Egg shell type metal catalyst, its preparing process and application method

A metal catalyst, eggshell-type technology, applied in the field of eggshell-type metal catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

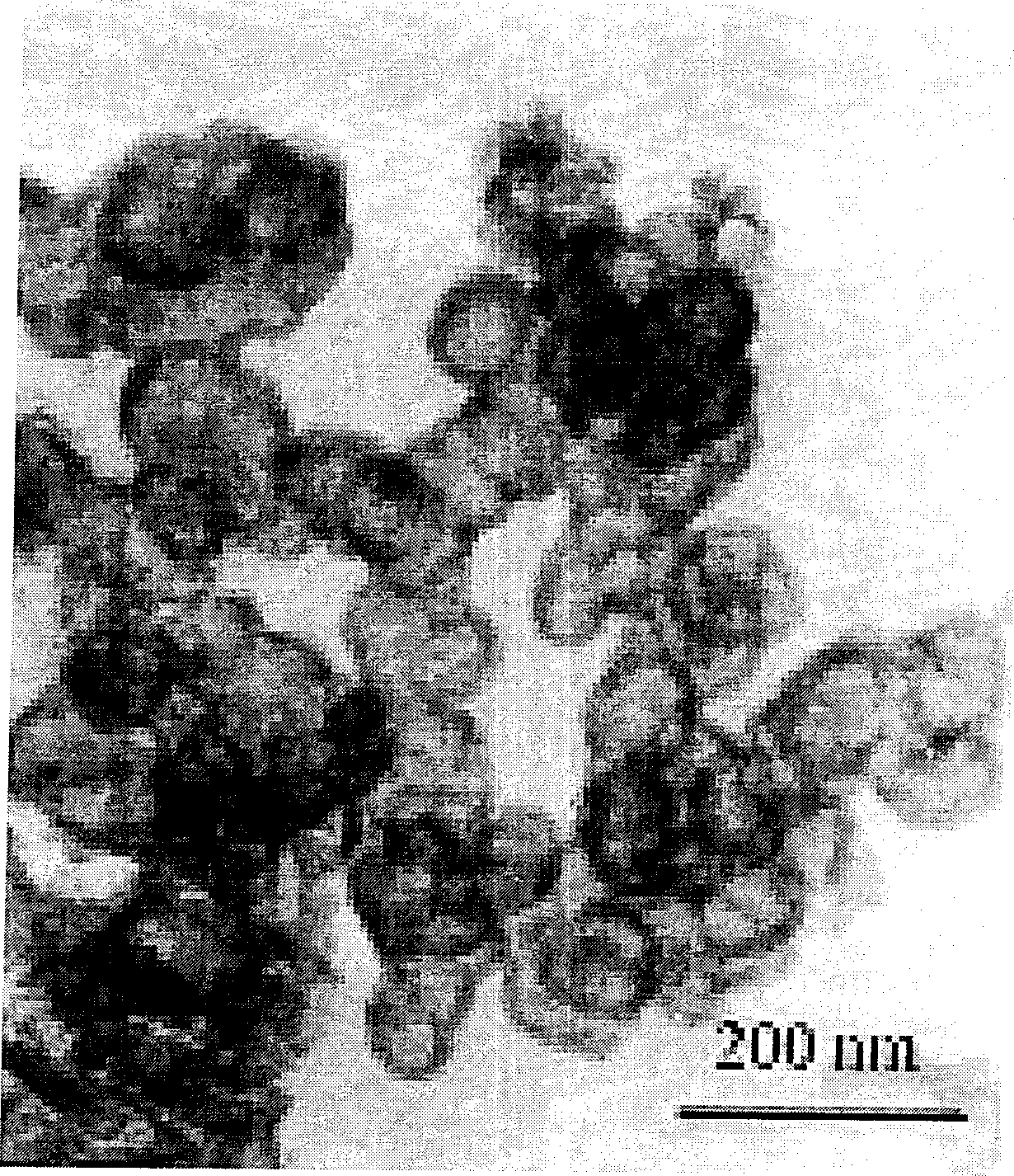

[0042] The cubic nano-calcium carbonate prepared by the super-gravity engineering research center of the Ministry of Education of Beijing University of Chemical Technology was prepared into a suspension with a concentration of 0.8mol / L, and 1000mL of the nano-calcium carbonate suspension was placed in the reactor and started to heat Warming up and stirring, the stirring speed is controlled at 400-500r / min; 500mL of sodium silicate solution with a concentration of 0.68mol / L and 10wt% dilute hydrochloric acid solution are prepared. When the temperature rises to 80°C, start to add sodium silicate solution, and add dilute hydrochloric acid at the same time, adjust the pH of the system between 8.5 and 9.5, and generate CaCO 3 / SiO 2 Core-shell structural materials. After all the sodium silicate solution is added dropwise into the system, stop adding acid, and stir and age at this reaction temperature, and the aging time is controlled at 4h, so that the SiO 2 in CaCO 3 Surface de...

