Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

634results about How to "Low reaction pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic reaction method

InactiveCN1507940AReduce dosageIncrease profitChemical/physical/physico-chemical moving reactorsPorous catalystMulti phase

The present invention discloses a catalytic reaction method. Said method can make the catalytic reaction be implemented in the supergravitational field. Said method utilizes the rotary bed supergravitational field equipment as reactor, on the rotor of said rotary bed supergravitational field equipment a porous catalyst layer and / or a porous filler layer are fixed, and the described catalytic reaction is homogeneous reaction or heterogeneous reaction. Said invention cal reduce catalyst consumption, raise utilization rate of catalyst, raise stability of catalyst and can reduce denergy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +2

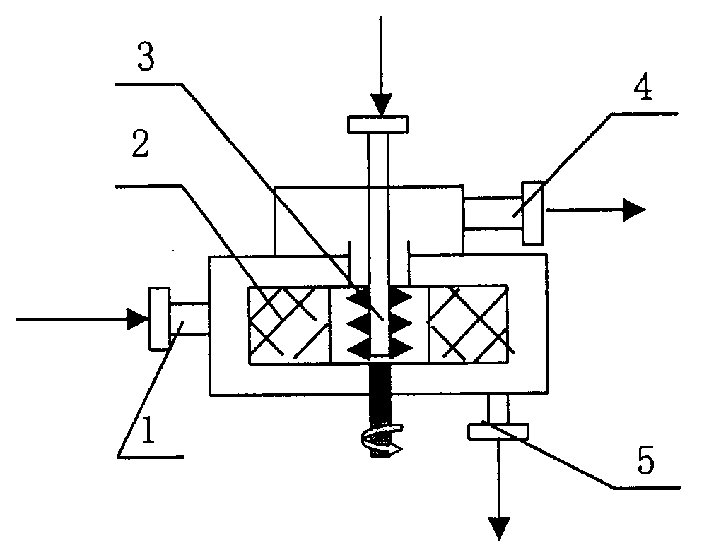

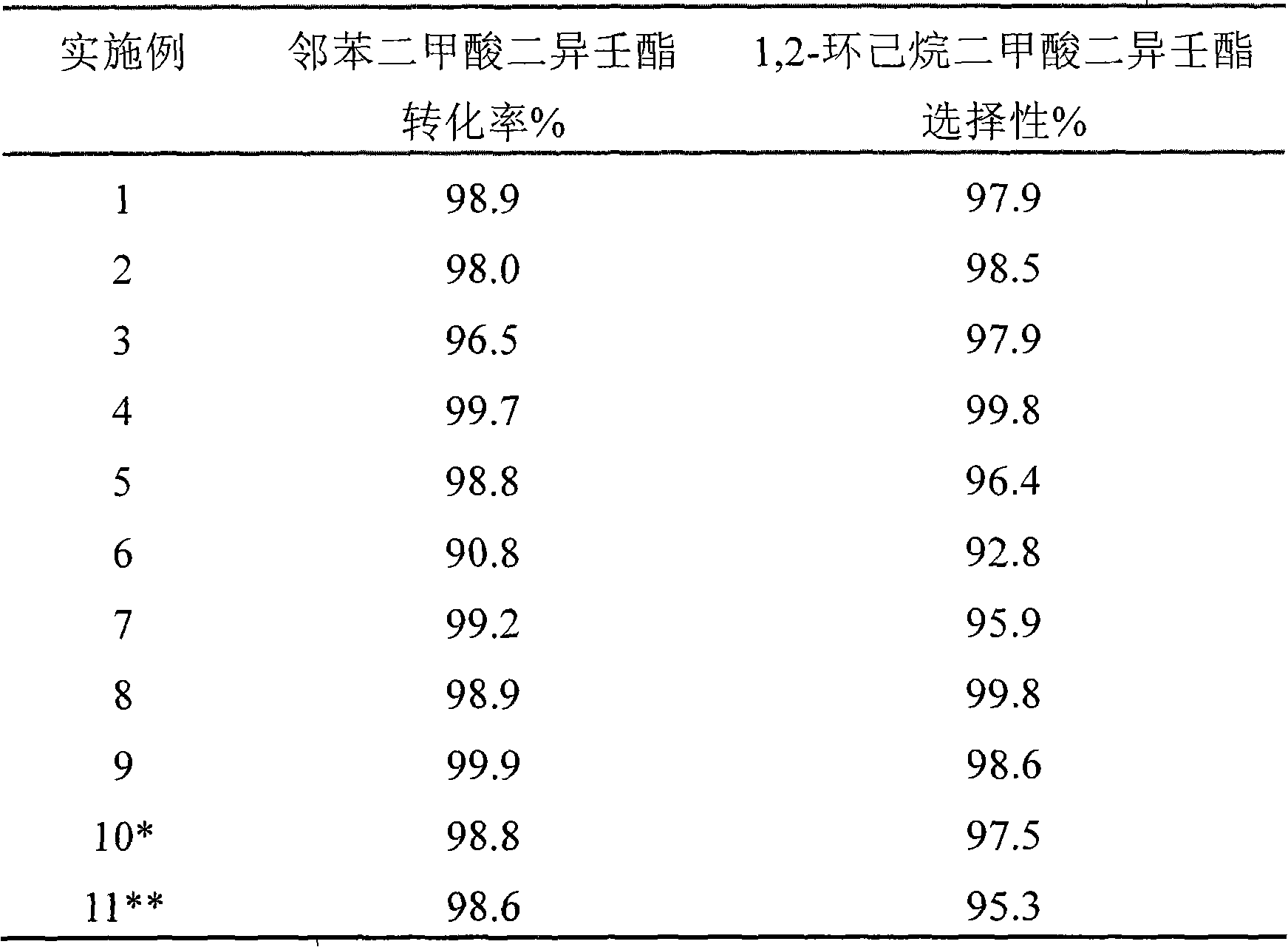

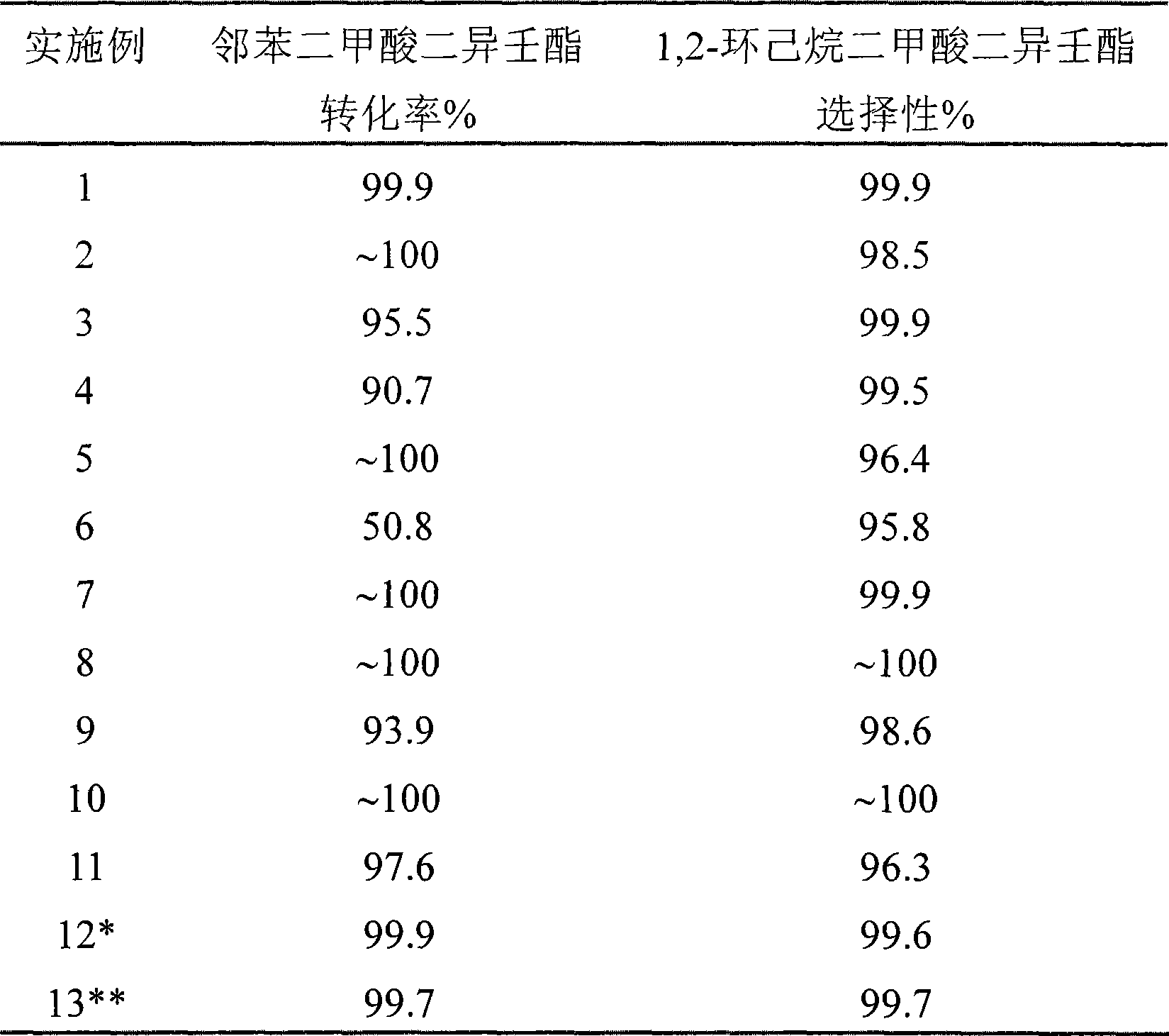

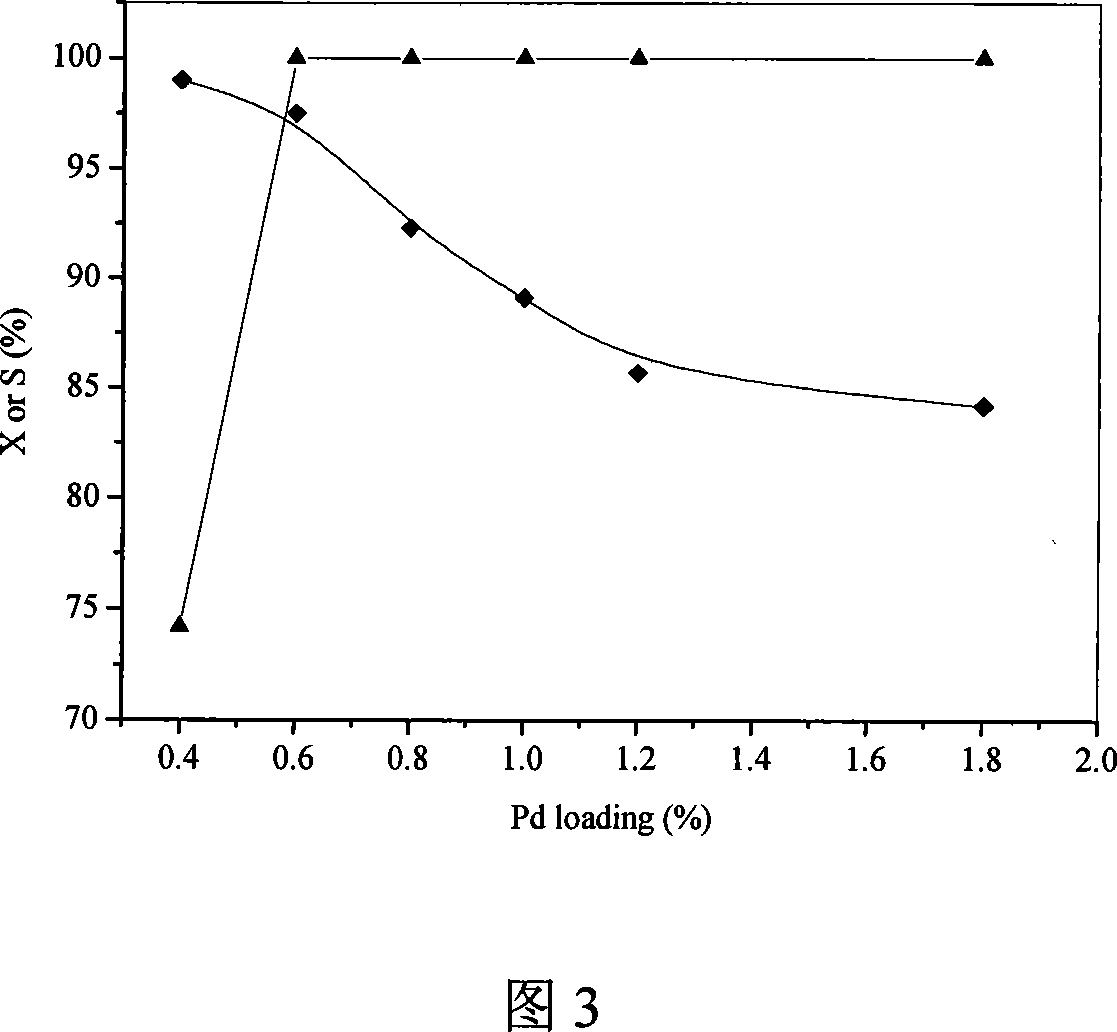

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

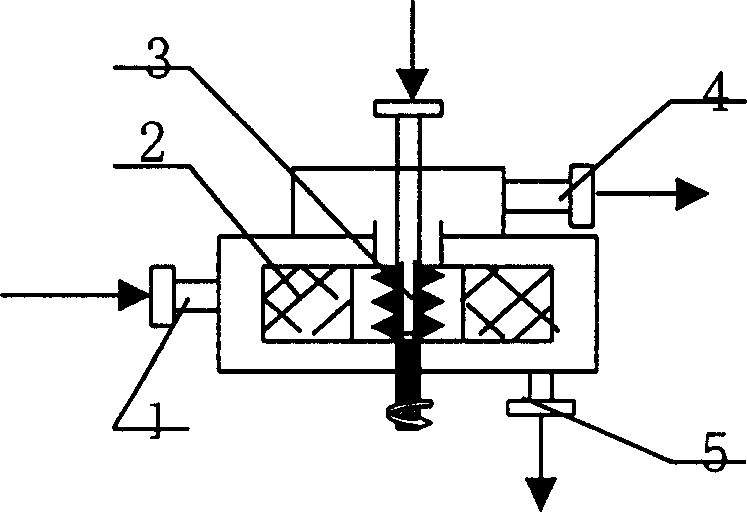

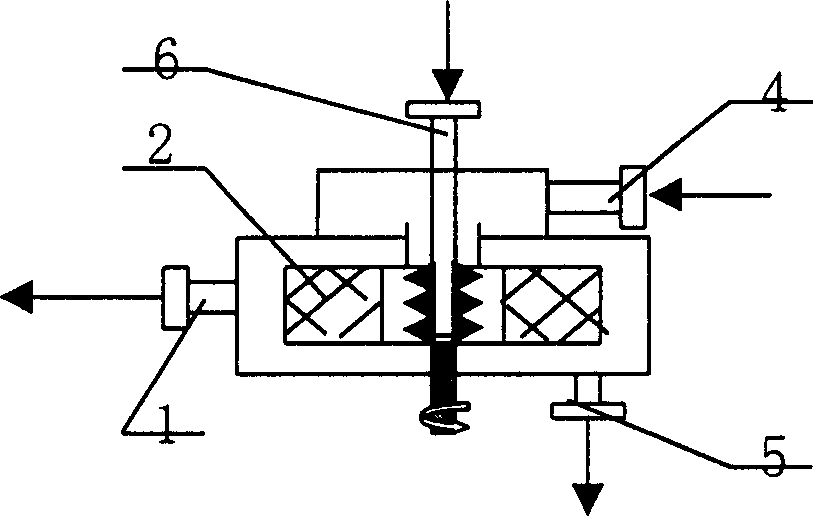

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

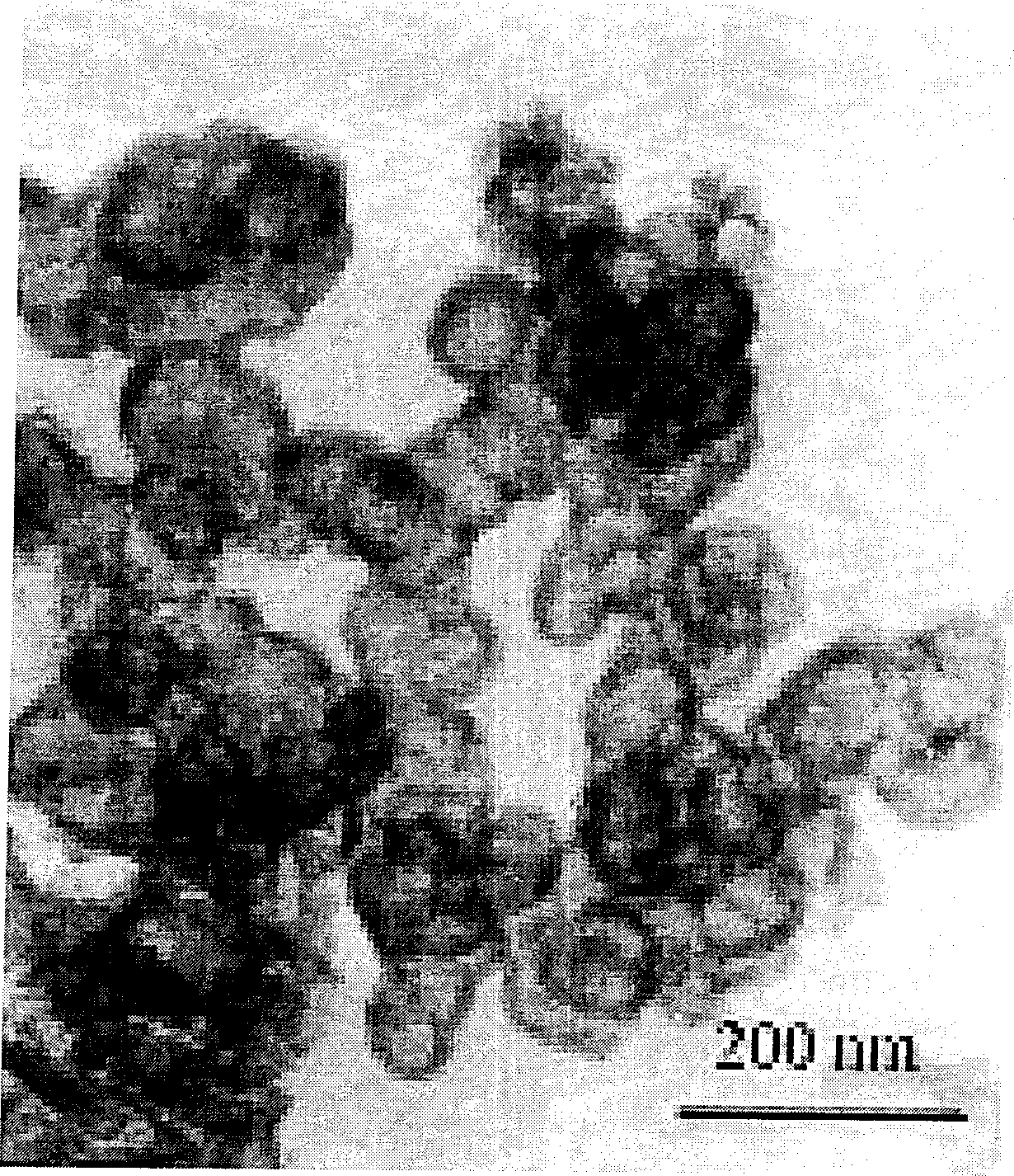

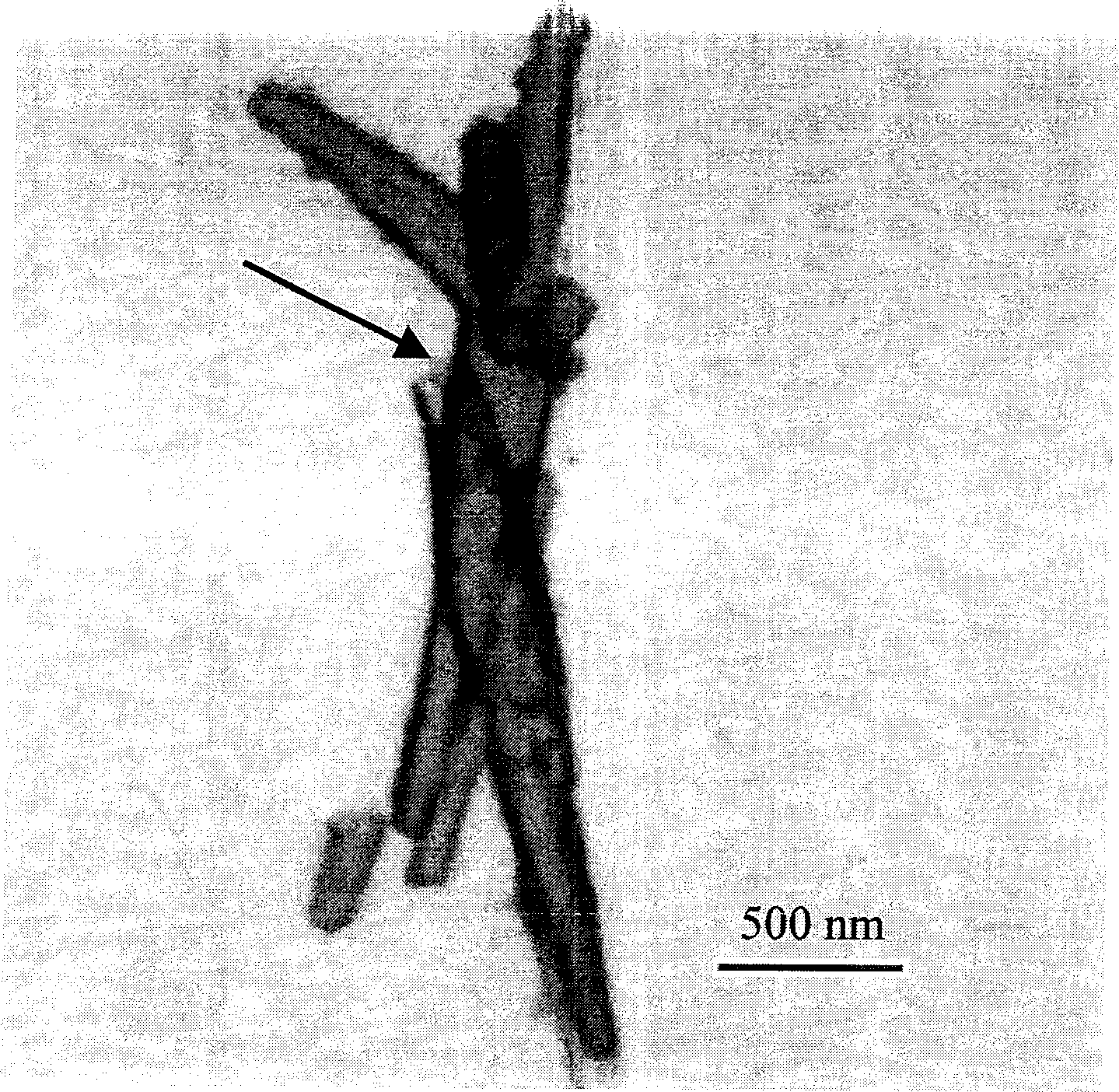

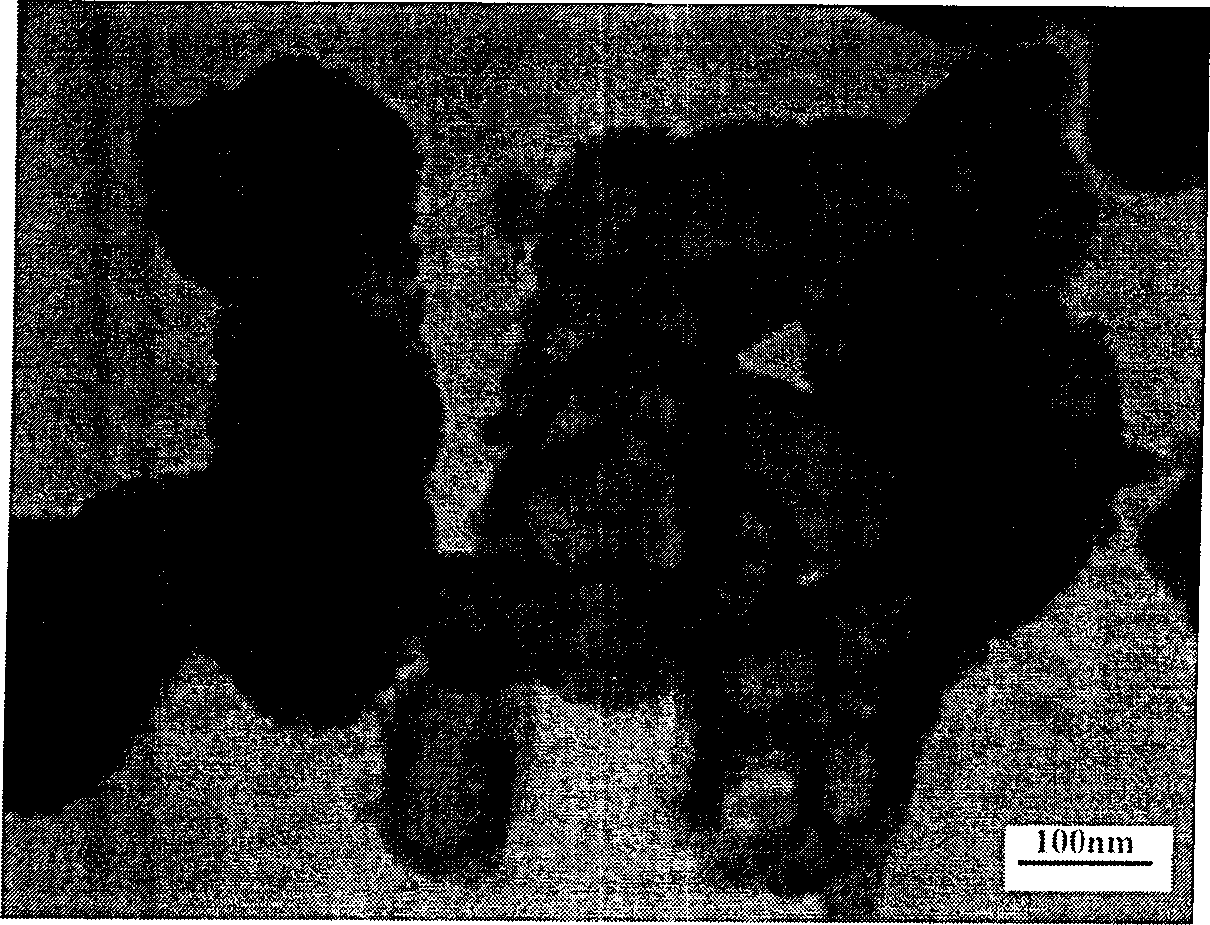

Egg shell type metal catalyst, its preparing process and application method

