Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Optical emission spectroscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical Emission Spectroscopy, or OES, is a well trusted and widely used analytical technique used to determine the elemental composition of a broad range of metals. The type of samples which can be tested using OES include samples from the melt in primary and secondary metal production,...

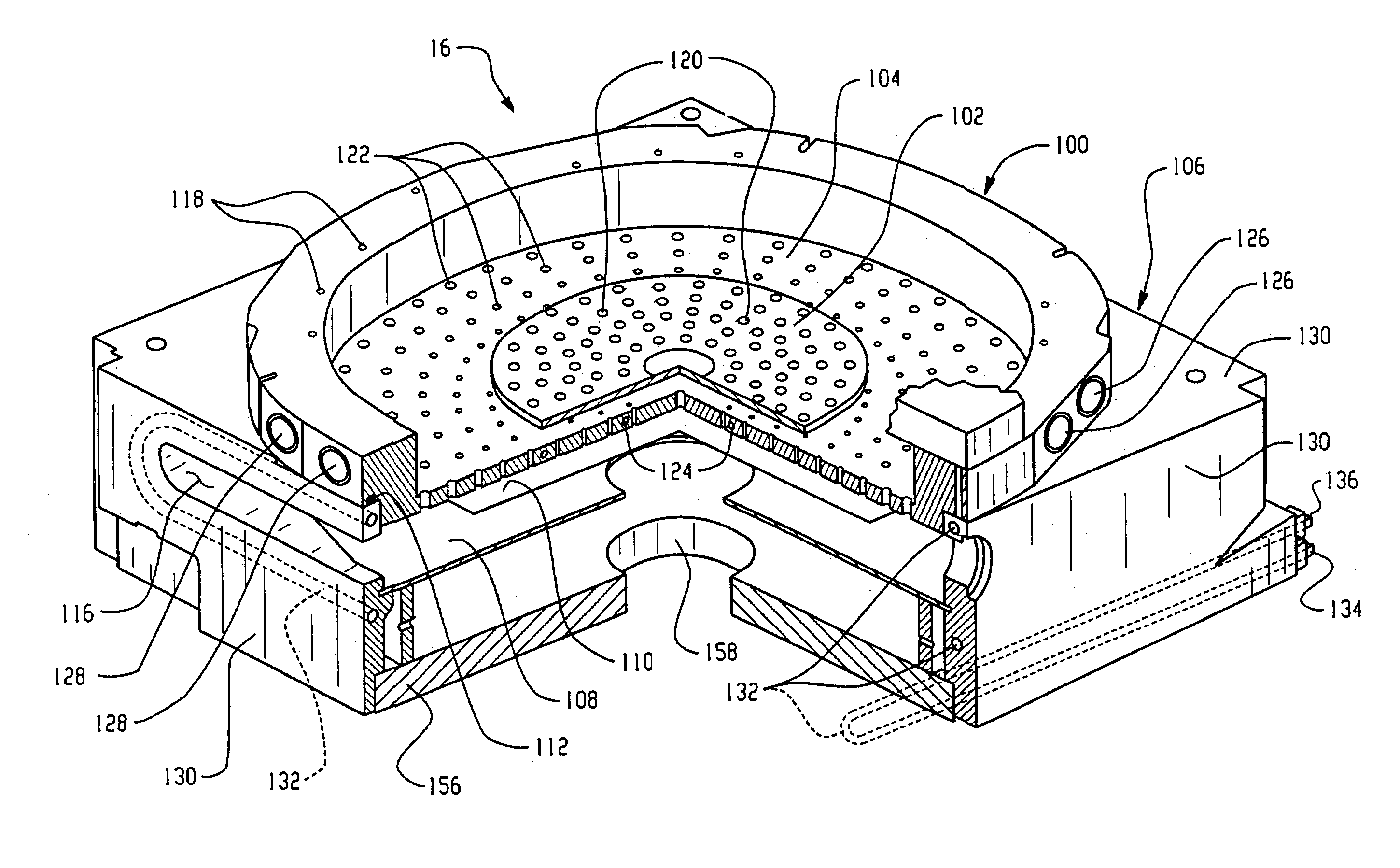

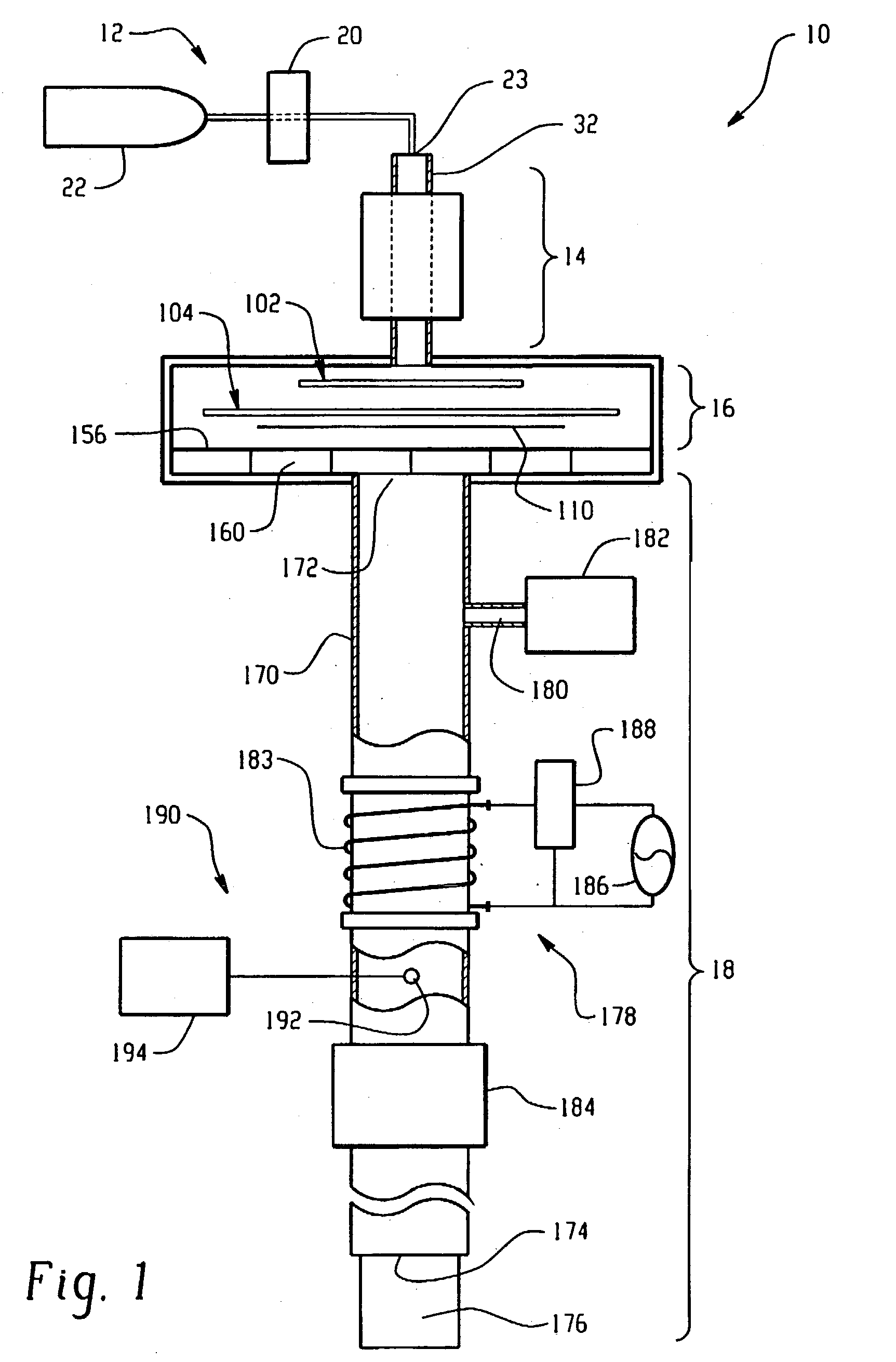

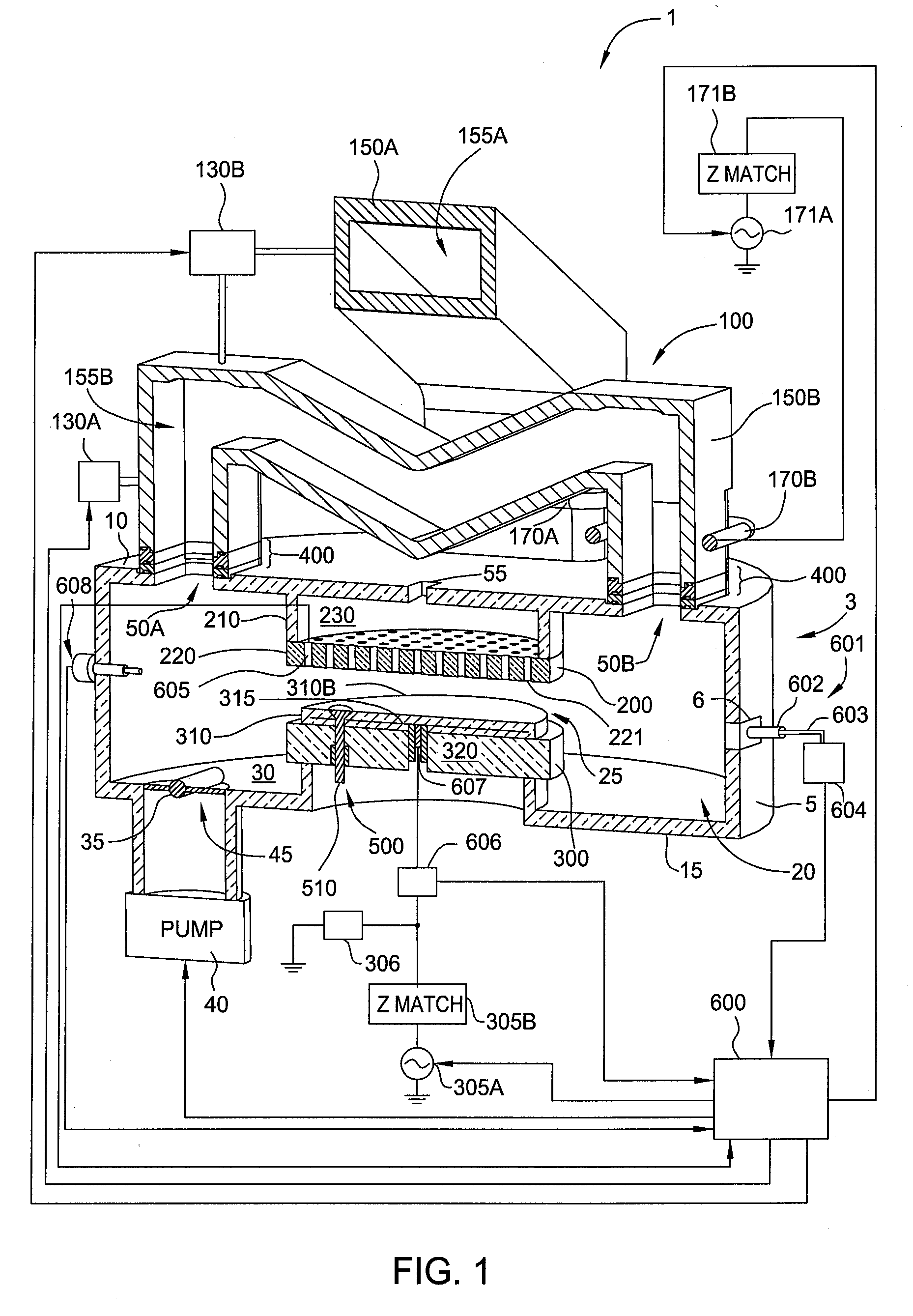

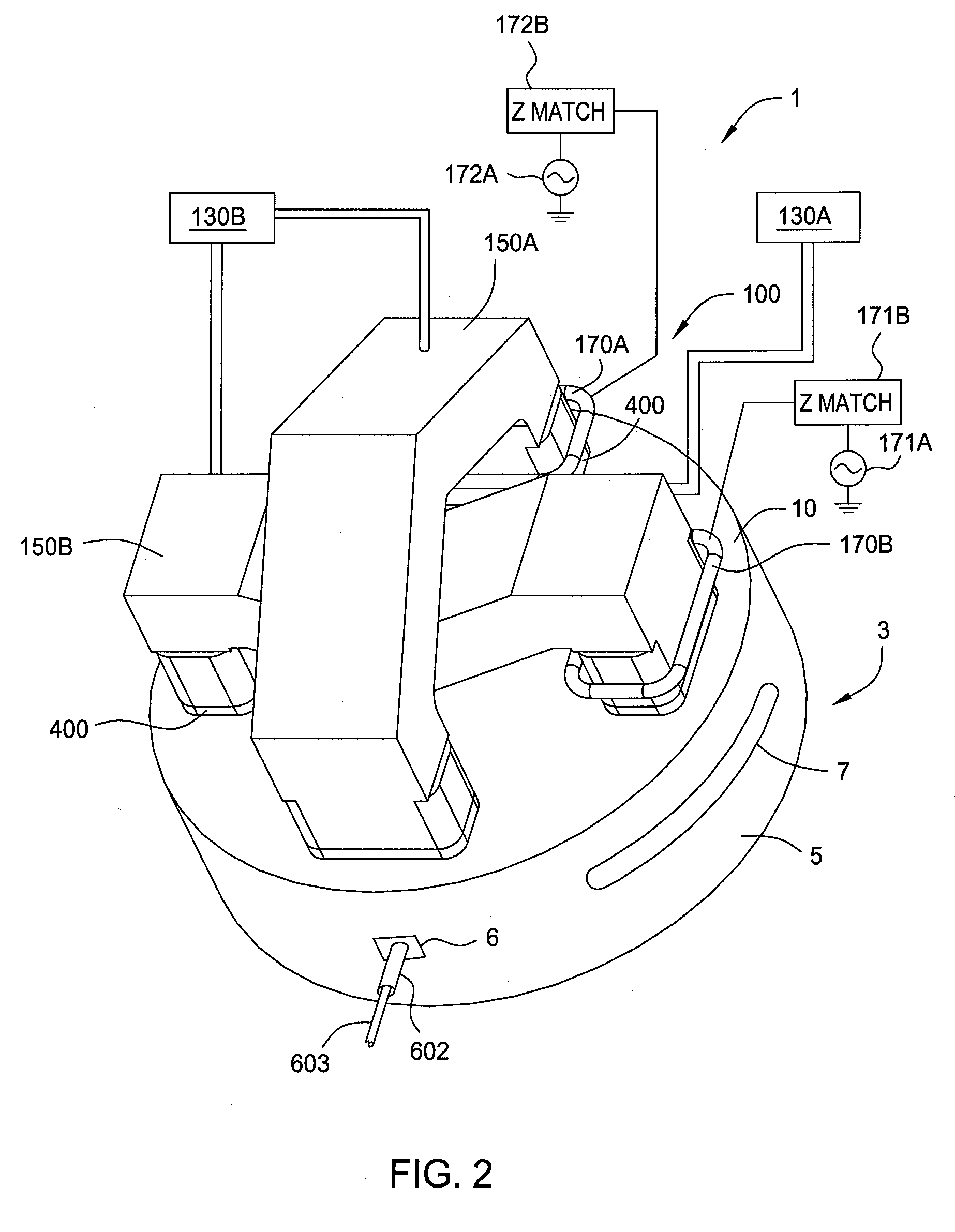

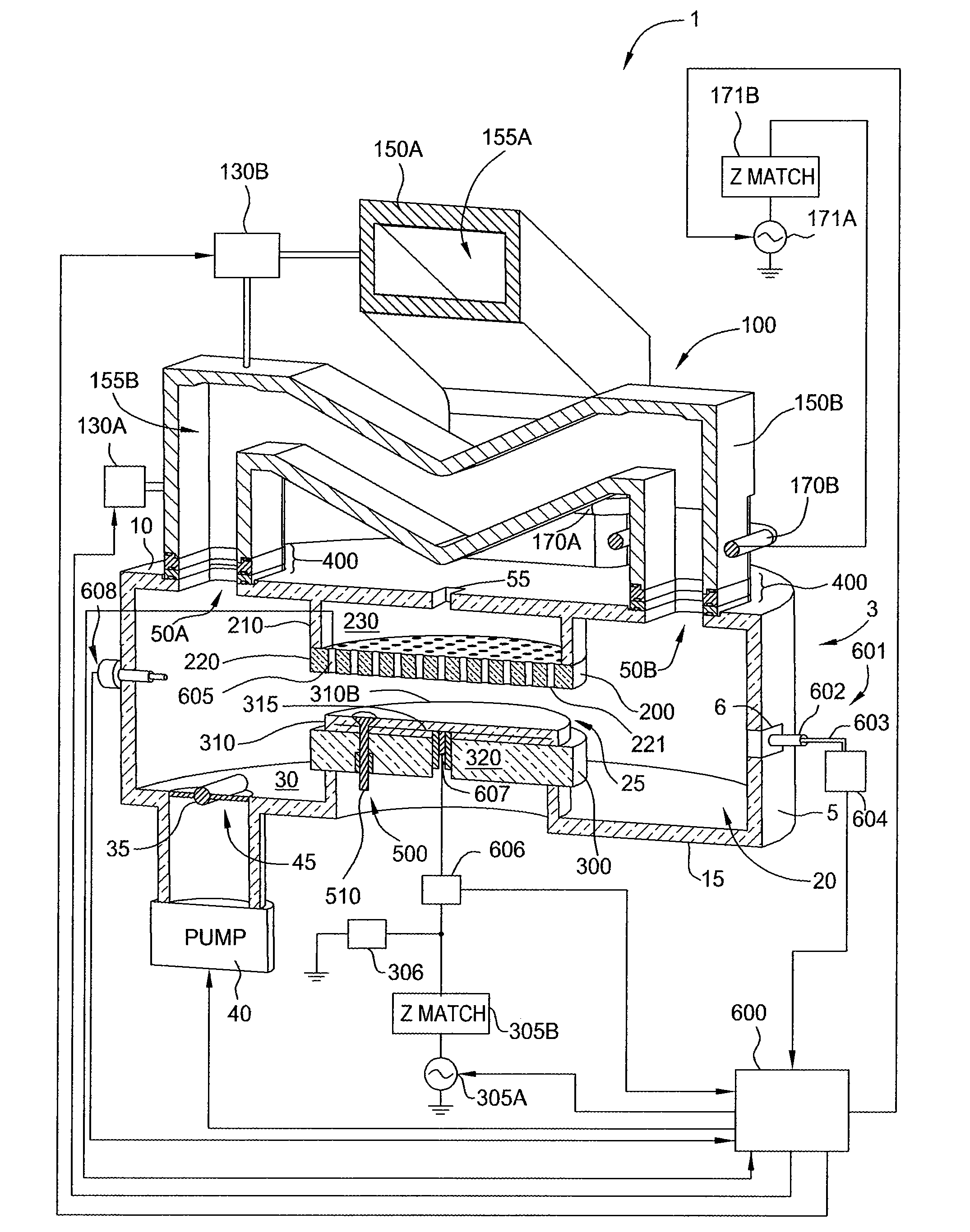

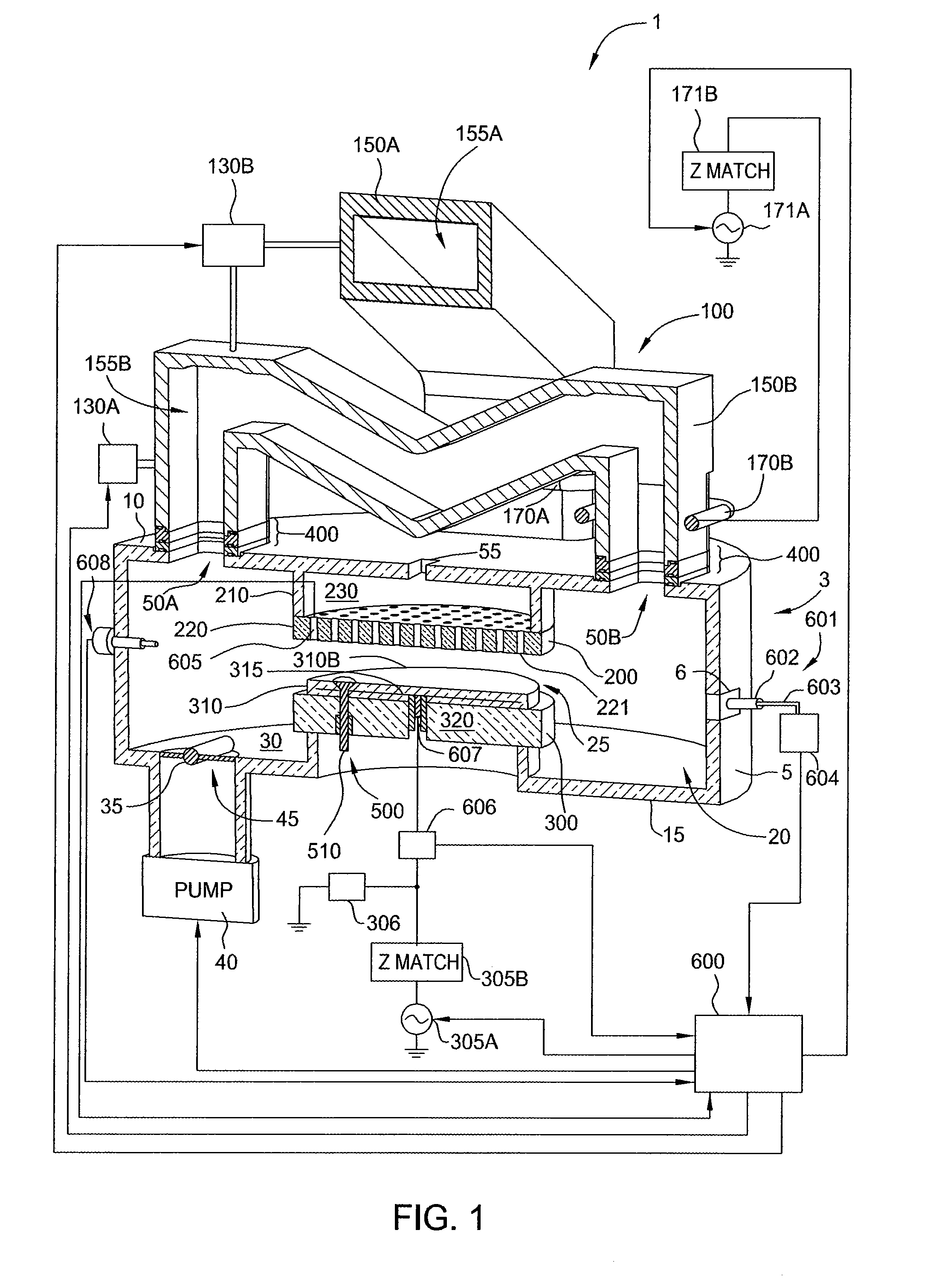

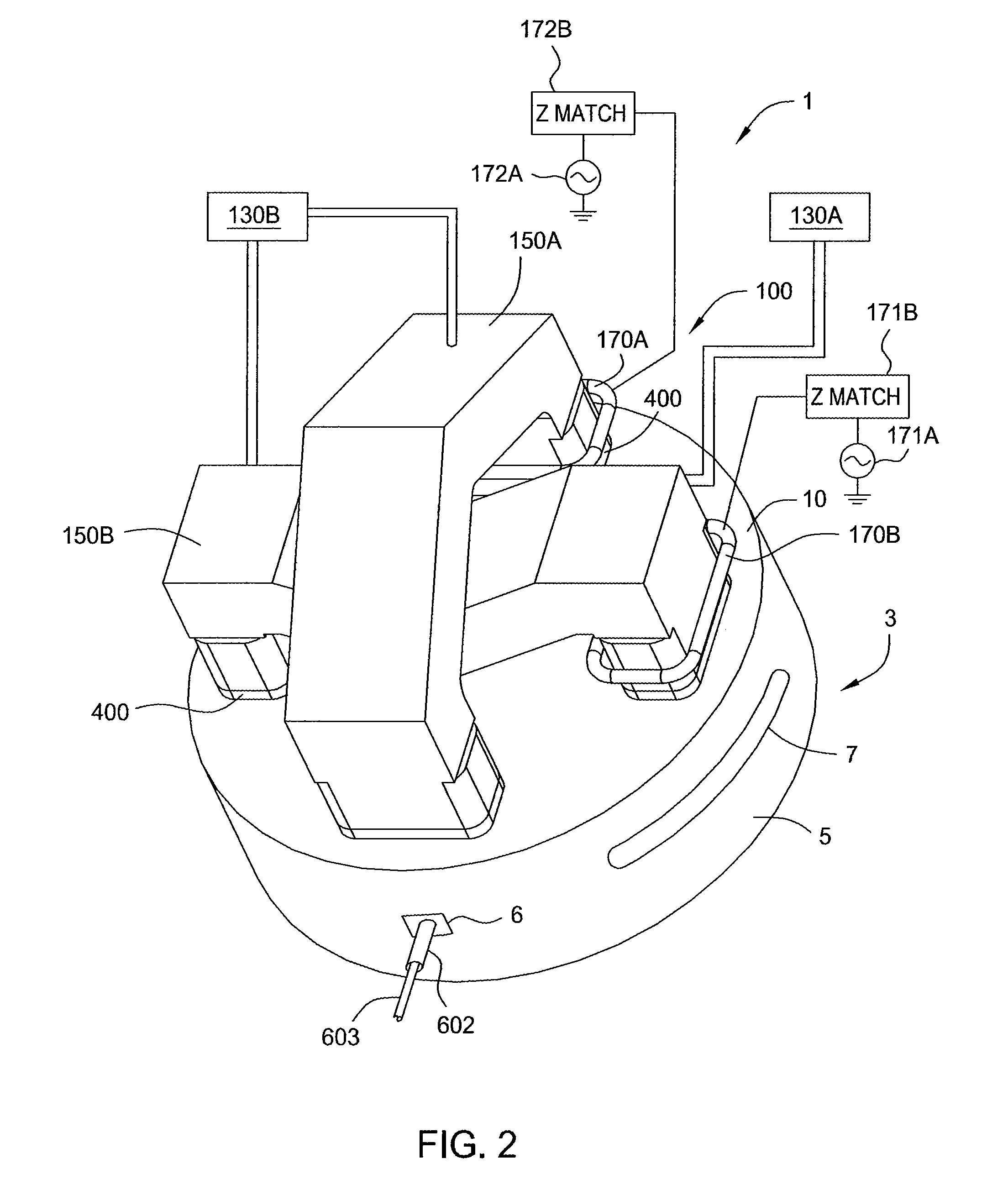

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

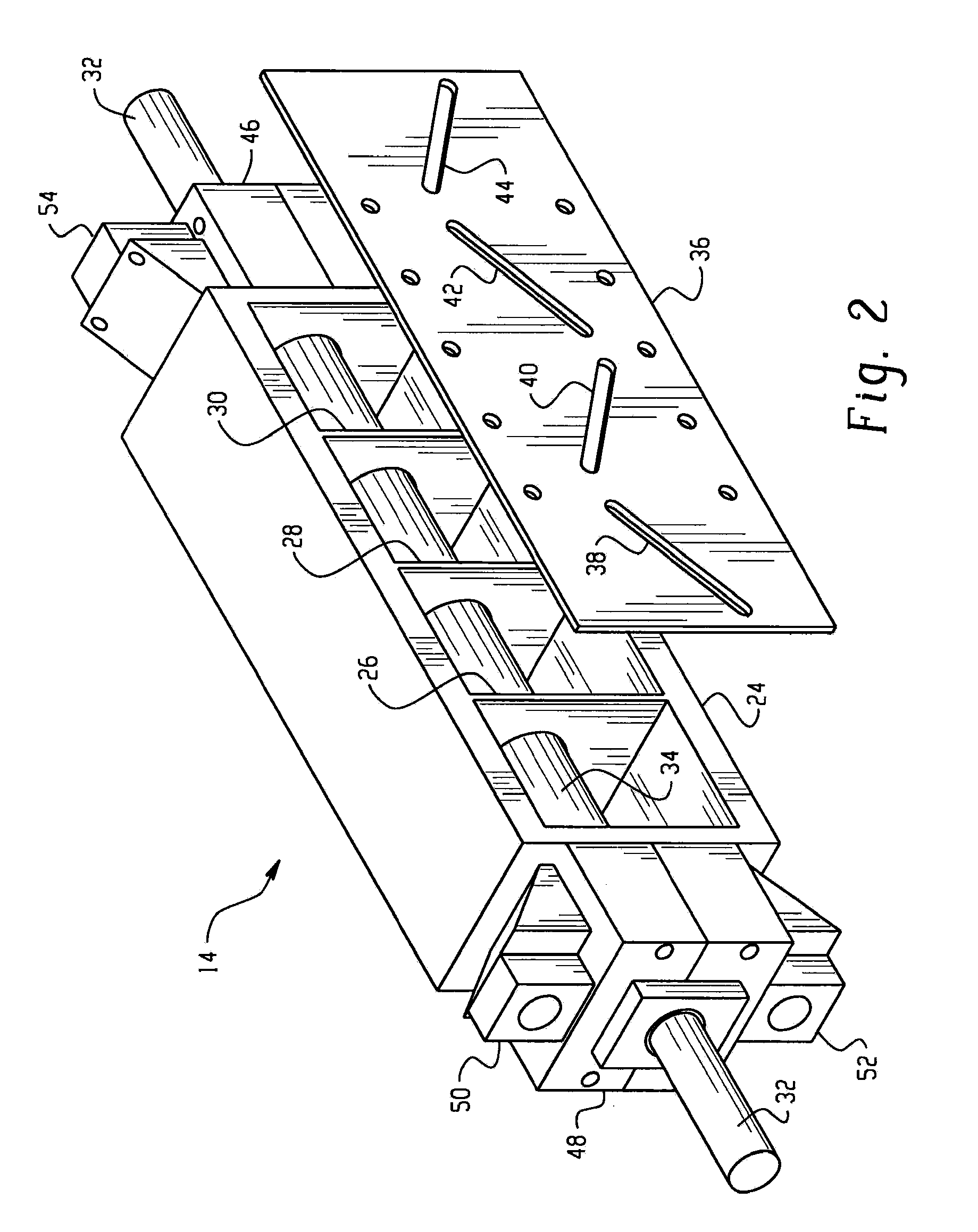

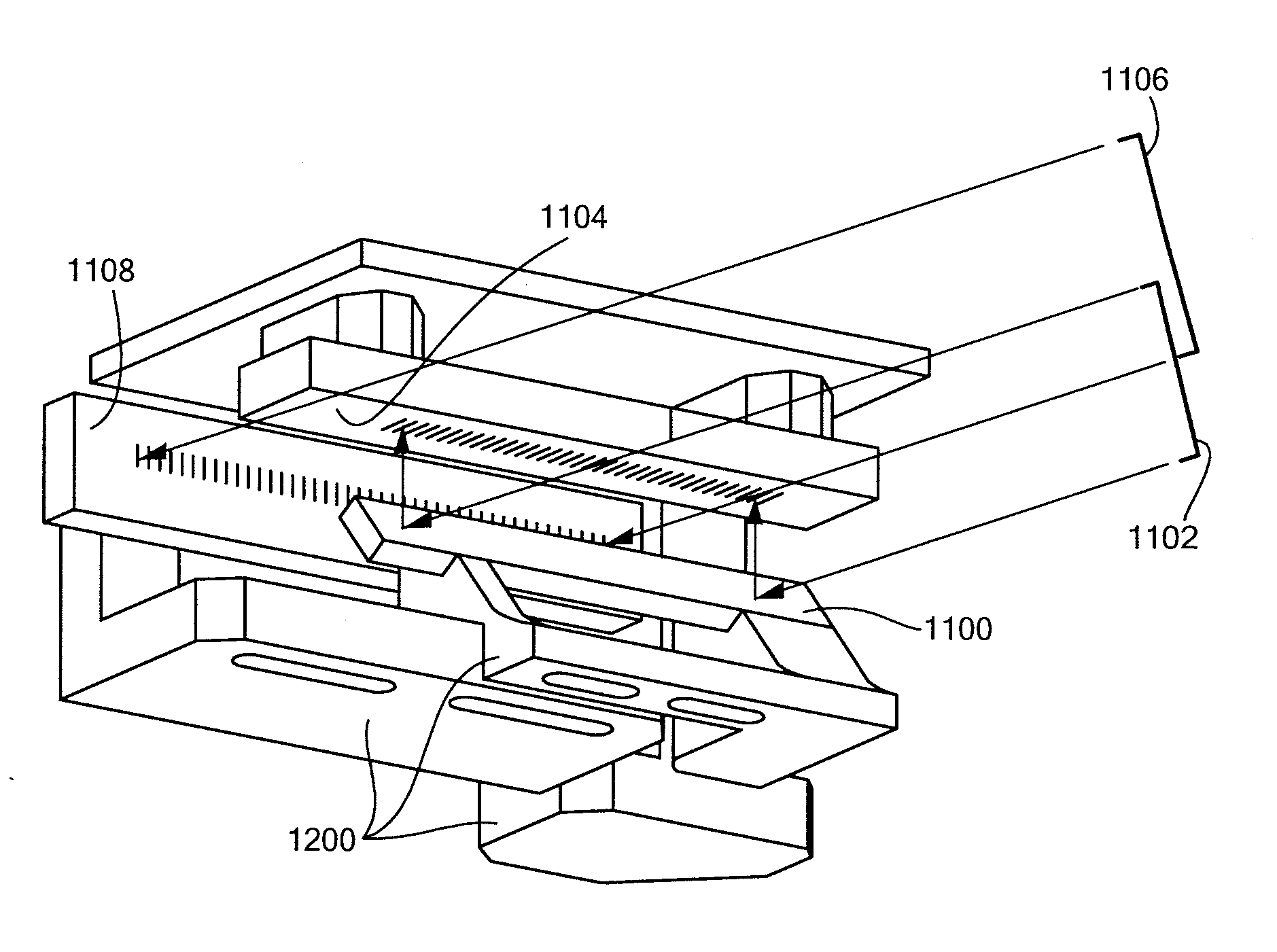

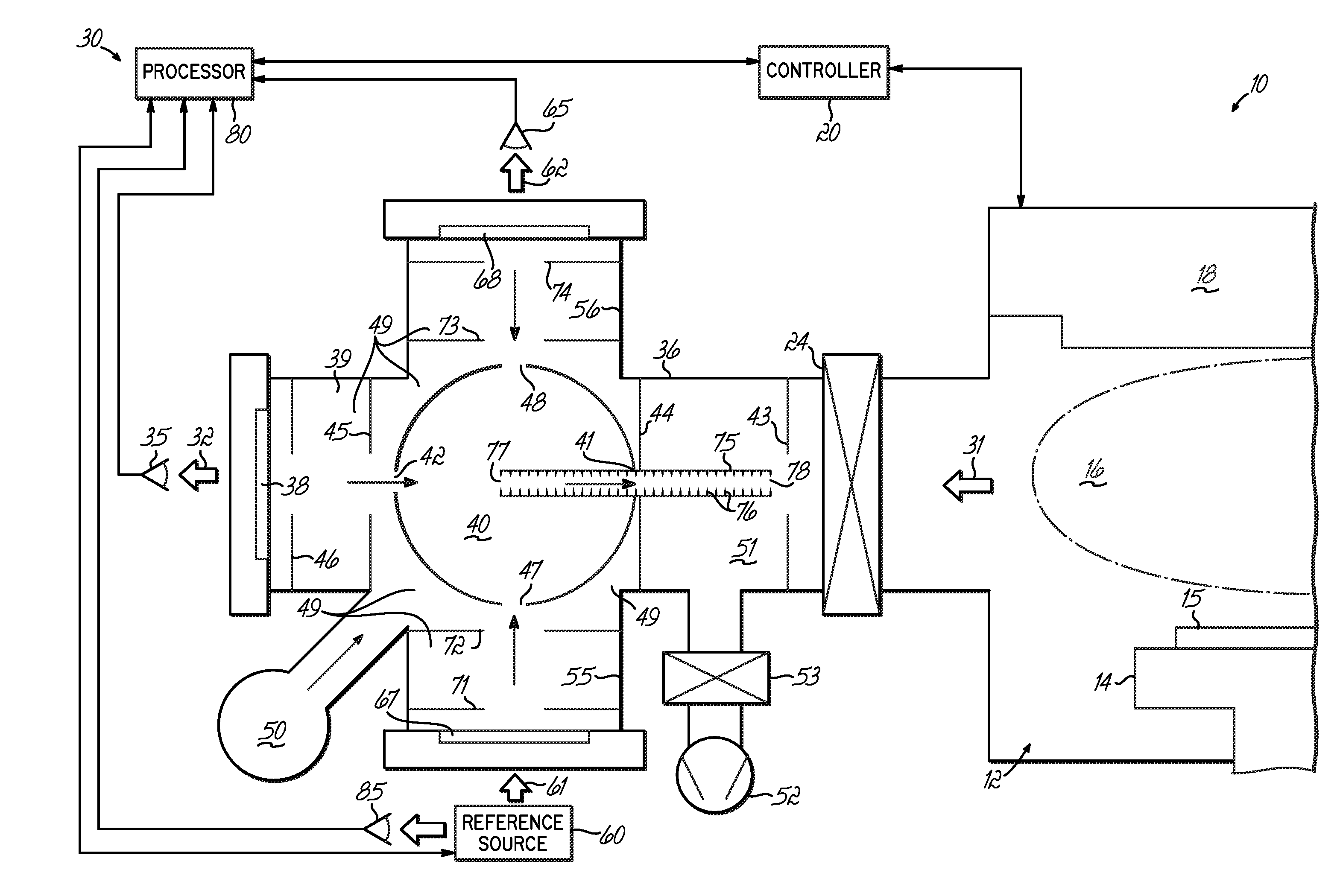

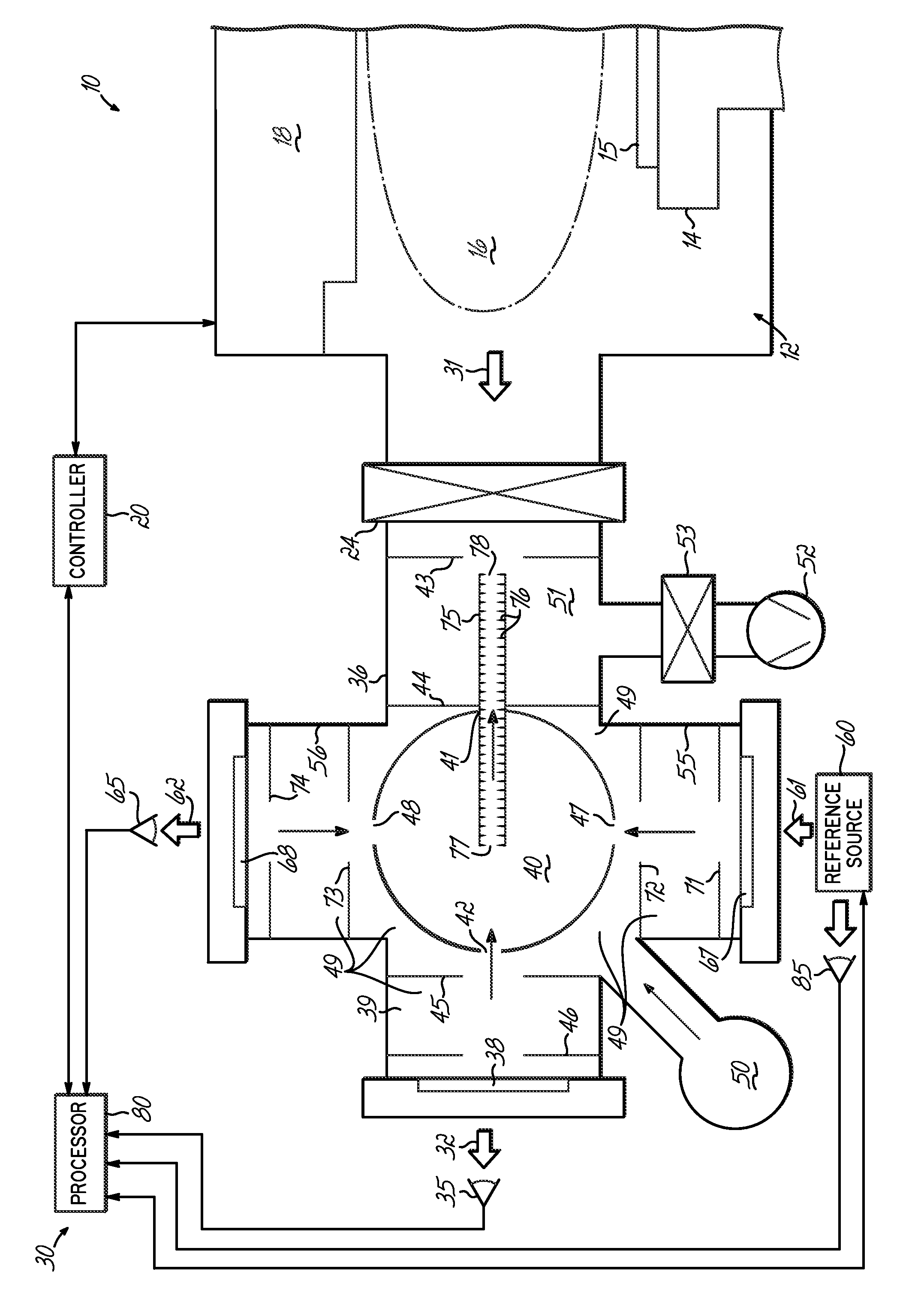

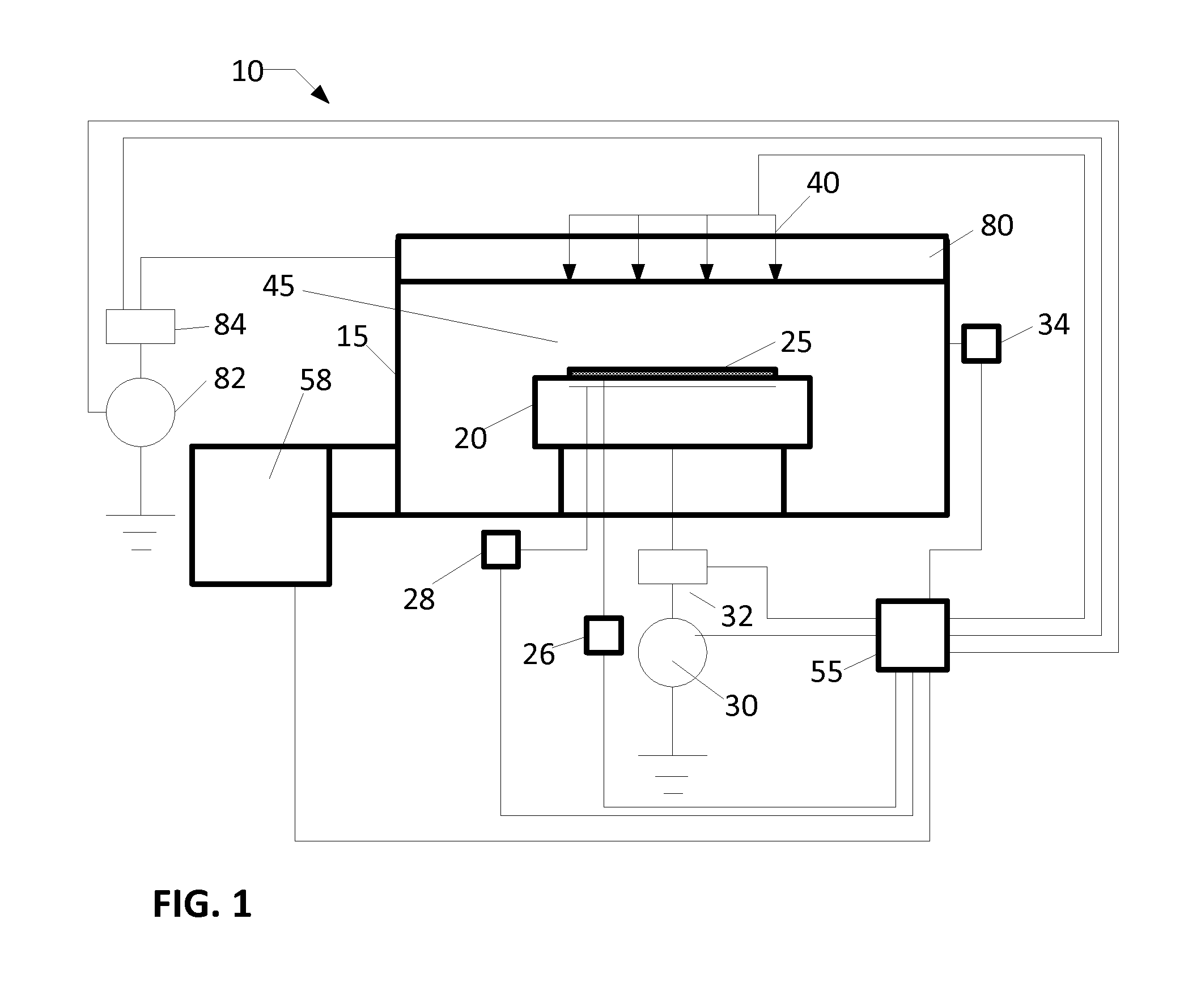

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

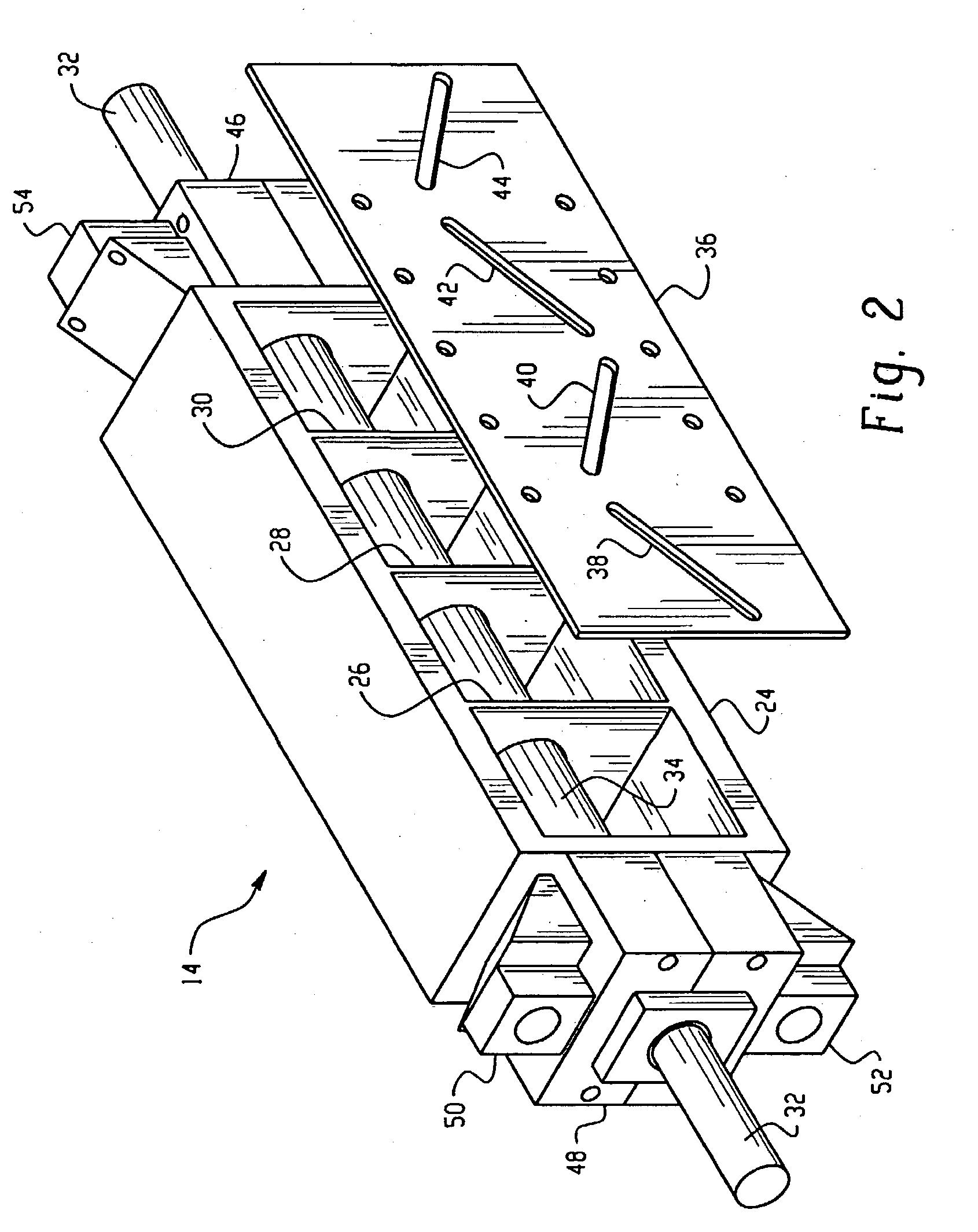

Dosimetry using optical emission spectroscopy/residual gas analyzer in conjuntion with ion current

ActiveUS20080075834A1Liquid surface applicatorsMaterial analysis using wave/particle radiationDosimetry radiationOptical emission spectrometry

The present invention generally provides methods and apparatus for controlling ion dosage in real time during plasma processes. In one embodiment, ion dosages may be controlled using in-situ measurement of the plasma from a mass distribution sensor combined with in-situ measurement from an RF probe.

Owner:APPLIED MATERIALS INC

Plasma ashing apparatus and endpoint detection process

InactiveUS20100055807A1Semiconductor/solid-state device testing/measurementElectric discharge tubesNitrogen plasmaHydrogen

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

Endpoint detection for high density plasma (HDP) processes

InactiveUS6919279B1Optimal plasma etching and cleaningAvoids over-cleaning/etching and under-cleaning/etchingElectric discharge tubesSemiconductor/solid-state device manufacturingSpectral emissionHigh density

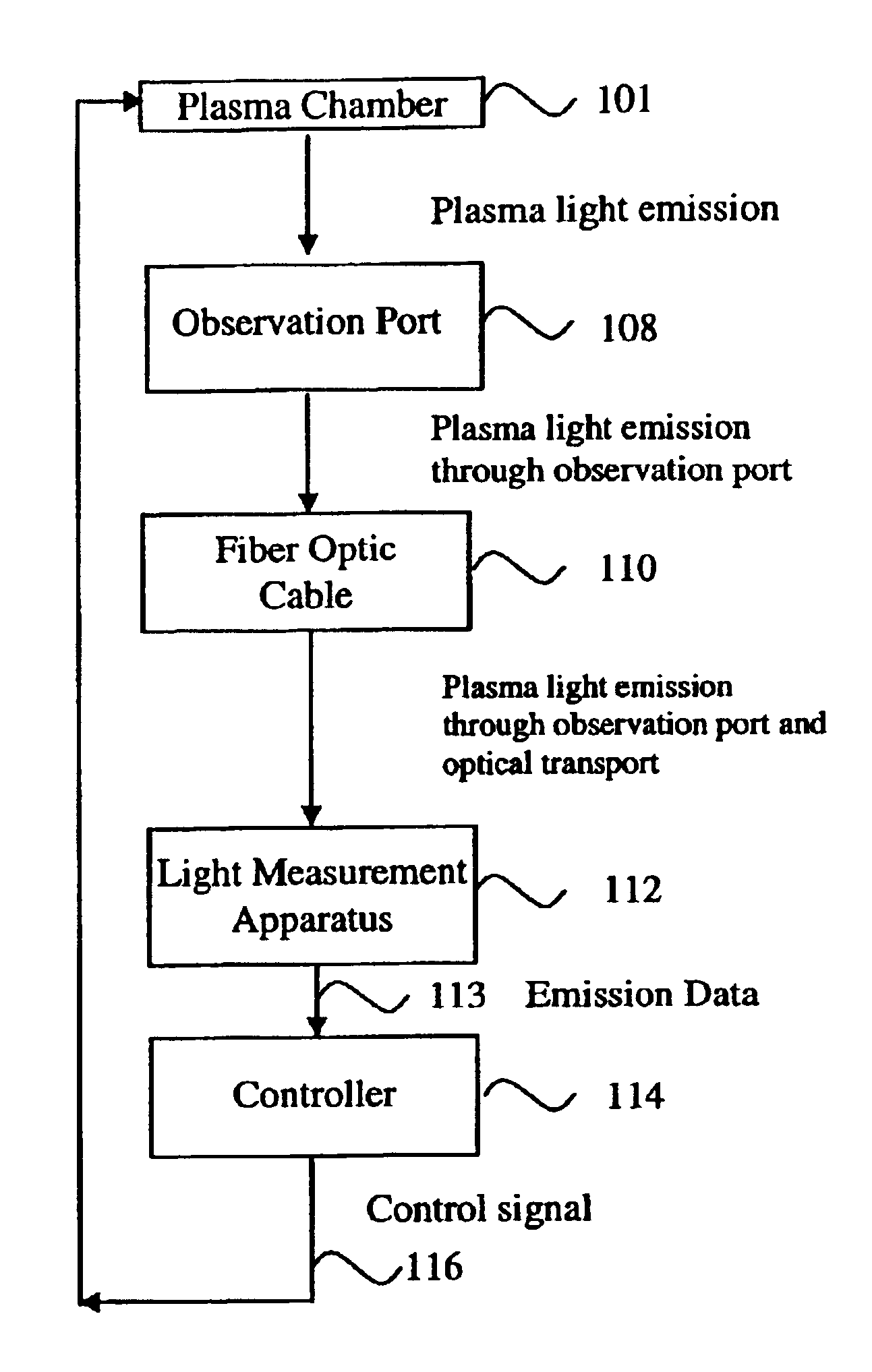

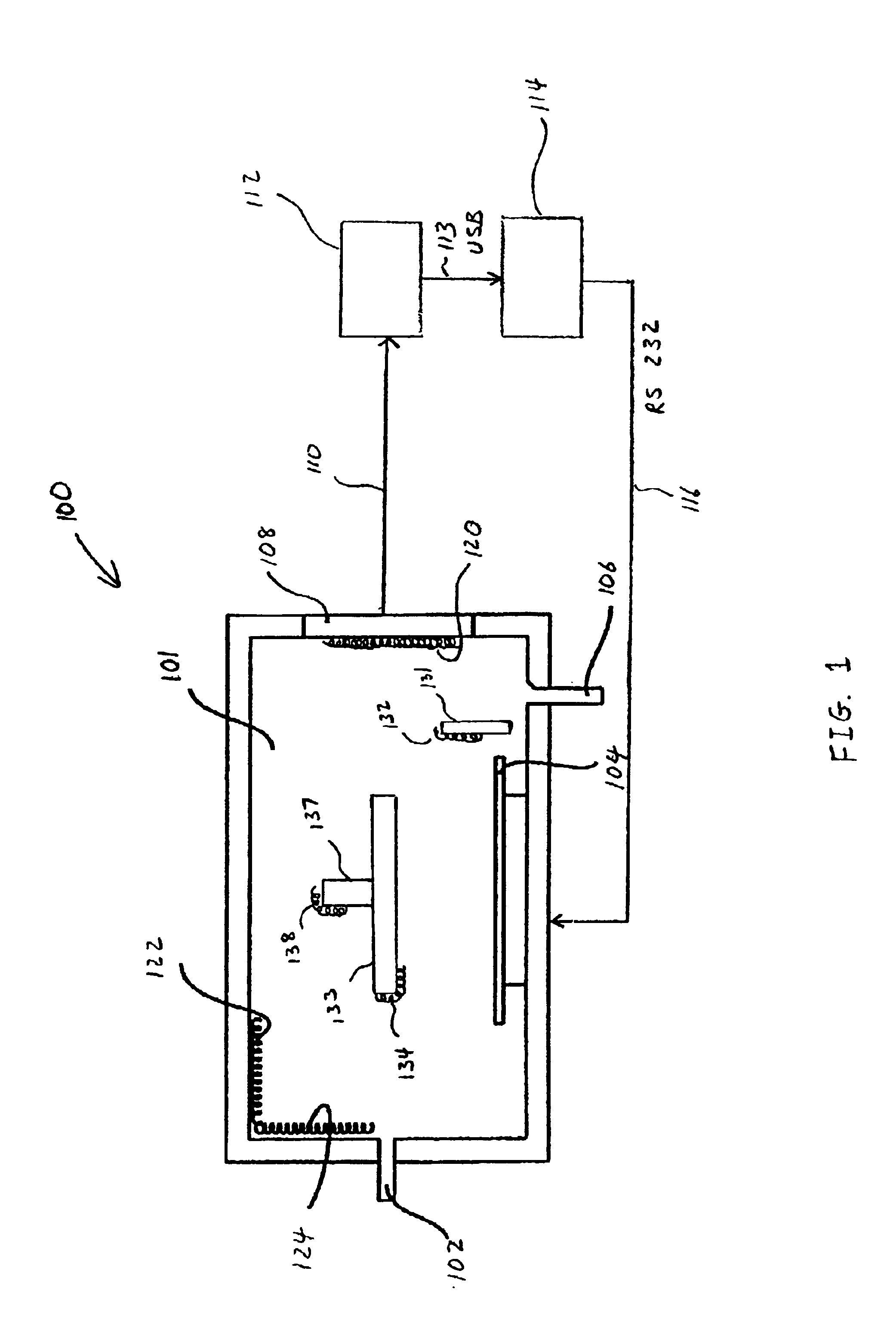

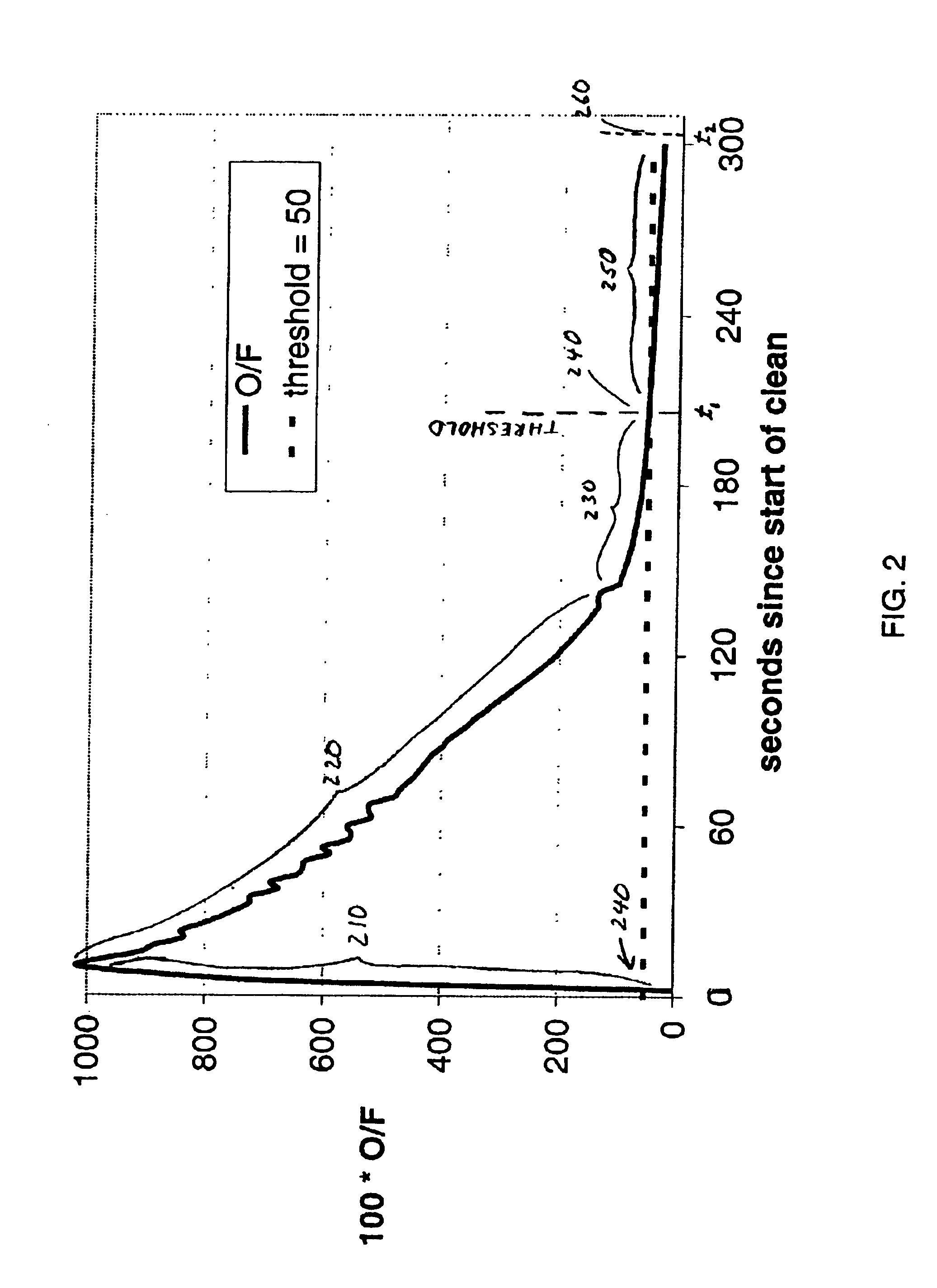

A method and system are provided for endpoint detection of plasma chamber cleaning or plasma etch processes. Optical emission spectroscopy is utilized to determine a spectral emission ratio of two or more light emitting reaction components at wavelengths in close proximity. When a spectral emission ratio or derivative thereof or mathematical function thereof falls below a selected threshold value, the plasma process may be terminated within a calculated time from the threshold value prior to an endpoint value cutoff. Advantageously, the system and methods of the present invention provide real-time, in-situ monitoring of plasma clean or etch processes to optimize the process and avoid under-cleaning or over-cleaning.

