Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

410 results about "M-xylylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film with outer layer composed of a polyamide composition

InactiveUS20070104971A1Layered product treatmentSynthetic resin layered productsPolymer sciencePolyamide

A decorative film having an outer layer containing a polyamide composition with the following components: a) from 50 to 100 parts by weight of polyamide prepared from: α) from 70 to 100 mol % of diamine selected from m-xylylenediamine, p-xylylenediamine and mixtures thereof, β) from 0 to 30 mol % of other diamines having from 6 to 14 carbon atoms, and γ) from 70 to 100 mol % of aliphatic dicarboxylic acids having from 10 to 18 carbon atoms and δ) from 0 to 30 mol % of other dicarboxylic acids having from 6 to 9 carbon atoms, and b) from 0 to 50 parts by weight of another polyamide, where a) and b) total 100, having good chemicals resistance, good stress cracking resistance, improved scratch resistance, and improved gloss.

Owner:EVONIK DEGUSSA GMBH

Method for producing container

ActiveUS20120146266A1High crystallinityMaintain good propertiesLaminationLamination apparatusPolyamideCarboxylic acid

Provided is a production method for a container, including the steps of: inflating a material in a mold by direct blowing, the material including a polyamide resin composition containing 0.01 to 2 parts by mass of a crystallization promoter and 100 parts by mass of a polyamide resin obtained by polycondensation of a diamine component containing 70 mol % or more of m-xylylenediamine and a dicarboxylic acid component including an α,ω-linear aliphatic dicarboxylic acid having 4 to 12 carbon atoms and an aromatic dicarboxylic acid at a molar ratio of 97:3 to 90:10; and retaining the material in the mold whose temperature is controlled to 0 to 60° C., for a time beginning immediately after the direct blowing and lasting for 30% or more of a semi-crystallization time at cooling of the polyamide resin composition under a constant temperature of 160° C.

Owner:MITSUBISHI GAS CHEM CO INC

Preparation method of methylene diphenyl diisocyanate

ActiveCN106748887AImprove conversion rateInhibition of byproductsIsocyanic acid derivatives preparationOrganic compound preparationReaction rateOrganic phosphorus

The invention provides a preparation method of methylene diphenyl diisocyanate. The method comprises the following steps: performing a salt forming reaction on m-xylylenediamine and hydrogen chloride gas to obtain m-xylylenediamine hydrochloride; mixing the m-xylylenediamine hydrochloride, an organic phosphorus compound and solid phosgene for reaction to obtain methylene diphenyl diisocyanate. In a process of preparing methylene diphenyl diisocyanate, according to the application, an organic phosphorus compound additive is introduced, so that the reaction of m-xylylenediamine hydrochloride is promoted, therefore, the reaction rate and the effective conversion rate are improved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

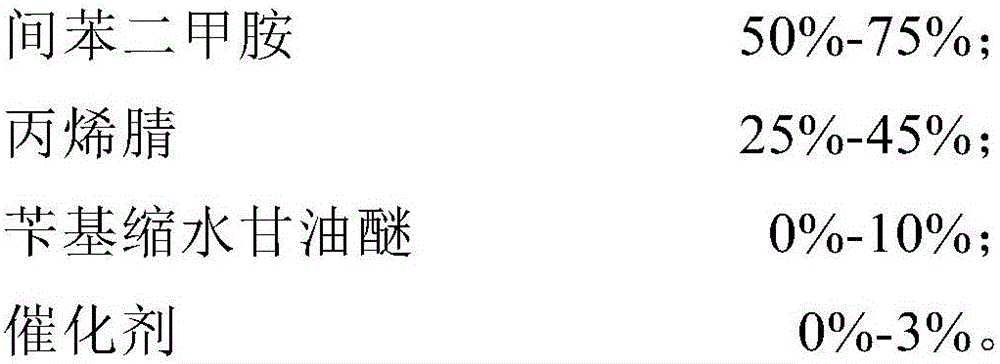

Amine epoxy resin curing agent, gas barrier epoxy resin composition comprising the curing agent, coating agent, and adhesive agent for laminate

ActiveUS20100160494A1Excellent gas barrier performanceOvercome short pot lifeSynthetic resin layered productsDomestic containersCarbamateAdhesive

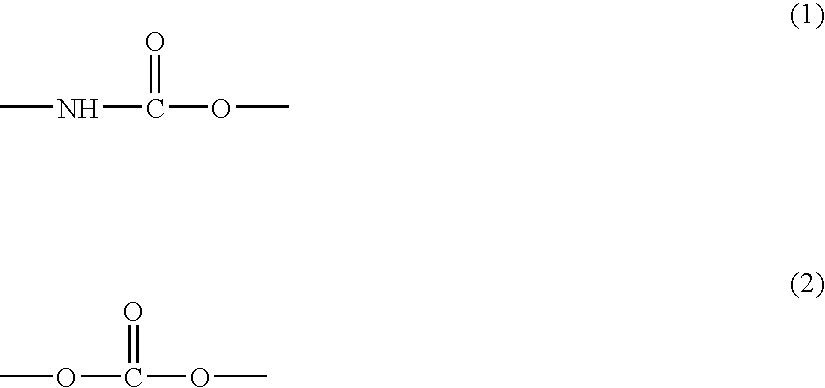

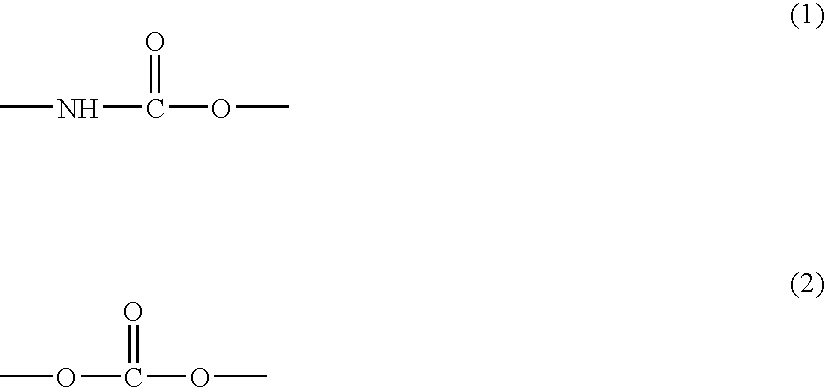

The present invention provides an amine based epoxy resin curing agent containing an epoxy resin and an amine compound capable of imparting a high gas barrier performance and a long pot life, in addition to excellent performances which an epoxy resin conventionally possesses, and an epoxy resin composition with a high gas barrier performance and a long pot life, which contains the subject curing agent. Also, the present invention provides an adhesive for laminate with excellent adhesiveness to various polymers, papers, metals, etc., which contains, as a main component, an epoxy resin composition containing an amine based resin curing agent with a high gas barrier performance and a long pot life.The amine based epoxy resin curing agent of the present invention is composed of a reaction product of the following (A), (B) and (D) or a reaction product of the following (A), (B), (C) and (D):(A) m-xylylenediamine or p-xylylenediamine,(B) a polyfunctional compound having at least one acyl group, which is capable of forming an amide group site through a reaction with a polyamine and forming an oligomer,(C) a monovalent carboxylic acid having from 1 to 8 carbon atoms and / or its derivative, and(D) a functional compound having at least one carbonate site represented by the formula (2), which is capable of forming a carbamate site represented by the formula (1) through a reaction with a polyamine:

Owner:MITSUBISHI GAS CHEM CO INC

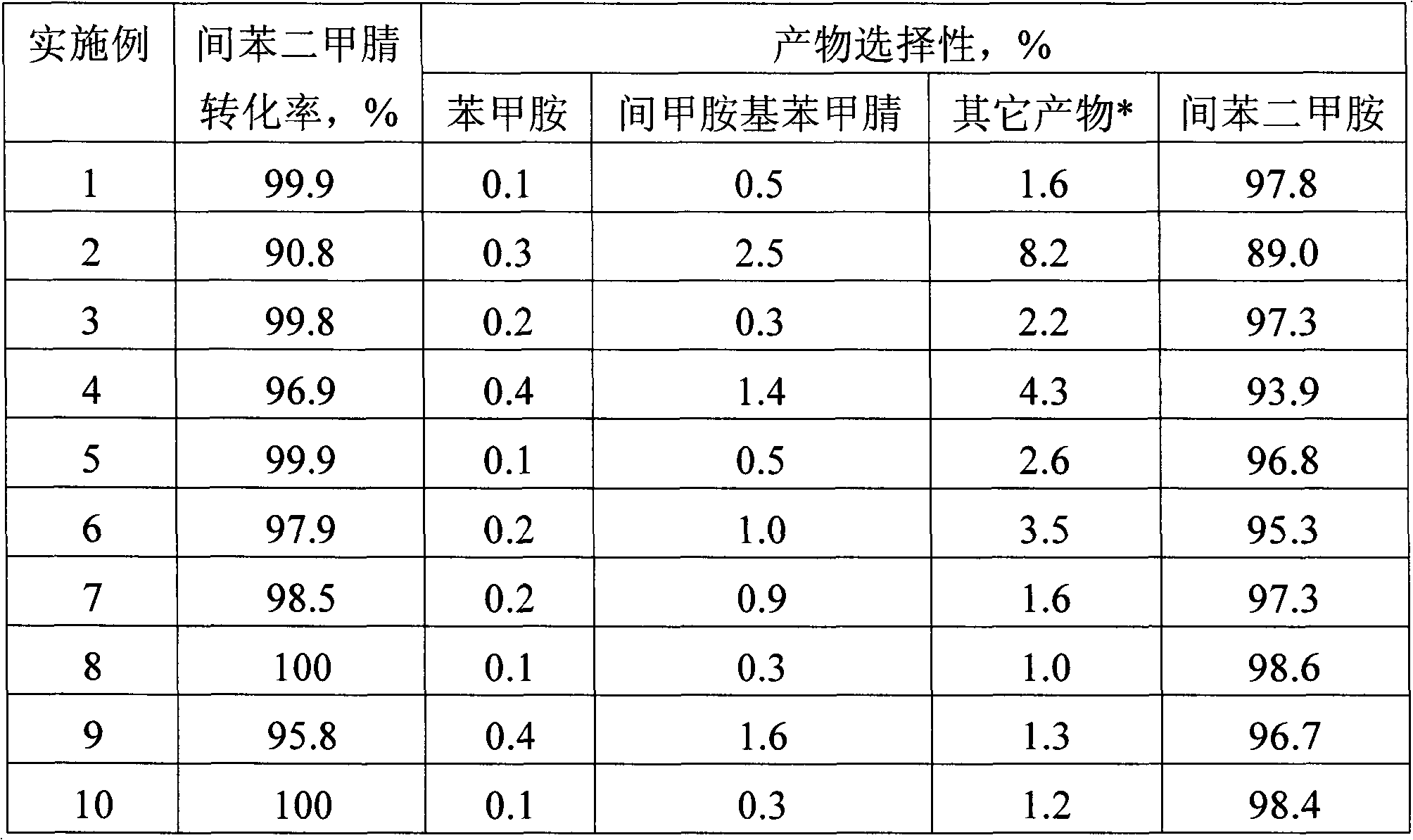

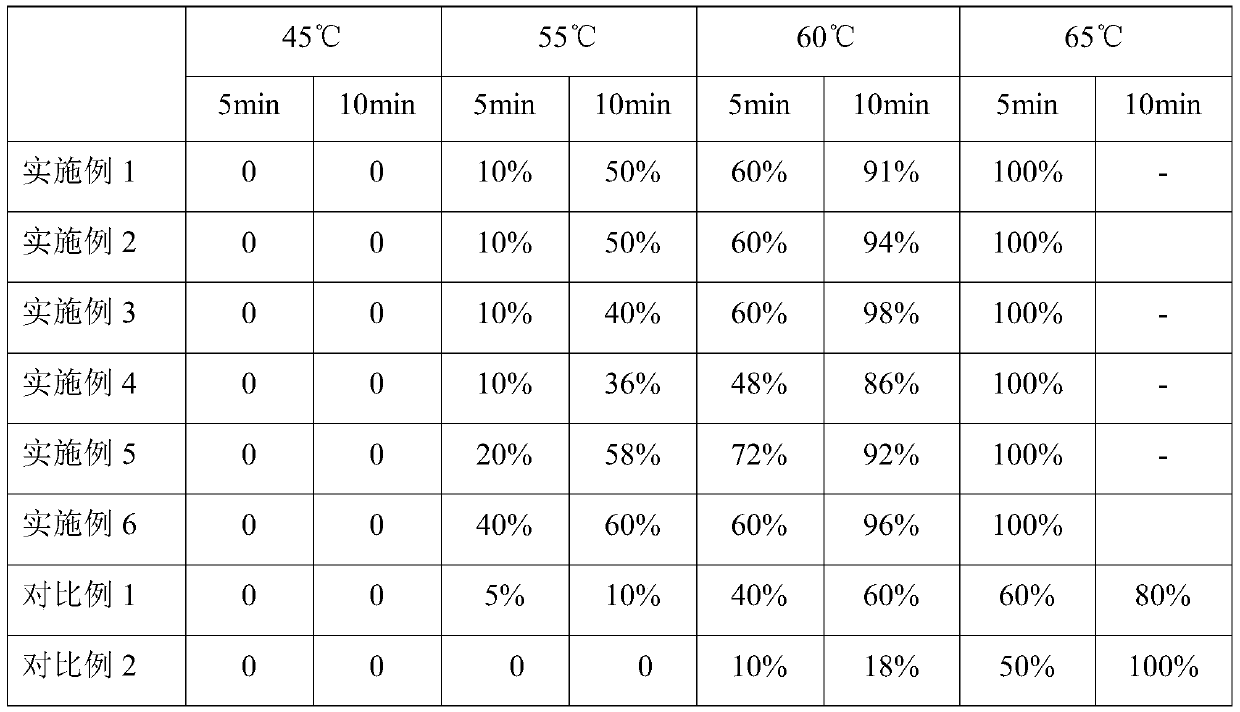

Catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions

ActiveCN102688763ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationAmino compound preparationFixed bedHigh activity

The invention discloses a catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of isophthalonitrile and hydrogen into m-xylylenediamine under ammonia reaction conditions and comprises a main active component, one or more auxiliary agents and a carrier. The main active component is a transition metal Ni or Co. The one or more auxiliary agents are selected from Re, Cu, Cr, Ru, Fe and their oxides. The carrier is diatomite, Al2O3 or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of isophthalonitrile and hydrogen into a plurality of amine products comprising m-xylylenediamine as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

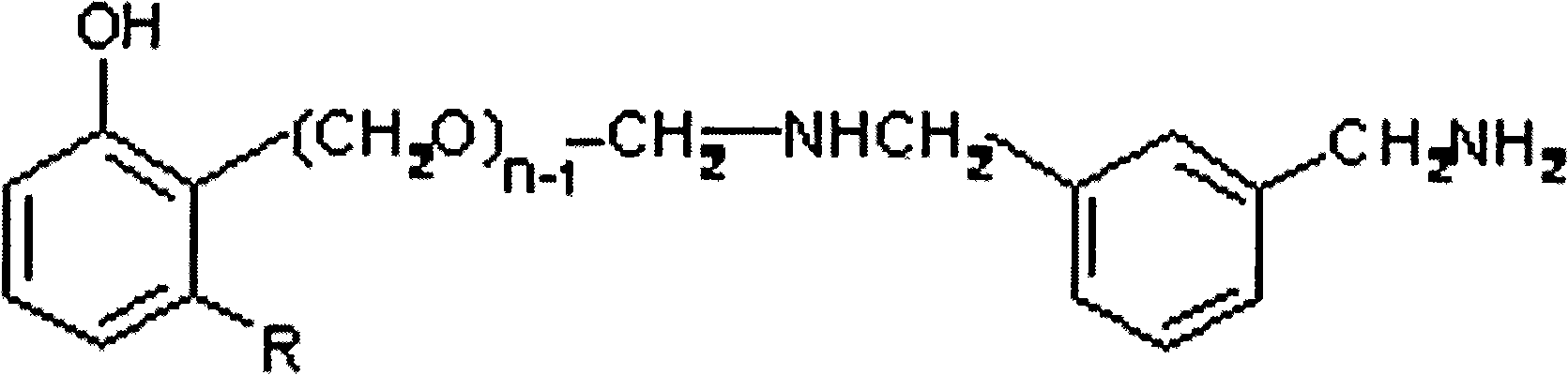

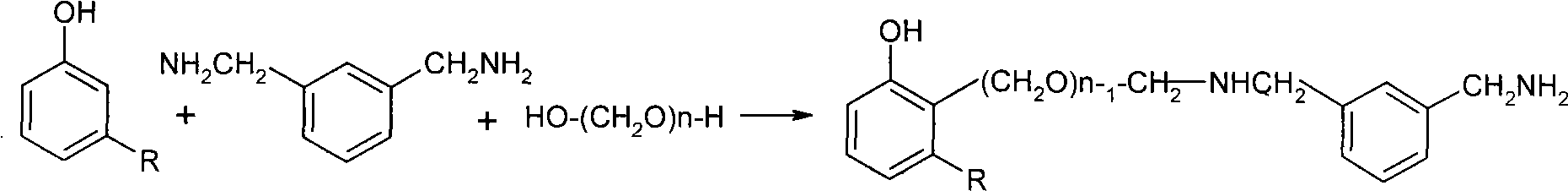

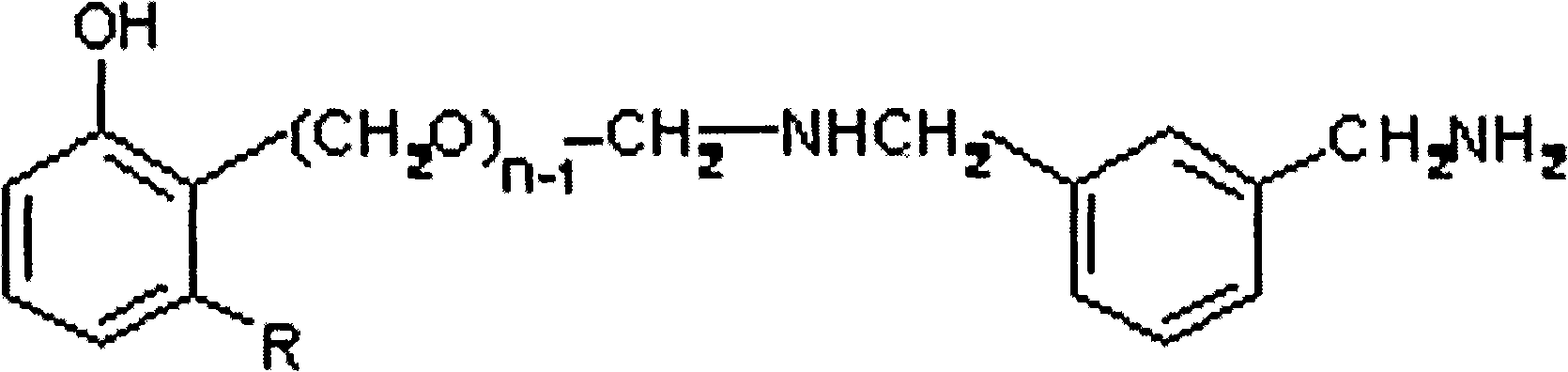

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

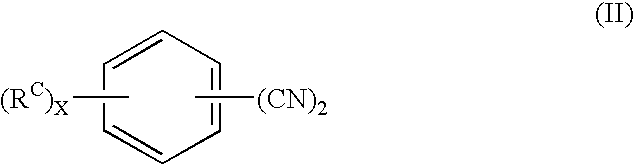

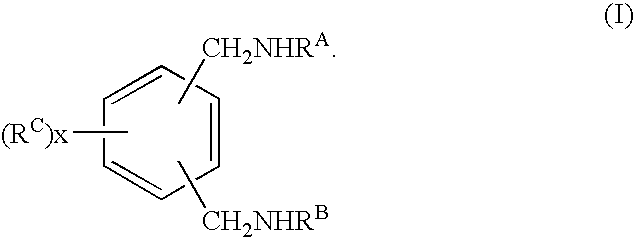

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

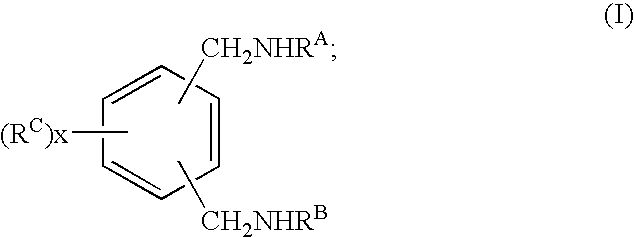

Curing agent for low temperature cure applications

ActiveUS20100048827A1Organic chemistryOther chemical processesLow temperature curingM-xylylenediamine

The present invention discloses both amine compositions and amine-epoxy compositions containing N,N′-dimethyl-meta-xylylenediamine. A novel process for producing amines such as N,N′-dimethyl-meta-xylylenediamine, and structurally similar amines, is also disclosed.

