Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6763 results about "Chemical substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., without breaking chemical bonds. Chemical substances can be simple substances, chemical compounds, or alloys. Chemical elements may or may not be included in the definition, depending on expert viewpoint.

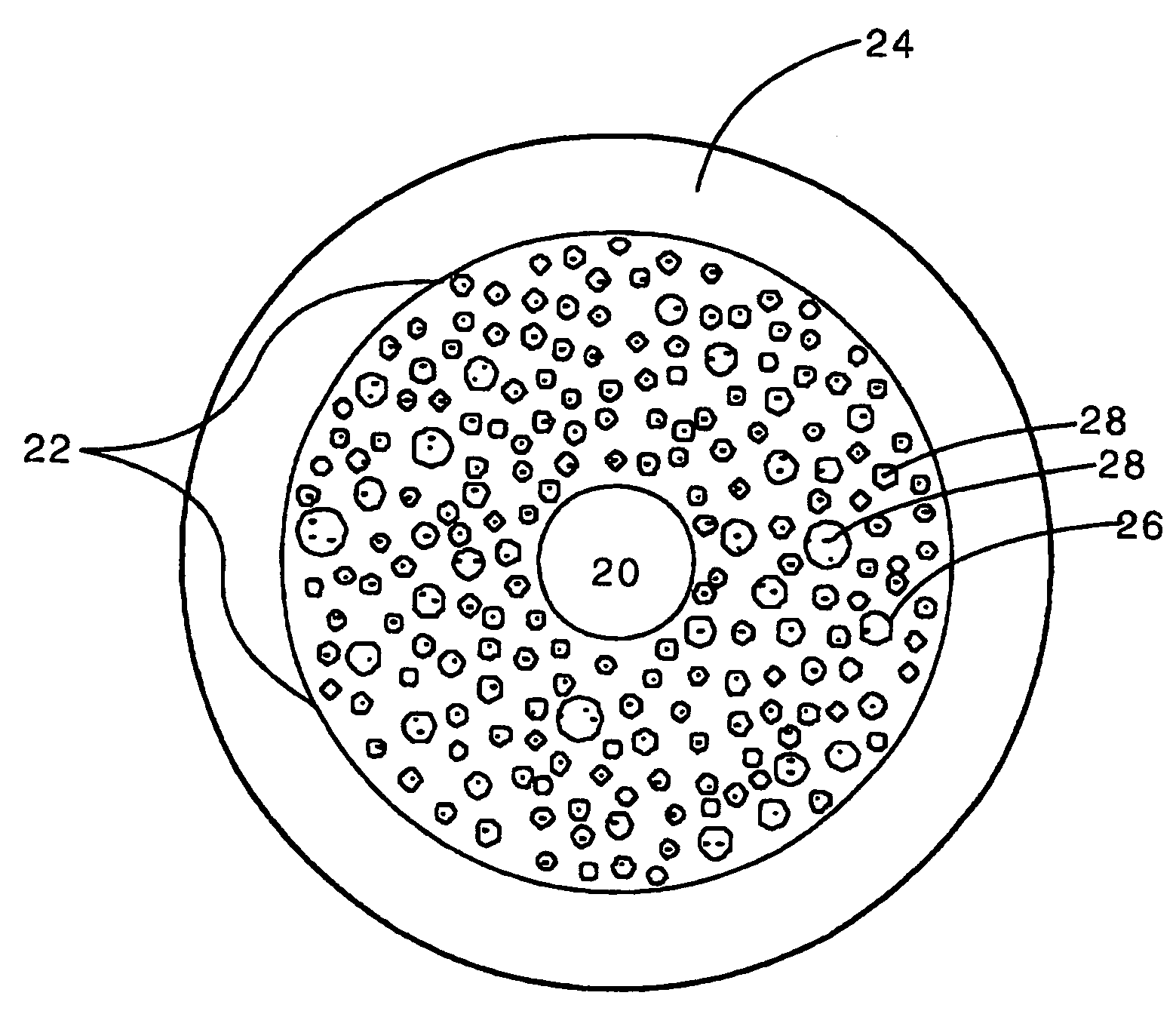

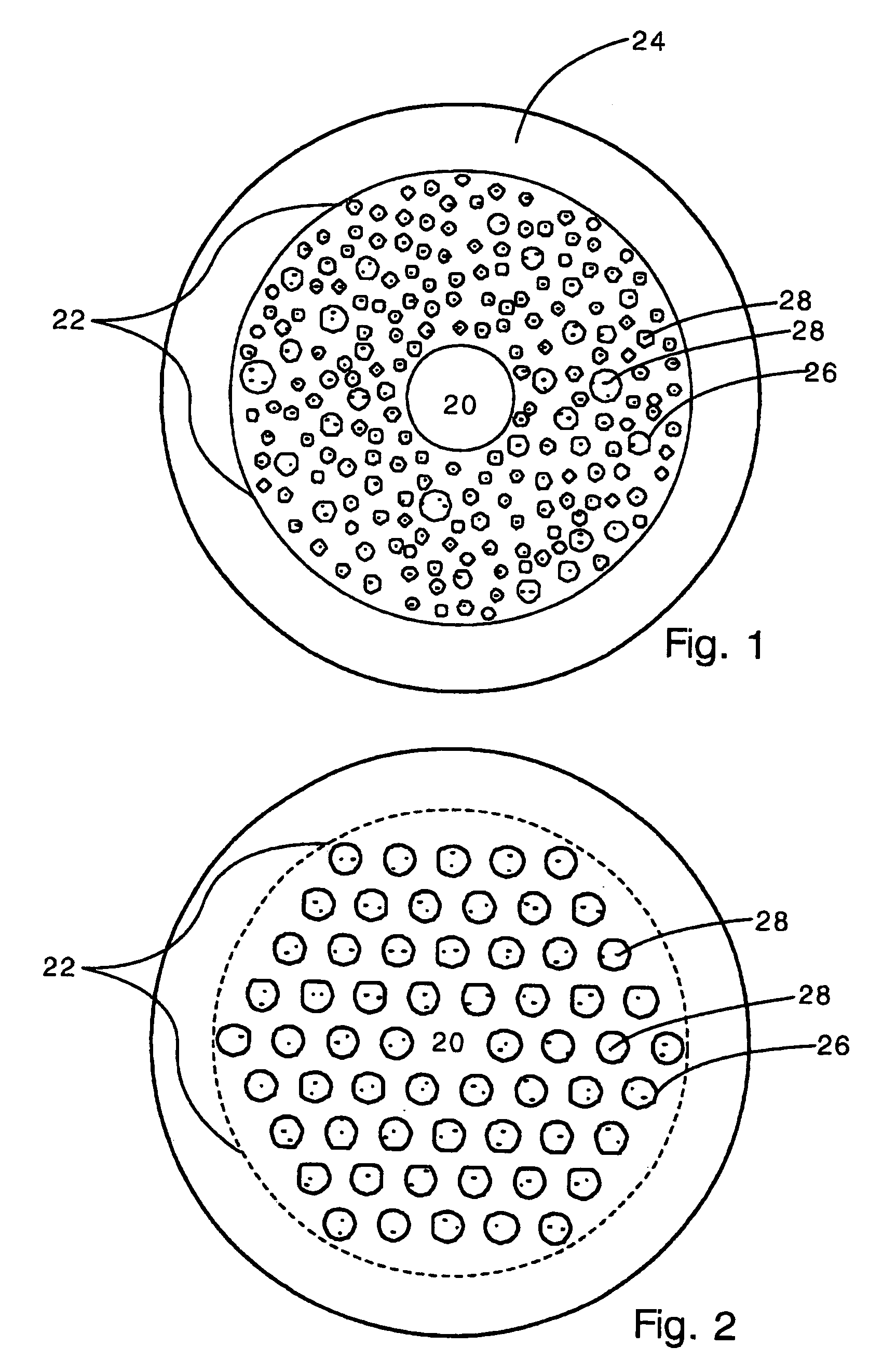

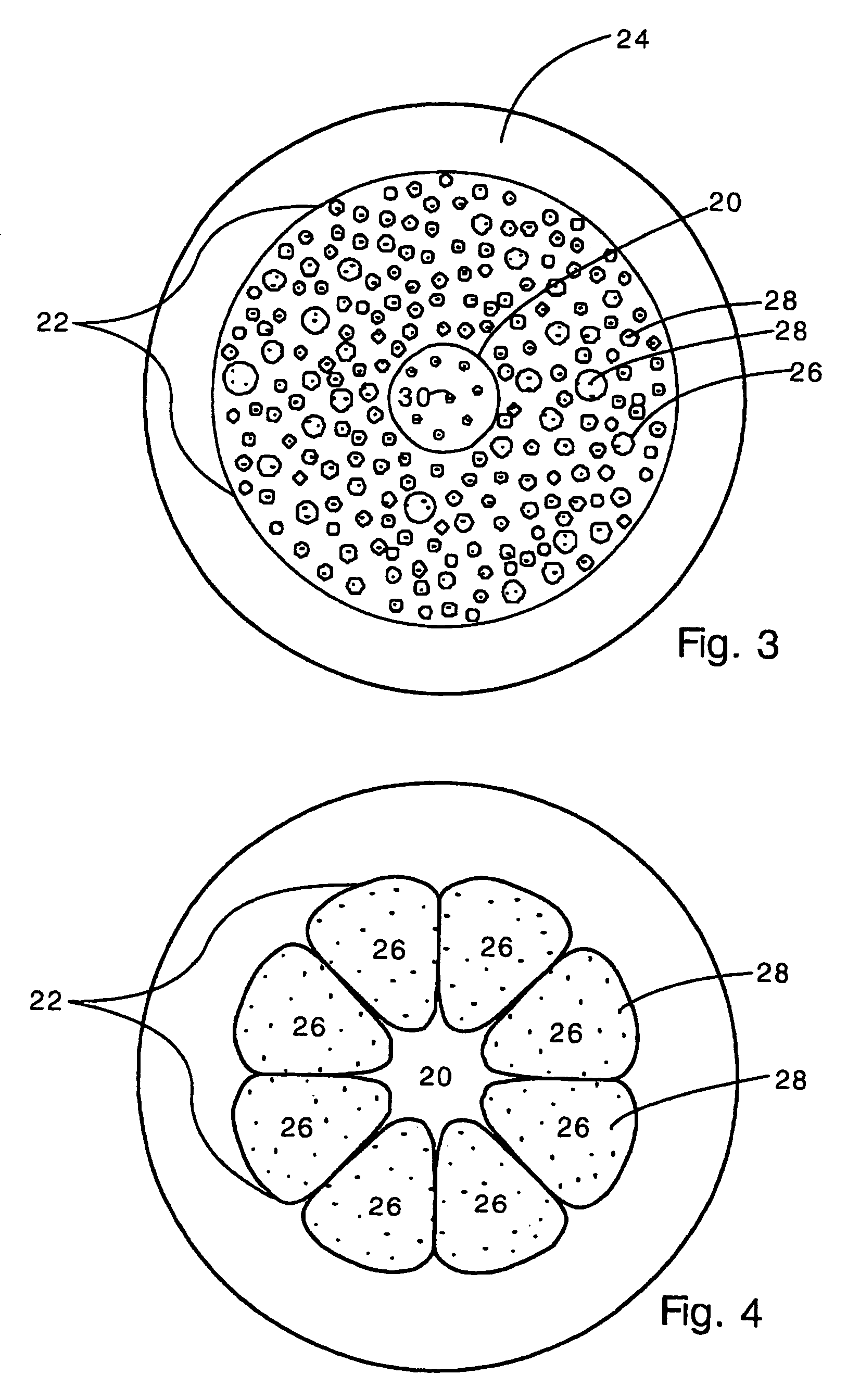

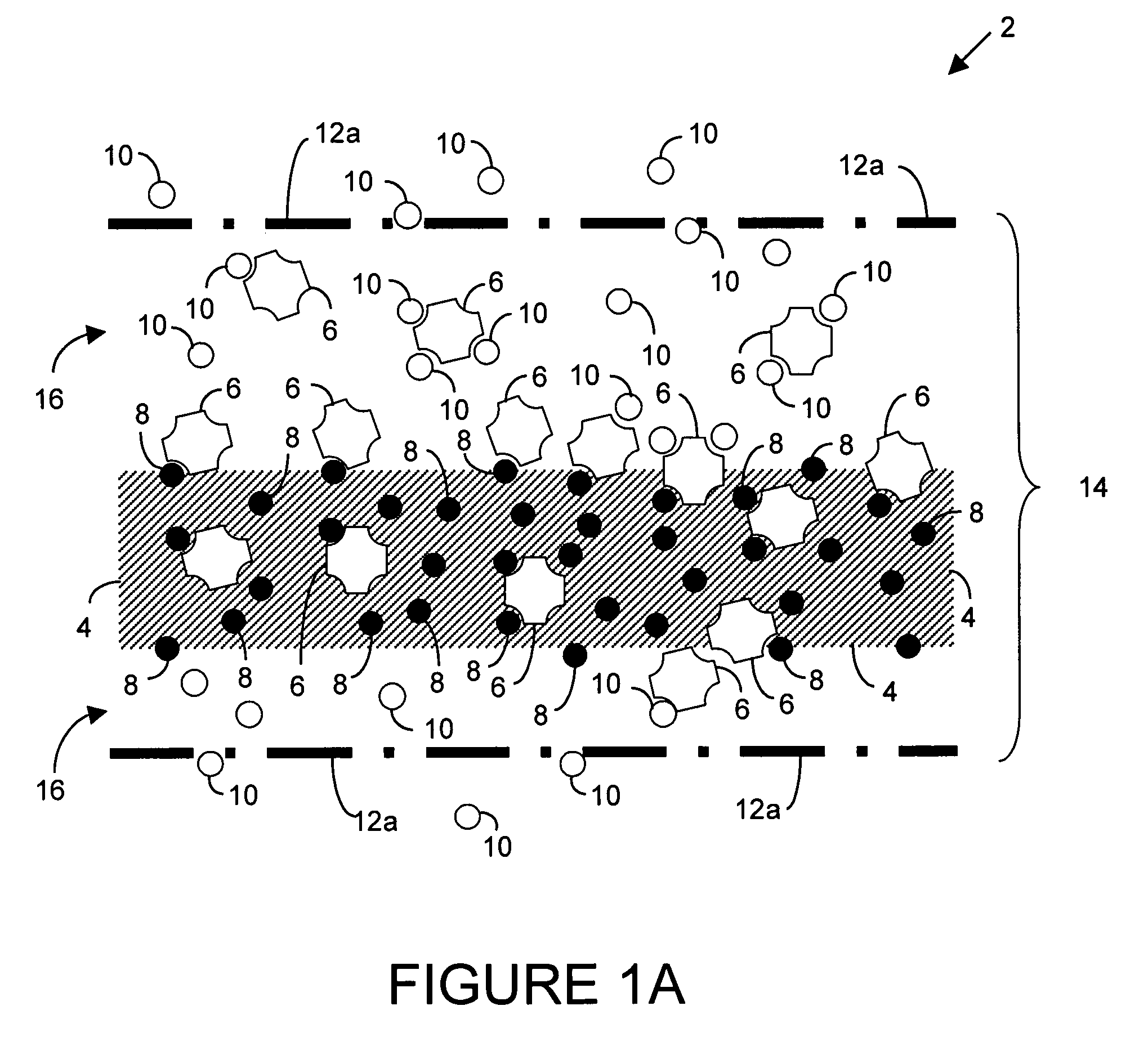

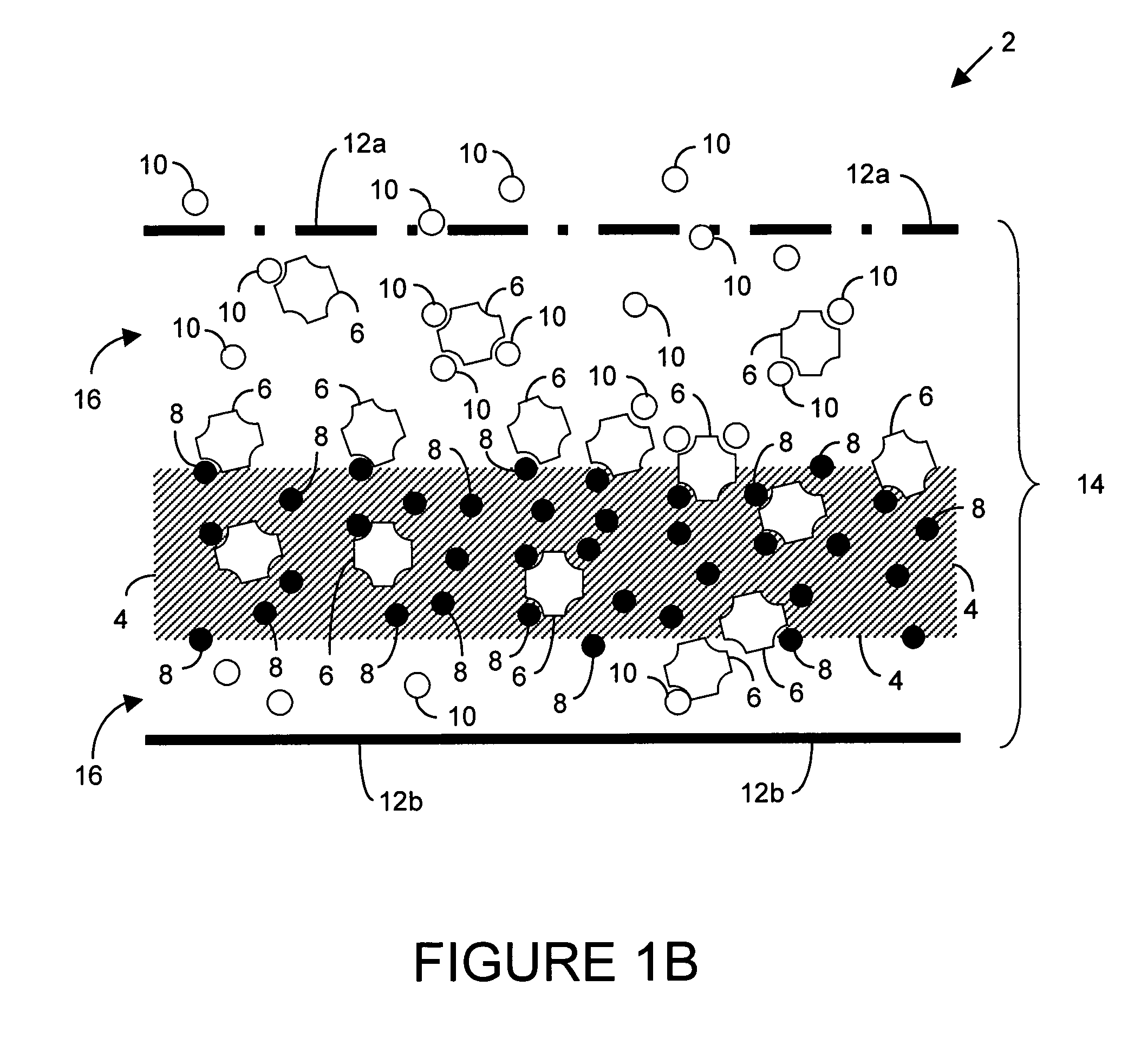

Optical fiber with quantum dots

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

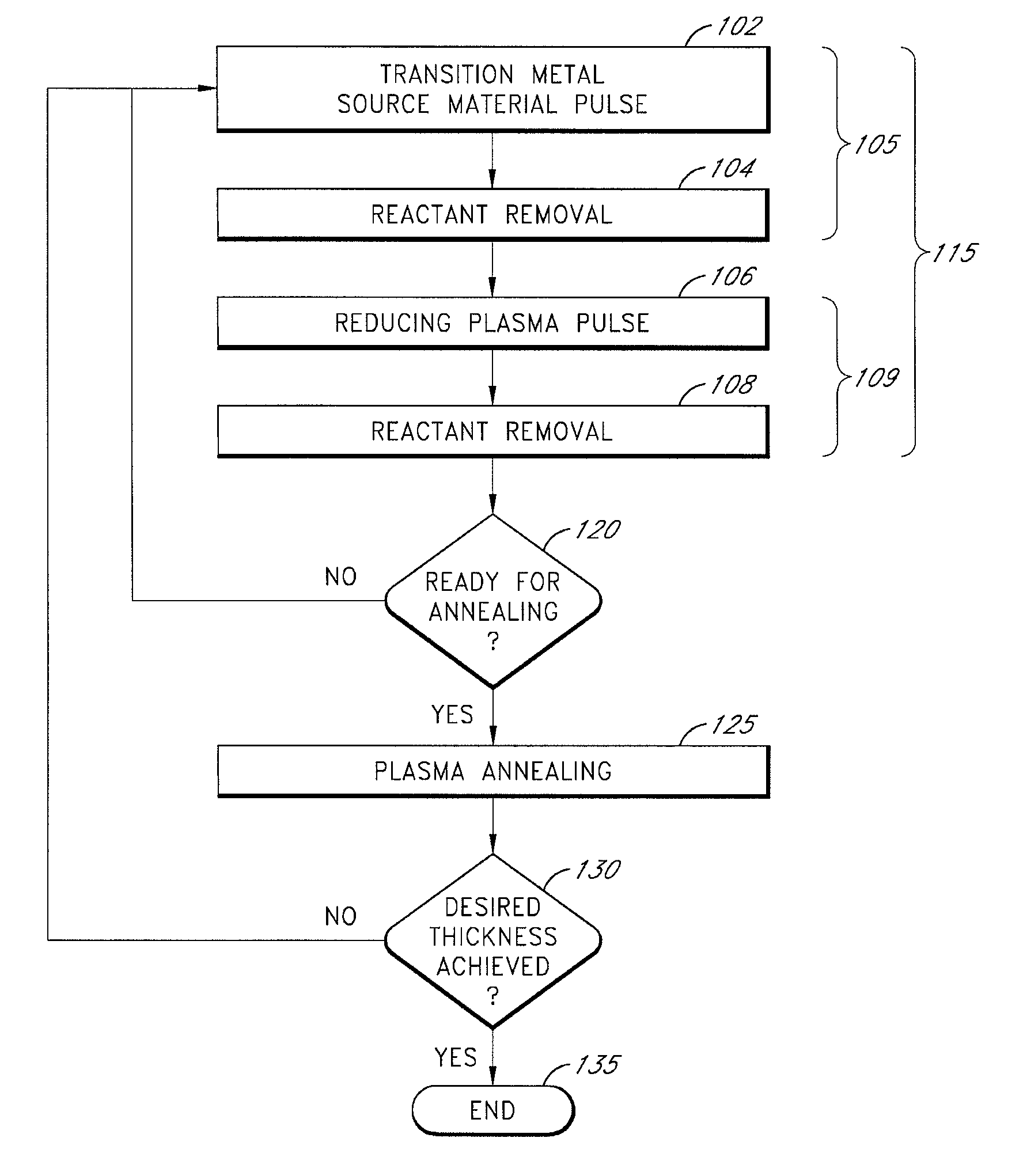

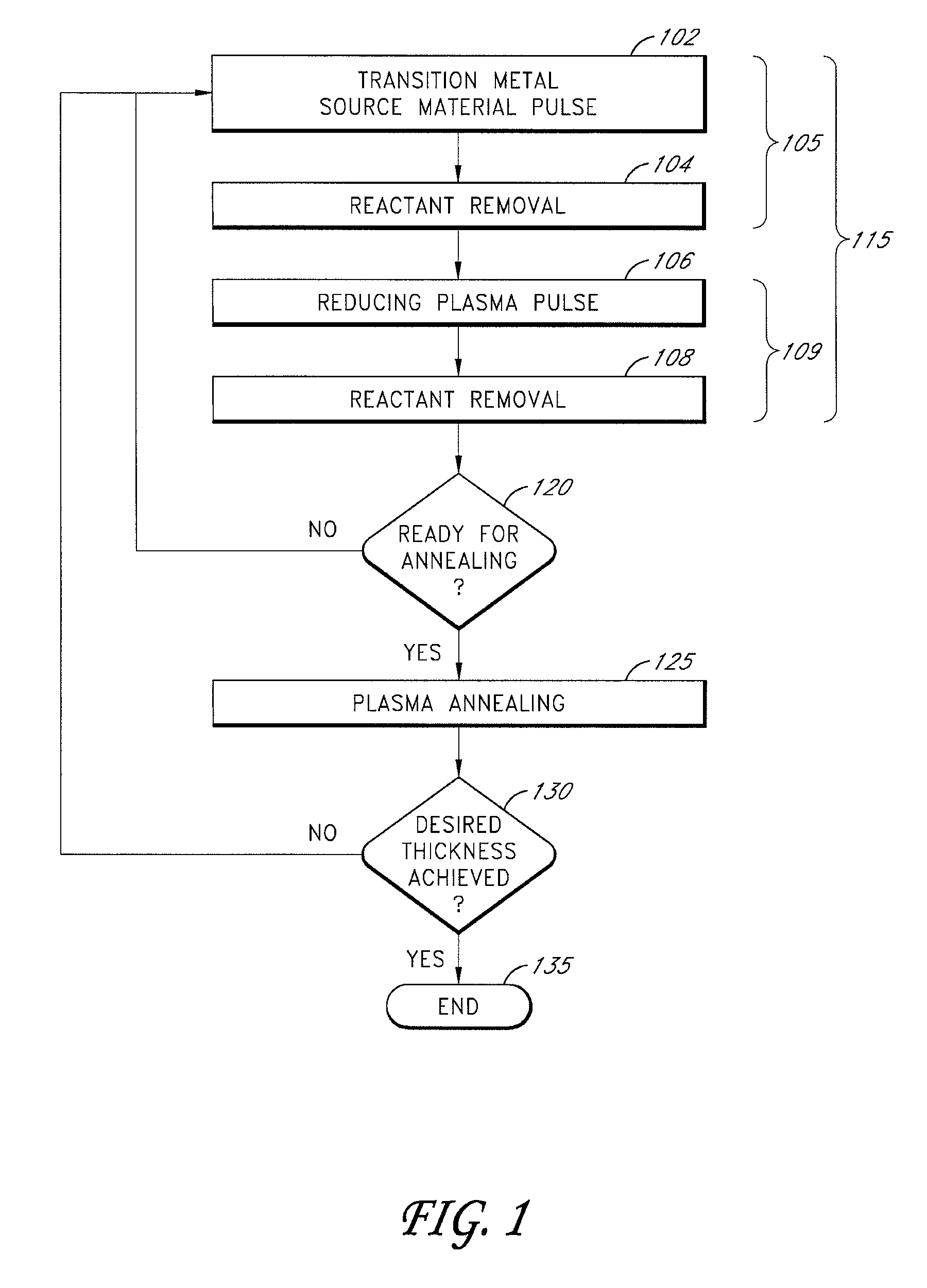

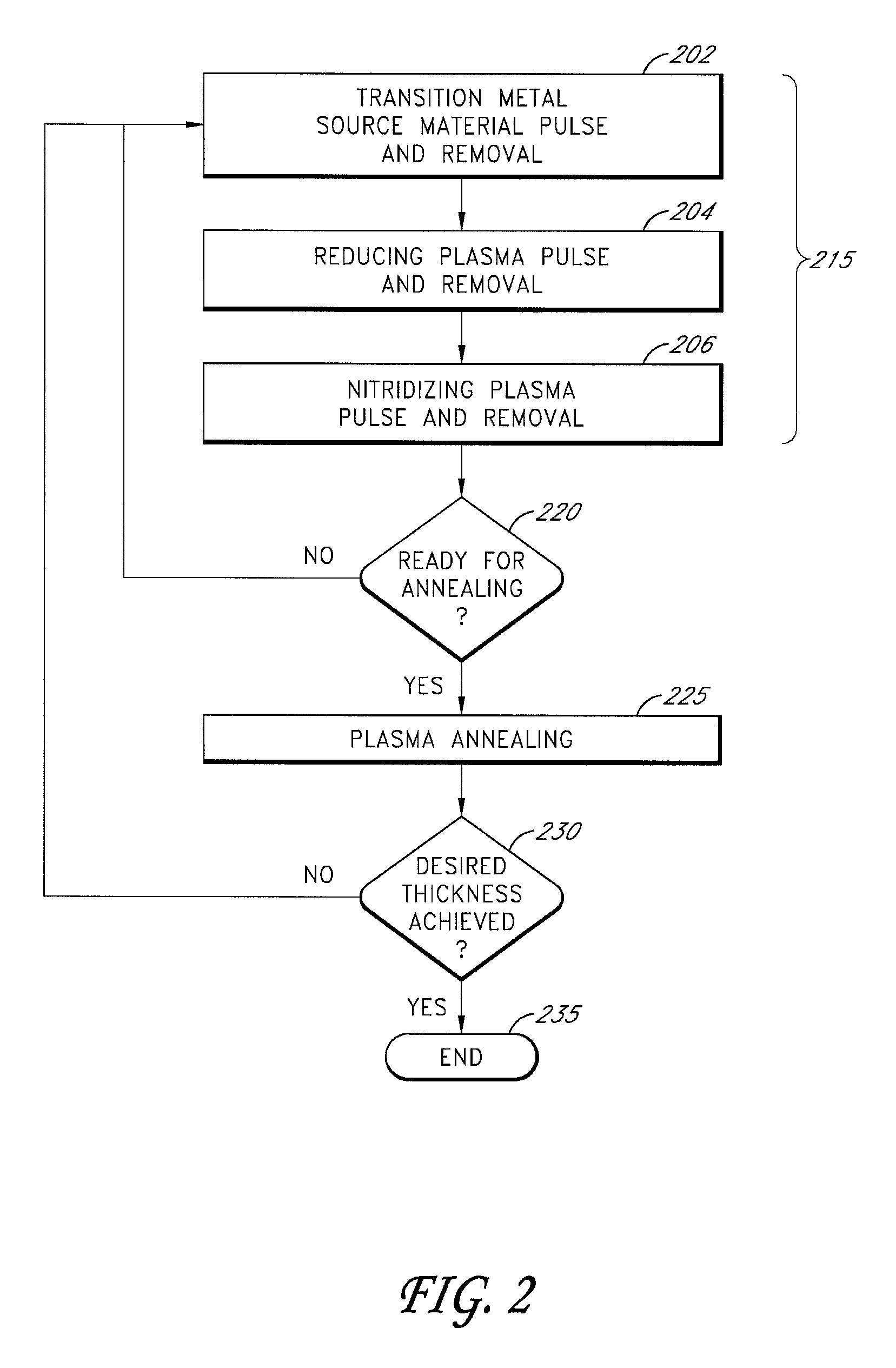

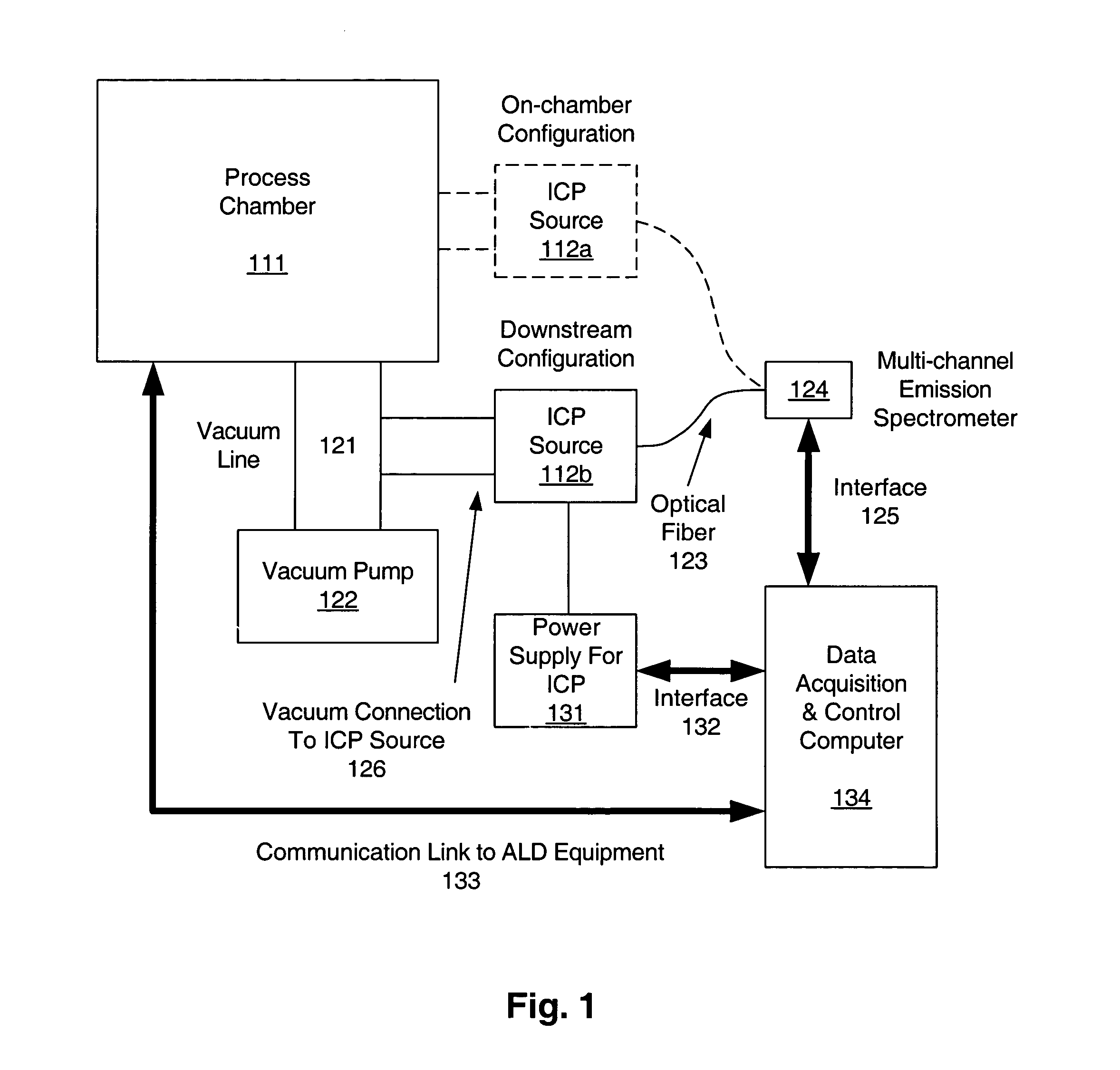

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

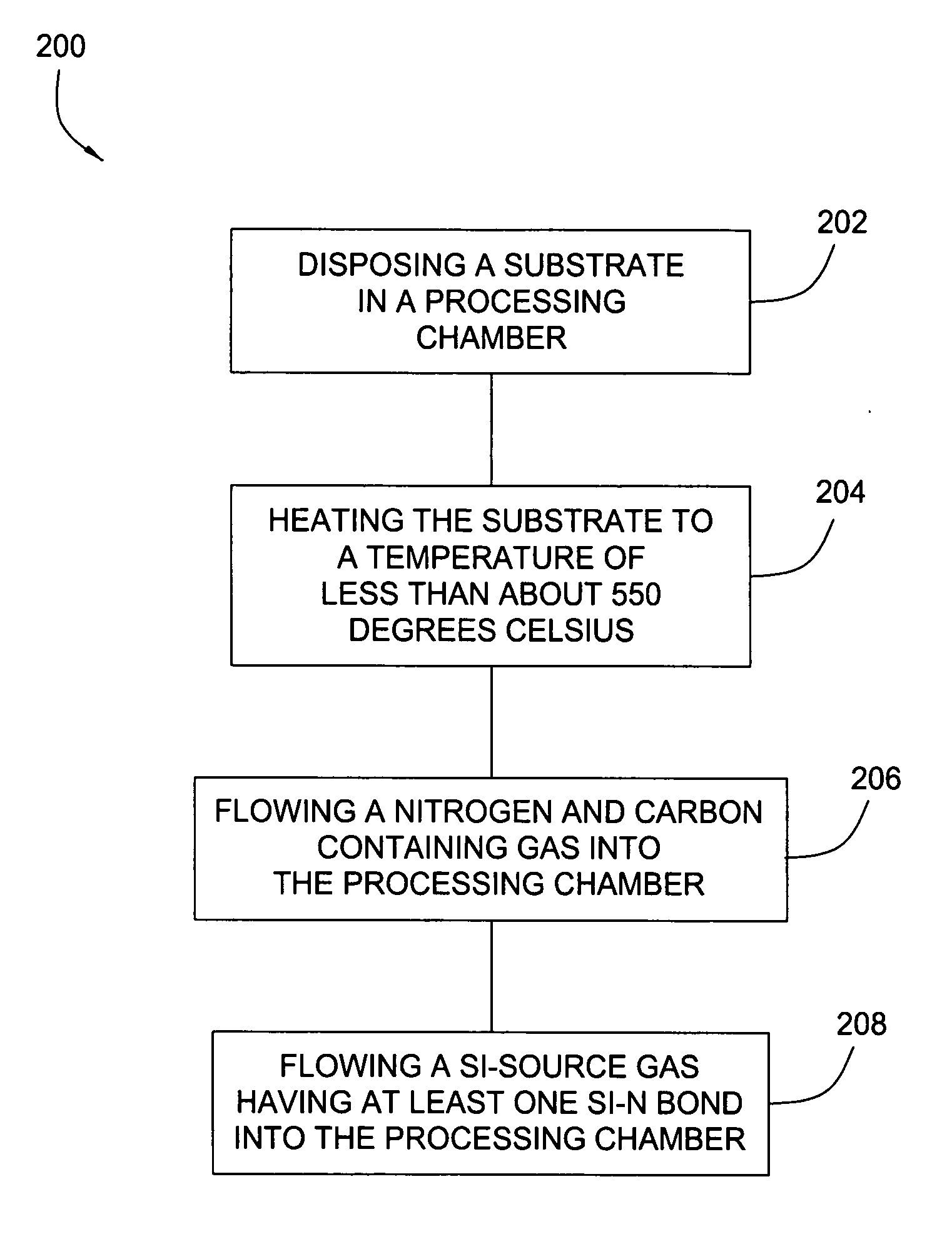

