Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

580results about How to "Improve rolling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

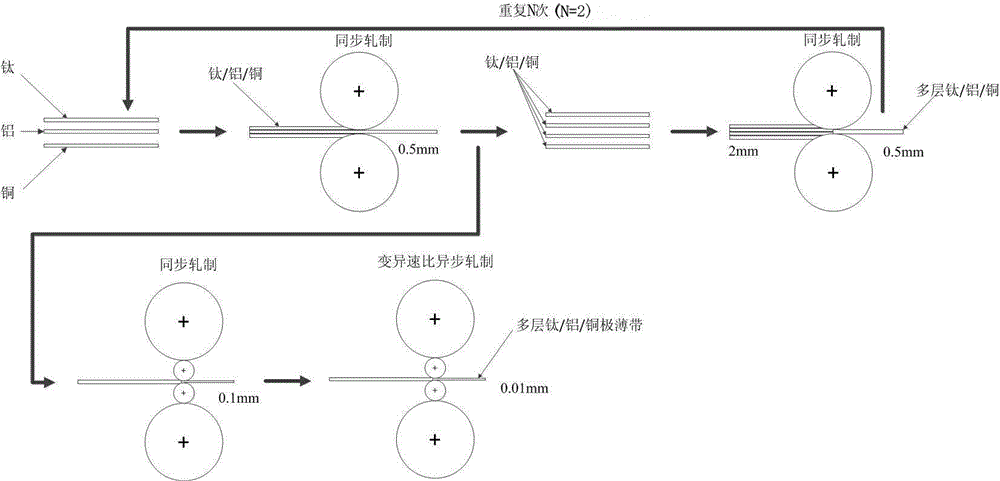

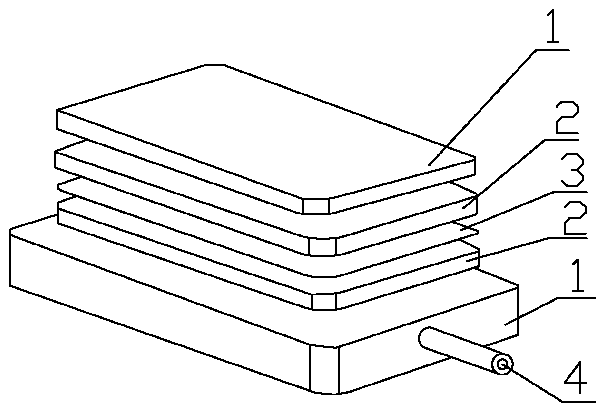

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

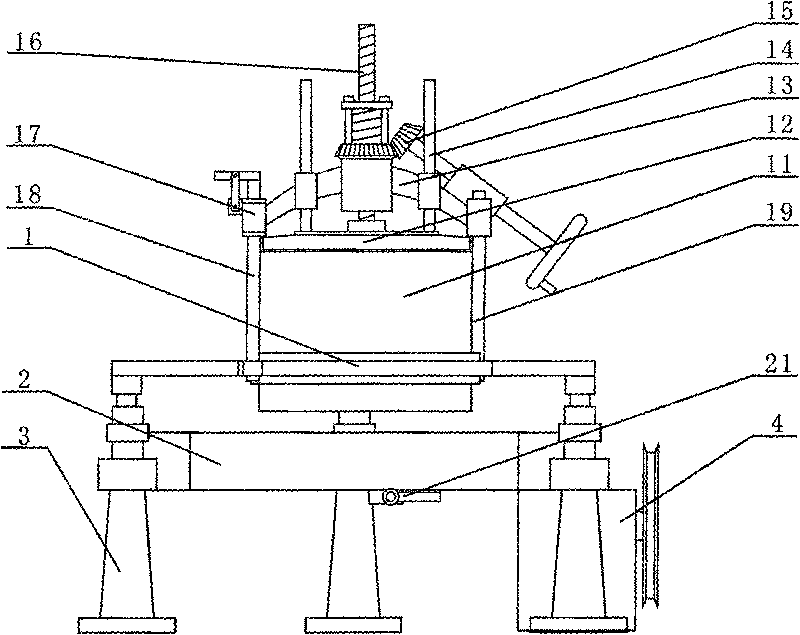

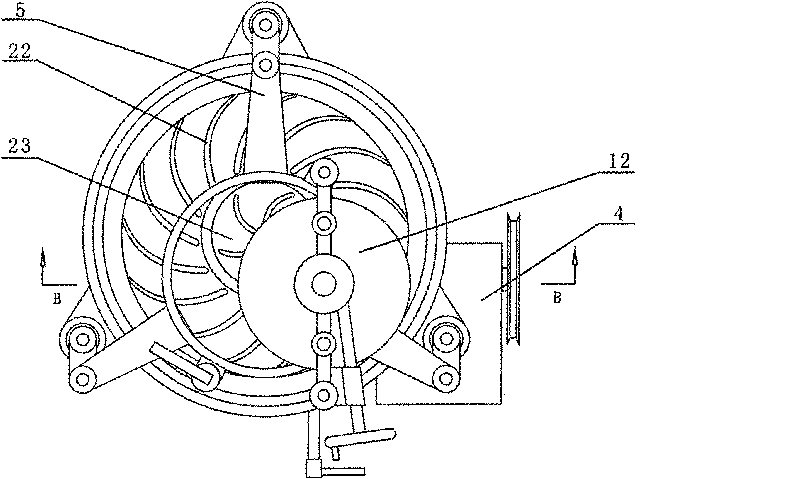

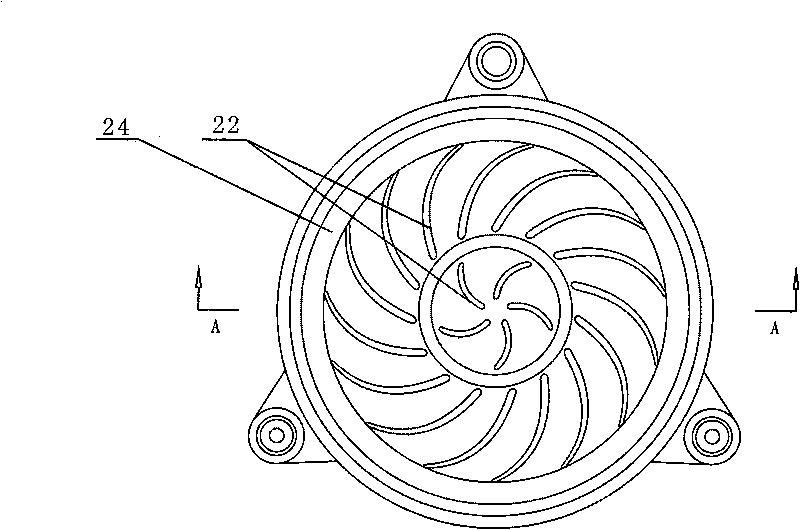

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

Rolling method for composite strip of stainless steel and straight carbon steel

InactiveCN102553918AShort process stepsImprove rolling efficiencyMetal rolling arrangementsSS - Stainless steelComposite plate

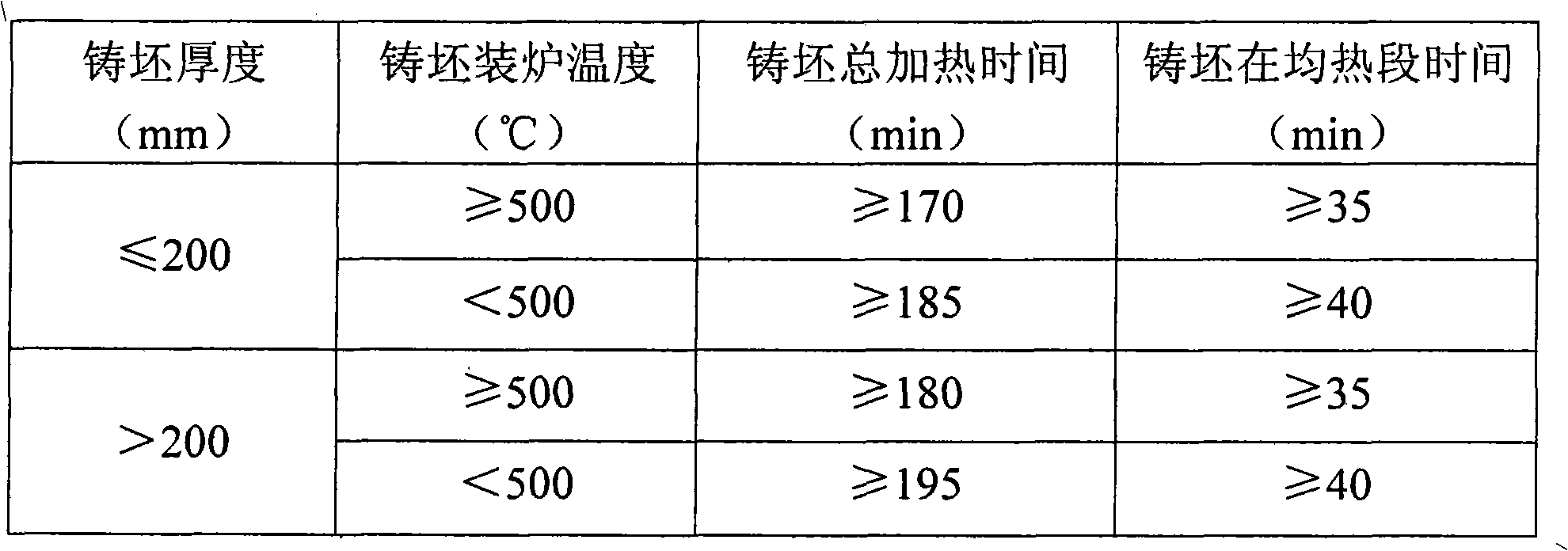

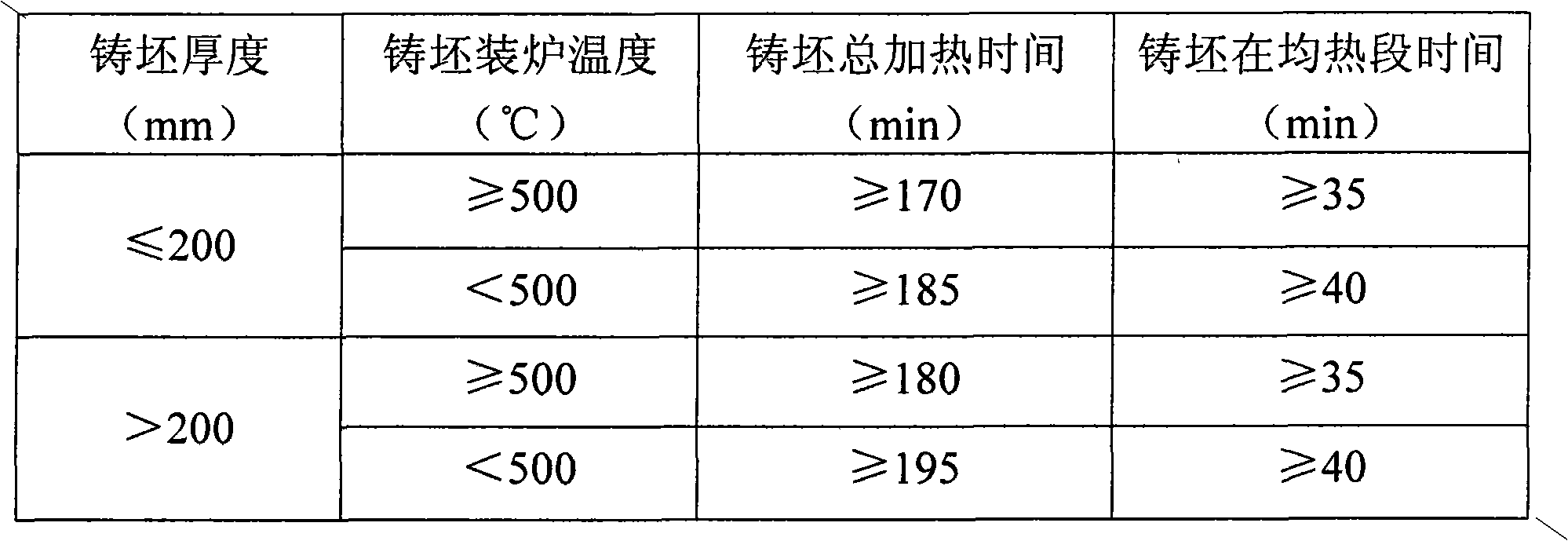

A rolling method for a composite strip of stainless steel and straight carbon steel belongs to the technical field of rolling of composite strips and comprises the steps of preparing materials; pretreatment; blank overlaying; heating and heat rolling; unreeling; cold rolling and heat treatment; and finishing. Leading an initial rolling plate into a cold-rolling mill for cold rolling to obtain a cold-rolling composite rolling plate, then conveying the cold-rolling composite rolling plate into a heat treatment furnace for heat treatment, and controlling the temperature for heat treatment to obtain a cold composite rolling plate; and performing finishing on the cold composite rolling plate and obtaining the composite strip of the stainless steel and the straight carbon steel. The rolling method for the composite strip of the stainless steel and the straight carbon steel has the advantages that the rolling method is short in process procedure and high in rolling efficiency so as to save energy; enables the integral combination effect of base plate blank made of the straight carbon steel and composite plate blank made of the stainless steel to be fully ensured; is high in finished product rate; and can meet the requirements of industrialized amplification production.