Owner:NOVELLUS SYSTEMS +1

Precise endpoint detection for etching processes

InactiveUS6258497B1Electric discharge tubesVacuum gauge using ionisation effectsGas phaseDislocation

A homogeneous marker is formed, possibly by the adsorption of trace amounts of an ambient material such as carbon monoxide gas, at a surface of a deposited material when the plasma in momentarily interrupted during plasma enhanced chemical vapor deposition or other deposition processes involving the presence of a plasma. When the deposited material is etched, the resulting crystal dislocations or adsorbed gas is detected as a marker by optical emission spectroscopy techniques. The accuracy of an end point determination of the etching process can be increased by providing a sequence of such markers within the bulk or volume of the deposited material. The markers, being merely an interface such as a slight crystal dislocation in otherwise homogeneous material, do not affect the electrical, chemical or optical properties of the remainder of the predetermined deposited material and thus the homogeneity of the deposited material is not significantly affected.

Owner:IBM CORP

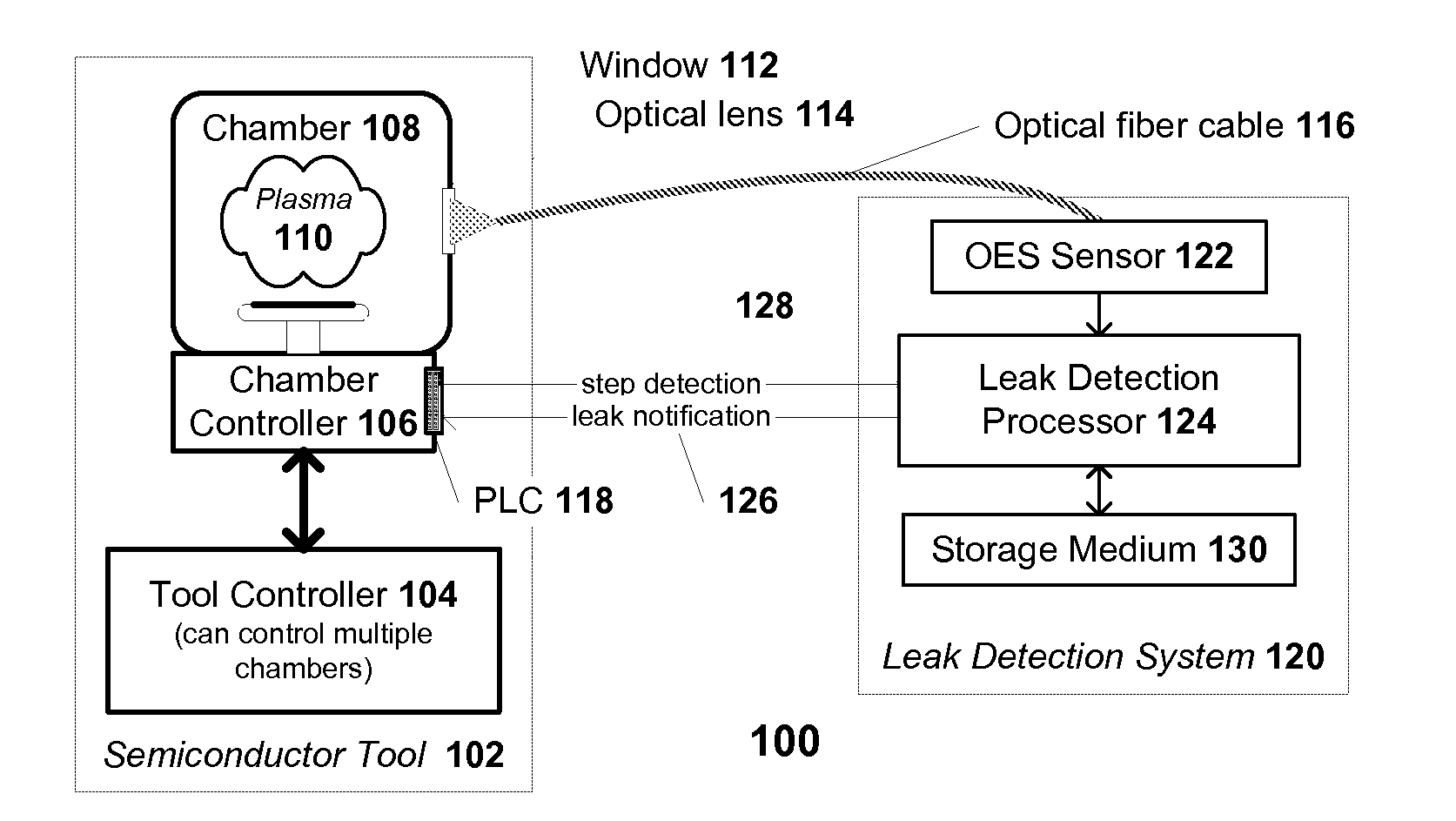

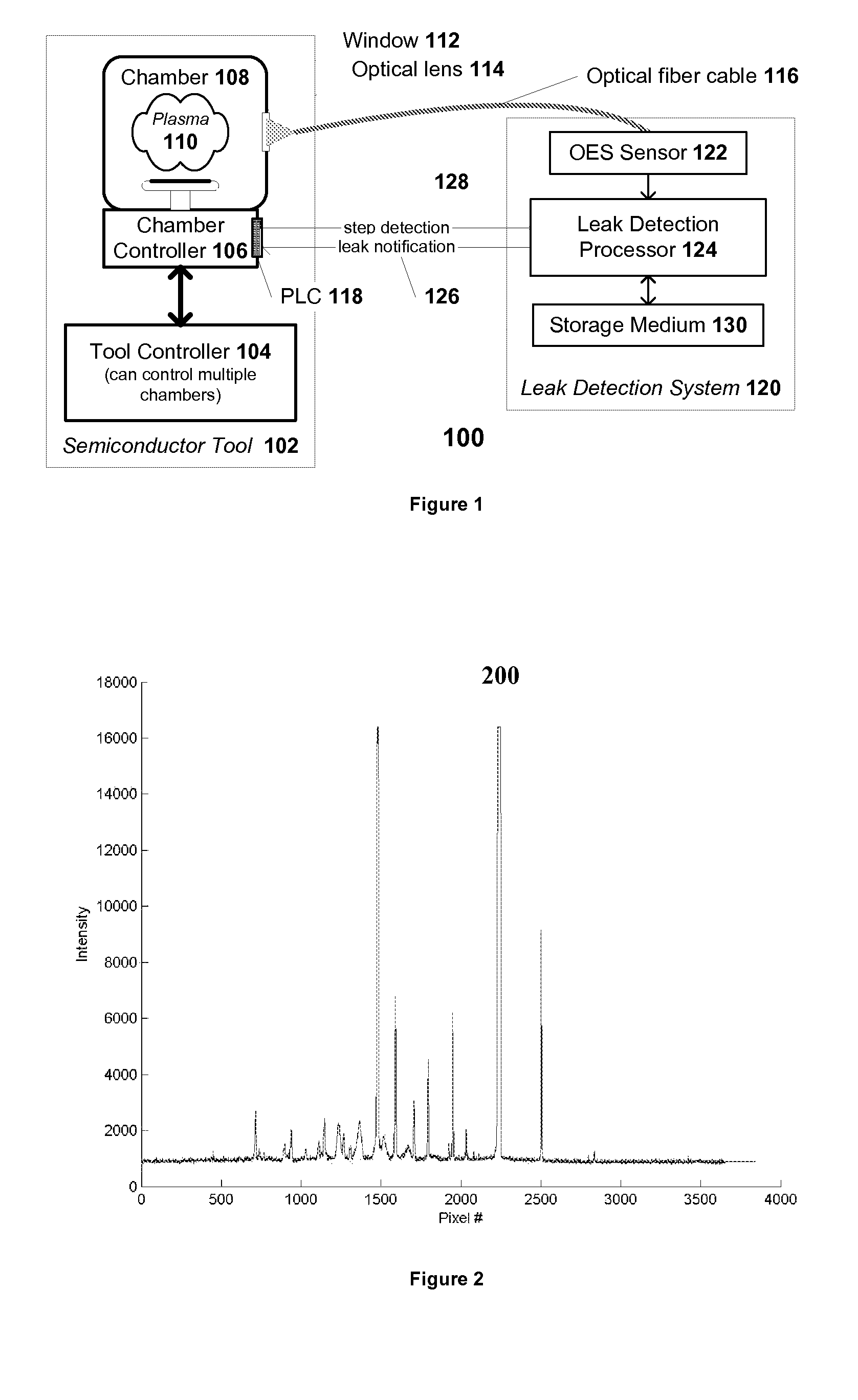

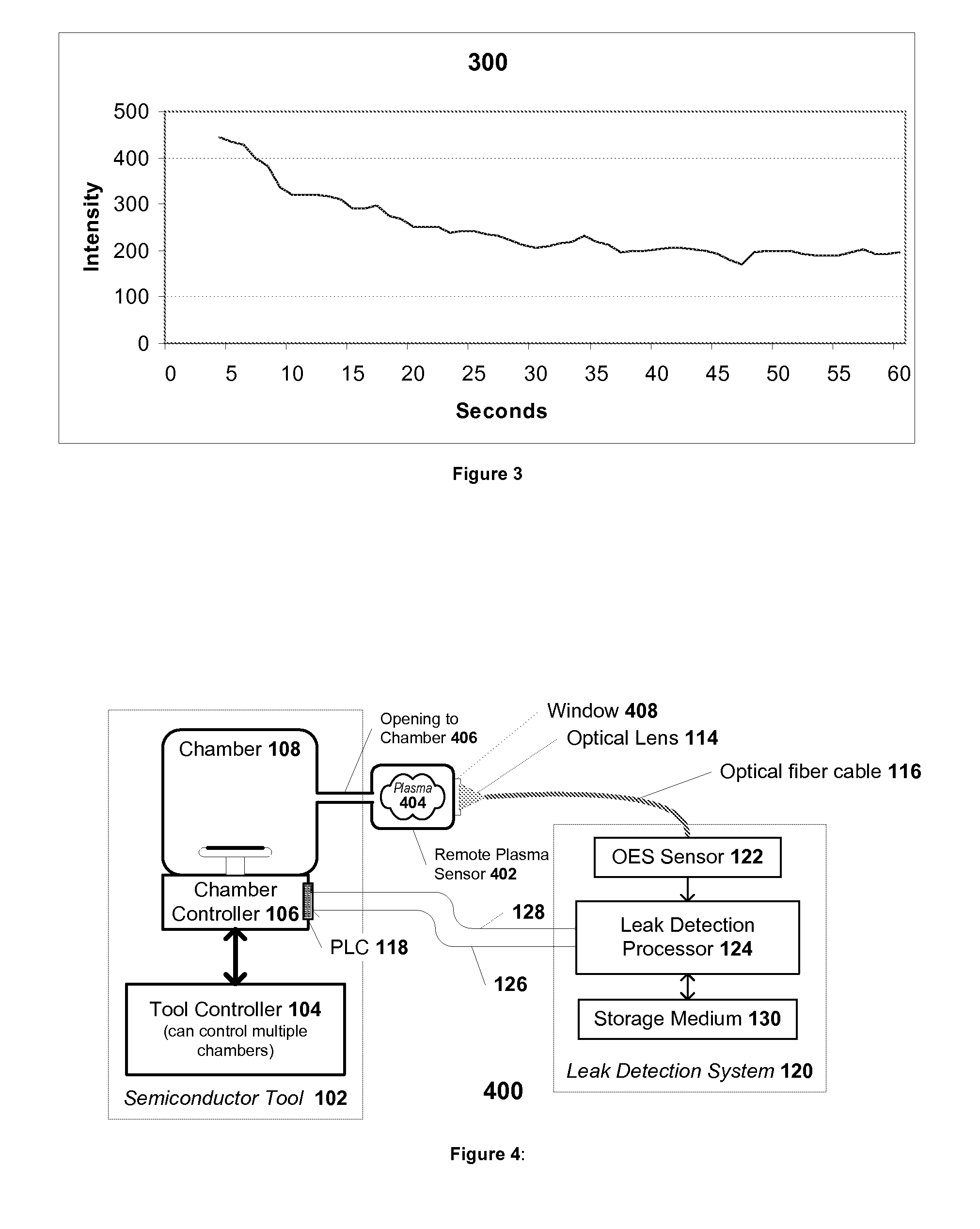

System and method for vacuum chamber leak detection

ActiveUS7590498B1Flow propertiesFluid pressure measurement by mechanical elementsEngineeringVacuum chamber

Leaks in a processing chamber, including “virtual leaks” resulting from outgassing of material present within the chamber, may be detected utilizing an optical emission spectroscopy (OES) sensor configured to monitor light emitted from plasma of a sample from the chamber. According to certain embodiments, gas introduced into the chamber by the leak may be detected directly on the basis of its optical spectrum. Alternatively, gas introduced by the leak may be detected indirectly, based upon an optical spectrum of a material resulting from reaction of the gas attributable to the leak. According to one embodiment, data from the OES sensor is received by a processor that is configured to compute a leak detection index. The value of the leak detection index is compared against a threshold to determine if a leak is detected. If the value of the index crosses the threshold, a notification of the existence of a leak is sent.

