Cooling system for intermediate steel billets

A cooling system and billet technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as low rolling efficiency and impact on enterprise benefits, and achieve low maintenance and operation costs, novel and reasonable structure, and high cooling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

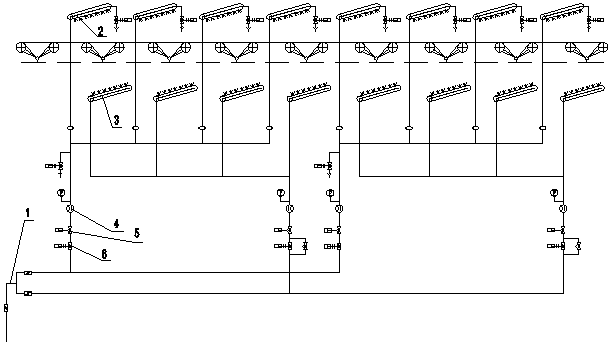

[0012] Steel billet intermediate billet cooling system, the system consists of water supply pipeline, PLC control system, upper and lower cooling water beams and infrared temperature measuring device, four branch water supply pipelines are separated from the water supply pipeline, and each branch water supply pipeline Four cooling water beams are connected on the road, and a group of flow control devices are set on each branch water supply pipeline. The flow control device is controlled by the PLC control system. flow meter, pneumatic flow control valve and pneumatic switch valve, the pipeline of the lower cooling water beam is provided with a bypass valve pipeline adjusted to a long-open state, and the system also includes an infrared temperature measurement system for detecting the temperature of the billet to be cooled device, the infrared temperature measuring device transmits temperature information to the PLC control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com