Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309results about How to "Improve desorption efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high effective sulfur transfer agent for catalytic cracking fume

InactiveCN1727052AImprove adsorption efficiencyImprove desorption efficiencyCatalytic crackingDispersed particle separationPolymer scienceCerium

A process for preparing the efficient sulfur transferring agent used for the catalytic cracking of fume includes such steps as preparing ZnMgAlCe hydrotalcite from the active components (Zn, Mg and Al) and assistant (Ce and V) by codeposition method, preparing V-dipped ZnMgAlCo hydrotalcite by anionic exchange method, proportionally mixing it with kaolin and Al sol, grinding, vacuum drying and calcining. Its advantages are high SOx adsorptivity and desorptivity and high mechanical strength.

Owner:EAST CHINA NORMAL UNIV

Nitrogen purging-assisted organic exhaust gas recycling method through pressure swing adsorption of adsorbent resin

ActiveCN104107621ALarge volume adsorption capacityNo chemical reactionDispersed particle separationSolubilityCollection system

The invention discloses a nitrogen purging-assisted organic exhaust gas recycling method through the pressure swing adsorption of adsorbent resin. The organic exhaust gas recycling method comprises the following steps: (1) adsorption, namely performing adsorption when exhaust gas including volatile organic compounds (VOCs) enters an adsorber filled with the macroporous adsorption resin by a gas collection system; (2) desorption, namely vacuumizing the adsorbent resin in the adsorber and purging the adsorbent resin by using nitrogen in an auxiliary manner to desorb the adsorbed VOCs from the adsorbent resin to obtain the desorbed gas; and (3) recycling, namely condensing or absorbing the desorbed gas to recycle the VOCs. The adsorbent adopted by the method disclosed by the invention is the macroporous adsorption resin, the surface of the macroporous adsorption resin has no catalytic performance and has the characteristics of being easy to regenerate, high in mechanical strength, great in volumetric adsorption capacity and the like. A adsorption technique assisted by nitrogen purging in vacuum at normal temperature is high in adsorption efficiency and has the very excellent recycling effect on VOCs gas which can be easily oxidized and hydrolyzed or is high in solubility.

Owner:NANJING UNIV

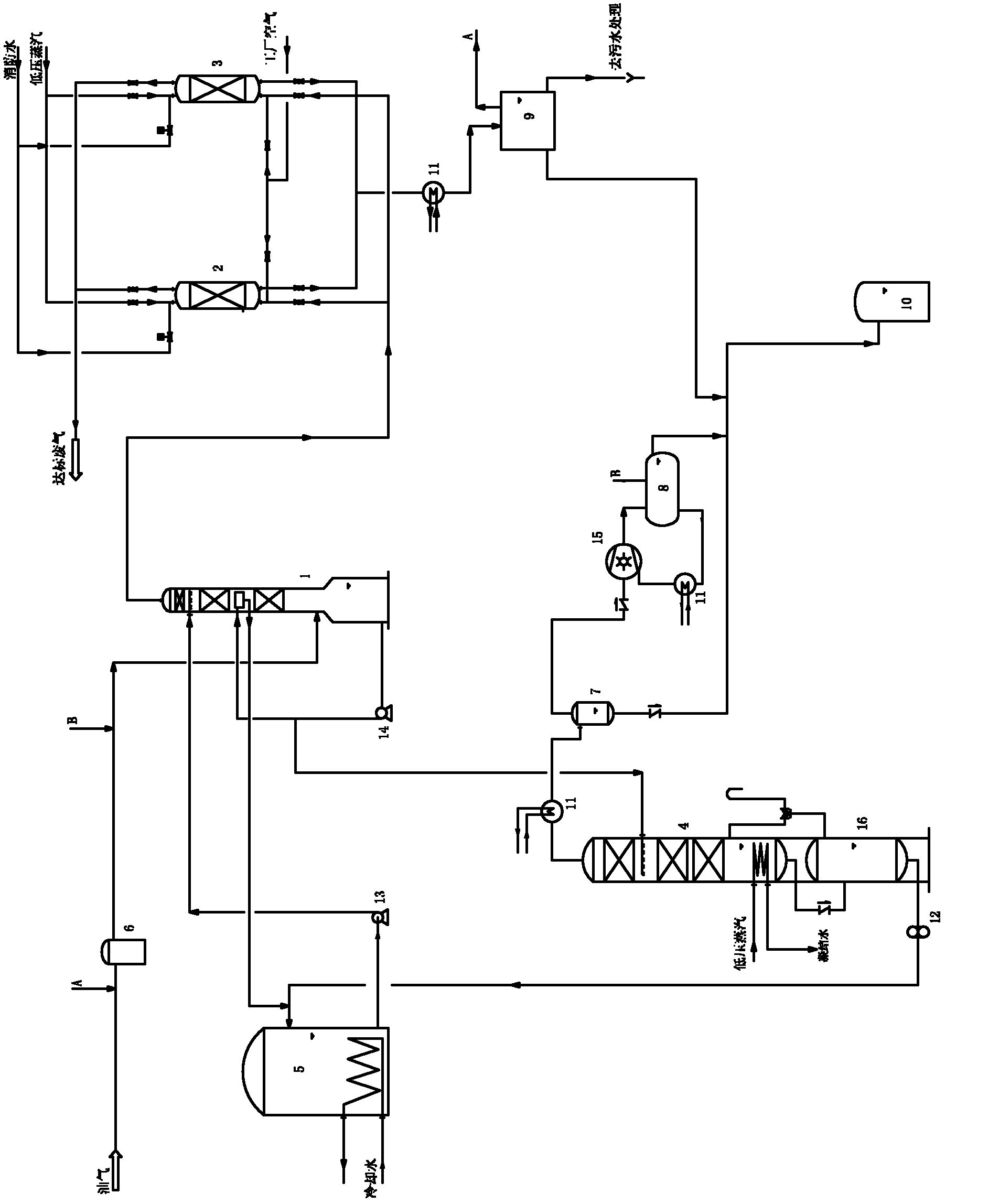

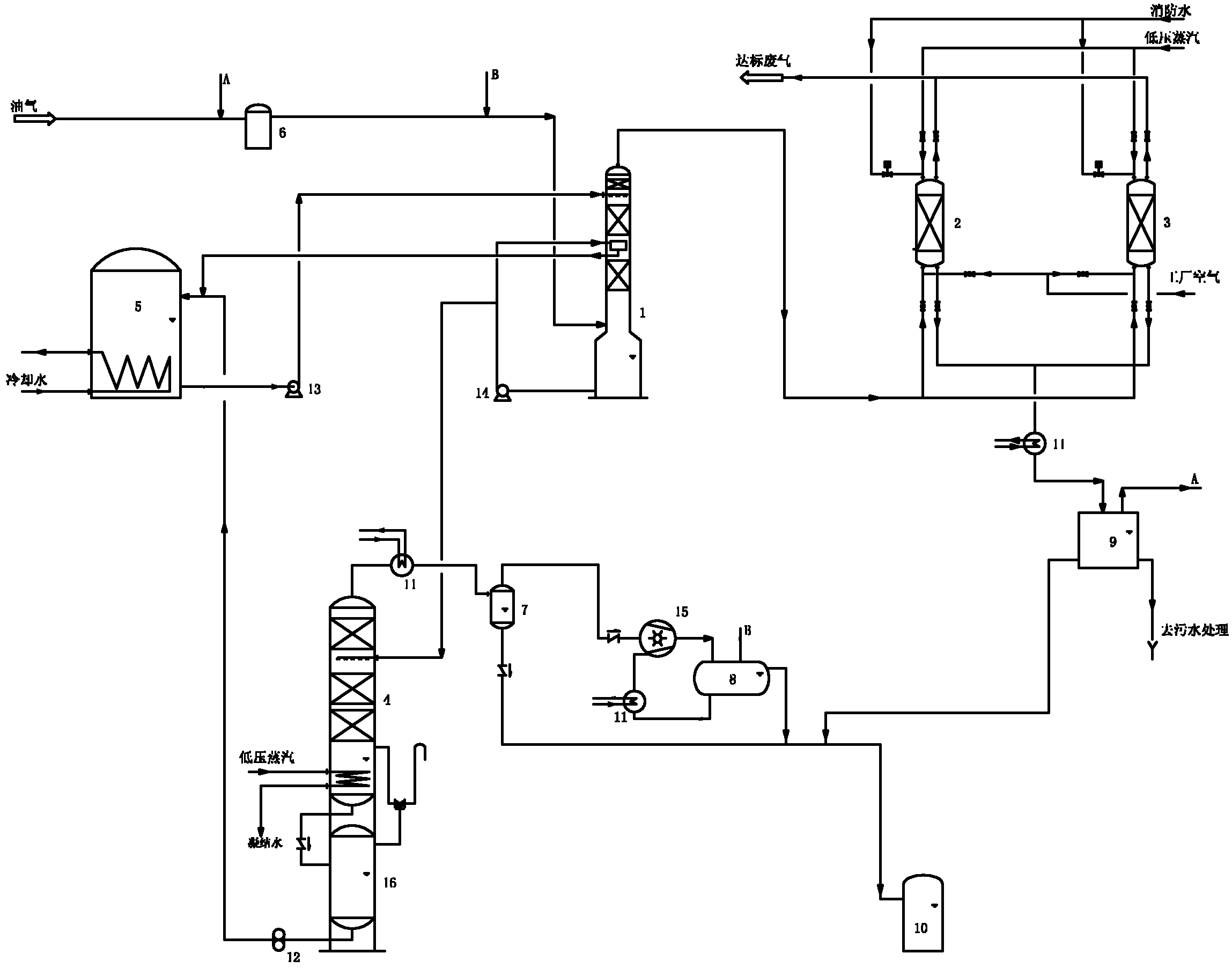

System and method for recovering oil gas

InactiveCN102580463AFlexible selectionExtended operating cycleDispersed particle separationRecovery methodDesorption

The invention relates to a recovering method and a recovering system for hydrocarbon and other volatile organic matters in refineries, chemical plants, large bulk plants, refuelling stations and the like. Oil gas is absorbed by two sections of stuffing in an absorption tower and then enters two activated carbon adsorption towers which run alternately; the oil gas reaches the standard after being absorbed by activated carbon, and then is discharged to the air; after the substance that is generated after desorption of the activated carbon is condensed and treated through oil-water separation, the obtained hydrocarbon liquid is conveyed to a storage tank, generated sewage is conveyed to a sewage treatment device to be treated, and a small amount of gas that is not condensed returns to the absorption tower; solvent that absorbs oil gas enters a desorption tower so as to desorb solvent and oil gas; and the hydrocarbon liquid is conveyed to the storage tank to be stored. The method and the system, which are provided by the invention, have the characteristics of smaller investment, longer operation period of equipment, high oil gas recovery rate and simple technological process.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

