Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1125 results about "Edge connector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An edge connector is the portion of a printed circuit board (PCB) consisting of traces leading to the edge of the board that are intended to plug into a matching socket. The edge connector is a money-saving device because it only requires a single discrete female connector (the male connector is formed out of the edge of the PCB), and they also tend to be fairly robust and durable. They are commonly used in computers for expansion slots for peripheral cards, such as PCI, PCI Express, and AGP cards.

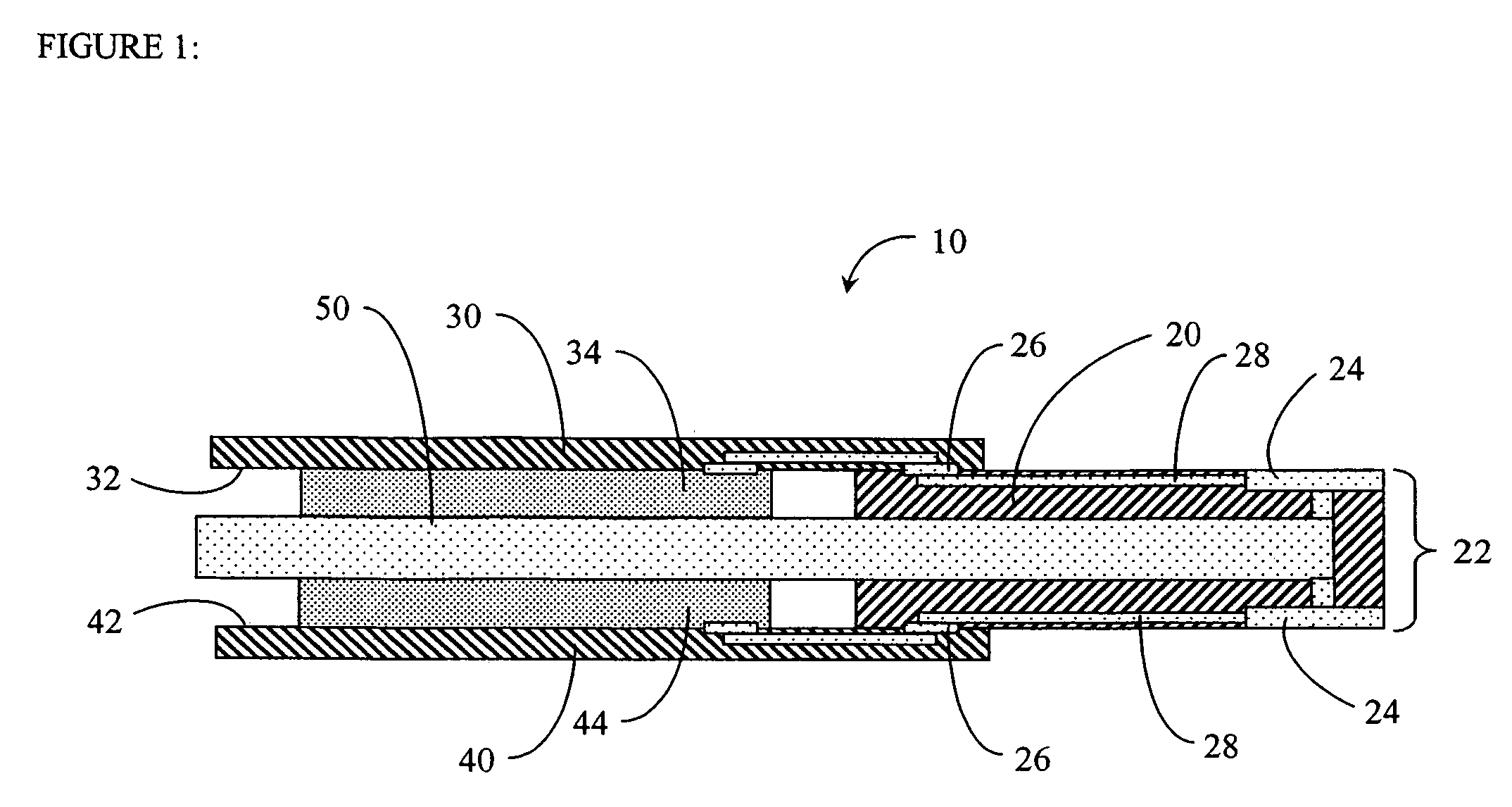

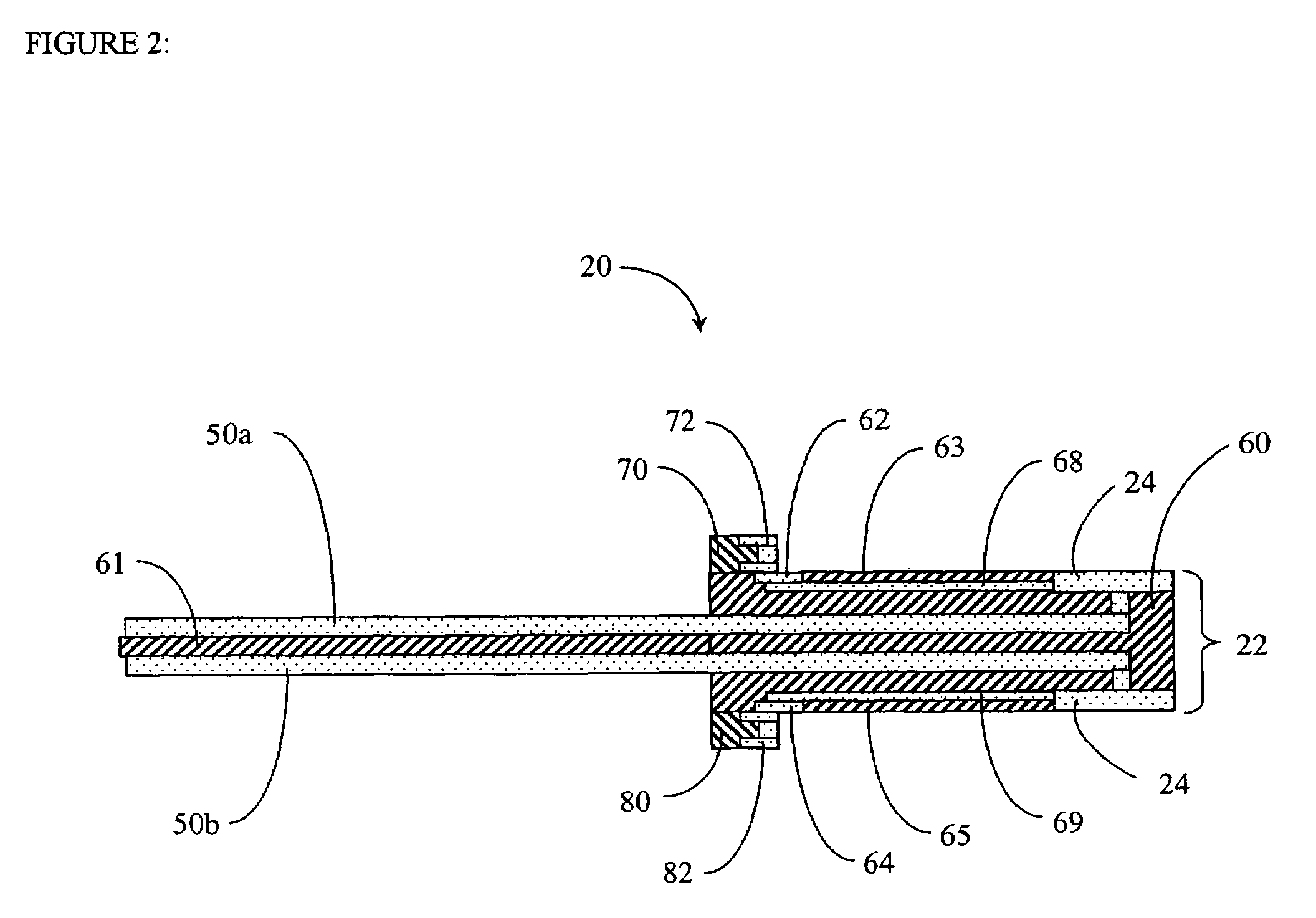

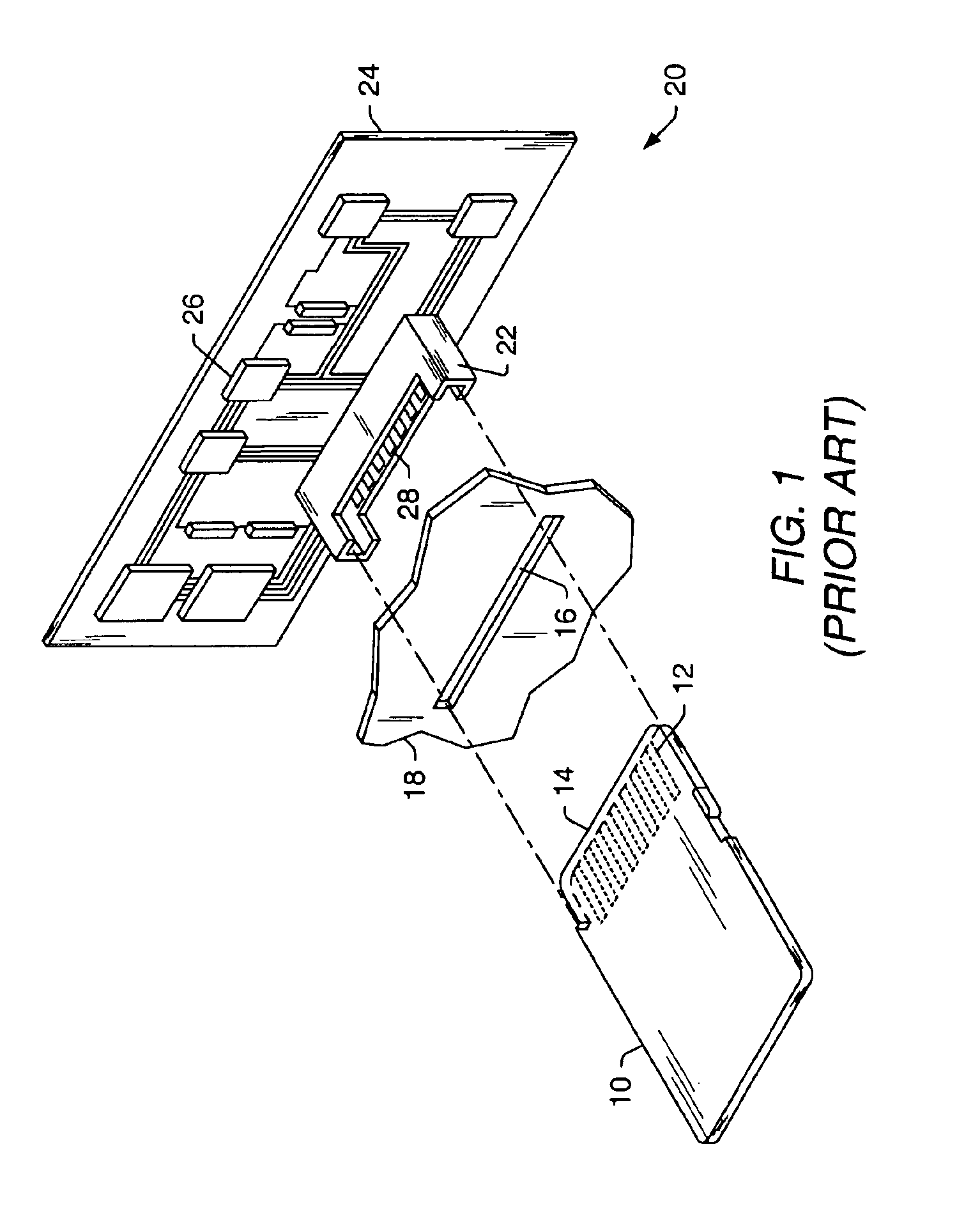

Method and apparatus for pluggable fiber optic modules

Owner:LUMENTUM OPERATIONS LLC

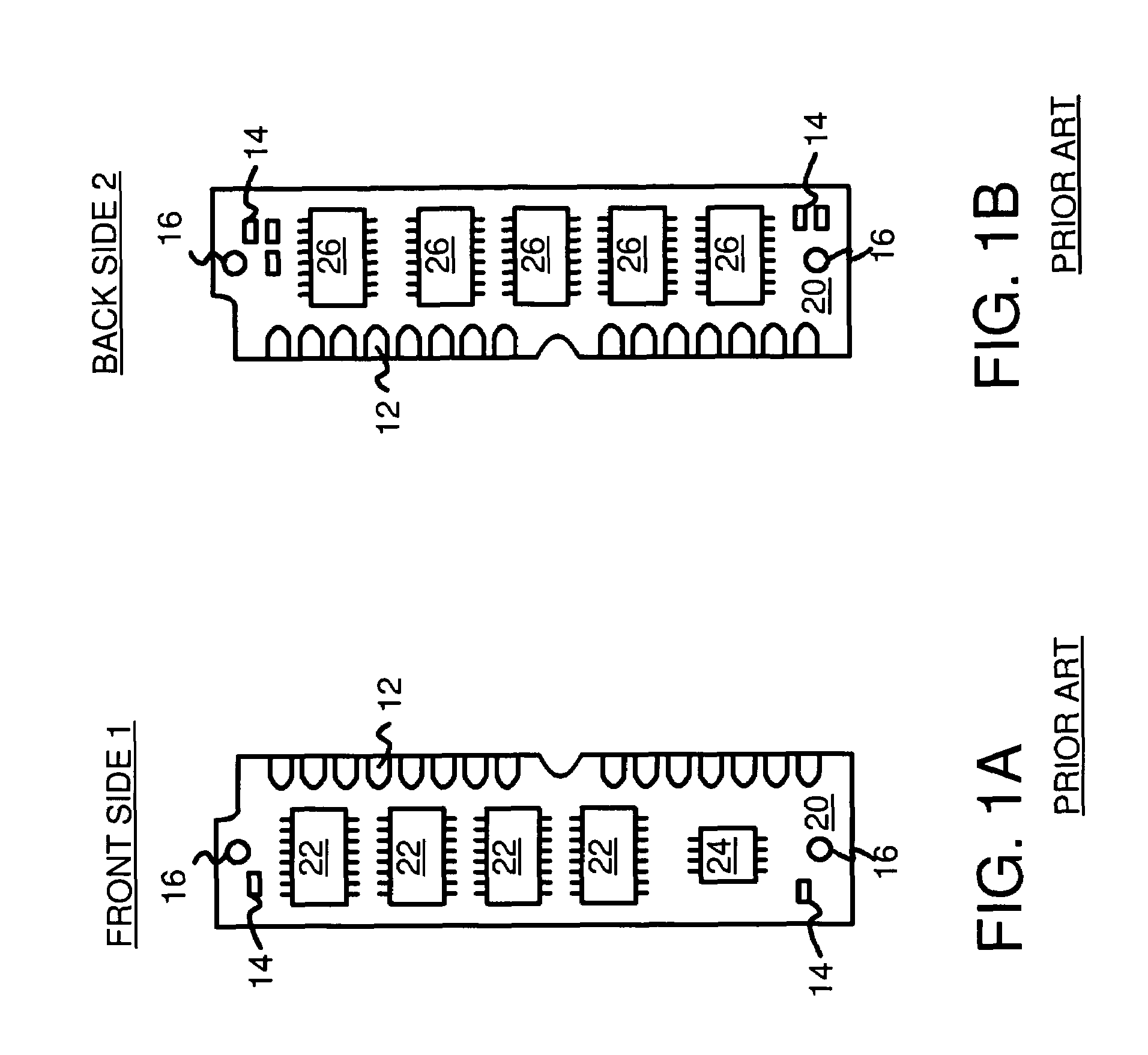

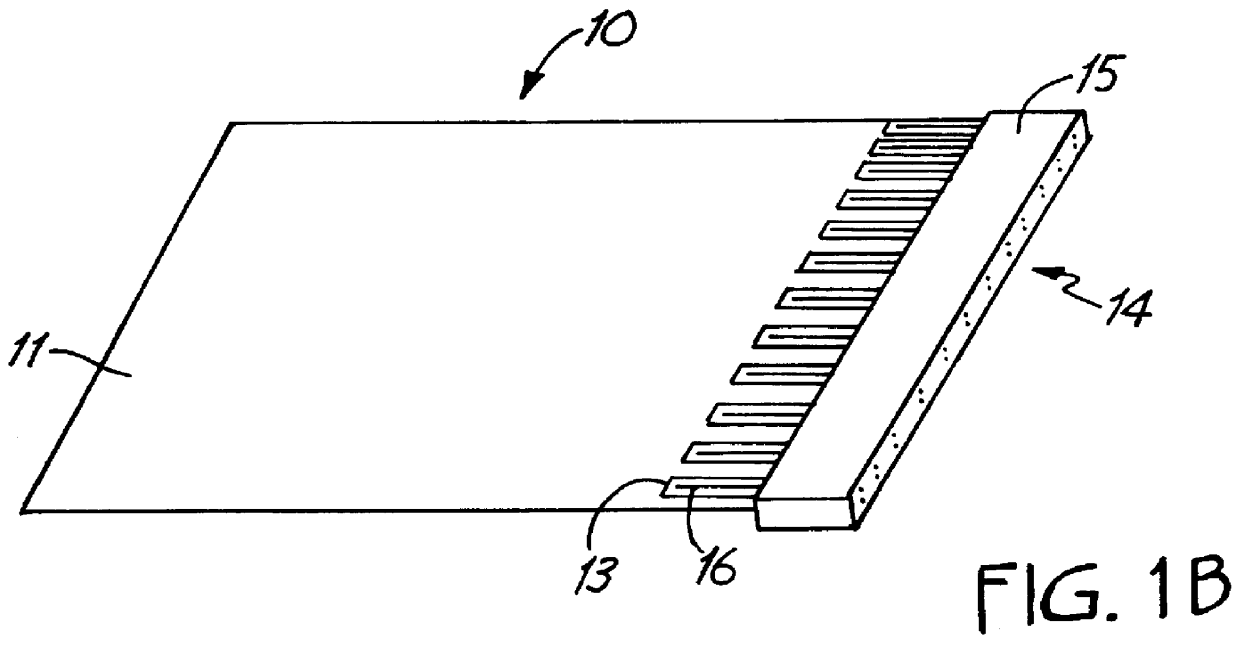

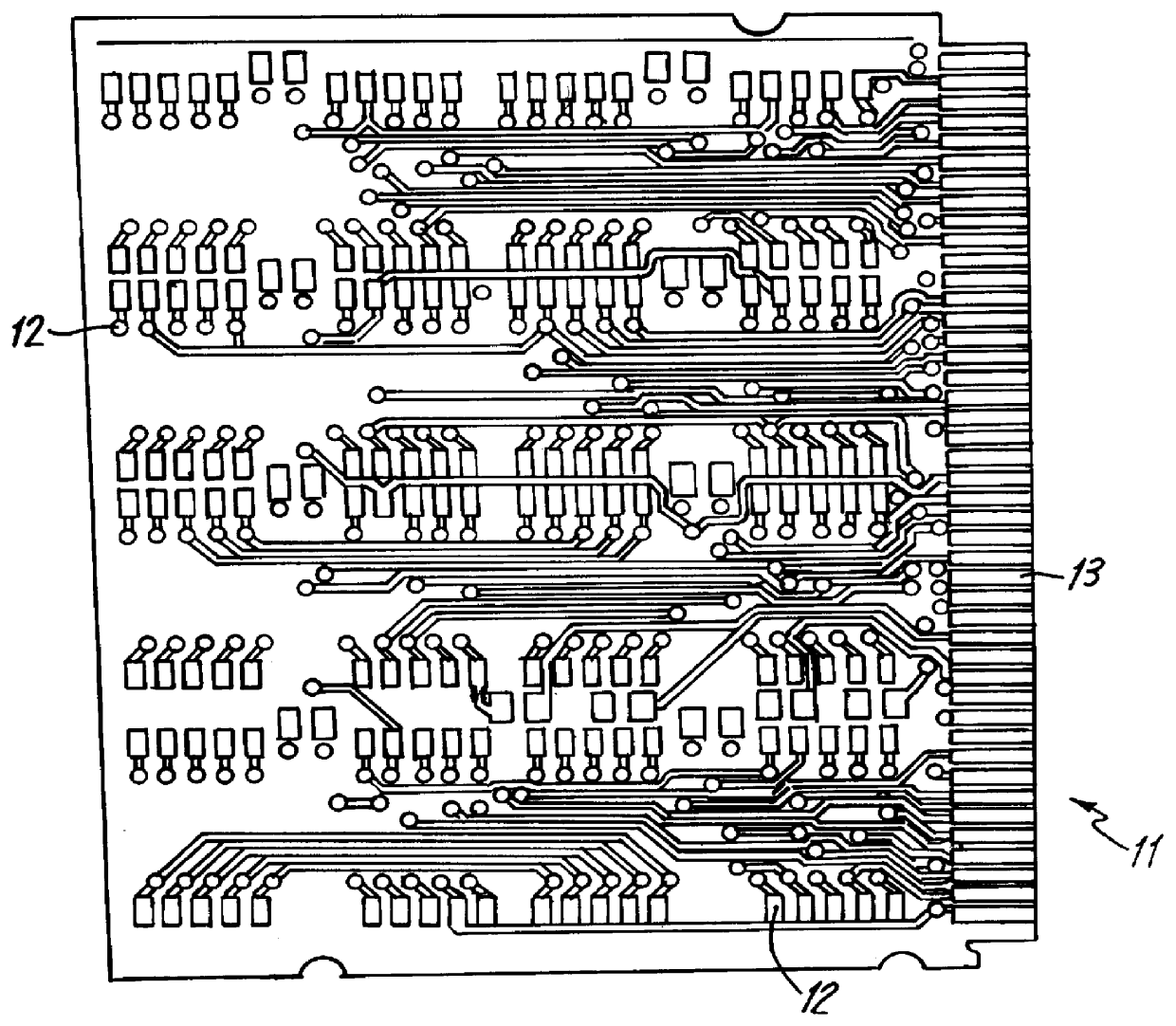

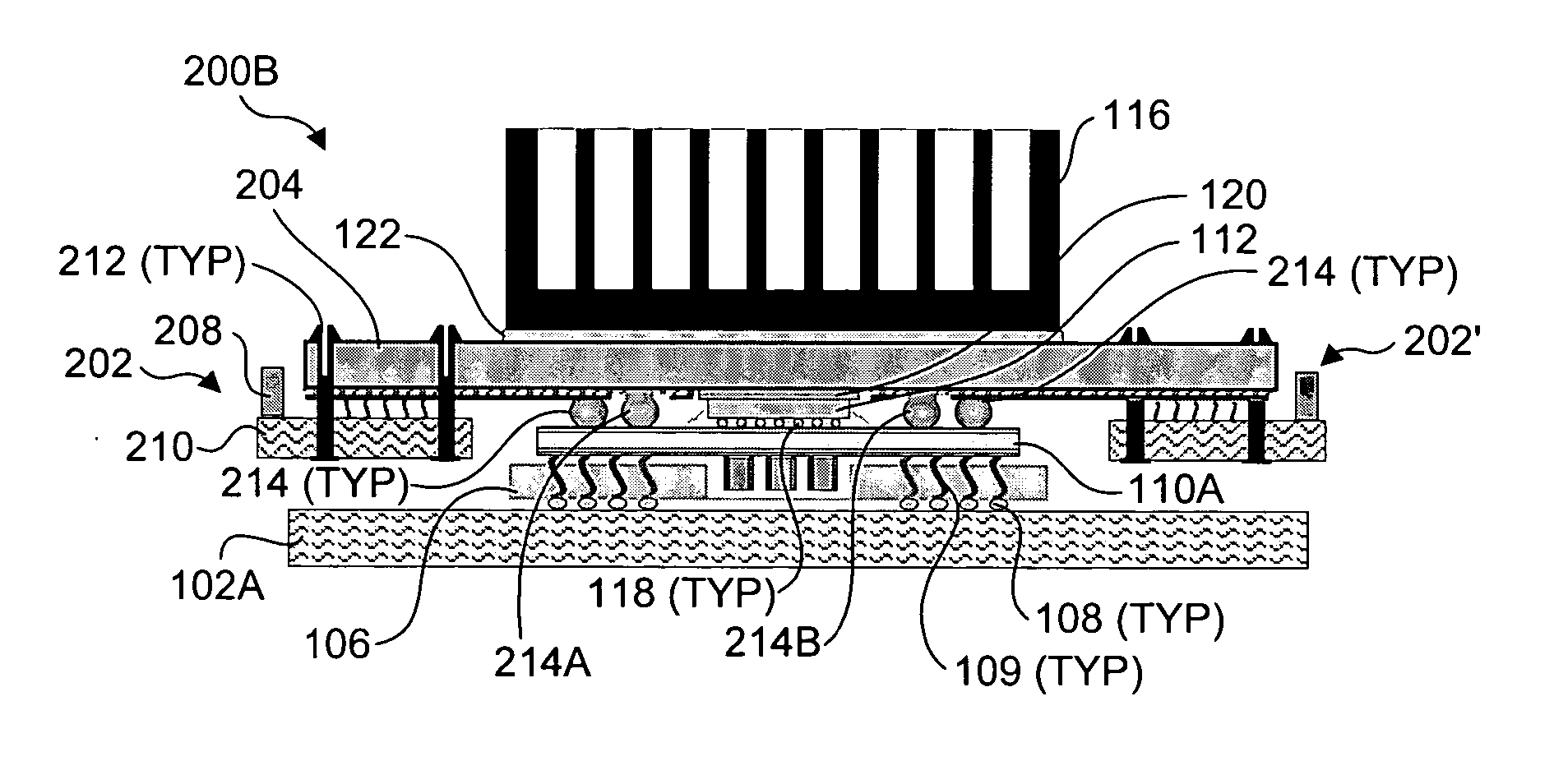

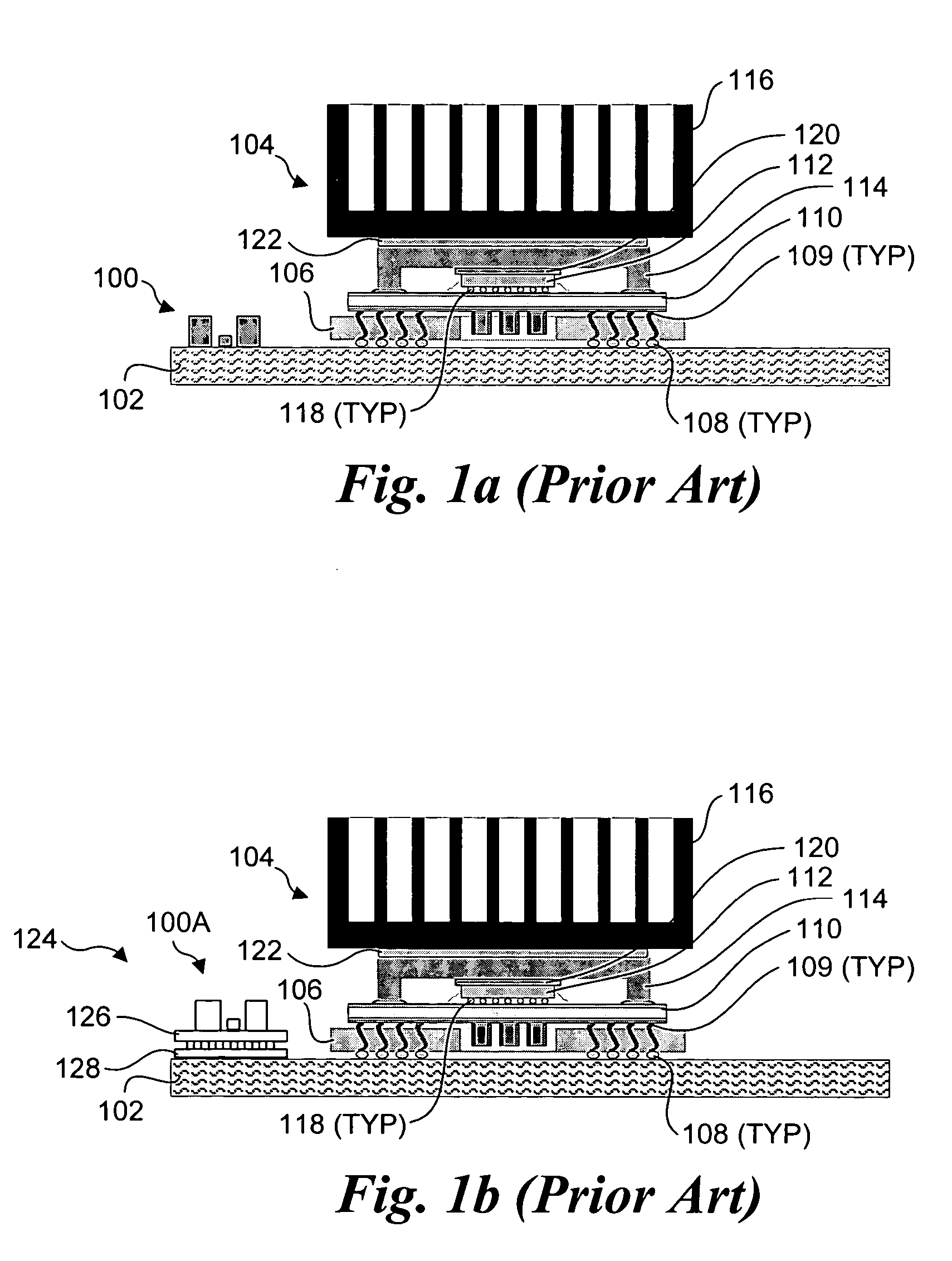

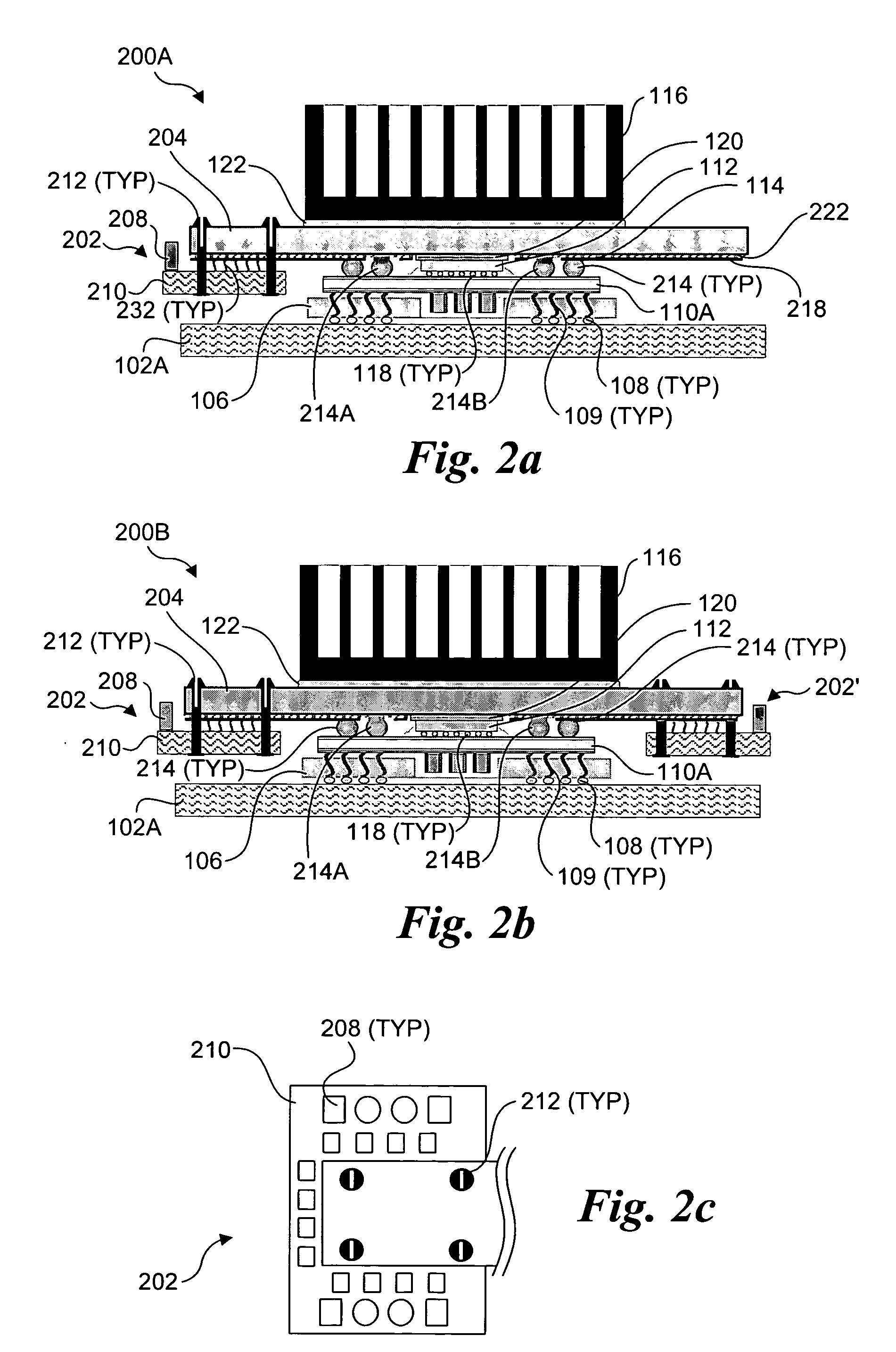

High density memory module using stacked printed circuit boards

ActiveUS7254036B2Semiconductor/solid-state device detailsPrinted circuit aspectsHigh densityComputerized system

Owner:NETLIST INC

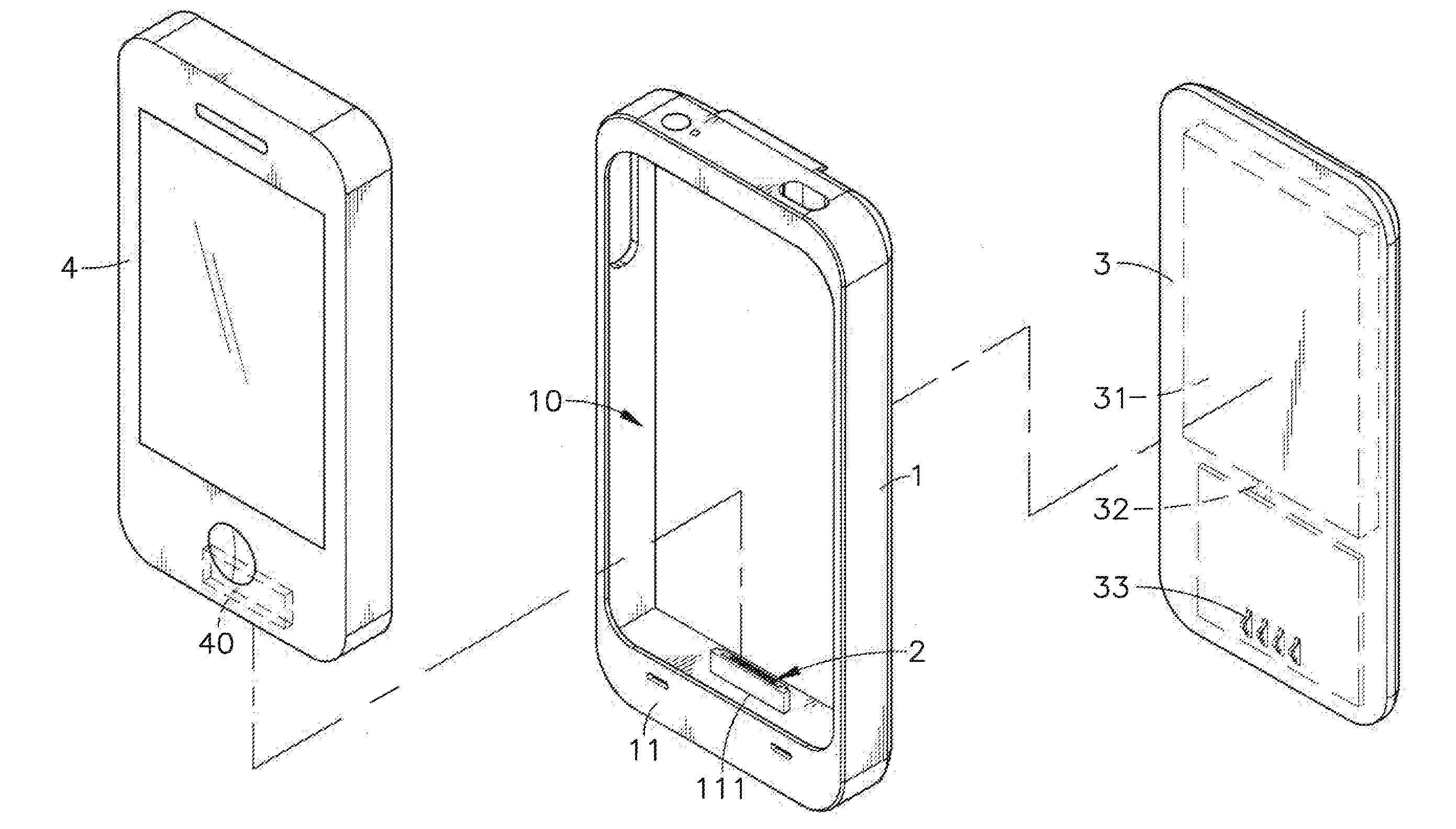

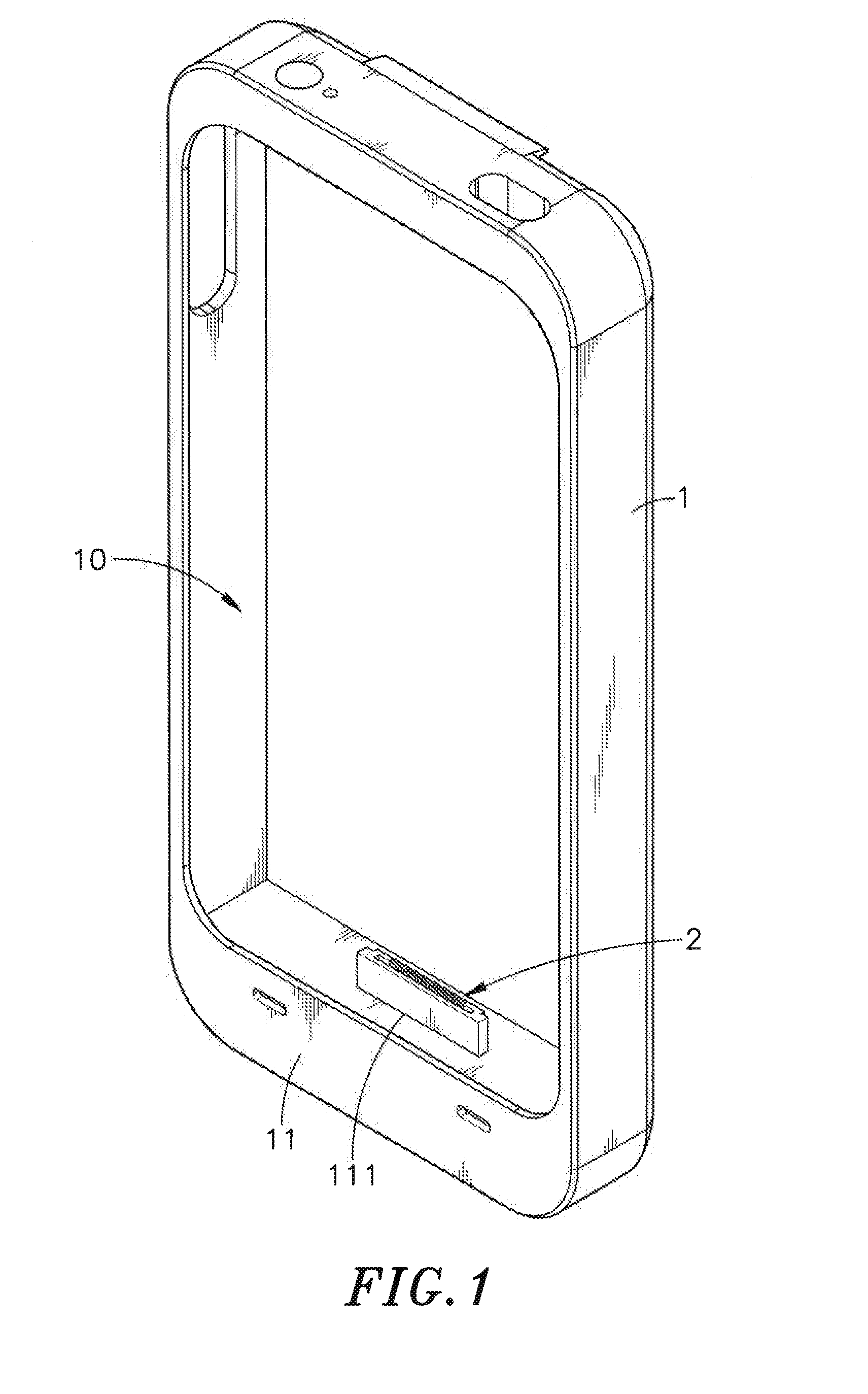

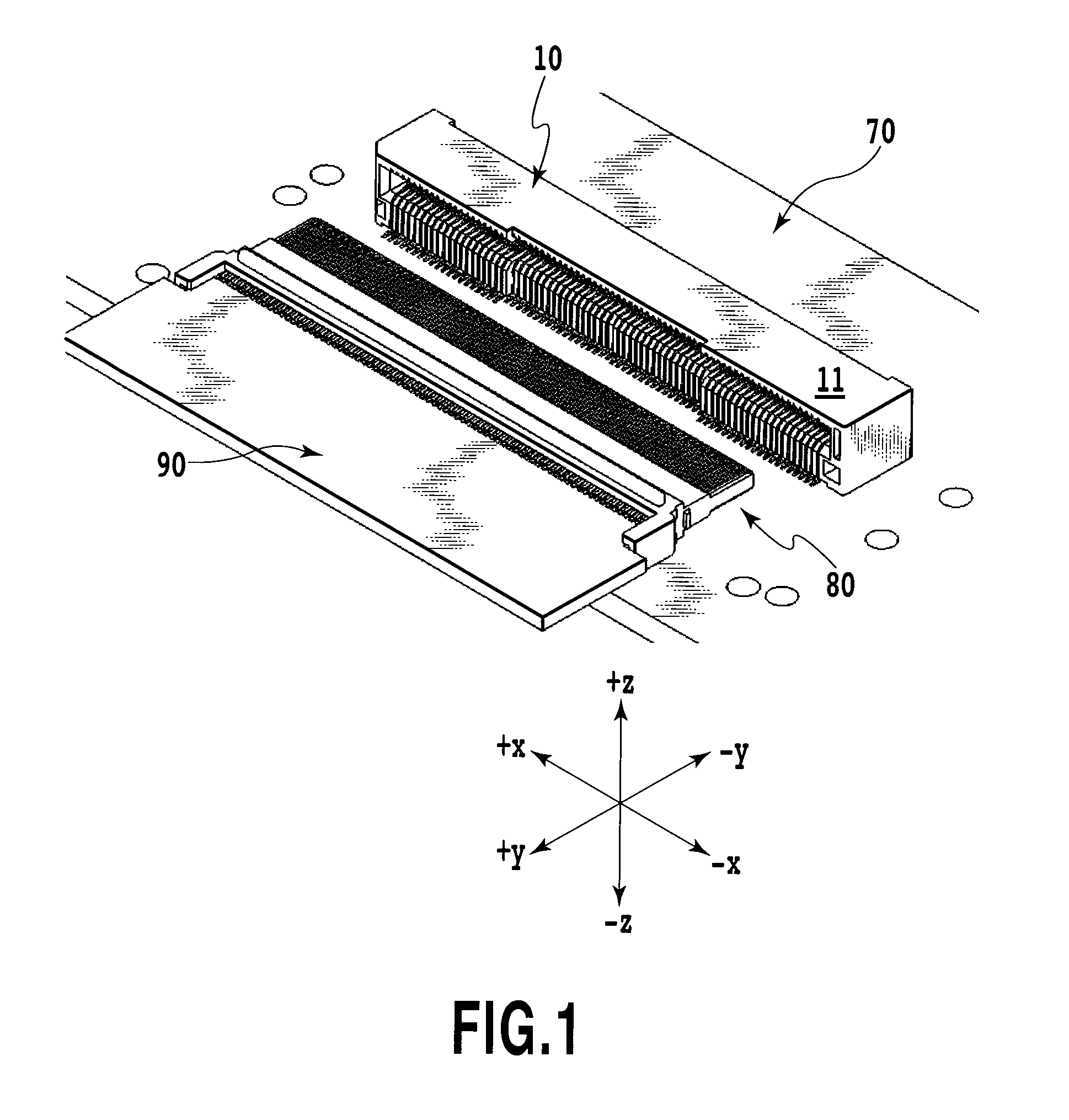

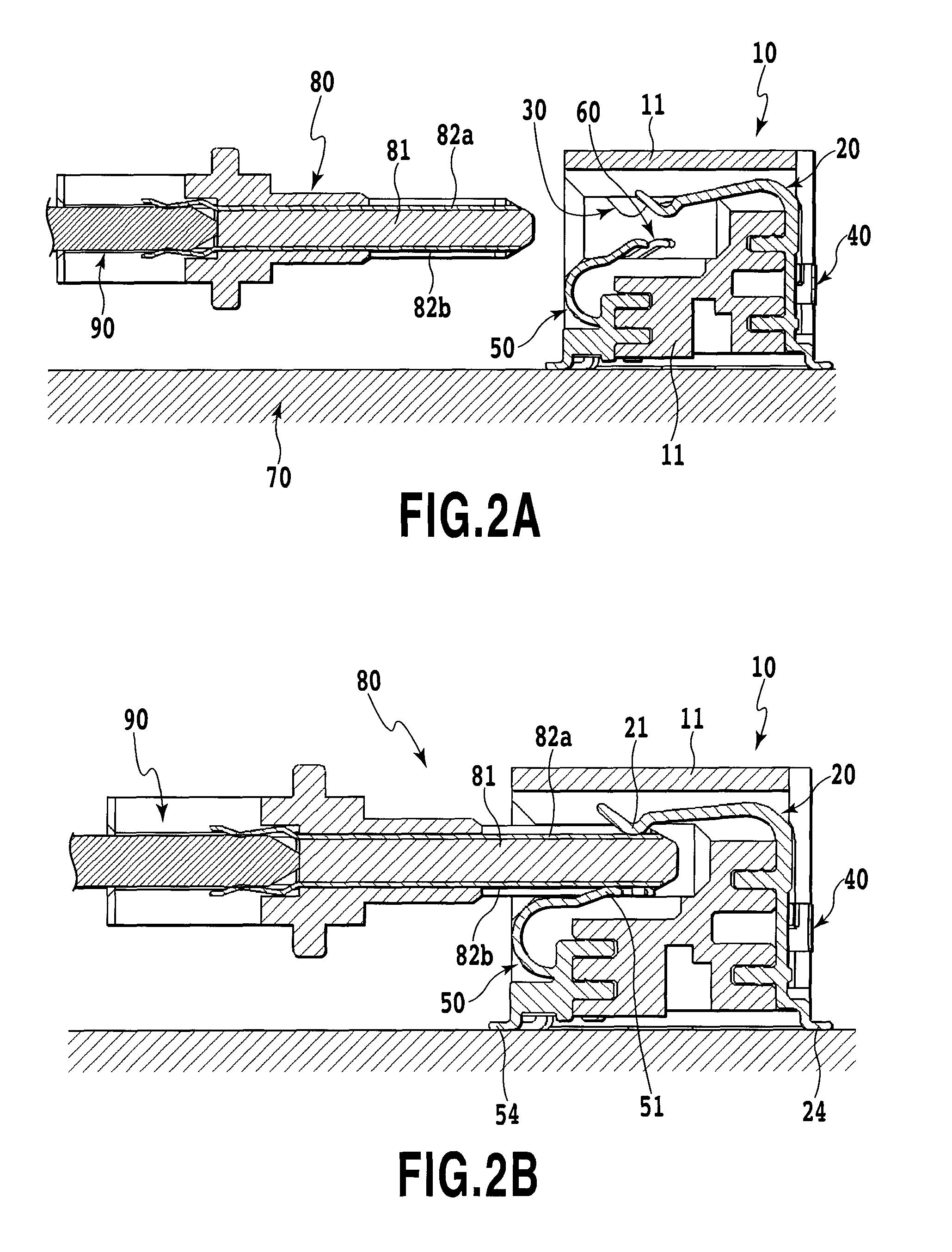

Auxiliary device for mobile electronic apparatus

InactiveUS20130273983A1Batteries circuit arrangementsDigital data processing detailsElectricityEngineering

An auxiliary device for mobile electronic apparatus includes an electrically insulative housing for accommodation a mobile electronic apparatus, an electrical connector slidably coupled to the electrically insulative housing and movable between an extended position to electrically connect a card-edge connector thereof to the accommodated mobile electronic apparatus in the electrically insulative housing and a received position to electrically disconnect the card-edge connector from the accommodated mobile electronic apparatus, and a back cover detachably mounted in a back side of the electrically insulative housing to electrically connect a storage battery cell to the electrical connector for charging the accommodated mobile electronic apparatus in the electrically insulative housing.