Owner:PIVOTAL SYST CORP

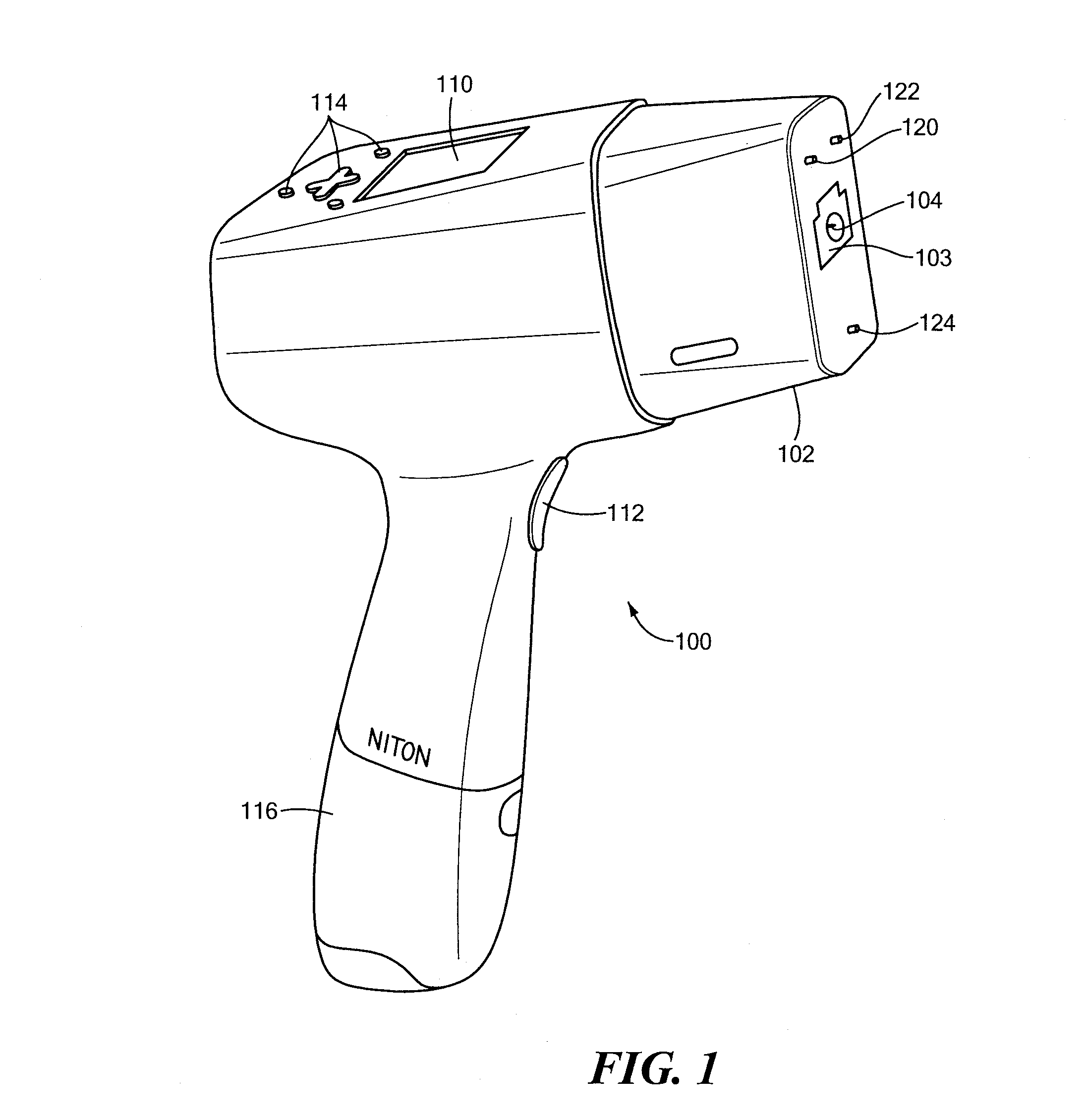

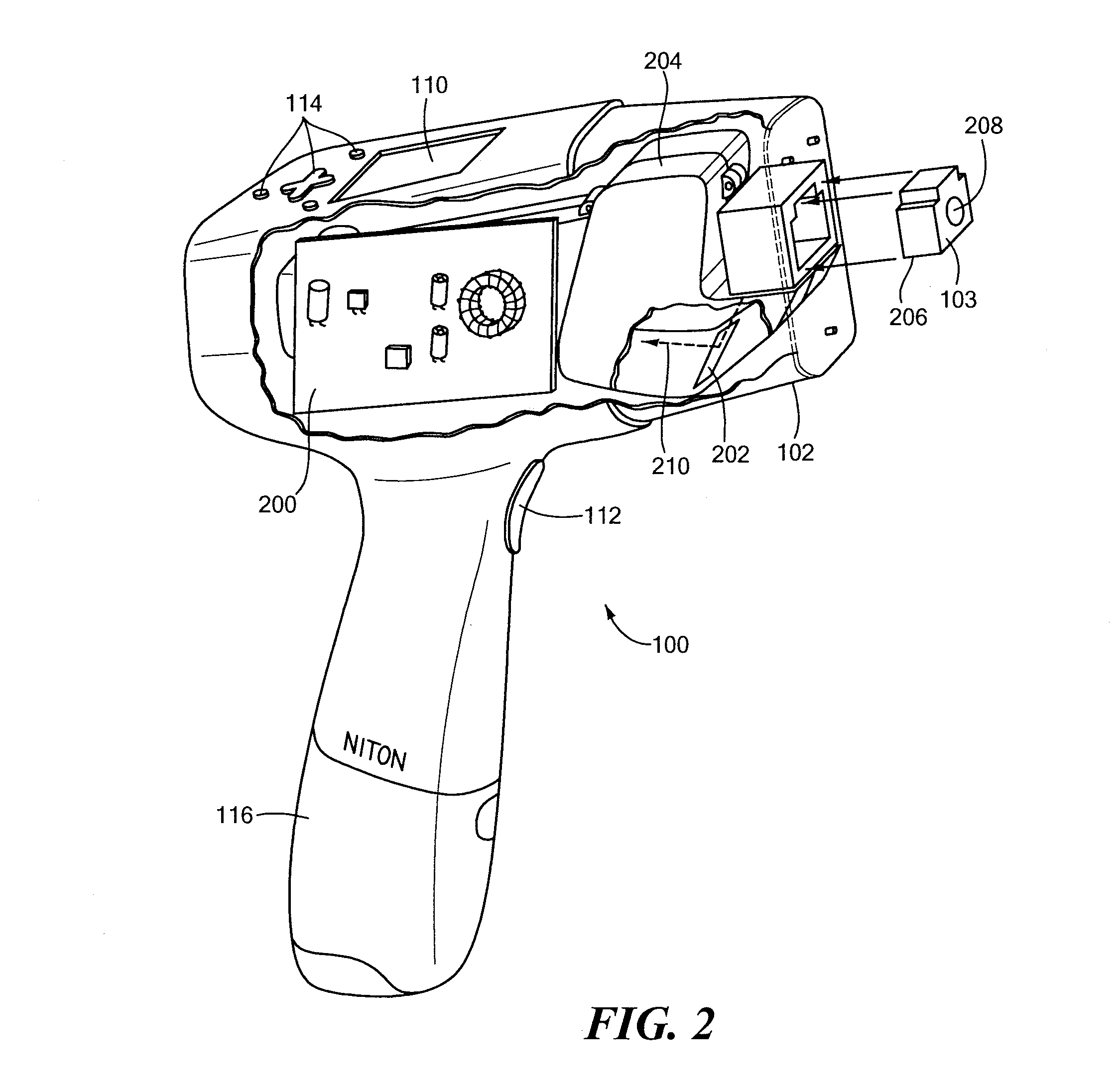

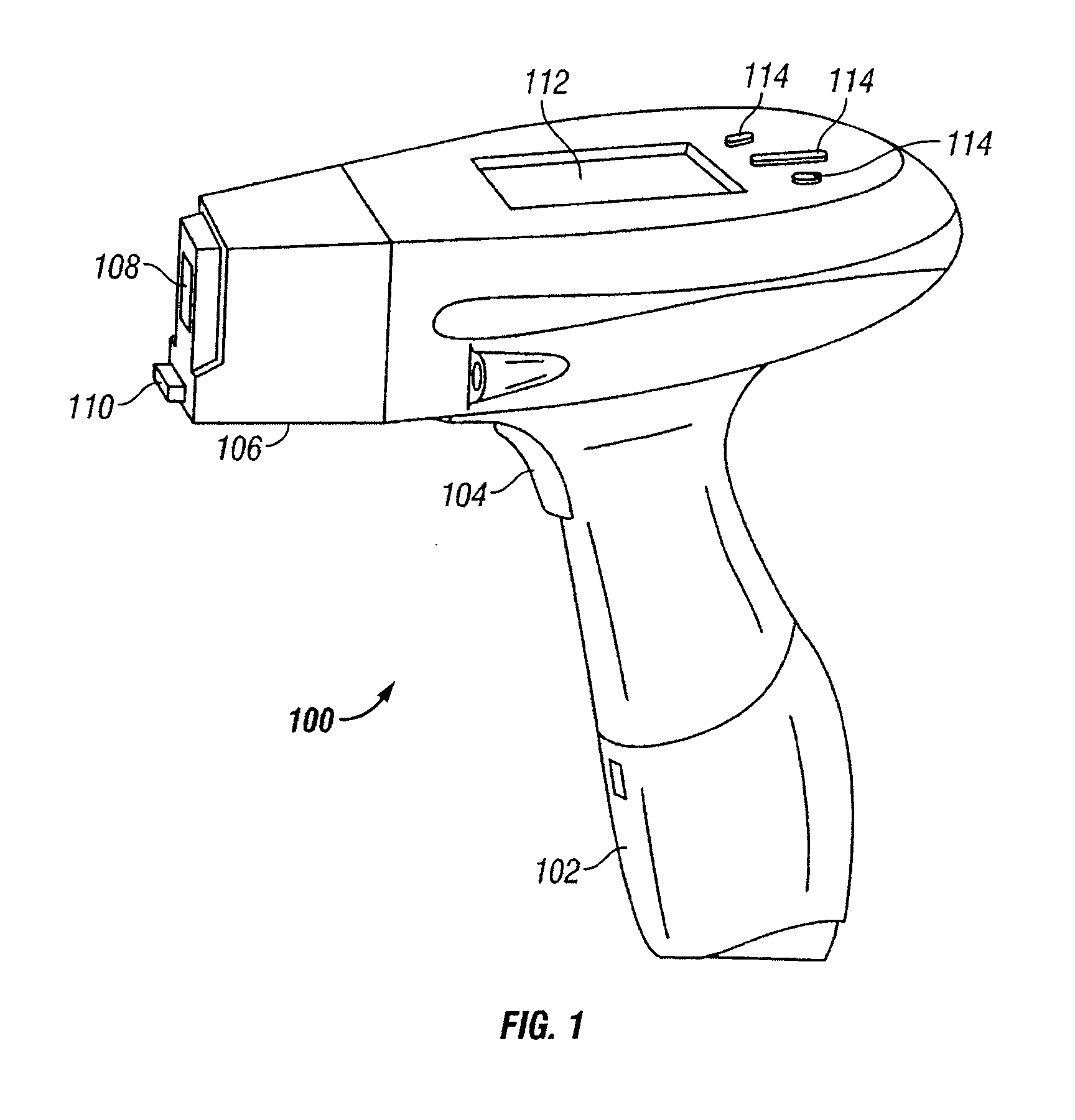

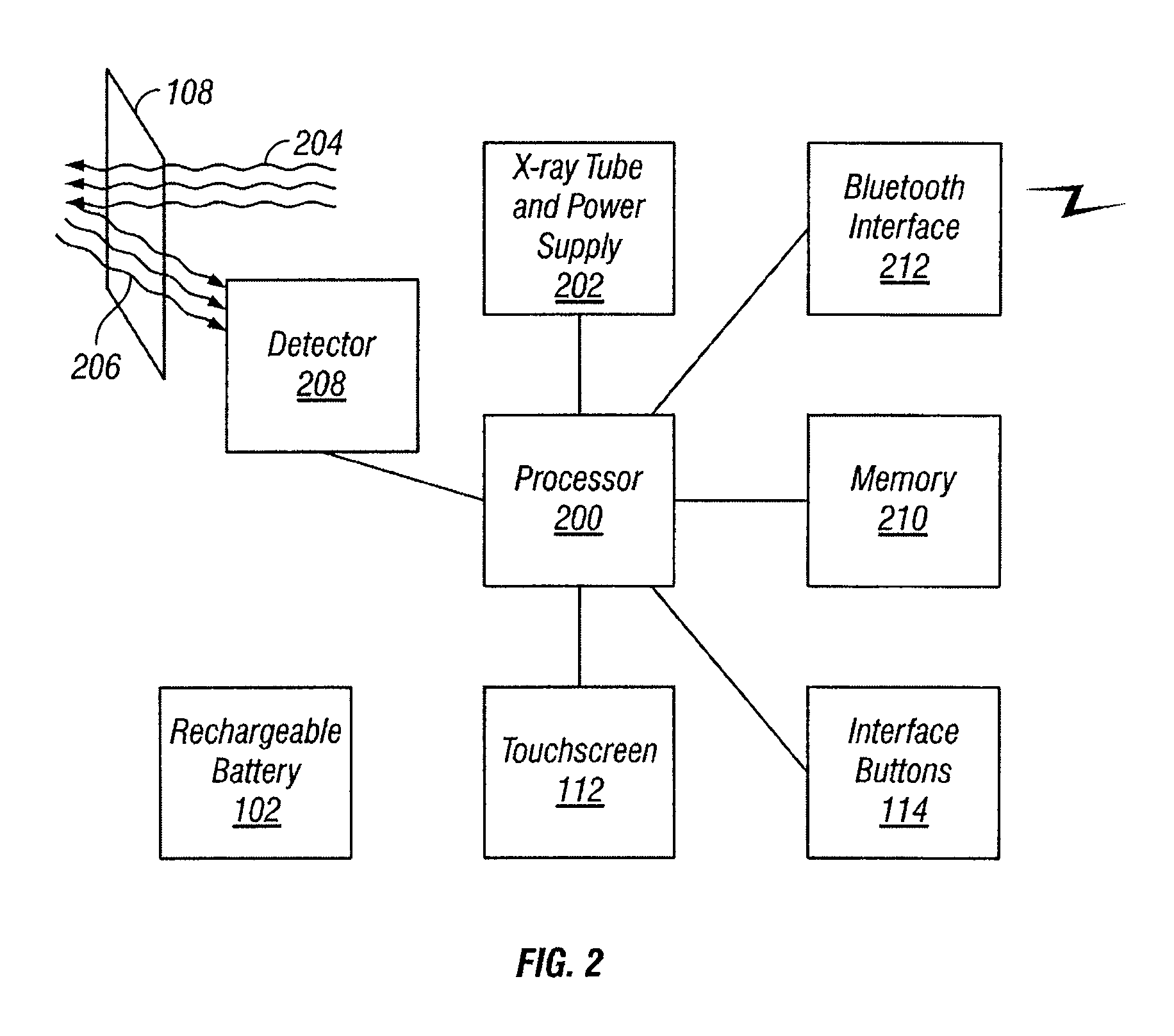

Hand-held, self-contained optical emission spectroscopy (OES) analyzer

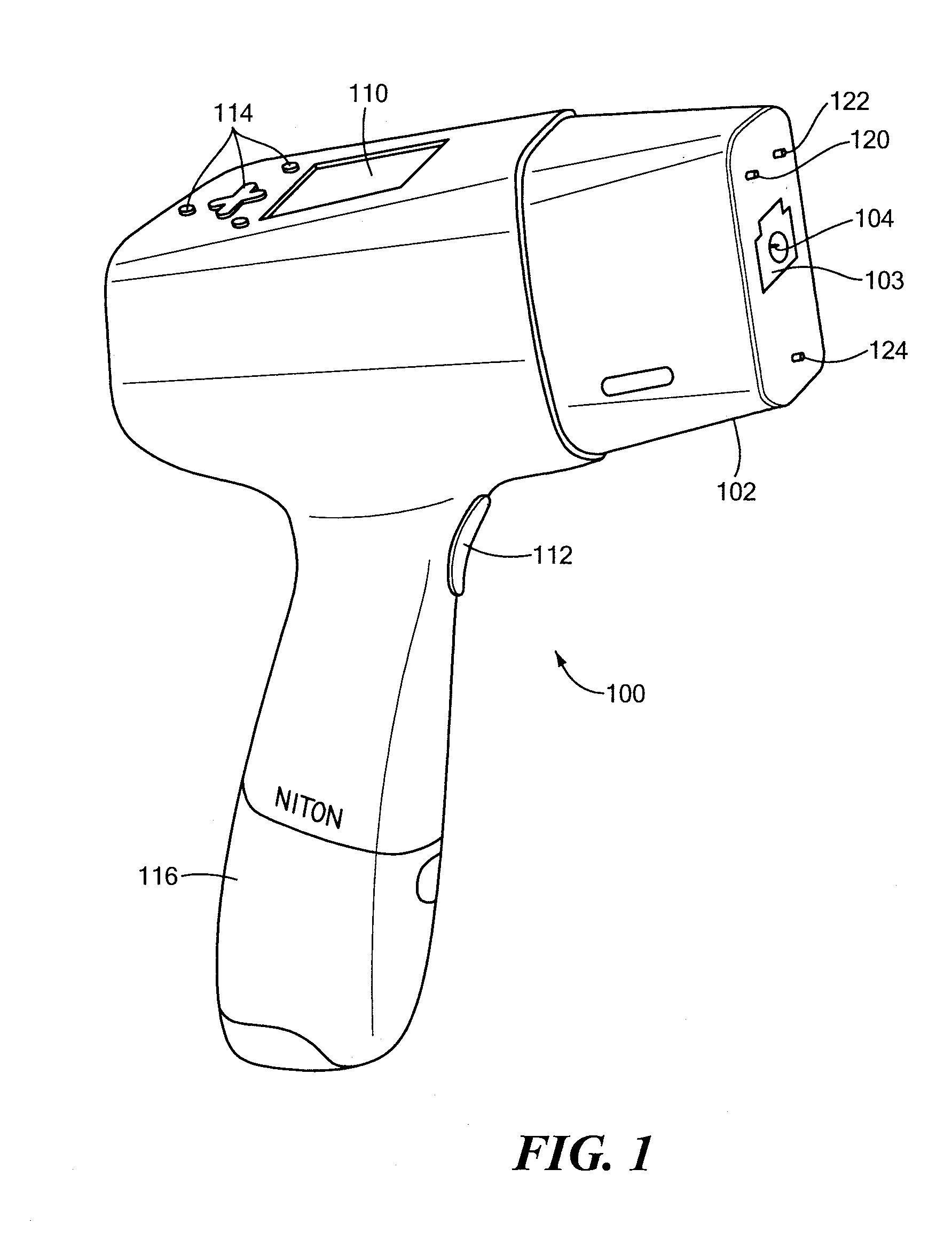

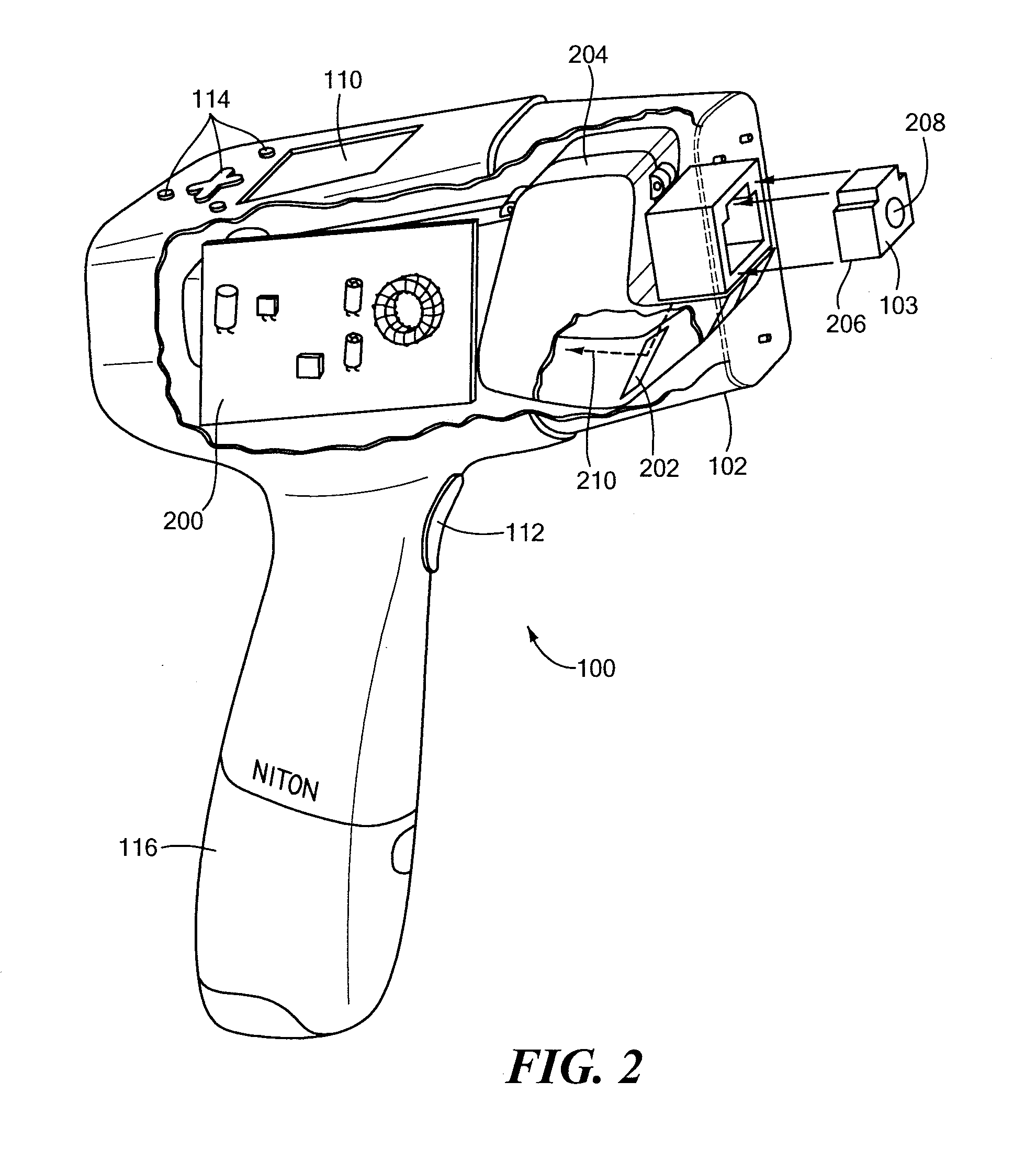

A hand-held, self-contained, battery-powered test instrument for analyzing composition of a sample includes an exciter for exciting at least a portion of the sample, a compact cross-dispersed spectrometer for receiving an optical signal from the excited portion of the sample and a processor for processing spectral data about the optical signal from the spectrometer. The exciter may include a spark generator and a counter electrode, a laser or other device for generating the optical signal from the sample portion. The spectrometer has a wavelength range broad enough to enable the test instrument to detect and determine relative quantities of carbon, phosphorous, sulfur, manganese, silicon, iron and other elements necessary to identify common alloys. The spectrometer includes a structural member made of a light-weight material having a small coefficient of thermal expansion (CTE). The spectrometer is dimensionally stable over a range of expected ambient temperatures, without controlling the temperature of the spectrometer.

Owner:THERMO SCI PORTABLE ANALYTICAL INSTR INC

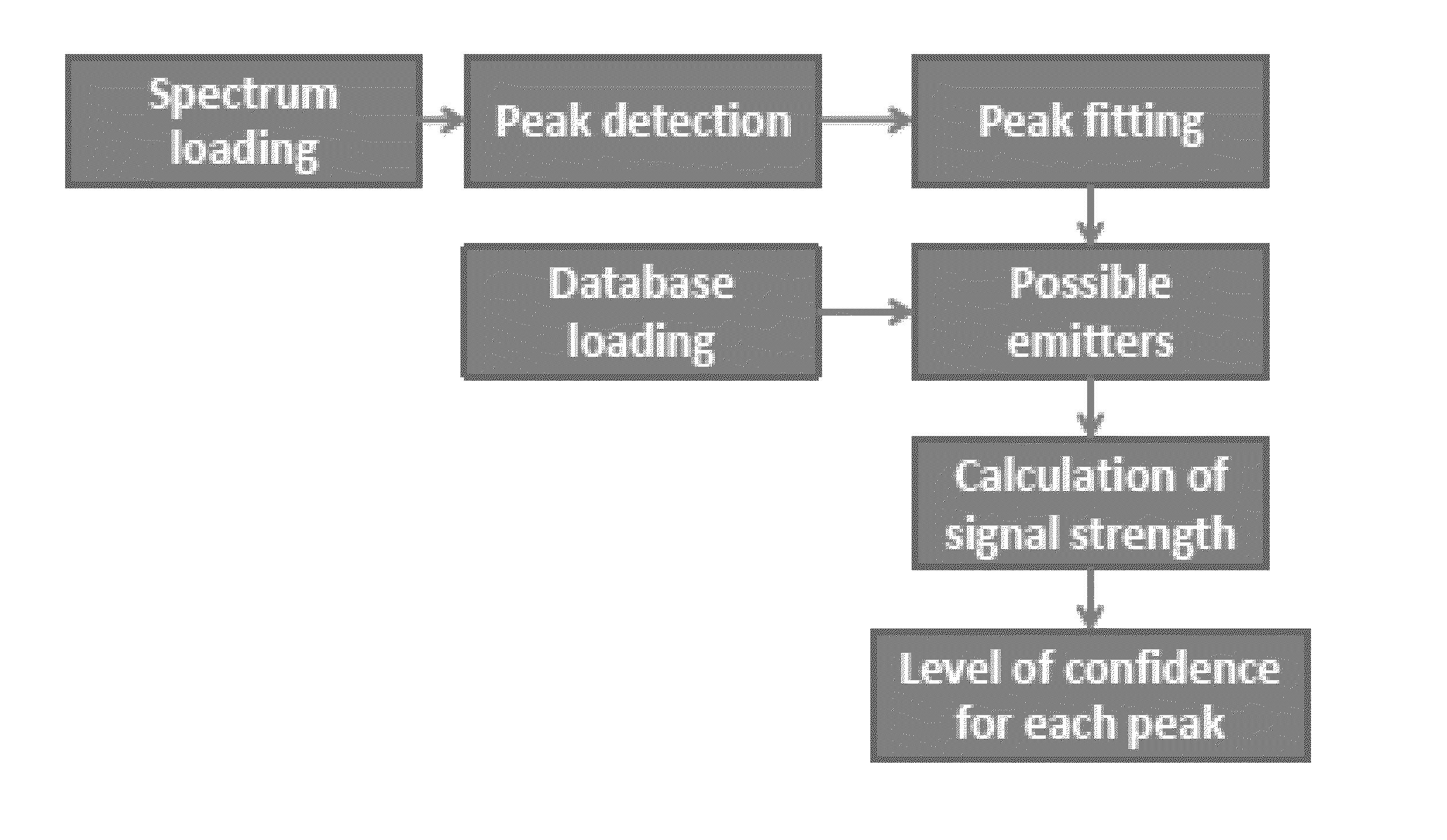

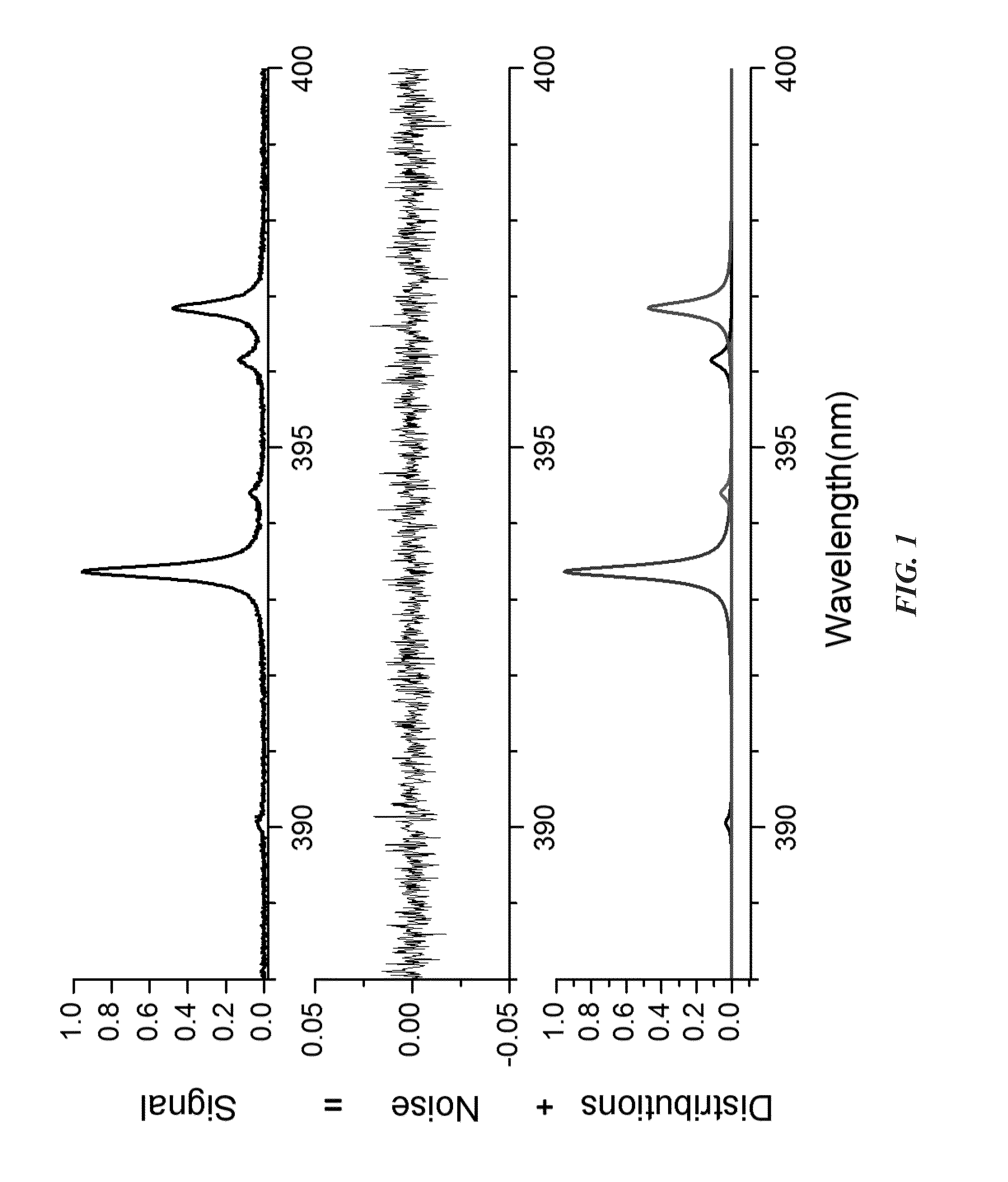

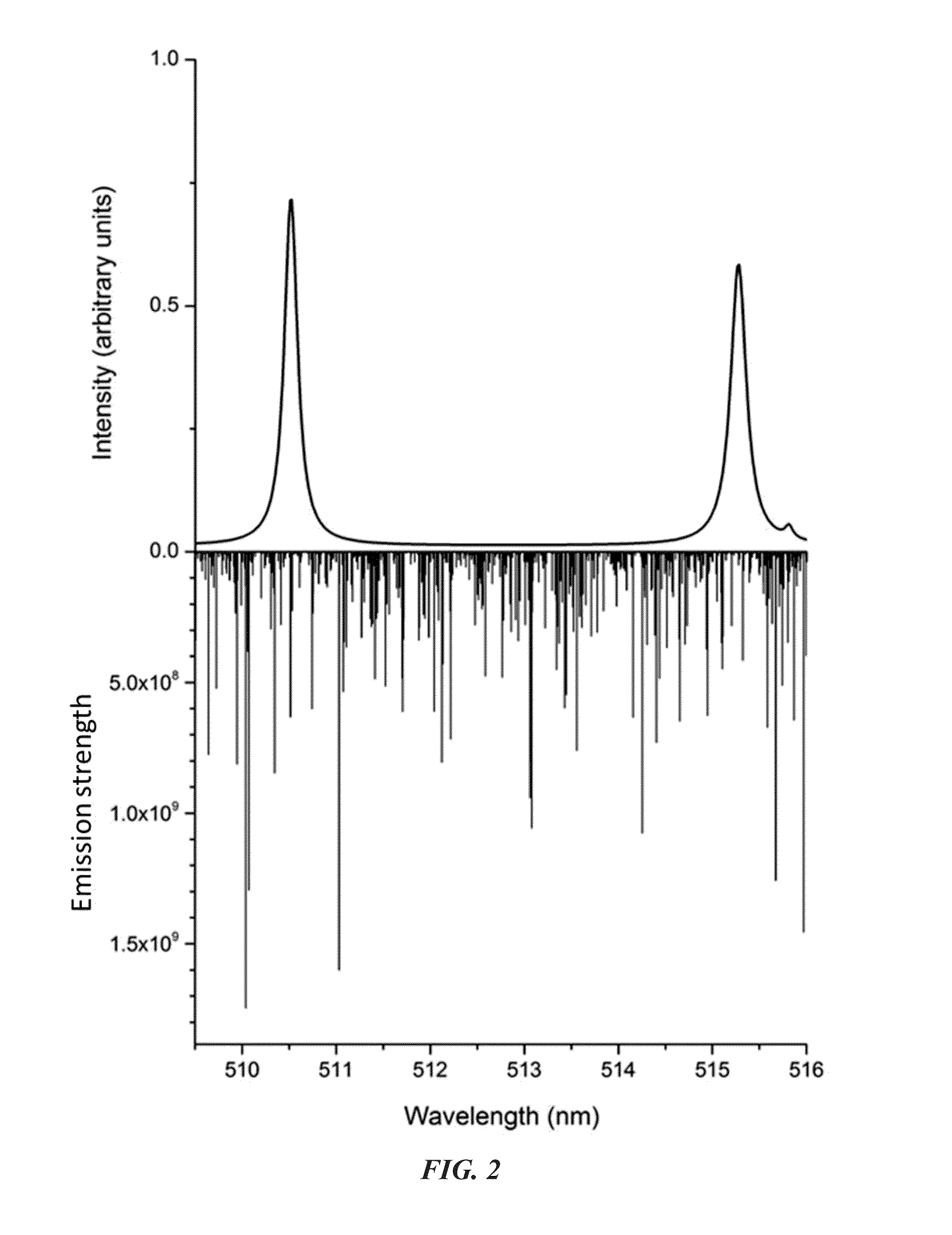

Quantitative elemental profiling in optical emission spectroscopy

ActiveUS20150153225A1Facilitate the spectrum beingAllocation is accurateSpectrum investigationAmplifier modifications to reduce noise influencePattern recognitionFrequency spectrum

The current invention considers the spectrum as a multimodal distribution over a list of structures containing the wavelength as the main entry and the other information mentioned above in the list as additional entries. Each line is then given a probability of contributing to the spectral line. In the case of multiple spectral lines, inference between spectral lines and their respective levels of confidence will provide a complete picture of the list of probable emitters with a probability factor for each line in order to provide a quantitative assignment of the spectral lines and profiling for a given spectrum.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Hand-Held, Self-Contained Optical Emission Spectroscopy (OES) Analyzer

A hand-held, self-contained, battery-powered test instrument for analyzing composition of a sample includes an exciter for exciting at least a portion of the sample, a compact cross-dispersed spectrometer for receiving an optical signal from the excited portion of the sample and a processor for processing spectral data about the optical signal from the spectrometer. The exciter may include a spark generator and a counter electrode, a laser or other device for generating the optical signal from the sample portion. The spectrometer has a wavelength range broad enough to enable the test instrument to detect and determine relative quantities of carbon, phosphorous, sulfur, manganese, silicon, iron and other elements necessary to identify common alloys. The spectrometer includes a structural member made of a light-weight material having a small coefficient of thermal expansion (CTE). The spectrometer is dimensionally stable over a range of expected ambient temperatures, without controlling the temperature of the spectrometer.

