Low-yield-ratio high-tenacity steel plate and manufacture method thereof

一种低屈强比、高韧性的技术,应用在屈服强度500MPa级,低屈强比高韧性钢板及其制造领域,能够解决屈强比和延伸率不能满足地震高发区等问题,达到冷弯性能优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

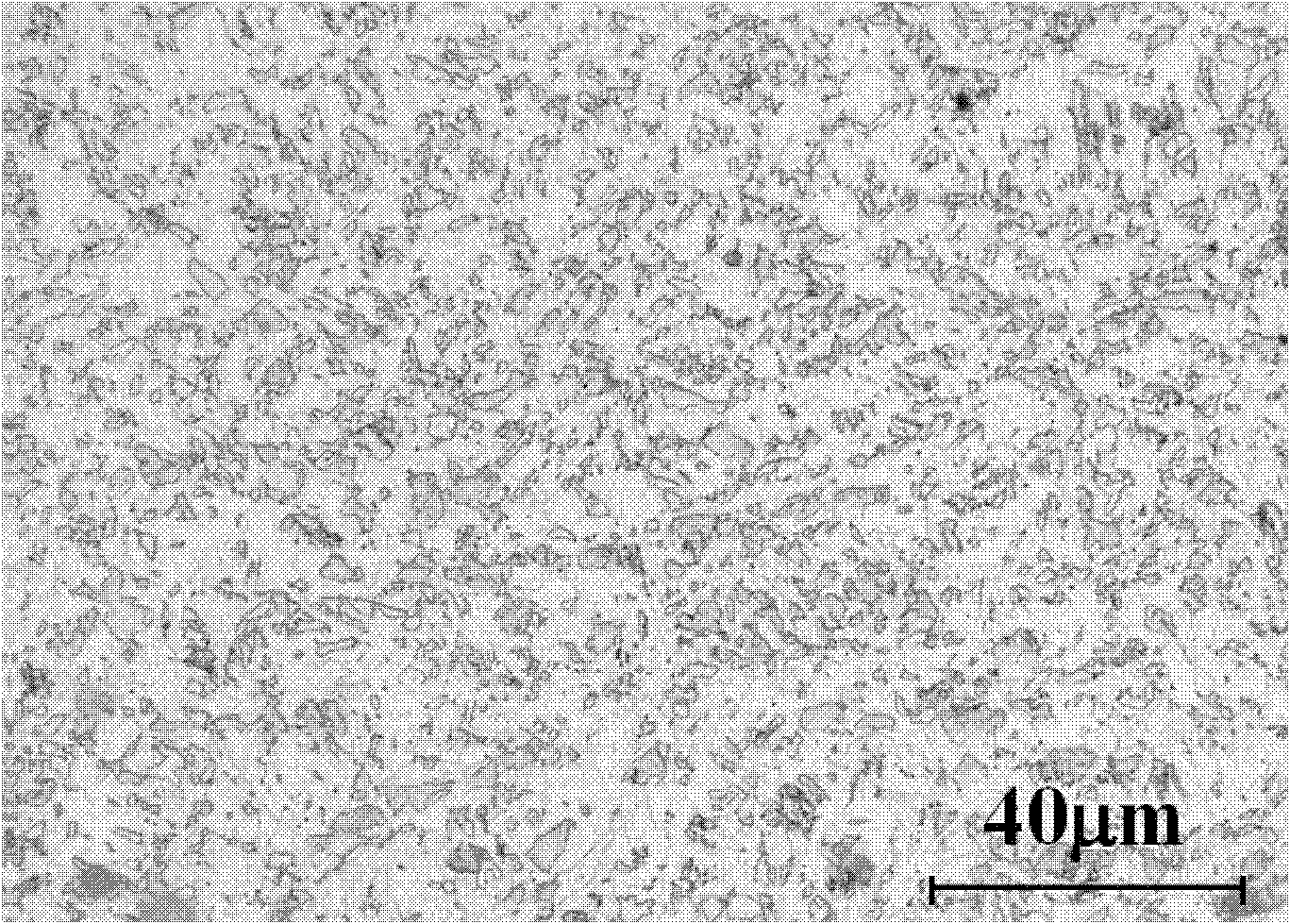

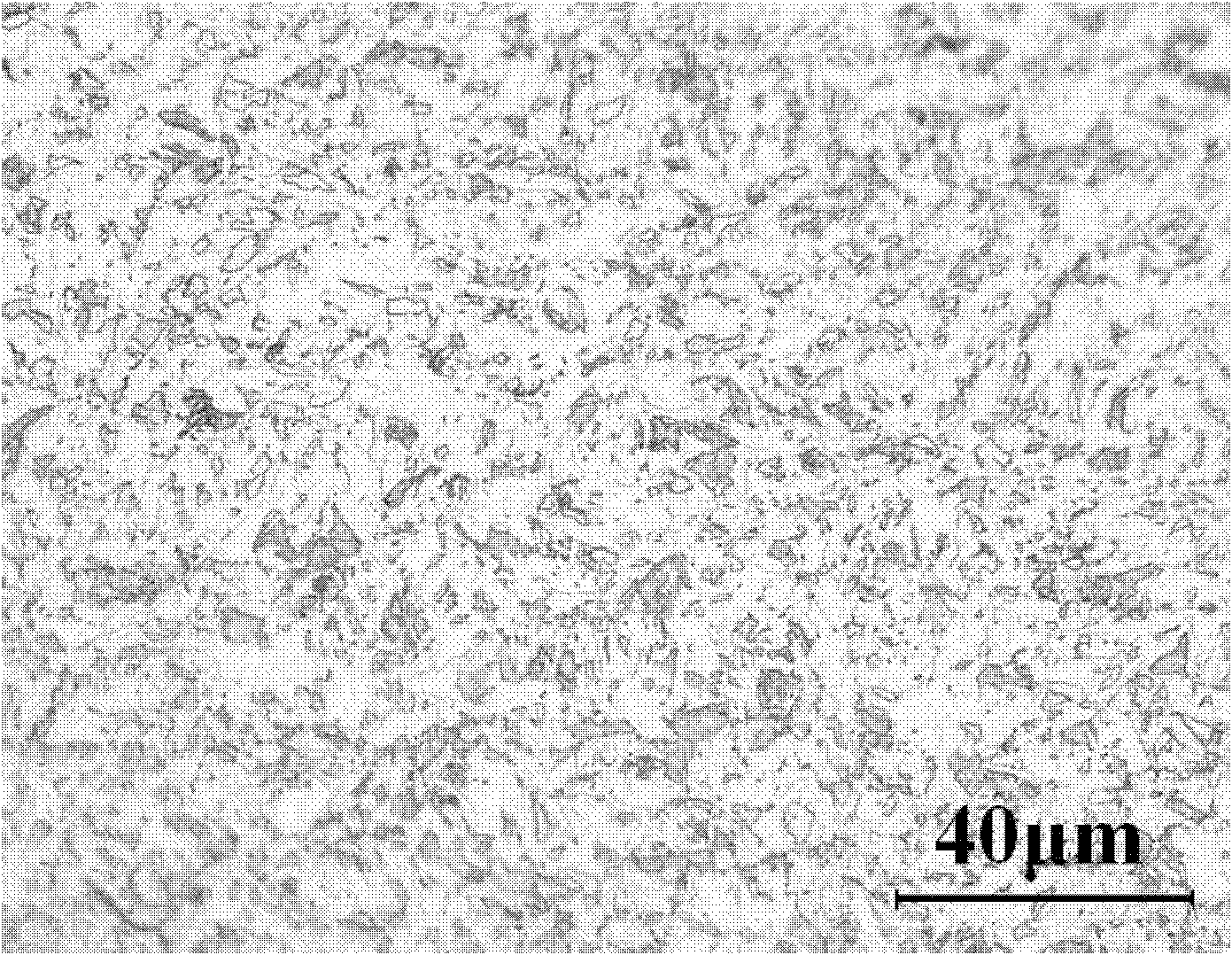

Image

Examples

Embodiment 1

[0060] The molten steel smelted according to the proportions in Table 1 is subjected to vacuum degassing treatment and then continuous casting or die