Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

595results about How to "Reduce reaction energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing ethandiol by catalyzing epoxyethane hydration

InactiveCN1463960AHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEpoxideEnergy consumption

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

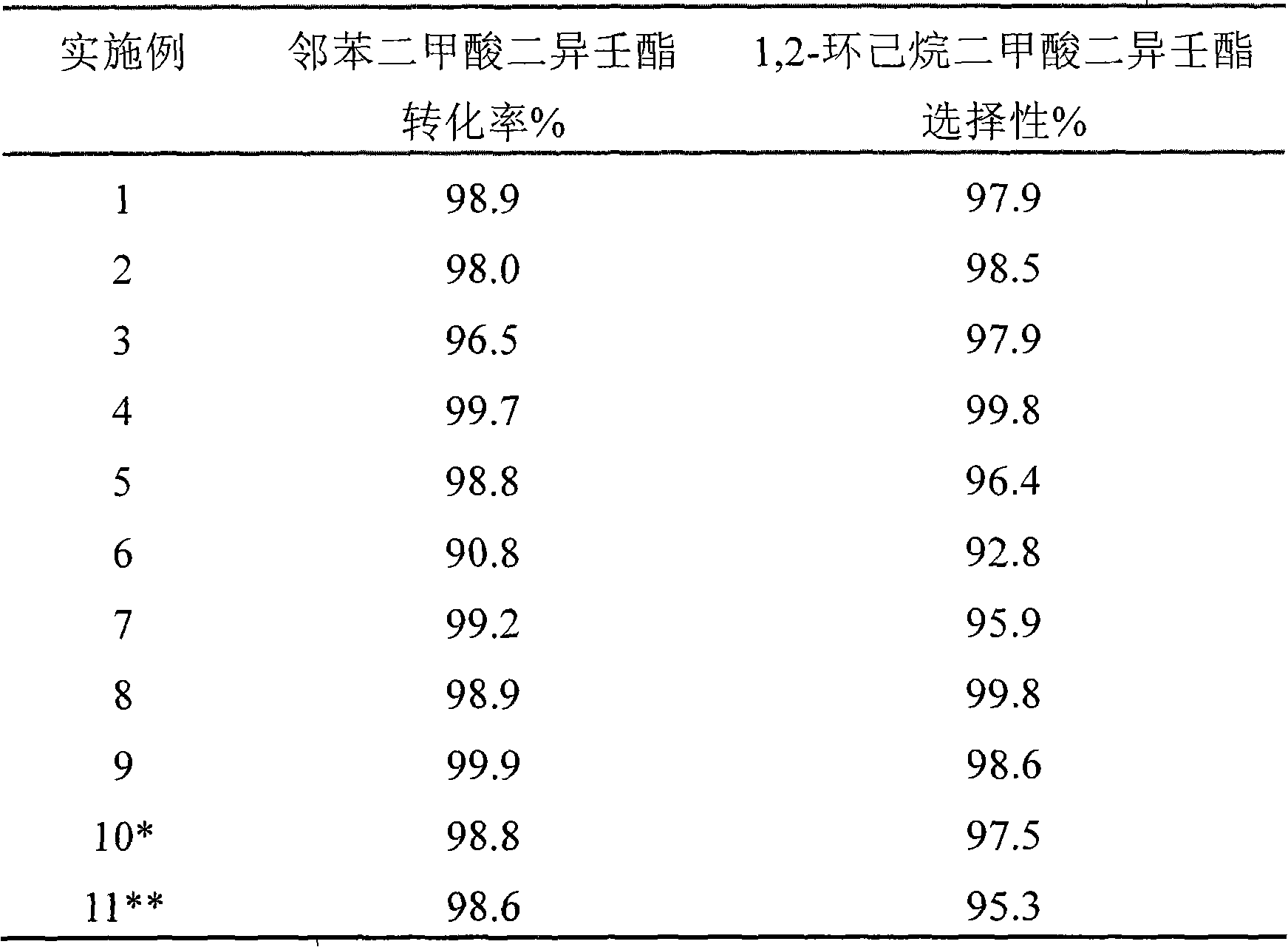

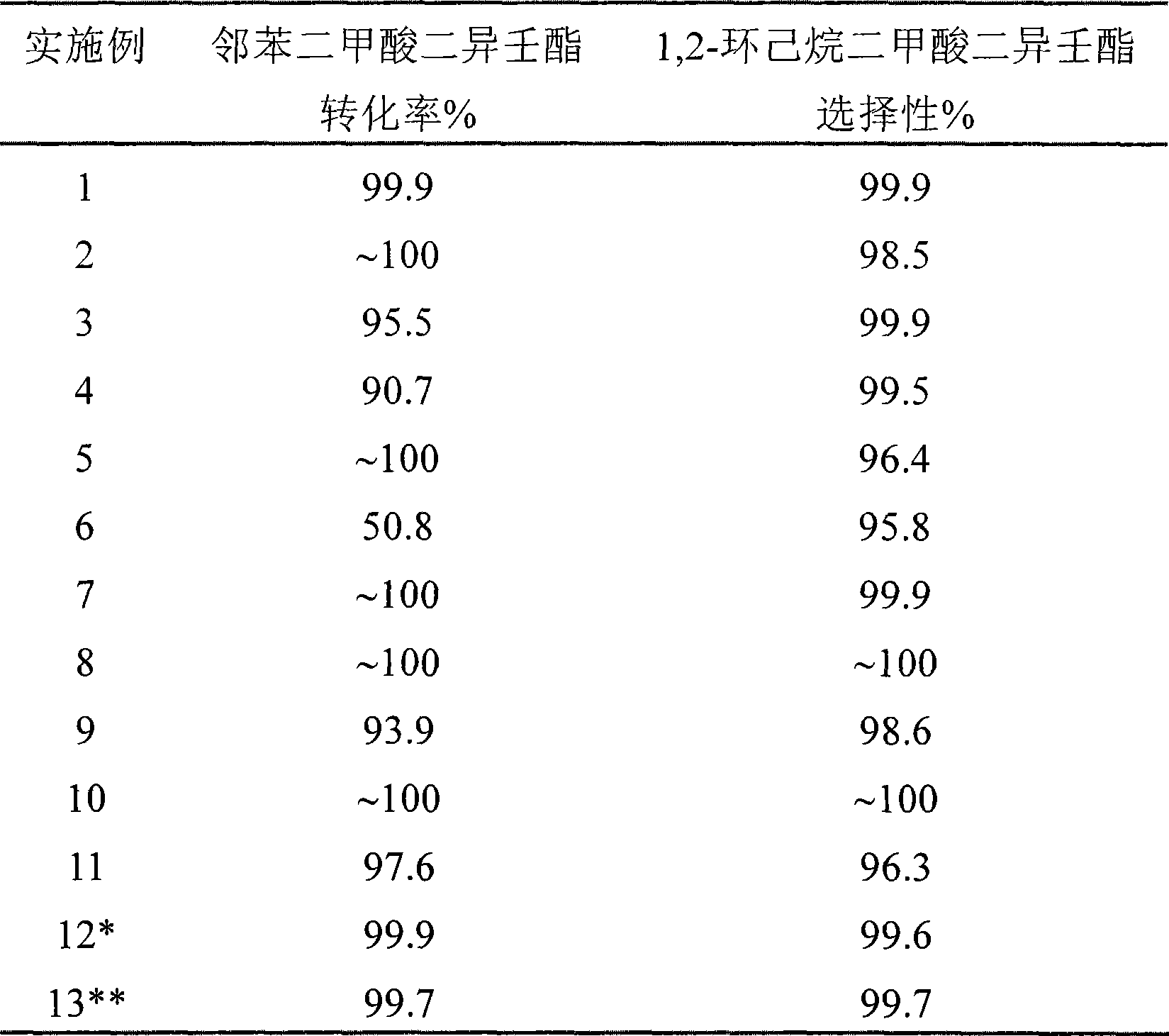

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

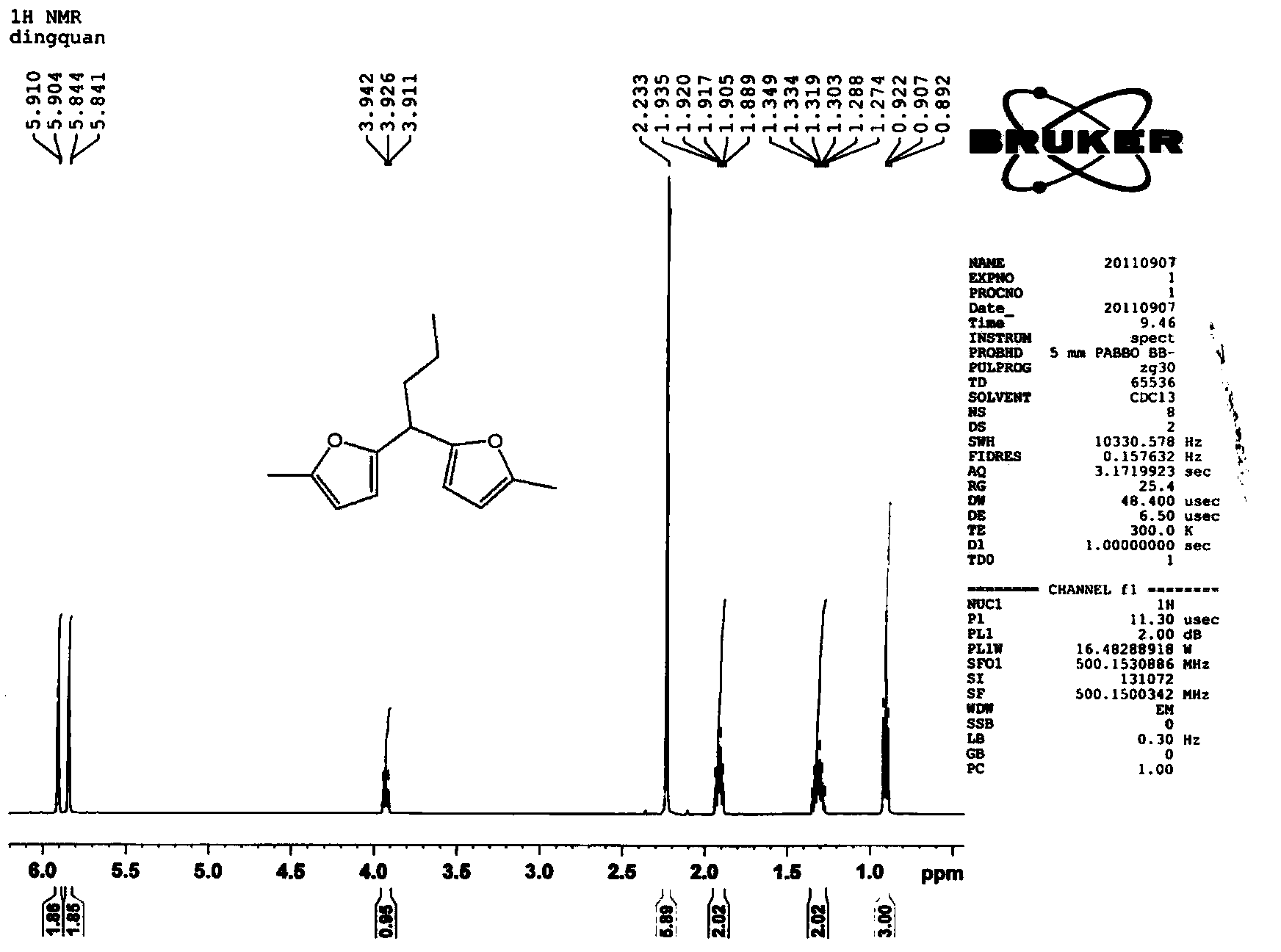

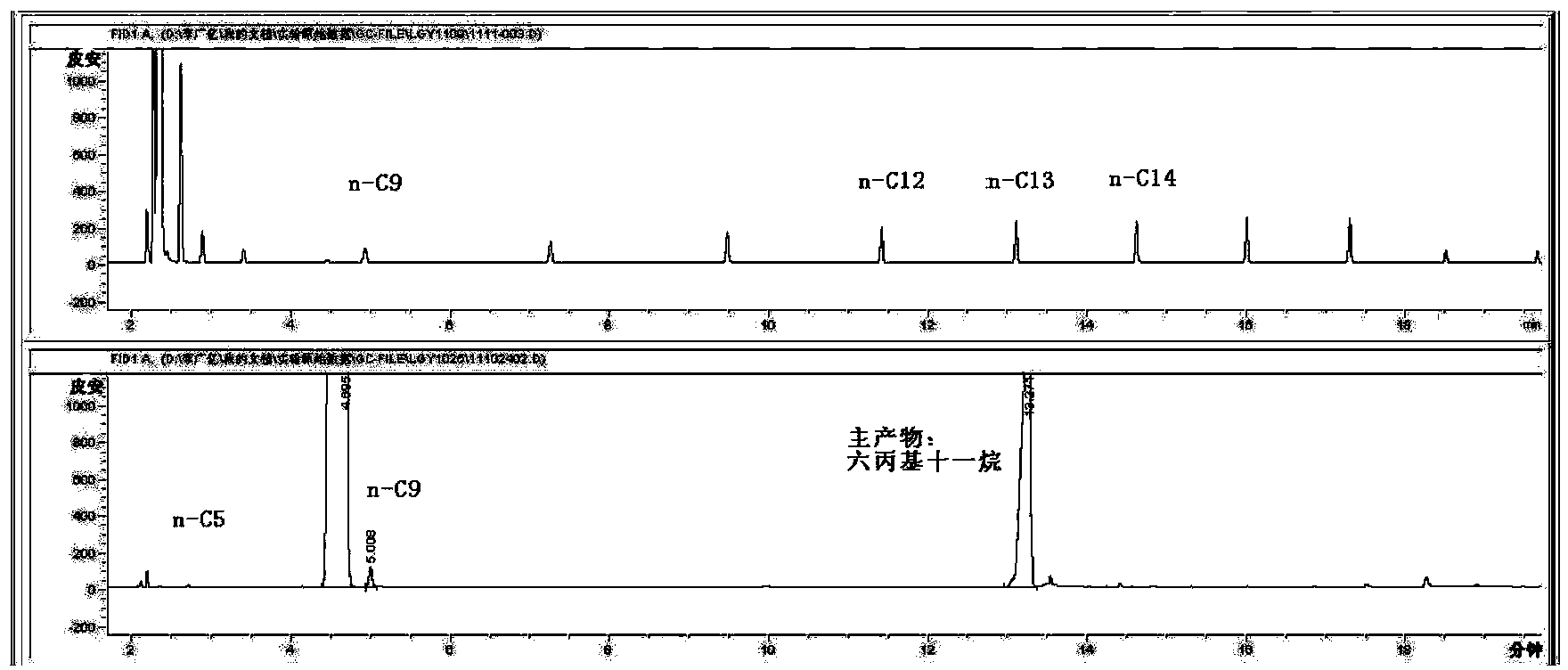

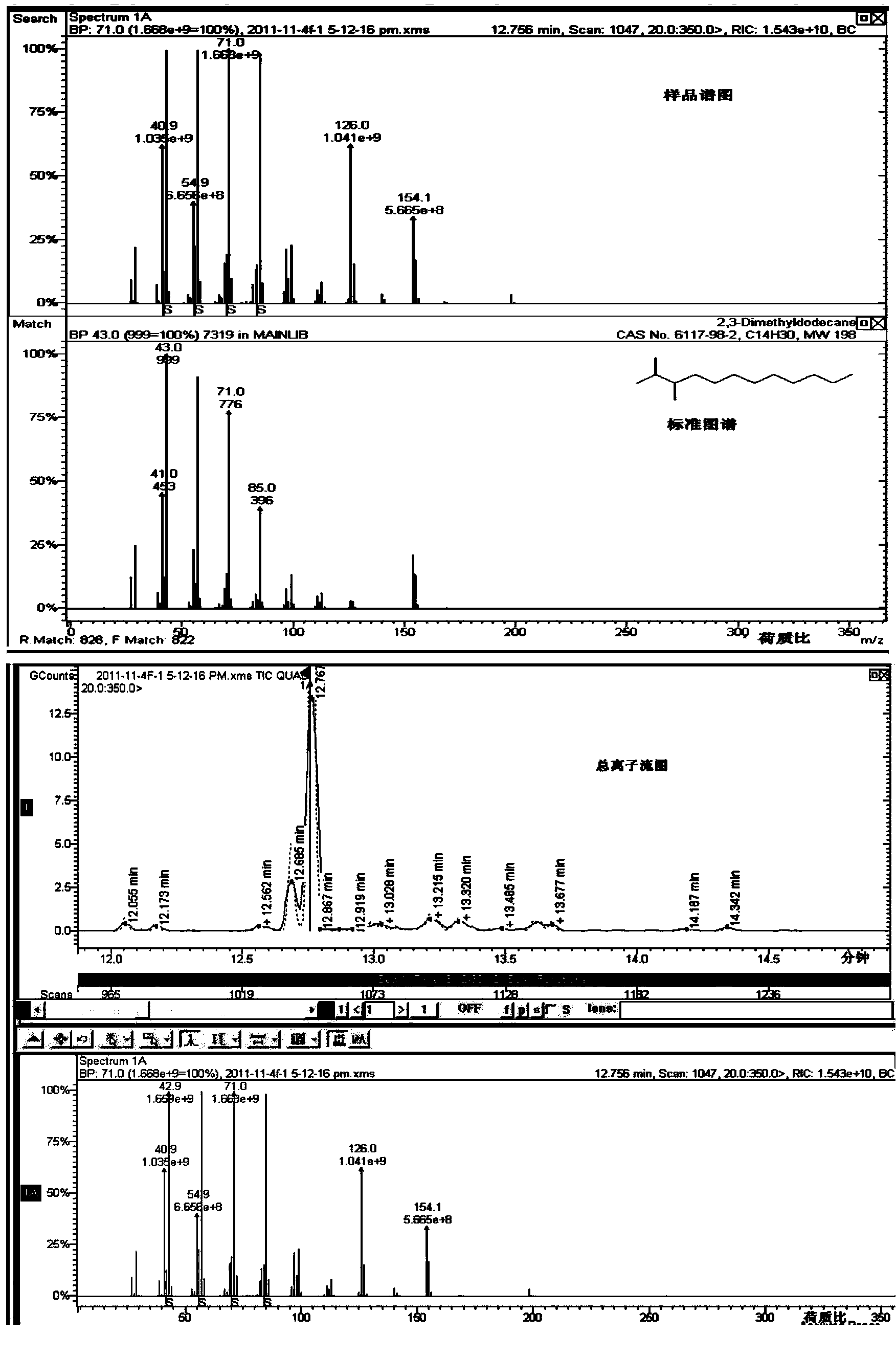

Method for preparing aviation kerosene from furyl oxygen-containing organic compounds by hydrogenation deoxidation

