Epoxy resin curing agent and preparation method thereof

A technology of epoxy resin curing and epoxy resin, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., which can solve the problems of poor impact resistance, wear resistance and corrosion resistance, low hardness of the coating film, and easy discoloration and other issues, to achieve the effect of improving weather resistance and high temperature resistance, good toughness and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

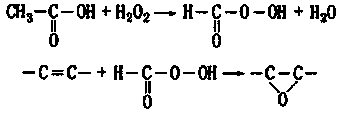

Method used

Image

Examples

Embodiment 1

[0064] In this embodiment, the polyamine compound is composed of isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine and triethylene tetramine is 1:1. The components and parts by weight of the epoxy resin curing agent of this embodiment are as follows: 15 parts of isophorone diamine, 15 parts of triethylenetetramine, 20 parts of benzyl alcohol, 5 parts of E-51 epoxy resin, carbonic acid 3 parts of acrylate, 10 parts of polyether 400 (molecular weight), and 0.05 parts of benzophenone-4.

[0065] The epoxy resin curing agent described in this embodiment is prepared through the following steps:

[0066] Step 1: Add isophorone diamine, triethylenetetramine, and benzyl alcohol into the reaction kettle in sequence, and mix them uniformly by stirring to obtain a mixture.

[0067] Step 2: After heating the mixture to a temperature of 40°C, start dripping epoxy resin, and the dripping is completed within 30 minutes, and then continue to react for 15 min...

Embodiment 2

[0077] In this embodiment, the polyamine compound is composed of isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine and triethylene tetramine is 4:1.

[0078] The components and parts by weight of the epoxy resin curing agent of this embodiment are as follows: 40 parts of isophorone diamine, 10 parts of triethylenetetramine, 40 parts of benzyl alcohol, 10 parts of E-44 epoxy resin, and carbonic acid 8 parts of acrylate, 20 parts of polyether 400 (molecular weight), and 0.1 part of benzophenone-3.

[0079] The epoxy resin curing agent described in this embodiment is prepared through the following steps:

[0080] Step 1: Add isophorone diamine, triethylenetetramine, and benzyl alcohol into the reaction kettle in sequence, and mix them uniformly by stirring to obtain a mixture.

[0081] Step 2: After heating the mixture to a temperature of 50° C., start dripping epoxy resin, and the dripping is completed within 30 minutes, and then continue to reac...

Embodiment 3

[0091] In this embodiment, the polyamine compound is composed of isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine and triethylene tetramine is 3:1. The components and parts by weight of the epoxy resin curing agent of this embodiment are as follows: 30 parts of isophorone diamine, 10 parts of triethylenetetramine, 30 parts of benzyl alcohol, 8 parts of E-51 epoxy resin, and carbonic acid 6 parts of acrylate, 15 parts of polyether 400, and 0.08 parts of ethylhexyl methoxycinnamate.

[0092] The epoxy resin curing agent described in this embodiment is prepared through the following steps:

[0093] Step 1: Add isophorone diamine, triethylenetetramine, and benzyl alcohol into the reaction kettle in sequence, and mix them uniformly by stirring to obtain a mixture.

[0094] Step 2: After heating the mixture to a temperature of 45°C, start dripping epoxy resin, and the dripping is completed within 30 minutes, and then continue to react for 15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com