Embodiment 2

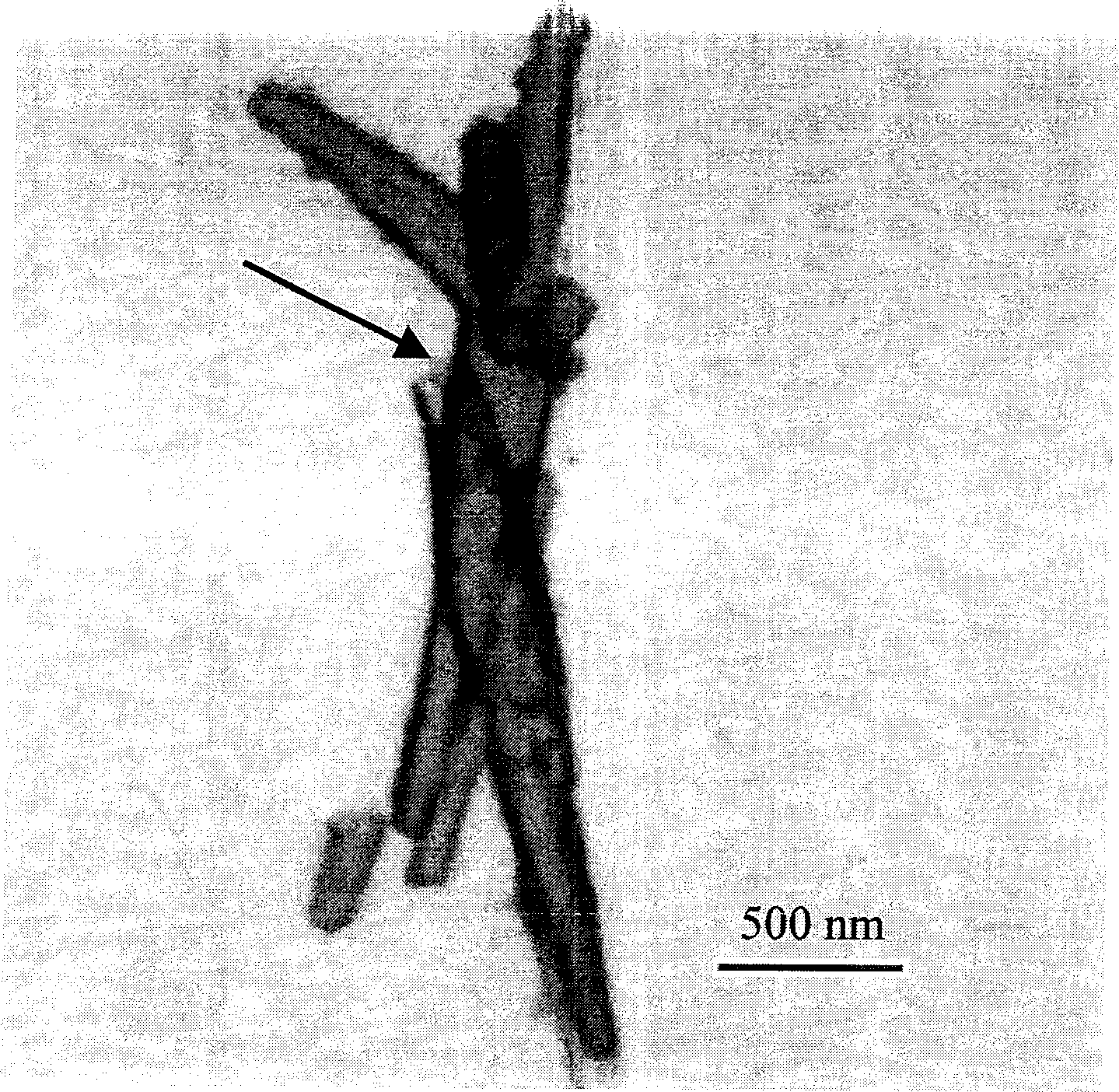

[0044] The needle-shaped nano-calcium carbonate prepared by the high-gravity technology of the Beijing University of Chemical Technology High Gravity Engineering Research Center is formulated into a suspension with a concentration of 0.8mol / L, and 1000mL of the nano-calcium carbonate suspension is placed in the reactor and stirred. Stirring speed is controlled at 400~500r / min; according to SiO 2 / CaCO 3 The ratio of mass ratio is 0.2. Weigh 26.7g of tetraethyl orthosilicate (containing Si mass fraction is 28%) and dissolve it with ethanol, add the ethanol solution of tetraethyl orthosilicate to the calcium carbonate slurry, and then add 100mL of 17wt% concentrated ammonia water, stirred at room temperature for 12h. After the reaction, the slurry was filtered and washed, dried at 105°C for 12 hours, crushed and sieved with a 250-mesh standard sieve, and then calcined in a muffle furnace with a heating rate of 4°C / min and a calcining temperature of 600-700°C. Time 6h. Dissolv...

