Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

935results about How to "Low heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and apparatuses for dynamic power control

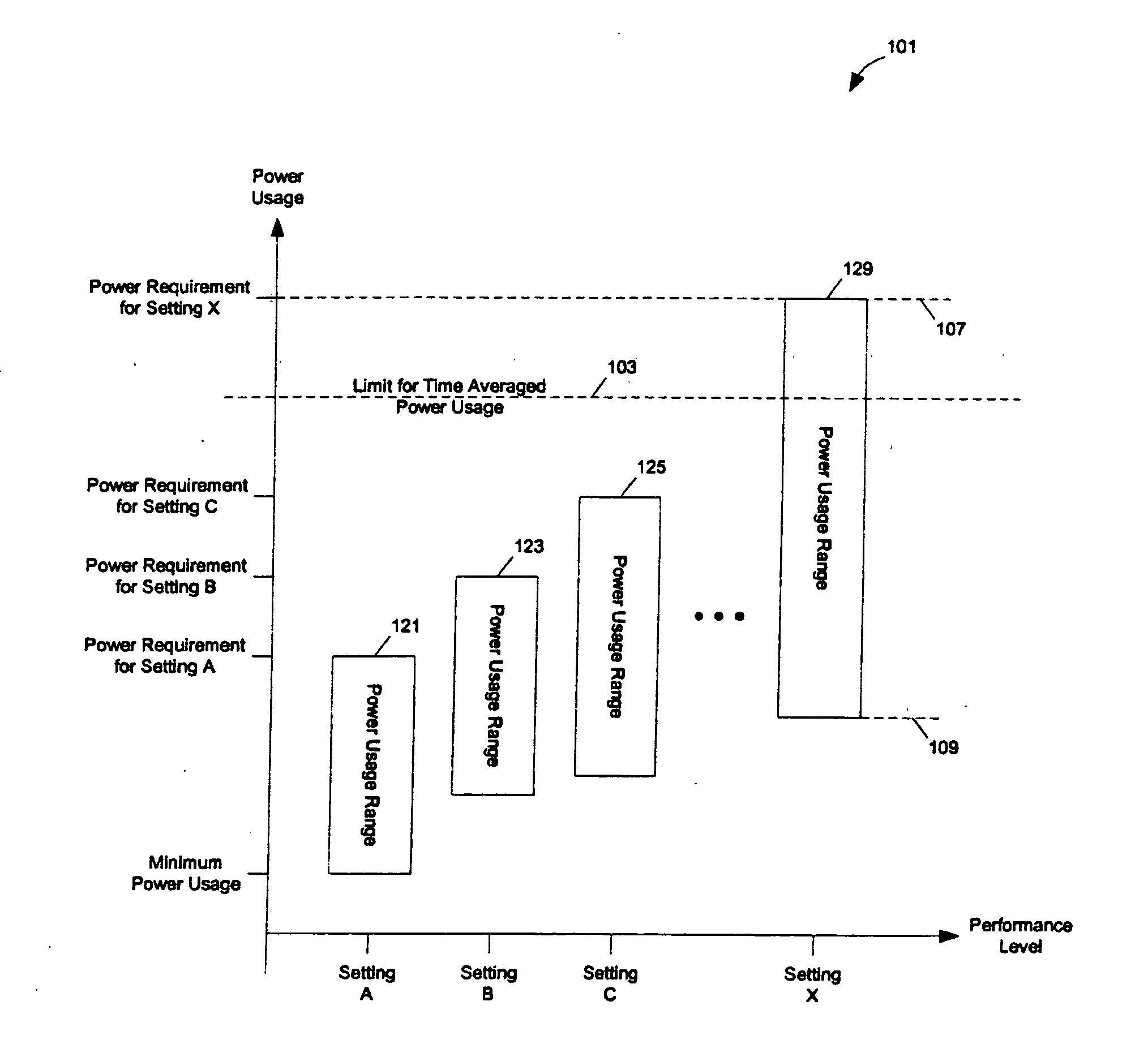

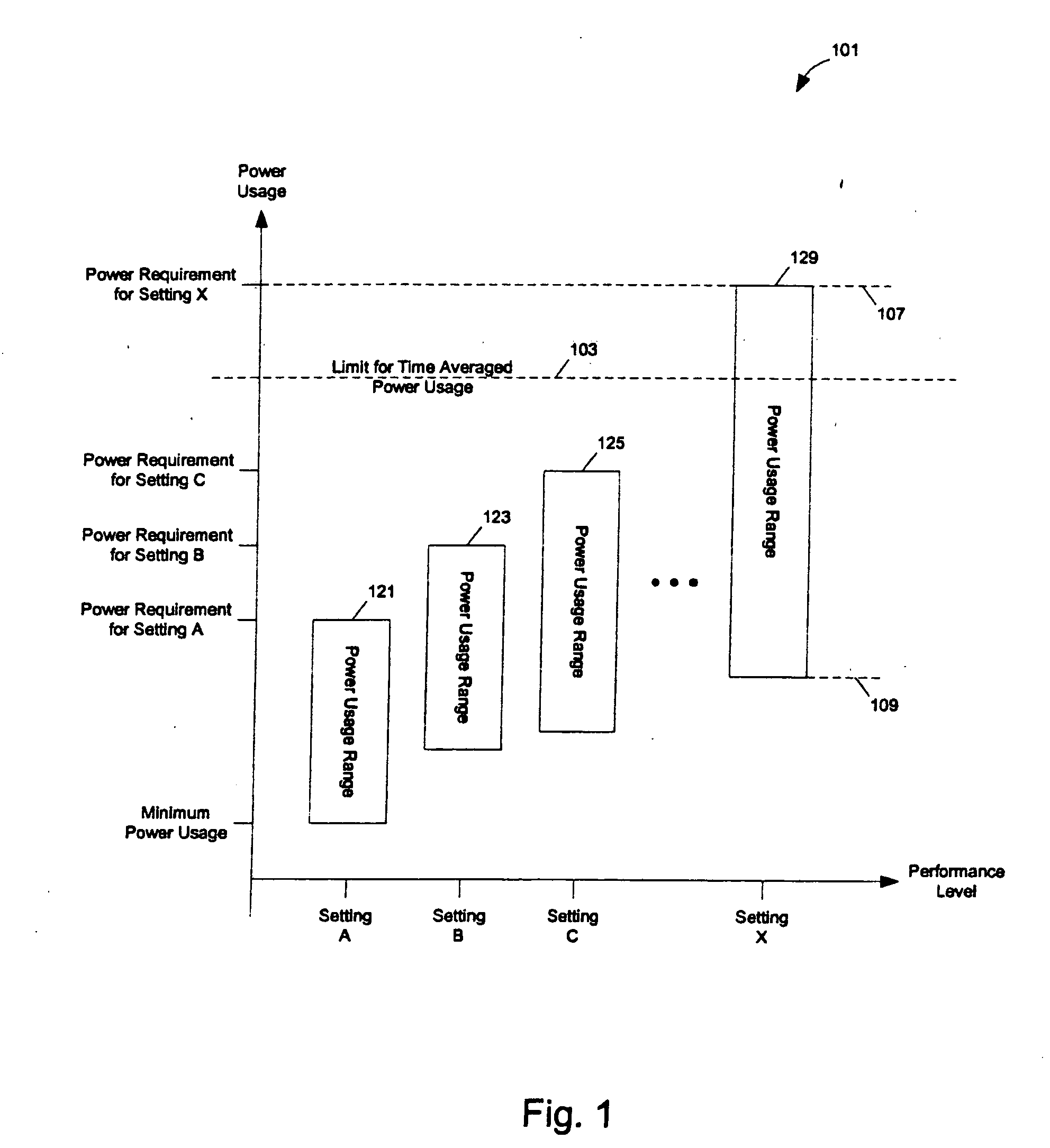

ActiveUS20070049134A1Improve efficiencyReduce coolingEnergy efficient ICTElectrically conductive connectionsTemperature controlEngineering

Exemplary embodiments of methods and apparatuses to provide a cooling arrangement for a system are described. The system includes a component coupled to a heat sink. A signal associated with a temperature control of the component is asserted. A target temperature of the heat sink is adjusted based on the signal. In one embodiment, a temperature control loop of the heat sink is operated. The temperature of the heat sink may be monitored using one or more sensors placed on the heat sink. An operation of the component, a cooling unit coupled to the heat sink, or both, may be adjusted based on a relationship between the temperature of the heat sink and an adjusted target temperature. Adjusting the target temperature of the heat sink based on the asserted signal increases efficiency of the system while decreasing cooling.

Owner:APPLE INC

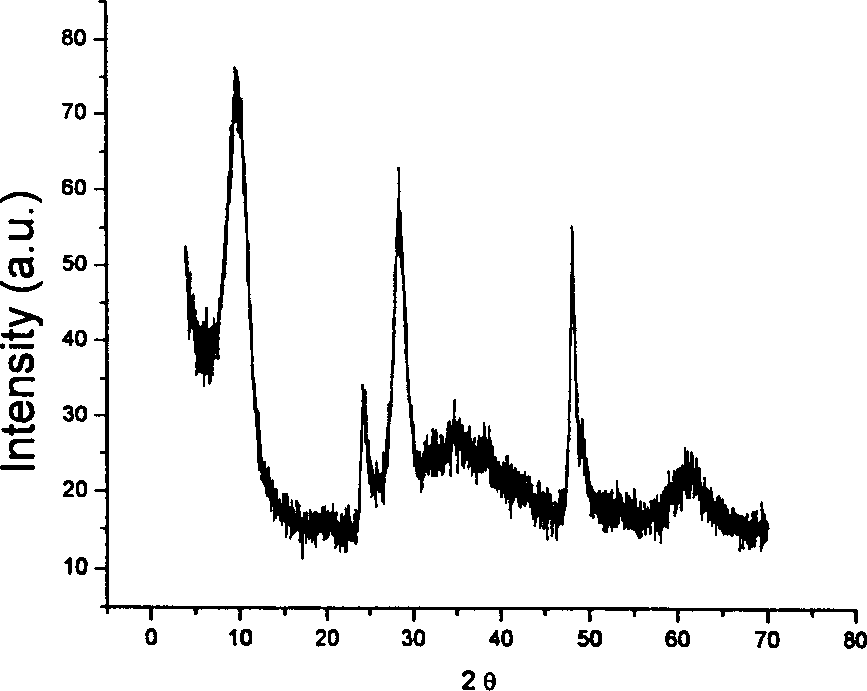

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

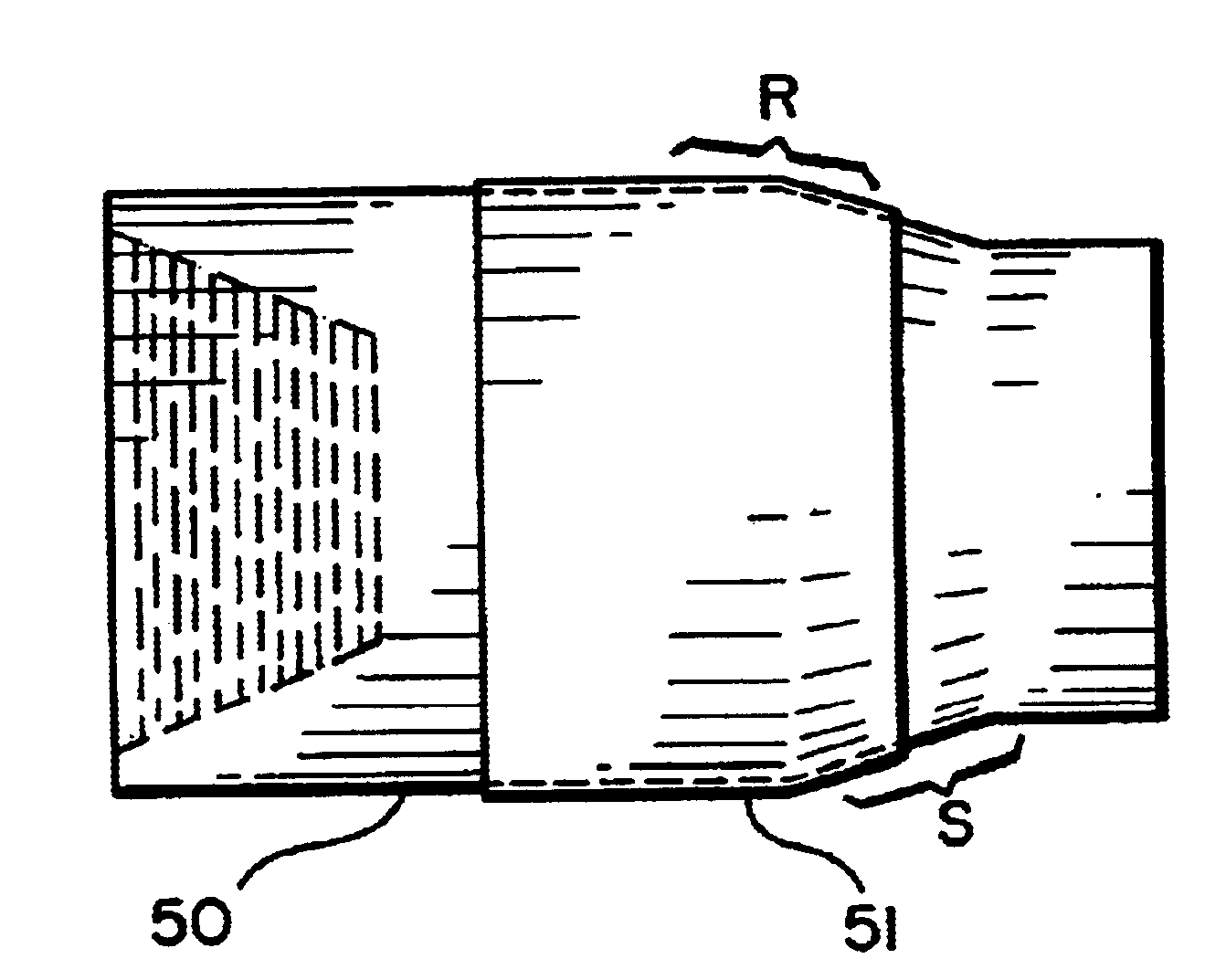

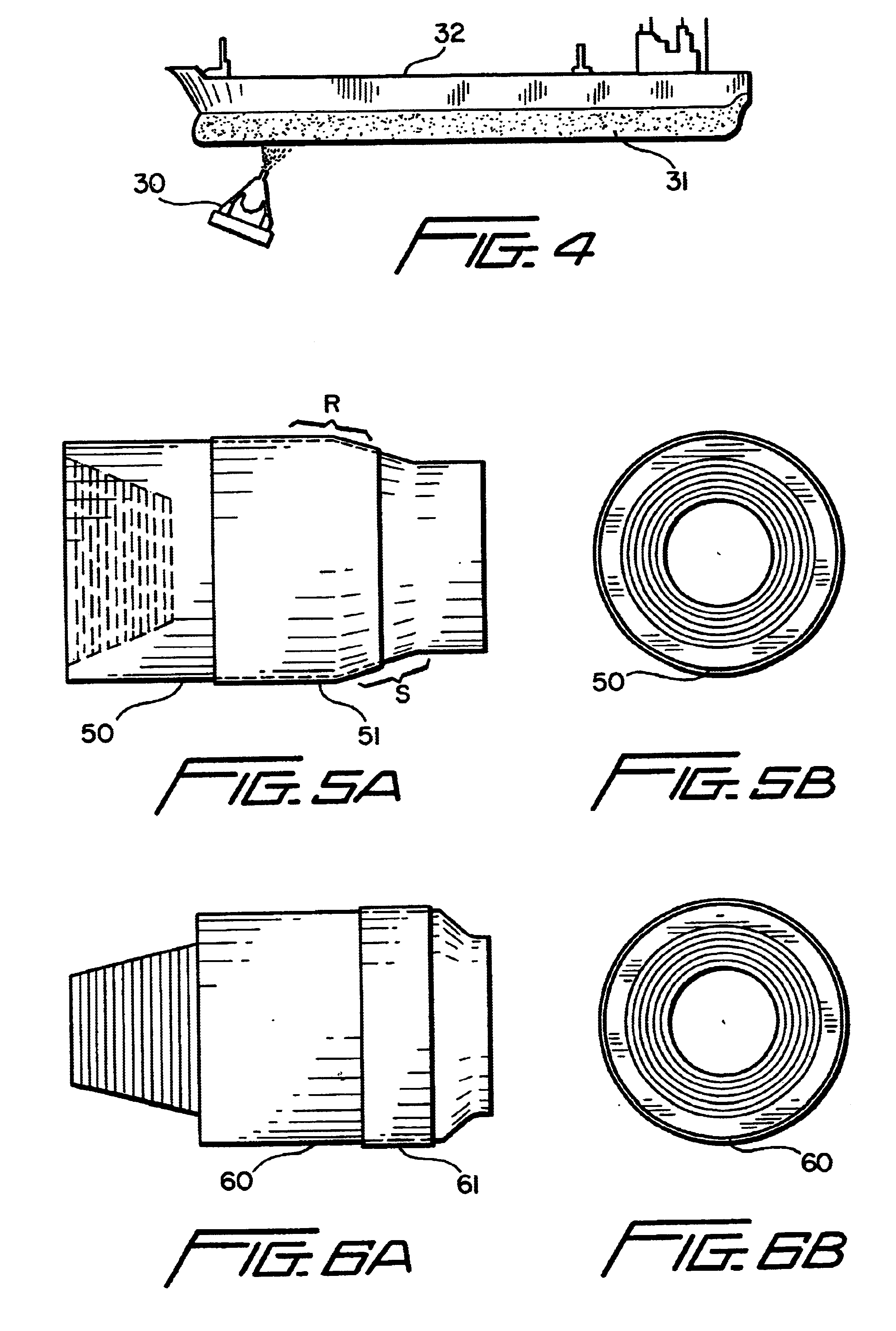

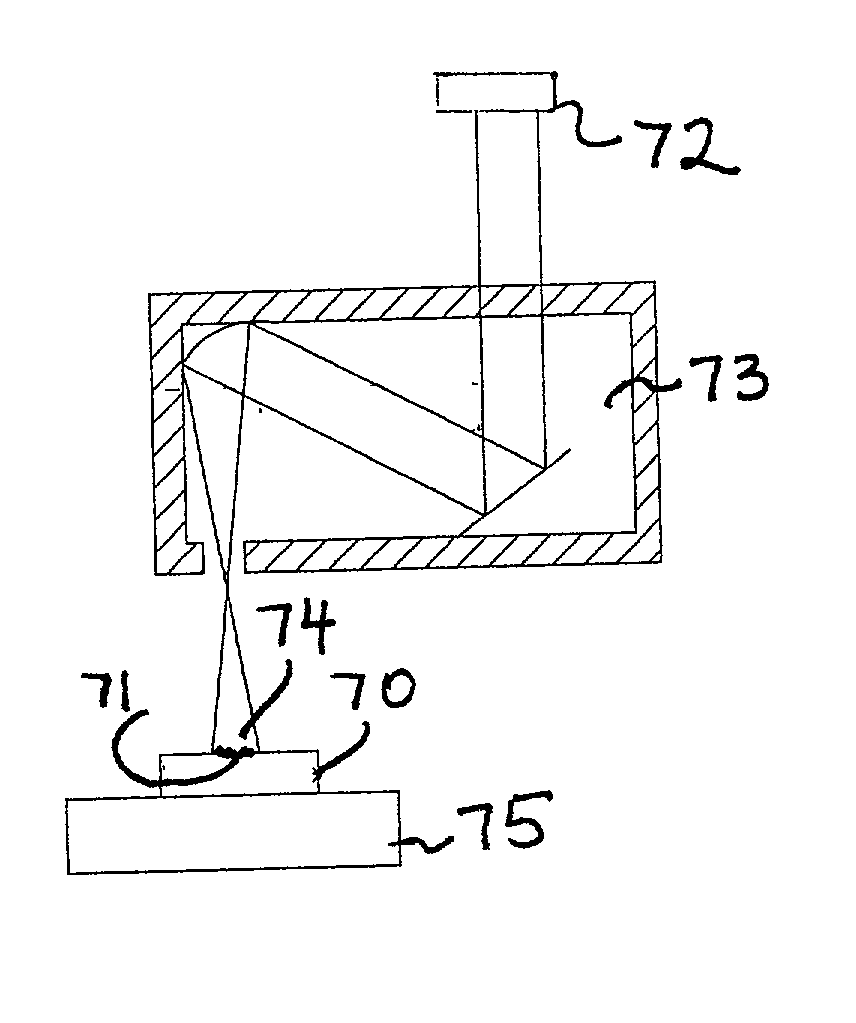

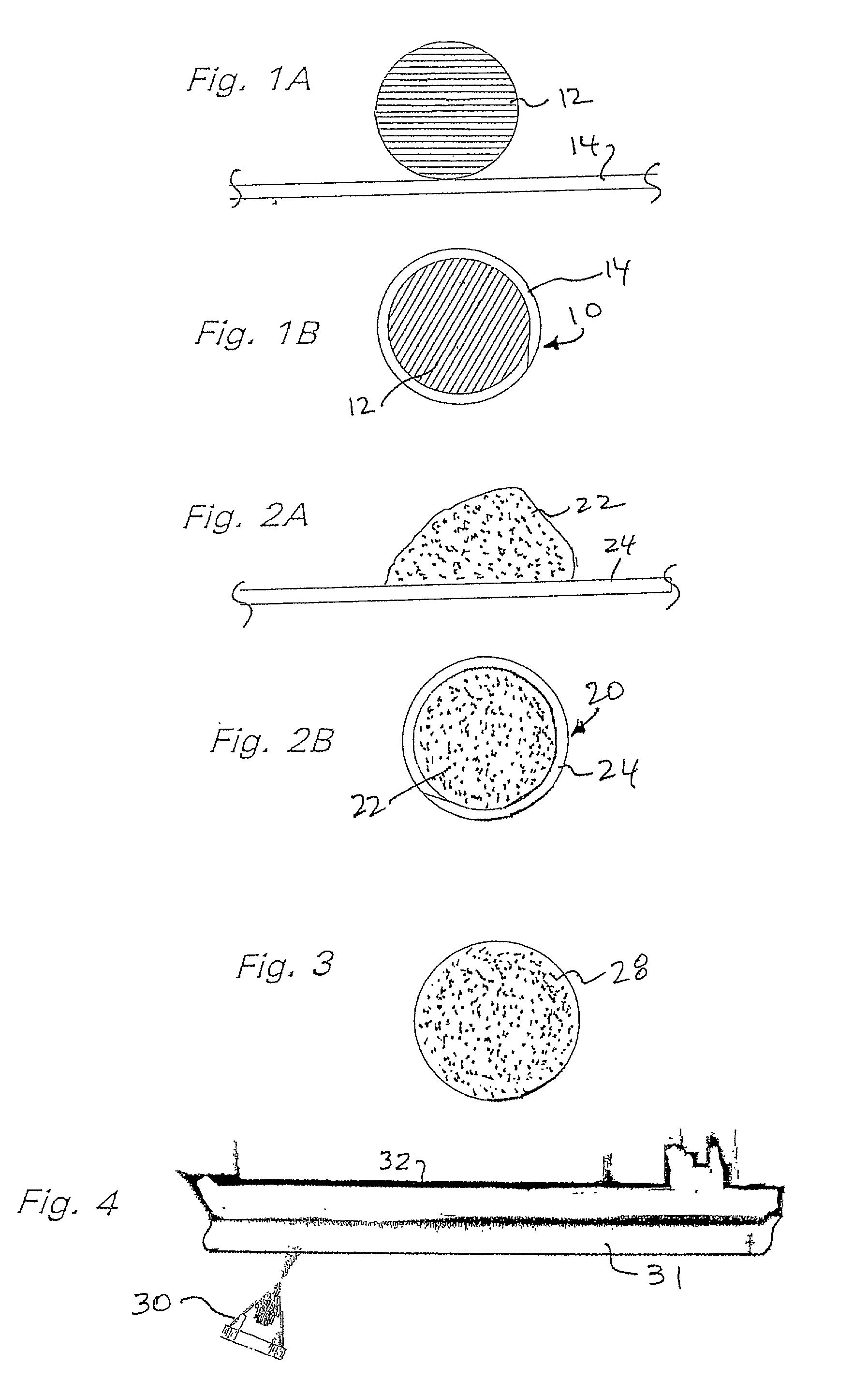

Methods for using a laser beam to apply wear-reducing material to tool joints

InactiveUS6861612B2Low heating temperatureExtremely wear resistant claddingElectric discharge heatingVacuum evaporation coatingMetallurgyLaser beams

A method for applying wear reducing material to a tool joint useful in a wellbore in drilling operations, the method, in at least certain aspects, including positioning the tool joint adjacent laser beam apparatus, delivering wear-reducing material to a location on the tool joint to which the wear-reducing material is to be applied, heating the wear-reducing material with the laser beam apparatus to a temperature not exceeding its melting temperature so that the wear-reducing material is welded to the tool joint; in one particular aspect, using a defocused laser beam to achieve desired heating temperatures; and, in one aspect, defocusing the laser so no plasma is formed.

