Device and method for preparing oxygen-containing liquid fuel by catalytically converting biological oil

一种液体燃料、催化转化的技术,应用在生物质资源利用领域,能够解决没有实现生物油全组分利用、工艺稳定性与连续性降低、催化剂易结焦等问题,达到解决催化剂结焦失活、接触时间长、产物收率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

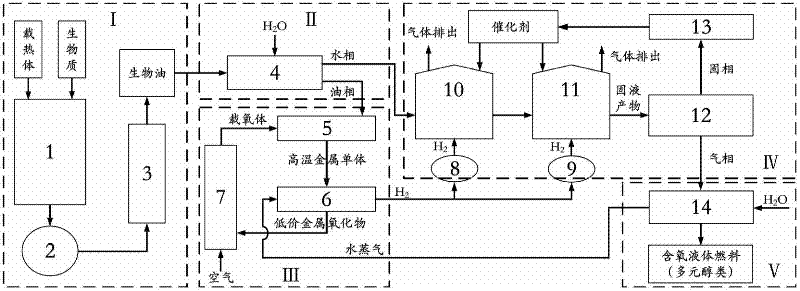

[0033] The present invention will be described below with reference to the accompanying drawings.

[0034] The invention provides a method and a device for preparing oxygen-containing liquid fuel through catalytic conversion of bio-oil. In this method, biomass is first subjected to thermal cracking to produce oil, and the obtained bio-oil is separated from the water phase and the oil phase, and hydrogen is produced from the oil-phase bio-oil through a chemical chain method to provide a "hydrogen source" for the water-phase bio-oil in the slurry bed Two-step catalytic hydrogenation, hydrogenated products (polyols) are directly separated and purified to obtain oxygenated liquid fuels. The device includes biomass fast thermal cracking device 1, gas-solid separator 2, fast condenser 3, oil-water phase separator 4, reduction reactor 5, steam hydrogen generator 6, air reactor 7, compressor one (first Compressor) 8. Compressor 2 (second compressor) 9. Slurry bed low-temperature cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com