Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1029 results about "Plasma chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

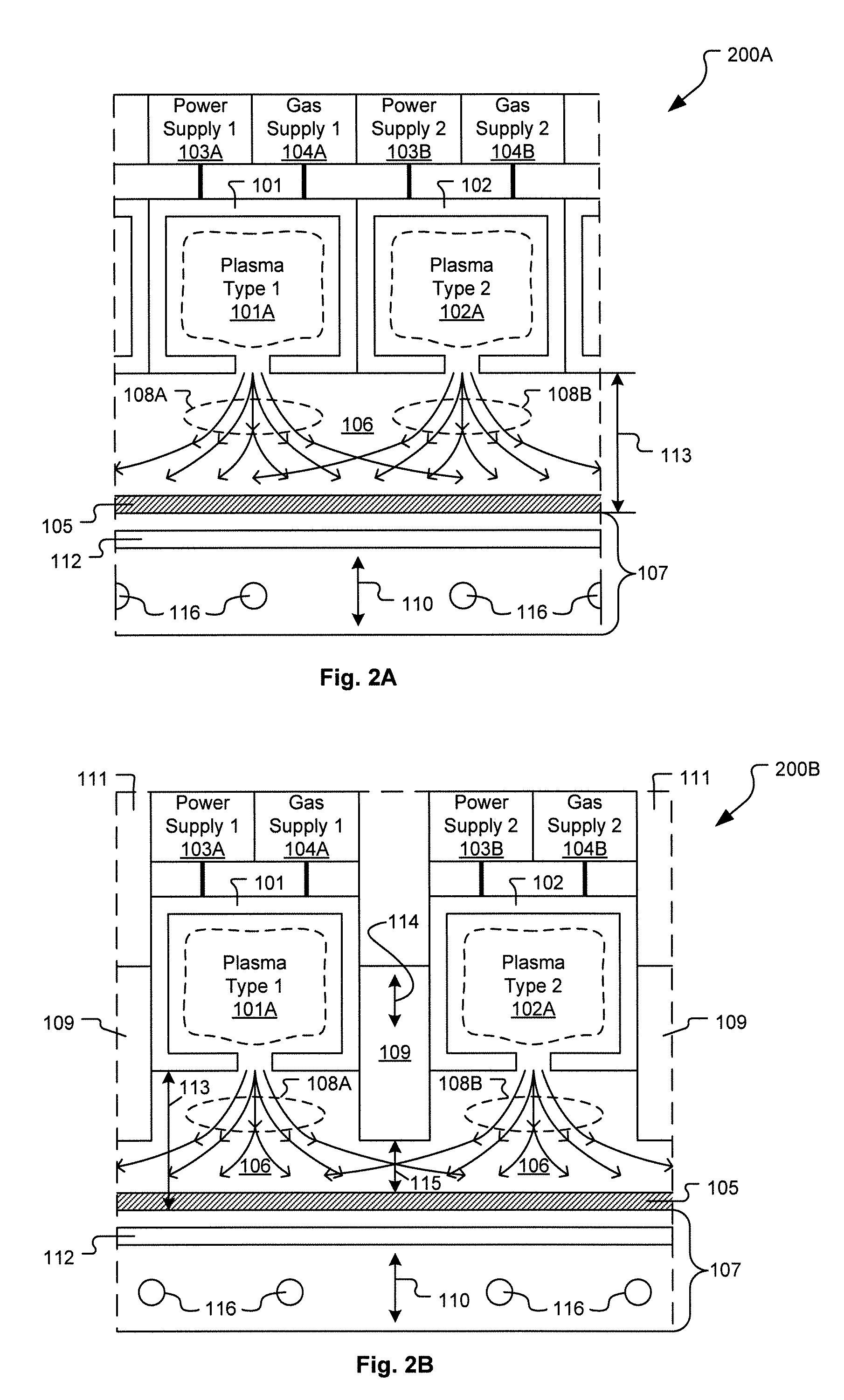

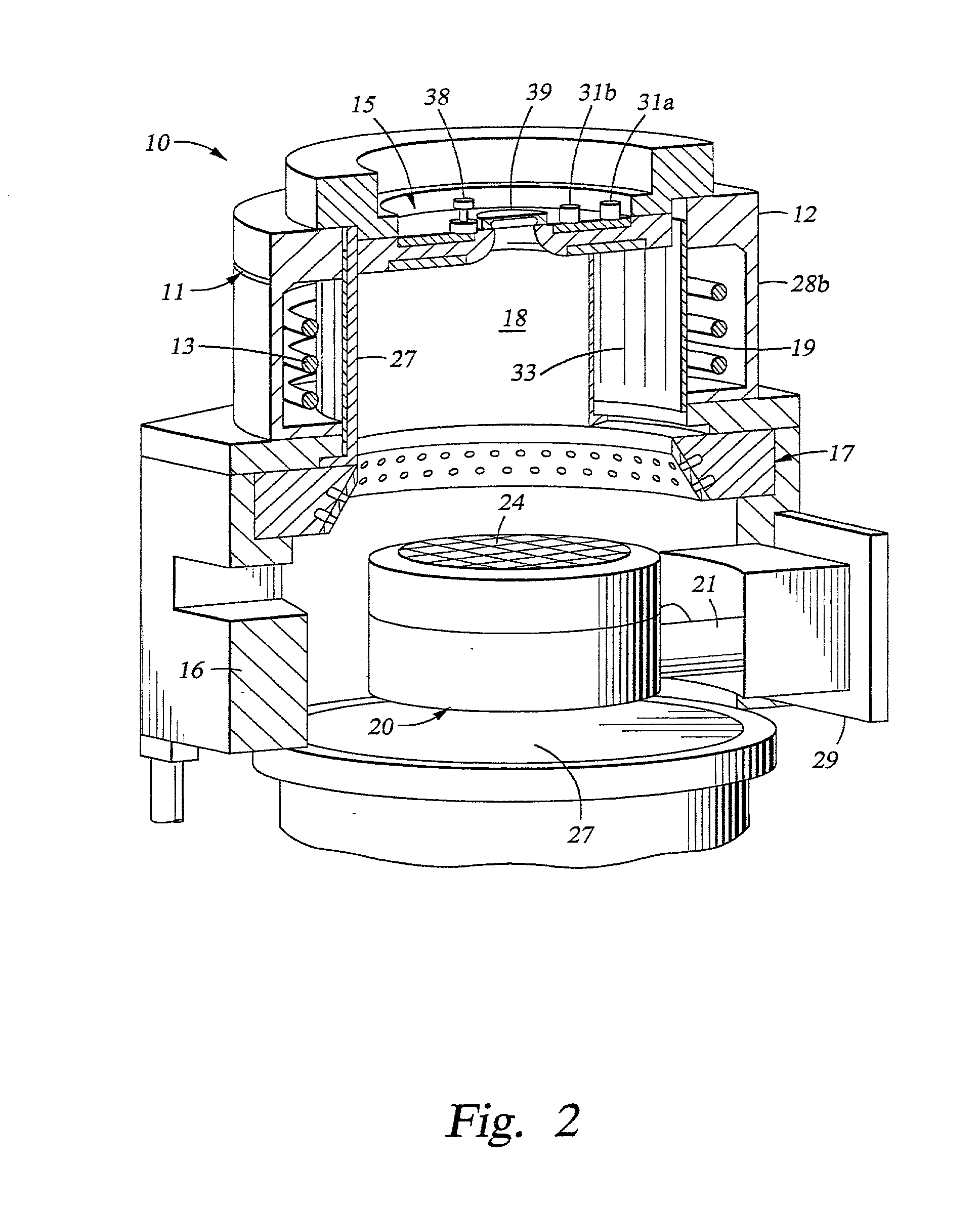

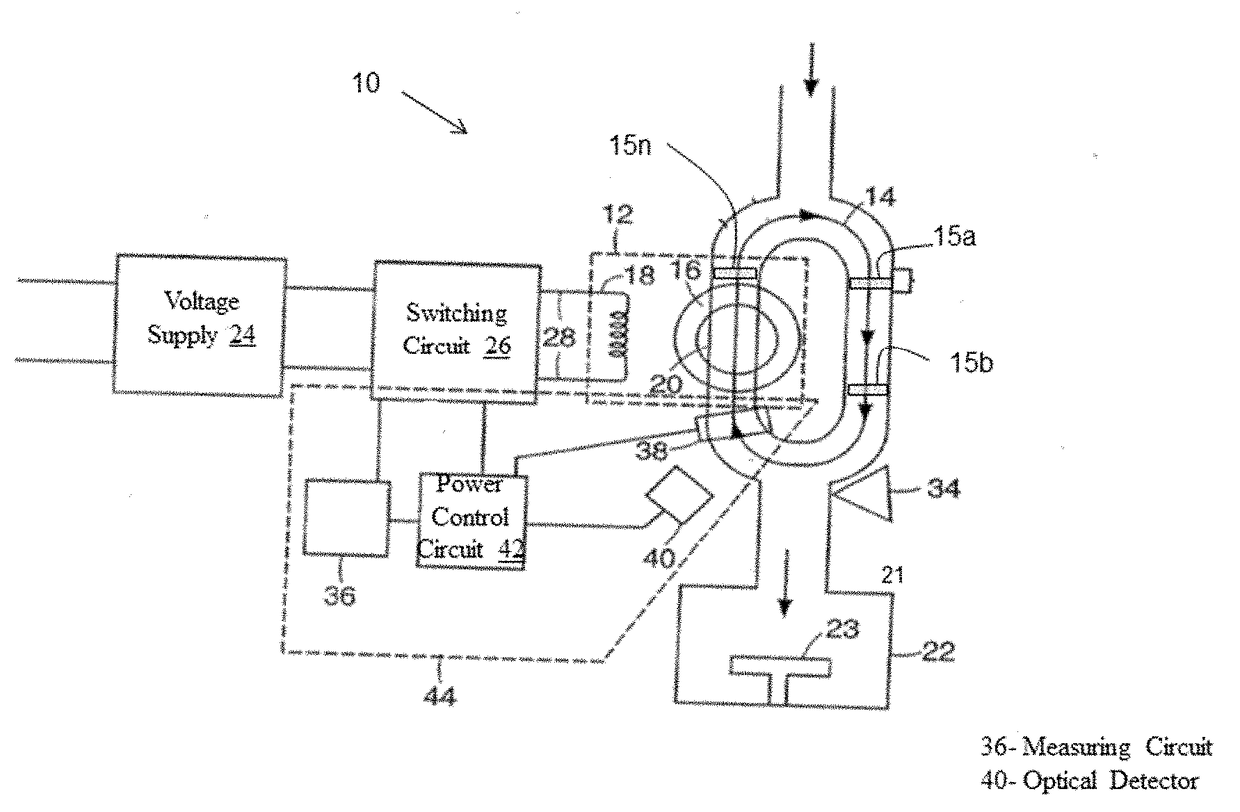

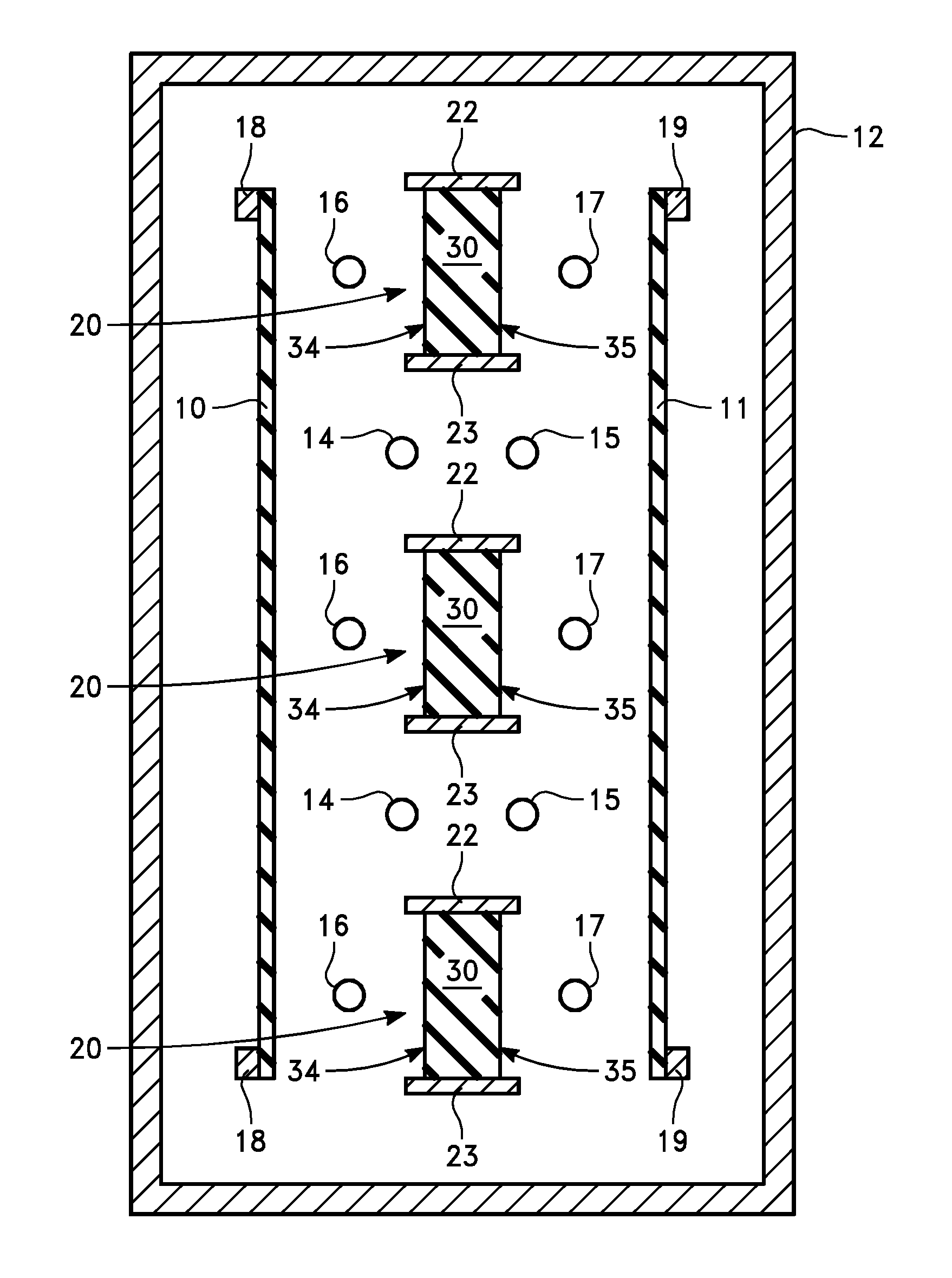

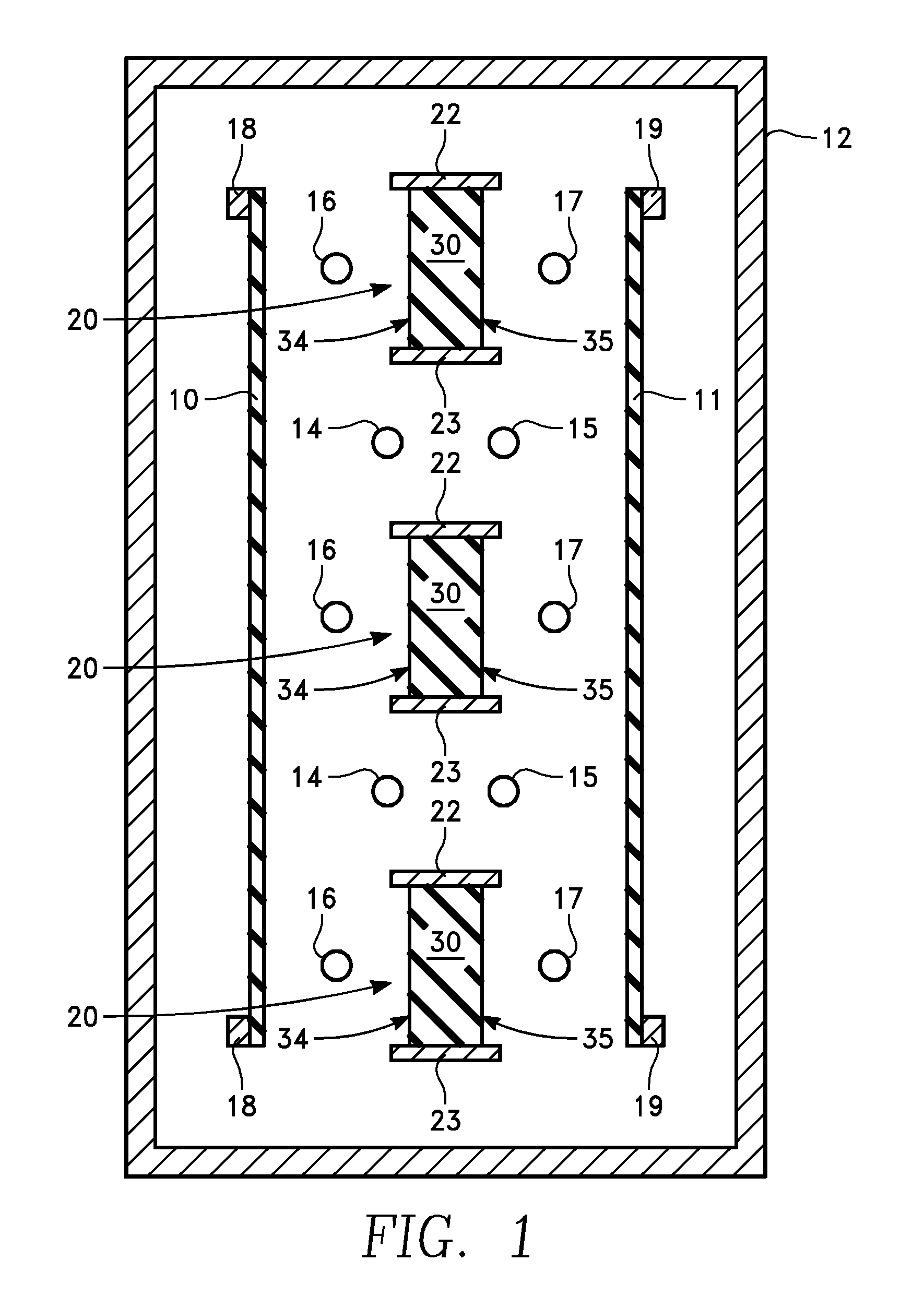

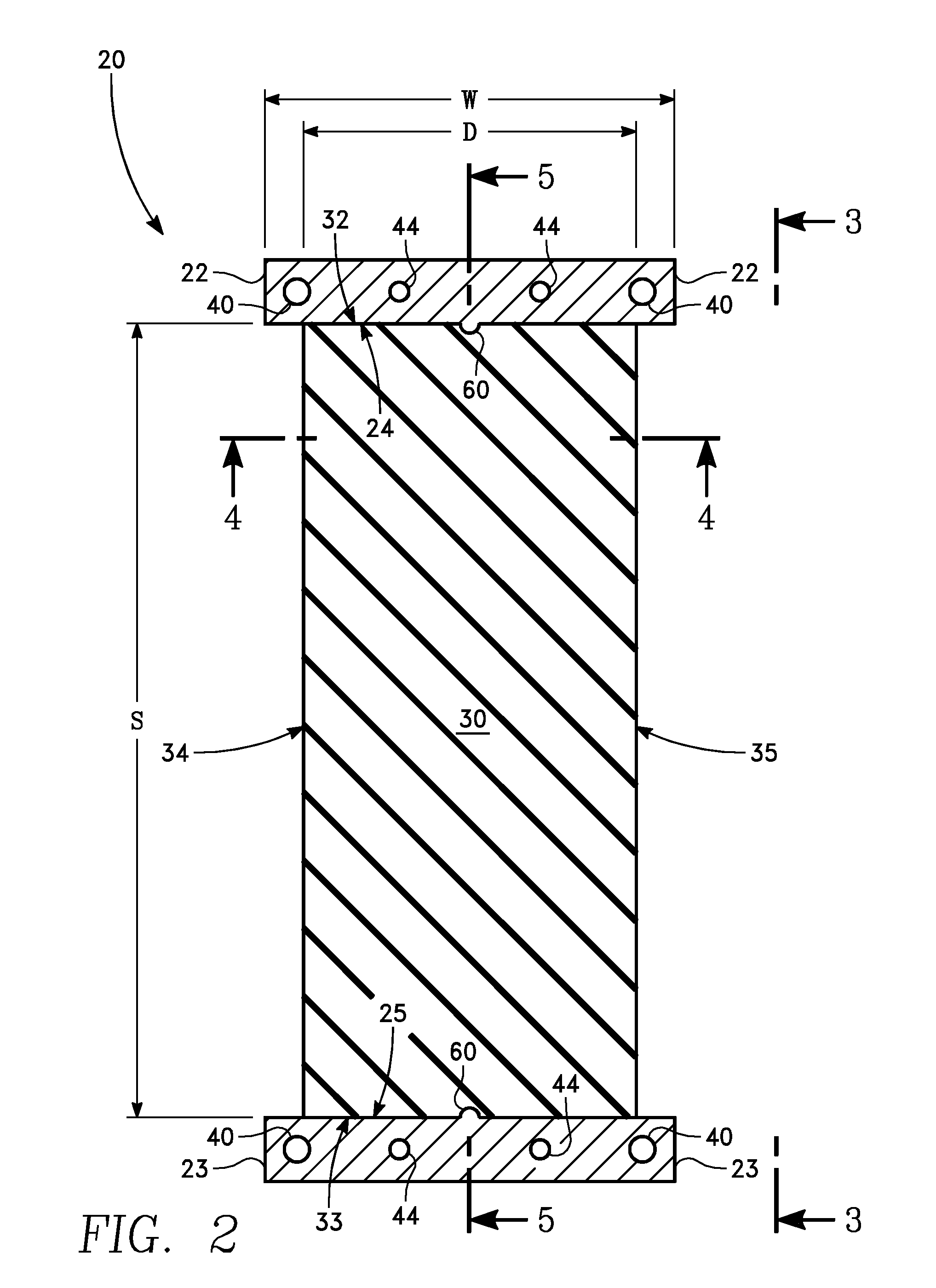

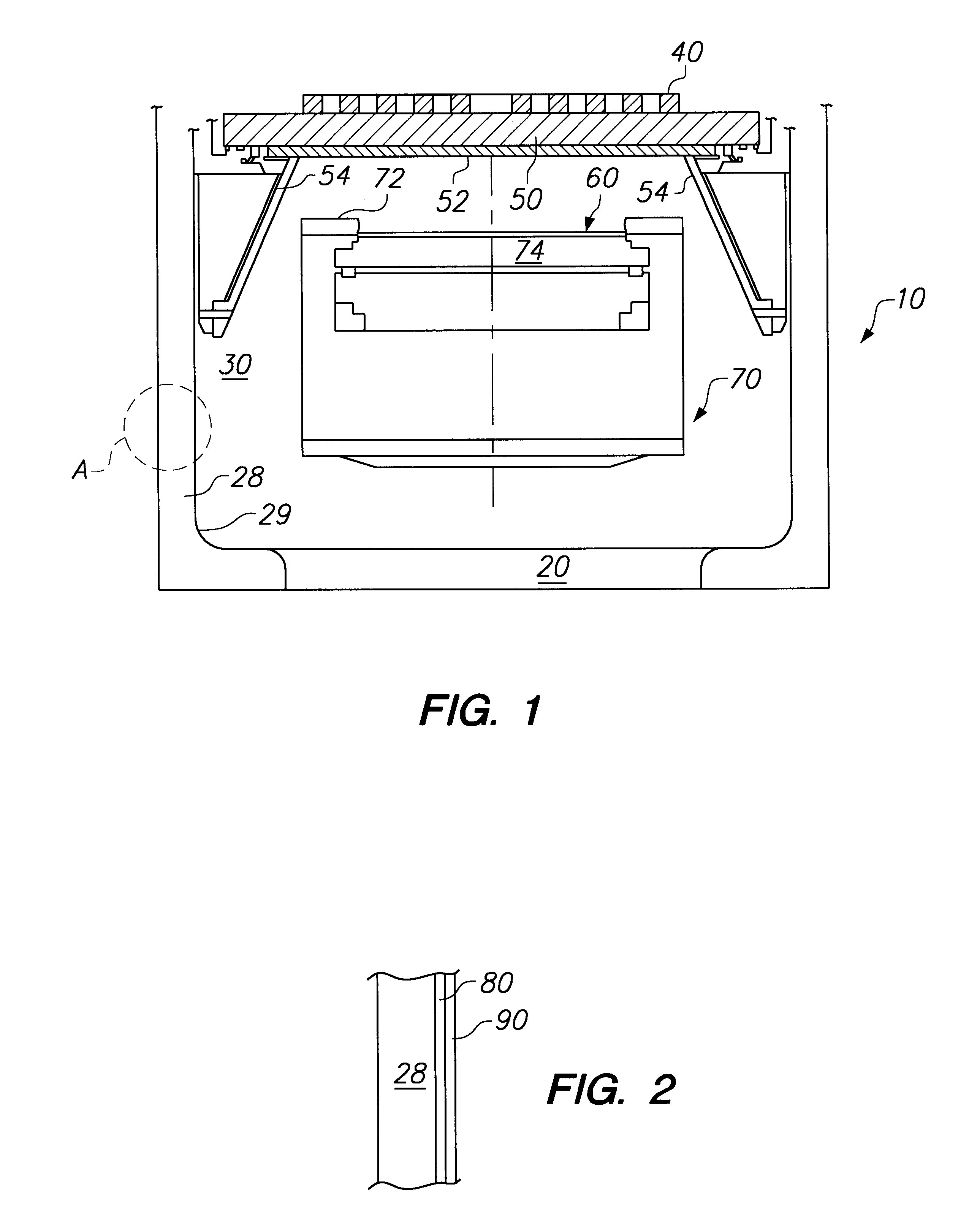

Radical Reactor with Multiple Plasma Chambers

InactiveUS20120114877A1Well mixedElectric discharge tubesChemical vapor deposition coatingAtomic layer depositionPlasma chamber

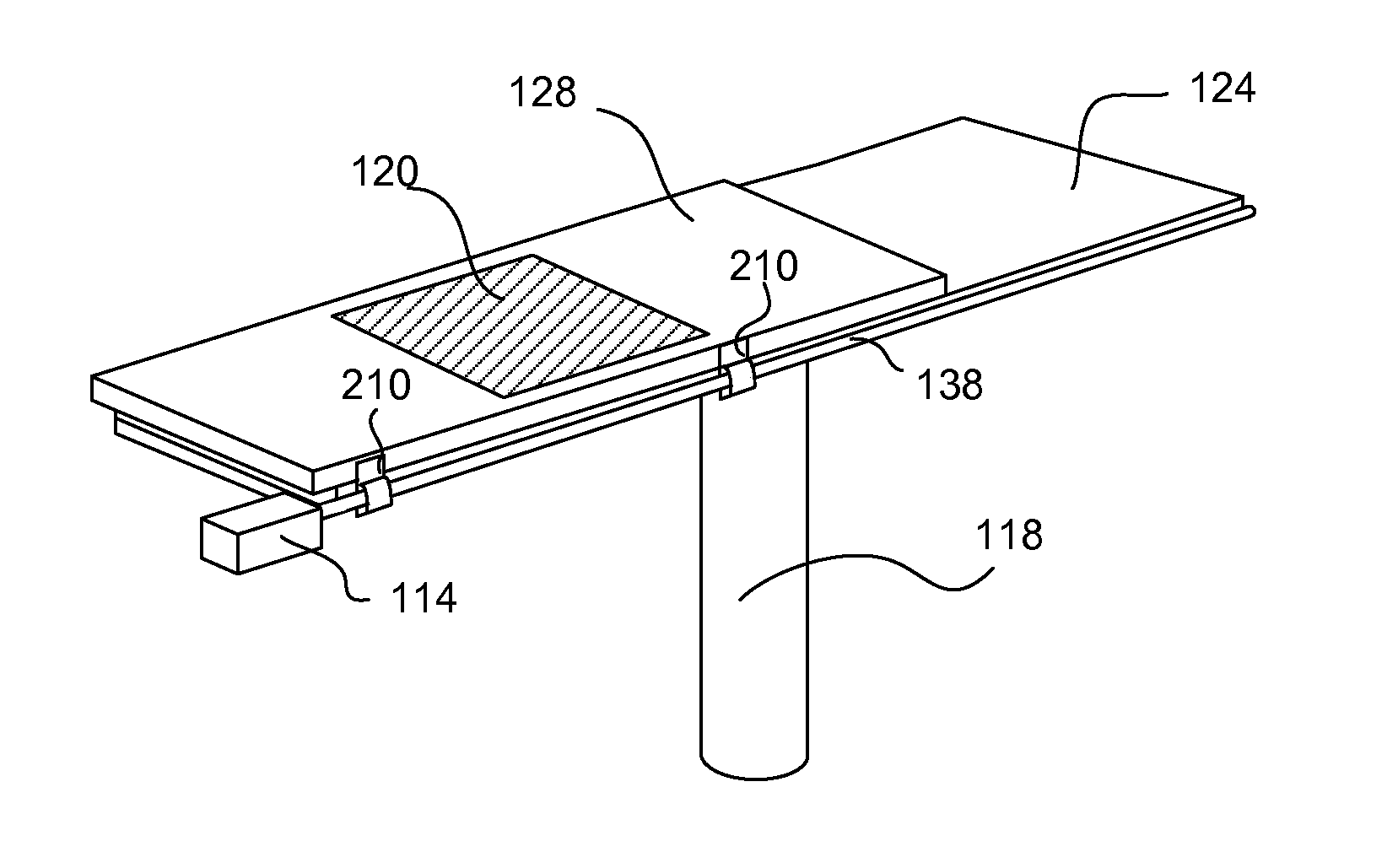

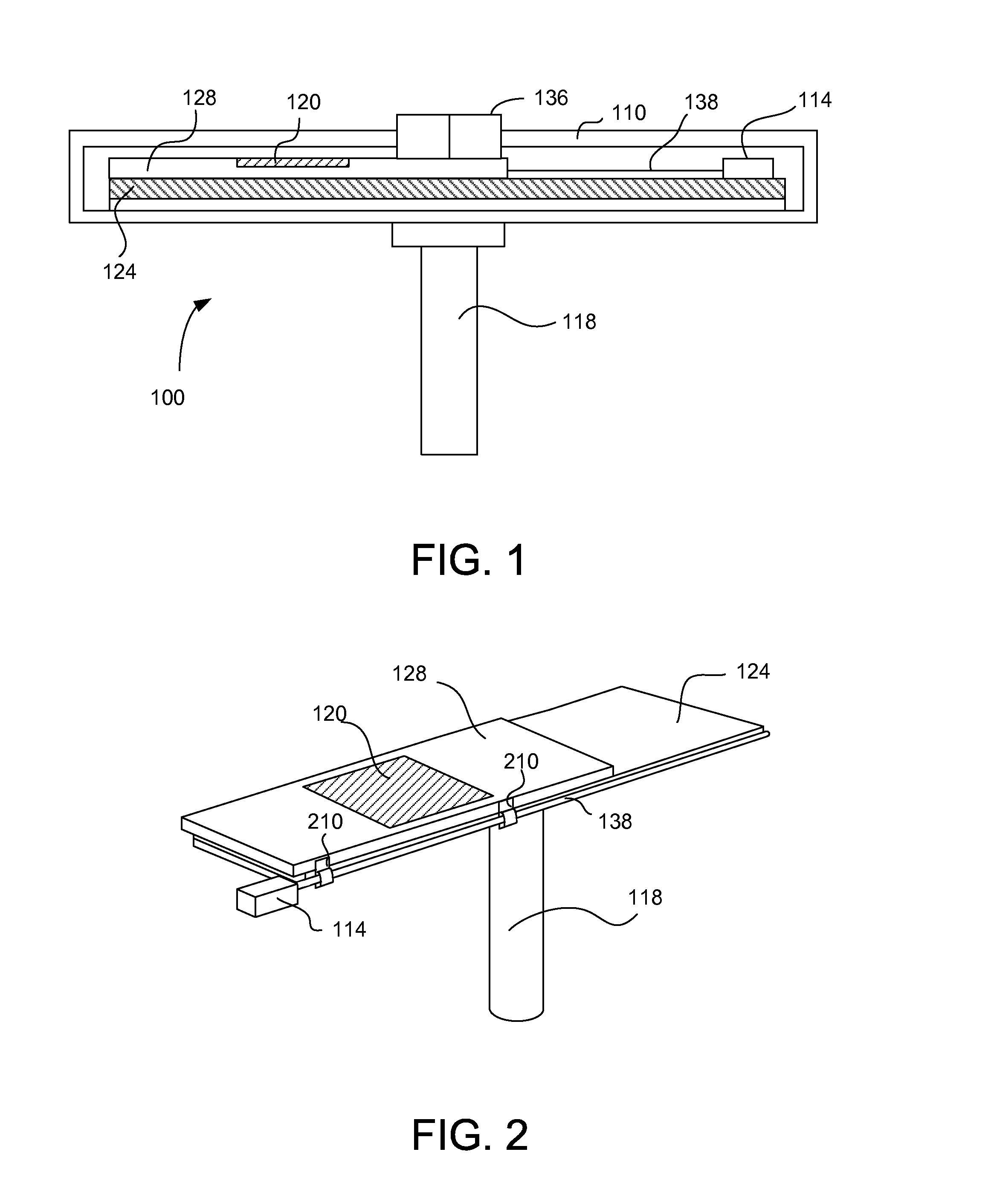

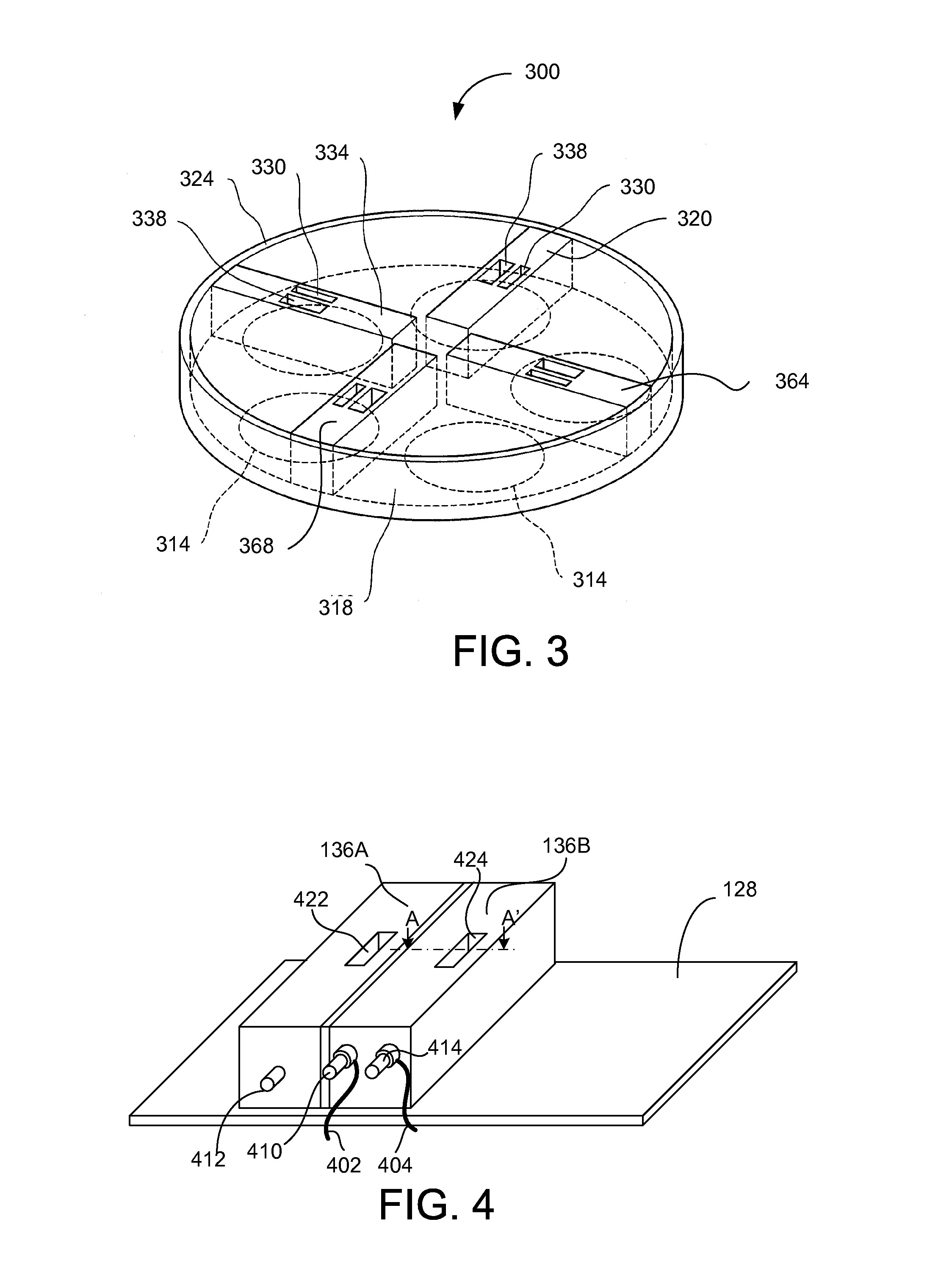

Two or more plasma chambers are provided in a radical reactor to generate radicals of gases under different conditions for use in atomic layer deposition (ALD) process. The radical reactor has a body with multiple channels and corresponding process chambers. Each plasma chamber is surrounded by an outer electrode and has an inner electrode extending through the chamber. When voltage is applied across the outer electrode and the inner electrode with gas present in the plasma chamber, radicals of the gas is generated in the plasma chamber. The radicals generated in the plasma chamber are then injected into a mixing chamber for mixing with radicals of another gas from another plasma chamber, and injected onto the substrate. By providing two or more plasma chambers, different radicals of gases can be generated within the same radical reactor, which obviates the need for separate radical generators.