InactiveCN1736604AImprove conversion rateHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon numberAlcohol

The invention discloses an egg- shell metallic catalyst and the method for preparation and the application. The catalyst is an egg- shell supported metallic catalyst with a carrier of hollow silica dioxide, which is a hollow material of certain wall and bore diameter, and comprises a noble metal of 0.1%- 5.0% and / or a transient metal of 5.0%- 40.0%, a non- noble metallic catalyst promoter of 0- 0.5% and a hollow silica dioxide carrier of 60.0%- 99.0%, with the weight ratio of catalyst as a datum level. The egg- shell metallic catalyst can prepare with immersion method or in- situ supporting method. The catalyst has good metal dispersibility, and the metal particle diameter is minor, dispersing on the external surface, inner surface and in the pore passage. And the egg- shell metallic catalyst can catalyze CO and CO2 to prepare lower carbon number hydrocarbons and alcohol, and it also can catalyze olefin and alkyne selectively.

Owner:BEIJING UNIV OF CHEM TECH

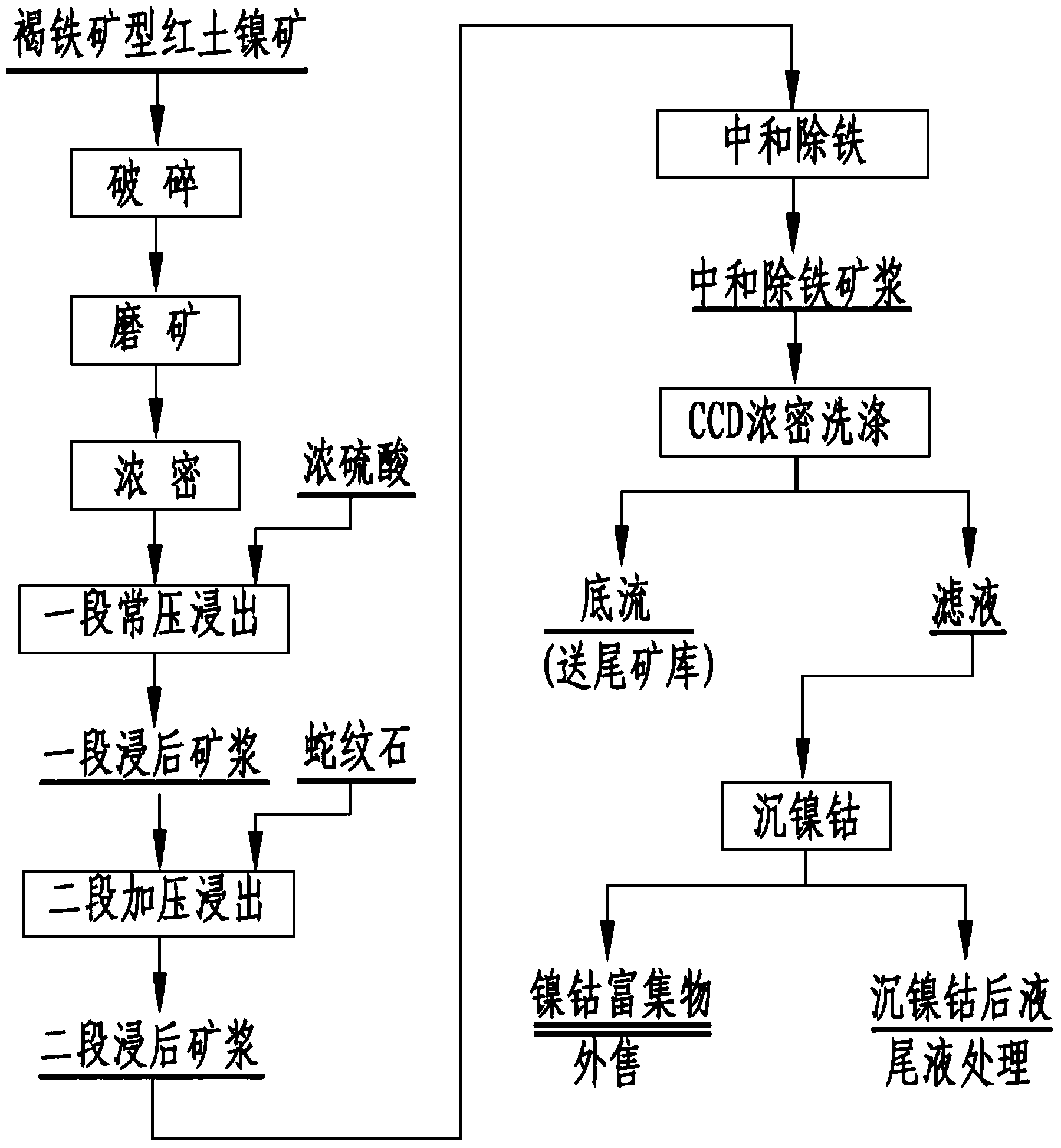

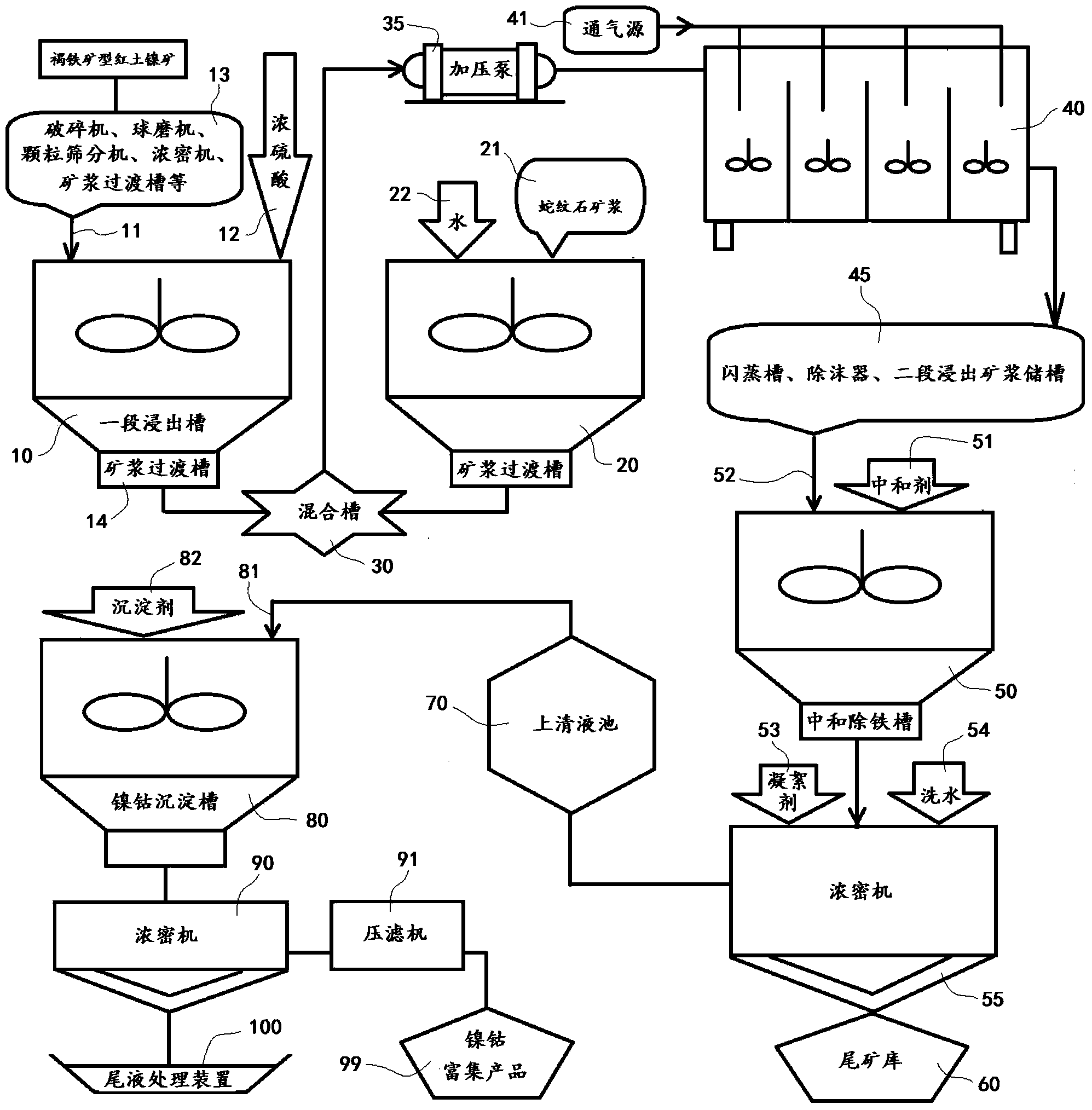

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

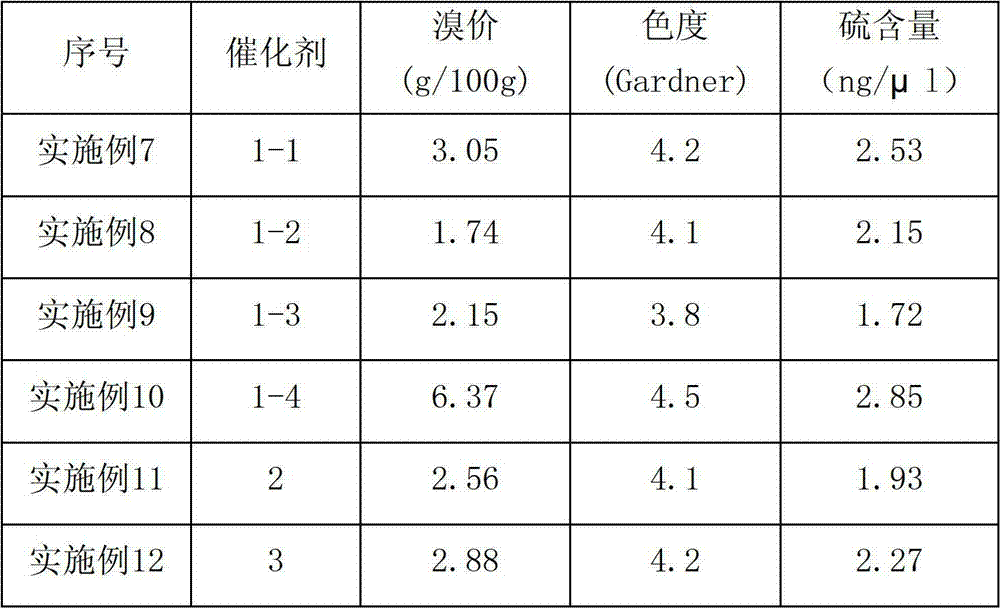

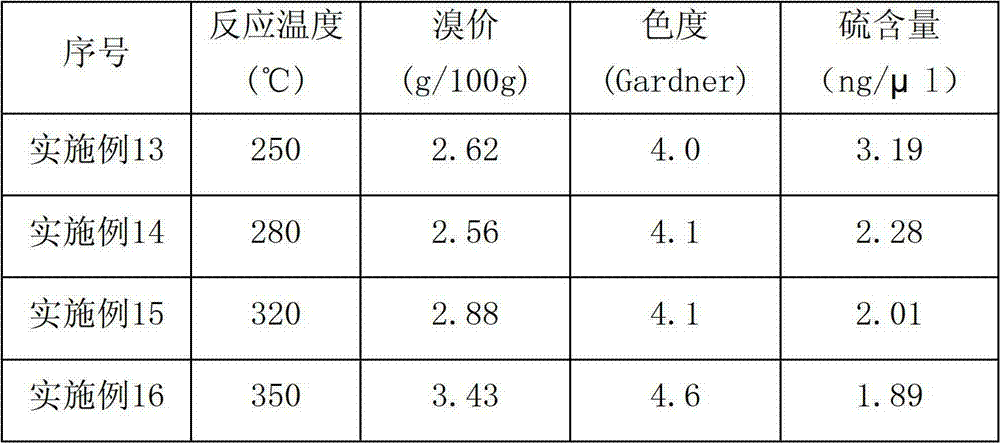

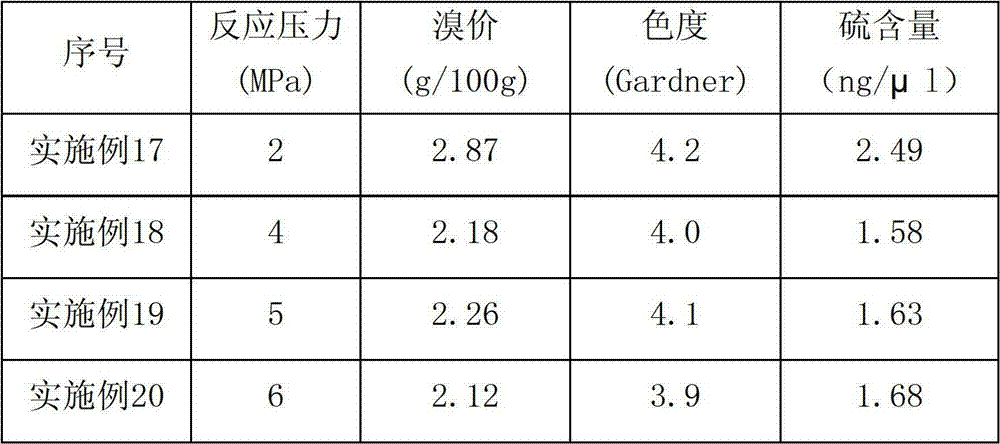

Preparation method for C9 hydrogenation petroleum resin

InactiveCN102924659AWide adaptabilityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSolvent

The invention relates to a preparation method for C9 hydrogenation petroleum resin. The C9 hydrogenation petroleum resin is dissolved in organic solvent, and the concentration of the C9 hydrogenation petroleum resin is 5wt %-30wt%. The C9 hydrogenation petroleum resin is filtered to remove undissolved substances, then subjected to a first section of hydrodesulfurization process and a second section of hydrogenation decoloration process, and finally subjected to the process of decompression rectification and solvent recovery to obtain C9 hydrogenation petroleum resin products. The preparation method adopts two-section hydrogenation, improves reaction activity, selectivity and impurity resistant capability, is wide in adaptability of C9 petroleum resin raw materials, and obtains C9 petroleum resin through adoption of thermal polymerization or catalytic polymerization. No matter impurity content in resin solution is high or low, particularly, when sulphur content is high in the resin solution, the two-step hydrogenation process can be carried out through the preparation method, and the C9 hydrogenation petroleum resin with high performance is obtained. Through the first section of hydrodesulfurization, hydrogenation noble metal catalyst in the second section is effectively protected. Service life of catalyst is greatly prolonged. Reaction pressure of the two-section hydrogenation is quite low, and industrial production cost is little.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

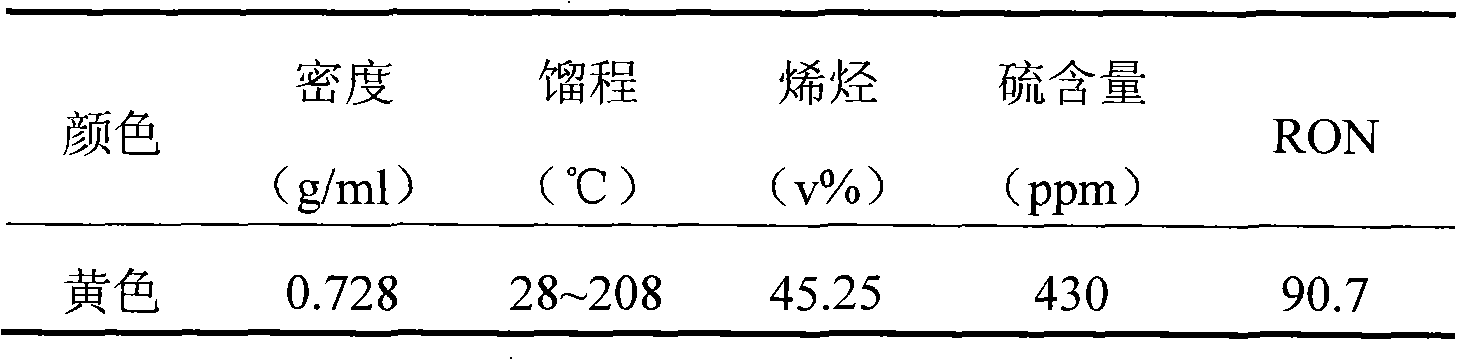

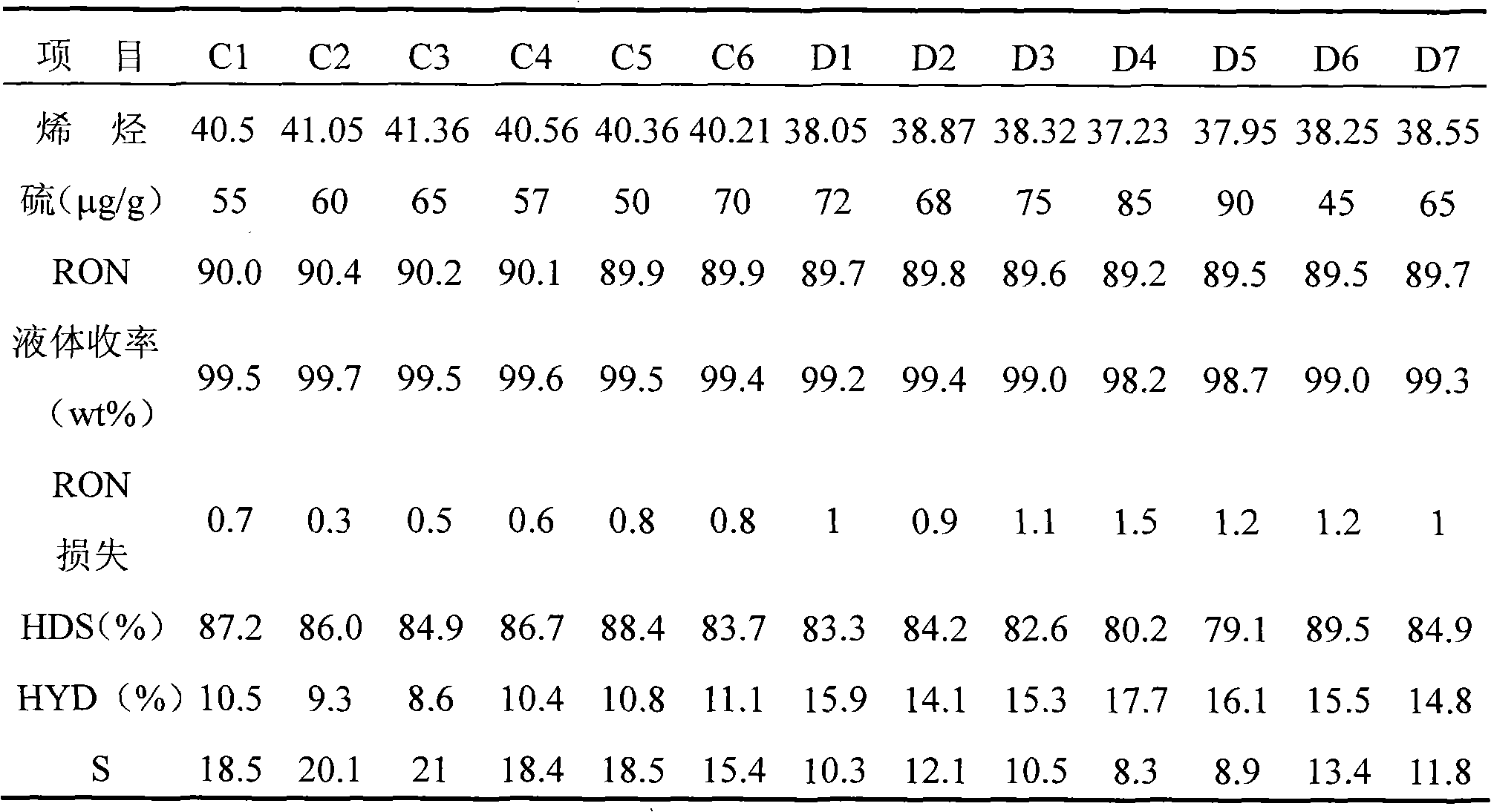

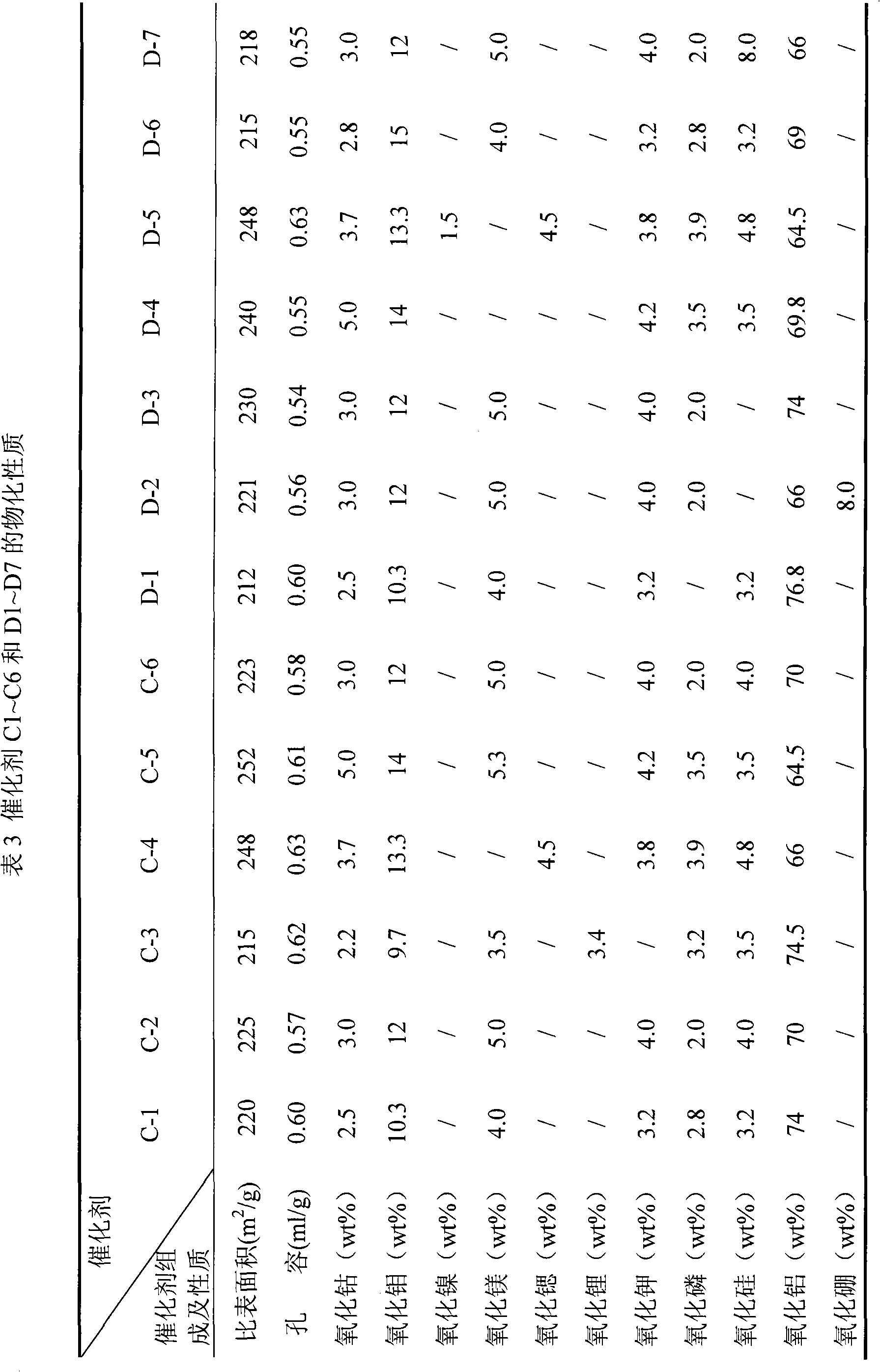

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Glycol catalyst synthesized by hydrogenating oxalic ester and preparation method and application thereof

InactiveCN101524646AImprove hydrogenation activityLow investment costOrganic compound preparationHydroxy compound preparationHigh activityMetal

The invention discloses a glycol catalyst synthesized by hydrogenating oxalic ester and a preparation method and an application thereof. The catalyst has the chemical formula of CuO-AOx / Al2O3, wherein A is one or more than one metallic element of Zn, Mn, Mg and Cr, x is half of the valence number of A, the content of CuO accounts for 40 percent to 80 percent of the catalyst mass, the content of AOx accounts for 5 percent to 40 percent of the catalyst mass and the content of Al2O3 accounts for 5 percent to 30 percent of the catalyst mass. The catalyst has high activity and selectivity at low temperature and under low pressure, the energy and power consumption in production can be reduced greatly and the catalyst has good stability and long service life. The preparation method of the catalyst is simple and raw materials as industrial products are easily obtained and have low price.

Owner:DANYANG DANHUA COAL CHEM

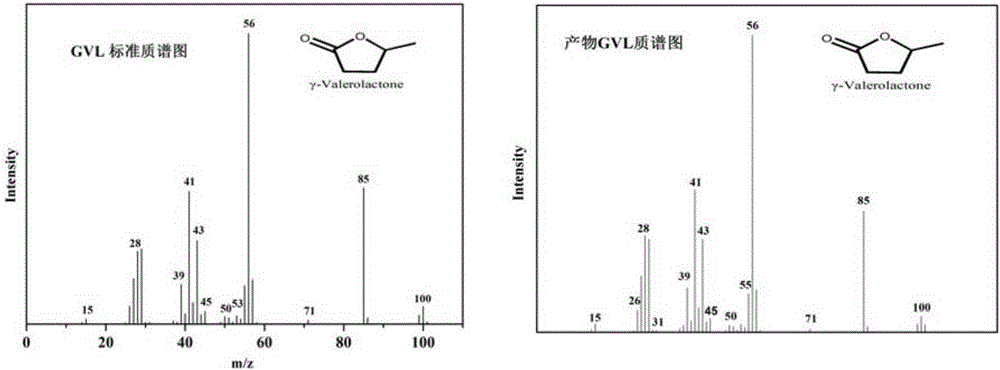

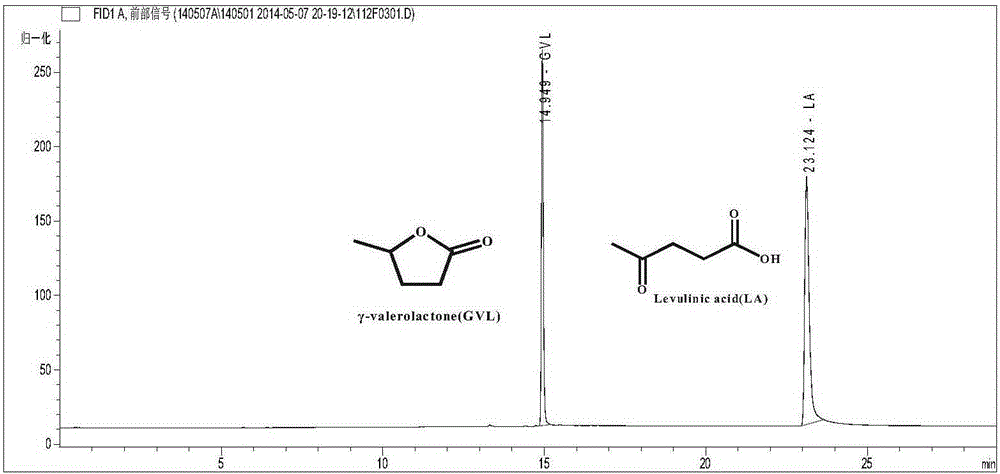

Method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation

ActiveCN105289592AHigh activityGood reaction selectivityOrganic chemistryMolecular sieve catalystsOrganic acidPtru catalyst

The invention discloses a method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation. Through high efficiency catalysis of levulinic acid hydrogenation based on a loaded ruthenium catalyst under mild conditions, gamma-valerolactone is prepared. The method has a levulinic acid conversion rate of 100% and gamma-valerolactone selectivity of 99.9%. The loaded ruthenium catalyst has a low active metal load capacity (less than 1.5w.t.%) and high activity (TOF, 7676h<1>), has good water and acid resistance and is suitable for an intermittent reactor and a continuous fixed bed reactor. The method solves the problem that the existing gamma-valerolactone preparation method needs a high temperature and high pressure and utilizes organic acids and bases and an organic solvent, improves preparation method economy and safety, utilizes a small amount of a catalyst, realizes catalyst recycle, has a high product yield and product separation easiness, and has a latent industrial application value.