ActiveCN104119943AReduce energy consumptionSimple operation processMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneFuran

The invention relates to a new method for preparing hydrocarbons in the scope of aviation kerosene from C8-C16 furyl oxygen-containing organic compounds as raw materials by hydrogenation deoxidation reaction, wherein the C8-C16 furyl oxygen-containing organic compounds are obtained by C-C coupling of lignocellulose based platform chemical compounds; low temperature direct hydrogenation deoxidation under the condition of no solvent of the furyl oxygen-containing organic compounds can be realized by use of a metal-solid acid dual-functional catalyst to obtain a series of low freezing point branched alkanes having the chain in the length range of the aviation kerosene in high yield. The catalyst is composed of two parts of an active metal A and an acid vector X. The catalyst related in the method ahs the characteristics of being in no need of a solvent, simple in operation process, mild in reaction conditions, good in aviation kerosene (or diesel) selectivity, and the like, and is an ideal hydrogenation deoxidation catalyst for preparing liquid fuels from the furyl oxygen-containing organic compounds by the hydrogenation deoxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing ethandiol by catalytic hydration of epoxyethane

InactiveCN1204103CHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEthylene oxideHigh activity

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

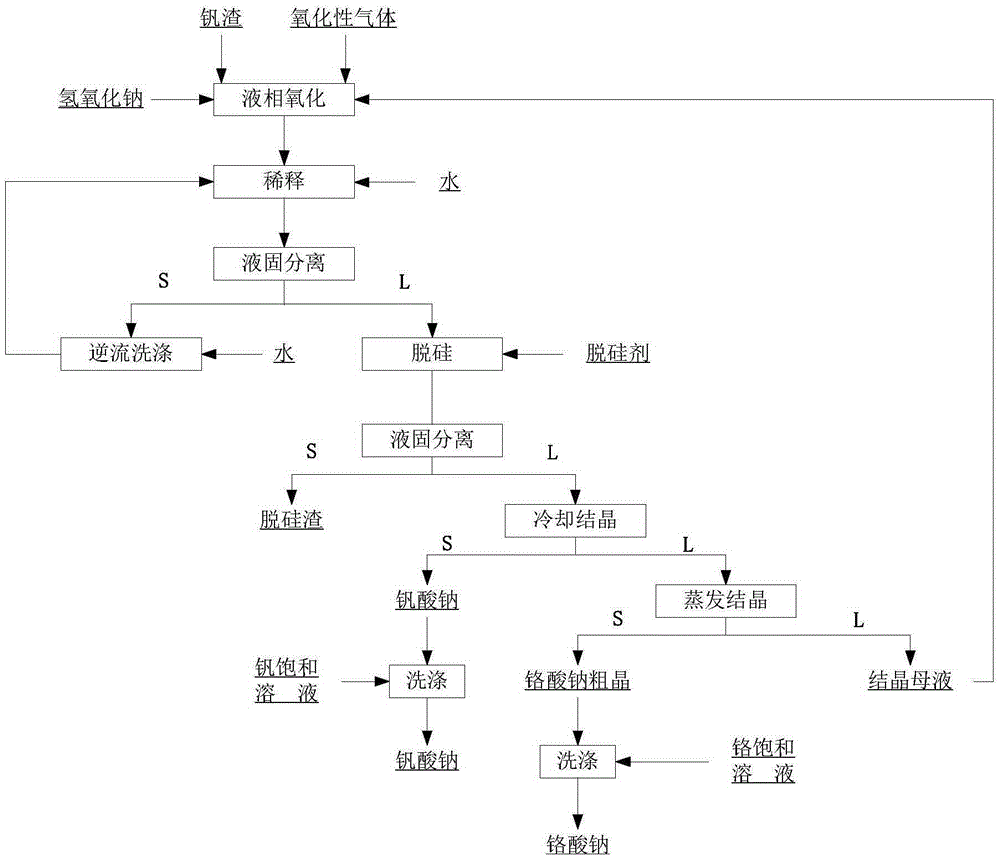

Method for extracting chromium and vanadium from vanadium slag at low temperature and normal pressure

ActiveCN105400967ALow reaction temperatureReduce reaction energy consumptionSlagReaction temperature

The invention relates to the field of vanadium slag hydrometallurgy and vanadium chemical engineering, in particular to a method for extracting chromium and vanadium from vanadium slag at a low temperature and the normal pressure. The method comprises the following steps that firstly, burdening, wherein the vanadium slag and a NaOH solution are mixed to form reaction slurry; secondly, reaction, oxide gas is led into the reaction slurry through a micro-hole arrangement device to carry out normal-pressure oxidative leaching, and after the reaction, solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4, water soluble impurity components and iron-rich tailings is obtained; thirdly, solid-liquid separation; fourthly, impurity removing; fifthly, sodium vanadate crystallization; and sixthly, sodium chromate crystallization. According to the method, chromium and vanadium efficient common extraction can be achieved, the extraction efficiency of both chromium and vanadium can be higher than 85%, more importantly, after the micro-hole gas distribution manner is adopted, the oxygen solubility can be obviously improved, the reaction temperature and alkali concentration are obviously reduced compared with those of an existing vanadium extraction method, the operation safety is greatly improved, and reaction energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Calcium carbide production method

The invention relates to a carbide preparation method belonging to the field of carbide preparation. The conventional carbide preparation technology adopts block materials and electric arc as a heat-supply, while the preparation method according to the invention adopts powdery carbon-containing materials and powdery calcium-containing materials, and the combustion of partial carbon-containing materials and oxygen-containing gas as a heat-supply at 1700-2300 DEG C to prepare carbide, wherein the carbon-containing materials is coal or coke, calcium-containing materials is calcium carbonate, calcium oxide, calcium hydroxide or carbide slag, the granularity of the carbon-containing materials and calcium-containing materials is less than 1mm, and the quality ratio is 0.5-3:1. The oxygen-containing gas for combustion is oxygen, oxygen-enriched air or air. The method solves the problems of high energy consumption and high pollution of the carbide preparation and has advantages of wide choice scope of materials, high energy utilization rate, continuous operation and large production capacity. The technology also couples with the process of carbon-containing materials coking and calcium-containing materials calcining, preheats the materials to 500-1500 DEG C utilizing the combustion of by-products CO of the carbide preparation and the assistant fuel, thereby further reducing the oxygen and energy consumption of the carbide preparation.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method and application of diethyl phosphinates

InactiveCN101891762AShort reaction timeTrigger fastGroup 5/15 element organic compoundsReaction rateUltraviolet lights

The invention discloses a preparation method and application of diethyl phosphinates, belonging to the field of green flame retardants. The preparation method of the diethyl phosphinates comprises the following steps of: making hypophosphorous acid and / or an alkali metal salt thereof react with ethylene under the irradiation of ultraviolet light in the presence of a photoinitiator in a solvent system to obtain diethyl phosphinic acid and / or an alkali metal salt thereof; and making the obtained diethyl phosphinic acid and / or the alkali metal salt thereof react with metallic compounds of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn and / or Fe to obtain corresponding diethyl phosphinates. In the invention, the photoinitiator is decomposed into free radicals under the irradiation of the ultraviolet light to initiate an additive reaction so that the reaction rate can be improved, the energy consumption required in the reaction can be reduced and the production cost of products can be lowered.

Owner:NANKAI UNIV

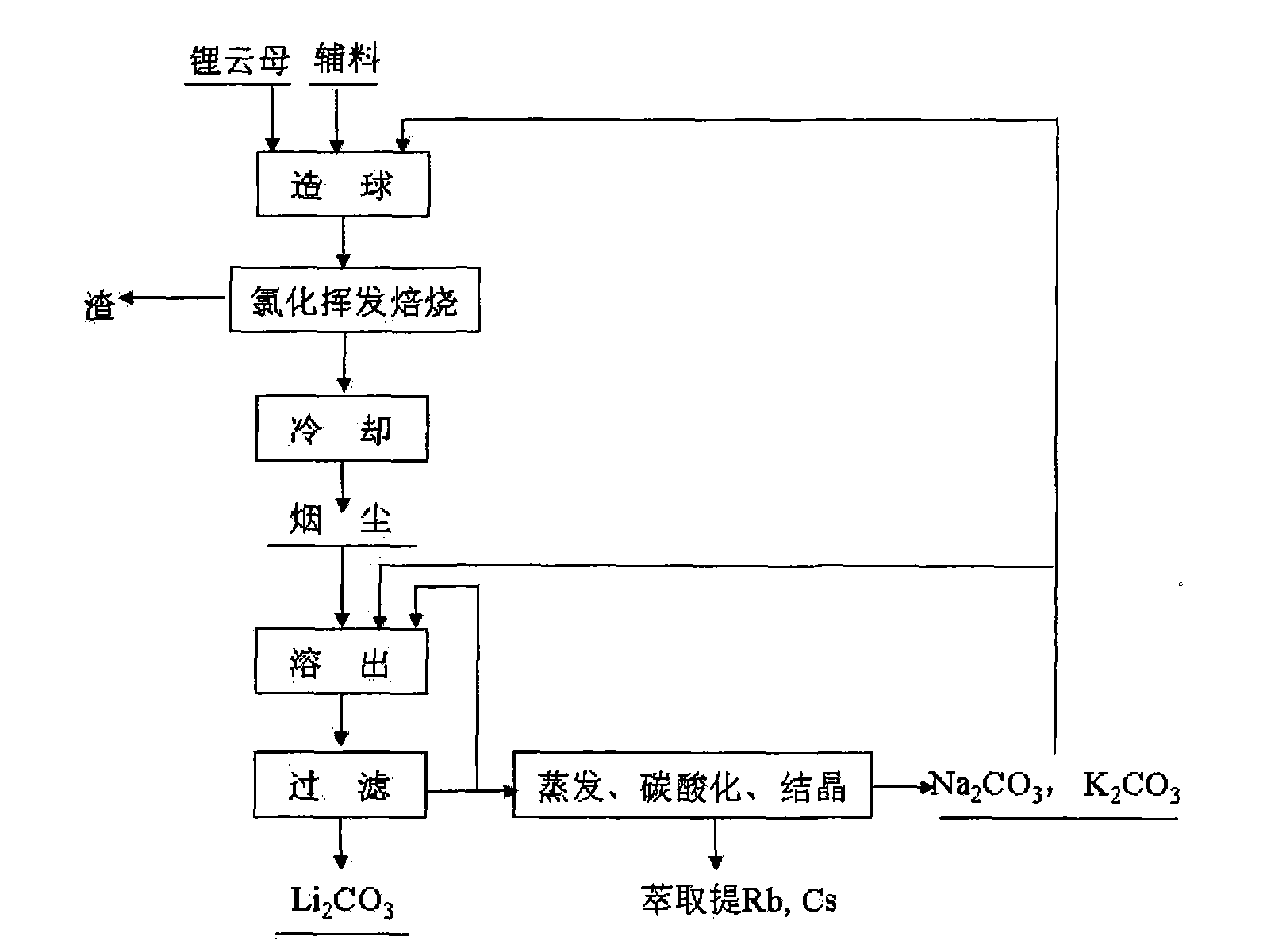

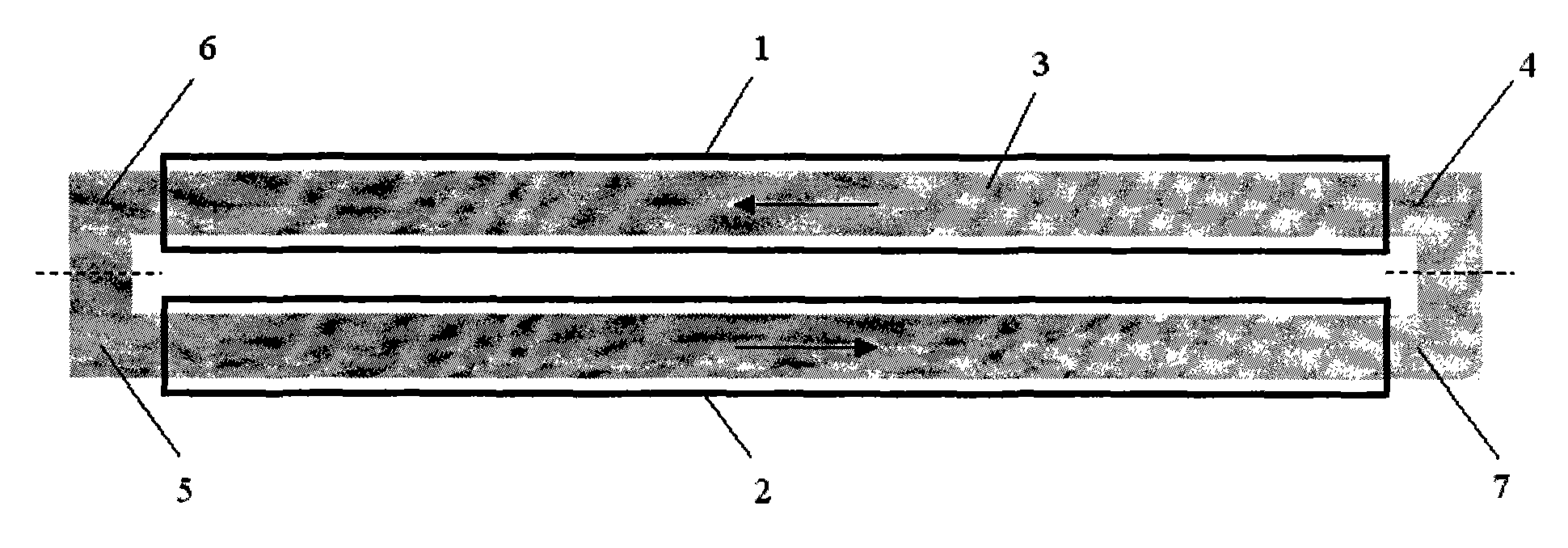

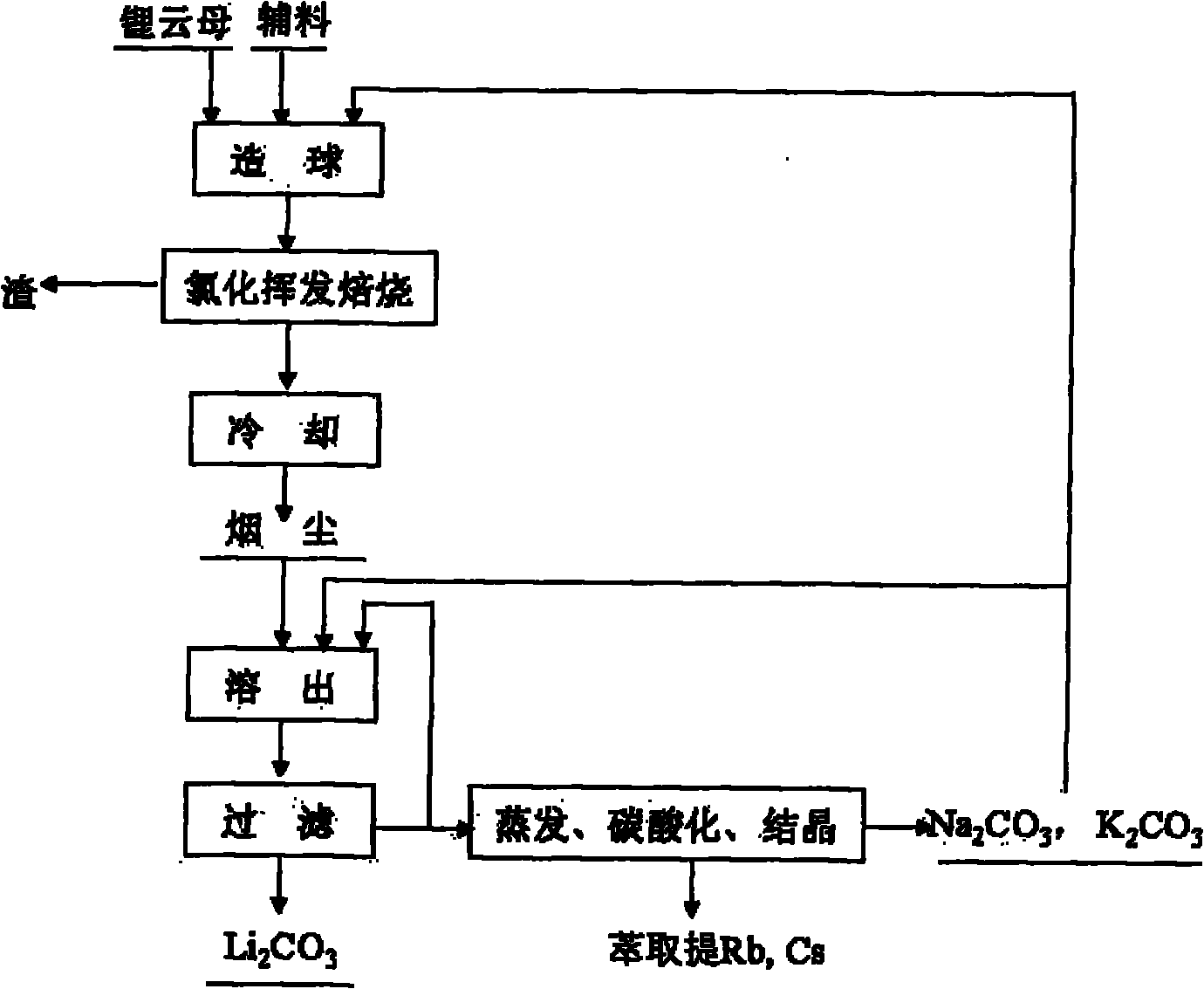

Method and device for extracting lithium from lapidolite by chloridizing roasting method

The invention discloses a method and a device for extracting lithium, which is used for preparing lithium carbonate, from a lapidolite ore by a chloridizing roasting method. The method comprises the following steps of: firstly, mixing the lapidolite ore, calcium chloride and sodium hydroxide with a compound bonding agent for pellet fabrication; secondly, performing chloridizing roasting in a square-frame shaped track type roasting furnace; thirdly, leaching out soot dust by using solution containing sodium carbonate and potassium carbonate to ensure that potassium, sodium, rubidium and cesium enter the solution and convert the lithium into lithium carbonate; fourthly, filtering the mixture to obtain a lithium carbonate solid, and circularly using the filtrated mother liquor to leach out the soot dust; fifthly, when an alkali metal salt is close to be saturated, indirectly heating the filtrated mother liquor by using the residual heat of the gas in the roasting furnace to evaporate part of water; sixthly, passing CO2 into the filtrated mother liquor to perform carbonation; and seventhly, performing cooling crystallization to separate out a mixed salt of the sodium carbonate and the potassium carbonate, returning part of the mixed salt which is used as an auxiliary material mixed and roasted with lapidolite for cyclic utilization, using another part of the mixed salt as a carbonate reagent needed in dissolution, and using the rest part of the mixed salt as byproducts of the sodium carbonate and the potassium carbonate. The method has the advantages of high lithium recovery rate, good material comprehensive utilization, large equipment productivity, high production efficiency, small water consumption in the process and less wastewater discharge.