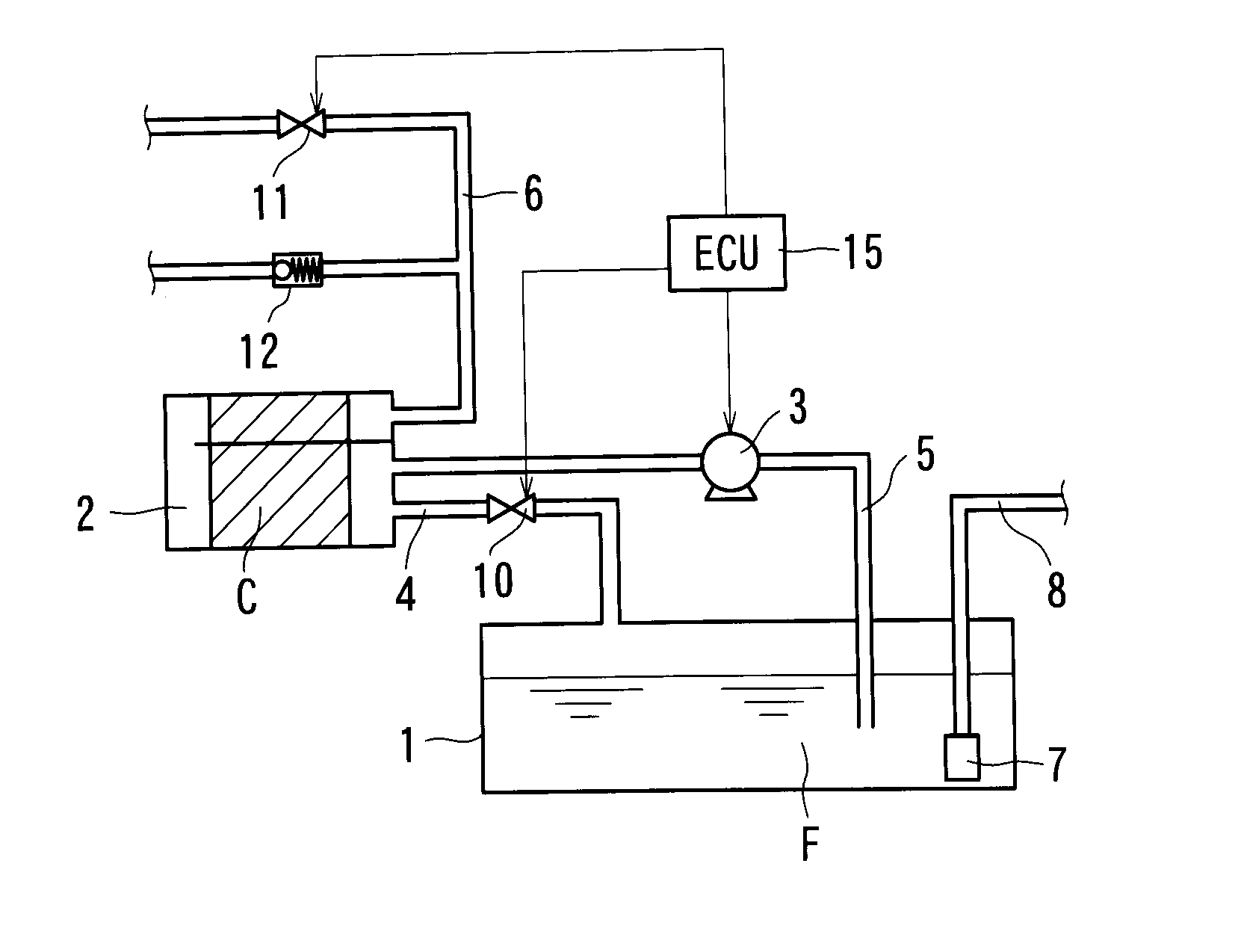

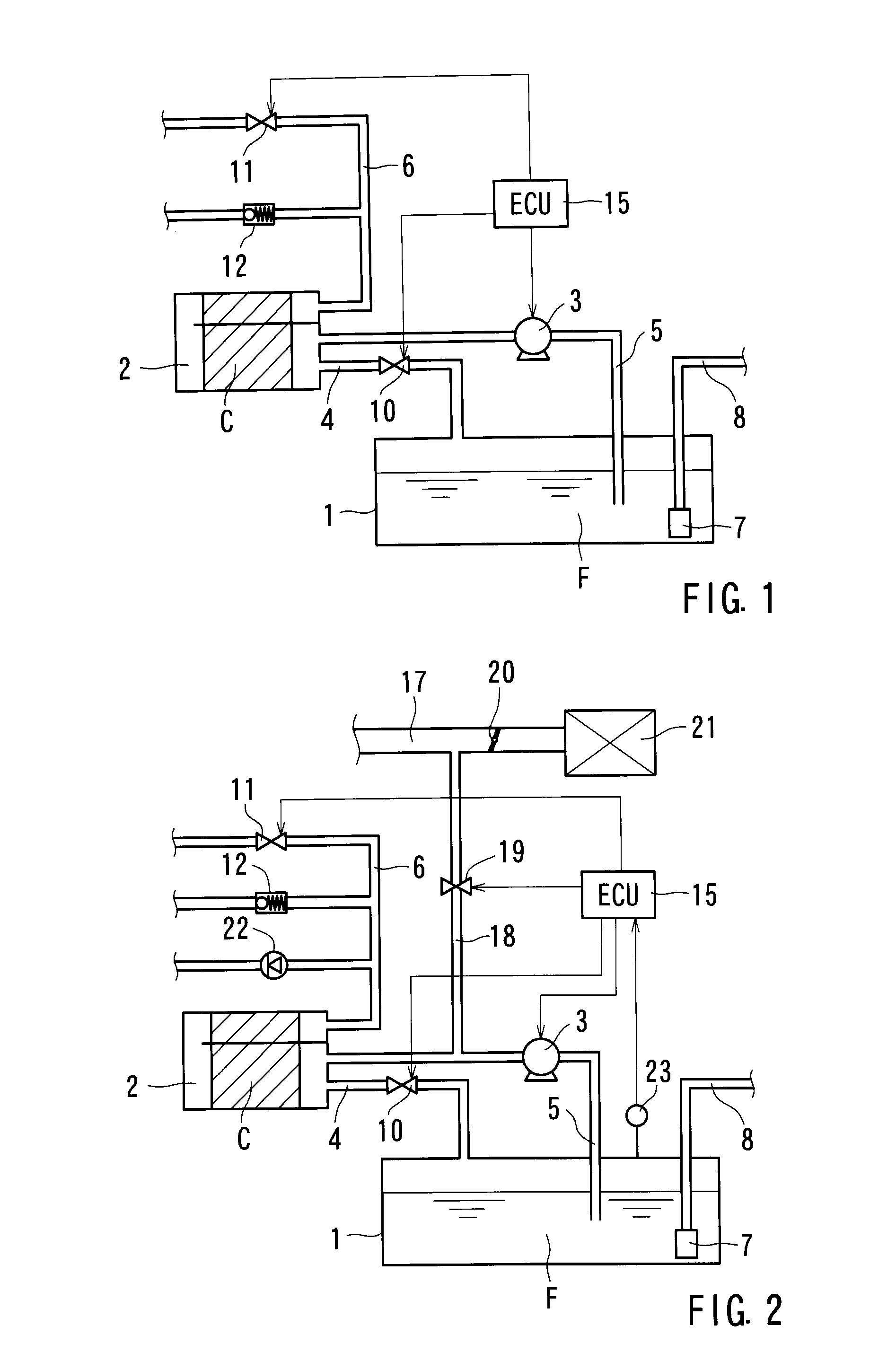

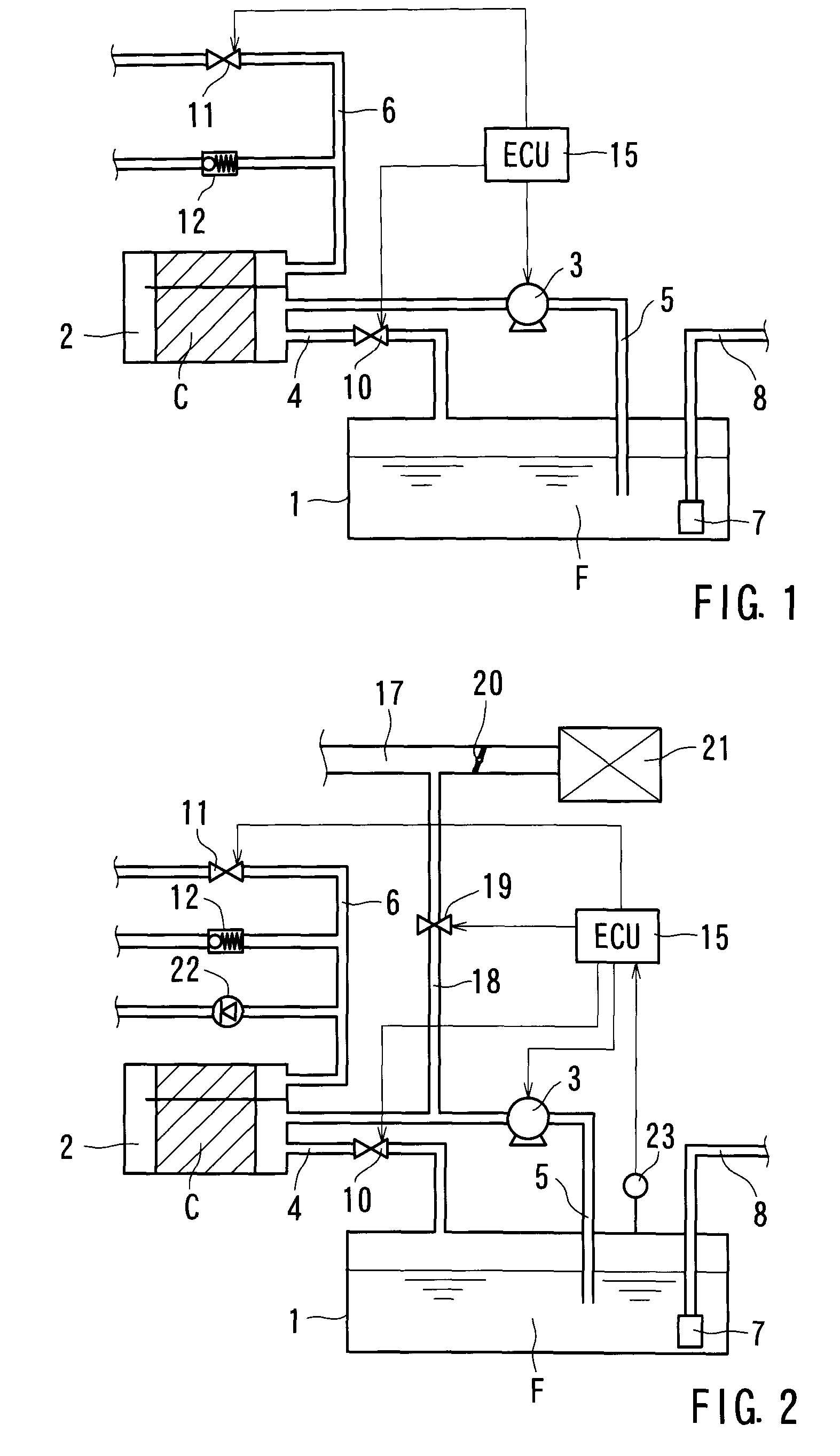

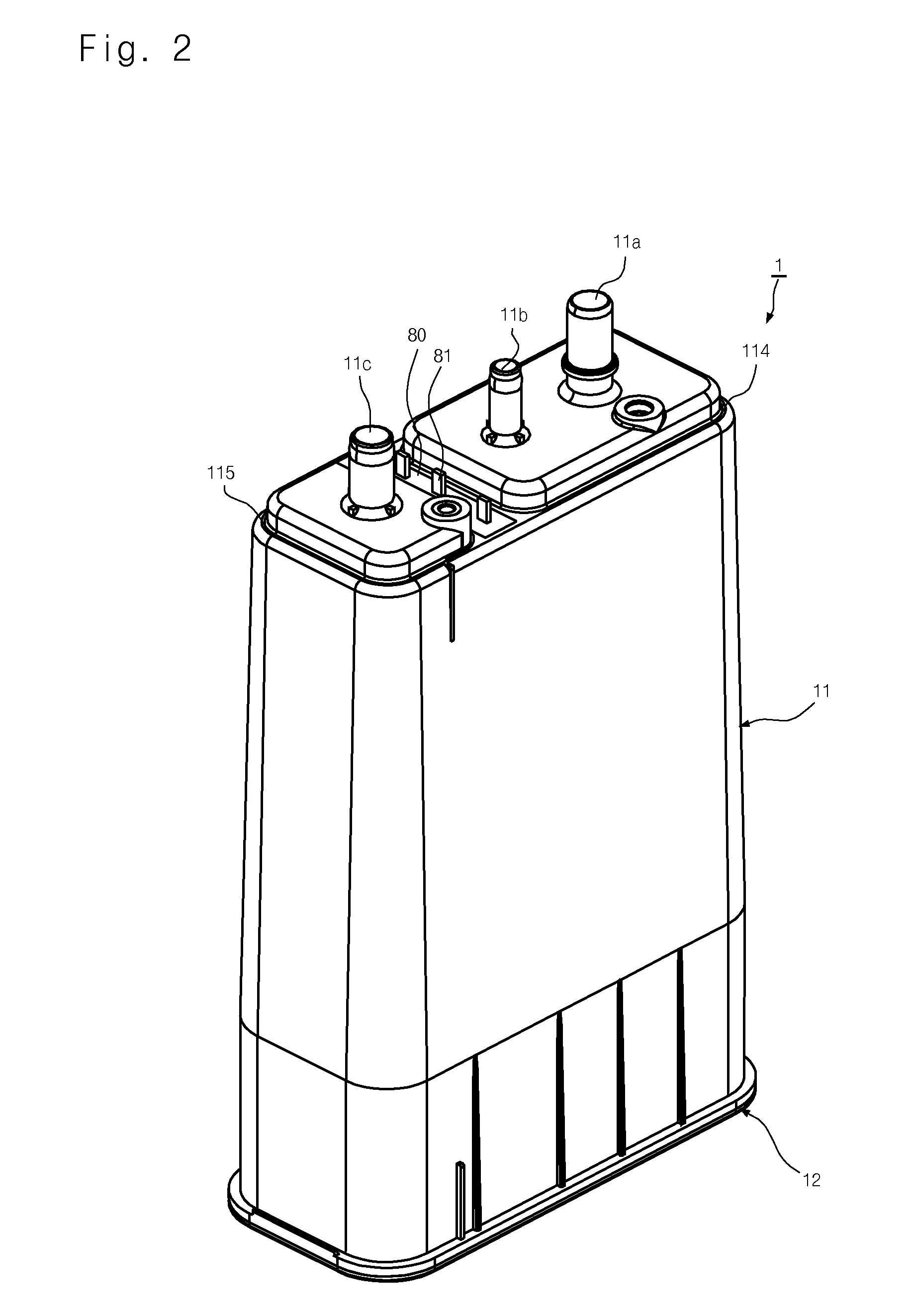

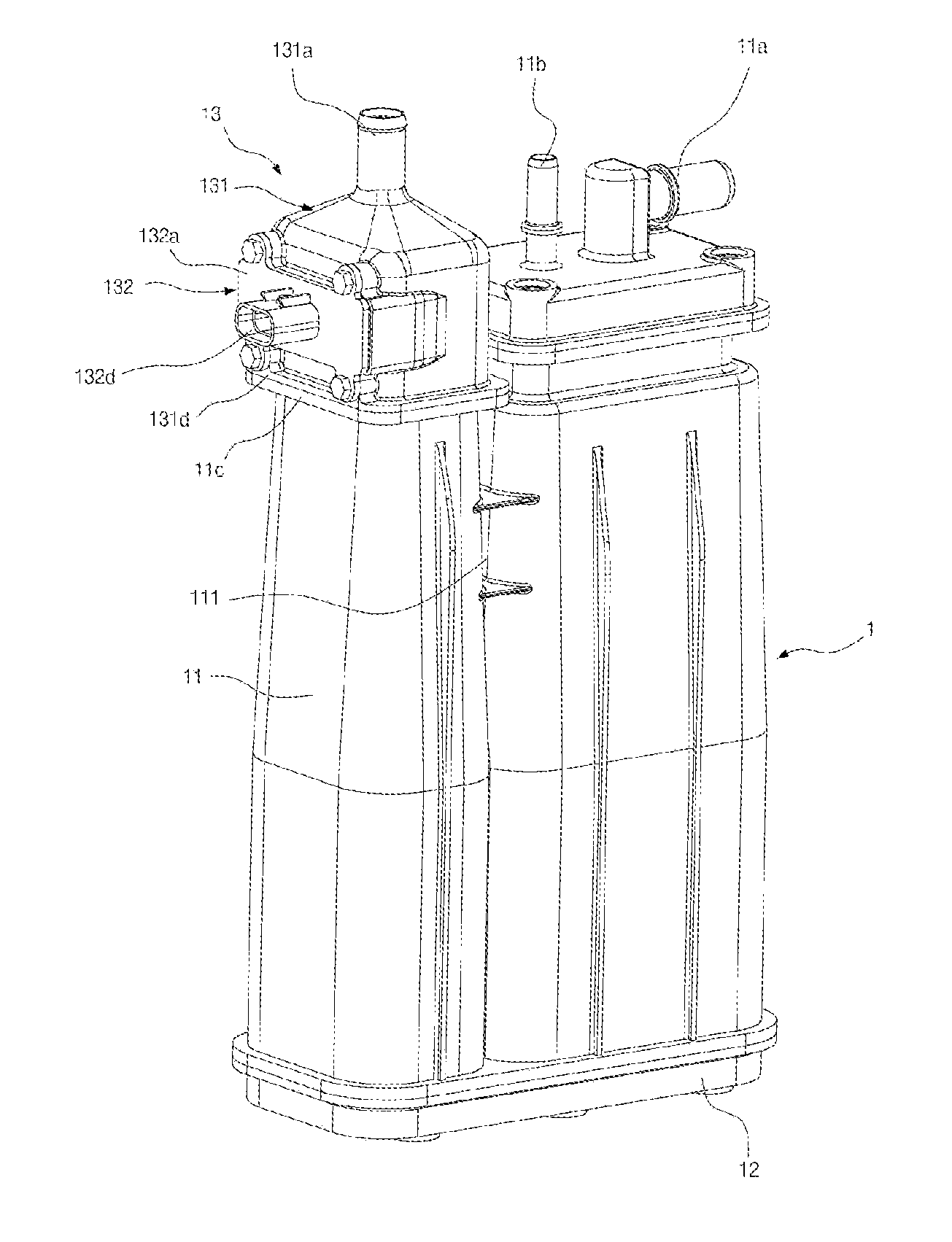

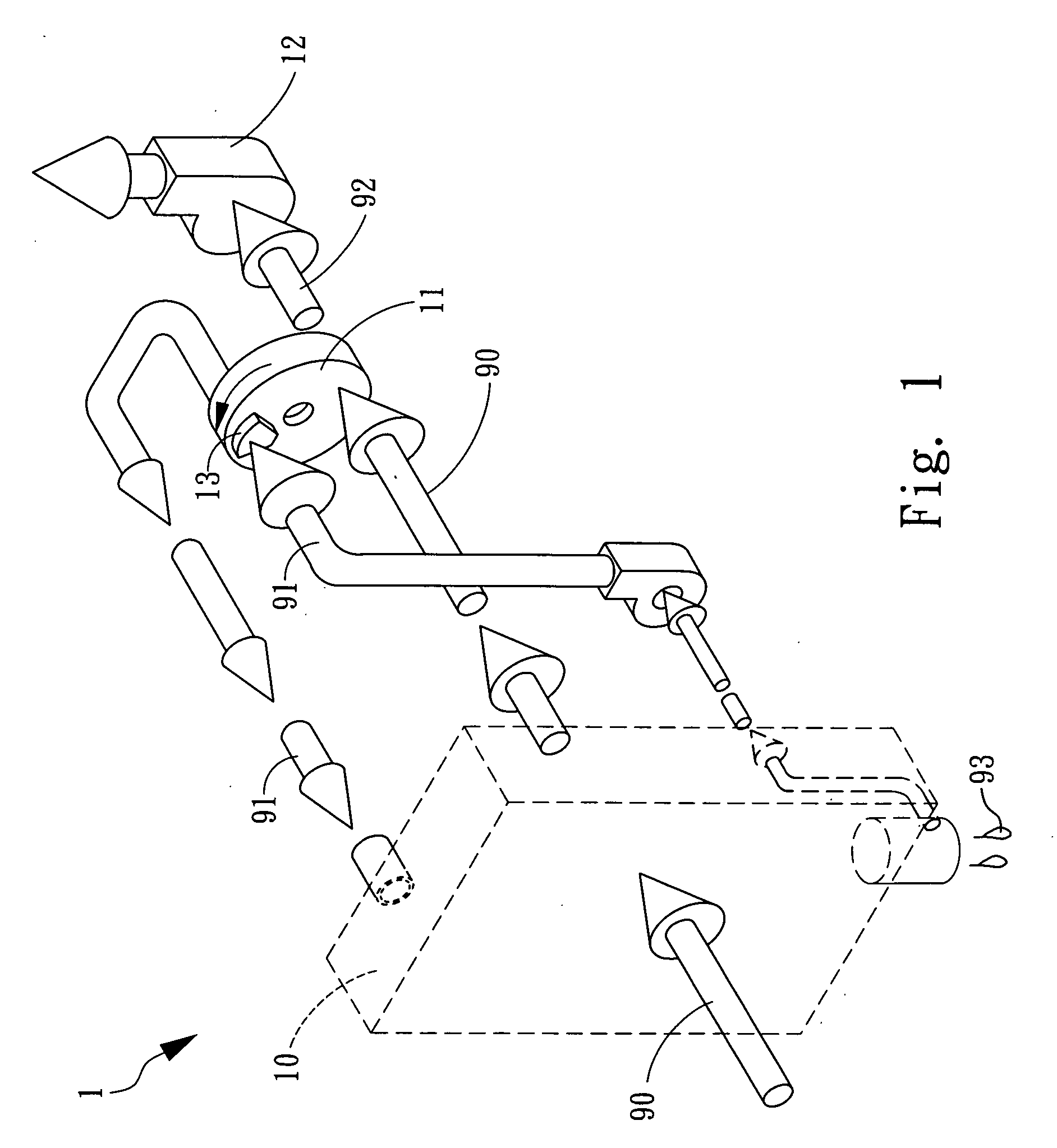

Fuel vapor processors

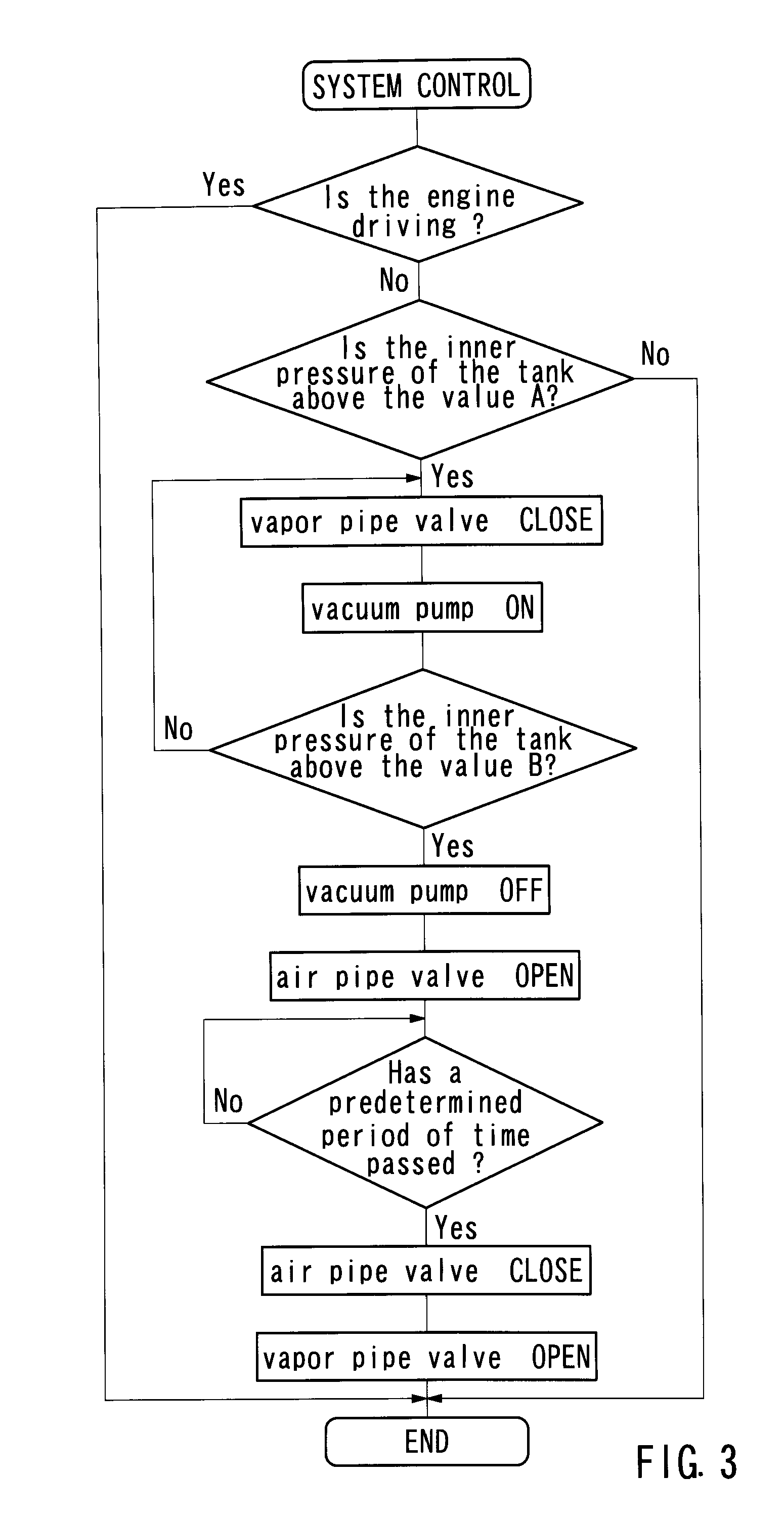

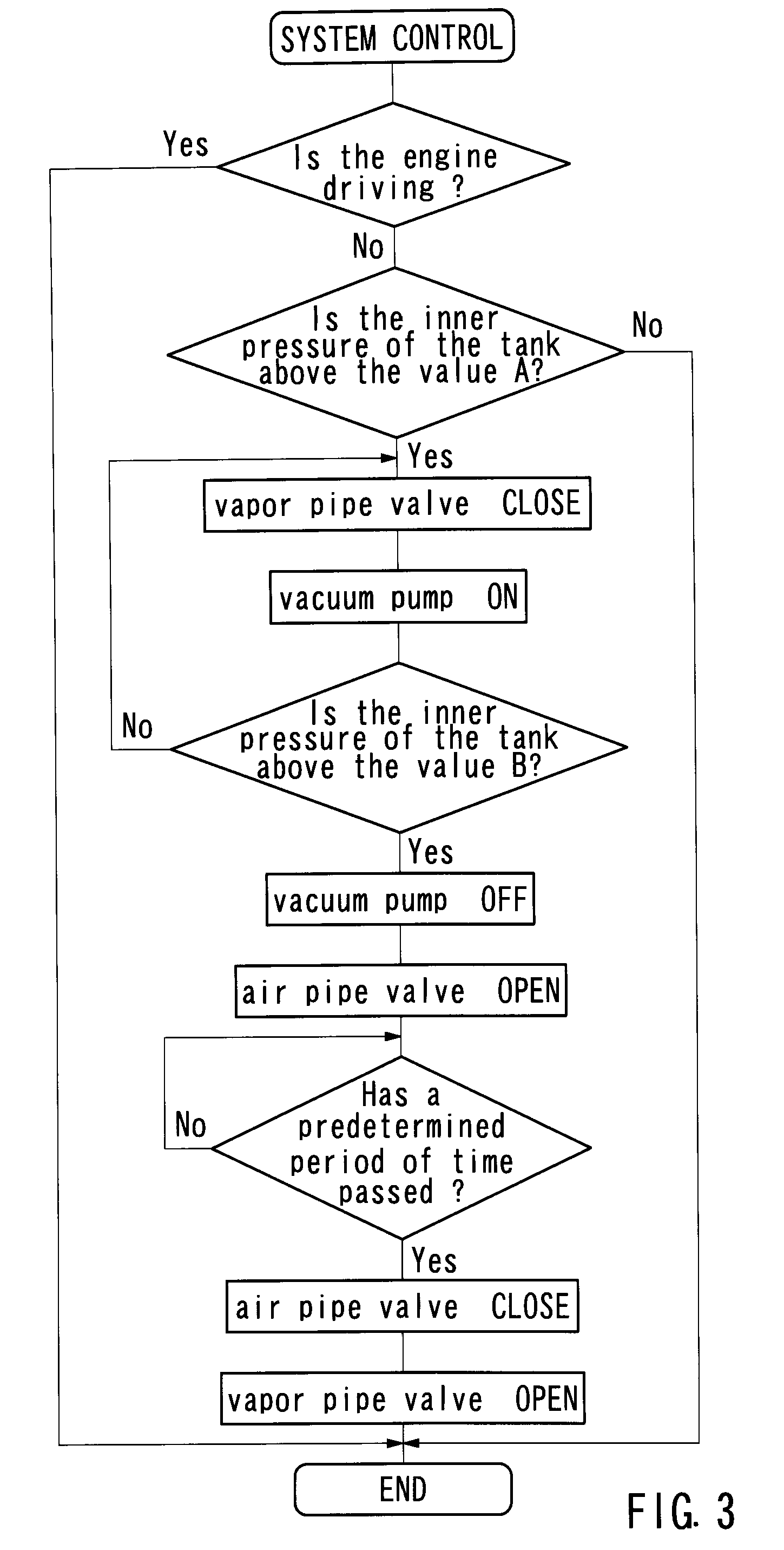

ActiveUS20110011264A1Improve desorption efficiencyRecovery amount is improvedGas treatmentNon-fuel substance addition to fuelAutomotive engineeringPressure regulator

A fuel vapor processor has a fuel tank, a canister, a vapor pipe, a recovery pipe, an air pipe, a suction device, a vapor pipe valve, an air pipe valve, and a pressure regulator. The vapor pipe leads fuel vapor generated in the fuel tank to the canister for trapping the fuel vapor in the canister. The recovery pipe recoveries the fuel vapor desorbed from the canister into the fuel tank. The air pipe communicates the canister with the atmosphere. The suction device is disposed on the recovery pipe for desorbing the fuel vapor trapped in the canister. The pressure regulator is communicated with the air pipe between the air pipe valve and the canister in order to allow gas flow from the atmosphere toward the canister. During desorption of the fuel vapor due to the suction device, the vapor pipe valve and the air pipe valve are closed, and negative pressure is kept in the canister such that the fuel vapor is desorbed from the canister and fresh air is led into the canister via the pressure regulator.

Owner:AISAN IND CO LTD

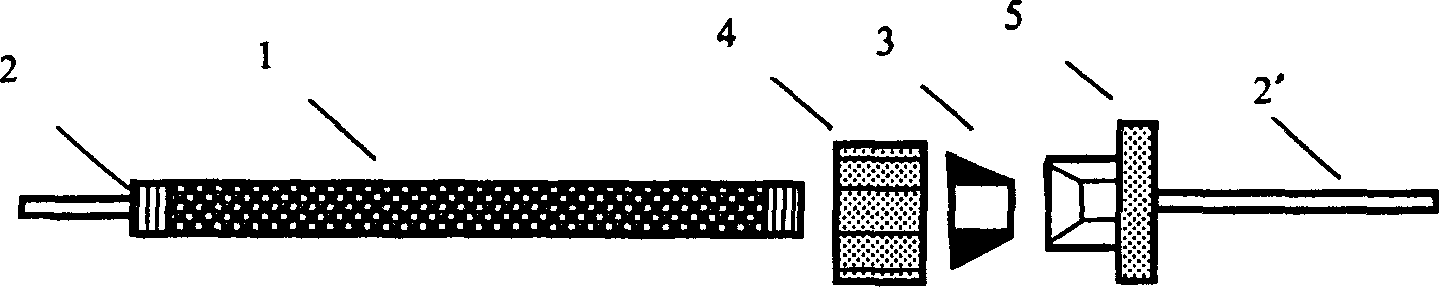

Sample-taking adsorption tube and its hydrolyzed adsorption device

InactiveCN1803252AImprove desorption efficiencyHigh quantitative repeatabilityDispersed particle separationGas phaseHeater Rod

The invention discloses a sampling adsorption pipe and heat desorber, wherein the sampling adsorption pipe is composed of reducing steel pipe with middle displaying thick diameter pipe; the adsorbent is filled with the thick diameter pipe with glass or quartz hair filling with two ends of adsorbent; two ends of sampling adsorption pipe is thin diameter pipe separately; one end of thin diameter pipe is an outlet pipe, which connects the thick diameter pipe stickly; the other end of thin diameter pipe is inlet pipe, which connects the thick diameter pipe through cap; the heat desorber is a metal block of internal heating bar with a cavity in the middle of metal block to contain the sampling adsorption pipe; the other end of heat desorber contains groove position to allocate the sampling adsorption pipe; when desorbed, the heat desorber is heated to preset temperature, which contains the thick diameter pipe of sampling adsorption pipe in the cavity to heat; the nut is inserted in the groove position of heat desorber, which takes the desorbed sample in the gas chromatograph analysis column.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sulfur transfer catalyst and and the preparation thereof