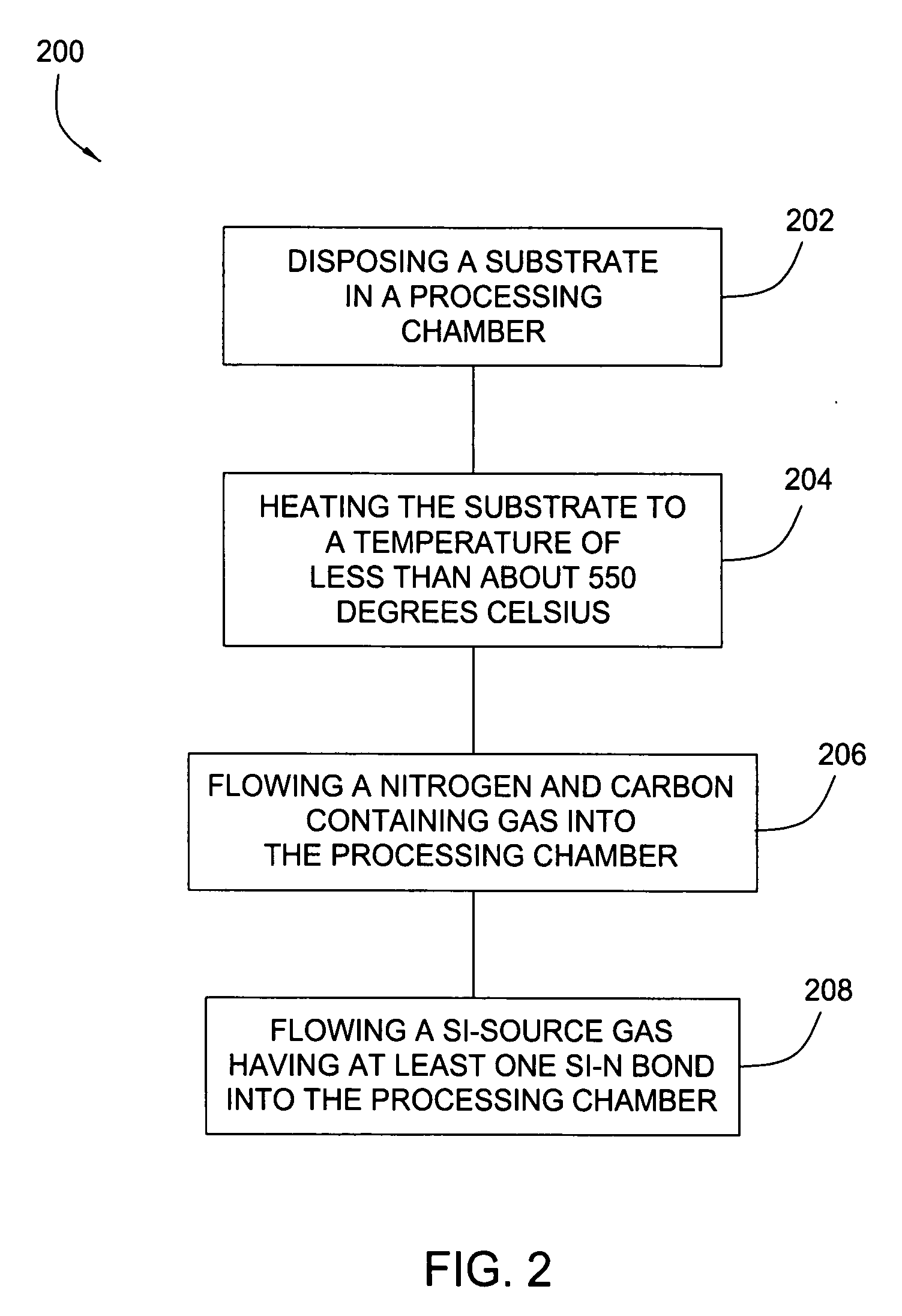

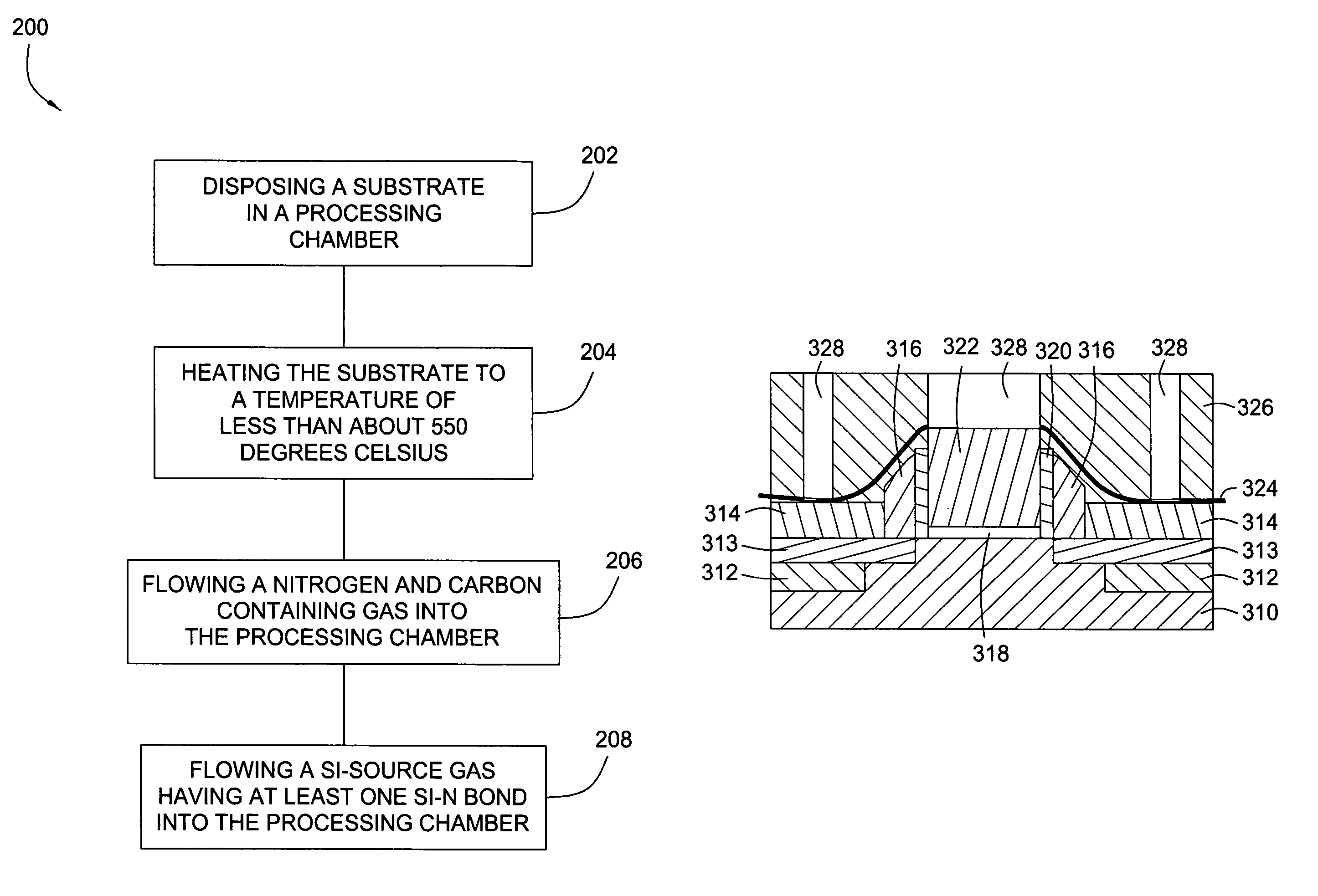

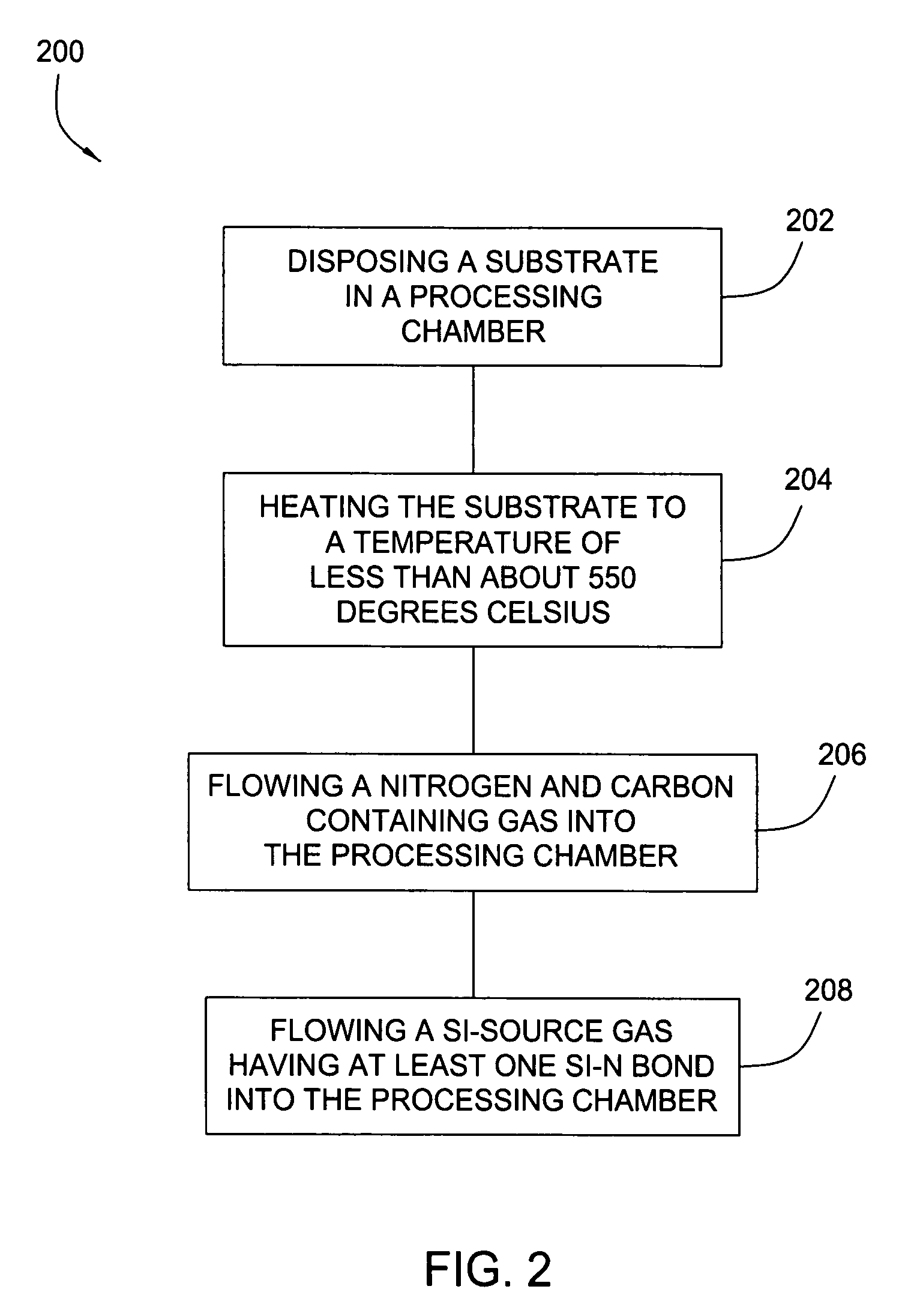

Method for silicon based dielectric chemical vapor deposition

InactiveUS20060286818A1TransistorSemiconductor/solid-state device manufacturingDielectricCelsius Degree

Embodiments of the invention generally provide a method for depositing silicon-containing films. In one embodiment, a method for depositing silicon-containing material film on a substrate includes flowing a nitrogen and carbon containing chemical into a deposition chamber, flowing a silicon-containing source chemical having silicon-nitrogen bonds into the processing chamber, and heating the substrate disposed in the chamber to a temperature less than about 550 degrees Celsius. In another embodiment, the silicon containing chemical is trisilylamine and the nitrogen and carbon containing chemical is (CH3)3—N.

