Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253results about How to "Lower reaction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Egg shell type metal catalyst, its preparing process and application method

InactiveCN1736604AImprove conversion rateHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon numberAlcohol

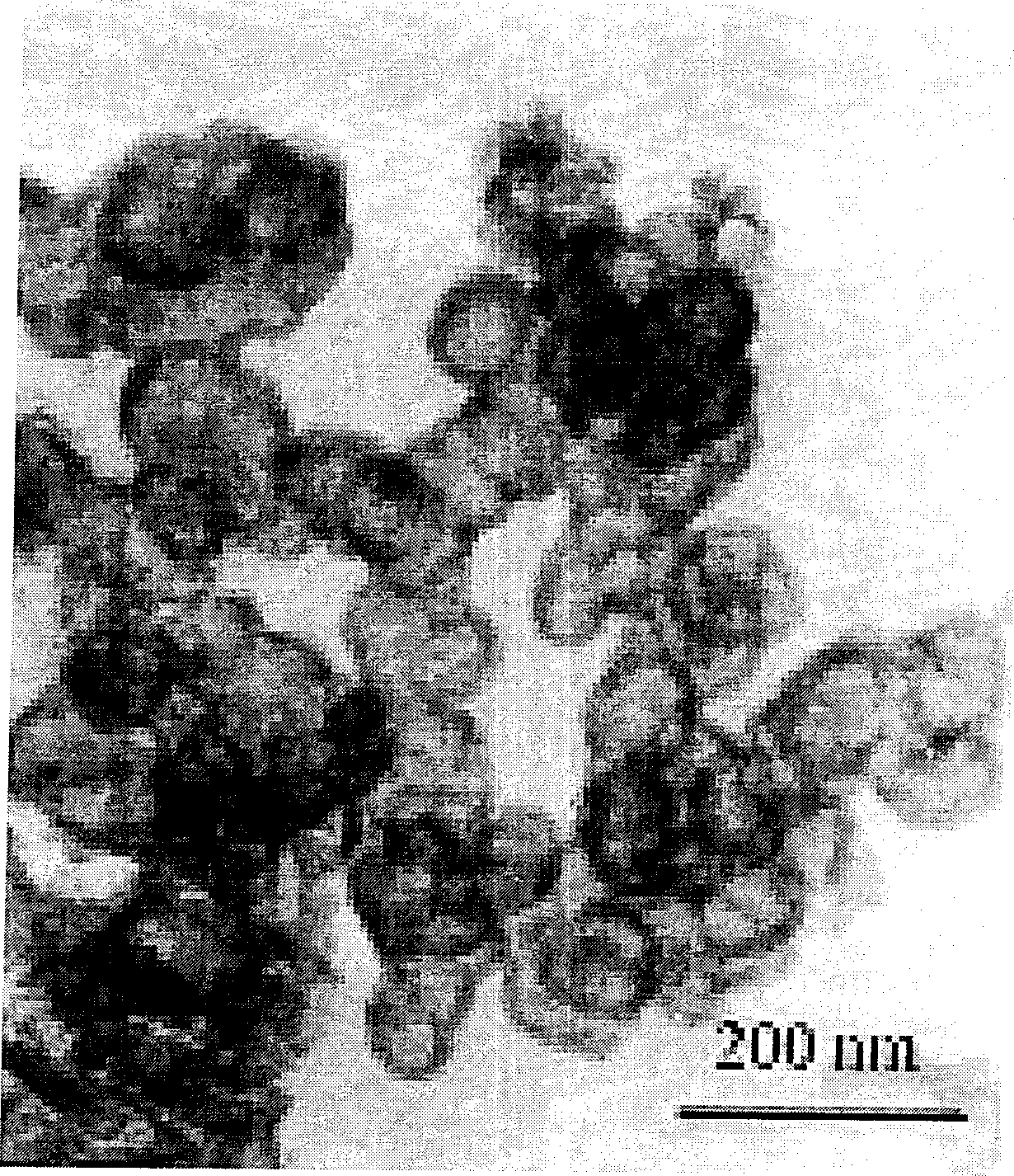

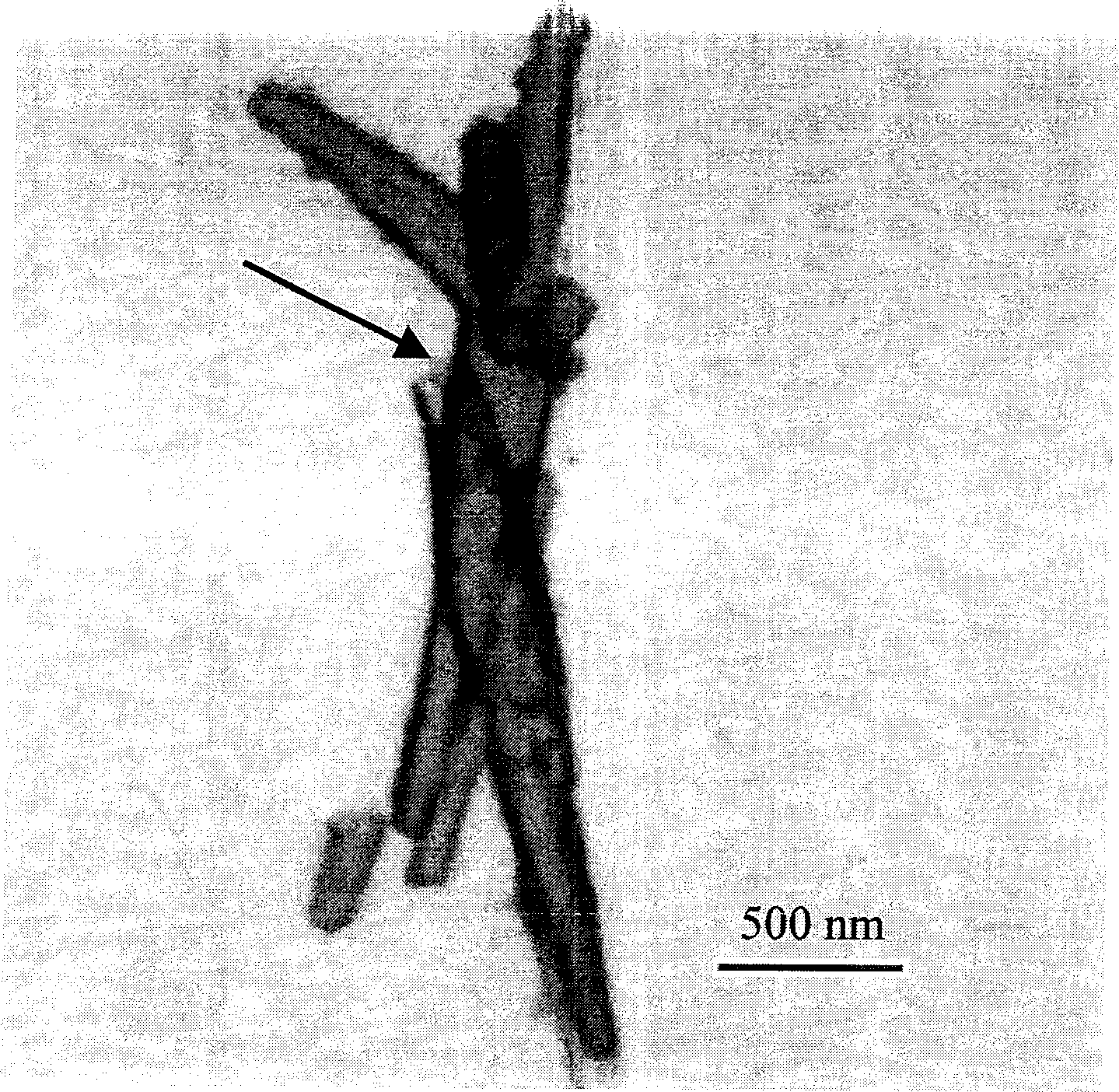

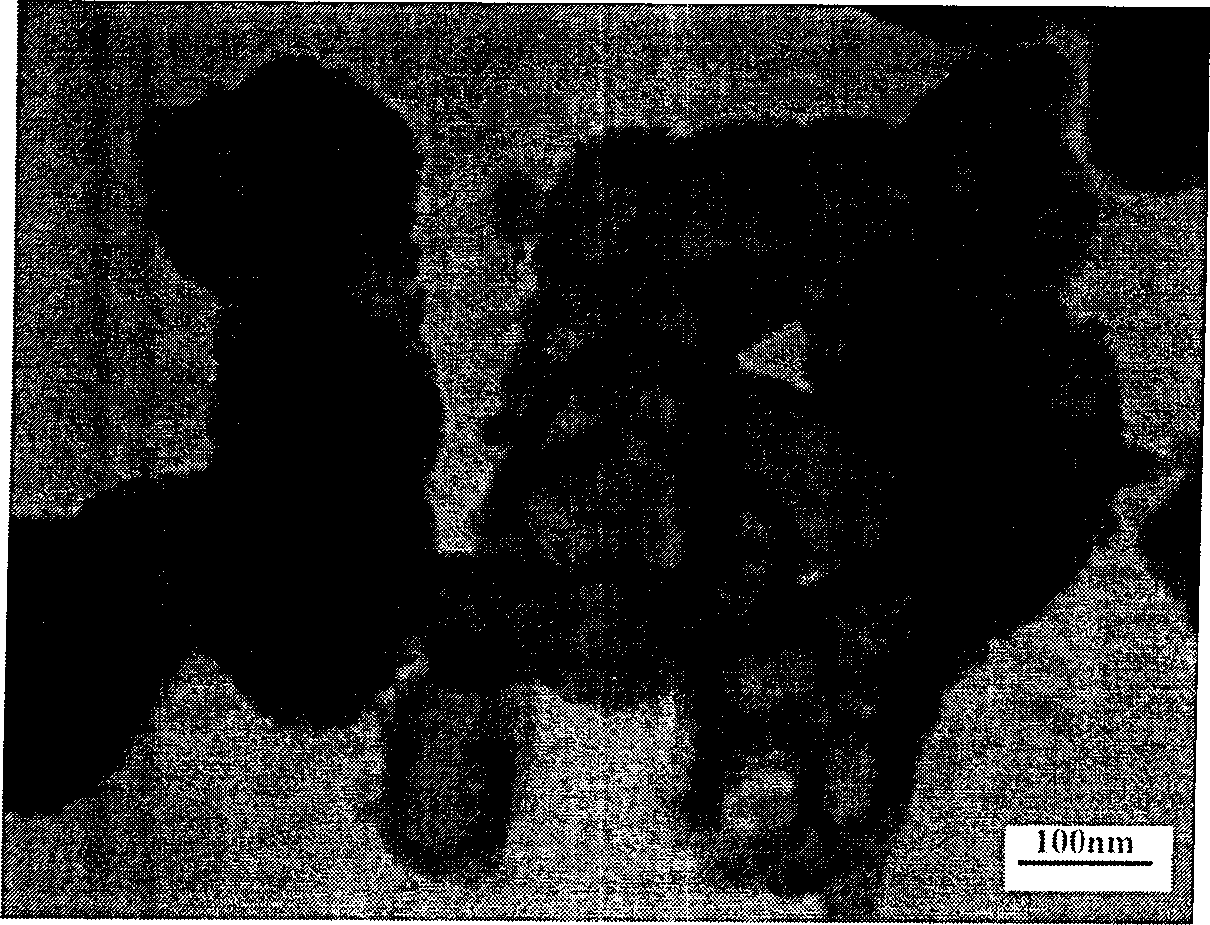

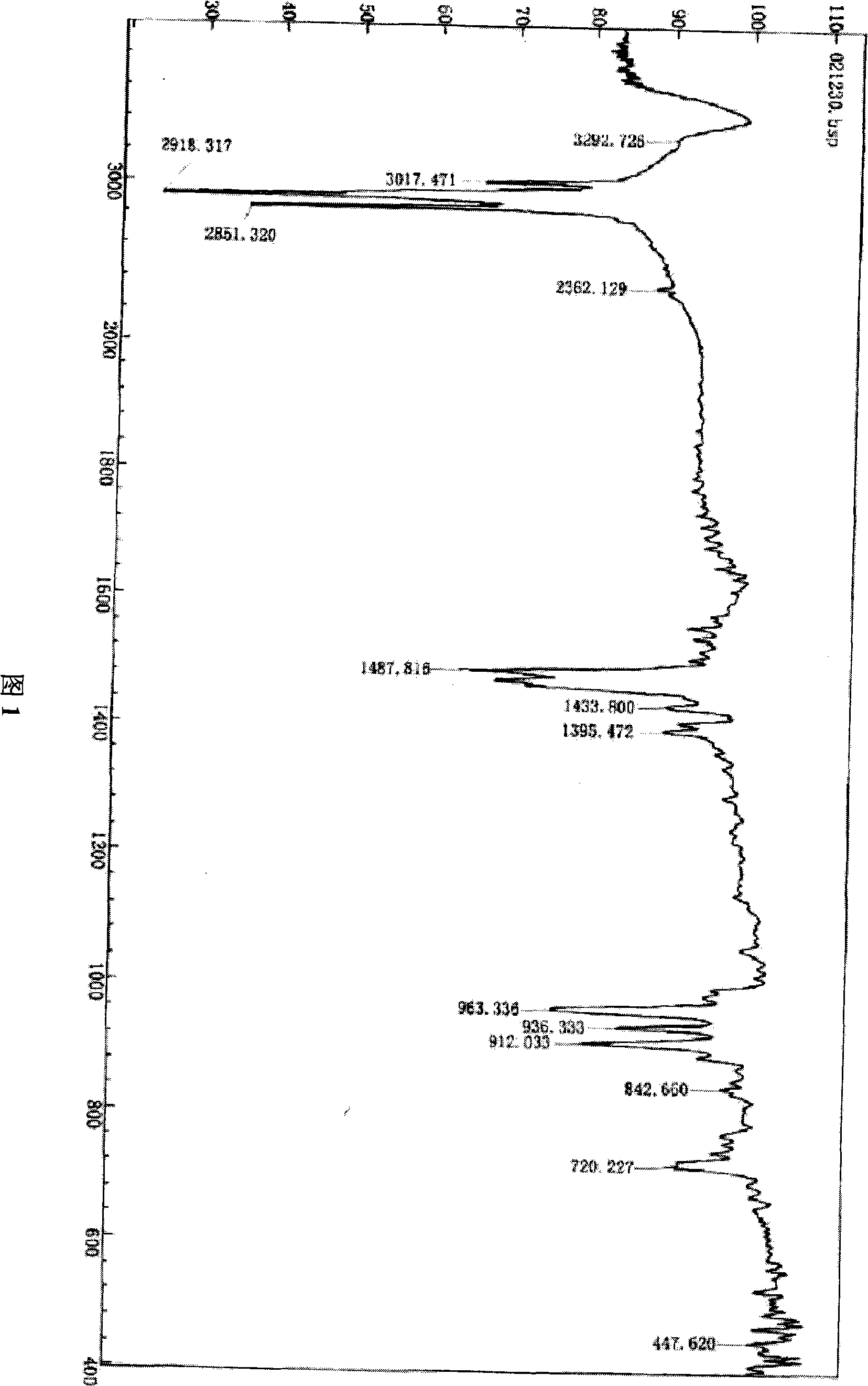

The invention discloses an egg- shell metallic catalyst and the method for preparation and the application. The catalyst is an egg- shell supported metallic catalyst with a carrier of hollow silica dioxide, which is a hollow material of certain wall and bore diameter, and comprises a noble metal of 0.1%- 5.0% and / or a transient metal of 5.0%- 40.0%, a non- noble metallic catalyst promoter of 0- 0.5% and a hollow silica dioxide carrier of 60.0%- 99.0%, with the weight ratio of catalyst as a datum level. The egg- shell metallic catalyst can prepare with immersion method or in- situ supporting method. The catalyst has good metal dispersibility, and the metal particle diameter is minor, dispersing on the external surface, inner surface and in the pore passage. And the egg- shell metallic catalyst can catalyze CO and CO2 to prepare lower carbon number hydrocarbons and alcohol, and it also can catalyze olefin and alkyne selectively.