Owner:江苏天成特种金属复合材料科技有限公司

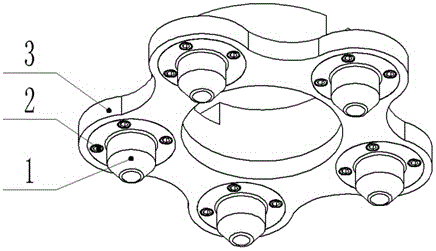

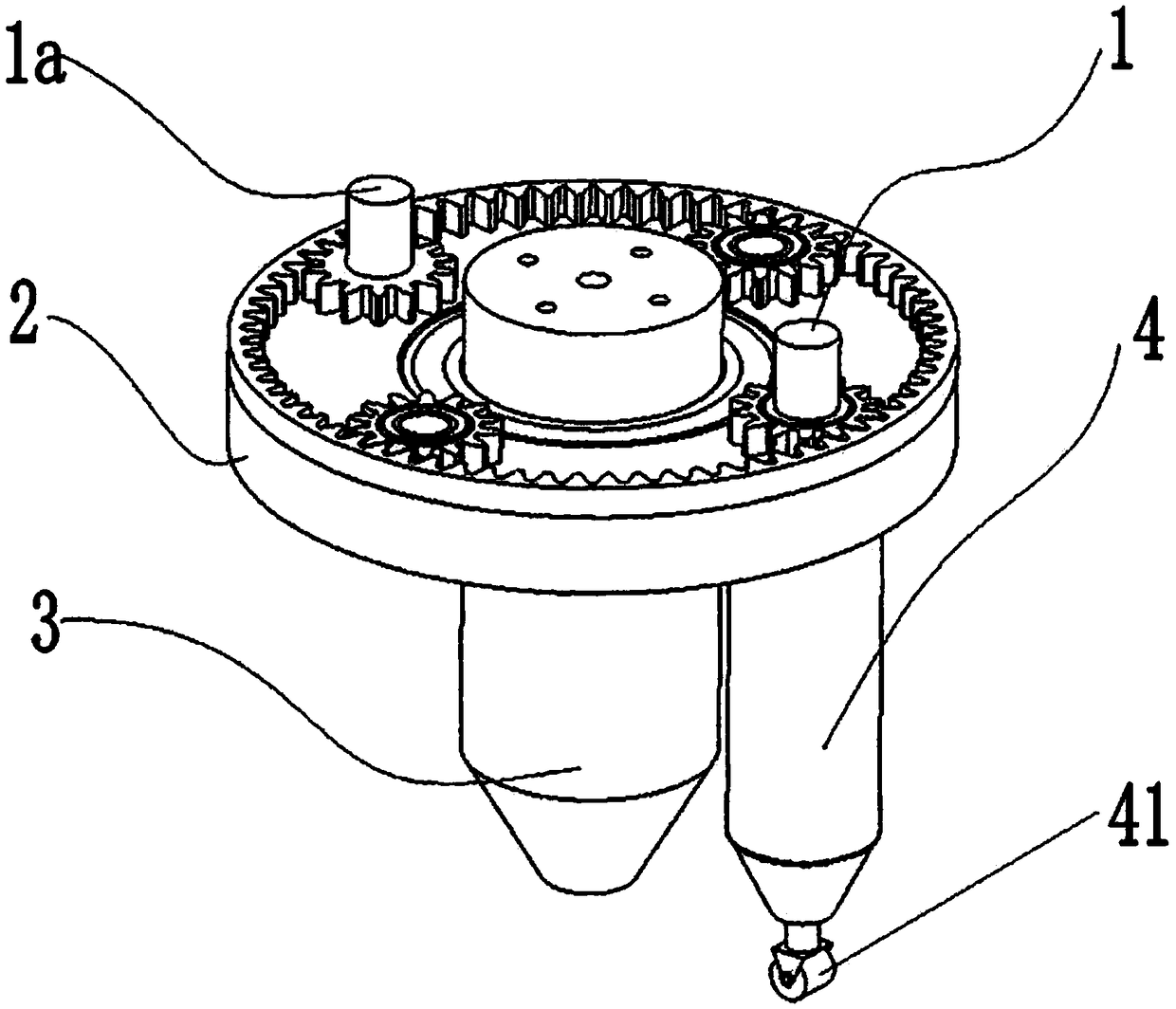

Multi-head rolling surface polishing cutter

InactiveCN104827239AEasy to adjust pressureSolve the problem of unregulated pressureWear resistantEngineering

The invention discloses a multi-head rolling surface polishing cutter, and belongs to the technical field of machining cutters. The multi-head rolling surface polishing cutter comprises a cutter rest and five cutter bits, wherein the cutter bits are rolling bits, and mainly consist of balls, support frames, wear resistant plates, lower pressing plates, compression springs, upper pressing plates, pressing screws and the like. The cutter rest can be connected with a machine tool spindle through a Morse taper handle and the like; the balls are put into the support frames, and are pressed with the wear resistant plates having circular grooves; the wear resistant plates are pressed with the lower pressing plates and the upper pressing plates; and the compression springs are mounted between the upper and lower pressing plates. The multi-head rolling surface polishing cutter has the following advantages: through the cutter bit mechanical rolling effect, the material surface smoothness and levelness are improved, the surface pressure stress is improved, the material surface grain size is reduced, and the material surface performance is enhanced; and through the cutter multi-head design, the cutter machining efficiency and using performance are improved.