Owner:APPLIED MATERIALS INC

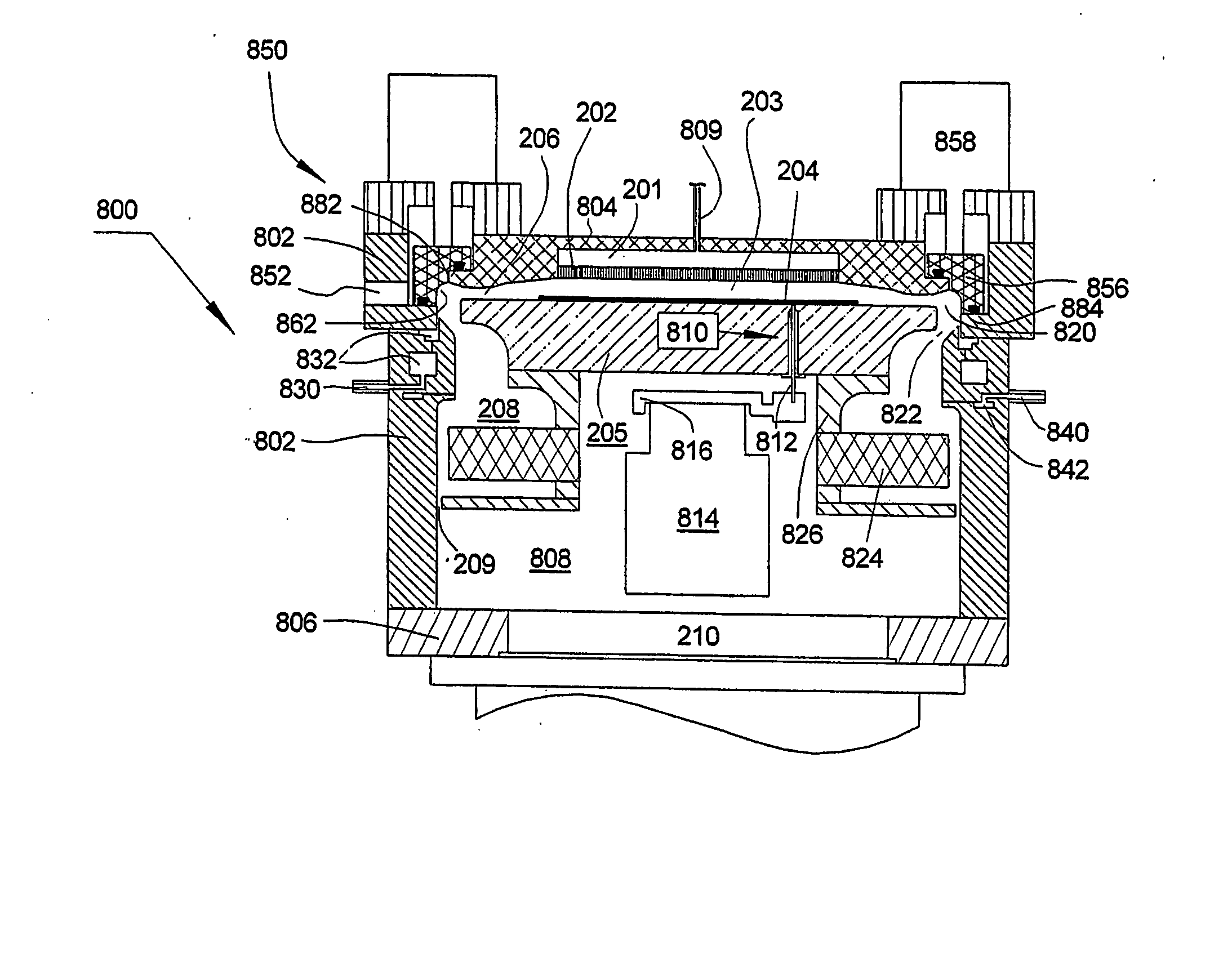

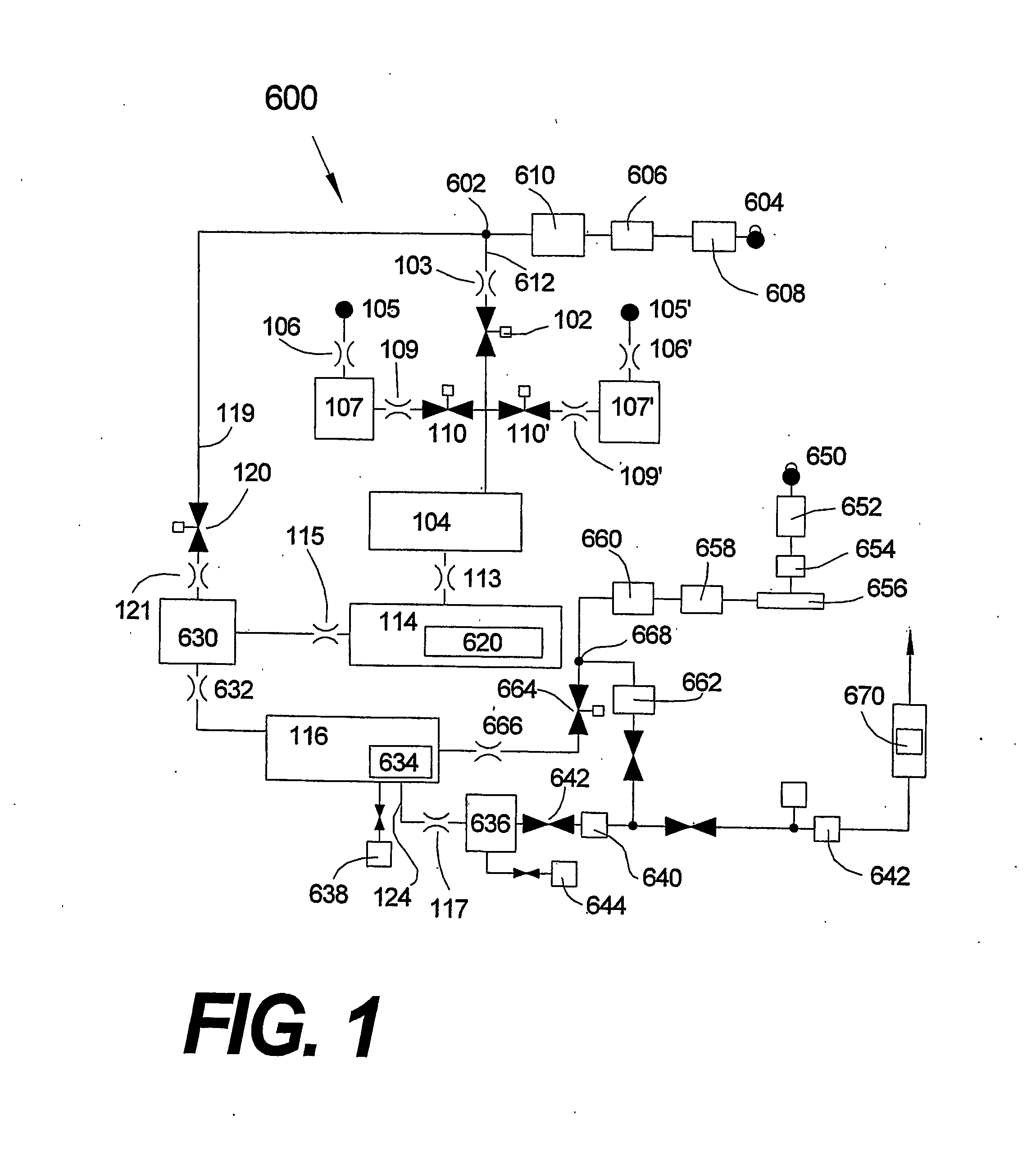

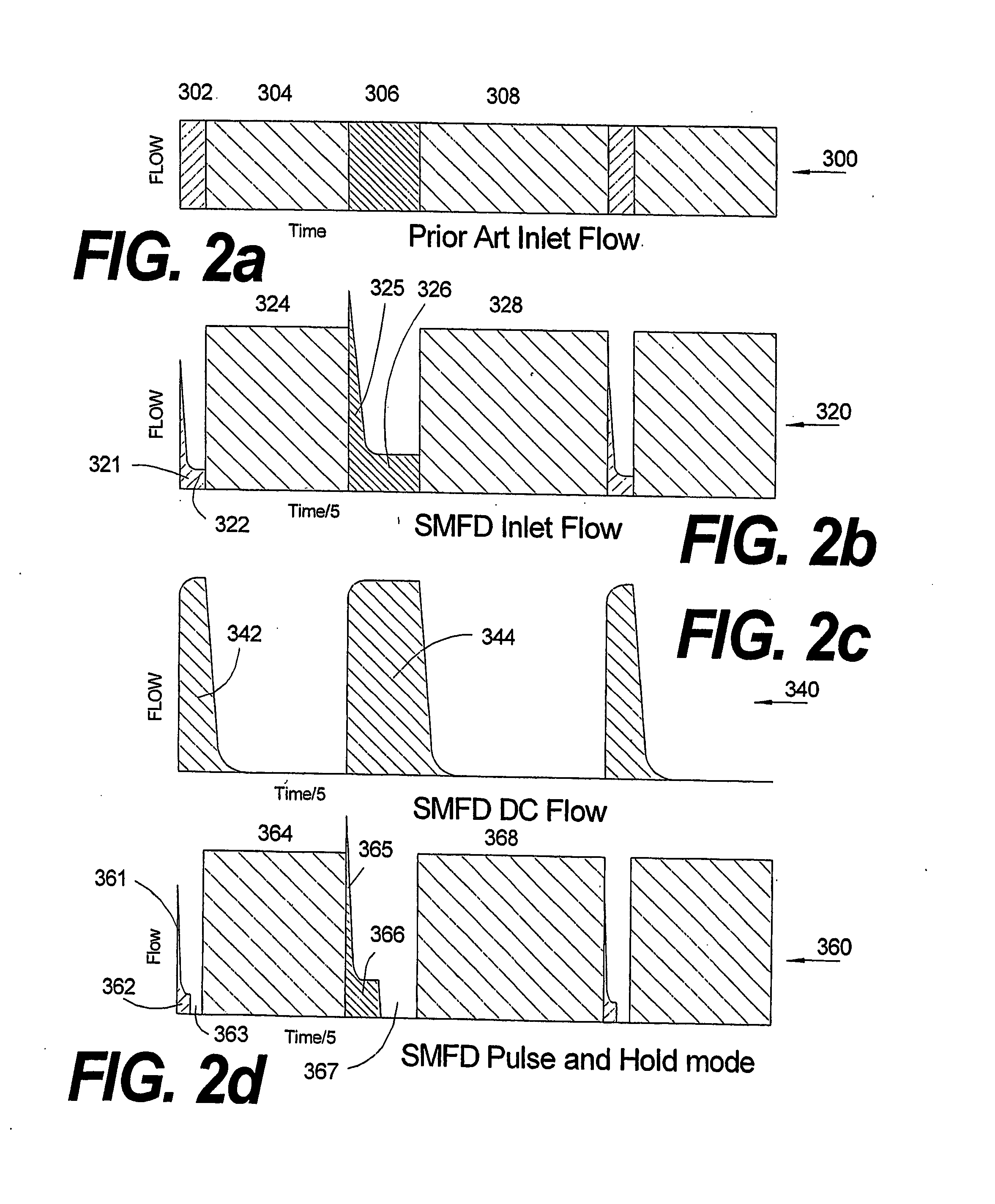

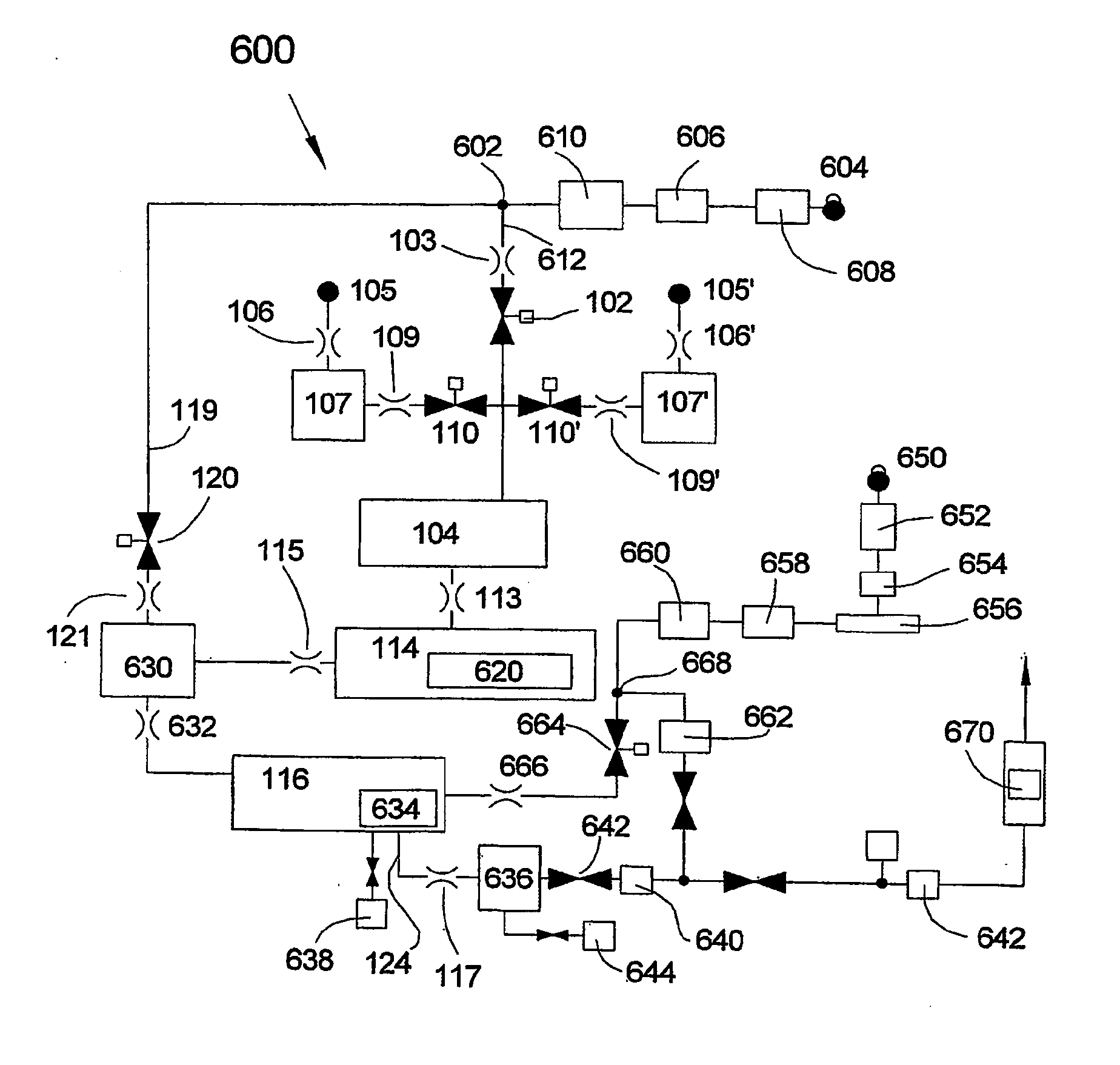

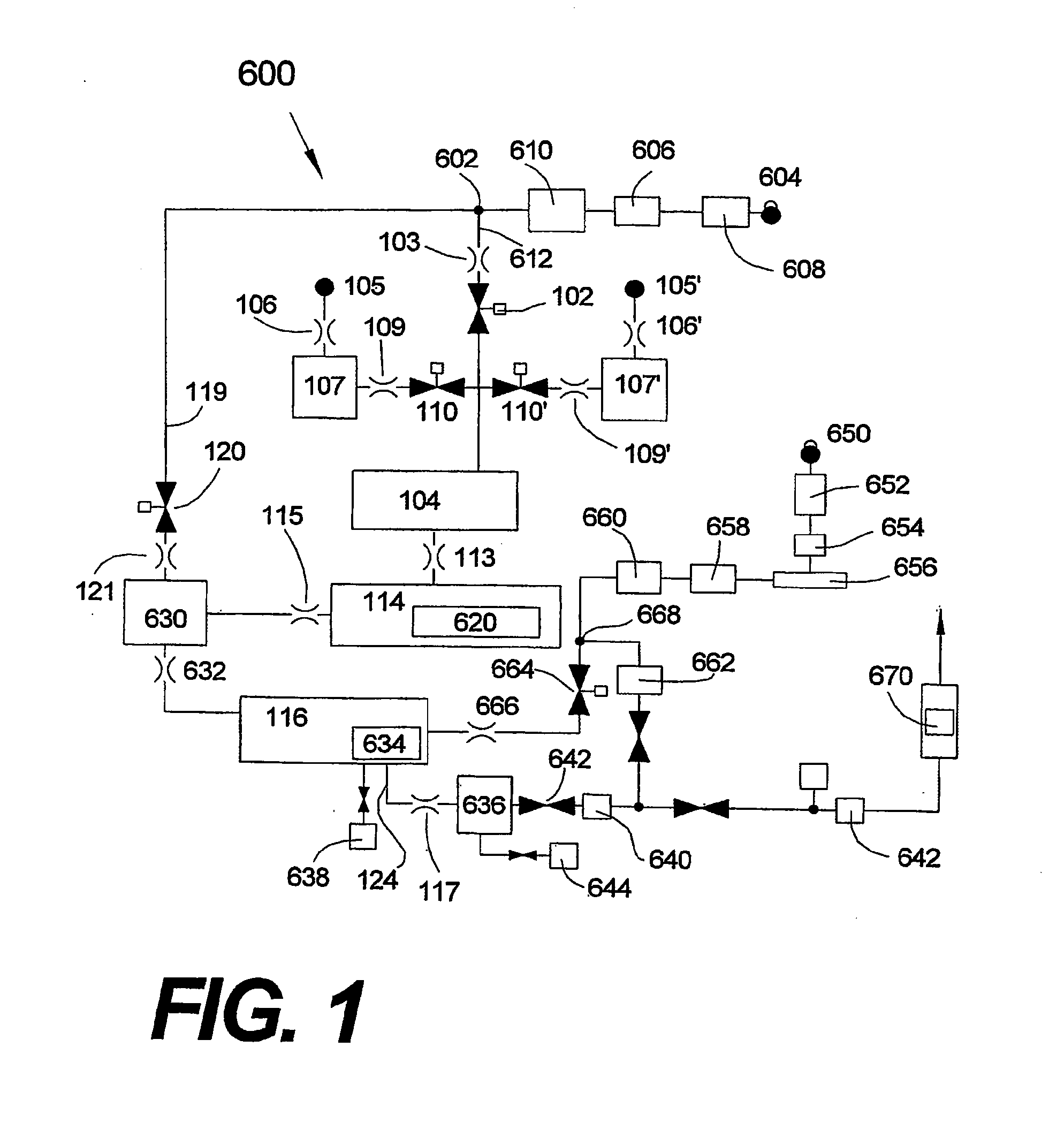

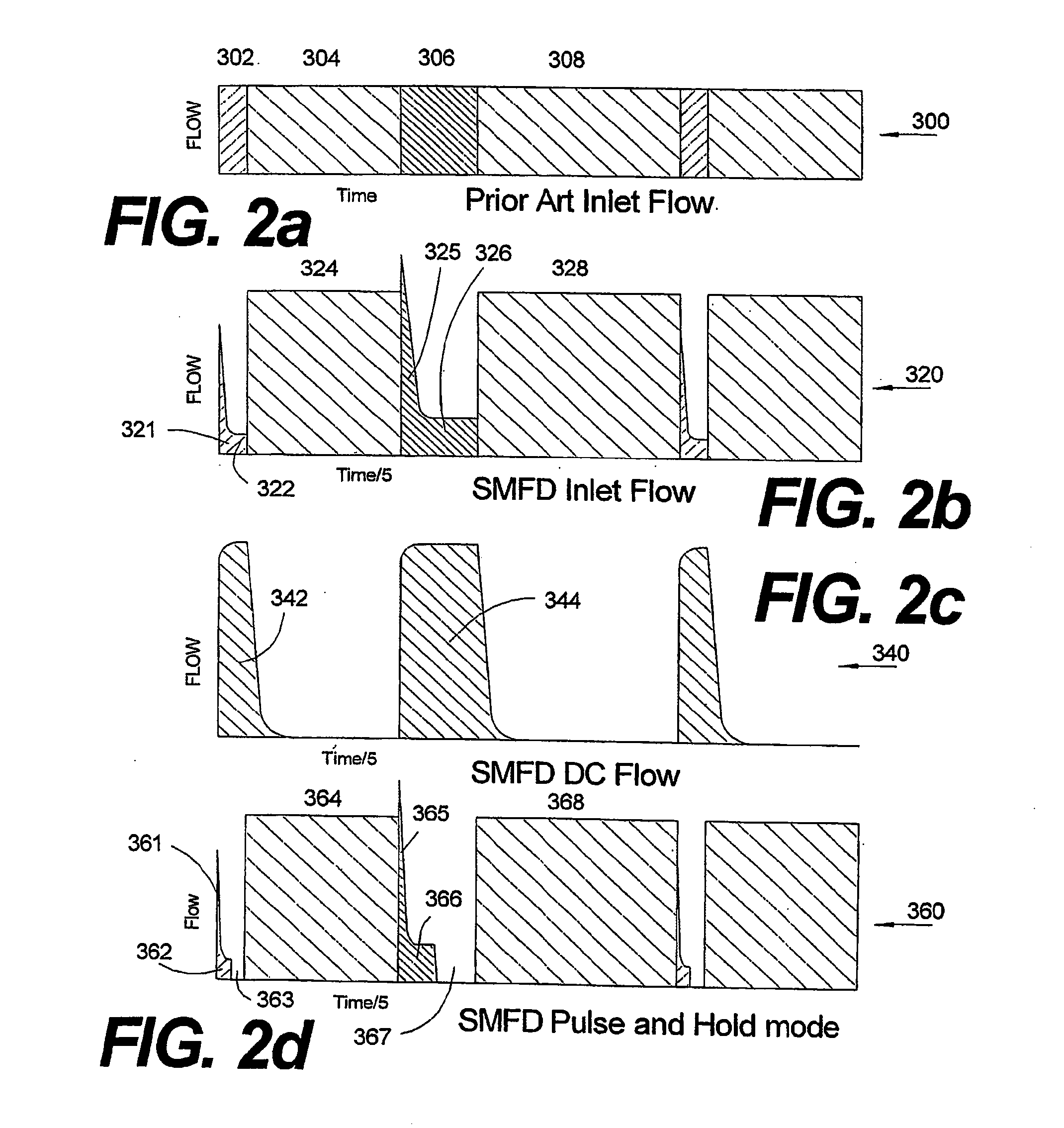

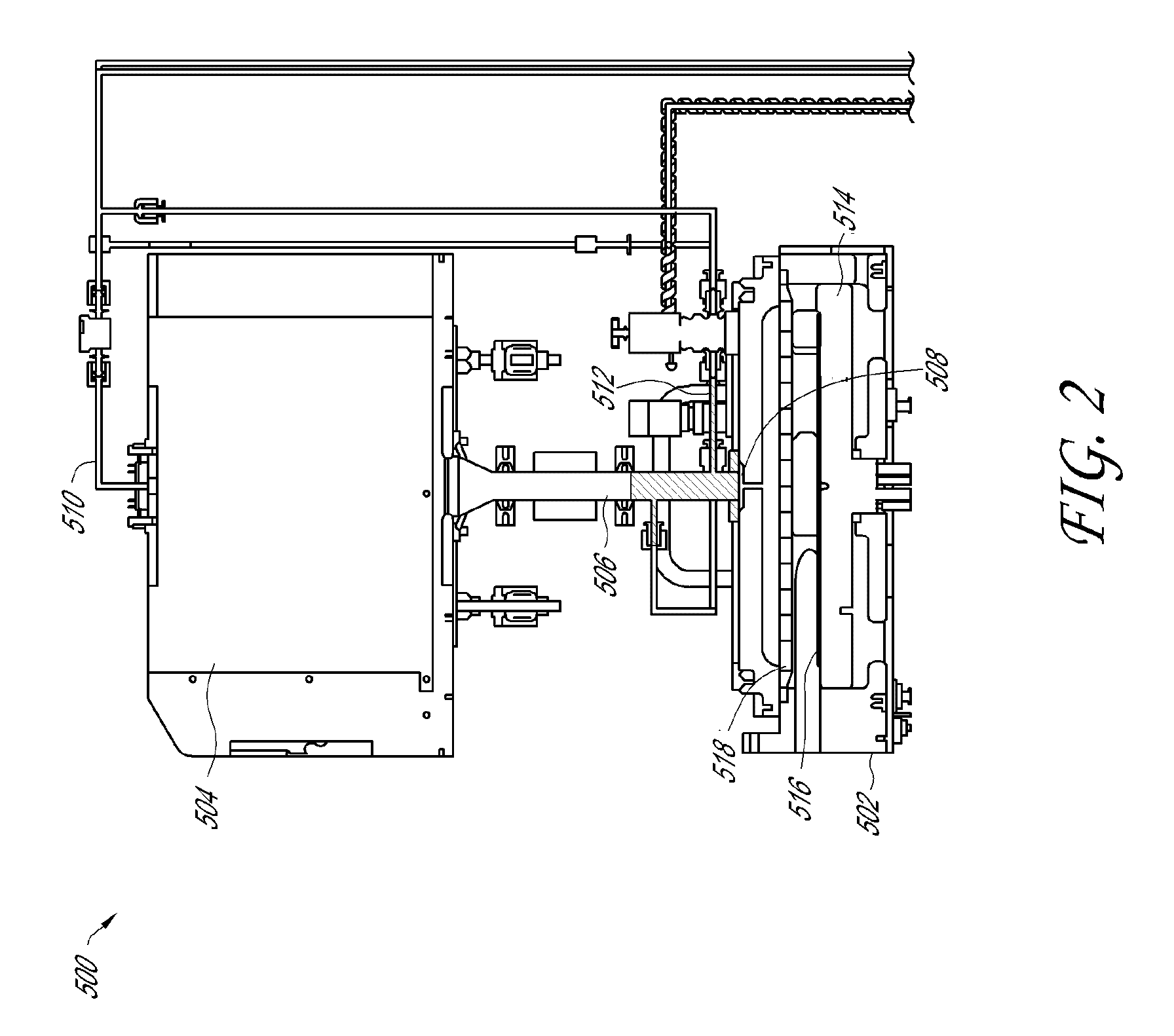

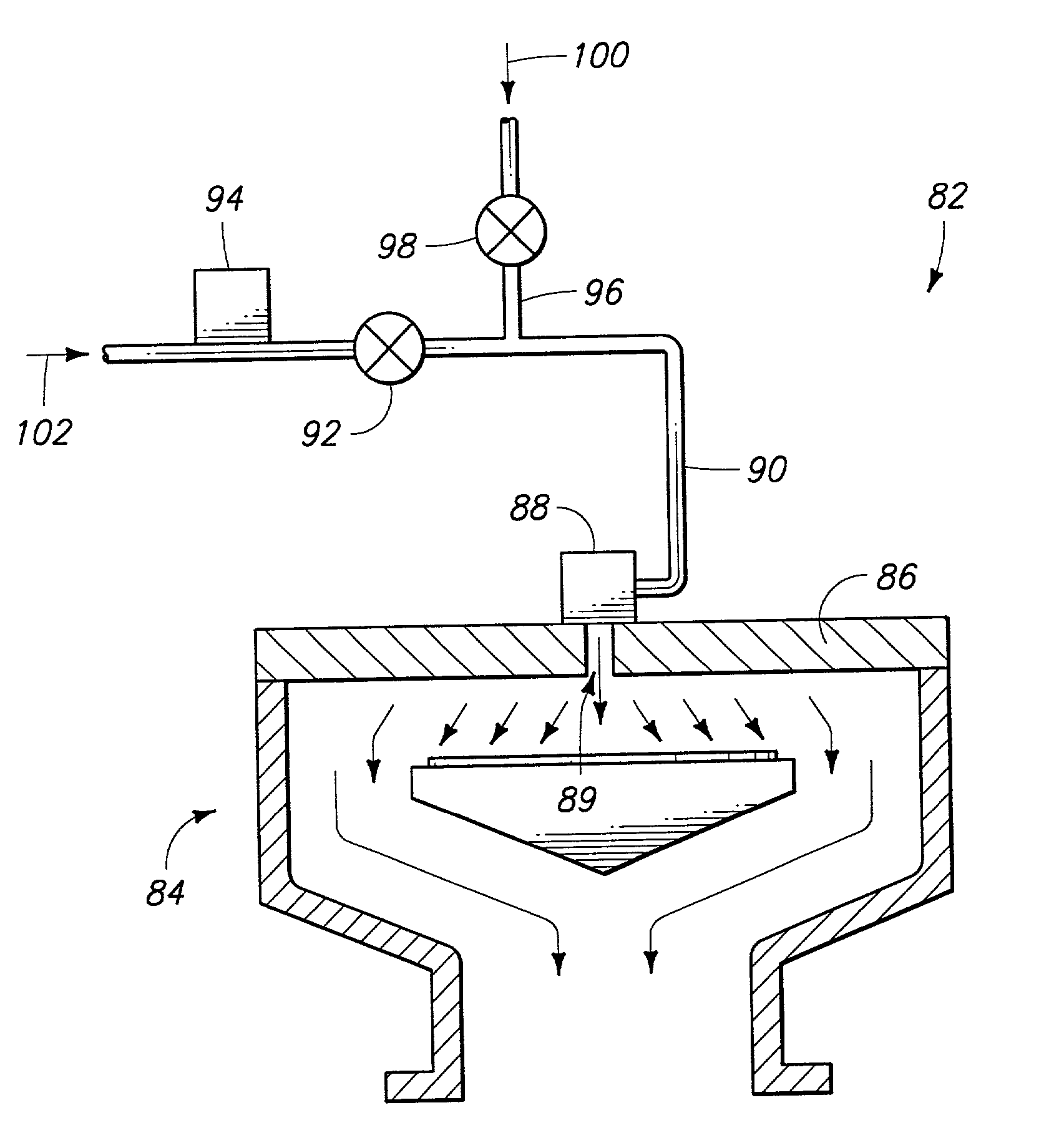

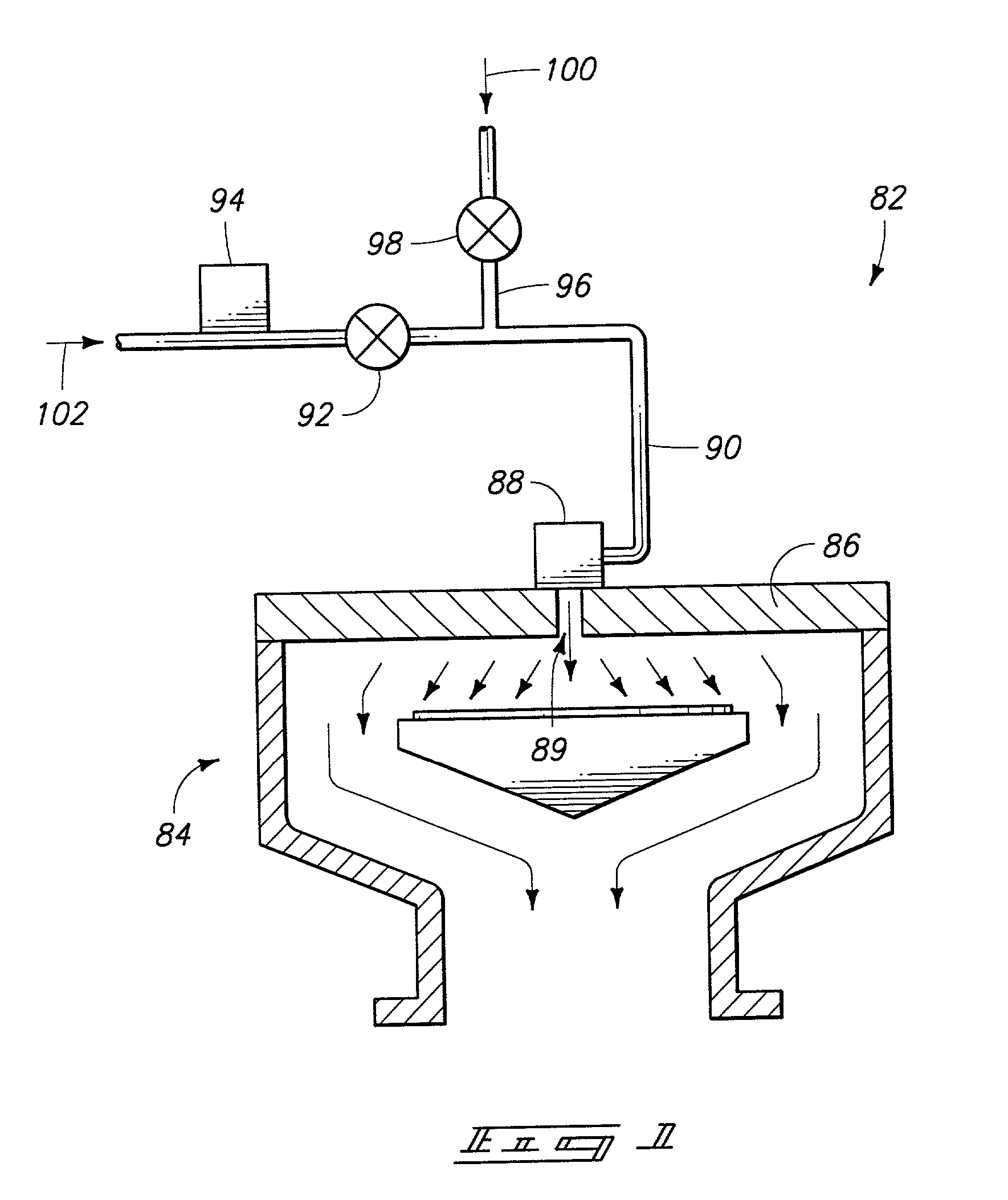

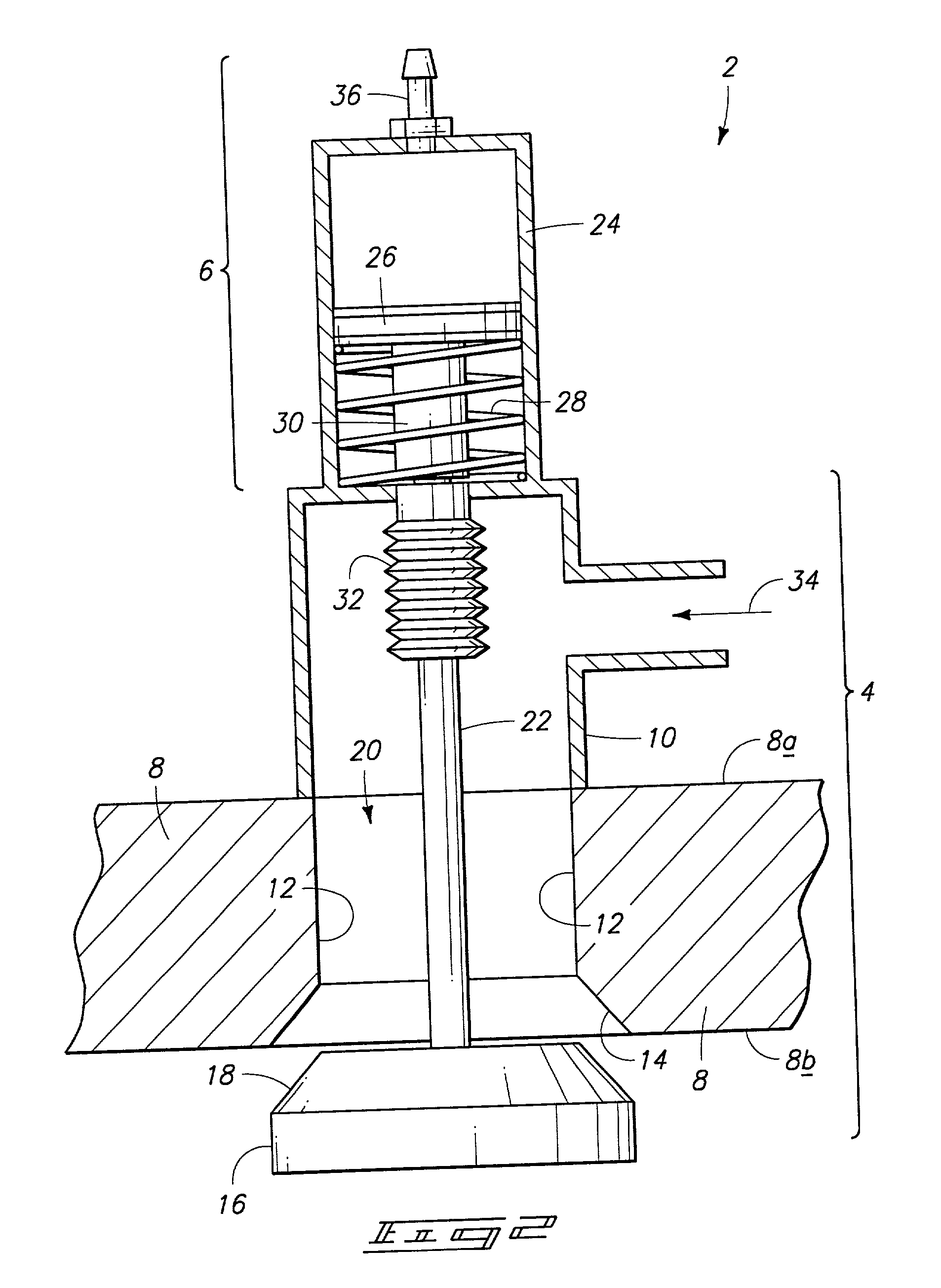

Ald Apparatus and Method

InactiveUS20070269983A1Enhanced advantageMaterial utilization efficiency is increasedLiquid surface applicatorsBy zone-melting liquidsCompound (substance)Engineering

Improved apparatus and method for SMFD ALD include a method designed to enhance chemical utilization as well as an apparatus that implements lower conductance out of SMFD-ALD process chamber while maintaining full compatibility with standard wafer transport. Improved SMFD source apparatuses (700, 700′, 700″) and methods from volatile and non-volatile liquid and solid precursors are disclosed, e.g., a method for substantially controlling the vapor pressure of a chemical source (722) within a source space comprising: sensing the accumulation of the chemical on a sensing surface (711); and controlling the temperature of the chemical source depending on said sensed accumulation.

Owner:SUNDEW TECH

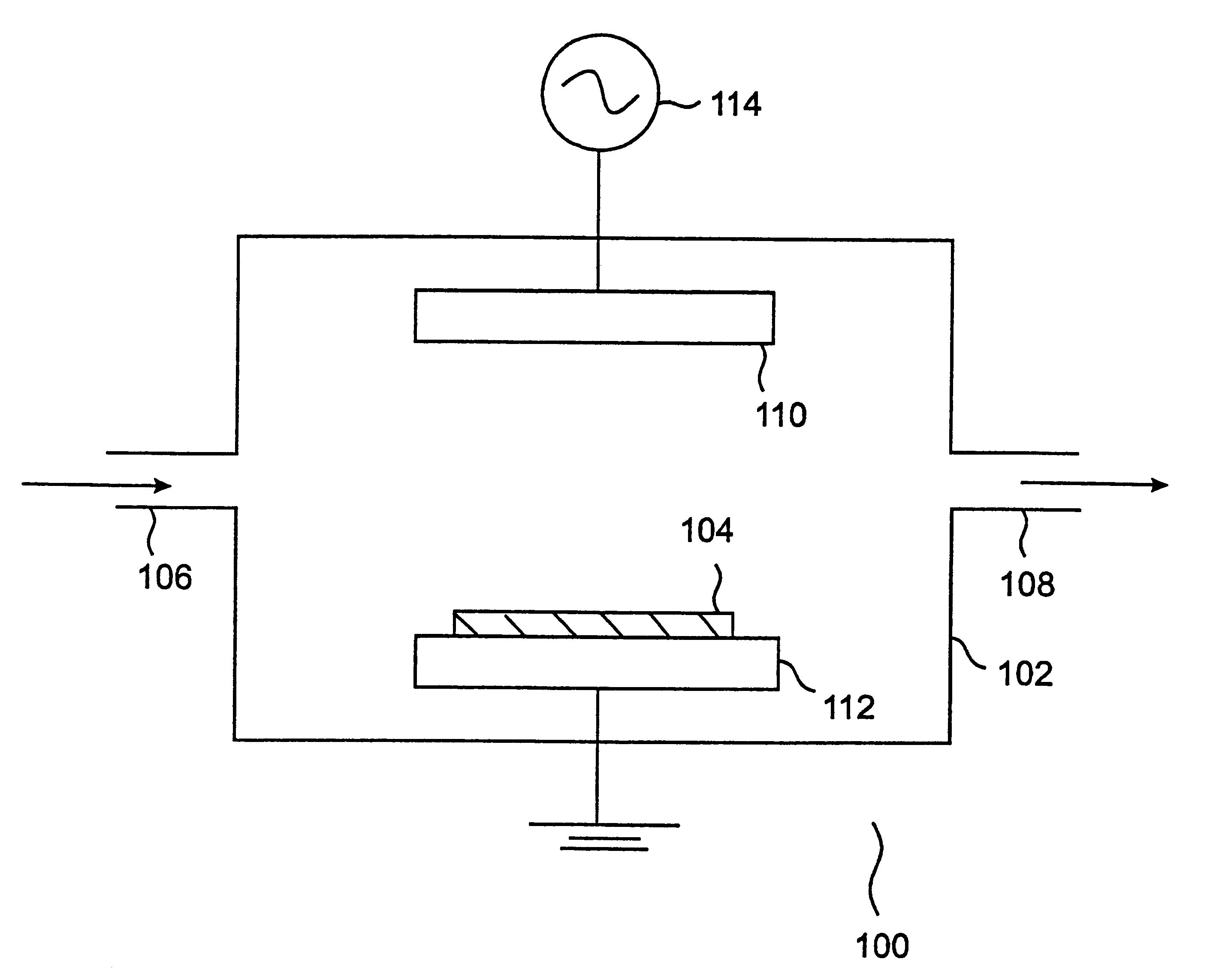

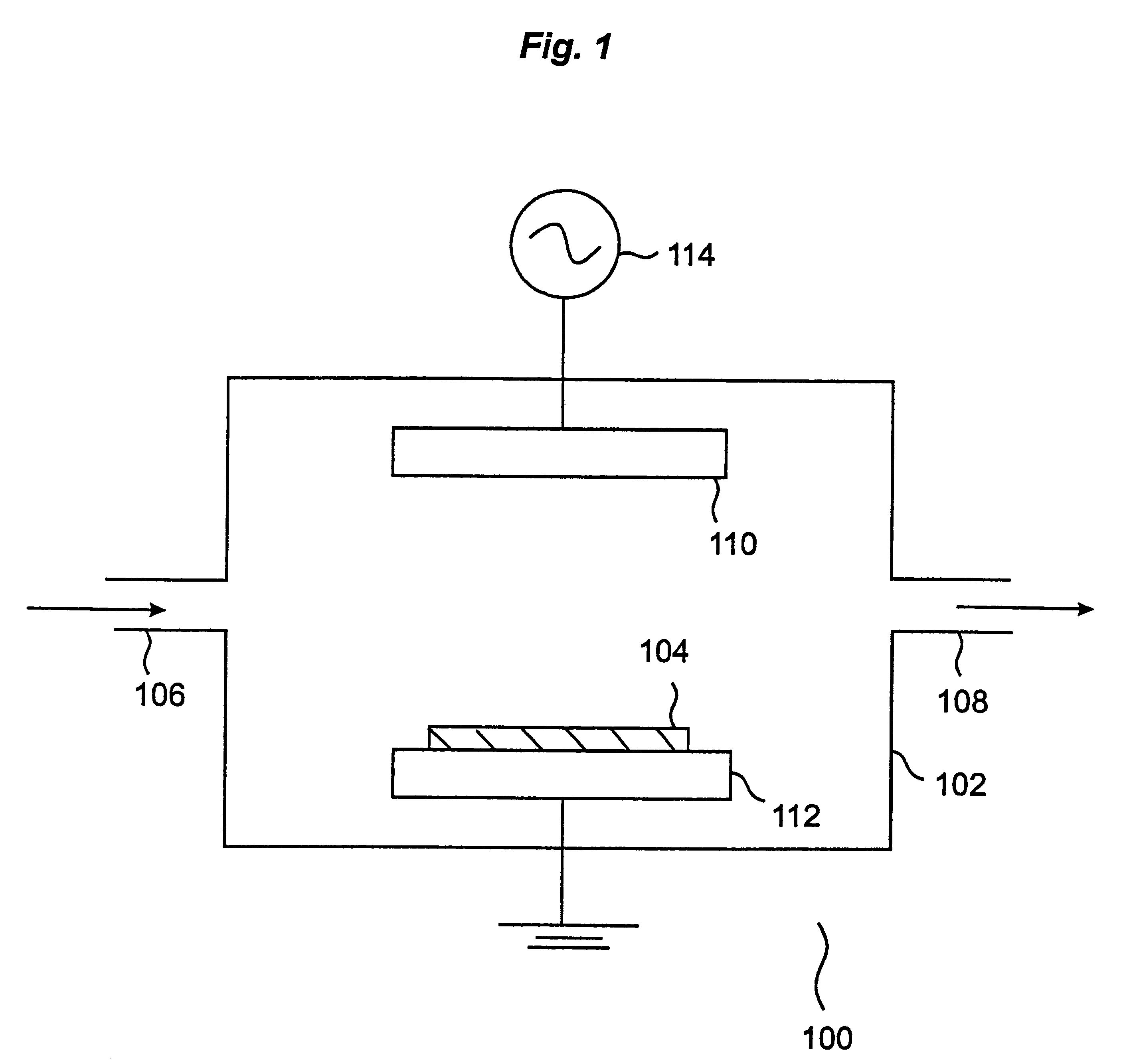

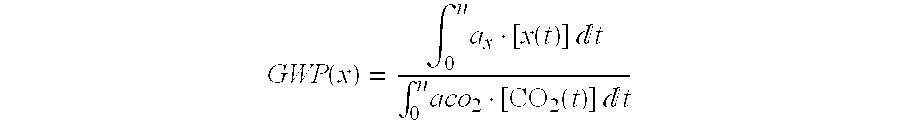

Plasma cleaning and etching methods using non-global-warming compounds

InactiveUS6242359B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrifluoroacetic anhydrideChemical vapor deposition

Provided is a novel method of cleaning a chemical vapor deposition processing chamber having deposits on an inner surface thereof is provided. The process involves forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound, and contacting active species generated in the plasma with the inner surface of the chamber, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. Also provided is a method of etching a layer on a silicon wafer. The method involves the steps of: (a) introducing a silicon wafer into a processing chamber, the silicon wafer comprising a layer to be etched; and (b) forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound. Active species generated in the plasma are contacted with the silicon wafer, thereby etching the layer, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. The chemistries in accordance with the invention provide environmentally benign alternatives to the conventionally used global-warming chemistries for chamber cleaning and semiconductor etching processes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