Owner:CENT SOUTH UNIV

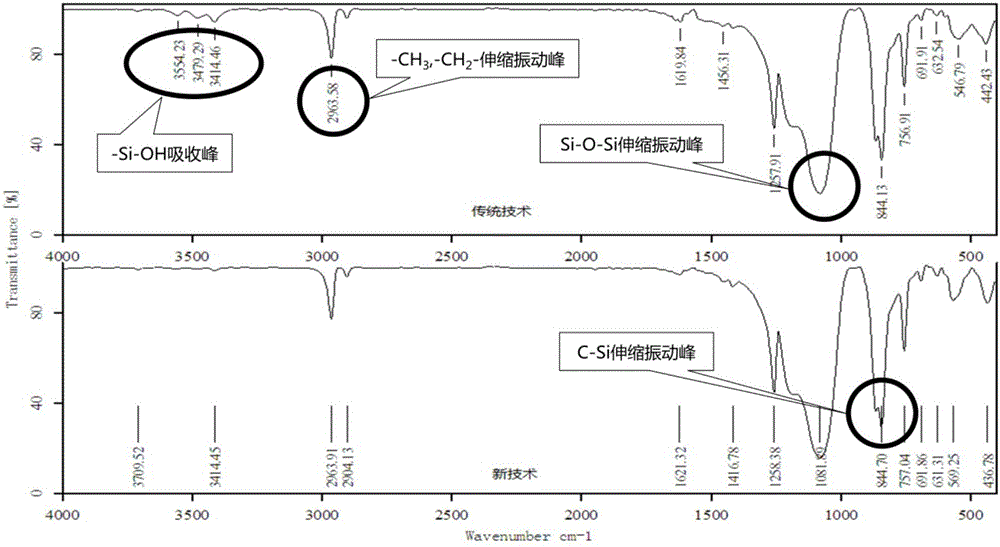

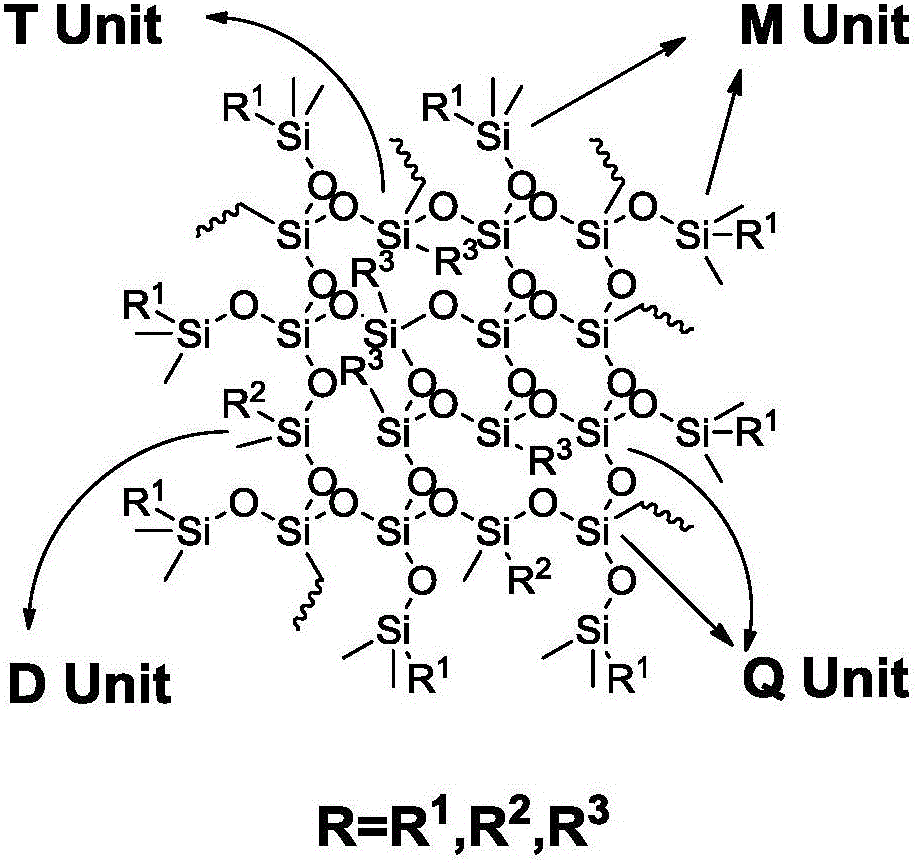

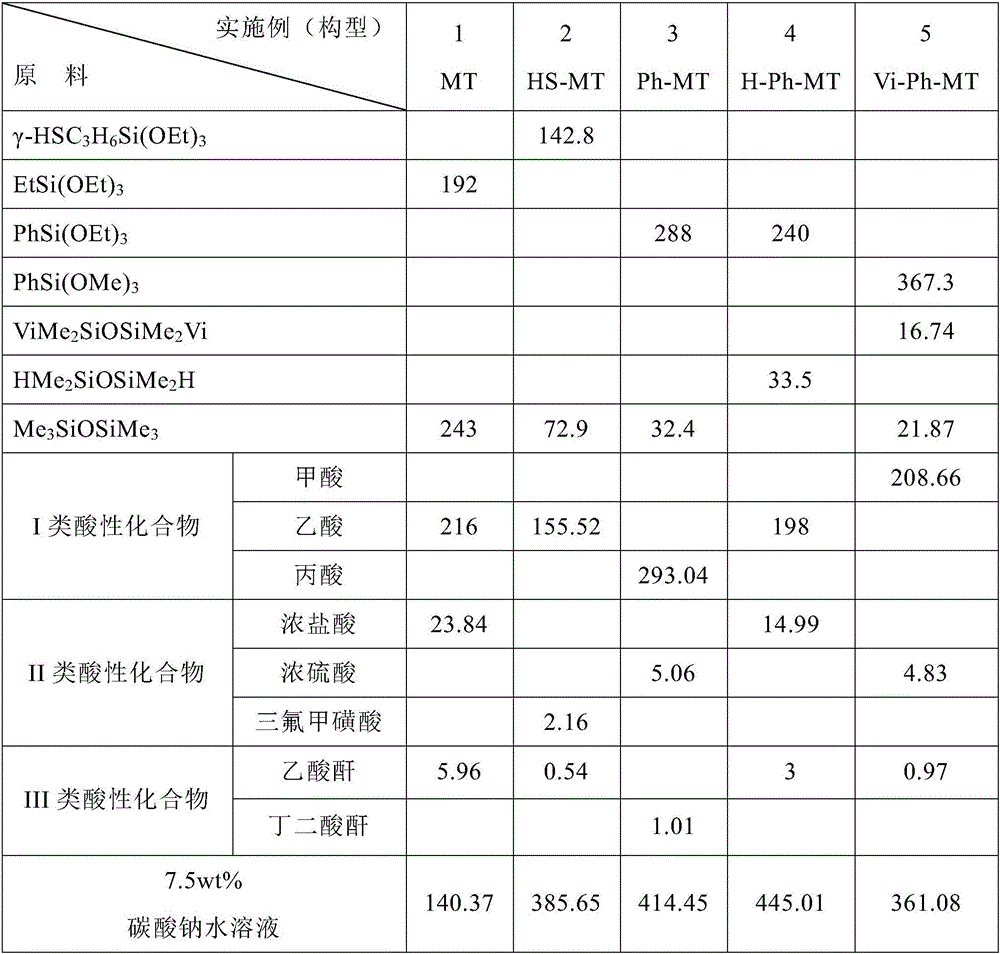

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

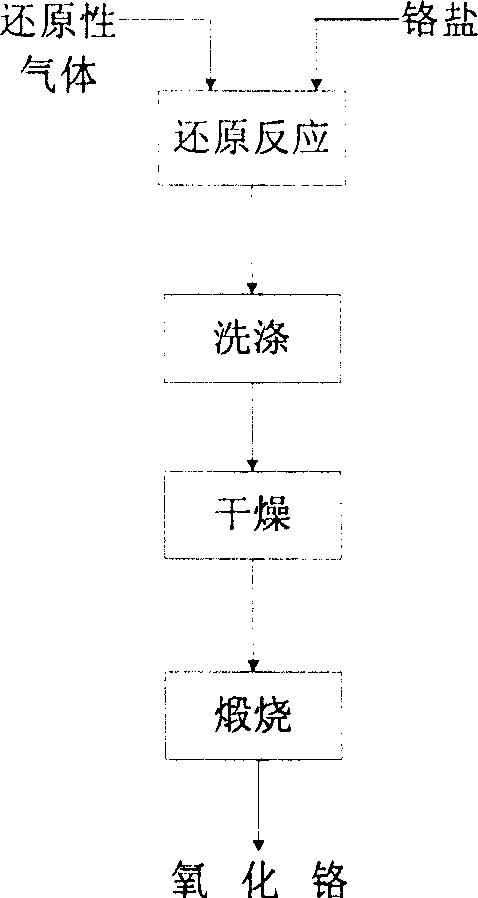

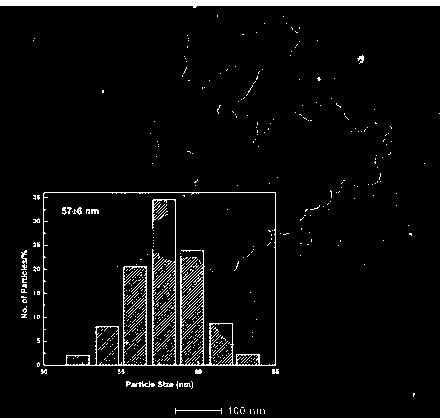

Method of preparing chromium oxide by reducing chromate with gaseous reducing agent at low temperature

InactiveCN1907865ASimple production processEasy to industrializeChromium oxides/hydratesHydrogenReaction temperature

This invention involves a preparation method for chromium oxide with chromium salt as raw materials and reducing gas as a reductant. Said method comprises carrying out reaction of chromium salt with superfluous reducing gas at 300~850DEG C for 0.5-3 h and cooling to obtain a reaction mixture, washing the mixture and drying, and calcining at 400~1100DEG C for 1-3 h to obtain the ultrafine chromium oxide powders, wherein the chromium salt is chromate or dichromate, and the reducing gas is hydrogen, natural gas, gas or their mixtures. Compared with existing technologies, this invention has the advantages of simple production process and being easy for industrialization. The obtained chromium oxide has high purity, uniform particle size distribution and small particle size. The whole process does not produce containing chromium-containing waste, and is environmental friendly. The reaction by-product can be reused, which greatly reduces the cost of production. Low reaction temperature greatly reduces the reaction energy.

Owner:中蓝义马铬化学有限公司

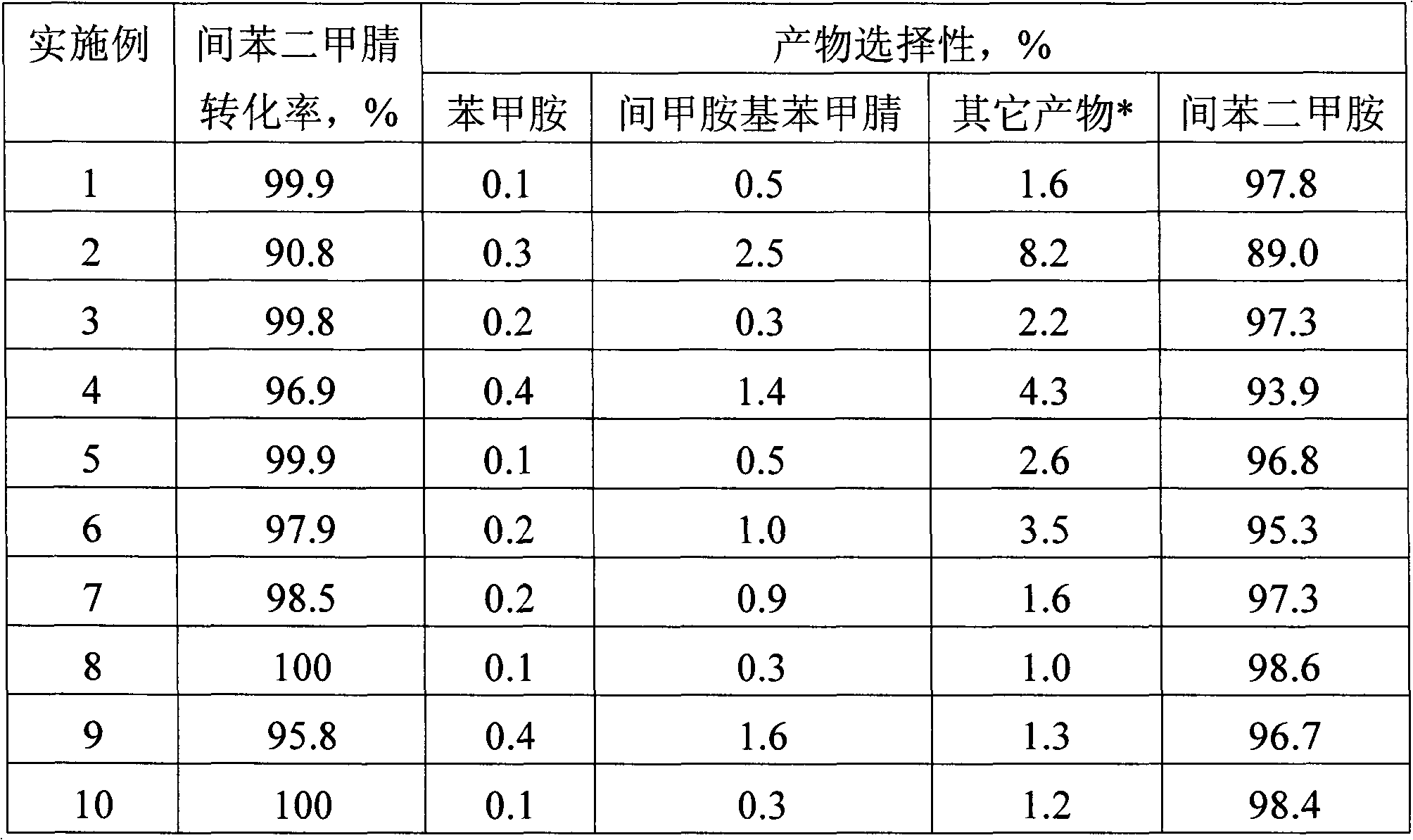

Catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions

ActiveCN102688763ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationAmino compound preparationFixed bedHigh activity

The invention discloses a catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of isophthalonitrile and hydrogen into m-xylylenediamine under ammonia reaction conditions and comprises a main active component, one or more auxiliary agents and a carrier. The main active component is a transition metal Ni or Co. The one or more auxiliary agents are selected from Re, Cu, Cr, Ru, Fe and their oxides. The carrier is diatomite, Al2O3 or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of isophthalonitrile and hydrogen into a plurality of amine products comprising m-xylylenediamine as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