Owner:MCCLUNG GUY L III

Methods for applying wear-reducing material to tool joints

InactiveUS20020098298A1Low heating temperatureLess aggressiveElectric discharge heatingVacuum evaporation coatingMetallurgyLaser beams

A method for applying wear reducing material to a tool joint useful in a wellbore in drilling operations, the method, in at least certain aspects, including positioning the tool joint adjacent laser beam apparatus, delivering wear-reducing material to a location on the tool joint to which the wear-reducing material is to be applied, heating the wear-reducing material with the laser beam apparatus to a temperature not exceeding its melting temperature so that the wear-reducing material is welded to the tool joint; in one particular aspect, using a defocused laser beam to achieve desired heating temperatures; and, in one aspect, defocusing the laser so no plasma is formed.

Owner:MCCLUNG GUY L III

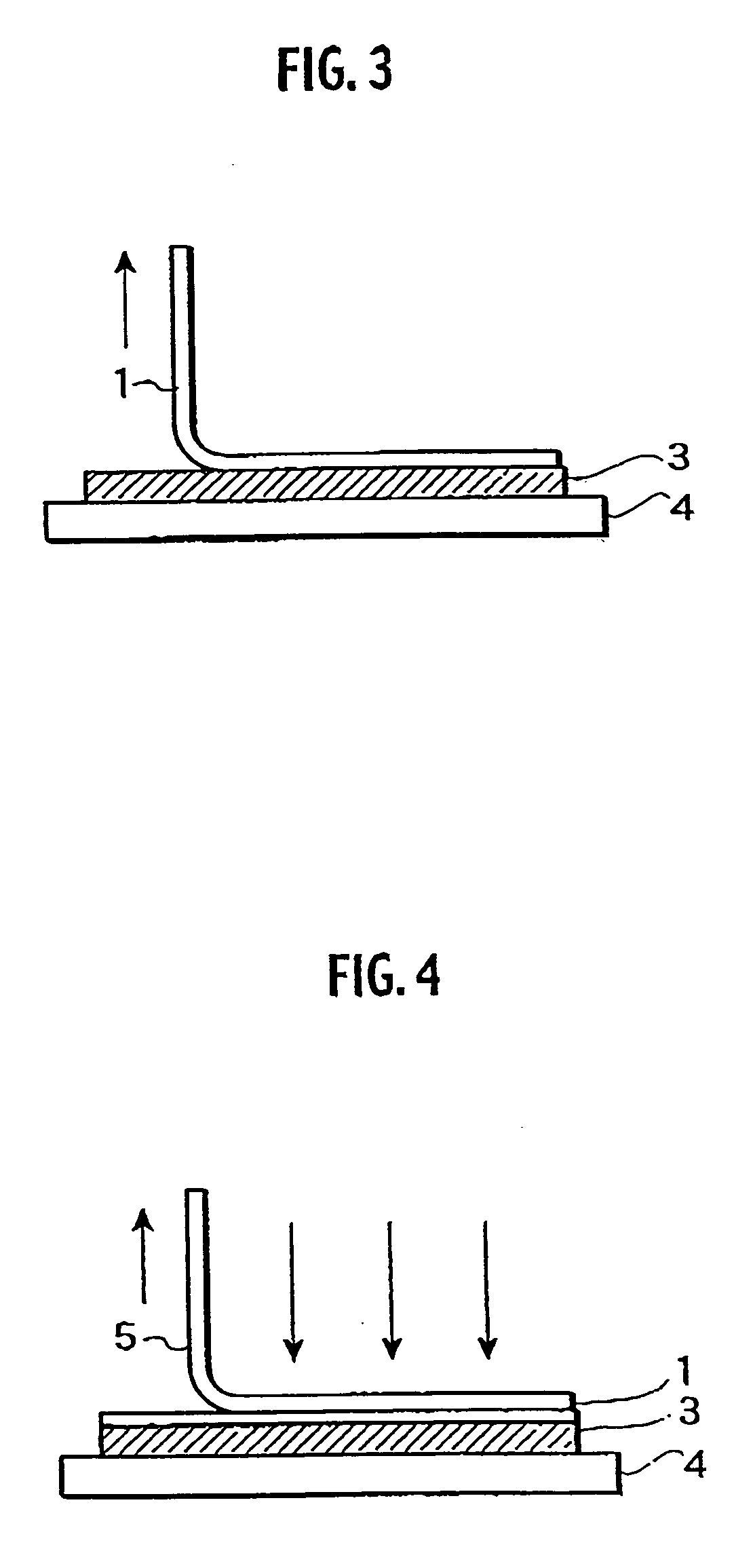

Adhesive film and process for preparing the same as well as adhesive sheet and semiconductor device

InactiveUS20070098995A1Improve workabilityLow heating temperatureNon-macromolecular adhesive additivesSynthetic resin layered productsHeat resistanceDicing tape

An object of the present invention is to provide a die-adhering adhesive film which can be laminated on a back of a wafer at a temperature lower than a softening temperature of a protecting tape for an ultra-thin wafer, or a dicing tape to be laminated, can reduce a thermal stress such as warpage of a wafer, can simplify a step of manufacturing a semiconductor device, and is excellent in heat resistance and humidity resistance reliance, an adhesive sheet in which the adhesive film and a dicing tape are laminated, as well as a semiconductor device.

Owner:HITACHI CHEM CO LTD

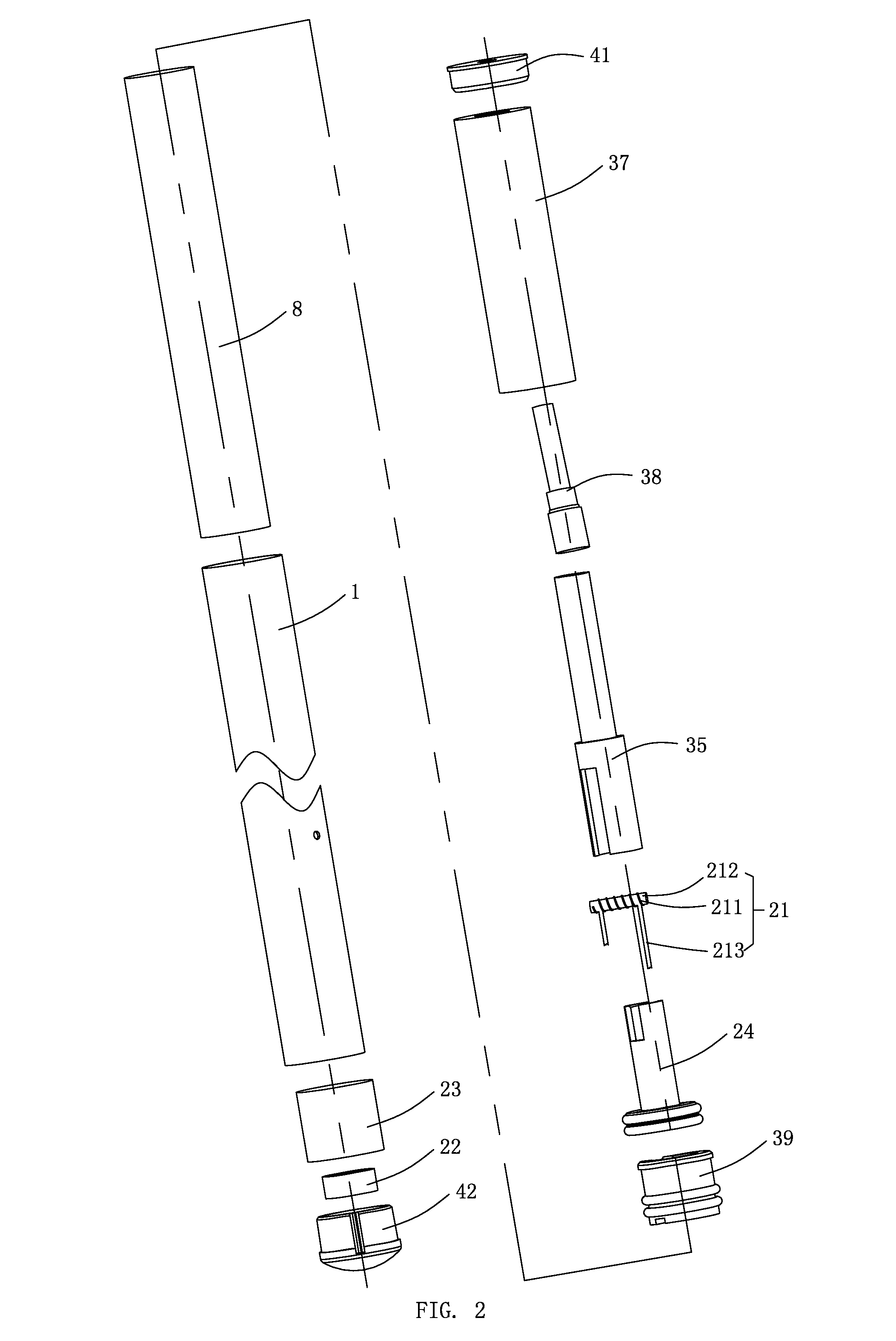

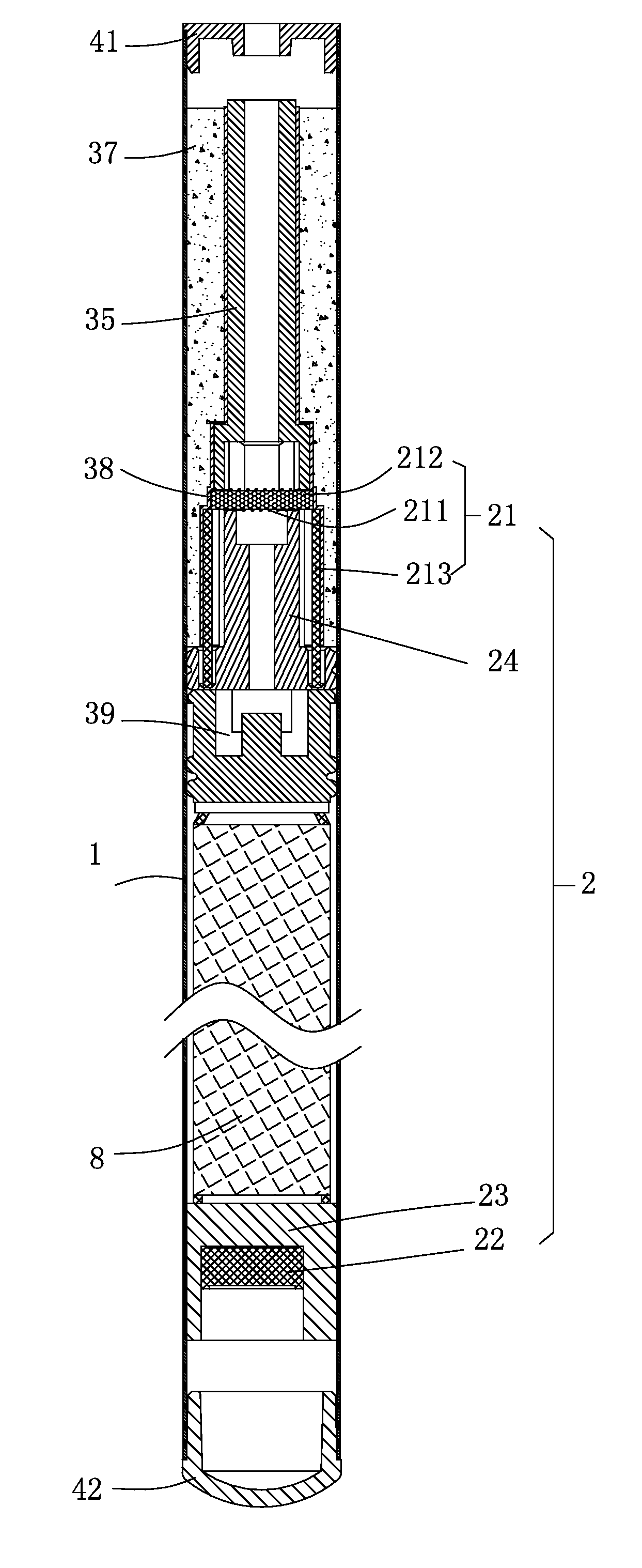

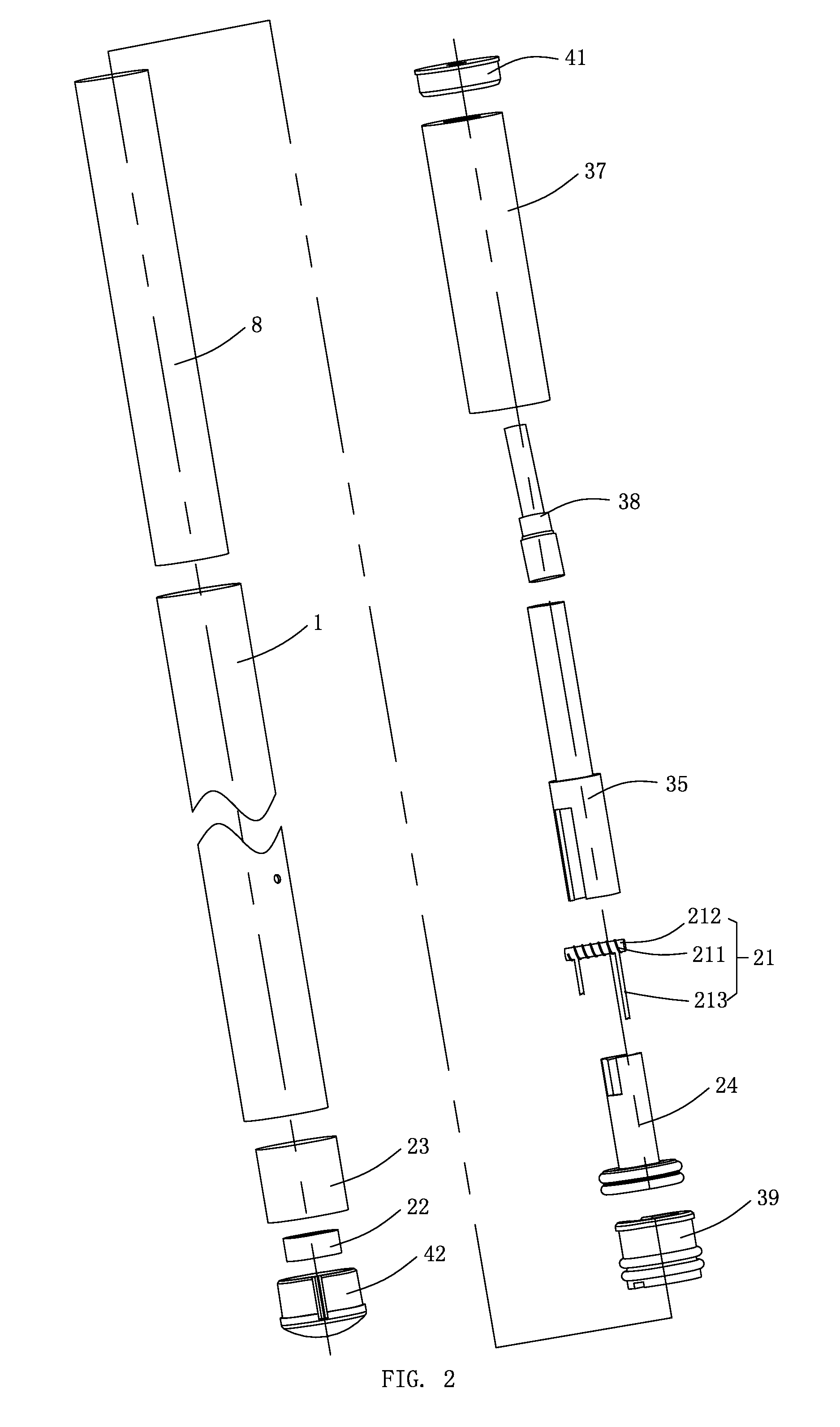

Electronic cigarette adopting organic cotton

InactiveUS9532601B2The internal structure is firm and reliableAvoid damageTobacco pipesTobacco devicesGlass fiberEngineering

An electronic cigarette adopting organic cotton includes a liquid storage component and an atomizing device, the atomizing device includes a hollow spiral heating wire, a liquid guiding member inserted in the heating wire, the liquid guiding member is made of non-fiberglass organic cotton materials; the atomizing device further includes a smog conduit inserted in the liquid storage component for supporting the liquid storage component and serving as a channel for the smog, the smog conduit comprises an outer sleeve and an inner sleeve, one inserted into another to position the liquid guiding member therebetween, and the liquid guiding member has its opposite ends respectively to be protruded out of an outer sidewall of the smog conduit and firmly abut against an inner sidewall of the liquid storage component. This kind of electronic cigarettes is harmless to the human body and has stable and reliable inner structure.

