Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1968 results about "Reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image processing apparatus and image processing method as well as computer program

InactiveUS20060098253A1Excessive of saturation can be preventedQuality improvementImage enhancementTelevision system detailsReduction rateImaging processing

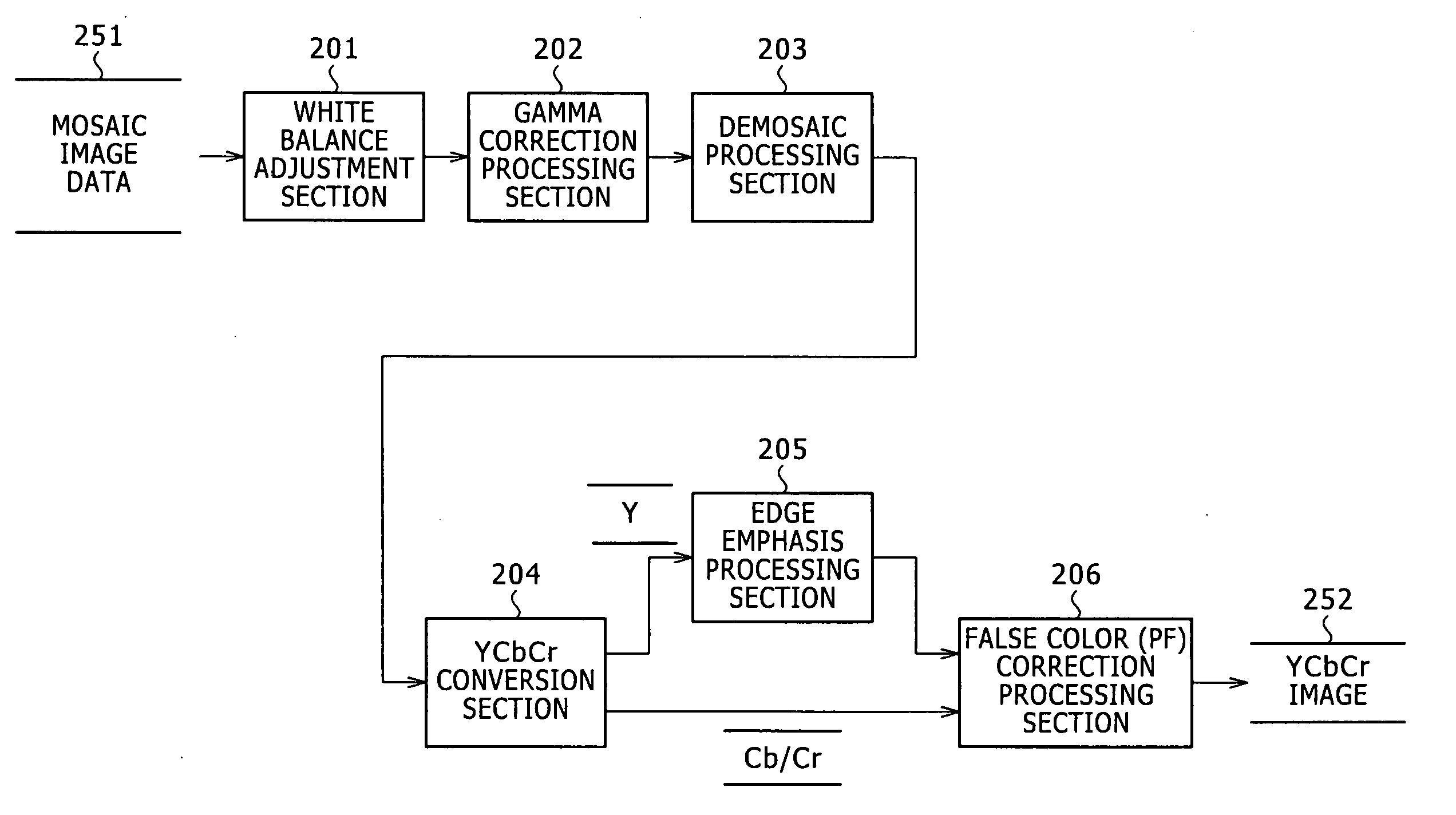

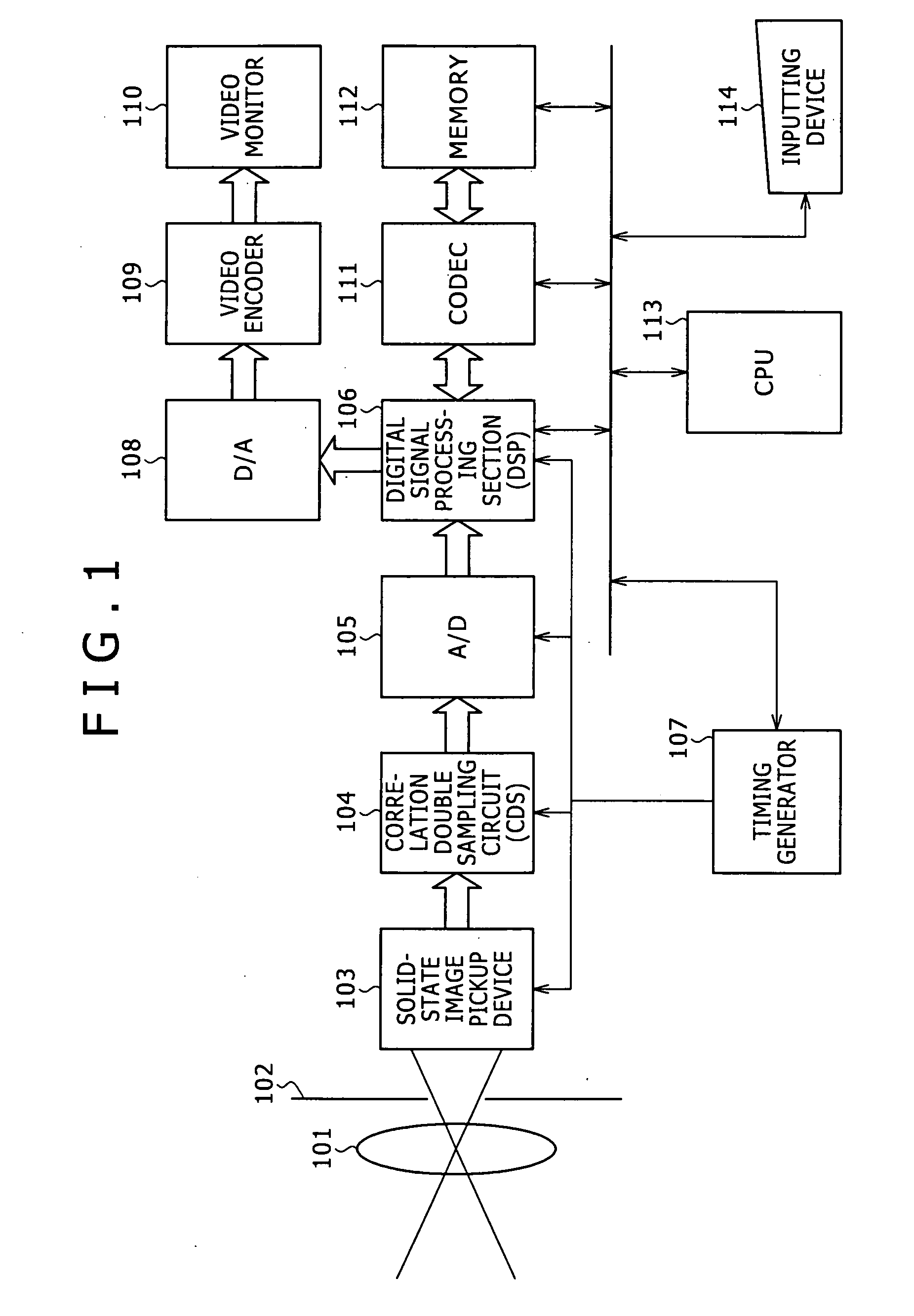

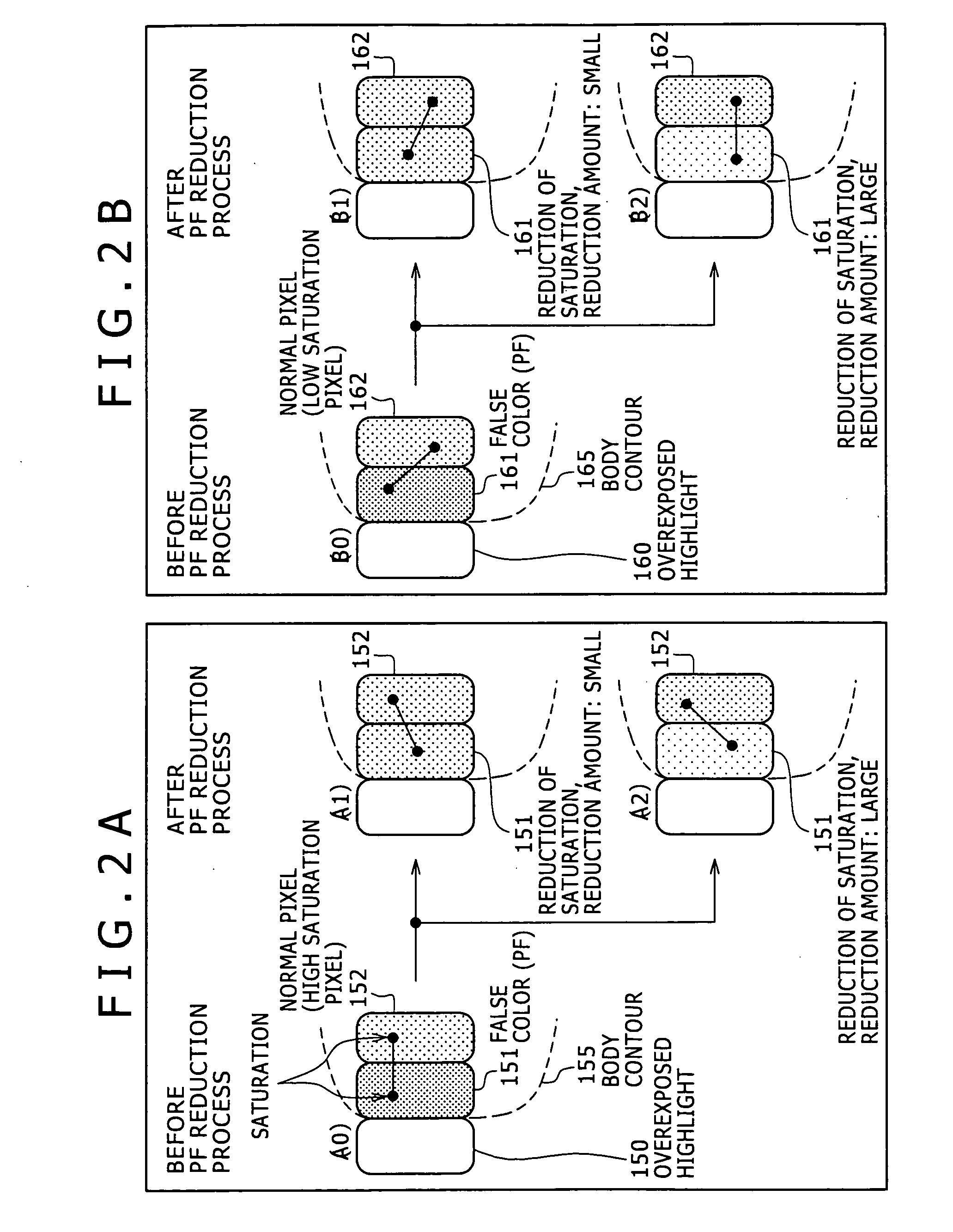

An image processing apparatus and an image processing method are disclosed by which an image correction process for a false color such as a purple fringe can be executed efficiently while excessive reduction of the saturation is prevented to produce image data of a high quality. A saturation reduction rate corresponding to each pixel is calculated, and saturation reduction of the pixel is executed based on the saturation reduction rate. Then, saturation correction is executed so that the difference between the hue of the pixel whose saturation has been reduced and a surrounding reference pixel may be reduced. Further, a surrounding pixel to be referred to in the saturation correction process is selected along a scanning line.

Owner:SONY CORP

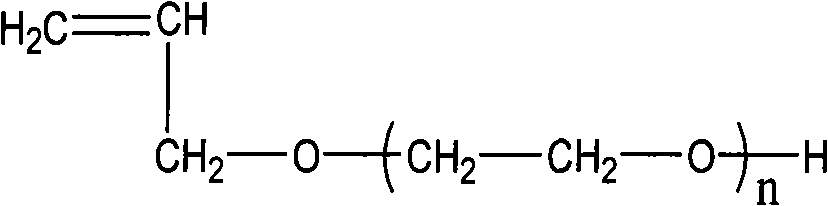

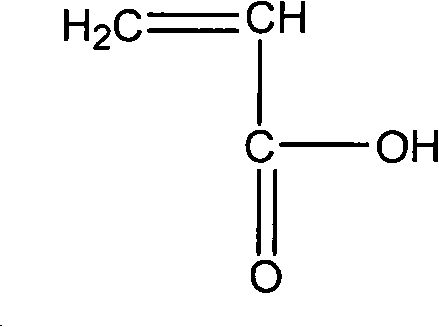

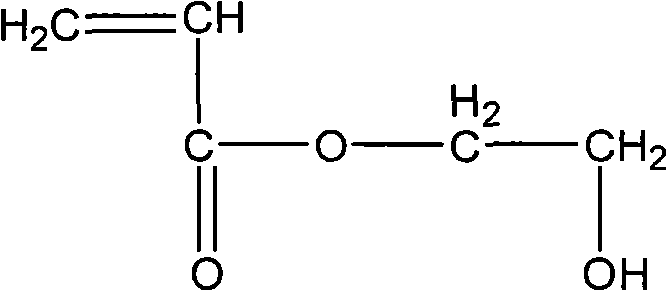

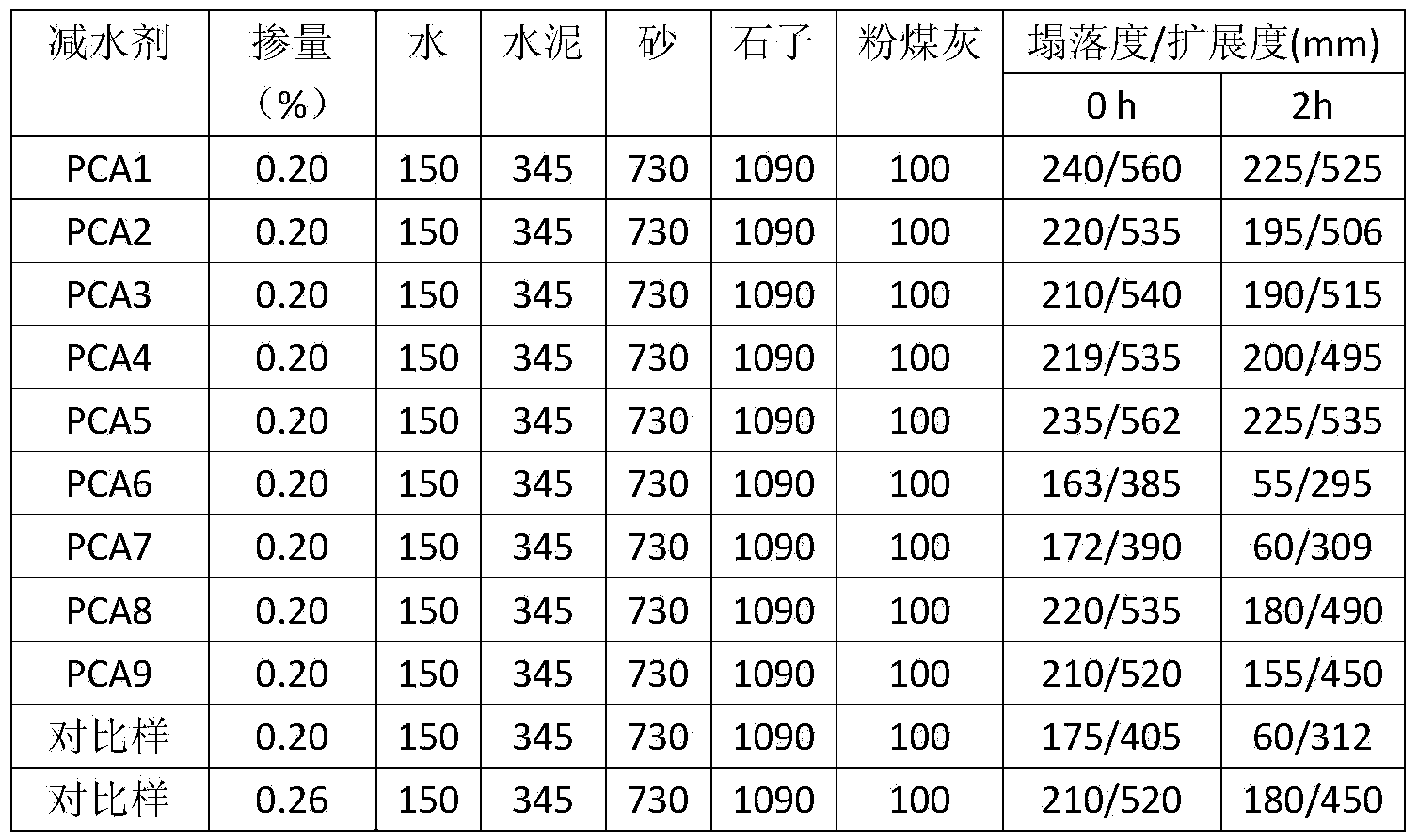

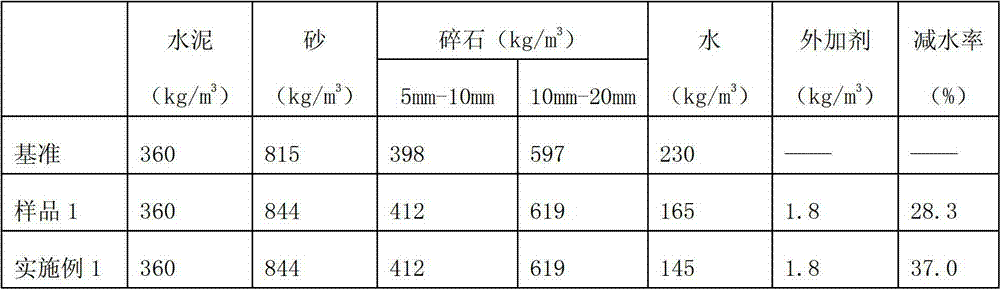

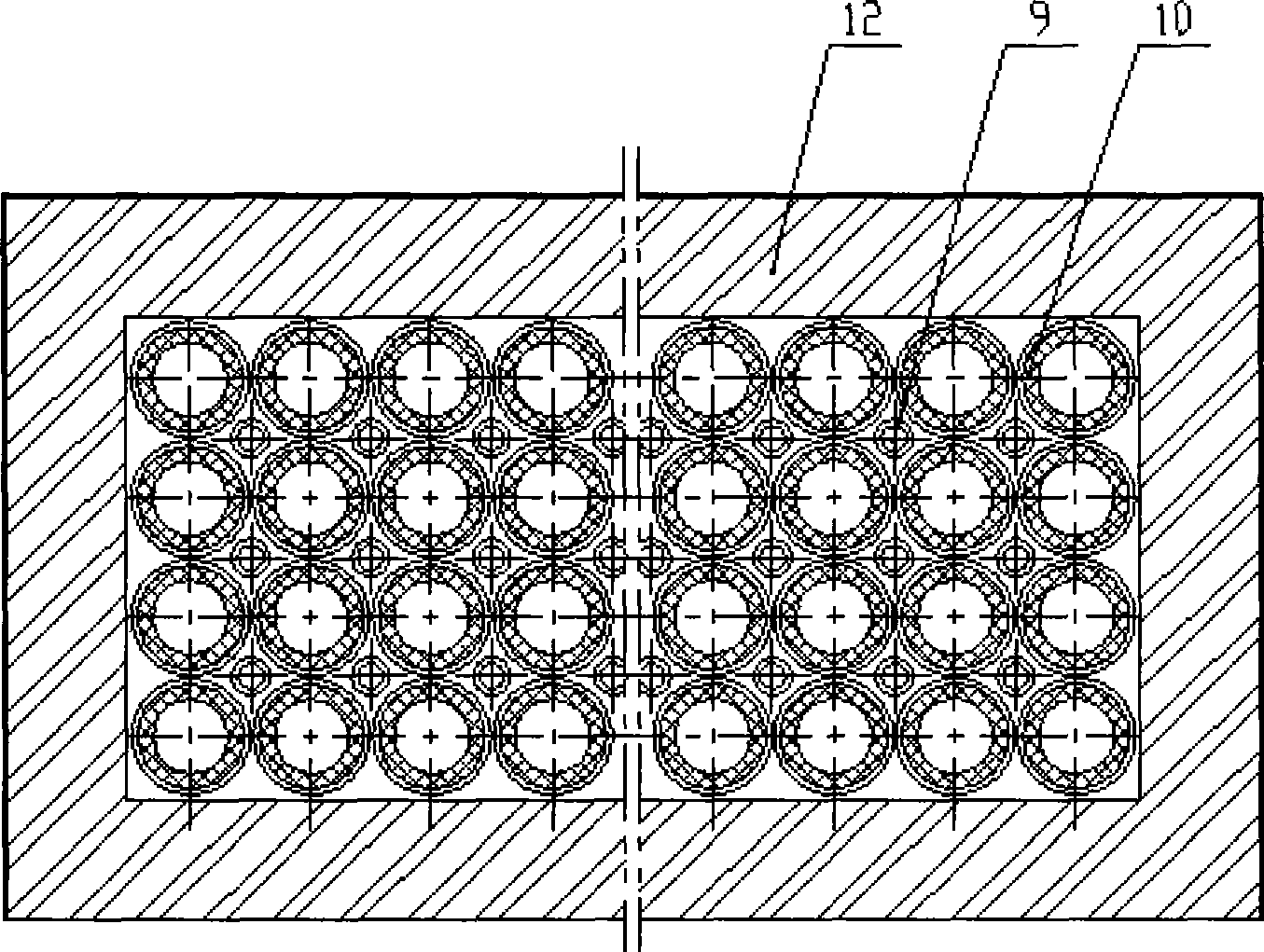

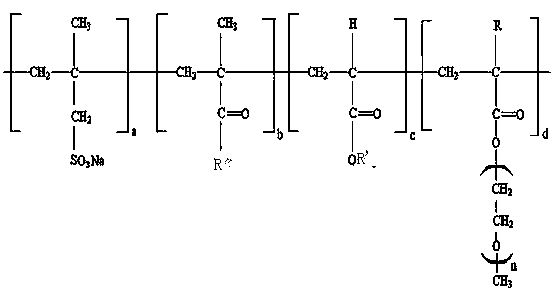

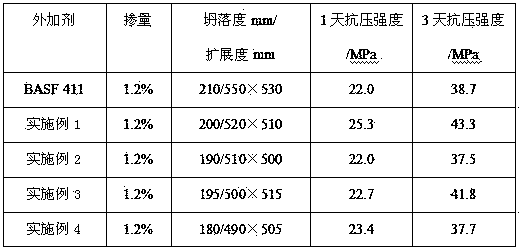

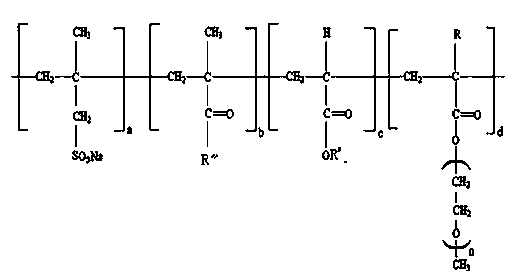

Ethers polycarboxylic acid water reducing agent and preparation

The invention discloses an ether polycarboxylic water reducing agent which is obtained through water solution copolymerization of three types of monomers of 10-70 percent of allyl polyxyethylated alcohol ether, 20-70 percent of acrylic acid and 10-30 percent of hydroxy-ethyl acrylate. Due to the introduction of hydroxy-ethyl acrylate, the ether polycarboxylic water reducing agent reduces the self-polymerization proportion of the acrylic acid, improves the copolymerization proportion, and greatly reduces the cost of the raw materials; in addition, the molecular weight of the polymer is controllable, the water reduction rate is high, the loss of slump constant with the time is low, and the prepared concrete has high fluidity, good workability, and enough early strength in the beginning of hardening. Besides, the preparation technique of the ether polycarboxylic water reducing agent is a one-step method, the operation is simple, the reaction conditions are easy to control, the production period is short, and the ether polycarboxylic water reducing agent is green and environment-friendly, has low cost and is applicable to industrial production on large scale.