Owner:PADTRON TECH L L C

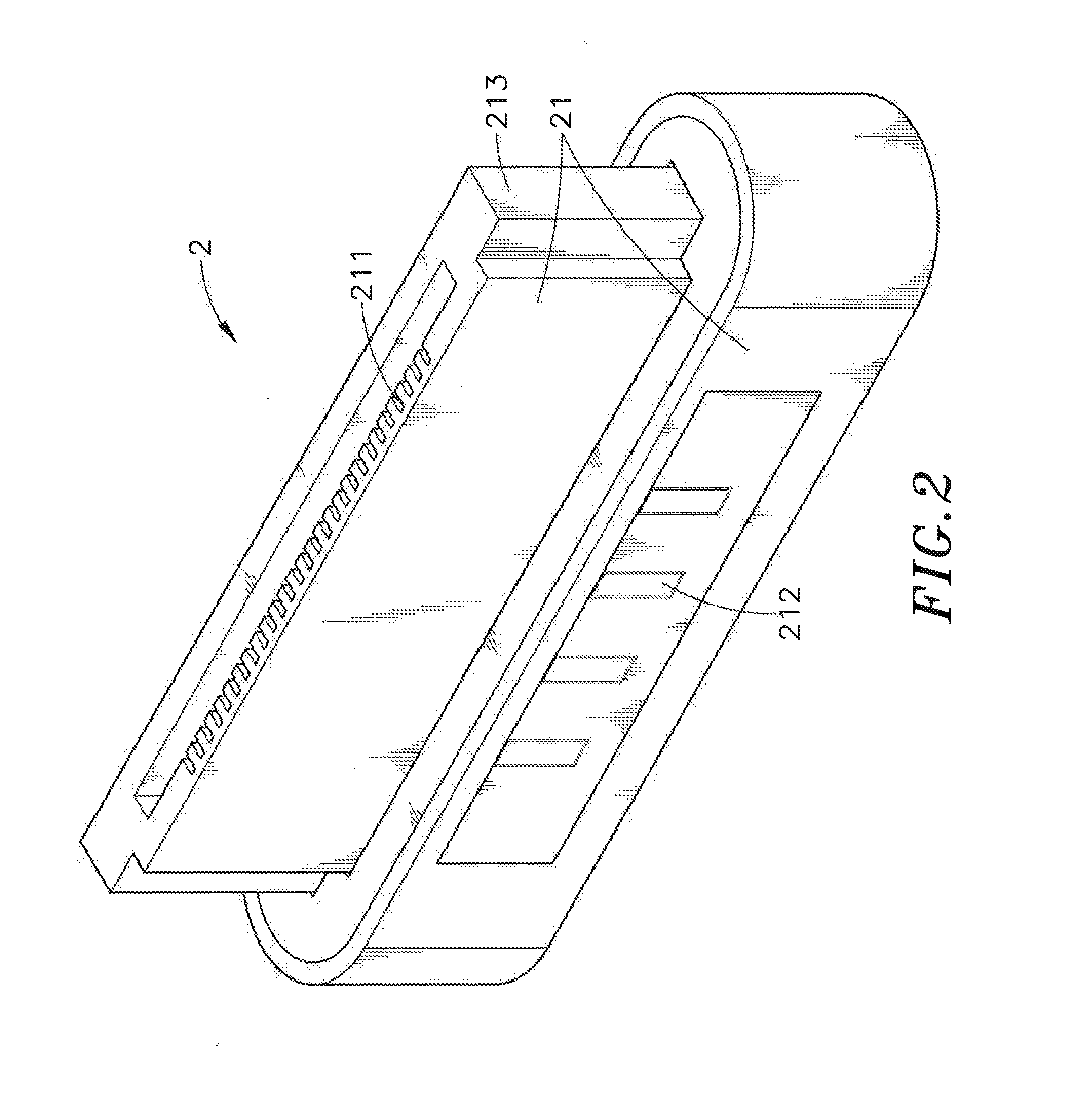

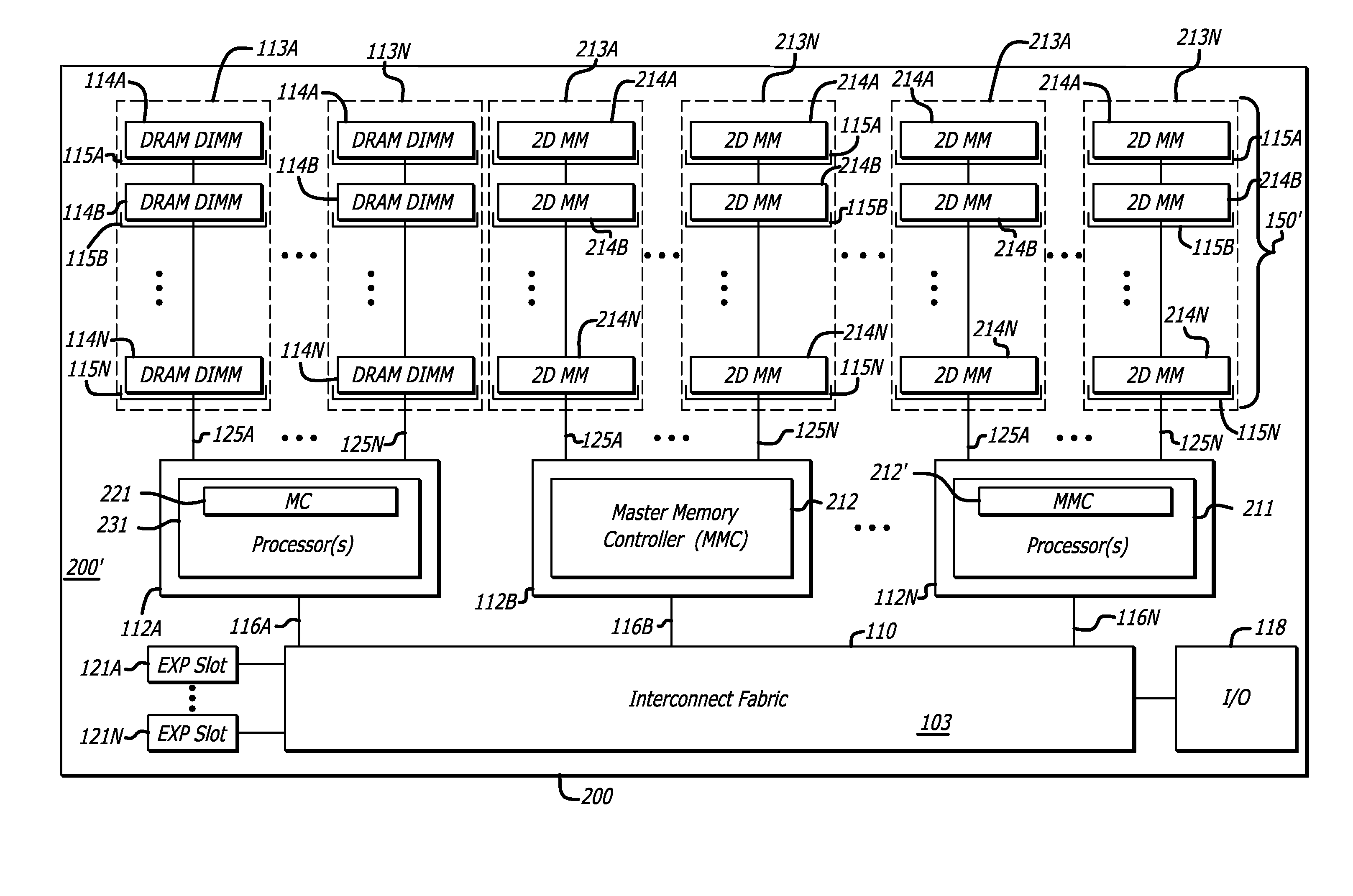

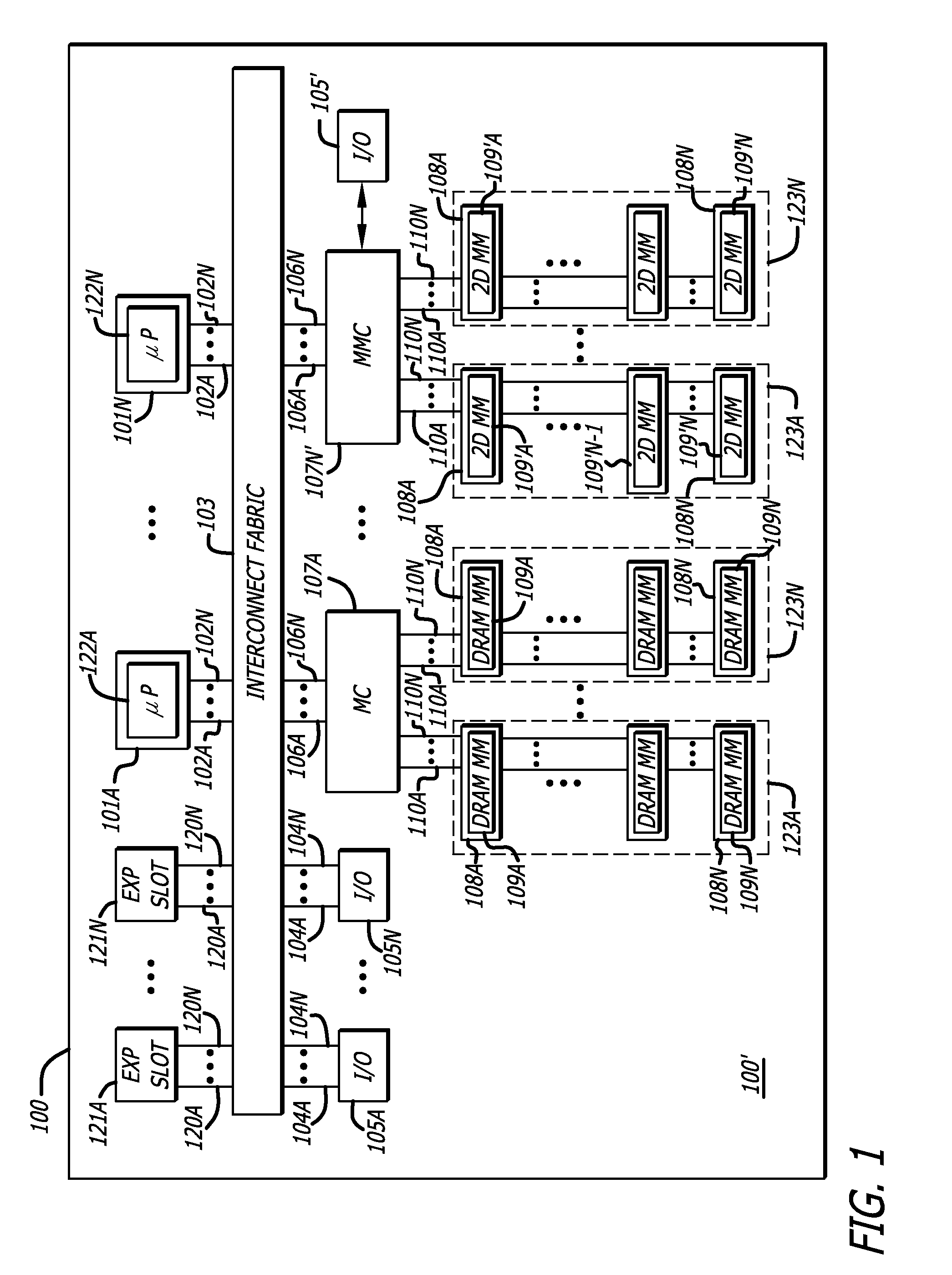

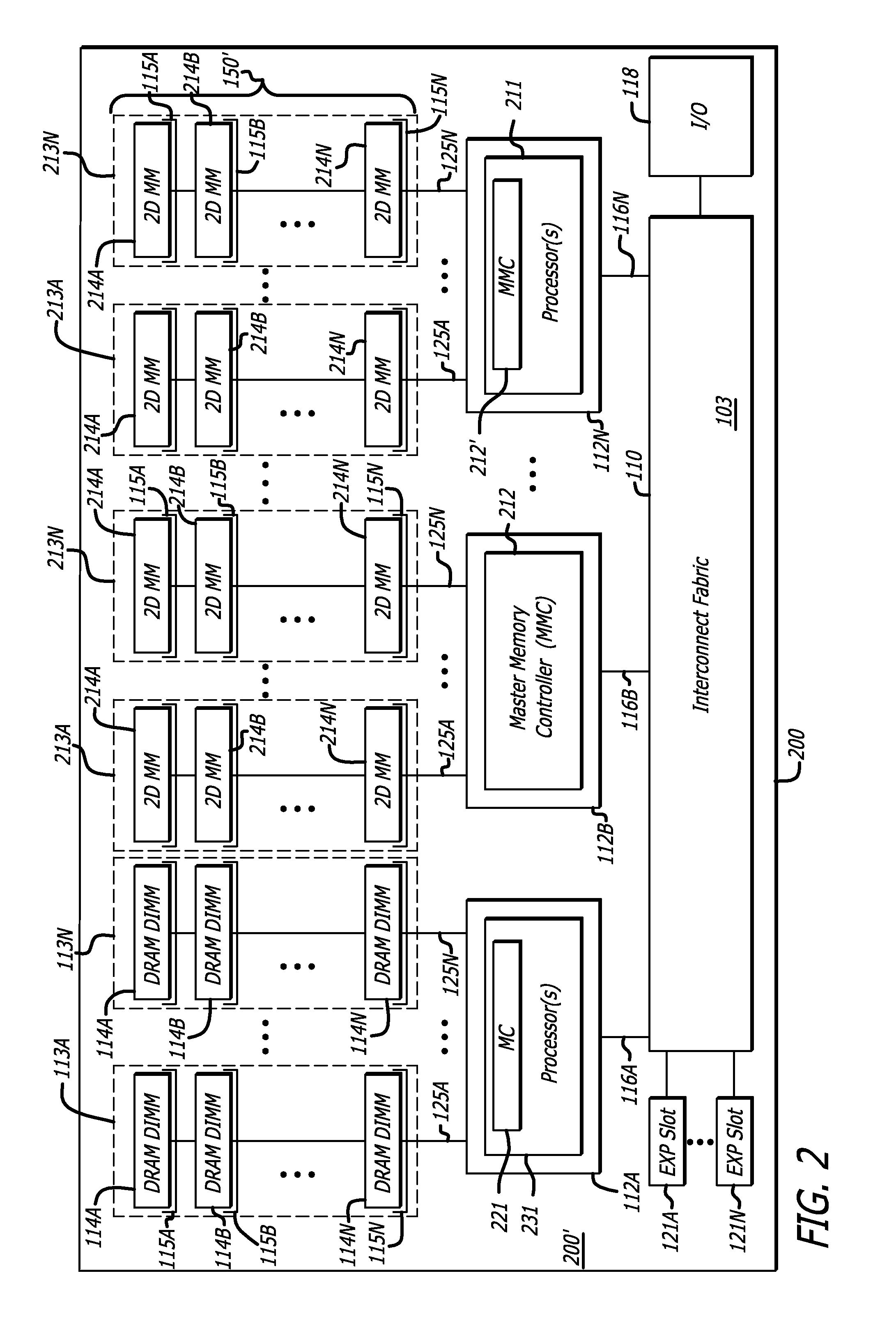

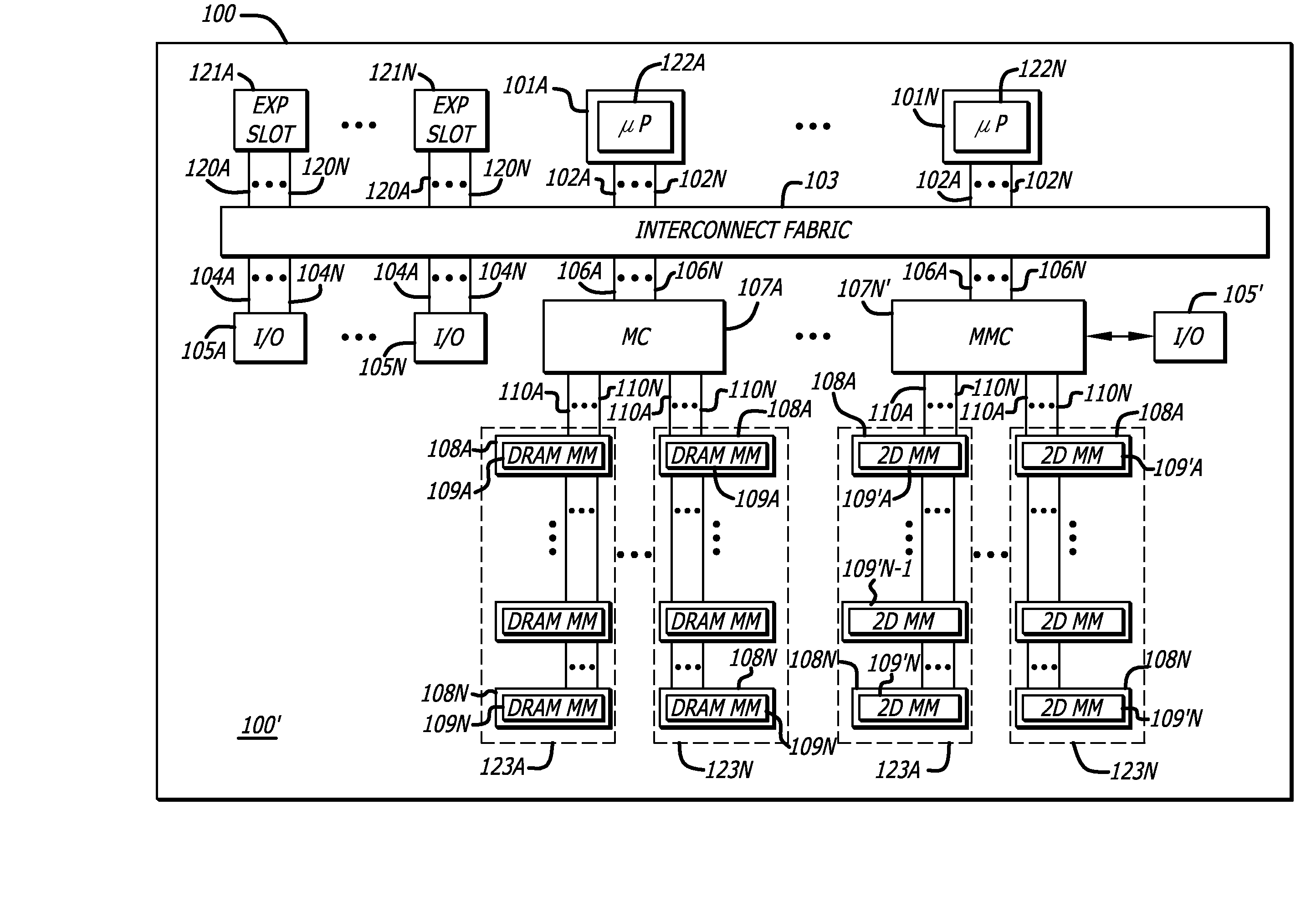

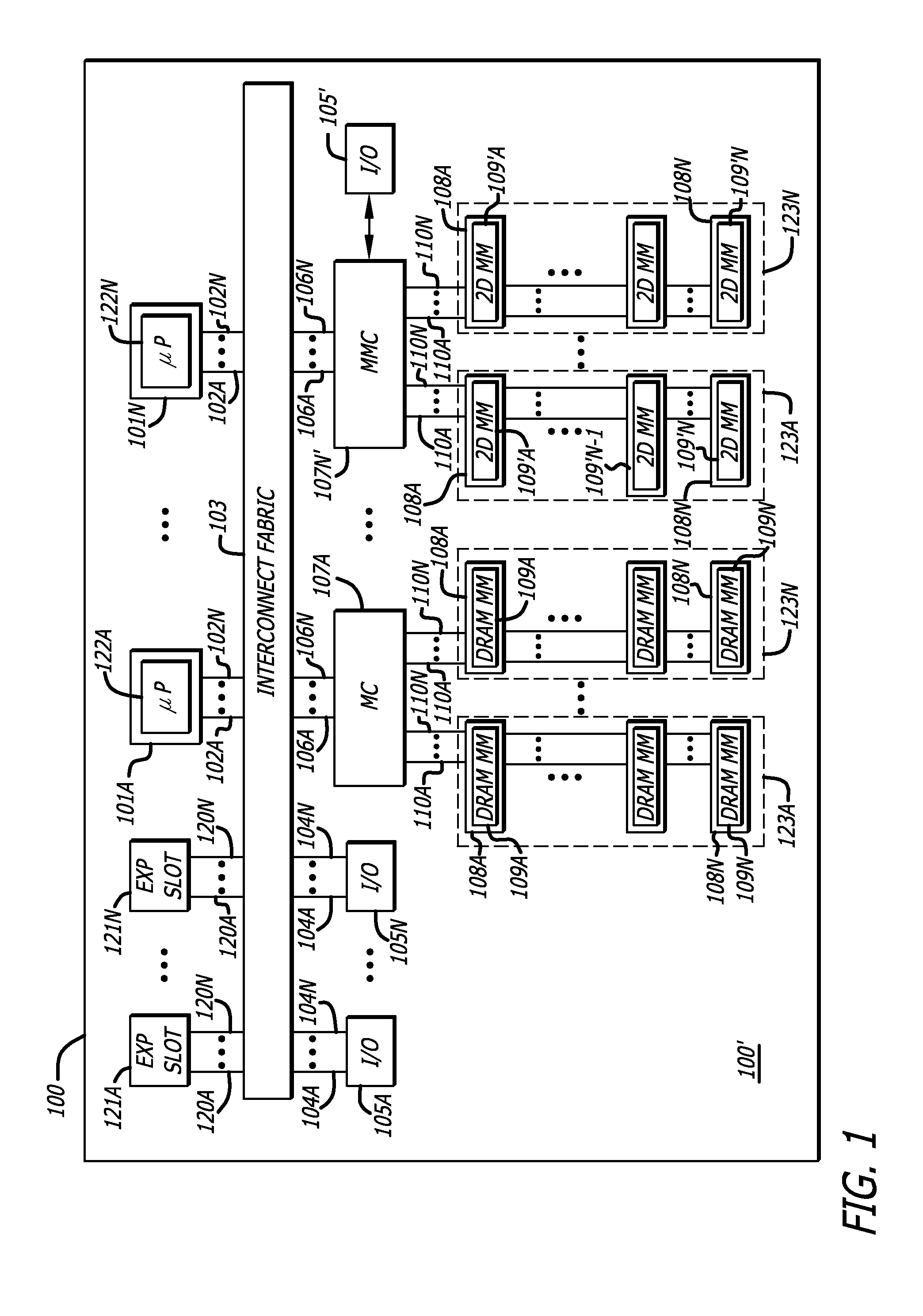

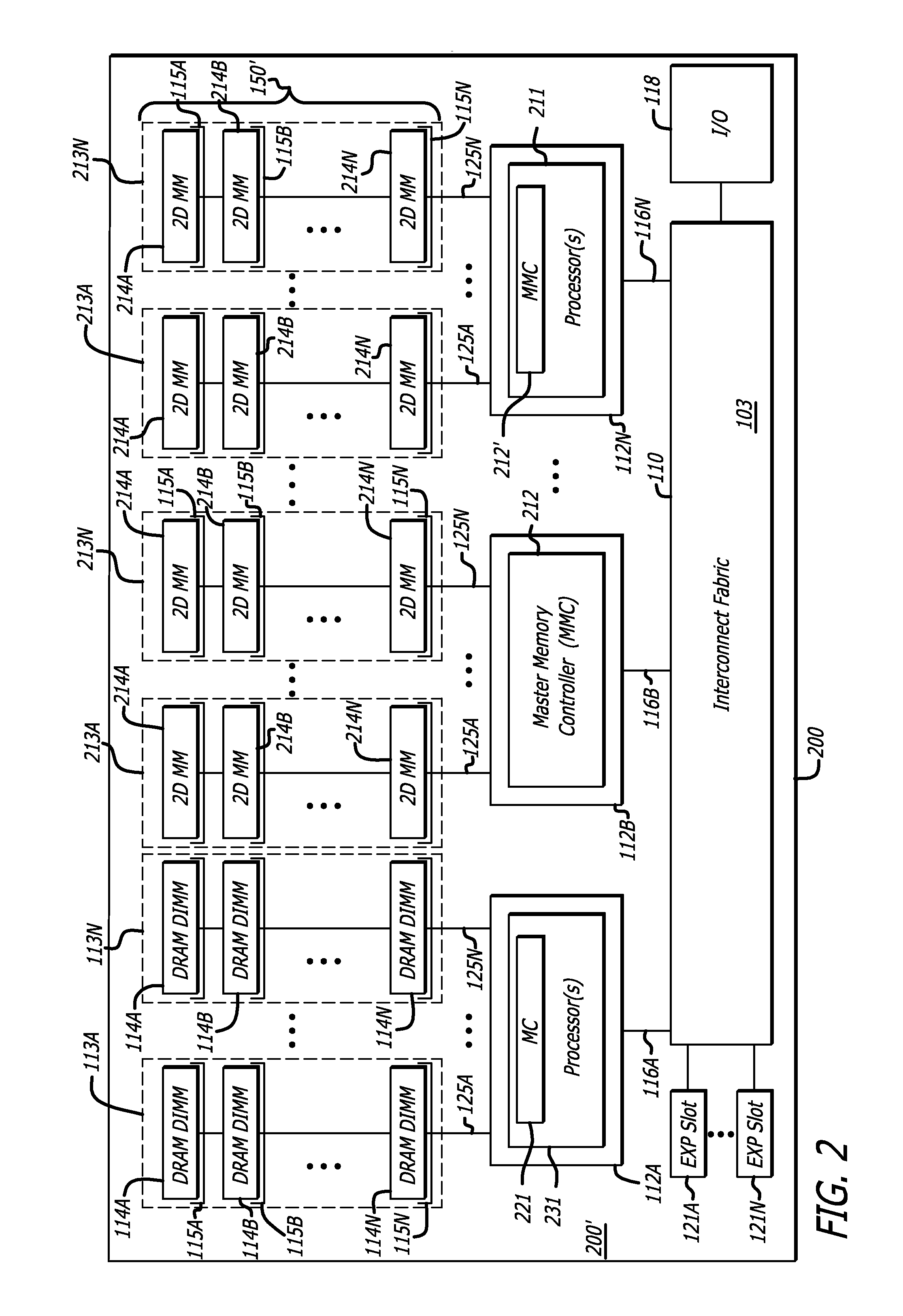

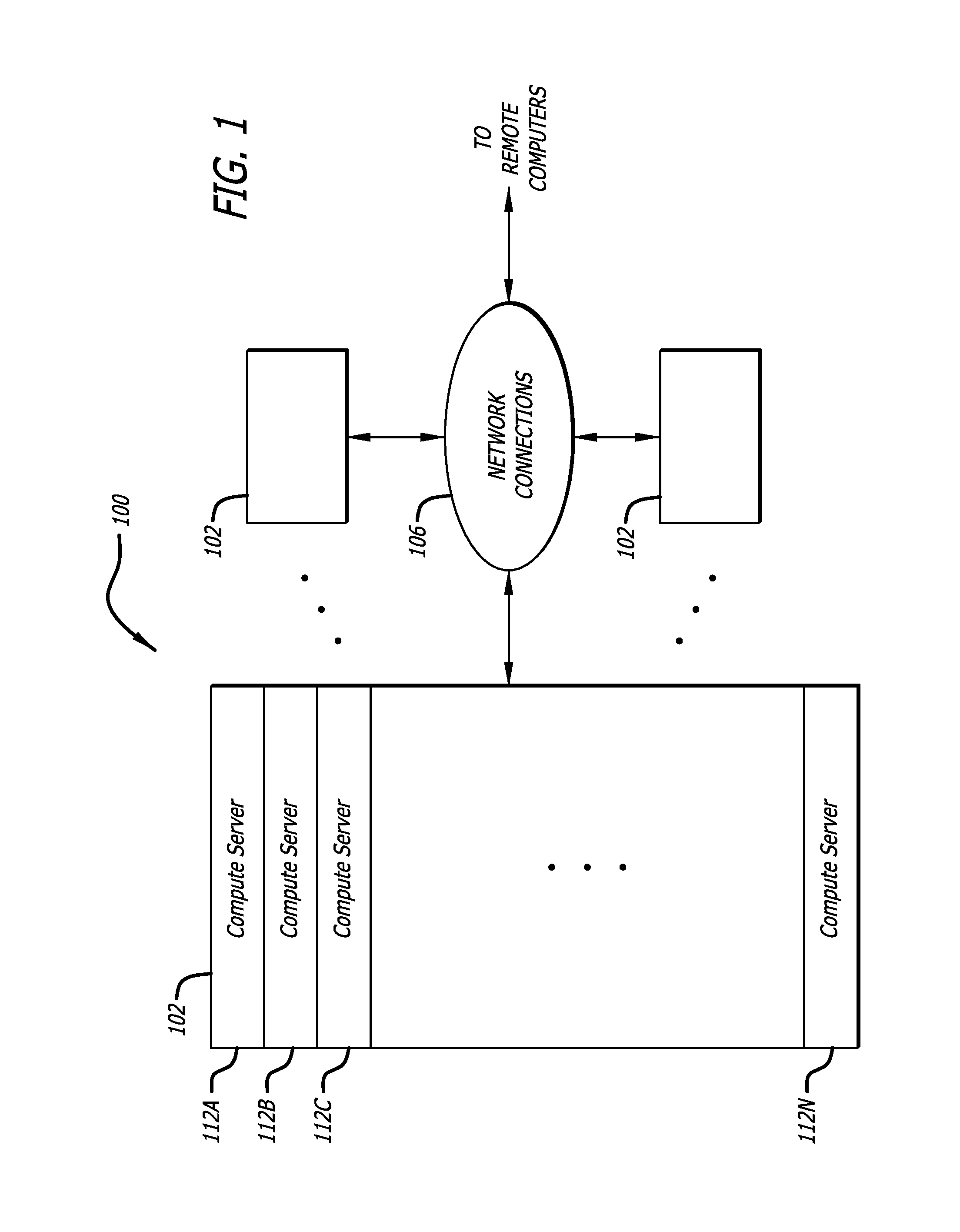

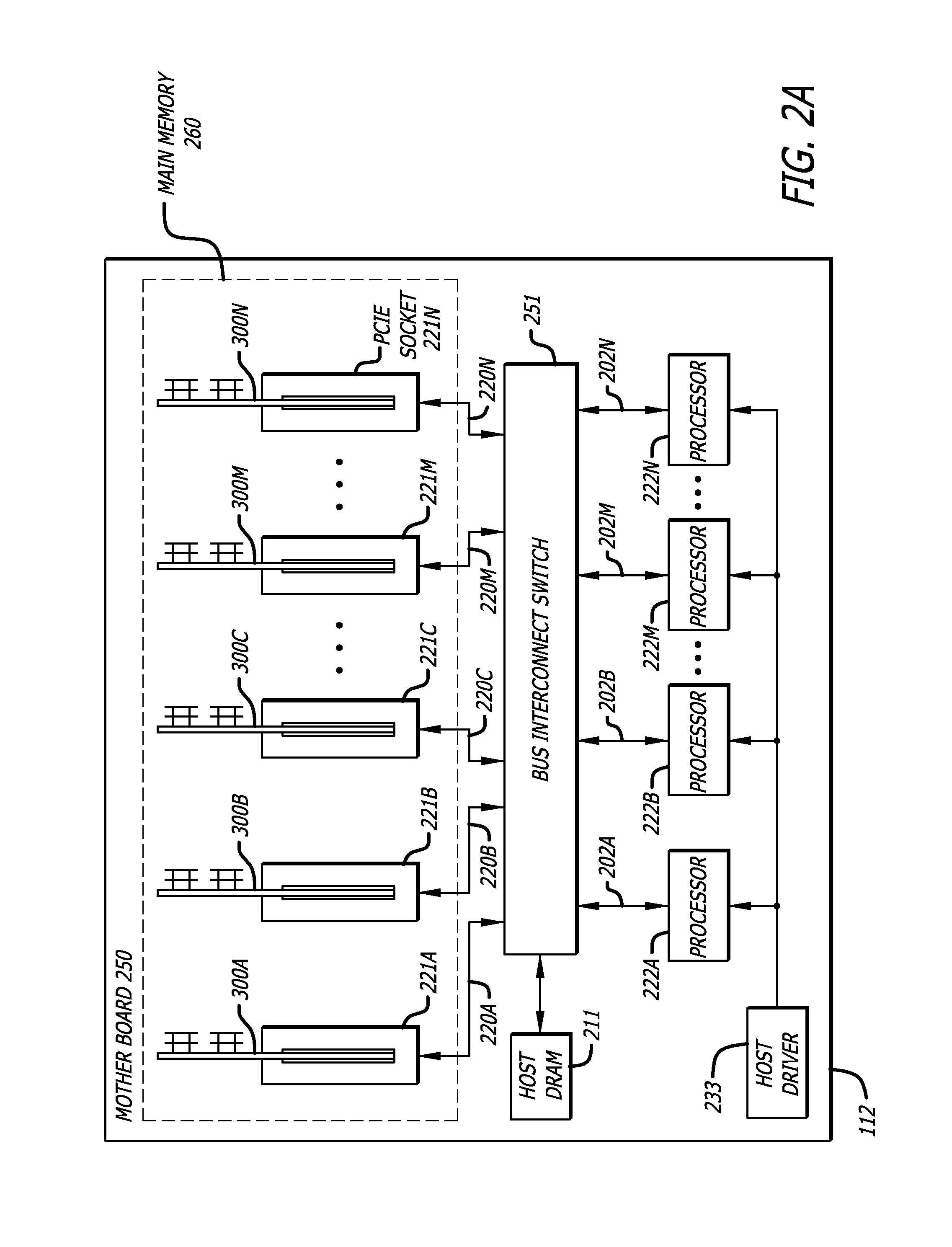

Methods and apparatus for two-dimensional main memory

ActiveUS20090254689A1Memory architecture accessing/allocationEnergy efficient ICTMemory controllerAddress control

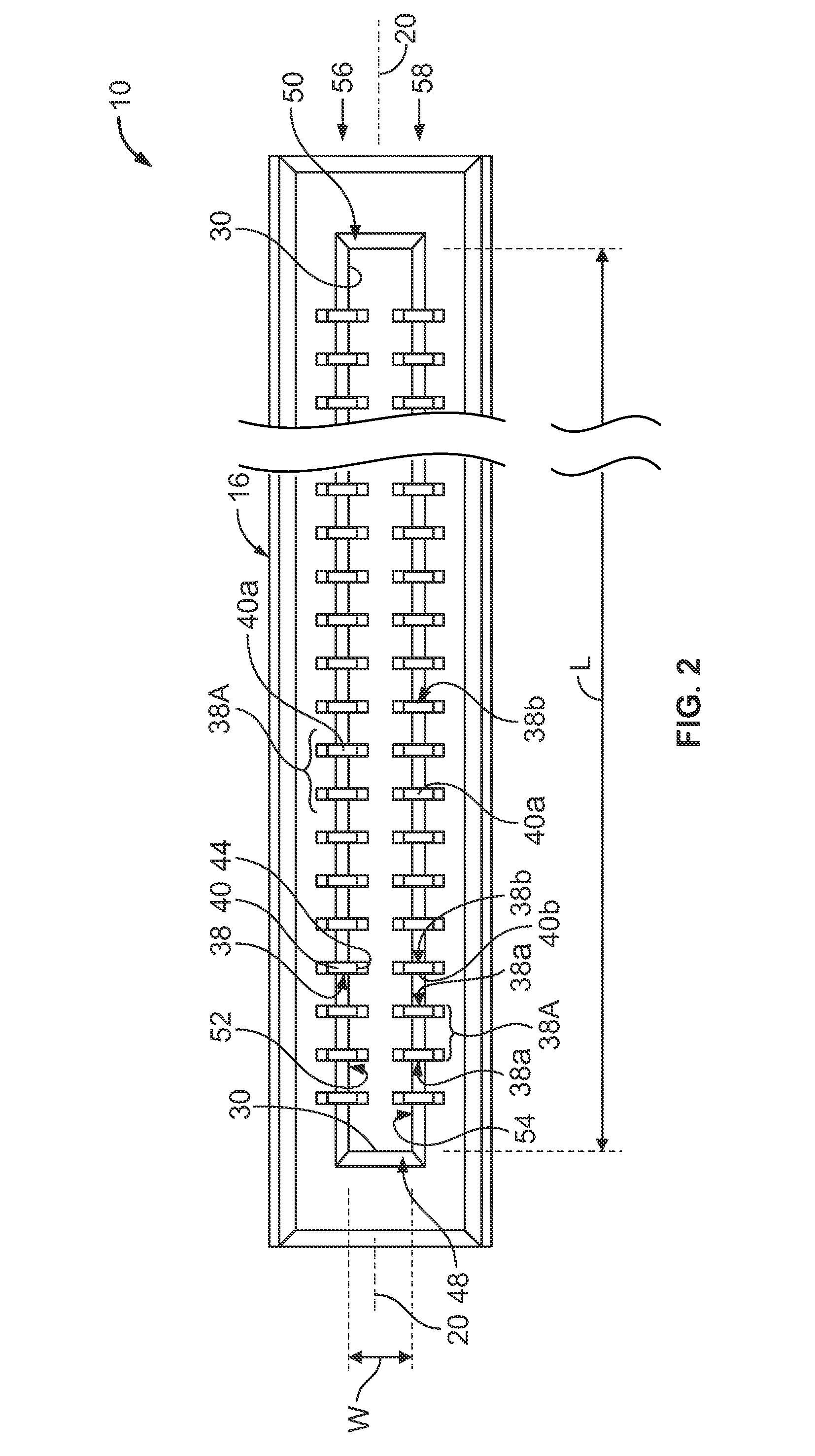

In one embodiment of the invention, a memory module is disclosed including a printed circuit board with an edge connector; an address controller coupled to the printed circuit board; and a plurality of memory slices. Each of the plurality of memory slices of the memory module includes one or more memory integrated circuits coupled to the printed circuit board, and a slave memory controller coupled to the printed circuit board and the one or more memory integrated circuits. The slave memory controller receives memory access requests for the memory module from the address controller. The slave memory controller selectively activates one or more of the one or more memory integrated circuits in the respective memory slice in response to the address received from the address controller to read data from or write data into selected memory locations in the memory integrated circuits.

