Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1639results about How to "Fast shipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

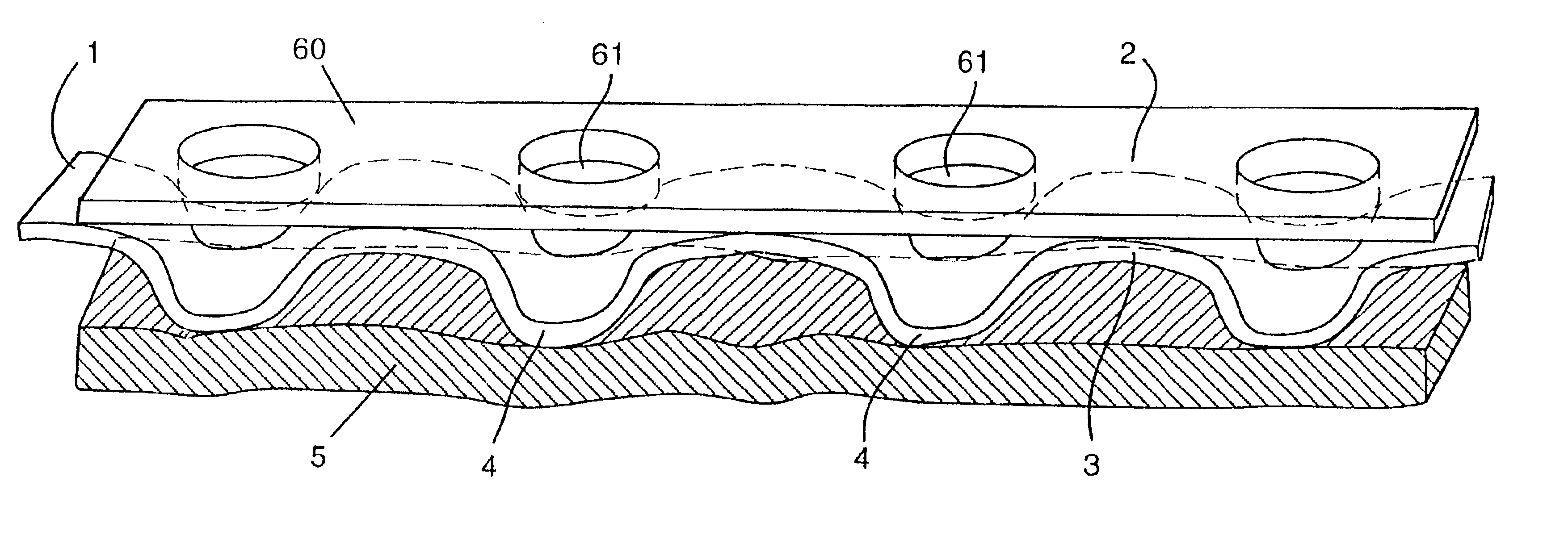

Dual-zoned absorbent webs

InactiveUS6911573B2Fast shippingImprove adaptabilityNatural cellulose pulp/paperMechanical working/deformationCelluloseEngineering

The present invention is a method for producing an absorbent article. A wet resillient, cellulosic basesheet having elevated and depressed regions with an Overall Surface Depth of at least 0.2 mm is prepared. The cellulosic basesheet has an upper surface and a lower surface. A contiguous, fibrous nonwoven web having a plurality of openings is integrally attached onto the upper surface of the cellulosic basesheet such that a portion of the openings are superposed over the depressed regions of the cellulosic basesheet. An absorbent core and an impervious web are attached to the lower surface of the cellulosic basesheet such that the absorbent core is sandwiched between the impervious web and the cellulosic basesheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

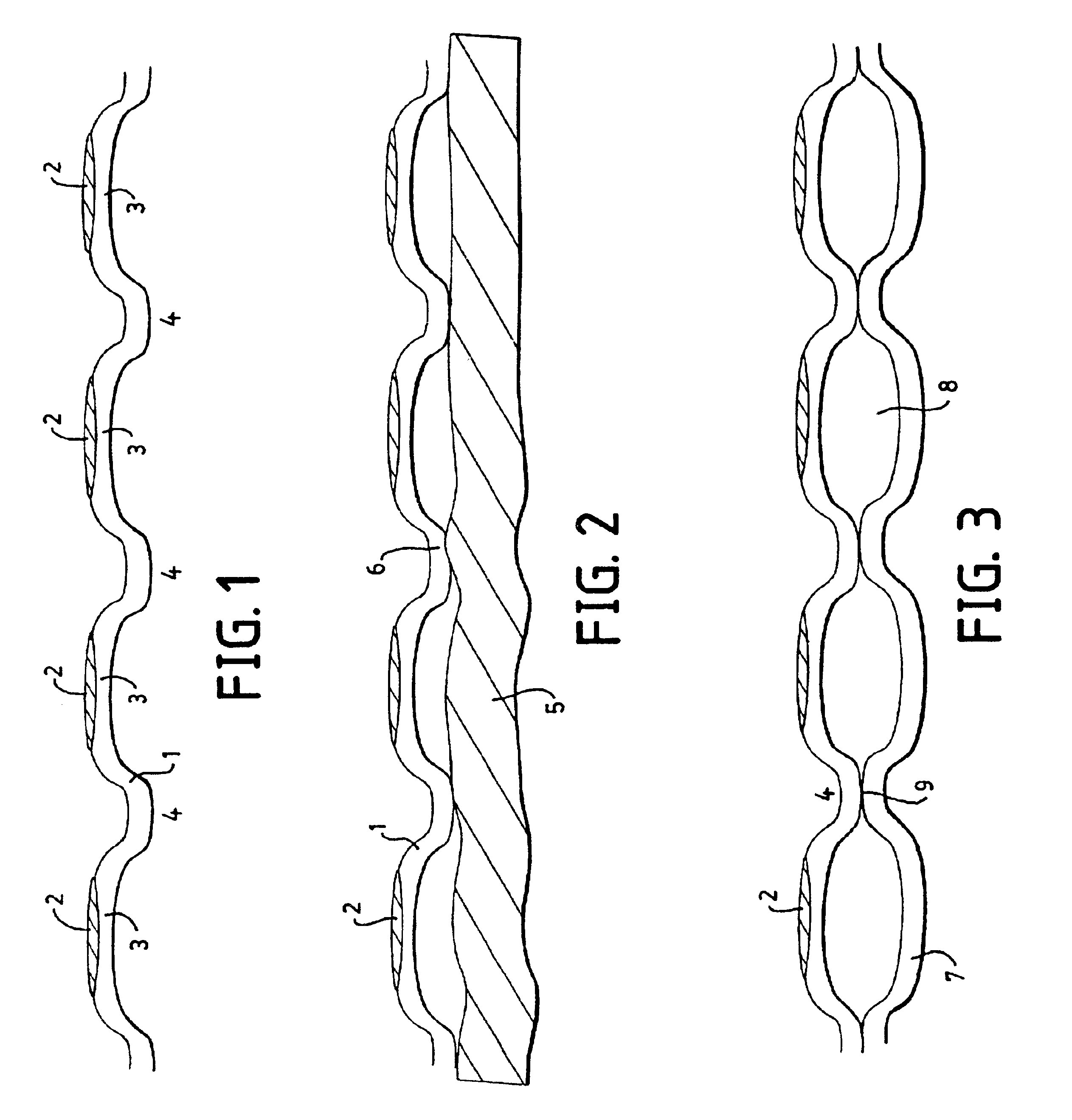

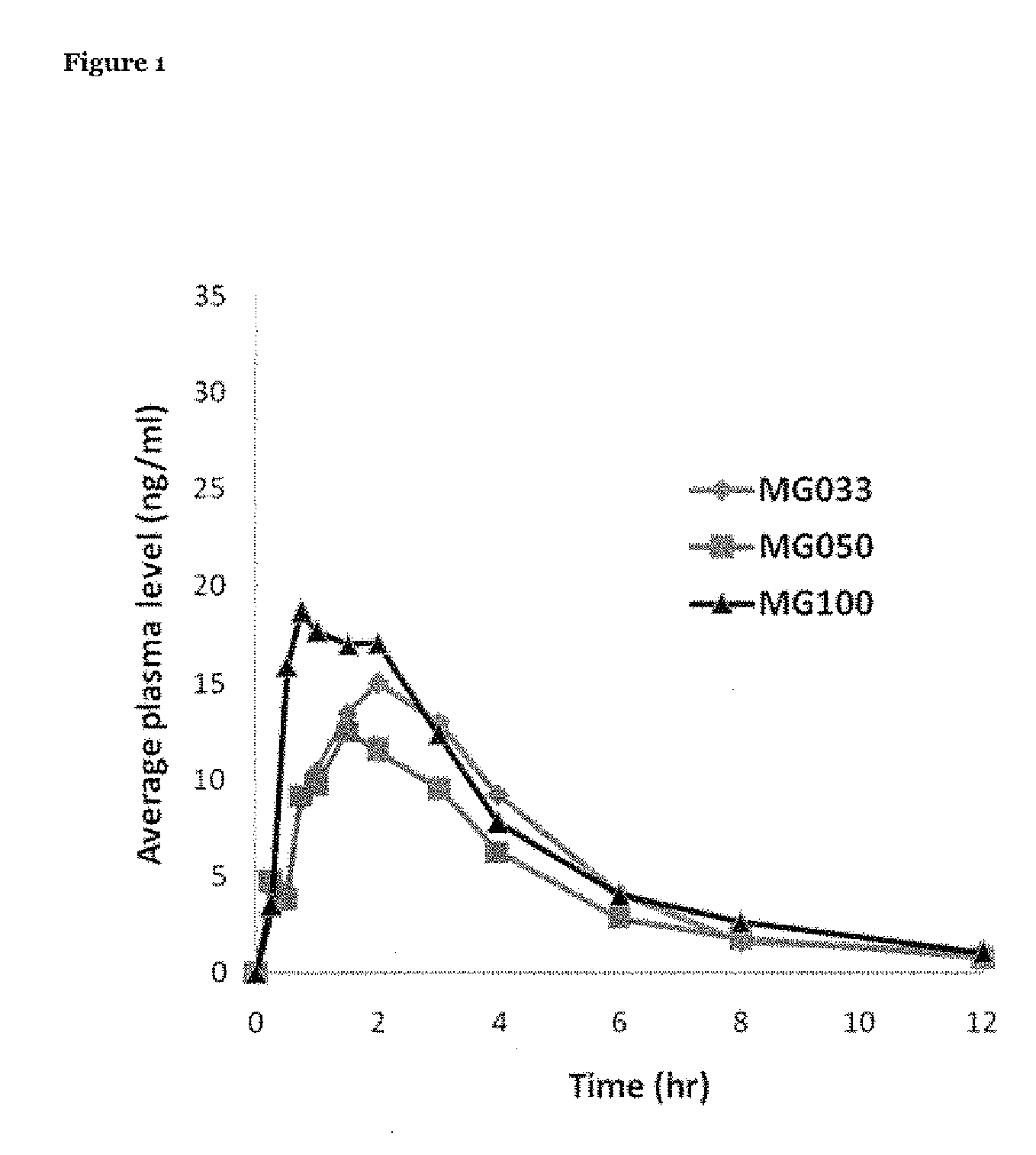

Dosage Form For Insertion Into The Mouth

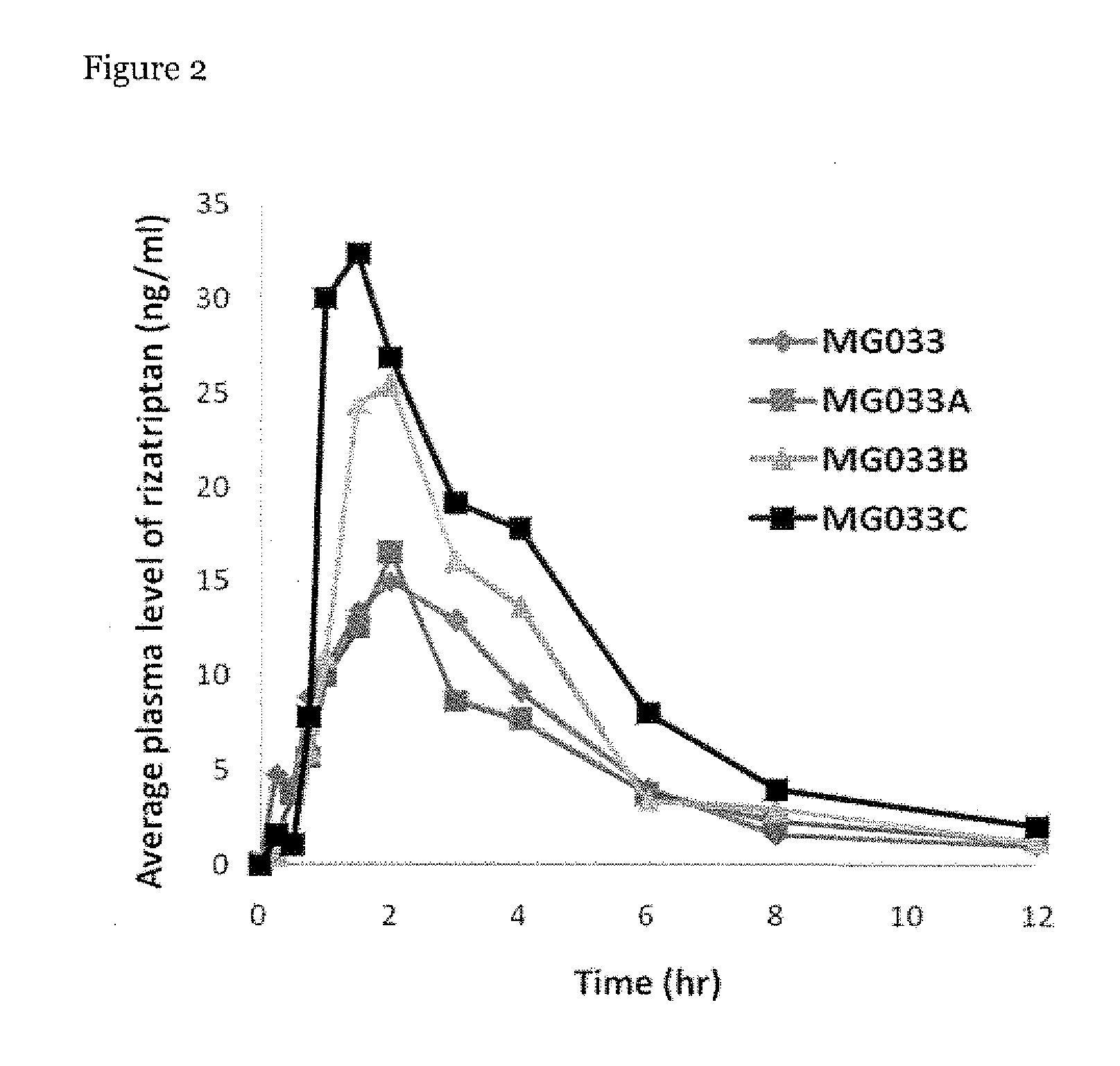

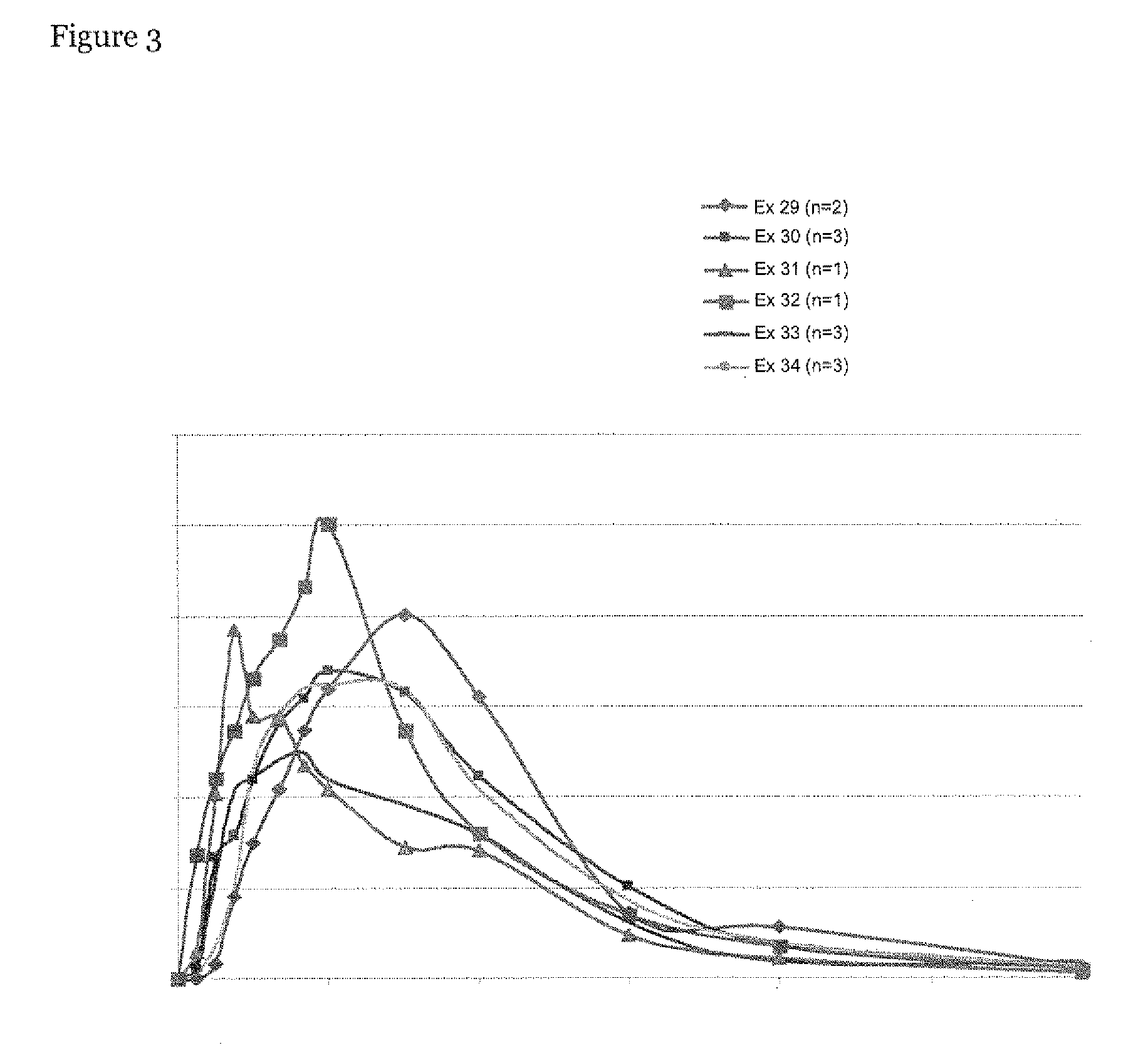

InactiveUS20100112050A1Efficient deliveryImproved bioavailability and deliveryPowder deliveryBiocideActive agentMigraine

Oral dosage forms as a biodegradable, water soluble film for delivering pharmaceutically active agents, particularly anti-migraine agents to patients through insertion into the mouth of patient and methods for administering pharmaceutically active agents to patients by insertion into the mouth to provide selective uptake of said agents through the mucosa and thus avoiding the gastrointestinal tract.

Owner:NAL PHARM LTD

Electric double layer capacitor

InactiveUS6466429B1Lower internal resistanceInhibit sheddingHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonLead dioxide

The present invention is directed to a novel capacitor. The capacitor may be used in electric double layer capacitors. The capacitors include a polarizable electrode including activated carbon and a non-polarizable electrode including lead dioxide and lead sulfate. The capacitors of the present invention provide considerably higher electric capacity, higher durability, and low resistance, while maintaining high conductivity. Additionally, the electrodes may be produced more quickly and inexpensively.

Owner:WAINWRIGHT D WALKER

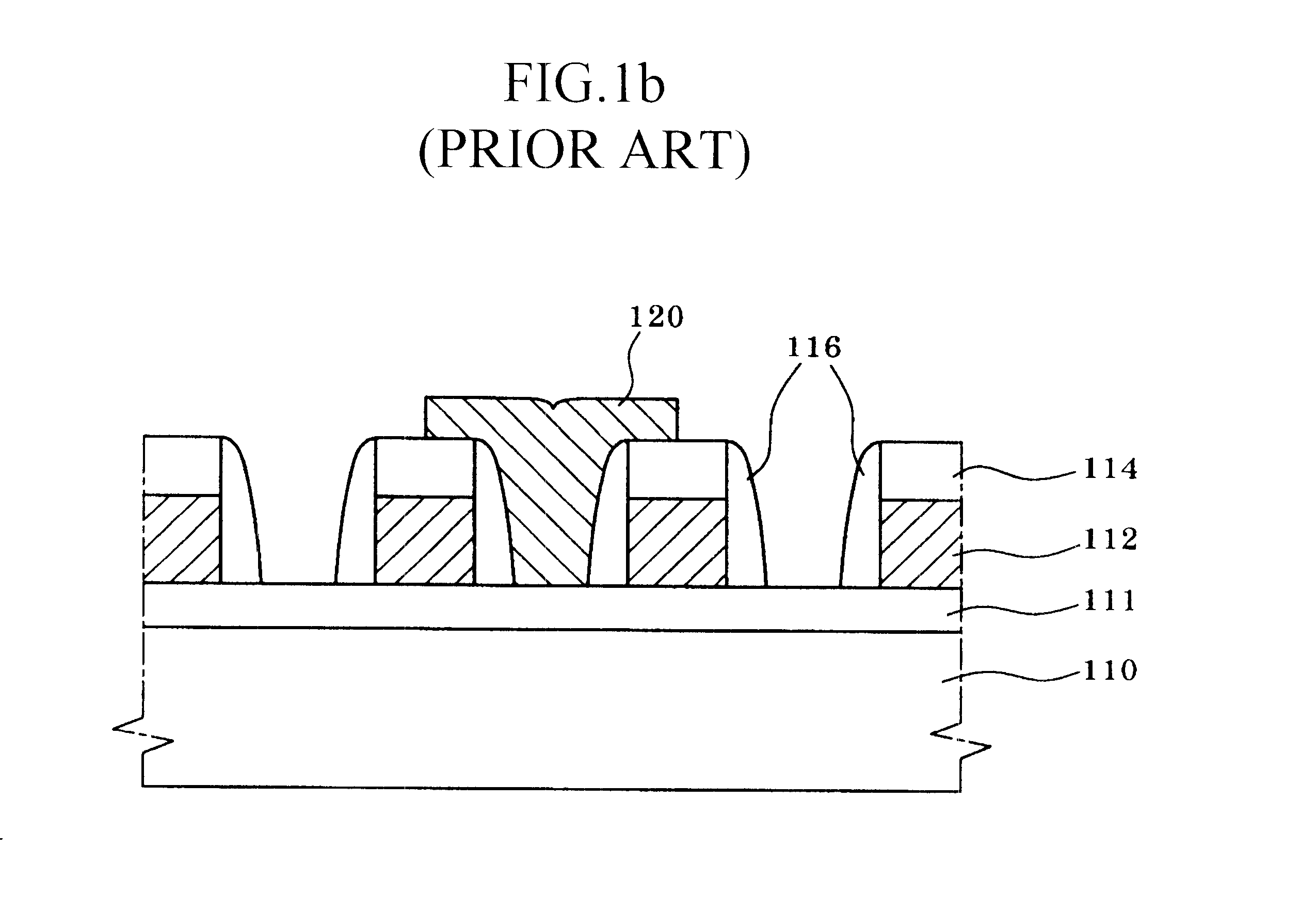

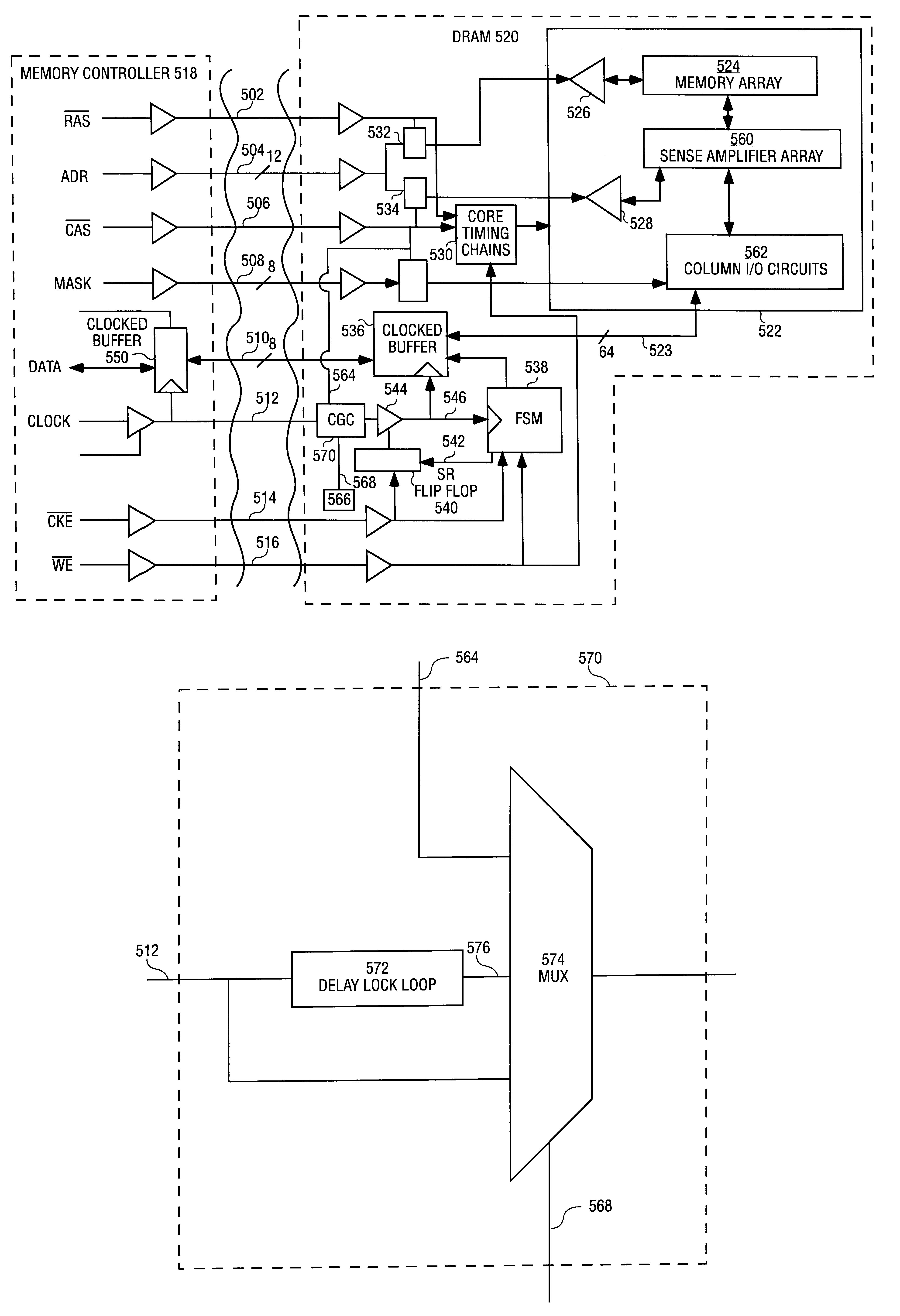

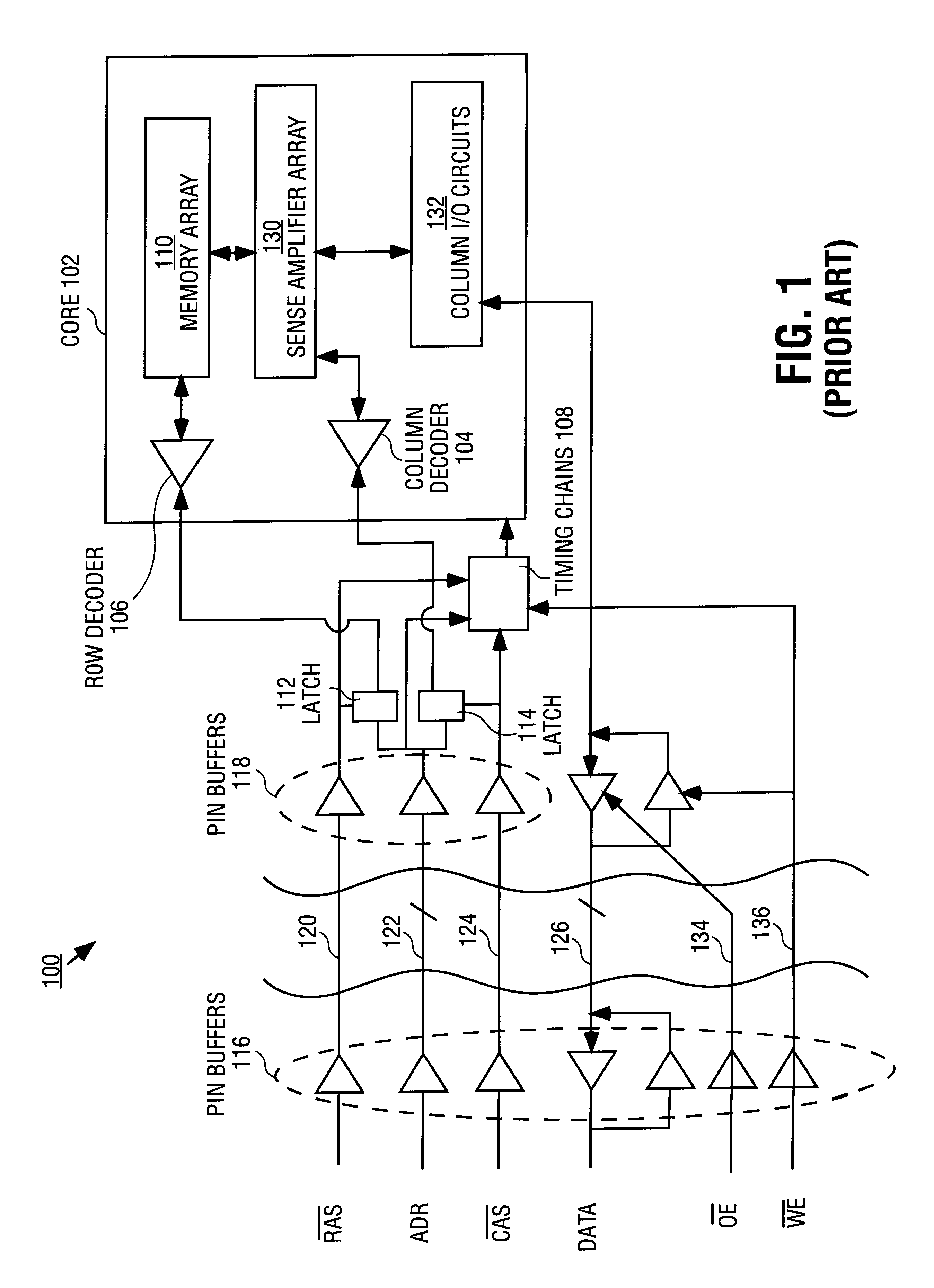

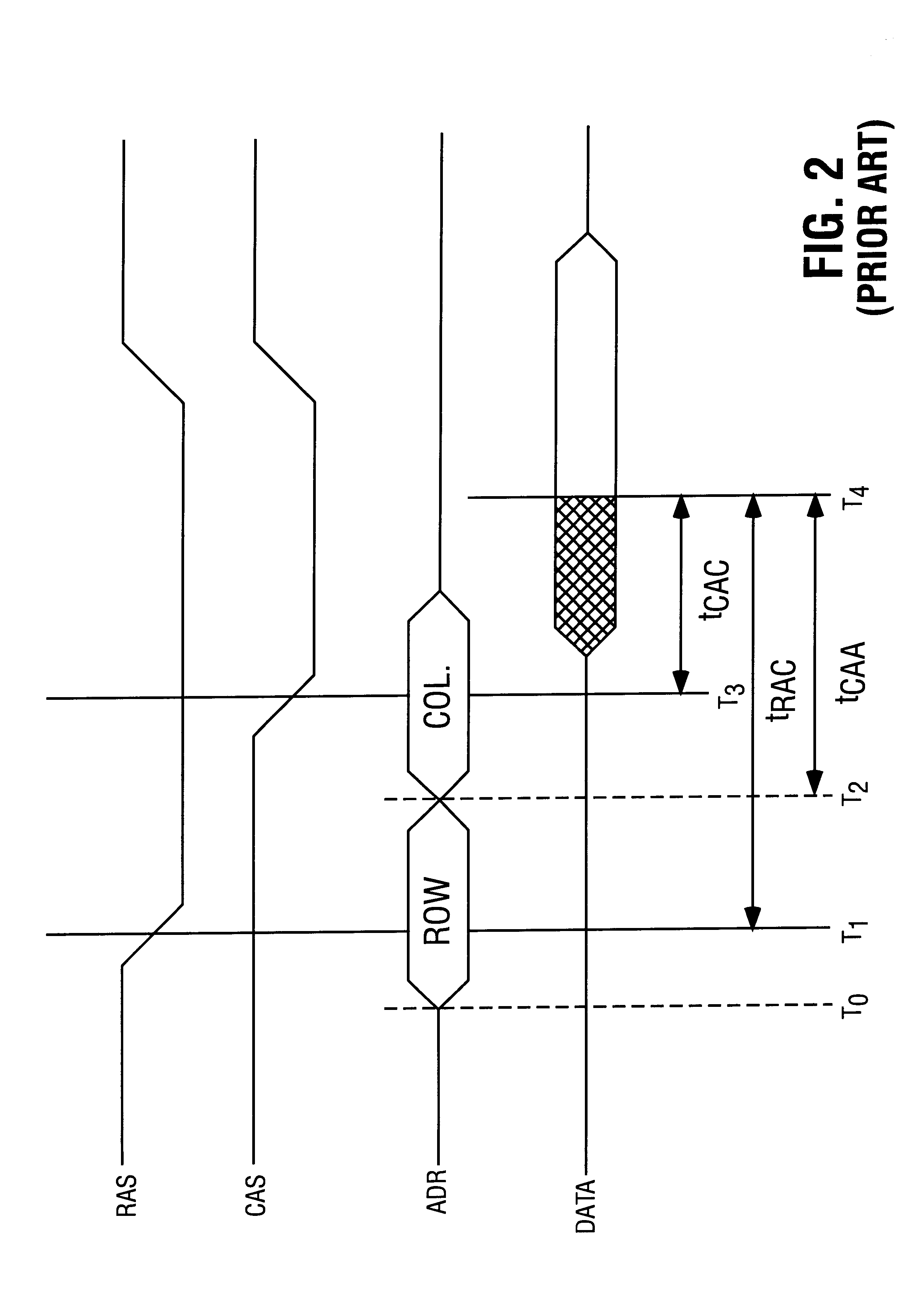

Asynchronous request/synchronous data dynamic random access memory

InactiveUS6209071B1Improve balanceReducing latency and power requirementEnergy efficient ICTDigital storagePower modeAsynchronous circuit

A method and system for transferring information within a computer system is provided. The system includes a memory device that has a lower power mode in which data transfer circuitry is not driven by a clock signal, and a higher power mode in which data transfer circuitry is driven by a clock signal. The system further includes a memory controller that sends control signals to the memory device to initiate a data transfer transaction. The memory device receives the control signals asynchronously, and assumes the second mode in response to one of the control signals. While the memory device is in the second mode, the memory controller sends a control signal to identify a particular clock cycle. The memory device synchronously transfers the data. The memory device determines when to begin the data transfer based on the identified clock cycle and the type of data transfer that has been specified.

Owner:RAMBUS INC

Adhesive bioerodible transmucosal drug delivery system

InactiveUS20070207192A1Suitable bioadhesive capabilityRapid onsetAntibacterial agentsBiocideWhole bodyIrritation

The present invention is directed to a mucoadhesive delivery system for the local or systemic administration of a pharmaceutical agent. The delivery system of the invention effectively and facilely enables transport of the pharmaceutical agent through mucosal membranes and into the vasculattire of the mucosa. The delivery system includes an at least partially water soluble bioadhesive layer and an at least partially water soluble backing layer. Incorporated within either or both of these layers are the pharmaceutical agent and a mucosal penetration enhancing agent. The mucosal penetration enhancing agent displays localized tissue irritation properties. The mucoadhesive delivery system may be in the form of a gel, film, disc or patch. It may be applied to any mucosal membrane of a patient including but not limited to those of the buccal and nasal cavities, throat, eye, vagina, alimentary tract and peritoneum.

