Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3424results about How to "Achieve preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

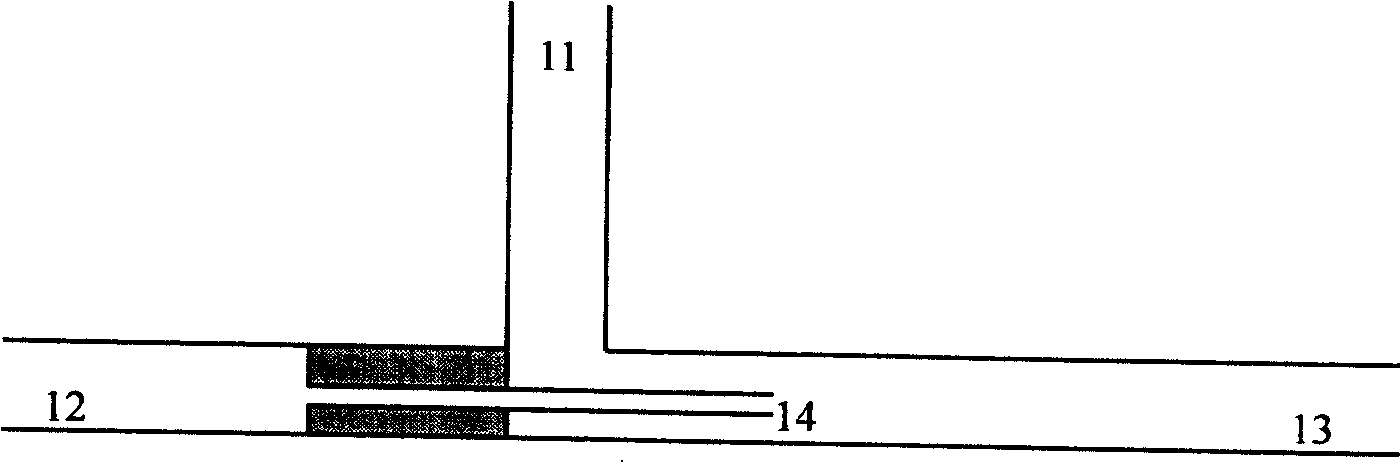

Preparation of microballoons based on microfluid

InactiveCN101279232ALow cost of preparationEasy integration and miniaturizationGranulation by liquid drop formationMicroballoon preparationMicrofluidic channelPolymer chemistry

Owner:NANJING DONGJIAN BIOLOGICAL TECH

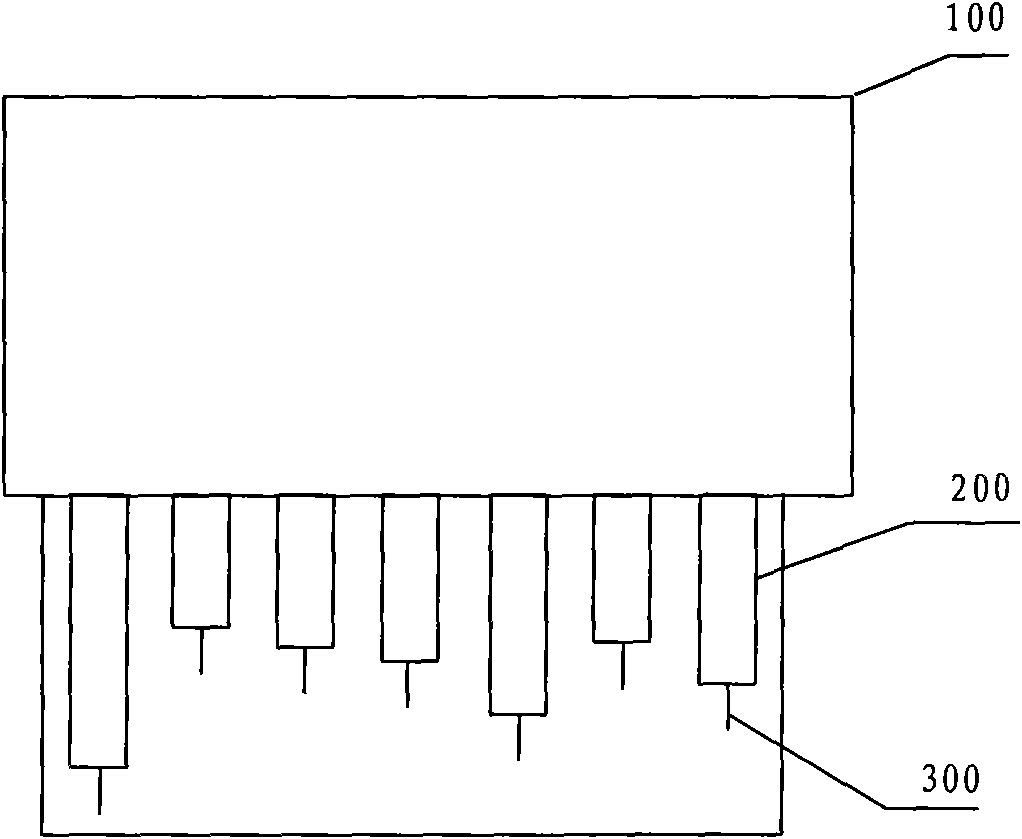

Method for manufacturing printed circuit board edge connector

ActiveCN101643927AAchieve preparationSolve residual problemsPrinted element electric connection formationEngineeringElectroplating

The invention discloses a method for manufacturing a printed circuit board edge connector, relates to the field of manufacturing process for a printed circuit board, and can solve the residue problemsof an edge connector plating lead of the printed circuit board. The method for manufacturing the printed circuit board edge connector comprises the following steps: forming the edge connector platinglead and an edge connector area on the printed circuit board once, wherein the width of adjacent parts of the edge connector plating lead and the edge connector area is equal to the width of the edgeconnector area; coating a covering substance to form an edge connector plating reserved area, and plating the edge connector plating reserved area to form the edge connector; and removing the covering substance, and etching the edge connector to obtain the edge connector without the plating lead. The method is suitable for manufacturing the edge connector without the lead for the printed circuitboard.

Owner:NEW FOUNDER HLDG DEV LLC +2

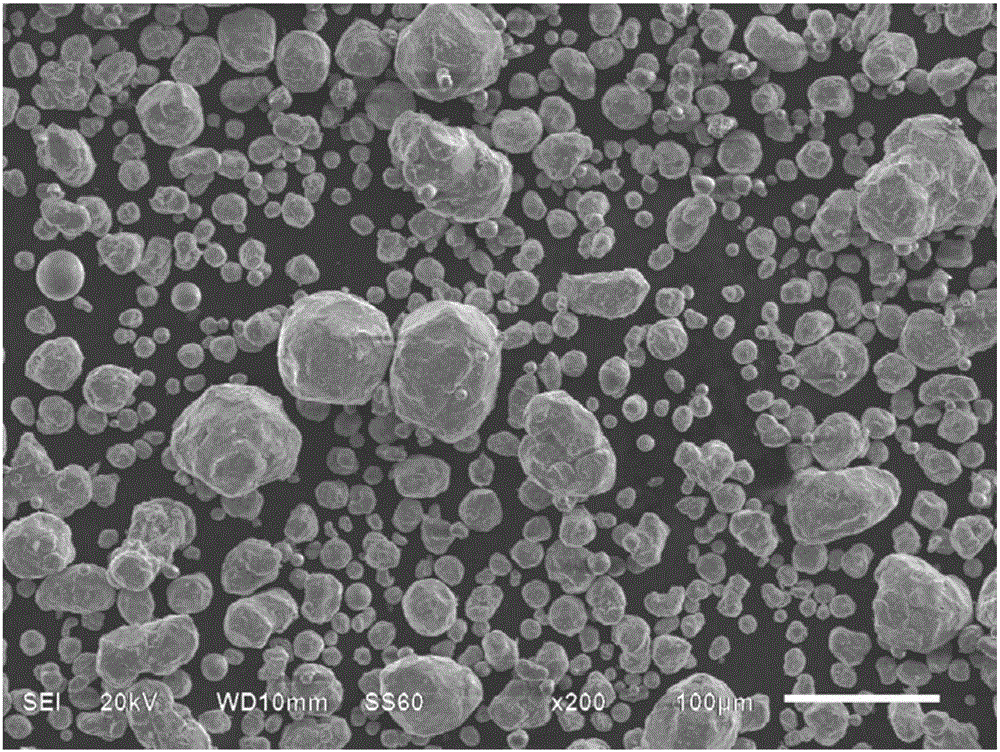

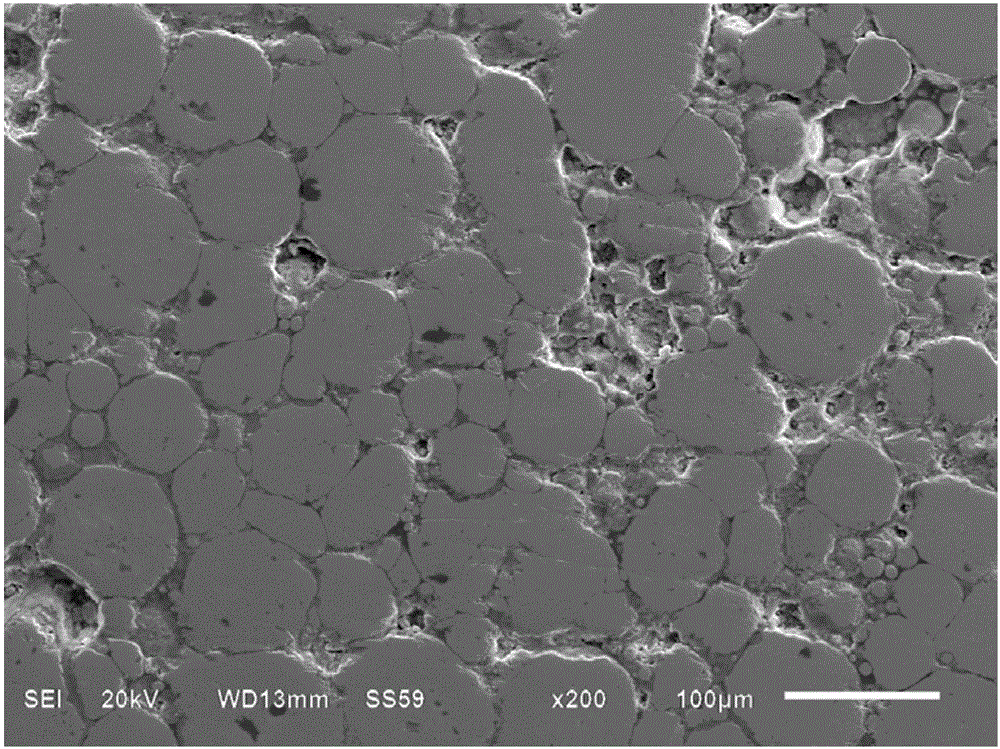

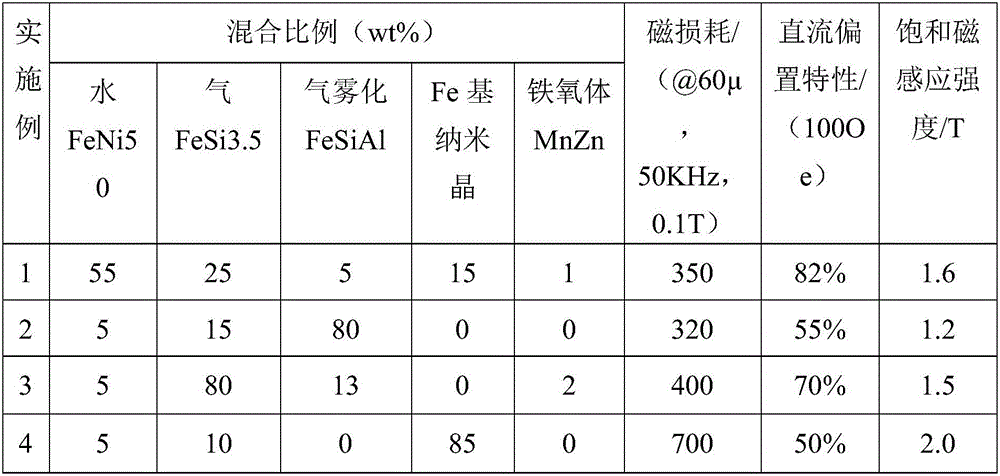

Soft magnetic composite powder and magnetic powder core preparation method thereof

InactiveCN106229104AHigh bulk densityCost-effectiveTransportation and packagingMetal-working apparatusPowder metallurgyMagnetic powder

The invention relates to soft magnetic composite powder and a magnetic powder core preparation method thereof, and belongs to the technical field of powder metallurgy and magnetic materials. According to different magnetic performance characteristics of metal soft magnetic powder, amorphous and nano-crystalline powder and ferrite powder, magnetic performances are linearly calculated and optimally designed, so that the requirements of different magnetic properties are met. Besides, powder sizes are calculated and coordinately designed, the powder is shaped, screened, annealed, coated in an insulated manner and mixed, and the powder with different components is respectively passivated and insulated, weighed according to weight ratio and uniformly mixed to form the composite powder. The prepared soft magnetic composite powder is regular in morphology and good in dispersity and has good apparent density and flowability. In addition, the magnetic performance of a magnetic powder core prepared from the soft magnetic composite powder can be calculated and designed as required, the magnetic powder core has high cost performance and good comprehensive magnetic performance, and the blank of the performance and application of an existing magnetic powder core is effectively filled in.

Owner:BEIJING COMPO ADVANCED TECH

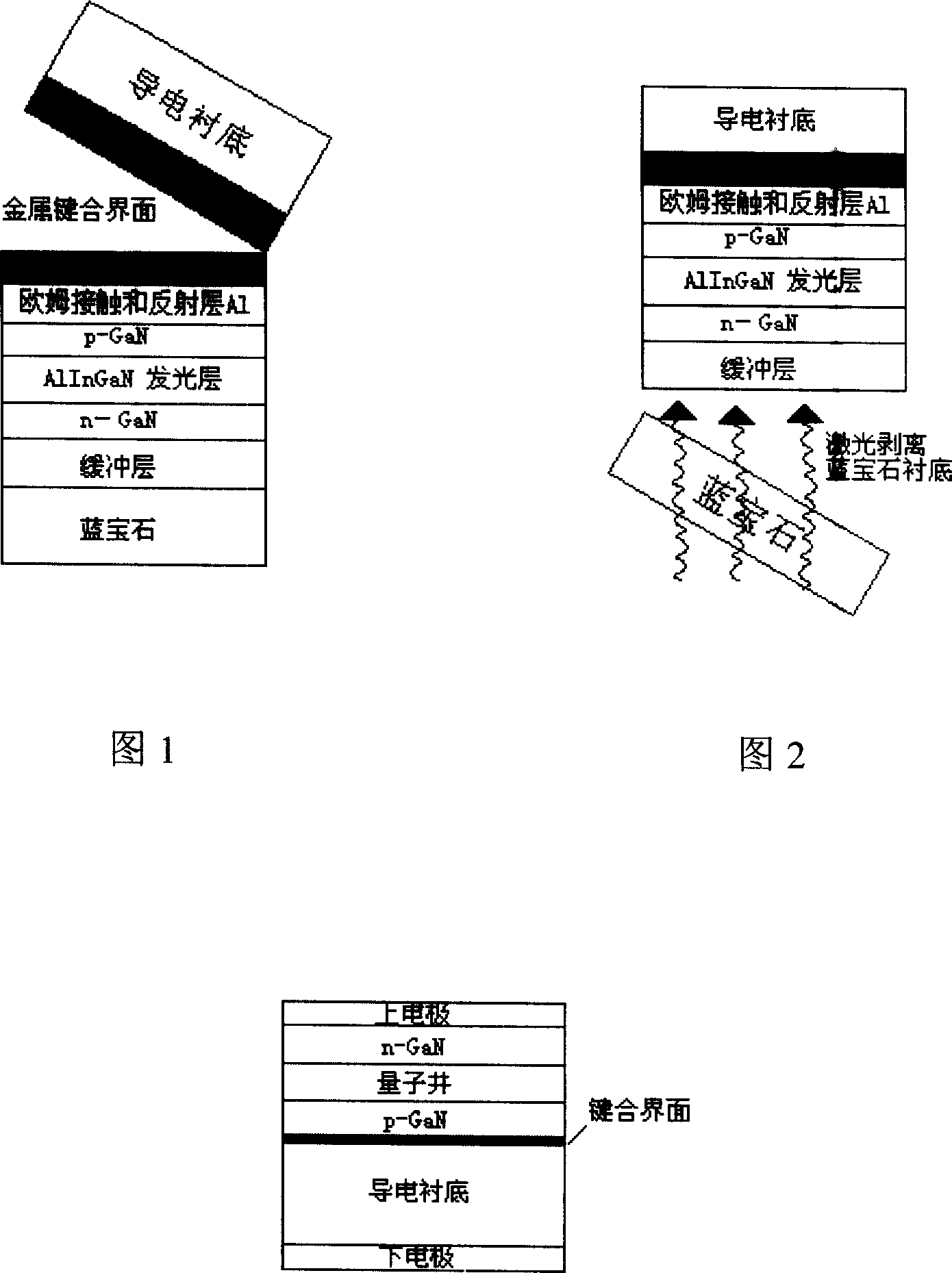

Method for realizing gallium nitride ELD vertical structure using metal bounding process

InactiveCN101005110AImprove yieldAchieve preparationSemiconductor devicesOhmic contactGallium nitride

Using metal bonding technique in diffusion bonding form, the method bonds gallium nitride LED developed and prepared on sapphire and silicon chip in low resistance together, and realizes ohmic contact. Advantages are: stable bonding technique, high ratio of good produced parts, small area, using material of luminous layer fully, as well as good conductivity and heat conductivity of substrate.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