Owner:VEECO ALD

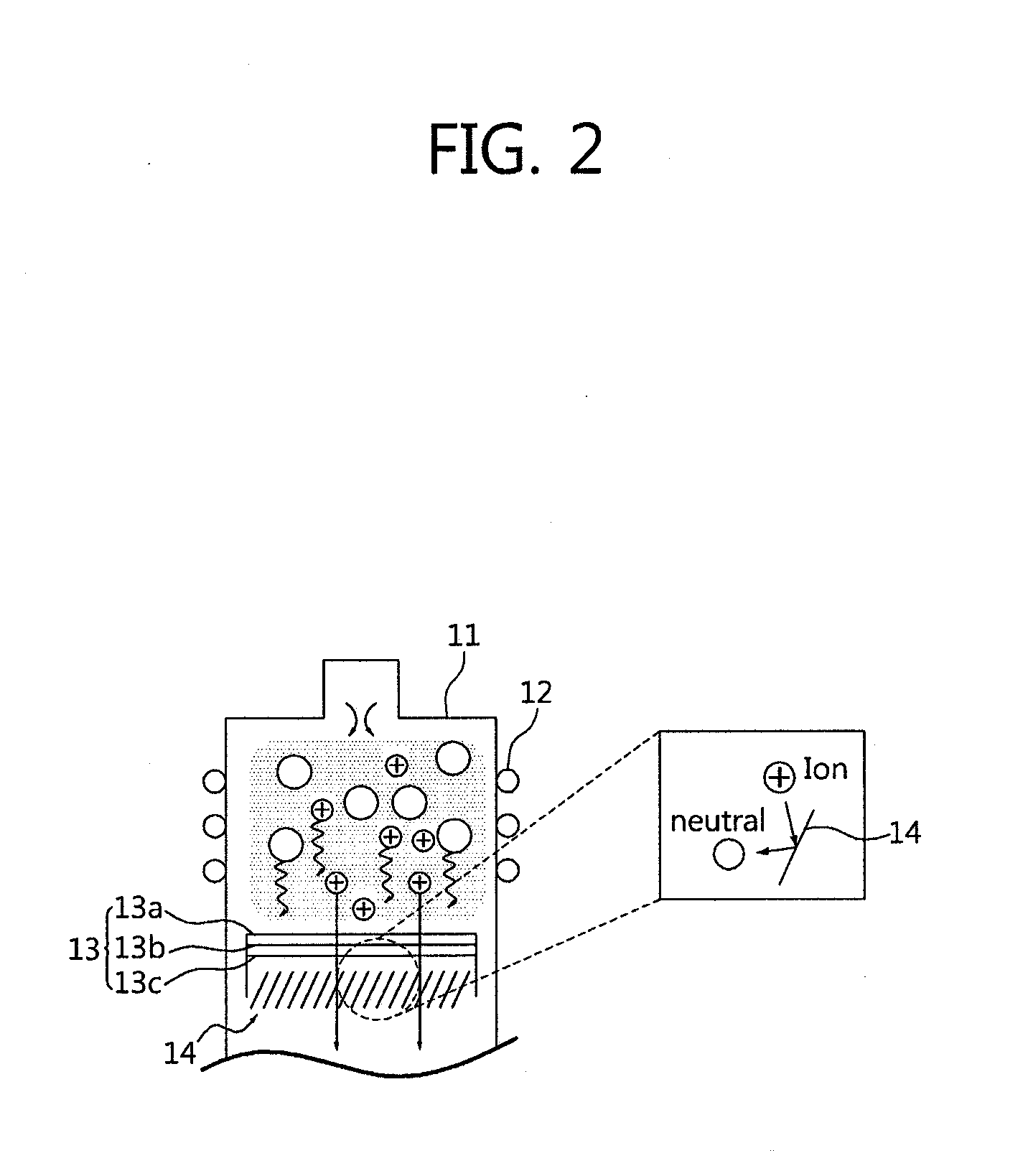

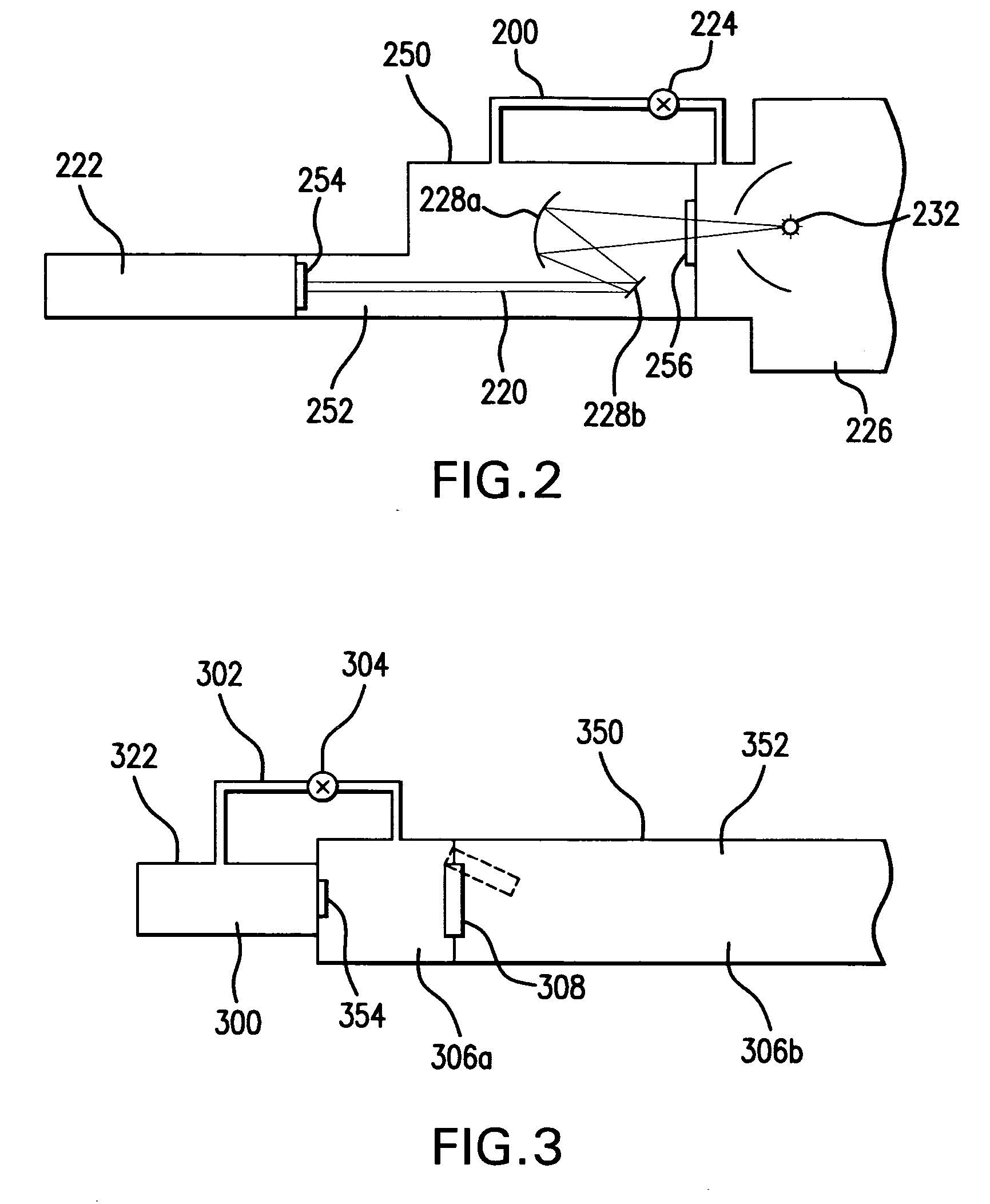

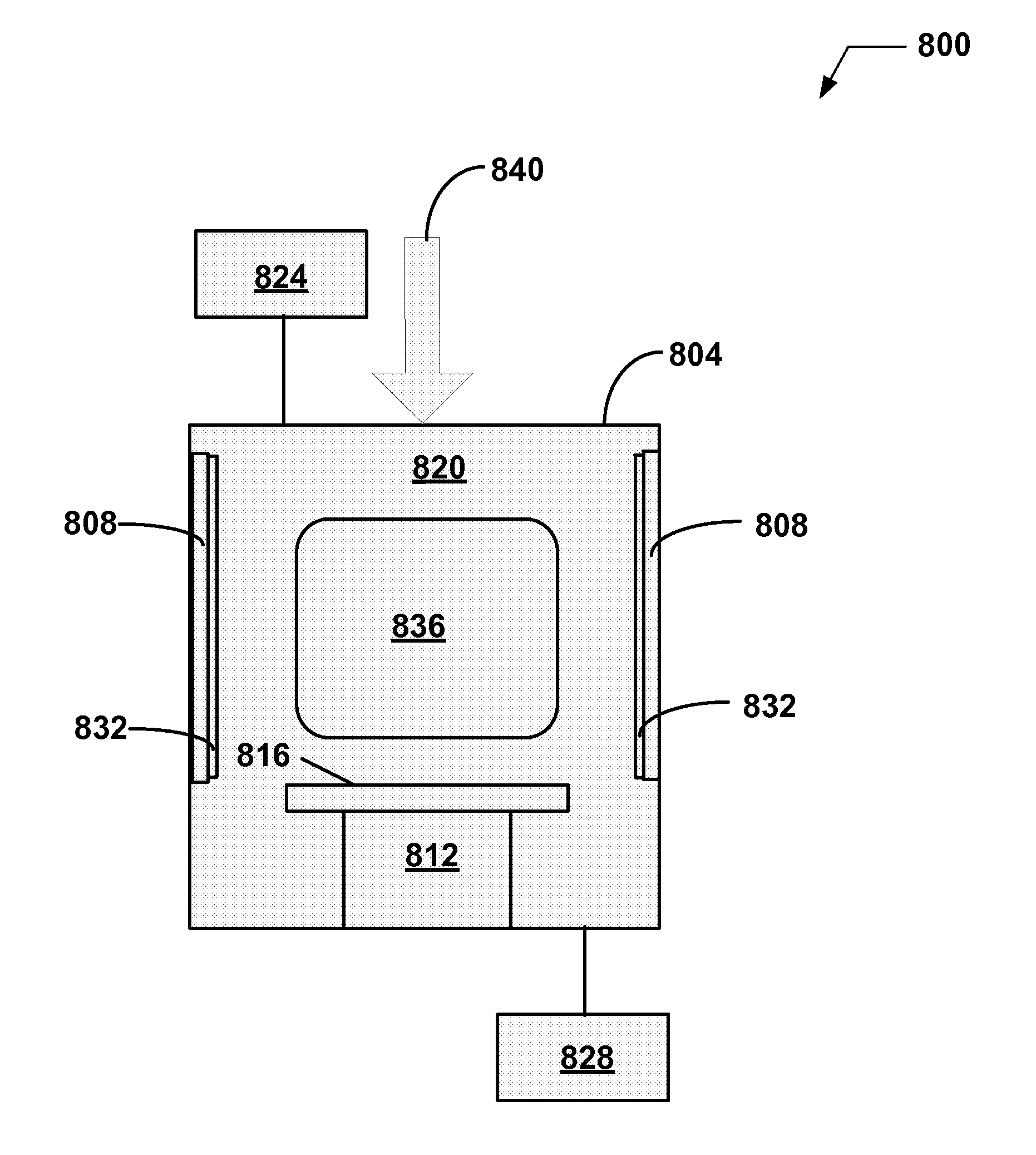

Atomic layer etching apparatus and etching method using the same

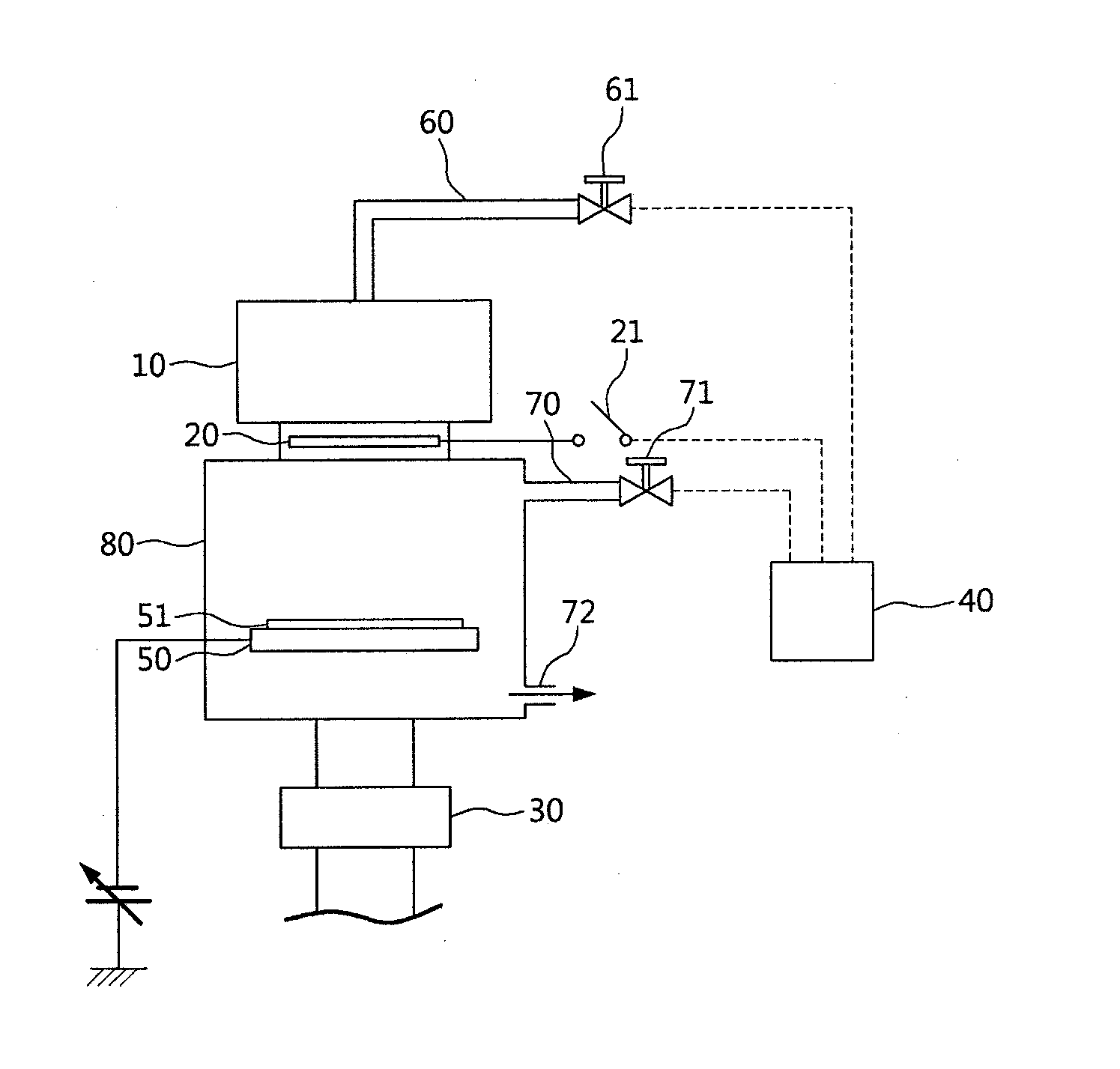

An atomic layer etching apparatus using reactive radicals and neutral beams and an etching method using the same are provided. The atomic layer etching apparatus includes a reaction chamber including a stage on which a substrate to be etched is seated, a plasma generator including a plasma chamber configured to supply reactive radicals and neutral beams into the reaction chamber and receive a source gas to generate plasma, an inductive coil configured to surround the exterior of the plasma chamber to generate an electric field, a grid assembly disposed at a lower part of the plasma chamber and including first, second and third grids for extracting ion beams, and a reflective body disposed under the grid assembly and configured to supply electrons to the ion beams to convert the ion beams into neutral beams, a shutter installed between the plasma generator and the reactive chamber and configured to adjust supply of the neutral beams into the reaction chamber, a purge gas supply part configured to supply a purge gas into the reaction chamber, and a controller configured to control supply of the source gas, an etching gas and the purge gas, and opening / closing of the shutter.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

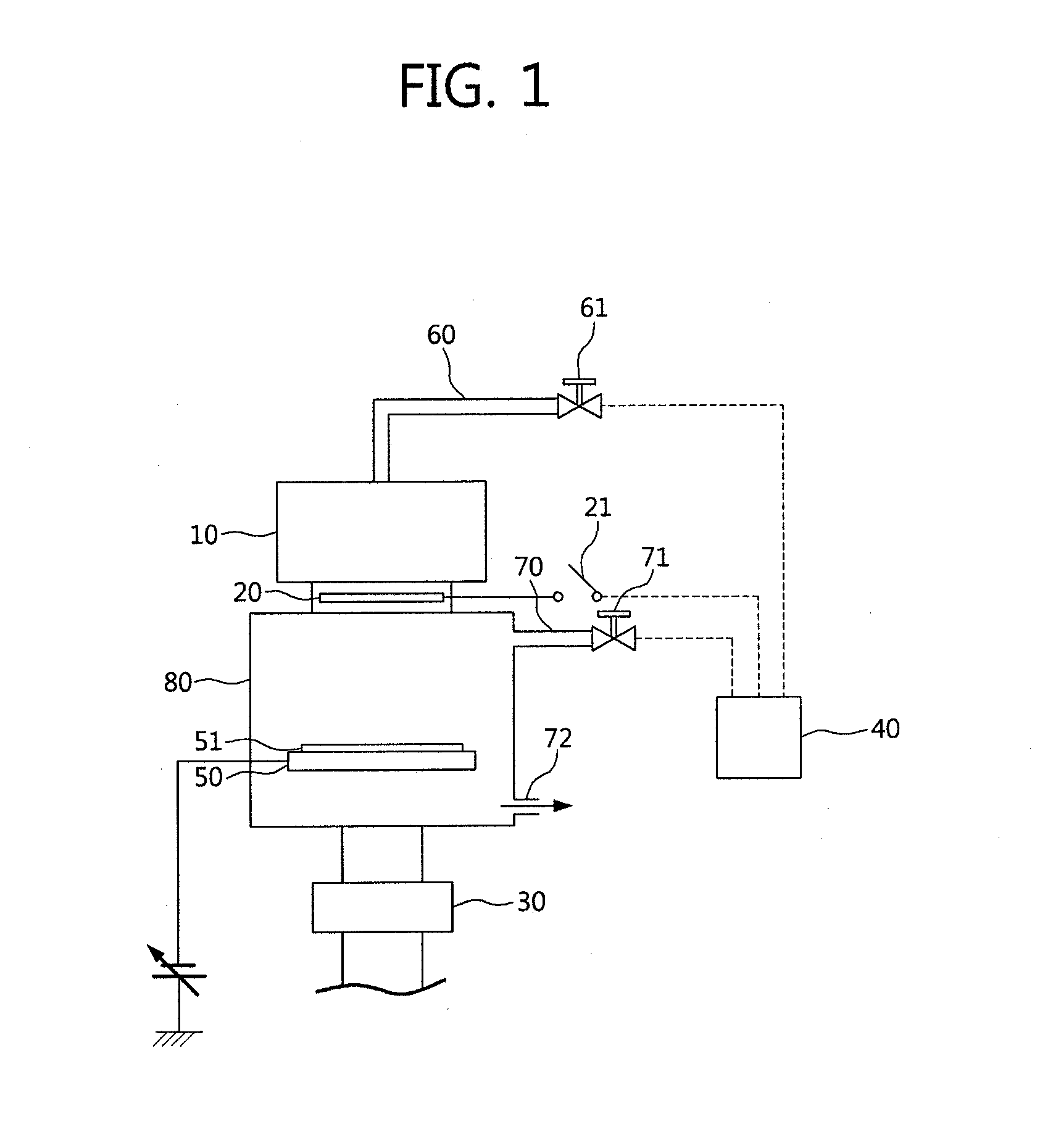

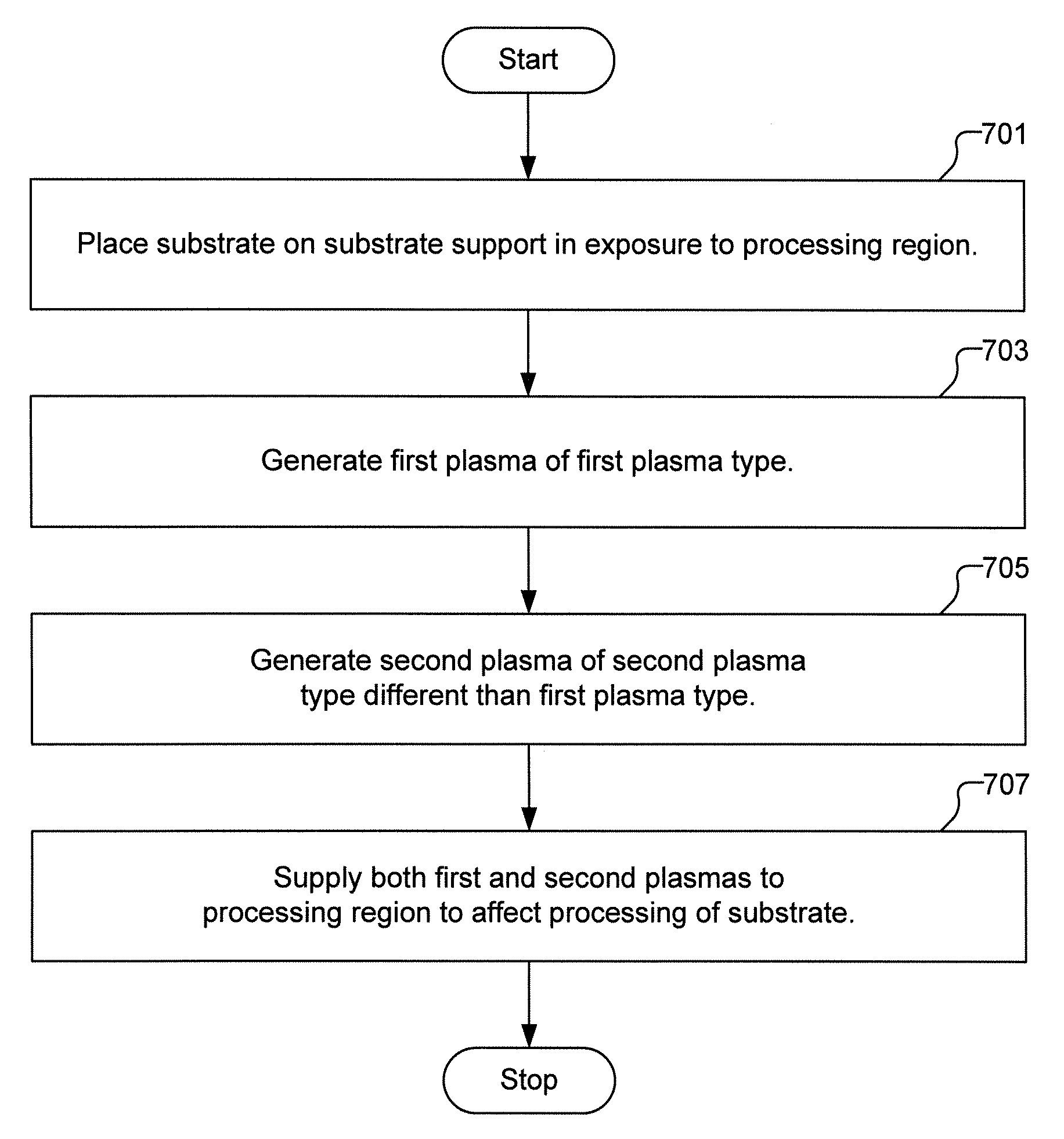

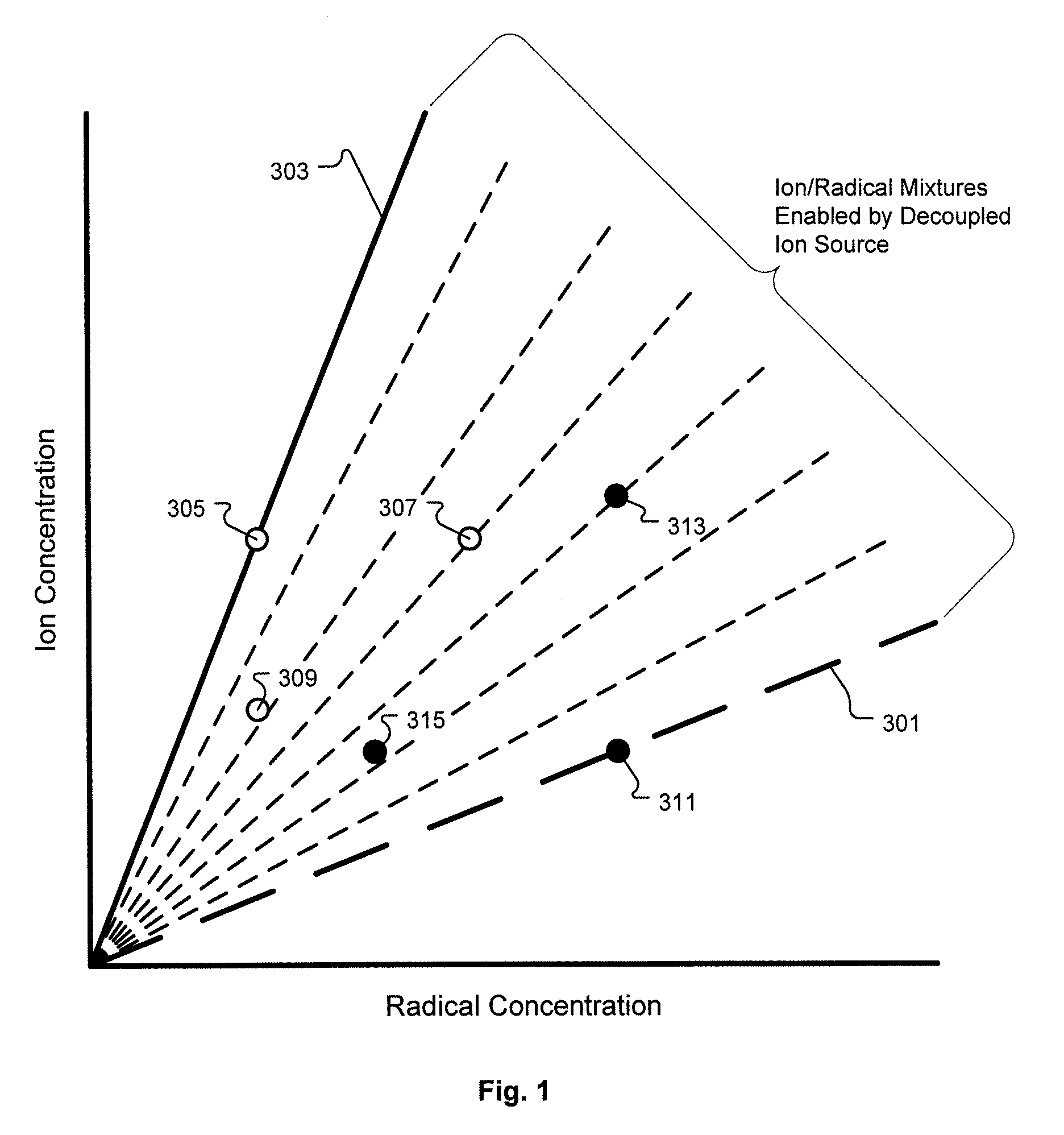

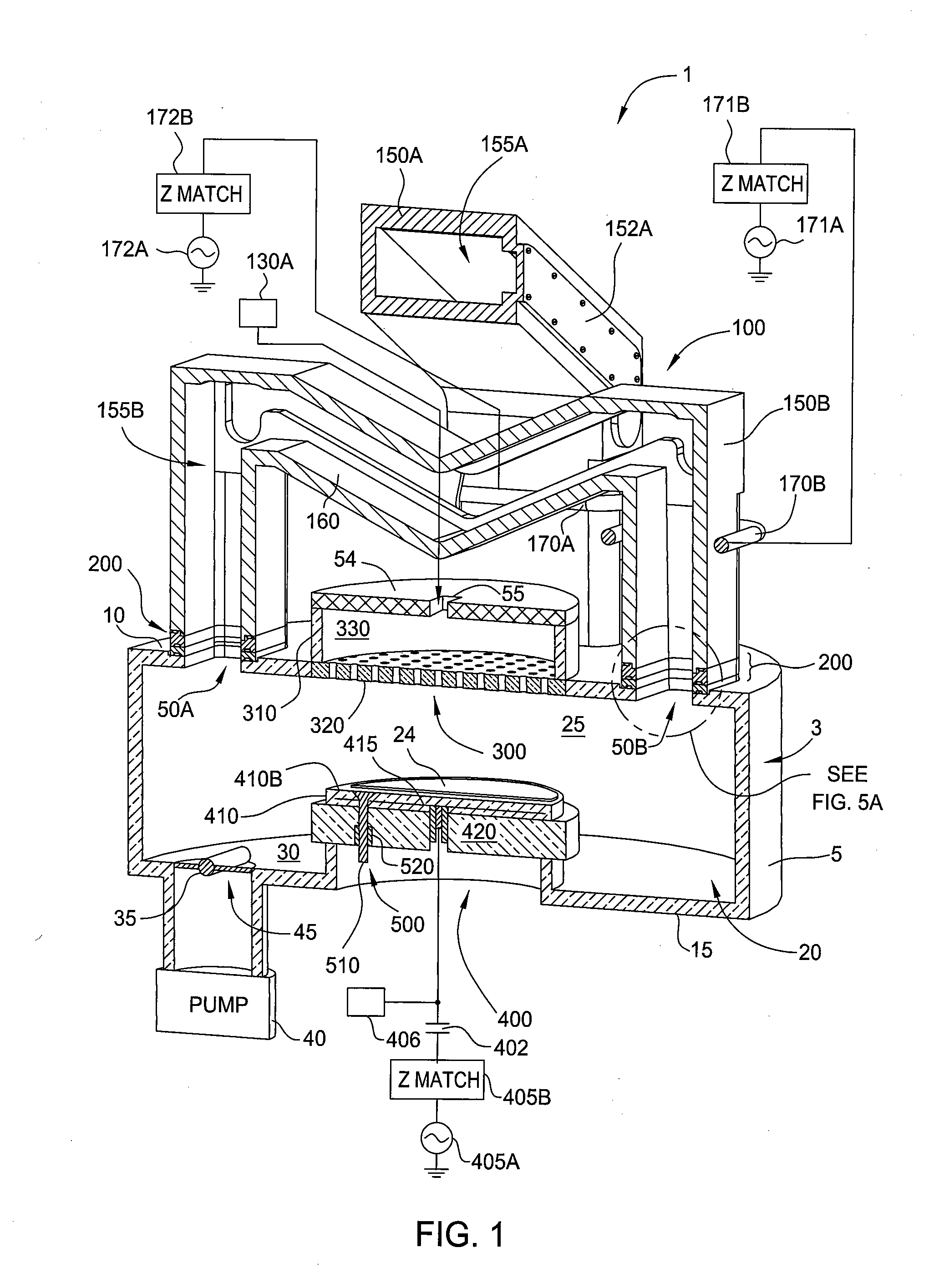

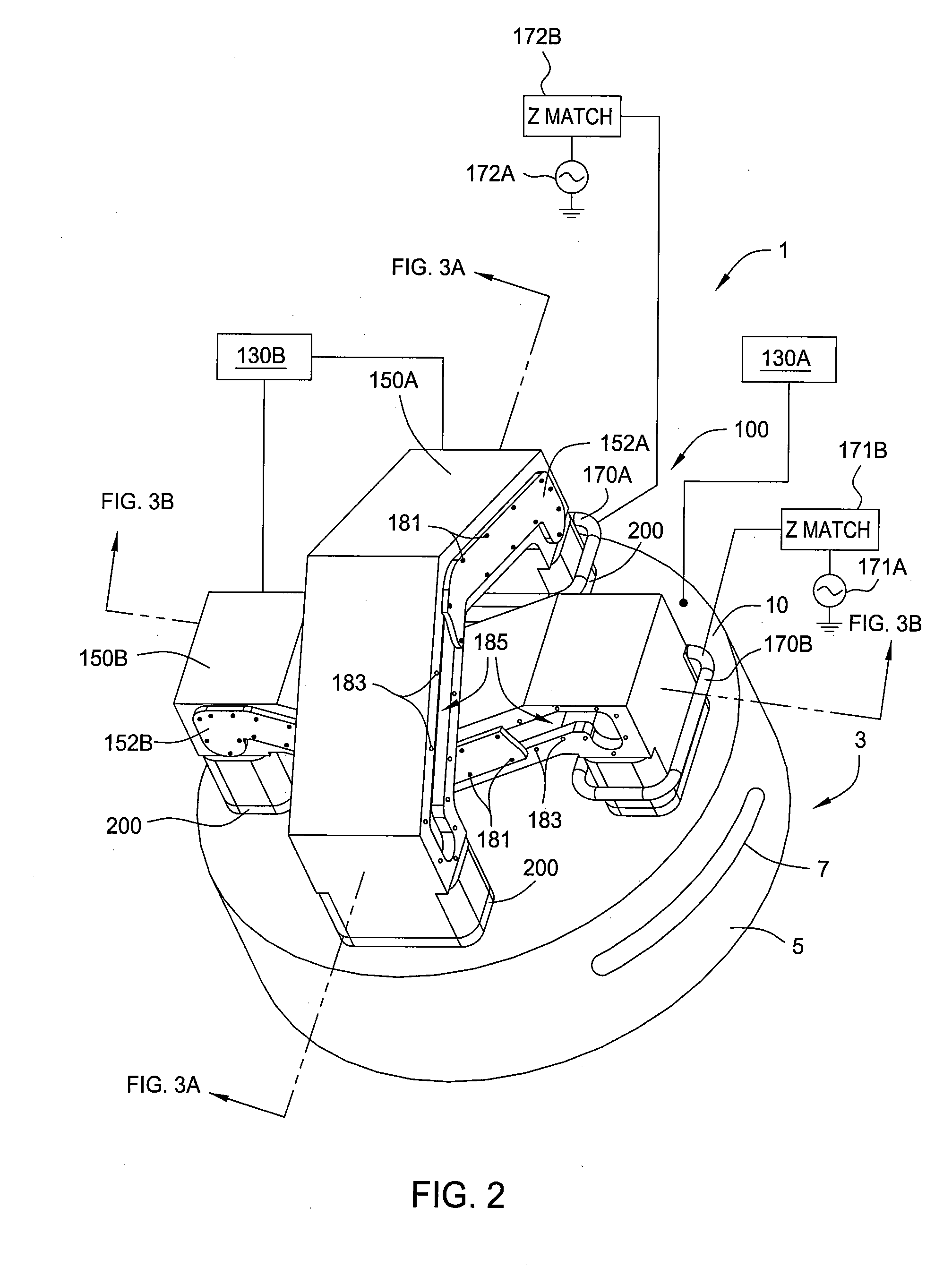

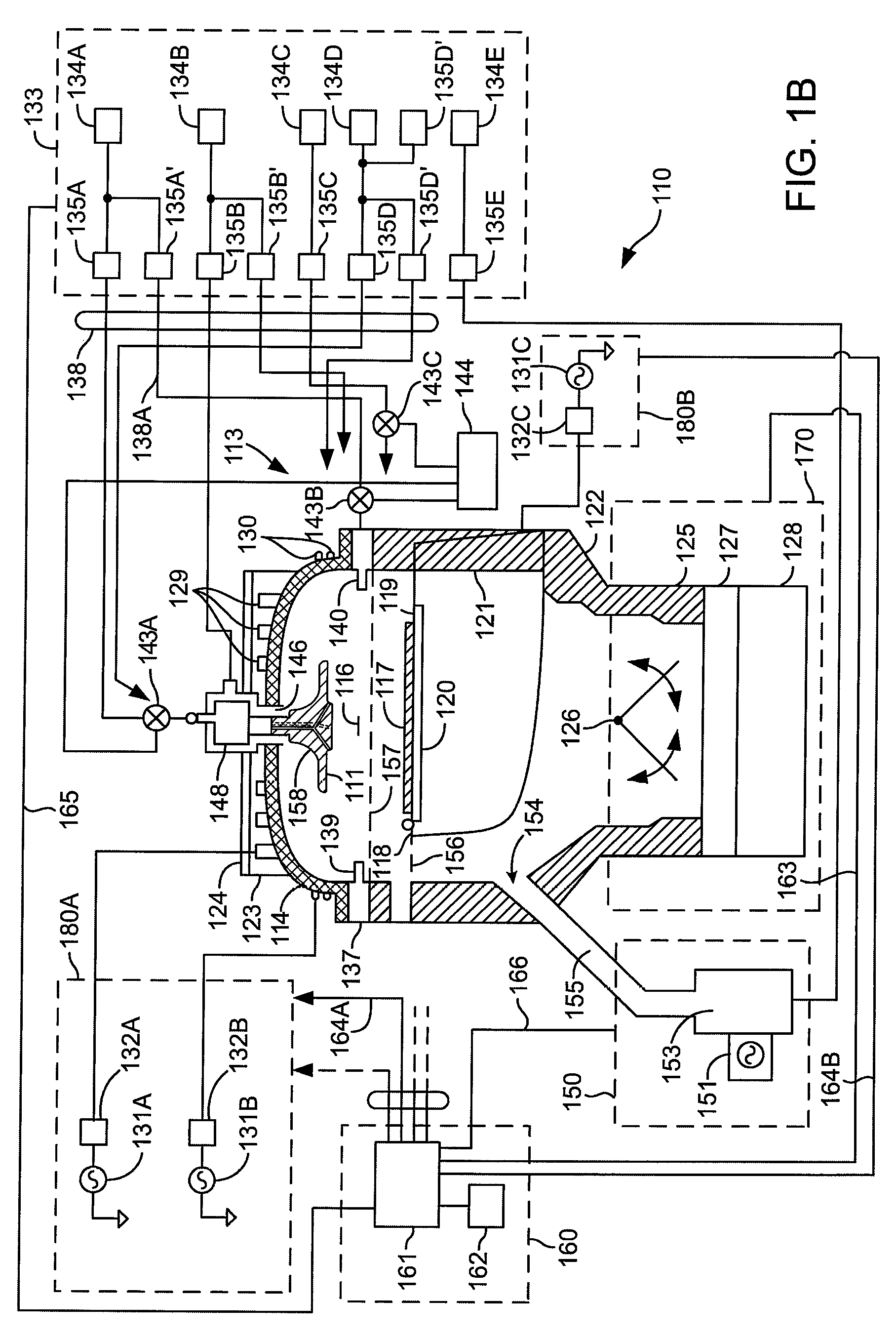

Semiconductor Processing System Having Multiple Decoupled Plasma Sources

InactiveUS20120289053A1Electric discharge tubesSemiconductor/solid-state device manufacturingSemiconductorPlasma chamber

A semiconductor substrate processing system includes a substrate support defined to support a substrate in exposure to a processing region. The system also includes a first plasma chamber defined to generate a first plasma and supply reactive constituents of the first plasma to the processing region. The system also includes a second plasma chamber defined to generate a second plasma and supply reactive constituents of the second plasma to the processing region. The first and second plasma chambers are defined to be independently controlled.

Owner:LAM RES CORP

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

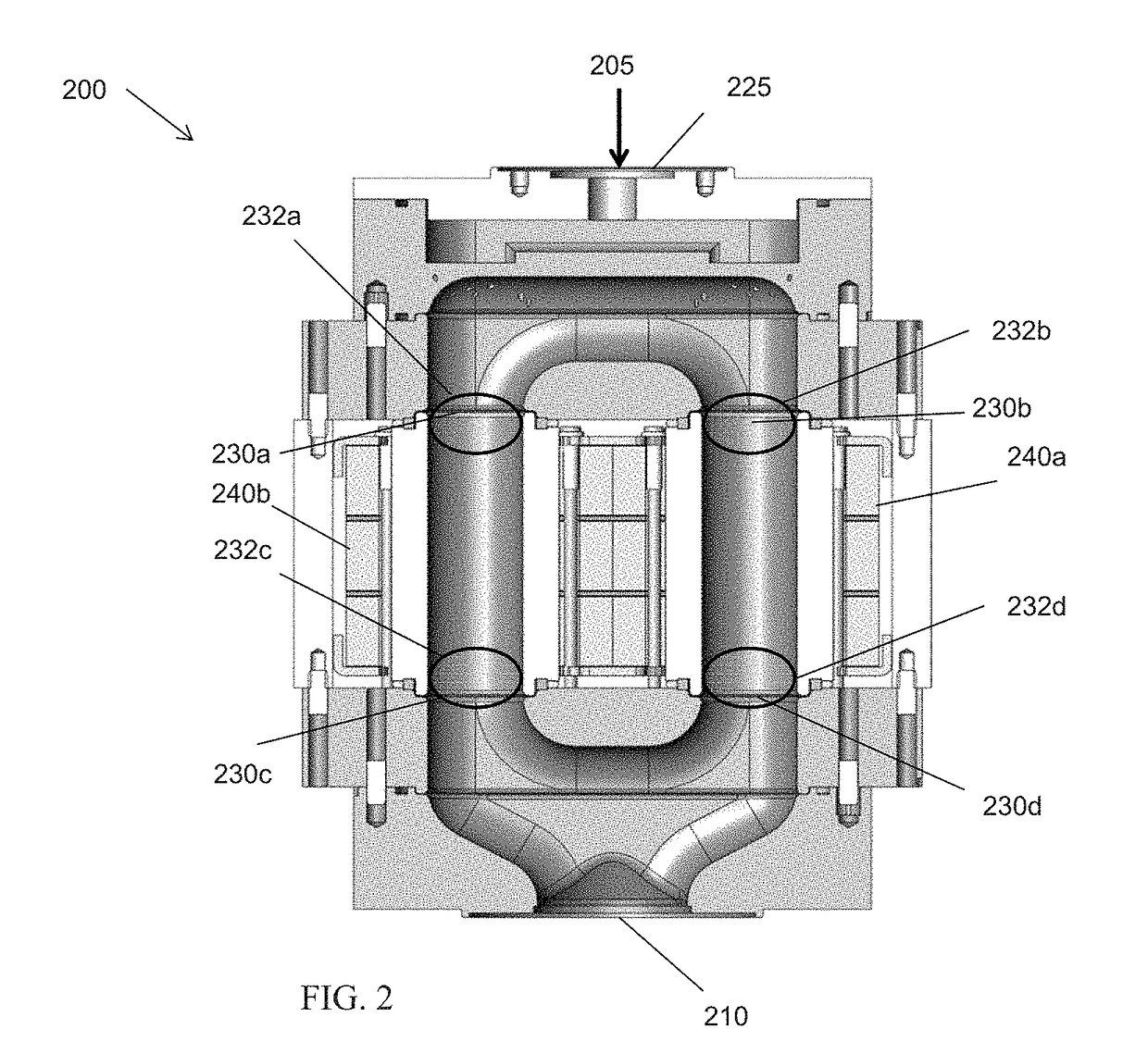

Plasma Immersion Chamber

Embodiments described herein generally provide a toroidal plasma source, a plasma channeling device, a showerhead, and a substrate support assembly for use in a plasma chamber. The toroidal plasma source, plasma channeling device, showerhead, and substrate support assembly are adapted to improve the usable lifetime of the plasma chamber, as well as reduce assembly cost, increase the plasma chamber reliability, and improve device yield on the processed substrates.