Owner:EVONIK OPERATIONS GMBH

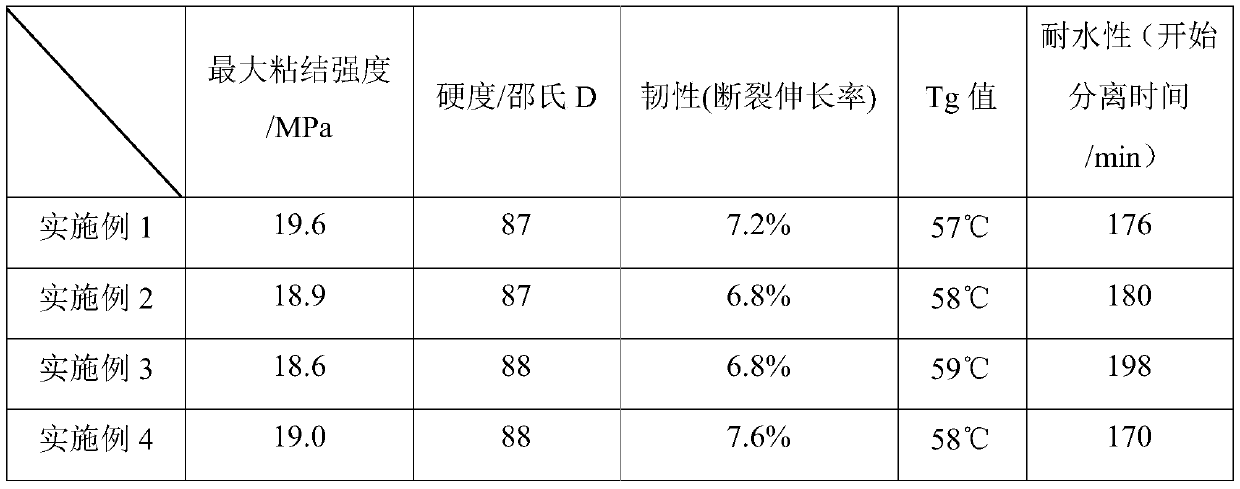

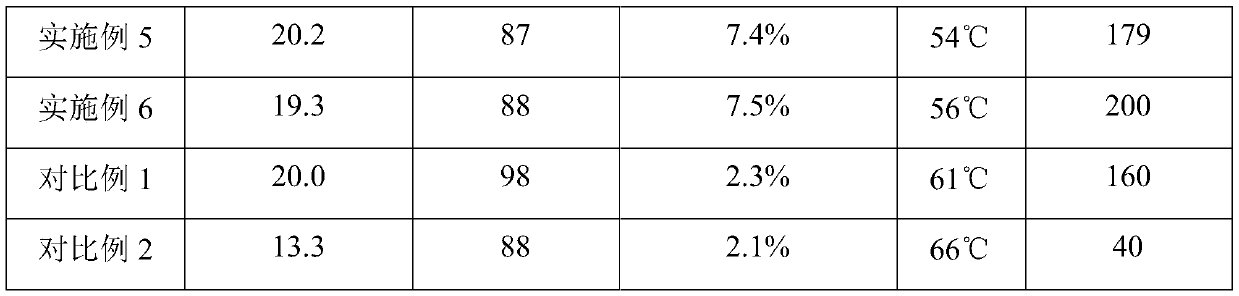

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

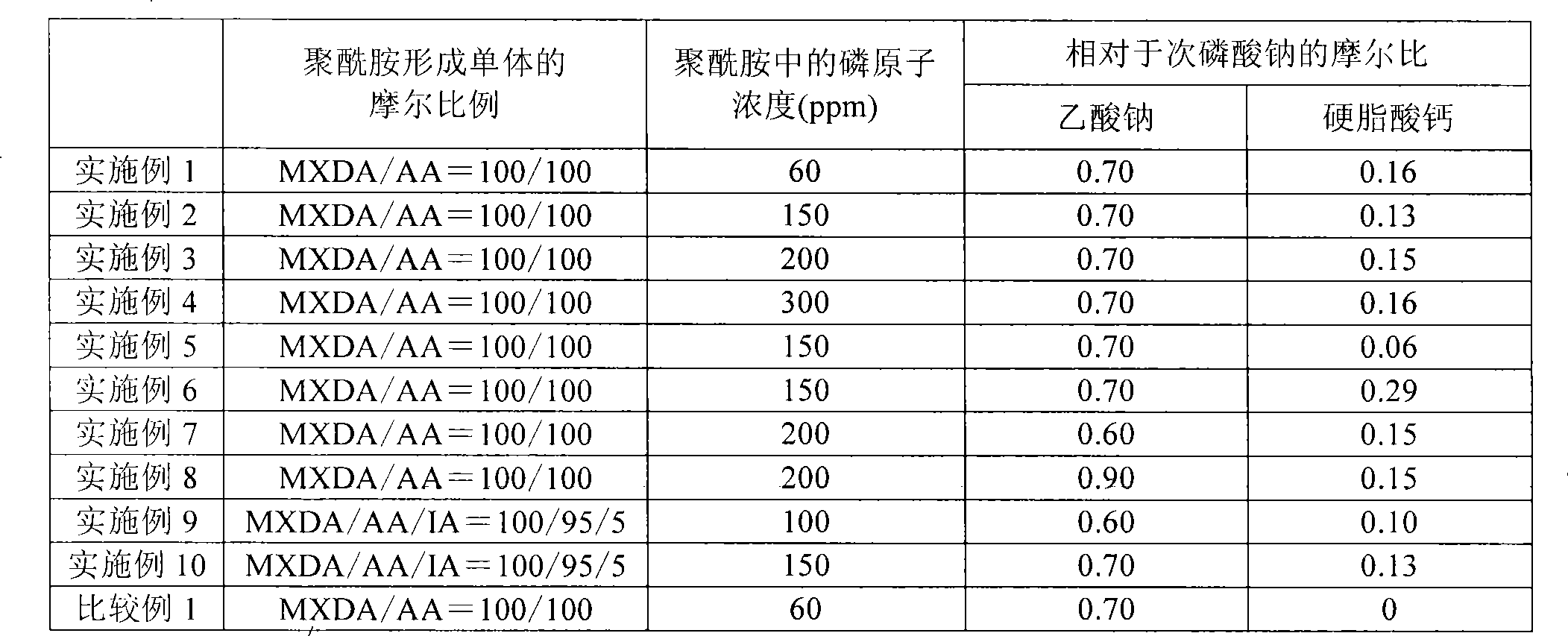

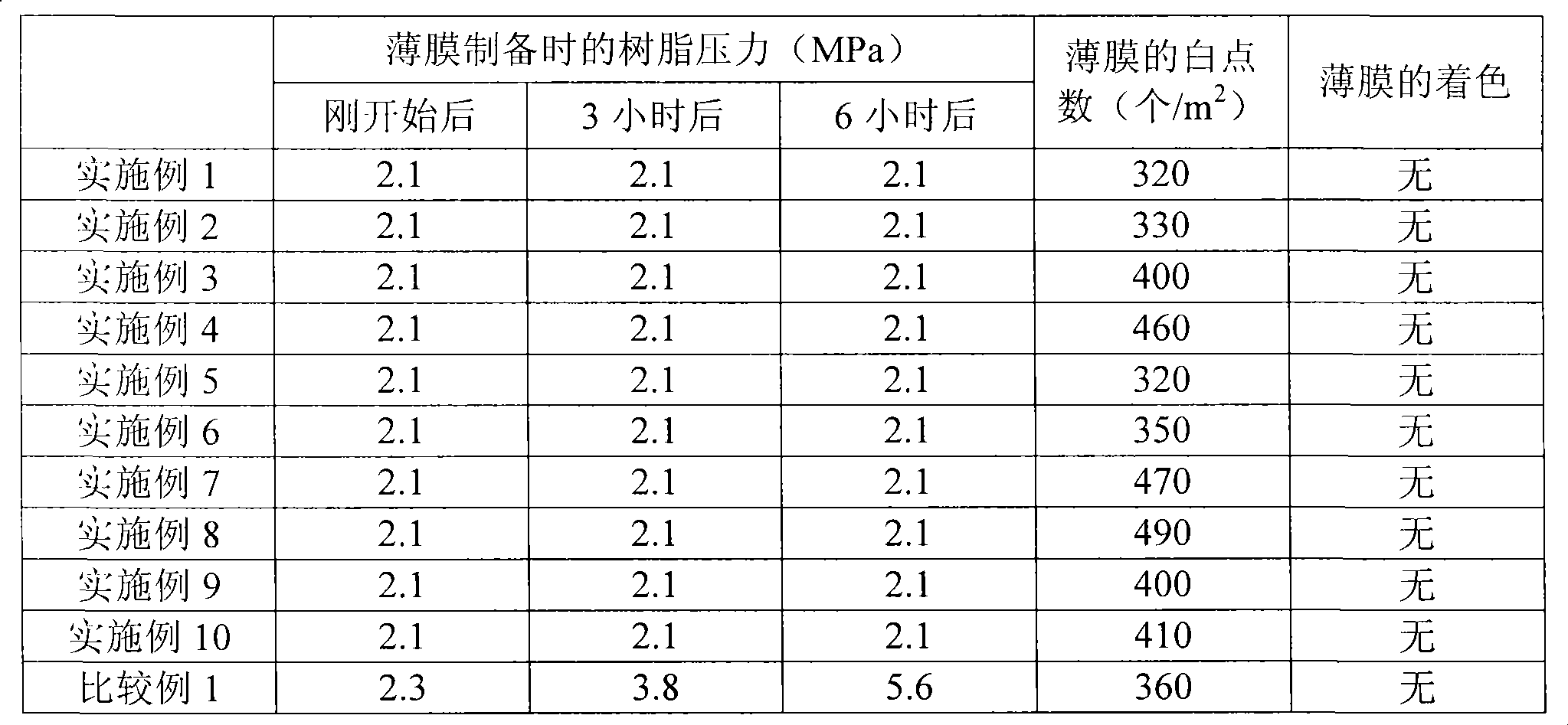

Polyamide resin composition

InactiveUS6166171AConvenient whiteningImprove mechanical propertiesSynthetic resin layered productsThin material handlingPolyamideCarboxylic acid

A polyamide resin composition comprising 100 parts by weight of a polyamide resin and 0.005 to 1.0 part by weight of at least one compound selected from the group consisting of a metal salt of a fatty acid, a diamide compound and a diester compound. The polyamide resin is obtained by solid phase-polymerizing a polyamide resin prepared by melt-polymerizing a diamine component containing 70 mol % or more of metaxylylenediamine and a dicarboxylic acid component containing 70 mol % or more of adipic acid, and preferably has a relative viscosity of 2.3 to 4.2 when measured at 25 DEG C. using a solution of 1 g polyamide resin in 100 ml of 96% sulfuric acid. By adding at least one compound selected from the group consisting of the specific metal salt of fatty acid, the diamide compound and the diester compound to a solid phase-polymerized polyamide resin, shaped articles such as films, sheets and hollow containers made of the solid phase-polymerized polyamide are improved in the resistance to whitening during storage tinder a high humid condition, upon contacting with water or boiling water, or upon heating to a glass transition temperature or higher.

Owner:MITSUBISHI GAS CHEM CO INC

Polyamide resin composition

A polyamide resin composition comprising a polyamide (X) having a diamine constituent unit which is mainly composed of a m-xylylenediamine unit and a dicarboxylic acid constituent unit which is mainly composed of an adipic acid unit; and specific amounts of a phosphorus acid antioxidant and alkaline component. The polyamide (X) is characterized by a specific range of terminal-group concentration balance and a specific amino-group reaction rate. This composition can simultaneously achieve inhabitation of yellow discoloration and reduction of number of gels or fish eyes.