Owner:HUIZHOU KIMREE TECH

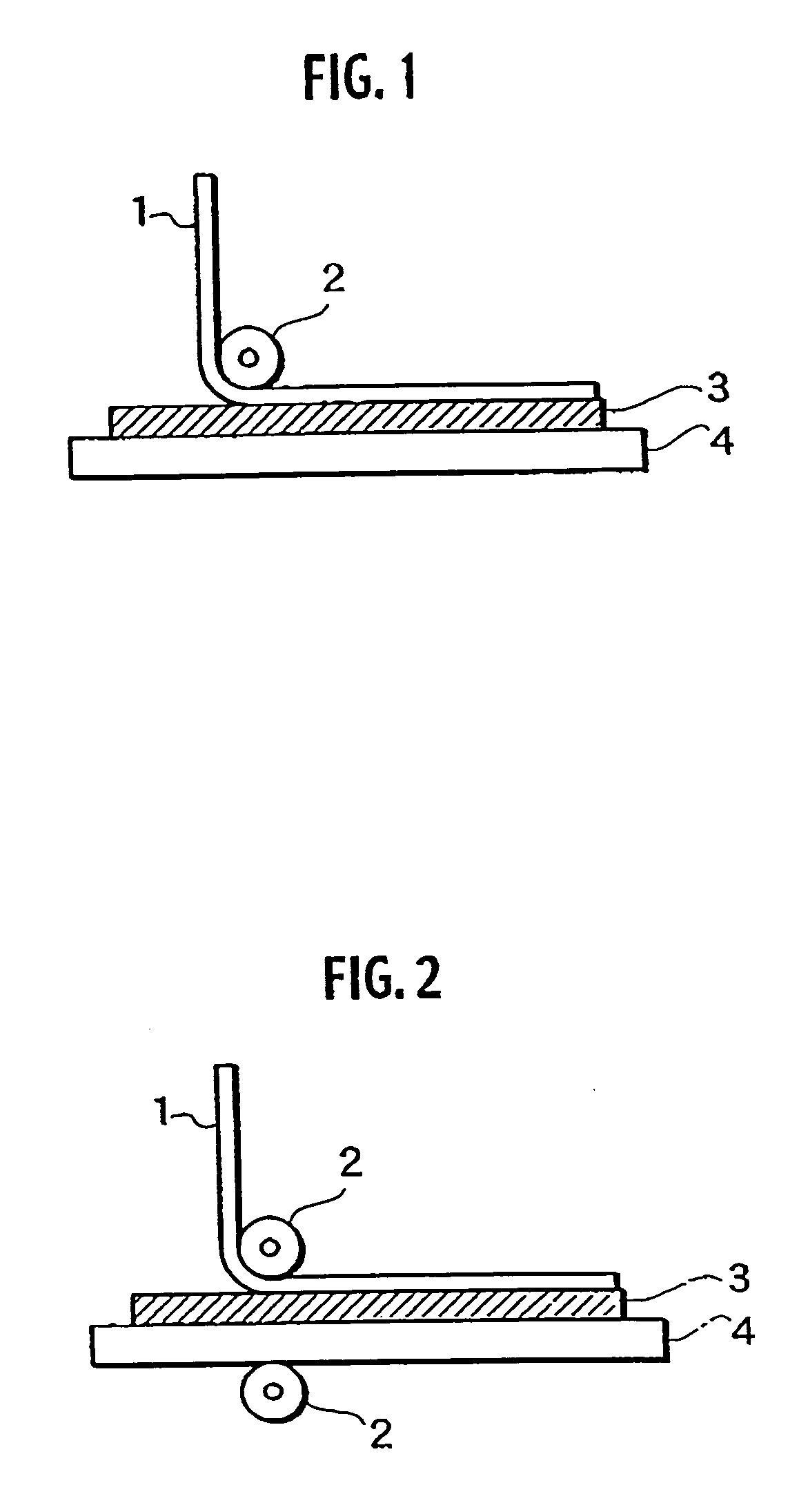

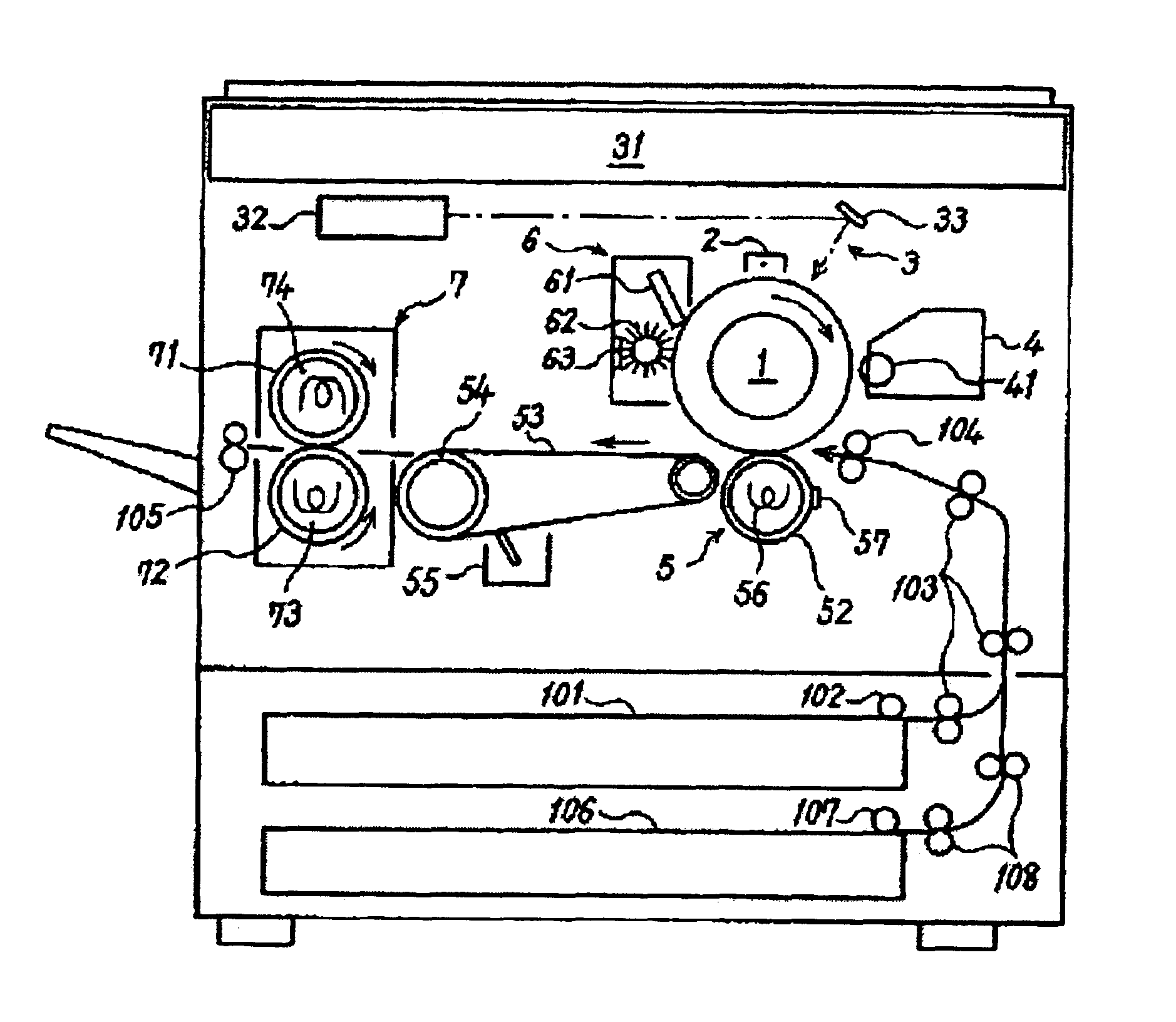

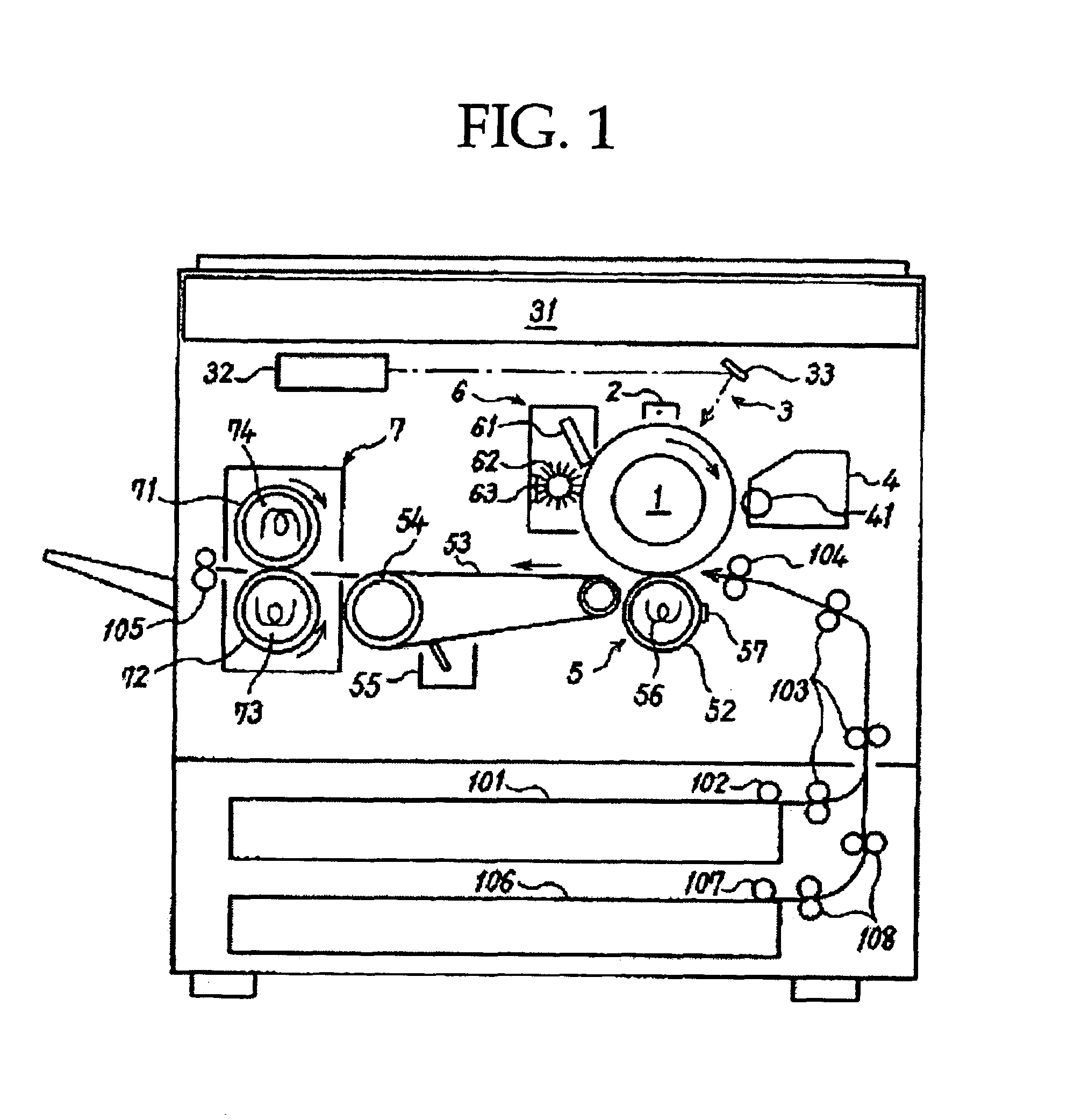

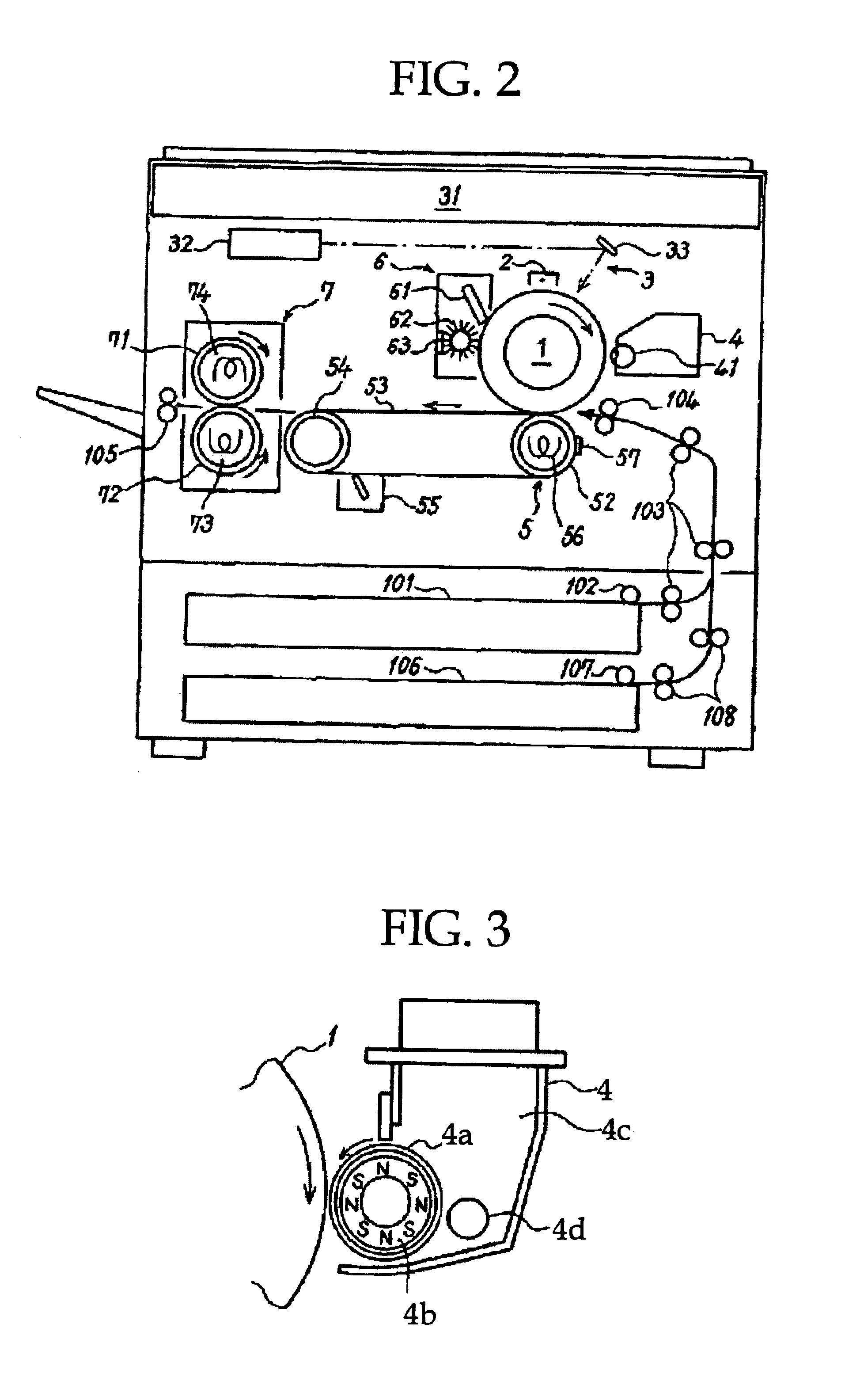

Image-forming apparatus and image-forming method

InactiveUS6934484B2Avoid damageSuppress image deteriorationElectrographic process apparatusTemperature controlElectrical conductor

In a copier which is an image-forming apparatus comprising a photoconductor 1, a developing apparatus 4, transfer apparatus 5 which transfers a toner image formed on the photoconductor 1 to a transfer material by heat and pressure using a transfer roller 52, and a fixing apparatus which fixes the toner image transferred to the transfer material, on the transfer material, a heater 56, temperature detection apparatus 57 and temperature control apparatus are provided which controls the temperature to within a range of from the glass transition temperature (Tg) to the softening temperature (Tm) of the toner, and lower than the fixing temperature of the fixing apparatus 7.

Owner:RICOH KK

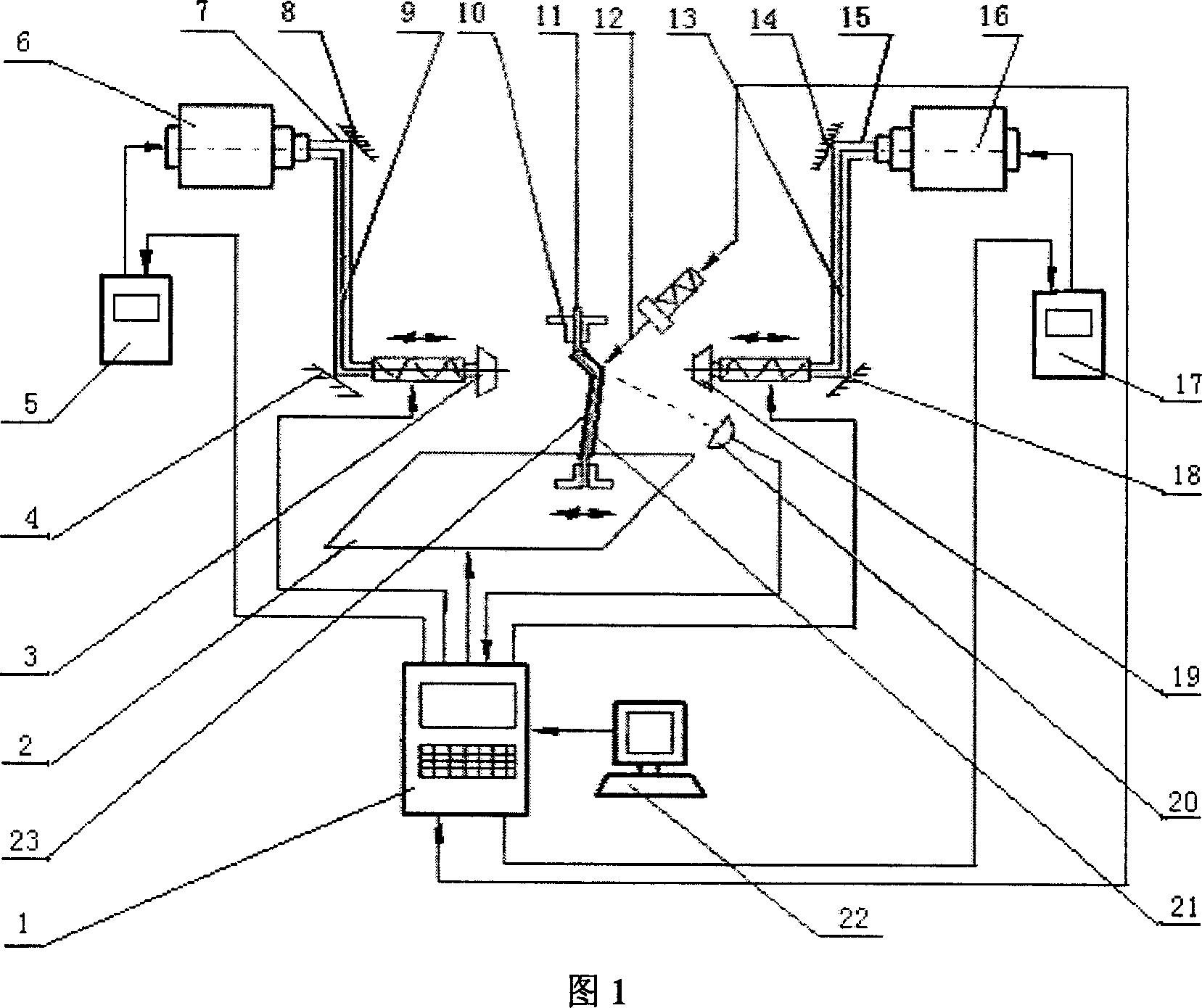

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

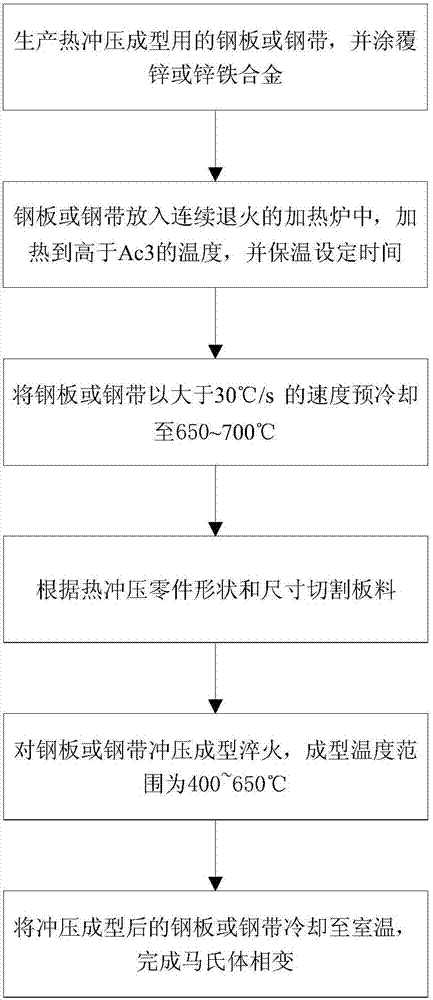

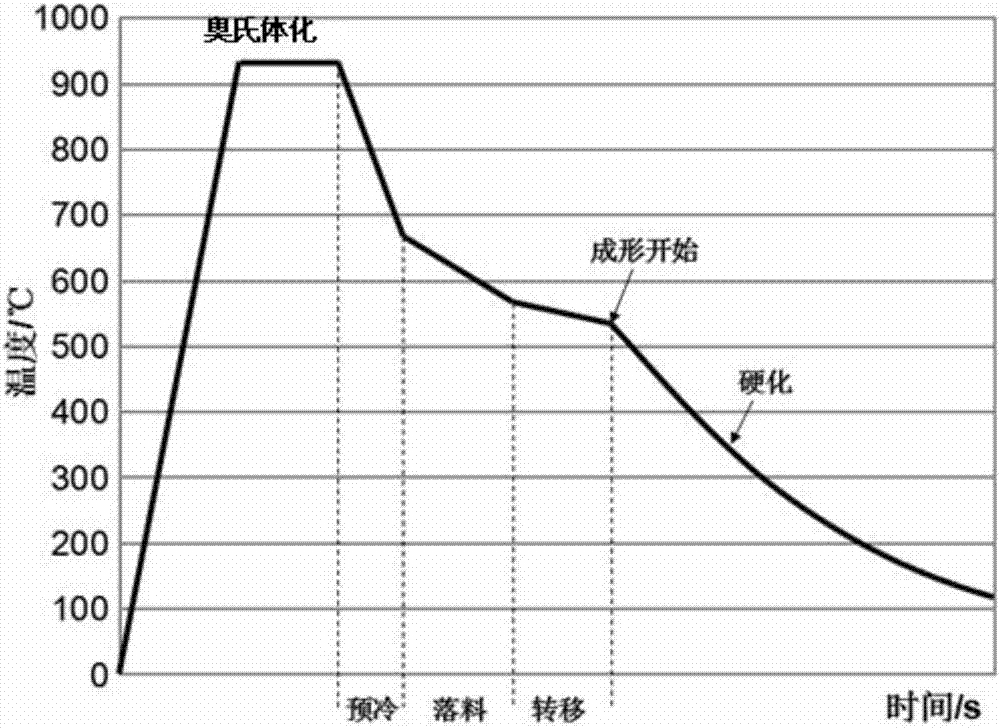

Hot-stamping forming method for zinc plating steel plate or steel strip

ActiveCN107127238ALow heating temperatureShort holding timeShaping toolsHot-dipping/immersion processesHot stampingSheet steel

The invention relates to a hot-stamping forming method for a zinc plating steel plate or a steel strip. According to the hot-stamping forming method, the steel plate or the steel strip is conveyed into a vertical heating annealing furnace, the temperature is kept for a certain time, the steel plate is completely austenitized, a pre-cooling device is used when the steel plate leaves the annealing furnace, the steel plate is cooled to 650-700 DEG C at the cooling rate higher than 30 DEG C / s, then blanking is performed according to the part shape and size, then the steel plate is quickly transferred into a mold for hot-stamping forming, the steel plate is hardened at the speed higher than 30 DEG C / s, and the hot-stamping forming temperature is kept between 400 DEG C and 650 DEG C. Base plate cracks caused by partial stress and liquid metal embrittlement (LME) can be avoided, and the method is used for solving the problem that the base plate cracks cannot be avoided for existing zinc-based hot-stamping formed steel.

