Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "High strength level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large thickness quenched high strength steel and production method thereof

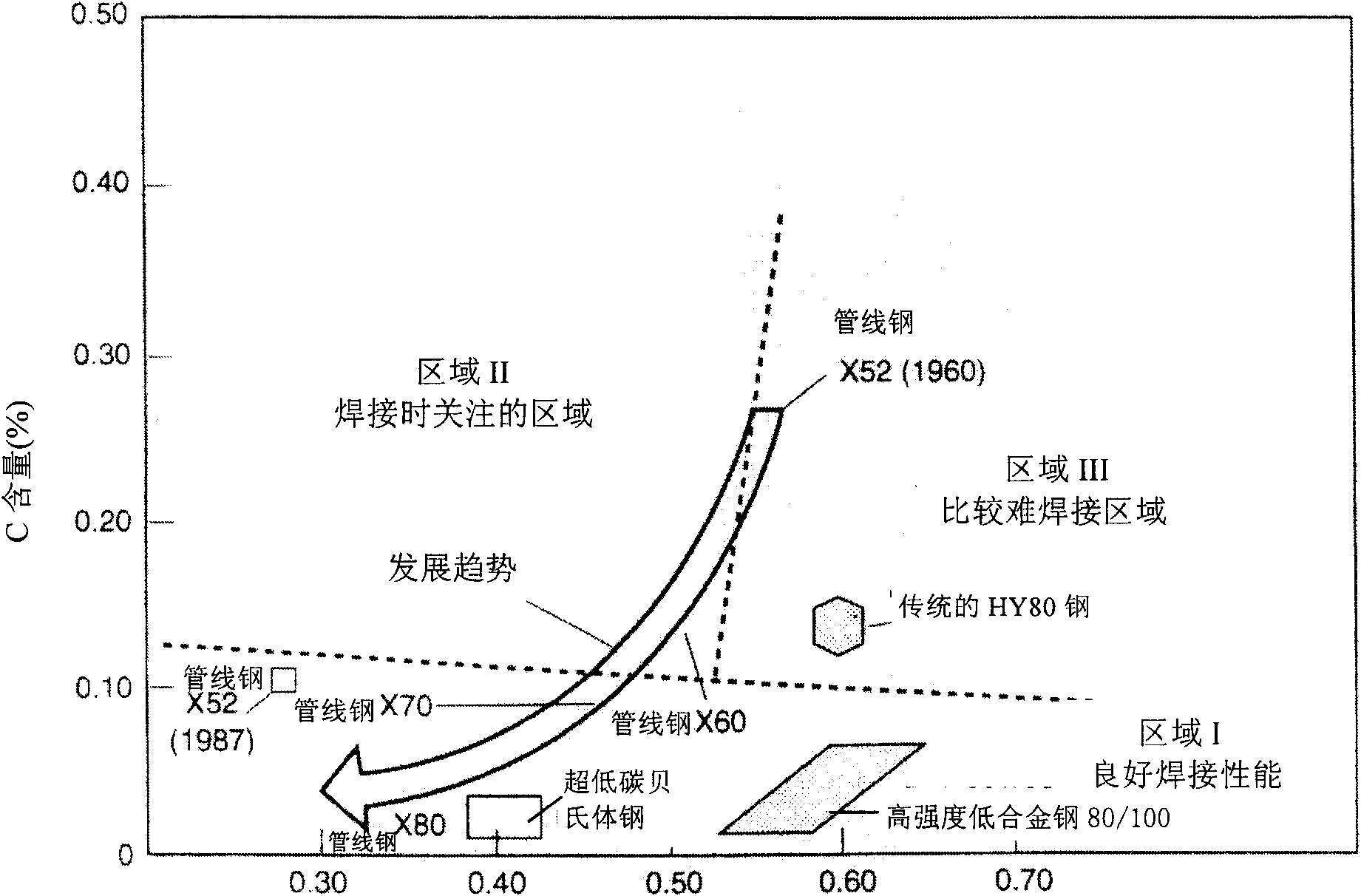

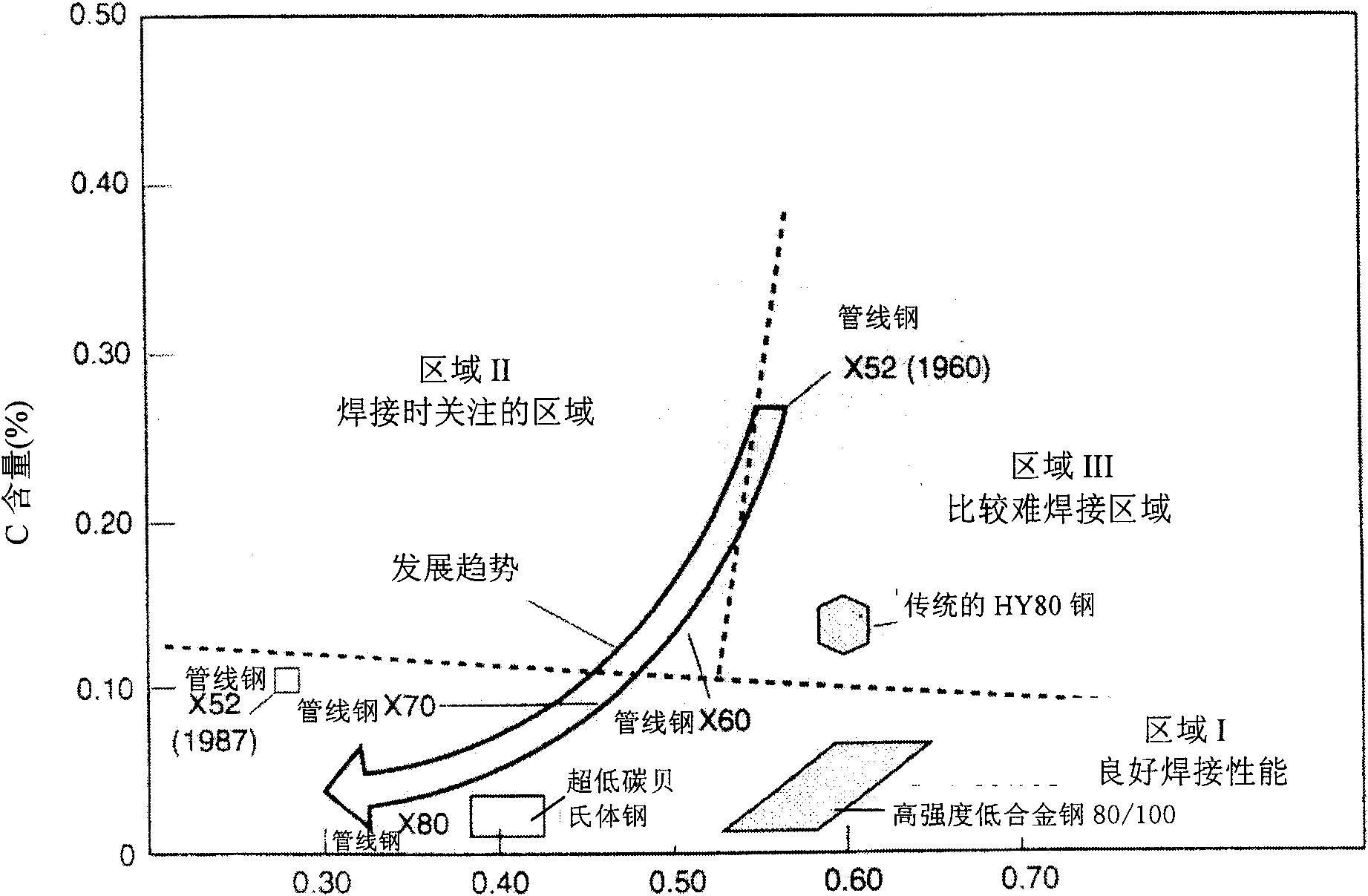

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

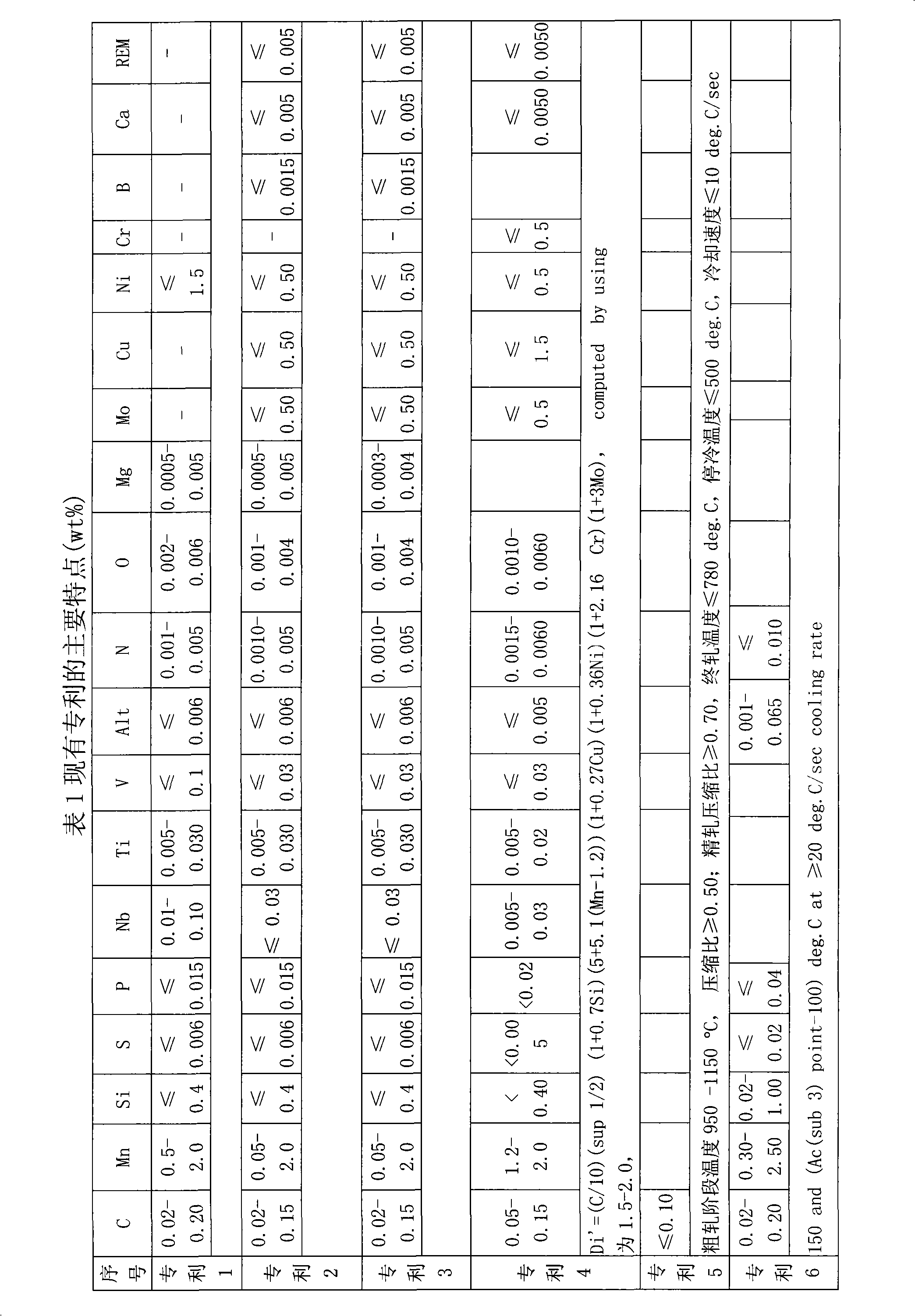

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Marine 40kg heat mechanical control rolling thick plate steel and manufacturing method thereof

InactiveCN101781737ASimple configuration of ingredientsReduce manufacturing costThick plateChemical composition

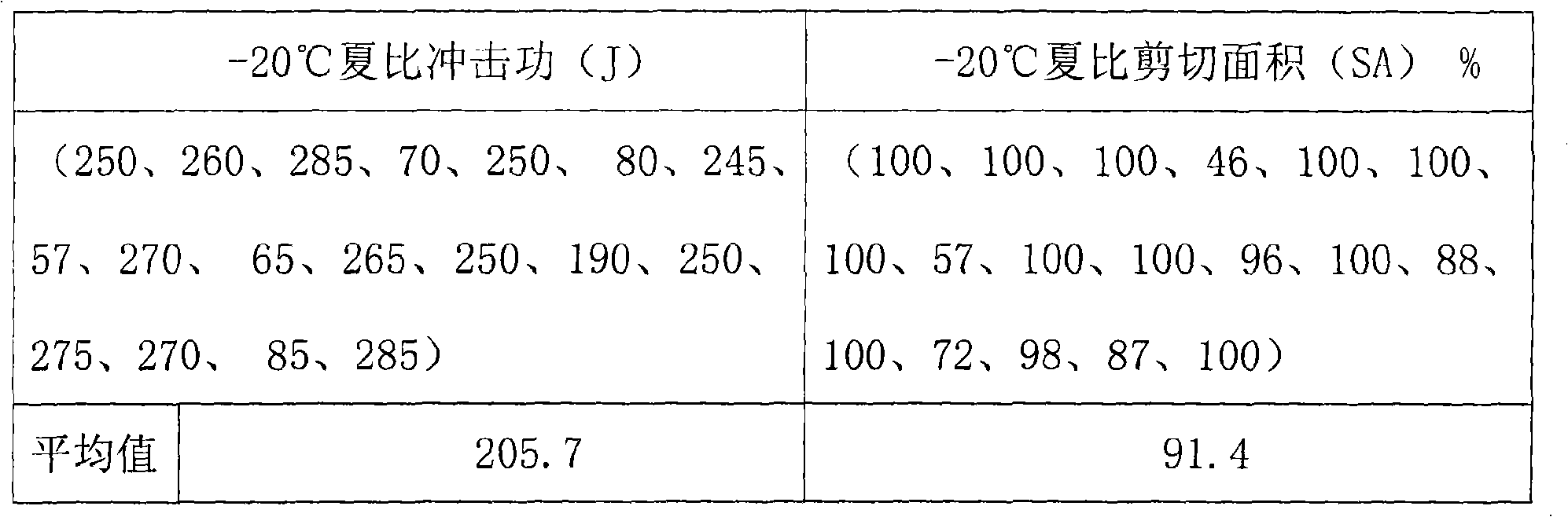

The invention discloses a TMCP-type F40 steel with excellent low-temperature toughness and a manufacturing method thereof. The TMCP-type F40 steel comprises the following chemical components in percentage by weight: 0.010-0.12 percent of C, 0.3-2.0 percent of Mn, less than 0.6 percent of Si, less than 0.0030 percent of S, less than 0.015 percent of P, 0.010-0.120 percent of Nb, 0.005-0.030 percent of Ti, less than 0.120 percent of V, less than 0.060 percent of Al, less than 0.60 percent of Mo, less than 1.2 percent of Cu, less than 1.5 percent of Ni, less than 1.2 percent of Cr, less than 0.0040 percent of B, less than 0.01 percent of Ca, 0.003-0.010 percent of N, 0.001-0.006 percent of O, less than 0.0001 percent of Mg, and the balance of Fe and other inevitable impurities. The manufacturing method comprises the steps of smelting by a revolving furnace or an electric furnace, external refining, casting, slabs reheating as well as rolling control and cooling control. The product has excellent toughness, intensity and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Pipeline steel with good and stable low-temperature flexibility and method for rolling hot rolled coils thereof

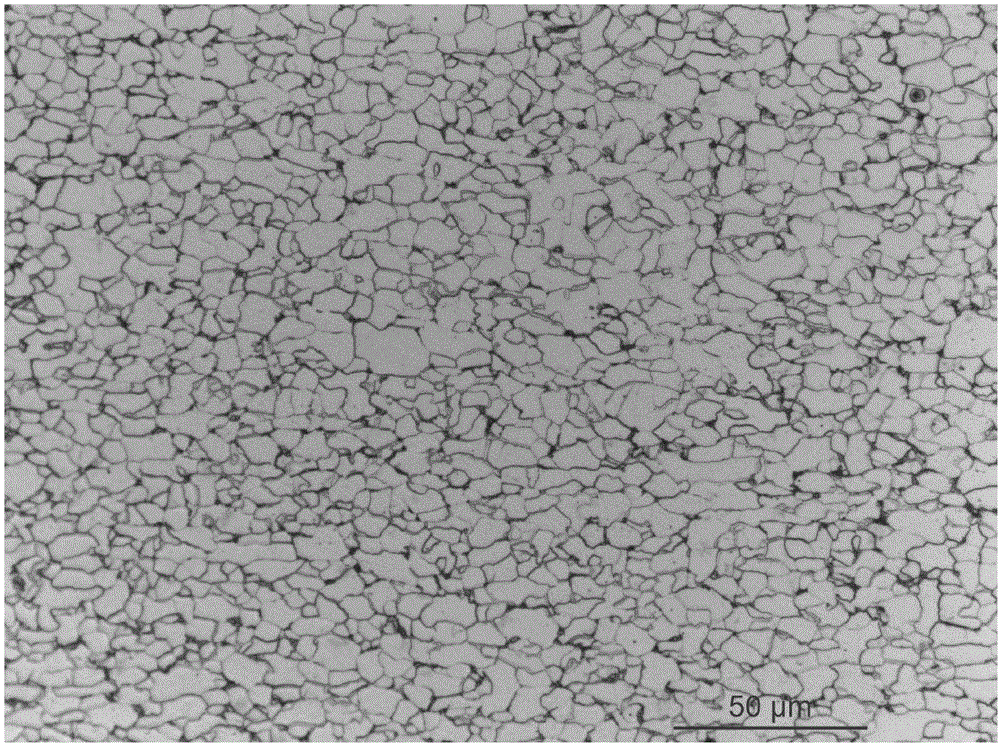

ActiveCN101514435AEliminates adverse effects on impact toughnessFine grainTemperature control deviceNiobiumManganese

The invention discloses pipeline steel with good and stable low-temperature flexibility and a method for rolling hot rolled coils thereof. The pipeline steel comprises the following compositions in percentage by weight: 0.03 to 0.070 percent of carbon, 0.19 to 0.30 percent of silicon, 1.50 to 1.90 percent of manganese, 0.010 to 0.020 percent of titanium, 0.015 to 0.040 percent of aluminum, less than or equal to 0.30 percent of nickel, less than or equal to 0.02 percent of chromium, less than or equal to 0.0002 percent of boron, less than or equal to 0.018 percent of phosphorus, less than or equal to 0.005 percent of sulfur, 0.002 to 0.003 percent of calcium, 0.20 to 0.40 percent of molybdenum, less than or equal to 0.30 percent of copper, 0.02 to 0.10 percent of niobium, less than or equal to 0.006 percent of nitrogen, less than or equal to 0.004 percent of oxygen, less than or equal to 0.00025 percent of hydrogen, and the balance of iron and impurities. The manufactured pipeline steel has the characteristics that sigma s is equal to be between 565 and 580 MPa; sigma b is equal to be between 665 and 690 MPa; and sigma s / sigma b is less than or equal to 0.85.

