Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

718 results about "Plasma cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

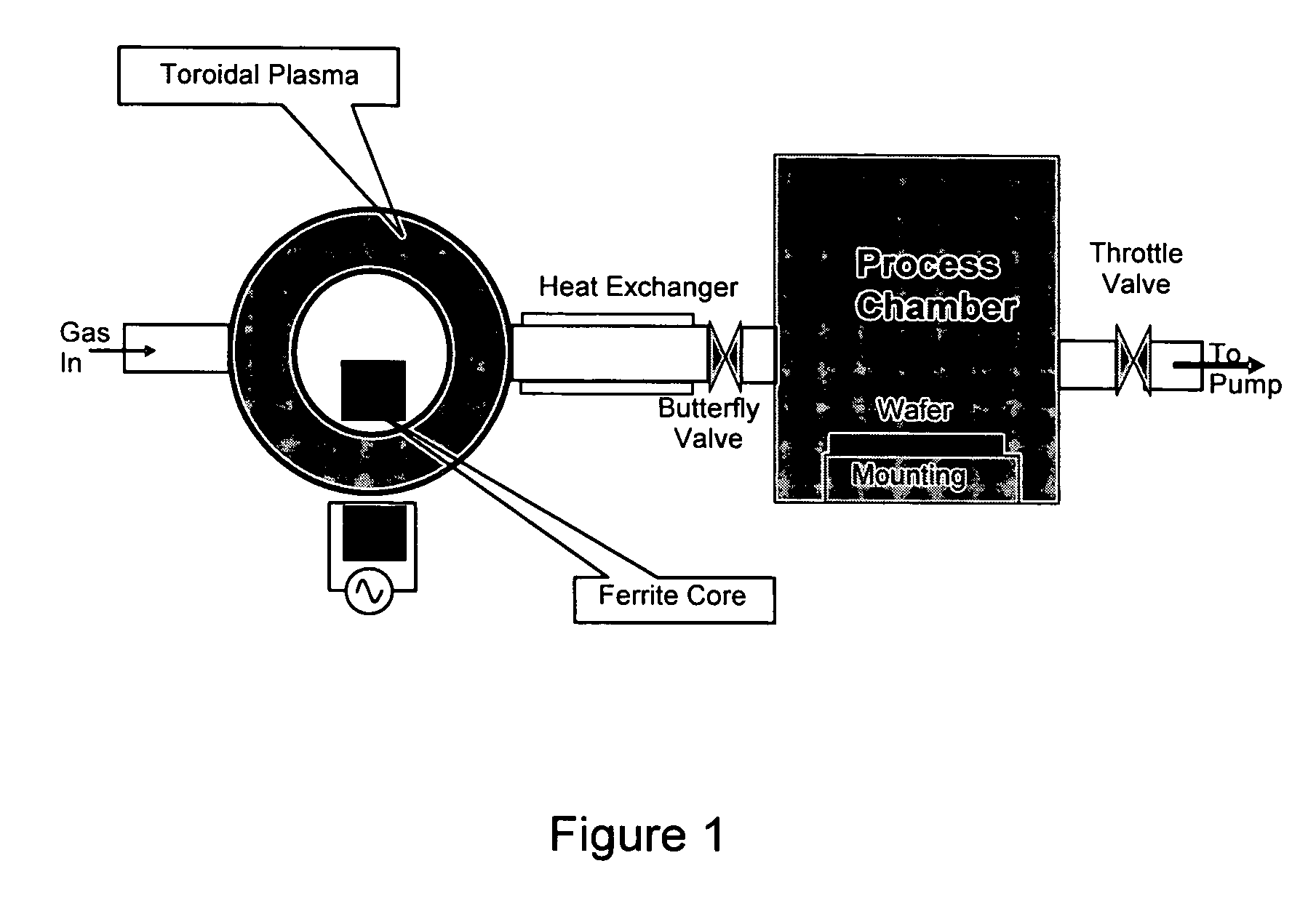

Plasma cleaning is the removal of impurities and contaminants from surfaces through the use of an energetic plasma or dielectric barrier discharge (DBD) plasma created from gaseous species. Gases such as argon and oxygen, as well as mixtures such as air and hydrogen/nitrogen are used. The plasma is created by using high frequency voltages (typically kHz to >MHz) to ionise the low pressure gas (typically around 1/1000 atmospheric pressure), although atmospheric pressure plasmas are now also common.

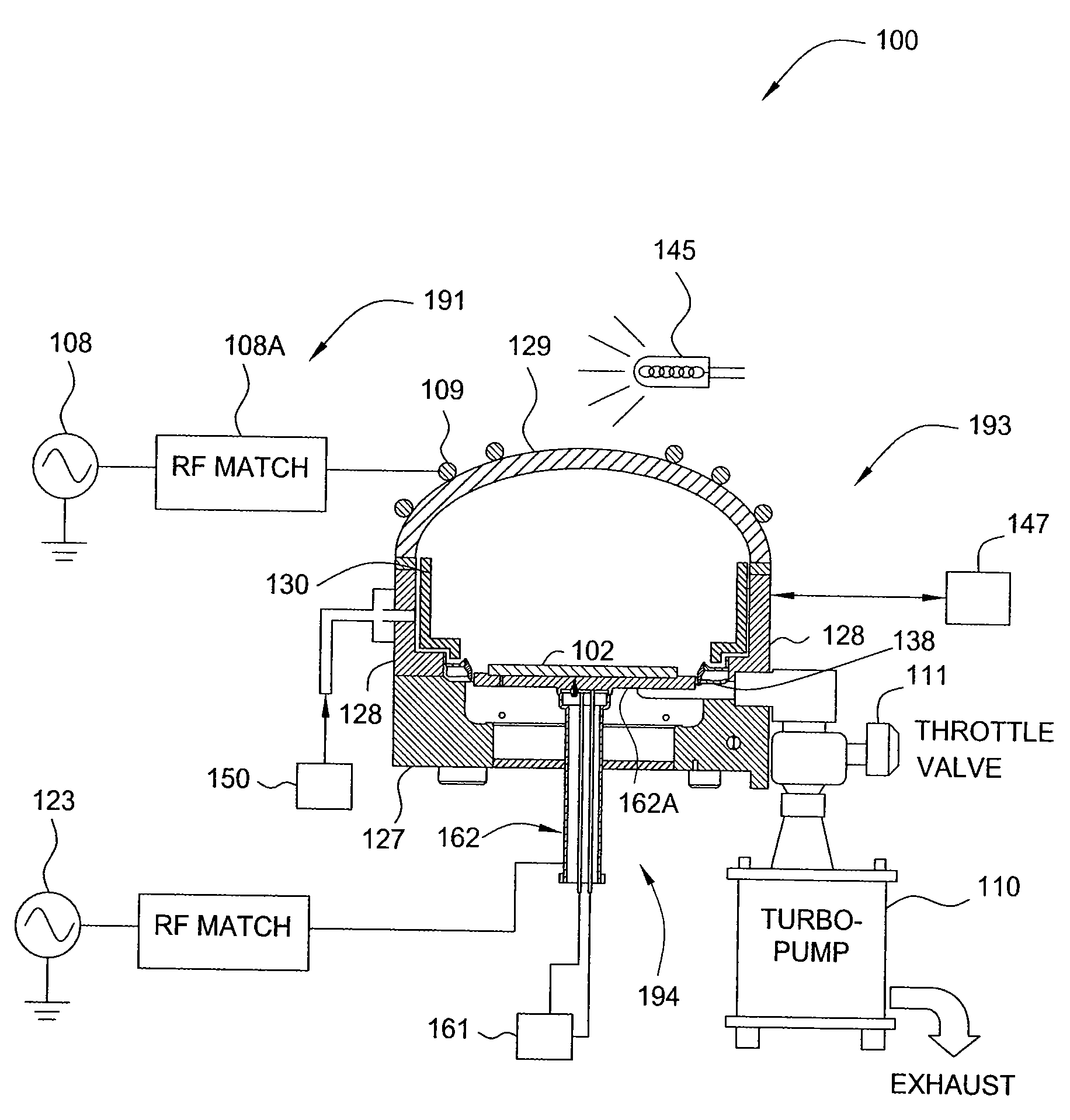

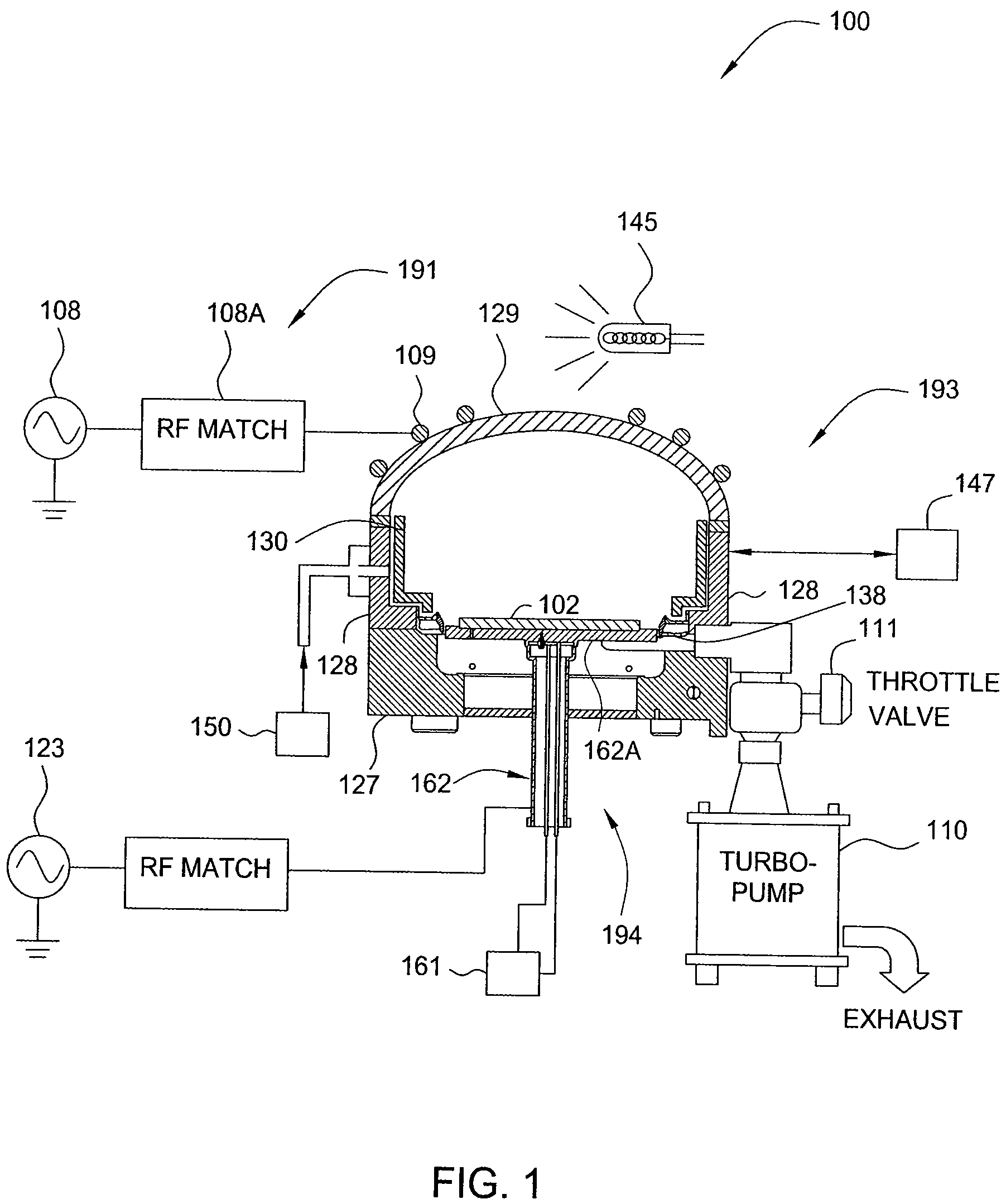

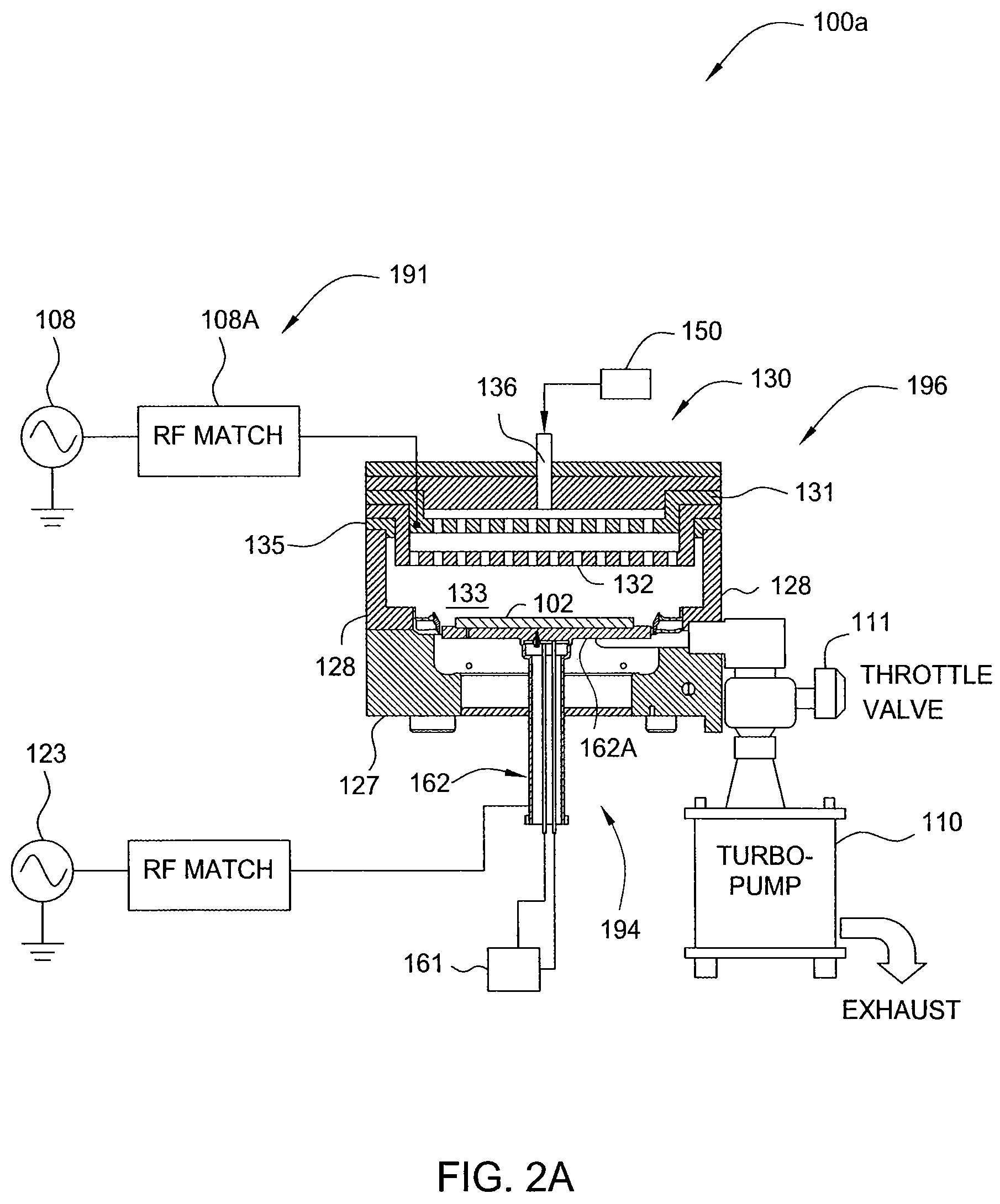

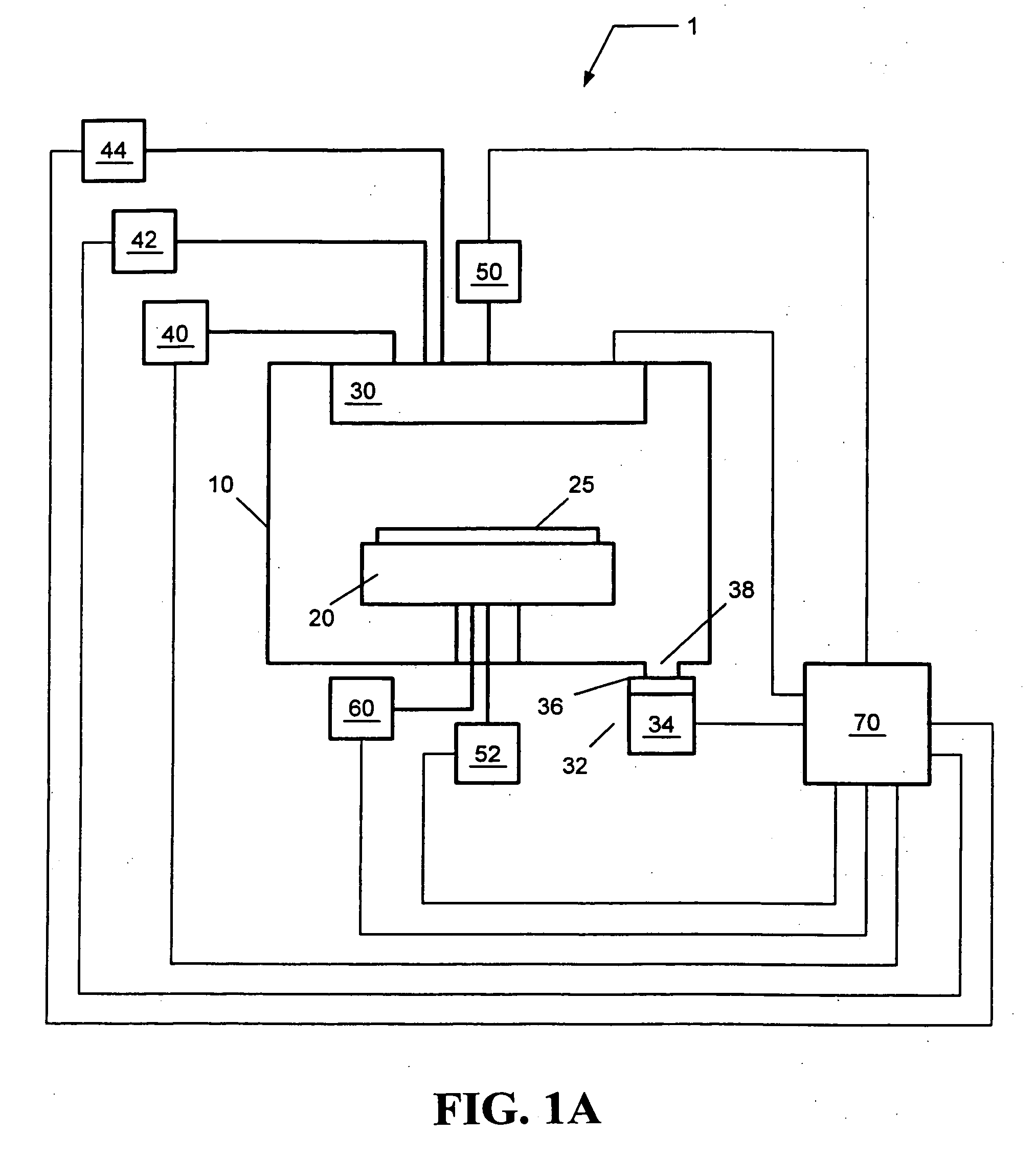

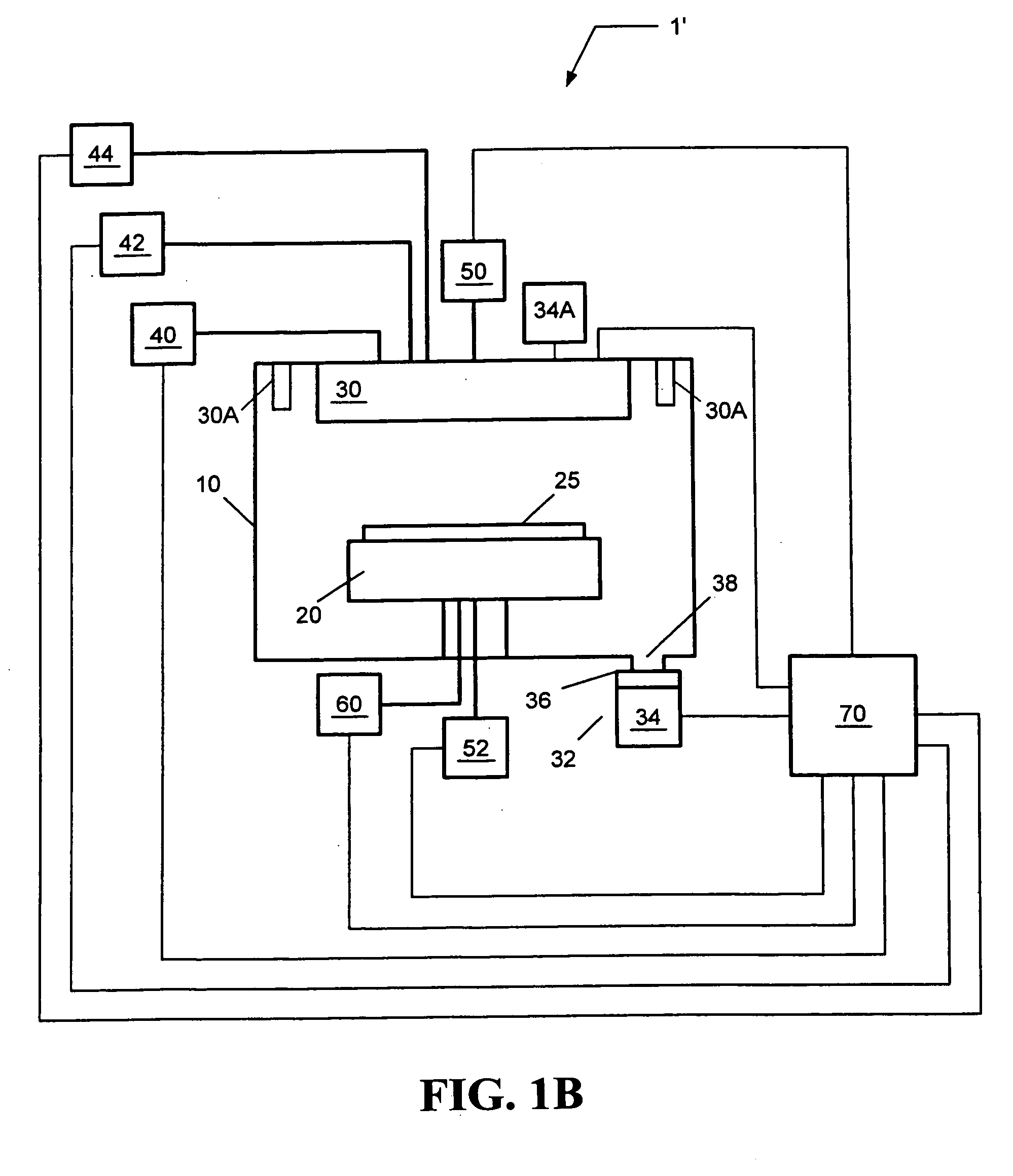

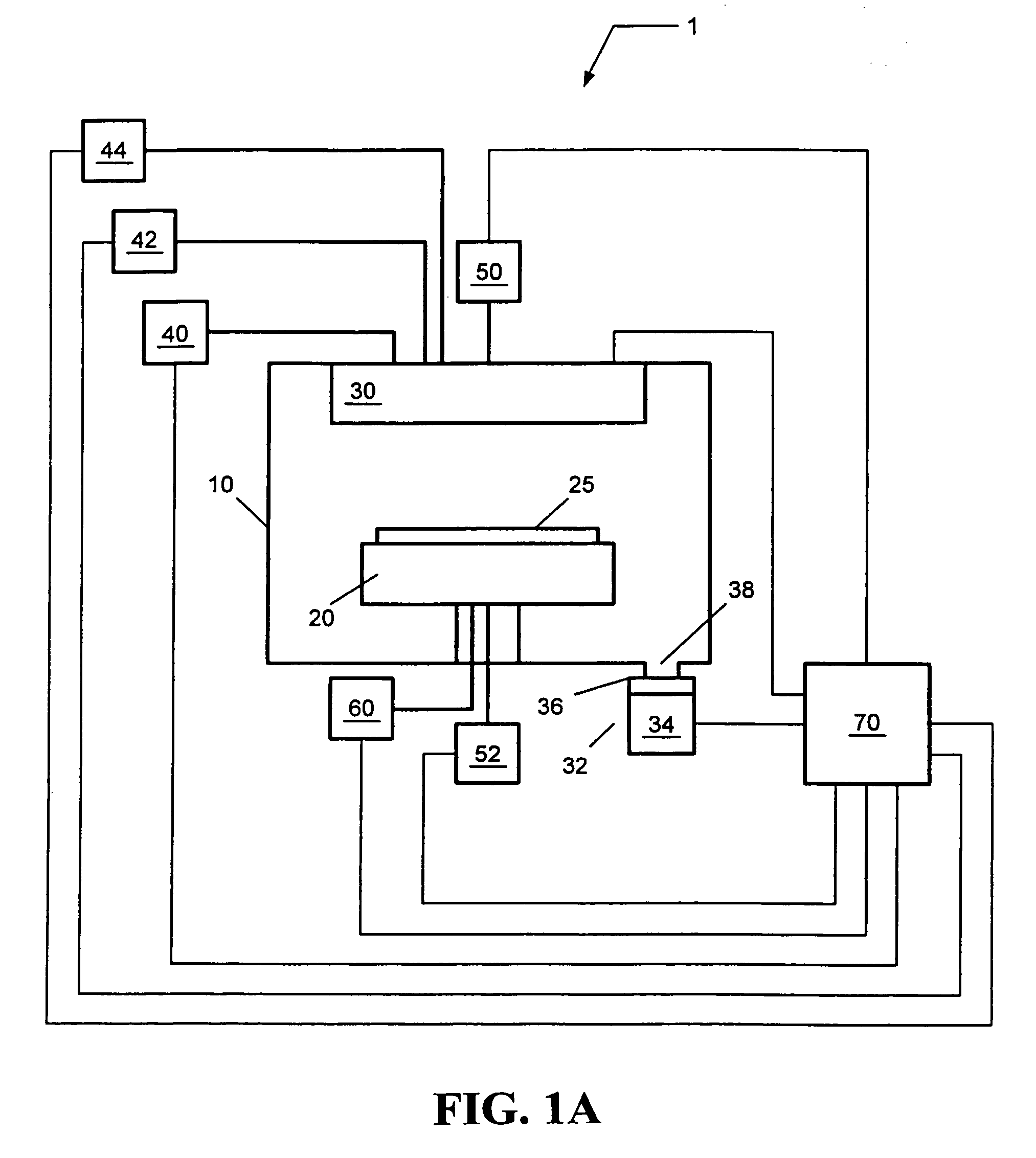

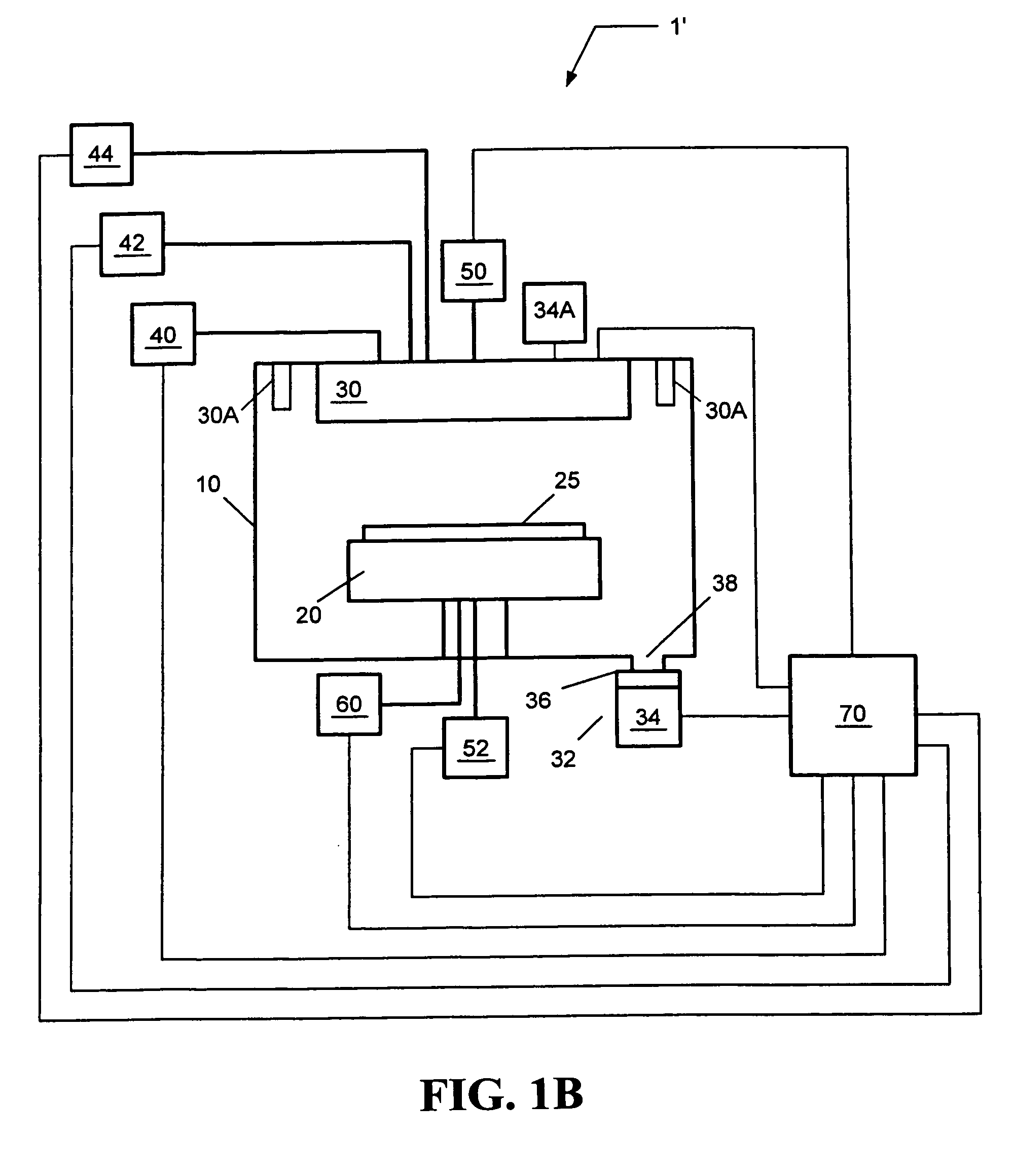

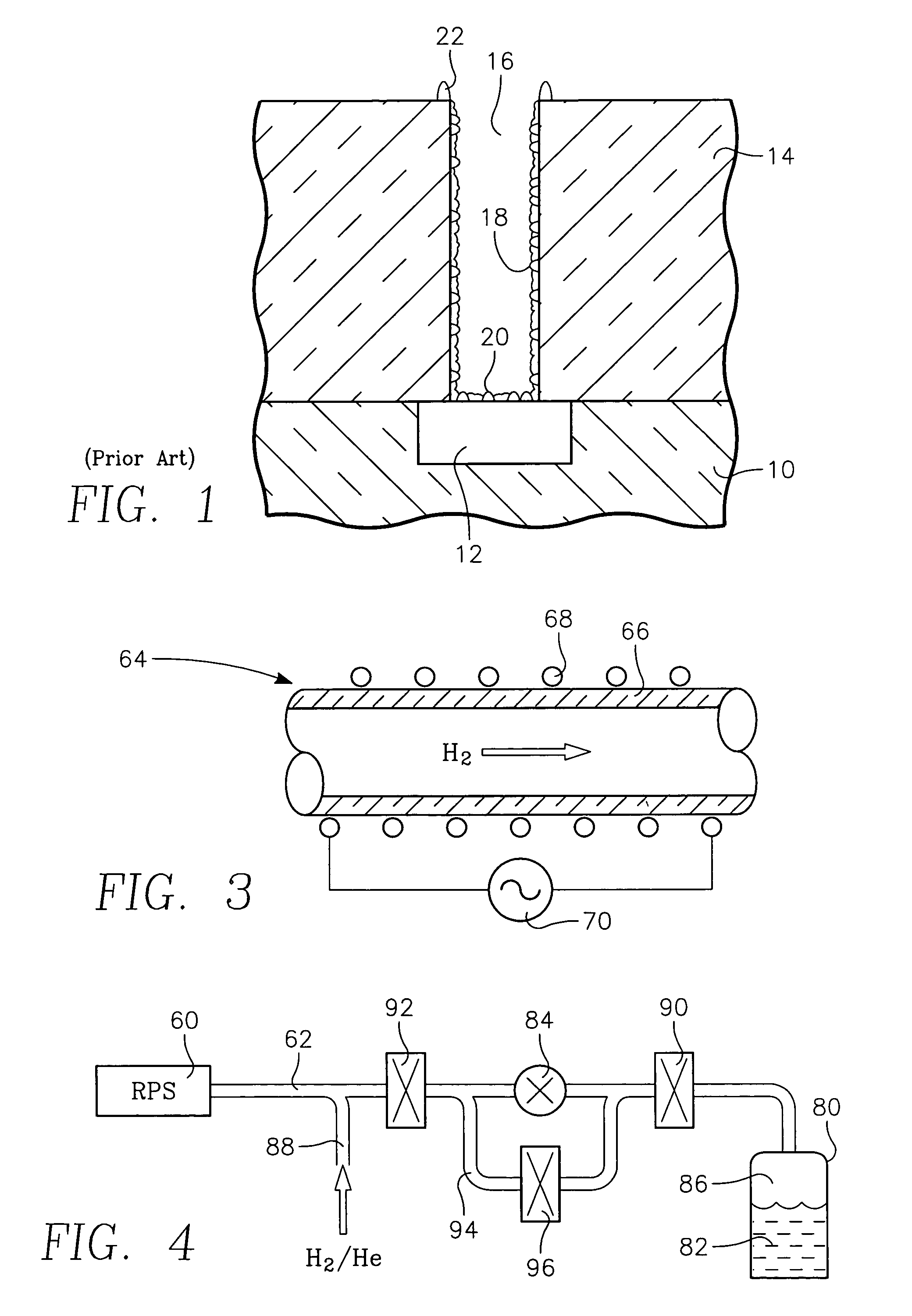

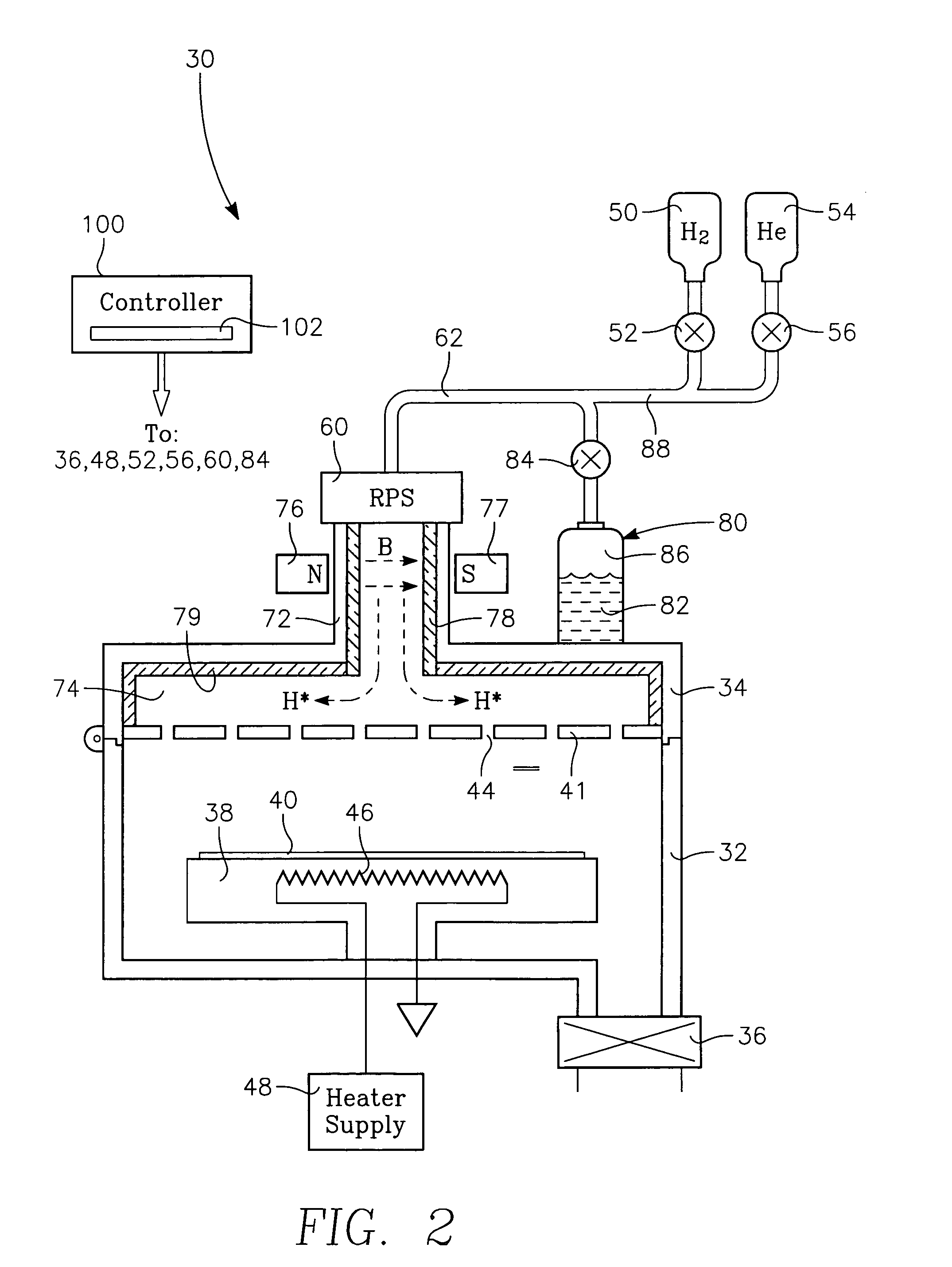

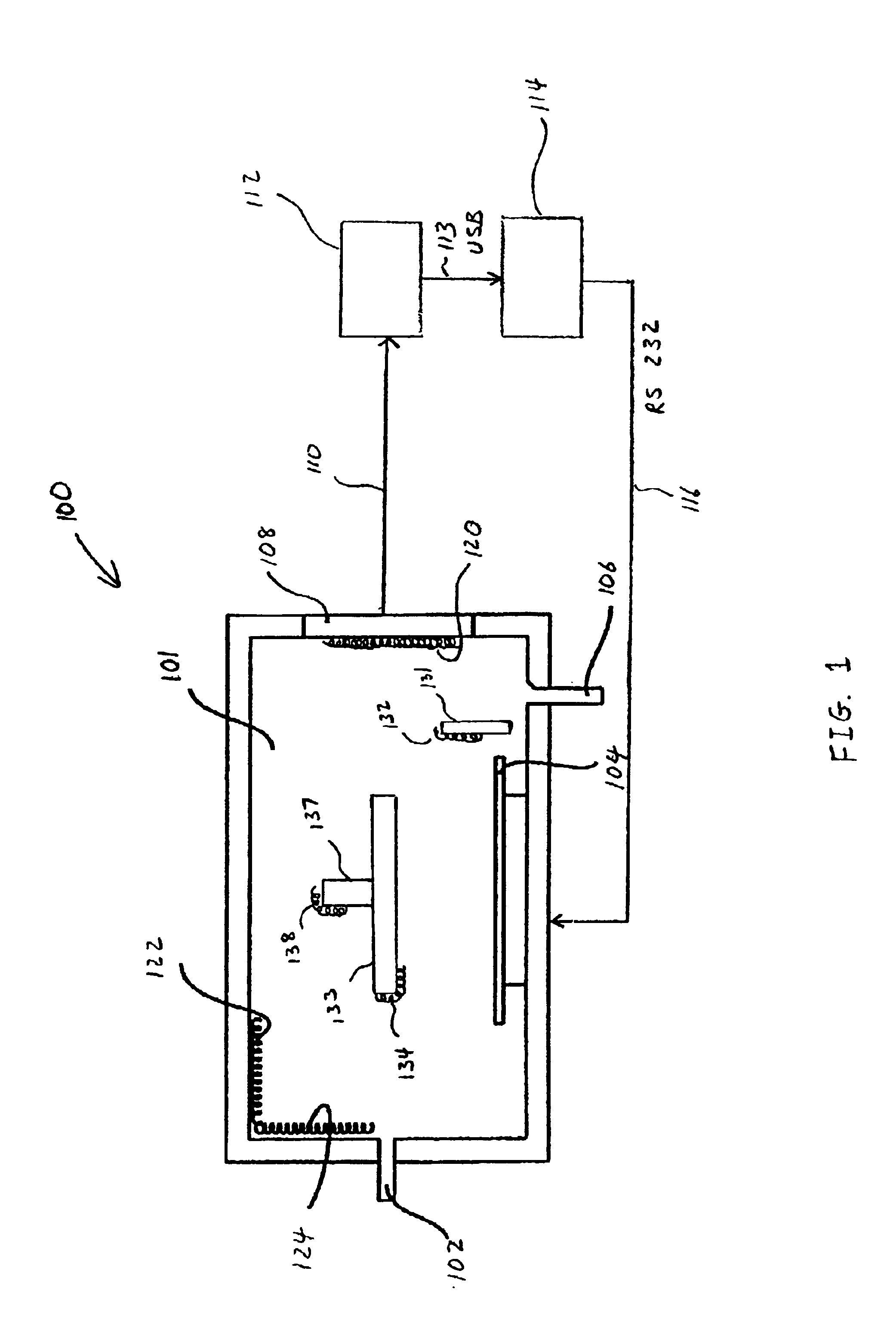

Method and apparatus for cleaning a substrate surface

ActiveUS20090029528A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringContamination

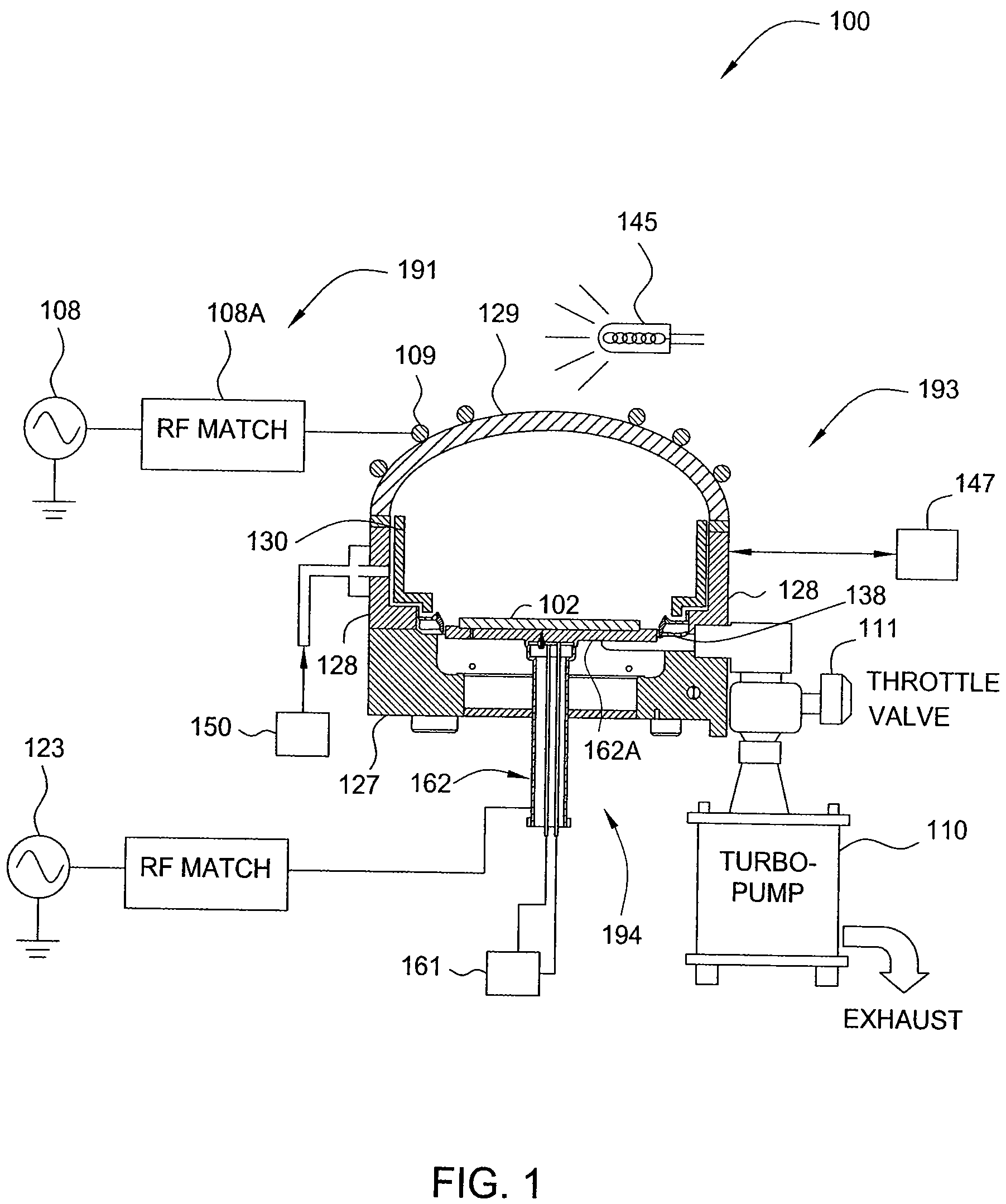

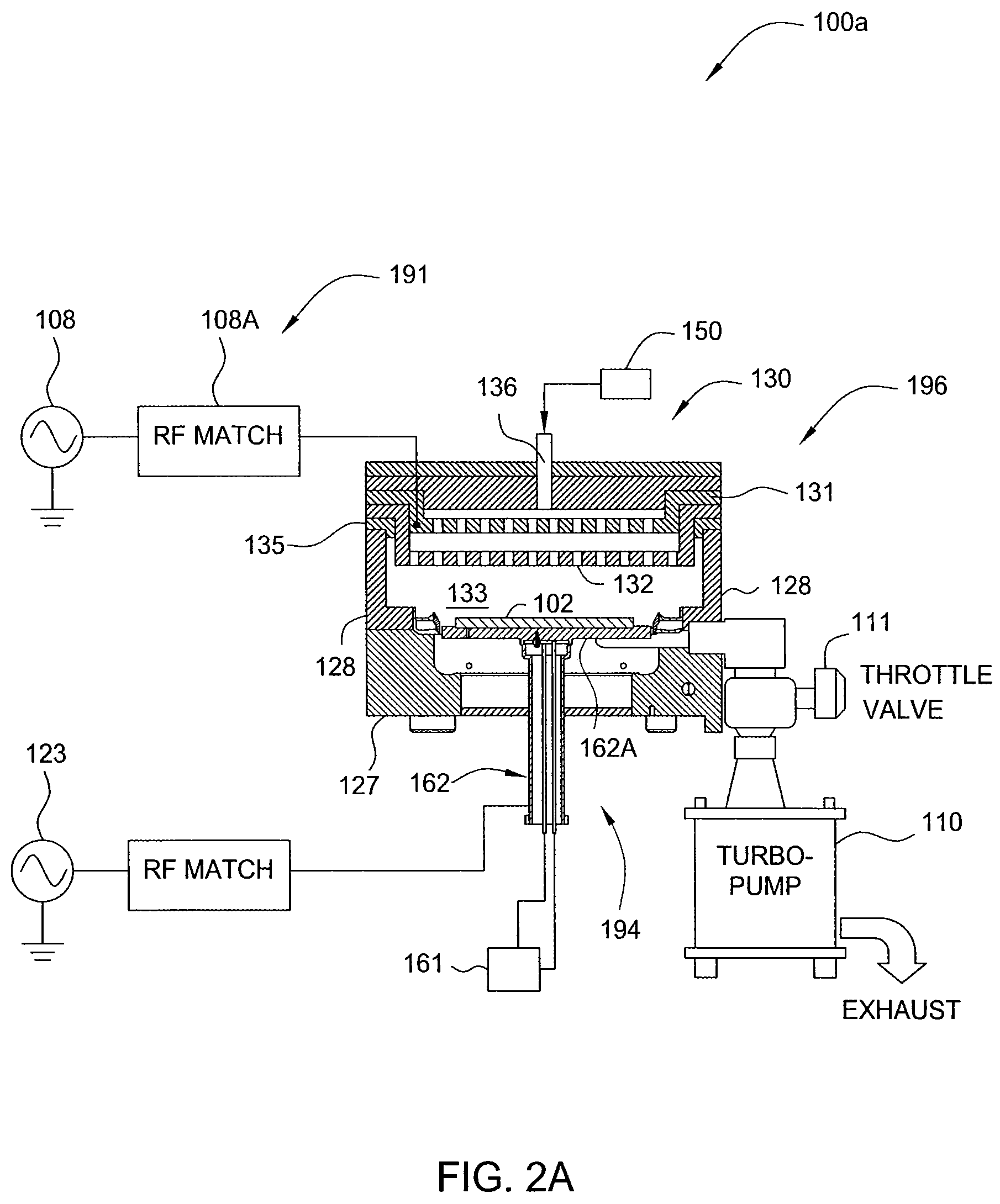

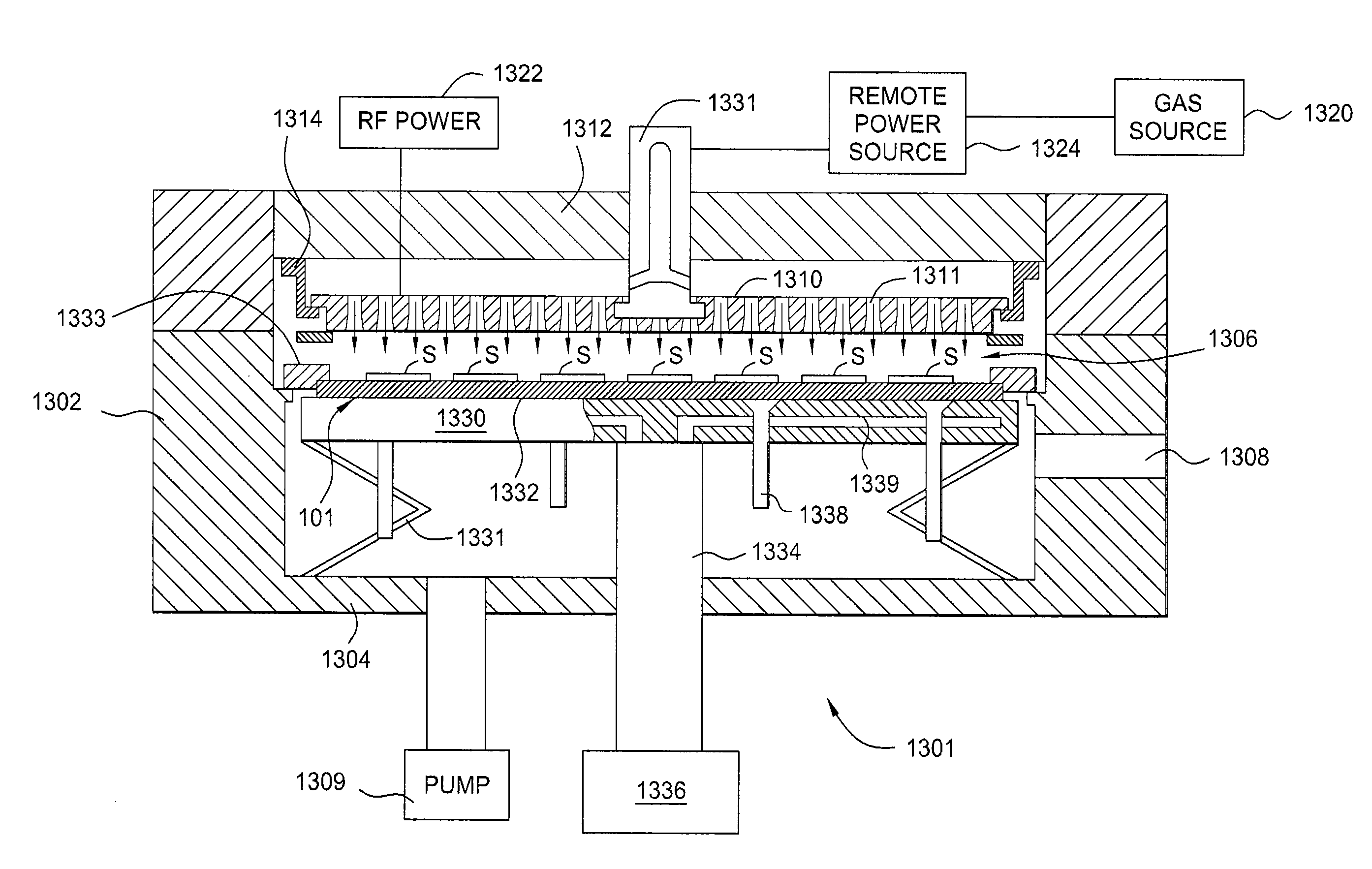

The present invention generally provides apparatus and method for forming a clean and damage free surface on a semiconductor substrate. One embodiment of the present invention provides a system that contains a cleaning chamber that is adapted to expose a surface of substrate to a plasma cleaning process prior to forming an epitaxial layer thereon. In one embodiment, a method is employed to reduce the contamination of a substrate processed in the cleaning chamber by depositing a gettering material on the inner surfaces of the cleaning chamber prior to performing a cleaning process on a substrate. In one embodiment, oxidation and etching steps are repeatedly performed on a substrate in the cleaning chamber to expose or create a clean surface on a substrate that can then have an epitaxial placed thereon. In one embodiment, a low energy plasma is used during the cleaning step.

Owner:APPLIED MATERIALS INC

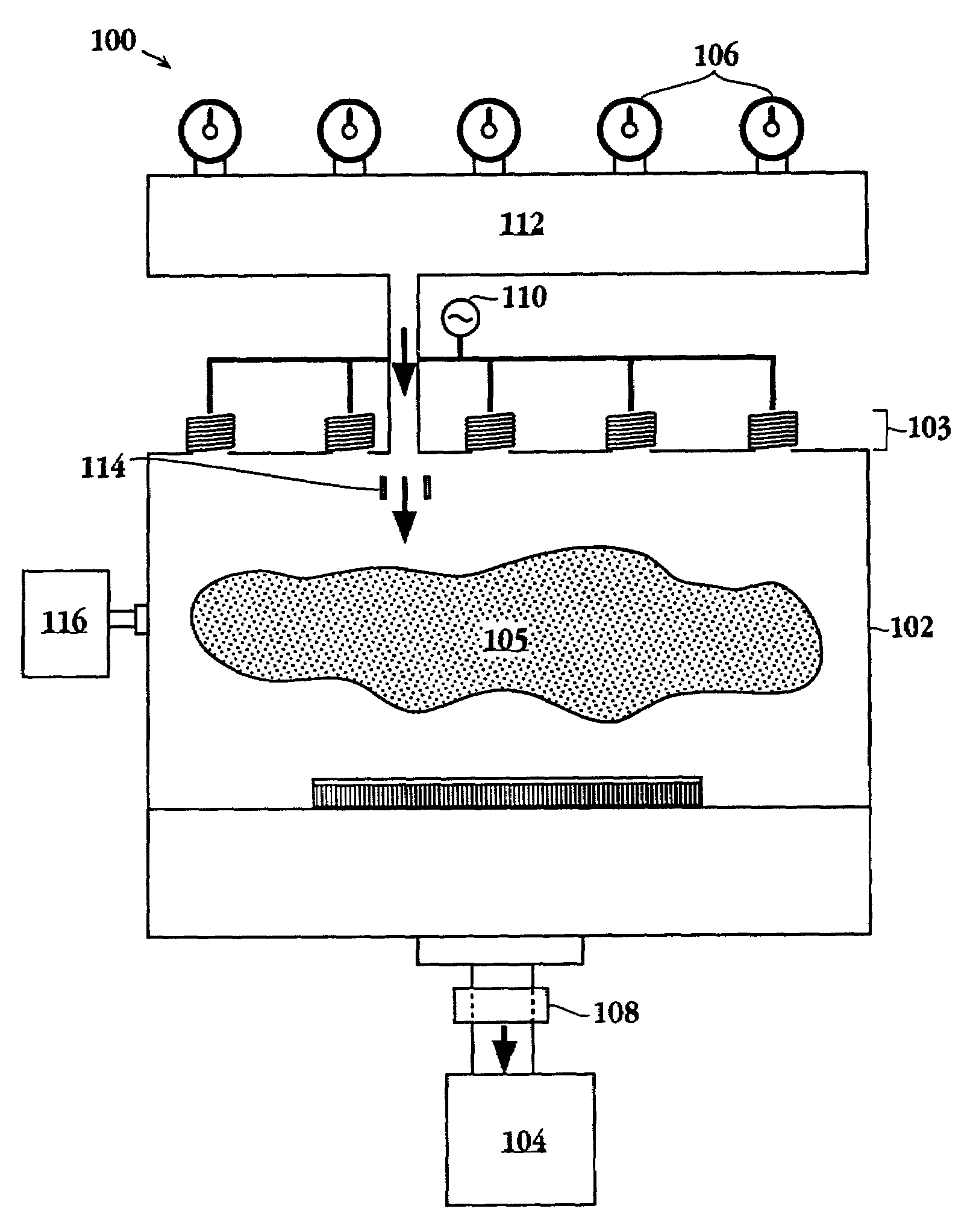

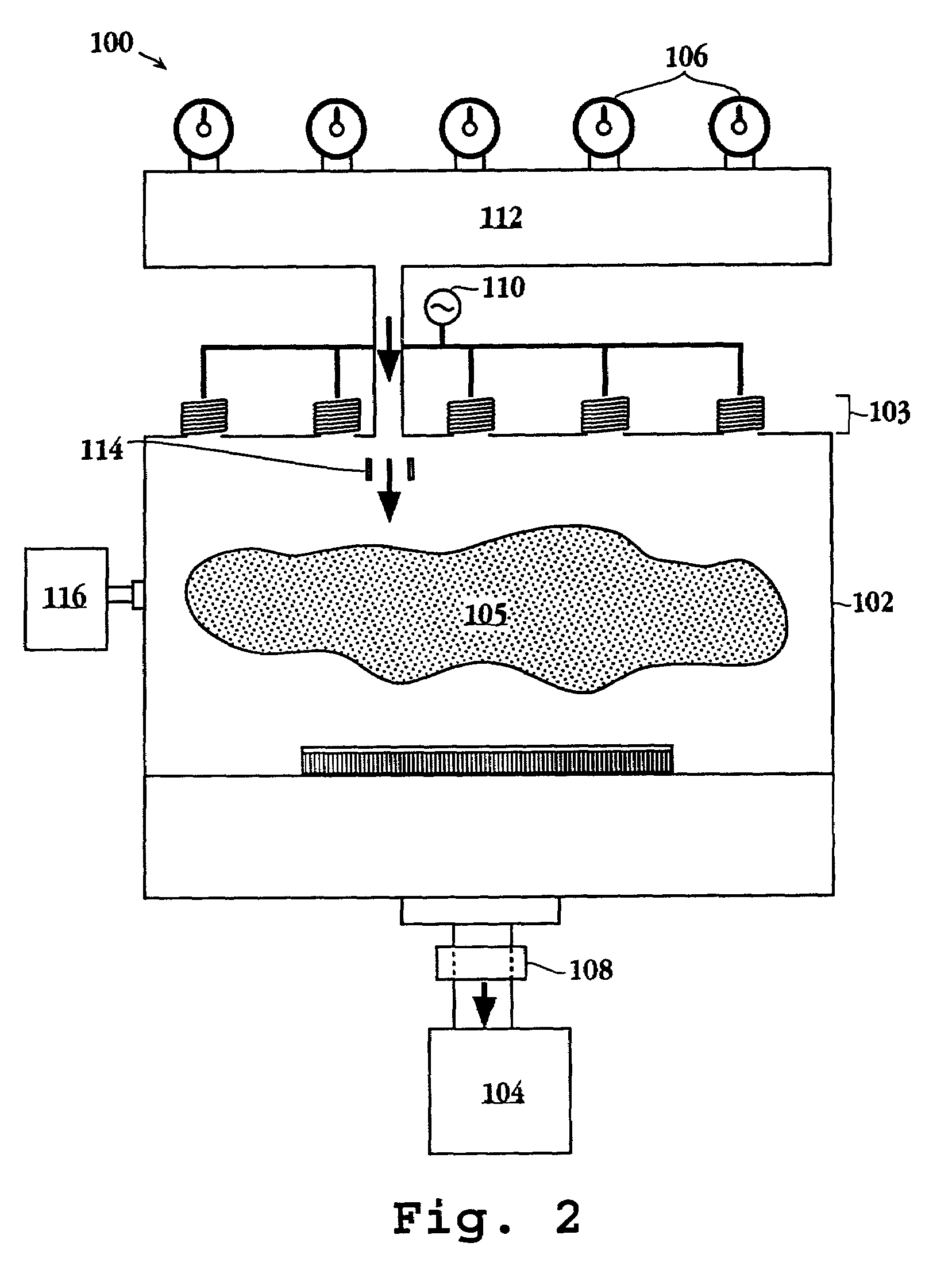

Plasma clean method for deposition chamber

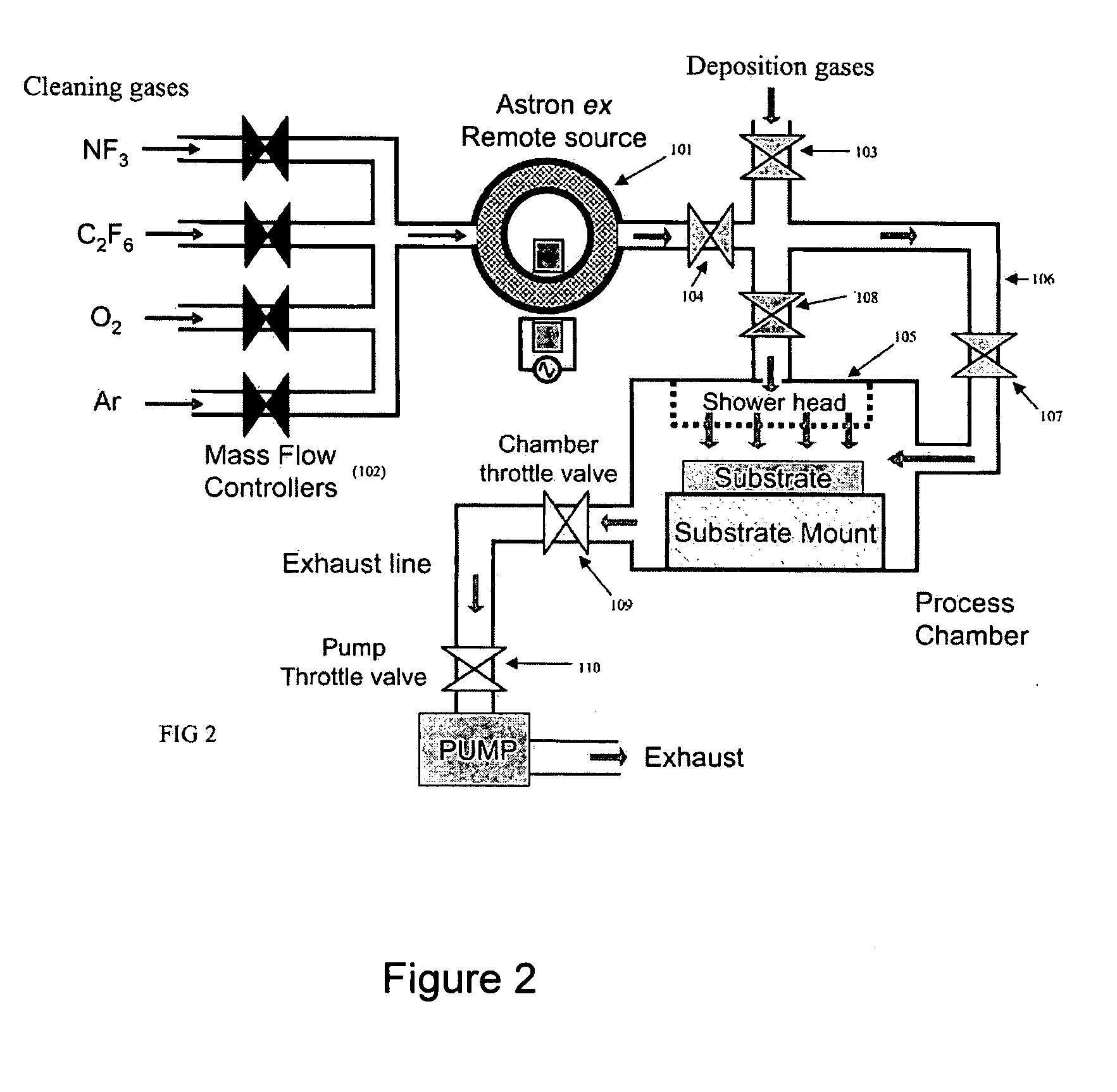

ActiveUS8591659B1Improve cleaning efficiencyEasy to cleanElectric discharge tubesDecorative surface effectsRemote plasmaImproved method