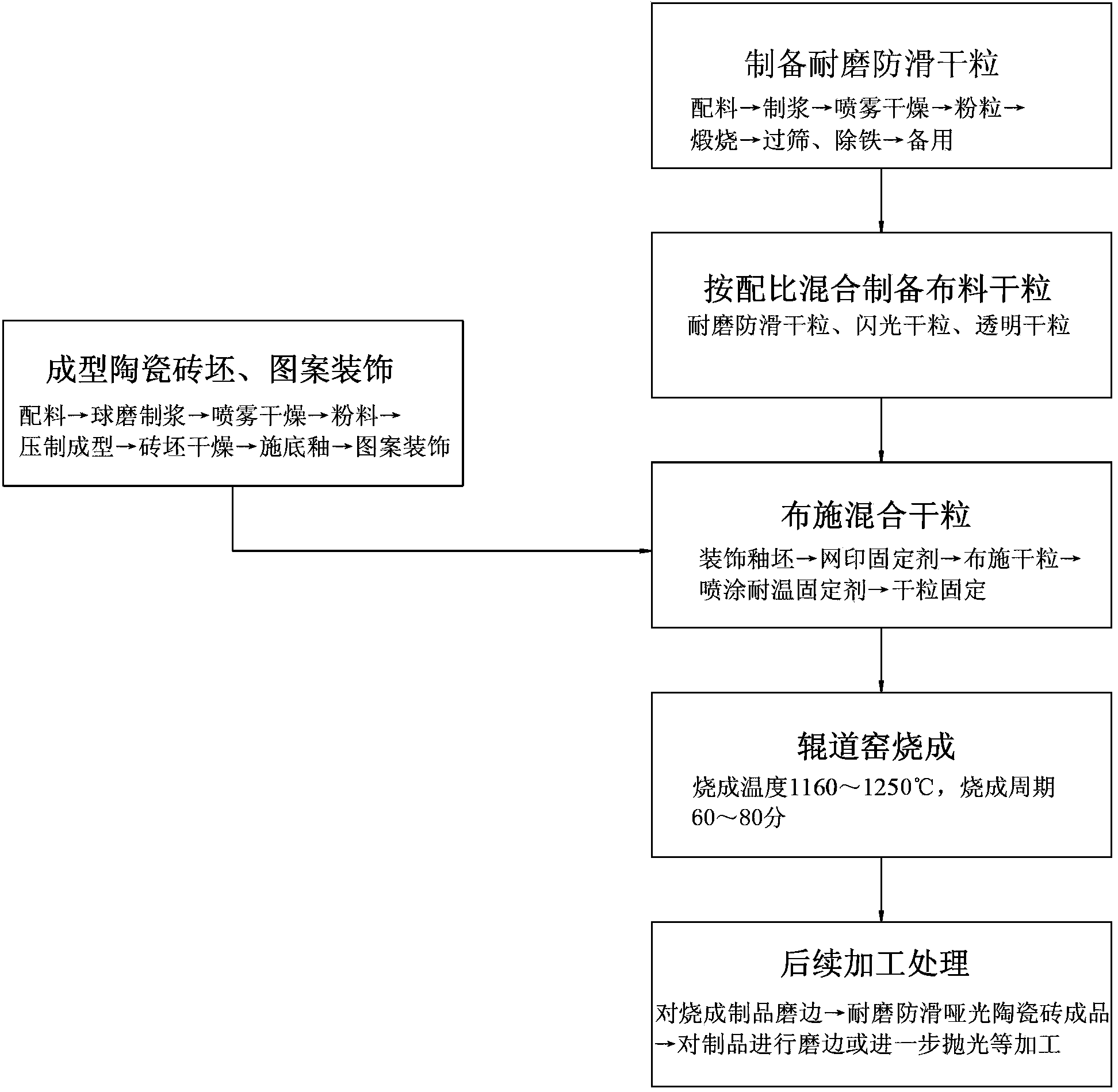

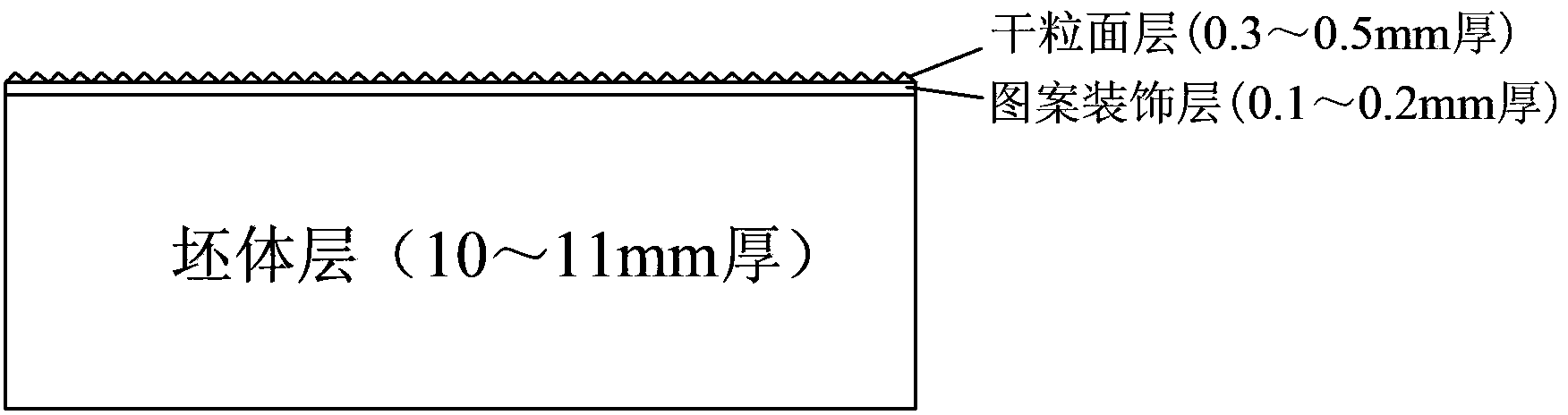

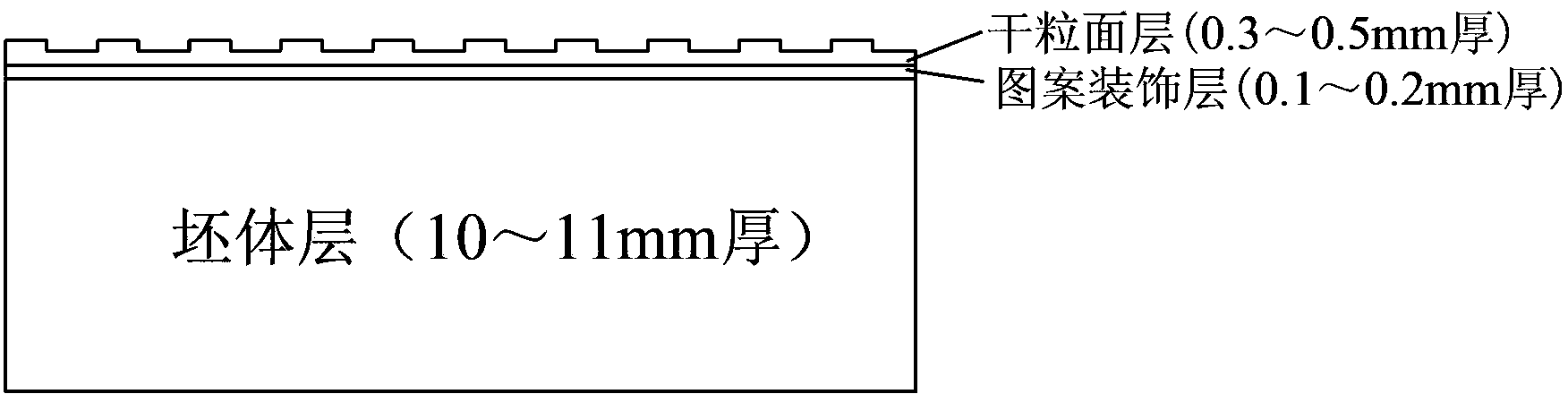

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

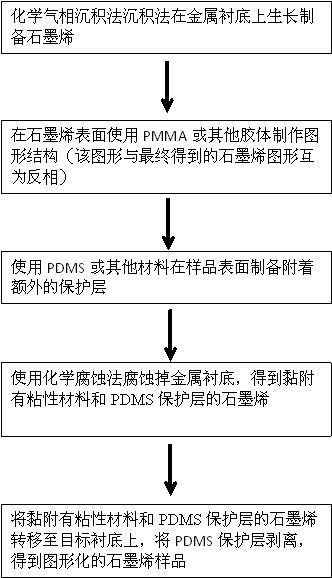

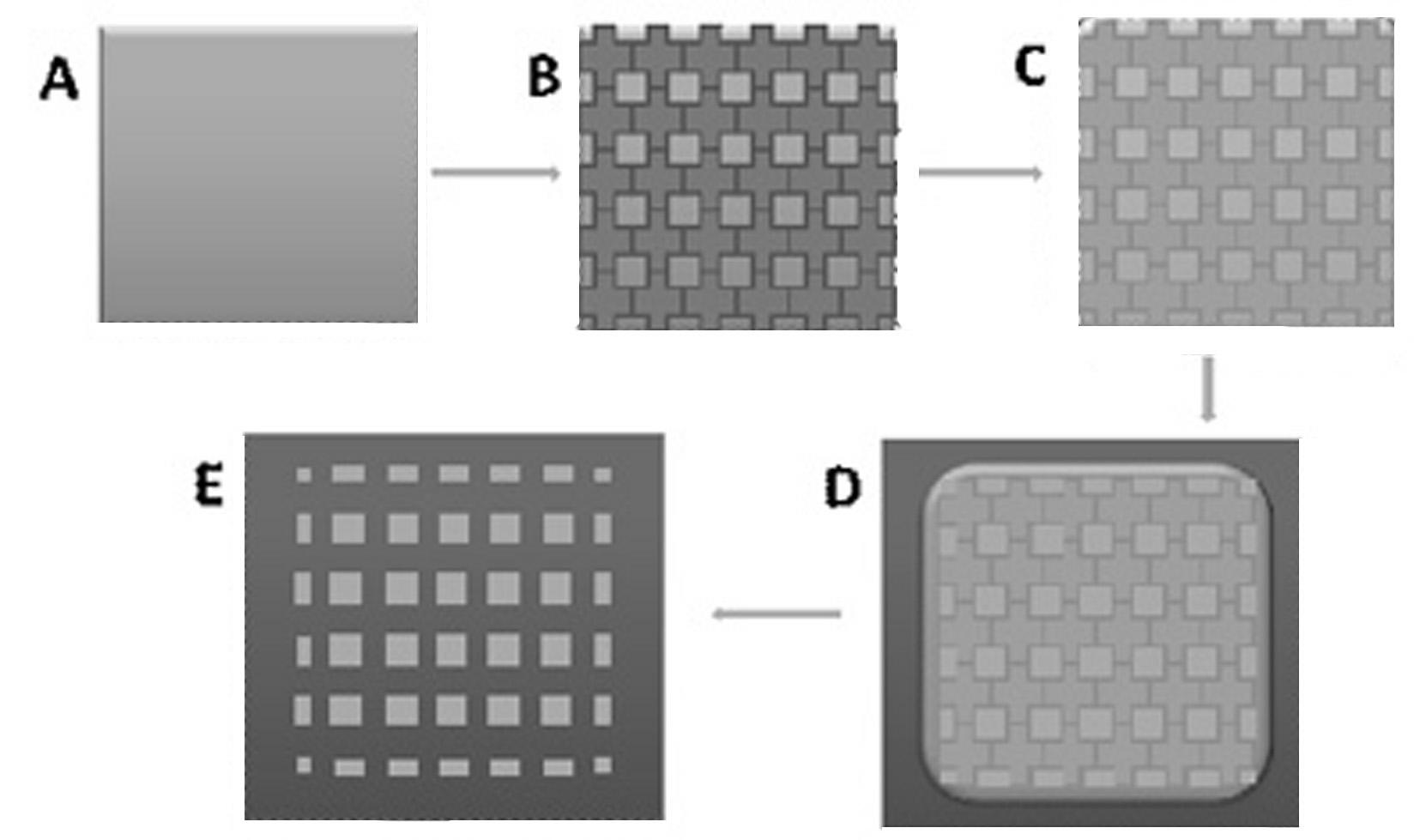

Transfer preparation method of patterned graphene

InactiveCN102637584ACause structural damageImprove cleanlinessSemiconductor/solid-state device manufacturingCvd grapheneAdhesive materials

The invention discloses a transfer preparation method of patterned graphene, which comprises the following steps: coating an adhesive material on a graphene surface, which grows on a catalytic metallic substrate, according to a designed pattern; coating a PDMS (polydimethylsiloxane) layer on the graphene surface, and thermosetting; soaking the obtained sample in an etching solution to remove the catalytic metallic substrate, so that the graphene with the adhesive material and the PDMS floats in the solution; transferring the graphene with the adhesive material and the PDMS onto a target substrate; and stripping the PDMS from the target substrate to obtain the patterned graphene. The method disclosed by the invention does not limit the use of materials of the target substrate; when stripping the PDMS, an expected pattern can be obtained without causing additional structure damage on the graphene, and meanwhile, the graphene surface is kept clean; and the invention can be used for preparing patterned graphene without expensive etching equipment.

Owner:LANZHOU UNIVERSITY

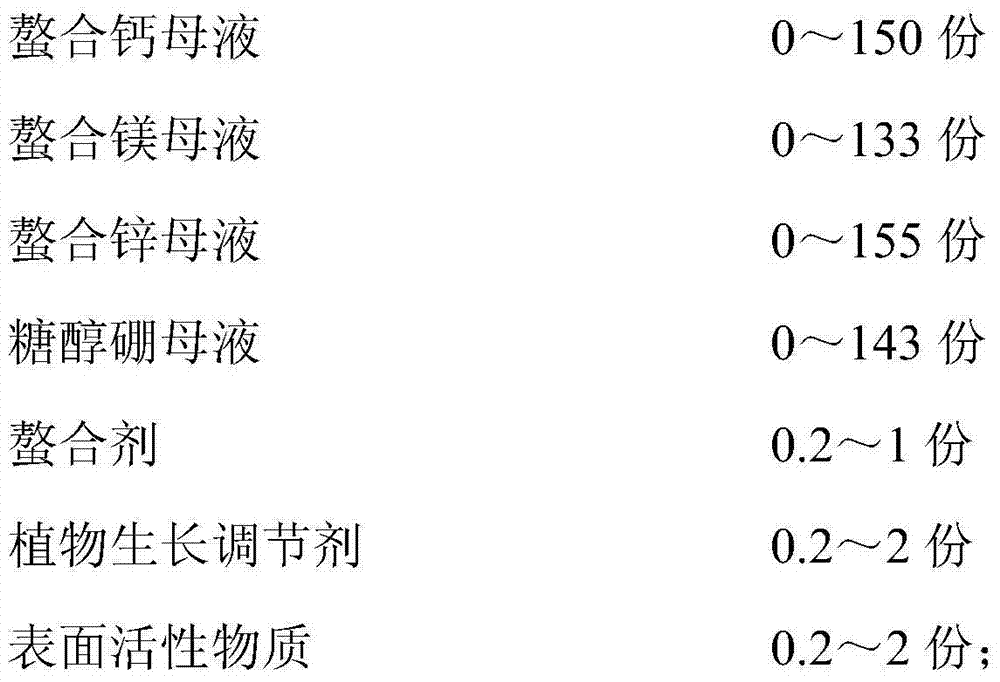

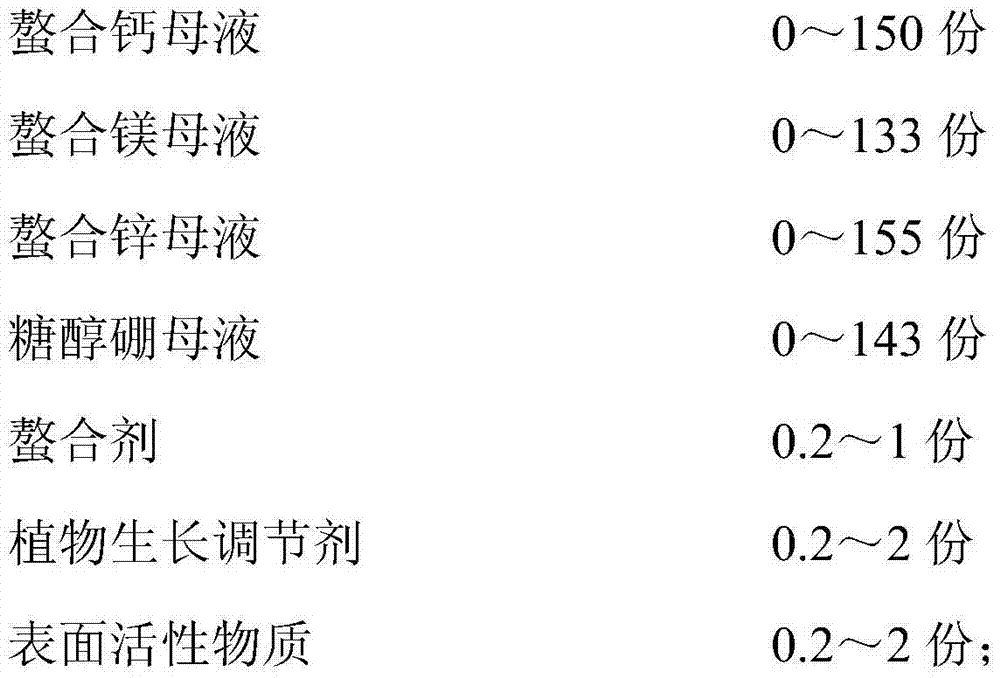

Sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and preparation method and applications thereof

ActiveCN103588564AAvoid reactionAchieve preparationFertilizer mixturesHigh concentrationMagnesium salt

The invention belongs to the field of agricultural production and discloses a sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and a preparation method and application thereof. The liquid fertilizer is prepared from various mother solutions, a chelating agent, a plant growth regulator and surface active materials. The preparation method comprises the following steps: causing sugar alcohol to respectively react with calcium salt, magnesium salt, zinc salt and boric acid to prepare calcium, magnesium, zinc and boron mother solutions, then mixing the mother solutions according to a certain ratio, and adding the chelating agent to cause the mother solutions to carry out secondary chelating reaction; after a while, adding the plant growth regulator and the surface active materials into reaction liquid, uniformly mixing, and cooling to the room temperature to obtain the high-concentration, stable and good-effect compound liquid fertilizer. The prepared liquid fertilizer provides adequate calcium, magnesium, zinc and boron and other nutrients for plants and can also carry out mixing of different elements and proportions according to the needs of different plants and different growth stages of plants.

Owner:SOUTH CHINA AGRI UNIV +1

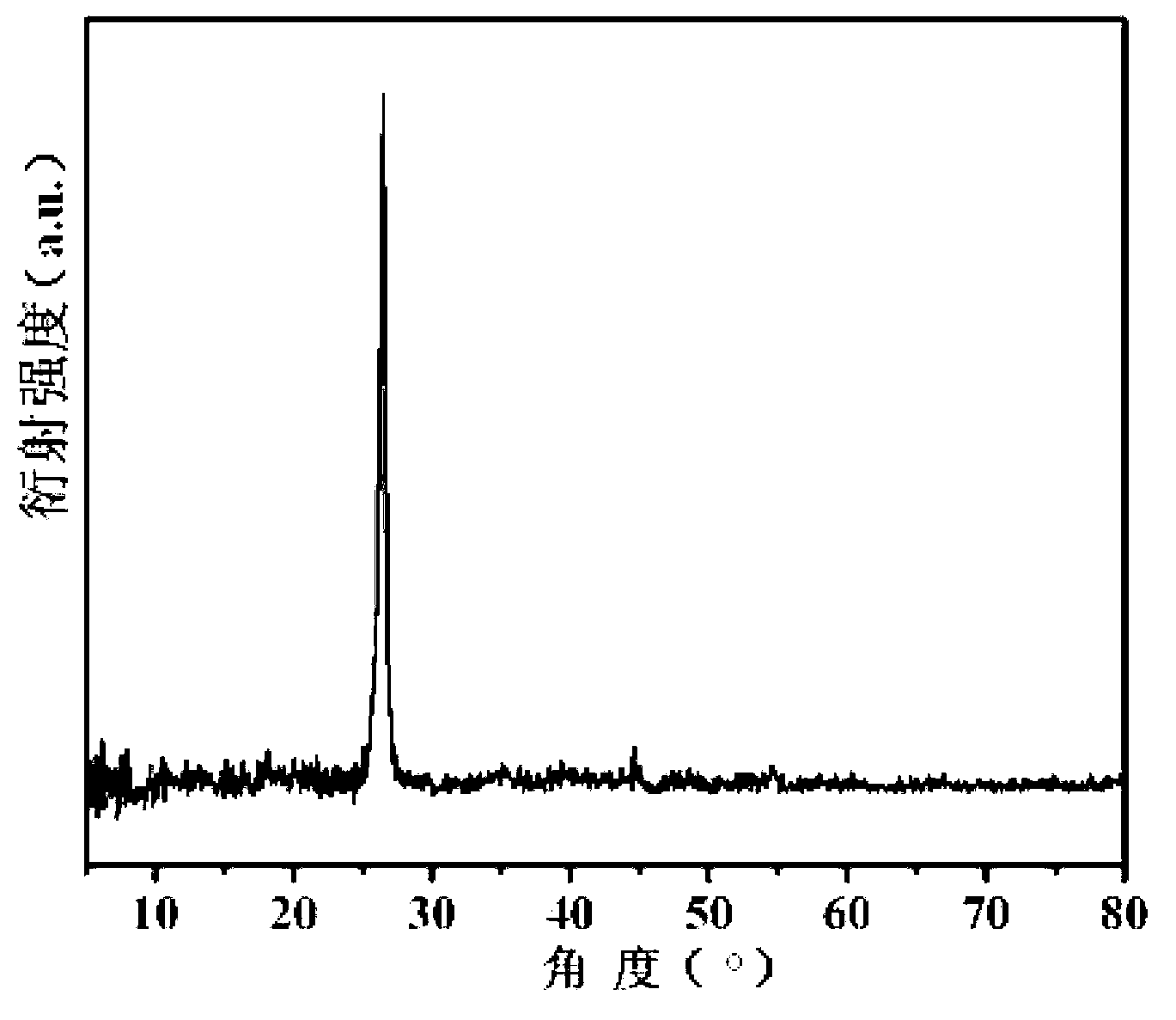

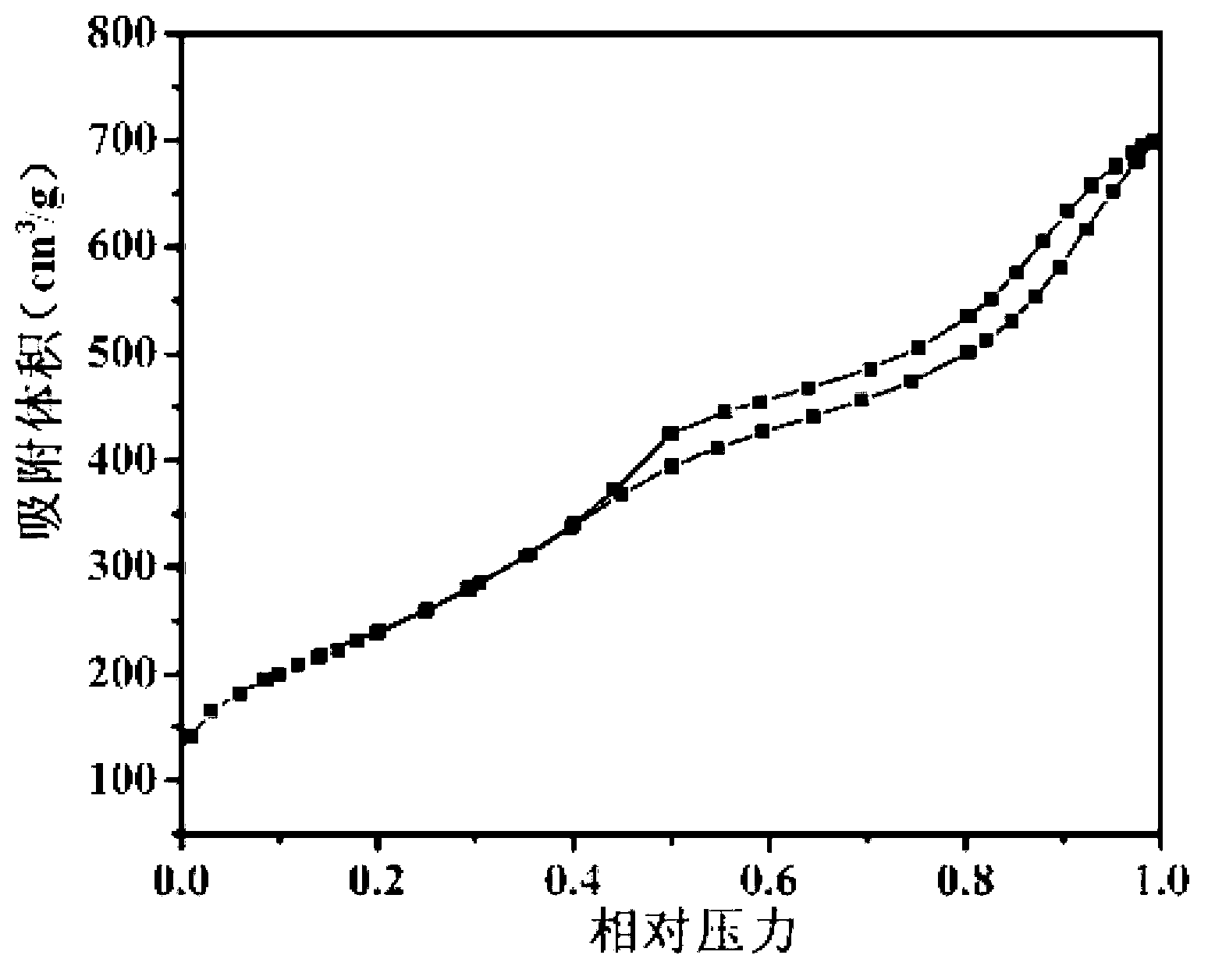

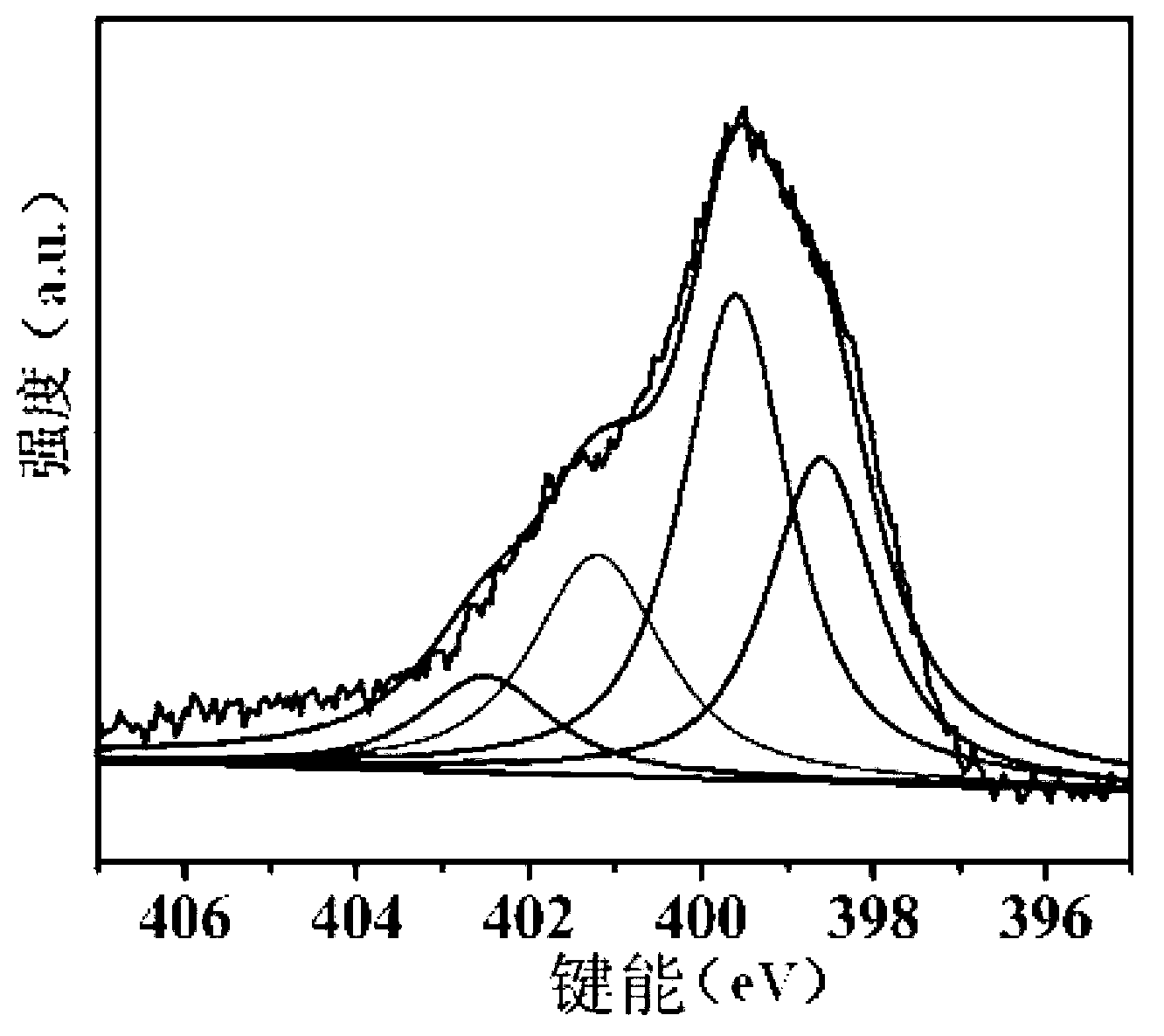

Preparation method of high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial

ActiveCN103303912AAchieve preparationHigh degree of graphitizationMaterial nanotechnologyNano-carbonLow nitrogenPore diameter

The invention discloses a preparation method of a high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial, relating to a preparation method of a carbon material and aiming at solving the problems of small specific surface area, low nitrogen content, low productivity, poor graphitizing degree and high cost of the nitrogen-doped graphitizing carbon nanomaterial prepared by the prior art. The preparation method comprises the steps of: I. preparing a complex; II. curing and carbonizing the complex; and III. carrying out acid leaching method treatment, and drying. Compared with an existing nitrogen-doped graphitizing carbon nanomaterial, the prepared high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has the advantages that the graphitizing degree is improved, the nitrogen content is increased, and the specific surface area is obviously increased, and the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has obvious pore diameter distribution. The preparation method is used for preparing the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial.