Owner:BAOSHAN IRON & STEEL CO LTD

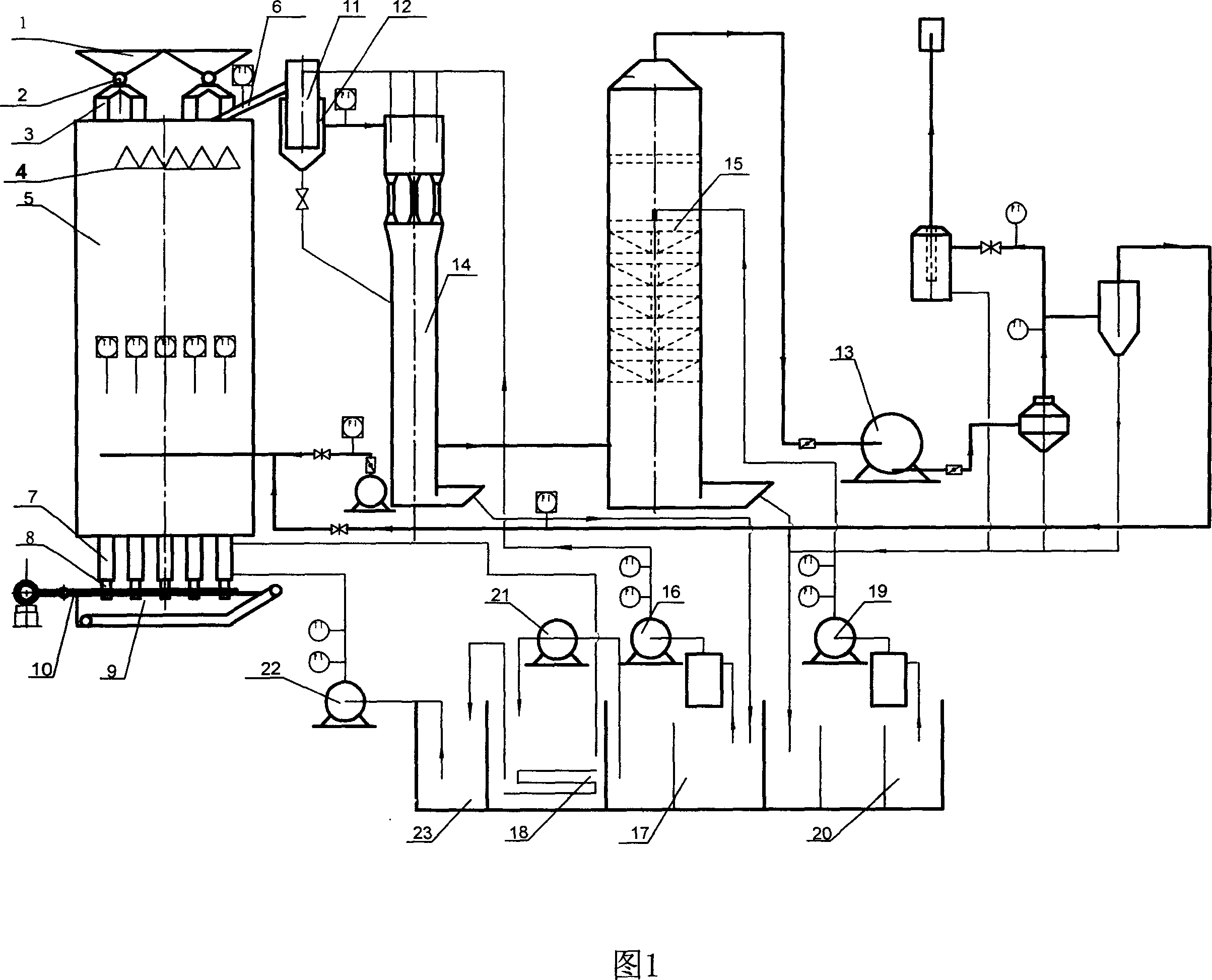

Low-temperature coal carbonization manufacturing technique

ActiveCN1966612AGive full play to the maximum capacityIncrease productionIndirect heating destructive distillationTemperature controlCarbonization

The invention disclosed a low temperature coal dry distillating process which includes the following steps: choosing the material coal; the coal goes through coal cup, roller, and assistant coalbox to get into collecting umbrella and being separated; pre-heating the coal in the drying stage; dry-distillating at 100-550DEG C for about 4h, the temperature of heating region is 700-800DEG C to decrease the content of semi-coal to less than 6%; cooling the semi-coal through the water-cooling jacket box. The heat in the stove is all absorbed by the coal in the invention. It needs less time to dry distillate the coal and it's quite direct and simple. The invention adopts big containing space, the heating gas is provided uniformly to the bottom of the stove so the stove throughput is 3 times more than the traditional stove; it can heat the material more uniformly and it need less temperature control; the tar yield has been increased and the recovery rate has been increased from less than 50% to 80% or more.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

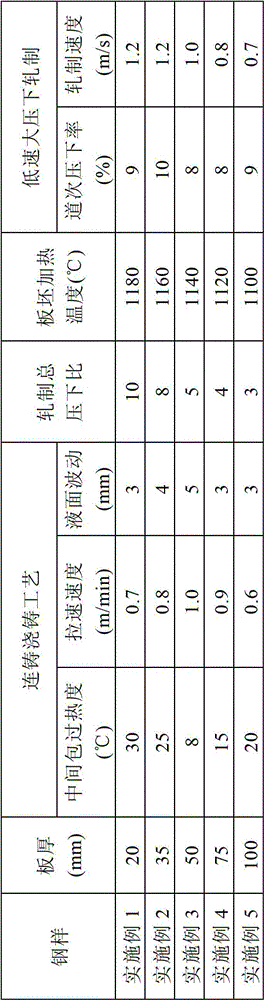

Low-compression ratio hot-rolled 9Ni steel thick plate and manufacturing method thereof

The invention discloses a low-compression ratio hot-rolled 9Ni steel thick plate and a manufacturing method thereof. The low-compression ratio hot-rolled 9Ni steel thick plate comprises, by mass, 0.035-0.075% of C, 0.15-0.25% of Si, 0.50-0.80% of Mn, less than or equal to 0.006% of S, less than or equal to 0.008% of P, 8.9-9.5% of Ni, 0.020-0.045% of Al and the balance Fe and impurities. The manufacturing method comprises the following steps of converter smelting, LF and RH refining, continuous casting of a thick plate blank having the thickness of 150mm, two-stage rolling, rolled workpiece laminar cooling, and heat treatment adopting an out-line quenching and tempering technology. The low-compression ratio hot-rolled 9Ni steel thick plate has simple alloy components and a low cost. Based on a low-compression ratio, the steel thick plate having the thickness above 35mm is rolled and has a good plate shape. After heat treatment, transverse impact energy at a temperature of -196 DEG C is greater than or equal to 160J. The low-compression ratio hot-rolled 9Ni steel thick plate has a good strength-toughness matching degree.

Owner:NANJING IRON & STEEL CO LTD +1

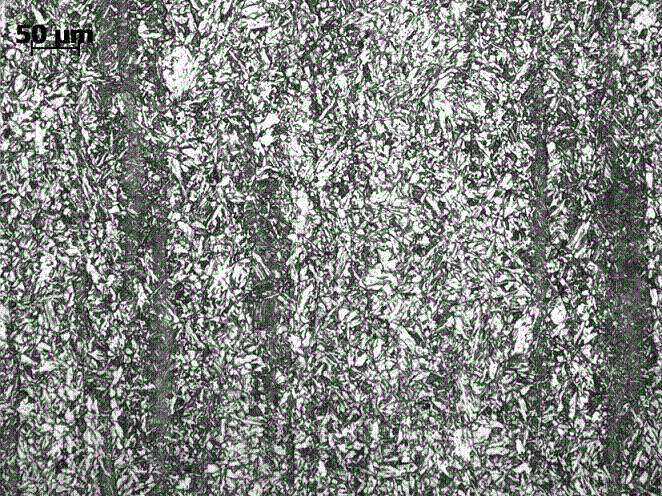

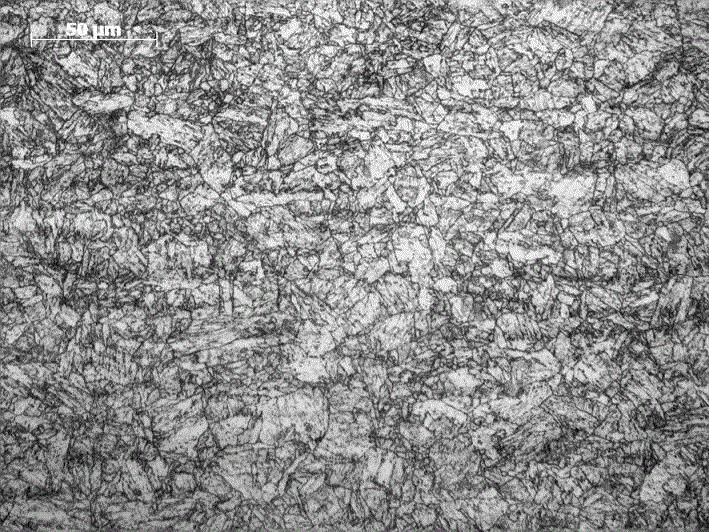

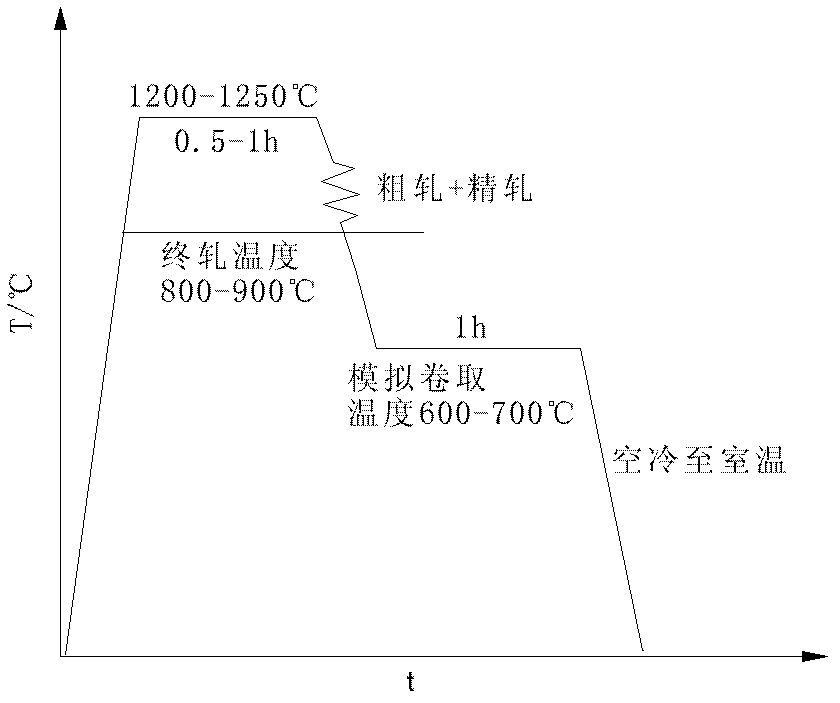

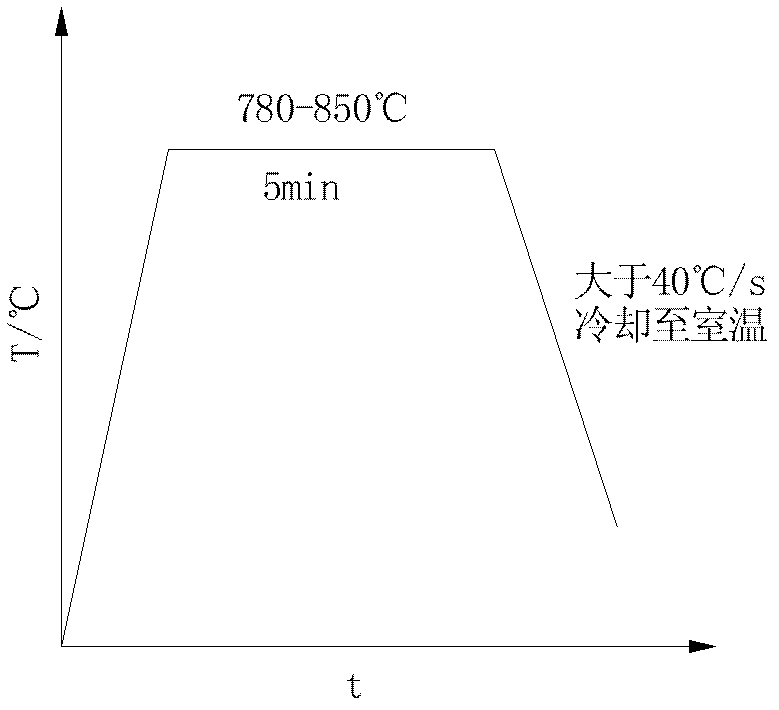

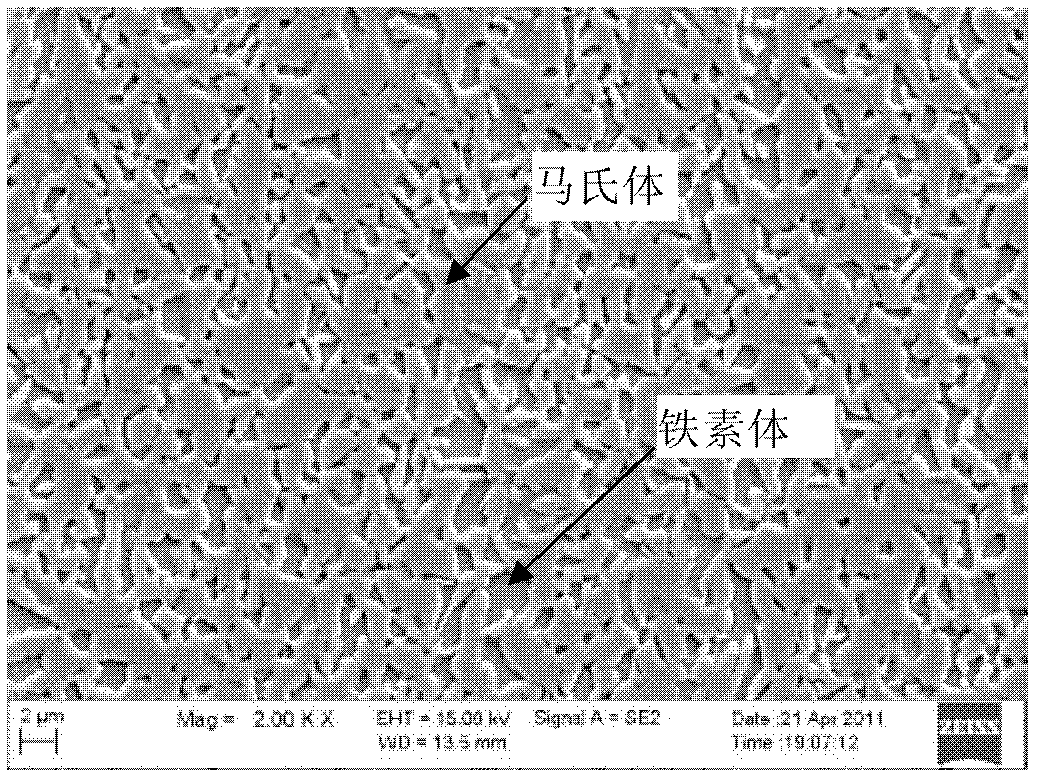

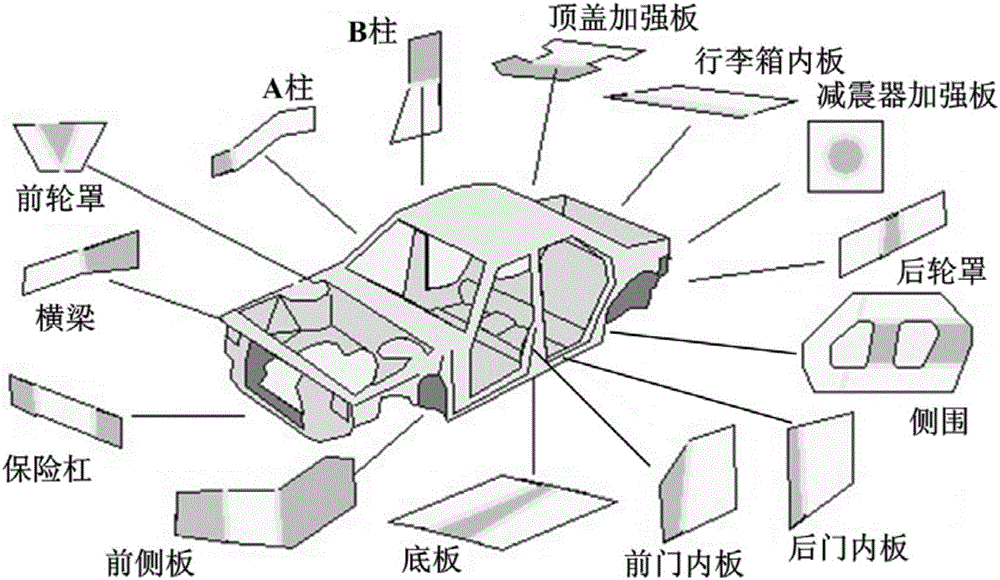

A kind of preparation method of dual-phase hot forming steel

The invention provides a preparation method for double-phase forming steel, which belongs to the technical field of high-intensity steel for automobiles. The steel comprises the following ingredients by mass percent: 0.1 to 0.5 percent of C, 0.3 to 2.5 percent of Si, 1.0 to 3.0 percent of Mn, 1.0 to 3.0 percent of Al, at most 0.02 percent of P, at most 0.01 percent of S, at most 0.01 percent of Nand the balance iron and unavoidable impurities. A production process comprises the following steps of: smelting, hot rolling and hot forming process simulation after the hot rolling. The controlled process parameters are as follows: hot rolling plate blanks are heated to 1200 to 1250 DEG C, the heat insulation is carried out for 0.5 to 1 hour, the final rolling temperature is 800 to 900 DEG C, and the coiling temperature is 600 to 700 DEG C. The hot forming process comprises the following steps of: carrying out heat insulation for 5min at the heating temperature being 750 to 850 DEG C and cooling the materials to the room temperature at the speed greater than 40 DEG C / s. The preparation method adopts the Al micro alloying treatment. Compared with the traditional thermal forming manganeseboron steel, the double-phase forming steel has the advantages that: 1, the hot forming heating temperature is low, and the surface oxidation is reduced; and 2, tissues after the hot forming are ferrite and martensite double-phase tissues.

Owner:UNIV OF SCI & TECH BEIJING

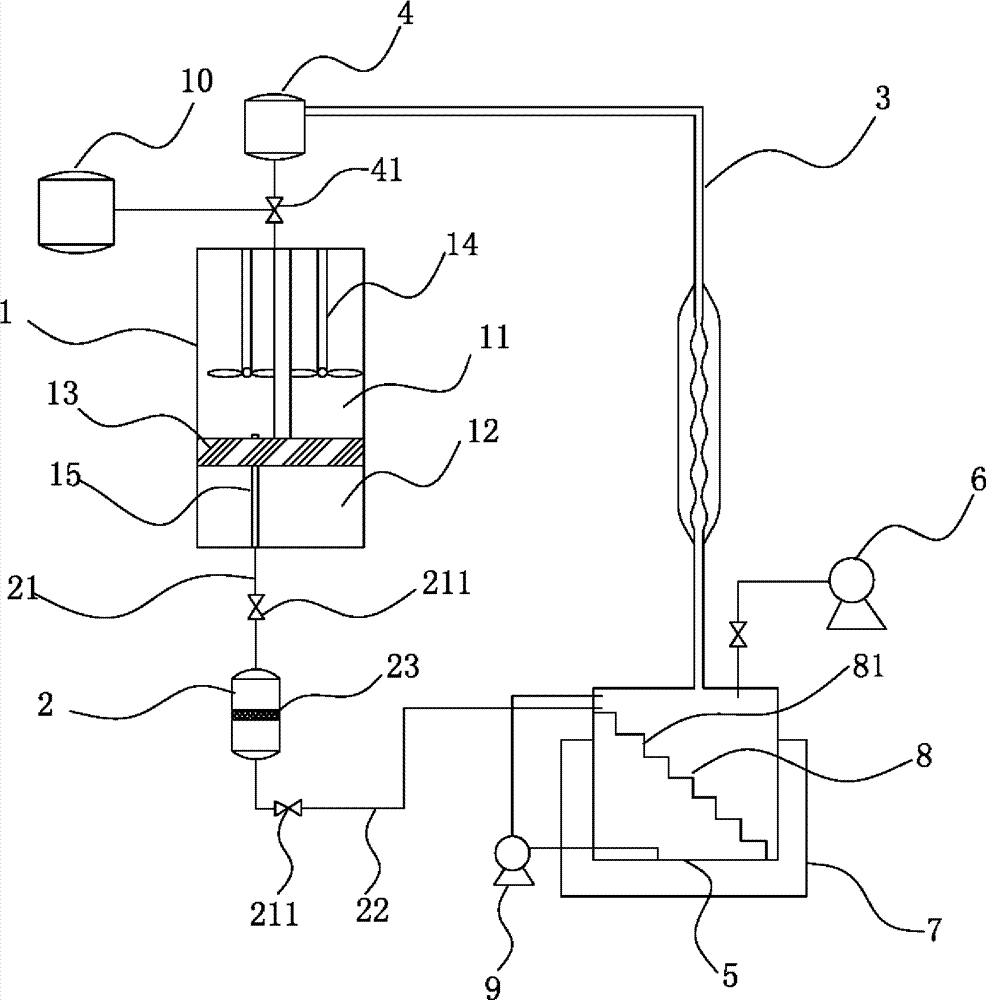

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614AIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

The invention relates to the technical field of extracting and concentrating of the traditional Chinese medicine, and in particular relates to a method and a device for extracting and concentrating the traditional Chinese medicine. The method for extracting and concentrating structurally comprises an extracting unit and a concentrating unit, wherein the extracting unit comprises an extracting tank and a liquid medicine storage tank, wherein a piston capable of moving up and down is arranged in the extracting tank; when the piston moves upwards under the action of the driving force, dredges of decoction in a pressurizing chamber are pressurized and further squeezed; the concentrating unit comprises a concentrating container, a vacuum pump and a heating device for heating up the concentrating container, wherein a step-shaped evaporation plate assembly of a liquid medicine thin film is formed in the concentrating container, so that the liquid medicine can be circulated and concentrated. Compared with the prior art, the extracting and concentrating efficiency is high, the heating time is short, and the damages to the active ingredients of the medicine are reduced.