Owner:ARIUS TWO

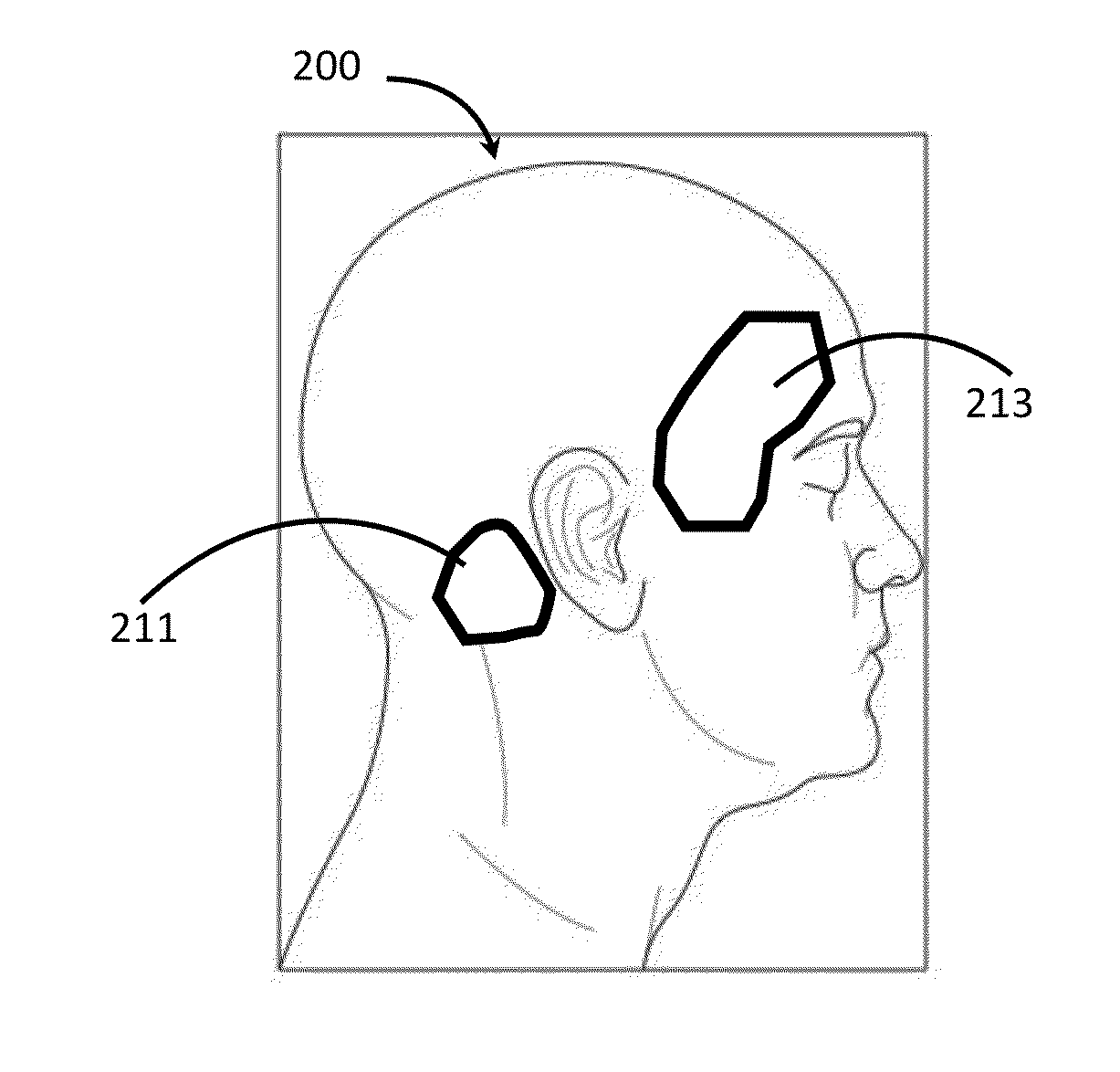

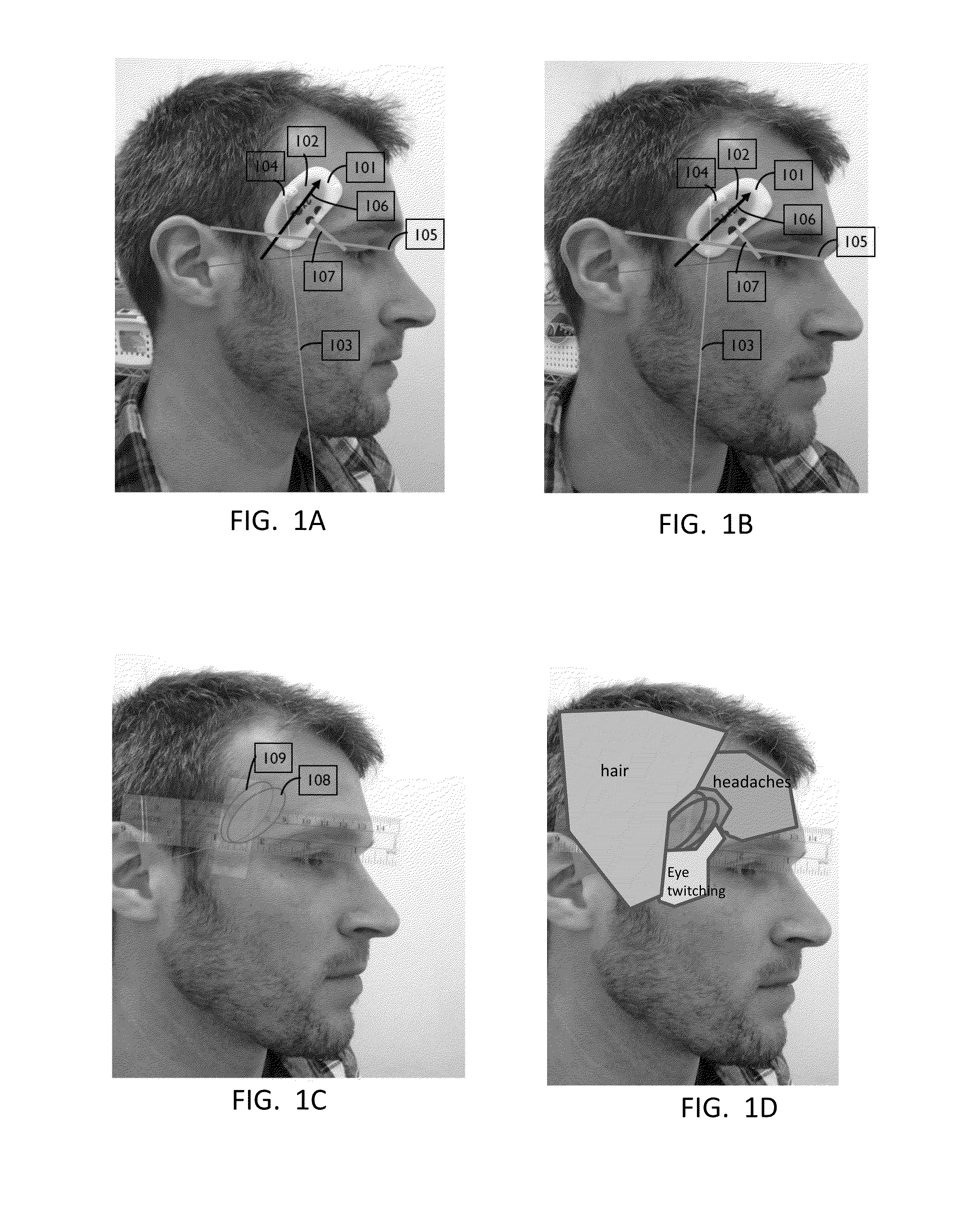

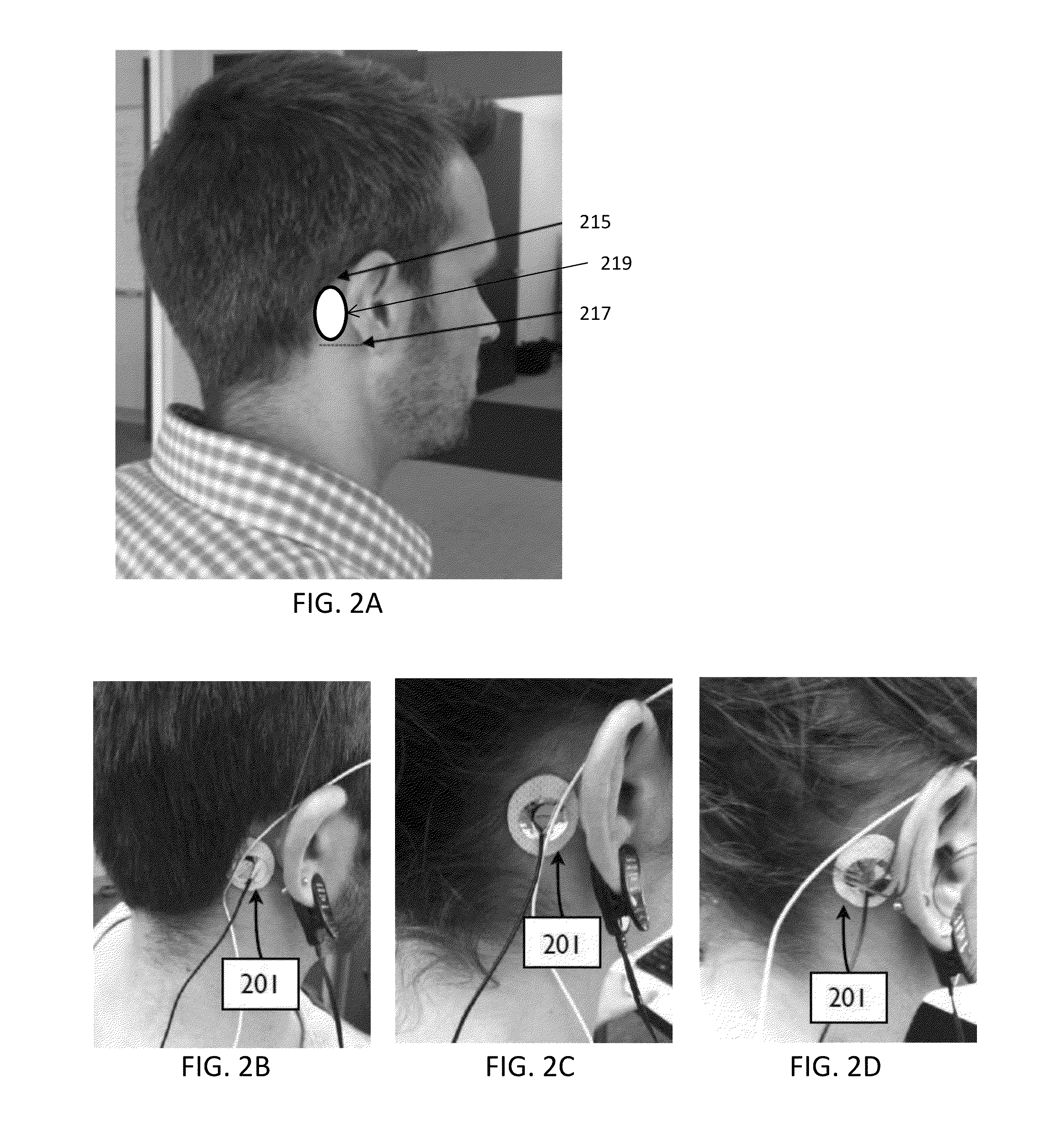

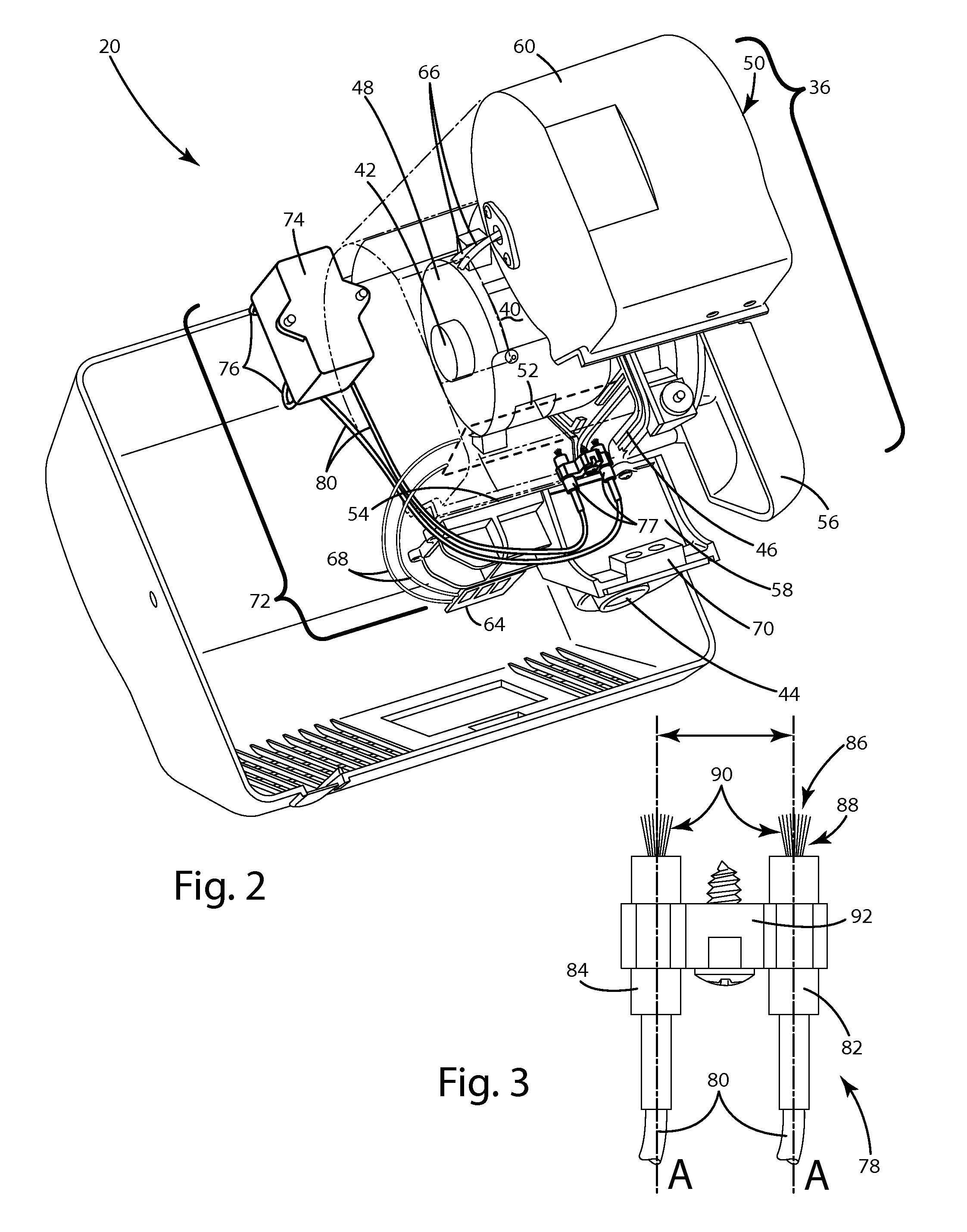

Transdermal electrical stimulation devices for modifying or inducing cognitive state

InactiveUS20150005841A1Quick transitionIncrease heightExternal electrodesArtificial respirationElectricityComputer module

Portable transdermal electrical stimulation (TES) applicators for modifying a subject's cognitive state. In general, the portable applicators described are specifically configured and adapted to be lightweight and may be wearable, and to deliver a high-intensity TES able to evoke or enhance a predetermined cognitive effect. These TES applicators may include a pair of electrodes and a TES control module comprising a processor, a timer and a waveform generator. TES control module is adapted to deliver a biphasic electrical stimulation signal of 10 seconds or longer between the first and second electrodes having a frequency of 400 Hz or greater, a duty cycle of greater than 10 percent, an intensity of 3 mA or greater, with a DC offset.

Owner:THYNC GLOBAL INC

Apparatus and processes for the mass production of photovoltaic modules

InactiveUS20050158891A1Time stableImprove throughputPolycrystalline material growthSemiconductor/solid-state device manufacturingAbrasive blastingVacuum pressure

An apparatus and processes for large scale inline manufacturing of CdTe photovoltaic modules in which all steps, including rapid substrate heating, deposition of CdS, deposition of CdTe, CdCl2 treatment, and ohmic contact formation, are performed within a single vacuum boundary at modest vacuum pressures. A p+ ohmic contact region is formed by subliming a metal salt onto the CdTe layer. A back electrode is formed by way of a low cost spray process, and module scribing is performed by means of abrasive blasting or mechanical brushing through a mask. The vacuum process apparatus facilitates selective heating of substrates and films, exposure of substrates and films to vapor with minimal vapor leakage, deposition of thin films onto a substrate, and stripping thin films from a substrate. A substrate transport apparatus permits the movement of substrates into and out of vacuum during the thin film deposition processes, while preventing the collection of coatings on the substrate transport apparatus itself.