Owner:HEILONGJIANG UNIV

Preparation method of continuous oxide fiber reinforced oxide ceramic based composite

ActiveCN105254320AAvoid Density GradientsAvoid fiber strength loss or pulverizationSolventOxide ceramic

The invention belongs to the preparation technology of a continuous fiber reinforced ceramic based composite, and relates to a preparation method of a continuous oxide fiber reinforced oxide ceramic based composite. The technology comprises the steps that an organic ceramic precursor solution is utilized to serve as solvent to prepare slurry with ceramic powder, the slurry is smeared on the surface of oxide fiber fabric to prepare oxide fiber prepreg, the technological processes of laminating, mold pressing and sintering are conducted on the prepreg, a low-porosity ceramic based composite preform is obtained, the repeated processes of soaking and splitting are conducted by adopting an organic ceramic precursor, and the continuous fiber reinforced ceramic based composite with the ideal density is obtained. According to the preparation method of the continuous oxide fiber reinforced oxide ceramic based composite, the organic ceramic precursor is adopted to serve as the solvent to prepare the ceramic slurry, the organic ceramic precursor can play a role of bonder for bonding the ceramic powder, low-temperature inorganic characteristics of the organic ceramic precursor can be utilized, fiber is protected against thermal damage caused by high temperature in the composite preparation process, and the composite strength is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

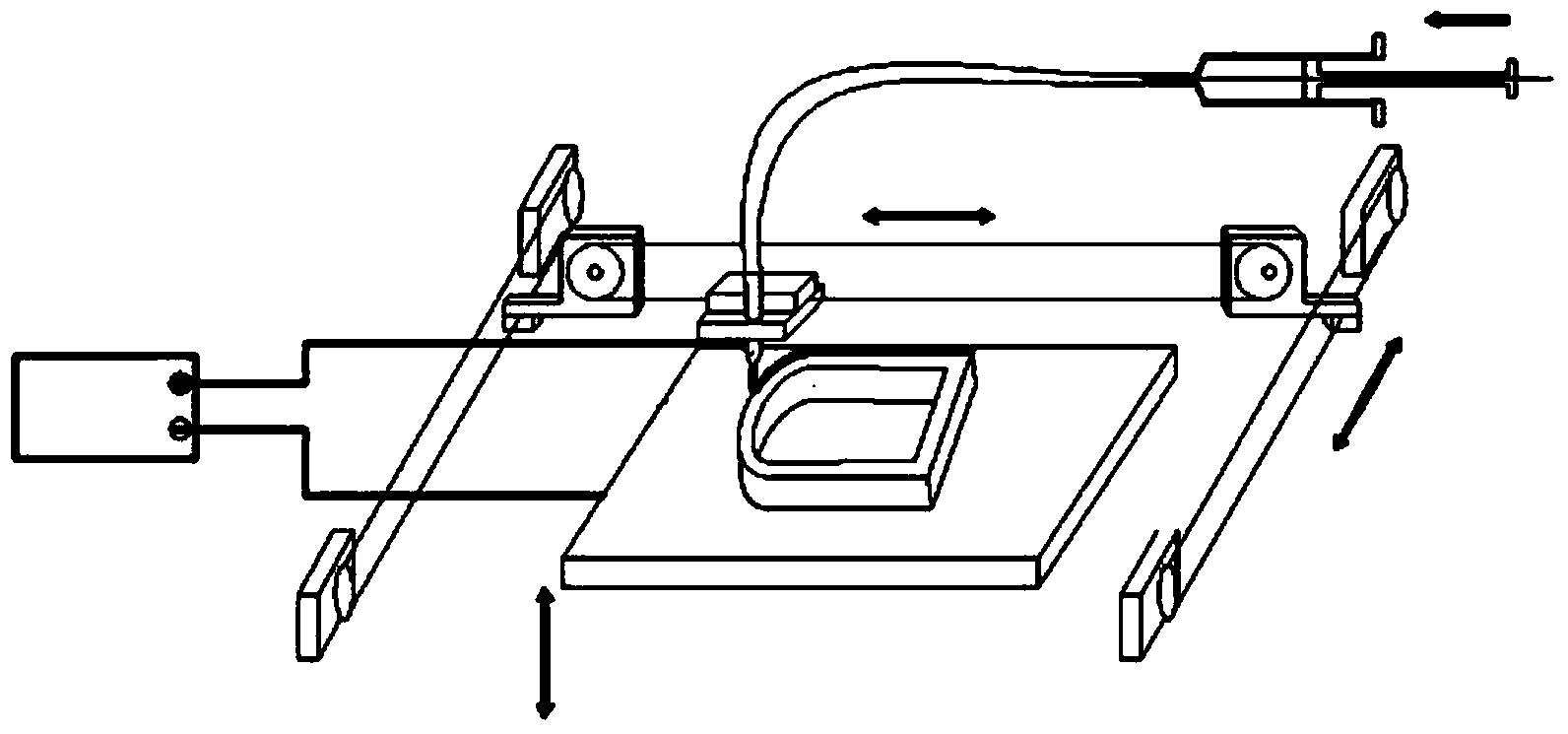

Three-dimensional (3D) printing method of micro-nano structure based on near-field electrostatic spinning

The invention discloses a three-dimensional (3D) printing method of a micro-nano structure based on near-field electrostatic spinning. According to the method, a layered manufacturing principle of a 3D printing technology is combined with a near-field electrostatic spinning droplet or micro-nano fiber filament forming control technology. The method comprises the following steps: firstly, designing a part model through a computer, and processing contour data and padding data of the model to obtain relative movement data of a spray nozzle and a receiving platform; secondly, preparing micro-nano liquid flow or micro-nano fiber filaments from material liquid by controlling factors such as voltage, receiving distance, flow speed, temperature and humidity; thirdly, orderly stacking the micro-nano liquid flow or the micro-nano fiber filaments through the relative movement of the spray nozzle and the receiving platform; and finally, performing layered manufacturing and layer-by-layer stacking to further form and manufacture the micro-nano structure. According to the method, the micro-nano structure can be quickly manufactured in a multi-material and low-cost manner.

Owner:XI AN JIAOTONG UNIV

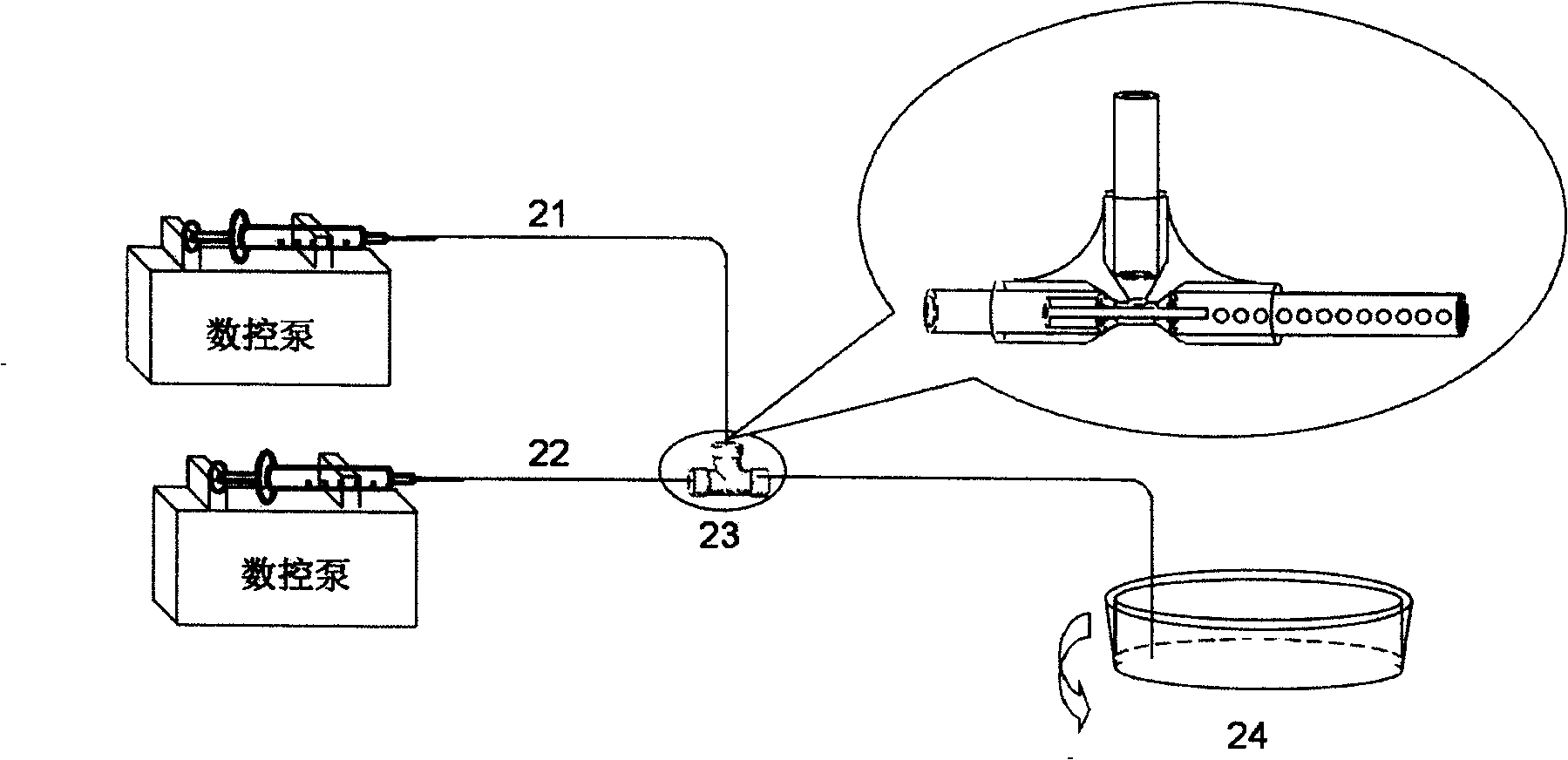

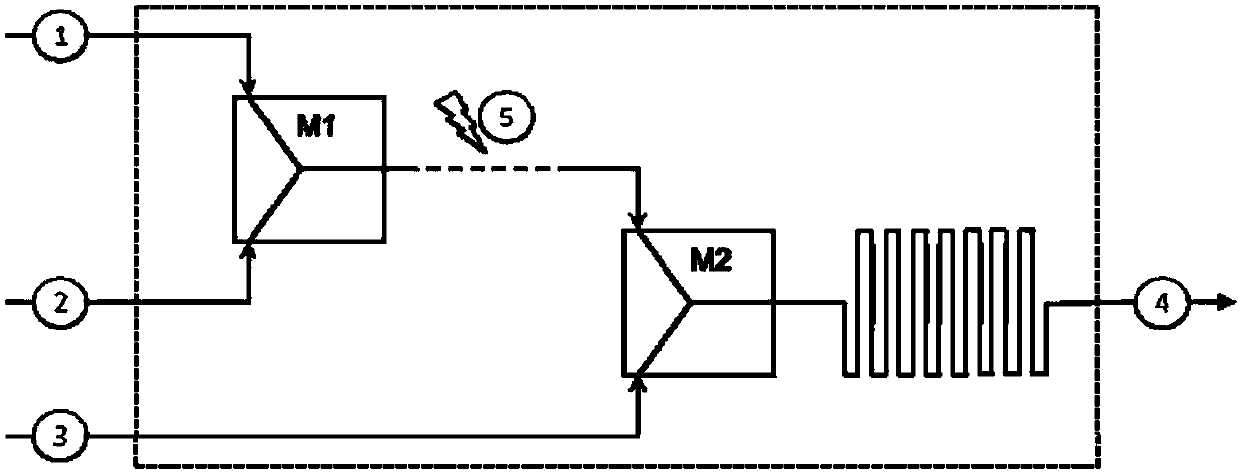

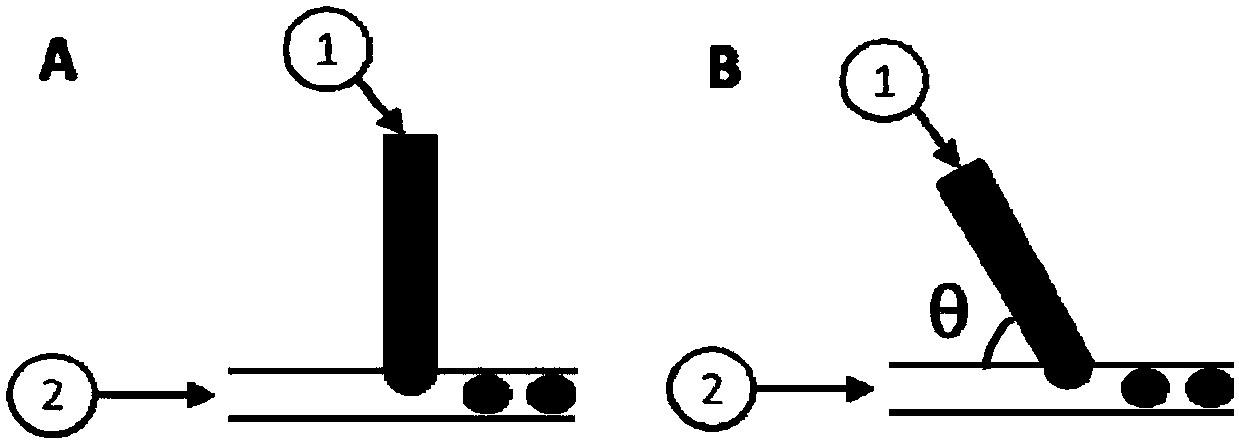

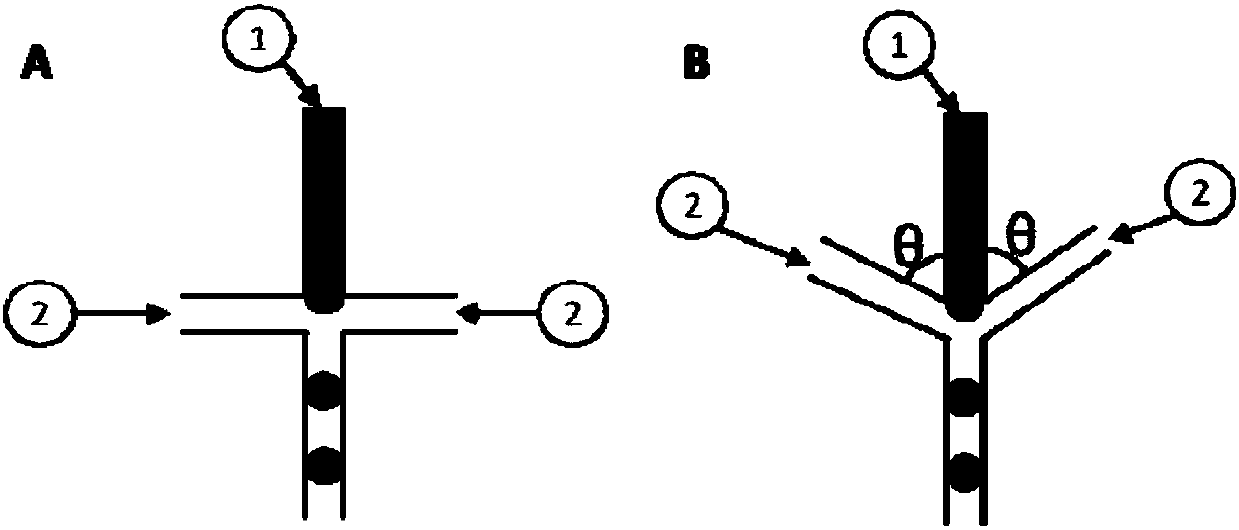

Microfluidic technology for one-step continuous preparation of calcium alginate microgel

ActiveCN107930542AFast shippingMaintain biological activityLaboratory glasswaresGel preparationOil phaseWater in oil emulsion

The invention relates to a microflow droplet technology-based method for one-step continuous preparation of multi-chamber calcium alginate microgel for immobilization of bioactive substances. The method realizes high-throughput continuous production of a microgel material. The method comprises forming a parallel and stable flow field through different hydrogel prepolymer solutions in a microfluidic channel, pouring the hydrogel prepolymer solutions for forming different chambers of the microgel into a microfluidic chip to form water phase solutions of multiple phase parallel fluids, mixing thewater phase solutions and an immiscible fluid (oil phase) through a T-shaped channel or a fluid focusing design to obtain water-in-oil emulsion drops and then alginic acid in the drops is linked immediately so that multi-chamber microgel is prepared, and cleaning the emulsion drops on the microfluidic chip so that the microgel is fast conveyed into a water phase. The method realizes one-step preparation of the calcium alginate microgel immobilized with bioactive substances and is suitable for industrial application.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

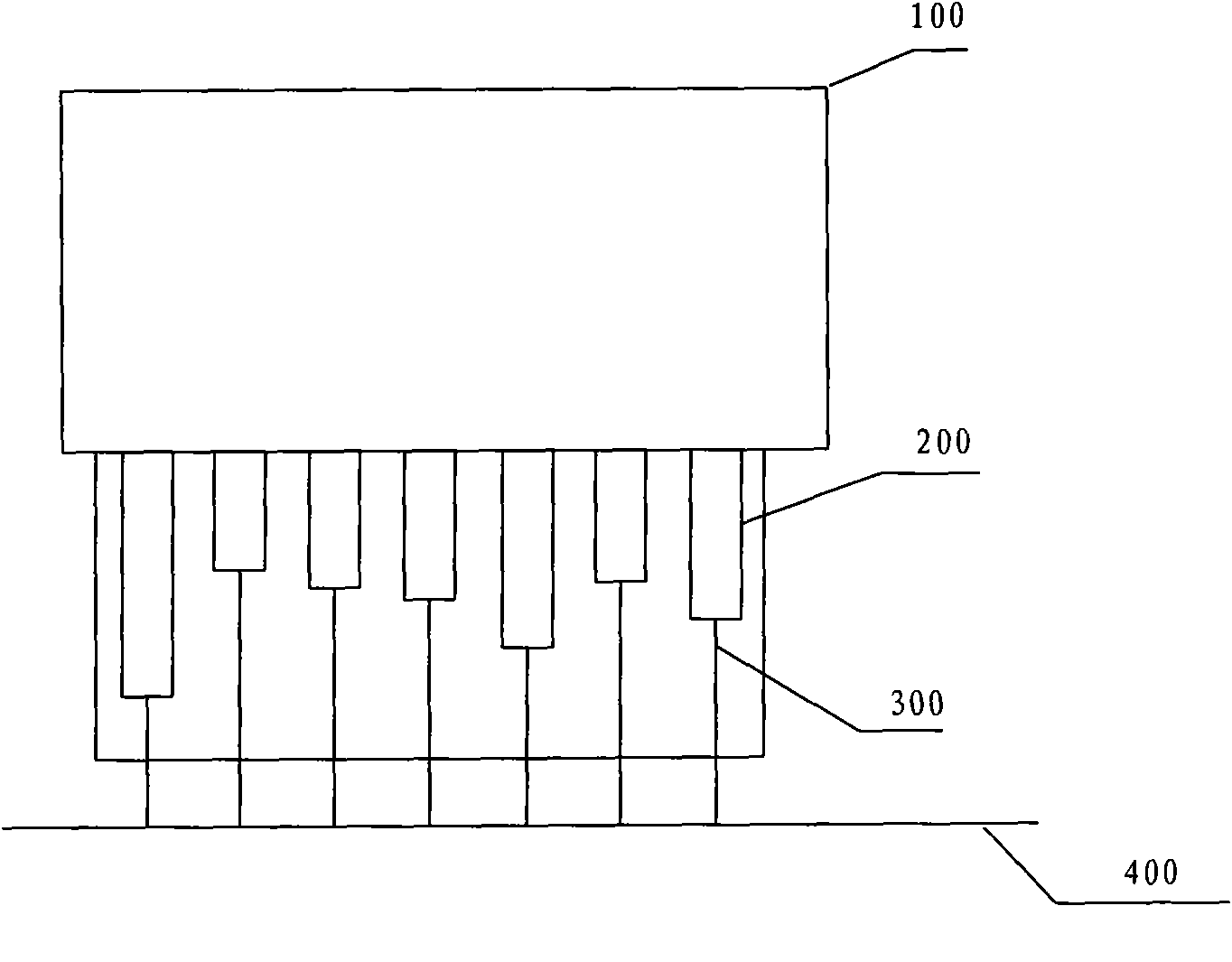

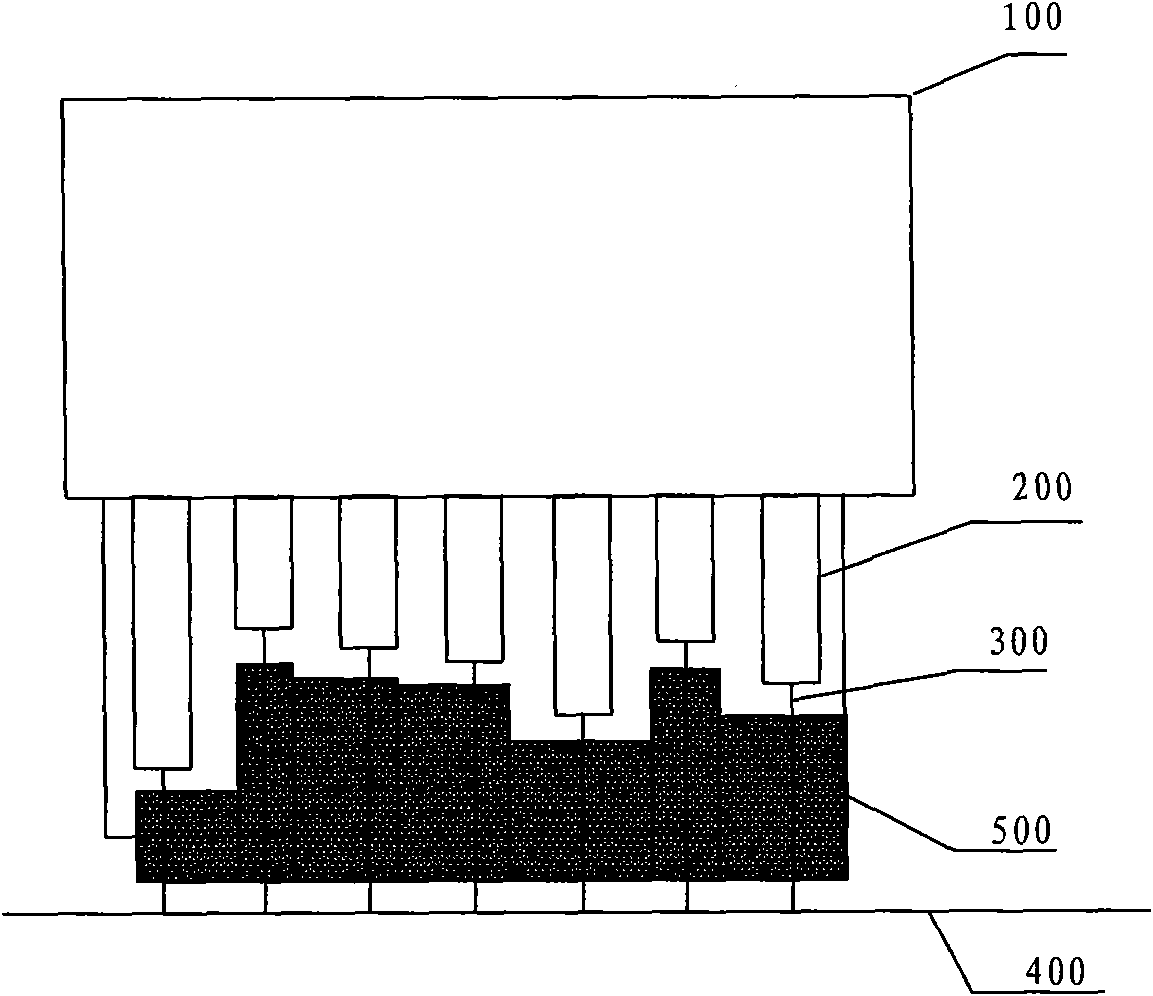

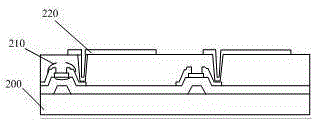

Pixel defining layer structure and manufacturing method thereof, display panel, and display apparatus

InactiveCN105206643ASmall sizeWon't overflowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a pixel defining layer structure and a manufacturing method thereof, a display panel, and a display apparatus. The pixel defining layer structure comprises a first pixel defining layer and a second pixel defining layer disposed on the first pixel defining layer, wherein the first pixel defining layer is provided with multiple first openings in one-to-one corresponding to the luminescence area of each sub pixel, and the second pixel defining layer is provided with multiple second openings shared by an area formed by connecting sub pixels having the same color. Through the pixel defining layer structure provided by the invention, the multiple sub pixels having the same color are combined together for simultaneous printing so that the deposition area of ink is increased by multiple times. Therefore, the dimension of each sub pixel can be effectively reduced, at the same time, it is ensured that the ink does not overflow due to too small area of the sub pixels, and finally, a printing type high-resolution display device is prepared.