Owner:APPLIED MATERIALS INC

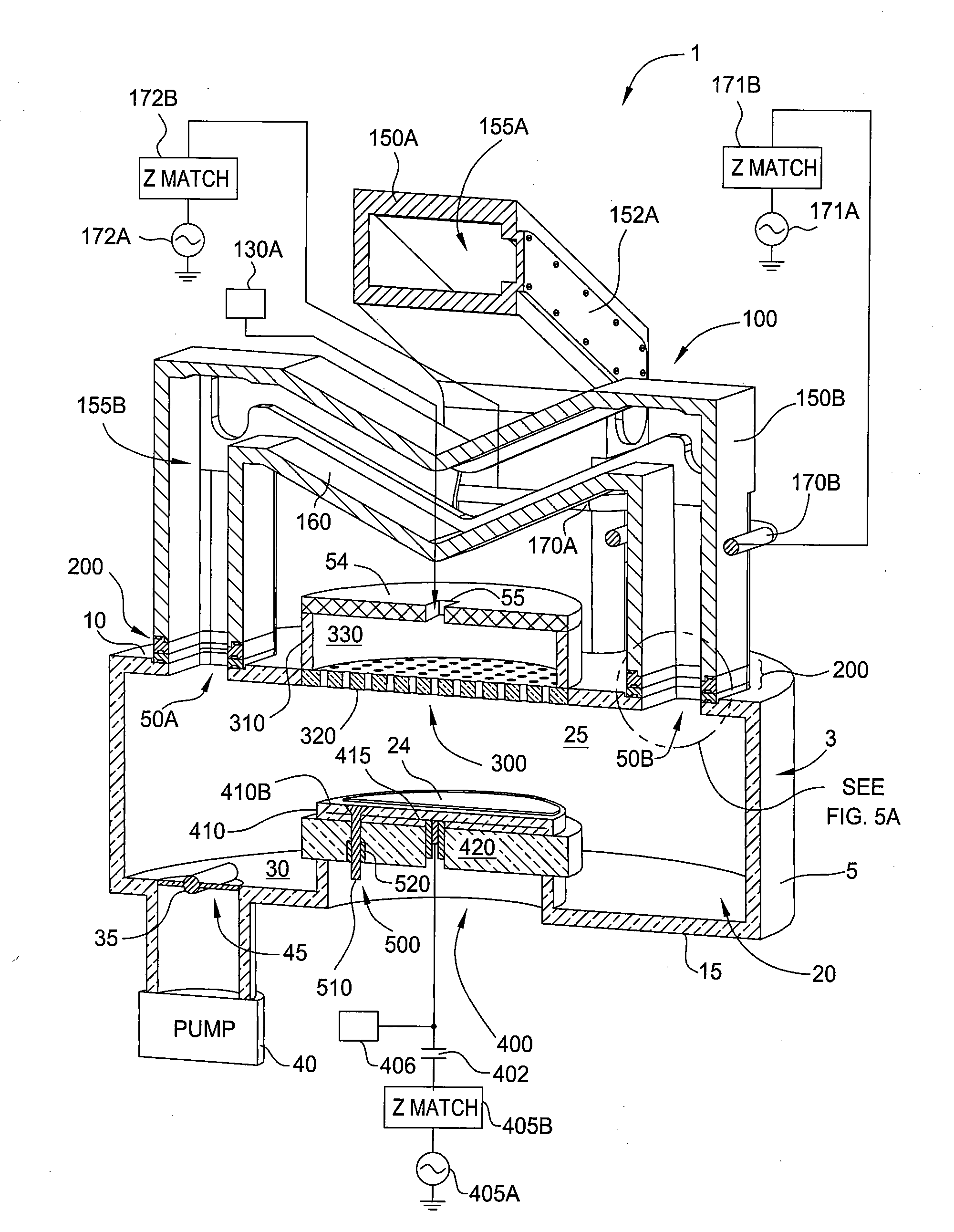

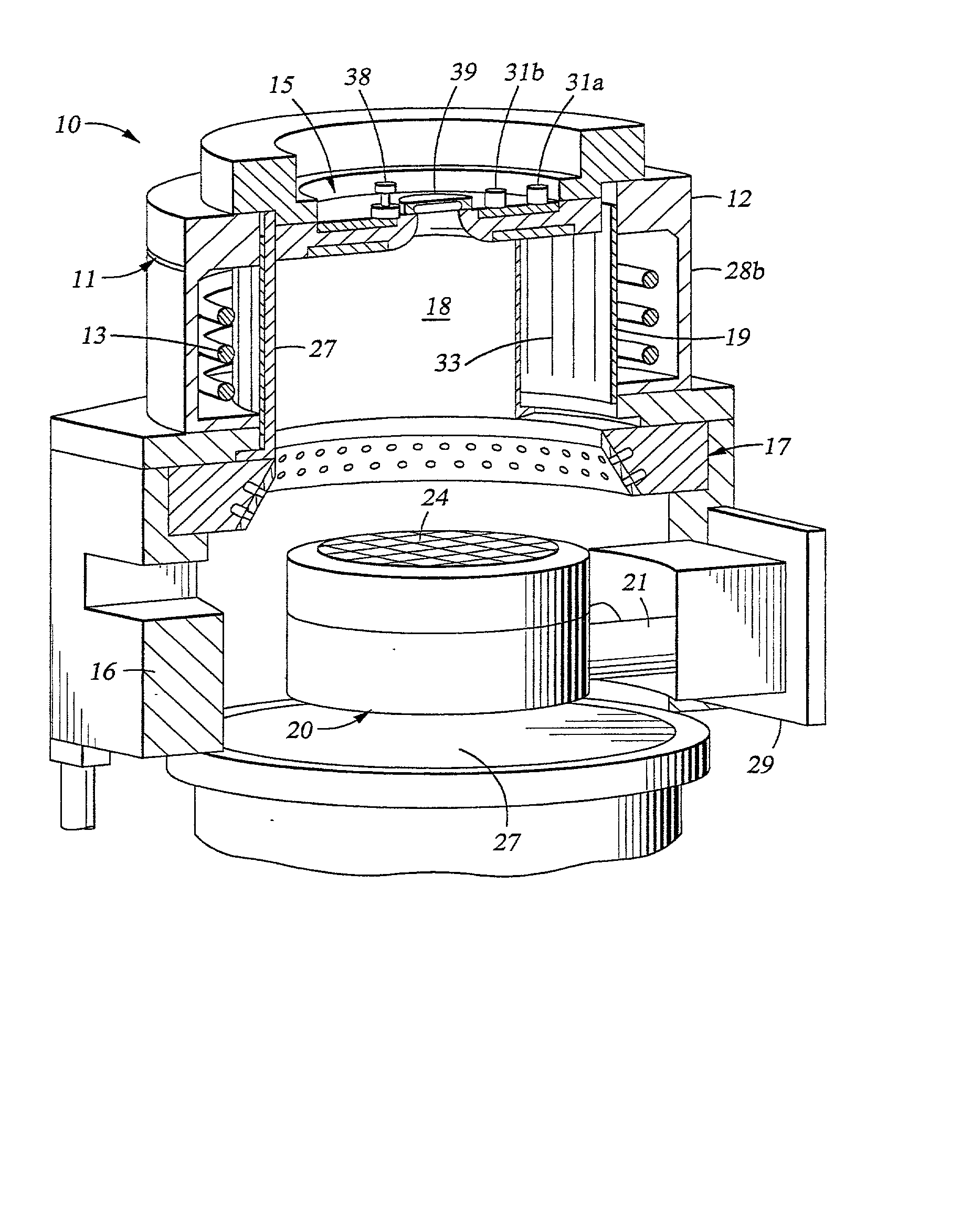

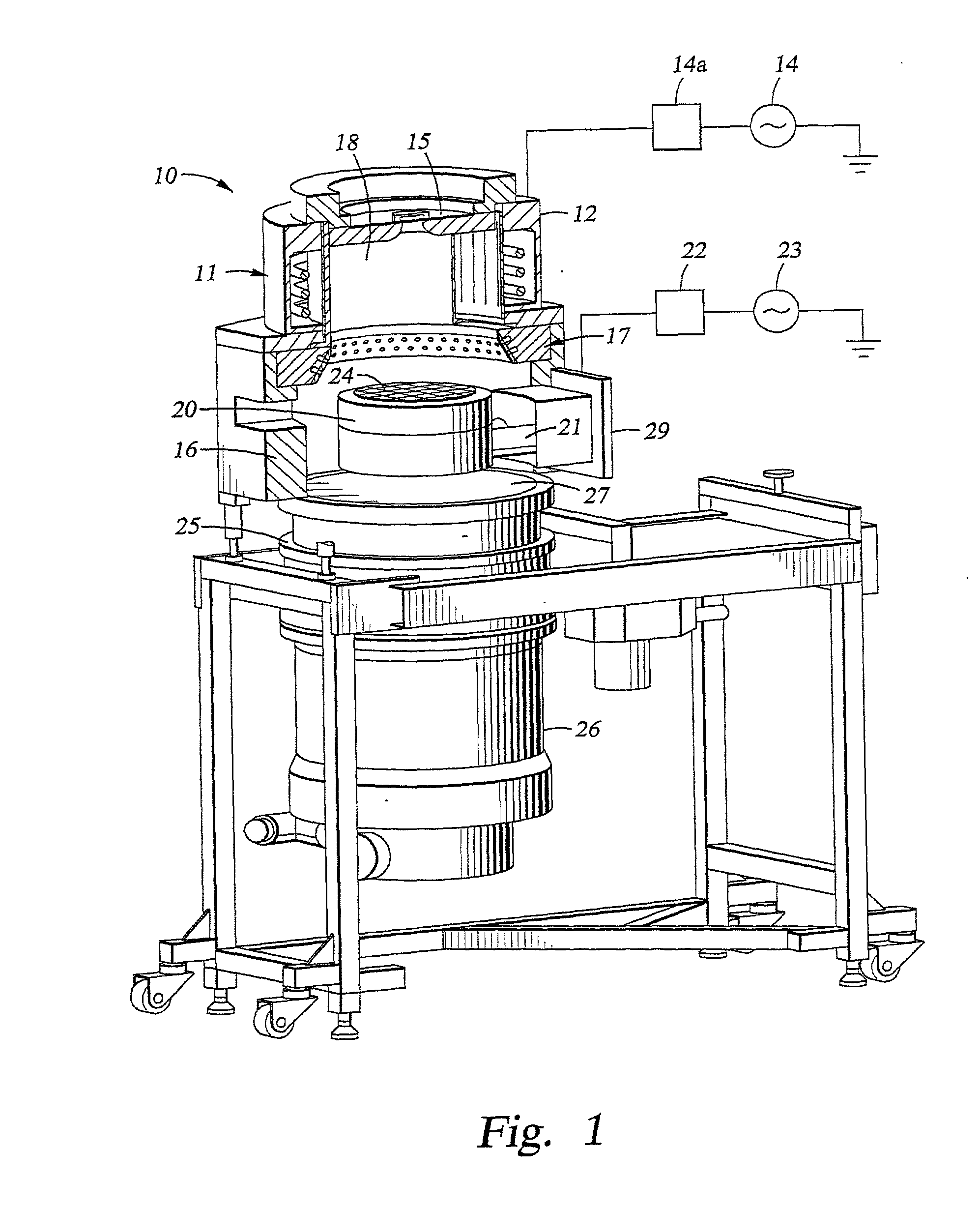

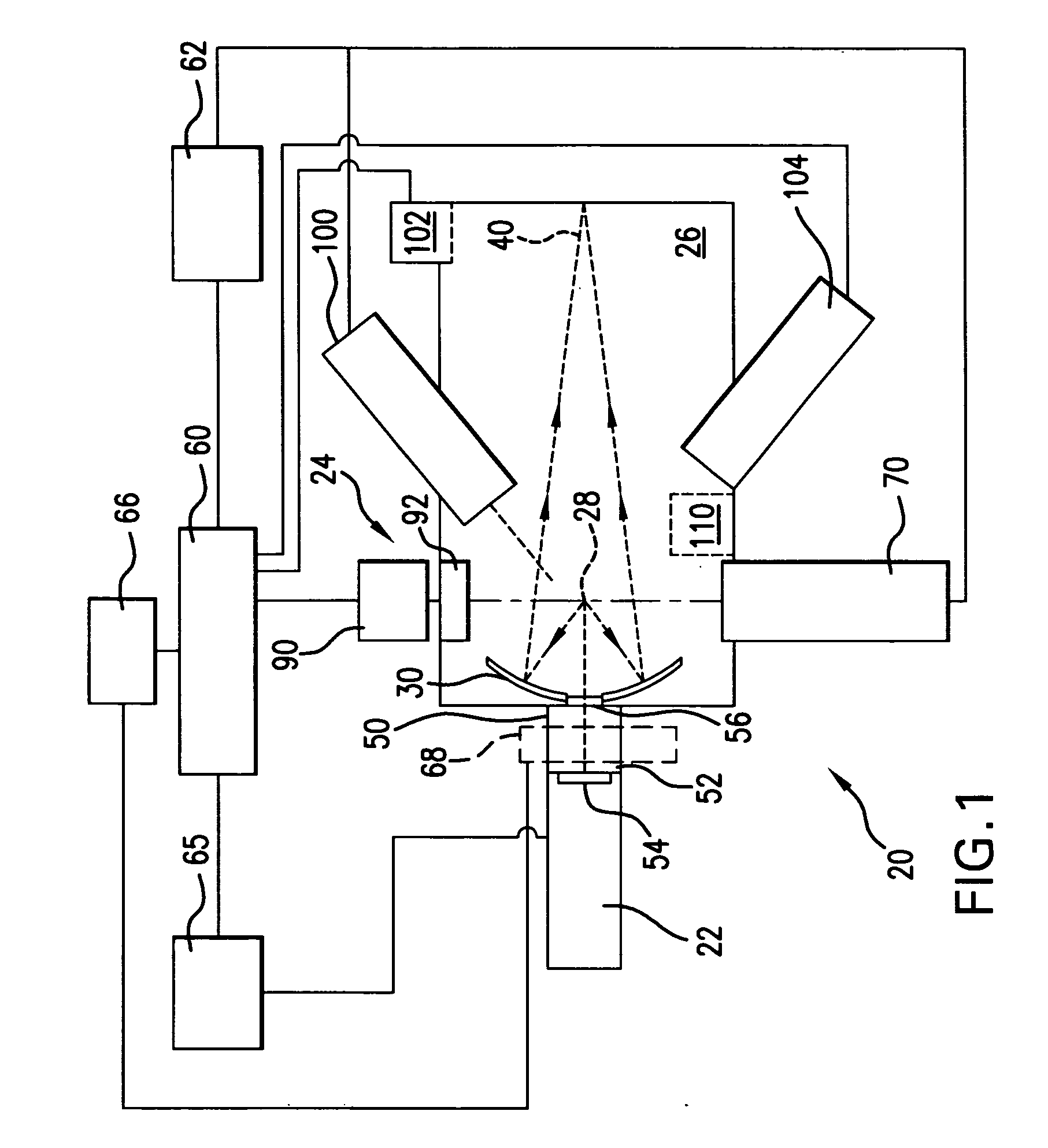

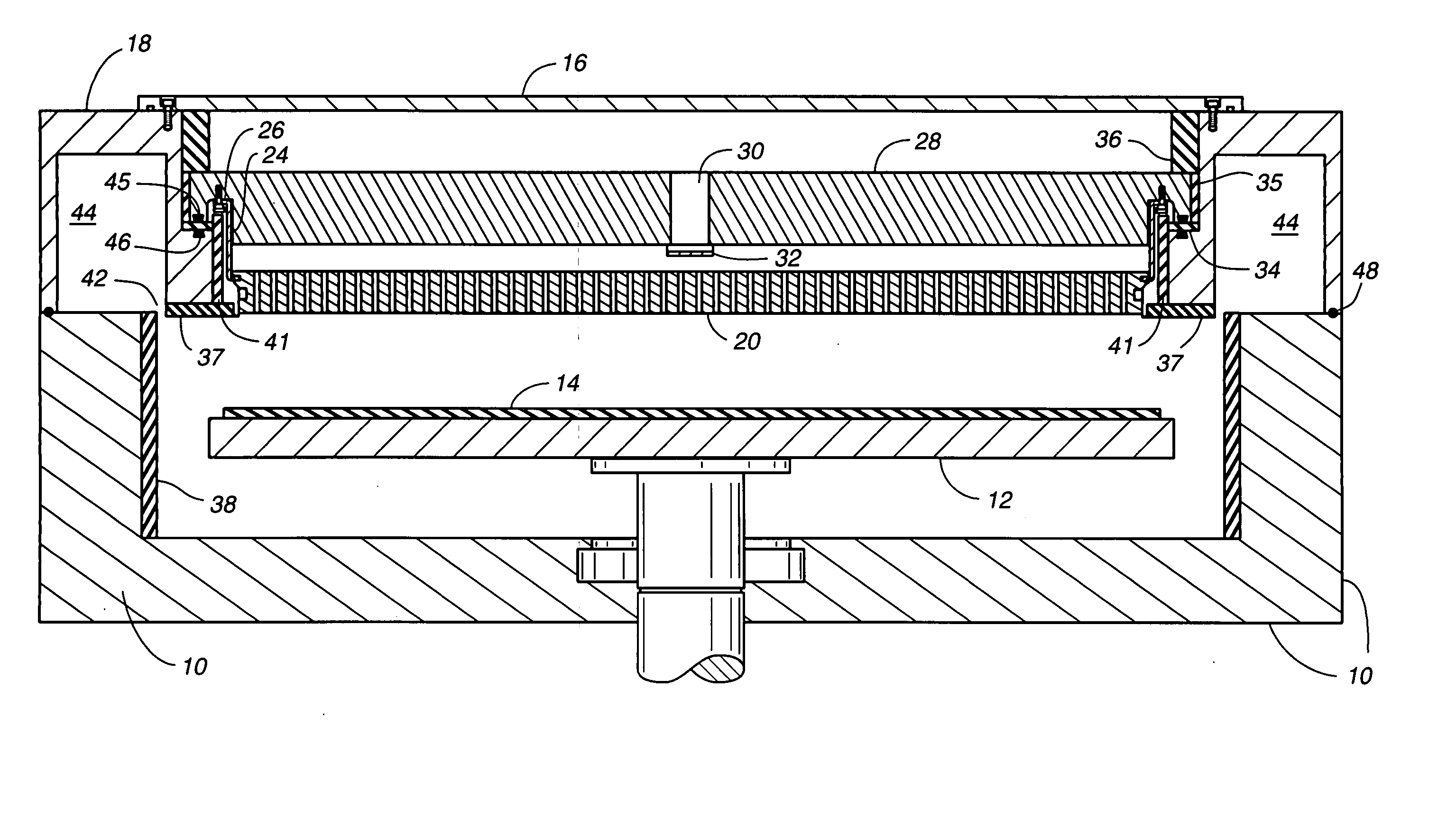

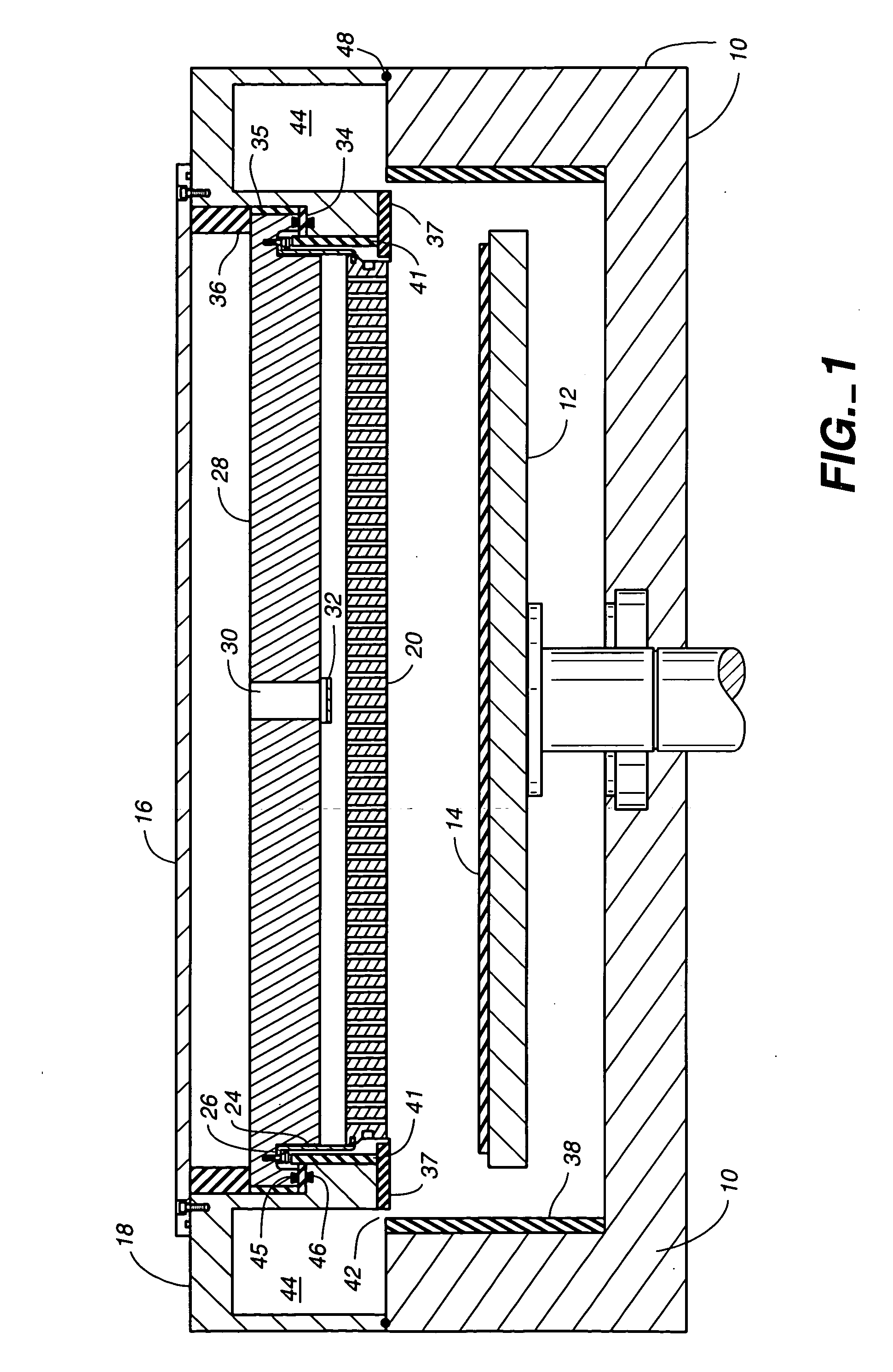

Plasma enhanced chemical processing reactor and method

InactiveUS20020078893A1Improve film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingChemical treatmentReactive gas

A plasma enhanced chemical processing reactor and method. The reactor includes a plasma chamber including a first gas injection manifold and a source of electromagnetic energy. The plasma chamber is in communication with a process chamber which includes a wafer support and a second gas manifold. The plasma generated in the plasma chamber extends into the process chamber and interacts with the reactive gases to deposit a layer of material on the wafer. The reactor also includes a vacuum system for exhausting the reactor. The method includes the steps of generating a plasma within the plasma chamber, introducing at least one gaseous chemical into the process chamber proximate to the wafer support and applying r.f. gradient to induce diffusion of the plasma to the area proximate the wafer support.

Owner:APPLIED MATERIALS INC

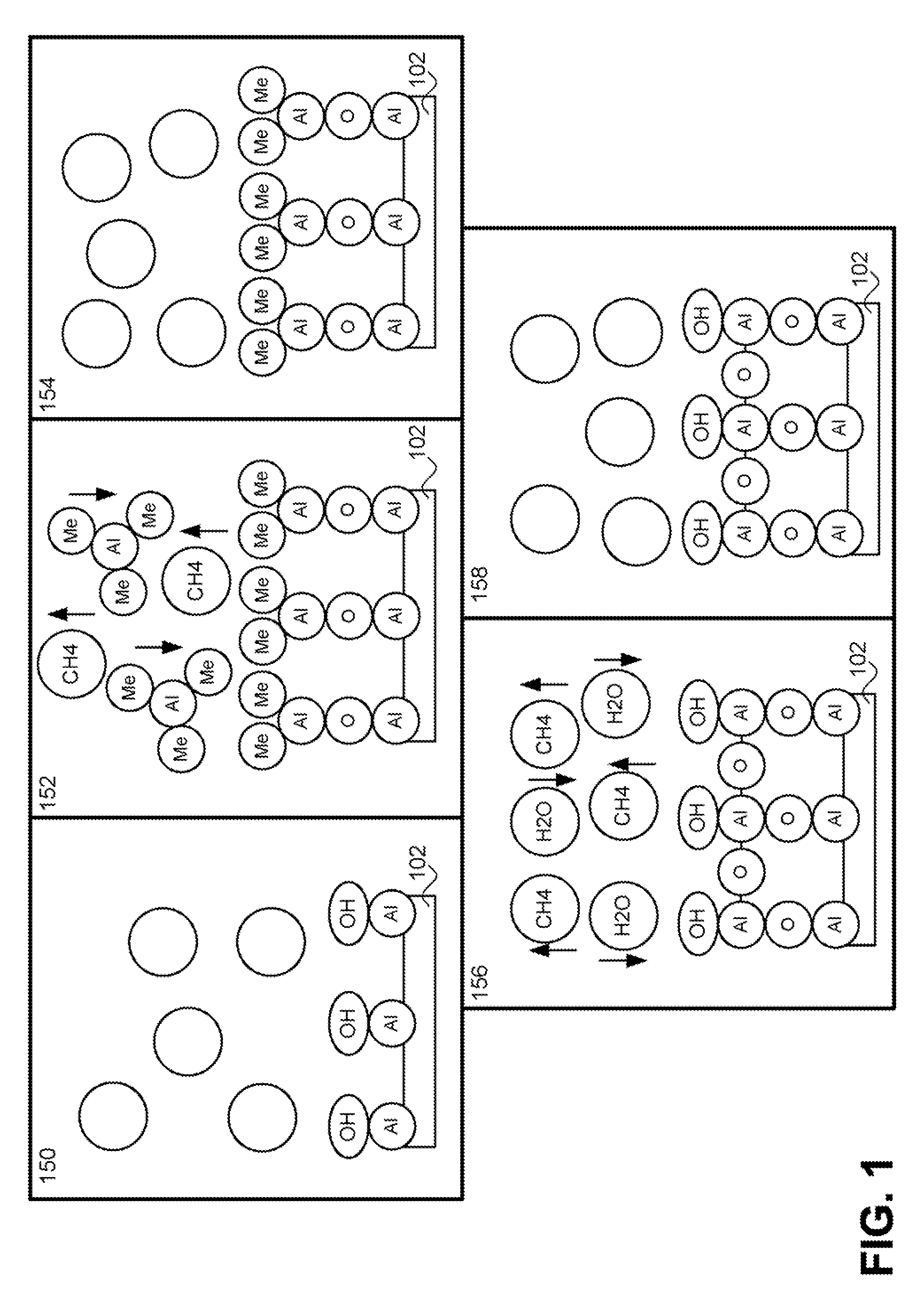

Atomic Layer Deposition of Oxides Using Krypton as an Ion Generating Feeding Gas

InactiveUS20070281105A1Improve abilitiesImprove efficiencyChemical vapor deposition coatingPlasma techniqueKryptonHigh density

An atomic layer deposition system and method utilizing radicals generated from a high-density mixed plasma for deposition is disclosed. A high-quality oxide or oxynitride can be deposited by exposing a substrate to a first precursor which is adsorbed onto the substrate during a first phase of one deposition cycle. After purging the deposition chamber, the substrate is exposed to a second precursor which includes oxygen radicals and krypton ions formed from the high-density mixed plasma. The ions and radicals are formed by introducing a radical generating feed gas (e.g., O2) and an ion generating feed gas into a plasma chamber and exciting the gases to form the high-density mixed plasma. The radicals and ions are then introduced to the substrate where they react with the first precursor to deposit a layer of the desired film. Krypton is preferably used as the ion generating feed gas because the metastable states of krypton lead to an efficient dissociation of oxygen into oxygen radicals when compared with other inert gases.

Owner:SANDISK TECH LLC

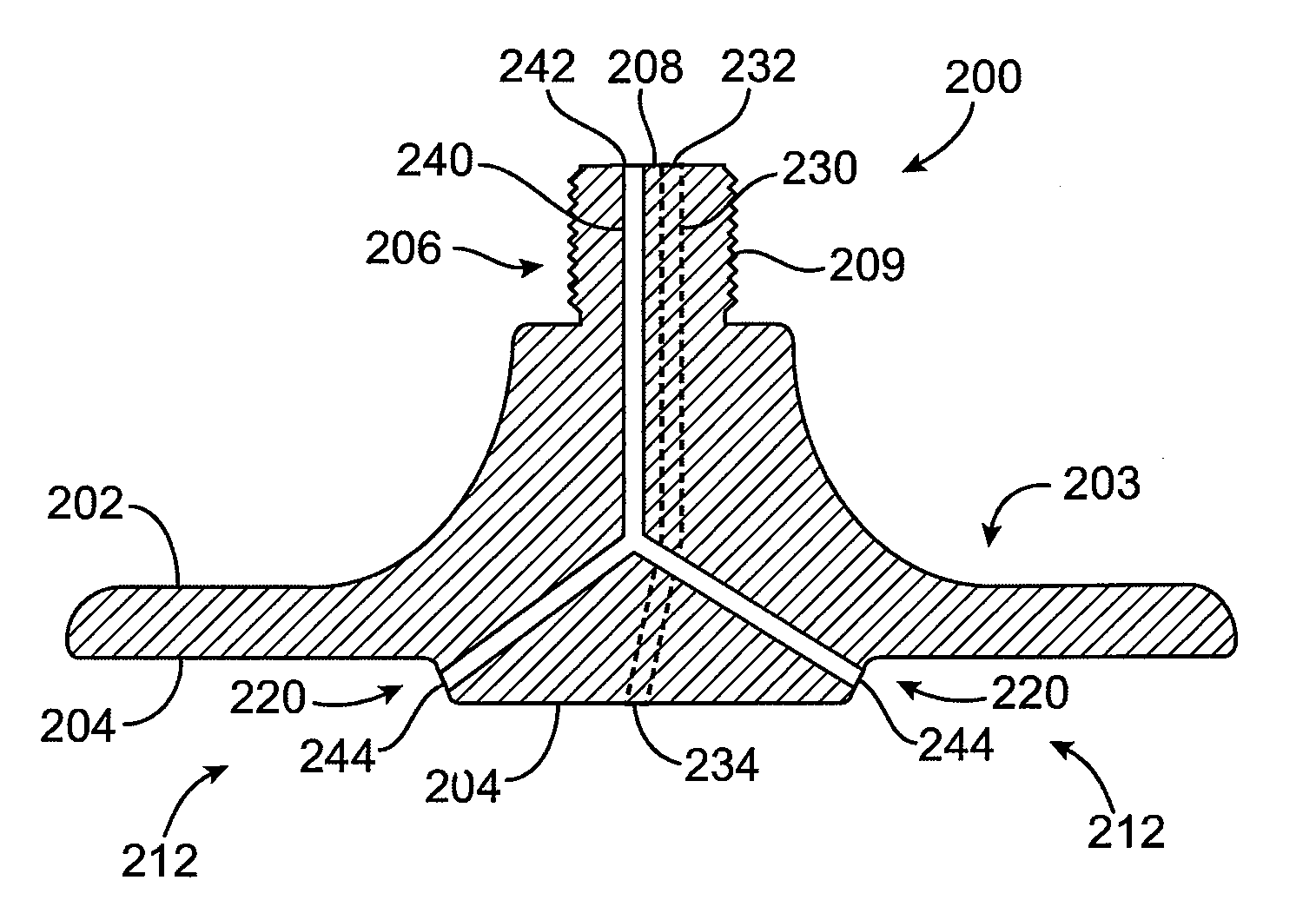

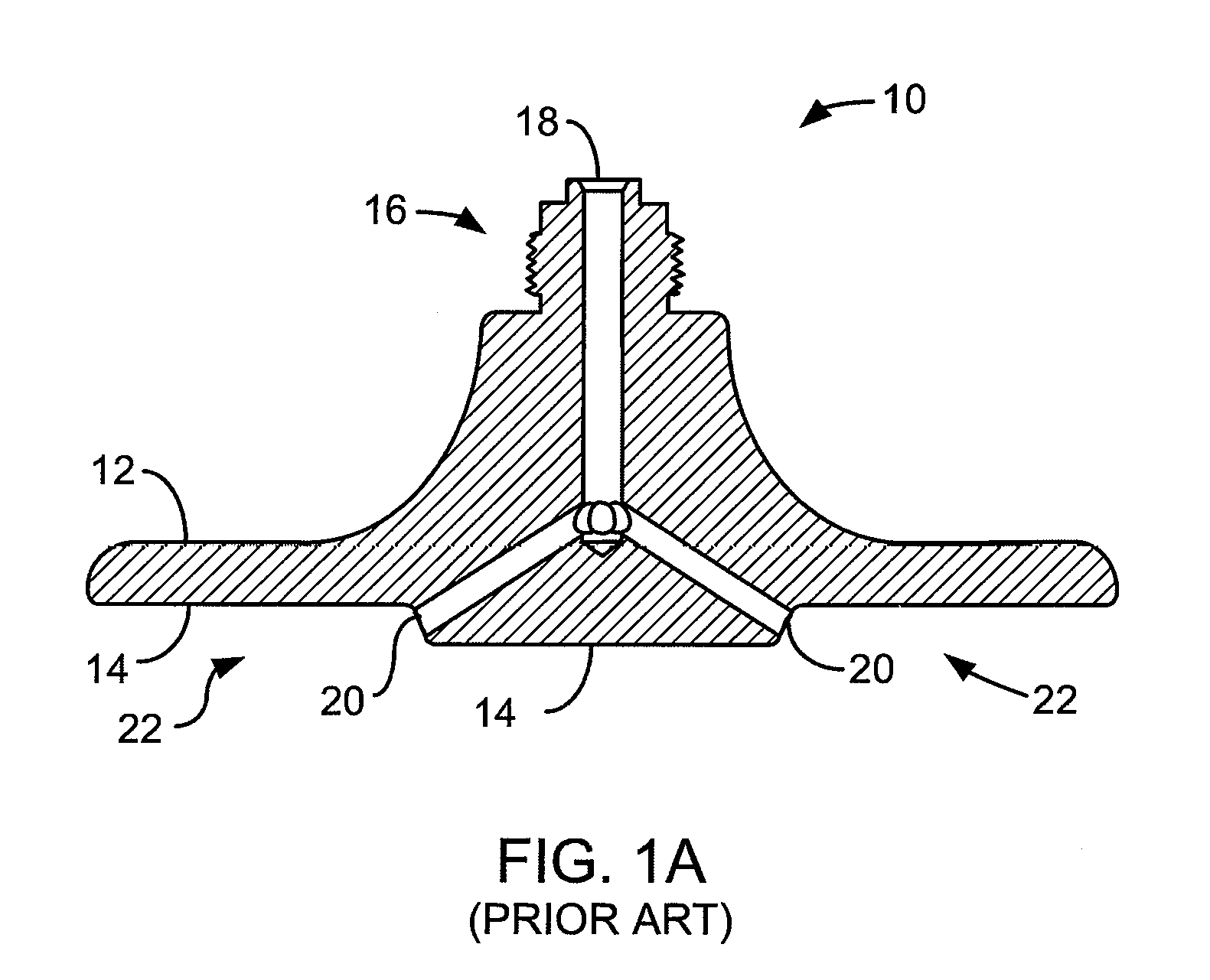

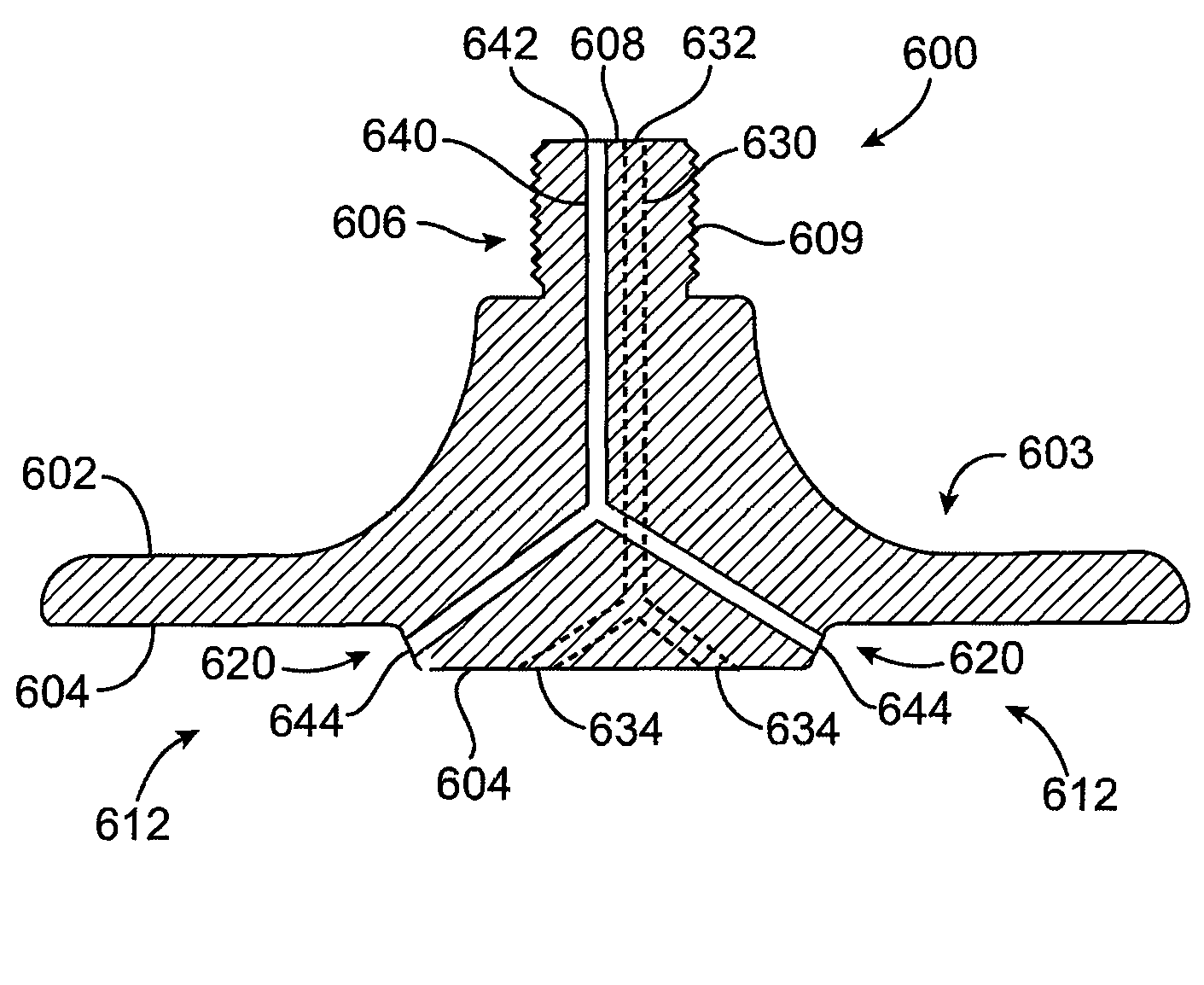

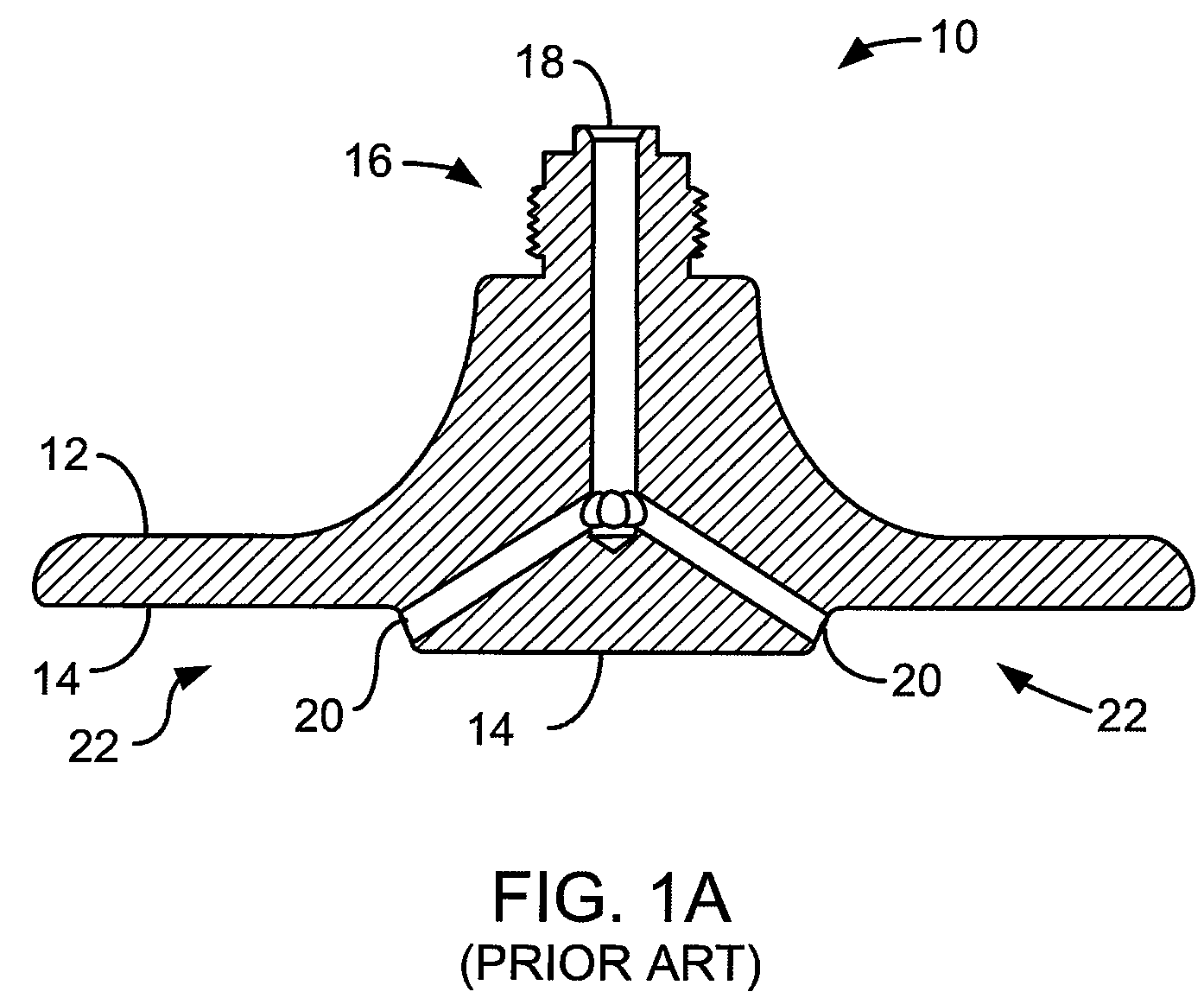

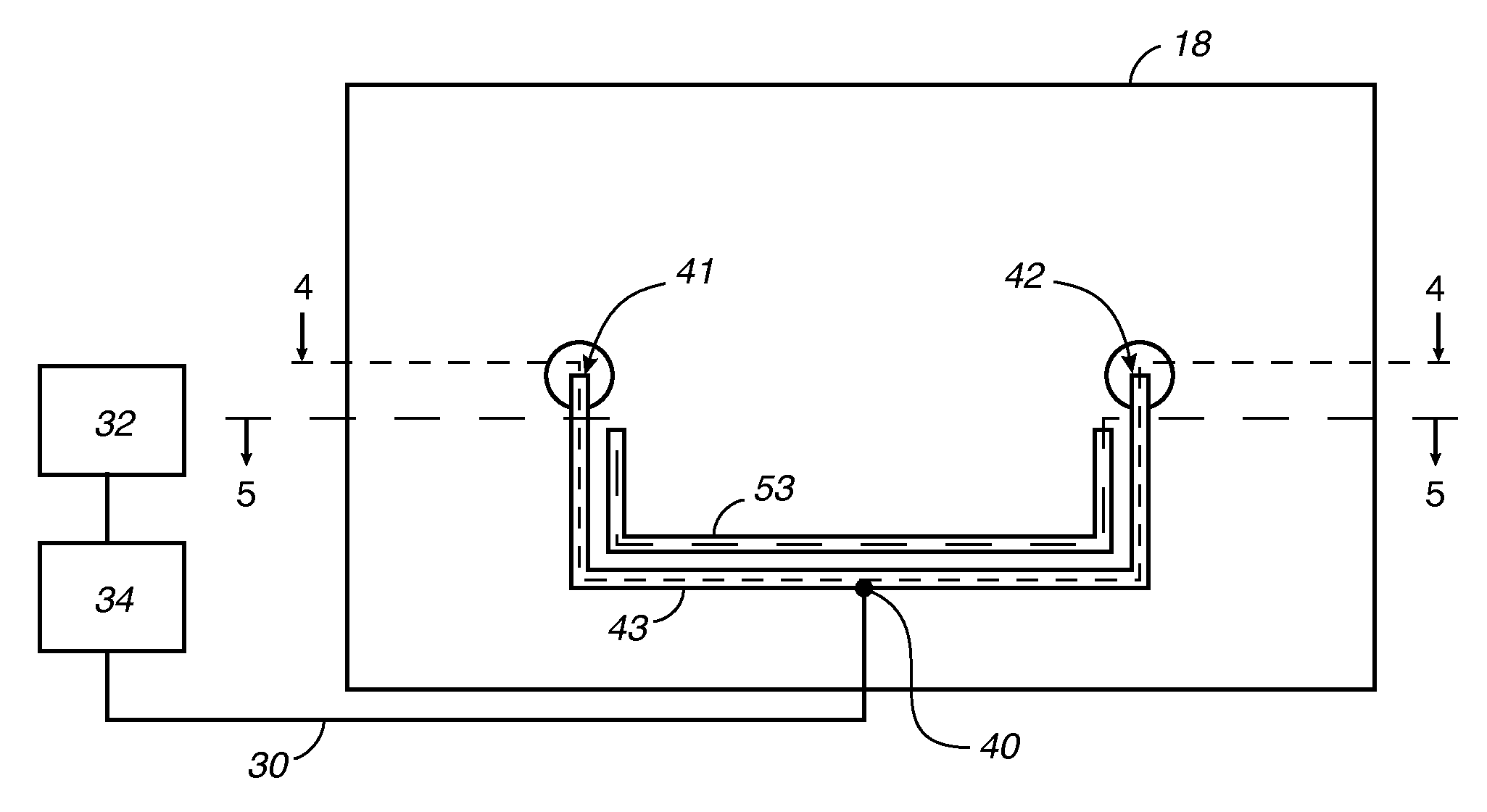

Dual top gas feed through distributor for high density plasma chamber

InactiveUS20080121177A1Improve uniformityUniform layersElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityProduct gas

A gas distributor for use in a semiconductor process chamber comprises a body. The body includes a first channel formed within the body and adapted to pass a first fluid from a first fluid supply line through the first channel to a first opening. A second channel is formed within the body and adapted to pass a second fluid from a second fluid supply line through the second channel to a second opening. The first and second openings are arranged to mix the fluids outside the body after the fluids pass through the openings.

