Electrostatic chuck and plasma device

A technology of electrostatic adsorption and plasma, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as difficult repairs, gas leakage, etc., and achieve the effects of reducing SCCM, reducing dissipation, and extending economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in the specification with respect to various embodiments in particular, that is, with respect to the use of an electrostatic adsorption chuck (ESC) in a plasma chamber. The present invention can also be applied to other forms of electrostatic adsorption trays and other forms of technology.

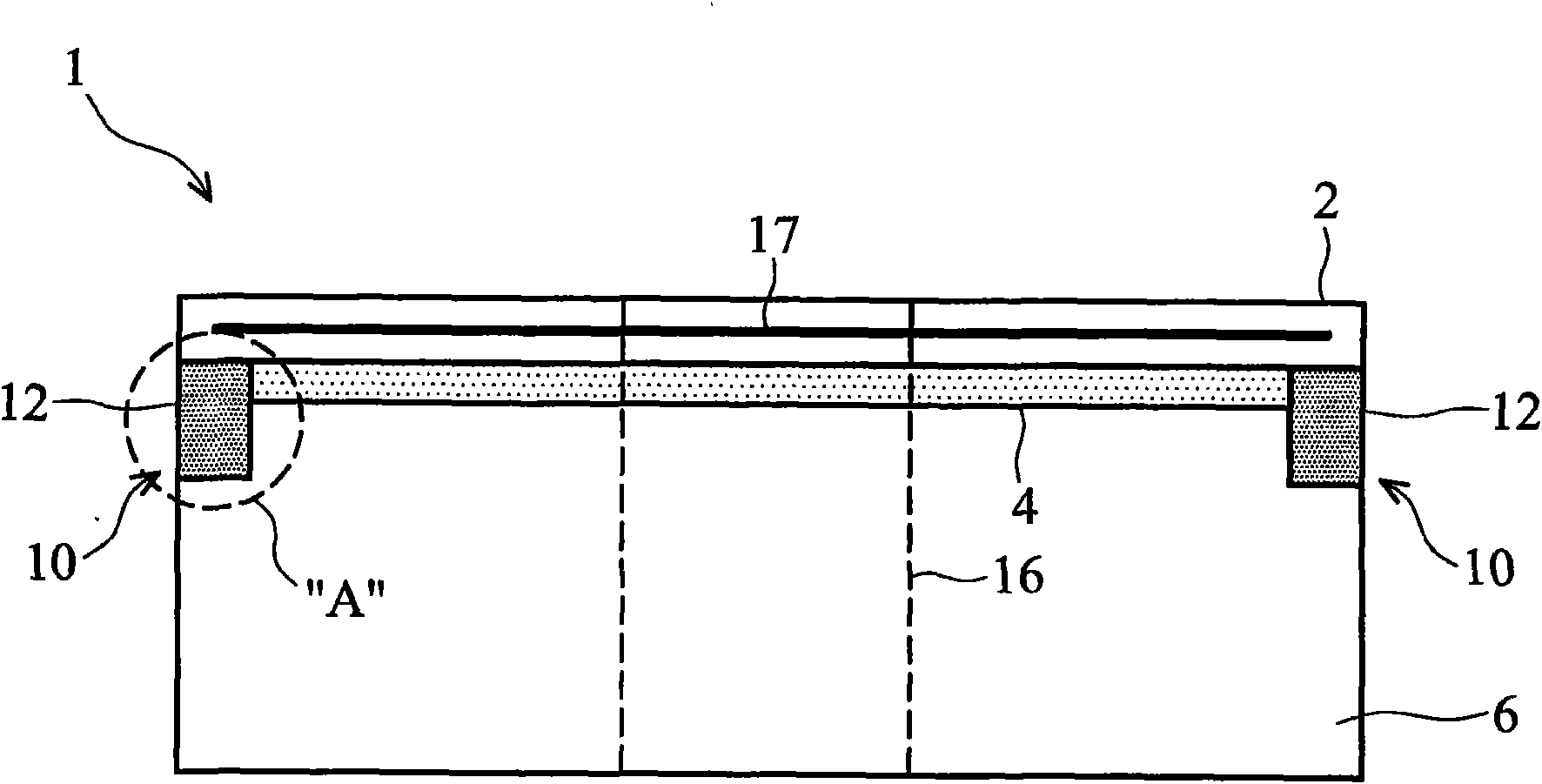

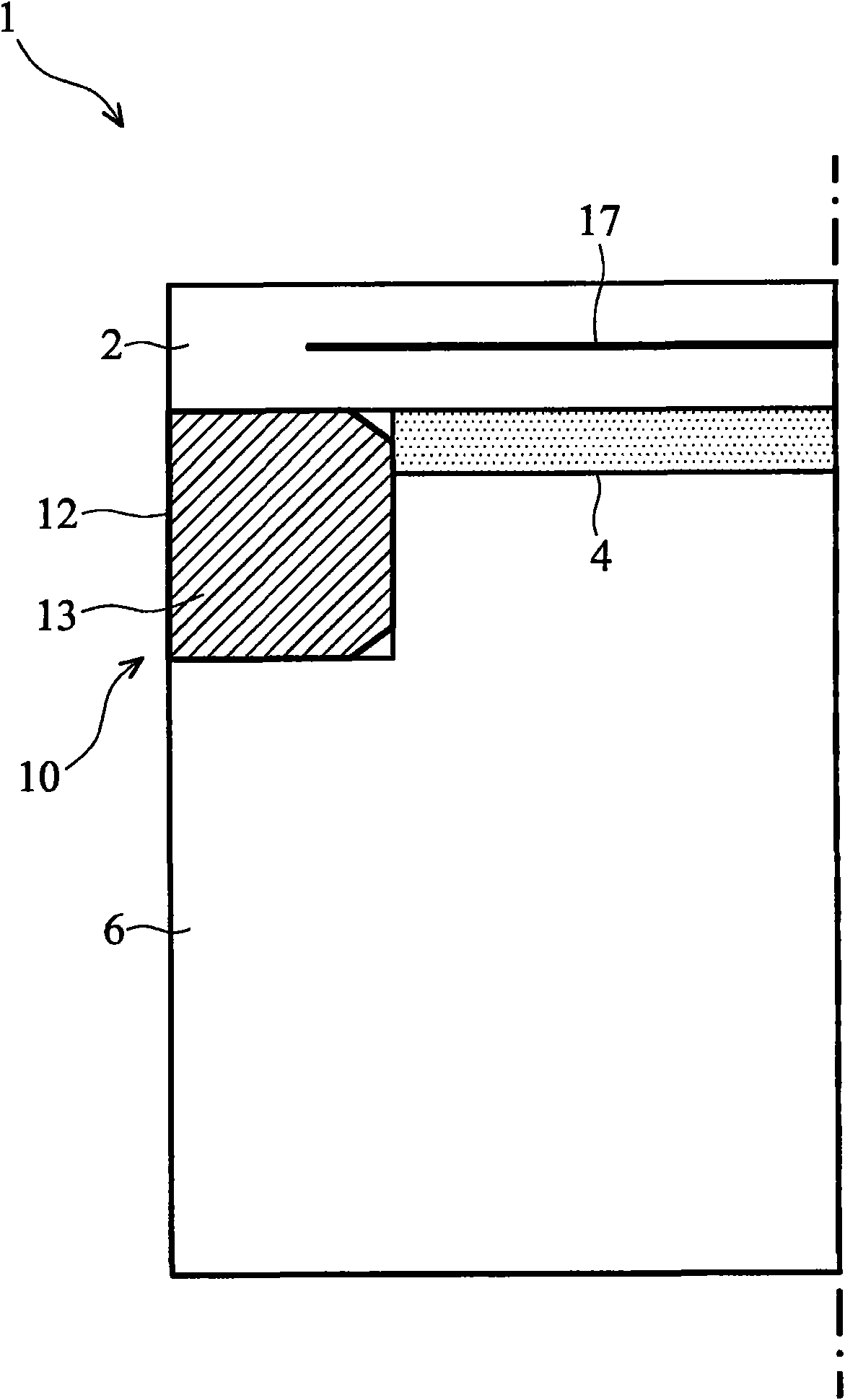

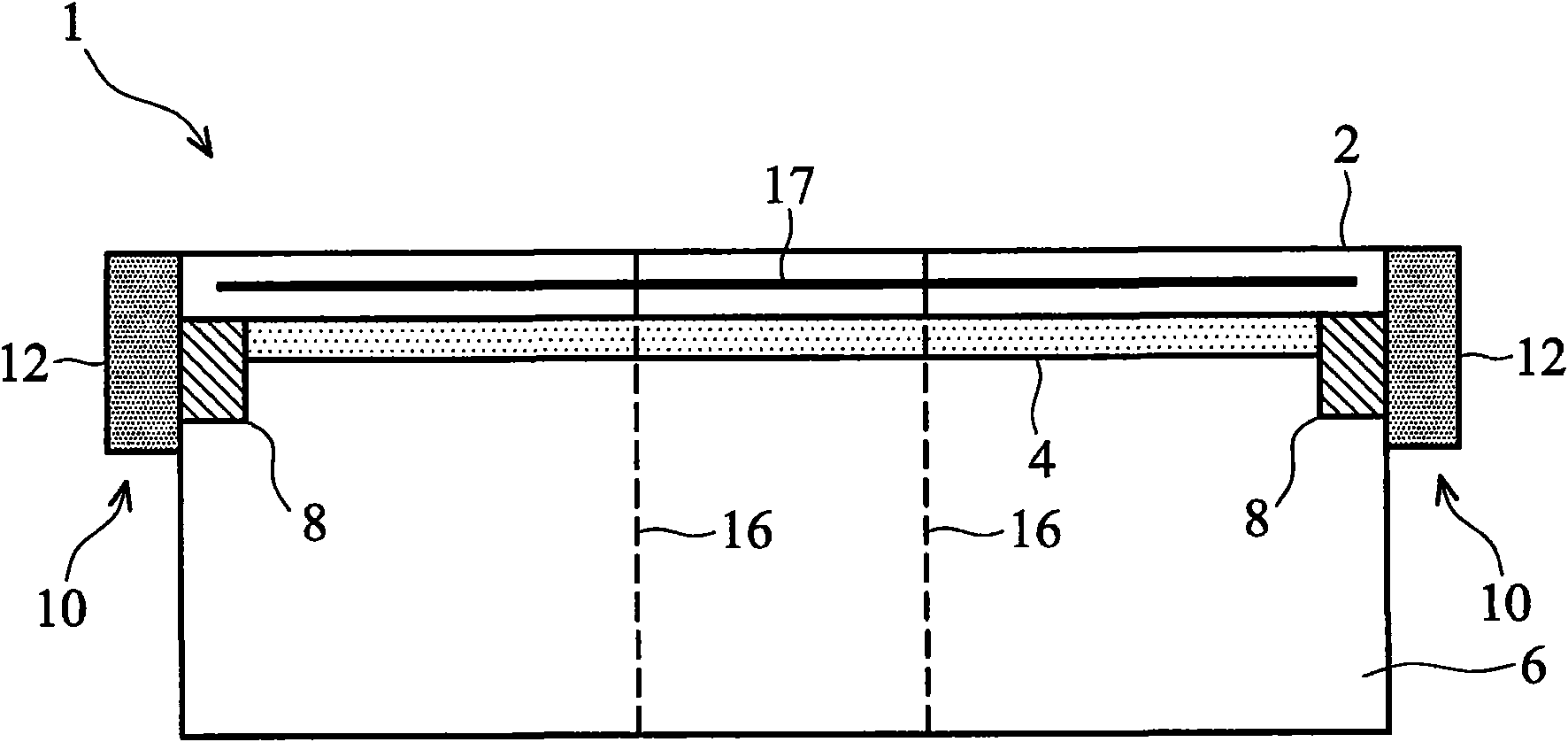

[0034] Now see the illustration, Figure 1A to Figure 1D Shown is the cross-sectional area of an electrostatic adsorption chuck (ESC) 1 . Such as Figure 1A In the illustrated embodiment, the ESC 1 includes an upper element 2 , a bonding layer 4 , a lower element 6 , a notch 10 , a replaceable sidewall shield 12 , an air hole 16 and a conductive electrode 17 .

[0035] The conductive electrode 17 includes a conductive material, such as tungsten, for receiving voltage and serving as an electrode. Lower member 6 receives heat transfer gas through vents 16 to transfer heat from the wafer (not shown) during the process. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com