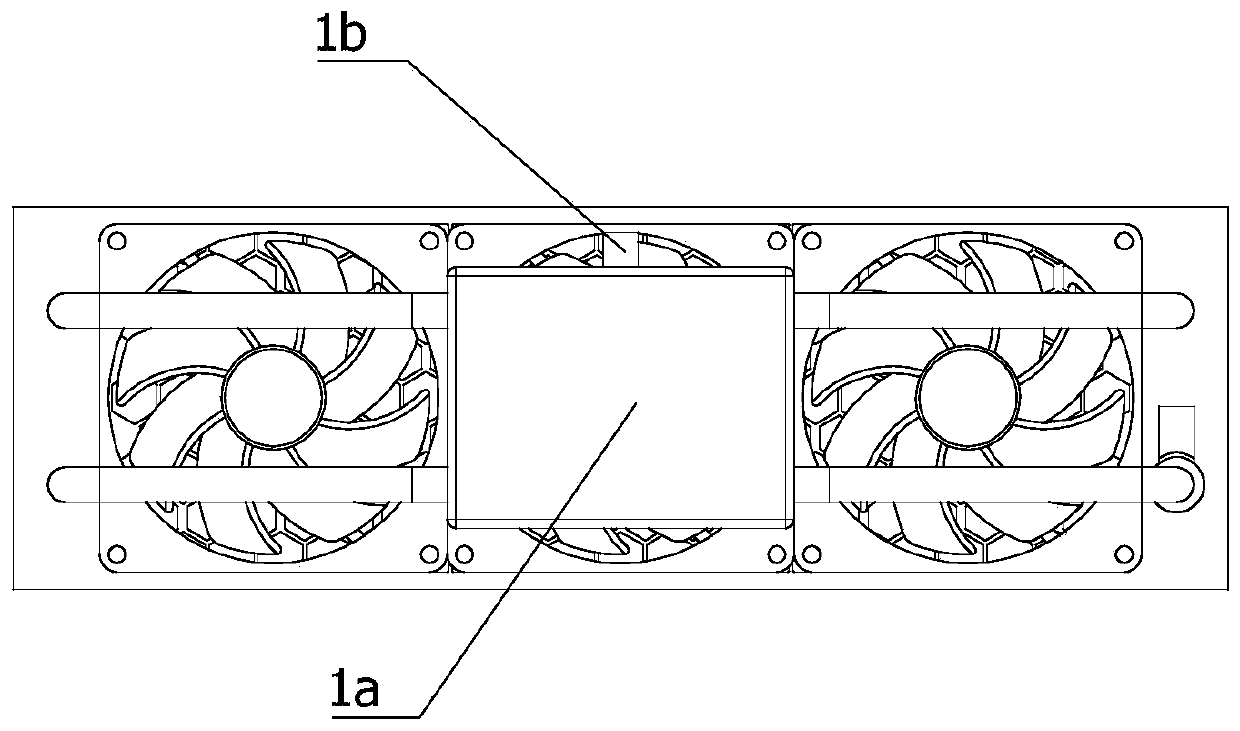

Liquid cooling heat dissipation device of electromechanical equipment

ActiveCN111372426AReduce fugitiveImprove cooling effectCooling/ventilation/heating modificationsHoneycomb structureComputer fan

The invention relates to the technical field of heat dissipation, in particular to a liquid cooling heat dissipation device of electromechanical equipment, which comprises a liquid cooling head, a heat conduction pipe, a heat exchanger, a heat dissipation fan, a flow sensor and a controller, the liquid cooling head, the heat conduction pipe and the heat exchanger are connected end to end to form aclosed circulation path, the heat dissipation fan is installed on the heat exchanger, the flow sensor is installed on a heat conduction liquid path of the heat conduction pipe, the heat conduction pipe is of a double-layer nested structure, gaps exist between the double layers, and the liquid cooling head, the heat dissipation fan and the flow sensor are electrically connected with the controller. According to the scheme, unnecessary dissipation of heat in the electromechanical equipment in the heat conduction liquid circulation process is reduced, the heat dissipation effect of the device isimproved through the honeycomb structure, the structure is simple, the cost is saved, and the application range is wide.