Owner:APPLIED MATERIALS INC

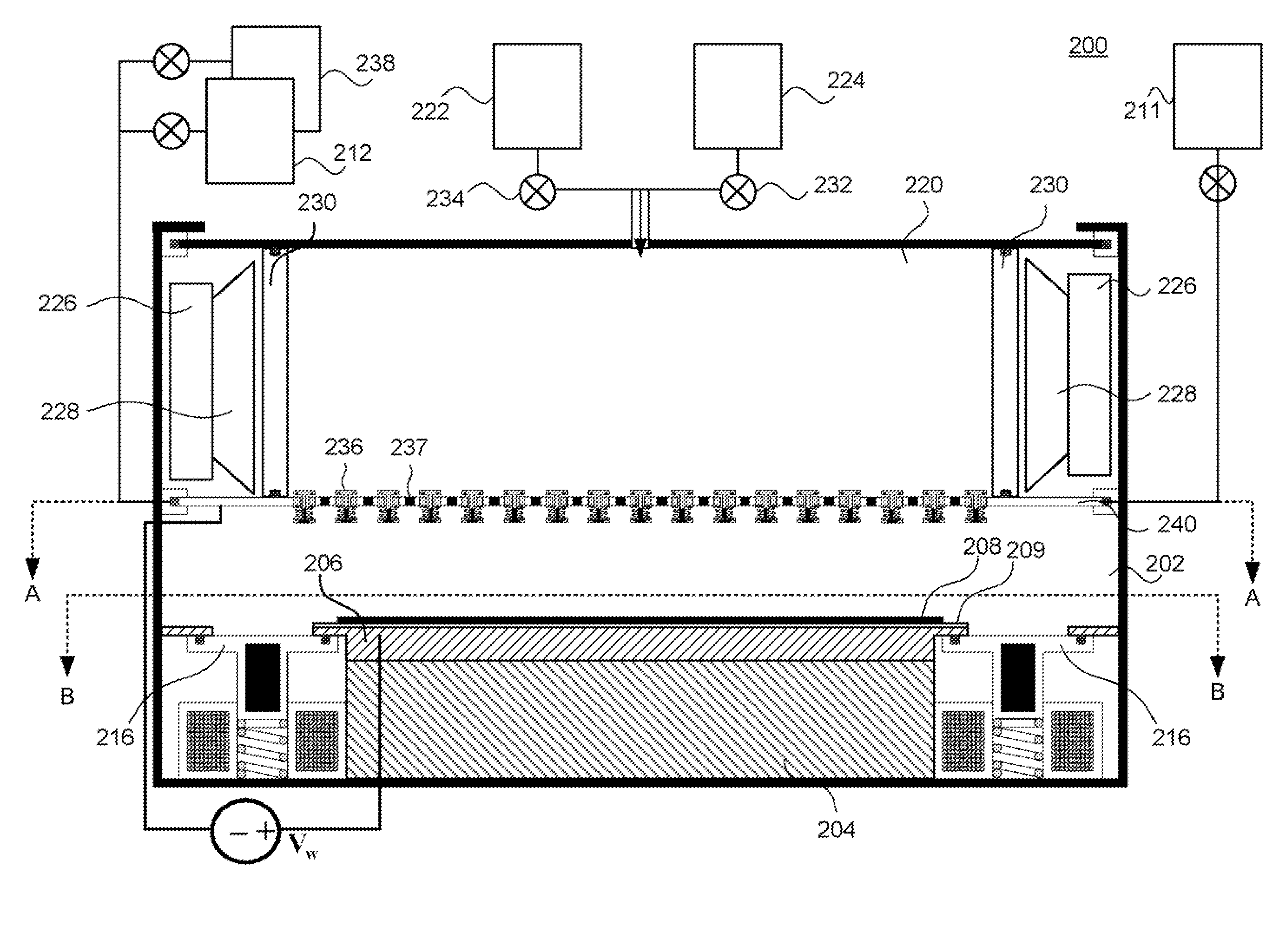

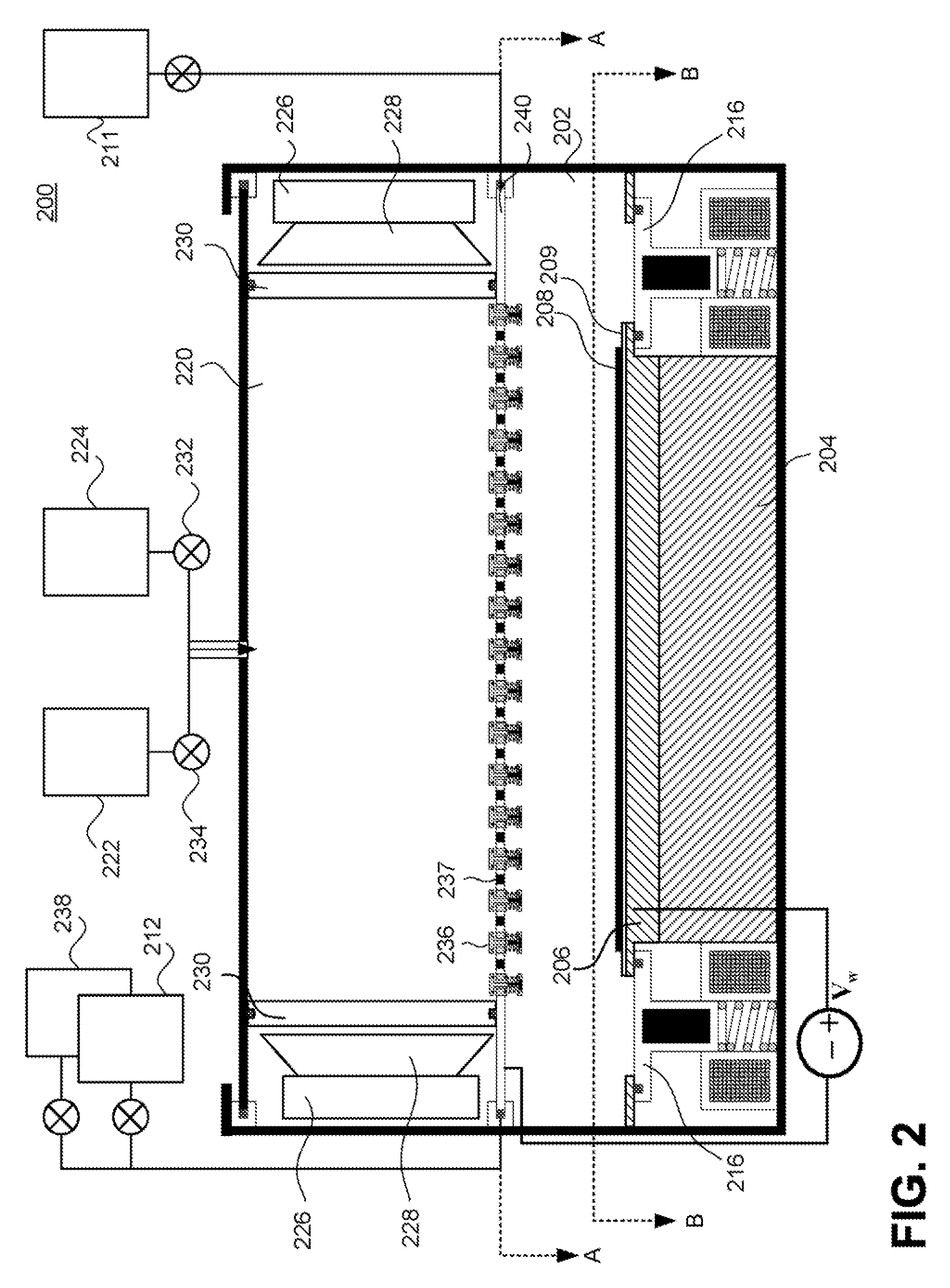

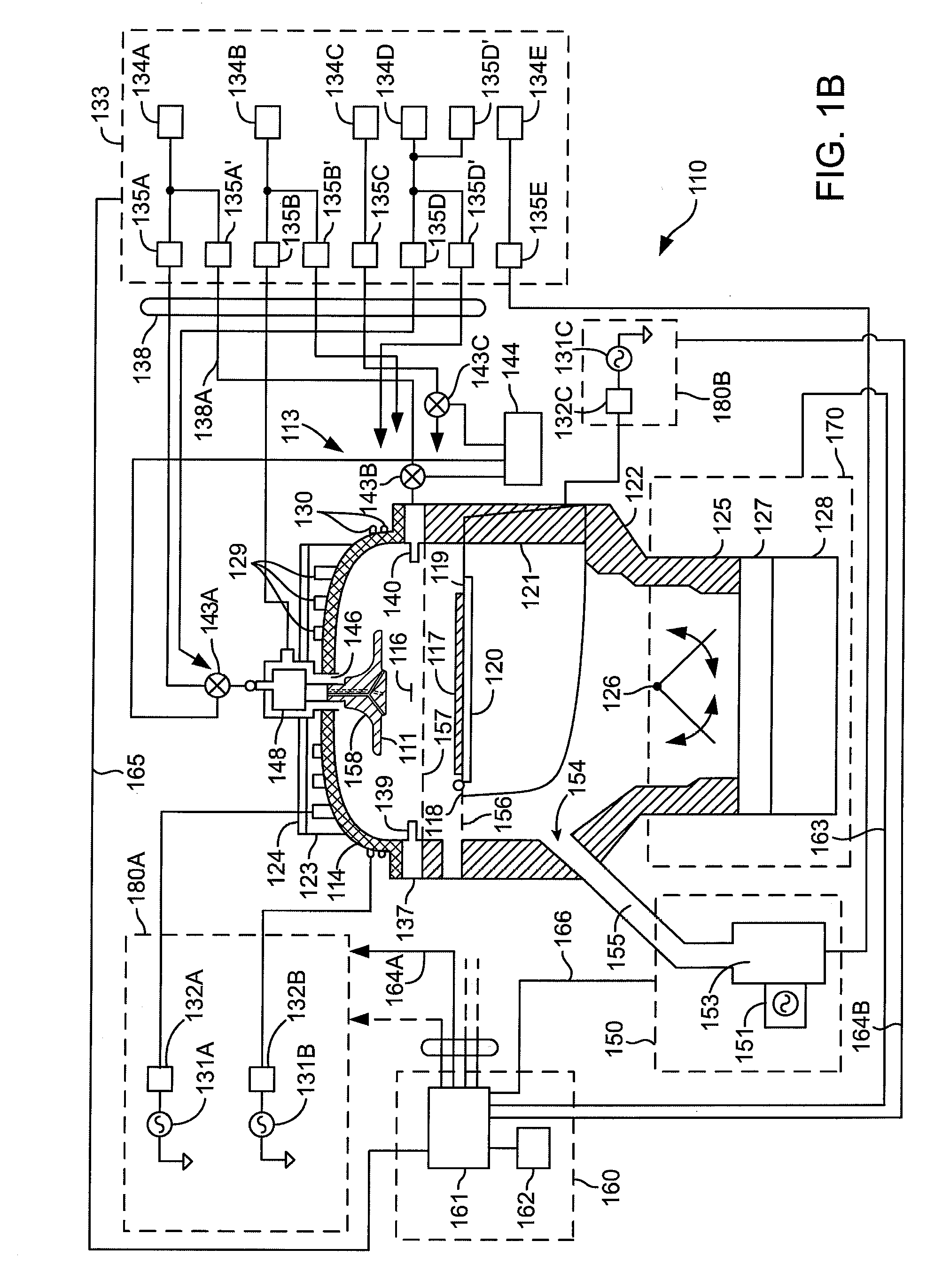

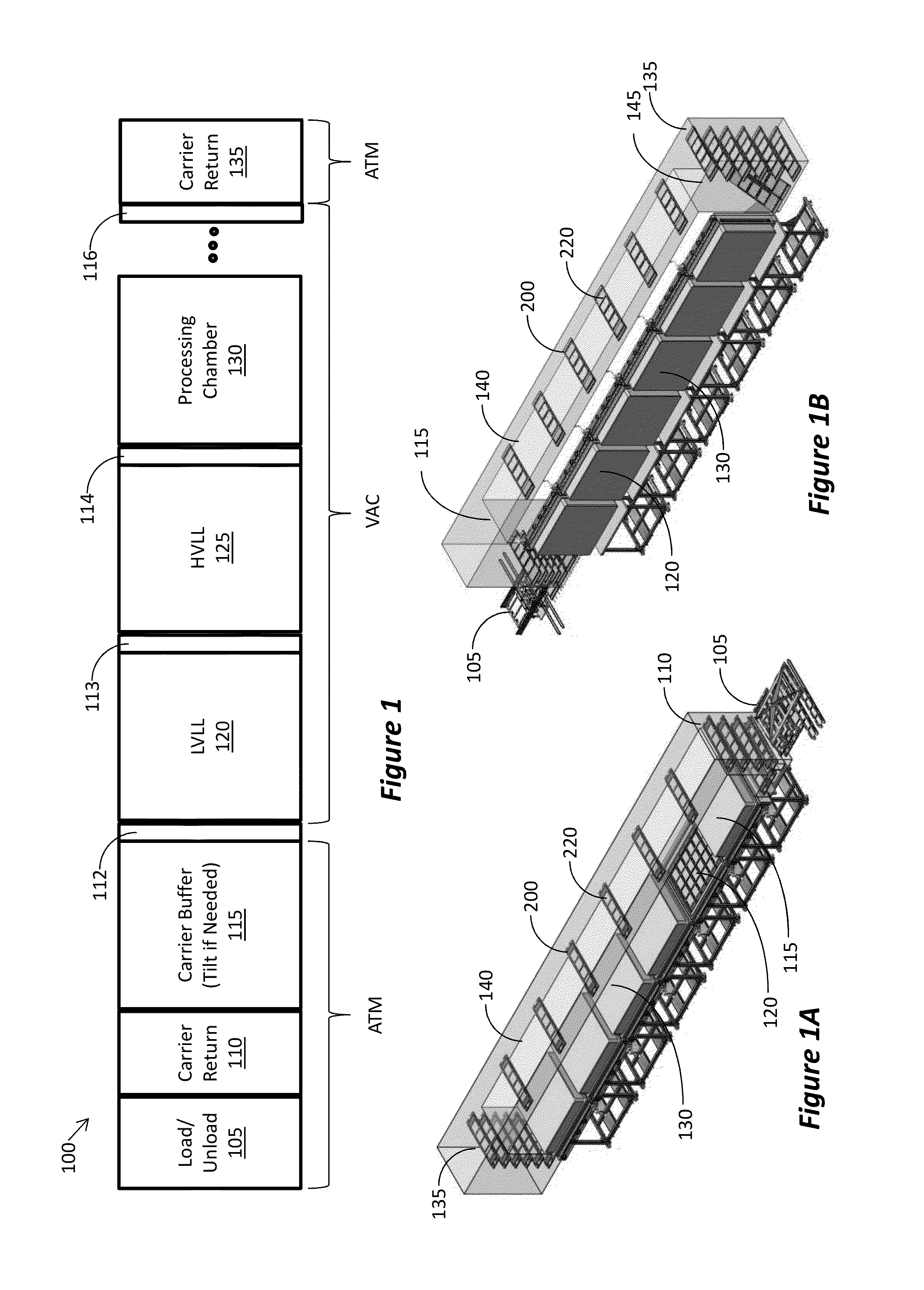

System architecture for vacuum processing

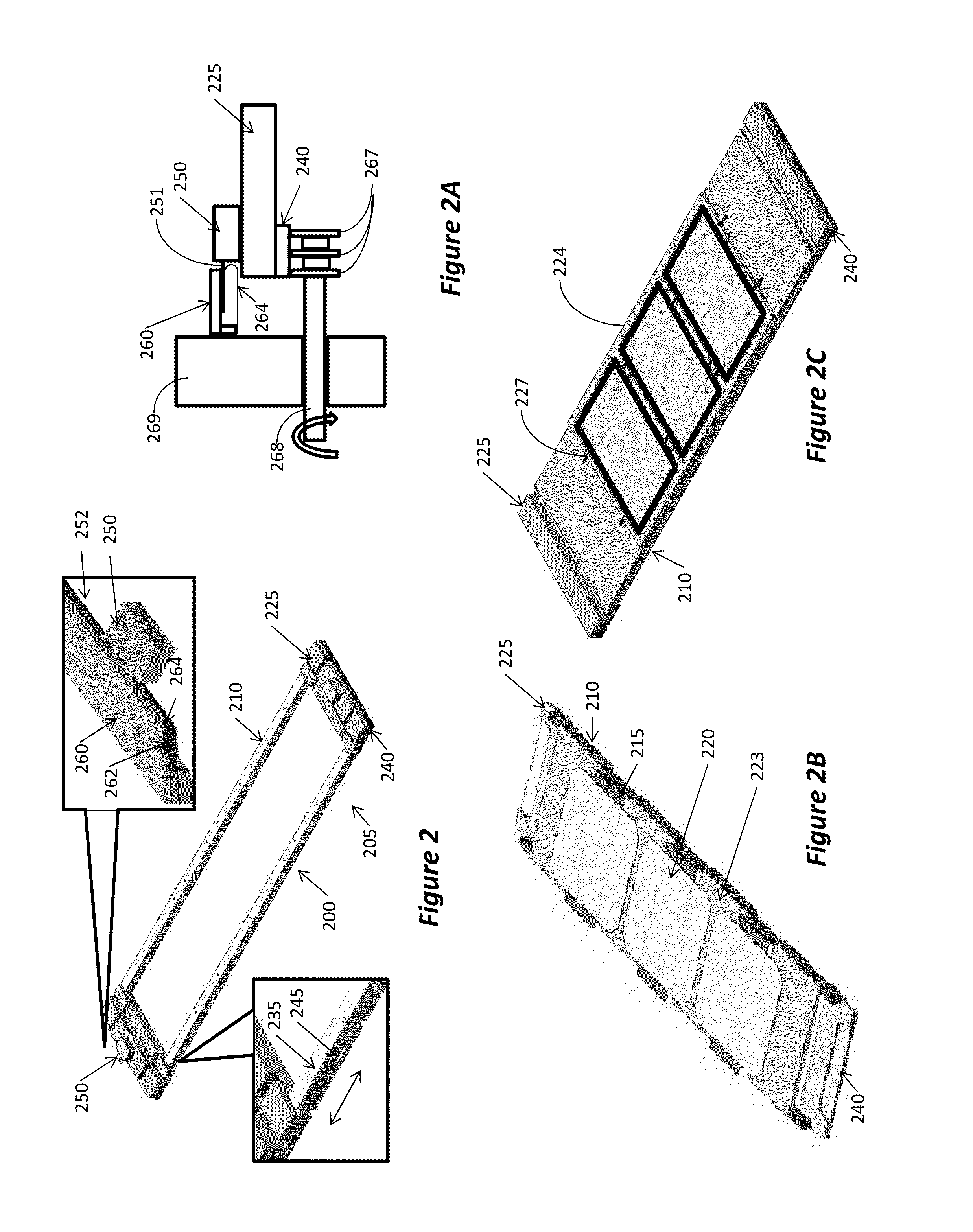

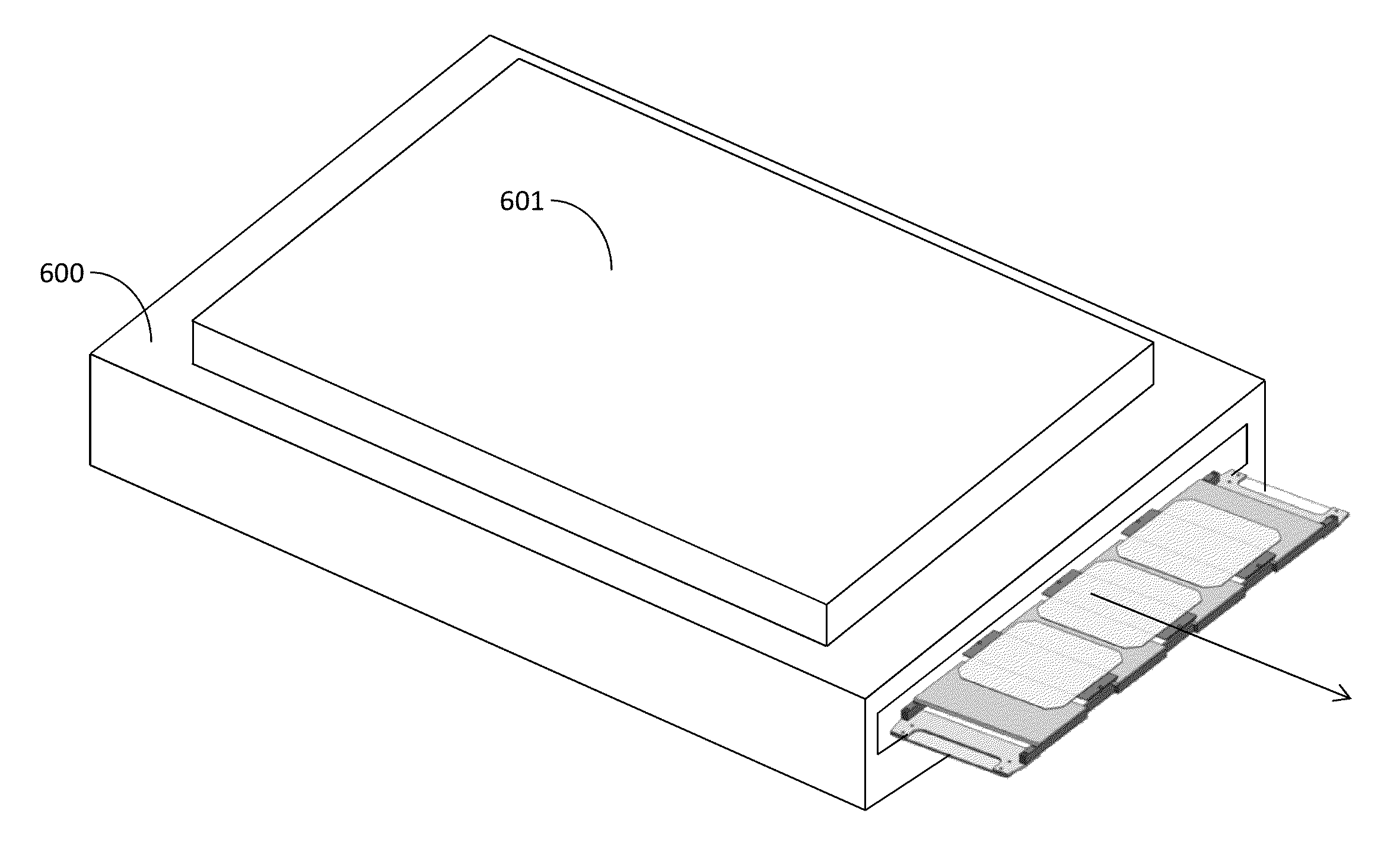

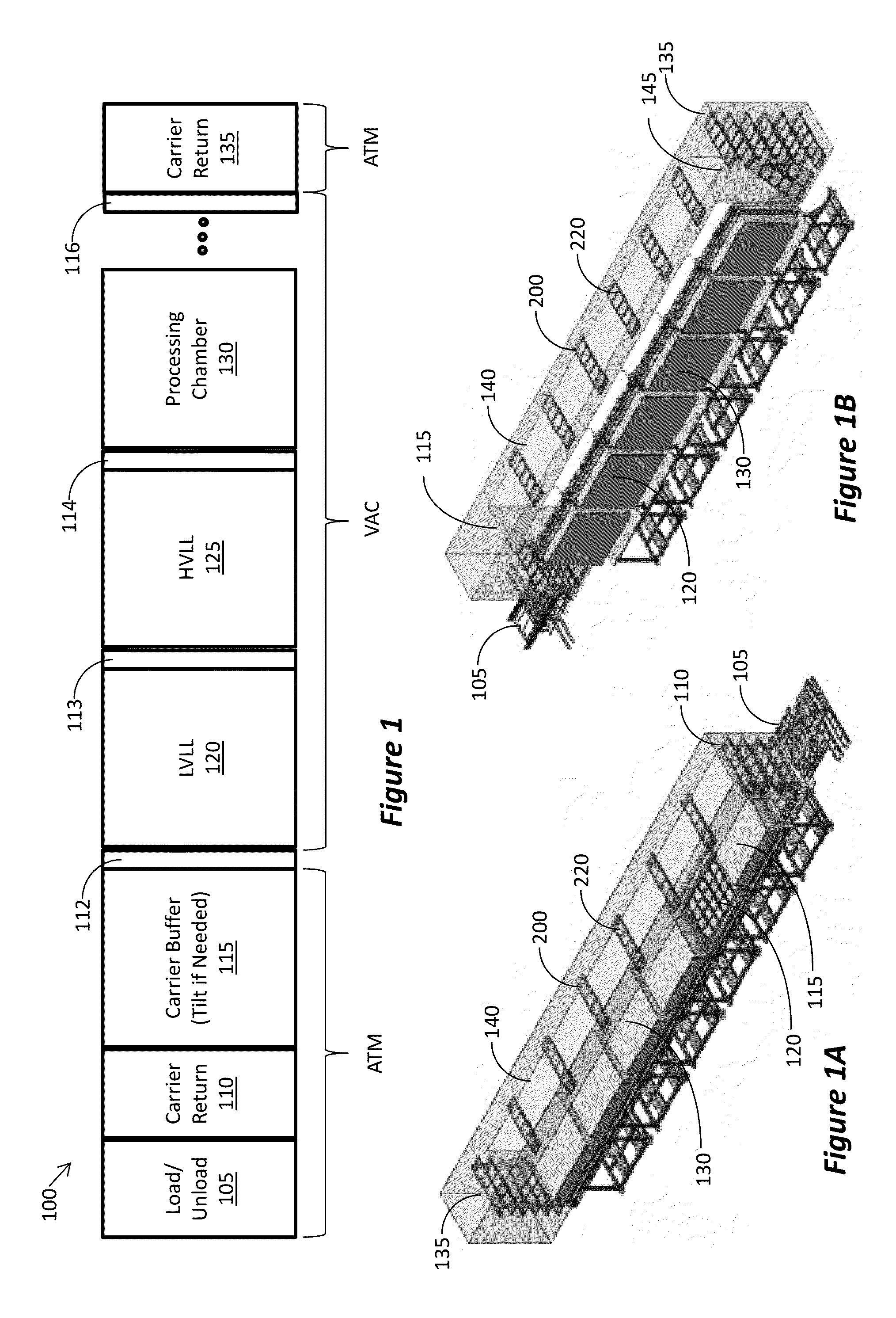

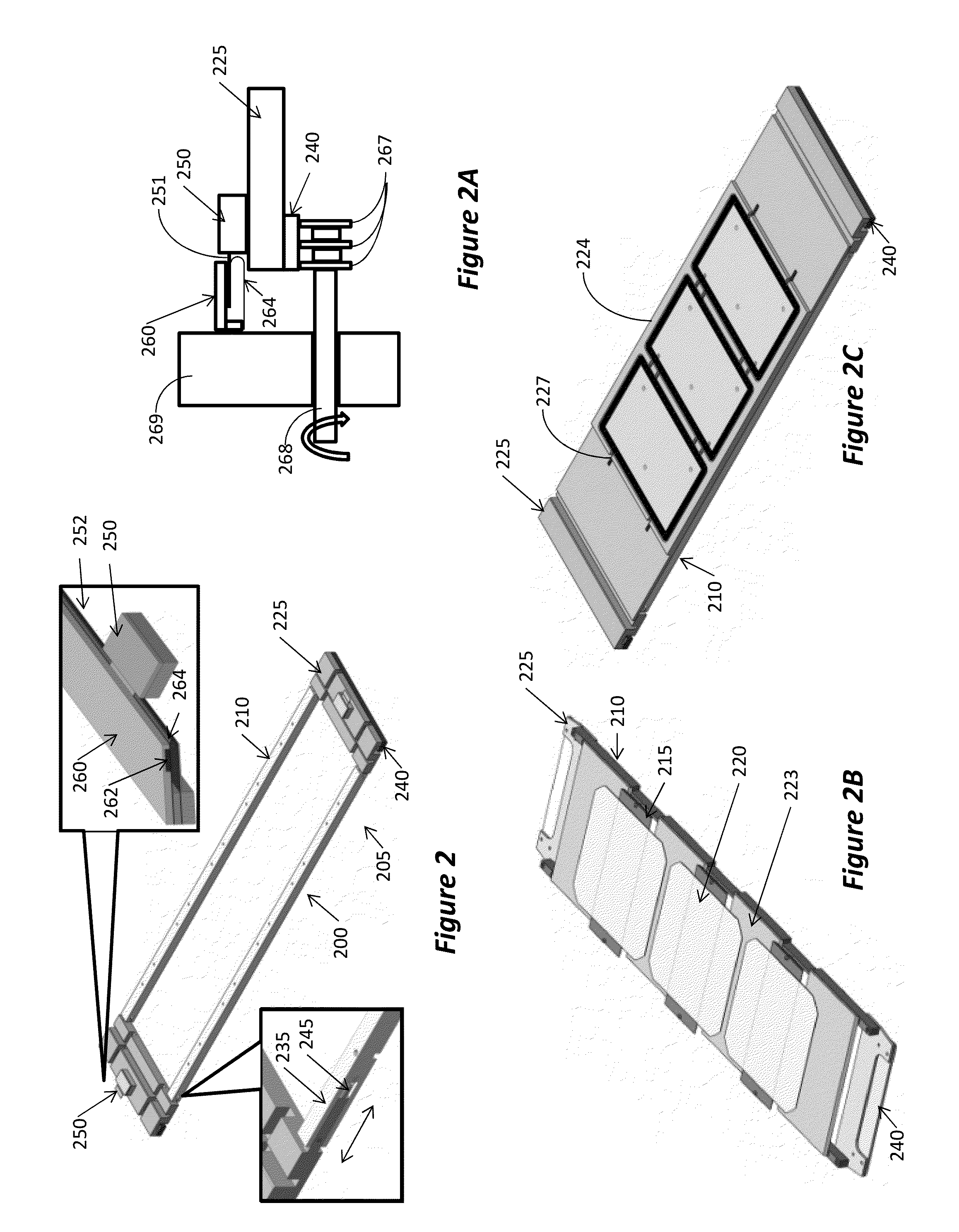

ActiveUS20130287526A1Improve cooling effectAvoid accidental movementSemiconductor/solid-state device manufacturingConveyor partsMechanical engineeringPlasma chamber

A system for processing substrates in plasma chambers, such that all substrates transport and loading / unloading operations are performed in atmospheric environment, but processing is performed in vacuum environment. The substrates are transported throughout the system on carriers. The system's chambers are arranged linearly, such that carriers move from one chamber directly to the next. A conveyor, placed above or below the system's chambers, returns the carriers to the system's entry area after processing is completed. Loading and unloading of substrates may be performed at one side of the system, or loading can be done at the entry side and unloading at the exit side.

Owner:INTEVAC

System and method for bi-facial processing of substrates

InactiveUS20150170947A1Improve cooling effectAvoid accidental movementSemiconductor/solid-state device manufacturingStorage devicesEngineeringFacial processing

A system for processing substrates in plasma chambers, such that all substrates transport and loading / unloading operations are performed in atmospheric environment, but processing is performed in vacuum environment. The substrates are transported throughout the system on carriers. The system's chambers are arranged linearly, such that carriers move from one chamber directly to the next. A conveyor, placed above or below the system's chambers, returns the carriers to the system's entry area after processing is completed. The carriers are configured for supporting substrates of different sizes. The carriers are also configured for flipping the substrates such that both surfaces of the substrates may be processed.

Owner:INTEVAC

Dual top gas feed through distributor for high density plasma chamber

InactiveUS7758698B2Improve uniformityAvoid depositionElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityDistributor

A gas distributor for use in a semiconductor process chamber comprises a body. The body includes a first channel formed within the body and adapted to pass a first fluid from a first fluid supply line through the first channel to a first opening. A second channel is formed within the body and adapted to pass a second fluid from a second fluid supply line through the second channel to a second opening. The first and second openings are arranged to mix the fluids outside the body after the fluids pass through the openings.