Owner:THERMO SCI PORTABLE ANALYTICAL INSTR INC

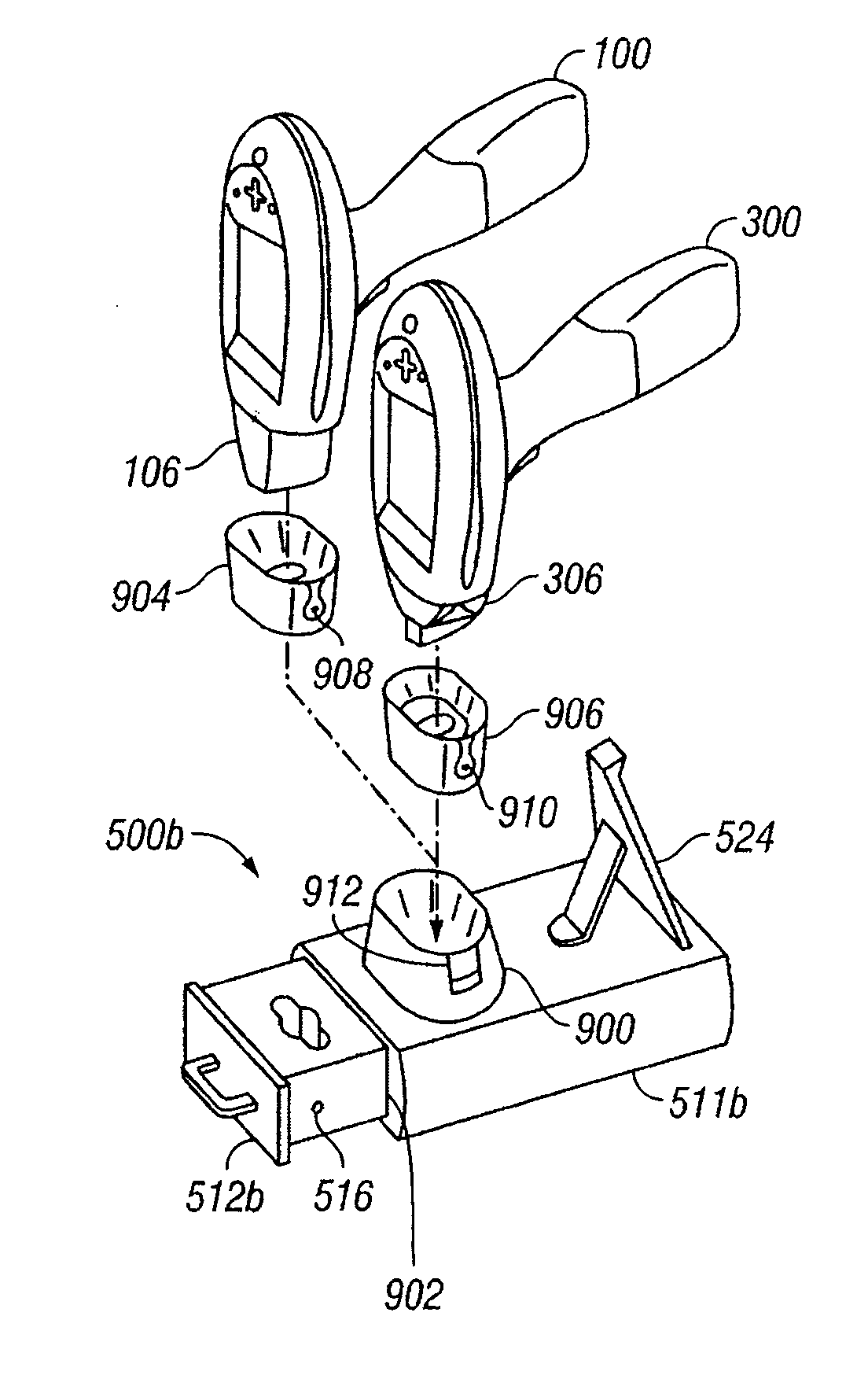

Elemental Analysis Based on Complementary Techniques

InactiveUS20110079734A1Accurately determineX-ray spectral distribution measurementMaterial analysis using wave/particle radiationTest sampleElemental analysis

Methods and apparatus for analyzing a test sample using complementary techniques, such as x-ray fluorescence (XRF) and optical emission spectroscopy (OES), are disclosed for registering two or more test instruments, in relation to the test sample, such that each of the instruments analyzes substantially the same region as is analyzed by the other instrument(s), and for communicating analytical results between or among the instruments, or between the instruments and another component, to enable one or more of the instruments, or the other component, to combine the results and, thereby, more completely and accurately determine the composition of the test sample. Such registration and communication enables, for example, separate XRF and OES instruments to collectively determine the composition of the test sample, including the absolute amounts of light and heavy elements in the test material.

Owner:THERMO NITON ANALYZERS

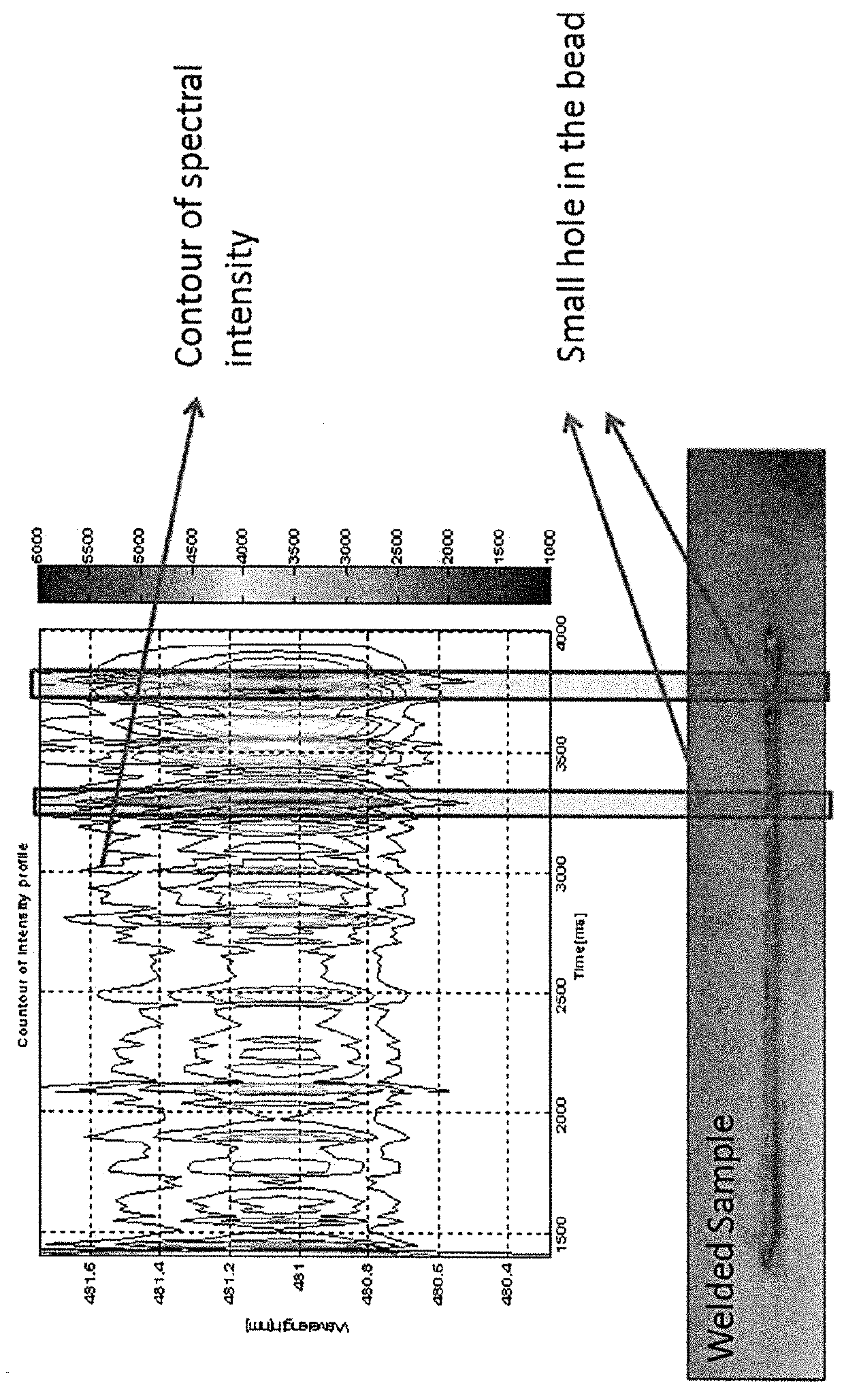

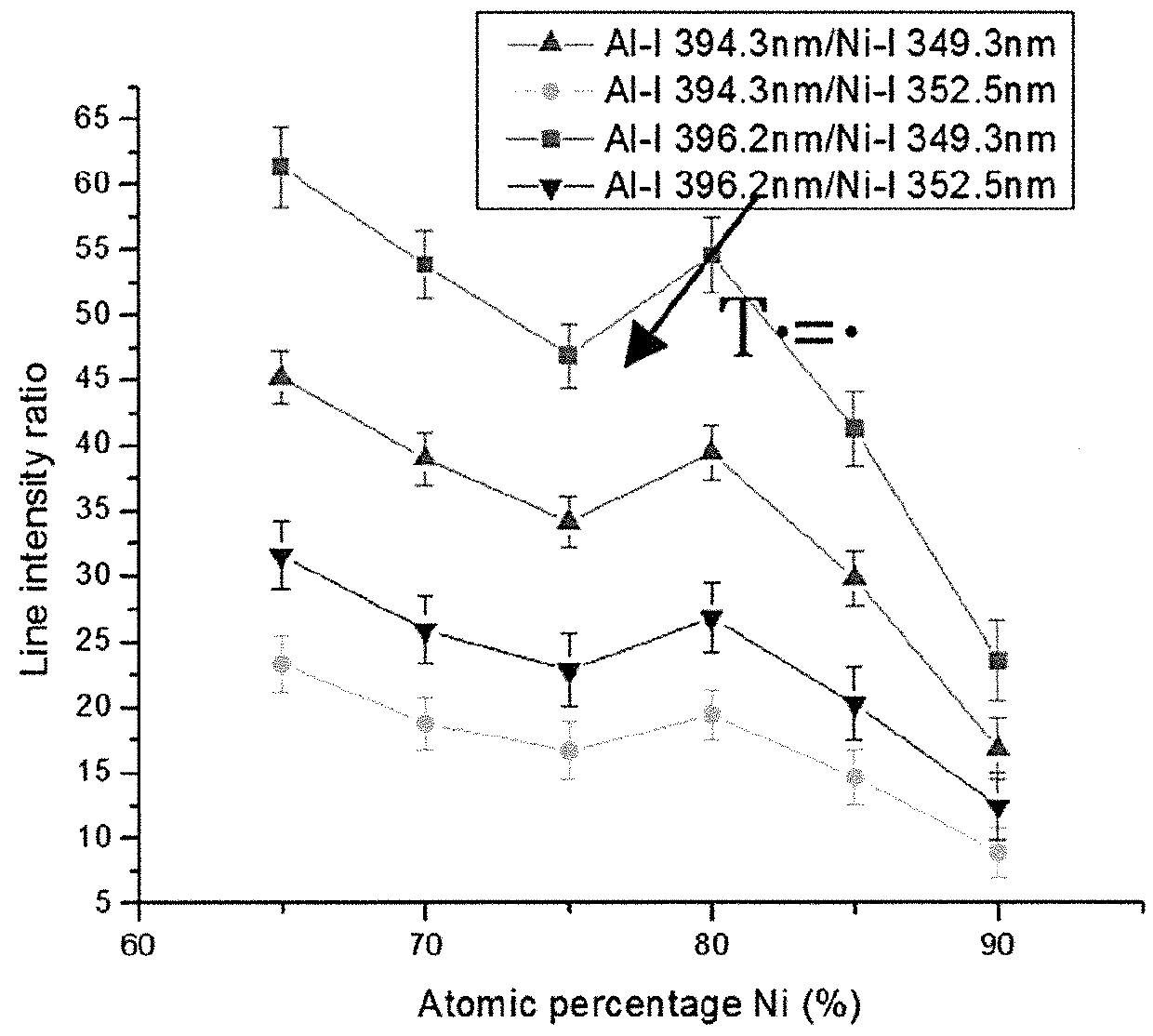

Smart additive manufacturing system (SAMS)

ActiveUS20160052086A1Additive manufacturing apparatusArc welding apparatusEngineeringOptical emission spectrometry

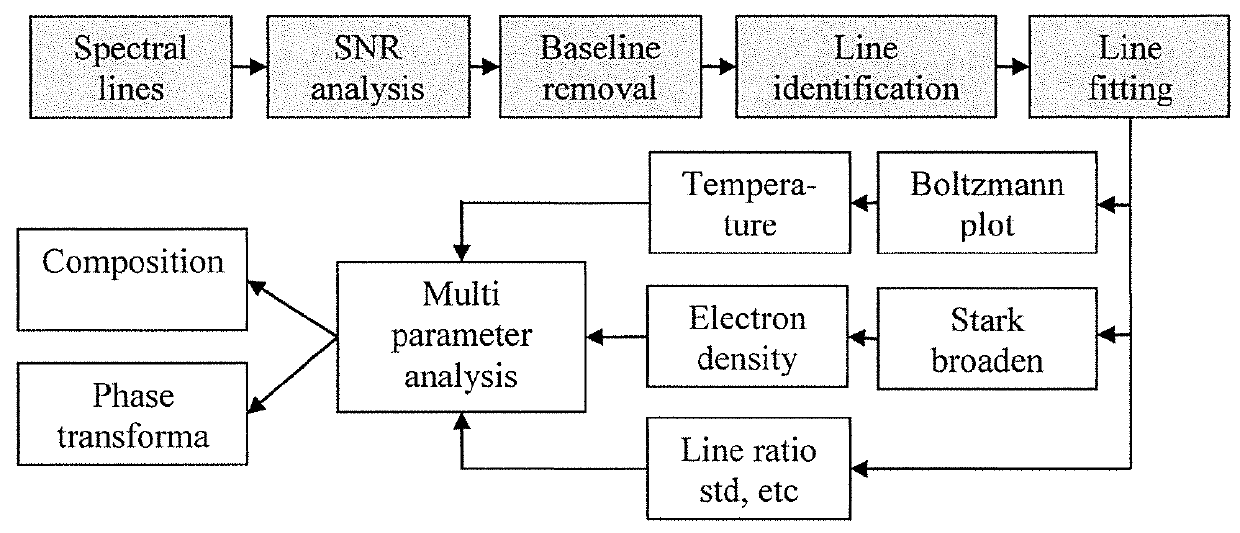

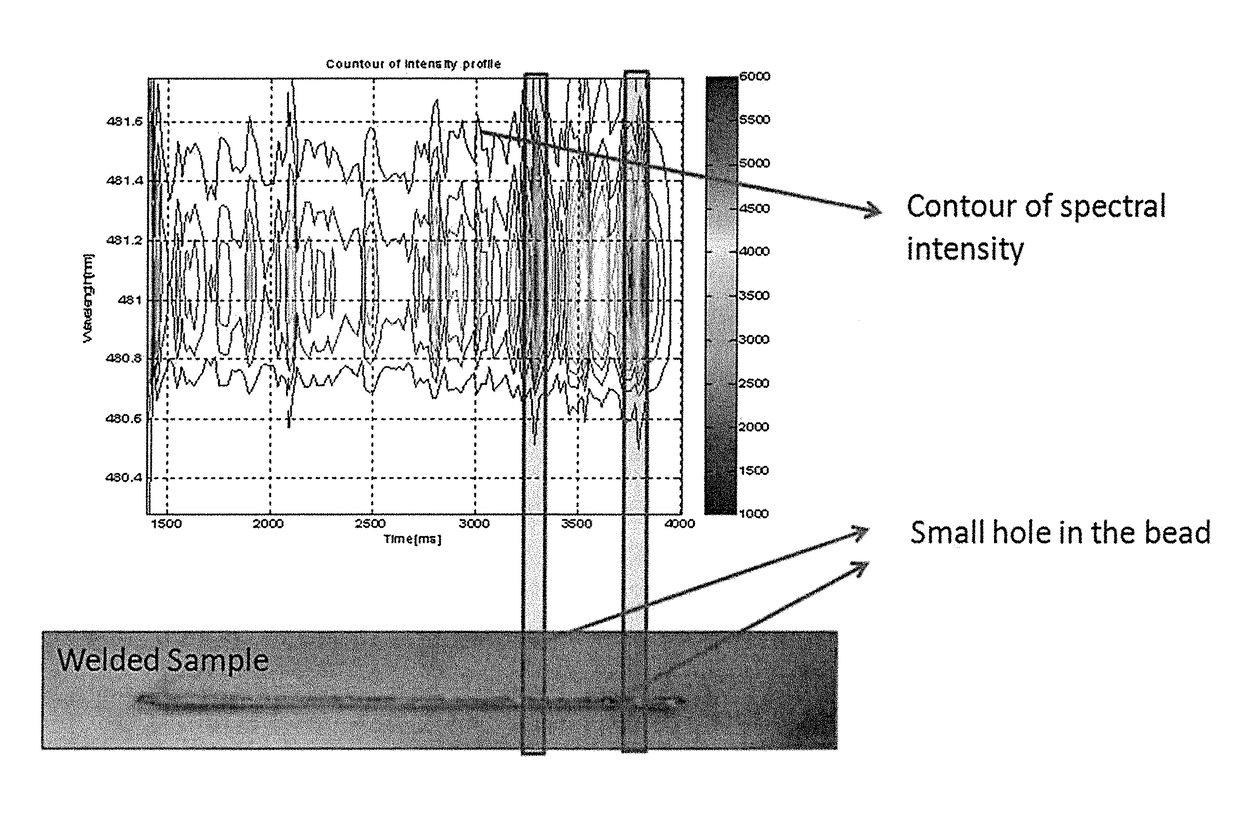

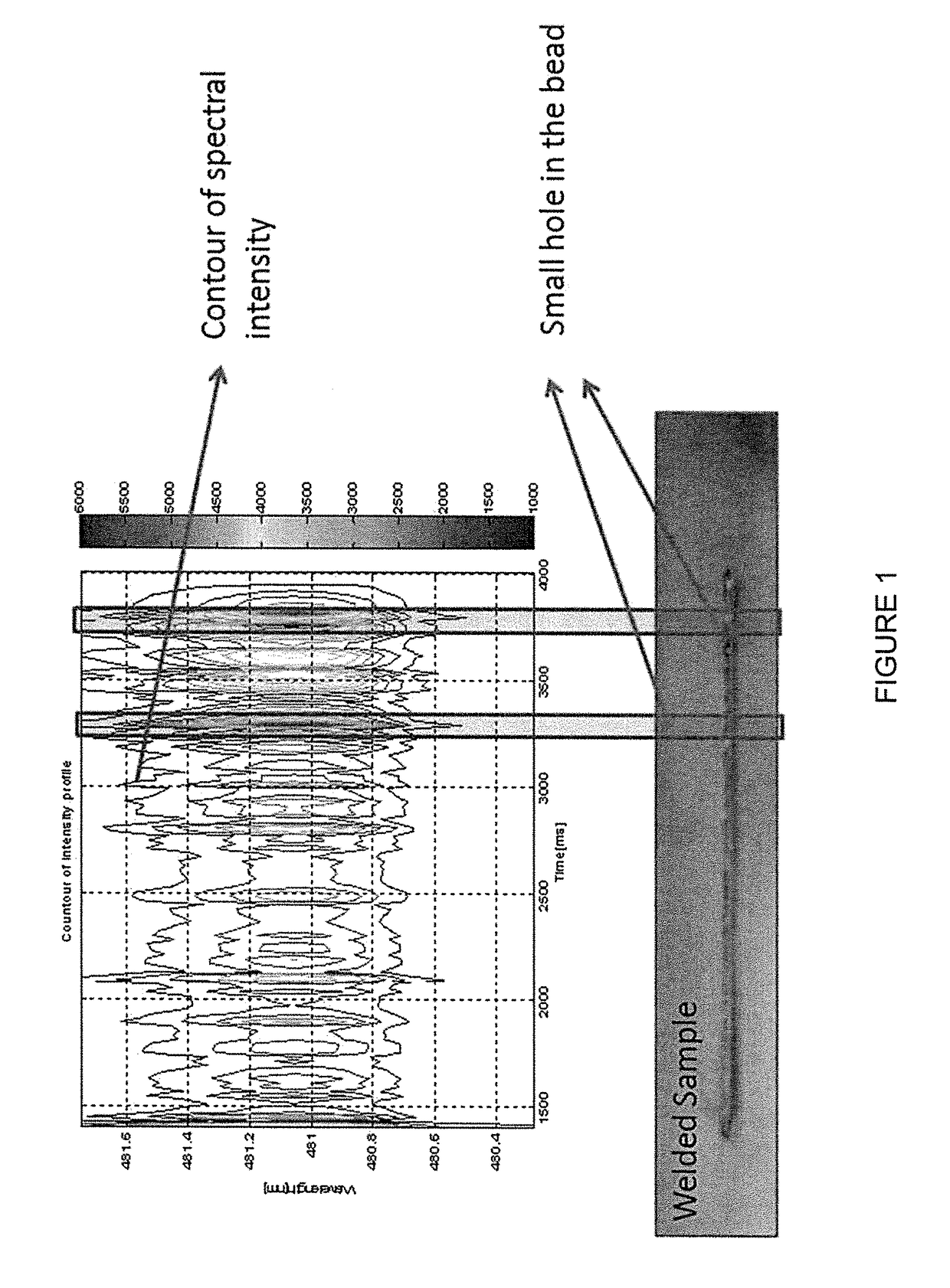

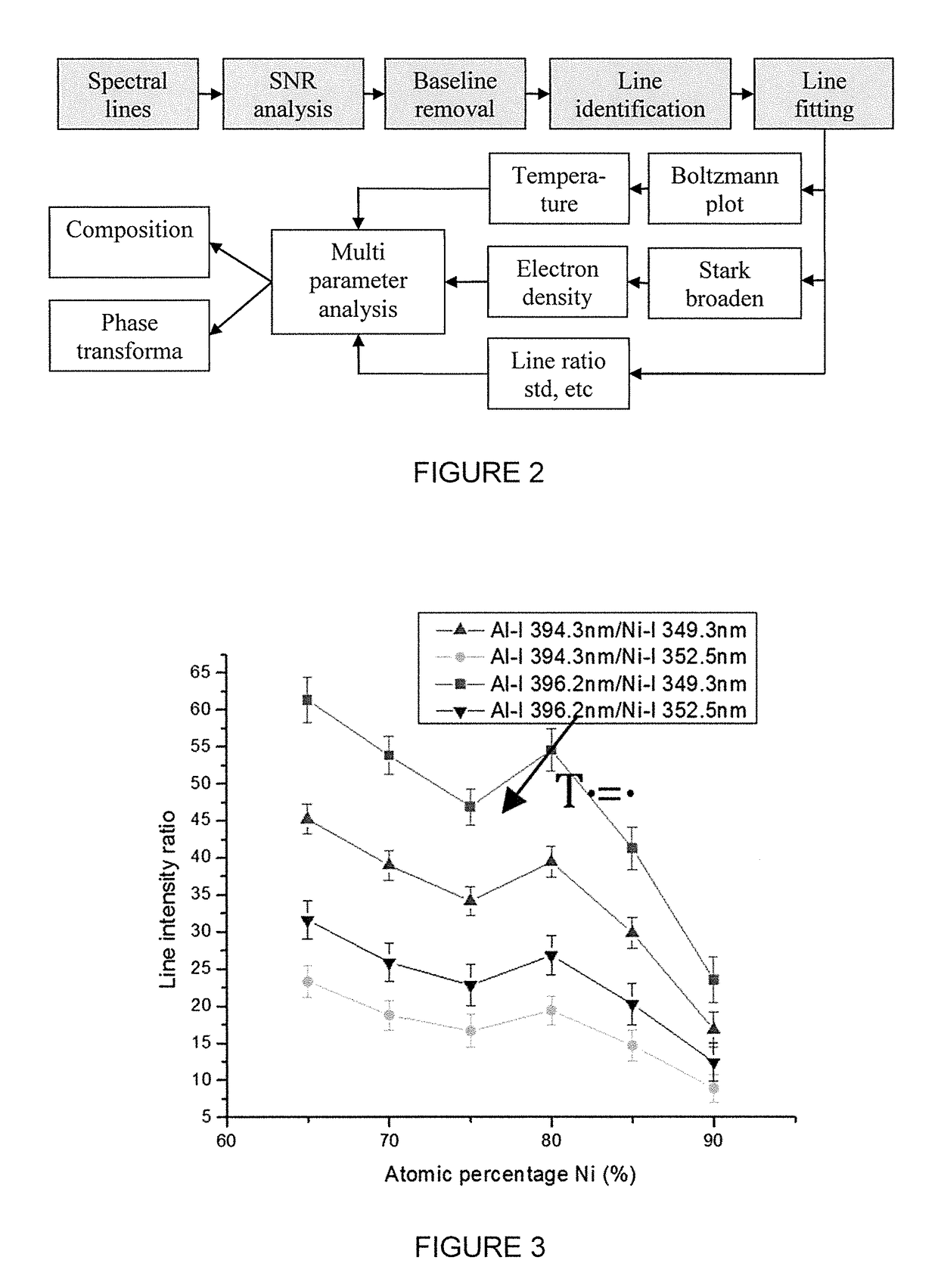

An additive manufacturing process is monitored, in situ, using optical emission spectroscopy to analyze the composition, phase transformation or manufacturing defects. The system or method may include an analysis of contours of the plasma line intensity, or pre-processing of the plasma spectral line including signal-to-noise ratio analysis, baseline removal, line identification, line de-convolution and fitting. Improvements may additionally involve consideration of plasma parameters such as plasma spectral line intensity, line ratio, plasma temperature and electron density using high-resolution optical emission spectroscopy in both visible and ultraviolet regions. Parameters of the plasma may be determined using an intensity ratio of the ions or atoms emission lines, a FWHM of the line profile for electron density estimation, or a Boltzmann plot for plasma temperature estimation. One or more techniques may be used to monitor when there is a lack of deposition.

Owner:MAZUMDER JYOTI +1

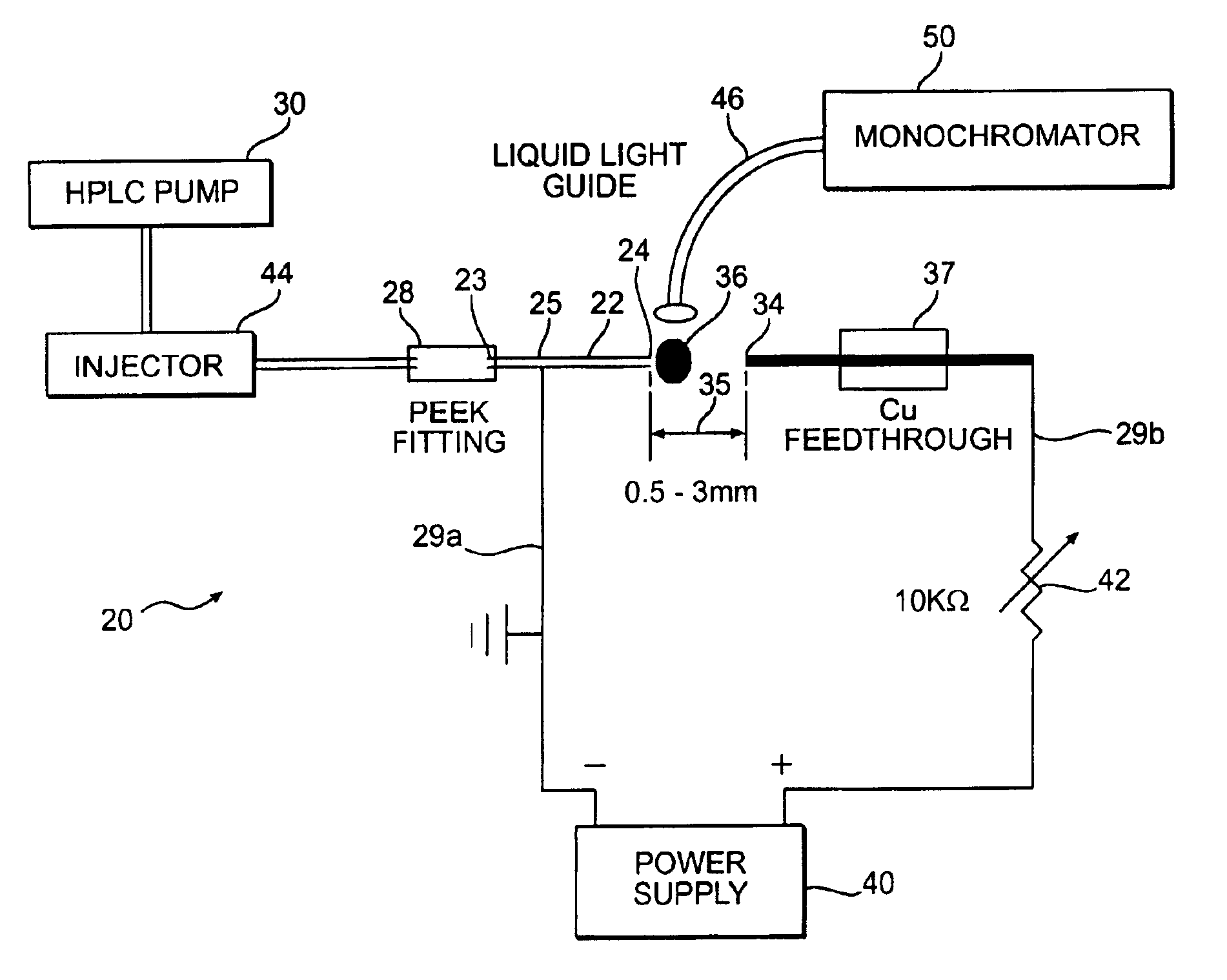

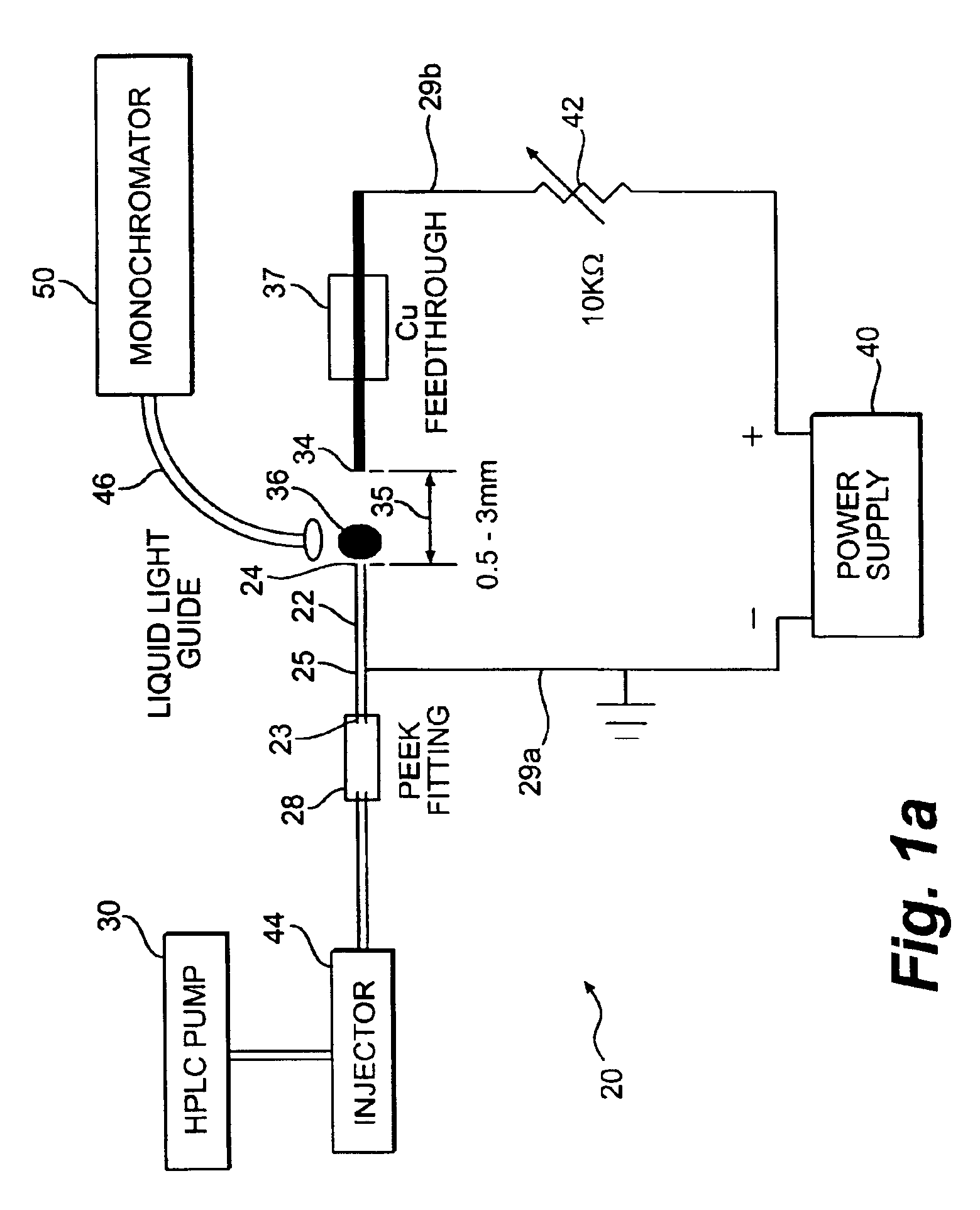

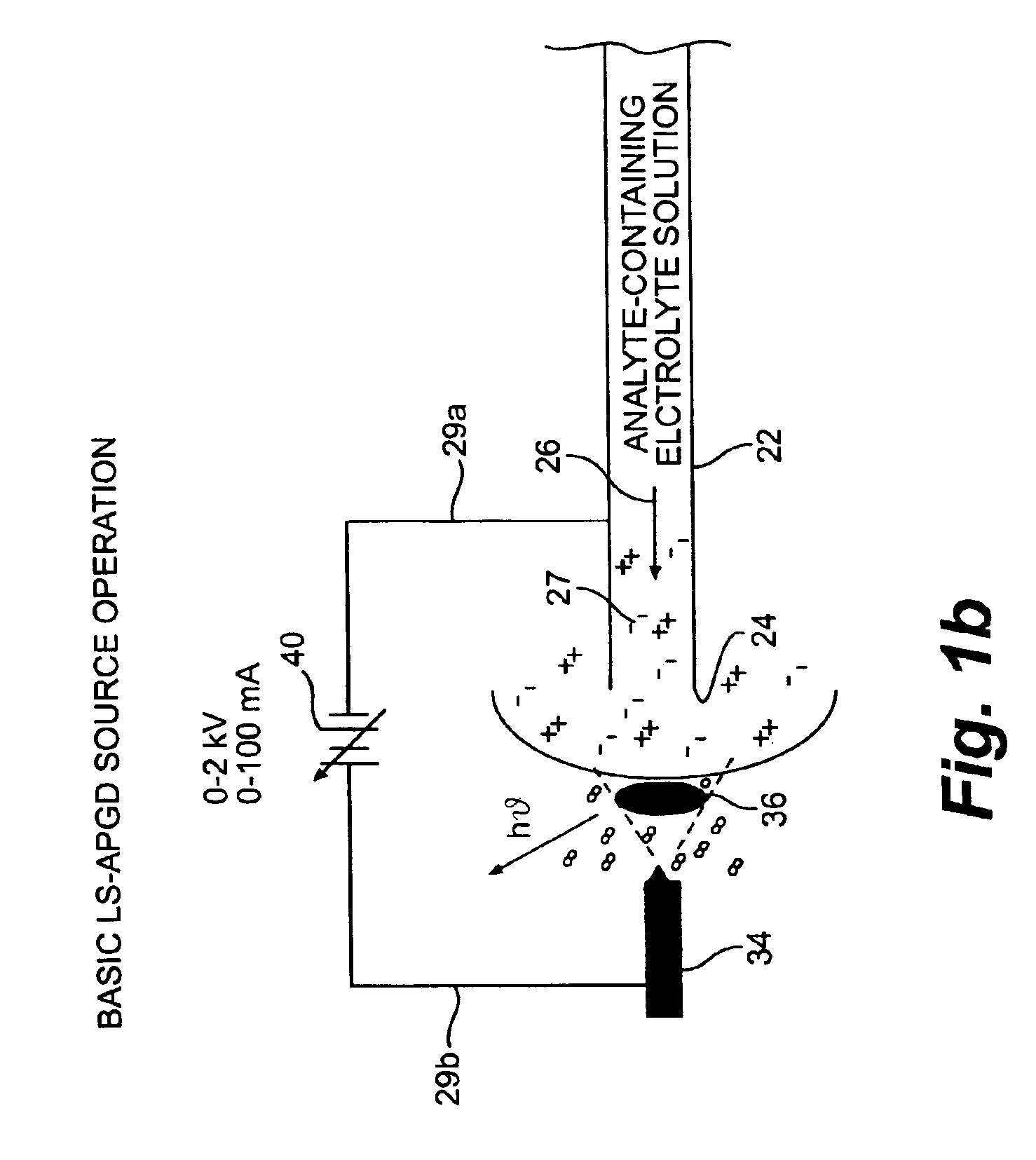

Atmospheric pressure, glow discharge, optical emission source for the direct sampling of liquid media

InactiveUS6852969B2Radiation pyrometryMaterial analysis using wave/particle radiationLiquid mediumGas phase

A glow discharge spectroscopy (GDS) source operates at atmospheric pressure. One of the discharge electrodes of the device is formed by an electrolytic solution 27 containing the analyte specimen. The passage of electrical current (either electrons or positive ions) across the solution / gas phase interface causes local heating and the volatilization of the analyte species. Collisions in the discharge region immediately above the surface of the solution results in optical emission and ionization that are characteristic of the analyte elements. As such, these analyte elements can be identified and quantified by optical emission spectroscopy (OES) or mass spectrometry (MS). The device uses the analyte solution as either the cathode or anode. Operating parameters depend on the electrolyte concentration (i.e. solution conductivity) and the gap 35 between the solution surface and the counter electrode. Typical conditions include discharge currents of about 10 to about 60 mA and potentials of about 200 to about 1000 volts. Electrolyte solutions of pH, pNa or pLi values of about 0.5 to about 2 and interelectrode gaps of about 0.5 to about 3 mm produce stable plasmas where the analyte solutions are totally consumed at flow rates of up to about 2.0 mL / min.

Owner:CLEMSON UNIVERSITY

Self-Calibrating Optical Emission Spectroscopy for Plasma Monitoring

InactiveUS20080078504A1Improve simplicityImprove reliabilityLiquid surface applicatorsElectric discharge tubesUltrasound attenuationEngineering

A plasma processing system and plasma monitor therefor is provided in which a plasma monitor housing is coupled to a plasma processing chamber such that a line-of-sight monitoring path extends through the housing to an optical sensor outside of a window. A separate reference signal path extends through the housing from a reference light source on one side of the housing to a reference optical sensor on the other side of the housing. The housing is configured so that deposits from the chamber affect all of the windows equally, and to retard the flow of contaminating film forming material onto the windows, using, for example, baffles, gas counterflow, and a balanced radial-leg housing. A processor uses the reference signal to determine window contamination and compensate for signal attenuation along the monitoring path caused by window coating, in the making of a measurement of plasma emissions. The measurement can be used by the processing system to control the plasma.