Owner:TCL CORPORATION

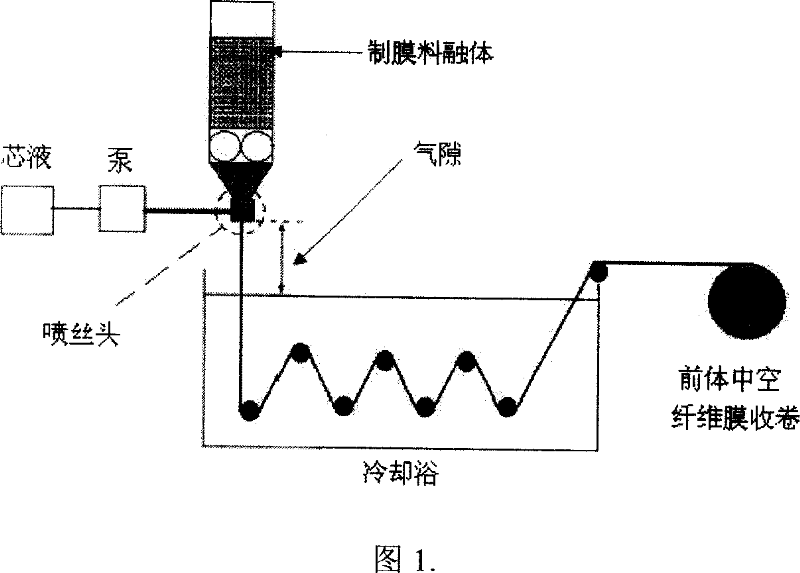

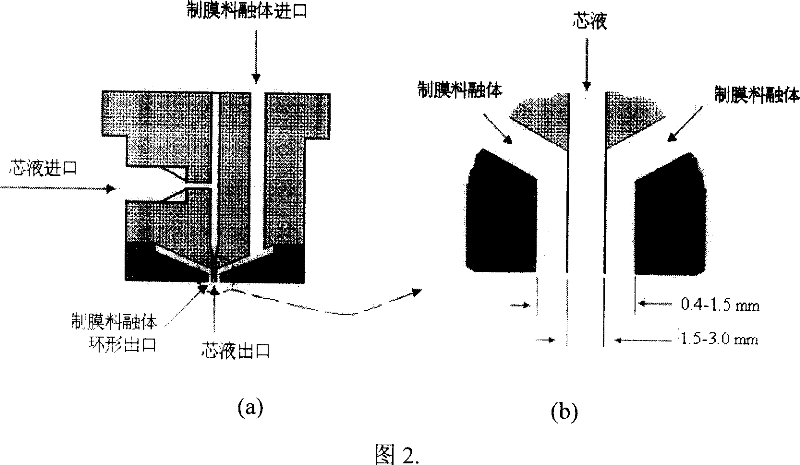

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

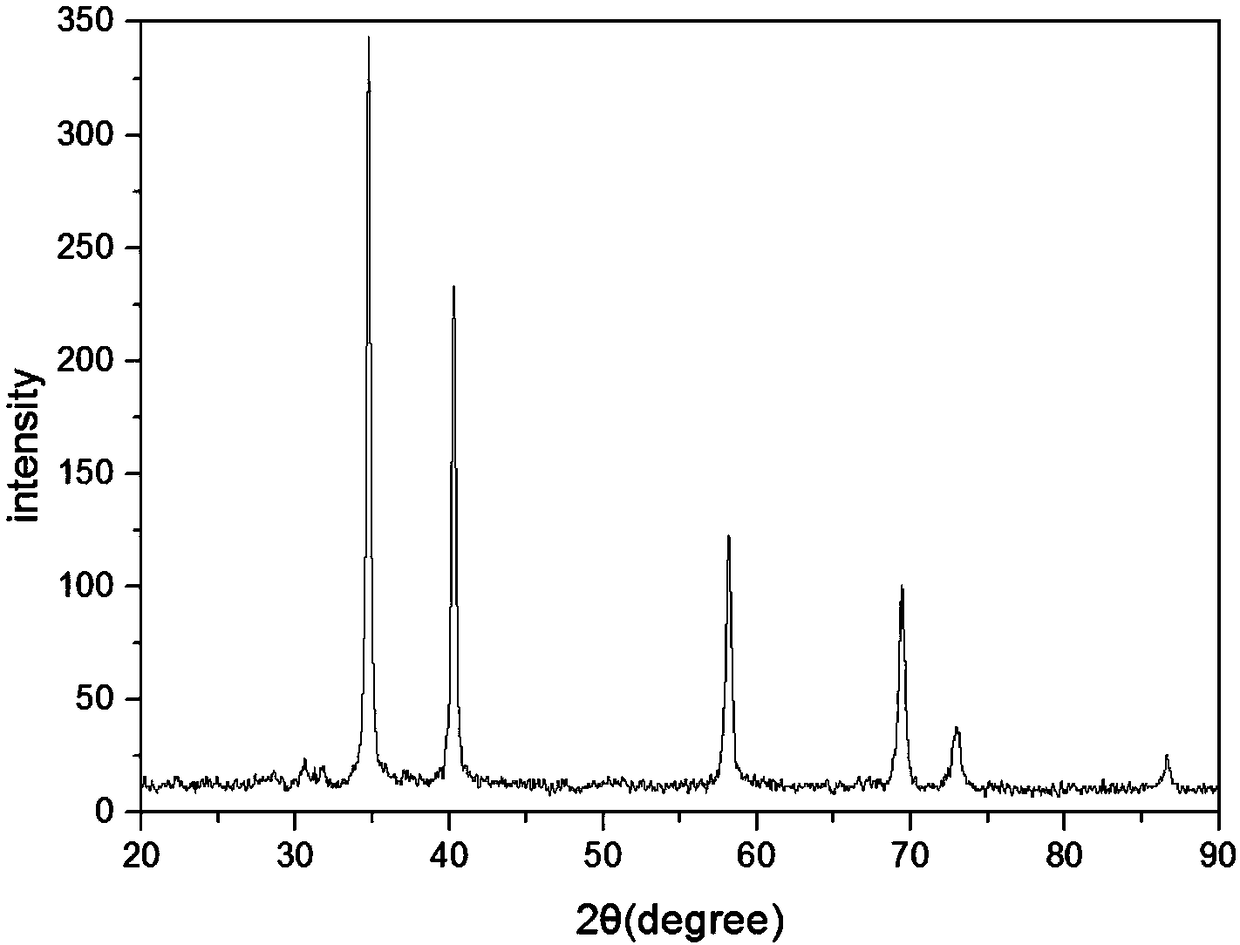

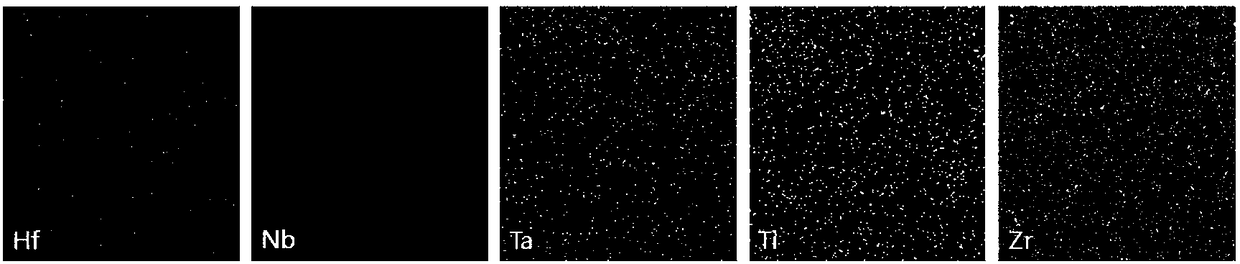

(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

The invention relates to (HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of the high-entropy ceramic powder and high-entropy ceramic blocks. Five-face centered cube (FCC) carbonizedpowder is made into ceramic powder through a high-energy ball milling method, then a discharging plasma method is adopted to realize preparation of the high-entropy ceramic blocks, and quick sintering of ceramic within a temperature range of 1700-2350 DEG C can be realized to obtain high-entropy ceramic with single-phase-face centered cube (FCC) structure. The preparation method of (HfTaZrTiNb) Chigh-entropy block ceramic is solved; the high-entropy ceramic with the FCC structure is finally obtained by strictly controlling parameters of a discharging plasma sintering furnace or a hot press furnace and characterizing XRD, so that the ceramic material system is enriched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

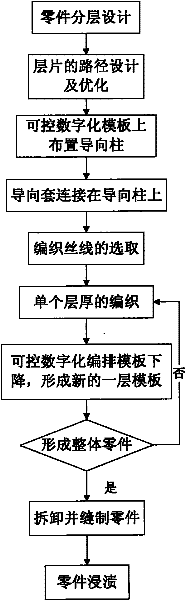

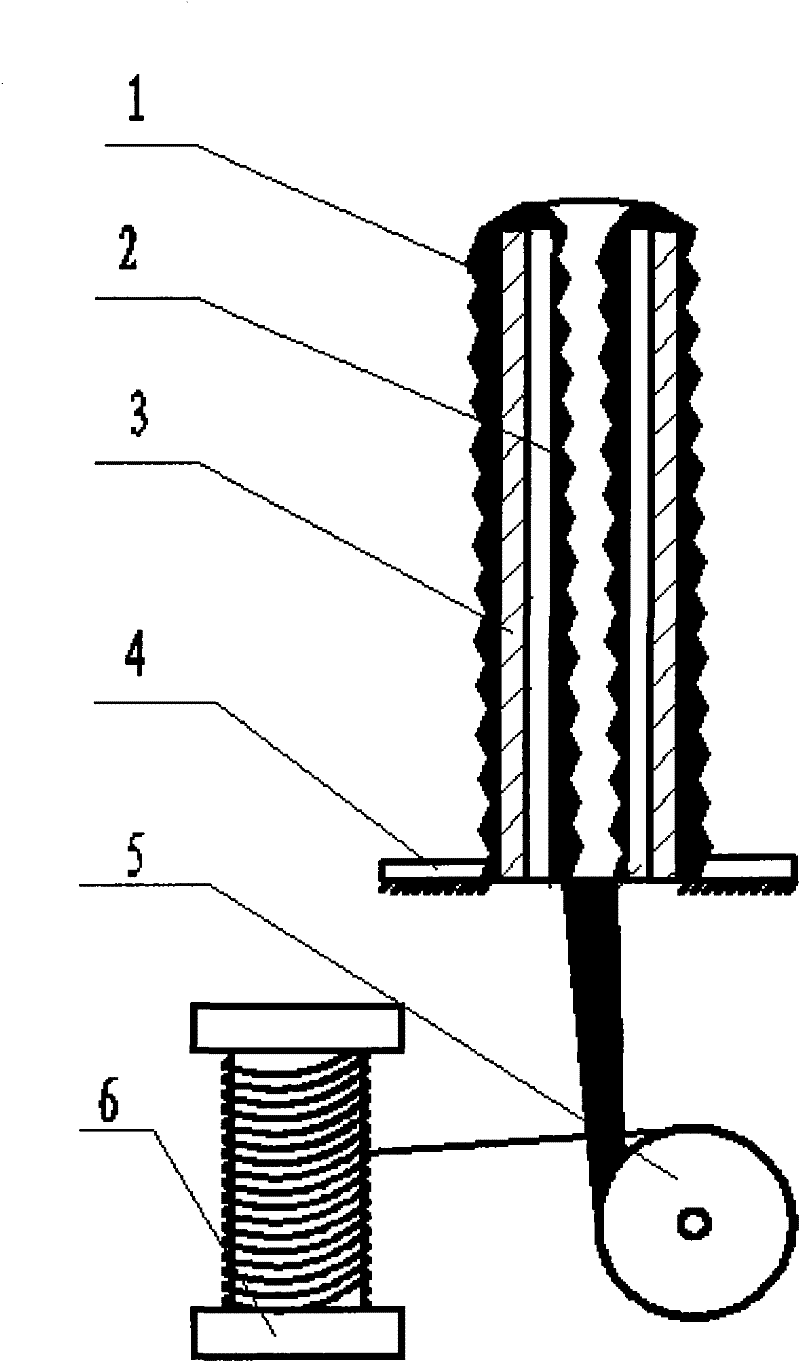

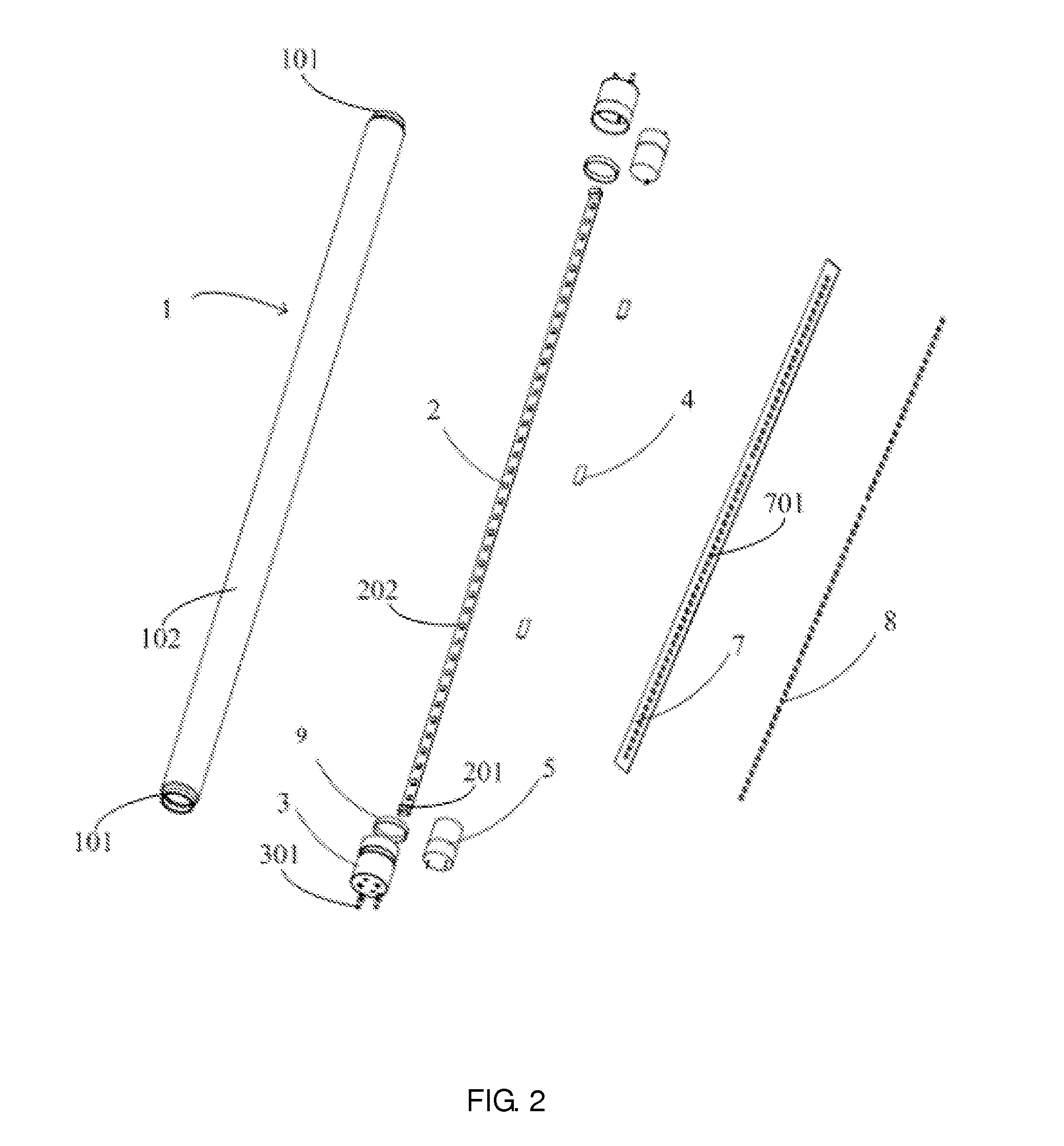

Three-dimensional weaving forming method for composite material

ActiveCN102192396ARealize 3D WeavingAchieve preparationAdditive manufacturing apparatusLoomsMaterials preparationEngineering

The invention discloses a three-dimensional weaving forming method for a composite material, and belongs to the cross field of weaving and manufacturing. The method comprises the following steps of: performing layered design according to the characteristics of a part structure, and optimizing a weaving path; arranging weaving guide posts on a controllable digital arrangement template at intervals according to certain rules; after a guide sleeve passes through the hollow guide posts along the Z direction and is turned outwards, fixing the guide sleeve on the controllable digital template; selecting a silk material for weaving the layer; after the weaving of one layer is finished, lowering the controllable digital arrangement template, and driving the guide sleeve to expose for a distance to form a new layer of arrangement template; weaving layer by layer till the weaving of the whole part is finished; detaching and sewing the part; and soaking the part into resin to form a composite material part. According to the method, the quick prototyping technology and the weaving technology are organically combined to realize three-dimensional weaving of the complex functional part; and meanwhile, composite material preparation and part formation are integrated, so that manufacture of the complex functional part is realized.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