Owner:ZHAOQING UNIV

Preheating process of dust remover for filtering combustible dusty gas

ActiveCN103961955AGuaranteed Safe FiltrationRealize circulating heatingDispersed particle filtrationThermodynamicsProcess engineering

The invention discloses a preheating process of a dust remover for filtering combustible dusty gas. The preheating process comprises a dust remover cold-air exhausting period, a temperature rise period and a gas replacement-adjustment period and specifically comprises the steps of inputting high-temperature gas through a hot air pipeline to exhaust low-temperature gas in the dust remover in the cold-air exhausting period, entering the temperature rise period after the low-temperature gas is exhausted, raising the temperature to 330-1200 DEG C, carrying out gas replacement and adjustment, and entering a conventional filtering-dust removal process link after adjusting the oxygen content in the dust remover to a safety range in the gas replacement-adjustment period. The preheating process is novel and ingenious, has a good utilization effect in a booting preheating link of the dust remover, realizes the innovation of the preheating process of the high-temperature dust remover, is suitable for preheating the dust remover for filtering the high-temperature and high-tar-content dusty gas and guarantees a good filtering effect, long service cycle and high economic benefit of a filter core.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

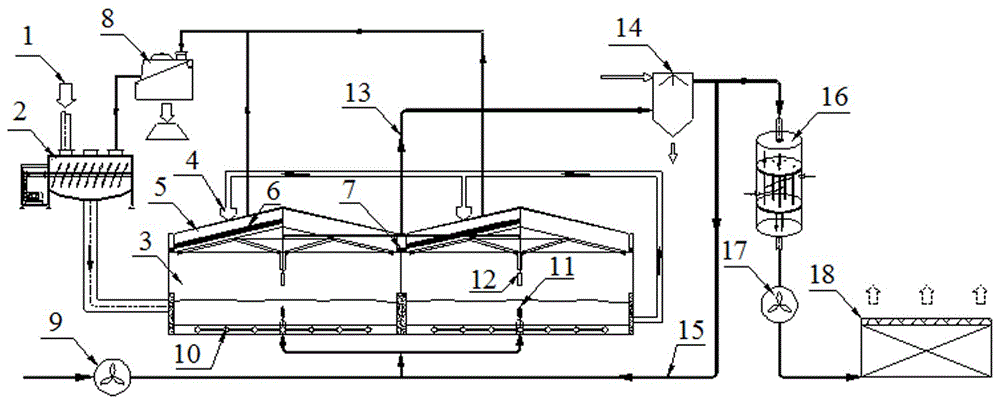

Vertical solar-enhanced deep biological sludge drying system

PendingCN106316031AEfficient and low consumption deep dryingImprove running stabilitySludge treatment by de-watering/drying/thickeningSludge processingThermal energySolar drying

The invention discloses a vertical solar-enhanced deep biological sludge drying system, capable of carrying out drying treatment on dewatered sludge by means of a biological drying and solar drying two-stage coupling technology. The system includes but not limited to a mixer, a biological drying chamber, a solar drying chamber, a vibrating screen, an air blower, an aerating system, a gas collection system, a gas scrubber, a gas circulation system, a heat exchange device, an induced draft fan and an underground soil biological filter bed. The solar drying chamber is vertically arranged above the biological drying chamber, a hydrophobic composite membrane is laid at the inner side of a roof, and stainless steel chain plate(s) is / are installed at the single side or double sides of the roof. The system utilizes the coupling effect of the biological heat energy generated by aerobic fermentation of microorganism and the clean and renewable energy-solar energy to realize rapid drying of the sludge, has the characteristics of being high in drying efficiency, low in running energy consumption, small in land occupation area, and the like, and improves the reduction level and the resource utilization level of the sludge.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Deodorization system of rubbish transfer station

PendingCN109999640AReduce fugitiveHarm reductionGas treatmentDispersed particle separationParticulatesHazardous substance