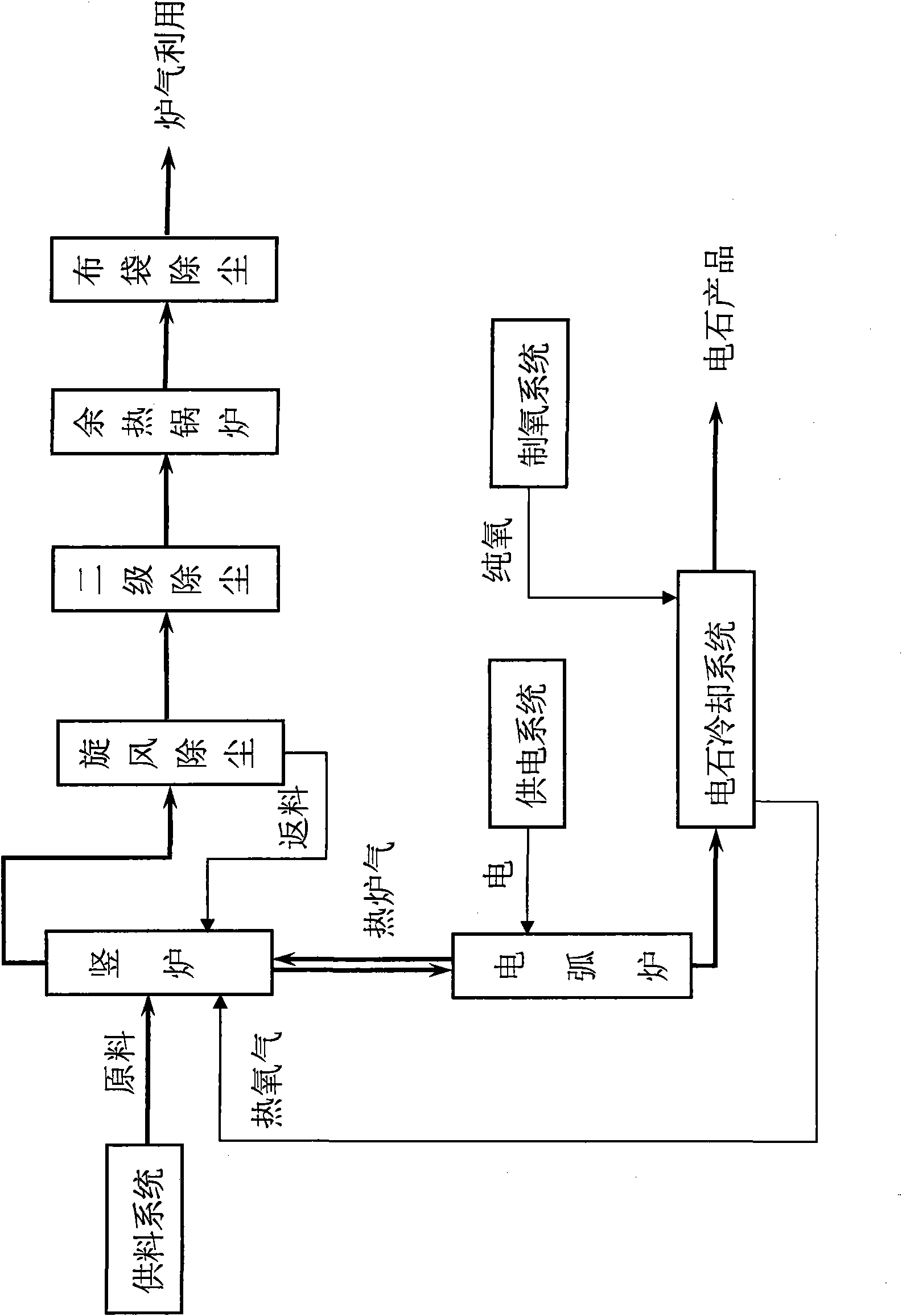

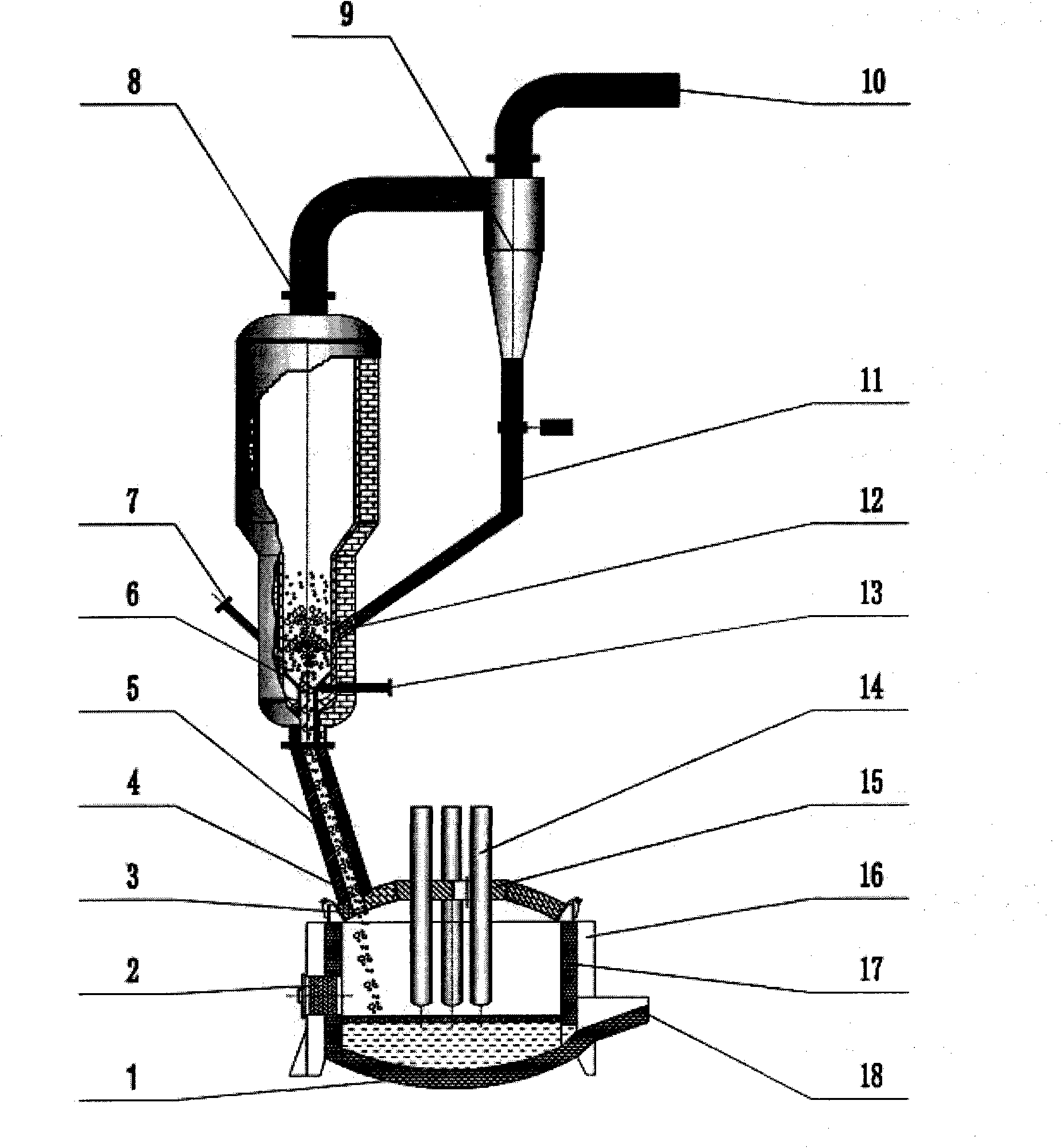

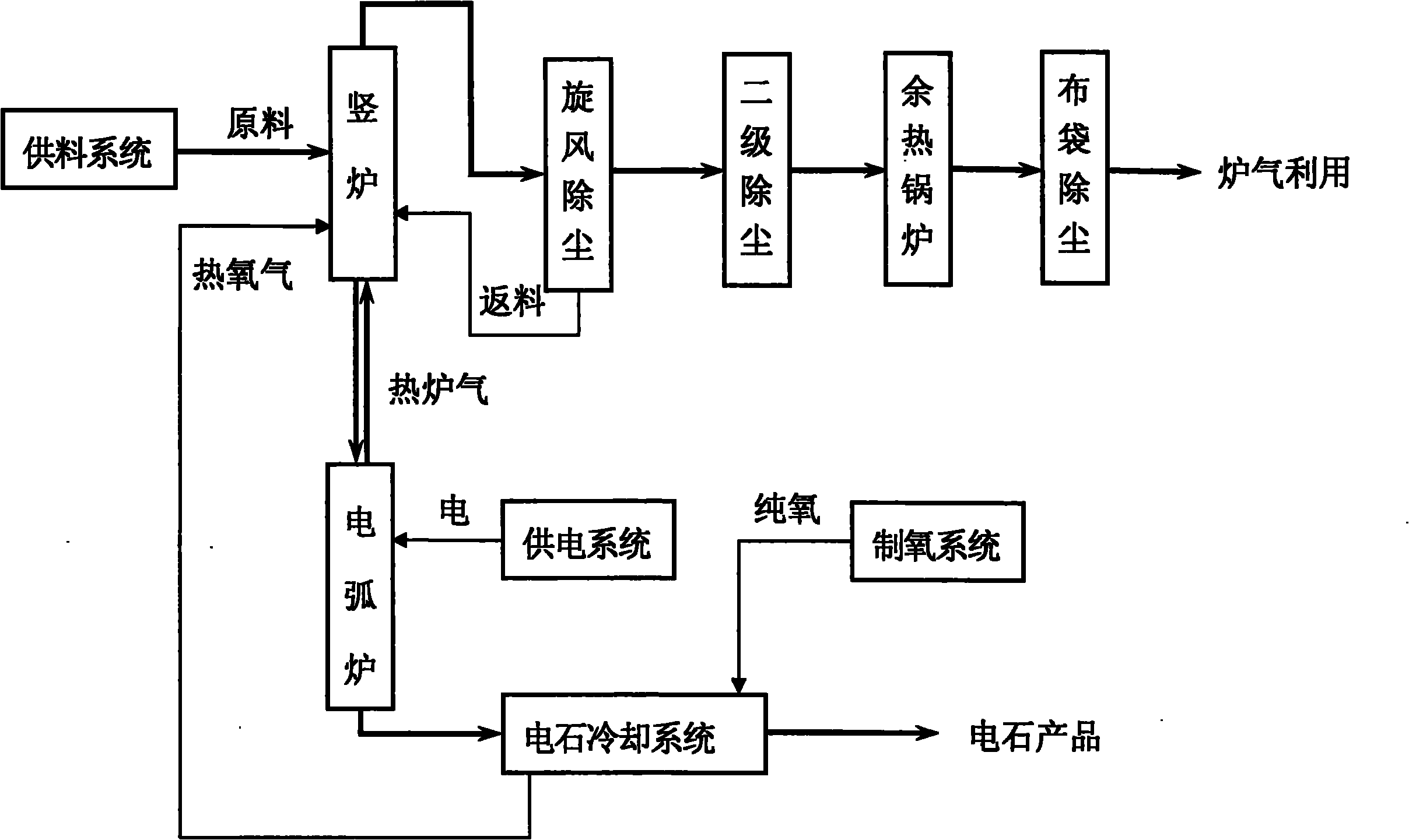

Process and device for producing calcium carbide by using powder raw materials through two-stage method

InactiveCN101817525AWide variety of sourcesIncrease profitEnergy inputCalcium carbideElectric arc furnaceOxygen

The invention relates to a process for producing calcium carbide by using powder raw materials through the two-stage method, which comprises the following steps: leading power carbon-containing material, powder calcium-containing material and oxygen to burn, increasing the temperature of furnace materials in a vertical furnace to above 1300 DEG C, leading the hot furnace materials discharged from the bottom of the vertical furnace to enter into an electric arc furnace, increasing the temperature of the hot furnace materials to 1700-2200 DEG C under the thermal effect of electric arc of an electrode, and carrying out reaction for generating the calcium carbide. Gas containing solids in the vertical furnace is discharged by a furnace gas outlet pipe at the top of the vertical furnace and separated by a cyclone dust collector from, secondary dust collection, residual heat recovery and cloth bag dust collection are carried out on the separated gas to reduce the dust content to below 1-5mg / Nm3, the temperature is reduced to 30-45 DEG C, and then the gas can be recycled as fuel gas or chemical raw material gas. The process has the advantages of powder raw materials, low energy consumption, low cost, continuous production and high grade of the calcium carbide.

Owner:山西亿众公用事业有限公司

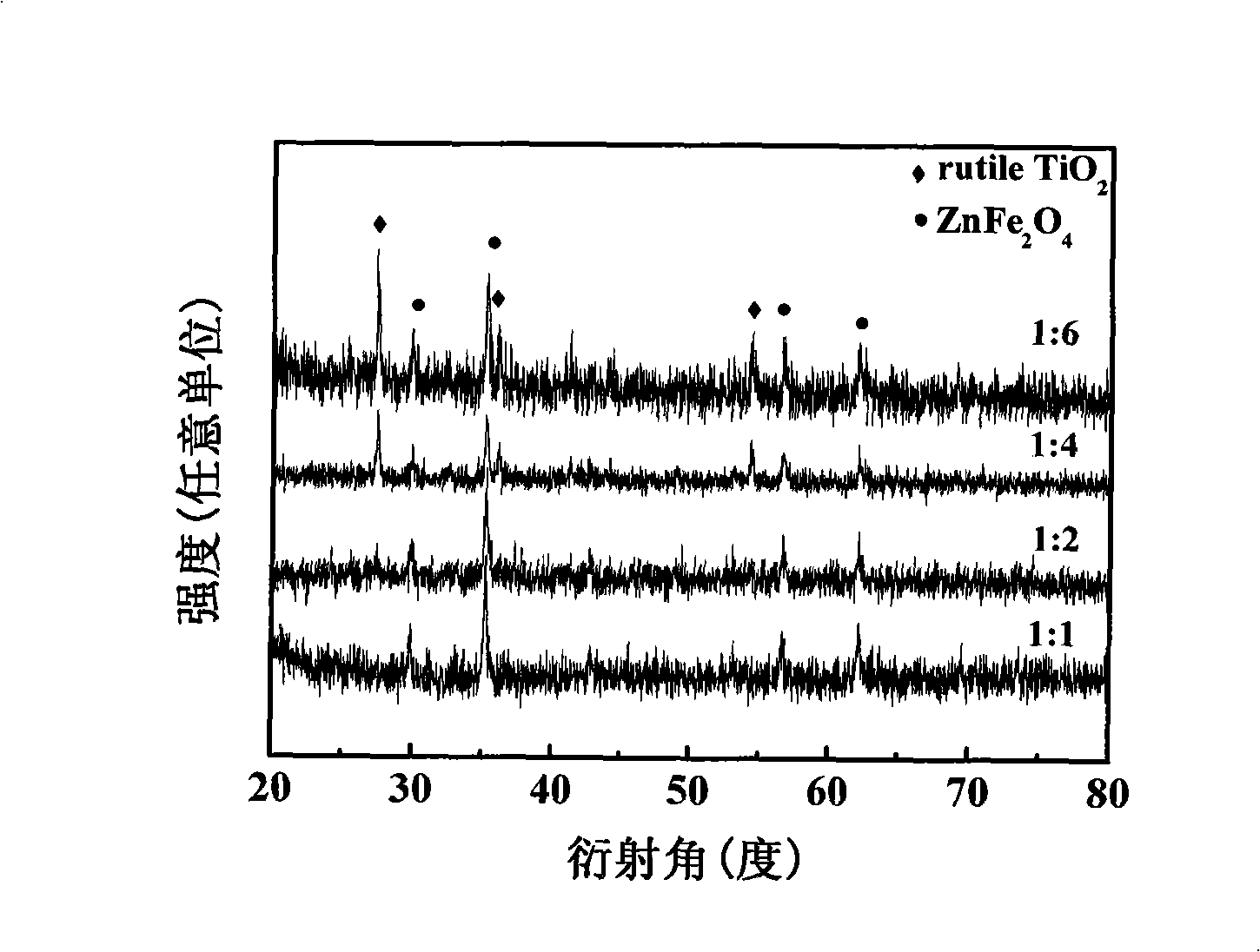

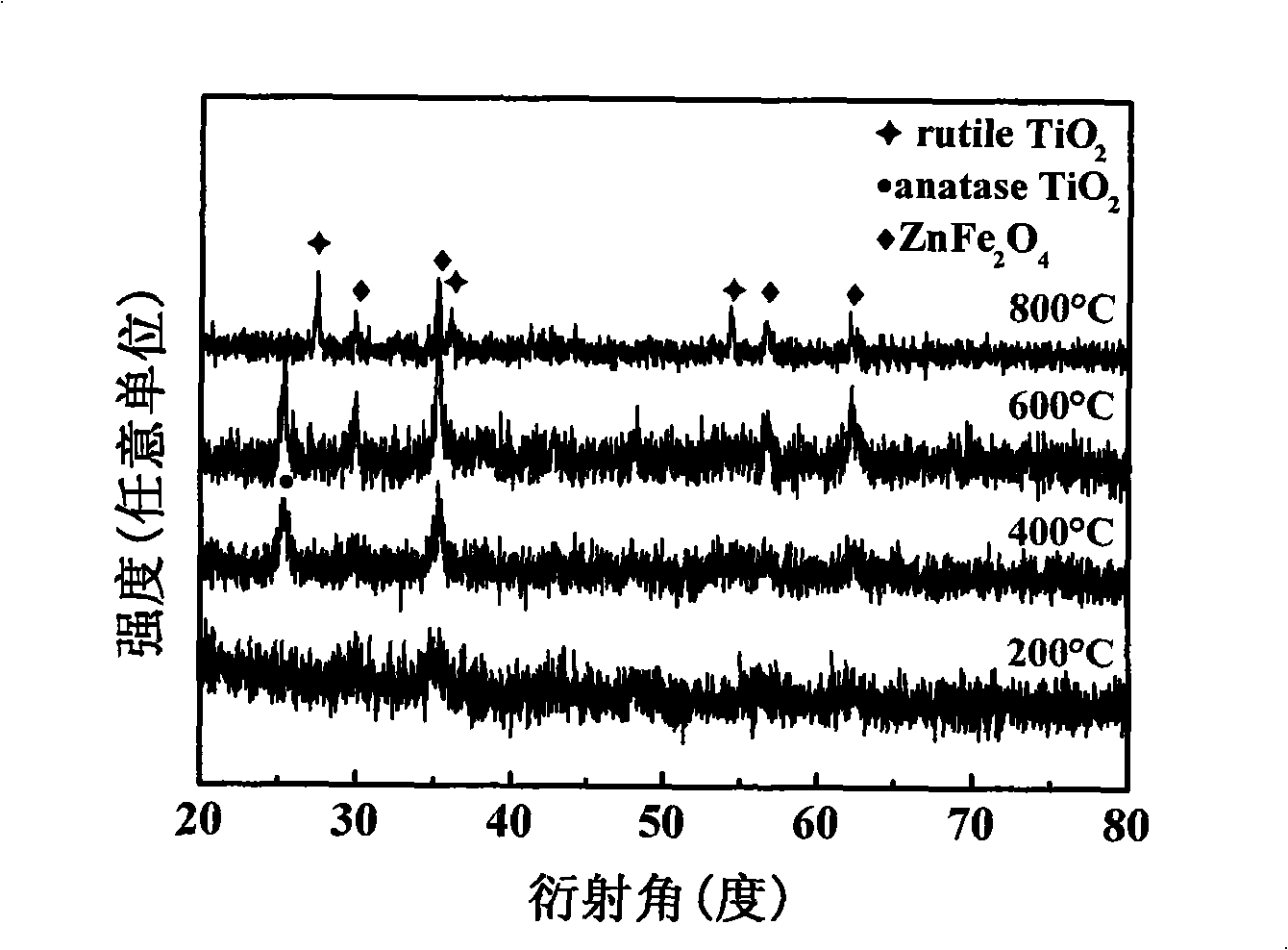

Preparation of TiO2/ZnFe2O4 magnetic composite photocatalyst

InactiveCN101264449AEasy to recycleQuality improvementMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationSeparation technology

The invention relates to a preparation method for TiO2 / ZnFe2O4 magnetic complex photocatalysis, belonging to the technical field of nanometer photocatalysis material preparation, which adopts magnetic material ZnFe2O4 as carrier, requiring no organic compounds or middle-tier; the magnetic material ZnFe2O4 is assembled into magnetic photocatalysis of complexs nanometer grain through the method of sol-gel. The preparation method has the advantages of not only ability to preserve perfect suspension property, and high photocatalysis activity, but also ability to conveniently and rapidly recover magnetic photocatalysis utilizing magnetism separation technology, to reach the purpose of repeated recycle and utilization.