Owner:MAANSHAN IRON & STEEL CO LTD

Technique for producing 500MPa level high-strength quake-proof reinforcing steel bar

The invention discloses a technique for producing 500MPa level high-strength quake-proof reinforcing steel bar. Nitrogen is blown into molten steel in a steel ladle by a microwave field in the process of steel taping, [N] in the molten steel ranges from 0.08% to 0.012%; reducible manganese oxide pellets are added in the metaphase of smelting; reducible vanadium oxide and niobium oxide pellets are added in the later stage of smelting; manganese family alloy, silicon family alloy and carburant are added in the process of steel taping, [Mn] in the molten steel ranges from 0.60% to 1.40%, [Si] in the molten steel ranges from 0.20% to 0.60%; ferrovanadium and ferroniobium are added in the process of steel taping to fine tunes vanadium and niobium in the steel, [V] in the steel ranges from 0.02% to 0.055%, [Nb] ranges from 0.02% to 0.055%; molten steel is cast into steel billets by a conticaster, the steel billets are heated by a heating furnace, heating temperature is between 1050 DEG C and 1250 DEG C, start rolling temperature is between 950 DEG C and 1150 DEG C, finishing temperature is between 950 DEG C and 1050 DEG C, and cooling speed after rolling is between 15 DEG C / s and 500 DEG C / s; Rel of the reinforcing steel bar produced by the method is between 530MPa and 560MPa, Rm is between 660MPa and 730MPa, A is between 18% and 25%, Rm / Rel is between 1.30 and 1.45, ageing lasts for three months, undulating quantity of Rel and Rm is less than 15MPa, welding performance is good, and popularization and application prospects are promising.

Owner:CENT SOUTH UNIV

Gas shield welding wire with high strength and tenacity

ActiveCN101722386AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaImpurityREL

The invention relates to a gas shield welding wire with high strength and tenacity, which is suitable for the welding of 800MPa-grade high-strength steel. The gas shield welding wire comprises the following ingredients in percentage by weight: 0.02-0.05 percent of C, 0.30-0.80 percent of SiO, 2.0-2.50 percent of Mn, less than 0.010 percent of P, less than 0.010 percent of S, 0.70-1.2 percent of Cr, 0.70-1.2 percent of Mo, 0.02-0.12 percent of Ti, 0.003-0.005 percent of B, 2.0-3.2 percent of Ni, 0.05-0.1 percent of RE, 0-0.06 percent of Nb, and the balance of Fe and unavoidable impurities. The welding wire has the advantages of simple ingredient design, low cost, good manufacturability, and the like; in addition, and weld metal has high tenacity and is suitable for the welding at the position with higher low-temperature tenacity requirement. Experiments show that the Rm of the weld metal welded by the welding wire is not less than 800MPa, and the ReL is more than 760MPa; and the impact energy at -50 DEG C of the weld metal is not less than 37J.

Owner:SHOUGANG CORPORATION

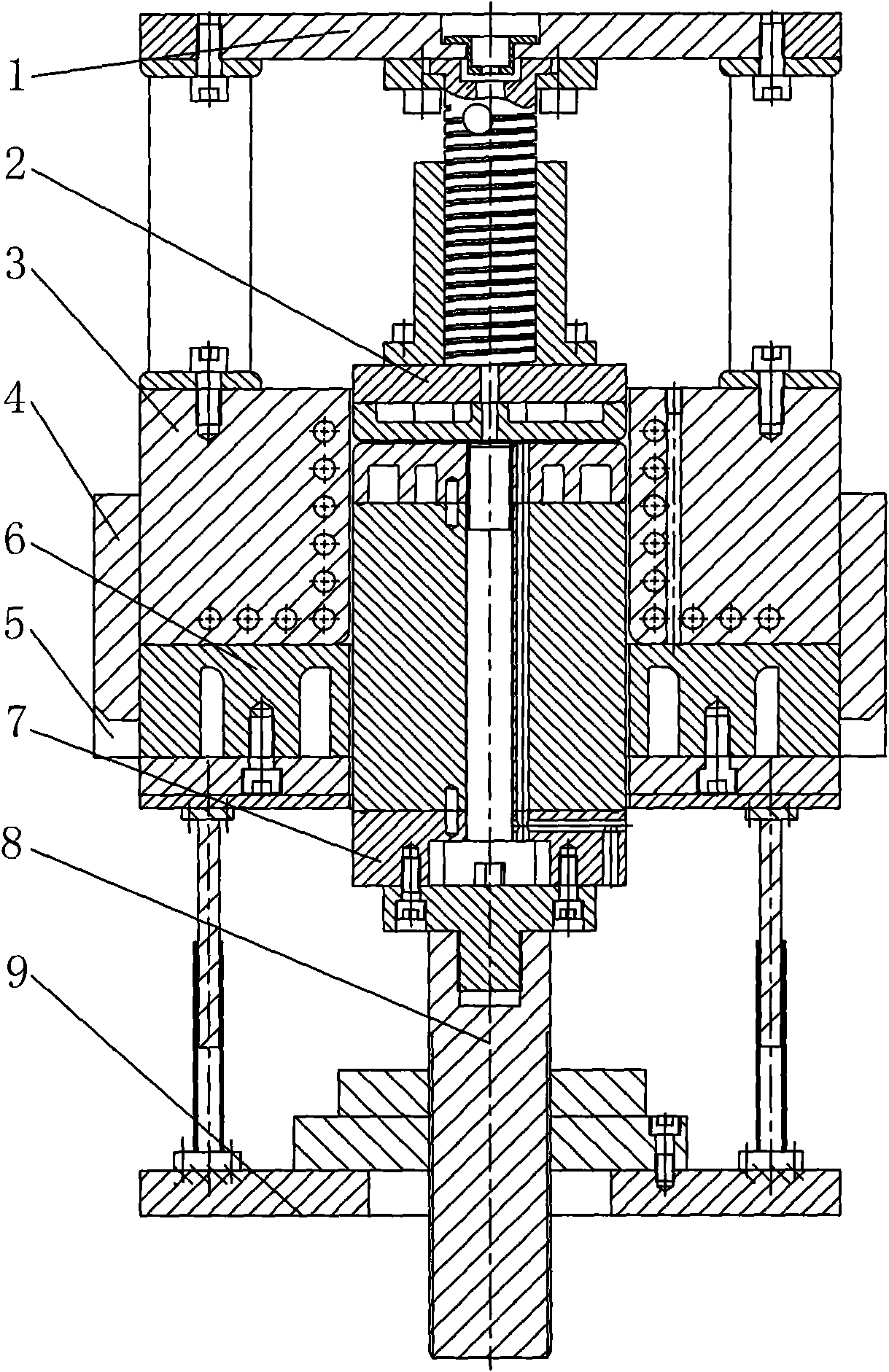

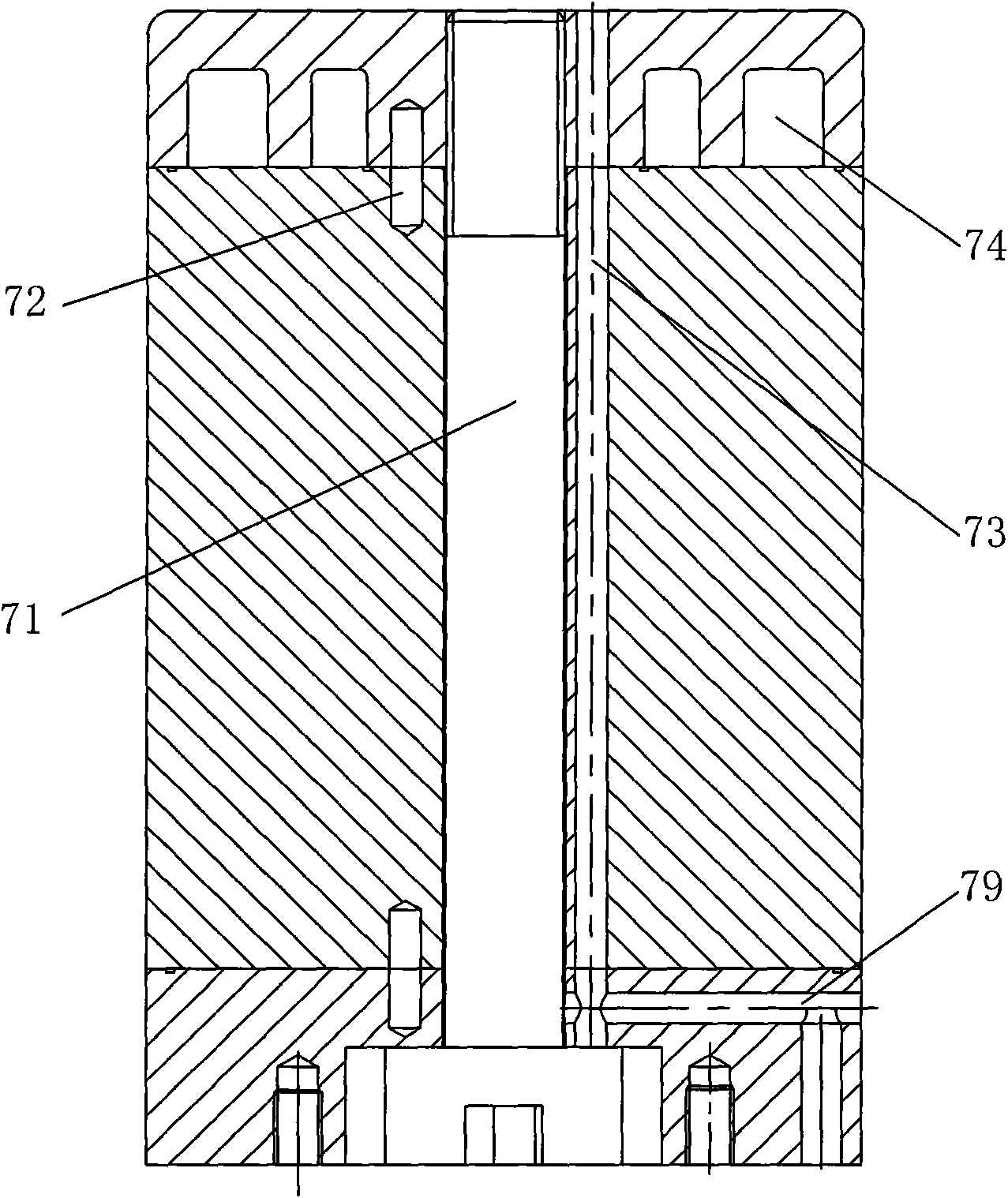

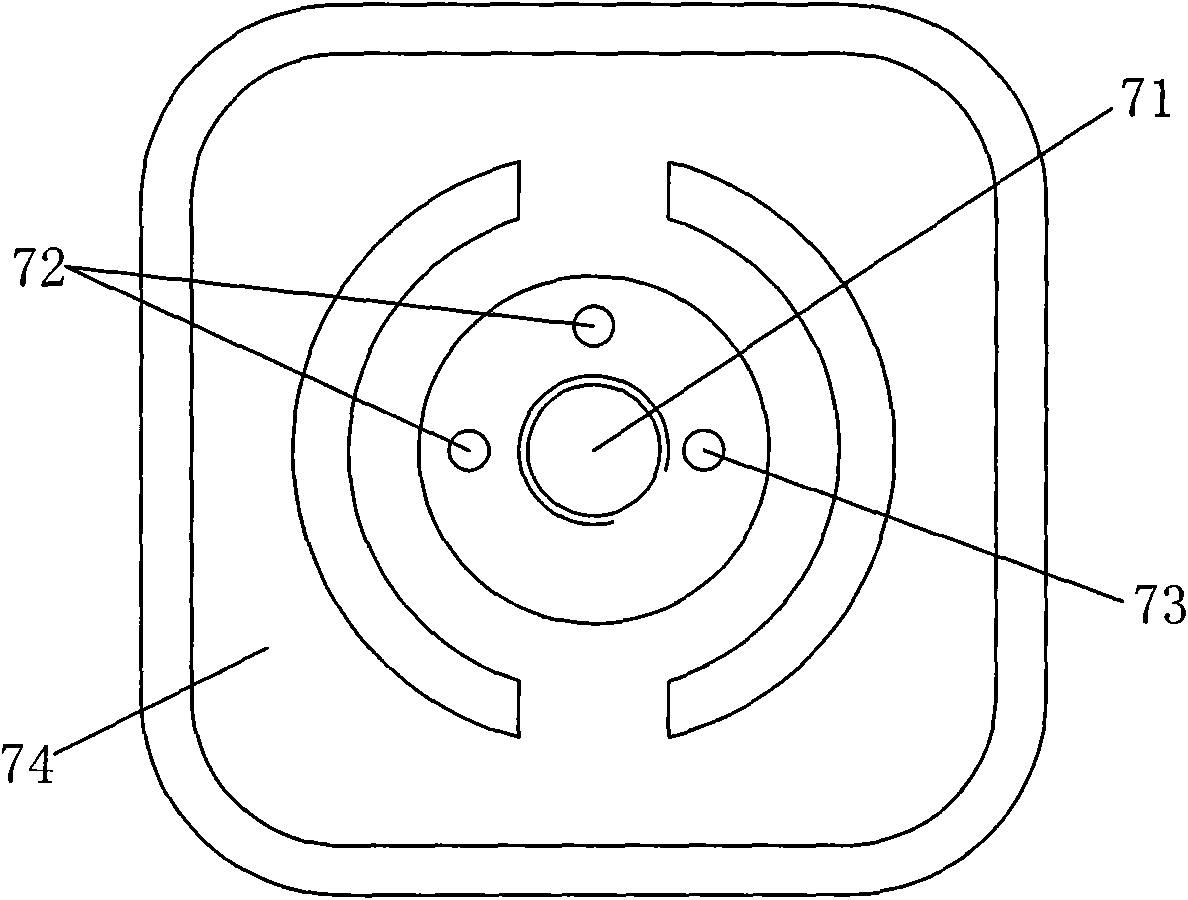

Hot stamping die for automobile parts

InactiveCN101992243AImproved shape stabilityHigh strength levelShaping toolsHot stampingWater channel

The invention belongs to the field of parts manufacturing, in particular to a hot stamping die for automobile parts. The hot stamping die for the automobile parts comprises an upper plate, a limit die, a female die, a guide plate, a guide block, a side pressing die, a male die, an ejector rod and a lower plate, wherein the female die, the male die and the side pressing die are in an enclosed type and are distributed with cooling water channels connected with cooling water pipelines. Parts manufactured and formed by means of the hot stamping die have the advantages that the strength grade can reach about 1500Mpa, and the shape stability of the formed parts is good. The hot stamping die is suitable for manufacturing automobile parts which have higher requirements on comfortableness and security and have the strength grade of about 1500MPa, such as bumper bars, crashproof beams, B posts, reinforced pieces thereof and the like; and the hot stamping die also can be used for replacing automobile body parts which have the strength grade of about 1000Mpa and are produced by the traditional process, especially automobile door crashproof bars, and has wide market application prospect in the fields of aviation, aerospace and engineering machinery in which stamping parts with higher strength grade are necessarily used.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing process for stress relaxation-resistant high-strength bolt

The invention relates to a manufacturing process of a high-strength bolt resisting stress relaxation. The manufacturing process sequentially comprises working procedures of quenching and tempering, drawing, cold upsetting thread billet inner diameter / rod part / hexagon head, thread rolling, stabilizing, surface treatment and peening or round corner rolling strengthening and defect detection. In the quenching and tempering working procedure, wire rod strength is finally controlled at 85-65% of a finished product; in the drawing working procedure, the drawing deformation is controlled at 15-40%, in the stabilizing working procedure, the heating temperature is 200-450 DEG C, the temperature is kept for 0.5-4h and the bolt is taken from the furnace for air cooling. The high-strength bolt resisting stress relaxation has the beneficial effects of being adapted to the development of machinery industry, especially automobile industry, solving a deformation problem of a long bolt in quenching treatment, further improving the performance of resisting stress relaxation during practical use, and being capable of further increasing the strength of the bolt up to 1300MPa.