InactiveCN1485132AAdvantages of preparation methodEase of industrial productionCatalyst carriersCatalytic crackingRare-earth elementActive component

A sulfur-transferring catalyst comprises a cerium oxide of 2í½30úÑ by weight as the active component and a spinel compound of 70í½98úÑ by weight containing magnetium and aluminum as the carrier. The spinel compound containing magnetium and aluminum comprises MgO of 5í½70úÑ, Al2O3 of 30í½ 95%, an oxide of a rare earth element of 0í½15 úÑ except cerium, V2O5 of 0í½10úÑ,relative to the total weight of the compound. Moreover, the invention provides a method of producing the catalyst. The sulfur-transferring catalyst has a high efficiency of absorbing and desorbing SO x.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel vapor processors

ActiveUS8273164B2Improve desorption efficiencyPromote recoveryGas treatmentNon-fuel substance addition to fuelDesorptionFresh air

A fuel vapor processor has a fuel tank, a canister, a vapor pipe, a recovery pipe, an air pipe, a suction device, a vapor pipe valve, an air pipe valve, and a pressure regulator. The vapor pipe leads fuel vapor generated in the fuel tank to the canister for trapping the fuel vapor in the canister. The recovery pipe recoveries the fuel vapor desorbed from the canister into the fuel tank. The air pipe communicates the canister with the atmosphere. The suction device is disposed on the recovery pipe for desorbing the fuel vapor trapped in the canister. The pressure regulator is communicated with the air pipe between the air pipe valve and the canister in order to allow gas flow from the atmosphere toward the canister. During desorption of the fuel vapor due to the suction device, the vapor pipe valve and the air pipe valve are closed, and negative pressure is kept in the canister such that the fuel vapor is desorbed from the canister and fresh air is led into the canister via the pressure regulator.

Owner:AISAN IND CO LTD

Method for removing residual rhodium catalyst from hydrogenated nitrile rubber

The present invention provides a process for removing rhodium catalyst from rubber liquor of hydrogenated nitrile rubber, and is characterized by that it adopts macroporous resin with special functional group to treat the above-mentioned rubber liquor or the hydrogenated nitrile rubber so as to can remove residual catalyst. Said functional group is the functional group containing two kinds of more than two kinds of mercapto-group, thiourea and isothiourea. It is specially suitable for industrial equipment, for industrial equipment, for example exchange column, to continuously treat rubber liquor.

