Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374results about "Pretreatment with alkaline reacting compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

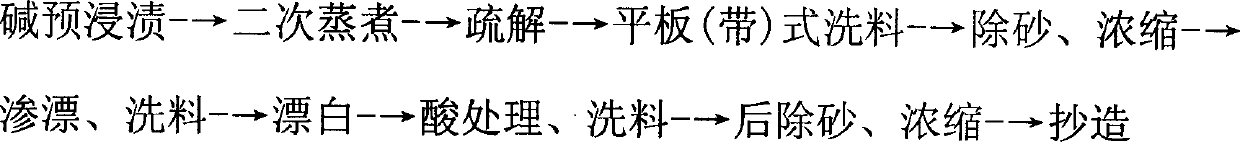

Bamboo pulp denatured productive technology

InactiveCN1385287AEmission reductionConducive to the sustainable development of productionPretreatment with alkaline reacting compoundsWood treatment detailsPulp and paper industryViscose fiber

The production process of bamboo fibre viscose pulp includes the following main steps: pre-alkalizing, secondary cooking, plate (belt) type washing and bleaching, and is characterized by mixing insoluble bamboo pulp undergo the process of modification treatment to produce soluble viscose bamboo pulp. As compared with cotton pulp production process it can reduce discharge of waste water by 35%, and is approaching to or superior to cotton pulp in quality.

Owner:上海第五化学纤维厂

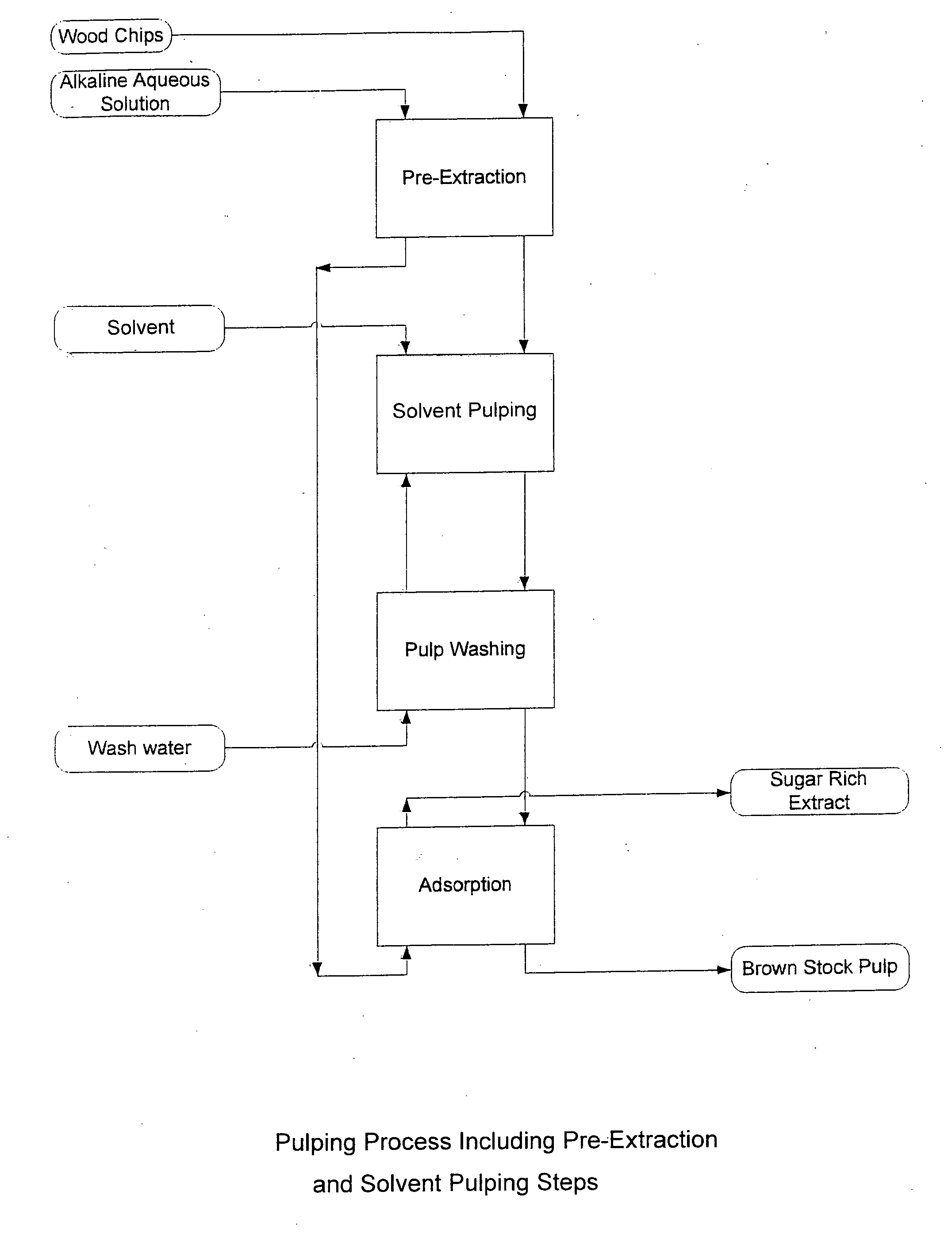

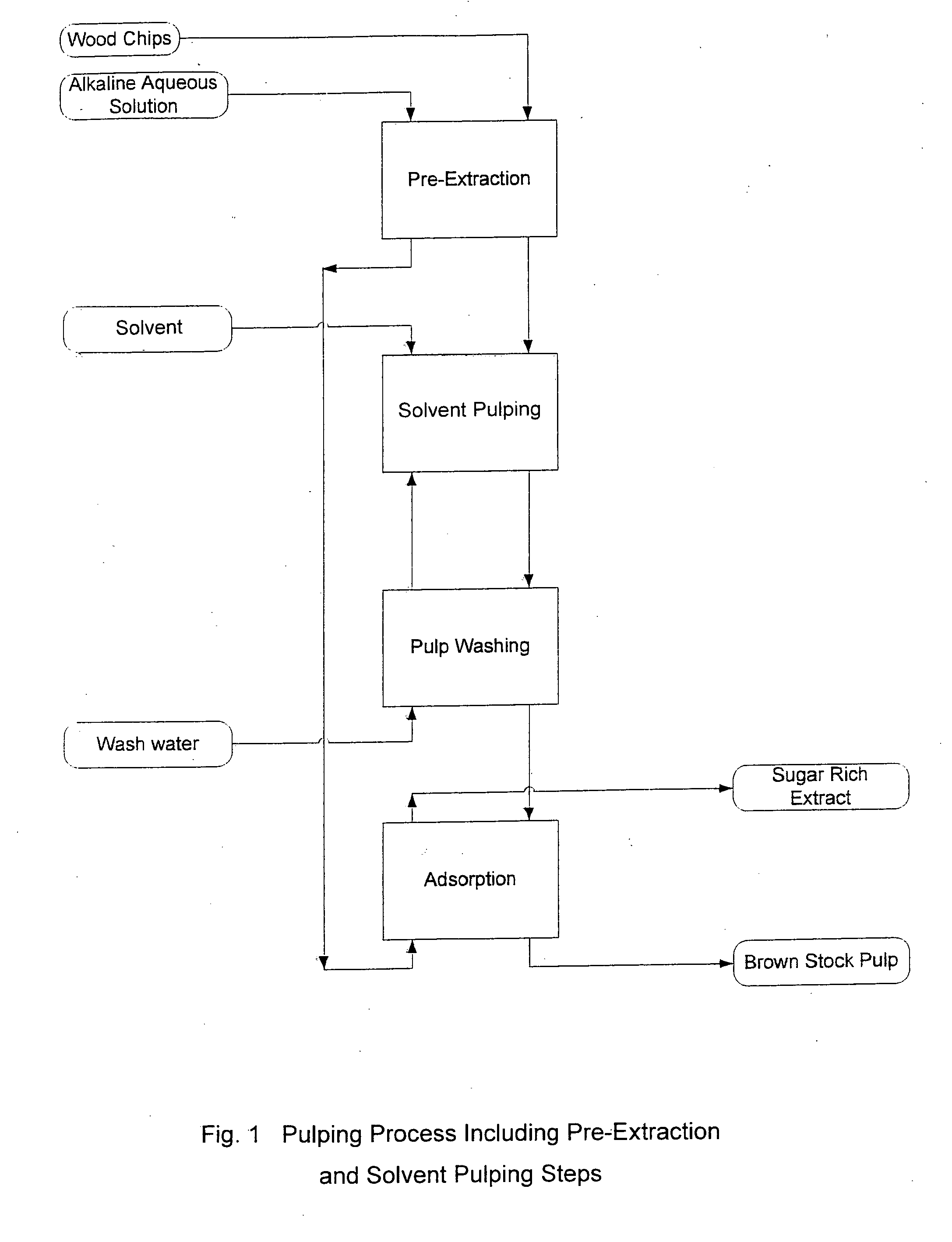

Pre-extraction and solvent pulping of lignocellulosic material

InactiveUS20080196847A1Pretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpBoiling pointSolvent

A process of treating a lignocellulosic material includes a pre-extraction step in which hemicellulose is extracted from the lignocellulosic material. Then, in a solvent pulping step, the lignocellulosic material is separated into pulp by contacting the lignocellulosic material with a cooking liquor comprising a solvent. In one embodiment, the solvent has a boiling point of at least about 150° C. In another embodiment, the cooking liquor comprises a mixture of solvent and water.