Owner:杭州传化建筑新材料有限公司

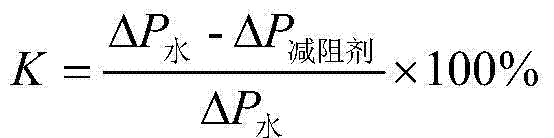

Shale gas acid fracturing drag reducer and reparation method thereof

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

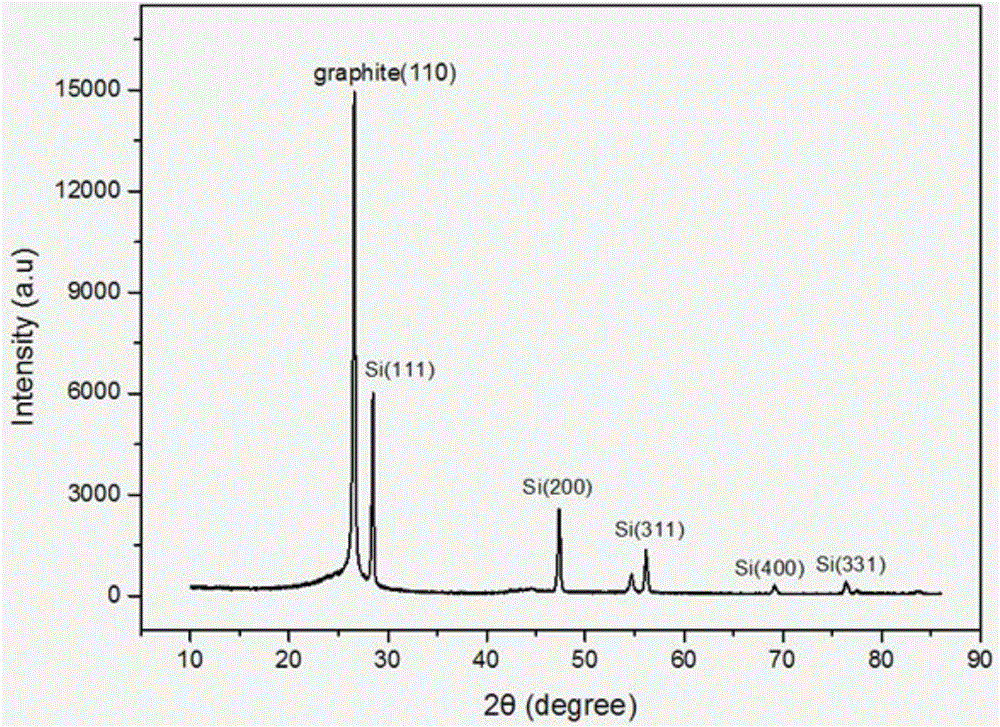

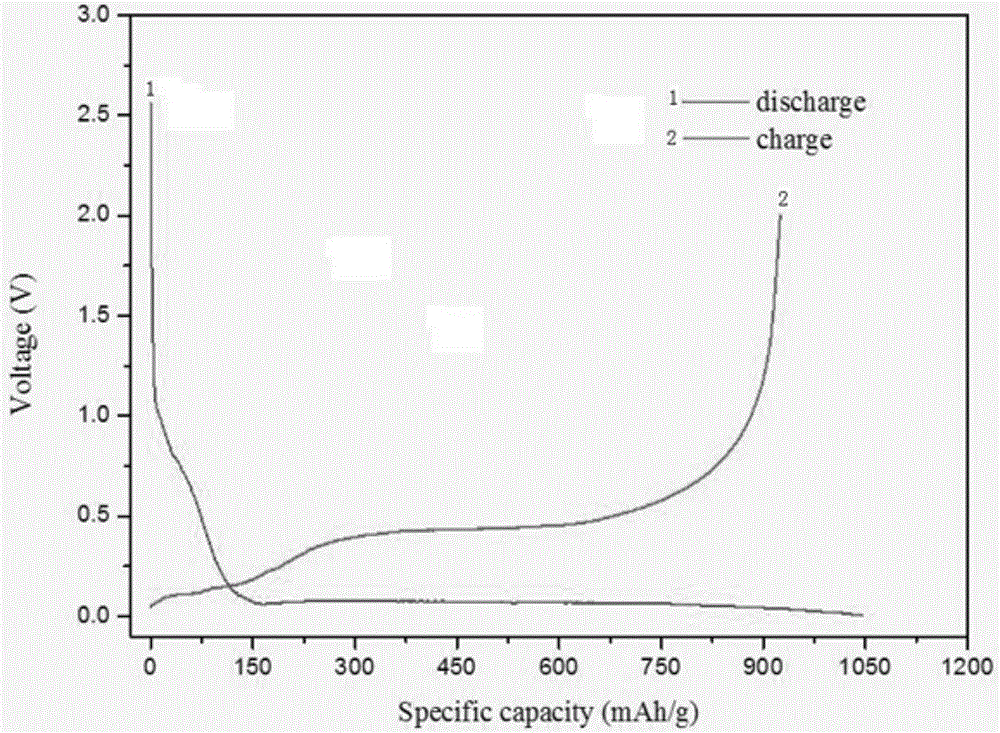

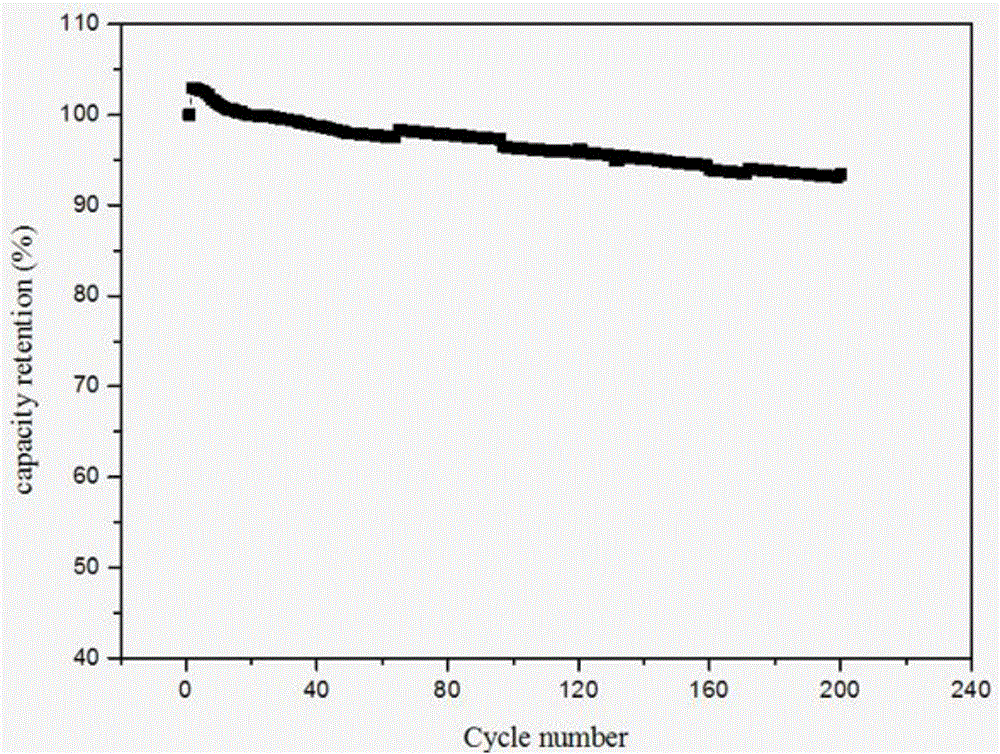

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

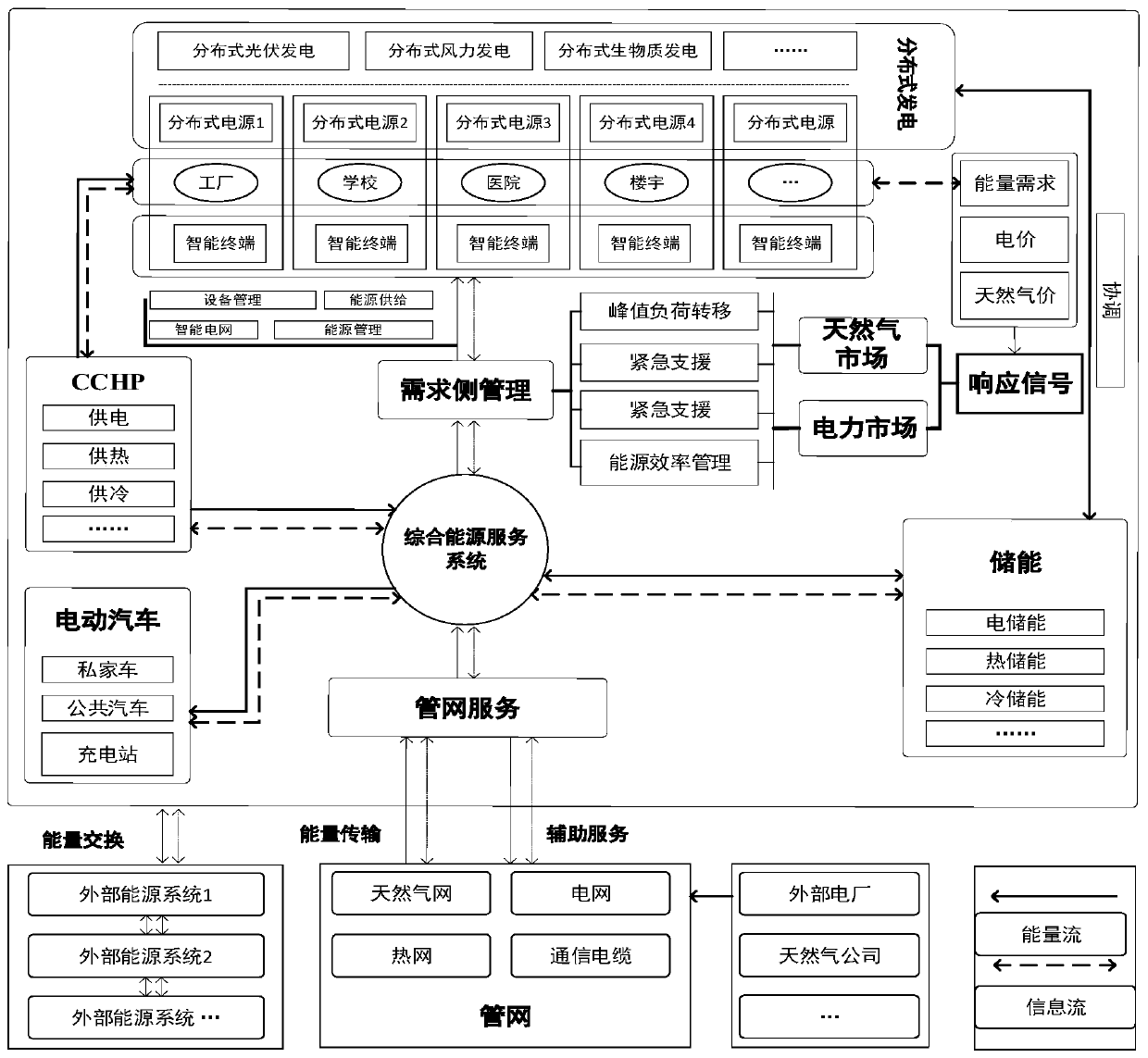

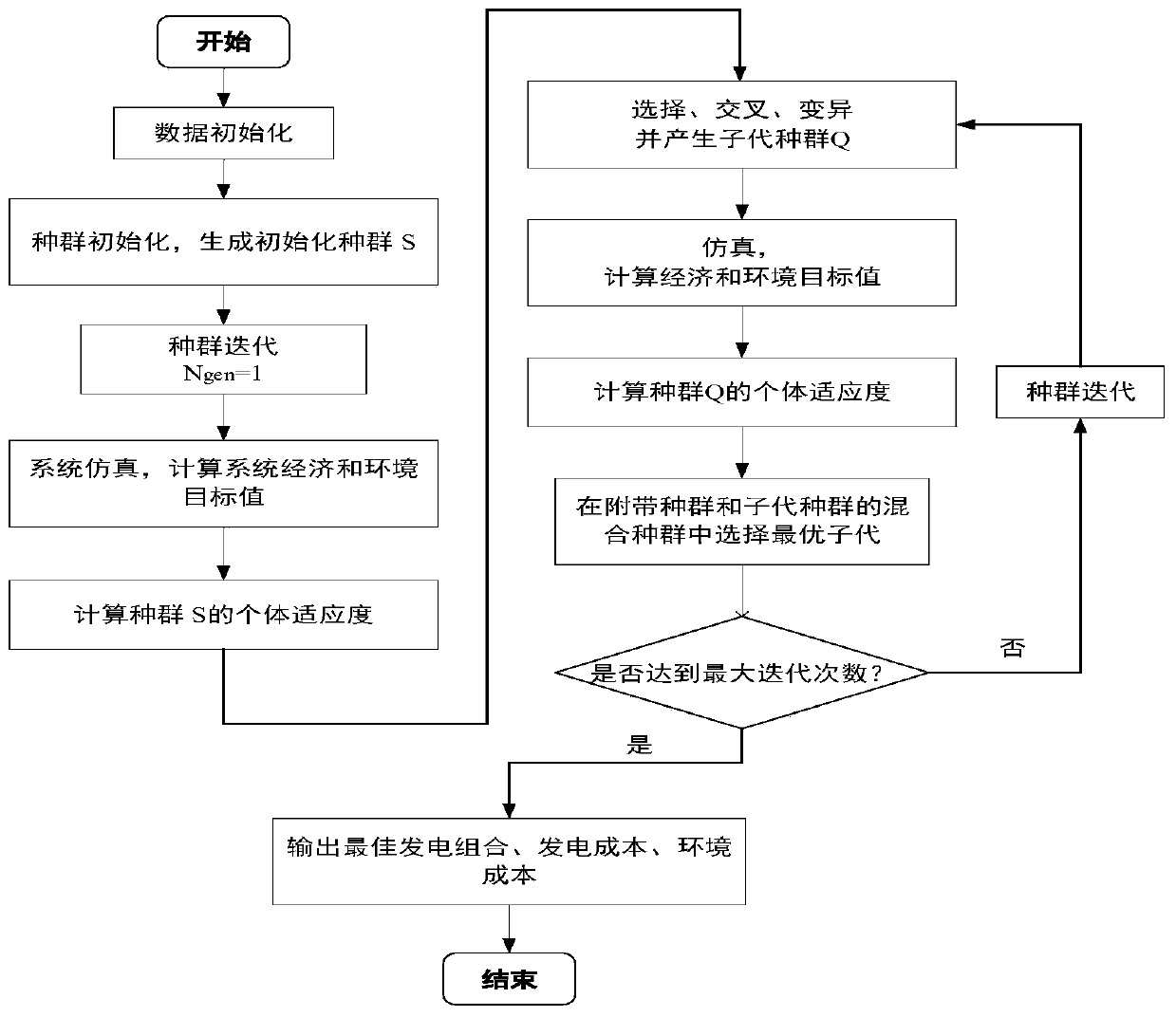

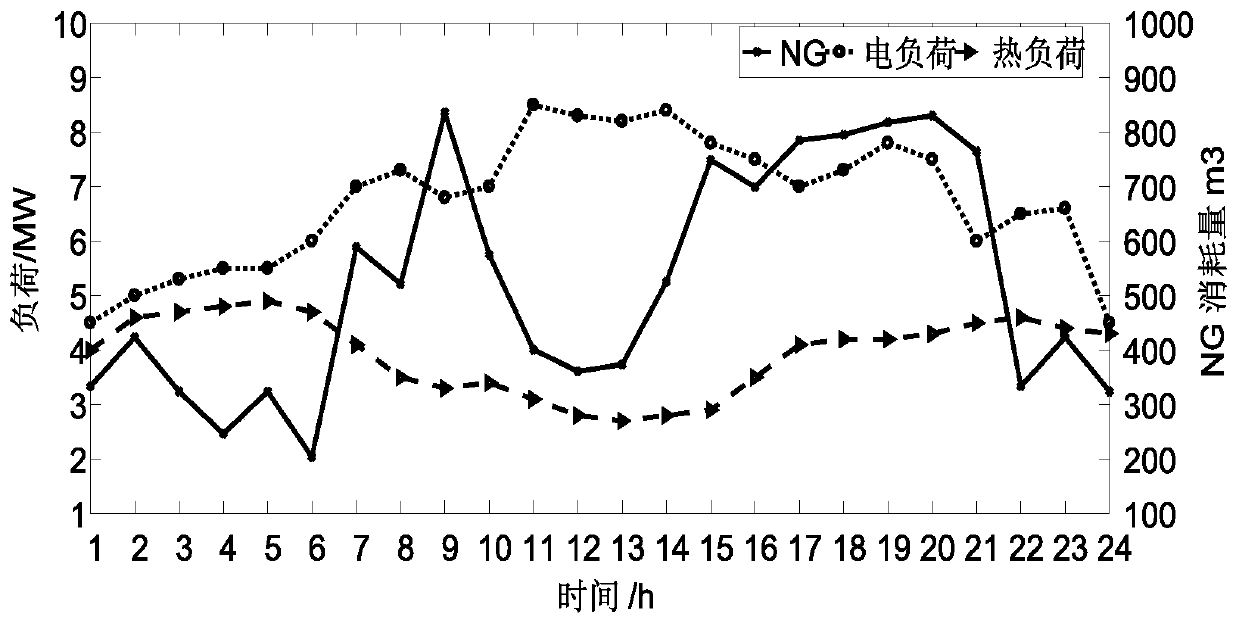

Regional integrated energy system optimization control method

InactiveCN109784569ALow operating costImprove reliabilityForecastingSystems intergating technologiesReduction rateEnergy system optimization

The invention discloses a regional integrated energy system optimization control method. The method comprises the following steps: S1, optimizing a control objective function of the regional integrated energy system; The purposes of the lowest total operation cost and the highest reliability and system emission reduction rate of the regional comprehensive energy system are achieved, and the objective function is divided into an operation cost model, an environment cost model and a system reliability model; including S11, constructing an objective function based on an operation cost model; S12,constructing an objective function based on an environment cost model; S13, constructing an objective function based on the system reliability model; S2, analyzing optimization control constraint conditions of the regional comprehensive energy system; S21, energy balance constraint analysis; S22, performing energy balance constraint analysis; And S23, system operation constraint. The control method aims at achieving the purposes that the total operation cost of the system is lowest, and reliability and system emission reduction rate are highest.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method and application of unsaturated polyether

The invention relates to a preparation method and application of unsaturated polyether. The preparation method comprises the following steps: (1) adding unsaturated alcohol and a catalyst into a first reactor, replacing with nitrogen, continuously adding epoxide with short branches and reacting to obtain an intermediate product A, wherein the unsaturated alcohol is one or a mixture of more than two of methyl allyl alcohol and isoamyl alcohol at any proportion and the mass ratio of the unsaturated alcohol to epoxide is 1.0:(0.1-5.0); and (2) putting the intermediate product A obtained in the step (1) and the catalyst into a second reactor, replacing with nitrogen, continuously introducing ethylene oxide and reacting to obtain polyether B, and neutralizing the pH value of the polyether B product to be 5-7 with a neutralizing reagent, wherein the mass ratio of the intermediate product A to ethylene oxide is 1.0:(15.0-51.0). The invention also provides the unsaturated polyether prepared by the preparation method, which is disclosed by the invention and application of unsaturated polyether in synthesis of polycarboxylic water reducer and the water reducer prepared from the unsaturated polyether synthesized by the method has the advantages of low doping amount, high water reduction rate, good slump-retaining agent and like.