Owner:NANJING INST OF TECH +2

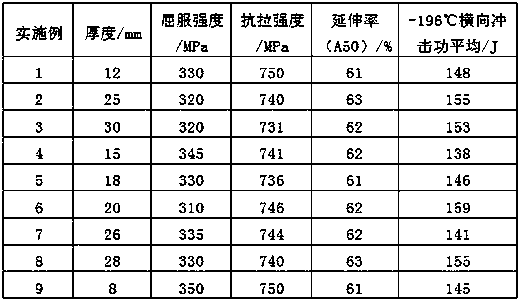

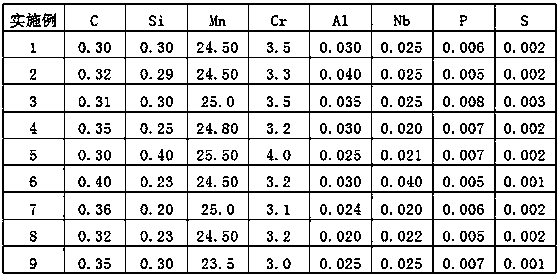

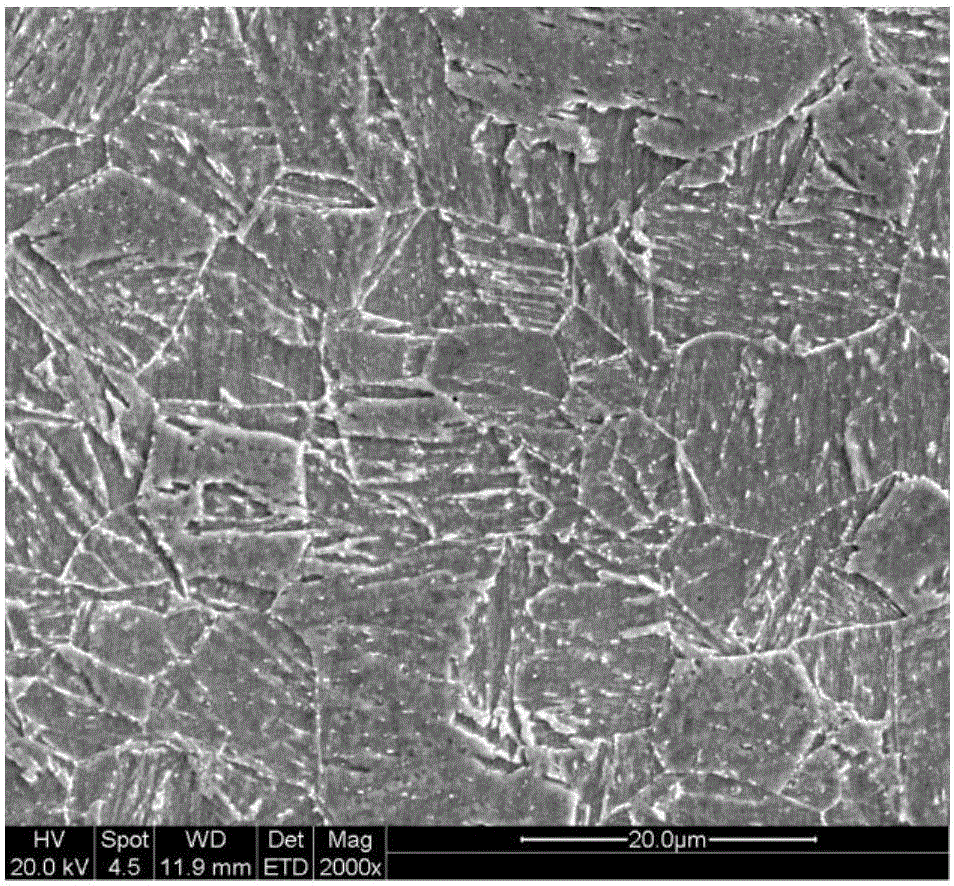

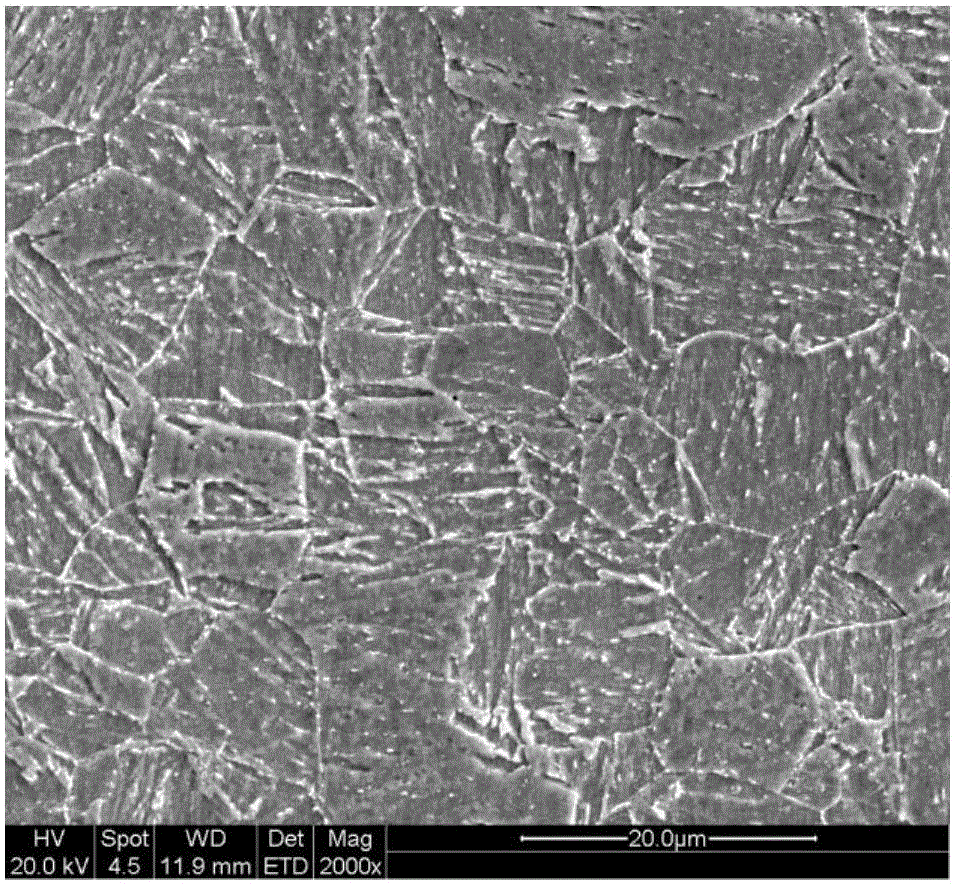

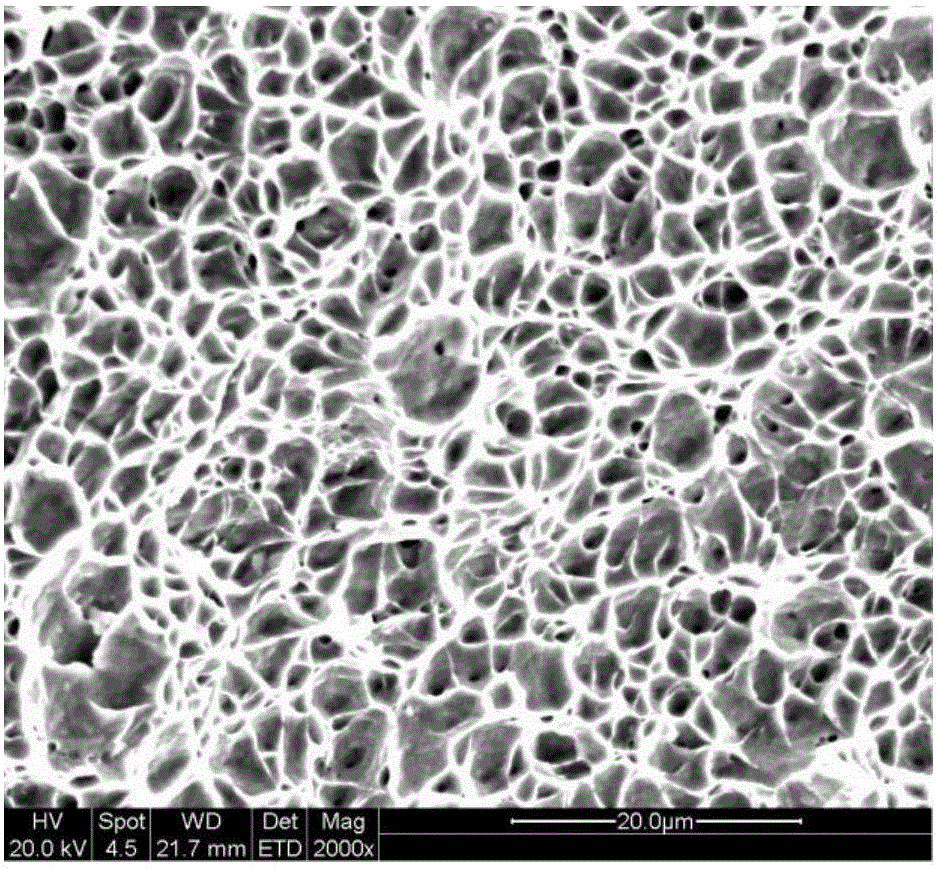

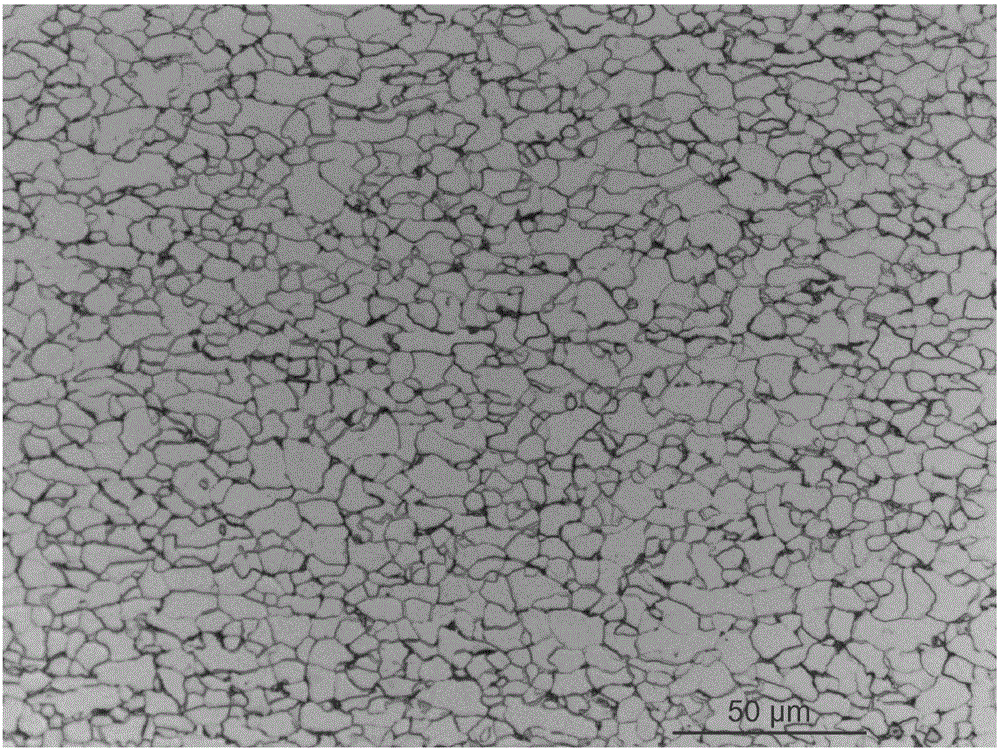

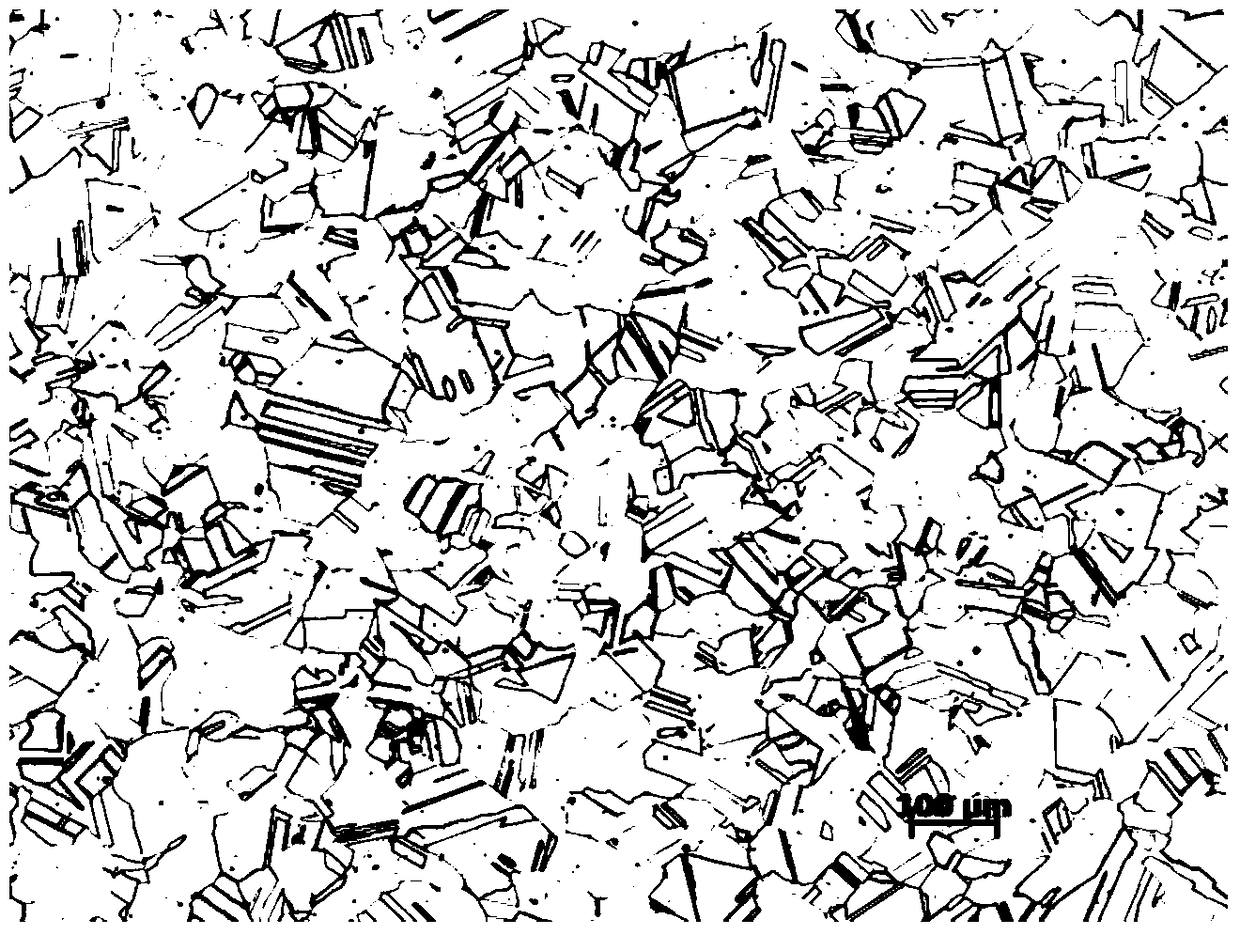

Low-yield-ratio high-toughness high-manganese steel plate and production method thereof

The invention discloses a low-yield-ratio high-toughness high-manganese steel plate and a production method of the low-yield-ratio high-toughness high-manganese steel plate. The steel plate comprises,by mass percentage, 0.30-0.40% of C, 0.20-0.40% of Si, 23.50-25.50% of Mn, 3.0-4.0% of Cr, 0.020-0.040% of Al, 0.020-0.040% of Nb, not larger than 0.008% of P, not larger than 0.003% of S and balanceFe and inevitable impurities. The production method of the steel plate comprises steelmaking, continuous casting, heating, rolling and heat treatment processes. According to the low-yield-ratio high-toughness high-manganese steel plate and the production method, the design of the chemical compositions is characterized in that solid solution strengthening is conducted on C, Mn and Cr, and the steel plate has the beneficial effects of being high in density, high in strength level, high in elongation, low in yield ratio, excellent in low-temperature impact toughness and the like, is capable of meeting the requirement of the low-yield-ratio high-toughness high-manganese steel plate, has the good comprehensive performance and welding performance and is low in cost.

Owner:WUYANG IRON & STEEL

Structure steel plate for bridge with yield strength being 690MPa and production method thereof

The invention discloses a structure steel plate for a bridge with the yield strength being 690MPa and a production method thereof. The structure steel plate comprises the following components in percent by weight: 0.040 percent to 0.080 percent of C, 0.20 percent to 0.25 percent of Si, 1.50 percent to 1.65 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.040 percent to 0.050 percent of Nb, 0.006 percent to 0.018 percent of Ti, 0.25 percent to 0.35 percent of Cr, 0.25 percent to 0.30 percent of Mo, 0.30 percent to 0.40 percent of Cu, 0.20 percent to 0.30 percent of Ni and the balance of Fe and unavoidable impurities, the sensitive composition of welding cracks meets the formula Pcm is less than or equal to 0.22, the carbon equivalent CEV is less than or equal to 0.50, 10C plus 4Cr plus Cu equals to 6.5 to 7.5. The structure steel plate designed and produced by the process has good toughness; the yield strength Rel is more than or equal to 690MPa, the tensile strength Rm is more than or equal to 770MPa, the elongation A is more than or equal to 18 percent, and -40 DEG C low-temperature impacting performance is more than or equal to 100J. Compared with the existing bridge steel technology, the structure steel plate disclosed by the invention has the advantages that the strength level is greatly improved; in addition, the welding performance of the steel plate is improved by strictly controlling the carbon equivalent CEV to be less than or equal to 0.50 and Pcm to be less than or equal to 0.22.