Owner:COLORADO STATE UNIVERSITY

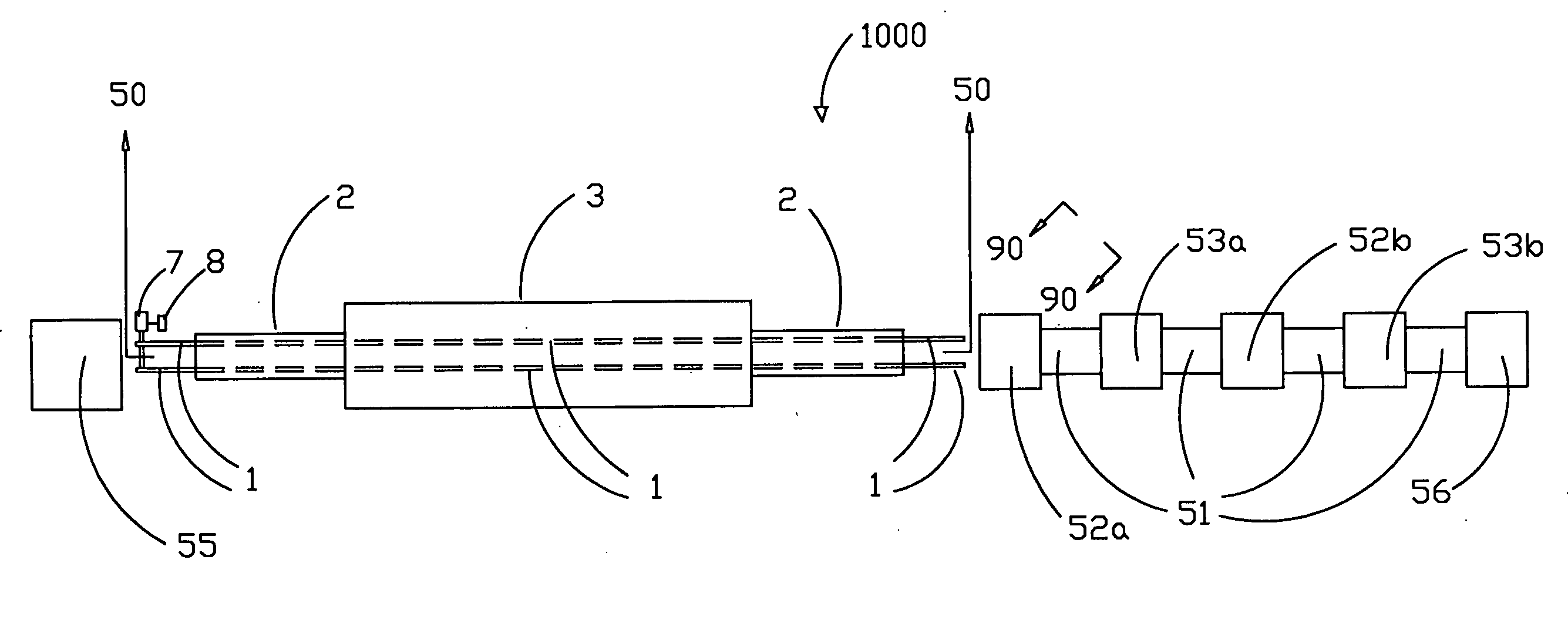

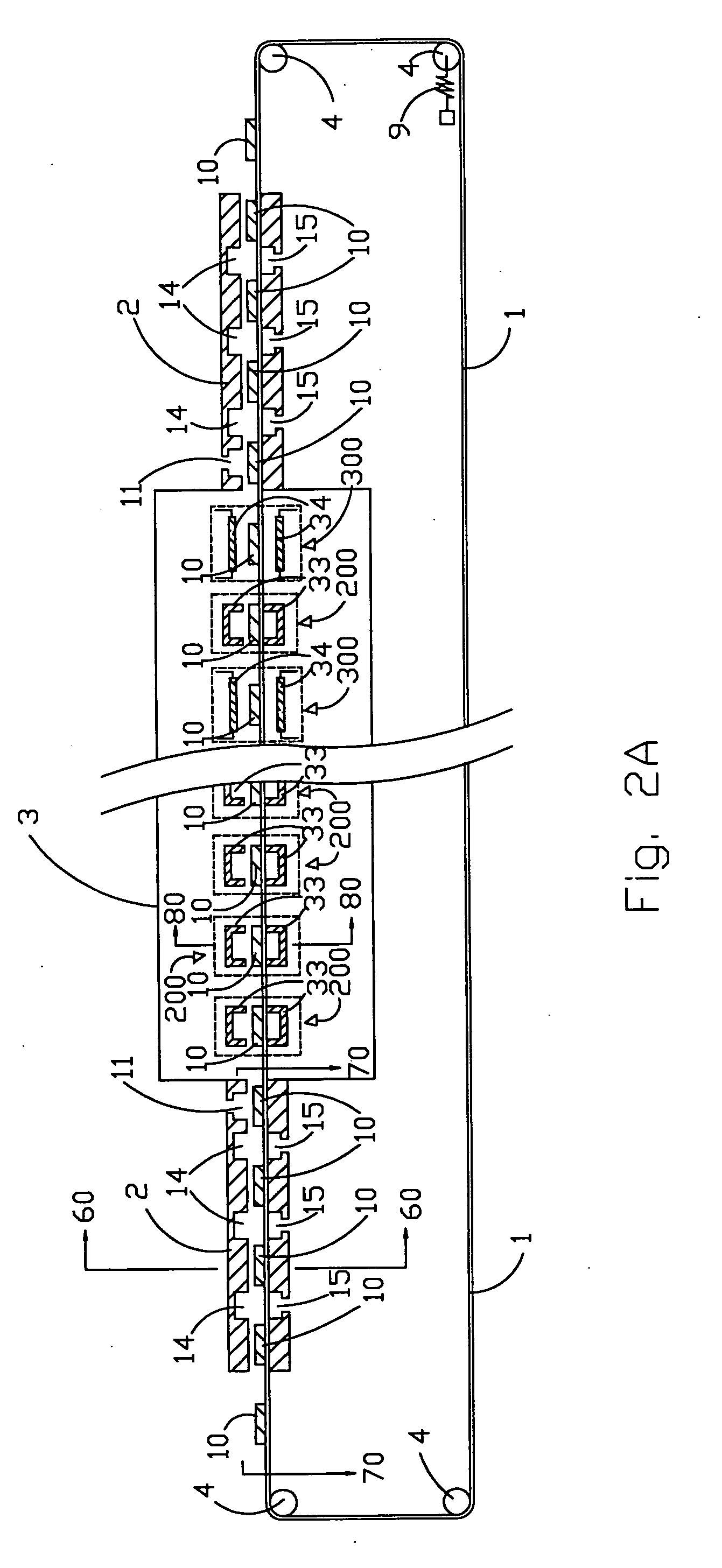

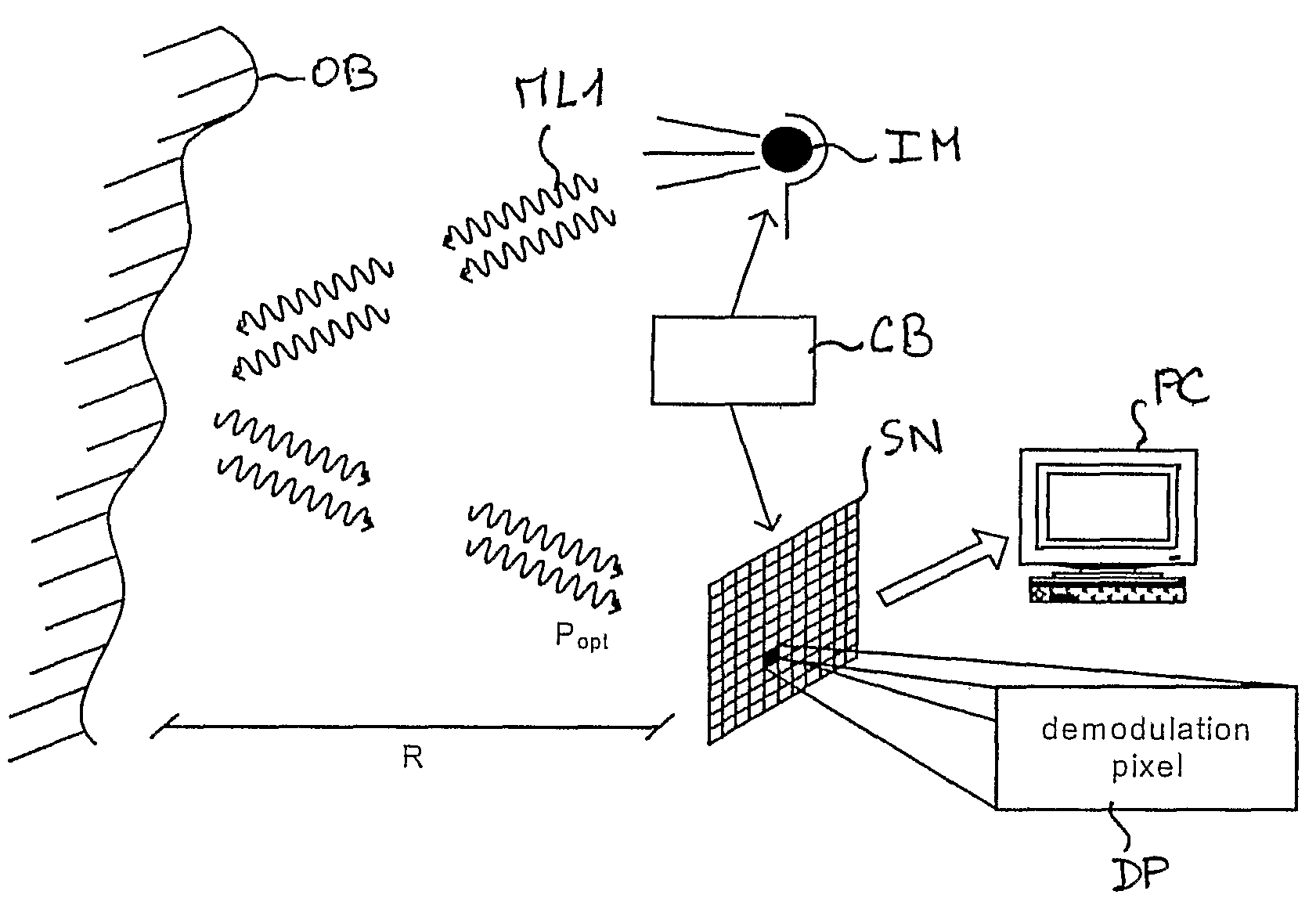

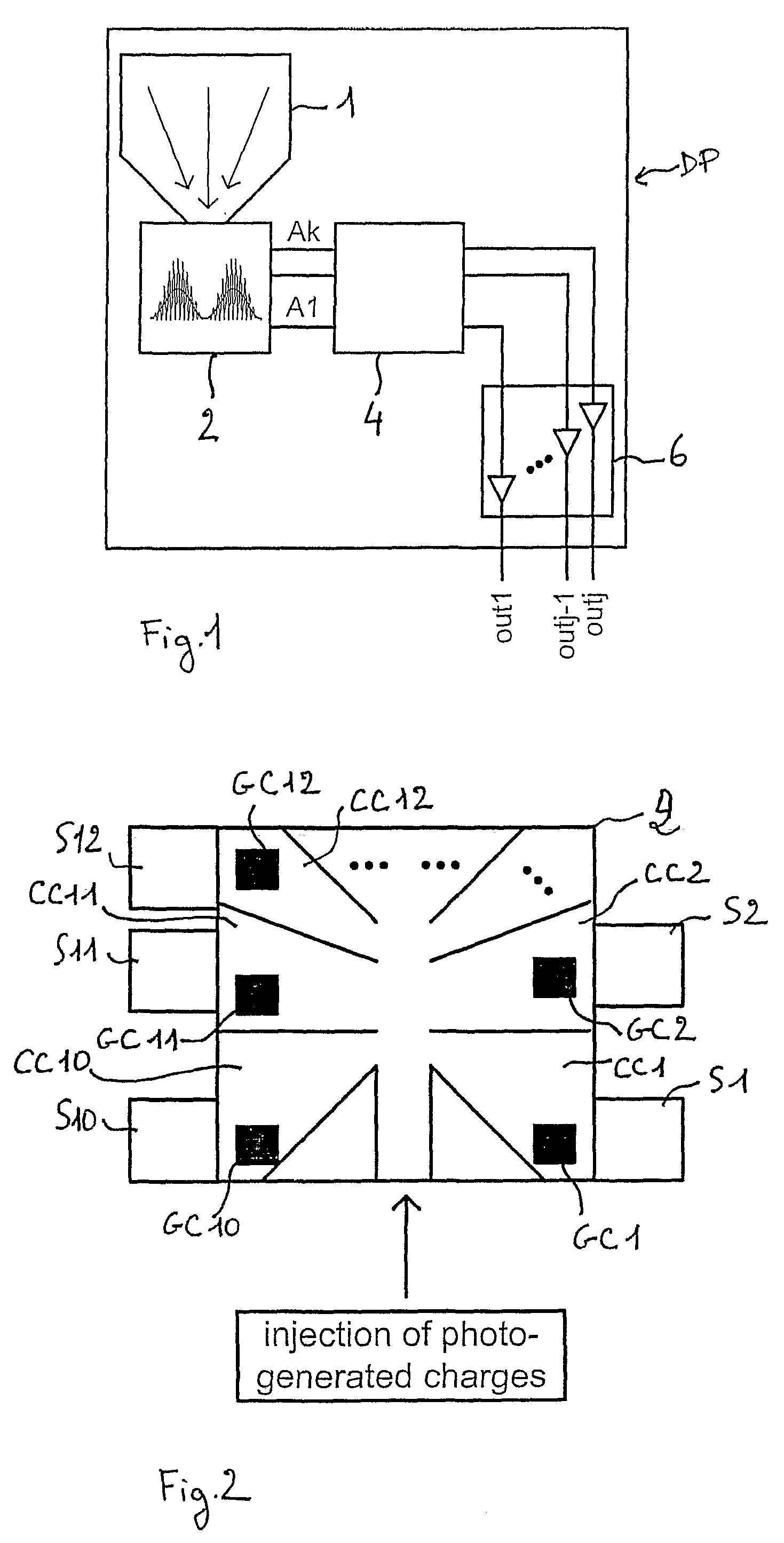

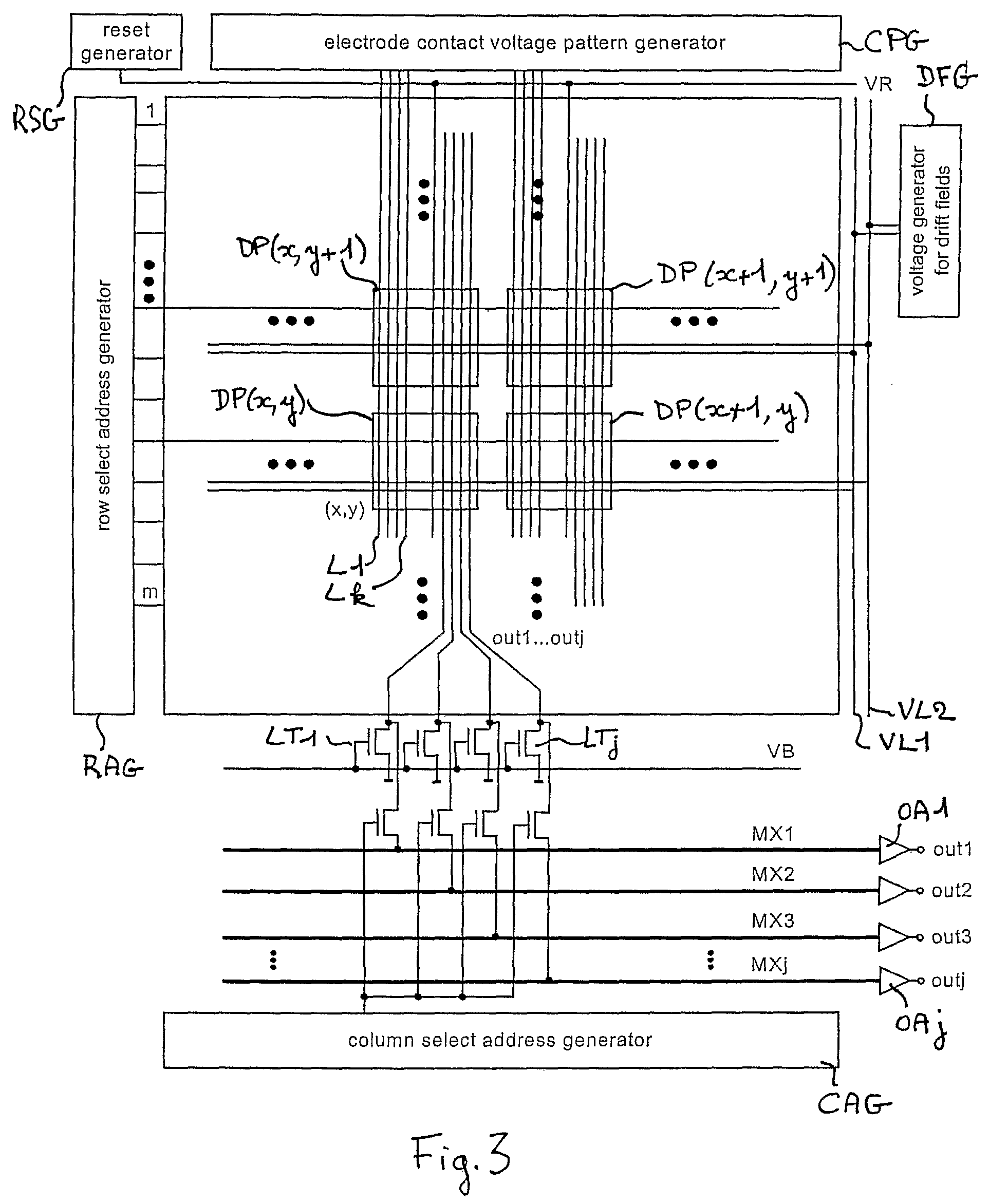

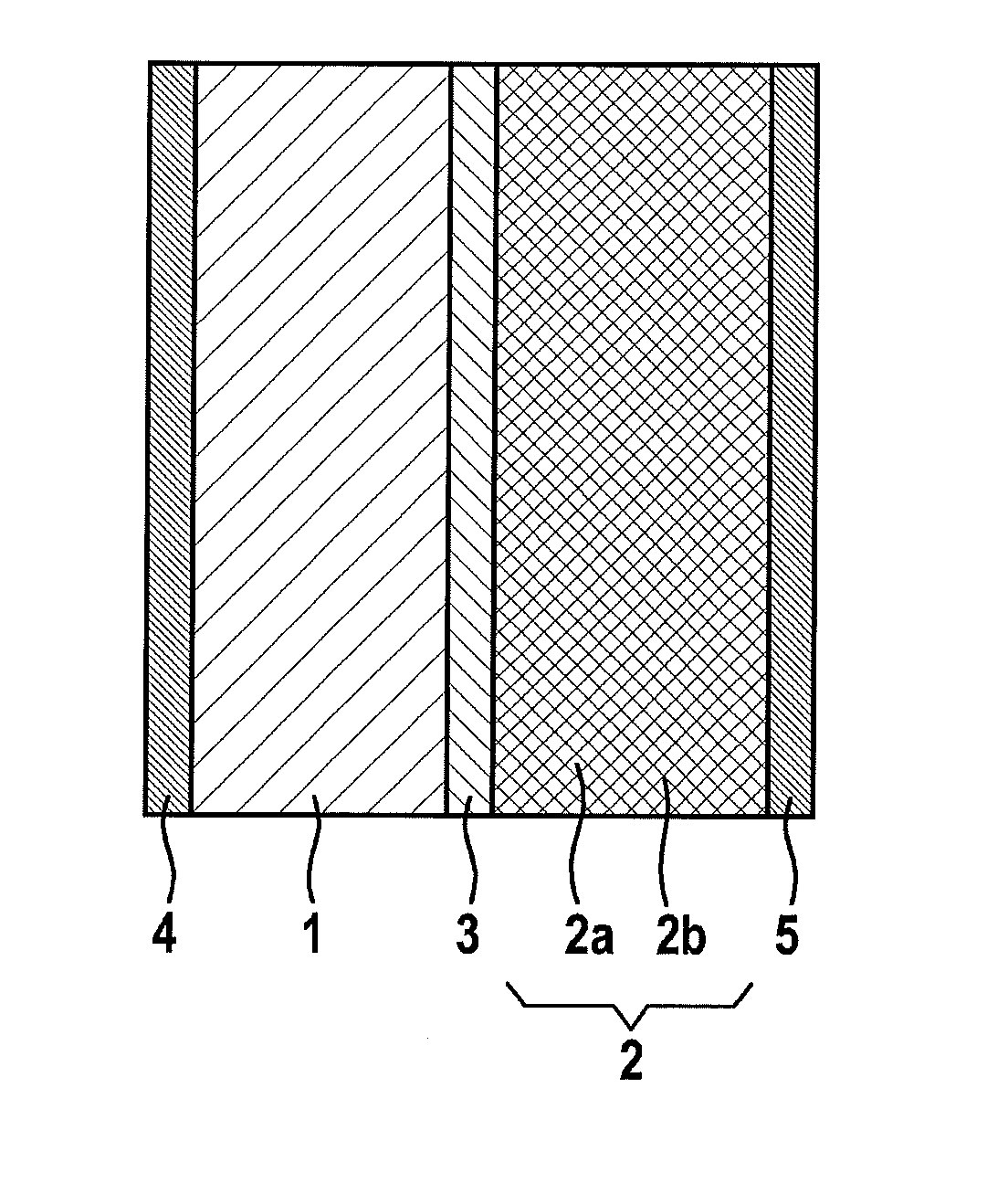

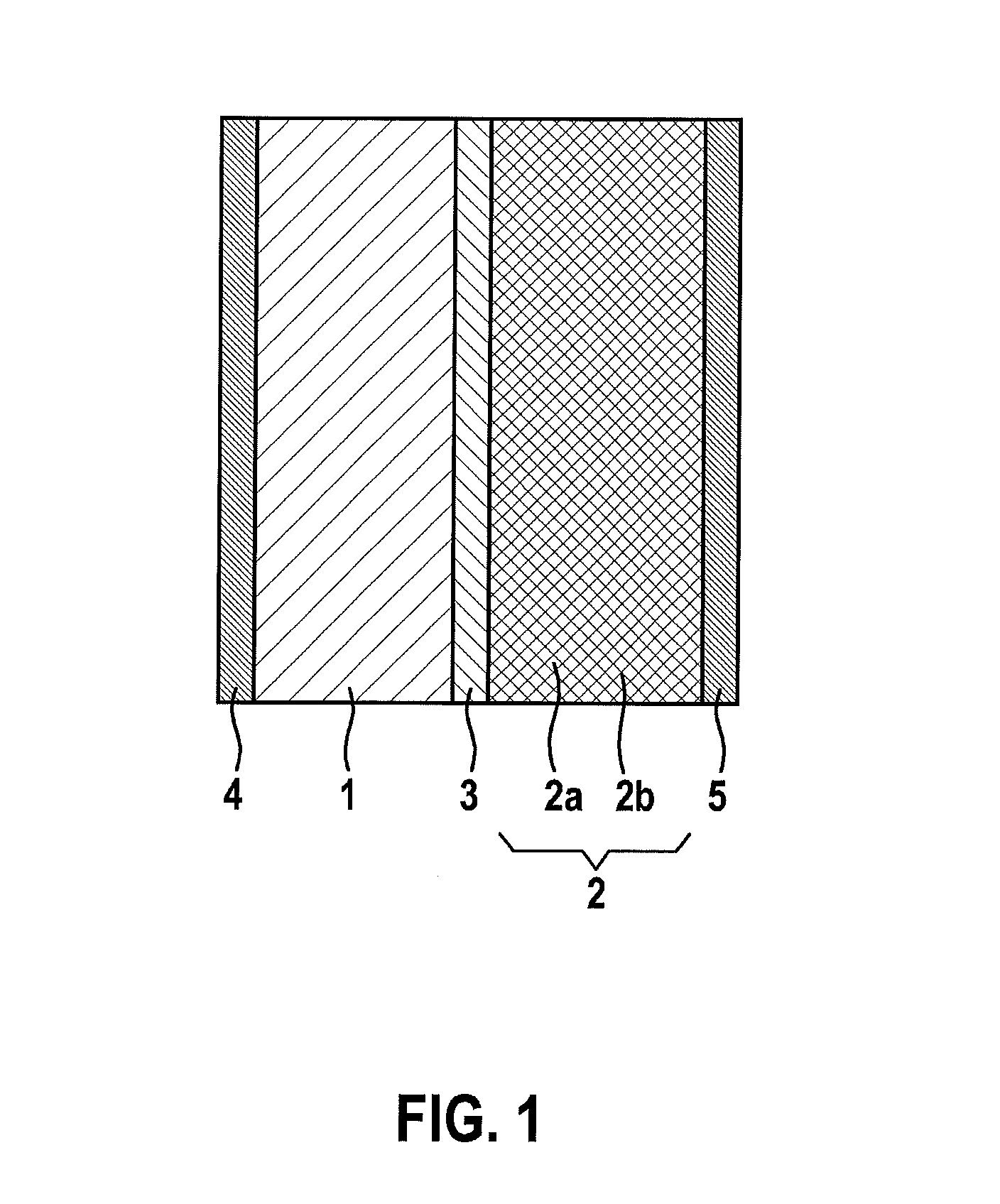

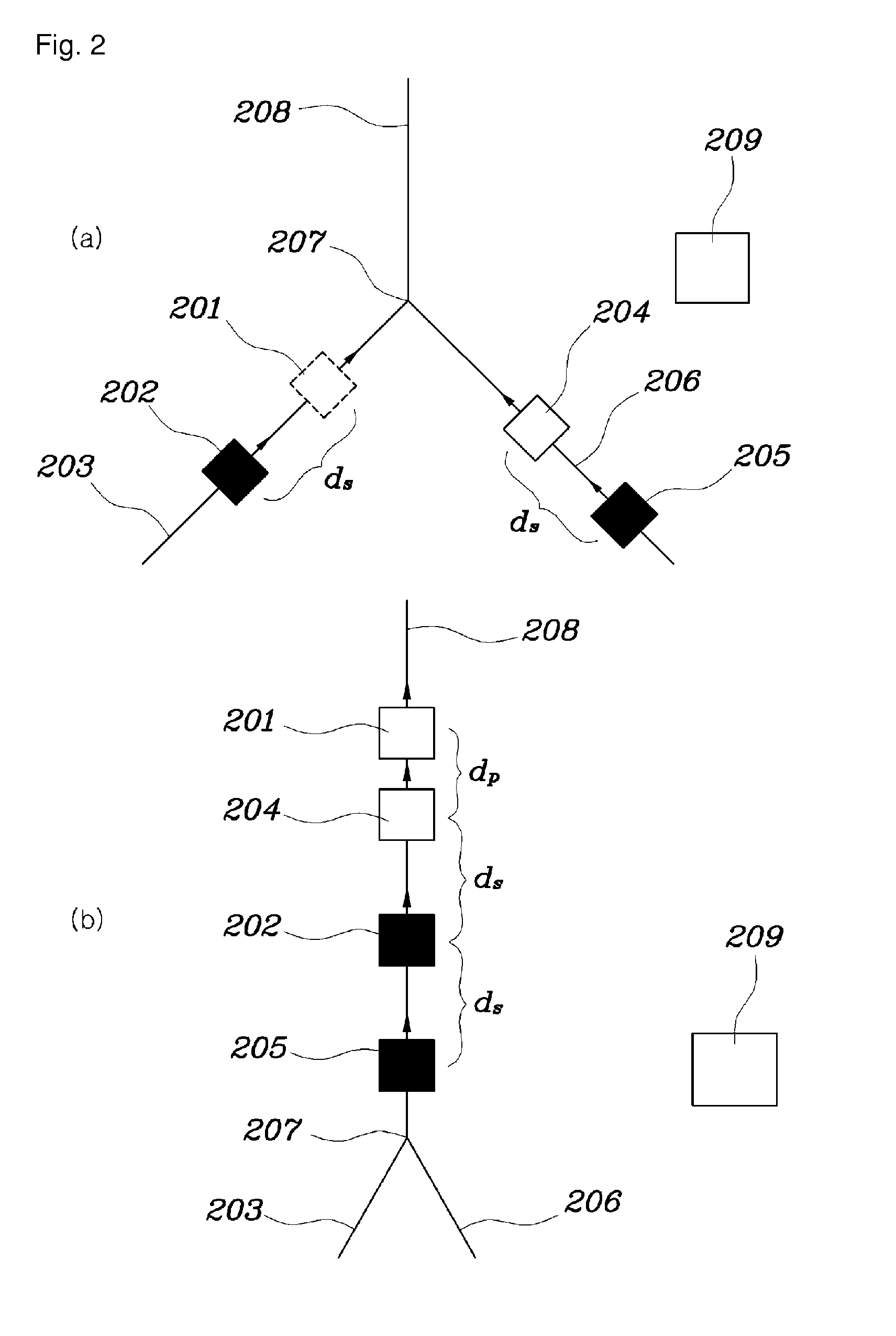

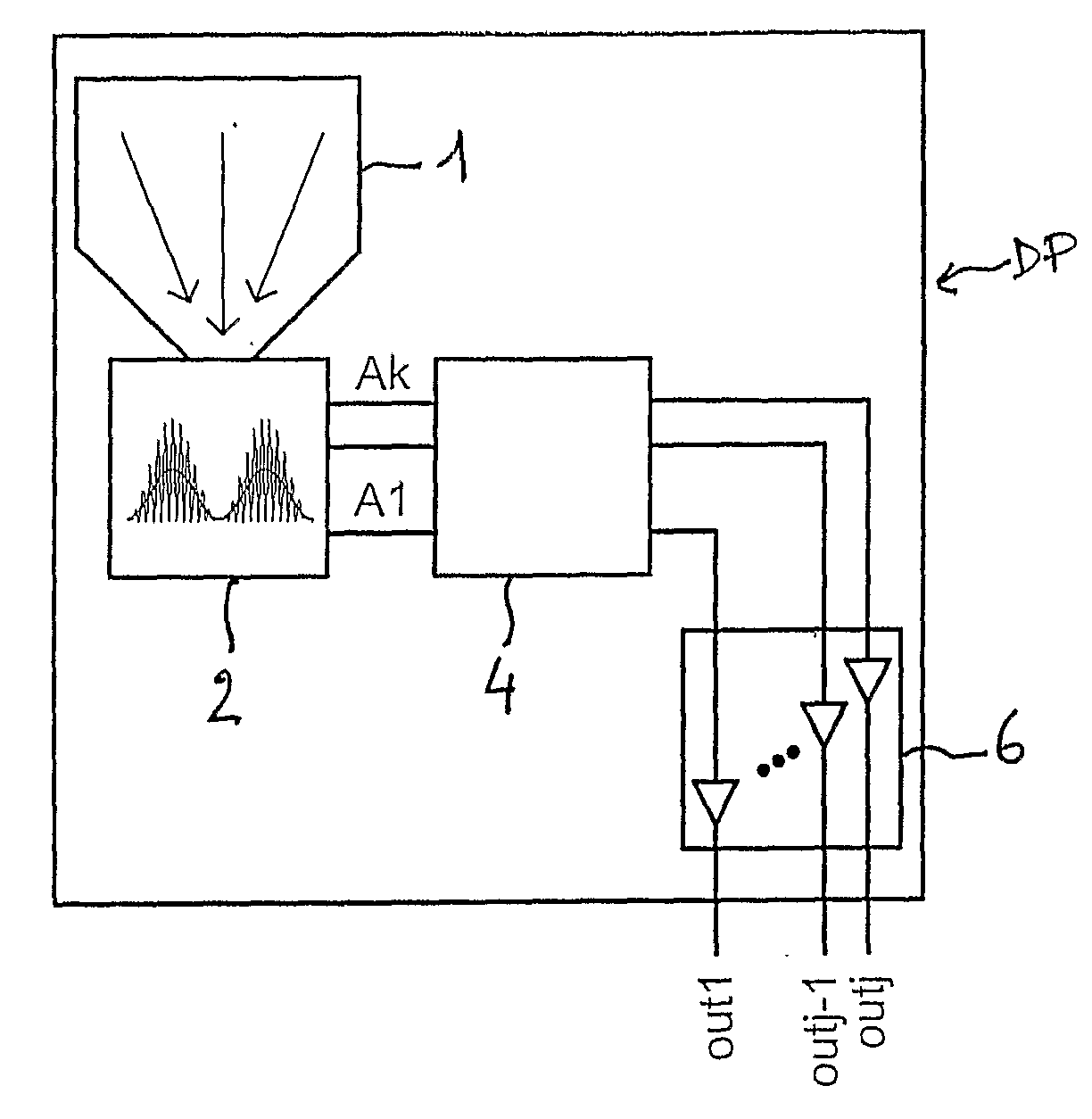

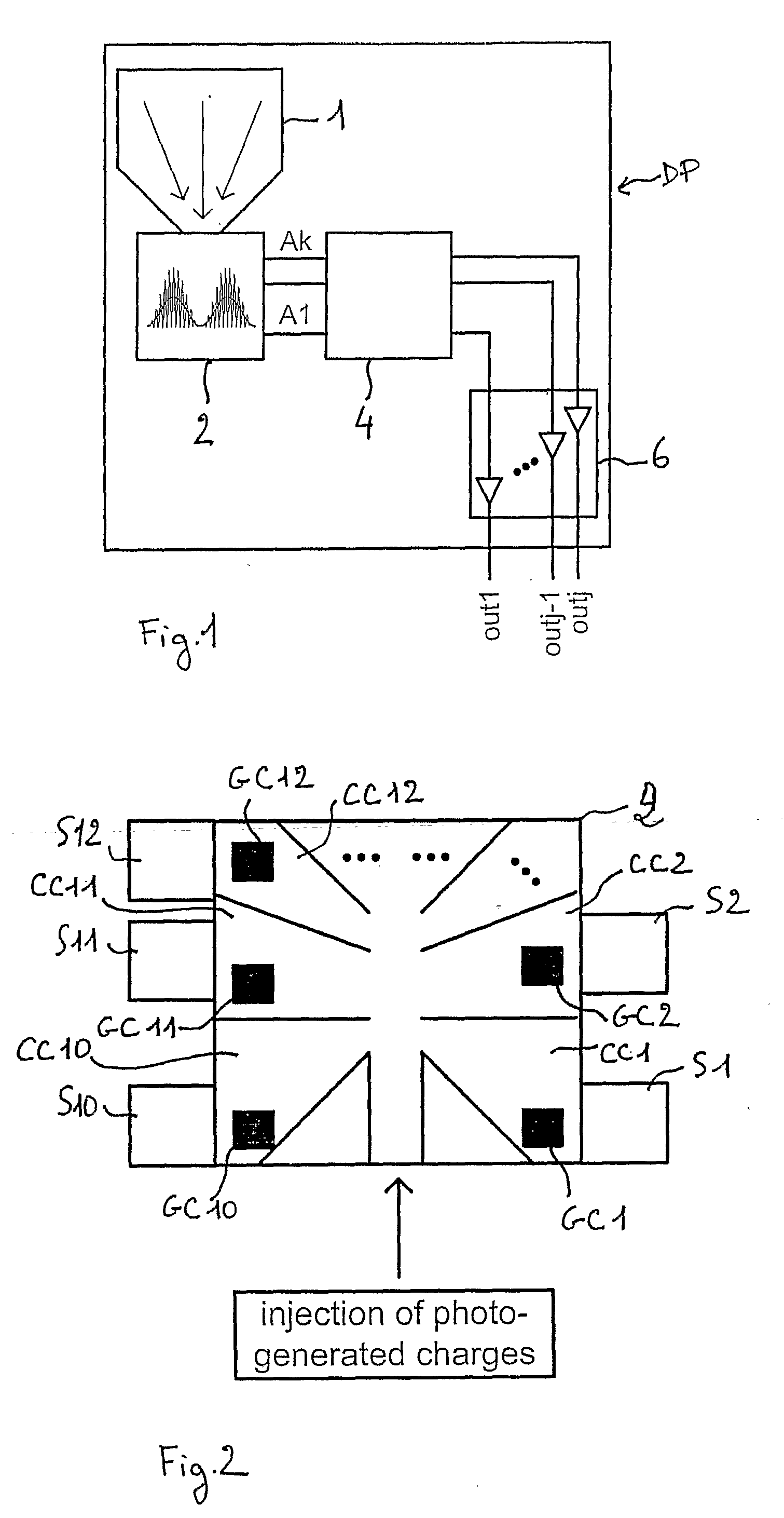

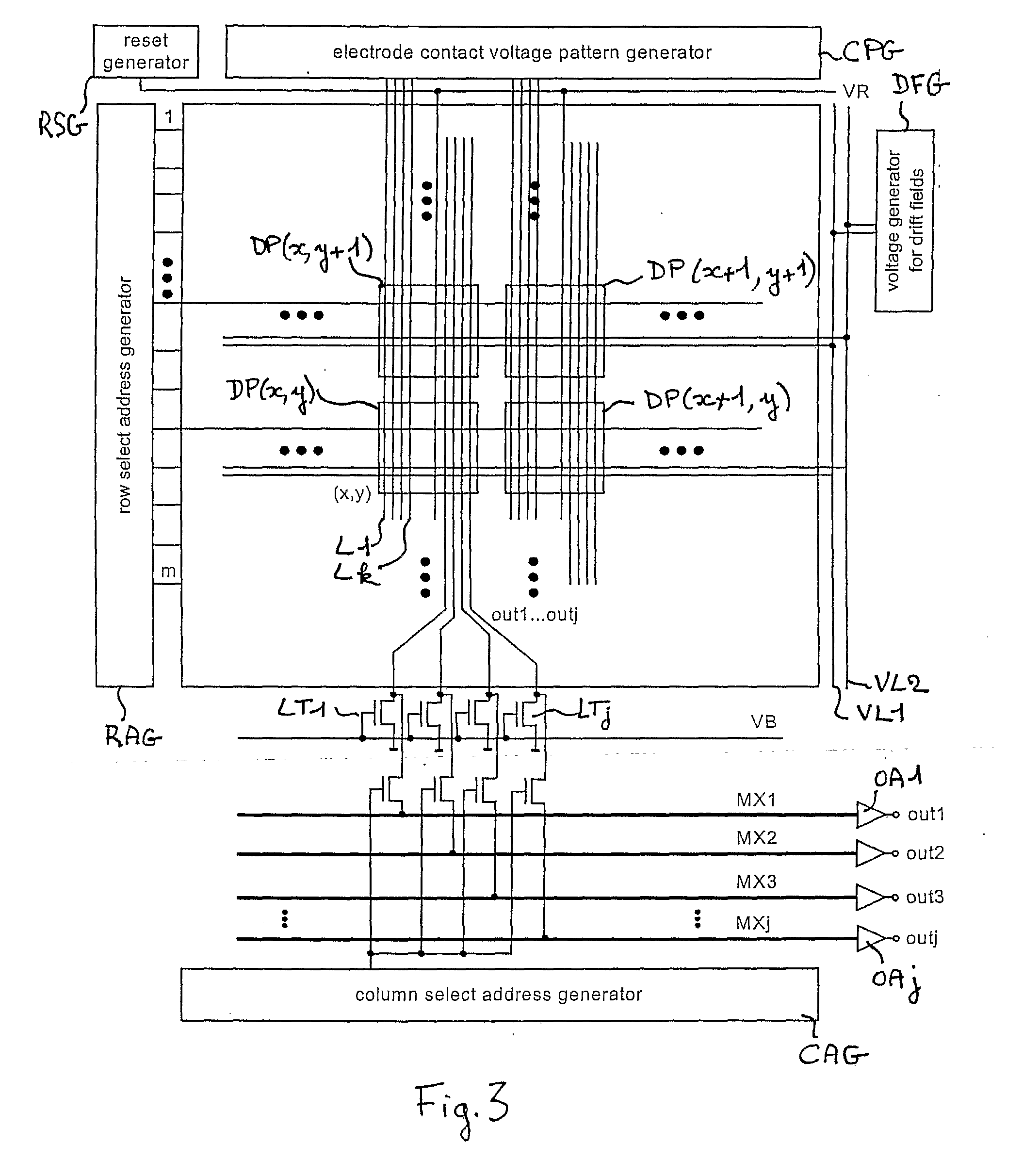

Device and method for the demodulation electromagnetic wave fields having separated detection and demodulation regions

ActiveUS7884310B2Increase speedFast shippingTelevision system detailsSolid-state devicesCharge currentWave field

