High wear-resistant ultraviolet curing diffusion film coating composition for PET (polyethylene terephthalate)

A diffusion film and ultraviolet light technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unsatisfactory surface effects, poor haze adjustability, slow curing speed, etc., and achieve huge environmental benefits And economic benefits, hardness enhancement, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

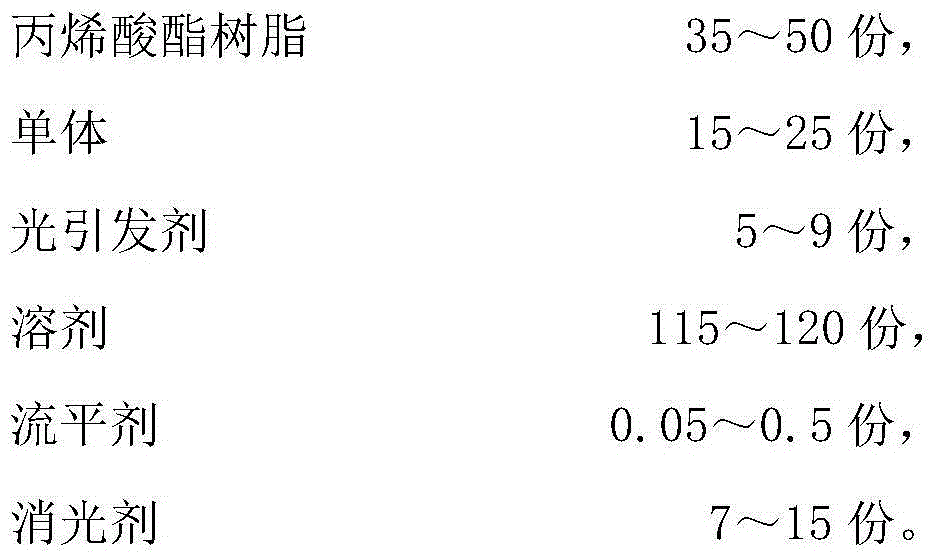

Method used

Image

Examples

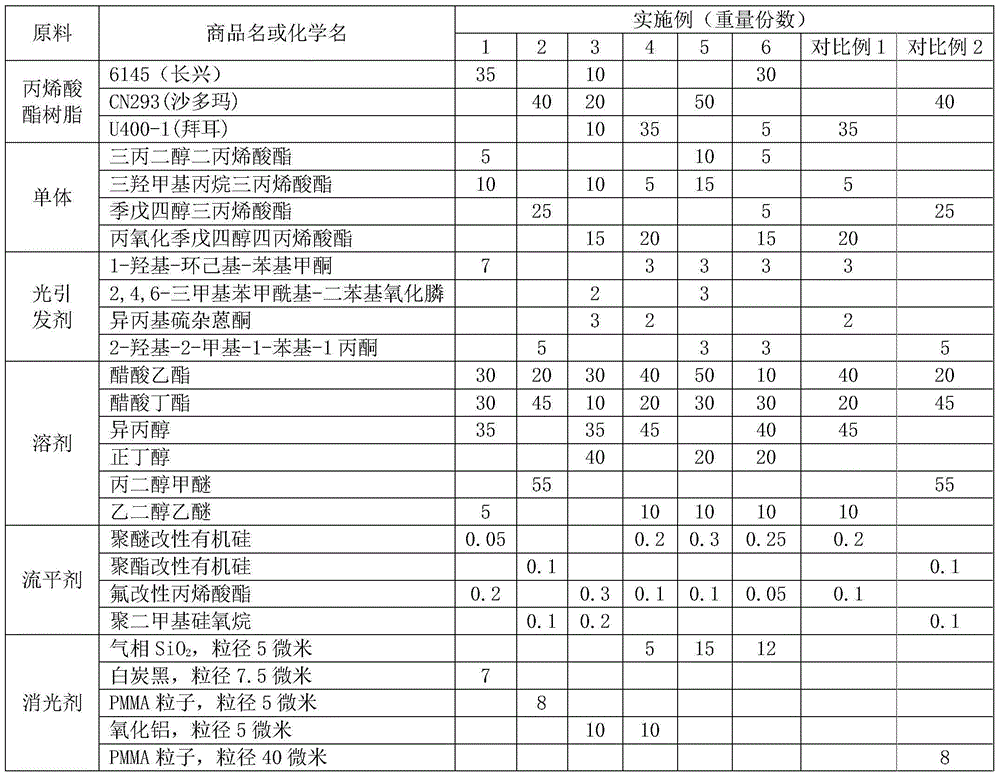

Embodiment 1

[0055] This embodiment relates to a high wear-resistant UV-curable diffusion film coating composition for PET, including the components and parts by weight shown in Table 1. During preparation, first add the components except the matting agent and stir evenly, then gradually add the matting agent under the condition of high-speed stirring (4000r / min), and continue stirring for 30 minutes.

[0056] The paint is coated on the PET film with a No. 6 wire bar, and after drying in an oven for 1 minute (60°C), it is heated by 700mJ / cm 2 The energy curing, the performance is as follows: hardness 3H, 500g; wear resistance 10 times / 1000g; adhesion 5B; haze 11.5, light transmittance 92.6%.

Embodiment 2

[0058] This embodiment relates to a high wear-resistant UV-curable diffusion film coating composition for PET, including the components and parts by weight shown in Table 1. The specific preparation is the same as in Example 1.

[0059]The paint is coated on the PET film with a No. 6 wire bar, and after infrared drying for 1 minute (60°C), it is heated by 700mJ / cm 2 The energy curing, the performance is as follows: hardness 3H, 500g; wear resistance 15 times / 1000g; adhesion 5B; haze 12.7, light transmittance 92.5%.

Embodiment 3

[0061] This embodiment relates to a high wear-resistant UV-curable diffusion film coating composition for PET, including the components and parts by weight shown in Table 1. The specific preparation is the same as in Example 1.

[0062] The paint is coated on the PET film with a No. 6 wire bar, and after infrared drying for 1 minute (60°C), it is heated by 700mJ / cm 2 The energy curing, the performance is as follows: hardness 3H, 500g; wear resistance 13 times / 1000g; adhesion 5B; haze 8.9, light transmittance 93.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com