Owner:武汉钢铁有限公司

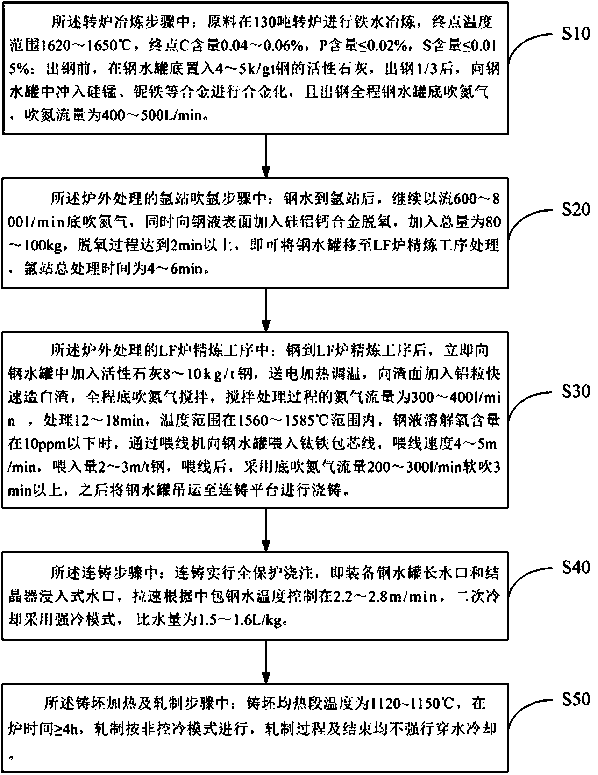

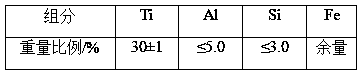

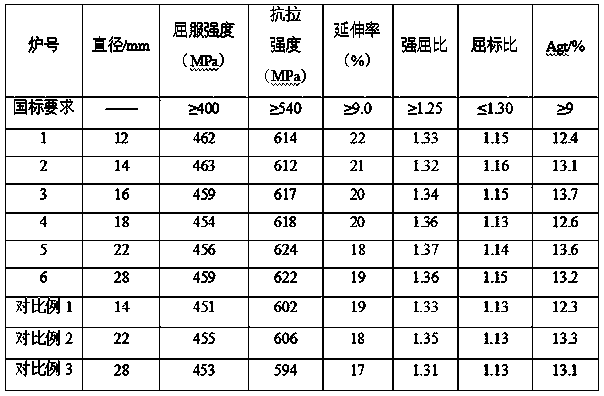

Niobium-titanium microalloying HRB400-scale screw-thread steel and manufacturing method thereof

The invention discloses a kind of niobium-titanium microalloying HRB400-scale screw-thread steel and a manufacturing method thereof. The screw-thread steel comprises C, Si, Mn, P, S, Nb, Ti, N and the balance Fe and impurities. The manufacturing method of the niobium-titanium microalloying HRB400-scale screw-thread steel comprises the following steps of smelting in a revolving furnace, treatment outside the furnace, continuous casting, casting blank heating and rolling. During smelting in the revolving furnace, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment. During treatment outside the furnace, argon is blown in an argon station, and refining is conducted in an LF furnace. In the process of refining in the LF furnace, a ferrotitanium core-spun yarn is fed for titanium microalloying treatment. According to the technical scheme, before tapping, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment, the ferrotitanium core-spun yarn is fed in the process of refining in the LF furnace for titanium microalloying treatment, after titanium is fused into molten steel, proper niobium-titanium microalloying treatment is conducted, the yield of the niobium-titanium alloy is increased, and stable, sustainable and low-cost production of the screw-thread steel is achieved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

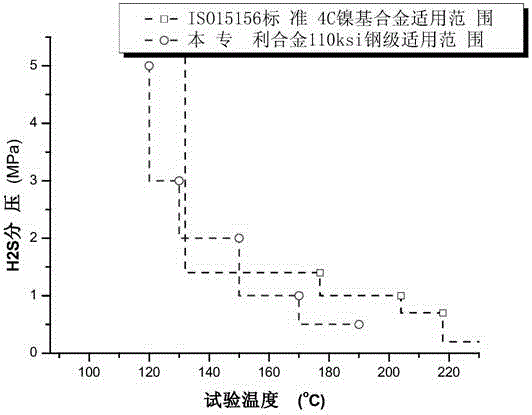

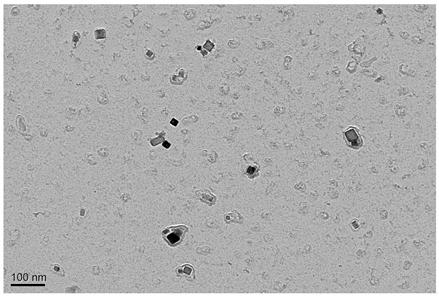

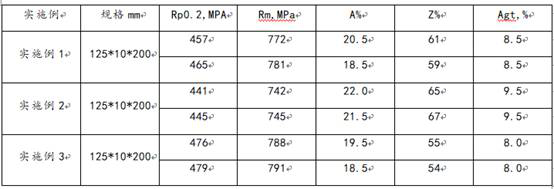

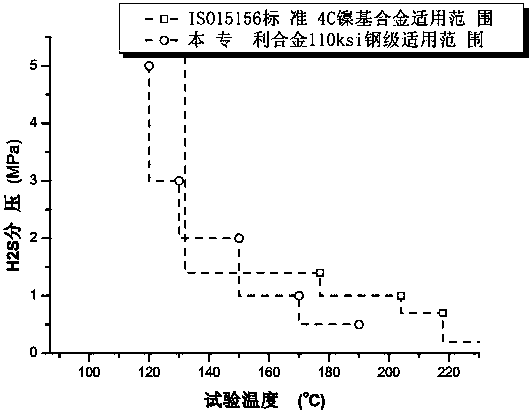

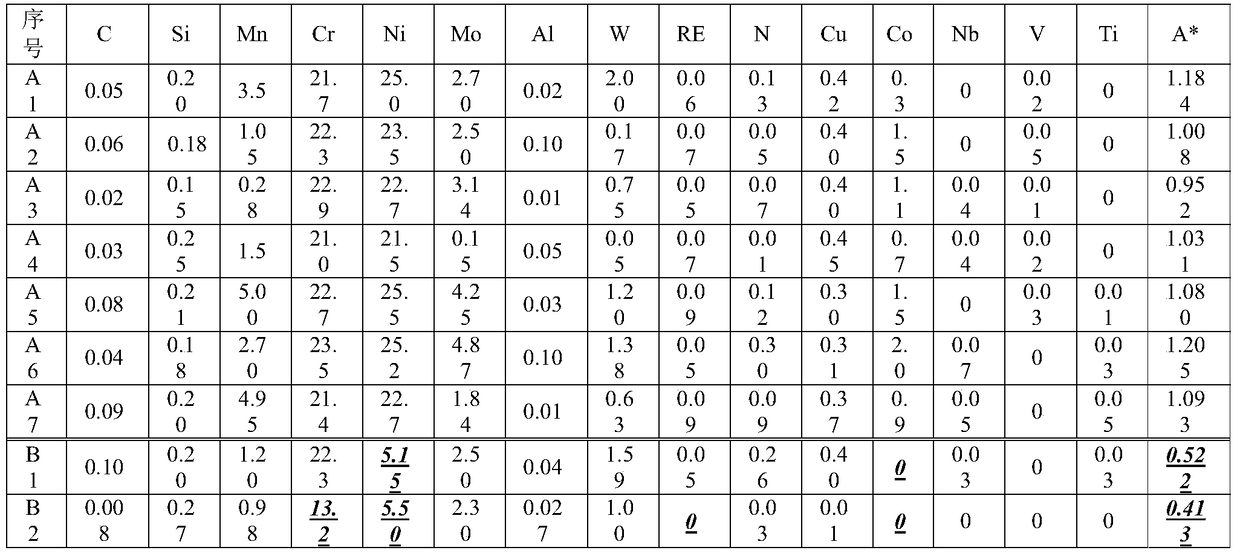

High-strength and anti-corrosion stainless steel, oil casing pipe and manufacturing method of oil casing pipe

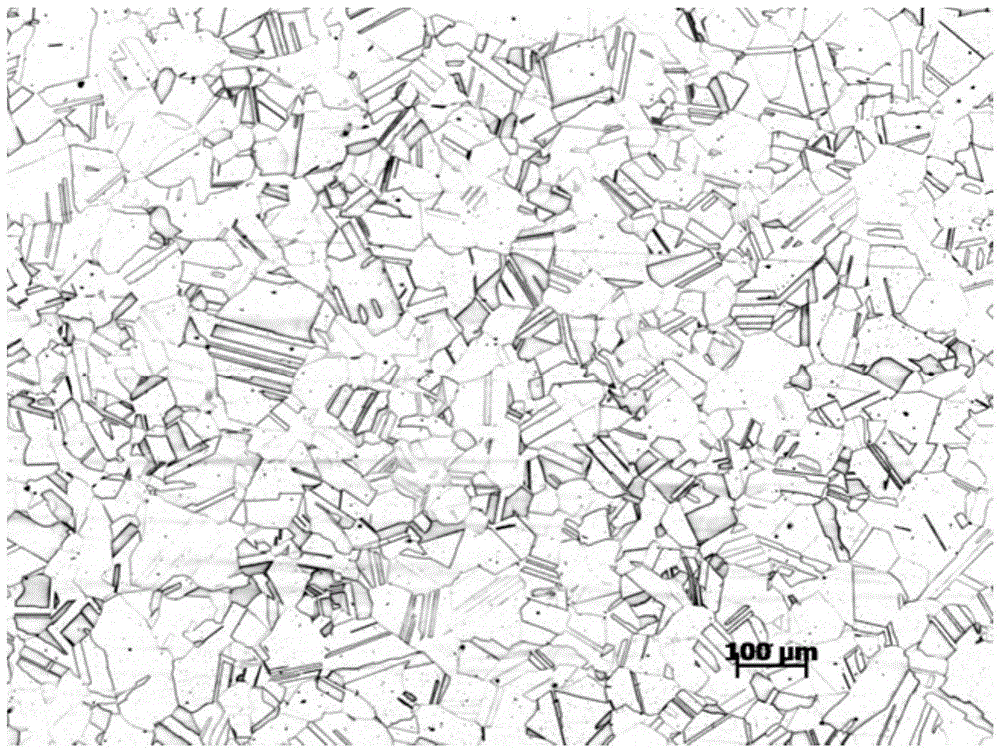

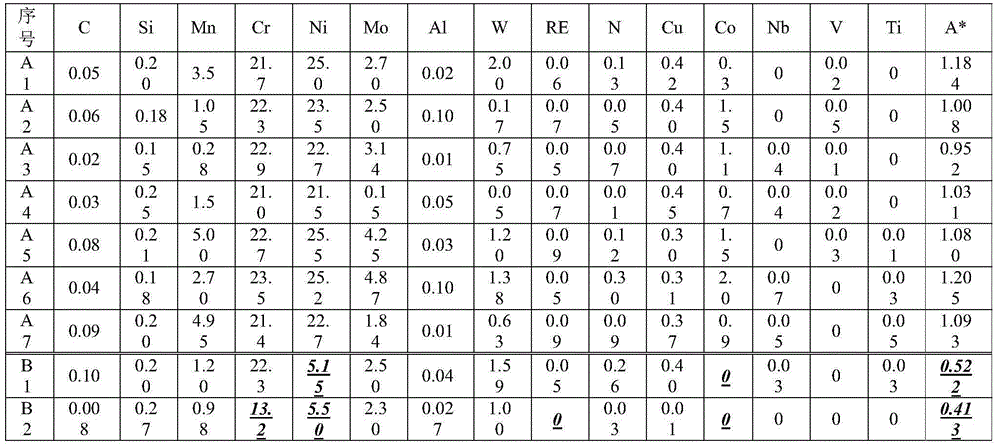

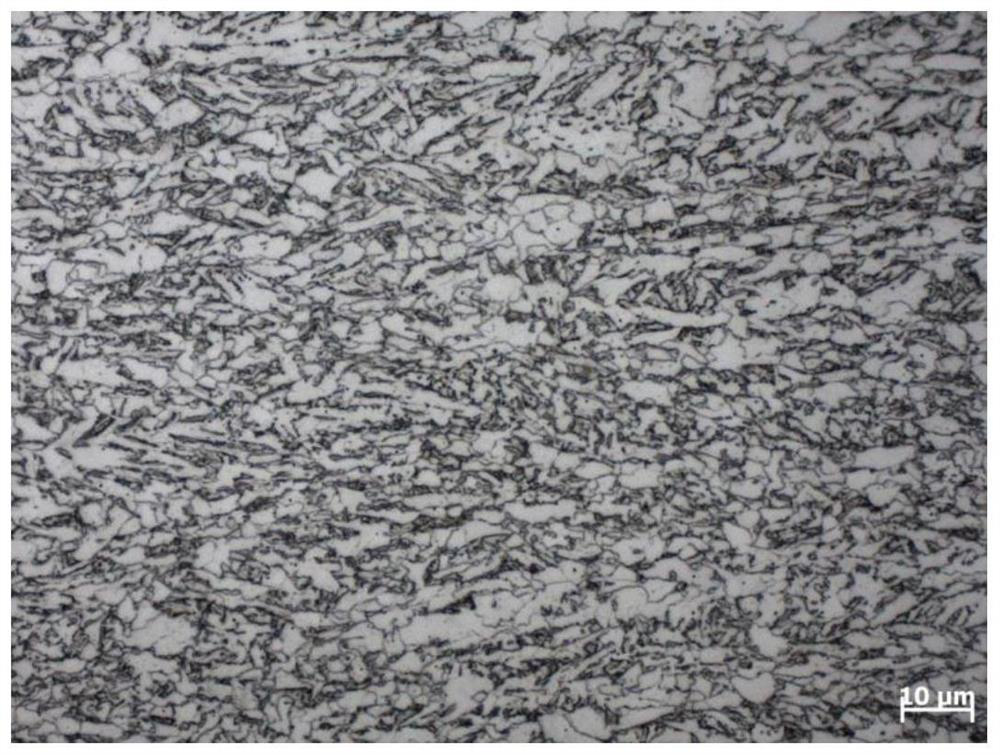

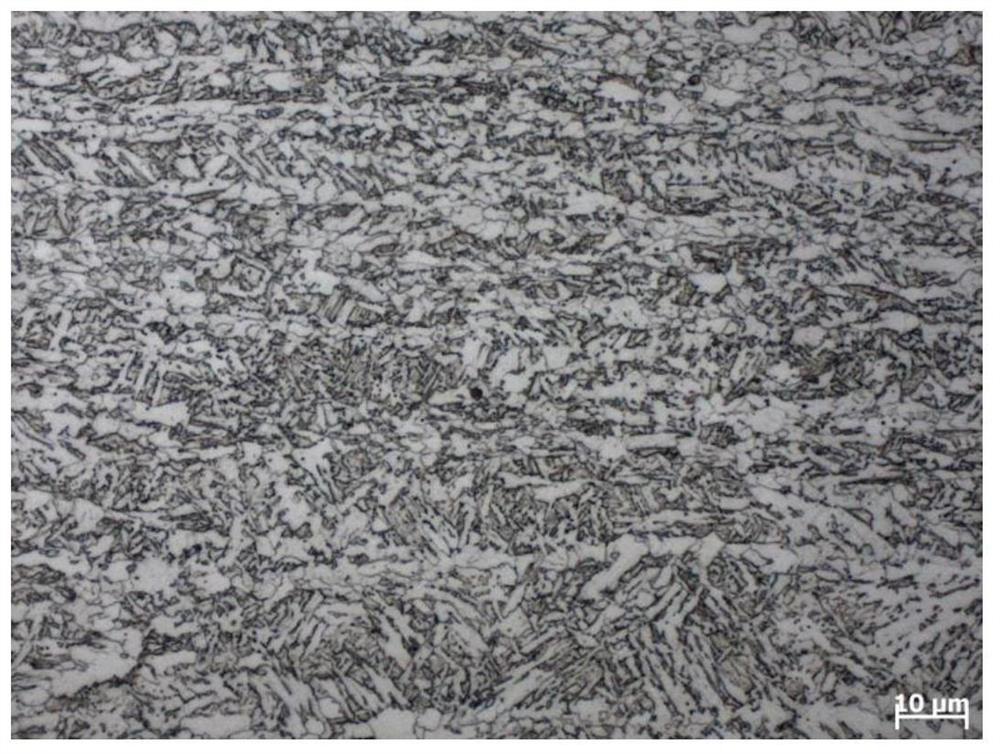

ActiveCN106555133AReduce precipitationImprove corrosion resistanceDrilling rodsFurnace typesCompound (substance)Chemical element

The invention discloses high-strength and anti-corrosion stainless steel. The high-strength and anti-corrosion stainless steel comprises chemical elements including, by mass percent, smaller than or equal to 0.1% of C, 0.1%-0.5% of Si, 0.1%-5% of Mn, 21.0%-23.5% of Cr, 21.5%-25.5% of Ni, 0.1%-5% of Mo, 0.01%-0.10% of Al, 0.01%-2.00% of W, 0.05%-0.10% of RE, 0.01%-0.3% of N, larger than 0% and smaller than or equal to 4.0% of Cu, larger than 0% and smaller than or equal to 2.0% of Co, and the balance Fe and other inevitable impurities. The high-strength and anti-corrosion stainless steel has good H2S and CO2 corrosion resisting performance and acidizing fluid corrosion resisting performance.