Owner:TOKYO ELECTRON LTD

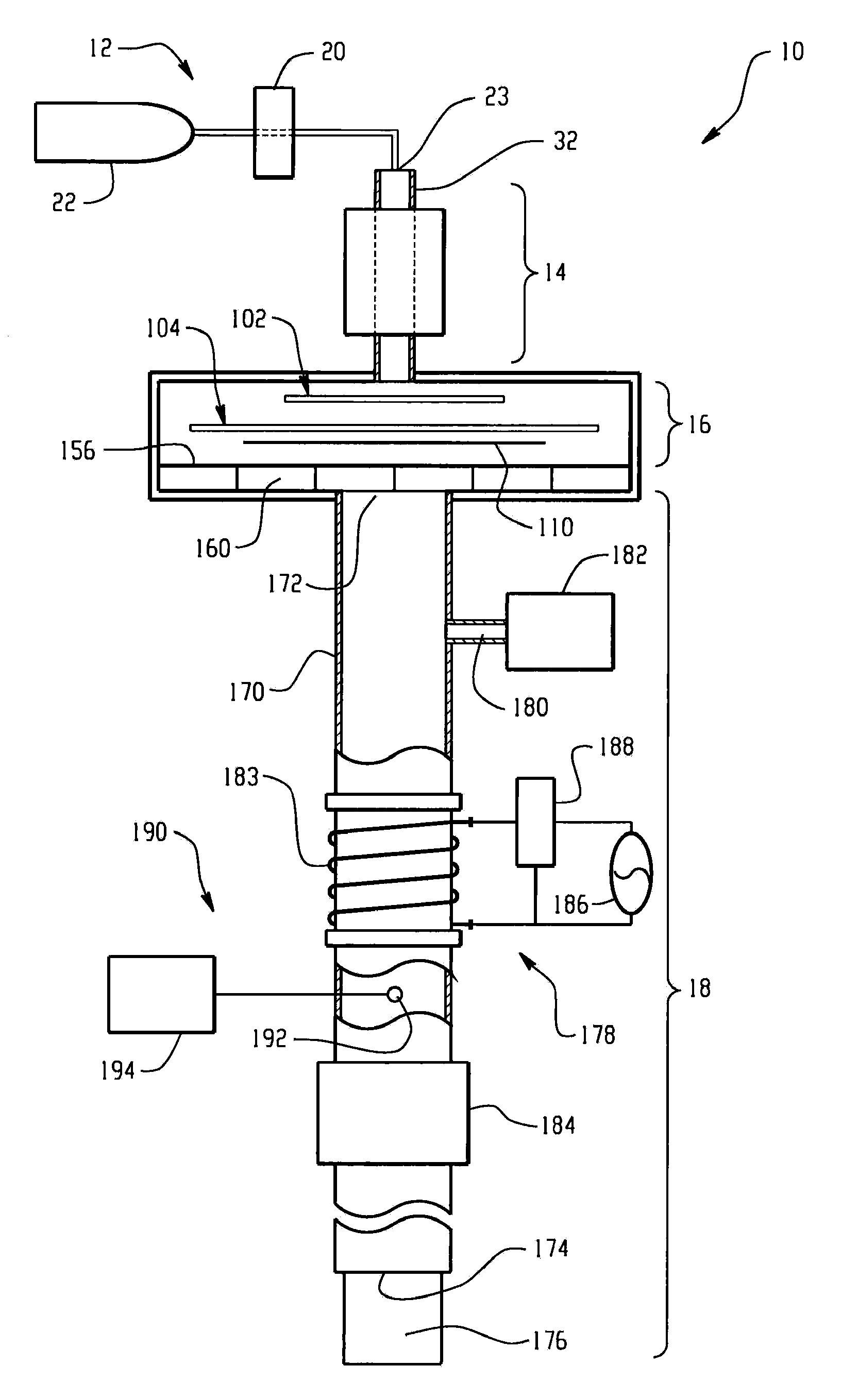

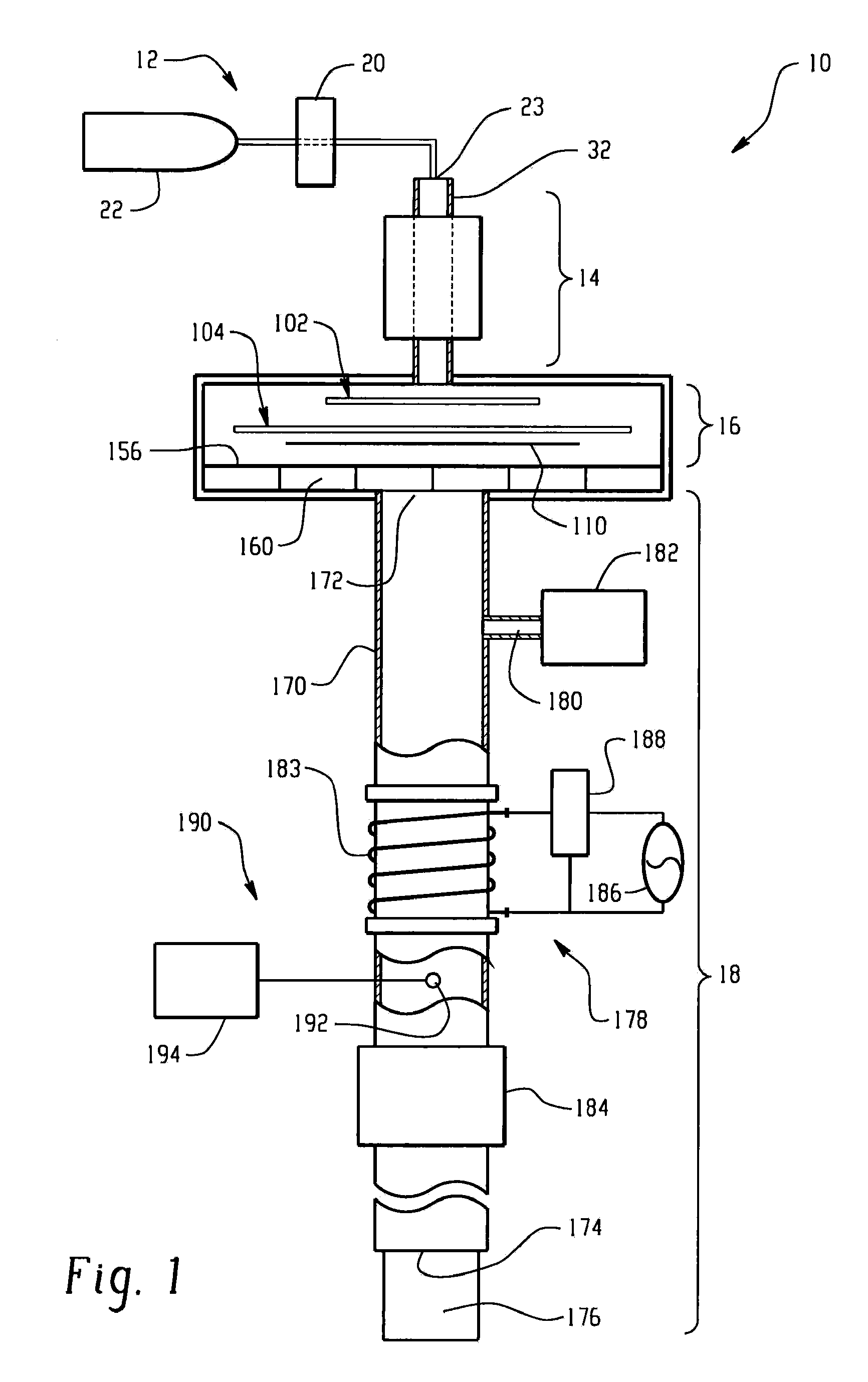

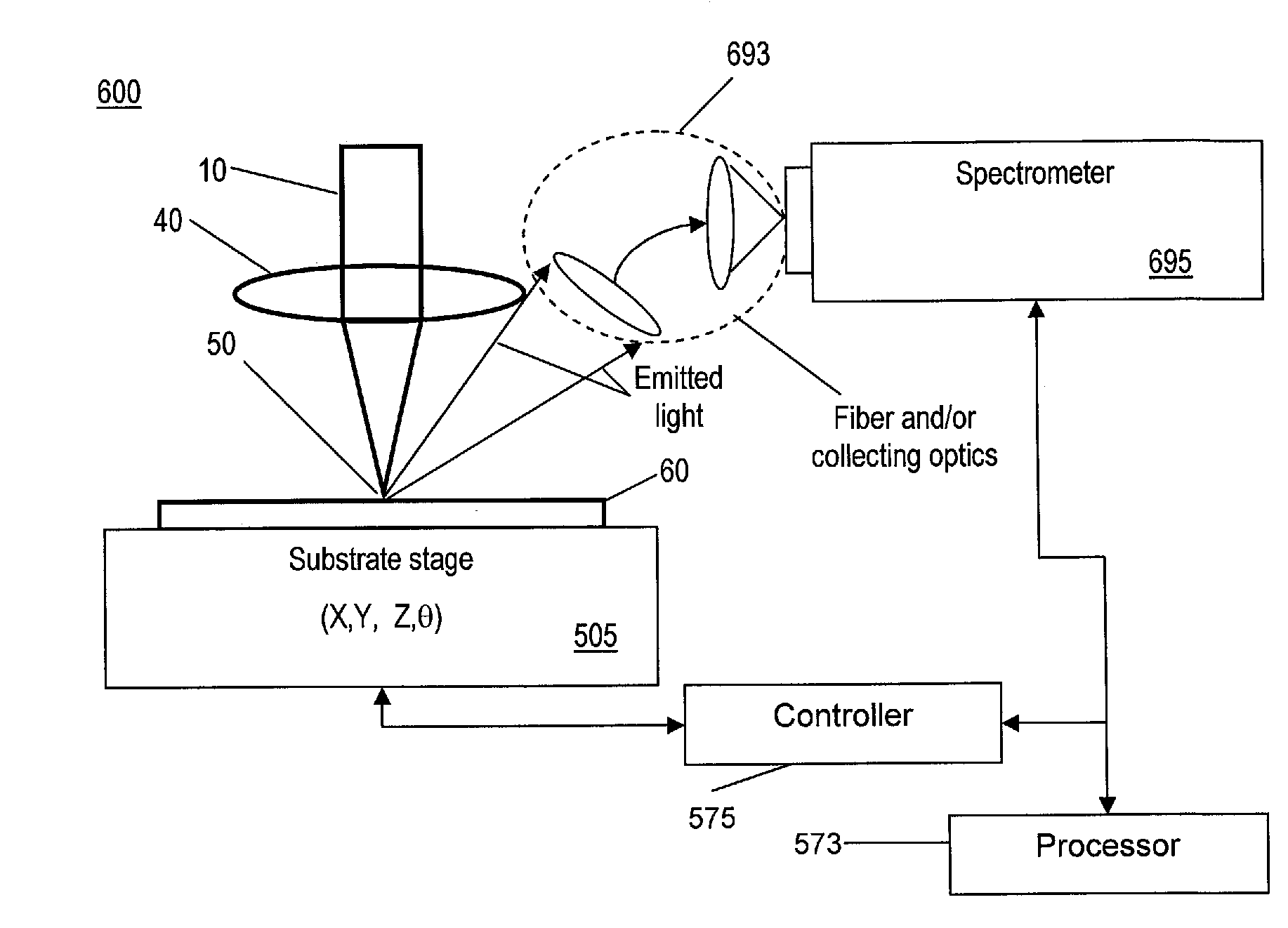

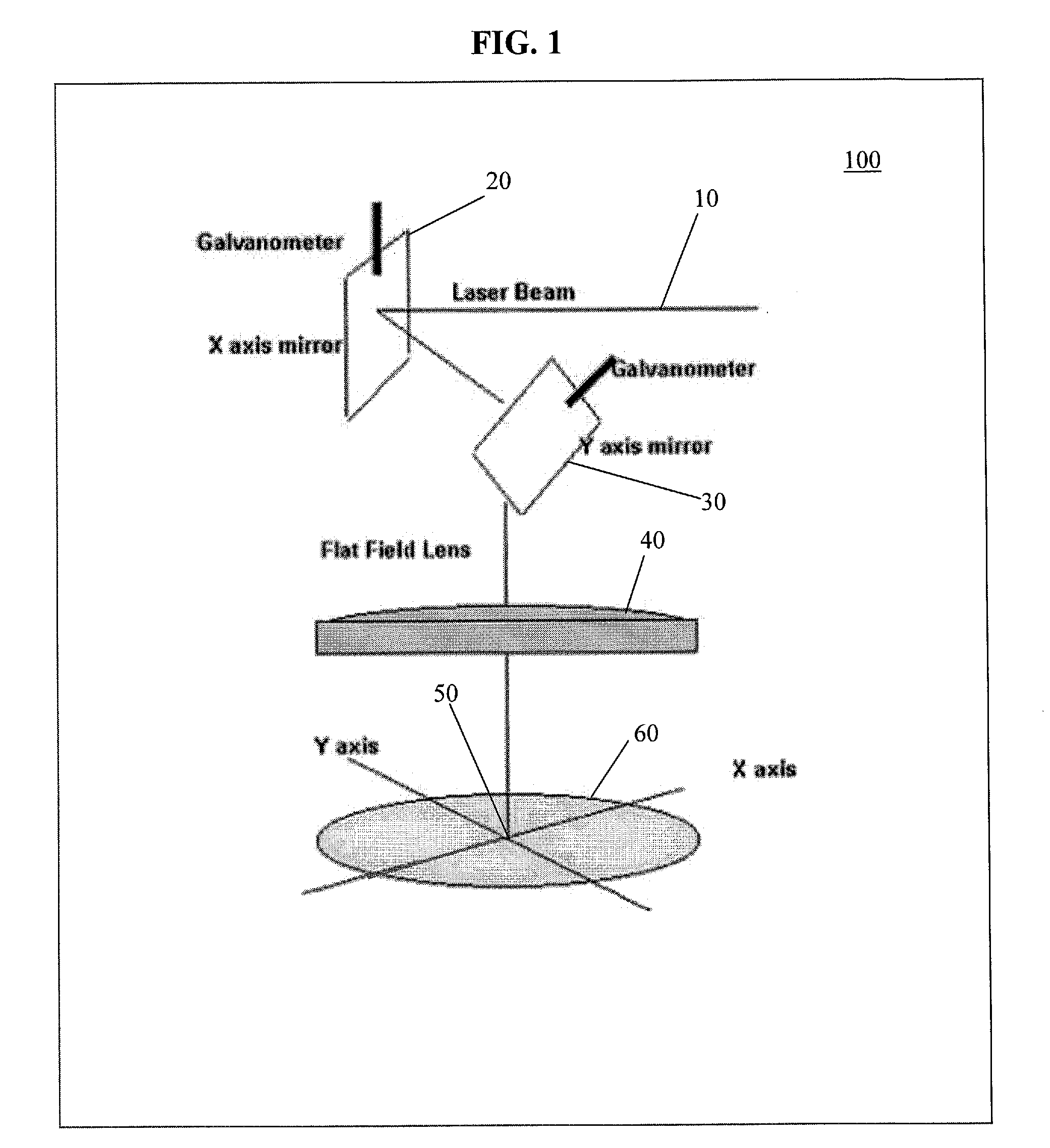

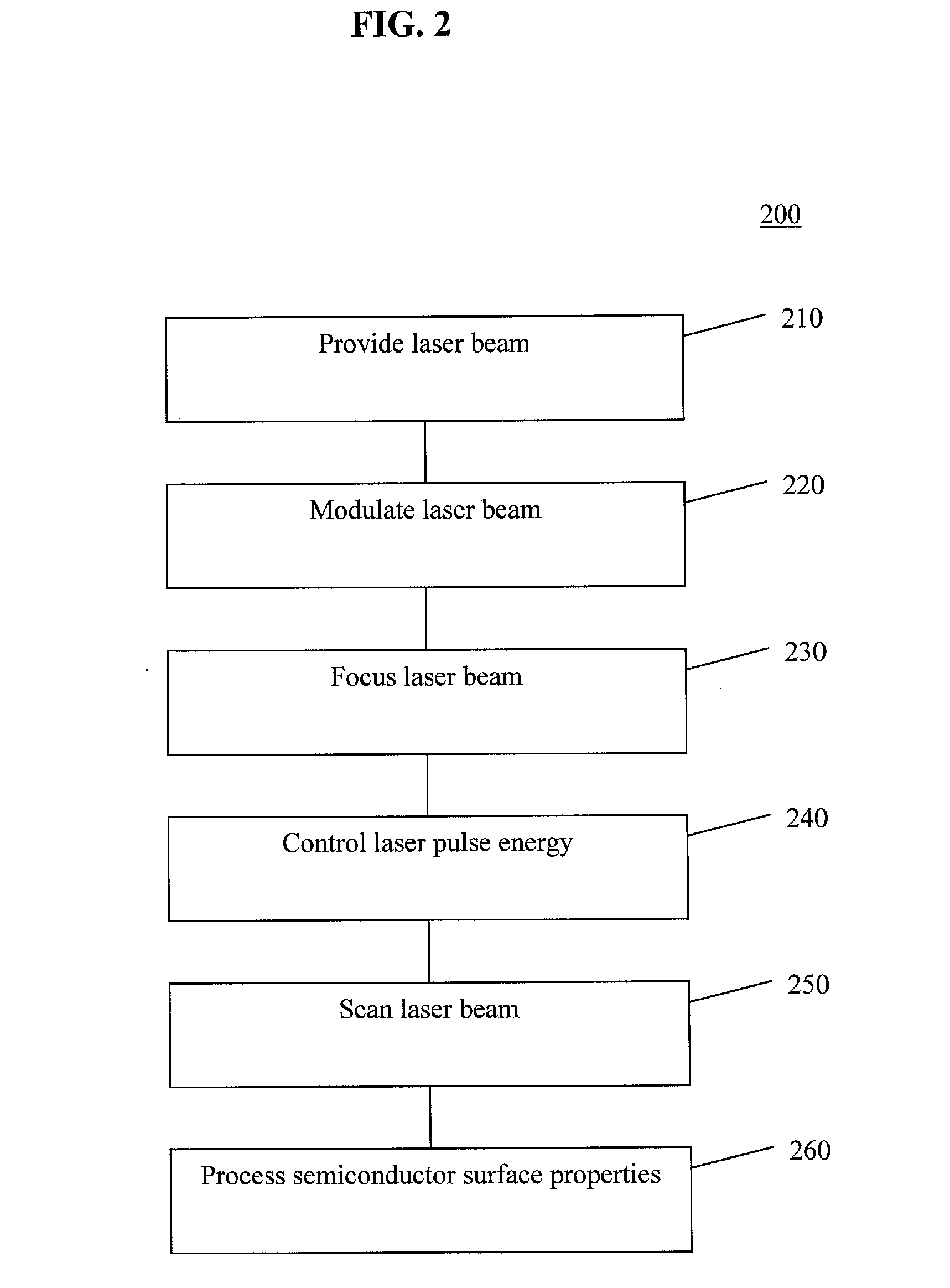

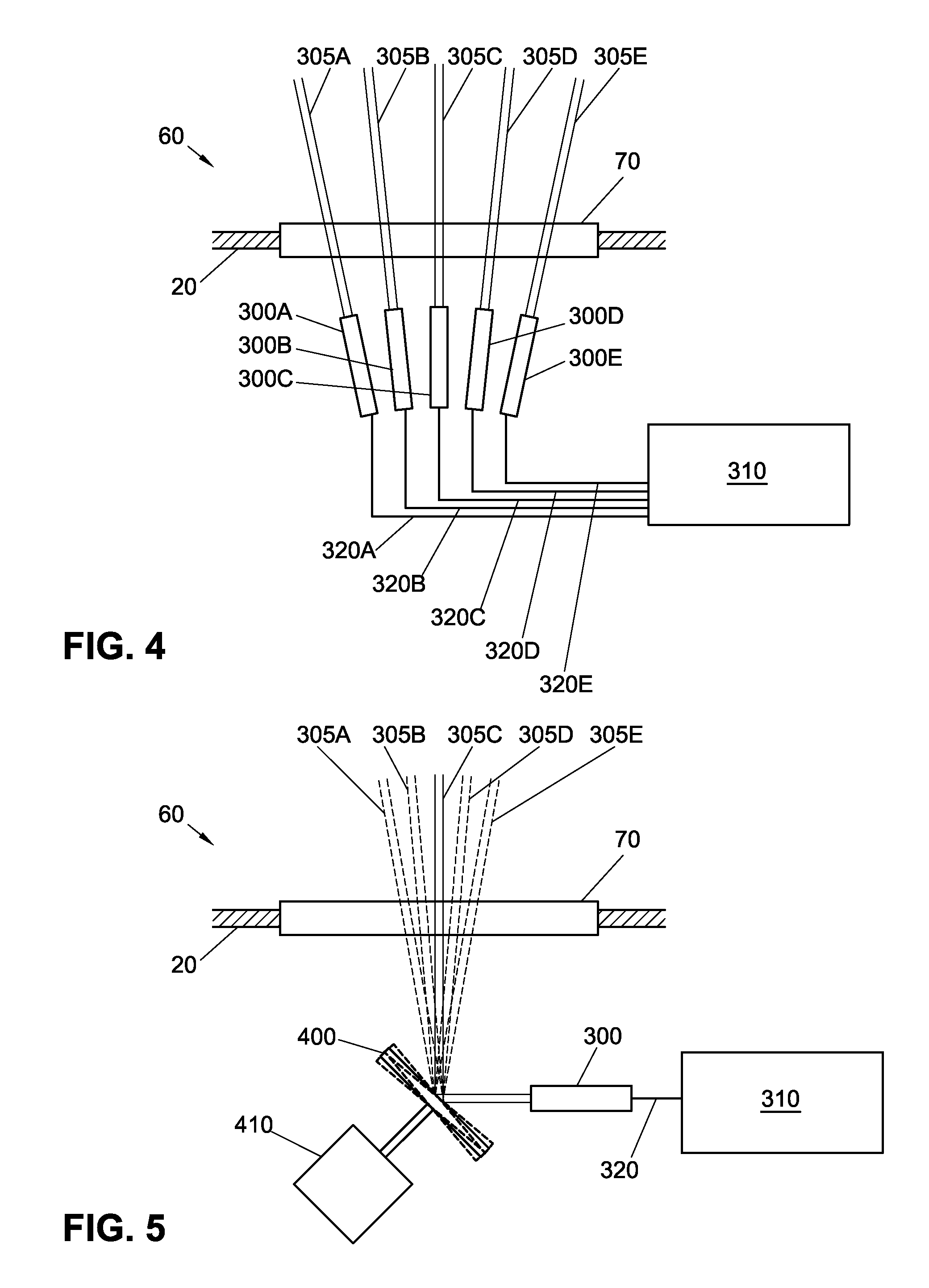

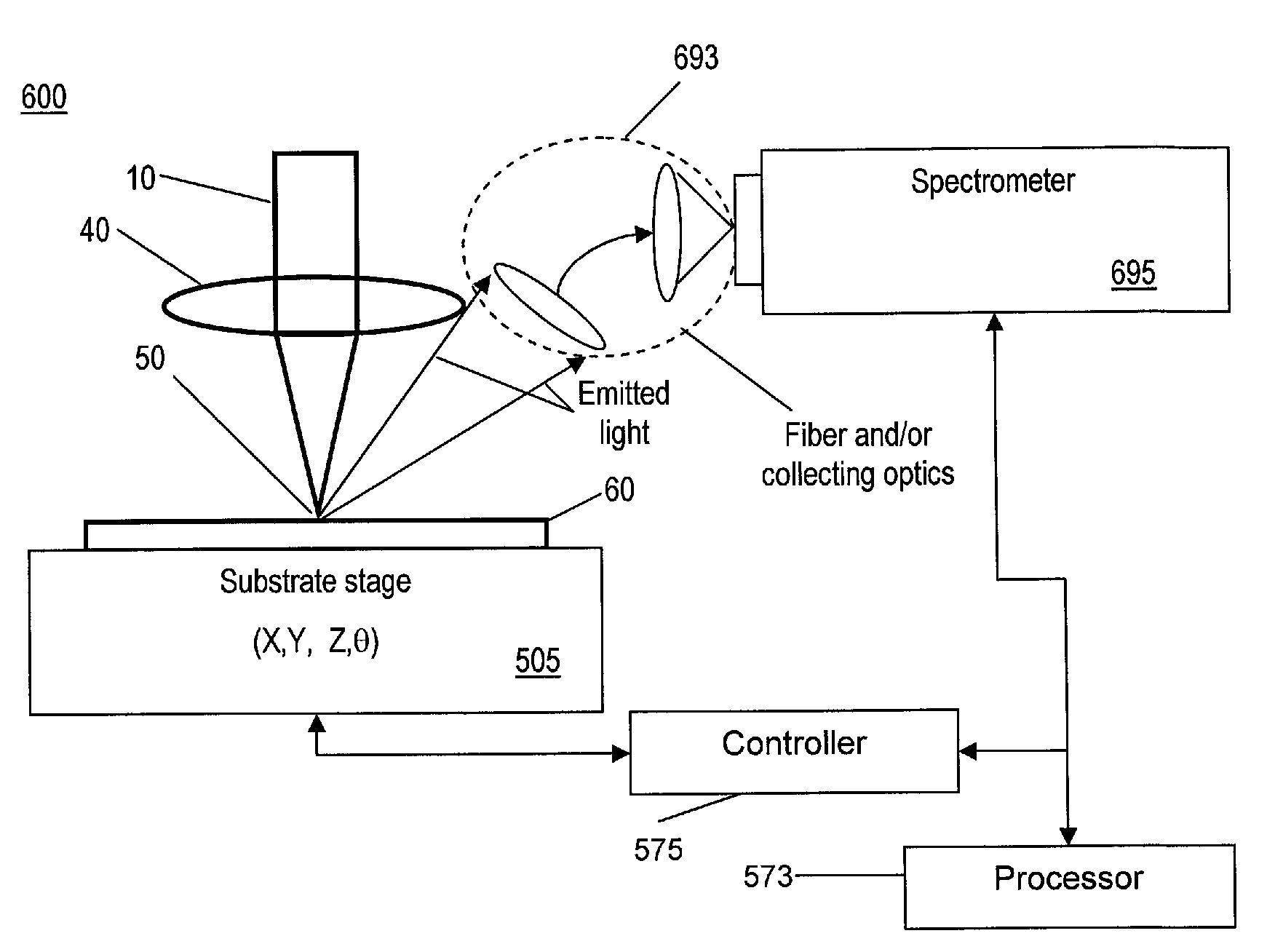

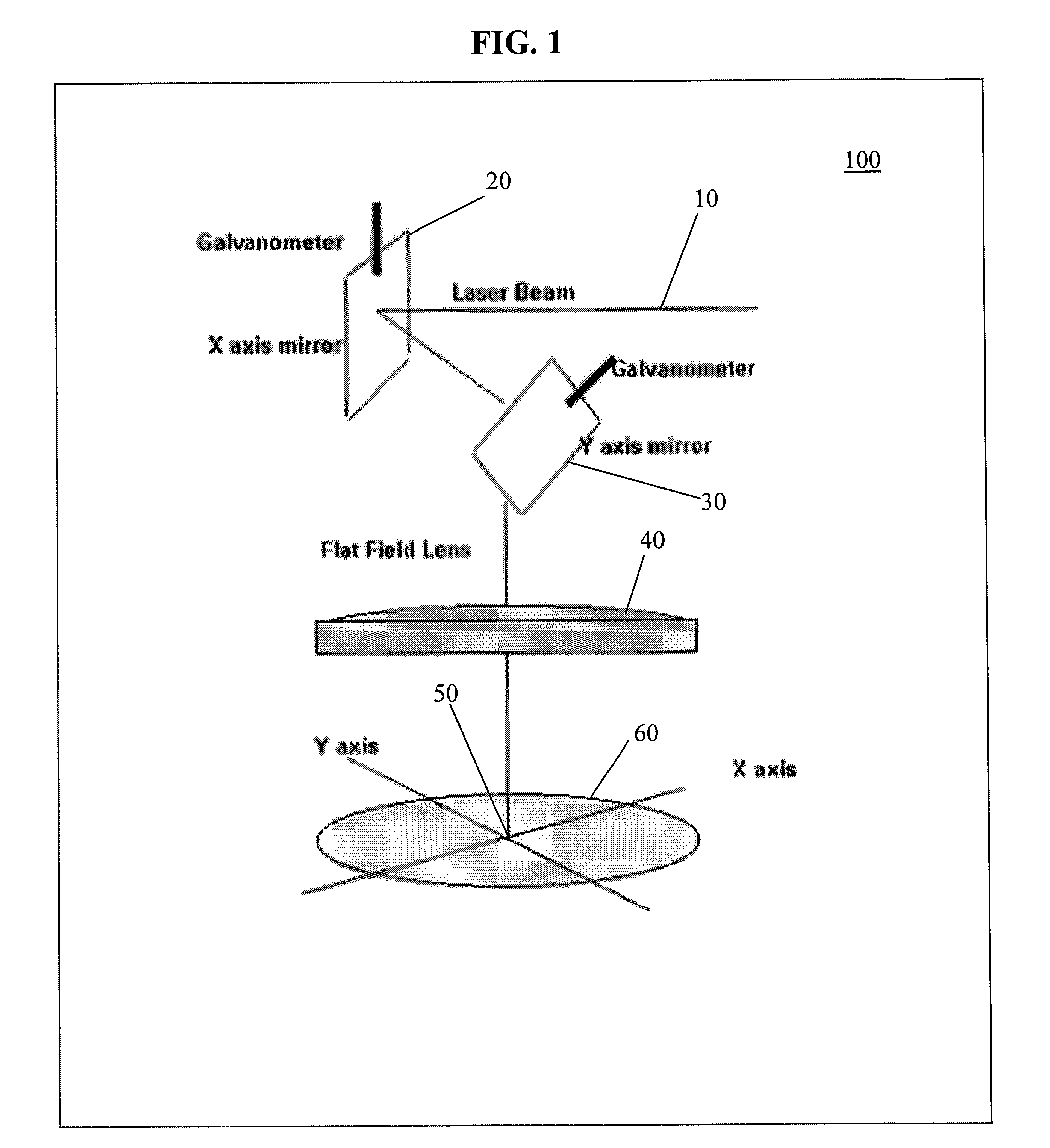

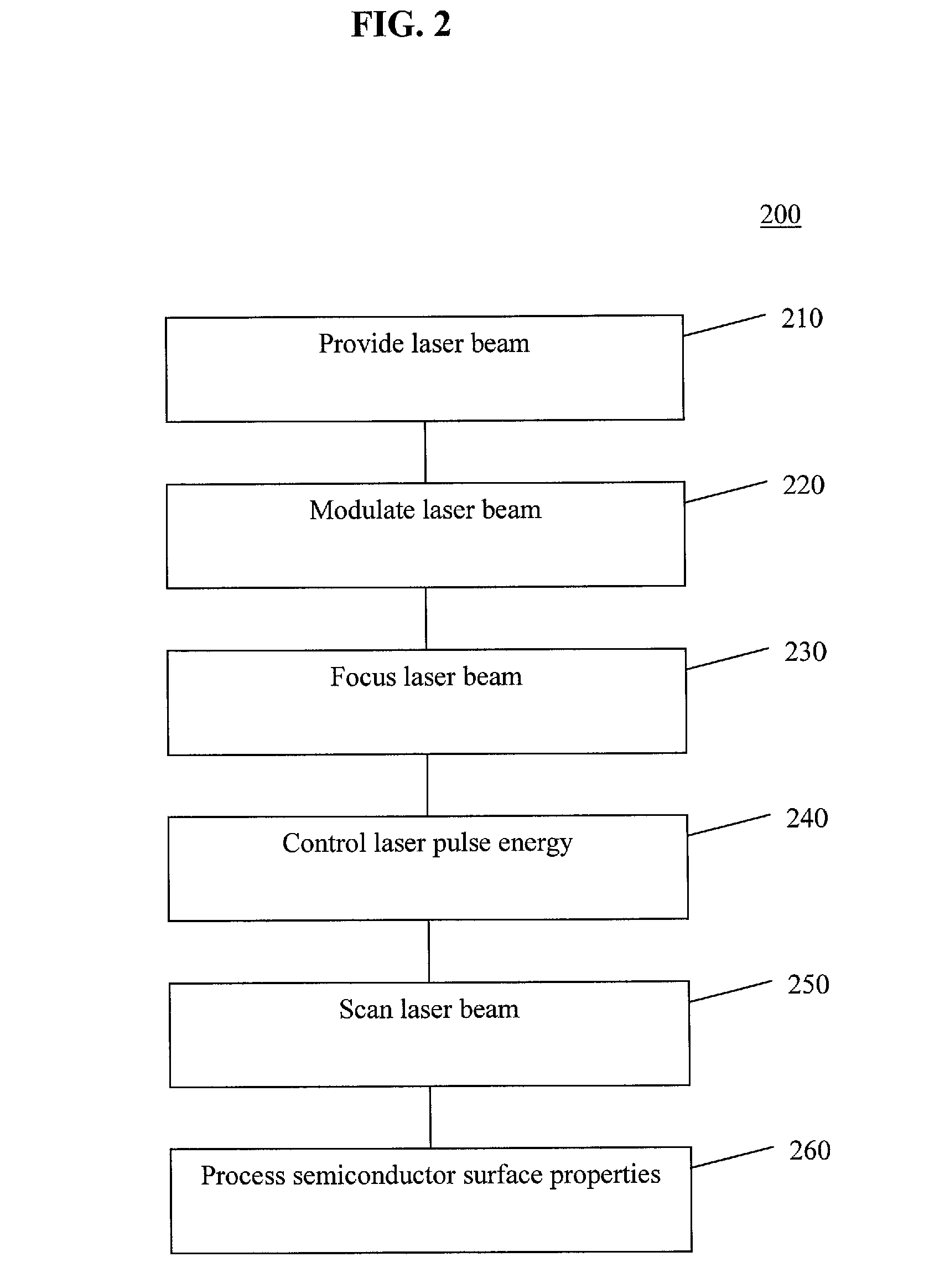

Optical Emission Spectroscopy Process Monitoring and Material Characterization

Methods and systems for control and monitoring processing of semiconductor materials with a focused laser beam. Laser light may be focused on a sample to excite optical emission at the sample surface during processing, which may include laser processing. Optical emission spectra produced may be analyzed for various properties effectively during the process. For example, process effects such as chemical composition analysis, species concentration, depth profiling, homogeneity characterization and mapping, purity, and reactivity may be monitored by optical spectral analysis. The wavelength may be selected to be appropriate for the process effect chosen.