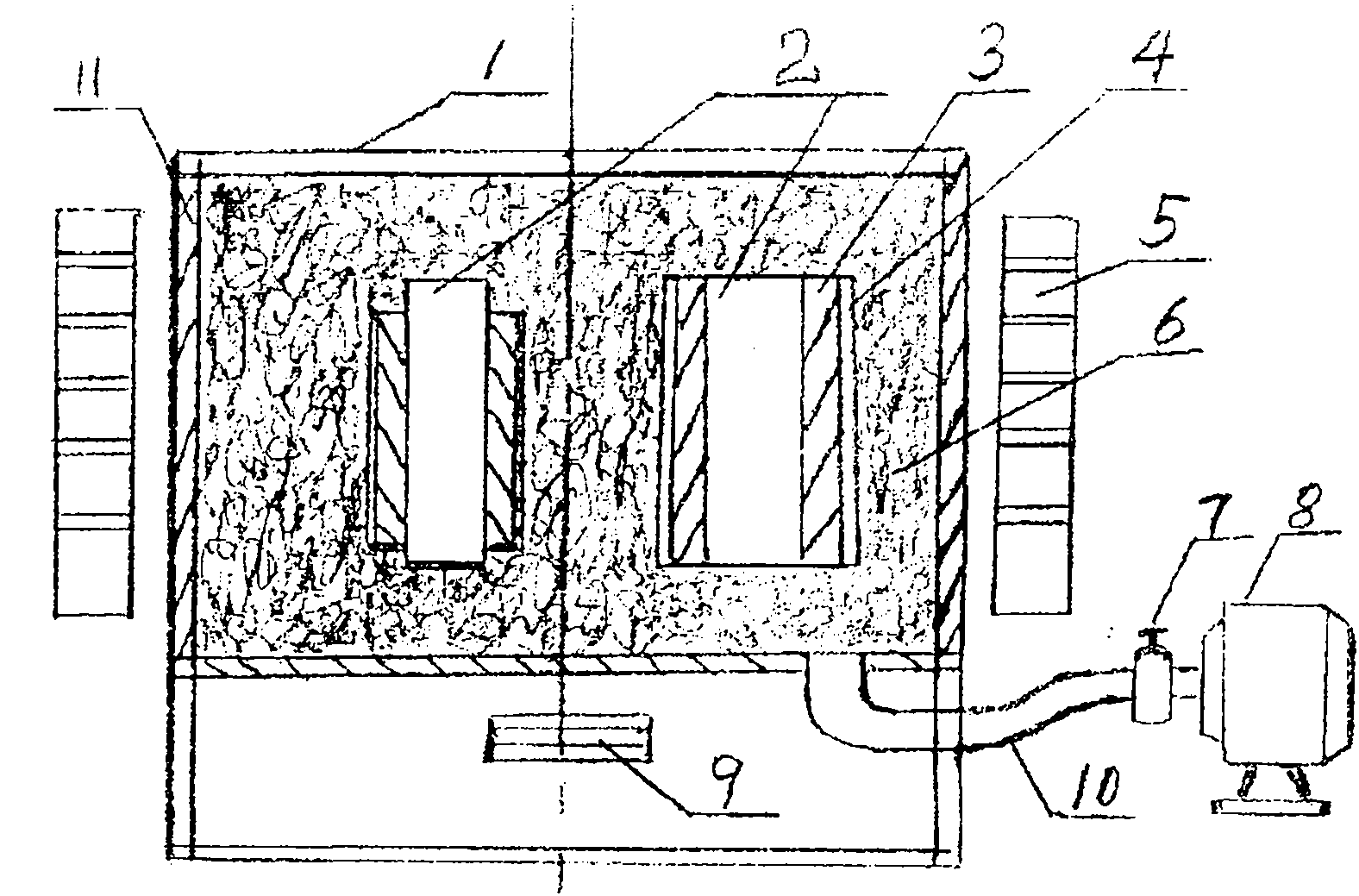

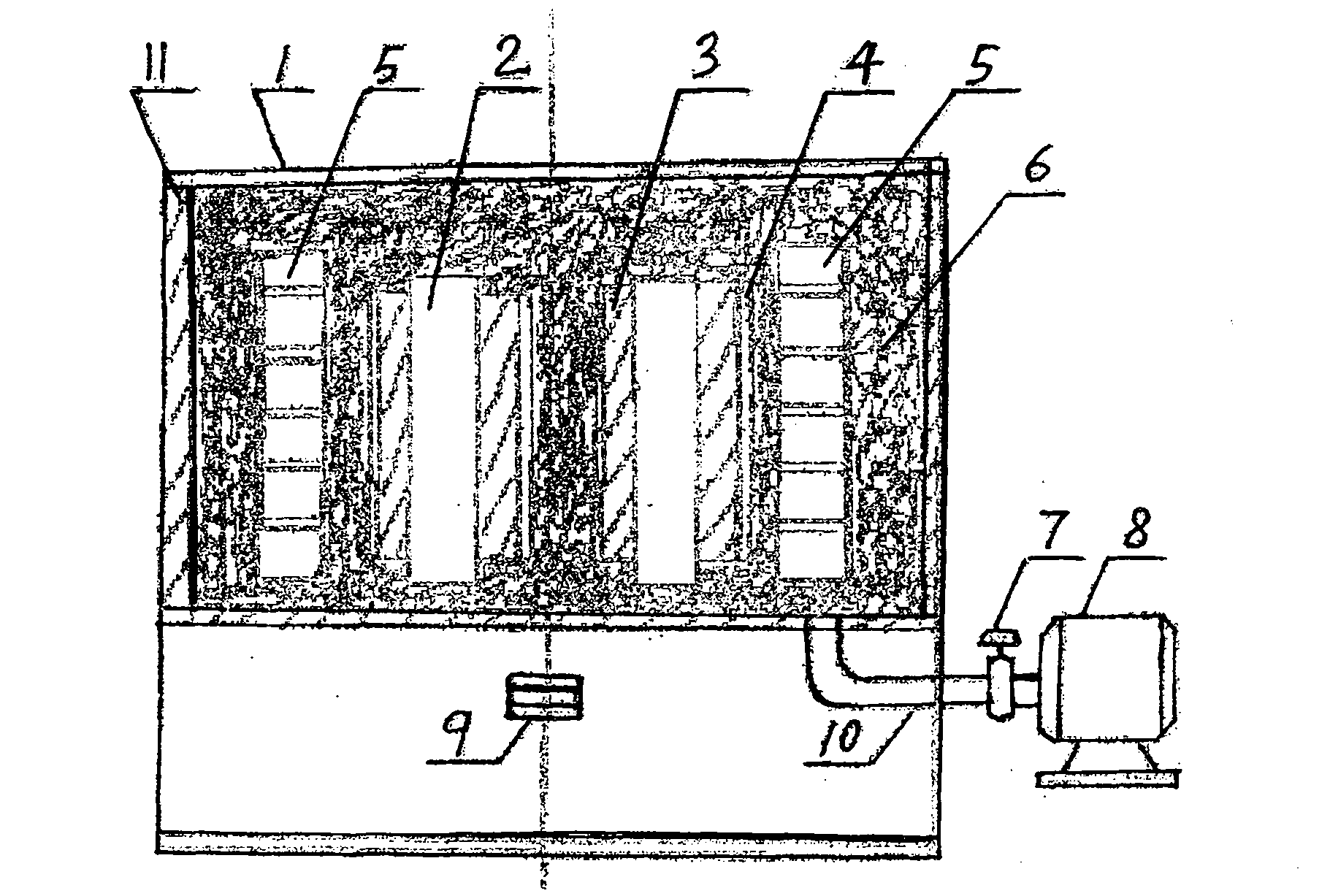

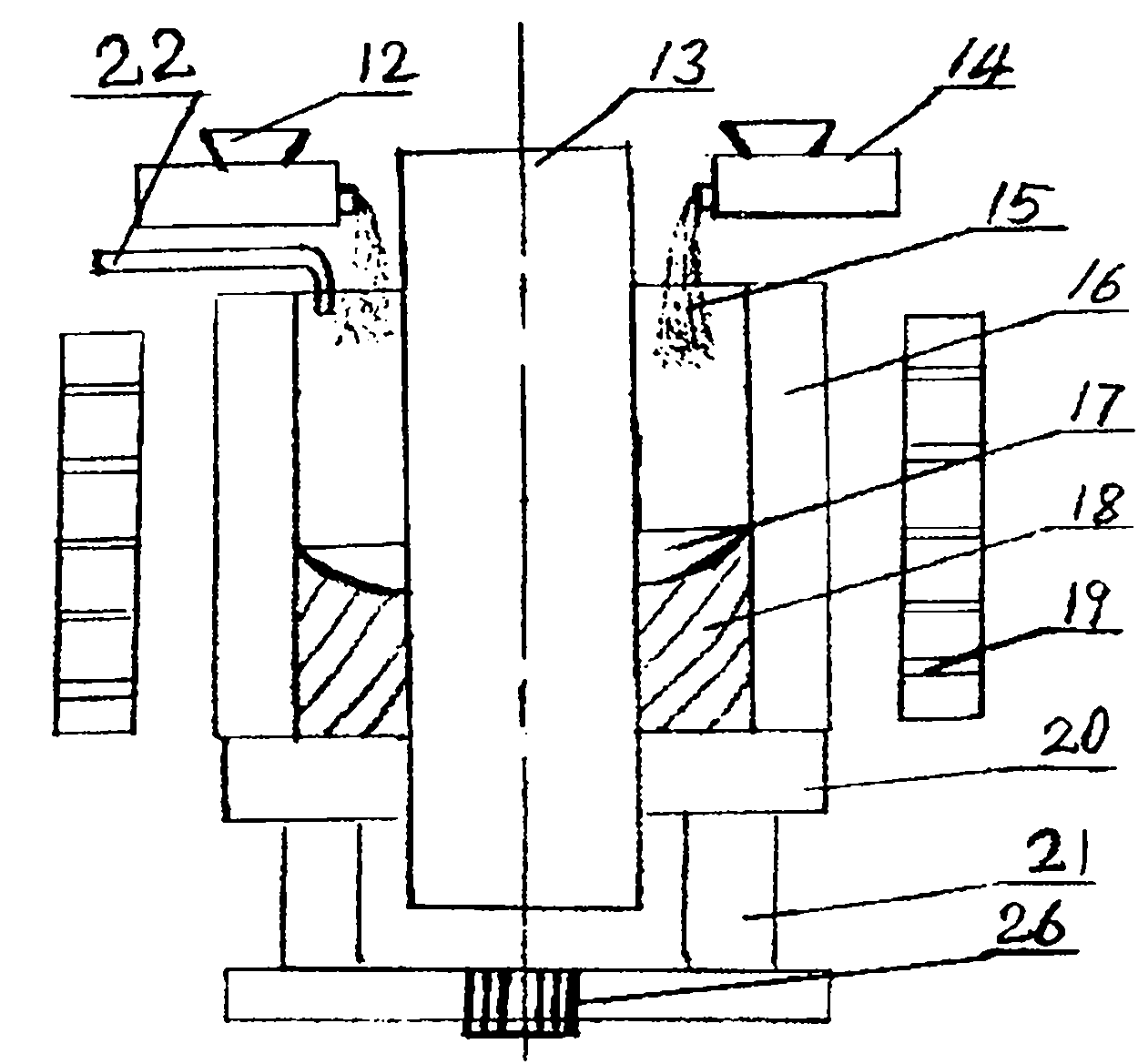

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

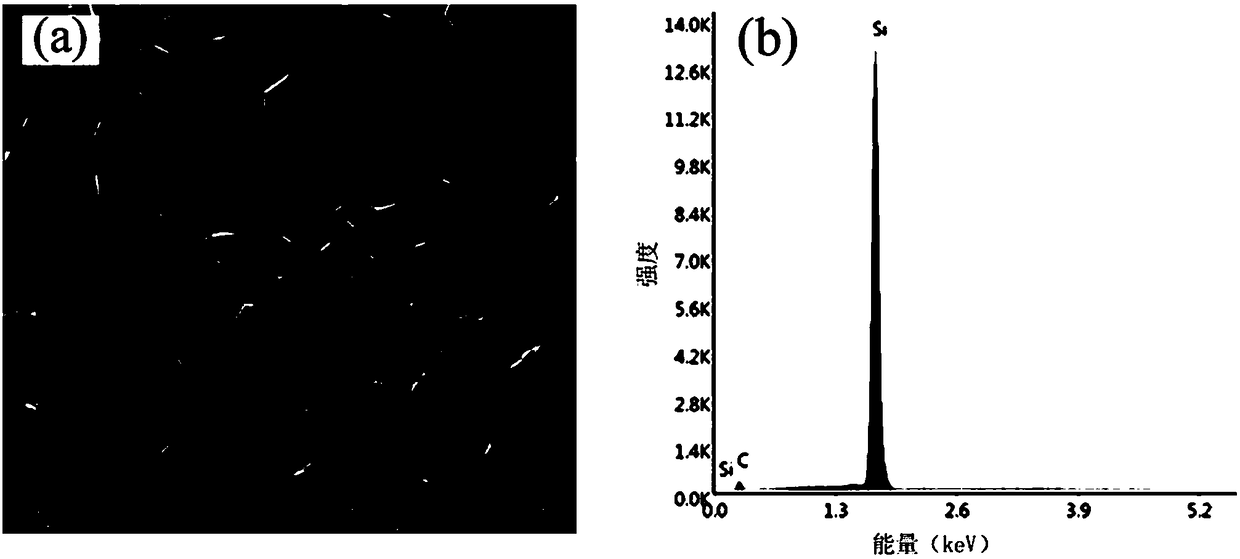

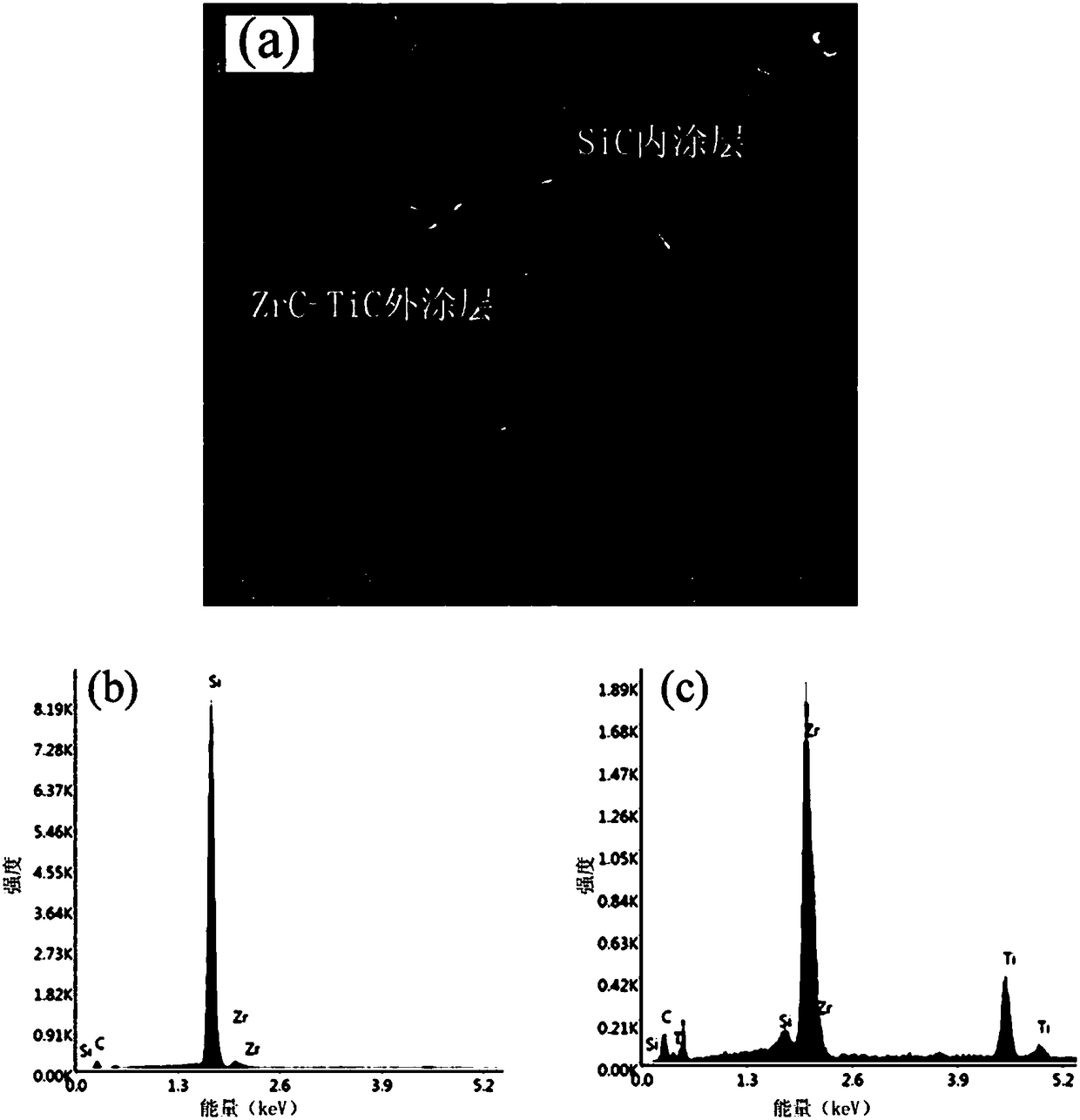

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

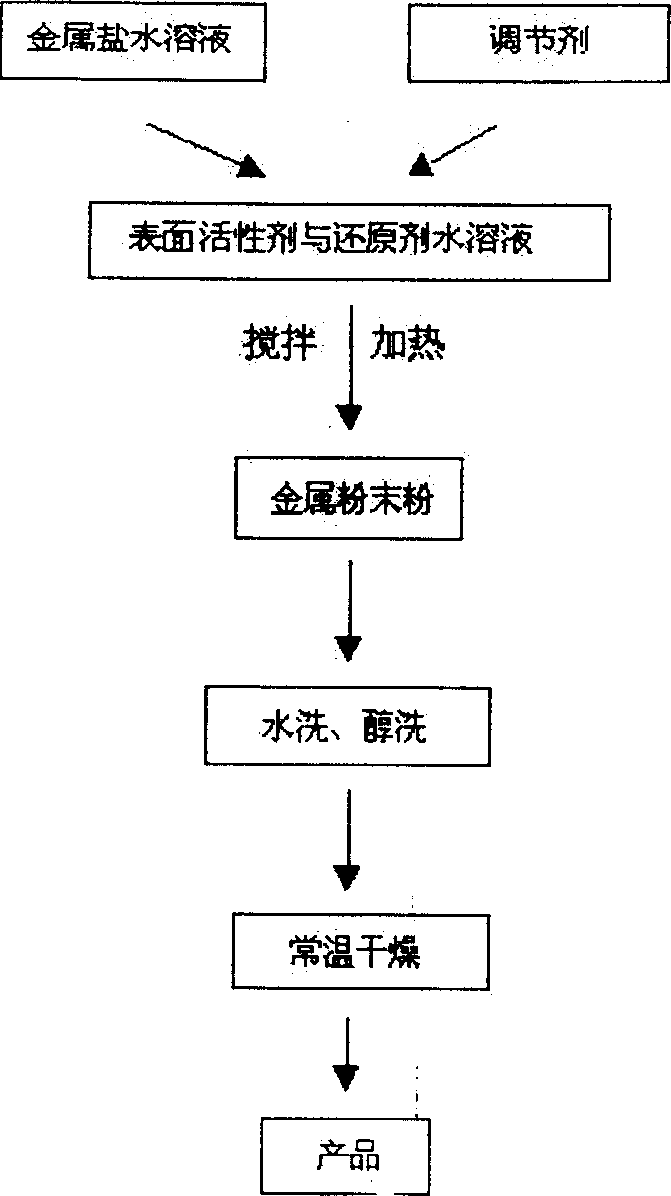

Preparation method of metallic nano powder

A process for preparing nano-class metal particles by dual-pouring method features that under the existance of protector and regulator, the metallic salt is reduced by reducing agent to obtain one ormore (30-100 nm) metallic particles. Its advantages are high dispersity, easy control of diameter, high output rate up to 95%, and preparing the particles of more metals by a single equipment.

Owner:TIANJIN ZHONGKE PHYSICAL & CHEM NEW MATERIAL TECH CO LTD

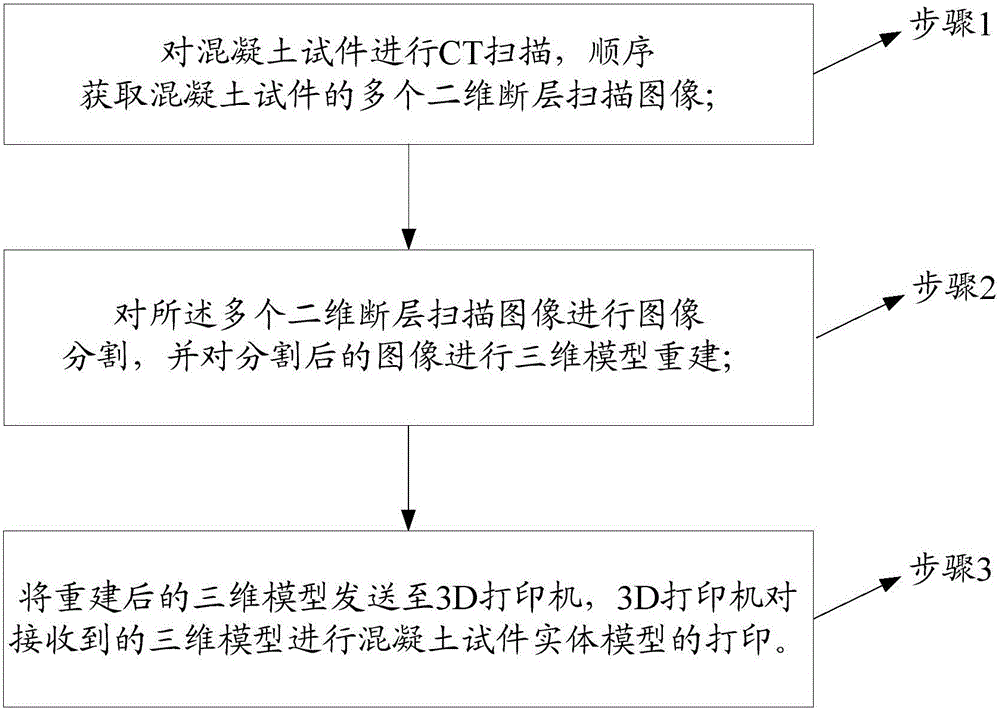

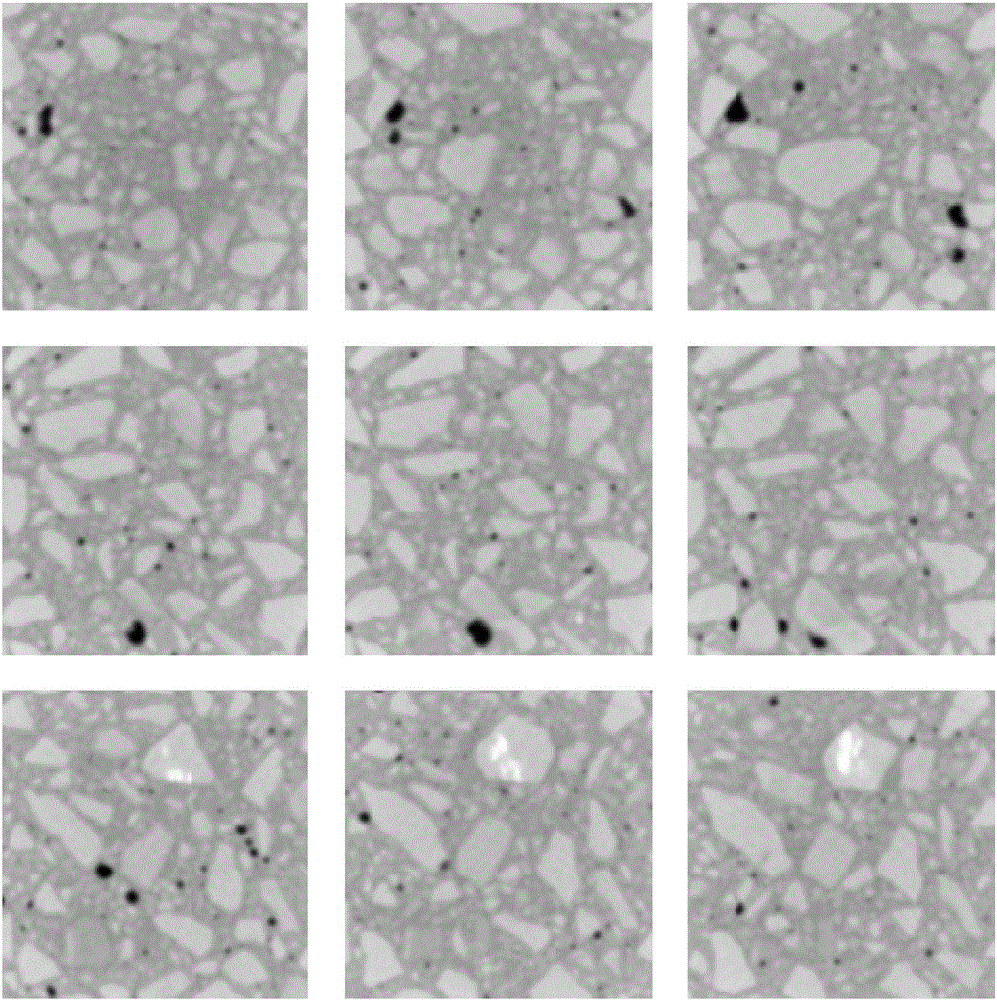

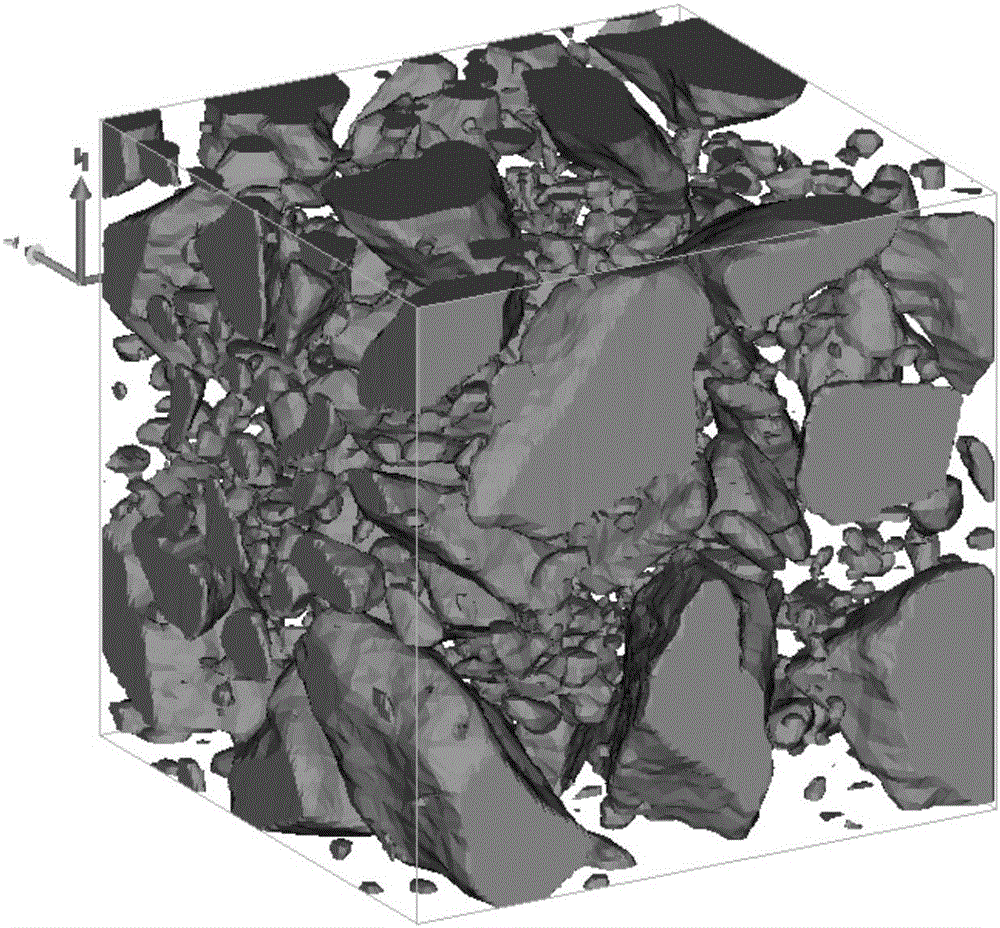

Concrete microscopic three-phase structure visualization method based on 3D printing technology

InactiveCN106053168AAchieve preparationEfficient printingPreparing sample for investigationNon destructiveComputed tomography

The invention belongs to the technical field of concrete structure non-destructive microscopic detection, and specifically discloses a concrete microscopic three-phase structure visualization method based on a 3D printing technology. The method comprises the following steps: step one, subjecting a concrete test piece to CT scanning to obtain a plurality of two-dimensional tomography images of the concrete test piece in sequence; step two, cutting the obtained two-dimensional tomography images, and subjecting the cut images to three-dimensional model reconstruction; step three, sending the reconstructed three-dimensional model to a 3D printing machine, and printing a solid model by the 3D printing machine according to the received three-dimensional model. The provided method is based on a three-dimensional digital model, and is combined with a 3D printing technology. Aiming at three phases: mortar in concrete, aggregate, and pores, different composite materials are adopted to carry out 3D printing, a concrete three-phase structure interior visualization model, which cannot be produced by a conventional manufacturing technology, can be produced, and the printing is high efficient and repeatable.