Owner:BAOSHAN IRON & STEEL CO LTD

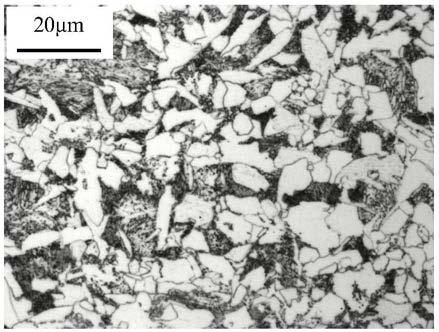

Thin-specification low-yield-ratio high-strength bridge steel and production method thereof

The invention discloses thin-specification low-yield-ratio high-strength bridge steel and a production method thereof. A steel plate adopts a component design of increasing Mn and Cr and reducing Nb and Ti, and chemical components include, by mass, C: 0.06-0.08%, Si: 0.15-0.25%, P: less than or equal to 0.015%, S: less than or equal to 0.008%, Ni: 0.2-0.4%, Mo: 0.1-0.2%, Al: 0.01-0.045%, Mn+Cr: 1.90-2.20%, Nb+Ti: 0.035-0.05% and the balance Fe and other inevitable impurities. By means of a rolling and cooling process of high-temperature finish rolling and after-rolling variable-speed cooling,a ferrite+bainite bidirectional tissue is acquired, and the steel plate has a yield strength 520-570 MPa, a tensile strength 670-760 MPa and a yield ratio 0.69-0.79, and realizes a good balance of a thickness 8-16 mm, a bridge steel strength 500-550 MPa and a yield ratio.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

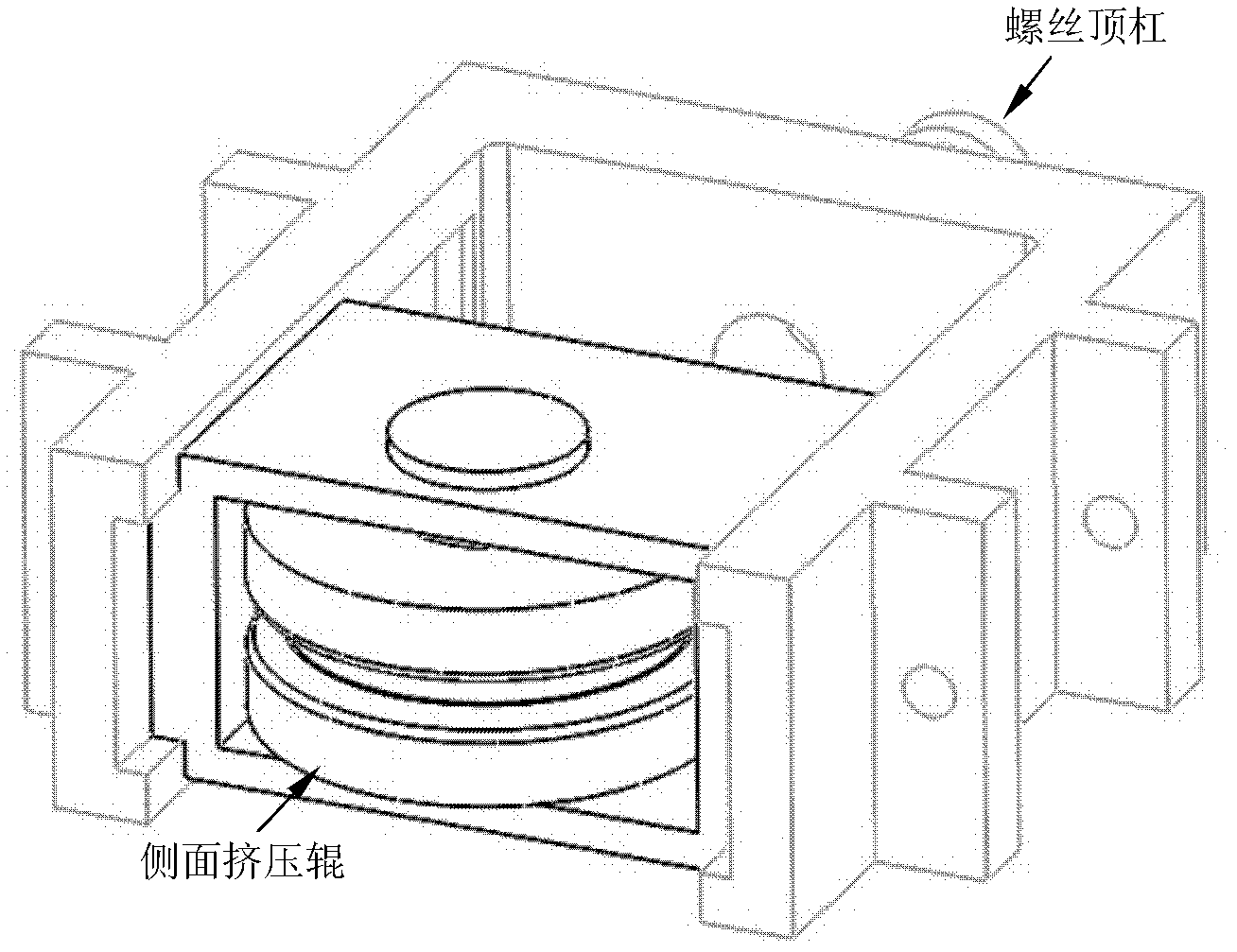

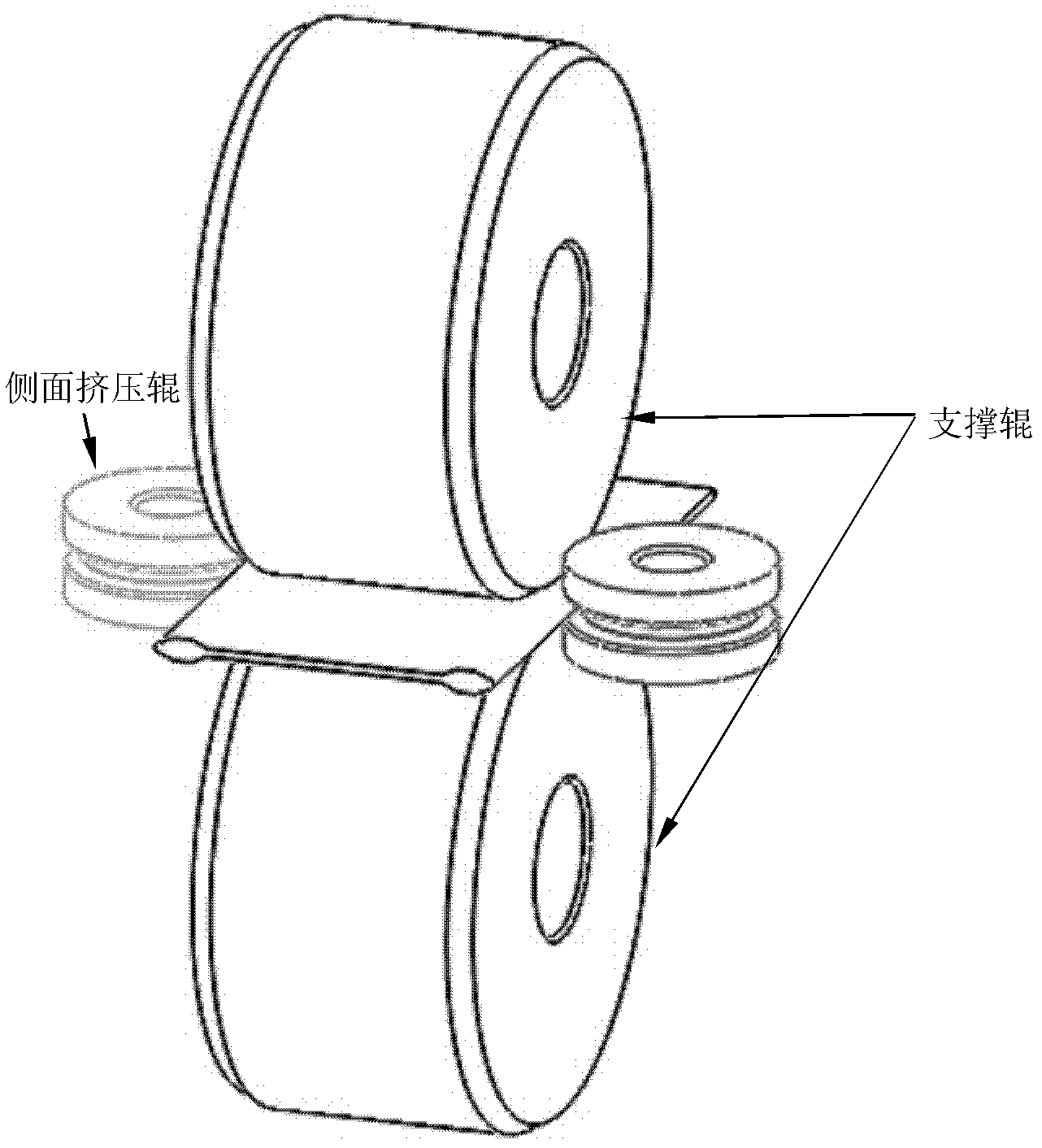

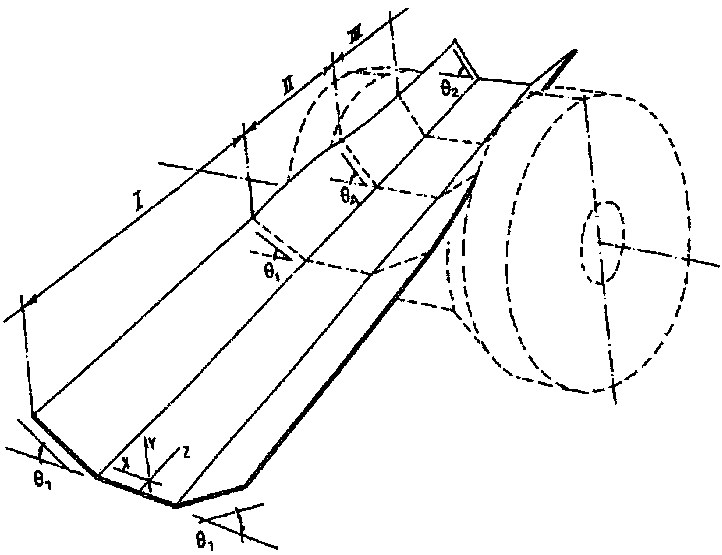

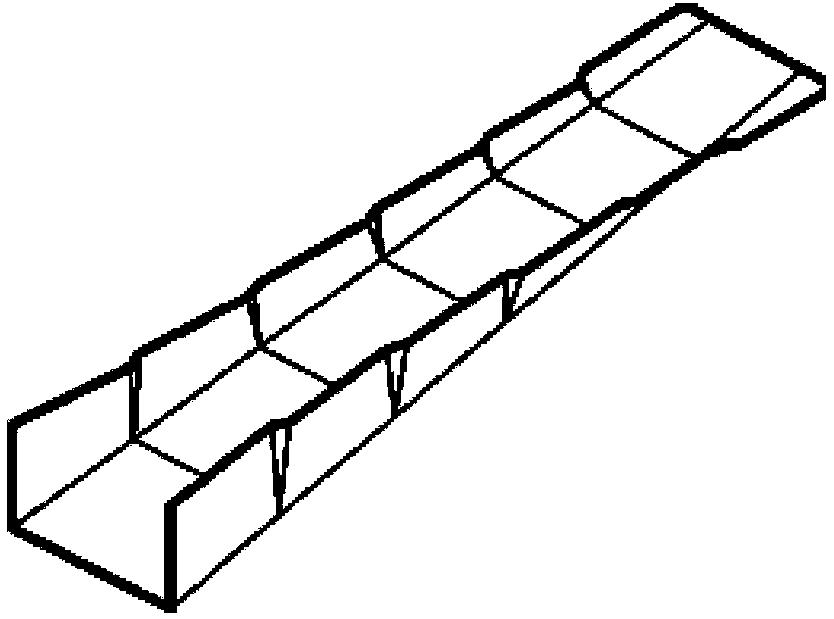

Molding method of cold-bending steel plate pile provided with non-uniform-thickness lock buckle

The invention provides a molding method of a cold-bending steel plate pile provided with a non-uniform-thickness lock buckle, which utilizes induction sensing equipment to heat edge parts of two edges of a flat plate material to 500-900 DEG C to form a molding region with good plasticity; utilizing a side-face extruding roller to gradually extrude the edge parts of the plate material path by path so as to flow the plate material at the edge parts along the thickness direction and further mold a needed non-uniform-thickness transition plate material; utilizing a molding roller to roll the non-uniform-thickness transition plate material into a non-uniform-thickness plate material with a target section; and coldly bending the plate material with the non-uniform-thickness lock buckle by the continuous molding paths to form the steel plate pile provided with the non-uniform-thickness lock buckle. The molding method disclosed by the invention utilizes the side-face extruding roller to gradually extrude the edge parts of the plate material into the non-uniform-thickness lock buckle, and overcomes the problems that the thicknesses of all parts of the traditional cold-bending steel plate pile are the same, the lock buckle part cannot be tightly clamped, the water cannot be stopped and the like.

Owner:UNIV OF SCI & TECH BEIJING

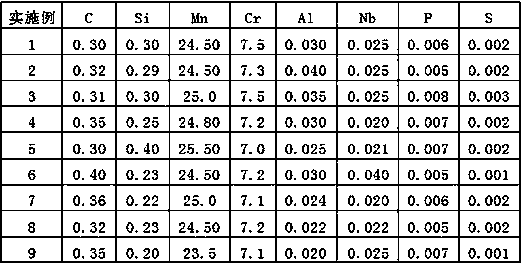

High-toughness austenite type high-manganese steel plate and production method thereof

InactiveCN107858602AAvoid or reduce low temperature brittle phenomenonGuaranteed yieldSheet steelChemical composition

The invention discloses a high-toughness austenite type high-manganese steel plate and a production method thereof. The steel plate consists of the following chemical components in percentage by massof 0.30-0.40% of C, 0.20-0.40% of Si, 23.50-25.50% of Mn, 7.0-7.5% of Cr, 0.020-0.040% of Al, 0.020-0.040% of Nb, less than or equal to 0.008% of P, less than or equal to 0.003% of S and the balance Fe and inevitable impurities. The production method for the steel plate comprises processes of steel-making, continuous casting, heating, rolling and thermal treatment. The chemical components of the steel plate adopt C, Mn and Cr solid solution strengthening; and the obtained steel plate has the characteristics of being high in compactness, relatively high in strength grade, high in ductility, lowin yield ratio, excellent in low-temperature impact toughness and the like, can meet requirements of the high-toughness austenite type high-manganese steel plate, has relatively good comprehensive performances and welding performances, and is relatively low in cost.