Owner:HONGBAOLI GRP CO LTD

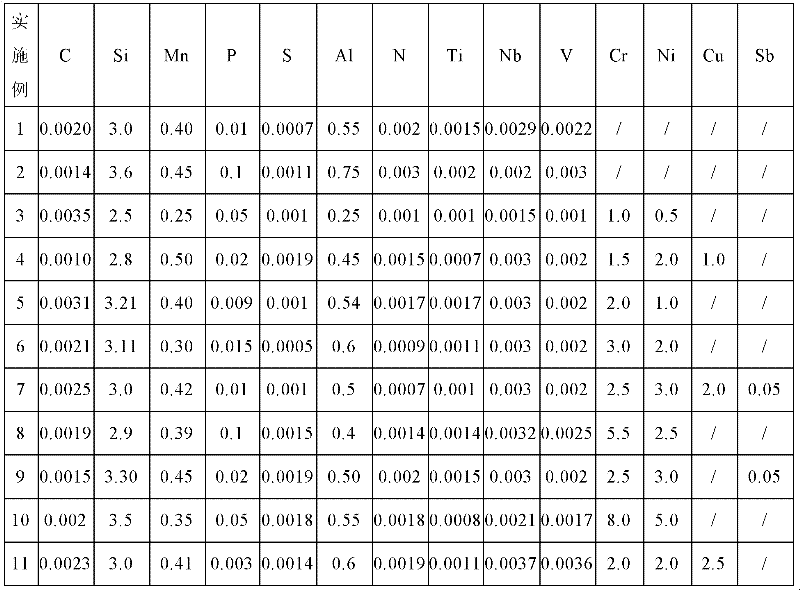

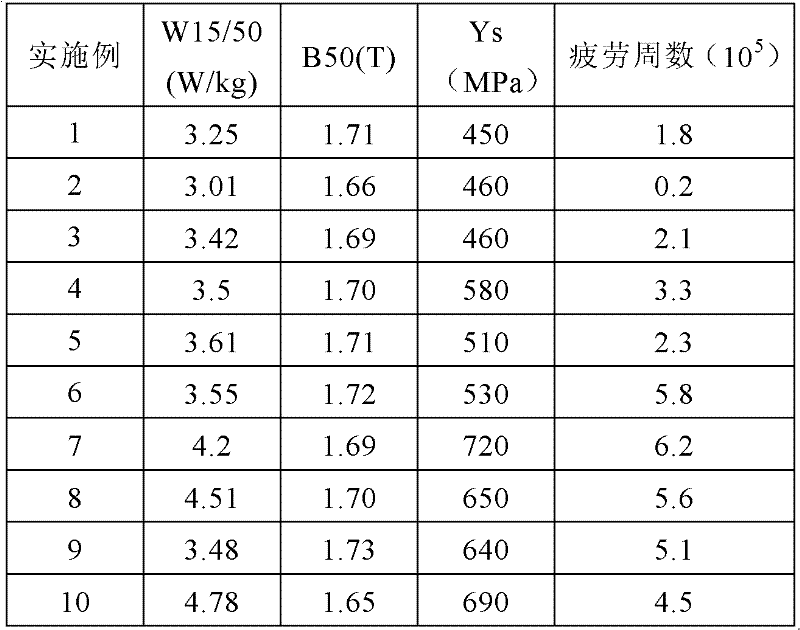

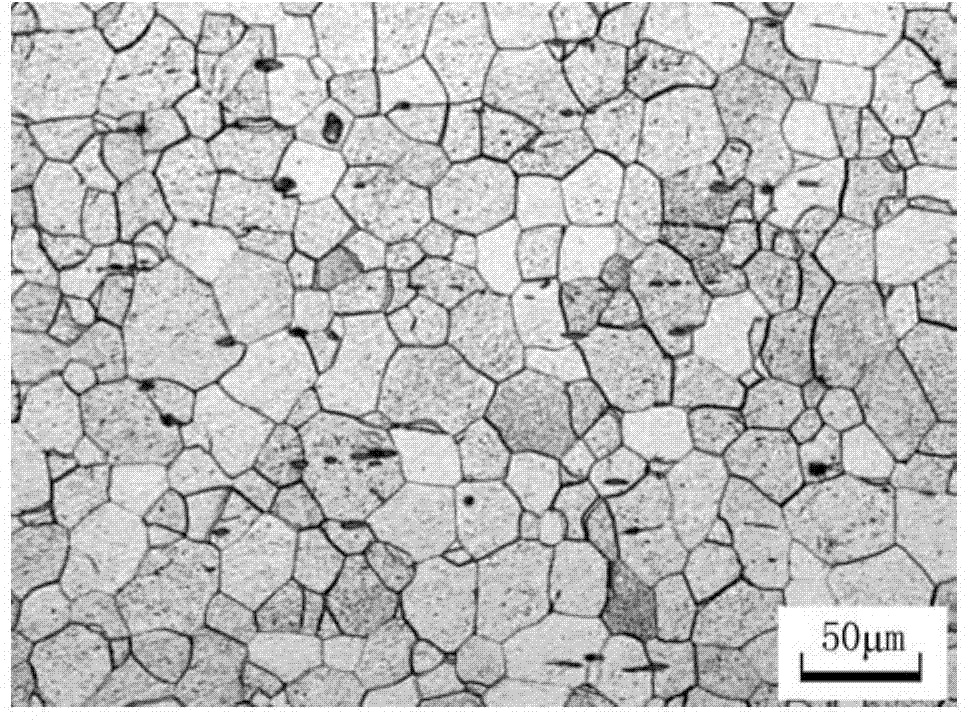

High-strength non-oriented electrical steel with high magnetic induction and manufacturing method thereof

InactiveCN102453838AHigh strengthSolve the problem of difficult rollingReduction rateElectrical steel

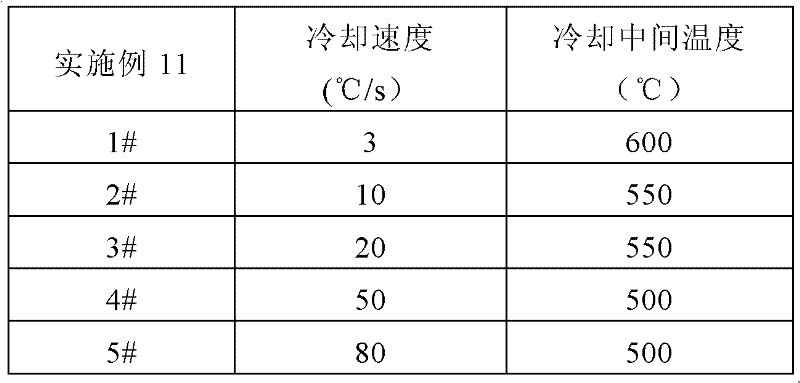

High-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof. The method comprises the following steps of: 1) smelting and casting, wherein the electrical steel comprises the following components by weight: not more than 0.0040% of C, 2.50-4.00% of Si, 0.20%-0.80% of Al, 1.0-8.0% of Cr, 0.5-5.0% of Ni, not more than 0.50% of Mn, not more than 0.30% of P, not more than 0.0020% of S, not more than 0.0030% of N, not more than 0.0030% of Ti, not more than 0.010% of Nb, not more than 0.010% of V, not more than 0.010% of C+S+N+Ti, and the balance of Fe; smelting, RH vacuum treatment, casting; 2) hot rolling; 3) normalization at a temperature of 850-950 DEG C for 0.5-3 min, slow cooling to 650-750 DEG C with a speed of 5-15 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C; 4) pickling and cold rolling with a total reduction rate of not less than 70%; 5) annealing at 800-1000 DEG C for 5-60 seconds, slow cooling to 650-750 DEG C with a speed of 3-10 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C. The method of the invention produces non-oriented electrical steel with both high strength and high-efficient magnetic properties without the increase of manufacturing difficulties.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling

ActiveCN103372567AExtended rolling kilometersImprove surface qualityWork treatment devicesMetal rolling arrangementsHydrofluoric acidReduction rate

A method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling comprises that (1), a five-rack serial type cold continuous rolling is performed, a five-rack serial type cold continuous rolling unit is adopted, the diameter of a working roll of each rolling mill is 300-500mm, and endless rolling is performed; the roughness degrees of the rolls of the first rack to the fourth rack are in a range of 0.5-1.0mum and decrease sequentially; the working roll of the fifth rack is subjected to roughening and chromium plating treatment; an emulsion lubrication rolling mode is adopted, the temperature of an emulsion is 50-60DEG C, the emulsion is sprayed to roll gaps for cooling and lubricating, the temperature of cold-rolled band steel is controlled below 150DEG C; the accumulated reduction rate of the first rack to the fourth rack is larger than 60%, the reduction rate of the fifth rack is in a range of 4-10%, and the roughness of the cold-rolled band steel is controlled in a range of 0.5-1.0mum; (2), the cold-rolled band steel is subjected to annealing acid picking treatment, heating and annealing are performed in a continuous horizontal gas furnace, the annealing temperature is in a range of 800-1000DEG C, and recrystallization of the band steel is finished; finished surfaces are obtained finally through electrolytic picking by Na2SO4 and H2SO4 solutions and soaking picking by a nitric acid and hydrofluoric acid mixed acid solution sequentially after annealing.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Post-treating method for steel-back aluminium-based semisolid-state clad plate

InactiveCN101117696AIncreased interfacial shear strengthSimple methodRoll mill control devicesMetal rolling arrangementsReduction rateRoom temperature

The present invention discloses a post-processing method for steel-back aluminum-base semisolid composite plates and relates to the post-processing research field of interfacial mechanical characteristic of steel-back aluminum-base semisolid composite plates. At room temperature, a steel-back aluminum-base semisolid composite plate is rolled with the reduction rate of 0.5-1.6 percent on a precision rolling mill, and the difference between shrinkages of the aluminum-base coating and the steel base in the coagulating and cooling process of the composition is redeemed by the difference between the deformation of the aluminum-base coating and the steel base produced in the rolling process, thereby, reducing the additional interfacial stress of the composite plate, simply and conveniently improving the interfacial shear strength of the composite plate, and solving the technical problems of large energy consumption and small increase amplitude of interfacial shear strength in post-processing method of diffusion annealing of aluminum-base semisolid composite plates.

Owner:BEIJING JIAOTONG UNIV

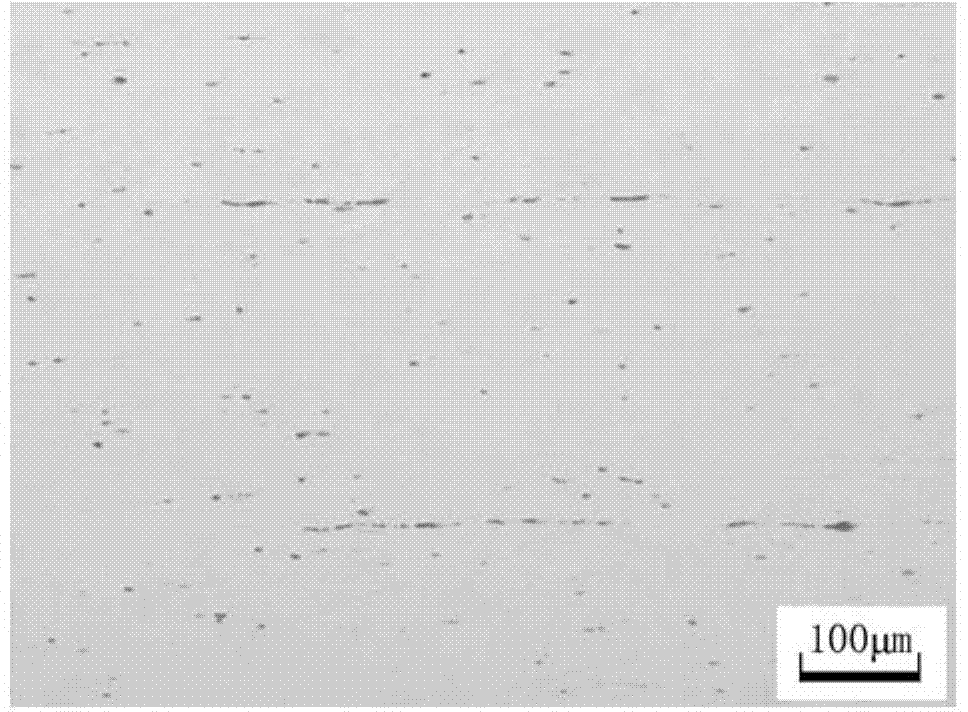

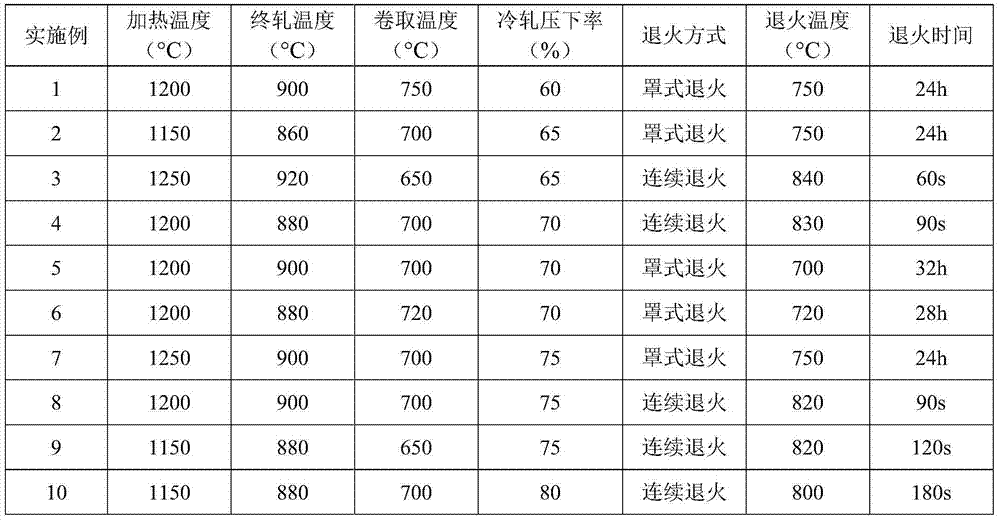

Enamel steel with scaling resistance and manufacturing method thereof

InactiveCN103484757ASimple chemical compositionReduce smelting costTemperature control deviceReduction rateAcid washing

The invention discloses enamel steel with scaling resistance. The enamel steel is prepared from the following components in percentage by weight: 0.0020-0.0050% of C, 0.30-0.50% of Mn, 0.0050-0.0100% of Si, 0.010-0.015% of P, 0.011-0.020% of S, 0-0.010% of Als, 0.011-0.020% of O and the balance of Fe and other inevitable impurities. A manufacturing method sequentially comprises the following steps: pretreatment of molten iron, smelting by a converter, refining, continuous casting, hot continuous rolling, acid washing, cold continuous rolling, annealing and finishing, wherein the heating temperature for hot continuous rolling is 1150-1250 DEG C, the finish rolling temperature is 860-920 DEG C, the winding temperature is 650-750 DEG C, and the cold rolling reduction rate of cold continuous rolling is 60-80%. The enamel steel disclosed by the invention has no scaling phenomenon and low production difficulty, and is suitable for being applied to the technical field of iron and steel smelting.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for reducing and decomposing phosphogypsum by sulfur

ActiveCN101708826AImprove recovery rateReduce reaction energy consumptionSulfur compoundsReduction rateSlag

The invention discloses a method for reducing and decomposing phosphogypsum by sulfur, which comprises the following steps: putting the phosphogypsum into a reactor, and raising the temperature to between 500 and 900DEGC for preheating for 10 to 30 minutes at an inert atmosphere; introducing gaseous sulfur in a molar percentage of 10 to 50 percent to perform reduction reaction with the phosphogypsum for 1 to 2 hours; grinding obtained a calcium sulfide block, and uniformly mixing the ground calcium sulfide with the phosphogypsum in a molar ratio of 1-1.5:3; sintering at a temperature between 1,000 and 1,400 DEG C for 0.5 to 3 hours at a non-oxidizing atmosphere; and taking CaO in the obtained solid slag as a cement clinker for cement production, taking the generated tail gas SO2 as a raw material gas for producing sulphuric acid. The reduction rate of CaSO4 is high, the decomposition ratio of the phosphogypsum can reach over 98 weight percent, the desulfurization ratio of the phosphogypsum can reach over 95 weight percent, and the method has the advantages of low energy consumption, simple and mature process, short production period, easy control and convenient promotion.