Owner:UNIV OF JINAN

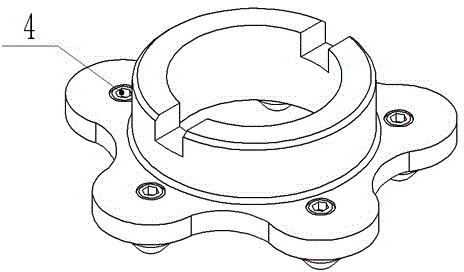

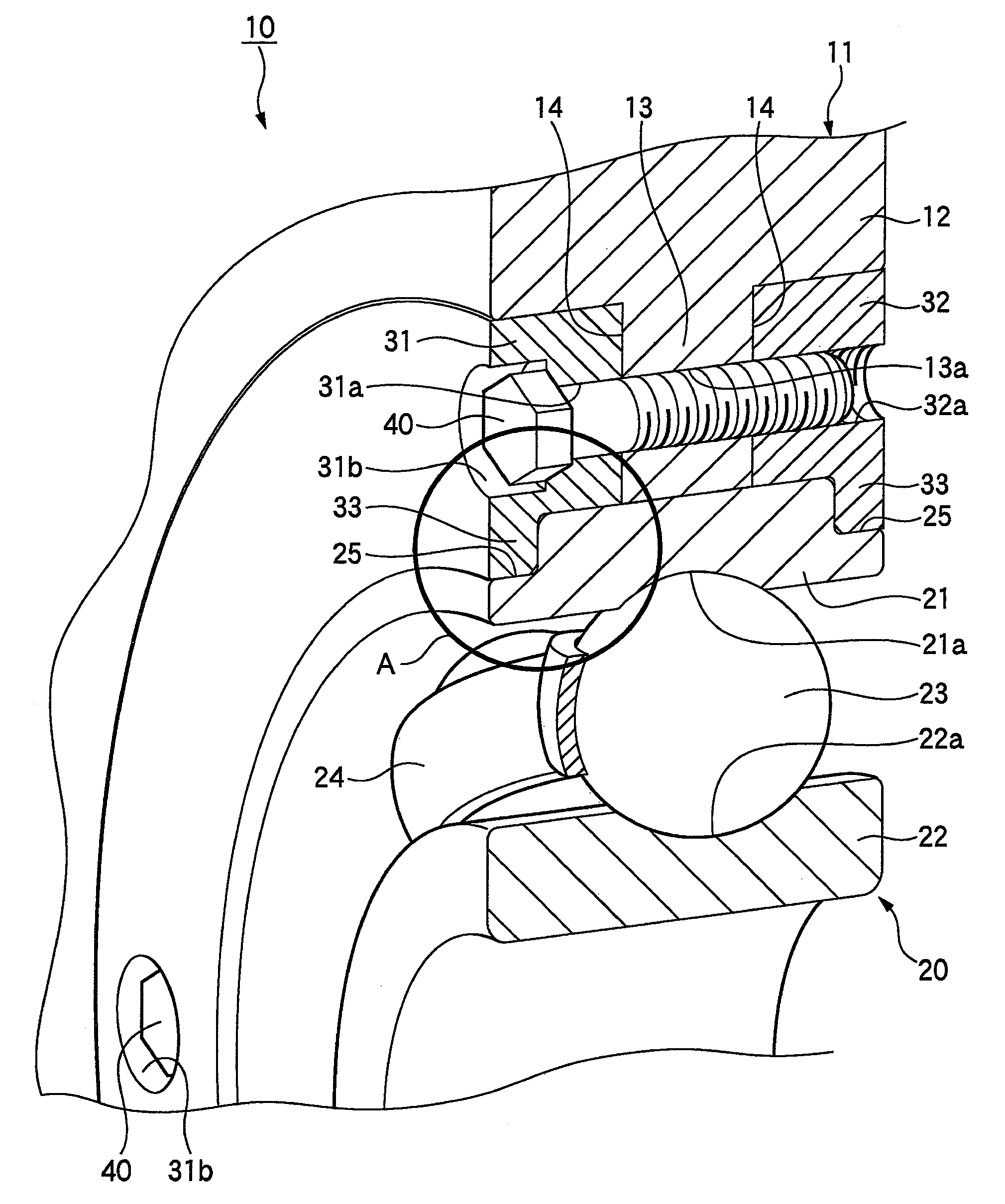

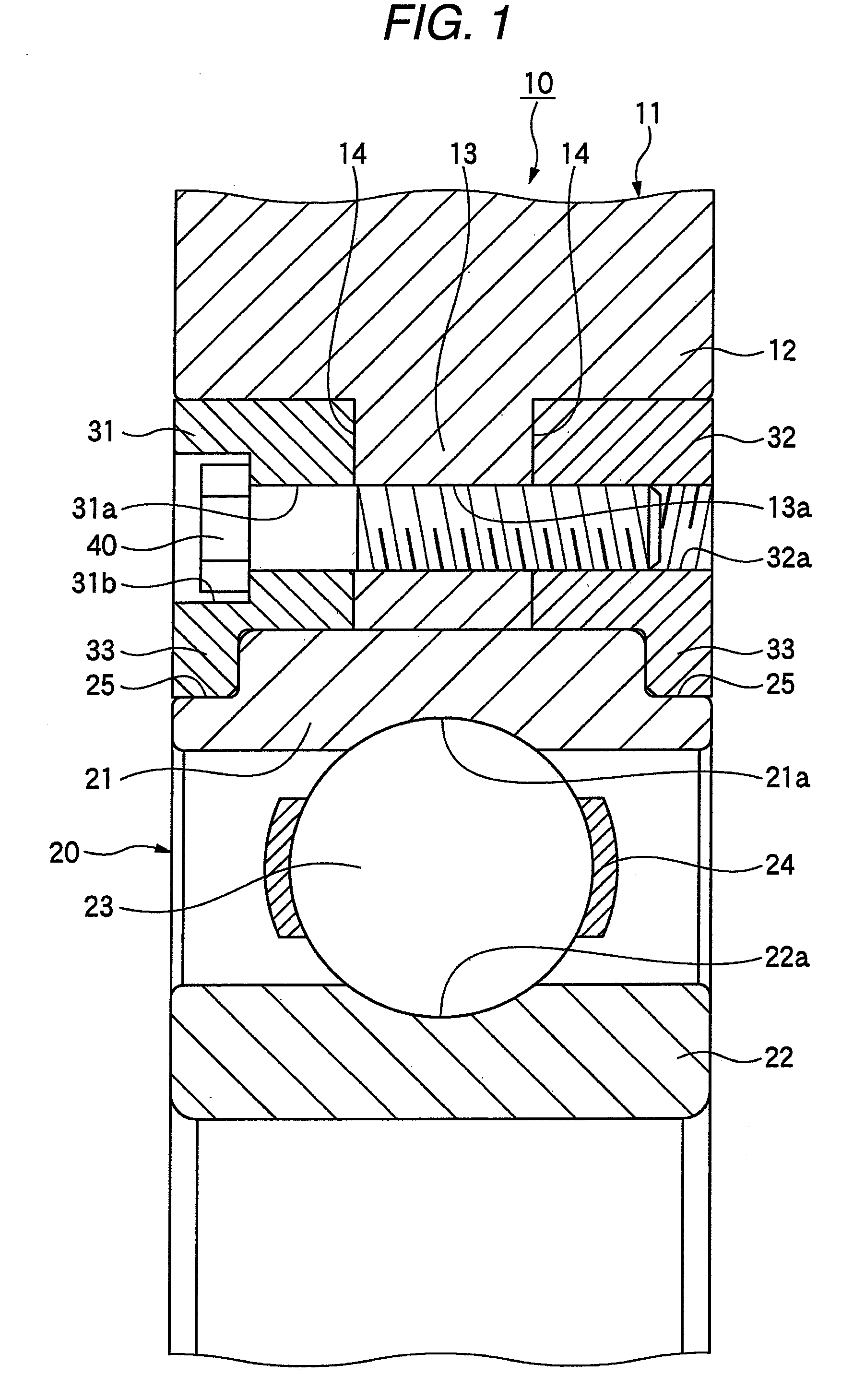

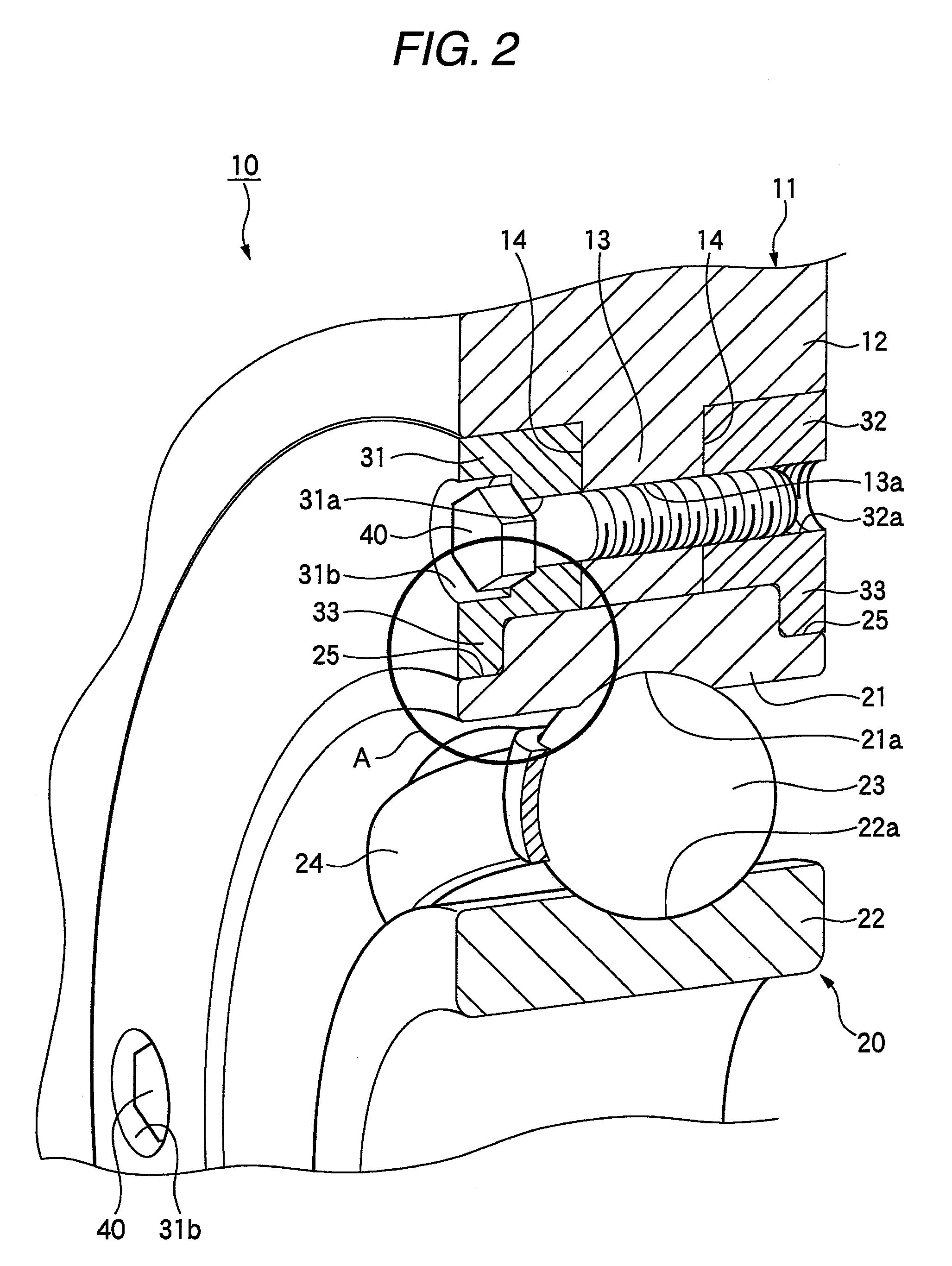

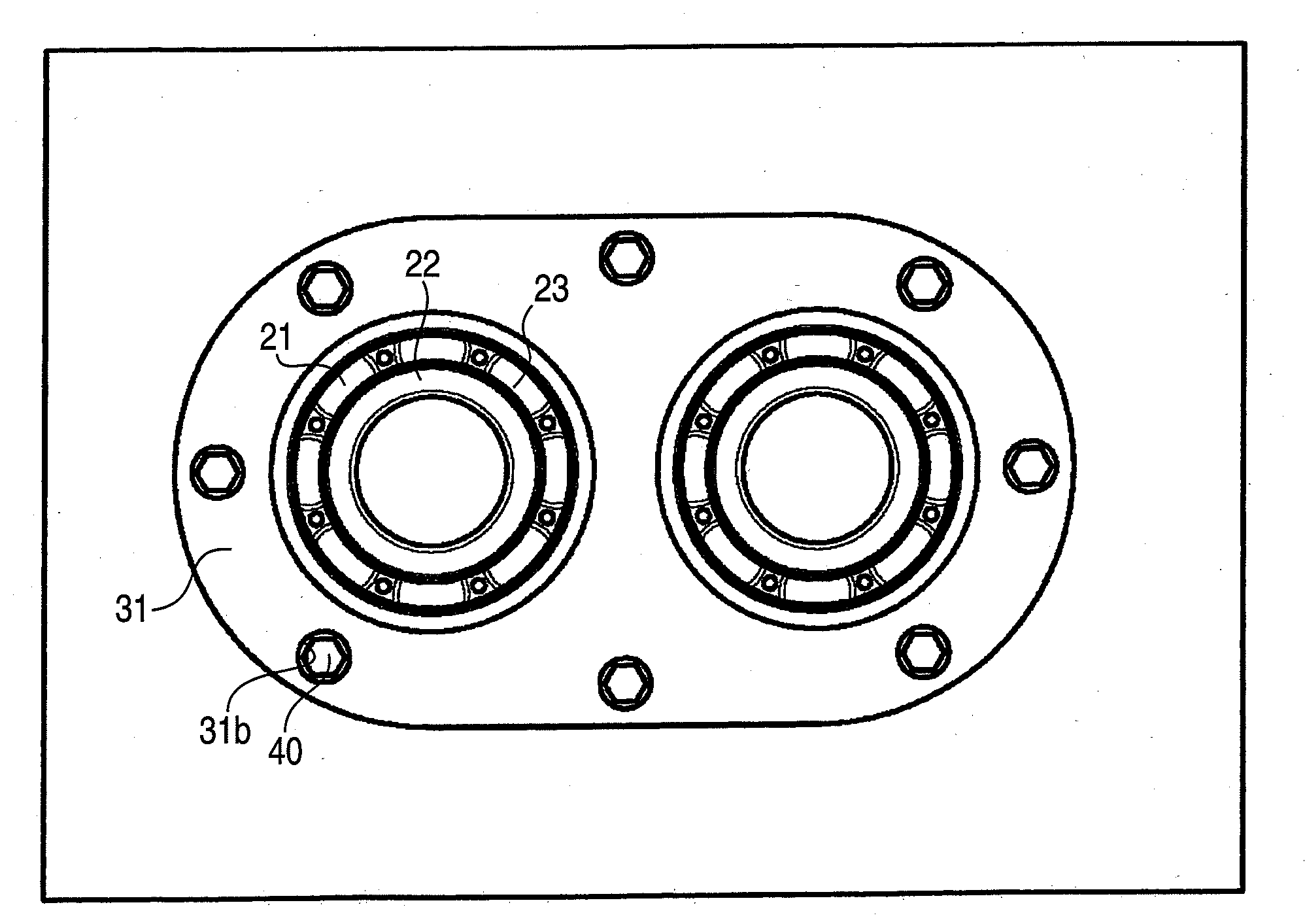

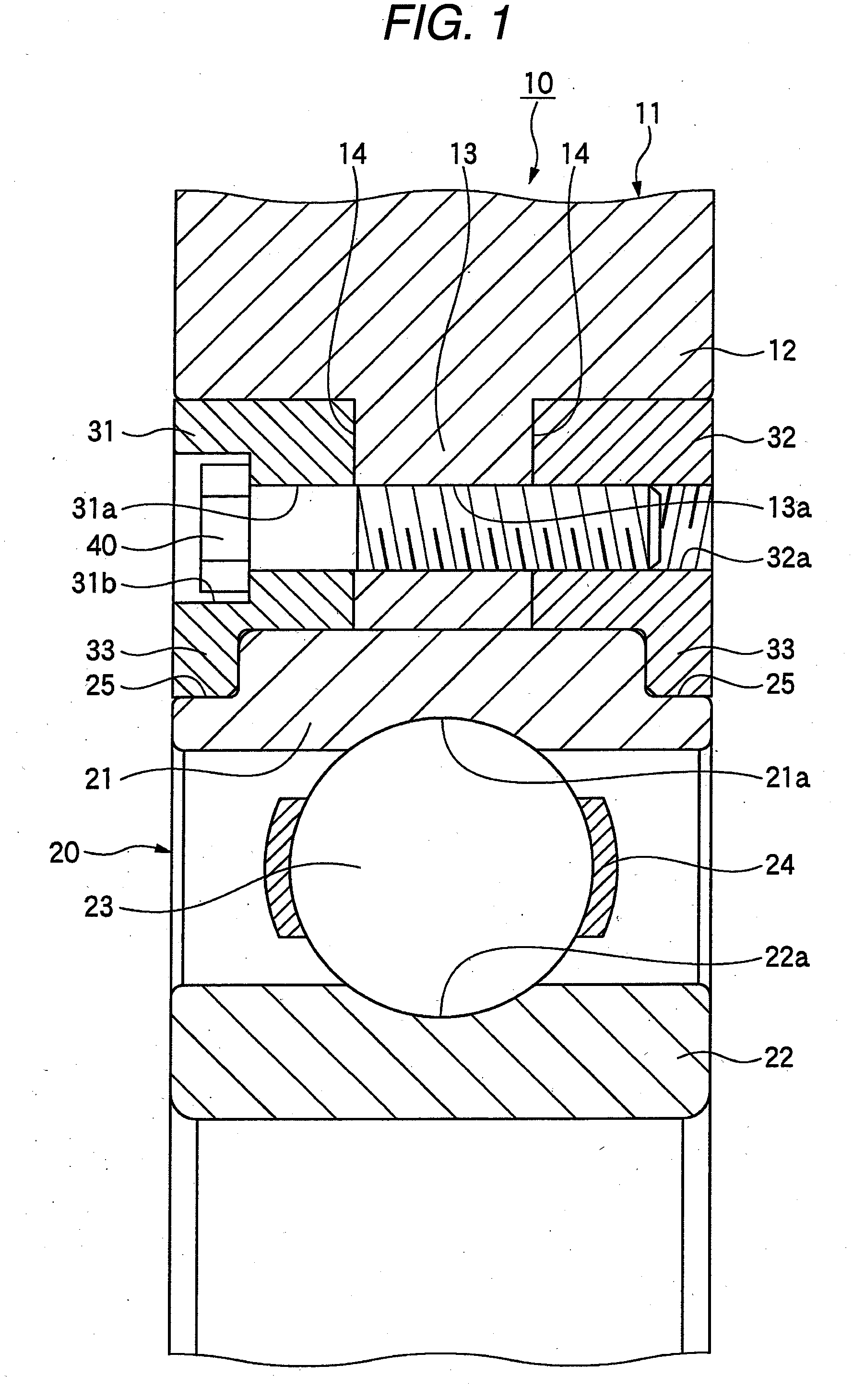

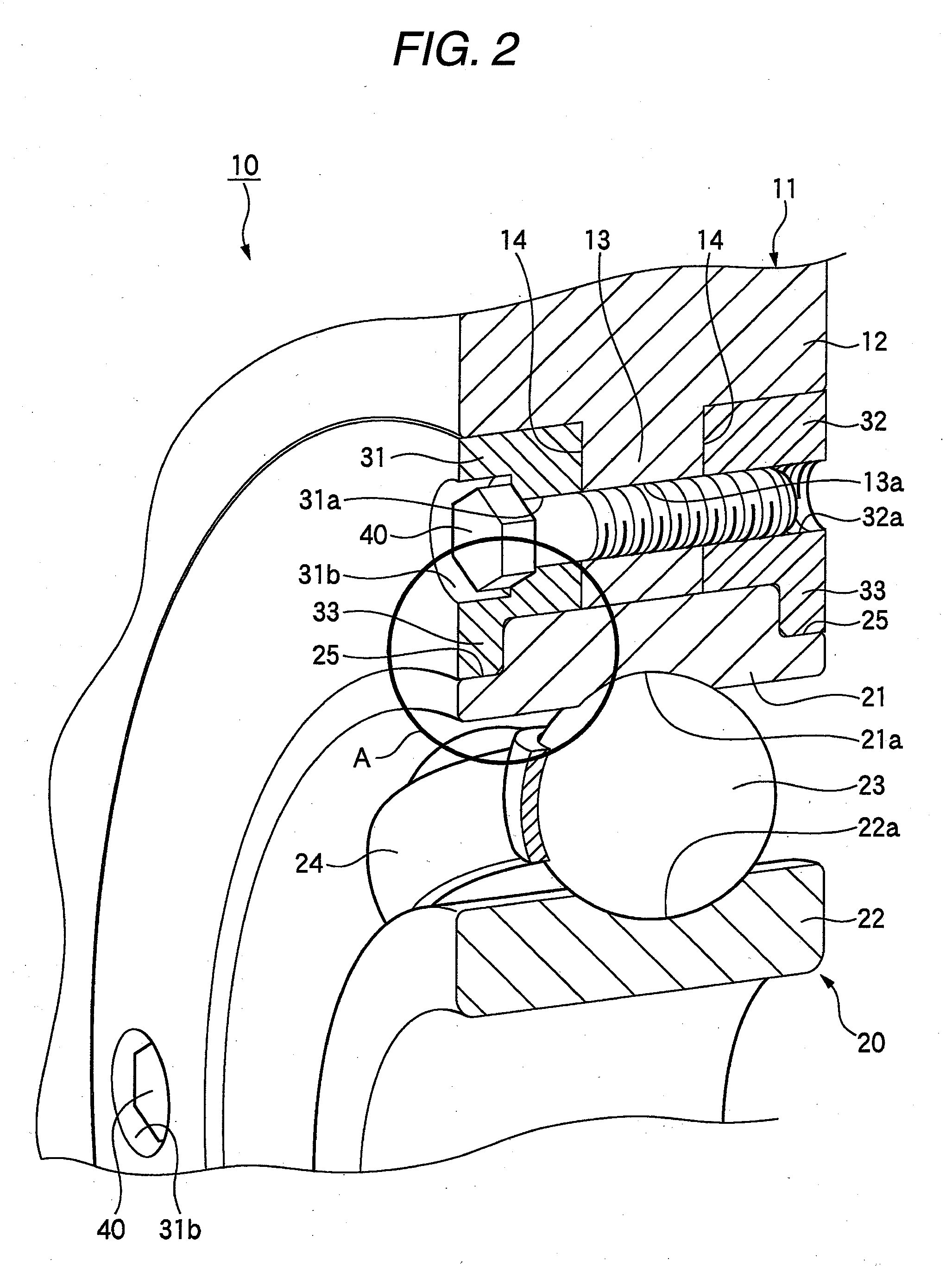

Bearing fixing device and bearing unit

ActiveUS8052331B2Easy to assembleDownsizing of the bearingPortable framesBearing assemblyEngineeringMechanical engineering

A rolling bearing fixing device includes at least one bearing having mutually rotatable inner and outer rings, a housing having at least one fitting hole into which the bearing is fitted and a bolt insertion hole, a pair of fixing plates having at least one large-diameter hole and a bolt insertion hole; and a bolt inserted from one axial end into the bolt insertion hole of one fixing plate, the bolt insertion hole of the housing, and the bolt insertion hole of the other fixing plate, and connects the housing with the pair of fixing plates. Both axial end parts of the outer ring are held by the pair of fixing plates in the axial direction, the inner ring is positioned further inwardly of the large-diameter hole of the fixing plates in the radial direction and the inner ring is rotatable with respect to the fixing plates.

Owner:NSK LTD

Warm machining method for making titanium or Ti-alloy pipe

A warm machining technology for making Ti or Ti-alloy pipe includes such steps as machining surface of pipe blank, preheating to a temp between ambient temp and recrystallizing temp, high-speed rolling at temp higher than recrystallizing temp, and fast cooling. Its advantages are simple process, high utilization rate of material, low cost and high quality.