casting. The thickness of the slab is 80 mm. After heating at 1200 ° C, the resulting billet is rolled in multiple passes within the range of austenite recrystallization temperature. , rolled into a steel plate with a thickness of 10mm, the total reduction rate is 88%, the final rolling temperature is 860°C, then water cooled to 535°C at a speed of 35°C / s, and then rapidly heated online to 640°C for tempering, and then air cooled to room temperature;

[0061] The detailed composition of Examples 2-5 is shown in Table 1, the process is as in Example 1, and the process parameters are shown in Table 2.

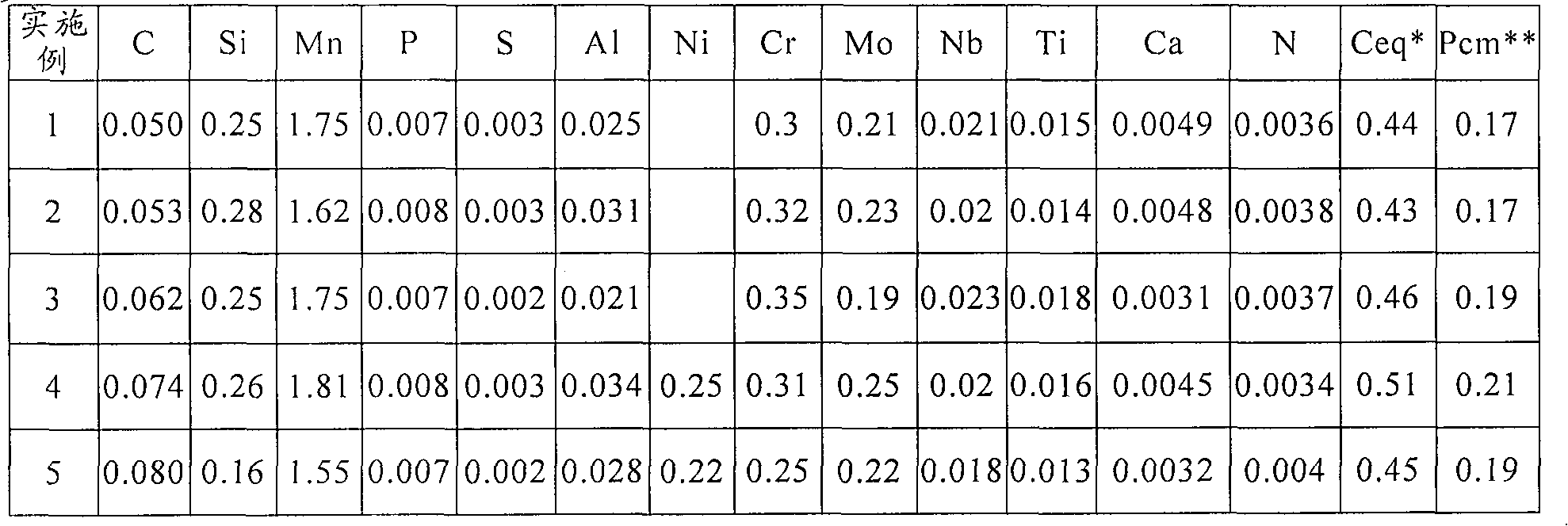

[0062] Table 1 Chemical composition, Ceq (wt%), Pcm of embodiment 1-5 of the present invention

[0063]

[0064] *Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 14

[0065] **Pcm=C+Si / 30+Mn / 20+Cu / 20+Ni / 60+Cr / 20+Mo / 15+V / 10+5B

[0066] Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com