System and method for recovering oil gas

An oil and gas recovery system, oil and gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as increasing refrigerant flow or shutting down to cool down, and achieves extended operation period, superior performance, and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

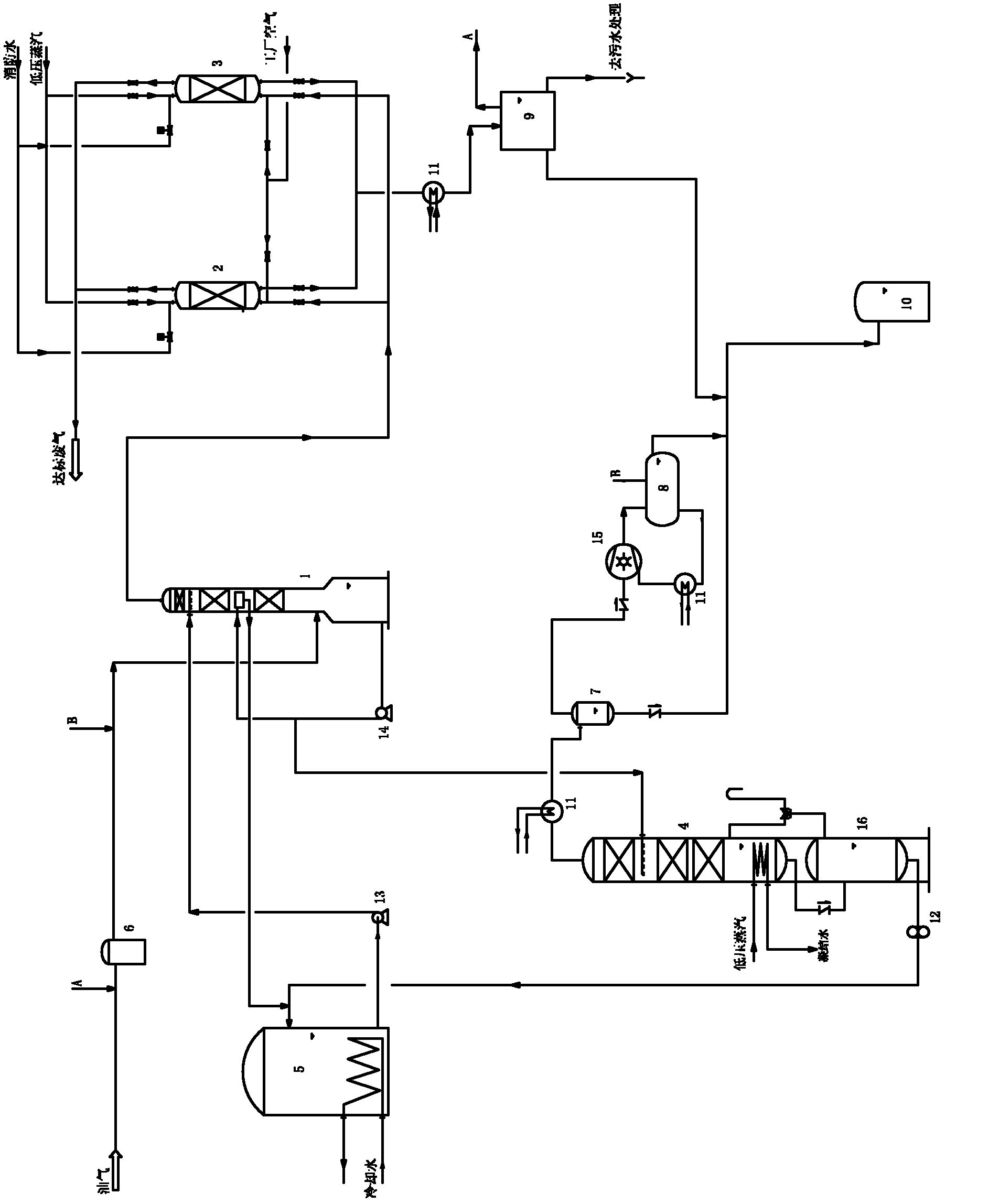

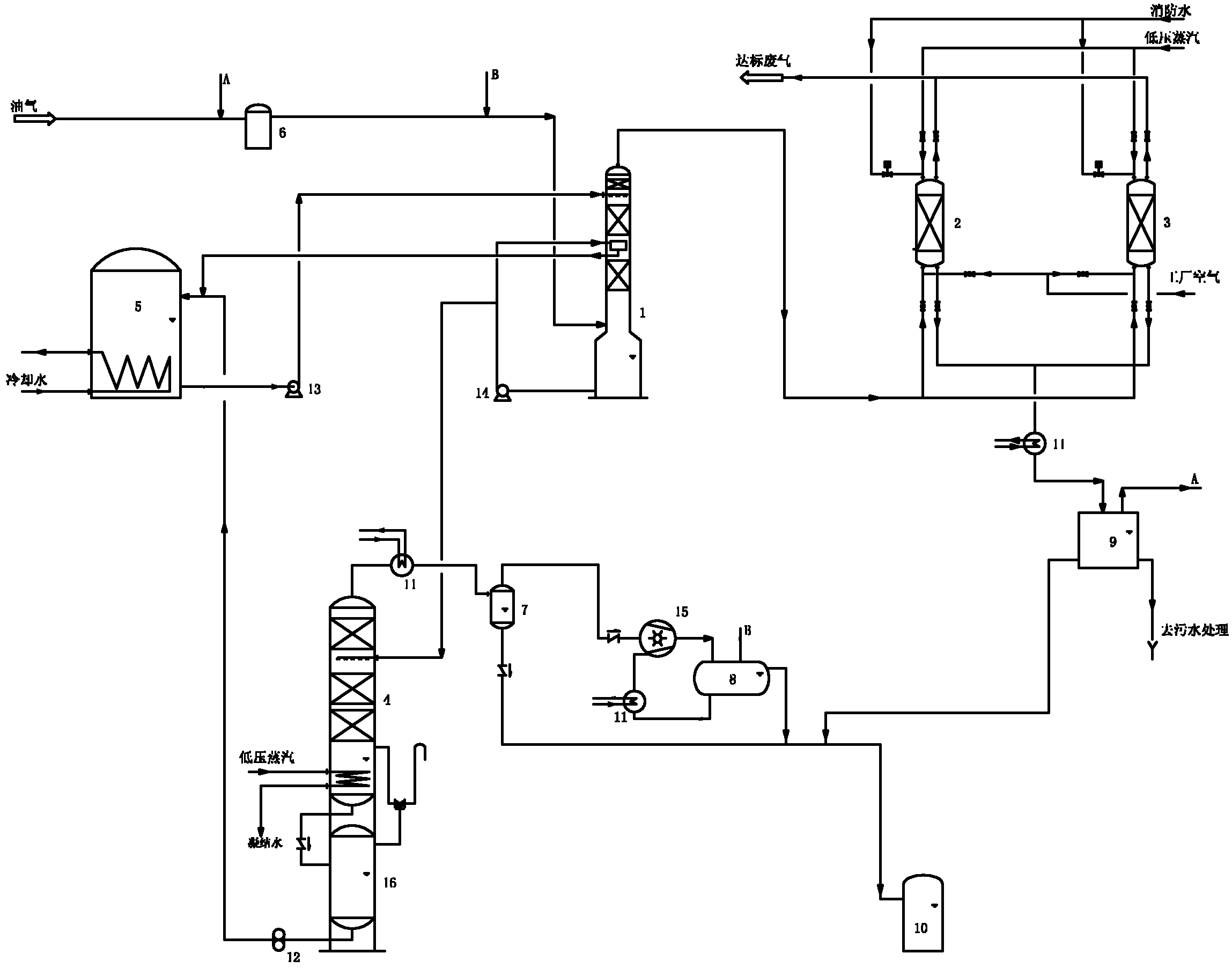

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings, examples and test data.

[0030] like figure 1 Shown, the oil gas recovery system of the present invention, used absorption solvent is diesel oil, comprises diesel oil storage tank 5, absorption tower 1, the first activated carbon adsorption tower 2, the second activated carbon adsorption tower 3 and desorption tower 4; Diesel oil storage tank 5 bottoms A cooling coil is installed at the end, and cooling water is passed through the pipe to cool the diesel oil to below 35°C, such as 30-35°C. The oil and gas pipeline is connected to the air inlet of the buffer tank 6, and the gas outlet of the buffer tank 6 is connected to the air inlet of the absorption tower 1. , the gas outlet at the top of the absorption tower 1 communicates with the gas inlets and outlets at the bottom of the activated carbon adsorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com