Owner:CHANGAN UNIV

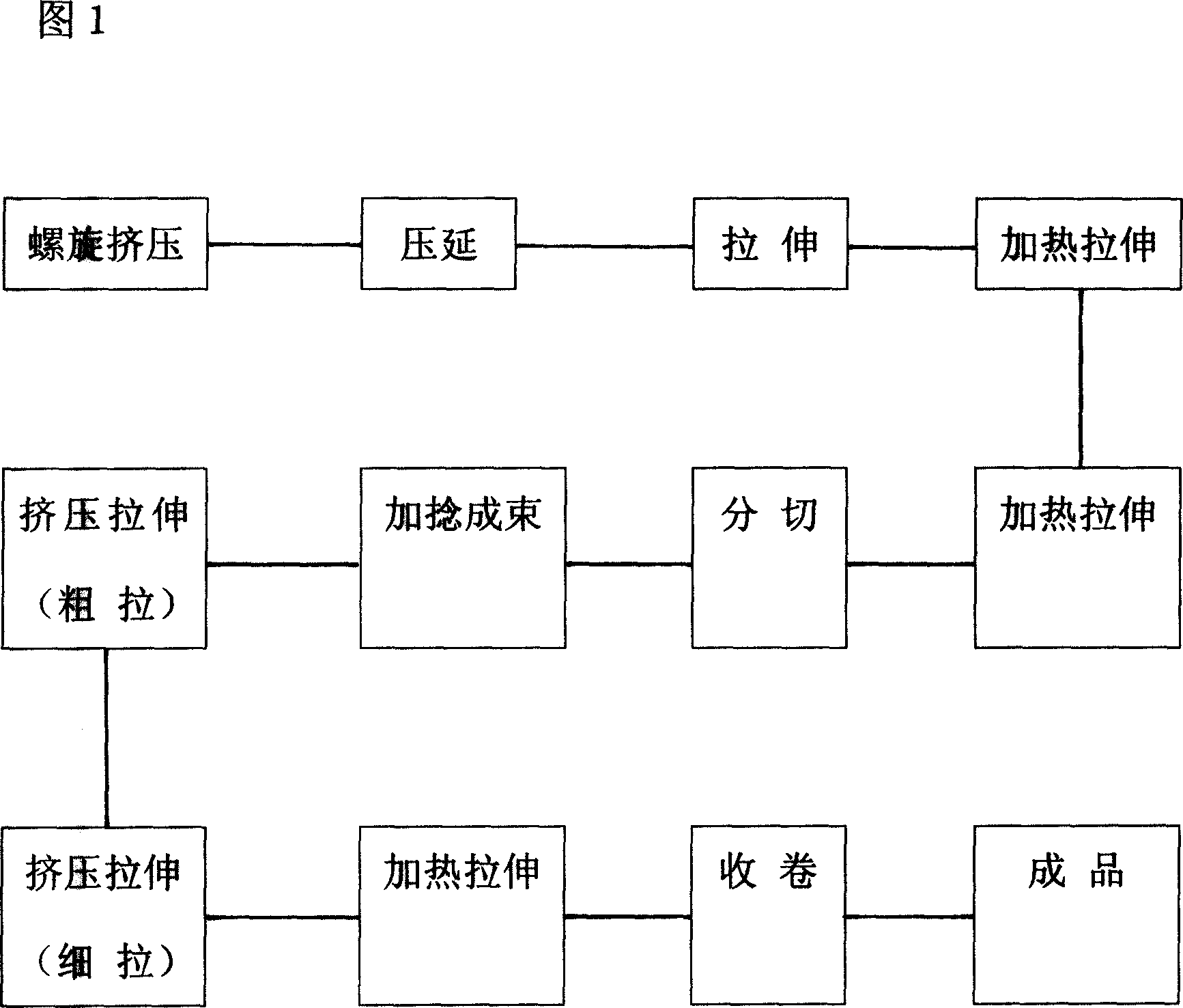

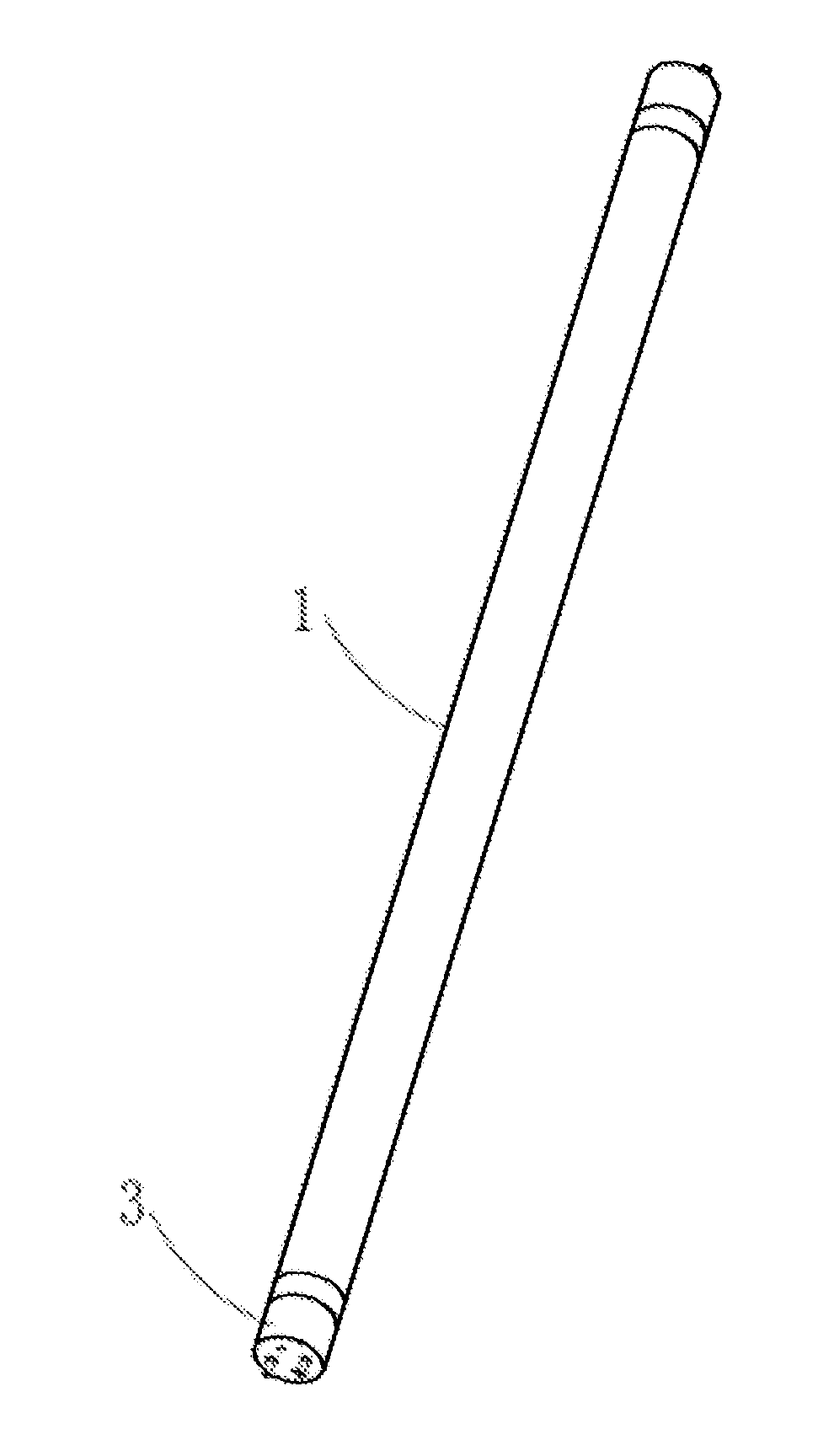

Method for producing polytef amosite

ActiveCN101074499AAchieve preparationExtended service lifeMelt spinning methodsMonocomponent halogenated hydrocarbon artificial filamentFiberProcess equipment

This invention provides one method for producing PTFE long fiber. The raw materials for this invention is 100% PTFE, the use of processing equipment includes spiral extrusion machine, calendar, stretching machine, heating tensile machine, Slitter, twisting machines, extrusion tensile machine, and roll-up. Firstly put the PTPE into spiral extruder and crash, secondly put into heating tensile machine to heat and stretch, do it once more, thirdly cut through slitter, twist into beam by twisting Machine, fourthly roughly stretch by squeeze tensile machine, and then stretch finely by squeeze tensile machine, finally put into heating tensile machine to heat and stretch, roll up by the roll-up machine, after which the production of PTFE long fiber is done. The PTFE long fiber in this invention can produce the monofilament long fiber and multi long fiber which can be used as the fabric filter substrate of bag filter as well as high-intensity industrial sewing thread which longer the durability of the filter bag for Teflon bag.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