Owner:WESTERN DIGITAL TECH INC

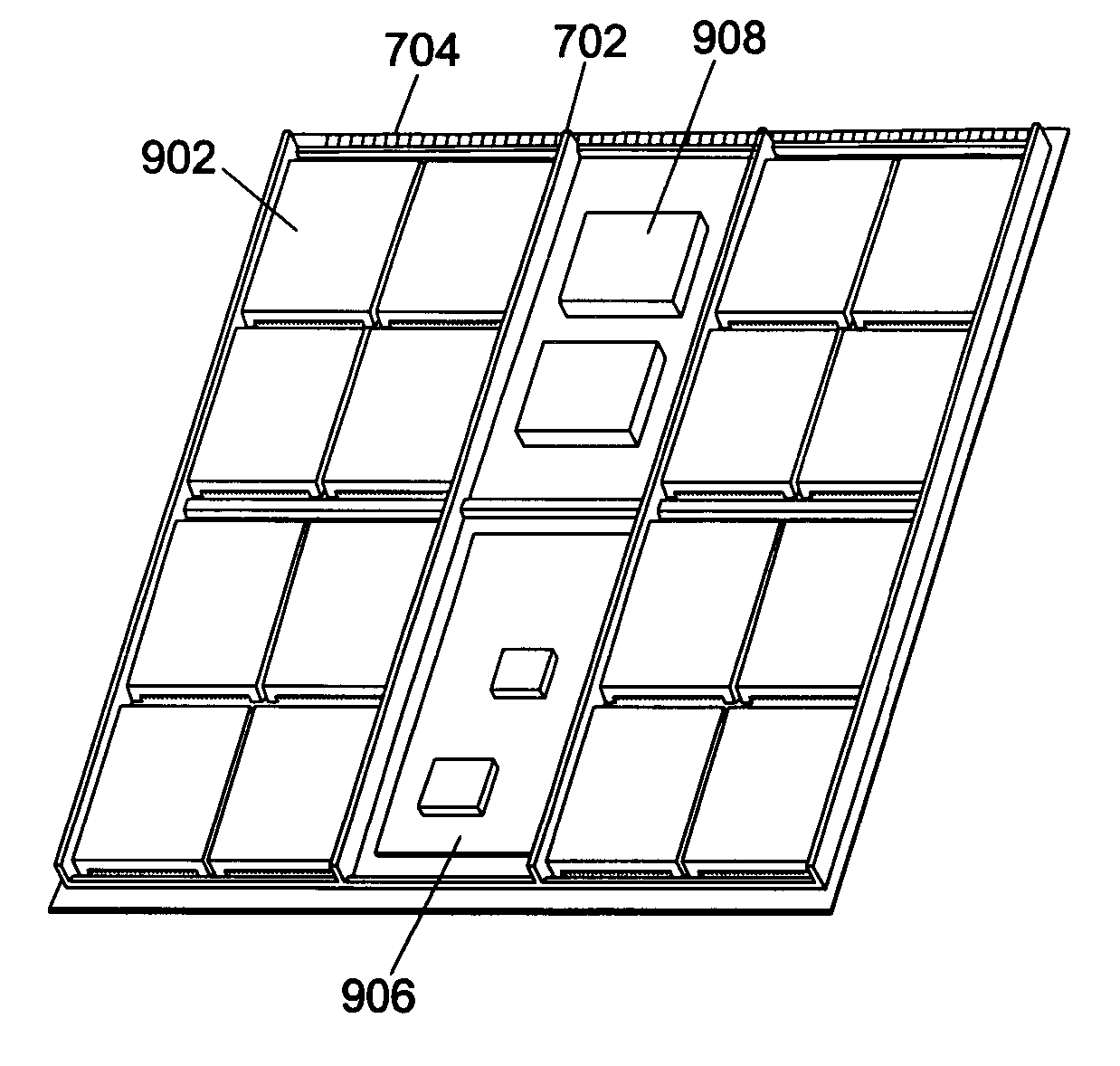

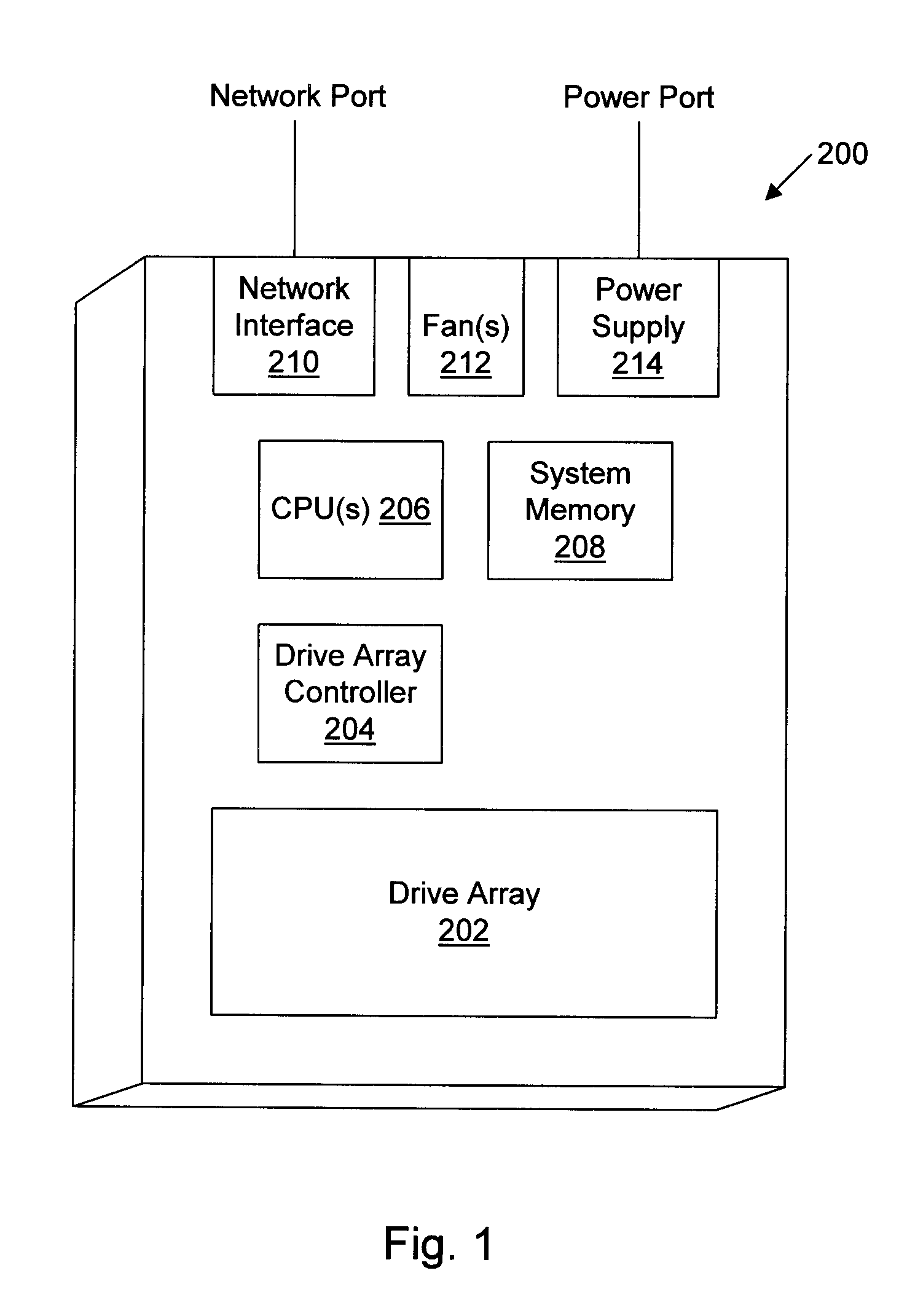

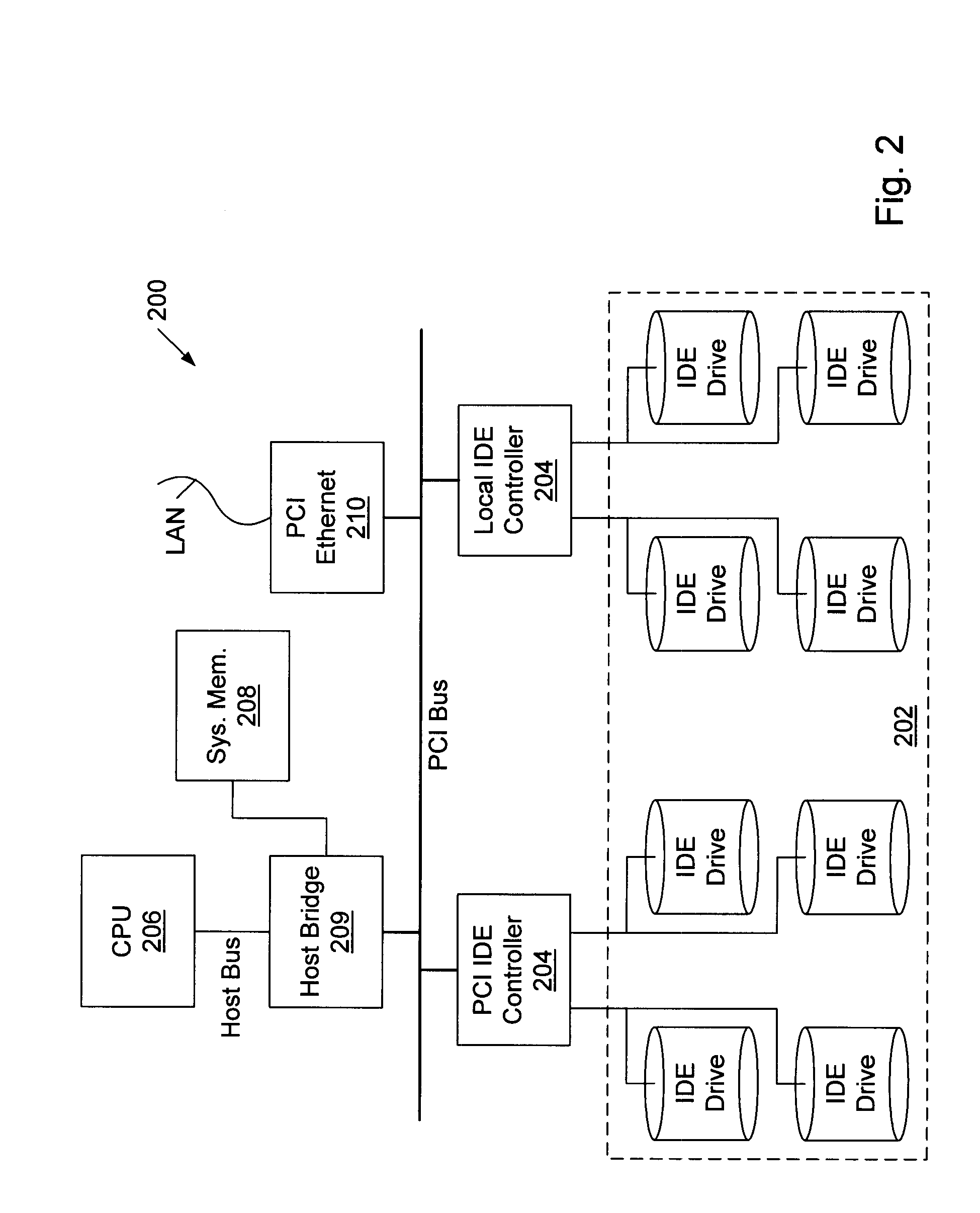

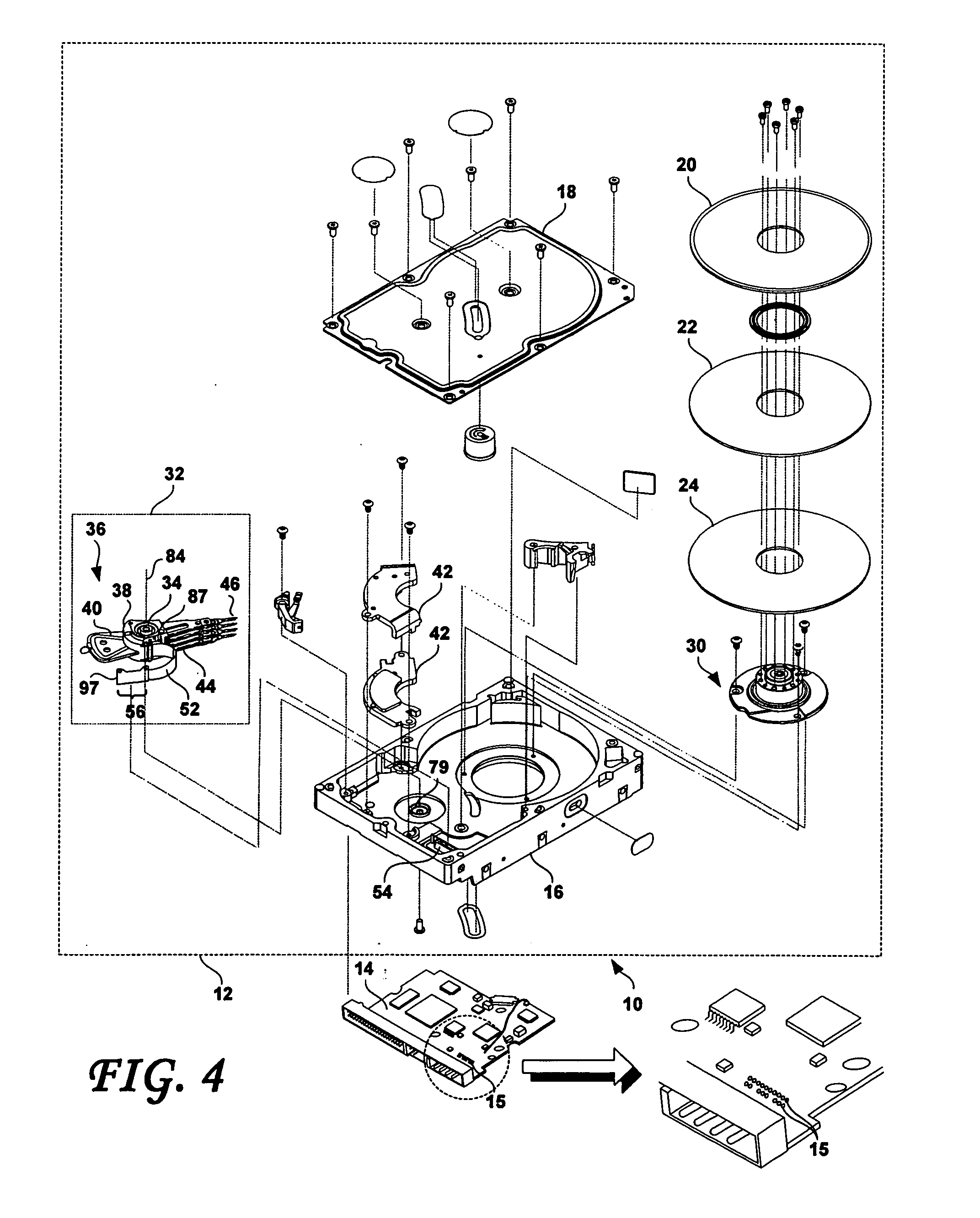

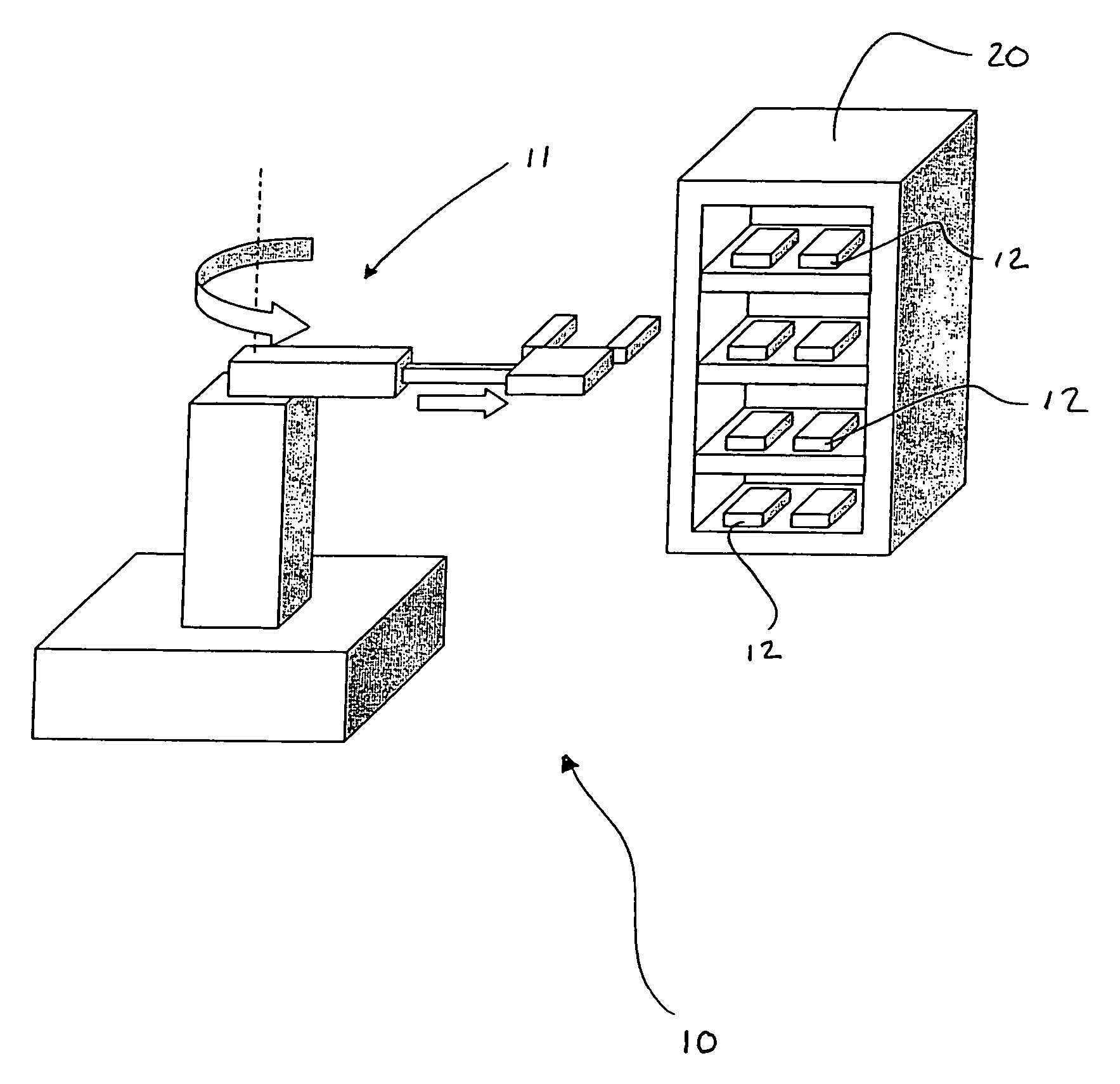

High density packaging for multi-disk systems

InactiveUS6510050B1Carrier constructional parts dispositionDigital data processing detailsElectricityHigh density

A substrate for packaging a storage or server system may include one or more sections of the substrate configured to hold a two-dimensional array of disk drives. Another section of this substrate may be configured to hold circuitry for accessing the array of disk drives. This circuitry may include one or more processors. The substrate also includes a first plurality of ribs positioned in the first access of the substrate. The first plurality of ribs separate the sections from one another. The section configured to hold the control circuitry may also be configured to hold one or more power supplies for supplying power to the array of disk drives and control circuitry. This section, as well as other sections, may be divided in two by one or more additional ribs in a transverse direction. The substrate may be configured to be mounted in a cage or rack and may include an edge connector at one edge of the substrate to provide electrical connectivity to a back plane in the cage or rack. A lateral protrusion may extend along each parallel edge of the substrate for mounting the substrate in the cage or rack by sliding the substrate into the cage or rack.

Owner:ORACLE INT CORP

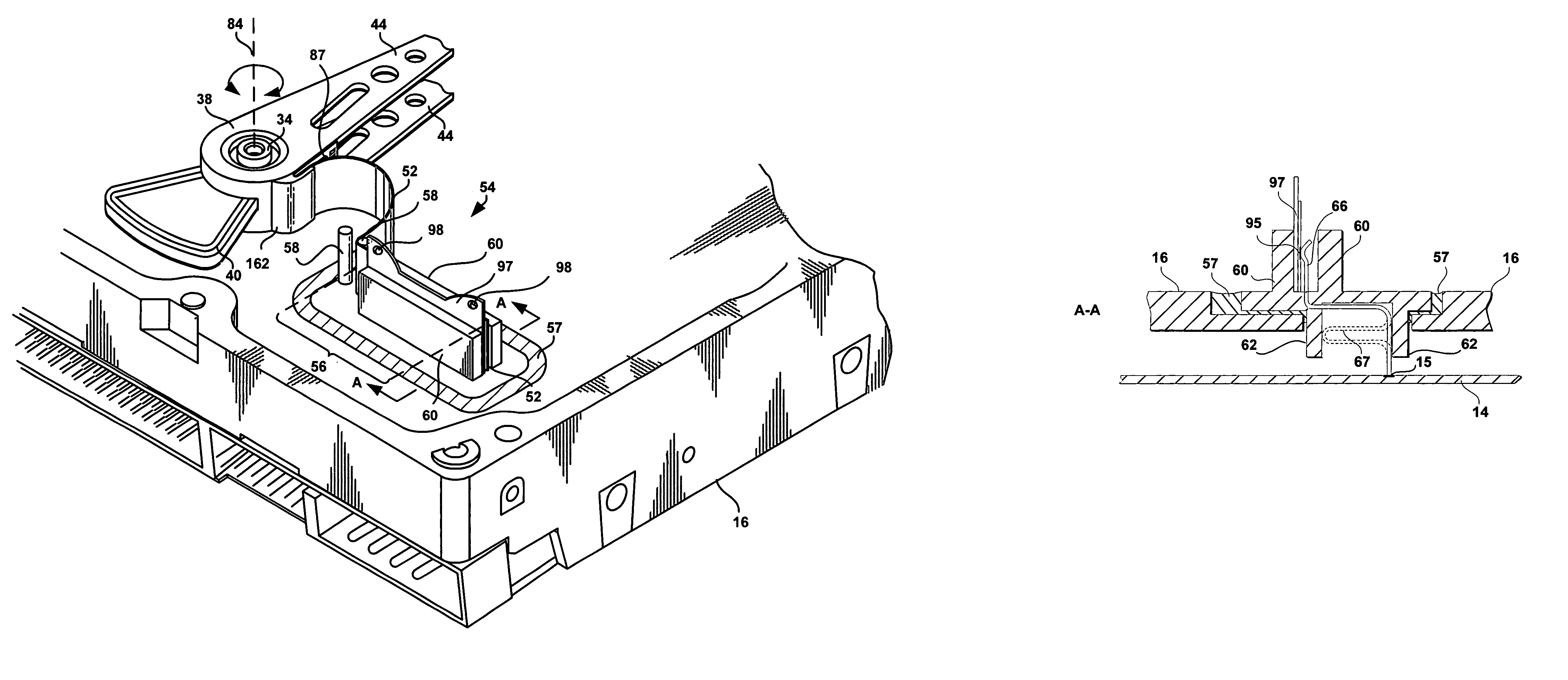

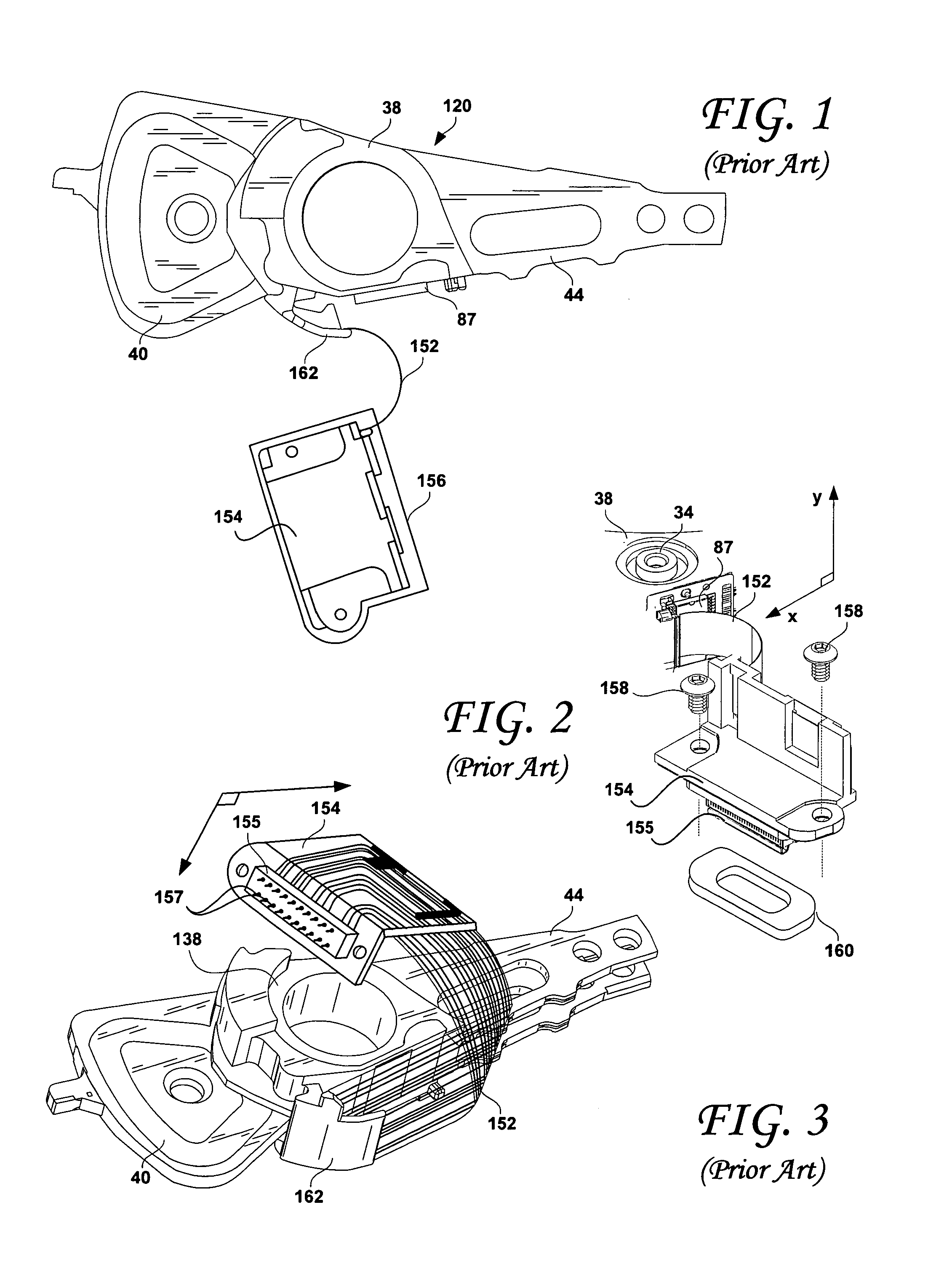

Disk drive including a base assembly having a flex-to-board edge connector

InactiveUS6934126B1Relieve pressureElectrical connection between head and armCarrier constructional parts dispositionEngineeringFlexible cable

A disk drive comprises a housing including a base; a disk rotatably attached to the base; a printed circuit board coupled to the base and including a plurality of circuit board pads; a head stack assembly pivotally coupled to the base about a pivot axis and a flex-to-board connector. The head stack assembly includes a head for reading and writing to the disk and a flex cable assembly that includes a flexible film including a plurality of conductive traces that are electrically coupled to the head. The flexible film includes a connecting portion in which each of the plurality of conductive traces defines a trace pad. Each trace pad is disposed on a surface of the flexible film that is generally parallel to the pivot axis. The flex-to-board connector is attached to the base and is configured to couple to the connecting portion of the flexible film and to maintain the surface of the flexible film on which the trace pads are disposed in an orientation that is generally parallel to the pivot axis. The flex-to-board connector includes a plurality of conductive fingers, each configured to electrically connect one of the trace pads to a corresponding one of the plurality of circuit board pads.

Owner:WESTERN DIGITAL TECH INC

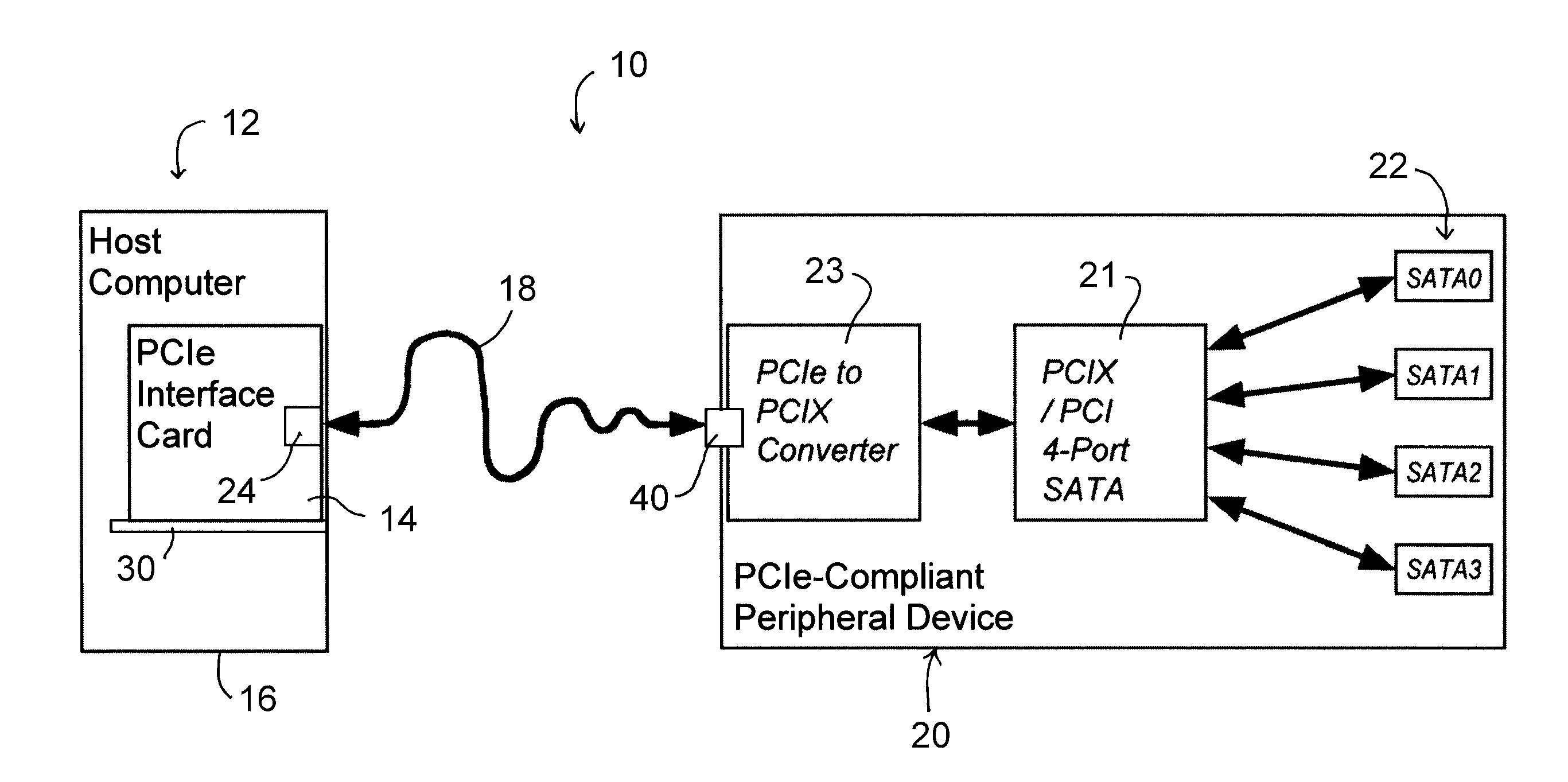

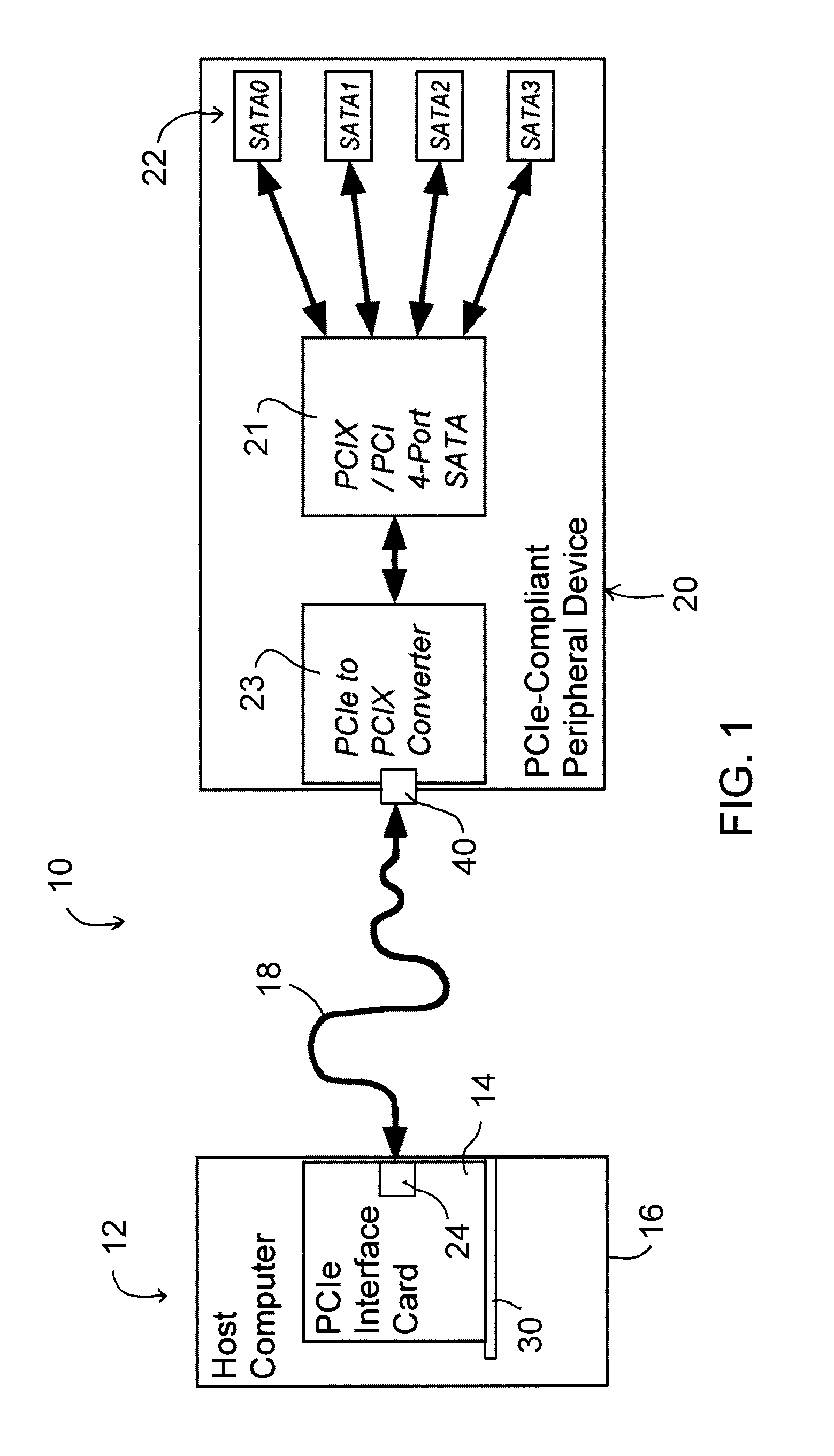

PCIe BUS EXTENSION SYSTEM, METHOD AND INTERFACES THEREFOR

ActiveUS20120033370A1Scaled-down, inexpensiveLine/current collector detailsDigital data processing detailsElectric power transmissionTransmitted power

A PCIe bus extension system, method, interface card and cable for connecting a PCIe-compliant peripheral device to a PCIe bus of a computer system. The interface card includes a printed circuit board, an edge connector adapted for insertion into a PCIe expansion slot on a motherboard of the computer system for transmitting PCIe signals between the motherboard and the interface card, an interface port configured to mate with a connector of the cable, and a logic integrated circuit on the printed circuit board, the logic integrated circuit functionally connecting the edge connector with the expansion slot and amplifying and propagating clock and data PCIe signals therebetween that are compliant with a PCIe standard. The interface card and cable lacks the capability of transmitting power therethrough to a PCIe-compliant peripheral device connected to the interface card through the interface port.