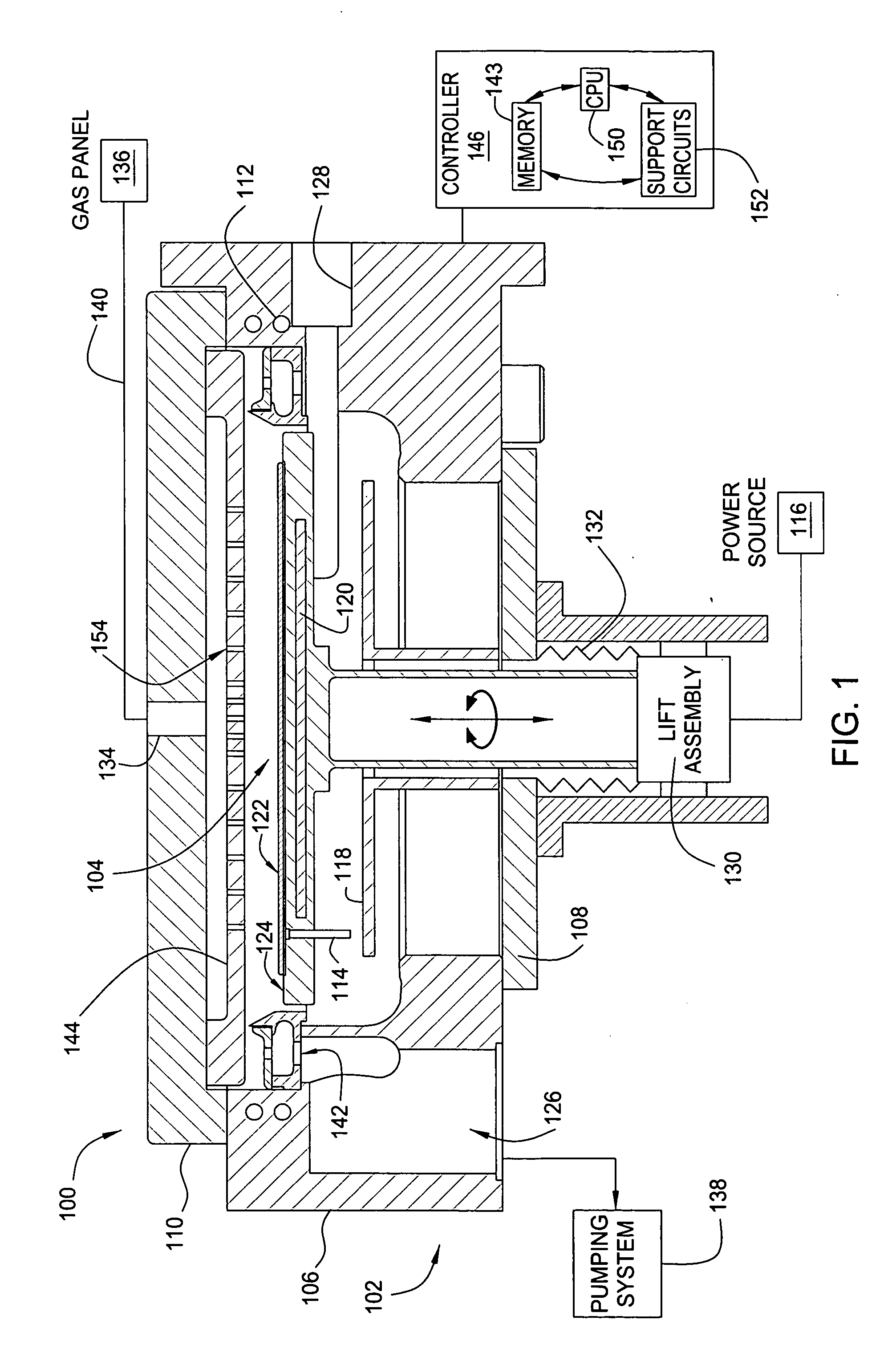

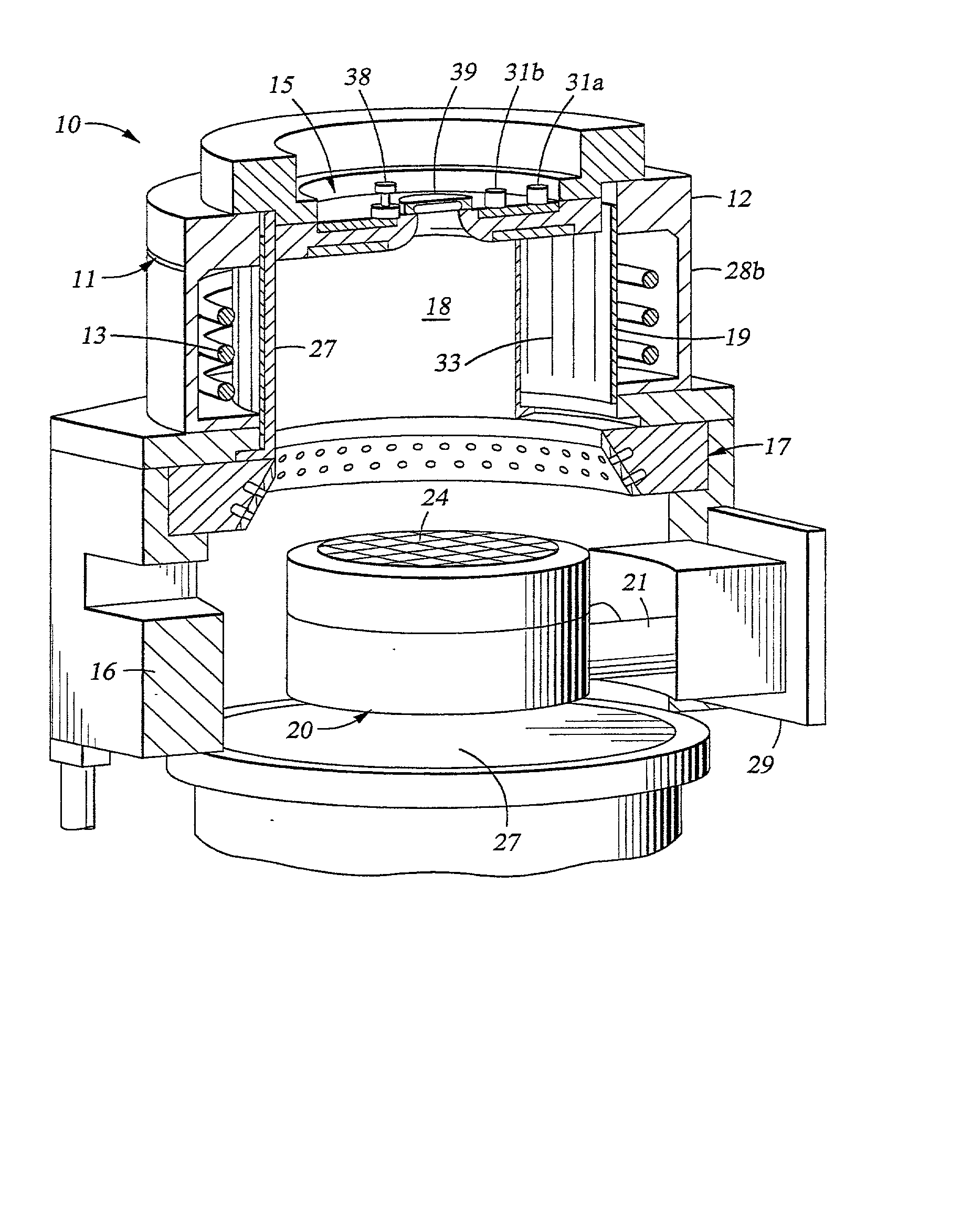

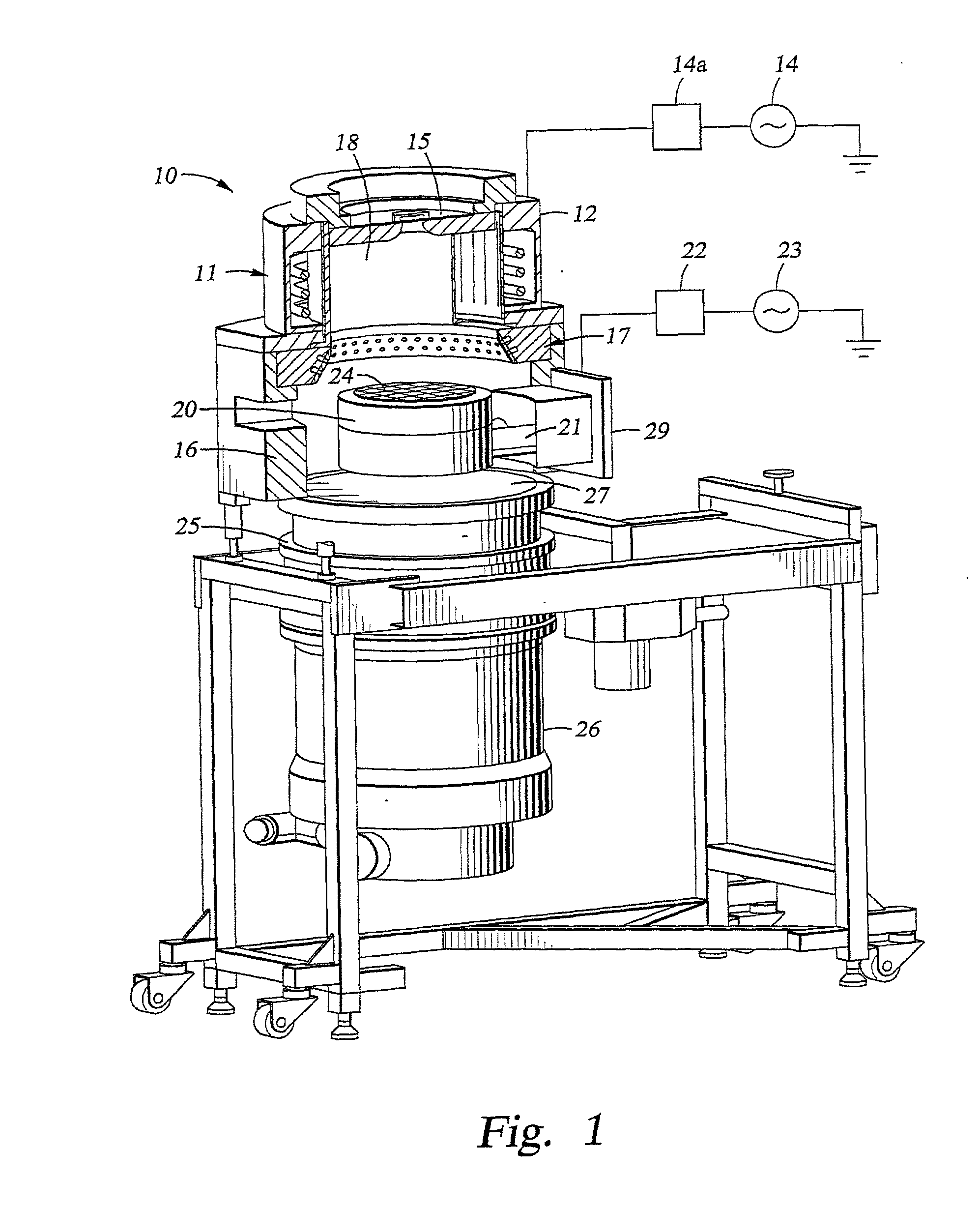

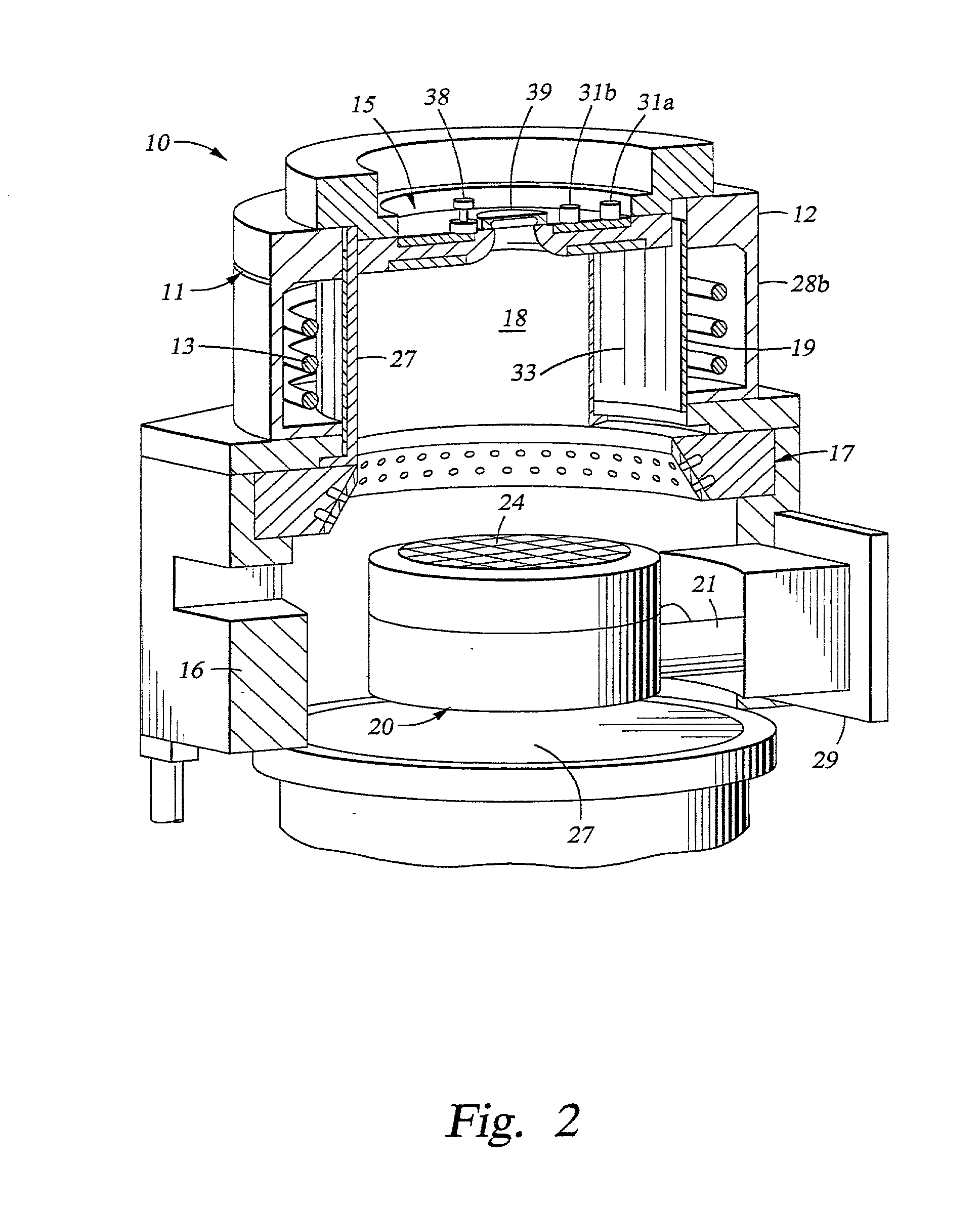

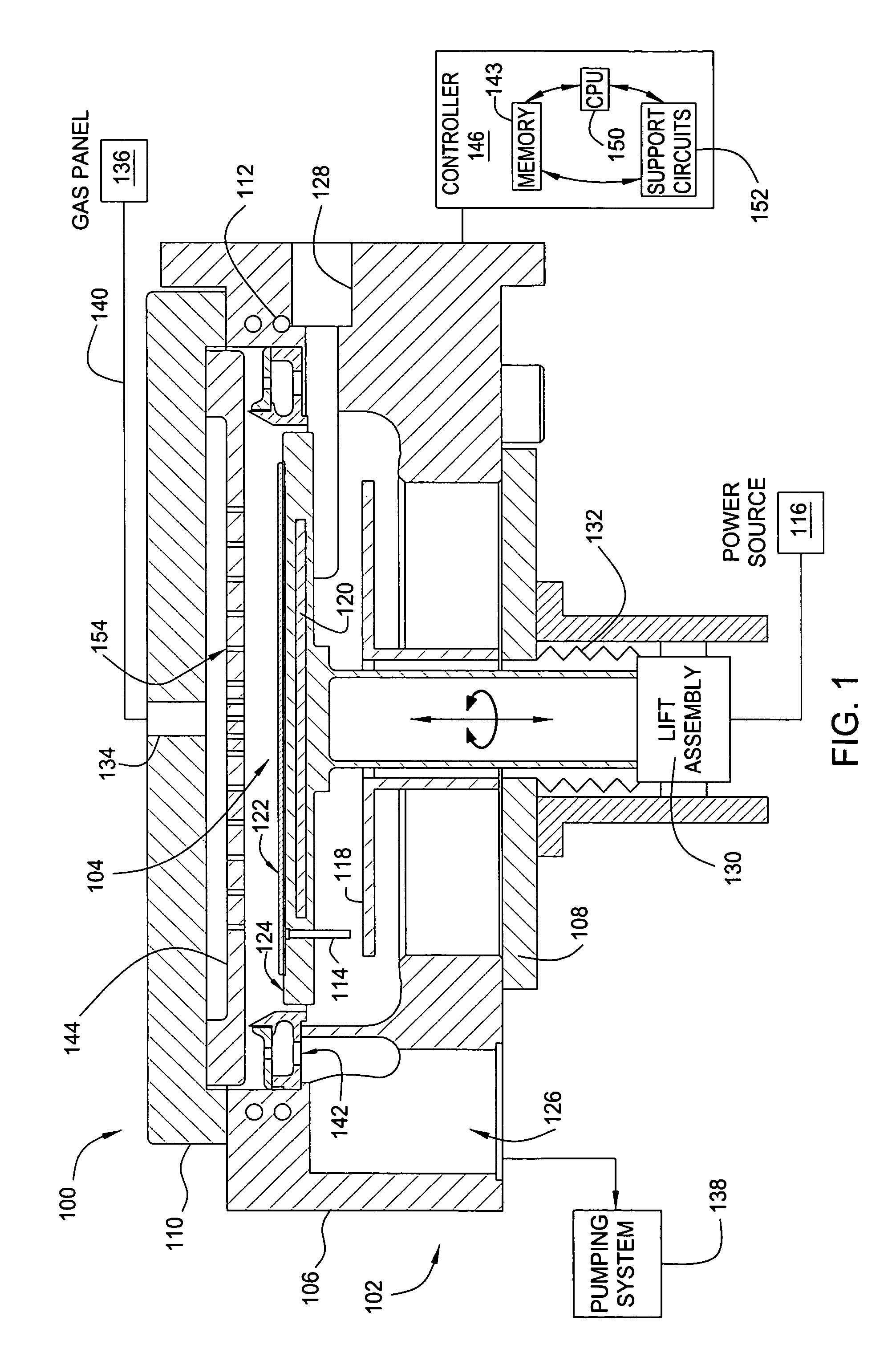

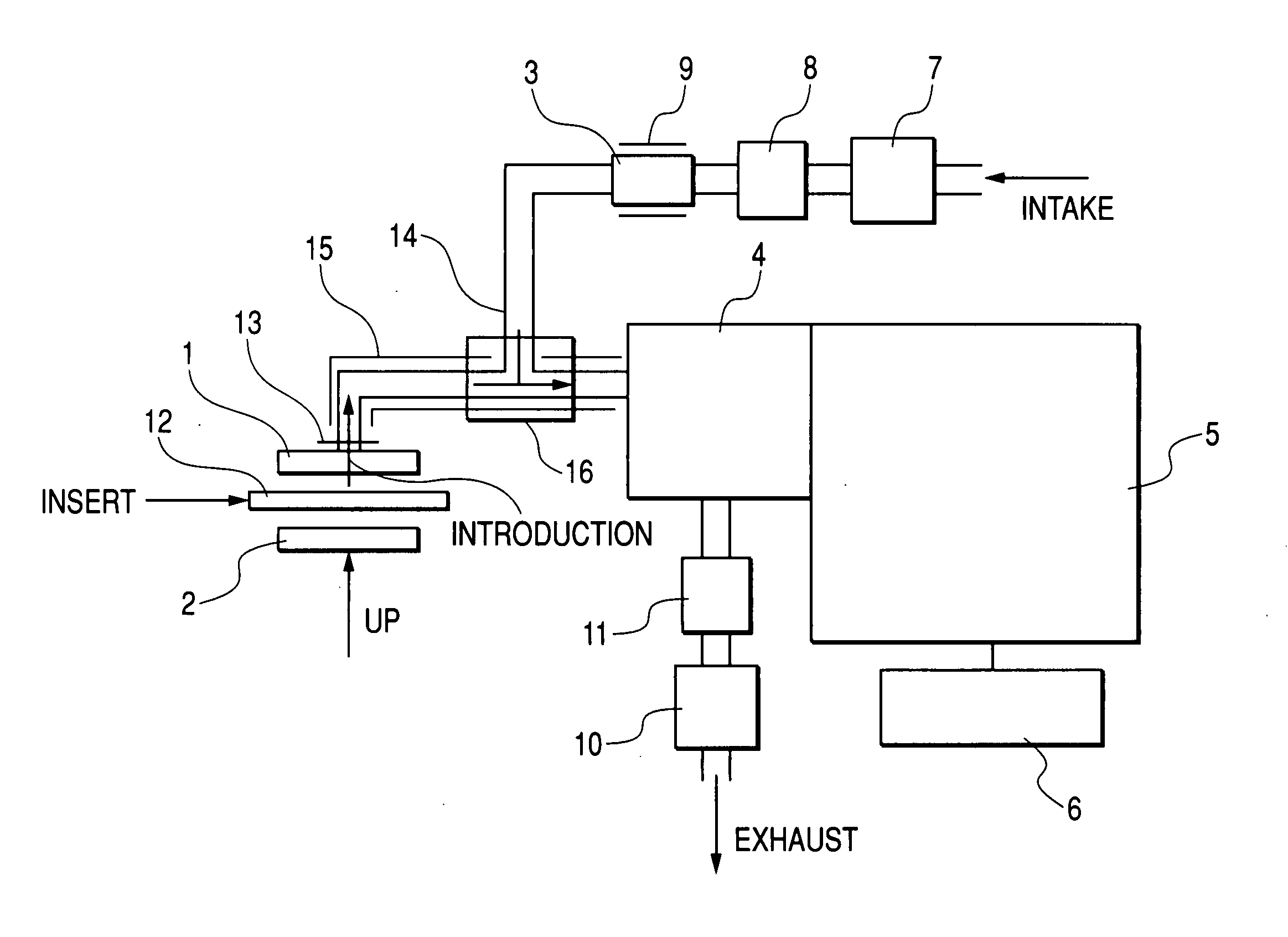

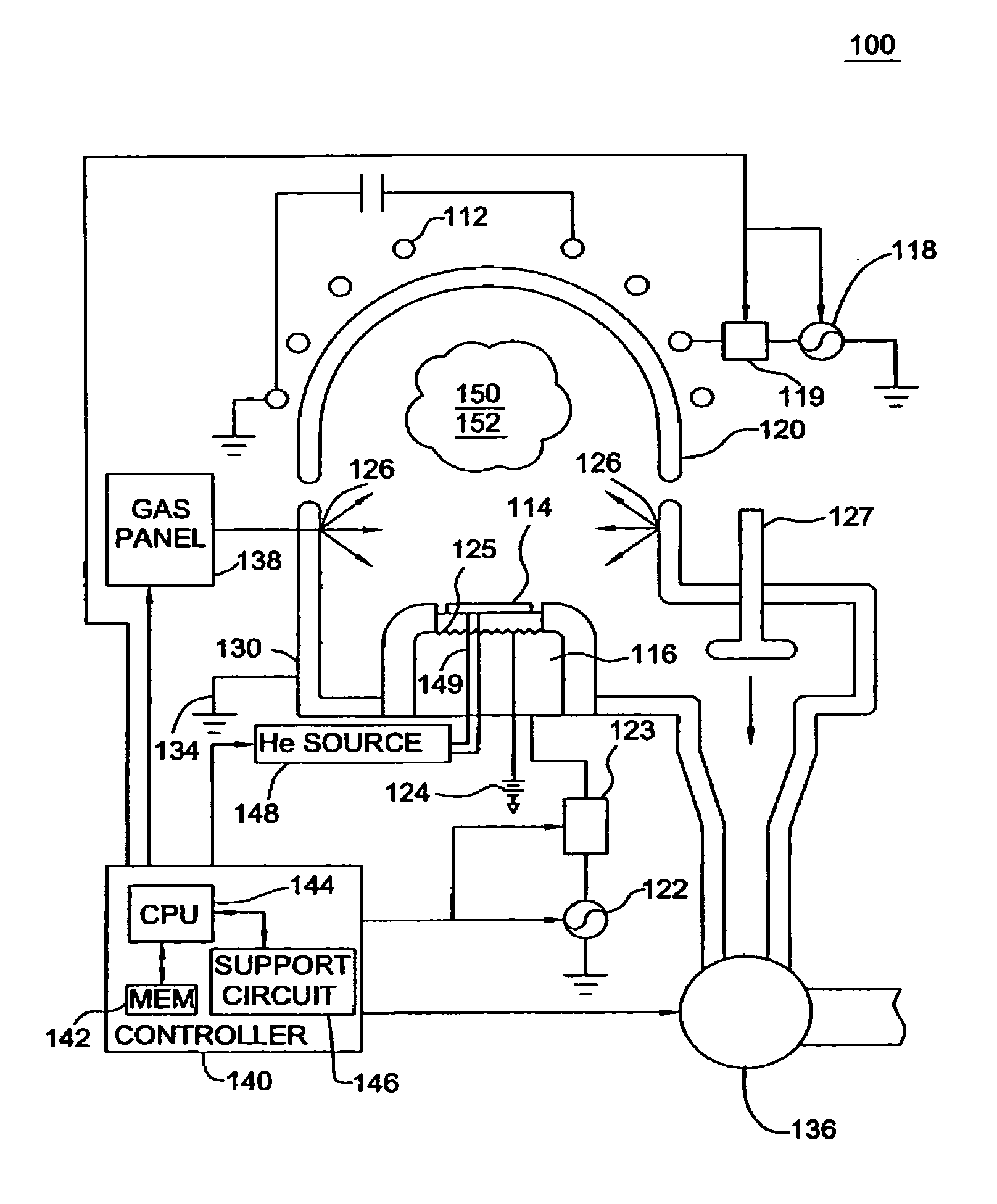

Plasma enhanced chemical processing reactor and method

InactiveUS20020078893A1Improve film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingChemical treatmentReactive gas

A plasma enhanced chemical processing reactor and method. The reactor includes a plasma chamber including a first gas injection manifold and a source of electromagnetic energy. The plasma chamber is in communication with a process chamber which includes a wafer support and a second gas manifold. The plasma generated in the plasma chamber extends into the process chamber and interacts with the reactive gases to deposit a layer of material on the wafer. The reactor also includes a vacuum system for exhausting the reactor. The method includes the steps of generating a plasma within the plasma chamber, introducing at least one gaseous chemical into the process chamber proximate to the wafer support and applying r.f. gradient to induce diffusion of the plasma to the area proximate the wafer support.

Owner:APPLIED MATERIALS INC

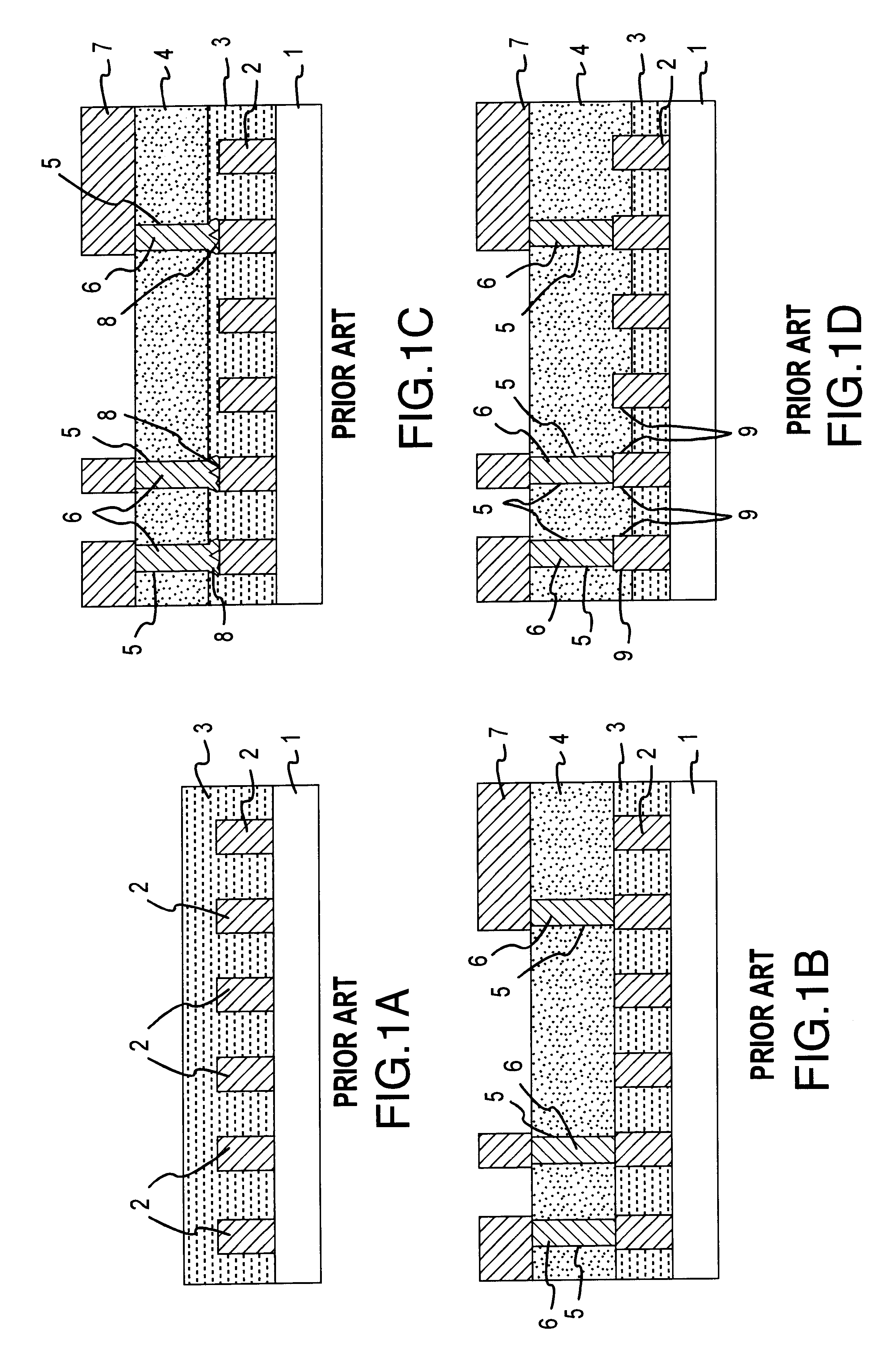

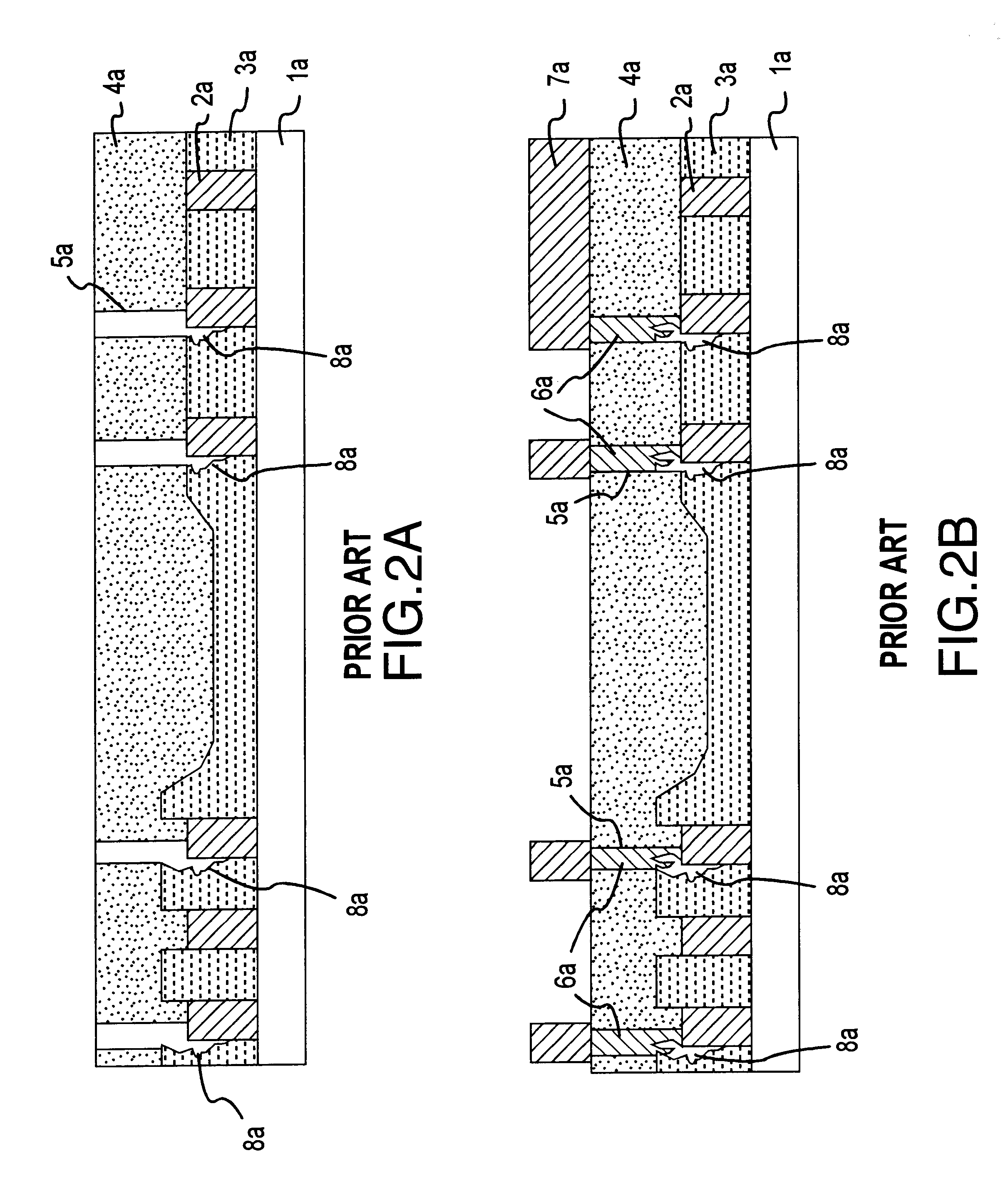

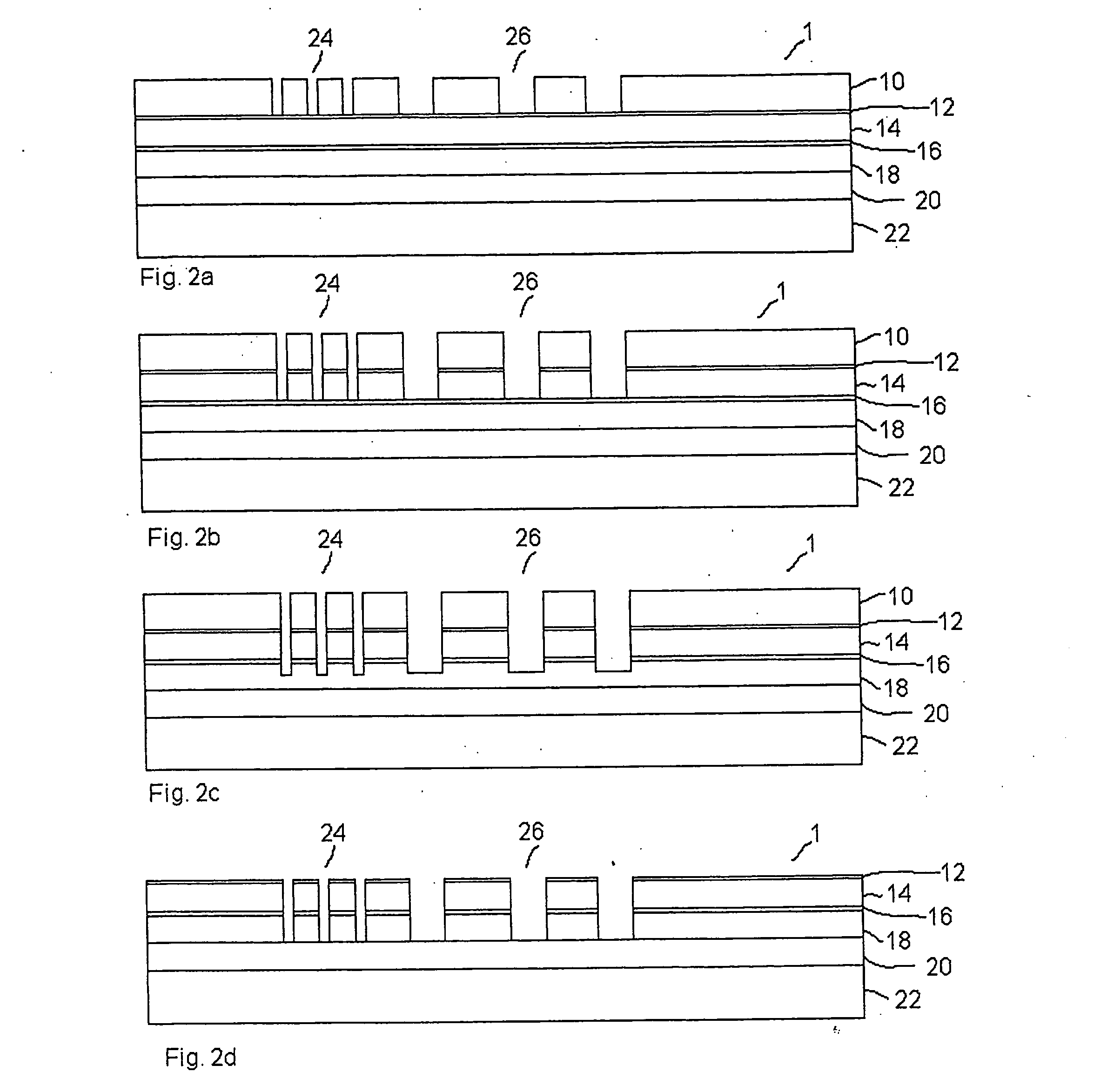

Interconnect with low dielectric constant insulators for semiconductor integrated circuit manufacturing

InactiveUS6187672B1Semiconductor/solid-state device manufacturingResistIntegrated circuit manufacturing

A method is provided for forming an improved interconnect structure on a semiconductor body. A first metal layer is deposited on the semiconductor body. A sacrificial layer having a height is deposited on the first metal layer. The sacrificial layer and the metal layer are patterned to form separate metal lines with the sacrificial layer remaining on said metal lines. A low-k material is then deposited to fill the gaps between metal lines and to cover the sacrificial layer. The low-k material is then removed to a level within the height of the sacrificial layer. The sacrificial layer is then removed. A protective layer is deposited on top of the metal lines and the low-k material. A dielectric layer is deposited over the protective layer. The protective layer protects the low-k material from attack by chemicals utilized by subsequent process steps to etch vias in the dielectric layer, to strip photo-resist, and to clean the vias. The protective layer is then selectively etched away to make contact between a via plug and the metal lines.

Owner:NEWPORT FAB

Ald apparatus and method

InactiveUS20100129548A1Enhanced advantageImprove utilization efficiencyLiquid surface applicatorsFrom chemically reactive gasesEngineeringElectric conductance

Improved apparatus and method for SMFD ALD include a method designed to enhance chemical utilization as well as an apparatus that implements lower conductance out of SMFD-ALD process chamber while maintaining full compatibility with standard wafer transport. Improved SMFD source apparatuses and methods from volatile and non-volatile liquid and solid precursors are disclosed, e.g., a method for substantially controlling the vapor pressure of a chemical source within a source space comprising: sensing the accumulation of the chemical on a sensing surface; and controlling the temperature of the chemical source depending on said sensed accumulation.

Owner:SUNDEW TECH

Method for silicon based dielectric chemical vapor deposition

Embodiments of the invention generally provide a method for depositing silicon-containing films. In one embodiment, a method for depositing silicon-containing material film on a substrate includes flowing a nitrogen and carbon containing chemical into a deposition chamber, flowing a silicon-containing source chemical having silicon-nitrogen bonds into the processing chamber, and heating the substrate disposed in the chamber to a temperature less than about 550 degrees Celsius. In another embodiment, the silicon containing chemical is trisilylamine and the nitrogen and carbon containing chemical is (CH3)3—N.

Owner:APPLIED MATERIALS INC

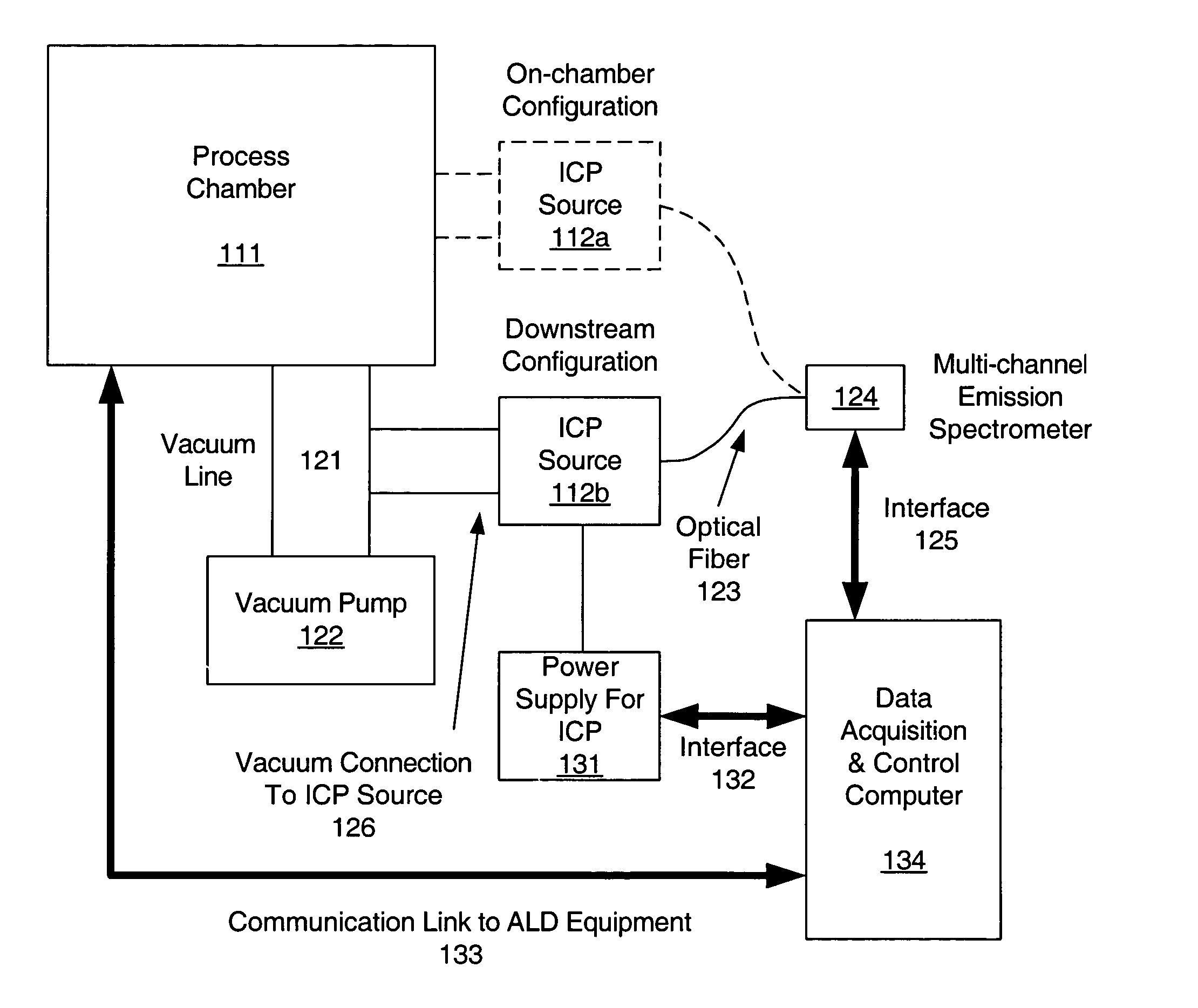

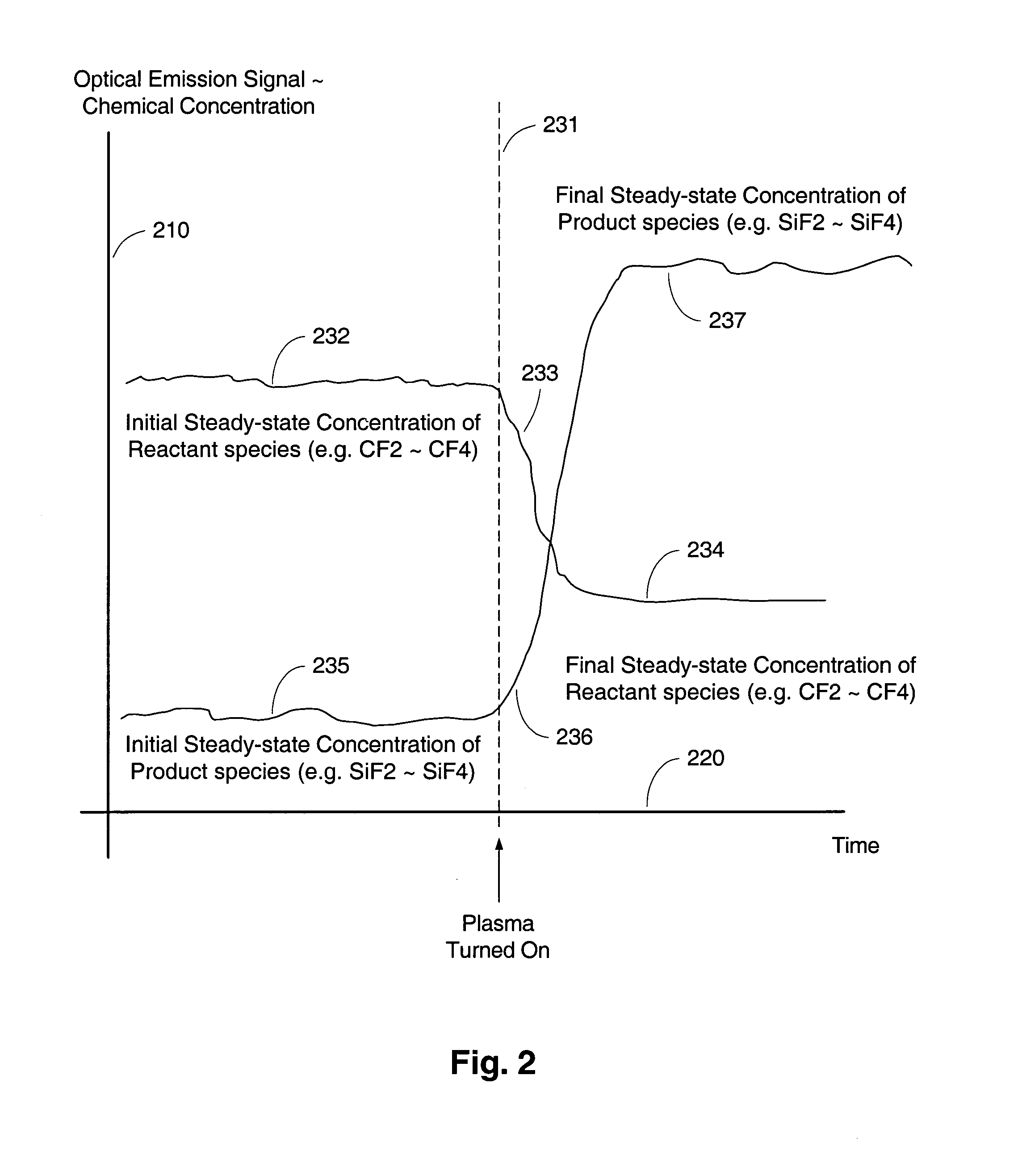

Method and apparatus for chemical monitoring

The present invention relates to monitoring chemicals in a process chamber using a spectrometer having a plasma generator, based on patterns over time of chemical consumption. The relevant patterns may include a change in consumption, reaching a consumption plateau, absence of consumption, or presence of consumption. In some embodiments, advancing to a next step in forming structures on the workpiece depends on the pattern of consumption meeting a process criteria. In other embodiments, a processing time standard is established, based on analysis of the relevant patterns. Yet other embodiments relate to controlling work on a workpiece, based on analysis of the relevant patterns. The invention may be either a process or a device including logic and resources to carry out a process.