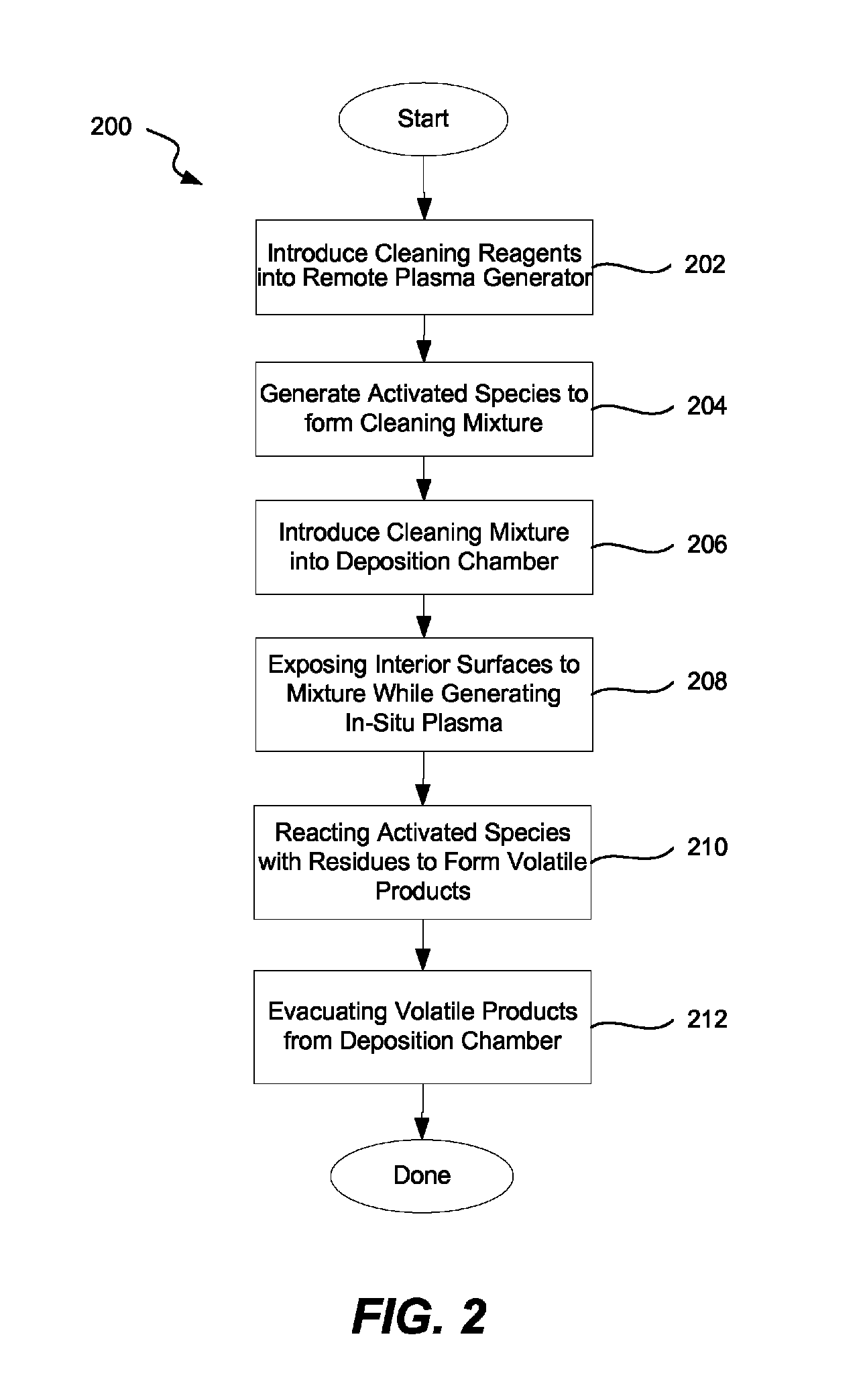

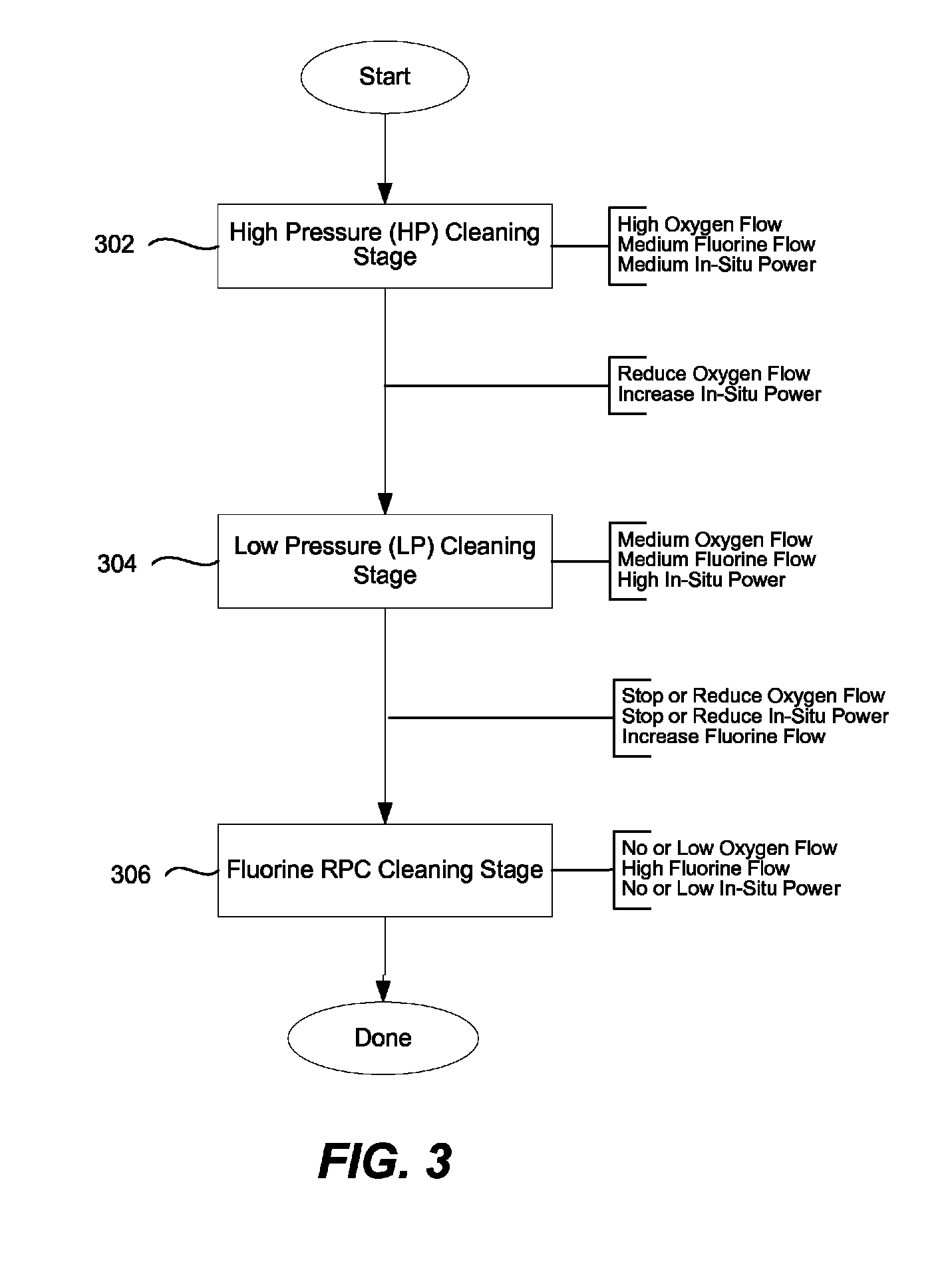

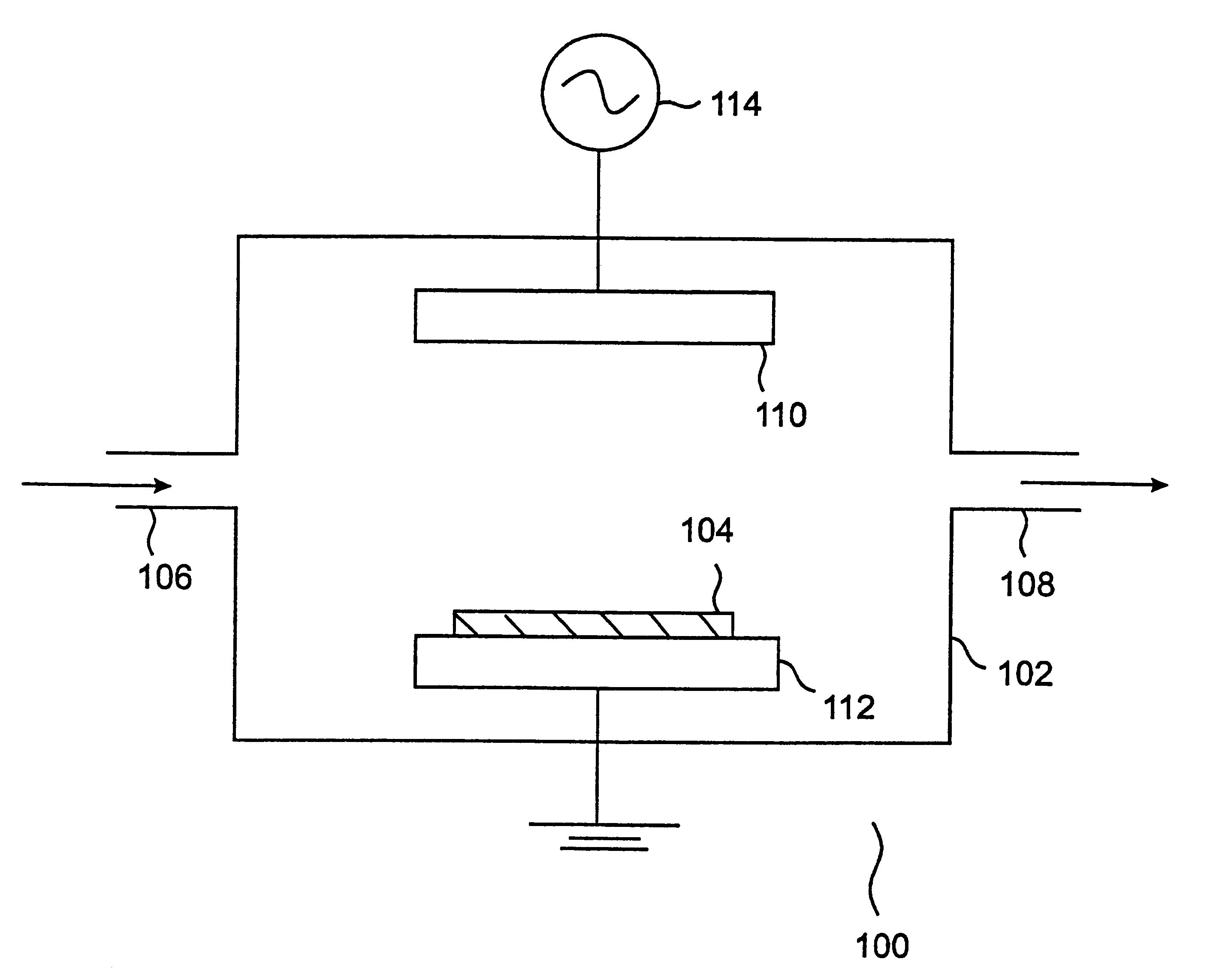

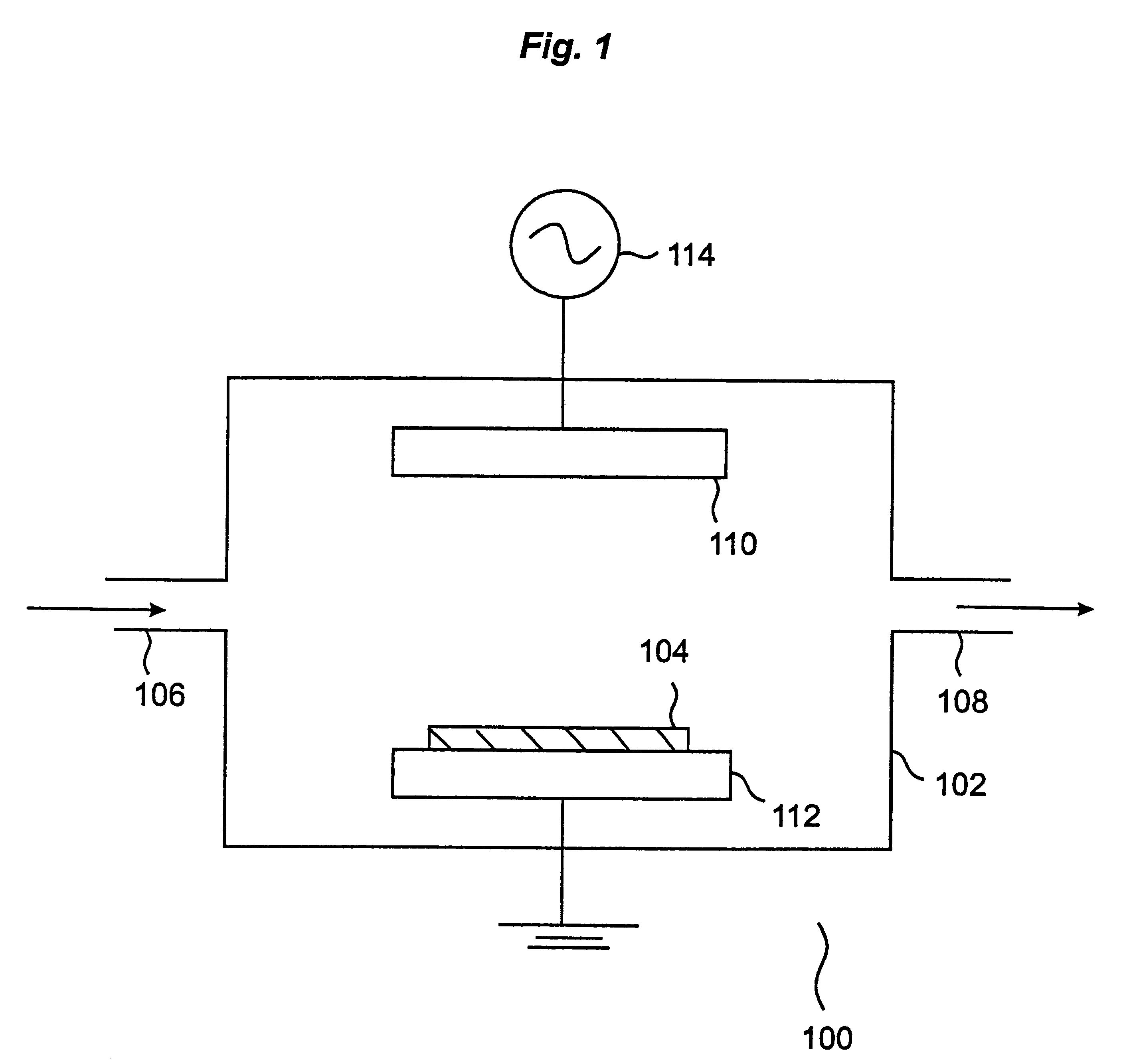

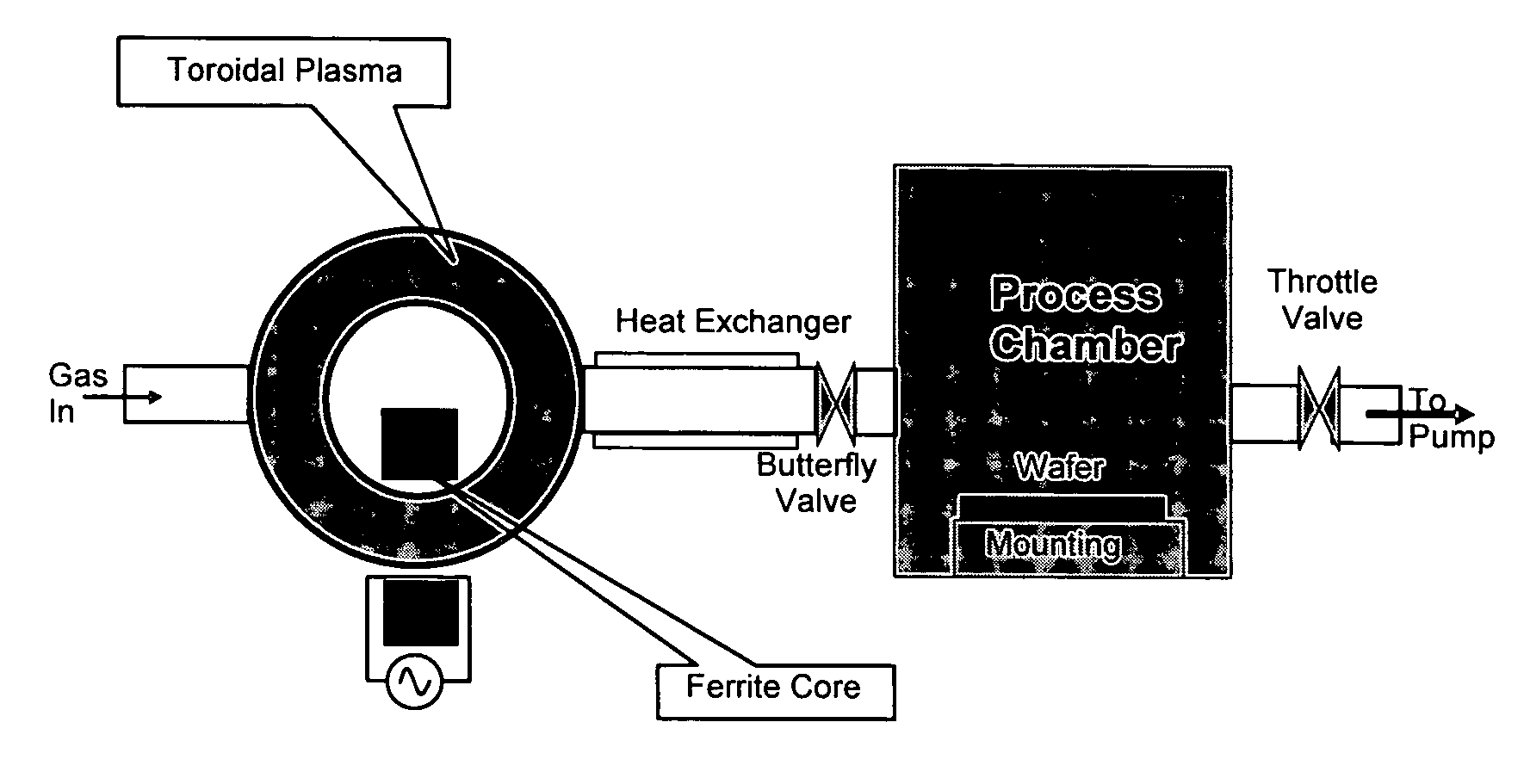

Improved methods and apparatuses for removing residue from the interior surfaces of the deposition reactor are provided. The methods involve increasing availability of cleaning reagent radicals inside the deposition chamber by generating cleaning reagent radicals in a remote plasma generator and then further delivering in-situ plasma energy while the cleaning reagent mixture is introduced into the deposition chamber. Certain embodiments involve a multi-stage process including a stage in which the cleaning reagent mixture is introduced at a high pressure (e.g., about 0.6 Torr or more) and a stage the cleaning reagent mixture is introduced at a low pressure (e.g., about 0.6 Torr or less).

Owner:NOVELLUS SYSTEMS

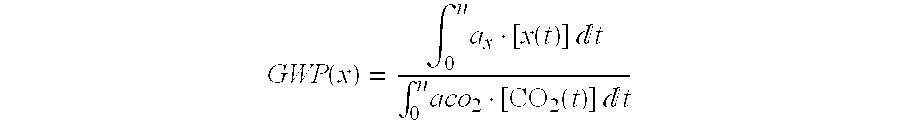

Plasma cleaning and etching methods using non-global-warming compounds

InactiveUS6242359B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrifluoroacetic anhydrideChemical vapor deposition

Provided is a novel method of cleaning a chemical vapor deposition processing chamber having deposits on an inner surface thereof is provided. The process involves forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound, and contacting active species generated in the plasma with the inner surface of the chamber, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. Also provided is a method of etching a layer on a silicon wafer. The method involves the steps of: (a) introducing a silicon wafer into a processing chamber, the silicon wafer comprising a layer to be etched; and (b) forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound. Active species generated in the plasma are contacted with the silicon wafer, thereby etching the layer, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. The chemistries in accordance with the invention provide environmentally benign alternatives to the conventionally used global-warming chemistries for chamber cleaning and semiconductor etching processes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Deposition system and method

ActiveUS20060211243A1Reduce pollutionReduce decreaseElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDeposition process

A method for processing a substrate includes disposing the substrate in a deposition chamber configured to perform a deposition process and depositing a film on the substrate using the deposition process. The substrate having the film thereon is then transferred from the deposition chamber into a treatment chamber and a plasma cleaning process is performed on the substrate in the treatment chamber. Further processing of the substrate is performed after the plasma cleaning process.

Owner:TOKYO ELECTRON LTD

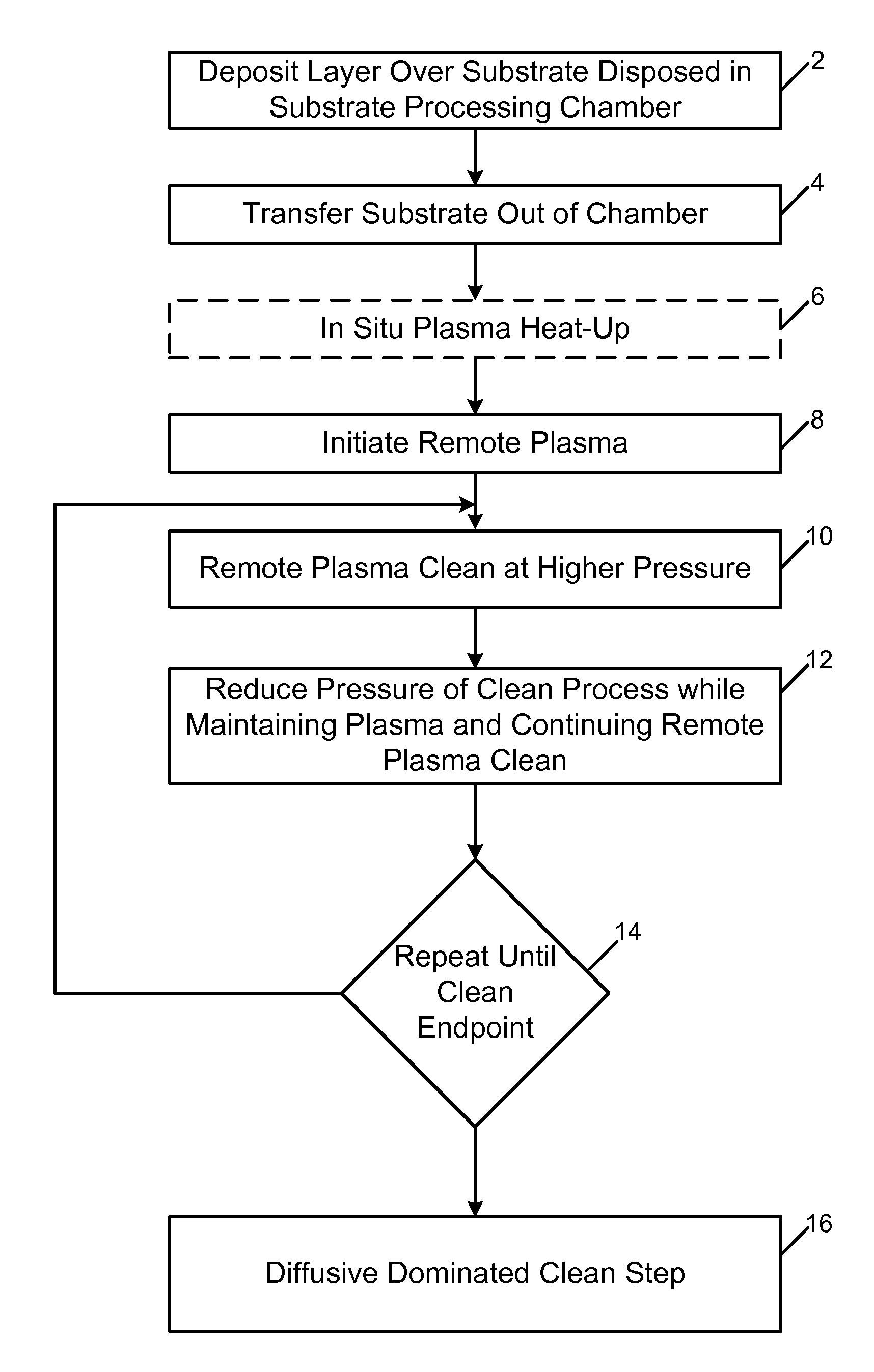

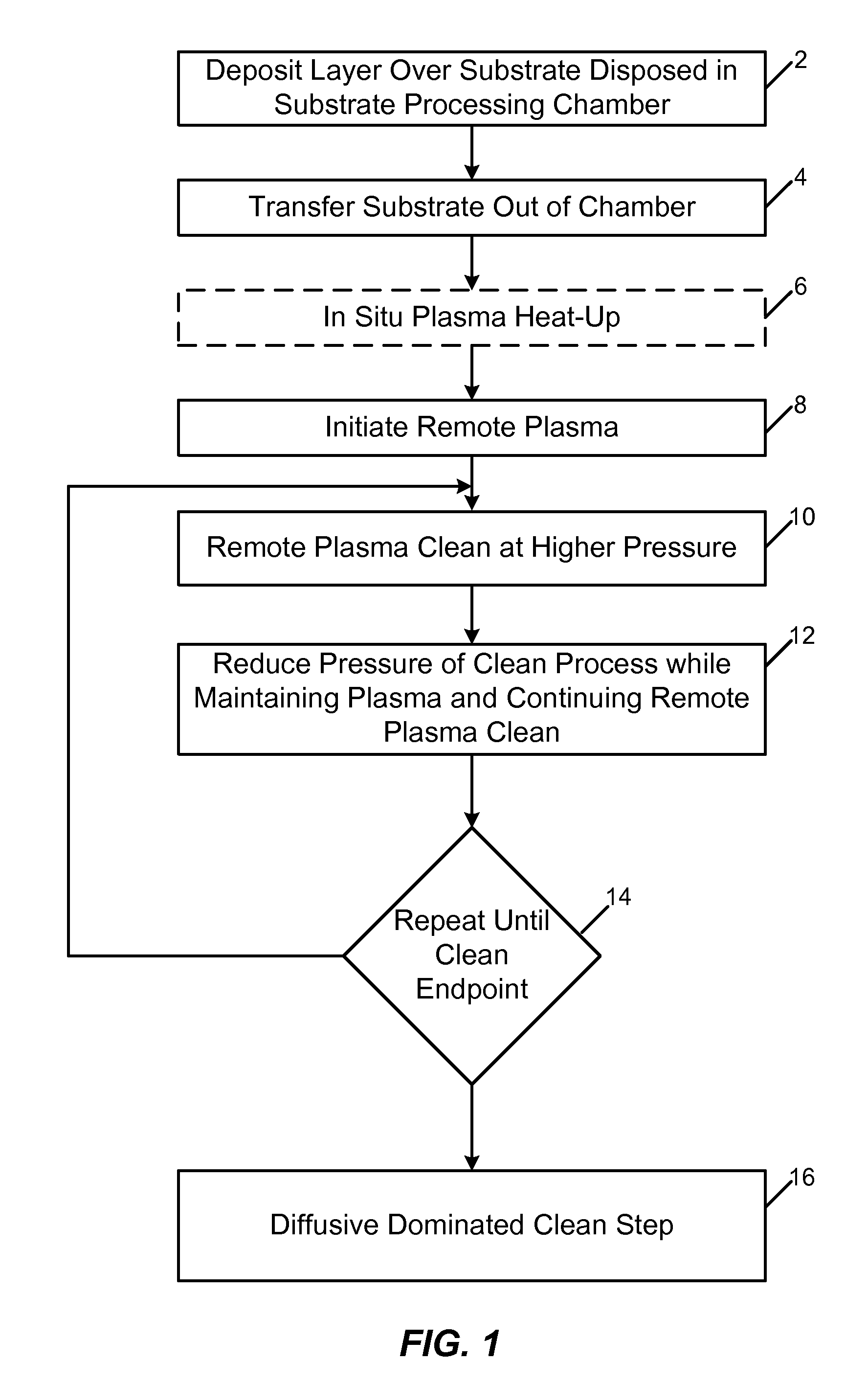

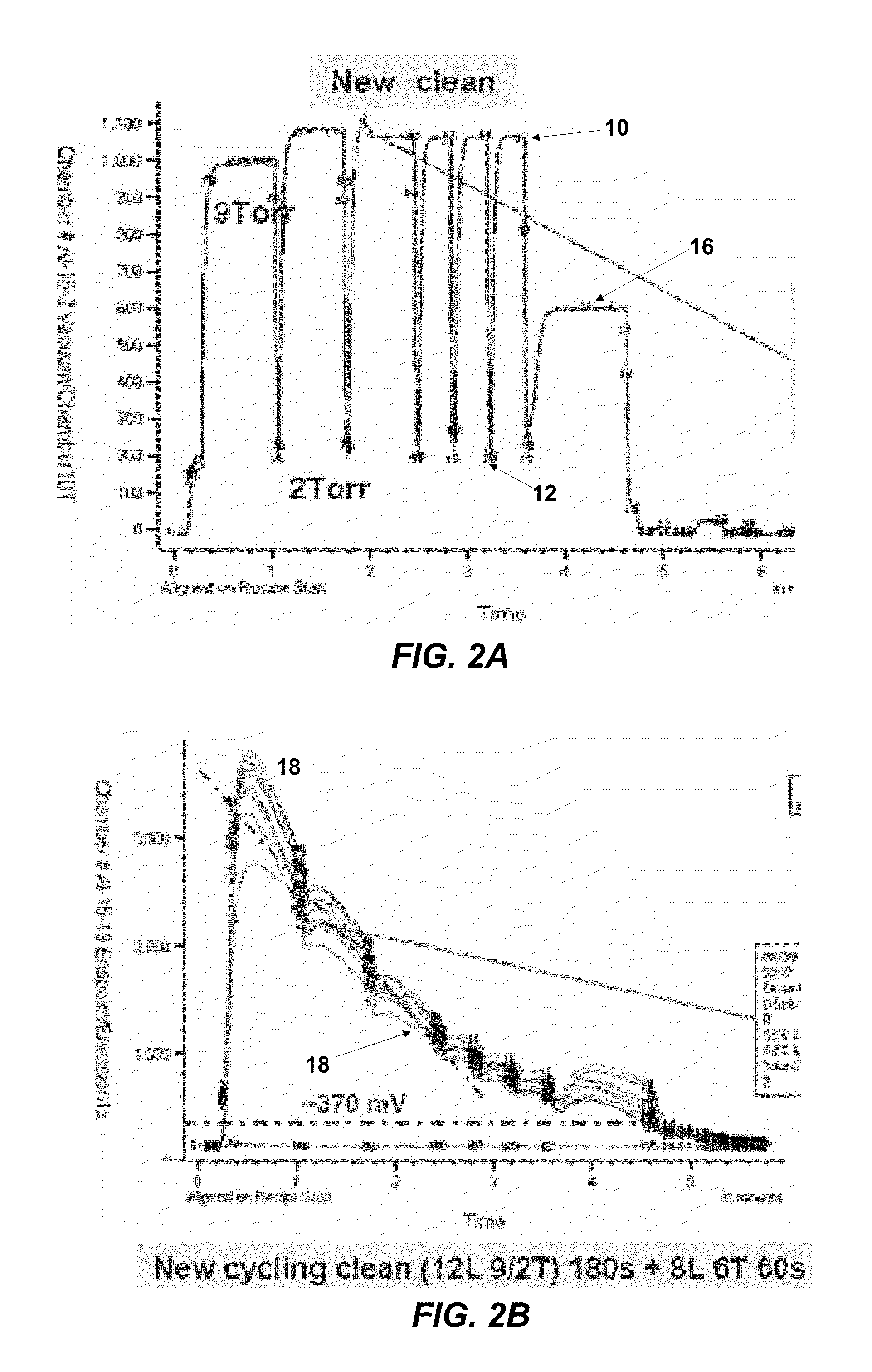

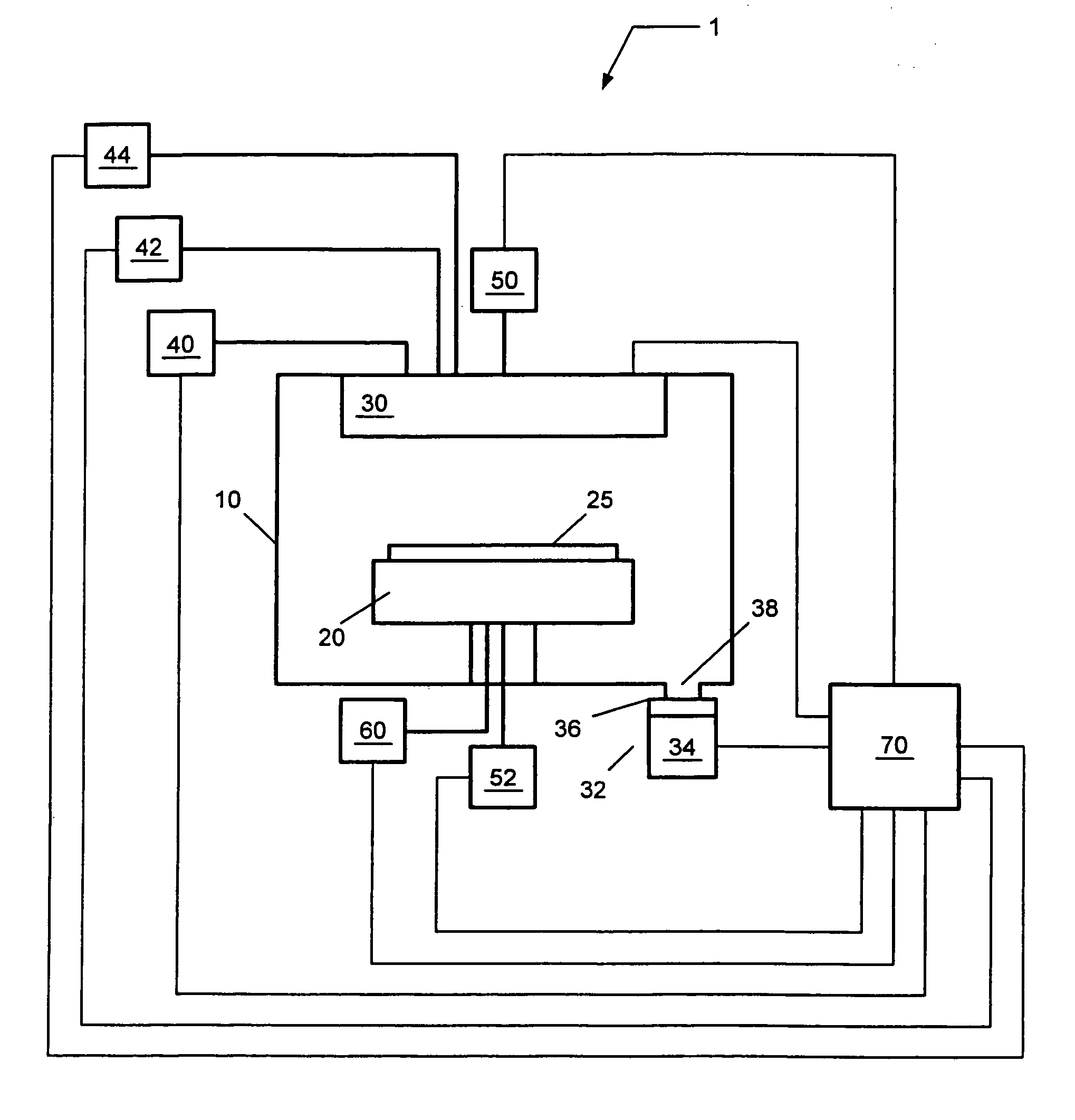

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

Post deposition plasma cleaning system and method

ActiveUS8974868B2Reduce decreaseElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDeposition process

A method for processing a substrate includes disposing the substrate in a deposition chamber configured to perform a deposition process and depositing a film on the substrate using the deposition process. The substrate having the film thereon is then transferred from the deposition chamber into a treatment chamber and a plasma cleaning process is performed on the substrate in the treatment chamber. Further processing of the substrate is performed after the plasma cleaning process.

Owner:TOKYO ELECTRON LTD

Passivation layer formation by plasma clean process to reduce native oxide growth

ActiveUS20080160210A1Format be limitLighting and heating apparatusVacuum evaporation coatingAmmoniaSubstrate surface

Embodiments described herein provide methods for removing native oxide surfaces on substrates while simultaneously passivating the underlying substrate surface. In one embodiment, a method is provided which includes positioning a substrate containing an oxide layer within a processing chamber, adjusting a first temperature of the substrate to about 80° C. or less, generating a cleaning plasma from a gas mixture within the processing chamber, such that the gas mixture contains ammonia and nitrogen trifluoride having an NH3 / NF3 molar ratio of about 10 or greater, and condensing the cleaning plasma onto the substrate. A thin film, containing ammonium hexafluorosilicate, is formed in part, from the native oxide during a plasma clean process. The method further includes heating the substrate to a second temperature of about 100° C. or greater within the processing chamber while removing the thin film from the substrate and forming a passivation surface thereon.

Owner:APPLIED MATERIALS INC

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

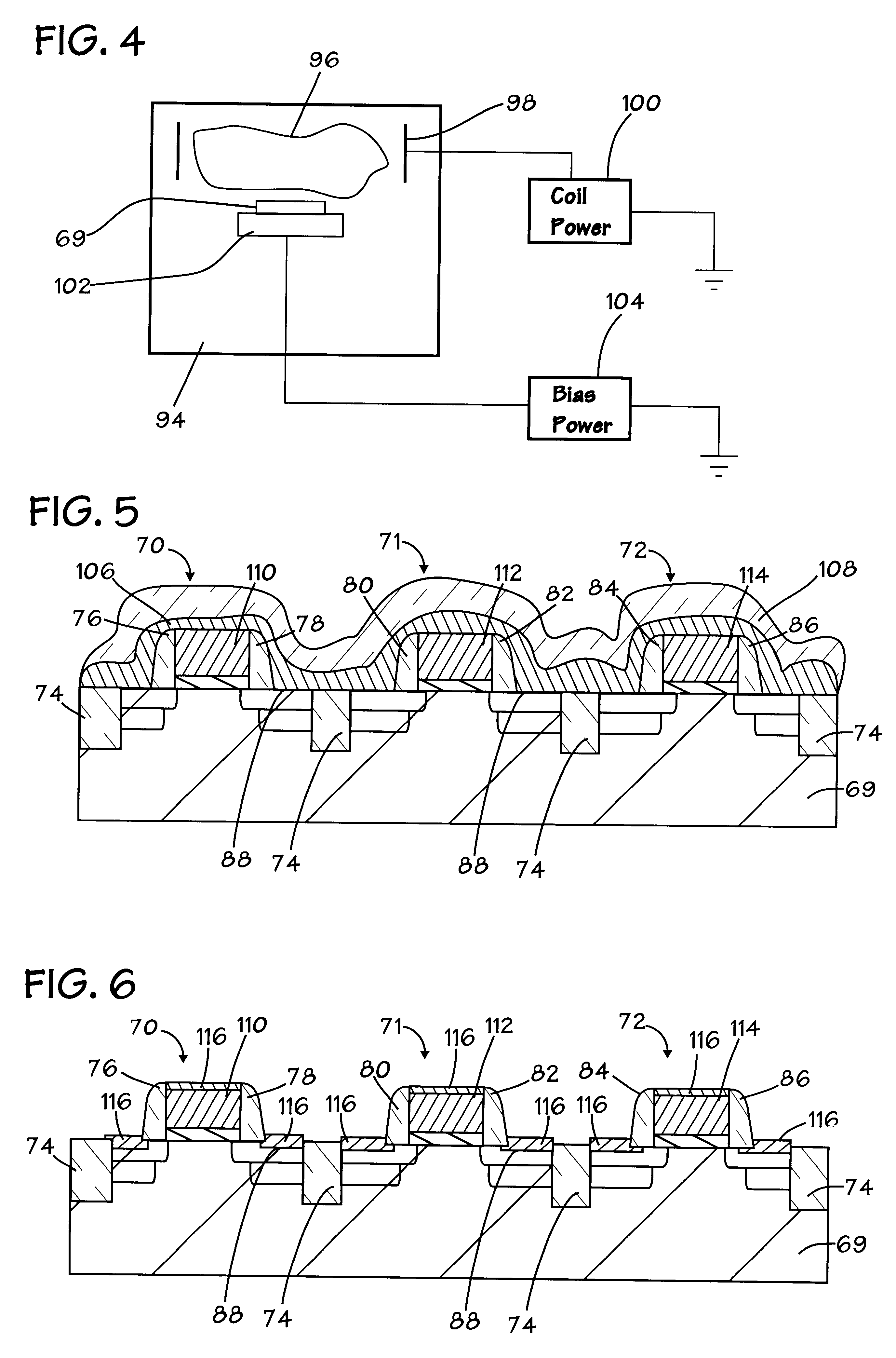

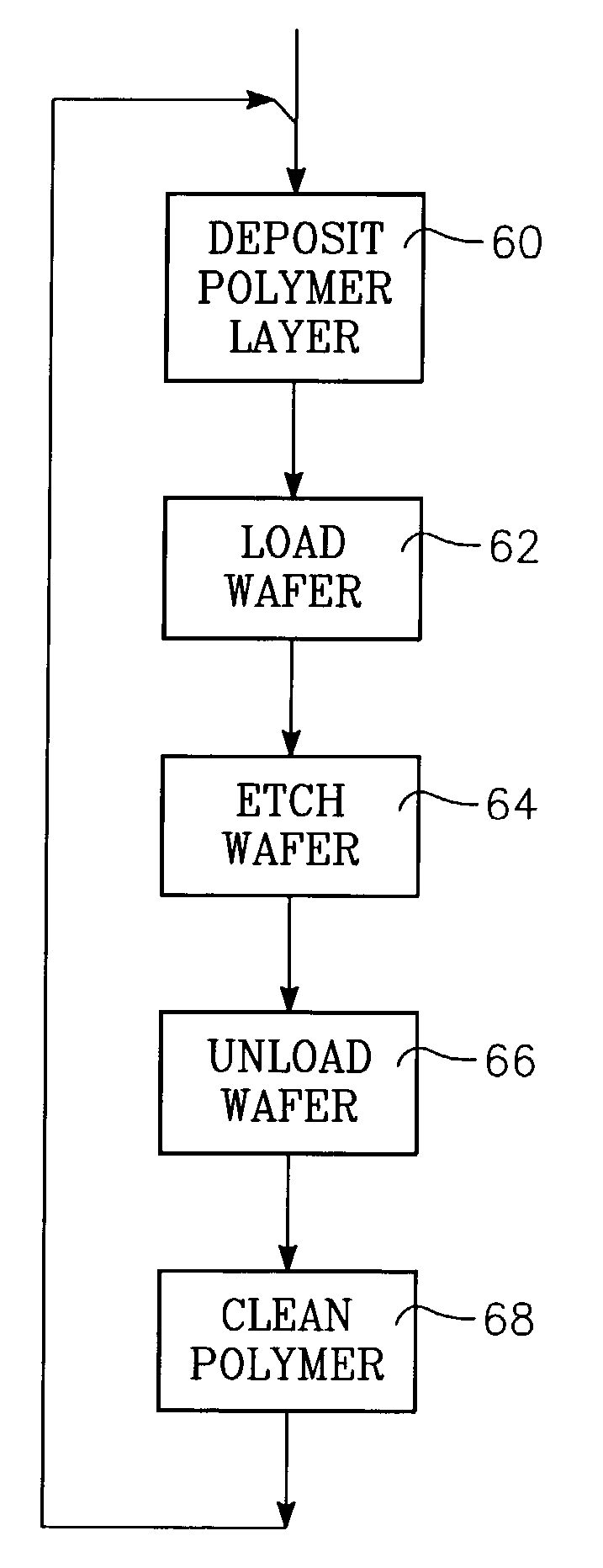

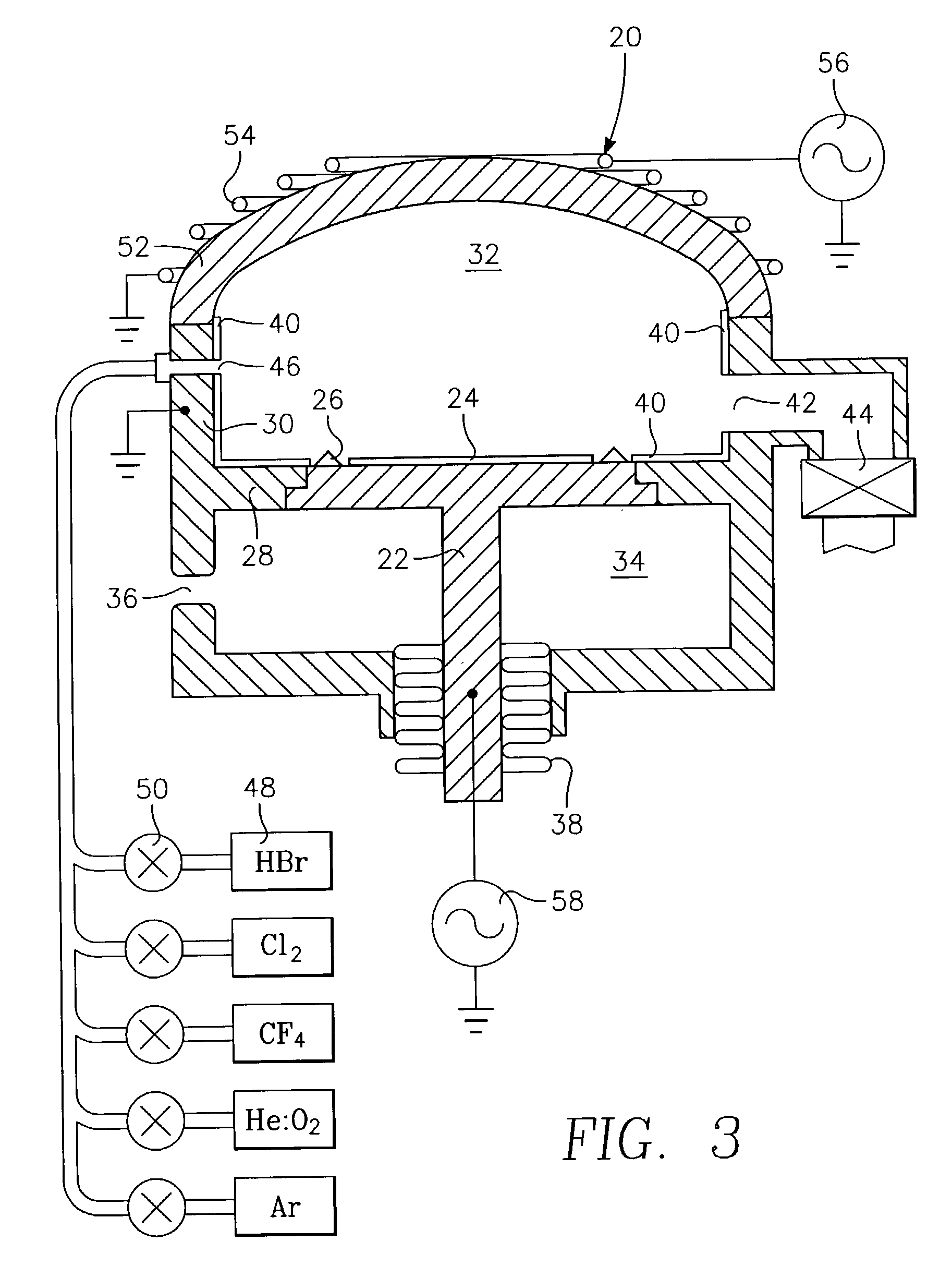

Method and apparatus for cleaning a substrate surface

ActiveUS8008166B2Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention generally provides apparatus and method for forming a clean and damage free surface on a semiconductor substrate. One embodiment of the present invention provides a system that contains a cleaning chamber that is adapted to expose a surface of substrate to a plasma cleaning process prior to forming an epitaxial layer thereon. In one embodiment, a method is employed to reduce the contamination of a substrate processed in the cleaning chamber by depositing a gettering material on the inner surfaces of the cleaning chamber prior to performing a cleaning process on a substrate. In one embodiment, oxidation and etching steps are repeatedly performed on a substrate in the cleaning chamber to expose or create a clean surface on a substrate that can then have an epitaxial placed thereon. In one embodiment, a low energy plasma is used during the cleaning step.