Owner:JIANGSU XINGRONG HI TECH

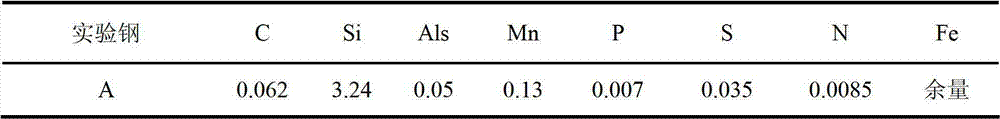

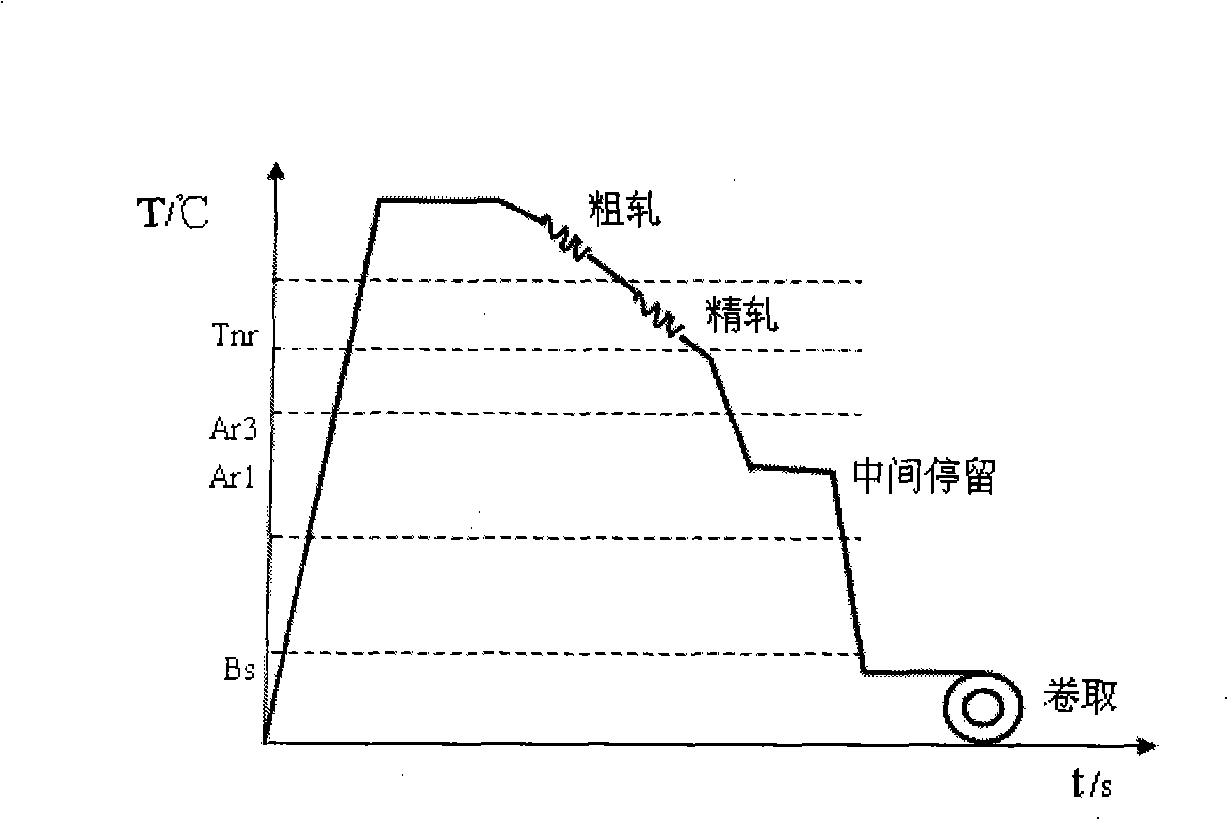

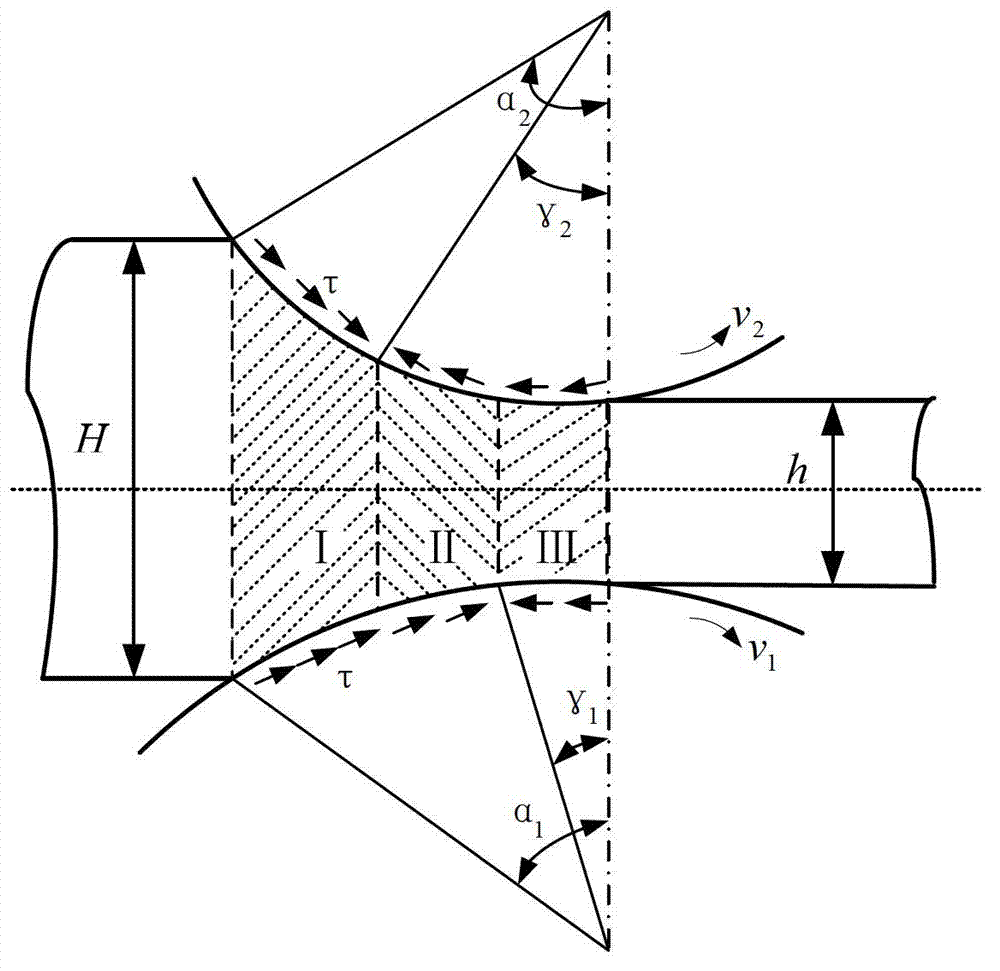

Method for preparing oriented silicon steel with asymmetrical rolling technique

ActiveCN103071677AImprove crushing effectGood effectTemperature control deviceTension/compression control deviceReduction rateWork roll

The invention relates to a method for preparing oriented silicon steel with an asymmetrical rolling technique for a roughing mill or a finishing mill. The method is characterized in that an asymmetrical rolling mode is comprehensively introduced in the rough rolling and finish rolling process of hot rolling: 1, all passes or the first two passes of the rough rolling stage adopt asymmetrical rolling and all passes or the last pass of asymmetrical rolling of the finish rolling; and 2, all passes or the first two passes of the rough rolling stage adopt asymmetrical rolling and all passes or the first pass and the last pass of asymmetrical rolling of the finish rolling. The method is as follows: 1) when the rotation speeds of working rolls are same, the asymmetry is realized through the difference of the diameters of a top working roll and a bottom working roll; 2) when the diameters of the top working roll and the bottom working roll are same, the asymmetry is realized through the difference of the rotation speeds of the working rolls; 3) when the diameters of the top working roll and the bottom working roll are same and the rotation speeds are same, the asymmetry is realized by changing the friction coefficient of the top and bottom working roll surfaces and a rolling piece; the circumferential speed ratio of the top working roll and the bottom working roll of an asymmetrical mill is 1:1.01-1:1.30, the total reduction rate of the rough rolling is at least 85 percent, and the pass reduction rate is 20-40 percent; and the total reduction rate of the finish rolling is at least 90 percent, and the pass reduction rate is 20-40 percent. The oriented silicon steel comprises the following ingredients by weight percent: 0.03-0.08 percent of C, 2.8-6.5 percent of Si, 0.05-0.2 percent of Mn, 0.013-0.035 percent of S, 0.01-0.05 percent of Al, 0.045-0.01 percent of N, at most 0.03 percent of P, 0.05-0.5 percent of Cu and the balance of Fe and other impurity elements.

Owner:NORTHEASTERN UNIV

Warm machining method for making copper or cu alloy pipe

InactiveCN1390677AReduce production processHigh yieldMetal rolling arrangementsCopperUtilization rate

A warm machining technology for making Cu or Cu-alloy pipe includes such steps as machining surface of pipe blank, preheating to a temp between ambient temp and recrystallizing temp, high-speed rolling at temp higher than recrystallizing temp and fast cooling. Its advantages are simple process, high utilization rate of material, low cost and high quality.

Owner:JIANGSU XINGRONG MEILE COPPER IND

Fast crushing equipment used for herb medicine

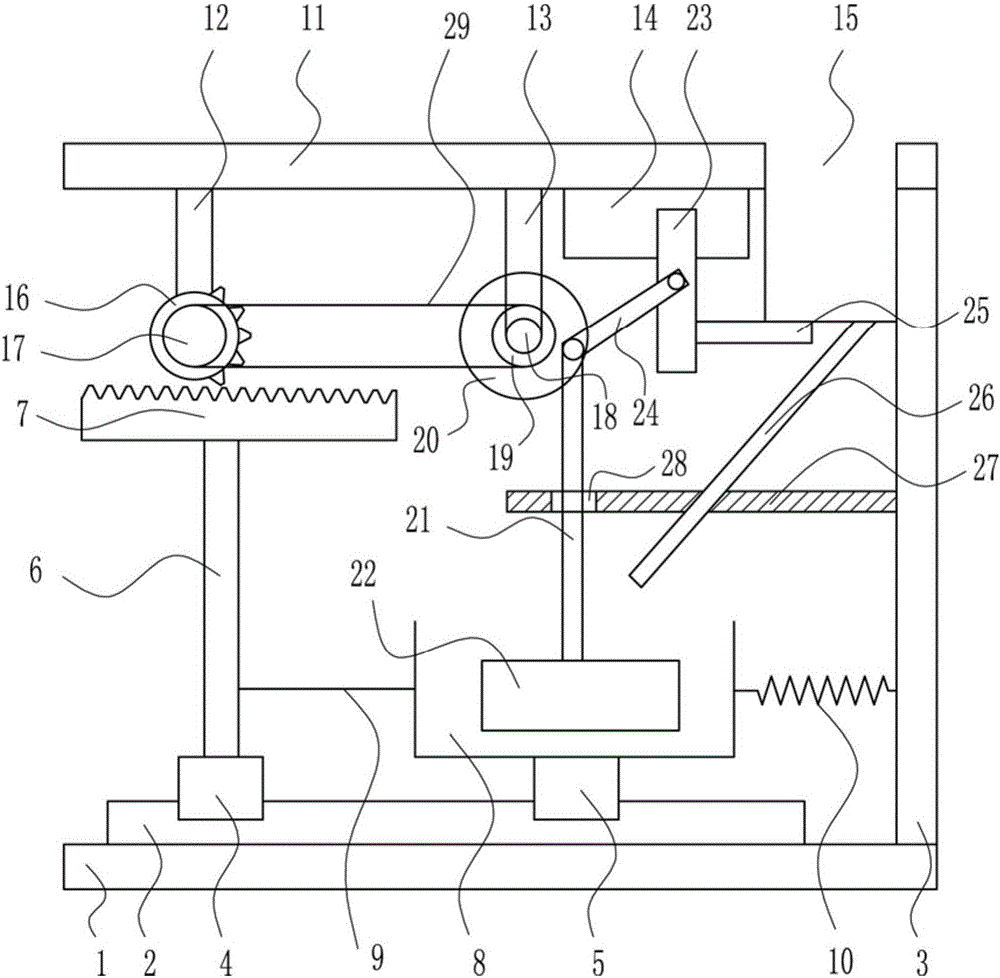

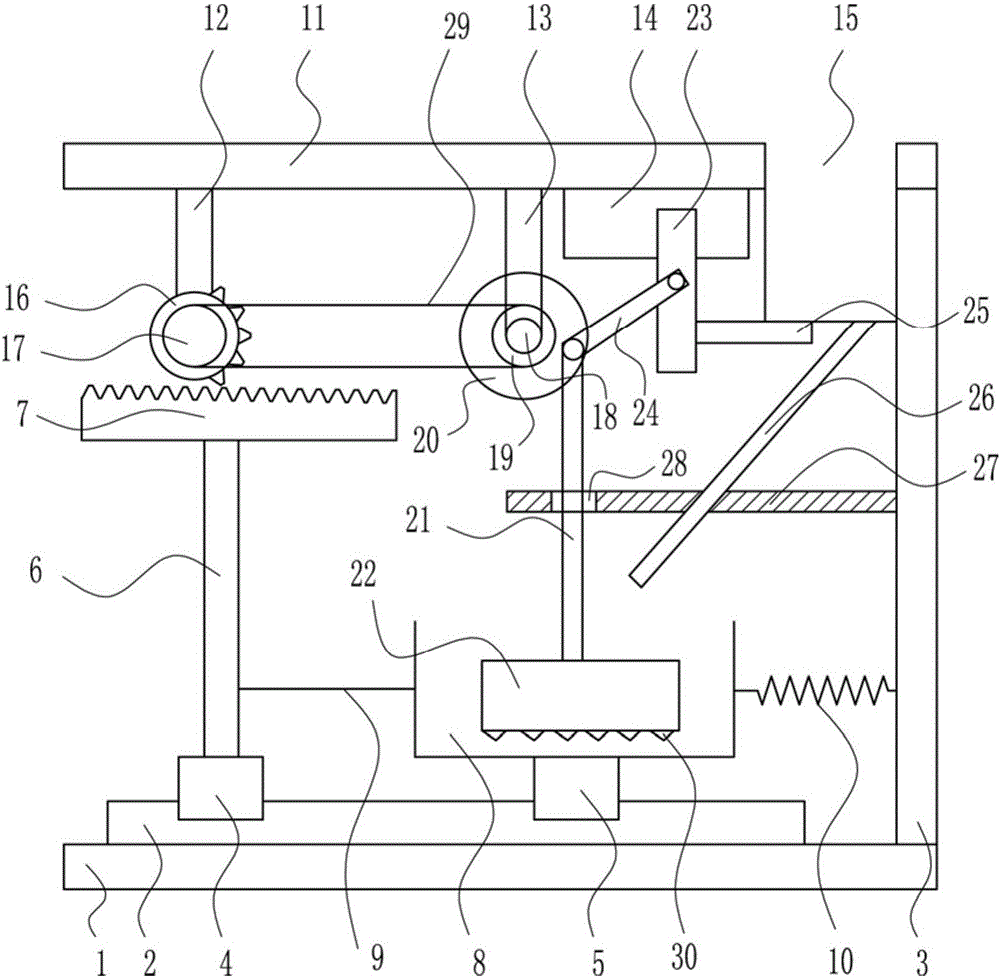

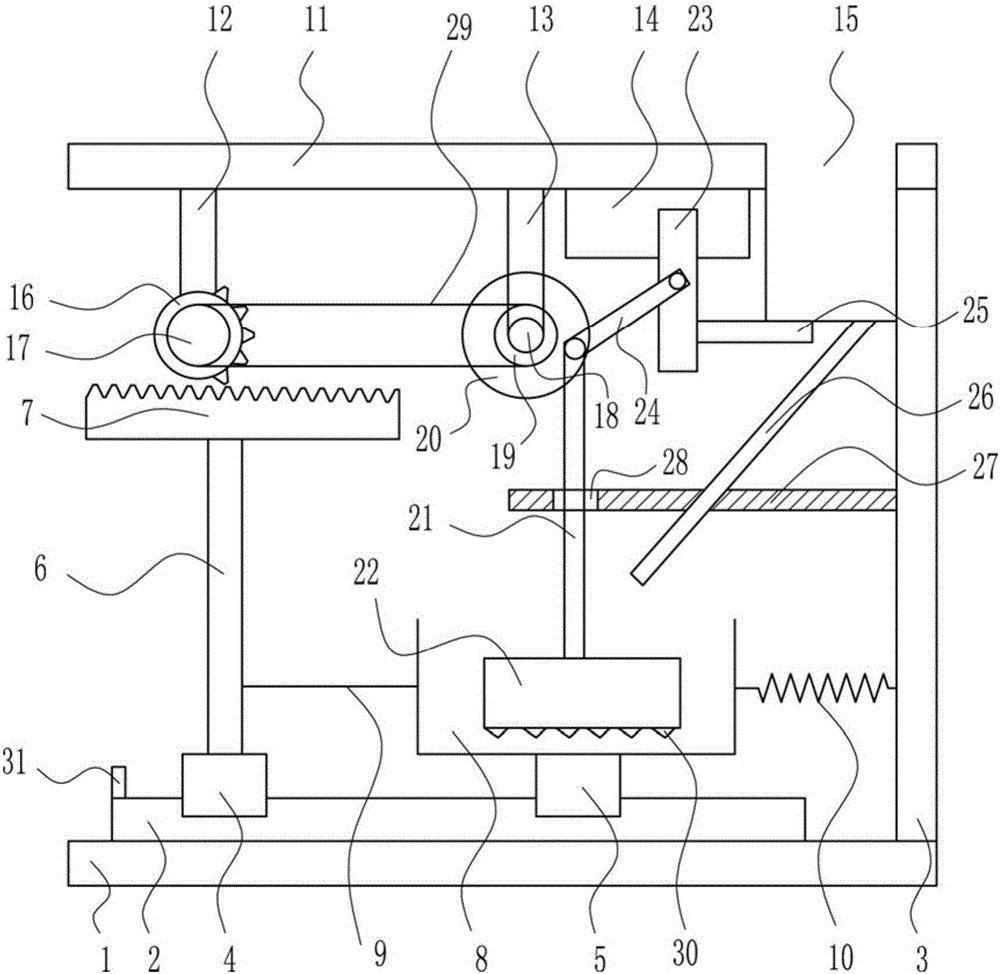

This invention relates to a kind of herb medicine crusher, especially a kind of efficient crusher of herb medicine. The technical issue solved by this invention is to provide an efficient herb medicine crusher which can save manpower and time. To solve this issue, this invention provides such an efficient herb medicine crusher which includes bottom plate, first sliding rail, right side plate, first sliding block, second sliding block,first supportive rod, rack, treatment basket, pull wire, elastic element, roof plate, second supportive rod, on the bottom plate there is first sliding rail and right side plate, the first sliding rail is located on the left side of right side plate, the first and second sliding blocks are connect to first sliding rail, the first sliding block is located on the left side of second sliding block. This invention provides fast crushing equipment of herb medicine used for medical care, which adopts electric motor to drive the pressure block to move up and down to crush the herb inside treatment basket.