Owner:PETROCHINA CO LTD

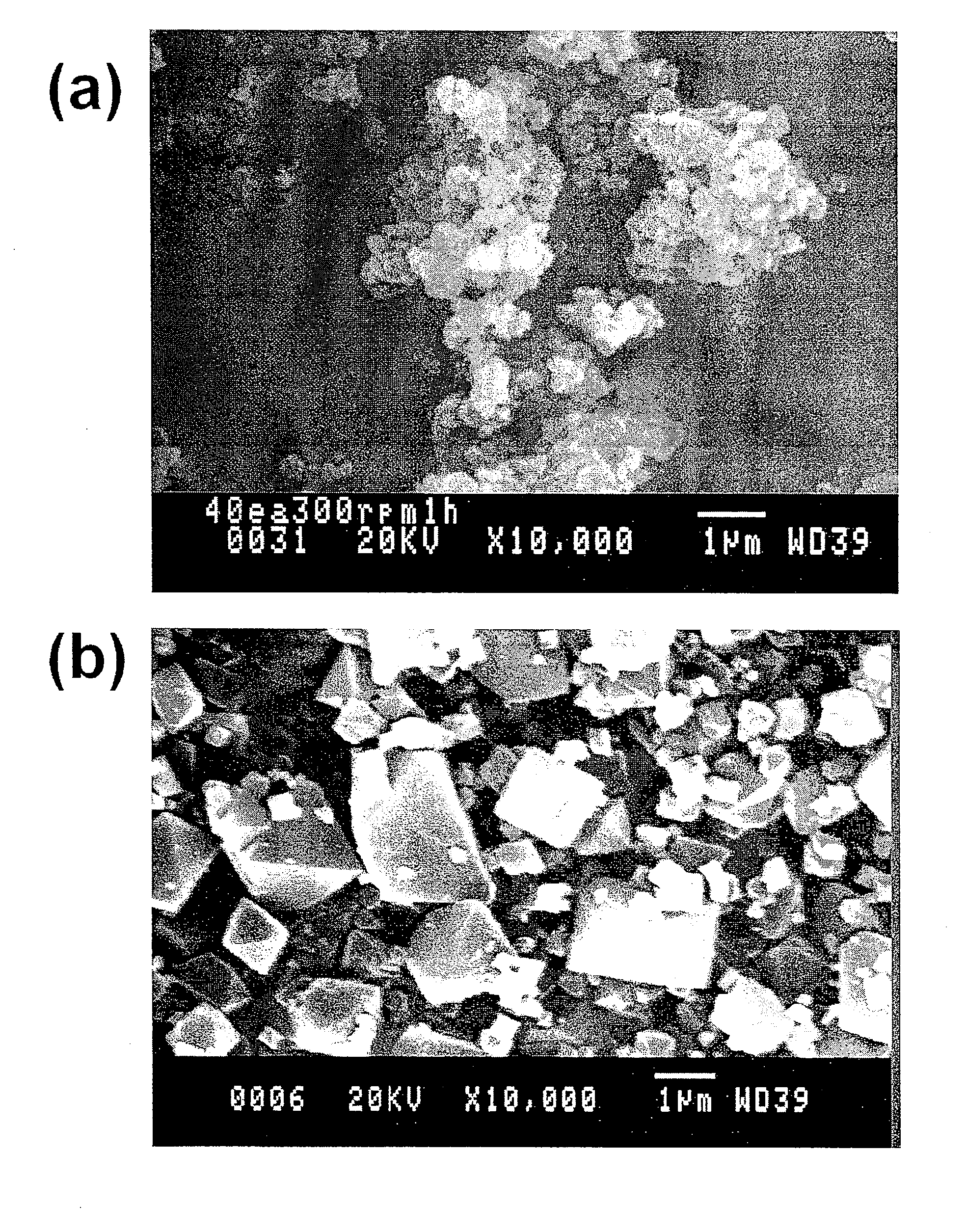

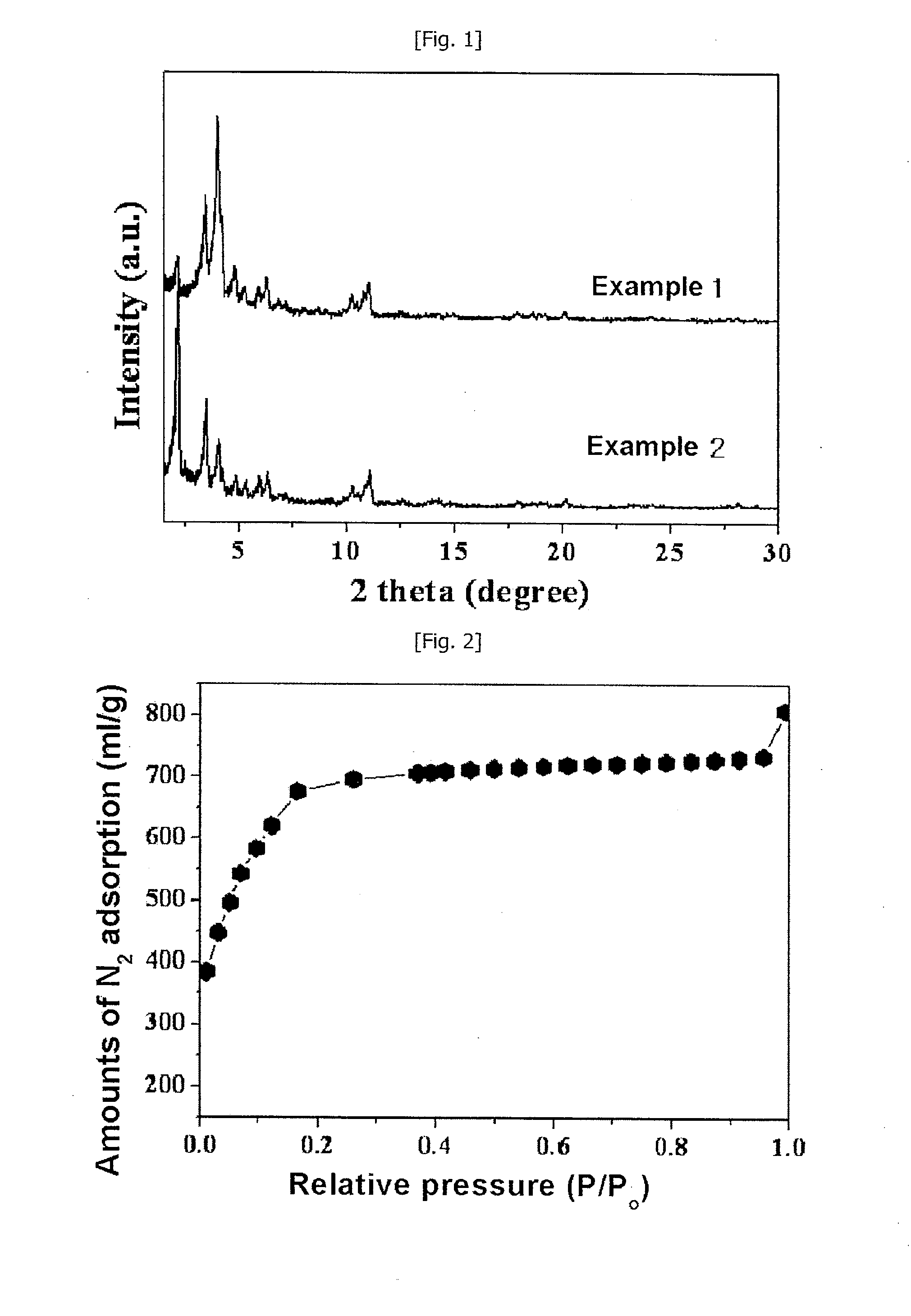

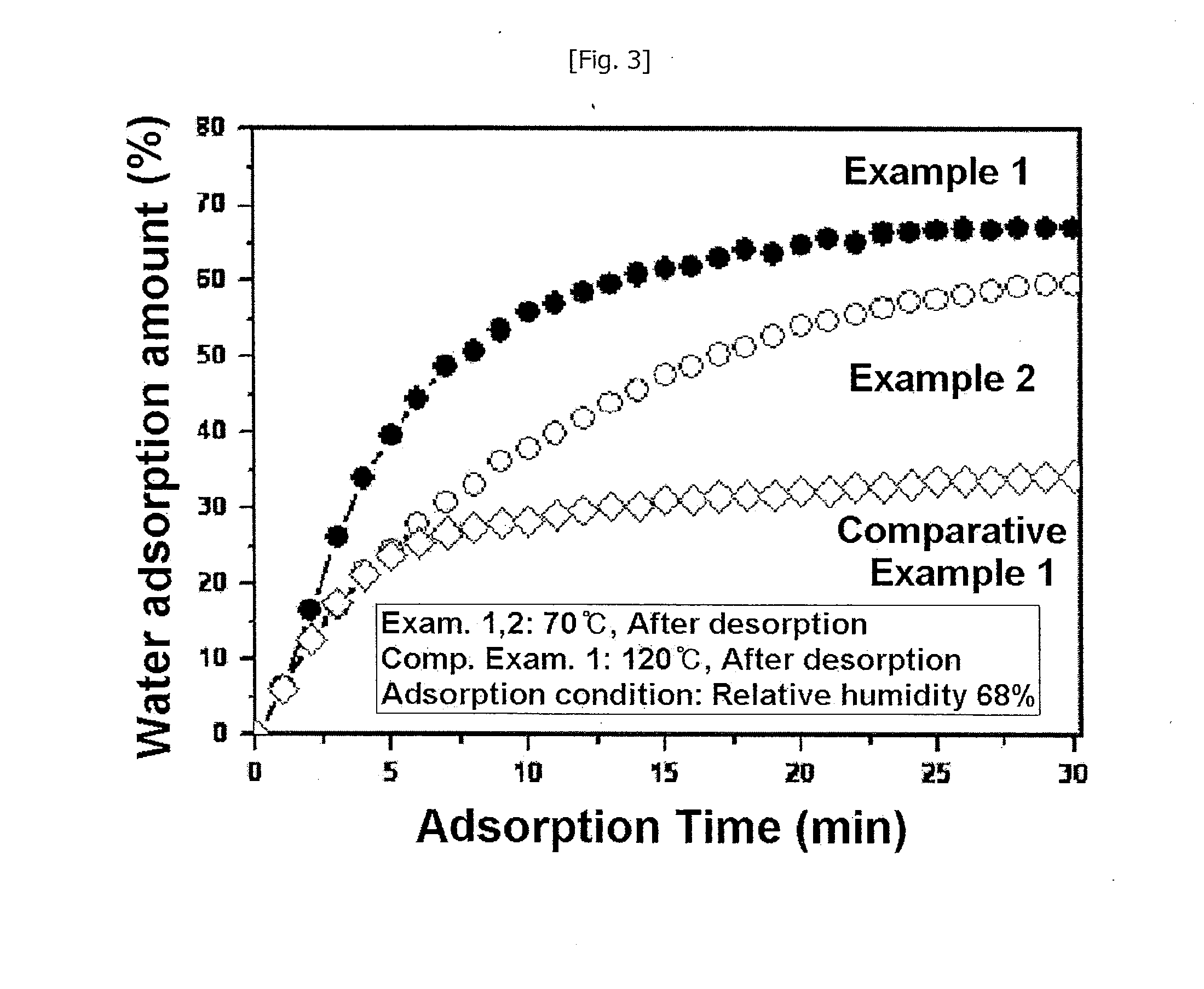

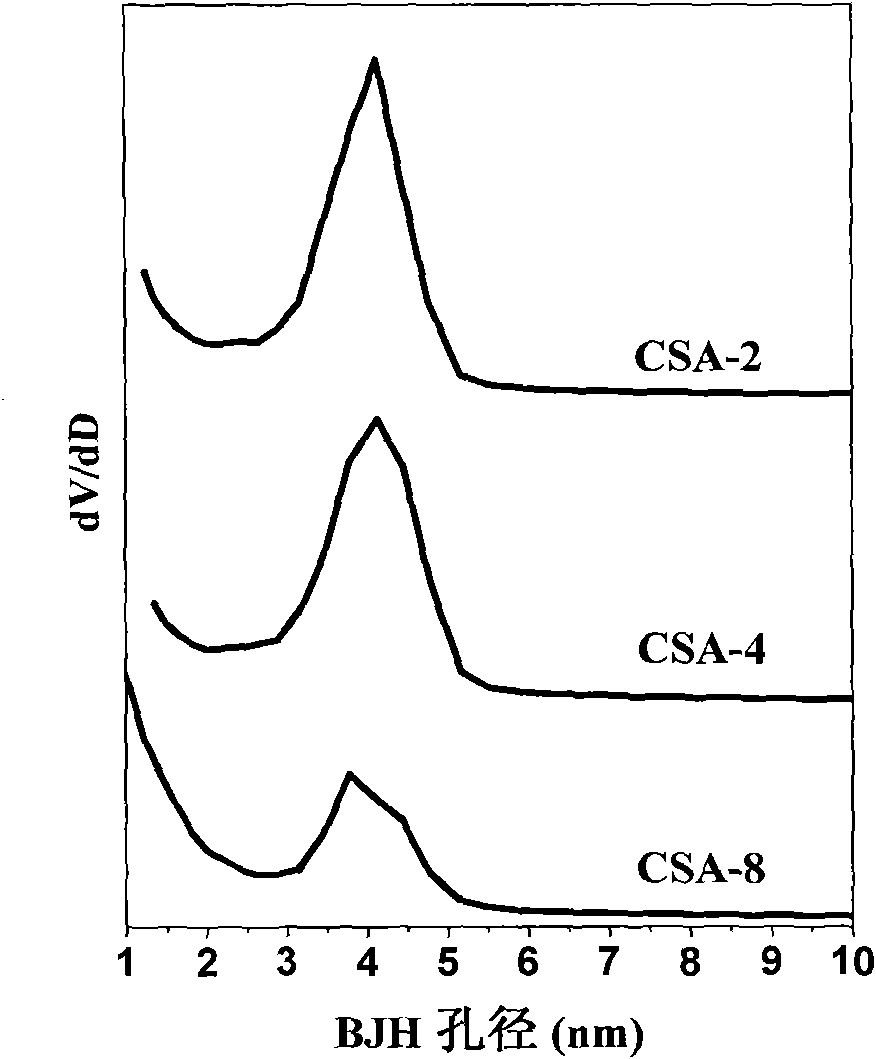

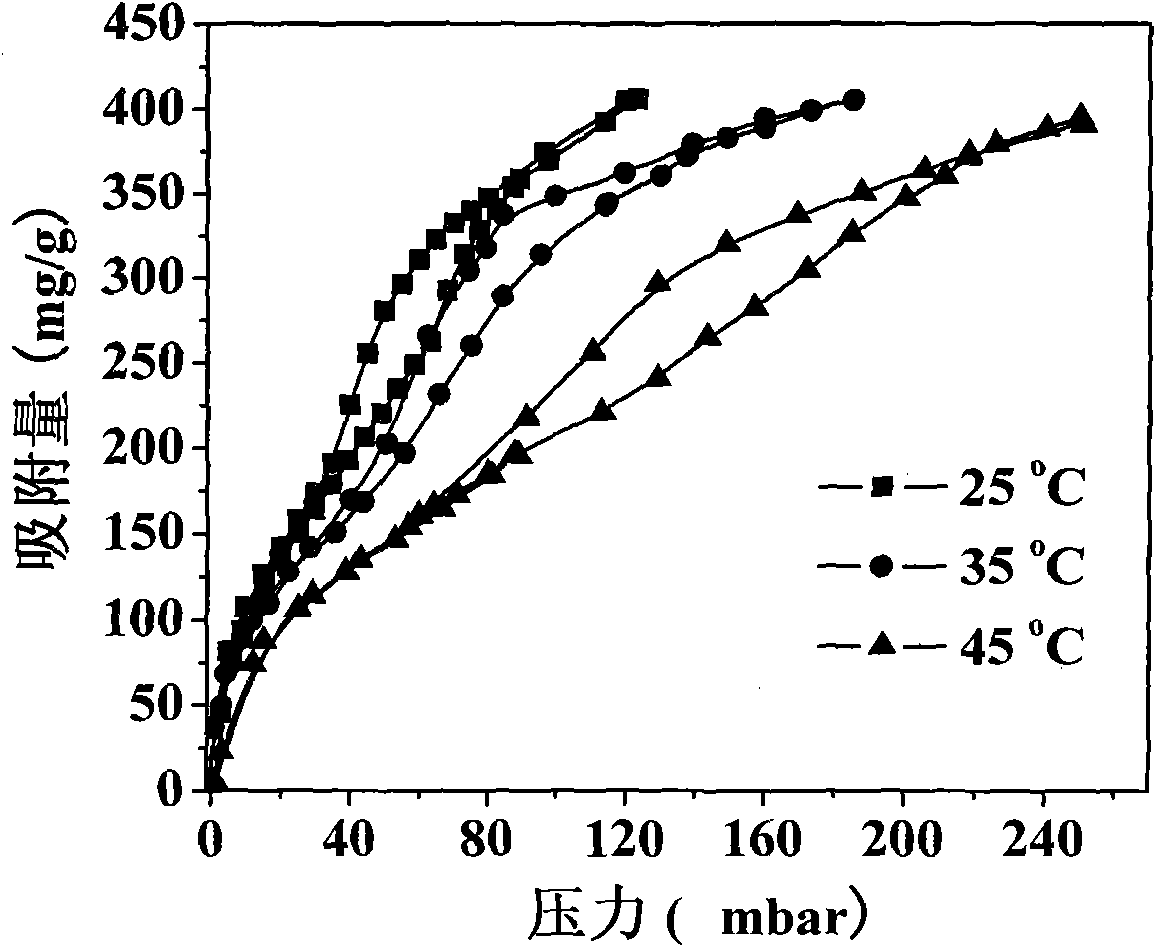

Porous organic-inorganic hybrid materials and adsorbent comprising the same

ActiveUS20090263621A1Large amount of waterMaintain good propertiesGroup 5/15 element organic compoundsGroup 3/13 element organic compoundsHydrofluoric acidSorbent

The present invention relates to an adsorbent using the porous organic-inorganic hybrid material(s) containing iron having a large surface area and a high pore volume, in particular, a water adsorbent. Also, it relates to an adsorbent that can be used in humidifiers, dehumidifiers, coolers / heaters, a refrigerating machine or an air conditioner, etc., which can easily absorb or desorb at 100° C. and below, and has a great adsorption amount per weight of the adsorbent.Also, the present invention relates to a novel preparation method of porous organic-inorganic hybrid material(s), in particular, a preparation method characterized by not using hydrofluoric acid, porous organic-inorganic hybrid material(s) prepared by said preparation method, and a use as an adsorbent thereof.

Owner:KOREA RES INST OF CHEM TECH

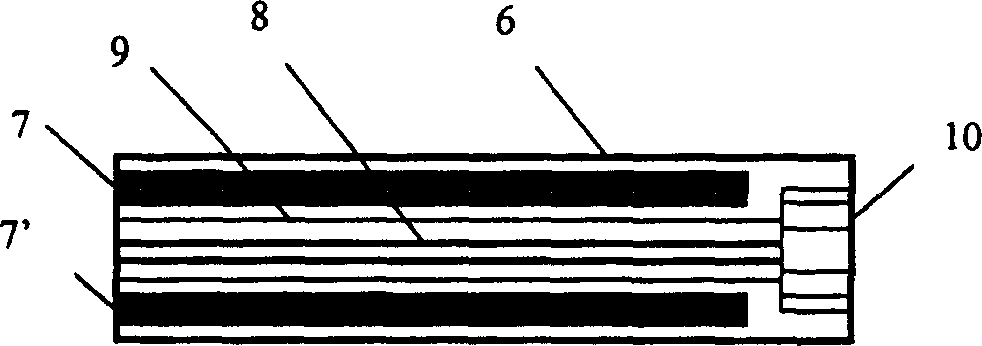

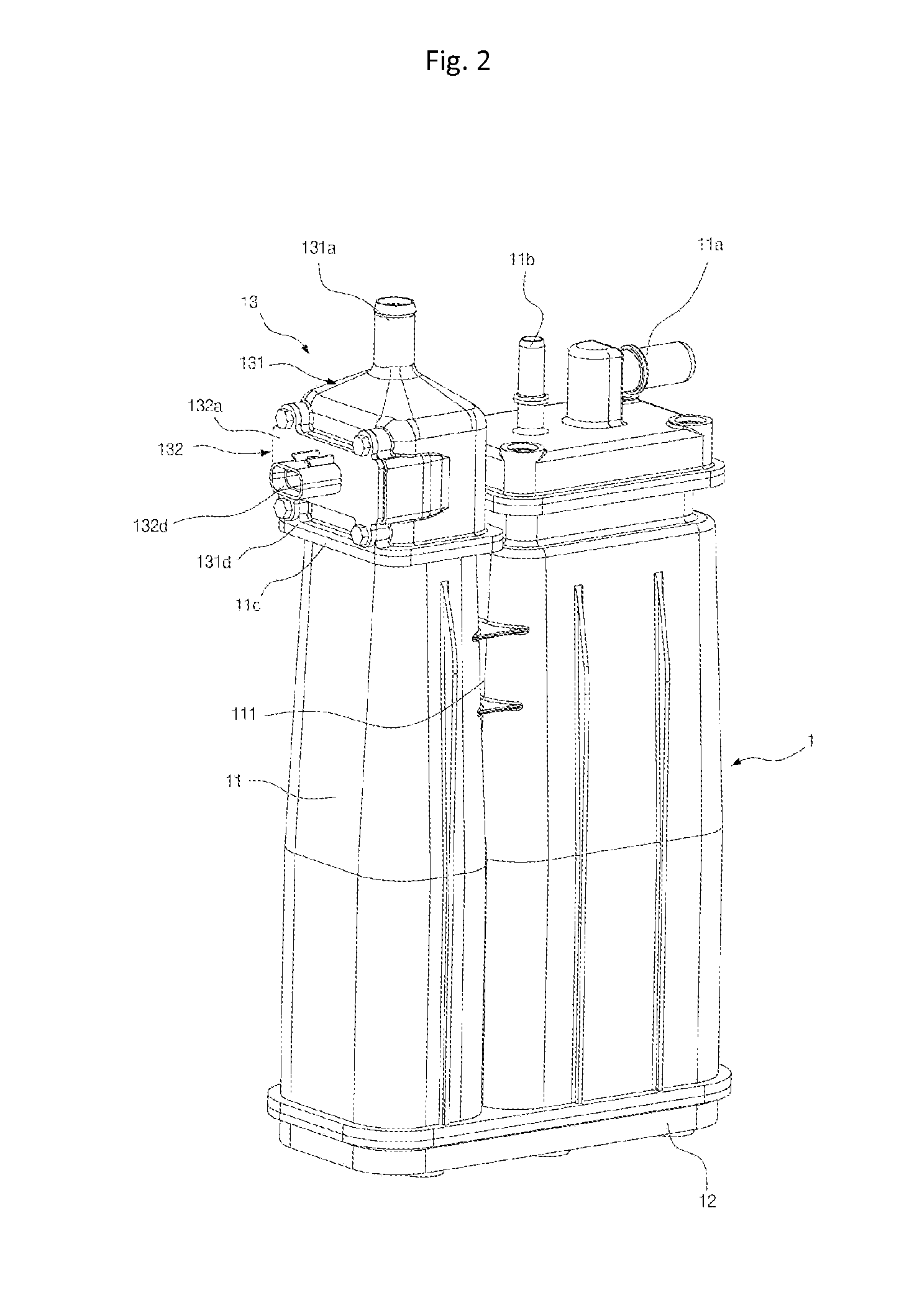

Canister with heater

InactiveUS20110247592A1Improve desorption efficiencyNon-fuel substance addition to fuelMachines/enginesActivated carbonDesorption

Disclosed herein is a canister mounted in a vehicle to reduce the discharge of fuel gas. The canister of the present invention includes at least one pocket installed in a canister housing. The pocket divides the inner space of the canister housing into first and second spaces. A heater is inserted into the pocket from the outside of the canister housing. The heater generates heat during running of an engine to heat active carbon filled in the canister. When the active carbon is heated, fuel gas adsorbed onto the active carbon in a liquid phase is easily evaporated and supplied to the engine. The heater can significantly improve desorption efficiency of the fuel gas by the active carbon.

