Thin-specification low-yield-ratio high-strength bridge steel and production method thereof

A technology with low yield strength ratio and production method, which is applied in the field of metallurgy, can solve the problems of large influence of thin-gauge steel plate shape, grain recovery and growth, and reduced production efficiency, so as to avoid grain recovery and growth, yield strength, etc. Easier to control and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

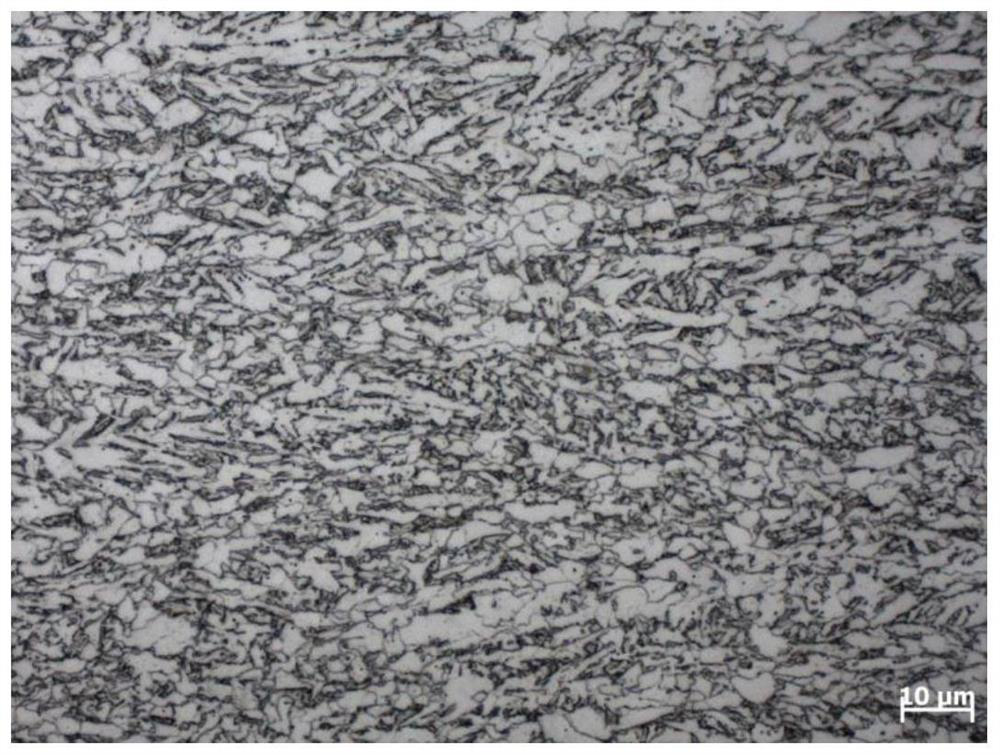

Image

Examples

Embodiment 1

[0037] The chemical composition of the steel plate includes by weight percentage: C 0.06%, Si 0.18%, Mn 1.5%, Cr 0.40%, Mo 0.15%, Ni 0.30%, Nb 0.035%, Ti 0.015%, Alt 0.030%, P 0.009% , S0.002%, the rest is Fe and unavoidable impurities.

[0038] In the continuous casting slab heating process, the ingot heating temperature is 1200°C; the rolling process is two-stage controlled rolling, the rough rolling start temperature is 1050°C, the finish rolling start temperature is 910°C, and the finish rolling temperature is 860°C.

[0039] The hot-rolled steel plate is subjected to variable-speed cooling, and the cooling steps are as follows: first, the hot-rolled plate is rapidly cooled to 730° C., and the cooling rate is 18° C. / s. Second, the steel plate is slowly cooled to 670°C at a cooling rate of 2°C / s. Finally, the steel plate is cooled to 300°C at a cooling rate of about 15°C / s.

[0040] The mechanical properties of the steel plate prepared by this composition and process are ...