Owner:王彩云

Bearing fixing device and bearing unit

ActiveUS20090001245A1DownsizingEasy to assemblePortable framesBearing assemblyRolling-element bearingMechanical engineering

A rolling bearing fixing device includes at least one bearing having mutually rotatable inner and outer rings, a housing having at least one fitting hole into which the bearing is fitted and a bolt insertion hole, a pair of fixing plates having at least one large-diameter hole and a bolt insertion hole; and a bolt inserted from one axial end into the bolt insertion hole of one fixing plate, the bolt insertion hole of the housing, and the bolt insertion hole of the other fixing plate, and connects the housing with the pair of fixing plates. Both axial end parts of the outer ring are held by the pair of fixing plates in the axial direction, the inner ring is positioned further inwardly of the large-diameter hole of the fixing plates in the radial direction and the inner ring is rotatable with respect to the fixing plates.

Owner:NSK LTD

Preparation method for titanium-steel composite plate with copper as middle layer

The invention belongs to the field of titanium-steel composite plate preparing and machining, and particularly relates to a preparation method for a titanium-steel composite plate with copper as a middle layer. The preparation method includes the following steps that a, assembly is conducted, wherein symmetrical assembly is conducted according to the sequence of a steel plate, a titanium plate, copper foil and a steel plate, and the steel plate, the titanium plate, the copper foil and the steel plate are welded together to form a combined blank; b, heating is conducted, wherein the combined blank is heated for 2 hours to 6 hours at the temperature of 760 DEG C to 860 DEG C; c, rolling is conducted, wherein at least two-pass rolling is conducted on the heated combined blank, the total rolling deformation is larger than or equal to 80%, and the rolling speed ranges from 0.1 m / s to 1 m / s; and d, finishing is conducted, wherein a titanium-steel interface is separated to obtain the titanium-steel composite plate. The method is simple in process, the situation that iron is dispersed into titanium to form Ti / Fe brittle phases can be blocked, the obtained titanium-steel composite plate is good in plate shape and good in combining effect, and the combining strength is larger than 190 MPa.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Hot-rolled polyphase steel plate and method for manufacturing same

ActiveCN101270436AGood extensibilityGood formabilityTemperature control deviceSheet steelYield ratio

The invention provides a hot-rolled multiphase steel plate and a preparation method thereof. The invention has the advantages of the economical, reasonable, environmental-friendly design of steel component, being favorable for effective utilization and recycling of resources, being implemented and controlled easily, the simple and convenient process control, the high strength of steel plate and the good performance of cold bending and welding. The thickness of plate is 2.5 to 6 milimeter, the tensile strength of the hot-rolled steel plate is larger than 1000Megapascal, the yield strength is greater than or equal to 500Megapascal, the yield ratio is low, the minimum yield ratio is equal to 0.51 and the maximum is not higher than 0.80, the elongation A80 i.e. the sample of 80 milimeter of JIS13A standard distance is greater than or equal to 11 percent and the highest value reaches 20 percent, and the longitudinal direction and the transverse direction of cold bending meets the requirement of not cracking when d is equal to 4t. The microstructure is mainly Bainite and Martensite of higher than 90 percent and few ferrite of possible residual Austenite.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving rolling stability of container thin material

ActiveCN101927263AImprove stabilityEasy to shapeTemperature control deviceFurnace typesTemperature controlEconomic benefits

The invention relates to a method for improving the rolling stability of a container thin material. By reasonably configuring a rolling plan, optimizing process technical parameters, improving a process schedule, taking temperature control as a principle line and adopting a series of effective technical measures such as strictly controlling a heating mechanism, a rough rolling production process, a finish rolling production process and the like, the rolling stability of the container thin material is improved; head folding, whipping and strip blocking accidents of stripped steel are reduced; punch mark and scratch phenomena of a roller, stripped steel deviation and loop fluctuation in a rolling process are avoided; and the strip shape and the surface quality of the container thin material are improved so that the rolling success ratio is up to 99 percent. Simultaneously, accident processing workload is reduced, rolling mill operating rate and product yield are improved, contract implementation rate is ensured and enterprise goodwill and economic benefit are improved.

Owner:ANGANG STEEL CO LTD

Osmunda japonica processing method

InactiveCN102696745AReduce labor intensityReduce generationFruits/vegetable preservation by heatingClimate change adaptationOsmunda japonica

The invention relates to an osmunda japonica processing method. The osmunda japonica processing method is characterized in that the osmunda japonica processing method includes the following operation steps: (a) picking of fresh osmunda japonica; (b) blanching; (c) blushing; (d) selection of a rolling machine; (e) rolling; (f) drying in the sun. The osmunda japonica processing method has the advantages that: the rolling efficiency is high; the rolling effect is good; as the mechanical rolling technique is popularized, the artificial growth and preliminary processing of osmunda japonica can gradually become large-scale and standard, and thereby large osmunda japonica bases and a big osmunda japonica industry can be truly established.

Owner:HUBEI CHANGYOU MODERN AGRI CO LTD

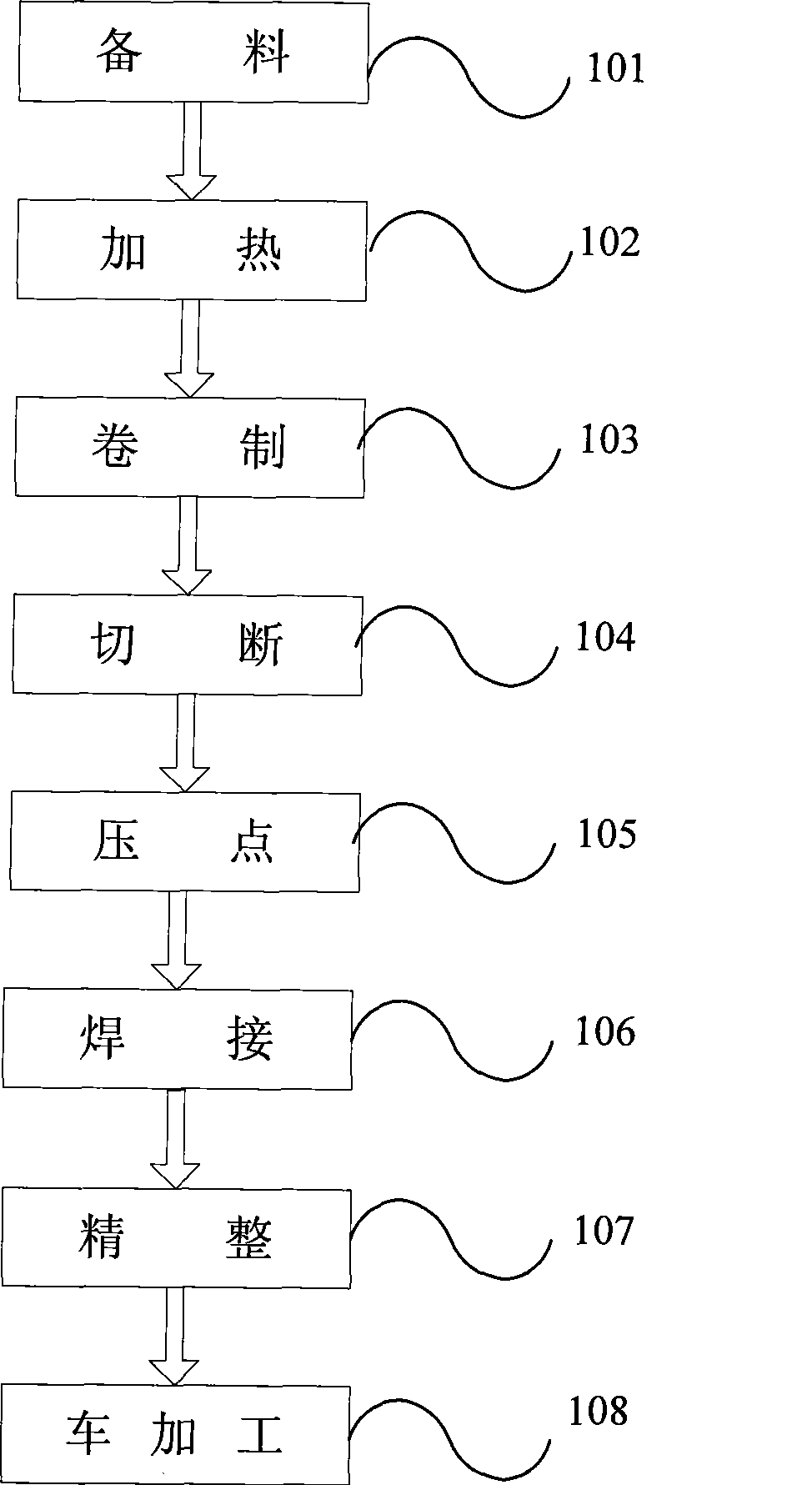

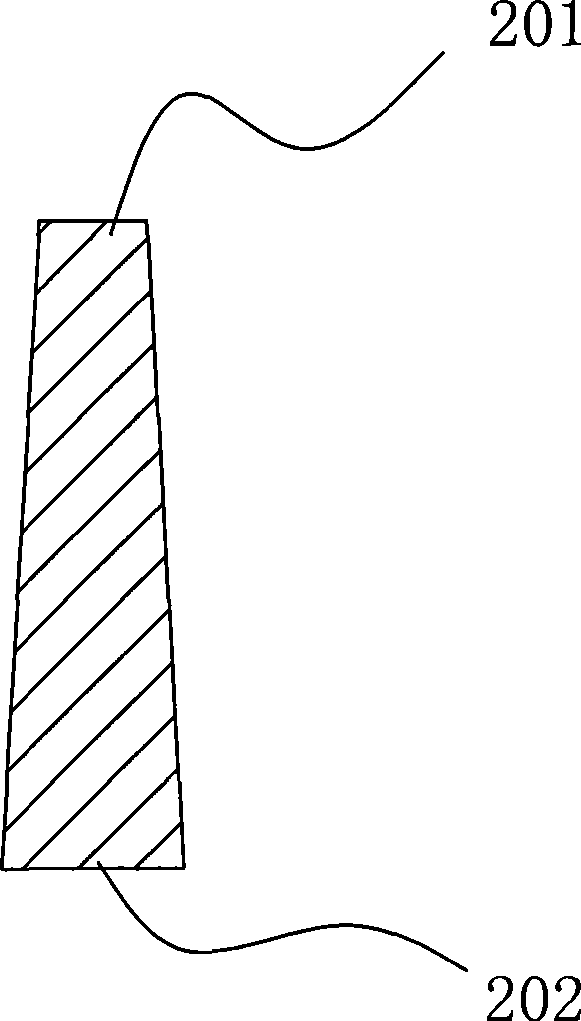

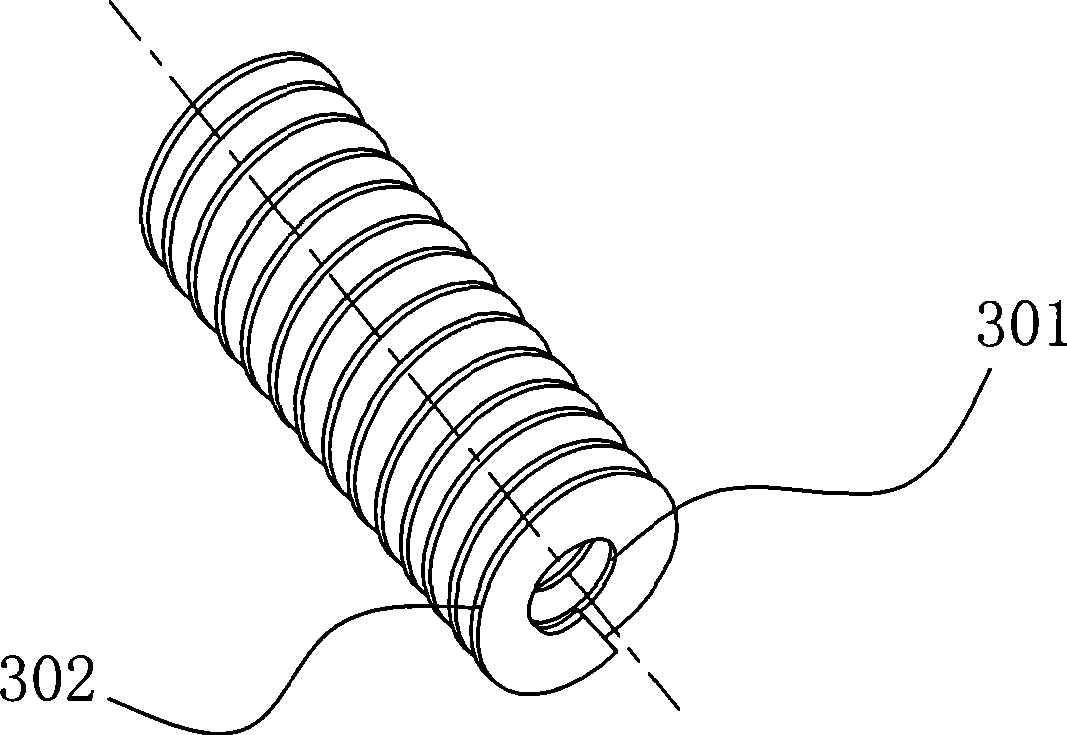

Technology for manufacturing wheeled engineering machinery vehicle spokerib board and special-purpose vertical coiling machine

InactiveCN101486140AReduce intensityIncrease profitMetal-working feeding devicesPositioning devicesWinding machineAgricultural engineering

The invention discloses a process for manufacturing a spoke plate of a wheel type construction machinery vehicle and a special vertical winding machine therefor, and belongs to the technical field of construction machinery. The process comprises the following working procedures: heating, wherein strips are heated to be between 650 and 750 DEG C to form heating strips; winding, wherein the heating strips are fed into the vertical winding machine and the strips are wound into vertical spiral blanks; cutting, wherein the spiral blanks are cut into separate blanks according to the specification of a prefabricated spoke plate; pressing spots, wherein cuts of the separate blanks are aligned for spot welding; welding, wherein the separate blanks after the spot welding are welded to form a spoke plate blank; finishing, wherein the dimensional precision of the welded blank is finished to form the spoke plate blank; and machining, wherein the spoke plate blank is machined to manufacture a spoke plate finished product. The invention is suitable for manufacturing the spoke plate of the wheel type construction machinery vehicle.