Owner:KOREA FUEL TECH

Canister with heater

ActiveUS20110308394A1Improve desorption efficiencyReduce power consumptionGas treatmentNon-fuel substance addition to fuelActivated carbonActive carbon

The present invention provides a canister mounted in a vehicle to reduce the discharge of fuel gas and, more particularly, a canister with a heater configured such that fuel gas adsorbed onto active carbon filled in the canister is more easily desorbed from the active carbon and introduced into an engine. The canister with the heater according to the present invention includes a canister housing including a tank port and a purge port, which are provided at the top thereof, and a plurality of inlet holes provided on one side thereof to introduce air; and a heater connected to the top of the plurality of inlet holes of the canister housing and including an air port provided at the top thereof, an open bottom, and a heater module provided therein.

Owner:KOREA FUEL TECH

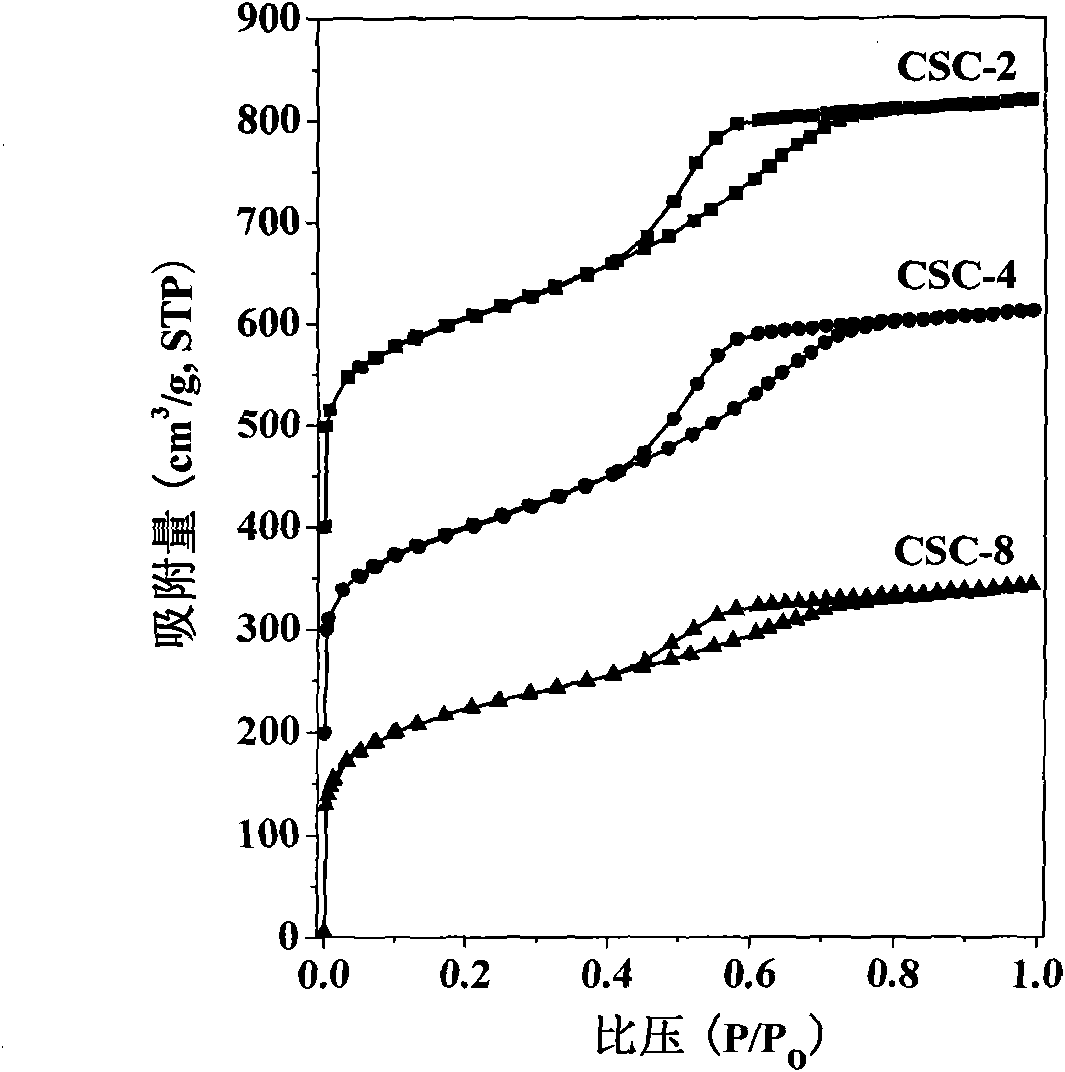

Active carbon-silicon aerogel complex for removing volatile organic pollutants

ActiveCN102125821AImprove adsorption capacityImprove desorption efficiencyOther chemical processesDispersed particle separationActivated carbonMass transfer resistance

The invention relates to an active carbon-silicon aerogel complex and a preparation method thereof, and belongs to the field of removal of volatile organic pollutants. The active carbon-silicon aerogel complex is prepared from active carbon granules serving as a skeleton structure and water glass serving as a silicon aerogel precursor by sol-gel reaction and normal-pressure drying. The active carbon-silicon aerogel complex is prepared from cheap raw materials, has a multistage pore structure, and is favorable for improving the adsorption quantity of volatile organic compounds (VOCs), reducingthe mass transfer resistance and improving the desorption efficiency.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Enzyme enhanced co2 capture and desorption processes

InactiveUS20130203155A1Low co2 desorption rateDecrease efficiencyBy-product recoveryGas treatmentChemistryCarbonic anhydrase

An enzyme-catalyzed desorption process for releasing CO2 gas from an ion-rich solution containing bicarbonate ions includes providing carbonic anhydrase in the ion-rich solution such that in a desorption unit the carbonic anhydrase is allowed to flow with the ion-rich solution while promoting conversion of the bicarbonate ions into CO2 gas and generating an ion-depleted solution and releasing the CO2 gas and the ion-depleted solution from the desorption unit. A CO2 capture process includes contacting a CO2-containing gas with a solution in an absorption unit, to convert CO2 into ions; feeding an ion-rich solution to a desorption unit wherein carbonic anhydrase is present within the ion-rich solution to generate an ion-depleted solution and, preferably, recycling the ion-depleted solution. Methods of decreasing the CO2 desorption temperature in a desorption unit, decreasing the CO2 desorption reactor size, and decreasing the CO2 desorption energy input in a desorption unit, are also described.

Owner:CO2 SOLUTION

Method and apparatus for desorption and dehumidifier using the same

InactiveUS20090229461A1Improve desorption efficiencyReduce power consumptionGas treatmentAir treatment detailsDesorptionAbsorbent material

A method and an apparatus for desorption and a dehumidifier are provided in the present invention, in which an electrical potential is applied to electrodes disposed on both ends of an absorbing material so as to desorb the substances absorbed within the absorbing material whereby the absorbing material is capable of being maintained for cycling the absorbing operation. By means of the method and the apparatus of the present invention, the desorbing efficiency can be enhanced and the energy consumption can be reduced during desorption.

Owner:IND TECH RES INST

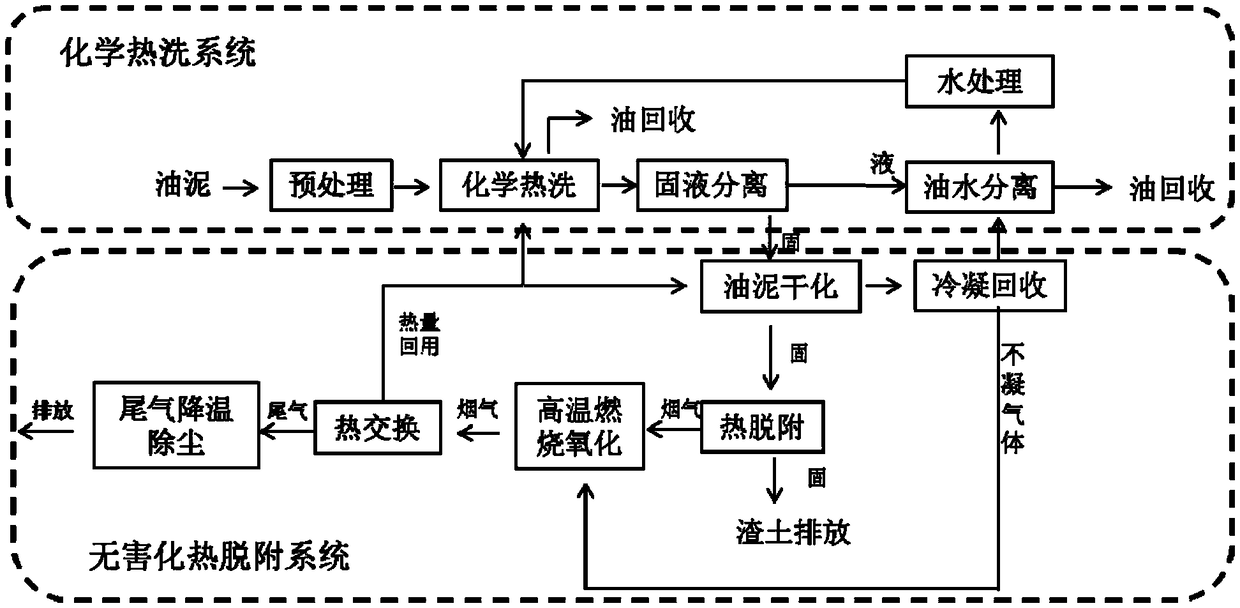

Green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge

ActiveCN108996859ALayering efficiency is fastHigh recovery rateSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesHigh concentrationWater storage tank

The invention discloses a green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge. The treatment method includes the treatment steps of homogeneous impurity removal pretreatment, chemical thermal washing treatment, solid-liquid separation and oil-water separation, oil sludge thermal desorption and high temperature combustion oxidation, heat exchange and tail gas cooling and dust removal. The treatment system includes an oil sludge chemical thermal washing system and an oil sludge harmless thermal desorption system. The oil sludge chemical thermal washing system is formed by connecting an oil sludge homogenization slot, an oil sludge chemical thermal washing tank, a high efficiency solid-liquid separator, an oil-water separator, a sewage integrated treatment system and a water storage tank successively. The oil sludge harmless thermal desorption system mainly consists of a sludge dryer, a condensation recoverysystem, a thermal desorption feeding system, a thermal desorption system, a high temperature combustion oxidation system, a waste heat boiler and a discharging system. With adopting of the combined application of the chemical thermal washing technology and the thermal desorption technology, multiple functions such as resource recovery and utilization of petroleum materials and heat, reduction ofoily sludge, harmlessness and the like can be simultaneously realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

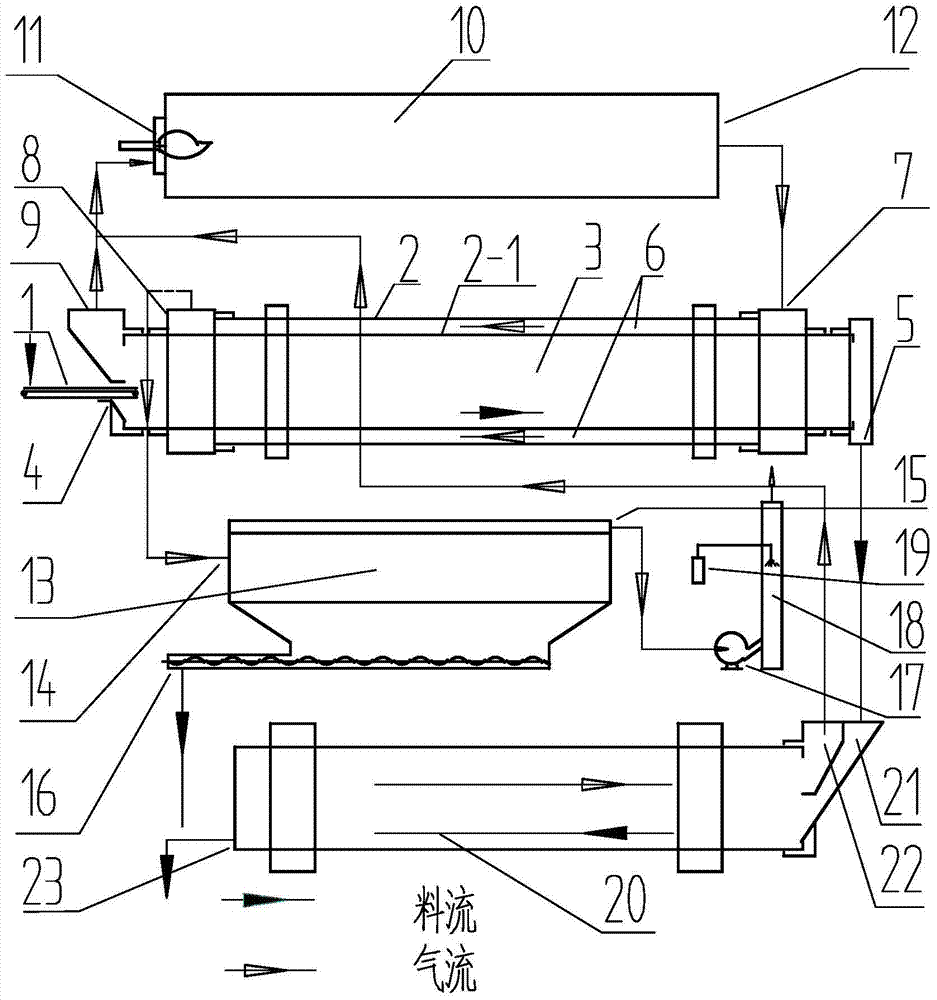

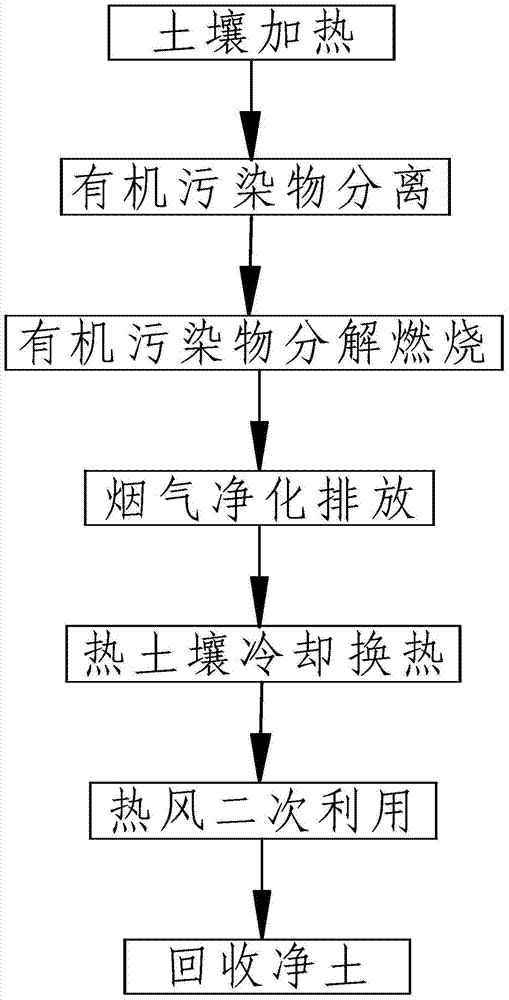

Organically-polluted soil remediation method

ActiveCN103495598AAchieve the purpose of repairPrevent leakageContaminated soil reclamationDesorptionEngineering

The invention discloses an organically-polluted soil remediation method which refers to a conveyer, a rotary kiln, a roasting furnace wall, a roasting chamber, a material inlet, a material outlet, a heating channel, a heating channel heat inlet, a heating channel heat outlet, a polluting gas outlet, a combustion furnace, a combustion furnace gas inlet, a combustion furnace heat outlet, a bag deduster, a bag deduster air inlet, a bag deduster smoke outlet, a soil particle outlet, an exhaust fan, a chimney, a deacidification device, a cooler, a cooler feed port, a cooler hot air outlet and a cooler discharge port. Since indirect heating desorption is adopted, hot air and soil are not in direct contact, energy consumption is low, desorption efficiency is high, and the soil can be thoroughly remedied; separated organic pollutants enter the combustion furnace to be completely combusted and decomposed by enriched oxygen, as a result, exhausted air quantity is small, secondary pollution is not caused, energy is saved, efficiency is improved, and investment is low.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