The invention provides a deodorization system of a rubbish transfer station. The deodorization system comprises a gas collection cover, a spraying washing device, a plasma reaction device, a filler tower and a sucking device which are sequentially communicated, wherein the gas collection cover is arranged at the rubbish transfer station in a covering manner and is used for collecting odorous gasesin the rubbish transfer station; the odorous gases in the rubbish transfer station are collected by the gas collection cover and are conveyed into the spraying washing device; a spraying liquid in the spraying washing device is acted with the odorous gases to remove soluble pollutants and particulate matters in the odorous gases; the odorous gases are further fed into the plasma reaction device;toxic and harmful substances in the odorous gases are converted and removed by active particulate matters generated in the plasma reaction device; acid substances and toxic and harmful substances leftafter treatment of the plasma reaction device in the odorous gases are absorbed by the filler tower; the sucking device is used for collecting and discharging purified gases treated by the filler tower. Refractory pollutants in odorous gases can be effectively removed by using a great amount of active particulate matters generated in the plasma discharge process, the odorous gas treatment efficiency can be improved, and deep purification can be achieved.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

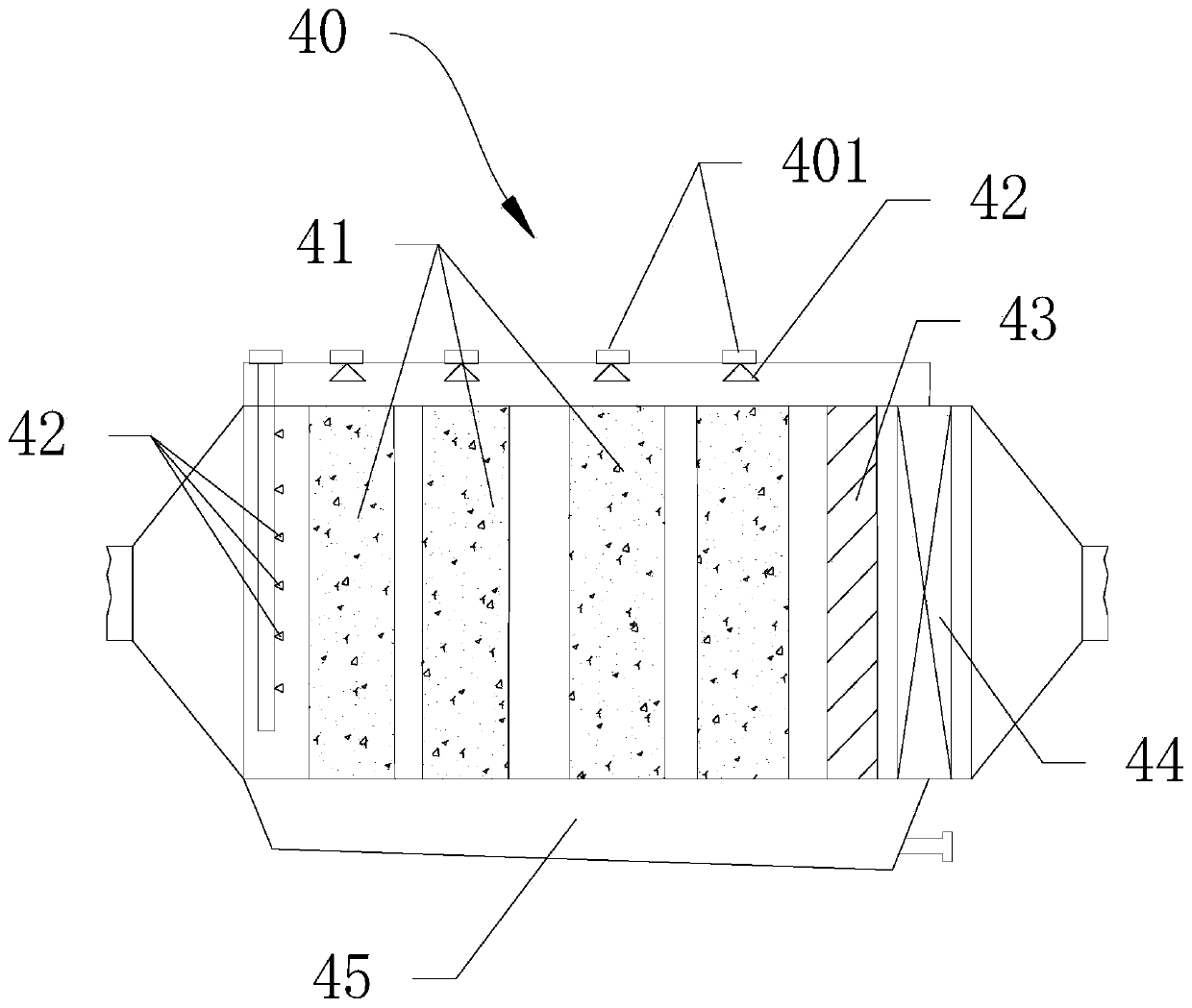

Garbage fermenting system and method of garbage incineration power plant

InactiveCN109503232AAvoid settingSimple structureBio-organic fraction processingBiological combination treatmentPower stationLitter