Owner:INT PAPER CO +1

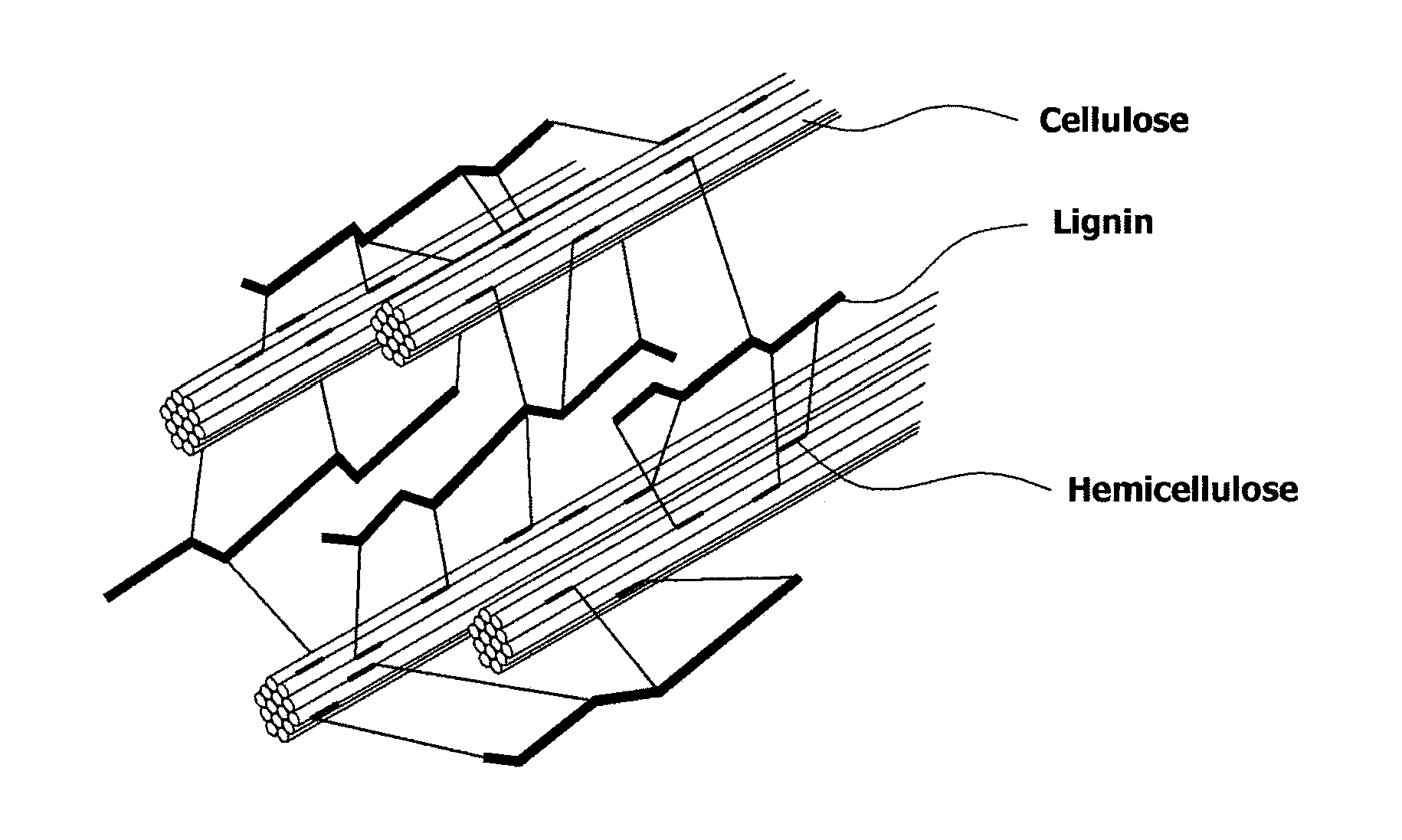

Method and apparatus for fractionating lignocellulose-based biomass

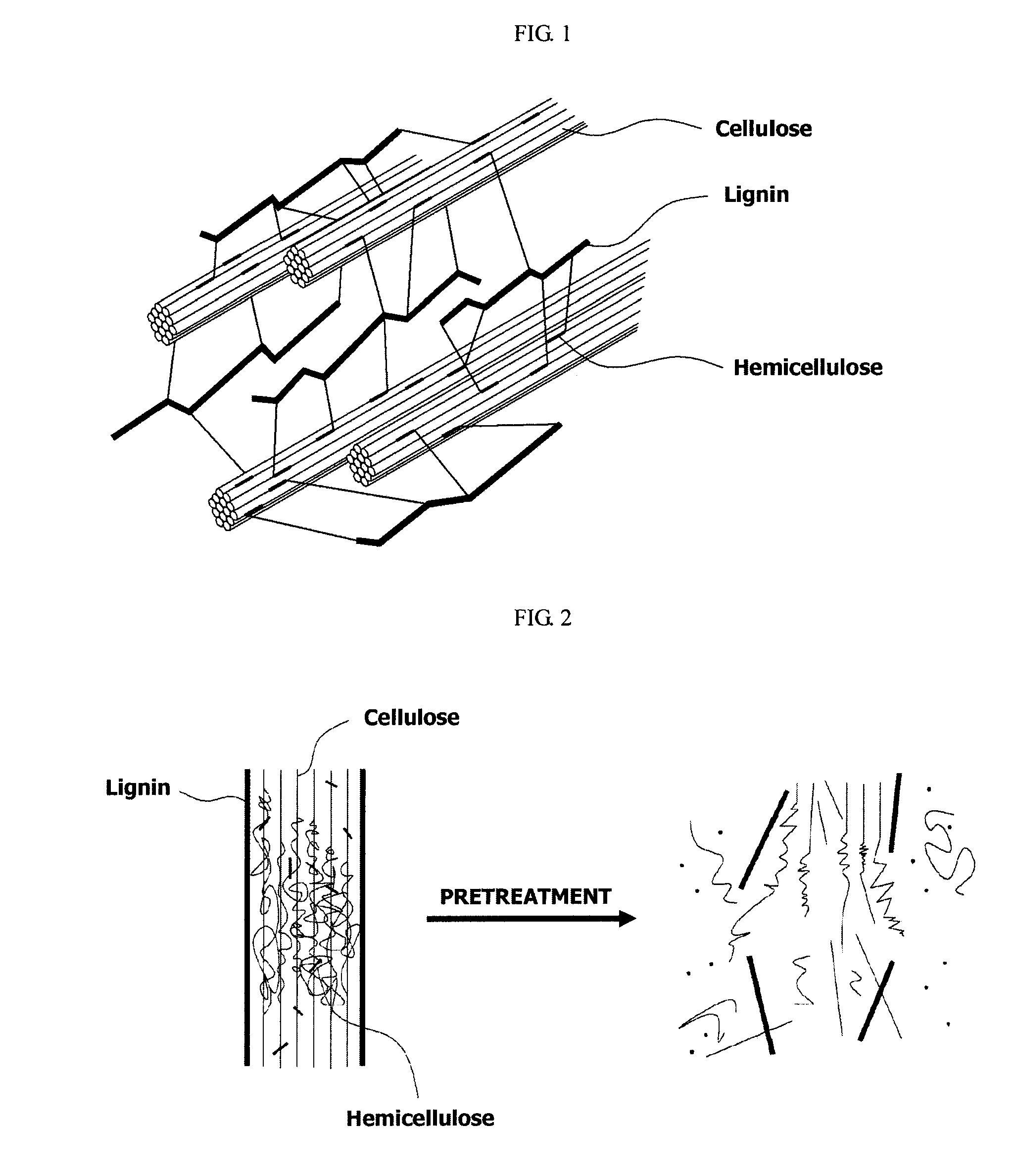

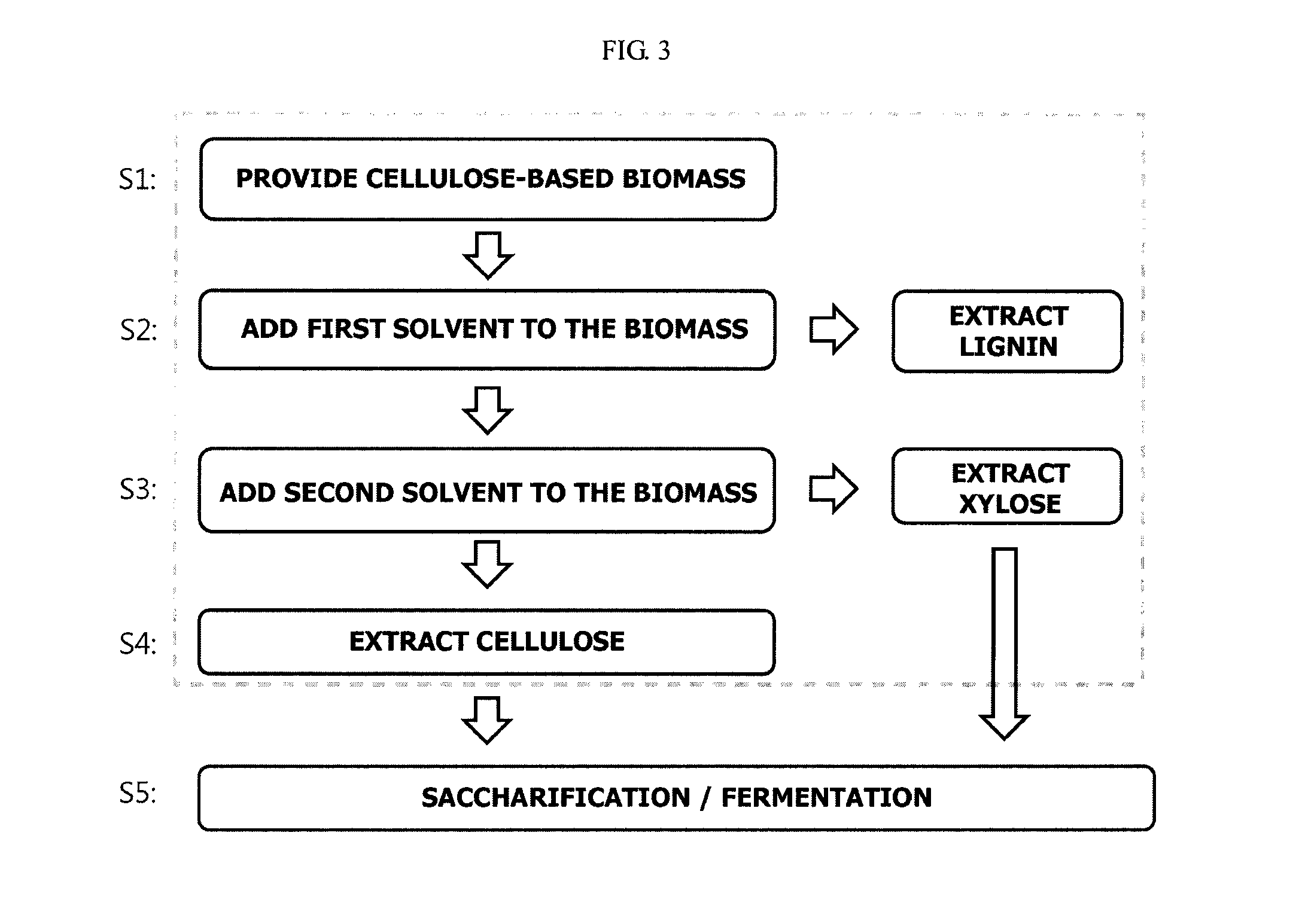

ActiveUS20100203605A1Improve processing efficiencyEnhanced interactionPressurized chemical processBiological substance pretreatmentsCelluloseLignin degradation

A method and apparatus for fractionating a lignocellulose-based biomass are provided. The method includes providing a lignocellulose-based biomass, extracting lignin from the biomass by adding a first solvent capable of dissolving the lignin, extracting xylose by adding a second solvent capable of dissolving hemicellulose to the biomass treated with the first solvent, and extracting the cellulose remaining in the biomass. In this method, a continuous process can be performed instead of a low efficiency batch-type process and components of the biomass can be obtained at high yield.

Owner:SAMSUNG ELECTRONICS CO LTD

A method for fractional separation of full components of agricultural and forestry cellulose biomass and preparation of fuel alcohol and xylooligosaccharides by using the separated components

InactiveCN102261007AHigh extraction rateImprove heat utilization efficiencyPretreatment with alkaline reacting compoundsBiofuelsChemical industryFiltration membrane

The invention discloses grading and separating of all components of forestry cellulose biomass and preparing of fuel alcohol and xylo-oligosaccharide by utilizing the separated components. The method comprises the following steps of: (a) crushing, immersing and filter pressing dry substances of the forestry cellulose biomass; (b) immersing the filter pressed solid phase part using an alkaline solution, adding an oxidizing agent, extracting and solidifying phase to form a cellulose crude product; (c) concentrating pressure filtrate through a nano-filtration membrane, adding alcohol with the final concentration of above 50% to the concentrated solution, filtering or centrifugally separating after standing to obtain precipitate and supernatant, wherein the precipitate is a hemi-cellulose crude product; and (d) adjusting the supernatant obtained in the step (c) to be acid, and filtering, separating and precipitating to obtain a lignin crude product. According to the method disclosed by the invention, the resource utilization is maximized; the independence on imported oil in our country can be reduced; the environment pollution is reduced; establishment of a new energy industry and a biological chemical industry can also be promoted; the economic growth pattern in our country is changed; and social and economic sustainable development can be realized.

Owner:陈方和

Biomass pretreatment process

ActiveUS8168840B2Pressurized chemical processPretreatment with alkaline reacting compoundsCelluloseLignocellulosic biomass

A process is described for pretreating lignocellulosic biomass. The process comprises swelling the lignocellulosic biomass with an aqueous liquid. The pretreated lignocellulosic biomass may be used as a feedstock for the enzymatic conversion to ethanol, or in a thermal conversion. process to produce bio-oil. The pretreatment results in a greater yield and, in the case of a thermal conversion process, a better quality of the bio-oil. The pretreatment process may be used to adjust the composition and amount of inorganic material present in the lignocellulosic biomass material.

Owner:MARD INC

Method for converting lignocellulosic biomass

InactiveUS20120064574A1Process stabilityEfficient executionPretreatment with alkaline reacting compoundsOrganic compound preparationChemistryBiomass

The present invention aims to develop a pretreatment technology for performing efficient saccharification without losing carbohydrates (in particular, free carbohydrates, starch, xylan, or the like) due to solid-liquid separation and washing steps, as a pretreatment for enzymatic saccharification of a lignocellulosic biomass feedstock (including a lignocellulosic biomass feedstock containing readily degradable carbohydrates). Provided are: a production method for a slurry to be used as a substrate for an enzymatic saccharification reaction, comprising: pulverizing an aerial part of a plant as a lignocellulosic biomass feedstock; preparing a slurry containing the biomass feedstock, calcium hydroxide, and water; subjecting the slurry to an alkali treatment; and neutralizing the slurry by introduction of and / or pressurization with carbon dioxide to decrease a pH to 5 to 7; an enzymatic saccharification method, comprising using, as a substrate, a slurry obtained by the production method for a slurry; and a production method for ethanol, comprising using, as a substrate, a saccharification product obtained by the enzymatic saccharification method.

Owner:NAT AGRI & FOOD RES ORG

Technique for chemomechanical pulp-making of poplar wood

InactiveCN101230552AHigh yieldGood optical performancePretreatment with alkaline reacting compoundsChemical/chemomechanical pulpWastewaterPre treatment

The invention relates to a pulp technology of aspen by using a chemical-mechanical method. Aspen sizing agent which is decatized and is extruded and dispersed for a space is infused in peroxide using magnesium hydrate as an alkali source and is mechanically grinded by adopting the enzyme pretreatment technique, then the sizing agent high density storage bleaching is acted, finally, chemical-mechanical pulp with high whiteness and high yield is manufactured through a second stage jordaning production. The method of the invention realizes that the pulp yield and the optical performance are increased, the energy consumption for jordaning is lowered, the load of wastewater pollution is lowered, and the scale formation problem is eliminated.