Owner:MITSUBISHI GAS CHEM CO INC

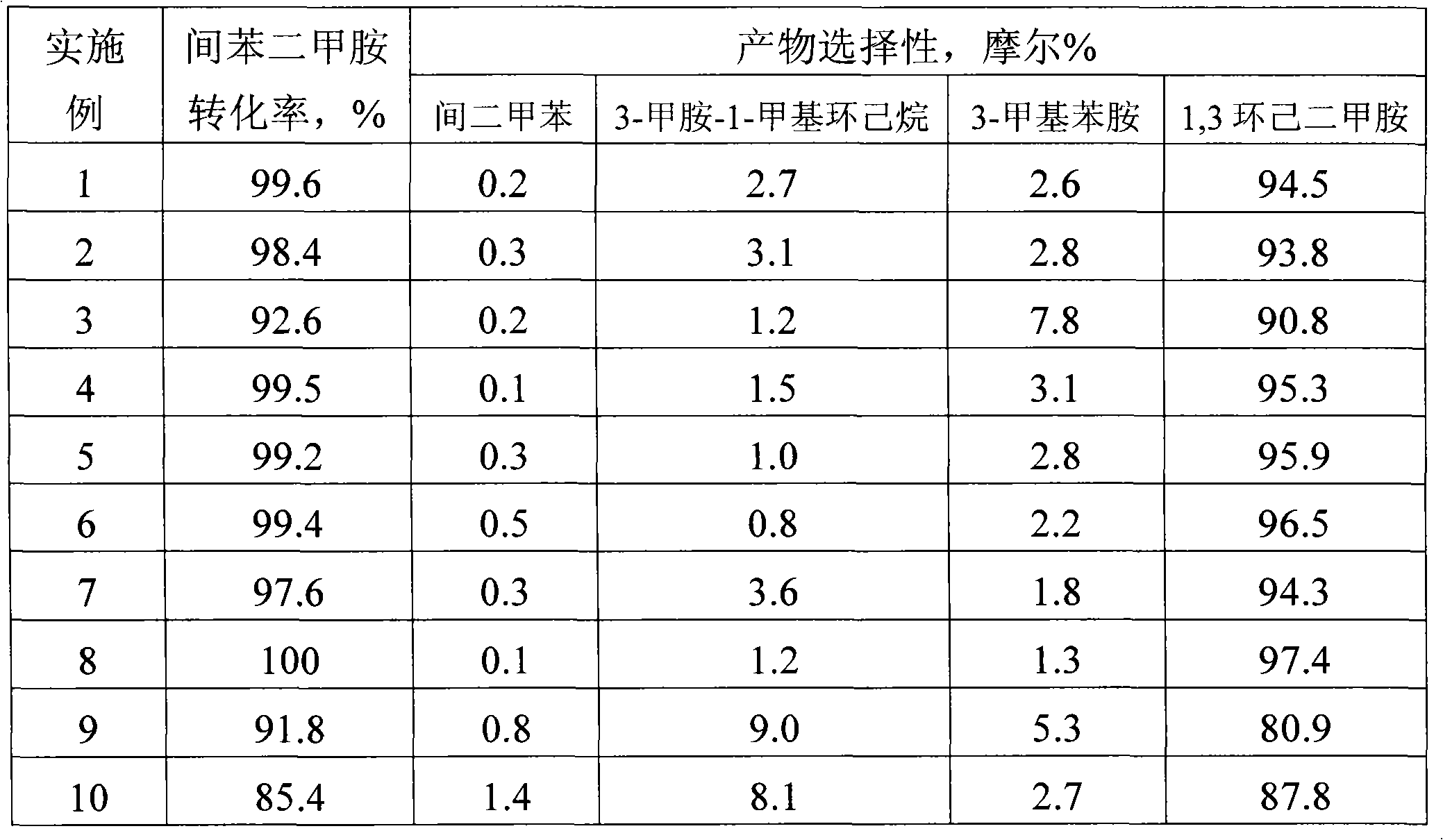

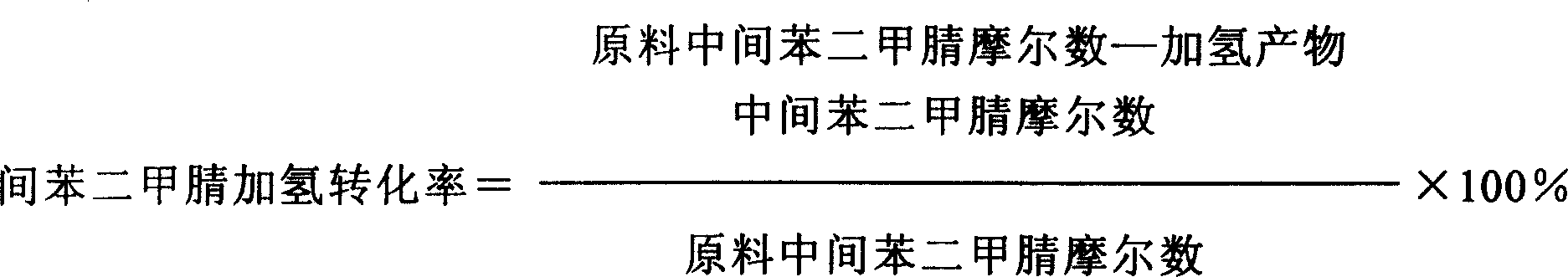

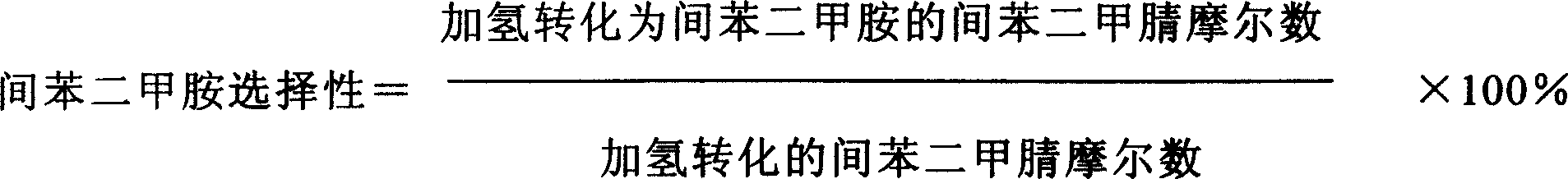

Catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions

InactiveCN102688766ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationFixed bedM-xylylenediamine

The invention discloses a catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of m-xylylenediamine and hydrogen into 1,3-cyclohexanebis(methylamine) under ammonia reaction conditions and comprises one or more main active components, one or more auxiliary agents and a carrier. The one or more main active components is / are precious metal Ru or / and Pd. The one or more auxiliary agents are selected from Ni, Cr, Co, Fe and their oxides. The carrier is Al2O3, active carbon or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of m-xylylenediamine and hydrogen into a plurality of amine products comprising 1,3-cyclohexanebis(methylamine) as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Isophthalonitrile catalytic hydrogenation method

InactiveCN101062898AReduce acidityHigh activityCatalyst carriersOrganic compound preparationM-xylylenediamineChemistry

The invention discloses an isophthalonitrile catalytic hydrogenation method, which comprises the following steps: introducing MgO into Ni / SiO2 activator; transforming isophthalonitrile to m-tolylenediamine with Ni / MgO-SiO2 activator; hydrotreating in two series tubular reactor. This invention can prolong durability of activator and improve hydrogenation receiving ratio distinctively.

Owner:上海博润石化科技发展有限公司

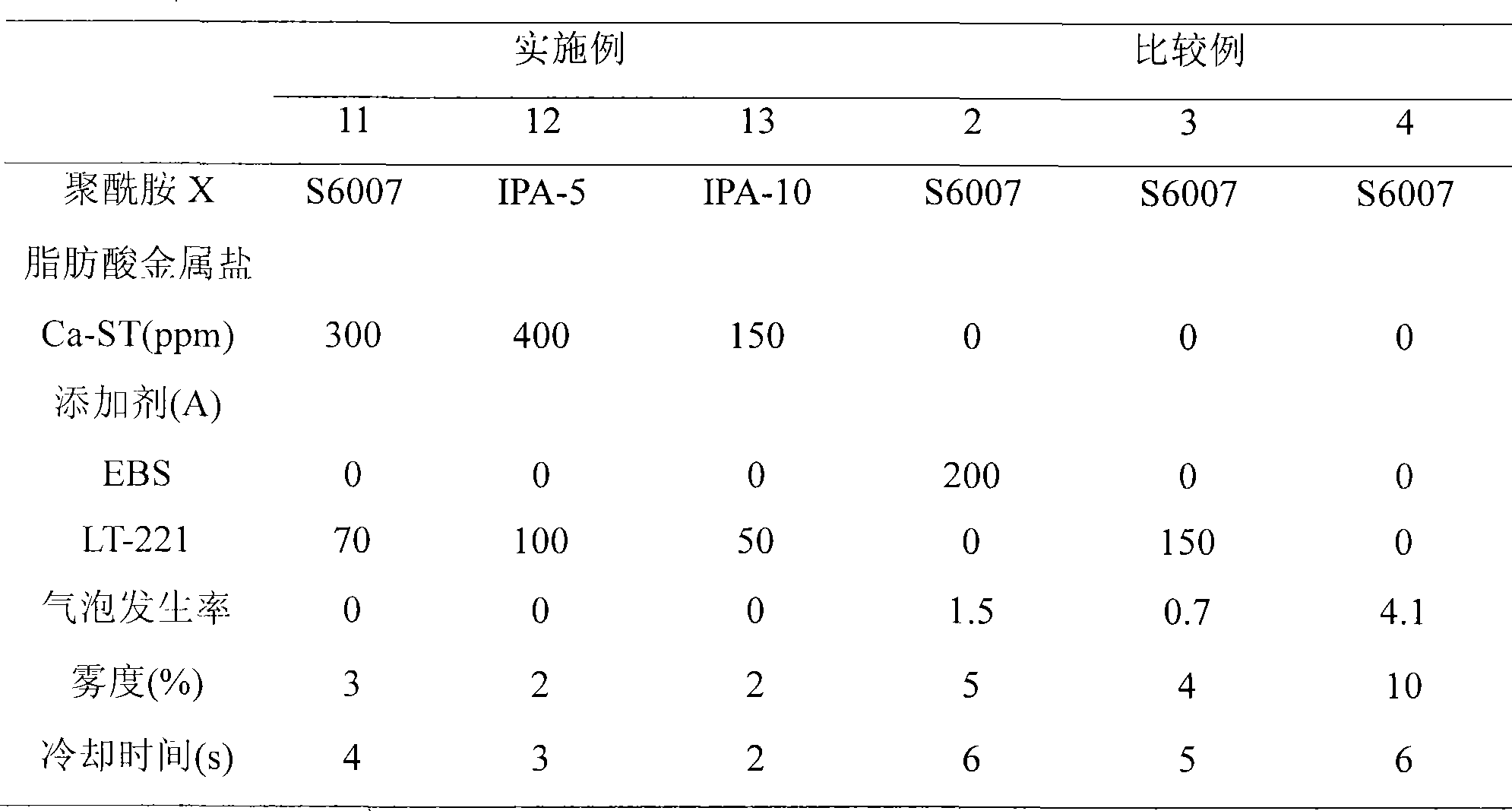

Polyamide resin composition

ActiveUS20090239013A1Less amountStably subjectedEnvelopes/bags making machineryBottlesPolymer scienceActive agent

A polyamide resin composition contains a resin component containing at least a polyamide (X) and a fatty acid metallic salt having from 10 to 50 carbon atoms, and contains arbitrarily an additive (A) and / or an additive (B). The polyamide (X) is obtained through melt polycondensation of a diamine component containing 70% by mol or more of m-xylylenediamine and a dicarboxylic acid component containing 70% by mol or more of an α,ω-linear aliphatic dicarboxylic acid. The additive (A) is at least one compound selected from the group consisting of a diamide compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diamine having from 2 to 10 carbon atoms, a diester compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diol having from 2 to 10 carbon atoms, and a surfactant, and the additive (B) is at least one compound selected from the group consisting of a metallic hydroxide, a metallic acetate salt, a metallic alkoxide, a metallic carbonate salt and a fatty acid.