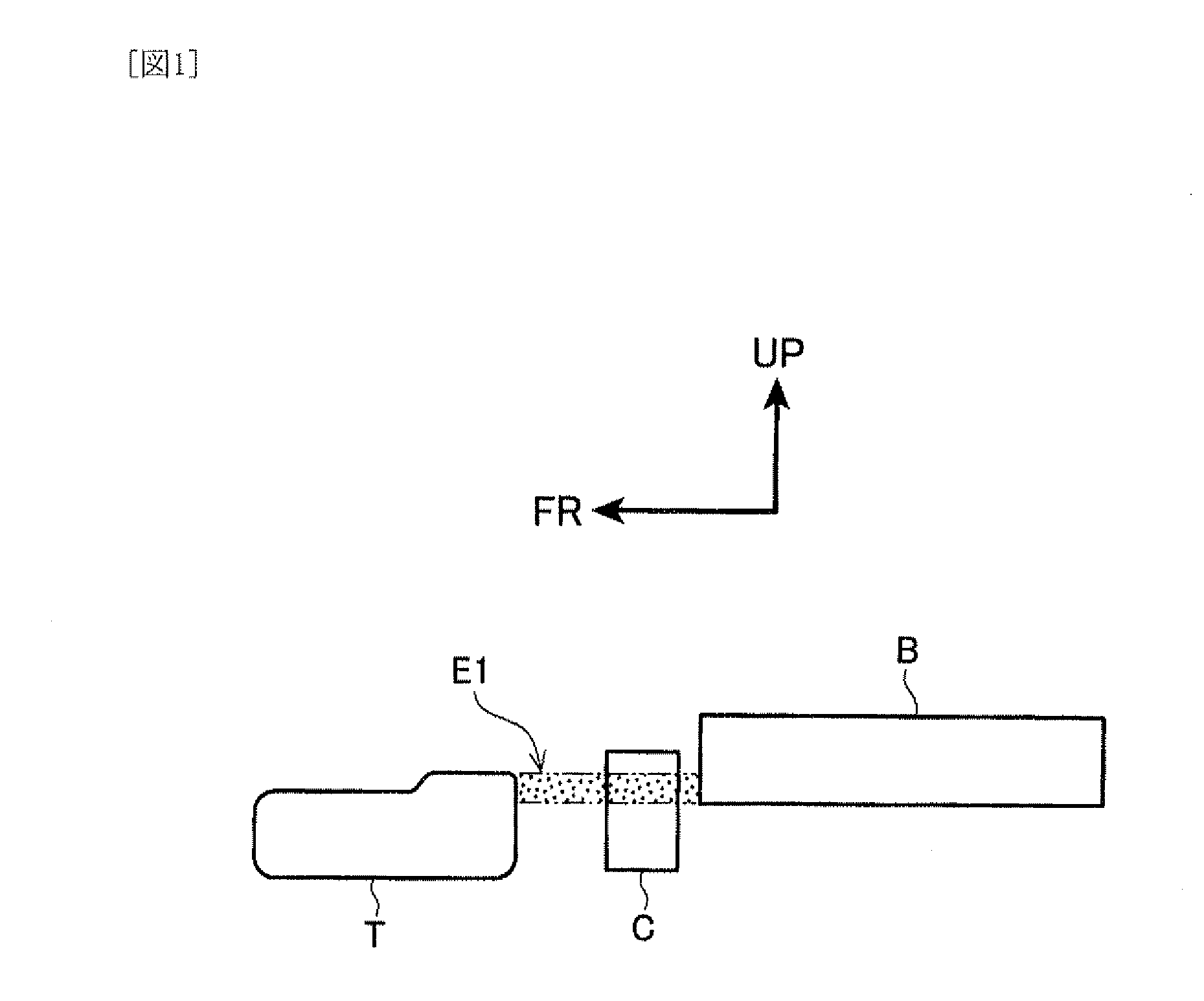

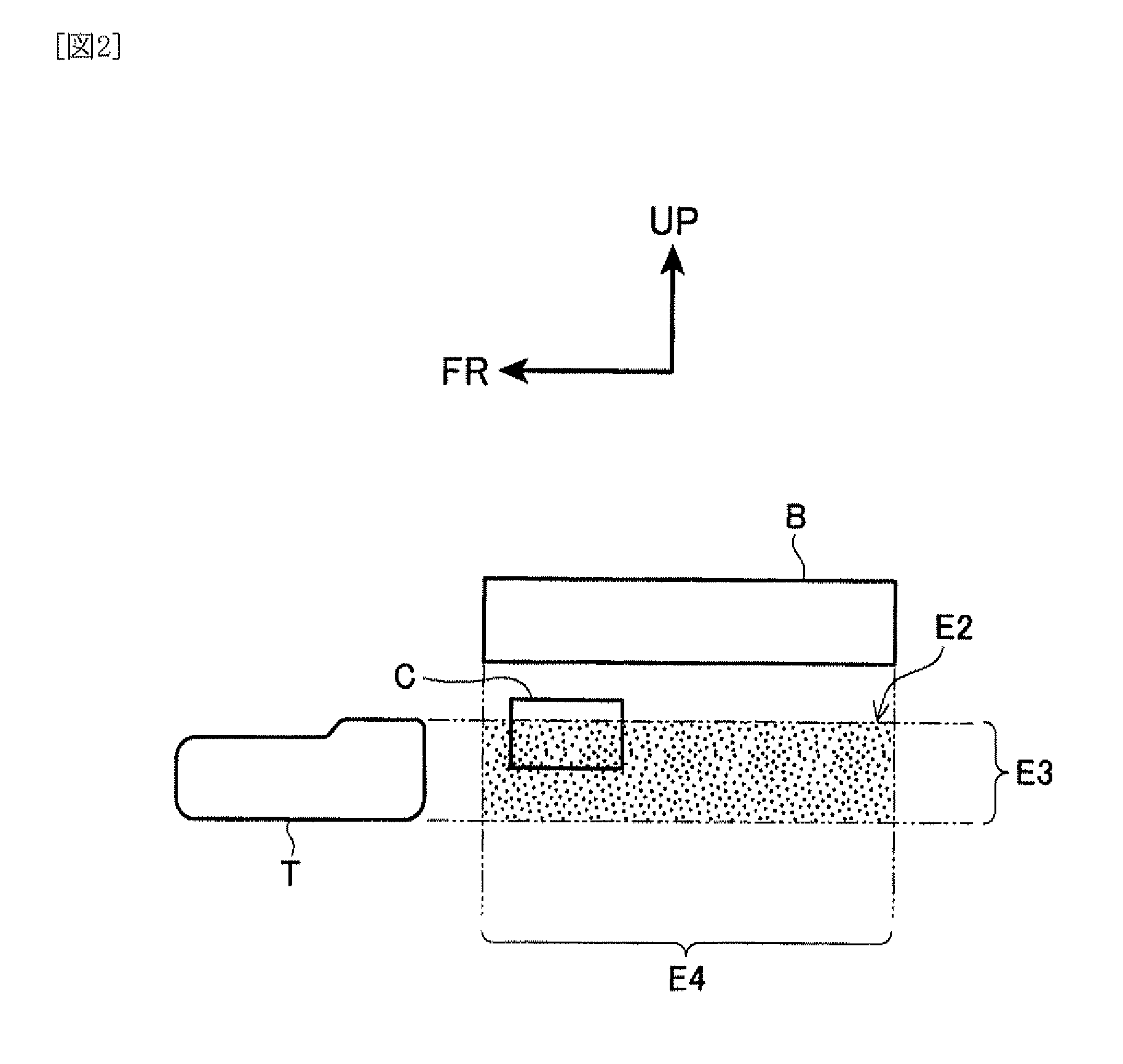

Device for treating evaporated fuel

InactiveUS20110297127A1Improve desorption efficiencyHybrid vehiclesNon-fuel substance addition to fuelDesorptionEngineering

In a vehicle that runs by drive power of a motor in addition to that of an engine, a device for treating evaporated fuel is provided that may heat a canister and improve desorption efficiency even in a state in which there is little exhaust heat from the engine. A vehicle is provided with a first battery and a second battery. A canister is disposed in front of the first battery and below the second battery. Because the canister is disposed near to the batteries, heat is transferred from the batteries to the canister and an adsorbing agent in the canister is heated.

Owner:TOYOTA JIDOSHA KK

Device for treating evaporated fuel

InactiveUS8887695B2Improve desorption efficiencyHybrid vehiclesNon-fuel substance addition to fuelDesorptionEngineering

In a vehicle that runs by drive power of a motor in addition to that of an engine, a device for treating evaporated fuel is provided that may heat a canister and improve desorption efficiency even in a state in which there is little exhaust heat from the engine. A vehicle is provided with a first battery and a second battery. A canister is disposed in front of the first battery and below the second battery. Because the canister is disposed near to the batteries, heat is transferred from the batteries to the canister and an adsorbing agent in the canister is heated.

Owner:TOYOTA JIDOSHA KK

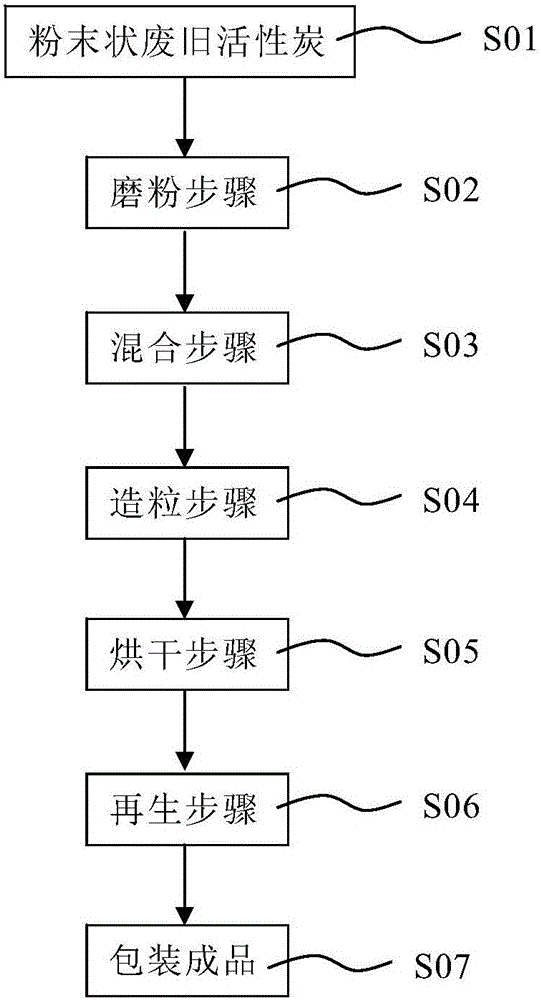

Method for manufacturing desulfurization denitration activated carbon by using waste activated carbon

InactiveCN105858650AReduce consumptionTo achieve the effect of emission reductionEnergy inputActivated carbonWater vapor

The invention discloses a method for manufacturing desulfurization denitration activated carbon by using waste activated carbon. The method comprises the steps of grinding, mixing, pelleting, drying and regeneration. In the step of grinding, waste carbon is ground into powder, and the through put of the powder passing through a sieve of 180-240 meshes according to the grain fineness is 98%; in the step of mixing, 68-80% of waste activated carbon, 18-30% of tar and 2% of potassium hydroxide or magnesium oxide are prepared in percentage by weight; in the step of pelleting, the carbon paste is prepared into particles of which the particle diameter is 2-10mm; in the step of drying, the cylindrical particles are dried; and in the step of regeneration, the waste activated carbon cylindrical particles are added into an internal-heated rotary furnace for heating without air, the temperature is controlled between 820 and 900 DEG C, the time is 30-40 minutes, and water vapor is introduced into the furnace. According to the method, a powdery waste activated carbon source can be recycled, and can be recycled for four times or more after being treated by the process provided by the invention, and finally, the carbon with too high ash content can be recycled as sewage treatment carbon.

Owner:LICHENG LANTIAN GAS DEV

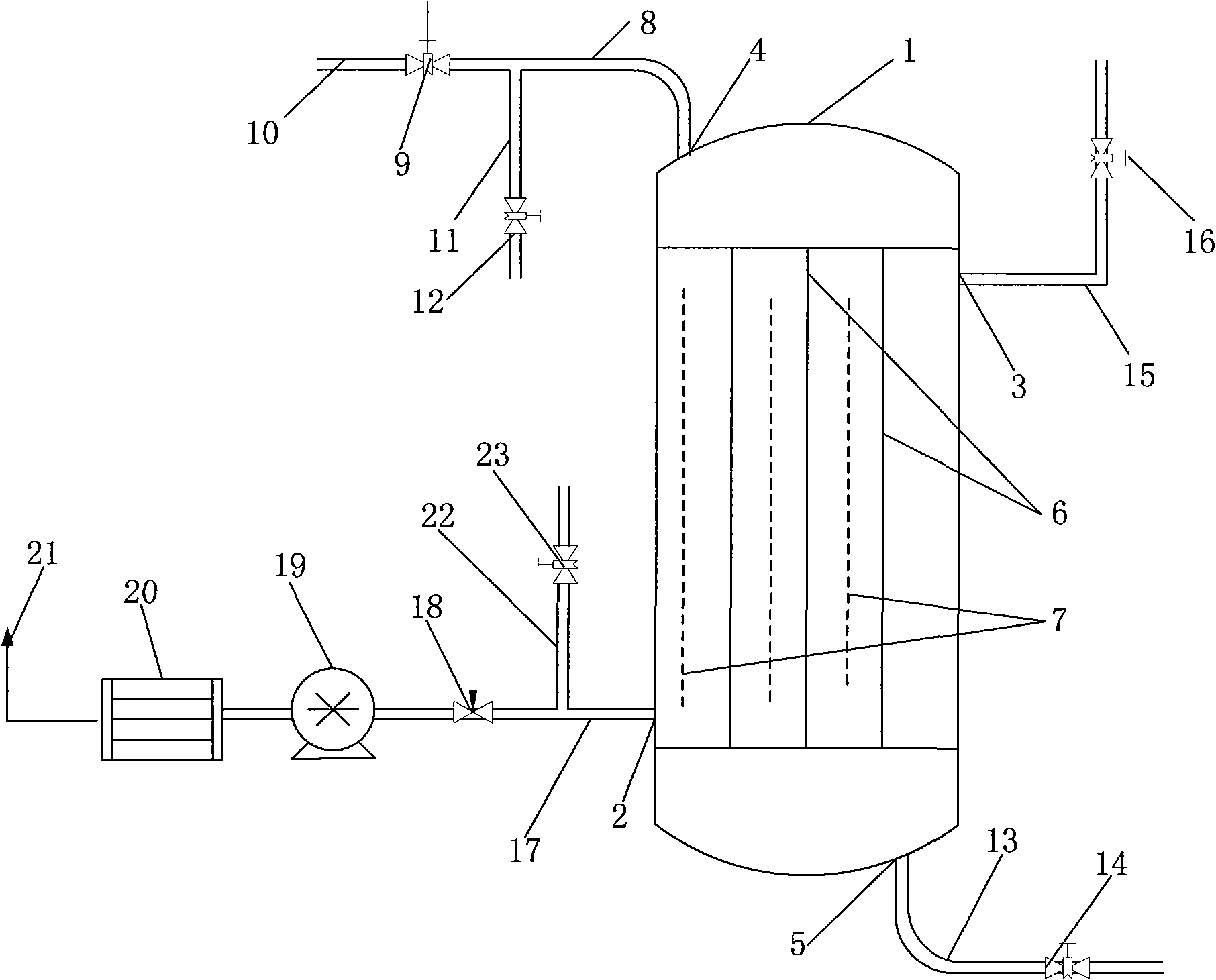

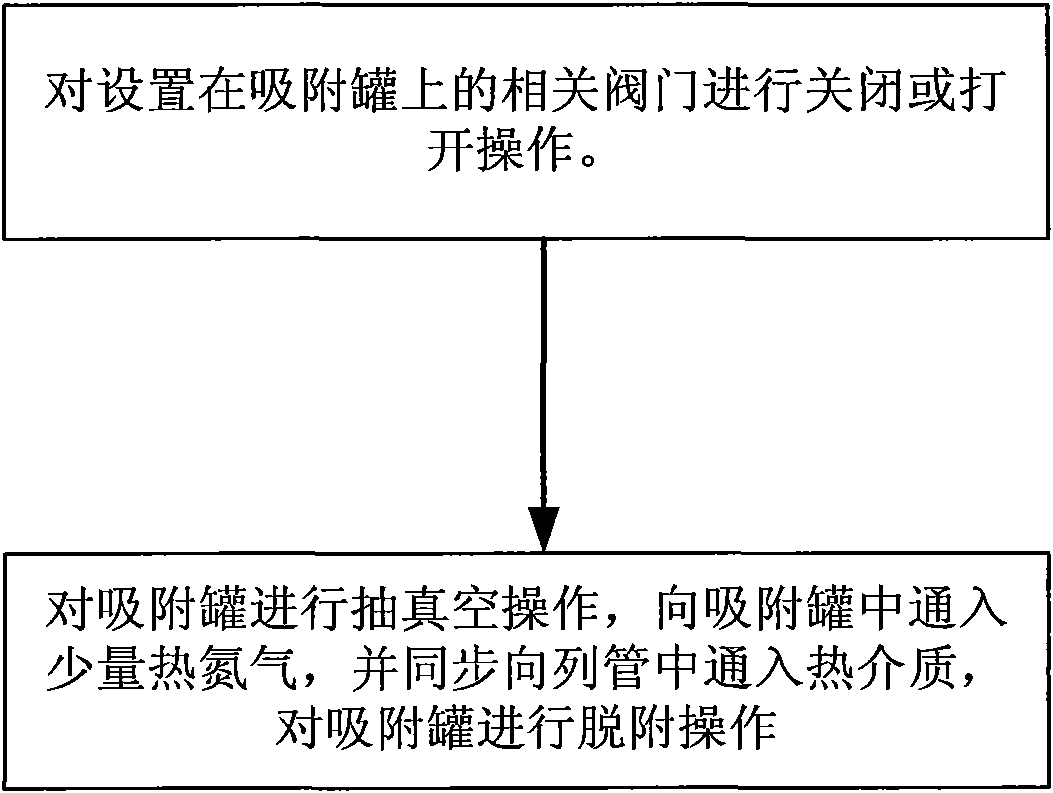

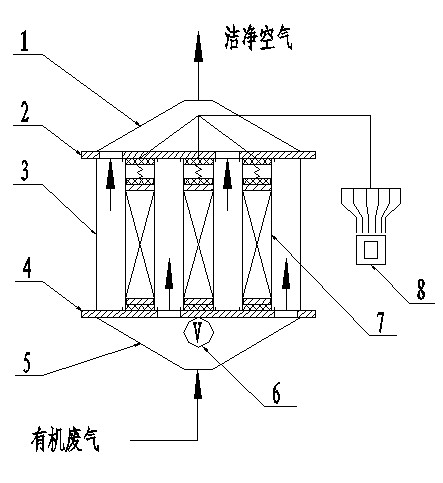

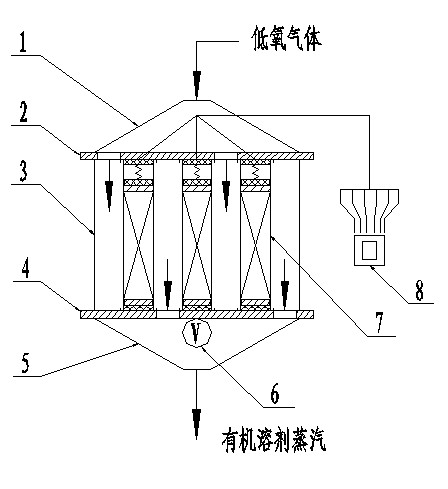

Cold and hot type adsorption-desorption device and adsorption-desorption method thereof