Owner:GUANGDONG MEDICAL UNIV

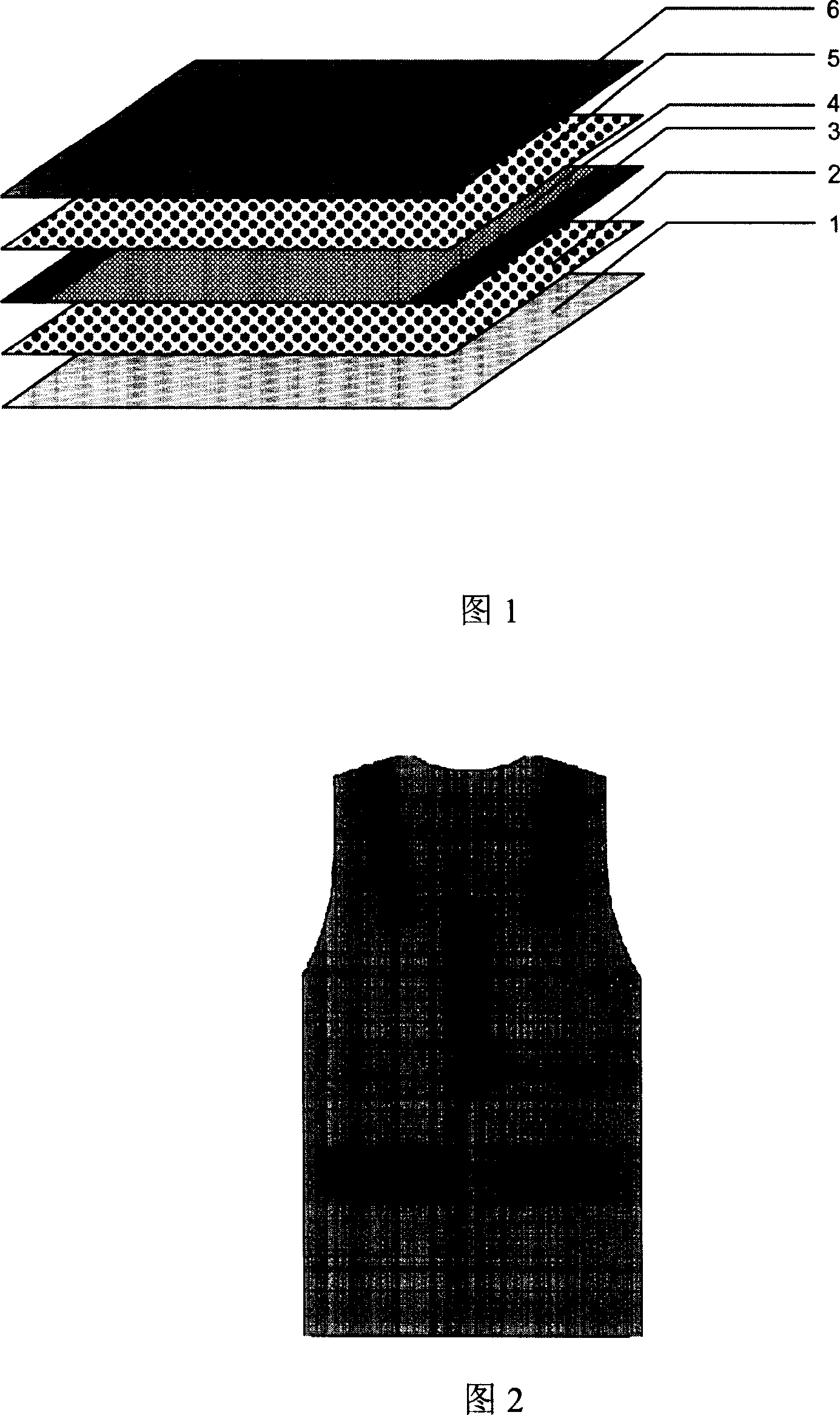

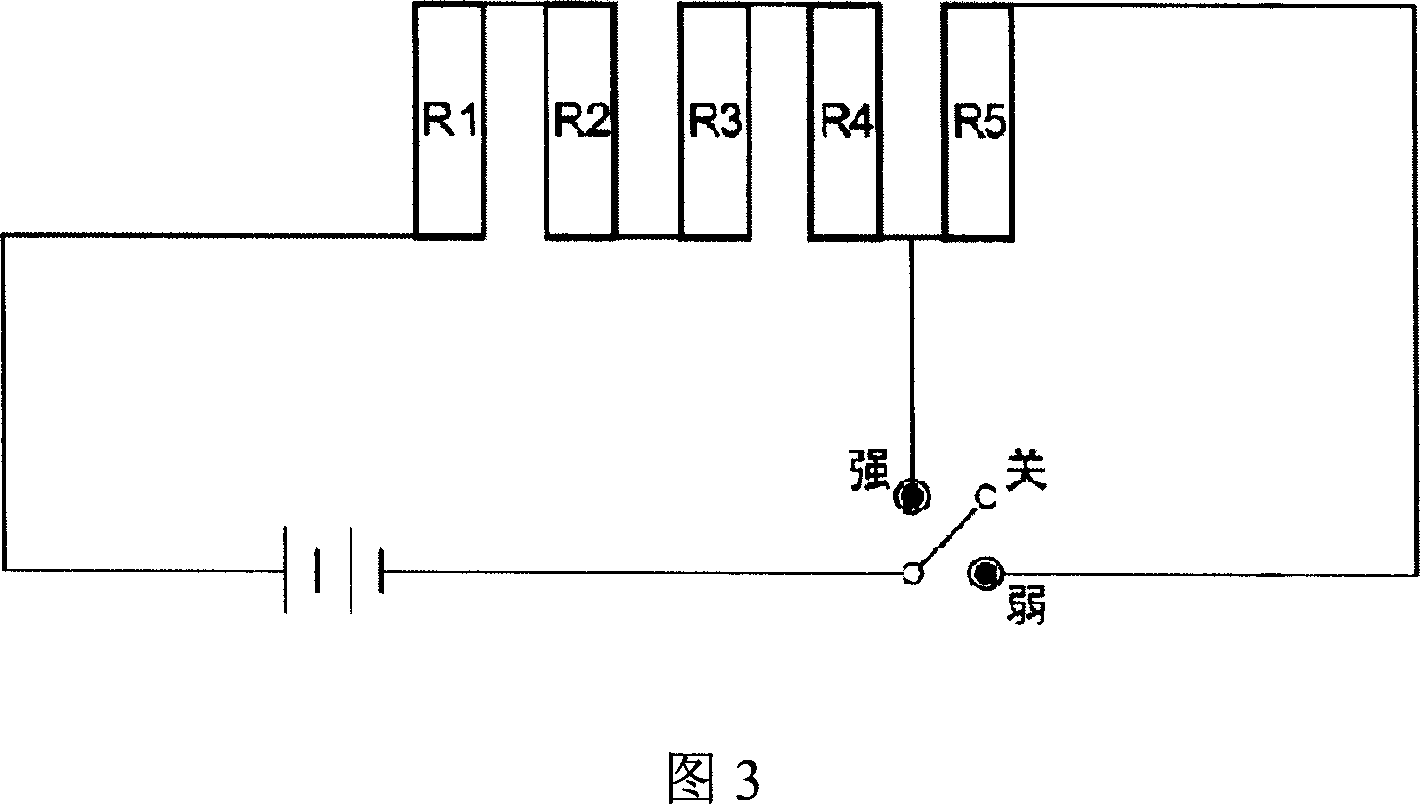

Far infrared flexible surface heating element with high emissivity

The invention discloses one high emission rate infrared flexible heating element, which comprises heat conductive isolation distribution layer, heat melt glue network film A, electrode, heating part, heat melt glue film B and isolation layer with each parts combined into one part by glue and sealing types. The invention also discloses the heating element main process and property and its process method.

Owner:DONGHUA UNIV +1

Bullet wire cable and its production process

Owner:JIANGSU FASTEN CO LTD

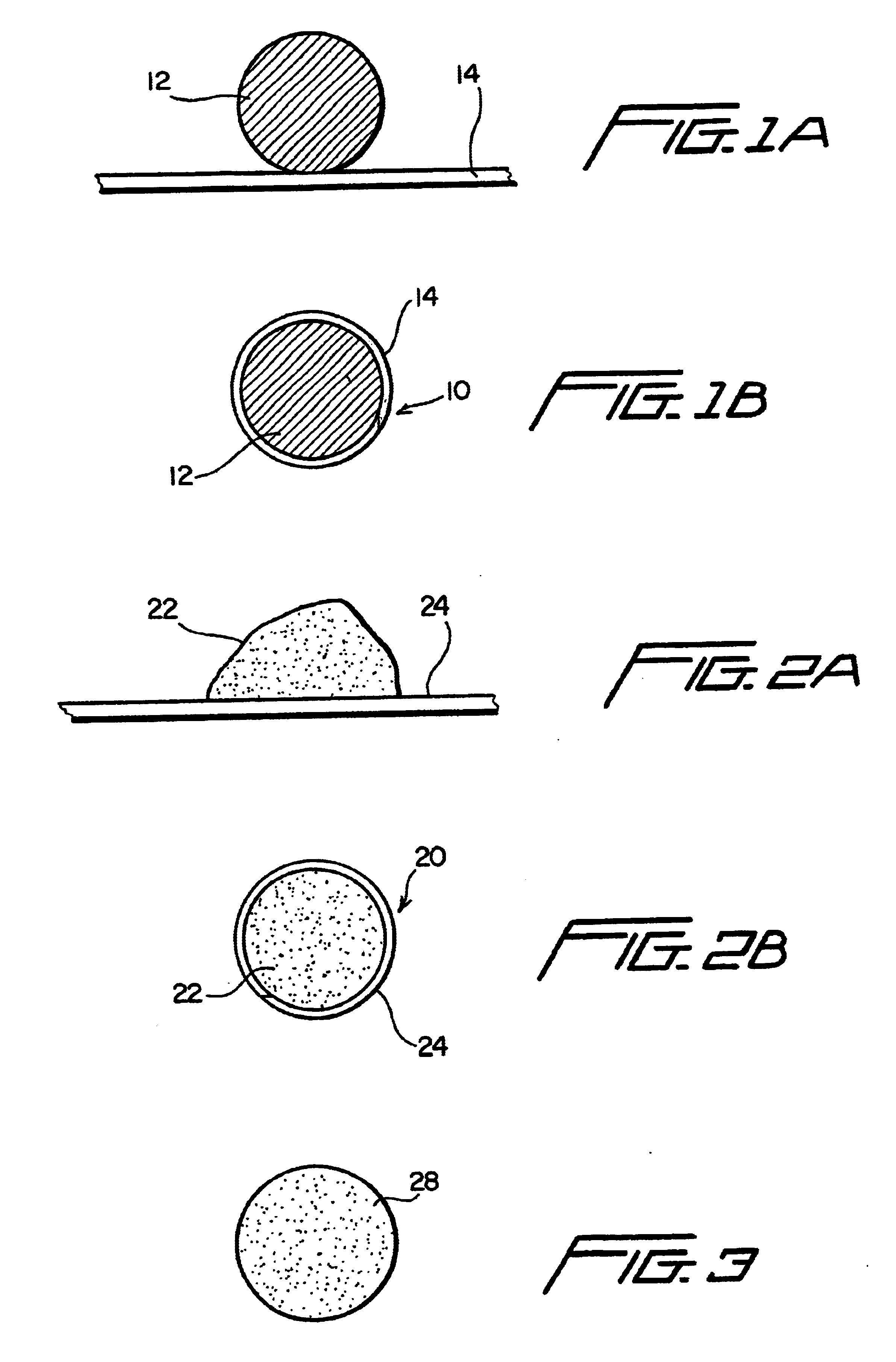

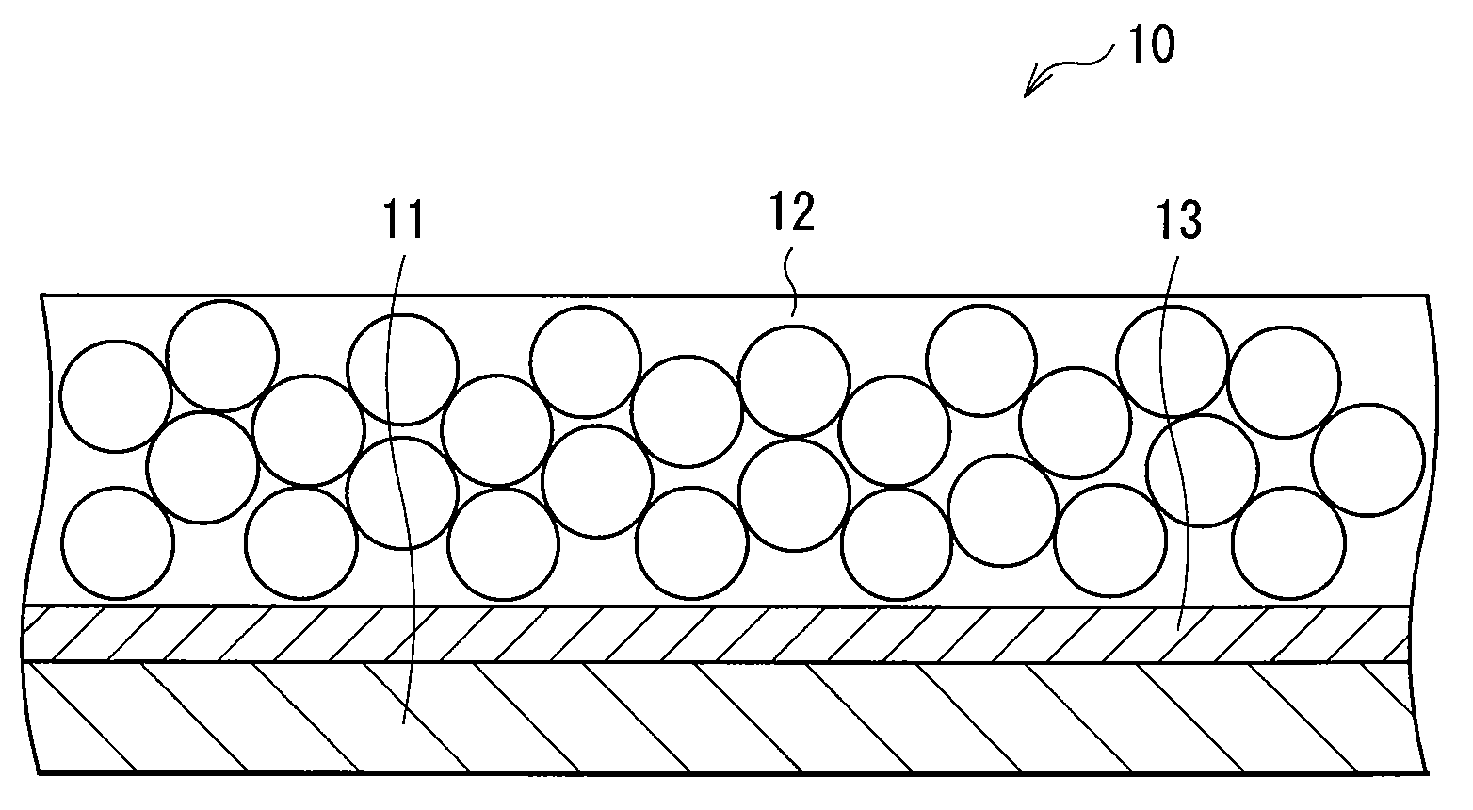

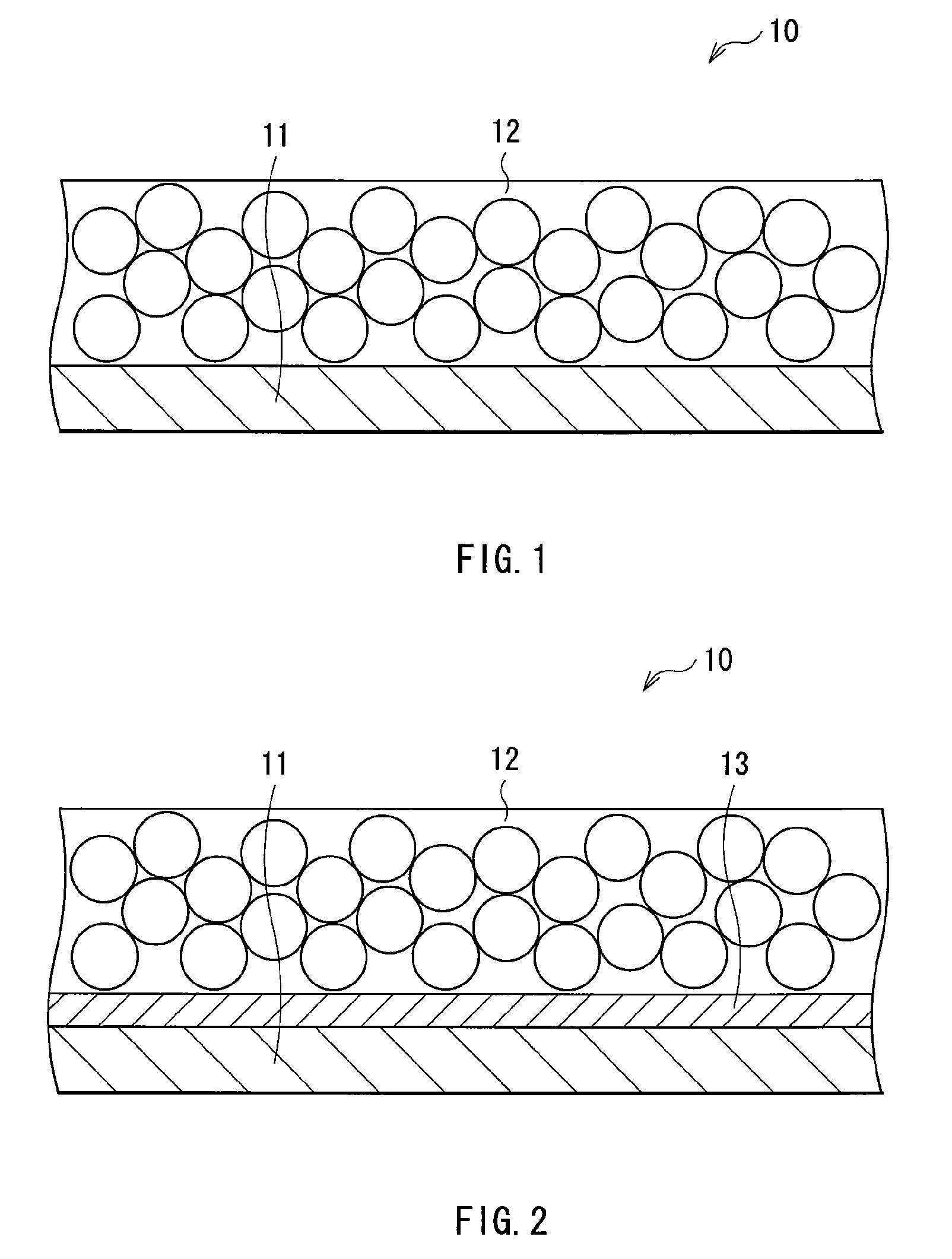

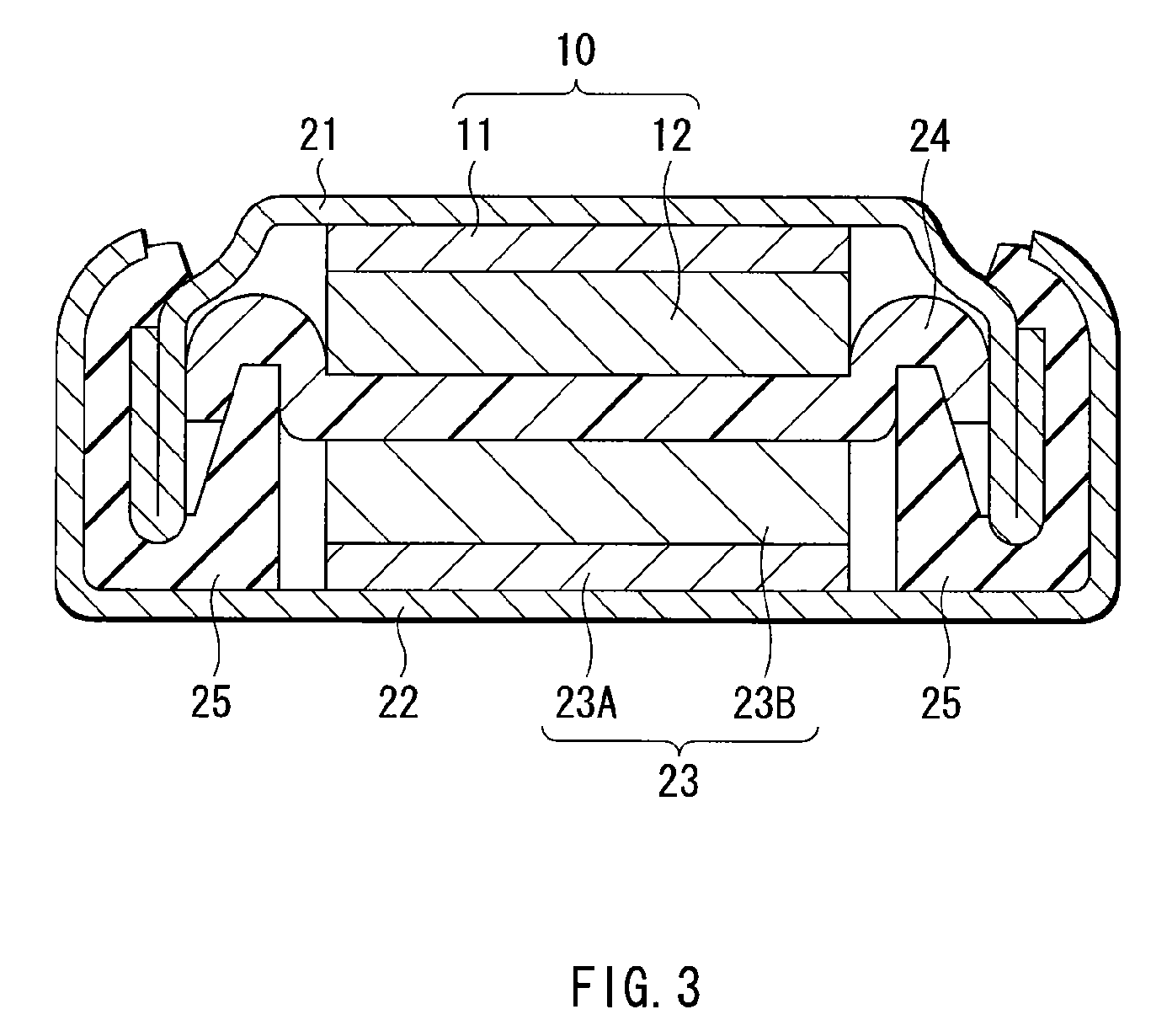

Anode, battery, and method of manufacturing same

InactiveUS20060216604A1Easily manufactureHeating temperature be lowerElectrode rolling/calenderingNitrogen compoundsMetallurgyAnode

A battery capable of improving cycle characteristics is provided. An anode active material layer is formed by forming a precursor layer containing active material particles containing Si and Li as an element, and then heating the resultant. Thereby, the active material particles are bound to each other by sintering or fusing, and united three-dimensionally. Since Li is contained therein, the active material particles can be sufficiently sintered even if the heating temperature is low, 600 deg C.