Owner:SYNFUELS CHINA TECH CO LTD

Catalyst for o-Fluoro nitrobenzene hydrogenation and its preparation and application

InactiveCN1631524AHigh yieldLower ground contentOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementBenzene

The invention concerns the reaction of benzene catalyst adding hydrogen, specific speaking, it's a kind of catalyst to produce 4-ammonia base-3-F benzene fen and its application. The catalyst is made of carrier, active parts and helping dose. The main active parts are: dear metal Pt, Pd or Rh, whose weight is of catalyst 0.1%--20%. Help doses are IA, ó�A, ó¾B, ó° or Sparse soil chemical element. The catalyst has the feature of high active in reactivation, good choosing ability and many reuses. The catalyst can also be used in other replacing nitric unit benzene adding hydrogen and catalyst process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Monolithic catalyst for catalyzing combustion of volatile organic compounds and preparation method of catalyst

InactiveCN105964254AEasy to manufactureImprove production efficiencyIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCordieriteManganese oxide

The invention belongs to the technical field of catalysis, and particularly discloses a monolithic catalyst for catalyzing combustion of volatile organic compounds and a preparation method of the catalyst. According to the catalyst, cordierite honeycomb ceramic serves as a carrier, and the carrier is coated with a coating containing a metal active component and an auxiliary, wherein the catalyst active component is selected from any one or a combination of noble metals of Pt and Pd, and the catalyst auxiliary is selected from one or a combination of metal oxides such as aluminum oxide, titanium oxide, chromic oxide, cobaltous oxide and manganese oxide. The preparation method of the catalyst is simple, and the catalyst has the advantages that the coating is not prone to disengagement, the initiation temperature is low, the activity is good, the high-temperature-resistant property is good, and the noble metal content is low; the catalyst can be widely used for purification treatment of organic waste gas.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

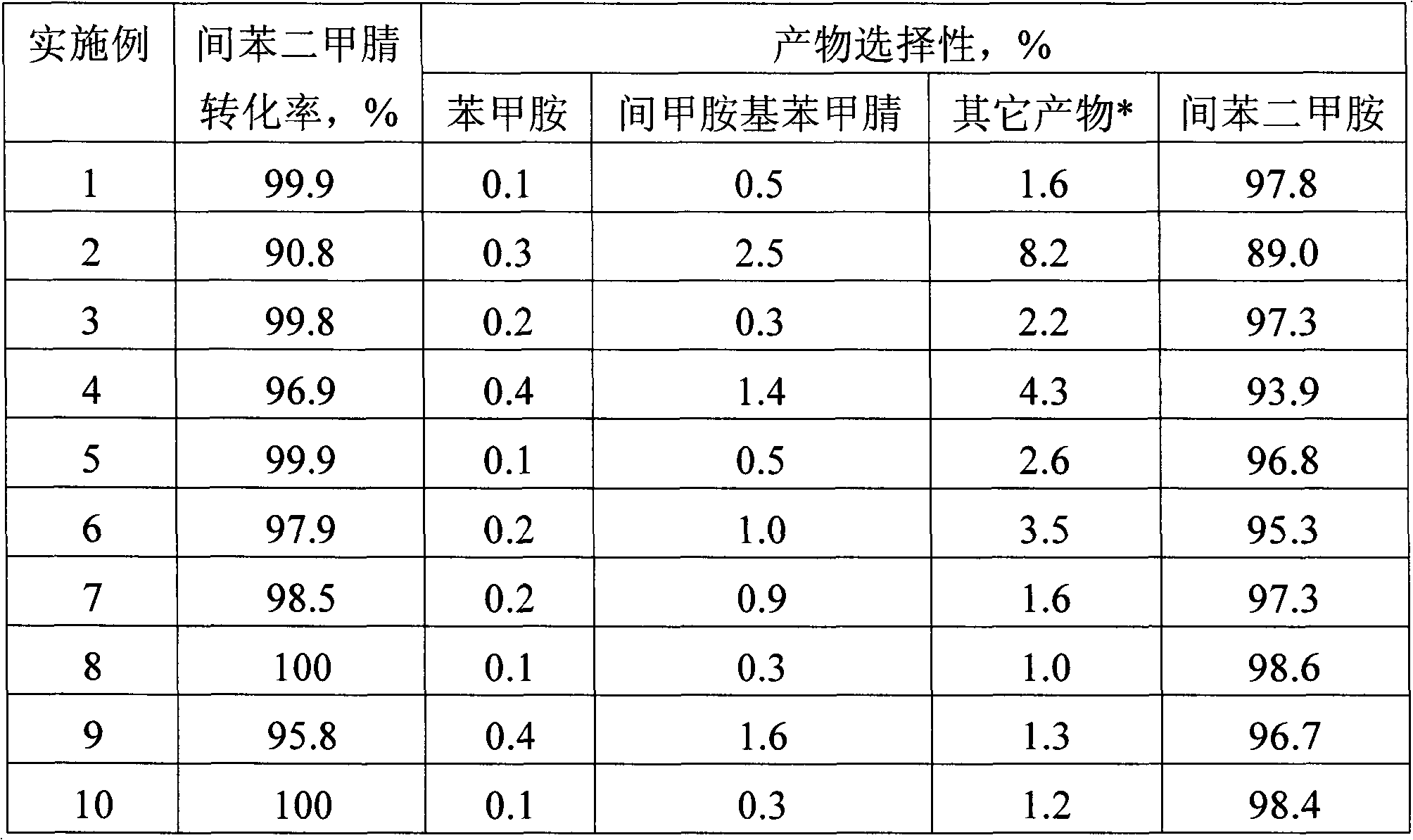

Catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions

ActiveCN102688763ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationAmino compound preparationFixed bedHigh activity

The invention discloses a catalyst for preparing m-xylylenediamine by isophthalonitrile hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of isophthalonitrile and hydrogen into m-xylylenediamine under ammonia reaction conditions and comprises a main active component, one or more auxiliary agents and a carrier. The main active component is a transition metal Ni or Co. The one or more auxiliary agents are selected from Re, Cu, Cr, Ru, Fe and their oxides. The carrier is diatomite, Al2O3 or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of isophthalonitrile and hydrogen into a plurality of amine products comprising m-xylylenediamine as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

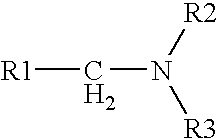

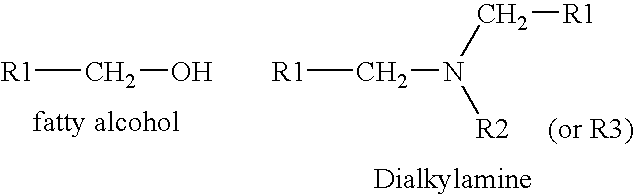

Process for obtaining amines by reduction of amides

InactiveUS20060287556A1Prolong lifeSimple process followOrganic compound preparationAmino compound preparationHydrogenFixed bed

Disclosed is a process for the preparation of primary, secondary and tertiary amines via a catalytic hydrogenation of unsubstituted, N-substituted, and N,N-disubstituted amides. The amide is led, together with an auxiliary amine, in vaporised form in a hydrogen containing gas flow over the catalyst. The process can be carried out at relatively low pressures, between 2 and 50 bars, using typical hydrogenation catalysts like CuCr-type catalysts. The amine is obtained with high yield and high selectivity. The process can be carried out in a continuous fixed bed reactor.

Owner:TAMINCO NV

Catalyst for preparing dichloroaniline through hydrogenization for dichloronitrobenzene, and preparation method

InactiveCN101049560ALow Pd contentApply many timesOrganic compound preparationAmino compound preparationActivated carbonActive component

A catalyst for preparing dichlorophenylamine by hydrogenating dichloronitrobenzene is composed of the activated carbon as carrier and the Pd as active component (0.2-2.0 Wt%) carried by said activated carbon. Its preparing process includes such steps as cyclically immersing activated carbon in diluted nitric acid, water washing until it becomes neutral, immersing in the aqueous solution of PdCl2, filtering, and baking the filtered cake. It has high catalytic performance and long cyclic service life.

Owner:EAST CHINA UNIV OF SCI & TECH

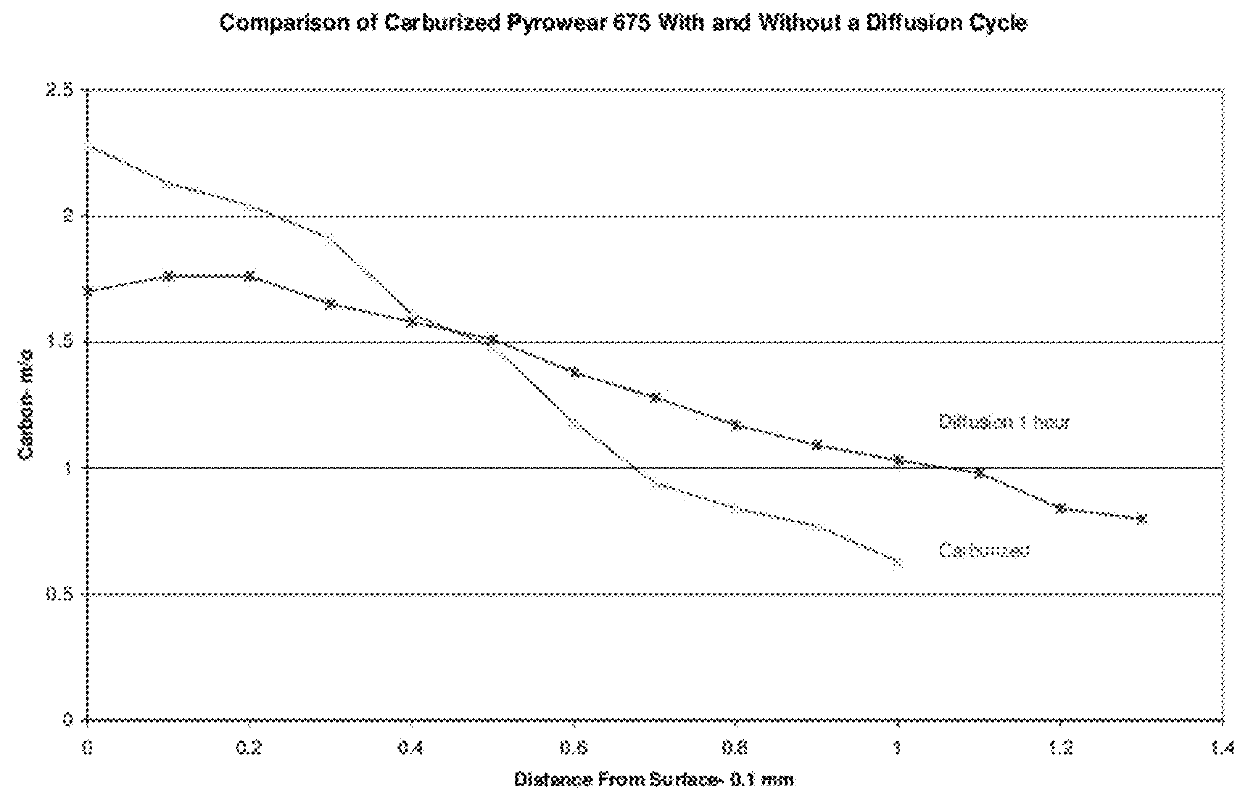

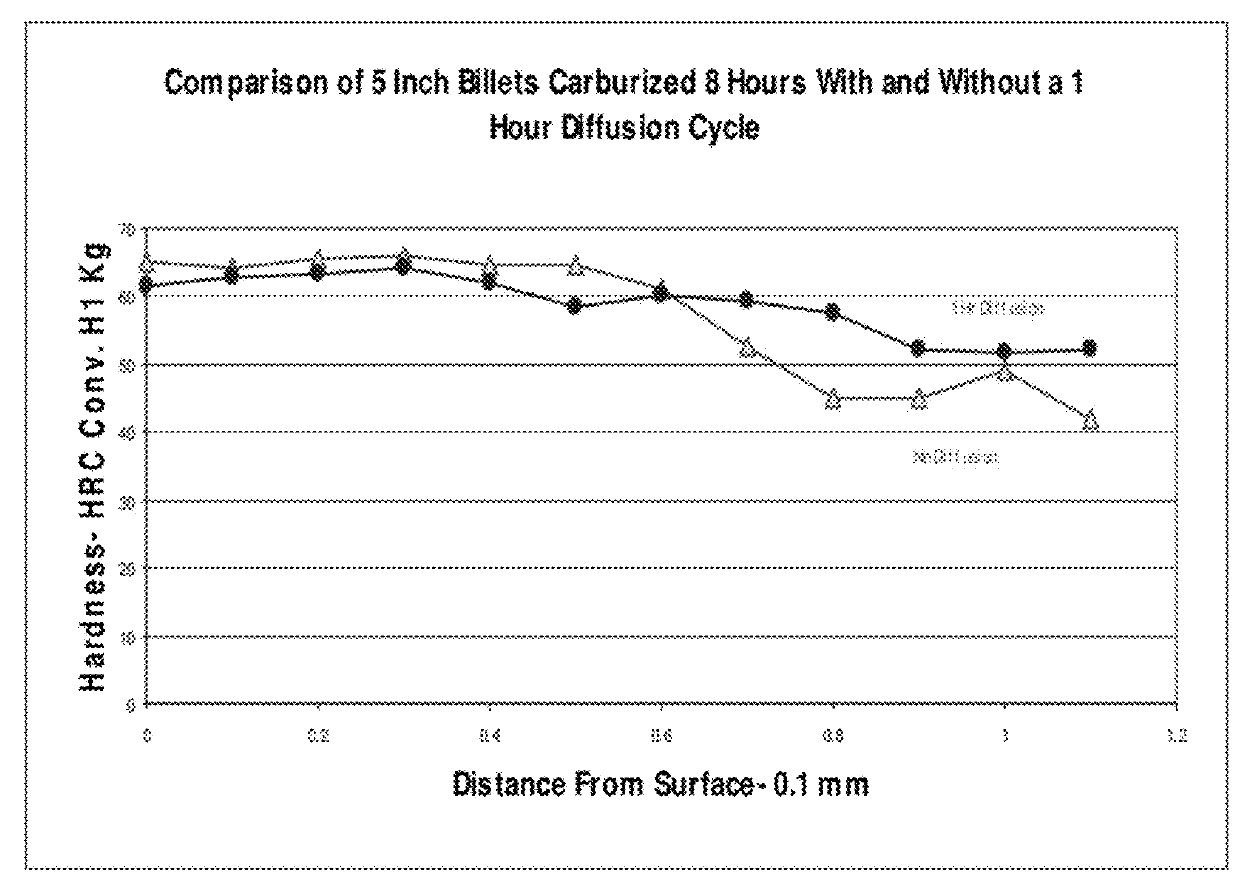

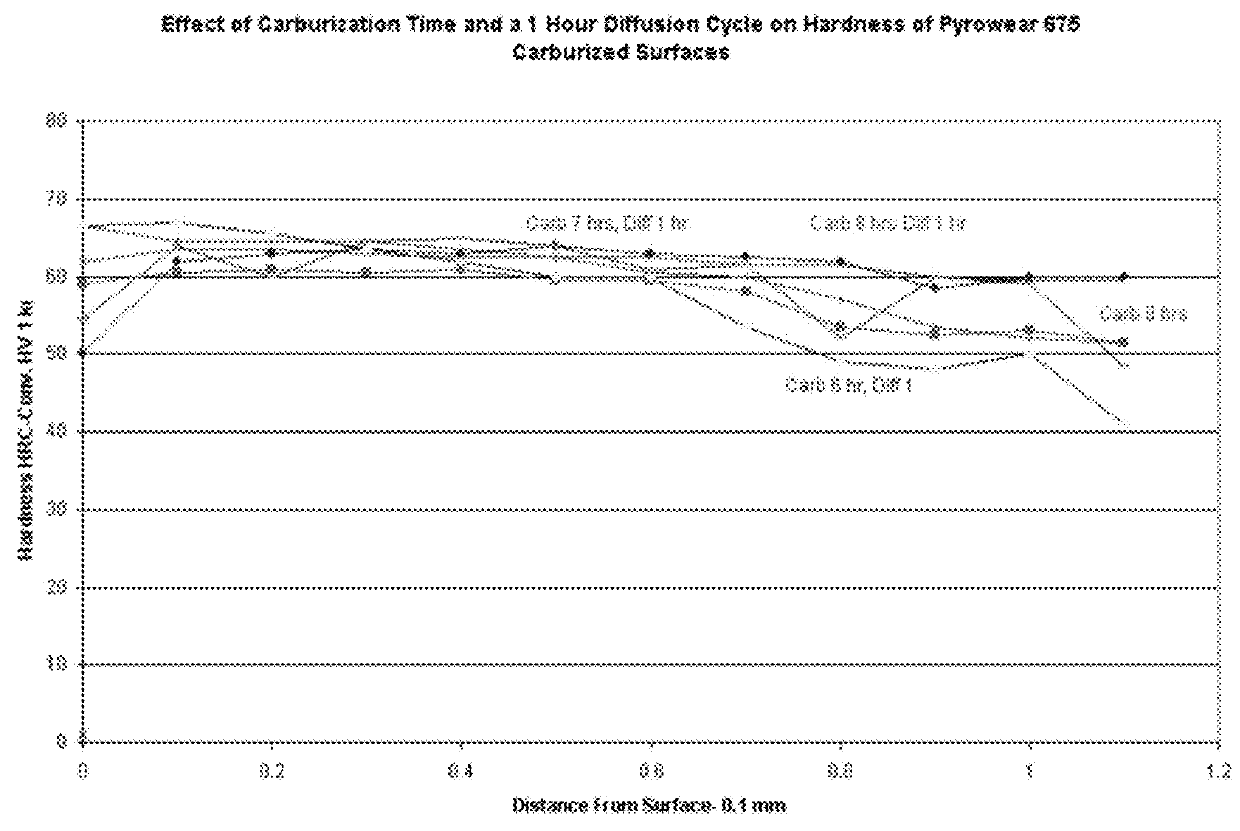

Novel Stainless Steel Carburization Process

InactiveUS20120111454A1Short cycleReaction pressure is loweredSolid state diffusion coatingVacuum furnaceHydrocarbon

A process for the high temperature carburization of steel comprising heating said steel in a vacuum furnace in the presence of a hydrocarbon carburizing gas in combination with hydrogen wherein said carburizing gas / hydrogen combination is administered to the vacuum furnace by cyclically reducing the pressure in the furnace followed by the pulsed addition of the hydrocarbon carburizing gas with hydrogen at partial pressure followed by a second diffusion cycle wherein the steel is further annealed for a time sufficient to allow for the additional deposition of from about 0.8% to about 3.0% m / o of said carbon onto the surface of said steel to permit the further migration of the carbon from the steel surface to the interior thereof.

Owner:MOYER KENNETH H

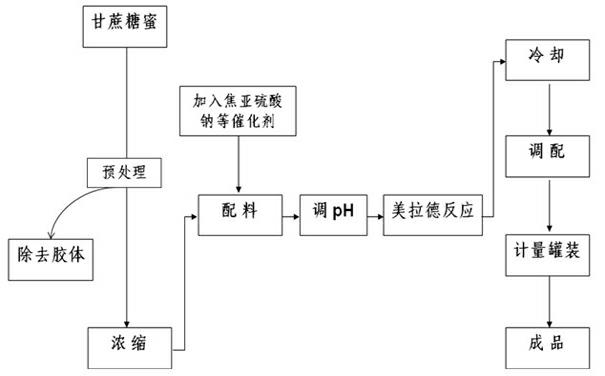

Method for producing high color ratio double-strength caramel using cane molasses

The invention provides a method for producing high color ratio double-strength caramel using cane molasses, which includes: a, pretreating cane molasses to remove gum, and filtering the molasses solution after neutralizing PH value; b, concentrating the pretreated molasses till the molasses accounts for 60%-80% of total molasses in weight percentage; c, adding solid catalysts, namely sodium pyrosulfite and ammonium bicarbonate; d, adding phosphoric acid to adjust the PH value to 5.5; e, heating and controlling temperature, and performing Maillard reaction; f, cooling caramel; g, blending, metering, and canning to obtain the finished product. The method overcomes a plurality of technical bottlenecks, and implements production of the high color ratio double-strength caramel using the cane molasses to replace white granulated sugar or glucose as material, and accordingly material cost is reduced greatly, and the molasses is turned into wealth. The color ratio of the double-strength caramel can be up to 120000EBC, and liquid catalysts such as traditional liquid ammonia, liquid sulfur dioxide and the like are replaced with the solid catalysts such as the sodium pyrosulfite and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