Owner:APPLIED MATERIALS INC

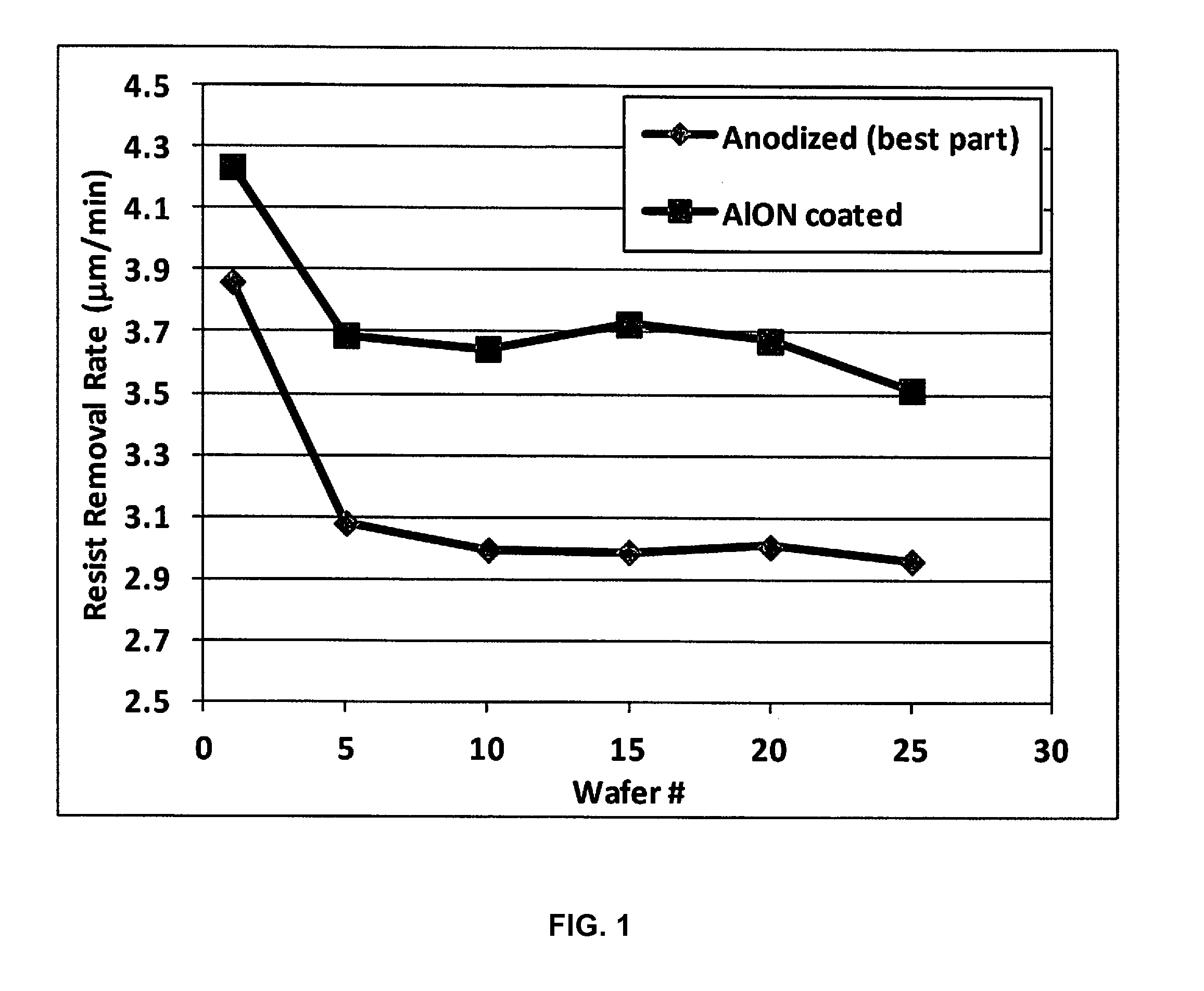

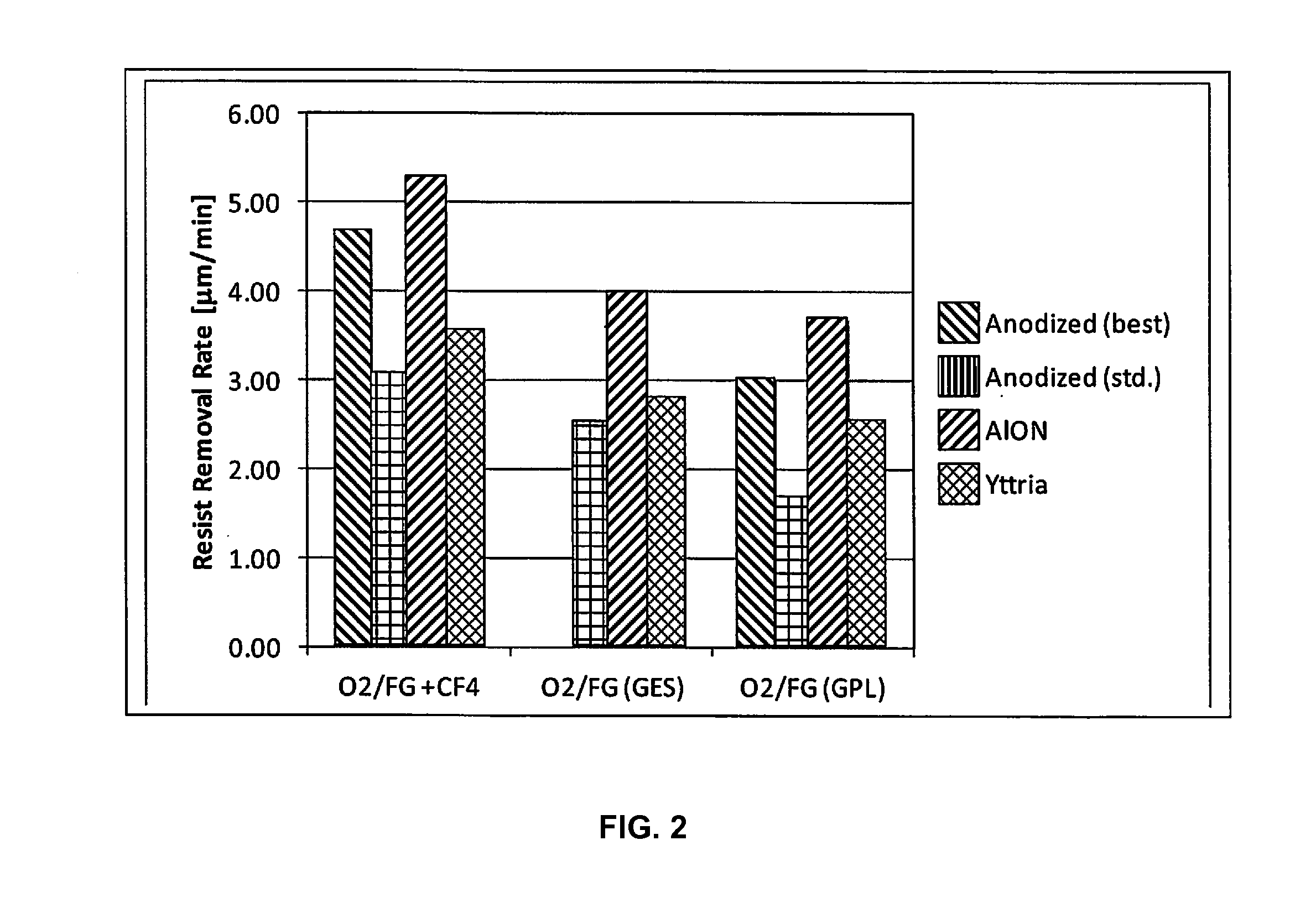

Surface coating for chamber components used in plasma systems

ActiveUS20170032942A1Low plasma surface recombination rateHigh trafficElectric discharge tubesVacuum evaporation coatingBlood plasmaPlasma chamber

Disclosed herein are surface coatings for plasma components that have the benefit of being robust against chemical and plasma physical attack in aggressive (e.g., fluorine-based) plasma environments. The coatings also provide low plasma surface recombination rates for active oxygen, nitrogen, fluorine, and hydrogen species when compared with other known surface treatments. The coatings can be applied to any plasma system component not requiring etching or plasma cleaning including but not limited to materials like quartz, aluminum, or anodized aluminum. Additionally, the efficiency of the system is increased by applying a non-reactive coating to system components thereby increasing the flow of excited plasma species to the plasma chamber of the system.

Owner:ENTEGRIS INC

Post etch copper cleaning using dry plasma

A method for post-etch copper cleaning uses a hydrogen plasma with a trace gas additive constituting about 3-10 percent of the plasma by volume to clean a copper surface exposed by etching. The trace gas may be atomic nitrogen or other species having an atomic mass of 15 or greater. The trace gas adds a sputtering aspect to the plasma cleaning and removes polymeric etch by-products and polymeric and other residuals formed during the deposition of dielectric materials or etch stop layers over the copper surface. An anti-corrosion solvent may be used to passivate the copper surface prior to formation of the dielectric materials or etch stop layers.

Owner:TAIWAN SEMICON MFG CO LTD

Method for removing surface deposits and passivating interior surfaces of the interior of a chemical vapor deposition reactor

InactiveUS20090047447A1Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGas phaseSulfur

The present invention relates to plasma cleaning methods for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The present invention also provides gas mixtures and activated gas mixtures which provide superior performance in removing deposits from a surface. The methods involve activating a gas mixture comprising a carbon or sulfur source, NF3, and optionally, an oxygen source to form an activated gas, and contacting the activated gas mixture with surface deposits to remove the surface deposits wherein the activated gas mixture acts to passivate the interior surfaces of the apparatus to reduce the rate of surface recombination of gas phase species.

Owner:MASSACHUSETTS INST OF TECH

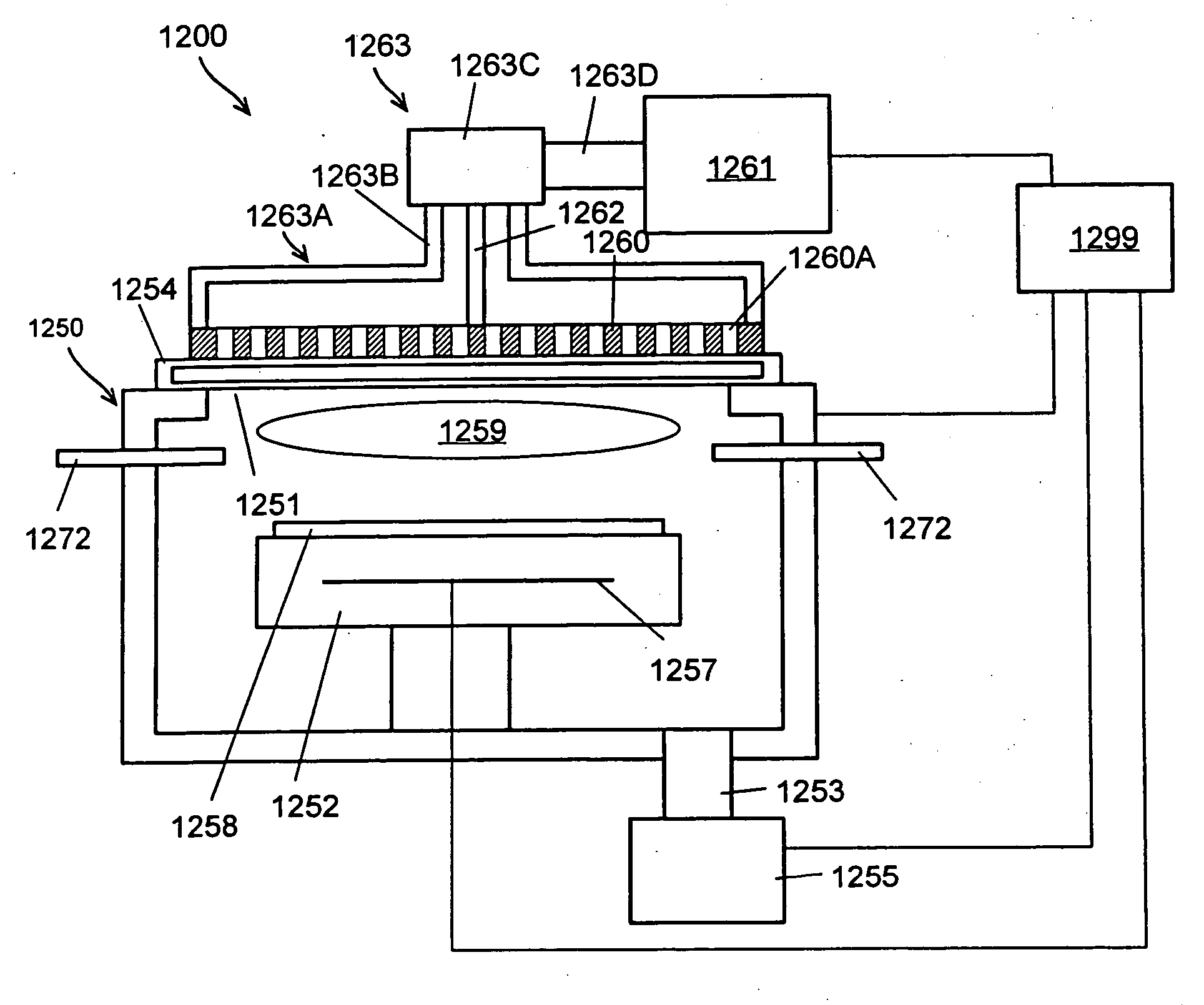

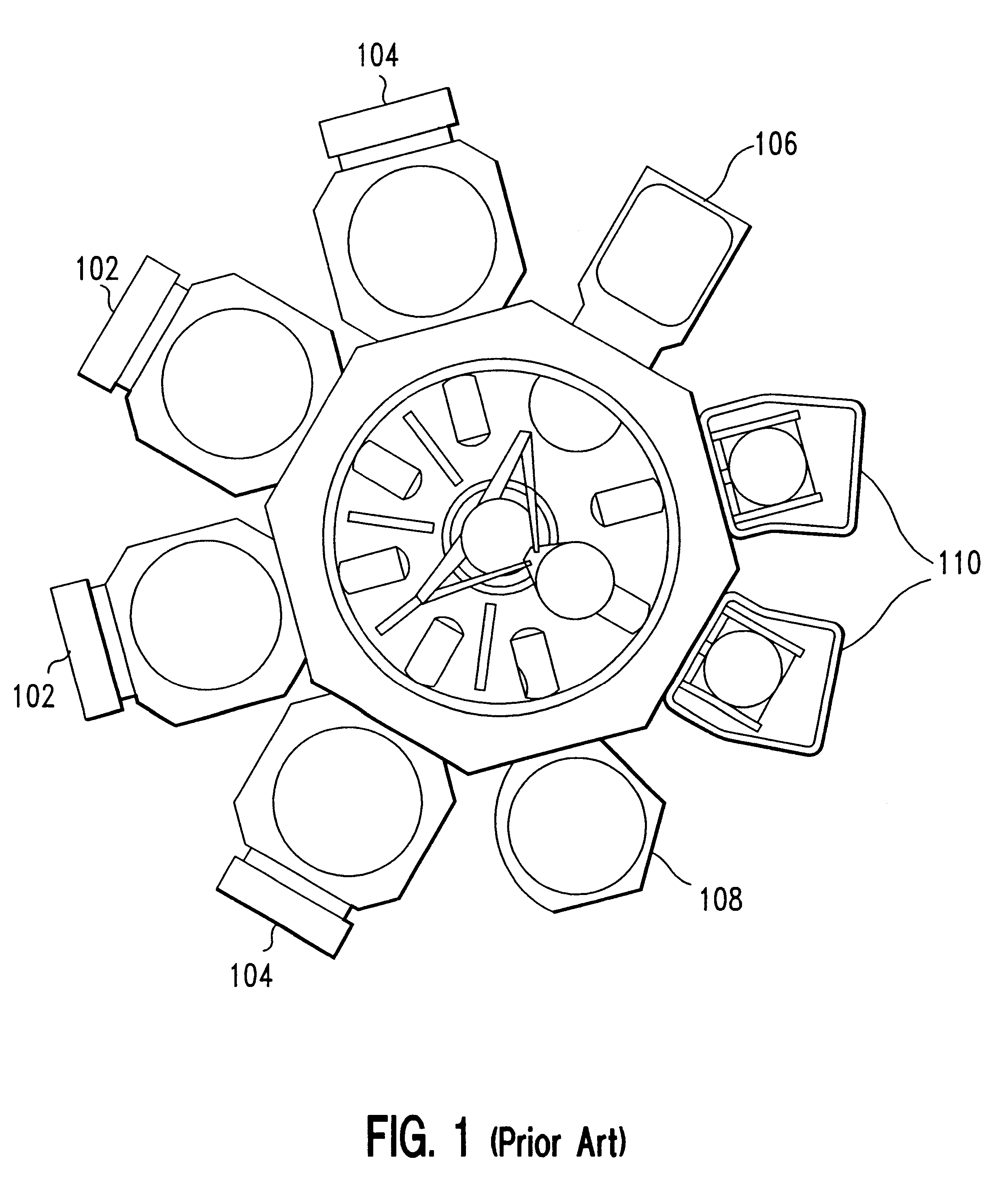

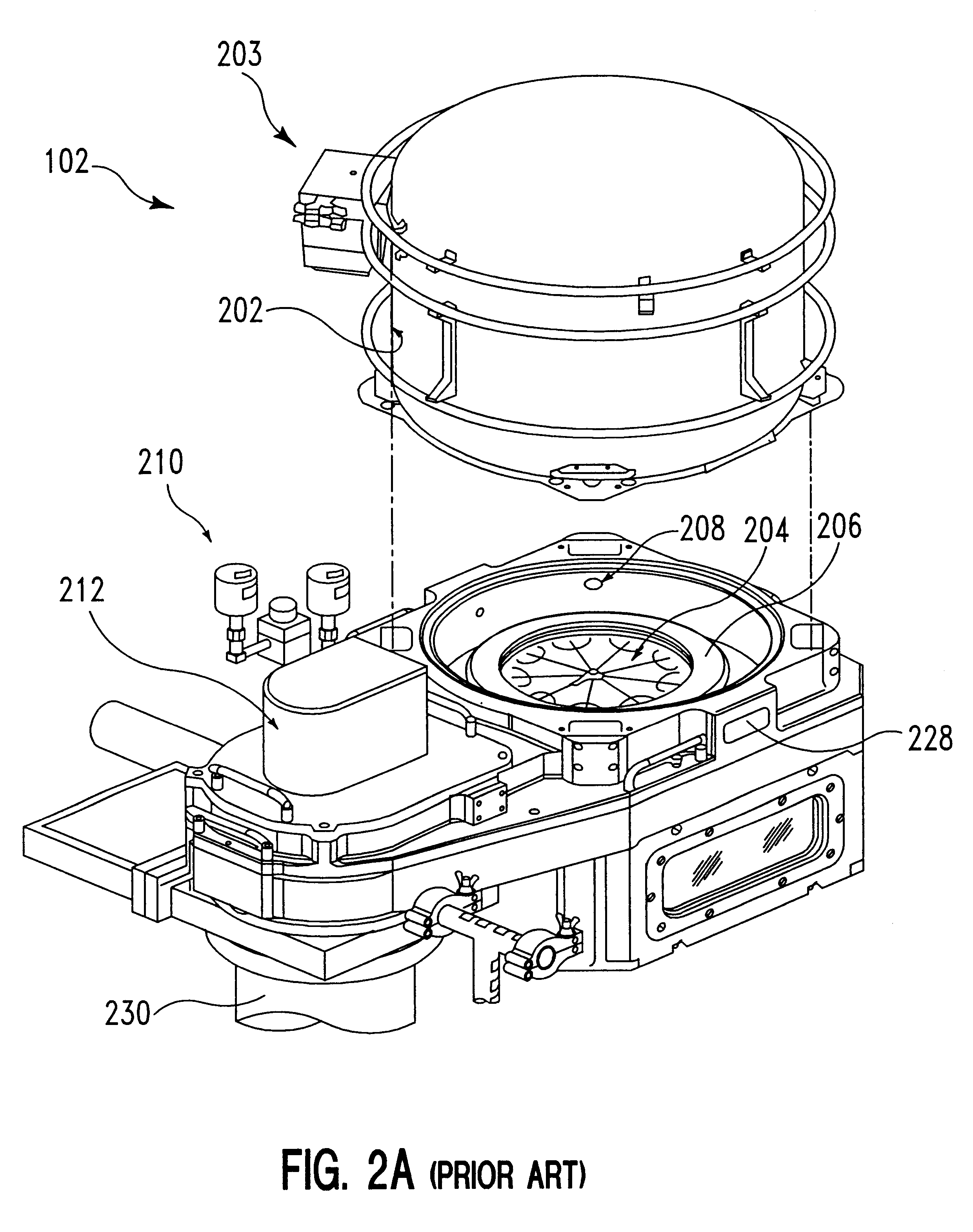

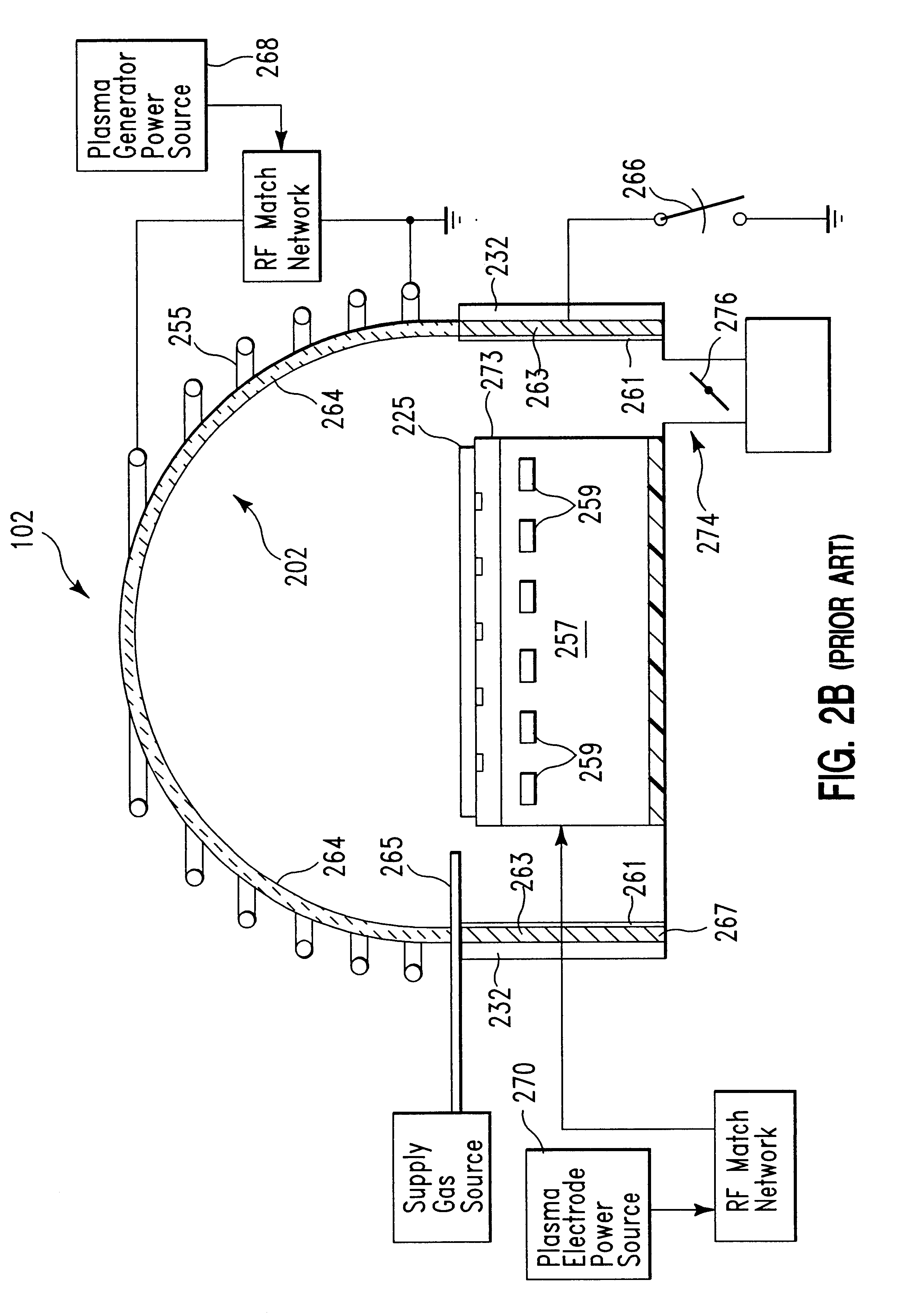

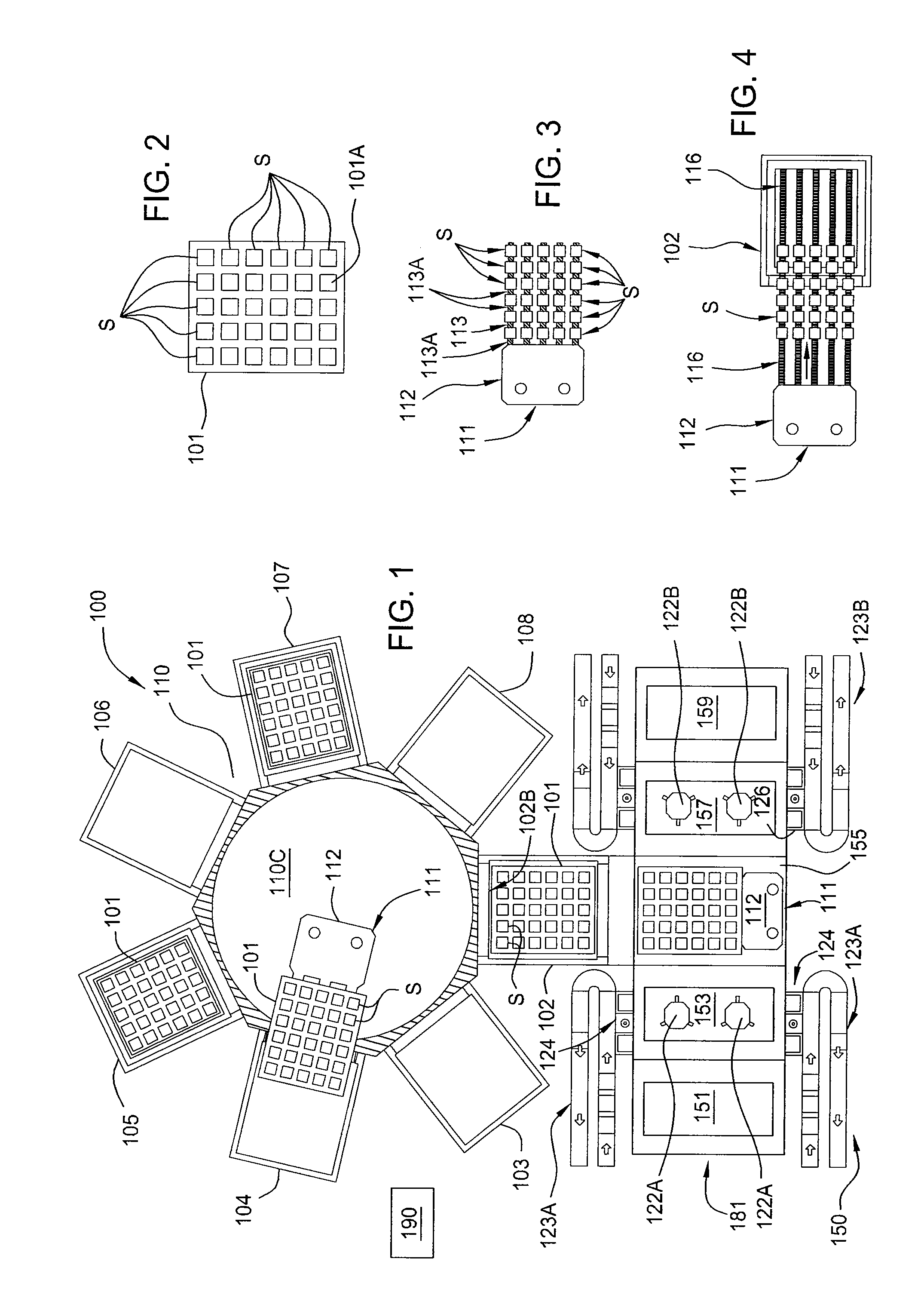

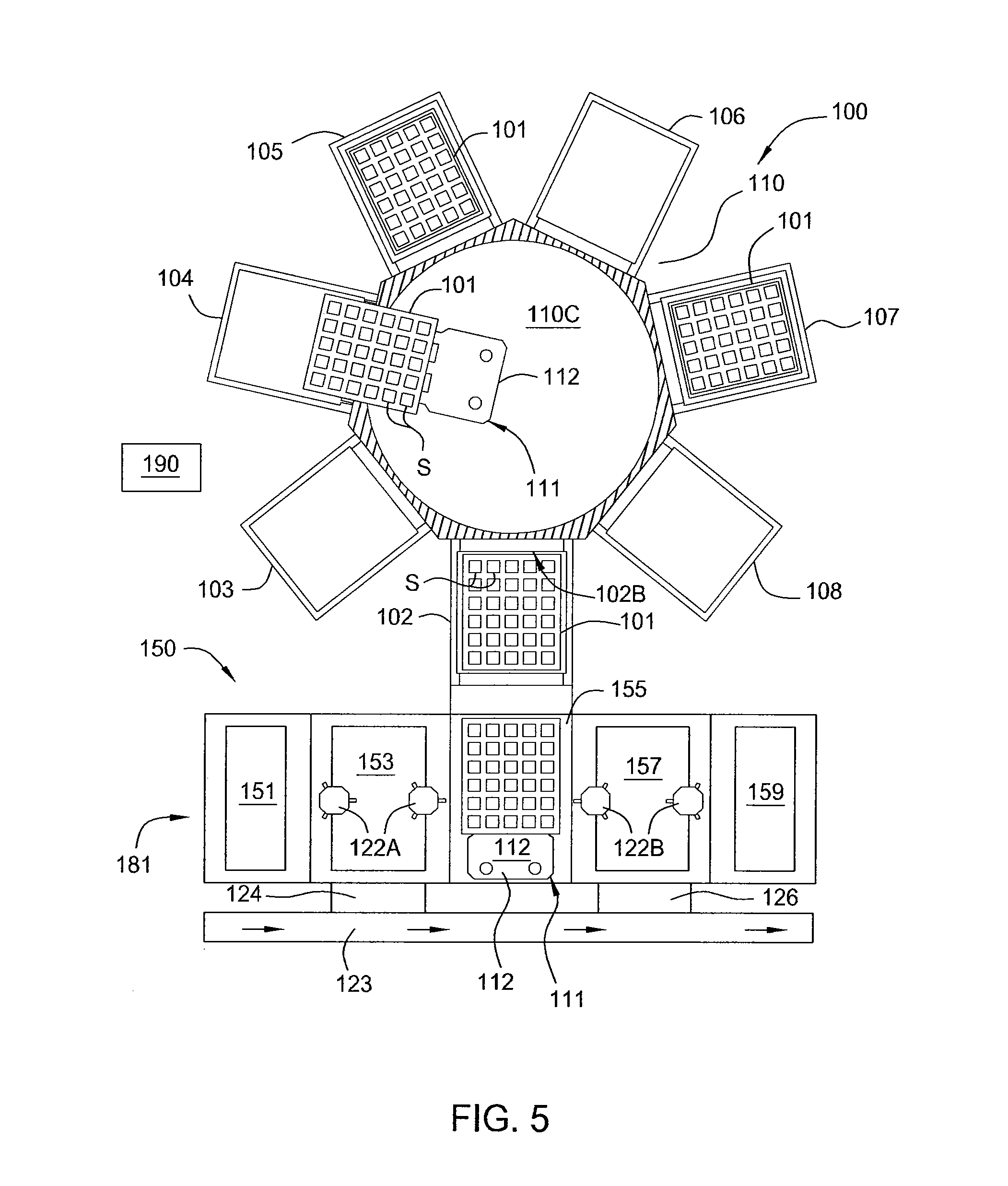

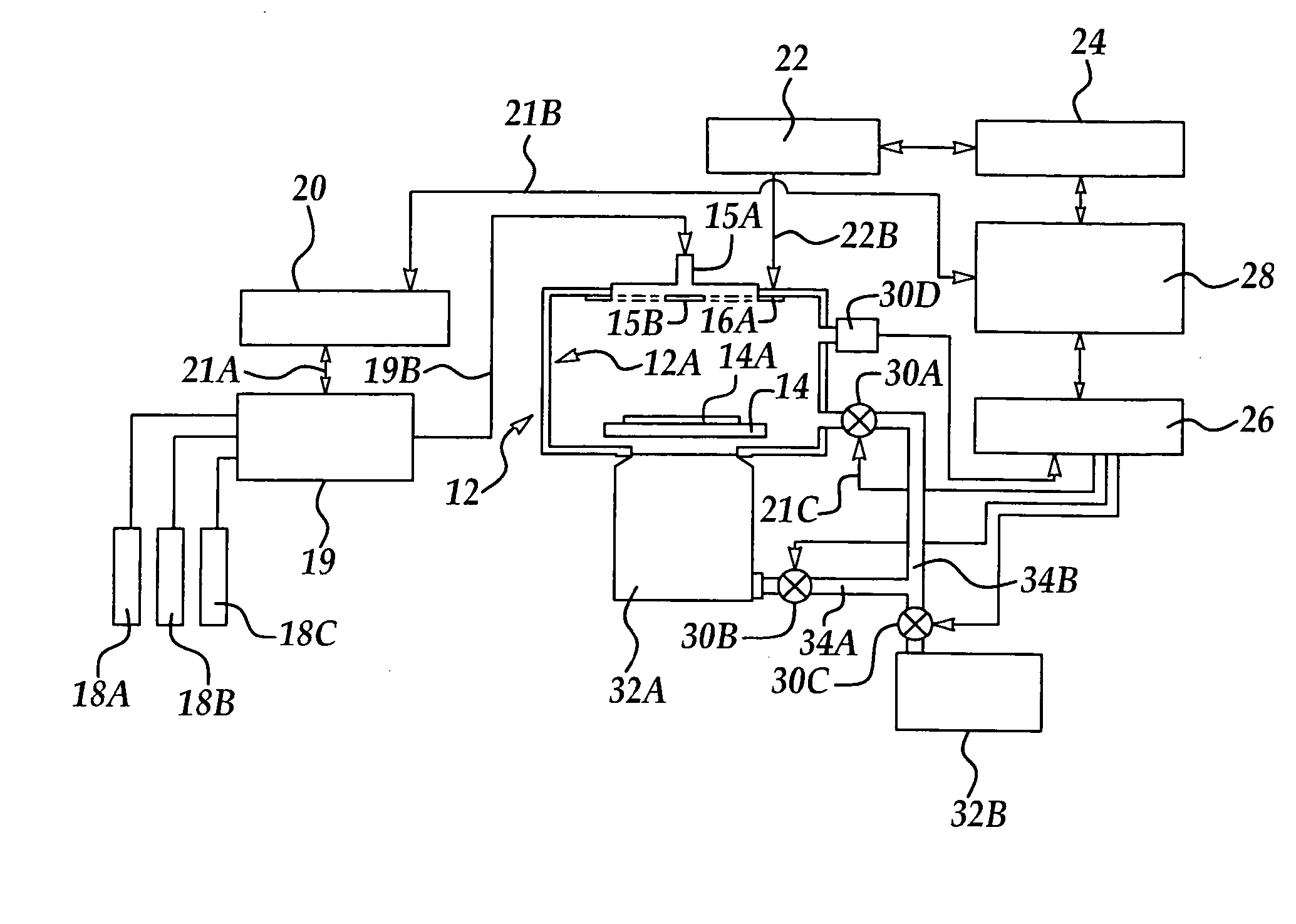

Advanced platform for processing crystalline silicon solar cells

InactiveUS20100087028A1Final product manufactureSemiconductor/solid-state device manufacturingGas phaseEngineering

The present invention generally provides a batch substrate processing system, or cluster tool, for in-situ processing of a film stack used to form regions of a solar cell device. In one configuration, the film stack formed on each of the substrates in the batch contains one or more silicon-containing layers and one or more metal layers that are deposited and further processed within the various chambers contained in the substrate processing system. The processing chambers may be, for example, physical vapor deposition (PVD) or sputtering chambers, plasma enhanced chemical vapor deposition (PECVD) chambers, low pressure chemical vapor deposition (LPCVD) chambers, hot wire chemical vapor deposition (HWCVD) chambers, plasma nitridation (DPN) chambers, ion implant / doping chambers, atomic layer deposition (ALD) chambers, plasma etching chambers, annealing chambers, rapid thermal oxidation (RTO) chambers, rapid thermal annealing (RTA) chambers, substrate reorientation chambers, laser annealing chambers, and / or plasma cleaning stations. In one embodiment, a batch of solar cell substrates is simultaneously transferred in a vacuum or inert environment to prevent contamination from affecting the solar cell formation process.

