All-inorganic SMD LED packaging method and structure

An LED packaging and inorganic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of device luminous flux, radiant flux attenuation, difficulty in inorganic sealing packaging technology, poor UV resistance, etc., to improve heat dissipation performance and save energy. The cost of gold wire and the effect of strong anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

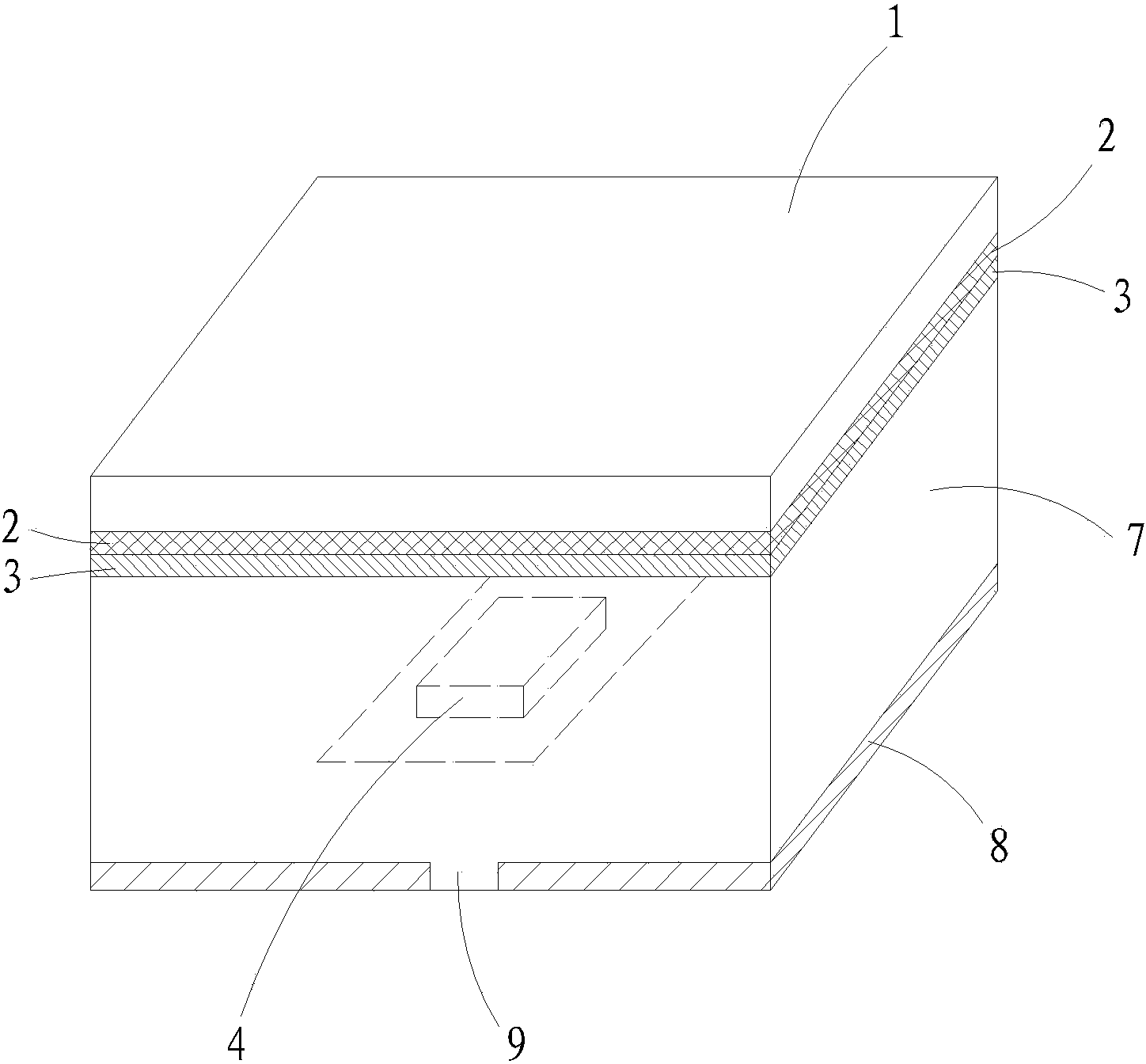