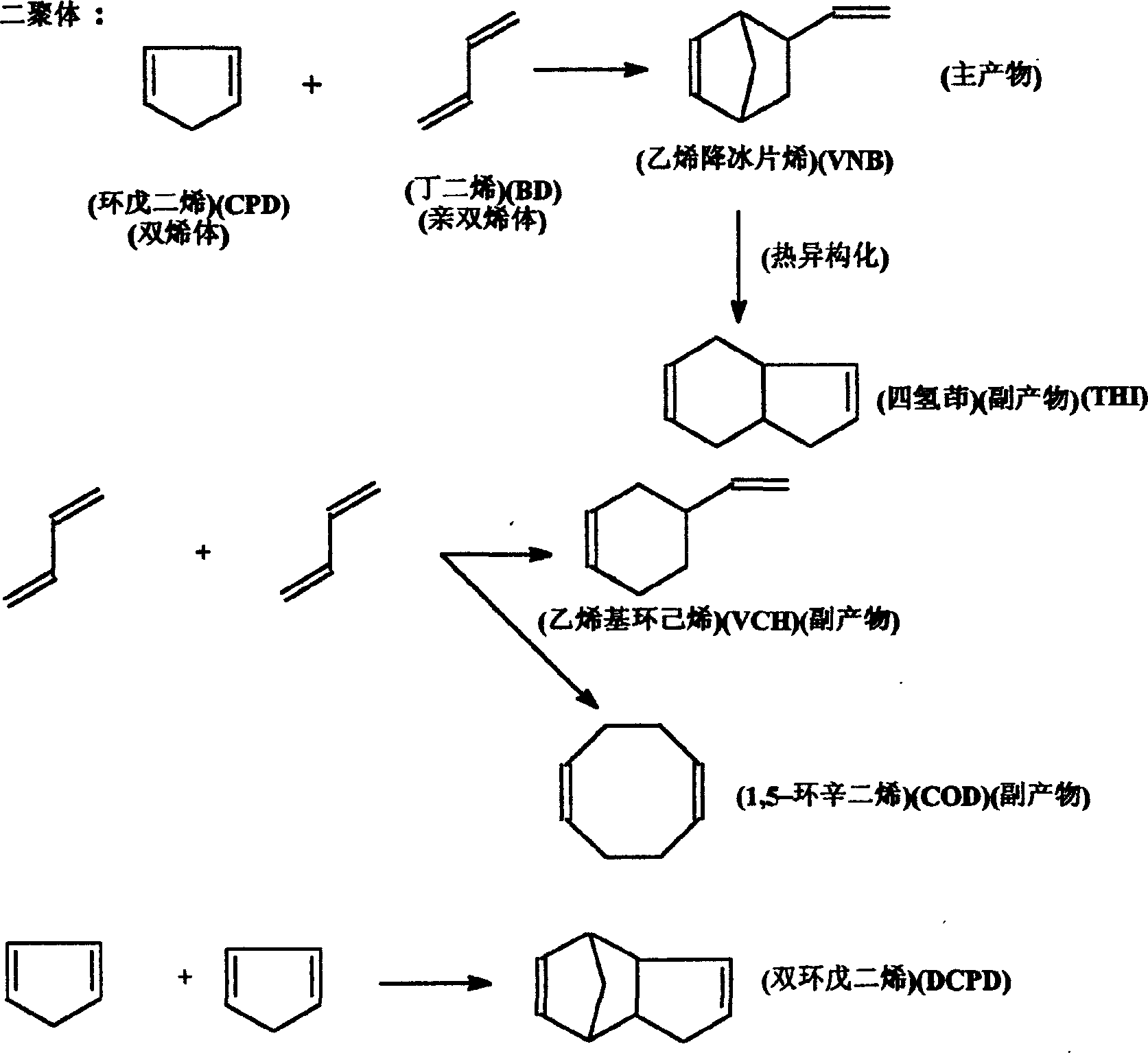

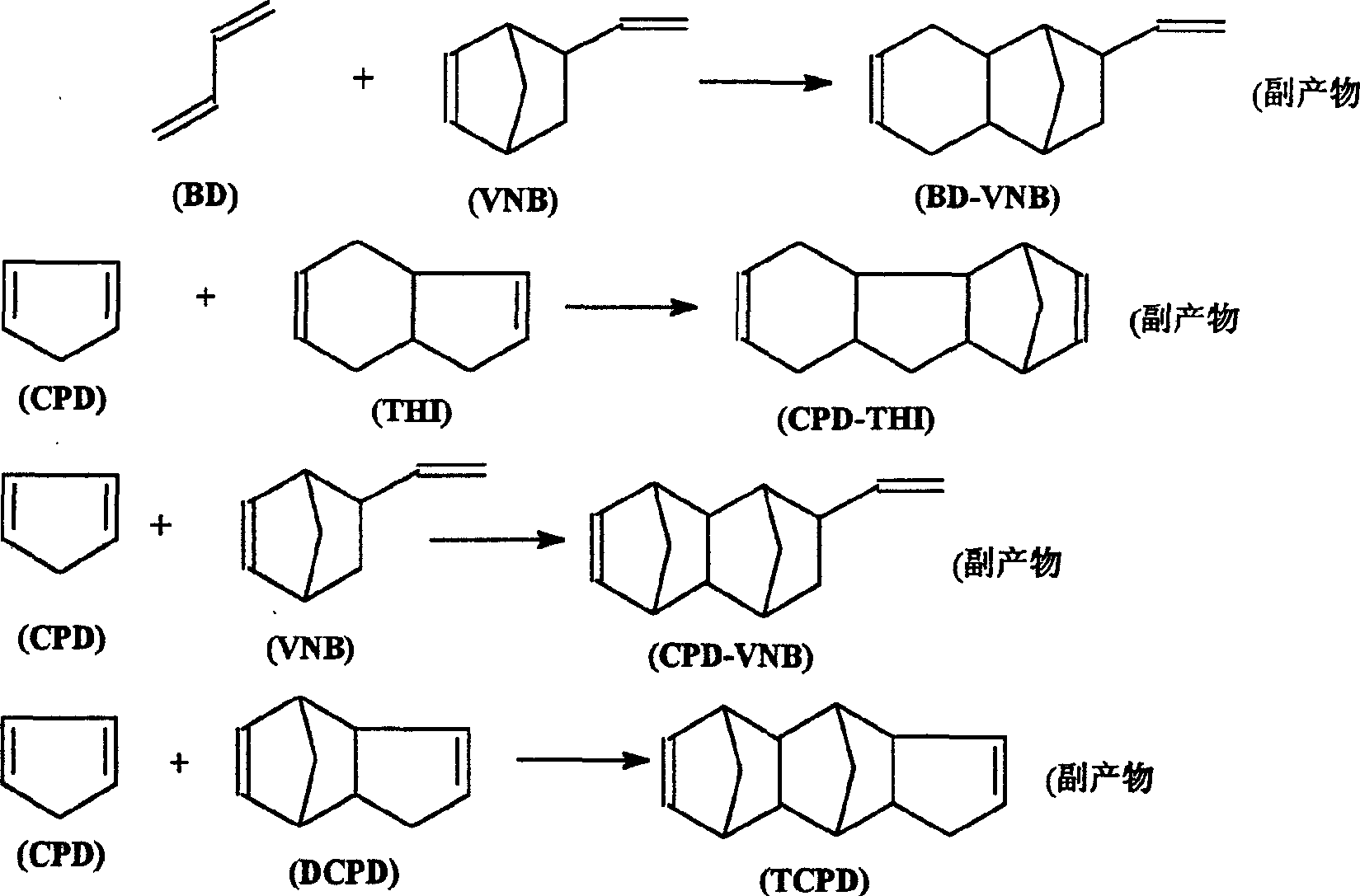

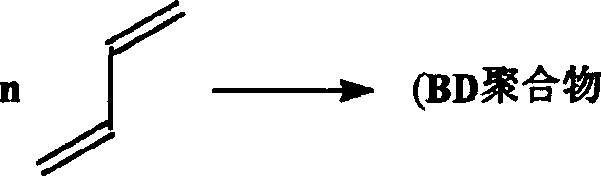

Method for synthesizing 5-vinyl-2-norbornaene

InactiveCN1580015AFlexible operationIncrease elasticityHydrocarbons from unsaturated hydrocarbon additionAlpha-naphtholToluene

The invention refers to the synthesizing method of 5-ethylene-2-norborene. The mol ratio of the butadiene and cyclopentadiene is 1-2:1. The invention chooses toluene or normal hexane as the solvent and the weight ratio of the reactants added to the solvent is between 20% and 30%. It chooses alpha-naphthol as the inhibitor and its dosage is between 50ppm and 3000ppm of the reactants. We put the material into the reaction kettle, increase the temperature when or after whisking and make them reacting for between 0.25 hour and 4 hours at the temperature of between 130deg.C and 160deg.C and at the pressure of between 1MPa and 8MPa. Or after being mixed we put the material into the reaction kettle or the tubular reactor and stay for between 0.25 hour and 1.0 hour at the temperature of between 130deg.C and 160deg.C and at the pressure of 1.8MPa. The weight ration of the dicyclopentadiene in the material of cyclopentadiene is less than between 5% and 8%. The invention obviously increases the yield of the turnoff by over 5mol%.

