Double C-type tube coriodis mass flow meter

A mass flow meter, Coriolis technology, applied in the field of Coriolis mass flow meters, can solve the problems of simplicity, vibration energy dissipation of sensitive tubes, stress relief, weight reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

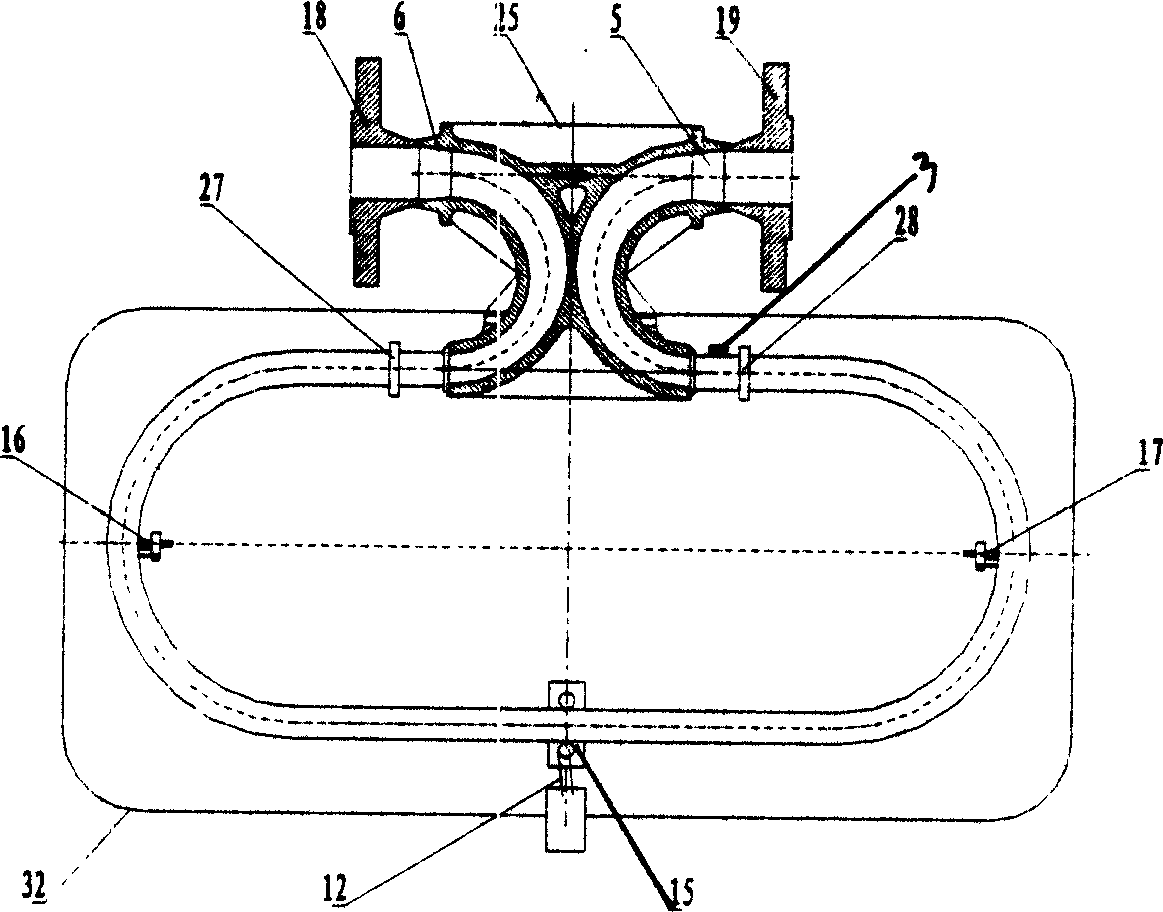

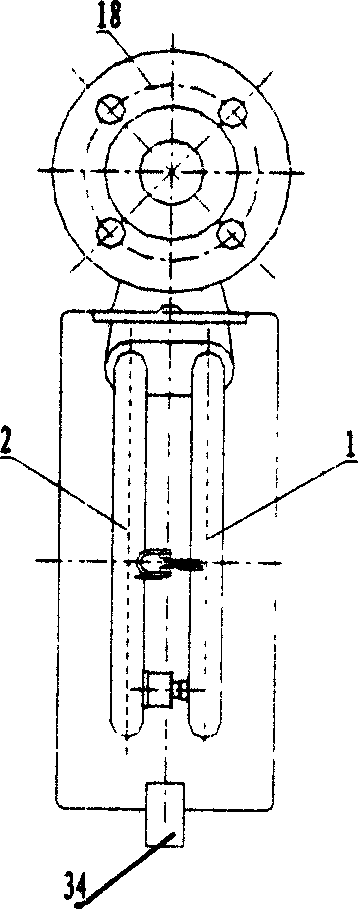

[0026] The Coriolis mass flowmeter of the present invention, such as figure 1 As shown, it includes two parallel C-type sensitive tubes 1 and 2. The fluid to be measured enters the flowmeter from the main body 25 input port 5 and is divided into two parts, flows into the sensitive tubes 1 and 2, and then flows from the sensitive tubes 1 and 2. The outlet flows into the main body into one, and the main pipe output port 6 flows to the external pipe through the flange 18. In the middle section of the sensitive pipes 1 and 2, a drive unit 15 is installed. When working, the two sensitive pipes resonate, and the symmetrical device is in the sensitive pipe 1. The displacement signals 16 and 17 in the middle part of the arc and 2 detect the phase difference signal proportional to the Coriolis force.

[0027] The Coriolis mass flowmeter of the present invention includes an approximately rigid input and output manifold body 25, which is composed of Figure 4 It can be seen that it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com