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

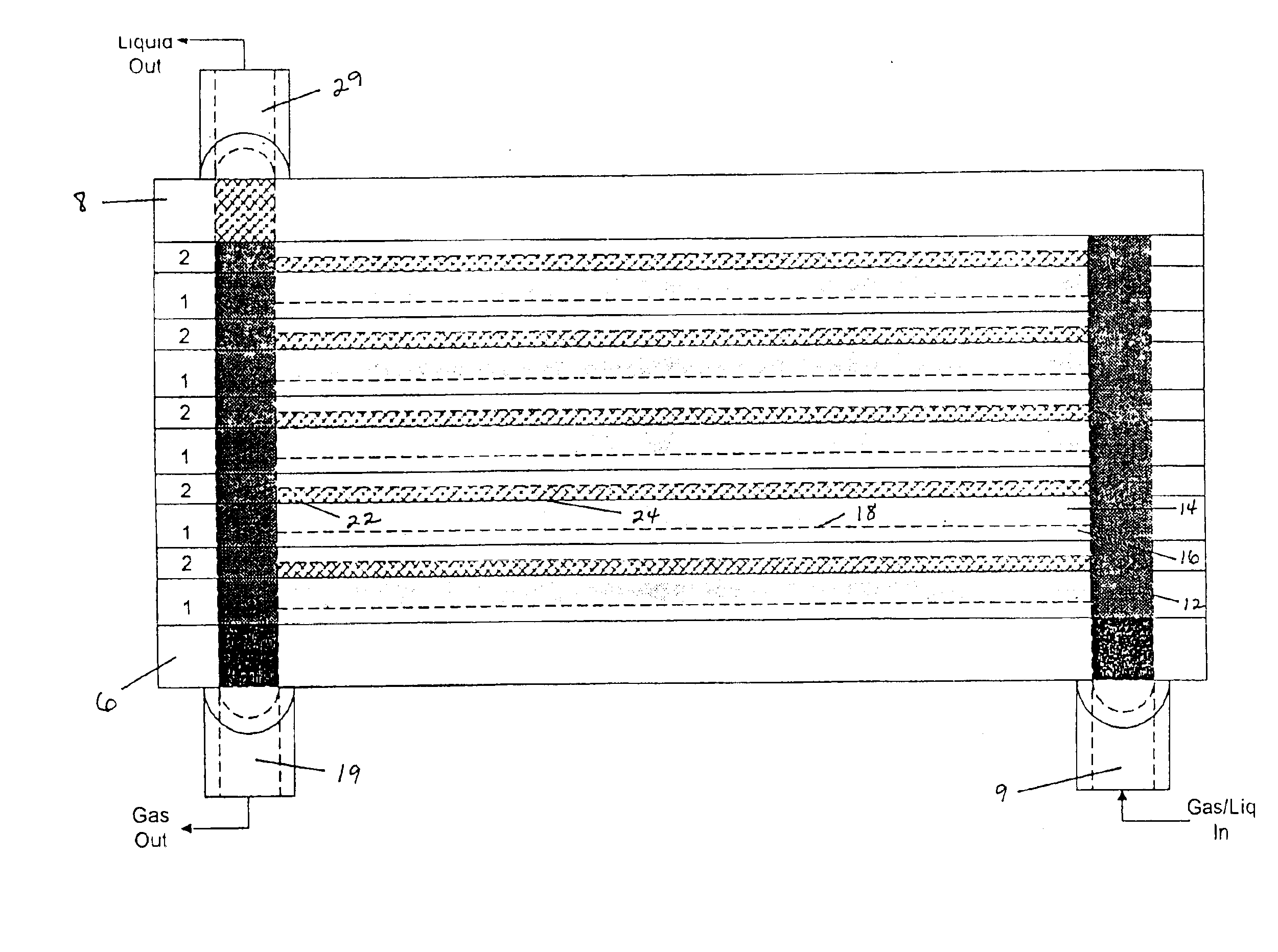

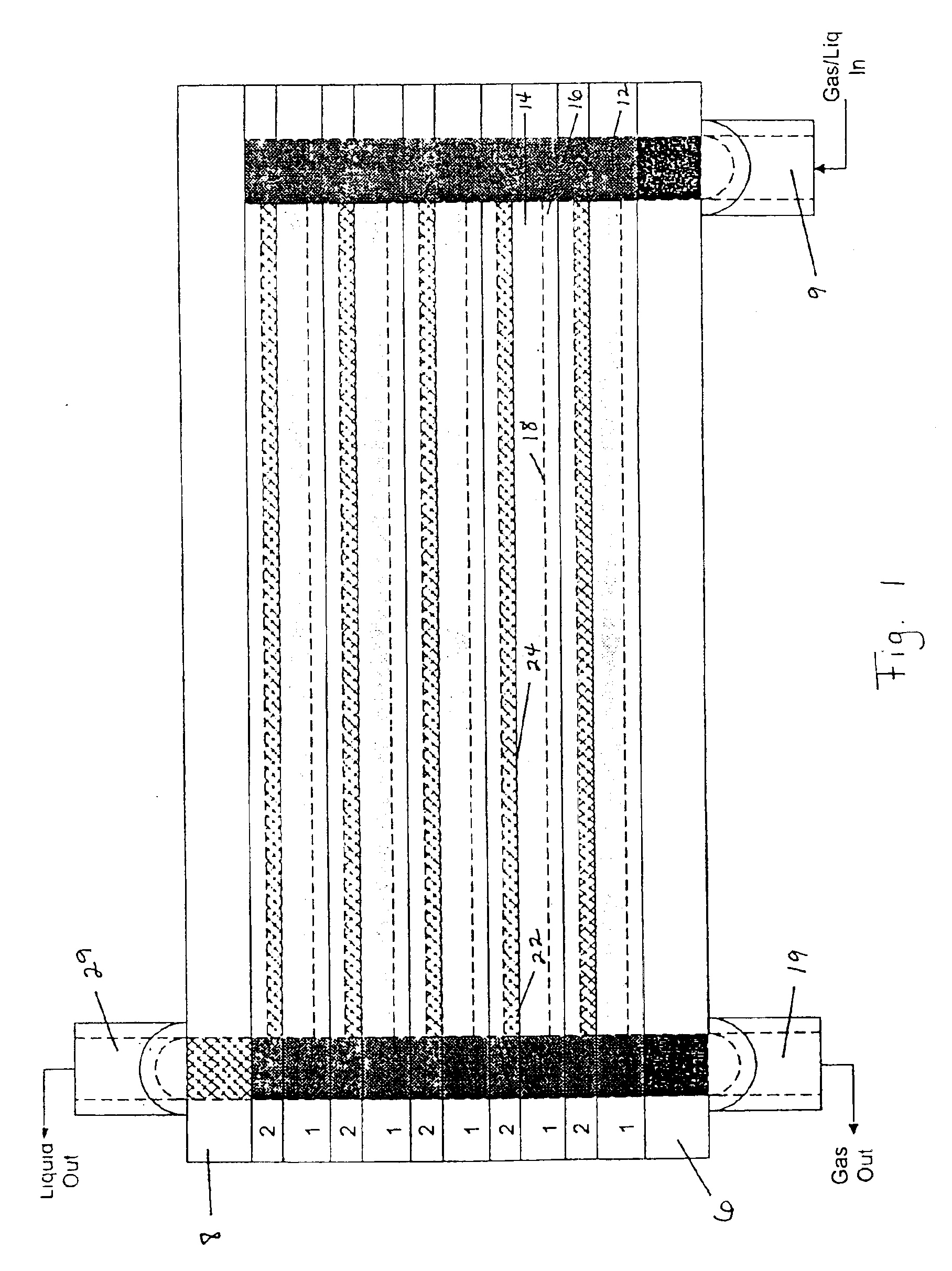

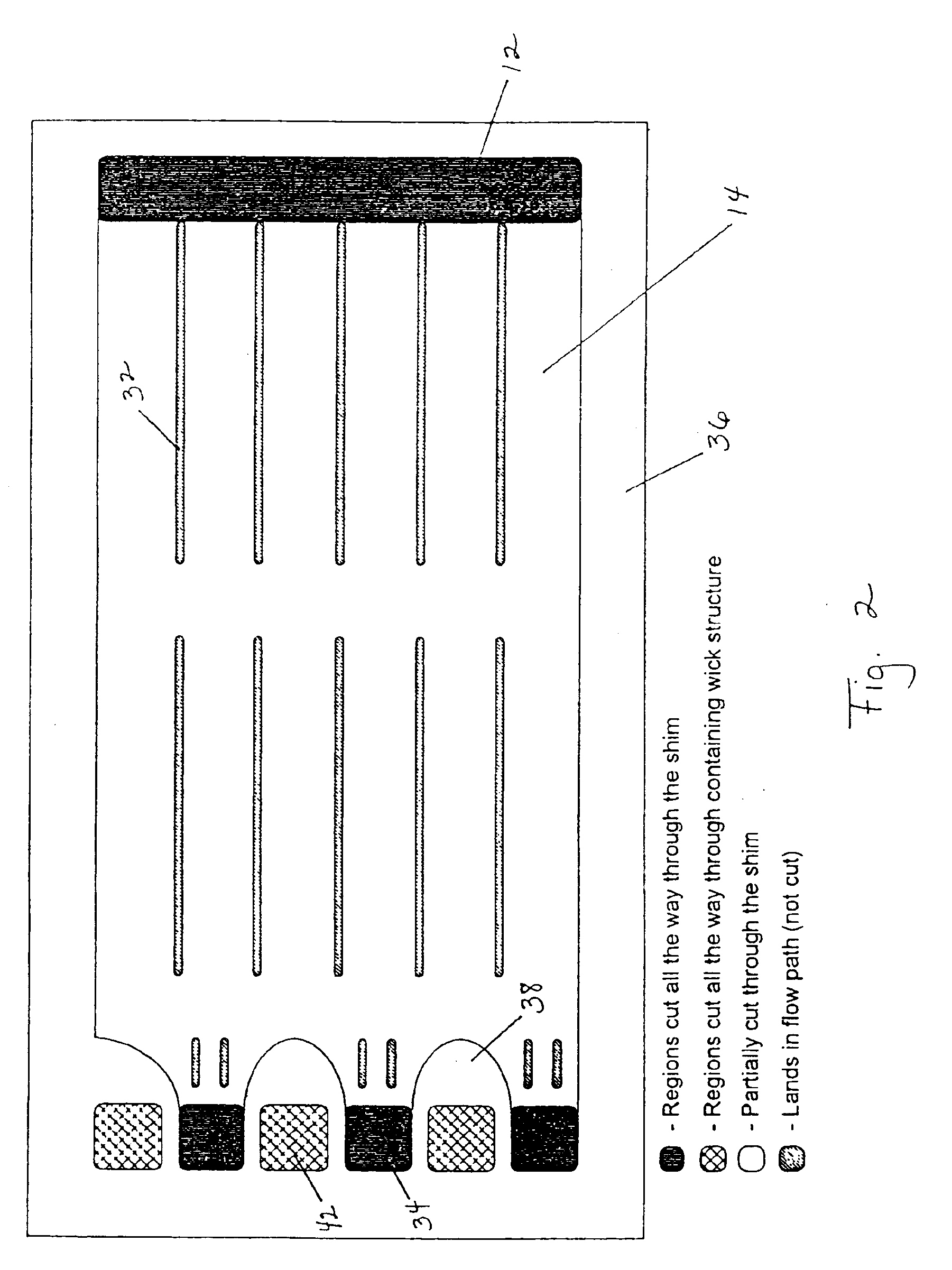

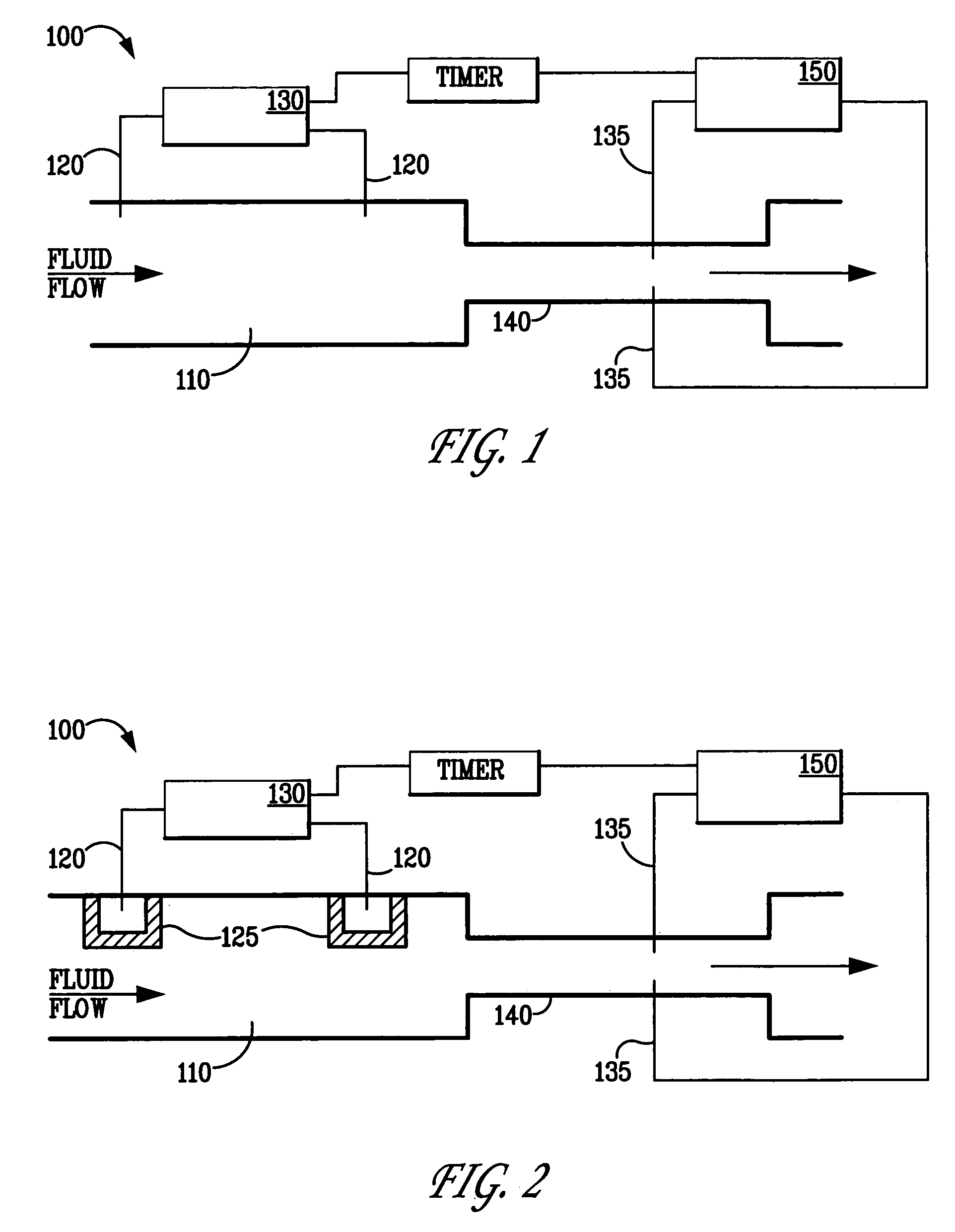

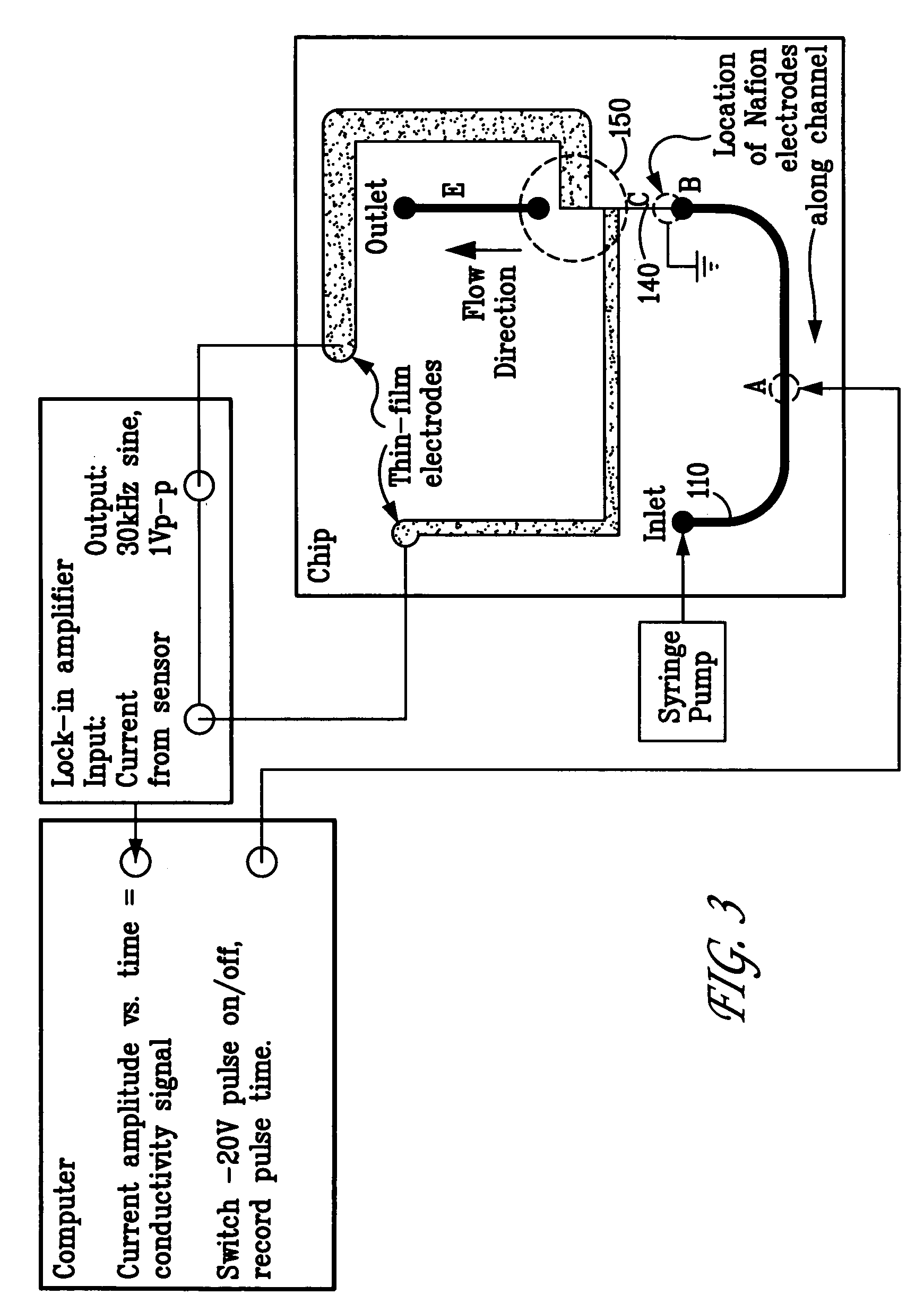

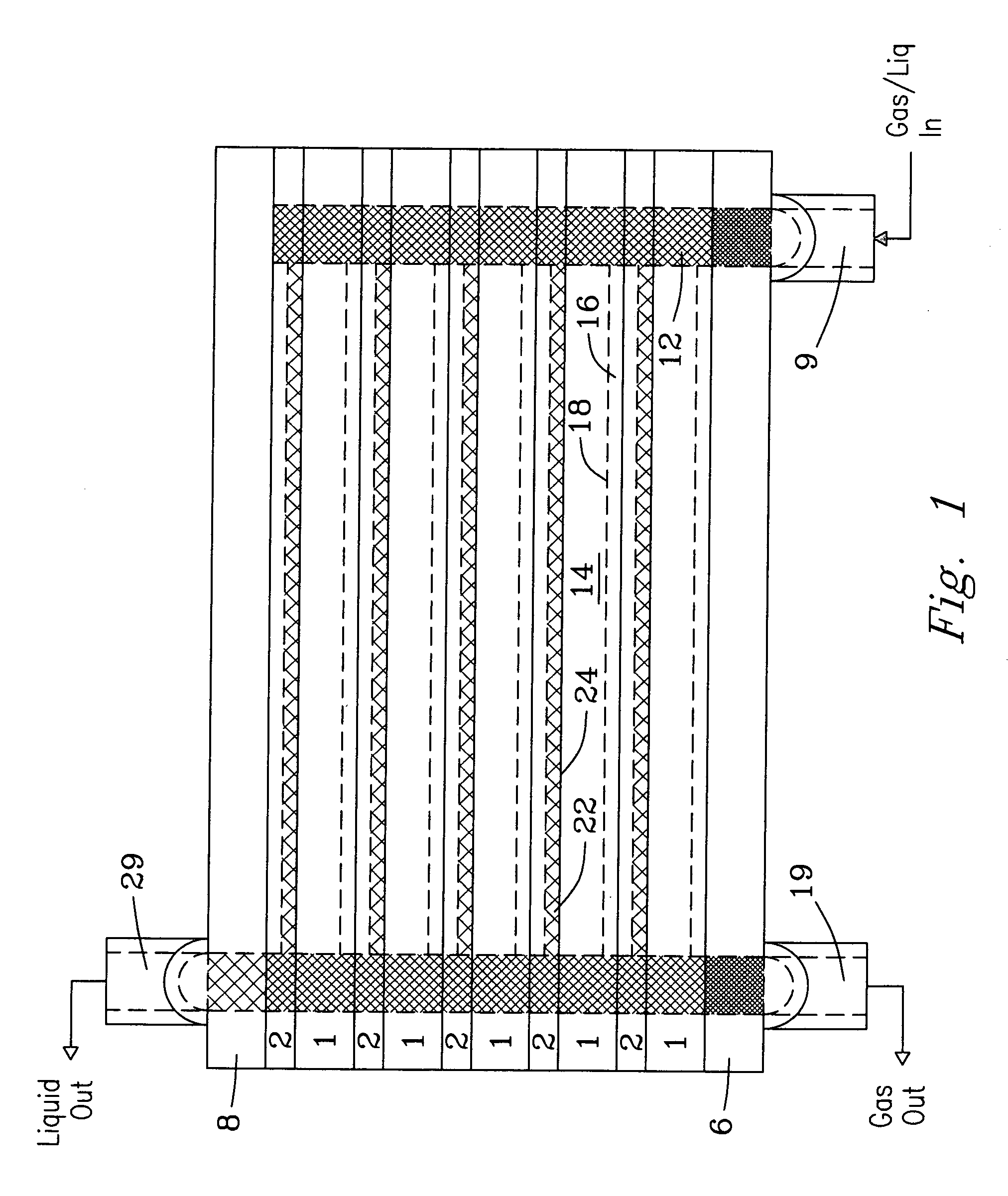

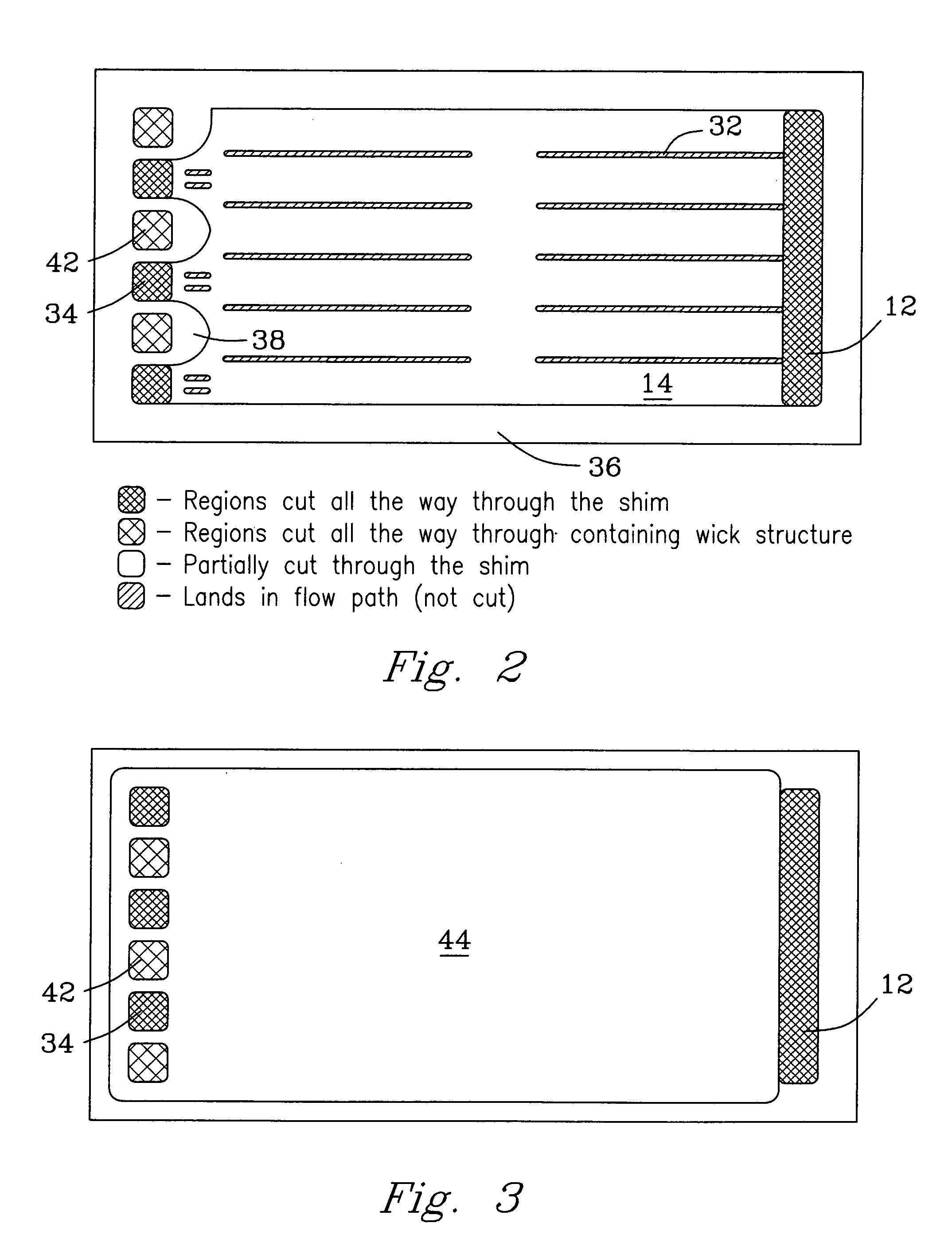

Conditions for fluid separations in microchannels, capillary-driven fluid separations, and laminated devices capable of separating fluids

InactiveUS6875247B2Rapid mass transportImprove heat transfer performanceCombination devicesAuxillary pretreatmentImproved methodChemistry

Owner:BATTELLE MEMORIAL INST

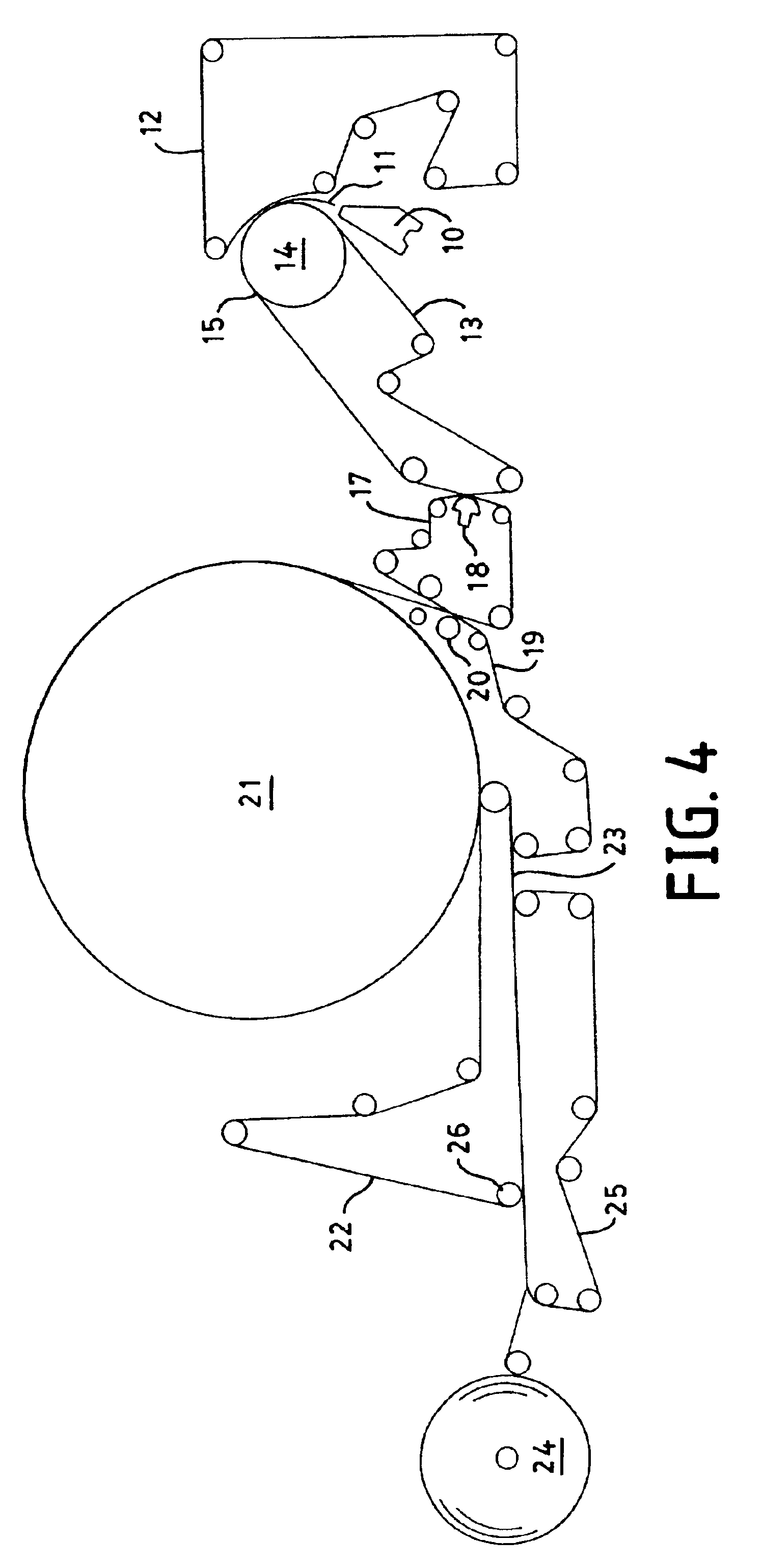

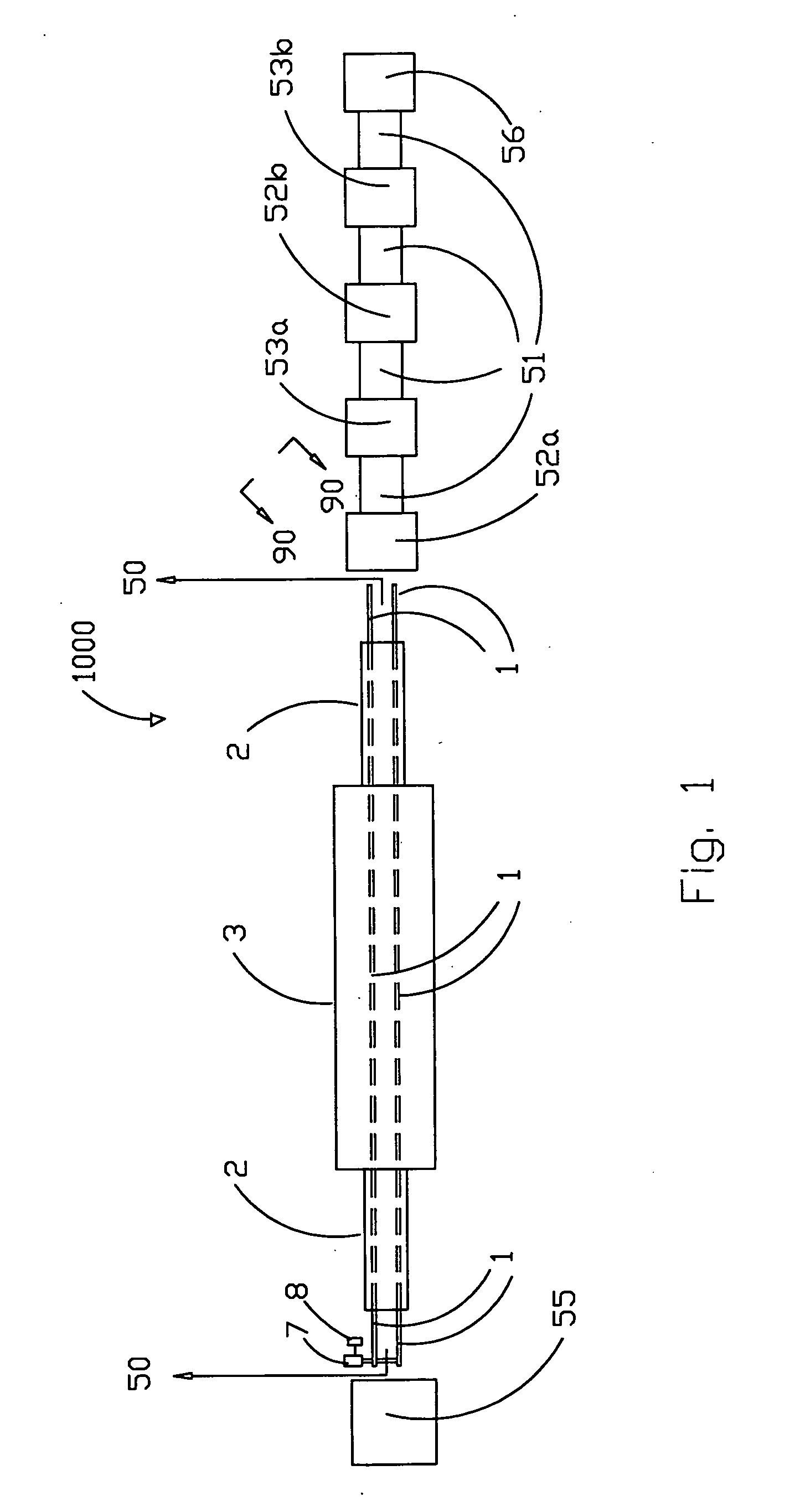

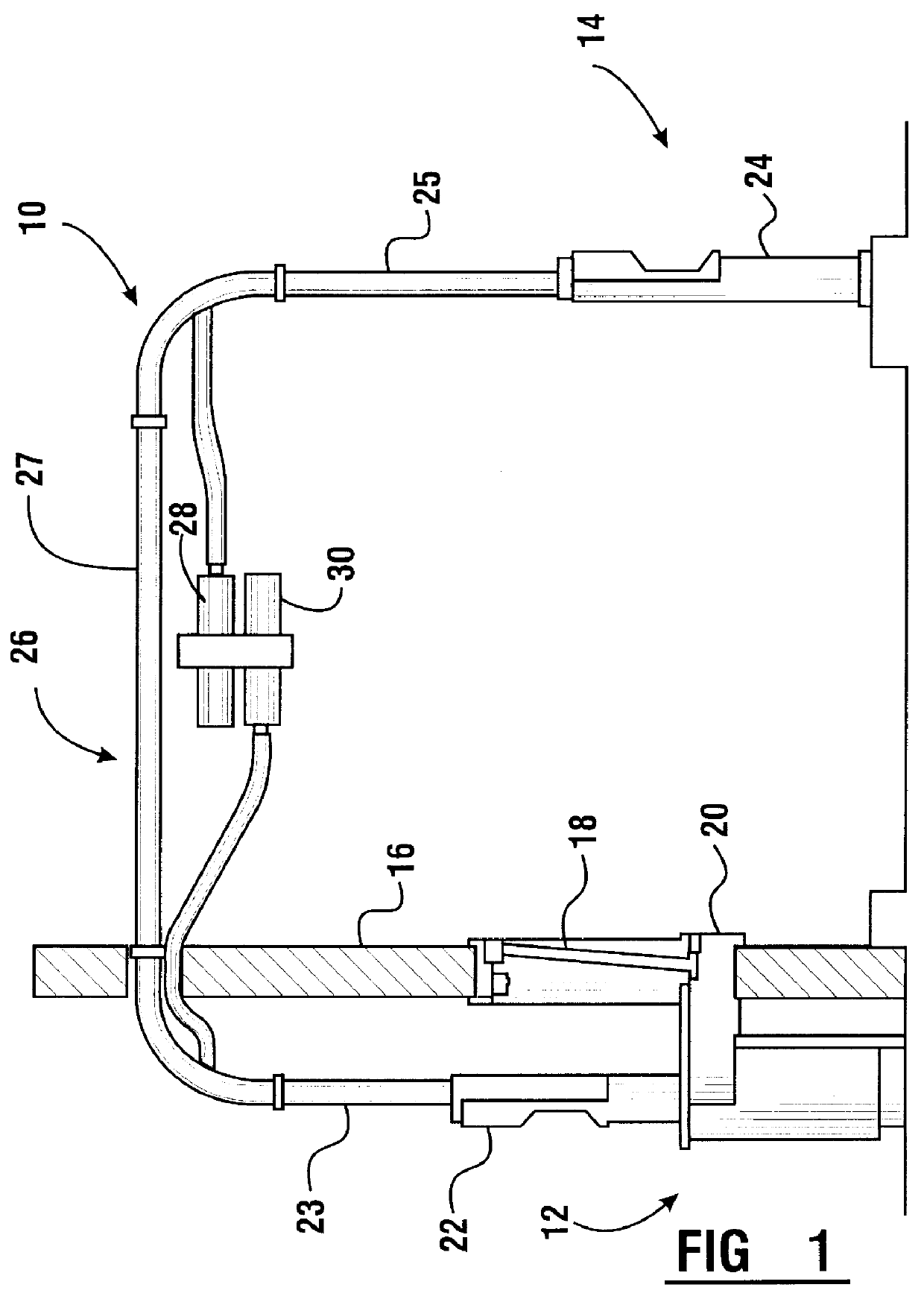

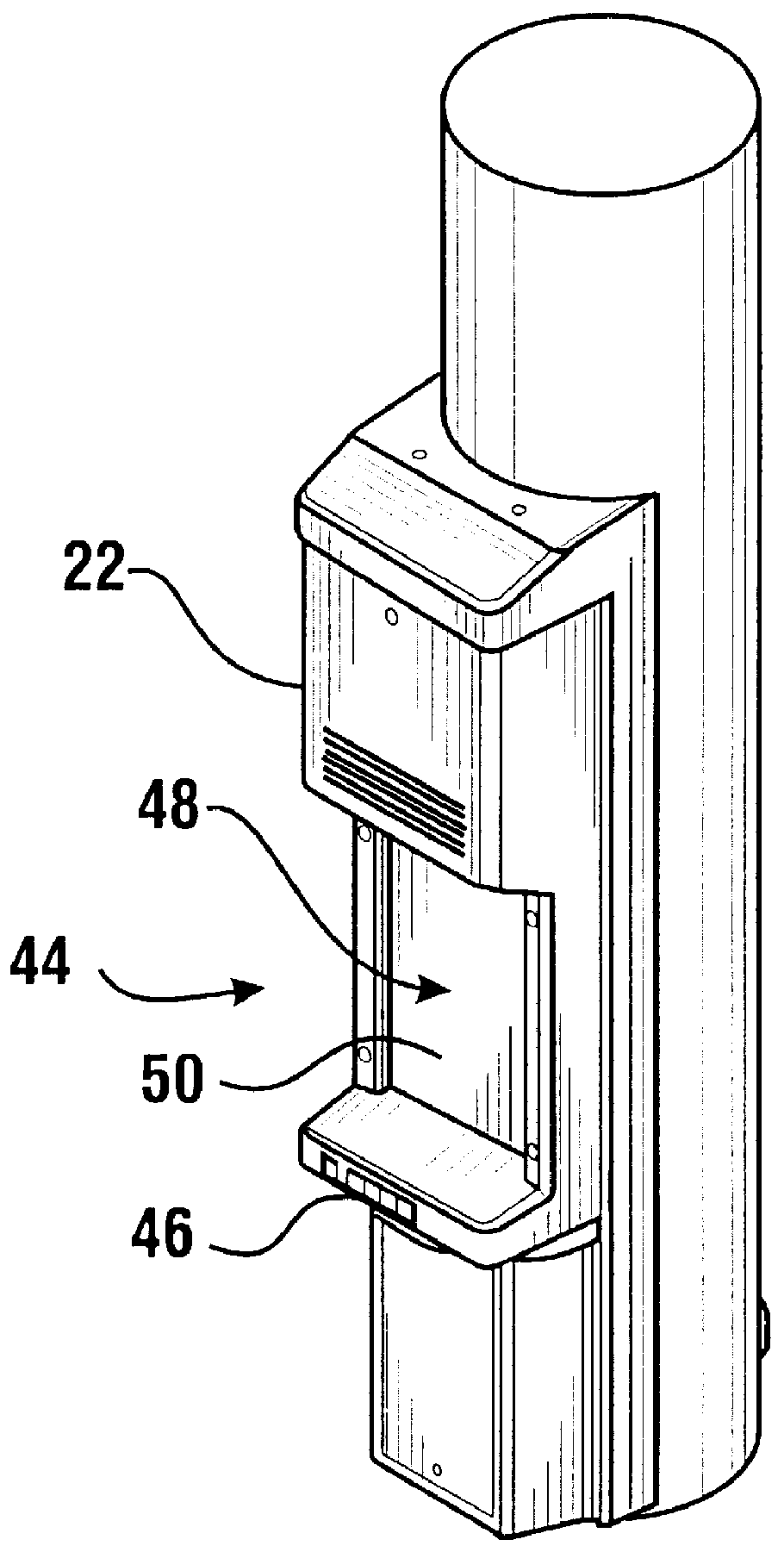

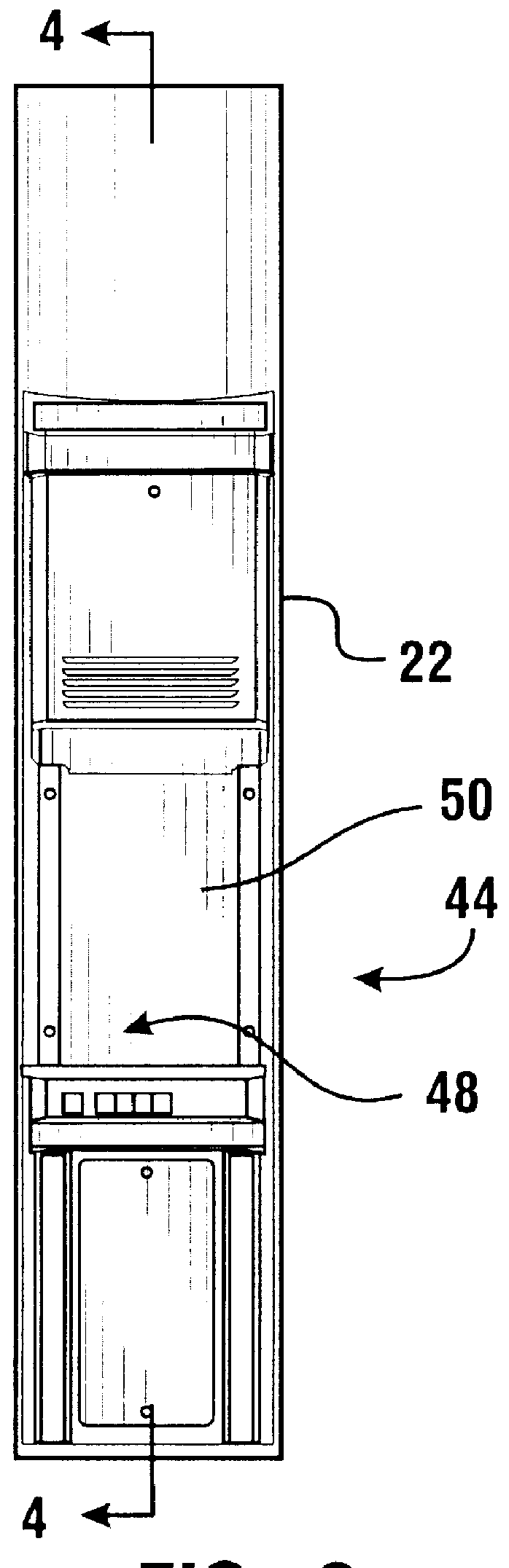

Pneumatic transfer apparatus

InactiveUS6146057ARisk minimizationFast shippingComplete banking machinesSafety transaction partitionDifferential pressureEngineering

A pneumatic transfer apparatus (10) includes a service provider terminal (22) and a customer terminal (24). A carrier (32) is moved through a transfer conduit (26) between the customer and service provider terminals by a differential pressure generating mechanism (28, 30). Each of the customer and service provider terminals includes an actuator mechanism (54, 82). The actuator mechanism is operative to orient an opening in the housing of the carrier with a transfer opening in the transfer conduit. The actuator mechanism is further operative to move an inner shell (100) relative to an outer shell (96) of the carrier so as to bring openings in said inner and outer shells into alignment which enables accessing the interior area of the carrier.

Owner:DIEBOLD NIXDORF

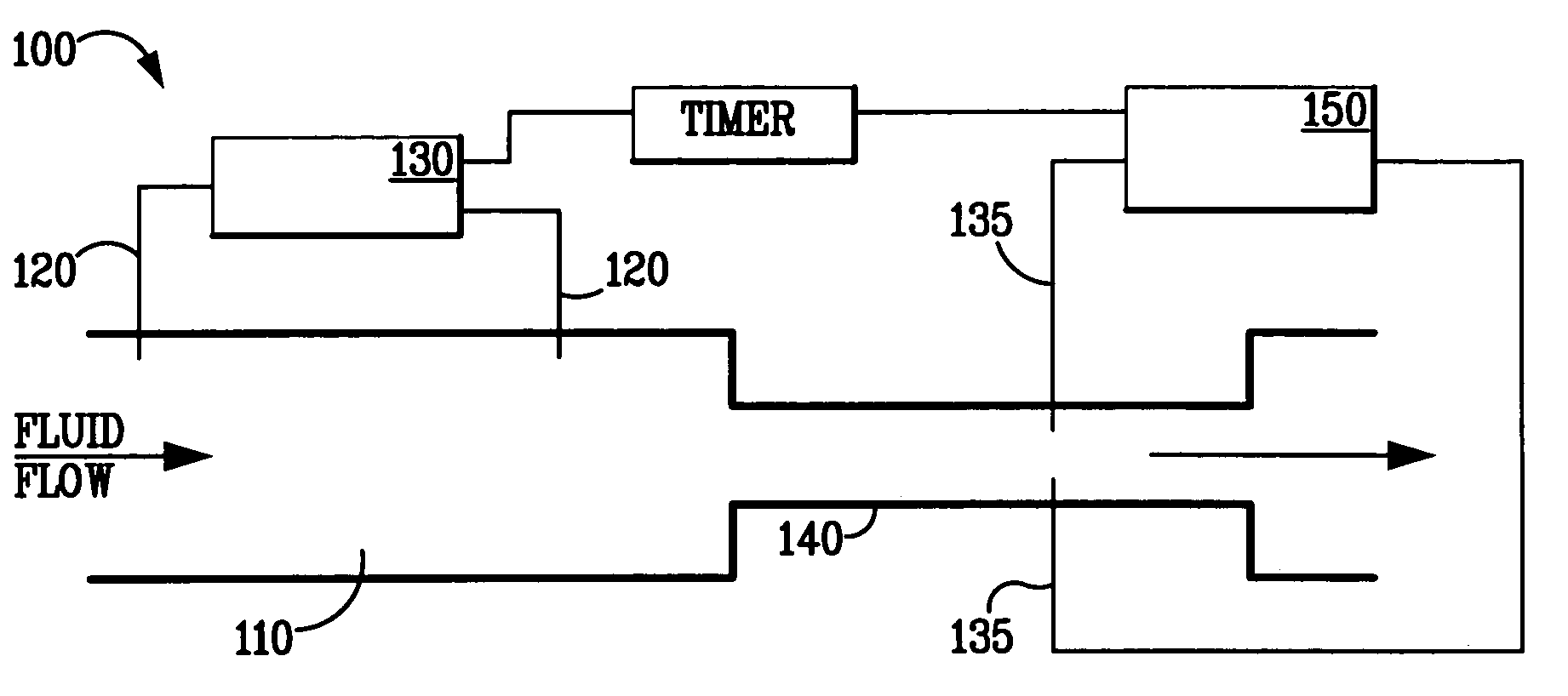

Composition pulse time-of-flight mass flow sensor

InactiveUS7225683B2Increase heat transfer rateHigh sensitivityVolume/mass flow by electromagnetic flowmetersElectrolysisSolvent

Owner:SANDIA NAT LAB

All-solid-state cell

ActiveUS20150044576A1Transportation is highImprove cycle stabilityAlkali titanatesTantalum compoundsAll solid stateSolid state electrolyte

An all-solid-state cell, which includes a lithium-containing anode, a cathode and a lithium ions-conducting solid-state electrolyte separator situated between the anode and the cathode. To improve the safety and cycle stability of the cell, the cathode includes a composite material including at least one lithium titanate and at least one lithium ions-conducting solid-state electrolyte. Furthermore, the invention relates to a corresponding all-solid-state battery and a mobile or stationary system equipped with it.

Owner:ROBERT BOSCH GMBH

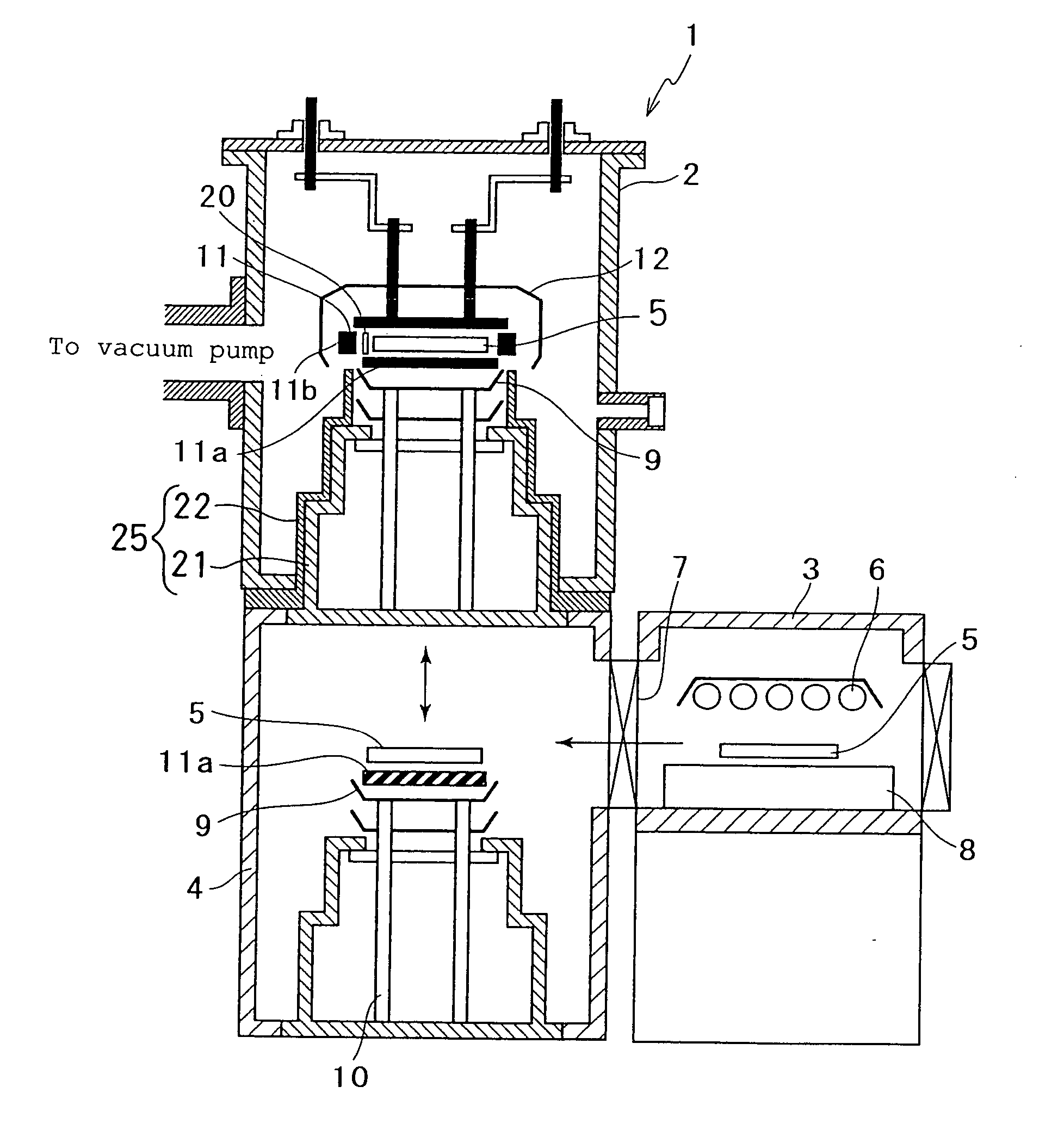

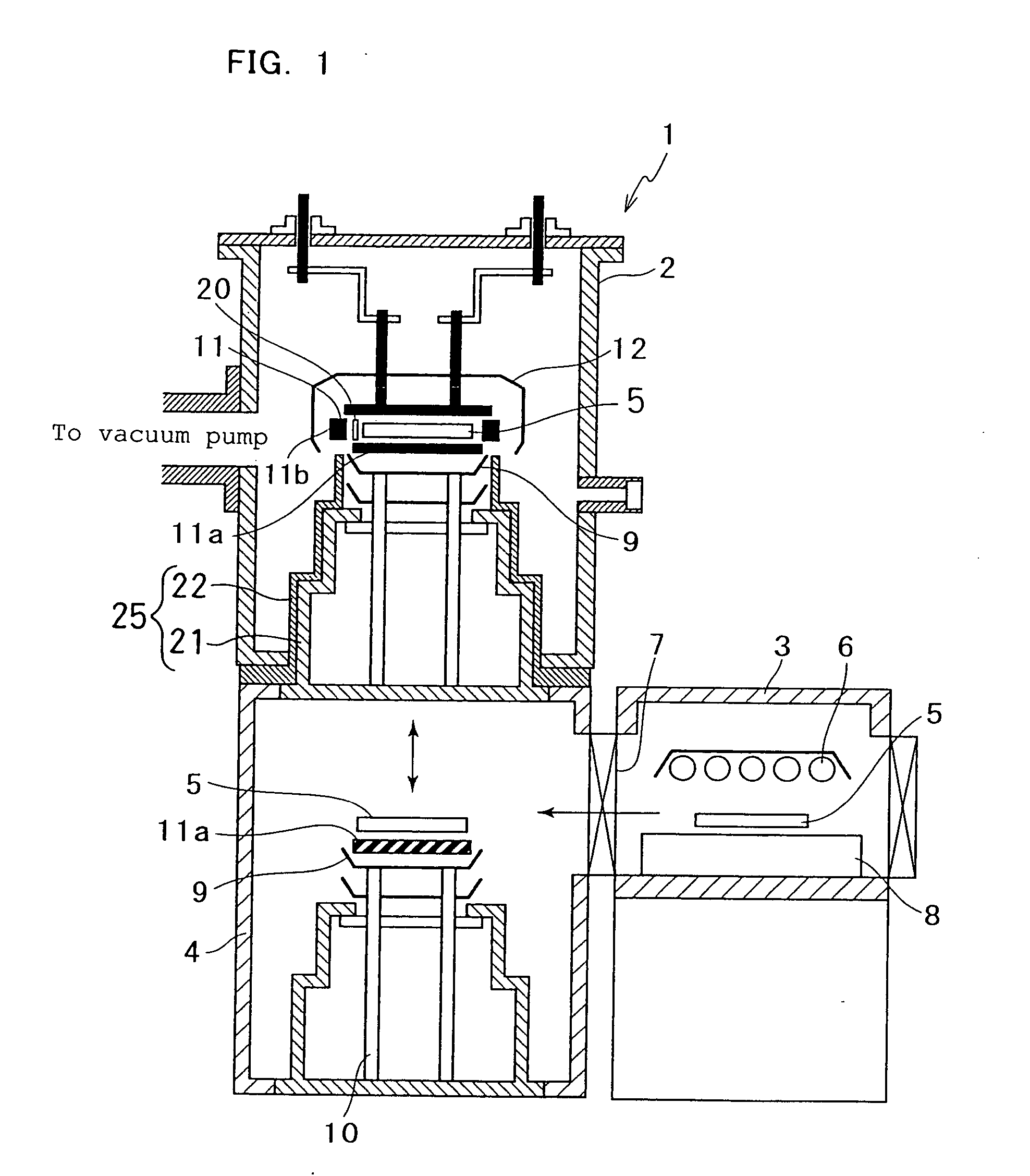

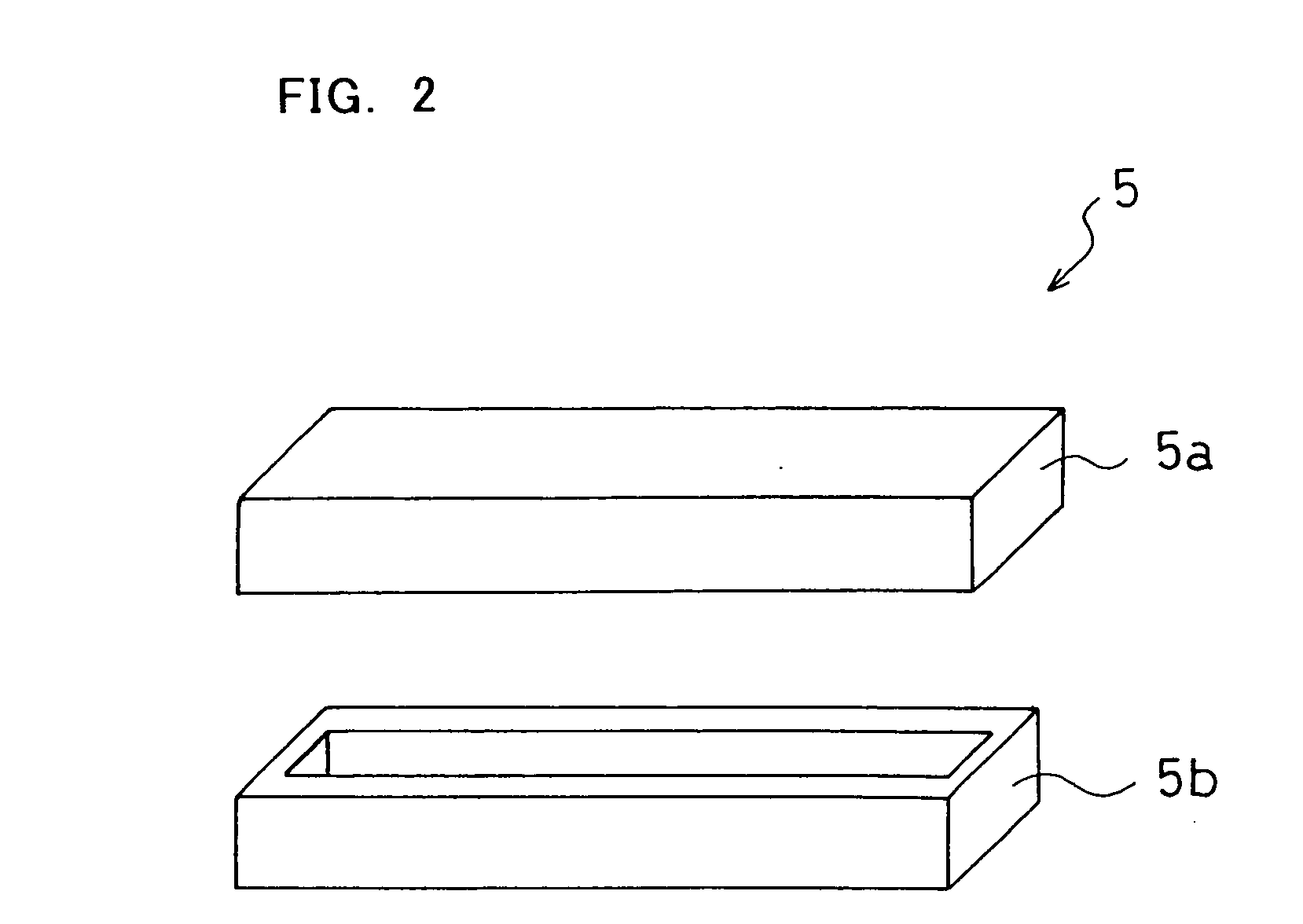

Method of heat treatment and heat treatment apparatus

InactiveUS20060249073A1No longer performedEfficient productionPolycrystalline material growthAfter-treatment detailsSeed crystalEquipment use

The present invention is a method suitable for heat treatment, or a heat treatment method for growing single crystal silicon carbide by a liquid phase epitaxial method, wherein a monocrystal silicon carbide substrate as a seed crystal and a polycrystal silicon carbide substrate are piled up, placed inside a closed container, and subjected to high-temperature heat treatment, by which very thin metallic silicon melt layer is interposed between the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate during heat treatment, and single crystal silicon carbide is liquid-phase epitaxially grown on the monocrystal silicon carbide substrate. The closed container is in advance heated to a temperature exceeding approximately 800° C. in an preheating chamber kept at a pressure of approximately 10−5 Pa or lower, the closed container is reduced in pressure to approximately 10−5 Pa or lower, and the container is transported and placed in the heat chamber, which is in advance heated to a prescribed temperature in a range from approximately 1400° C. to 2300° C., in a vacuum at a pressure of approximately 10−2 Pa or lower or in an inert gas atmosphere at a prescribed reduced pressure, by which the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate are heated in a short time to a prescribed temperature in a range from approximately 1400° C. to 2300° C. to produce single crystal silicon carbide which is free of fine grain boundaries and approximately 1 / cm2 or lower in density of micropipe defects on the surface. Further, the present invention is heat treatment equipment used in carrying out the heat treatment method.