Owner:APPLIED MATERIALS INC

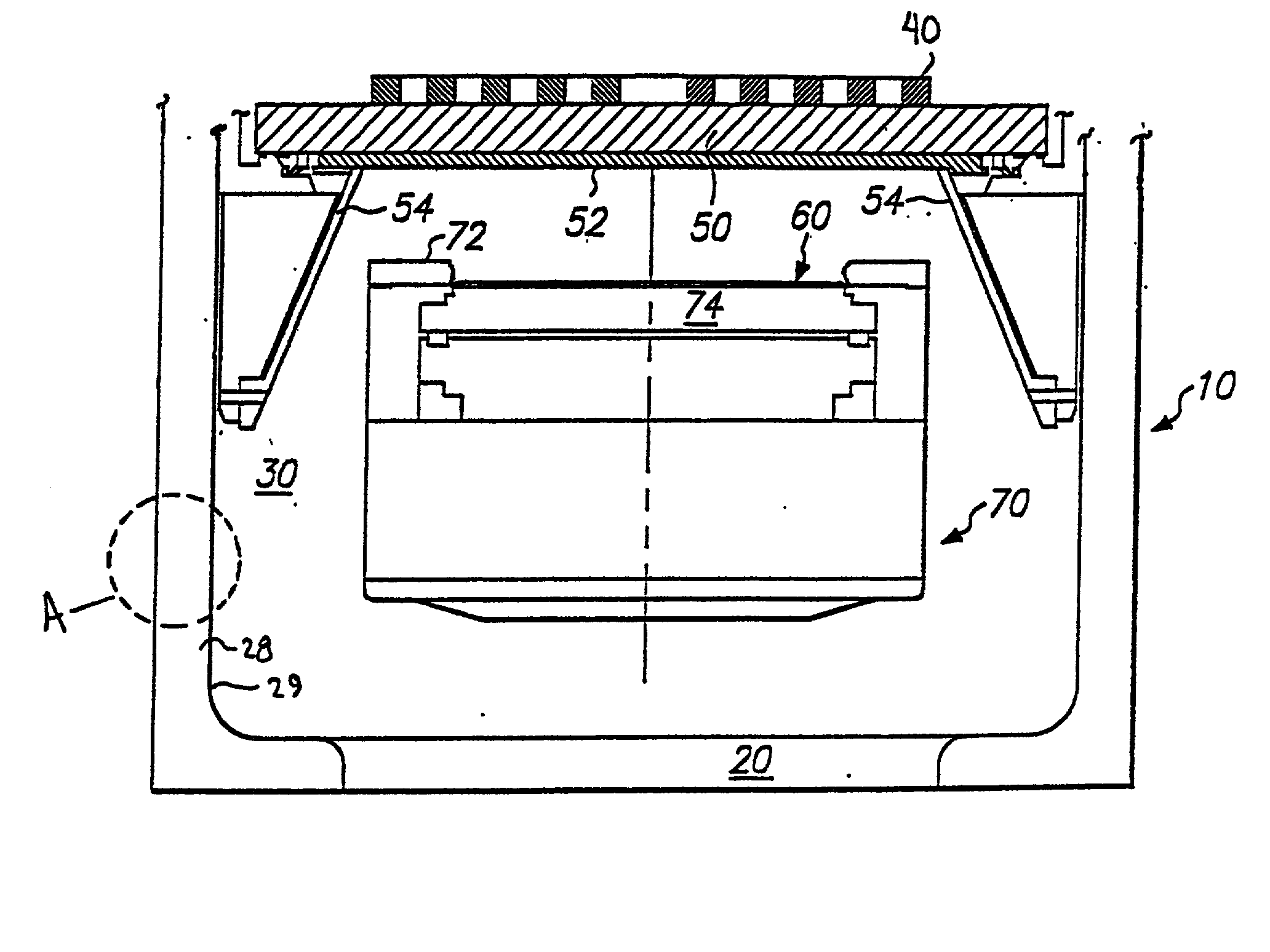

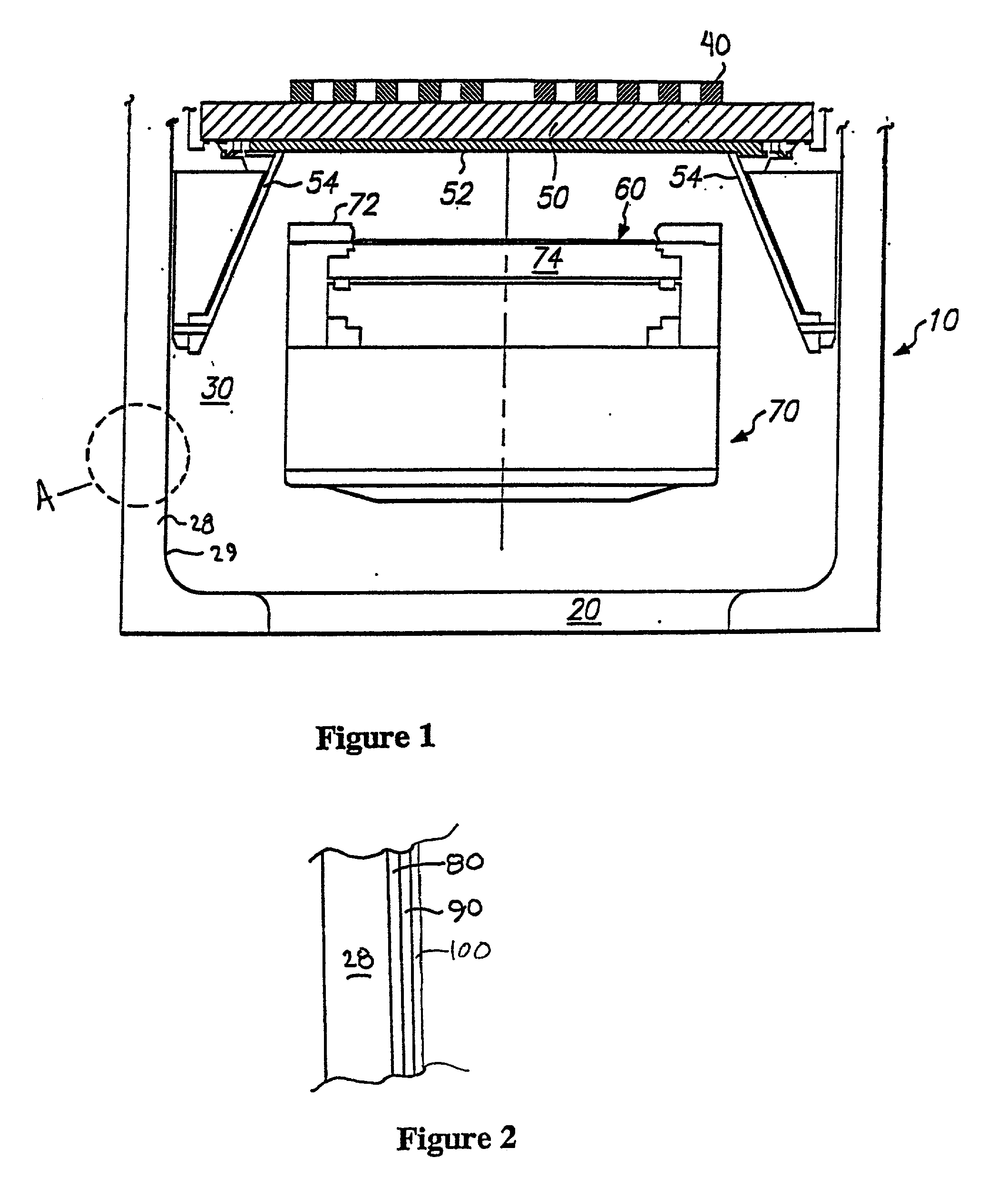

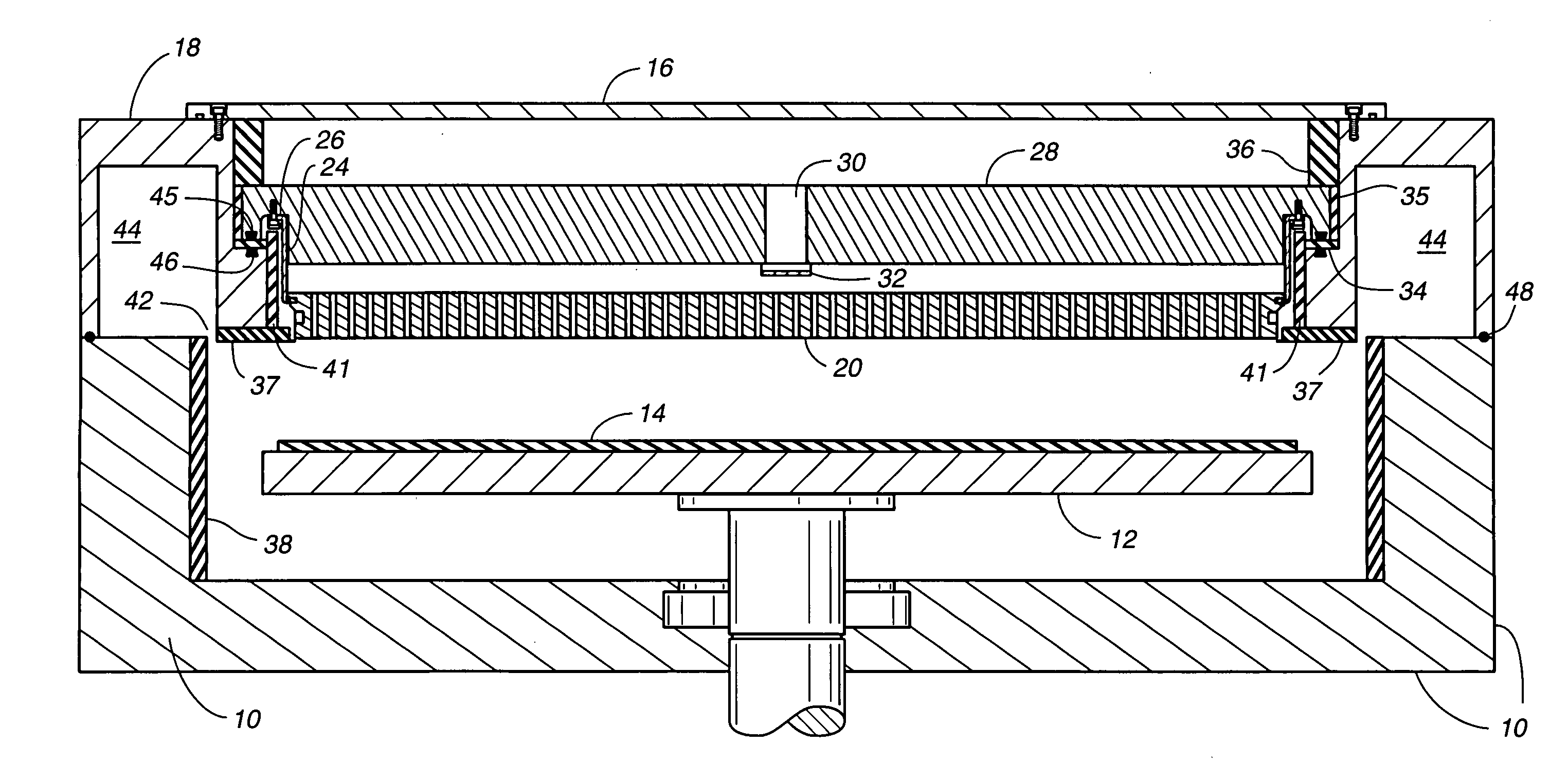

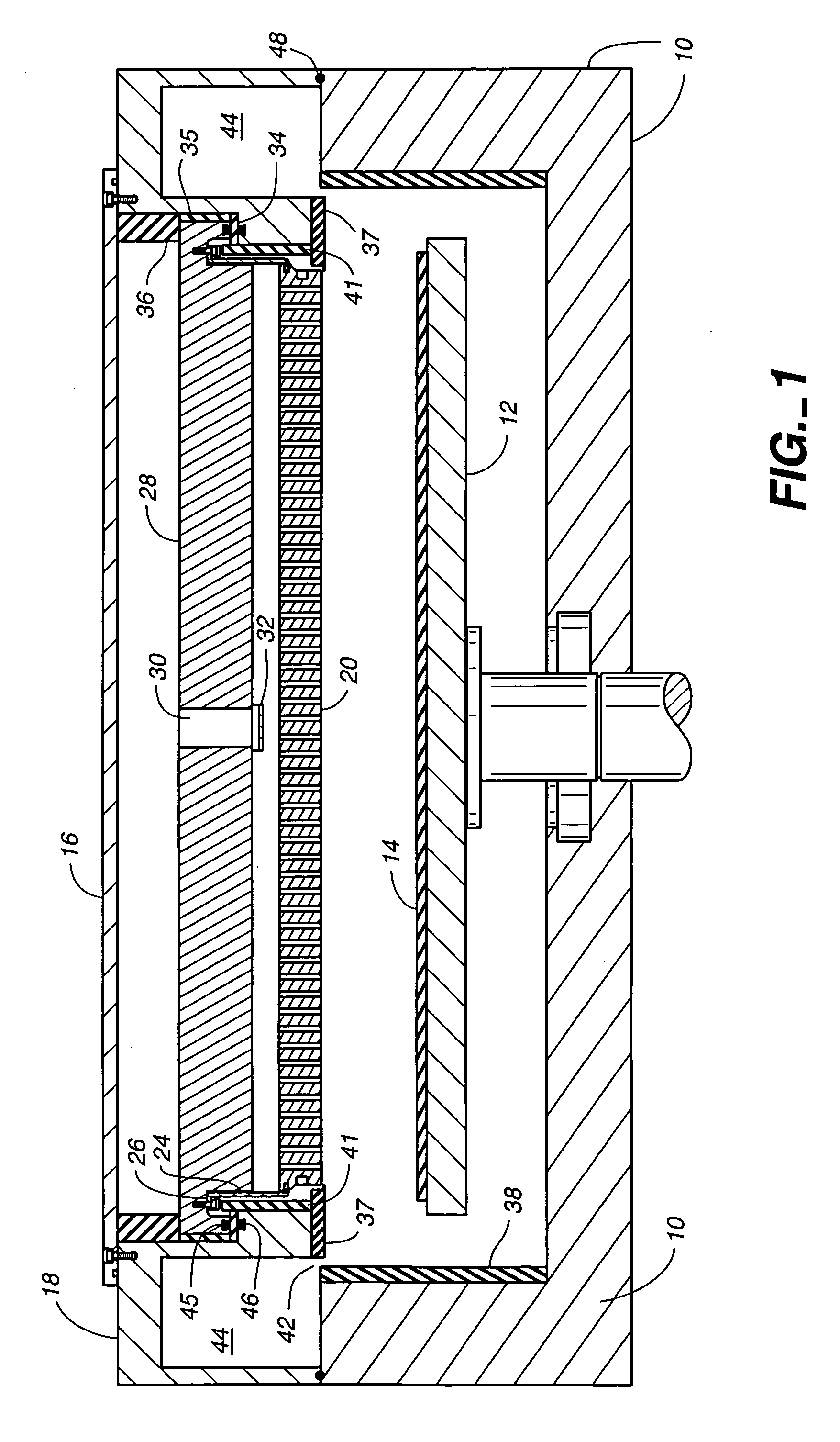

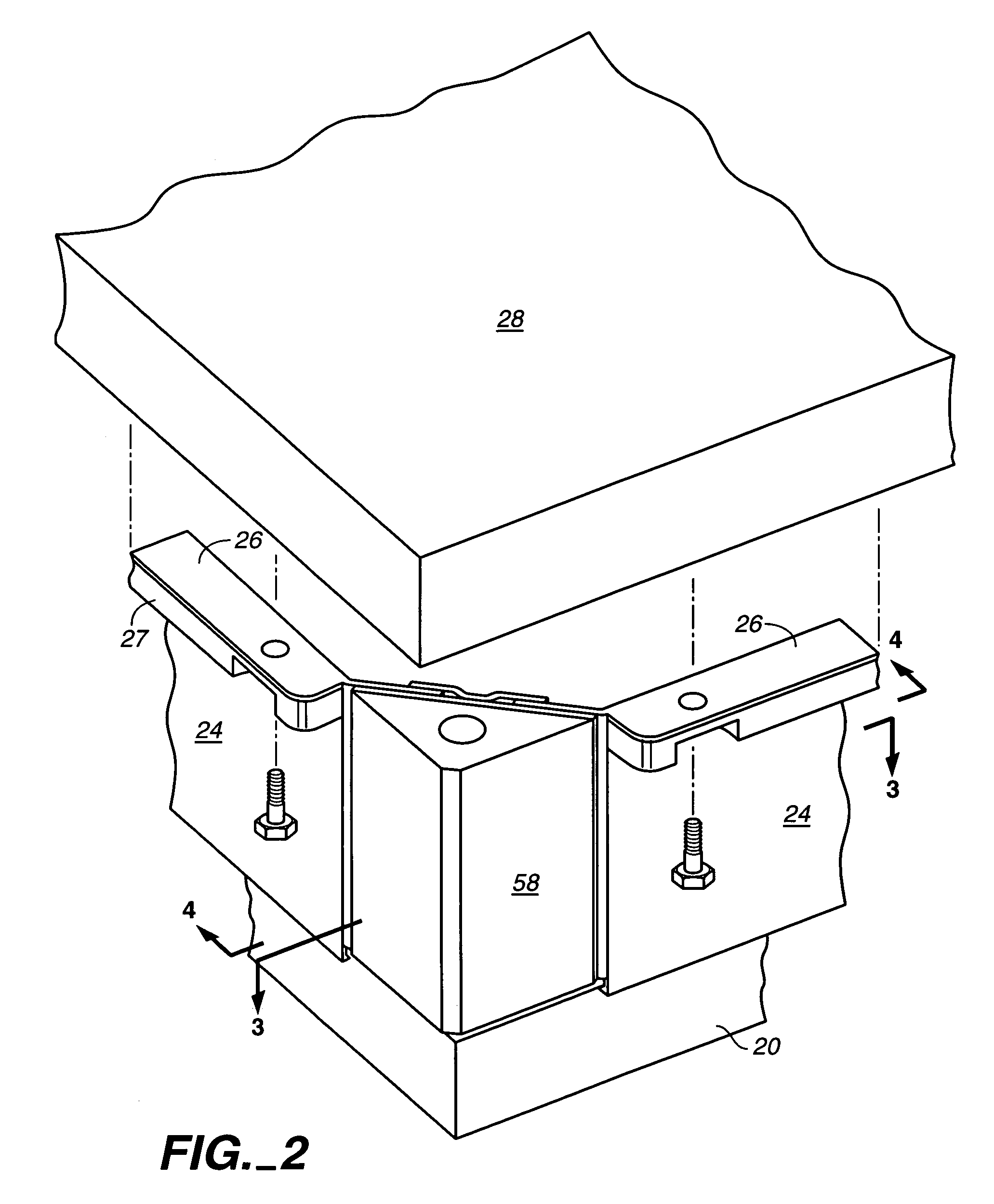

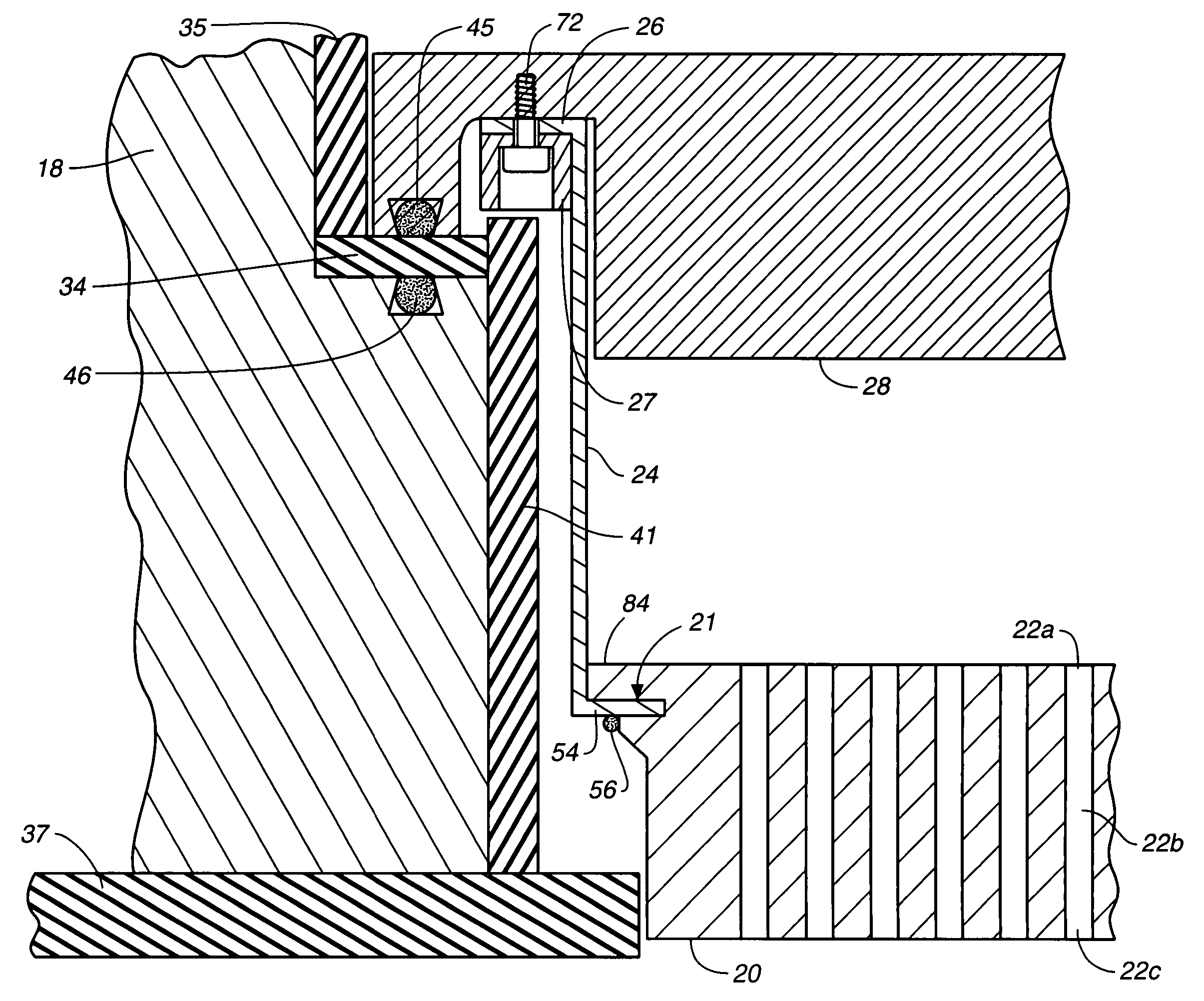

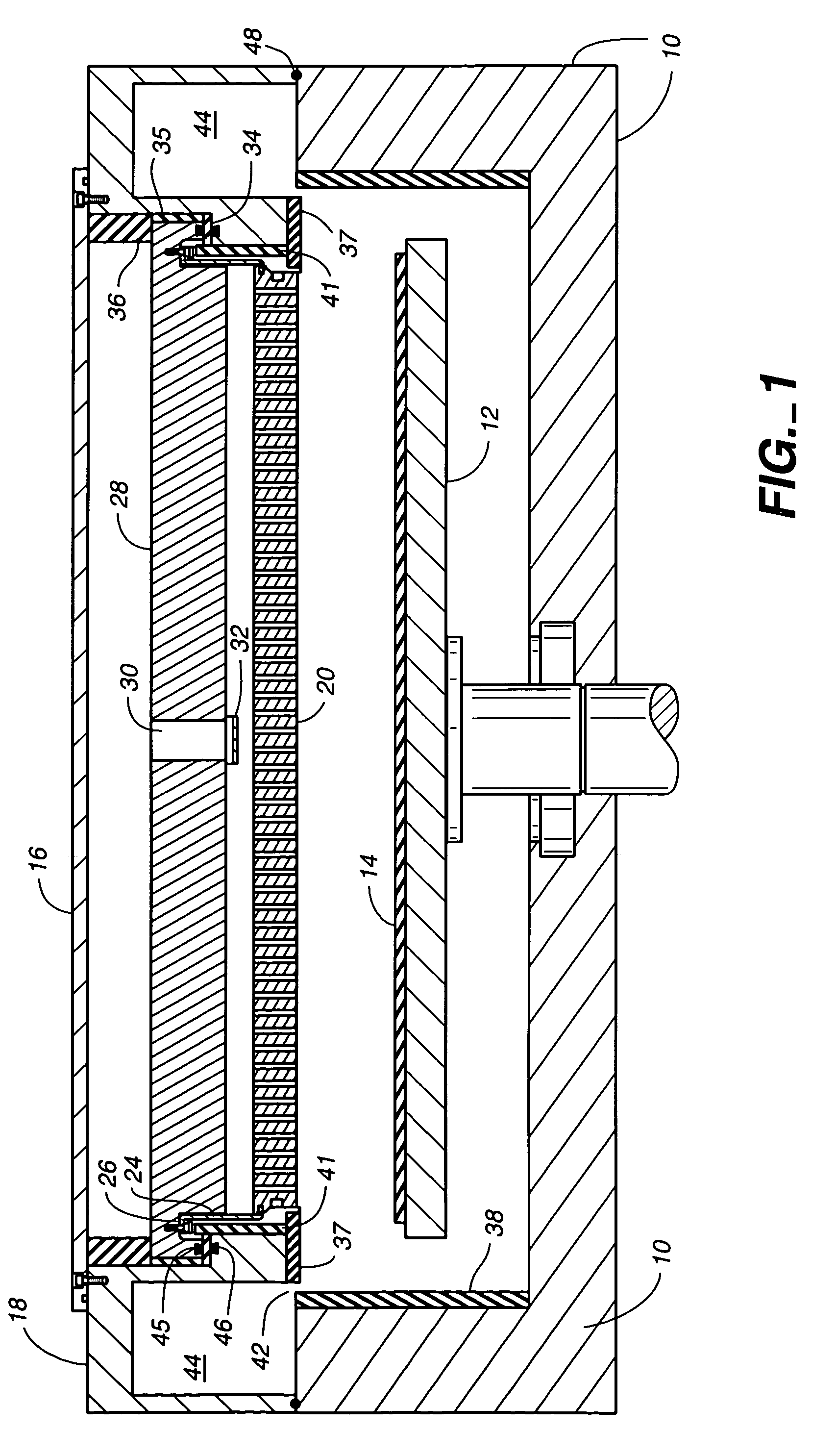

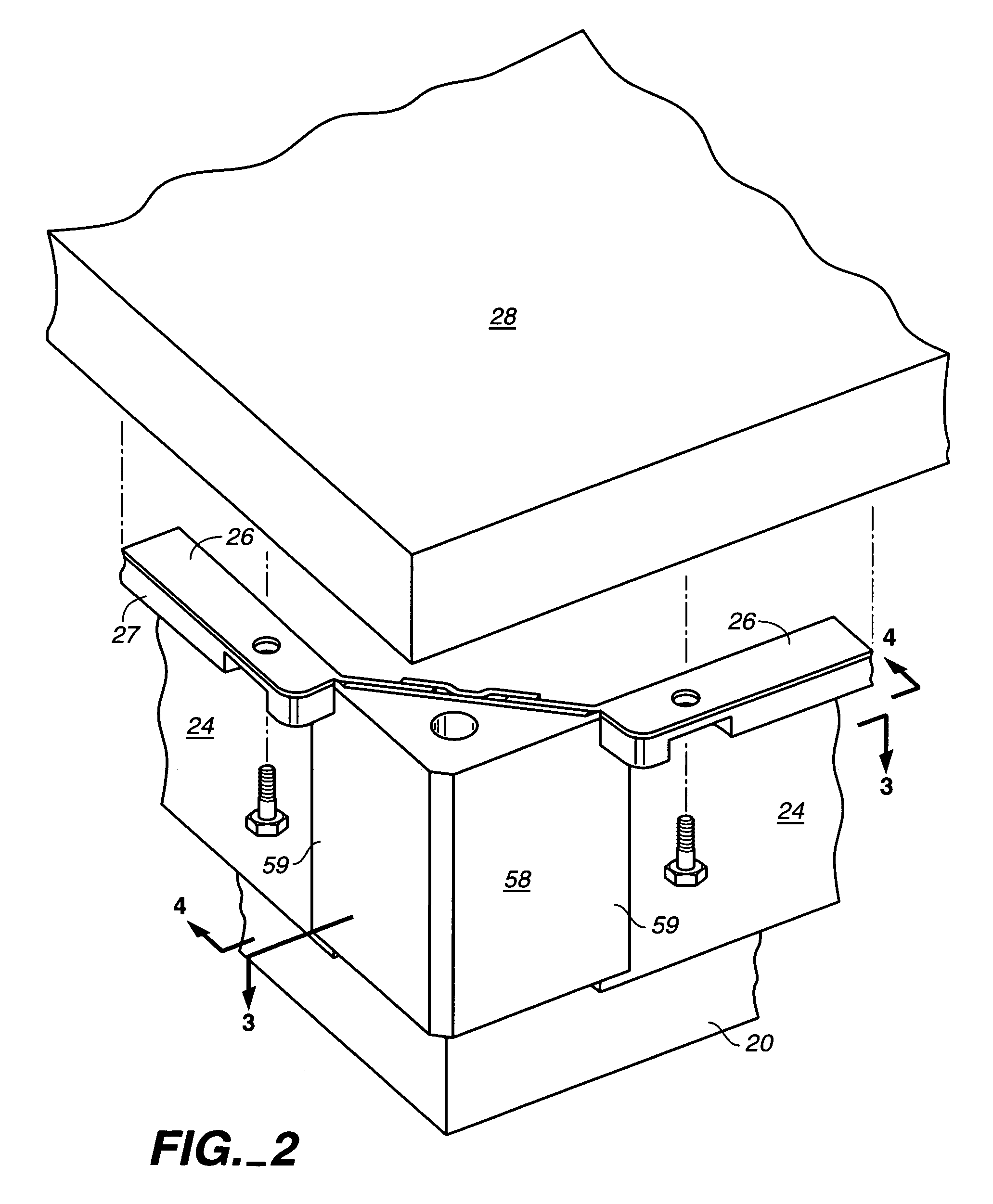

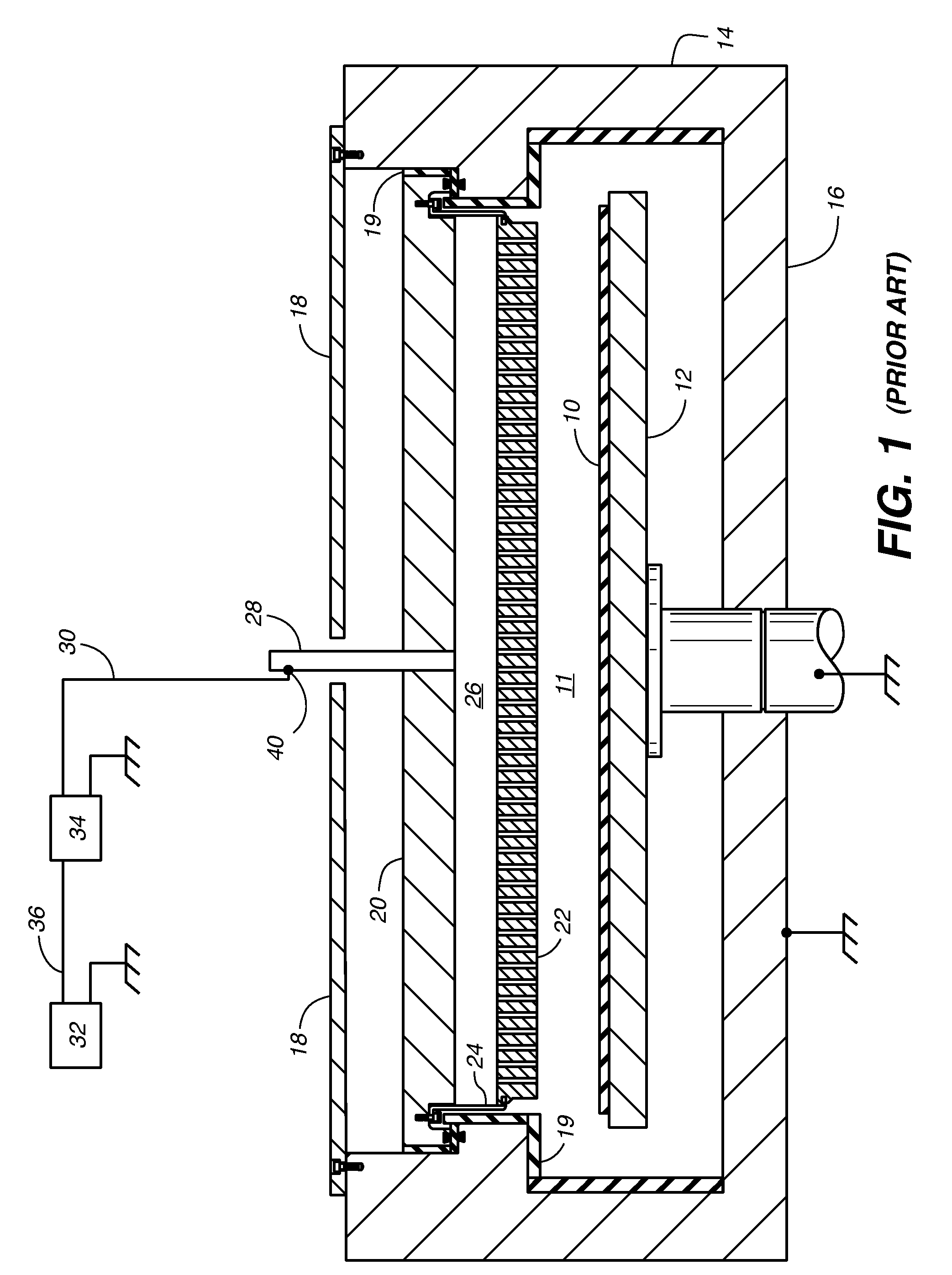

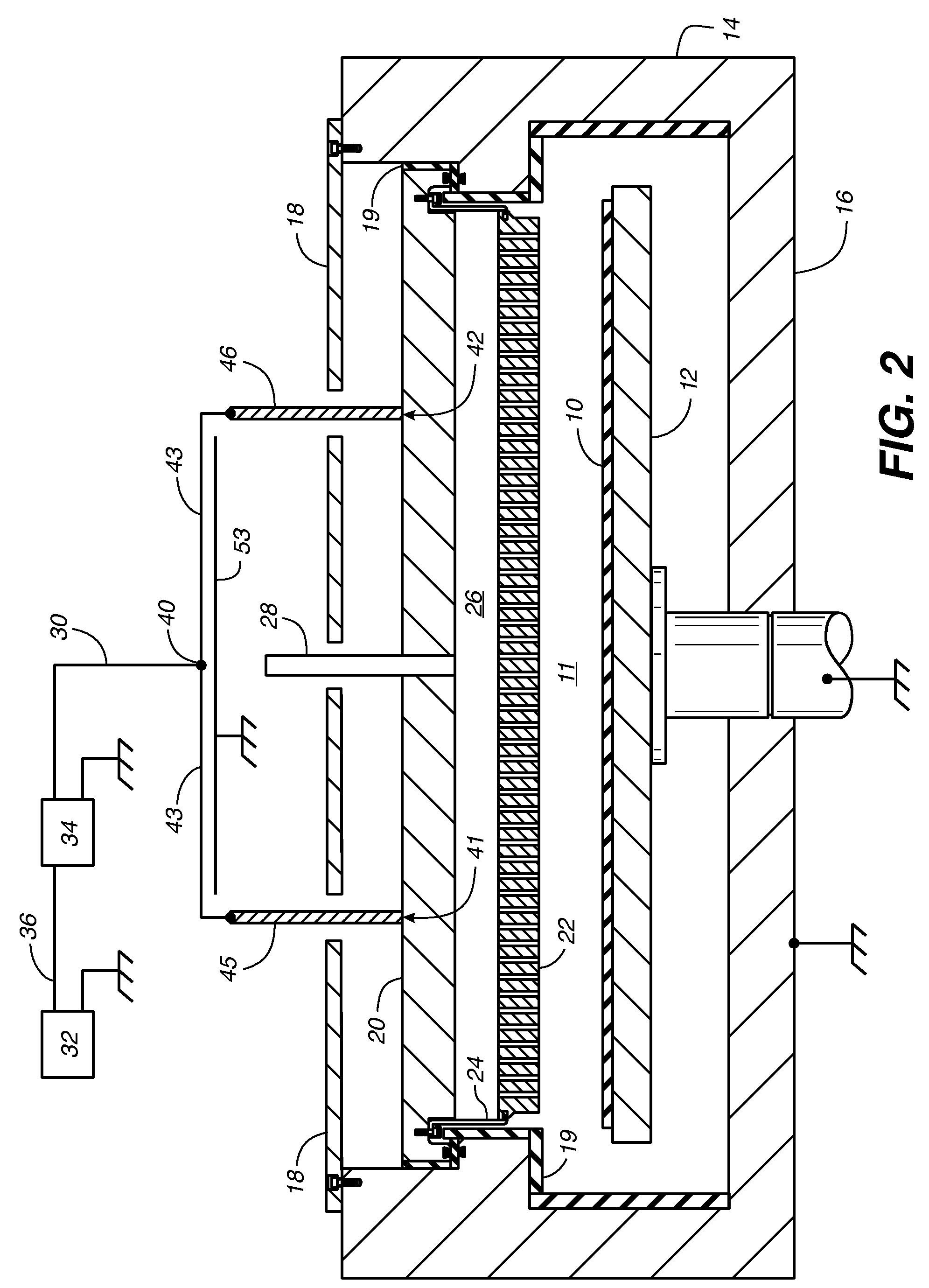

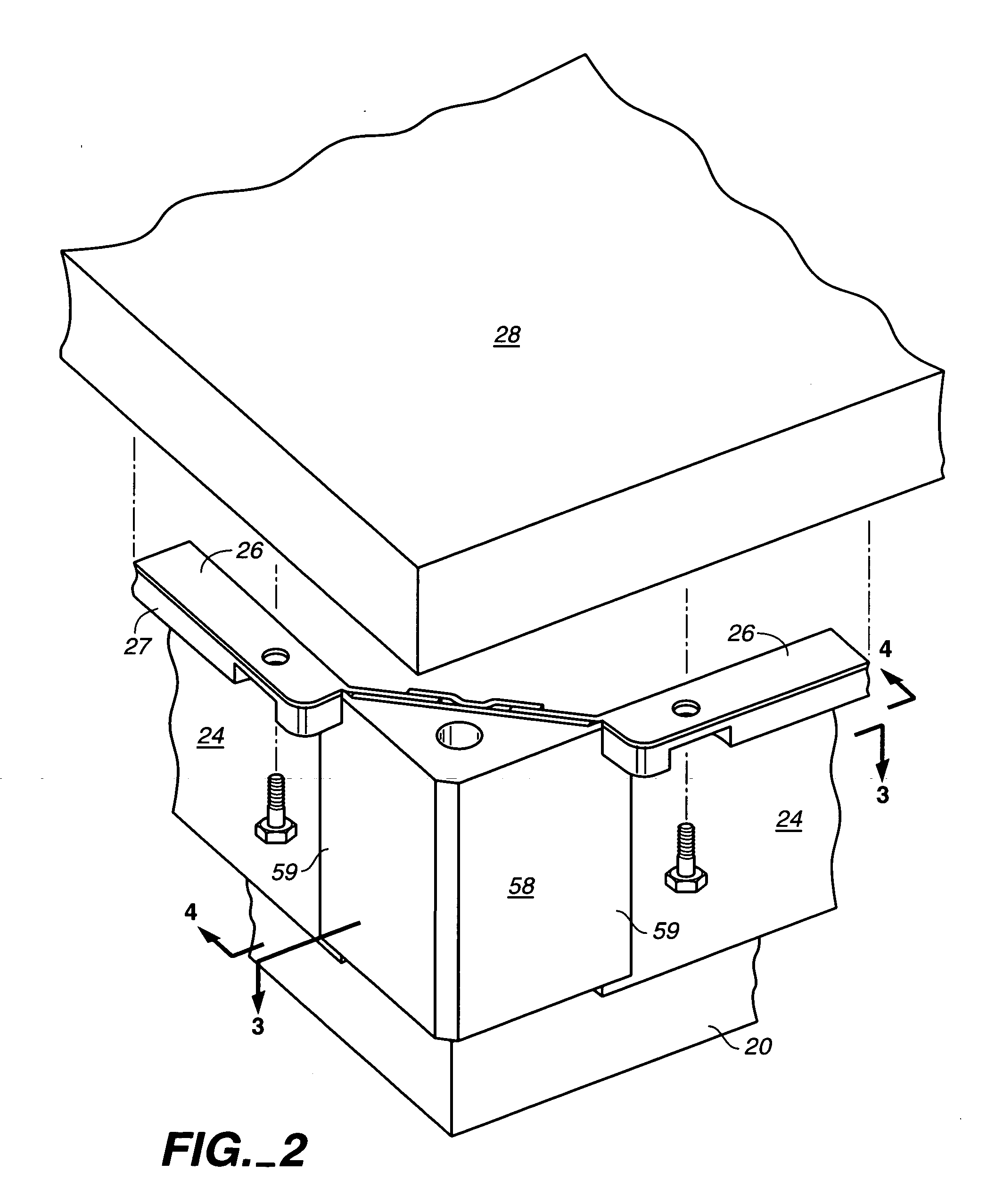

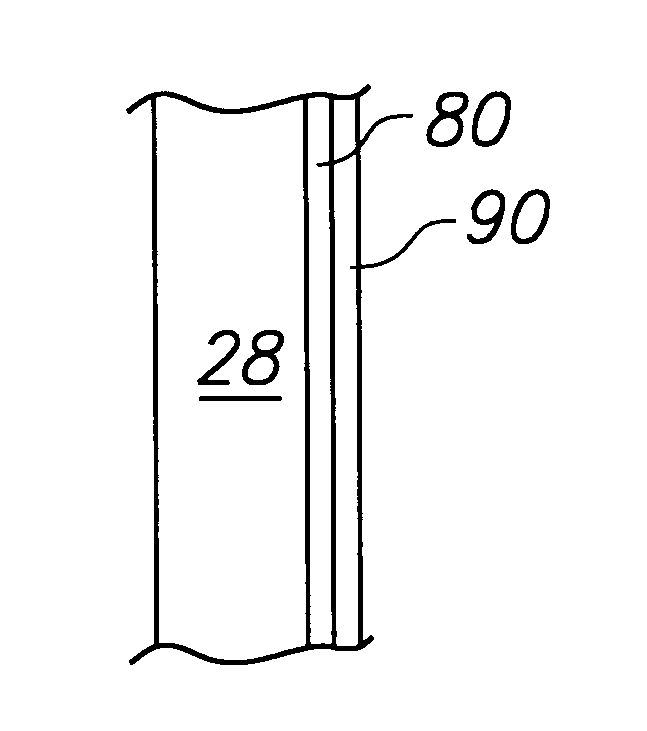

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

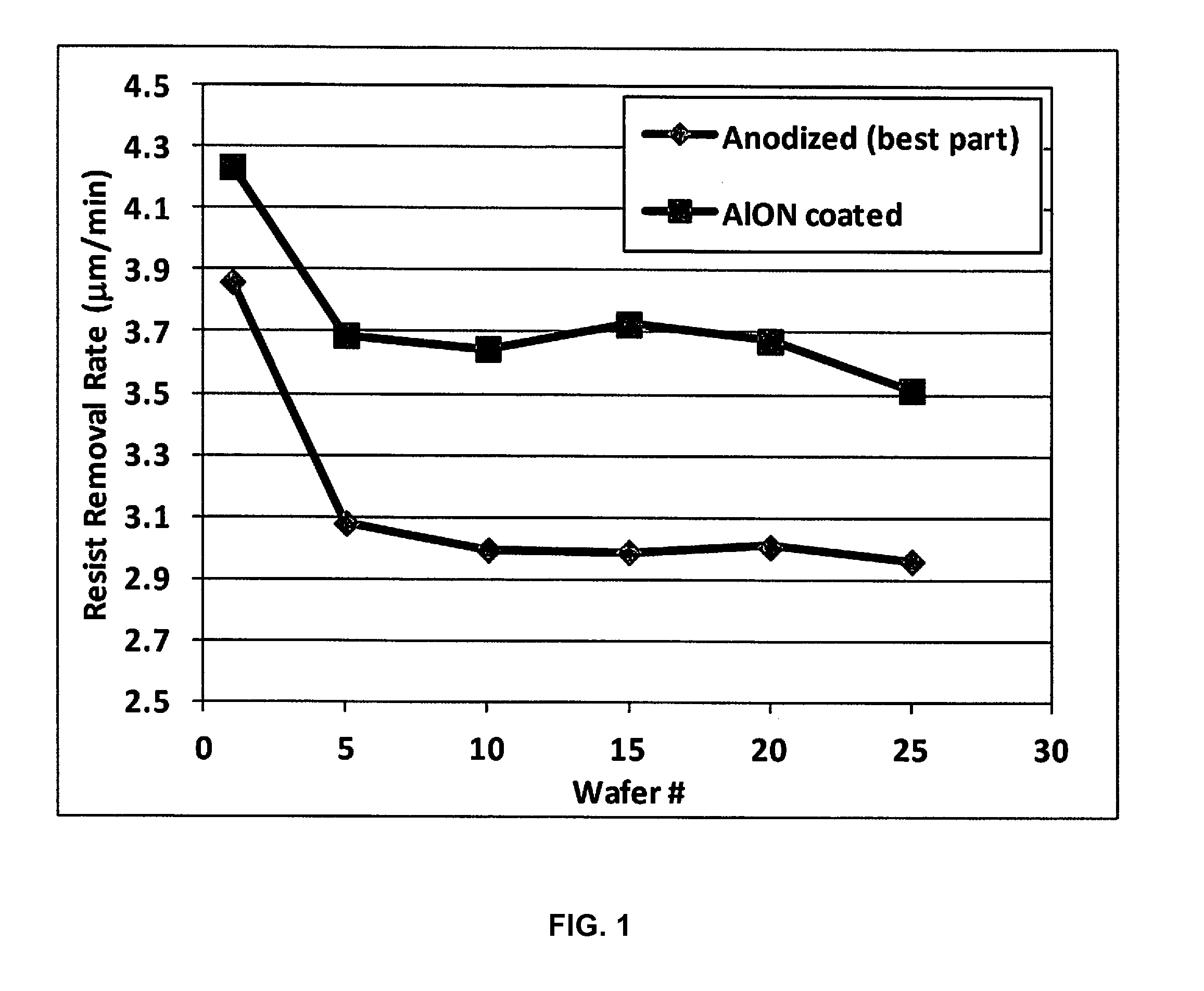

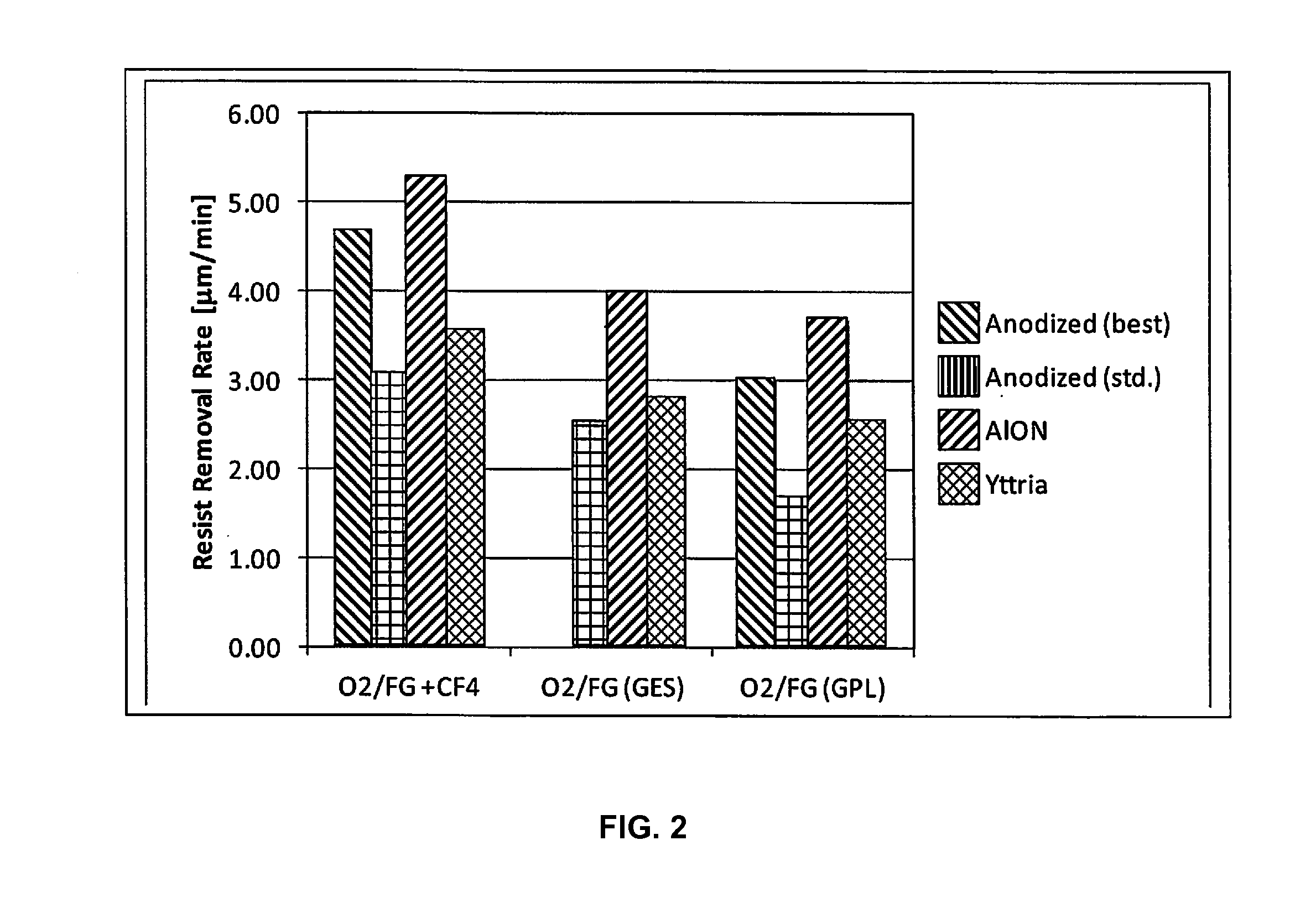

Surface coating for chamber components used in plasma systems

ActiveUS20170032942A1Low plasma surface recombination rateHigh trafficElectric discharge tubesVacuum evaporation coatingBlood plasmaPlasma chamber

Disclosed herein are surface coatings for plasma components that have the benefit of being robust against chemical and plasma physical attack in aggressive (e.g., fluorine-based) plasma environments. The coatings also provide low plasma surface recombination rates for active oxygen, nitrogen, fluorine, and hydrogen species when compared with other known surface treatments. The coatings can be applied to any plasma system component not requiring etching or plasma cleaning including but not limited to materials like quartz, aluminum, or anodized aluminum. Additionally, the efficiency of the system is increased by applying a non-reactive coating to system components thereby increasing the flow of excited plasma species to the plasma chamber of the system.

Owner:ENTEGRIS INC

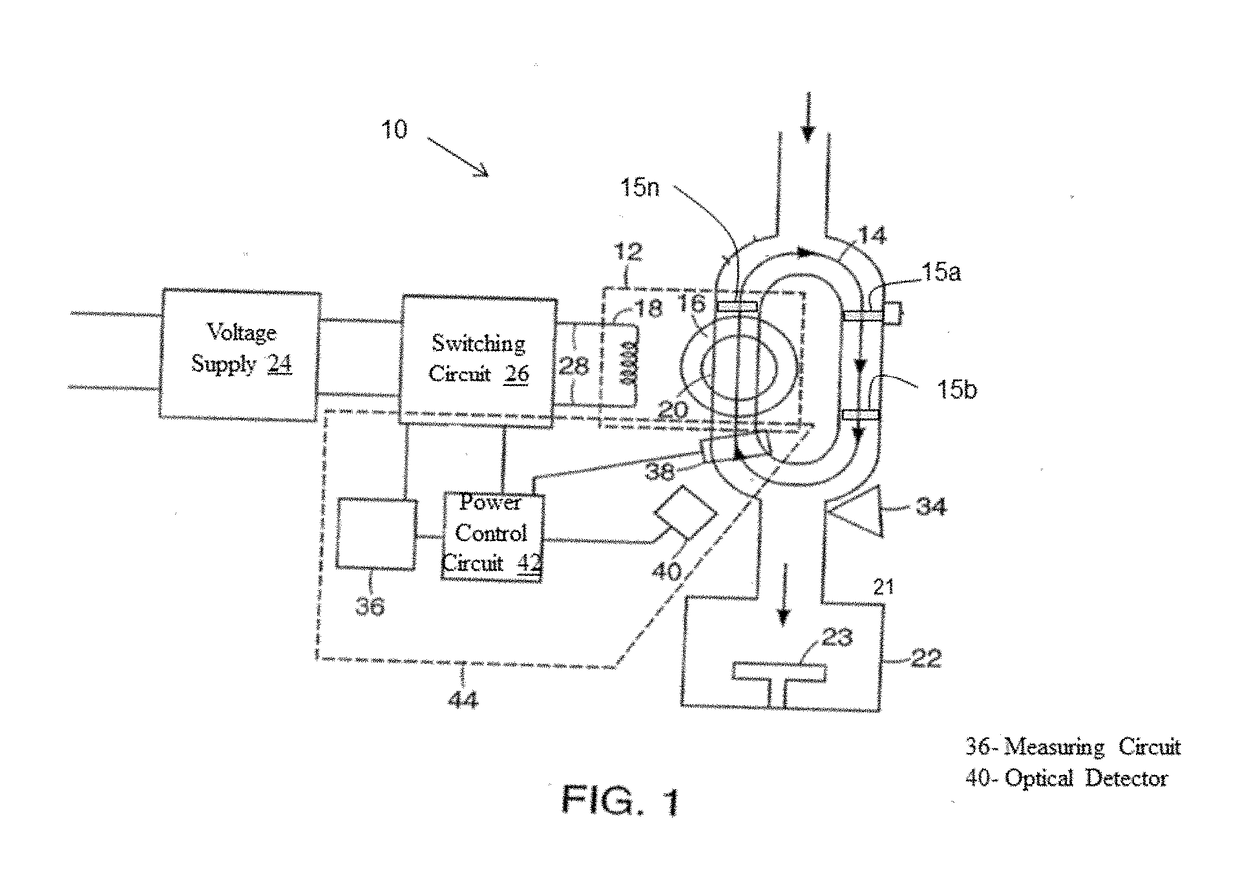

Apparatus and Method for Plasma Ignition with a Self-Resonating Device

ActiveUS20170303382A1Reduce frequencyMinimizationElectric discharge tubesPlasma techniqueEngineeringIonization

Methods and apparatus for igniting a process plasma within a plasma chamber are provided. One or more self-resonating devices are positioned within a plasma chamber relative to a plasma generation volume within the plasma chamber. The plasma generation volume is defined by the plasma chamber. Each of the self-resonating devices generates an ignition plasma. The ignition plasmas cause a partial ionization of an ignition gas. The partially ionized ignition gas allows for ignition of a process plasma by applying an electric field to the plasma generation volume.

Owner:MKS INSTR INC

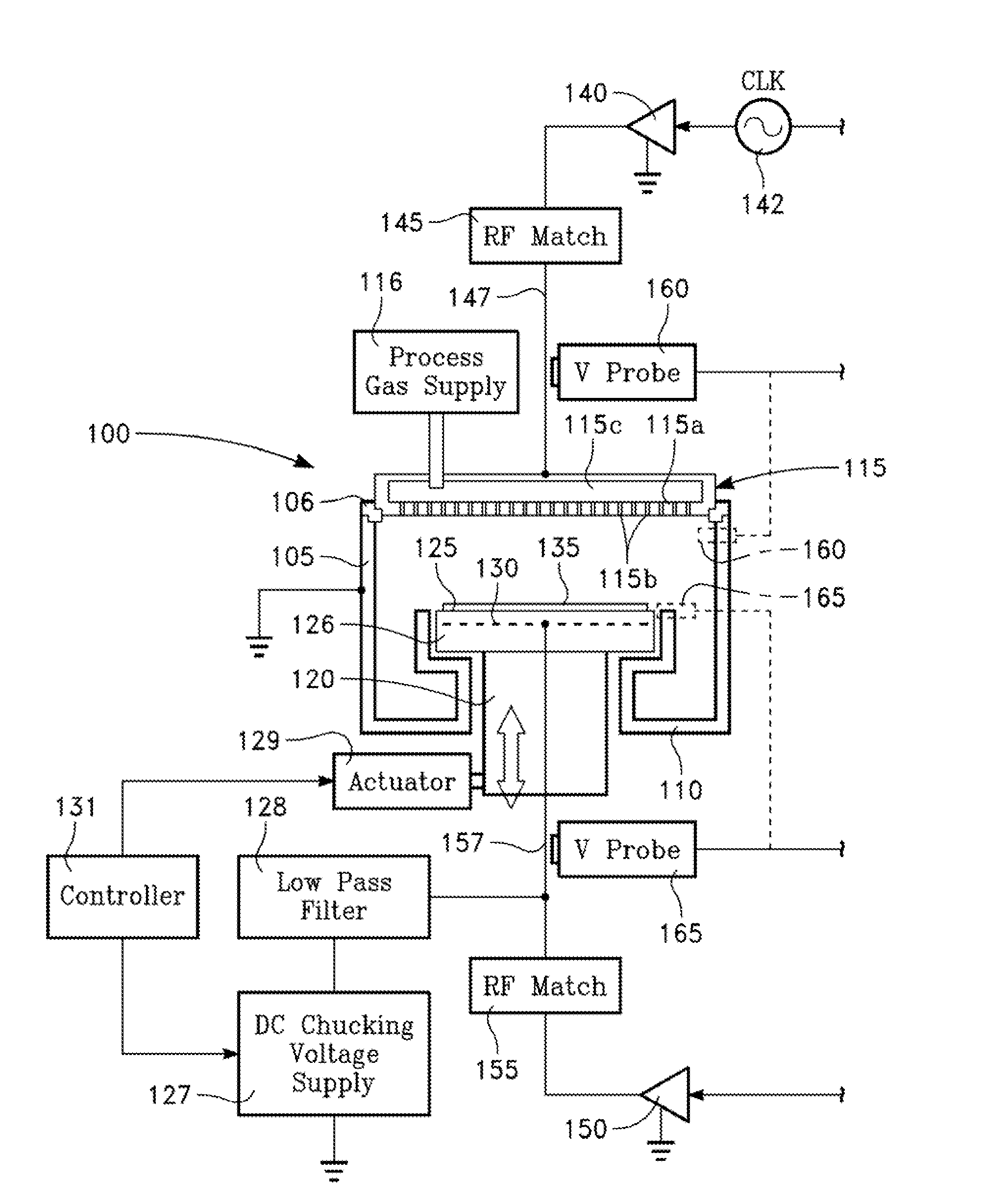

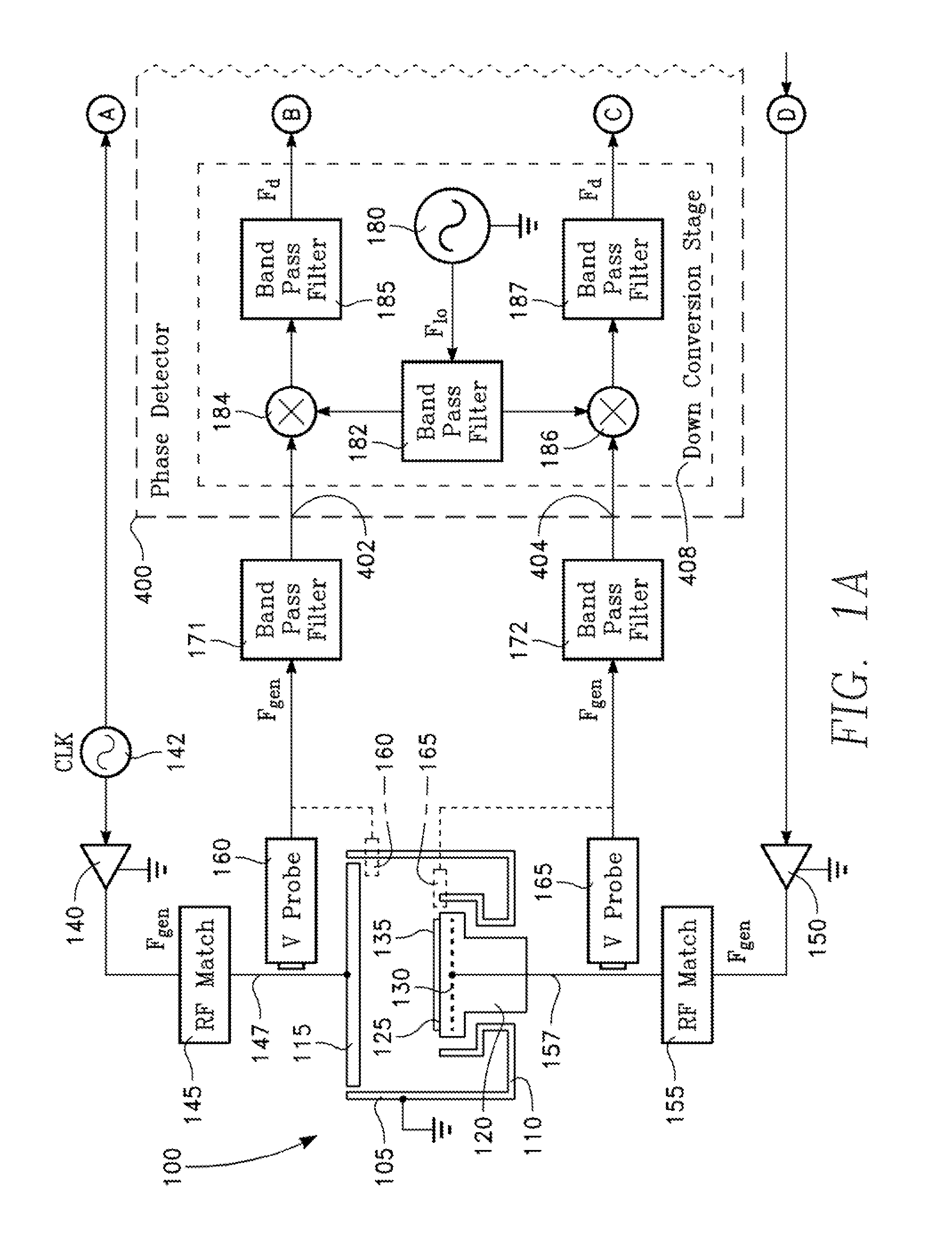

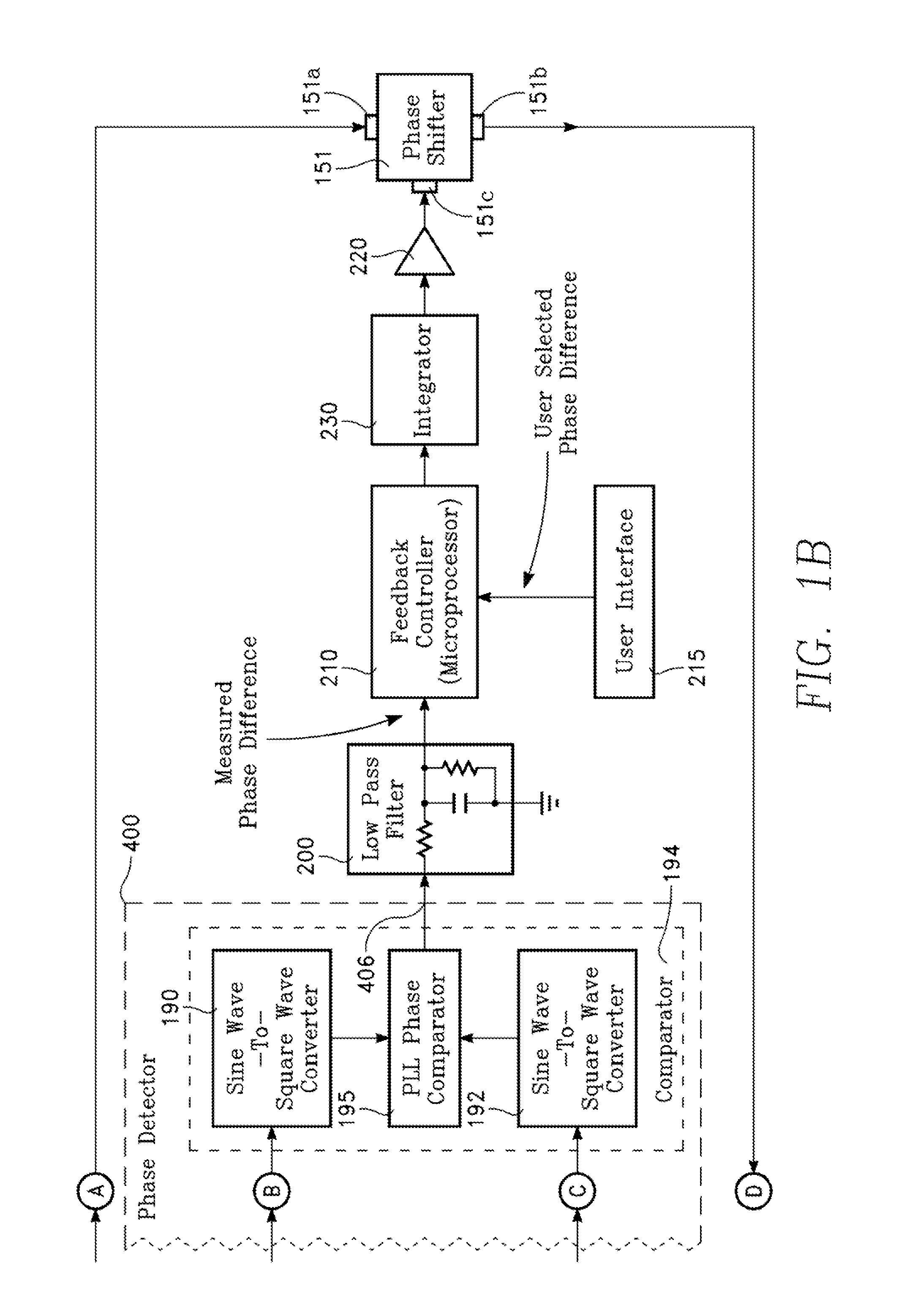

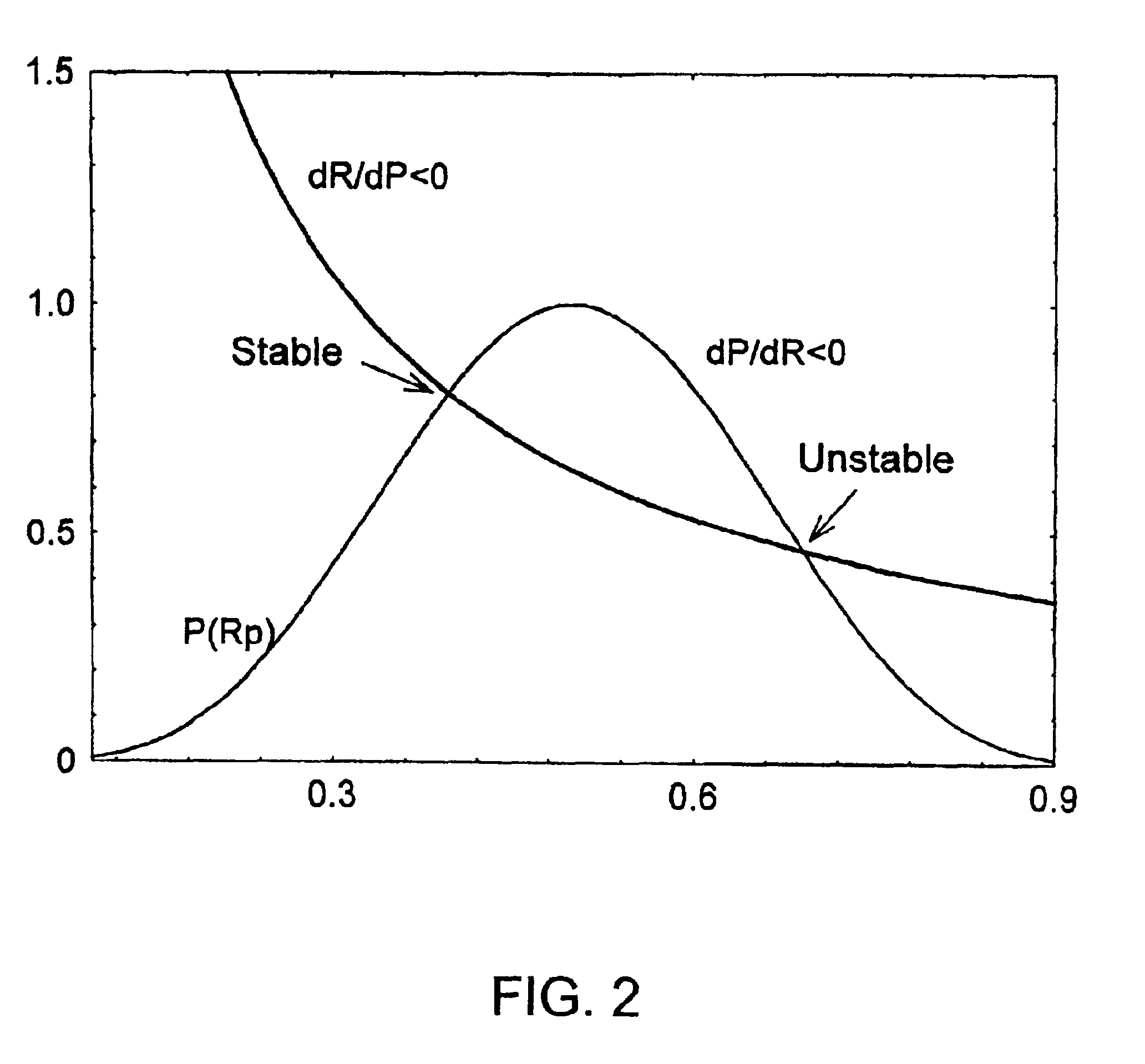