Owner:BEIJING UNIV OF CHEM TECH

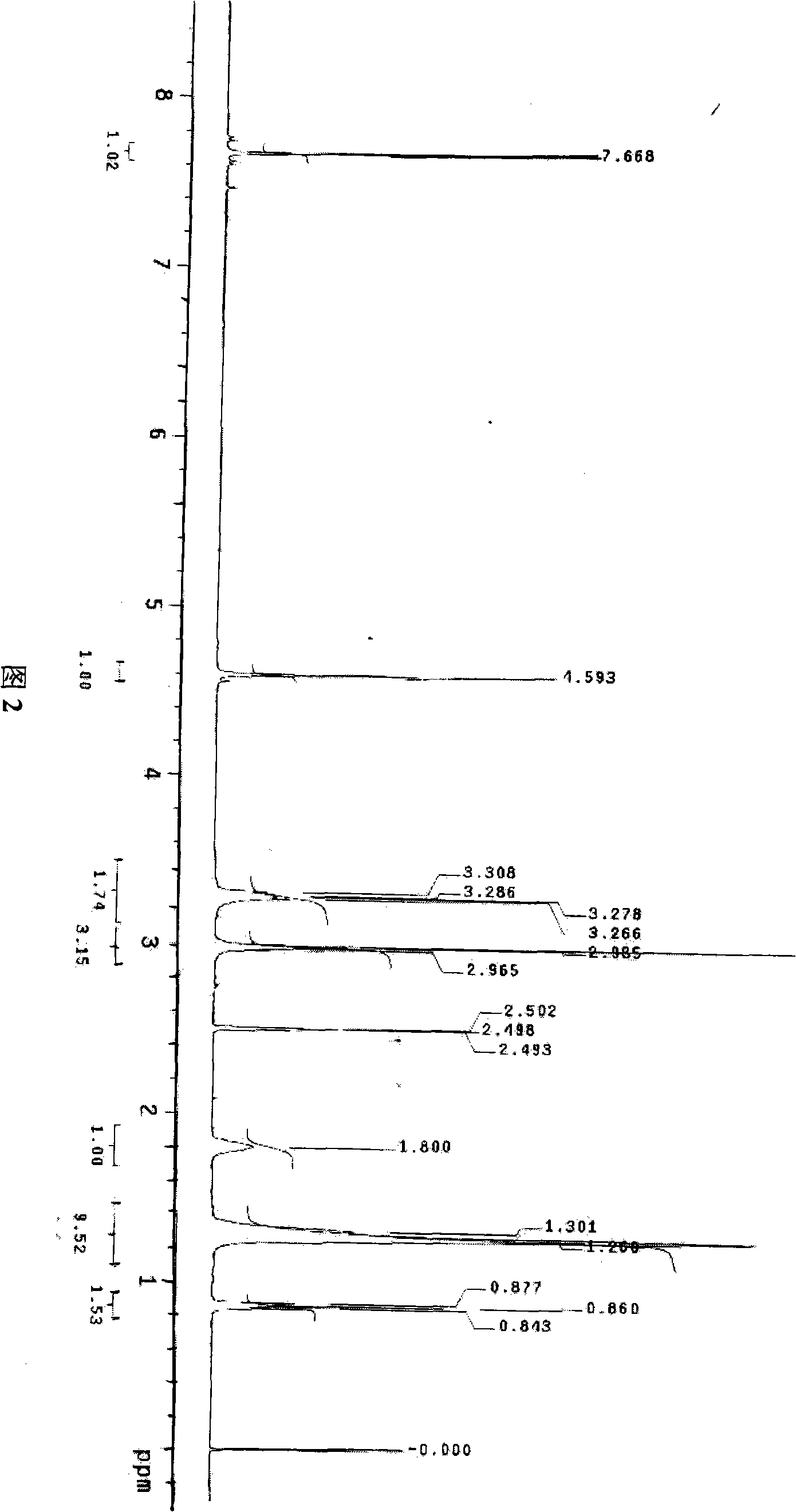

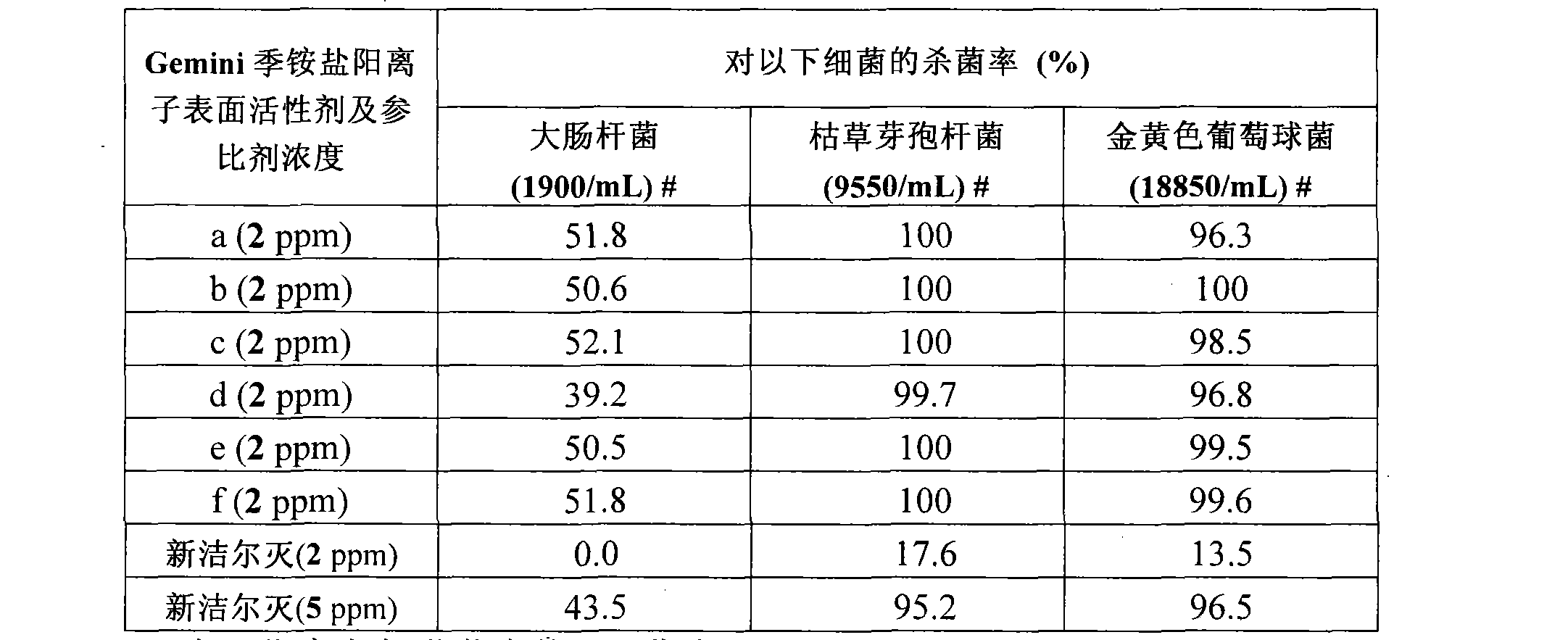

Bis-quaternary ammonium salt cationic surfactant, preparation and use thereof

InactiveCN101279219AReduce consumptionLower reaction conditionsTransportation and packagingMixingChemical reactionFatty amine

The invention discloses a Gemini quaternary ammonium salt cationic surfactant with sterilization effect. The preparation method of the Gemini quaternary ammonium salt cationic surfactant disclosed by the invention relates to that a dihalide and a fatty amine are reacted in an organic solvent, i.e. a dibromo-matter and an alkyl tertiary amine perform chemical reaction in an ethanol (or acetone or ethyl acetate) solution at the room temperature or at a low temperature and normal pressure condition, so as to synthesize a series of Gemini quaternary ammonium salt cationic surfactants. The method for synthesizing the Gemini quaternary ammonium salt cationic surfactant is simple and convenient, stable in reaction process, easy for operating and controlling with a higher product purity and yield; besides, compared with the novel geramine, the method has better sterilization effect and has important application in the aspect of oil field germicide at the same time.

Owner:TIANJIN NORMAL UNIVERSITY

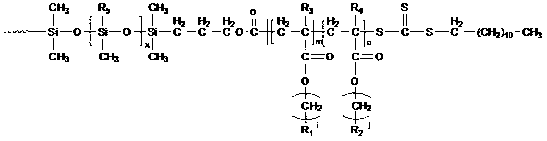

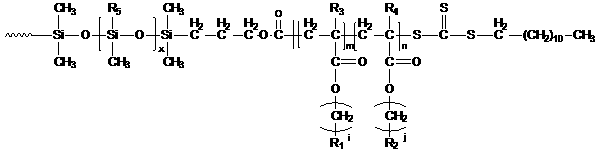

POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and preparation method thereof

InactiveCN102775567AMild surface energyLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceCopolymer

The invention discloses a POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and a preparation method thereof. The preparation method includes subjecting hydrogen-terminated polysiloxane and vinylcarbinol to reaction to obtain hydroxy-terminated polysiloxane; subjecting the hydroxy-terminated polysiloxane and carboxyl thiocarbonic acid ester to reaction to obtain polysiloxane macromolecular RAFT (reversible addition-fragmentation chain transfer polymerization) reagent; polymerizing the polysiloxane macromolecular RAFT reagent, acrylate monomer and POSS monomer with initiator to prepare the POSS contained polyacrylate-polysiloxane block copolymer. The method has the advantages of simple operation and mild reaction conditions, reaction products have better surface performance and bonding performance with substrates, and further, the reaction products can be used in low-surface-energy lyophobic coating materials and used for preparing ice and snow preventive and antifouling coatings.