Owner:SICHUAN UNIV

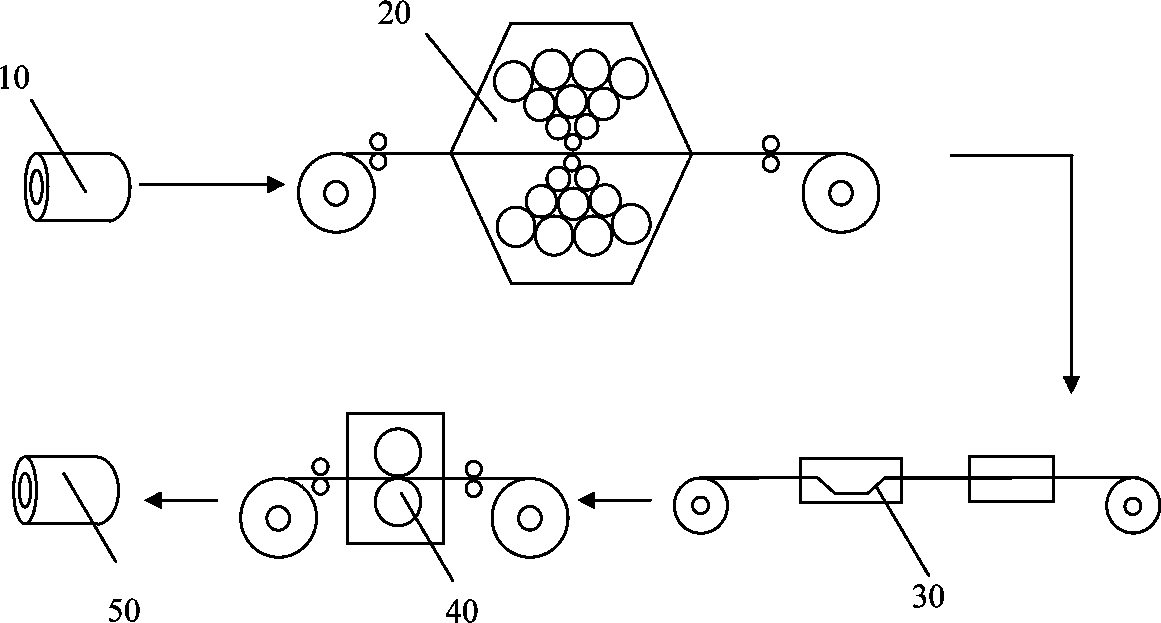

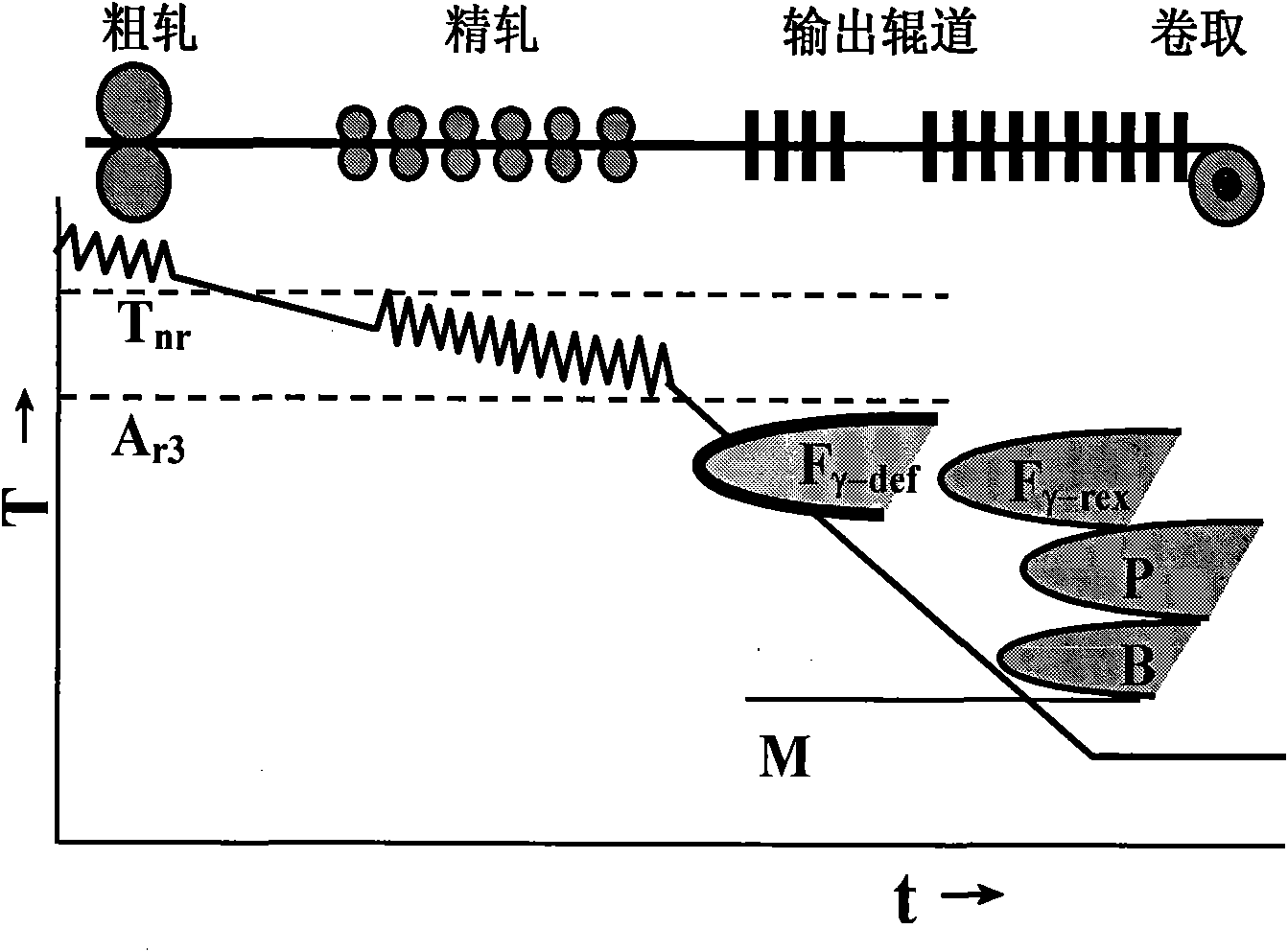

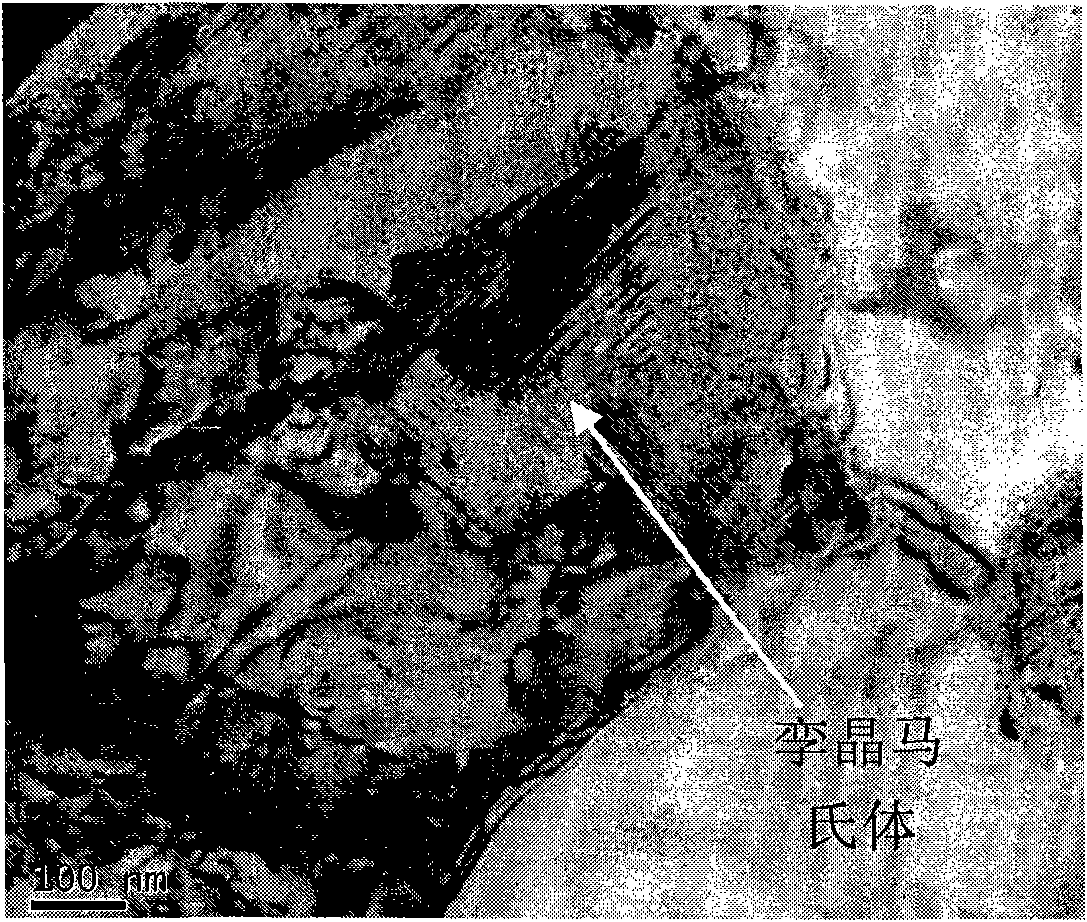

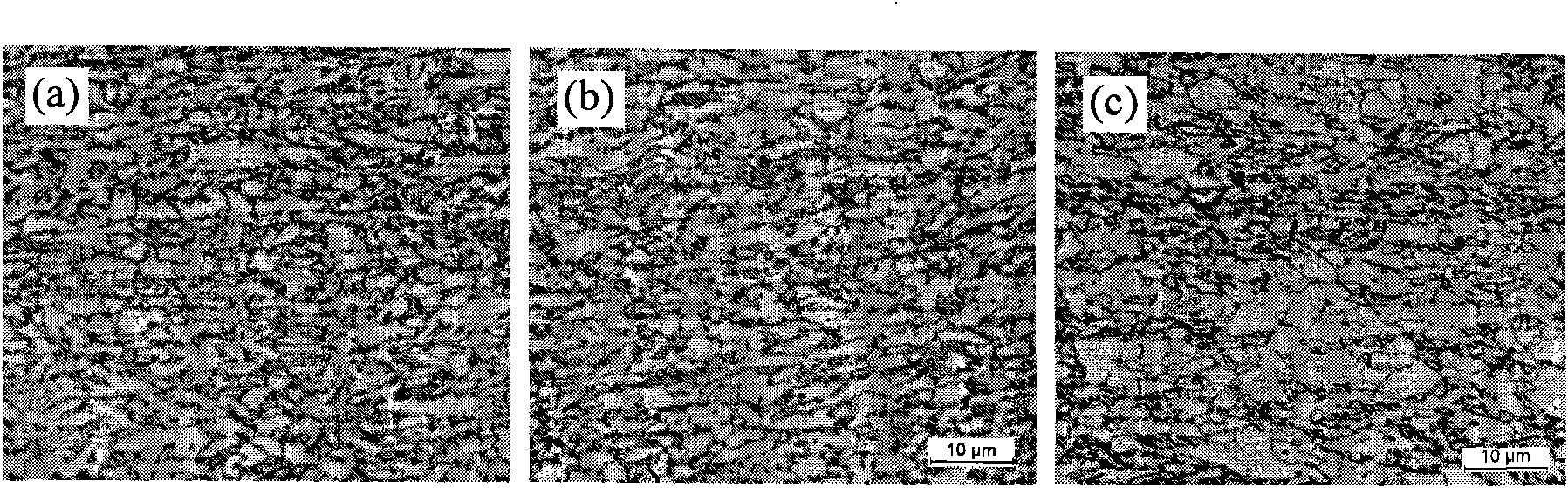

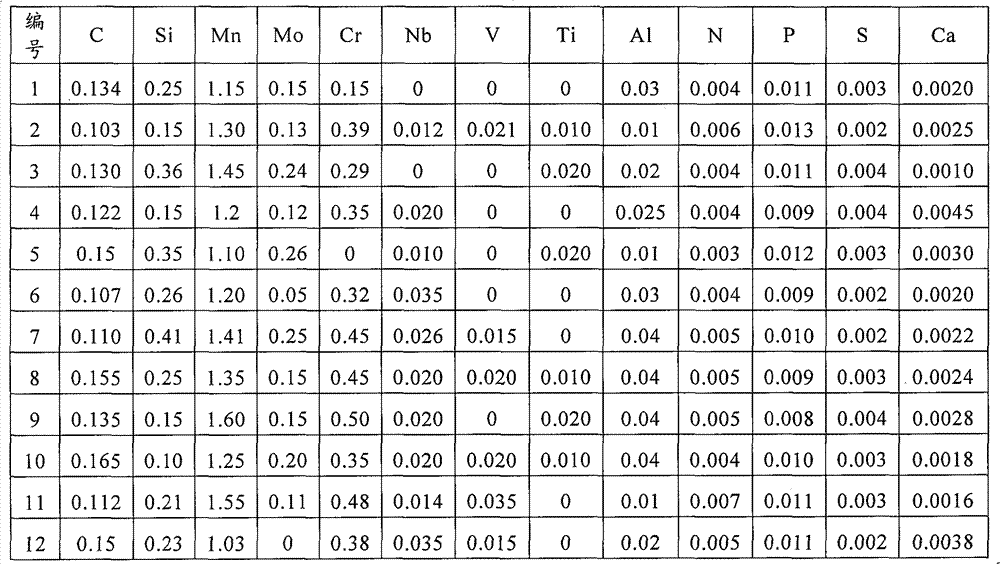

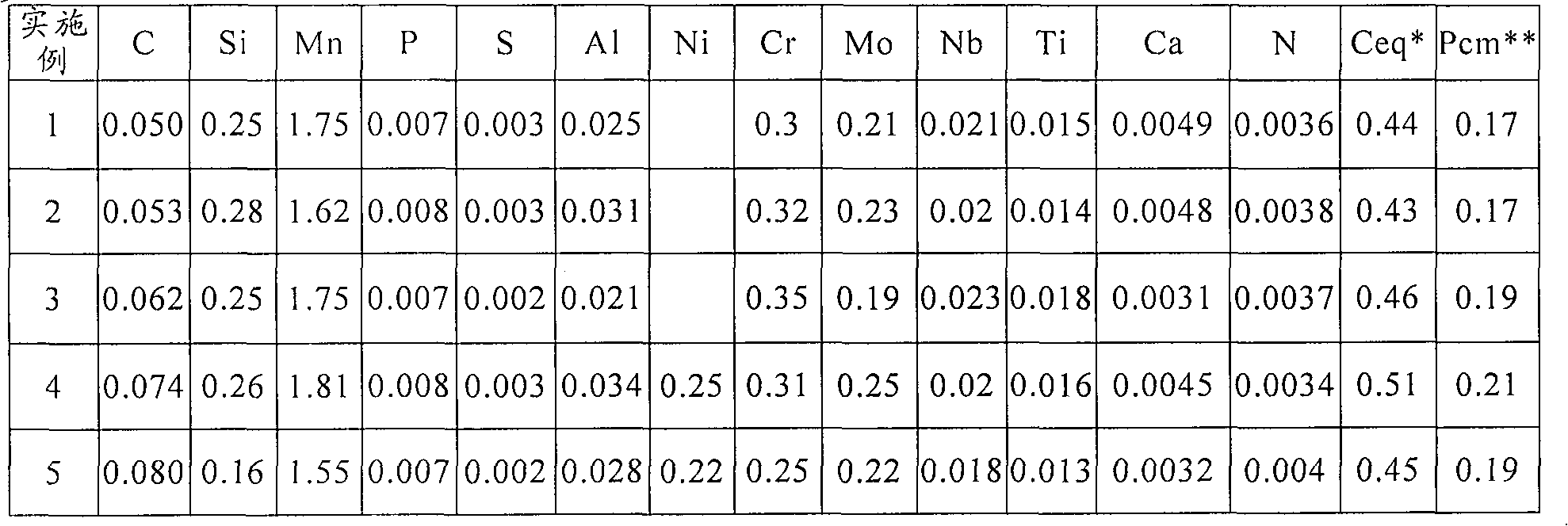

Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

The invention relates to ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and a manufacturing method of a plate thereof, belonging to the technical field of steel rolling, and the dual-phase steel comprises the following chemical components by weight percentage: 0.06-0.16% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, 0.02-0.06% of Al, 0.01-0.08% of Nb, 0-0.03% of Ti, not more than 0.1 of P, not more than 0.05 of S and the balance of Fe. The manufacturing method of the dual-phase steel comprises the following steps: 1) heating, heating a plate blank with the thickness of not less than 60mm to 1100-1250 DEG C, and keeping the temperature for 1-4h; 2) rolling and adopting the two-stage controlled rolling, wherein the reduction rate in a recrystallization zone is larger than 60%, the reduction rate in a non-recrystallization zone is larger than 70%, the initial rolling temperature of the recrystallization zone is 1100-1150 DEG C, the initial rolling temperature of the non-recrystallization zone is 880-940 DEG C, and the final rolling temperature is 770-860 DEG C; and 3) cooling, and adopting the continuous cooling after final rolling, wherein the cooling rate is 30-40 DEG C / s, the coiling temperature is lower than 350 DEG C, and the thickness of a finished product is 2-10mm. The manufacturing method can obtain the high-performance steel plate with high strength, low yield-strength ratio and good extension property, and the steel plate can be suitable for forming processing of high-strength automobiles, other industrial mechanical parts and the like.

Owner:NORTHEASTERN UNIV

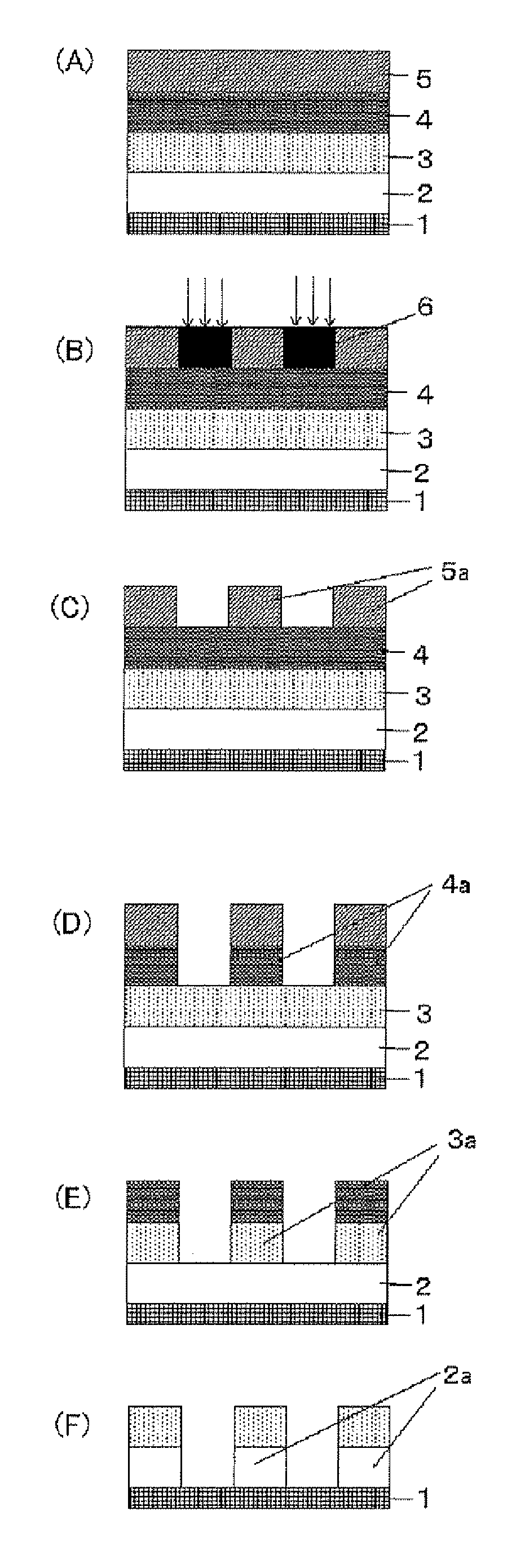

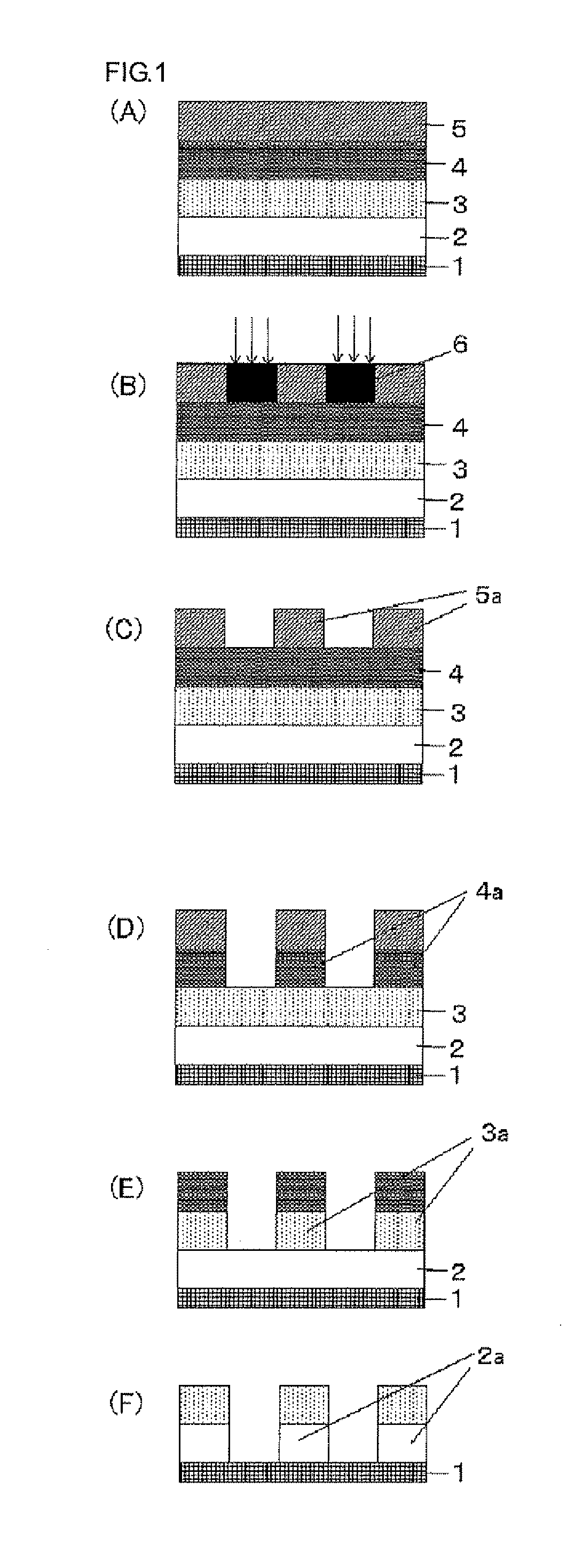

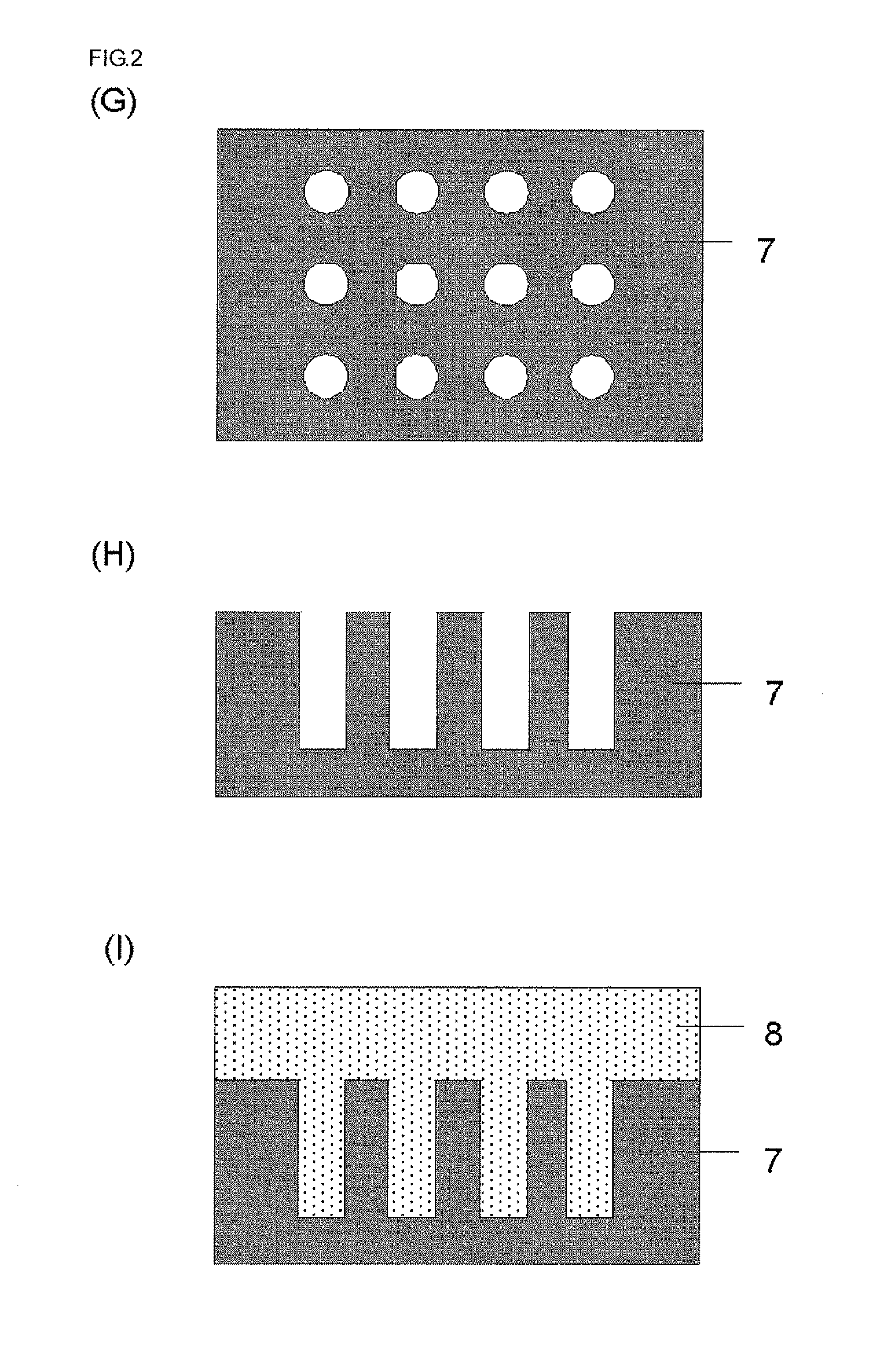

Organic film composition, method for forming organic film and patterning process using this, and heat-decomposable polymer

ActiveUS20130302990A1Excellent filling-upExcellent flattening characteristicOrganic chemistryOrganic compound preparationOrganic filmReduction rate

The invention provides an organic film composition comprises (A) a heat-decomposable polymer, (B) an organic solvent, and (C) an aromatic ring containing resin, with the weight reduction rate of (A) the heat-decomposable polymer from 30° C. to 250° C. being 40% or more by mass. There can be provided an organic film composition having not only a high dry etching resistance but also an excellent filling-up or flattening characteristics.