Owner:KIOXIA CORP

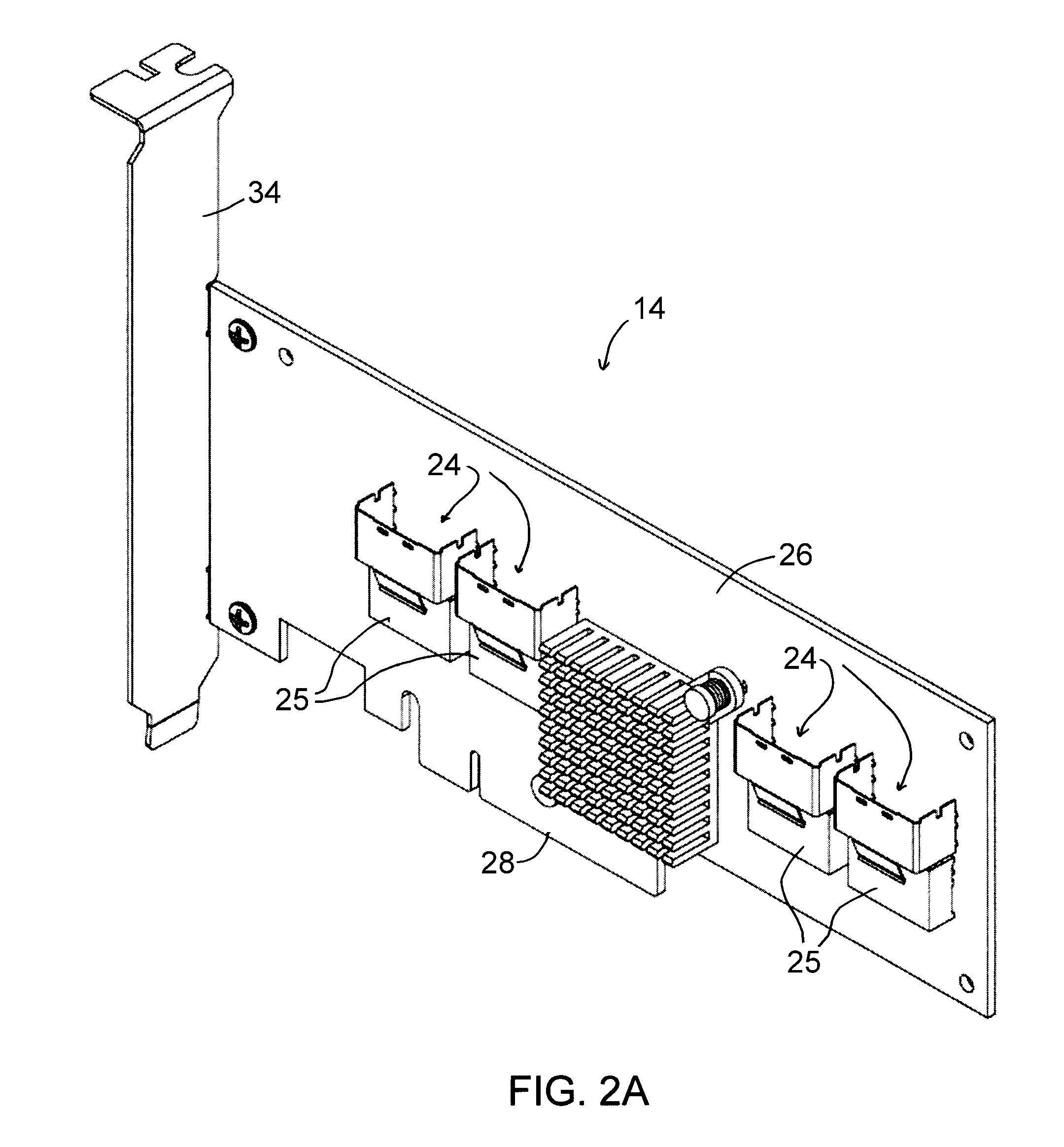

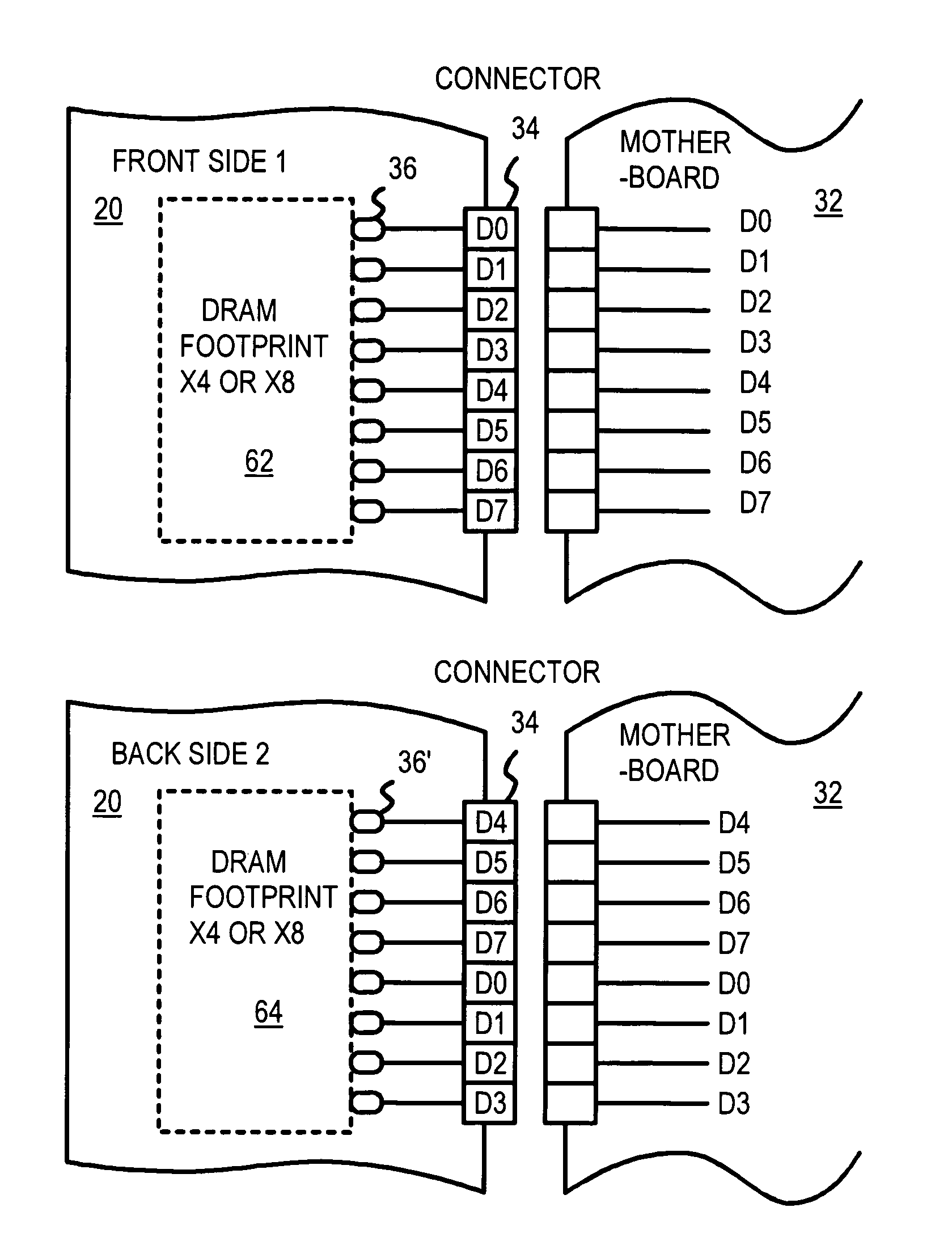

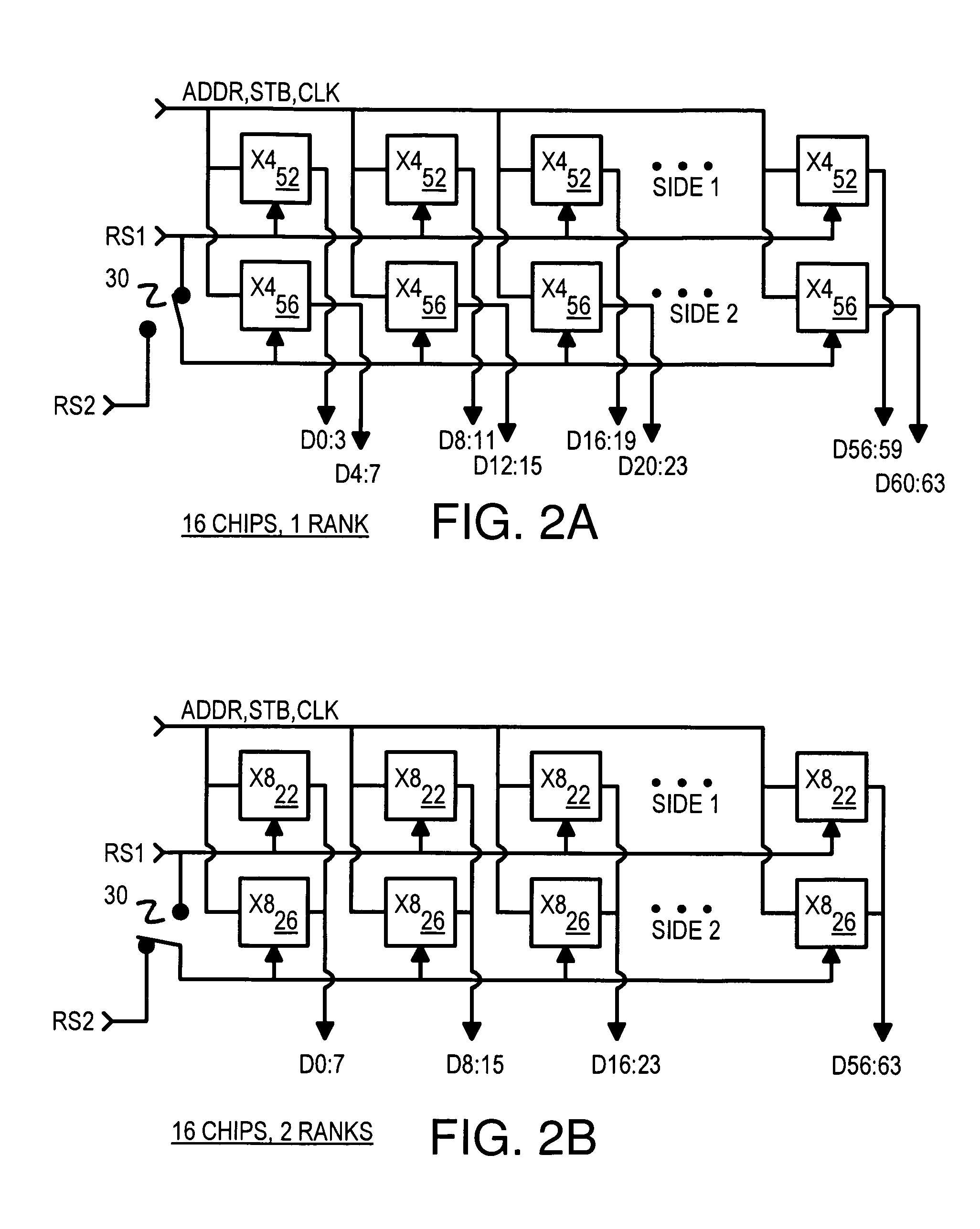

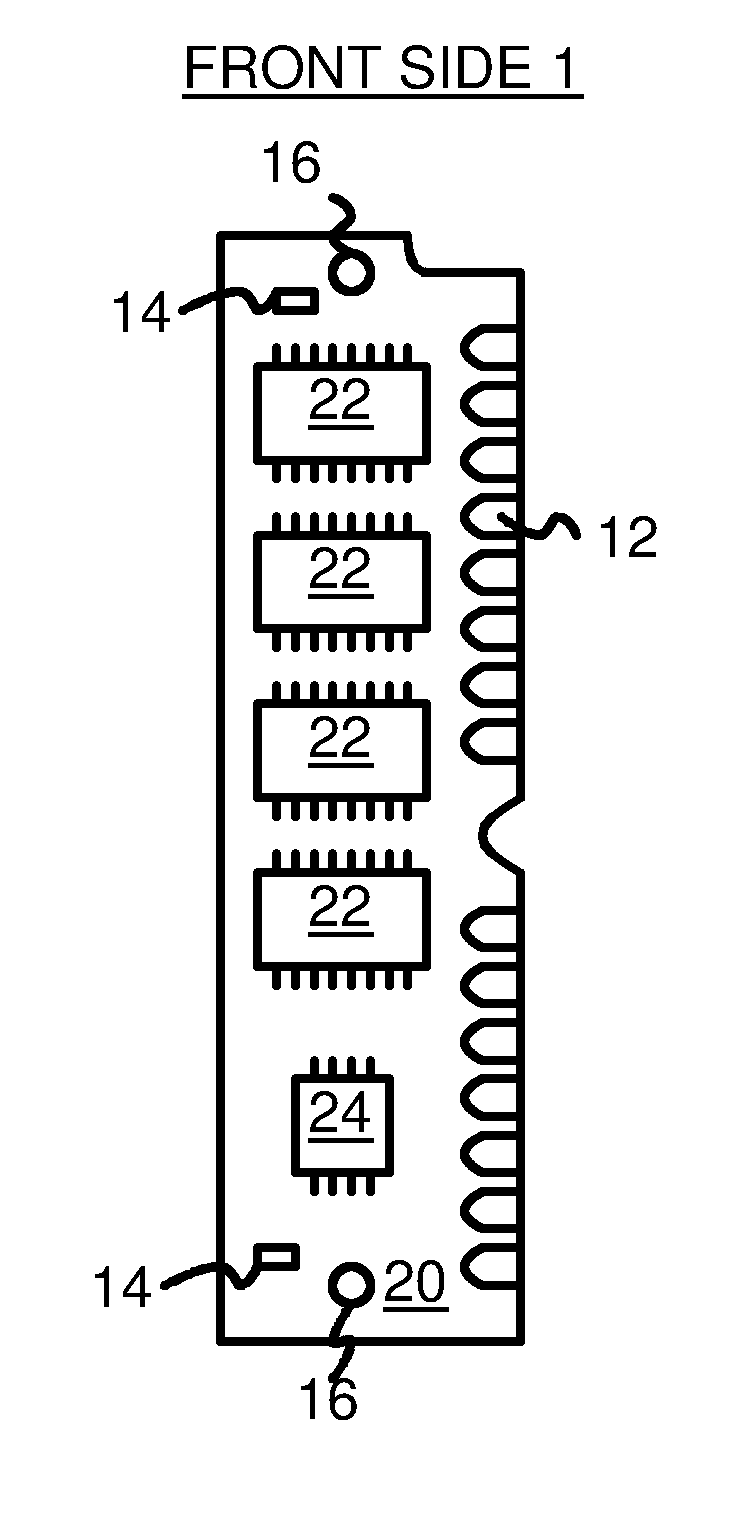

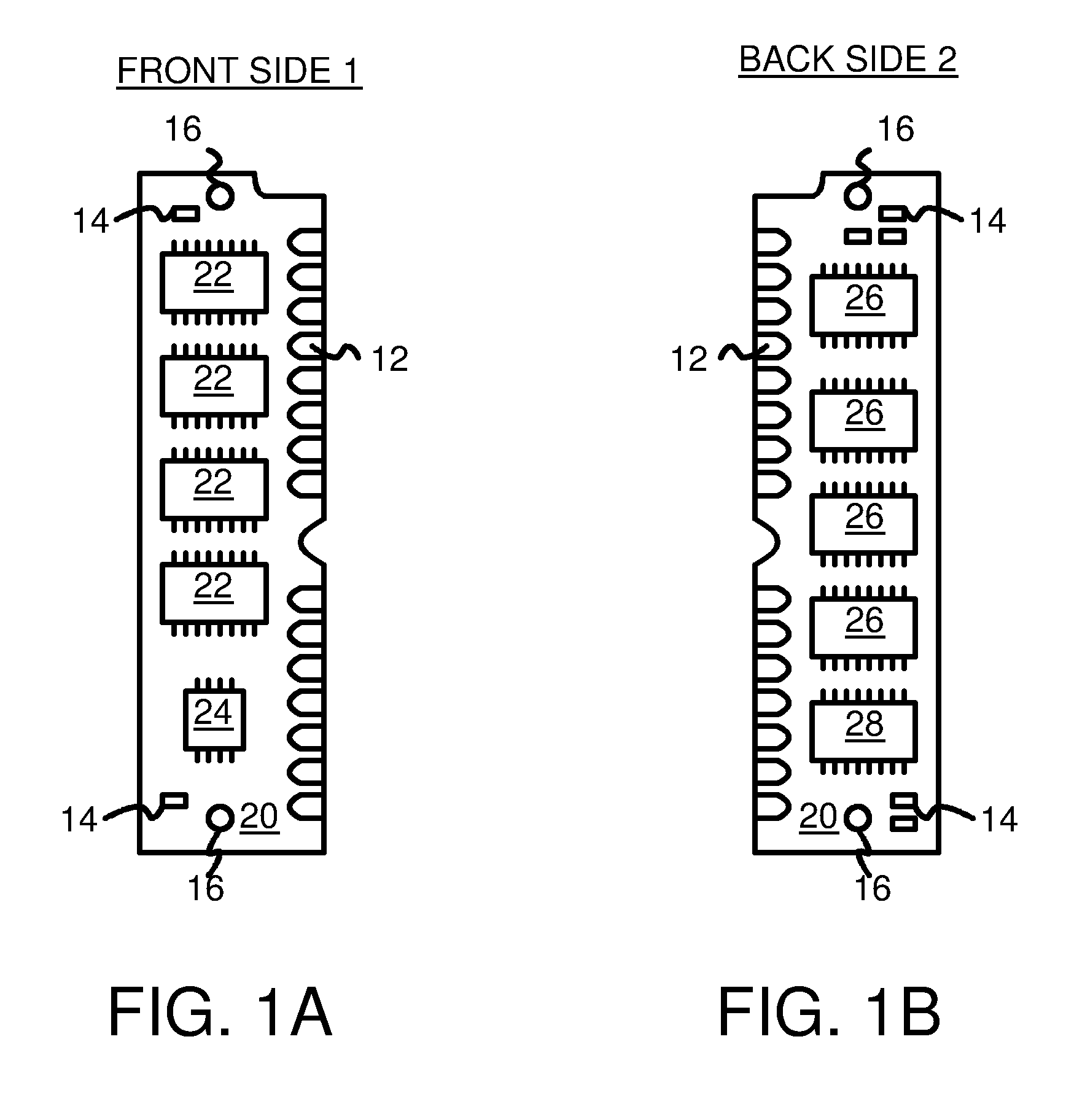

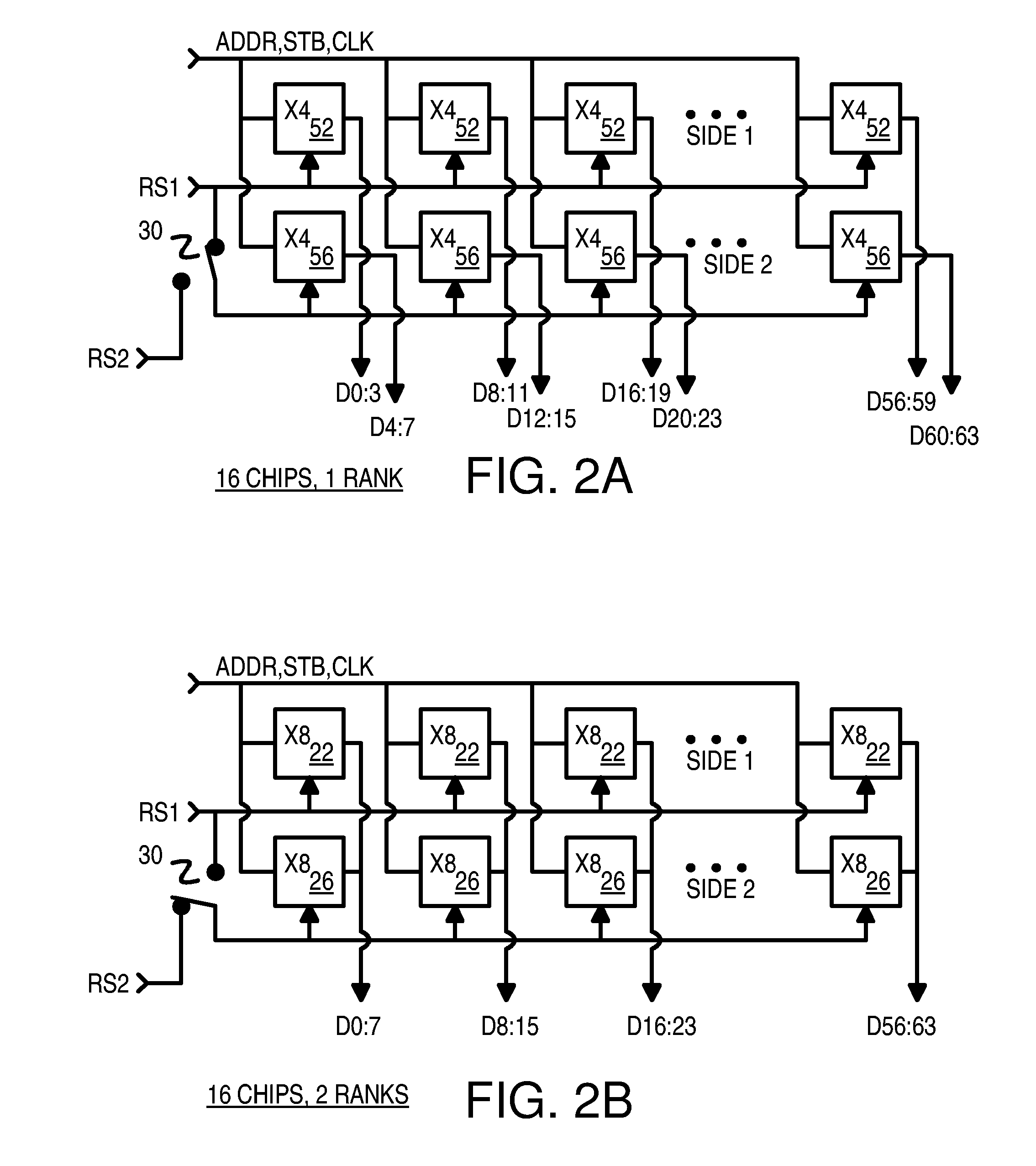

Memory-module board layout for use with memory chips of different data widths

A memory module substrate printed-circuit board (PCB) has multi-type footprints and an edge connector for mating with a memory module socket on a motherboard. Two or more kinds of dynamic-random-access memory (DRAM) chips with different data I / O widths can be soldered to solder pads around the multi-type footprints. When ×4 DRAM chips with 4 data I / O pins are soldered over the multi-type footprints, the memory module has a rank-select signal that drives chip-select inputs to all DRAM chips. When ×8 DRAM chips with 8 data I / O pins are soldered over the multi-type footprints, the memory module has two rank-select signals. One rank-select drives chip-select inputs to front-side DRAM chips while the second rank-select drives chip-select inputs to back-side DRAM chips. Wiring traces on the PCB cross-over data nibbles between the solder pads and the connector to allow two ×4 chips to drive a byte driven by only one ×8 chip.

Owner:KINGSTON DIGITAL CO LTD

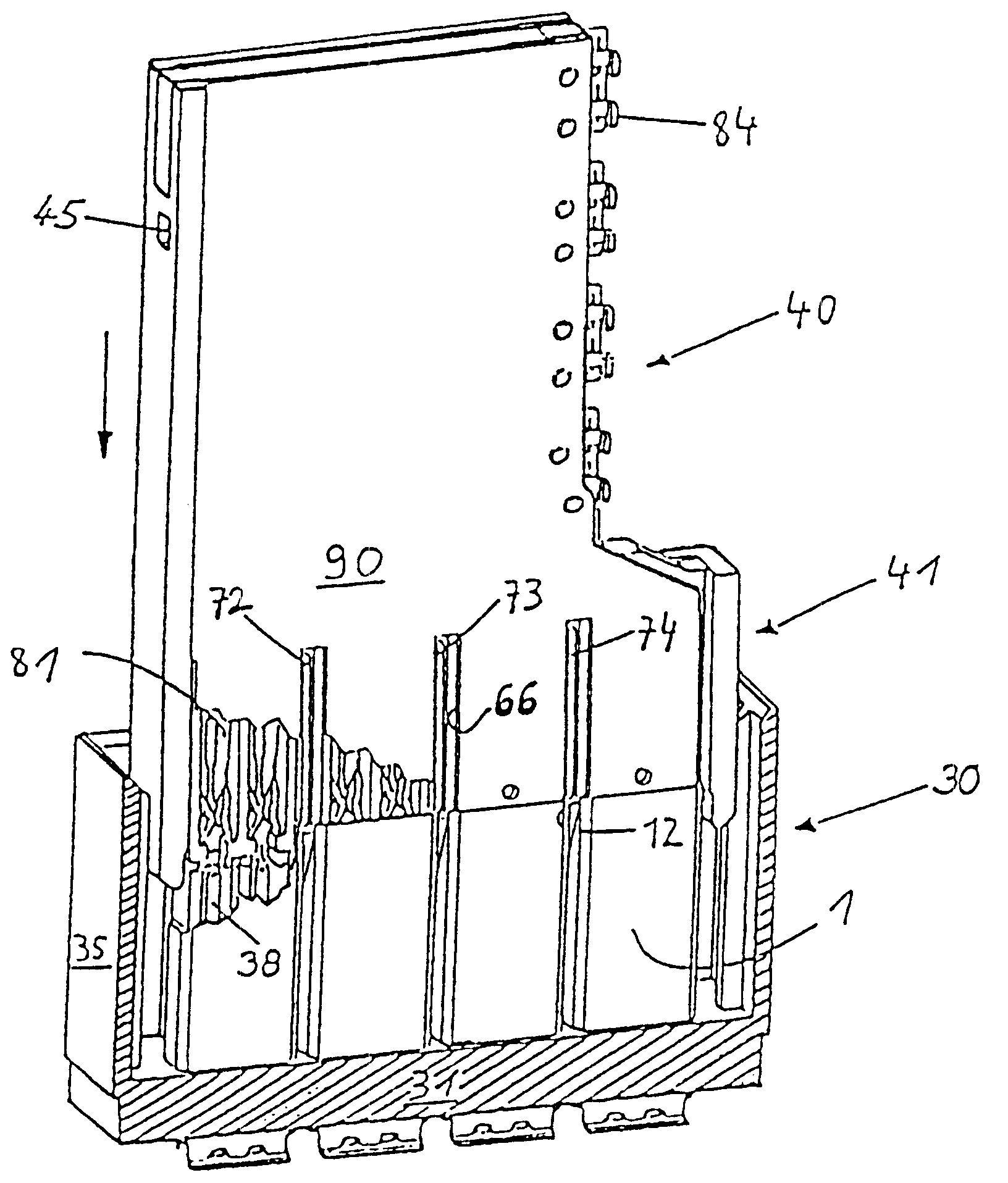

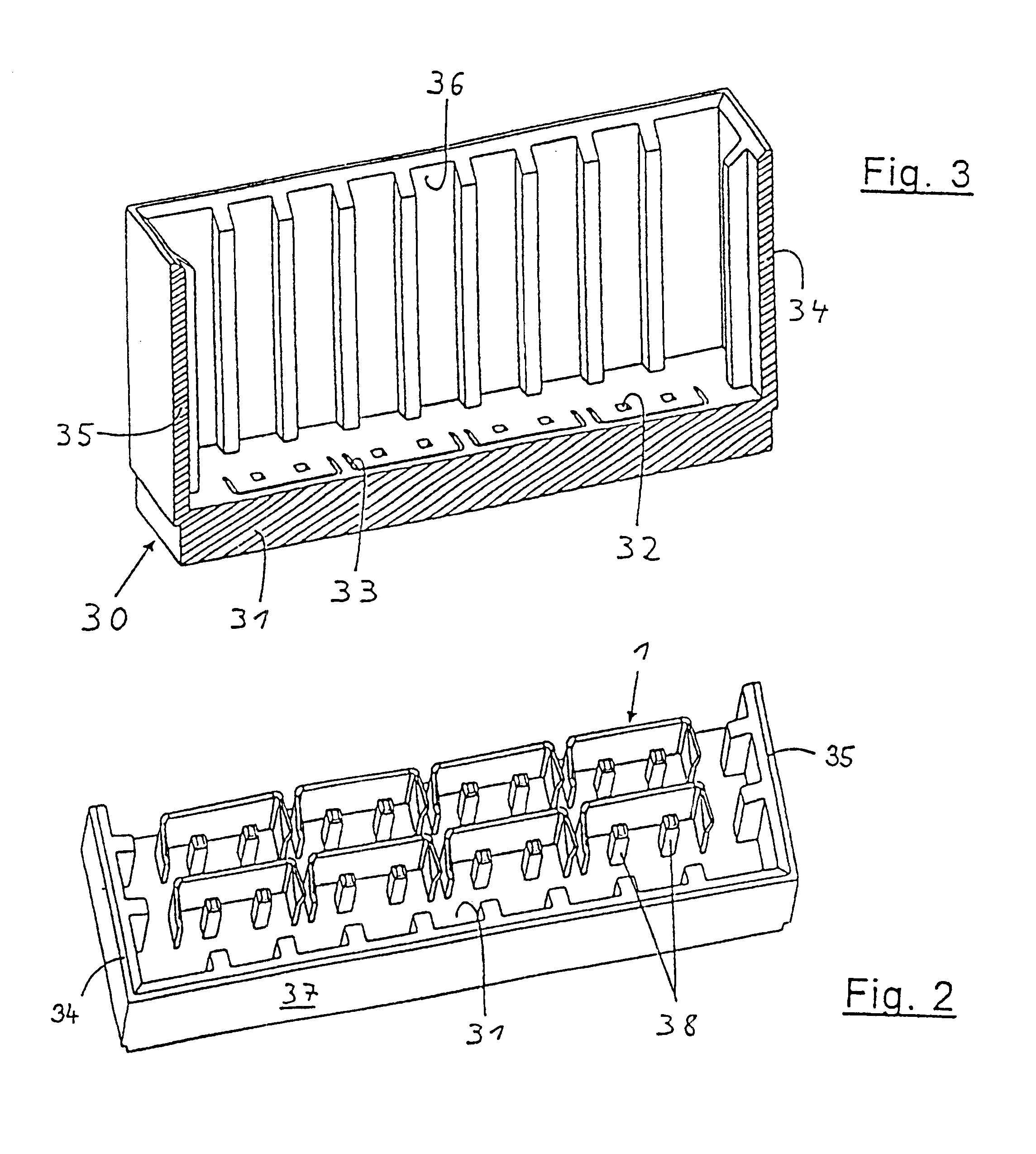

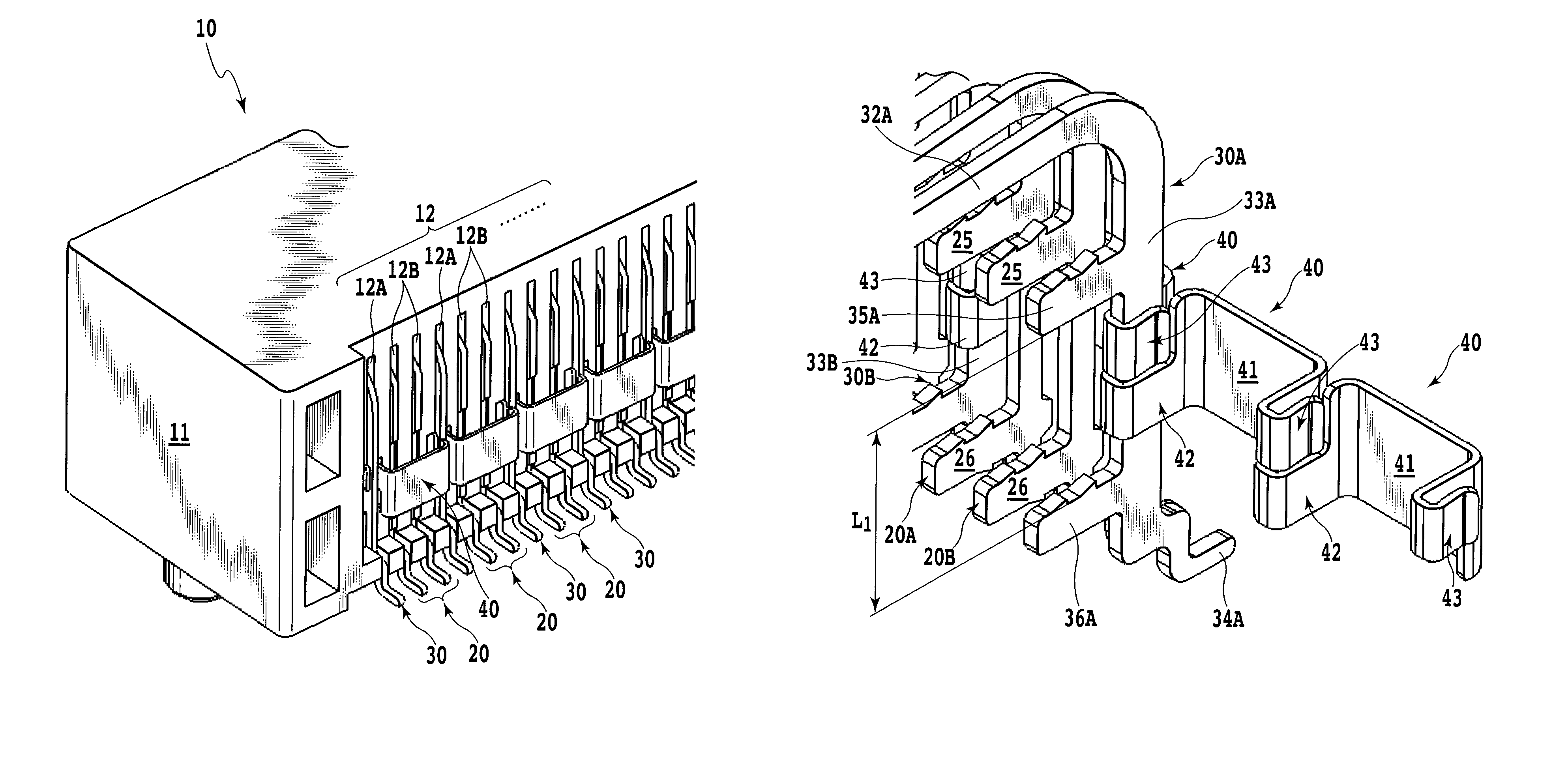

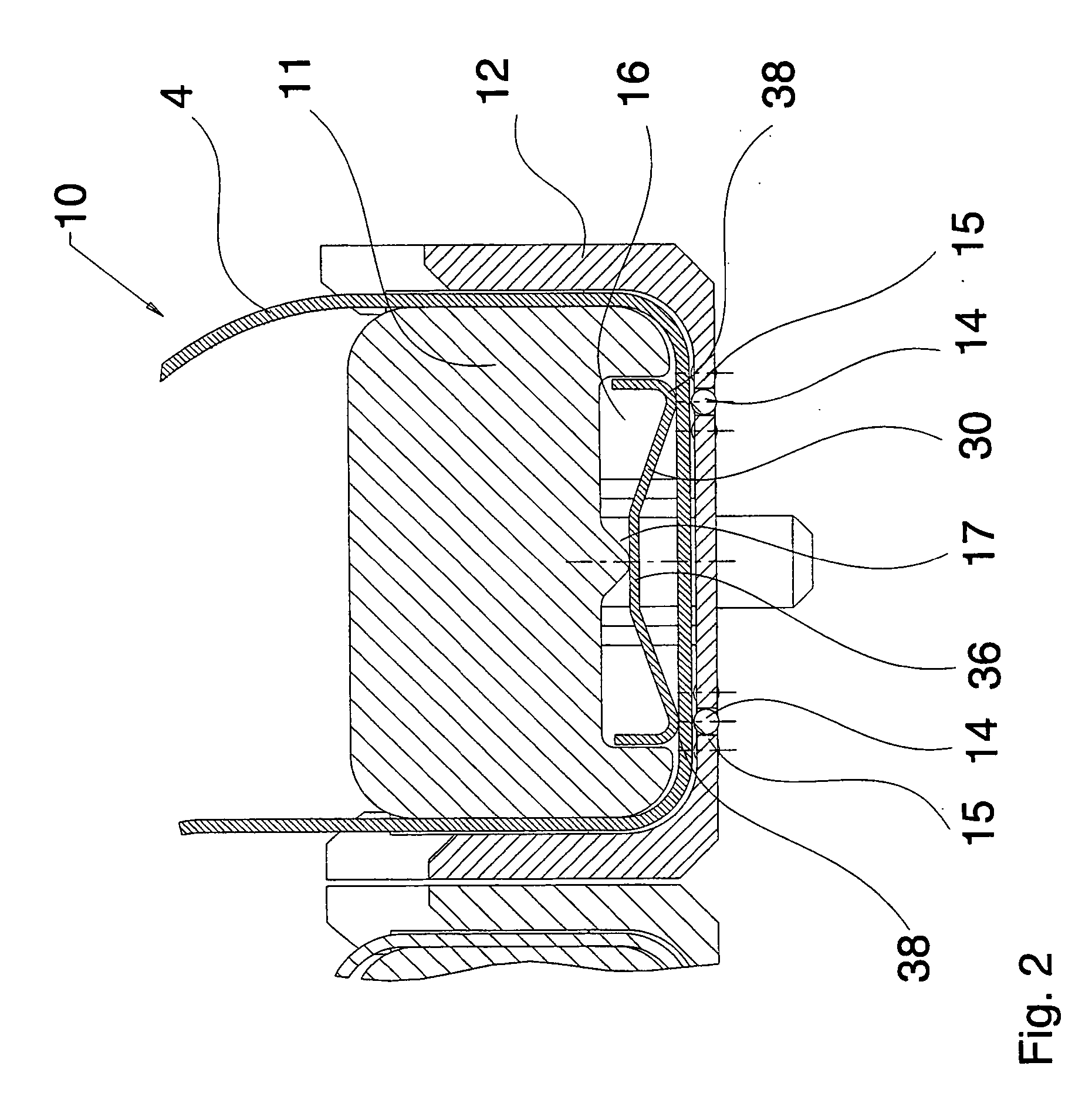

Shielded plug-in connector

InactiveUS6471549B1Low manufacturing expenditureMinimal expenditureTwo-part coupling devicesFixed connectionsBody areaEngineering

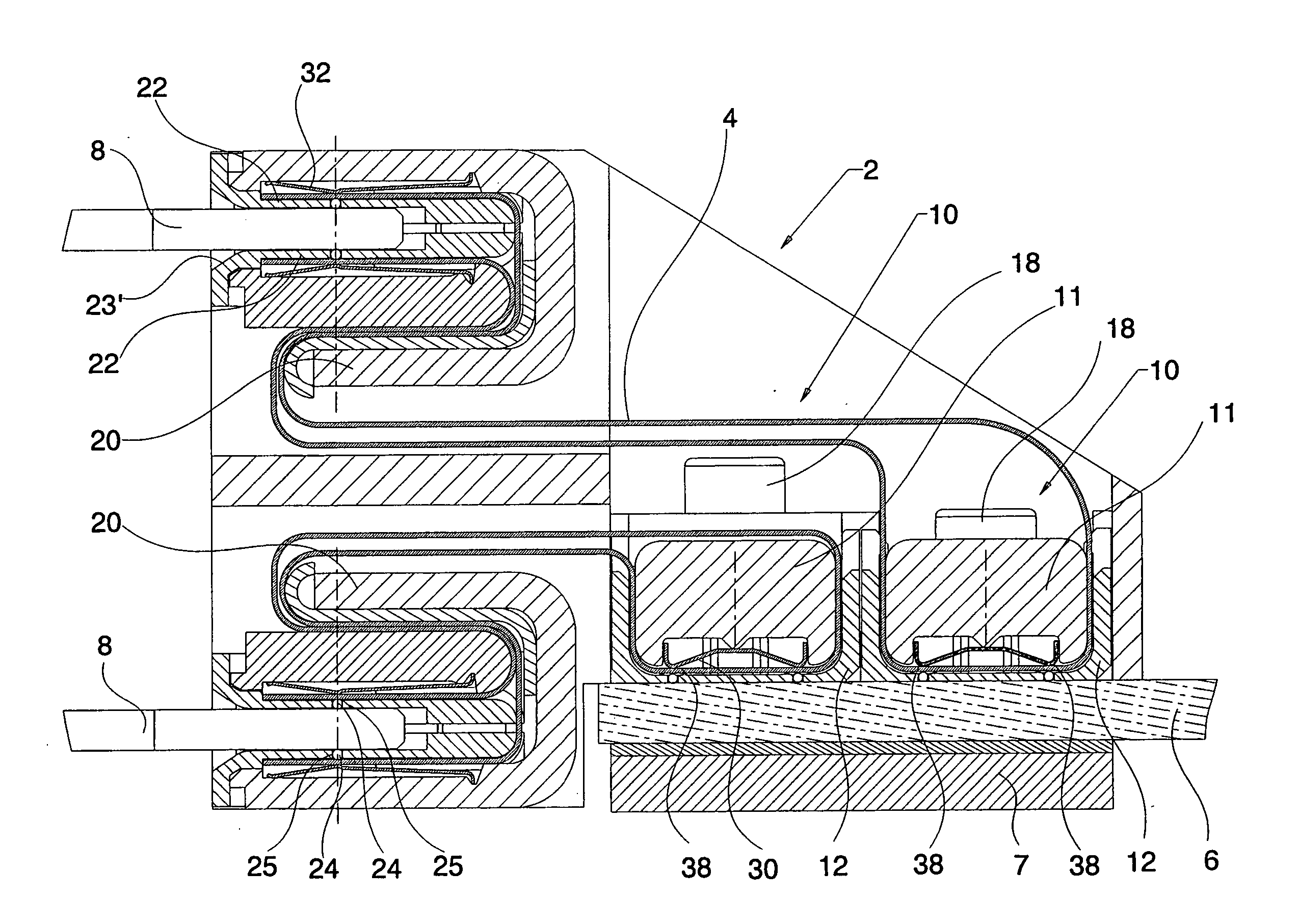

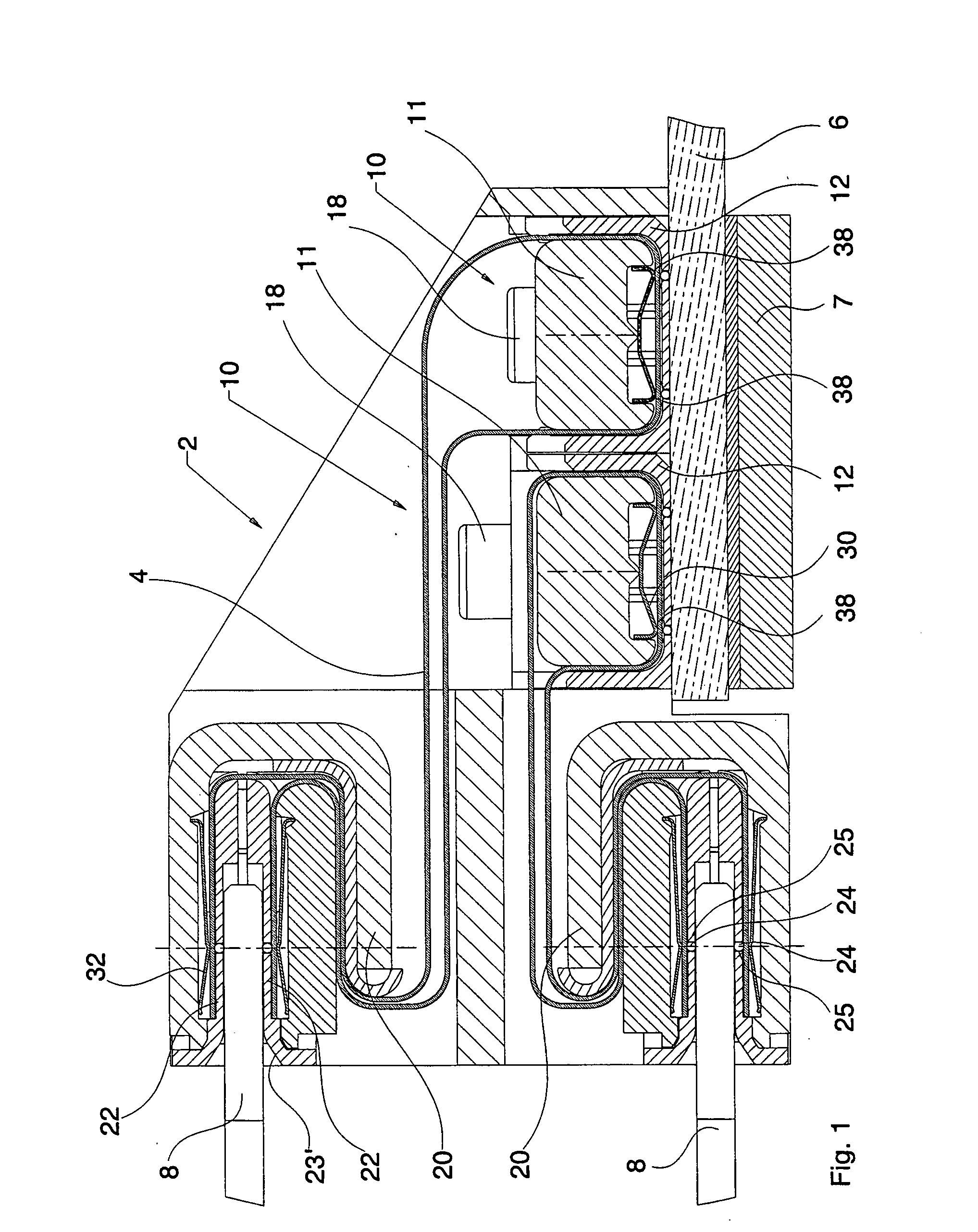

A shielded plug-in connector has a jack-in-blade strip having at least one first contact element and an edge connector having at least one second contact element corresponding to the first contact element. The edge connector, on or in its outer body areas, has at least partially shielding sheets. Shielding of the plug-in connector is achieved by, in addition to the shielding sheets provided on the edge connector, a shielding group with at least one first element arranged in the jack-in-blade strip. The first element of the shielding group is a base part in the form of a U-shaped rail. The shielding sheets on the edge connector have a planar body and angled stays. Two of the angled stays and a portion of the planar body between the two angled stays form a counterpart to the base part, wherein the counterpart and the base part together substantially encapsulate the first and second contact elements.

Owner:LAPPOHN JURGEN

Memory modules for two-dimensional main memory

In one embodiment of the invention, a memory module is disclosed including a printed circuit board with an edge connector; an address controller coupled to the printed circuit board; and a plurality of memory slices. Each of the plurality of memory slices of the memory module includes one or more memory integrated circuits coupled to the printed circuit board, and a slave memory controller coupled to the printed circuit board and the one or more memory integrated circuits. The slave memory controller receives memory access requests for the memory module from the address controller. The slave memory controller selectively activates one or more of the one or more memory integrated circuits in the respective memory slice in response to the address received from the address controller to read data from or write data into selected memory locations in the memory integrated circuits.

Owner:WESTERN DIGITAL TECH INC

Method for manufacturing printed circuit board edge connector

ActiveCN101643927AAchieve preparationSolve residual problemsPrinted element electric connection formationEngineeringElectroplating

The invention discloses a method for manufacturing a printed circuit board edge connector, relates to the field of manufacturing process for a printed circuit board, and can solve the residue problemsof an edge connector plating lead of the printed circuit board. The method for manufacturing the printed circuit board edge connector comprises the following steps: forming the edge connector platinglead and an edge connector area on the printed circuit board once, wherein the width of adjacent parts of the edge connector plating lead and the edge connector area is equal to the width of the edgeconnector area; coating a covering substance to form an edge connector plating reserved area, and plating the edge connector plating reserved area to form the edge connector; and removing the covering substance, and etching the edge connector to obtain the edge connector without the plating lead. The method is suitable for manufacturing the edge connector without the lead for the printed circuitboard.