Owner:TIANJIN UNIV

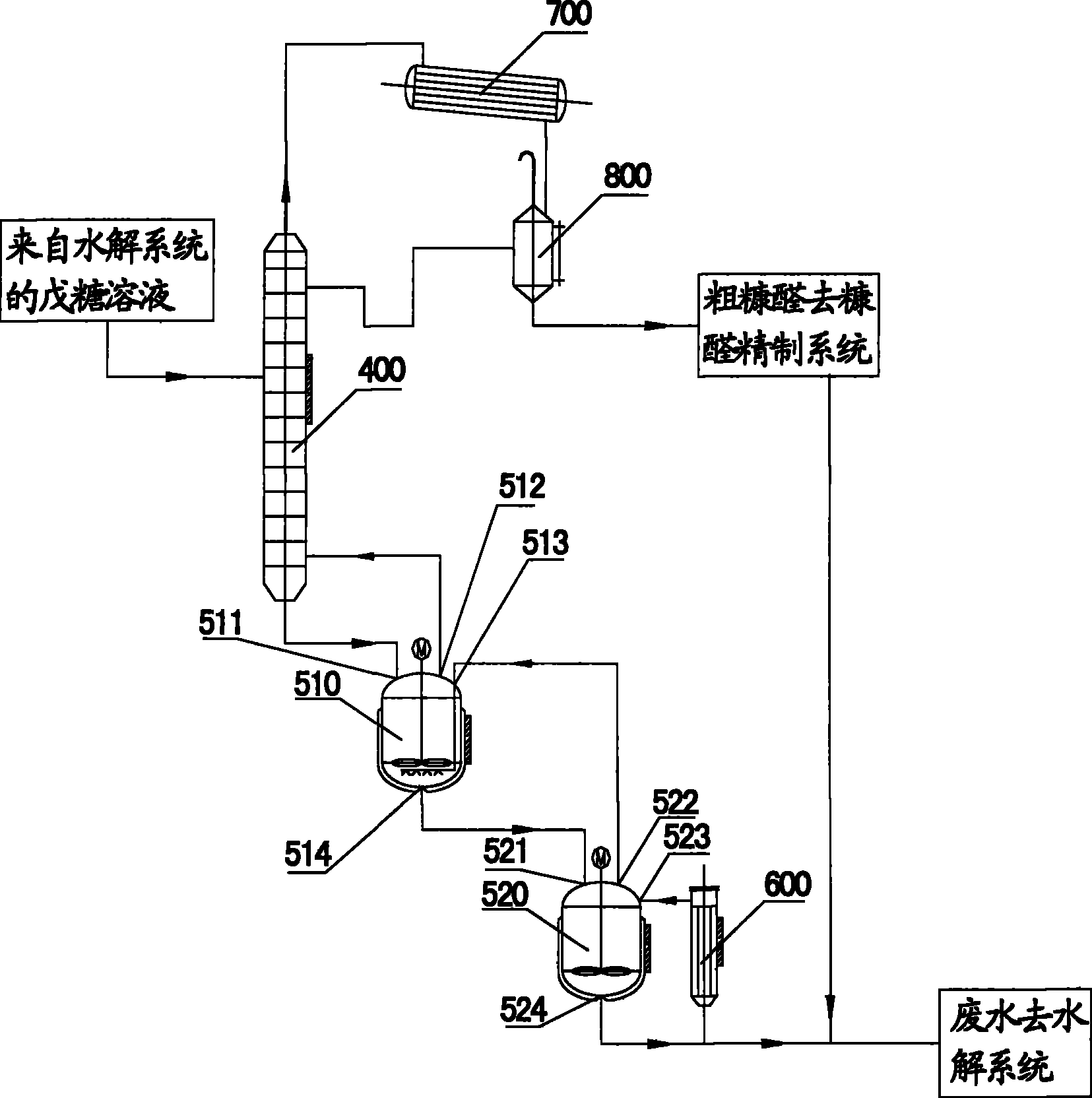

System and method for producing furol by using agricultural and forestry castoff

The invention discloses a system and method to produce furfural with agricultural wastes, which is characterized by the following: choosing two-step method; comprising hydrolysis system and dehydration distilling system; setting the hydrolysis system as N grade hydrolysis autoclave with end-to-end; proceeding continuous hydrolysis for the agricultural wastes; generating pentose solution; setting the dehydration distilling system as dehydration distilling unit and dehydration reclaiming unit; dewatering and distilling for the pentose solution with the dehydration distilling unit; getting furfural steam; setting the dehydration reclaiming unit as at least one grade dewatering reactor; further-dewatering; generating furfural steam; sending into dehydration distilling tower; distilling continuously; sending the waste water from the dehydration reclaiming unit back to dehydration system; realizing zero discharge for waste water. This invention possesses high productivity, low energy consumption and warm reacting condition, which can be used as raw material to produce alcohol.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Anti-corrosion super-hydrophobic heat reflecting paint and preparation method thereof

ActiveCN105925073AImprove lotus leaf effectImprove hydrophobicityAnti-corrosive paintsReflecting/signal paintsNano sio2Water contact

The invention discloses an anti-corrosion super-hydrophobic heat reflecting paint and a preparation method thereof. The anti-corrosion super-hydrophobic heat reflecting paint is prepared from the following raw materials: modified nano TiO2, modified nano SiO2, micron TiO2 and / or SiO2, fluorocarbon resin, a solvent, a curing agent, a defoaming agent, a wetting dispersant and a flatting agent. After experiments, the heat reflecting rate of the obtained product reaches 90 percent or more, the water contact angle reaches 145 degrees or more, and the product can meet the requirements on a coating under outdoor severe environments.

Owner:SHANDONG UNIV OF SCI & TECH

Process for preparing benzaldehyde by catalytic oxidation of phenylethene

InactiveCN101306986AEasy to makeLow costMolecular sieve catalystsCarbonyl compound preparation by oxidationBenzaldehydeCatalytic oxidation

The invention provides a method for preparing benzaldehyde by catalyzing and oxidizing styrene. The method comprises the following steps that: raw materials of the styrene, oxidant, solvent and catalyzer are respectively added into a reaction vessel; the reaction vessel is heated to a temperature of between 40 and 120 DEG C and the raw materials react at a constant temperature for 1 to 15 hours; after the reaction is finished, the raw materials are cooled and separated to produce a benzaldehyde finished product, wherein, the catalyzer is an SBA-15 molecular sieve containing one or a plurality of hetero atoms; and the molar ratio between a silicon atom and a hetero atom in the catalyzer is between 5 and 200; the oxidant is a peroxide aqueous solution and a peroxyacetic acid aqueous solution; and the solvent is a monohydric alcohol, ketone and nitrile class. As the method provided by the invention adopts the SBA-15 molecular sieve containing one or the plurality of the hetero atoms as the catalyzer, the method can acquire higher styrene conversion rate and benzaldehyde selectivity; and the catalyzer has simple preparation, low cost and high stability and can be repeatedly used for a plurality of times.

Owner:HUNAN UNIV

Preparation method for silicon dioxide aerogel

The invention relates to a preparation method for silicon dioxide aerogel. The method includes the following steps: (1) under the acidic condition that pH is equal to 3 to 5, stirring silicon tetrachloride and water for reaction, then adding ammonia water to regulate pH to 8 to 10, adding water and ethanol, and after hydrolytic polycondensation reaction, forming alcogel; (2) carrying out extraction, and removing water / alcohol mixture contained in the alcogel; taking gel solution, adding anhydrous methanol or ethanol, and replacing the water / alcohol mixture in gel pores with the anhydrous methanol or ethanol; (3) adding trimethyl chlorosilane and alkane to alkylate Si-OH on the surface of the gel skeleton, and after drying under the normal pressure, the SiO2 aerogel is produced. The invention has the following advantages that: (1) since the silicon tetrachloride as byproduct produced in a large amount by the organosilicon industry is used as raw material, the material cost in the process of production is greatly reduced; (2) compared with the conventional supercritical drying, the adopted normal-temperature drying can greatly reduce conditions needed by reaction; and (3) the invention cannot destroy the nanopore structure of the SiO2 aerogel, and can stably increase the reaction speed at the same time.

Owner:应城市东诚有机硅有限公司

Method for extracting aluminum oxide

InactiveCN103693666AHigh purityReduce side effectsAluminium oxide/hydroxide preparationCoal gangueAluminium salts

The invention relates to a method for extracting aluminum oxide. The method comprises the following steps: heating and decomposing ammonium sulfate to generate ammonium hydrogen sulfate or ammonia gas, preparing an ammonium hydrogen sulfate solution, and collecting the ammonia gas for preparing ammonia water; grinding coal ash, mixing the coal ash with the ammonium hydrogen sulfate solution according to a certain ratio, heating while stirring, and reacting to generate ammonium aluminum sulfate; re-crystallizing and purifying ammonium aluminum sulfate to prepare an ammonium aluminum sulfate solution, and reacting with the ammonia water to generate aluminum hydroxide; drying aluminum hydroxide and roasting to generate aluminum oxide. According to the method, aluminum oxide can be extracted from not only the coal ash but also aluminum-containing raw materials such as coal gangue, slag, bauxite, red mud, tailings, kaolin and mullite; the technological process is shorter, equipment is simple, and large-scale industrialization production is easy to realize.

Owner:BEIJING JIAYI CHUANGJING SCI & TECH

Preparation method of active carbon

The invention provides a preparation method of active carbon. The preparation method comprises the following processes: a pre-oxidation process: performing pre-oxidation reaction on coal direct liquefaction asphalt to obtain pre-oxidized asphalt; a carbonization process: mixing the pre-oxidized asphalt with an activating agent, and performing carbonization reaction to obtain carbonized asphalt; and an activation process: performing heating activation on the carbonized asphalt to obtain active carbon. The coal direct liquefaction asphalt is subjected to pre-oxidation at first to ensure that small-molecular substances and macromolecular substances in the asphalt can be crosslinked with each other to form high-melting-point pre-oxidized asphalt, so that the coal direct liquefaction asphalt can be beneficially inhibited from melting in the carbonization process; and then, the pre-oxidized asphalt is subjected to the processes of carbonization and quick activation to prepare the active carbon with a relatively high specific surface area. The preparation method of the active carbon, provided by the invention, is more moderate in reaction condition and simpler in process flow.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

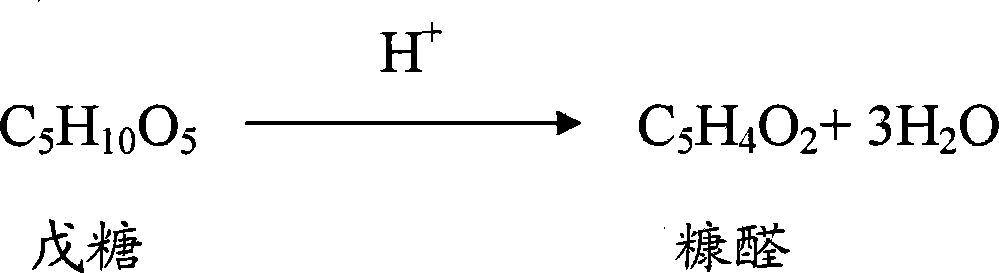

Synthesizing method of epoxy resin by autocatalysis of lignin

The invention relates to a method for preparing bisphenol-A epoxy resin partially substituted with lignin in a normal-pressure low-temperature water-bath condition through autocatalysis of lignin from papermaking black liquor.. The method comprises the following steps: removing impurities of the papermaking black liquor through acid out; filtering to obtain a lignin alkaline solution; mixing bisphenol-A, epichlorohydrin and the lignin alkaline solution, and sufficiently reacting in a heating and stirring condition by utilizing the autocatalytic effect of the lignin alkaline solution; filtering the product, and distilling the filtrate under reduced pressure to obtain epoxy resin brown viscous liquid finally. The method has the advantages that discharge of papermaking black liquor is reduced, waste utilization is realized, the nontoxic and harmless lignin is utilized as the raw material, and safety of the epoxy resin is improved; reaction conditions are mild, other catalysts or modifying agents are not added, the operation process, is simple, the effects of energy saving and cost reduction are achieved, and economical and social value are created; therefore the method has very important practical significance.