Owner:THE NEW IND RES ORG

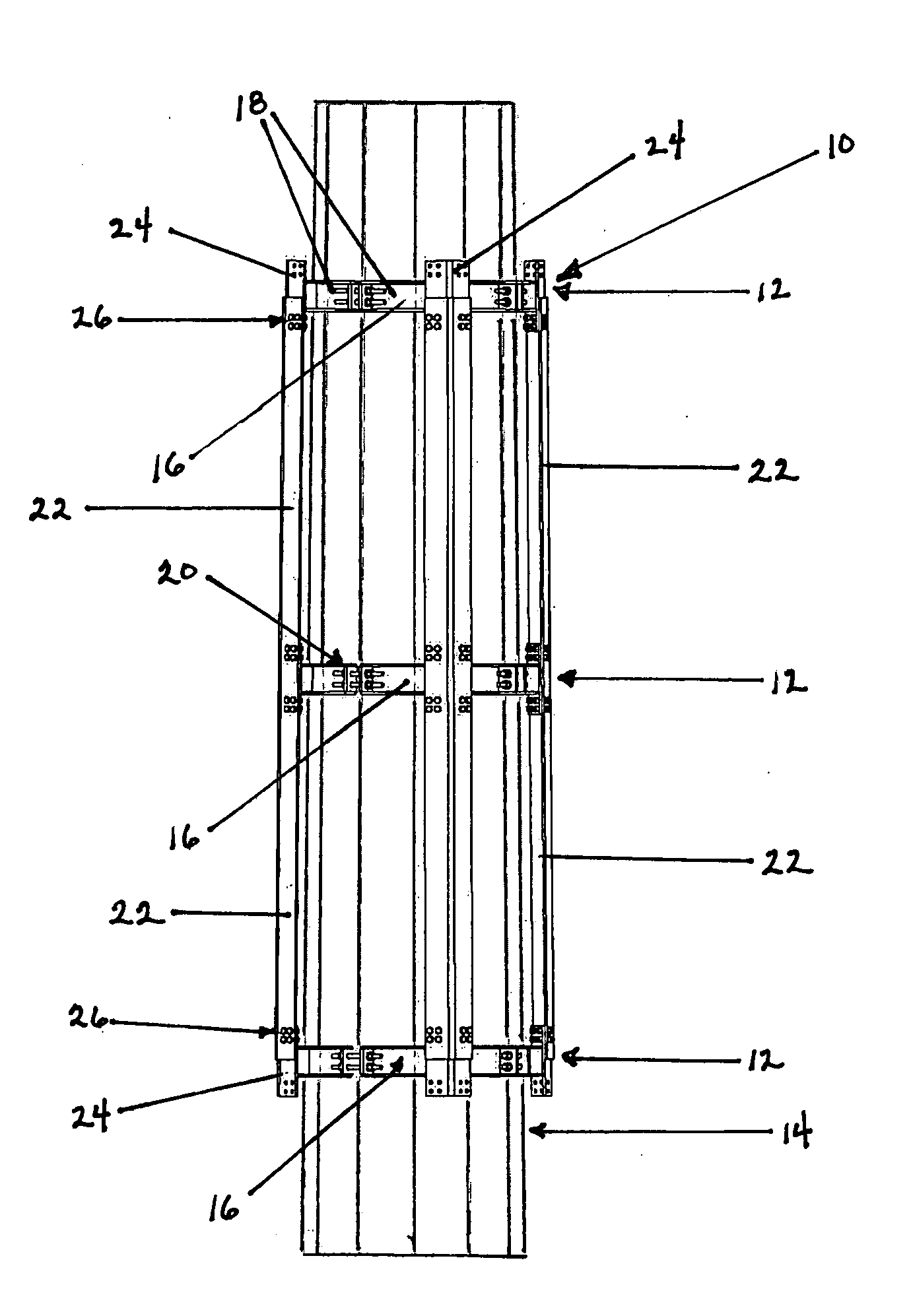

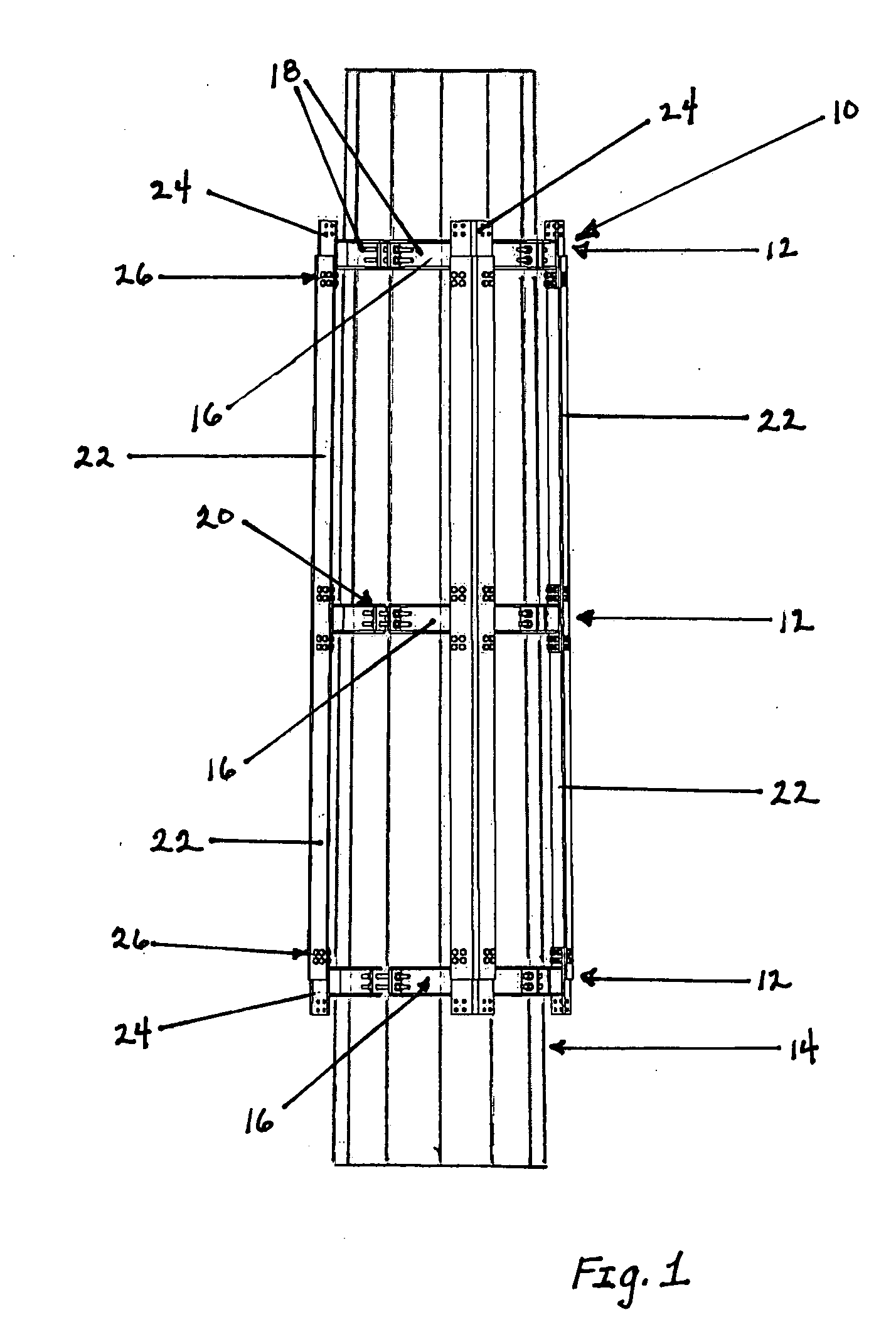

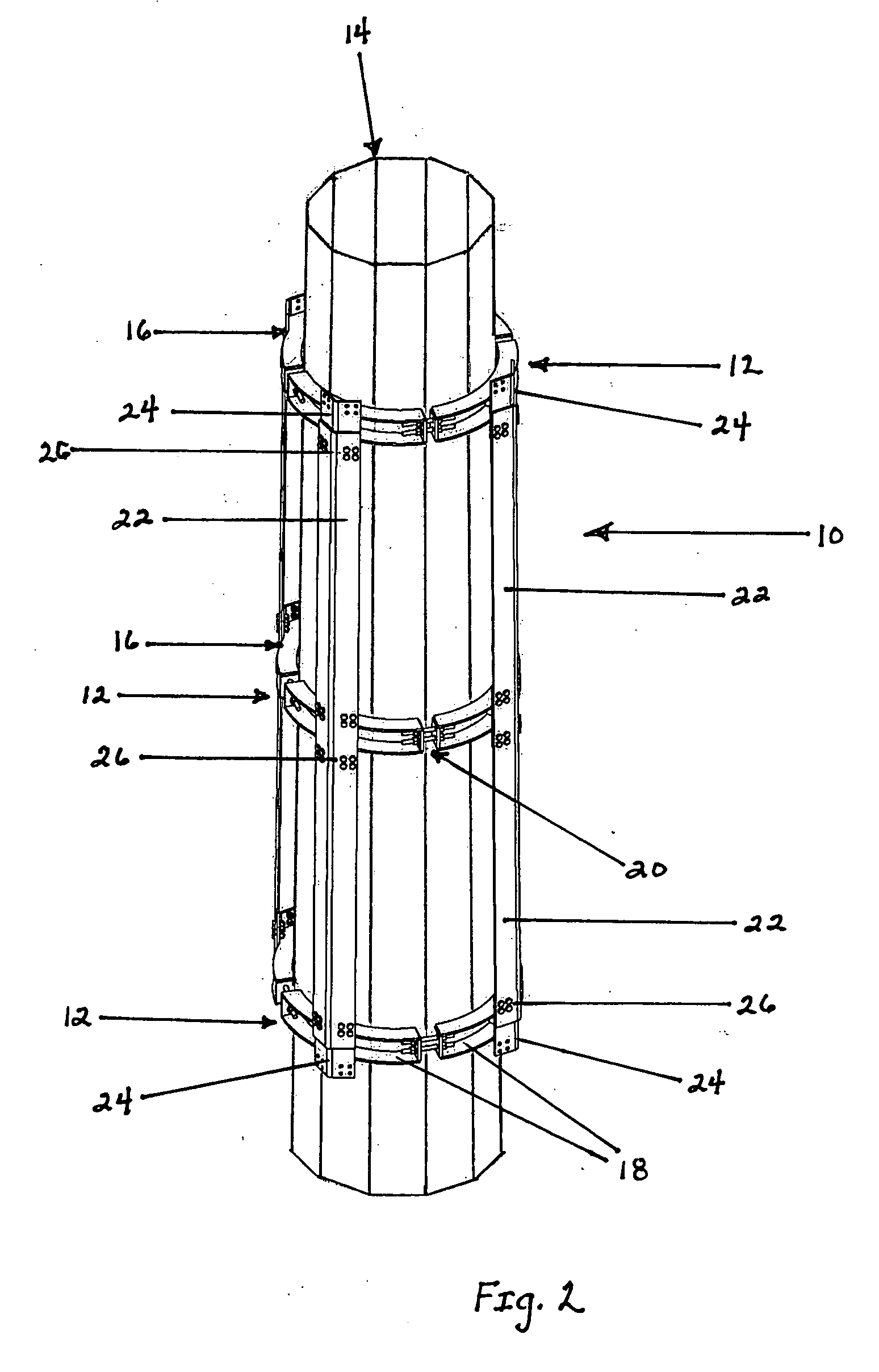

Structural reinforcement member and method of utilizing the same to reinforce a longitudinal section of an antenna support tower

InactiveUS20070256388A1Eliminates and lessens fire dangerIncrease tenant carrying capacityTowersStructural loadEngineering

An assembly for reinforcing a longitudinal section of a pole, includes at least two load transfer rings formed by sleeve segments having radically opposed mating ends. The rings are adapted to fit onto the outer surface of the pole so as to circumferentially encompass the pole. The sleeve segments are connected at their ends by a nut and bolt assembly, wherein tightening of the nut and bolt assembly creates a radial clamping force to squeeze the load transfer rings onto the outer surface of the pole for holding the rings in fixed relation thereon. Elongated stiffener members are fixedly attached to the load transfer rings by a nut and bolt assembly or by welding. The load transfer rings may also be partially welded to the exterior of the pole if structural load bearing demands require additional capacity.

Owner:NELLO

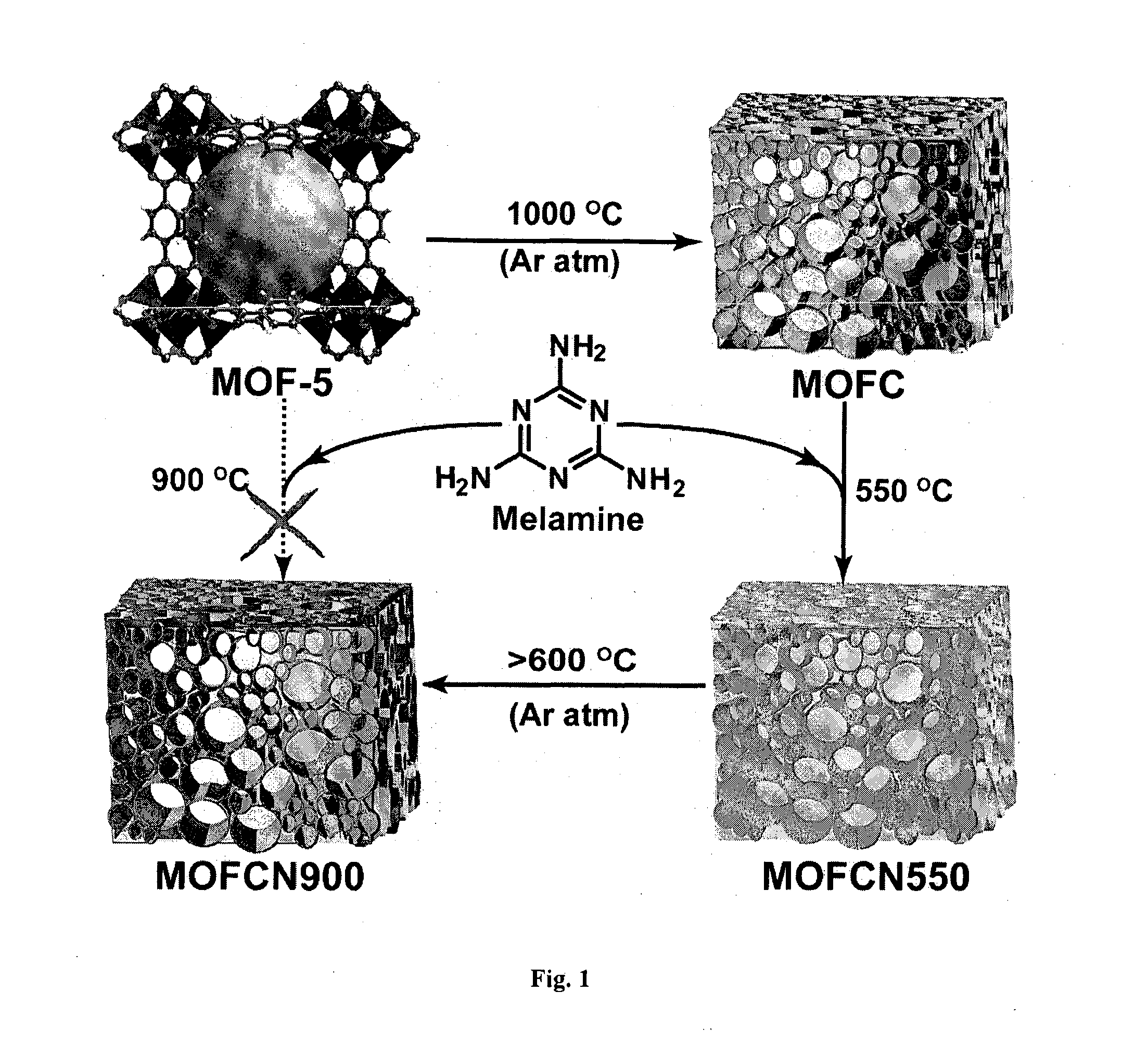

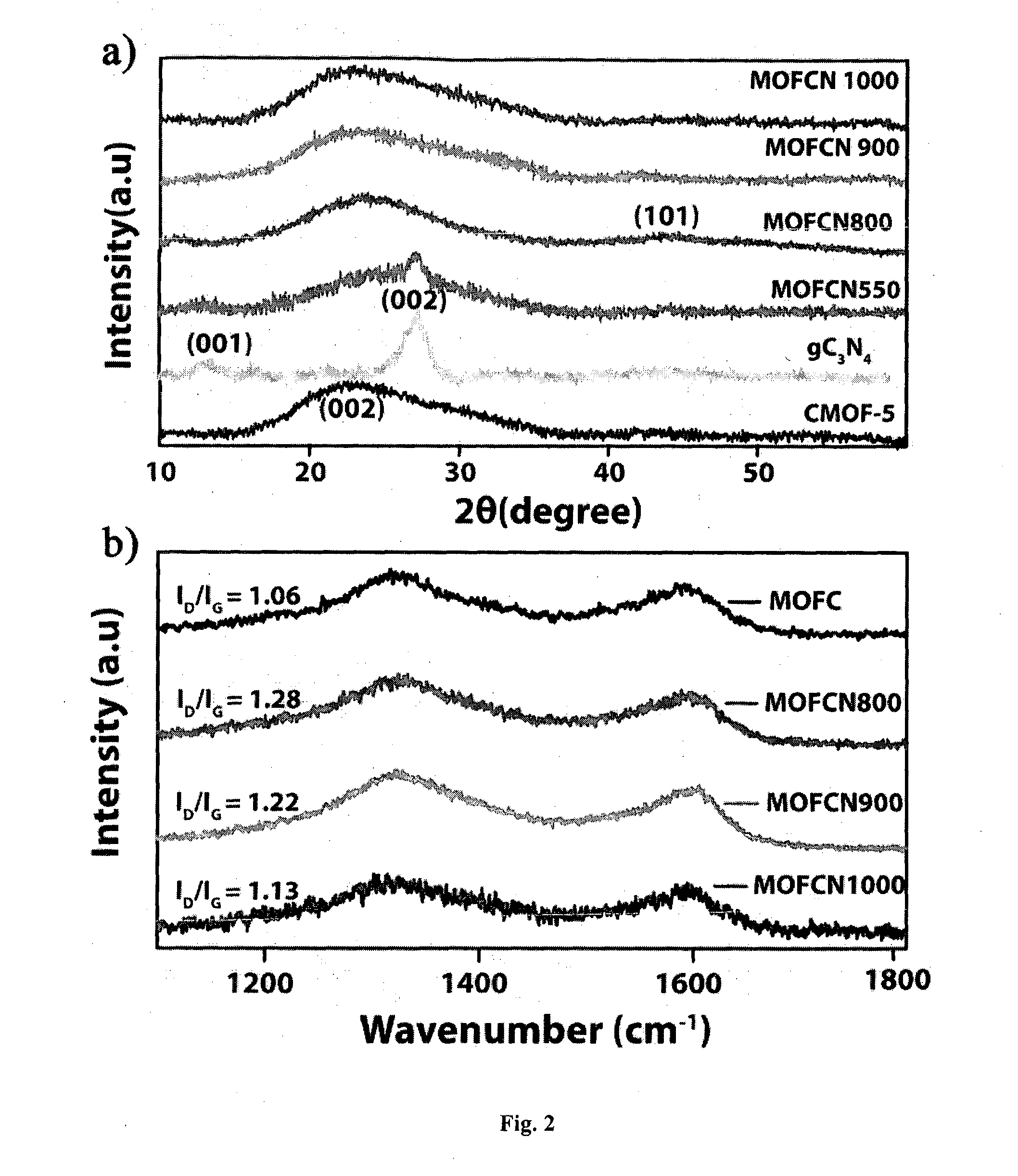

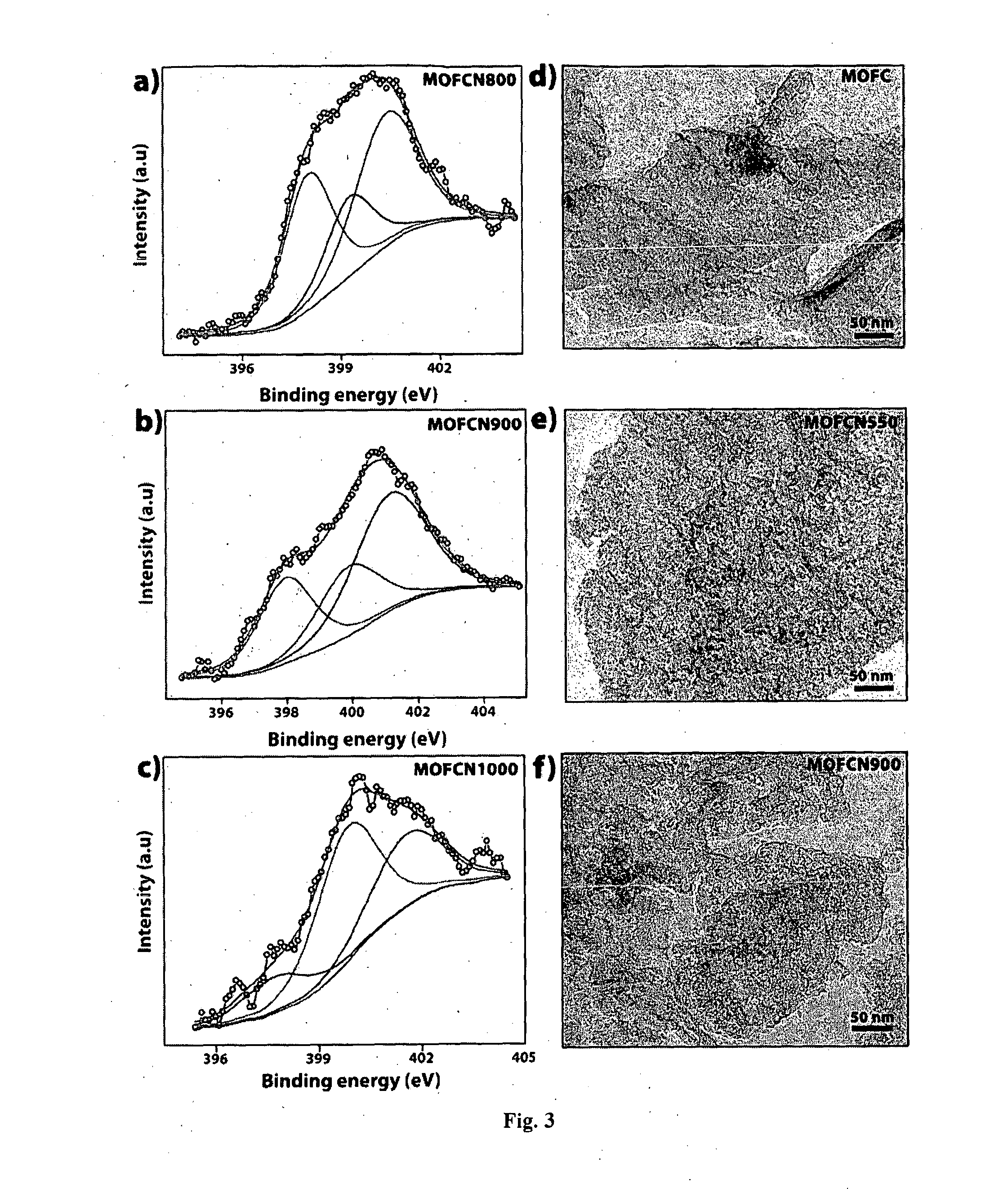

N-doped porous carbon electrocatalyst and process for preparation thereof

ActiveUS20160211529A1Optimize volumeFast shippingPhysical/chemical process catalystsCell electrodesPorous carbonMetal-organic framework

The present invention relates to an efficient, non-metal, N-doped porous carbon electrocatalyst for oxygen reduction reaction and a process for the preparation of using g-C3N4 as a nitrogen precursor, metal organic frameworks (MOF) as a carbon template having high specific surface area, large number of active sites and large pore volume.

Owner:COUNCIL OF SCI & IND RES

Graphene/MXene composite electrode material and application thereof

ActiveCN107633954AGood hydrophilicityLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureIonCvd graphene

The invention relates to a graphene / MXene composite electrode material and application thereof. The graphene / MXene composite electrode material comprises two materials of graphene and MXene. A preparation method of the graphene / MXene composite electrode material comprises the steps of uniformly mixing a graphene oxide suspension liquid and an MXene material suspension liquid, adding hydrazine hydrate and the performing reduction, freezing and drying to obtain the graphene / MXene composite electrode material, wherein the mass ratio of graphene oxide and the MXene material is 1:(0.05-0.5). When graphene and MXene are combined, an irregularly-shaped MXene particle material can be used as an insertion agent and a dispersing agent and enters graphene sheet layers, the agglomeration effect amongthe graphene sheet layers is overcome, and the available specific area of the graphene / MXene composite electrode material is expanded; and moreover, the MXene material has excellent hydrophilcity andconductivity, and thus, the electrochemical performance and the capacitance deionization performance of the composite material can be further improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

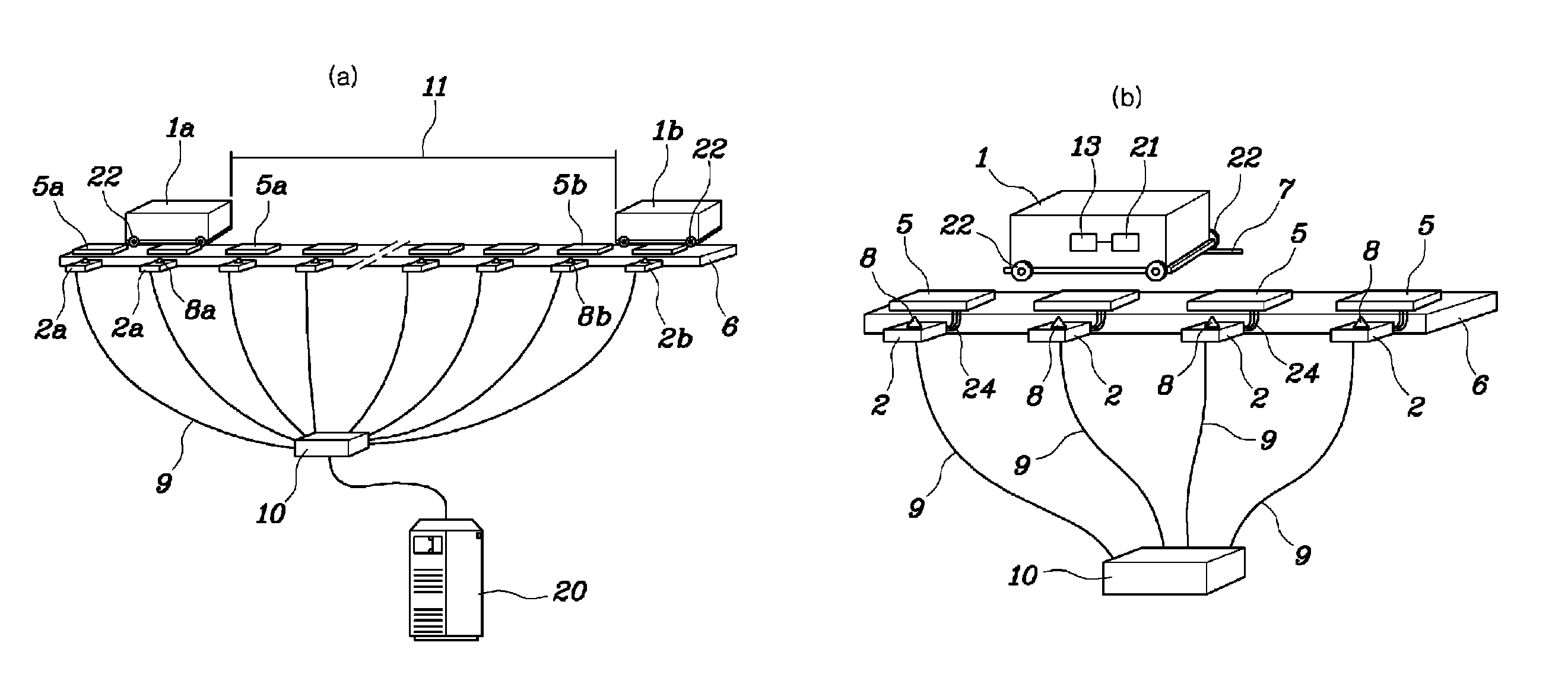

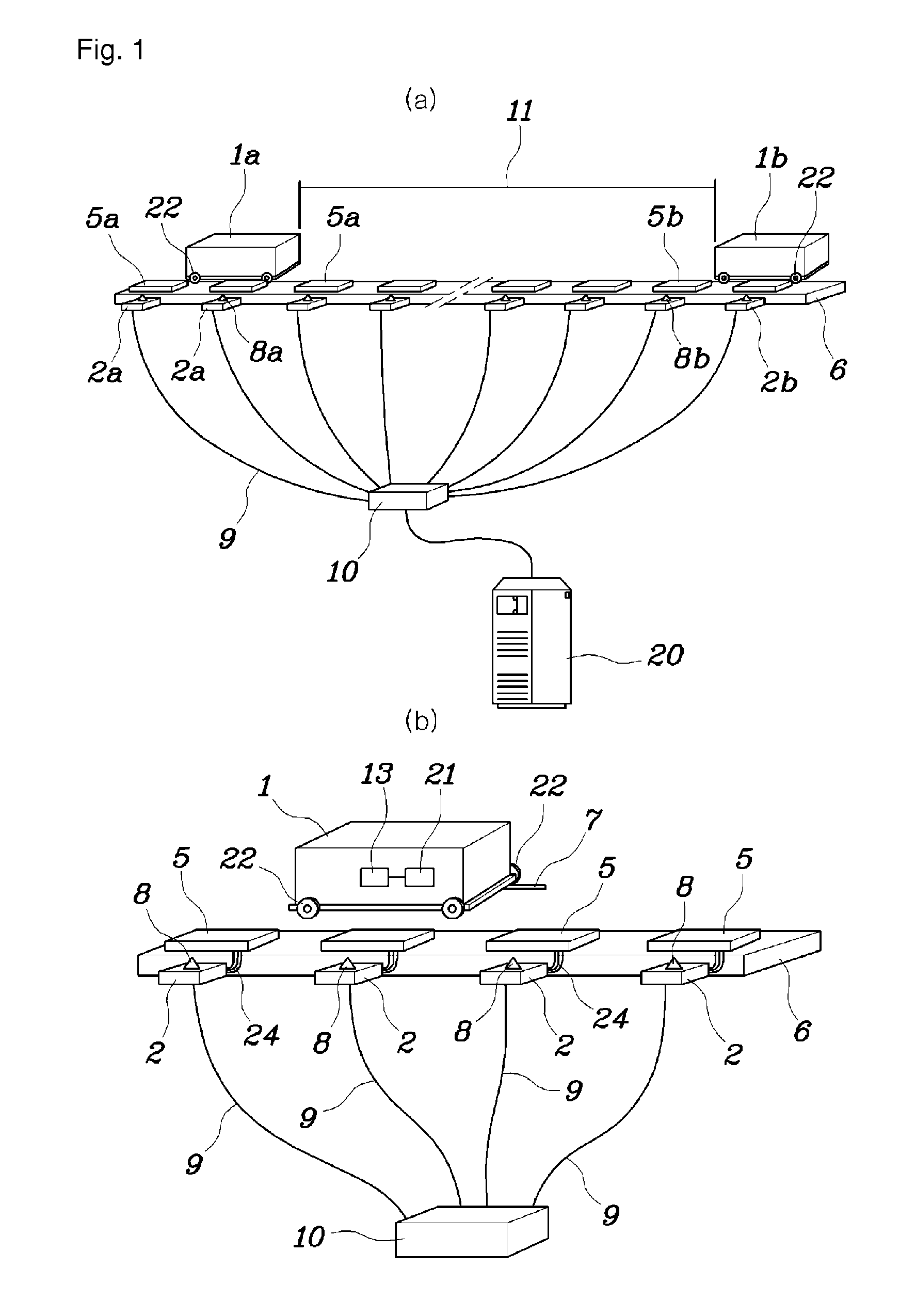

Method for platooning of vehicles in an automated vehicle system

InactiveUS8682511B2Operation is avoidedReduce distanceControlling traffic signalsArrangements for variable traffic instructionsEngineering

Disclosed is a method of increasing track capacity in an automated vehicle system, the automated vehicle system comprising a network of tracks along which vehicles are adapted to travel, the network comprising at least one merge point at which at least two up stream tracks merge to form a downstream track, at least one diverge point at which one upstream track diverges to form at least two down-stream tracks and a plurality of stations at which passengers may board and / or disembark from the vehicles; wherein the method comprises controlling vehicles so as to cause empty vehicles to travel as at least one sequence of vehicles defined as a platoon; and controlling the empty vehicles of the at least one sequence to travel with a first safety distance between each other, the first safety distance being shorter than a second safety distance between vehicles being at least partially loaded.