Owner:WAFERMASTERS

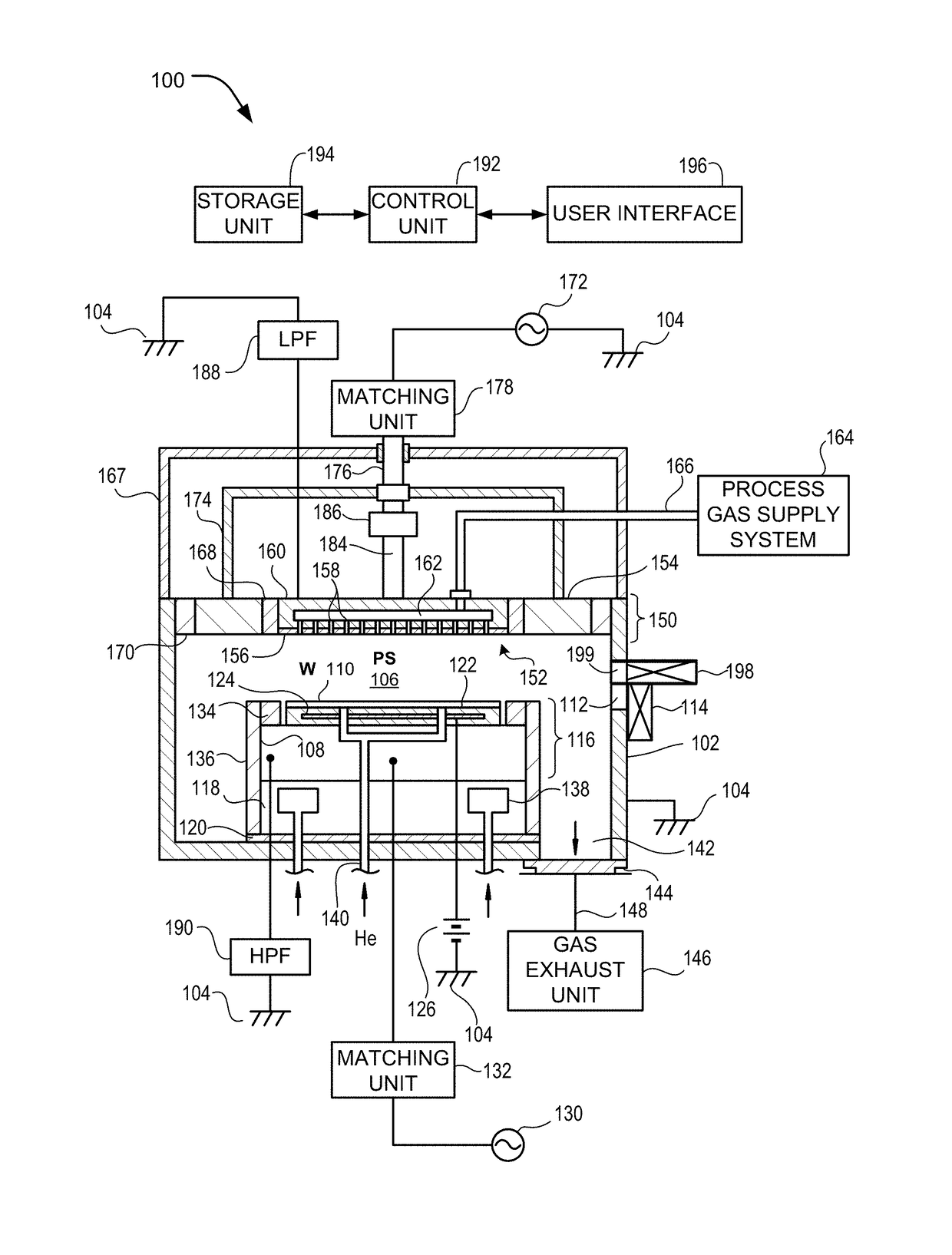

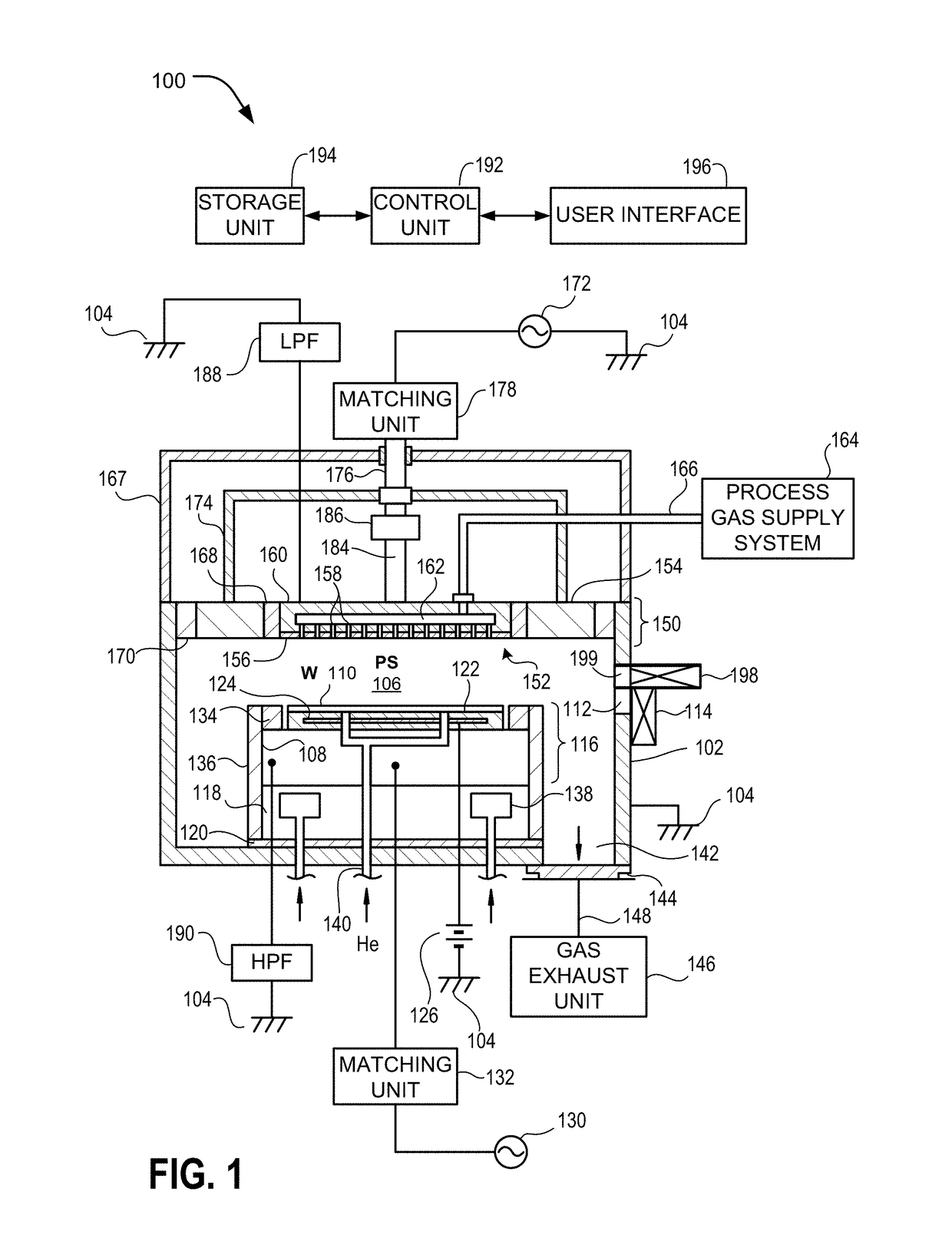

Controlling dry etch process characteristics using waferless dry clean optical emission spectroscopy

InactiveUS20170287791A1Slow changeMinimize deposition build-upSemiconductor/solid-state device testing/measurementElectric discharge tubesOptical emission spectrometryEngineering

Described herein are architectures, platforms and methods for acquiring optical emission spectra from an optical emission spectroscopy system by flowing a dry cleaning gas into a plasma processing chamber of the plasma processing system and igniting a plasma in the plasma processing chamber to initiate the waferless dry cleaning process.

Owner:TOKYO ELECTRON LTD

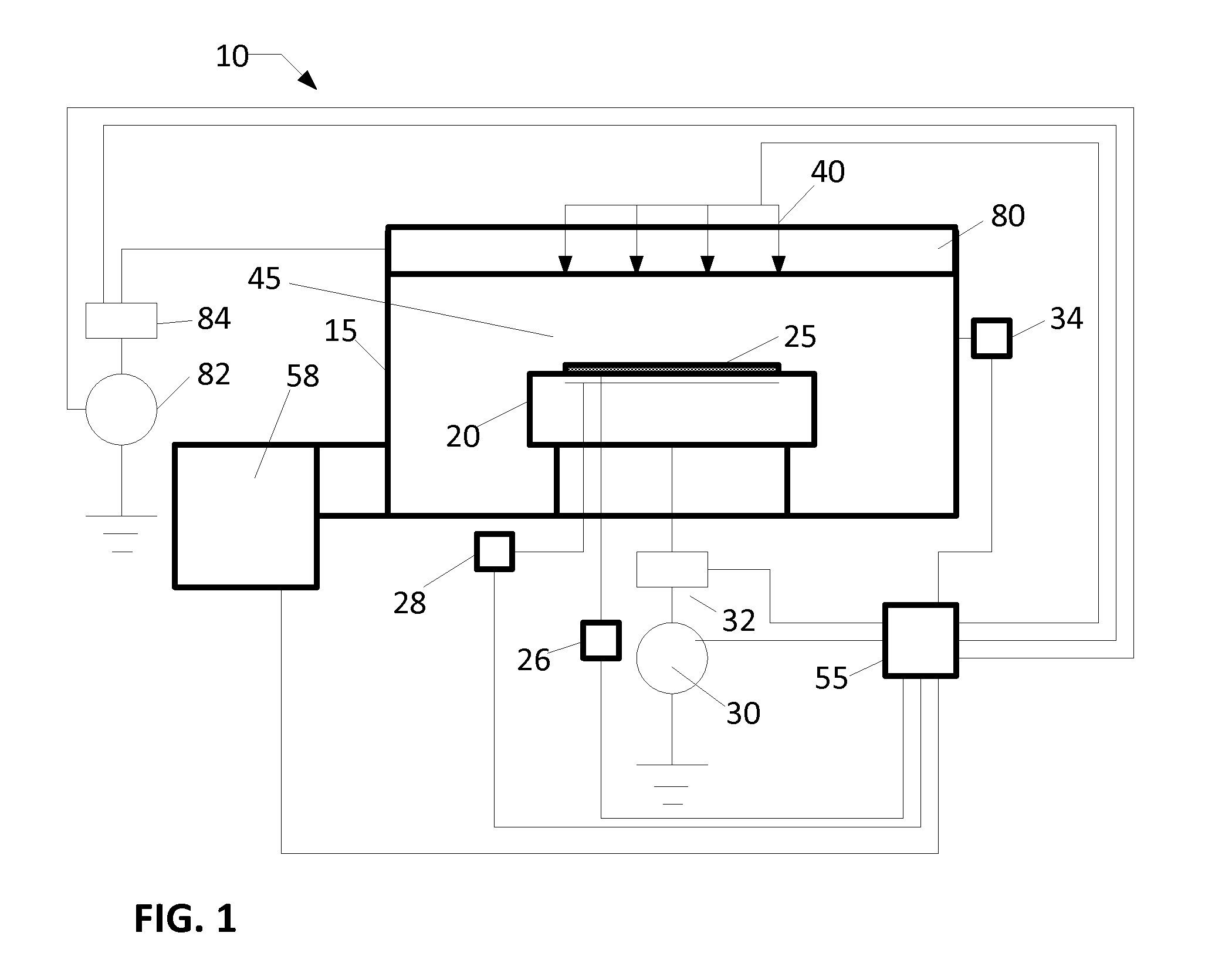

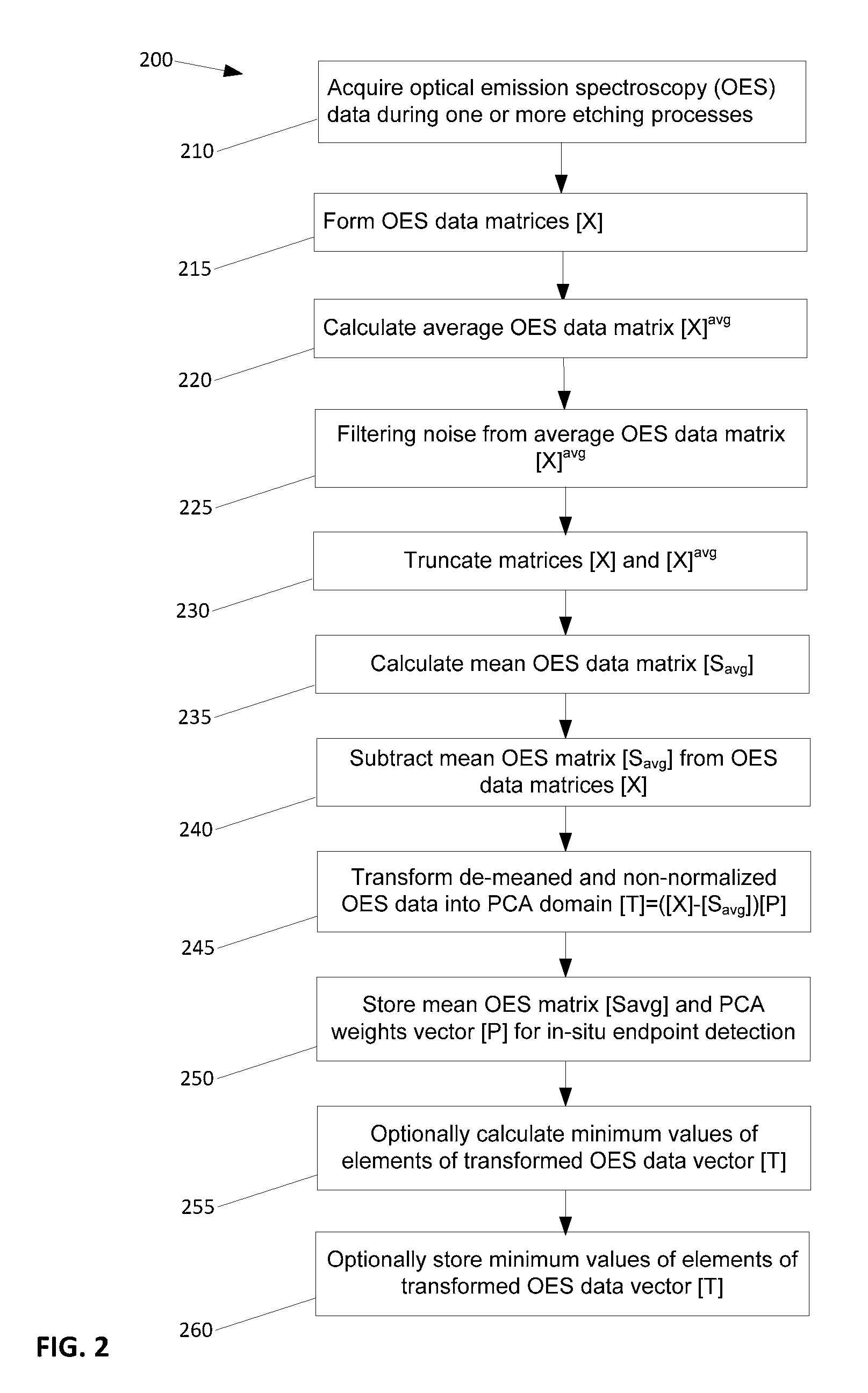

Method of endpoint detection of plasma etching process using multivariate analysis

ActiveUS20140106477A1Cancel noiseImprove data qualityAmplifier modifications to reduce noise influenceSemiconductor/solid-state device testing/measurementPrincipal component analysisOptical spectrometer

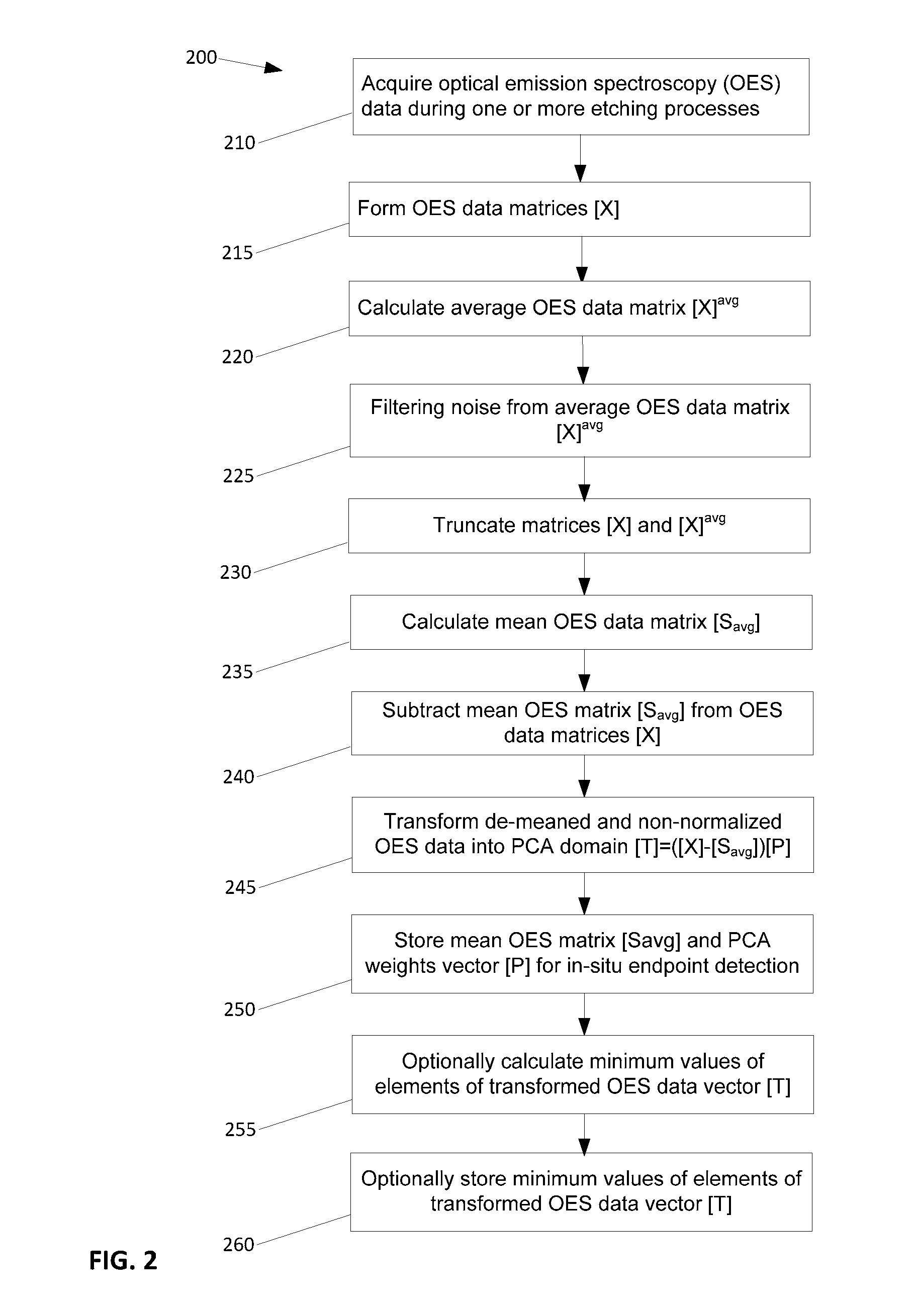

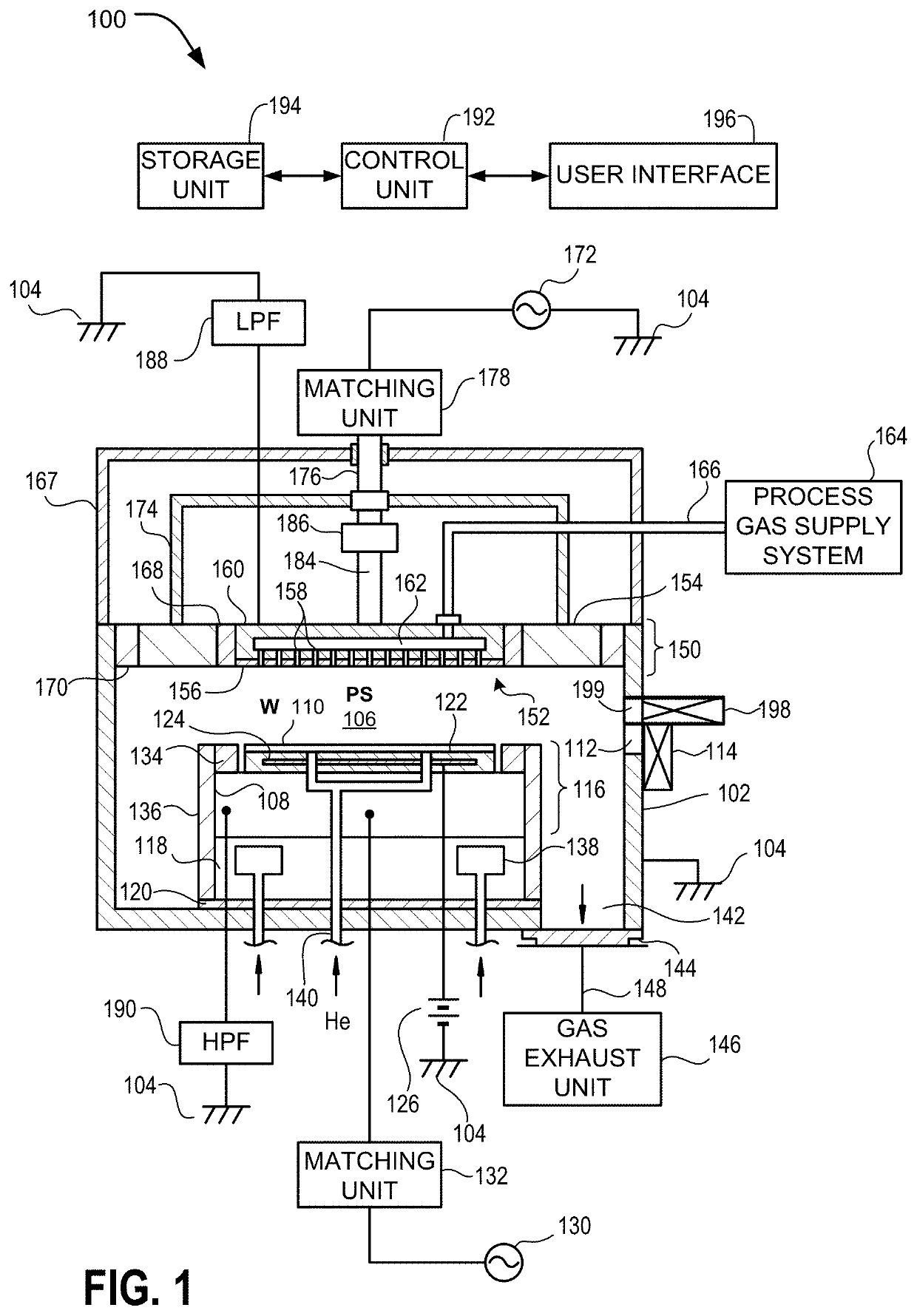

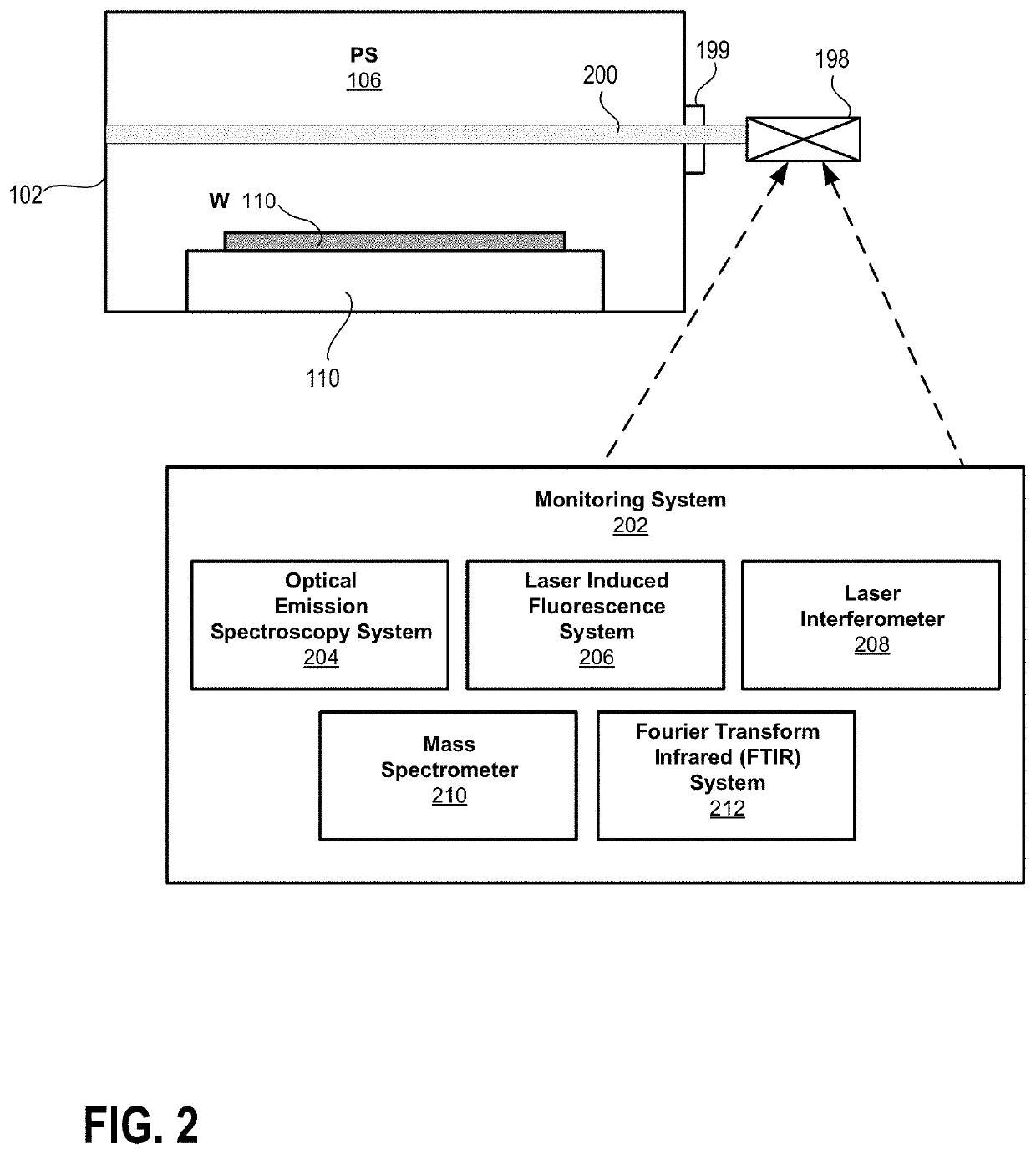

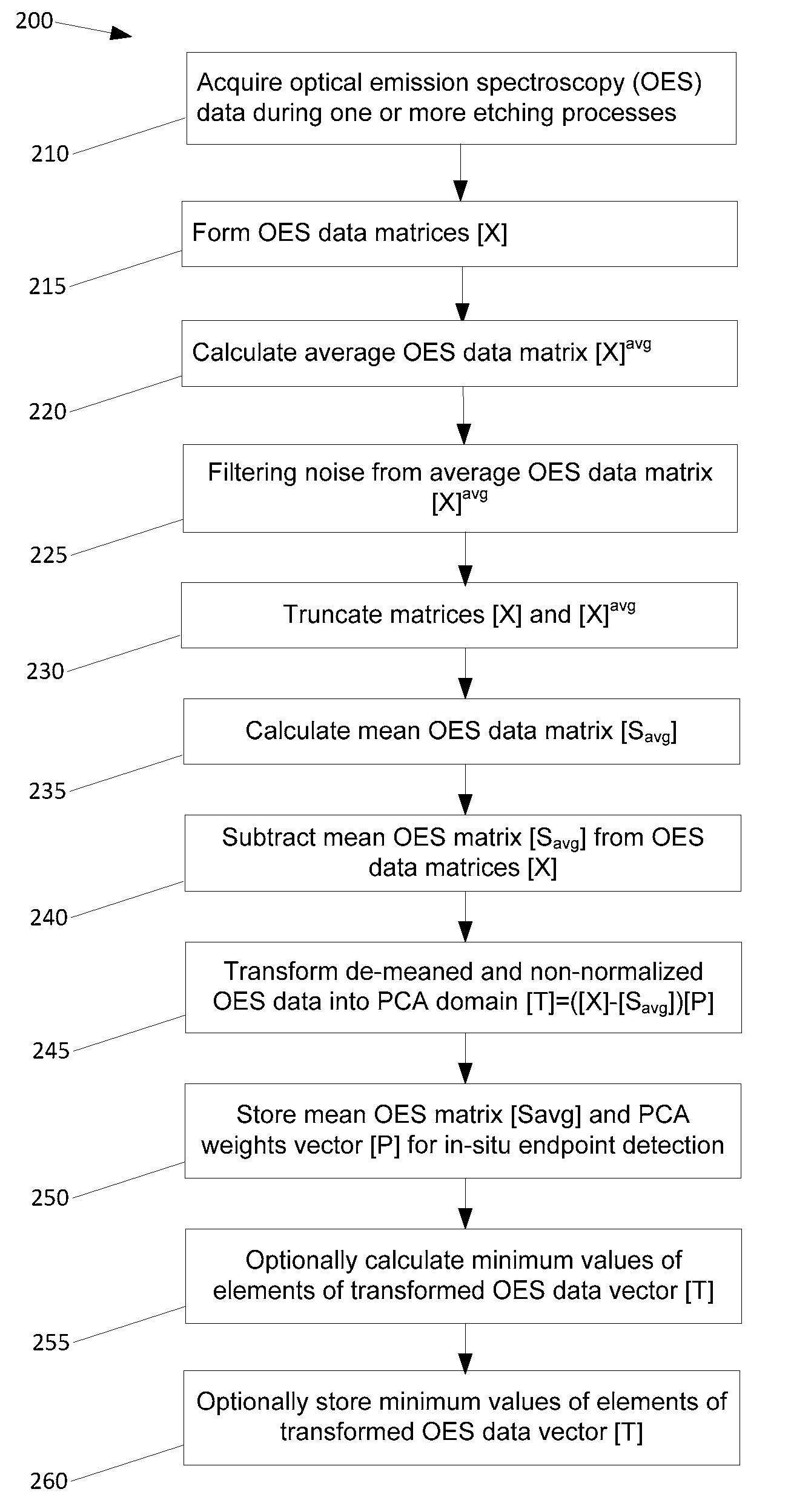

Disclosed is a method for determining an endpoint of an etch process using optical emission spectroscopy (OES) data as an input. Optical emission spectroscopy (OES) data are acquired by a spectrometer attached to a plasma etch processing tool. The acquired time-evolving spectral data are first filtered and demeaned, and thereafter transformed into transformed spectral data, or trends, using multivariate analysis such as principal components analysis, in which previously calculated principal component weights are used to accomplish the transform. A functional form incorporating multiple trends may be used to more precisely determine the endpoint of an etch process. A method for calculating principal component weights prior to actual etching, based on OES data collected from previous etch processing, is disclosed, which method facilitates rapid calculation of trends and functional forms involving multiple trends, for efficient and accurate in-line determination of etch process endpoint.

Owner:TOKYO ELECTRON LTD

Controlling dry etch process characteristics using waferless dry clean optical emission spectroscopy

ActiveUS10773282B2Minimize deposition build-upEasy to controlSemiconductor/solid-state device testing/measurementElectric discharge tubesPhotochemistryPlasma processing

Described herein are architectures, platforms and methods for acquiring optical emission spectra from an optical emission spectroscopy system by flowing a dry cleaning gas into a plasma processing chamber of the plasma processing system and igniting a plasma in the plasma processing chamber to initiate the waferless dry cleaning process.