Owner:JILIN UNIV

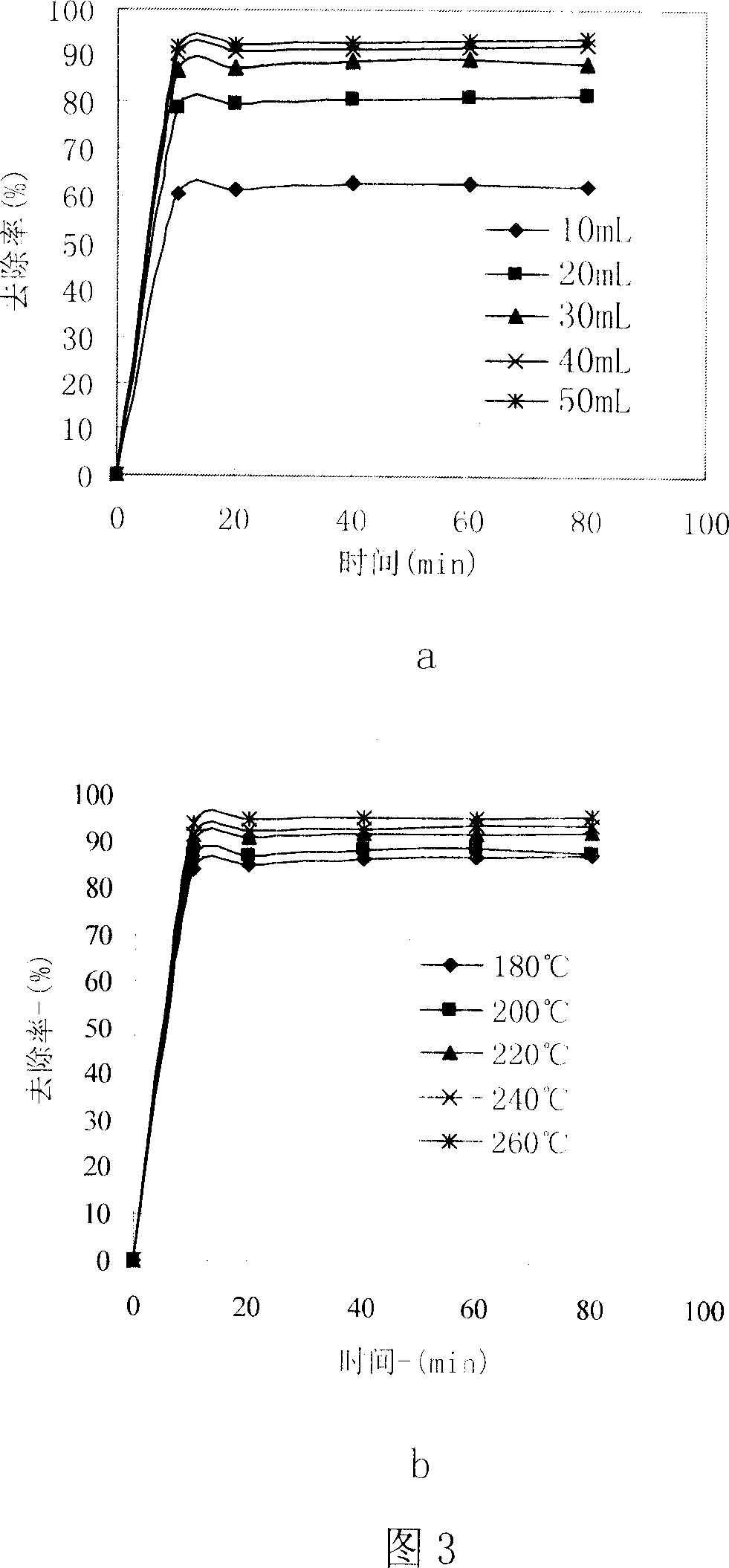

Method for catalytic wet oxidation of industrial sludge

InactiveCN105776794ALow solidsAchieve reductionSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeOrganic content

The invention relates to a method for catalytic wet oxidation of industrial sludge. The method includes the steps of (1), uniformly mixing industrial sludge raw materials with a catalyst, delivering the mixture into a reaction kettle, and feeding oxygen into the reaction kettle so as to subject the industrial sludge to wet oxidation; (2), delivering the industrial sludge subjected to wet oxidation into a cooler to cool, and delivering the cooled industrial sludge into a three-phase separator so as to obtain solid sludge at the bottom of the three-phase separator; (3), subjecting the solid sludge to dehydration treatment. Compared with the prior art, the method for catalytic wet oxidation of the industrial sludge has the advantages that the industrial sludge is reduced remarkably, refractory organics are removed to kill harmful pathogenic bacteria, treated sludge organic content is low to facilitate subsequent treatment, a liquid phase obtained after solid waste separation returns to an industrial wastewater treatment system to supplement a carbon source, and wet oxidation conditions can be lowered remarkably by the catalyst, so that energy consumption is reduced.

Owner:SHANGHAI HUANGU INVESTMENT MANAGEMENT CO LTD

Method of zyme catalyzing cyclo-olefin oxidation

InactiveCN101109016AAvoid Potential ContaminationReduced mass productionFermentationEpoxyCyclohexene

The invention relates to a method of enzyme catalyzing olefin expoxidation. In the aqueous solution, the bromine peroxidase is applied for biological catalyst and hydrogen peroxide or oxygen is taken as oxygen source to oxidate the olefin into expoxidation. Take the cyclohexen as example. The hydrogen peroxide is applied as the source. They react under the 20 DEG C. to 70 DEG C. for two to ten hours. The yield of epoxy cyclohexane to the hydrogen peroxide is more than 50 per cent and the selectivity of the epoxy cyclohexane is more than 85 per cent. After the reaction, the water phase is separated from the organic phase automatically, and the enzymes left in the water phase can be recycled. Boasting easy technical process, recycled enzymes and easy yield separation, the method is an environment-friendly green chemical process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

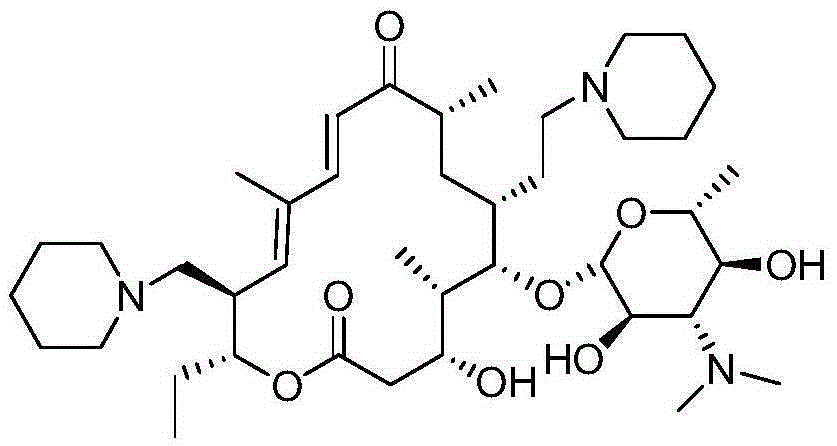

Tildipirosin preparation method

InactiveCN105384788AReduce usageLower reaction conditionsSugar derivativesSugar derivatives preparationIodineHydrolysis

The present invention provides a tildipirosin preparation method, tylosin as a starting reactant is used for preparation of 23-hydroxyl-5-O-mycaminose-tylosin lactone, 14-aldehyde-5-O-mycaminose-tylosin lactone is further prepared, and finally tildipirosin(IV) is prepared; by determining of reasonable oxidizing conditions, the use of expensive iodine can be avoided, the reaction conditions can be reduced; by controlling of the reaction conditions, two times of hydrolysis reaction can be performed in one pot, the operation steps can be reduced, the technical purpose of overall cost reduction can be achieved, and the method is less in step, simple in process, low in cost, and suitable for large-scale industrial production need.