Owner:NEW FOUNDER HLDG DEV LLC +2

Reflow soldering method

InactiveUS6010061APrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

With the present invention, a reflow soldering method is provided for soldering a nonvertically approaching lead, which is part of a nonvertically approaching device (e.g, an edge connector), to a corresponding soldering surface (e.g., a pad on a circuit card) that includes solder. The soldering surface and solder are heated in an oven to melt the solder. While the solder is liquids, the nonvertically approaching lead is mated with the soldering surface as it is inserted into the solder. The soldering surface, solder, and nonvertically approaching lead are then cooled, and the solder solidifies to conductively mount the nonvertically approaching lead to the soldering surface.

Owner:PLEXUS PROPERTY HLDG +2

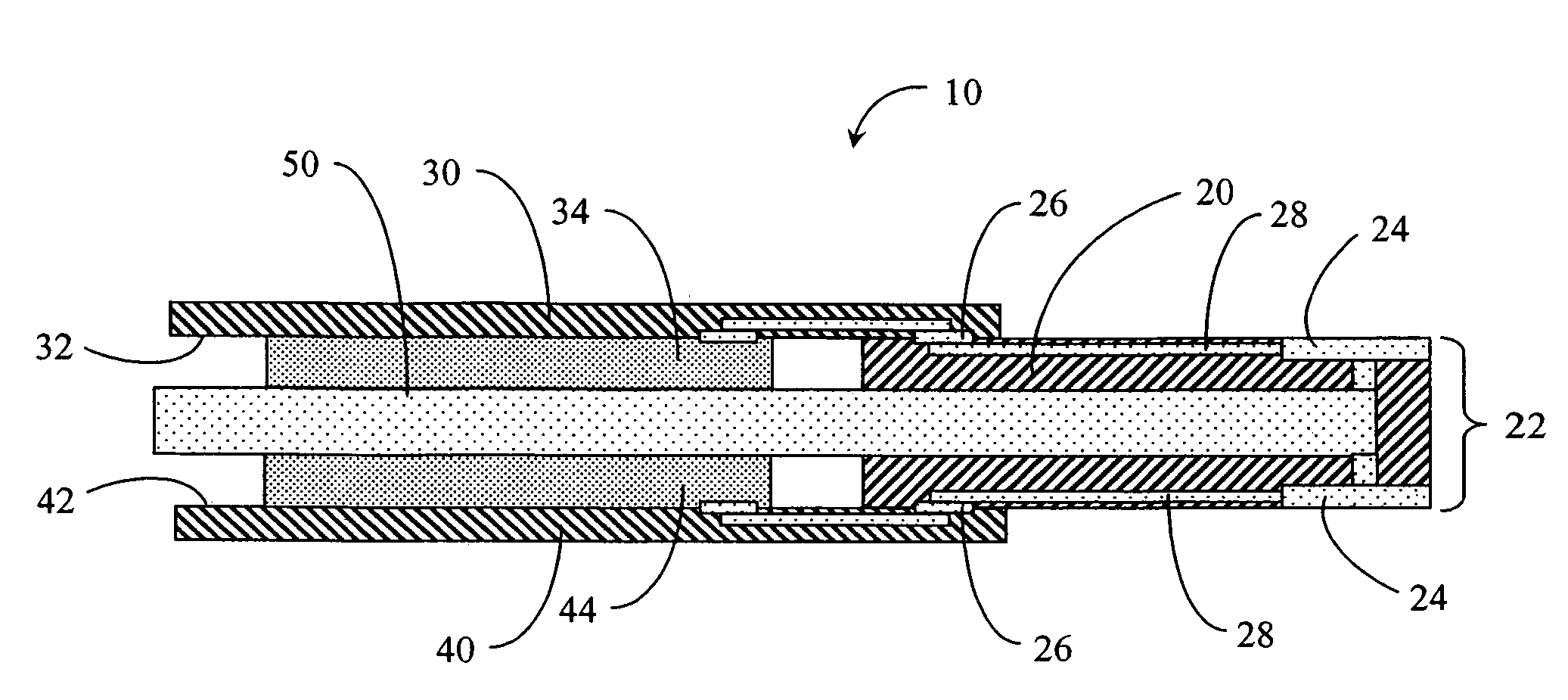

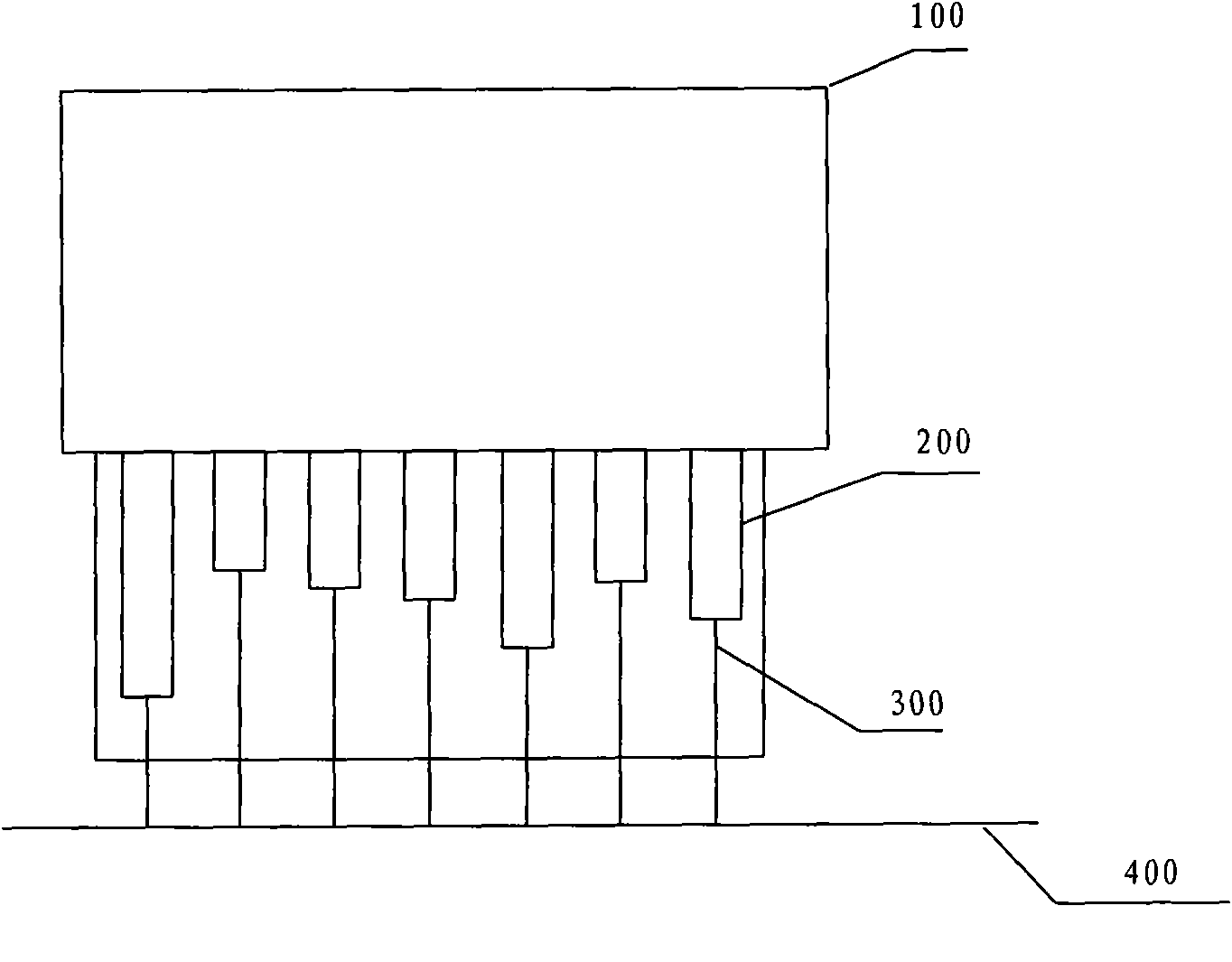

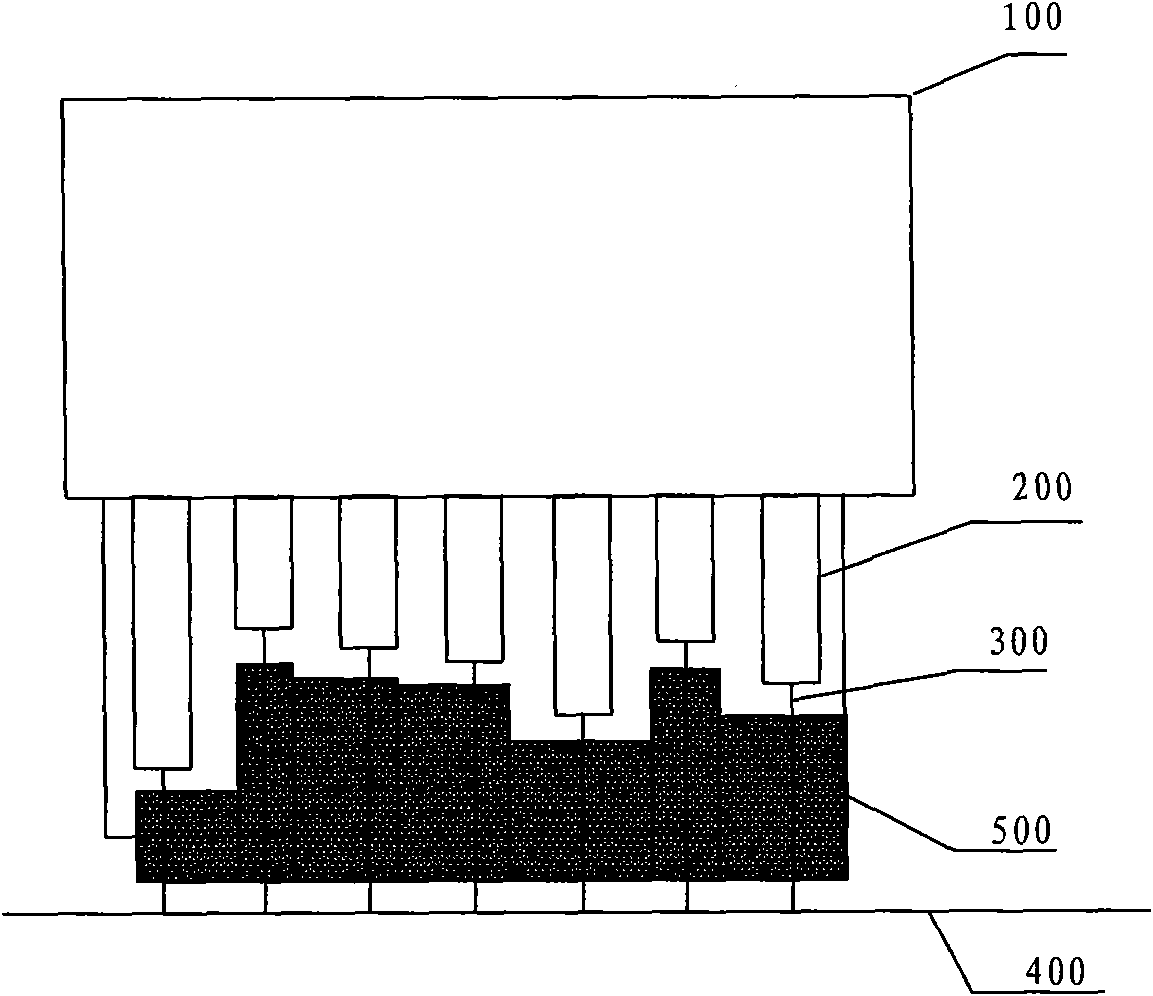

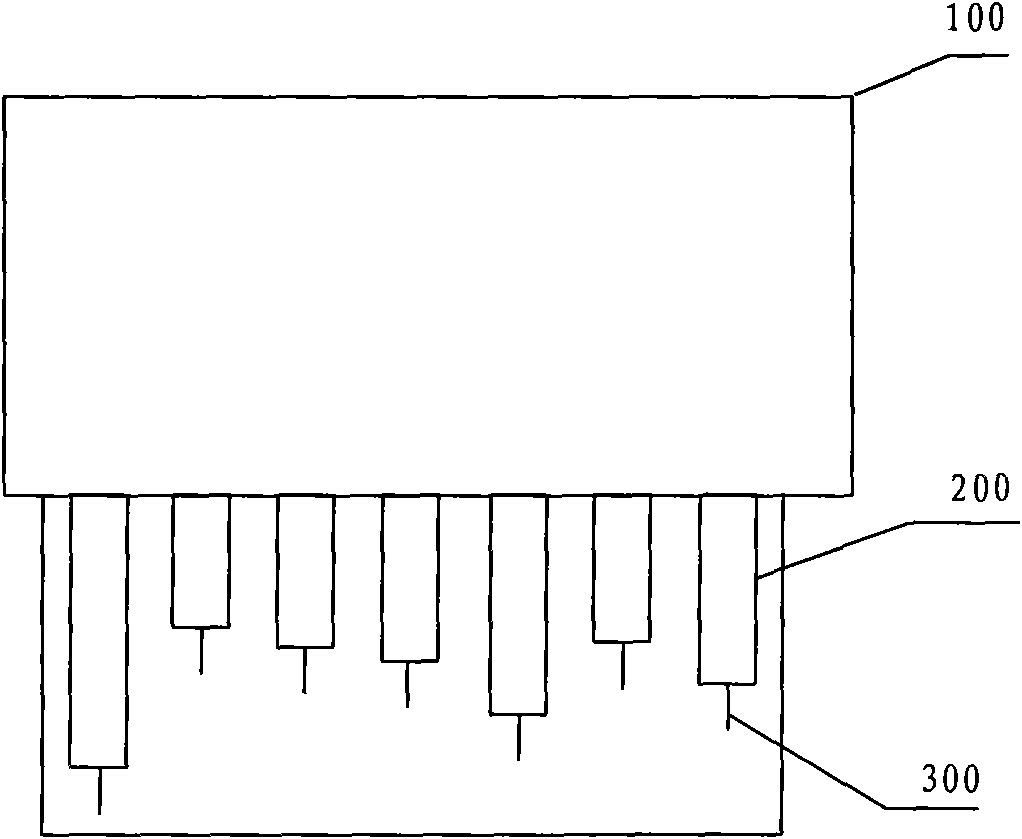

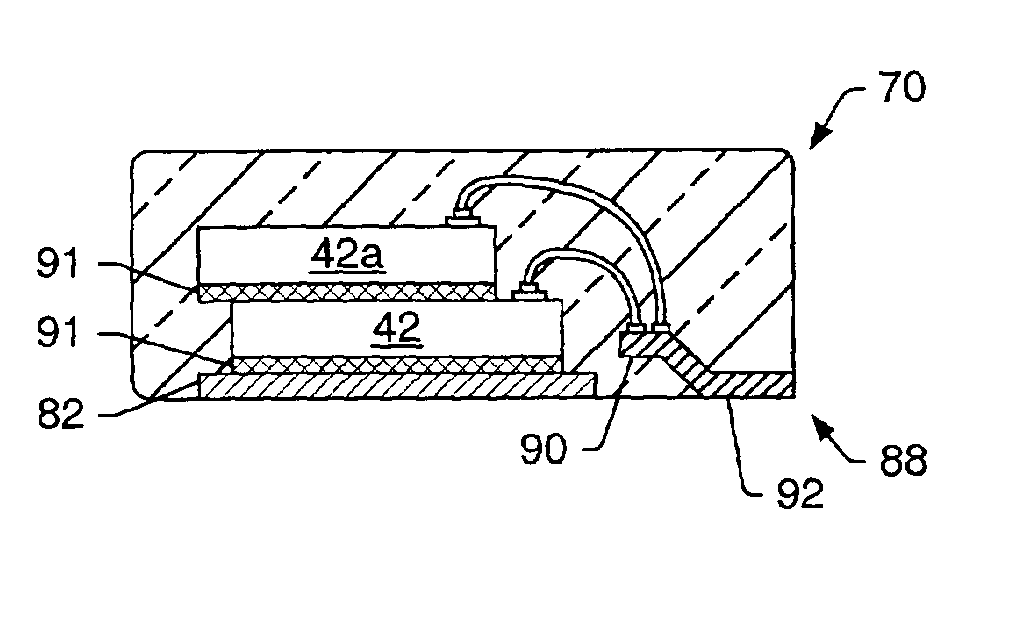

Molded memory module and method of making the module absent a substrate support

InactiveUS6843421B2Avoid restSemiconductor/solid-state device detailsSolid-state devicesConventional memoryElectrical conductor

An improved memory module and method of manufacture are presented. The memory module takes on the same outer dimensions as conventional memory cards. The memory module includes an integrated circuit and a conductor encased within molded resin. The conductor can be taken from a tape or a lead frame, and can include bumps or wires extending from the conductor to corresponding bonding pads on the integrated circuit. The bonded integrated circuit can thereafter be placed within a cavity formed inside a mold housing, where resin may be injected to form the memory module. The conductor can also be shaped so as to extend on multiple planes from the connection point on or near the bonding pad to an edge connector residing near one edge only of the memory module. The conductor is thereby connected to the integrated circuit and provides slide-in, releasable coupling to a receptor.

Owner:SANDISK TECH LLC

Memory-Module Board Layout for Use With Memory Chips of Different Data Widths

ActiveUS20060267172A1Final product manufactureSemiconductor/solid-state device detailsMemory chipNibble

A memory module substrate printed-circuit board (PCB) has multi-type footprints and an edge connector for mating with a memory module socket on a motherboard. Two or more kinds of dynamic-random-access memory (DRAM) chips with different data I / O widths can be soldered to solder pads around the multi-type footprints. When ×4 DRAM chips with 4 data I / O pins are soldered over the multi-type footprints, the memory module has a rank-select signal that drives chip-select inputs to all DRAM chips. When ×8 DRAM chips with 8 data I / O pins are soldered over the multi-type footprints, the memory module has two rank-select signals. One rank-select drives chip-select inputs to front-side DRAM chips while the second rank-select drives chip-select inputs to back-side DRAM chips. Wiring traces on the PCB cross-over data nibbles between the solder pads and the connector to allow two ×4 chips to drive a byte driven by only one ×8 chip.

Owner:KINGSTON DIGITAL CO LTD

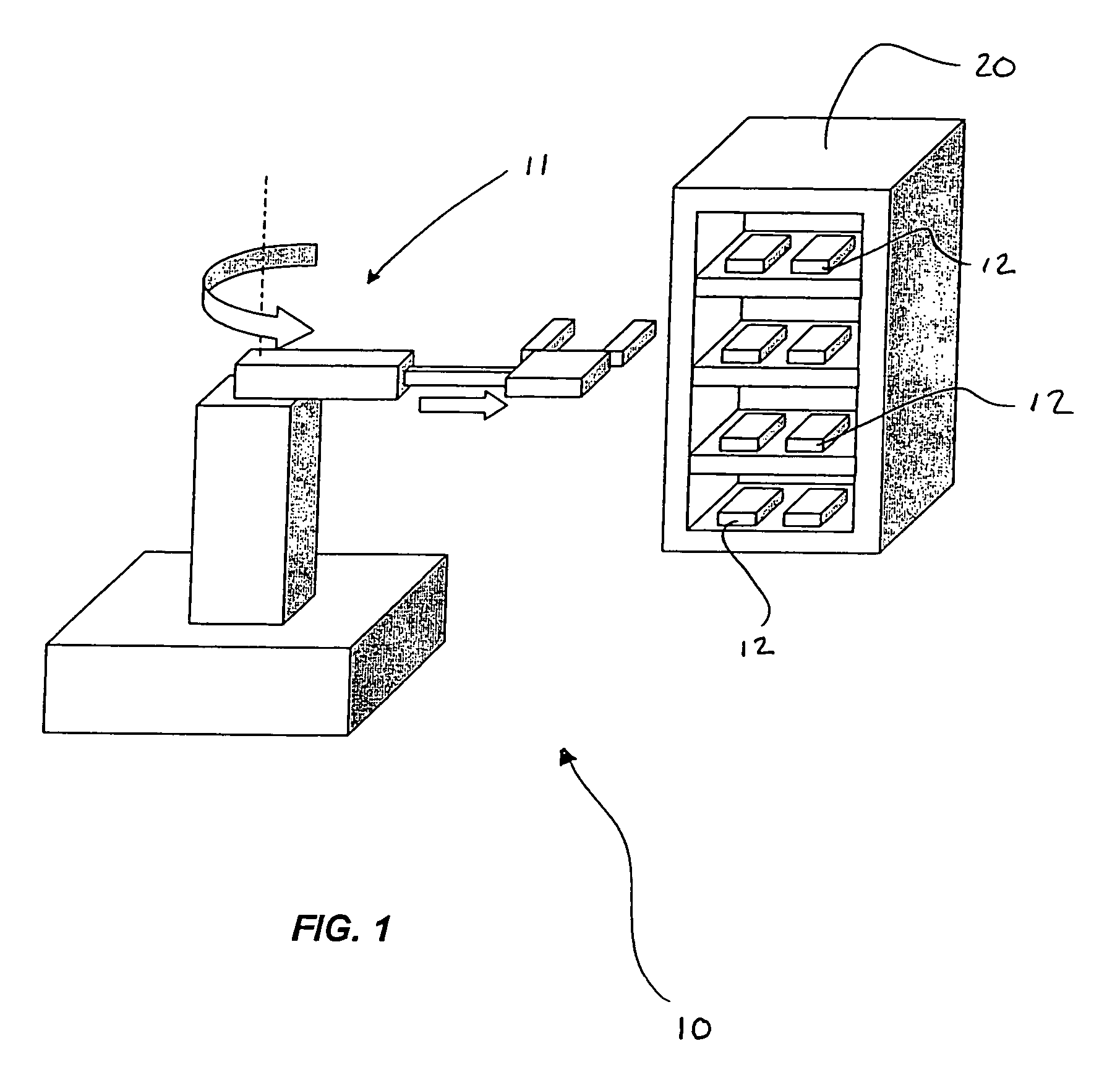

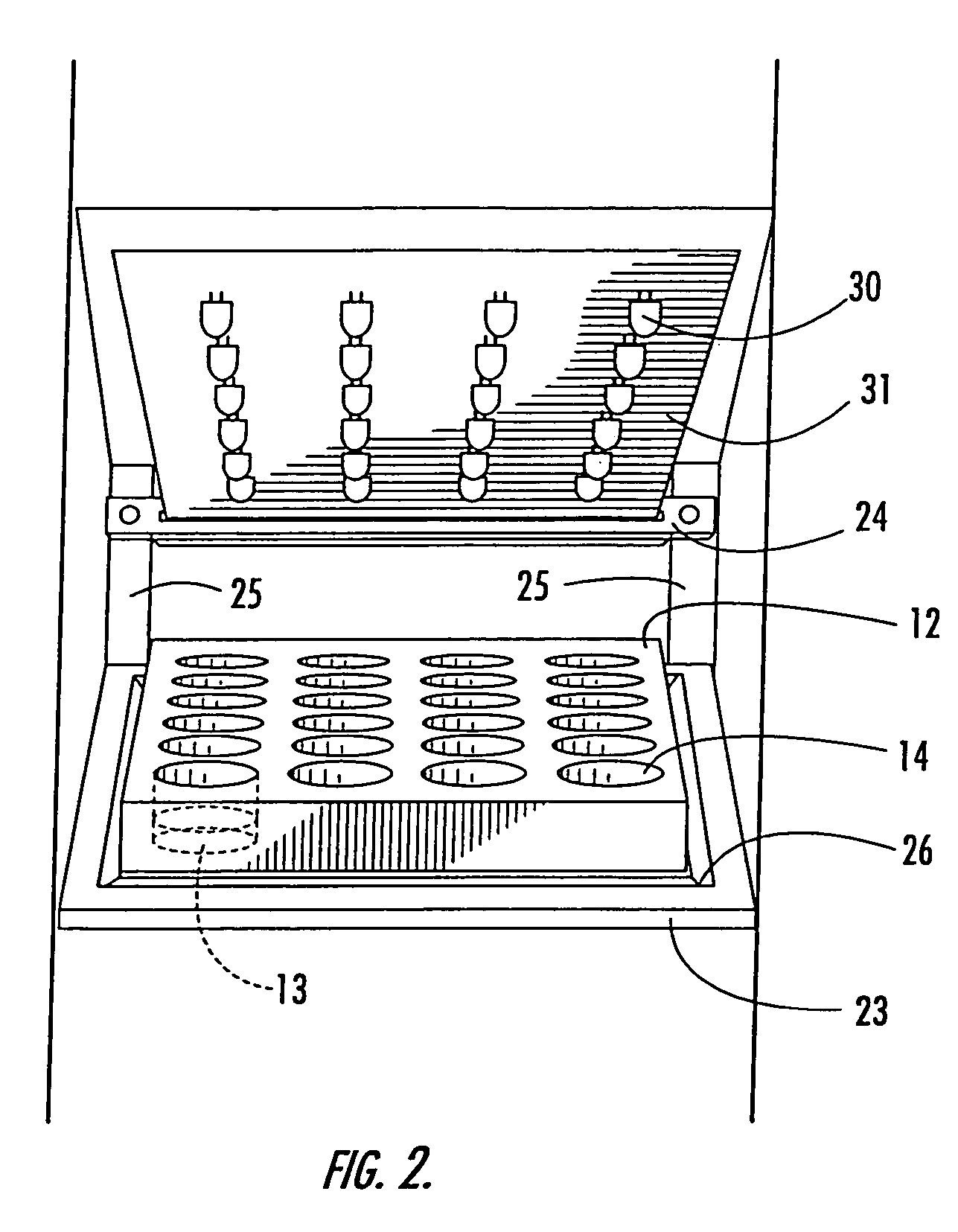

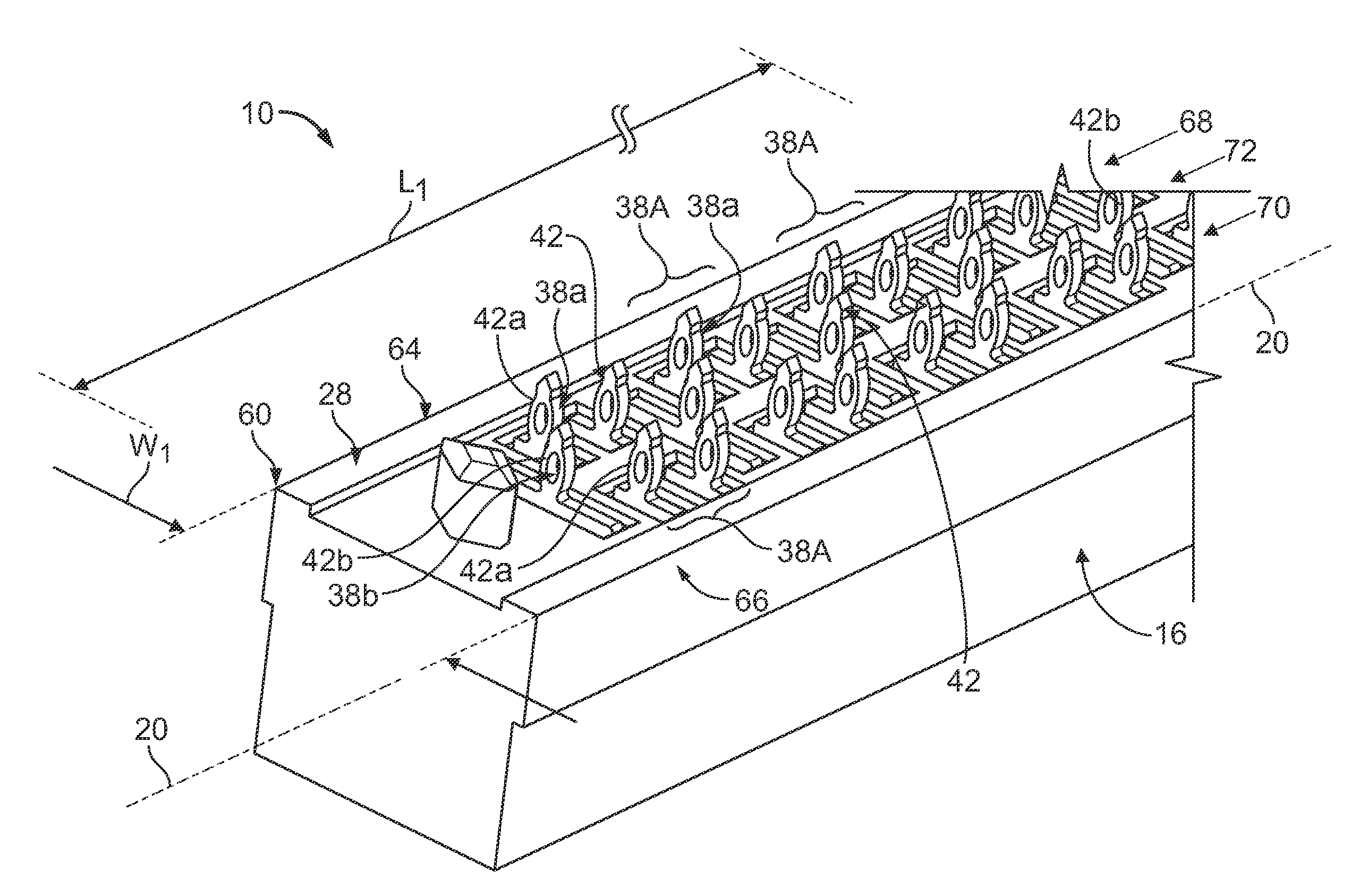

LED array for illuminating cell well plates and automated rack system for handling the same

InactiveUS7160717B2Improve storage efficiencyReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellPlant tissue

An assembly for promoting the growth of plant tissues that includes a plurality of plates each defining an array of wells wherein each of the wells contains a tissue sample. Support for the plates is provided by a rack having a plurality of vertically stacked shelves that may include one or more register depressions that urge the plates into predetermined positions. Light for the tissue samples is provided by a plurality of light-emitting diode arrays each mounted on a circuit board. Each circuit board is supported by a respective card edge connector of the rack so that the light-emitting diodes are in proximity to the plates supported on one of the shelves therebelow. Preferably, the light-emitting diode array corresponds to the well array supported in the registered position on the shelf therebelow so that each light-emitting diode is centered above a respective one of the wells.

Owner:BIOLEX THERAPEUTICS INC

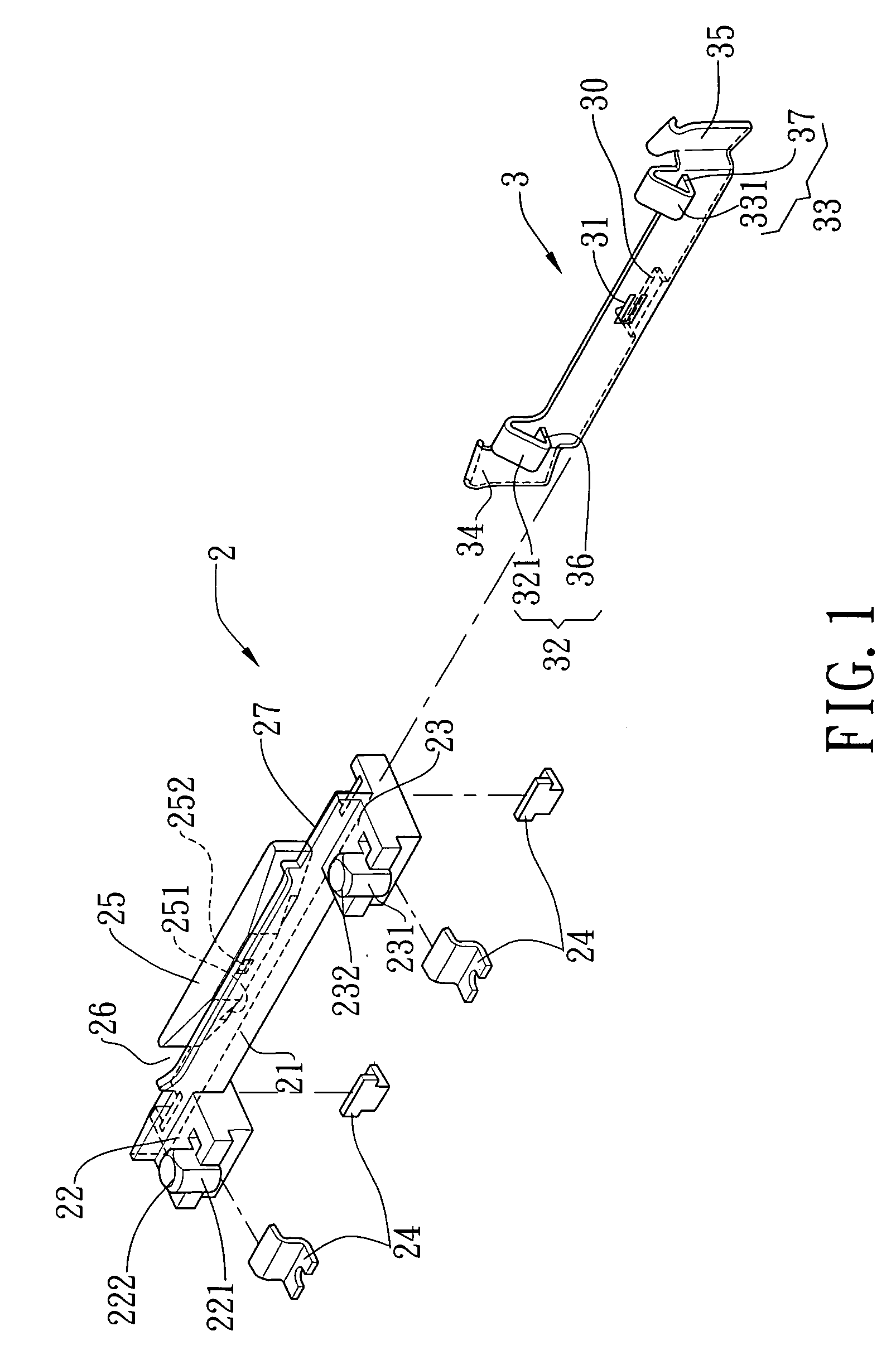

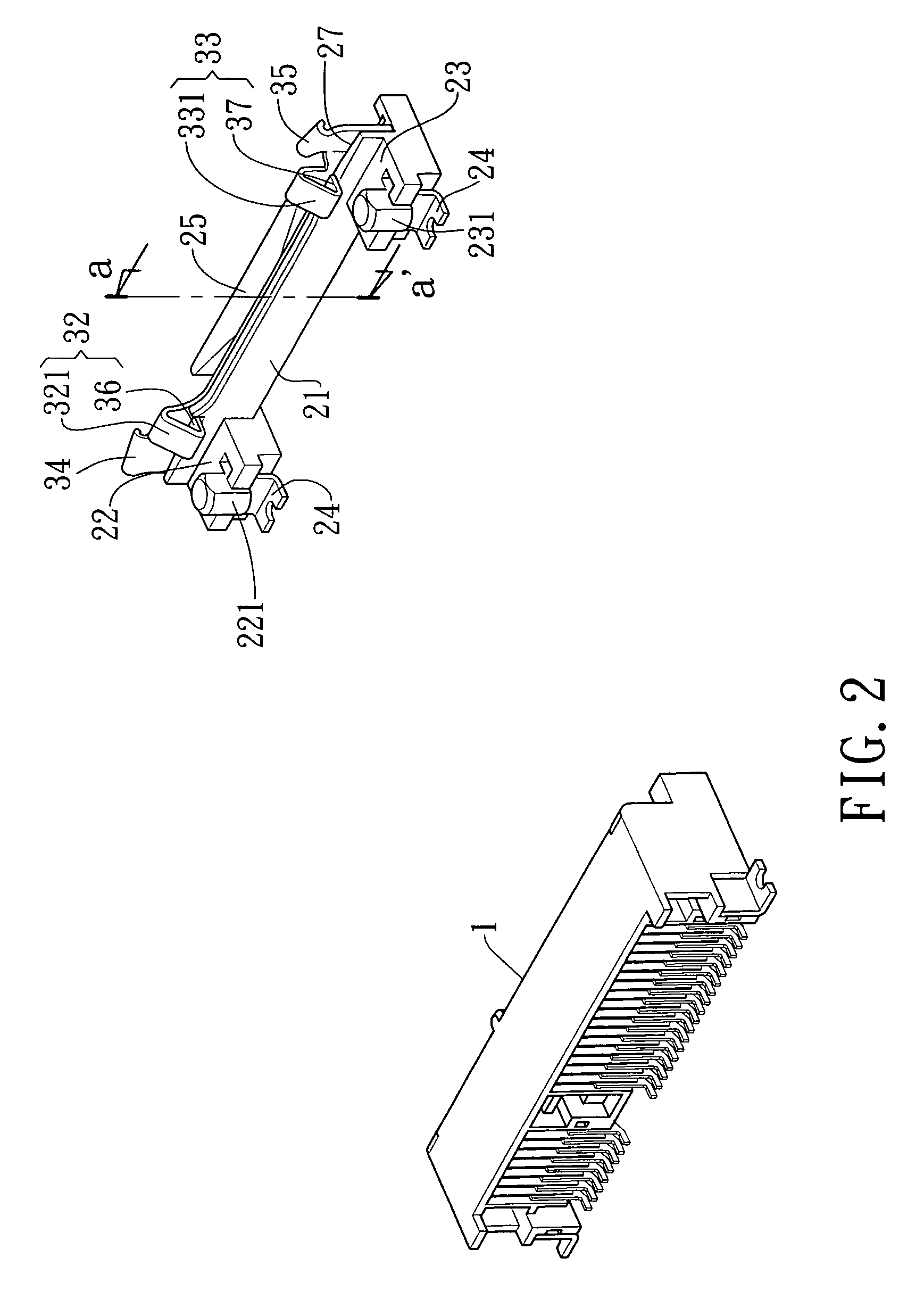

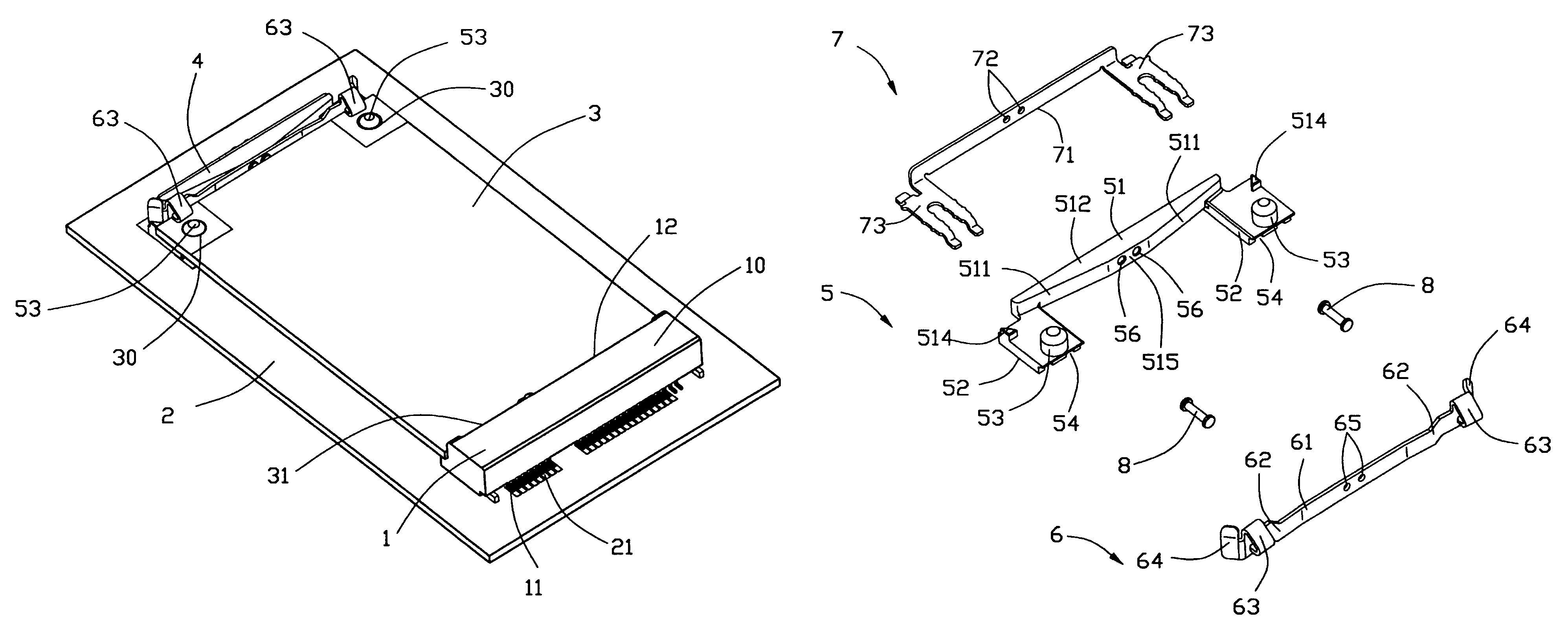

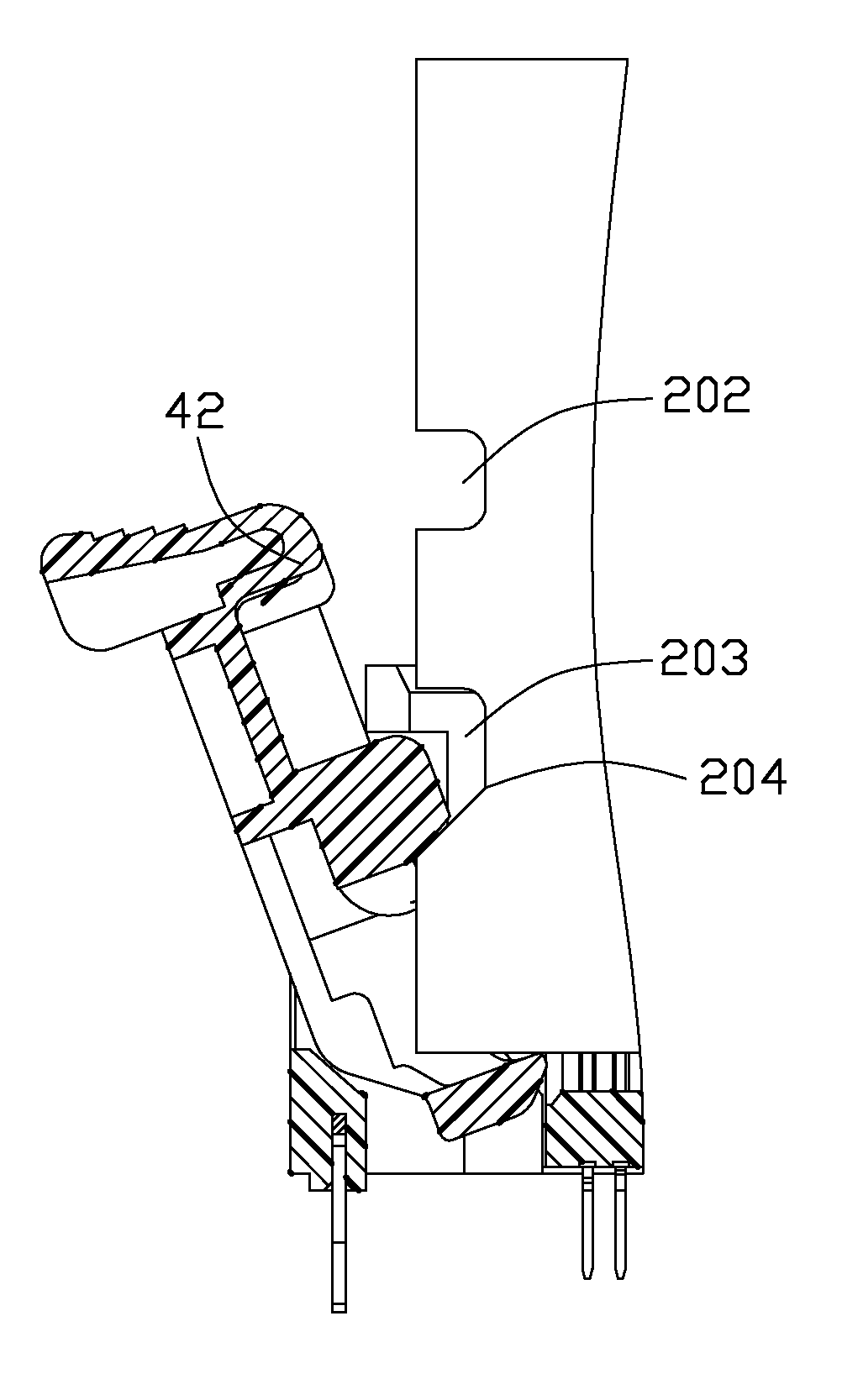

Latch of a card edge connector

InactiveUS7134896B1Simple structureEasy to assembleEngagement/disengagement of coupling partsClamping/extracting meansEngineeringMechanical engineering

A latch of a card edge connector comprising: an elongated body, having a outside wall with an extending wall, wherein a trench is formed between the outside wall and the extending wall, and the extending wall has an opening and a pin; and a latching device, having a knot and a pinhole used for joining the opening and the pin of the extending wall respectively, and having at least a buckle and a chuck, the buckle is used for locking a circuit card when a side part of the circuit card is pressed down the buckle, then the chuck is used for driving the buckle moving and releasing the circuit card.