Owner:APPLIED MATERIALS INC

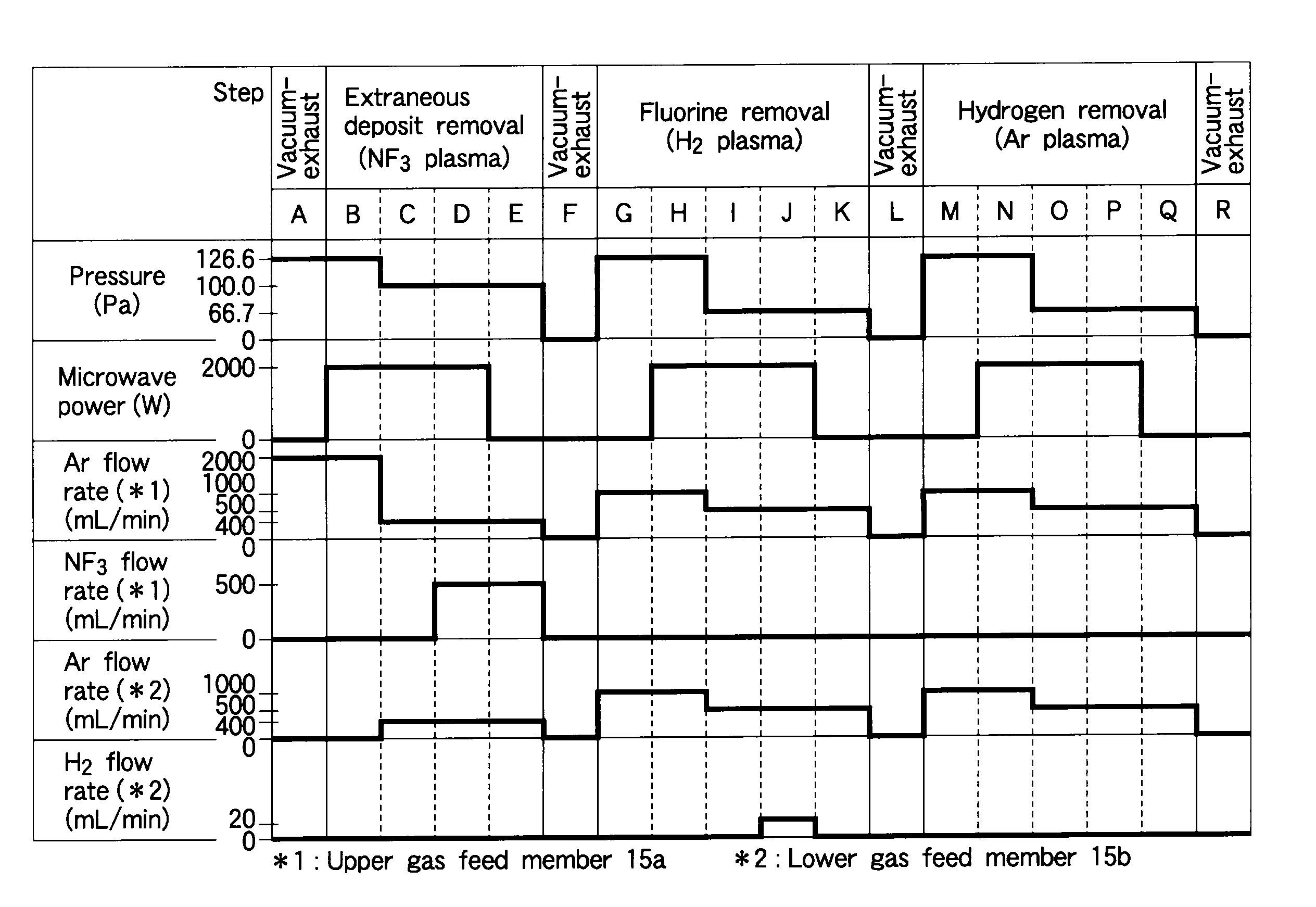

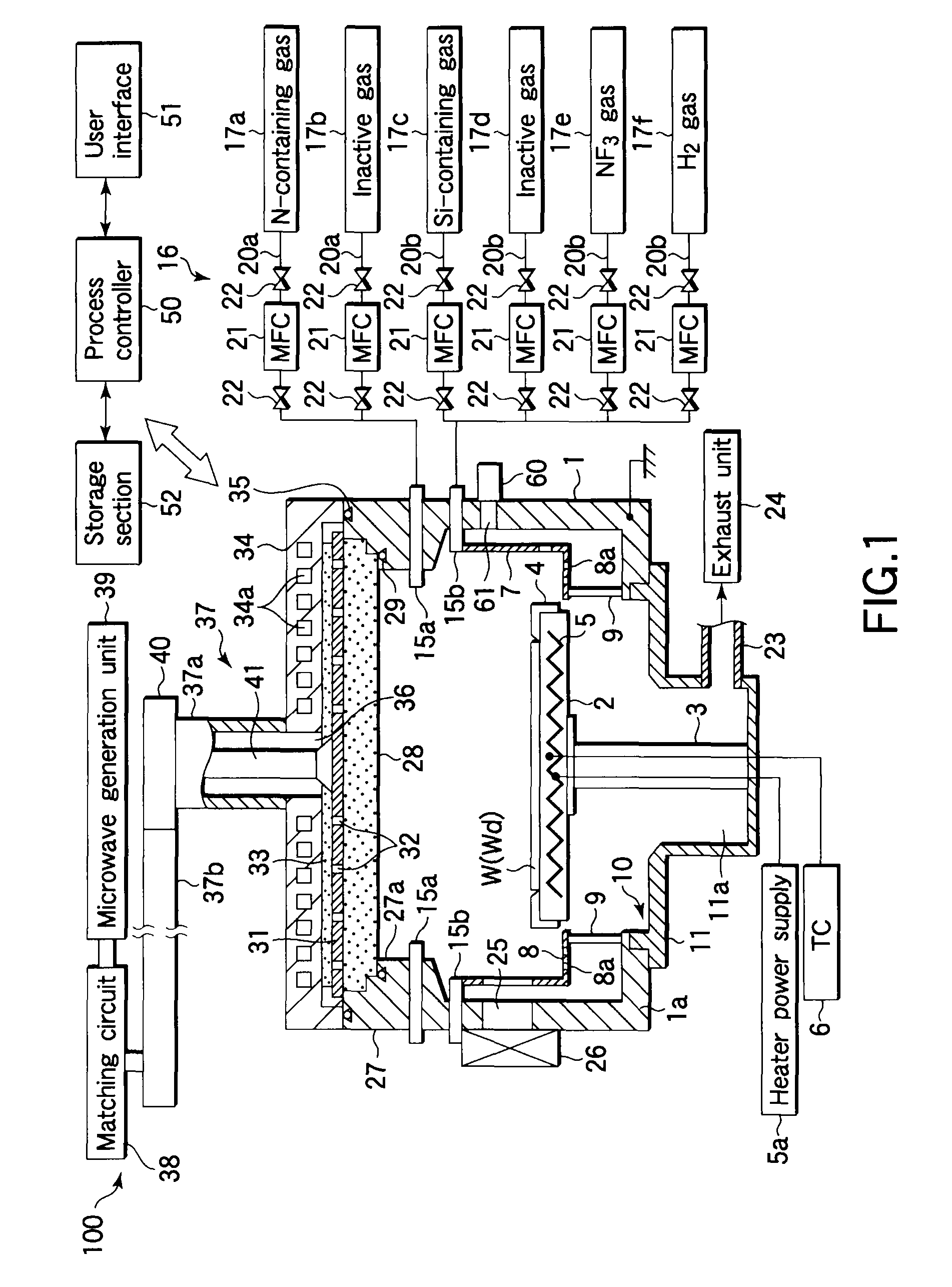

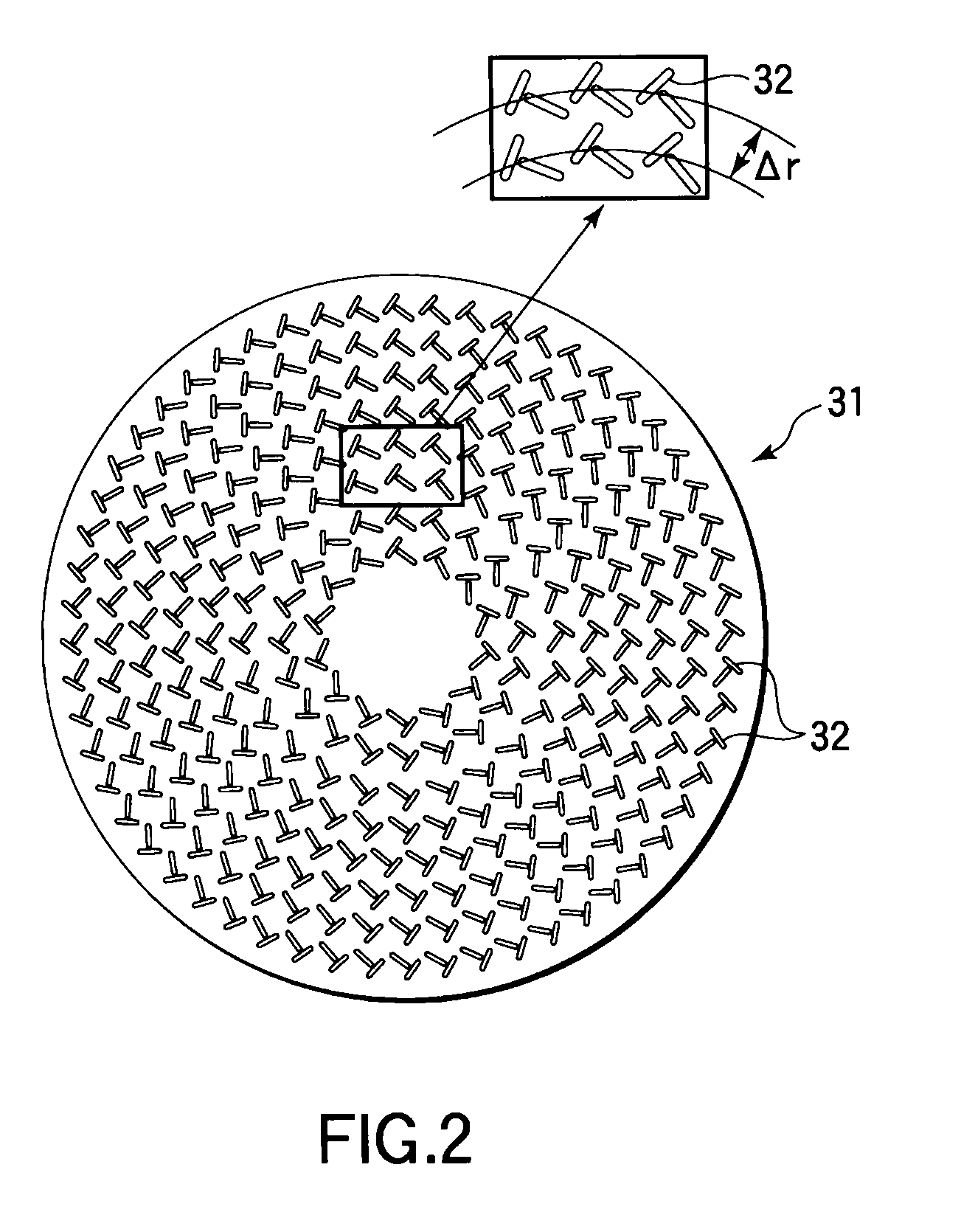

Plasma cleaning method and plasma CVD method

ActiveUS8366953B2Reliably decrease residual fluorineImprove throughputElectric discharge tubesVacuum gauge using ionisation effectsHydrogenNoble gas

A plasma cleaning method is performed in a plasma CVD apparatus for depositing a silicon nitride film on a surface of a target substrate, and includes a stage (S1) of supplying a cleaning gas containing NF3 gas into a process container, thereby removing extraneous deposits formed on portions inside the process container; a stage (S2) of supplying a gas containing hydrogen gas into the process container and generating plasma thereof, thereby removing residual fluorine inside the process container; and a stage (S3) of supplying a gas containing a rare gas into the process container and generating plasma thereof, thereby removing residual hydrogen inside the process container.

Owner:TOKYO ELECTRON LTD

Method and system for modifying the wettability characteristics of a surface of a medical device by the application of gas cluster ion beam technology and medical devices made thereby

InactiveUS20090074834A1Improve wettabilityLow wettabilityElectric discharge tubesPharmaceutical containersEtchingGas cluster ion beam

Irradiation of a surface of a material with a gas cluster ion beam modifies the wettability of the surface. The wettability may be increased or decreased dependent on the characteristics of the gas cluster ion beam. Improvements in wettability of a surface by the invention exceed those obtained by conventional plasma cleaning or etching. The improvements may be applied to surfaces of medical devices, such as vascular stents for example, and may be used to enable better wetting of medical device surfaces with liquid drugs in preparation for adhesion of the drug to the device surfaces. A mask may be used to limit processing to a portion of the surface. Medical devices formed by using the methods of the invention are disclosed.

Owner:EXOGENESIS CORP

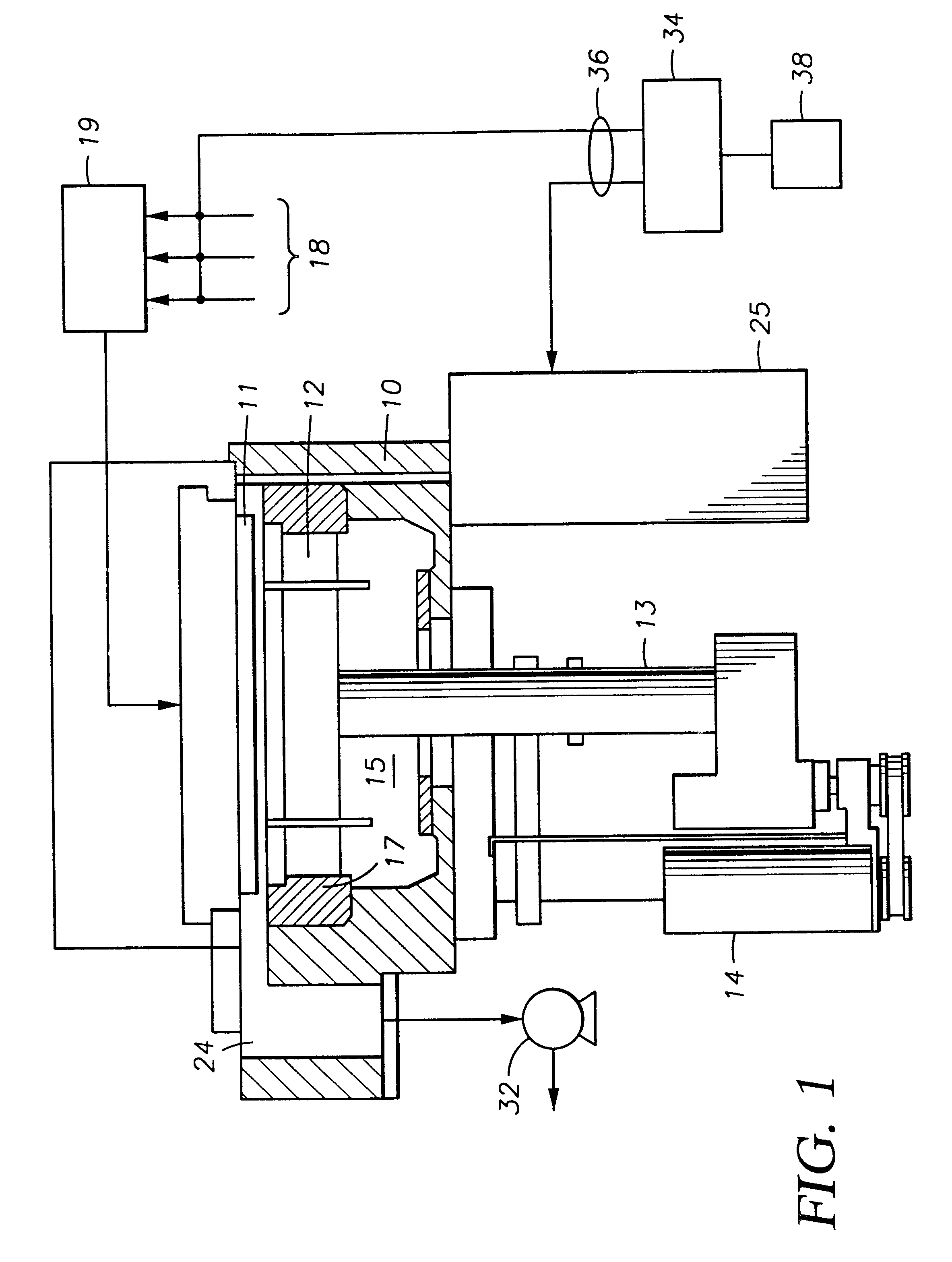

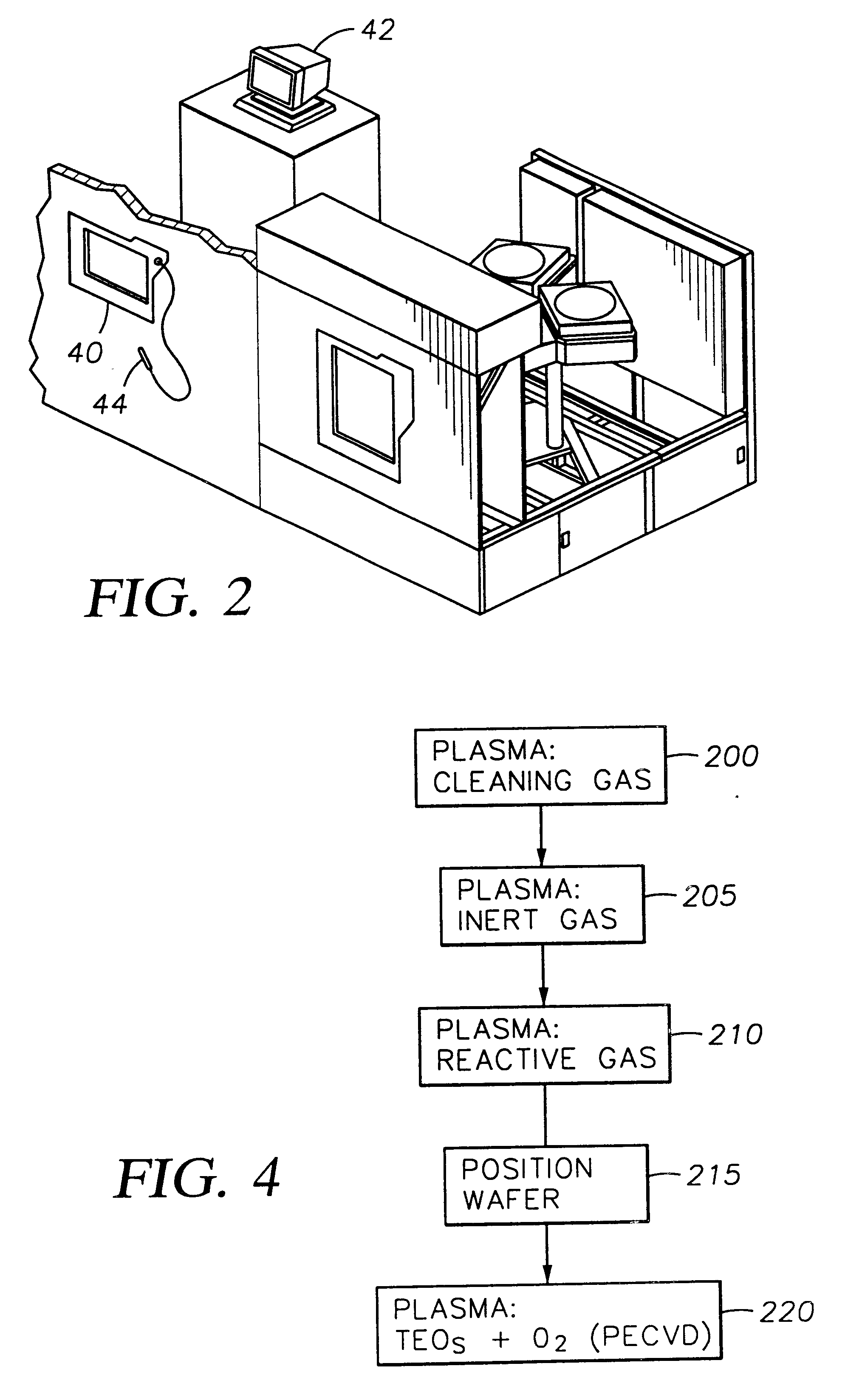

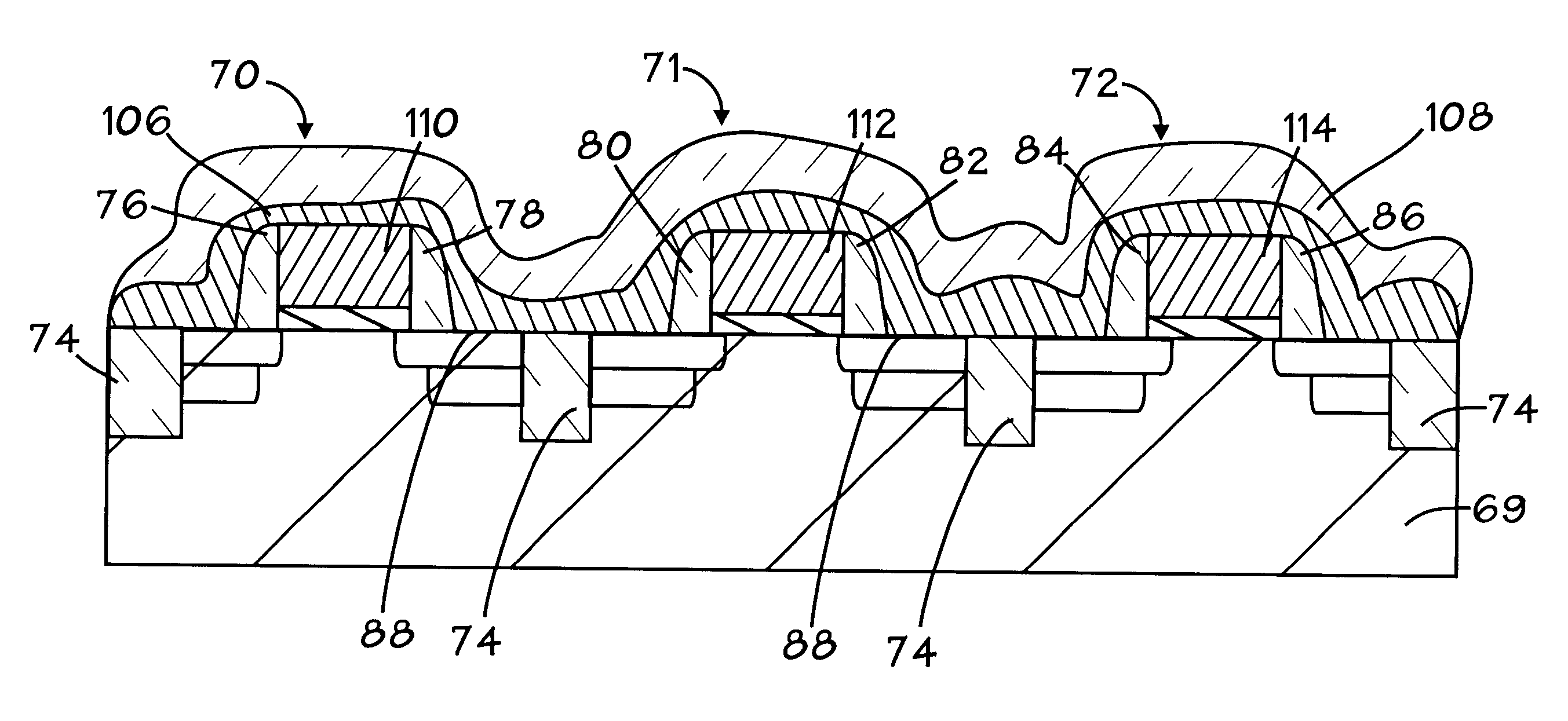

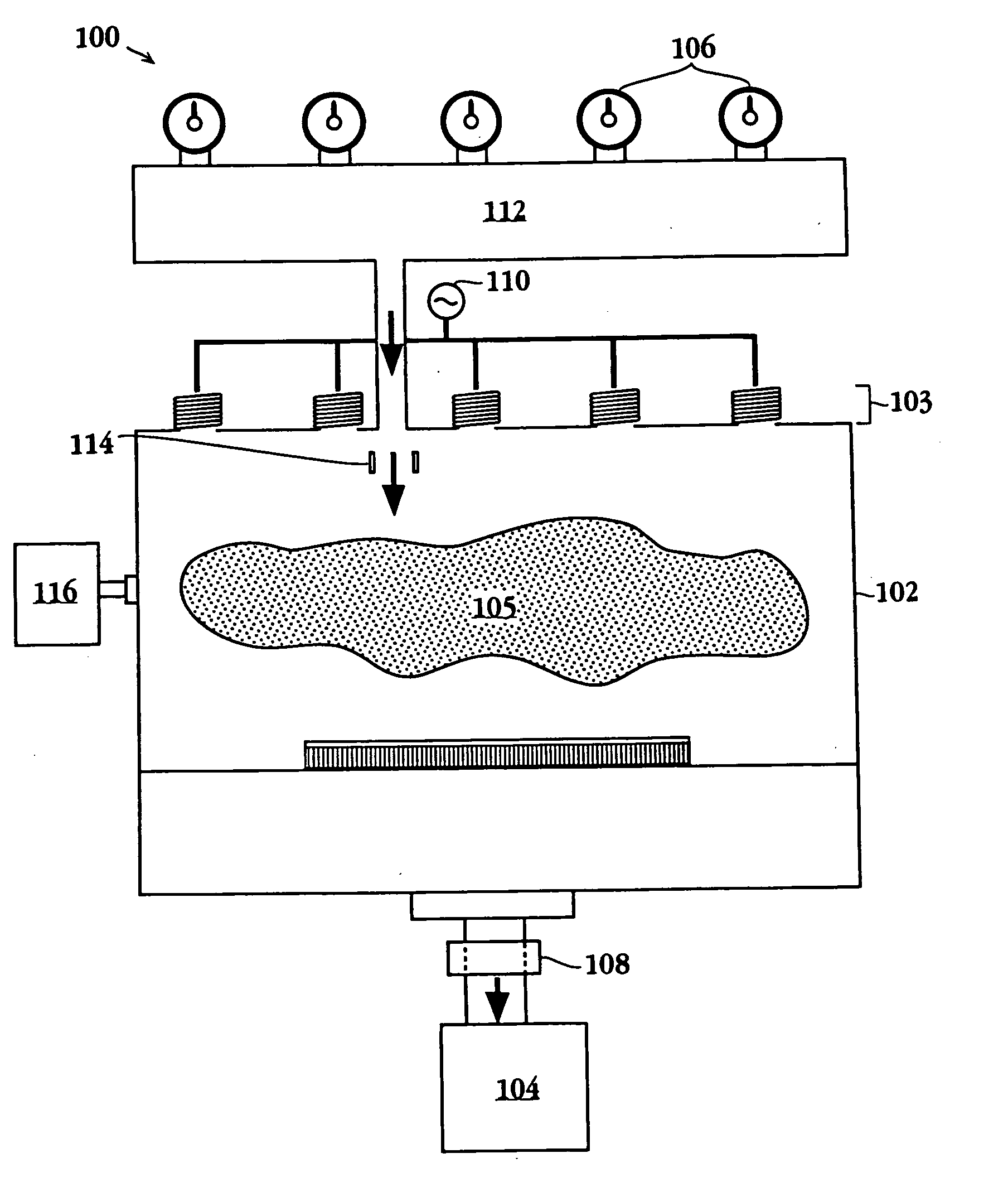

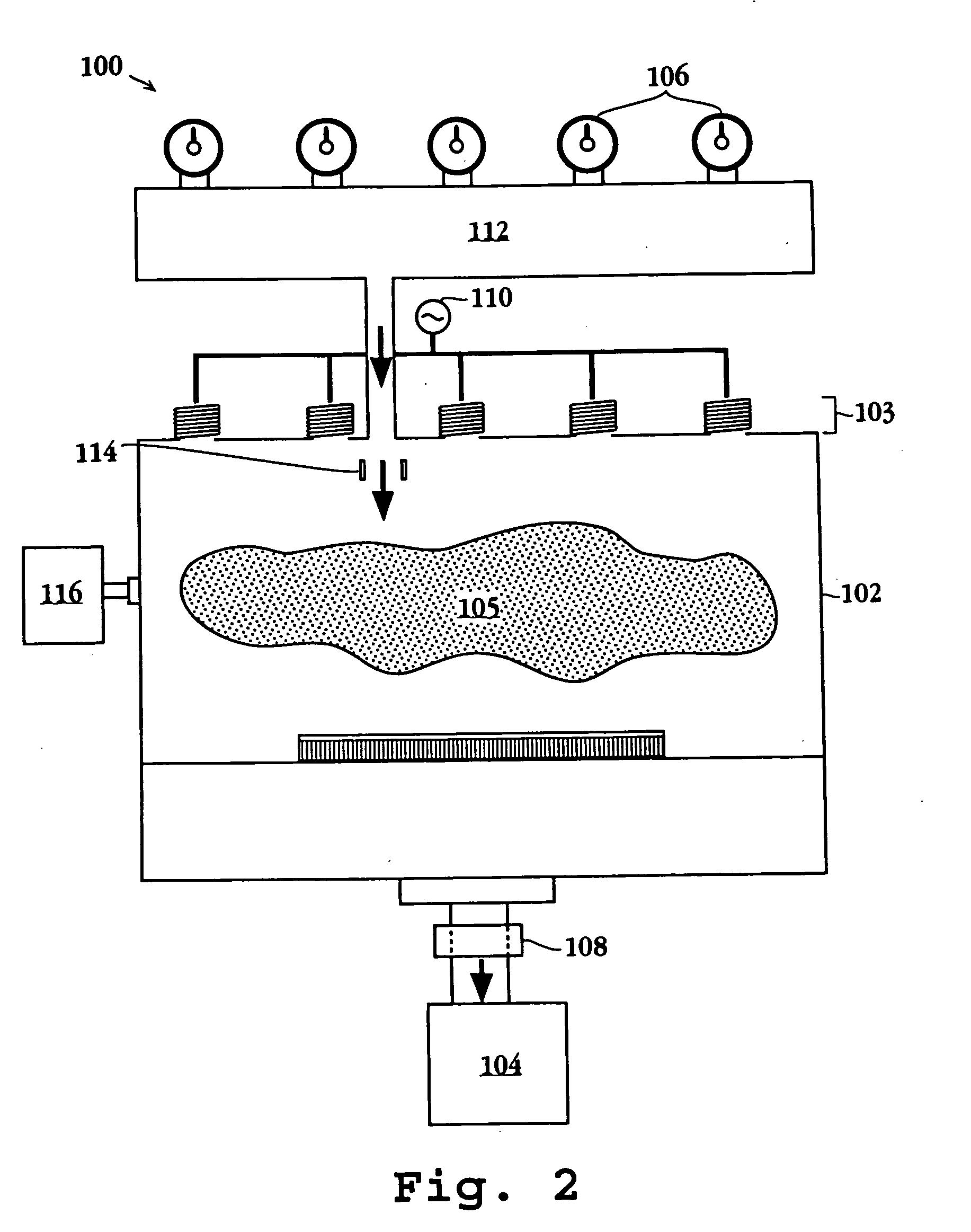

Decontamination of a plasma reactor using a plasma after a chamber clean

A method and apparatus for reducing fluorine and other sorbable contaminants in plasma reactor used in chemical vapor deposition process such as the deposition of silicon oxide layer by the reaction of TEOS and oxygen. According to the method of the present invention, plasma of an inert gas is maintained in plasma reactor following chamber clean to remove sorbable contaminants such as fluorine. The plasma clean is typically followed by seasoning of the reactor to block or retard remaining contaminants. According to one embodiment of the invention, the combination of chamber clean, plasma clean, and season film is conducted before PECVD oxide layer is deposited on wafer positioned in the plasma reactor.