Owner:QILU UNIV OF TECH

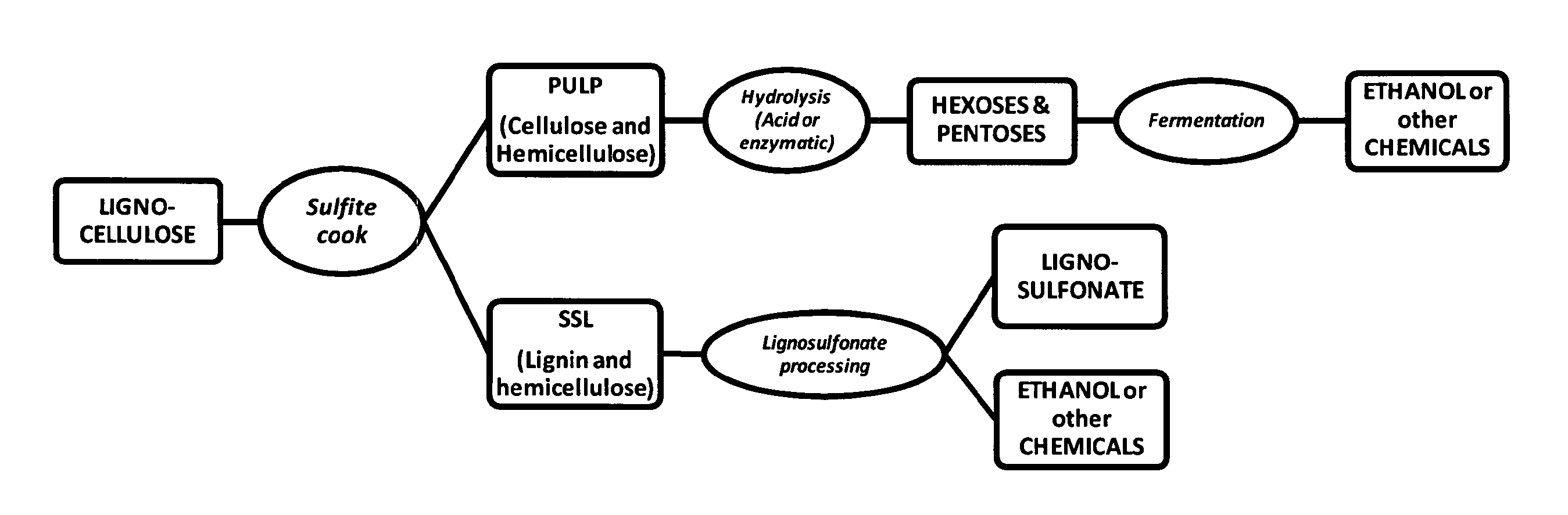

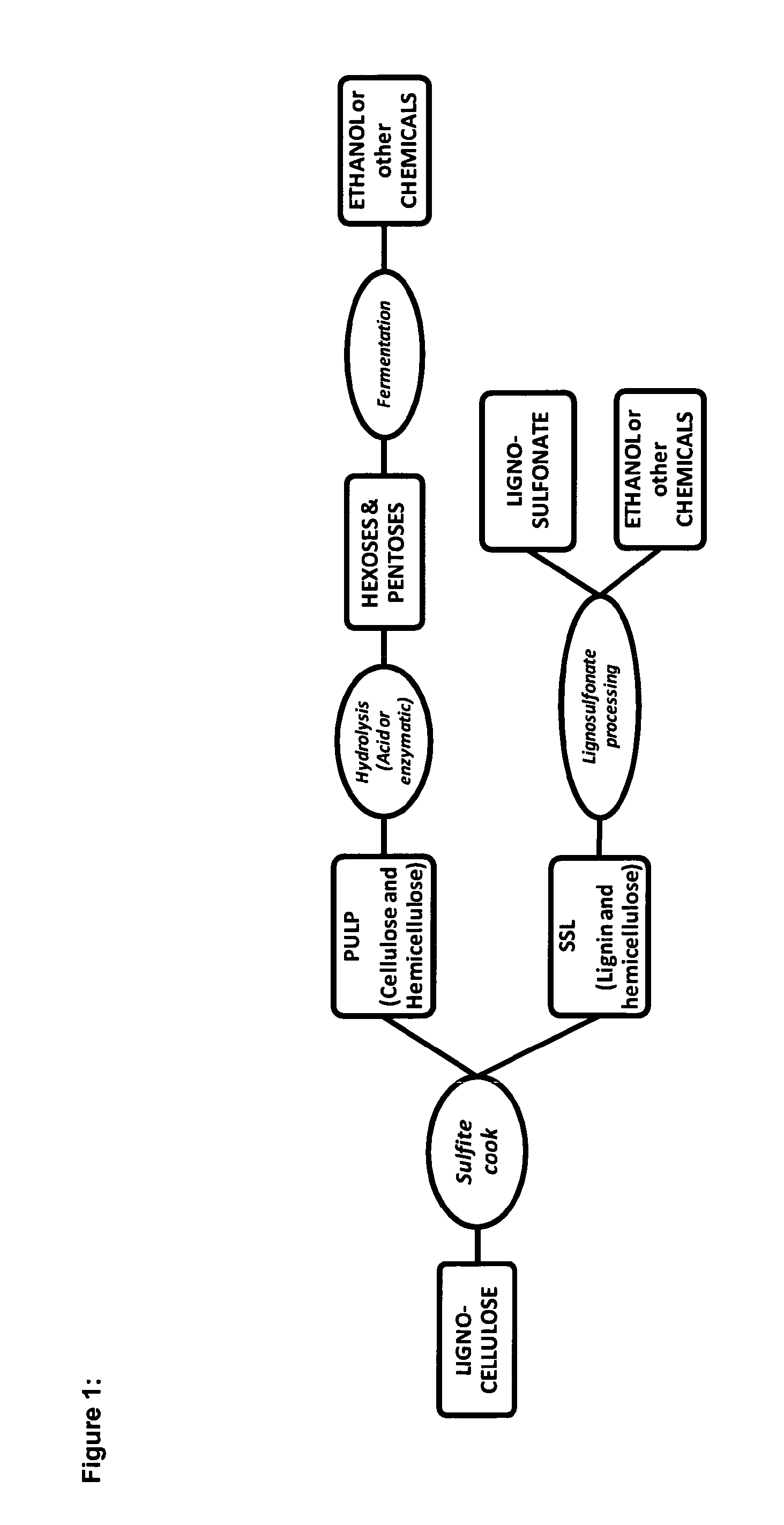

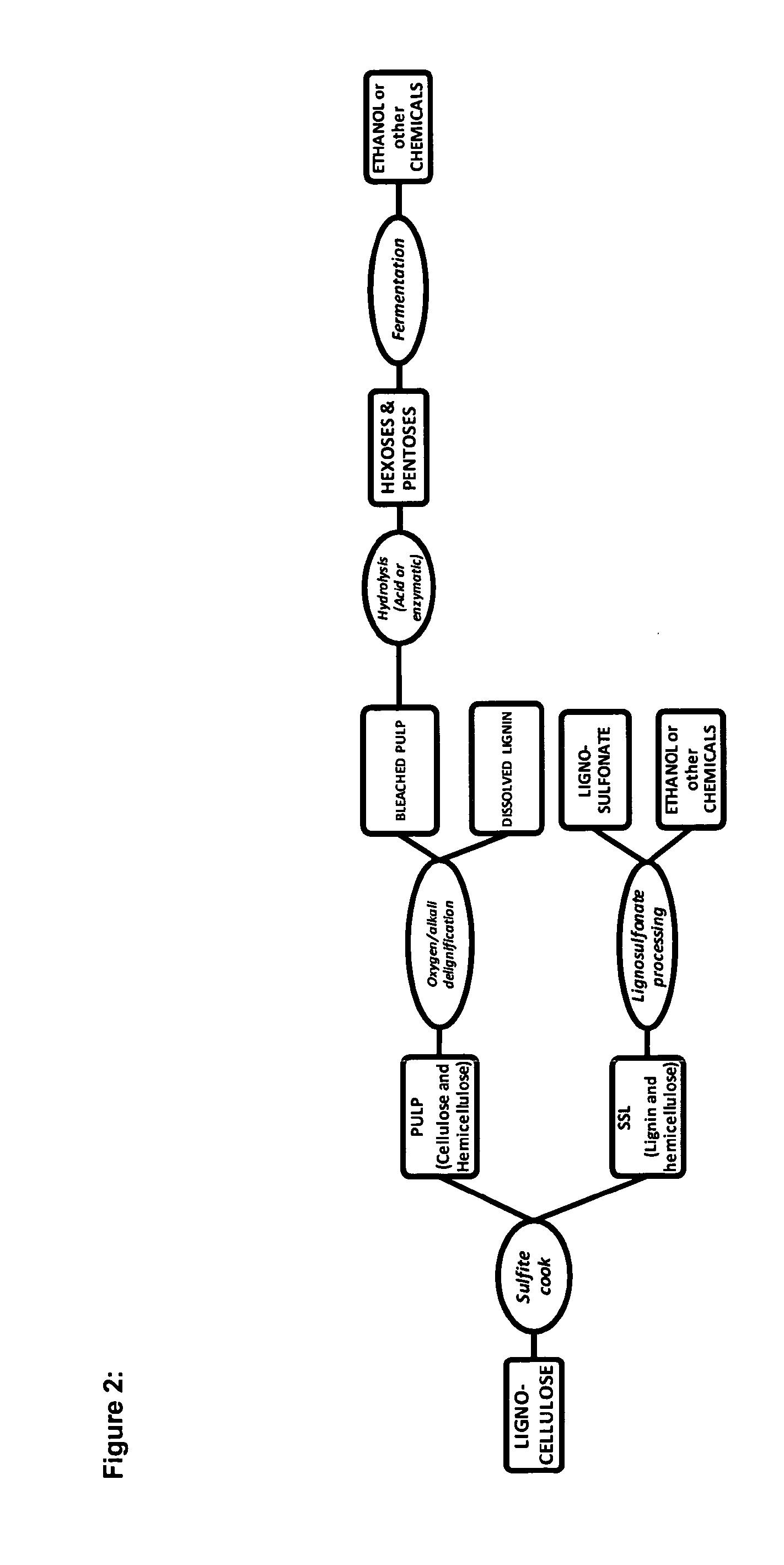

Lignocellulosic biomass conversion

ActiveUS20110250638A1Easy to separateMaintain good propertiesSugar derivativesPretreatment with alkaline reacting compoundsCelluloseSingle-cell protein

The present invention relates to a process for the production of second generation biofuels and / or sugar based chemicals—for example ethanol, butanol etc—and / or materials—for example plastics, single cell proteins etc.—together with sulfonated lignin from lignocellulosic biomass, in particular from lignocellulosic biomass comprising, among others, annual plants, agricultural waste, or wood. In particular, the present invention relates to a process for the production of sugar based chemicals, biofuels or materials together with sulfonated lignin from lignocellulosic biomass comprising the pretreatment of a lignocellulosic biomass in a sulfite cooking step.