Embodiment 3

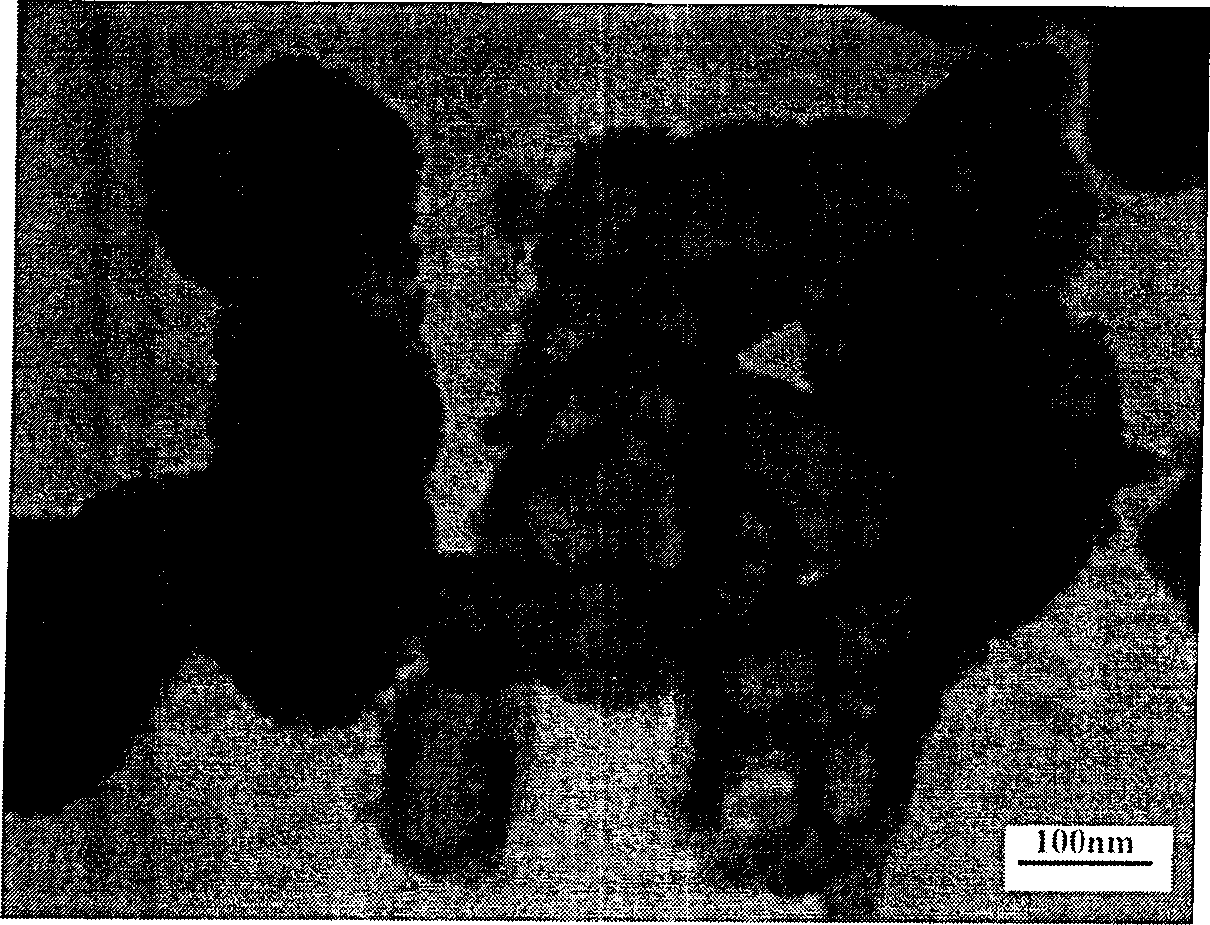

[0046] Weigh 0.1666g PdCl 2 For solid powder, add 10mL deionized water and 10mL 35% concentrated hydrochloric acid, shake well, heat to dissolve, and heat to boiling until the solution becomes clear and transparent. PdCl 2 Solution is cooled to room temperature, takes by weighing 2g spherical hollow SiO prepared by embodiment 1 2 carrier, added to PdCl 2 In the solution, stir and dip at the same time. The stirring time is 12h, the loading temperature is controlled at about 35°C, then vacuum filtration is performed and washed to remove unloaded Pd 2+ , the filtered filter cake was dried at 120°C, the heating rate was 10°C / min, and the drying time was 12h. The dried powder is sieved with a 250-mesh standard sieve, and the sieved powder is calcined at a temperature of 450 °C, a heating rate of 1 °C / min, and a calcining time of 6 h, and the mass fraction of Pd loaded can be obtained as 3.35% eggshell type precious metal palladium catalyst. image 3 is a TEM photograph of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com