Owner:BEIJING UNIV OF TECH

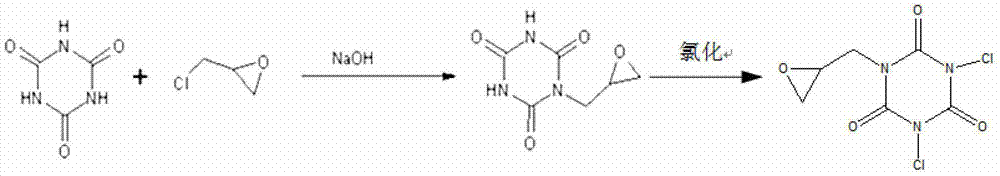

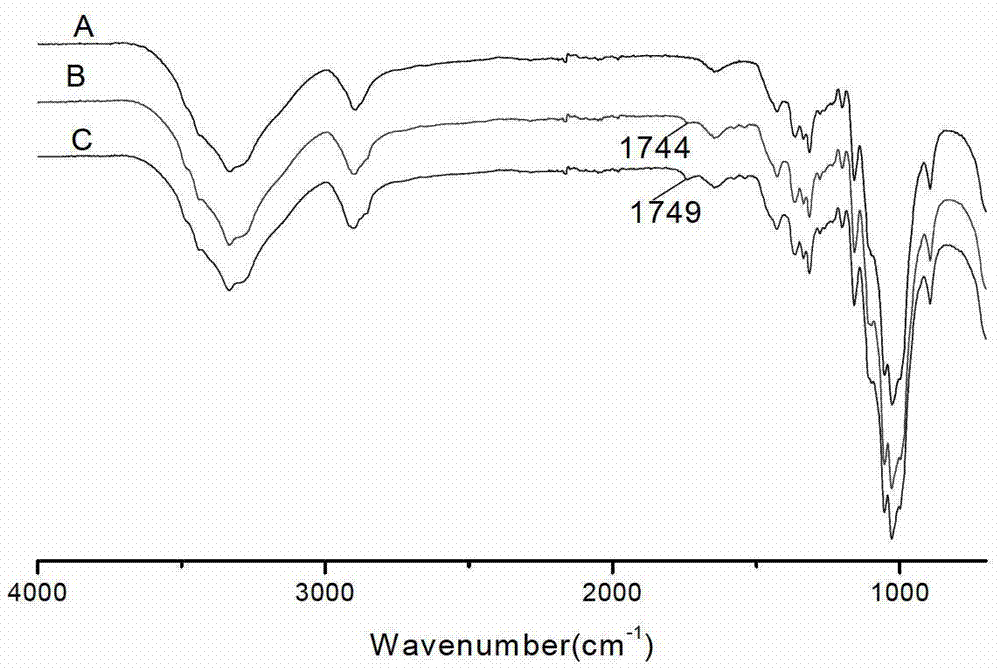

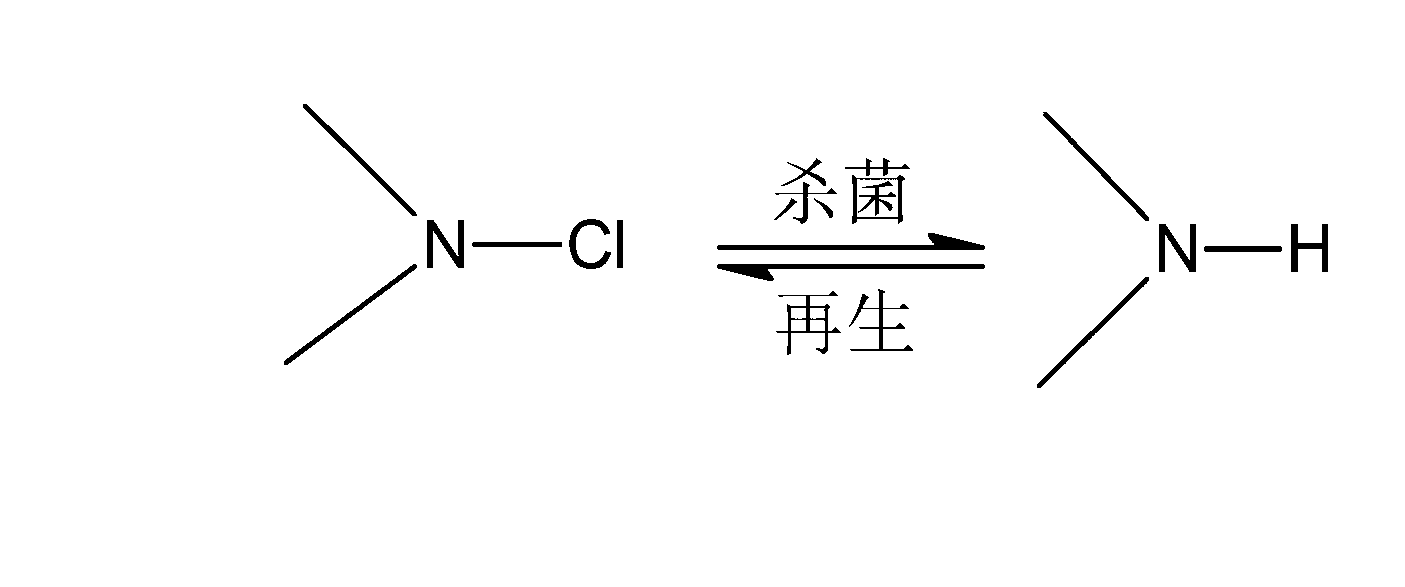

Halamine antibacterial agent and synthetic method and application thereof

InactiveCN102875536AReduce manufacturing costMild reaction conditionsBiocideOrganic chemistryCyanuric acidWater soluble

The invention provides a halamine antibacterial agent and a synthetic method and application thereof. The halamine antibacterial agent is a compound with a structure which is shown as a formula (I) or a formula (II). The synthetic method comprises the following steps of: reacting by taking epoxy chloropropane and cyanuric acid or a derivative of the cyanuric acid as synthetic raw materials at the temperature of between 5 and 50 DEG C for 6 to 12 hours, filtering, removing impurities to obtain a halamine antibacterial agent precursor with a structure which is shown as a formula (III) or a formula (IV), and performing halogenating reaction to obtain a finished product of the halamine antibacterial agent. According to the application of the halamine antibacterial agent to the preparation of an antibacterial material, the antibacterial material is prepared by the following steps of: treating a material to be treated by a working solution prepared from the halamine antibacterial agent precursor, taking the material out, drying, treating at the temperature of between 80 and 200 DEG C for 3 to 60 minutes, and performing halogenating reaction. According to the method, reaction condition is mild, a process is simple, and raw materials are low in cost and readily available; and the halamine antibacterial agent synthesized by the method and the halamine antibacterial agent precursor are water-soluble, high in yield, safe and non-toxic, and can be prepared into antibacterial textiles with high antibacterial performance.

Owner:JIANGNAN UNIV

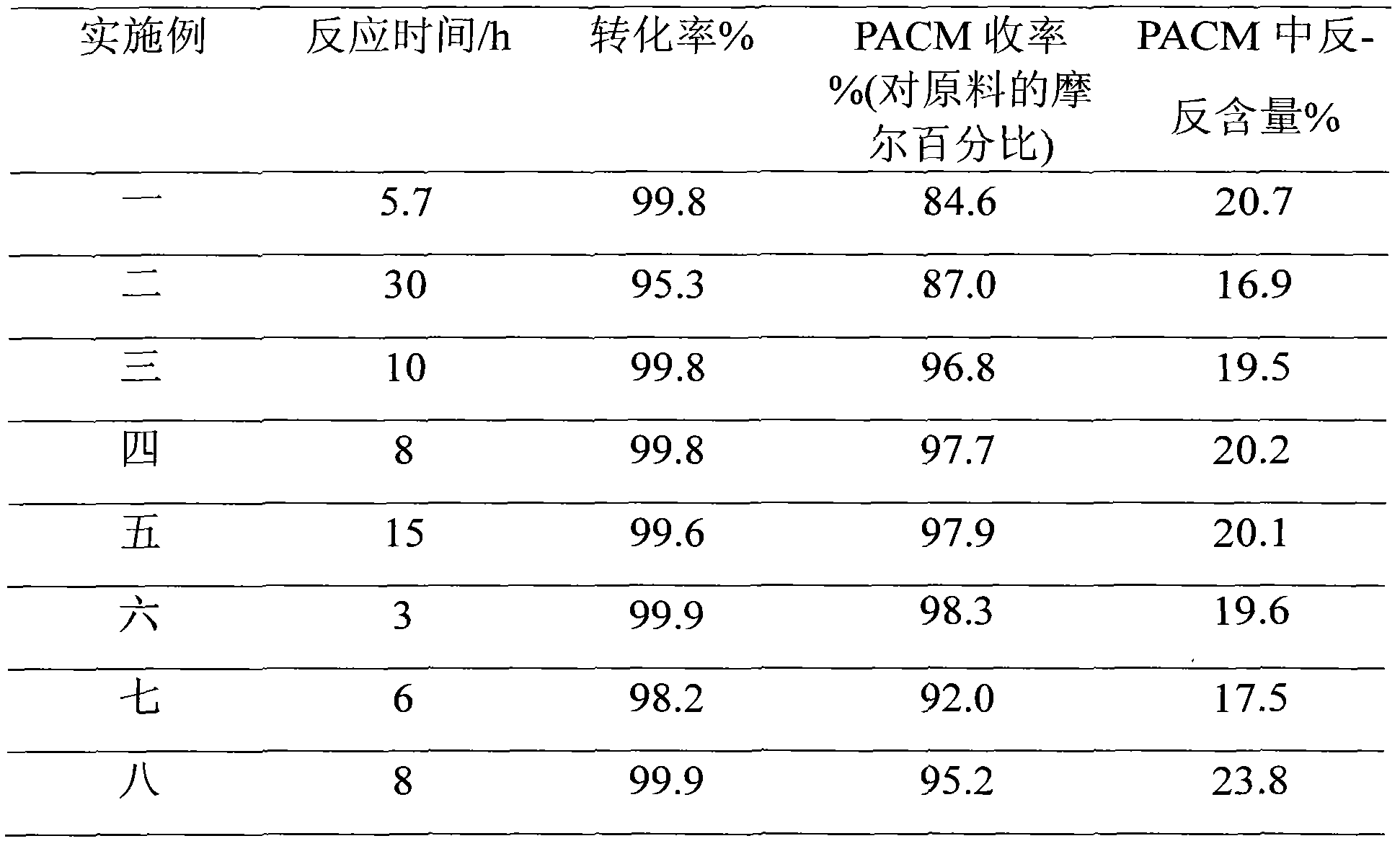

Hydrogenation catalyst and preparation method of 4,4'-diamino-dicyclohexyl methane

InactiveCN101966456ALow costEasy to prepareOrganic compound preparationAmino compound preparationDiphenylmethaneActive component

The invention discloses a hydrogenation catalyst and a preparation method of 4,4'-diamino-dicyclohexyl methane. The hydrogenation catalyst comprises a carrier used as mesoporous carbon and an active component used as ruthenium, wherein the load capacity of the active component is 0.5-10 percent by mass of the hydrogenation catalyst. in the preparation method of low transisomer 4,4'-diamino-dicyclohexyl methane, the catalyst of the invention is adopted to selectively hydrogenate and generate a target product under the conditions of solvents and hydrogenation. In the invention, the catalyst and the method reduce the generation of byproducts while the higher conversion ratio of the 4,4'-diamino-diphenylmethane is remained, and decrease the content of the transisomer of the 4,4'-diamino-dicyclohexyl methane. Meanwhile, the catalyst is low in cost and simple and convenient in preparation and is suitable for industrial application.

Owner:CHANGZHOU UNIV +1

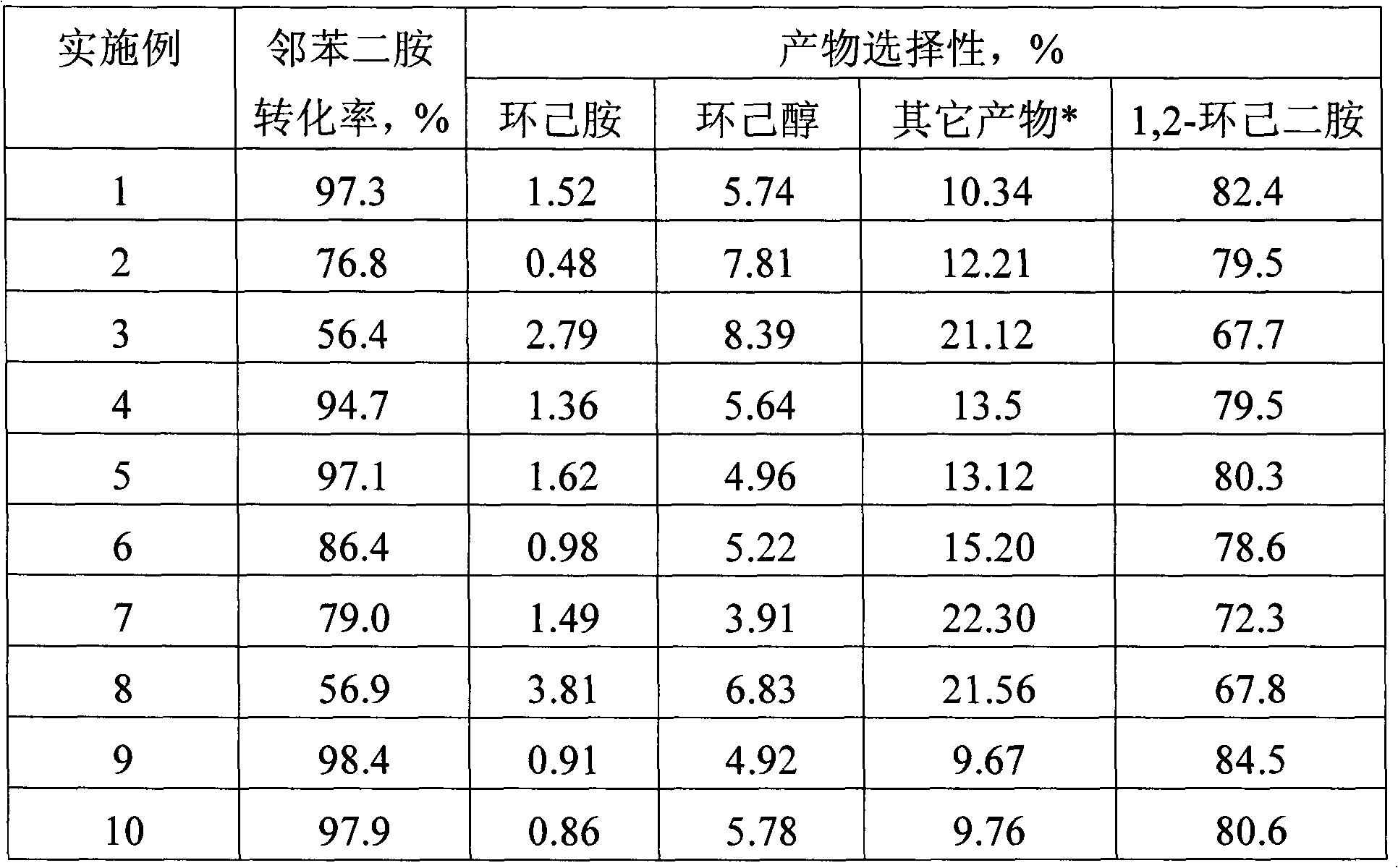

Catalyst for preparing cyclohexanediamine by phenylenediamine hydrogenation under ammonia reaction conditions

InactiveCN102688757ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationSlurryHigh activity

