Hot-rolled enameled steel plate and preparation method thereof

A technology of steel plate and enamel, which is applied in the field of hot-rolled enamel steel plate and its preparation, can solve the problems of hot-rolled enamel steel, etc., and achieve the effects of good anti-scaling performance, good formability, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A hot-rolled enamel steel plate, its chemical composition is shown in Table 3 by weight percentage, and its thickness is 7.5mm.

[0074] The above-mentioned preparation method of hot-rolled enamelled steel plate comprises the following steps:

[0075] Step 1, the molten iron is pretreated, converted into steel and refined to obtain molten iron with the composition ratio of the hot-rolled enamel steel plate; wherein, the chemical composition of the hot-rolled enamel steel plate is shown in Table 3 by weight percentage;

[0076] Among them, the KR desulfurization deep desulfurization technology is adopted, and after the KR desulfurization is completed, the S in the molten iron is ≤0.002%, so as to ensure that the S in the finally obtained enamelled steel is <0.005%.

[0077] Step 2, continuous casting:

[0078] The refined molten iron is subjected to continuous casting to obtain cast slabs; wherein, the casting speed of the continuous casting process is 1m / min.

[0079]...

Embodiment 2

[0094] A hot-rolled enamel steel plate, its chemical composition is shown in Table 3 by weight percentage, and its thickness is 7.5mm.

[0095] The above-mentioned preparation method of hot-rolled enamelled steel plate comprises the following steps:

[0096] Step 1, the molten iron is pretreated, converted into steel and refined to obtain molten iron with the composition ratio of the hot-rolled enamel steel plate; wherein, the chemical composition of the hot-rolled enamel steel plate is shown in Table 3 by weight percentage;

[0097] Among them, the KR desulfurization deep desulfurization technology is adopted. After the KR desulfurization is completed, the S in the molten iron is ≤0.002%, so as to ensure that the S in the final enamelled steel is <0.005%;

[0098] Step 2, continuous casting:

[0099] The refined molten iron is subjected to continuous casting to obtain cast slabs; wherein, the casting speed of the continuous casting process is 1m / min.

[0100] Step 3, heatin...

Embodiment 3

[0114] A hot-rolled enamel steel plate, its chemical composition is shown in Table 3 by weight percentage, and its thickness is 8mm.

[0115] The above-mentioned preparation method of hot-rolled enamelled steel plate comprises the following steps:

[0116] Step 1, the molten iron is pretreated, converted into steel and refined to obtain molten iron with the composition ratio of the hot-rolled enamel steel plate; wherein, the chemical composition of the hot-rolled enamel steel plate is shown in Table 3 by weight percentage;

[0117] Among them, the KR desulfurization deep desulfurization technology is adopted, and after the KR desulfurization is completed, the S in the molten iron is ≤0.002%, so as to ensure that the S in the finally obtained enamelled steel is <0.005%.

[0118] Step 2, continuous casting:

[0119] The refined molten iron is continuously cast to obtain a cast slab; wherein, the casting speed of the continuous casting process is 1.1m / min.