Owner:LIGHTWIND CORP

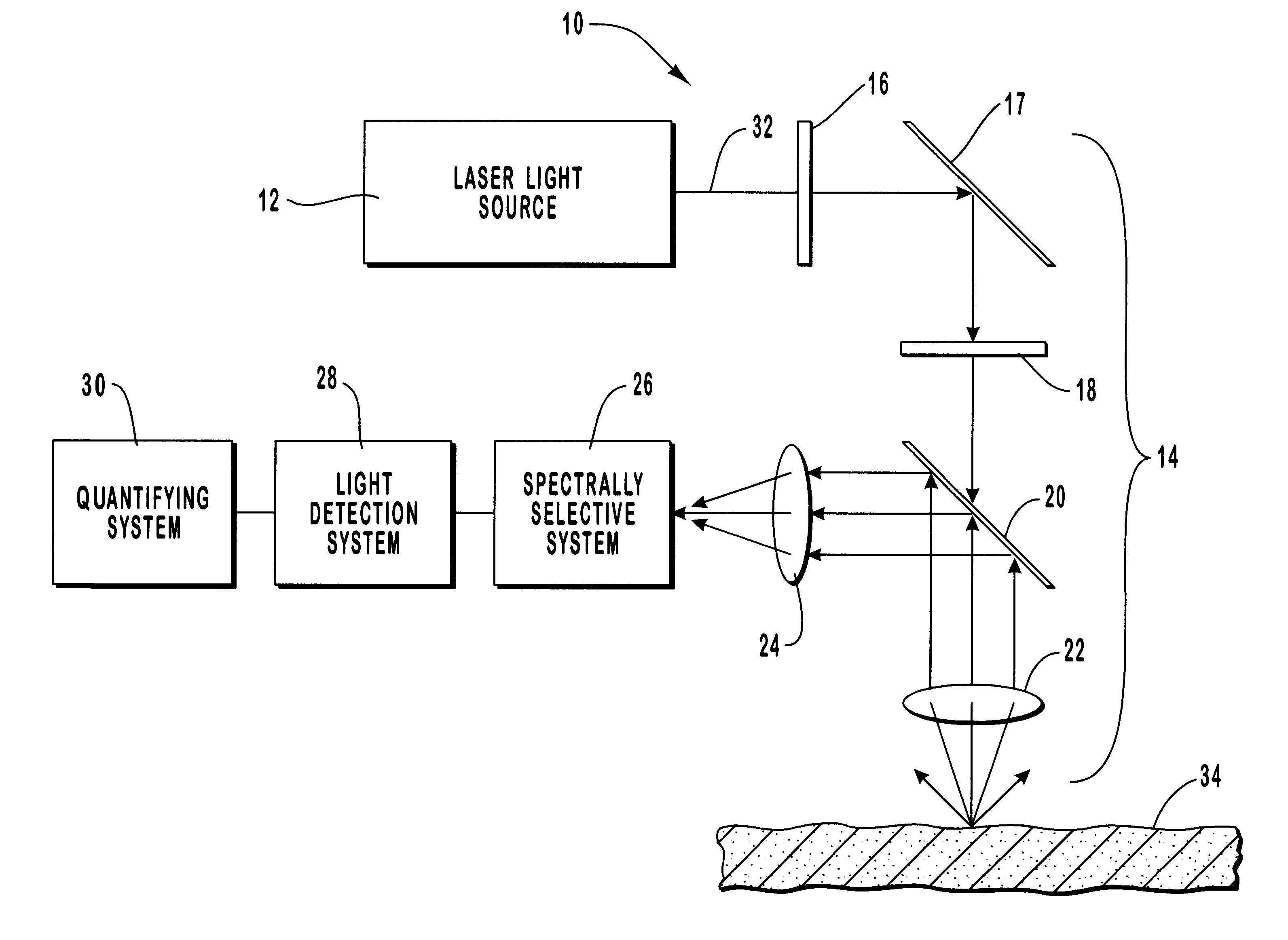

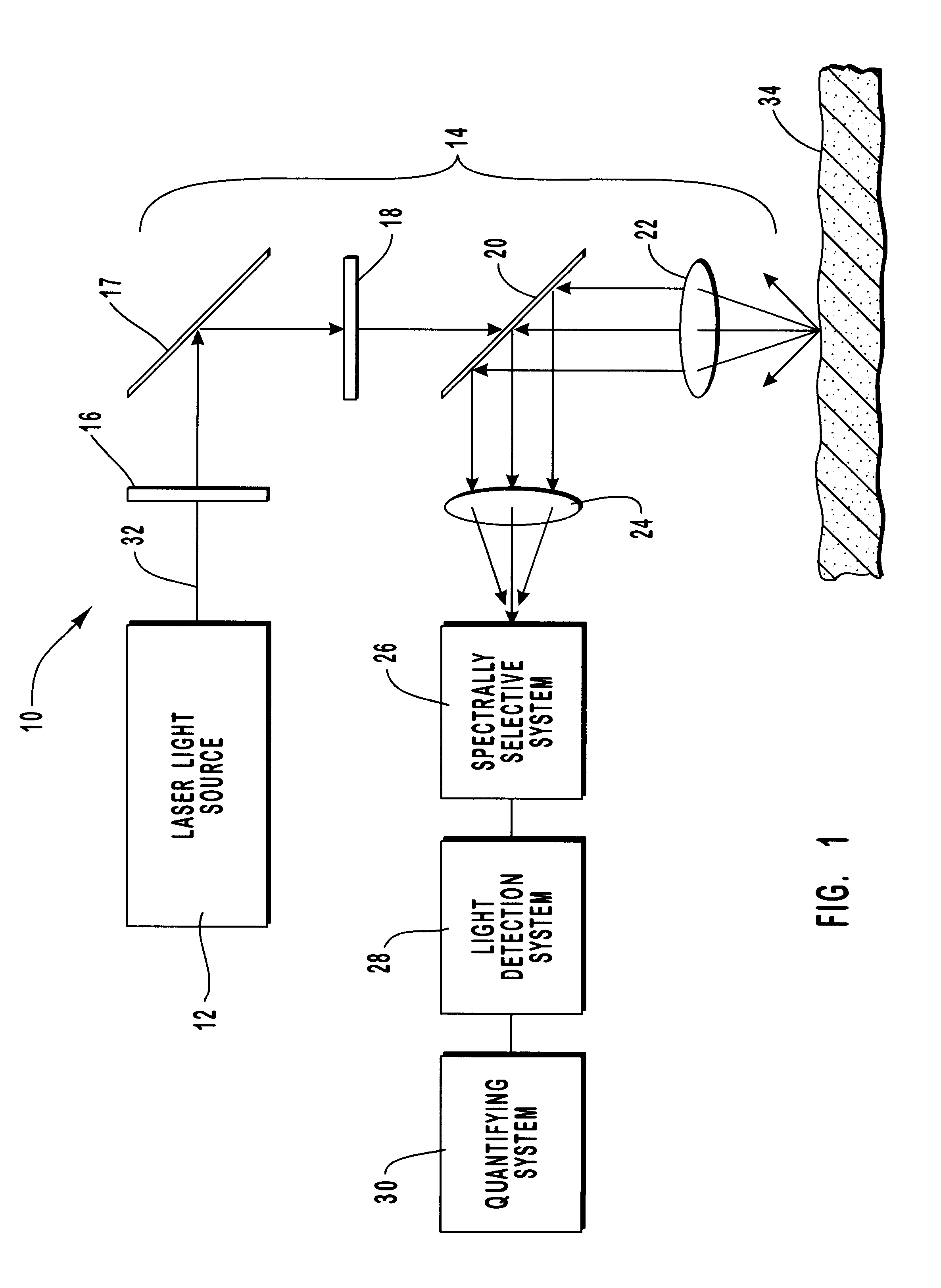

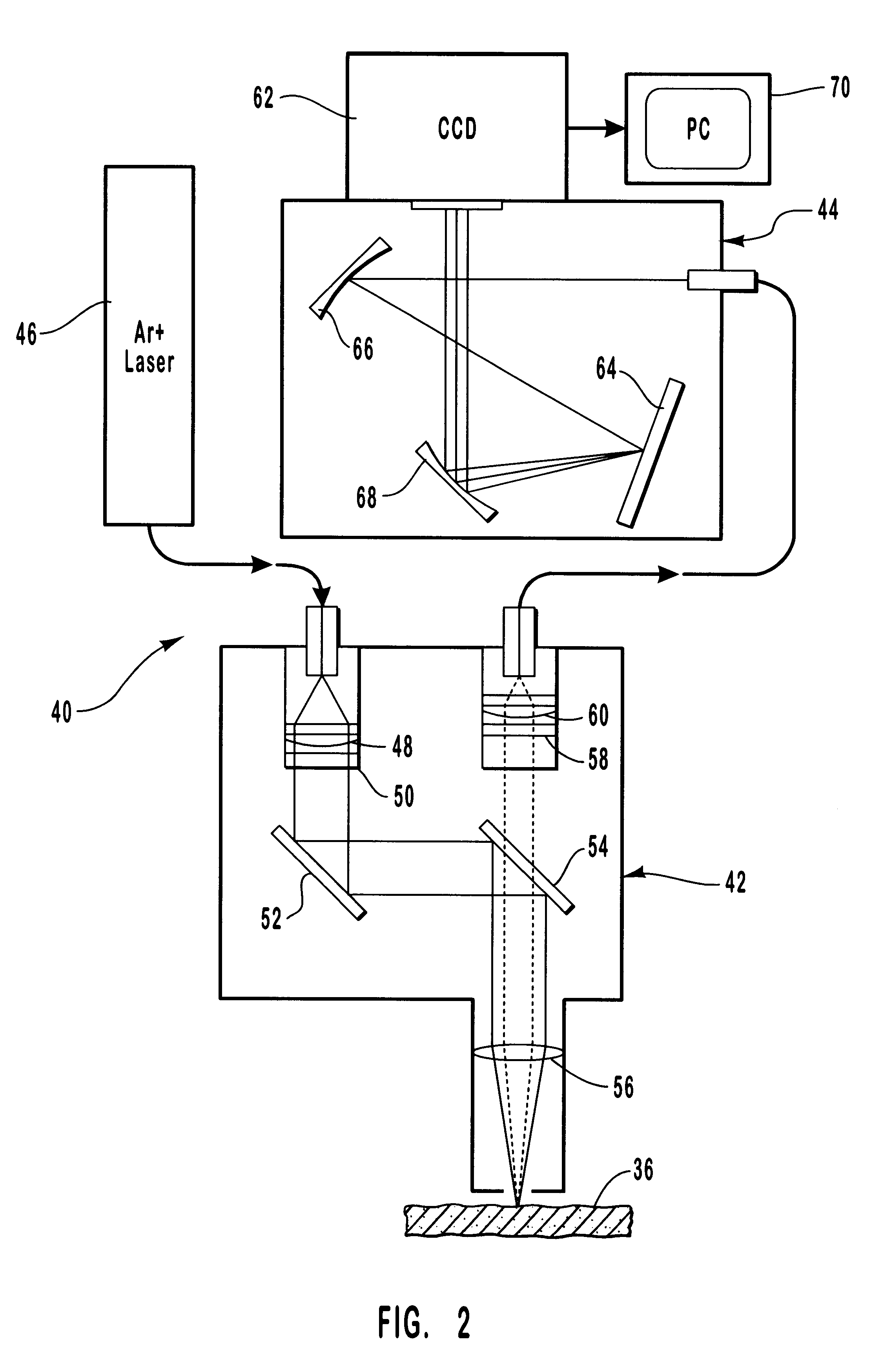

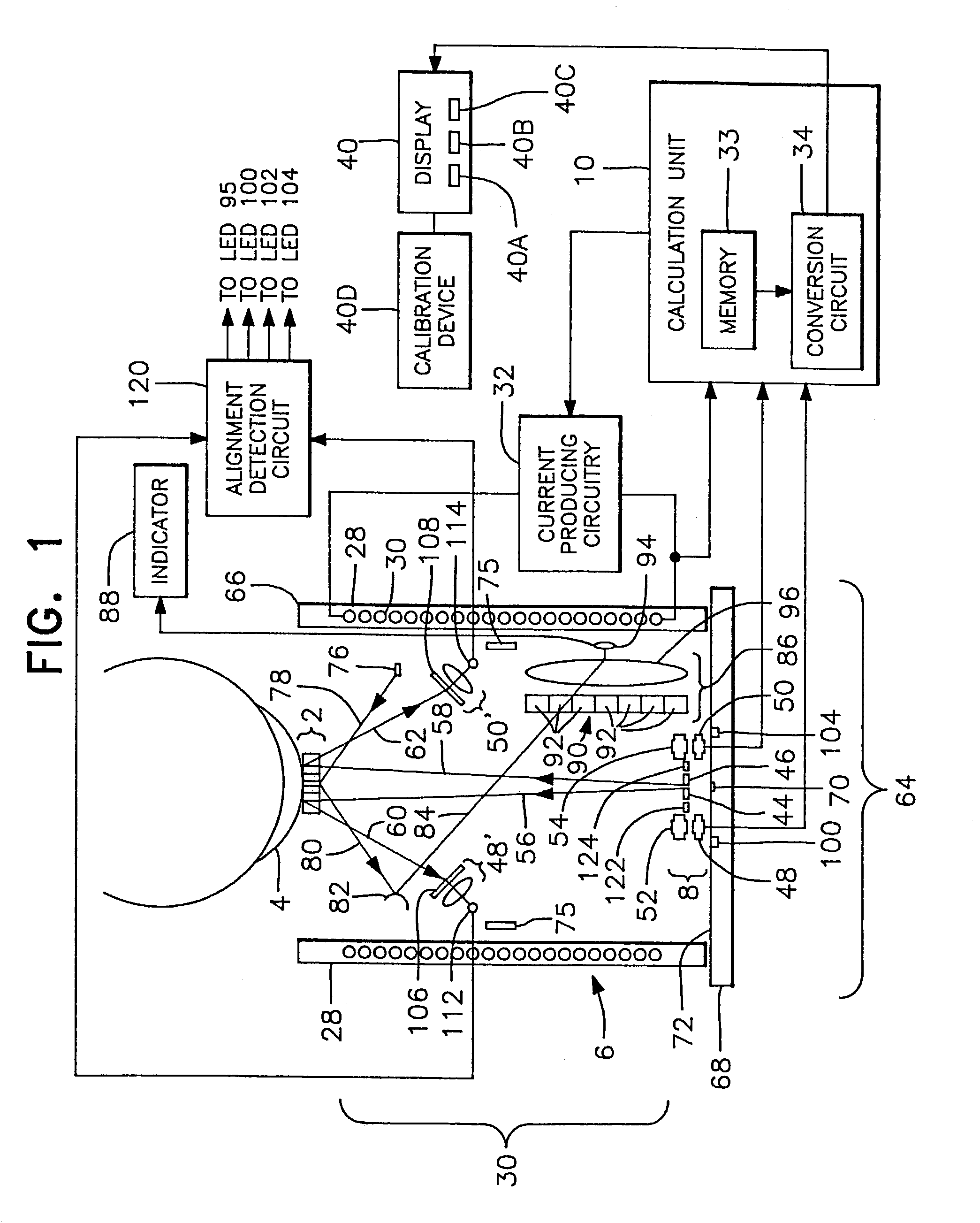

Method and apparatus for noninvasive measurement of carotenoids and related chemical substances in biological tissue

InactiveUS6205354B1Rapid and noninvasive and quantitative measurementRiskRadiation pyrometrySurgeryResonance Raman spectroscopyAntioxidant

A method and apparatus are provided for the determination of levels of carotenoids and similar chemical compounds in biological tissue such as living skin. The method and apparatus provide a noninvasive, rapid, accurate, and safe determination of carotenoid levels which in turn can provide diagnostic information regarding cancer risk, or can be a marker for conditions where carotenoids or other antioxidant compounds may provide diagnostic information. Such early diagnostic information allows for the possibility of preventative intervention. The method and apparatus utilize the technique of resonance Raman spectroscopy to measure the levels of carotenoids and similar substances in tissue. In this technique, laser light is directed upon the area of tissue which is of interest. A small fraction of the scattered light is scattered inelastically, producing the carotenoid Raman signal which is at a different frequency than the incident laser light, and the Raman signal is collected, filtered, and measured. The resulting Raman signal can be analyzed such that the background fluorescence signal is subtracted and the results displayed and compared with known calibration standards.

Owner:UNIV OF UTAH RES FOUND

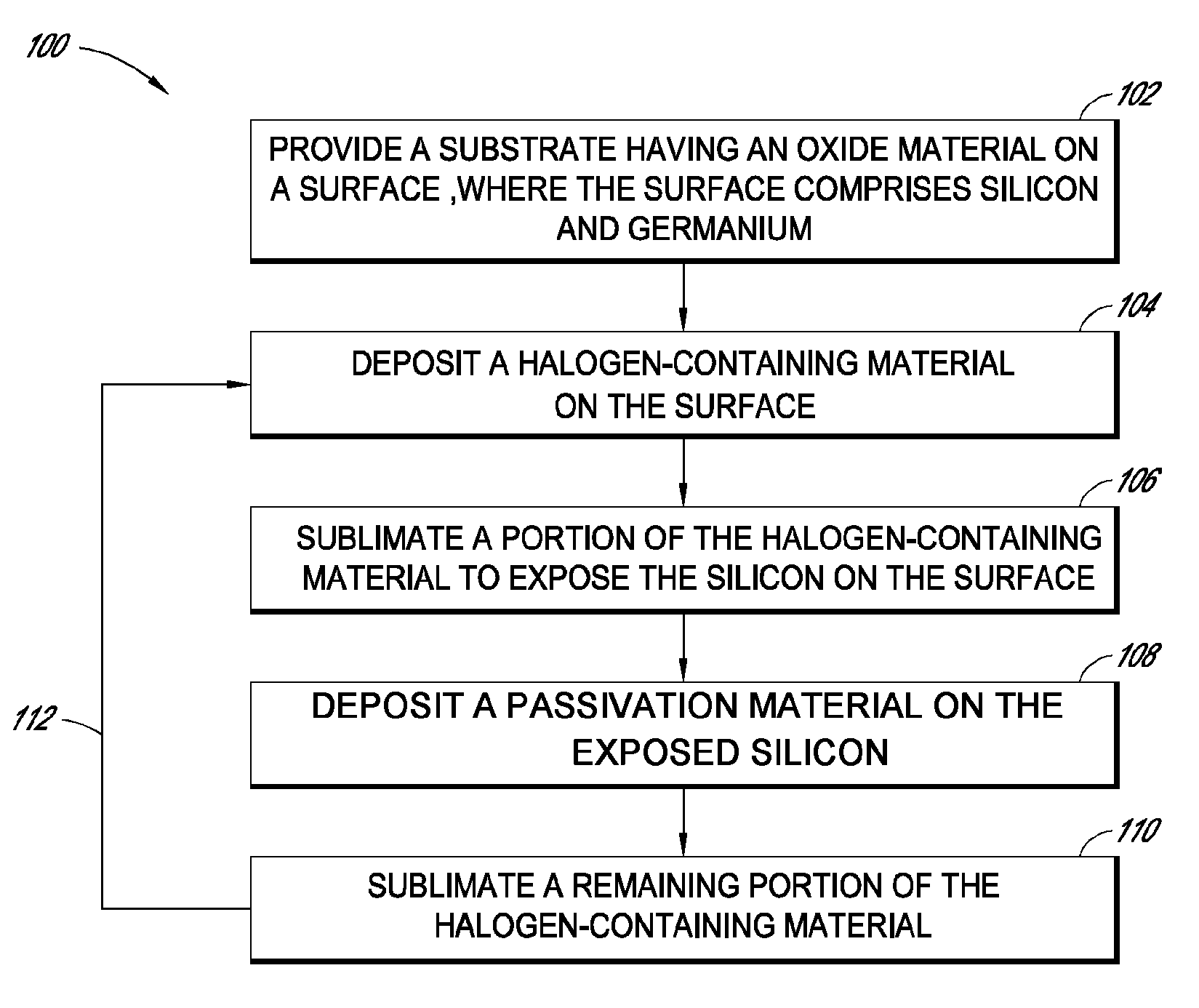

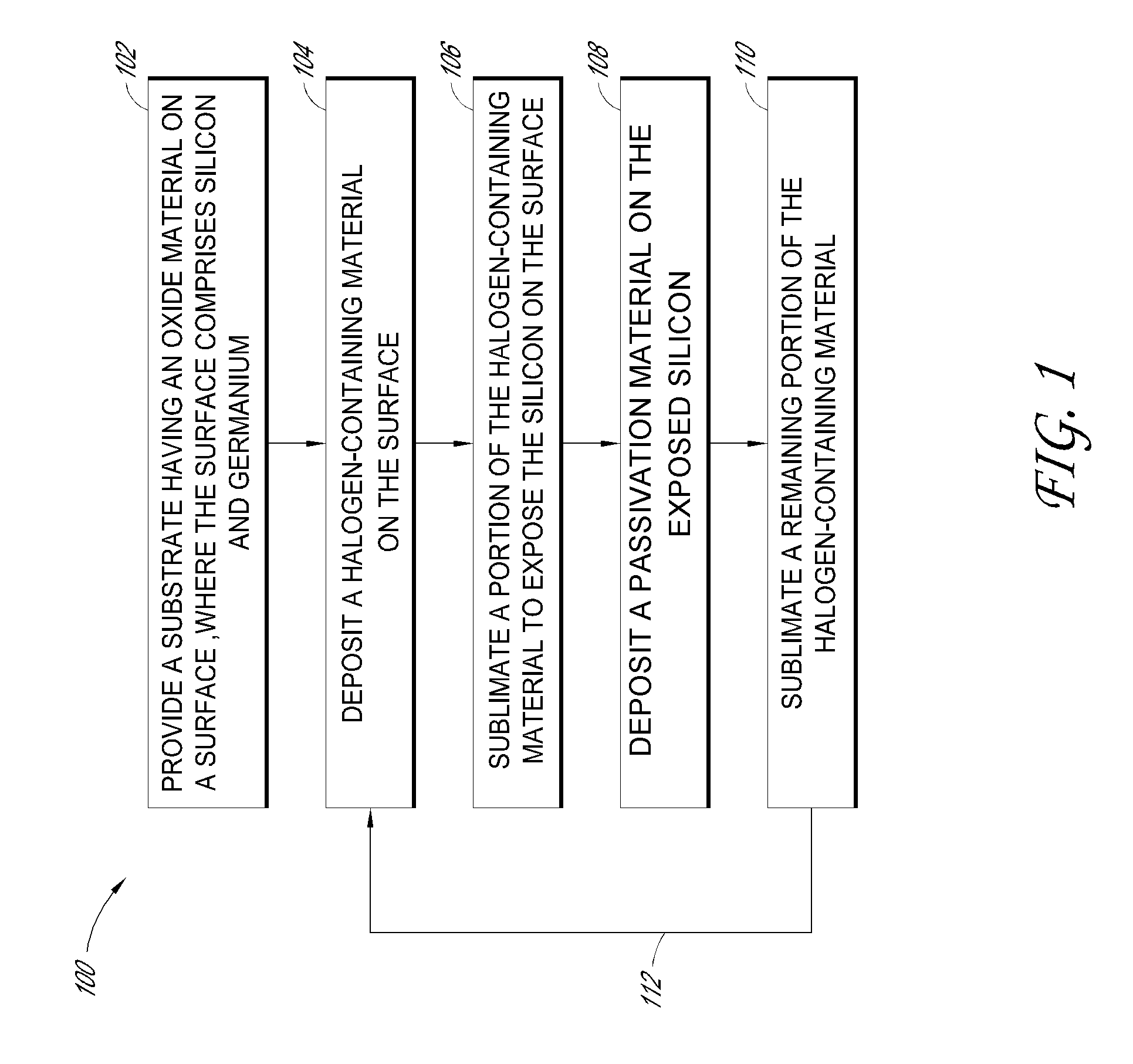

Germanium oxide pre-clean module and process

ActiveUS9474163B2Printed circuit liquid treatmentSemiconductor/solid-state device manufacturingChemical speciesHalogen

In some embodiments, a method for integrated circuit fabrication includes removing oxide material from a surface of a substrate, where the surface includes silicon and germanium. Removing the oxide material includes depositing a halogen-containing pre-clean material on a silicon oxide-containing surface and sublimating a portion of the halogen-containing pre-clean material to expose the silicon on the surface. A passivation film is deposited on the exposed silicon. The passivation film may include chlorine. The passivation film may prevent contamination of the silicon surface by chemical species from the later sublimation, which may be at a higher temperature than the earlier sublimation. Subsequently, a remaining portion of the halogen-containing pre-clean material and the passivation film are sublimated. A target material, such as a conductive material, may subsequently be deposited on the substrate surface.

Owner:ASM IP HLDG BV

Porous silicon particulates for lithium batteries

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

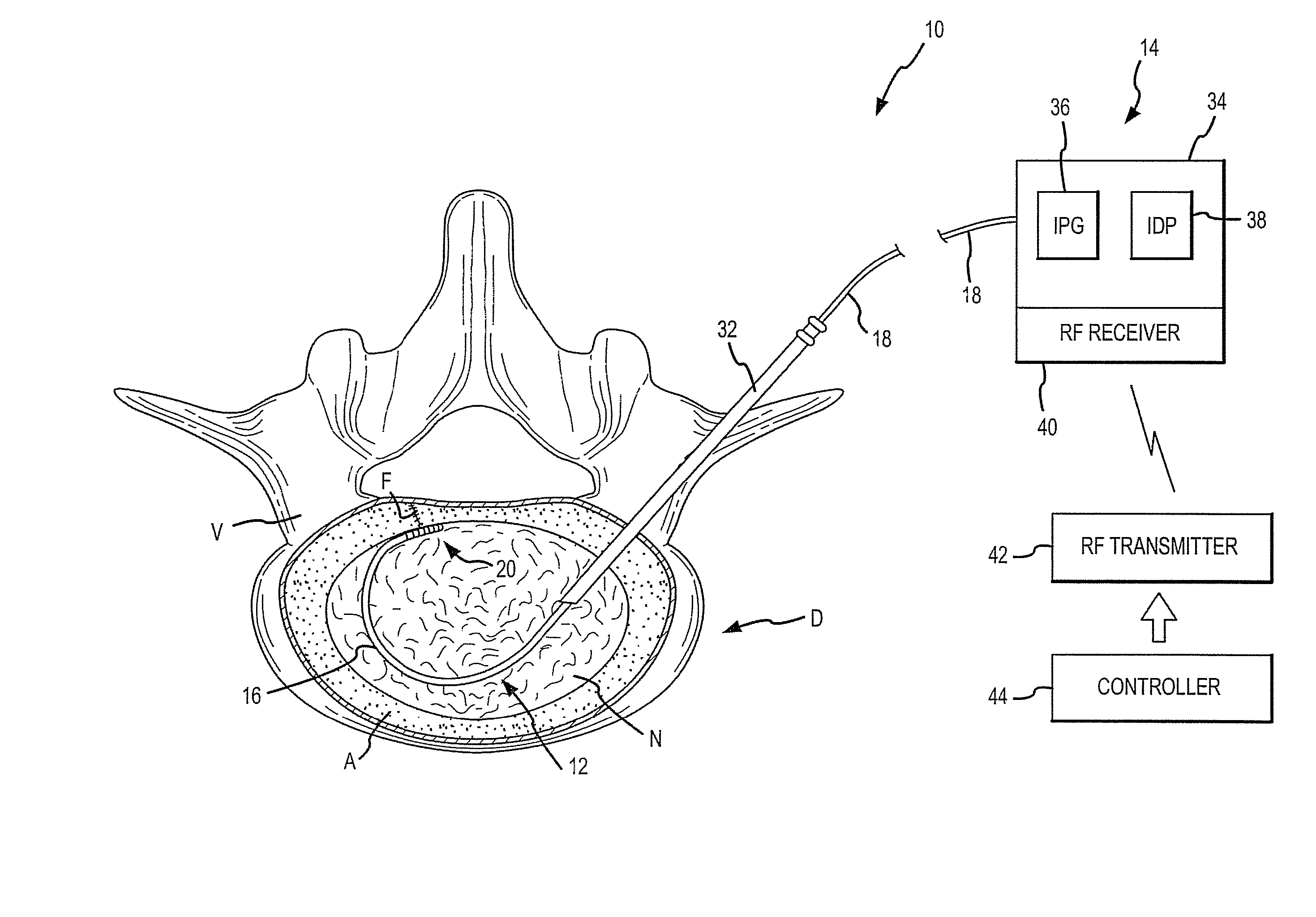

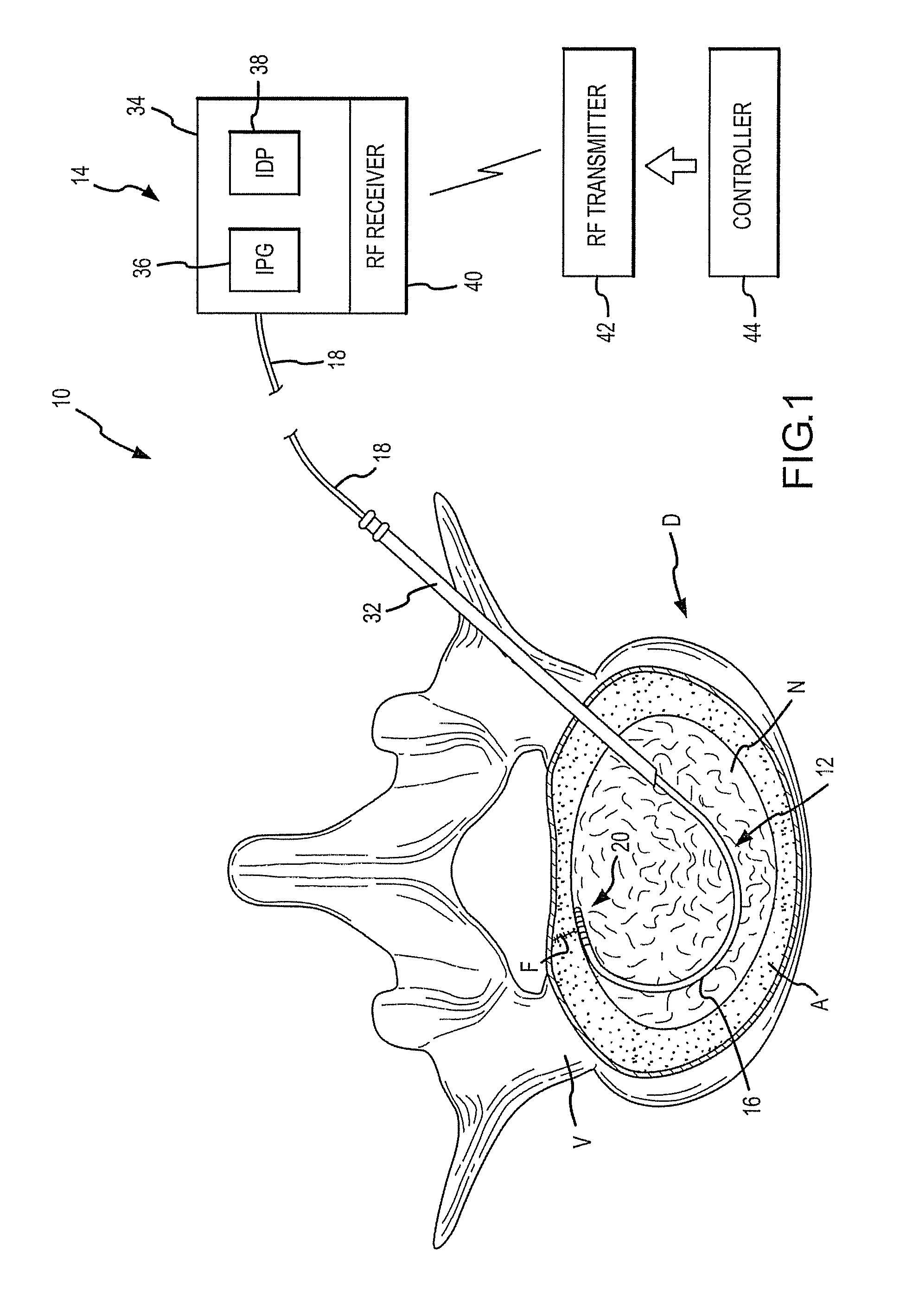

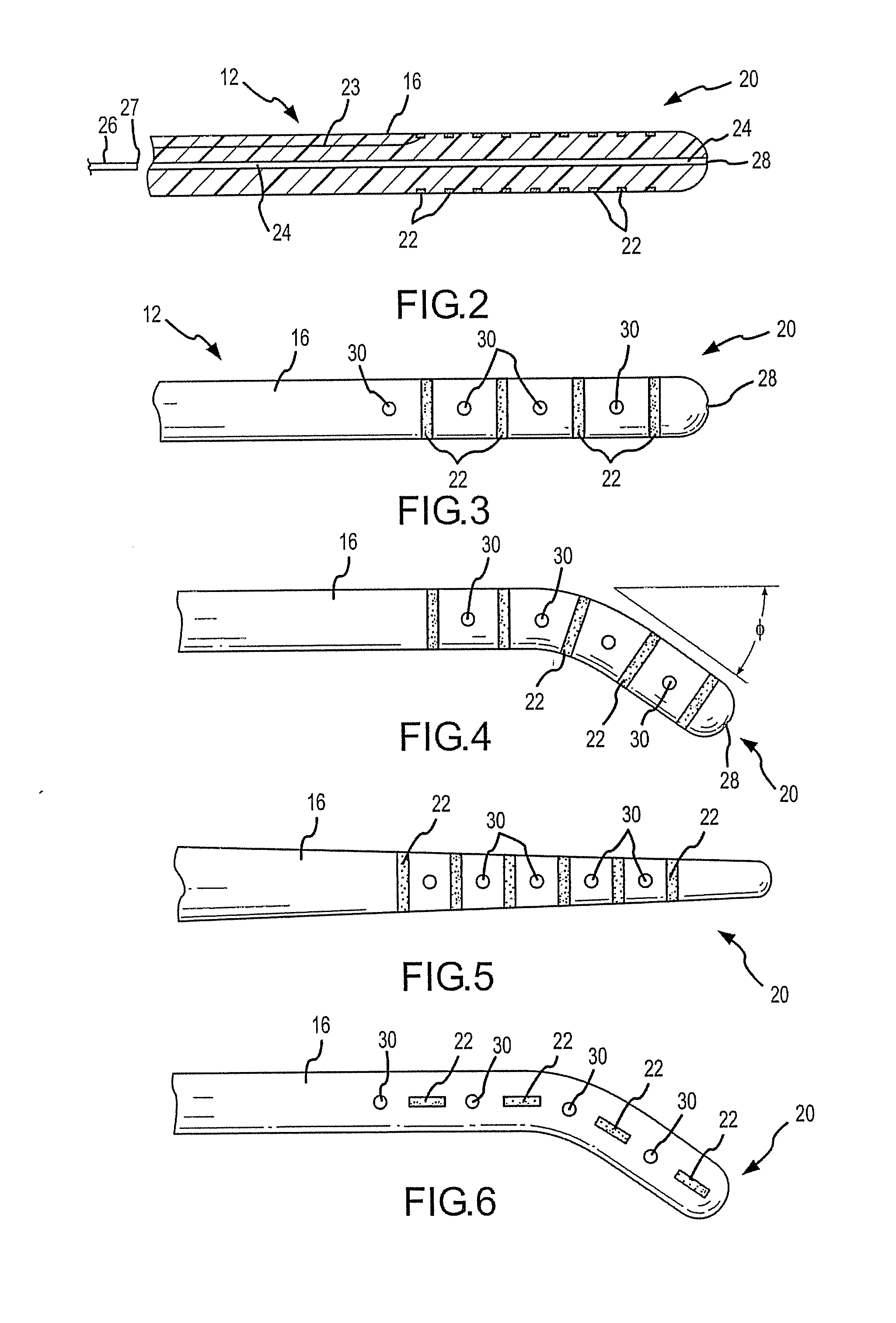

Combination Electrical Stimulating and Infusion Medical Device and Method

InactiveUS20080009927A1Prevent inadvertent bucklingAvoid displacementSpinal electrodesSurgical needlesElectricityChemical stimuli

A combined electrical and chemical stimulation lead is especially adapted for providing treatment to the spine and nervous system. The stimulation lead includes electrodes that may be selectively positioned along various portions of the stimulation lead in order to precisely direct electrical energy to ablate or electrically stimulate the target tissue. Embodiments of the stimulation lead include single or multiple lead elements. The multiple lead element embodiments can be selectively deployed to cover a targeted area. The lead may also includes central infusion passageway(s) or lumen(s) that communicates with various infusion ports spaced at selected locations along the lead to thereby direct the infusion of nutrients / chemicals to the target tissue. Some embodiments utilize a disposable sheath in combination with a reusable stimulation lead.