Owner:APPLIED MATERIALS INC

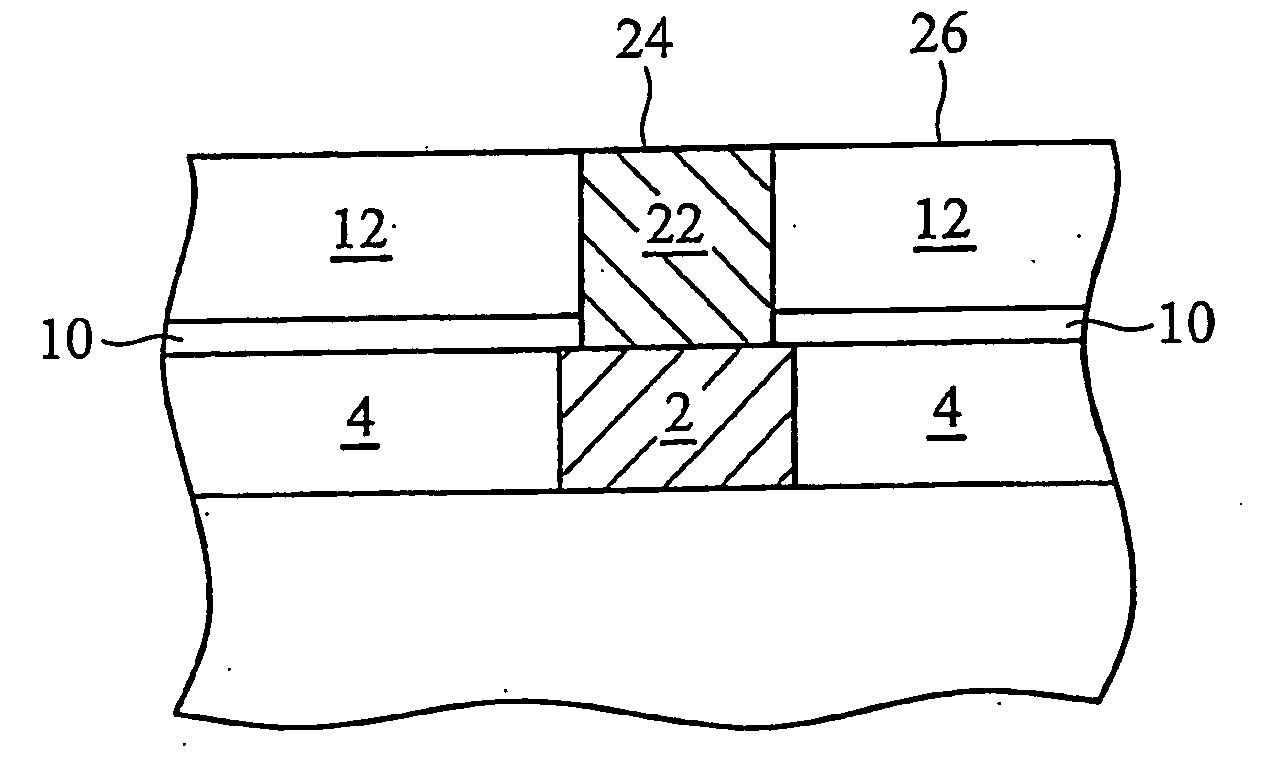

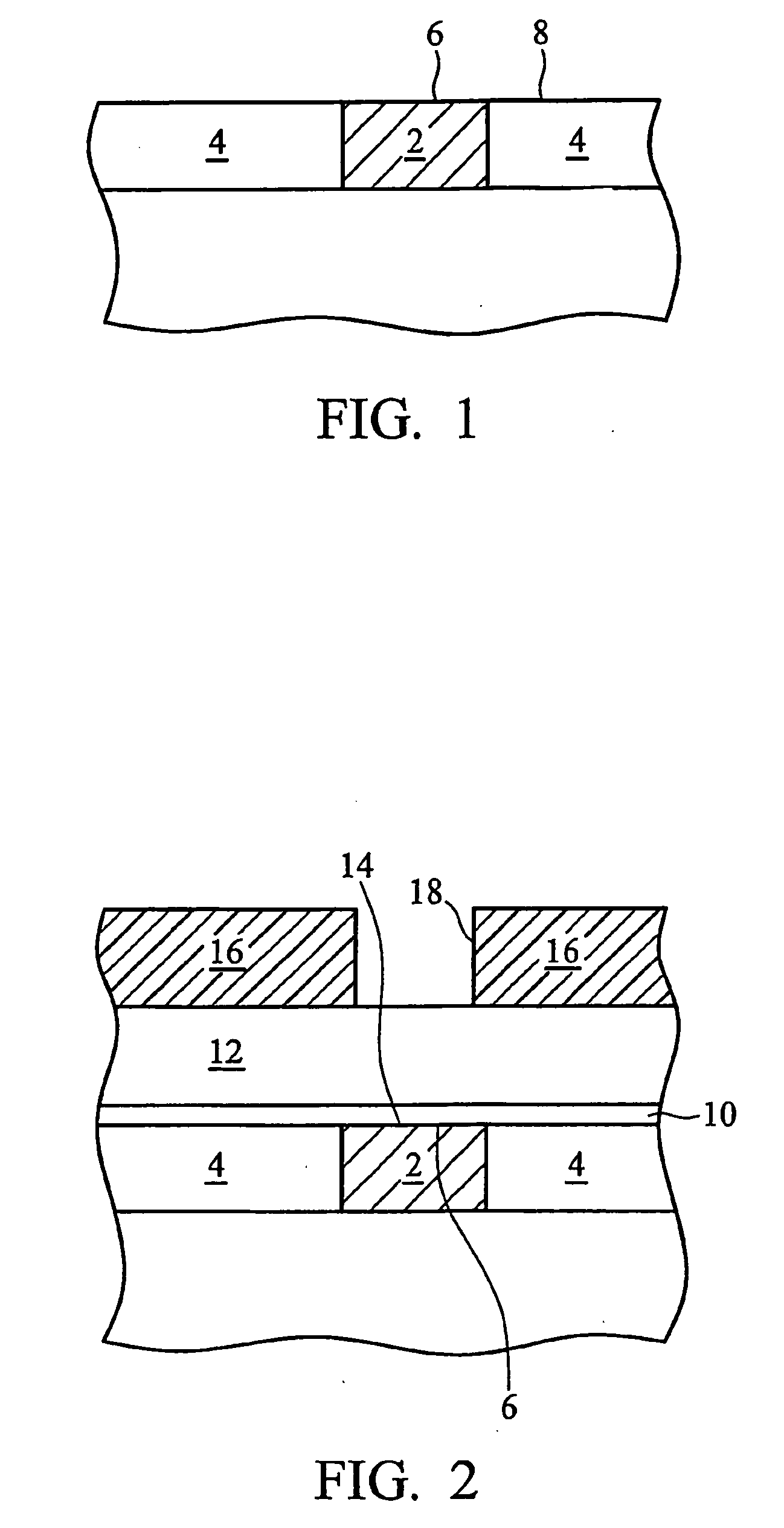

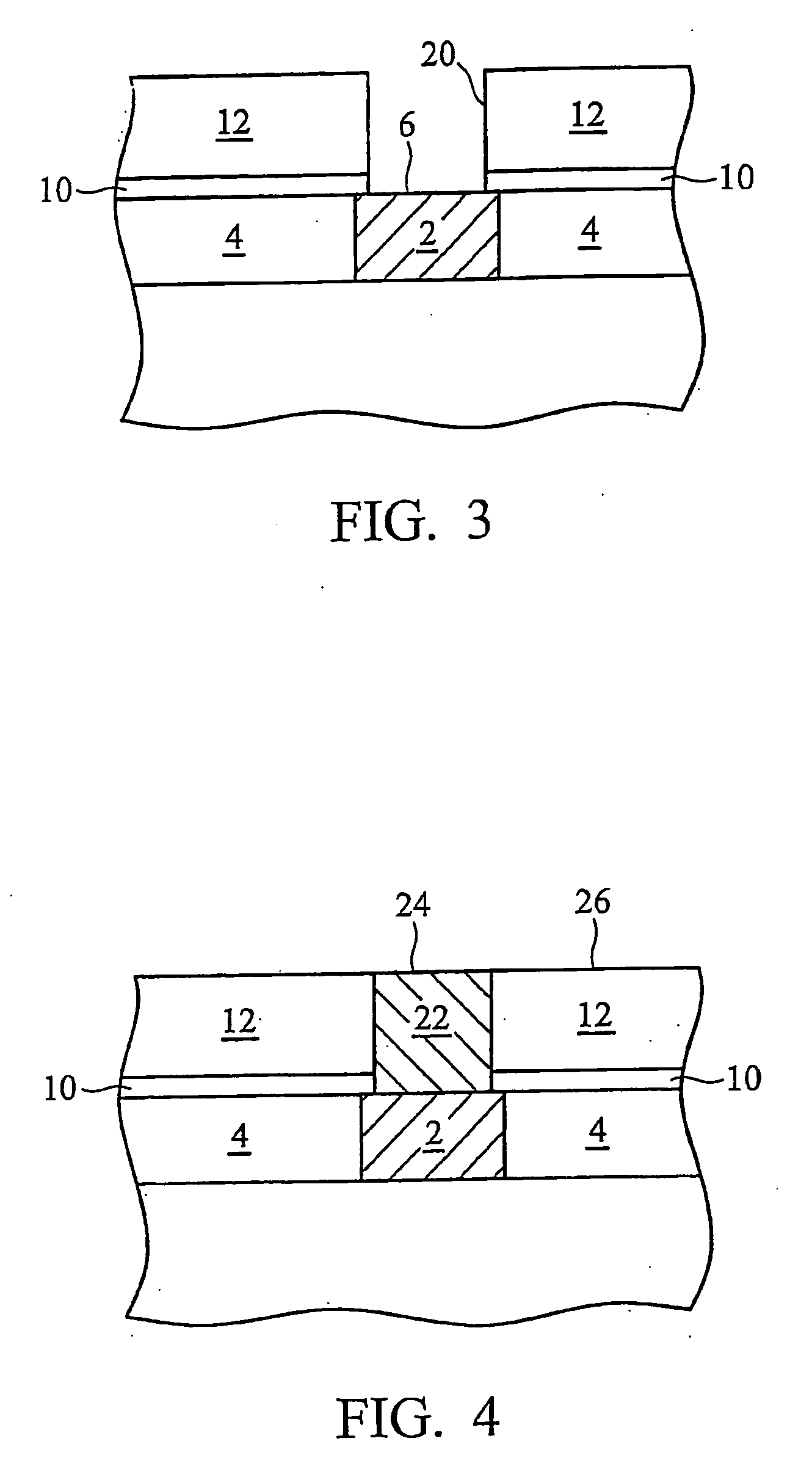

Advanced cobalt silicidation with in-situ hydrogen plasma clean

Various methods of fabricating a silicide structure are provided. In one aspect, a method of fabricating a circuit structure on a silicon surface is provided that includes exposing the silicon surface to a plasma ambient containing hydrogen and an inert gas, and depositing a metallic material capable of forming silicide on the silicon surface. The metallic material is heated to form a metal silicide on the silicon surface. The method provides for low sheet resistance silicide structures by eliminating native oxide films without the risk of spacer material backsputtering.

Owner:ADVANCED MICRO DEVICES INC

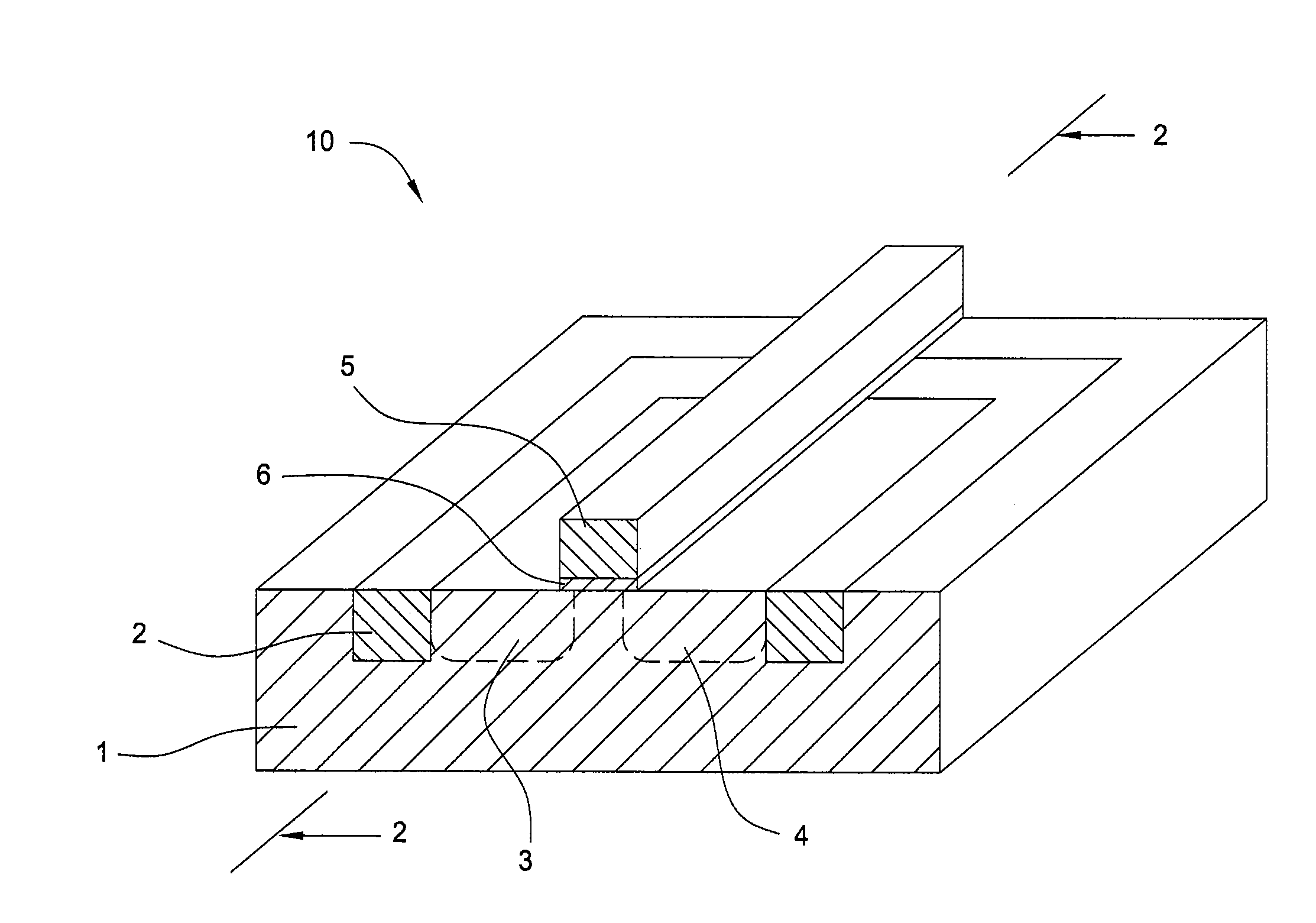

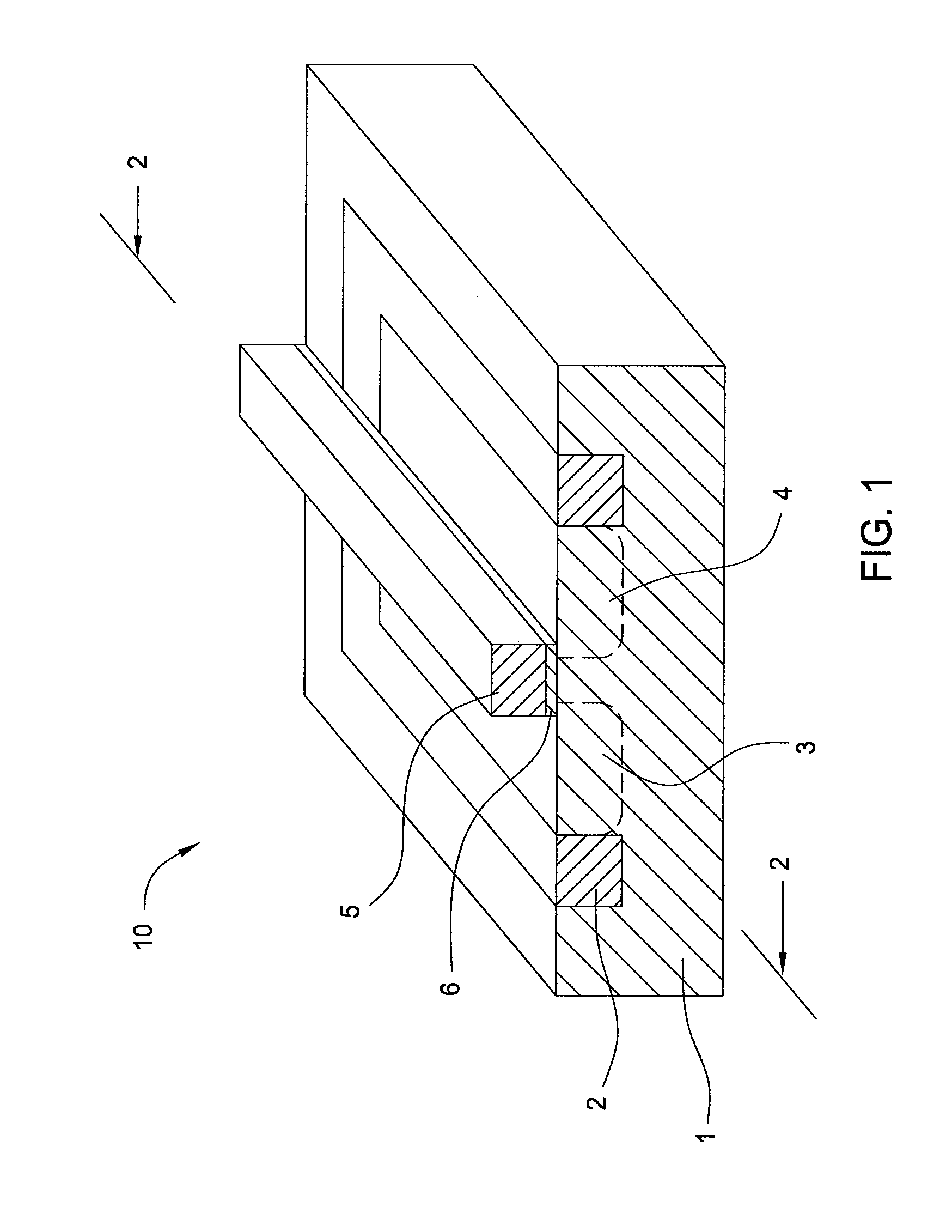

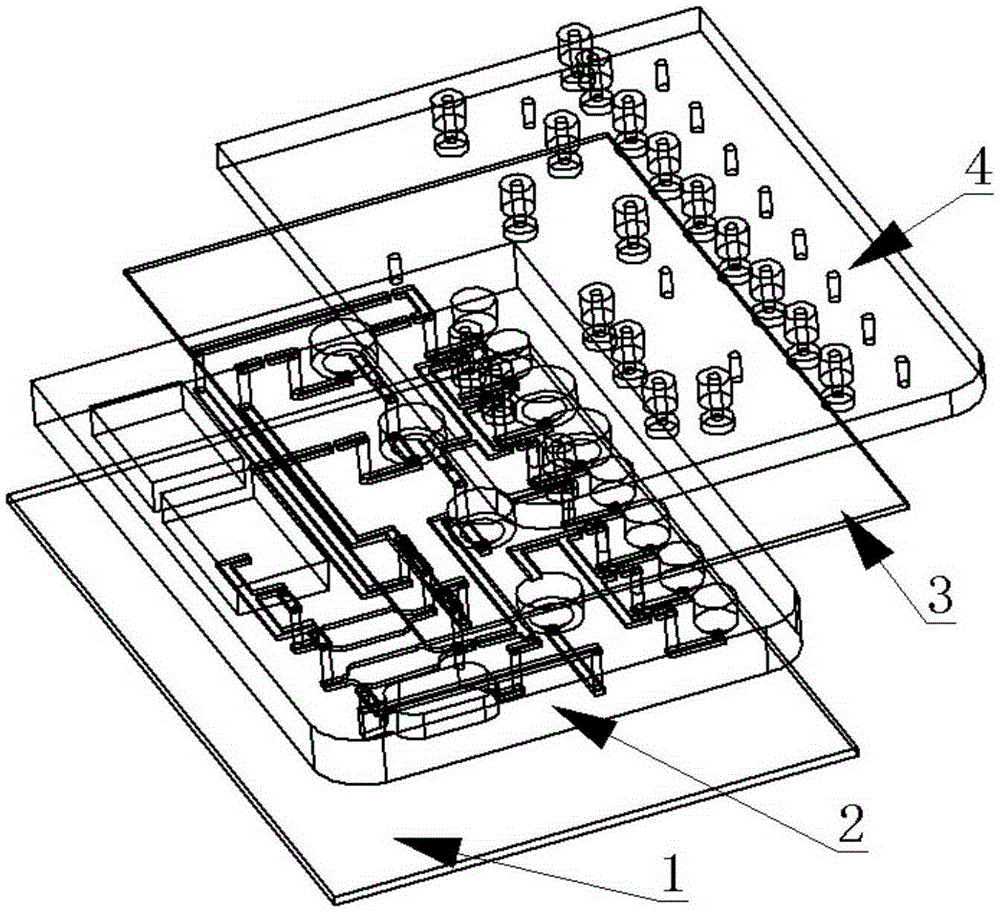

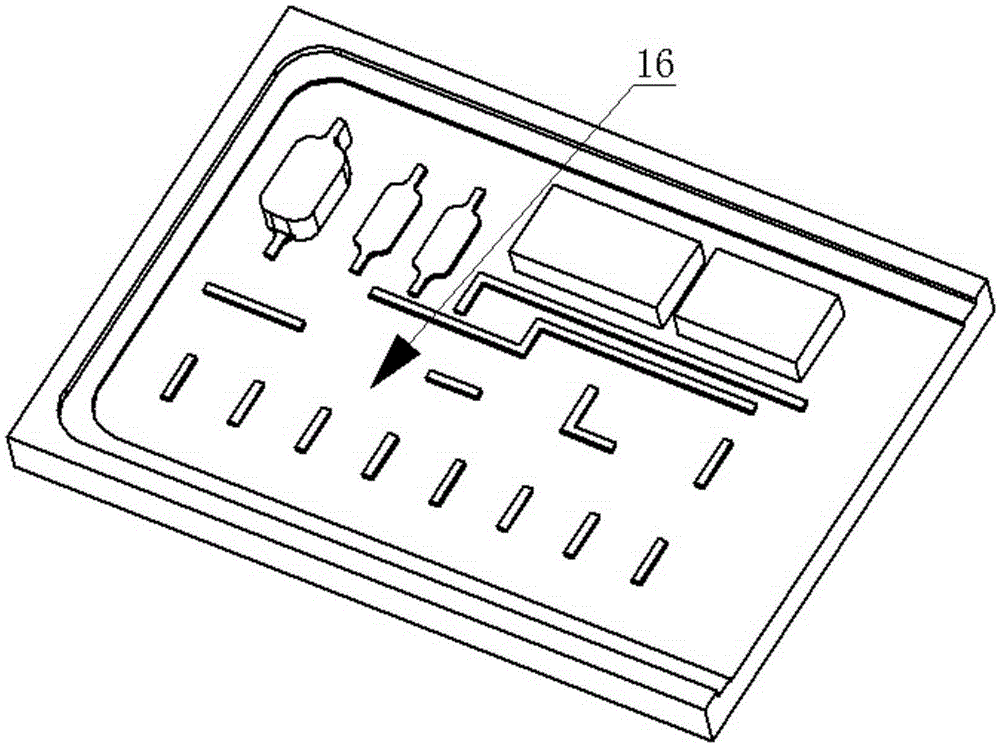

Multifunctional integrated microfluidic nucleic acid analysis chip and preparation and analysis method thereof

ActiveCN105349401AQuick buildEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsInjection mouldingMultiple layer

The invention provides a multifunctional integrated microfluidic nucleic acid analysis chip. The chip is prepared by preparing a combination mould according to 3D printing or micromachining technology, generating a microfluidic substrate according to an injection moulding method, and completing bonding of multiple layers including a chip substrate, a liquid circuit layer, an elastic film, a gas circuit layer and the like by means of plasma cleaning to finally obtain the complete chip. The chip integrates various structures including reagent cavities, mixing cavities, a splitting cavity, a DNA (deoxyribonucleic acid) extraction cavity, amplification reaction cavities, a microvalve, a microchannel and the like and has functions of sample loading, reagent mixing, heating for splitting, DNA adsorption, cleaning, eluting, amplification reaction and the like. The multifunctional integrated microfluidic nucleic acid analysis chip has the advantages that totally-closed automatic operation of 'sample input-result output' is realized, complicated manual operations are avoided, and detection efficiency is improved.

Owner:合肥中科易康达生物医学有限公司

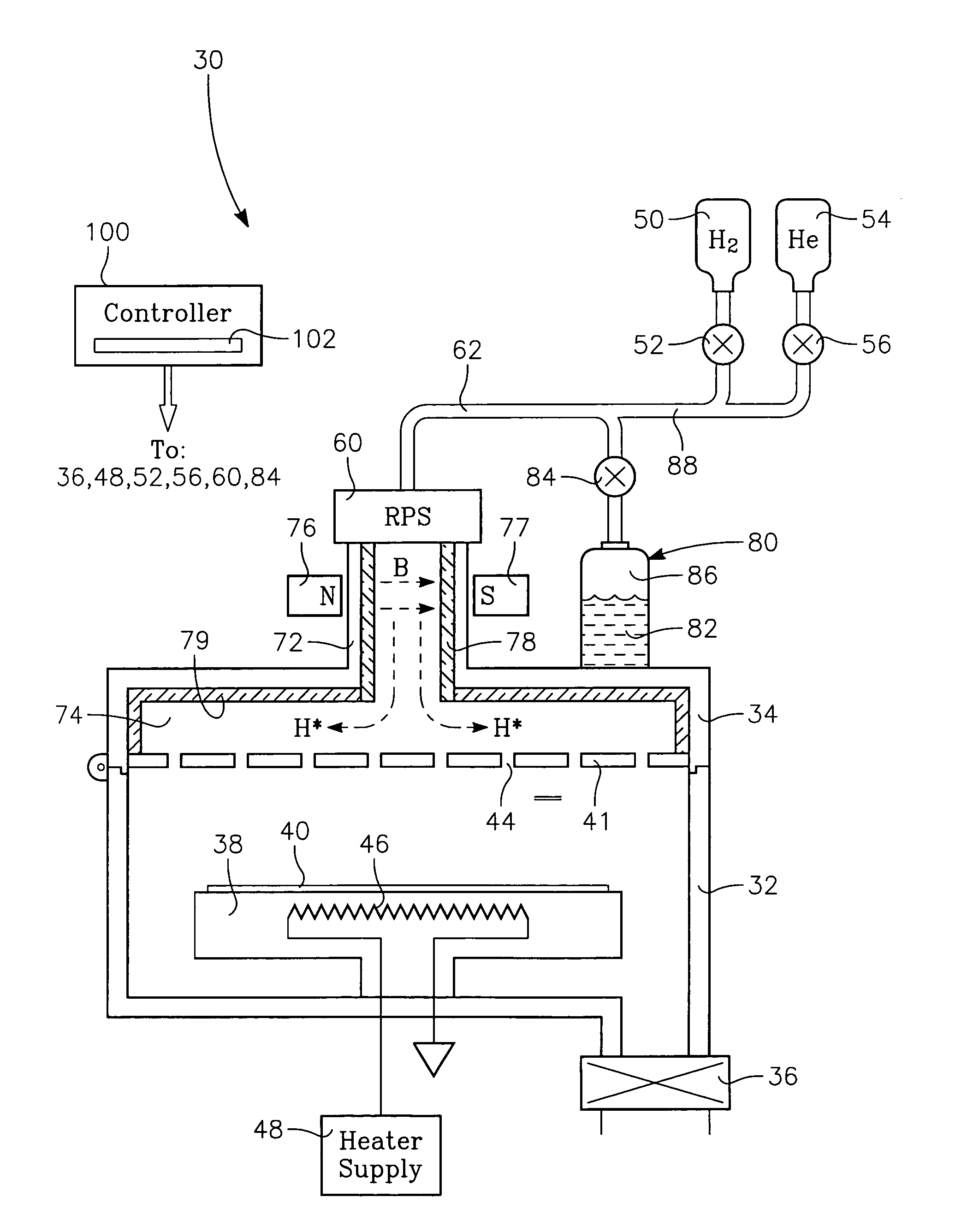

Water vapor passivation of a wall facing a plasma

InactiveUS7695567B2Easy to cleanHollow article cleaningVacuum evaporation coatingRemote plasmaWater vapor

A chamber passivation method particularly useful for hydrogen plasma cleaning of low-k dielectrics prior to coating a barrier layer into a via hole with hydrogen radicals are provided from a remote plasma source. For each wafer, the chamber is passivated with water vapor (or other gas even more chemabsorbed on plasma facing walls) passed through the remote plasma source prior to the ignition of the hydrogen plasma. The water vapor is absorbed on walls, such as alumina and quartz parts of the remote plasma source, and forms a protective mono-layer that endures sufficiently long to protect the walls during the generation of the hydrogen plasma. Thereby, the plasma facing walls, particularly of a dielectric such as alumina, are protected from etching.

Owner:APPLIED MATERIALS INC

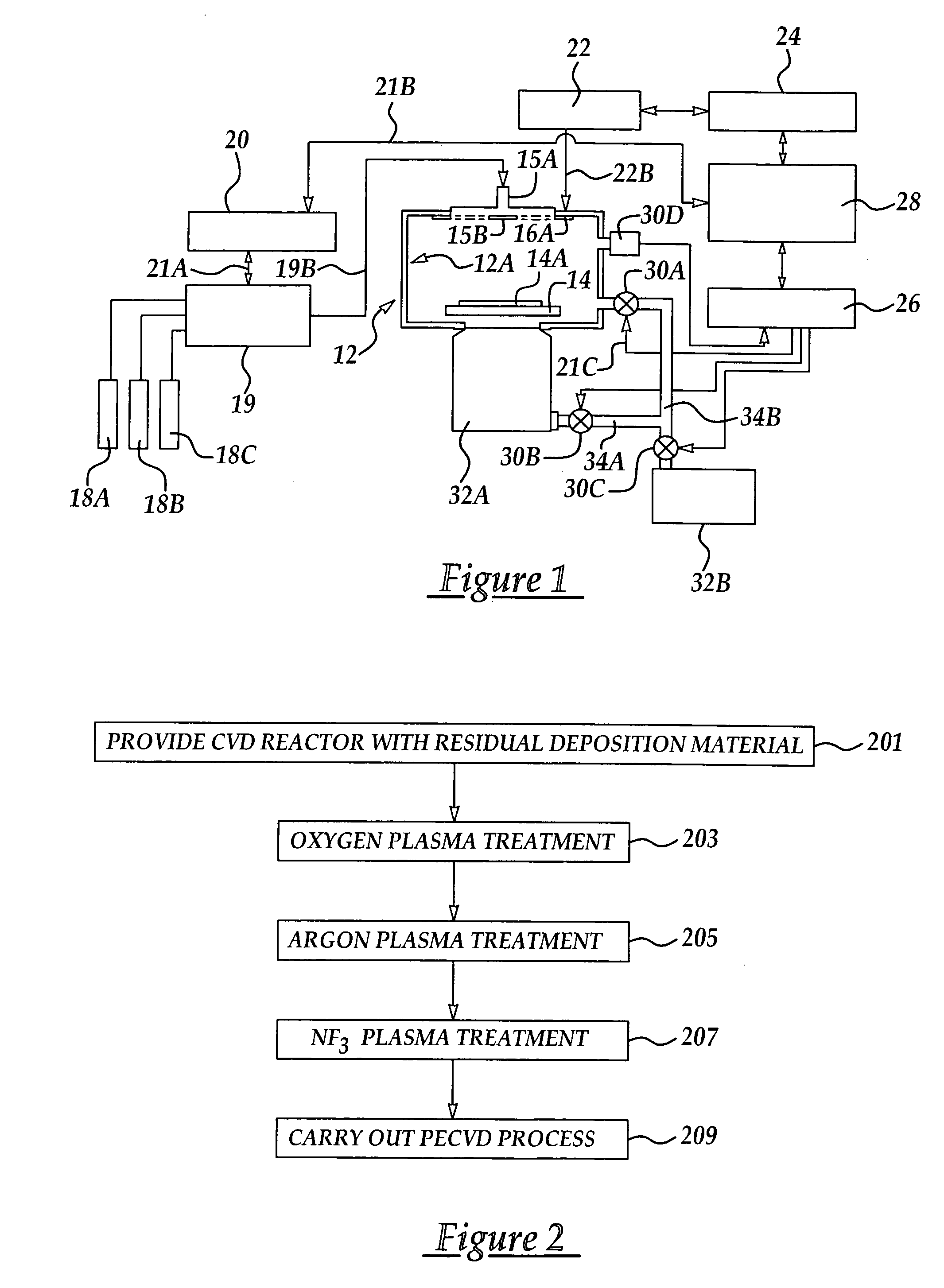

Method for cleaning a plasma enhanced CVD chamber

A method for plasma cleaning a CVD reactor chamber including providing a plasma enhanced CVD reactor chamber comprising residual deposited material; performing a first plasma process comprising an oxygen containing plasma; performing a second plasma process comprising an argon containing plasma; and, performing a third plasma process comprising a fluorine containing plasma.

Owner:TAIWAN SEMICON MFG CO LTD

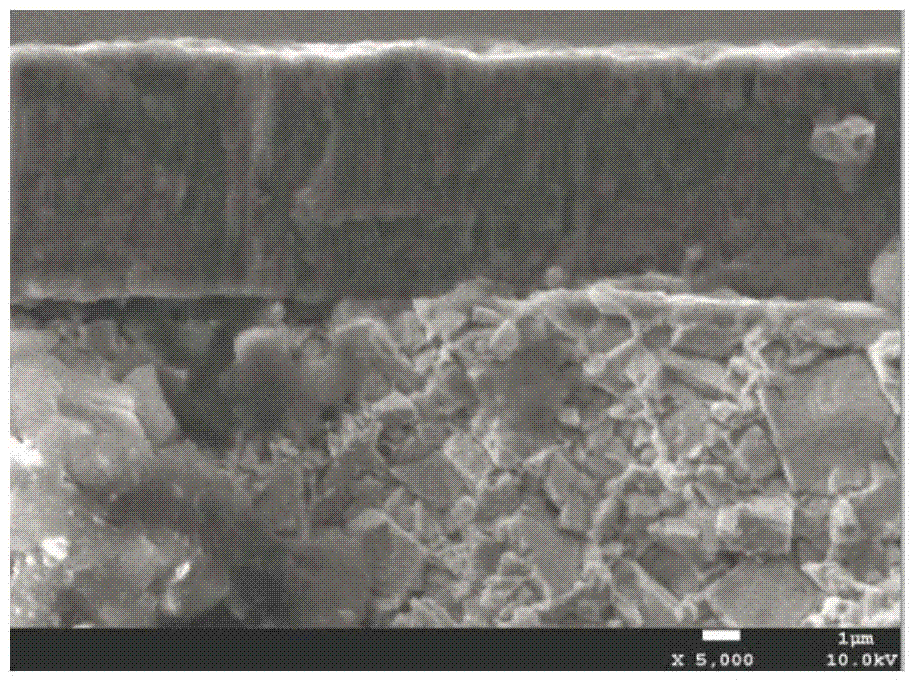

Method for metallizing surface of microwave dielectric ceramic

InactiveCN106747675AEliminate pollutionStrong adhesionVacuum evaporation coatingSputtering coatingDielectricEnvironmental resistance

The invention discloses a method for metallizing the surface of a microwave dielectric ceramic. The method comprises (1) surface treatment: carrying out fine grinding on the surface of a microwave dielectric ceramic and carrying out ultrasonic cleaning and vacuum plasma cleaning, (2) depositing an underlying metal through a magnetron sputtering method under low magnetron sputtering atmospheric pressure of 0.1-0.2 pa, and (3) depositing a metallized film system through the magnetron sputtering method under conventional magnetron sputtering atmospheric pressure of 0.3-0.7 pa. Compared with the other microwave dielectric ceramic surface metallization methods, the method utilizes a two-step atmospheric pressure sputtering method to deposit a multiple-layer metallized film system, effectively improves the adhesion of a metallized film layer on the surface of a microwave dielectric ceramic, has a simple and reasonable process design, has industrial production feasibility, is environmentally friendly and does not produce pollution in production.