Owner:POHANG IRON & STEEL CO LTD

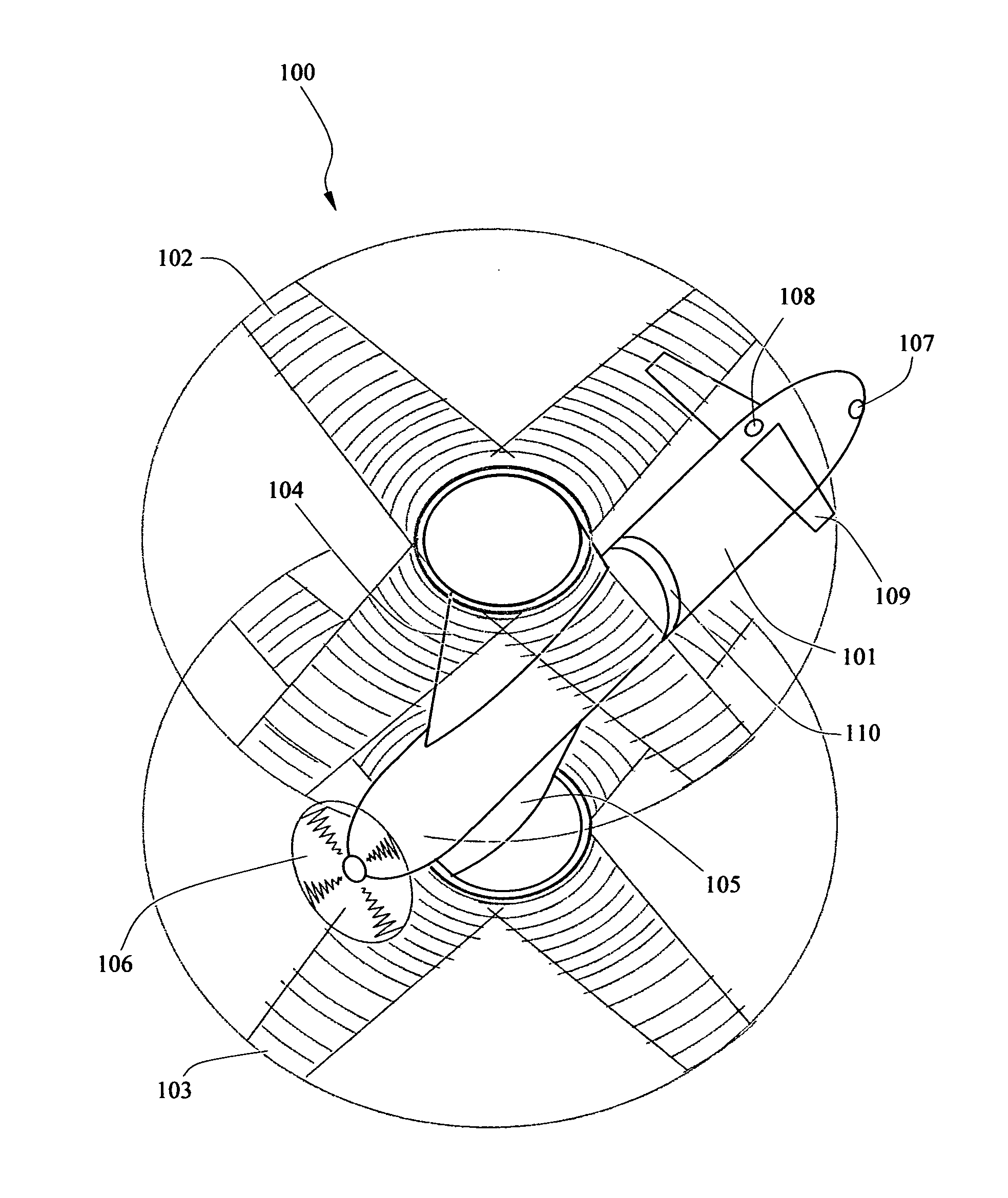

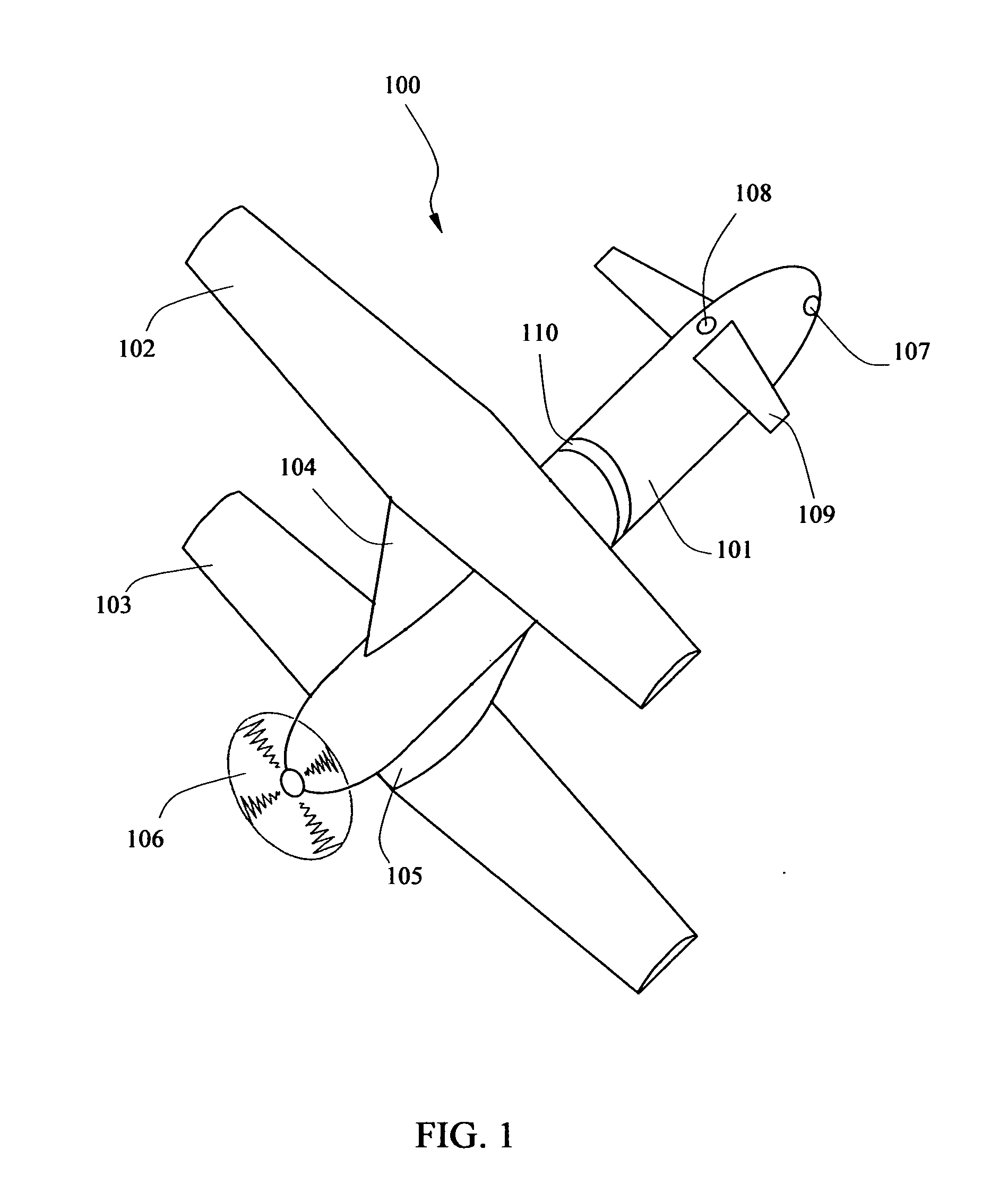

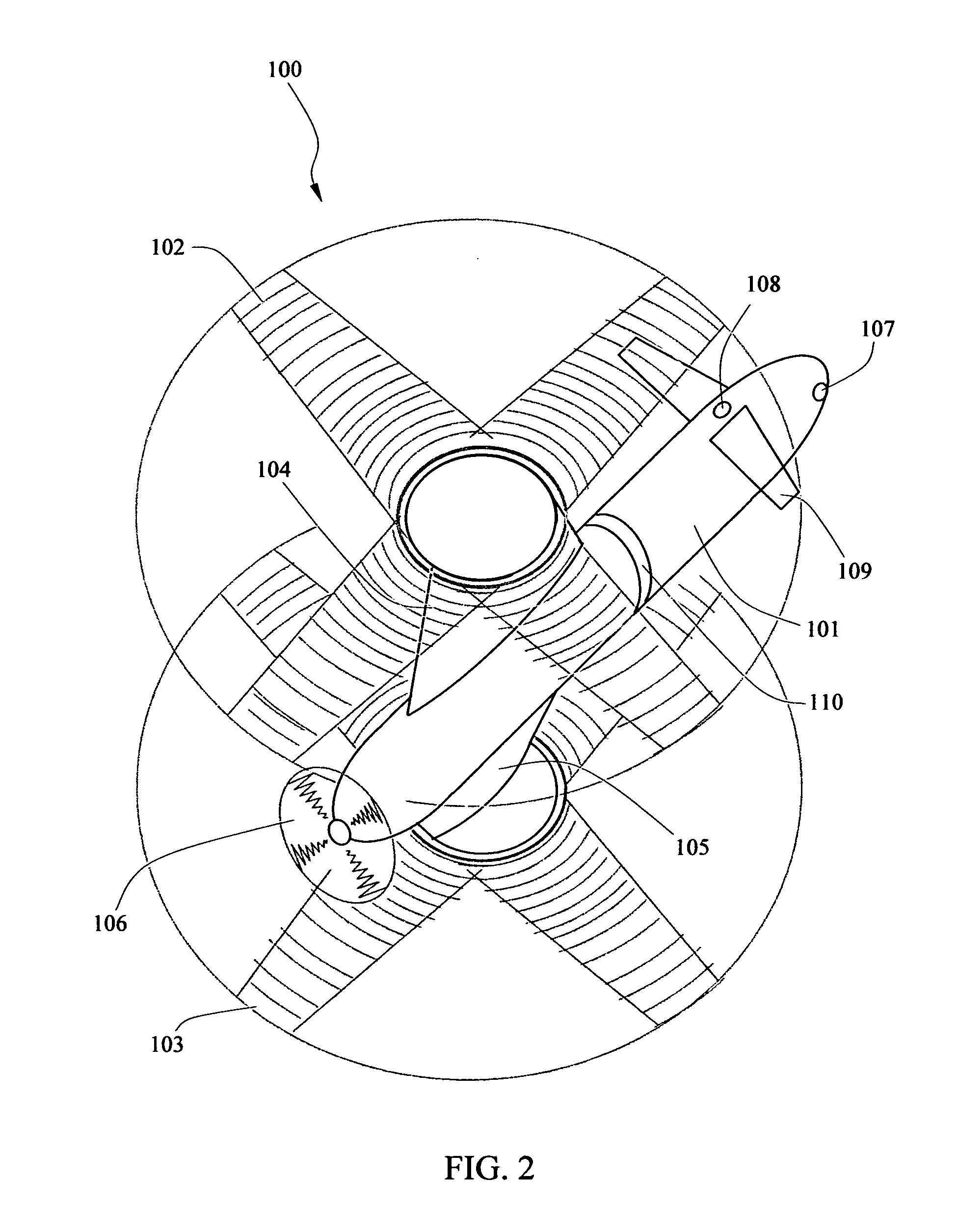

Coaxial rotor/wing aircraft

InactiveUS20140312177A1Efficient and safe transitionFast shippingRotocraftRotational axisFlight vehicle

A system and method which enable efficient, rapid and safe transition between rotary-wing and fixed-wing flight mode in rotor / wings aircrafts is disclosed. The aircraft comprises of two rotor / wings on the same axis of rotation, one above the fuselage and the other one under the fuselage. During rotary-wing mode, the rotor / wings rotate coaxially and provide vertical lift. During transition between rotary-wing and fixed-wing modes, the synchronised operation of the two rotor / wings maintains lateral symmetry of lift on the aircraft. The reaction of the rotor / wings on the fuselage is also canceled. During fixed-wing flight mode, the two rotor / wings are stopped and locked in a biplane configuration, both providing lift as fixed wings. The rotor / wings may be further reconfigured for higher subsonic or supersonic speed. Tandem and multiple rotor / wings aircrafts with increased cargo capacity, speed and range, comprise of multiple of these coaxial rotor / wings.

Owner:GAONJUR RAJESH

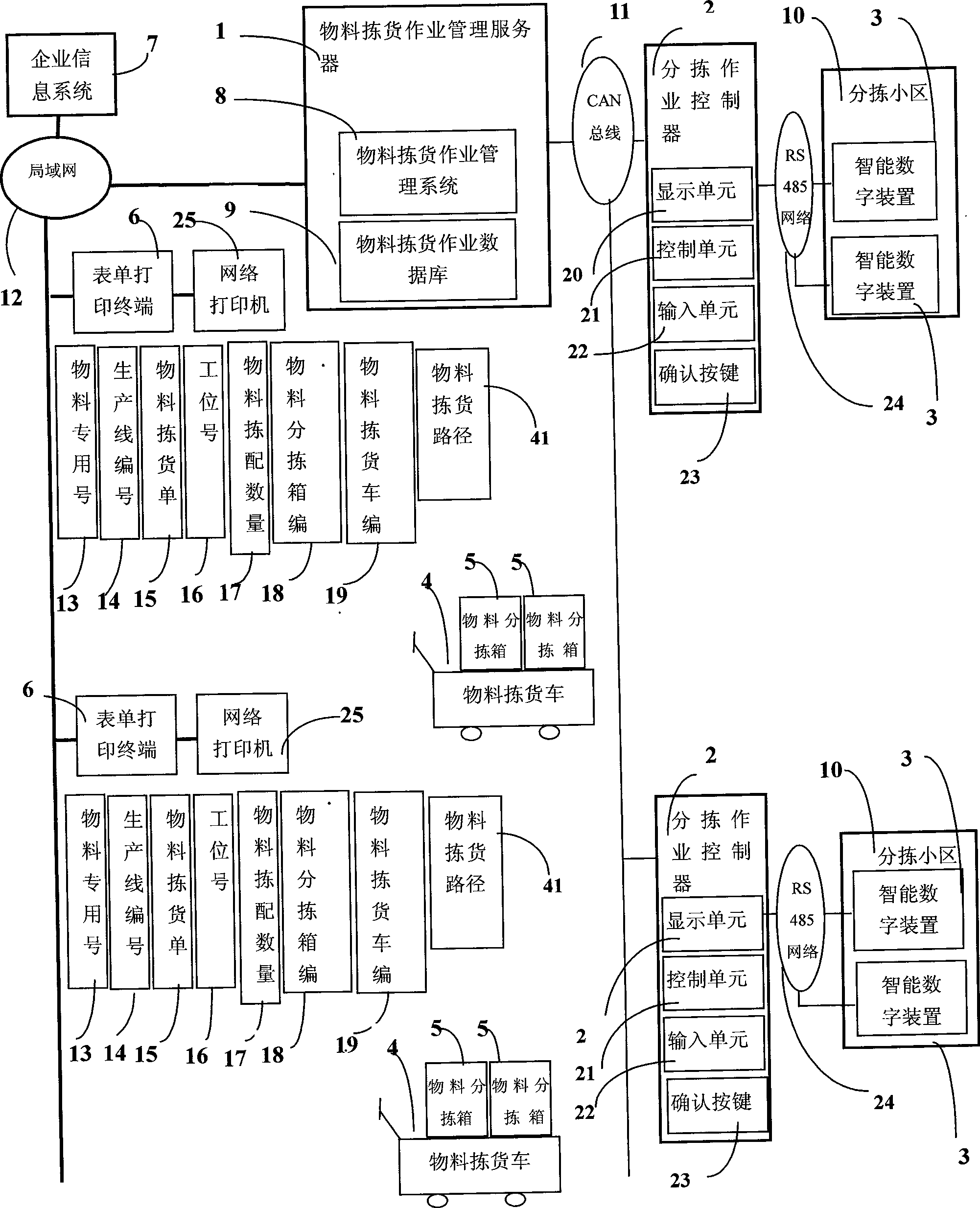

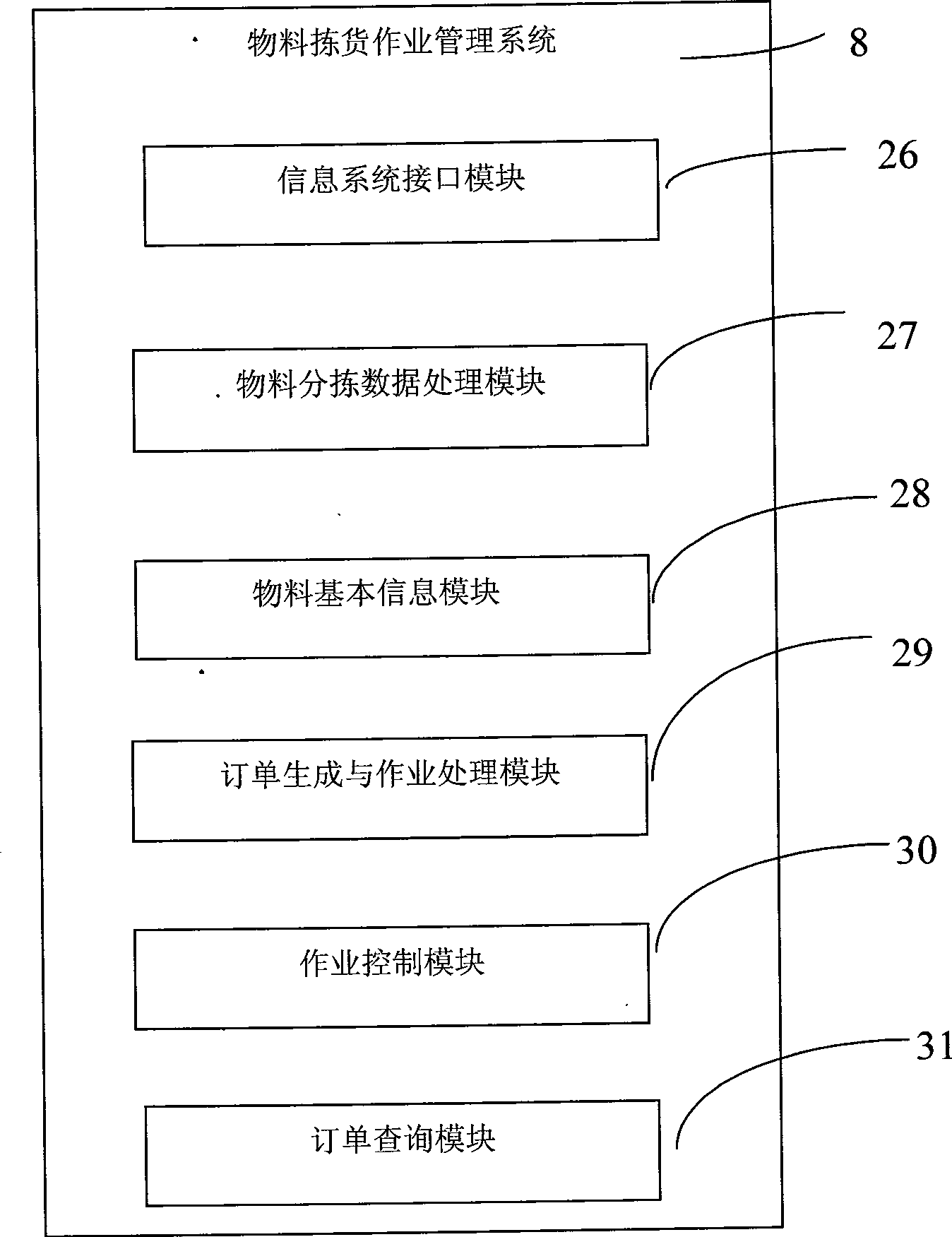

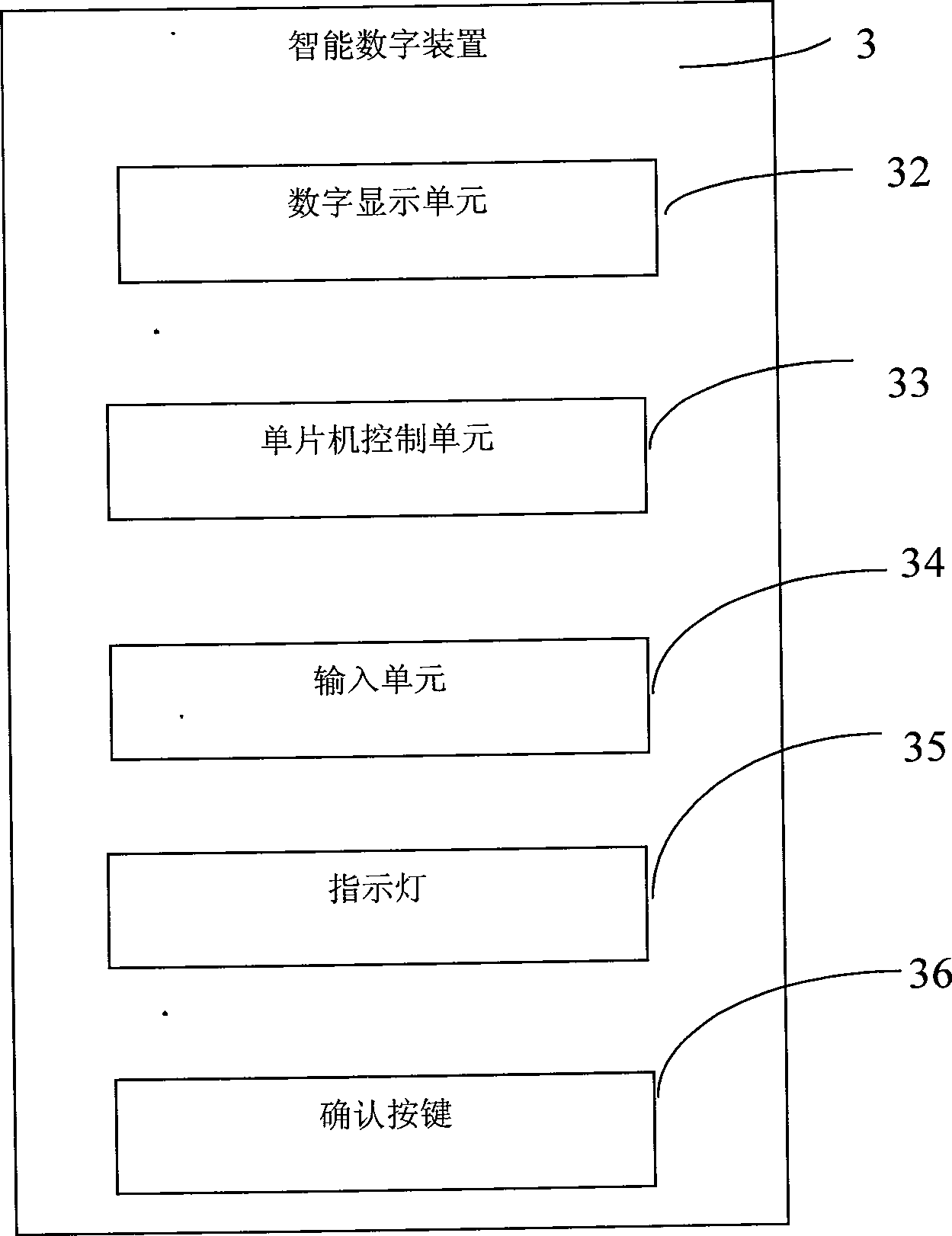

System and method for managing and controlling material picking operation on production line

The invention relates to a system and a method for managing and controlling the material picking operation on a production line. The system comprises a management server, at least one picking operation controller, a plurality of intelligent digital devices, at least one list printing terminal, at least one material picking vehicle, a plurality of material picking boxes and at least one printer. A picker and a material picking wagon form a picking combination; the management server assigns a picking task by taking the material picking wagon as unit; the picker obtains picking data at the printing terminal; the system provides an optimal picking path according to the position of the picker; the intelligent digital devices display the material picking information after the picker inputs wagon numbers in the picking operation controller; and the picker checks the materials according to dedicated material numbers, takes the materials according to displayed quantity, and puts the picked materials into corresponding material picking boxes according to station numbers. The system can directly deliver materials to a production station from a storehouse accurately, automatically generate vouchers for the delivered materials and transmit the vouchers to enterprise information system in real time.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

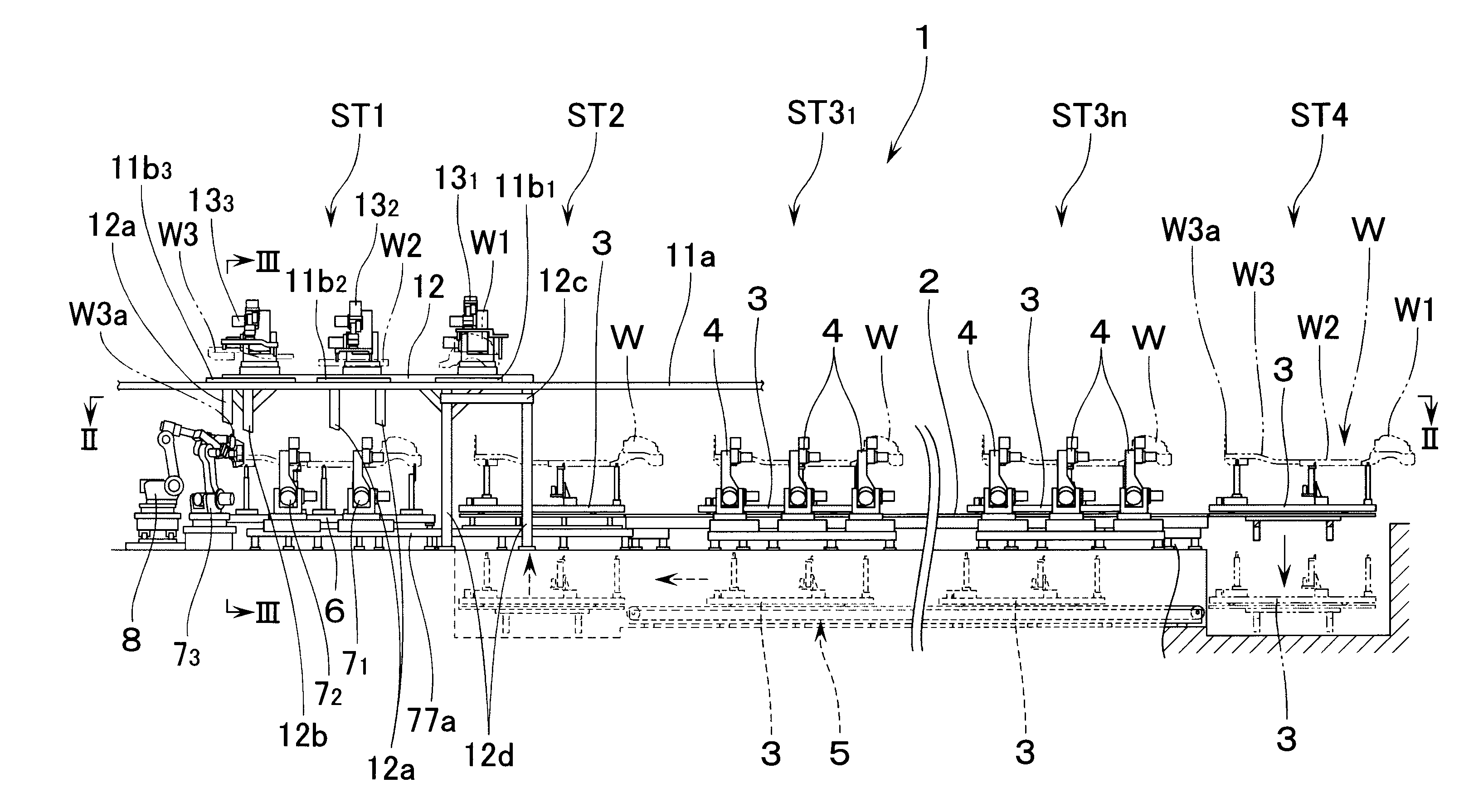

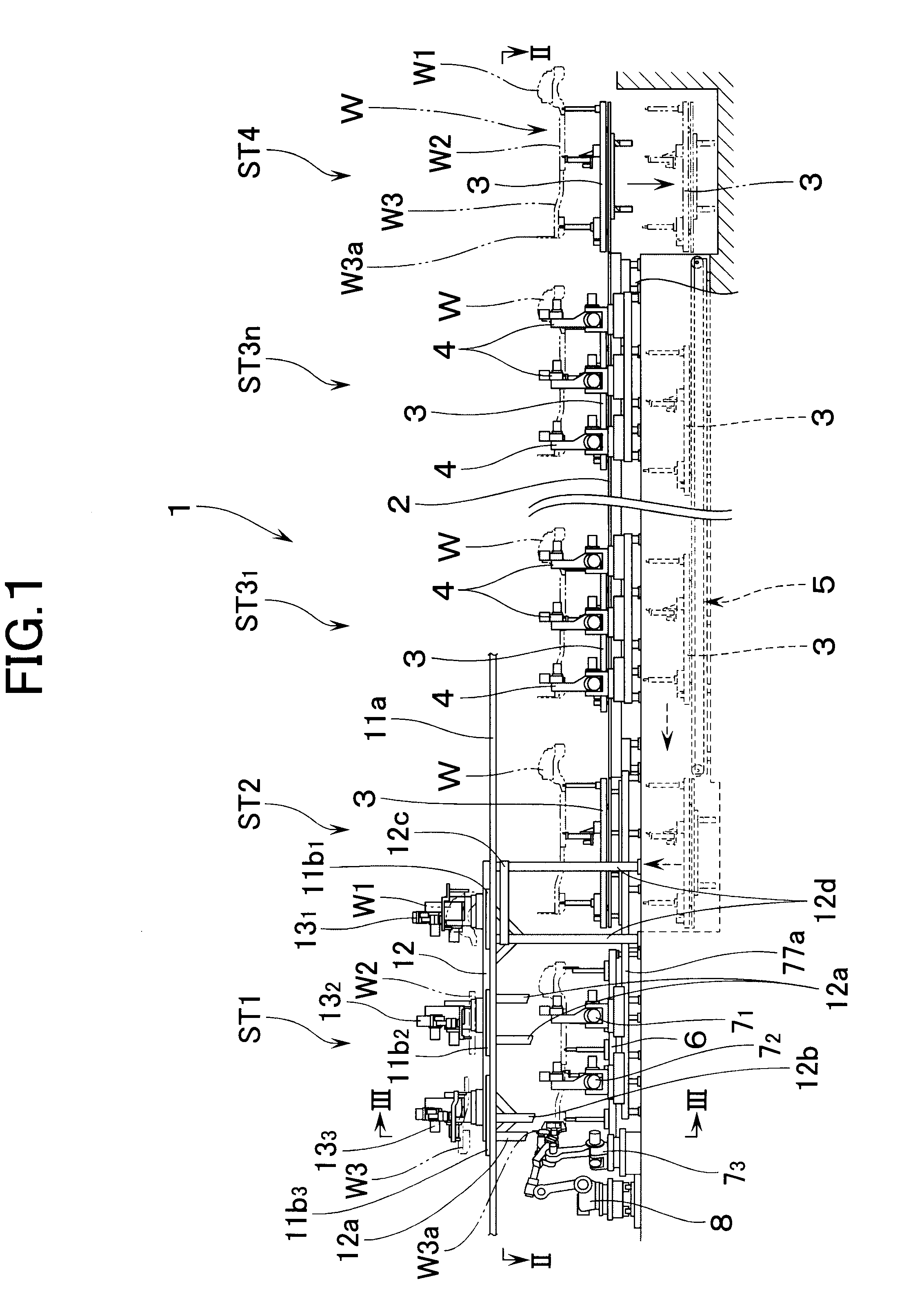

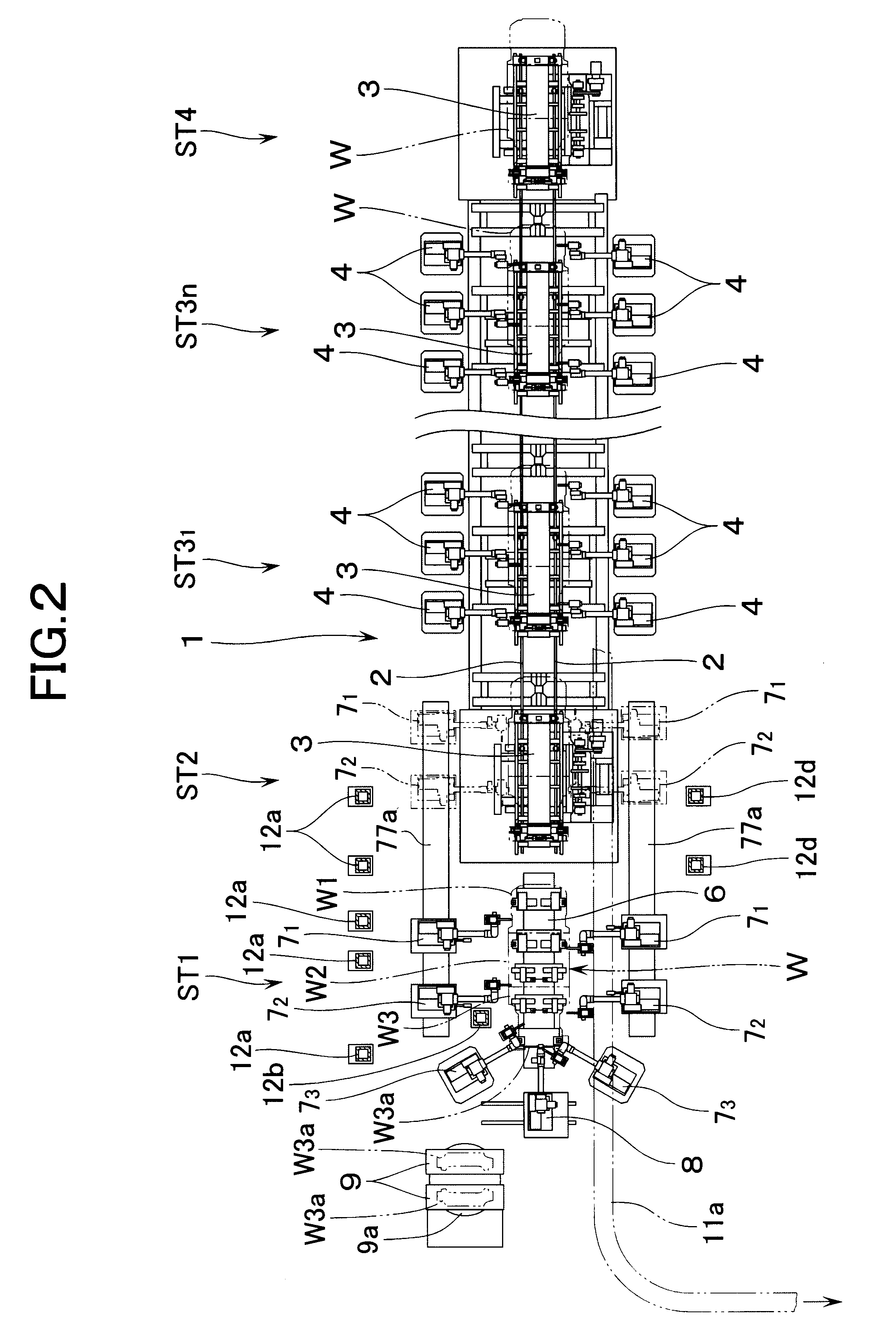

Apparatus for assembling floor of vehicle

InactiveUS6339204B1Small sizeFast shippingResistance electrode holdersWelding/cutting auxillary devicesDual purposeWelding

The floor of a motor vehicle which is assembled in a floor assembly station is transported to a subsequent station using at least two welding robots on each lateral side of the floor assembly station. These welding robots are constituted into dual-purpose welding robots for performing both welding work and transporting work. After the assembling of the floor has been finished, the floor is supported at four lateral and longitudinal jack-up points through the workpiece receiving member by the cooperation of these dual-purpose welding robots, and is transported from the floor assembly station to the subsequent station.