Two-phase operation of plasma chamber by phase locked loop

InactiveUS20130284369A1Liquid surface applicatorsElectric discharge tubesPhase differenceEngineering

Plasma distribution is controlled in a plasma reactor by controlling the phase difference between opposing RF electrodes, in accordance with a desired or user-selected phase difference, by a phase-lock feedback control loop.

Owner:APPLIED MATERIALS INC

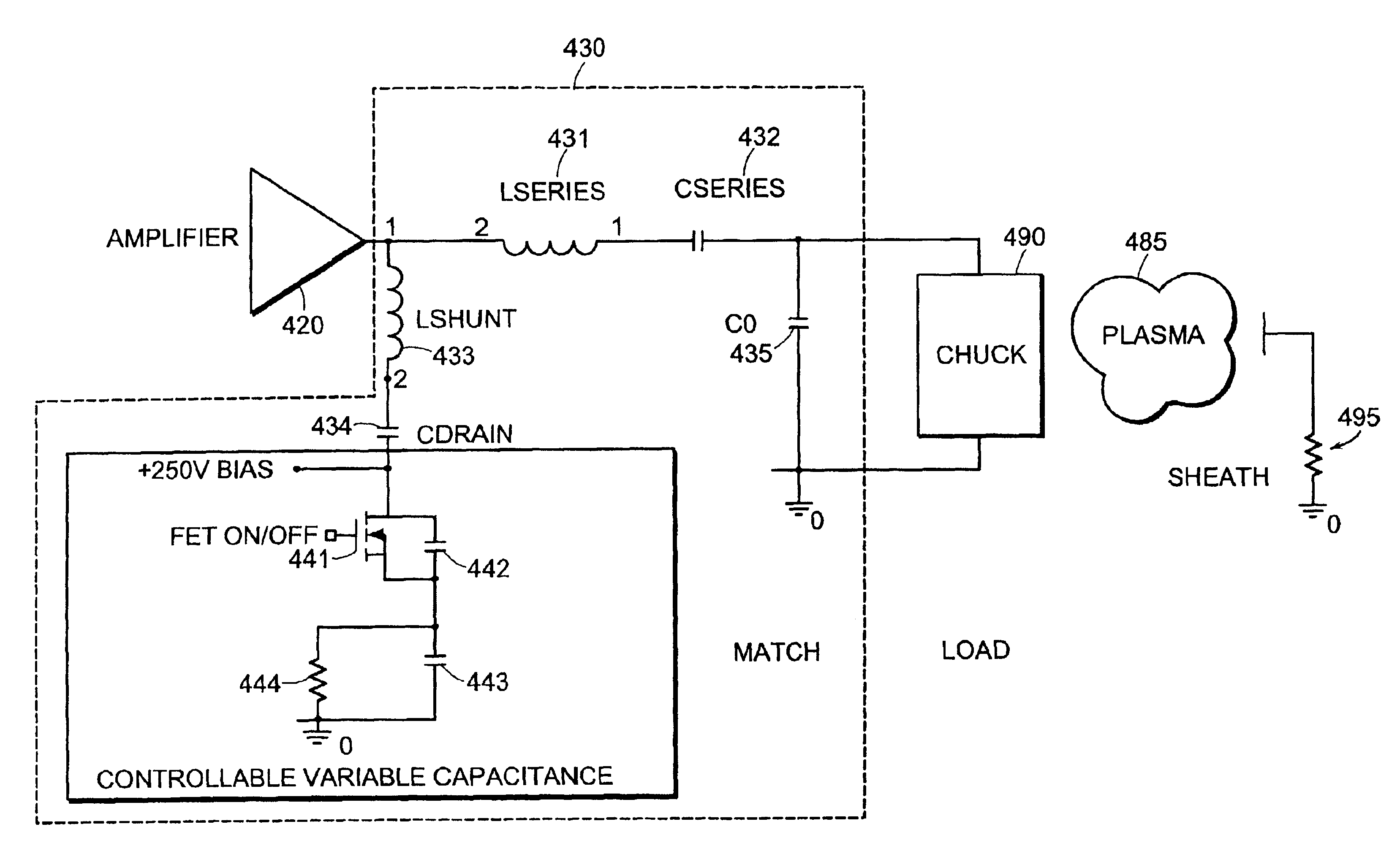

RF power supply with integrated matching network

InactiveUS6887339B1Eliminate useConstant powerMultiple-port networksElectric discharge tubesElectromagnetic couplingPlasma generator

The invention features an RF plasma generator. The RF plasma generator includes a variable frequency RF generator, comprising an H-bridge and an RF output. The RF generator generates electromagnetic radiation having a power. The RF plasma generator further includes a matching network that includes at least one variable impedance component. The matching network also includes a first port that is electromagnetically coupled to the output of the RF generator and a second port. The RF plasma generator also includes a load that is electromagnetically coupled to the second port of the matching network, and a plasma chamber for containing a plasma having a power. The plasma chamber is electromagnetically coupled to the load and receives electromagnetic radiation having a power from the load. Adjusting at least one of the frequency of the RF generator and the variable impedance component in the matching network changes the power in the plasma.

Owner:MKS INSTR INC

Guided wave applicator with non-gaseous dielectric for plasma chamber

InactiveUS9397380B2Readily and inexpensivelyConvenient lengthElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

A guided wave applicator comprising two electrically conductive waveguide walls and a waveguide dielectric. The volume of the waveguide dielectric is composed of non-gaseous dielectric material and is positioned between the two waveguide walls. The waveguide dielectric includes first and second longitudinal ends and includes first, second, third and fourth sides extending longitudinally between the two longitudinal ends. The first waveguide wall is positioned so that it covers the first side of the waveguide dielectric, and the second waveguide wall is positioned so that it covers the second side of the waveguide dielectric. In operation, electrical power can be supplied to one or both longitudinal ends of the waveguide dielectric, whereby the power can be coupled to a plasma through the exposed sides of the waveguide dielectric.