Owner:ANYANG HONGYUAN SECTION STEEL

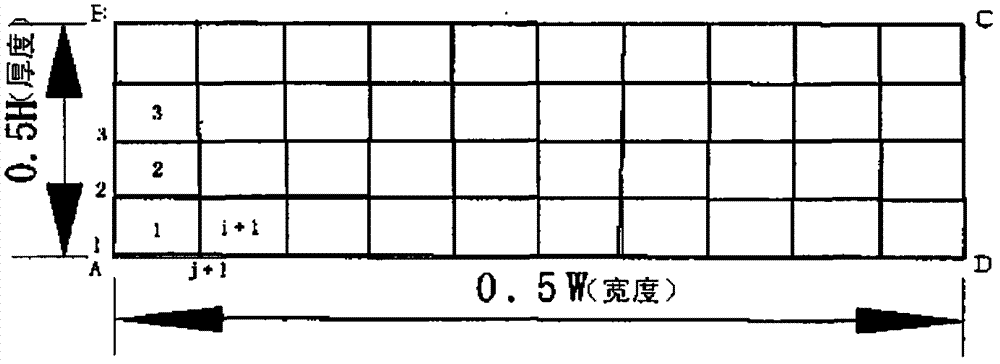

Method for predicting strip surface coefficients of heat transfer in hot rolling procedures

ActiveCN103761370AImprove forecast accuracyDetailed and accurate informationSpecial data processing applicationsElement modelPredictive methods

The invention discloses a method for predicting strip surface coefficients of heat transfer in hot rolling procedures. The method includes predicting strip surface coefficients of heat transfer by the aid of a finite-element model and heat transfer modifier formulas; determining the strip surface coefficients of heat transfer according to comparison values of measured temperatures and computed temperatures of strips. The method has the advantages that the method is specially used for predicting the strip surface coefficients of heat transfer in the strip hot rolling procedures, change of the strip surface coefficients of heat transfer in the integral rolling procedures can be acquired, information is detailed and accurate, the strip surface coefficients of heat transfer are high in prediction precision, and setting and optimizing parameters can be provided for the rolling procedures; the method is high in applicability and computational efficiency and is applicable to roughing mills and finishing mills in hot continuous rolling procedures.

Owner:NORTHEASTERN UNIV

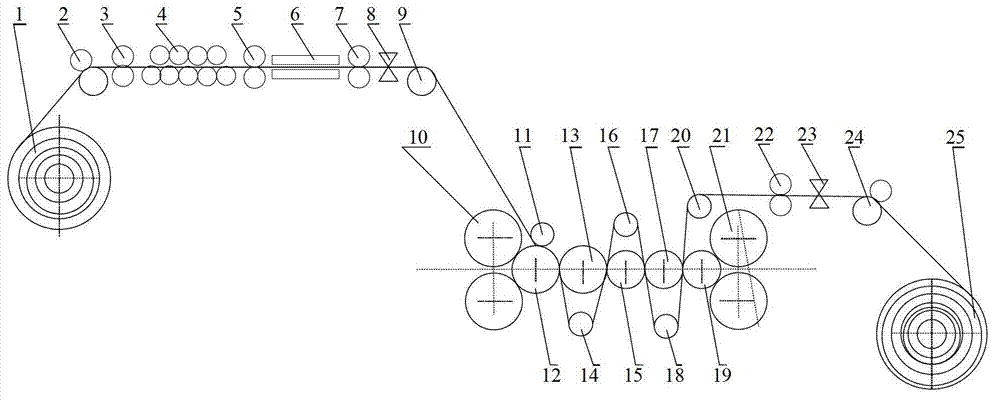

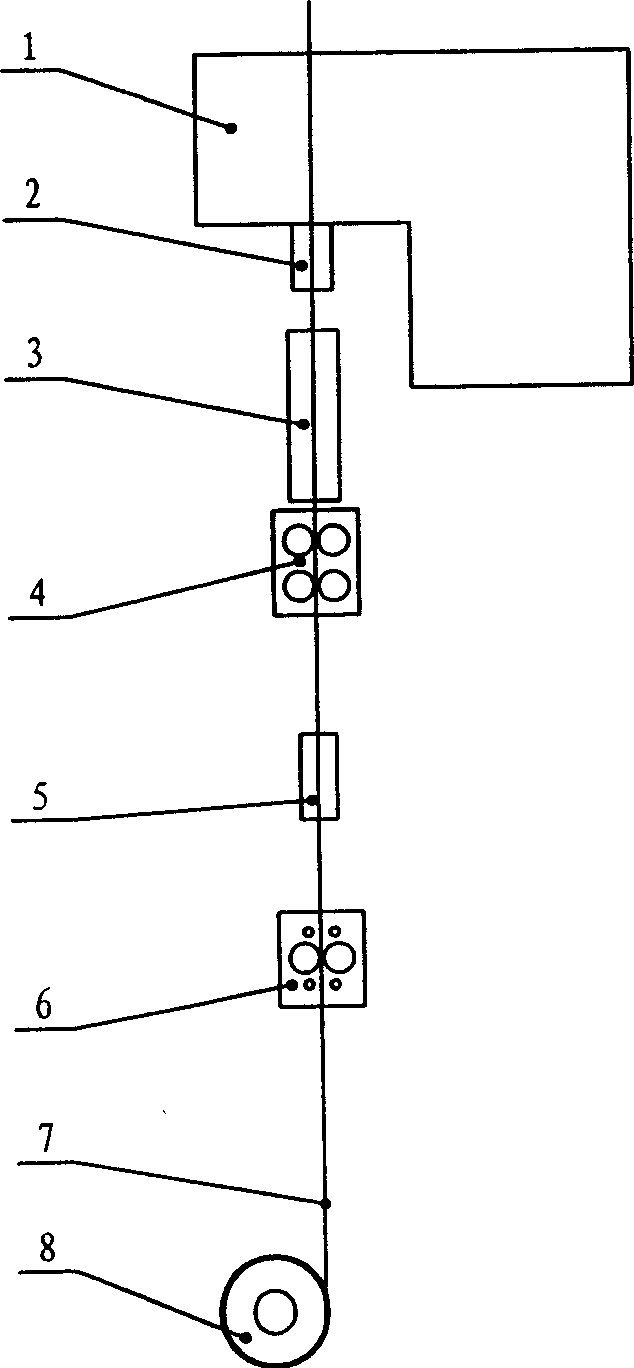

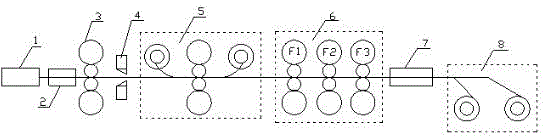

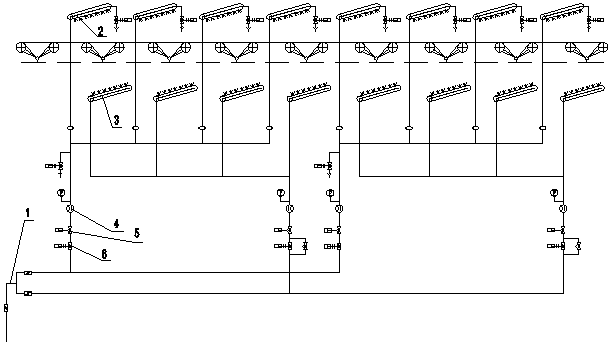

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

High-temperature preparation method of titanium-steel composite plate with copper as middle layer

InactiveCN104874636ASolve the problem of interface oxidationEliminate the effects of bond strengthMetal rolling arrangementsCopper foilTitanium

The invention belongs to the field of preparation and machining of a titanium-steel composite plate, and particularly relates to a preparation method of the titanium-steel composite plate with copper as a middle layer. The method comprises the following steps: a, assembling: symmetrically assembling according to the sequence of steel plate / titanium plate / copper foil / steel plate, and welding to obtain a combined blank; b, heating: heating the combined blank at 980-1,050 DEG C for 2-6 hours; c, rolling: rolling the heated combined blank for at least two times, wherein the total deformation of the rolling is greater than or equal to 80 percent, and the rolling speed is 0.1-1 m / s; d, refining: separating the titanium-steel interface to obtain the titanium-steel composite plate. The process of the method is simple, the problem of interface oxidation in the preparation process of the titanium-steel composite plate can be solved, the obtained titanium-steel composite plate has a good shape, the binding effect is good, and the binding strength is greater than 260 MPa.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Aluminum matrix composite plate rolling method

ActiveCN106424196AImprove performanceImprove billet structureTemperature control deviceMetal rolling arrangementsHigh intensityLarge deformation

The invention discloses an aluminum matrix composite plate rolling method and belongs to the field of metal matrix composite molding machining. According to the method, on the basis that the density of a composite billet used for rolling is regulated, a plate blank is manufactured through multidirectional free forging and extruding, and the thickness of a rolled plate is 1-150 mm; sectional temperature rolling is adopted, cogging and reversing rolling are both conducted in a recrystallization temperature region so as to avoid detects generated in subsequent rolling, the rest of passes are subjected to large deformation rolling at a dynamic recovery temperature, and the rolling efficiency is improved; the regions of the rolling temperature and the rolling speed are narrowed so that organization can be precisely controlled and detects can be avoided; and medium and low temperature finish rolling is adopted so as to ensure the plate performance. In this way, the manufactured aluminum matrix composite plate has high strength and good corrosion resistance and fatigue resistance, and efficient rolling of large-size plates can be achieved.

Owner:中科复材(滨州)新材料有限公司

900MPa-grade hot-rolled automobile beam steel and manufacturing method thereof

ActiveCN109097699AEasy to controlImprove rolling efficiencyHigh volume manufacturingUltimate tensile strength

The invention discloses a 900MPa-grade hot-rolled automobile beam steel and a production method thereof. The 900MPa-grade hot-rolled automobile beam steel comprises raw material chemical ingredients in percentage (%) by weight as follows: 0.06 to 0.08% of C, less than or equal to 0.10% of Si, 1.5 to 1.7% of Mn, greater than or equal to 0.005% of S, greater than or equal to 0.015% of P, 0.040 to 0.050% of Nb, 0.07 to 0.09% of Ti, greater than or equal to 40 ppm of N, 0.025 to 0.060% of Als, greater than or equal to 0.002% of H, and the balance of Fe. Yield strength of a hot-rolled steel plate produced by the method disclosed by the invention is greater than or equal to 650 MPa, tensile strength of the hot-rolled steel plate is greater than or equal to 900 MPa, and elongation percentage of the hot-rolled steel plate is greater than or equal to 12%, the steel plate has an excellent plate shape, unevenness of the steel plate is less than or equal to 0.6%, and carbon equivalent w is less than or equal to 0.35%, and the steel plate has excellent welding performance. The method adopts simple process flow, does not need to add any equipment, and has the advantages of mass production, economy, easiness and stable performance.

Owner:武汉钢铁有限公司

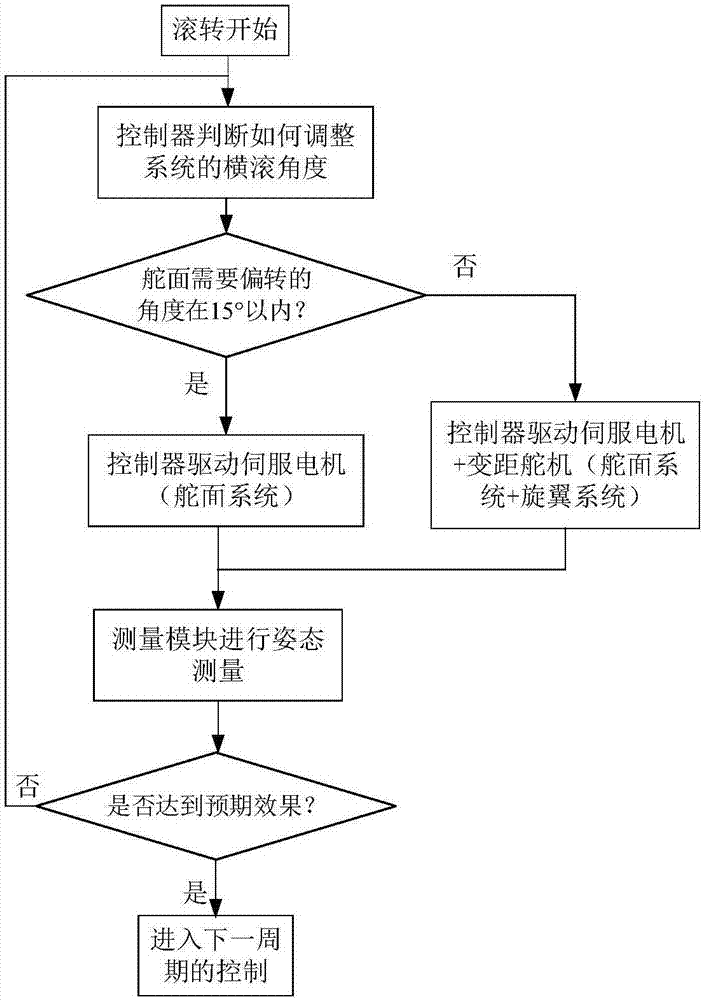

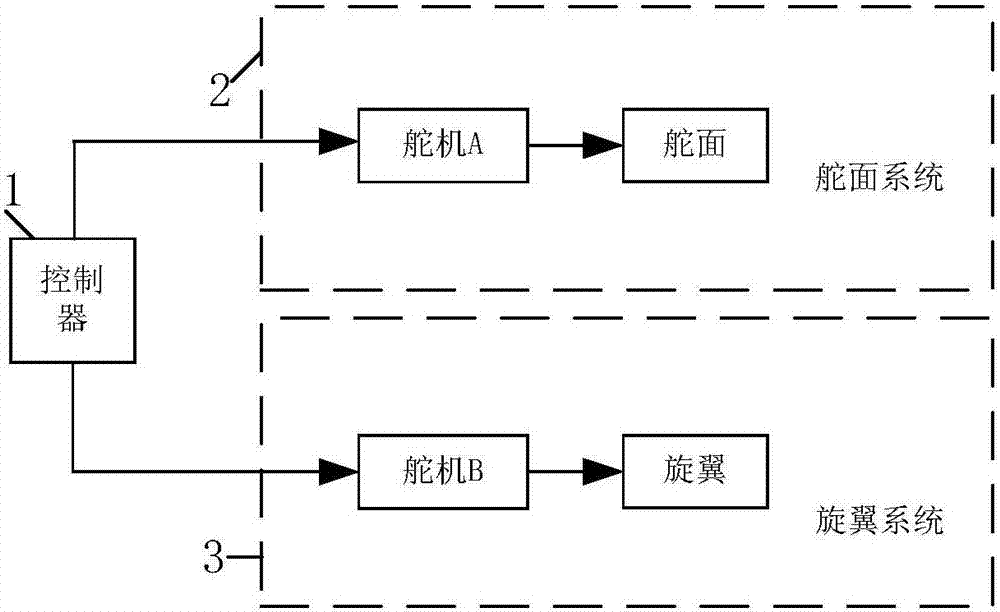

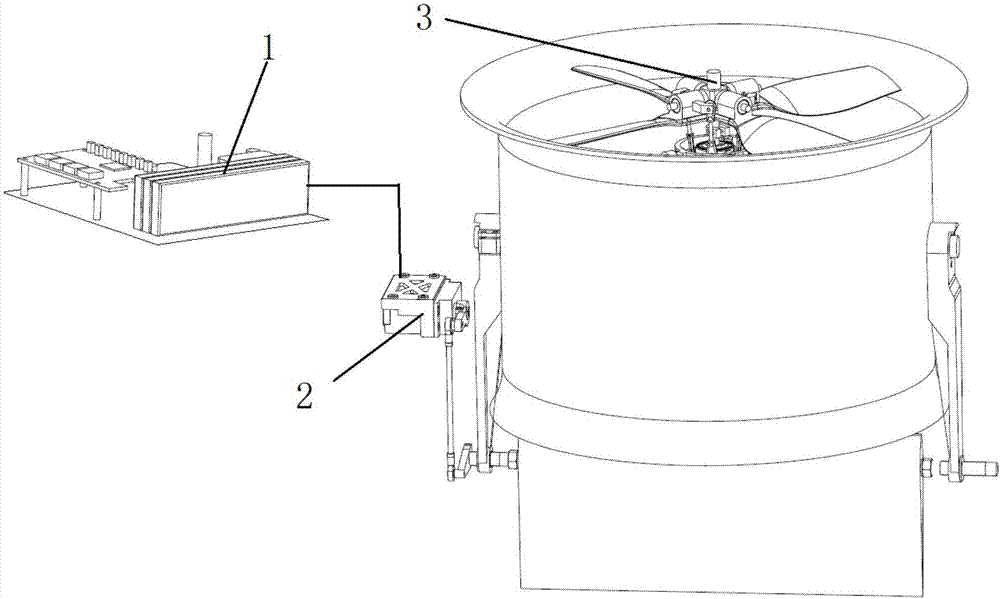

Novel composite rolling attitude control system and method

ActiveCN107215454ALow structural costLow weight costConjoint controlsWith power amplificationResponse sensitivityControl system