Owner:SONY CORP

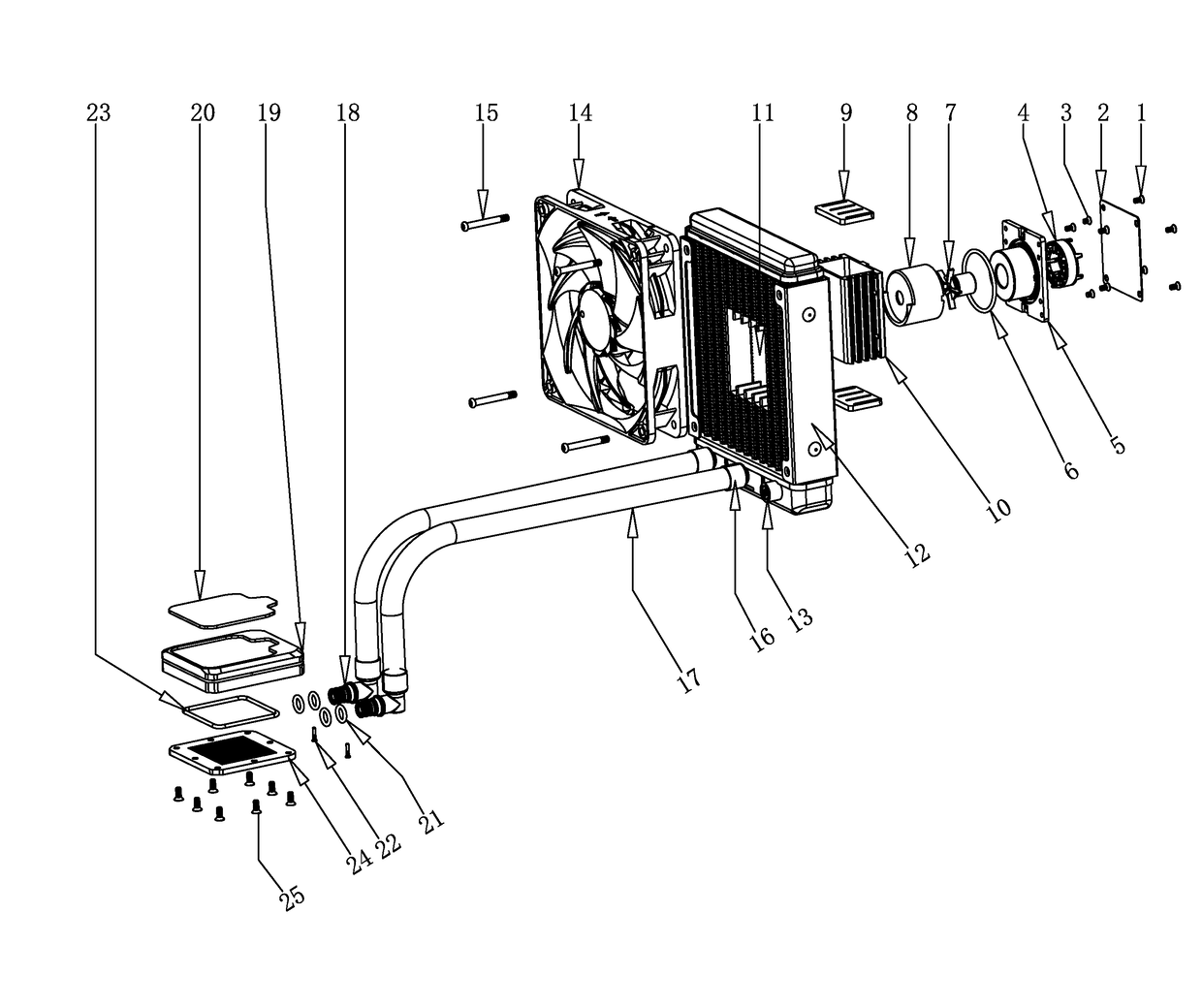

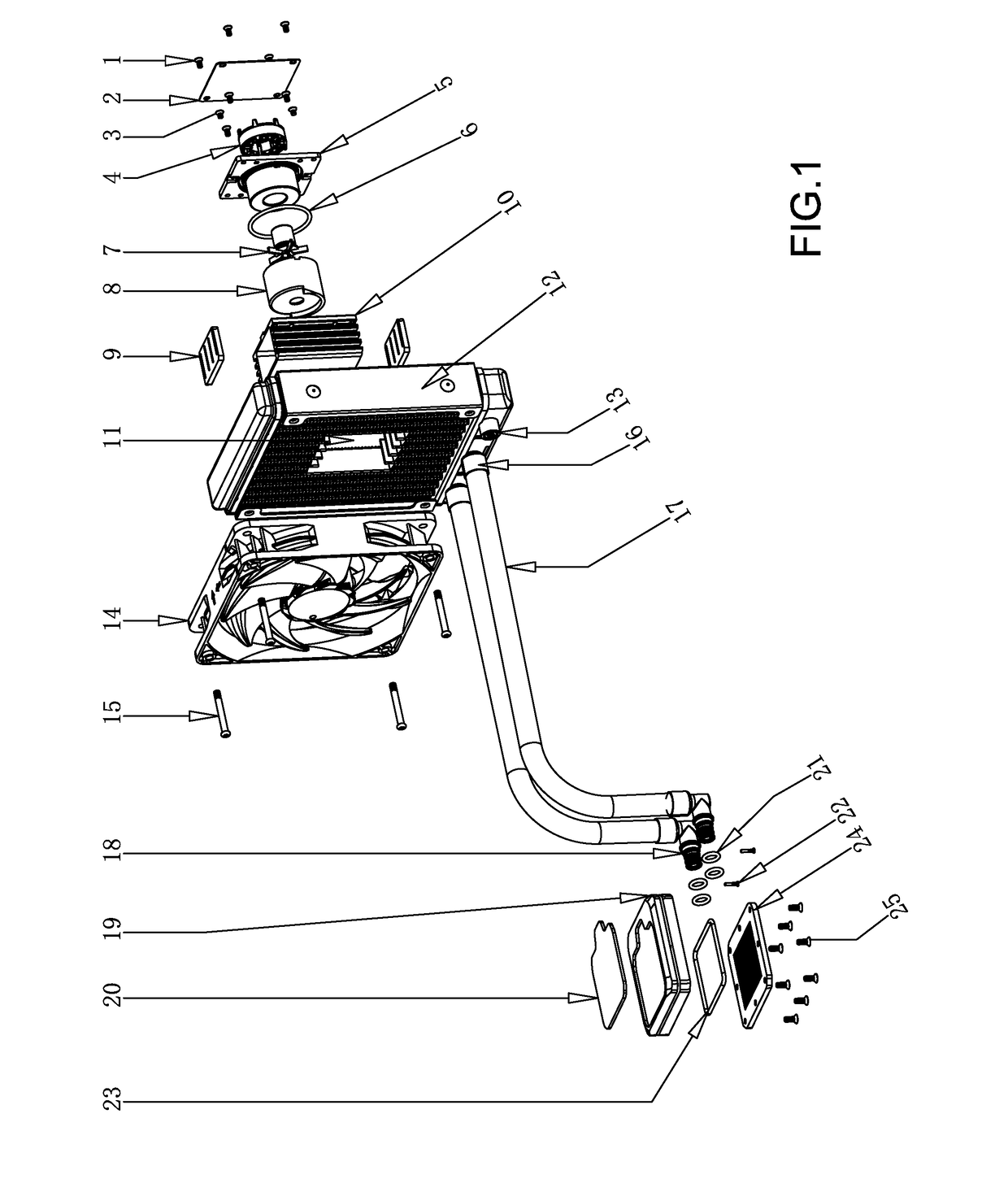

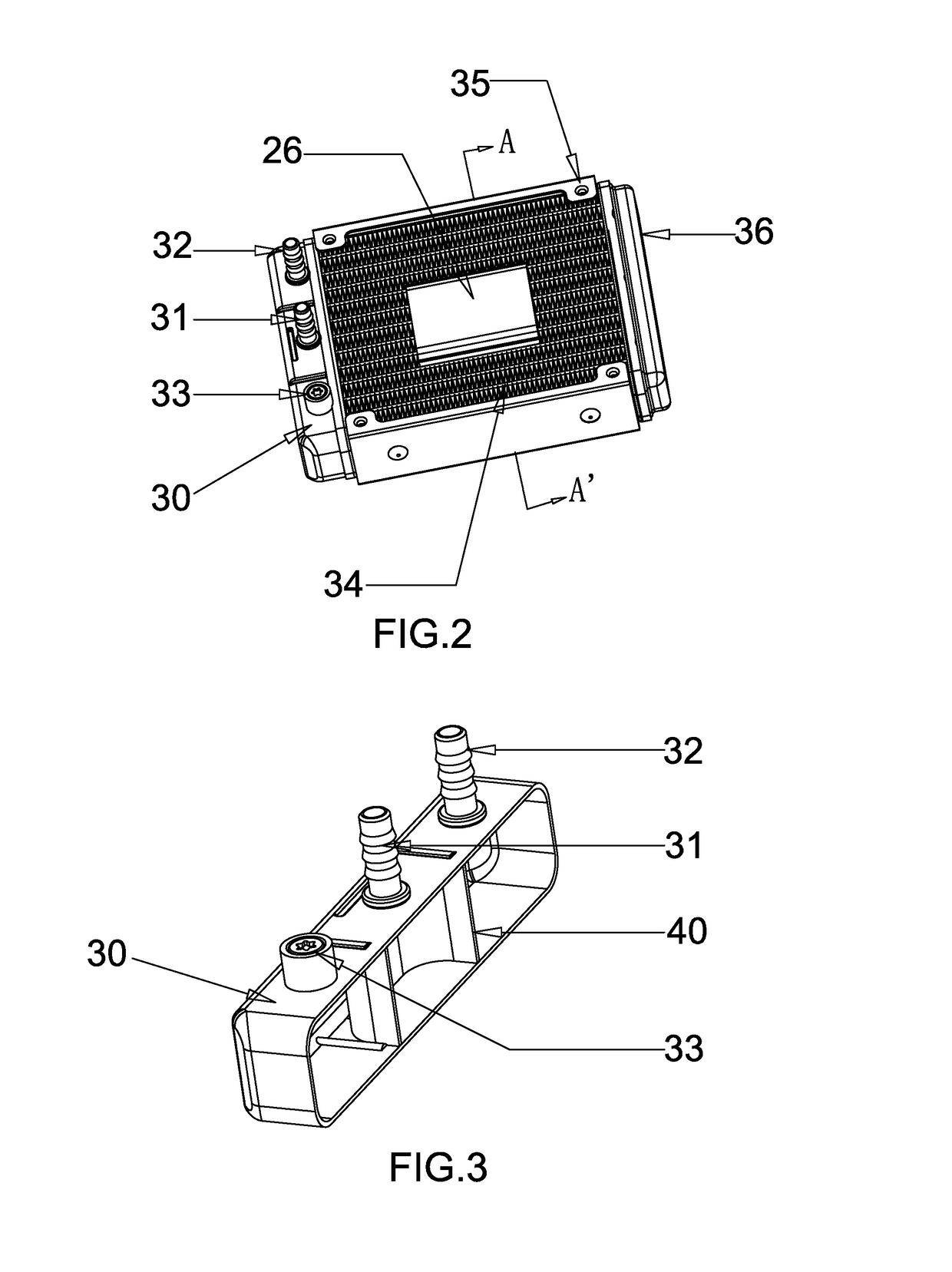

Liquid Cooling Radiation System and Liquid Radiator Thereof

ActiveUS20170367217A1Improve heat transfer effectSimple processDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringHeat transfer efficiency

Disclosed is a liquid cooling radiation system. The technical solution used by the present invention to solve the technical problem is: the liquid cooling radiation system comprises: a radiation device, comprising cooling pipes and a radiation structure device arranged on the cooling pipes; a pumping device, integrally arranged between the cooling pipes and generating power so that a coolant circulates within the cooling pipes; a heat absorption device, attached to a heating device and having a heat conduction effect with the heating device; a pipeline, used for connecting the radiation device and the heat absorption device. On the basis of existing products, the present invention utilises a solution wherein a liquid pump main body and a radiator are integrally arranged together. Thus, the radiation of a fan is used to take away heat on the radiator and heat generated by a pump power main body (i.e. a motor) itself is also taken away, thereby extending the service life of the motor. In addition, the occupied space is significantly reduced, the heat transfer effect is significantly improved, and the production and assembly costs are reduced, so that product assembly is convenient and efficiency is high.

Owner:APALTEK CO LTD

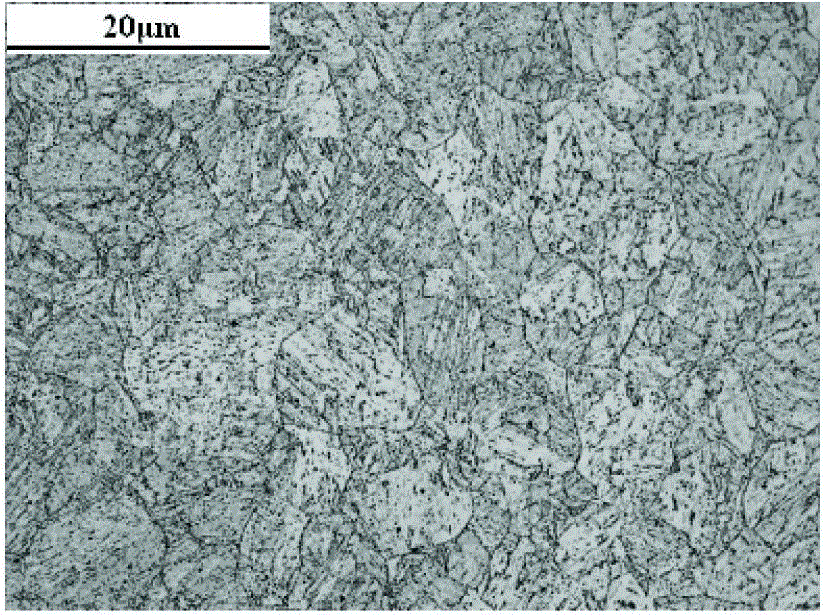

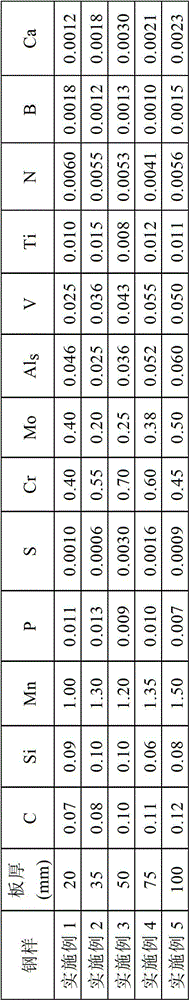

Nickel-free high-toughness 80kg-grade high-strength steel and manufacturing method thereof

ActiveCN102719757ASimple welding processHigh strengthHeat treatment process controlNickel freeToughness

The invention relates to nickel-free high-toughness 80kg-grade high-strength steel and a manufacturing method thereof. A component system of ultralow C, ultralow Si, medium Mn and Ti, V and B microalloy steel is used as a basis; the acid-soluble Als content in steel is properly improved, the Als is not less than 10*[(%Ntotal)-0.292(%Ti)], Mn / C is not less than 12, (%C)*(%Si) is not more than 0.01, and [(%Cr)+1.3(%Mo)]*[(%V)+(%C)] is not less than 0.087; Ca treatment is carried out, the Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)<0.18> is not more than 2.5*10<-3>; F*DI index number * zeta is not less than 2.0* finished steel plate thickness, wherein zeta is on-line DQ (direct quenching) hardenability contribution factor, and F is B element hardenability contribution factor; DQ (thermo mechanical control process: TMCP) and off-line tempering process (T) are optimized; the microscopic structure of the steel plate is fine low-carbon tempered martensite and tempered lower bainite; the steel has the average colony size below 20 mu m, has excellent strength and plasticity and strong toughness, and is particularly suitable for hydroelectric pressure water pipes, steel branch pipes, scrolls, ocean platforms, large-sized engineering machines and other large-sized steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