The invention discloses a garbage fermenting system and a garbage fermenting method of a garbage incineration power plant. The garbage fermenting system comprises a fermenting tank, a feeding system and a discharging system, wherein a top cover is arranged on the top of the fermenting tank; a partition board is arranged above supporting columns inside the fermenting tank; the partition board partitions an inner cavity of the fermenting tank into a fermentation chamber and a filtrate storage chamber; a liquid draining pipe is arranged at one end of the filtrate storage chamber; a filtrate purifying system is connected to the end part of the liquid draining pipe; a gas inlet pipe is arranged at the other end of the filtrate storage chamber; a blast blower and a temperature adjusting chamberare mounted on the gas inlet pipe; the feeding system comprises a material mixing tank and a screw feeder; a garbage inlet and a fermenting agent storage tank are arranged on the top of the material mixing tank; the discharging system is a discharging bin; a gas exhausting main pipe is mounted on the top of the fermenting tank; a deodorizing tower is mounted on the end part of a gas exhausting pipe. By adopting the garbage fermenting system and the garbage fermenting method, the fermentation temperature in the fermenting tank and the fermentation time can be controlled, environmental odor canbe quickly and effectively eliminated, generation and escape of the odor can be reduced and leachate produced in the garbage fermenting process can also be effectively treated.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