Owner:BORREGAARD INDS

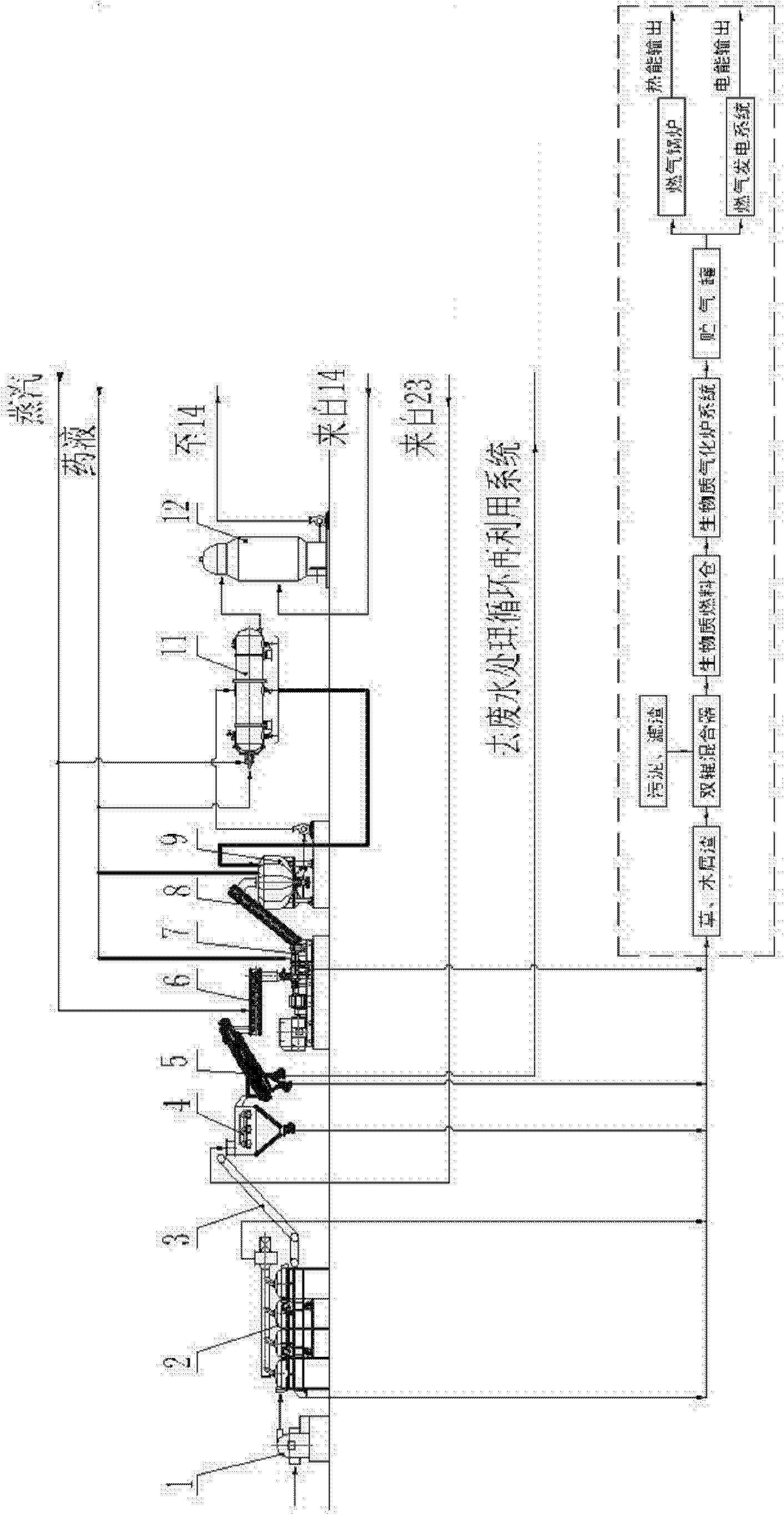

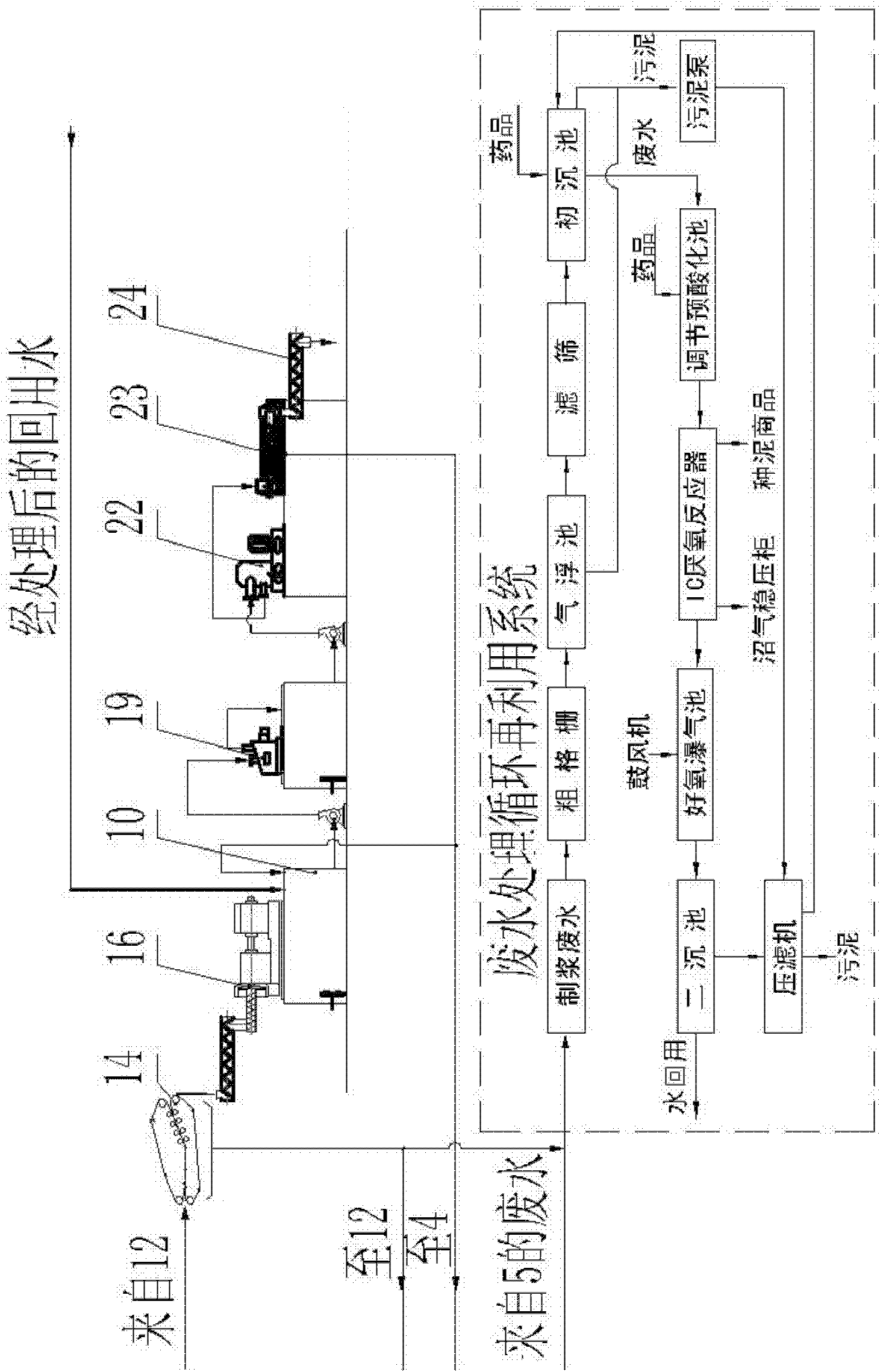

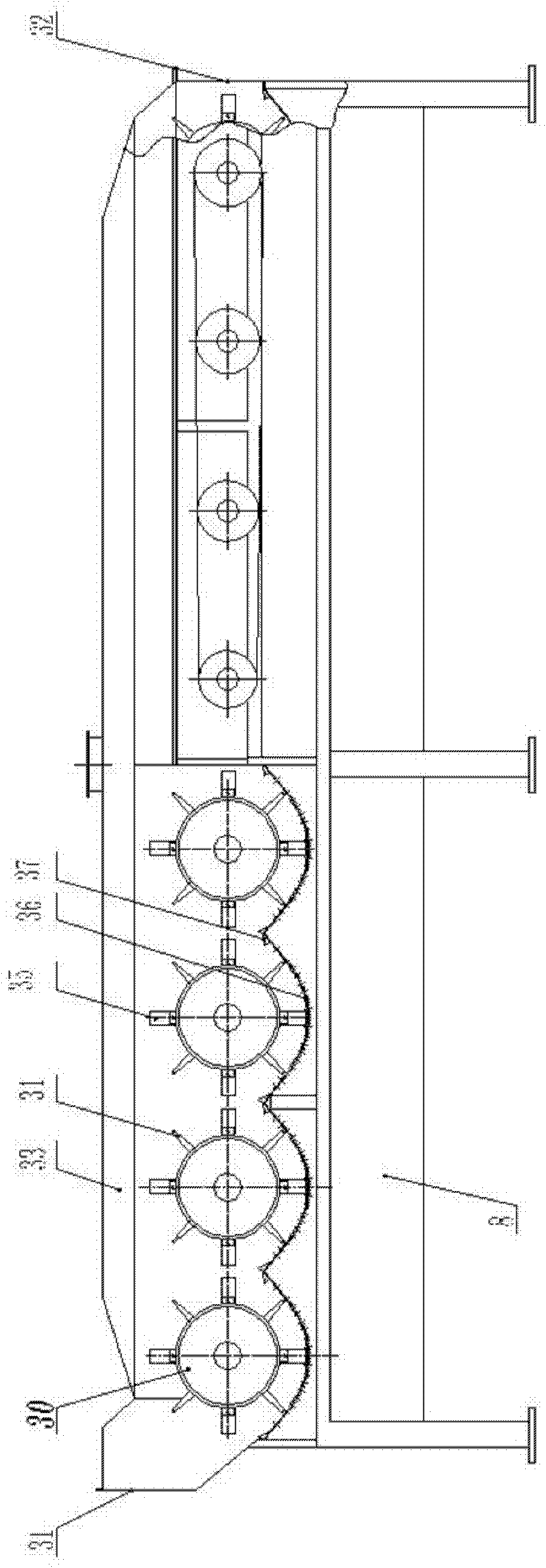

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

Paper-making grade softwood pulp plate modifying production technique

ActiveCN101158125AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpTO-18Cooking methods

The invention provides a denaturizing production technique of paper making needle wood pulp plate, which solves the problems of uneven dipping, slow hemicelluloses stripping, difficult accumulation descending, uneven cooking, single cooking method, single bleaching method and violent conditions existing in denaturizing production technique of wood pulp in the prior art. The invention comprises the following steps: wood pulp plate paging, alkali soaking, pressing, untwining and dispersion, cooking, washing, impurity removal, bleaching, a secondary washing and pulping; wherein, the wood pulp plate paging, alkali soaking, pressing, untwining and dispersion are to send papers into a alkali dipping barrel with concentration of 6 percent to 18 percent after the paper making bleaching wood pulp plates are separated by a paging device. When the wood pulp plates are changed into pulp with concentration of 3 percent to 6 percent, the pulp with concentration of 3 percent to 6 percent is sent to a squeezer to be squeezed and to untwine and disperse fiber. By adopting the invention, the quality of the dissolved viscose fiber wood pulp can be better and more stable; furthermore, the invention provides wider selection range of raw material.