Owner:EGBON ELECTRONICS +1

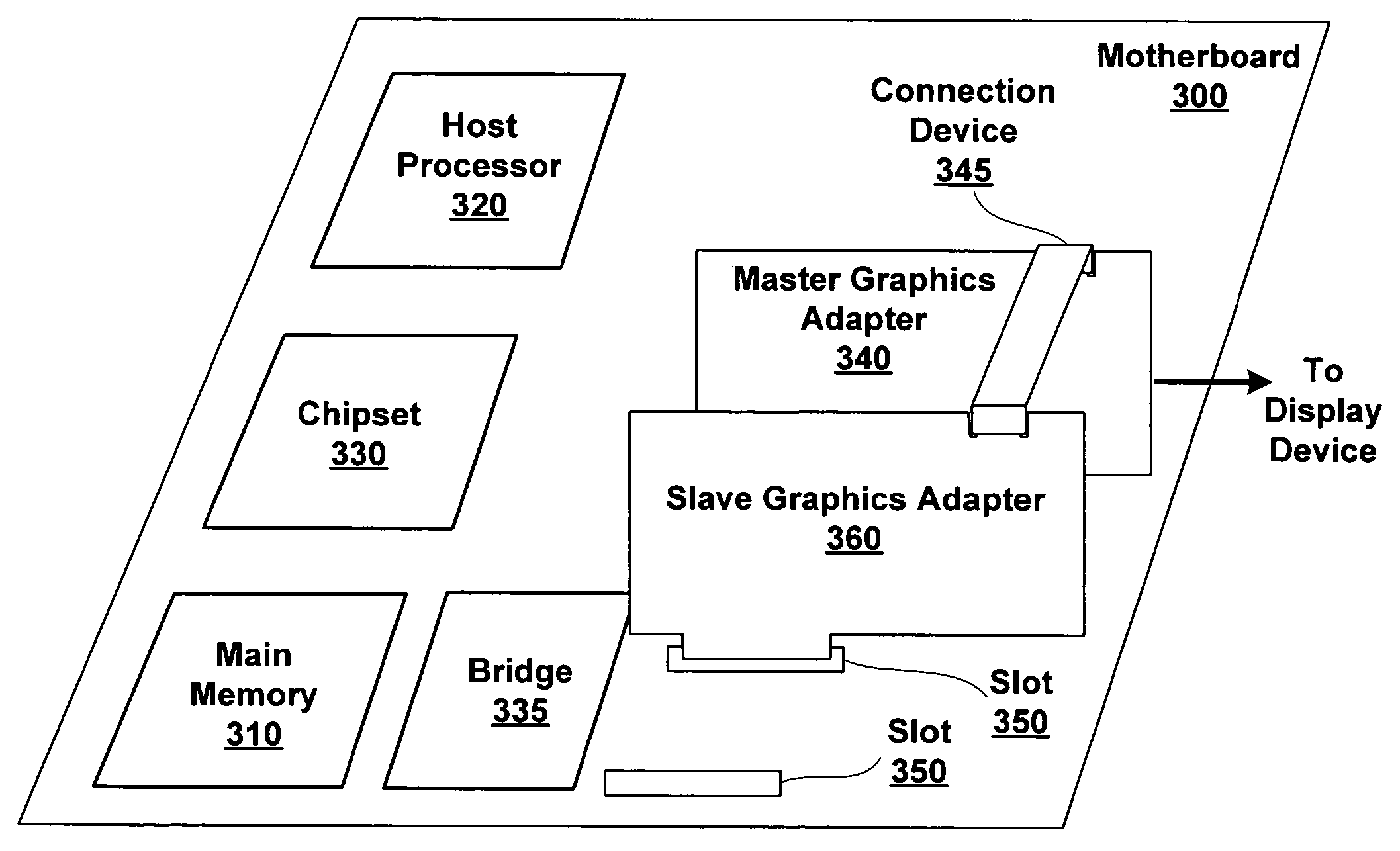

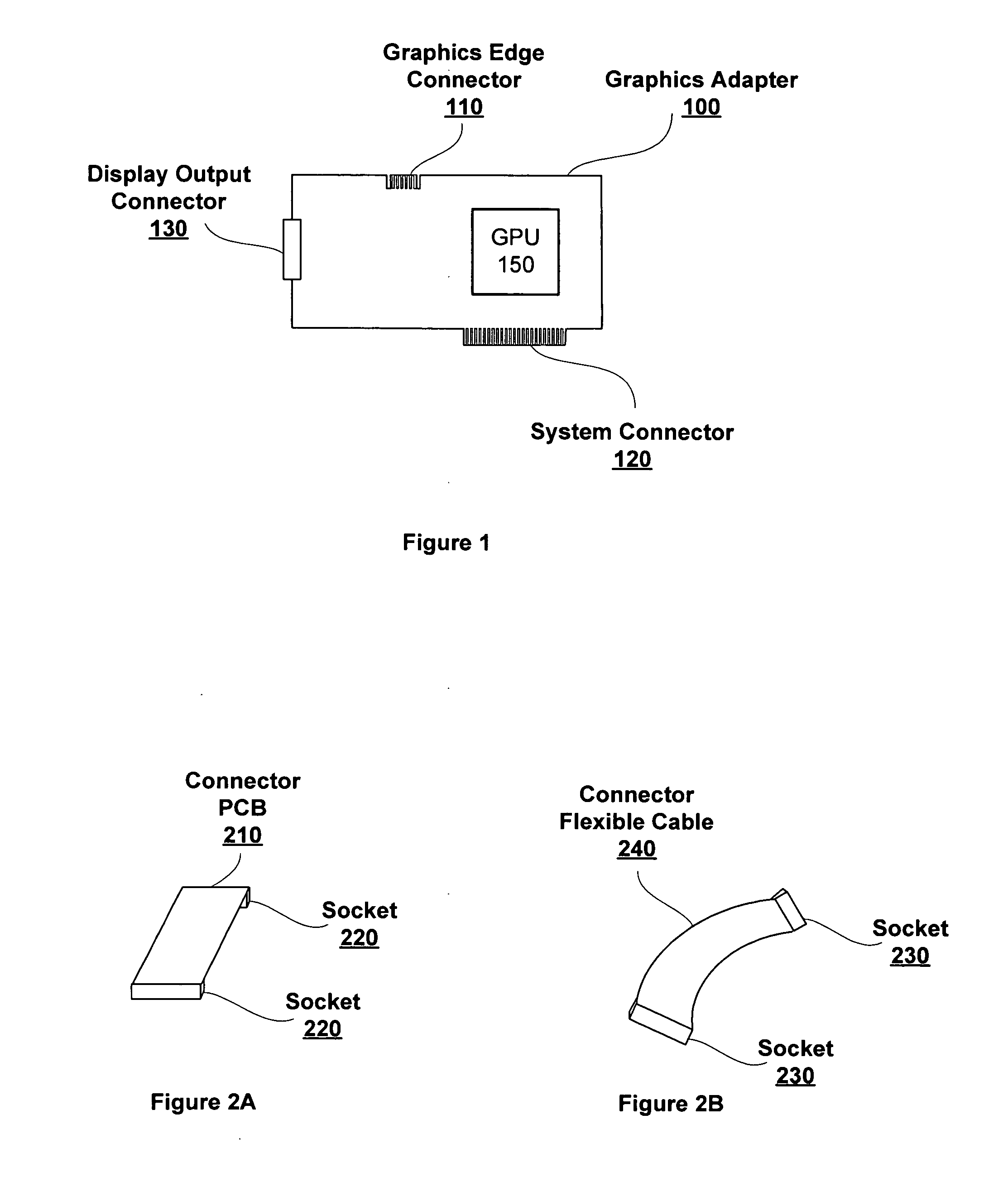

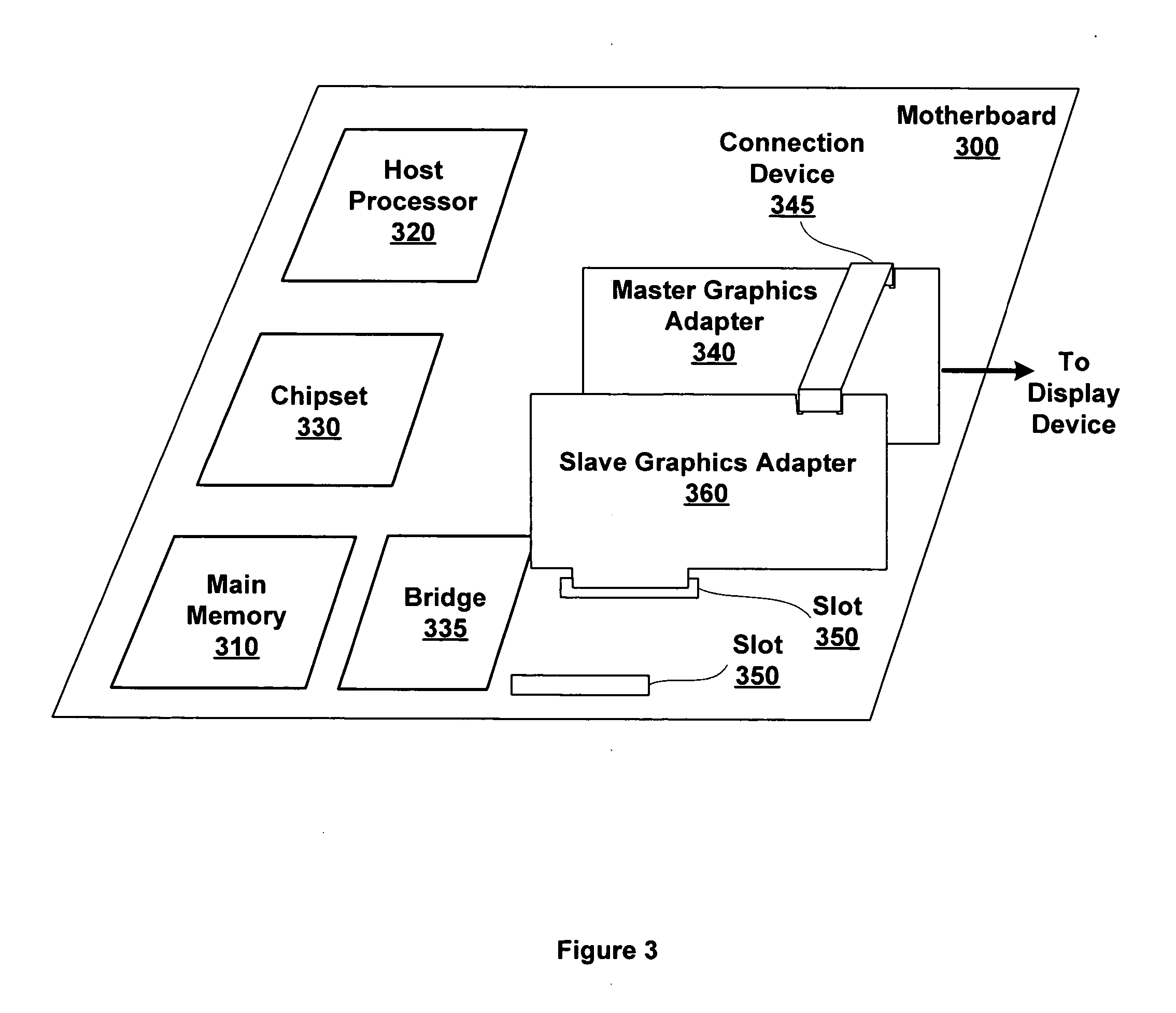

Multiple graphics adapter connection systems

ActiveUS20060274073A1Digital data processing detailsCathode-ray tube indicatorsGraphicsGraphics processing unit

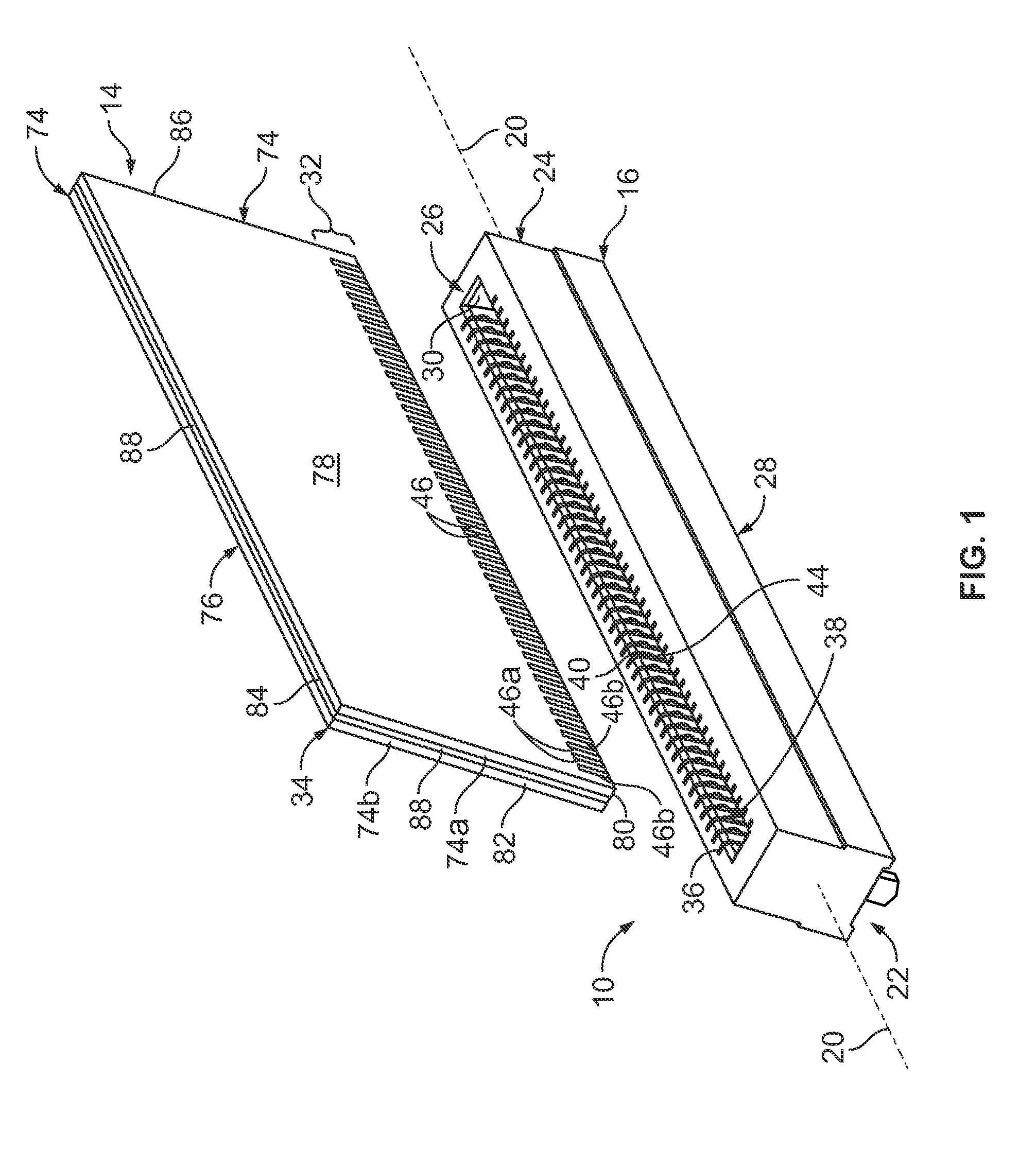

A system provides a digital multi-bit connection between two or more graphics adapters. Each graphics adapter is manufactured as a printed circuit board including a finger-type edge connector. When two or more graphics adapters are installed in a system the edge connectors of each graphics adapter may be coupled to each other via a connection device that provides a portion of the digital multi-bit connection. The remainder of the digital multi-bit connection is provided by conductive traces coupling each finger of the edge connector to a graphics processing unit that is affixed to the graphics adapter. The connection device may be installed by an end-user as each additional graphics adapter is installed in the system.

Owner:NVIDIA CORP

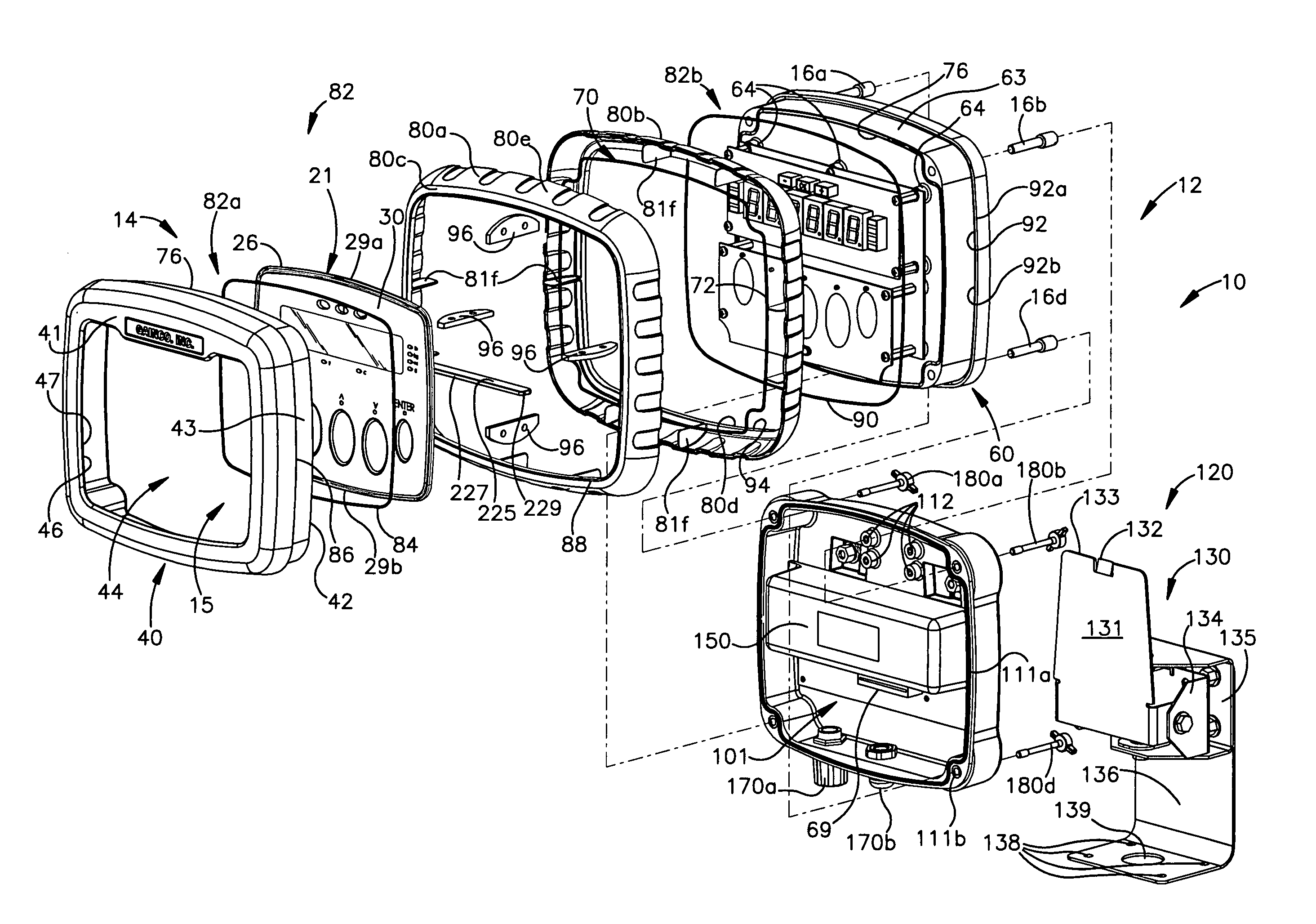

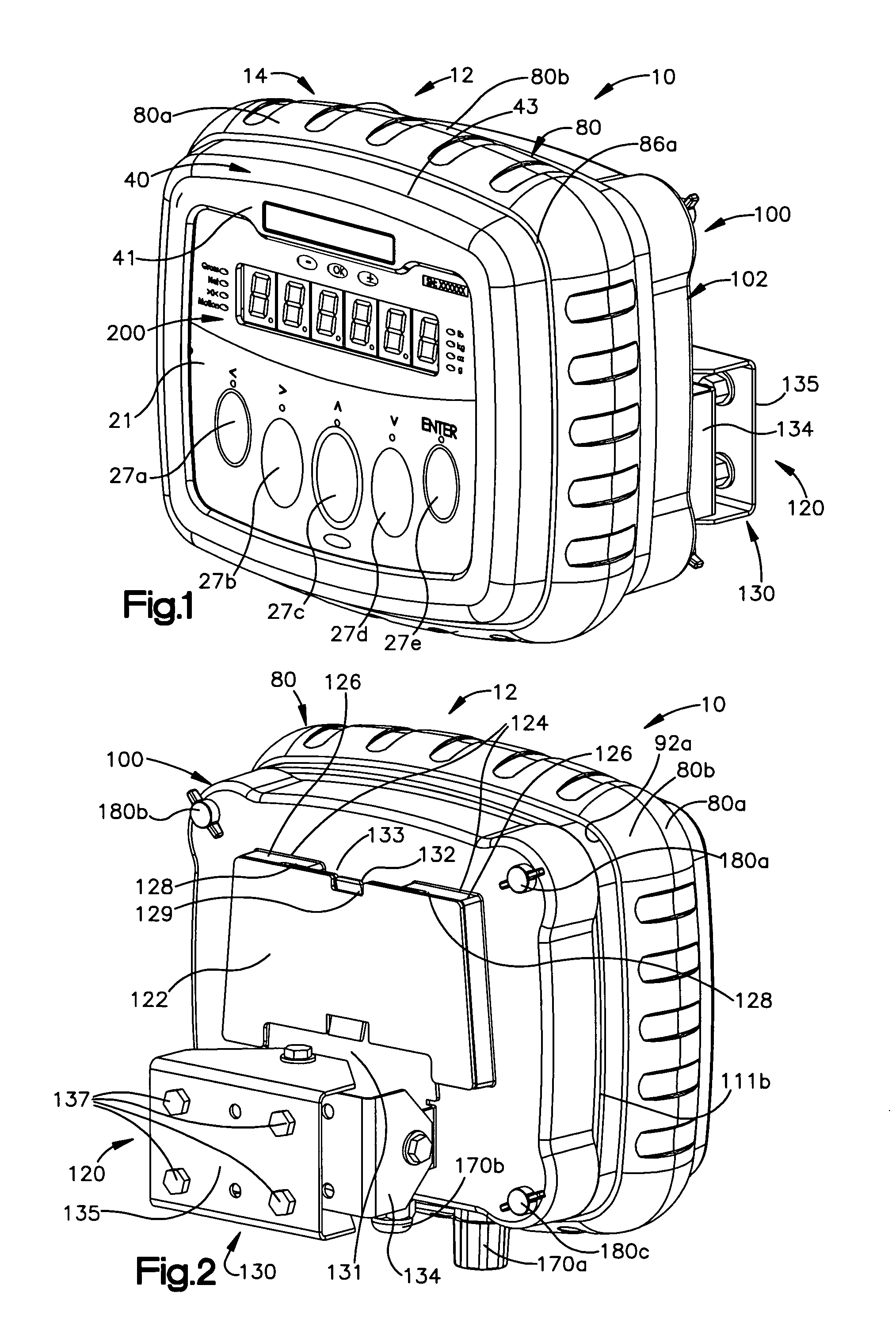

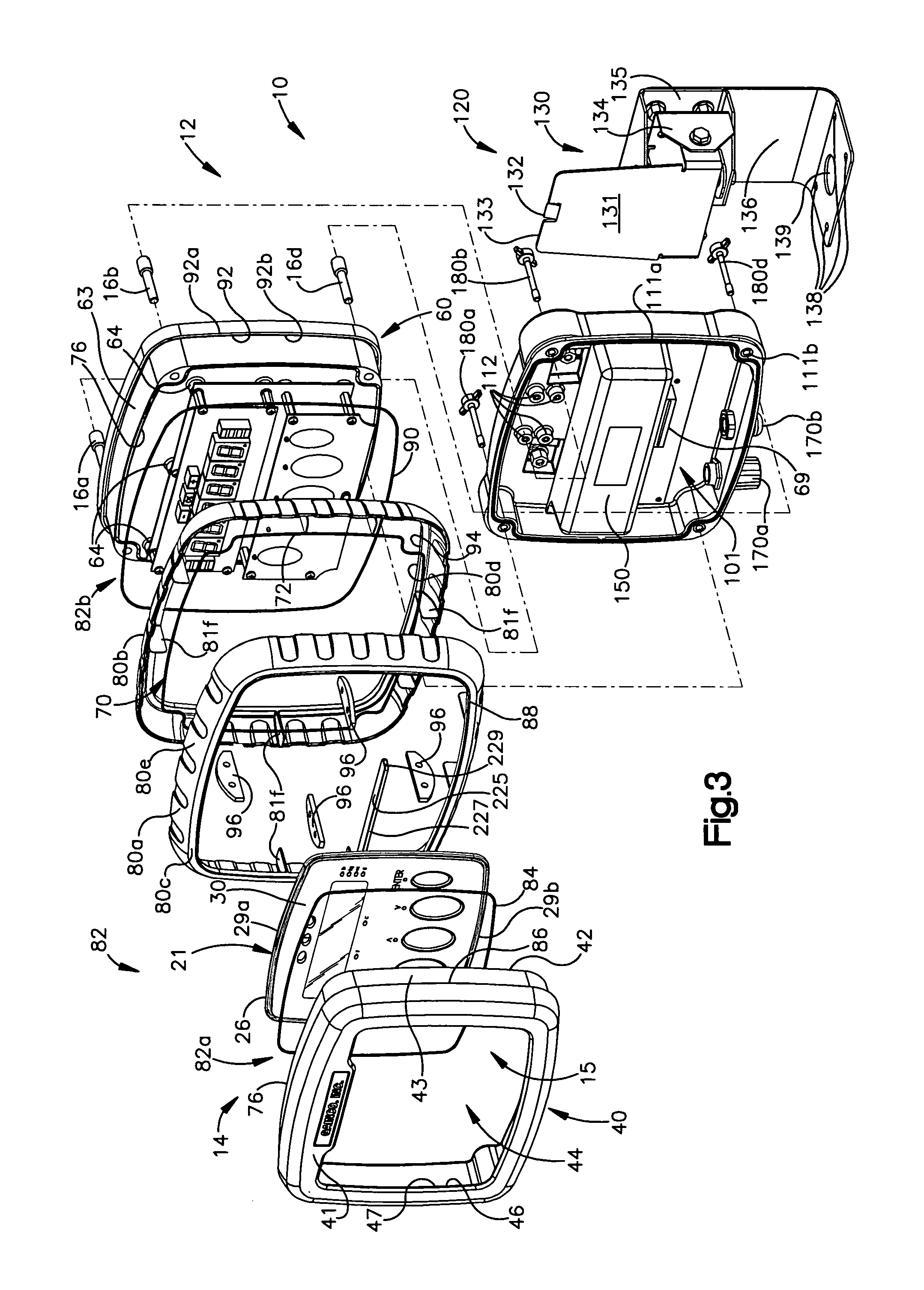

Housing for scale or load cell controller

ActiveUS20060054335A1Digital data processing detailsCathode-ray tube indicatorsUser inputDisplay device

A housing for a scale or load cell controller suitable for use in harsh environments. The housing includes a moisture-resistant front display unit coupled to a rear interface and mounting unit. The front display unit includes a front housing, a back housing, and a frame overlying a boundary or seal region between the front and back housings to provide a double moisture-resistant seal between the front and back housings. The front display unit defines an interior region including a display and a plurality of user input keys and controller circuitry. The front display unit is removably attachable to the rear interface unit. A moisture-resistant seal is also provided between the front display unit and the rear interface and mounting unit. The rear interface and mounting unit defines a recessed area supporting a battery pack, a power supply and an interface circuit board. Circuitry in the front display unit is electrically coupled to circuitry in the rear interface and mounting unit via an edge connector circuit card that extends through an opening in the front display unit and mates with an edge connector socket supported in the rear interface and mounting unit.