Owner:TIANJIN ZHONGSHENG TIAOZHAN BIOTECH

Method for preparing large-area single-layer WSe2 monocrystals

InactiveCN108193277ALower reaction conditionsPrecisely control the amount of introductionPolycrystalline material growthSingle crystal growth detailsTemperature controlTube furnace

The invention discloses a method for preparing large-area single-layer WSe2 monocrystals and mainly solves the problems of complicated process and poor controllability of a traditional preparation method. The method comprises implementing steps as follows: 1, substrates are selected and subjected to RCA standard cleaning, and two substrates are selected, subjected to ultrasonic cleaning with deionized water, acetone and isopropyl alcohol in sequence for 5 min and air-blown; 2, the cleaned substrates are put in a tubular furnace, two quartz boats are prepared and taken as a W boat and an Se boat respectively, and an NaCl solution is dropwise added to the front end of the first substrate and then heated on a hot plate until deionized water is completely vaporized; WO3 is arranged on the first substrate, the first substrate is covered with the second substrate, then the W boat is placed in a high-temperature area, Se is arranged in the Se boat, and the Se boat is placed in a low-temperature area; 3, a cavity is purged, the high-temperature area and the low-temperature area of the tubular furnace are subjected to temperature control respectively, WO3 and Se are subjected to a reaction,WSe2 is produced, and a product is sealed. The method is lower in cost, high in controllability and suitable for preparing the repeatable large-area single-layer WSe2 material.

Owner:XIDIAN UNIV

Method for preparing nano metallic nickel in spent electroless nickel plating solution

InactiveCN101892389ALower reaction conditionsLess investmentProcess efficiency improvementElectroless nickelLiquid waste

The invention discloses a method for preparing nano metallic nickel in spent electroless nickel plating solution. The method comprises the following steps: adding 0.20 to 0.33 grams of reducer thiourea dioxide into every 100ml of the spent electroless nickel plating solution; then, adjusting the spent electroless nickel plating solution to be alkalic with 3 to 7 grams of sodium hydroxide, and heating the spent electroless nickel plating solution to the temperature of between 70 and 100 DEG C; reacting at constant temperature for 5 to 20 minutes, and cooling the solution to the temperature of between 10 and 30 DEG C; filtering the spent electroless nickel plating solution; and washing the filtered substances with deionized water and absolute ethanol respectively; and drying the substances in a vacuum drier to prepare the nano metallic nickel. The method effectively solves the problem of spent electroless nickel plating solution pollution, simultaneously recycles noble metal nickel, and realizes double assurance of social benefit and economic benefit for enterprises. Furthermore, the reducer thiourea dioxide has lower requirement to the reaction condition, less investment, no toxic or side effect and environmental protection.

Owner:王昊杨

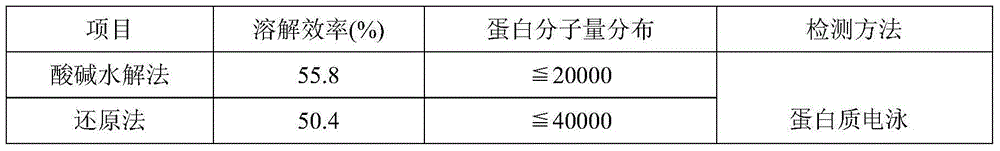

Preparation method for wool keratin regenerated cellulose fiber

ActiveCN104005114AImprove hydrolysis effectImprove degradation efficiencyConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolymer scienceViscose

A provided preparation method for wool keratin regenerated cellulose fiber comprises the concrete steps: firstly preparing a viscose-rayon spinning solution, then preparing a wool keratin solution, then mixing the viscose-rayon spinning solution and the wool keratin solution, then adding a crosslinking agent, mixing and performing wet-process spinning, so as to obtain wool keratin regenerated cellulose fiber. The wool keratin regenerated cellulose fiber prepared by employing the method has the protein content of 6% or more, and the production technology is simple in process and high in production efficiency.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

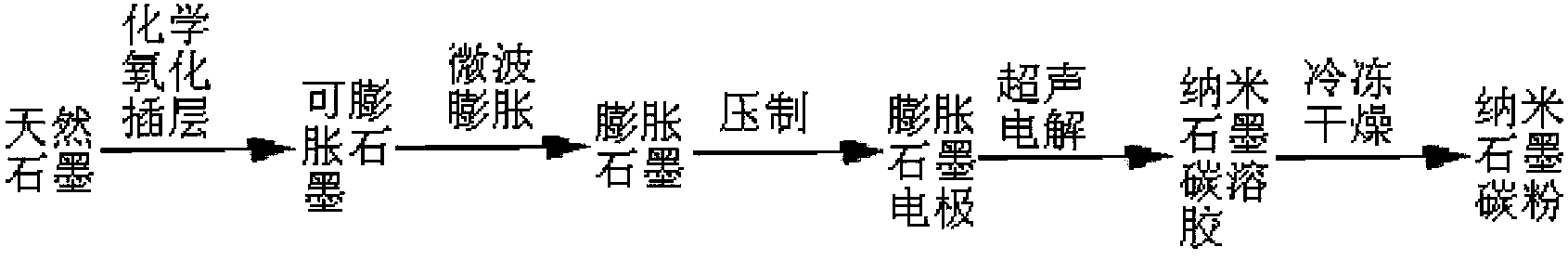

Preparation method of nano-graphite carbon powder

ActiveCN103395777AImprove electrolysis efficiencyShorten electrolysis timeMaterial nanotechnologyGraphiteElectrolysisFreeze-drying

The invention relates to a preparation method of nano-graphite carbon powder. The method comprises the steps of: (1) preparing expansible graphite by a chemical oxidation intercalation process; (2) preparing expanded graphite by a microwave process; (3) pressing the expanded graphite into a expanded graphite sheet, putting it into a microporous filter membrane sieving assembly, conducting pressing and sealing, then placing the assembly at the anode and cathode of an electrolytic bath, taking a chlorate solution as an electrolyte solution, carrying out ultrasonic electrolysis at a temperature below 60DEG C, controlling the electrolytic current at 5-18A / cm<2>, the voltage at 6-20V, the ultrasonic oscillation power at 200-600W, and the frequency at 20-40kHz, inverting the anode and the cathode at an interval of 8-15min, completing electrolysis when the concentration of sol in the electrolytic bath is 2-5%, thus obtaining nano-graphite carbon sol; and (4) adding ammonium sulphate into the nano-graphite carbon sol till the mass concentration of ammonium sulfate reaches 5-8%, stirring them uniformly, then performing freeze drying, thus obtaining the nano-graphite carbon powder. The method has the advantages of mild reaction condition and high speed, thus being suitable for industrialized mass production.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Preparation process for ammonium paratungstate

ActiveCN109019691AImprove purityLower reaction conditionsTungsten compoundsAmmonium paratungstateDecomposition

The invention discloses a preparation process for ammonium paratungstate. The preparation process comprises preparation of sodium tungstate, preparation of sodium tungstate ammonium, decomposition, washing and impurity-removal, and purifying and re-crystallization. The process adopts an electro-catalysis way to prepare an intermediate product sodium tungstate, so that the reaction conditions are reduced, reaction is easier, and production energy consumption is reduced; and ammonium paratungstate is subjected to impurity-removal and purification through a cleaning, re-crystallizing and purifying way, so that purity of ammonium paratungstate prepared in the process is relatively high.

Owner:江西省修水赣北钨业有限公司

Method for absorbing and separating carbon dioxide

InactiveCN101734658APromote absorptionImprove desorption efficiencyCarbon compoundsLiquid productAlcohol

The invention discloses a method for absorbing and separating carbon dioxide, which comprises absorption and desorption of the carbon dioxide at certain temperature and specifically comprises the following steps: mixing alcamines compounds and ethylene glycol compounds to form solution so as to obtain an absorbent; making the absorbent contact the gas to be absorbed in gas-liquid mass transfer equipment to obtain a liquid product; and desorbing and separating the liquid product to obtain the carbon dioxide so as to realize the regeneration of the carbon dioxide. The absorbent adopted by the method can efficiently absorb the carbon dioxide, has little corrosion to the equipment, and can realize the regeneration of the carbon dioxide and the cyclic utilization of the absorbent.

Owner:TSINGHUA UNIV

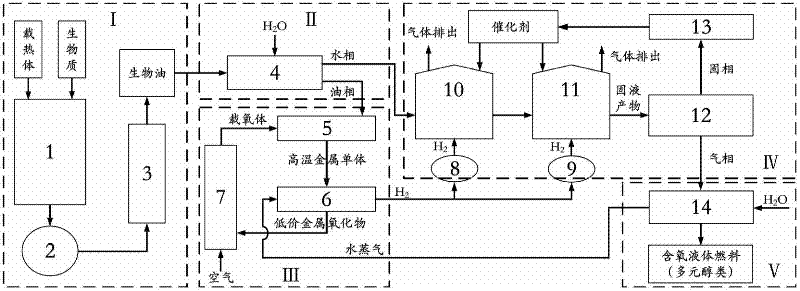

Device and method for preparing oxygen-containing liquid fuel by catalytically converting biological oil

InactiveCN102653691AHigh yieldReduce processing costsDirect heating destructive distillationBiofuelsCatalytic transformationLiquid fuel

The invention provides a device and a method for preparing oxygen-containing liquid fuel by catalytically converting biological oil. The device comprises a biomass rapid thermal cracking oil preparing system (I), a biological oil oil-water phase separation system (II), an oil phase biological oil chemical chain hydrogen production system (III) and a hydrogen output water supply phase biological oil catalytic hydrogenation system (IV), wherein the biomass rapid thermal cracking oil preparing system is used for preparing the biological oil; the biological oil oil-water phase separation system is used for receiving the biological oil and separating the biological oil into oil-phase biological oil and water-phase biological oil to be respectively output to the oil phase biological oil chemical chain hydrogen production system (III) and the hydrogen output water supply phase biological oil catalytic hydrogenation system (IV). The method comprises the following steps of: carrying out heat cracking on a biomass to prepare oil; carrying out water phase and oil phase separation on the obtained biological oil; carrying out chemical chain method on the oil-phase biological oil to produce hydrogen; and providing a'hydrogen source' to the water-phase biological oil to carry out two-step catalytic hydrogenation in a slurry bed; and directly separating and extracting a hydrogenated product to obtain the oxygen-containing liquid fuel. The device and method disclosed by the invention can be used for realizing full-component'graded conversion' of the biological oil.