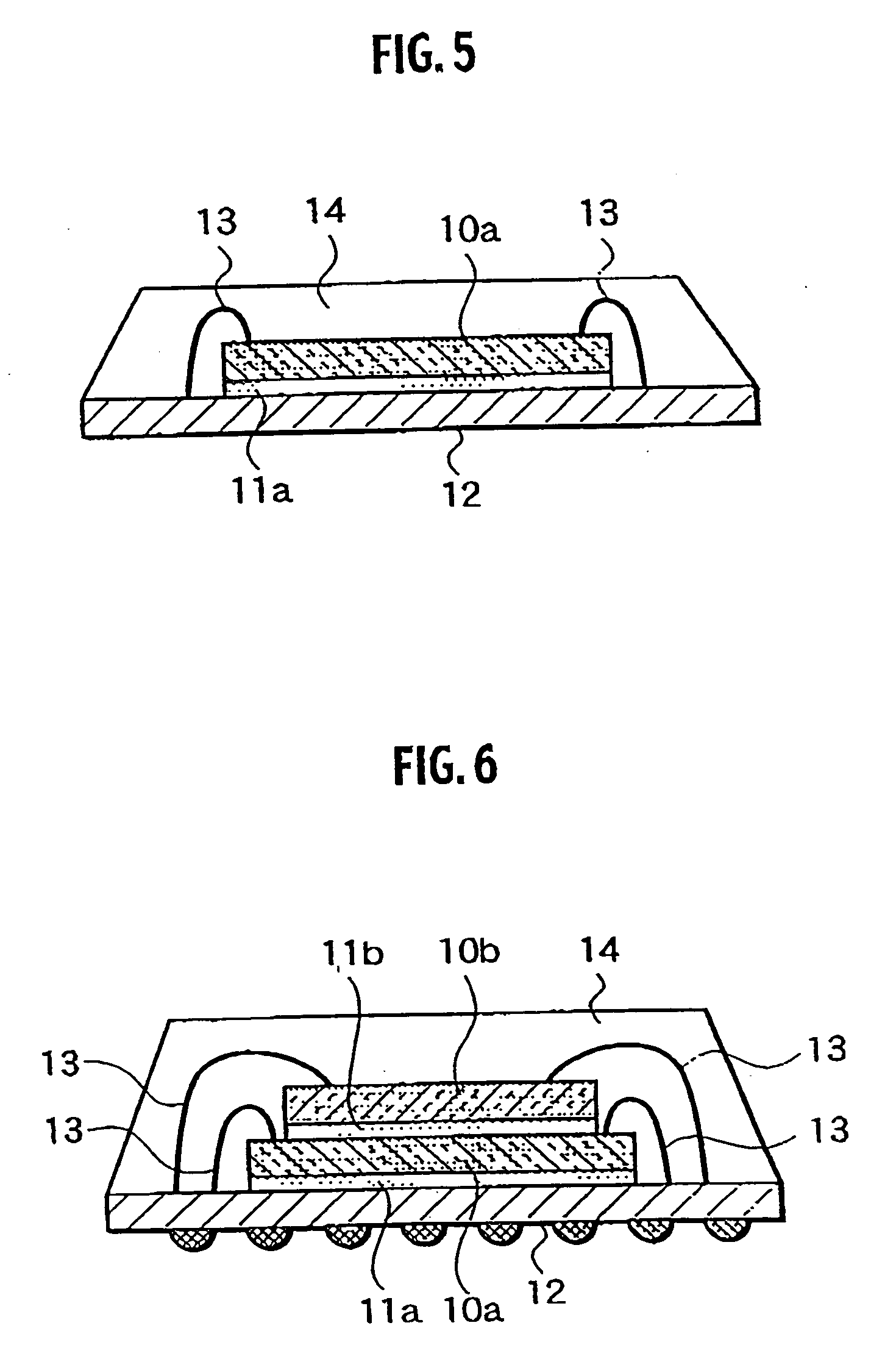

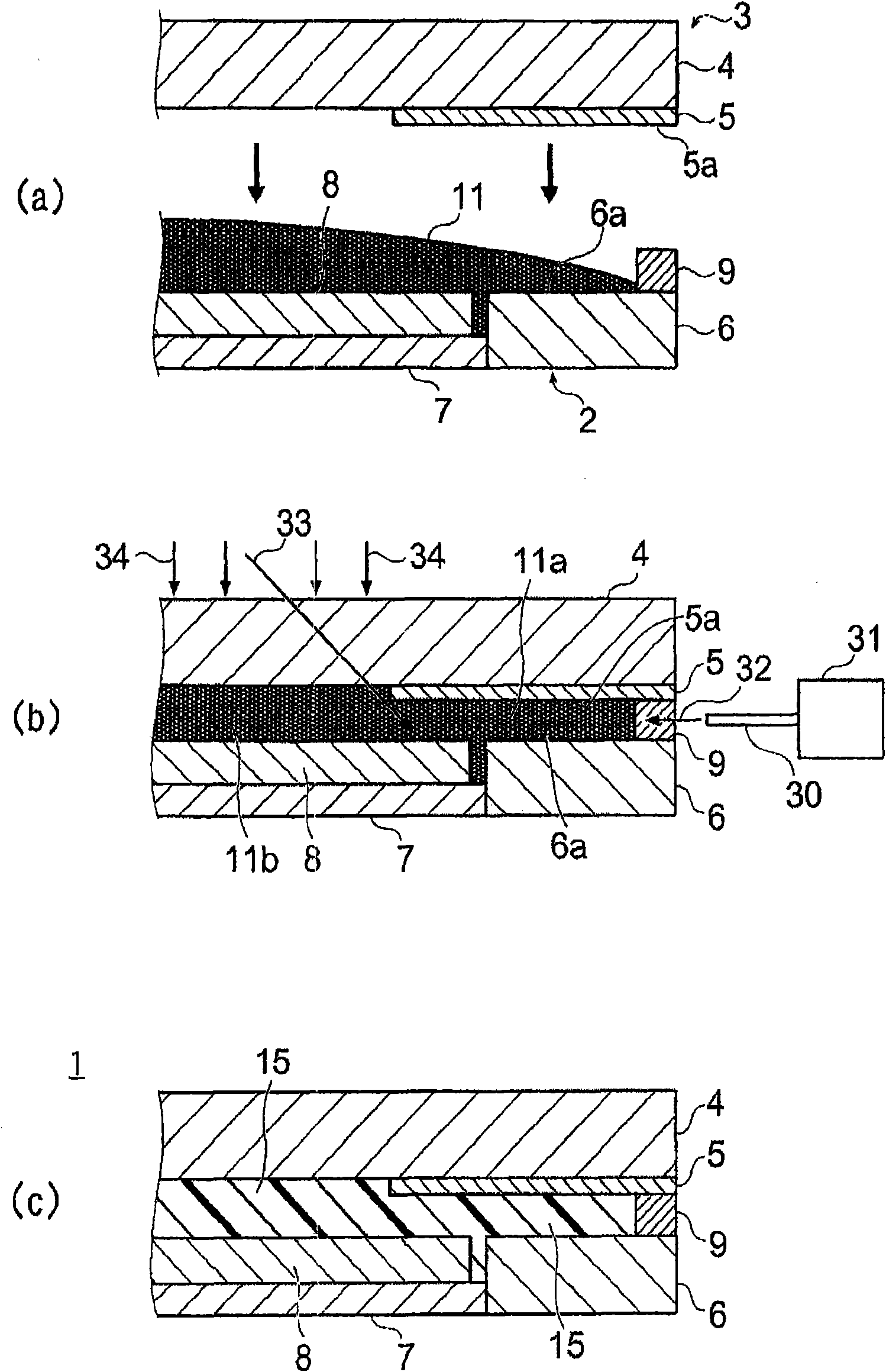

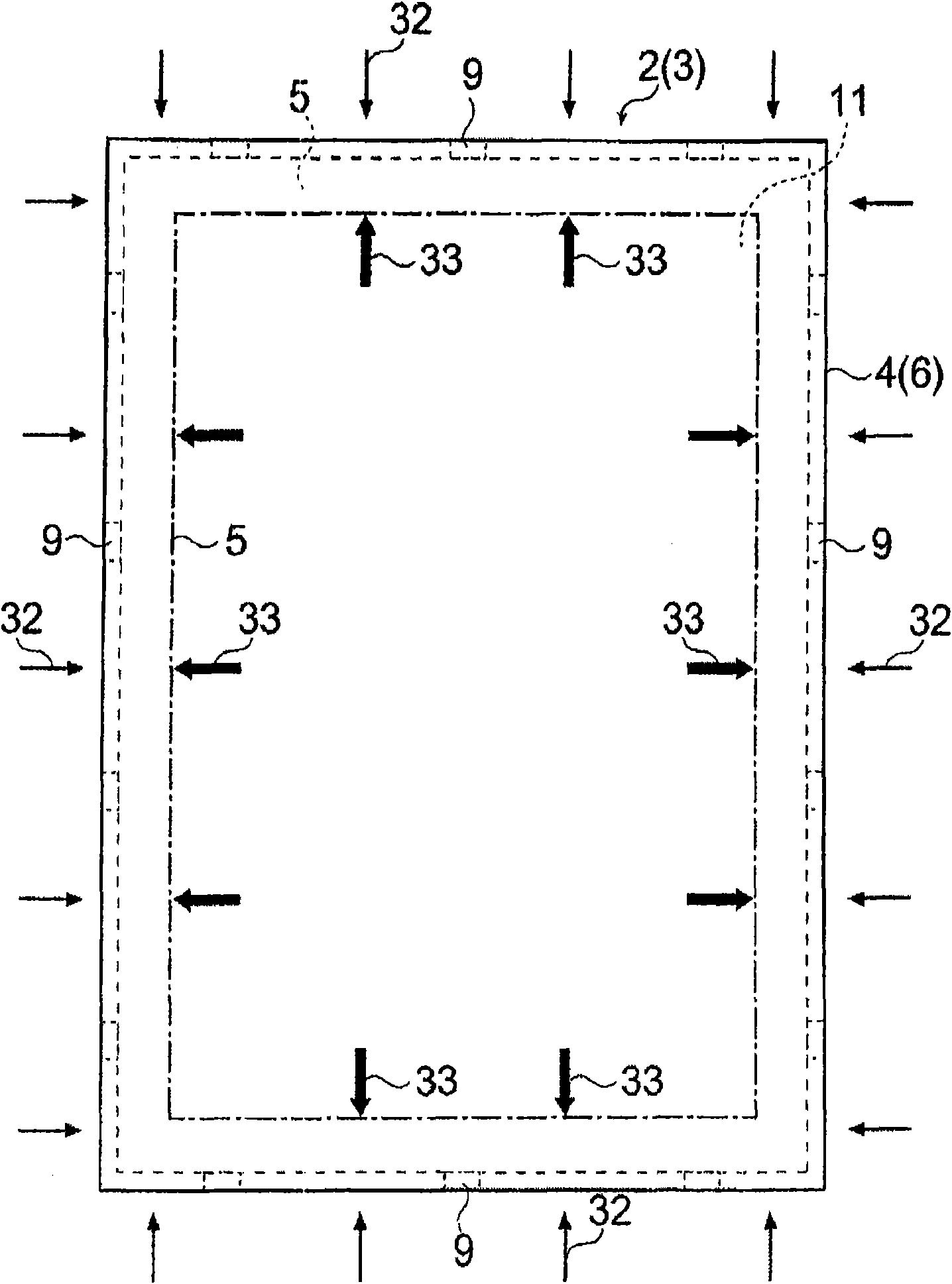

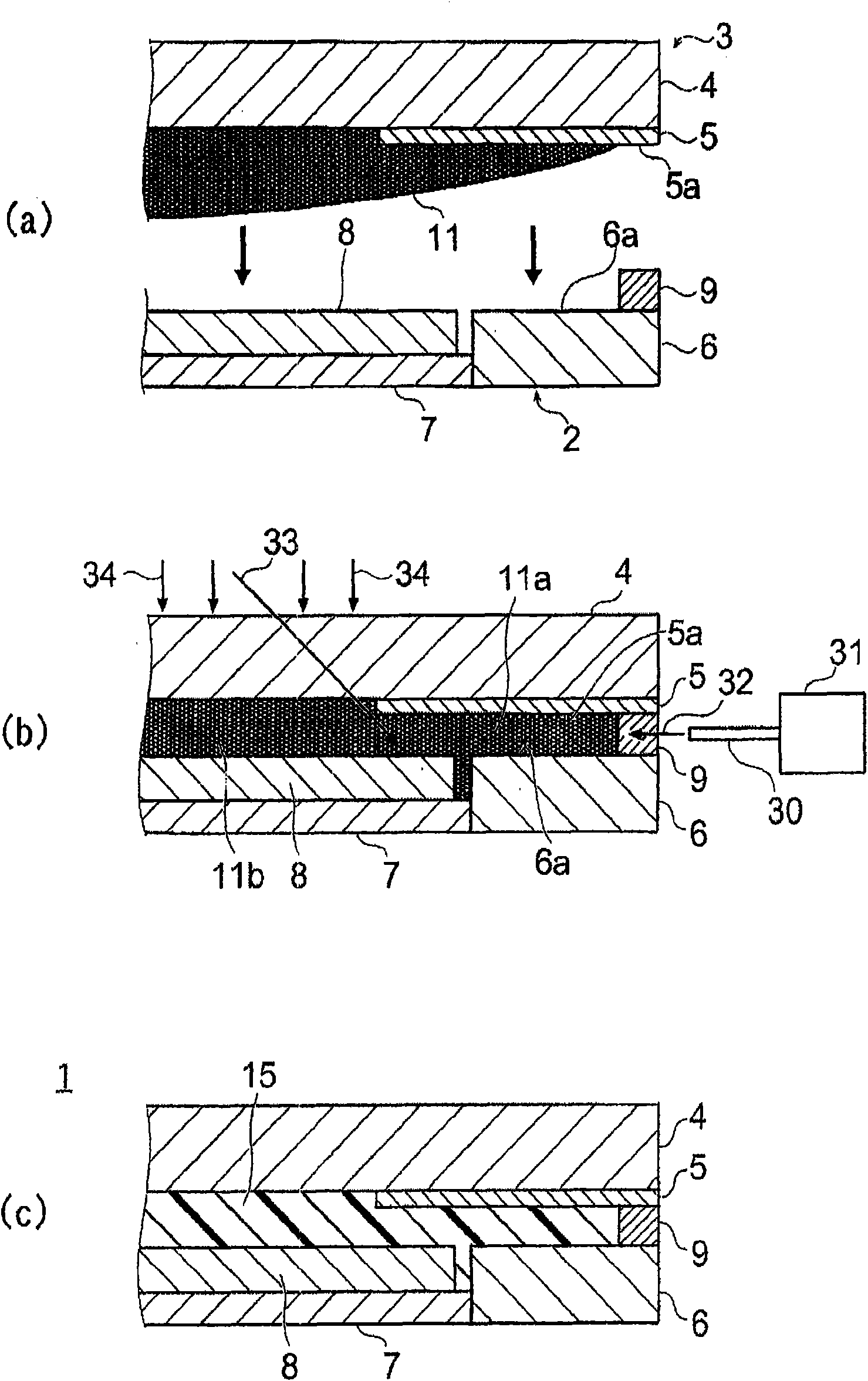

Method for manufacturing image display

ActiveCN101652803APrevent orientation confusionFully curedNon-linear opticsIdentification meansHigh contrastTransmittance

Disclosed is a method for manufacturing an image display (1), which comprises a step wherein a photocurable resin composition (11) is interposed between a base unit (2) having an image display unit such as a liquid crystal display panel (8) and a light-transmitting protective unit (3) having a light-shielding portion (5), and a cured resin layer (15) is formed by photocuring the resin composition(11). In this method, a resin composition having a curing shrinkage rate of not more than 5% and a storage modulus of the cured product at 25 DEG C of not more than 1.0 OE10<7> Pa, which enables to obtain a cured resin layer (15) having a visible light transmittance of not less than 90% is used as the photocurable resin composition (11). The method further comprises a step wherein a curable resincomposition (11a) containing a thermal polymerization initiator is interposed at least between the light-shielding portion (5) and the base unit (2) and then the curable resin composition (11a) is heated. Consequently, the resin in a forming-region of the light-shielding portion (5) is sufficiently cured, while attaining a high-luminance, high-contrast display without having display defects due todeformation of the image display unit (8), during manufacture of the thin image display (1) wherein the resin is interposed between the protective unit (3) having the light-shielding portion (5) andthe image display unit (8).

Owner:DEXERIALS CORP

Method for preparing selenide or sulfide semiconductor film material of copper-indium-gallium

InactiveCN1547239AEliminate condensationAvoid deformationFinal product manufactureVacuum evaporation coatingWater bathsIndium

The invention refers to a manufacturing method for selenide or sulfide of copper, indium or gallium. In the manufacturing process of copper, indium or gallium selenide and / or sulphur optical absorbing layer film, uses vacuum magnetism control splattering, heating and evaporating method or chemical water bath electrodeposition method to deposit a metal preprocessed layer with chemical formula proportion of Cu, In, Ga on the natrium calcium glass Mo substrate, then carries on optical selenide or / and sulfide reaction in the thermal process vacuum room, the character lies in: the battery base board deposited with the preprocessed layer are heated upon the two surfaces, the back surface of the base board is heated with contacting heat reservoir, the surface coated with metal preprocessed layer is heated with light irradiation, when the temperature rises to the 400-560oC evenly and quickly, carries on the cooperative heating with contacting heat reservoir and light irradiation to the selenium source or the sulphur source, makes the metal preprocessed layer converted into the compound semiconductor photoelectric film material.

Owner:NANKAI UNIV

Stratum catalytic oxidation thick oil thermal recovery method

InactiveCN101539012AReduce mining costsLow heating temperatureFluid removalCatalytic oxidationSurface-active agents

The invention relates to a stratum catalytic oxidation thick oil thermal recovery method which is as follows: a catalyst with a catalytic oxidation function and a cracking function is injected during a thick oil steam gorge and disgorge or steam drive process, and a certain amount of air is injected in an auxiliary way; catalytic oxidation and cracking reaction is generated inside a stratum during soaking and the steam drive to enable crude oil to lightly reduce viscosity, and a surface active agent which can improve the liquidity of the crude oil is also generated, thus the purpose of enhancing the thick oil recovery effect of thick oil is achieved. The invention is integrated with multiple modes such as the thick oil steam gorge and disgorge or the steam oil drive, stack gas oil drive, surface active agent oil drive and thin oil dilution method oil recovery and is a compound high-efficiency oil recovery technique; the thick oil inside an oil layer generates stack gas, hydrocracks, reduces the viscosity, generates the surface active agent and reduces the tension of an oil-water boundary on the spot under the action of the catalytic oxidation; and in addition, the stratum catalytic oxidation thick oil thermal recovery method can reduce the steam usage amount, the heating temperature of the oil layer and the thick oil recovery cost.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

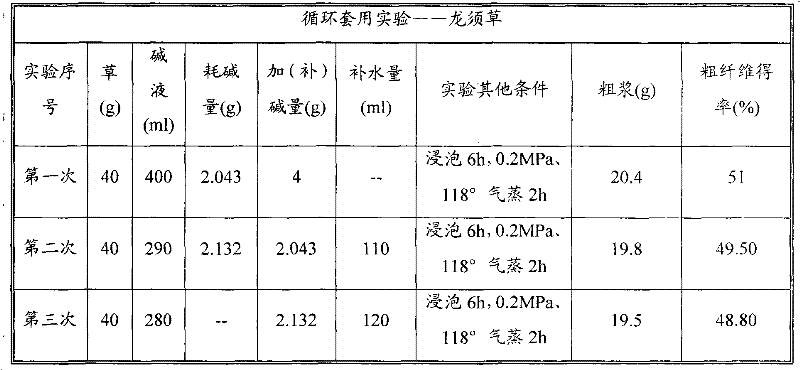

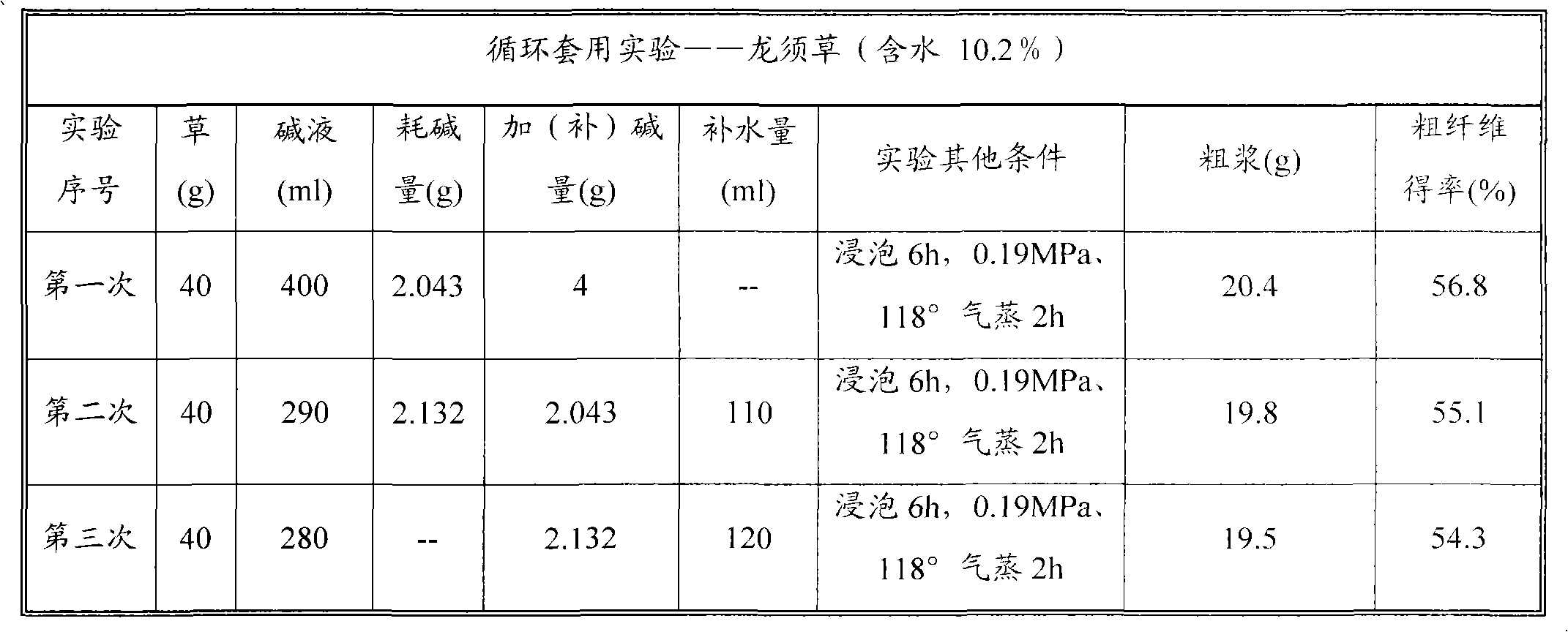

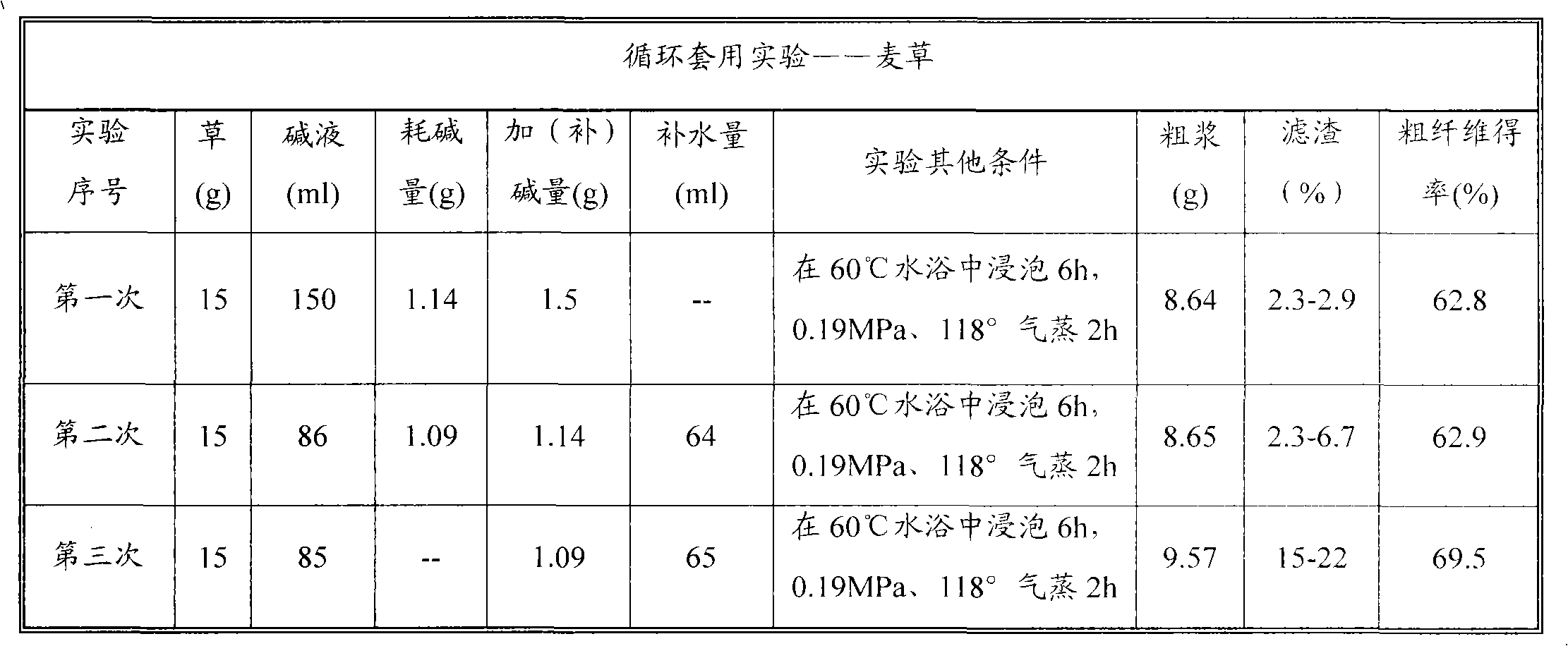

Novel cellulose extraction process

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

Electronic cigarette adopting organic cotton

InactiveUS20140196717A1The internal structure is firm and reliableAvoid damageTobacco devicesInhalatorsGlass fiberEngineering

An electronic cigarette adopting organic cotton includes a liquid storage component and an atomizing device, the atomizing device includes a hollow spiral heating wire, a liquid guiding member inserted in the heating wire, the liquid guiding member is made of non-fiberglass organic cotton materials; the atomizing device further includes a smog conduit inserted in the liquid storage component for supporting the liquid storage component and serving as a channel for the smog, the smog conduit comprises an outer sleeve and an inner sleeve, one inserted into another to position the liquid guiding member therebetween, and the liquid guiding member has its opposite ends respectively to be protruded out of an outer sidewall of the smog conduit and firmly abut against an inner sidewall of the liquid storage component. This kind of electronic cigarettes is harmless to the human body and has stable and reliable inner structure.