The invention discloses a catalyst for preparing cyclohexanediamine by phenylenediamine hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of phenylenediamine and hydrogen into cyclohexanediamine under ammonia reaction conditions and comprises a main active component, one or more auxiliary agents and a carrier. The main active component is a precious metal Ru or Pd. The one or more auxiliary agents are selected from Re, Co, Ni, Fe and their oxides. The carrier is active carbon, Al2O3 or SiO2. In a slurry-bed reactor, at a certain temperature, under the action of ammonia and catalyst, the high activity and high selectivity transformation of phenylenediamine and hydrogen into a plurality of amine products comprising cyclohexanediamine as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

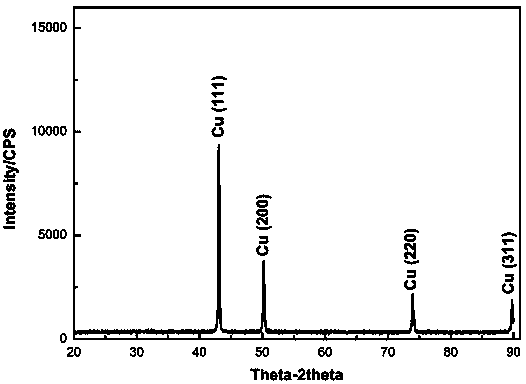

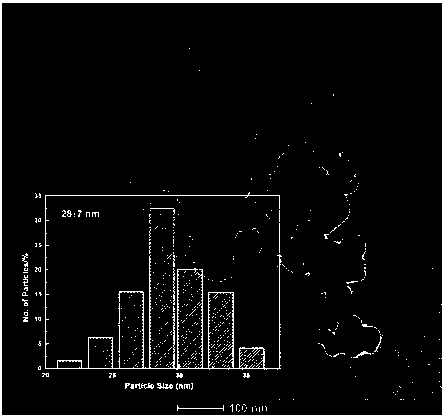

Method for utilizing low co-fusion type ionic liquid electro-deposition to manufacture nanometer copper powder

The invention relates to a method for utilizing low co-fusion type ionic liquid electro-deposition to manufacture nanometer copper powder and is mainly applied to the field of material preparation. The method comprises the steps of mixing choline chloride and urea after performing vacuum drying on choline chloride and urea, performing reaction to obtain low co-fusion type ionic liquid, adding a copper precursor to perform uniform mixing, and obtaining an ionic liquid-copper salt compound electrolyte; finally under the inert atmosphere, enabling stainless steel, a nickel sheet or a titanium sheet to serve as a negative pole, enabling graphite or an inertial positive pole to serve as a positive pole, performing electro-deposition in the ionic liquid-copper salt compound electrolyte, and obtaining the nanometer copper powder with the grain size of 30-50nm on the surface of the negative pole. The method has the advantages that the method is low in cost and reaction energy consumption, short in production flow, free of pollution and simple in process, product quality is stable, and added values are high.

Owner:KUNMING UNIV OF SCI & TECH

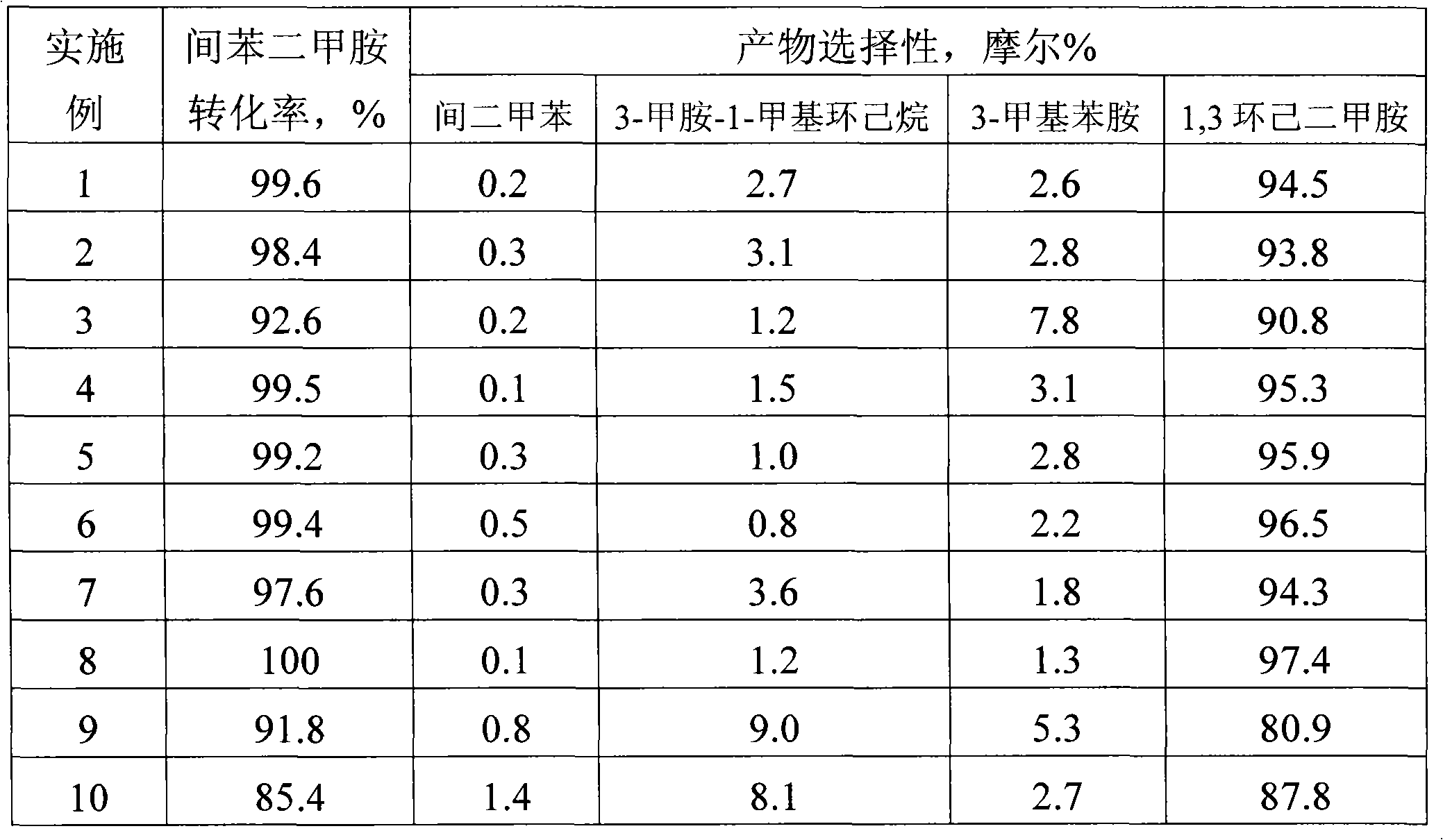

Catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions

InactiveCN102688766ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationFixed bedM-xylylenediamine

The invention discloses a catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of m-xylylenediamine and hydrogen into 1,3-cyclohexanebis(methylamine) under ammonia reaction conditions and comprises one or more main active components, one or more auxiliary agents and a carrier. The one or more main active components is / are precious metal Ru or / and Pd. The one or more auxiliary agents are selected from Ni, Cr, Co, Fe and their oxides. The carrier is Al2O3, active carbon or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of m-xylylenediamine and hydrogen into a plurality of amine products comprising 1,3-cyclohexanebis(methylamine) as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

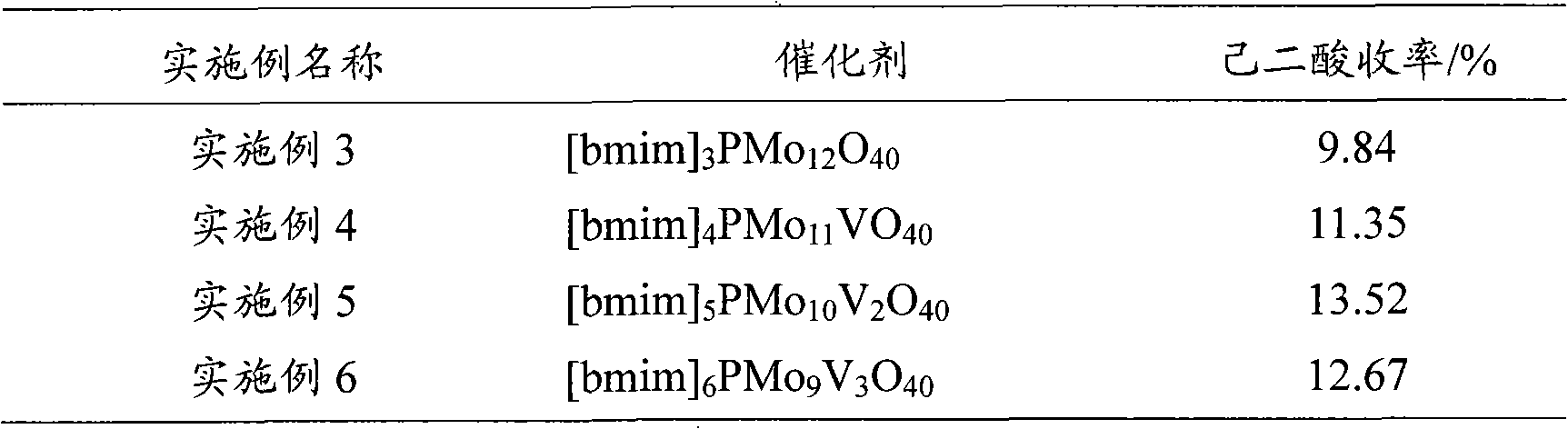

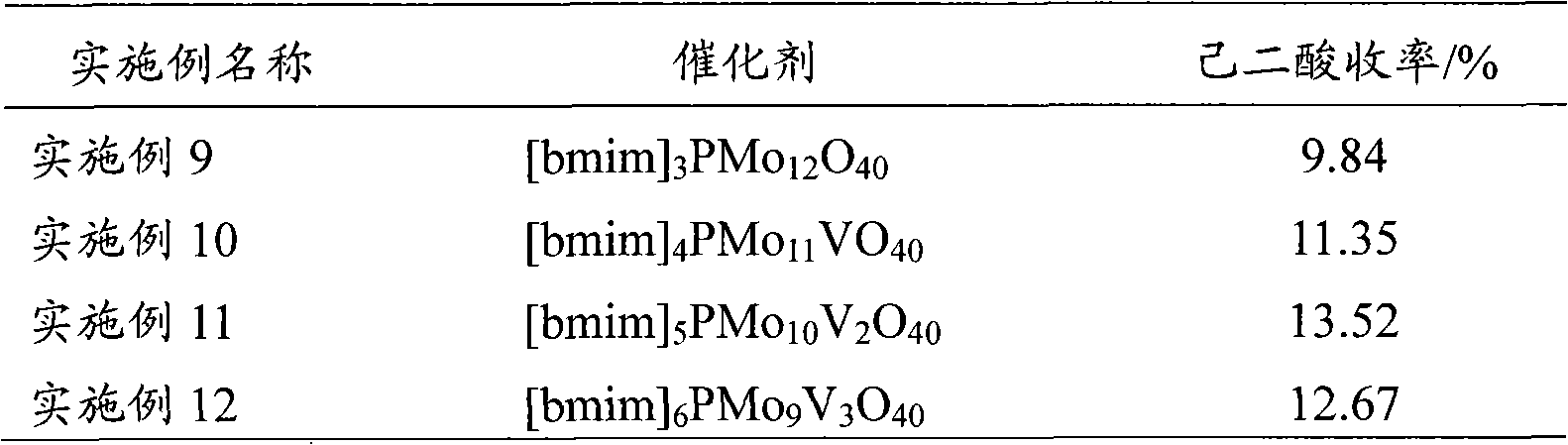

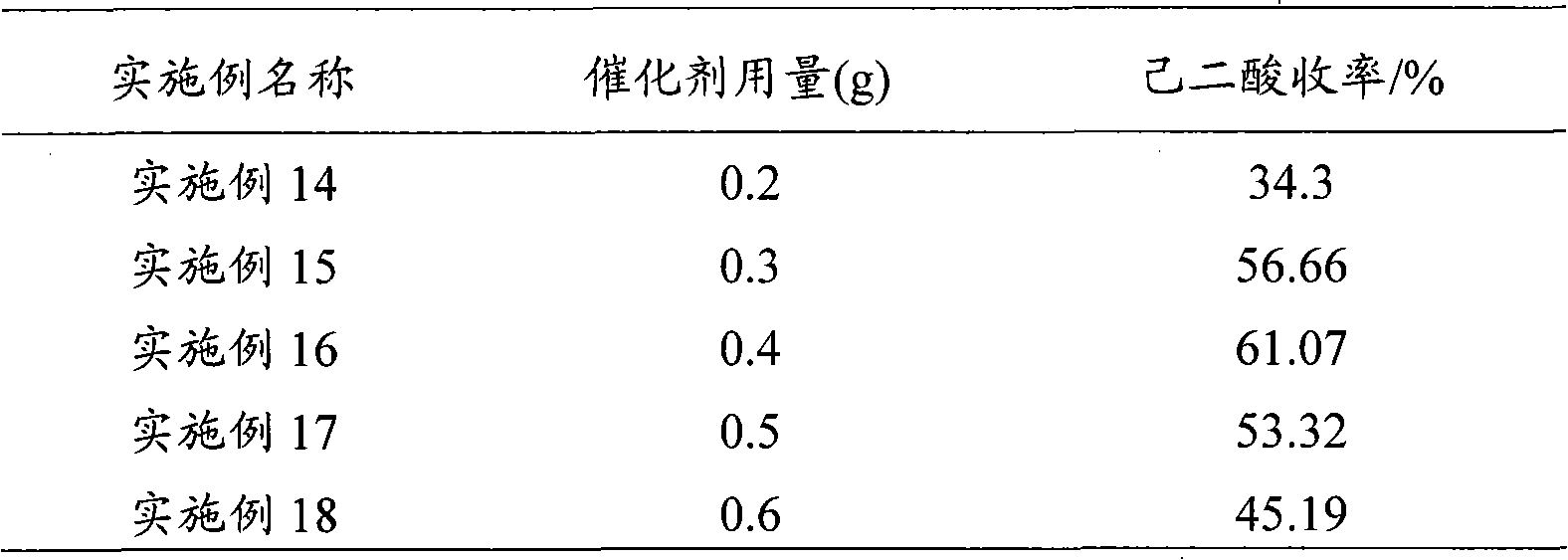

Method for preparing hexane diacid by liquid-phase catalytic oxidation of cyclohexanol

InactiveCN101302147AAvoid it happening againReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidHeteropoly acid

The invention provides a method for preparing adipic acid through liquid-phase catalytic oxidation of cyclohexanol. H2O2 is taken as oxidant, a heteropoly acid imidazole salt is taken as catalyst, the cyclohexanol undergoes the catalytic oxidation to prepare the adipic acid, the catalyst can be phosphotungstic acid 1-butyl-3-methylimidazolium bmim3PW12O40, phosphomolybdic acid 1-butyl-3-methylimidazolium bmim3PMo12O40, and molybdovanadophosphoric heteropolyacid 1-butyl-3-methylimidazolium bmim3+xPMo12-xVxO40 (x is equal to between 1 and 3) and so on, and the bmim represents a 1-butyl-3-methyl-imidazolium cation. Compared with the method of preparing the adipic acid by industrially using nitric acid (nitrate) to oxidize the cyclohexanol, the method can not produce poisonous oxynitride N2O, and avoids the harm to the environment; and in a reaction system, phase shift catalyst and addition agent are not used, which avoids the potential environmental pollution and has apparent economic and social significance.