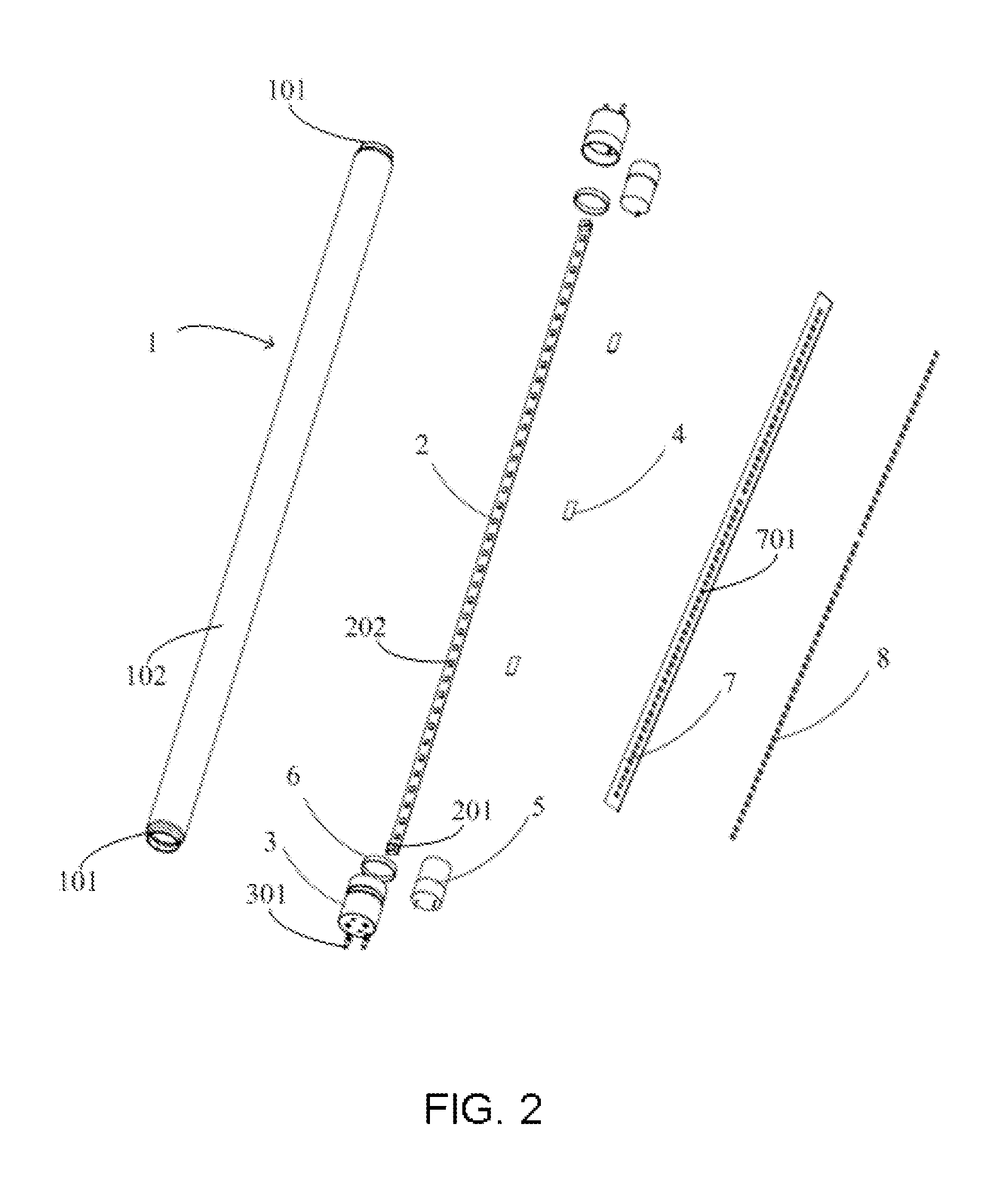

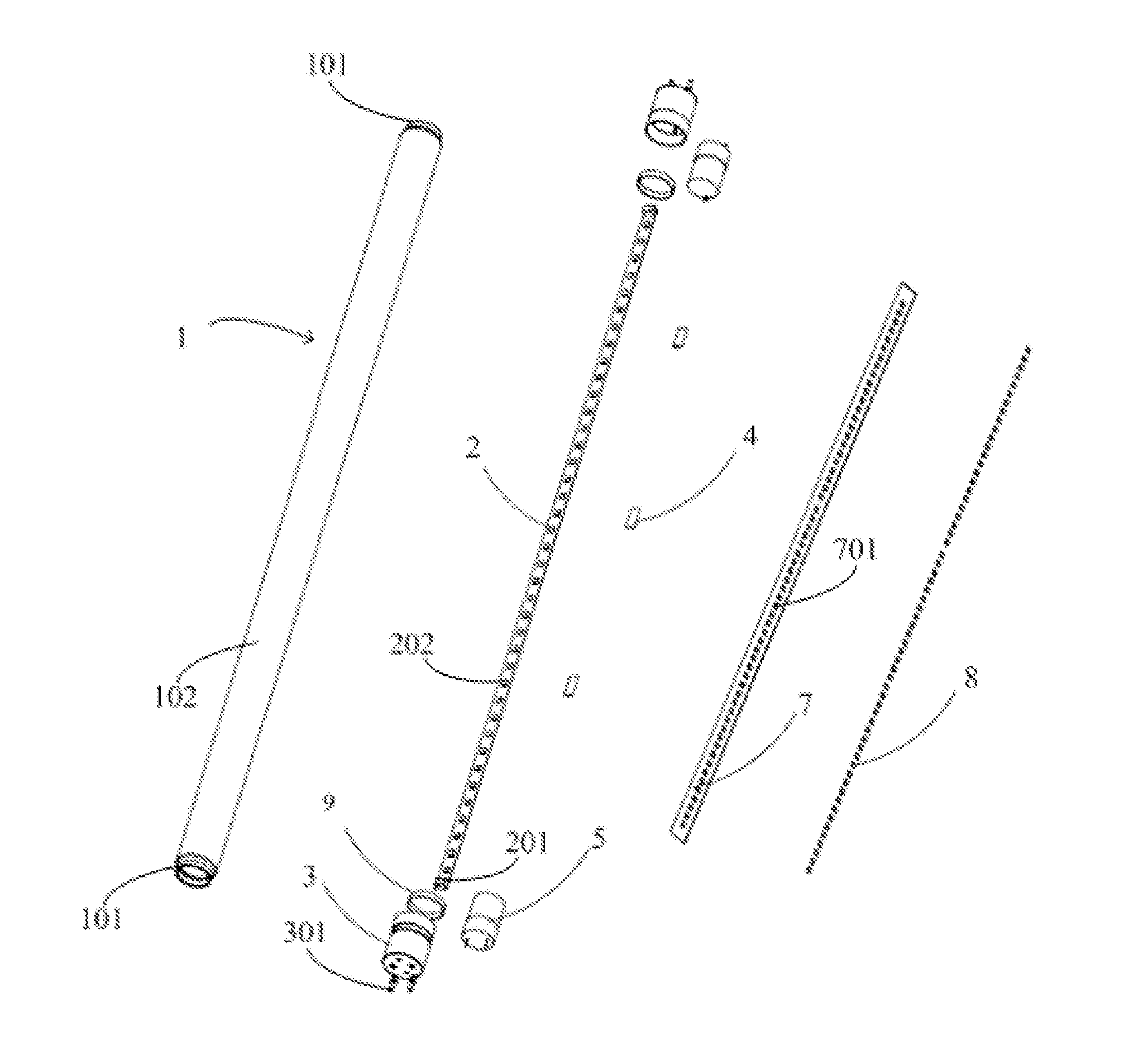

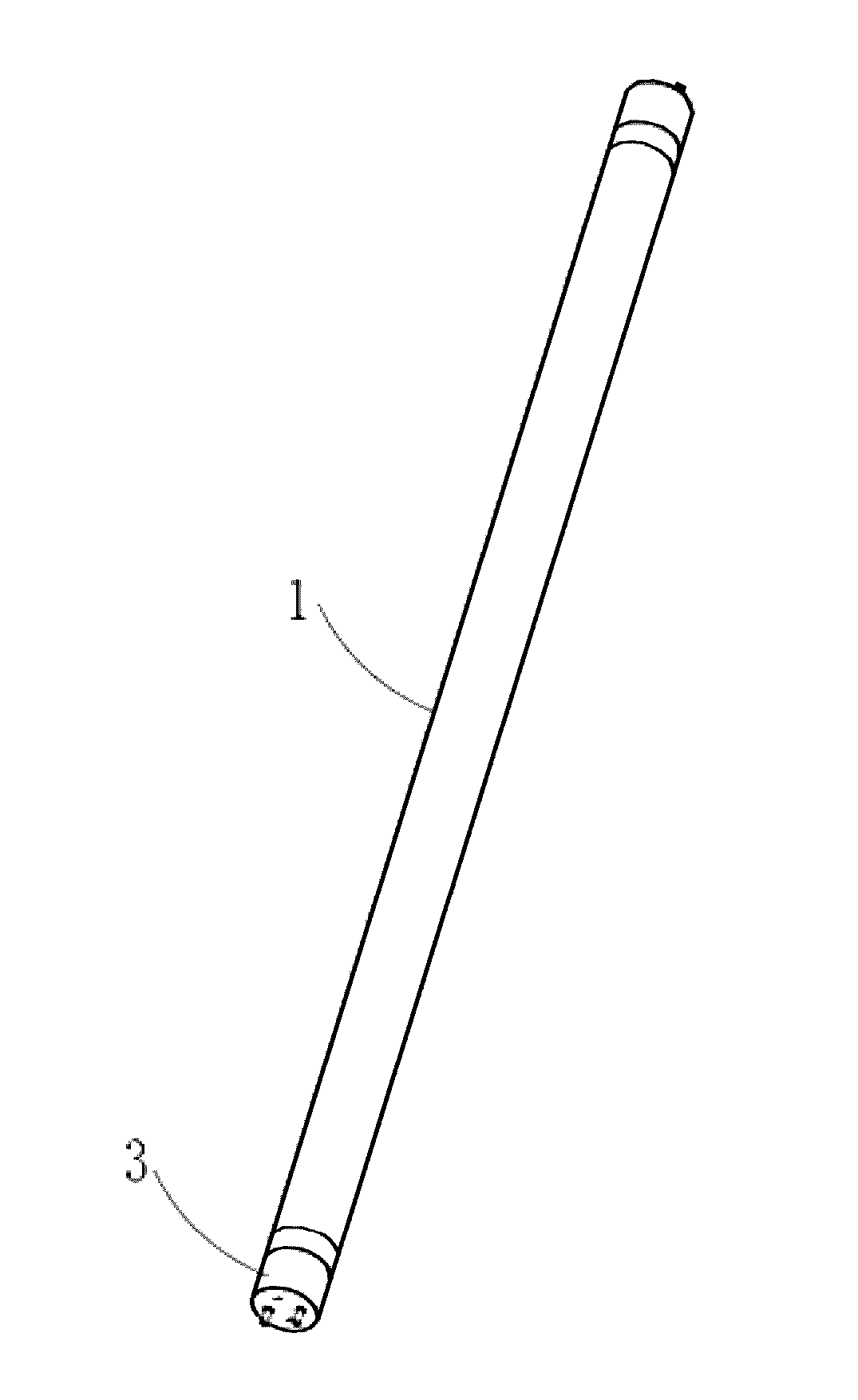

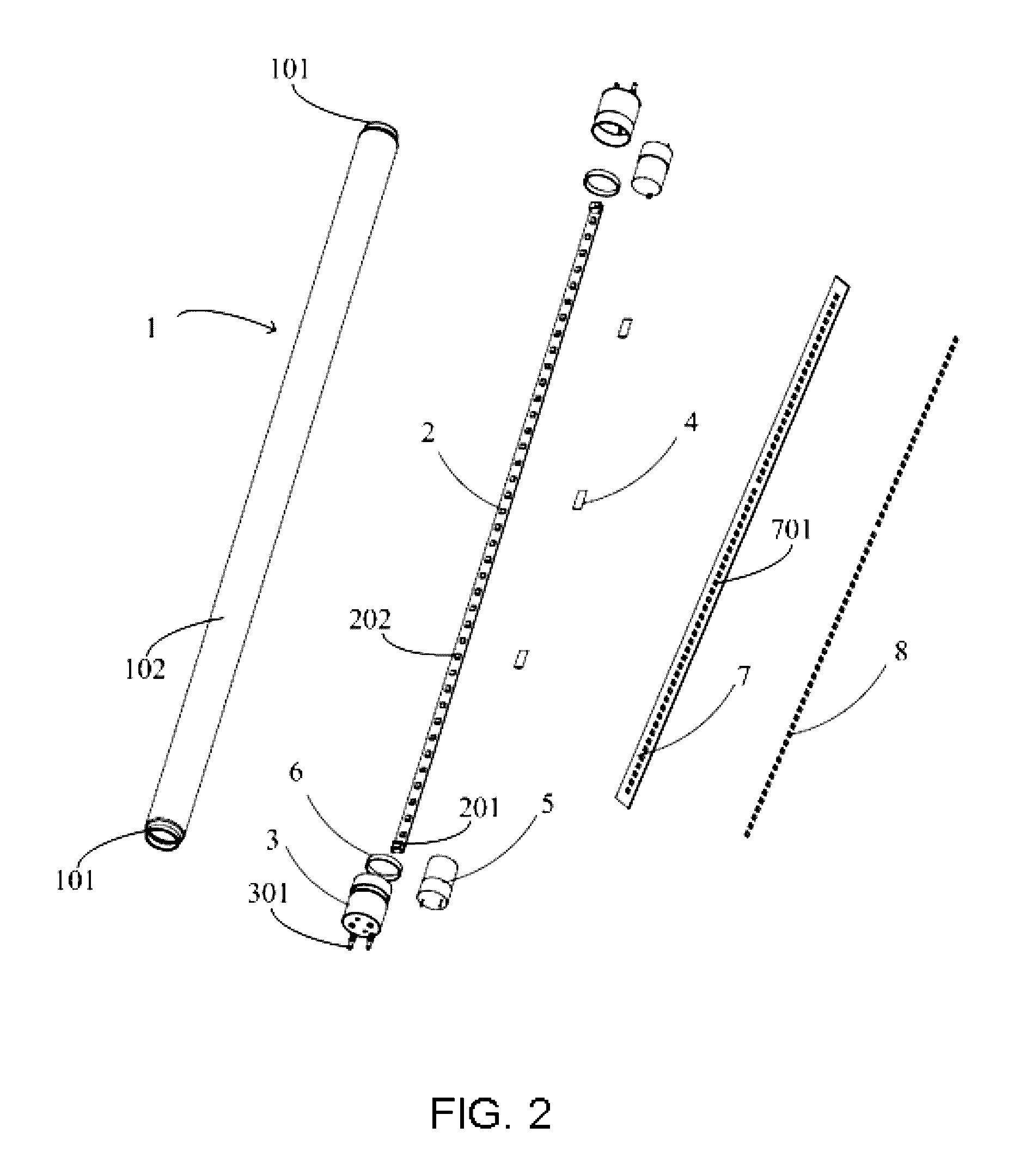

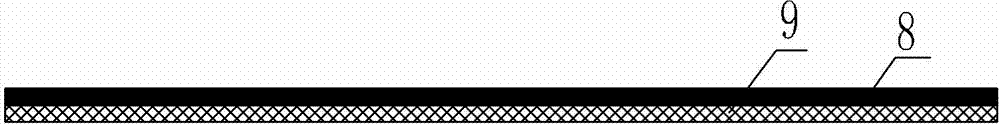

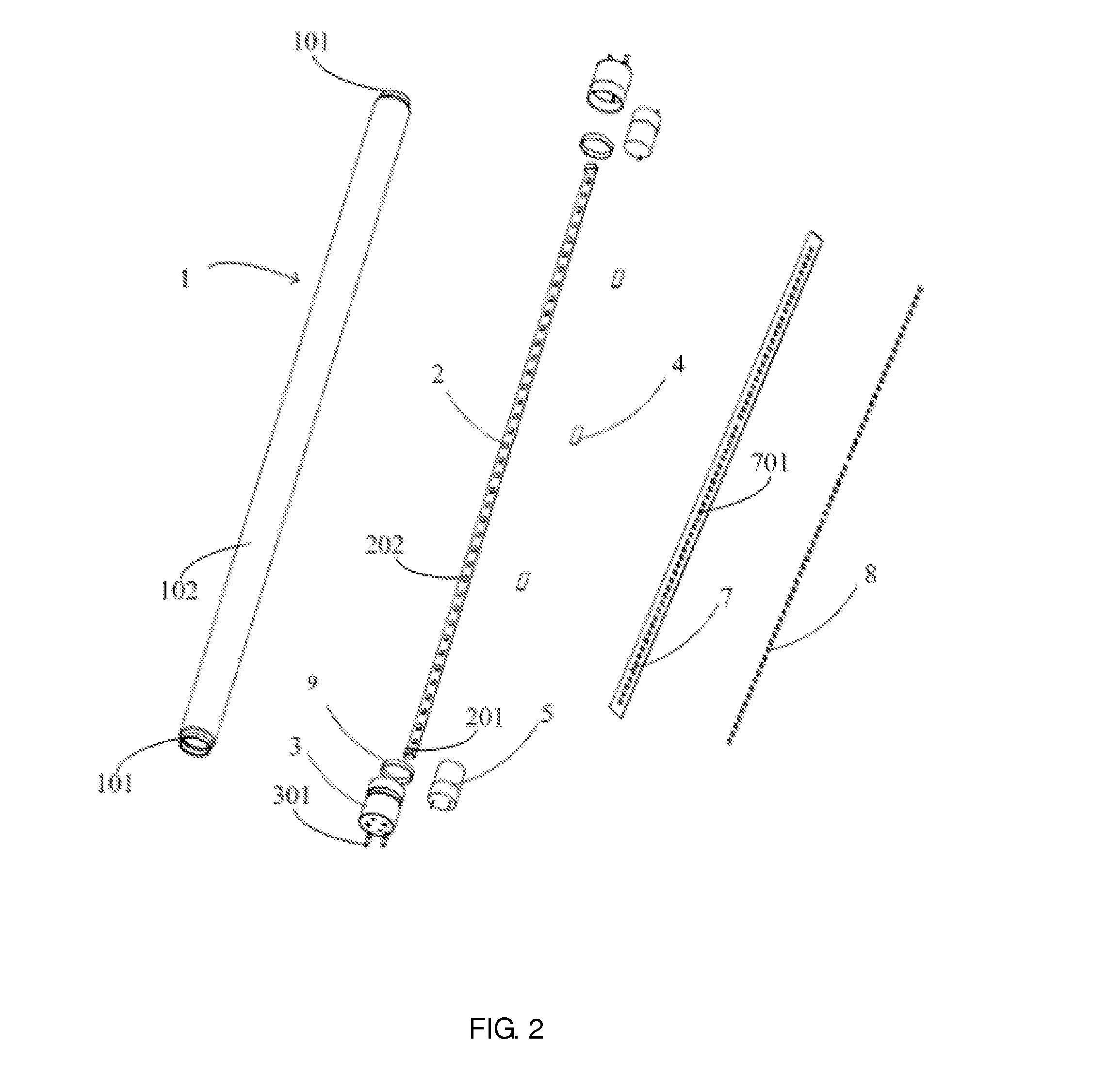

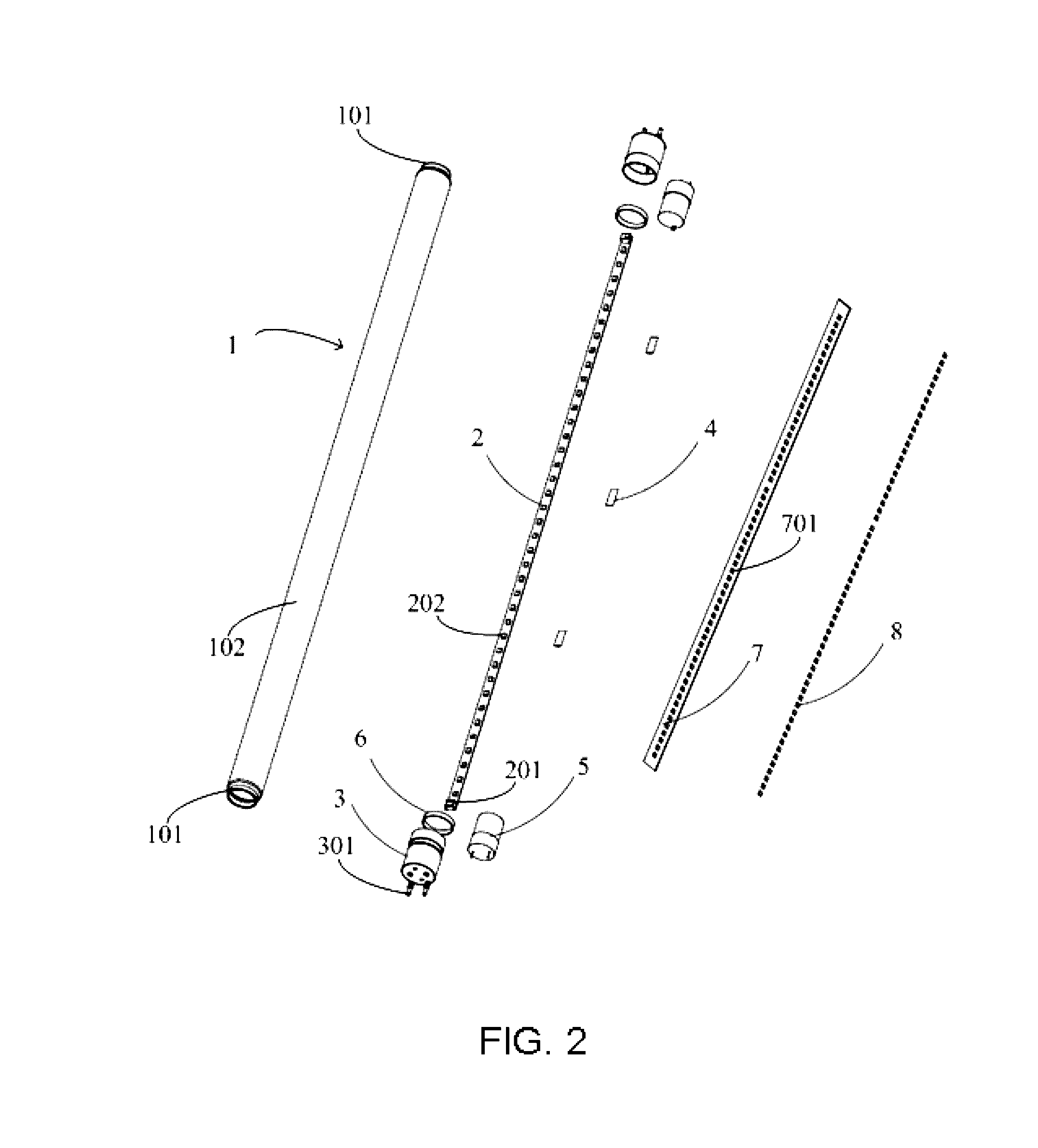

LED tube light with bendable circuit board

ActiveUS20160091156A1Increase flexibilityImprove bendabilityElongate light sourcesElectric circuit arrangementsEngineeringLED lamp

An LED tube light having LED light sources, a light tube, end cap, power supply, and an LED light bar is disclosed. LED light bar is a bendable circuit board. One end of the light tube is attached to the end cap; a power supply disposed in end cap and the LED light bar is disposed inside light tube, LED light sources are mounted on LED light bar, the LED light sources and the power supply are electrically connected. LED light bar being bendable circuit board, includes a conductive layer, electrically connected to power supply, and a dielectric layer, the two layers are stackingly arranged, dielectric layer is disposed on the conductive layer away from the LED light sources, and fixed to an inner circumferential surface of the light tube. Bendable circuit board, at two ends thereof, is not fixed to an inner circumferential surface of the light tube.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

LED tube lamp

ActiveUS20160290598A1Unified performanceImproving LED tube lamp production efficiencyElongate light sourcesElectric lightingEngineeringLED lamp

An LED tube lamp having LED light sources, a lamp tube, end cap, power supply, a reflective film layer and an LED light bar is disclosed. The LED light bar is a bendable circuit sheet. One end of the lamp tube is attached to the end cap; a power supply disposed in end cap and the LED light bar is disposed inside lamp tube. The end cap includes an electrically insulating tubular part, sleeved with the end of the lamp tube and a magnetic metal object disposed between an inner circumferential surface of the electrically insulating tubular part and the end of lamp tube. The reflective film layer is disposed on inner circumferential surface of lamp tube, and occupying a portion of inner circumferential surface of lamp tube along circumferential direction thereof. LED light sources are disposed above or adjacently to one side of reflective film layer.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

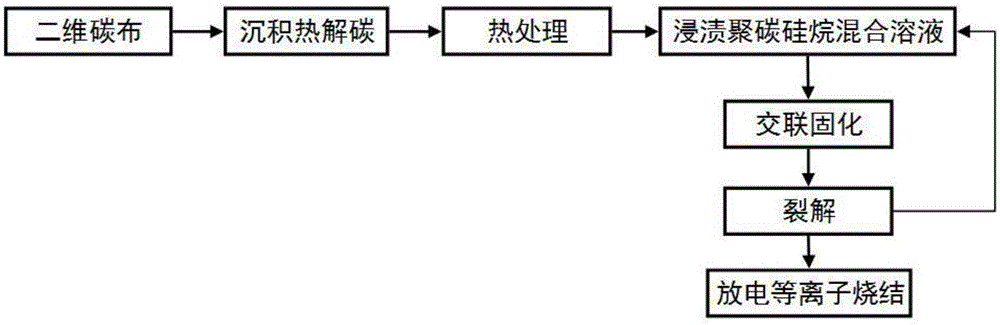

Rapid preparation method for C/SiC composite material

The invention relates to a rapid preparation method for a C / SiC composite material. The method is characterized by including the steps of: 1. depositing a pyrolytic carbon interface on a thin layer carbon fiber preform surface by a chemical vapor deposition process; 2. infiltrating the thin layer carbon fiber perform of the deposited PyC interface in a polycarbosilane mixed solution, and then carrying out cross-linking curing and pyrolysis in order under protective atmosphere to obtain a thin layer C / SiC composite material; 3. repeating the previous step 2-3 times; and 4. stacking a plurality of single-layer composite materials in a graphite die to conduct spark plasma sintering (SPS), thus rapidly obtaining a compact C / SiC composite material finally. The method provided by the invention makes full use of the characteristics of short thin layer infiltration time of PIP (precursor infiltration and pyrolysis) method and rapid sintering of SPS method to realize preparation of the C / SiC composite material, is suitable for compaction of small compact components, saves 95% of time than the traditional CVI (chemical vapor infiltration) method and PIP method, also significantly improves the compactness of the composite material, and reduces the making cost of the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

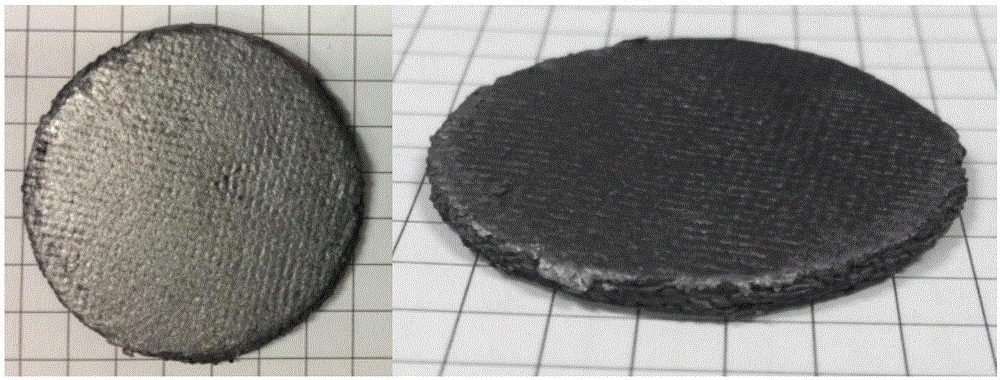

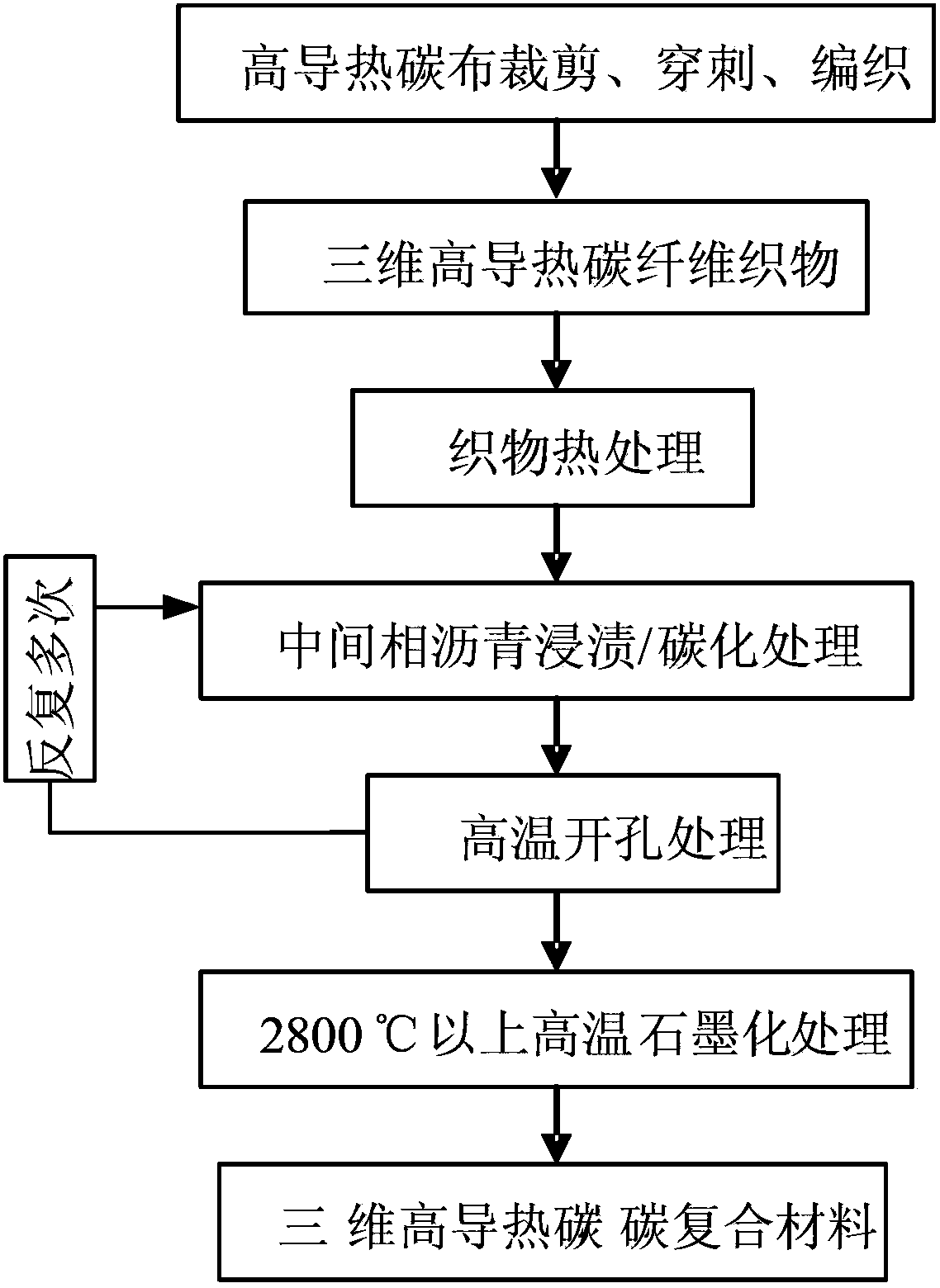

Three-dimensional mesophase pitch-based carbon/carbon composite material with high heat conductivity and preparation technology thereof

The invention relates to a three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity and a preparation technology thereof. The preparation technology comprises the following steps: firstly, by taking a mesophase pitch-based carbon fiber cloth with high heat conductivity as a reinforced body in the XY direction and a high-modulus carbon fiber as a reinforced fiber in the Z direction, preparing three-dimensional carbon fiber fabric with high heat conductivity by adopting a carbon cloth puncturing technology; secondly, by taking mesophase pitch as a precursor of matrix carbon, performing densifying treatment on the three-dimensional carbon fiber fabric with high heat conductivity by adopting a dipping / carbonizing technology; finally, performing graphitization treatment at a high temperature of 2800 DEG C above on the obtained materials, so as to obtain the three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity. Through the adoption of the technology method, the heat conductivity, modulus and dimensional stability of the carbon / carbon composite material are greatly improved, and the highest heat conductivity reaching 3600 w / mK of the material in the XY direction is increased by more than 5 times as compared with the common three-dimensional carbon / carbon composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