The invention belongs to the technical field of an unmanned aerial vehicle, and discloses a novel composite rolling attitude control system and method. The control method integrates a principle for adjusting a flight attitude by utilizing a rudder surface and a conventional helicopter tipping tray periodically-pitch-variable principle; by utilizing a redundant control concept, an aerocraft rolling passage is controlled by a rudder system, the auxiliary compensation for the rolling passage is carried out by virtue of a rotary wing system, an airflow direction is limited by virtue of a duct, and the rudder system is controlled; and the control system comprises a controller, a rudder system, a rotary wing system and a duct. The novel composite rolling attitude control system is high in air passing capacity, compact in structure, reasonable in design and capable of realizing automatic hovering and precise attitude control and has advantages of small space size, large effective load, high control response sensitivity, high system stability, high robustness and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Casting-milling process method for manufacturing copper and copper alloy band

InactiveCN1730181AIncrease the elongation factorReduce energy consumptionWork treatment devicesMetal rolling arrangementsNitrogen gasDynamic recrystallization

The invention relates to a processing method for copper and copper alloy strip, which pertains to sheet metal strip casting, heat-rolling and machining technology. Specifically, the invention adopts continuous casting, hot rolling, thermomechanical treatment and machining principle and subjects band of horizontal continuous casting and downward continuous casting to heat preservation and samming, rapidly cooling after directly hot-rolling, on-line surface milling and rolling to built-up coil. Rolling is operated under the condition of exceeding recrystallization temperature and nitrogen protection. In the rolling, dynamic recrystallization of band structure takes place. The invention provides photo-quality and high-accuracy blank for cold rolling of end product.

Owner:JIANGSU XINGRONG HI TECH

Pulse current assisting titanium-TiAl composite plate non-sheath rolling method

ActiveCN110711774AImprove organizational formImprovement ingredientsForging/pressing devicesMetal rolling arrangementsBond interfaceTitanium

The invention relates to the field of preparing of alloy materials, in particular to a pulse current assisting titanium-TiAl composite plate non-sheath rolling method. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method aims at solving the problems that a plate prepared through an existing foil metallurgy method for titanium-TiAl composite plates is small in size, not uniform in thickness, large in component deviation and low in strength and plasticity, and the problems that a sheath hot rolling method is high in cost, complex in technology and high in rolling temperature, and the quality and performance of composite plates need to be further improved are solved. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method includes thespecific steps that firstly, a titanium alloy plate is prepared; secondly, a TiAl alloy plate is prepared; thirdly, non-sheath assembling is conducted; fourthly, pulse current auxiliary hot rolling is conducted; and fifthly, separating and subsequent treatment are conducted, and a titanium-TiAl composite plate can be obtained. The composite plate obtained in the pulse current assisting titanium-TiAl composite plate non-sheath rolling method is good in surface quality, free of oxide layer disengagement, free of edge portion and end portion cracking, uniform and small in plate organization, good in bonding interface and good in mechanical performance.

Owner:TAIYUAN UNIV OF TECH

Edge-controlling rolling method for wide magnesium alloy plate

ActiveCN105170660AEffective control of head and tail defectsImprove performanceProfile control deviceControl systemMetallic materials

The invention belongs to the field of machining of metal materials, and particularly relates to an edge-controlling rolling method for a wide magnesium alloy plate. In order to solve the problems of serious edge cracking, anisotropic protrusions and the like of an existing rolling process for the magnesium alloy plate, widening rolling and Mizushima automatic plan view pattern control system (MAS) rolling are recombined and optimized, and a method for determining the prefabricated convexity is given definitely specific to magnesium alloy materials. The convexity of the edge of a rolled piece is prefabricated before cross rolling and axial rolling, so that the flow amount of metal at the edge is improved, and the flaws of the head and the tail of a common rolled piece are compensated. Coordinate deformation of the edge and the middle of the rolled piece with low fracture toughness is achieved during rolling and deformation, and therefore edge cracking is relieved or eliminated, the rolling yield of the wide magnesium alloy plate is improved, and the cost is reduced. Meanwhile, orthogonal rolling is achieved in the axial-cross-axial rolling process, the anisotropic defect in the common rolling process is effectively relieved, and the performance of the materials is improved. By means of the edge-controlling rolling method for the wide magnesium alloy plate, the edge cracking and anisotropic defects during rolling of the wide magnesium alloy plate are effectively relieved or controlled, the yield and the performance of the materials are further improved, and the cost is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sand grinding equipment

InactiveCN105170895AIncrease the amount of rollingAvoid accumulationMould handling/dressing devicesEngineeringMechanical engineering

The invention discloses sand grinding equipment. The sand grinding equipment comprises a support, a grinding box, a first rotating shaft, a driving device and at least one grinding roller, wherein the grinding box is mounted on the support; a feed port is formed in the upper part of the grinding box; a discharge port is formed in the lower part of the grinding box; a discharge door is detachably mounted in the position corresponding to the discharge port of the grinding box; the first rotating shaft is rotationally mounted in the grinding box; the driving device is connected with the first rotating shaft and drives the first rotating shaft to rotate; each grinding roller comprises a main grinding roller body and a second rotating shaft, the main grinding roller body is rotationally mounted on the second rotating shaft, the second rotating shaft is mounted on the first rotating shaft through an elastic piece, and the second rotating shaft and the first rotating shaft are perpendicular to each other in the axial direction. According to the sand grinding equipment, the grinding quantity of materials each time can be increased, and the grinding effect of the materials can be guaranteed effectively.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

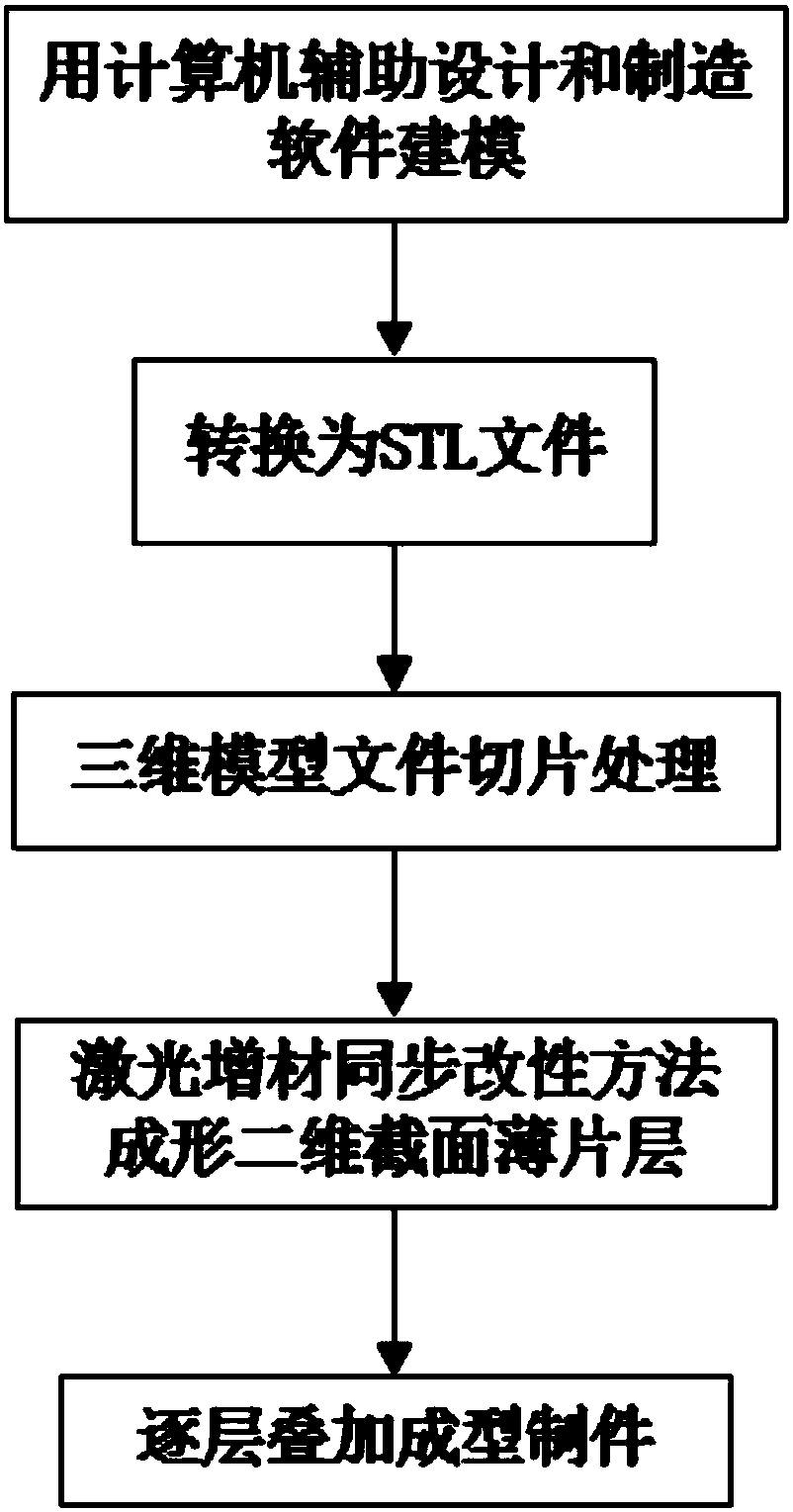

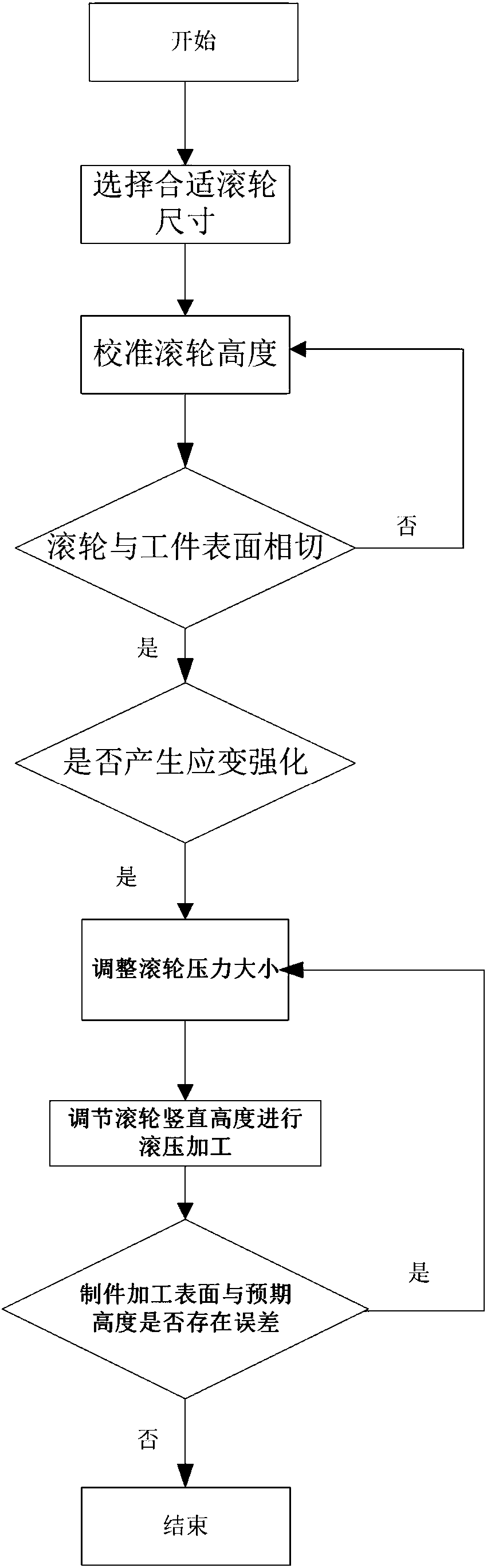

Method for conducting synchronous modification on powder-feeding type laser additive manufacturing manufactured workpiece

ActiveCN108247056AReduce surface roughnessHigh surface hardnessAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingMachining process

The invention discloses a method for conducting synchronous modification on a powder-feeding type laser additive manufacturing manufactured workpiece. A synchronous following rolling process is addedin the machining process of the laser additive manufacturing manufactured workpiece, the method comprises the steps that a suitable rolling wheel size is selected; the height of a rolling wheel for achieving the rolling function is calibrated; as for the rolling wheel with the height being calibrated, the rolling force magnitude range is judged according to the rolling machining effect to be reached by the manufactured workpiece, and the feed amount of the rolling wheel is adjusted accordingly; a 3D print nozzle runs on a printed substrate according to the printing path; the rolling force magnitude can be adjusted according the relative height of current manufactured workpiece machining in the printing process; the rolling wheel with adjusting of the rolling force magnitude being finishedis subjected to synchronous following rolling work; and the printing layers are stacked layer by layer, and the metal manufactured workpiece is formed after cooling. The method for conducting synchronous modification on the powder-feeding type laser additive manufacturing manufactured workpiece can improve the inner quality and internal structure of the metal manufactured workpiece without changing the shape of the workpiece, the compactness of the manufactured workpiece is increased, and the strength of the manufactured workpiece is improved.