Owner:HONDA MOTOR CO LTD

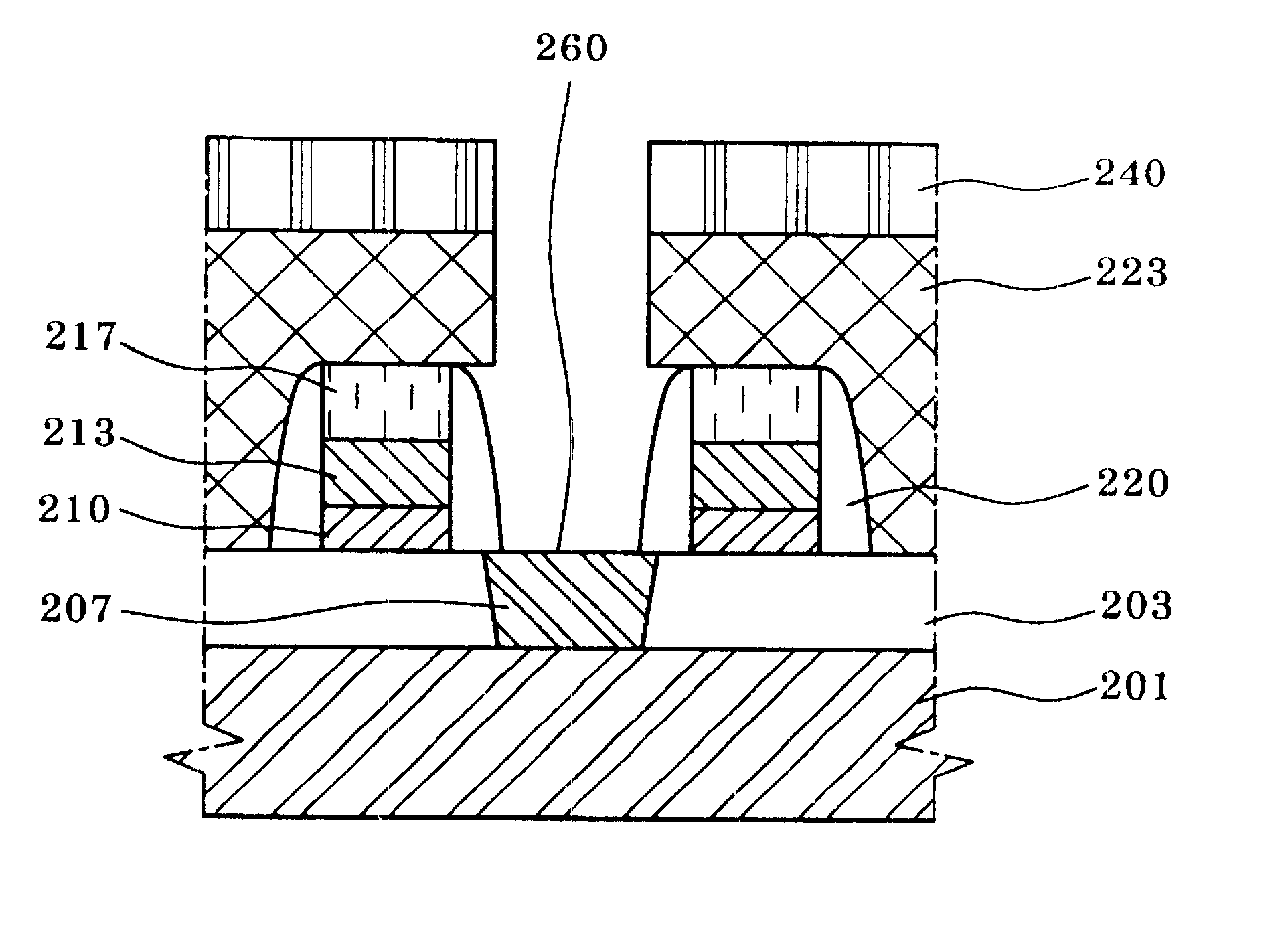

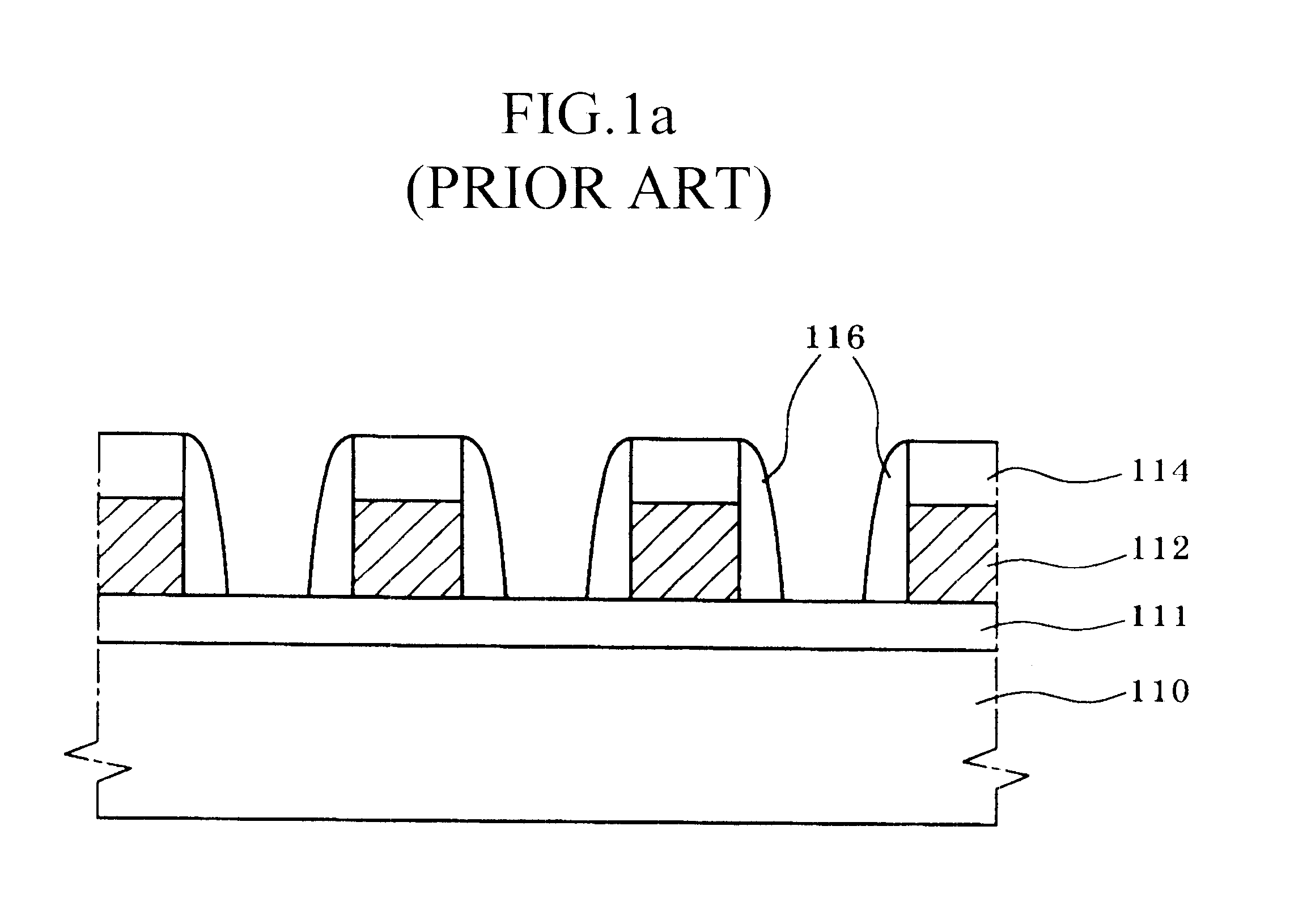

Device and Method for the Demodulation Electromagnetic Wave Fields

ActiveUS20080239466A1Less susceptibleLess susceptibilityTelevision system detailsSolid-state devicesCharge currentWave field

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

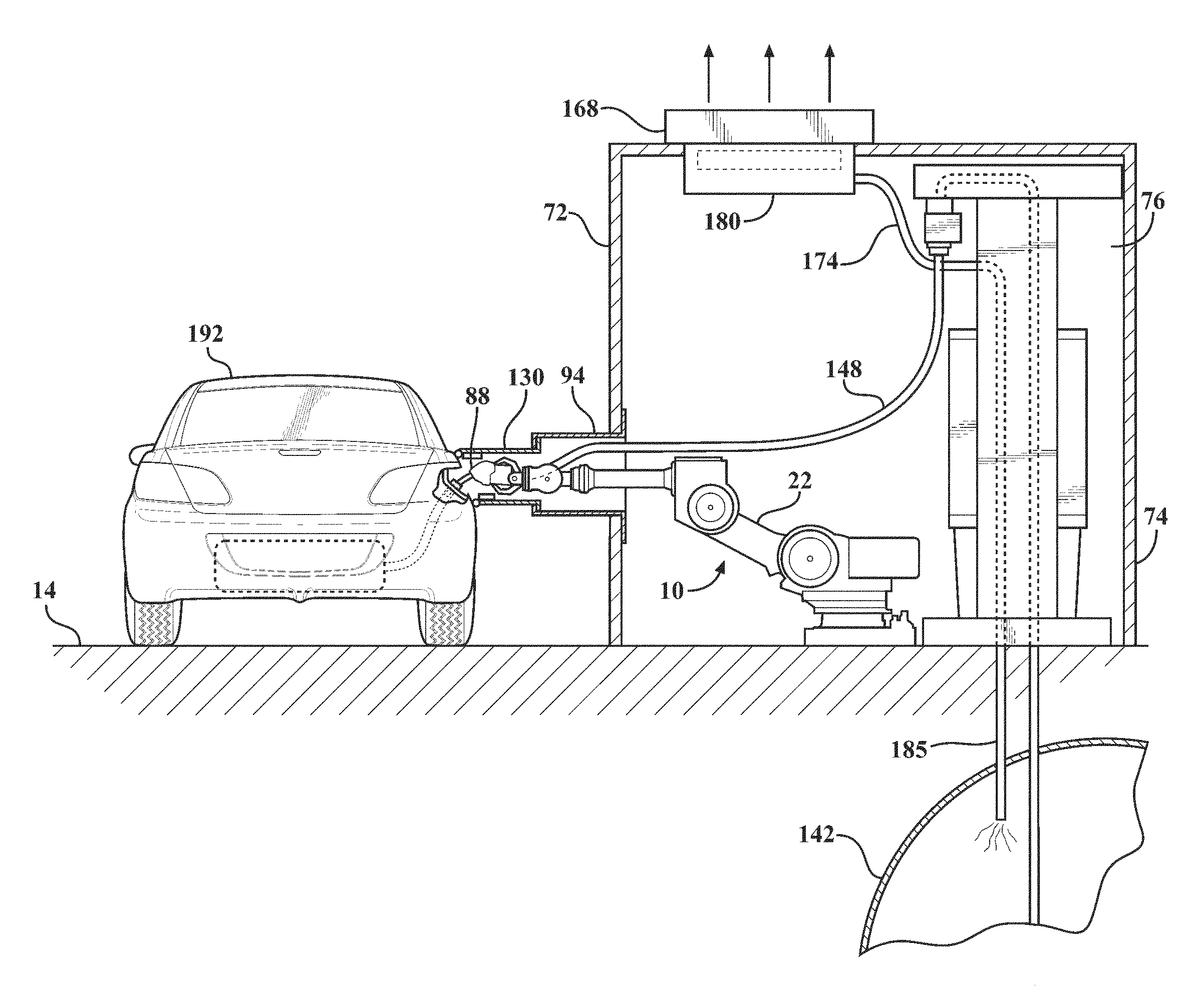

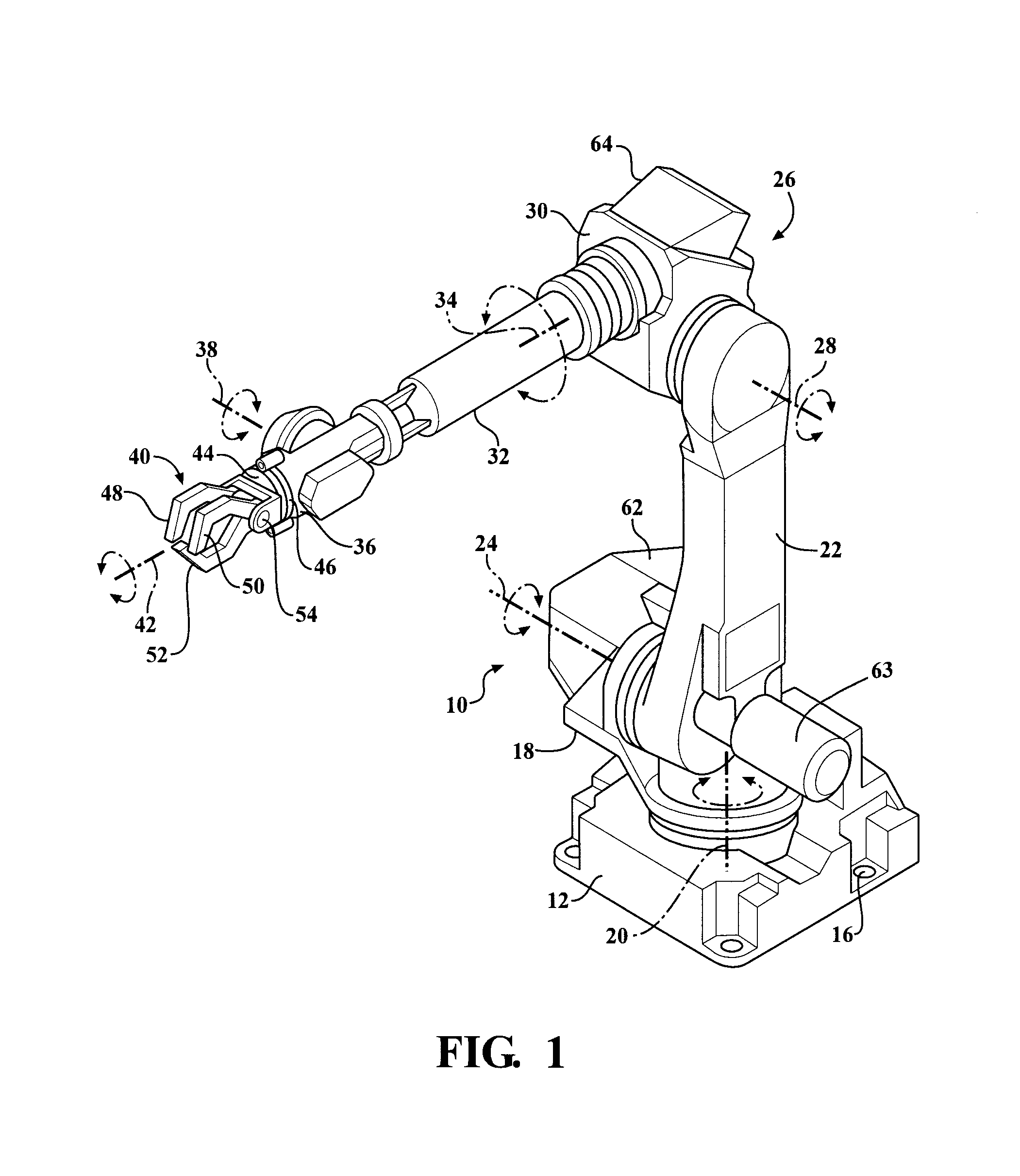

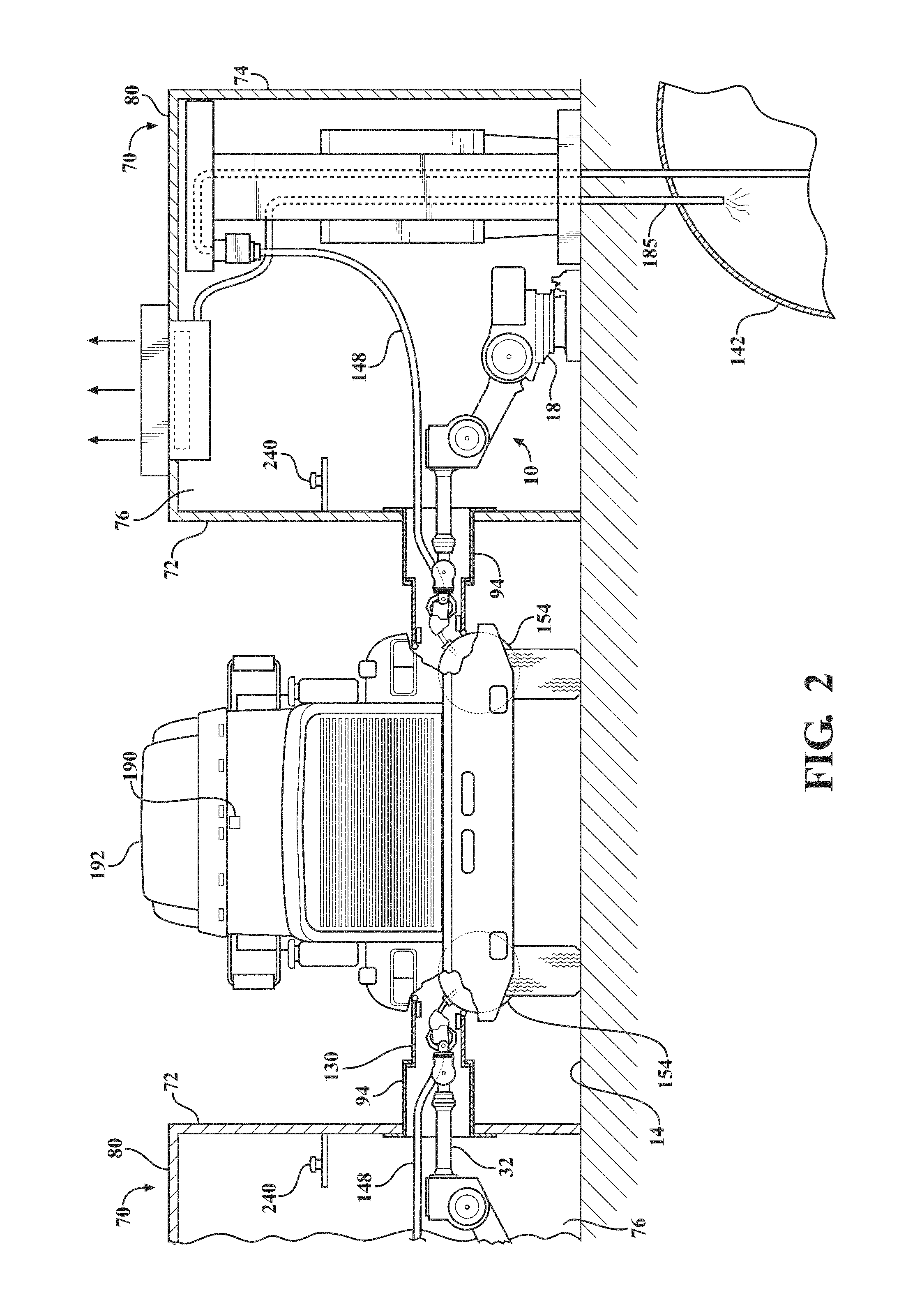

Automated vehicle fueling apparatus and method

InactiveUS8393362B1Free from damageFast shippingLiquid fillingLiquid transferring devicesEngineeringMulti axis

A multi axis robot is mounted in a fuel transfer housing. A programmable controller is connected to the robot. A control console receives instructions, from a vehicle operator who remains in an operator's station, and transmits instructions to the controller. Cameras locate the vehicle fueling port. A tube is extended from the transfer housing toward the fueling port. The port is opened by robot arm and tools extending through the tube. The cap is stored. A fuel discharge is connected to the port. A fuel pump is activated and then deactivated. The fuel discharge is removed from the port. The robot retrieves the fuel cap, closes the port and closes other port covers. The tube is retracted into the transfer housing. During fueling air and fuel vapors are sucked into the housing. Filters separate air. Captured fuel is returned to storage. The operator and vehicle separate from the fuel housing.

Owner:HOLLERBACK JAMES A

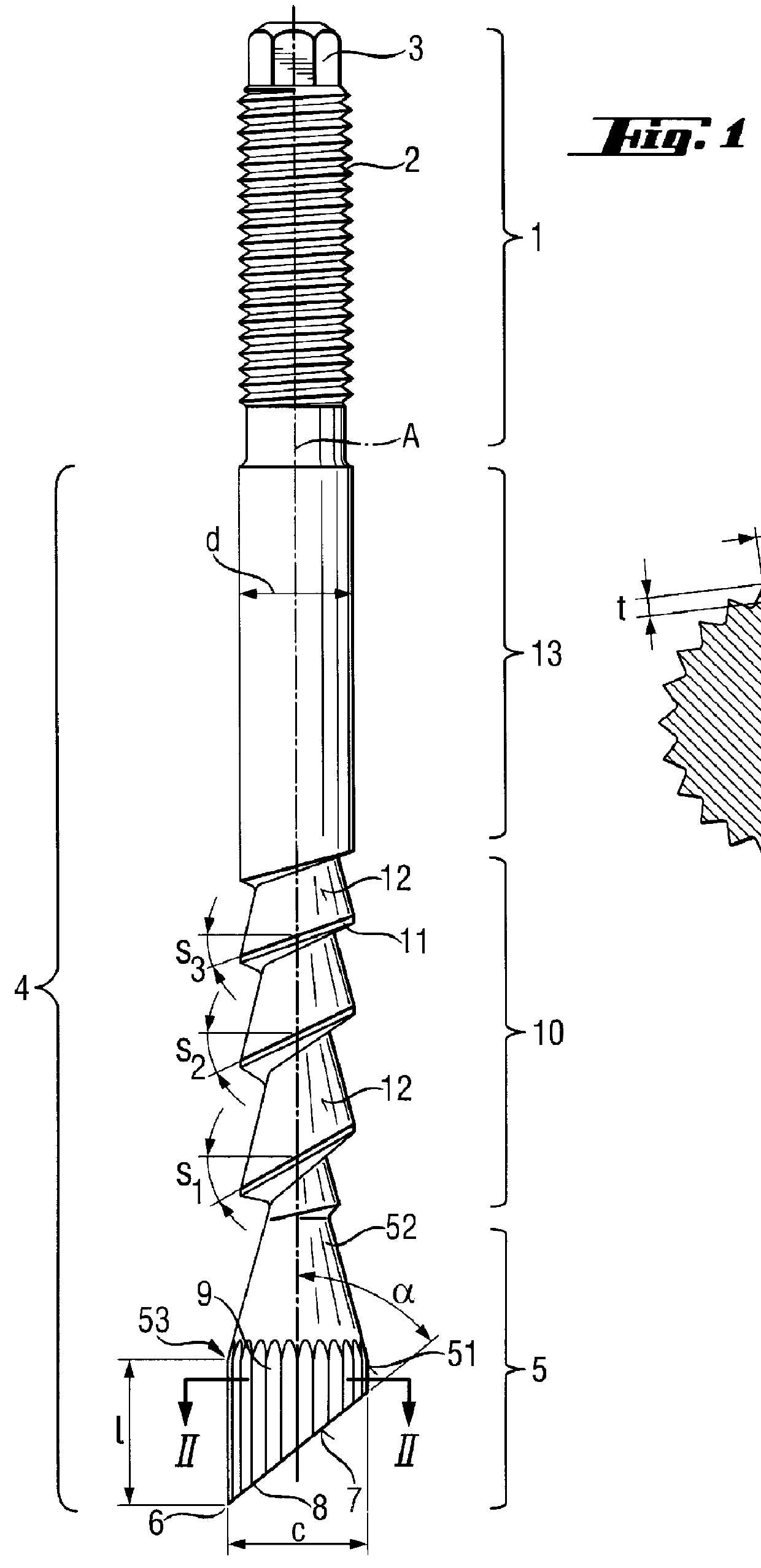

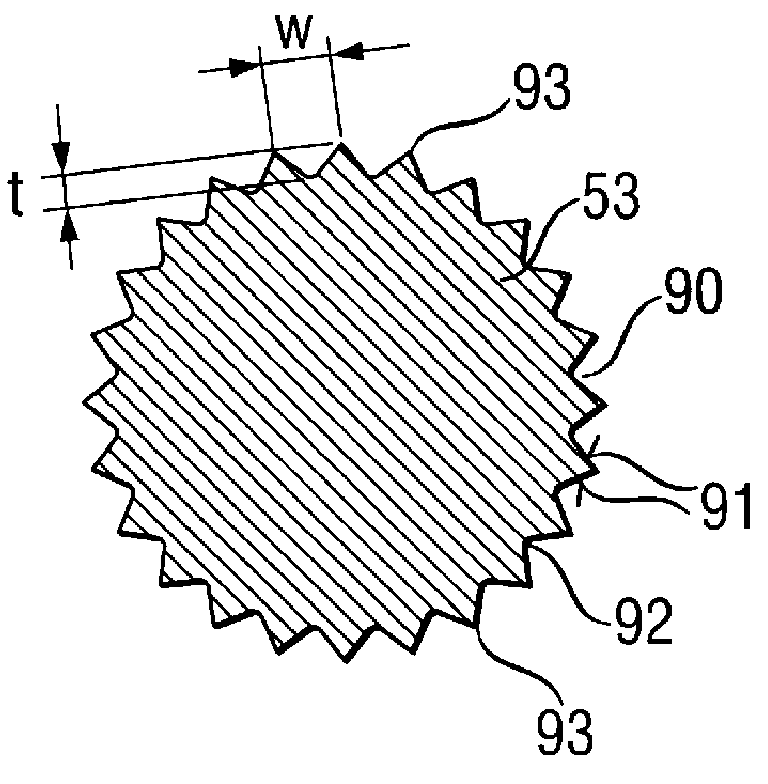

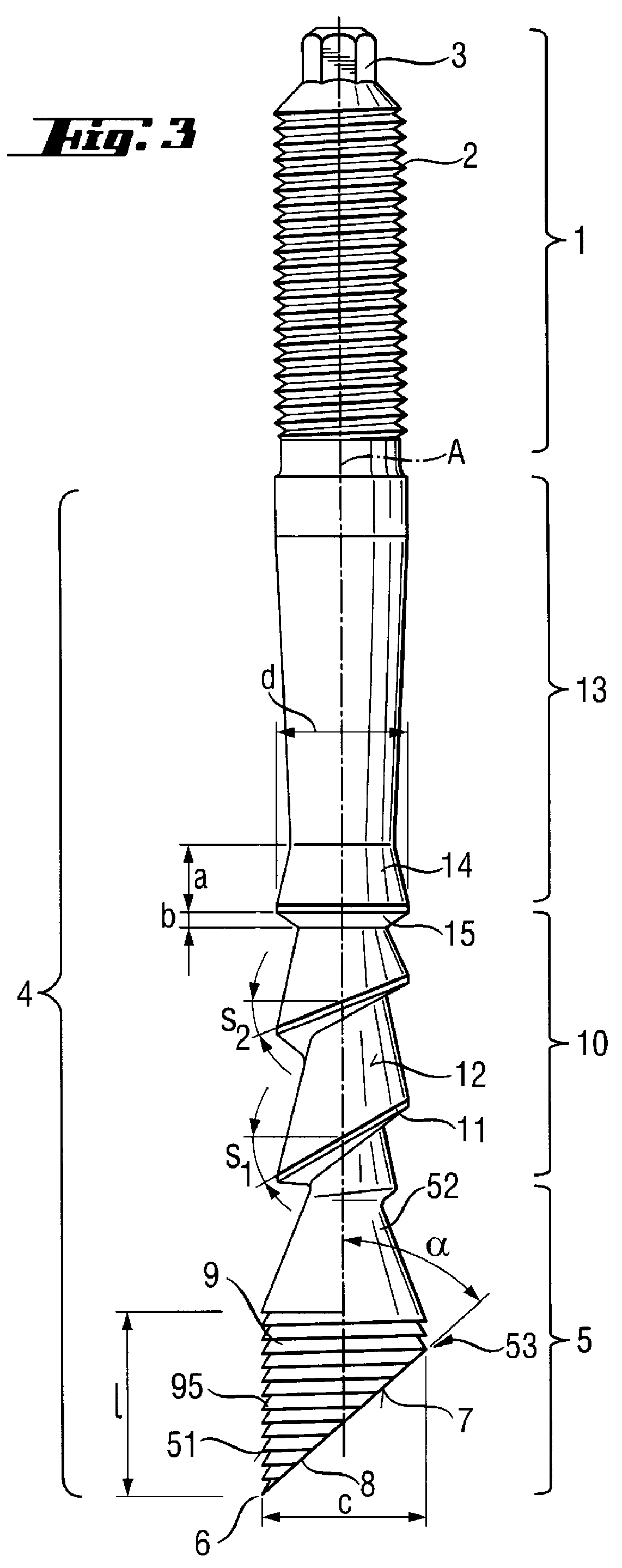

Anchor rod for an attachment anchor

An anchor rod for an attachment anchor including a trailing region (1) provided with a load application element (2), and an anchoring region (4) submergeable in a hardenable inorganic and / or organic mortar mass and having a mixing section formed of a head portion (5) provided at its free end (6) with a cutter (7) extending substantially transverse to the axis (A) of the anchor rod, a transporting section (10) adjoining the mixing section, and a compression section (13) adjoining the transporting section (10), with the head portion (5) having a region (53), the outer diameter (c) of which is larger than the largest diameter (d) of the transporting and compression sections (10,13) of the anchoring region (4), and provided with a mortar mass transporting arrangement (9).

Owner:HILTI AG

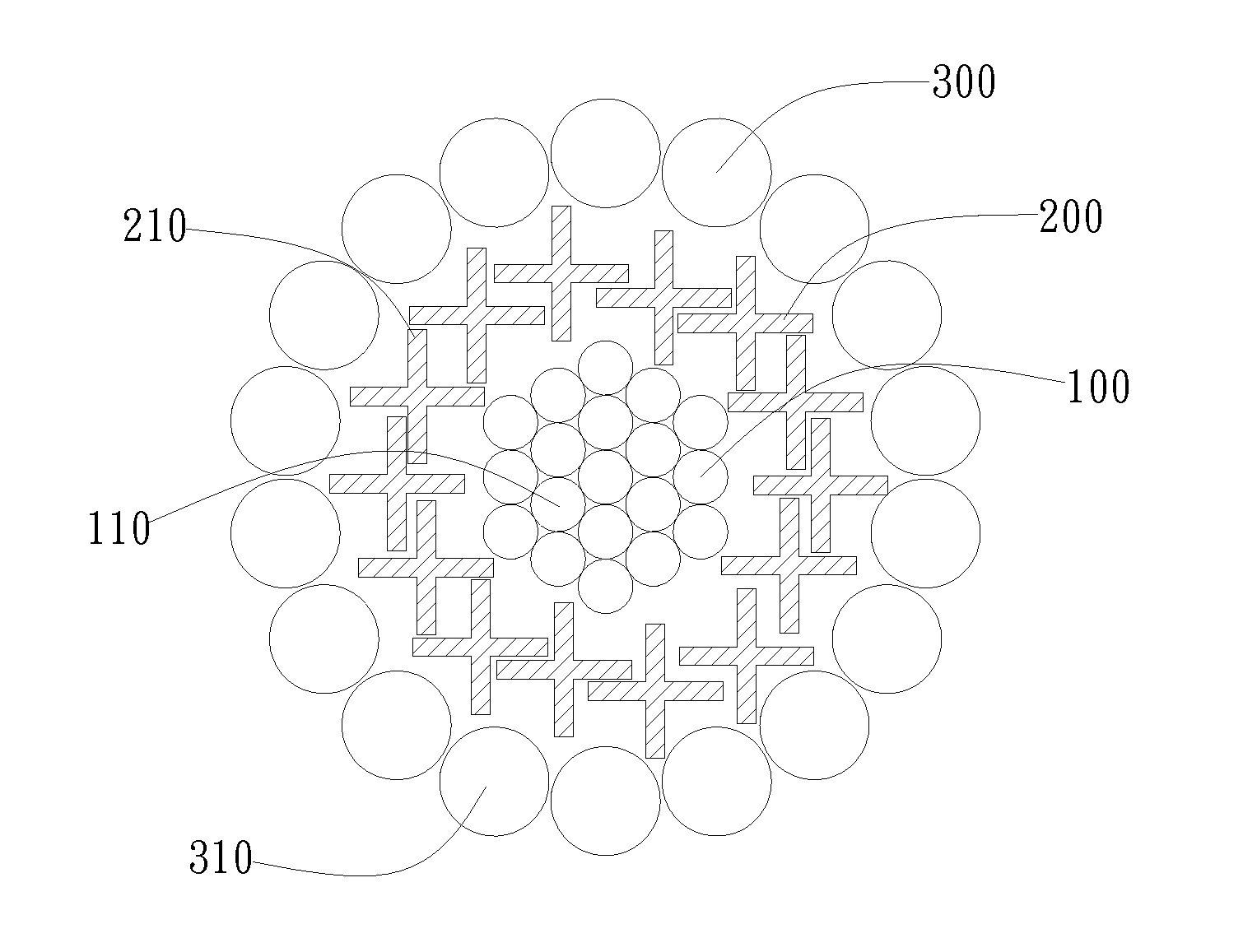

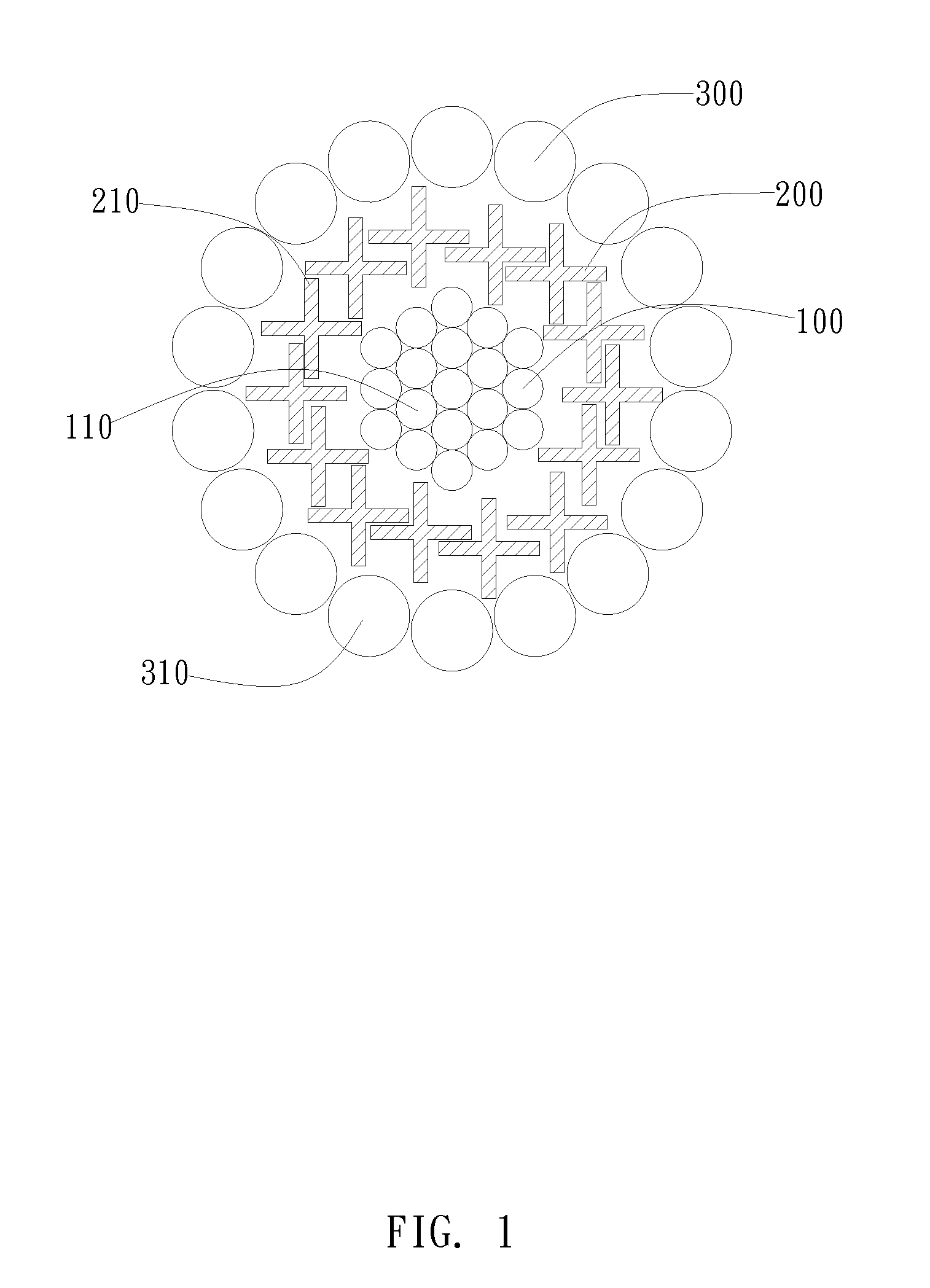

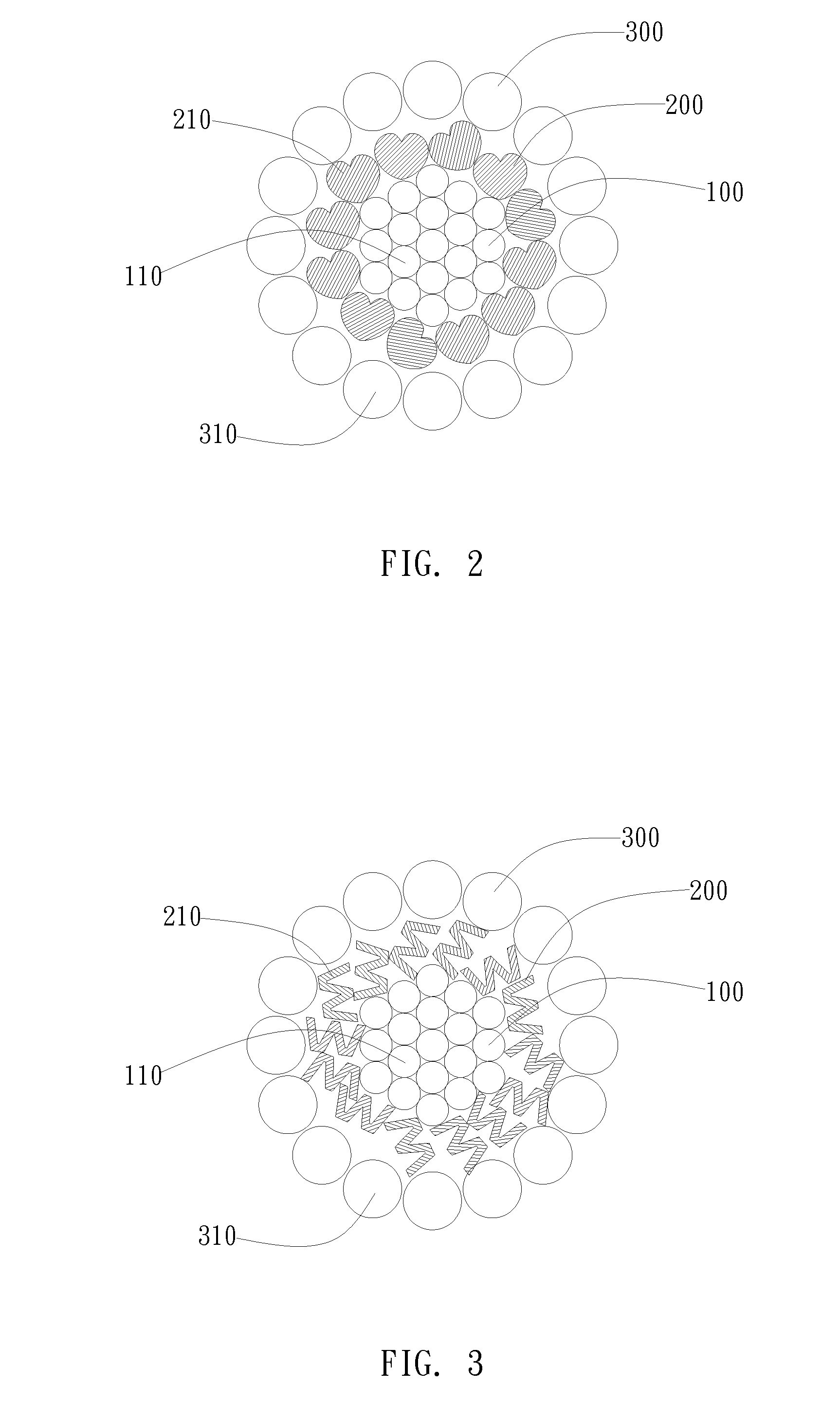

Multi-layer yarn structure and method for making the same

A multi-layer yarn structure and a method for making the same are provided. The multi-layer yarn structure includes a core layer, a layer of noncircular fibers, and an outer layer. The core layer has a plurality of hydrophobic fibers. The noncircular fibers surround the core layer to form a middle layer. The outer layer surrounds the middle layer and has a plurality of hydrophilic fibers. The method spins different fibers into multi-layer yarn for making textile with a soft, smooth, and thick feel. By utilizing inherent characteristics of the multi-layer yarn structure, the textile may regulate moisture released from the human body and keep the body dry and comfort.