Owner:吉林市大宇化工有限公司

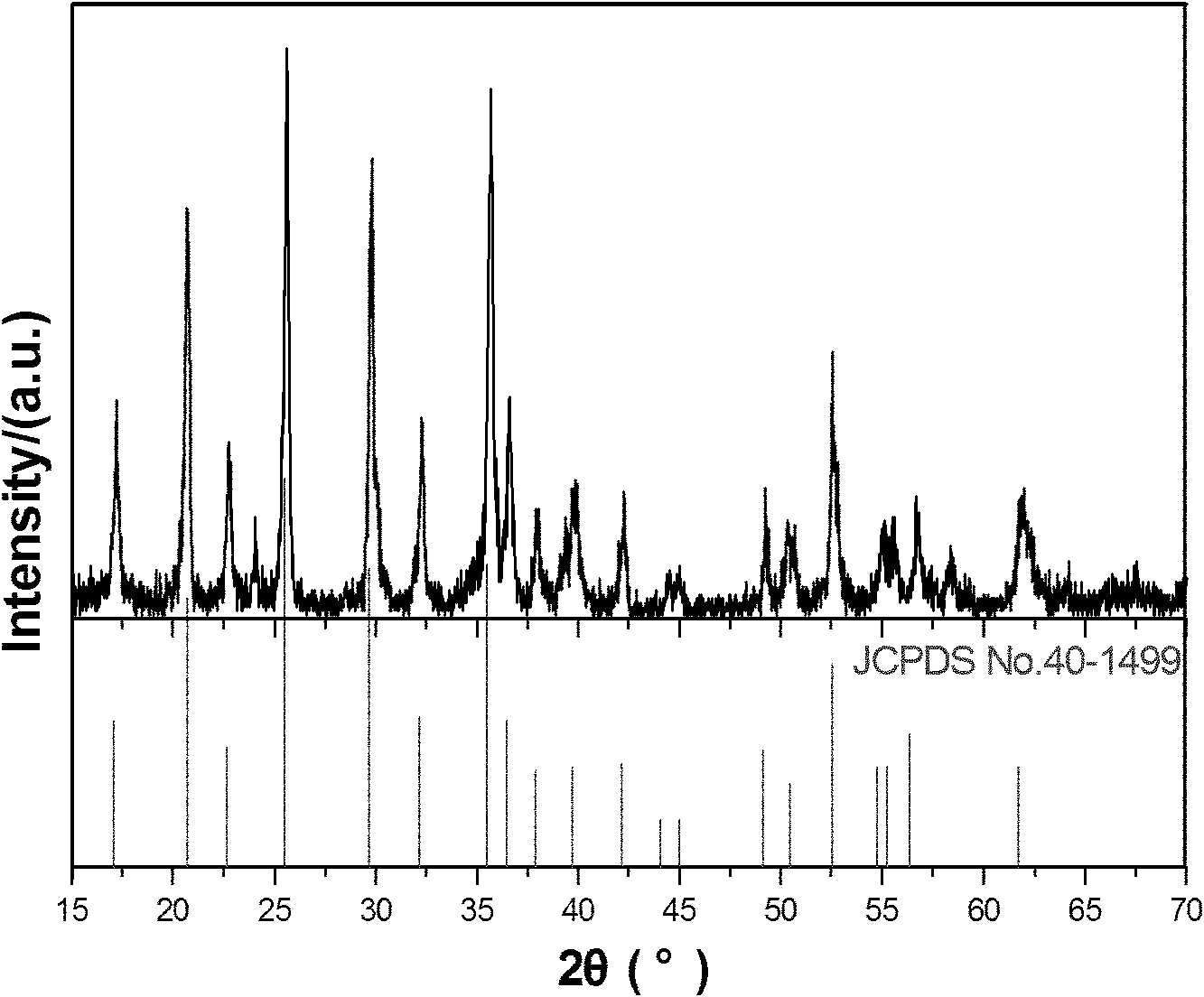

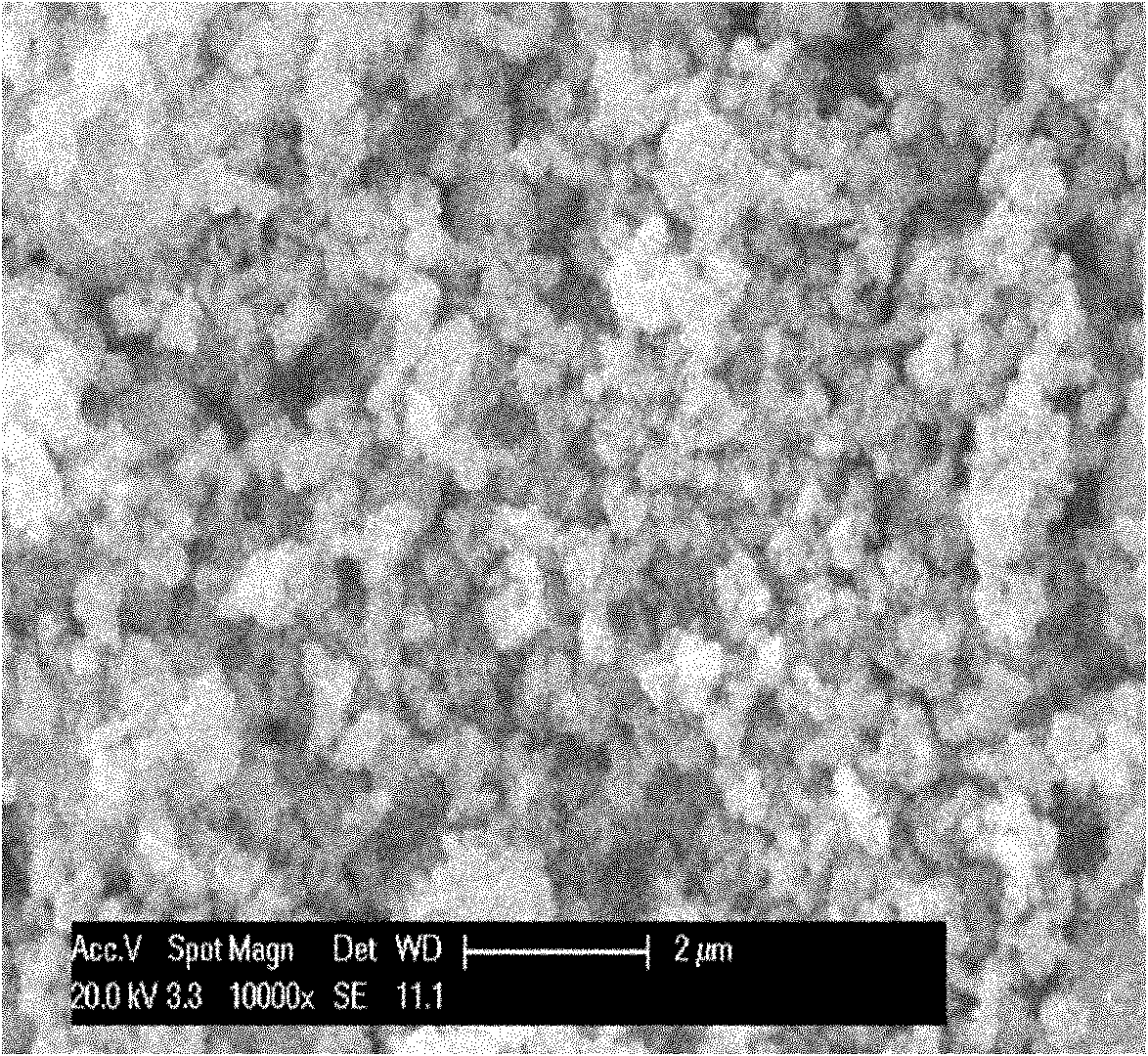

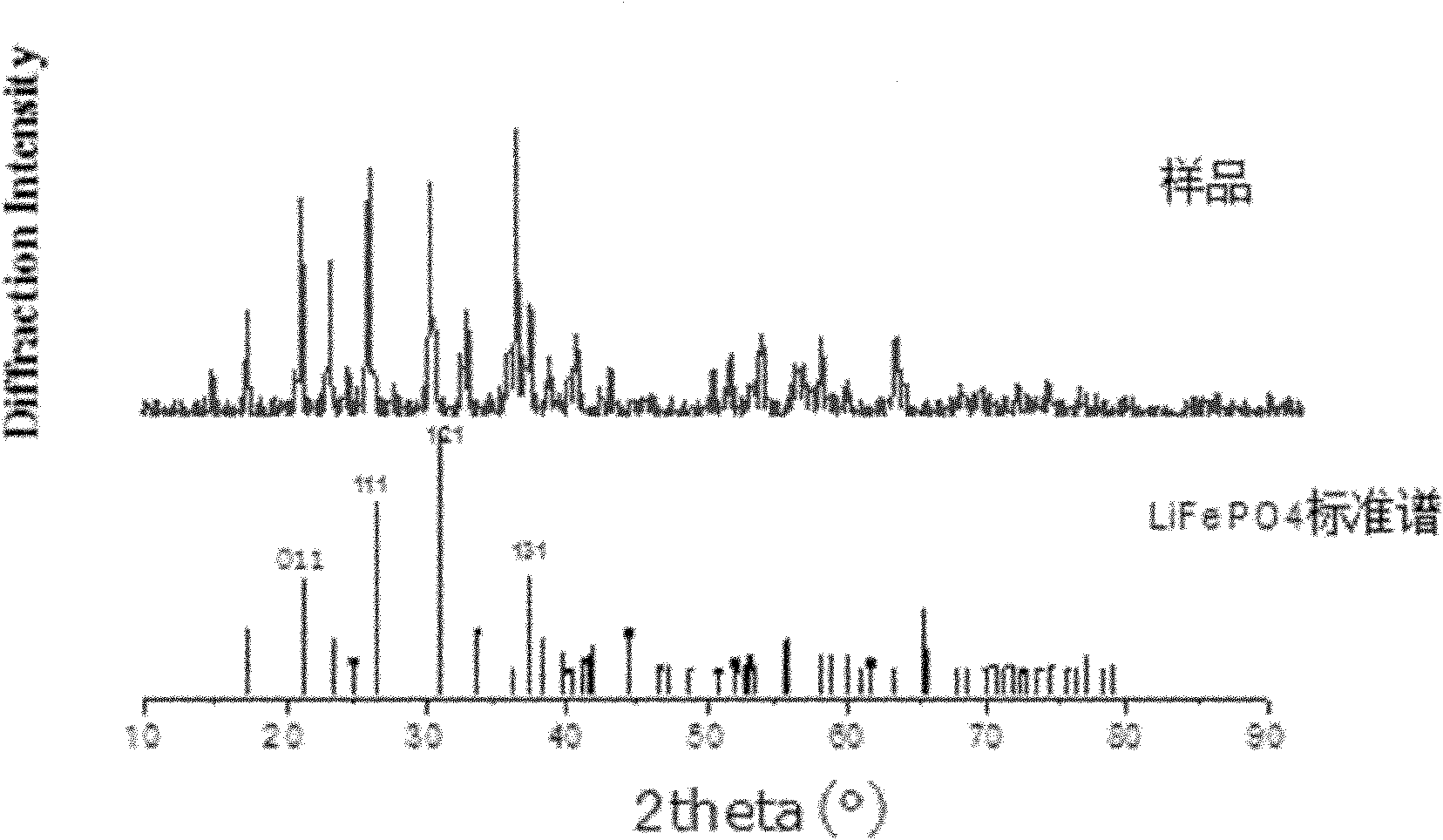

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

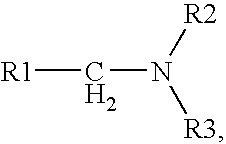

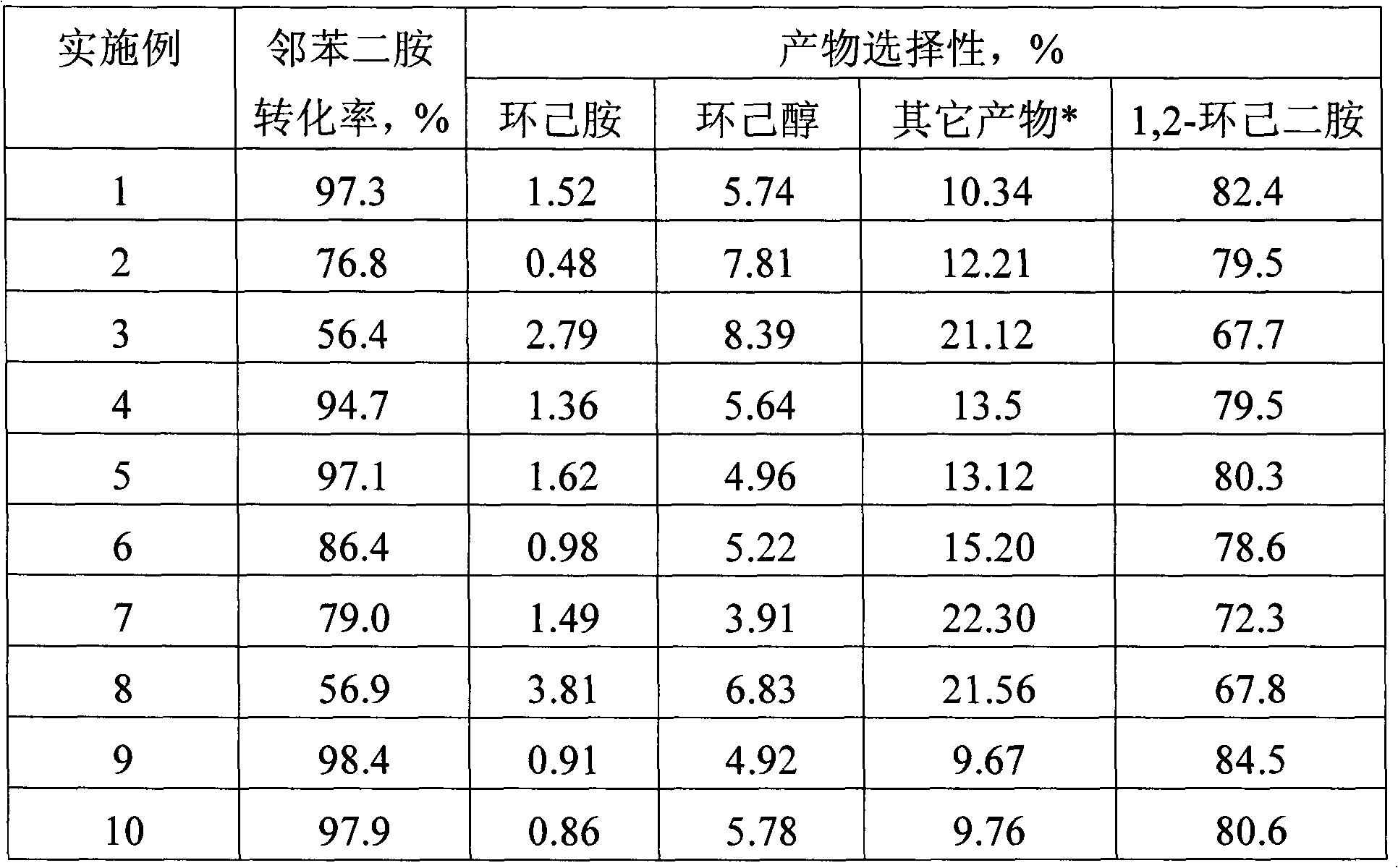

Catalyst for preparing cyclohexanediamine by phenylenediamine hydrogenation under ammonia reaction conditions

InactiveCN102688757ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationSlurryHigh activity

The invention discloses a catalyst for preparing cyclohexanediamine by phenylenediamine hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of phenylenediamine and hydrogen into cyclohexanediamine under ammonia reaction conditions and comprises a main active component, one or more auxiliary agents and a carrier. The main active component is a precious metal Ru or Pd. The one or more auxiliary agents are selected from Re, Co, Ni, Fe and their oxides. The carrier is active carbon, Al2O3 or SiO2. In a slurry-bed reactor, at a certain temperature, under the action of ammonia and catalyst, the high activity and high selectivity transformation of phenylenediamine and hydrogen into a plurality of amine products comprising cyclohexanediamine as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

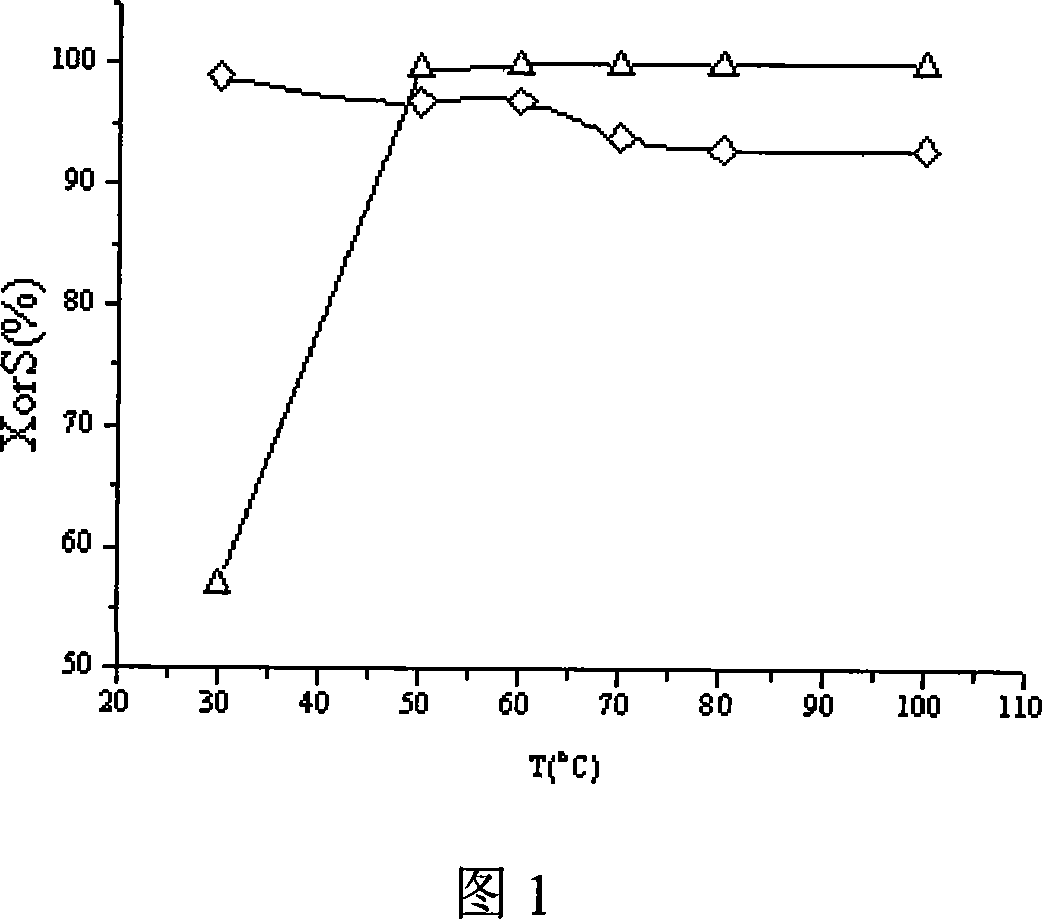

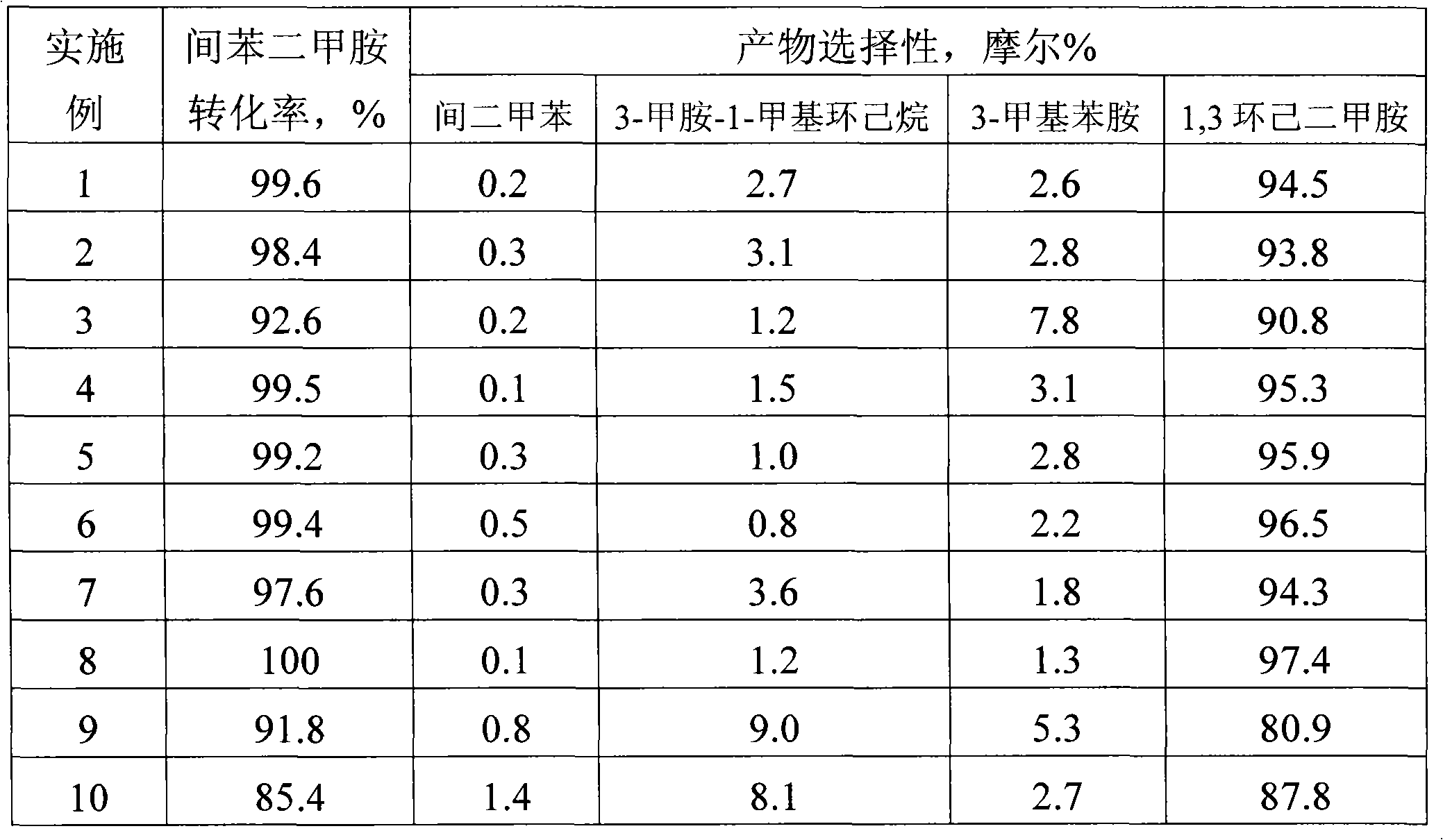

Catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions

InactiveCN102688766ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationFixed bedM-xylylenediamine

The invention discloses a catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions. The catalyst realizes the transformation of m-xylylenediamine and hydrogen into 1,3-cyclohexanebis(methylamine) under ammonia reaction conditions and comprises one or more main active components, one or more auxiliary agents and a carrier. The one or more main active components is / are precious metal Ru or / and Pd. The one or more auxiliary agents are selected from Ni, Cr, Co, Fe and their oxides. The carrier is Al2O3, active carbon or SiO2. In a fixed bed reactor, at a certain temperature, under the action of ammonia pressure and the catalyst, the high activity and high selectivity transformation of m-xylylenediamine and hydrogen into a plurality of amine products comprising 1,3-cyclohexanebis(methylamine) as a main product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

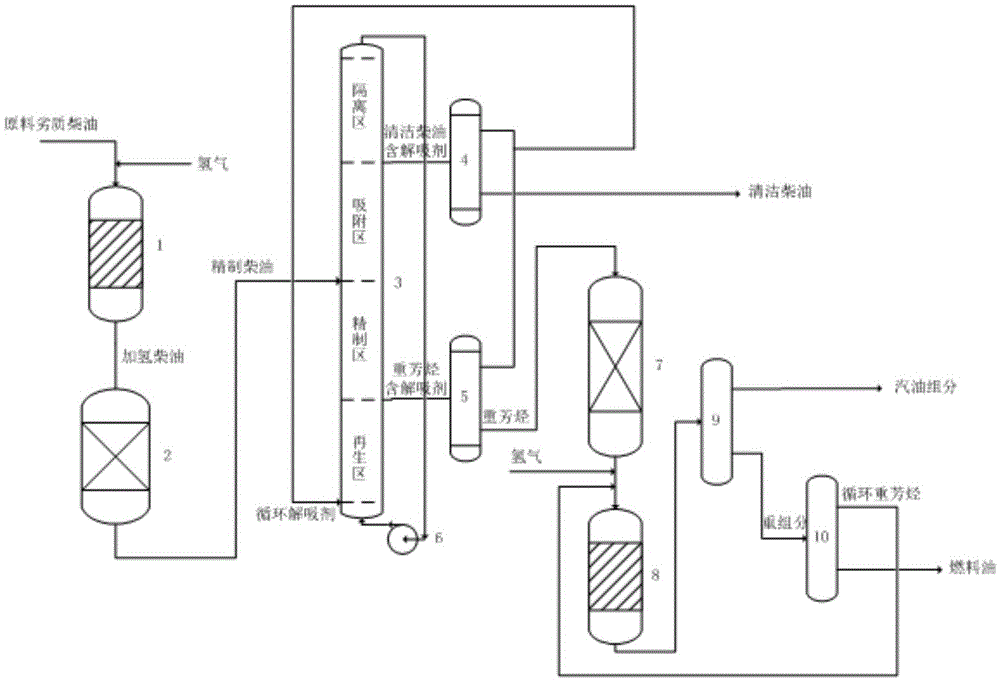

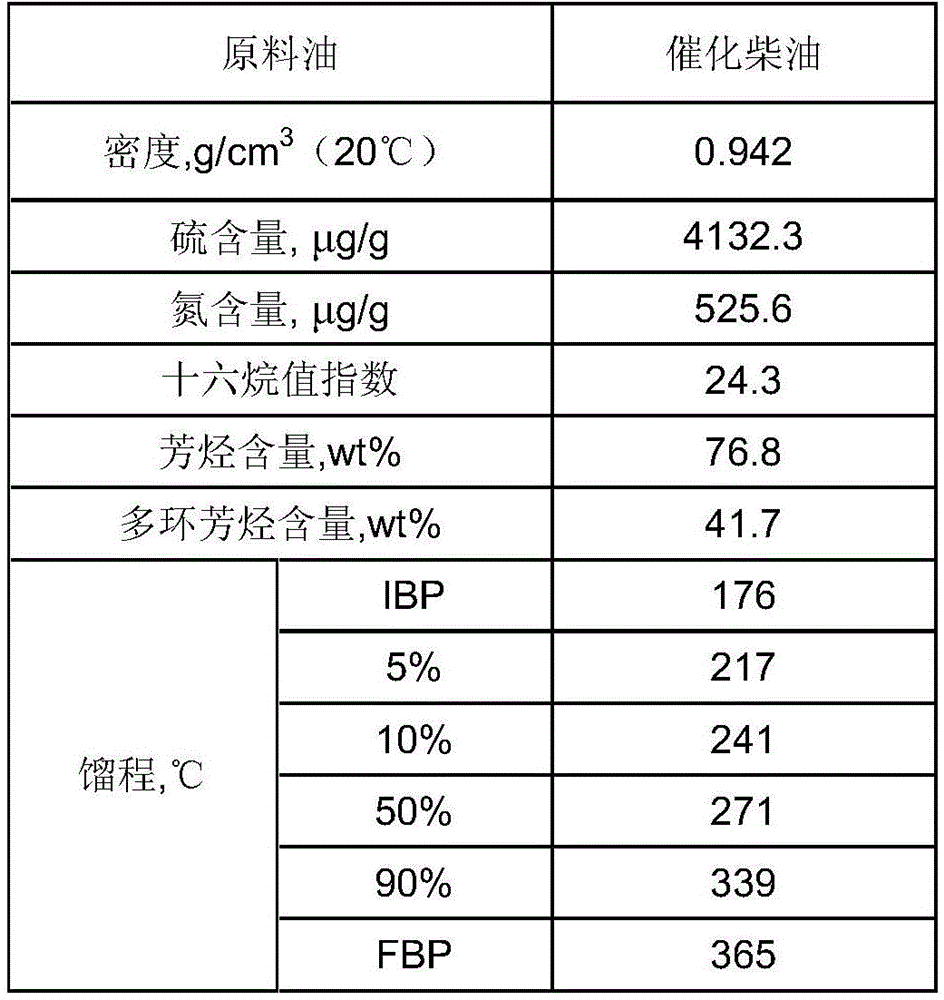

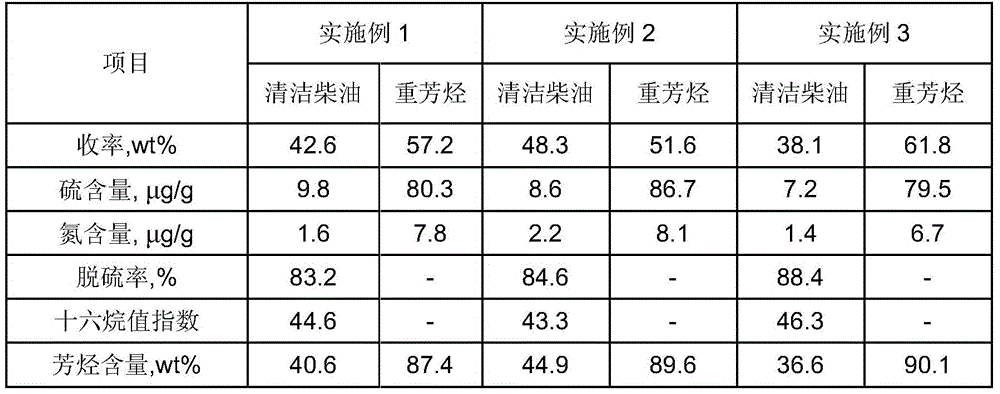

Method for producing clean diesel oil and light aromatic hydrocarbons from inferior diesel oil

ActiveCN105542849ALow reaction pressureLess loss of aromaticsTreatment with hydrotreatment processesHydrocarbon oils treatment productsSimulated moving bedSulfide

The invention relates to a method for producing clean diesel oil and light aromatic hydrocarbons from inferior diesel oil. The method includes the following steps: (1) carrying out low-medium pressure hydrogenation on the inferior diesel oil to remove sulfur and nitrogen compounds, olefins and colloids, to obtain hydrofined diesel oil; (2) adsorbing and separating the refined diesel oil through a simulated moving bed to remove aromatic hydrocarbons and sulfides, to obtain the clean diesel oil and heavy aromatic hydrocarbons; and (3) allowing the heavy aromatic hydrocarbons to enter a lightening reactor, carrying out a hydrogenation reaction under low and medium pressure to produce BTX light aromatic hydrocarbons, a gasoline component and a small amount of light hydrocarbons. The process for producing the clean diesel oil and the light aromatic hydrocarbons from the inferior diesel oil can treat catalytic cracked diesel oil and coked diesel oil, produces the clean diesel oil and the gasoline components which can meet the country V standard, and simultaneously by-produces the BTX light aromatic hydrocarbons.