Owner:BETTCHER INDUSTRIES

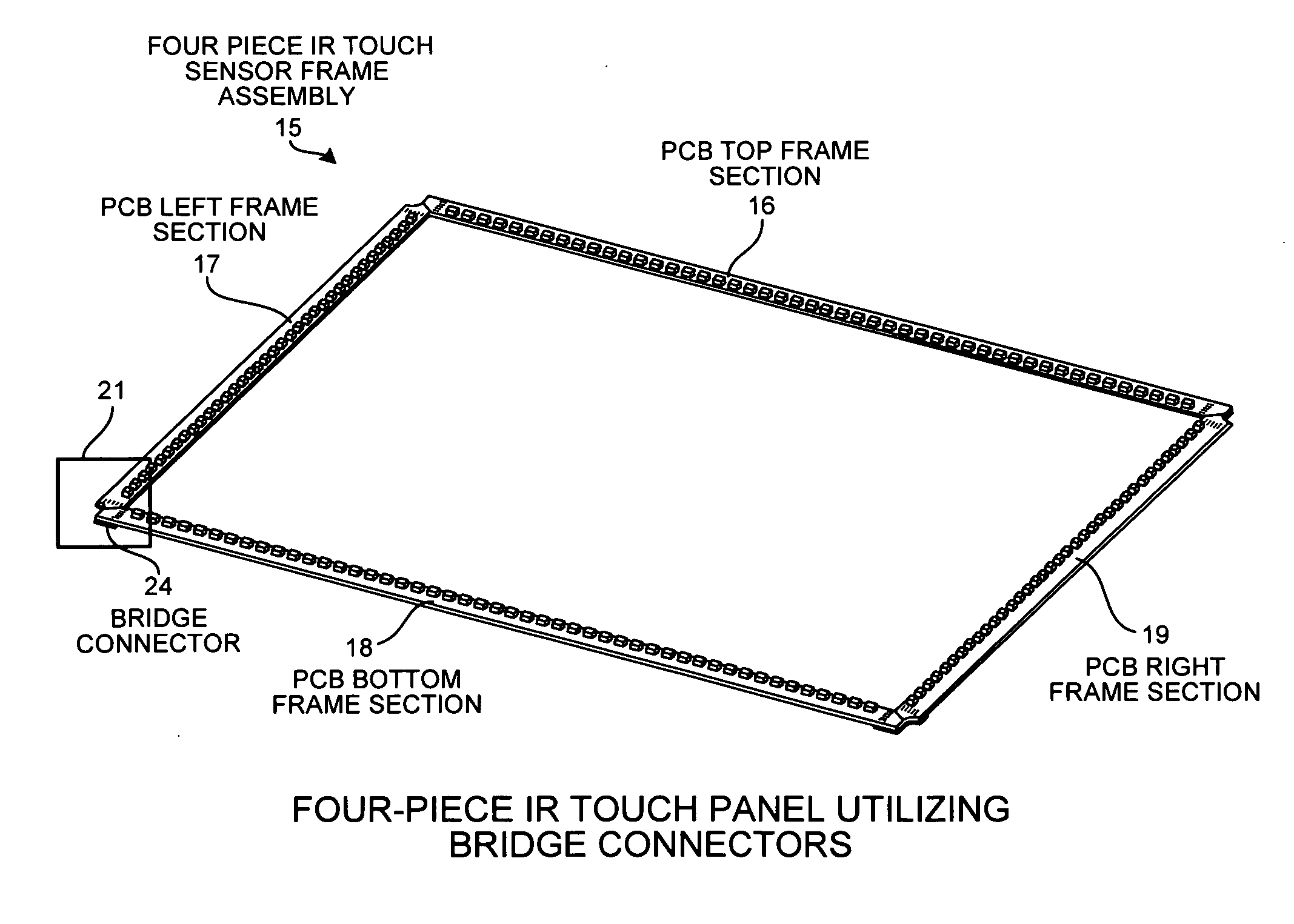

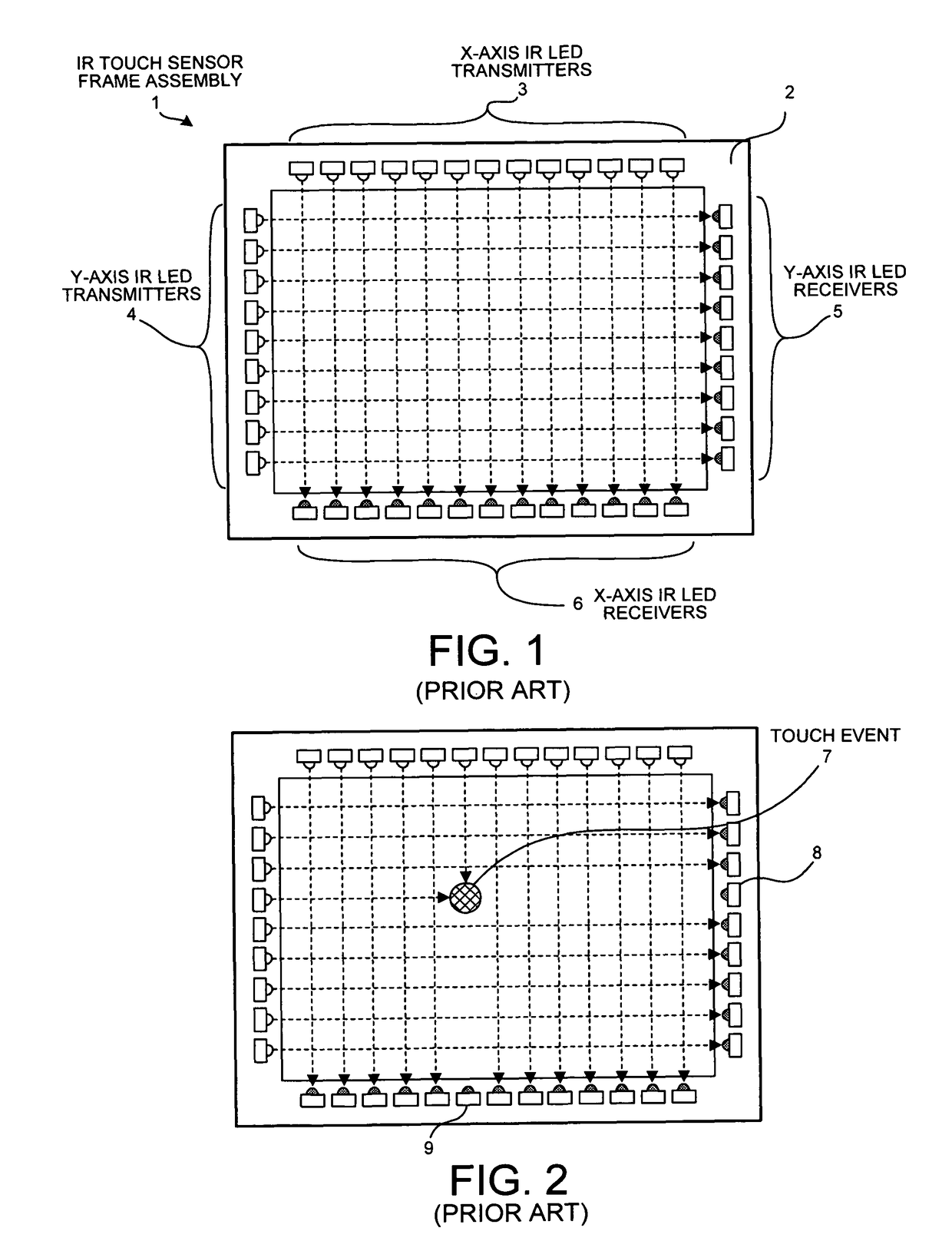

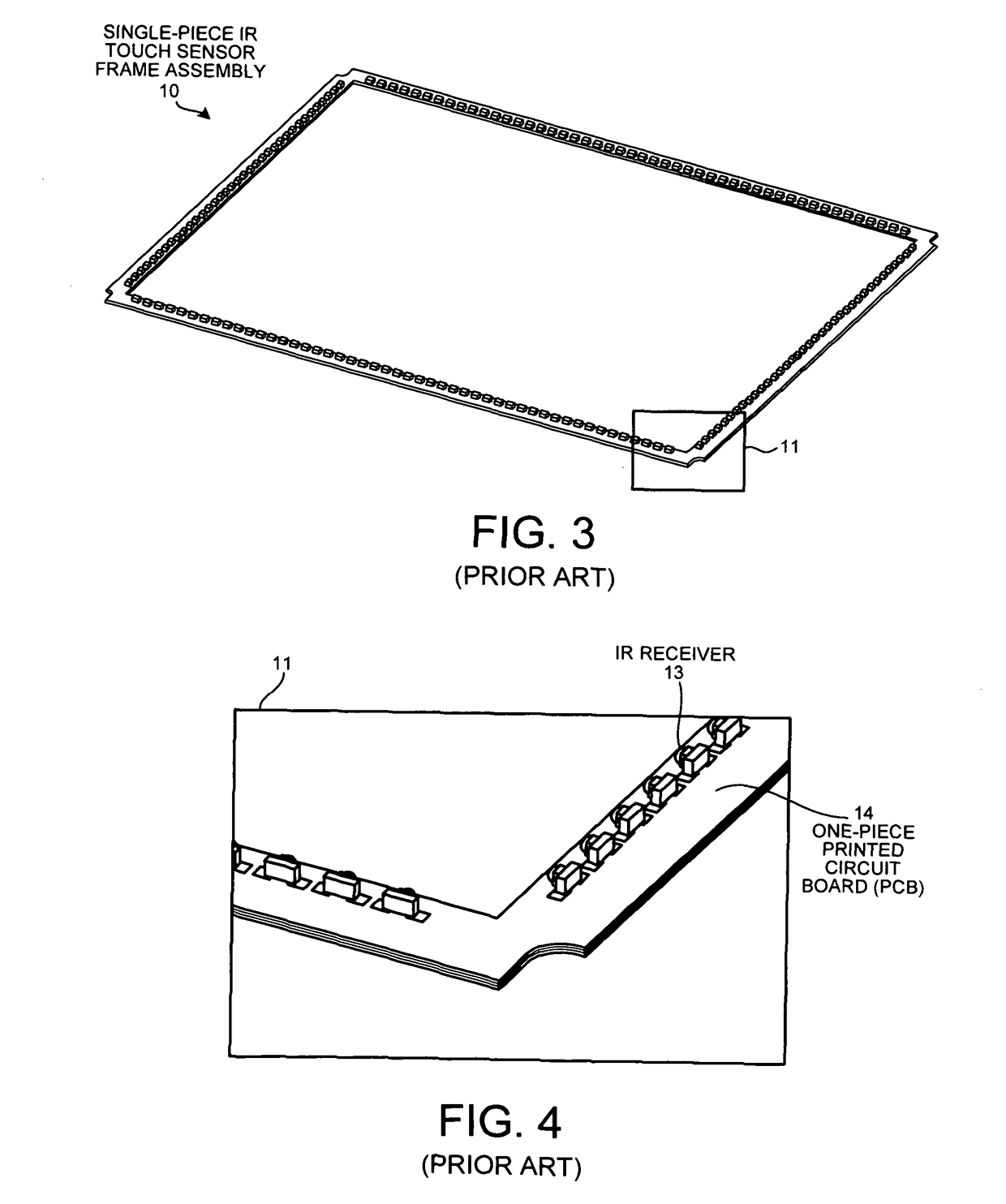

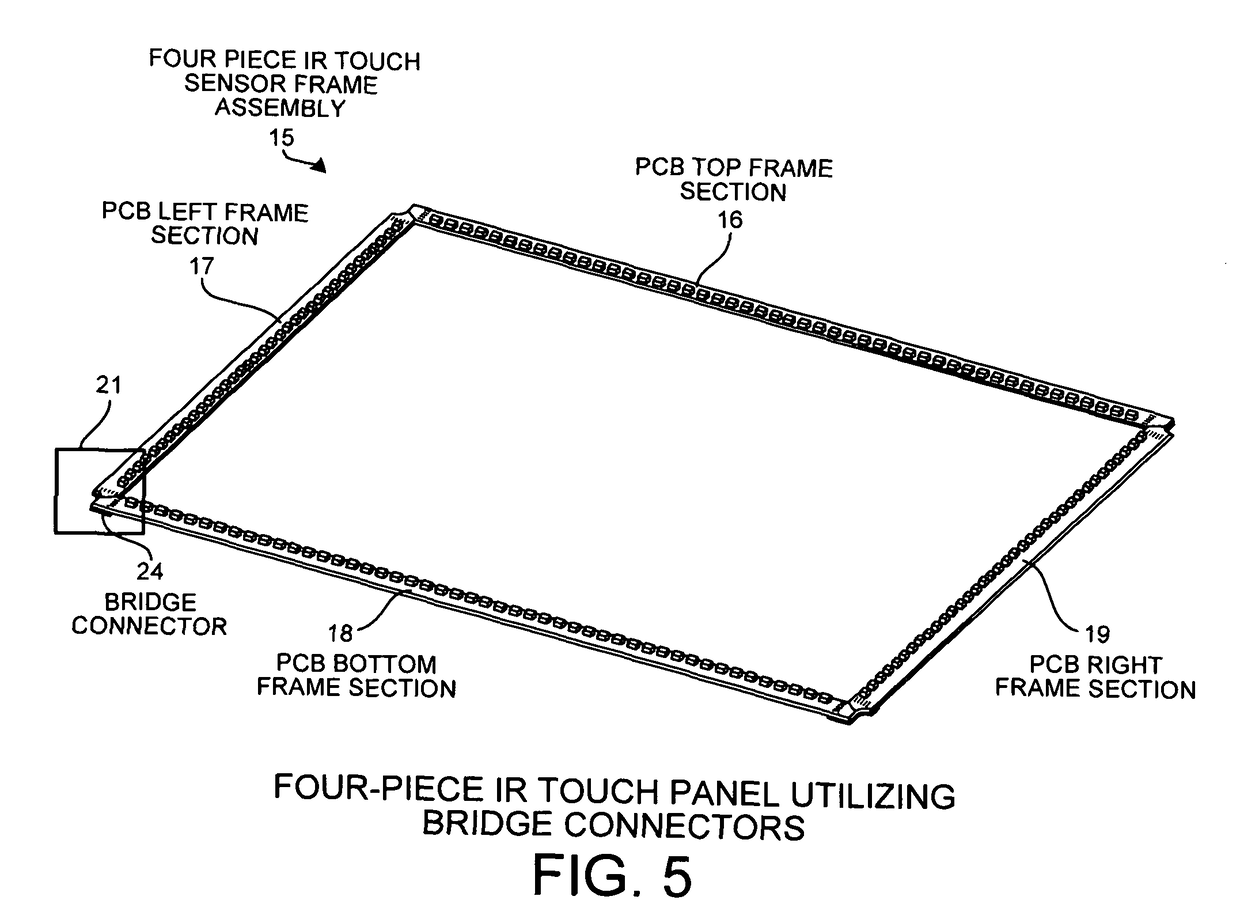

PCB bridge connector for connecting PCB devices

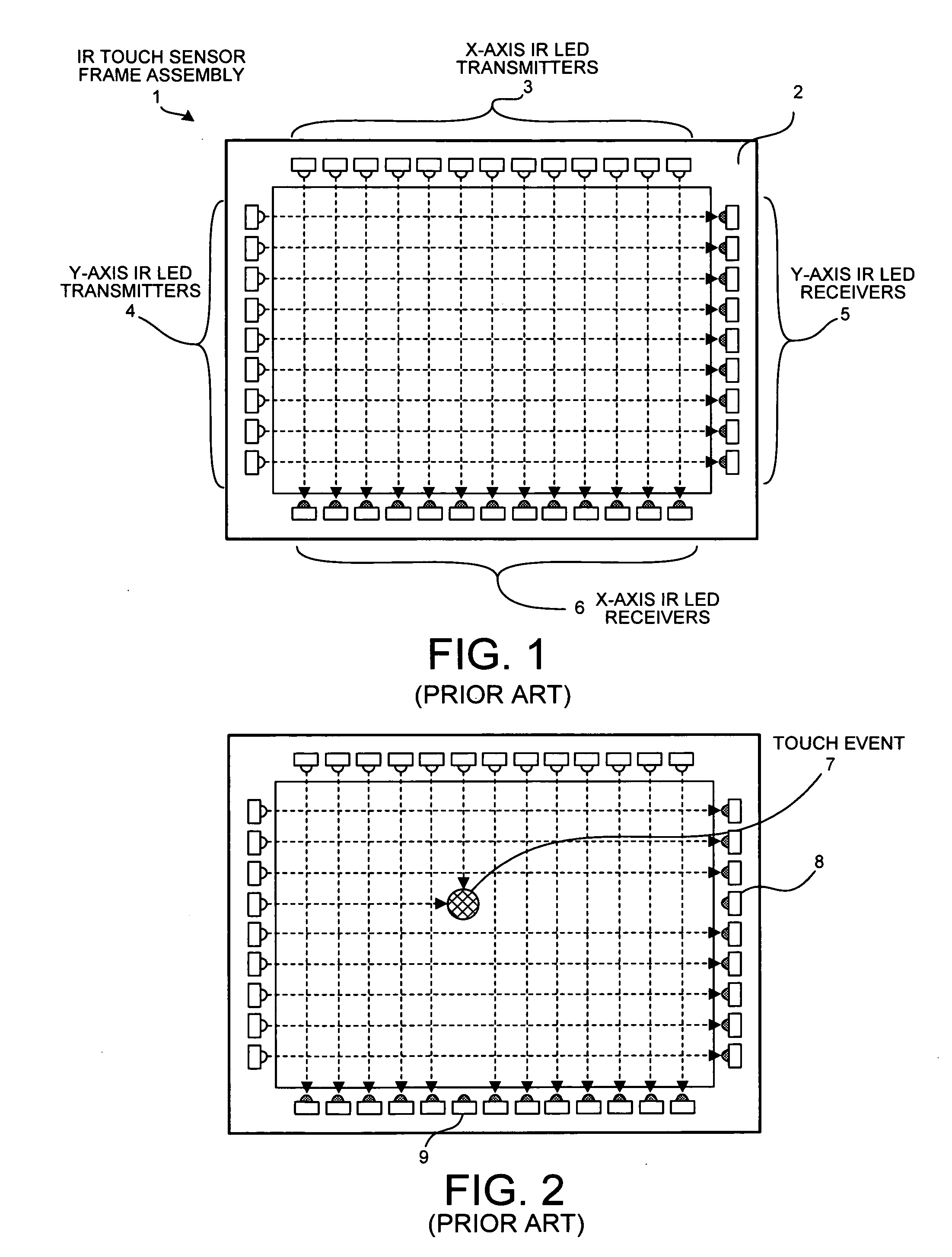

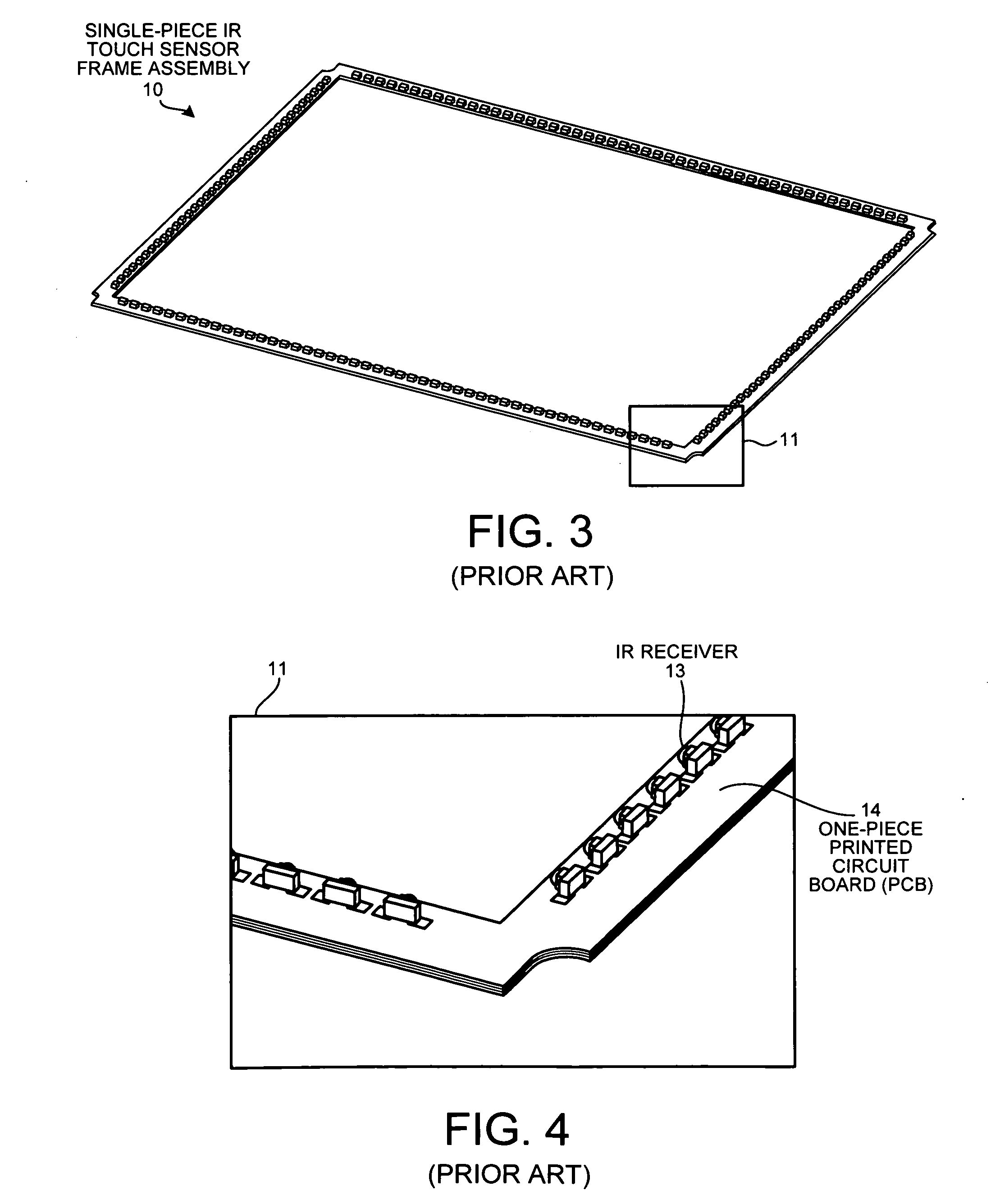

InactiveUS20100112833A1Shipping and repairing an IR touch sensor frame using four PCB frame sections is easier and less expensiveCoupling device connectionsPrinted circuit aspectsElectrical conductorEngineering

A bridge connector made of PCB material has a first plurality of press-fit pins on one portion of the bridge connector and a second plurality of press-fit pins on another portion of the bridge connector. Within the connector is a set of signal conductors. Each conductor connects a press-fit pin of the first plurality of press-fit pins to a corresponding press-fit pin of the second plurality of press-fit pins. When the connector is attached to a printed circuit board (PCB), the press-fit pins extend into and engage corresponding plated through holes in the PCB. The press-fit pins exert enough retention force to mechanically couple two PCB frame sections. The PCB frame sections are electrically connected through the press-fit pins and corresponding signal conductors of the bridge connector. A bridge connector attached at each corner of an infrared touch sensor frame assembly allows the assembly to be solidly assembled from four sections of PCB: a top, bottom, left, and right PCB frame section.

Owner:CNPLUS

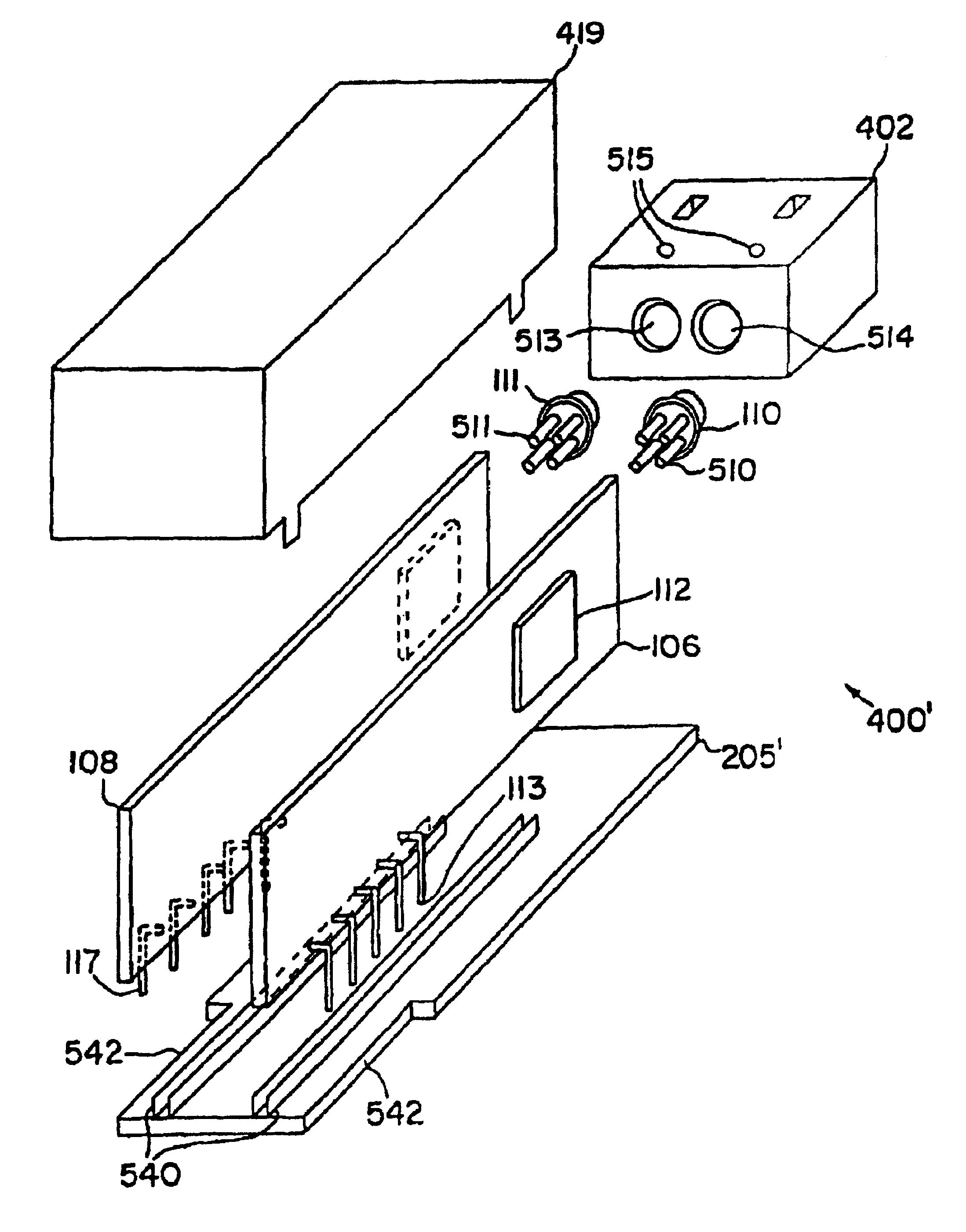

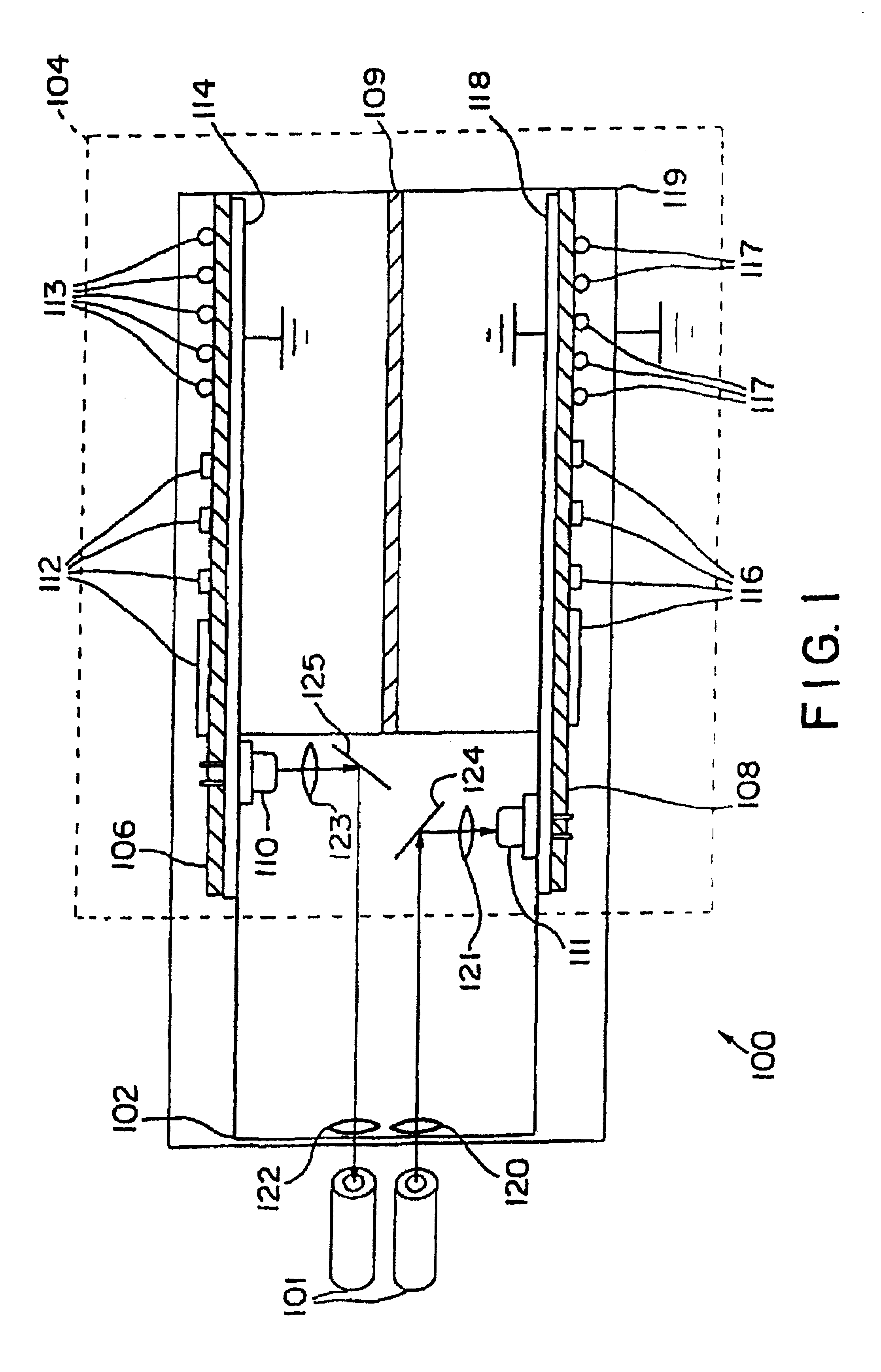

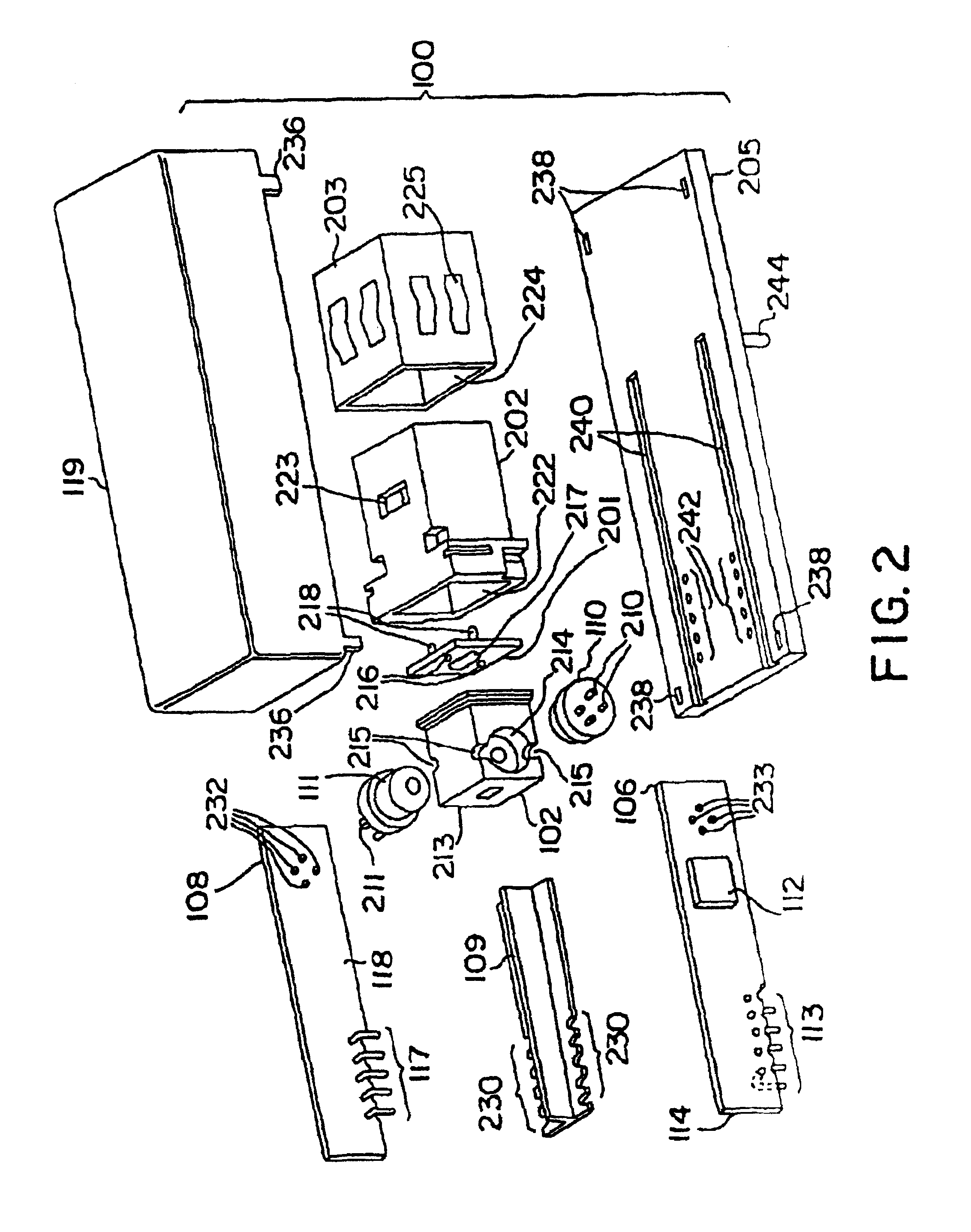

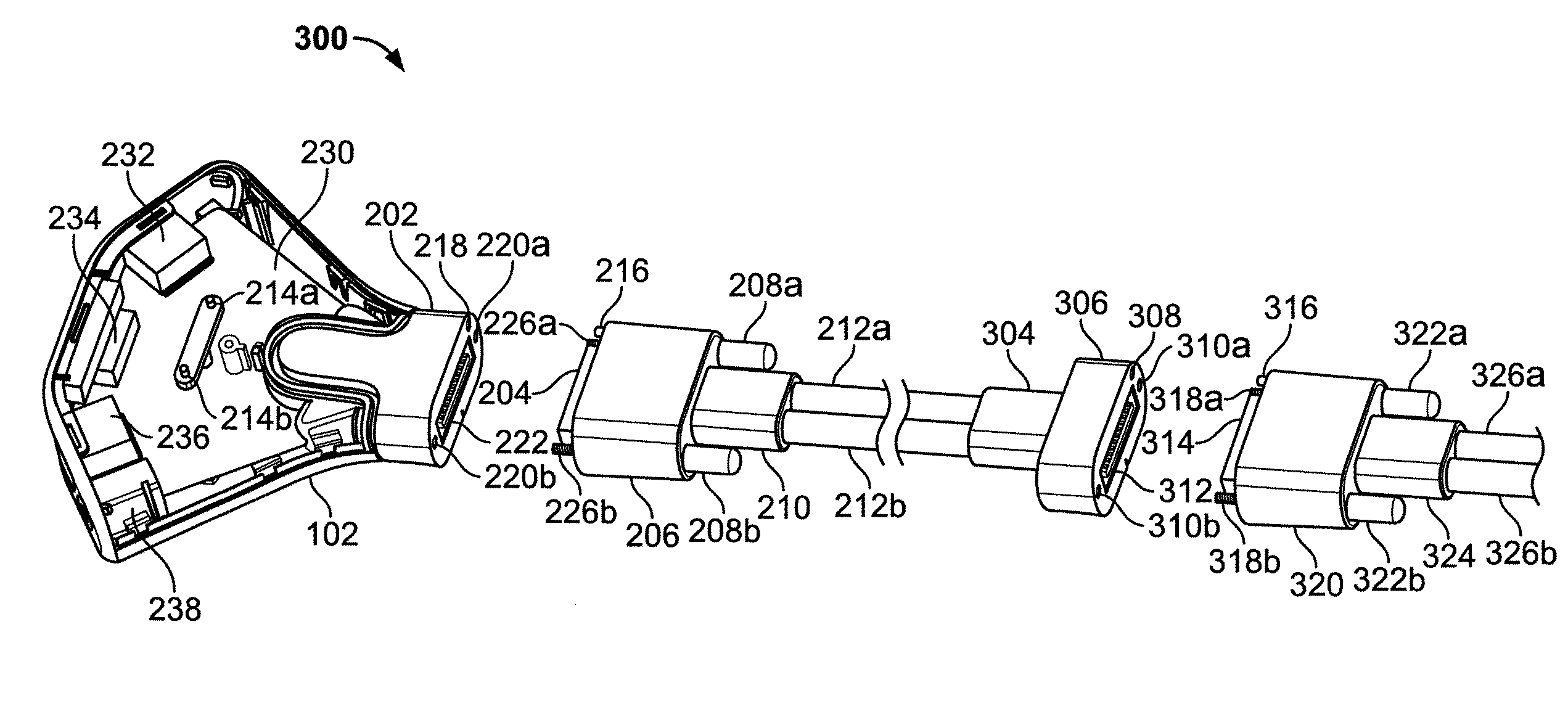

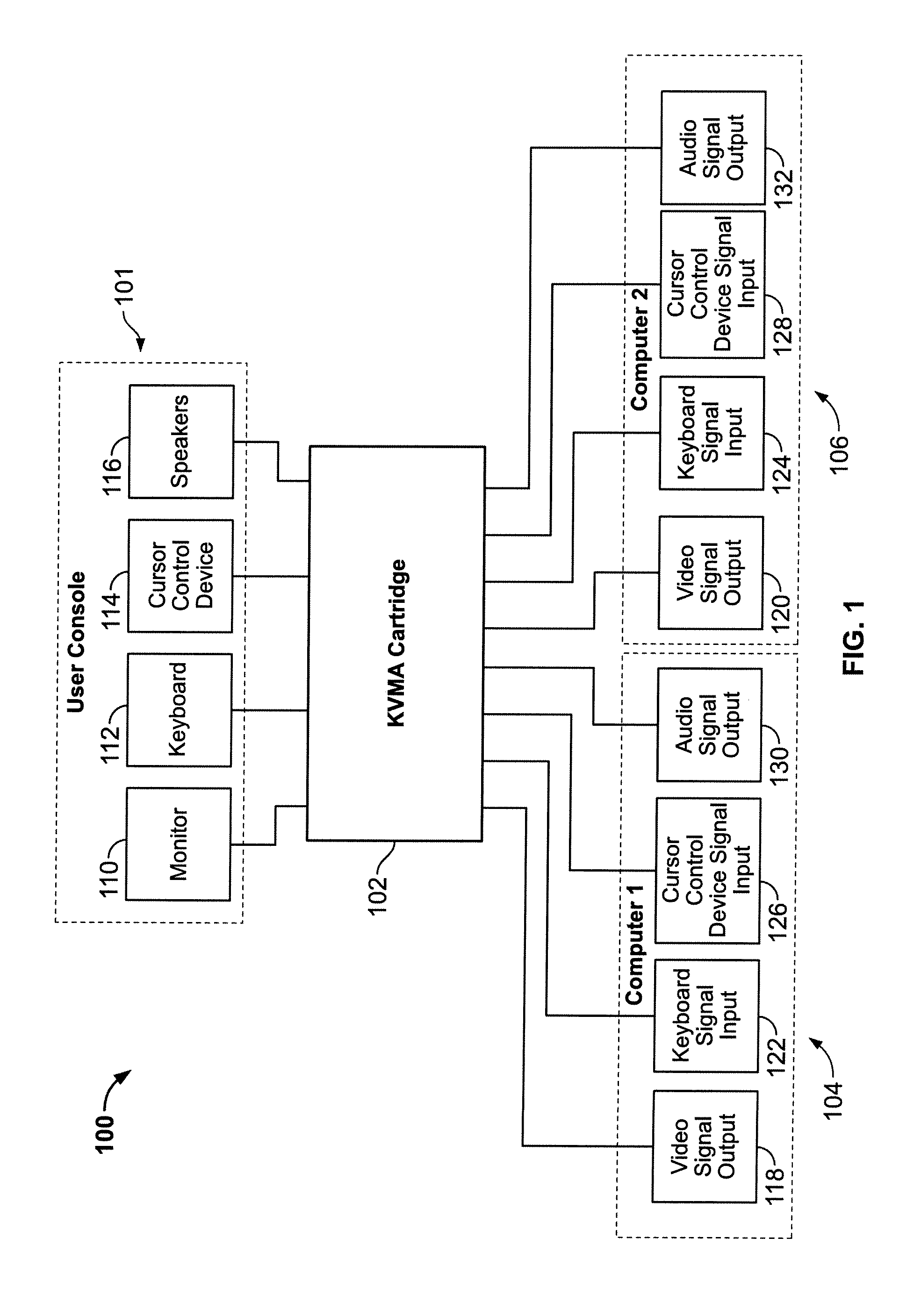

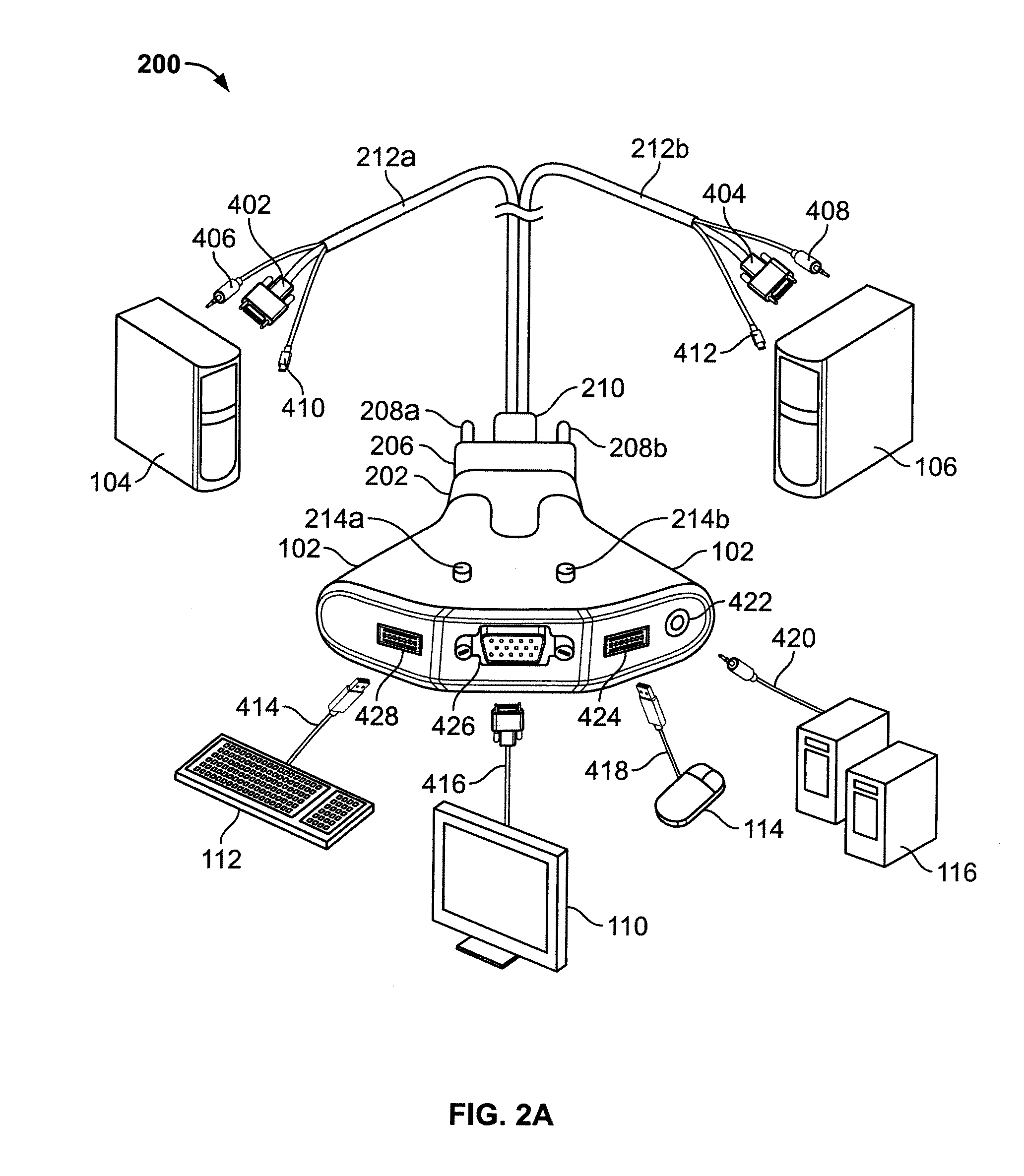

Apparatus for managing multiple computers with a cartridge connector

ActiveUS7318750B1Extended cable lengthElectric discharge tubesDigital data processing detailsLeading edgeEngineering

A computer management apparatus is provided for interconnecting a user console including peripheral devices such as a keyboard, a video display unit, a mouse, and speakers for connecting to a plurality of host computers, selectively accessed via the user console (“KVMA cartridge”). The host computers interface with the KVMA cartridge via a removable edge connector with a first set of cables that attach to the plurality of host computers. The KVMA cartridge connects to the edge connector via a leading edge of a circuit board having a plurality of traces on the leading edge with electrical leads connected to a switching circuit within the KVMA cartridge. In one embodiment, the user may increase the length of the first set of cables by inserting an extension cartridge with a second set of cables between the KVMA cartridge and the edge connector with the first set of cables.