Owner:WUYANG IRON & STEEL

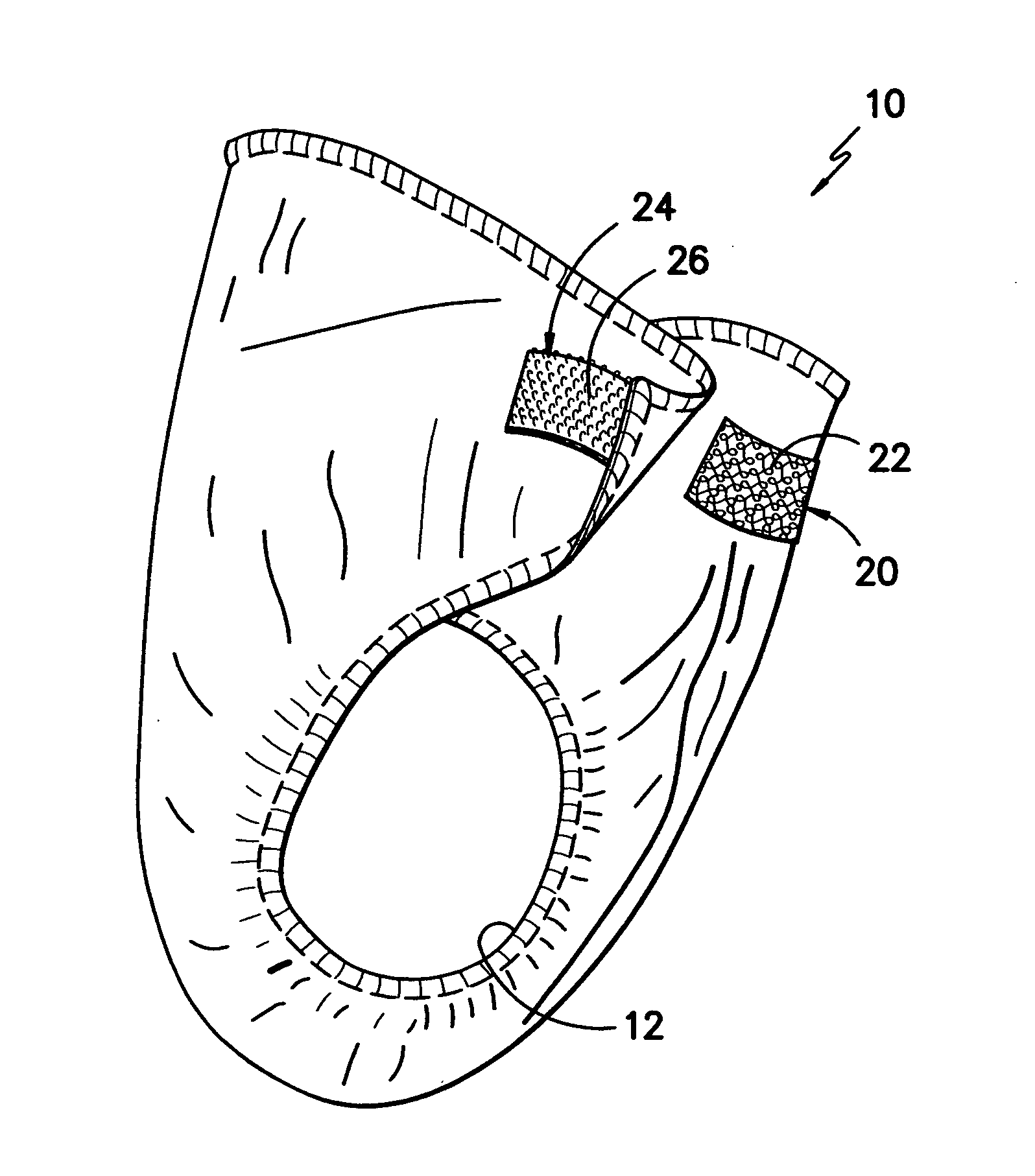

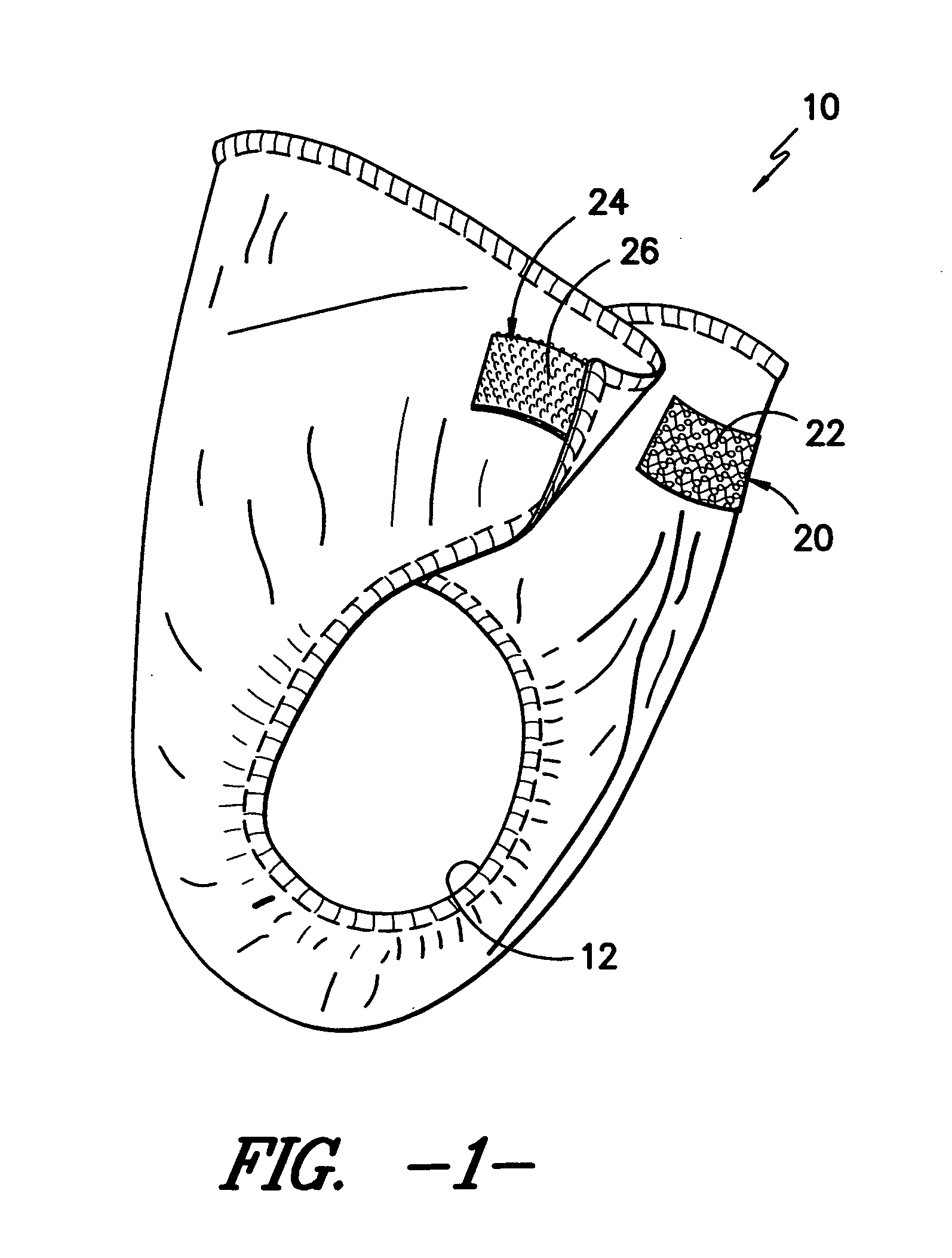

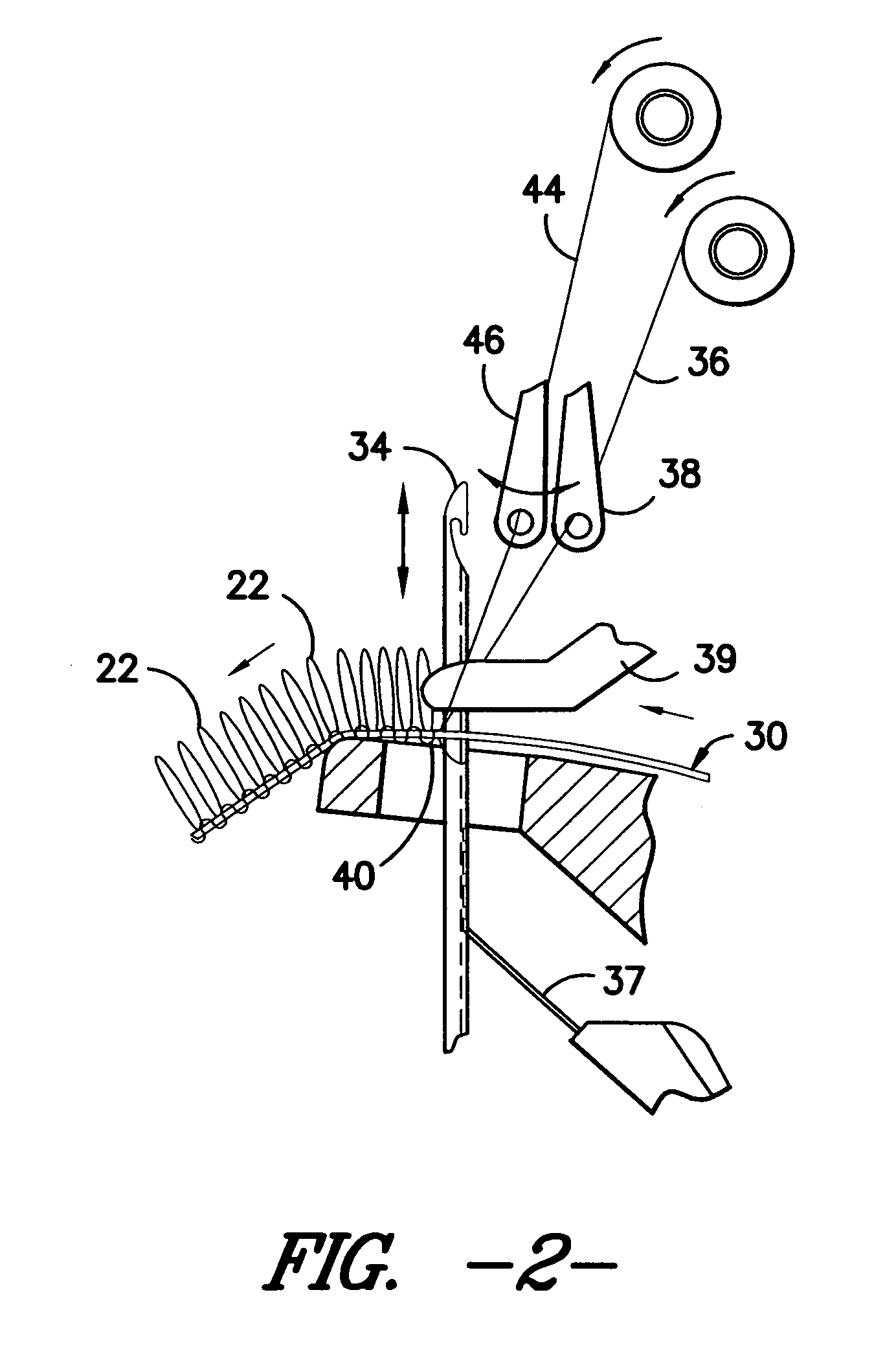

Two bar stitch bonded loop fastener for diaper and related method

ActiveUS20110028936A1High peel strength strengthHigh strength shear strengthLamination ancillary operationsWarp knittingYarnEngineering

A tear away diaper fastening system including a segment of loop material having a plurality of outwardly projecting loop elements adapted to engage cooperating hooking elements in juxtaposed contacting relation. The loop material includes a composite sheet of stitch bonded construction including a polymer film substrate layer. A first plurality of yarn elements extends in stitched relation through the substrate layer to define a plurality of parallel stitch lines of flat stitches extending along the machine direction of the sheet material to form a ground layer substantially covering an upper surface of the substrate layer. A second plurality of yarn elements extends in stitched relation through the substrate layer in zigzag crossing relation between parallel needle lines to define a plurality of raised loops extending above the ground layer.

Owner:TIETEX INT

Hot-rolled enameled steel plate and preparation method thereof

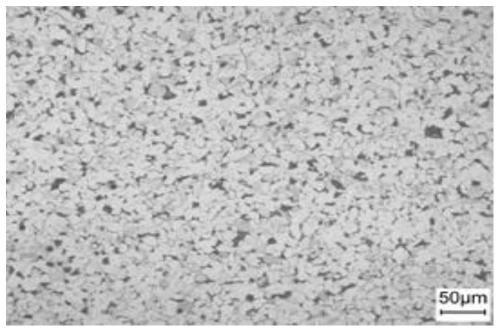

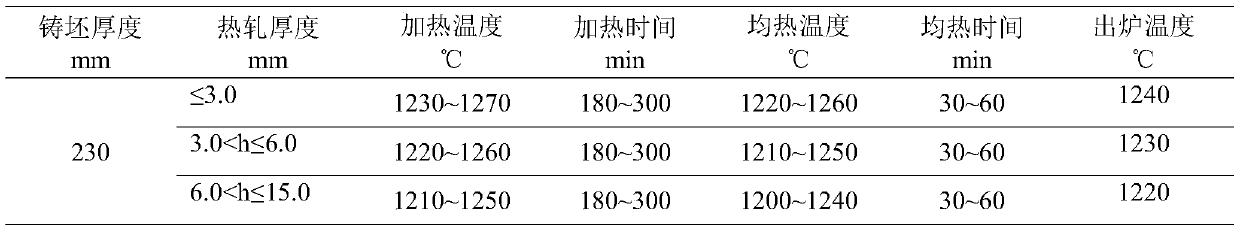

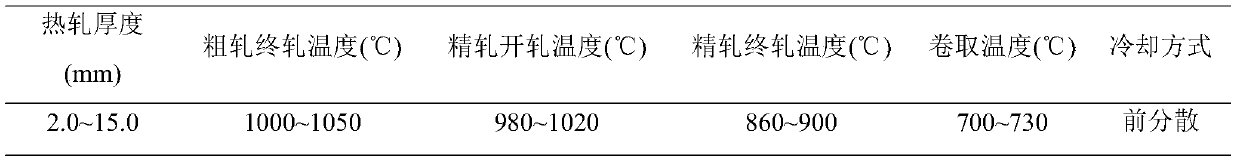

The invention discloses a hot-rolled enameled steel plate and a preparation method thereof. The hot-rolled enameled steel plate comprises, by weight, 0.061%-0.089% of C, 0.11%-0.20% of Si, 0.60%-0.70% of Mn, 0-0.015% of P, 0-0.005% of S, 0.020%-0.050% of Alt, 0.1%-0.2% of Ti, 0-0.006% of N, and the balance Fe and inevitable impurities. According to the mass ratio, the ratio of the Ti to the C is 1.1-3.3. The method includes the steps that (1) molten iron is subjected to pretreatment, converter steelmaking and refining to obtain casting blank molten iron; (2) the molten iron is subjected to continuous casting, and accordingly a casting blank is made; (3) the casting blank is heated and the tapping temperature is controlled; (4) multi-pass rough rolling and finish rolling are carried out, so that a finish-rolled plate is obtained; and (5) reeling is performed at a certain temperature after laminar cooling, and a finished product can be obtained. According to the steel plate prepared through the method, the yield strength is 550-620MPa, the tensile strength is 630-730MPa, and the elongation at break is 22%-30%. According to the hot-rolled enameled steel plate after application of enamel, the yield strength is 350-410MPa, the tensile strength is 430-530MPa, the elongation at break is 33.5%-37%, and the enamel adhesive force reaches level A.

Owner:NORTHEASTERN UNIV +1

Niobium-nitrogen-containing micro-alloyed HRB 400 E steel bar and production method thereof

PendingCN110819892AQuality improvementReduce dosageManufacturing convertersElectric furnaceNiobiumPhysical chemistry

The invention provided a niobium-nitrogen-containing micro-alloyed HRB 400 E steel bar and a production method thereof. The method is characterized in that the precipitation strengthening effect of niobium and nitrogen on the steel bar is utilized, parts of solid solution strengthening element manganese and silicon are replaced, parts or all of micro-alloyed element vanadium are replaced, and meanwhile, microalloying treatment is carried out on the steel bar by means of cheap nitrogen element, and the precipitation strengthening effect of the micro niobium and nitrogen are exerted. The steel bar is characterized in that Rel is 435-490 MPa, Rm is 590-650 MPa, A is 24%-35%, Rm / Rel 1.30-1.42, A<gt> is 11.5%-19%, the cold bending yield is 100%, and Ceq is less than or equal to 0.48%. Accordingto the steel bar and the method, the production cost is reduced by 30-80 yuan / ton compared with the production cost of a traditional method, three-month natural aging is performed, the fluctuation value of Rel and Rm is less than 10 MPa, the welding performance is good, and meanwhile, the performance index of the obtained steel bar is far more than GB / T 1499.2-2018 standard requirement.

Owner:长沙东鑫环保材料有限责任公司 +1

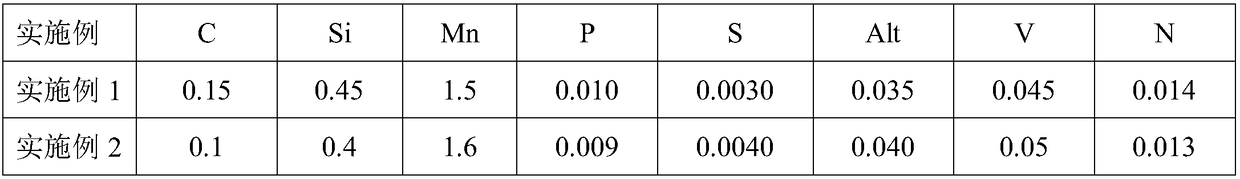

High service strength enameled steel plate and preparation method thereof

The invention discloses a high service strength enameled steel plate and a preparation method thereof. The steel plate is prepared from the following chemical components in percent by weight: 0.1-0.15% of C, 0.3-0.5% of Si, 1-1.8% of Mn, less than 0.013% of P, less than 0.005% of S, 0.020-0.050% of Alt, 0.04-0.07% of V, 0.011-0.015% of N and the balance ferrum and impurities. The preparation method comprises the following steps: 1) carrying out pre-treatment, converter steelmaking and refining on molten iron to obtain casting blank molten iron; 2) continuously casting the molten iron to prepare a casting blank; 3) heating the casting blank; 4) carrying out multi-pass rough rolling and finish rolling to obtain a finish rolled plate; and 5) carrying out laminar cooling to coil to obtain a finished product. The yield strength of the steel plate is 460-550 MPa, the yield strength of the enameled steel plate is 400-460 MPa, and the enameled steel plate can be used for manufacturing a lowertank wall of an enameled spliced tank, the moisture storage capacity of which is greater than 9000 m<3>.