ActiveCN101648102AHigh adsorption capacityReduce damageDispersed particle separationCombustible gas purificationEngineeringCryo-adsorption

The invention discloses a cold and hot type adsorption-desorption device and an adsorption-desorption method thereof, belonging to a device and a method for treating organic waste gas. The device comprises an adsorption tank which is provided with an opening used for leading in waste gas and vacuumizing, a clean gas outlet, a tube pass inlet used for leading in cold medium or hot medium and a tubepass outlet used for leading out cold medium or hot medium; the adsorption tank is internally provided with tube arrays which are evenly distributed in the adsorption tank, and the two ends of the tube arrays are respectively communicated with the tube pass inlet and the tube pass outlet; a shell pass of the adsorption tank is internally filled with adsorbing medium which surrounds the tube arrays; and the adsorption tank also carries out low temperature adsorption and high temperature desorption operations. In the invention, the adsorption tank is provided with tube arrays, and cold medium or hot medium can be led into the tube arrays, thus realizing low temperature adsorption and high temperature desorption operations, reducing the level of vacuumizing, saving energy consumption, substantially reducing requirements on the device in the desorption process, improving the adsorption and desorption efficiency, prolonging the service life of the adsorption medium and saving production cost.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

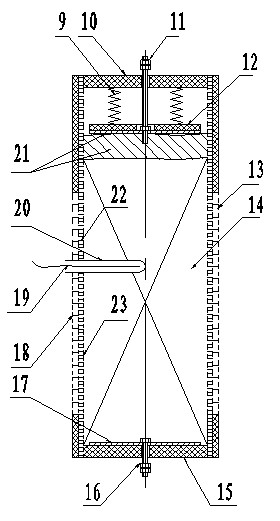

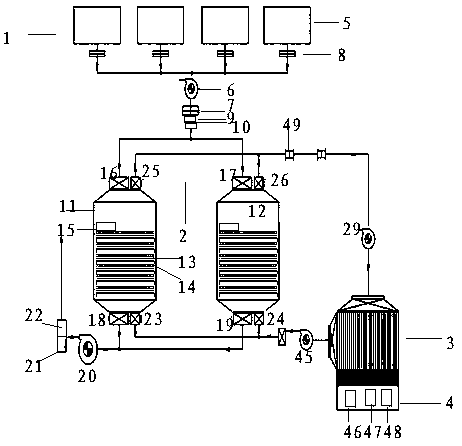

Adsorption purification unit and adsorption recycling device for recycling organic solvent from waste gas

The invention relates to an adsorption purification unit for recycling organic solvent from waste gas, comprising a shell and an active carbon bed layer filled in the shell, the side wall of the shell is provided with an air inlet and an air outlet, the two ends of the active carbon bed layer are provided with electrodes, an elastic compacting device is arranged between the shell and the active carbon bed layer, the active carbon bed layer is internally provided with electric couplers, and the electrodes and the electric couplers are respectively connected with an electrothermal controllers. In the invention, granular active carbon is adopted as adsorbent, the loading density is high, the adsorption capacity is high, the work cycle is long, the loss caused by loading density of activated carbon fibers and frequent adsorption-desorption switching on equipment can be avoided, the replacement cycle of the adsorbent is long, and the maintenance cost is low; the recycled solvent contains no water, the purity is high, and the quality is high, thus the solvent can be directly recycled for production; no waste water is produced, no secondary pollution is caused, and discharge reaching thestandard can be realized; the energy consumption is low, the operating cost is low, and the adsorption purification unit can be applied to recycling of high-boiling point solvent, thus the application field of solvent recycling equipment is expanded.

Owner:ZHENGZHOU ZHONGSIDA ENVIRONMENTAL TECH +1

Automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants

InactiveCN102172461AShorten desorption timeReduce power consumptionDispersed particle filtrationIncinerator apparatusActivated carbonActive carbon

The invention relates to an automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants, which is characterized in that: (1) both opposite side walls of an active carbon bed body of an adsorption bed are set into side walls with hollow structures, an active carbon clapboard is set into an active carbon clapboard with a hollow structure, the active carbon clapboard with the hollow structure is communicated with the side walls with the hollow structures, and the two side walls with the hollow structures are respectively provided with a hot air inlet and a hot air outlet; and (2) a catalytic combustion bed is connected with a plate-type heat exchanger, and the plate-type heat exchanger is connected with the hot air inlets on the side walls withthe hollow structures of the adsorption bed through an adsorption bed heating fan. The automatic high-efficiency energy-saving purification system for the for industrial volatilizable organic pollutants has a simple and reasonable structure, can effectively reduce energy consumption, improve the purifying rate, prolong the service life of a catalyst, shorten the desorption process time, improve the purifying efficiency and reduce the operating cost, and is safe and reliable.

Owner:赛智环保科技(天津)有限公司

Method for absorbing and separating carbon dioxide

InactiveCN101734658APromote absorptionImprove desorption efficiencyCarbon compoundsLiquid productAlcohol

The invention discloses a method for absorbing and separating carbon dioxide, which comprises absorption and desorption of the carbon dioxide at certain temperature and specifically comprises the following steps: mixing alcamines compounds and ethylene glycol compounds to form solution so as to obtain an absorbent; making the absorbent contact the gas to be absorbed in gas-liquid mass transfer equipment to obtain a liquid product; and desorbing and separating the liquid product to obtain the carbon dioxide so as to realize the regeneration of the carbon dioxide. The absorbent adopted by the method can efficiently absorb the carbon dioxide, has little corrosion to the equipment, and can realize the regeneration of the carbon dioxide and the cyclic utilization of the absorbent.

Owner:TSINGHUA UNIV

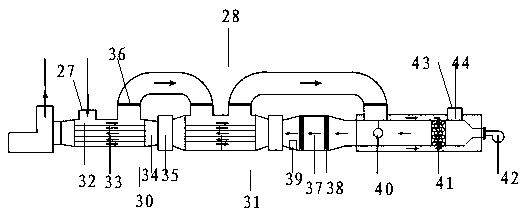

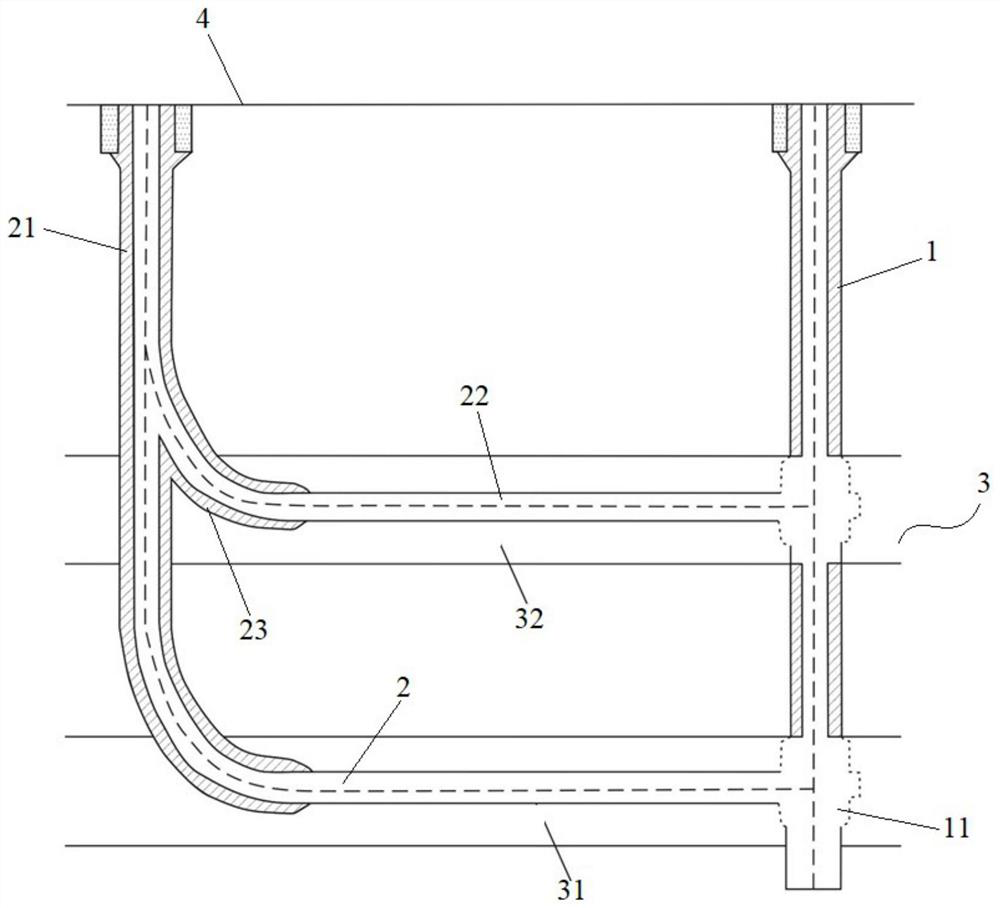

Organic waste gas treatment system and treatment method thereof

PendingCN108273358AImprove desorption efficiency and adsorption performanceProvide service lifeGas treatmentDispersed particle separationChemistryVariable-frequency drive

The invention relates to an organic waste gas treatment system and a treatment method thereof. The organic waste gas treatment system comprises a plurality of organic waste gas supply devices (1), anadsorption and desorption device (2), a catalytic combustion device (3) and a control device (4); and the adsorption and desorption device (2) comprises a first adsorption and desorption chamber (11)and a second adsorption and desorption chamber (12) which are used alternately, the catalytic combustion device (3) comprises a wind dividing cutting heat exchanging part (28), a heat storage part (37) and a catalytic combustion part (40), the control device (4) comprises a frequency converter (46) controlling the flow velocity or the flow quantity, a constant temperature control unit enabling a preset temperature, a first rising temperature, a second rising temperature and a heating temperature of heating of a burner to be constant within a preset range, and a treatment unit (78) which is connected with the frequency converter (46) and the constant temperature control unit (47). The treatment method automatically conducts high-efficiency purification treatment on a plurality of organic waste gas sources simultaneously, the heat is utilized maximumly, and the purifying effect is stable.

Owner:山东亚泰新材料科技有限公司

New method for extracting gallium from Bayer mother liquor through chelating resin

ActiveCN102321802AHigh gallium contentImprove electrolysis efficiencyPhotography auxillary processesProcess efficiency improvementElectrolysisDesorption

The present invention discloses a method for extracting gallium from Bayer mother liquor through chelating resin. The method comprises the following steps that: (1) gallium extracting resin is filled into a resin column, the Bayer mother liquor containing the gallium flows through the gallium extracting resin column to enable the gallium extracting resin to achieve adsorption saturation; (2) the saturated gallium extracting resin is washed through water; (3) a prepared acid solution is filled in a buffer tank, and forms a series connection with the gallium extracting resin column and a gallium enriching resin column; the acid solution in the buffer tank is controlled through a pump, sequentially flows through the extracting resin column and the enriching resin column, and finally flows back to the buffer tank, the operations are circularly performed; (4) when the gallium enriching resin achieves adsorption saturation, an alkaline solution is adopted for desorption of the gallium enriching resin; (5) the resulting desorption solution of the gallium enriching resin is directly subjected to electrolysis to obtain the metal gallium. According to the present invention, with the method provided by the present invention, the disadvantages in the prior art are overcome; the method has advantages of high desorption efficiency, good gallium recovery rate and the like; the obtained desorption solution has high gallium content; the pretreatment process of the electrolysis is simple; the cost can be substantially saved.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

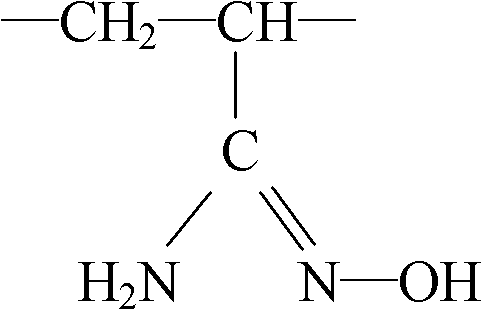

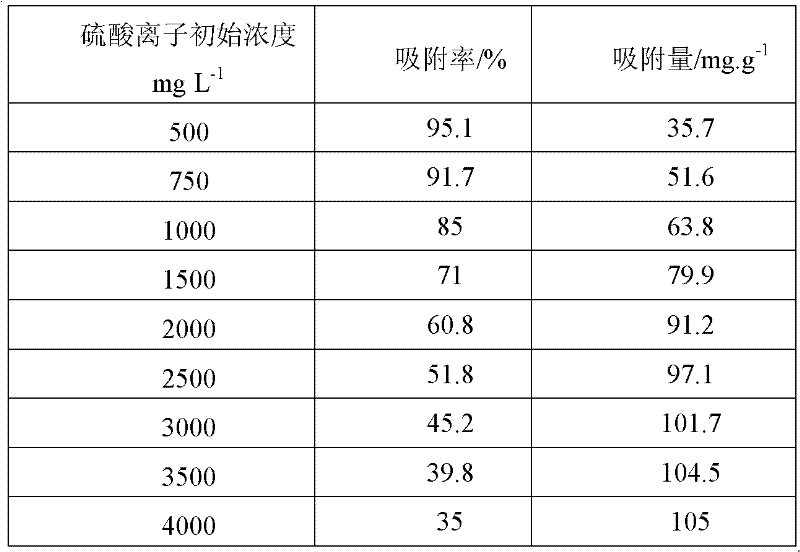

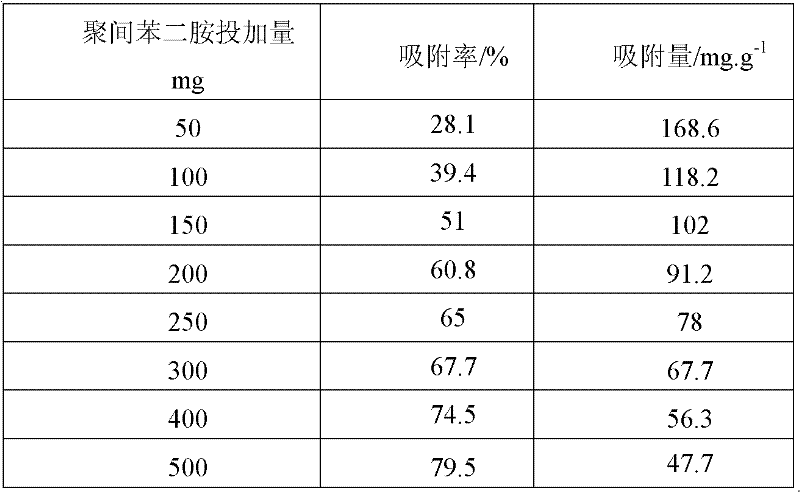

Adsorbent for removing sulfate ions contained in water body as well as preparation and application thereof

InactiveCN102247818AThe synthesis process is simpleNo production requirementsOther chemical processesWater/sewage treatment by sorptionAdsorption equilibriumSulfate radicals

The invention relates to an adsorbent for removing sulfate ions contained in a water body as well as preparation and application thereof. The adsorbent is a poly (m-phenylenediamine) adsorbent obtained through chemical oxidation polymerization reaction at room temperature by taking m-phenylenediamine as a monomer and ammonium persulfate as an oxidant. The poly (m-phenylenediamine) adsorbent disclosed by the invention has the advantages of simple synthetic process, low cost, good removing effect on sulfate radicals contained in the water body, adsorption quantity reaching more than 107 mg.g<-1> and no secondary pollution; by means of the poly (m-phenylenediamine) adsorbent disclosed by the invention, the treatment effect on waste water with sulfate ion concentration lower than 500 mg.L<-1> can reach more than 95 percent, adsorption rate is high, and adsorption equilibrium can be achieved within 10 minutes; in addition, multiple adsorption results indicate that the desorption rate of poly (m-phenylenediamine) is about 95 percent, and the poly (m-phenylenediamine) can be effectively recycled.

Owner:CENT SOUTH UNIV

Evaporated fuel treatment apparatus

InactiveUS20120312281A1Enhanced efficiencyEffectively heatNon-fuel substance addition to fuelFuel injection apparatusAutomotive engineeringFuel tank

An evaporated fuel treatment apparatus is mounted in a vehicle having an engine, a fuel tank storing fuel for the engine, and a battery, the evaporated fuel treatment apparatus adsorbing evaporated fuel in the fuel tank on an adsorbent in a canister container, desorbing the evaporated fuel adsorbed on the adsorbent therefrom during engine running, and directing the evaporated fuel to an intake passage of the engine. The adsorbent in the canister is heated by heat generated by the battery.