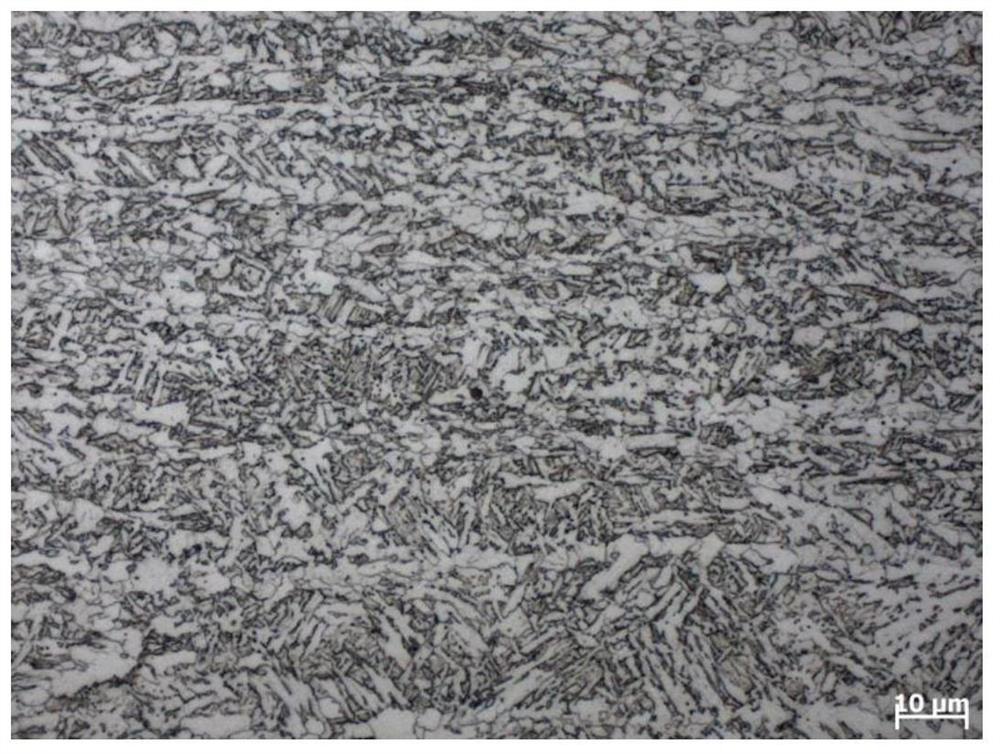

Embodiment 2

[0042] The chemical composition of the steel plate includes by weight percentage: C 0.06%, Si 0.20%, Mn 1.55%, Cr 0.45%, Mo 0.10%, Ni 0.20%, Nb 0.025%, Ti 0.015%, Alt 0.030%, P 0.010% , S0.001%, the rest is Fe and unavoidable impurities.

[0043] In the continuous casting slab heating process, the ingot heating temperature is 1200°C; the rolling process is two-stage controlled rolling, the rough rolling start temperature is 1060°C, the finish rolling start temperature is 890°C, and the finish rolling temperature is 830°C.

[0044] The hot-rolled steel plate is subjected to variable-speed cooling, and the cooling steps are as follows: first, the hot-rolled plate is rapidly cooled to 700° C., and the cooling rate is 15° C. / s. Second, the steel plate is slowly cooled to 645°C at a cooling rate of 3°C / s. Finally, the steel plate is cooled to 290°C at a cooling rate of about 20°C / s.

[0045] The mechanical properties of the steel plate prepared by this composition and process are...

Embodiment 3

[0047] The chemical composition of the steel plate includes by weight percentage: C 0.07%, Si 0.20%, Mn 1.65%, Cr 0.55%, Mo 0.10%, Ni 0.20%, Nb 0.020%, Ti 0.015%, Alt 0.030%, P 0.008% , S0.002%, the rest is Fe and unavoidable impurities.

[0048] In the continuous casting slab heating process, the steel ingot heating temperature is 1200°C; the rolling process is two-stage controlled rolling, the rough rolling start temperature is 1060°C, the finish rolling start temperature is 930°C, and the finish rolling temperature is 850°C.

[0049] The hot-rolled steel plate is subjected to variable-speed cooling, and the cooling steps are as follows: first, the hot-rolled plate is rapidly cooled to 680° C., and the cooling rate is 18° C. / s. Second, the steel plate is slowly cooled to 620°C at a cooling rate of 4°C / s. Finally, the steel plate is cooled to 250°C at a cooling rate of about 25°C / s.

[0050] The mechanical properties of the steel plate prepared by this composition and proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com