Owner:SOUTHEAST UNIV

CO2 mineralization method capable of co-producing potassium-enriched solution by high temperature method

InactiveCN102701253AMineralization achievedImplement extractionCalcium/strontium/barium carbonatesPotassium fertilisersPotassium ionsChloride

The invention discloses a CO2 mineralization method capable of co-producing potassium-enriched solution by a high temperature method, which mainly comprises the following steps of: adequately and evenly mixing smashed potash feldspar-enriched ore power and calcium chloride, and carrying out conversion reaction under the condition that the temperature is not lower than 600 DEG C; putting material which is adequately converted into a reactor, adding water, charging CO2, and carrying out mineralization reaction under the condition that the CO2 partial pressure is 0.3-15MPa, and the temperature is 50-350 DEG C; and charging material liquid which is adequately mineralized into separation equipment to separate the solid from the liquid, wherein the liquid phase is the potassium ion-enriched potassium-enriched solution, and the solid phase is the calcium carbonate-containing mineralized product. The CO2 is mineralized by the technical method disclosed by the invention, and the conversion rate of the potash feldspar component in the ore reaches 96%, so that compared with the highest conversion rate 13% of the existing CO2 mineralization method capable of co-producing the potassium-enriched solution, the conversion rate of the CO2 mineralization method is improved by over 6.3 times.

Owner:SICHUAN UNIV

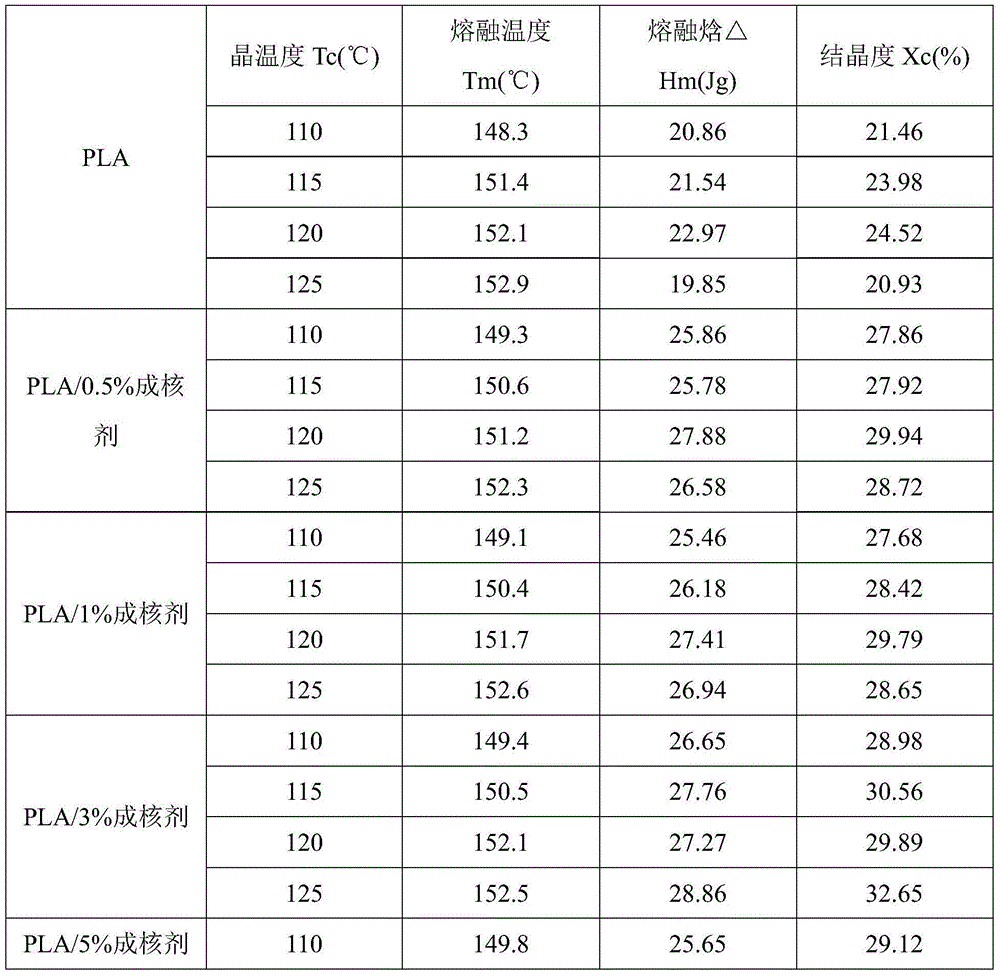

Method for modifying fast-crystallization high-crystallinity polylactic acid

The invention discloses a method for modifying fast-crystallization high-crystallinity polylactic acid, and provides fast-crystallization high-crystallinity polylactic acid prepared by taking a phenyl phosphate nucleating agent and polylactic acid as main raw materials. The method comprises the following steps of firstly preparing a high-crystallinity nucleating agent by utilizing raw materials, namely phosphenylic acid, chloride, alkali and the like; then adding experimental raw materials, namely the nucleating agent, the polylactic acid and the like, to an HAAKE torque rheometer according to a polymer crystallizing principle for blending so as to prepare a sample. According to the method, the obtained modified polylactic acid is reduced in crystallization temperature to 109 DEG C and enhanced in crystallinity by about 107% in a crystallization process, and the half-crystallization time of the modified polylactic acid is reduced by about 15 times compared with the half-crystallization time of pure polylactic acid.

Owner:常州龙骏天纯环保科技有限公司 +1

Method oxidation degradating m-nitrobenzene sodium sulfonate by catalytic wet method

InactiveCN100999355ACompletely degradedImprove processing efficiencyPhysical/chemical process catalystsWater contaminantsSulfonateCatalytic oxidation

This invention discloses a method of catalysis wet process oxygenizing and degrading sodium metanitrobenzene sulphonate, which relates to industry nickel decoating waste water. It belongs to catalytic oxidation technique domain. Add sodium metanitrobenzene sulphonate solution which has certain TOC density in reactor, of which volume is 11. Add hydrogen dioxide and oxygen as oxidizing agent, add cupric nitrate as catalytic agent, seal up; import oxygen of which incipient pressure is 0.1-15MPa, mix, heat to 150-300deg, degrade, react 0.5h-2.5h, cool, process to finish, measure total organic carbon. After 30 minutes, removal rate of total organic carbon is 95.94%; After 2 hours, removal rate of total organic carbon is 96.51 %.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

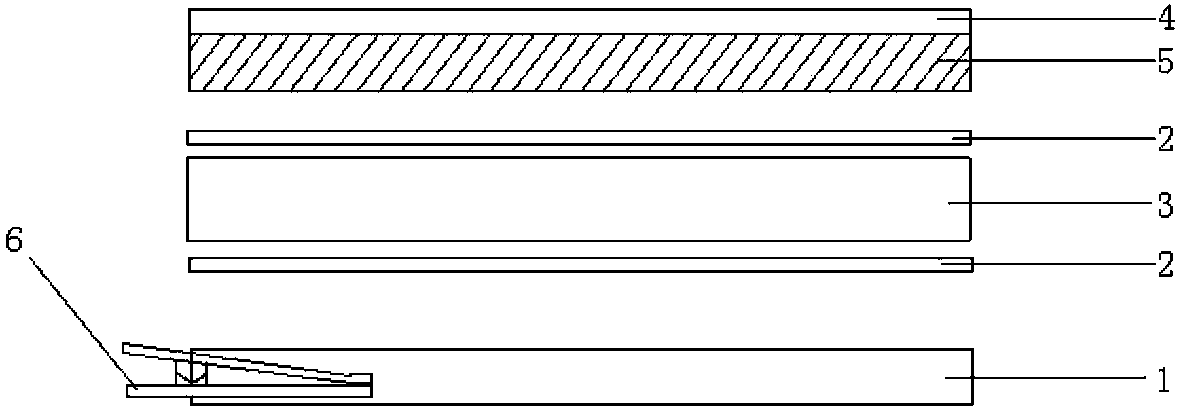

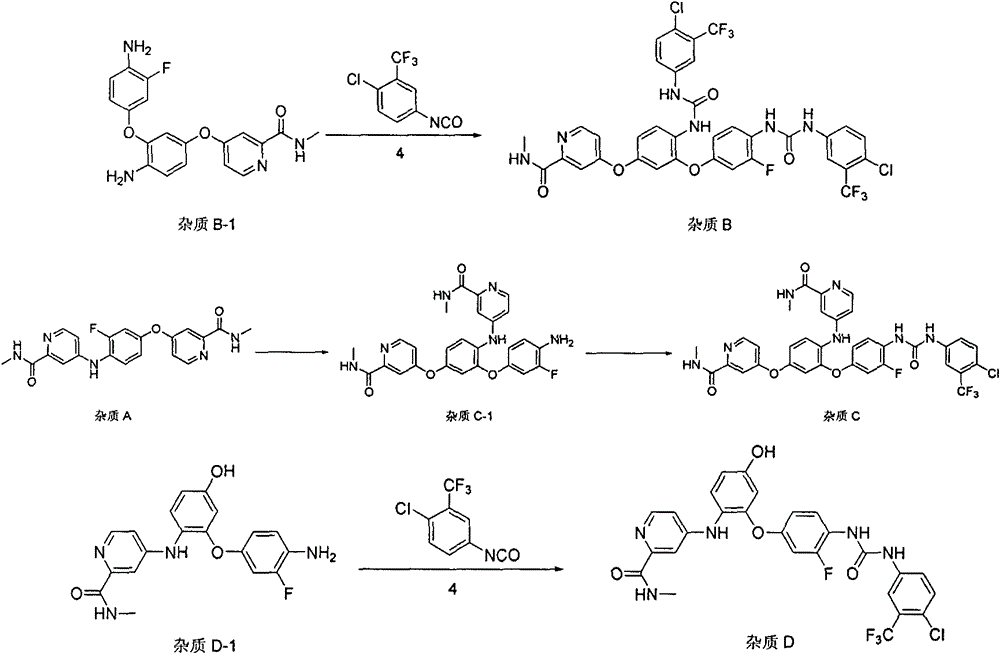

Preparation method for high-purity regorafenib

InactiveCN105218440ALower reaction conditionsAvoid demandingOrganic chemistryRegorafenibPhase-transfer catalyst