Owner:CHINA NAT OFFSHORE OIL CORP +2

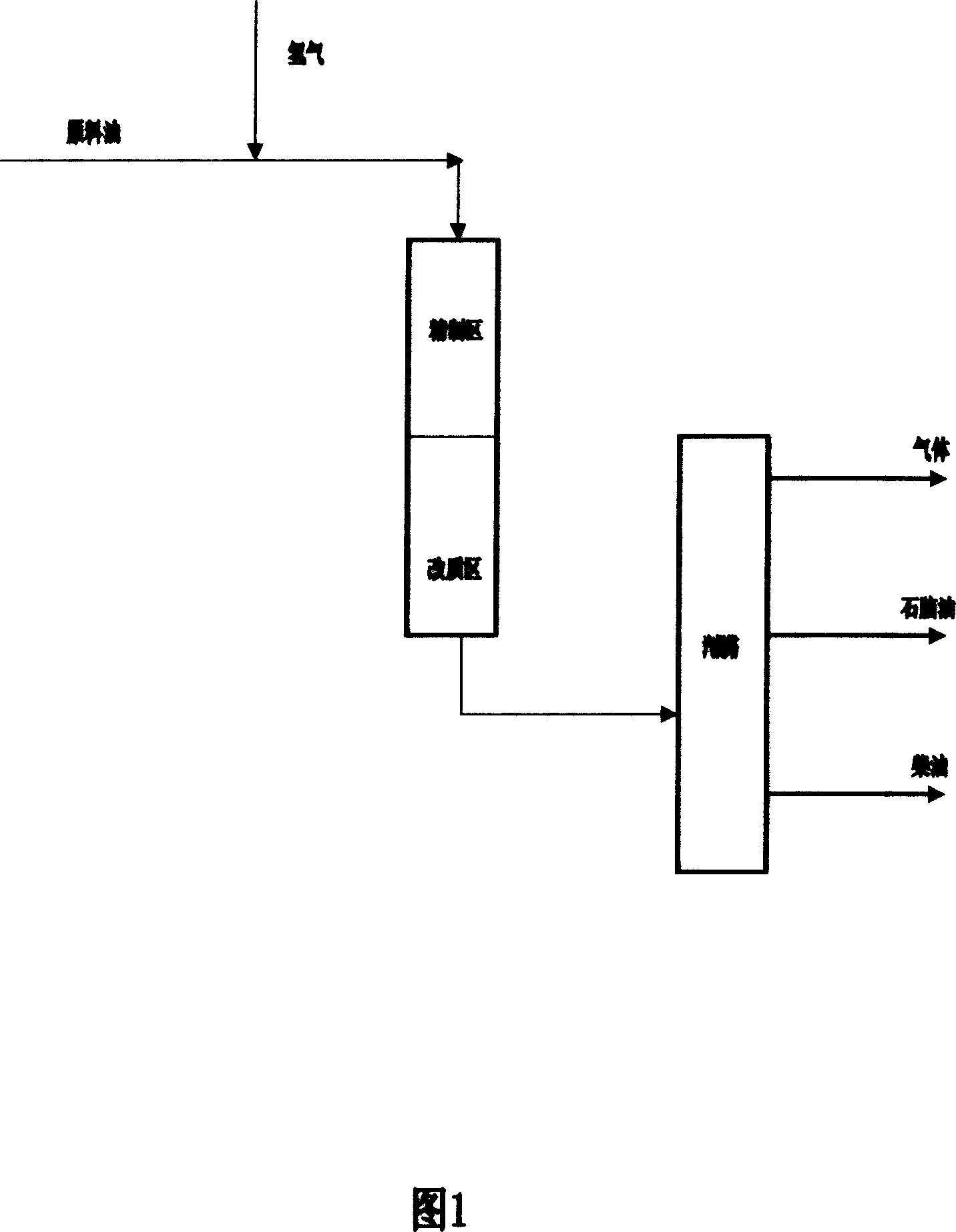

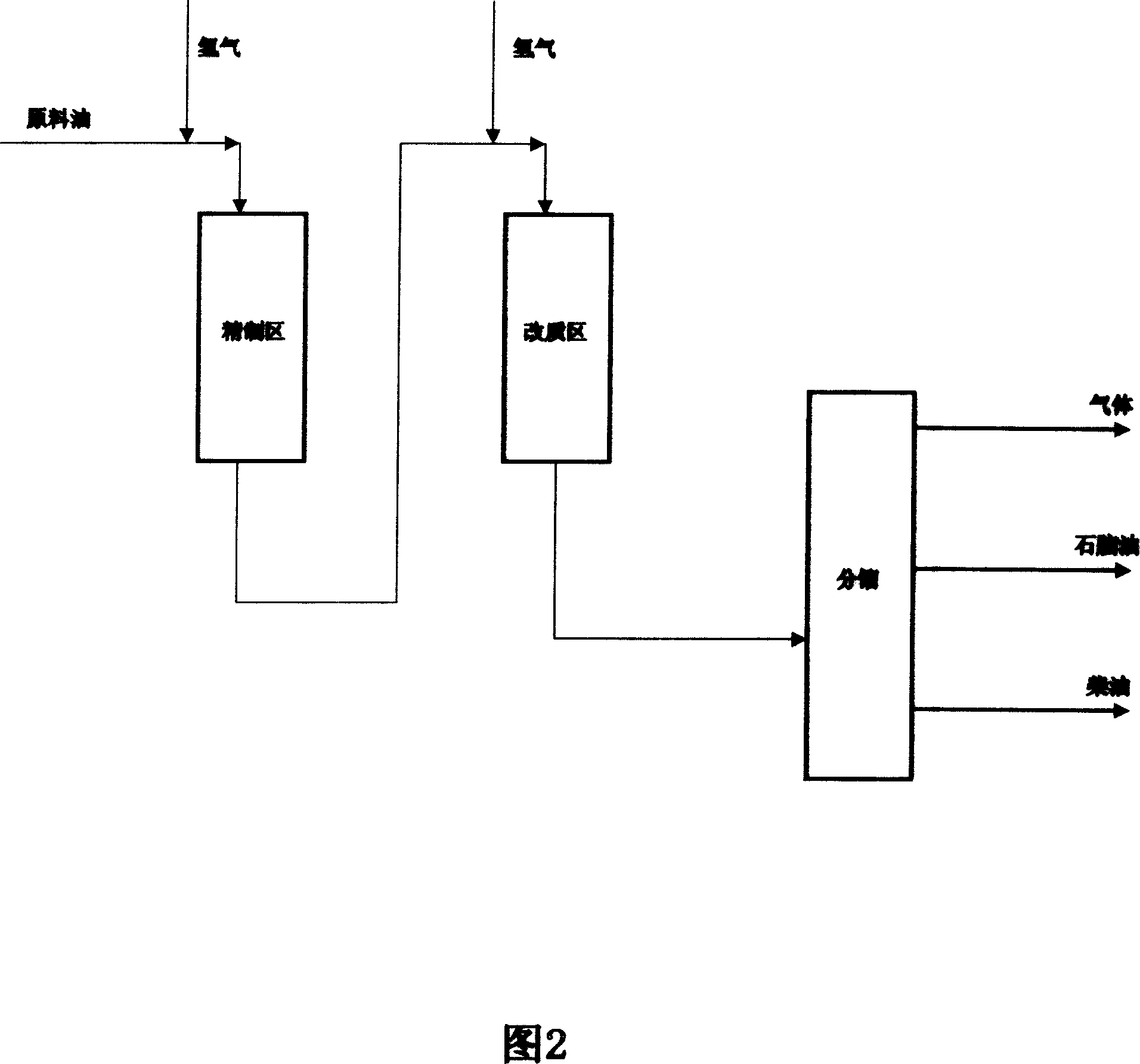

Diesel oil fraction upgrading and pour point reducing process

ActiveCN101089135AReduce usageReduce contentRefining to eliminate hetero atomsHydrogenOxidation stability

The diesel oil fraction upgrading and pour point reducing process has the mixture of diesel oil material and hydrogen passing through the hydroupgrading reaction region to result in diesel oil with low solidification point through reaction under certain condition. The catalyst in the hydroupgrading reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst, and at least one kind of upgrading catalyst containing beta-zeolite. The present invention can lower the solidification point, 95 vol% point temperature and sulfur content of diesel oil, and raise cetane number and oxidation stability under mild condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

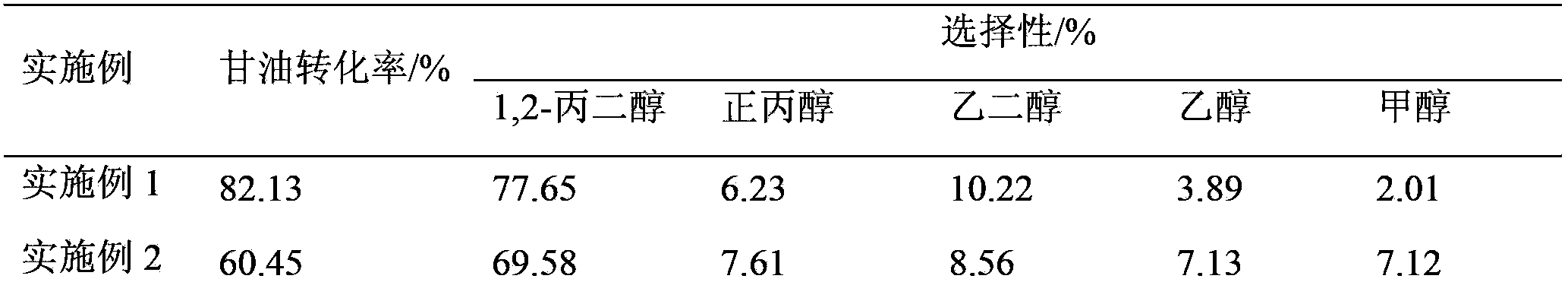

Catalyst for preparing 1,2-propylene glycol by glycerinum hydrogenation and preparation method thereof

ActiveCN103657730AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by OH group eliminationHeteropoly acidGlycerol

The invention discloses a catalyst for preparing 1,2-propylene glycol by glycerinum hydrogenation and a preparation method of the catalyst, and belongs to a catalyst containing metal or a metallic oxide. The catalyst is characterized by comprising the following raw material components in percentage by weight: 10%-40% of heteropoly acid, 30%-90% of a carrier, 5%-20% of active components, and 0.5%-10% of a modified component. The catalyst and the preparation method thereof provided by the invention have the advantages that the activity is high, the selectivity is good, a reaction condition is mild, the reaction speed is high, the conversion rate of the raw materials is high, and the energy consumption is low. The catalyst provided by the invention has an acid site and a metal hydrogenation site, is a dual-function catalyst, is high in reactivity, selectivity and stability, still keeps the high efficiency at the large air speed, and has good industrial application prospect; the catalyst provided by the invention has the advantages that the operating pressure is low, the equipment investment is saved, the energy consumption is low, and the glycerinum conversion rate can achieve 90.12%.

Owner:CHINA PETROLEUM & CHEM CORP

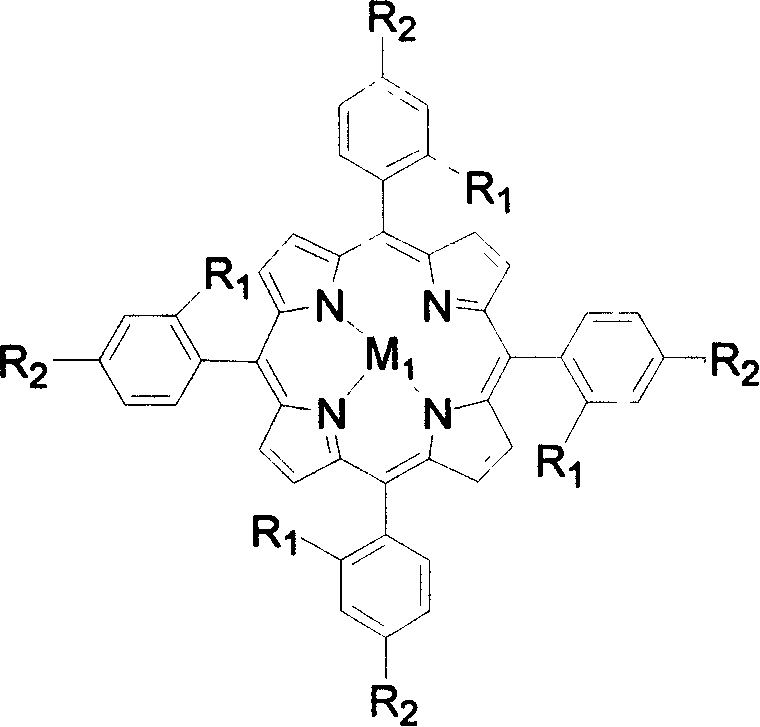

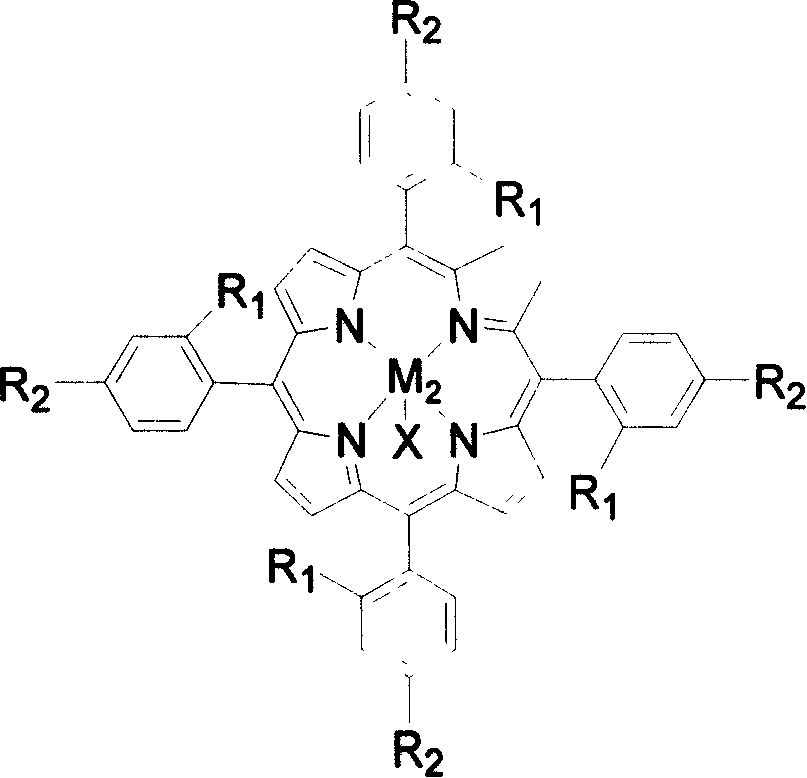

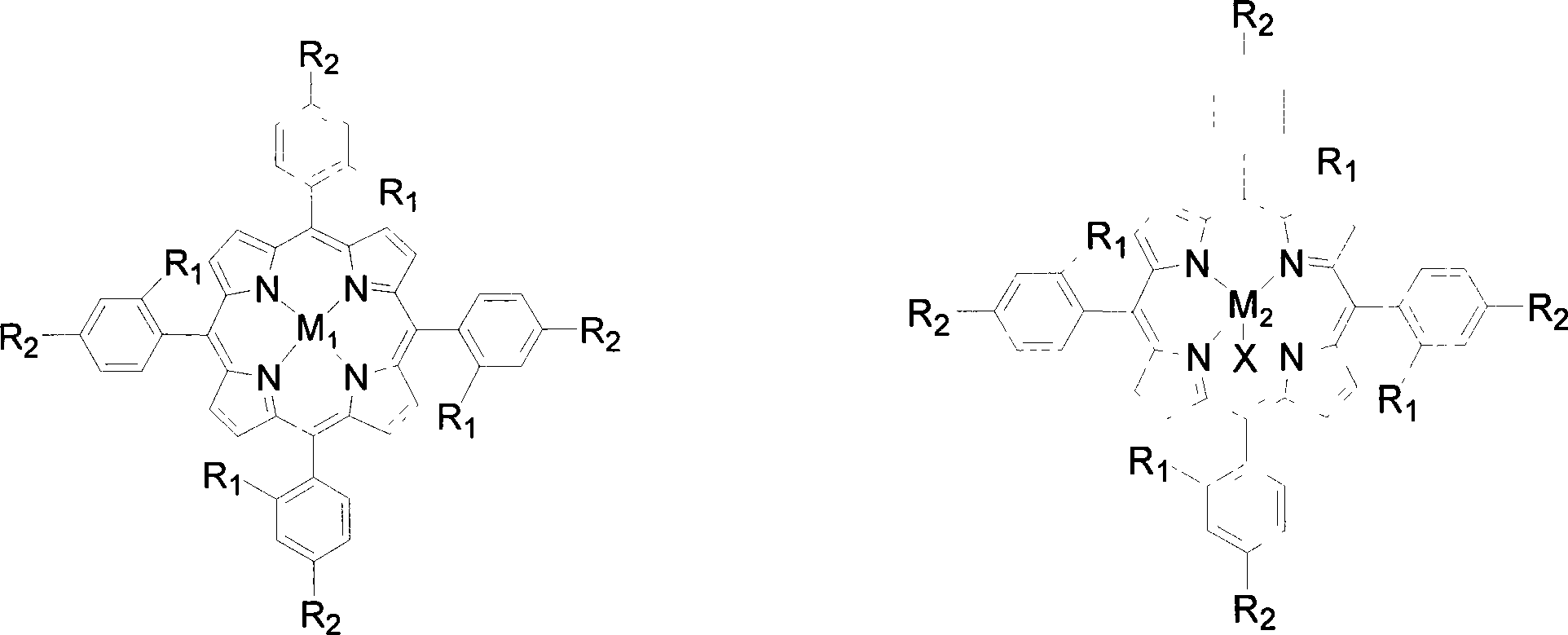

Method for preparing epoxy compound by oxidating olefin or cycloolefine through bionic catalysis oxygen

InactiveCN1915983AMild reaction conditionsReduce reaction temperature and pressureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxideDichloromethane

This invention relates to a method for preparing epoxide from olefin or cycloolefin by biomimetic catalytic oxygen oxidation. The method uses mononuclear metalloporphyrin or mu-O-binuclear metalloporphyrin as the catalyst, which has similar structure to bioenzyme. The concentration of the catalyst is 0.1-100 ppm. Besides, methane dichloride, benzene, toluene, methanol or ethyl acetate is used as the solvent. And isobutylaldehyde or n-butyraldehyde is also added at a mol ratio of 1 : (0.1-2) to the reactant. The reaction is performed at 40-160 deg.C in 0.1-2.0 MPa oxygen atmosphere for 5-12 h. The method has such advantages as low catalyst amount, low reaction temperature and pressure and easy operation. The catalyst has good catalytic performance on olefin or cycloolefin oxidation to obtain epoxide.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing high-performance rubber type chlorinated polyethylene by water-phase method

The invention discloses a manufacturing method for high-performance rubber-type chlorinated polyethylene with the water-phase method. The manufacturing method comprises the following steps of: softening hot water, dispersing agent, emulsifying agent and polyethylene powder are added in a proportioning tank in turn and are stirred to form suspension feed liquid, then completing discharging; the suspension feed liquid in the proportioning tank is fed in a chlorination reaction kettle, and then initiator is added; when the mixture is heated to 75 DEG C under a sealed condition, chlorine gas is pumped into the reaction kettle, thereby obtaining the mother liquor of rubber-type chlorinated polyethylene after 2 to 3 hour reaction under 75 to 140 DEG C and pressure less than or equal to 0.45MPa; and the mother liquor is fed to a rinsing kettle to be filtered and then is neutralized through a neutralization kettle, and is made into a high-performance rubber-type chlorinated polyethylene finished product after washing, dehydration and drying. The manufacturing method has high production efficiency and stable product quality and can realize the recycling of waste water after treatment.