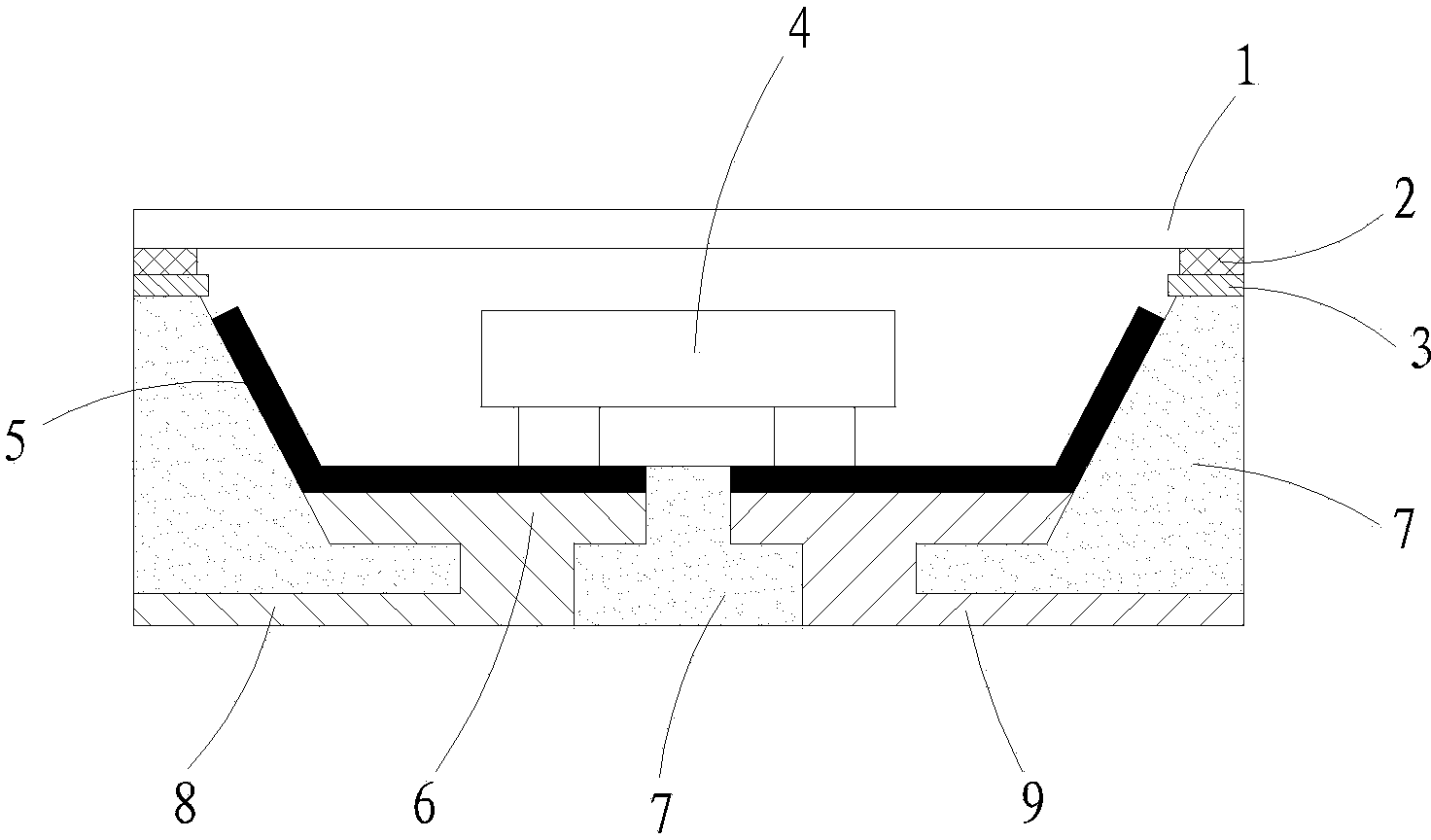

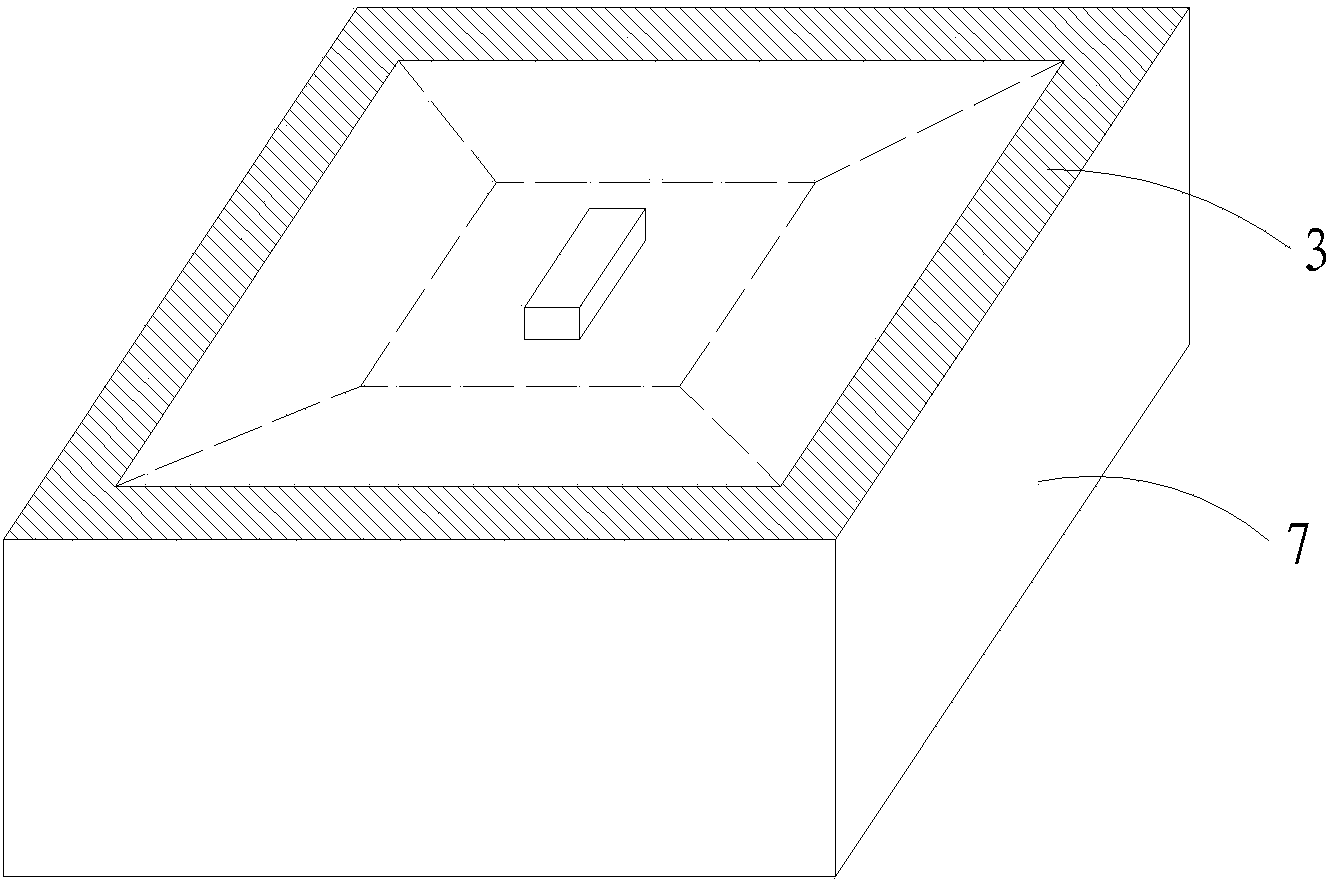

[0031]A kind of all-inorganic patch LED package structure of the present invention, see Figure 1-Figure 4 , including a bracket 7 made of a ceramic substrate, on which a glass cover 1 matching the structure of the bracket 7 is provided to just cover the bracket 7; Groove, the bracket 7 is provided with a first metal layer 3 along the periphery and at the peripheral position of the groove, the edge of the glass cover 1 is provided with a circle of second metal layer 2, and the expansion of the material of the second metal layer 2 The coefficient is similar to that of the glass cover plate, the materials of the first metal layer 3 and the second metal layer 2 have similar melting points and can be well welded, and the second metal layer 2 and the first metal layer 3 are connected together by resistance welding. The purpose of using the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com