Owner:SHIN ETSU CHEM IND CO LTD

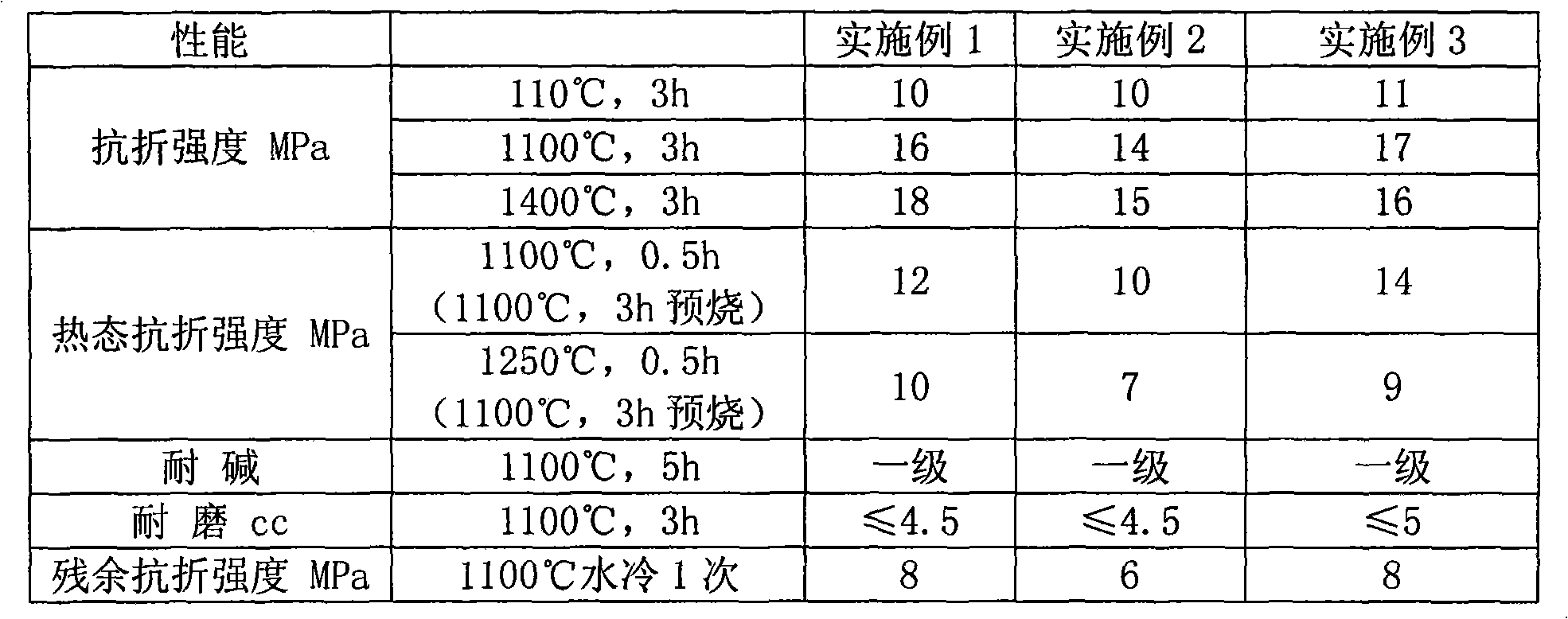

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

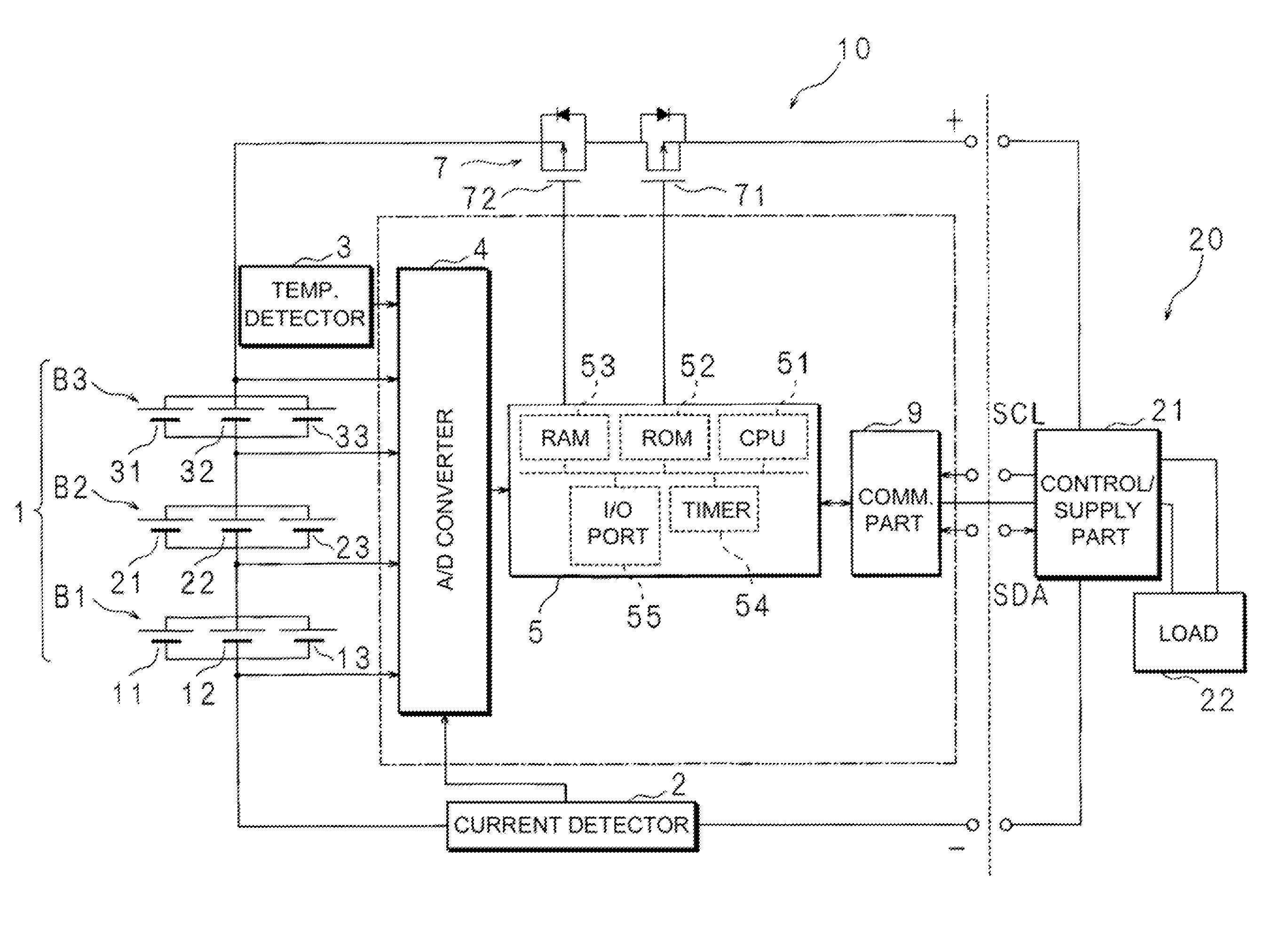

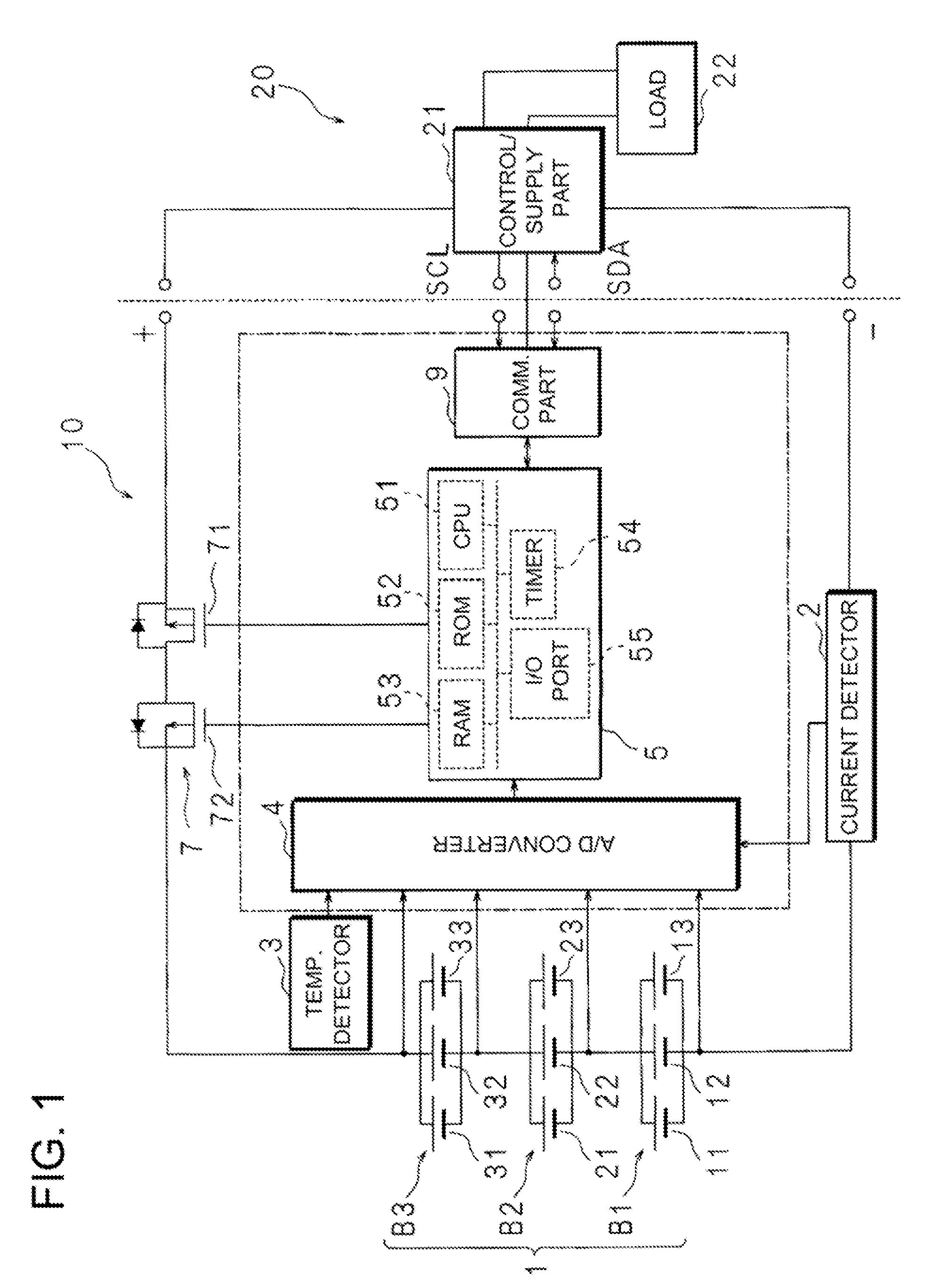

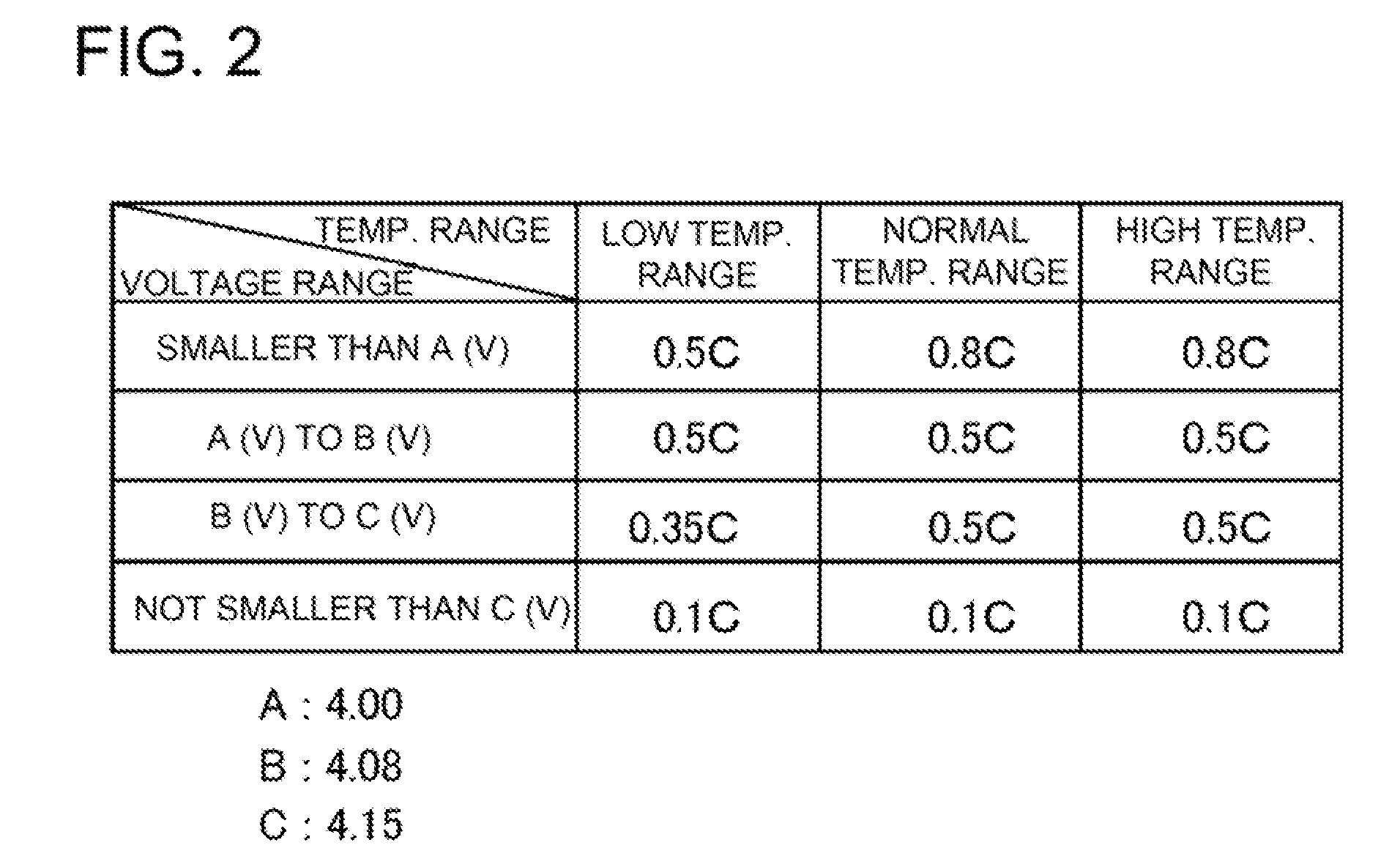

Rechargeable battery charging method, rechargeable battery charge controlling device and battery pack

ActiveUS20110204850A1Reducing value of targetMaximizing characteristicSecondary cells charging/dischargingElectric powerReduction rateBattery charge

If a protection voltage (or setting voltage value) is continuously exceeded for two times (three times) by all of the voltage values of a battery block that are read periodically at a period of 250 ms, it is determined that the voltage of the battery block exceeds the protection voltage value of 4.32 V (or setting voltage value of 4.30 V) so that a target value of charging current is reduced to 0.1 C (or reduced to a value smaller than the currently-set target value) at the first determination. Every when it is detected that the voltage value exceeds the setting voltage value, the target value is reduced at a predetermined reduction rate. As a result, charging current is exponentially reduced whereby keeping the charging operation. At the second determination where the voltage of the battery block exceeds the protection voltage, a circuit breaker cuts off the charging current.

Owner:SANYO ELECTRIC CO LTD

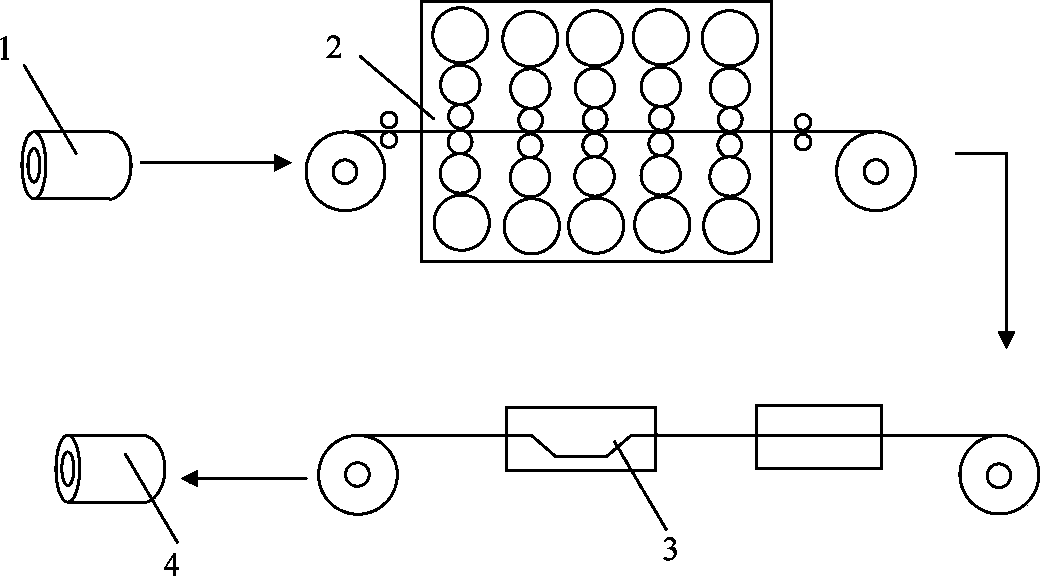

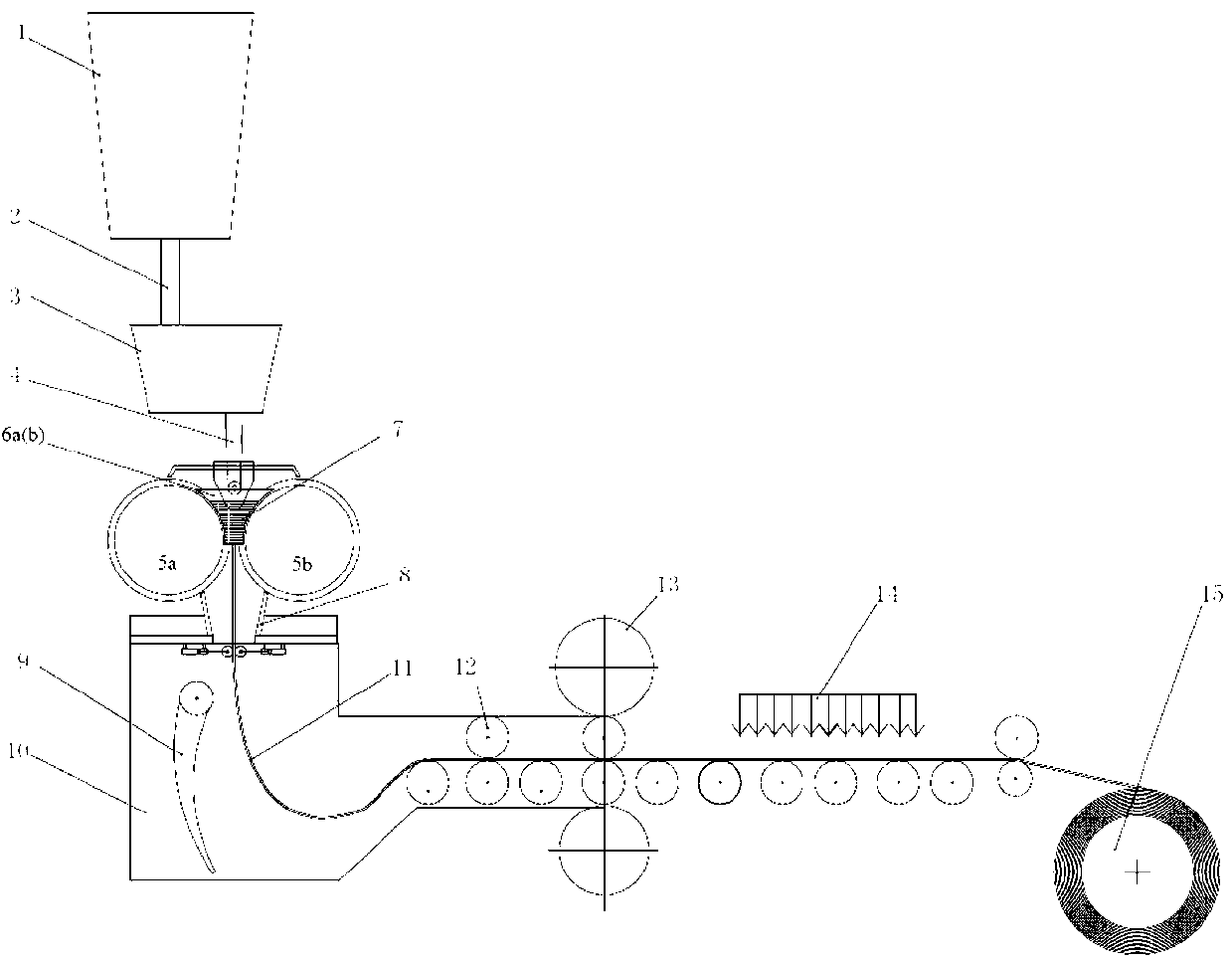

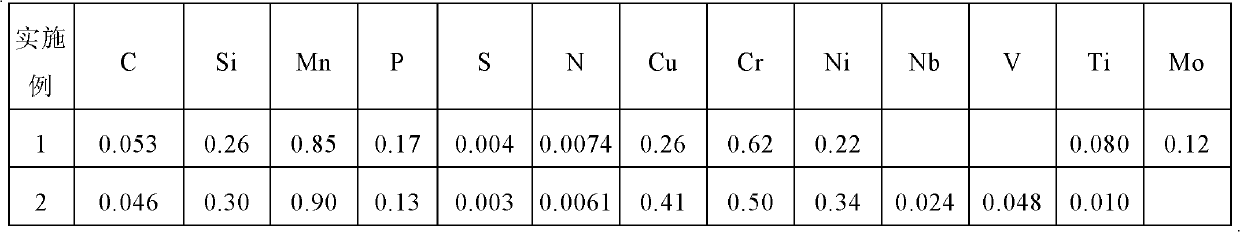

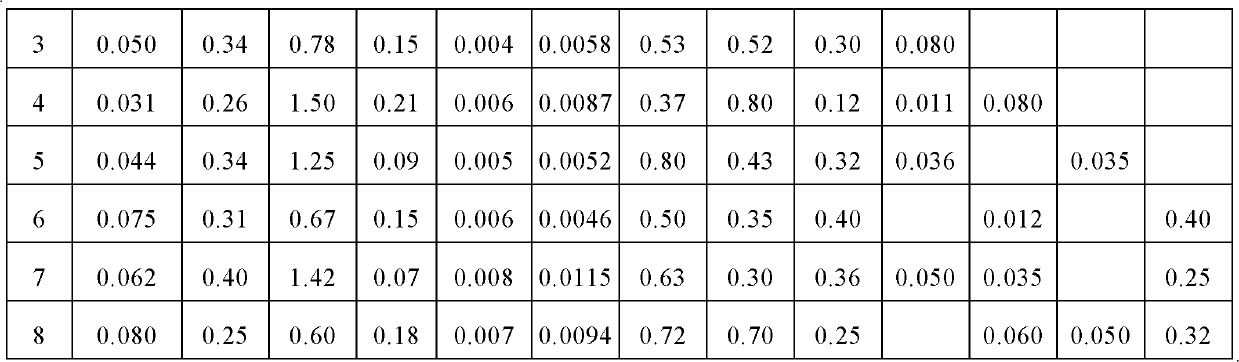

Method for manufacturing 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting

ActiveCN103305770AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsReduction rateChemical composition

The invention provides a method for manufacturing a 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting. The method comprises the following steps of: 1) smelting, wherein molten steel comprises the following chemical components: 0.03-0.08% of C, not more than 0.4% of Si, 0.6-1.5% of Mn, 0.07-0.22% of P, not more than 0.01% of S, not more than 0.012% of N, 0.25-0.8% of Cu, 0.3-0.8% of Cr, 0.12-0.4% of Ni, at least one of microalloy elements including 0.01-0.08% of Nb, 0.01-0.08% of V, 0.01-0.08% of Ti and 0.1-0.4% of Mo, and the balance of Fe and inevitable impurities; 2) strip continuous casting: directly casting a cast strip with thickness of 1-5mm; 3) strip cooling, wherein the cooling rate is more than 20 DEG C / s; 4) online hot rolling of the cast strip, wherein the hot rolling temperature is 1050-1250 DEG C, the reduction rate is 20-50% and the deformation rate is more than 20s<-1>; online austenite recrystallization happens after hot rolling; and the hot-rolled strip is 0.5-3.0mm in thickness; and 5) cooling and coiling, wherein the cooling rate is 10-80 DEG C / s, and the coiling temperature is 570-720 DEG C. The microstructure of the obtained steel strip is mainly formed by fine polygonal ferrite and pearlite.