Owner:ZHEJIANG UNIV OF TECH

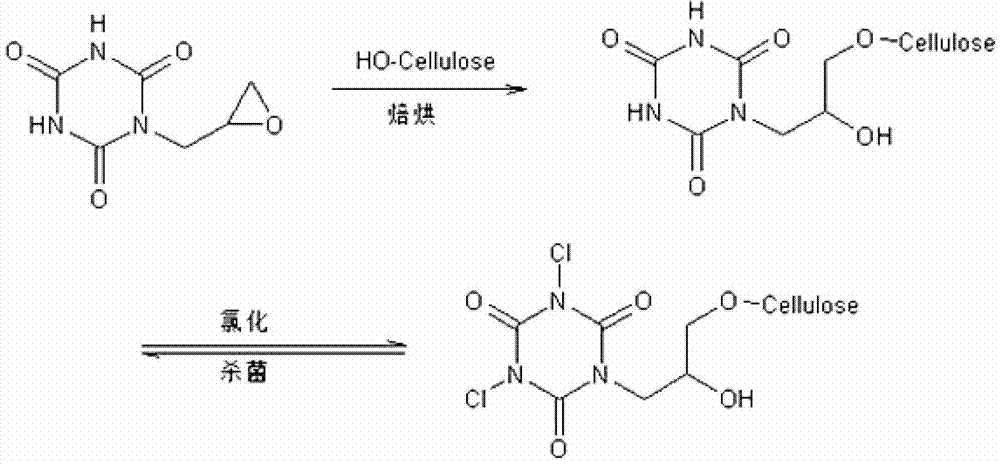

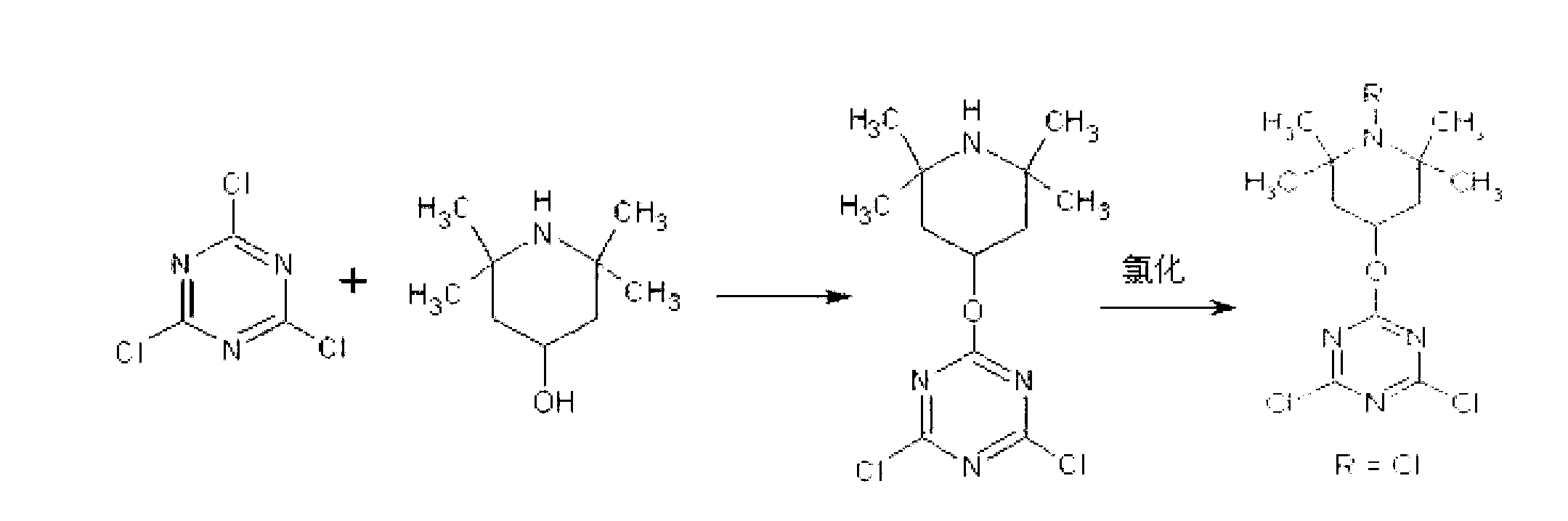

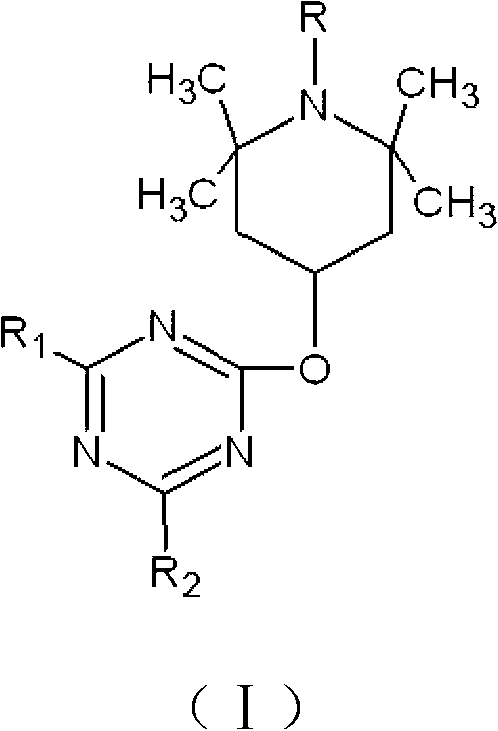

Halamine antibacterial agent, its preparation method and application

ActiveCN102797150ALow priceShort reaction timeOrganic chemistryFibre treatmentReaction temperatureAntibacterial agent

The invention provides a halamine antibacterial agent, its preparation method and application. The halamine antibacterial agent is a compound with a structure shown in formula (I). The preparation method consists of: in the presence of an acid-binding agent, taking cyanuric chloride or cyanuric fluoride or their derivative, and 2, 2, 6, 6-tetramethyl-4-piperidinol as synthesis raw materials to prepare a halamine antibacterial agent precursor with a structure shown in formula (II), and then reacting the precursor with a sodium hypochlorite solution to prepare a halamine antibacterial agent finished product. The halamine antibacterial agent can be applied in textile antibacterial finishing. Specifically, a textile to be treated is dipped in a finishing solution containing the halamine antibacterial agent precursor and a metal salt catalyst for finishing, and finally a halogenation reaction is carried out so as to obtain an antibacterial textile. The method provided in the invention for preparation of the halamine antibacterial agent has the advantages of low cost, simple process, low reaction temperature, no toxicity or pollution, and is in line with the requirements of ecological textile antibacterial finishing. According to the invention, the application process has the characteristics of simple operation and low reaction energy consumption, and antibacterial textiles with good antibacterial properties can be prepared.

Owner:JIANGNAN UNIV

Method for preparing nanometer calcium carbonate

InactiveCN1843927AFulfill control requirementsSuppresses gas-liquid mass transfer problemsCalcium/strontium/barium carbonatesCrystal systemCarbonate

The invention discloses a method for preparing nanometer calcium carbonate, employing reversed phase and microemulsion system for reaction in liquid to prepare cubic crystal nanometer calcium carbonate. It mainly comprises following steps: mixing hydrocarbon solvent, emulsifying agent and alcohols; adding water-soluble calcium salt solution on condition of stirring; then adding emulsifying agent and stirring continuously, getting transparent emulsion; then adding solid powder of water-soluble carbonate and getting nanometer calcium carbonate emulsion; and getting final product after saponification. The invention changes the air-solid reaction between carbon dioxide and calcium hydroxide to reaction in liquid, which avoids mass transfer for air and liquid in current process; the calcium ion and carbonate positive ion are only used as carriers and do not consume chemical substance, which can reduce production cost; and the reverse microemulsion is used as reaction medium, which can short process and reduce investment. The cubic crystal nanometer calcium carbonate is characterized by homogenous crystal system and granular size.

Owner:HUNAN UNIV

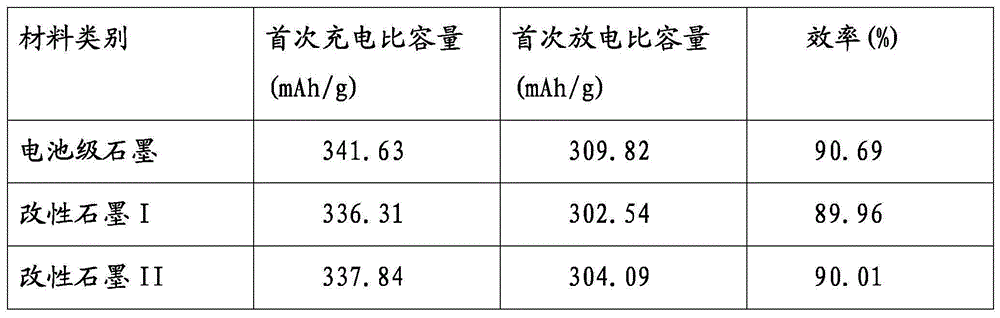

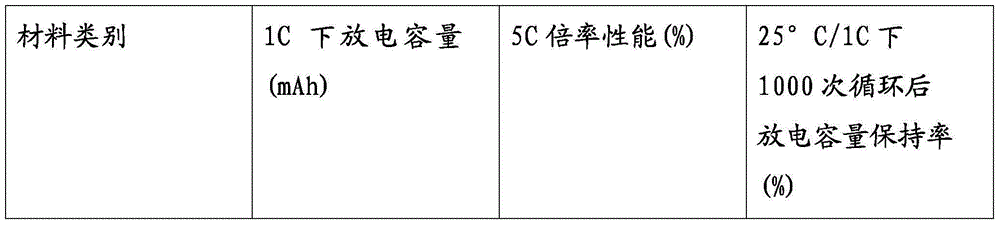

Recycling method for anode graphite material for invalid prismatic lithium-ion battery

ActiveCN105186059AReduce reaction energy consumptionRealize recycling of resourcesWaste accumulators reclaimingBattery recyclingWater bathsFiltration

The invention discloses a recycling method for an anode graphite material for an invalid prismatic lithium-ion battery. The method comprises the following steps: completely discharging the invalid prismatic lithium-ion battery, dismantling a negative pole piece and putting the negative pole piece into a dilute hydrochloric acid solution for ultrasonic dissolution; stopping ultrasound after completely separating graphite flakes from a current collector, taking out the separated current collector, and finishing recovery of the current collector after washing and drying; carrying out filtration, low-temperature vacuum drying and sieving on residual graphite slurry to obtain primarily purified graphite material, carrying out ultrasonic treatment on an oxidizing agent solution in a water bath, and carrying out centrifuging, washing, low-temperature vacuum drying and sieving to obtain secondarily purified graphite material; and carrying out ultrasonic reaction in low-temperature nitrogen atmosphere when steeping the graphite material into a reducing solution in the water bath, repairing the graphite material in the nitrogen atmosphere through thermal treatment, and cooling and sieving the graphite material, so as to obtain battery-grade modified graphite powder. The energy consumption of the reaction in the method is relatively low; and recovery is efficient.

Owner:安徽巡鹰新能源集团有限公司

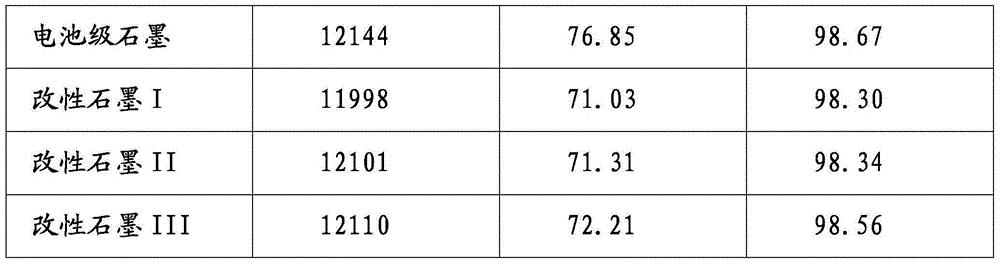

Method for preparing carboxymethyl modified starch

ActiveCN101624424AElimination of crystalline structuresImprove permeabilitySodium chloroacetateMicrowave method

The invention discloses a method for preparing carboxymethyl modified starch, which uses non-crystallization granule state starch as a basis and a microwave method as a core, and combines a part of processes of a drying method and a solvent method. The method comprises the following steps : (1) mixing certain amount of pure water with 95 percent of ethanol; adding the starch at a stirring state, keeping stirring and keeping a reaction container to be obturated, maintaining the temperature of a reaction system, and stirring to react for several minutes; (2) crushing a filter cake at the stirring state, spraying the prepared sodium hydroxide solution to stir at 25 DEG C and react for several minutes, again spraying a sodium chloroacetate ethanol liquid after the reaction is finished, stirring and evenly mixing; (3) evenly spreading a reaction mixture and placing the reaction mixture in a microwave oven to irradiate for several minutes; (4) washing the reaction product after being irradiated by microwave with the ethanol and centrifuging; and (5) drying, pulverizing and screening to prepare the carboxymethyl modified starch. The carboxymethyl starch with high substitution degree prepared through the method has the advantages of high reaction efficiency, short reaction period and low reaction energy consumption.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

Preparation method of high quality magnetic material Mn3O4 ultrafine powder

InactiveCN1830814ASmall particlesSimple production processManganese oxides/hydroxidesCyclohexanoneGranularity

A superfine Mn3O4 powder as the high-quality magnetic material with large specific surface area, controlled granularity and high magnetic and catalytic performance is prepared through dissolving the potassium permanganate in the aqueous solution of sodium hydroxide, adding cyclohexanone, stirring, hydrothermal reaction, natural cooling, pump-filtering, washing with distilled water and drying.

Owner:YANGZHOU UNIV

Preparation method of dopamine modified sepiolite adsorbent

InactiveCN105195085AImprove adsorption capacityAchieve mass productionOther chemical processesSilicon compoundsBüchner funnelSorbent

The invention relates to a preparation method of a dopamine modified sepiolite adsorbent. The method comprises the steps that S1, sepiolite powder is weighed and put in a beaker, a hydrochloric acid solution is added, continuous magnetic stirring is conducted, and the mixture is transferred to a Buchner funnel, repeated washing is conducted through deionized water, suction filtration is conducted, and a gel filter cake is collected; S2, the gel filter cake is transferred into a wide-mouth bottle, the wide-mouth bottle is placed in a drying oven for 12 h, the gel filter cake in the wide-mouth bottle is taken out, and grinding is conducted on the gel filter cake to obtain acid-activated sepiolite; S3, the sepiolite which is activated through acid and dopamine hydrochloride is added in a trihydroxymethyl aminomethane buffer solution, and a magnetic stirring reaction is conducted at the room temperature; S4, the deionized water is used for water washing, centrifugation is conducted for multiple times through a centrifugal machine, drying is conducted in a vacuum drier for 24 h, and the dopamine modified sepiolite adsorbent is obtained. The preparation method of the dopamine modified sepiolite adsorbent has the advantages of being simple in technology, low in cost and high in efficiency.