Owner:APPLIED MATERIALS INC

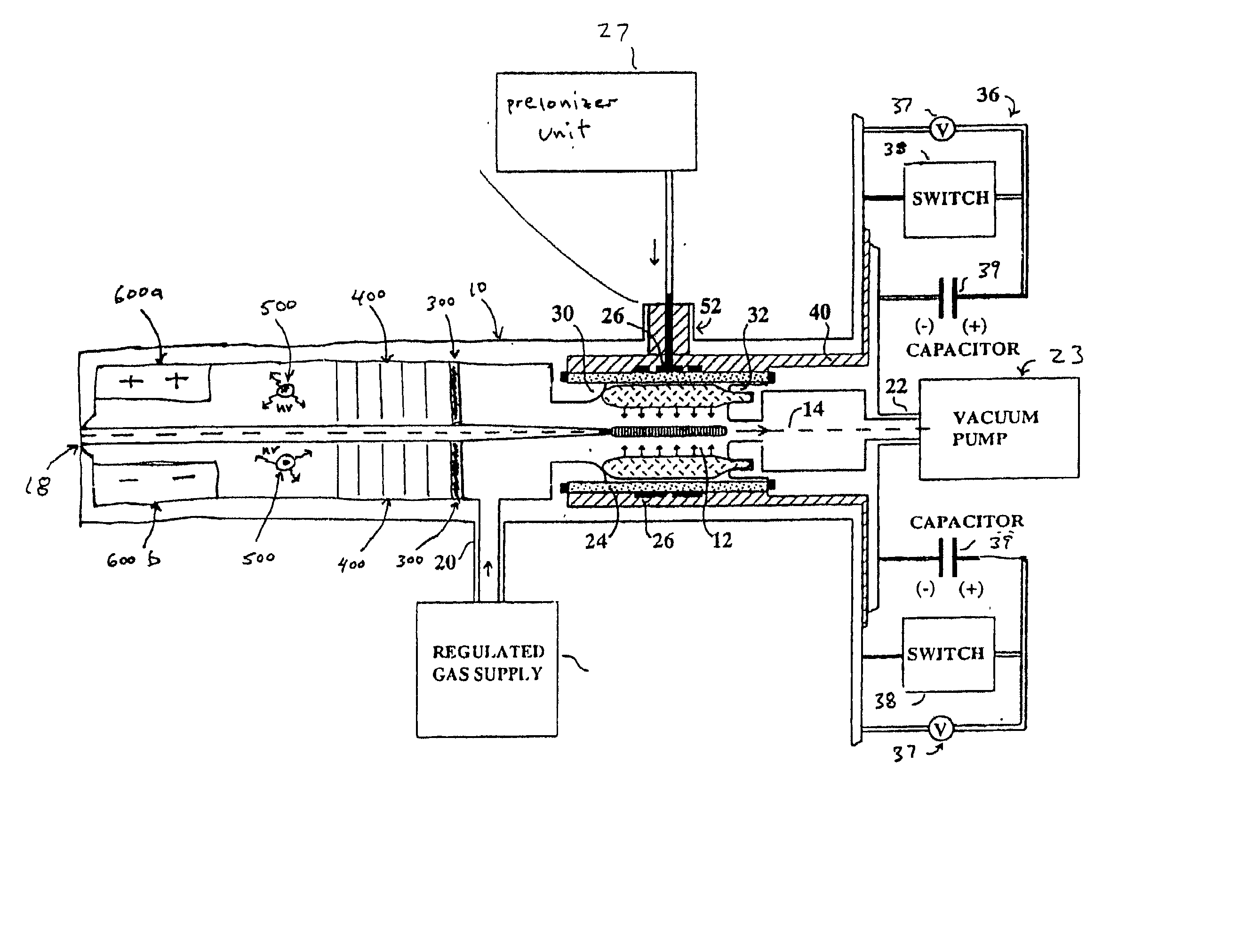

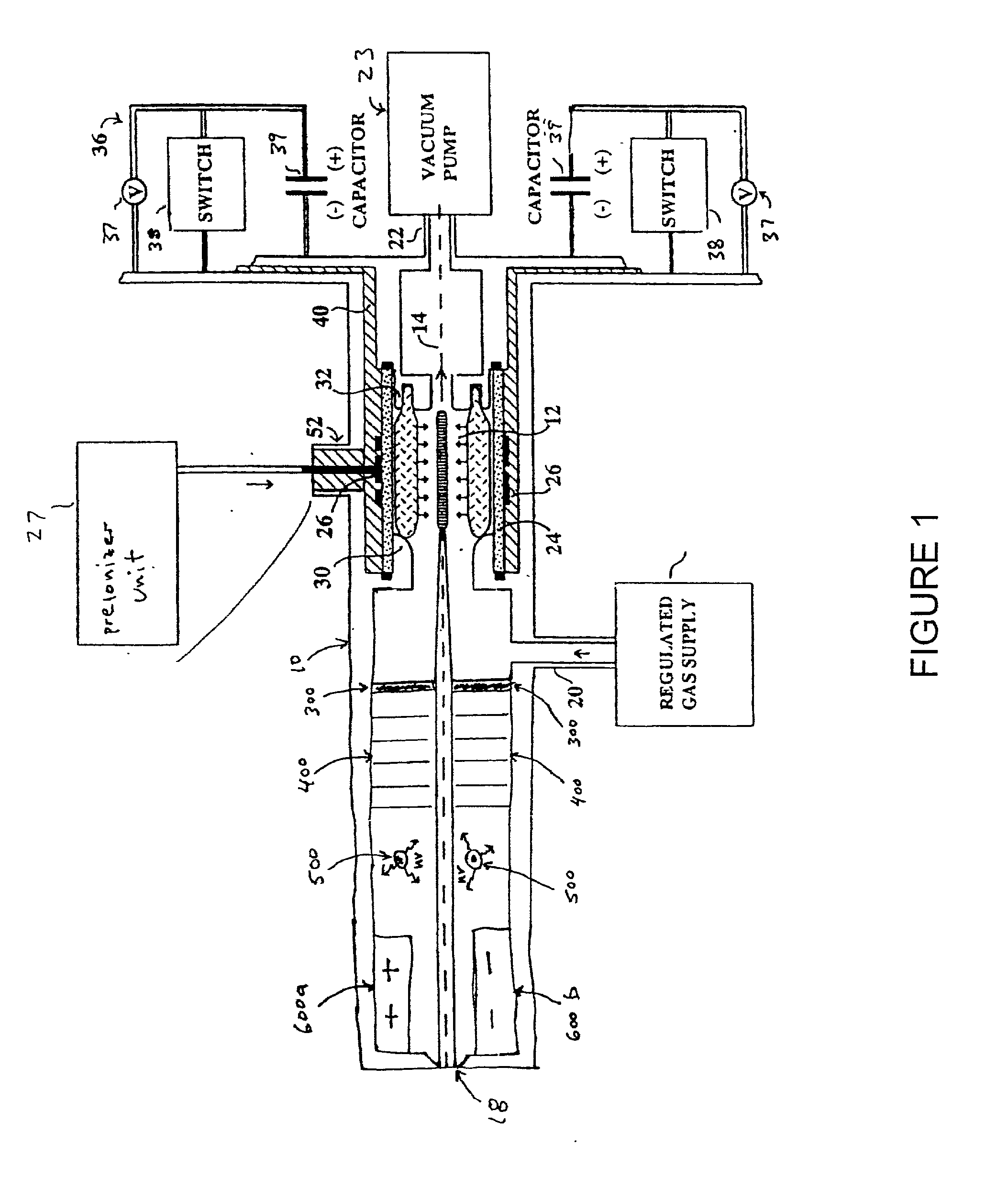

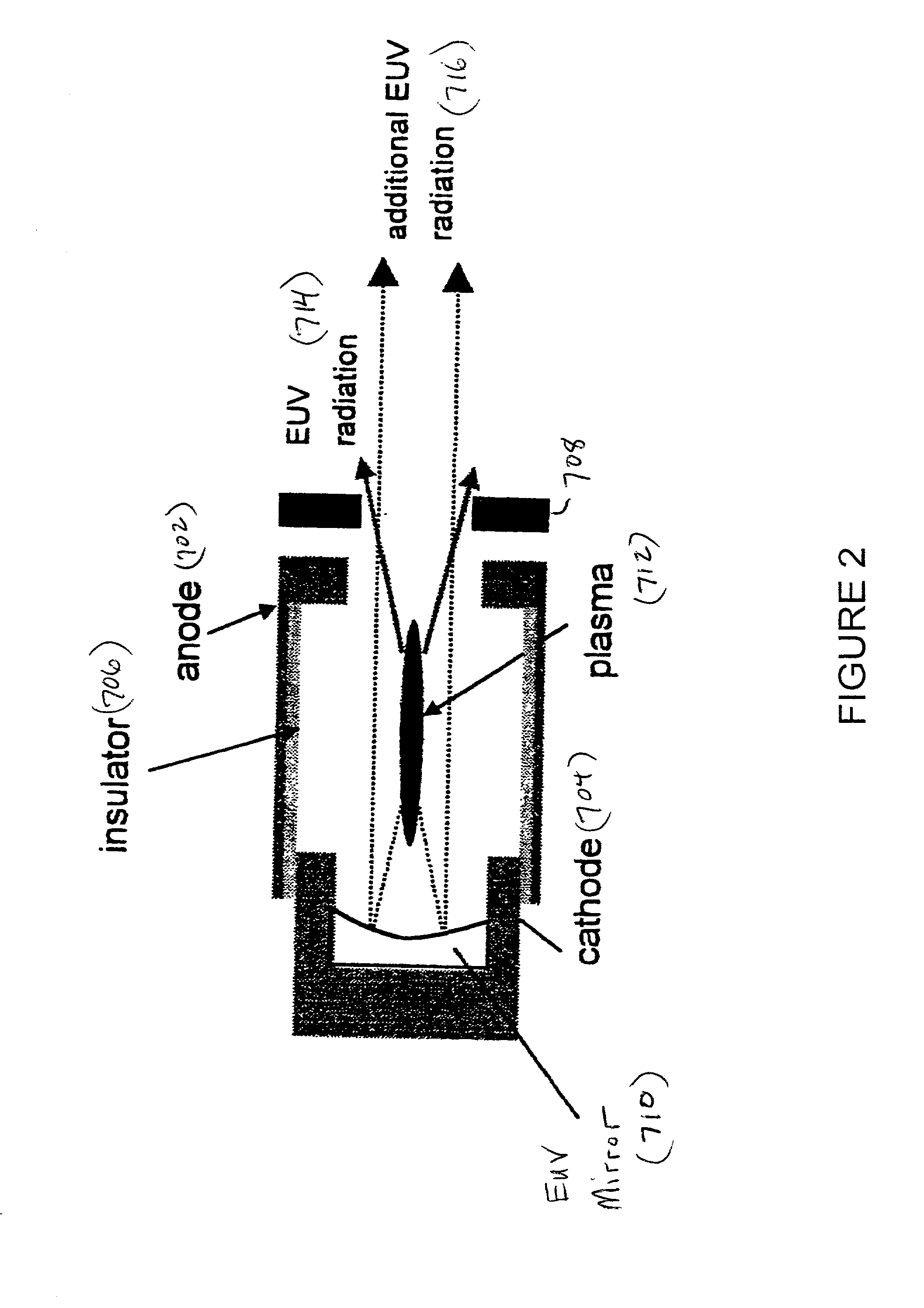

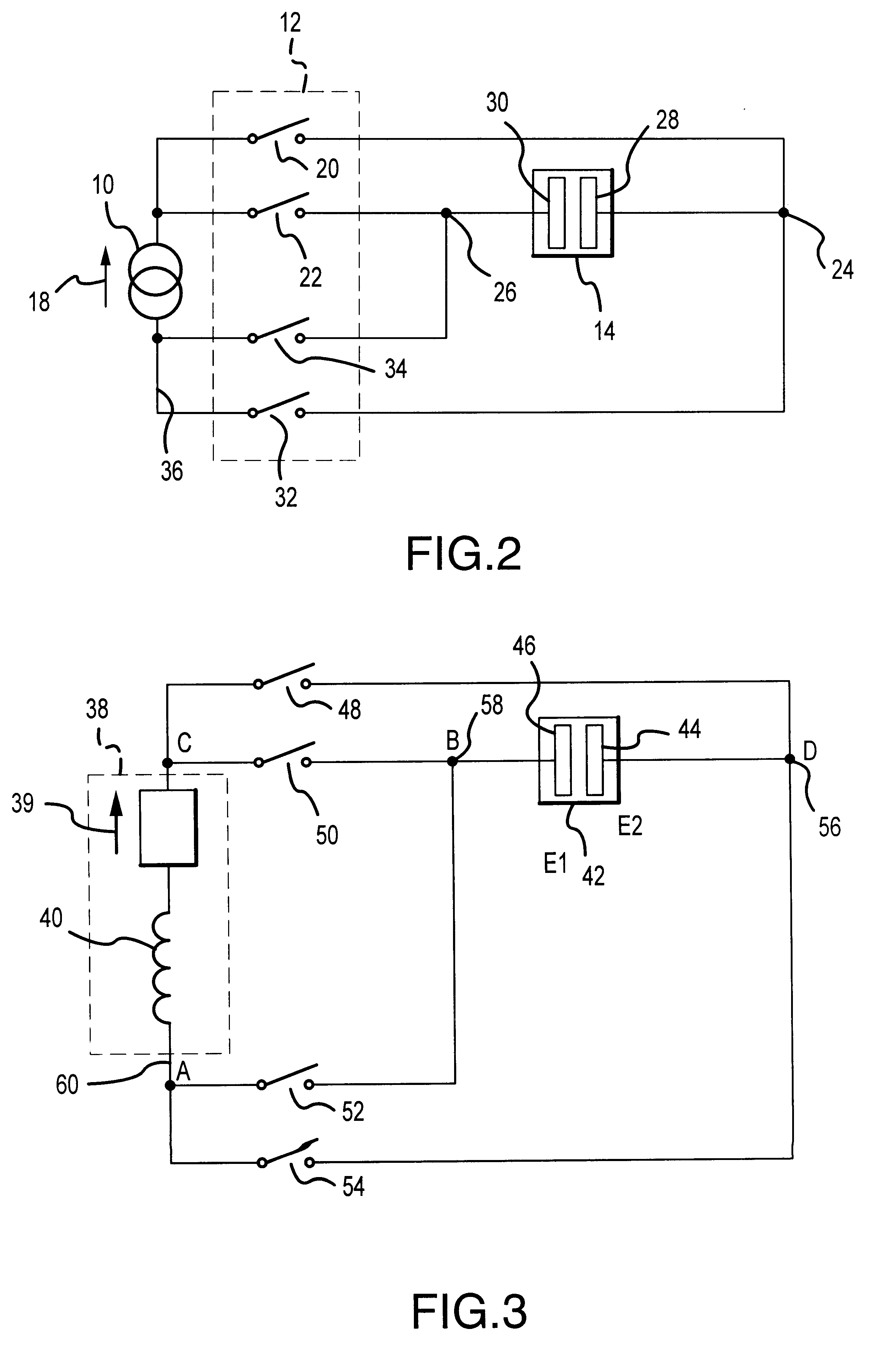

Method and apparatus for generating high output power gas discharge based source of extreme ultraviolet radiation and/or soft x-rays

InactiveUS20020168049A1Avoid reflectionsReduce reflectionRadiation/particle handlingNanoinformaticsSoft x rayUltraviolet radiation

An EUV photon source includes a plasma chamber filled with a gas mixture, multiple electrodes within the plasma chamber defining a plasma region and a central axis, a power supply circuit connected to the electrodes for delivering a main pulse to the electrodes for energizing the plasma around the central axis to produce an EUV beam output along the central axis, and a preionizer for ionizing the gas mixture in preparing to form a dense plasma around the central axis upon application of the main pulse from the power supply circuit to the electrodes. The EUV source preferably includes an ionizing unit and precipitator for collecting contaminant particulates from the output beam path. A set of baffles may be disposed along the beam path outside of the pinch region to diffuse gaseous and contaminant particulate flow emanating from the pinch region and to absorb or reflect acoustic waves emanating from the pinch region away from the pinch region. A clipping aperture, preferably formed of ceramic and / or Al2O3, for at least partially defining an acceptance angle of the EUV beam. The power supply circuit may generates the main pulse and a relatively low energy prepulse for homogenizing the preionized plasma prior to the main pulse. A multi-layer EUV mirror is preferably disposed opposite a beam output side of the pinch region for reflecting radiation along the central axis for output along the beam path of the EUV beam. The EUV mirror preferably has a curved contour for substantially collimating or focusing the reflected radiation. In particular, the EUV mirror may preferably have a hyperbolic contour.

Owner:USHIO DENKI KK

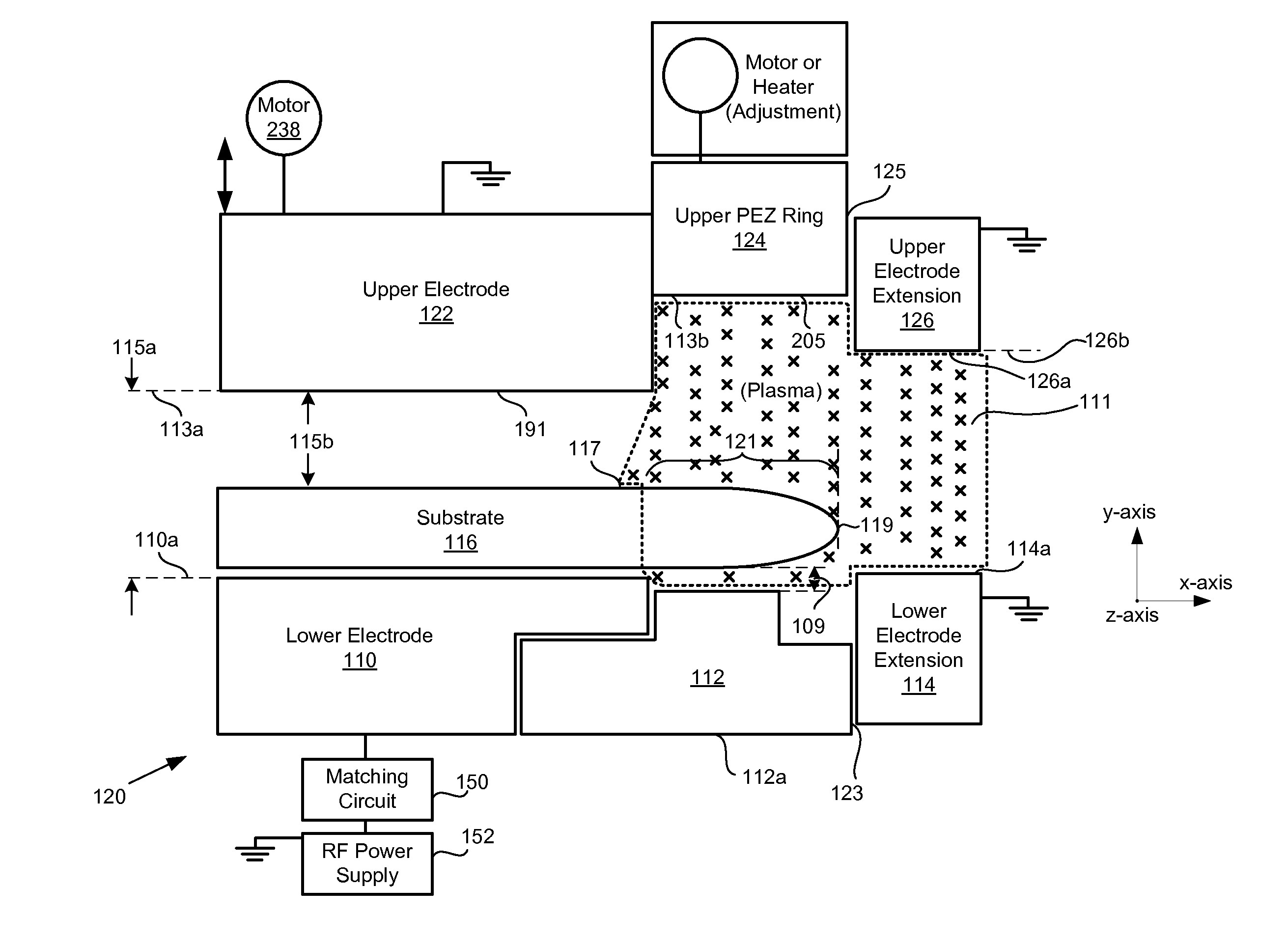

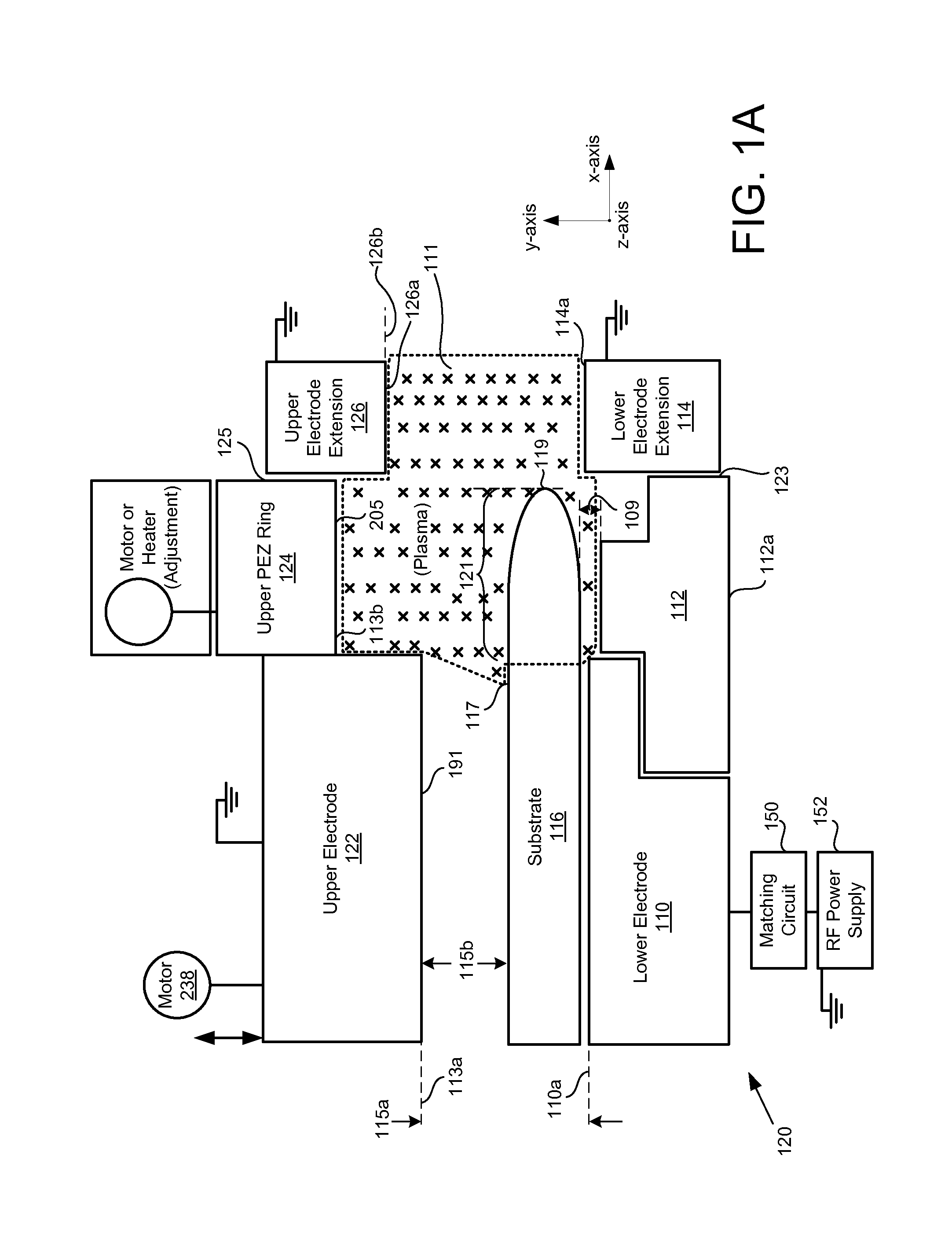

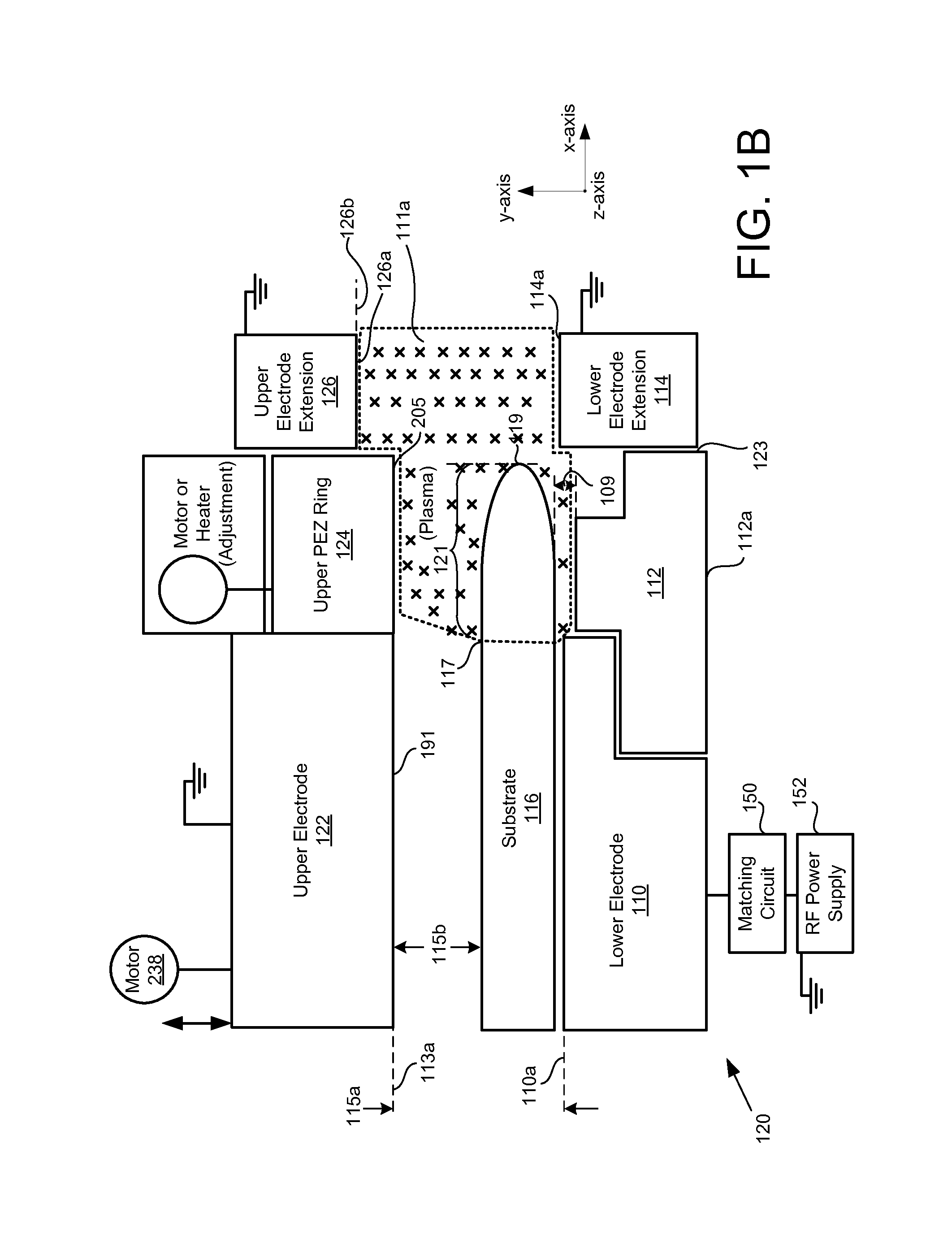

Edge exclusion control with adjustable plasma exclusion zone ring

ActiveUS20140020708A1Increase blockingAvoid plasma unconfinement issuesElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

Systems and methods for edge exclusion control are described. One of the systems includes a plasma chamber. The plasma processing chamber includes a lower electrode having a surface for supporting a substrate. The lower electrode is coupled with a radio frequency (RF) power supply. The plasma processing chamber further includes an upper electrode disposed over the lower electrode. The upper electrode is electrically grounded. The plasma processing chamber includes an upper dielectric ring surrounding the upper electrode. The upper dielectric ring is moved using a mechanism for setting a vertical position of the upper dielectric ring separate from a position of the upper electrode. The system further includes an upper electrode extension surrounding the upper dielectric ring. The upper electrode extension is electrically grounded. The system also includes a lower electrode extension surrounding the lower dielectric ring. The lower electrode extension is arranged opposite the upper electrode extension.

Owner:LAM RES CORP

RF bus and RF return bus for plasma chamber electrode

ActiveUS8992723B2Reduce inductanceReduce peak voltageElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

For coupling RF power from an RF input of a plasma chamber to the interior of a plasma chamber, an RF bus conductor is connected between the RF input and a plasma chamber electrode. In one embodiment, an RF return bus conductor is connected to an electrically grounded wall of the chamber, and the RF bus conductor and the RF return bus conductor have respective surfaces that are parallel and face each other. In another embodiment, the RF bus conductor has a transverse cross section having a longest dimension oriented perpendicular to the surface of the plasma chamber electrode that is closest to the RF bus conductor.

Owner:APPLIED MATERIALS INC

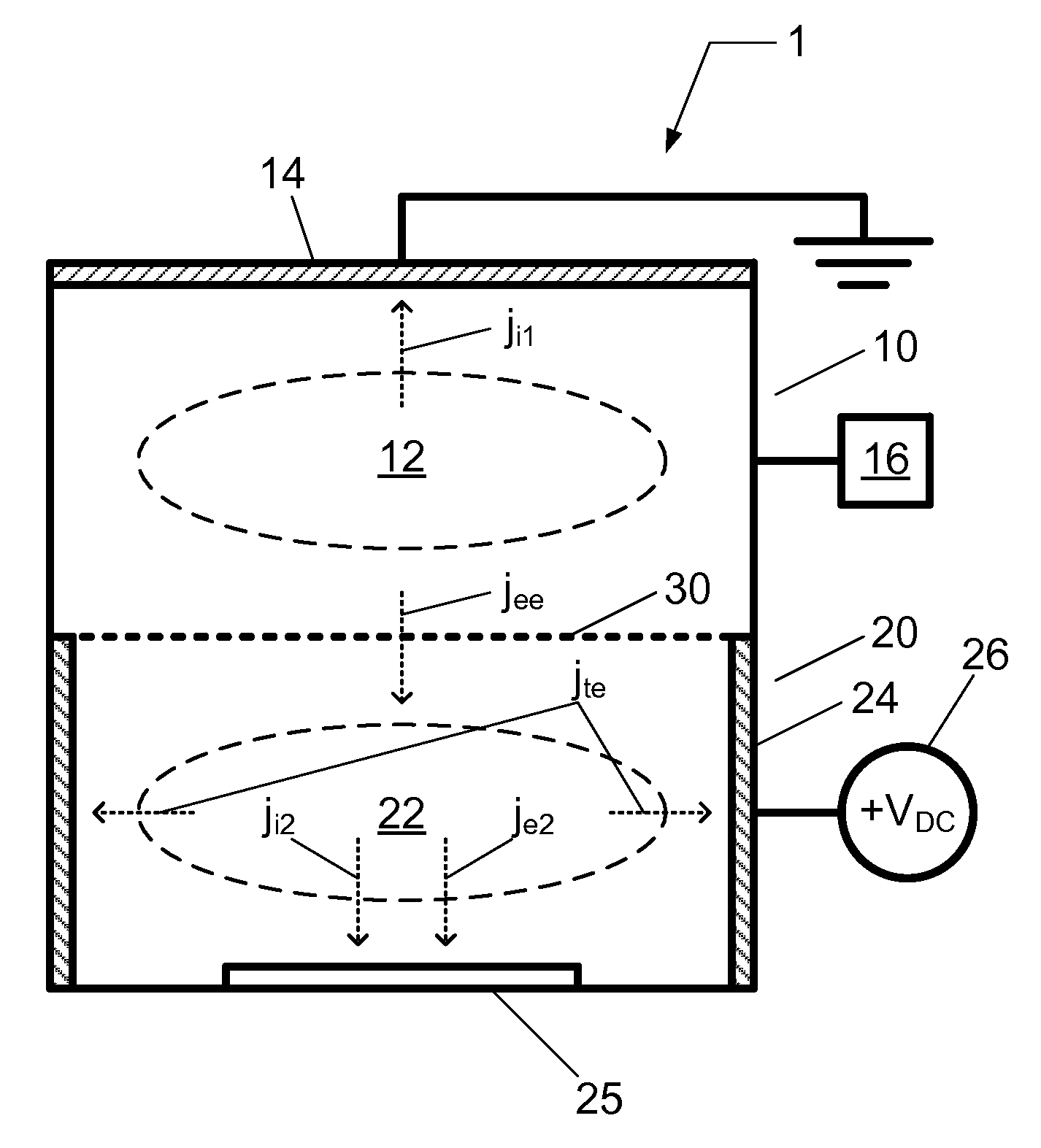

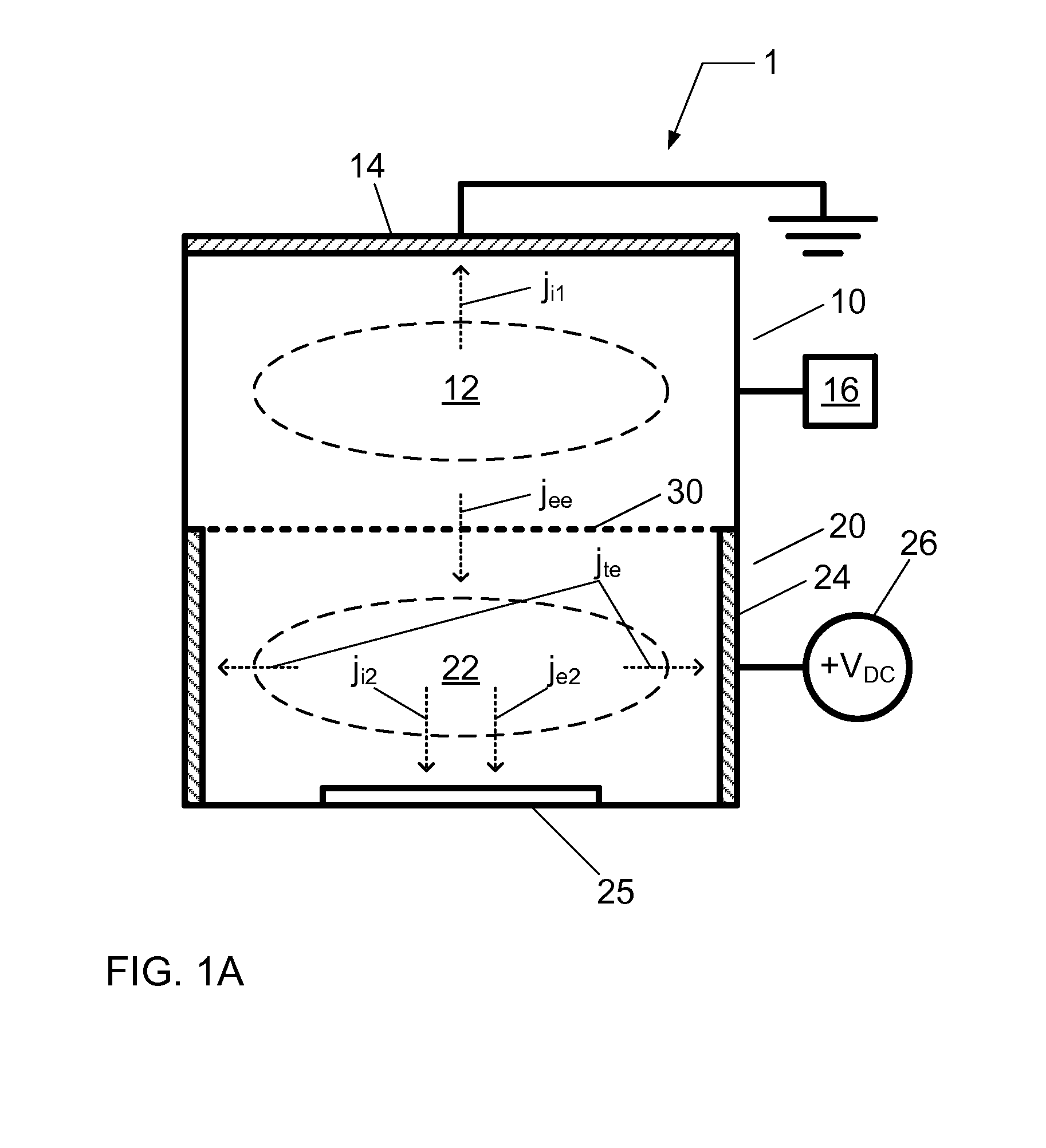

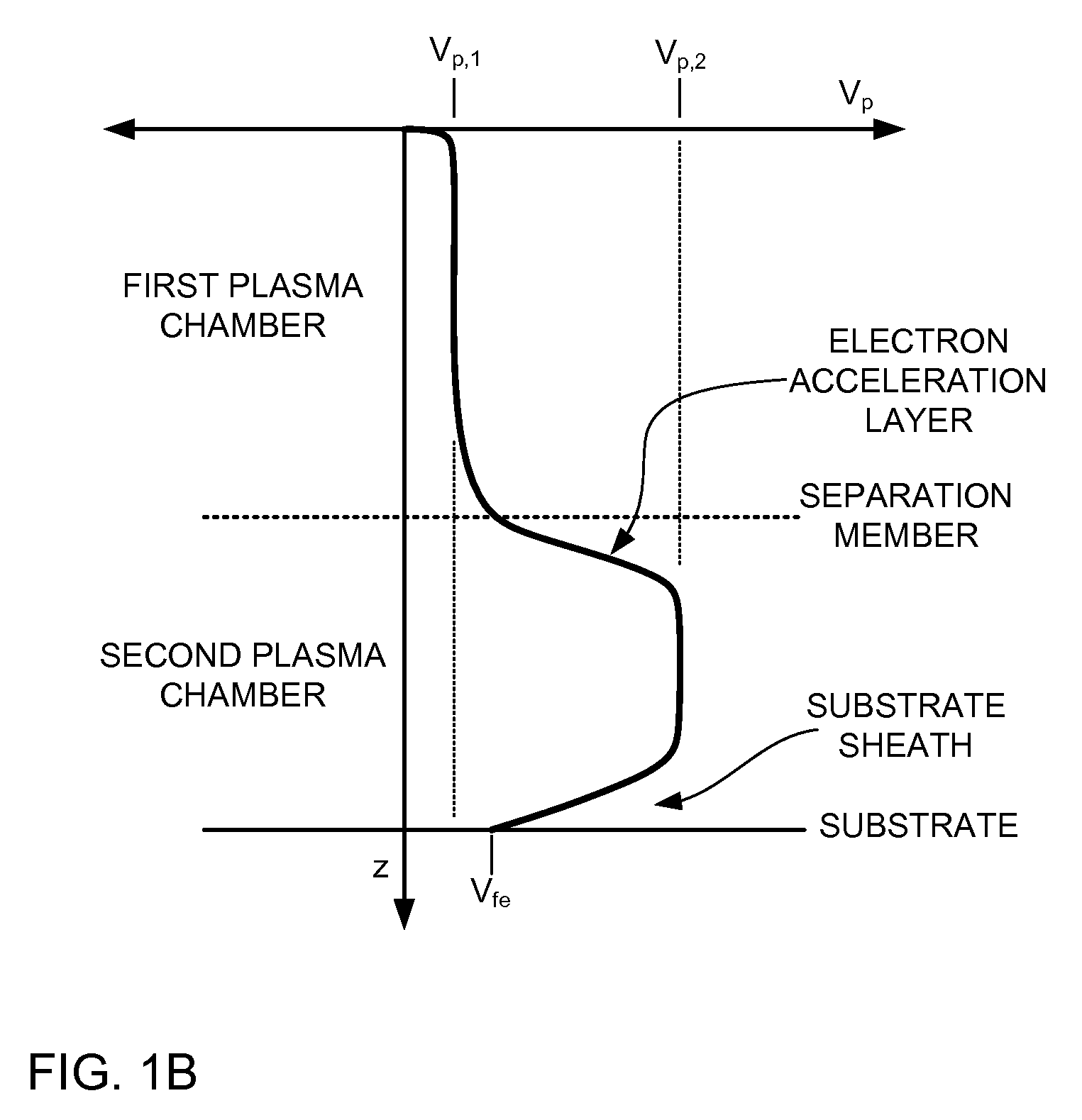

Mono-energetic neutral beam activated chemical processing system and method of using

ActiveUS20090236314A1Electric discharge tubesDecorative surface effectsChemical treatmentCompound (substance)

A chemical processing system and a method of using the chemical processing system to treat a substrate with a mono-energetic space-charge neutralized neutral beam-activated chemical process is described. The chemical processing system comprises a first plasma chamber for forming a first plasma at a first plasma potential, and a second plasma chamber for forming a second plasma at a second plasma potential greater than the first plasma potential, wherein the second plasma is formed using electron flux from the first plasma. Further, the chemical processing system comprises a substrate holder configured to position a substrate in the second plasma chamber.