Owner:SHOUGANG CORPORATION +1

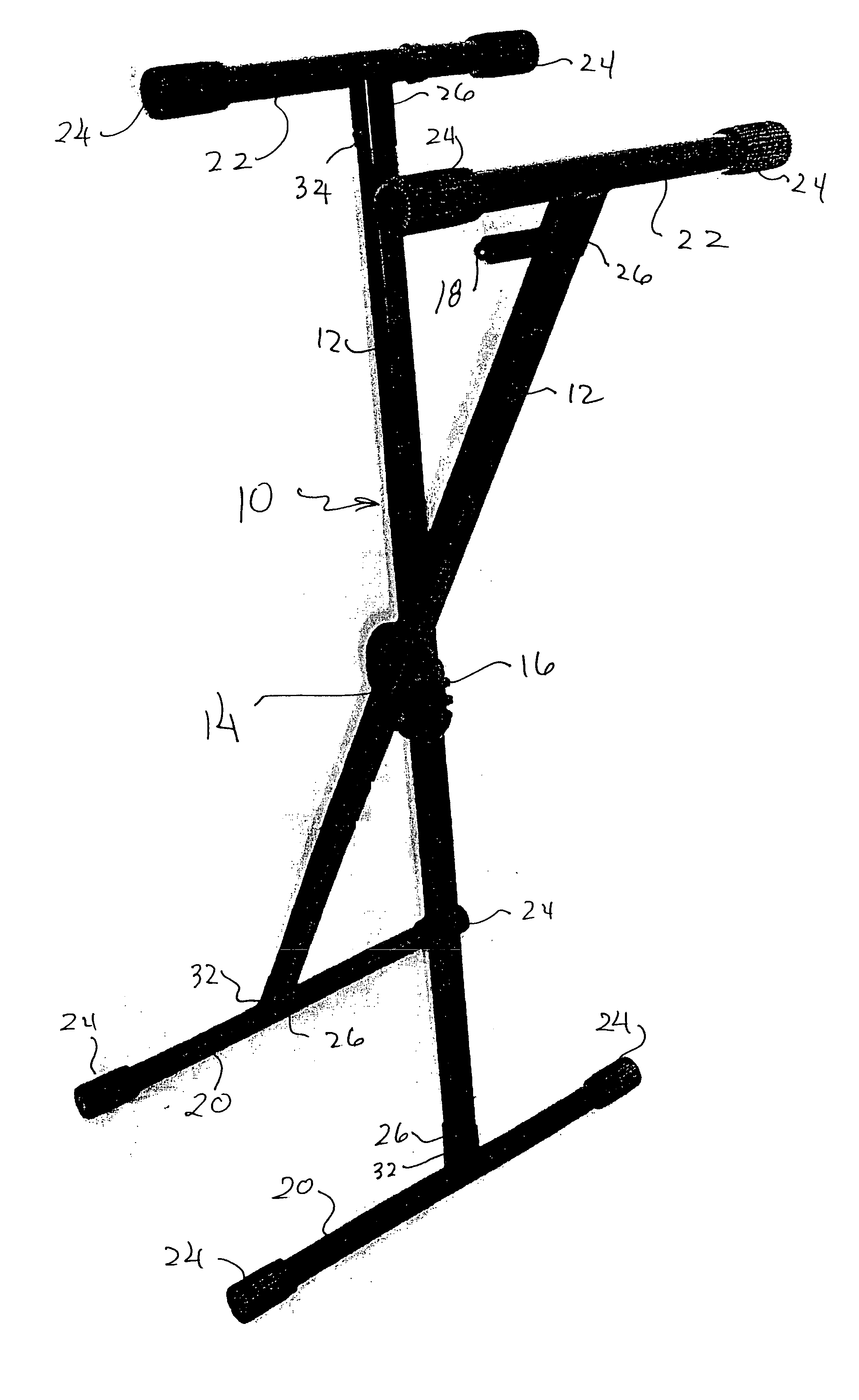

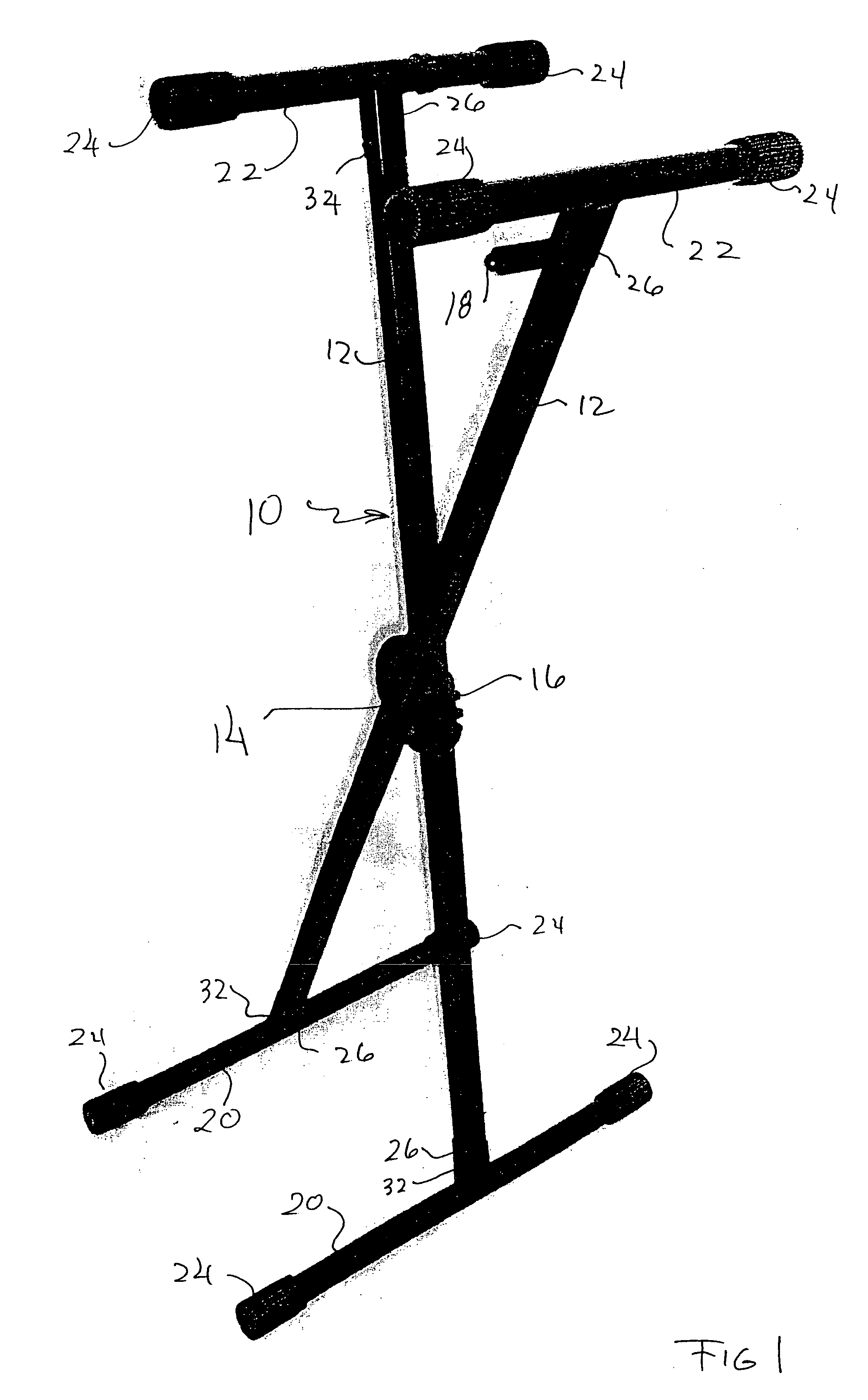

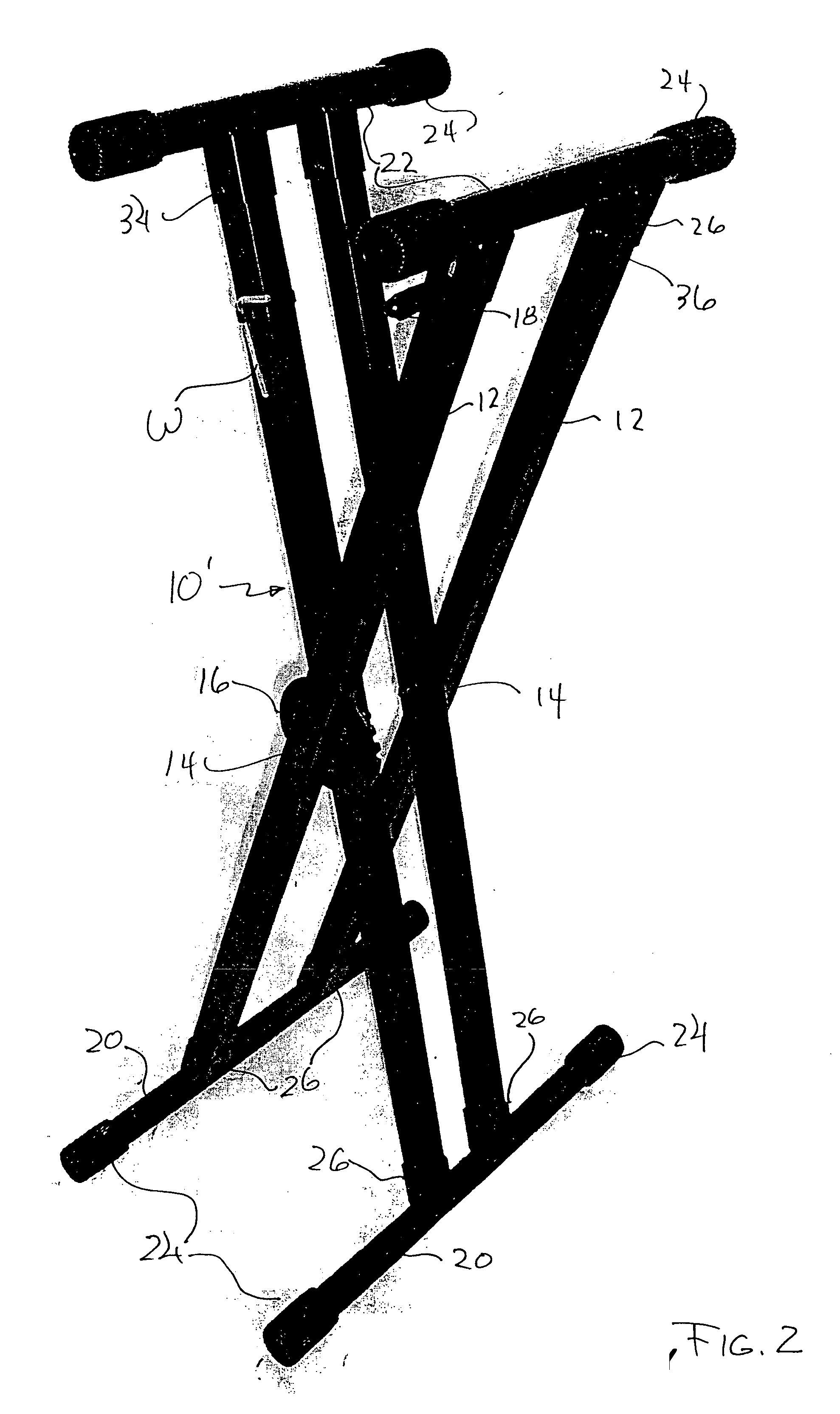

X-style stand having disengageable crosspieces, and packaging combination including the same

InactiveUS20050121566A1Improve stabilityHigh strength levelElectrophonic musical instrumentsStands/trestlesEngineeringFastener

The support members of an X-style stand are separate from the brace assembly, and are assembled therewith by telescopic interengagement of at least one sleeve piece on the support member with the end portion of a leg of the brace, the sleeve piece being affixed to the support member with weldments that extend parallel to the longitudinal axis of the member. The sleeve pieces are fastened to the brace legs by elongate fasteners that extend through aligned apertures, which are also oriented parallel to the axis of the crosspiece. The disassembled stand is contained in a package that is of substantially reduced volume, as compared to the space required to contain an equivalent stand of conventionally welded construction.

Owner:HENNESSEY JAMES R +1

Weathering-resistant steel for high-strength low-yield-strength-ratio weathering-resistant carriage and preparation method thereof

InactiveCN110093568AHigh strength levelSuitable for mass productionChemical compositionHigh intensity

The invention discloses weathering-resistant steel for a high-strength low-yield-strength-ratio weathering-resistant carriage. The weathering-resistant steel comprises the following chemical components of, by mass, 0.10%-0.12% of C, 0.30%-0.50% of Si, 0.30%-0.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.050% of Al, 0.26%-0.36% of Cu, 0.50%-0.60% of Cr, 0.15%-0.25% of Ni, less than or equal to 50 ppm of N and the balance Fe and inevitable inclusions, wherein the mass fraction is 100% in total. The invention also discloses a preparationmethod of the weathering-resistant steel for the high-strength low-yield-strength-ratio weathering-resistant carriage. According to the weathering-resistant steel for the high-strength low-yield-strength-ratio weathering-resistant carriage and the preparation method thereof, the chemical components and the production process of the product are adjusted, and a heat preservation cover in a storehouse is adopted for slow cooling, so that unqualified products caused by the fact that no slow cooling facility exist in the finished product warehouse can be effectively eliminated.

Owner:BAOTOU IRON & STEEL GRP

Low-alloy and high-strength steel plate for anticorrosion, and production method thereof

The invention discloses a low-alloy and high-strength steel plate for anticorrosion, and a production method thereof. The steel plate comprises, by mass, 0.07-0.10% of C, 0.30-0.40% of Si, 0.65-0.85%of Mn, 0.010% or less of P, 0.005% or less of S, 0.30-0.50% of Al, 2.15-2.35% of Cr, 0.35-0.50% of Mo, 0.20% or less of Cu, 0.20% or less of Ni, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the following processes: smelting, continuous casting, heating, rolling and heat treatment. The steel plate has the characteristics of high density, moderate strength level, moderate hardness, excellent -20 DEG C low temperature impact toughness, excellent hydrogen sulfide corrosion resistance, good comprehensive performances and good welding performance, and meets the requirements of pressure containers for hydrogen sulfide corrosion resistant steel.

Owner:WUYANG IRON & STEEL

Hydrogen sulfide corrosion preventing thin steel sheet subjected to long-time simulated post weld heat treatment and production method

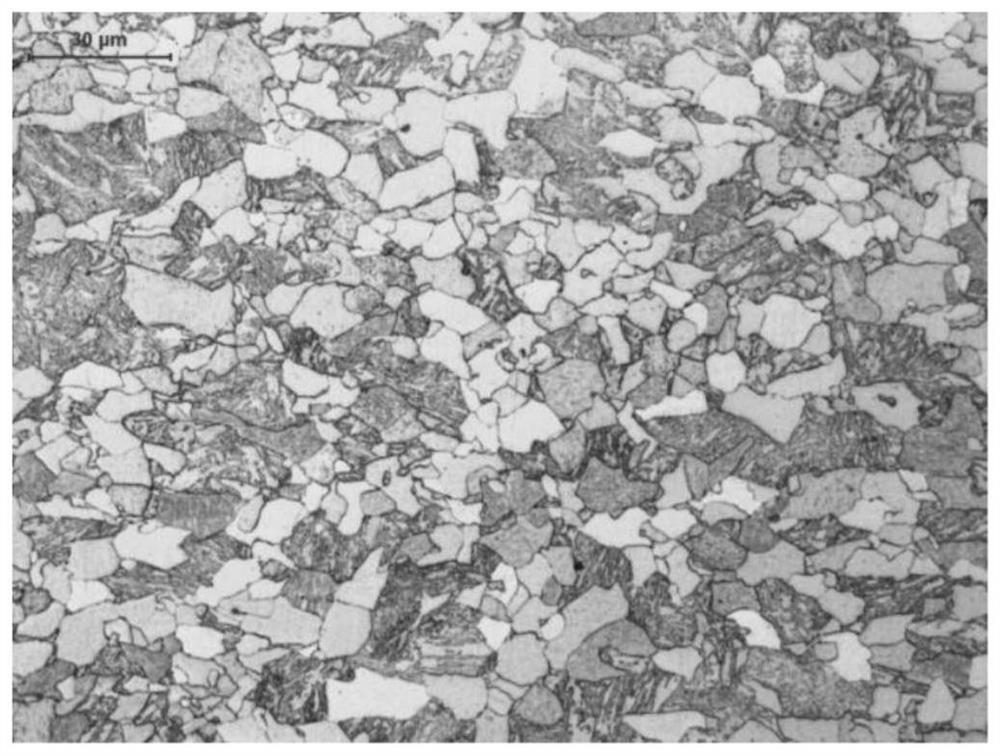

ActiveCN107619999AImprove organizationImprove mechanical propertiesChemical compositionSolid solution strengthening

The invention discloses a hydrogen sulfide corrosion preventing thin steel sheet subjected to long-time simulated post weld heat treatment and a production method. The thin steel sheet comprises the chemical components of, by mass, 0.16%-0.19% of C, 0.20%-0.40% of Si, 1.15%-1.30% of Mn, no more than 0.010% of P, no more than 0.005% of S, 0.020%-0.050% of Al and the balance Fe and inevitable impurities. The production method comprises the heating, rolling and heat treatment processes. The rolling process adopts a two-stage rolling technique, and the heat treatment process adopts a quenching andtempering technique. C and Mn solid solution strengthening is adopted; the steel sheet is high in density and strength grade, excellent in -30 DEG C low-temperature impact toughness, moderate in hardness and excellent in hydrogen sulfide corrosion preventing performance, the requirement for hydrogen sulfide corrosion preventing steel, subjected to long-time simulated post weld heat treatment, fora pressure vessel can be met, and good comprehensive performance and welding performance are achieved; the number of banded structures is 0; and the thickness specification of the thin steel sheet is8-20 mm.

Owner:WUYANG IRON & STEEL

Continuous induction heat treatment process for high-strength finish-rolled spiral steel bar

InactiveCN1234887CReduce oxidationHeating fastIncreasing energy efficiencyFurnace typesChemical compositionInduction heater

The present invention is heat treatment process of high-strength finish-rolled spiral steel bar. The finish-rolled spiral steel bar in rotary state is fed from the feeding system of the continuous heat treatment apparatus to the roller conveyer at the speed of 2-6 m / min, heated to 800-1000 deg.c in one induction heater, quenched in the cooler at temperature lower than 300 deg.c, and tempered in one other induction heater at 500-700 deg.c to produce finish-rolled spiral steel bar of higher strength grade. The finish-rolled spiral steel bar through said heat treatment process has obviously raised mechanical performance, thick hardened layer, fined crystal grains, stable performance, high strength and high toughness.

Owner:ANGANG STEEL CO LTD

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101BEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsChemical compositionPower station

Owner:WUYANG IRON & STEEL

Structural steel plate for bridge with yield strength 690mpa and production method thereof

The invention discloses a structure steel plate for a bridge with the yield strength being 690MPa and a production method thereof. The structure steel plate comprises the following components in percent by weight: 0.040 percent to 0.080 percent of C, 0.20 percent to 0.25 percent of Si, 1.50 percent to 1.65 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.040 percent to 0.050 percent of Nb, 0.006 percent to 0.018 percent of Ti, 0.25 percent to 0.35 percent of Cr, 0.25 percent to 0.30 percent of Mo, 0.30 percent to 0.40 percent of Cu, 0.20 percent to 0.30 percent of Ni and the balance of Fe and unavoidable impurities, the sensitive composition of welding cracks meets the formula Pcm is less than or equal to 0.22, the carbon equivalent CEV is less than or equal to 0.50, 10C plus 4Cr plus Cu equals to 6.5 to 7.5. The structure steel plate designed and produced by the process has good toughness; the yield strength Rel is more than or equal to 690MPa, the tensile strength Rm is more than or equal to 770MPa, the elongation A is more than or equal to 18 percent, and -40 DEG C low-temperature impacting performance is more than or equal to 100J. Compared with the existing bridge steel technology, the structure steel plate disclosed by the invention has the advantages that the strength level is greatly improved; in addition, the welding performance of the steel plate is improved by strictly controlling the carbon equivalent CEV to be less than or equal to 0.50 and Pcm to be less than or equal to 0.22.