Owner:VILIMS BRADLEY D

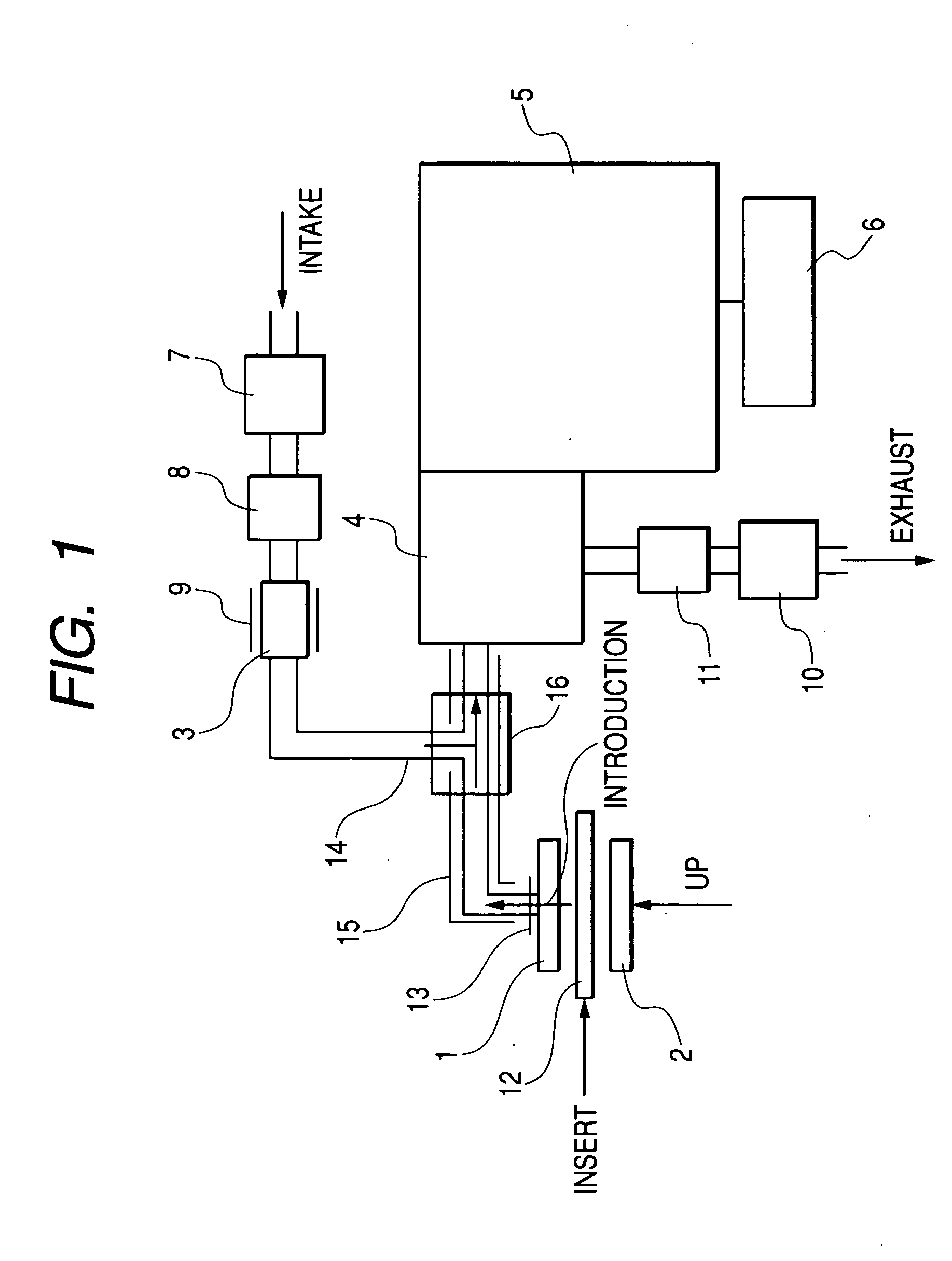

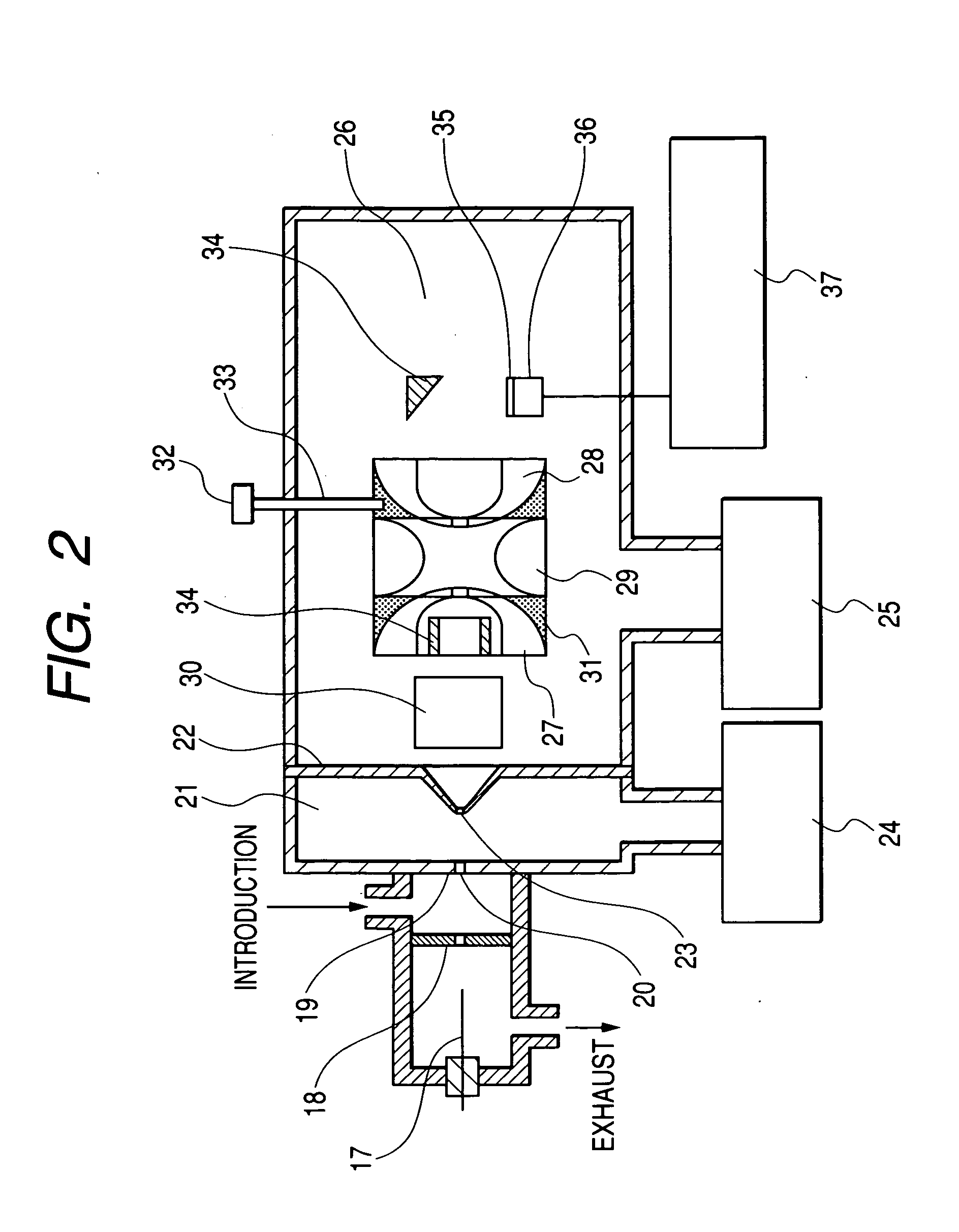

Apparatus for detecting chemical substances and method therefor

ActiveUS20050061964A1High detection sensitivityPrevent false detectionStability-of-path spectrometersAnalysis using chemical indicatorsNon detectionData treatment

An apparatus for detecting chemical substances which is high in sensitivity and selectivity is provided. An organic acid or an organic acid salt is used to generate an organic acid gas from an organic acid gas generator 3 to be mixed with a sample gas for introduction into an ion source 4 for ionization, thereby obtaining a mass spectrum by a mass analysis region 5. A data processor 6 determines the detection or non-detection of a specific m / z of an organic acid adduct ion obtained by adding a molecule generated from the organic acid to a molecule with specific m / z generated from a target chemical substance to be detected based on the obtained mass spectrum. When there is an ion peak with the m / z of the organic acid adduct ion, the presence of the target chemical substance to be detected is determined, and an alarm is sounded. False detection can be prevented.

Owner:HITACHI LTD

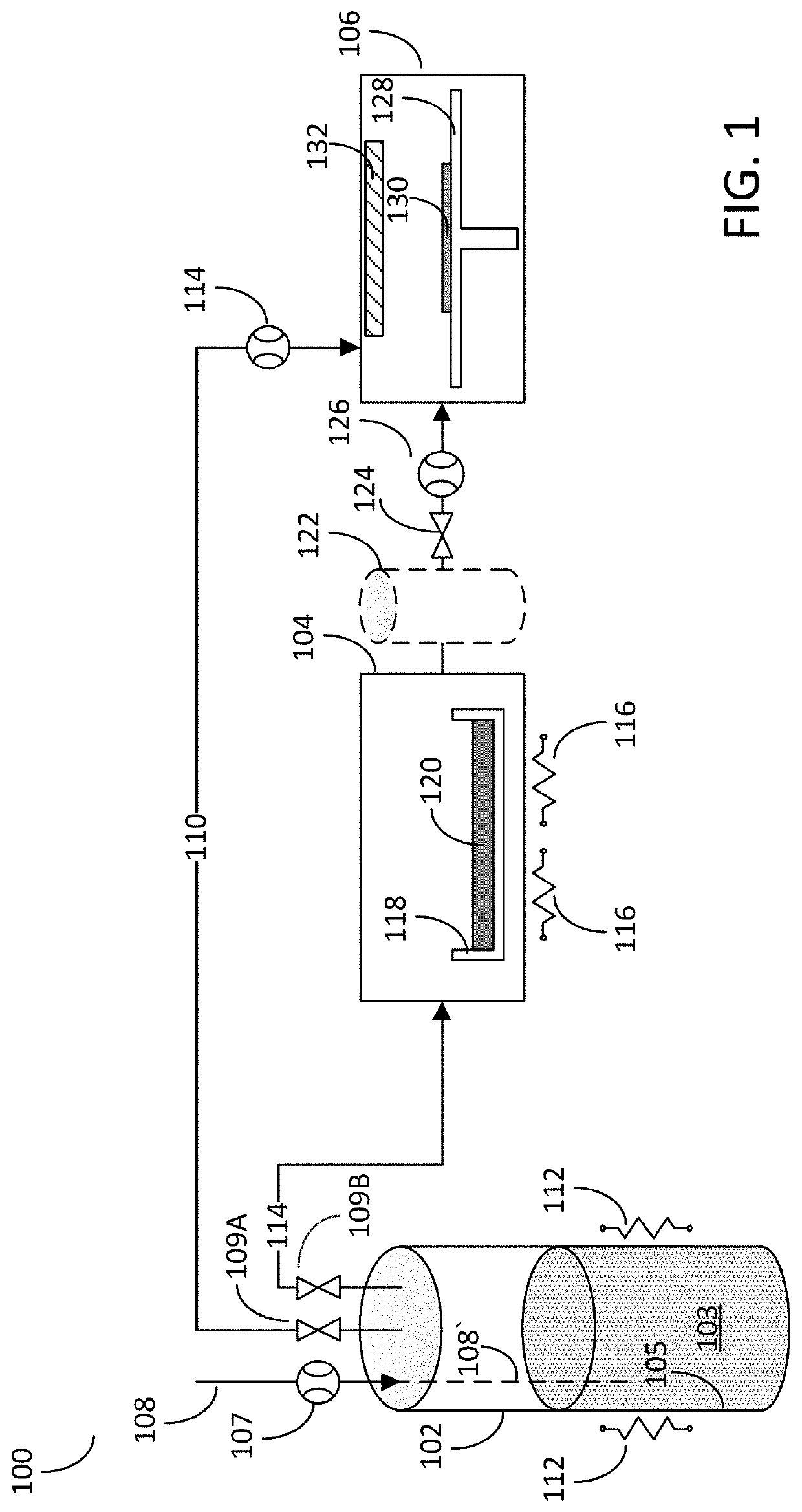

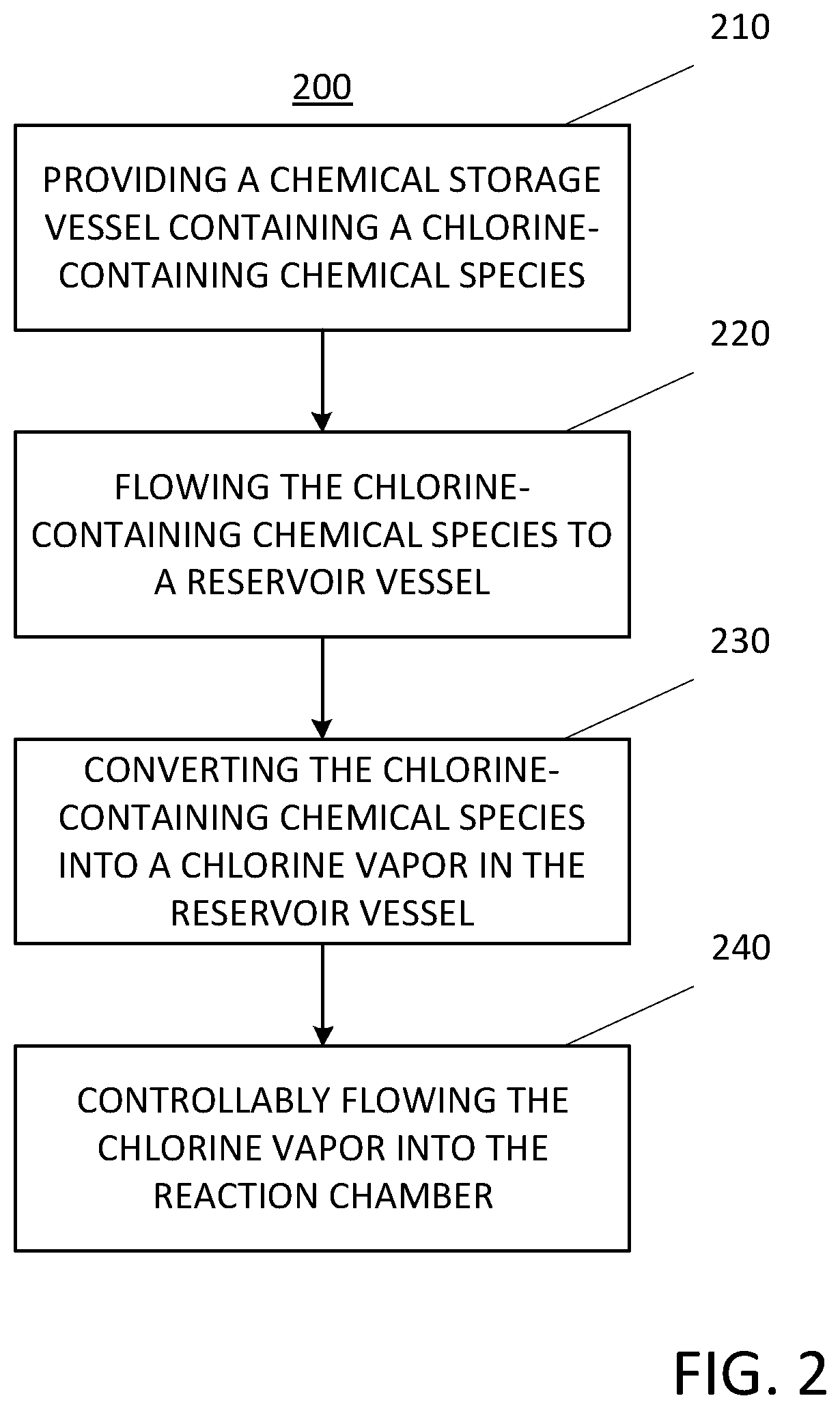

Chemical dispensing apparatus and methods for dispensing a chemical to a reaction chamber

ActiveUS20200279758A1Electric discharge tubesSemiconductor/solid-state device manufacturingChemical storageChemical species

A chemical dispensing apparatus for providing a chlorine vapor to a reaction chamber is disclosed. The chemical dispensing apparatus may include: a chemical storage vessel configured for storing a chlorine-containing chemical species, a reservoir vessel in fluid communication with the chemical storage vessel, the reservoir vessel configured for converting the chlorine-containing chemical species to the chlorine vapor, and a reaction chamber in fluid communication with the reservoir vessel. Methods for dispensing a chlorine vapor to a reaction chamber are also disclosed.

Owner:ASM IP HLDG BV

Chemical vapor deposition apparatuses and deposition methods

InactiveUS20020129768A1Polycrystalline material growthFrom chemically reactive gasesCompound (substance)Chemical vapor deposition

A chemical vapor deposition (CVD) apparatus includes a deposition chamber defined partly by a chamber wall. The chamber wall has an innermost surface inside the chamber and an outermost surface outside the chamber. The apparatus further includes a valve body having a seat between the innermost and outermost surfaces of the chamber wall. The chamber wall can be a lid and the valve can include a portion of the lid as at least a part of the seat. The valve body can include at least a part of a valve housing between the innermost and outermost surfaces of the chamber wall. Such a valve body can even include a portion of the chamber wall as at least part of the valve housing. The deposition apparatus can further include at least a part of a process chemical inlet to the valve body between the innermost and outermost surfaces of the chamber wall. In one example, the chamber wall can form at least a part of the chemical inlet. A deposition method includes temporarily isolating a process chemical supply line from a deposition chamber at a chamber wall of the deposition chamber. While isolated at the chamber wall, the supply line can be filled to a first pressure with chemical through a supply valve upstream from the chamber wall. The chemical can be released from the supply line into the deposition chamber at the chamber wall. The supply line can be again temporarily isolated from the deposition chamber at the chamber wall.

Owner:MICRON TECH INC

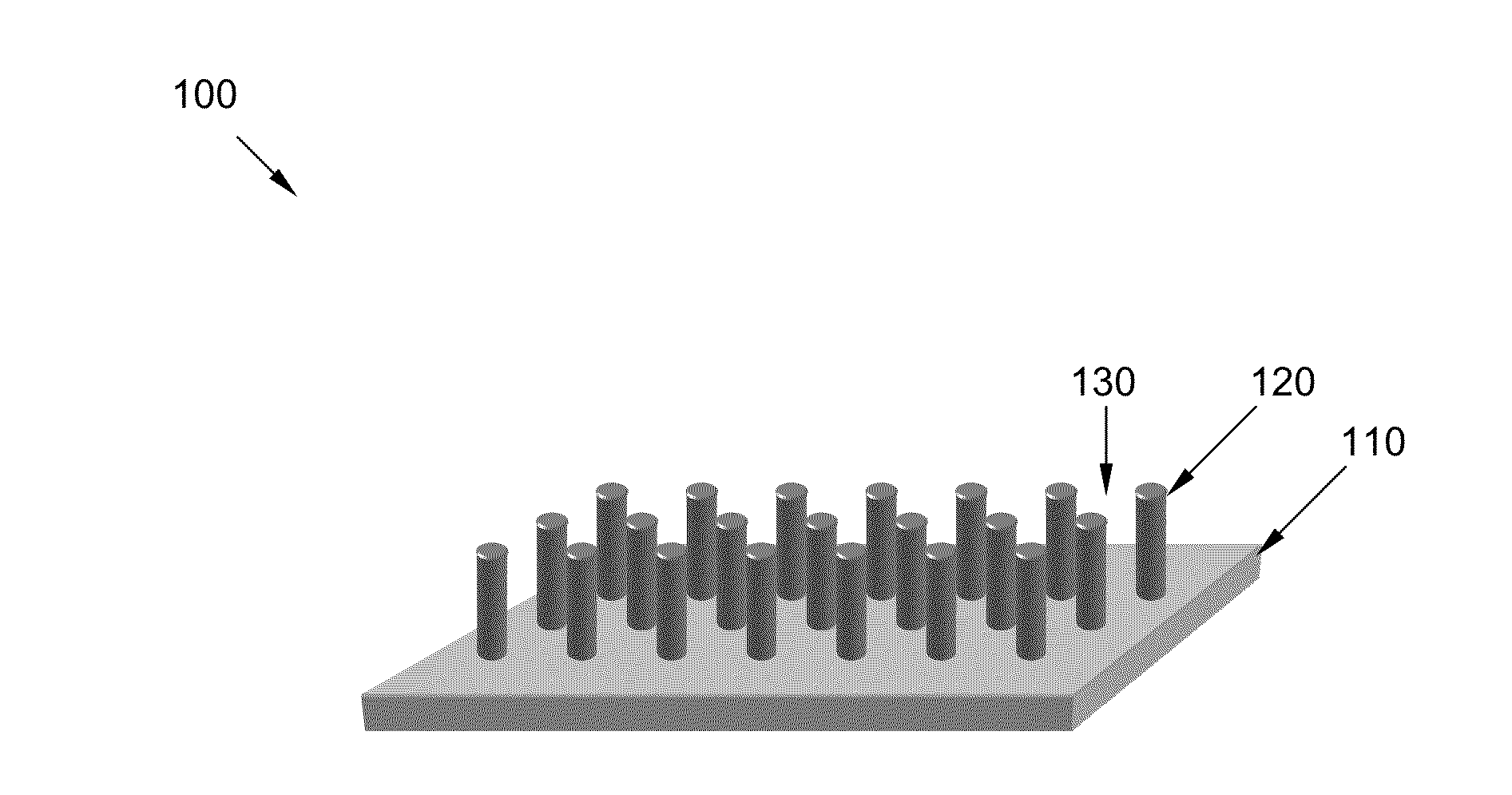

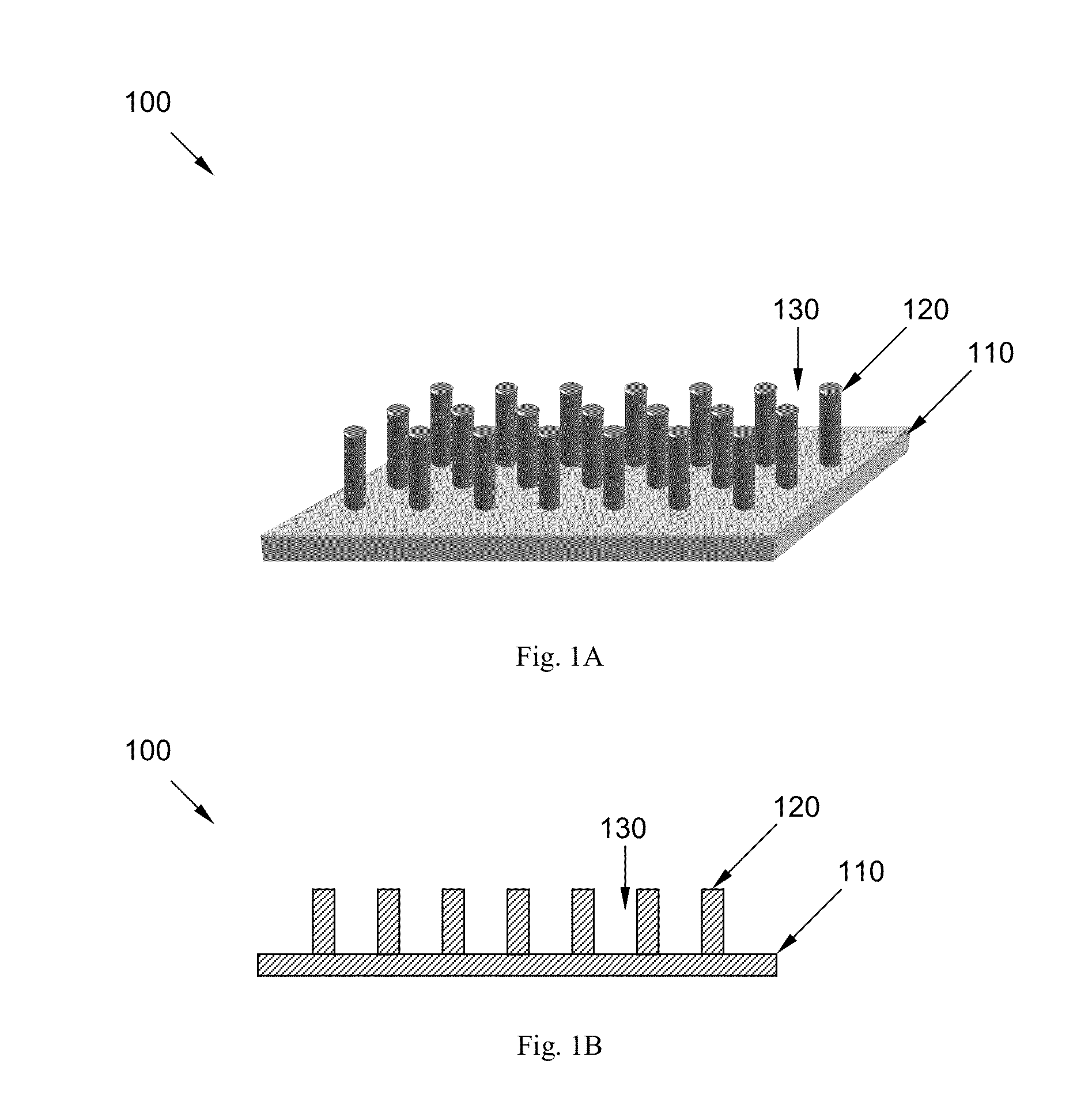

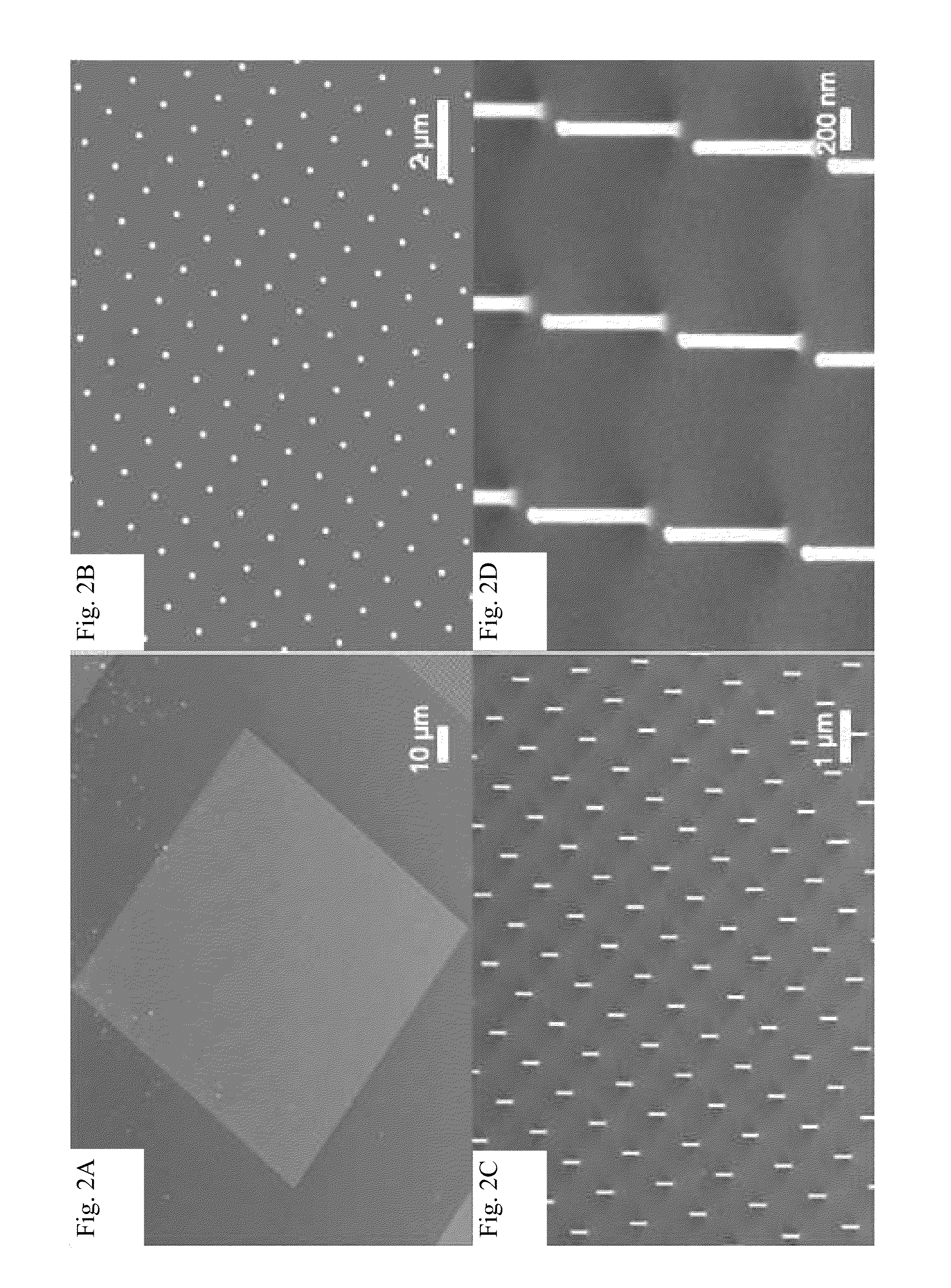

Light absorption and filtering properties of vertically oriented semiconductor nano wires

InactiveUS9000353B2Optical radiation measurementMaterial nanotechnologyPhotovoltaic detectorsPhotodetector

A nanowire array is described herein. The nanowire array comprises a substrate and a plurality of nanowires extending essentially vertically from the substrate; wherein: each of the nanowires has uniform chemical along its entire length; a refractive index of the nanowires is at least two times of a refractive index of a cladding of the nanowires. This nanowire array is useful as a photodetector, a submicron color filter, a static color display or a dynamic color display.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