Owner:AISAN IND CO LTD

Coal underground gasification and coalbed methane collaborative mining method and structure and construction method

PendingCN112081558ADraining is safe and efficientGuarantee safe miningConstructionsFluid removalCoalbed methane extractionPetroleum engineering

The invention relates to the technical field of coal mining, in particular to a coal underground gasification and coalbed methane collaborative mining method and structure and a construction method. The coal underground gasification and coalbed methane collaborative mining method comprises the following steps that in a target coalbed, coal underground gasification is carried out on a lower coalbed, and coalbed methane extraction is carried out on an upper coalbed at the same time, wherein the lower coalbed is adjacent to the upper coalbed, and the lower coalbed is located below the upper coalbed. The method aims to combine coal underground gasification with coalbed methane exploitation, fully exploit coal underground gasification for complex difficult-to-exploit coalbeds, fully utilize heat generated by coal underground gasification, further assist in extraction of coalbed gas in the upper coalbed, further reduce the content of coalbed gas in the coalbeds and guarantee safe and efficient extraction of coal.

Owner:XIAN UNIV OF SCI & TECH +1

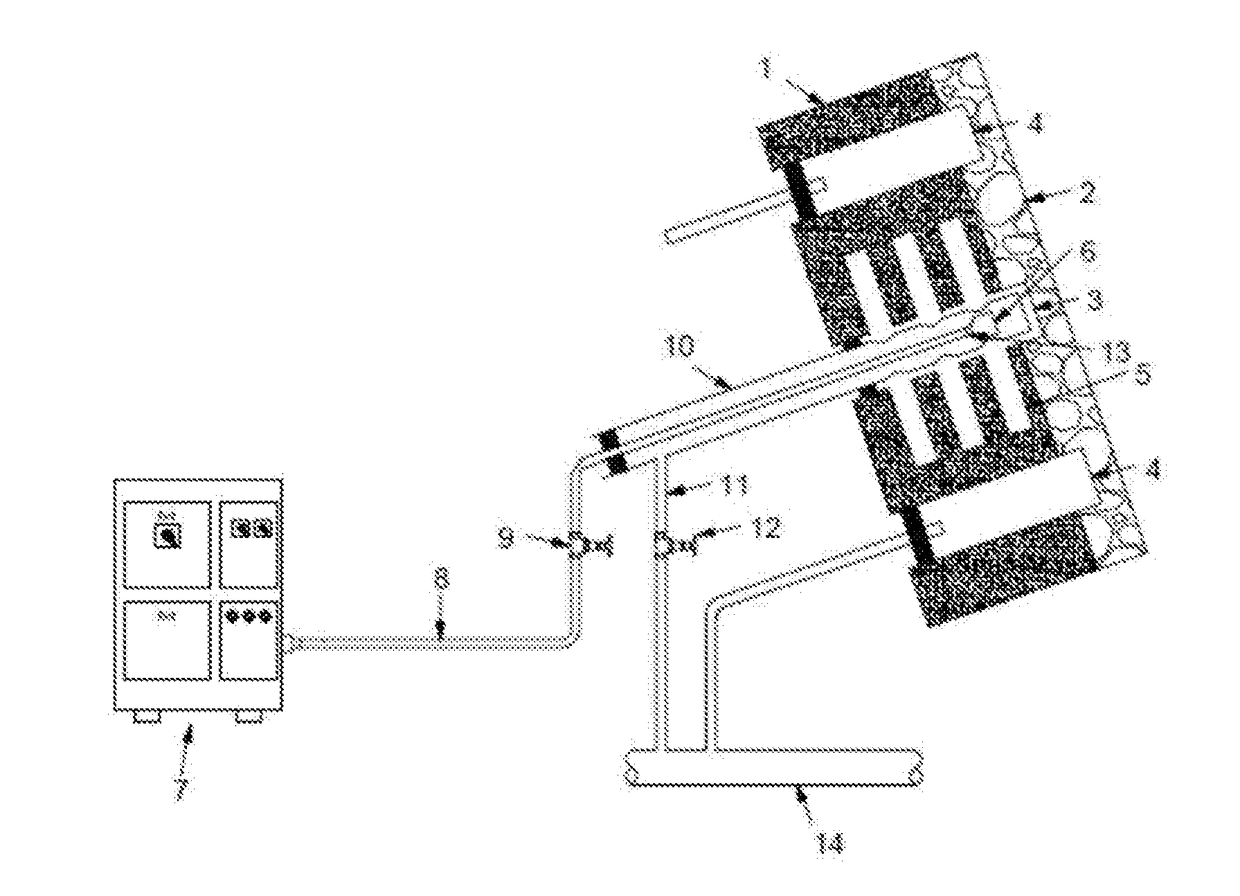

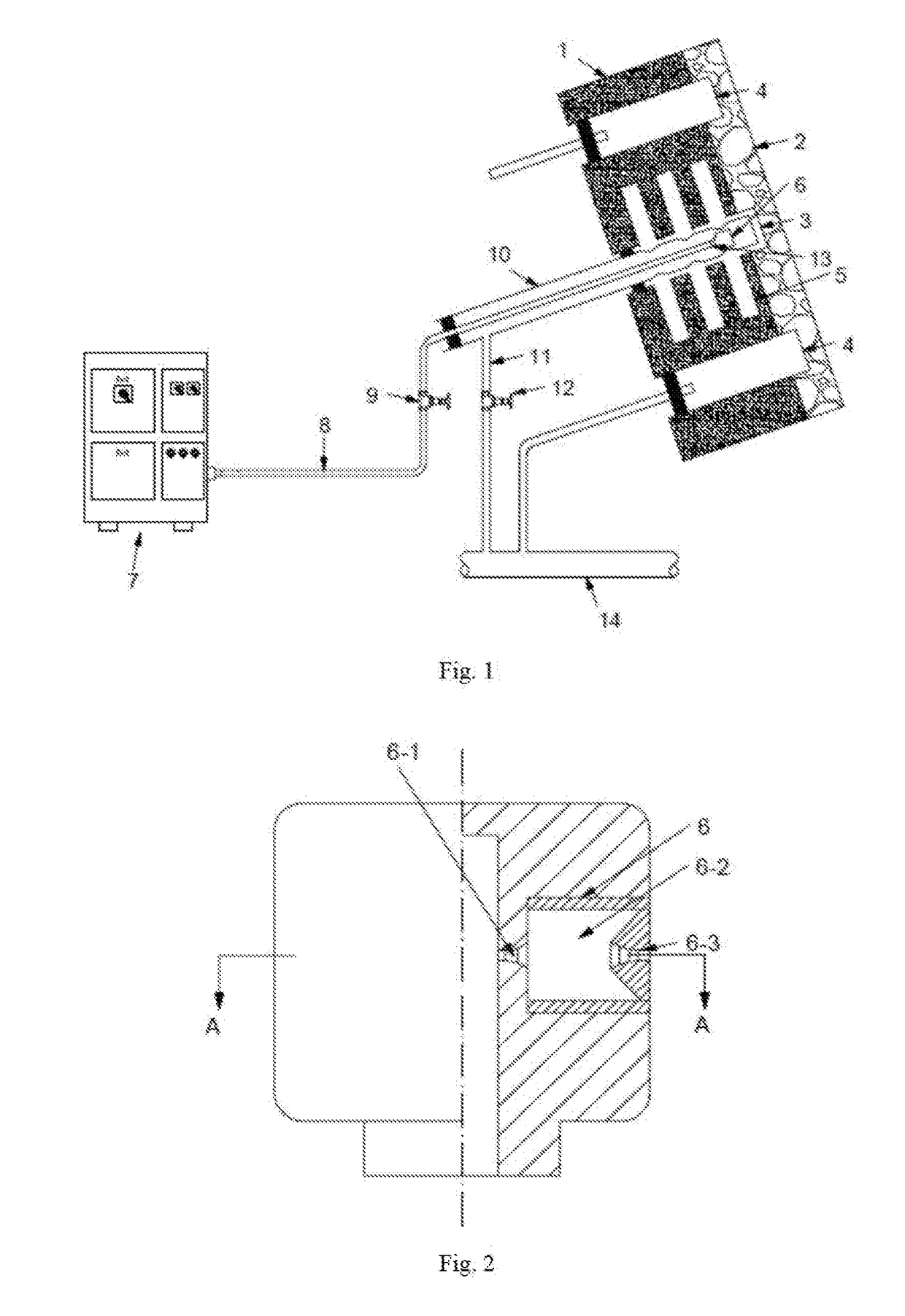

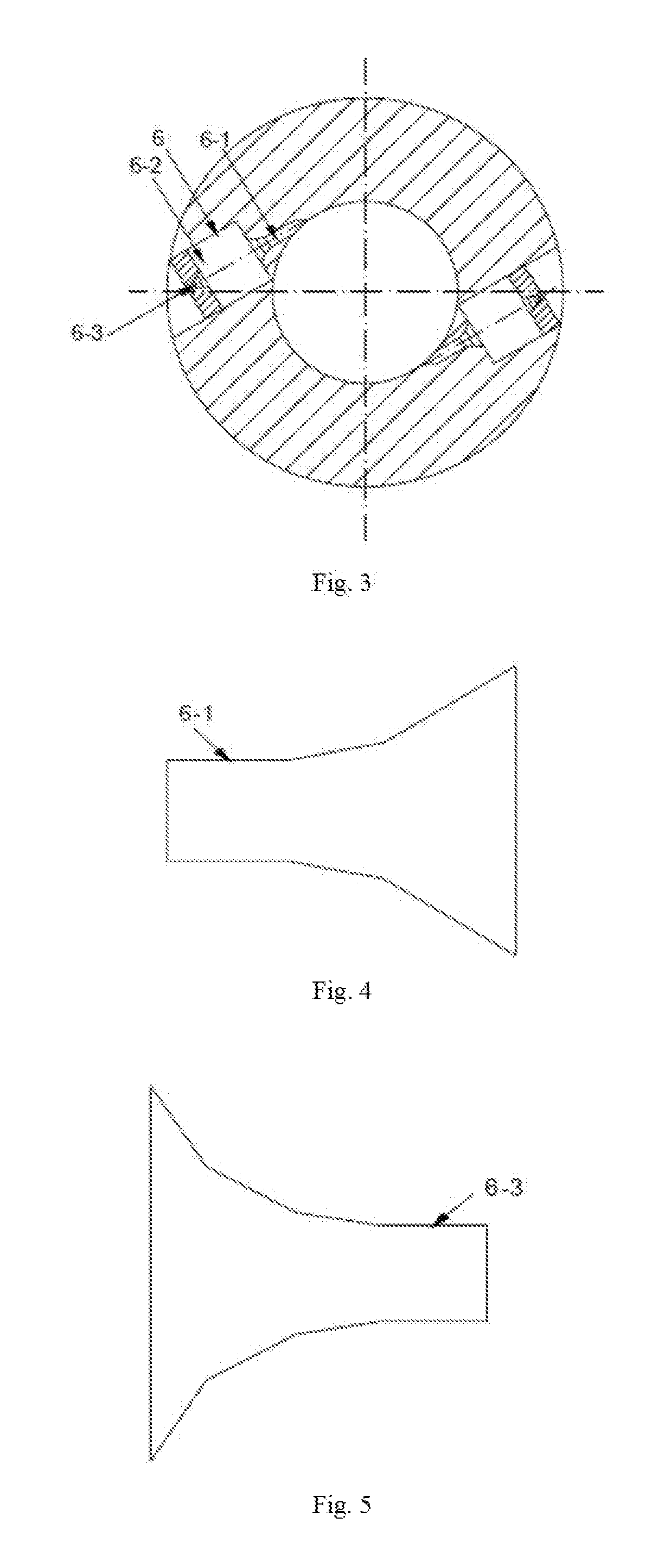

Method for integrated drilling, slotting and oscillating thermal injection for coal seam gas extraction

ActiveUS20180209255A1Easy to operateRemarkable improvement effectLiquid/gas jet drillingFluid removalEngineeringHigh pressure

A method for combining integrated drilling and slotting with oscillating thermal injection to enhance coalbed gas extraction, applicable to managing gas extraction from microporous, low-permeability, high-adsorption coal seam areas. A number of slots are formed within a thermal injection / extraction borehole by means of integrated drilling and slotting technology; a steam generator, is then used to three high-pressure, cyclically temperature-changing steam into said borehole; the steam passing through a spinning, oscillating-pulse jet nozzle forms an oscillating superheated steam, heating the coal body. The present method overcomes the limitations of simple permeability-increasing techniques, the slotting by means of hydraulic. pressure significantly increasing the pressure relief range of a single borehole and forming a fracture network that provides channels for passage of the superheated steam, while oscillating variation in steam temperature and pressure also promote crack propagation and perforation of the coal body; the combined effect of the two enhances the efficiency of gas desorption and extraction.

Owner:CHINA UNIV OF MINING & TECH

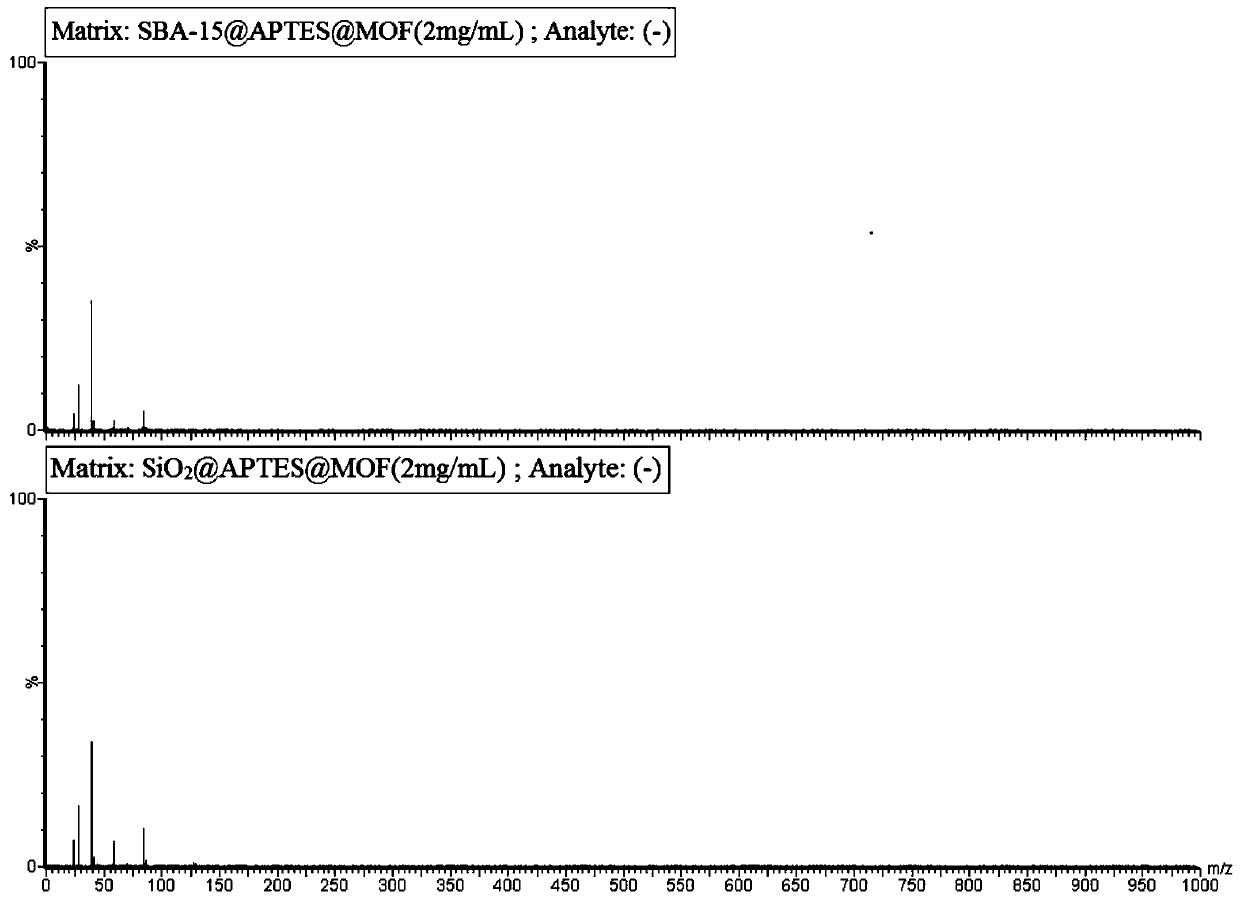

Metal organic framework-silicon based composite material, and preparation method and application thereof

ActiveCN110694589AImprove ionization efficiencyImprove desorption efficiencyOther chemical processesMaterial analysis by electric/magnetic meansMetal-organic frameworkMass Spectrometry-Mass Spectrometry

The invention provides a metal organic framework-silicon based composite material, and a preparation method and application thereof, and belongs to the technical field of mass spectrometry analysis. The metal organic framework-silicon based composite material provided by the invention is formed by a condensation reaction of a metal-organic framework material containing a pi-pi conjugated structureand a siloxane modified silicon based material, and the advantages of the metal-organic framework material and the siloxane modified silicon based material are combined. In the composite material, the metal-organic framework material can enhance ionization efficiency of a target in MALDI-TOF MS analysis process, and the siloxane modified silicon based material can promote desorption efficiency ofthe target in MALDI-TOF MS analysis, so that the composite material can be well applied to MALDI-TOF MS detection of small molecular compounds, the problem of serious background interference caused in traditional matrix detection of small molecular compounds can be effectively overcome, and detection sensitivity can be improved.

Owner:INST OF ENVIRONMENTAL MEDICINE & OCCUPATIONAL MEDICINE ACAD OF MILITARY MEDICINE ACAD OF MILITARY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com