Owner:TOKYO ELECTRON LTD

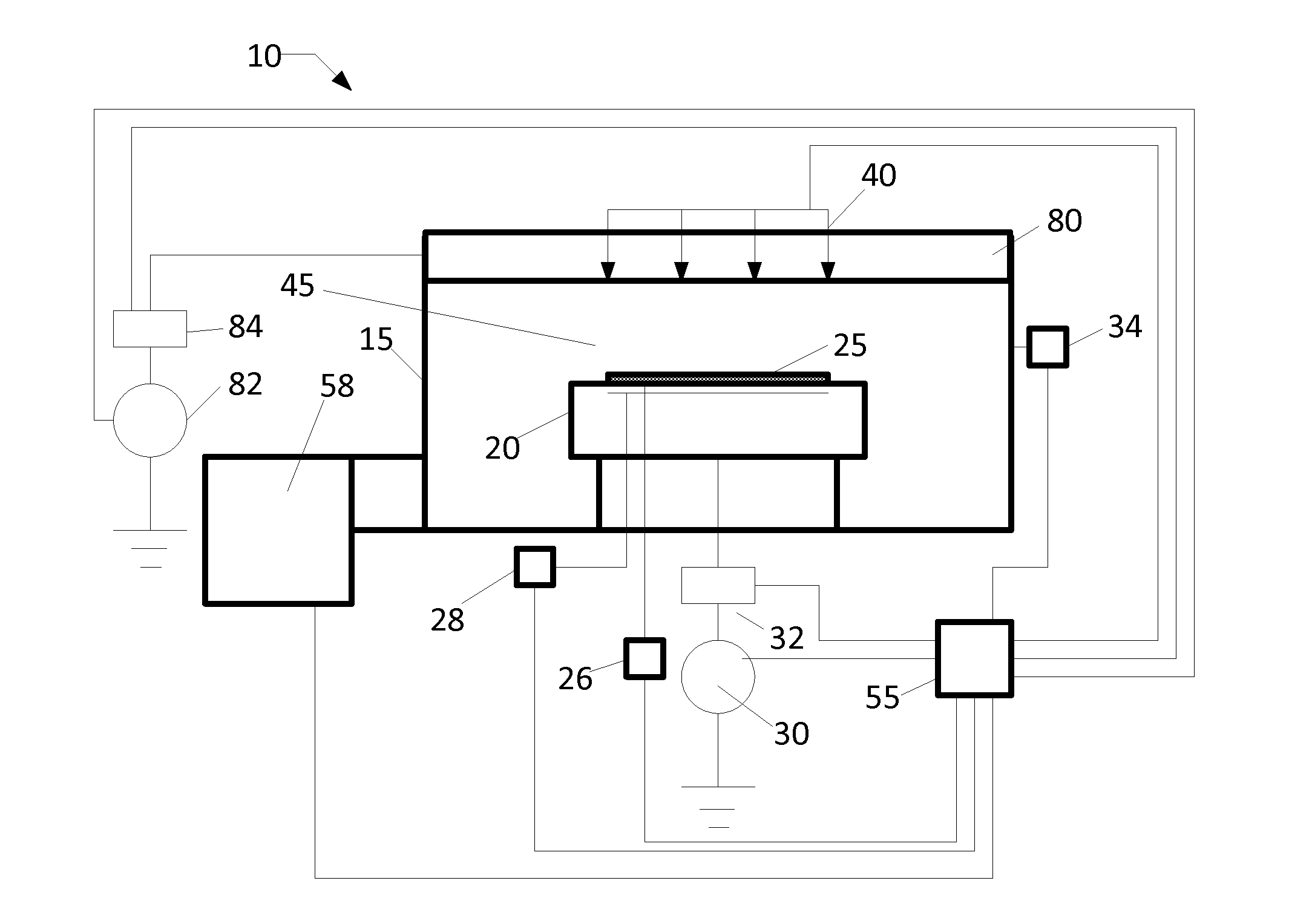

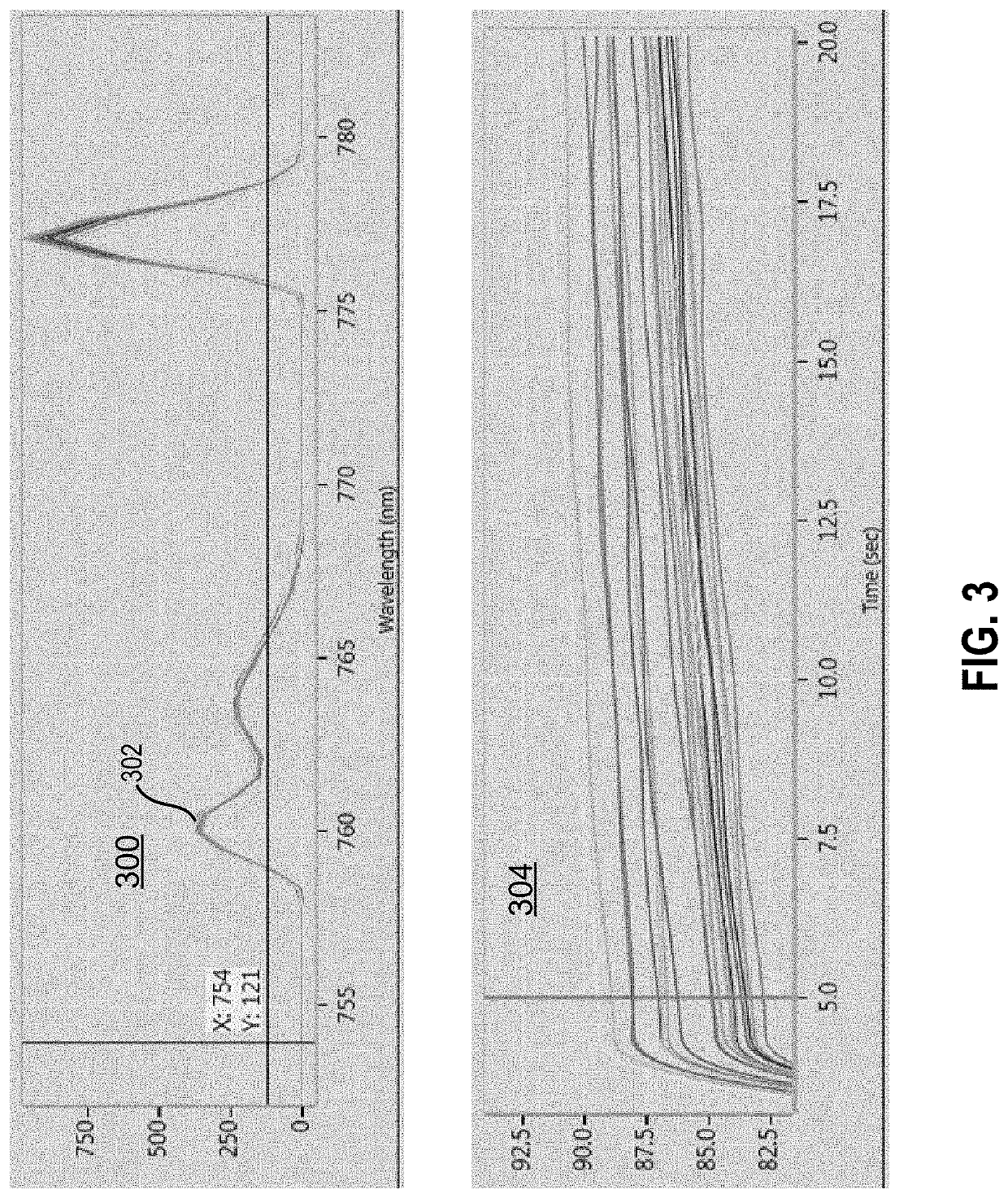

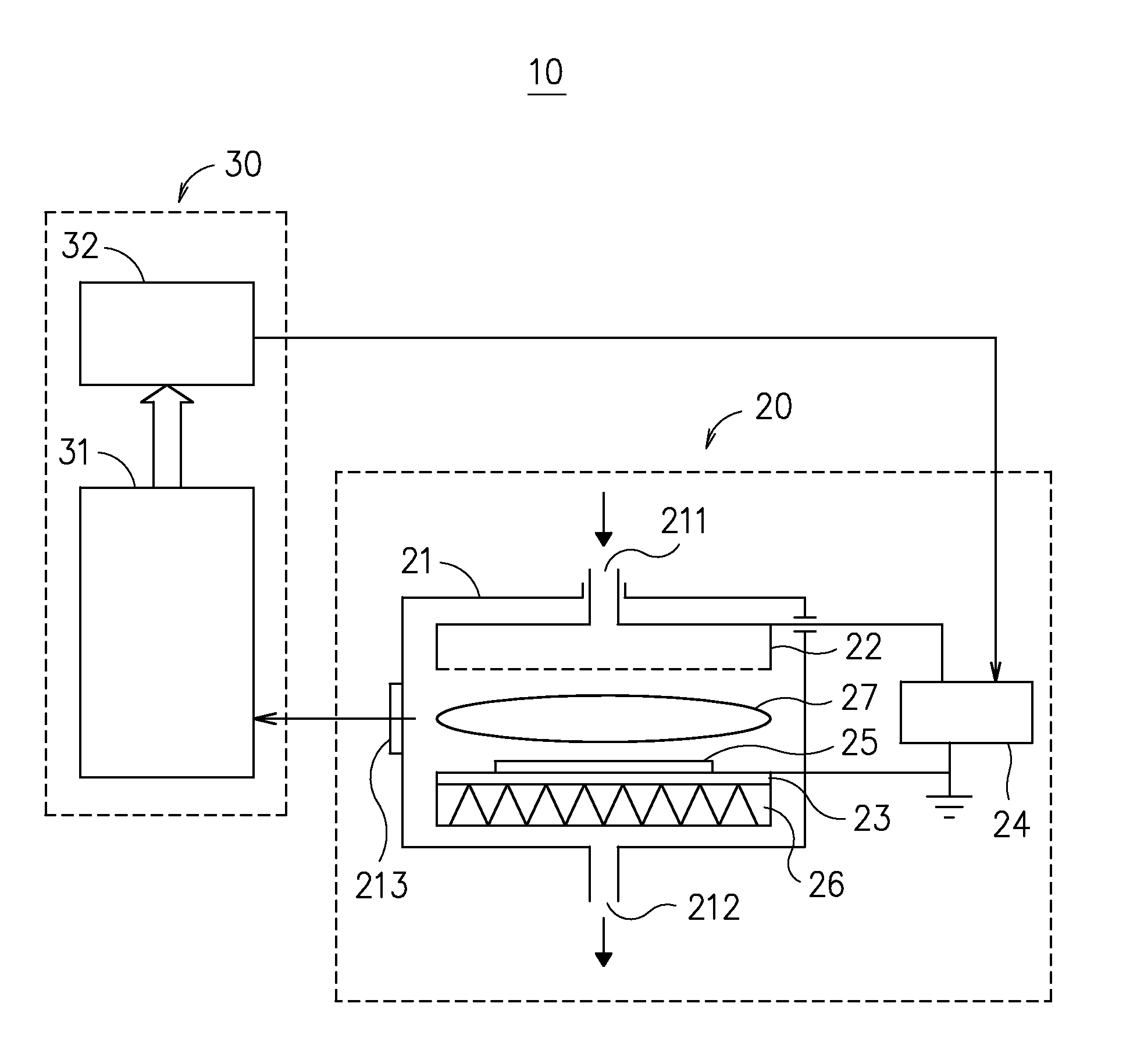

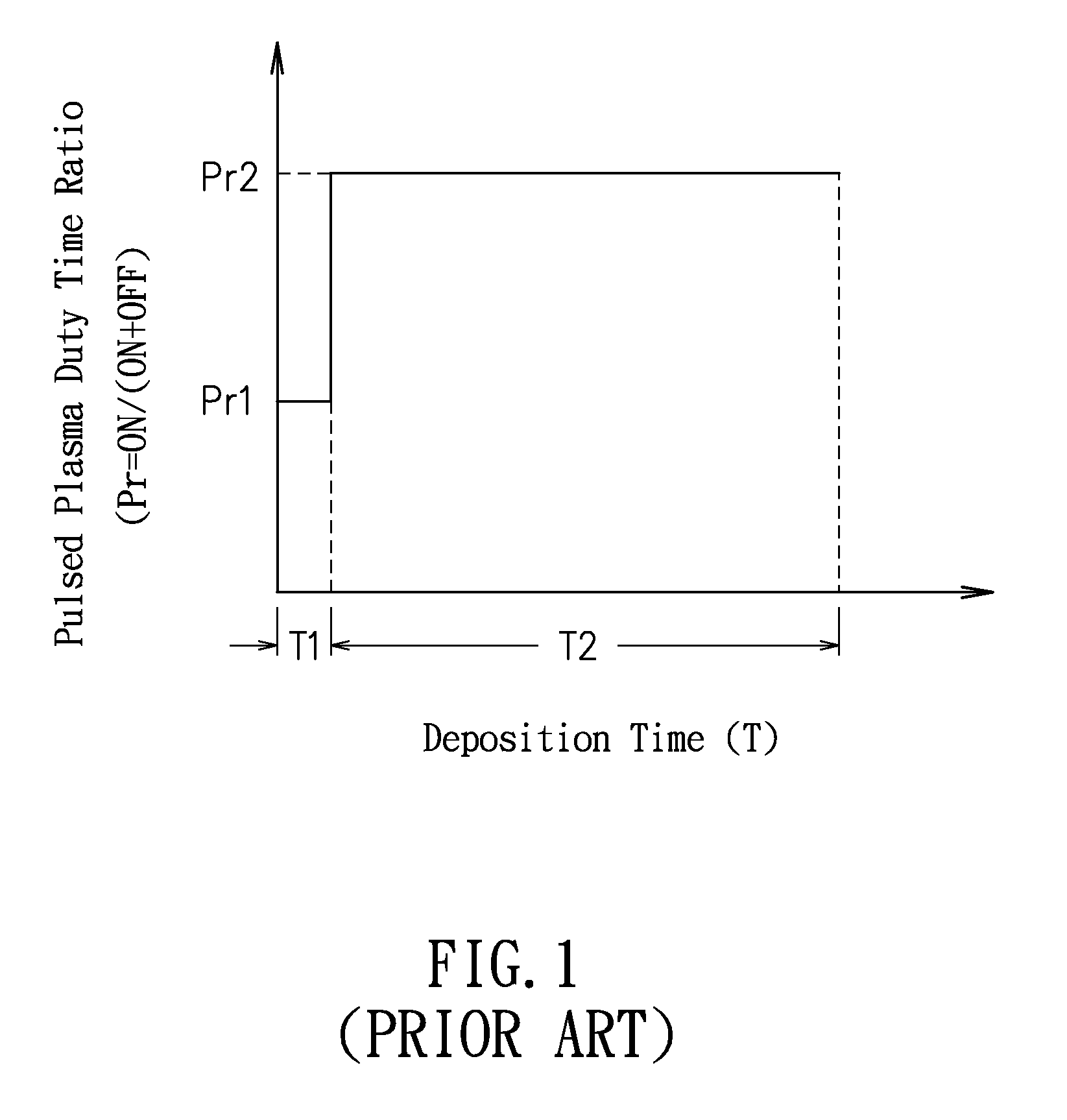

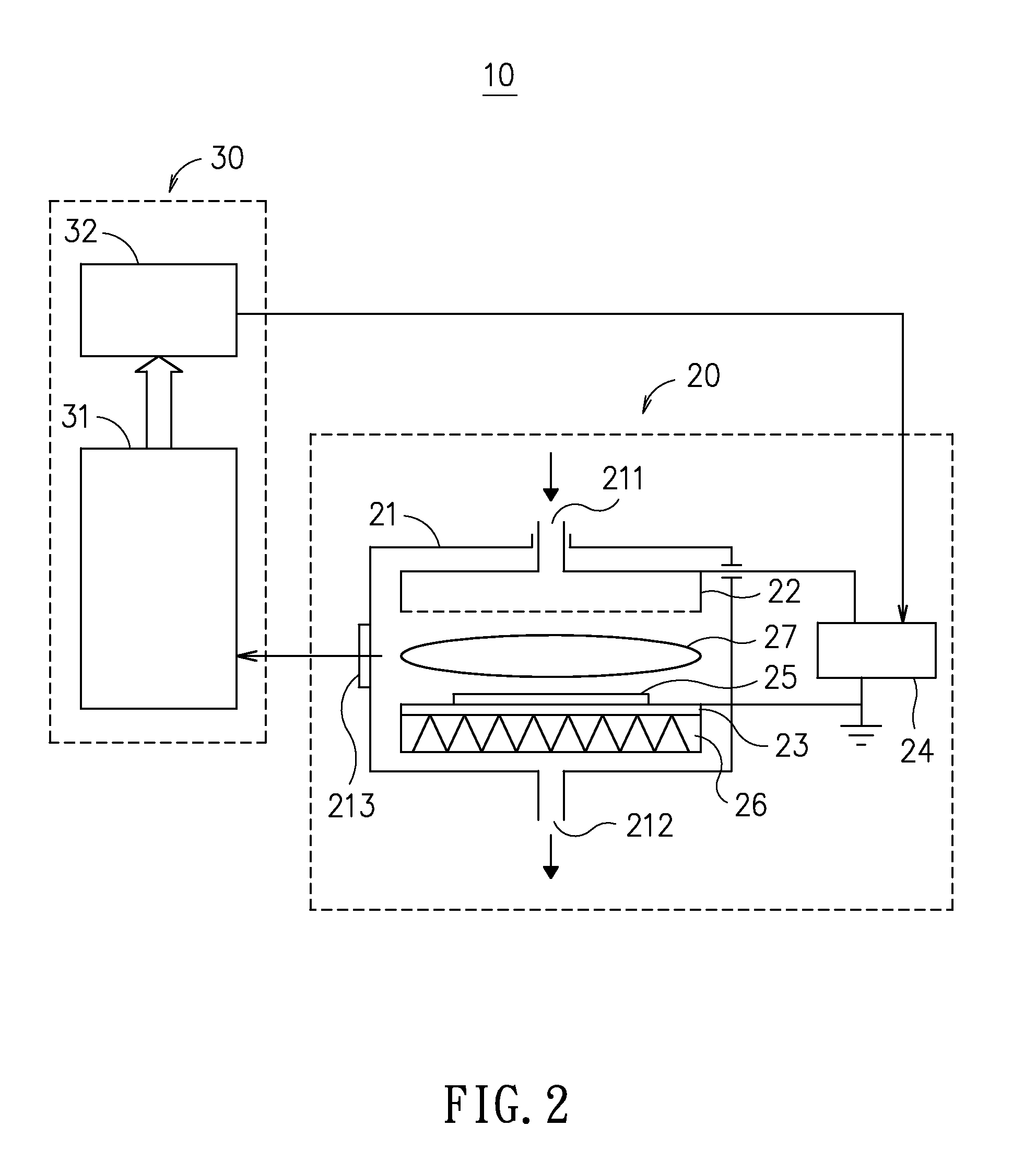

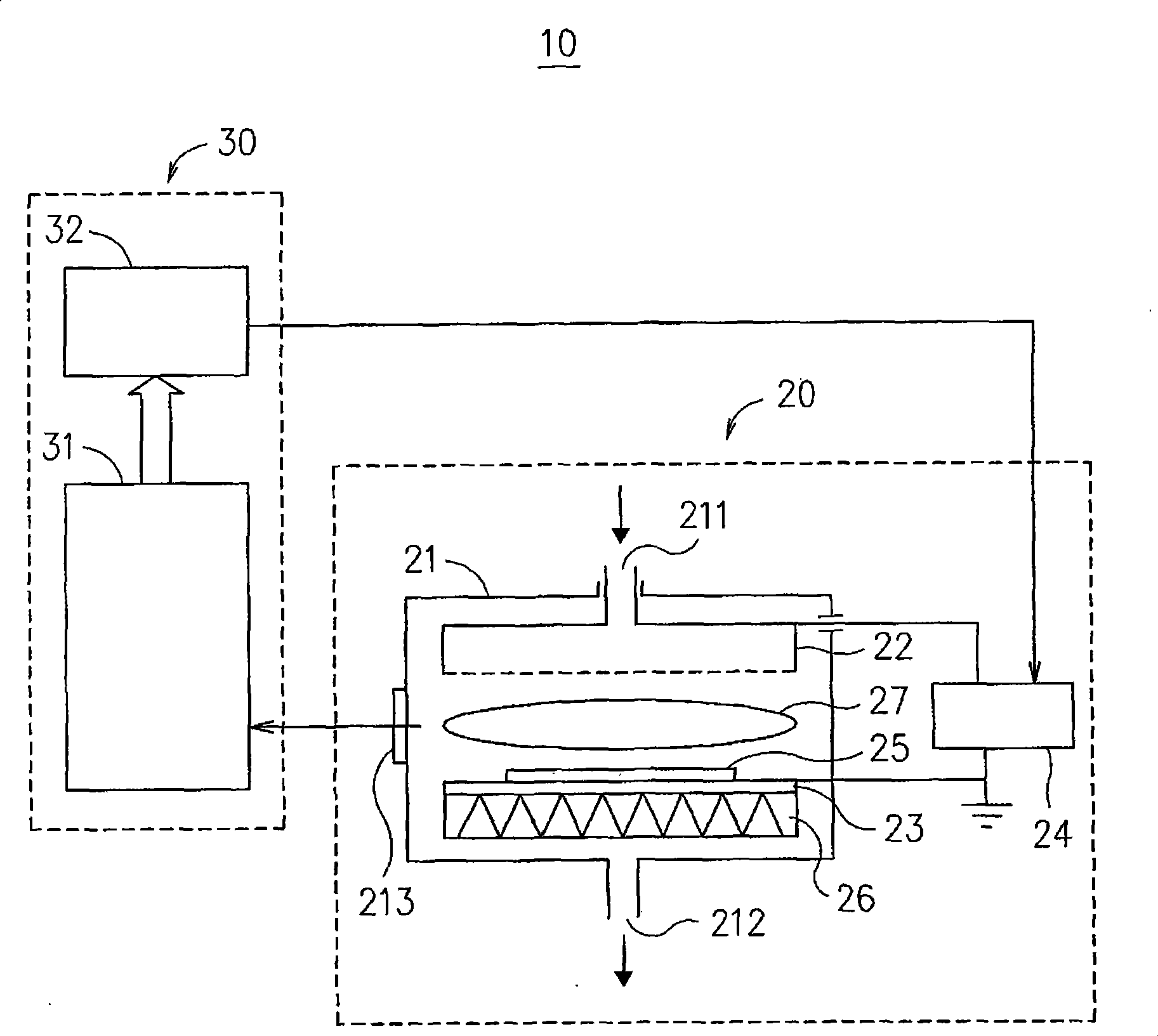

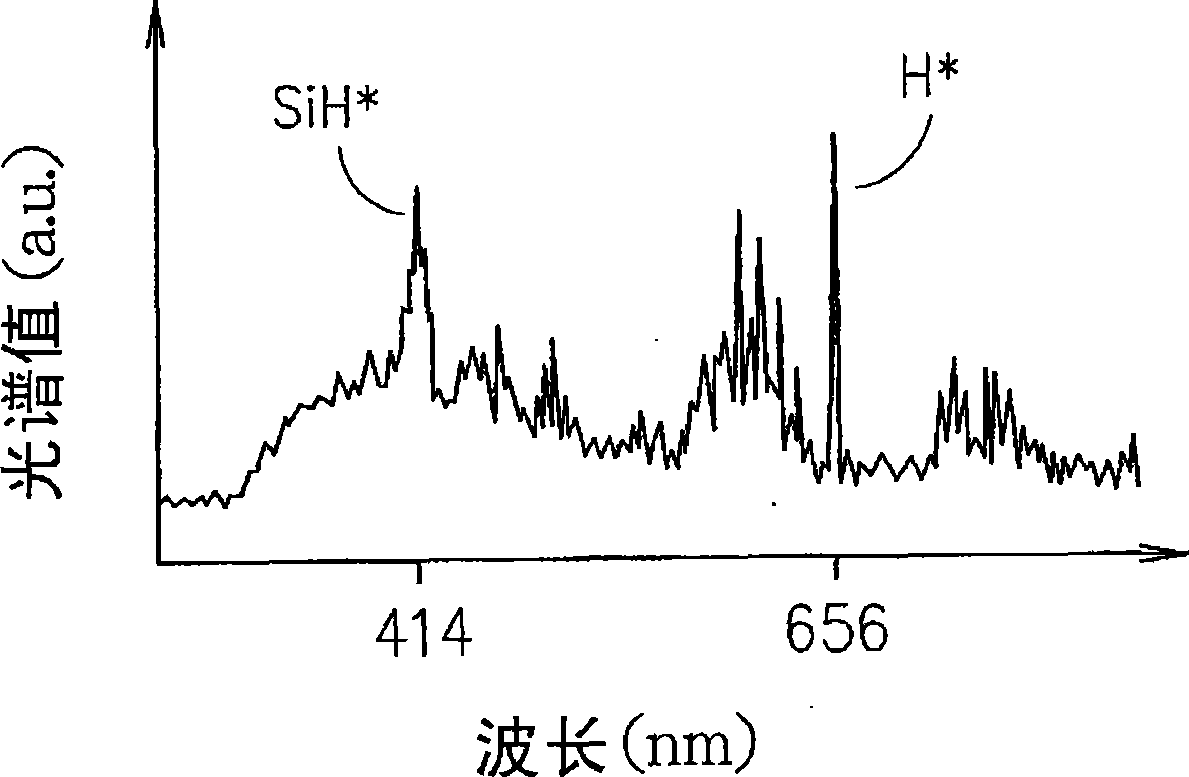

System and method for plasma enhanced thin film deposition

InactiveUS20090090616A1Thin film depositionIncrease deposition rateCellsVacuum evaporation coatingReactive gasMolecular physics

A system and a method for plasma enhanced thin film deposition are disclosed, in which the system comprises a plasma enhanced thin film deposition apparatus and a plasma process monitoring device. The plasma enhanced thin film deposition apparatus receives pulsed power and a reactive gas, whereby plasma discharging occurs to ionize the reactive gas into a plurality of radicals for thin film deposition. The plasma process monitoring device comprises an optical emission spectroscopy (OES) and a pulsed plasma modulation device, in which the OES detects spectrum intensities of the radicals and the pulsed plasma modulation device calculates a spectrum intensity ratio of the radicals so as to modulate the plasma duty time of pulsed power, thereby high deposition rate as well as real-time monitoring on thin film deposition quality can be achieved.

Owner:IND TECH RES INST

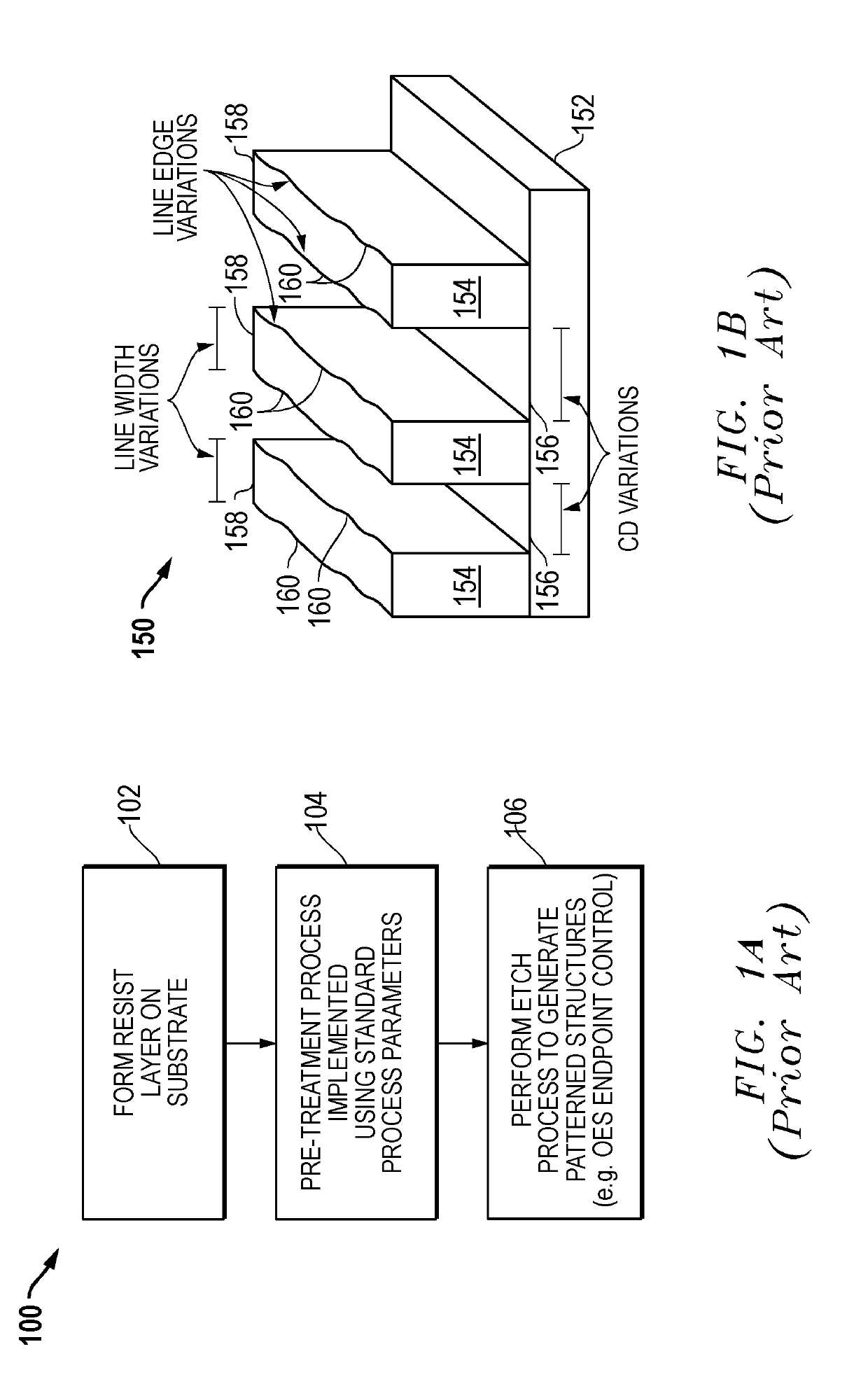

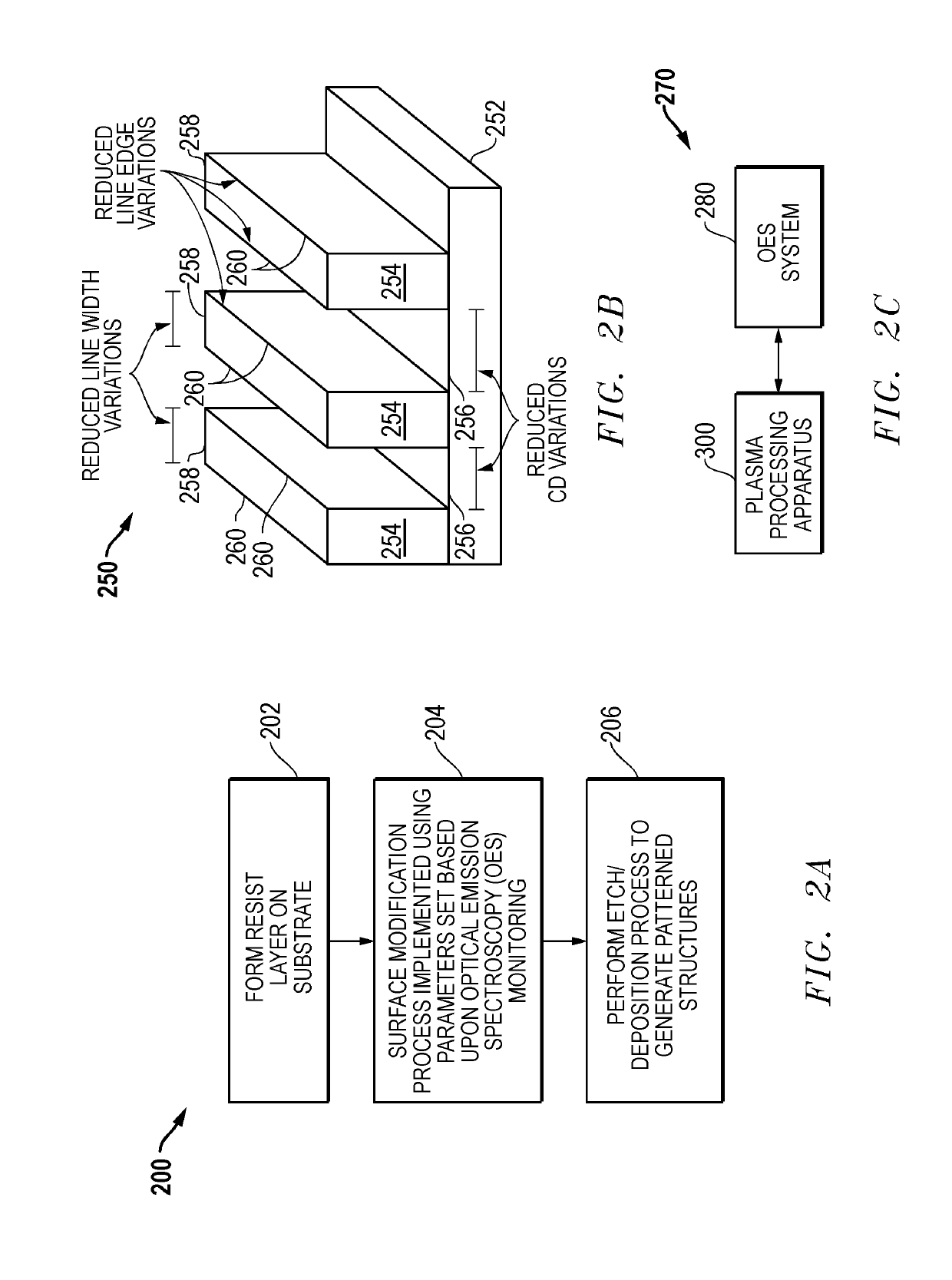

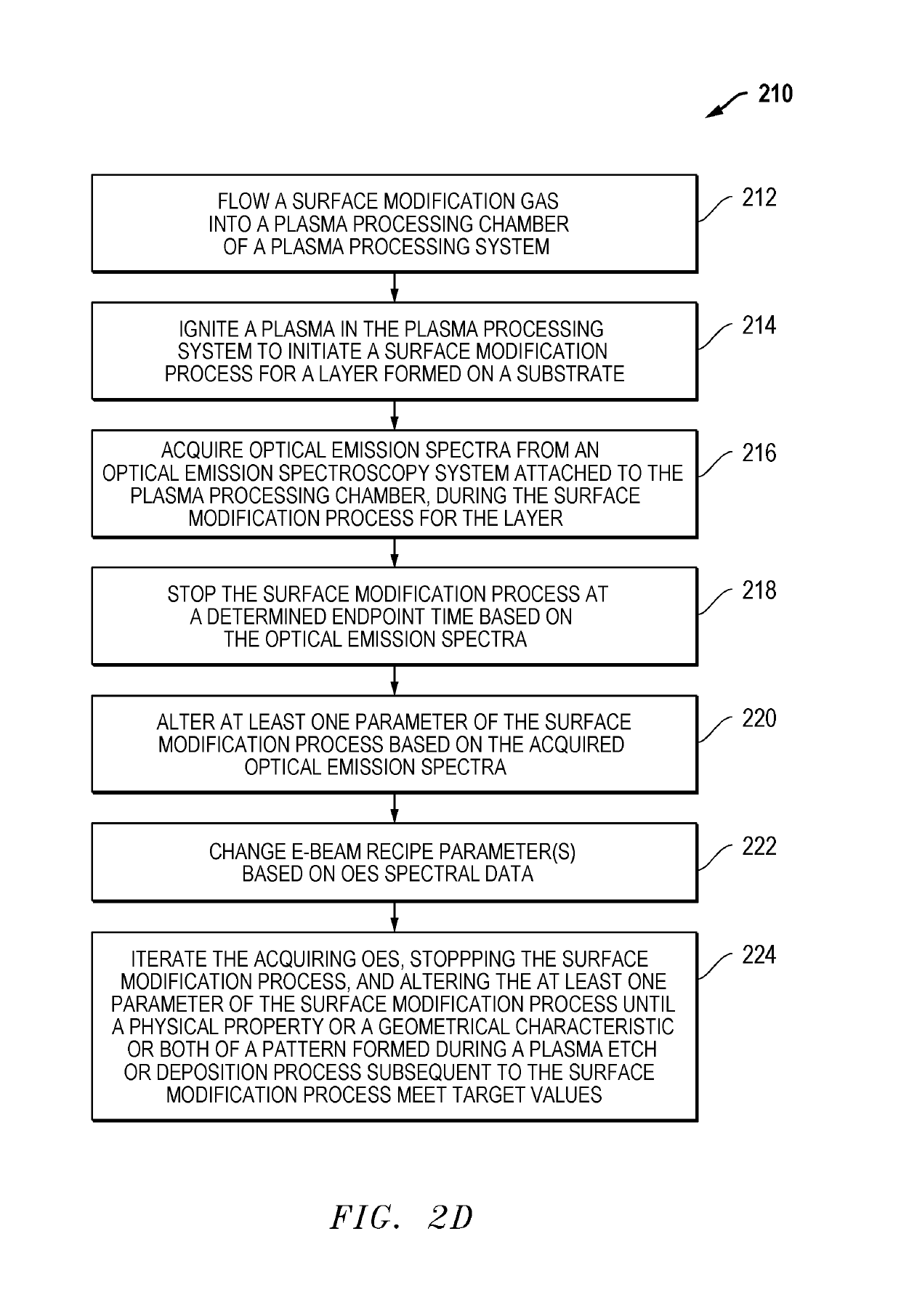

Surface modification control for etch metric enhancement

ActiveUS10446453B2Reduce the possibilitySemiconductor/solid-state device testing/measurementElectric discharge tubesUltimate tensile strengthPlasma processing

Owner:TOKYO ELECTRON LTD

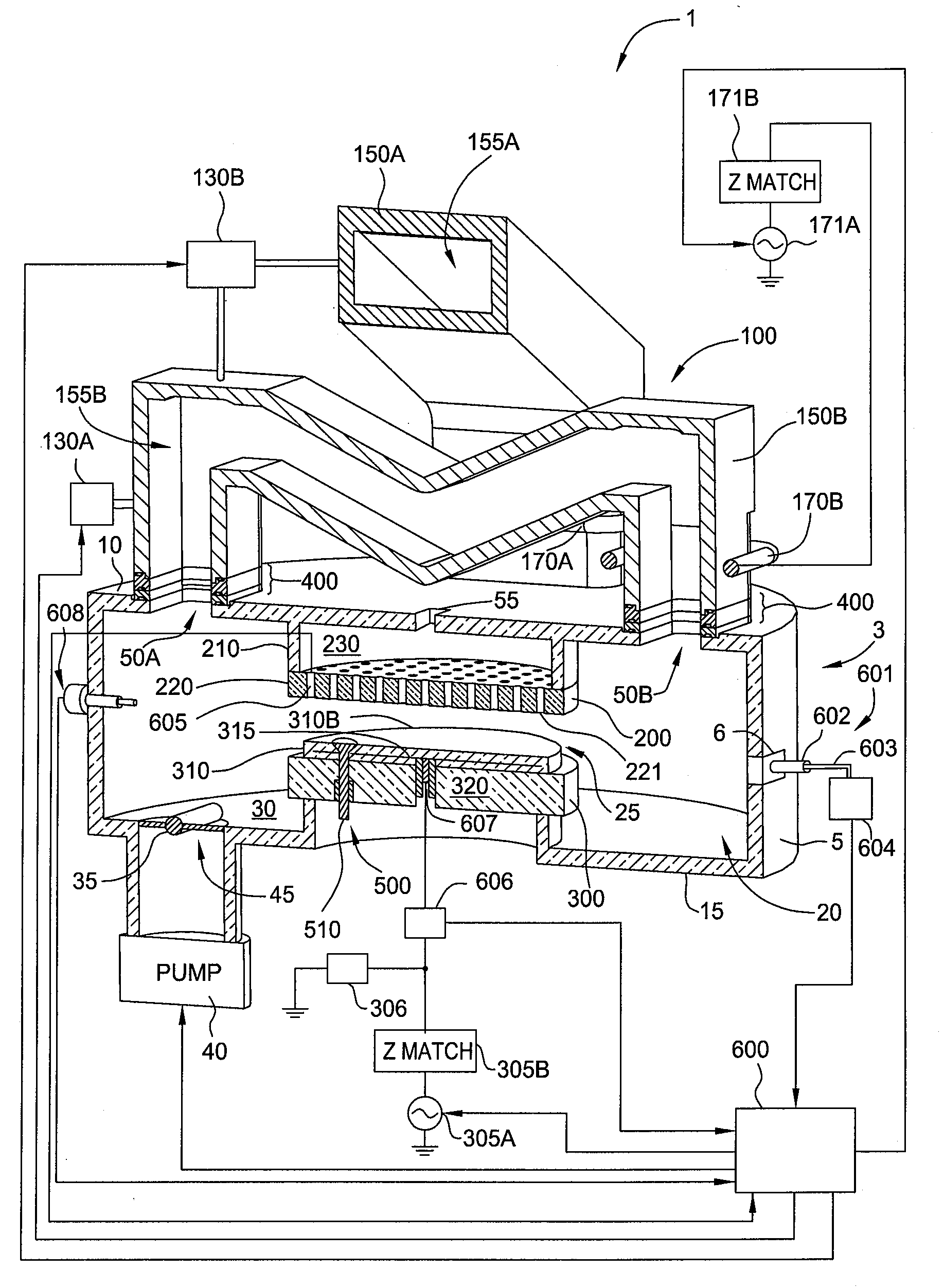

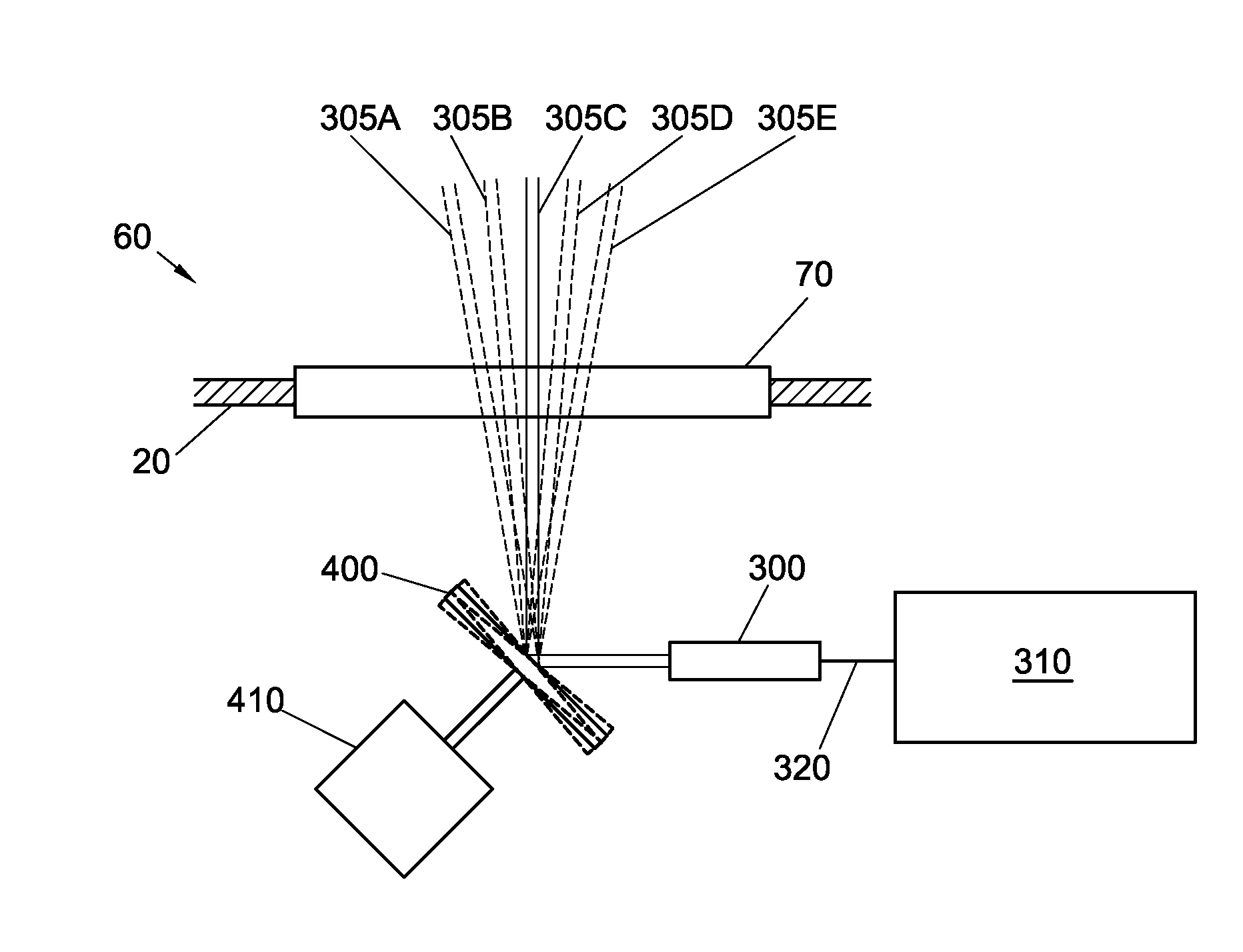

Spatially resolved optical emission spectroscopy (OES) in plasma processing

ActiveUS20150124250A1Emission spectroscopyRadiation pyrometryProcess developmentOptical emission spectrometry

Disclosed is a method, computer method, system, and apparatus for measuring two-dimensional distributions of optical emissions from a plasma in a semiconductor plasma processing chamber. The acquired two-dimensional distributions of plasma optical emissions can be used to infer the two-dimensional distributions of concentrations of certain chemical species of interest that are present in the plasma, and thus provide a useful tool for process development and also for new and improved processing tool development. The disclosed technique is computationally simple and inexpensive, and involves the use of an expansion of the assumed optical intensity distribution into a sum of basis functions that allow for circumferential variation of optical intensity. An example of suitable basis functions are Zernike polynomials.