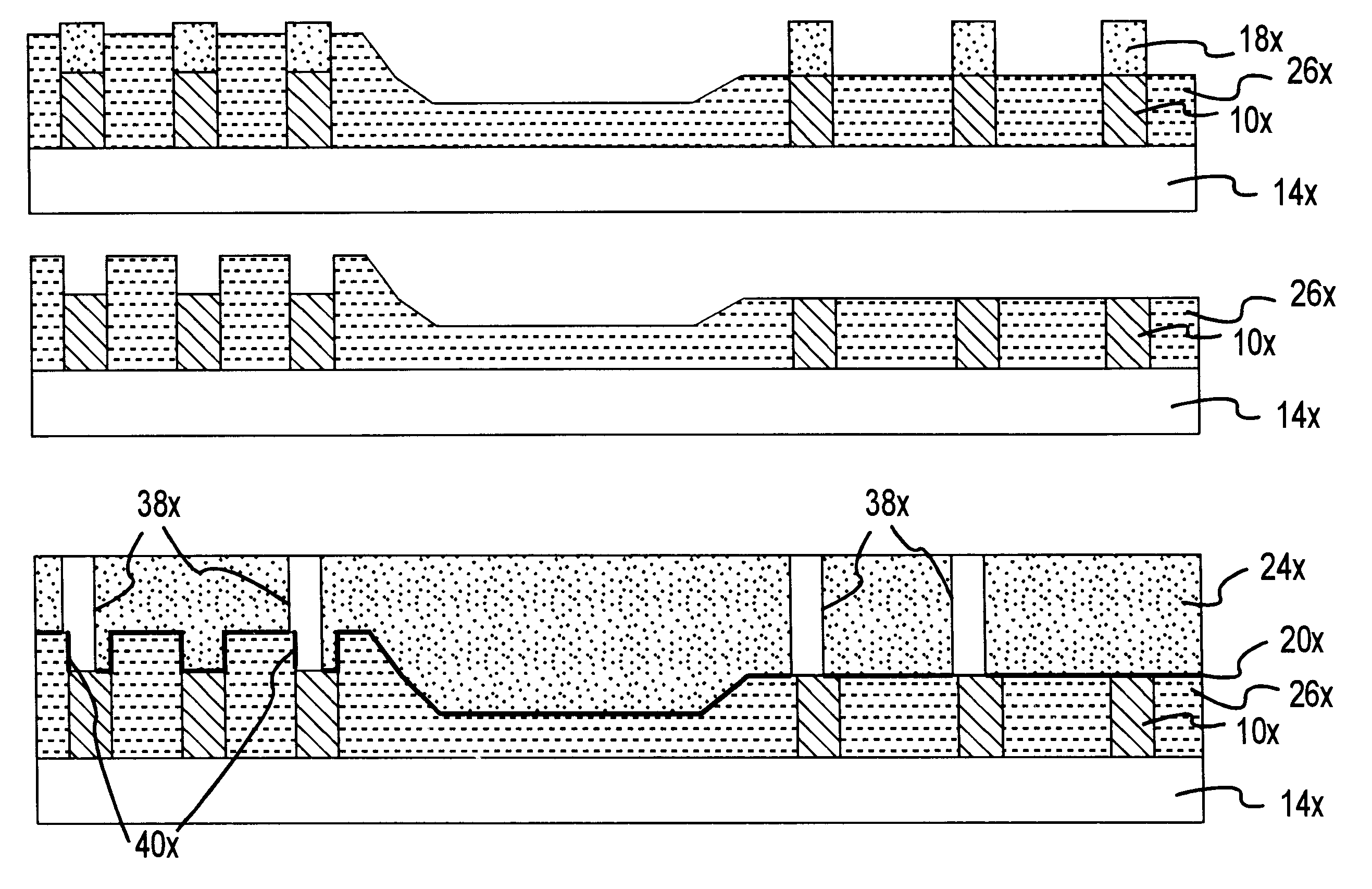

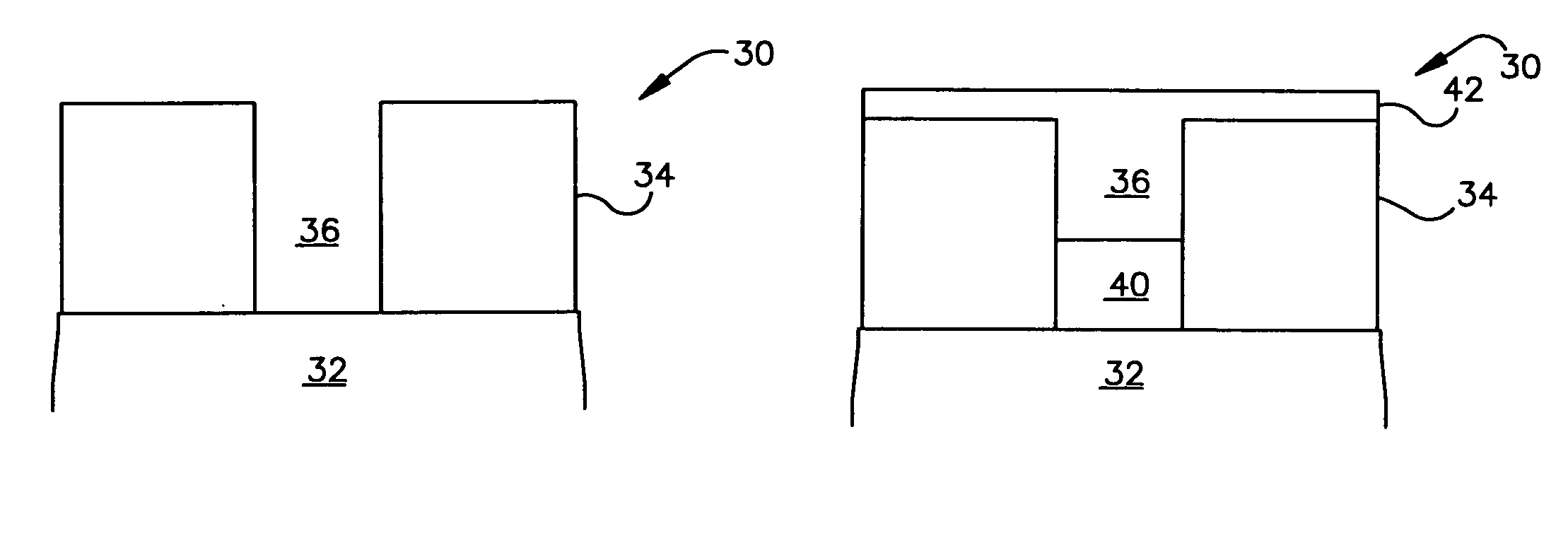

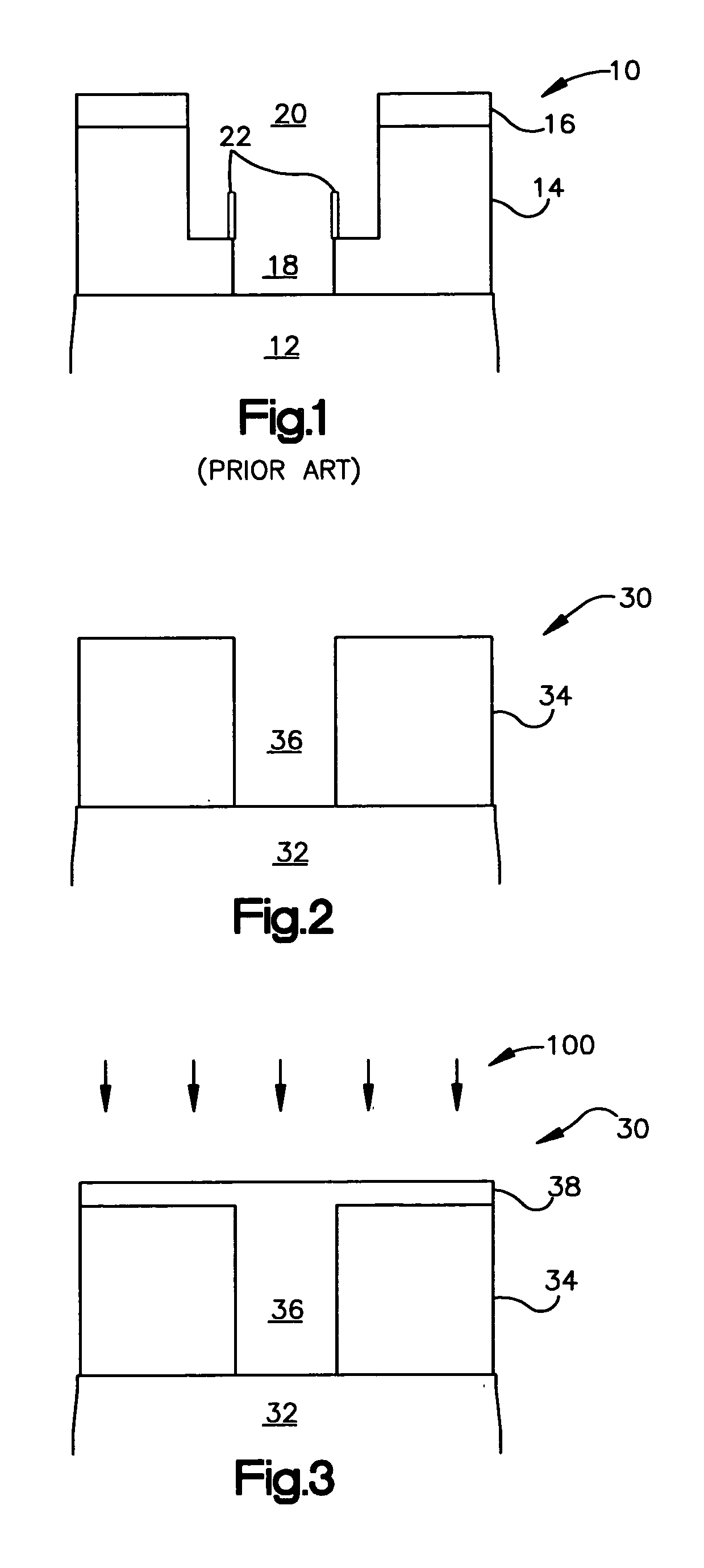

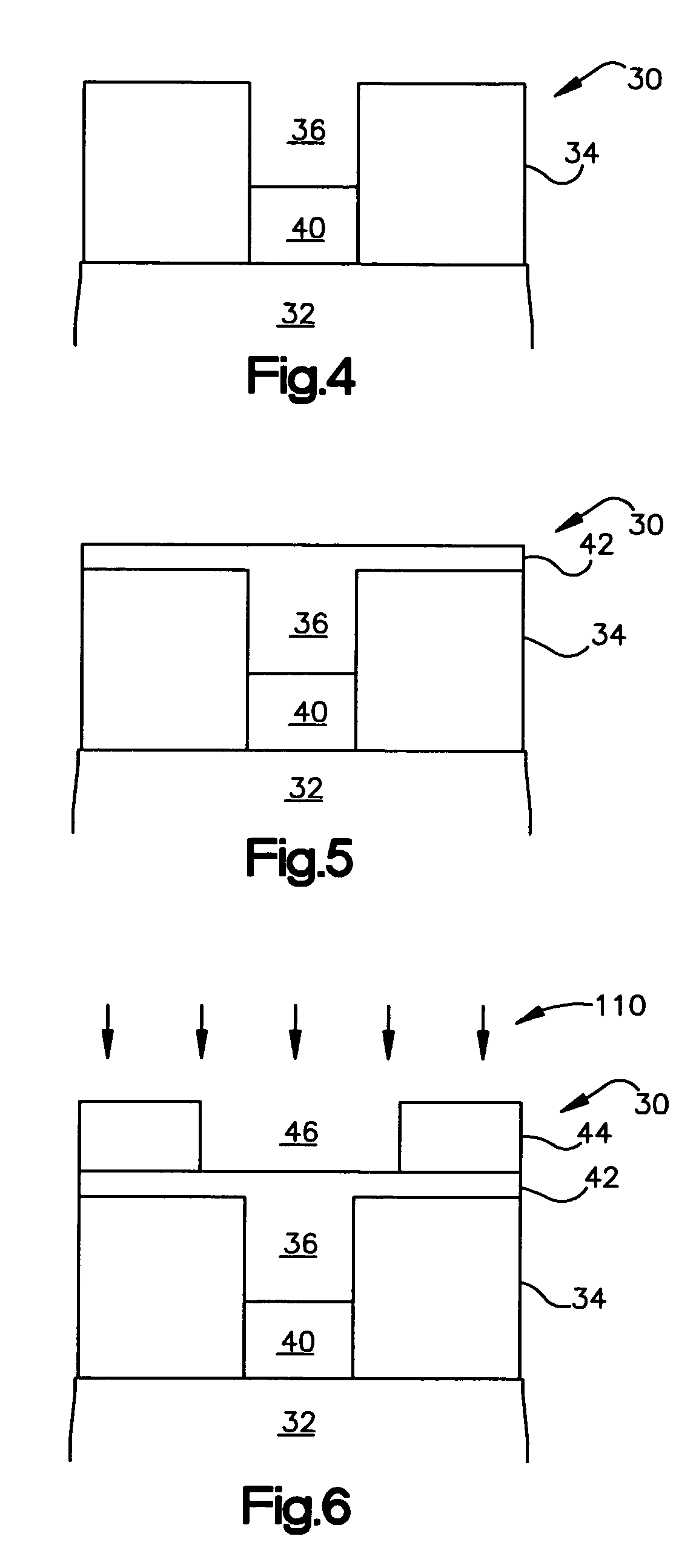

Method of eliminating etch ridges in a dual damascene process

ActiveUS20060024956A1Inhibition formationSemiconductor/solid-state device manufacturingAnti-reflective coatingFilling materials

A dual damascene process employs a via fill material (38) with an etch rate that is within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which a trench (48) and via (50) are being formed. In one embodiment, an organic via fill material plug (40) is employed in conjunction with a bottom anti-reflective coating (BARC) material layer (42). Both the organic via fill material plug (40) and the BARC material layer (42) are selected to have a material with an etch rate that within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which the trench (48) and via (50) are formed.

Owner:TEXAS INSTR INC

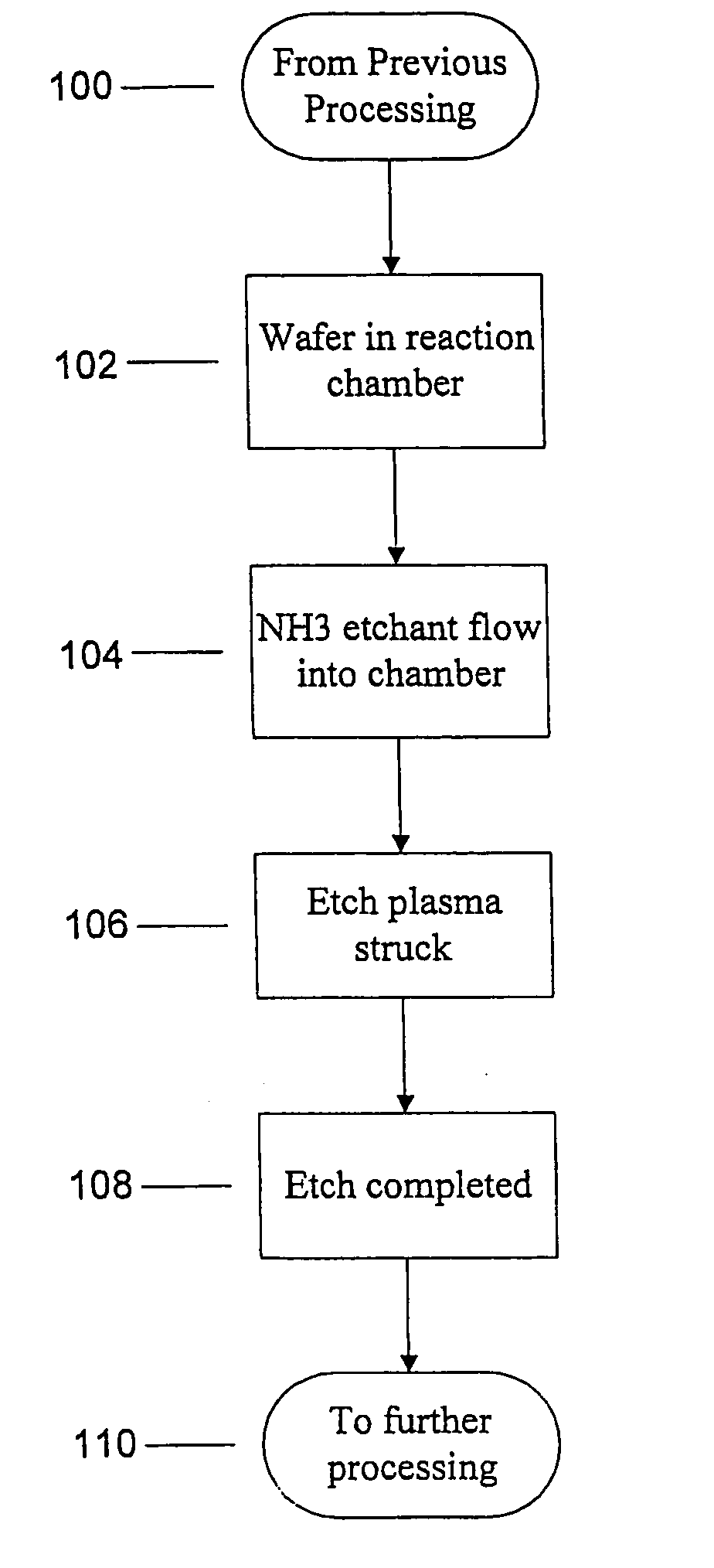

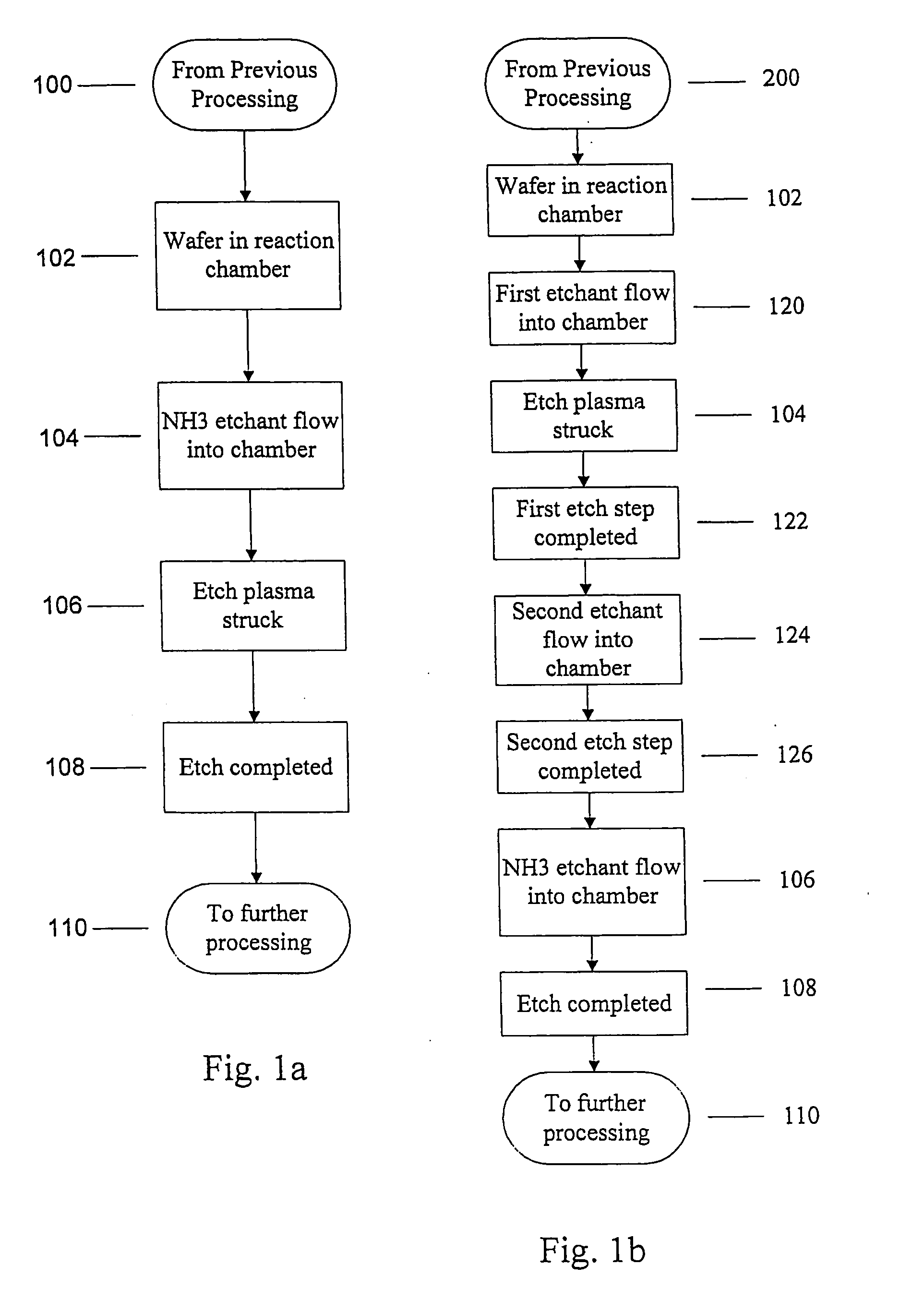

Use of ammonia for etching organic low-k dielectrics

InactiveUS20050003676A1Increase etch rateHigh selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingProcess chemistryElectricity

Method for etching organic low-k dielectric using ammonia, NH3, as an active etchant. Processes using ammonia results in at least double the etch rate of organic low-k dielectric materials than processes using N2 / H2 chemistries, at similar process conditions. The difference is due to the much lower ionization potential of NH3 versus N2 in the process chemistry, which results in significantly higher plasma densities and etchant concentrations at similar process conditions.

Owner:LAM RES CORP

Process for preparing materials for extraction

InactiveUS20060122410A1Improve extraction efficiencyQuality improvementFungiUnicellular algaeArachidonic acid supplementationFermentation

The present invention relates to a process for preparing a biomass, such as from a microbial fermentation, for an extraction process to separate desired chemicals, nutritional products, bioactive components, proteins, carbohydrates, and lipids, from the biomass. Particularly preferred substances to extract include docosahexaenoic acid, docosapentaenoic acid, and arachidonic acid. The present invention also includes extracting the prepared biomass. Biomasses to be treated in accordance with the methods of the invention include plant, animal, and microbial biomass, particularly a microorganism such as Crypthecodinium cohnii and a fungus such as Mortierella alpina.

Owner:MARTEK BIOSCIENCES CORP

Systems and methods for managing the development and manufacturing of a drug

InactiveUS20070192715A1Easy to optimizeManagement complexityComputer-assisted medical data acquisitionTechnology managementGraphicsChemical reaction

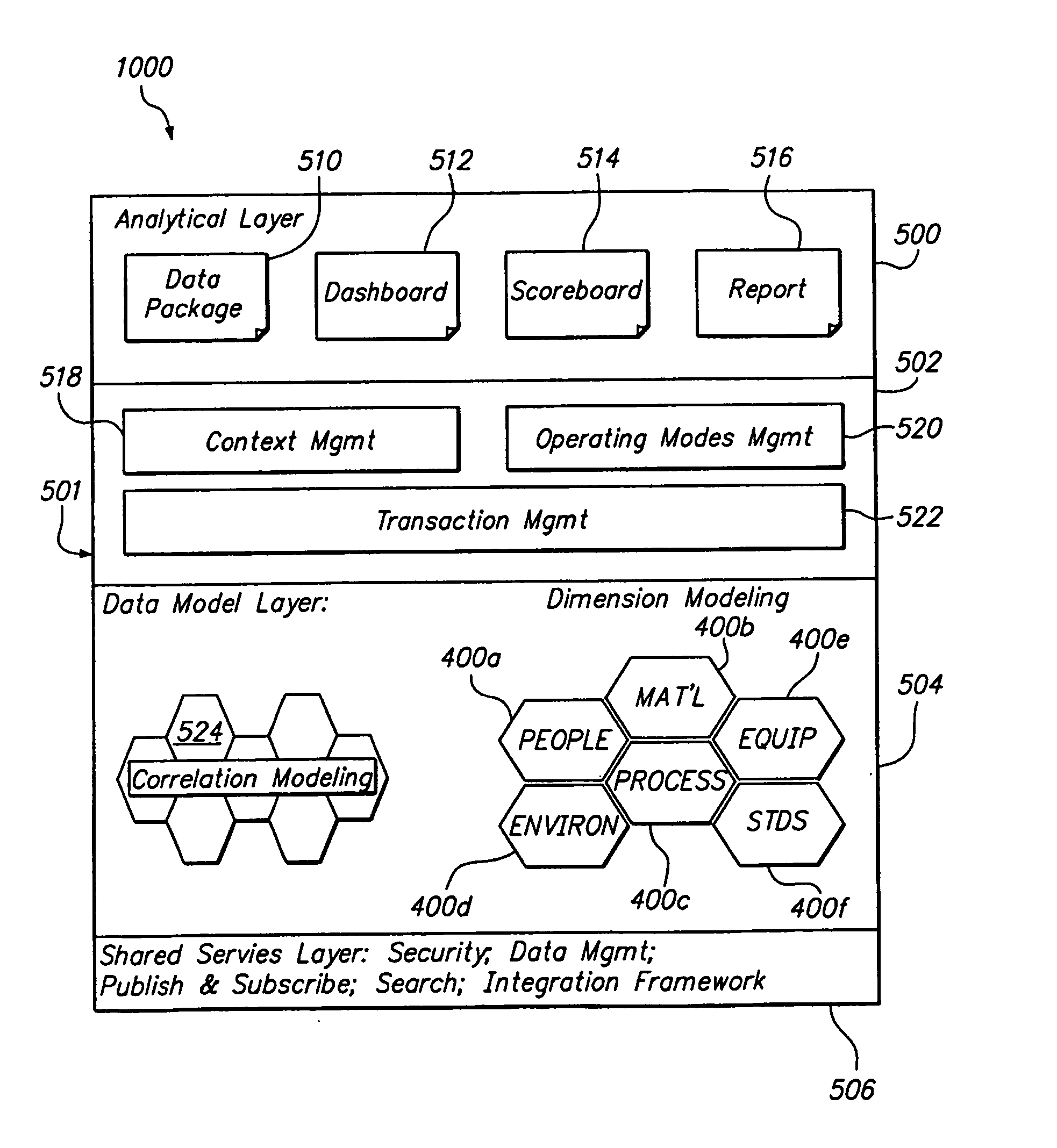

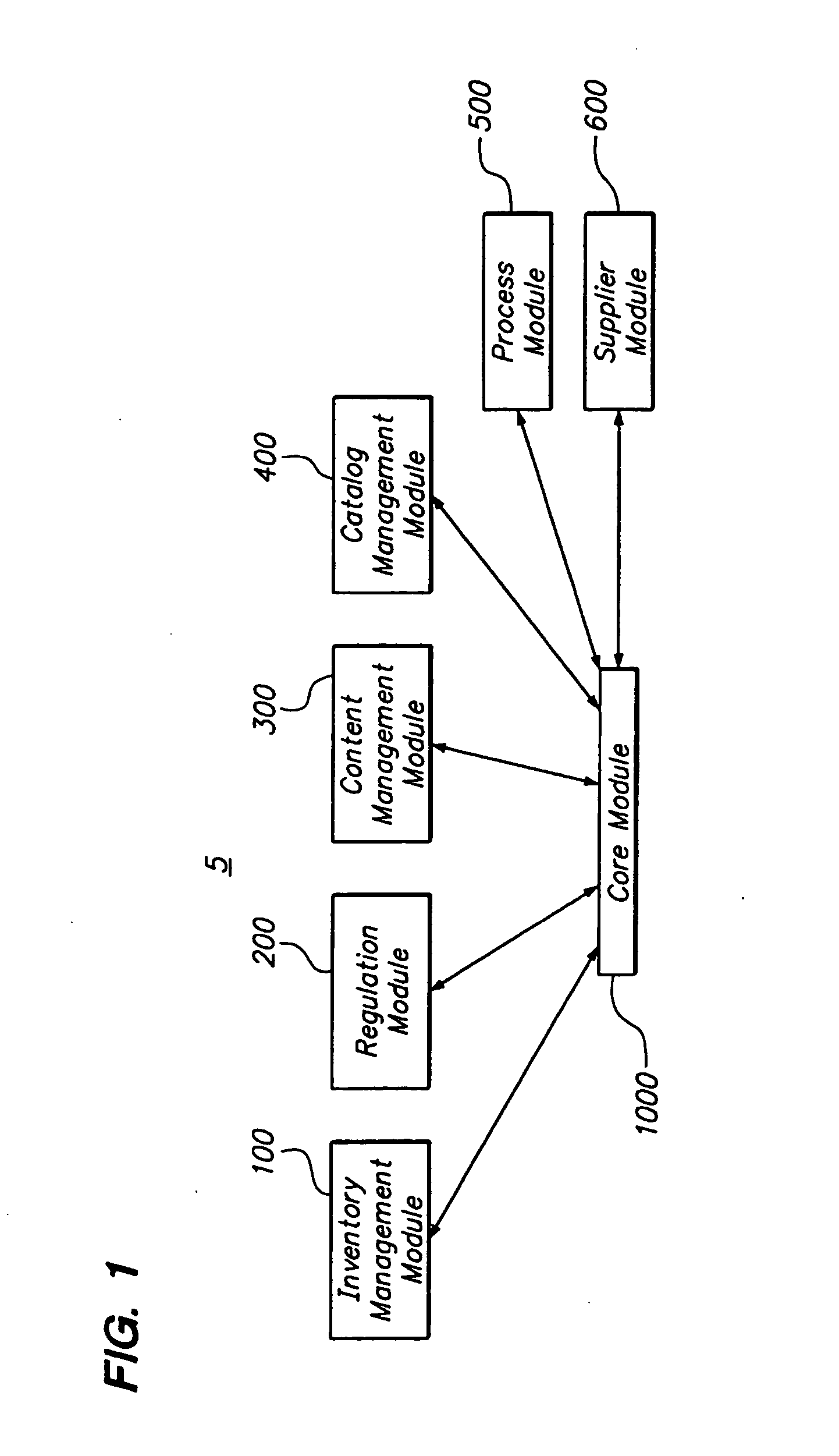

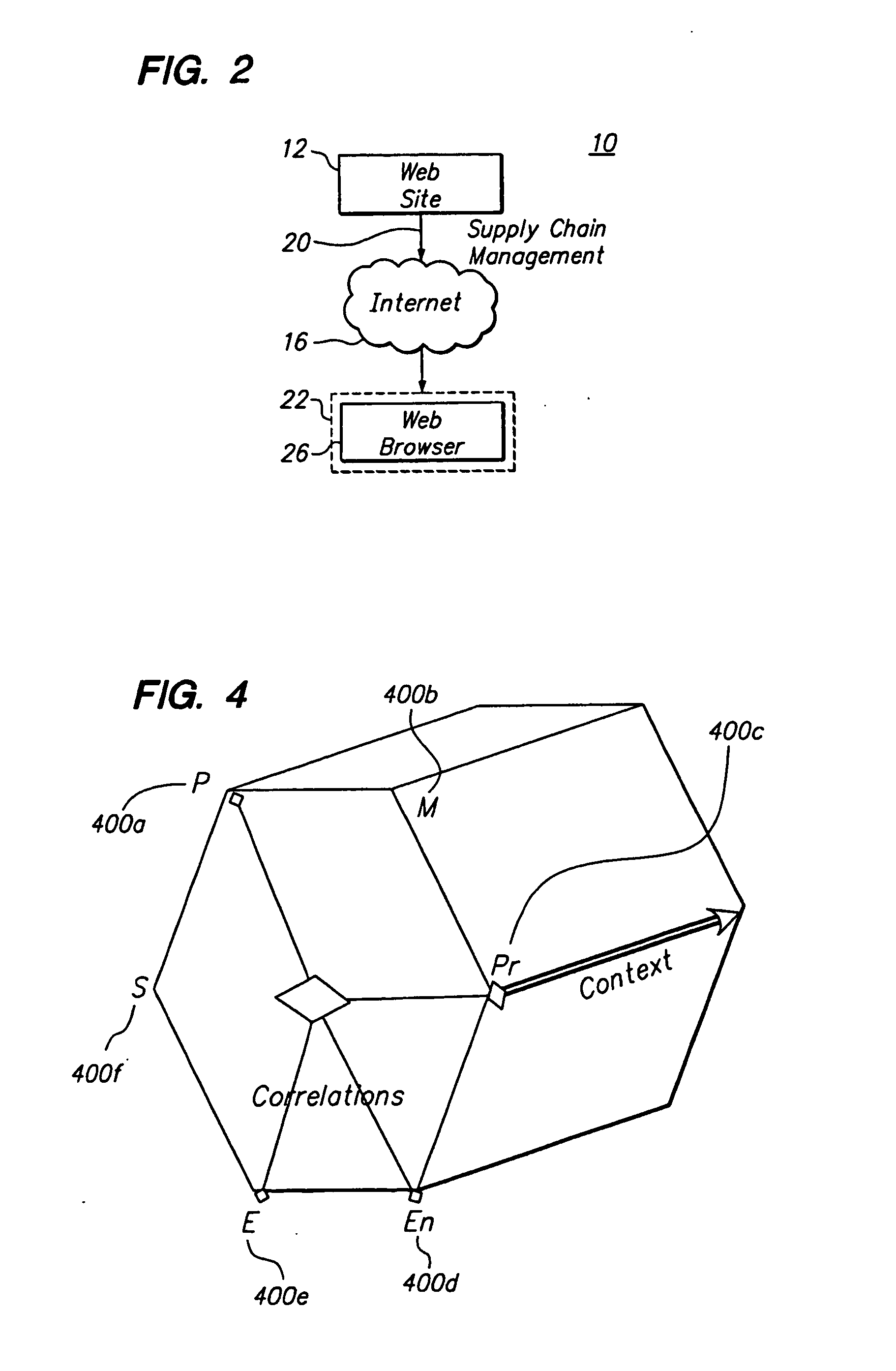

Graphical user interfaces, computer readable media, and computer systems for monitoring a chemical process. An administration module sets a plurality of user preferences associated with the chemical process. A people management module defines a user role in the chemical process. An organization module defines an organizational structure of an organization that runs the chemical process. An equipment module defines equipment used in the chemical process. A material module controls a chemical used in the chemical process. A process module defines a chemical reaction in the chemical process.

Owner:ORACLE INT CORP

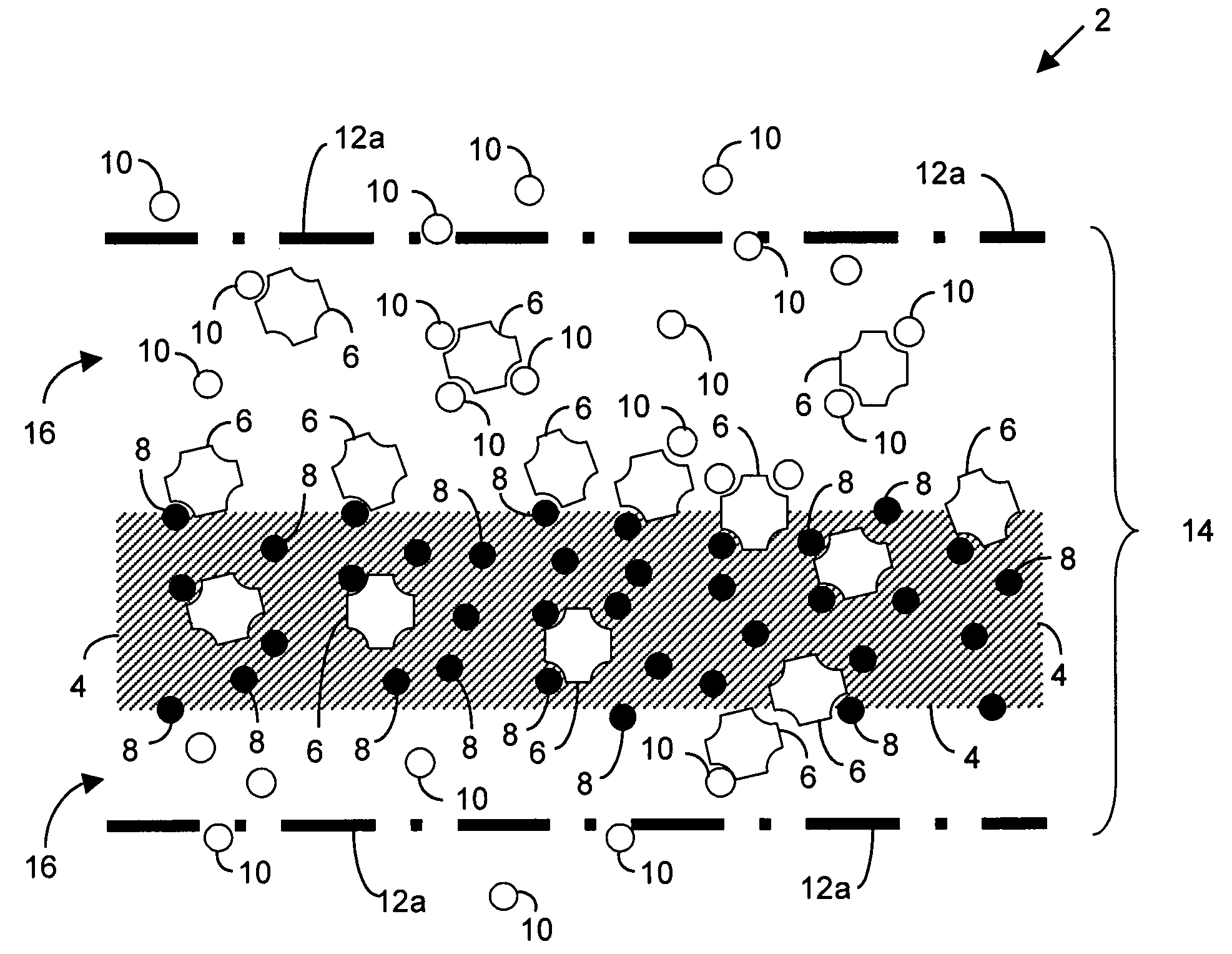

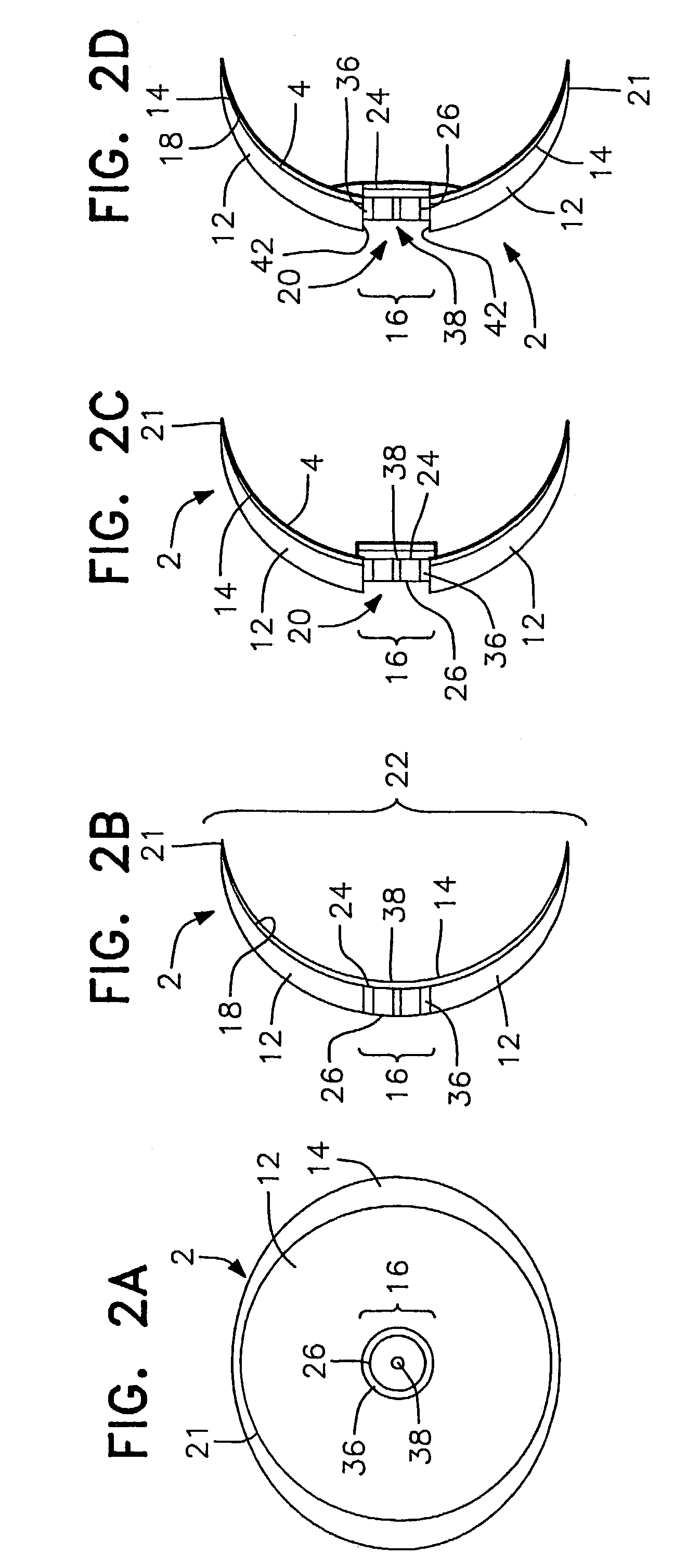

System, device and method for determining the concentration of an analyte

There are many inventions described and illustrated herein. In one aspect, the present invention is a system, a device and a method for sensing the concentration of an analyte in a fluid (for example, a fluid sample) or matrix. The analyte may be glucose or other chemical of interest. The fluid or matrix may be, for example, the fluid or matrix in the body of an animal (for example, human), or any other suitable fluid or matrix in which it is desired to know the concentration of an analyte. In one embodiment, the invention is a system and / or device that includes one or more layers having a plurality of analyte-equivalents and mobile or fixed receptor molecules with specific binding sites for the analyte-equivalents and analytes under analysis (for example, glucose). The receptor molecules, when exposed to or in the presence of analyte (that resides, for example, in a fluid in an animal), bind with the analyte (or vice versa). As such, some or all (or substantially all) of the receptor molecules within a given layer may bind with the analyte, which results in a change in the optical properties of one or more of the layers. These layer(s) may be examined or interrogated, via optical techniques, whereby the optical response of the layers and / or, in particular, the substance within the layer(s), may be measured, evaluated and / or analyzed.