Owner:MITSUBISHI GAS CHEM CO INC

Rough stone block reinforcement adhesive and using method thereof

The invention relates to a rough stone block reinforcement adhesive and a using method thereof. According to the reinforcement adhesive, a component A is prepared from low-viscosity epoxy resin, reactive diluent, hydroquinone, ultraviolet absorber, and a wetting agent, and a component B is prepared from methyl cyclo pentamethylene diamine, m-xylenediamine, polyether amine, ketimine, an anti-yellowing agent, curing accelerator, a coupling reagent, and benzyl alcohol; and before using, the component A and the component B are uniformly mixed to form the rough stone block reinforcement adhesive. The invention also discloses the using method for the rough stone block reinforcement adhesive. The method is characterized in that a pressing and injecting head performs pressurization by using compressed air to inject the reinforcement adhesive into rough stone block cracks. The reinforcement adhesive has the advantages of low viscosity, strong osmotic force and yellowing resistance, and can be cured under the conditions of low temperature and moisture; and the using method for the reinforcement adhesive has the characteristics that the adhesive is injected by pressurization, and is convenient to use; and the pressing and injecting head can be used repeatedly.

Owner:HUNAN KOSEN NEW MATERIAL

Polyamide resin composition

Disclosed is a polyamide resin composition comprising a resin component containing at least a polyamide (X) and a fatty acid metal salt having 10-50 carbon atoms. This polyamide resin composition may optionally contain an additive (A) and / or an additive (B). The polyamide (X) is obtained by melt polycondensation of a diamine component containing not less than 70 mol% of meta-xylylenediamine and a dicarboxylic acid component containing not less than 70 mol% of an alpha,omega-linear aliphatic dicarboxylic acid. The additive (A) is composed of one or more compounds selected from the group consisting of diamide compounds obtained from a fatty acid having 8-30 carbon atoms and a diamine having 2-10 carbon atoms, diester compounds obtained from a fatty acid having 8-30 carbon atoms and a diol having 2-10 carbon atoms, and surface active agents. The additive (B) is composed of one or more compounds selected from the group consisting of metal hydroxides, metal acetates, metal alkoxides, metal carbonates, and fatty acids.

Owner:MITSUBISHI GAS CHEM CO INC

Epoxy resin mortar and preparation method

In the invention, epoxy, meidum plain emergy, diluent and curing agent are used as raw material, their weight percentage are (wt%): epoxy 12-16, medium plain emergy 73-82, diluent 1.5-2.5, curing agent 4.5-8.5. epoxy is optimum selected A-type E44 epoxy, medium plain emery can be river sand or quartz sand, diluent can be epoxy propane butyl ether, curing agent is optimum selected modified M-phthalic amine curing agent. Modifying method of said M-phthalic amine curing agent is that M-phthalic amine curing agent and monocycle oxo-compound do chemical combining reaction to generate liquid amine compound, then to be modified by acylate.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Preparation method of mixed cresol modified meta-xylylene diamine epoxy resin curing agent

InactiveCN102532449AEfficient removalTemperature controlAnti-corrosive paintsEpoxy resin coatingsXylyleneIrritation

The invention provides a preparation method of a mixed cresol modified meta-xylylene diamine epoxy resin curing agent. The method comprises the following steps of: adding meta-xylylene diamine into an N2-charged reaction kettle; raising the temperature to 80-95 DEG C; adding hydroquinone; fully mixing; adding cardanol; keeping the temperature at 85-95 DEG C till a solution is clear and transparent; adding a catalyst; gradually adding polyformaldehyde in batches simultaneously; lowering the temperature to 70-80 DEG C; vacuumizing and dehydrating; after dehydrating, raising the temperature to 130-150 DEG C; undergoing a polymerization reaction; cooling to 70-85 DEG C; filtering the catalyst; diluting to 15-25 percent by using an organic solvent; and discharging to obtain the mixed cresol modified meta-xylylene diamine epoxy resin curing agent. A product prepared with the method has the advantages of stable performance, high curing speed, low toxicity, high transparency, unremarkable whitening phenomenon, nontoxicity and freeness of irritation, can be applied to underwater construction, and is a superior sea heavy-duty coating.

Owner:上海美东生物材料股份有限公司

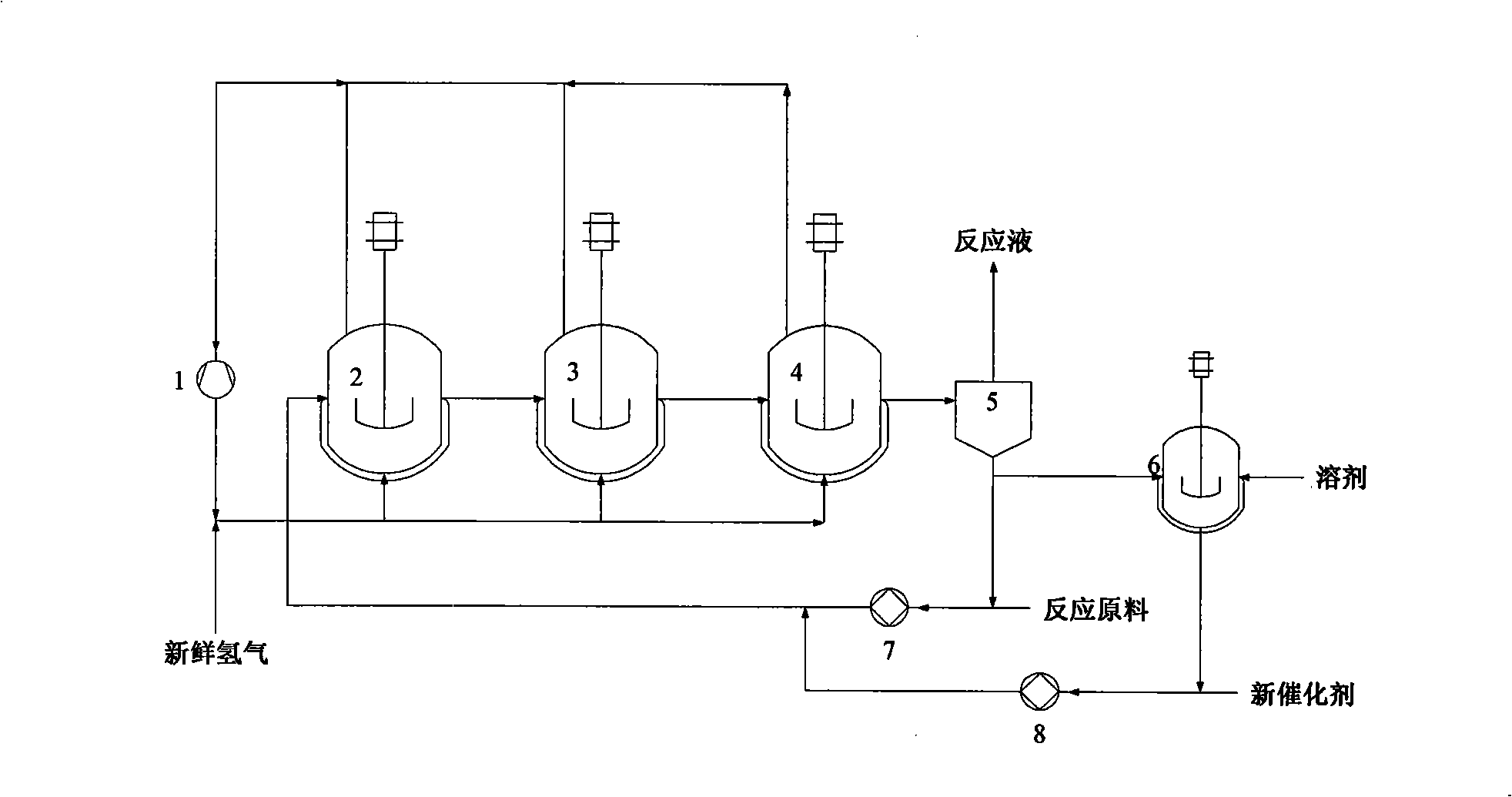

Method for preparing m-xylylenediamine from m-phthalodinitrile through hydrogenation

ActiveCN103539676AImprove stabilityExtend your lifeOrganic compound preparationAmino compound preparationPore distributionHigh pressure

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyamide resin composition

A polyamide resin composition comprising: a polyamide (X) having a diamine constituent unit which mainly comprises a metaxylylenediamine unit and a dicarboxylate constituent unit which mainly comprises an adipate constituent unit; and specific amounts of a phosphate-type antioxidant and alkaline component. The polyamide (X) is characterized by a specific terminal group concentration balance and a specific amino group reaction rate. By using the polyamide resin composition, both of the prevention of yellow discoloration and the reduction of gelatinization or fisheye formation can be achieved.

Owner:MITSUBISHI GAS CHEM CO INC

Preparation method for polyamide composite nanofiltration membrane

InactiveCN103768963AHigh retention rateReduce retentionSemi-permeable membranesFiltration membranePolyamide

The invention provides a preparation method for a polyamide composite nanofiltration membrane. The preparation method comprises the following steps: firstly soaking a polysulfone base membrane in an m-xylylene diamine solution for 10-90 seconds, taking out the base membrane, and removing liquid on the surface; soaking the treated base membrane in a trimesoyl chloride solution, reacting for 5-30 seconds, taking out the base membrane and removing liquid on the surface; and finally airing the base membrane, and then putting in a drying oven for treating for 10-20 minutes, thus obtaining the polyamide composite nanofiltration membrane. According to the preparation method, the filtration membrane can obtained through compound within short time, with simple technique and low cost, and the water flux of the polyamide composite nanofiltration membrane is above 60L / h*m<2>, and the polyamide composite nanofiltration membrane has high rejection rate to divalent metal ion organic salts, and lower rejection rate to monovalent metal organic salts.