Owner:BEIJING XINYUAN ENVIRONMENT CO LTD

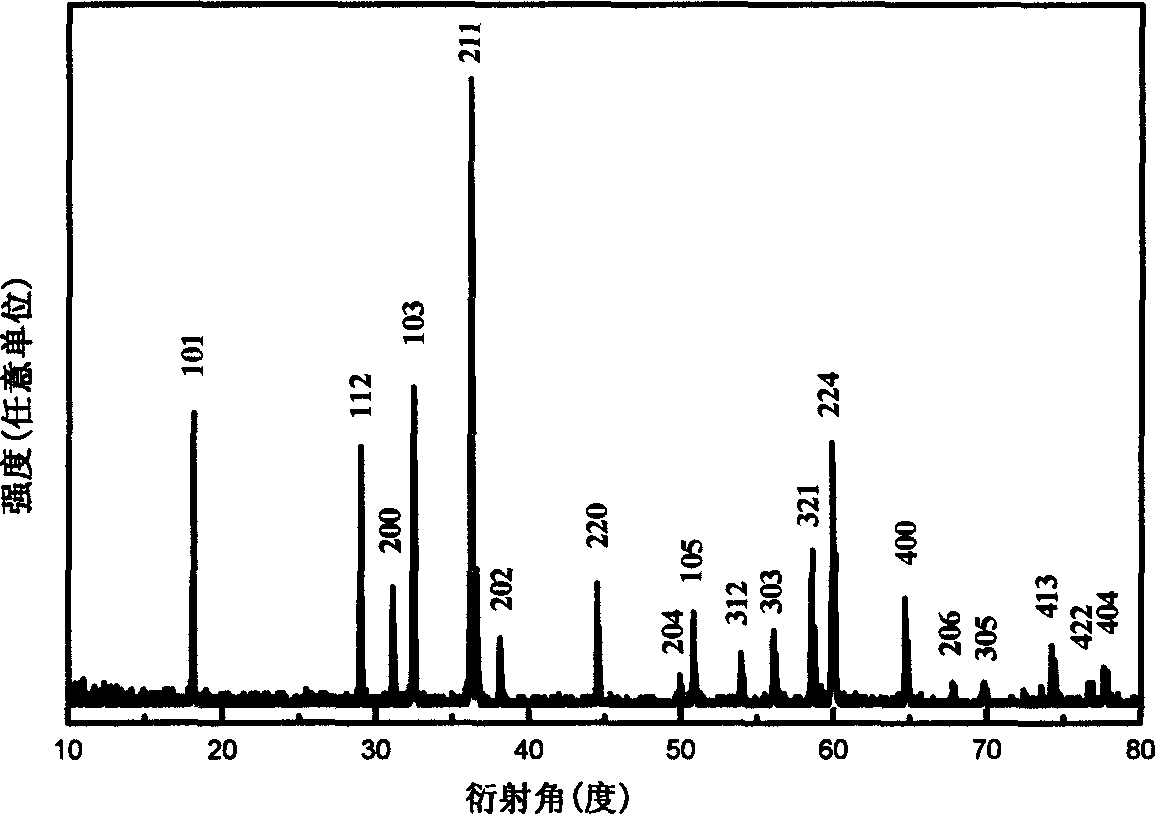

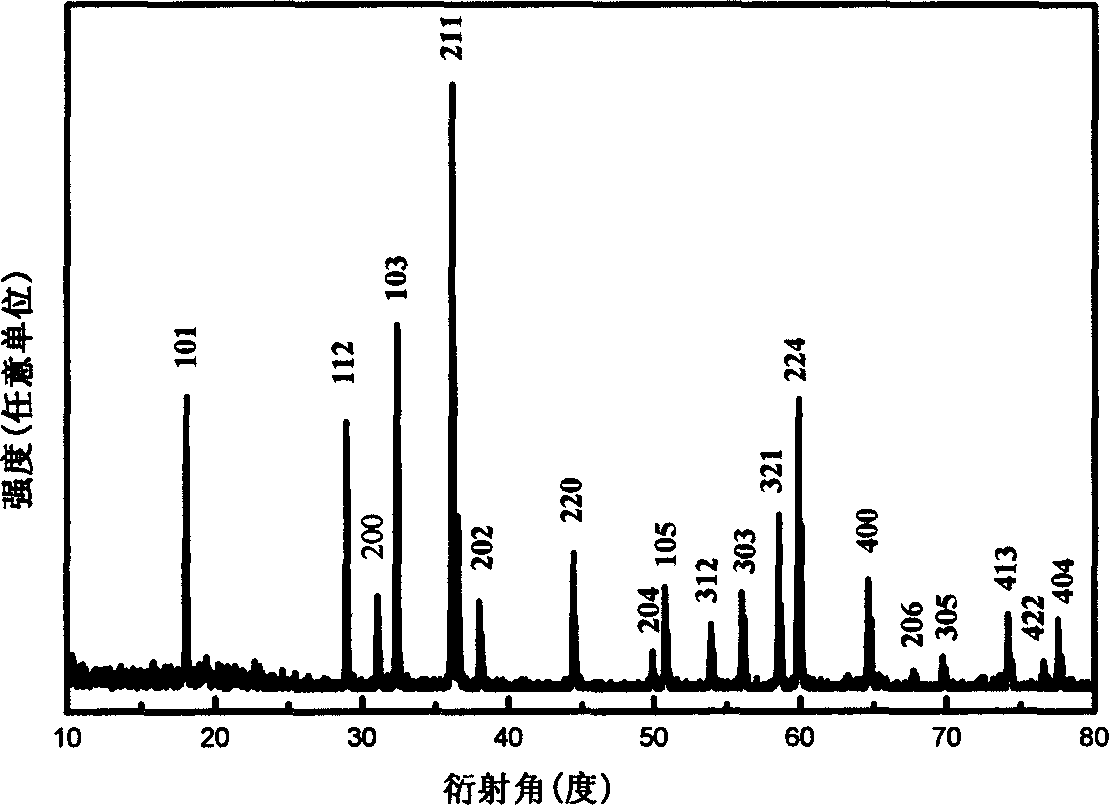

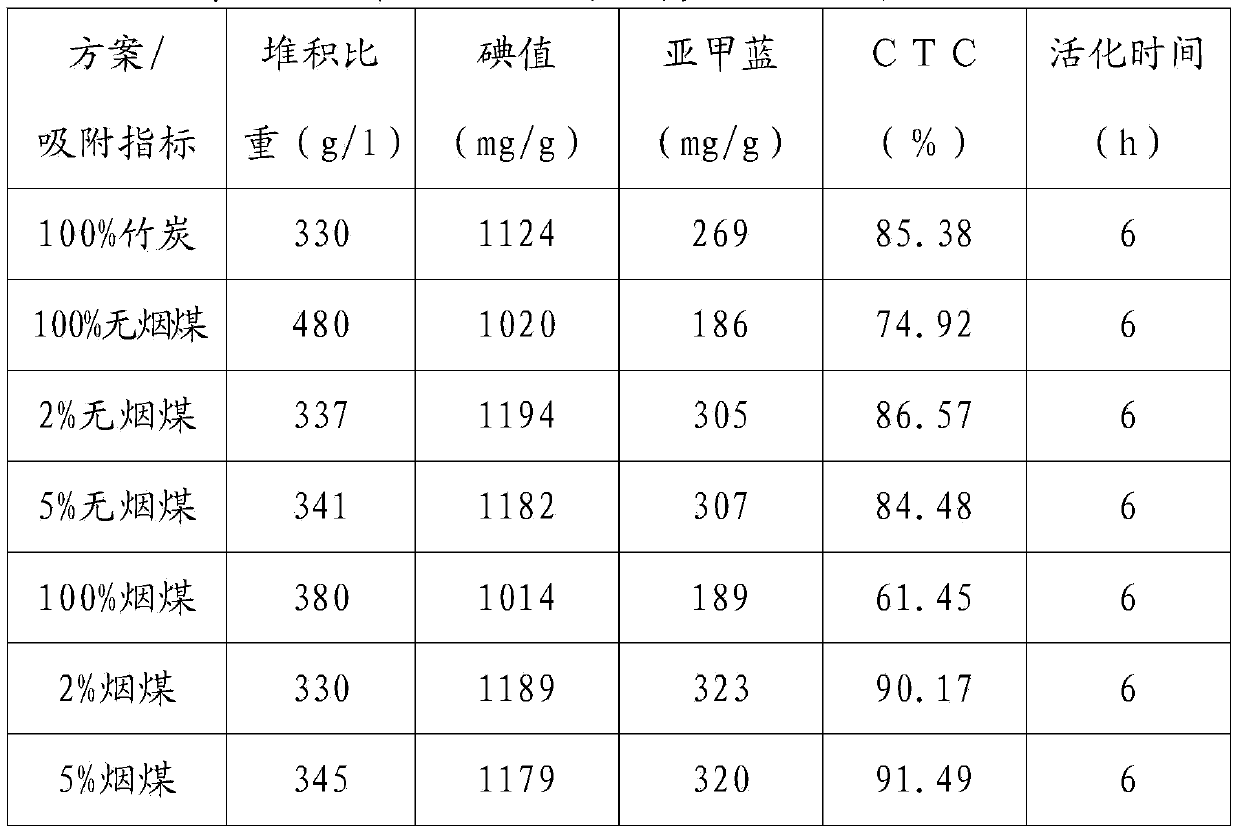

Preparation method of columnar bamboo activated carbon

ActiveCN104211061AMeet size requirementsMaximize fixed carbon contentCarbon compoundsActivated carbonPhysical chemistry

The invention belongs to the field of activated carbon production, and particularly relates to a preparation method of columnar bamboo activated carbon. The preparation method comprises the following steps: a primary anaerobic dry distillation process; drying and grinding; kneading; extruding and molding; conserving and sizing; a secondary anaerobic dry distillation process; and activation. Twice anaerobic dry distillation processes are adopted in the production process, a basic guarantee is provided for molding the columnar bamboo activated carbon by the primary anaerobic dry distillation process of the bamboo material, the strength of a columnar molding product is ensured by controlling the inventory and the kiln rotating speed by the secondary anaerobic dry distillation process, and meanwhile, 0.5-5% of coal particles are doped during activation, so that the gas atmosphere in the activating furnace is improved, the unsaturated basic structure of the columnar bamboo activated carbon is generated, the strength and the adsorption property of the columnar bamboo activated carbon are improved, the preparation process is simple, the product carbon does not need to be cleaned, environmental pollution and corrosion to equipment are reduced, and energy consumption in reaction is reduced.

Owner:NINGXIA HUAHUI ACTIVATED CARBON

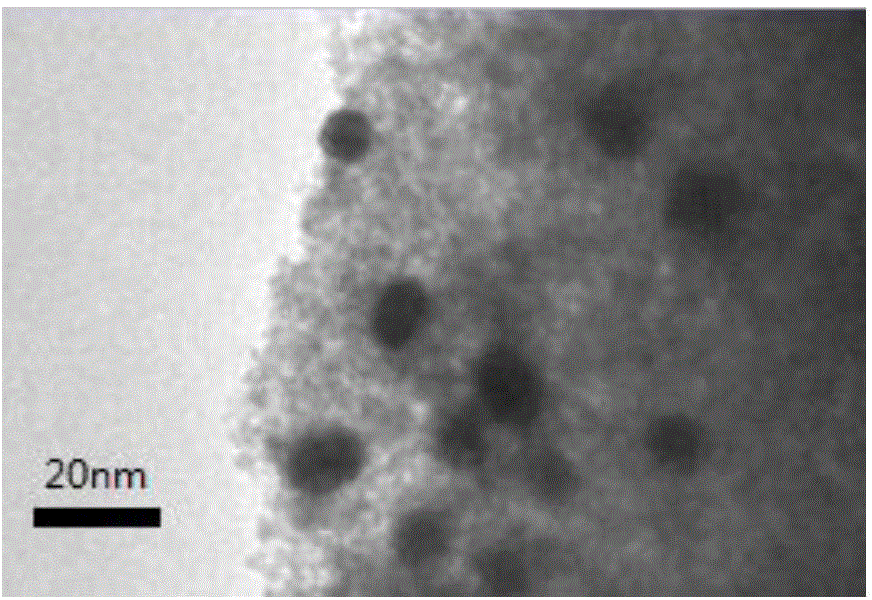

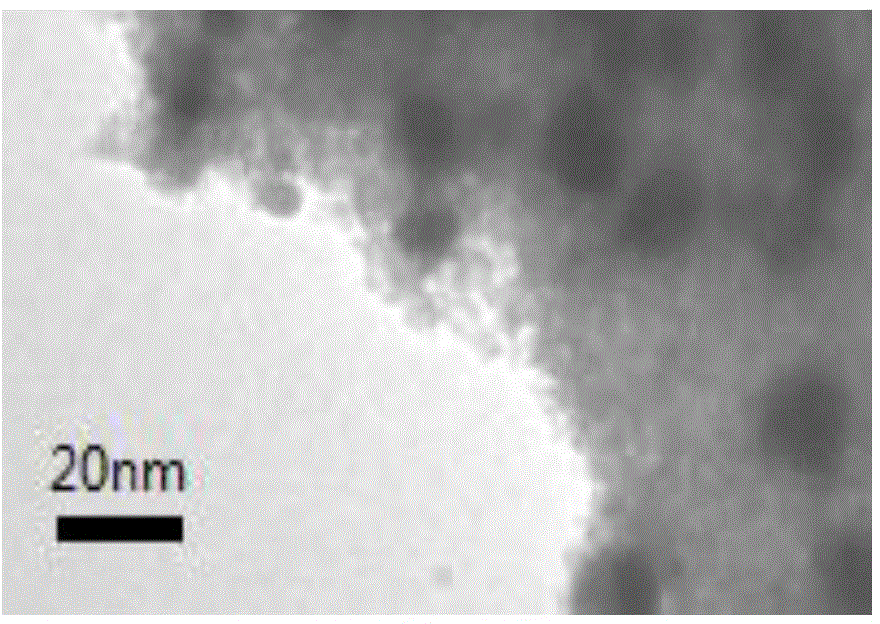

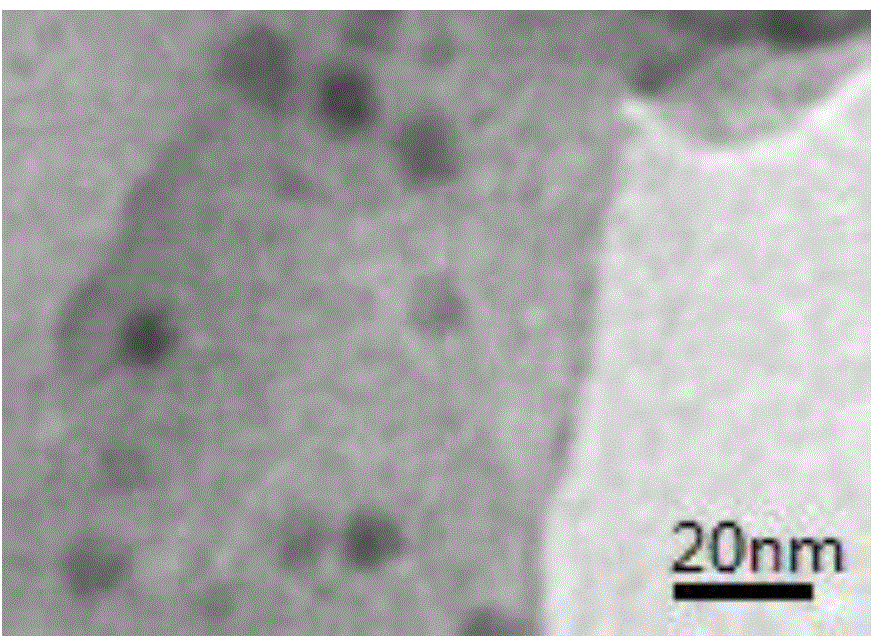

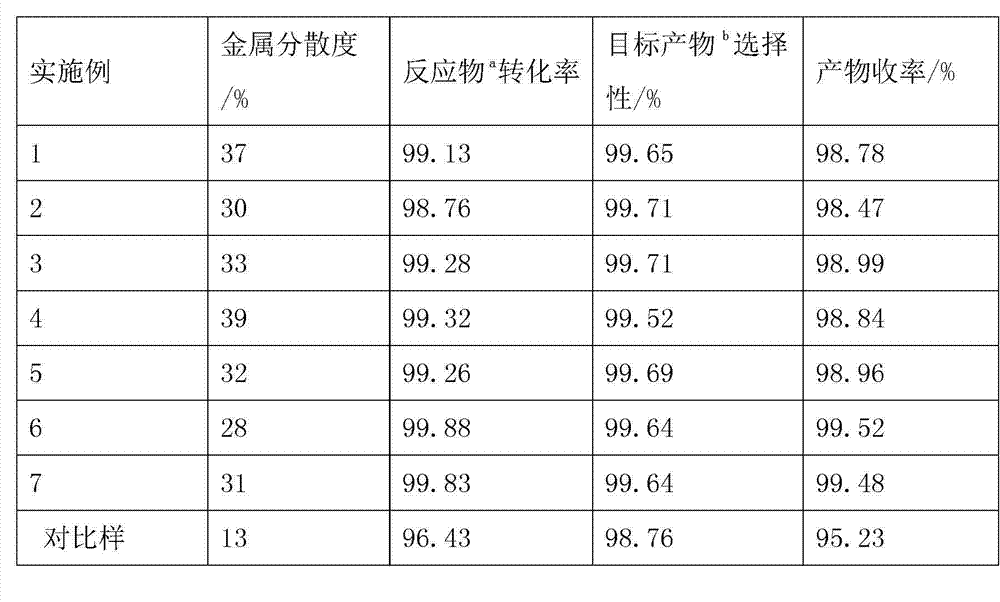

Preparation method of noble metal catalyst

InactiveCN104056621AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsUltrasound - actionDistilled water

The invention relates to a preparation method of a noble metal catalyst. The method comprises the following steps: (1) mixing a carrier, a salt solution of noble metal, and a dispersant, and performing dispersion in the presence of ultrasonic wave to obtain a mixture; (2) adding the mixture in a reductant and performing reduction under microwave radiation to obtain a solid product; and (3) washing the solid product with distilled water, and drying the solid product to obtain the noble metal catalyst. The preparation method is simple and easy to operate; metal is dispersed uniformly on the carrier, the particle size of the metal is small, the reaction time is short and the energy consumption in reaction is low.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

Preparation method of catalyst for producing 1,2-cyclohexane dicarboxylic ester through hydrogenation

InactiveCN102921409AImprove conversion rateHigh selectivityOrganic compound preparationCarboxylic acid esters preparationActive componentSilicon dioxide

The invention discloses a preparation method of catalyst for producing 1,2-cyclohexane dicarboxylic ester through hydrogenation. The preparation method is characterized in that the catalyst comprises Ru and / or Pd as active components; Ru is 0.01-5.0% of the catalyst in percentage by mass, and Pd is 0.01-3% of the catalyst in percentage by mass; and a carrier is a mesoporous oxide which is selected from aluminum oxide, amorphous silica-alumina or silicon dioxide. The preparation method is carried out by the following steps of: a, drying the mesoporous oxide carrier; b, diluting a hydrochloric acid aqueous solution of a calculated quantity of Ru compound and / or a hydrochloric acid aqueous solution of Pd compound with a certain amount of deionized water, and evenly mixing; c, dipping a noble metal solution on the mesoporous carrier through an equivalent-volume dipping method, wherein the impregnation time is 1-10h; d, drying the catalyst for 10h at a temperature of 110 DEG C after the dipping process, raising the temperature to 200-500 DEG C through programs and roasting for 3h; e, washing the catalyst for 1-10 times by using 0.1-5wt% of NaOH aqueous solution; and f, stoving the catalyst for 10h at 120 DEG C after the catalyst is dried.

Owner:CHINA NAT OFFSHORE OIL CORP +1

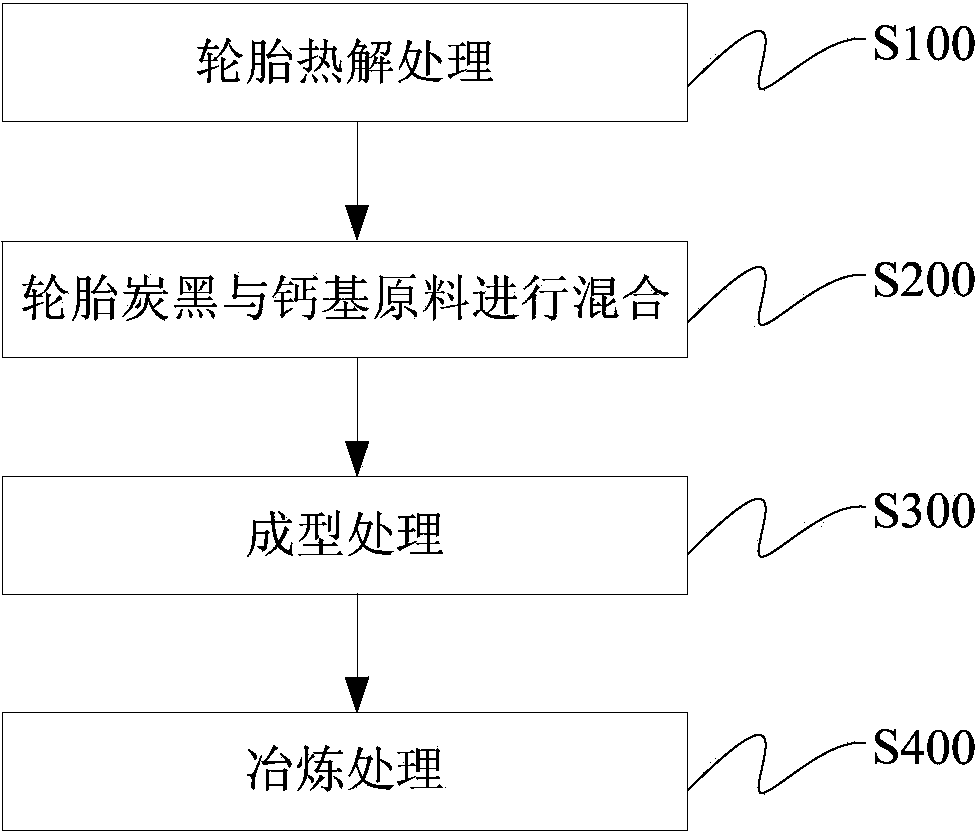

Method for preparing calcium carbide

InactiveCN103708458AReduce manufacturing costLow reaction temperatureCalcium carbideElectric arc furnaceEnergy consumption

The invention discloses a method for preparing calcium carbide, which comprises the following steps: pyrolyzing junked tires to obtain high-temperature oil gas, iron wires and tire carbon black; mixing the tire carbon black with a calcium-base raw material to obtain a mixture; forming the mixture to obtain a massive furnace raw material; and smelting the massive furnace raw material in an arc furnace to obtain the calcium carbide. The technique can obviously lower the temperature and energy consumption, thereby lowering the production cost of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com