Owner:YIBIN GRACE GROUP CO LTD

Novel cellulose extraction process

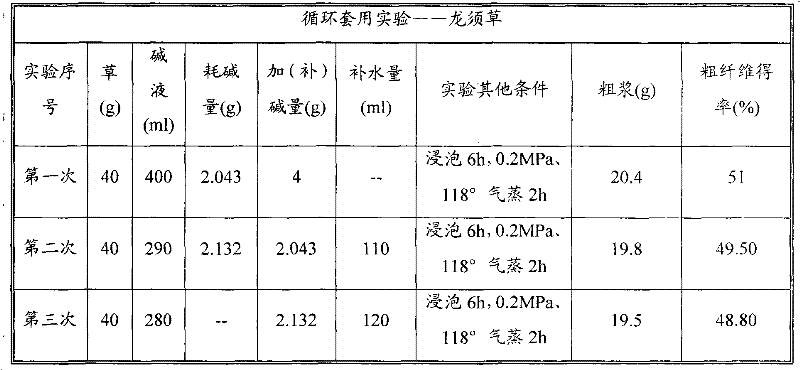

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

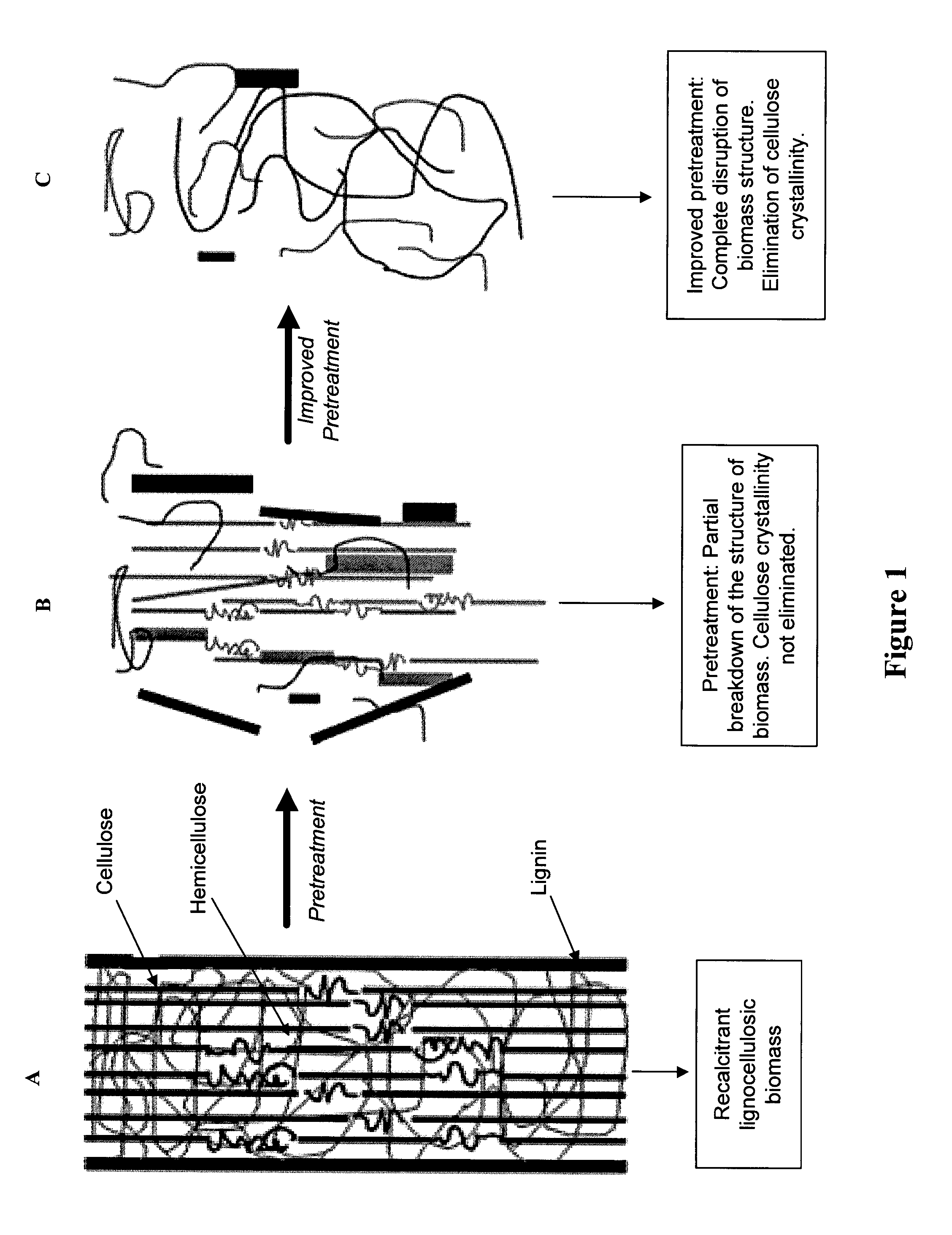

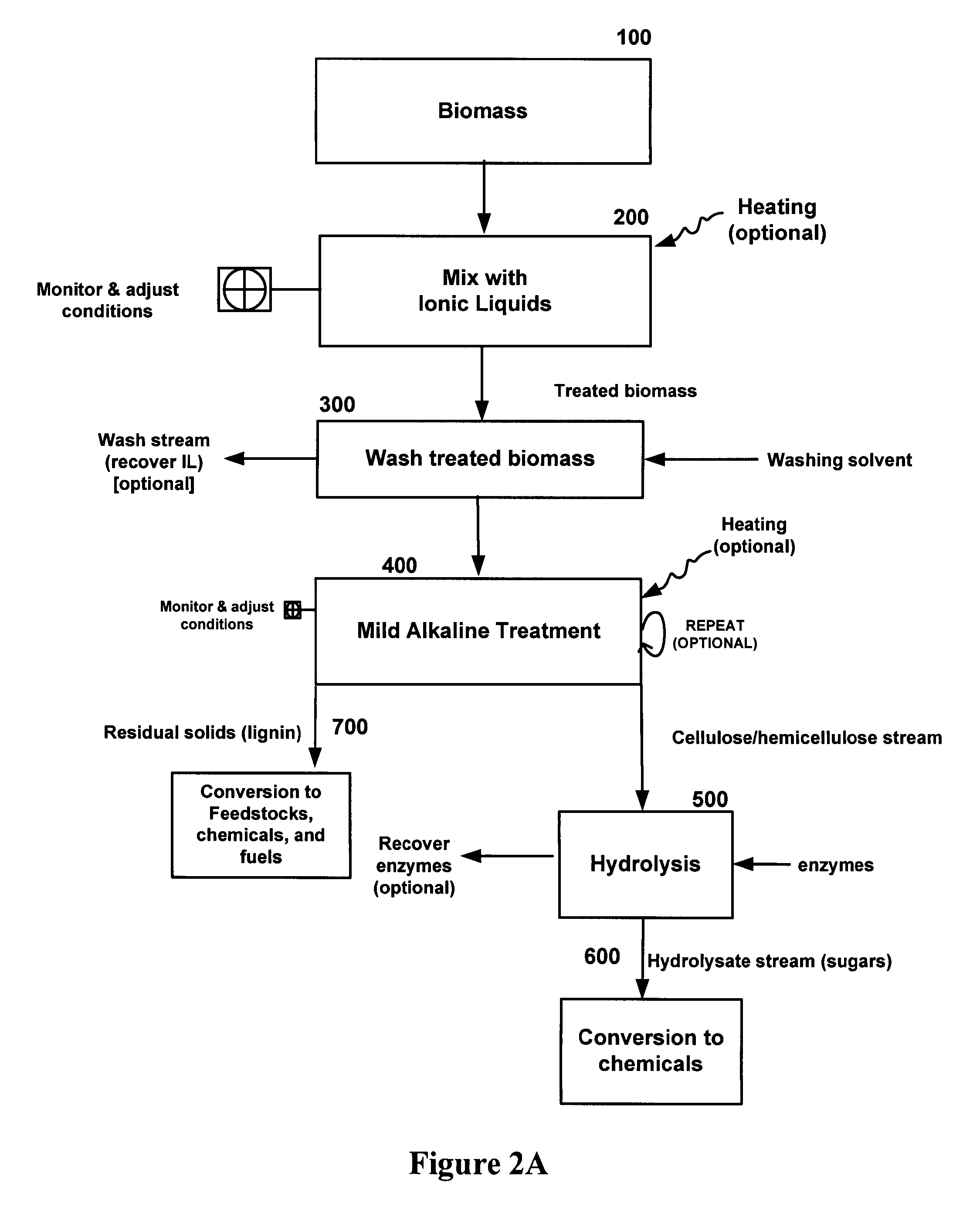

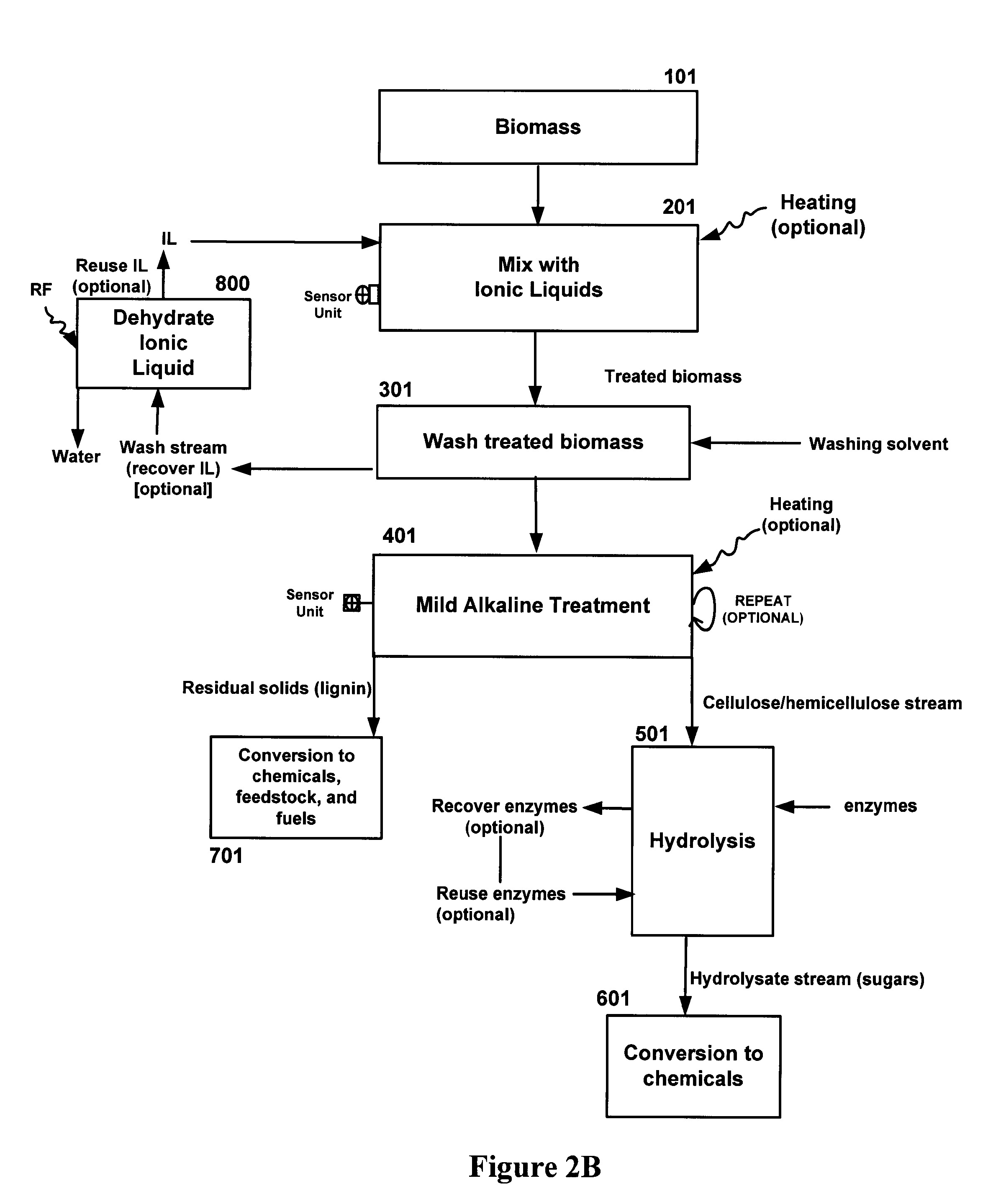

Pretreatment and fractionation of lignocellulosic biomass

InactiveUS20140273104A1Pulp liquor regenerationPretreatment with alkaline reacting compoundsCelluloseFractionation

Method and apparatus for enhanced production of sugars and lignin via fractionation of lignocellulosic biomass through sequential ionic liquid pretreatment and mild alkaline treatment. The resulting biomass is easily fractionated and amenable to efficient and rapid hydrolysis and catalytic conversion to valuable products with high recovery of the enzymes used in the hydrolysis.