Owner:JILIN UNIV

Method and system for rolling 410S ferrite stainless steel

InactiveCN104785521AFulfil requirementsGood effectMetal rolling arrangementsReduction rateSS - Stainless steel

The invention discloses a method for rolling 410S ferrite stainless steel. The method includes the steps of 1, carrying out heating, wherein 410S ferrite stainless steel plate slabs are heated through multi-walking-beam type heating furnaces, the furnace staying time ranges from 180 minutes to 240 minutes, the tapping temperature ranges from 1140 DEG C to 1160 DEG C, and the amount of residual oxygen in the furnaces ranges from 3.0% to 5.0%; 2, carrying coarse rolling, wherein the heated plate slabs are descaled through a plate slab descaling machine to enter a four-roller coarse rolling machine to be rolled seven times to form intermediate slabs, and the reduction rate of each time of coarse rolling ranges from 18% to 30%; 3, rolling intermediate products, wherein after the heads and the tails of the intermediate slabs are cut off through a flying shear cutter, the intermediate slabs enter a steekle mill to be rolled three times to form the intermediate products, the each-time reduction rate of the steekle mill ranges from 32% to 49%, and the temperature of a reeling furnace ranges from 1110 DEG C to 1140 DEG C; 4, carrying out fine rolling, wherein the intermediate products sequentially enter a fine rolling unit to be continuously rolled to be at the finished-product thickness, and the reduction rate of each time of fine rolling ranges from 12% to 28%; 5, cooling finished products. The invention further discloses a system for rolling the 410S ferrite stainless steel. By means of the technological method, the production efficiency is high, the product quality is stable, and the difference between the heads and the tails of steel tape is small.

Owner:SHANDONG TAISHAN STEEL GROUP

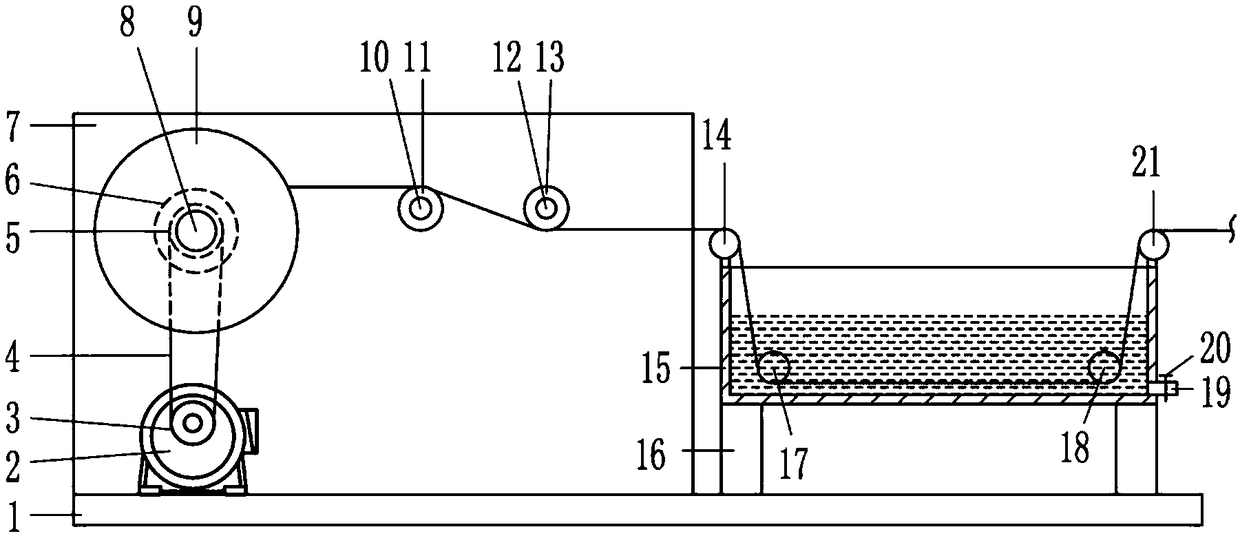

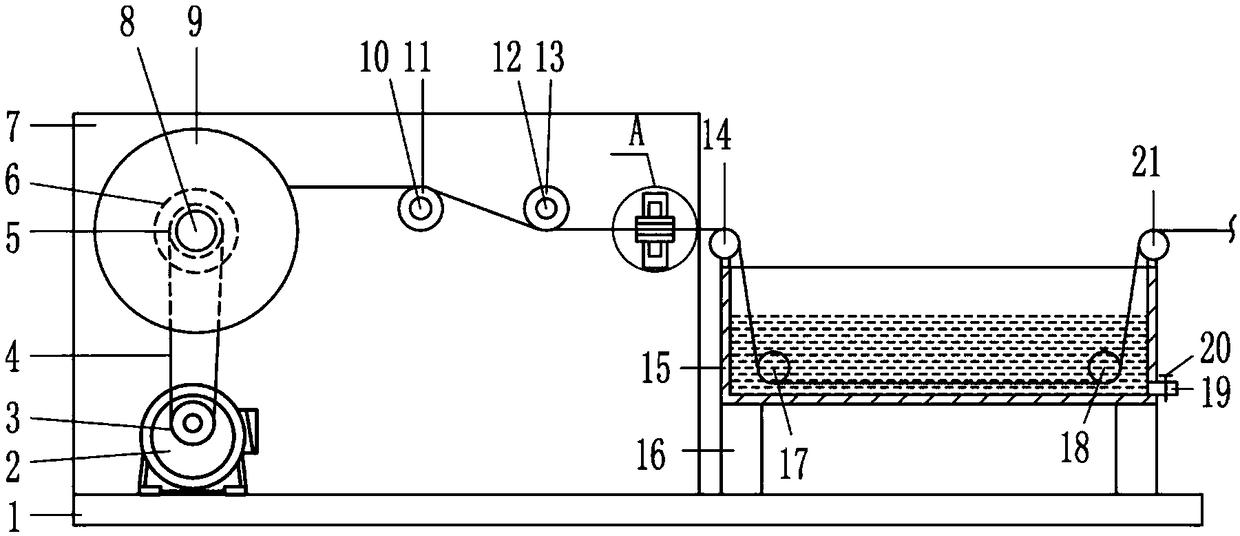

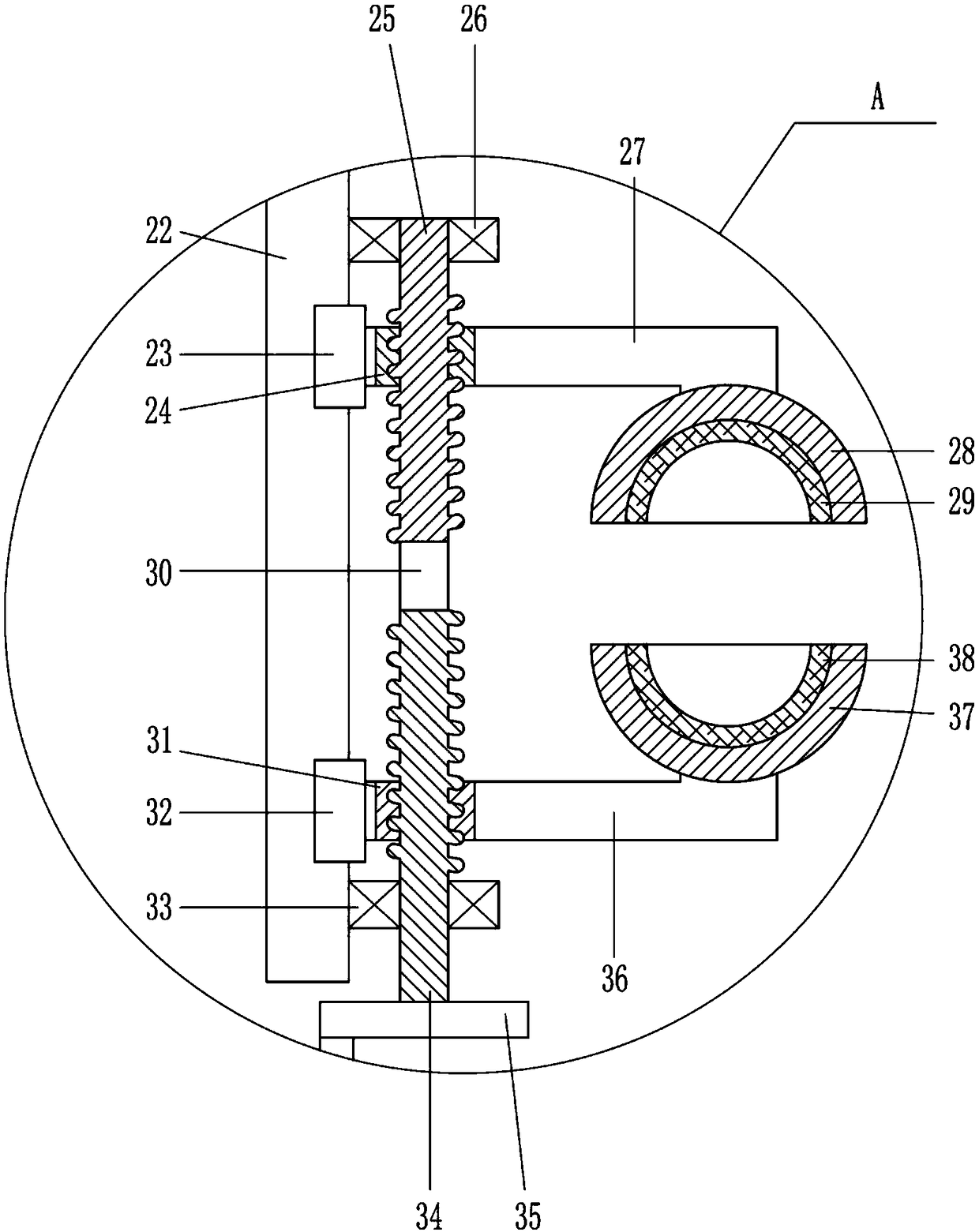

Cable cleaning type coiling machine

ActiveCN109230850APackaging is not affectedImprove rolling efficiencyFilament handlingEngineeringMachining

The invention belongs to the field of cable machining, and particularly relates to a cable cleaning type coiling machine. In order to solve the technical problems, the cable cleaning type coiling machine which can clean cable coils and ensure the cleanliness of cable surfaces is provided. The cable cleaning type coiling machine comprises a first installation plate, a motor, a first belt wheel, a flat belt, a second belt wheel, a first bearing pedestal, a second installation plate, a rotating shaft, a coiling plate, a first guide rod, a first guide wheel, a second guide rod, a second guide wheel, a third guide wheel, a cleaning frame, a supporting base, a fourth guide wheel, a fifth guide wheel, a water outlet pipe, a valve and a sixth guide wheel. The motor is fixedly connected to one sideof the first installation plate. By means of the cable cleaning type coiling machine, the cable surfaces are cleaned and then coiled, it is ensured that the coiled cable plate package is not affected, and the coiling efficiency is improved.

Owner:国网河南省电力公司辉县市供电公司 +2

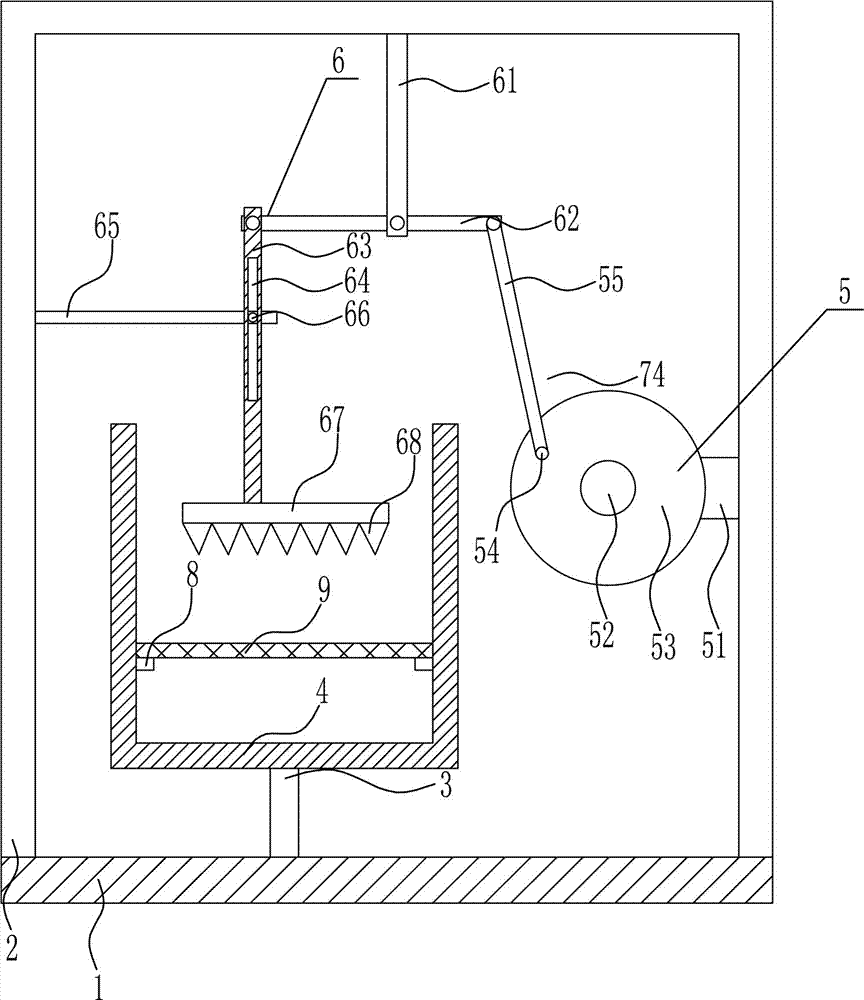

Rapid extraction equipment for plant coloring agent for textile

The invention relates to rapid extraction equipment for a plant coloring agent, in particular to the rapid extraction equipment for the plant coloring agent for the textile. The invention aims to provide the rapid extraction equipment for the plant coloring agent for the textile which is high in extraction efficiency, is sufficiently uniform in rolling compacting, and is capable of timely separating a liquid from plant residues during extraction. The rapid extraction equipment for the plant coloring agent for the textile comprises a bottom plate and the like; the top of the bottom plate is provided with an n-shaped frame, a driving mechanism is arranged on the right side in the n-shaped frame, a rolling compacting mechanism is arranged at the inner top of the n-shaped frame, a first supporting rod is arranged in the middle of the top of the bottom plate, and a box body is connected to the top end of the first supporting rod. According to the equipment, the effects that the extraction efficiency is high, rolling compacting is sufficiently uniform, and the liquid can be separated from the plant residues timely during extraction are achieved; and the driving mechanism works to drive the rolling compacting mechanism to roll and compact the plant to extrude out the juice, and a lifting mechanism enables the plant residues and the extraction liquid to be separated timely, so that theextraction speed is accelerated.

Owner:邱有萍

Cooling system for intermediate steel billets

InactiveCN103624093AReduce waiting timeQuality improvementWork treatment devicesMetal rolling arrangementsControl systemEngineering

The invention relates to a cooling system for intermediate steel billets. The cooling system is composed of a water supply pipeline, a PLC control system, upper cooling water beams, lower cooling water beams and an infrared temperature measuring device, wherein the water supply pipeline is divided into four branch water supply pipelines, each branch water supply pipeline is connected with four cooling water beams and is provided with a set of flow control device, and the flow control devices are controlled by the PLC control system. The cooling system for the intermediate steel billets is novel and reasonable in structure, high in degree of automation and cooling precision, and low in maintenance and operation cost, and can be applied to cooling before rolling of steel billets, steel plates and structural steel in the metallurgical industry.

Owner:JIANGSU BOJI SPRAYING SYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com