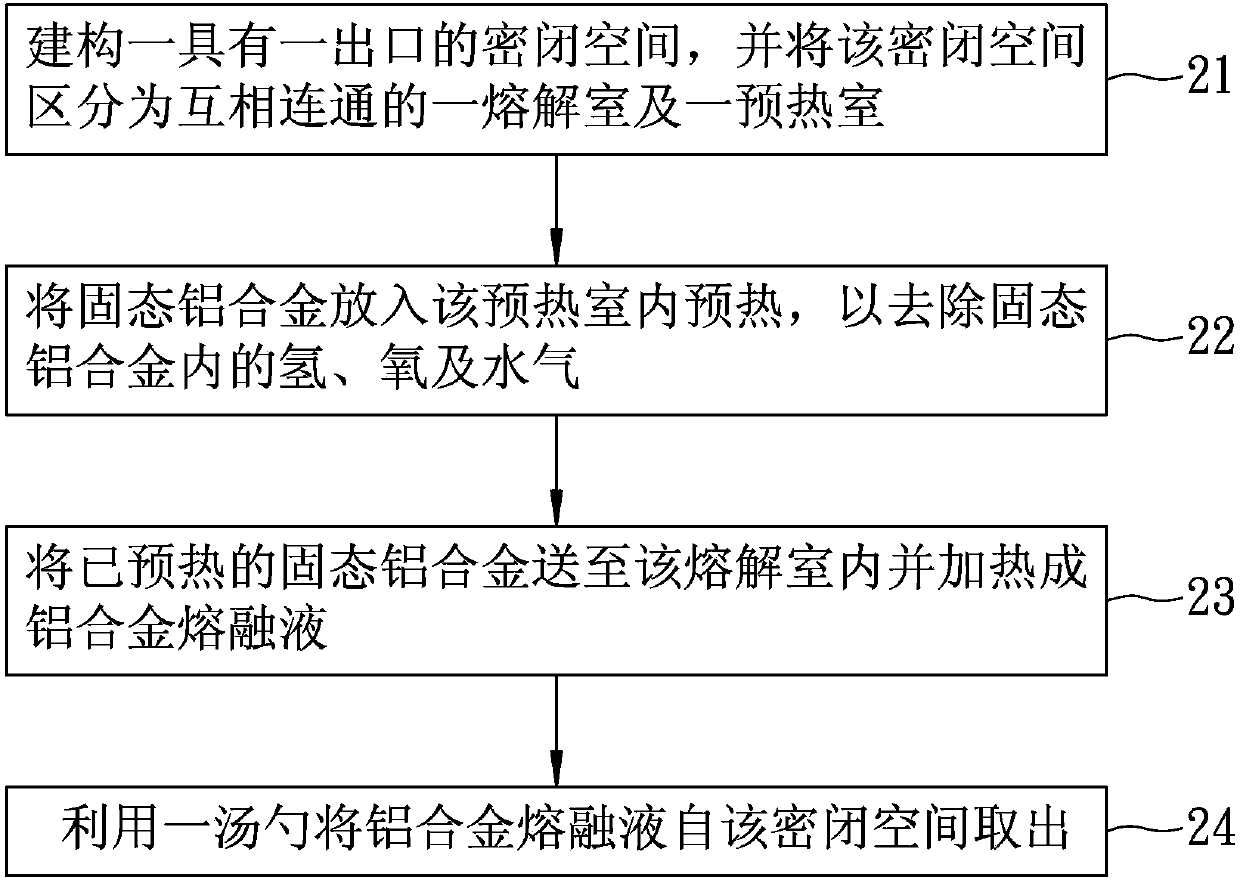

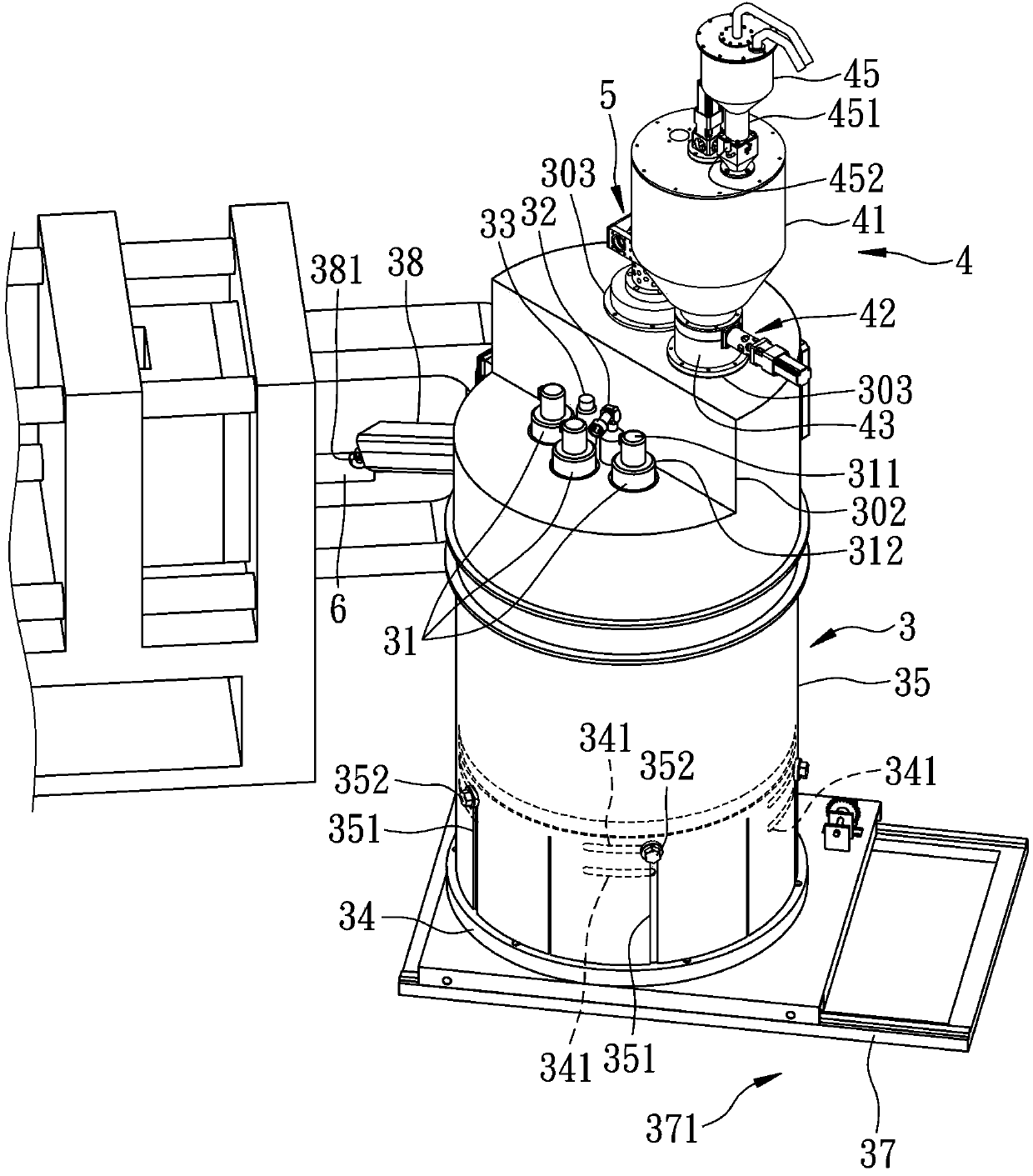

Method and apparatus for providing aluminum alloy meltwater

InactiveCN103624243AReduce fugitiveImprove yieldMelt-holding vesselsCharge manipulationHydrogenOxygen

The invention provides a method and an apparatus for providing aluminum alloy meltwater. The method comprises the steps of building a sealing space with an outlet and dividing the sealing space into a melting chamber and a preheating chamber, which are mutually communicated; feeding solid aluminum alloy to the preheating chamber for preheating and removing hydrogen, oxygen and steam from the