The invention discloses an improved preparation method for high-purity regorafenib (a compound I), particularly a preparation method for a compound 3 (a regorafenib intermediate) with the structure shown in the description, wherein the compound 3 is further used for industrial preparation of regorafenib with extremely excellent purity. By adopting a phase transfer catalyst, the method is simple and convenient to operate and environmental-friendly, can effectively inhibit generation of impurities, is low in requirement on equipment and is suitable for industrial production of high-purity regorafenib on a large scale.

Owner:HENAN UNIV OF CHINESE MEDICINE

Butynediol ethoxylate modified bola type organosiloxane and preparation method thereof

The invention discloses butynediol ethoxylate modified bola type organosiloxane and a preparation method thereof. The preparation method includes: butynediol ethoxylate and tetramethyl dihydro disiloxane have reaction under the effects of a platinum catalyst and an amine composite catalyst to obtain butynediol ethoxylate modified tetramethyl disiloxane; balanced copolymerization is performed under the effect of a catalyst to obtain the butynediol ethoxylate modified bola type organosiloxane. The preparation method has the advantages that the method is large in grafted hydrophilic group proportion, high in grafting rate, free of solvent adding and suitable for large-scale industrial production; the prepared hydrophilic group butynediol ethoxylate modified bola type organosiloxane is good in water solubility, good in wetting and spreading ability, high in surface activity and high in defoaming / foam inhibiting performance.

Owner:CHINA RES INST OF DAILY CHEM IND

Preparation method of medical biodegradable polymer material polylactate geycollic acid

ActiveCN110283305AAdjustable weight average molecular weightShort reaction timeBiodegradable polymerMonomer

The invention provides a preparation method of medical biodegradable polymer material polylactate geycollic acid (PLGA). A mass polymerization method is adopted for manufacturing the polylactate geycollic acid (PLGA), the production technology is simple, conditions needed by the reaction are low, the reaction speed is high, and the reaction time is short; a catalytic system adopting an organic metal compound as a main catalyst and adopting a substance containing reactive hydrogen as an initiator is adopted as an efficient catalytic system, the reaction time is shorter compared with a single catalyst, the weight-average molecular weight of the product is adjustable, the lowest molecular weight distribution index can reach 1.40, the catalytic activity is high, and the PLGA is non-toxic basically; the reaction product is precipitated three times, unreacted monomers and low-molecular-weight by-products can be removed, the molecular weight distribution index is lowered, and the product purity is improved.

Owner:SHANDONG GUYUCHUN BIOTECHNOLOGY CO LTD

Method for preparing natural high-molecular material by utilization of rare earth metal ion coordination

InactiveCN106243240AOvercome toxicityOvercome compatibilityProsthesisDiffusion methodsStructural regularity

The invention discloses a method for preparing a natural high-molecular material by the utilization of rare earth metal ion coordination. Through strong coordination between rare earth metal ion and oxygen atom in carboxyl function group, the rare earth metal ion coordinated natural high-molecular material is prepared by an ion permeation and diffusion method. According to the method, carboxyl-modified graphene oxide is introduced into the natural high-molecular material such that mechanical strength of the material is enhanced and structural regularity of the material also can be boosted. By selecting one ingredient from sodium alginate and xanthan gum as the base material, the material can be endowed with good biocompatibility and biodegradability. The method of the invention is simple and feasible. Reaction condition is mild. The prepared natural high-molecular material has good biocompatibility and strong mechanical properties.

Owner:SOUTHEAST UNIV

Preparation technique of lithium-ion battery anode material lithium iron phosphate

InactiveCN101552331AEasy to separateEasy to operateElectrode manufacturing processesPhosphorus compoundsIron powderLithium iron phosphate

The invention discloses a preparation technique of the lithium-ion battery anode material lithium iron phosphate, which belongs to the preparation method of the battery anode material. The lithium iron phosphate is prepared by taking iron powder Fe, lithium hydroxide LiOH or lithium carbonate LI2CO3 and phosphoric acid (H3PO4) as raw materials according to the following processing steps of preparation of acid phosphate ferrous, preparation of iron lithium phosphate, and sintering. The preparation technique has the advantages of simple production process, easy operation, safety and reliability, pure product, stable quality, low costs, and no pollution to the environment.

Owner:XUZHOU HAITIAN GREEN ENERGY TECH

Method for preparing water-white highly-hydrogenated rosin

InactiveCN102212314AHigh activityGood choiceNatural resin chemical modificationFiltrationDistillation

The invention relates to a method for preparing water-white highly-hydrogenated rosin. The method comprises the following step that rosin serving as a raw material is subjected to catalytic hydrogenation in the presence of a loading type nano palladium-based catalyst to obtain the water-white highly-hydrogenated rosin. In the method, the nano loading type palladium-based catalyst is utilized for the hydrogenation of the rosin, the reaction temperature is between 100 and 180 DEG C, the reaction pressure is 1.0 to 10.0MPa, and the reaction time is 2.0 to 5.0 hours; and the catalyst is removed by filtration, the solvents are removed by decompressed distillation, and the water-white highly-hydrogenated rosin is obtained. The method has the advantages of low reaction conditions, easy process operation, less consumption and long service life of catalyst, low production cost, good product quality, flexible operation, low equipment cost and the suitability for industrialized production.

Owner:盘锦和运新材料有限公司 +1

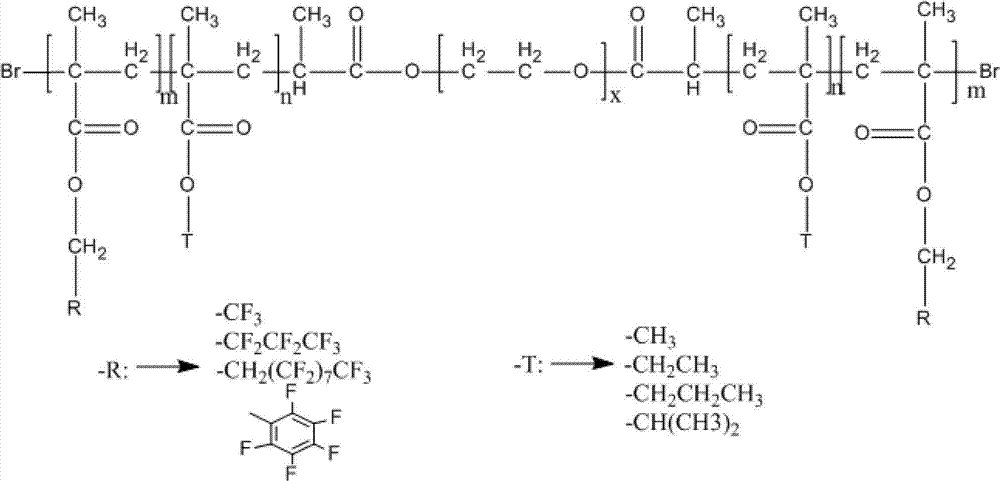

Amphiphilic fluorinated acrylate penta-block copolymer and preparation method thereof

The invention relates to an amphiphilic fluorinated acrylate penta-block copolymer and a preparation method thereof. The technical characteristics are that a name is amphiphilic fluorinated acrylate penta-block copolymer, namely poly-fluorinated acrylate-b-polymethacrylate-b-polyethylene glycol-b-polymethacrylate-b-poly-fluorinated acrylate. A synthetic method uses a bromine-terminated polyethylene glycol as a macro-molecule initiator and uses a one-pan way to gradually charge, that is performs an atom transfer radical polymerization reaction of the macro-molecule initiator with methacrylate, and after the reaction ends, directly adds the fluorinated acrylate to obtain the amphiphilic fluorinated acrylate penta-block copolymer through the atom transfer radical polymerization reaction. The copolymer and the preparation method have advantages of mild reaction condition, simple operation, reduced steps, high product yield, reduced cost, clear product structure and narrow molecular weight distribution, can save time and raw materials, and has potential application in fields of LCD, aerospace coating, photoconductive material, nano-carbon material, pharmaceutical carriers, etc.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com