Cable cleaning type coiling machine

A clean, coiling machine technology, applied in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of long transportation distance, easy contamination of cables with large dirt, affecting cable packaging effect and cable quality. , to achieve the effect of improving the rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

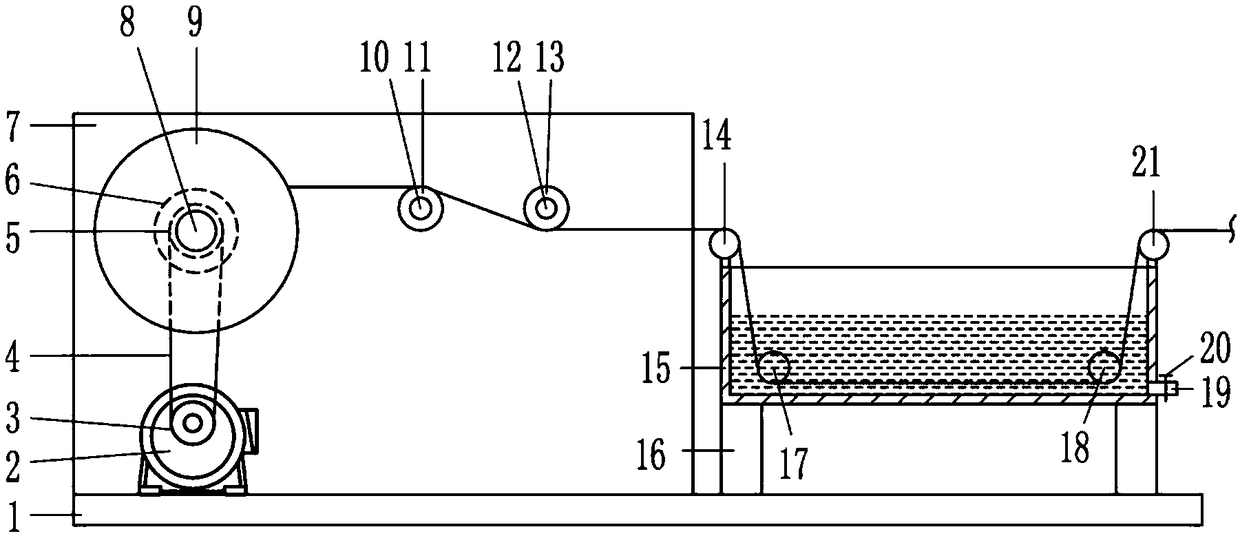

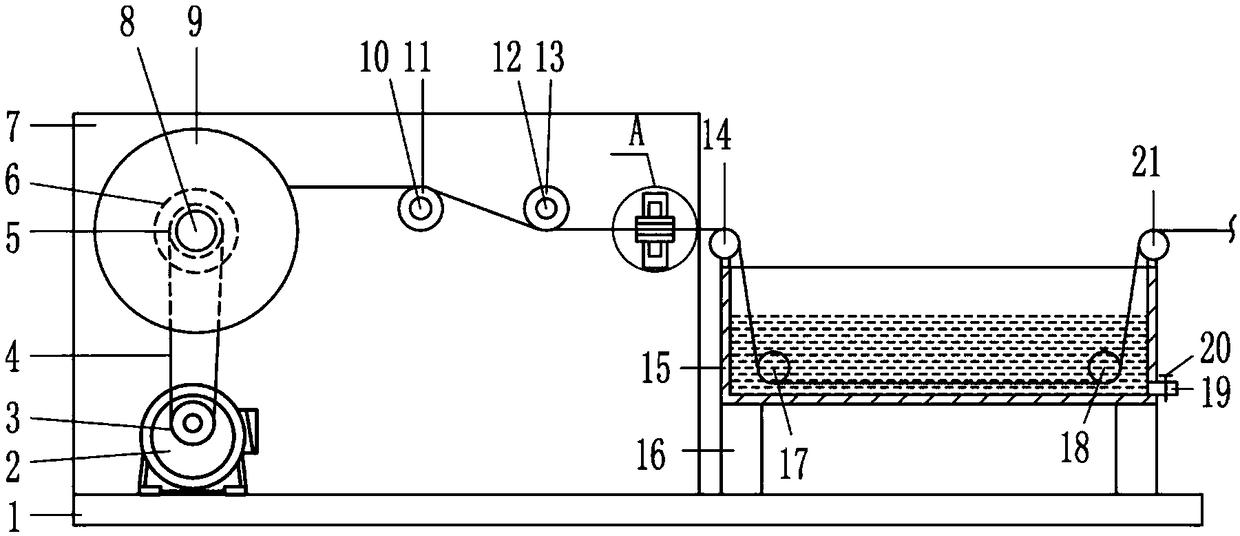

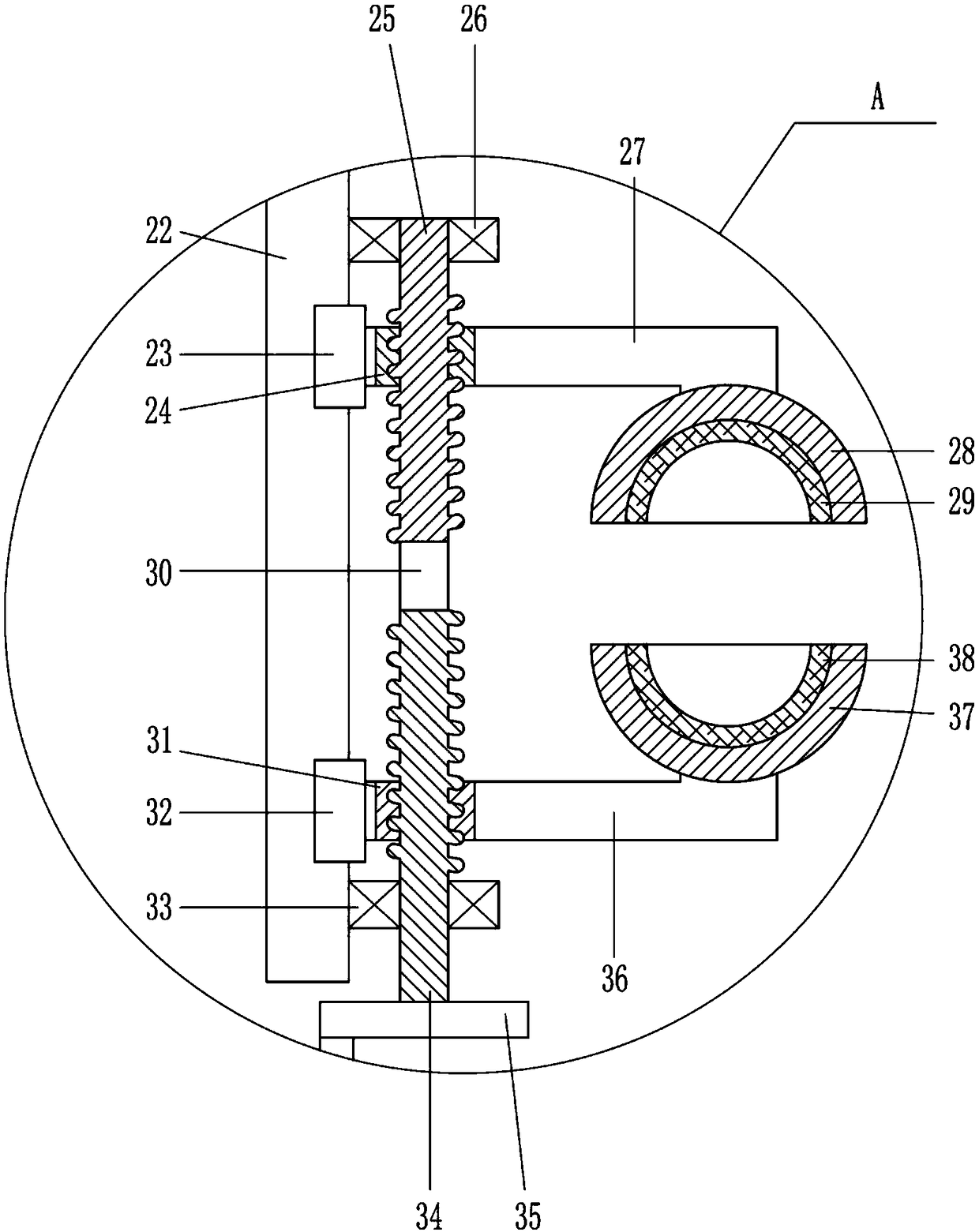

[0029] A cable cleaning type coiling machine such as Figure 1-8 As shown, it includes a first mounting plate 1, a motor 2, a first pulley 3, a flat belt 4, a second pulley 5, a first bearing seat 6, a second mounting plate 7, a rotating shaft 8, a reel 9, the first Guide rod 10, first guide wheel 11, second guide rod 12, second guide wheel 13, third guide wheel 14, cleaning frame 15, support base 16, fourth guide wheel 17, fifth guide wheel 18, outlet pipe 19. The valve 20 and the sixth guide wheel 21; the motor 2 is fixed on one side of the first installation plate 1, and the cleaning frame 15 is fixed on the other side of the first installation plate 1 through the support seat 16; the first pulley 3 and The output end of the motor 2 is connected by transmission, the second mounting plate 7 is fixedly connected to the rear side of the first mounting plate 1, the first bearing seat 6 is fixedly connected to the second mounting plate 7, and one end of the rotating shaft 8 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com