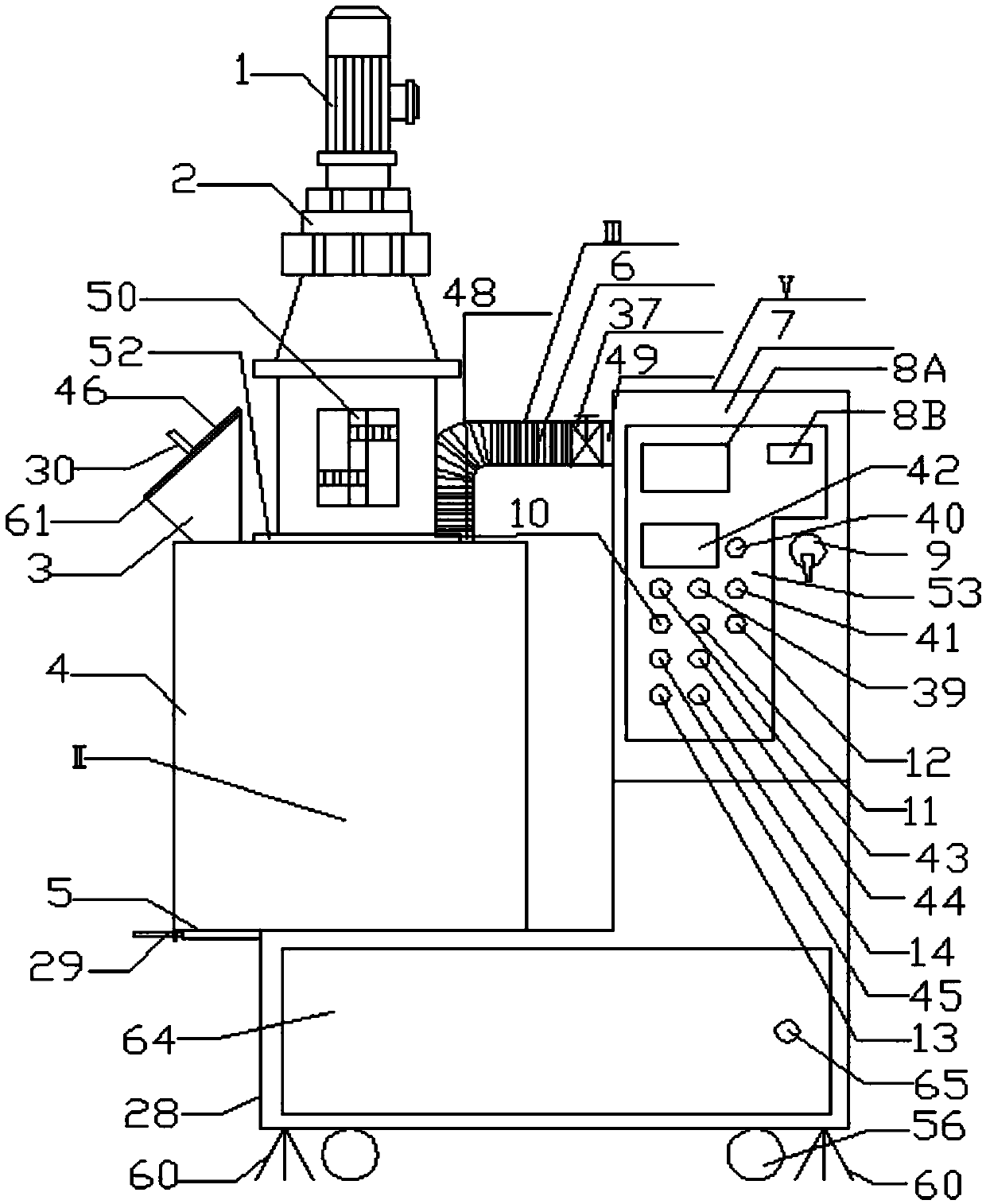

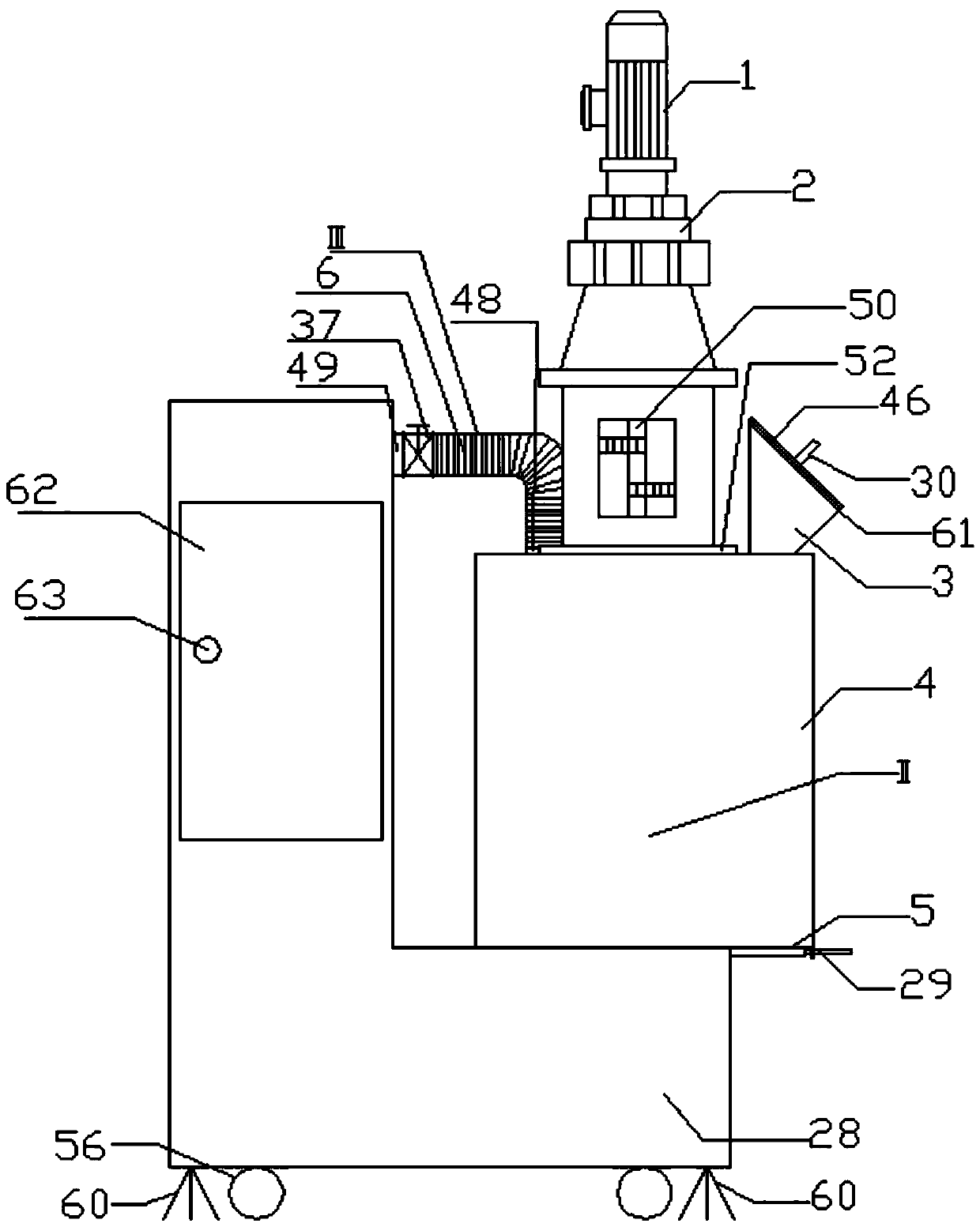

Integrated high-temperature aerobiotic organic waste processor

A technology of organic waste and processing machine, which is applied in the direction of bio-organic part treatment, organic fertilizer, organic fertilizer equipment, etc., which can solve the problems of poor tail gas treatment, low high-temperature fermentation efficiency, and large floor area, etc., to improve The effect of high temperature fermentation efficiency, uniform turning, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: main material: appropriate amount of kitchen waste after simple pretreatment; auxiliary material: special bacteria strain, old fermentation material, crop waste straw, mushroom slag, etc. Close the discharge port 5, put the kitchen waste into the fermentation tank 4 through the feed hopper 3, close the feed hopper cover 46 to ensure airtightness, turn on the power button 10, press the mixer button 12, the mixer indicator light 40 is on, and rotate the mixer to adjust The knob 41 controls the stirring speed, the motor 1 starts, and the reducer 2 drives the stirring shaft 26 to rotate. The spiral stirring blades 16A, 16B, 16C, and 16D stir at the same time so that the materials are evenly turned up and down in the inner cavity 47 of the fermenter. The digital display screen Ⅱ8B displays and monitors the stirring speed, turn the air compressor knob 14 to set and adjust the air supply volume of the air compressor 18, the air compressor indicator light 44 is on, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com