Owner:BAOSHAN IRON & STEEL CO LTD

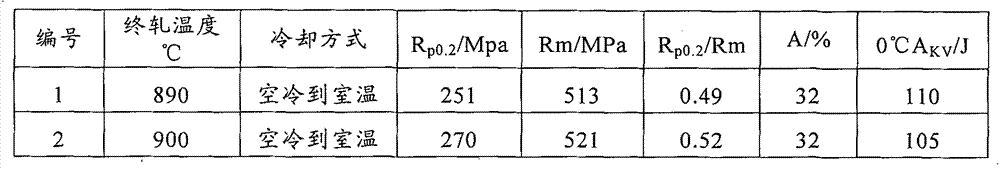

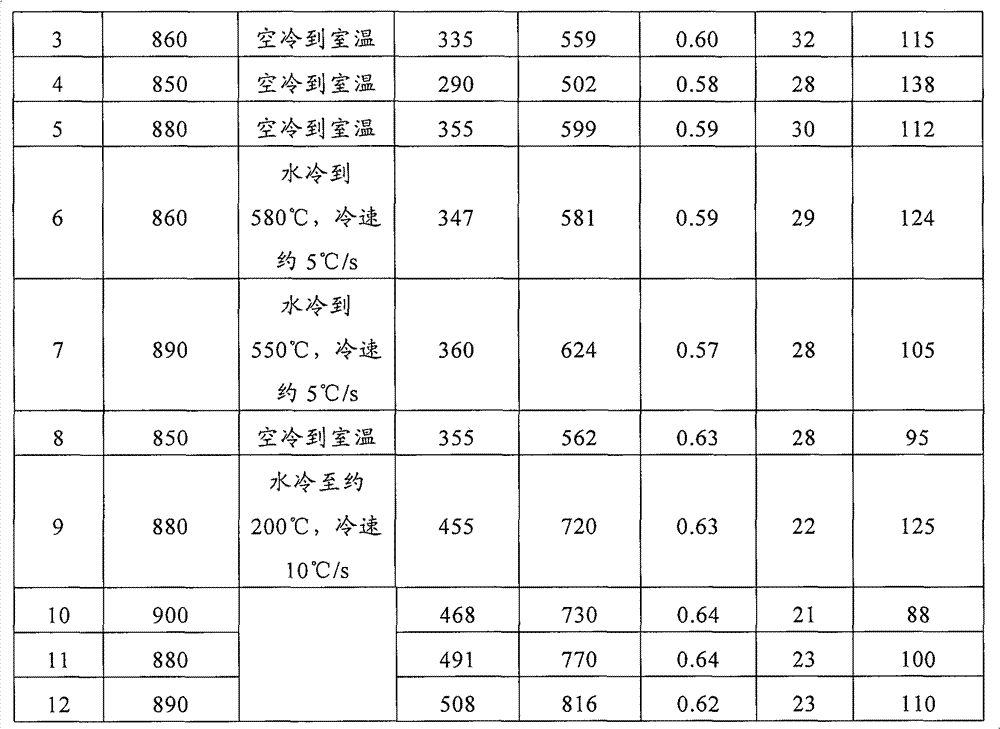

Fire-resistant and earthquake-resistant steel for construction and production method thereof

ActiveCN102952994AImprove fire resistanceSimple mechanical propertiesReduction rateEarthquake resistance

The invention relates to a fire-resistant and earthquake-resistant steel for construction. The steel comprises the following components by weight percent: 0.1-0.18 % of C, 0.1-0.50 % of Si, 1-1.80 % of Mn, less than or equal to 0.025 % of P, less than or equal to 0.015 % of S, less than or equal to 0.50 % of Cr, less than or equal to 0.30 % of Mo, less than or equal to 0.04 % of Al, less than or equal to 0.007 % of N, less than or equal to 0.006 % of Ca, one or two or more of less than or equal to 0.050 % of Nb, less than or equal to 0.055 % of V and less than or equal to 0.035 % of Ti, with Nb+V+Ti being <= 0.055 %, and the balance being Fe and unavoidable impurities. A production method comprises heating under a temperature of 1180 DEG C, insulating for 3 hours, rolling with a starting temperature of not less than 1180 DEG C, an accumulated reduction rate of last three controlled rolling being not less than 35 %, and a terminating temperature of 860 to 900 DEG C, and then directly air-cooling to a room temperature or cooling with a rate of 5 to 15 DEG C per second to the room temperature. The obtained steel is excellent in fire resistance, low in yield ratio (Rp0.2 / Rm <= 0.75), and good in earthquake-resistance performance, with Rp0.2 (yield strength at 600 DEG C) / Rp0.2 (yield strength at the room temperature) >= 2 / 3.

Owner:BAOSHAN IRON & STEEL CO LTD +1

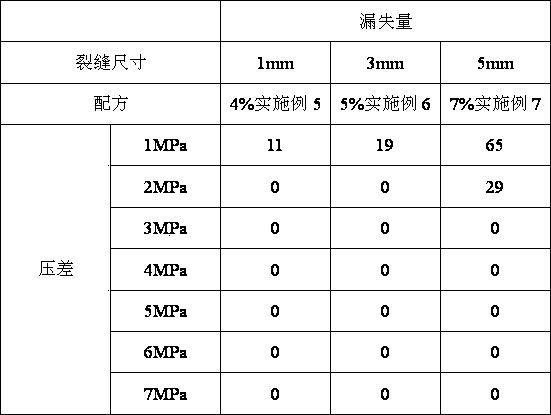

Composite type leakage plugging agent for oil-based drilling fluid and preparation method thereof

ActiveCN105368409AGood lipophilic dispersibilityGood dispersionDrilling compositionReduction rateFiber

The invention provides a composite type leakage plugging agent for an oil-based drilling fluid. The composite type leakage plugging agent for the oil-based drilling fluid comprises the raw materials by the weight percentage: 20%-50% of a leakage plugging material, 0.5%-2% of a fiber material, 5%-20% of an oil swelling material, 20%-40% of a lipophilic superfine particle material, and 10%-20% of a lipophilic flaky material. The leakage plugging agent mainly aims at leakage prevention and plugging requirements of permeable formation and fractured leakage formation encountered by an oil-based drilling fluid system during drilling, and the compressive strength can reach 7 MPa for 5 mm cracks; in sand bed evaluation tests, the invasion depth reduction rate is more than 90%. The composite type leakage plugging agent can significantly improve the leakage plugging success rate of the oil-based drilling fluid and enhances the formation bearing ability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

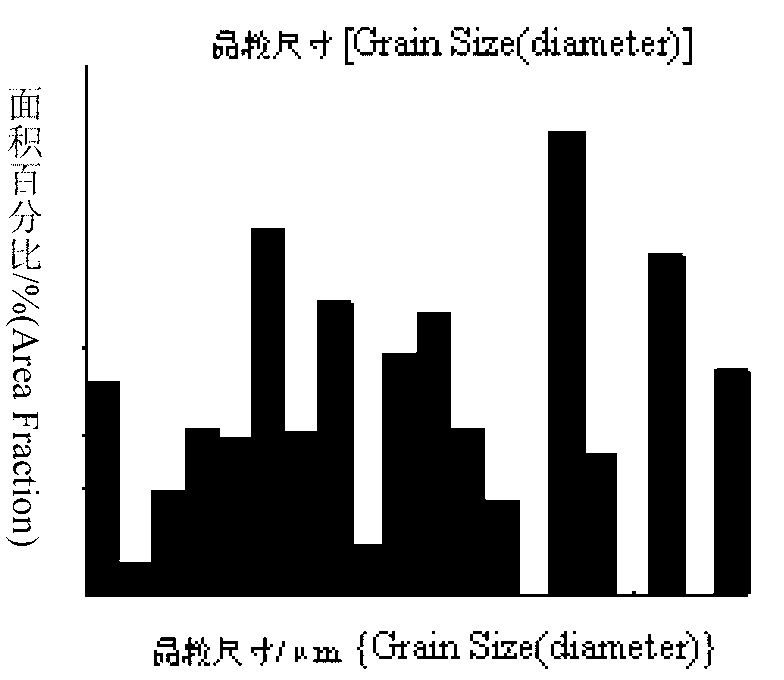

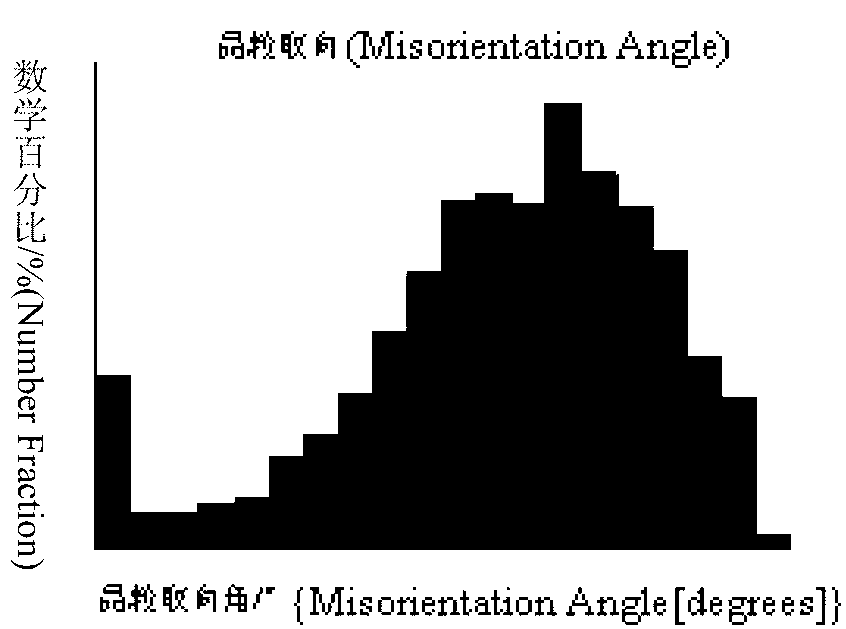

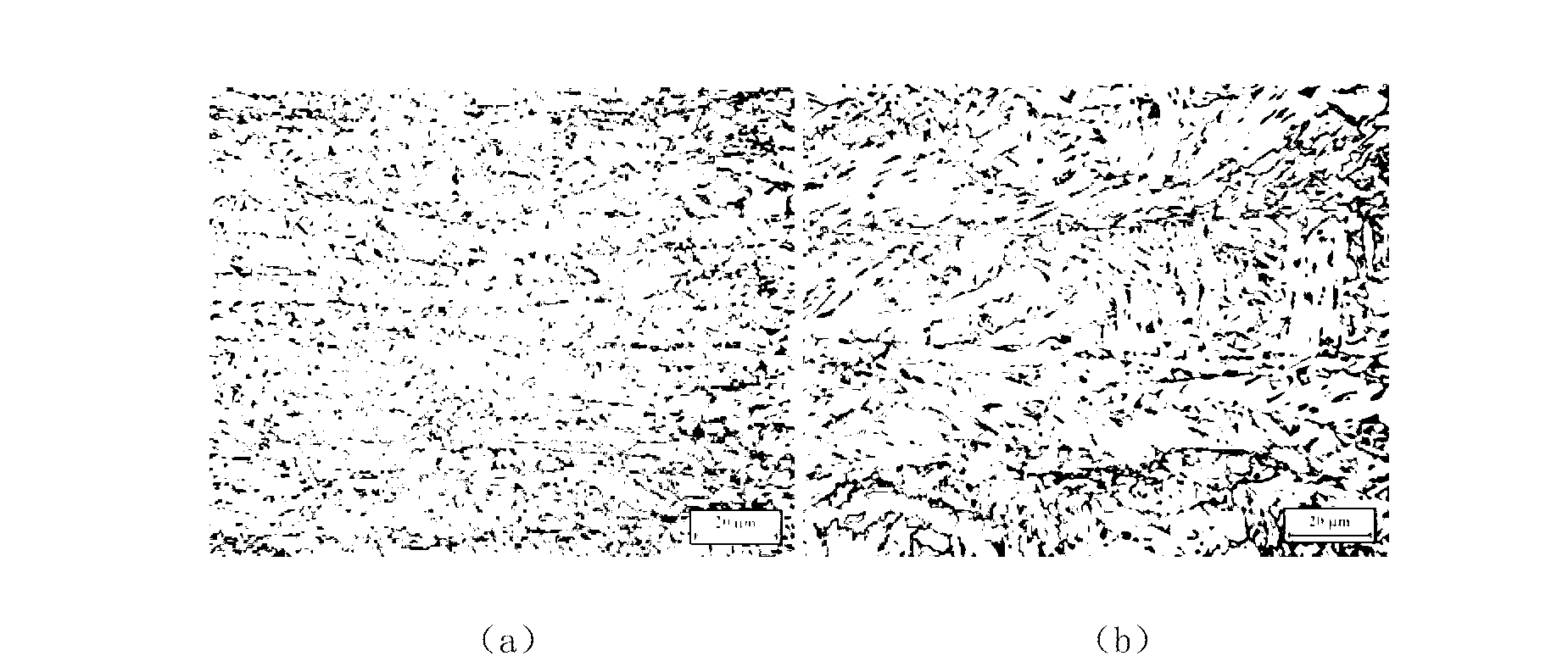

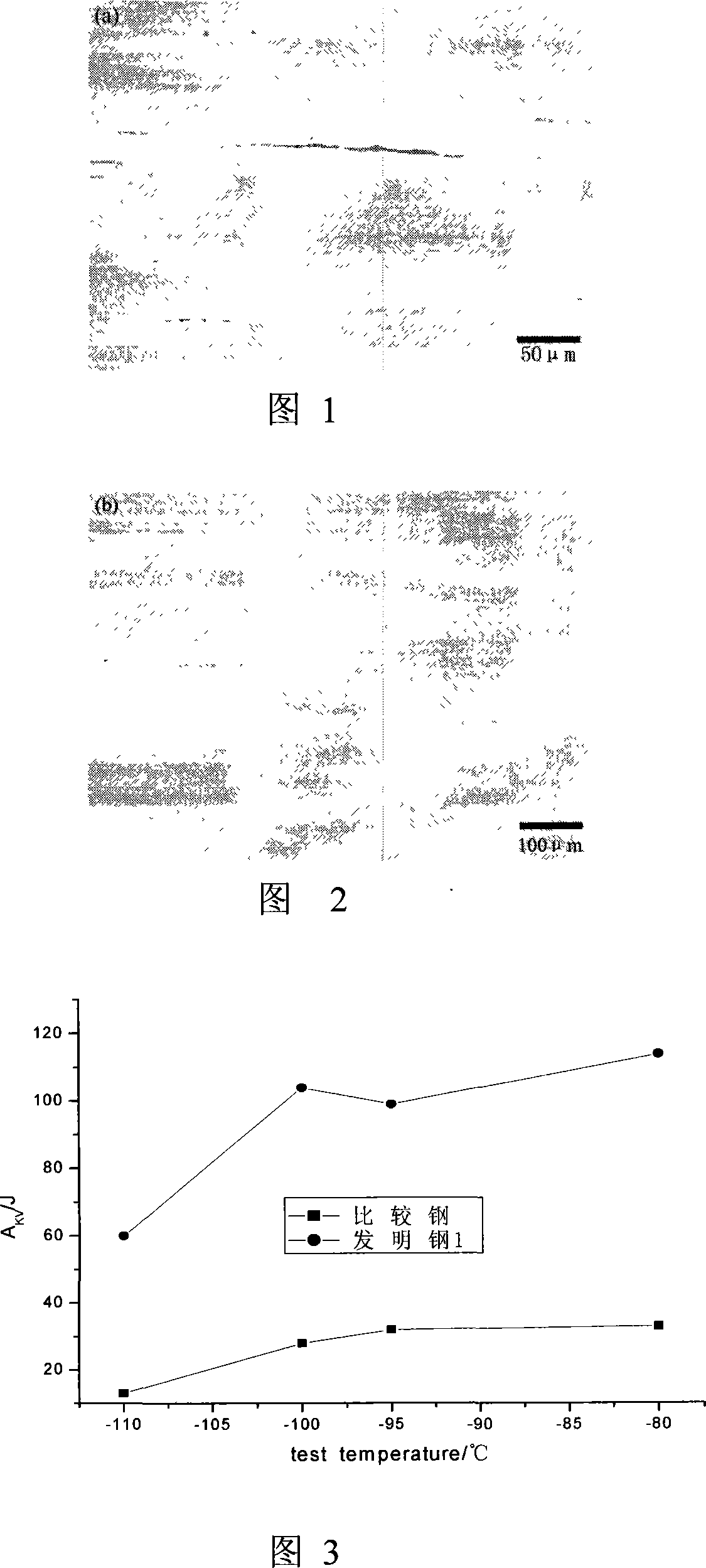

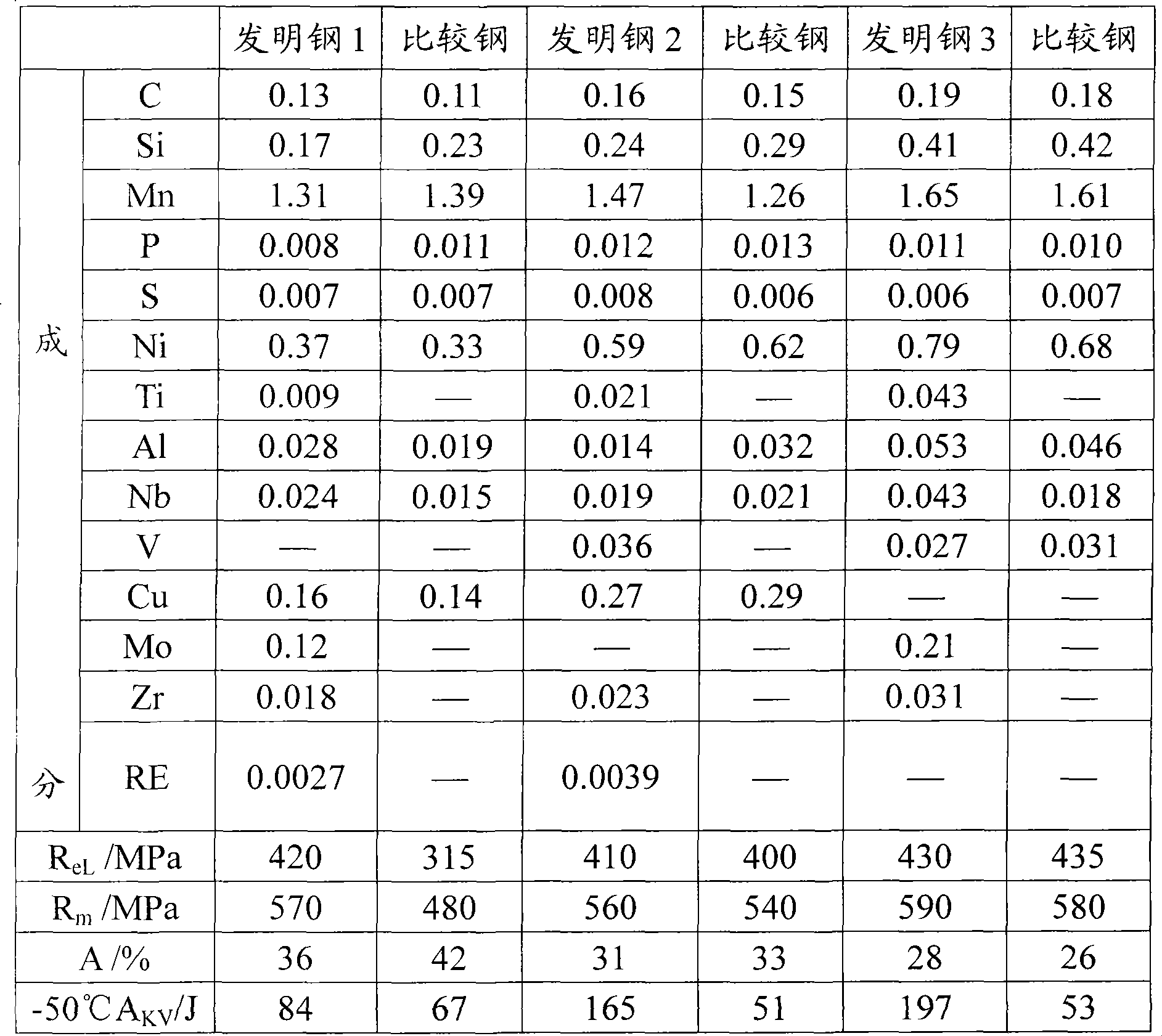

High ductility negative 110 degree low-temperature steel and manufacturing method thereof

InactiveCN101235466AStable and excellent low temperature toughnessExcellent -110℃ low temperature toughnessMetal rolling arrangementsReduction rateToughness

The invention relates to high toughness -110 DEG C low temperature steel and a method for manufacturing the low temperature steel, the steel is composed of components with following weight percent: C 0.02-0.12, Si 0.10-0.35, Mn 0.30-0.80, P<=0.015, S<=0.010, Ni 3.20-3.80, Ti 0.005-0.05a and Al 0.005-0.10, the low temperature steel also comprises two or more than two of Nb<=0.050, V<=0.10, Cu<=2.0, Mo<=0.50, Zr<=0.040 and RE<=0.020, and allowance is Fe. The method for manufacturing comprises: coating anti-oxidation coating on the surface of casting billets and controlling proper technological parameter such as the initial rolling temperature of steel, the controlled rolling accumulated reduction rate, each operation secondary reduction rate for last three operations, the finish rolling temperature, the normalizing heat preservation temperature, the heat preservation time, the tempering heat preservation temperature and the like. The method has the advantages of pure steel quality, stable organization, stable and excenlent-110DEG C low temperature toughness, simple technique and low cost, and is beneficial for extending and applying.