Owner:BELKIN INT

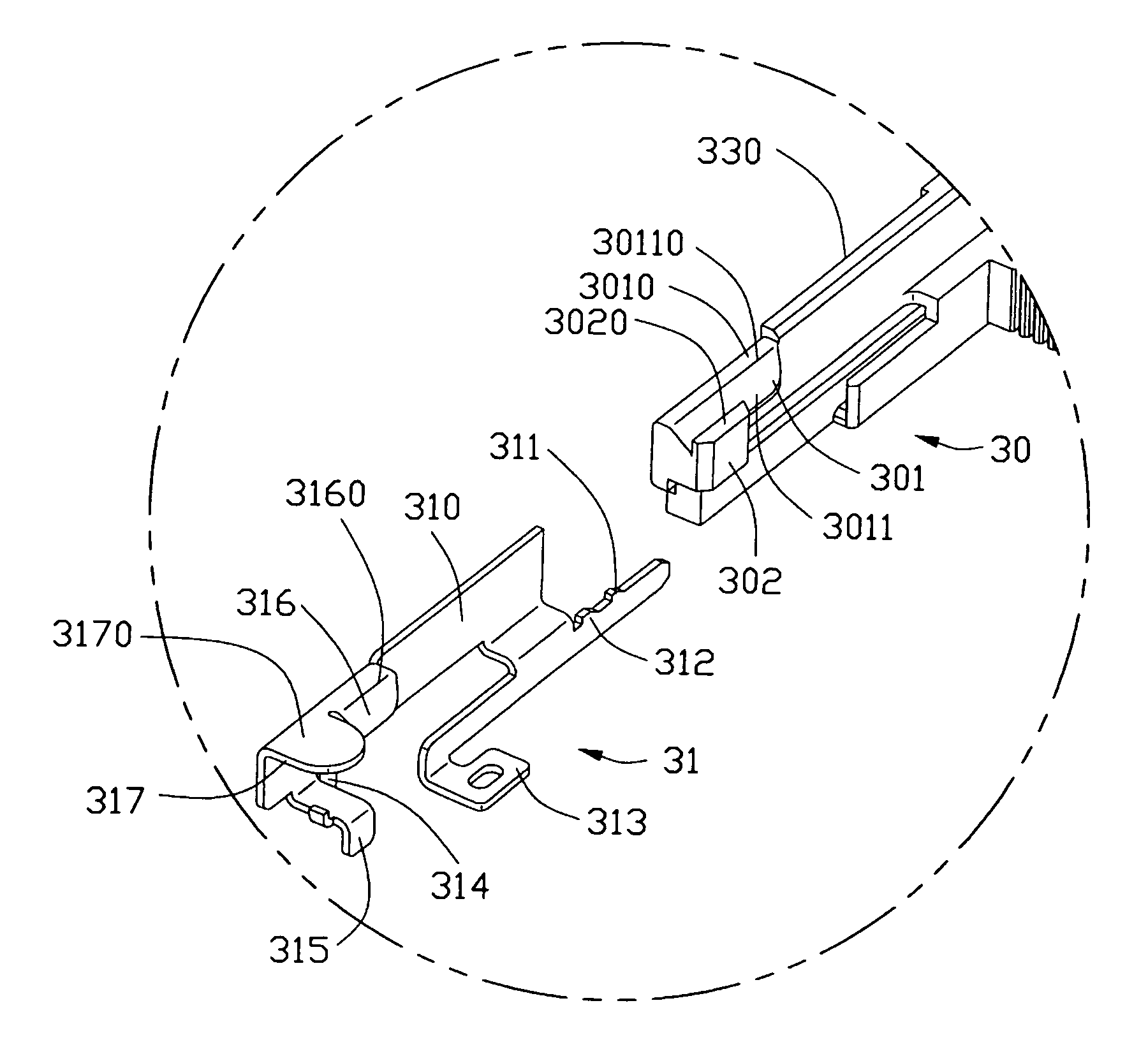

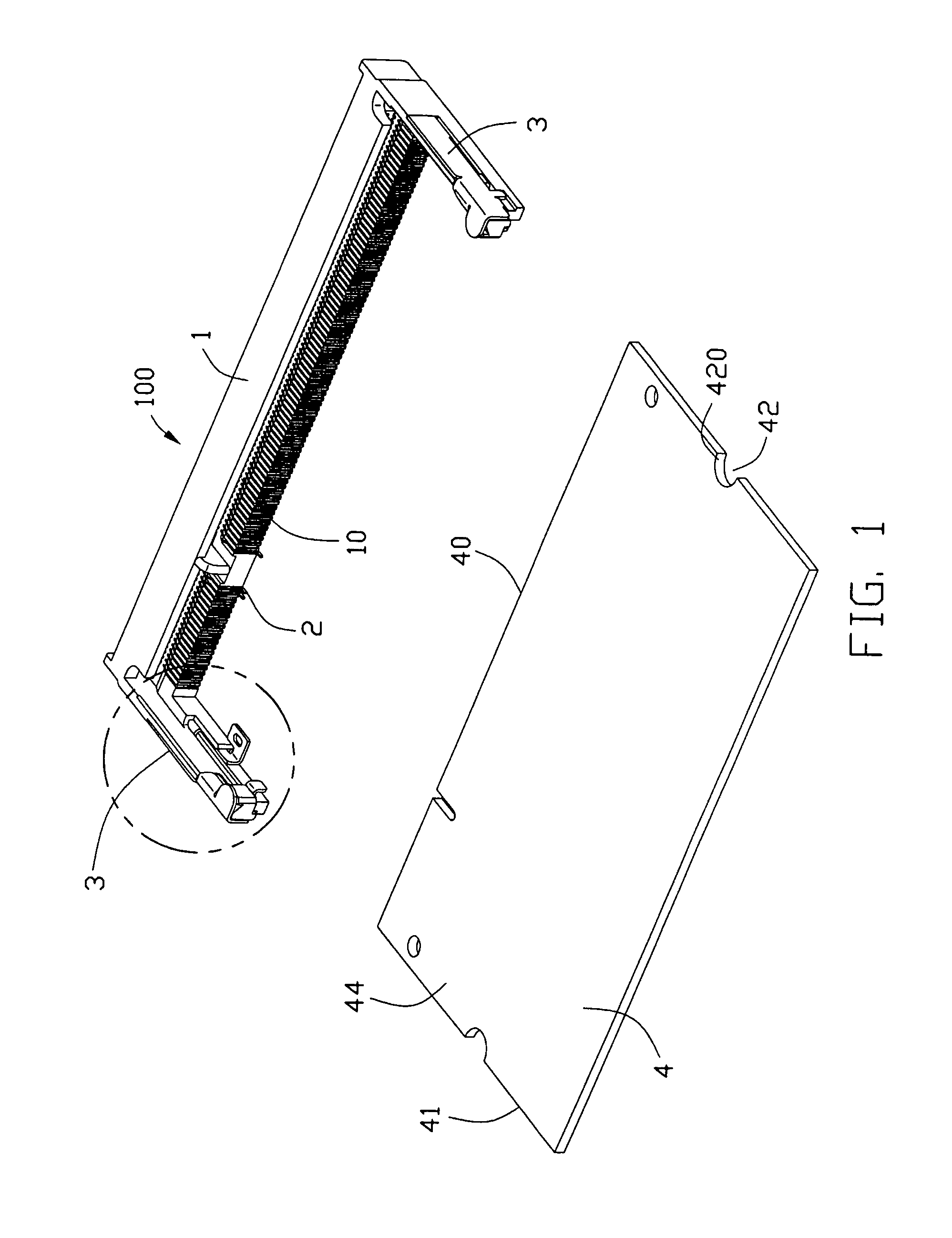

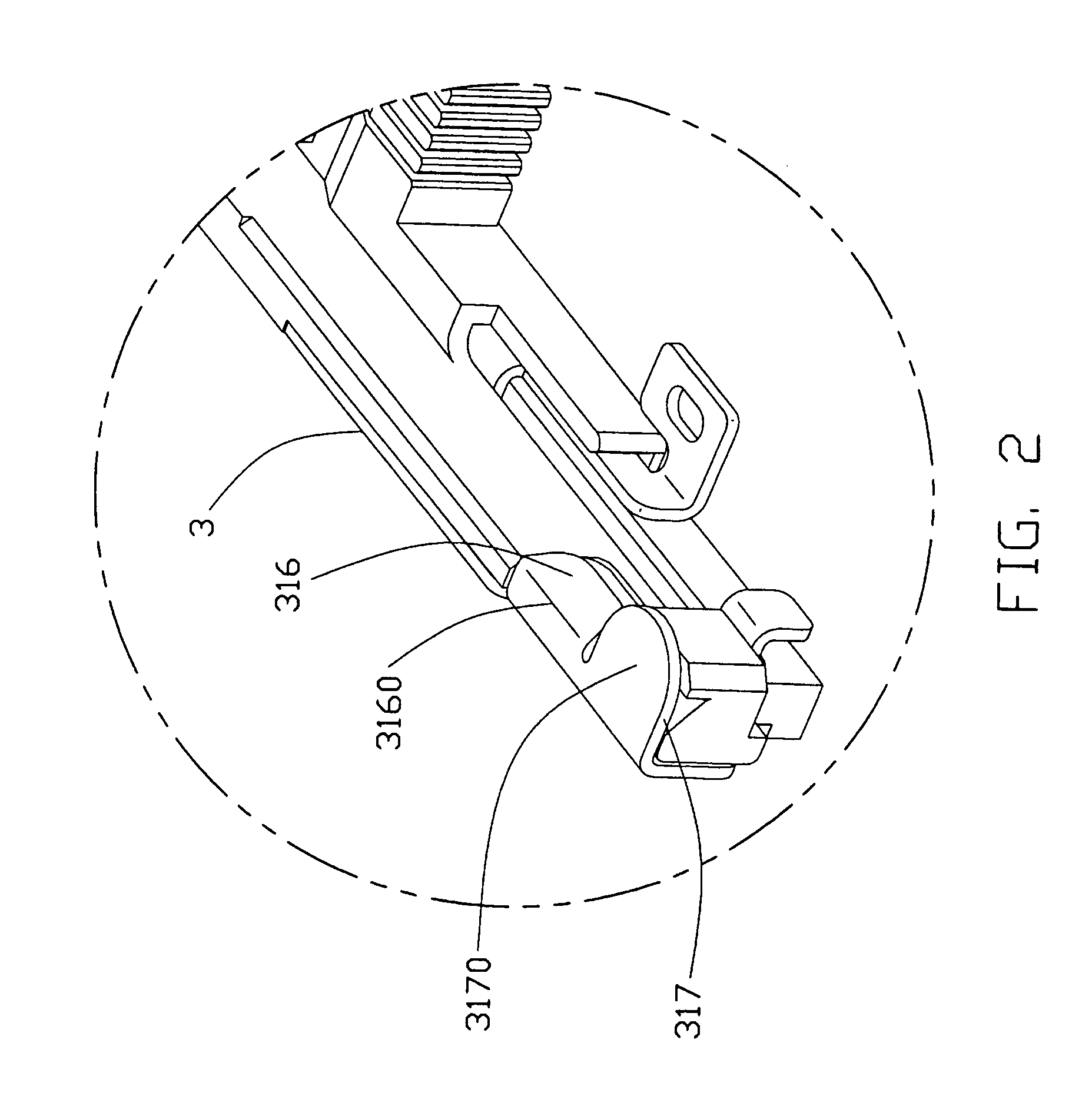

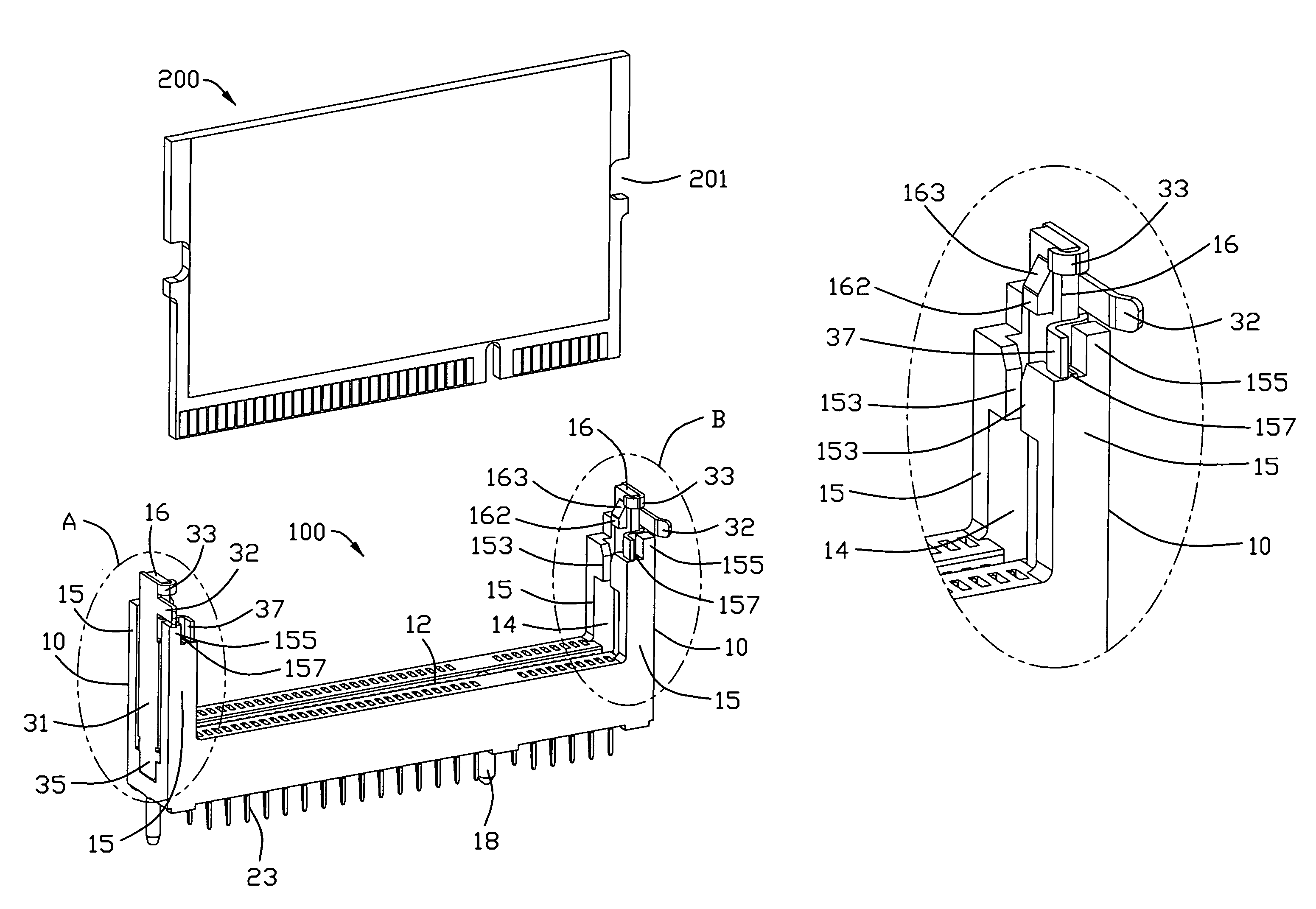

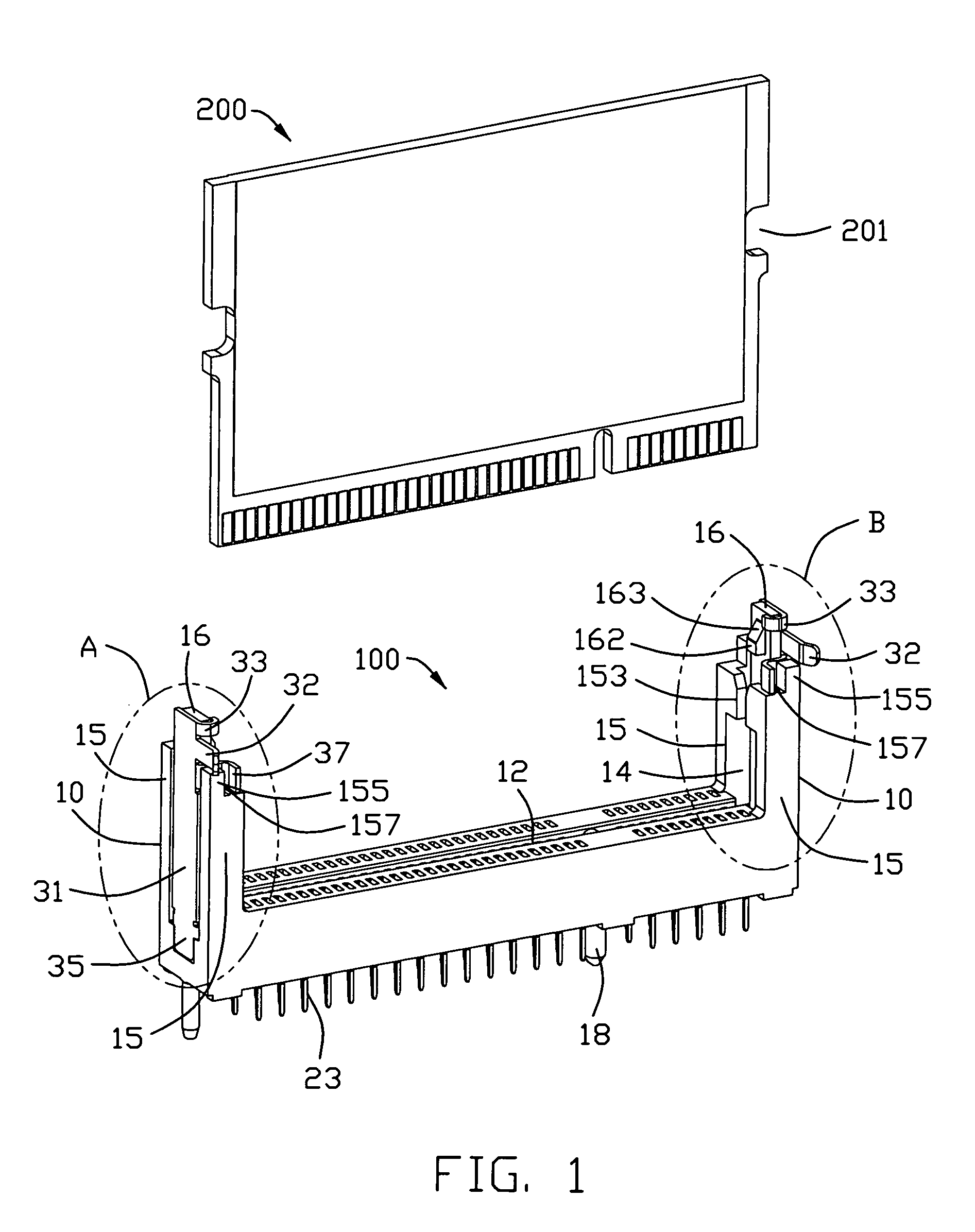

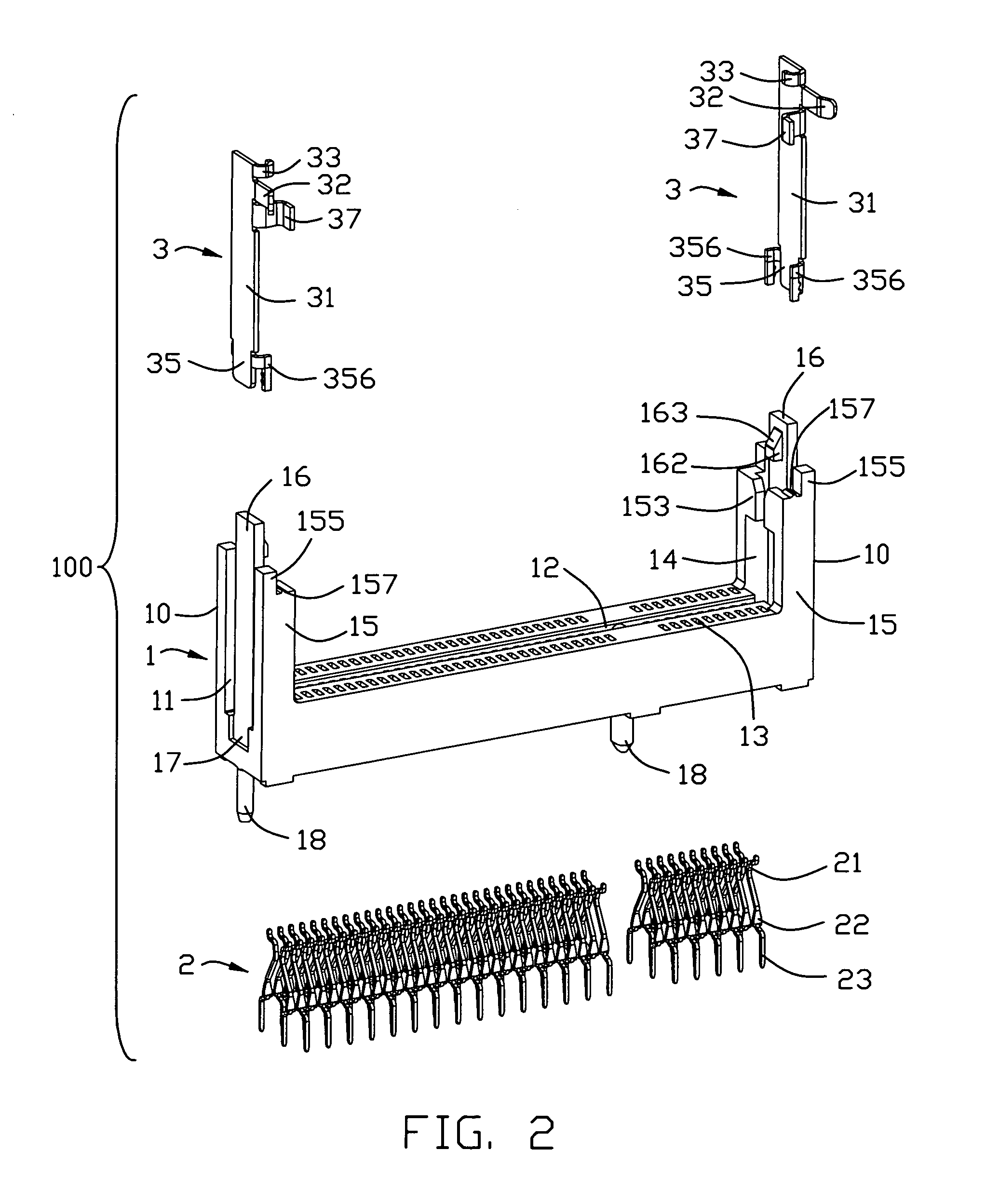

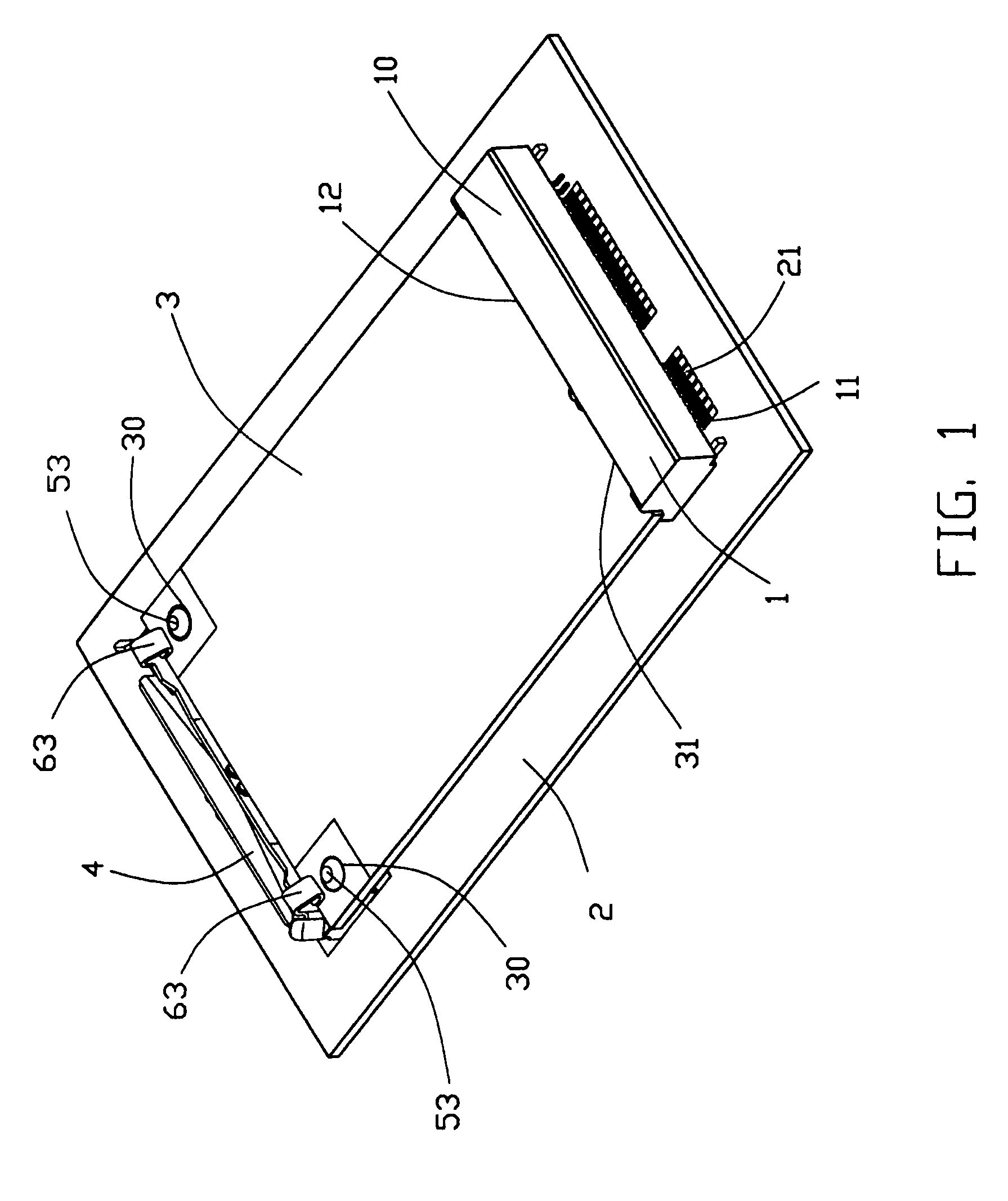

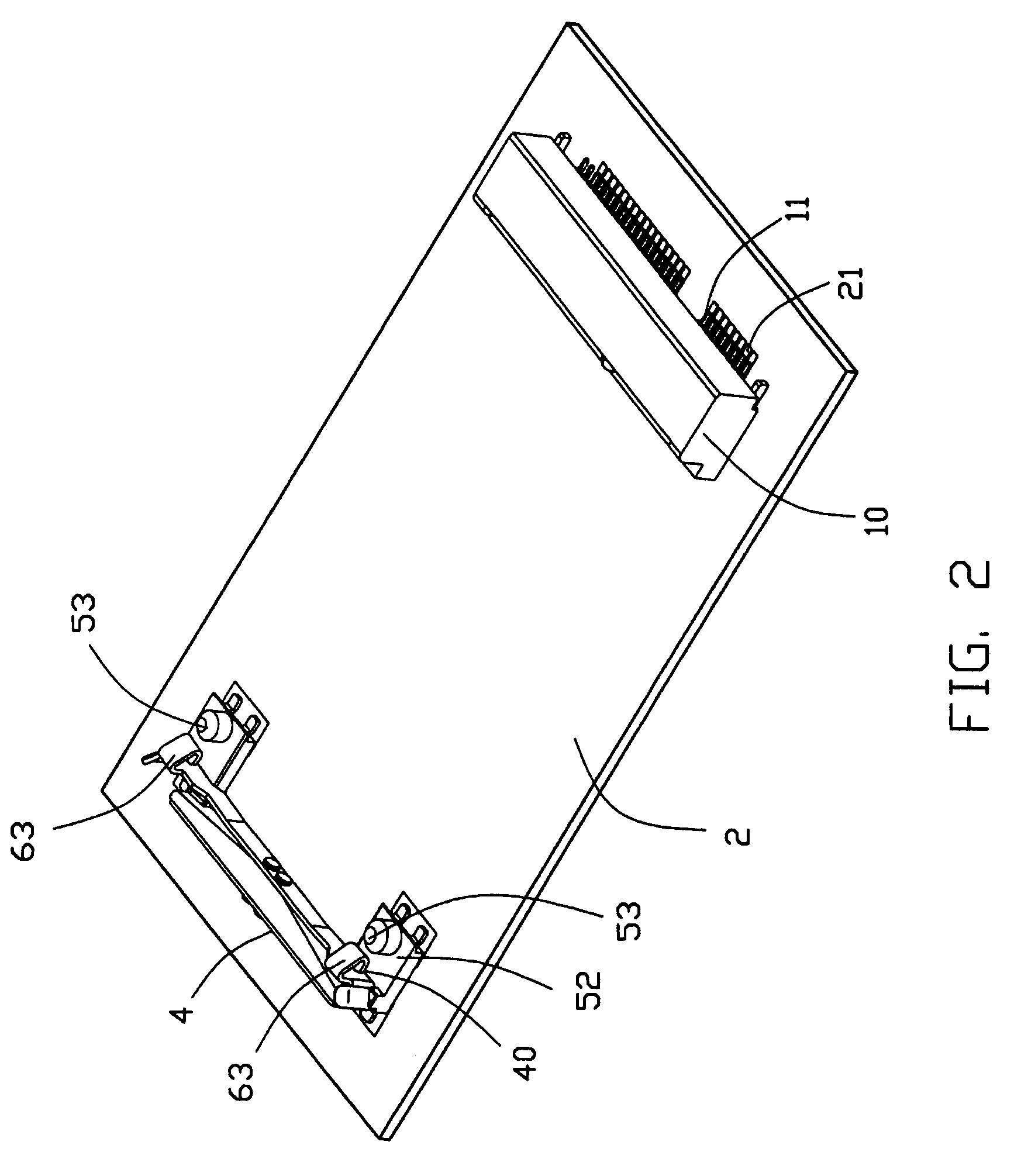

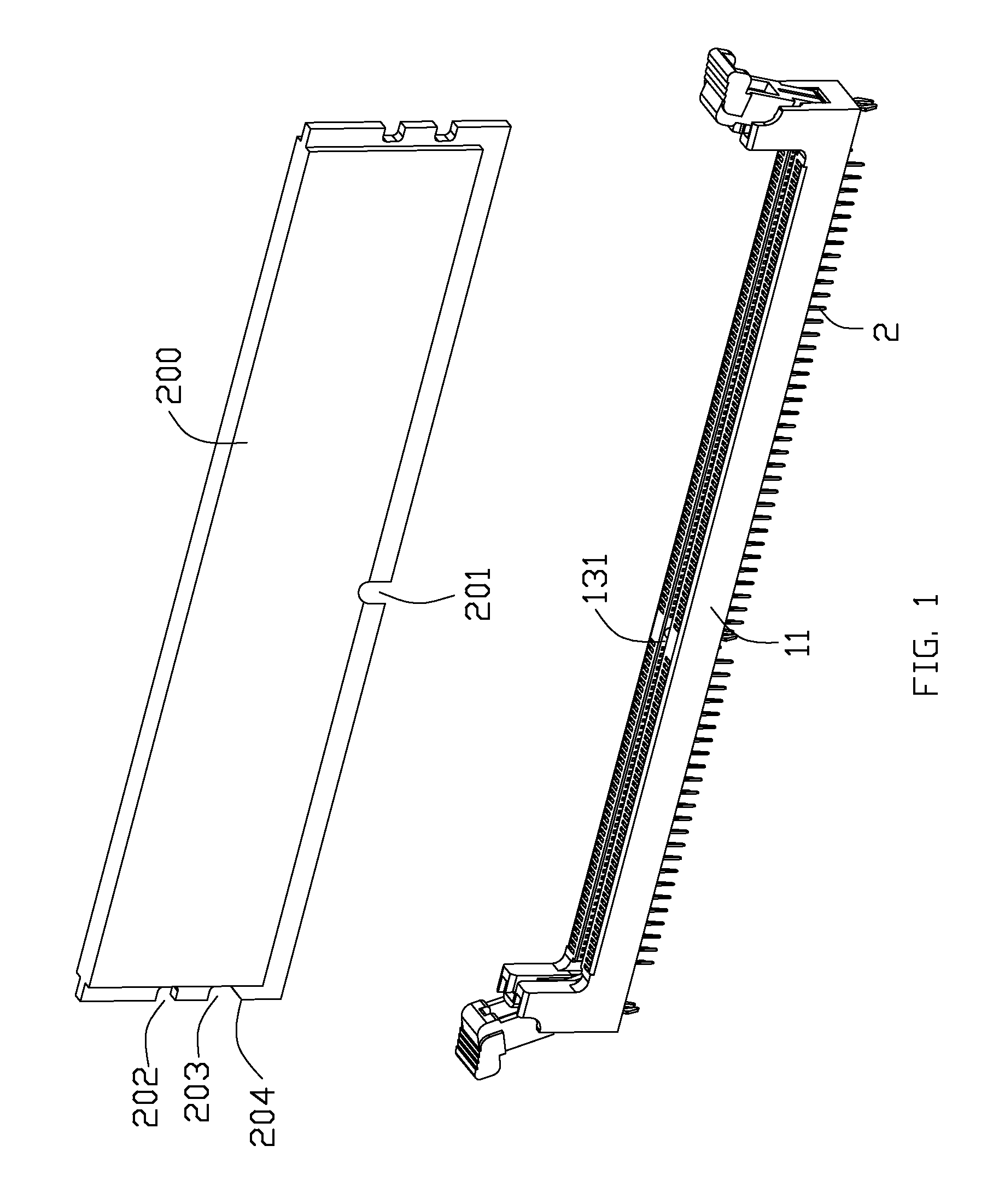

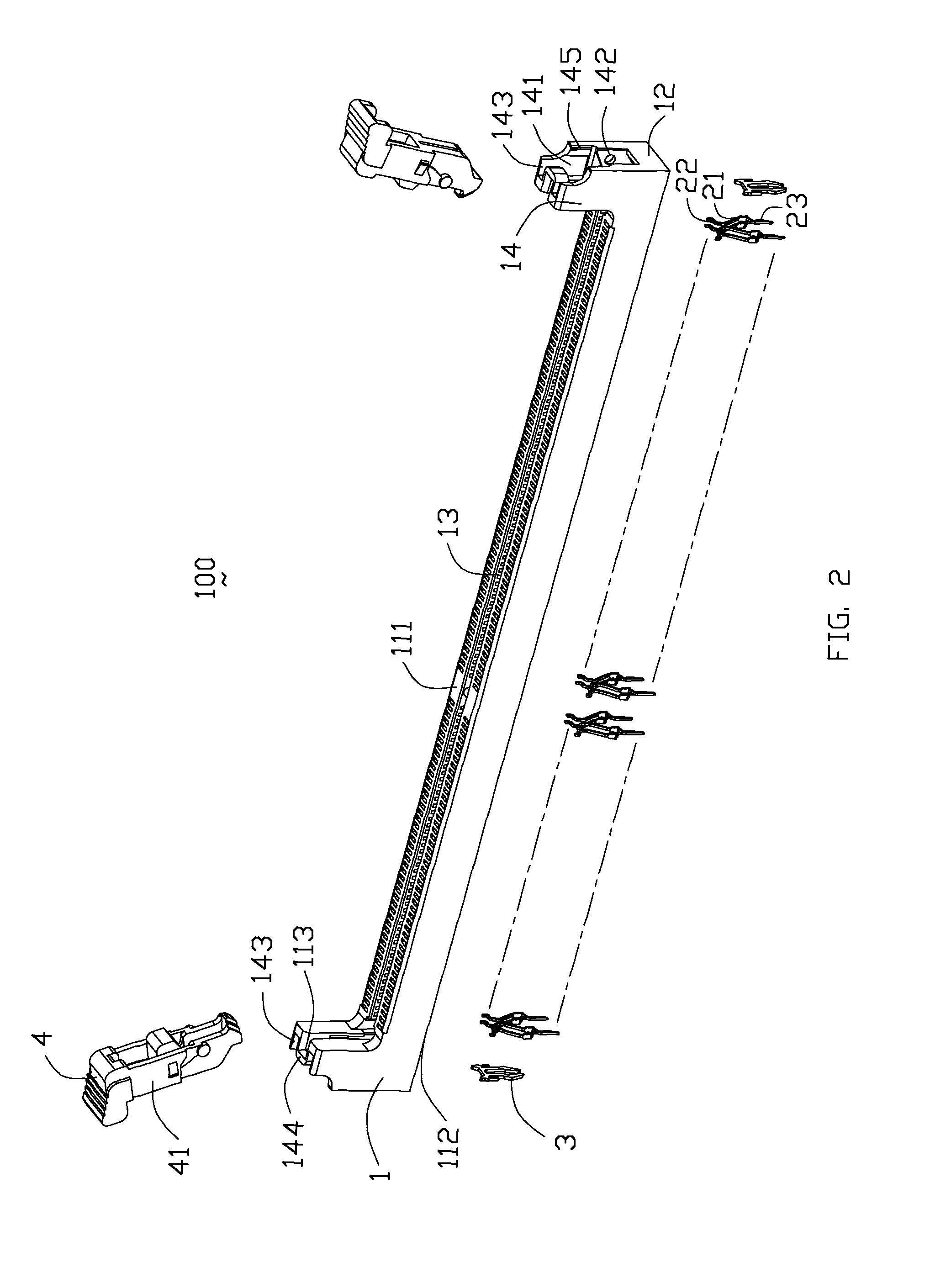

Card edge connector with latching arms

Owner:HON HAI PRECISION IND CO LTD

Card edge connector

ActiveUS8167631B2Reduce crosstalkInhibitionTwo-part coupling devicesCoupling protective earth/shielding arrangementsGround contactCrosstalk

The present invention provides a card edge connector as a high-speed differential signal connector configured to equalize electric potentials of ground contacts adjacent to signal line contacts, and thus to reduce crosstalk between adjacent signal line contacts. The card edge connector serves as a female connector in which multiple signal line contacts and multiple ground contacts are arranged in parallel in at least one row. In the card edge connector, the signal line contacts and the ground contacts are arranged in a way that every two signal line contacts for high-speed signals to send and return respectively therethrough are interposed between two ground contacts, and all of the multiple ground contacts arranged in the one row are electrically connected to one another by use of a common contact.

Owner:YAMAICHI ELECTRONICS

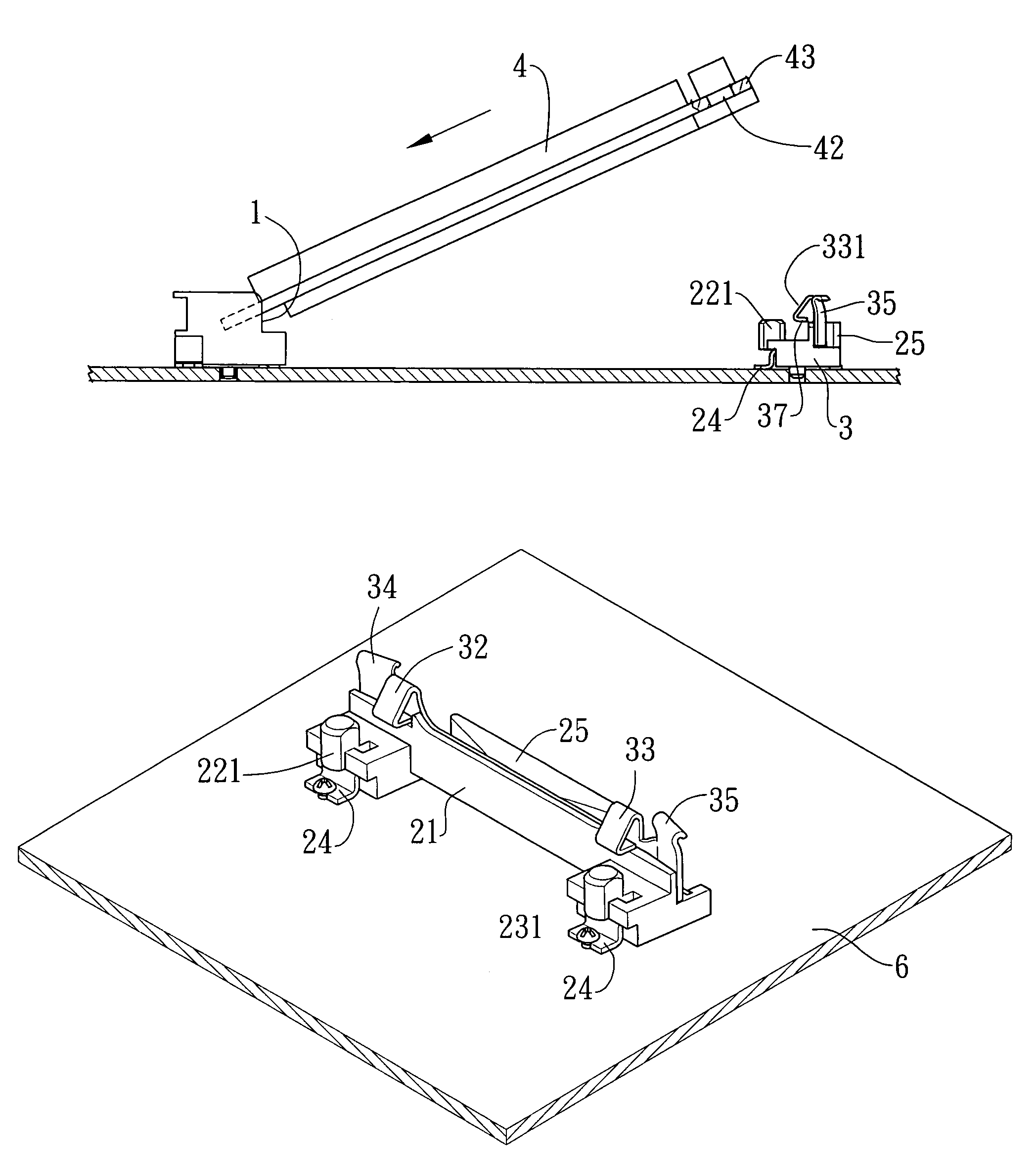

Card edge connector with a metallic reinforcement piece

A card edge connector (100) for receiving a module (200), includes an insulative housing (1) having a receiving slot (12) for receiving the module and a pair of arm portions (10) located at opposite ends thereof. Each arm portion has a pair of side walls (15) and a resilient arm (16) with a retaining embossment (162) for locking the module. The side walls are integrally formed on the insulative housing and include a projection (157). A number of terminals (2) are mounted on said insulative housing and extend into the receiving slot thereof. A pair of latches (3) are attached to the arm portions and move with the resilient arms. Each latch includes a base (31) and a stopping plate (37) extending from the base. The stopping plates engage with said projections of the side walls thereby open said resilient arms when the module detaches from the card edge connector.

Owner:HON HAI PRECISION IND CO LTD

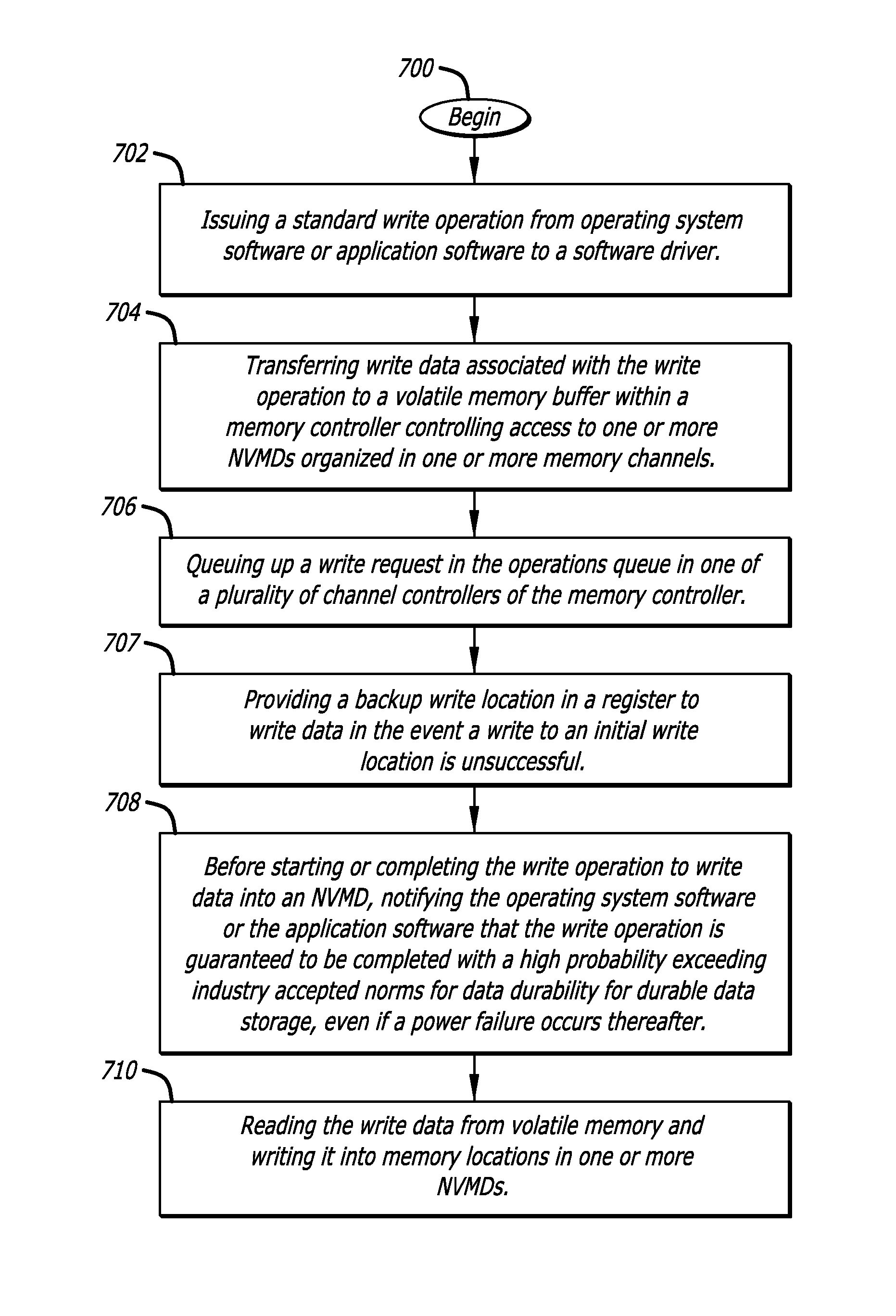

Methods for early write termination with non-volatile memory

ActiveUS8850091B1Memory architecture accessing/allocationError detection/correctionMemory controllerComputer science

In one embodiment of the invention, a memory apparatus for improved write performance is disclosed. The memory apparatus includes a base printed circuit board (PCB) having an edge connector for plugging into a host server system; a card level power source to provide card level power during a power failure; a memory controller coupled to the card level power source and having one or more memory channels; and one or more non-volatile memory devices (NVMDs) coupled to the card level power source and organized to respectively couple to the memory channels controlled by the memory controller. Each memory controller provides queuing and scheduling of memory operations on a channel for each NVMD in the memory channels. Responsive to power failure, the memory controller receives card level power and changes the scheduling of memory operations to the NVMDs in each memory channel.

Owner:WESTERN DIGITAL TECH INC

PC board assembly

InactiveUS7182618B1Shorten the timeSave moneyEngagement/disengagement of coupling partsClamping/extracting meansEdge connector

The latching mechanism includes an insulative fixing device, a metallic spring latching device and a metallic grounding device, wherein the fixing device includes the card supporting portion and a positioning post upwardly extending therefrom corresponding to the positioning hole of the electronic card. The latching device includes a connection portion connected to the fixing device, the spring arm extending from the connection portion and the hook portion located on the spring arm and extending toward the card edge connector for locking the rear portion of the electronic card. The grounding device is electrically connected to the latching device and includes mounting legs mechanically and electrically engaged with the corresponding grounding pads formed on the printed circuit board for grounding.

Owner:HON HAI PRECISION IND CO LTD

Card edge connector

A card edge connector for receiving a module and includes an insulative housing having a mounting face, a pair of side walls with a central slot formed therebetween, a tower portion extending upwardly from the side wall; a number of contacts mounted to the housing and each defining a retaining portion to fix with the housing, a deflectable contacting arm extending upwardly from the retaining portion and a soldering portion extending downwardly from the retaining portion and projecting beyond the mounting face; and an ejector rotatably mounted on the tower portion of the housing. The ejector includes a base portion, an ejecting portion extending inwardly from the base portion and protruding into the central slot to eject the memory module from the central slot and a cam lobe extending inwardly from the base portion to drive the module down, the cam lobe is located above the ejecting portion.

Owner:HON HAI PRECISION IND CO LTD

Card edge connector

ActiveUS8231411B1Coupling protective earth/shielding arrangementsConnection contact member materialGround contactEngineering

A card edge connector is provided for mating with a printed circuit board (PCB) having a card edge. The connector includes a housing having an elongate card slot and a mounting side. The card slot extends a slot length and is configured to receive the card edge of the PCB therein. The mounting side extends a side length and a width. The side length of the mounting side extends in a direction that extends along a direction of the slot length of the card slot. Signal contacts are held by the housing. The signal contacts include first signal contacts and second signal contacts. The first and second signal contacts have respective first and second signal mounting segments that are arranged in first and second signal rows, respectively, that extend along the side length of the mounting side of the housing. The first and second signal rows are spaced apart from each other along the width of the mounting side. Ground contacts are held by the housing. The ground contacts include ground mounting segments arranged in a ground row that extends along the side length of the mounting side. The ground row extends between the first and second signal rows along the width of the mounting side of the housing.

Owner:TE CONNECTIVITY CORP

Connector for connecting printed circuit boards

InactiveUS20050009382A1High signal line densityPromote exchangeCoupling contact membersPrinted circuitsElectrical conductorBand shape

In order to produce an electric connection between at least two printed circuit boards, the invention proposes a connector with a mating side and a terminal side, in which an arrangement of several support members is provided in a housing. Spherical contacts for realizing the electric contacting of the strip conductors are arranged in said support members. At least one first support member is rigidly connected to a base circuit board with a terminal side while at least one second support member with a mating side is provided for inserting an edge-connector circuit board therein. The electric connection between the two support members is realized with strip conductors that are applied on a flexible conductive foil and contacted by the spherical contacts.

Owner:WHITE BOX +1

Detachable on package voltage regulation module

InactiveUS20050093120A1Semiconductor/solid-state device detailsVolume/mass flow measurementVoltage regulationEngineering

An integrated circuit (IC) package that includes an on-package voltage regulation module (VRM). An IC die is flip-bounded to a substrate having a plurality of connections to couple to a socket or to be mounted directly to a circuit board. An integrated heat spreader (IHS) is thermally coupled to the IC die and coupled (both electrically and mechanically) to the substrate. A VRM is coupled to the IHS. The IHS, which serves as an interconnect member, includes interconnect provisions for electrically coupling the VRM to the substrate. In one embodiment, the body of the IHS serves as a ground plane, while a separate interconnect layer includes electrical traces for routing electrical signals between the VRM and substrate. The VRM may comprise a detachable package that is coupled to the IHS via one of several means including fasteners, edge connectors and a parallel coupler.

Owner:INTEL CORP

PCB bridge connector for connecting PCB devices

InactiveUS8118611B2Shipping and repairing an IR touch sensor frame using four PCB frame sections is easier and less expensiveCoupling device connectionsPrinted circuit aspectsElectrical conductorEdge connector

A bridge connector made of PCB material has a first plurality of press-fit pins on one portion of the bridge connector and a second plurality of press-fit pins on another portion of the bridge connector. Within the connector is a set of signal conductors. Each conductor connects a press-fit pin of the first plurality of press-fit pins to a corresponding press-fit pin of the second plurality of press-fit pins. When the connector is attached to a printed circuit board (PCB), the press-fit pins extend into and engage corresponding plated through holes in the PCB. The press-fit pins exert enough retention force to mechanically couple two PCB frame sections. The PCB frame sections are electrically connected through the press-fit pins and corresponding signal conductors of the bridge connector. A bridge connector attached at each corner of an infrared touch sensor frame assembly allows the assembly to be solidly assembled from four sections of PCB: a top, bottom, left, and right PCB frame section.

Owner:CNPLUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com