Owner:BIO TEX LTD INC

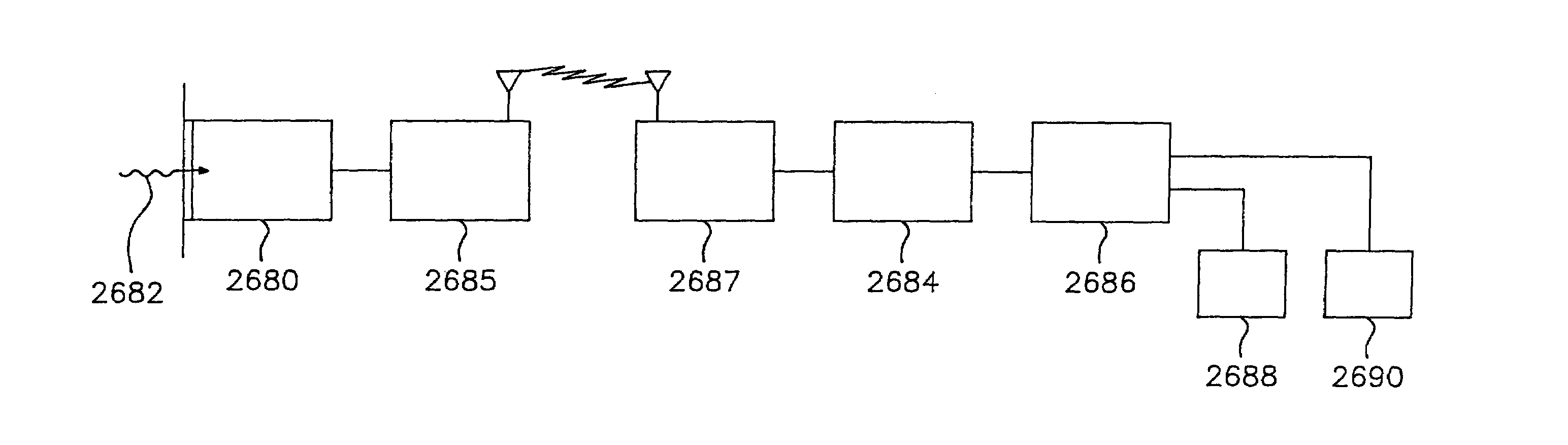

Noninvasive measurement of chemical substances

InactiveUS7041063B2High densityEarly diagnosisOrganic active ingredientsHeart defibrillatorsConjunctivaInfrared

Utilization of a contact device placed on the eye in order to detect physical and chemical parameters of the body as well as the non-invasive delivery of compounds according to these physical and chemical parameters, with signals being transmitted continuously as electromagnetic waves, radio waves, infrared and the like. One of the parameters to be detected includes non-invasive blood analysis utilizing chemical changes and chemical products that are found in the conjunctiva and in the tear film. A transensor mounted in the contact device laying on the cornea or the surface of the eye is capable of evaluating and measuring physical and chemical parameters in the eye including non-invasive blood analysis. The system utilizes eye lid motion and / or closure of the eye lid to activate a microminiature radio frequency sensitive transensor mounted in the contact device. The signal can be communicated by wires or radio telemetered to an externally placed receiver. The signal can then be processed, analyzed and stored. Several parameters can be detected including a complete non-invasive analysis of blood components, measurement of systemic and ocular blood flow, measurement of heart rate and respiratory rate, tracking operations, detection of ovulation, detection of radiation and drug effects, diagnosis of ocular and systemic disorders and the like.

Owner:GEELUX HLDG LTD

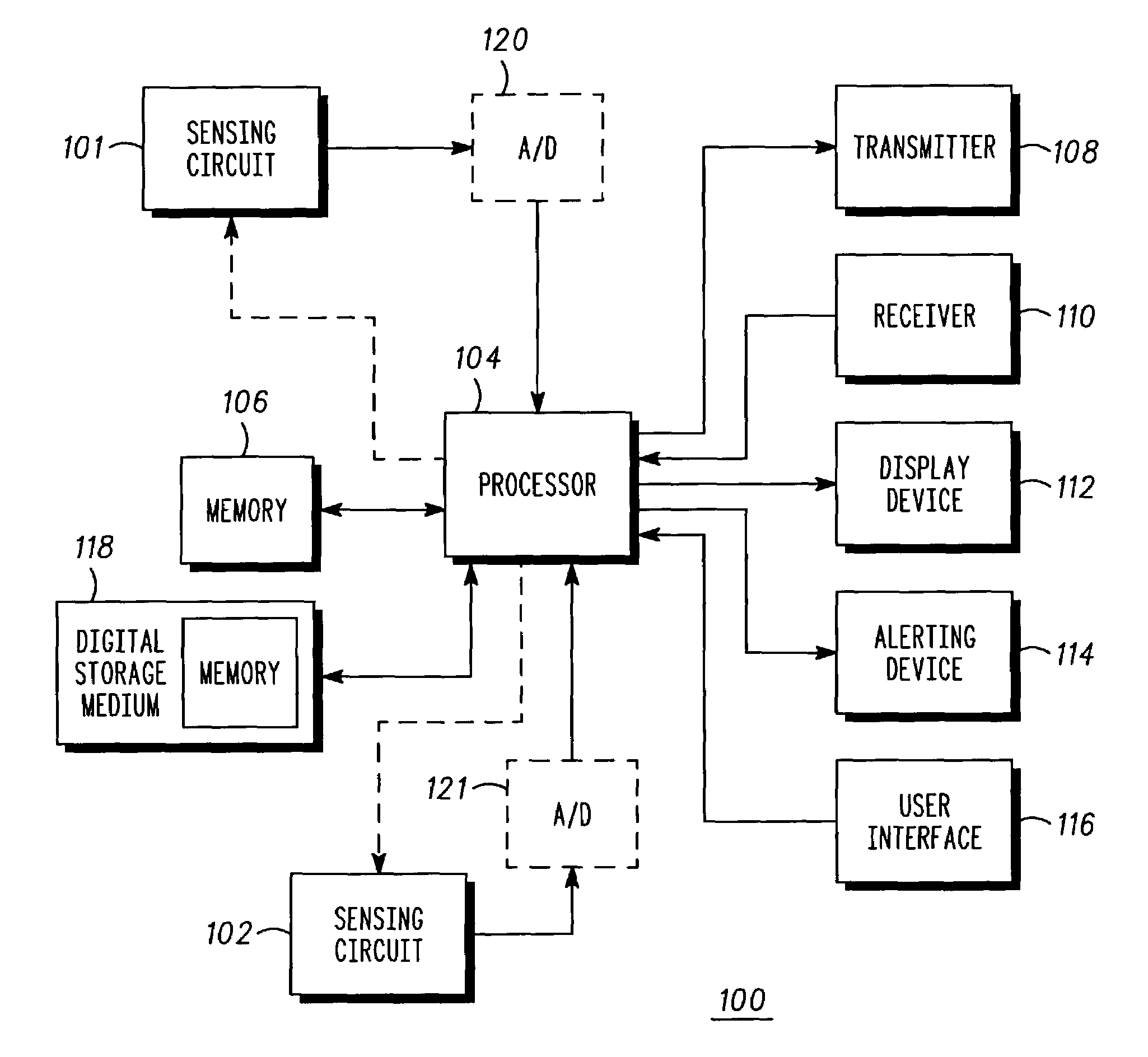

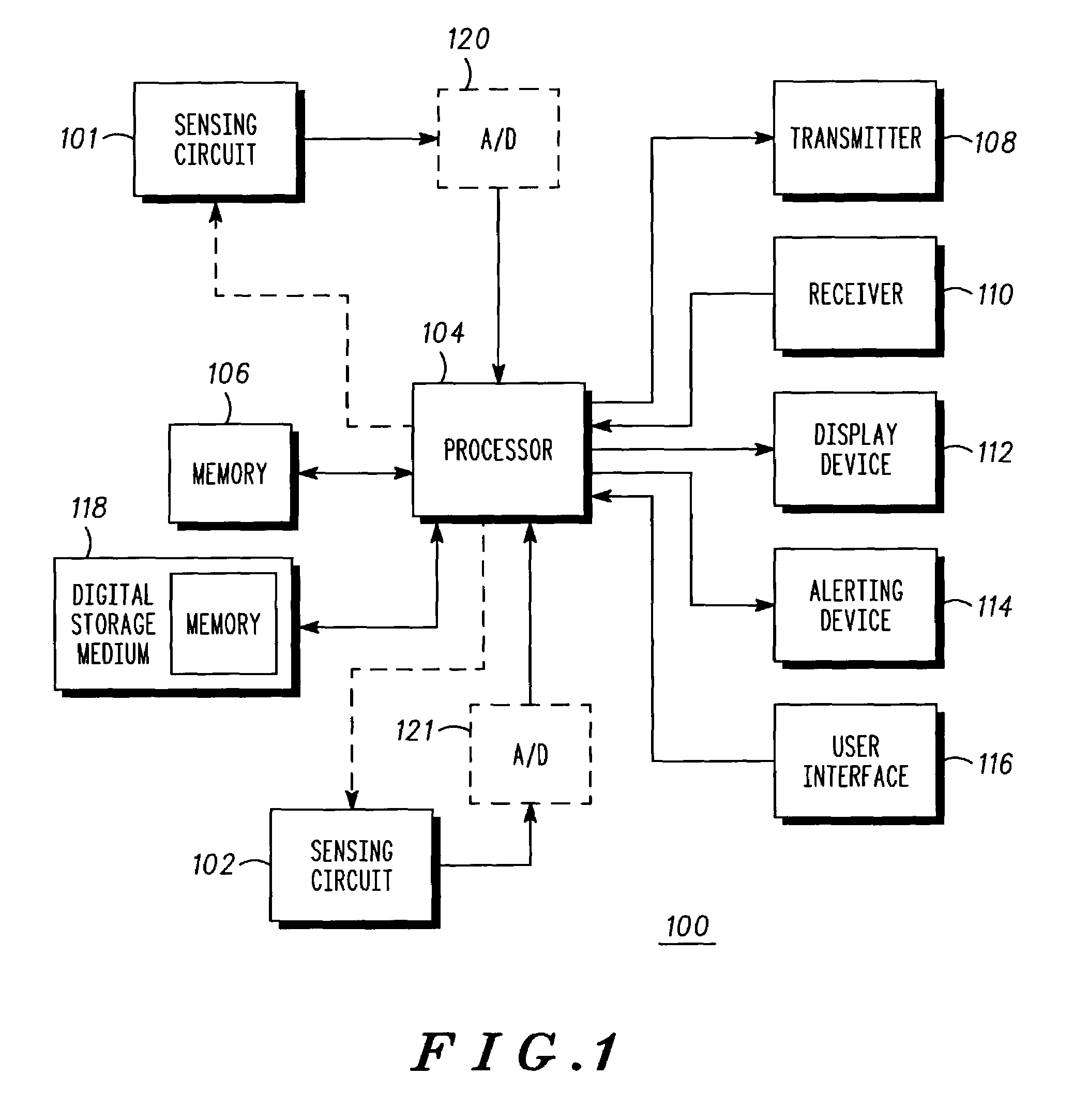

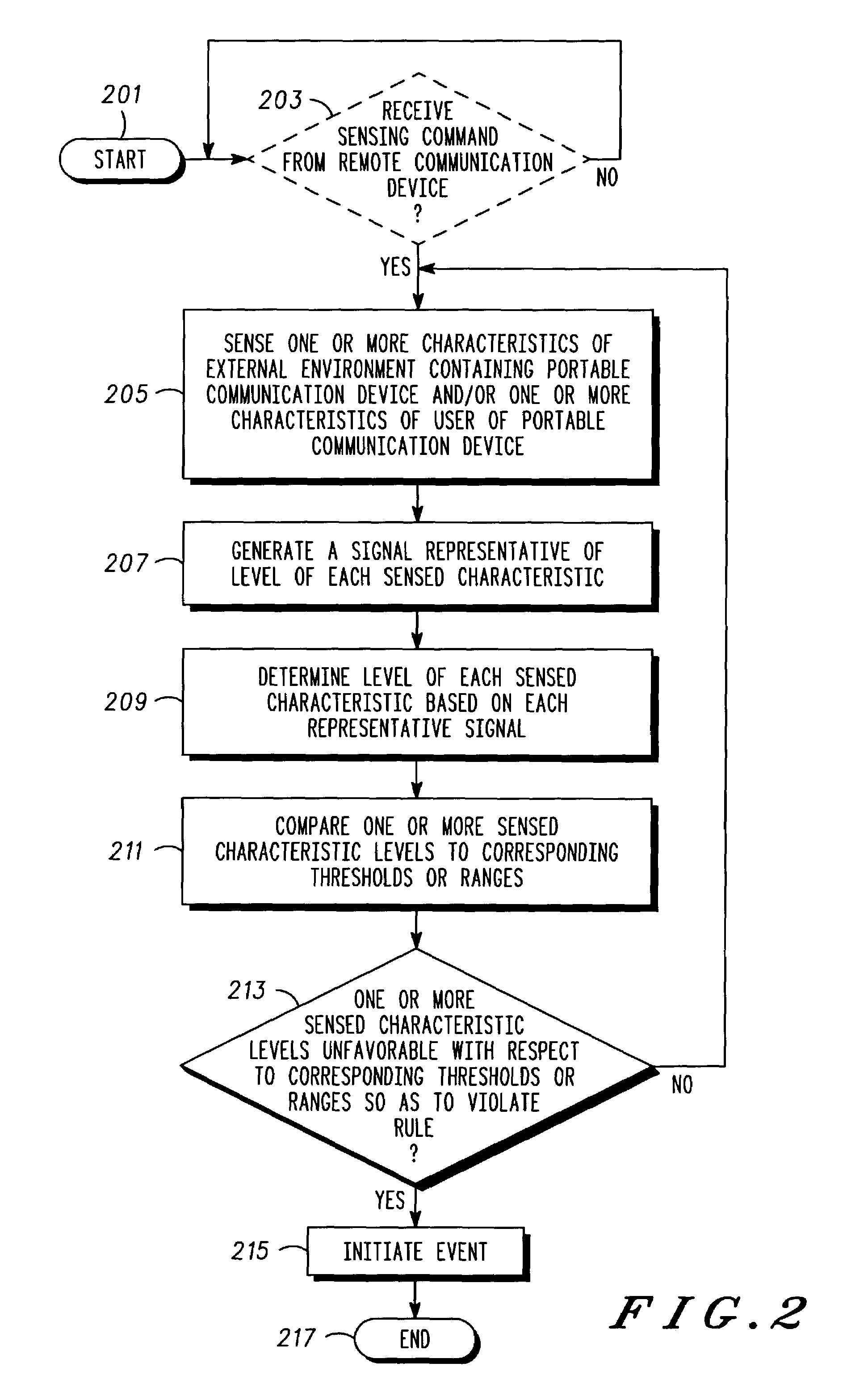

Portable communication device and corresponding method of operation

InactiveUS6992580B2Electric signal transmission systemsDiagnostic recording/measuringCompound (substance)Long-haul communications

A portable communication device (100) includes at least one sensing circuit (101) and a processor (104), and operates in accordance with a corresponding method of operation. The sensing circuit detects (205) either a characteristic of an external environment containing the portable communication device (e.g., a chemical in the air or acceleration of the device) or a characteristic of the portable communication device user (e.g., heart rate or blood sugar content), and generates a signal (207) representative of a feature of the sensed characteristic. The processor receives the signal and initiates an event based at least on the feature of the sensed characteristic as represented by the signal. Events include, but are not limited to, one or more of the following: alerting the device user, transmitting a signal (e.g., an emergency call) to a remote communication device, re-sensing the characteristic or sensing another characteristic, and modifying a setting or profile of the device.

Owner:GOOGLE TECH HLDG LLC

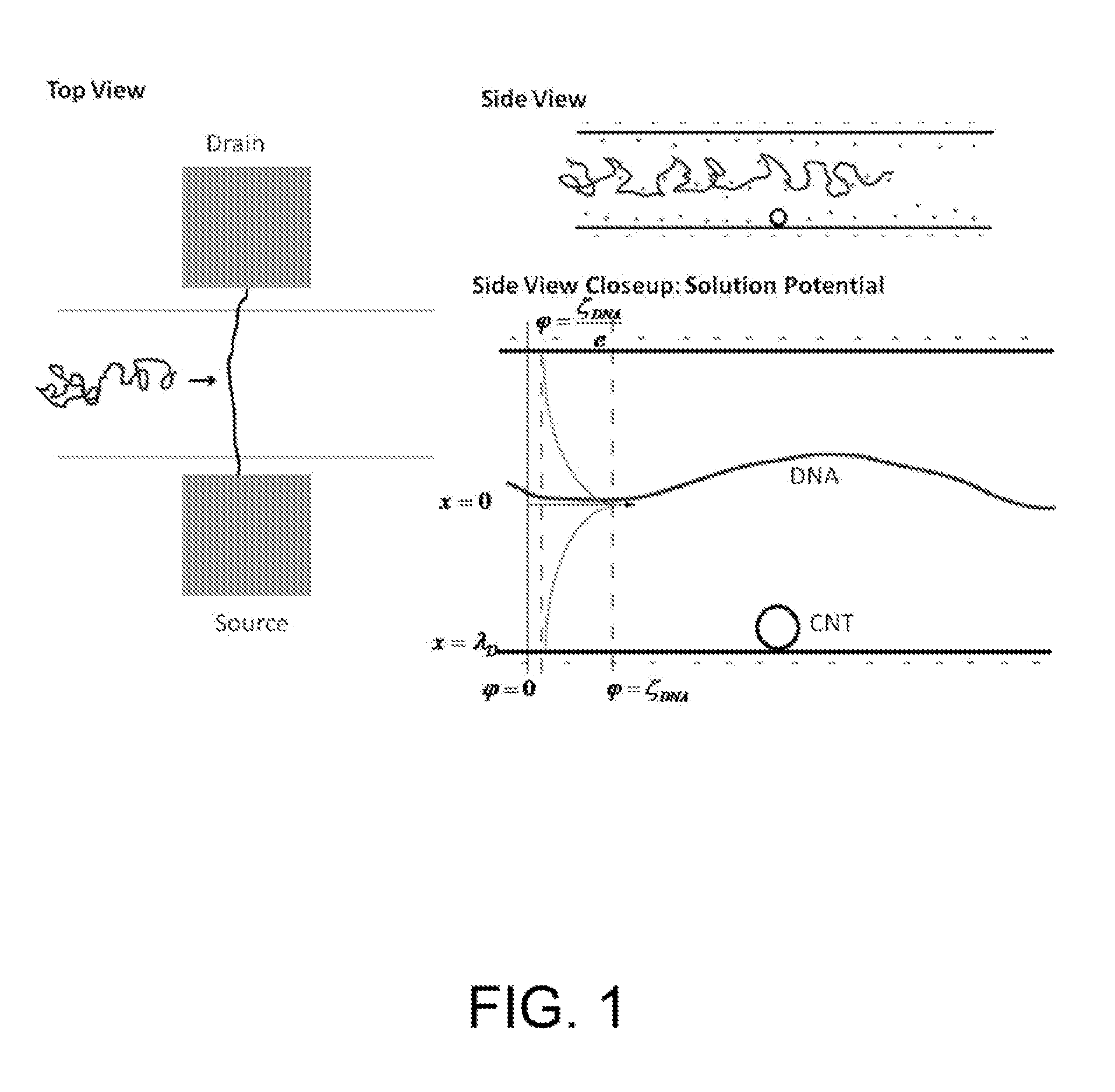

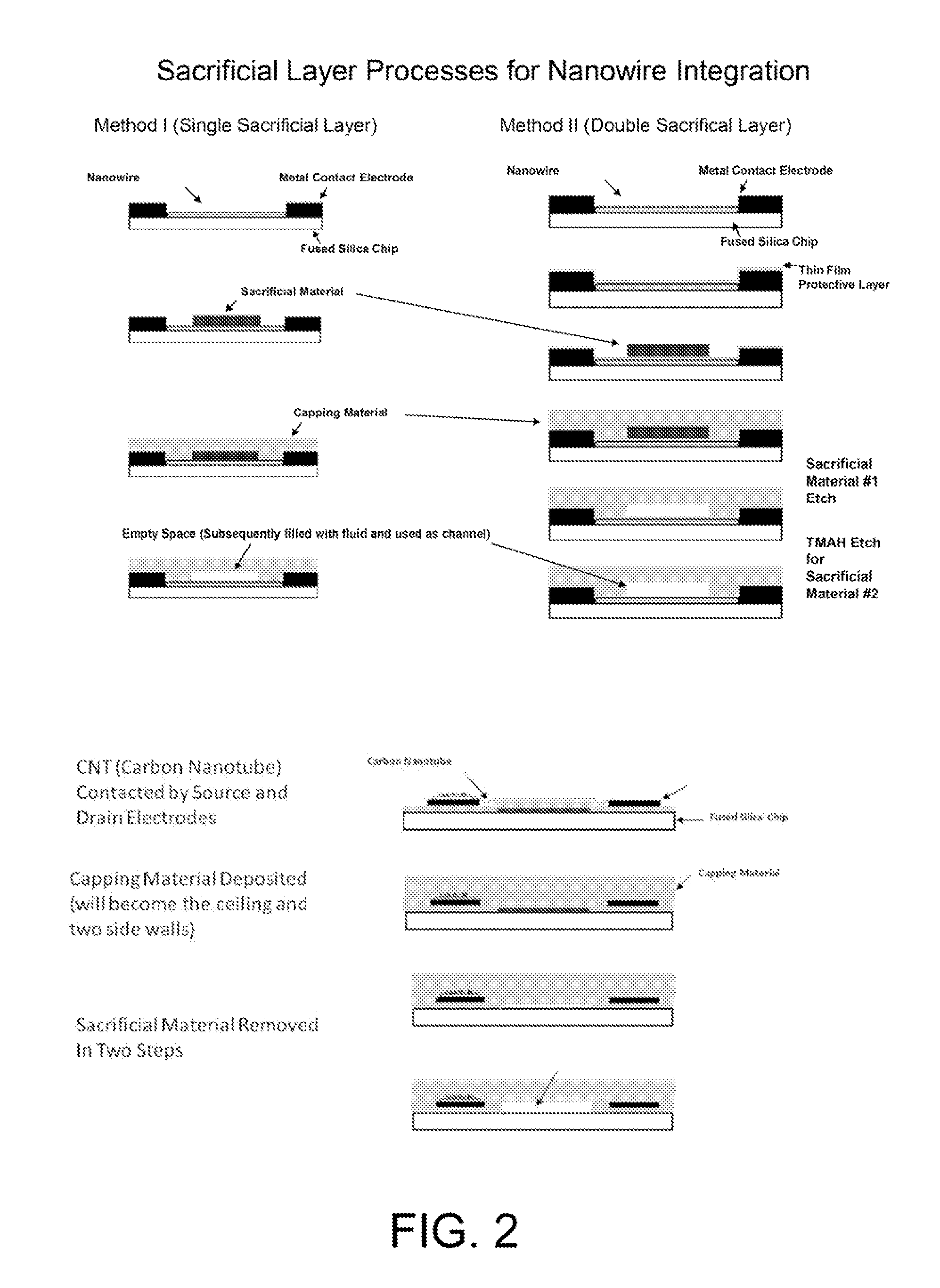

Nanofluidic channels with integrated charge sensors and methods based thereon

An electrical detector is provided that comprises a nanofluidic channel with an integrated nanoscale charge sensor. The charge sensor can be an unfunctionalized nanowire, nanotube, transistor or capacitor and can be of carbon, silicon, carbon / silicon or other semiconducting material. The nanofluidic channel depth is on the order of the Debye screening length. Methods are also provided for detecting charged molecules or biological or chemical species with the electrical detector. Charged molecules or species in solution are driven through the nanofluidic channel of the electrical detector and contact the charge sensor, thereby producing a detectable signal. Methods are also provided for detecting a local solution potential of interest. A solution flowing through the nanofluidic channel of the electrical detector contacts the charge sensor, thereby producing a detectable local solution potential signal.

Owner:CORNELL UNIVERSITY

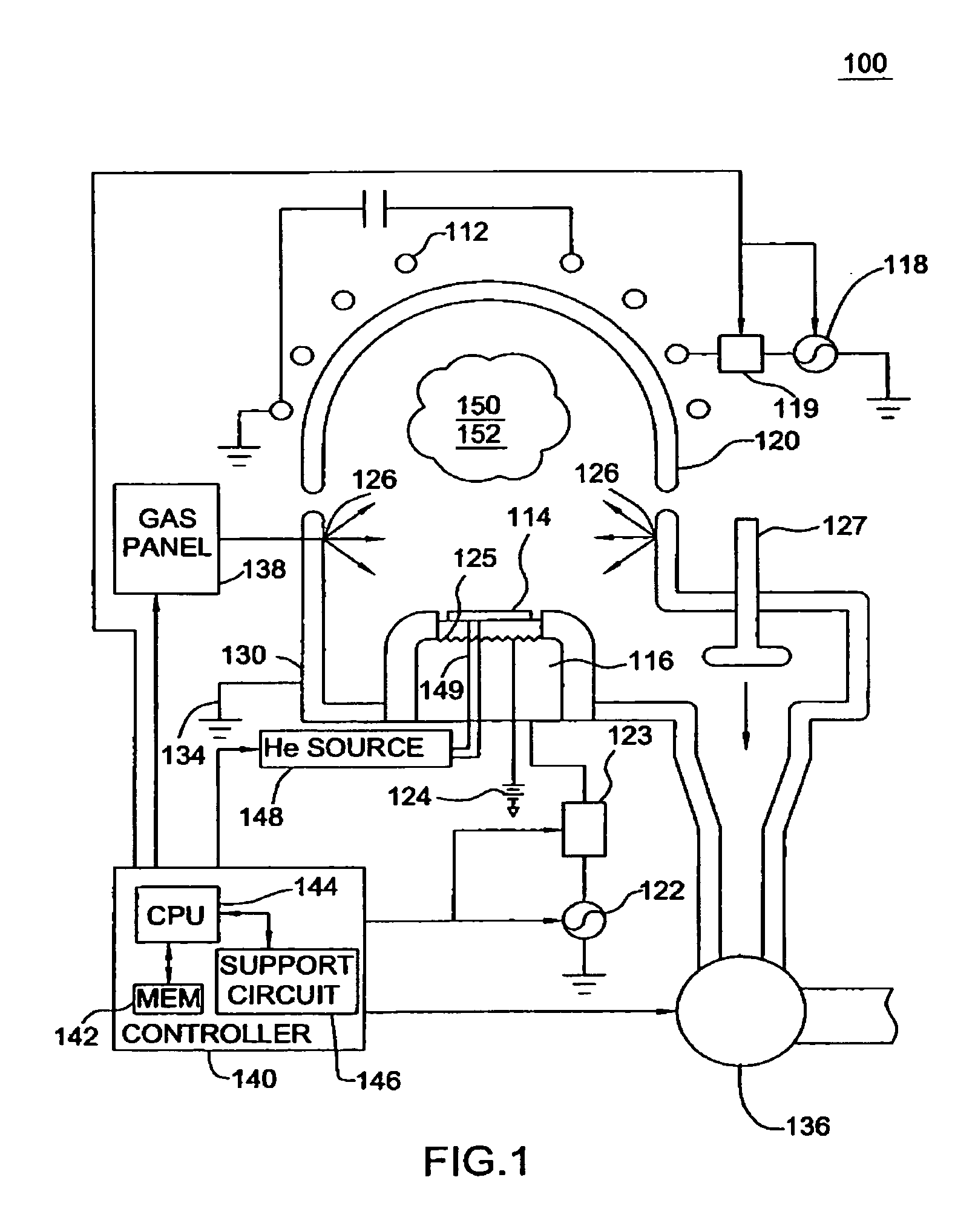

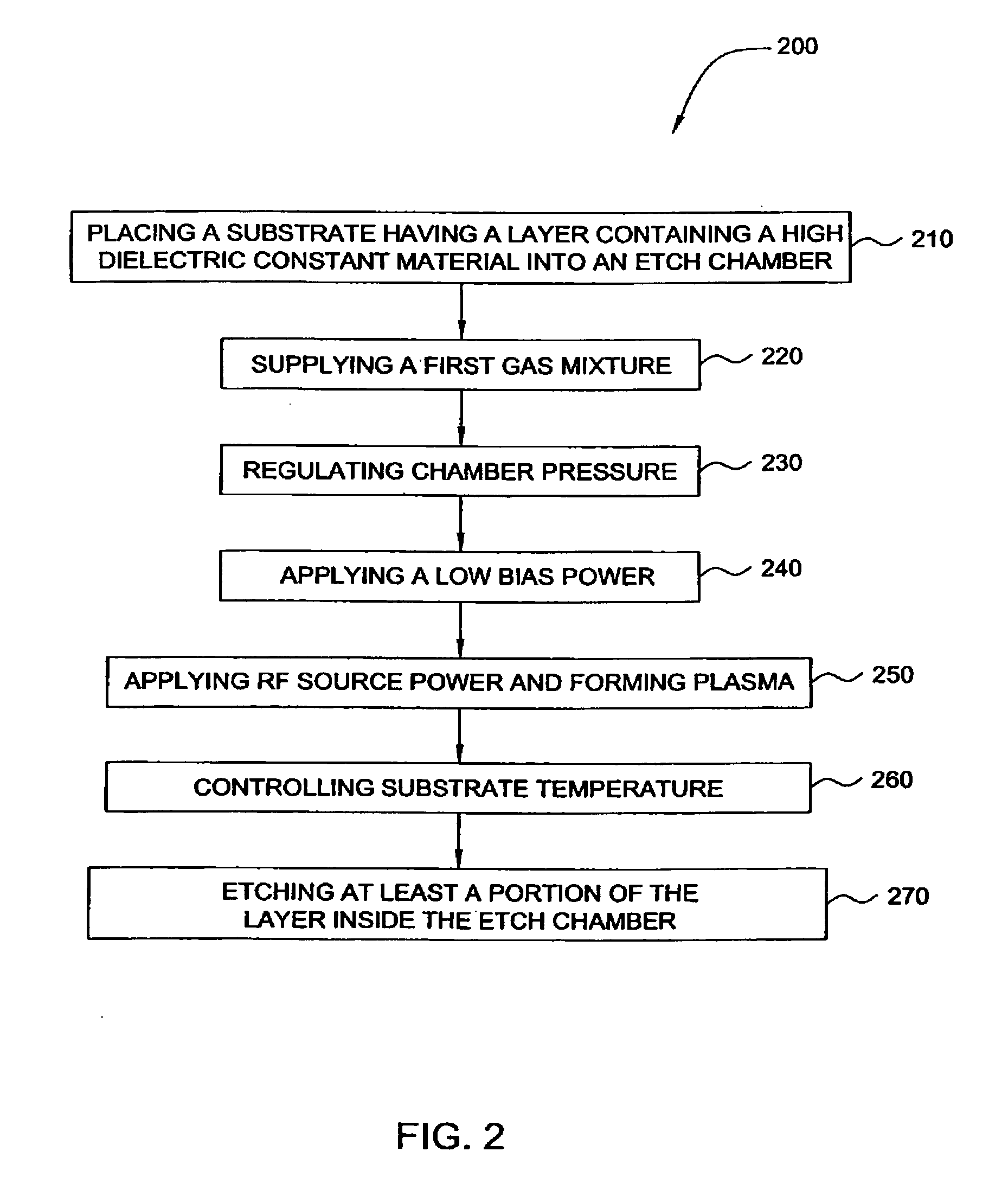

Etching high-kappa dielectric materials with good high-kappa foot control and silicon recess control

InactiveUS20060252265A1High selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingDielectricHalogen

An apparatus and a method for etching high dielectric constant (high-κ) materials using halogen containing gas and reducing gas chemistries are provided. One embodiment of the method is accomplished by etching a layer using two etch gas chemistries in separate steps. The first etch gas chemistry contain no oxygen containing gas in order to break through etching of the high dielectric constant materials, to dean any residues left from previous polysilicon etch process resulting in less high-κ foot, and also to control silicon recess problem associated with an underlying silicon oxide layer. The second over-etch gas chemistry provides a high etch selectivity for high dielectric constant materials over silicon oxide materials to be combined with low source power to further reduce silicon substrate oxidation problem.

Owner:APPLIED MATERIALS INC

Text influenced molecular indexing system and computer-implemented and/or computer-assisted method for same

InactiveUS20020087508A1Chemical property predictionMathematical modelsSingular value decompositionAlgorithm

Owner:AXONTOLOGIC

Process for preparing materials for extraction

InactiveUS7678931B2Improve extraction efficiencyQuality improvementFungiUnicellular algaeArachidonic acid supplementationFermentation

The present invention relates to a process for preparing a biomass, such as from a microbial fermentation, for an extraction process to separate desired chemicals, nutritional products, bioactive components, proteins, carbohydrates, and lipids, from the biomass. Particularly preferred substances to extract include docosahexaenoic acid, docosapentaenoic acid, and arachidonic acid. The present invention also includes extracting the prepared biomass. Biomasses to be treated in accordance with the methods of the invention include plant, animal, and microbial biomass, particularly a microorganism such as Crypthecodinium cohnii and a fungus such as Mortierella alpina.

Owner:MARTEK BIOSCIENCES CORP

Method for etching chromium thin film and method for producing photomask

ActiveUS20060102587A1Decorative surface effectsSemiconductor/solid-state device manufacturingResistChemical species

An object to be processed has a chromium-based thin film made of a material containing chromium. The thin film is etched using a resist pattern as a mask. The thin film is etched by the use of a chemical species produced by preparing a dry etching gas containing a halogen-containing gas and an oxygen-containing gas and supplying a plasma excitation power to the dry etching gas to thereby excite plasma. The thin film is etched using, as the plasma excitation power, a power lower than a plasma excitation power at which plasma density jump occurs.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com