solid aluminum alloy; transmitting the preheated solid aluminum alloy to the melting chamber and heating the preheated solid aluminum alloy into aluminum alloy meltwater; taking out the aluminum alloy meltwater from the sealing space by means of a soup spoon. Accordingly, the solid aluminum alloy is melted into the aluminum alloy meltwater in the sealing space, heat energy dissipation can be effectively reduced, and the aim of saving power can be achieved, and the casting yield can be improved.

Owner:游家龙

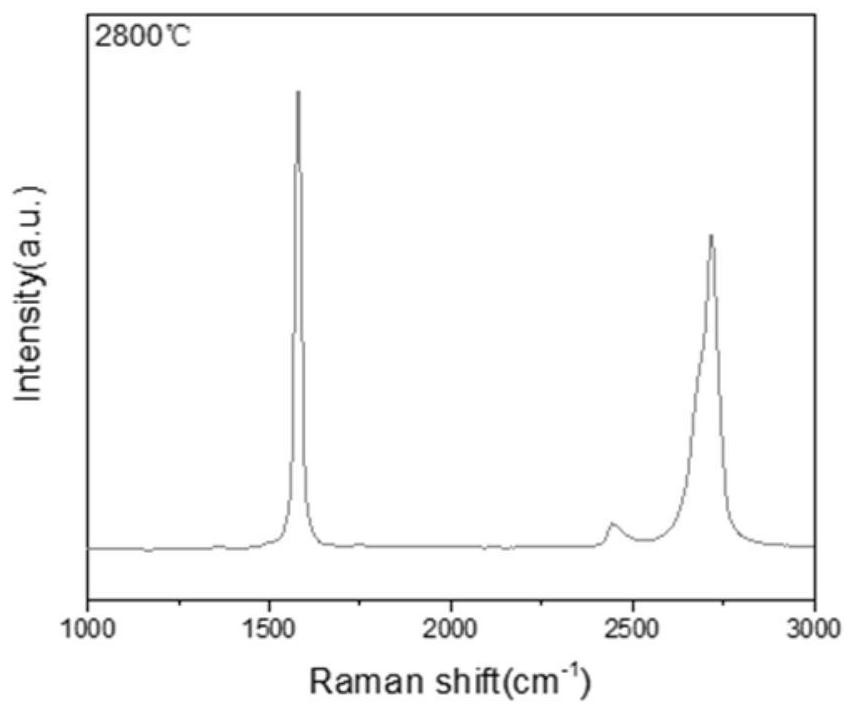

Thickness-controllable high-performance graphene film and preparation method thereof