Owner:ZHEJIANG UNIV

Method for cleaning plasma etch chamber structures

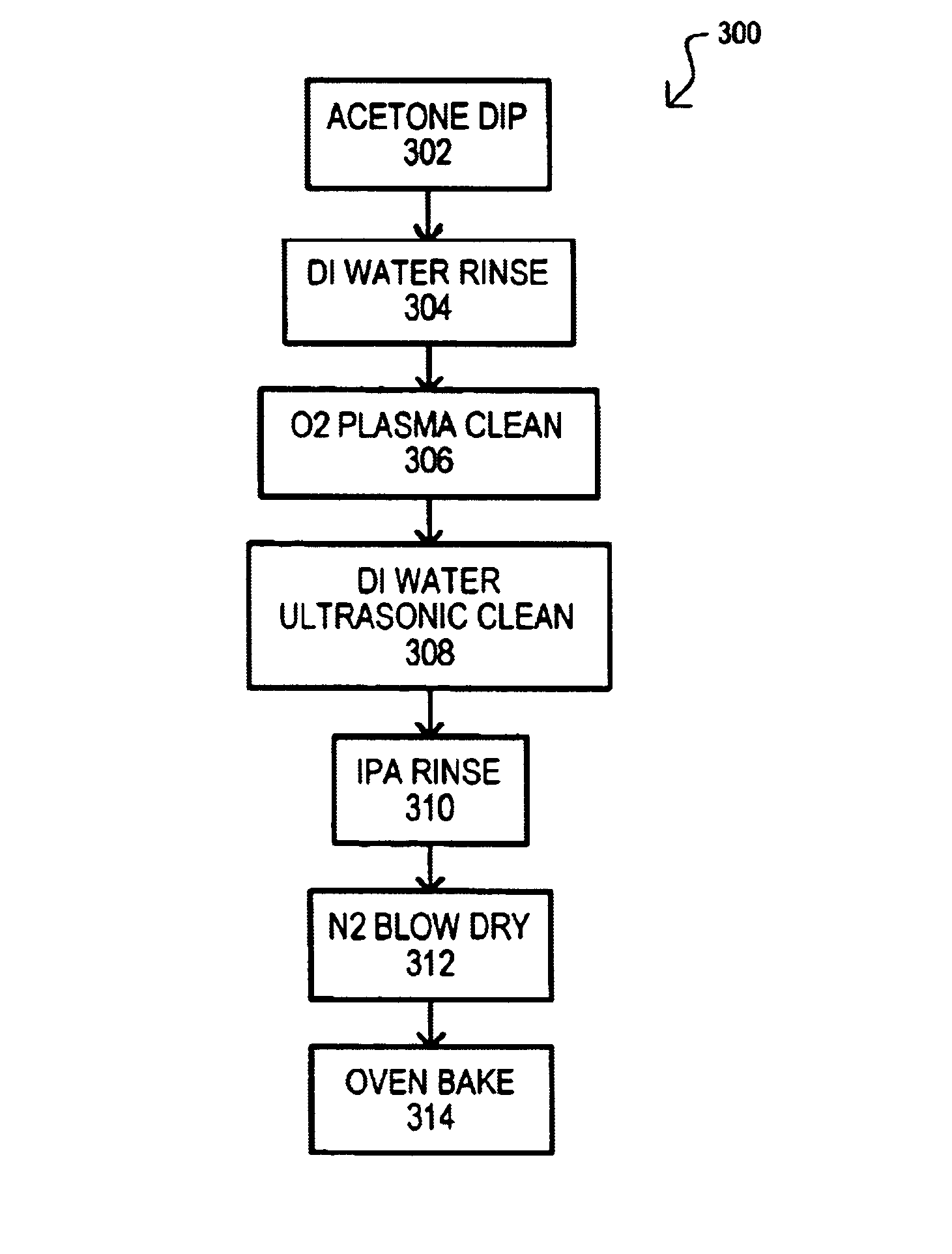

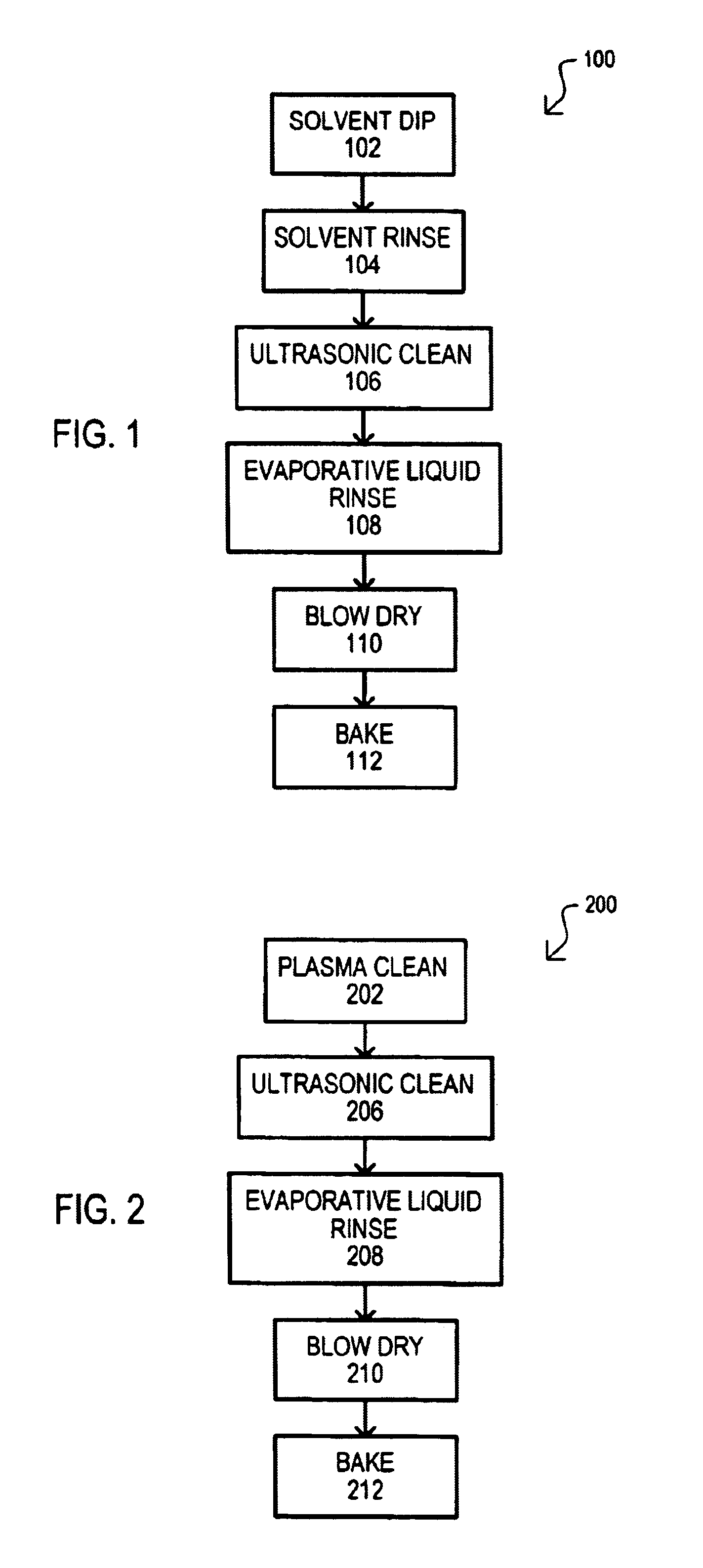

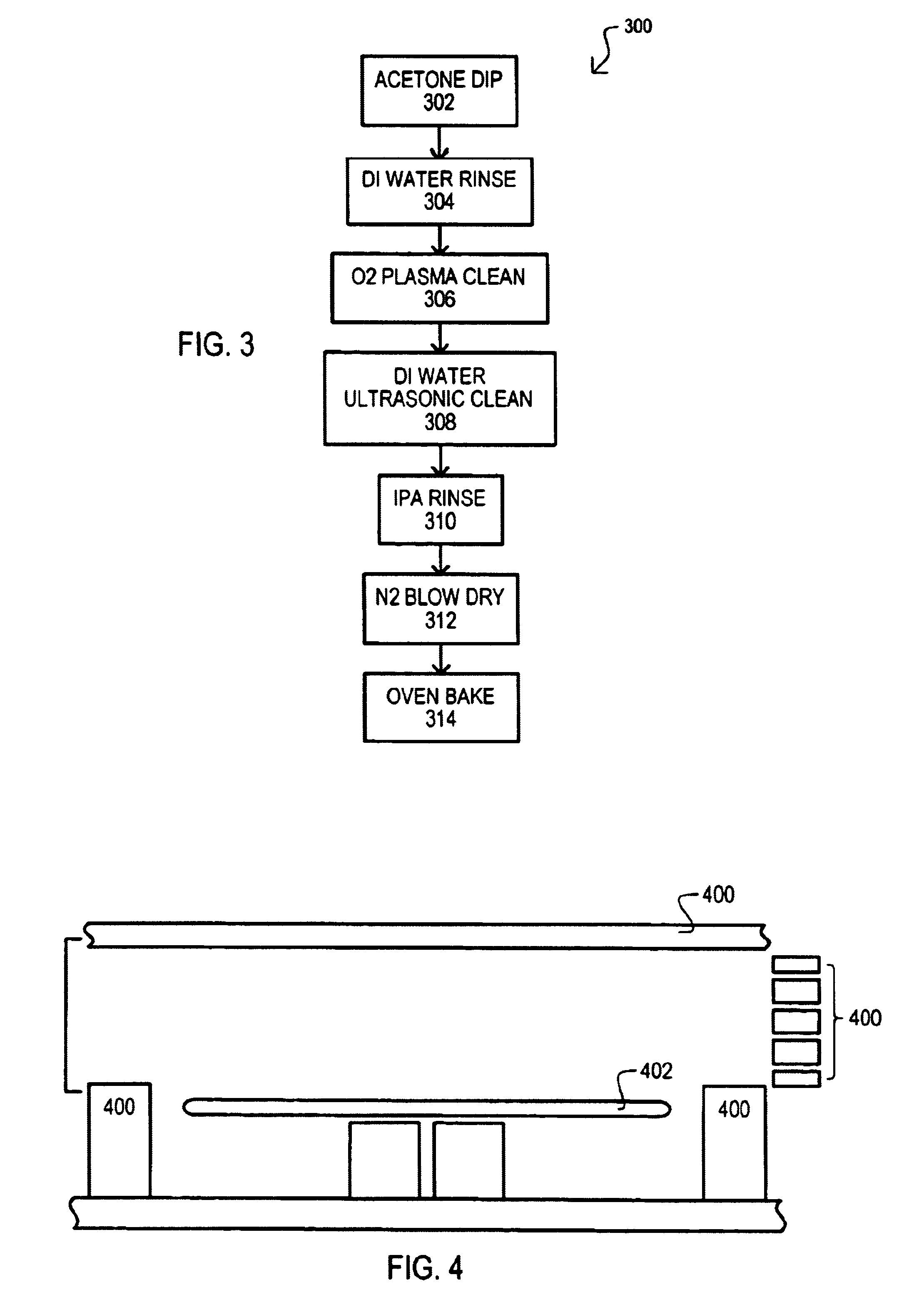

A method for cleaning a plasma reactor clamber part (100) may include dipping the chamber part in a solvent (102) that may dissolve a material that has been redistributed on the chamber part by a reactive plasma. A chamber part may then be rinsed (104), ultrasonically cleaned (106) in a ultrasonic cleaning liquid, and then rinsed again with a liquid that may evaporate at a lower temperature than an ultrasonic cleaning liquid (108). A chamber part may then be blown dry (110) and baked (112). In addition, or alternatively, a method may also include plasma cleaning a chamber part (202).

Owner:MONTEREY RES LLC

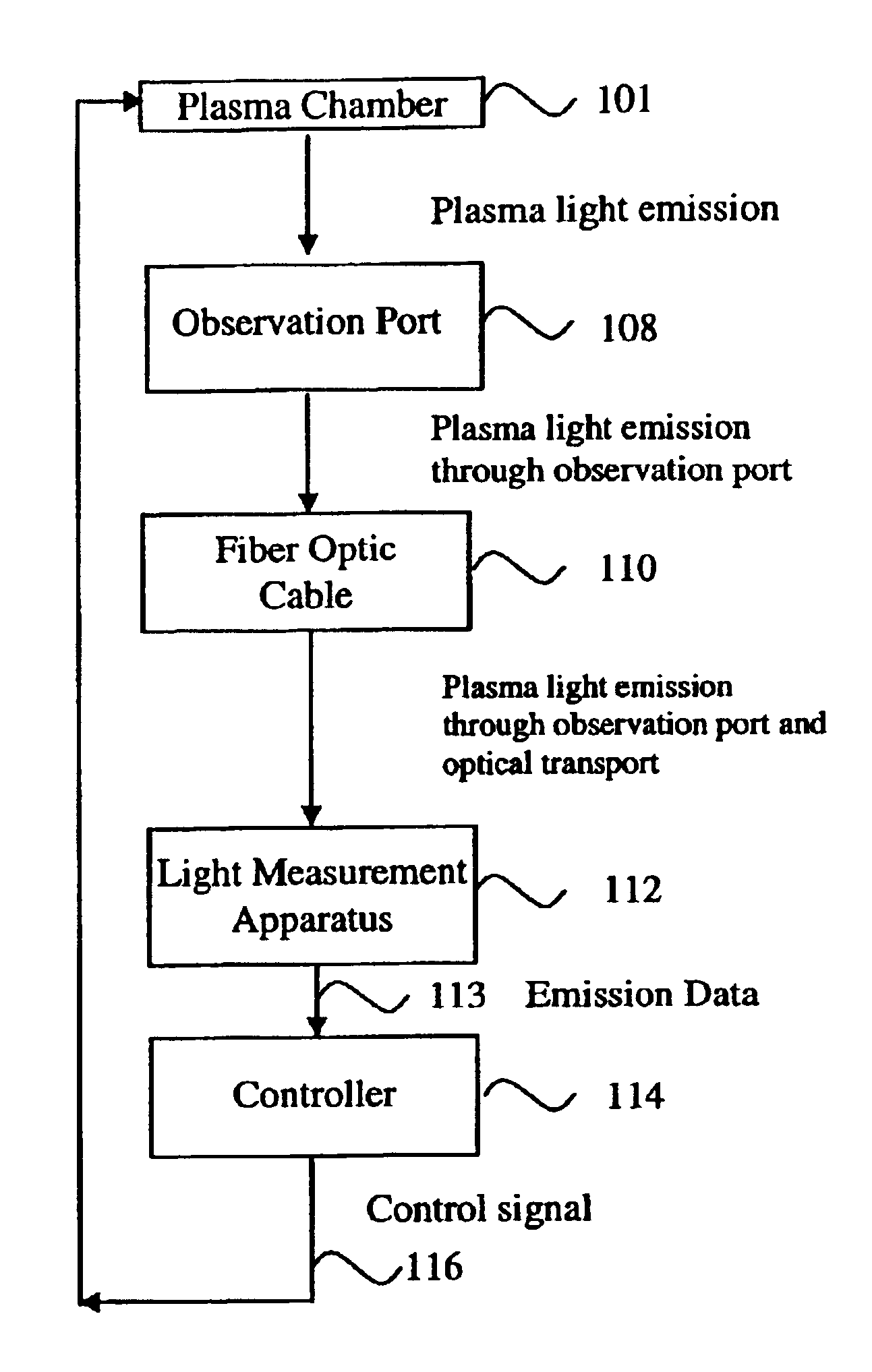

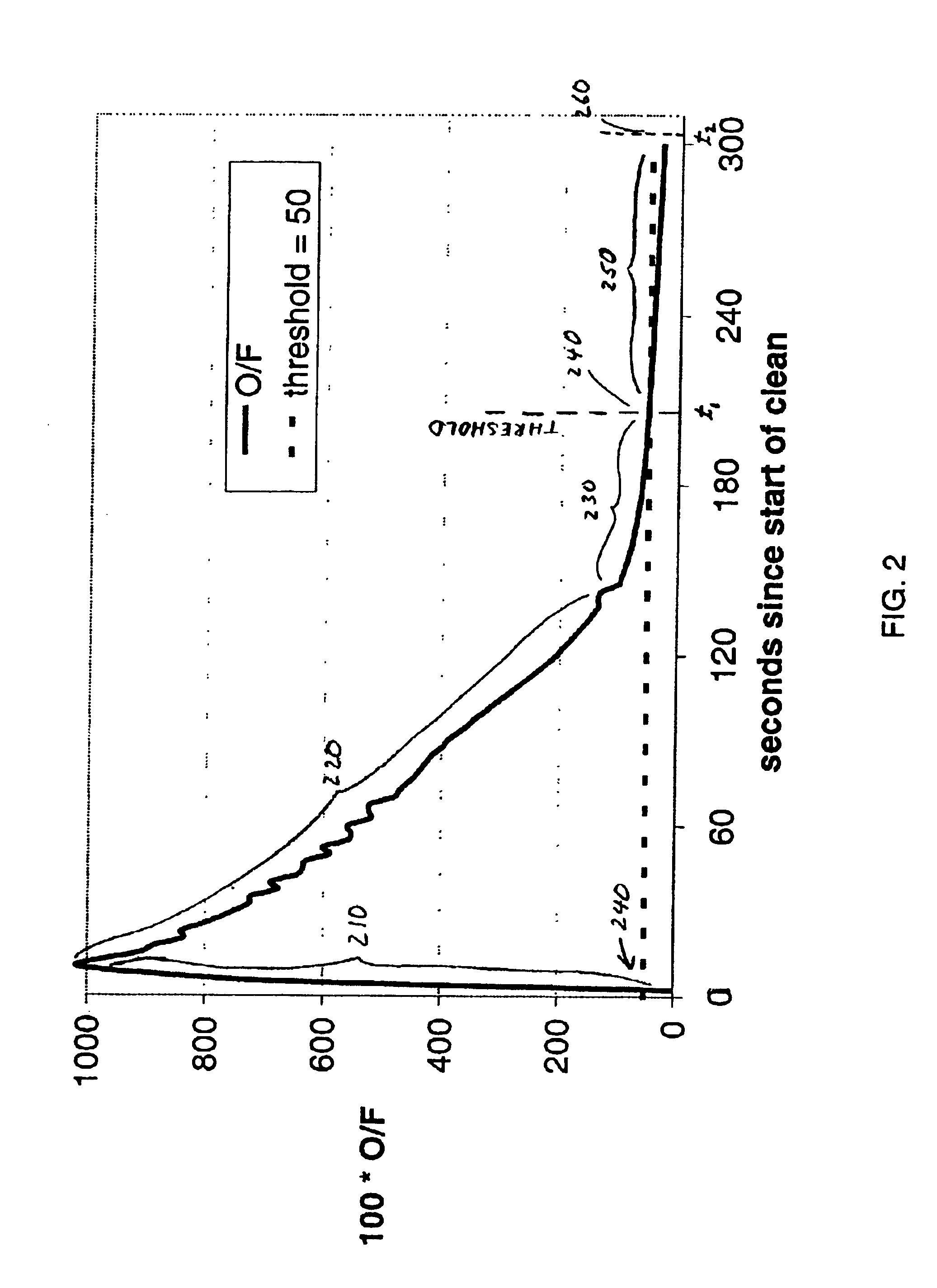

Endpoint detection for high density plasma (HDP) processes

InactiveUS6919279B1Optimal plasma etching and cleaningAvoids over-cleaning/etching and under-cleaning/etchingElectric discharge tubesSemiconductor/solid-state device manufacturingSpectral emissionHigh density

A method and system are provided for endpoint detection of plasma chamber cleaning or plasma etch processes. Optical emission spectroscopy is utilized to determine a spectral emission ratio of two or more light emitting reaction components at wavelengths in close proximity. When a spectral emission ratio or derivative thereof or mathematical function thereof falls below a selected threshold value, the plasma process may be terminated within a calculated time from the threshold value prior to an endpoint value cutoff. Advantageously, the system and methods of the present invention provide real-time, in-situ monitoring of plasma clean or etch processes to optimize the process and avoid under-cleaning or over-cleaning.

Owner:NOVELLUS SYSTEMS +1

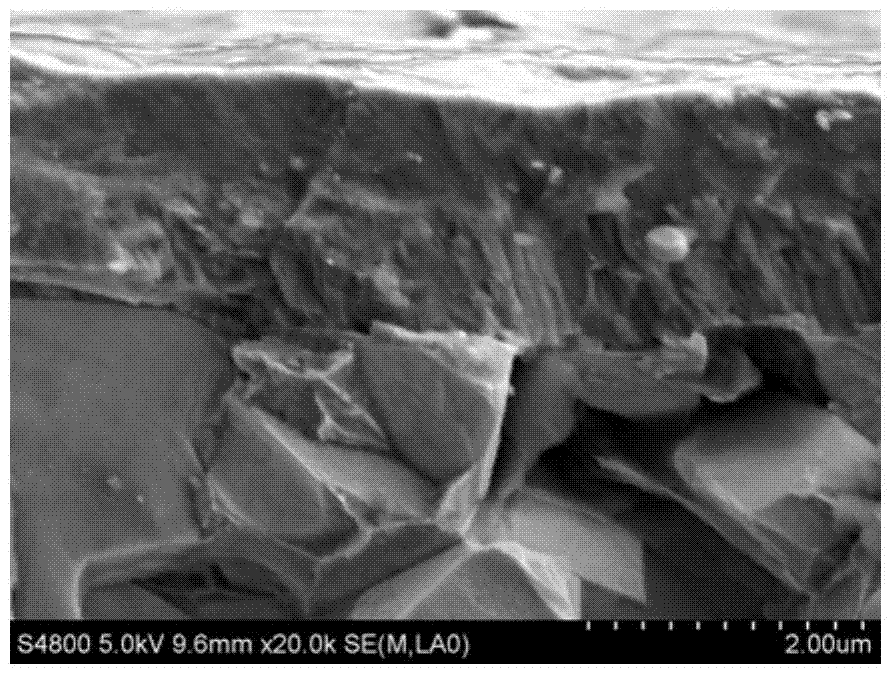

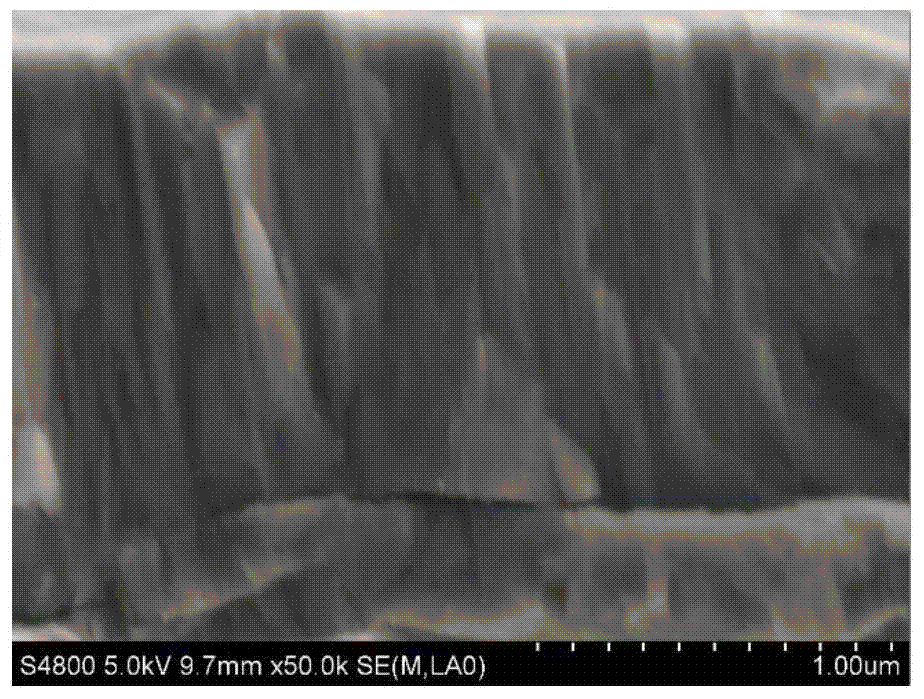

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

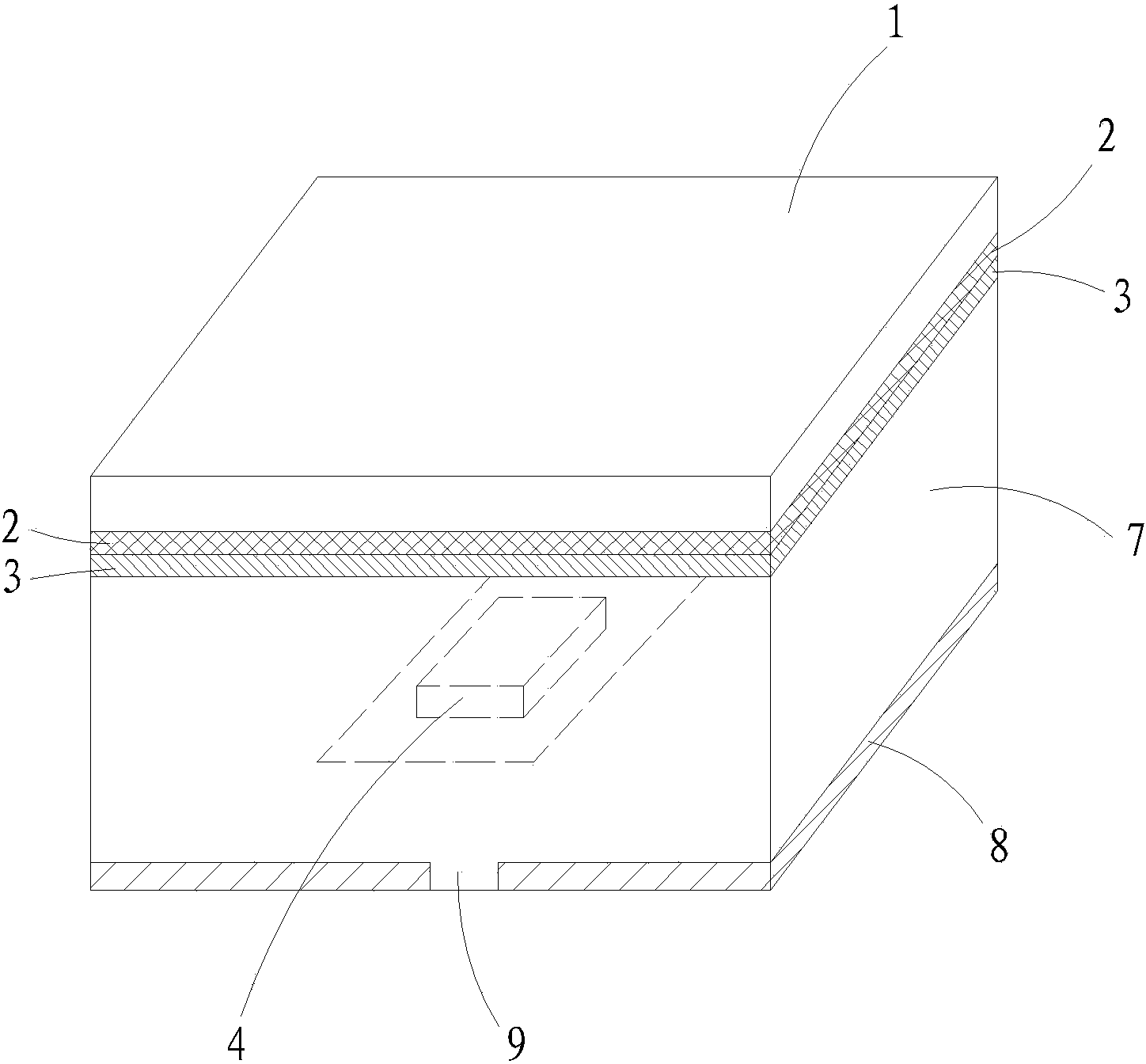

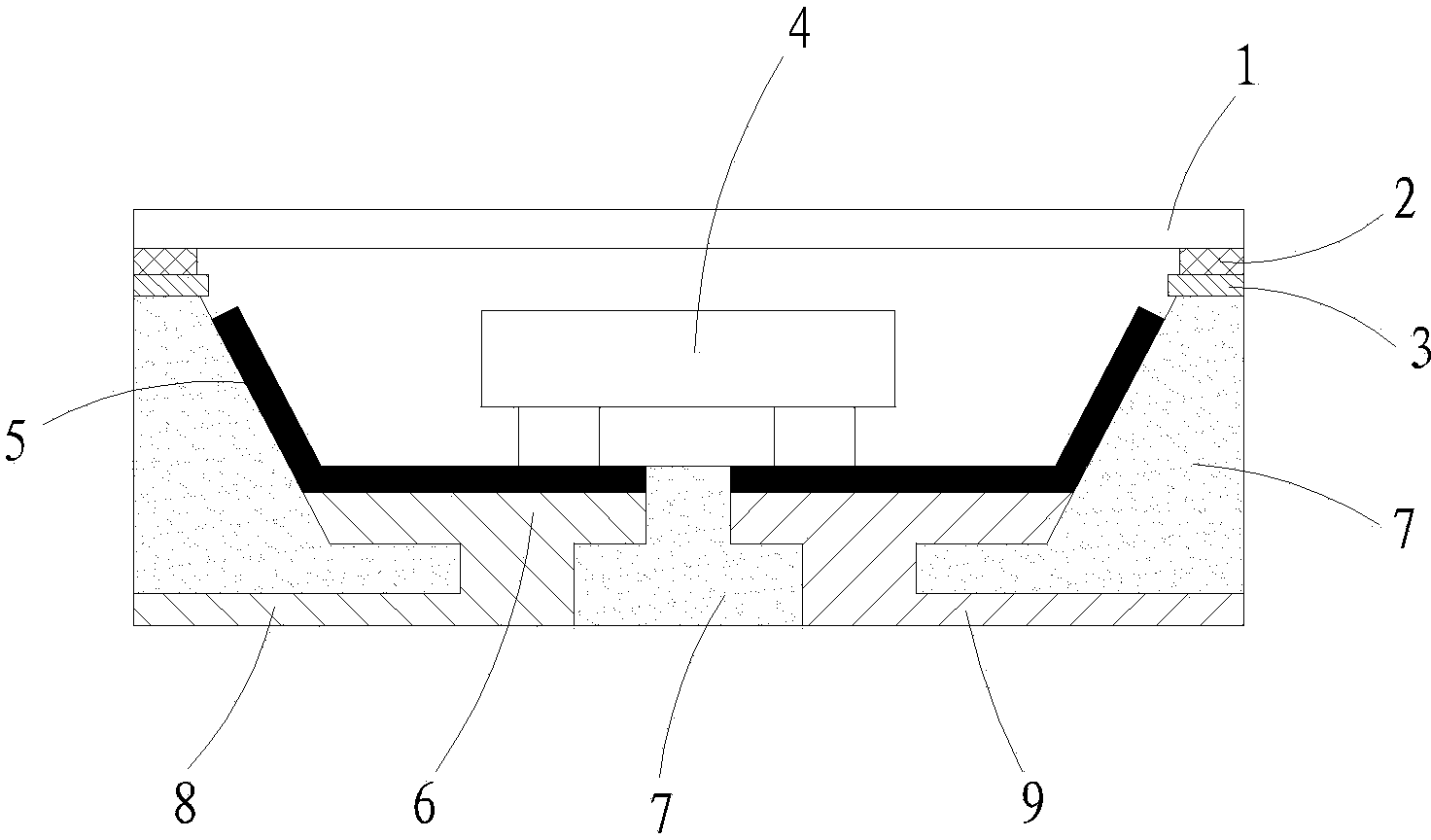

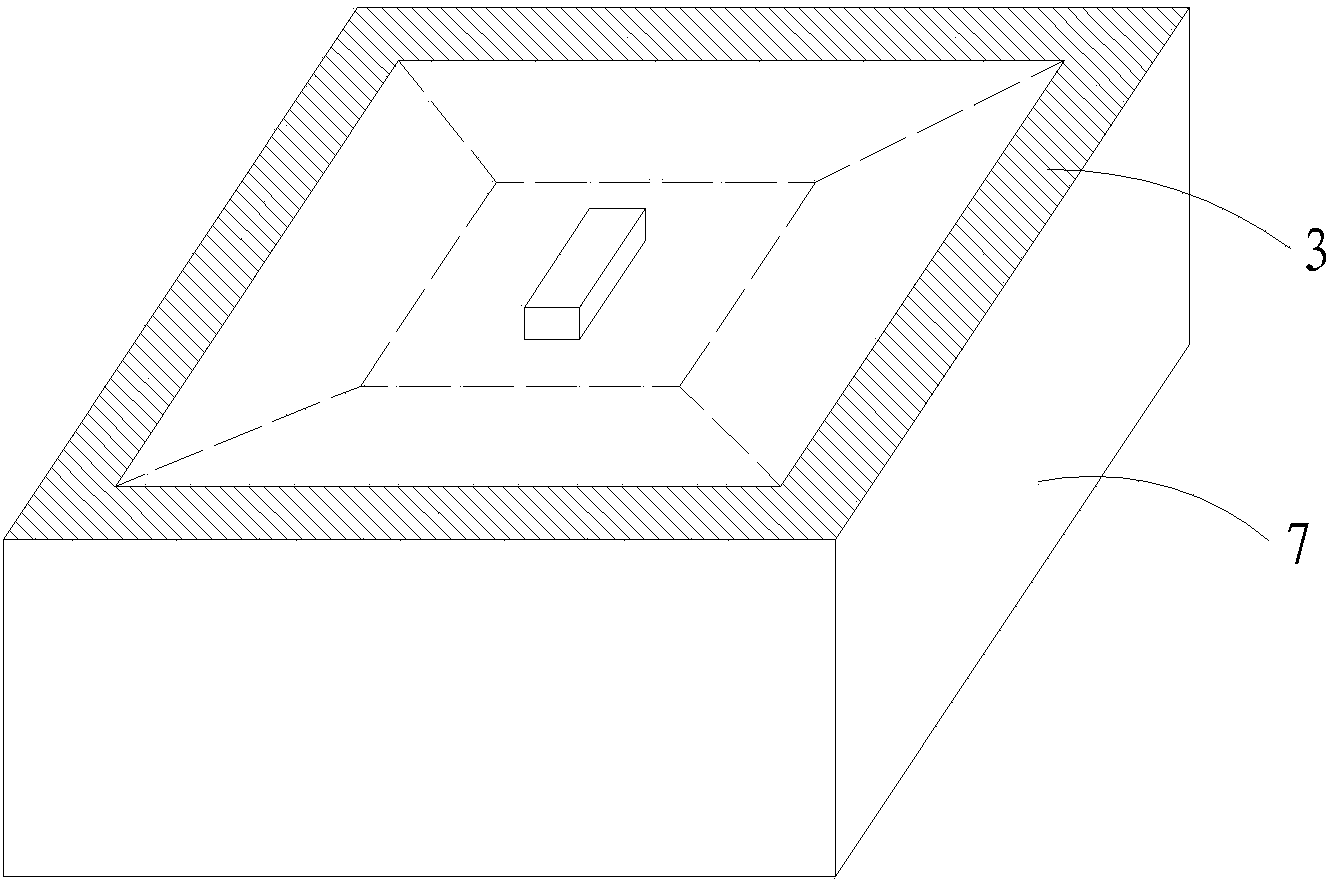

All-inorganic SMD LED packaging method and structure

The invention discloses an all-inorganic SMD LED packaging method. The method includes the following processes that firstly, a support is manufactured, secondly, dehumidification, baking and plasma cleaning are conducted on the whole ceramic support, thirdly, wafer expanding is conducted on a flip chip, fourthly, a ceramic substrate is baked, fifthly, a glass cover plate is closed, and a second metal layer and an LED support are welded in a seamless mode, and sixthly, cutting is conducted. The first process particularly includes the following steps that the ceramic substrate is prepared; the ceramic substrate with a circuit is manufactured; the glass cover plate is manufactured; the edge of the ceramic substrate obtained through the twelfth process and the edge of the glass cover plate obtained through the thirteenth step are ground respectively; a first metal layer is arranged around the ceramic substrate, the second metal layer is arranged around the side, covering the ceramic substrate, of the glass cover plate, and then a metalized ceramic substrate frame and a glass cover plate frame which have high heat conduction performance are formed; a groove of the ceramic plate is plated with silver; a metal heat sink body and a metal bonding pad are arranged. In the fifth process, LED device indirect high-temperature heating rapid inorganic material airtight packaging is achieved.