Owner:HUIZHOU KIMREE TECH

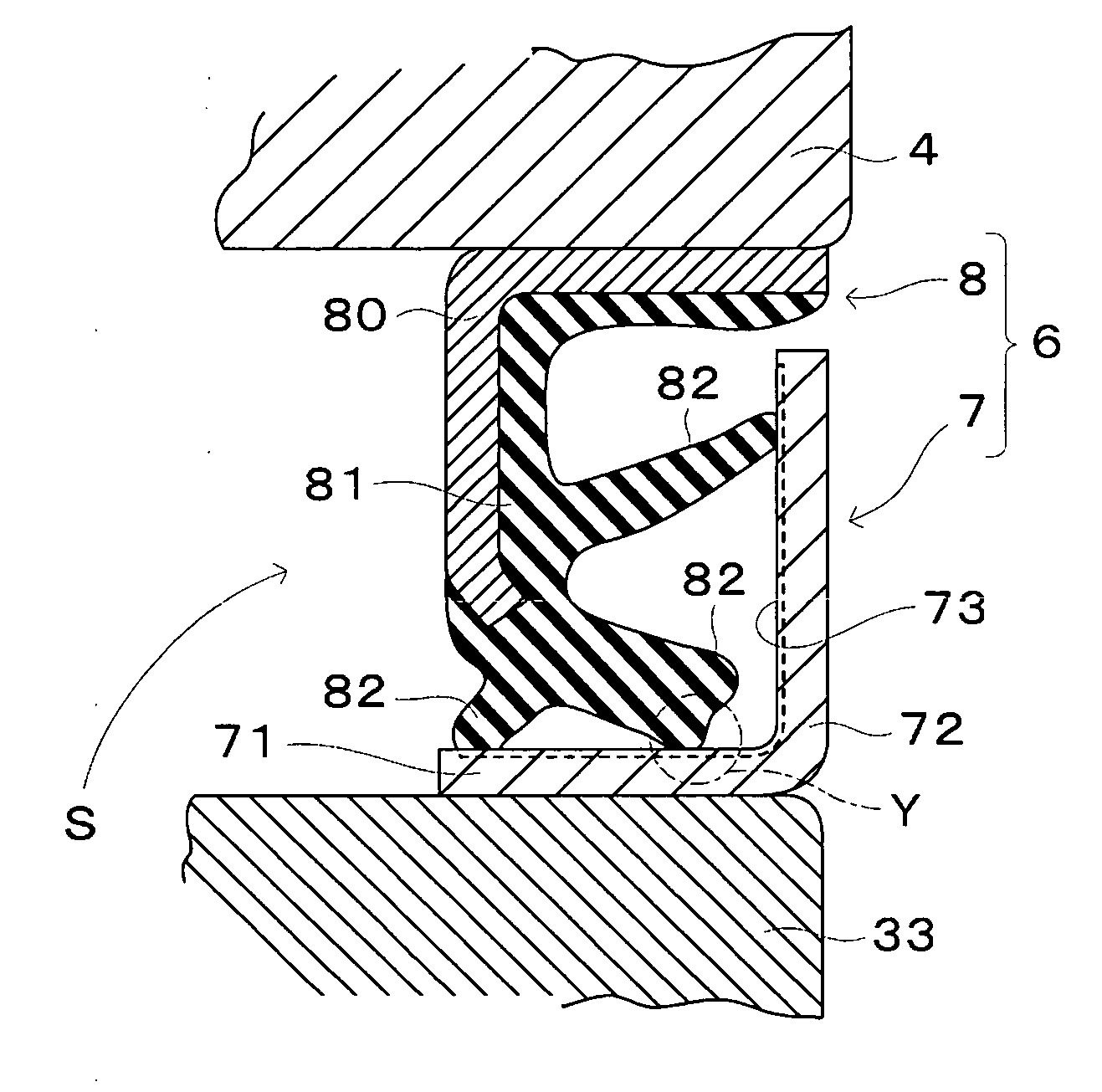

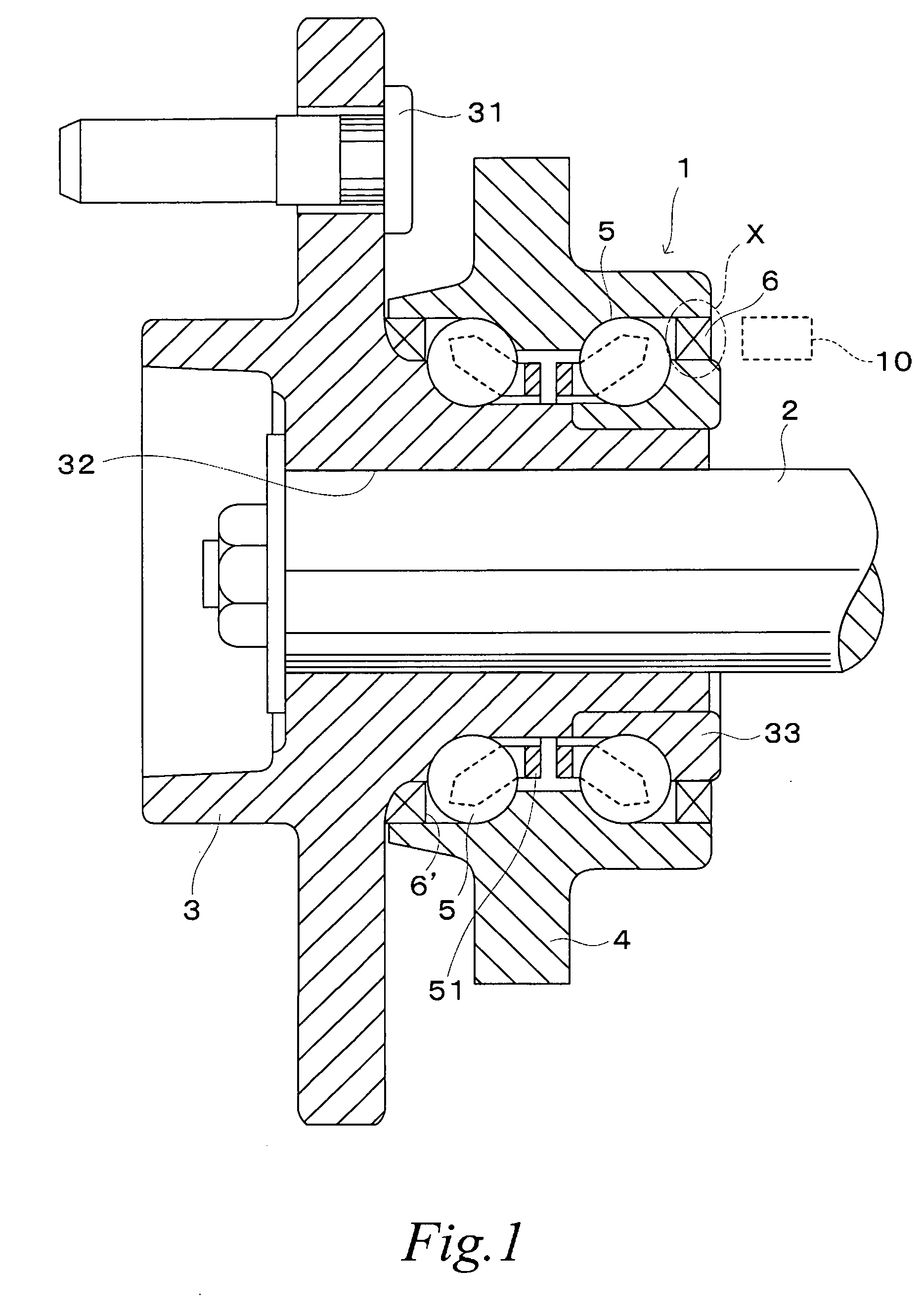

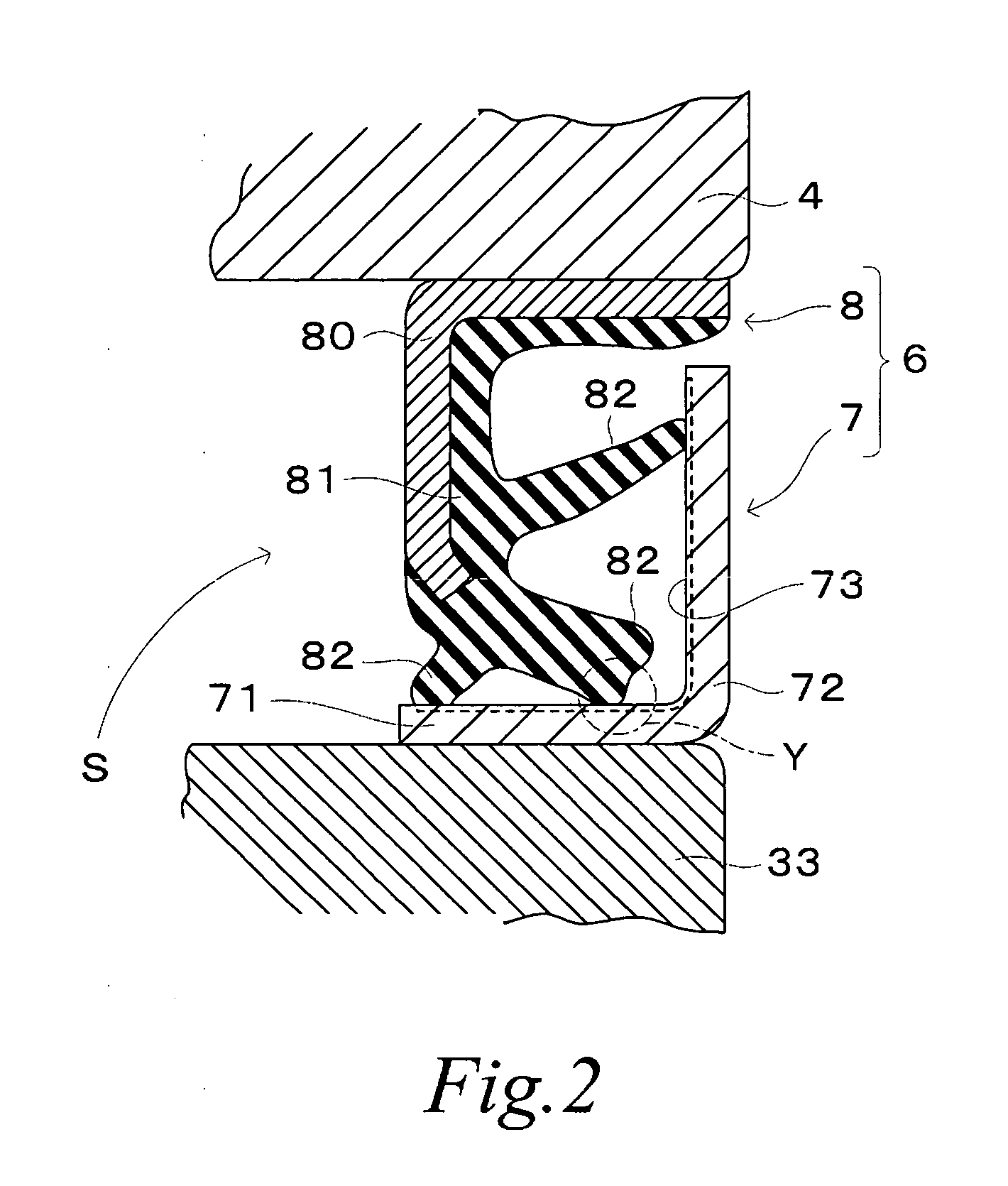

Sealing device

ActiveUS20100052262A1Reduce frictional resistanceRotary torque can be reducedEngine sealsRolling contact bearingsRoot mean squareSurface finishing

A sealing device for sealing space between two members concentrically and relatively rotating comprising a core member fixedly fitted into one of the two members, a metal slinger fixedly fitted into the other of the two members, and an elastic seal member fixedly attached to the core member and having a seal lip which elastically and slidably contacts the slinger. The slinger has a slidably contacting treated surface for the seal lip as is processed such a surface-treatment as defined by the following parameters: arithmetic mean roughness Ra in the range from 0.5 μm to 1.5 μm, root-mean-square roughness Rq in the range from 0.6 μm to 2.0 μm, mean surface irregularity interval Sm in the range from 0.05 mm to 0.17 mm and peak count Pc (50%) in the range from 20 to 60.

Owner:UCHIYAMA MFG

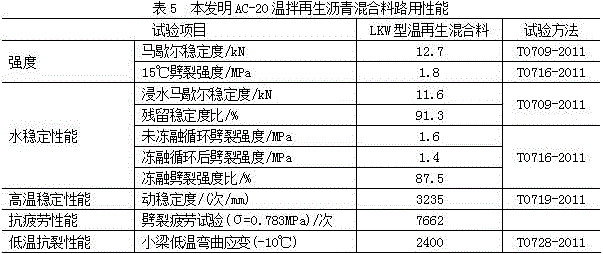

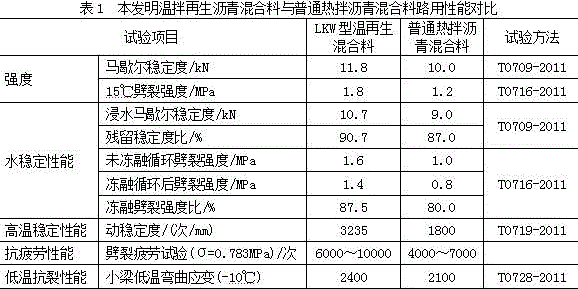

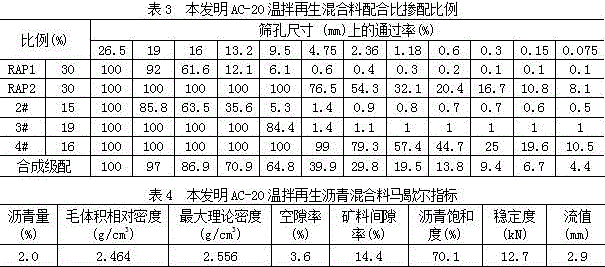

Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

InactiveCN106186837AHigh strengthImprove fatigue resistanceSolid waste managementClimate change adaptationLow emissionMaterials science

The invention provides a warm mix recycled asphalt mixture with a high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and a preparation method of the warm mix recycled asphalt mixture, and belongs to the technical field of highway construction materials. The mixture is prepared from the following components in percentage by mass: 50 to 70 percent of RAP material, 28.2 to 47.2 percent of aggregate and 1.8 to 2.8 percent of newly-doped asphalt and warm mix regenerant; the content of the warm mix regenerant is 0.3 to 0.5 percent of the mass of the newly-doped asphalt. The preparation method comprises the following steps of reclaiming and stacking of the RAP material, crushing and screening of a reclaimed material, stacking and detection of a reference material in different bins, and preparation of the warm mix recycled asphalt mixture. The RAP material, the aggregate, the asphalt and the warm mix regenerant are taken according to the requirement of raw material proportioning and are subjected to mixing treatment according to a conventional production technique of a hot-mixed asphalt mixture, wherein the mixing temperature is 120 to 140DEG C, and the mixing time is 20 to 35s, and finally the recycled asphalt mixture is obtained. The warm mix recycled asphalt mixture has the advantages of high RAP mixture ratio, low heating and constructing temperature, good constructability, easiness and pavement performance, low energy consumption, low emission and the like.

Owner:云南省公路科学技术研究院

Green process for extracting fibers from plants

ActiveCN101899794ATime consuming to overcomeOvercome efficiencyDigestersPulping with inorganic basesFiberSlag

The invention relates to a sectional green process for extracting fibers from plant raw materials with high efficiency and high yield, which comprises the steps of: firstly, infiltrating or / and soaking plant raw materials with lime water (or carbide slag water solution) or dilute alkali; then steaming or boiling the raw materials; and finally, beating or steaming discharge and pulp washing to prepare fibers. The green process can also be comprehensively used for exploiting the utilization of lignin and extract, so as to realize the full-rate development of plants. The extract in the process can be recycled as a nutrient source for organisms such as plants, microbes, alga and the like, which breaks through the key technical bottleneck of the green and ecological industry, has significant theoretic and application values on the recycling economy, the sustainable development strategy and acquisition of energy sources, advanced materials and biological nutrient source from biomasses, and has extremely profound social benefits, economic benefits and ecological benefits.

Owner:BEIJING INSIGHT BIOMASS

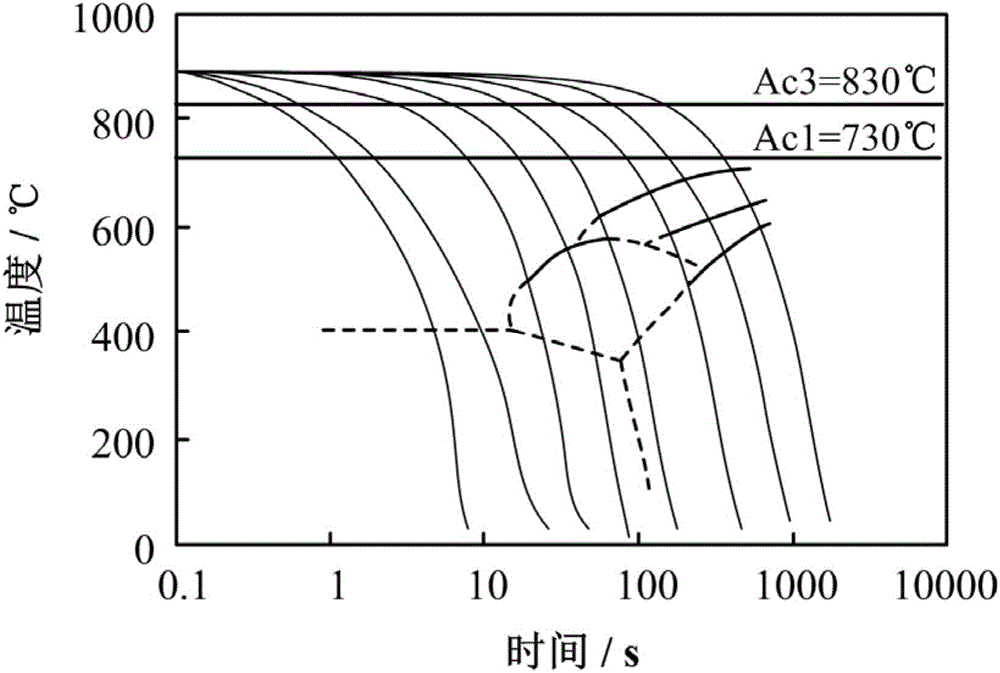

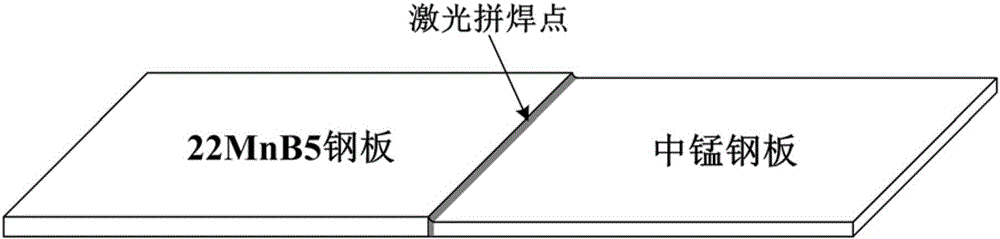

Laser tailor-welded high-strength steel warm forming preparation method

InactiveCN106350741AReduce manufacturing costLow quenching rateLaser beam welding apparatusThree-phaseQuenching

The invention discloses a laser tailor-welded high-strength steel warm forming preparation method. The laser tailor-welded high-strength steel warm forming preparation method is characterized by comprising the following steps: manufacturing a 22MnB5 steel plate and a medium manganese steel plate into a steel part for later use; carrying out laser tailor-welded connection treatment; carrying out heating treatment on the steel part for later use, which is subjected to laser tailor-welding; transferring the steel part onto a stamping mold to carry out stamping forming and quenching; finally obtaining a two-phase or three-phase microstructure formed by lots of ferrite, martensite or bainite in the 22MnB5 steel area of the tailor-welded steel part; and obtaining a martensite organization structure in the medium manganese steel area, thereby forming a warm forming technology of the laser tailor-welded high-strength steel, which has no need for coating treatment in advance and has gradient distributed mechanical property. The laser tailor-welded high-strength steel warm forming preparation method has the beneficial effects that the process combination of laser tailor-welding and the warm forming technology is realized; the warming forming technology is used for enabling 22MnB5 steel to form the two-phase or three-phase microstructure; the two-phase or three-phase microstructure is matched with medium manganese steel having martensitic structure in the end to obtain a custom-made warm forming part with gradient distributed performances; the technological process is simplified; and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

Method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method

InactiveCN101550491ALow heating temperatureImprove heat utilizationProcess efficiency improvementExhaust gasNon-ferrous metal

The present invention relates to a technique for extracting non-ferrous metal, and specifically to a method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method. The aim of the invention is to settle the technical problem for extracting nickel or cobalt from nickel ore. The method of the invention comprises the following steps: grinding the dried powder of nickel ore, mixing the nickel ore with ammonium chloride, then putting the mixed compound into a sealed kiln for calcining, directly leaching the roasted product, adjusting the pH value of leaching liquid with the ammonia water recycled from end gas in the kiln, and controlling the pH value to 6.5-7.5 for recycling the nickel or cobalt. The grade of nickel or cobalt concentrate recycled by deposition according to the invention is high and can obtain more than 30% of nickel content. The subsequent processing and utilizing are facilitated. No exhaust gas or wastewater is discharged in the industrial process. The requirement of green production is satisfied.

Owner:谢永巨 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com