Owner:TOKYO ELECTRON LTD

Optical emission spectroscopy process monitoring and material characterization

InactiveUS7599048B2Emission spectroscopyRadiation pyrometrySemiconductor materialsChemical composition

Methods and systems for control and monitoring processing of semiconductor materials with a focused laser beam. Laser light may be focused on a sample to excite optical emission at the sample surface during processing, which may include laser processing. Optical emission spectra produced may be analyzed for various properties effectively during the process. For example, process effects such as chemical composition analysis, species concentration, depth profiling, homogeneity characterization and mapping, purity, and reactivity may be monitored by optical spectral analysis. The wavelength may be selected to be appropriate for the process effect chosen.

Owner:WAFERMASTERS

Smart additive manufacturing system (SAMS)

ActiveUS9981341B2Additive manufacturing apparatusWelding/soldering/cutting articlesOptical emission spectrometryEngineering

An additive manufacturing process is monitored, in situ, using optical emission spectroscopy to analyze the composition, phase transformation or manufacturing defects. The system or method may include an analysis of contours of the plasma line intensity, or pre-processing of the plasma spectral line including signal-to-noise ratio analysis, baseline removal, line identification, line de-convolution and fitting. Improvements may additionally involve consideration of plasma parameters such as plasma spectral line intensity, line ratio, plasma temperature and electron density using high-resolution optical emission spectroscopy in both visible and ultraviolet regions. Parameters of the plasma may be determined using an intensity ratio of the ions or atoms emission lines, a FWHM of the line profile for electron density estimation, or a Boltzmann plot for plasma temperature estimation. One or more techniques may be used to monitor when there is a lack of deposition.

Owner:MAZUMDER JYOTI +1

Rapid determination method of ash components

InactiveCN101819152AShorten analysis and measurement timeReduce pollutionPreparing sample for investigationAnalysis by thermal excitationHydrofluoric acidInductively coupled plasma

The invention relates to a rapid determination method of ash components, in particular to a rapid determination method of desulfuration ash components, which comprises the steps of: 1, fully crushing a fully combusted ash sample, taking 0.0500-0.1000g of sample as an analysis sample; 2, putting the analysis sample in a polytetrafluoroethylene inner pipe of a digestion tank, sequentially adding concentrated hydrochloric acid, concentrated nitric acid and hydrofluoric acid, carrying out microwave digestion under a certain condition to obtain a digestion product; 3, completely dissolving the digestion sample into a polypropylene volumetric flask by using a diluted nitric acid solution to obtain an analysis solution by meter volume; and 4, determining contents of all components in the analysis solution by using an inductively coupled plasma optical emission spectroscopy. The invention has short determining time and simple process and can be used for determining multiple and complete components.

Owner:HEBEI ELECTRIC POWER RES INST

Method of endpoint detection of plasma etching process using multivariate analysis

ActiveUS9330990B2Cancel noiseImprove data qualitySemiconductor/solid-state device testing/measurementElectric discharge tubesPrincipal component analysisMultivariate analysis

Disclosed is a method for determining an endpoint of an etch process using optical emission spectroscopy (OES) data as an input. Optical emission spectroscopy (OES) data are acquired by a spectrometer attached to a plasma etch processing tool. The acquired time-evolving spectral data are first filtered and demeaned, and thereafter transformed into transformed spectral data, or trends, using multivariate analysis such as principal components analysis, in which previously calculated principal component weights are used to accomplish the transform. A functional form incorporating multiple trends may be used to more precisely determine the endpoint of an etch process. A method for calculating principal component weights prior to actual etching, based on OES data collected from previous etch processing, is disclosed, which method facilitates rapid calculation of trends and functional forms involving multiple trends, for efficient and accurate in-line determination of etch process endpoint.

Owner:TOKYO ELECTRON LTD

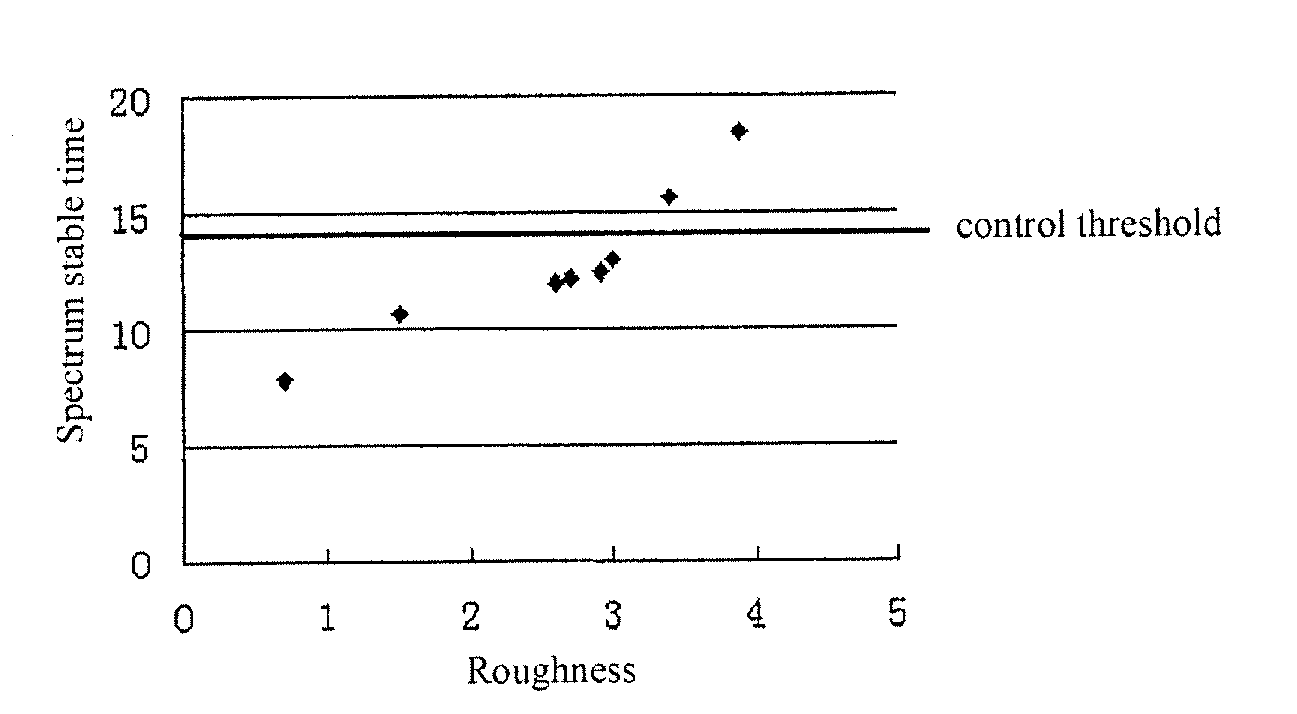

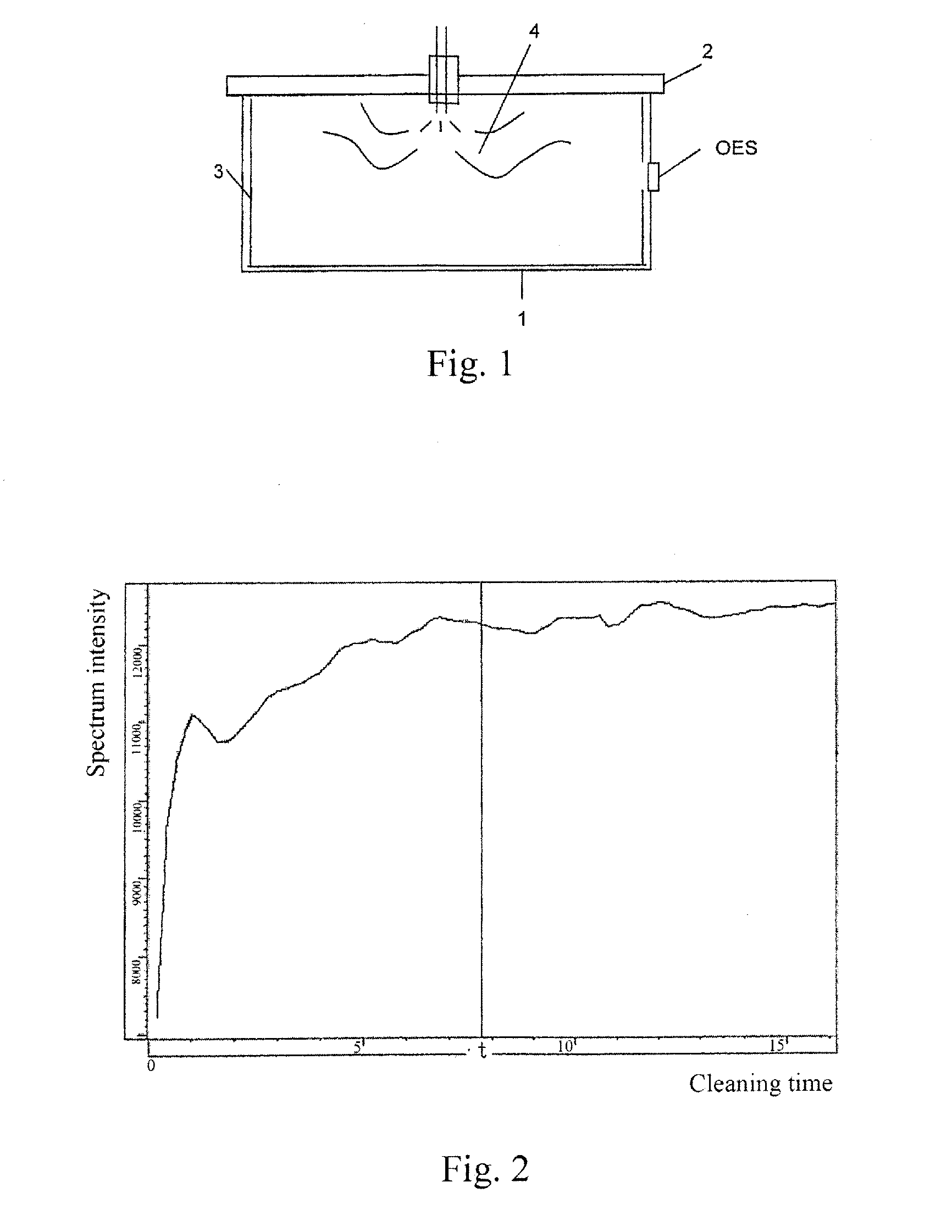

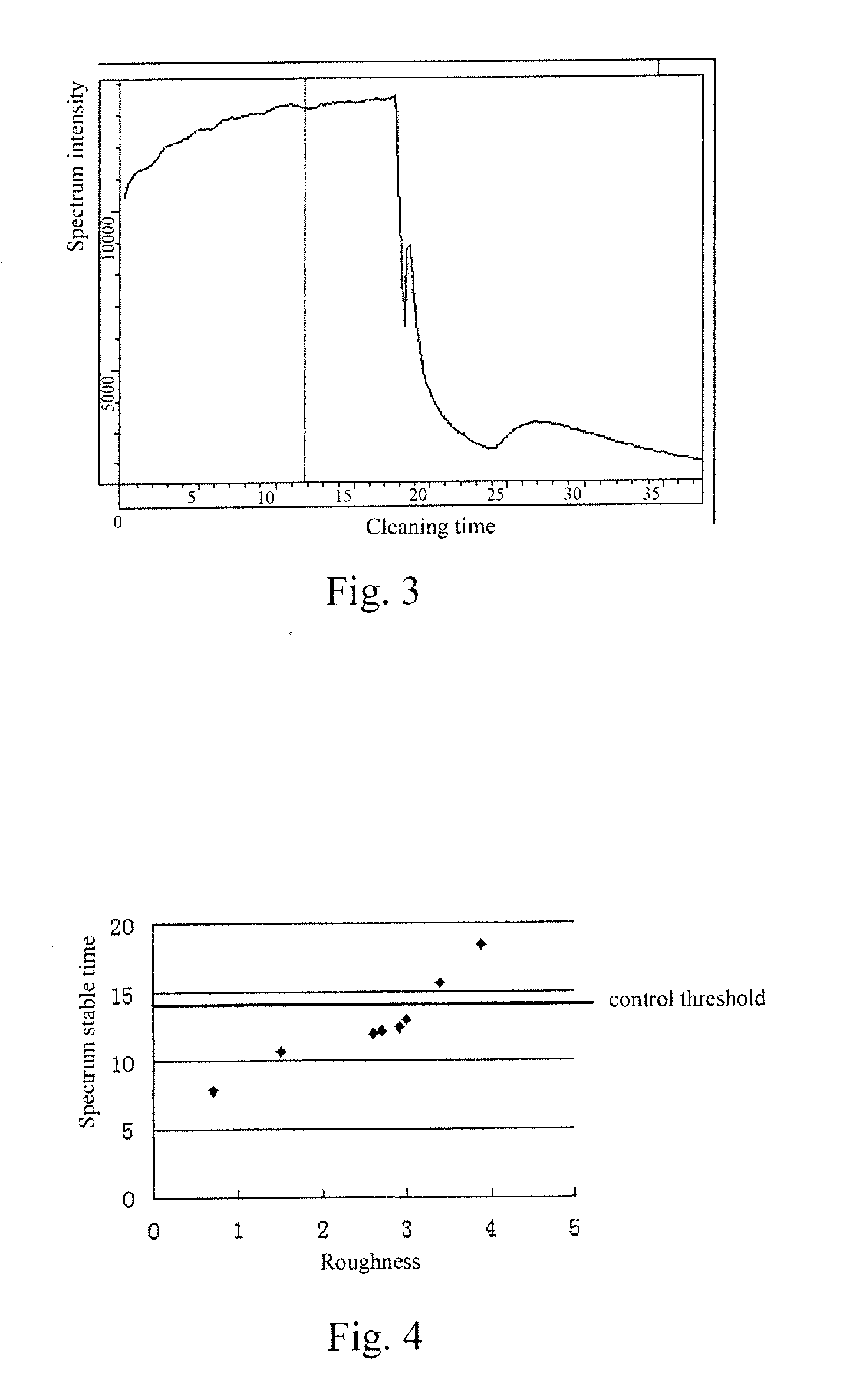

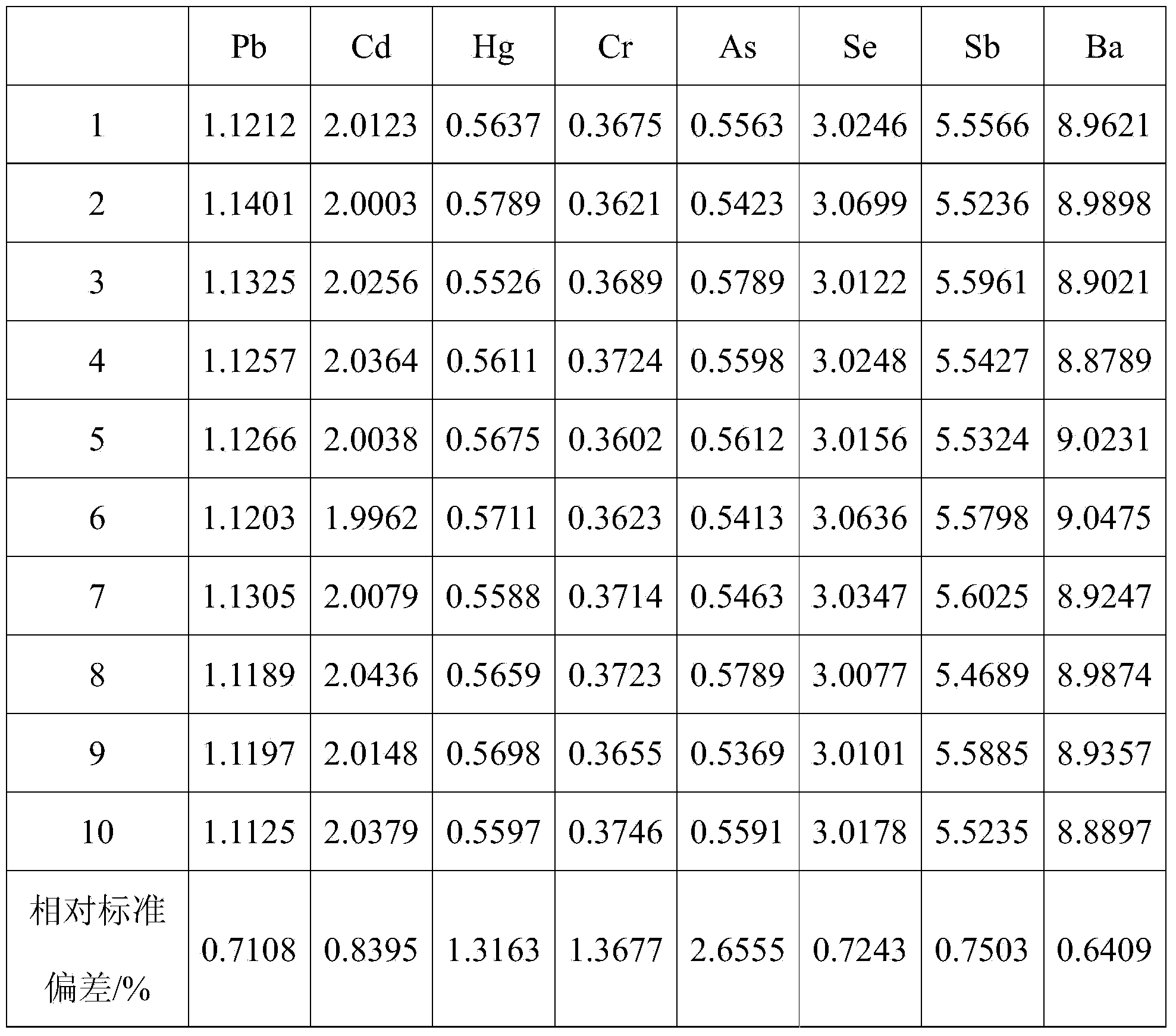

Method of online predicting maintenance of an apparatus

ActiveUS20100042452A1Low costImprove processing efficiencyRadiation pyrometrySemiconductor/solid-state device manufacturingLine sensorProduction rate

A method of online predicting maintenance of an apparatus is disclosed. Using an optical emission spectroscopy (OES) positioned on the apparatus and the change of emission spectrum intensity detected by the OES in the process, according to the detected results, measuring the parameter in the process, the function relation between the process parameter and spectrum intensity is acquired. A control threshold is decided by the processing requirement to the apparatus. When the parameter exceeds the control threshold, maintenance to the etching apparatus is engaged in order to avoid processing error caused by frequent shutdown or deficient maintenance which is estimated by experience, and hence decreasing the cost and increasing processing efficiency of substrates (such as silicon wafers) without changing apparatus and adding other online sensor, and improving production rate by avoiding waste substrates caused by error processing results. The method is suitable for semiconductor substrate etching maintenance of the apparatus and also other maintenance of the apparatus.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

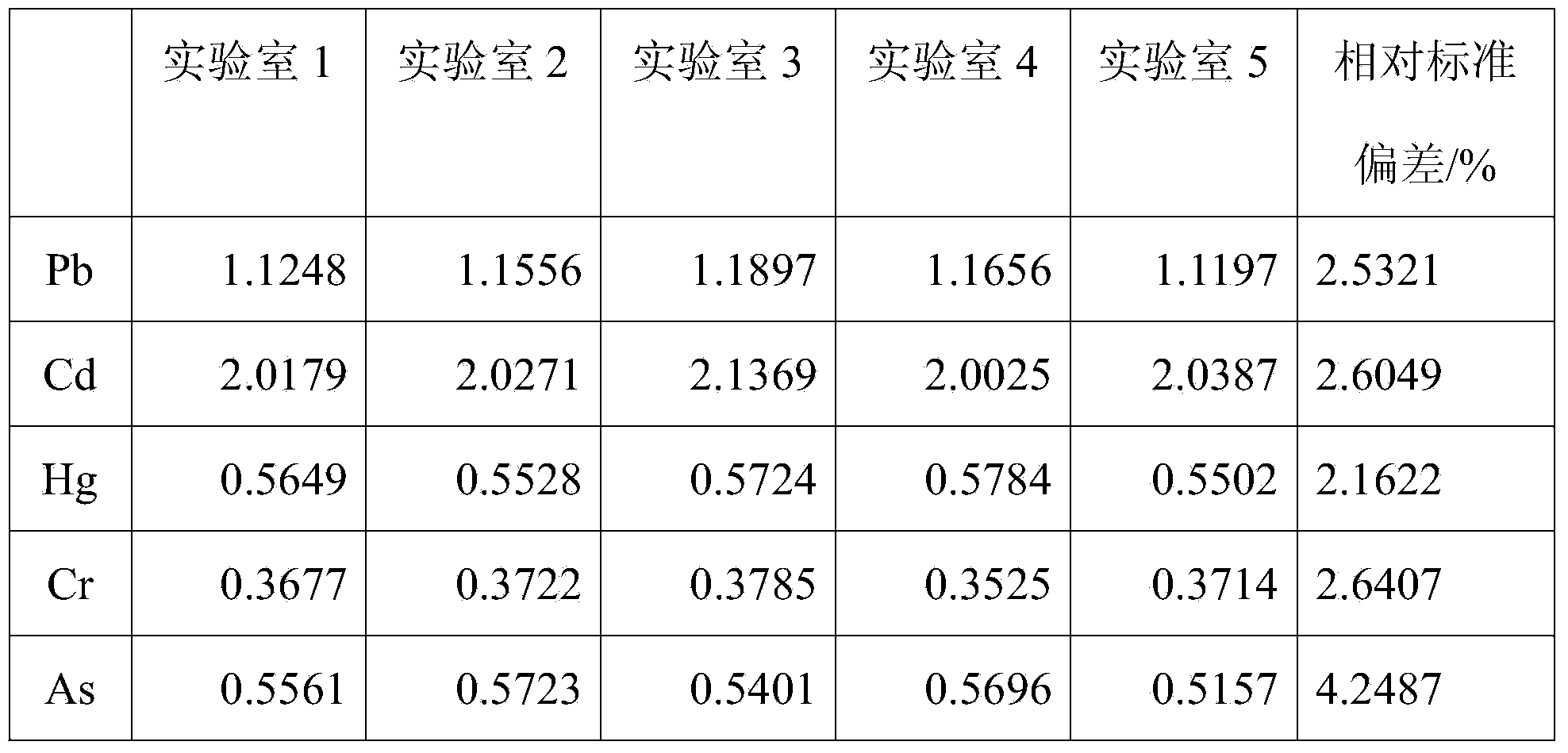

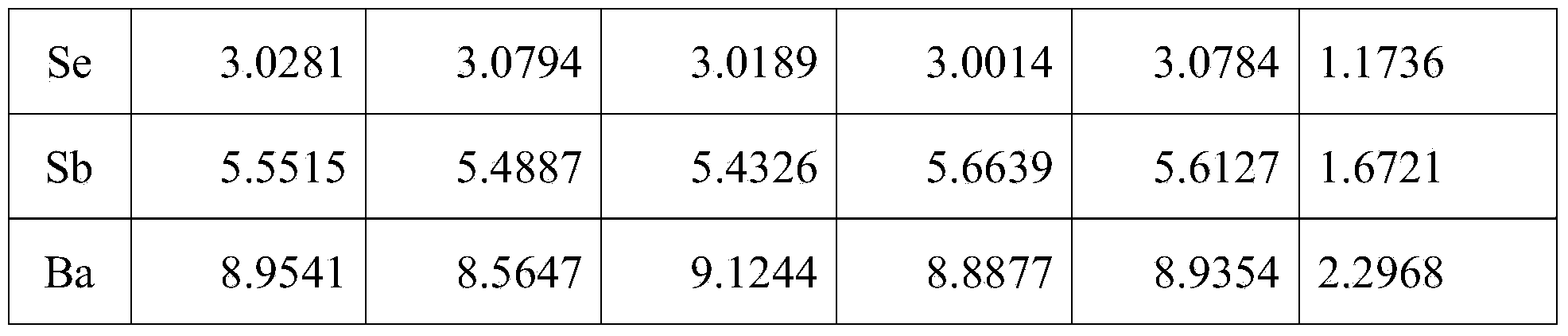

Method for detecting content of heavy metal elements in metal or alloy material

InactiveCN103901019AAccurately obtainedImprove accuracyPreparing sample for investigationAnalysis by thermal excitationInductively coupled plasmaAlloy

The invention discloses a method for detecting content of heavy metal elements in metal or an alloy material. The method comprises the following steps: (a) processing a sample into grains which are not heavier than 0.2g; (b) adding the sample processed in the step (a) into a mixture solution of analysis pure nitric acid and analysis pure hydrochloric acid to completely dissolve the sample, wherein the ratio of the sample to the mixture solution is 1:(15-25g / ml), and the volume ratio of the analysis pure nitric acid to the analysis pure hydrochloric acid in the mixture solution is (1-5):1; (c) putting the completely filtered dissolved solution into a volumetric flask, and achieving a constant volume, wherein the ratio of the quantified volume to the sample mass is (150-250):1ml / g; and (d) performing inductively coupled plasma-optical emission spectroscopy (ICP-OES) analysis on the solution obtained in the step (c). The analysis method provided in the invention is rapid, and high in repeatability and reproducibility.

Owner:昆山洛丹伦生物科技有限公司

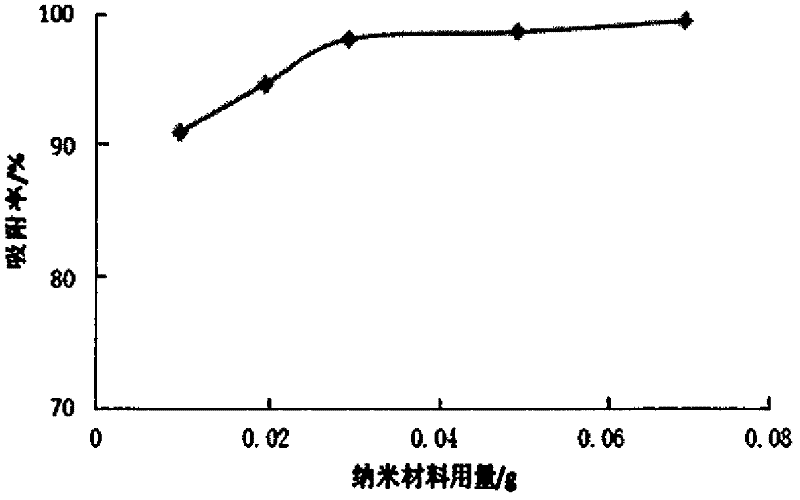

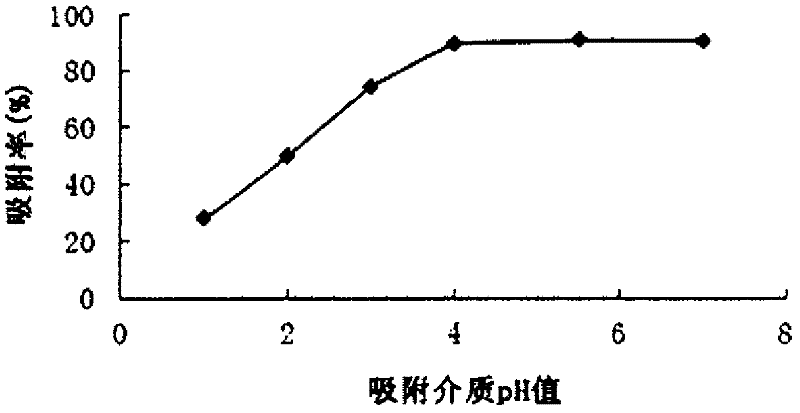

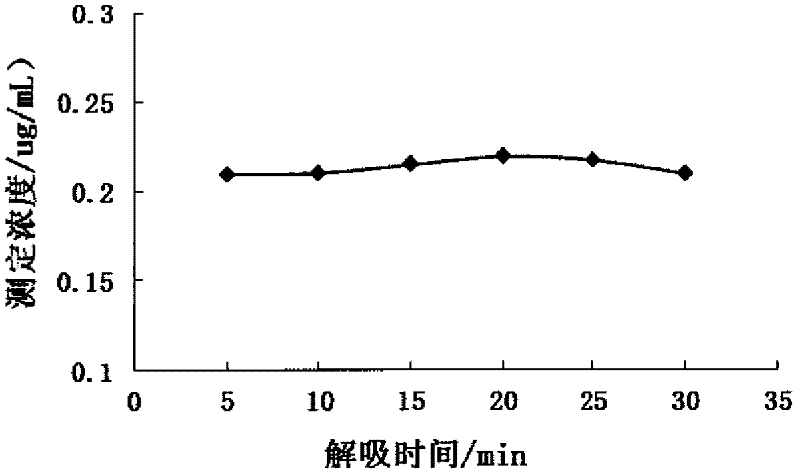

Method for determining trace lead in textile products

InactiveCN102455293AHigh in heavy metalsHigh measurement sensitivityPreparing sample for investigationAnalysis by thermal excitationPhysical chemistryInductively coupled plasma

The invention discloses a method for determining trace lead in textile products, which comprises the following steps of: after a heavy metal Pb in a textile product is extracted by using acidic perspiration, gathering a trace heavy metal Pb in an extracting solution by using nano TiO2; and then, carrying out determination by using an ICP-OES (inductively coupled plasma optical emission spectroscopy) method. Because the content of the heavy metal Pb in the solution subjected to gathering is high, the determination sensitivity is improved, and a determination operation can be performed by using an ICP (inductively coupled plasma) emission spectrum; and in the process of gathering, the salt content in a textile-product extracting solution is reduced, thereby reducing the matrix interference in the process of spectrum determination.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

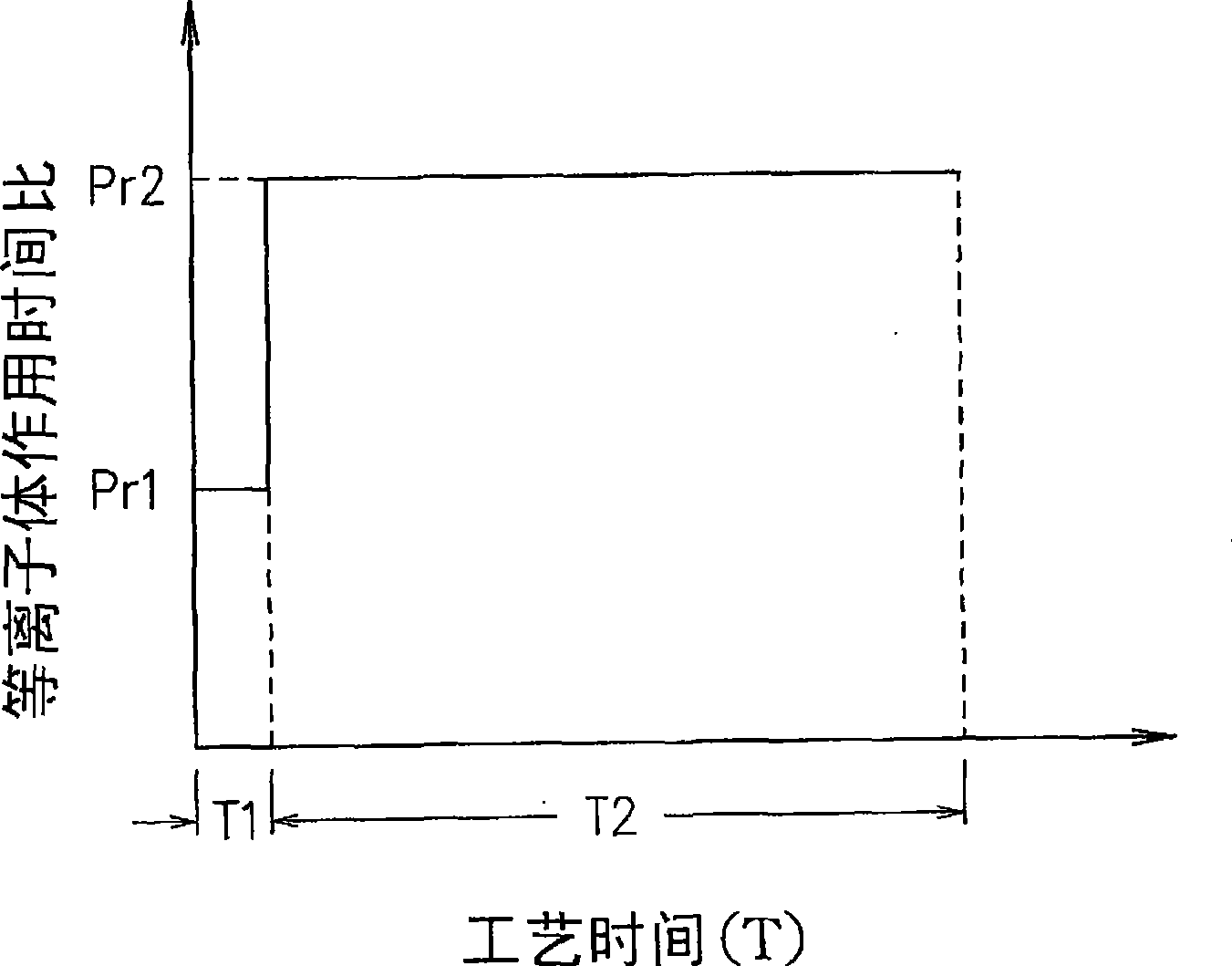

System and method for plasma assisted film deposition

The invention relates to a film deposition system through the assistance of plasma and a method thereof. The system mainly consists of a plasma film deposition device and a plasma process monitoring device; the plasma film deposition device can be used for inputting pulse power and process reaction gas; the pulse power and process reaction gas act to produce an active species in reaction gas for a plasma discharge and dissociation process so as to carry out a film deposition process; the plasma process monitoring device comprises a plasma composition optical emission spectroscopy and a pulse plasma modulation program device; the value of spectral intensity of the active species in a plasma composition is measured through the plasma composition optical emission spectroscopy; and the spectral intensity ratio between the active species is calculated through pulse plasma modulation program device, so as to modulate the proper action time and power of the pulse power plasma, obtain high sedimentation rate within the sedimentation range of microcrystal silicon and master the optimal sedimentation quality of the film in real time.

Owner:IND TECH RES INST

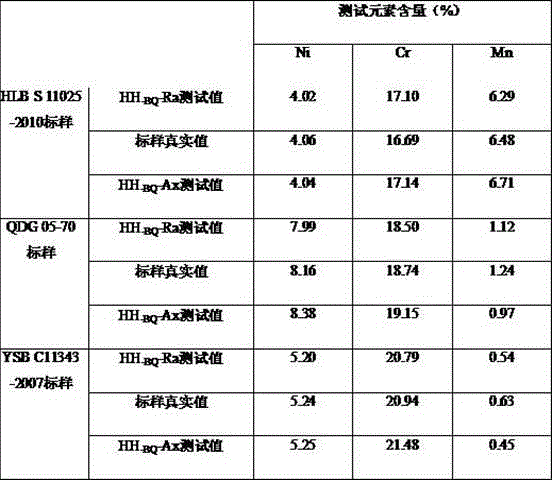

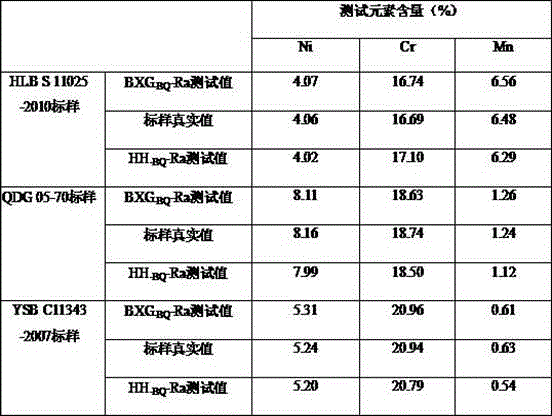

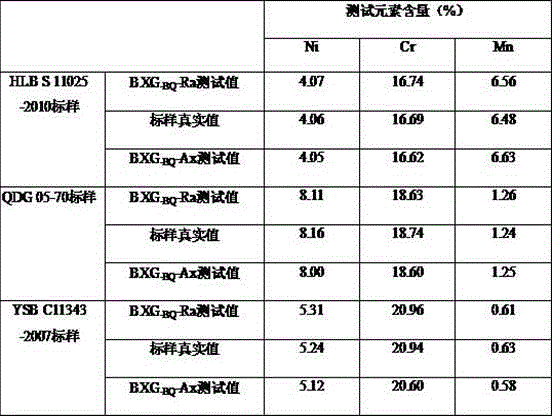

Method for detecting chemical components comprising nickel, chromium and manganese of stainless steel

InactiveCN104089947AEliminate distractionsEasy to operateAnalysis by thermal excitationPhysical chemistryManganese

The invention discloses a method for detecting chemical components comprising nickel, chromium and manganese of stainless steel. The method comprises the following steps: (1) preparing a standard stainless steel solution; (2) preparing a mixed standard solution; and (3) carrying out an ICP-OES (Inductively Coupled Plasma-Optical Emission Spectroscopy) detection method. By virtue of the method, series of standard stainless steel samples are used for establishing standard curves of the detected elements, and target elements are detected and determined by using the ICP-OES technology. The method focuses on the research of the detection of the contents of main elements Ni, Cr and Mn in the stainless steel. Compared with a current main detection method, the method according to the invention has the advantages that the standard stainless steel samples are used for establishing the standard curves of the detected elements, so that the matrix interference is fully removed, a detection result is relatively accurate, and the operation of preparing the standard sample solution is relatively simple and convent. The invention discloses a relatively accurate, simple and convenient method so as to provide detection basis for accurately detecting the chemical components of stainless steel products.

Owner:NANJING INST OF PROD QUALITY INSPECTION

Dosimetry using optical emission spectroscopy/residual gas analyzer in conjunction with ion current

InactiveUS20090195777A1Radiation pyrometryLiquid surface applicatorsResidual gas analyzerDosimetry radiation

The present invention generally provides methods and apparatus for controlling ion dosage in real time during plasma processes. In one embodiment, ion dosages may be controlled using in-situ measurement of the plasma from a mass distribution sensor combined with in-situ measurement from an RF probe.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com