Method for producing high heat input welding Q345-level steel plate

A large heat input welding and production method technology, applied in the field of iron and steel products, to achieve good performance, good cold bending performance, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

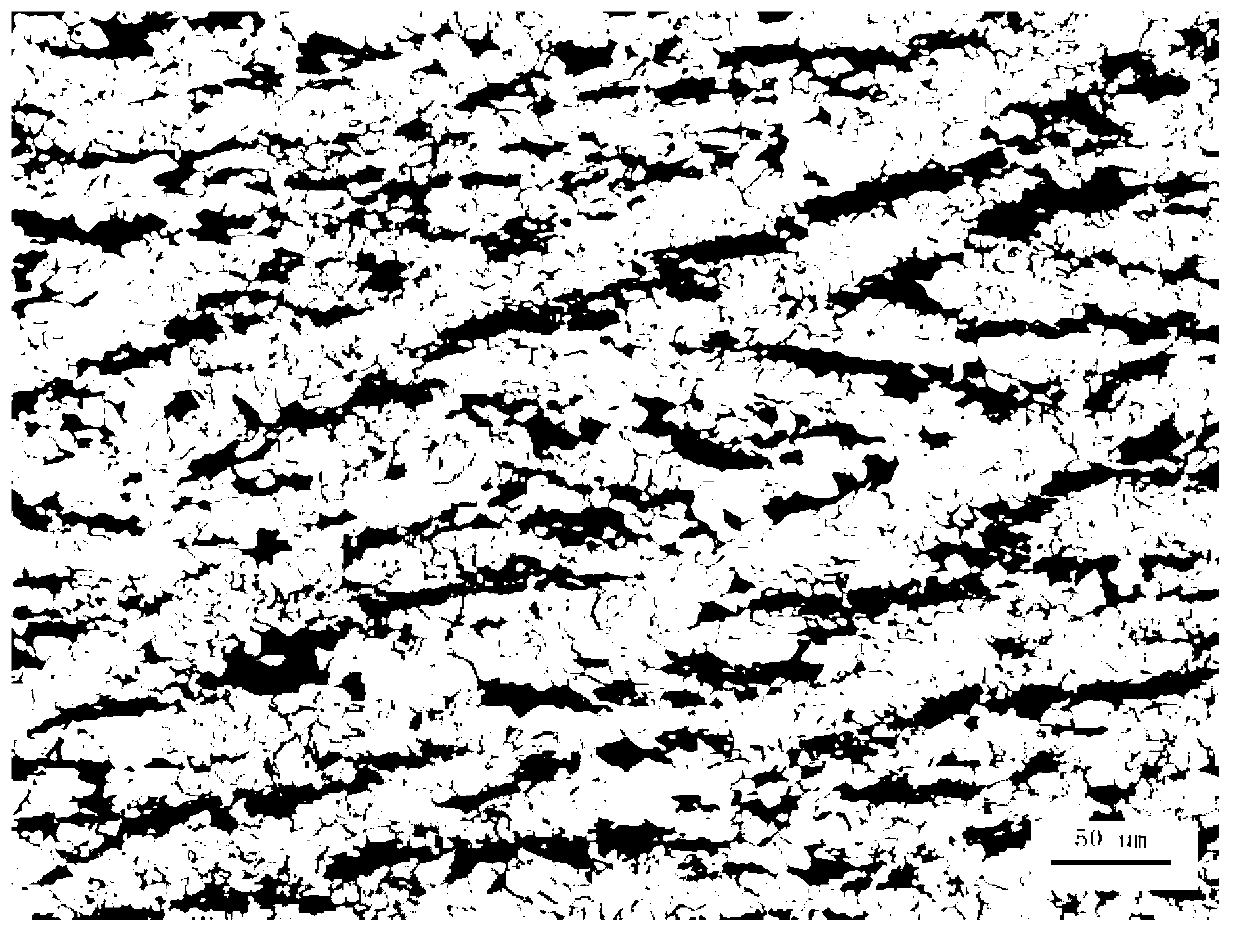

Image

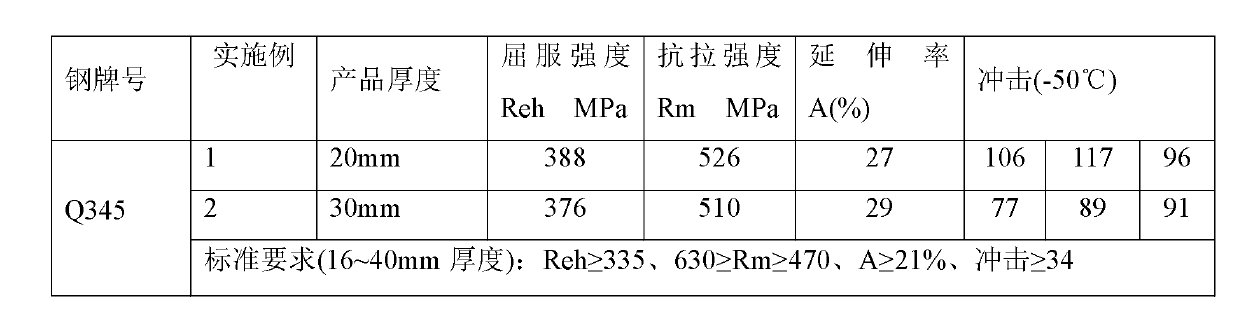

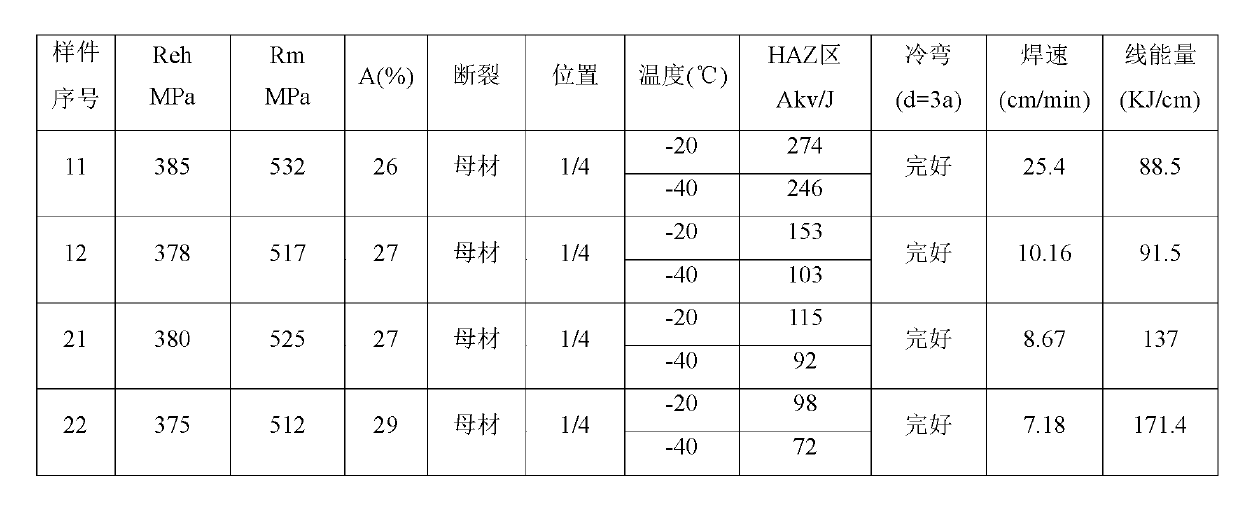

Examples

Embodiment 1

[0021] The present invention is a production method of large heat input welding Q345 grade steel plate, and its technological process includes smelting, continuous casting, heating, dephosphorization, controlled rolling and controlled cooling, hot straightening, stacking and slow cooling, and fire cutting to finished products, aiming at three Key points to be controlled: smelting composition design, controlled rolling and controlled cooling, and cooling after final rolling. The specific controls are as follows

[0022] 1) Smelting composition design (wt%): C: 0.12%, Si: 0.30%, Mn: 1.30%, Nb: 0.2%,, Ti: 0.15%, P≤0.01%, S≤0.003%, [N]0.05 %, CEV0.35, the rest is iron and unavoidable trace impurities; where Ti / [N]=3;

[0023] During smelting, the molten steel is first smelted in an electric furnace and then sent to an LF refining furnace for refining. During the refining process, white slag is strengthened for secondary desulfurization to ensure that S≤0.003%.

[0024] 2) Casting...

Embodiment 2

[0031] The present invention is a production method of large heat input welding Q345 grade steel plate. The technological process includes smelting, continuous casting billet, heating, dephosphorization, controlled rolling and controlled cooling, hot straightening, stacking and slow cooling, cutting and inspection to finished products. The key points are controlled: smelting composition design, controlled rolling and controlled cooling, and cooling after final rolling. The specific control is as follows

[0032] 1) Smelting composition design (wt%): C: 0.13%, Si: 0.40%, Mn: 1.40%, Nb: 0.3%,, Ti: 0.10%, P≤0.01%, S≤0.003%, [N]0.04 %, CEV0.34, the rest is iron and unavoidable trace impurities; where Ti / [N]=2.5;

[0033] During smelting, the molten steel is first smelted in an electric furnace and then sent to an LF refining furnace for refining. During the refining process, white slag is strengthened for secondary desulfurization to ensure that S≤0.003%.

[0034] 2) Casting: Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com