Owner:江苏天腾化工有限公司

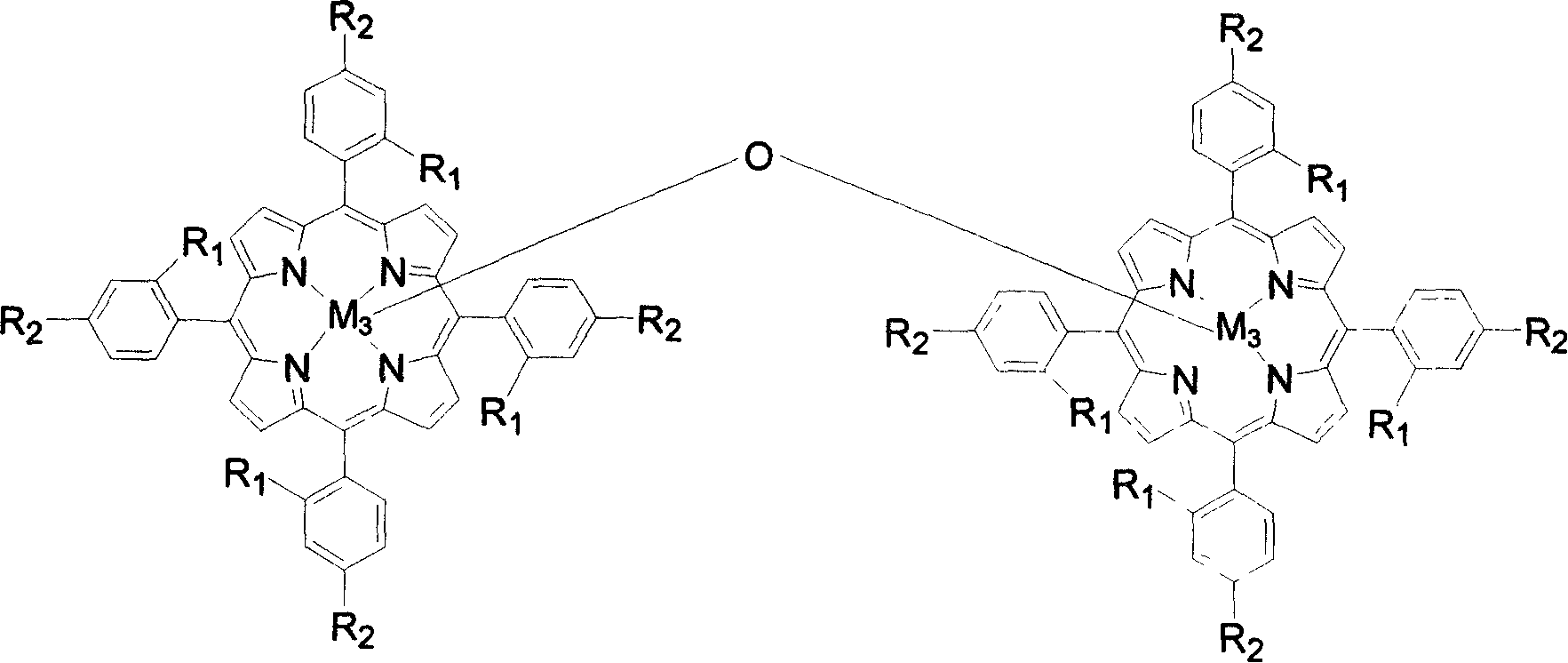

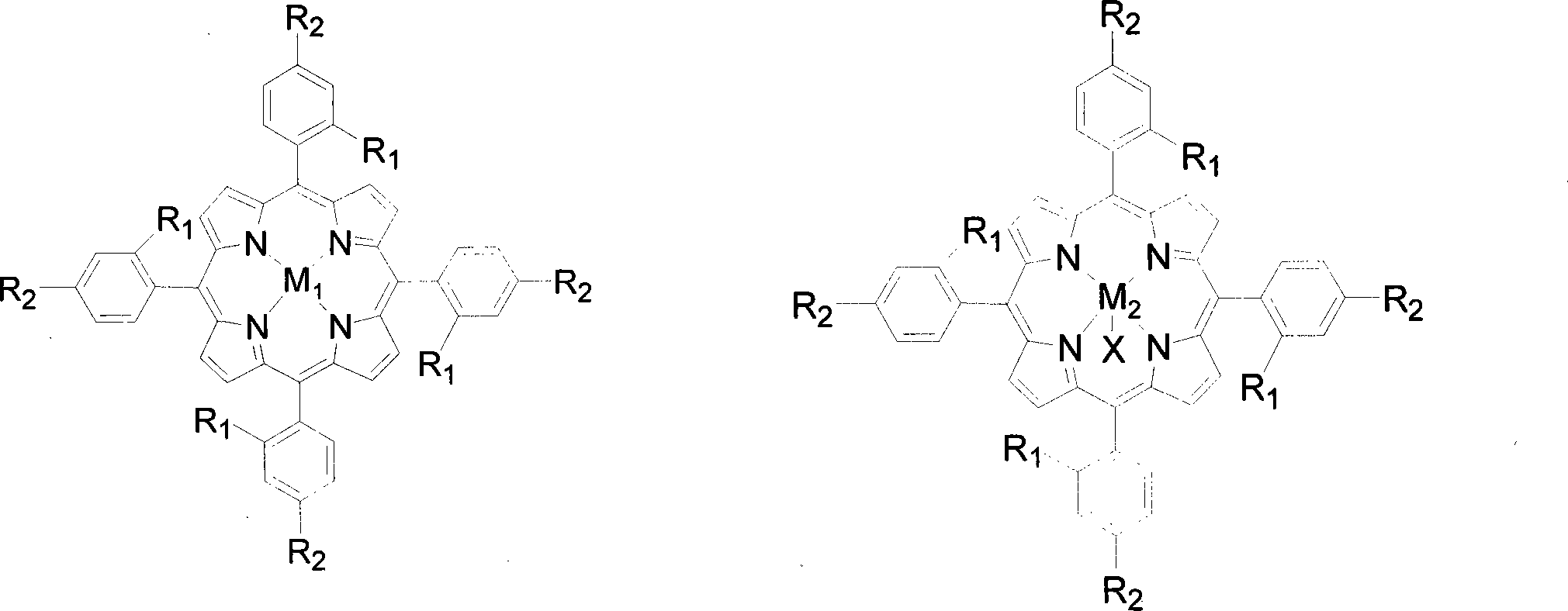

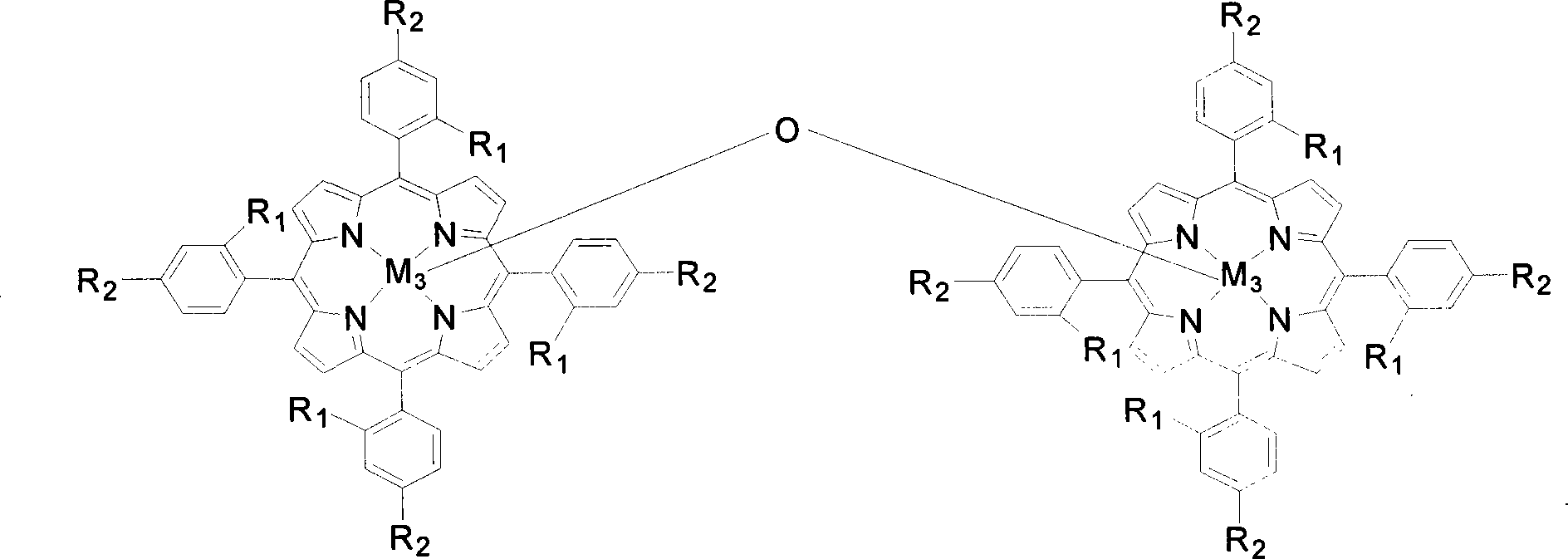

Method for preparing lactones by biomimetic catalytic oxidation of ketone compounds

InactiveCN101205225AMild reaction conditionsLow reaction temperatureOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBenzaldehydeReaction temperature

The invention discloses a method for putting the oxydone compounds into the biomimetic catalysis to prepare the lactone. With the ketone compounds as the raw materials, the invention selects the mononuclear metalloporphyrins with structure in the general formulas (I) and (II) or Mu-oxygen-binuclear metalloporphyrins with structure in the general formula (III) as the catalysts; the concentration of the catalysts ranges from 2 multiplied by 10<-5>mol / L to 2 multiplied by 10<-2>mol / L and the concentration of the ketone compounds ranges from 0.02mol / L to 0.8mol / L; with the benzene, the toluene, the xylene, the benzotrifluoride or the cyclohexane as the solvents, the benzaldehyde, isobutyraldehyde or butyraldehyde with a molar ratio to the ketone compounds ranging from 0.5 to 1 to 20 to 1 is added in the mixtures; the oxygen with a pressure ranging from 0.1MPa to 1.6MPa is pumped in the mixtures; the reaction temperature is controlled to a range from 40 DEG C to 150 DEG C and the reaction time is controlled to a range from 1 to 10 hours. The invention has the advantages of gentile reaction conditions, a small dosage of catalysts, good catalytic effects, and high product selectivity, etc.

Owner:SOUTH CHINA UNIV OF TECH

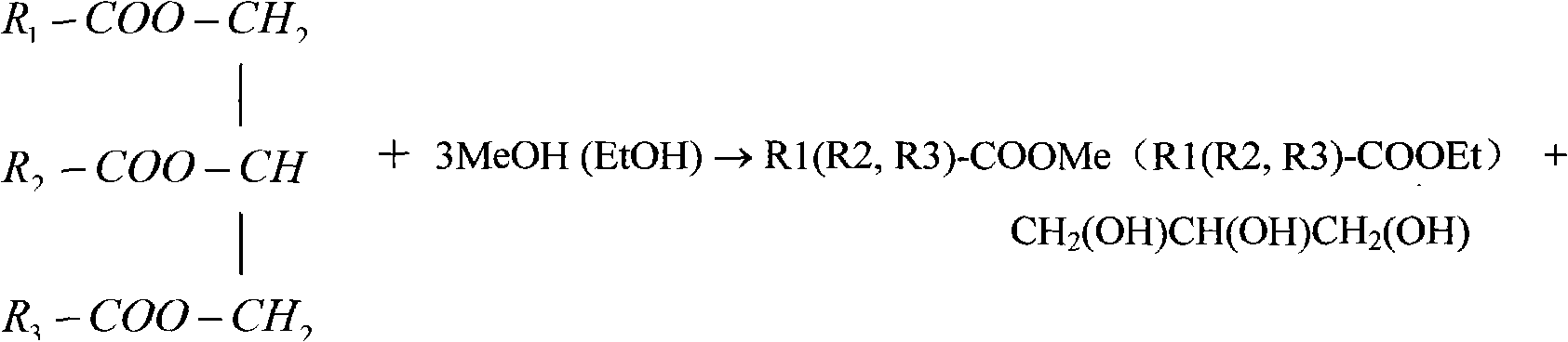

Quick and clean process for preparing biological diesel oil with esterification/ester exchange reaction

InactiveCN101319169ALess investment in equipmentReduce energy consumptionFatty acid esterificationBiofuelsVegetable oilBiodiesel

The invention relates to a novel process for preparing biodiesel through natural oil which has different acid numbers and a rapid esterification / ester interchange reaction with catalysts of minute quantity at an alcohol-oil consolute temperature. The process comprises the following steps of: taking animal and vegetable oil as raw materials, adding the oil and methanol into a reaction kettle according to an alkyd mol ratio of 2 to 1-10 to 1 for rapid esterification, and adding the acid catalyst of minute quality which is 0.01-1 per mille of the weight of the oil with reaction conditions of 120-200 DEG C, 2.0-8.0Mpa, and 10-30min; after neutralization deacidification, adding refined oil and methane into a high-pressure reaction kettle according to a mol ratio of 1 to 6-1 to 20 for rapid ester interchange, and adding a base catalyst of minute quality which is 0.01-1 per mille of the weight of the refined oil with reaction conditions of 140-200 DEG C, 2.0-8.0Mpa, and 5-20min; carrying out the sedimentation or centrifuge of a reaction product, and generating a qualified biodiesel product after removing methane through upper layer liquid phase distillation. The process uses minute quantity of catalysts and does not need separation with quick reaction and simple procedure without pollution and corrosion. The process has the advantages of mild conditions, environmental protection and remarkable efficiency.

Owner:SICHUAN UNIV

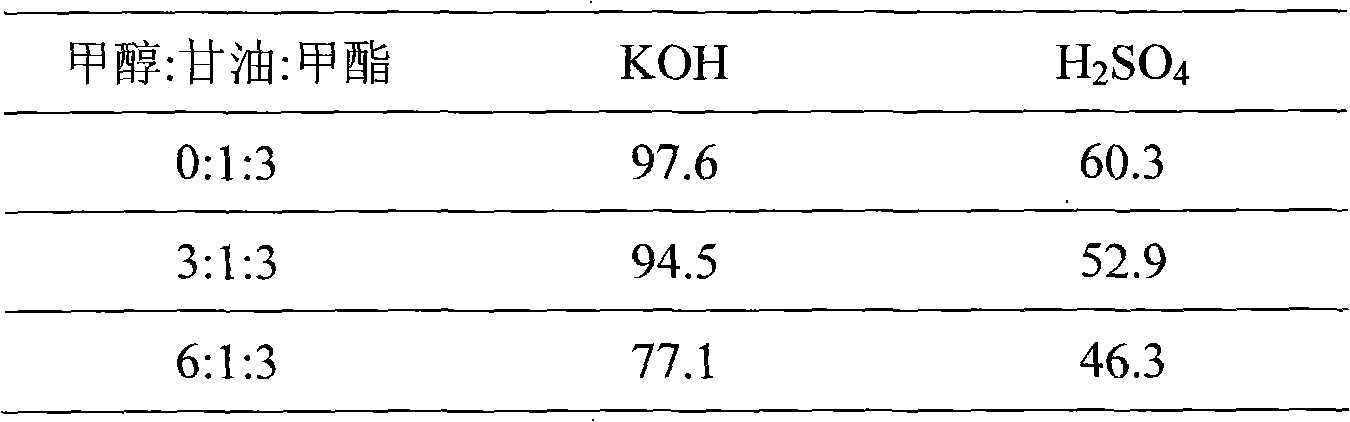

Preparation method of cyclohexane

ActiveCN101205163ASolve the problem of heat transferStable reaction temperatureHydrocarbon by hydrogenationBenzeneHydrogen

A method for preparing a cyclohexane comprises the following steps: a benzene and a hydrogenation catalyst are driven to enter a distillation tower from the tower top and the hydrogen goes into the distillation tower from the tower bottom; the tower bottom is heated by the steam and a reaction in which the benzene hydrogenation is used for generating the cyclohexane is conducted in the tower; the condensate at the tower top refluxes and the discharged materials from the tower bottom are subject to the flash separation so as to obtain the cyclohexane. The method of the invention can lower the content of the methyl cyclopentane in the products and is beneficial to the stabilized operation and the enhancement of the hydrogen utilization ratio and the effective reaction volume of the tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

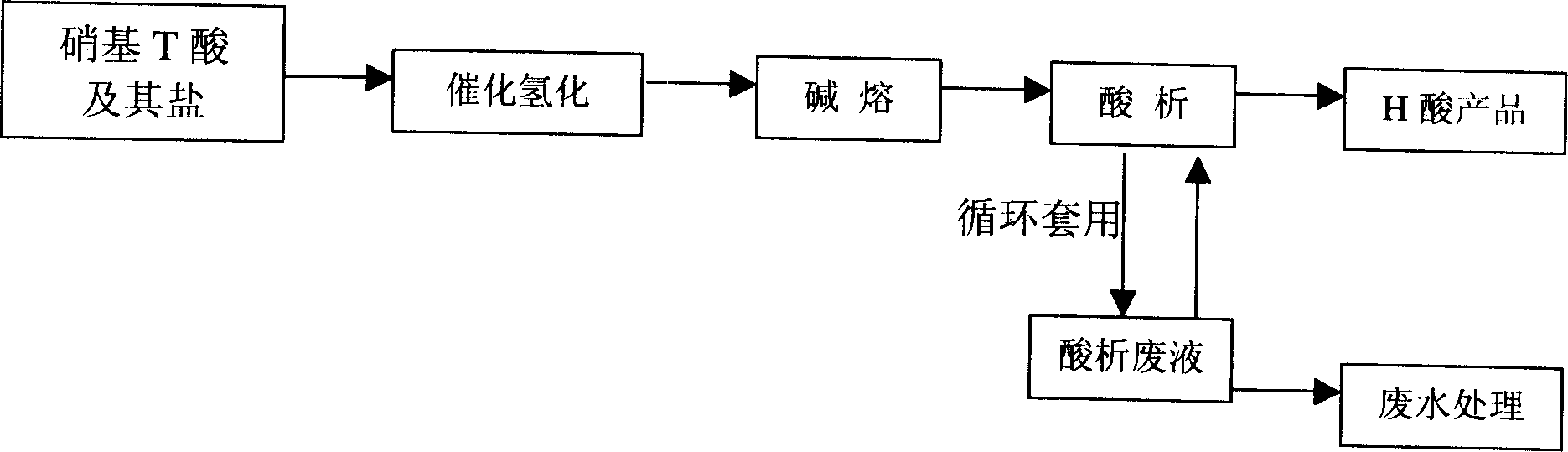

Catalytical hydrogenation process to produce II acid

ActiveCN1810779AImprove performanceLow reaction pressureSulfonic acid preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation processReaction temperature

The present invention relates to catalytical hydrogenation process to produce H acid, and solves the technological problem of providing one new type of catalyst to lower the reaction pressure, reaction temperature and production cost effectively. The process includes the following steps: 1. regulating the nitroso value of nitro T acid and its solution as material to 15-45 g / L and the pH value to 7-10; 2. catalytical hydrogenation through adding the regulated solution and Ni-Co catalyst with Co content of 0.5-25 wt% and in the amount of 0.1-5 wt% of nitro T acid into high pressure reactor, introducing H2 of 1.0-4.5 Mpa pressure at 90-220 deg.c, and hydrogenating catalytically for 2-5 hr to obtain amino T acid and its solution; 3. alkali fusing; and 4. acid out to obtain the product.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com