Owner:SUGANIT SYSTEMS INC

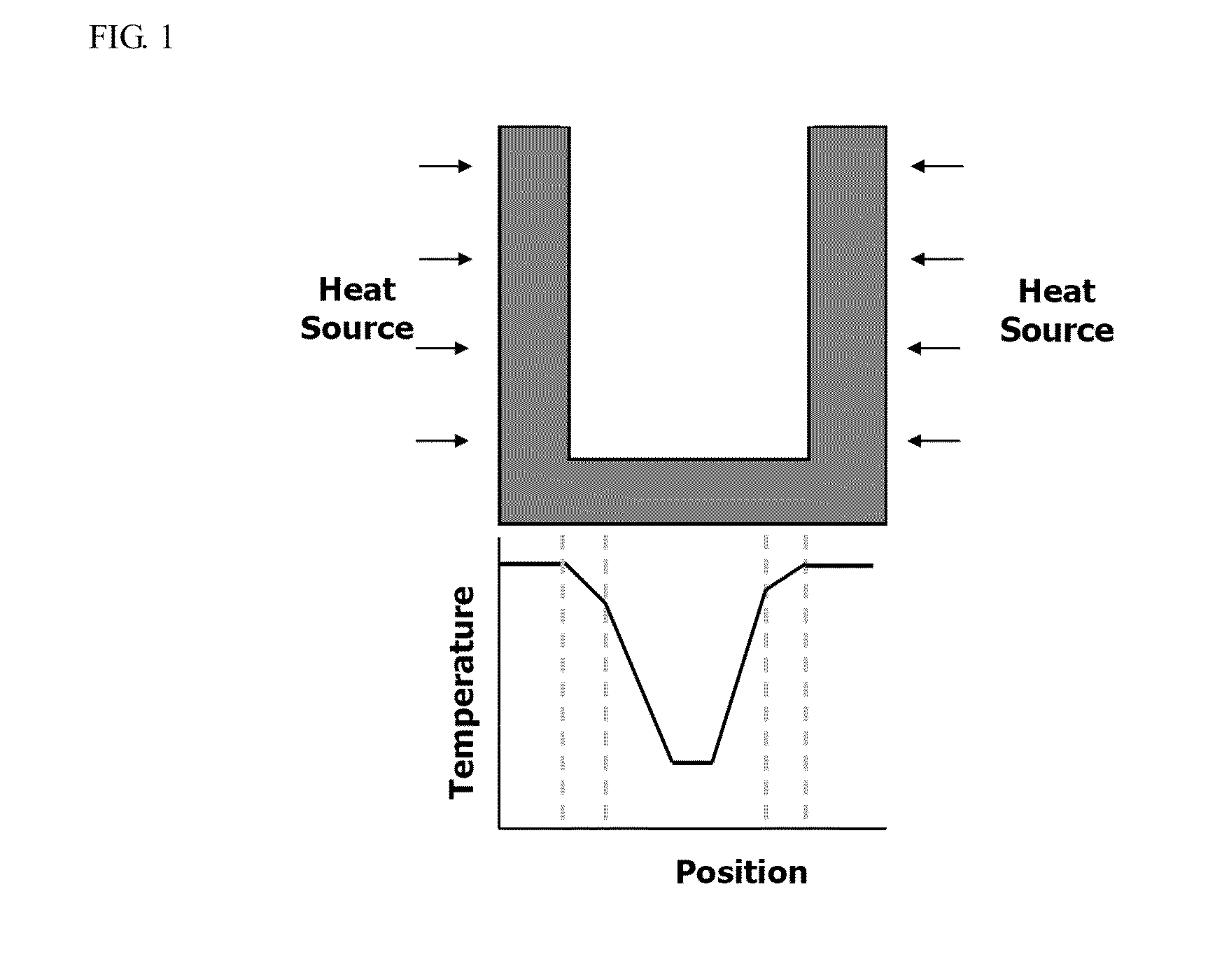

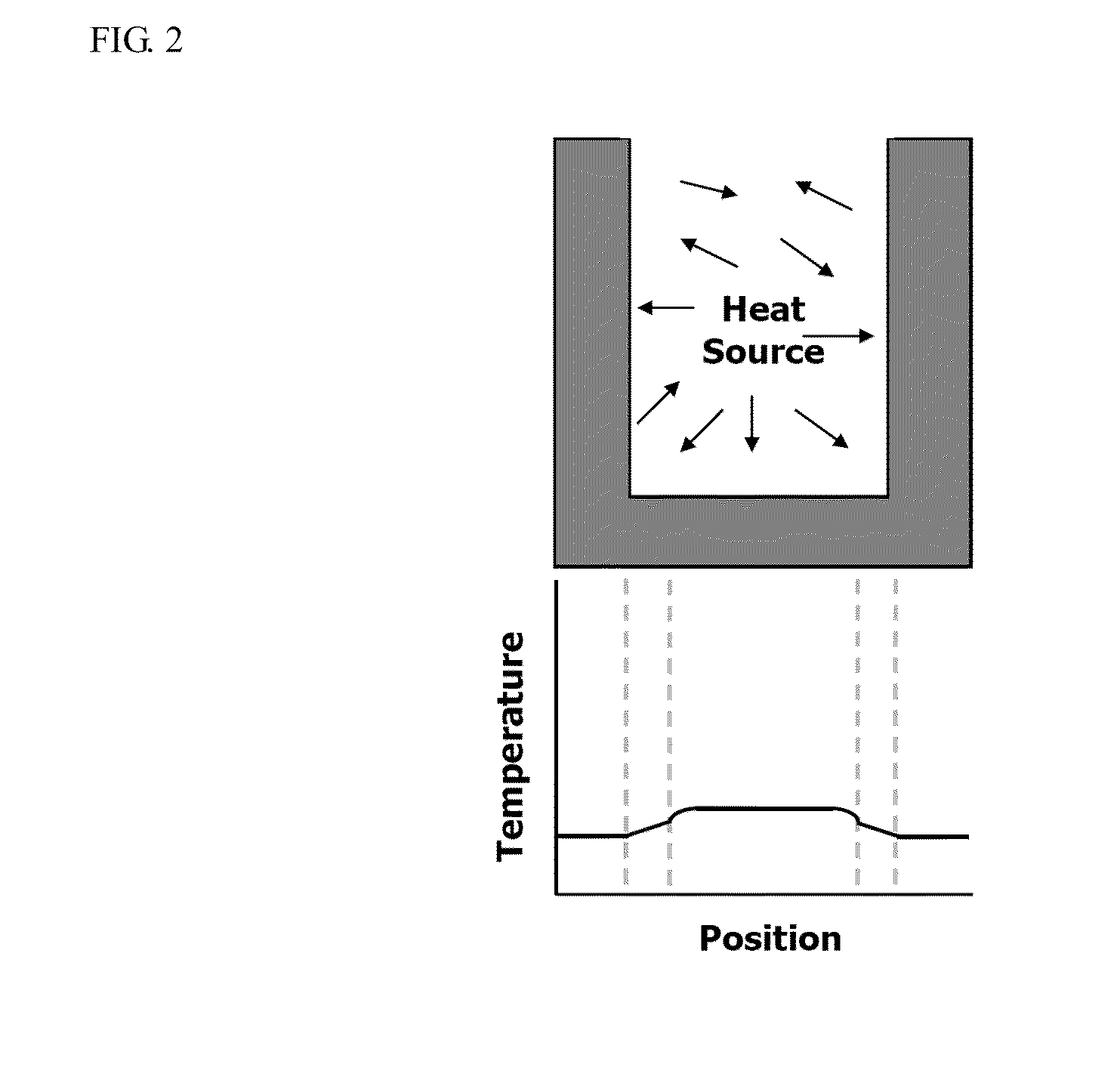

Method and apparatus for pretreating biomass using internal heat

ActiveUS20110143412A1Bioreactor/fermenter combinationsPretreatment with water/steamWater-reactiveProcess engineering

A method for pretreating a biomass, in which a water-reactive anhydride contacts a biomass, is disclosed. The biomass is pretreated using internal heating by an exothermic reaction. Further, an apparatus for pretreating a biomass having a reaction part including an inlet part and an outlet part for the water-reactive anhydride is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

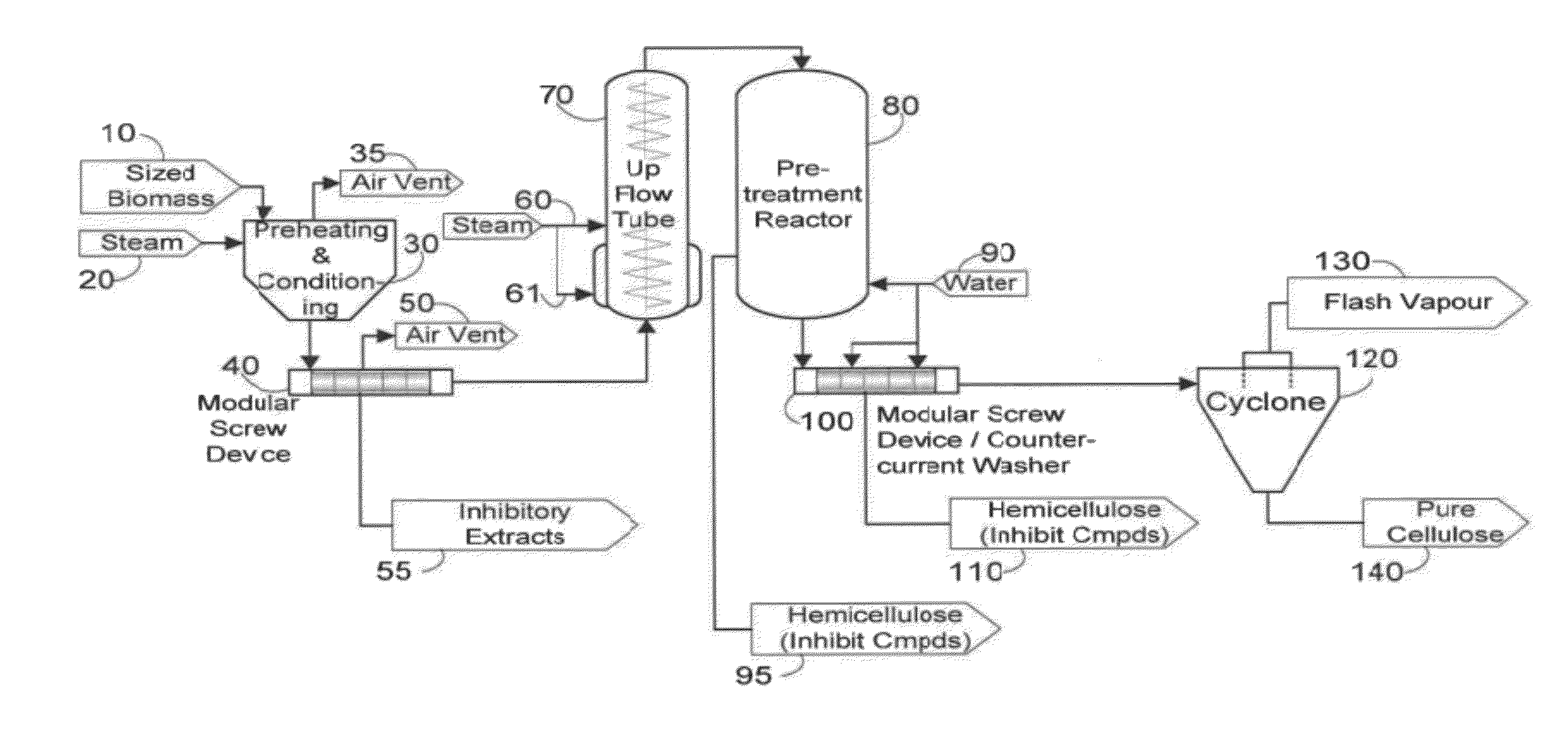

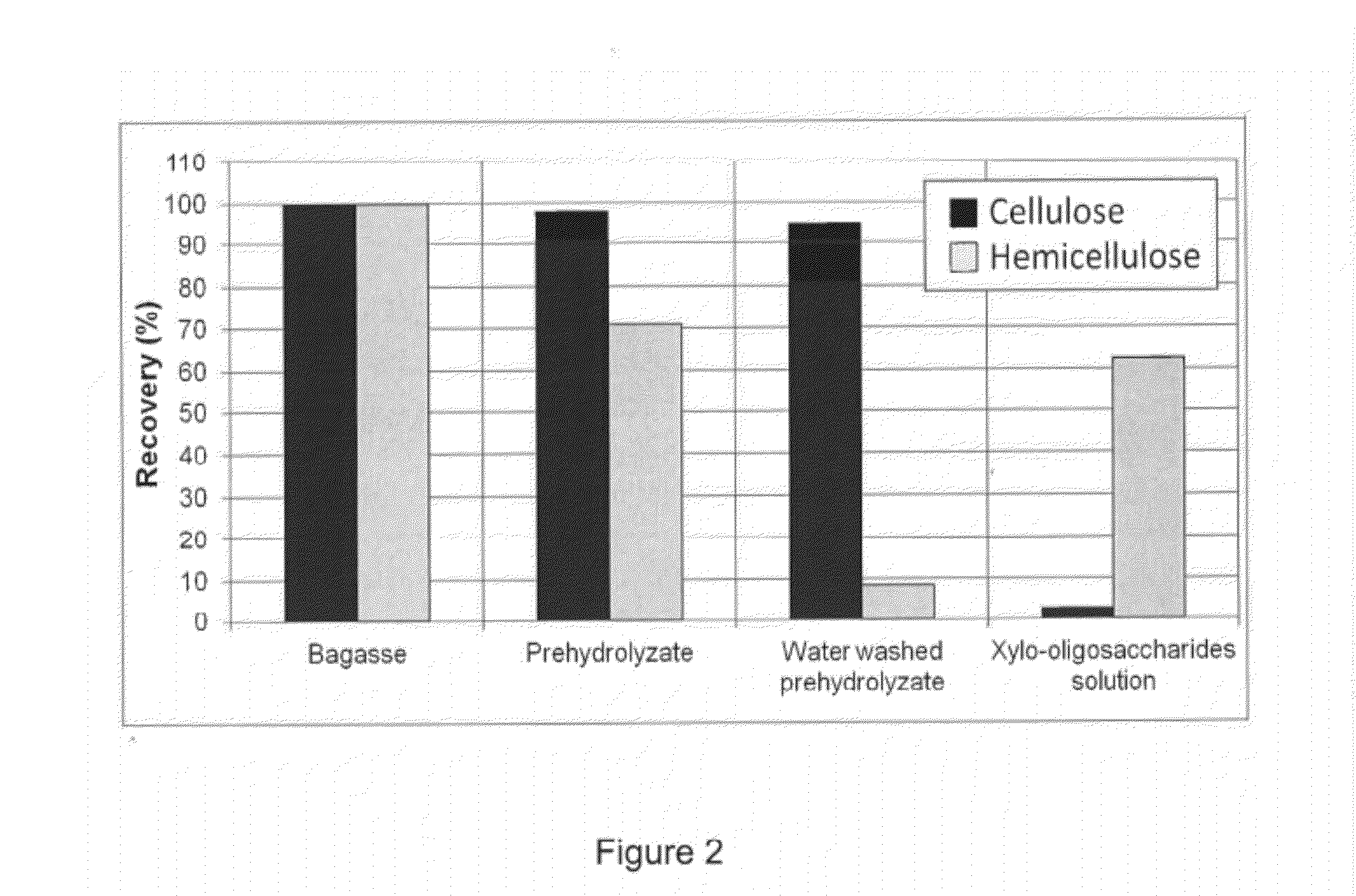

Bagasse fractionation for cellulosic ethanol and chemical production

InactiveUS20120111514A1Reduce contentHigh lignin contentPretreatment with water/steamPretreatment with alkaline reacting compoundsEnzymatic hydrolysisFractionation