Owner:武汉钢铁有限公司

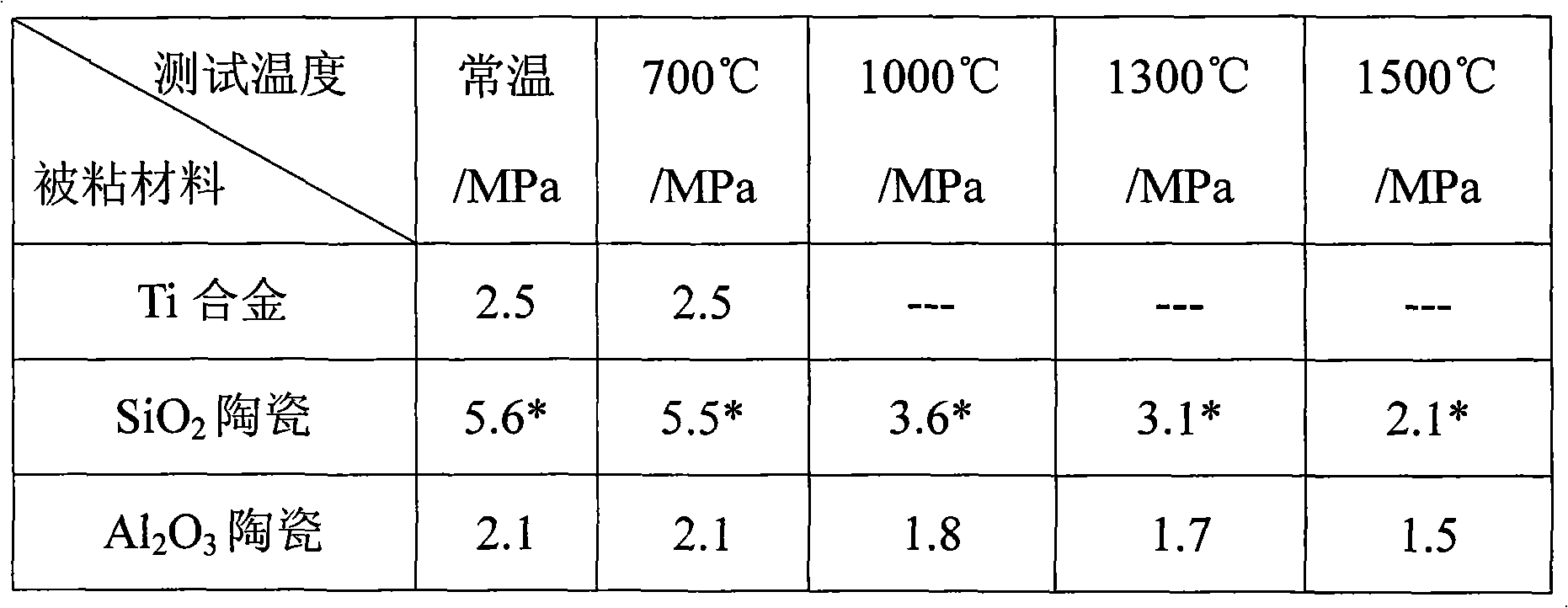

Phosphates adhesive and preparation method thereof

The present invention discloses a phosphate adhesive and a preparation method thereof, which relate to an adhesive and a preparation method thereof. The present invention resolves the problem that the curing and heat-resisting capabilities of the prior phosphate adhesive are impaired under the room temperature. The phosphate adhesive of the present invention is prepared with phosphoric acid solution, aluminum hydroxide powder, aluminum oxide powder, zirconium oxide powder and zinc oxide powder or aluminum nitride powder. The preparation method includes the following steps: (1) the materials are weighed out; (2) the phosphoric acid solution is mixed with the aluminum hydroxide powder so that aluminum dihydrogen phosphate matrix resin can be made; (3) the aluminum oxide powder, the zirconium oxide powder and the zinc oxide powder or the aluminum nitride powder are mixed together so that curing agent is prepared; (4) the aluminum dihydrogen phosphate matrix resin and the curing agent are mixed together, and after being cured under the room temperature, the phosphate adhesive is prepared. The phosphate adhesive of the present invention can be cured under the room temperature and can resist a temperature up to 1580 DEG C, moreover, the water-resisting property of the phosphate adhesive of the present invention is good, and after the phosphate adhesive is soaked in tap water under the room temperature for 100 days, the reduction rate of the adhering strength of the phosphate adhesive is less than 10 percent.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

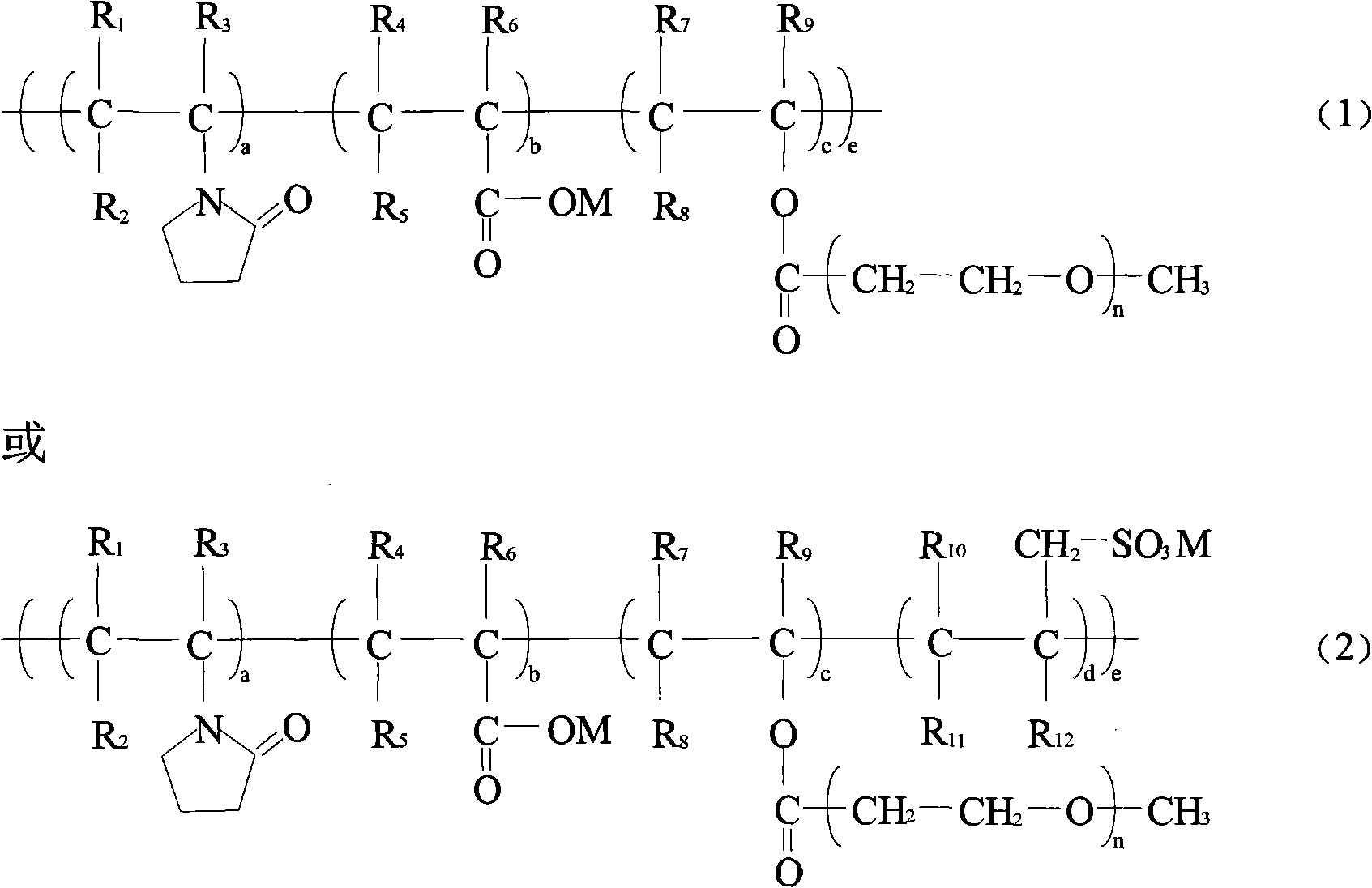

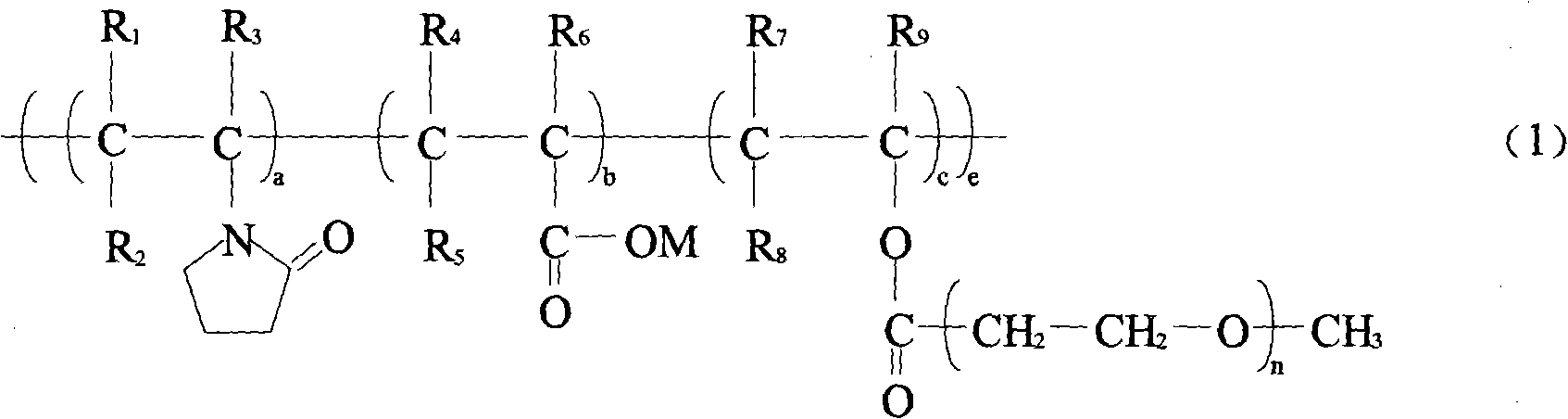

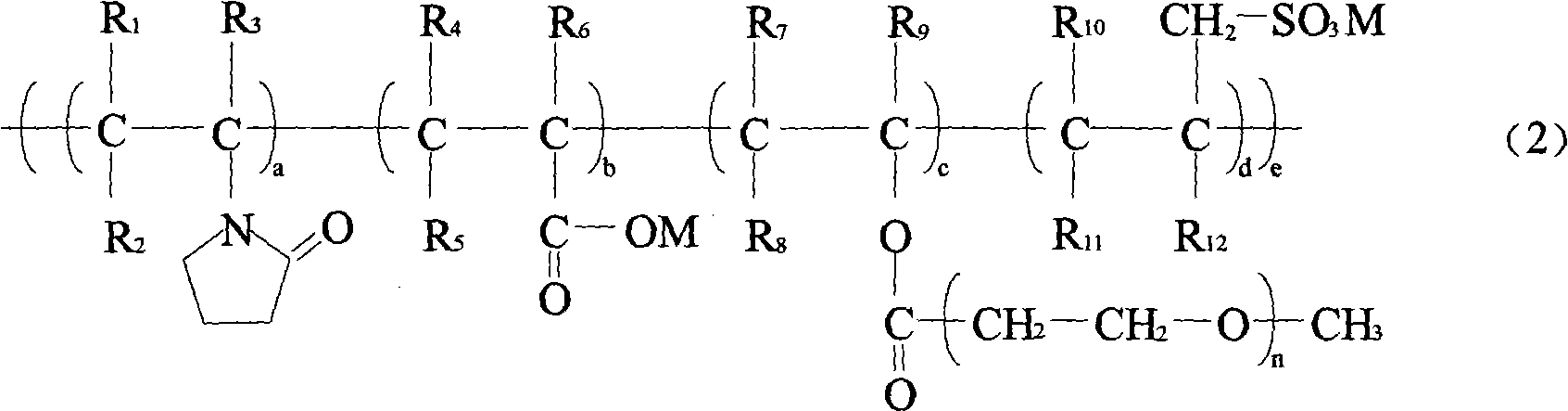

Cement concrete superplasticizer and method for preparing same

The invention discloses a concrete superplasticizer and a preparation method. Based on weight proportion, 1-50% of nitrogen-containing functional monomer a, 5-50% of unsaturated carboxylic acid and the derivative b of the unsaturated carboxylic acid, 15-94% of polyoxyethylene vinyl propionate ester ene single-ether and the derivative c of the polyoxyethylene vinyl propionate ester ene single-ether, as well as 0-50% of allyl sulfonate d are mixed to prepare a mixed monomer solution; the initiator which takes up 0.5-15% of the total weight of the mixed monomer, and the chain transfer agent which takes up 0-15% of the total weight of the mixed monomer are added into the mixed monomer solution so as to prepare the concrete super plasticizer through ternary or quaternary copolymerization. Without going through analysis purification, the invention can directly obtain the product and has simple synthetic process, less equipment investment, simple operation and easily controlled reaction conditions; the obtained product has better compatibility with cement and good adaptability with other additives, and is free from segregation and bleeding phenomena; the product also has good concrete slump retentivity and high water reduction rate.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

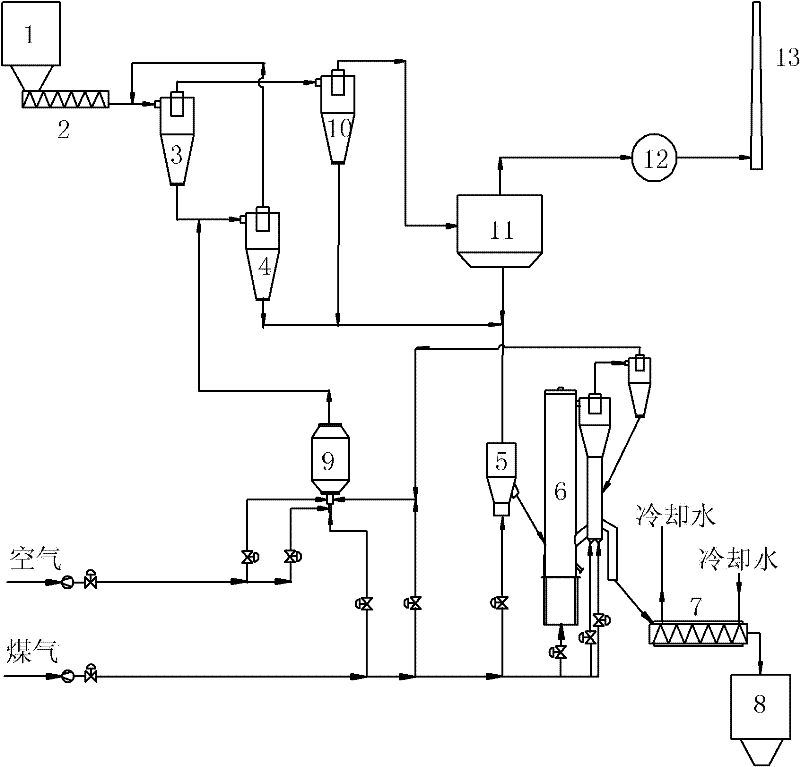

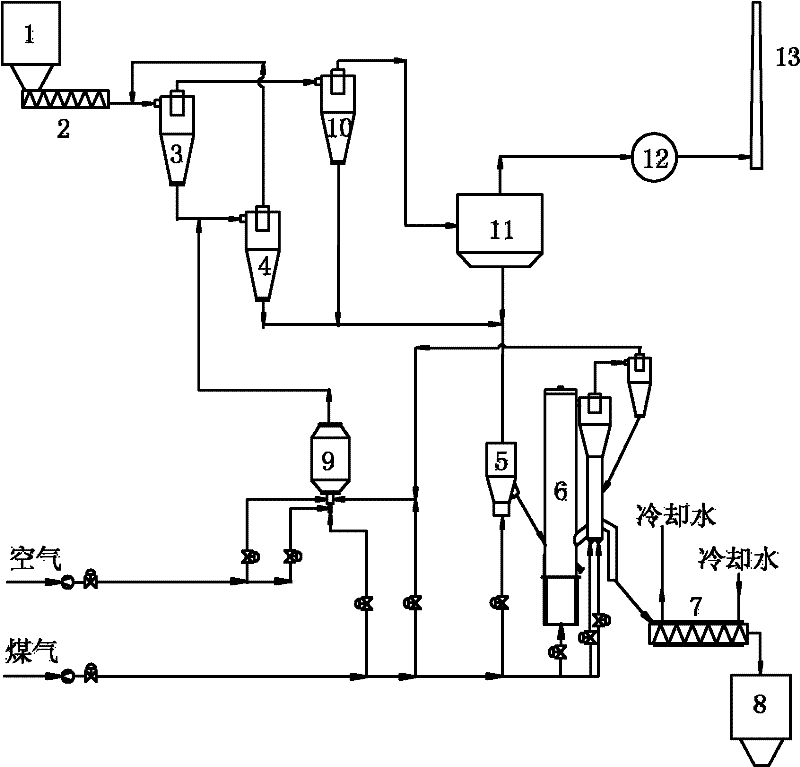

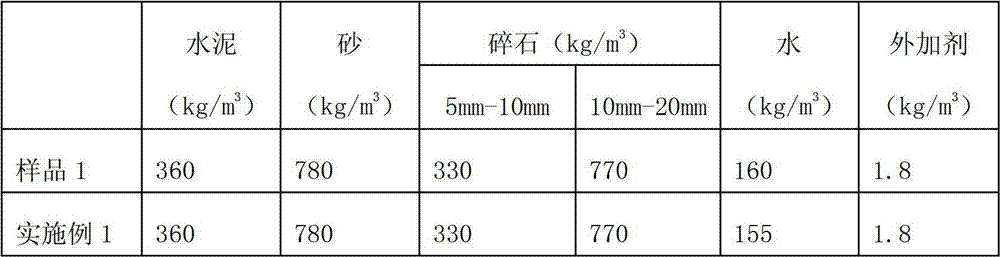

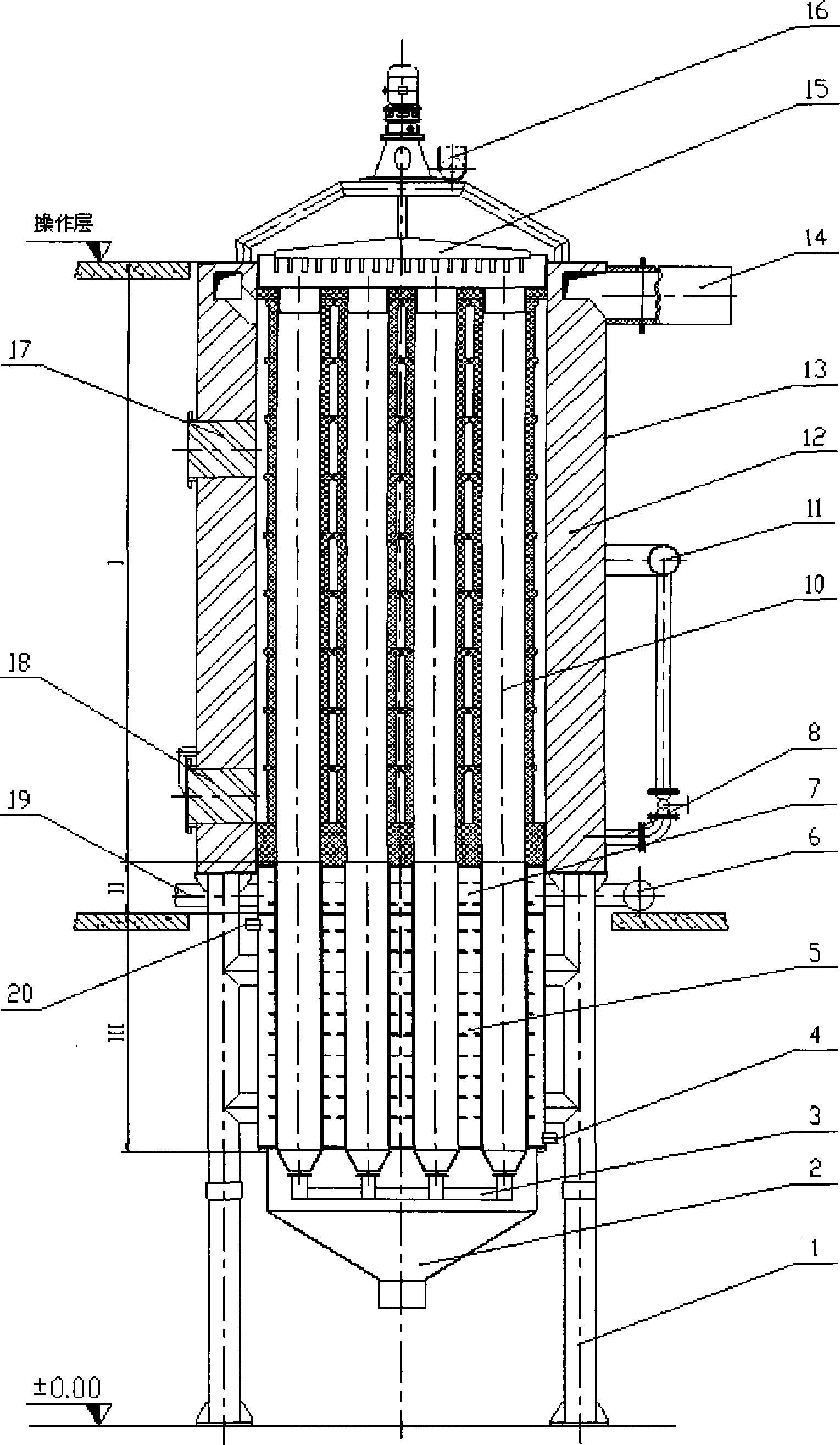

Fluidized low-temperature reduction device and reduction method for powdery manganese oxide ores

The invention relates to a fluidized low-temperature reduction device and a fluidized low-temperature reduction method for powdery manganese oxide ores. The device comprises a feeding unit, a preheating unit, a reduction roasting unit and a cooling unit which are connected from top down, wherein the reduction roasting unit is connected with a combustion chamber; and the combustion chamber is connected below the preheating unit. In the reduction method, tail gas formed in the reduction process enters the combustion chamber combusts with supplementary gas and air to form flue gas; and the flue gas is subjected to countercurrent heat exchange with the manganese oxide ores. The fluidized low-temperature reduction device and the reduction method have the advantages that: the gas can be used as a reducer and also can be used as fuel; and the utilization rate of the gas is 100 percent. In the reduction device, the reduction temperature of the manganese oxide ores is low, so a manganese-containing phase which is insoluble to sulfuric acid is avoided, and heat carried by the manganese oxide ores is reduced by over 30 percent. The manganese oxide ores in a fluidized reduction roasting furnace are in the bubbling fluidized state, the heat transfer efficiency, the mass transfer efficiency and the reaction efficiency are high, the distribution of retention time is uniform, and the reduction rate of the manganese oxide is more than 98 percent.