The invention discloses a thickness-controllable high-performance graphene film and a preparation method thereof. The preparation method comprises the following steps: uniformly compounding graphene and a polymer by adopting a centrifugal spraying technology to construct a submicron graphene film, assembling the submicron graphene film serving as a structural unit and an adhesive layer by layer, and finally obtaining the graphene composite film with controllable thickness after high-temperature sintering. According to the invention, a multi-stage gas dissipation channel is constructed by utilizing different gas dissipation behaviors of various polymers, so that formation of micro-airbags in a traditional graphene film is avoided, and delamination structures are reduced. In addition, graphene can induce the polymer to form graphene; the polymer can promote AB stacking of graphene, and the polymer and the AB have a synergistic effect to jointly form a high-crystallinity graphene film. The material has excellent thermal conductivity, electrical conductivity and thermal stability, and can be applied to thermal homogenization of aerospace vehicles. In addition, the cost of the graphitizable polymer is far lower than that of graphene, so that the production cost for preparing the composite graphite film is greatly reduced.

Owner:HANGZHOU GAOXI TECH CO LTD

Gas injection device for automobile

InactiveCN105604743AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityHeat conducting

The invention discloses a gas injection device for an automobile. The gas injection device comprises a gas inlet pipe and a hollow pipe, wherein a groove of which the section is a major arc is formed in the inner wall of the hollow pipe; injection holes are just opposite to the arc bottom of the groove; a plurality of electric heating tubes are arranged in the groove; a guide block is arranged at the bottoms of the electric heating tubes; a guide groove matched with the guide block is formed in the bottom of the groove; each electric heating tube comprises a tube body, an insulated material filling the inside of the tube body and an electric heating wire arranged inside the tube body; a binding post is connected to the tail end of each electric heating wire, penetrates through a small hole and is connected with a wiring plug board; a heat conducting board covers the opening end of the groove. The plurality of electric heating tubes are arranged in the arc groove; the side end of the groove is sealed by the wiring plug board, so that the heat dissipation can be reduced; meanwhile, the electric hating tubes are favorably taken and placed, i.e., a user can determine the number of the electric heating tubes in real time according to the supply amount of gas, so that stable operation for gas output flow is finished at the minimum heating cost.

Owner:CHENGDU DUJIA ELECTRICAL

RH vacuum powder spraying refining device and powder spraying method thereof

The invention discloses an RH vacuum powder spraying refining device and a powder spraying method thereof, and belongs to the technical field of molten steel external refining. The RH vacuum refiningpowder spraying device comprises a vacuum molten steel circulating device and a powder spraying device. The vacuum molten steel circulating device comprises a vacuum chamber, a dip pipe, a steel ladleand a lifting gas pipeline. The powder spraying device comprises a powder spraying element, a powder supply pipe, a buffer gas chamber and a quick connecting part. The powder spraying method comprises but is not limited to refining and alloying functions of desulfurization, deoxidation, inclusion removal, alloy addition and the like. The RH vacuum powder spraying refining device and the powder spraying method thereof have the advantages that the bottom of a vacuum tank is improved on the basis of an RH conventional structure, and spray pipe mounting parameters can be adjusted to meet the process requirements of different steel types; and implementation is easy, maintenance is convenient, the production efficiency can be improved, the production cost is saved, and the application prospectsare good.

Owner:CENT IRON & STEEL RES INST

Vertical micro-fluidic chip and method for PCR detection

PendingCN113832027APrecise feedingAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

The invention discloses a vertical micro-fluidic chip and a method for PCR detection. The micro-fluidic chip comprises a chip body, a first communication piston, a second communication piston and a driving piston, wherein the chip body is provided with a separation and purification cavity, a reagent cavity and a reaction cabin; the first communication piston can be rotatably inserted into the chip body and is provided with a first liquid flow groove capable of communicating the separation and purification cavity with the reagent cavity; the second communication piston can be rotatably inserted into the chip body and is provided with a second liquid flow groove capable of communicating the separation and purification cavity with the reaction cabin; the driving piston is movably arranged in the piston cavity of the chip body; the piston cavity is divided into a first piston cavity part and a second piston cavity part by the piston; the first piston cavity part communicates with the separation and purification cavity; the first communication piston is also provided with a first airflow groove capable of communicating the reagent cavity with the second piston cavity part; and the second communication piston is also provided with a second airflow groove capable of communicating the reaction cavity with the second piston cavity part. By use of the vertical micro-fluidic chip, liquid quantification is accurate, and aerosol pollution is avoided.

Owner:上海邦先医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com