Owner:NANTONG SUTONG SEPARATION ENG & TECH

High wear-resistant epoxy coating, preparation method thereof and coating layer

The invention relates to high wear-resistant epoxy coating, a preparation method of high wear-resistant epoxy coating and a high wear-resistant epoxy coating layer. The high wear-resistant epoxy coating provided by the invention is characterized by being prepared from an A component and a B component, wherein (1) the A component is prepared from the following raw materials in percentage by mass: 45 to 55 percent of epoxy resin, 3 to 5 percent of toughening agent, 3 to 5 percent of diluting agent, 5 to 10 percent of accelerator, 2 to 5 percent of silane coupling agent, 20 to 25 percent of abrasive aggregates, 5 to 10 percent of filler and appropriate percent of pigment; (2) the B component is prepared from the following raw materials in percentage by mass: 15 to 20 percent of MXDA (M-Xylylenediamine), 15 to 20 percent of IPDA (Isophorone Diamine), 3 to 5 percent of 1,3-BAC (1,3-bis(aminomethyl)-cyclohexan), 25 to 35 percent of polyether amine D230, 25 to 30 percent of styrenated phenol and 5 to 10 percent of TMPTA (Trimethylolpropane triacrylate); the A component and the B component are mixed according to a proportion of 1:5. The high wear-resistant epoxy coating disclosed by the invention has excellent wear resistance, high hardness, good heat resistance and water resistance, good chemical reagent corrosion resistance, high fullness, high construction efficiency, convenience in construction and a wide application range.

Owner:SHANGHAI ZHENGOU IND

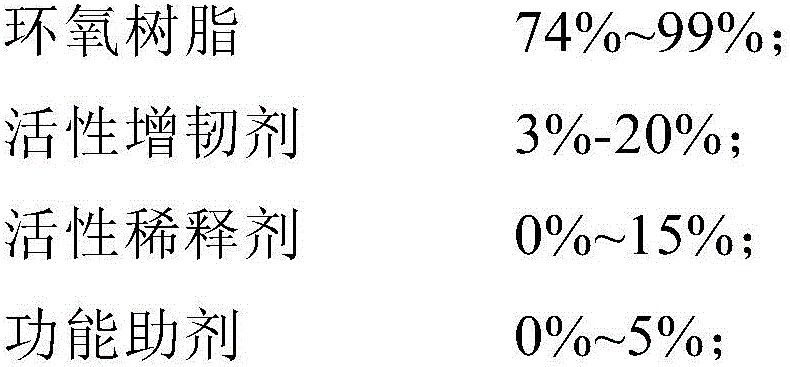

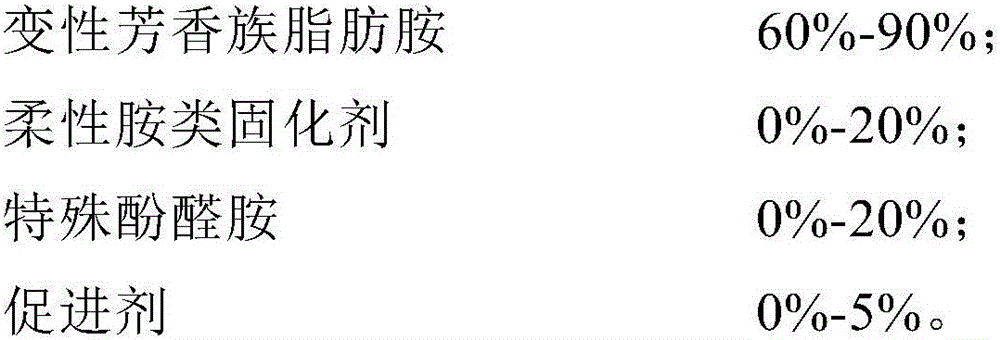

Epoxy-based pouring sealant for end capping of PVDF ultrafiltration membrane assembly and preparation method of epoxy-based pouring sealant

ActiveCN106753131AAbandon the corrosion discoloration effectCorrosion discoloration effect eliminationMacromolecular adhesive additivesEpoxy resin adhesivesFatty amineSewage treatment

The invention discloses an epoxy-based pouring sealant for end capping of a PVDF ultrafiltration membrane assembly and a preparation method of the epoxy-based pouring sealant. The epoxy-based pouring sealant comprises a component A and a component B. The component A is prepared from epoxy resin, an active flexibilizer, an active diluent and a functional assistant. The component B is prepared from degenerative aromatic fatty amine, a flexible amine curing agent, special phenolic aldehyde amine and an accelerant. Degenerative aromatic fatty amine is degenerated based on m-xylylenediamine. Epoxy glue has high toughness, certain flexibility is achieved for the root of membrane silk of the ultrafiltration membrane assembly, and therefore the silk breakage problem is relieved; corrosion of the epoxy glue to the PVDF membrane silk is eliminated, the reddish brown blackening phenomenon of the membrane silk of the ultrafiltration membrane assembly is eliminated, and the membrane silk is kept intact. The requirements of the end capping process of ultrafiltration membrane assemblies of multiple types can be met, adhesion is excellent after end-capping curing is completed, chemical medium resistance is good, the durable ultrafiltration membrane assembly can be prepared, and the ultrafiltration membrane assembly is suitable for being applied to the field of industrial sewage treatment of wide occasions.

Owner:康达新材料(集团)股份有限公司

Epoxy resin curing agent and preparation method thereof

PendingCN109824869AShort curing timeImprove adhesionAnti-corrosive paintsEpoxy resin coatingsDiethylenetriaminePolyamide

The invention relates to an epoxy resin curing agent. The epoxy resin curing agent comprises, by weight , 30-50 parts of polyamine compound, 20-40 parts of benzyl alcohol, 5-10 parts of epoxy resin, 3-8 parts of propylene carbonate, 10-20 parts of polyether 400, 0.05-0.1 part of yellow-resistant auxiliary and 1-10 parts of amino-terminated hyperbranched polyamide surface grafted graphene oxide, wherein the polyamine compound comprises one or two of aliphatic polyamine and cycloaliphatic polyamine; the aliphatic polyamine is diethylenetriamine, triethylene tetramine or hexanediamine; the cycloaliphatic polyamine is m-xylylenediamine or isophorone diamine; the polyamine compound comprises isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine to the triethylene tetramine is (1-4):1.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