Owner:武汉钢铁有限公司

Microalloy HRB500E steel bar containing chrome and nitrogen and production method thereof

The invention discloses a microalloy HRB500E steel bar containing chrome and nitrogen and a production method thereof. By fully utilizing the strengthening effect and the corrosion-proof effect of chrome on the steel bar, solid solution strengthening elements, namely manganese and silicon, are partially substituted, and a microalloy element, namely vanadium or columbium is partially or fully substituted; a cheap nitrogen element is used for performing microalloy treatment on the steel bar, so that the micro nitrogen separating strengthening effect is achieved; by the production method, the HRB500E steel bar can be produced; Rel of the steel bar is 520 to 580MPa, Rm of the steel bar is 640 to 730 MPa, A is 22 to 32 percent, Rm / Rel is 1.30 to 1.40, the cold bending qualified rate is 100 percent, the welding carbon equivalent weight is less than or equal to 0.50, and the comprehensive cost of one ton of steel bar is 40-100 yuan lower than that of one ton of the steel bar produced by the conventional method; during aging of three months, the fluctuation values of the Rm value and the Rel value are less than 10MPa; and the steel bar has excellent welding performance and good corrosion-proof property.

Owner:长沙东鑫环保材料有限责任公司

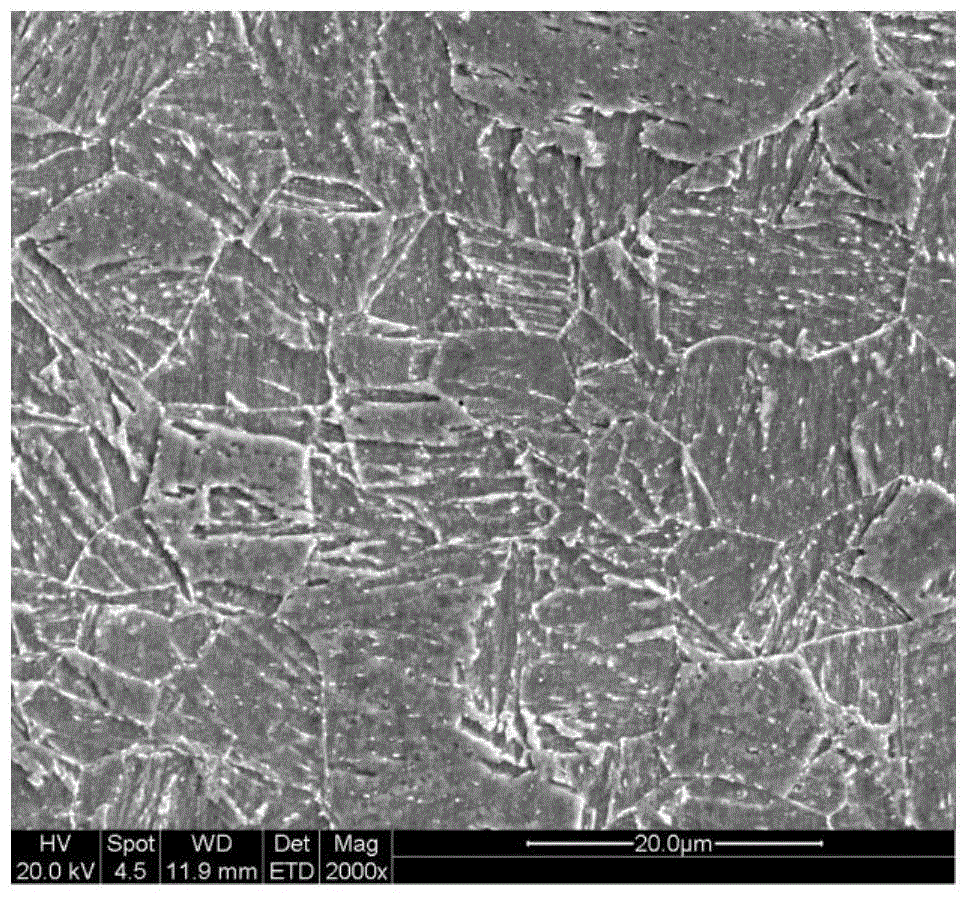

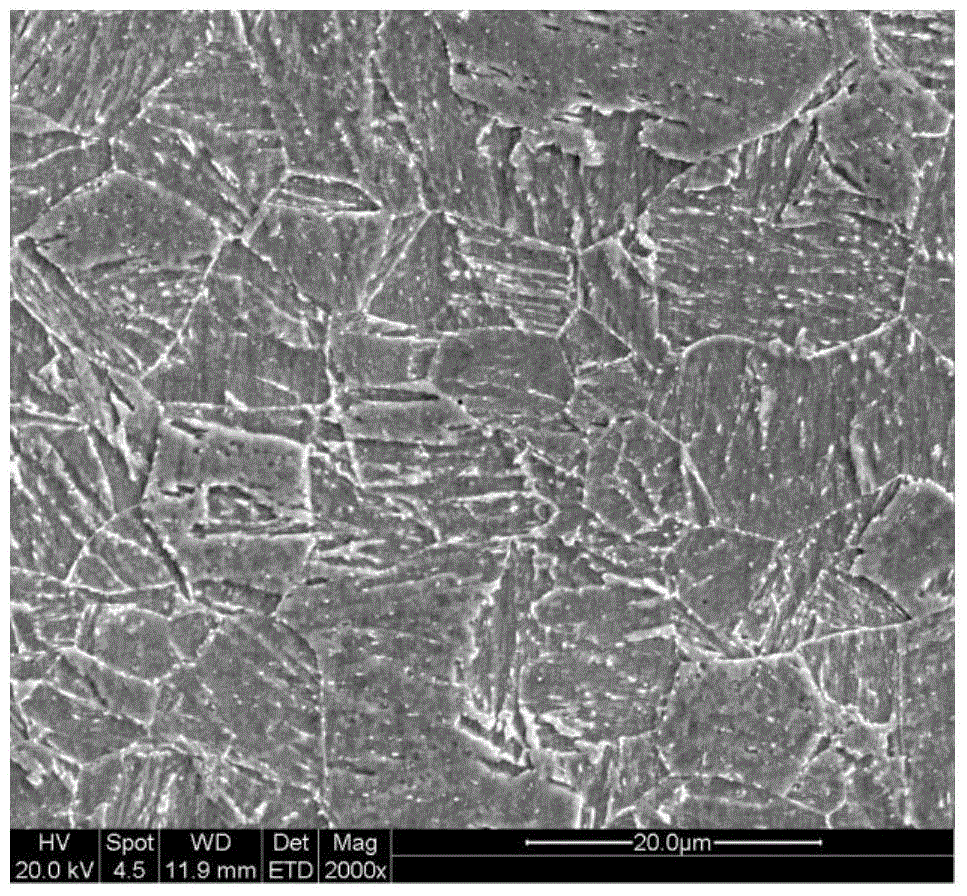

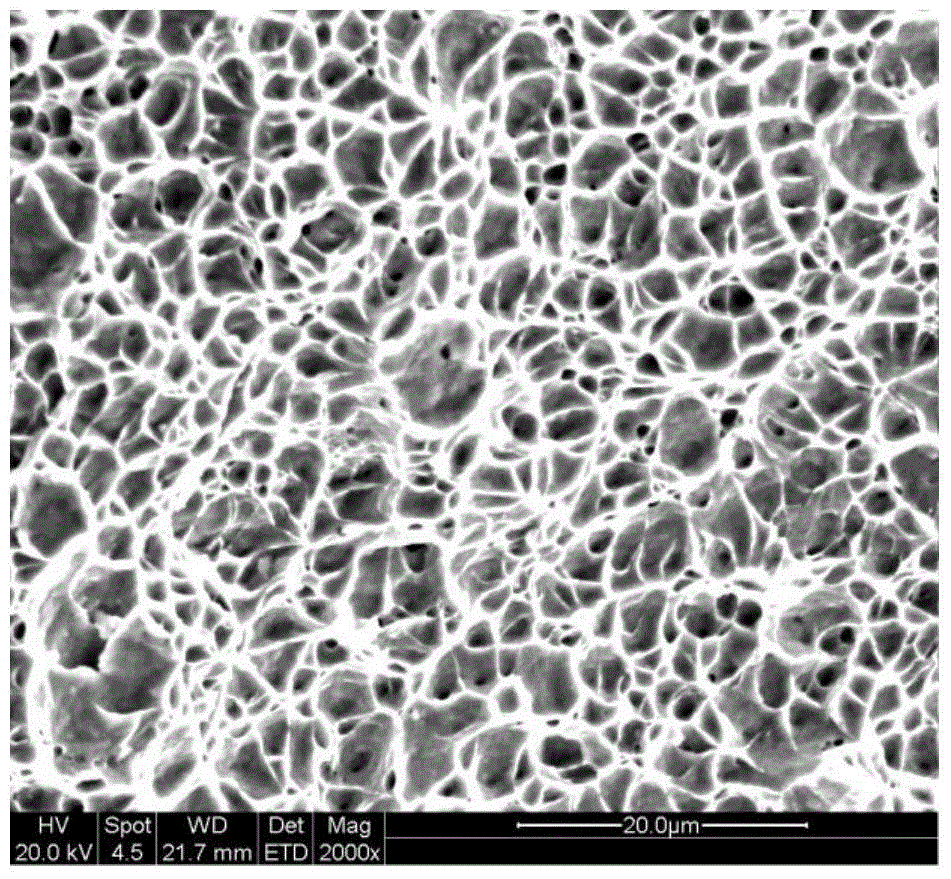

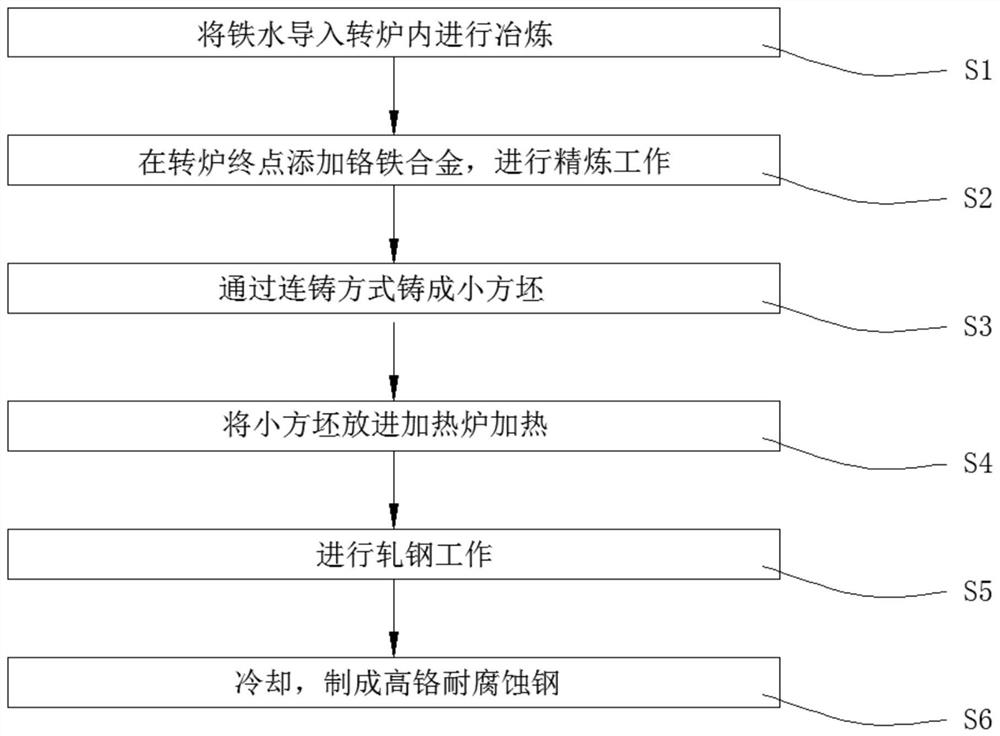

A kind of high chromium corrosion-resistant steel and its preparation method and application

ActiveCN110964982BAccelerated corrosionExcellent strength levelChemical compositionPhysical chemistry

The invention relates to a high-chromium corrosion-resistant steel and its preparation method and application, and belongs to the technical field of corrosion-resistant steel. The high-chromium corrosion-resistant steel provided by the invention includes the following chemical components in mass fractions: C: 0.03-0.05%, Si : 0.5‑0.7%, Mn: 0.5‑0.7%, P: ≤0.02%, S: ≤0.01%, Cr: 6.5‑8.0%, N: 0.0040‑0.01%, and the rest are Fe and unavoidable impurities. The high chromium corrosion-resistant steel provided by the invention does not need to add expensive alloys, and has excellent corrosion performance, such as buildings and bridges with high strength and high plasticity and toughness. When chromium corrosion-resistant steel is tested for corrosion resistance, it is corroded in 1.5-2.5% NaCl alkaline solution for 70-74 hours by a periodic immersion tester. The experimental temperature is 40-50°C and the humidity is 65-75%.

Owner:SHOUGANG CORPORATION

High vibration resistance construction structural steel and production process thereof

InactiveCN107746918AHigh strength levelImprove seismic performanceShock resistanceUltimate tensile strength

The invention discloses a high vibration resistance construction structural steel and a production process thereof. The steel comprises, by weight, 0.18-0.35% of C, 0.15-0.50% of Si, 1.35-1.55% of Mn,no more than 0.015% of P, no more than 0.015% of S, no more than 0.025% of P and S, 0.03-0.055% of Nb, 0.20-1.30% of Cr, 0.10-0.20% of Mo, 0.20-0.50% of Ni, 0.1-0.2% of Cu, 0.05-0.12% of W, 0.0015-0.0025% of B, 0.01-0.015% of Co, and the balance Fe. The high vibration resistance construction structural steel is high in vibration resistance performance, high in stretchability, high in strength grading, and high in toughness; the higher degree of vibration resistance requirements can be met; the production process is simple; the construction cost is low; and the high vibration resistance construction structural steel is suitable for large-scale promotion and application in high-rise buildings.

Owner:YANAN UNIV

A kind of high-strength anti-corrosion stainless steel, oil casing and manufacturing method thereof

ActiveCN106555133BReduce precipitationImprove corrosion resistanceDrilling rodsFurnace typesImpurityAnti-corrosion

The invention discloses high-strength and anti-corrosion stainless steel. The high-strength and anti-corrosion stainless steel comprises chemical elements including, by mass percent, smaller than or equal to 0.1% of C, 0.1%-0.5% of Si, 0.1%-5% of Mn, 21.0%-23.5% of Cr, 21.5%-25.5% of Ni, 0.1%-5% of Mo, 0.01%-0.10% of Al, 0.01%-2.00% of W, 0.05%-0.10% of RE, 0.01%-0.3% of N, larger than 0% and smaller than or equal to 4.0% of Cu, larger than 0% and smaller than or equal to 2.0% of Co, and the balance Fe and other inevitable impurities. The high-strength and anti-corrosion stainless steel has good H2S and CO2 corrosion resisting performance and acidizing fluid corrosion resisting performance.

Owner:BAOSHAN IRON & STEEL CO LTD

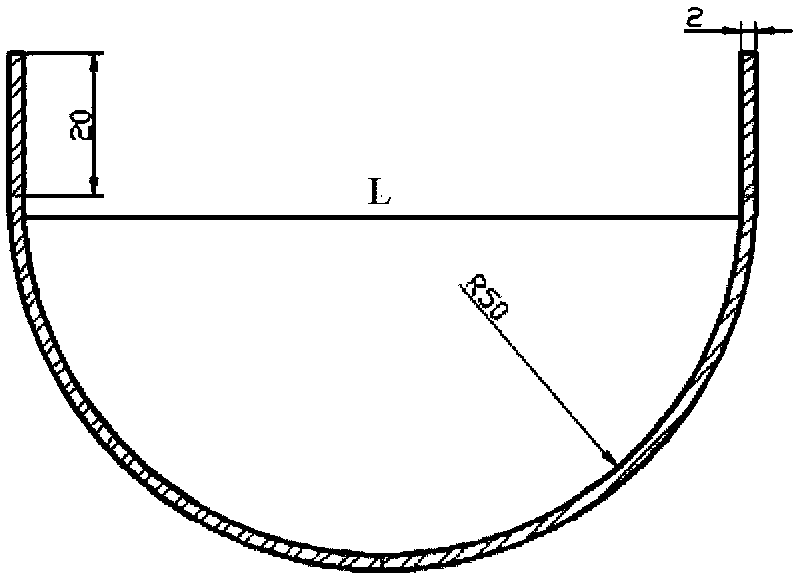

Method for producing cold-formed steel of U-shaped davit arm

InactiveCN102672014BImprove plasticityGuaranteed high plasticity requirementsSheet steelHigh intensity

The invention relates to a method for producing the cold-formed steel of a U-shaped davit arm. The method comprises the following steps of: leading strong-strength sheet steel or a strong-strength steel coil into a roll for first formation, wherein the strong-strength sheet steel or the strong-strength steel coil is formed totally for 3 to 6 times; between the first formation and second formation, arranging induction heating equipment, and while forming profile steel, performing induction heating and stretching and straightening the sheet steel by utilizing roll speed differences produced by different roll diameters in the formation of each time by using the induction heating equipment; actually measuring the actual temperature of the sheet steel in the formation of each subsequent time in field according to sheet steel feeding velocity v, and controlling the temperature in an additional heating way; and performing subsequent operation such as cooling and shearing until strong-strength semicircular large-radius profile steel meeting target requirements is formed. The processes of induction heating, synchronous stretching and straightening of the roll, and the like are introduced into the conventional cold forming process, so that the low cost and high efficiency of the cold-formed steel and the characteristics of weak forming force, optimized size and the like of heat-formed sheet steel are integrated.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com