A process is defined for the continuous steam pretreatment and fractionation of bagasse to produce a concentrated cellulose solid stream that is sensitive to enzymatic hydrolysis. Valuable chemicals are recovered by fractionating the liquid and vapor stream composed of hydrolysis and degradation products of the hemicellulose. Cellulosic derived glucose is produced for fermentation to biofuels. A hemicellulose concentrate is recovered that can be converted to value added products including ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Method for preparing straw cellulose nano crystal whisker

InactiveCN104805722AReduce crystallinityReduce intensityPretreatment with alkaline reacting compoundsRaw material divisionHazardous substanceWhiskers

The invention provides a method for preparing straw cellulose nano crystal whisker. The method is characterized by comprising the steps: utilizing crop straws as raw materials, performing pretreatment and cellulose purifying treatment, mechanically grinding into straw cellulose powder; performing DMSO (Dimethylsulfoxide) treatment and TEMPO (Tetramethylpiperidine) oxidation treatment and stirring at high speed, thereby obtaining straw cellulose powder suspension liquid; performing centrifugal treatment, decentralized treatment and freezing and drying, thereby obtaining straw cellulose nano crystal whisker. The preparation process is simple and has high yield and low energy consumption; no toxic and harmful matters are discharged during production and the preparation process has a capability of large-scale promotion and application; utilized straws can be wastes of plant crops such as rice straws, wheat straws and oilseed rape straws; the raw material has wide source and cost is low; pollution to the environment is solved and additional value of straws is improved.

Owner:DONGHUA UNIV

Paper-making-stage bamboo wood pulp plate denaturalization producing technique

ActiveCN101148836ADip evenlyFully impregnatedPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making bamboo pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making bamboo pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

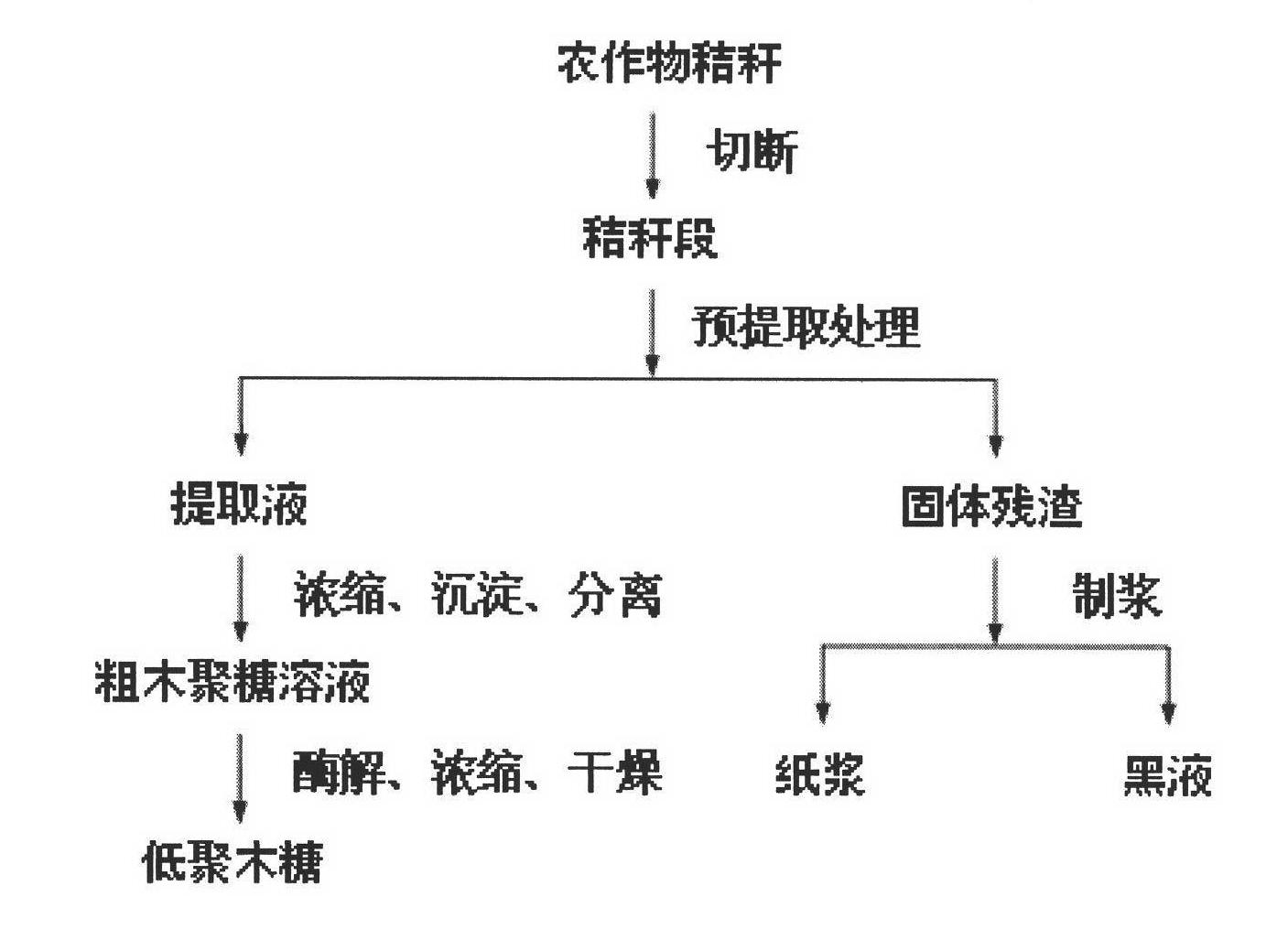

A kind of method for preparing xylo-oligosaccharide and paper pulp

ActiveCN102277761AImprove fiber qualityImprove physical performance indicatorsPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberOligosaccharide

The invention discloses a method for preparing oligosaccharide and paper pulp, belonging to the technical fields of pulping and the comprehensive utilization of pulping. The method comprises the steps of: using crop straws as raw materials, pre-treating the raw materials to obtain a pre-extracting solution, concentrating the pre-extracting solution by a membrane separation method, then obtaining a crude xylan solution via precipitation and centrifugal separation, and then preparing oligosaccharide via enzymolysis, vacuum concentration and frozen-drying. The pre-treated solid residues are stewed via an alkaline process so as to prepare unbleached paper pulps of which the indexes such as fiber length, whiteness, fracture length, tear resistance, folding strength and the like are all improved. The generated black liquid has the characters of low viscosity and high heat productivity. The method for preparing oligosaccharide and paper pulp integrates the comprehensive utilization method with the biomass transformation method on the premise of optimizing the traditional alkaline chemical pulping technique to prepare products with high additional values, namely oligosaccharide, thereby increasing the quality of the paper pulp and the extraction, vaporization and combustion performances of the black liquid.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Biomass pretreatment process

ActiveUS20110114876A1Pressurized chemical processPretreatment with alkaline reacting compoundsCelluloseLignocellulosic biomass

A process is disclosed for pretreating lignocellulosic biomass. The process comprises swelling the lignocellulosic biomass with an aqueous liquid. The pretreated lignocellulosic biomass may be used as a feedstock for the enzymatic conversion to ethanol, or in a thermal conversion process to produce bio-oil. The pretreatment results in a greater yield and, in the case of a thermal conversion process, a better quality of the bio-oil.The pretreatment process may be used to adjust the composition and amount of inorganic material present in the lignocellulosic biomass material.

Owner:MARD INC

Bamboo fiber processing process

InactiveCN1587504AApplicable to the needs of comprehensive utilizationImprove mechanical propertiesPretreatment with alkaline reacting compoundsContinuous pulping processPre treatmentFiber orientation

The present invention relates to the technological scheme of treating bamboo fiber. The treating process of bamboo fiber includes the following steps: pre-treating via cutting bamboo, scraping out green skin and rolling; soaking the pre-treated bamboo in pre-treatment pond with Ca(OH)2 solution of 5-10 wt% concentration for 10-30 days to obtain coarse bamboo fiber; and flushing in the flushing pond to eliminate impurity and obtain pure bamboo fiber. The present invention features that additive mixture comprising NaOH, Na2CO3 and NaHCO3 is added into pre-treatment pond. The present invention has the advantages of less investment, low cost, fast effect, cheap processing solution of Ca(OH)2 and small amount of additive, short processing period and raised mechanical performance of bamboo fiber.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Method of preparing bleaching dissolved pulp from corn stem

InactiveCN101058953AImprove use valueImprove economyPretreatment with alkaline reacting compoundsDigestersSlurryDissolving pulp

The present invention discloses method which prepares bleaching dissolved pulp using corn-straw, it slurries using the alkali mode of one boiling and three heating-up after impregnating corn-straw in alkaline solution. It includes the production steps: preparing raw materials, dipping, feeding, boiling, washing materials, beating, former classification, chlorin-alkalization, bleaching, acid treatment, washing in water, rear classification, coarsing pulp and preparing the products. The method can produces the corn-straw into high grade slurry used for preparing viscose fiber, the slurry boiled is easier to be bleached, and the method has simple technology and easy operation, it greatly reduces the heavy environmental pollution caused by the waste disposals of pulping waste liquid after pulping production.

Owner:CHTC HELON

Preparation process of nano cellulose whisker

InactiveCN104674586AReduce usageCreate pollutionPretreatment with alkaline reacting compoundsPulp bleachingTest sampleWhiskers

The invention relates to a preparation process of a nano cellulose whisker. The preparation process comprises the following steps: (1) preparing a test sample; (2) carrying out pretreatment, and removing green bark; (3) carrying out flash explosion-ultrasonic degumming; (4) carrying out bleaching; and (5) preparing a mulberry bark nano cellulose whisker suspension solution. By adopting a flash explosion-ultrasonic degumming process, compared with those when a chemical degumming process is adopted, the use amount of a chemical reagent can be reduced, consumed energy is reduced, the environment pollution is avoided, the dispersion property of the mulberry bark nano cellulose whisker can be improved, and the subsequent processing can be relatively well facilitated.

Owner:HAO YU ADDITION AGENT

Etherification and oxidization method for preparing cellulose nano crystal whiskers

InactiveCN104805723AAchieve preparationIncrease added valuePretreatment with alkaline reacting compoundsRaw material divisionFiberMechanical crushing

The invention provides an etherification and oxidization method for preparing cellulose nano crystal whiskers. The etherification and oxidization method is characterized by comprising the following steps: taking plant fibers with low cellulose content as raw materials; carrying out pre-treatment, etherification treatment and alkali treatment; carrying out mechanical crushing to obtain plant cellulose powder; carrying out TEMPO oxidization treatment, and stirring at a high speed to obtain a plant cellulose powder suspension solution; and carrying out centrifugal treatment, dispersion treatment, freezing and drying to prepare the cellulose nano crystal whiskers. The etherification and oxidization method has a simple preparation process, high yield and low energy consumption; in a production process, no toxic and harmless substances are discharged, and the method has a large-scale popularization and application potential; the used plant fibers can be jutes, straws, cotton stalk peels and the like, and have a wide raw material source and low cost; the environmental pollution problem is solved and the addition value of the plant fibers is also improved.

Owner:DONGHUA UNIV

Novel cellulose extraction process

ActiveCN101748633ALight colorThe solution cannot be appliedPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

Biomass treatment for hydrothermal hydrocatalytic conversion

InactiveUS20150167238A1Reduced effectivenessMinimize amount of waterPretreatment with water/steamPretreatment with alkaline reacting compoundsCatalytic transformationHydrodeoxygenation

A selective removal of metal and its anion species that are detrimental to subsequent hydrothermal hydrocatalytic conversion from the biomass feed prior to carrying out catalytic hydrogenation / hydrogenolysis / hydrodeoxygenation of the biomass in a manner that does not reduce the effectiveness of the hydrothermal hydrocatalytic treatment while minimizing the amount of water used in the process is provided.