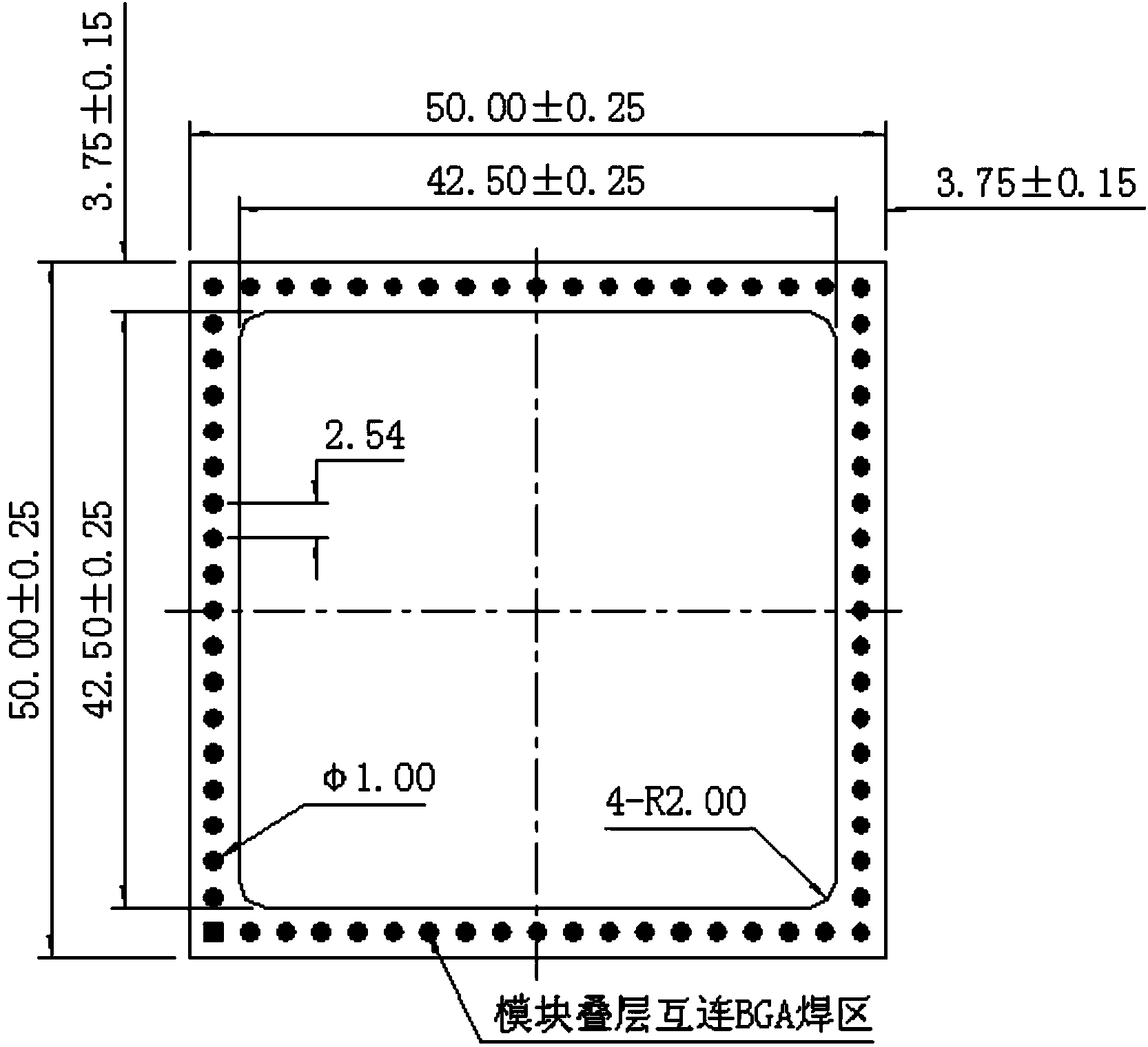

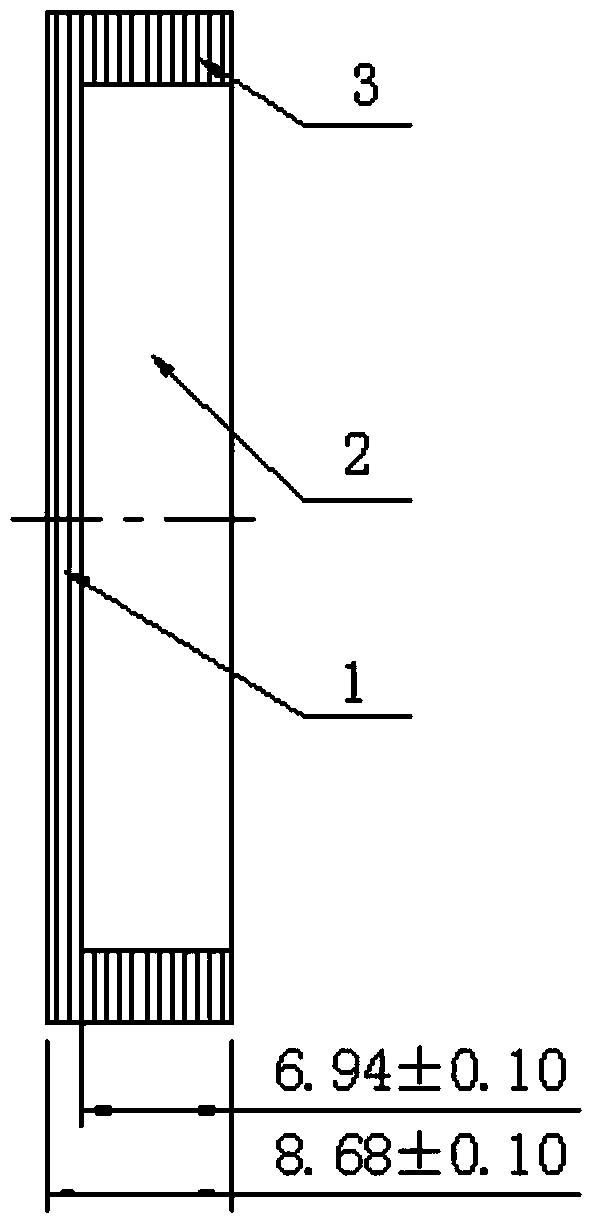

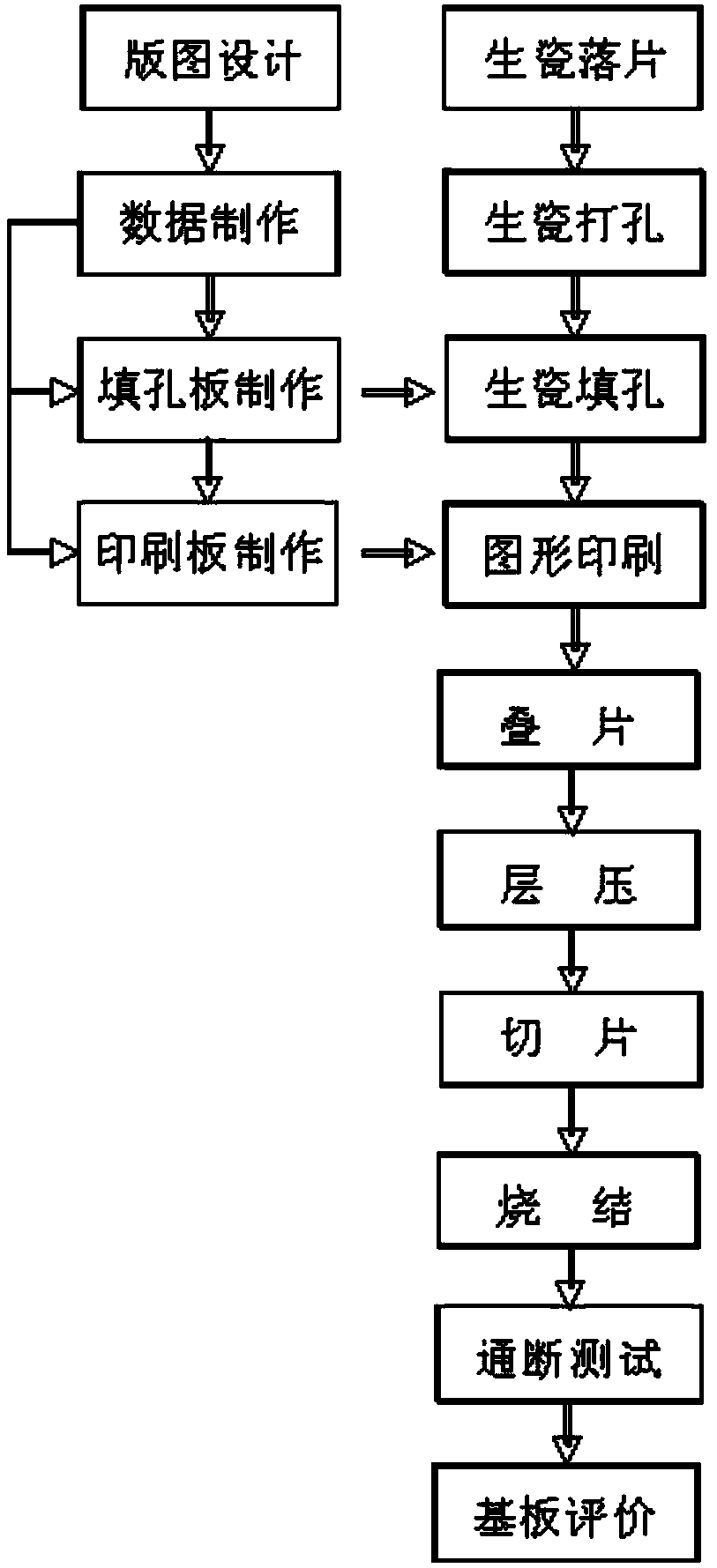

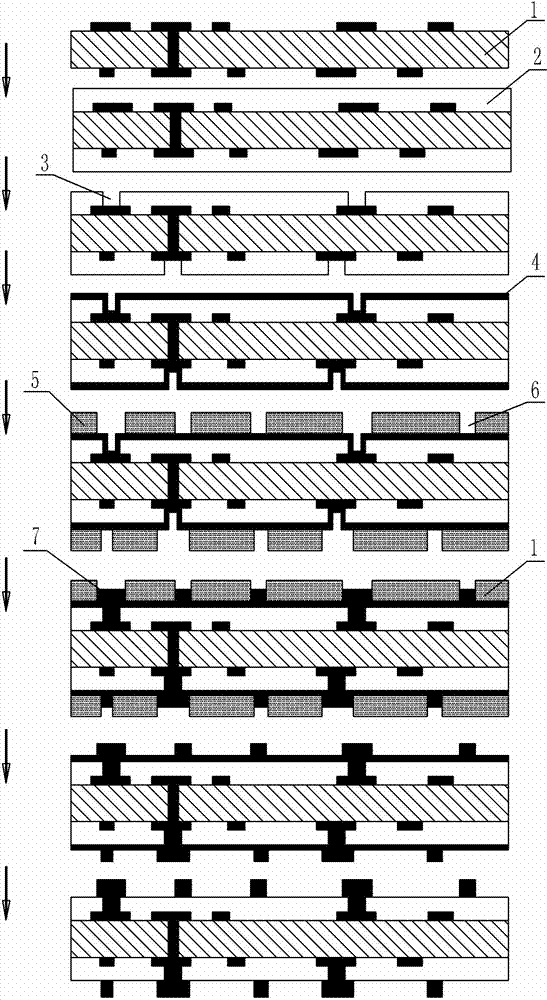

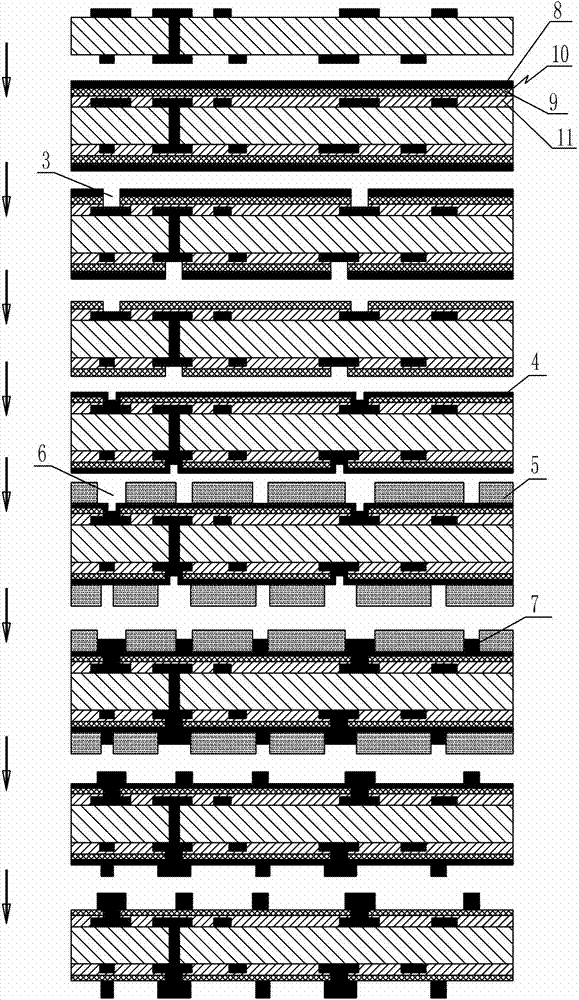

Ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology

ActiveCN104284534AAchieve preparationEasy to operateMultilayer circuit manufacturePrinted element electric connection formationScreen printingManufacturing technology

The invention discloses an ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology. A conventional solid flat plate LTCC substrate machining technology is broken through, after hole filling and screen printing, a cavity window in an unglazed porcelain layer is formed in a laser-cutting-up mode, the non-operability problem of hole filling and screen printing technologies on a large-size window unglazed porcelain piece is avoided, and the contraction amount and the unevenness of an unglazed porcelain piece obtained after filling and printing before piece stacking are lowered. After cofiring, an abrasive wheel cuts a ripe porcelain plate in a rotating mode, and the fact that an LTCC substrate which is regular in shape, accurate in size, thin in wall and ultra-deep in cavity is machined is guaranteed. Network multi-through-hole connecting is used in an ultra-deep-cavity ultra-multi-layer unglazed porcelain side wall, and the connecting pass rate is guaranteed through redundancy. Through a lamination tool set and an optimized overlying technology method, the lamination and stacking technology of the deep-large-cavity ultra-thick LTCC substrate is guaranteed. An abrasive wheel dicing saw is used for opposite cutting of a ripe porcelain body LTCC substrate from the bottom face and the top face of the ultra-thick substrate, and the problem that the maximum thickness can only reach 5 mm during blade unglazed porcelain hot cutting and abrasive wheel ripe porcelain rotating cutting is solved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

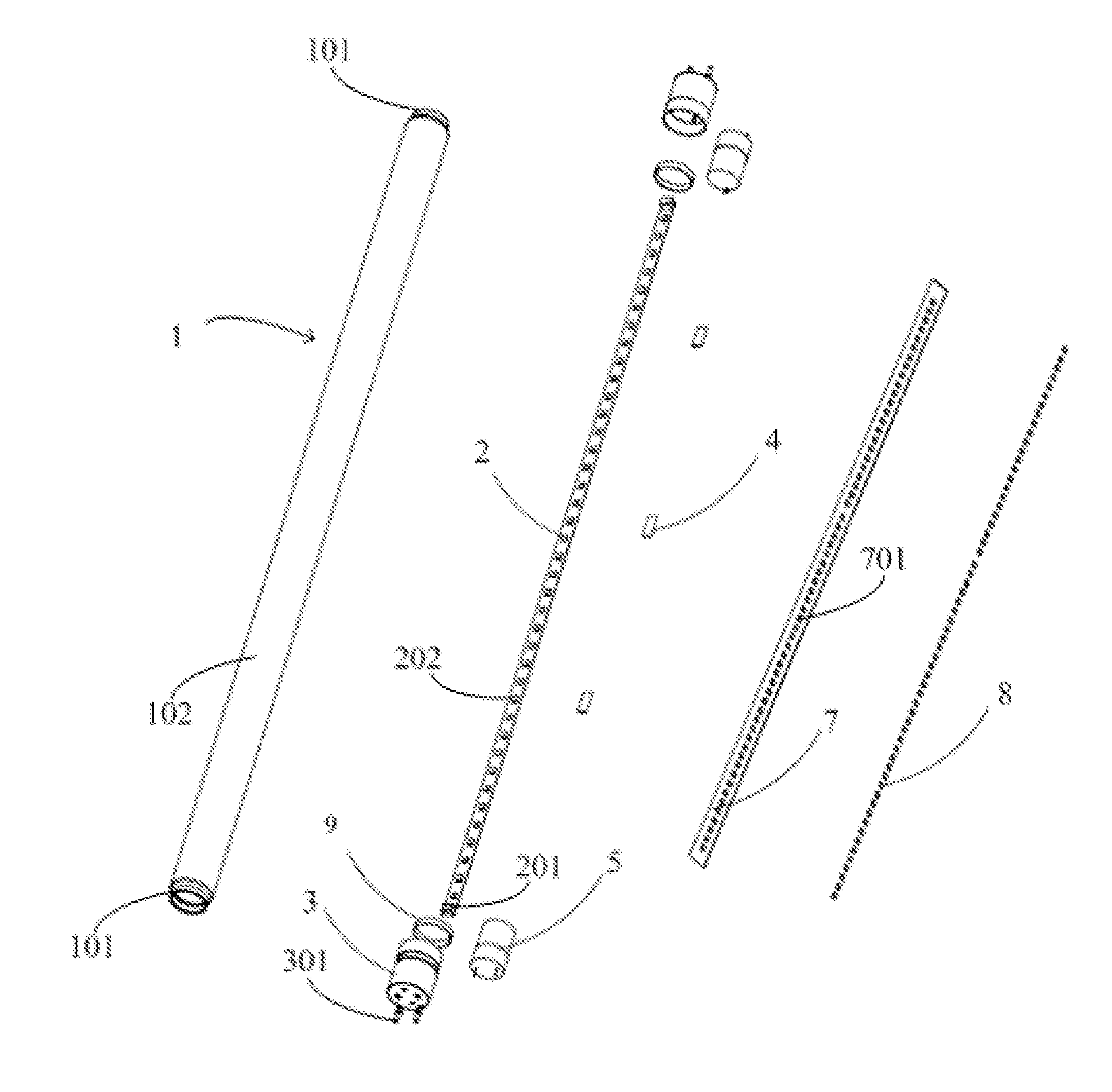

LED tube light with LED leadframes

ActiveUS20160290566A1Reducing unappealingImprove light extractionLight source combinationsElongate light sourcesEngineeringTroffer

An LED tube light which includes LED light sources mounted in LED leadframes is disclosed. The LED leadframe has a recess, a first sidewall and a second sidewall. Each LED light source includes an LED leadframe and an LED chip, in which LED chip is disposed in recess of LED leadframe. A height of first sidewall of LED leadframe is lower than a height of second sidewall thereof. Inner surface of the first sidewall is a sloped flat or curved surface facing towards outside the recess. First sidewalls of the LED leadframe are arranged along a length direction of the light tube, and second sidewalls of the LED leadframe are arranged along a width direction of the light tube. The LED tube light further includes an LED light bar. The LED light sources together with the LED leadframes are mounted on the LED light bar.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

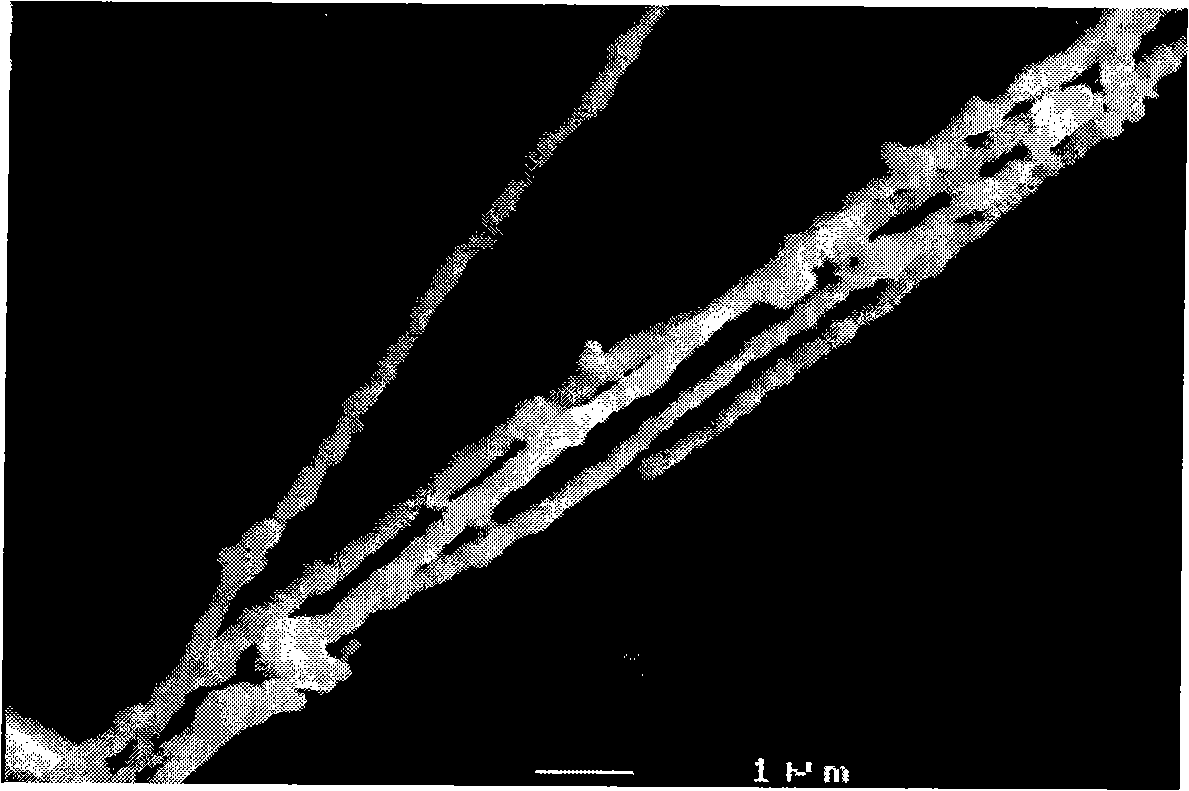

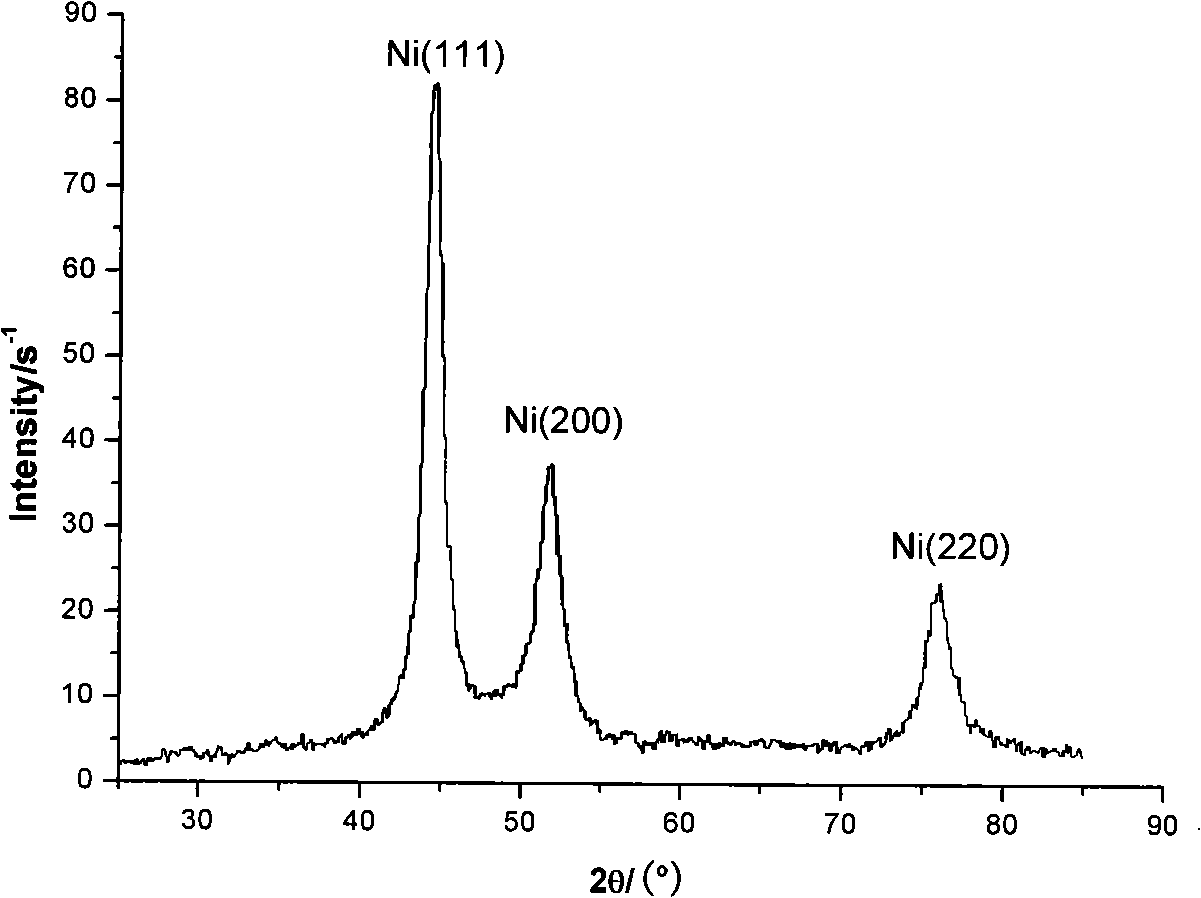

Method for preparing metallic nickel nano-wire

The invention discloses a chemical preparation method of nickel nano-wire which belongs to the field of the nanometer technology. The invention utilizes the mixed solution of water and ethanol to prepare the nickel ion solution which reacts with sodium hydroxide solution to generate nickel hydroxide precipitation, then utilizes hydrazine hydrate to dissolve precipitation and reduces the nickel ion under the heating condition and in the applied uniform magnetic field, finally the nickel nano-wire is assembled. Compared with the prior art, using the invention can prepare the nickel nano-wire which is 217 to 1900 nanometer in diameter, 15 to 69 micrometer in length, 20 to 300 in length-diameter ratio and has the composition of pure nickel. The invention has the advantages that the beforehand preparation process of formwork is not required, the chemical process is simple, the preparation cycle is short, the preparation cost is low and the mass preparation can be realized.

Owner:SHANGHAI JIAO TONG UNIV

Method for manufacturing circuit board layer-adding structure

ActiveCN103491732AMeet processing needsAchieve preparationInsulating layers/substrates workingMultilayer circuit manufactureCopper platingEtching

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

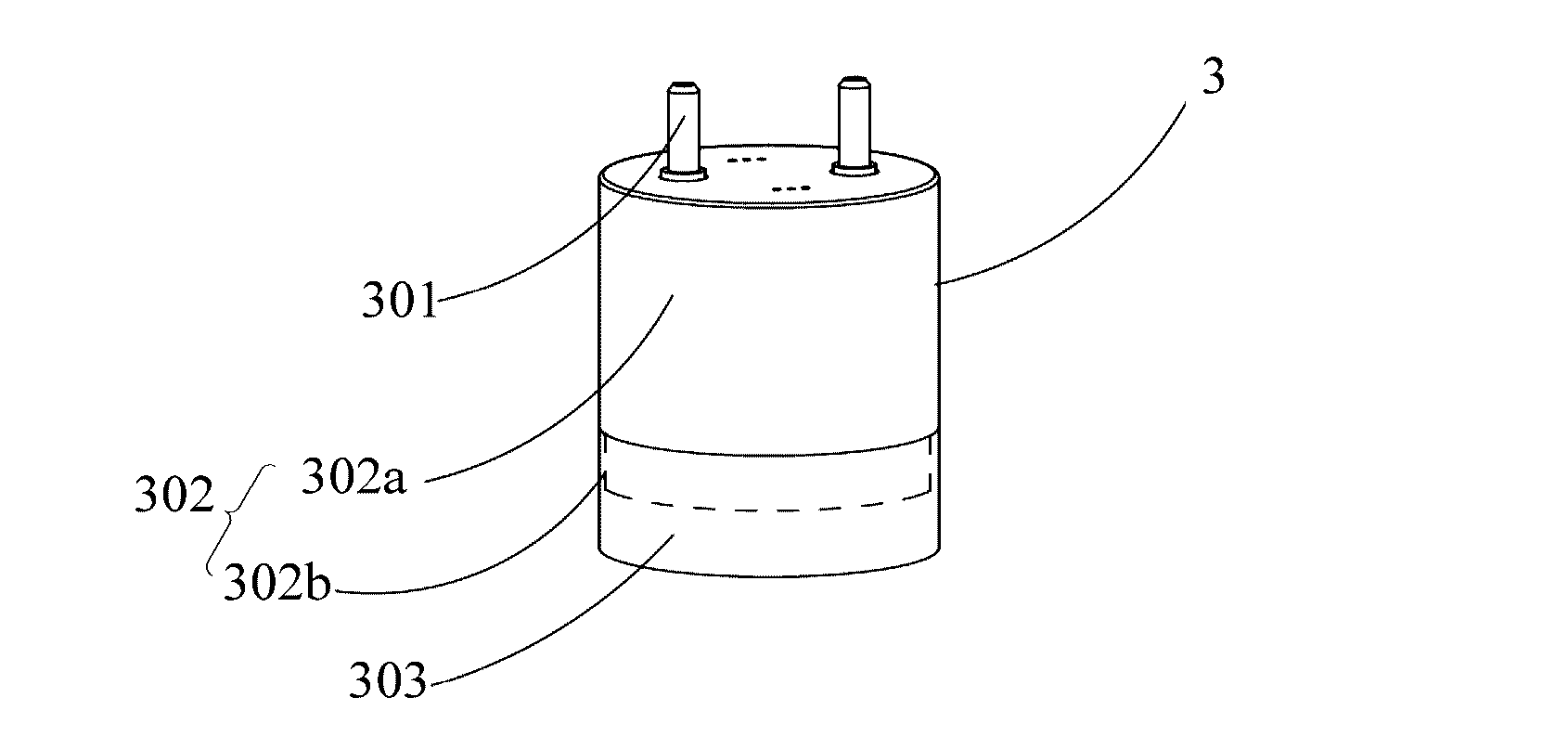

LED tube lamp

ActiveUS20160290568A1Unified performanceImproving LED tube lamp production efficiencyElongate light sourcesCoupling device detailsEngineeringLED lamp

An end cap for LED tube lamp along with the LED tube lamp adopting thereof is disclosed. LED tube lamp includes a lamp tube. One end of the lamp tube is attached to the end cap; a LED light bar is disposed inside the lamp tube. The end cap includes an insulating tubular part, sleeved with the end of the lamp tube and a magnetic object disposed between an inner circumferential surface of the insulating tubular part and the end of the lamp tube. The magnetic object being of a magnetic metal member and the lamp tube are adhesively bonded by a hot melt adhesive. An inner circumferential surface of the magnetic metal member can be fully covered by the hot melt adhesive. Magnetic metal member can be in the structure of a circular or oval ring, with at least one opening, and has indentation structure on a surface thereof.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

End cap of LED tube light with thermal conductive ring

ActiveUS20160290570A1Improving LED tube light production efficiencyAchieve preparationLight source combinationsPoint-like light sourceMetalLight tube

LED tube light including light tube and end cap, in which end cap includes an insulating tubular part and a thermal conductive ring, thermal conductive ring fixedly arranged on outer circumferential surface of insulating tubular part, end cap sleeved over an end of light tube, and thermal conductive ring adhesively bonded to light tube is disclosed herein. Insulating tubular part has first and second tubular parts that are connected along axial direction of light tube, outer diameter of second tubular part is less than outer diameter of first tubular part, and thermal conductive ring is sleeved over second tubular part, in which outer surface of thermal conductive ring and outer circumferential surface of first tubular part are substantially flush with each other. End of second tubular part has notches, spatially arranged along circumferential direction thereof. Thermal conductive ring can be tubular metal ring, and insulating tubular part can be plastic.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com