Owner:厦门多彩光电子科技有限公司

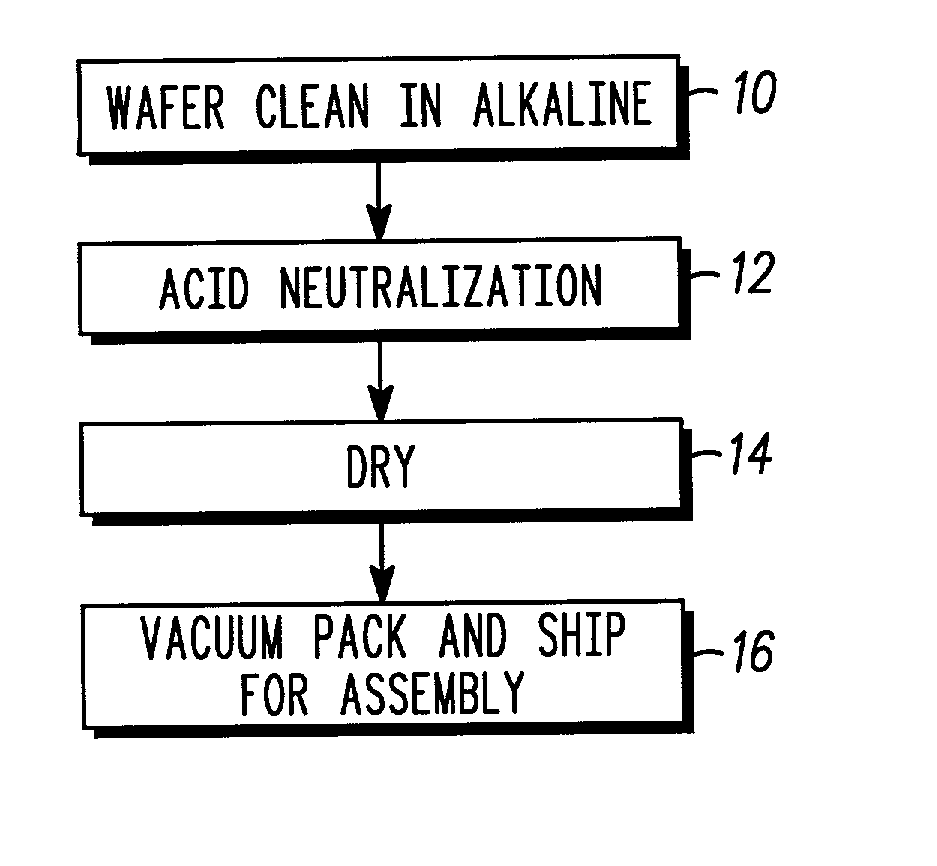

Method of preparing copper metallization die for wirebonding

InactiveUS20020127825A1Semiconductor/solid-state device detailsSolid-state devicesLead bondingAnti oxidant

A method of preparing a semiconductor wafer having a integrated circuits formed on it that have pads formed of copper includes the steps of removing oxide from the copper pads and then the vacuum packing the wafer in a shock-proof container. The oxide may be removed from the copper pads in a number of ways. A first way includes cleaning the wafer in an alkaline solution, performing acid neutralization on the cleaned wafer, and then drying the wafer. A second way includes cleaning the wafer with an acid solution, rinsing the acid cleaned wafer with water, applying an anti-oxidant activator to the surface of the copper pads, rinsing the wafer with water after the application of the anti-oxidant activator, and then drying the water rinsed wafer. Yet a third way includes plasma cleaning the copper pads using a combination of about 5-10% Hydrogen and about 90-95% Argon and then sputtering a very thin layer of aluminum on a surface of the copper pads. The layer of aluminum has a thickness of about 1-5 nanometers.

Owner:NORTH STAR INNOVATIONS

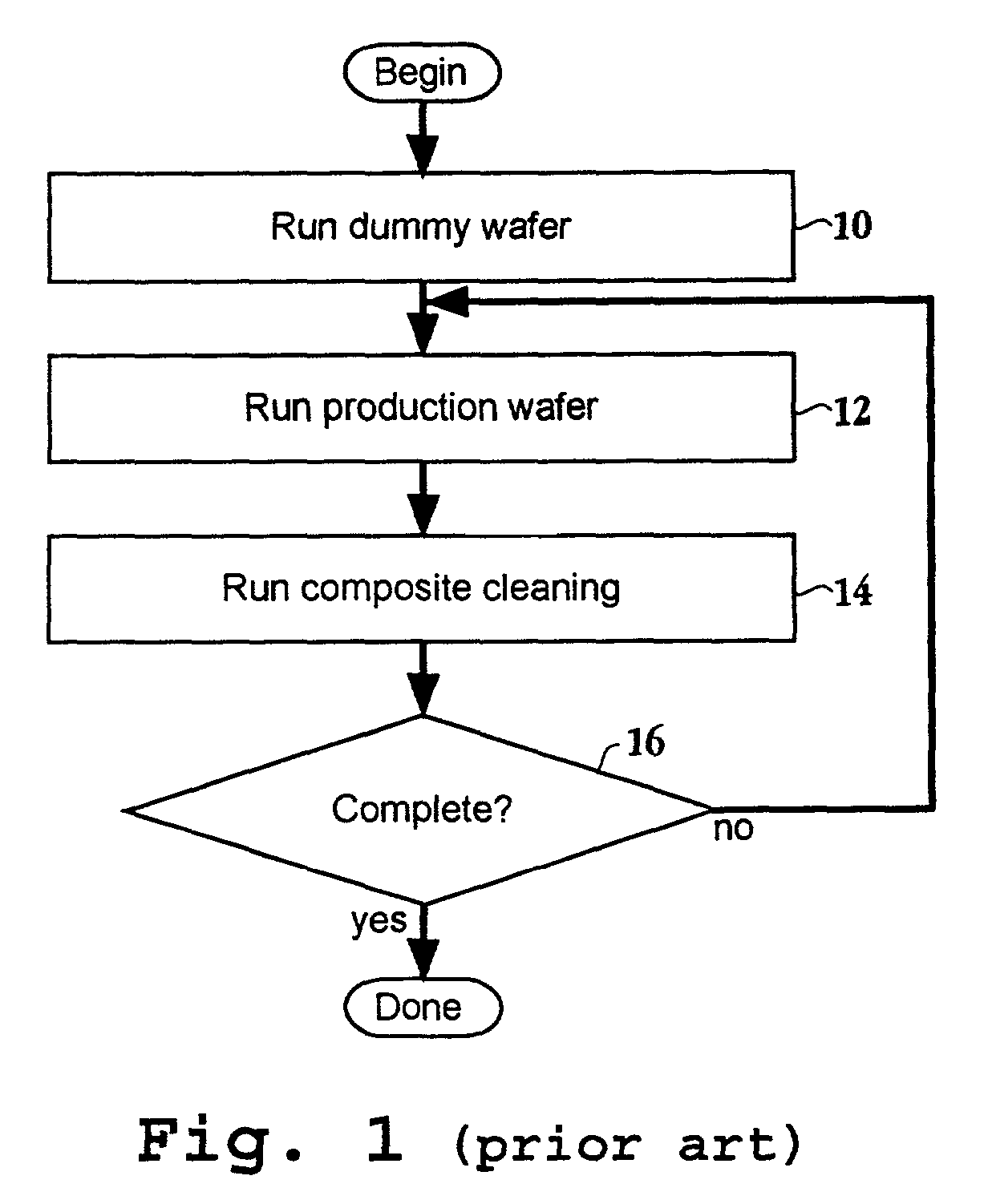

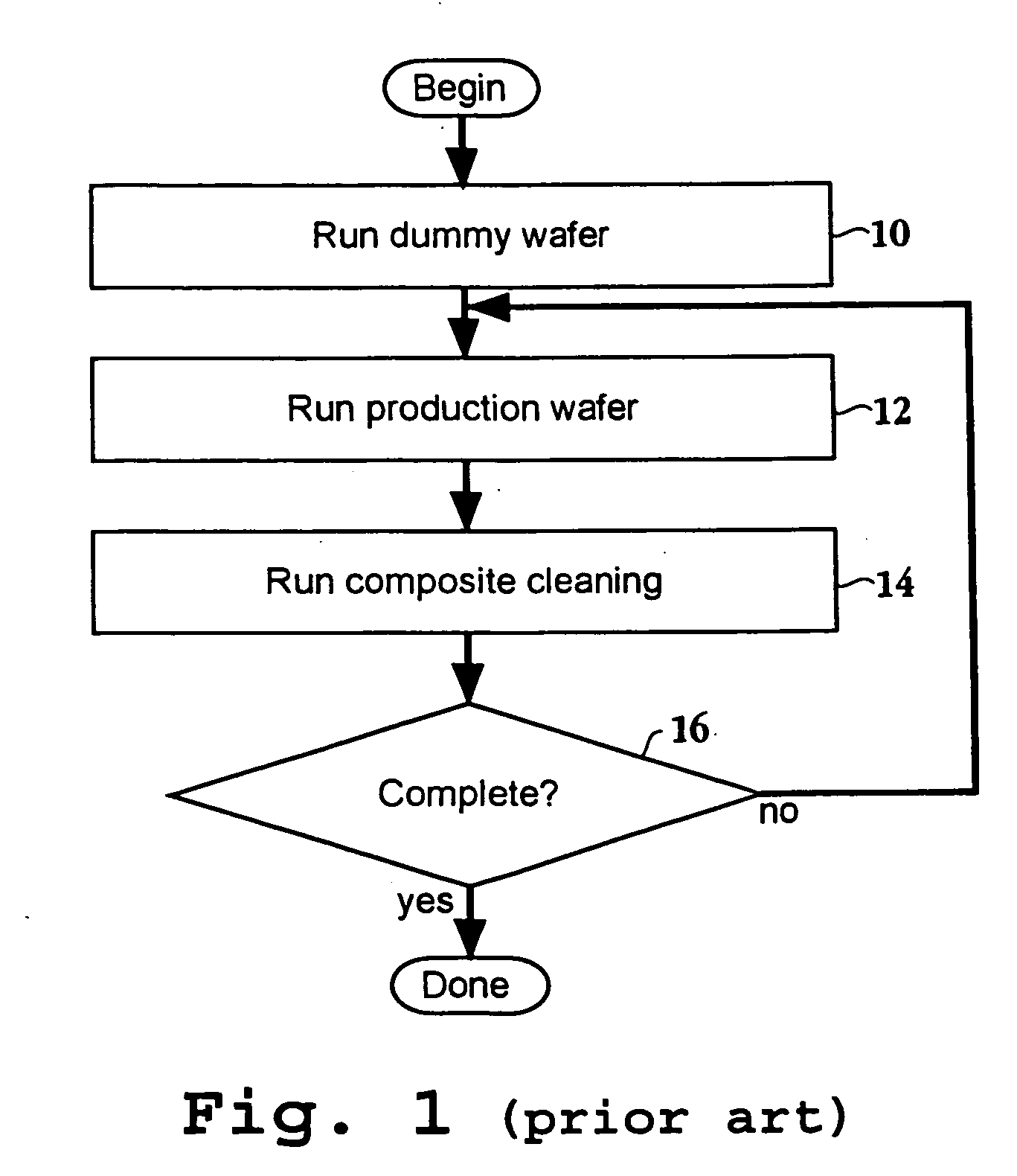

Plasma cleaning of deposition chamber residues using duo-step wafer-less auto clean method

A method involving plasma cleaning of deposit residues in process chamber using duo-step wafer-less auto clean method is detailed. Specifically, the method involves cleaning the processing chamber by flowing a first gaseous composition with at least about 75% of fluorine-containing compound of the formula XyFz, into a processing chamber and then forming a first etchant plasma which removes silicon and silicon based byproducts from the interior surfaces of the processing chamber. The method then involves flowing a second gaseous composition into the processing chamber with a composition of at least about 50% O2 and forming a plasma from the second gaseous composition to provide a second etchant plasma which removes carbon and carbon based byproducts from the interior surfaces of the processing chamber. A system configured to execute the two step cleaning process is also provided.

Owner:LAM RES CORP

Plasma cleaning of deposition chamber residues using duo-step wafer-less auto clean method

InactiveUS20060130873A1Electric discharge tubesSemiconductor/solid-state device manufacturingCleaning methodsFluorine containing

A method involving plasma cleaning of deposit residues in process chamber using duo-step wafer-less auto clean method is detailed. Specifically, the method involves cleaning the processing chamber by flowing a first gaseous composition with at least about 75% of fluorine-containing compound of the formula XyFz, into a processing chamber and then forming a first etchant plasma which removes silicon and silicon based byproducts from the interior surfaces of the processing chamber. The method then involves flowing a second gaseous composition into the processing chamber with a composition of at least about 50% O2 and forming a plasma from the second gaseous composition to provide a second etchant plasma which removes carbon and carbon based byproducts from the interior surfaces of the processing chamber. A system configured to execute the two step cleaning process is also provided.

Owner:LAM RES CORP

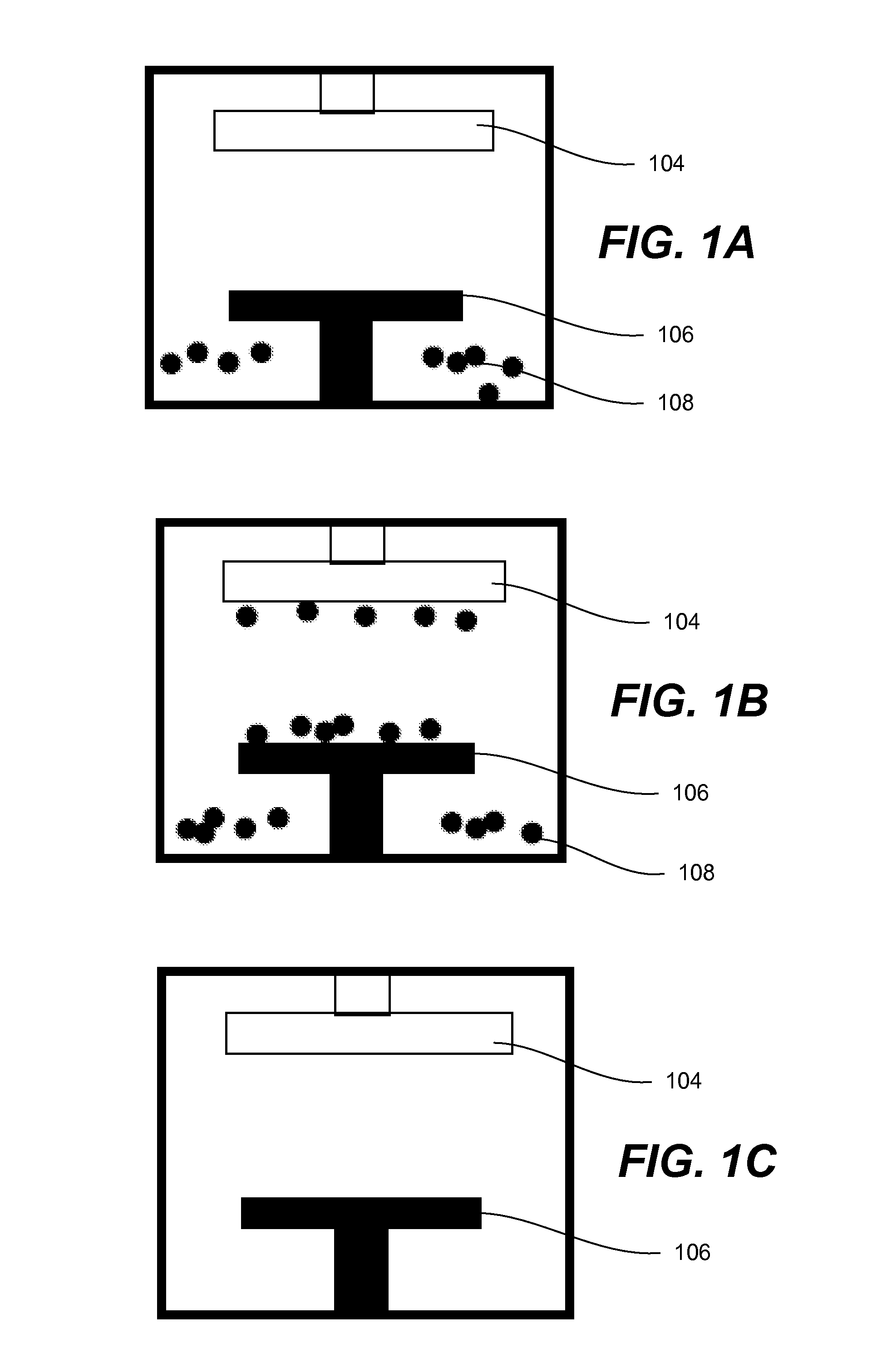

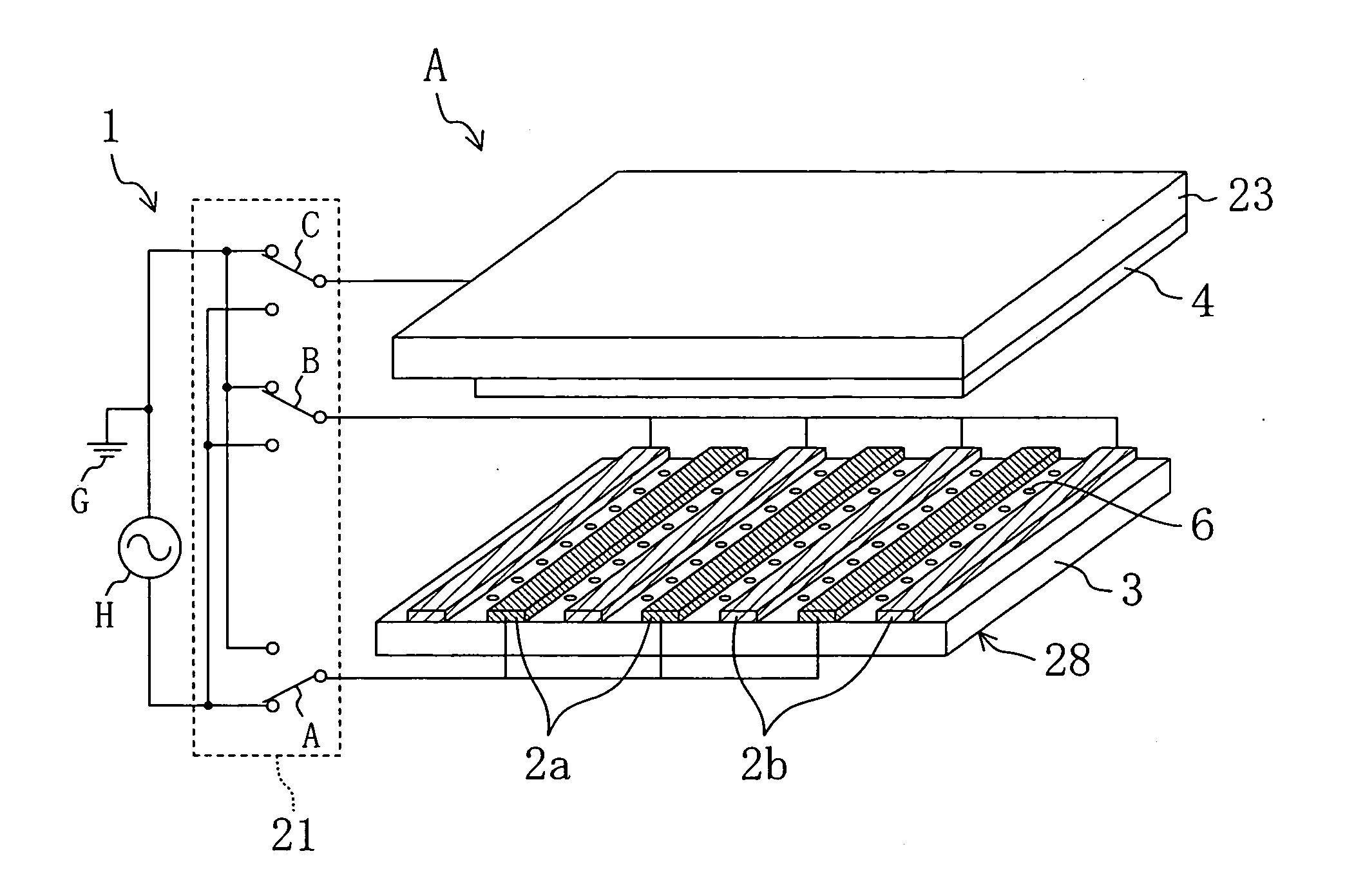

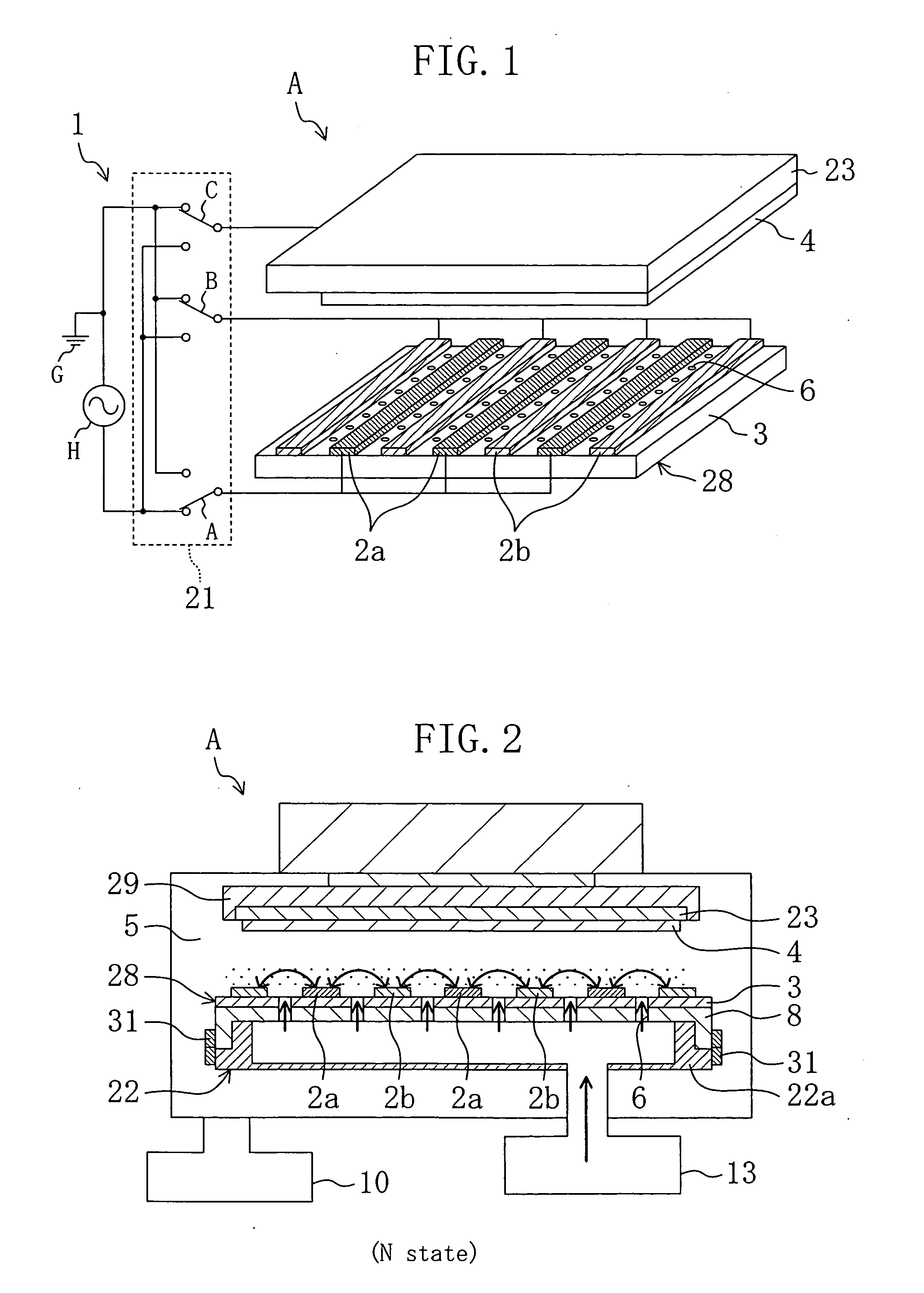

Plasma processing system and cleaning method for the same

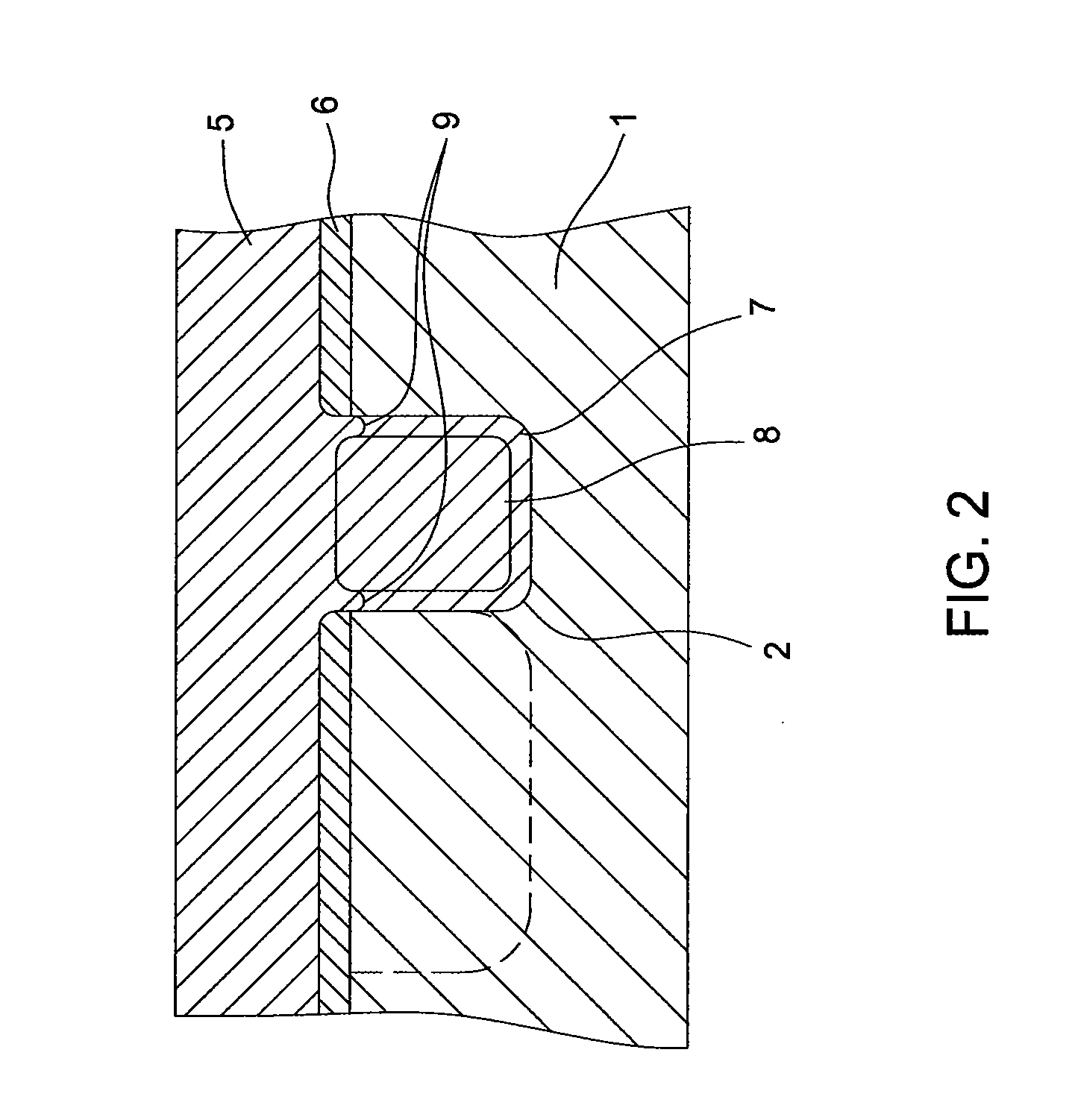

InactiveUS20050022740A1Efficient removalSimple structureElectric discharge tubesSemiconductor/solid-state device manufacturingComposite electrodeEngineering

A plasma processing system includes a processing chamber, a substrate holder provided within the processing chamber for holding a target substrate, a composite electrode provided within the processing chamber so as to oppose the substrate holder and having a plurality of first electrodes and second electrodes for generating plasma, and a gas supply section for supplying a material gas into the processing chamber. The system further includes a plasma region increasing / reducing section for increasing or reducing a plasma region formed in the processing chamber, and a cleaning section for plasma cleaning the inside of the processing chamber by using plasma generated in the plasma region increased or reduced by the plasma region increasing / reducing section. Thus, the quality of a film to be deposited can be improved by eliminating ion impact against the target substrate, and the system cost can be lowered by efficiently removing, with a simple structure, particles produced in the processing chamber.

Owner:SHARP KK

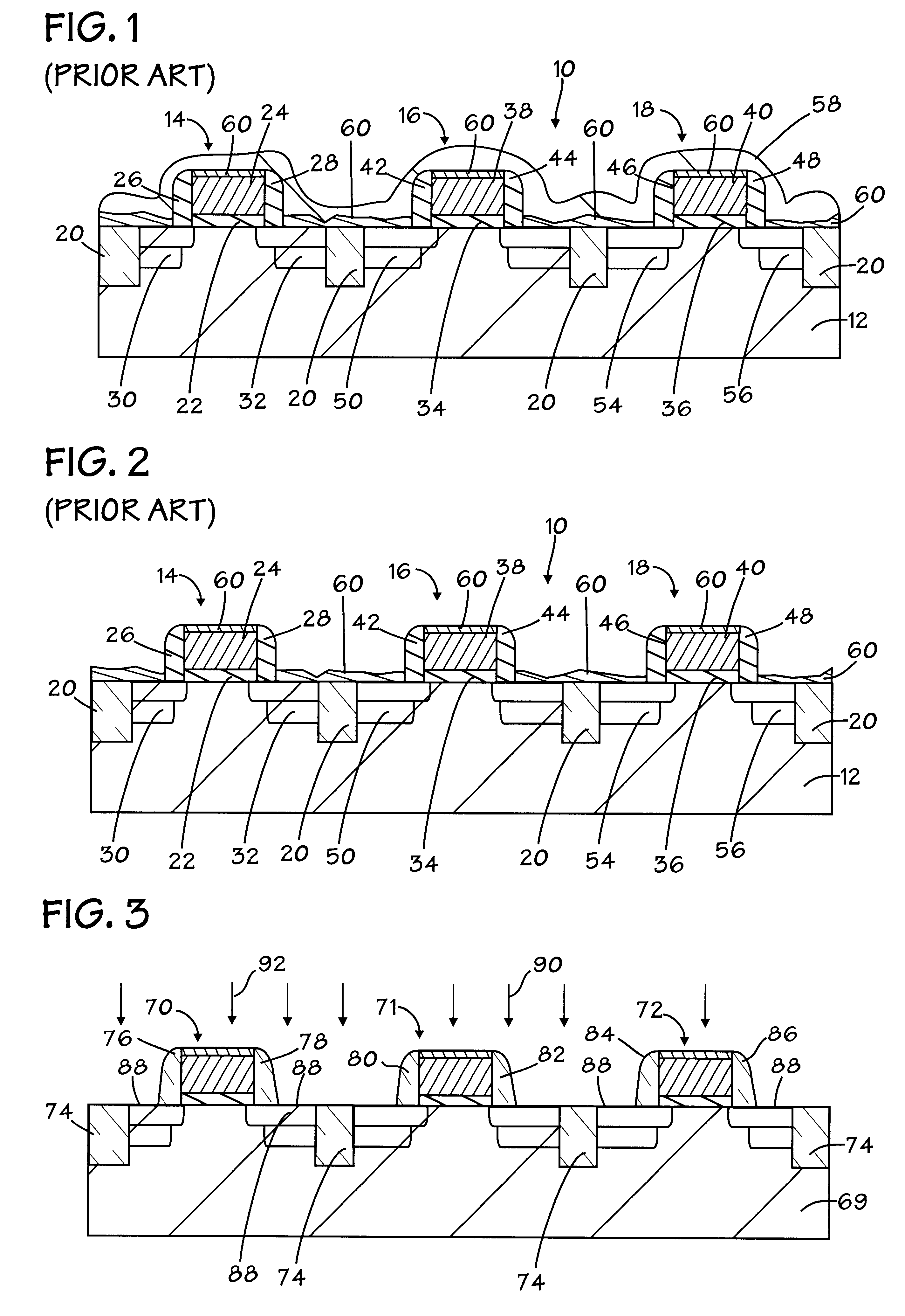

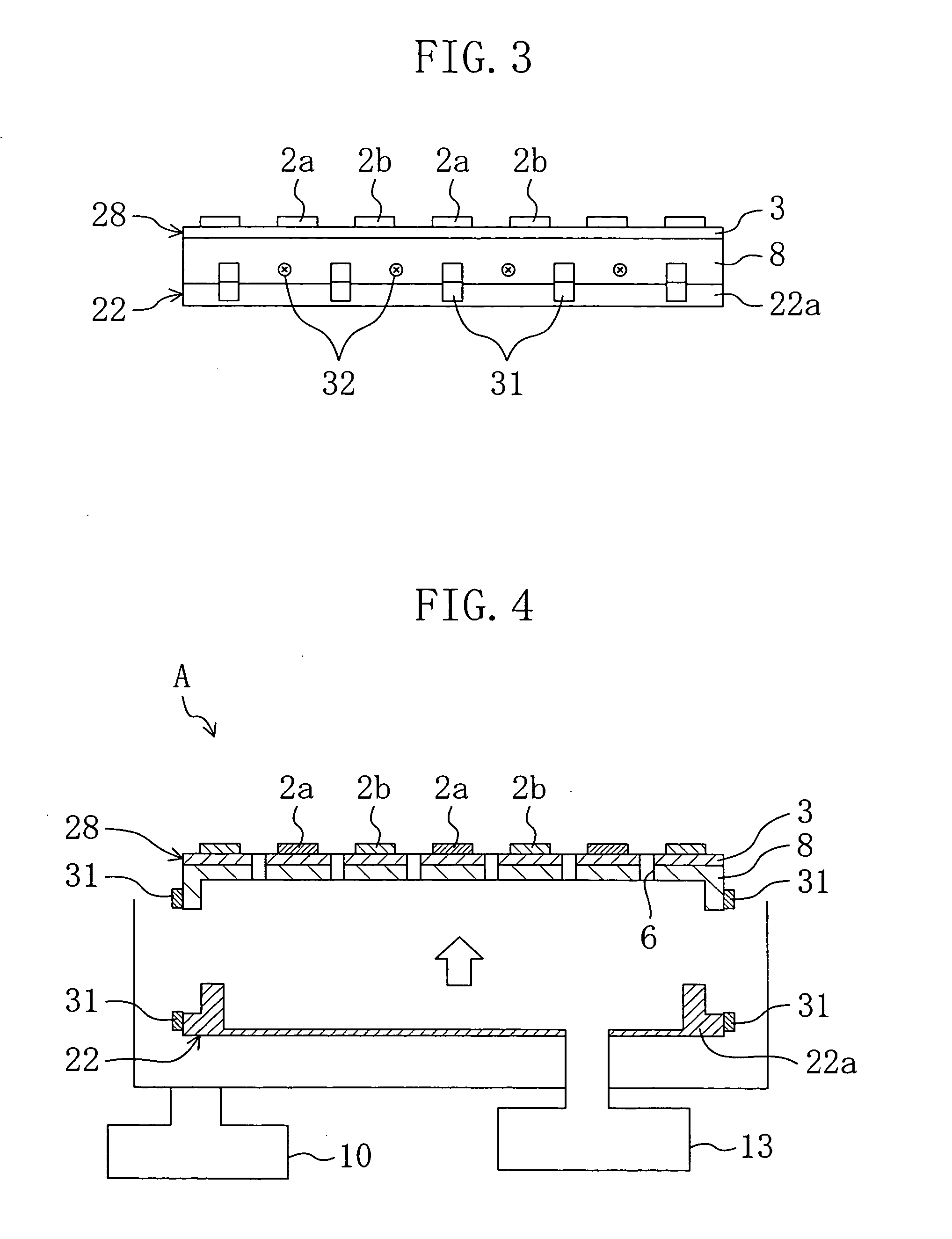

Controlled polymerization on plasma reactor wall

An integrated etch process, for example as used for etching an anti-reflection layer and an underlying aluminum layer, in which the chamber wall polymerization is controlled by coating polymer onto the sidewall by a plasma deposition process prior to inserting the wafer into the chamber, etching the structure, and after removing the wafer from the chamber, plasma cleaning the polymer from the chamber wall. The process is process is particularly useful when the etching is performed in a multi-step process and the polymer is used for passivating the etched structure, for example, a sidewall in an etched structure and in which the first etching step deposits polymer and the second etching step removes polymer. The controlled polymerization eliminates interactions of the etching with the chamber wall material, produces repeatable results between wafers, and eliminates in the etching plasma instabilities associated with changing wall conditions.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com