Owner:深圳中科九台资源科技有限公司

Low-yield-ratio high-tenacity steel plate and manufacture method thereof

ActiveCN103014554AGood cold bending performanceRoll force/gap control deviceTemperature control deviceReduction rateYield ratio

The invention relates to a low-yield-ratio high-tenacity steel plate. The steel plate comprises the following chemical constituents in percentage by weight: 0.05 to 0.08 percent of C, 0.15 to 0.30 percent of Si, 1.55 to 1.85 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.005 percent of S, 0.015 to 0.04 percent of Al, 0.015 to 0.025 percent of Nb, 0.01 to 0.02 percent of Ti, 0.20 to 0.40 percent of Cr, 0.20 to 0.30 percent of Mo, smaller than or equal to 0.006 percent of N, smaller than or equal to 0.004 percent of O, smaller than or equal to 0.005 percent of Ca, smaller than or equal to 0.40 percent of Ni, and the balance of iron and inevitable impurities, wherein Ca / s is larger than or equal to 1.5. The steel plate is manufactured through the following method: heating a continuous casting or steel billet at 1150 to 1220 DEG C and performing multi-pass rolling, wherein the total reduction rate is larger than or equal to 80 percent, and the finish rolling temperature is larger than or equal to 850 DEG C; performing rapid water cooling on a rolled steel plate at the speed of 15 to 50 DEG C / s to a temperature range from Bs-60 DEG C to Bs-100 DEG C, and then performing air cooling for 5 to 60 seconds; and heating the cooled steel plate in an on-line induction heating furnace to Bs plus 20 DEG C at the speed of 1 to 10 DEG C / s, tempering for 40 to 60 seconds, then discharging from the furnace and performing air cooling. The thickness of the steel plate is 10 to 25mm, the yield strength is larger than or equal to 500MPa, the yield ratio is smaller than or equal to 0.75, the ductility A50 is larger than or equal to 20 percent, and Akv at minus 60 DEG C is larger than or equal to 200J.

Owner:BAOSHAN IRON & STEEL CO LTD

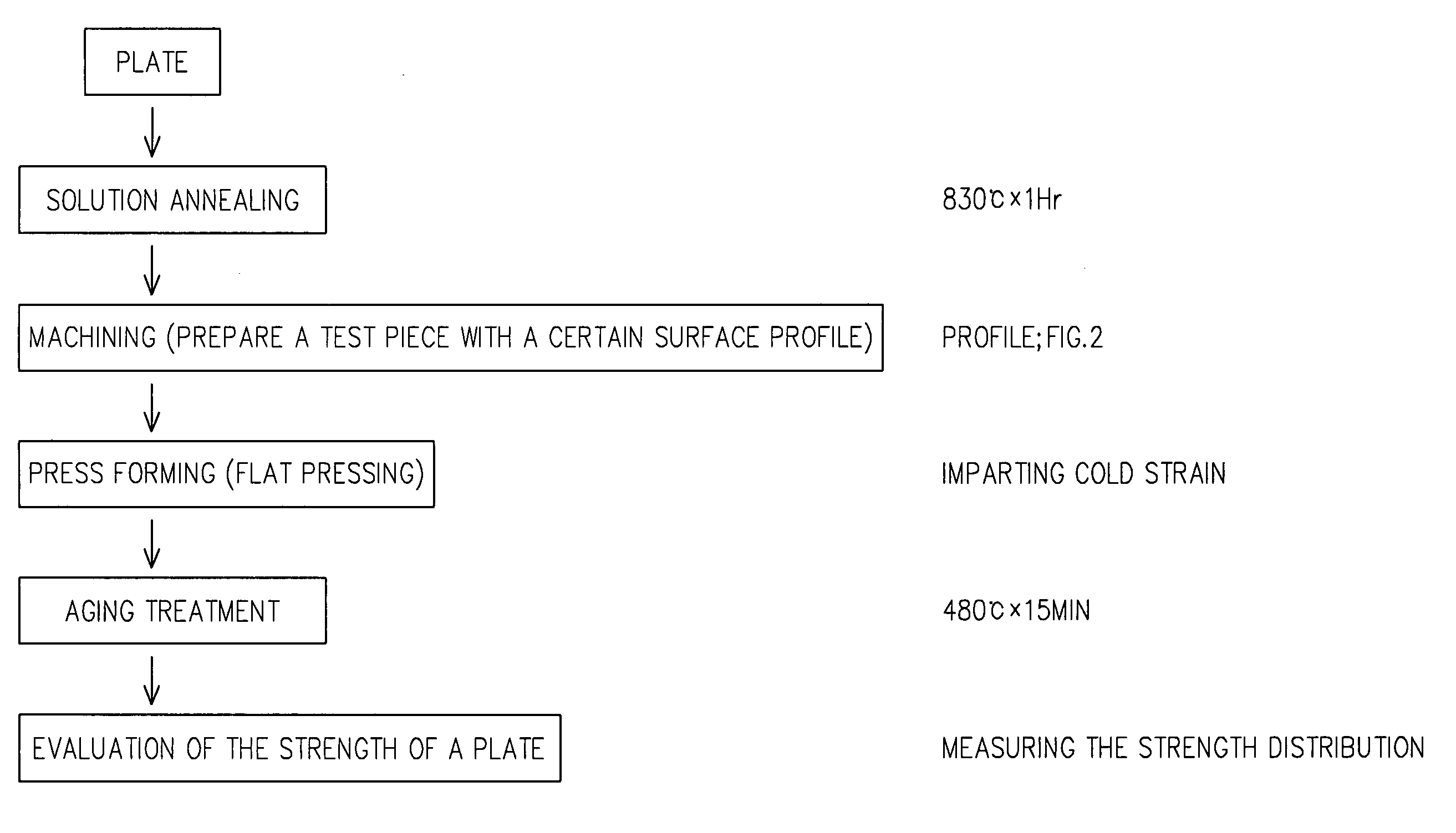

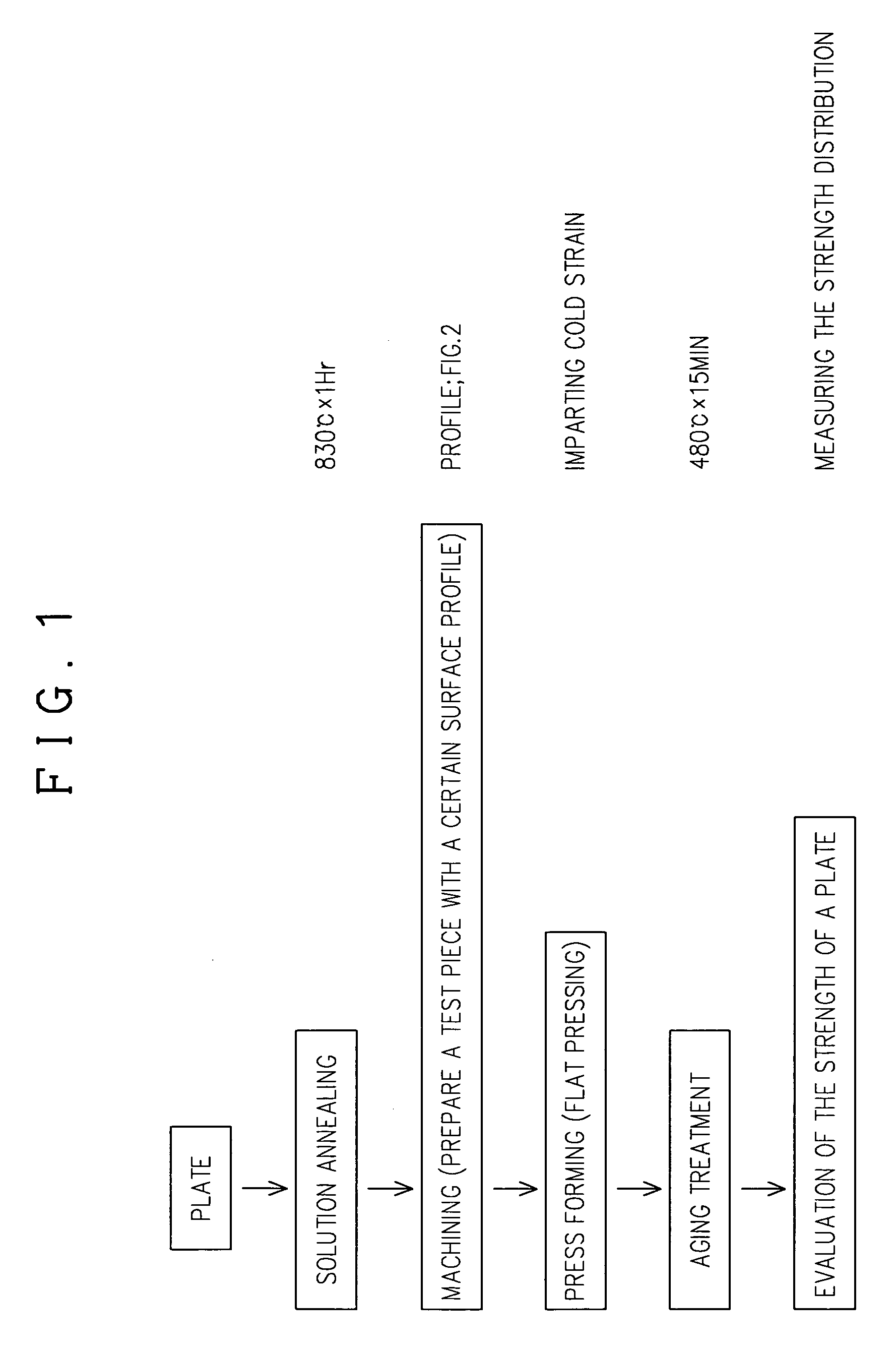

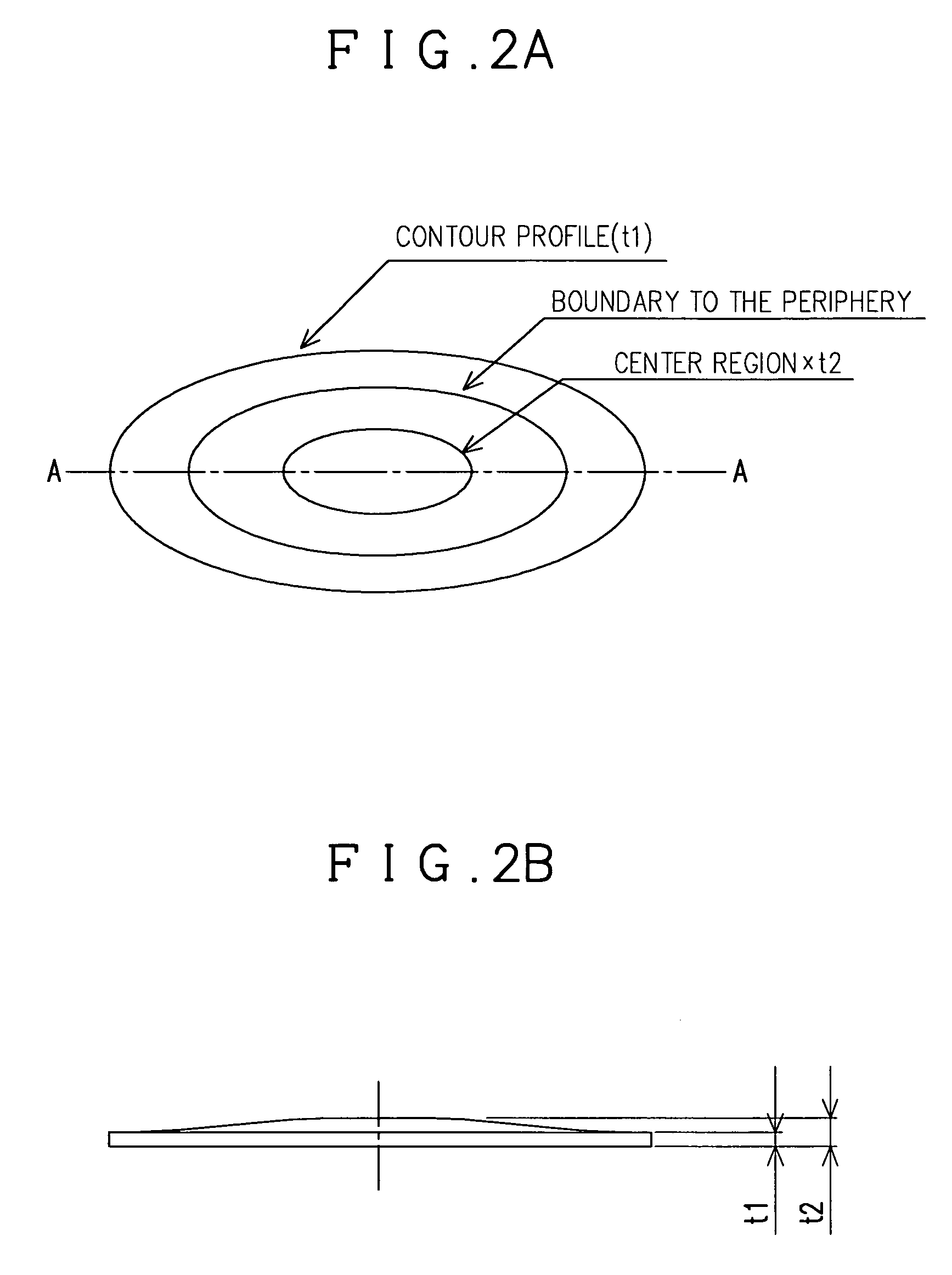

Process for making a work piece from a beta-type titanium alloy material

A process for making a work piece from a β-type titanium alloy material includes subjecting the β-type titanium alloy material to cold working with controlling the reduction rate thereof to vary the reduction rate depending on a position across a plain direction of the β-type titanium alloy material, and then subjecting the β-type titanium alloy material to an aging treatment.

Owner:NIPPON STEEL CORP

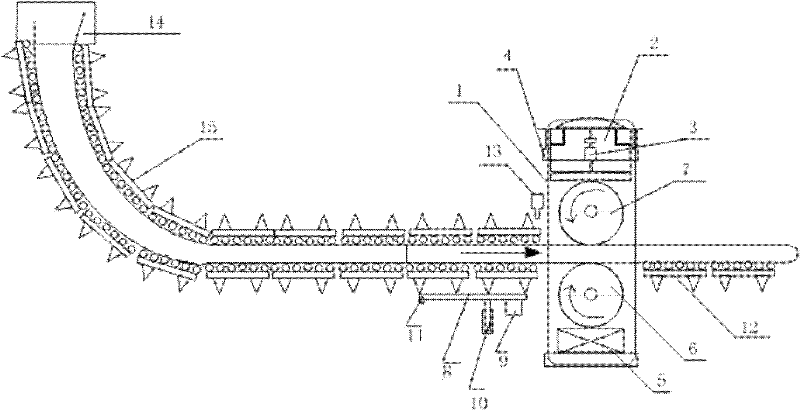

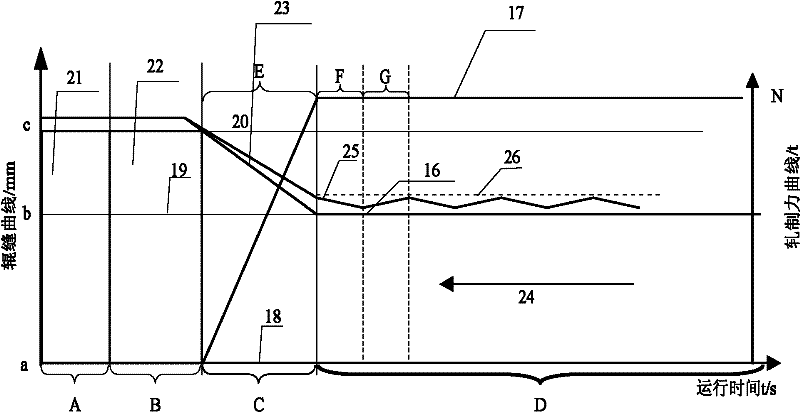

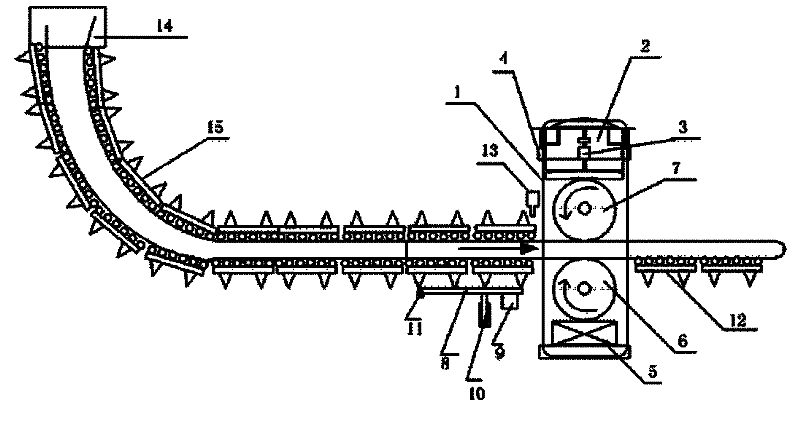

Method for rolling liquid core under heavy reduction rate by virtue of online thickness regulating roll by utilizing continuous casting machine

ActiveCN102189102AQuality improvementExempt from reheatingRoll force/gap control deviceMetal rolling arrangementsReduction rateLiquid core

The invention relates to a method for rolling a liquid core under heavy reduction rate by virtue of an online thickness regulating roll by utilizing a continuous casting machine. The method comprises the following steps of: when two rolling mills are loaded, setting a target thickness, feeding back the thickness value in real time and detecting oil pressure, carrying out conversion on a rolling force to judge whether the rolling force is higher than a limit value, if the rolling force is lower than the limit value, stabilizing rolling until the rolling is finished; if the rolling force is higher than the limit value, regulating and judging the rolling force again; if the target thickness is changed in the rolling process, calculating thickness variation by virtue of a rolling process computer, regulating roll gap of the two rolling mills to be the target thickness, and judging whether the rolling force is higher than the limit value again. In the method provided by the invention, a rolling signal can be changed to change the target thickness in the rolling process, and a wedge-shaped blank is rolled. By applying the method provided by the invention, the quality of a continuous casting can be better improved, the continuous casting and the wedge-shaped blank can be rolled, and the time of a process is reduced while the yield is improved; meanwhile, structure of equipment is simple, investment is less, control is simple, reliability is high, and energy can be greatly saved, thus the method has a good popularization and application prospect.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

High intensity and high ductility -50 DEG C low-temperature steel and manufacturing method thereof

InactiveCN101381841AHigh strengthStable and excellent low temperature toughnessReduction rateChemical composition

The invention discloses high-strength high-toughness low-temperature steel at 50 DEG C below zero and a manufacturing method thereof, and belongs to the manufacturing field of low alloy steel. The low-temperature steel comprises chemical compositions in percentage by weight: 0.12 to 0.20 percent of C, 0.15 to 0.50 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.30 to 1.00 percent of Ni, 0.005 to 0.050 percent of Ti, 0.005 to 0.10 percent of Al, 0.010 to 0.050 percent of Nb, one or more than one of less than or equal to 0.10 percent of V, less than or equal to 1.0 percent of Cu, less than or equal to 0.50 percent of Mo, less than or equal to 0.040 percent of Zr, and less than or equal to 0.20 percent of RE, and the balance being Fe. The manufacturing method for the steel comprises the following steps: the heating temperature of steel billets is between 1, 150 and 1, 280 DEG C, the heating rate is between 8 and 14 minute / centimeter, the initial rolling temperature of the steel is more than or equal to 1, 100 DEG C, the accumulated reduction rate of control rolling is more than or equal to 60 percent, the reduction rate of each of final three passes is more than or equal to 10 percent, and the final rolling temperature is between 780 and 860 DEG C; and the normalizing heat treatment is adopted, the keeping temperature of the normalization is between 850 and 930 DEG C, and the keeping time is 30-50 minutes+plate thickness (millimeters) x 1 minute / millimeter.

Owner:武汉钢铁有限公司

Sustained-release polycarboxylic high-performance water reducing agent and preparation method thereof

The invention relates to a sustained-release polycarboxylic high-performance water reducing agent and a preparation method thereof. The water reducing agent comprises: 0.13mol of monomer methyl alkenyl polyoxyethelene or allyl polyoxyethylene ether or polyoxypropylene ether, 0.32mol of monomer acrylic acid or methacrylic acid, 0.01mol of monomer sodium methallyl sulfonate, 0.12mol of monomer acrylamide or 2-acrylamide-methylpropanesulfonic acid, and 0.05mol of monomer ethyl acetate or styrene. Deionized water is adopted as a reaction medium, and the materials are subjected to a reaction with an initiating agent and a chain transfer agent for 4-6h with a maintained temperature of 58-62 DEG C. Copolymerization is carried out, such that a polymer with a molecular weight of 50000-120000 is obtained; the temperature is reduced to below 40 DEG C, and an alkali solution is added for regulating the pH of the system to 6-8, such that the water reducing agent is obtained. The sustained-release polycarboxylic high-performance water reducing agent provided by the invention has high water reduction rate. When an equivalent solid dosage is 0.2%, a water reduction rate can reach 35%. A slump performance is good. Concrete slump and extension degree have no loss in 3h. The water reducing agent is widely adaptable with concrete raw materials.

Owner:广西云鹰新材料科技有限公司

Manganese ore reduction calcination method and apparatus

The invention discloses a method and a device for reducing and roasting manganese dioxide into manganese monoxide in electrolytic manganese industry. The method comprises the following steps: dried manganese dioxide mineral powder is ground, well mixed with reducing powder and conveyed to a feeding bin on the top of a roasting furnace, and then enters hermetic roasting devices; a plurality of burners are arranged among the hermetic roasting devices; fuel is burnt so as to roast manganese dioxide ore; the manganese dioxide ore and the reducing powder are heated and roasted to 900 to 970 DEG C in the hermetic roasting devices with no oxygen supplement; under the circumstance of oxygen-free contact after reaction in the lower ends in the hermetic roasting devices, the temperature of roasted manganese ore is lowered, so as to recover heat and cool the manganese ore; and finally, the manganese ore is discharged out of a furnace by an automatic discharging device and then is subjected to a subsequent process. The method and the device can reduce and roast the high / low-grade manganese dioxide ore, have the advantages of low production cost, simple process and convenient operation, can control the reduction rate of manganese dioxide and other metals through the automatic discharging device, and improve the quality of final products.

Owner:朱军

High-early-strength polycarboxylate water reducer and preparation method thereof

The invention discloses a high-early-strength polycarboxylate water reducer and a preparation method thereof. The high-early-strength polycarboxylate water reducer is a liquid, and has a solid content of 40%. The water reducer containing an esterified alcohol amine group, a sulfonic group, an amido group, a carboxyl group and a methylallyl polyoxyethylene ether side chain is prepared through polymerizing monomers comprising methylallyl polyoxyethylene ether, acrylamide, sodium methylallyl sulfonate, acrylic acid or methacrylic acid, acrylated amine and the like under the action of a molecular weight chain initiator and a chain transferring agent, and neutralizing. The high-early-strength polycarboxylate water reducer has the advantages of low alkali content, high water reduction rate, short coagulation time, suitableness for the construction of prefabricated components, pile tubes, duct pieces and bridges, simple production technology, easily controlled reaction condition, and no environmental pollution.

Owner:湖南加美乐素新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com