[0120] Step 3, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

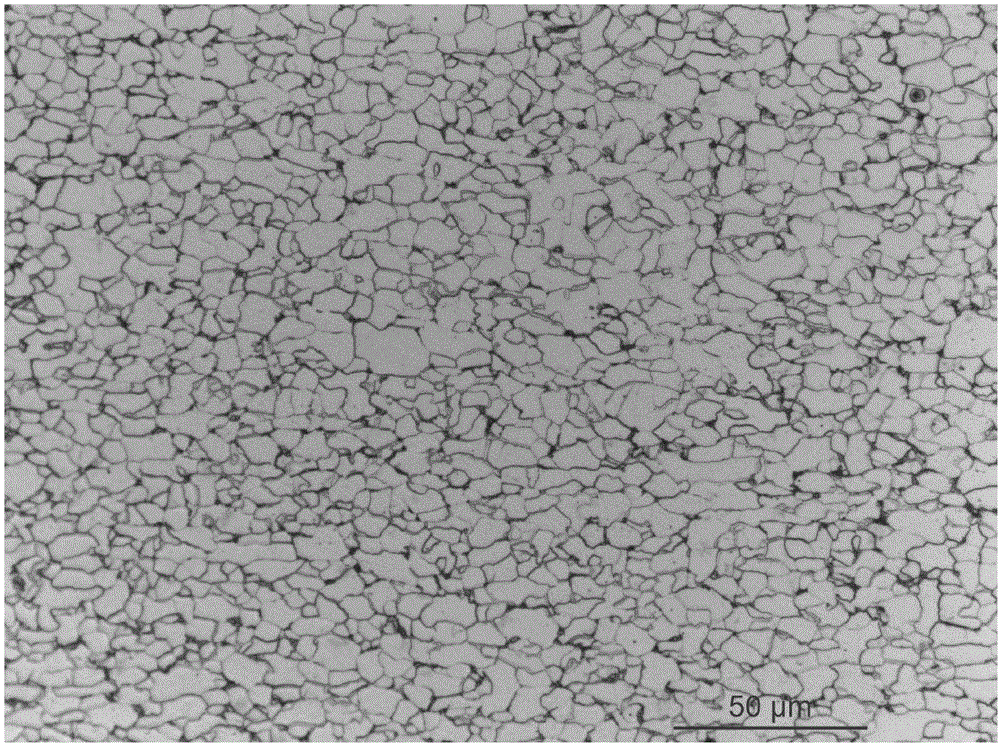

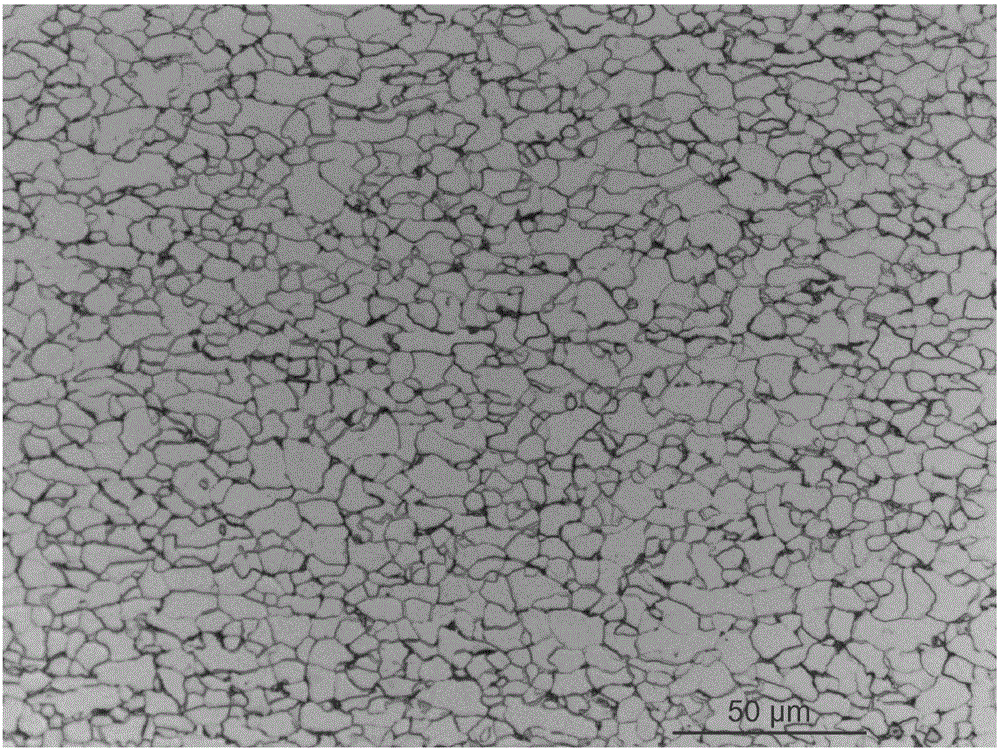

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com