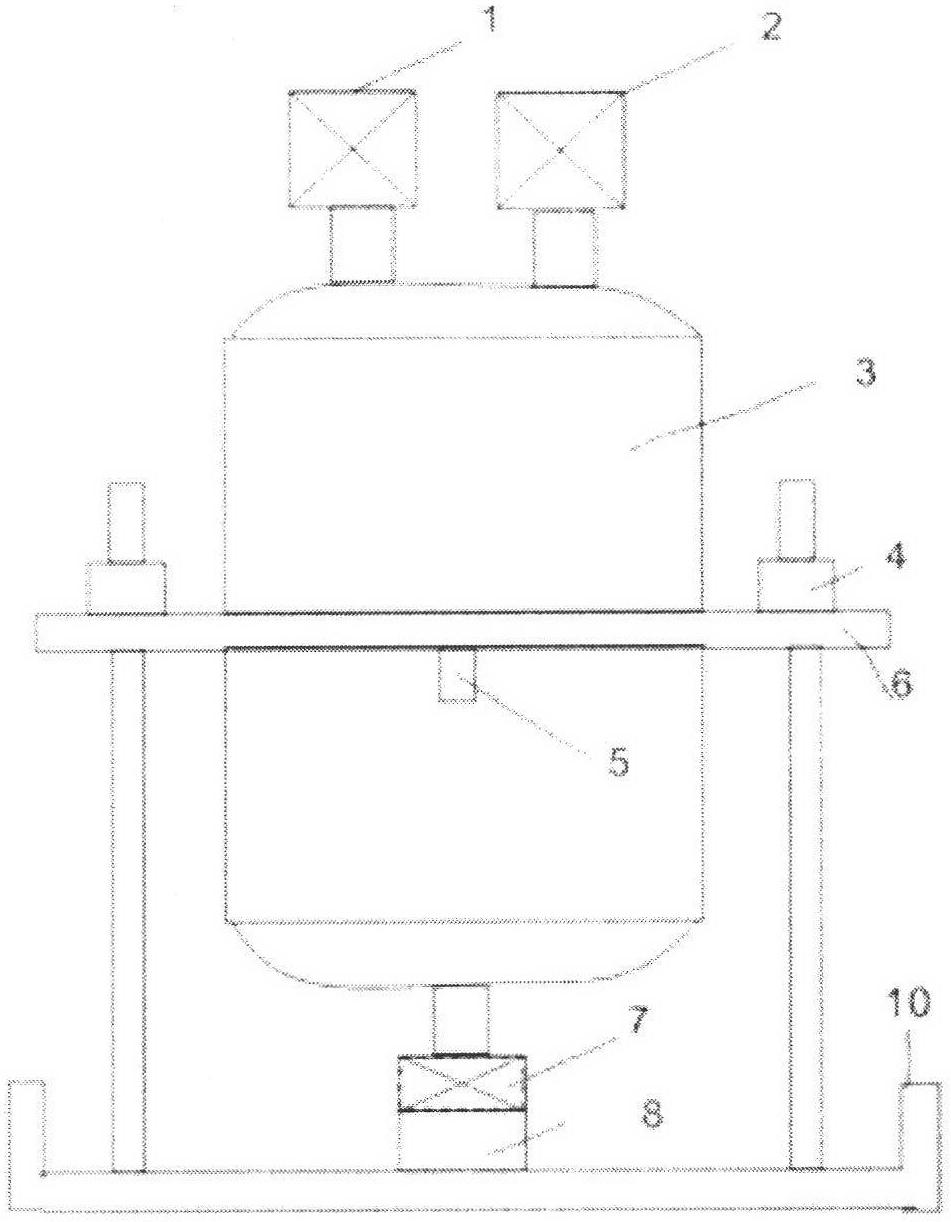

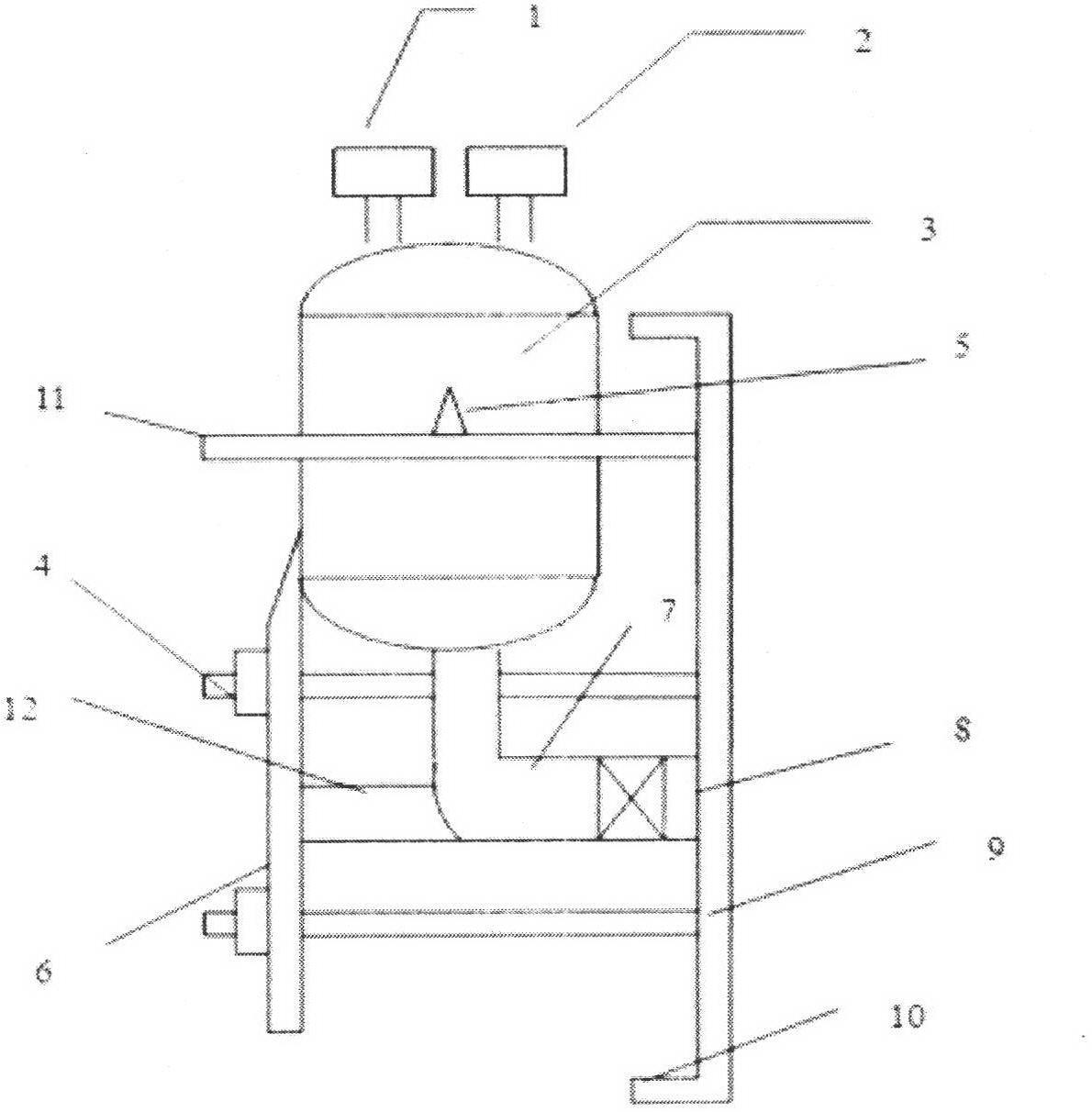

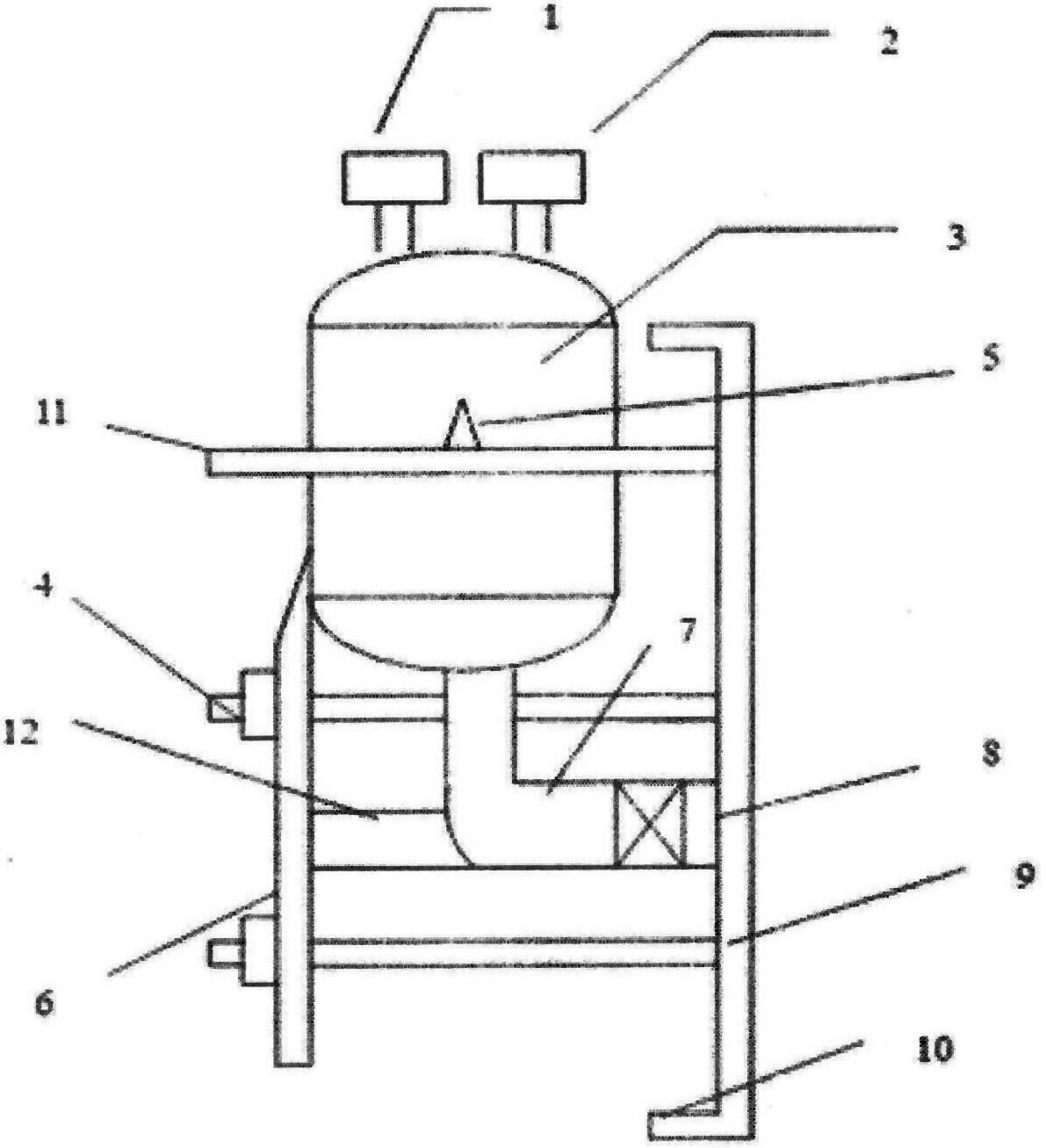

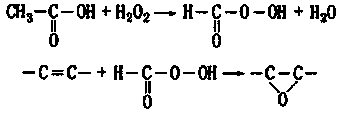

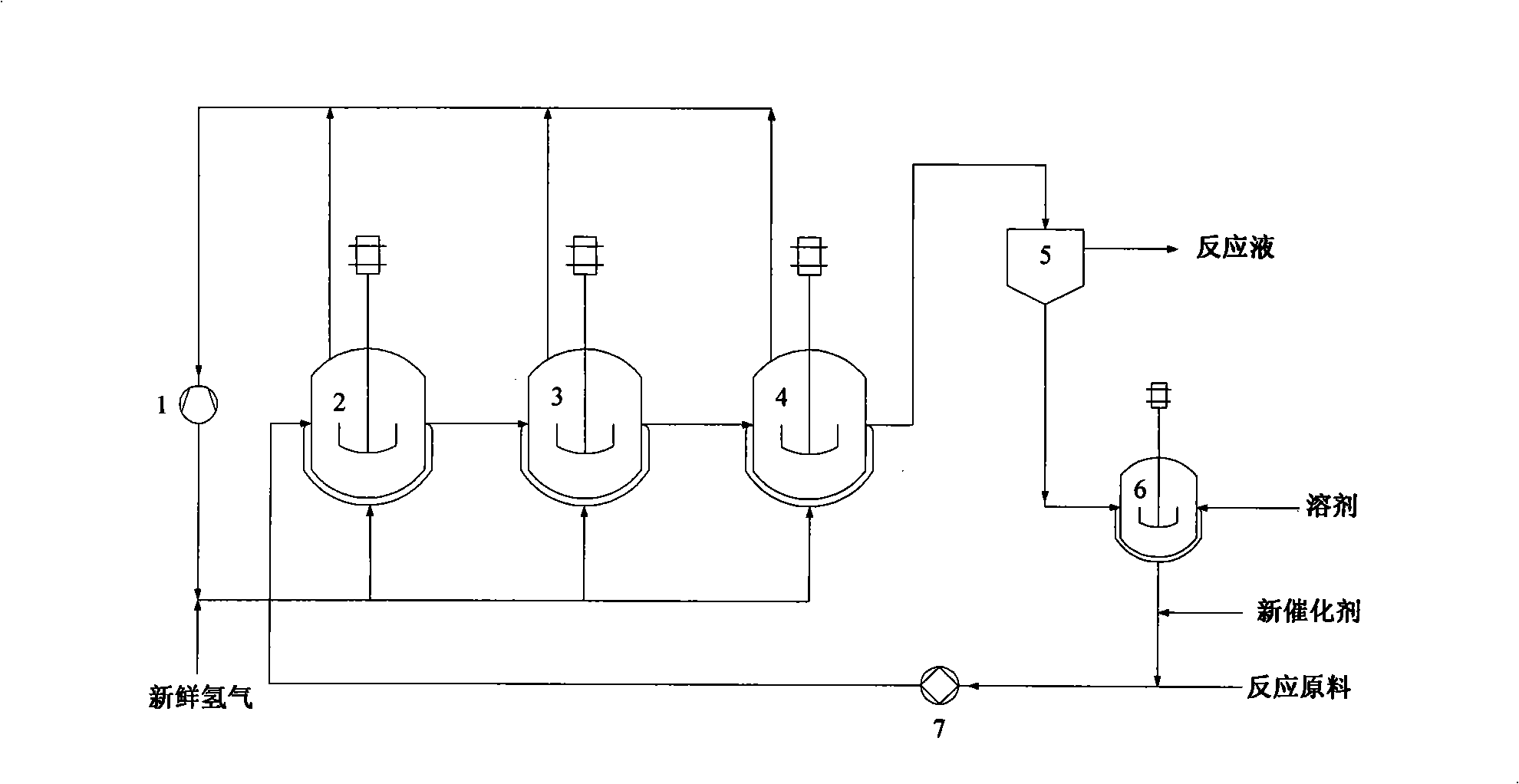

Process for preparation of meta-benzene dimethanamine by continuous hydrogenation reaction in stirring vessel

ActiveCN101337894AHigh yieldSuppress generationOrganic compound preparationChemical recyclingPhthalonitrileSolvent

The invention discloses a method for preparing m-xylene diamine by continuous hydrogenation in a stirring kettle, which adopts m-phthalonitrile as the raw material and carries out multi-phase hydrogenation. The method is characterized in that the mixture of m-phthalonitrile and a solvent and hydrogen contact a granular solid catalyst in a hydrogenation reactor including at least two stirring kettles connected with each other in series to carry out continuous hydrogenation reaction; the reactive solution and the solid catalyst flowing from the end-stage stirring kettle are continuously fed into a separator for liquid-solid separation; the separated reactive solution is separated to obtain the final product; and the separated catalyst can be recycled after regeneration and returned to the hydrogenation reactor. Compared with the intermittent hydrogenation process, the method has the advantages of simple operation, high equipment utilization rate and hydrogenation efficiency, and continuous regeneration and cycle use of the catalyst, and can achieve automatic continuous production of m-xylene diamine.