Owner:TOKYO ELECTRON LTD

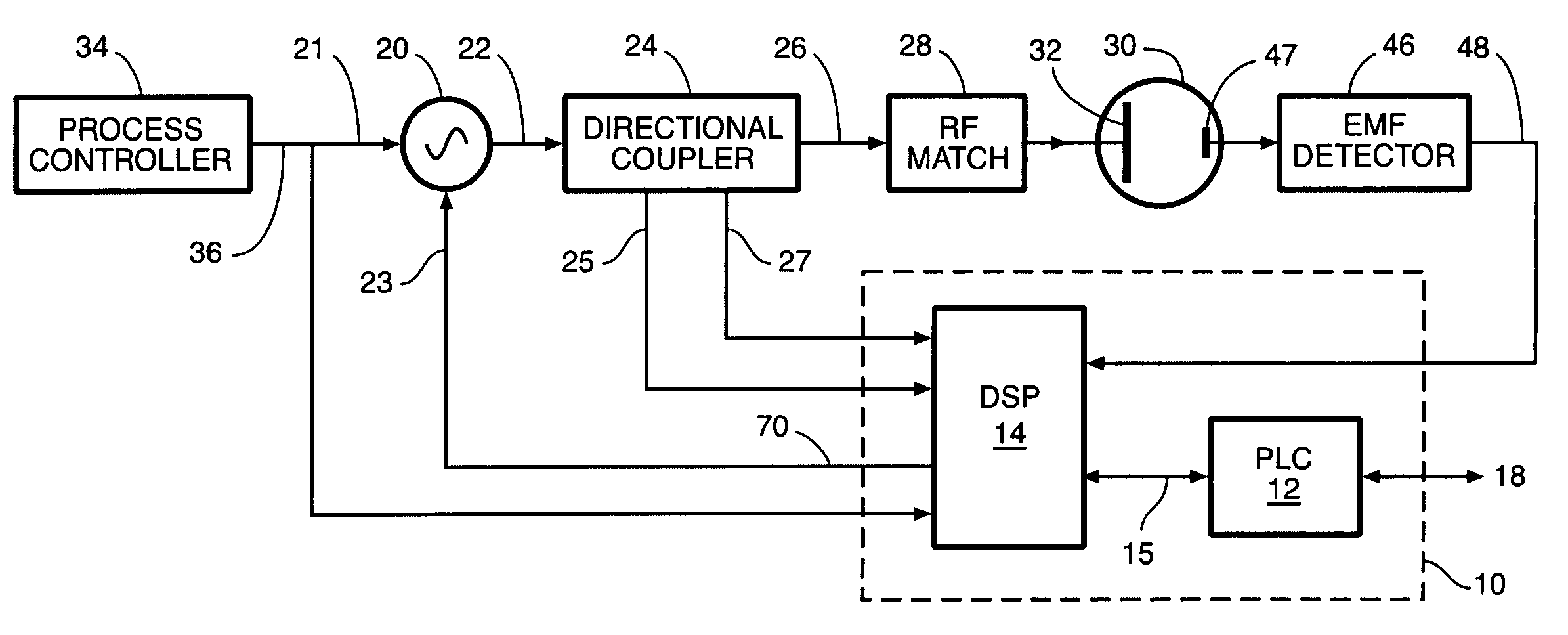

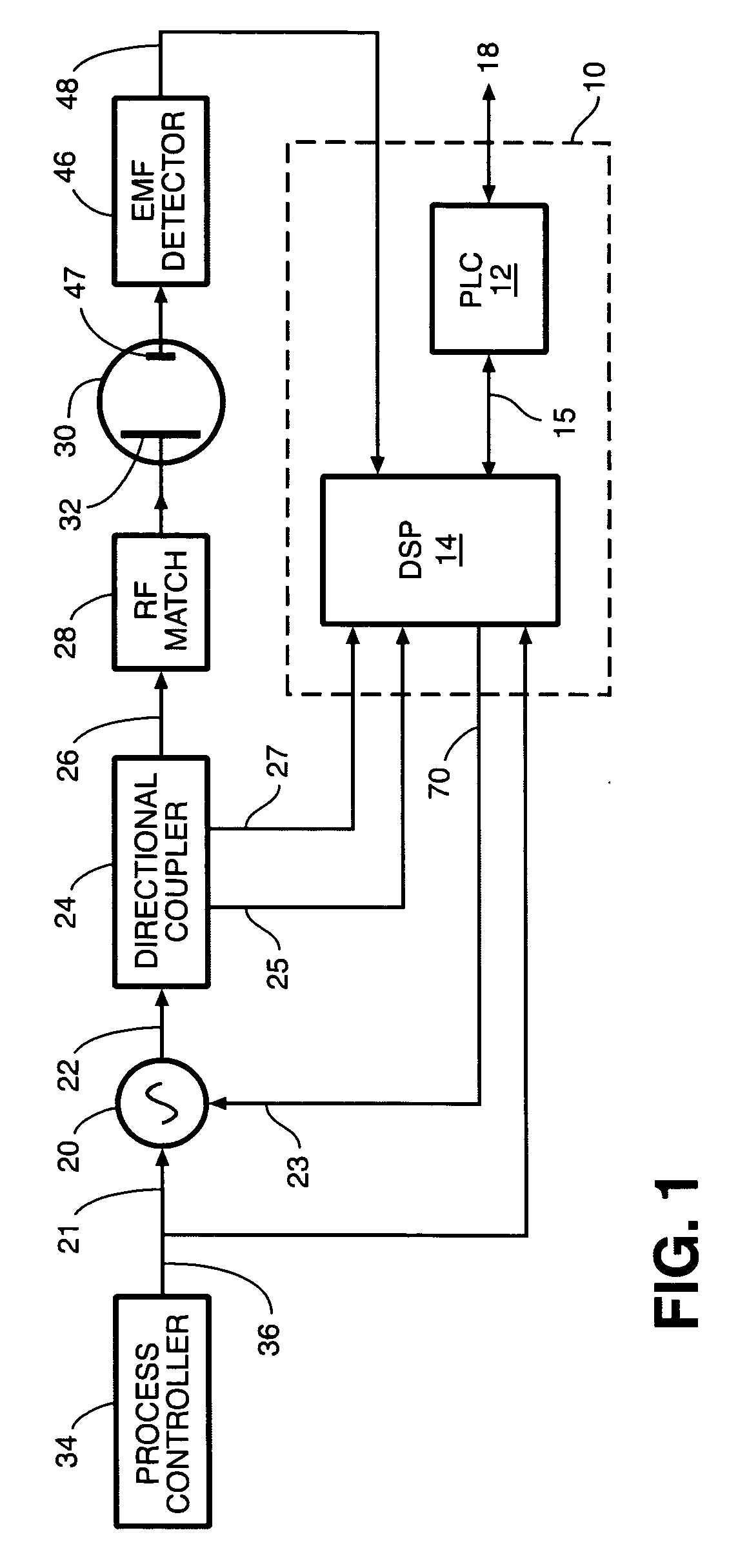

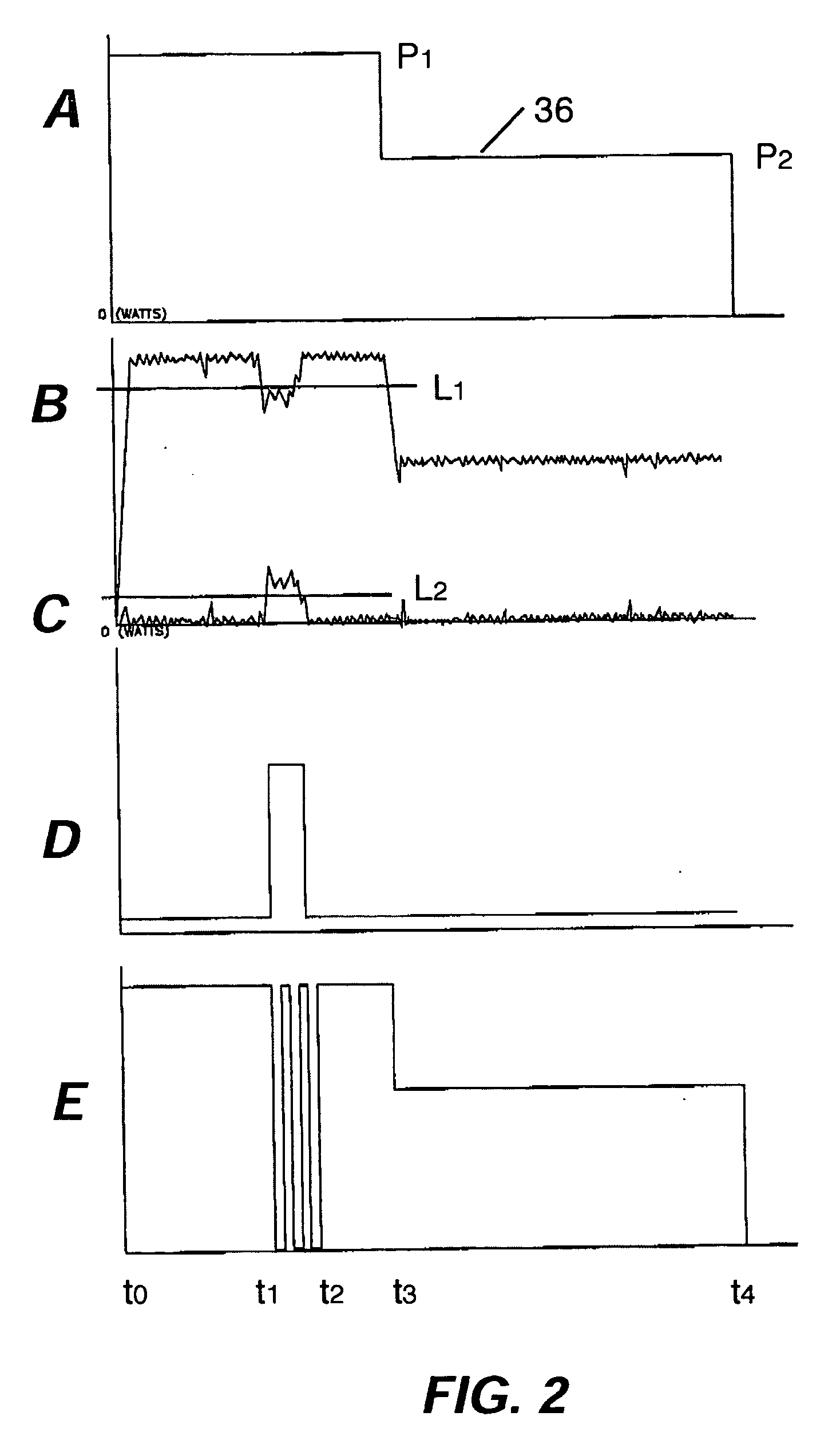

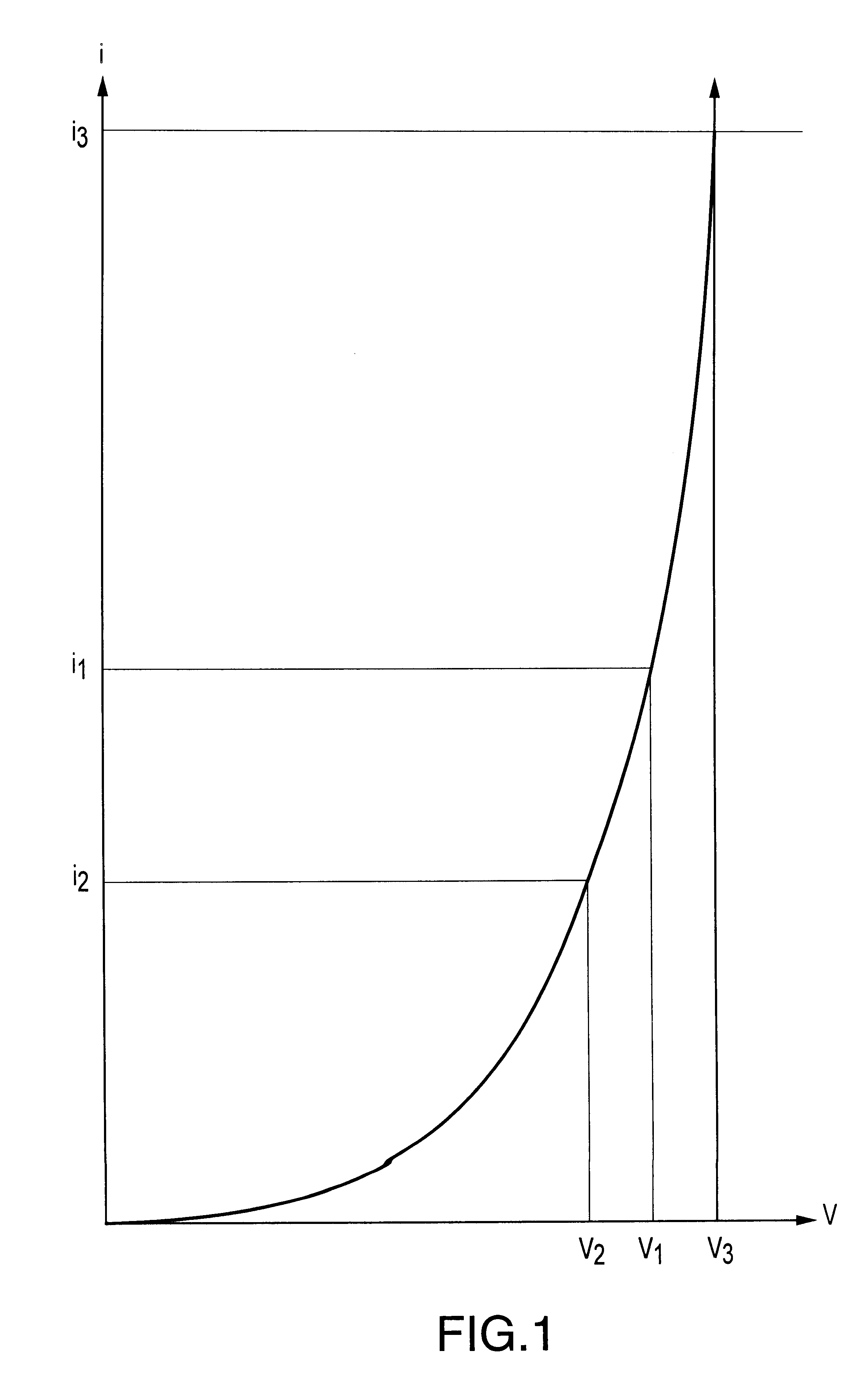

Detection and suppression of electrical arcing

ActiveUS20060049831A1Eliminate exceptionsGuaranteed uptimeTesting dielectric strengthMaterial analysis by electric/magnetic meansElectrical resistance and conductanceDisplay device

Method and apparatus for detecting or suppressing electrical arcing or other abnormal change in the electrical impedance of a load connected to a power source. Preferably the load is a plasma chamber used for manufacturing electronic components such as semiconductors and flat panel displays. Arcing is detected by monitoring one or more sensors. Each sensor either responds to a characteristic of the electrical power being supplied by an electrical power source to the plasma or is coupled to the plasma chamber so as to respond to an electromagnetic condition within the chamber. Arcing is suppressed by reducing the power output for a brief period. Then the power source increases its power output, preferably to its original value. If the arcing resumes, the power source repeats the steps of reducing and then restoring the power output.

Owner:APPLIED MATERIALS INC

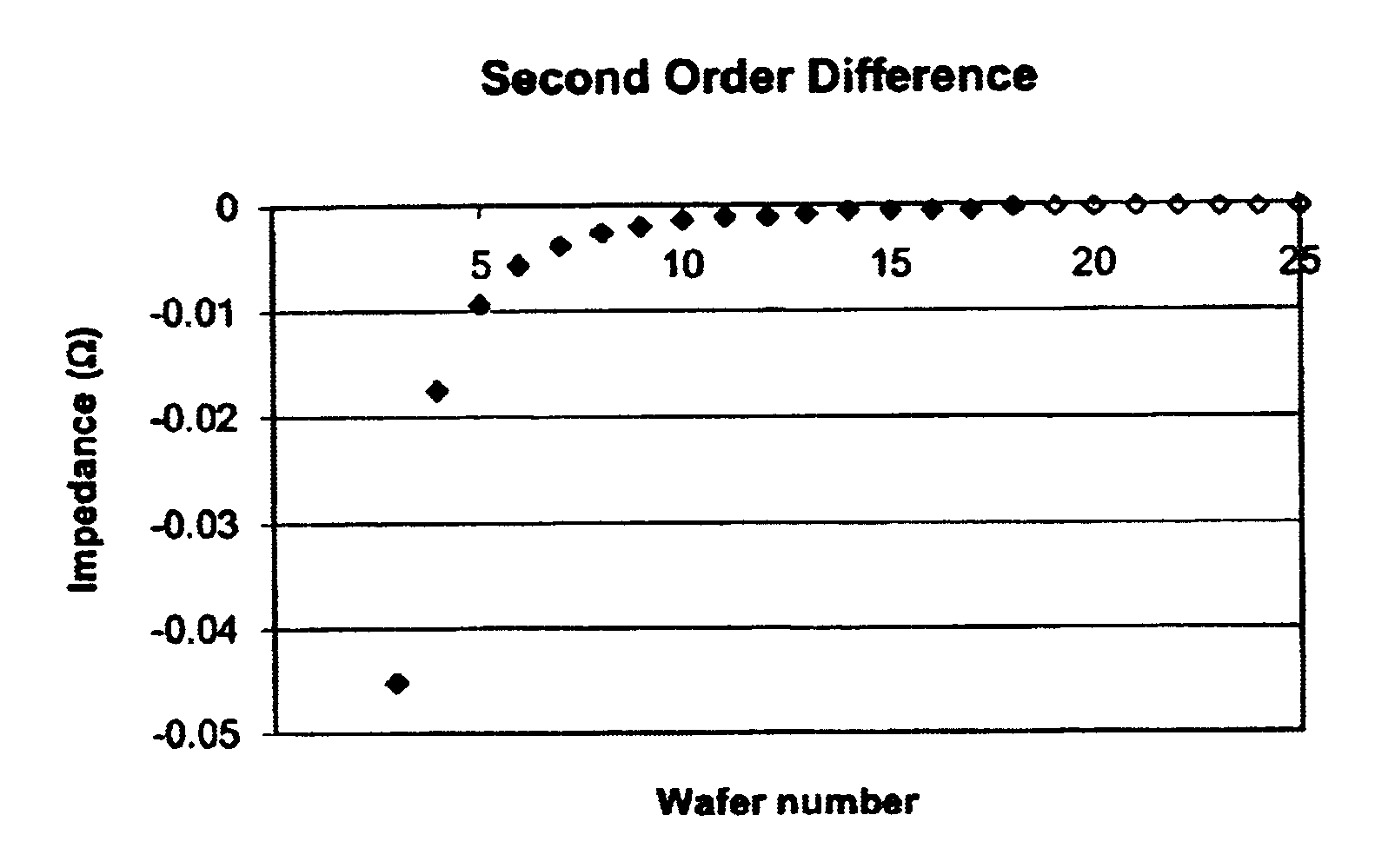

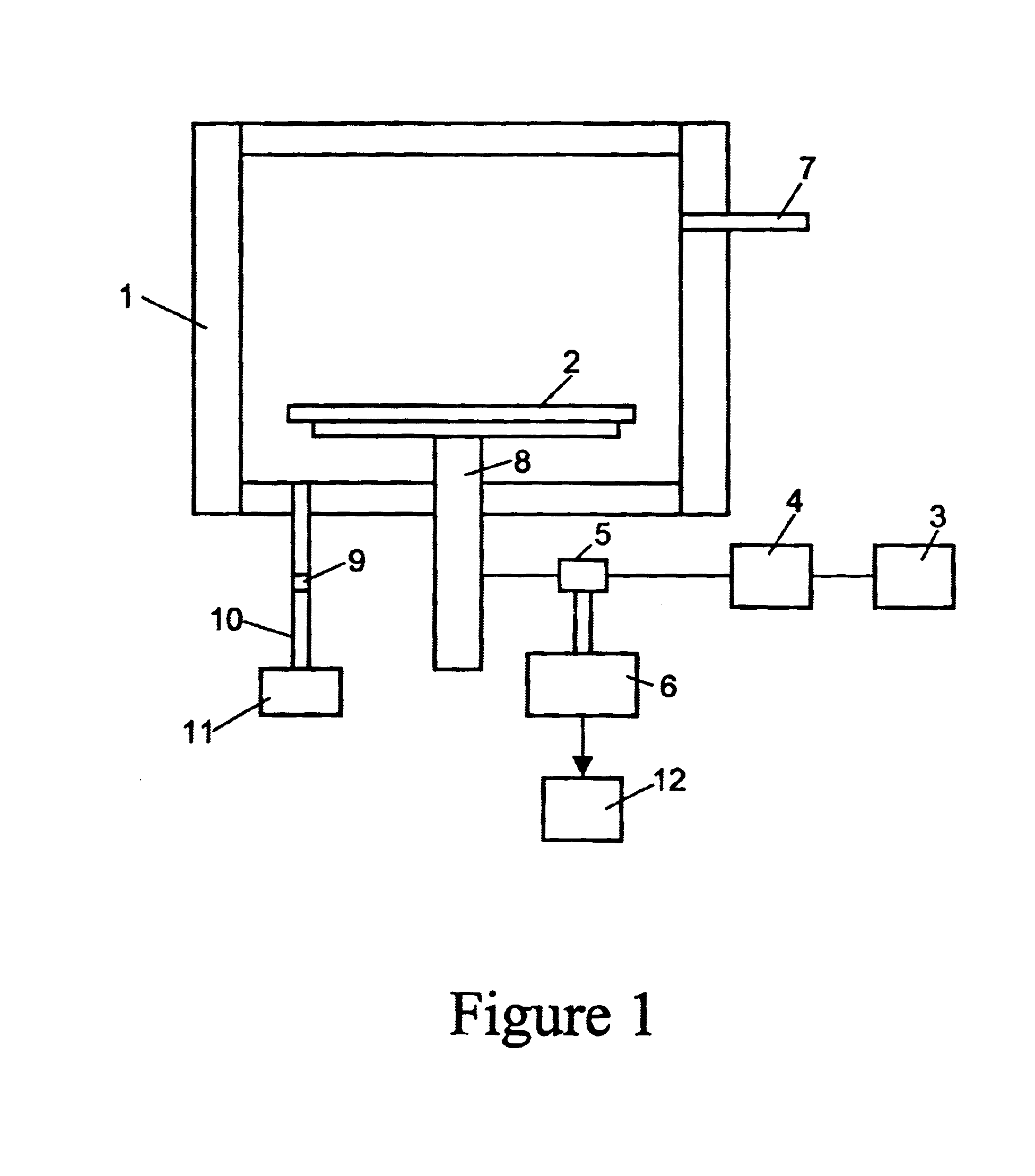

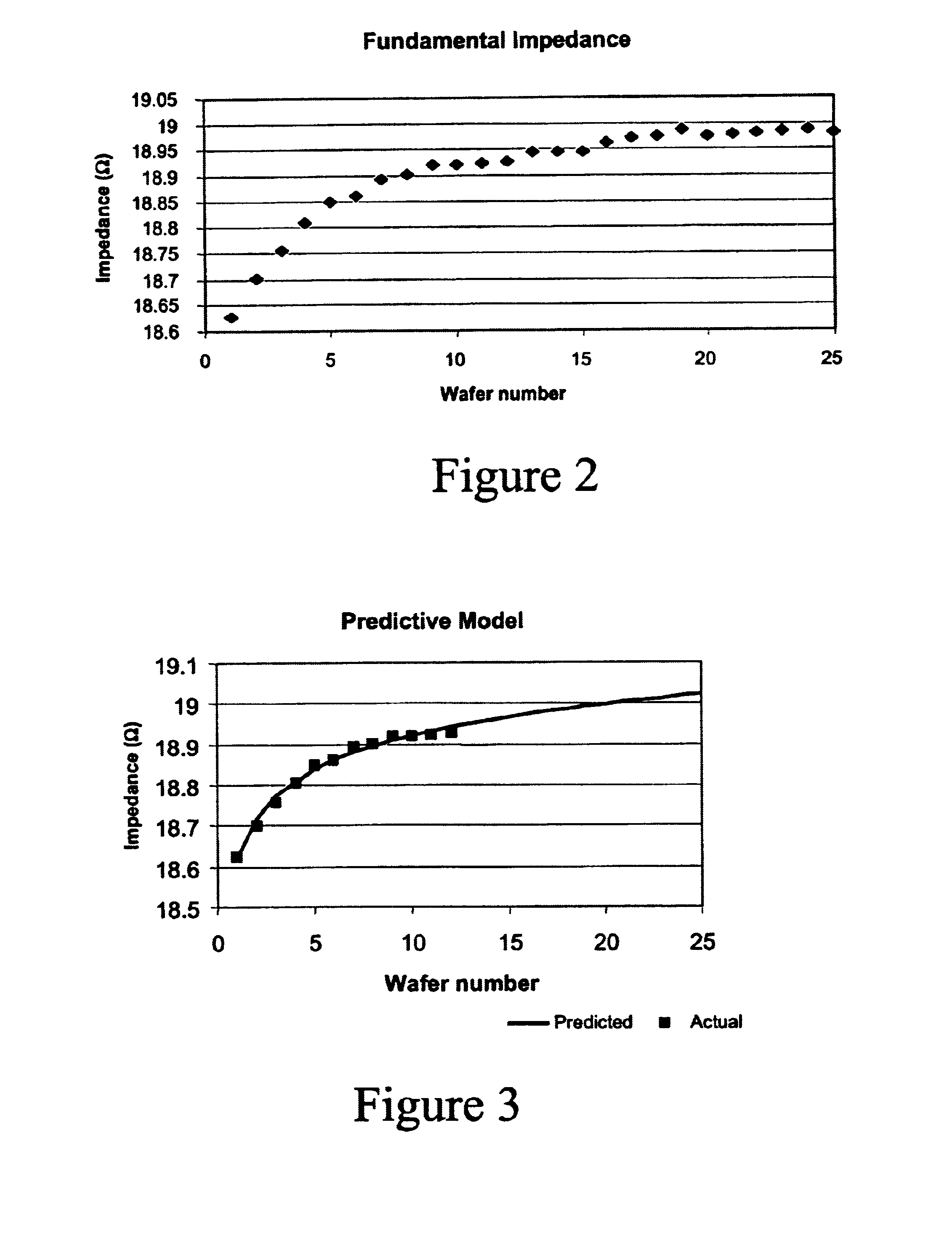

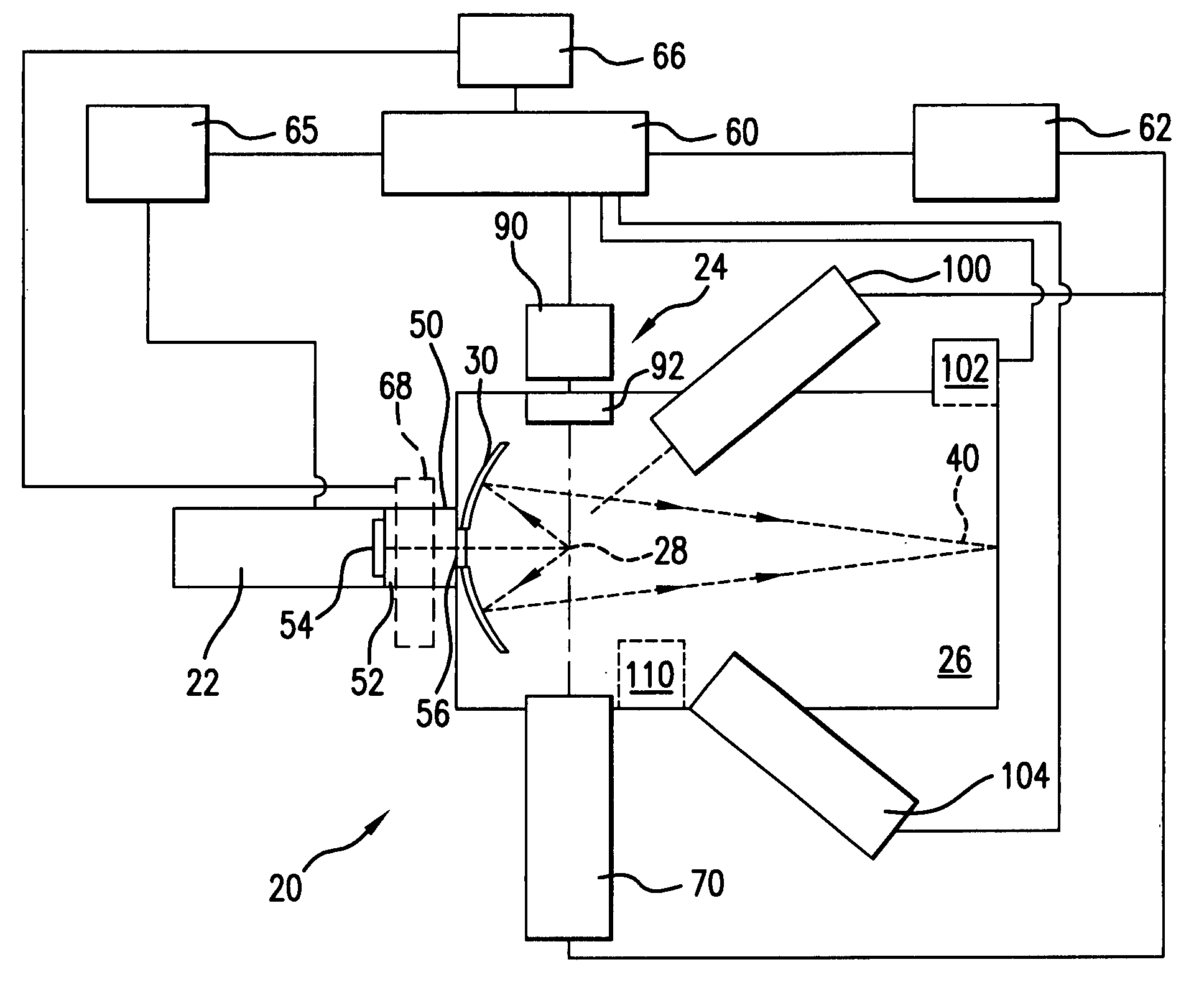

Plasma chamber conditioning

InactiveUS6656848B1Quantity minimizationReduce in quantityElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityPolymer

A method for determining the optimum number of conditioning wafers to be run following a wet clean of the walls of an RF plasma chamber 1 is based on an electrical precursor signal. Polymer build up on a plasma chamber wall during normal chamber conditioning is monitored by observing components of the fundamental RF signal. After a pre-determined number of wafers has been run, a predictive model is used to determine the total number of wafers needed to complete the conditioning cycle.

Owner:LAM RES CORP

Laser produced plasma EUV light source

ActiveUS20060219957A1Increase the rate of chemical reactionsRadiation pyrometryNanoinformaticsLine tubingLight beam

An EUV light source is disclosed that may include a laser source, e.g. CO2 laser, a plasma chamber, and a beam delivery system for passing a laser beam from the laser source into the plasma chamber. Embodiments are disclosed which may include one or more of the following; a bypass line may be provided to establish fluid communication between the plasma chamber and the auxiliary chamber, a focusing optic, e.g. mirror, for focusing the laser beam to a focal spot in the plasma chamber, a steering optic for steering the laser beam focal spot in the plasma chamber, and an optical arrangement for adjusting focal power.

Owner:ASML NETHERLANDS BV

Suspended gas distribution manifold for plasma chamber

InactiveUS20050000432A1Minimize gas leakagePermit some movementElectric discharge tubesSemiconductor/solid-state device manufacturingThermal dilatationThermal isolation

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by a side wall comprising one or more sheets. The sheets preferably provide flexibility to alleviate stress in the gas distribution plate due to thermal expansion and contraction. In another aspect, the side wall provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

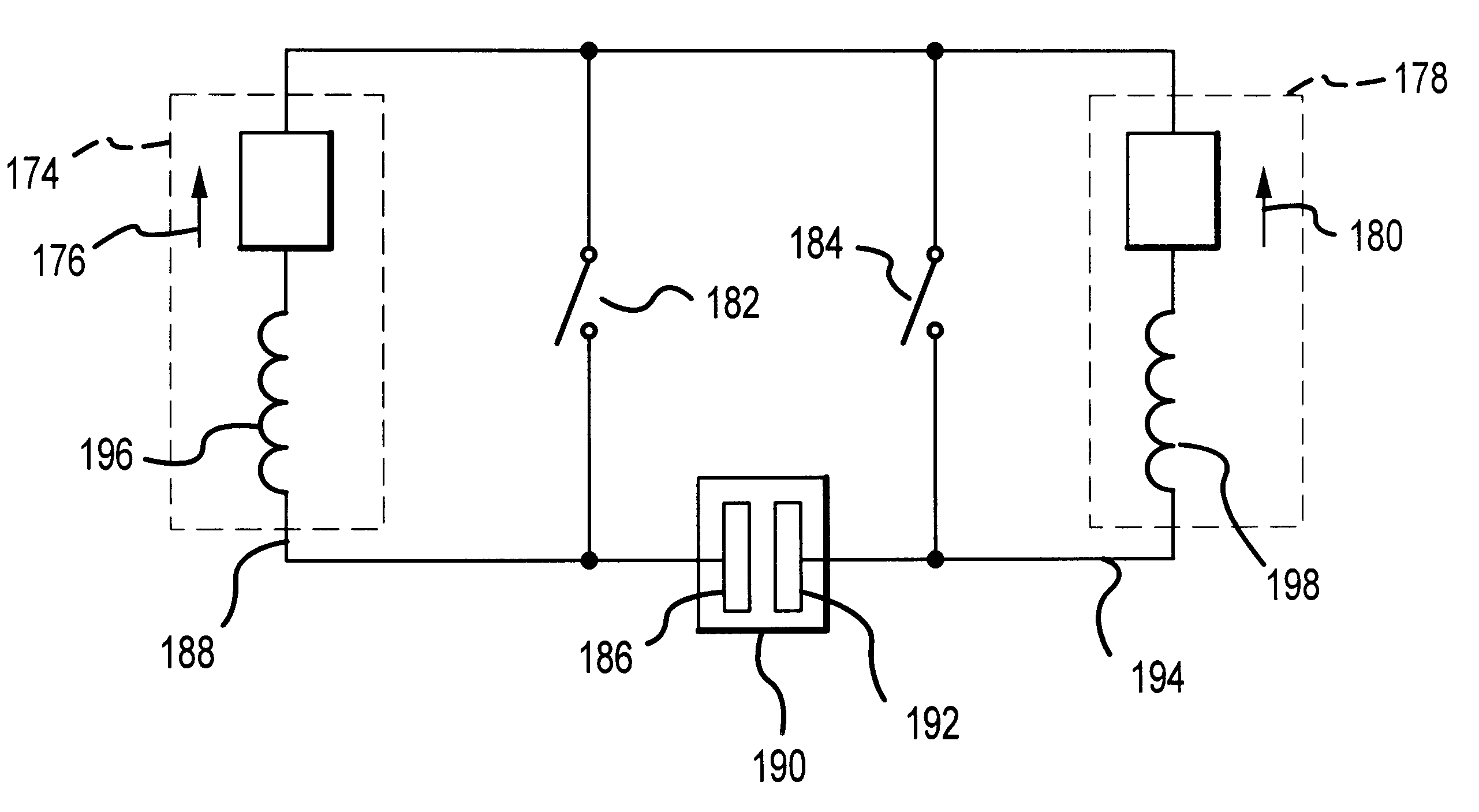

Plasma generator pulsed direct current supply in a bridge configuration

InactiveUS6222321B1Easy to controlIncrease depositionCellsElectric discharge tubesDc currentPulsed DC

Current controlled power sources are disclosed that are capable of generating currents in low resistance, high temperature plasmas that are regulated to prevent the generation of excessive currents in the plasma. Current reversing switches are provided that control the flow of a direct current in a plasma chamber between various electrodes. Multiple power sources are provided in association with shunt switches for delivering a plurality of sources of direct current in various directions between electrodes in a plasma chamber. Inductive impedance can be provided in switch paths to cause a source of direct current to flow through a plasma chamber in various directions between electrodes.

Owner:ADVANCED ENERGY IND INC

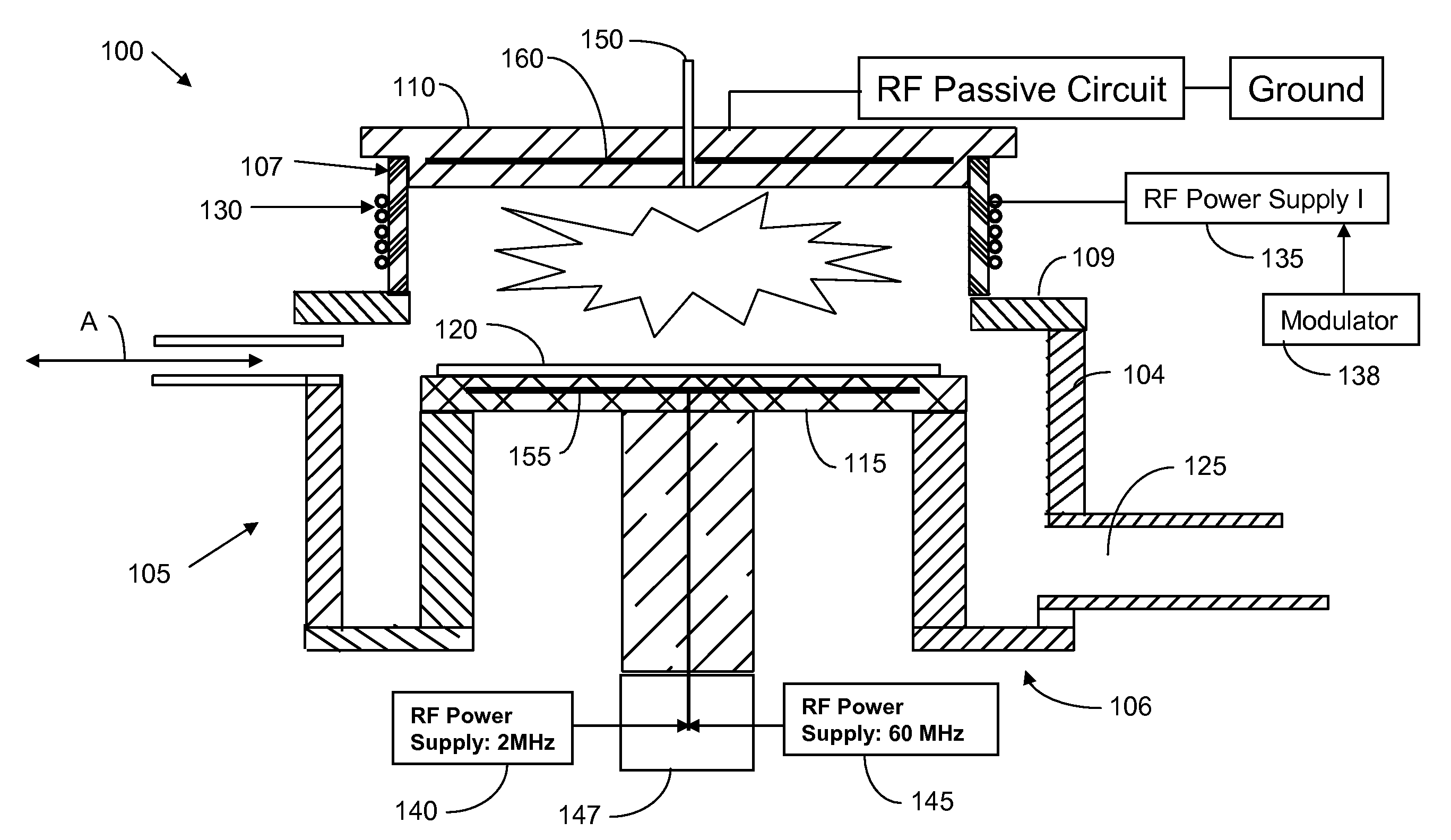

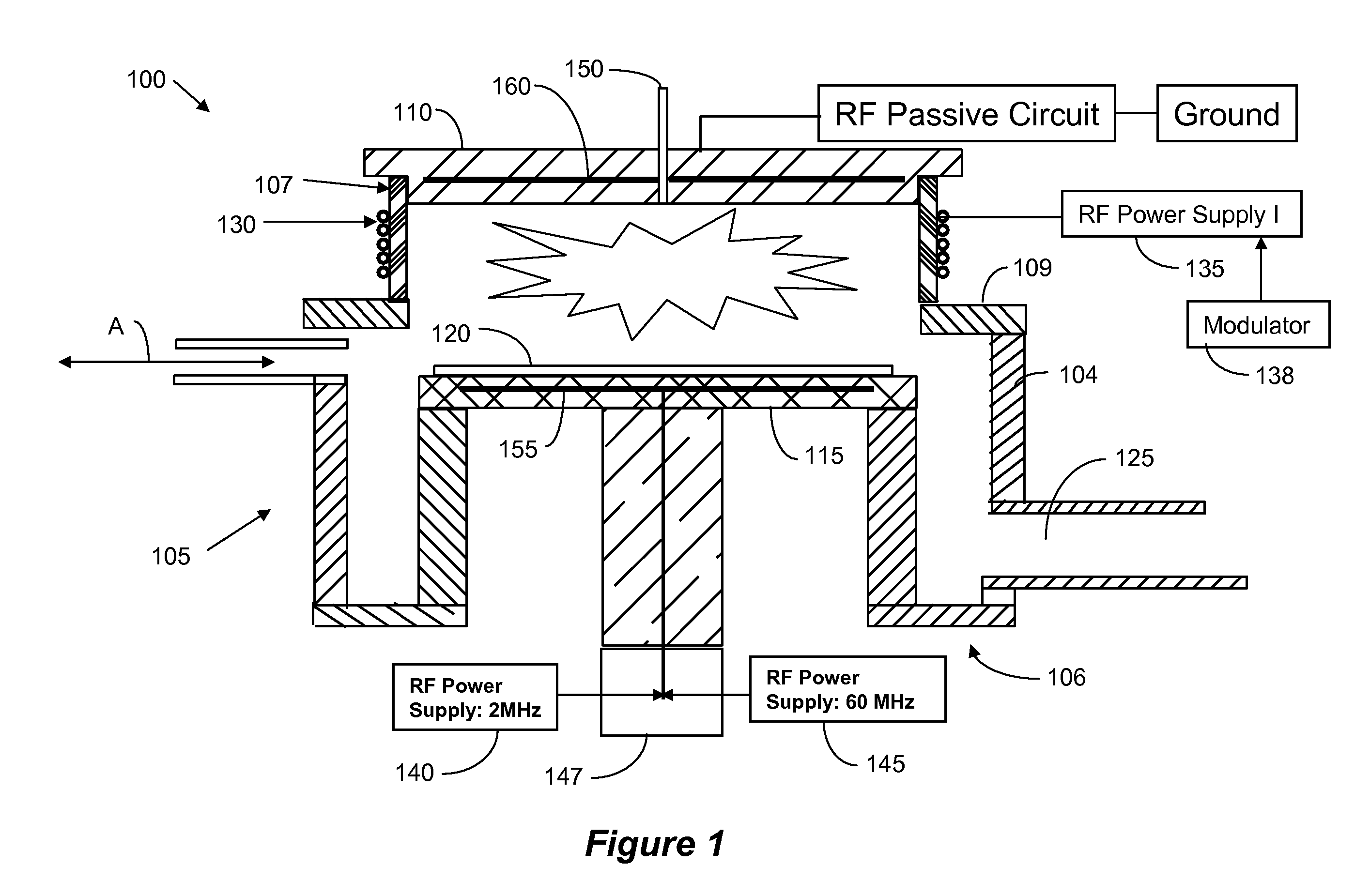

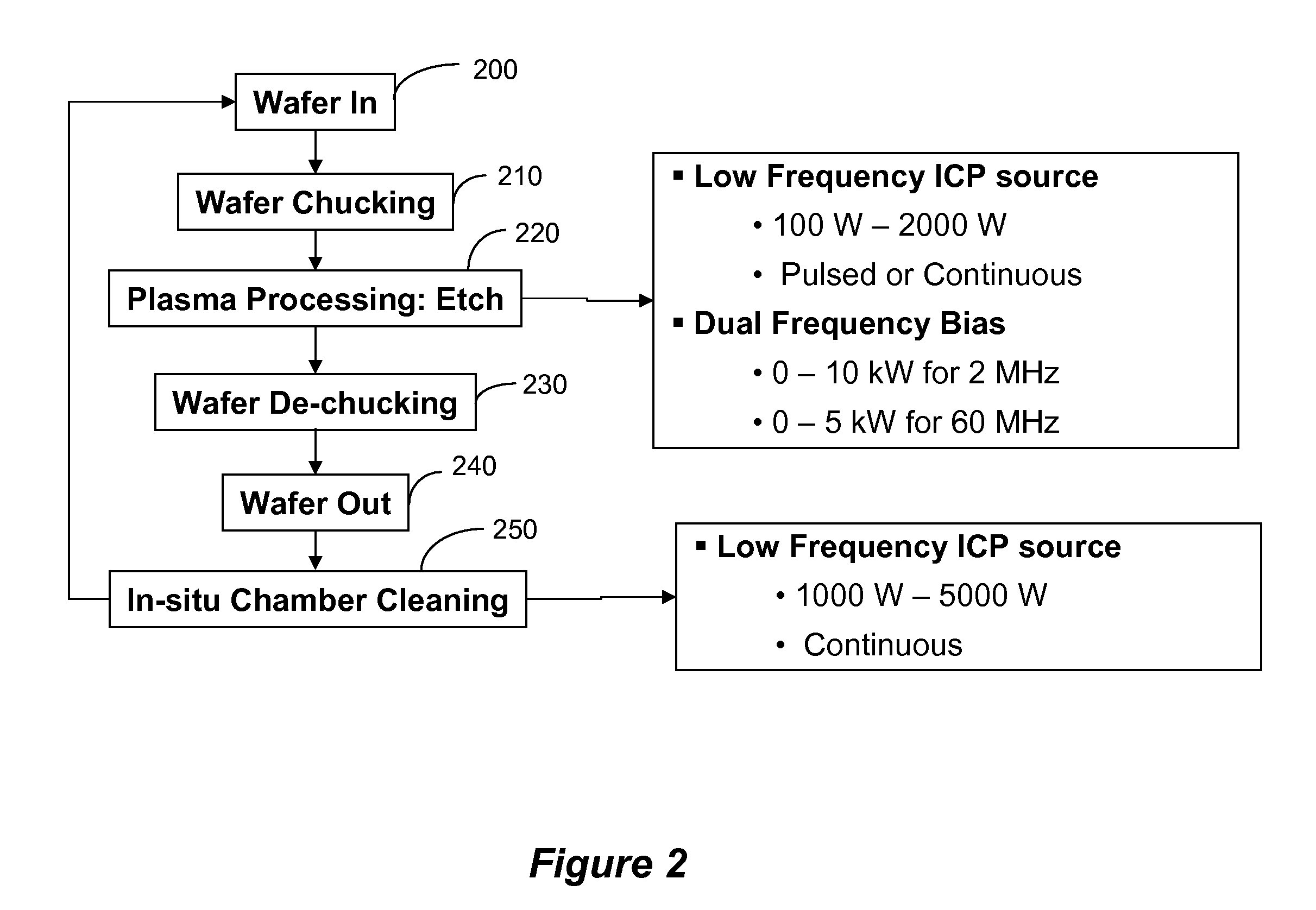

Hybrid etch chamber with decoupled plasma controls

InactiveUS20090004873A1Electric discharge tubesSemiconductor/solid-state device manufacturingDual frequencyCapacitance

A dielectric etch chamber and method for improved control of plasma parameters. The plasma chamber comprises dual-frequency bias source that capacitively couples the RF energy to the plasma, and a single or dual frequency source that inductively couples the RF energy to the plasma. The inductive source may be modulated for improved etch uniformity.

Owner:INTEVAC

Controlling etch rate drift and particles during plasma processing

The invention is an plasma processing system with a plasma chamber for processing semiconductor substrates, comprising: a radio frequency or microwave power generator coupled to the plasma chamber; a low pressure vacuum system coupled to the plasma chamber; and at least one chamber surface that is configured to be exposed to a plasma, the chamber surface comprising: a YxOyFz layer that comprises Y in a range from 20 to 40%, O in a range from ≦60%, and F in a range of ≦75%. Alternatively, the YxOyFz layer can comprise Y in a range from 25 to 40%, O in a range from 40 to 55%, and F in a range of 5 to 35% or Y in a range from 25 to 40%, O in a range from 5 to 40%, and F in a range of 20 to 70%.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com