Owner:SHELL OIL CO

Bamboo shoot shell treatment technique for dinnerware and method for producing dinnerware from bamboo shoot shell

InactiveCN101148829AReduce pollutionIncrease incomePretreatment with alkaline reacting compoundsDomestic articlesFiberAdhesive

The present invention discloses process of treating bamboo shoot coating for producing tableware and process of producing tableware with bamboo shoot coating. The process of treating bamboo shoot coating includes the following steps: 1. sorting material; 2. cutting, boiling in water, digesting in solution of sodium percarbonate or hydrogen peroxide and rinsing in water; and 3. dewatering, leveling, stoving and eliminating hair to form soft sheet of bamboo shoot coating fiber. The process of producing tableware with bamboo shoot coating includes the following steps: 1. cutting soft sheet of bamboo shoot coating fiber; 2. applying adhesive and intersectionally superposing; 3. high temperature molding and curing to form the semi-finished product; and 4. deburring to obtain the finished product. The production process is simple, environment friendly, low in power consumption and suitable for industrial production.

Owner:吴双登 +1

Process for treating biomass

ActiveUS20130289268A1Promote digestionIncrease enzyme digestibilityPretreatment with water/steamSugar derivativesMarine engineeringWater content

This invention is directed to a process for treating biomass. The biomass is treated with a biomass swelling agent within the vessel to swell or rupture at least a portion of the biomass. A portion of the swelling agent is removed from a first end of the vessel following the treatment. Then steam is introduced into a second end of the vessel different from the first end to further remove swelling agent from the vessel in such a manner that the swelling agent exits the vessel at a relatively low water content.

Owner:MICHIGAN BIOTECH INST

Clean pulping technology for high-polymerization-degree bamboo pulp

InactiveCN103382671ASolve difficult governance problemsReduce shockPretreatment with alkaline reacting compoundsPulp de-wateringMaterials preparationDissolving pulp

The invention belongs to the field of paper pulp manufacturing and particularly relates to a method for utilizing a bamboo raw material to produce high-polymerization-degree dissolving pulp. The method is characterized by comprising the steps of material preparation, prehydrolysis, hot alkali extraction, alkaline method cooking, oxygen bleaching, bleaching and acid treatment and the like, and the clean pulping method for the high-polymerization-degree bamboo pulp solves the problems that existing production raw materials for the high-polymerization-degree dissolving pulp is sufficient, the technology falls behind, and pollution is severe, and the like. The polymerization degree of the manufactured bleached bamboo pulp is over 2000, the whiteness is over (90+ / -2)%ISO, a-cellulose is over 96%, the ash content is below 0.1%, the Fe ion is below 20ppm, S18 is below 3%, S10 is below 4%, and (S10-S18) is below 2%.

Owner:SICHUAN KANGQI BIOTECH CO LTD

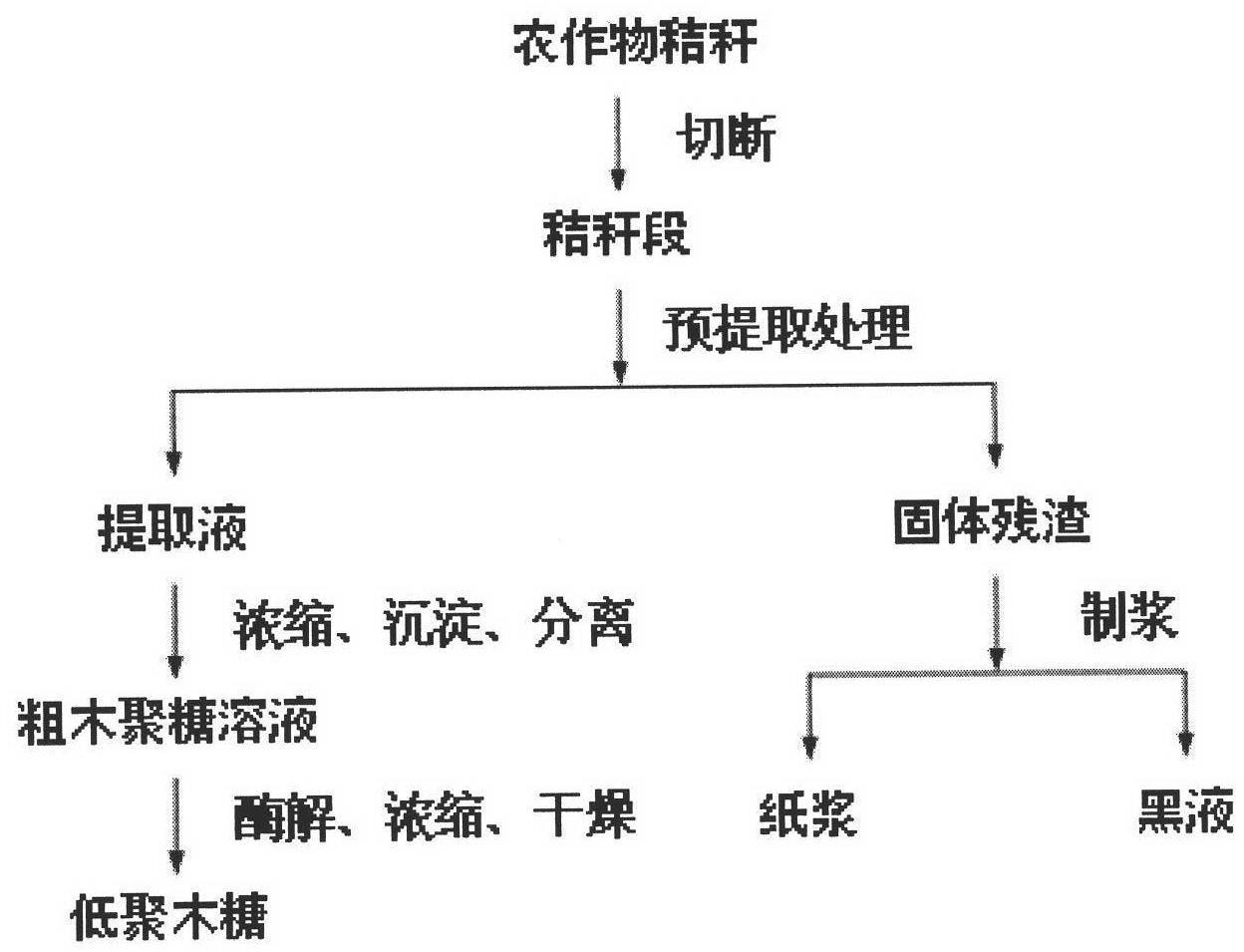

Alkaline process and system for producing pulp

InactiveCN101068977APretreatment with water/steamPretreatment with alkaline reacting compoundsCelluloseBlack liquor

A process and an apparatus for producing pulp from lignocellulosic material by an alkaline cooking process, in which process preheated chips are treated in an impregnation stage with impregnation liquor, which is taken from the impregnation stage, and concentrated to obtain both a high inorganic and organic dry solid content. The temperature is higher than in the heating of the chips and in the removal of air, and sufficient to enable the finishing of the reactions in the impregnation stage before the cooking stage. The majority of the alkali is added to the impregnation stage. In the cooking stage alkali is added to enable the delignification to be performed to a desired degree, and at the end of the cook black liquor is added to regulate the liquid-to-wood ratio. The process can be applied both to a continuous cook and to a batch cook.

Owner:METSO PAPER INC

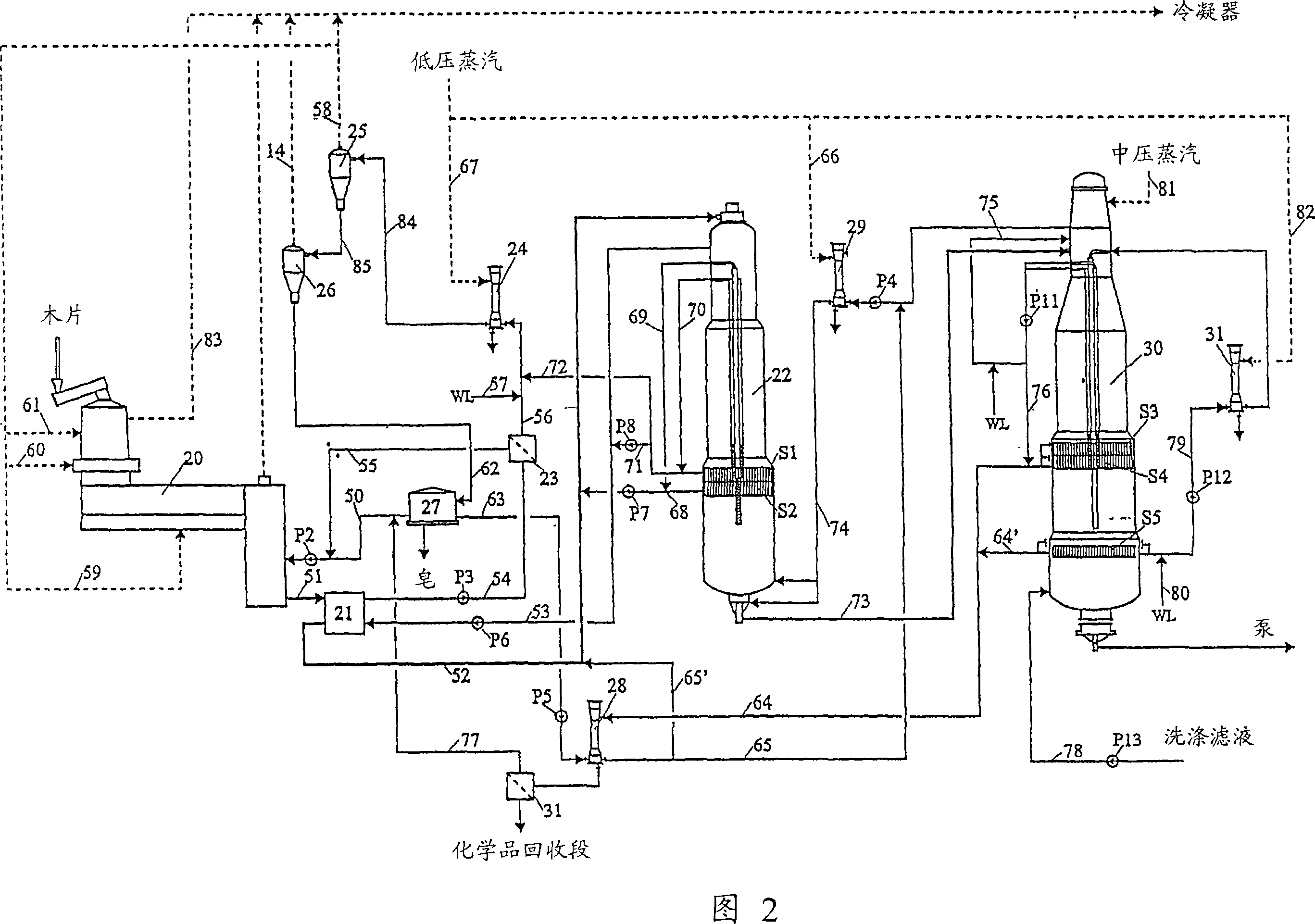

Paper making method for straw fiber pulping by 'enzymatic conversion and puffing'

InactiveCN1924187AReduce consumptionSimplify the pulping processPretreatment with alkaline reacting compoundsPaper/cardboardFiberWater discharge

This invention relates to one enzyme and puffing weed fiber pastry paper processing method, which combines biological science, life science and mechanic process to realize paper process without dirty water discharge. The method is characterized by the following: through grinding for clutter and mixture removing and cutting into short weed fiber materials into press machine; adding H2O2 solution and fiber enzyme B and induce agent C for pressing then for enzyme transmission and sending into puffing machine to get rough pastry.

Owner:汤兴然

Method and chemical composition to improve efficiency of mechanical pulp

InactiveUS20100224333A1Improved papermaking processReduce energy consumptionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpChemical compositionBrightness perception

The invention provides a composition of matter and a method, which enhance the process of mechanically pulping paper precursors. The composition of matter includes a small quantity of a reducing agent and a source of alkali. When added to the pulped material, e.g., wood chips, before or during mechanical pulping, the composition reduces the energy cost of the operation. In addition, not only does the composition also does not reduce the brightness of pulp, the composition can also enhance the effectiveness of subsequent bleaching processes.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com