Owner:江苏德纳化学股份有限公司

Polyamide laminated film

InactiveUS6294263B1Excellent gas barrier performanceIncrease resistanceSynthetic resin layered productsDomestic articlesElastomerXylylene

The present invention is to provide a polyamide laminated film comprising a resin layer A and a resin layer B formed on at least one surface of the resin layer A,the resin layer A being composed mainly of a m-xylylene group-containing polyamide polymer (a-1) which is one prepared from monomer components containing a xylylenediamine compound as a main diamine component and an alpha,omega-aliphatic dicarboxylic acid having from 6 to 12 carbon atoms as a main dicarboxylic acid component, the xylylenediamine compound being m-xylylenediamine alone or a mixture of m-xylylenediamine and p-xylylenediamine, andthe resin layer B being mainly composed of a mixed polymer (b-3) which is a mixture of from 99 to 80% by weight of an aliphatic polyamide (b-1) and from 1 to 20% by weight of an elastomer (b-2).The laminated film is good in a gas barrier property and also in a flexural fatigue resistance and a transparency.

Owner:TOYO TOYOBO CO LTD

Polyamide resin composition and molded article

InactiveUS20090280311A1Increase the rate of crystallizationGood crystallization performanceSynthetic resin layered productsMicaFiberPolyamide

In the present invention, there is provided a polyamide resin composition for portable electronic devices, which is excellent in mechanical strength, thin-wall moldability, crystallinity and warping property.A polyamide resin composition comprising 30 to 80% by weight of a polyamide MP (A), 20 to 70% by weight of a polyamide resin (B) having a melting point not less than 245° C. (with the total amount of both being 100% by weight). The composition additionally comprises a filler (C) comprising a fibrous filler (C1) as an optional component and a plate-like filler (C2) as an essential component, wherein a content ratio (C1):(C2) is 0:10 to 9:1. The filler (C) is present in an amount of 30 to 250 parts by weight per 100 parts by weight of the sum of the polyamide MP (A) and the polyamide resin (B). The polyamide MP (A) is a polyamide resin obtained by polycondensation of a mixed diamine, which comprises 90 to 50% by mole of metaxylylenediamine and 10 to 50% by mole of paraxylylenediamine, with an α,ω-linear aliphatic dibasic acid and / or an aromatic dibasic acid.

Owner:MITSUBISHI ENG PLASTICS CORP

Polyamide resin

InactiveUS6841651B2Excellent melt viscosity stabilityEnvelopes/bags making machinerySynthetic resin layered productsPolyamideCarboxylic acid

The polyamide resin of the present invention is produced by polycondensation of a diamine component comprising 70 mol % or more of m-xylylenediamine and a dicarboxylic acid component comprising 70 mol % or more of a C4-C20 α, ω-straight-chain aliphatic dicarboxylic acid in the presence of at least one phosphorus compound selected from the group consisting of phosphinic acid compounds and phosphonous acid compounds and in the presence of an alkali metal compound of a weak acid. The weak acid has a dissociation constant lower than a first dissociation constant of a dicarboxylic acid mainly constituting the polyamide resin. The polyamide resin satisfies the following requirements (A), (B) and (C):14000≦a≦40000 (A)b≦1.000 (B)0.9930≦b−1.1a2×10−11+3.2a×10−7≦0.9980 (C)wherein a and b are as defined in the disclosure.

Owner:MITSUBISHI GAS CHEM CO INC

Gas-barrier multi-layer structure

ActiveUS7258929B2Easy to processLess discoloration and malodor generationSynthetic resin layered productsFlexible pipesPolymer sciencePolyamide

The gas-barrier multi-layer structure of the present invention comprises at least one gas-barrier layer A and at lease one thermoplastic resin layer B. The gas-barrier layer A comprises a crystallizable polyamide resin which is produced by the polycondensation of a diamine component mainly comprising m-xylylenediamine with a dicarboxylic acid component comprising a C4-C20 α,ω-linear aliphatic dicarboxylic acid and isophthalic acid in a specific proportion so as to have a particular crystallization behavior. The gas-barrier multi-layer structure is excellent in the fabricability such as deep drawing ability and can be fabricated into a highly transparent shaped article with less discoloration and malodor generation.

Owner:MITSUBISHI GAS CHEM CO INC

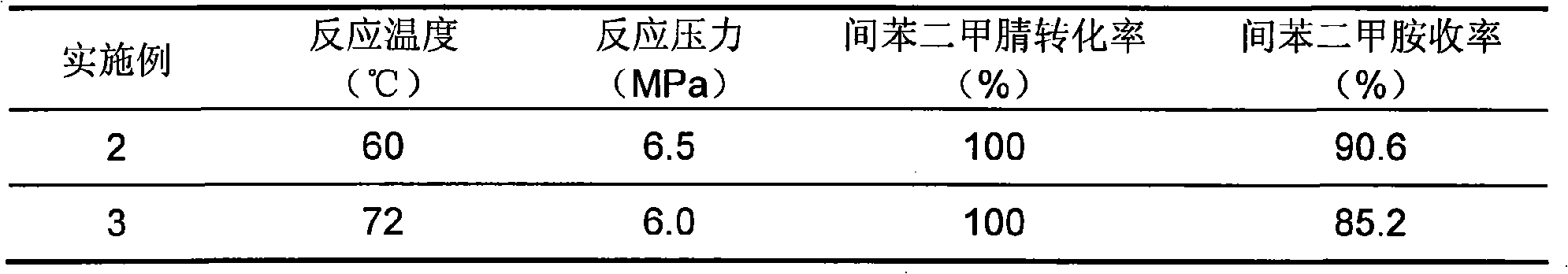

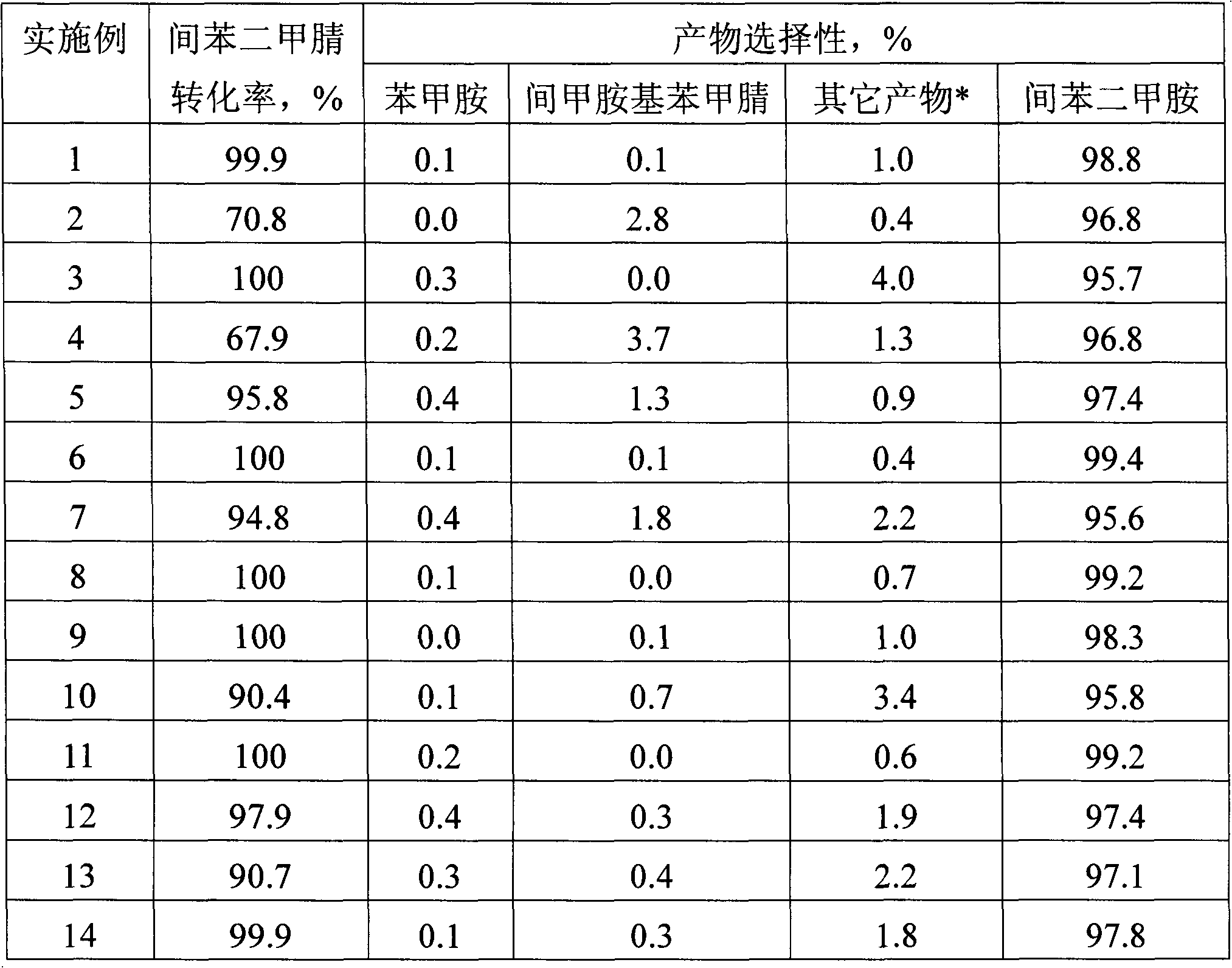

Method for preparing m-xylylenediamine

InactiveCN102690205AHigh selectivityLow reaction pressureOrganic compound preparationAmino compound preparationFixed bedReaction temperature

The invention discloses a method for preparing m-xylylenediamine. The method is characterized in that a reaction system comprises isophthalonitrile, ammonia, hydrogen and a catalyst; a reaction temperature is in a range of 60 to 100 DEG C; reaction pressure is in a range of 1.0 to 20.0MPa; a mole ratio of H2 to isophthalonitrile is in a range of 10-200; a weight ratio of isophthalonitrile to m-xylylenediamine to NH3 is (3-20): (3-20): (60-94); an airspeed of an isophthalonitrile liquid is in a range of 0.3 to 1.8h<-1>; the catalyst adopts diatomite, Al2O3, active carbon or SiO2 as a carrier and is loaded with one or more of transition metals of Ni and Co as active ingredients and preferably, is loaded with Ni; one or more auxiliary agents are selected from Re, Cu, Cr, Ru, Fe and their oxides; and in a fixed bed reactor, under the ammonia reaction of the catalyst, the high activity and high selectivity transformation of an isophthalonitrile / m-xylylenediamine solution into m-xylylenediamine is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyamide and bioresourced reinforcement compositions having improved mechanical properties

One subject of the present invention is a composition that combines at least one polyamide having at least one MXD entity, MXD denoting meta-xylylenediamine or a mixture of meta-xylylenediamine and of para-xylylenediamine, with a bioresourced reinforcement. The invention also relates to the conversion of these compositions, by injection moulding or extrusion, into objects that have good mechanical properties, said objects corresponding to technical application specifications such as may be found, for example, in the automotive industry, construction, sport and in electrical or electronic fields.

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com