Owner:RUENTEX INDS

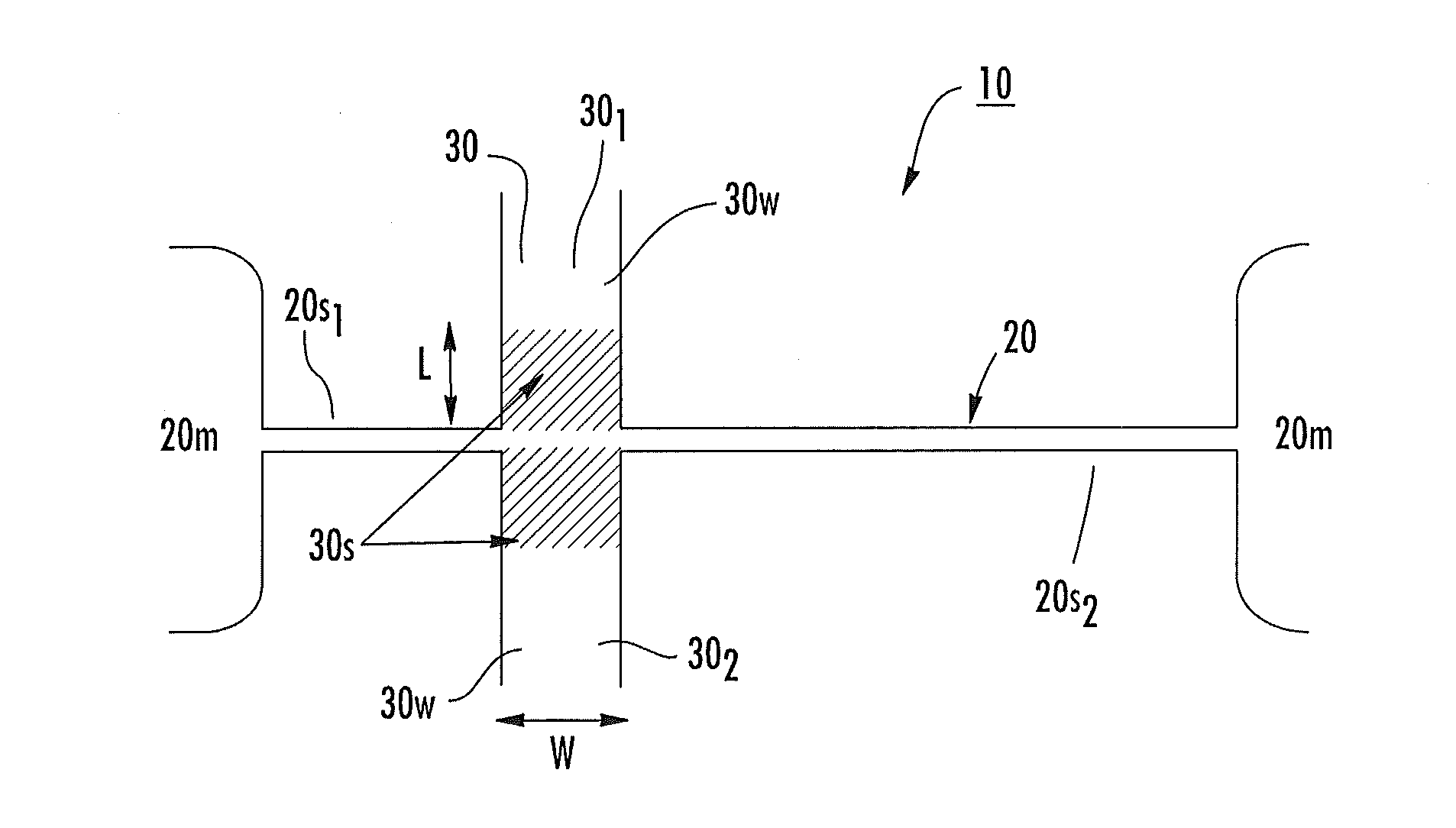

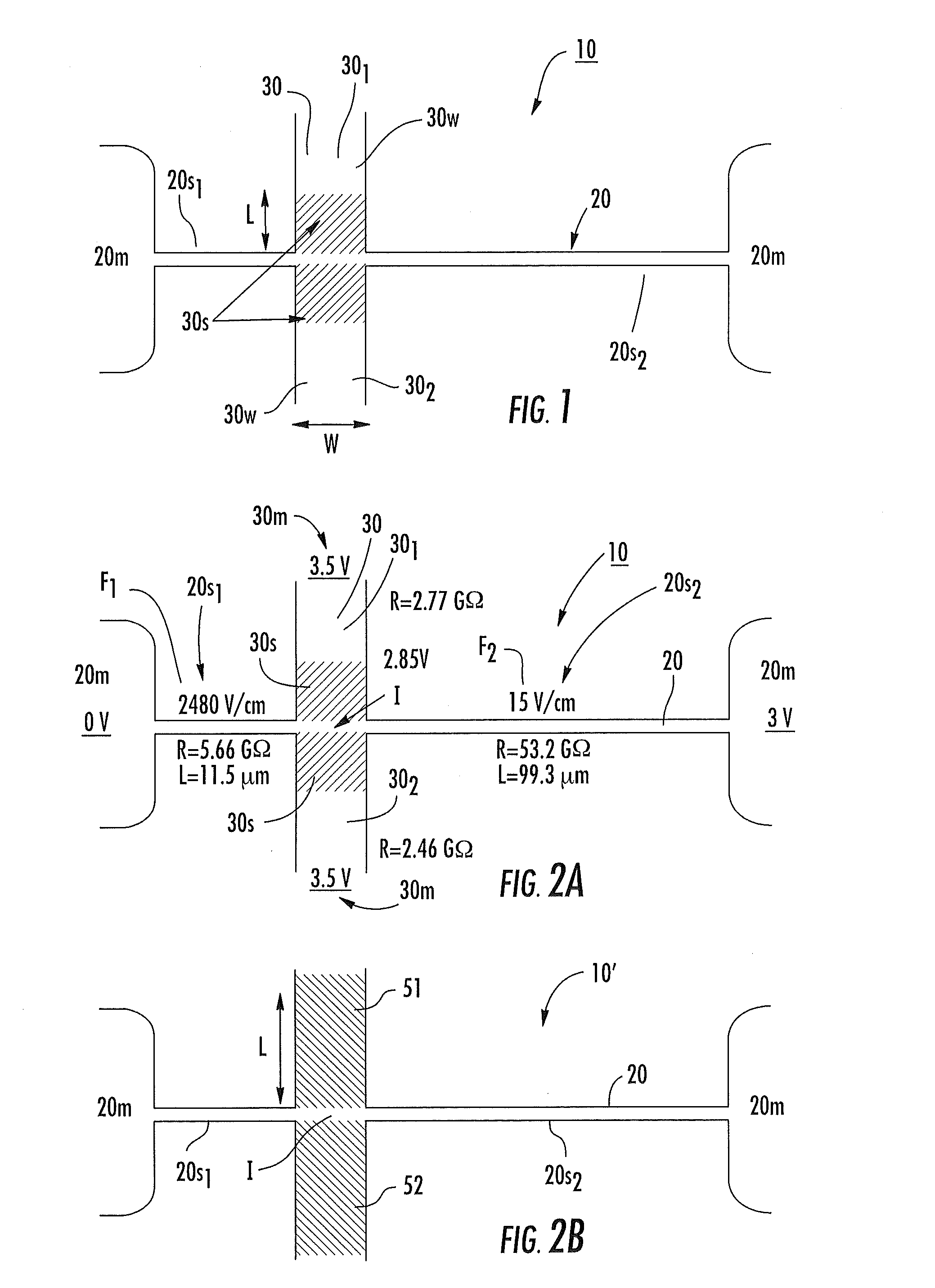

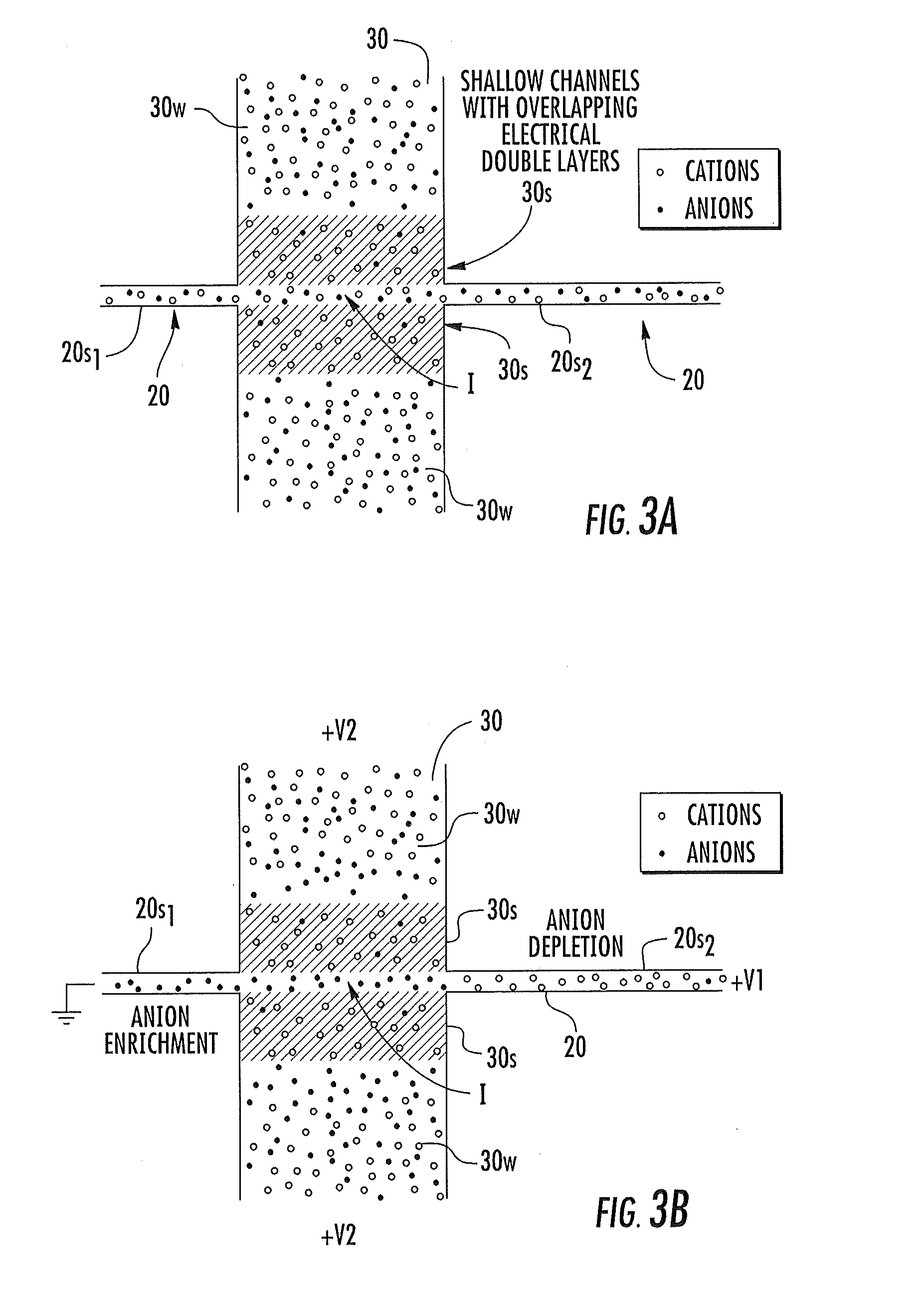

Nanofluidic devices with integrated components for the controlled capture, trapping, and transport of macromolecules and related methods of analysis

ActiveUS20140238856A1Easy to captureEasy to trapSludge treatmentVolume/mass flow measurementMolecular identificationTrapping

Devices for controlling the capture, trapping, and transport of macromolecules include at least one fluidic transport nanochannel that intersects and is in fluid communication with at least one transverse nanochannel with (shallow) regions and / or with integrated transverse electrodes that enable fine control of molecule transport dynamics and facilitates analyses of interest, e.g., molecular identification, length determination, localized (probe) mapping and the like.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

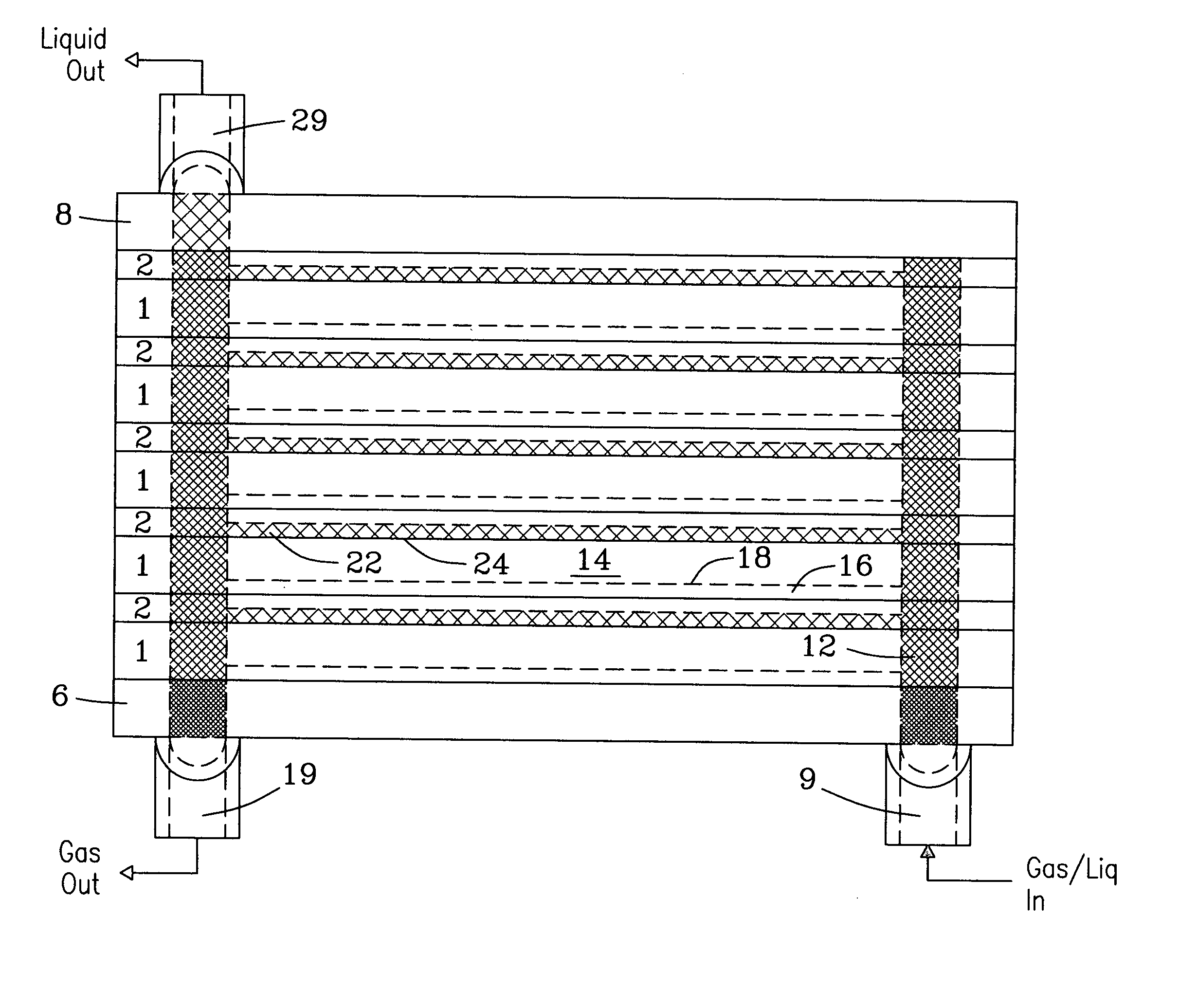

Conditions for fluid separations in microchannels, capillary-driven fluid separations, and laminated devices capable of separating fluids

InactiveUS20050229553A1Fast shippingHigh heat transfer rateCombination devicesChemical/physical/physico-chemical microreactorsProduct gasImproved method

Owner:BATTELLE MEMORIAL INST

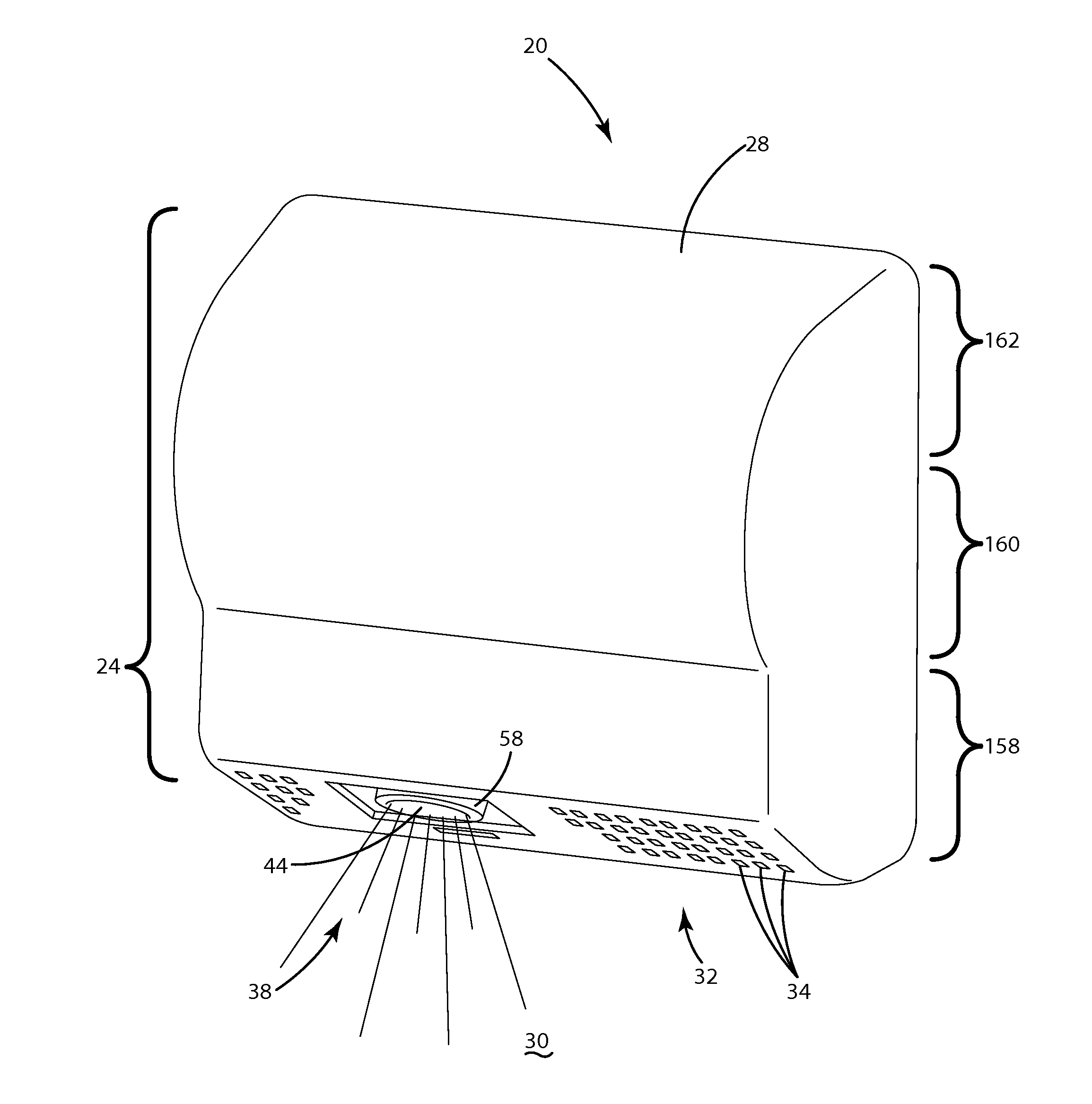

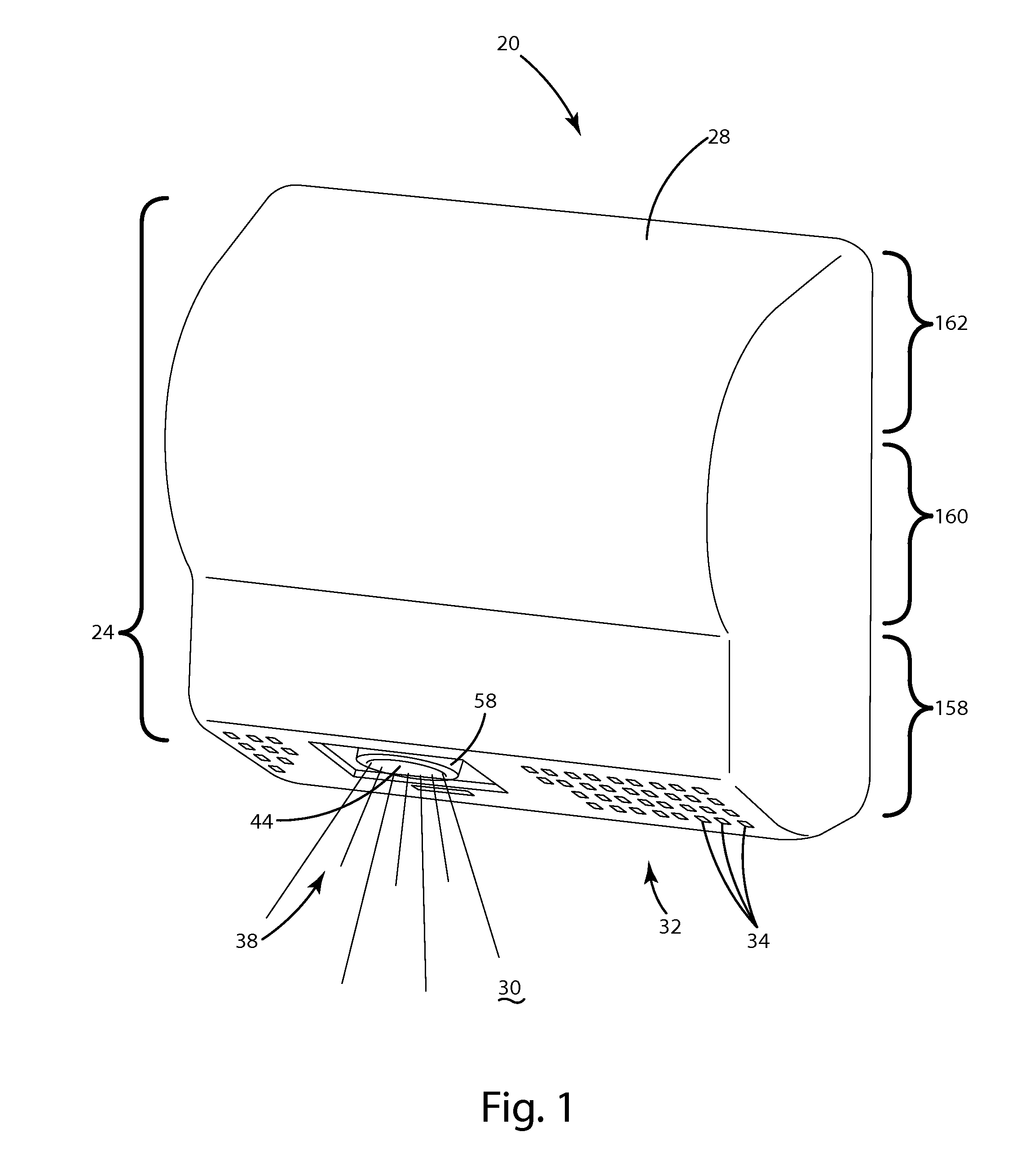

Hand Dryer With Sanitizing Ionization Assembly

ActiveUS20130232807A1FocusReduce the amount requiredElectrode carrying meansDrying gas arrangementsEngineeringIonization

A hand dryer assembly including a blower assembly for generating a moving air stream. The moving air stream passes through an air channel to an air outlet where it exits the hand dryer assembly. An ionization assembly is disposed along the air channel and emits charged ions directly into the moving air stream, sanitizing the hands of the user, the moving air steam, and the ambient air that is entrained into the moving air stream.

Owner:AMERICAN DRYER LLC

Process for making nonwoven articles

InactiveUS20060121099A1Minimal interferenceHigh loadNon-fibrous pulp additionFibre treatmentEngineeringRubbing

Method for preparing an active-containing nonwoven article involving fixing active ingredients on the surface of non-woven webs and cellulosic mats. The active ingredients can be released (deposited) onto a surface by normal triggering mechanisms, which include the action of a liquid or by friction or rubbing. The fixative systems described herein provide the ability to control high load levels while not interfering with wettability of the fabric or paper. Additionally, ingredients incompatible and reactive with each other can be treated onto the same web and kept as separate particles fixed to the surface until released.

Owner:AKZO NOBEL NV

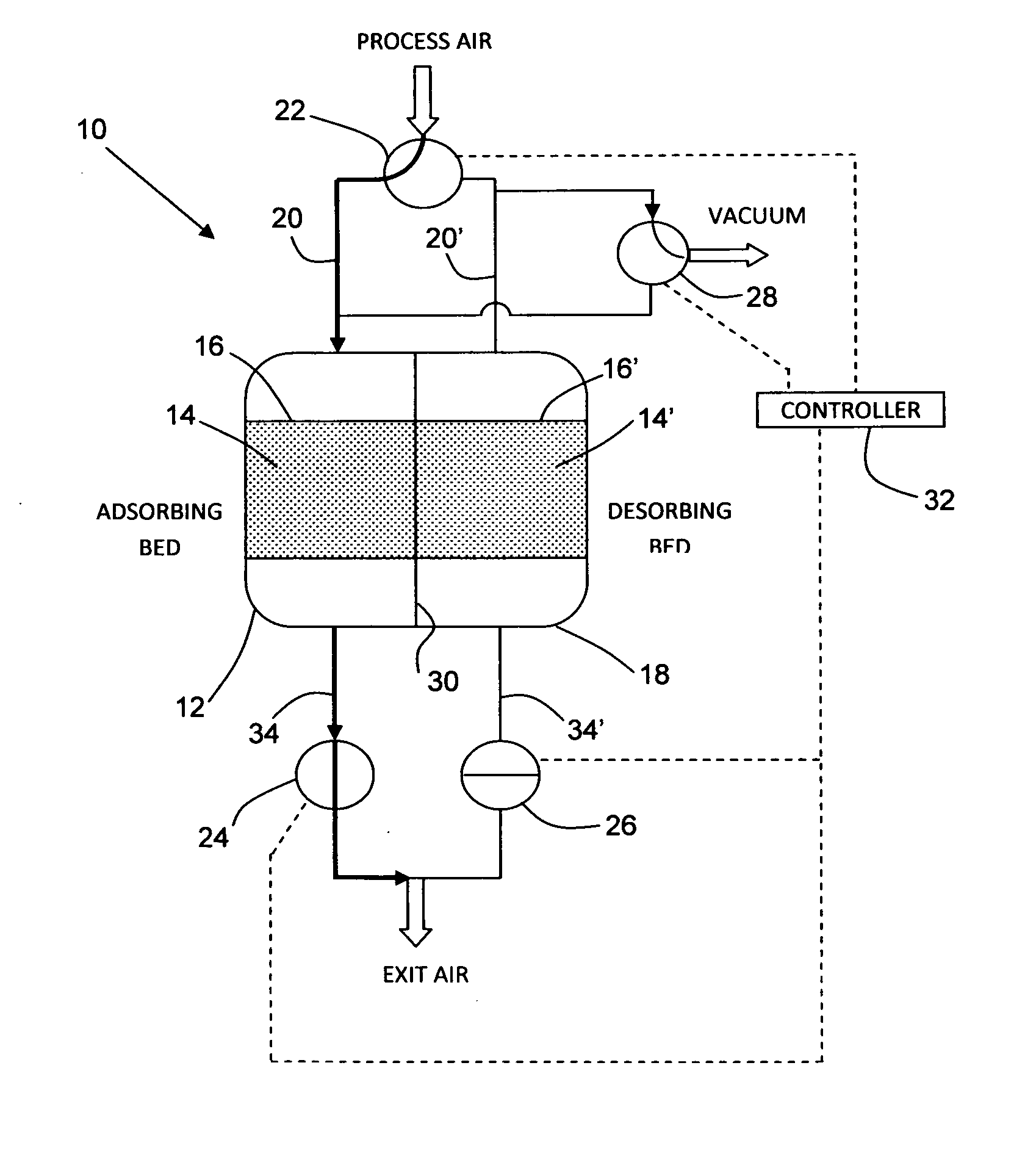

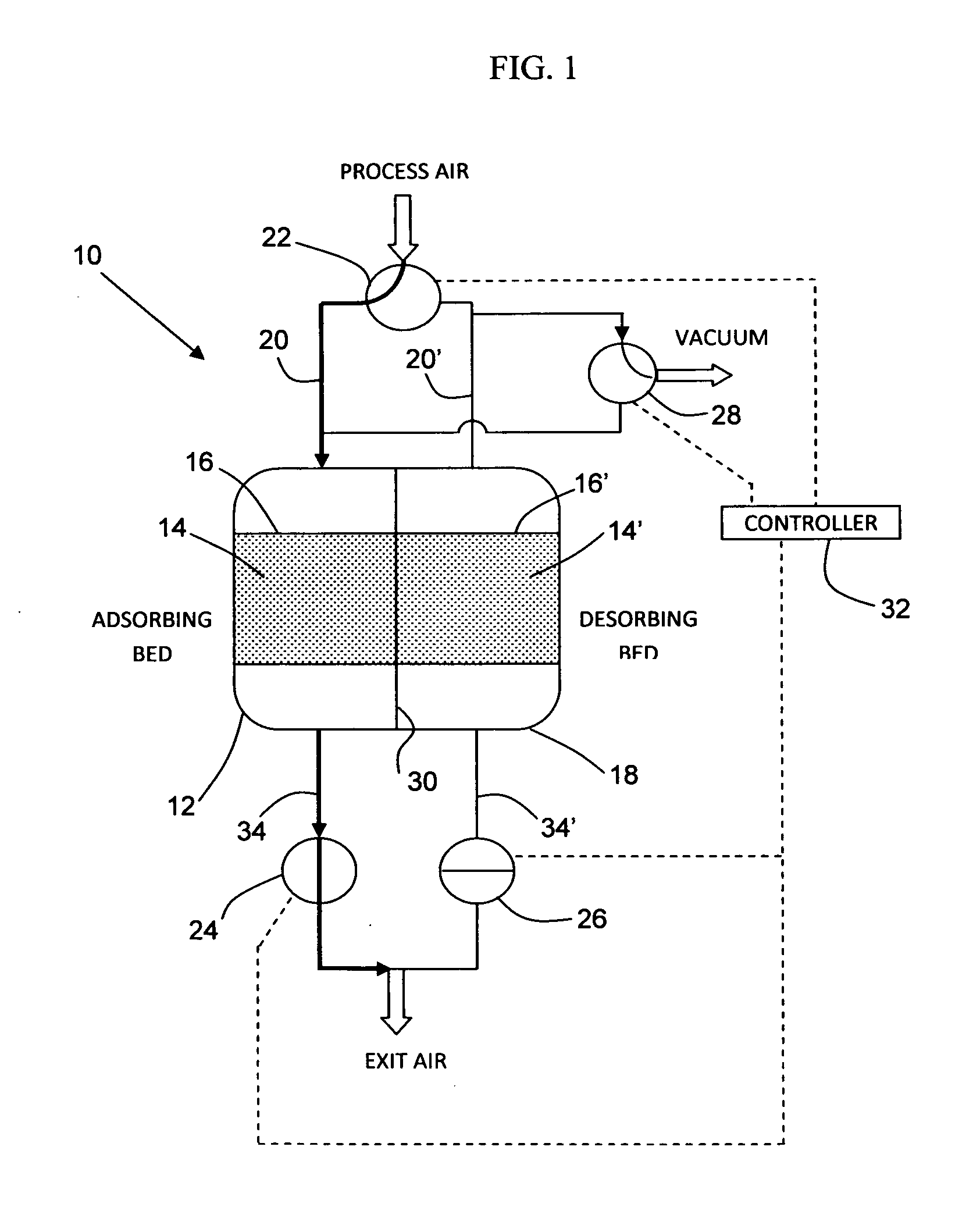

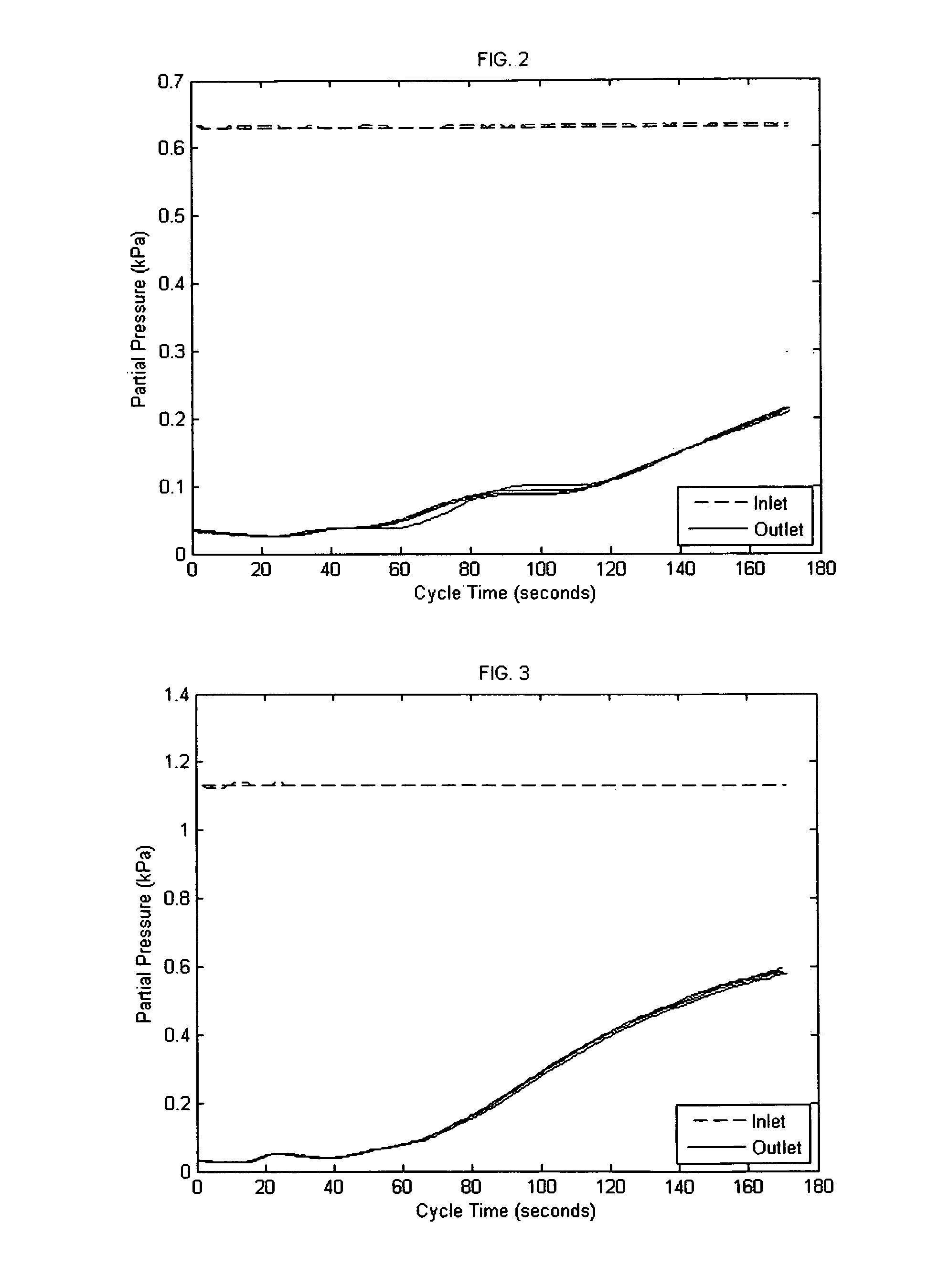

Adsorption-desorption apparatus and process

InactiveUS20120006193A1Light in massSmall volumeGas treatmentDispersed particle filtrationSorbentAdsorption desorption

An apparatus and process for thermally-linked adsorption-desorption. The process involves (a) at least one pair of adjacent sorbent beds, referenced herein as first and second sorbent beds, each pair of adjacent beds being thermally-linked one to the other through a thermally conductive wall; wherein each sorbent bed comprises a heat conductive foam, such as a reticulated metallic foam or sponge, having a sorbent coated thereon; then (b) alternating a flowstream between the beds such that at least one bed operates in adsorption cycle to remove target compound(s) from the flowstream with generation of heat of adsorption, which is conductively transferred away from the first bed towards the second bed, while operating the second bed in desorption cycle to remove the adsorbed target compound(s).

Owner:PRECISION COMBUSTION

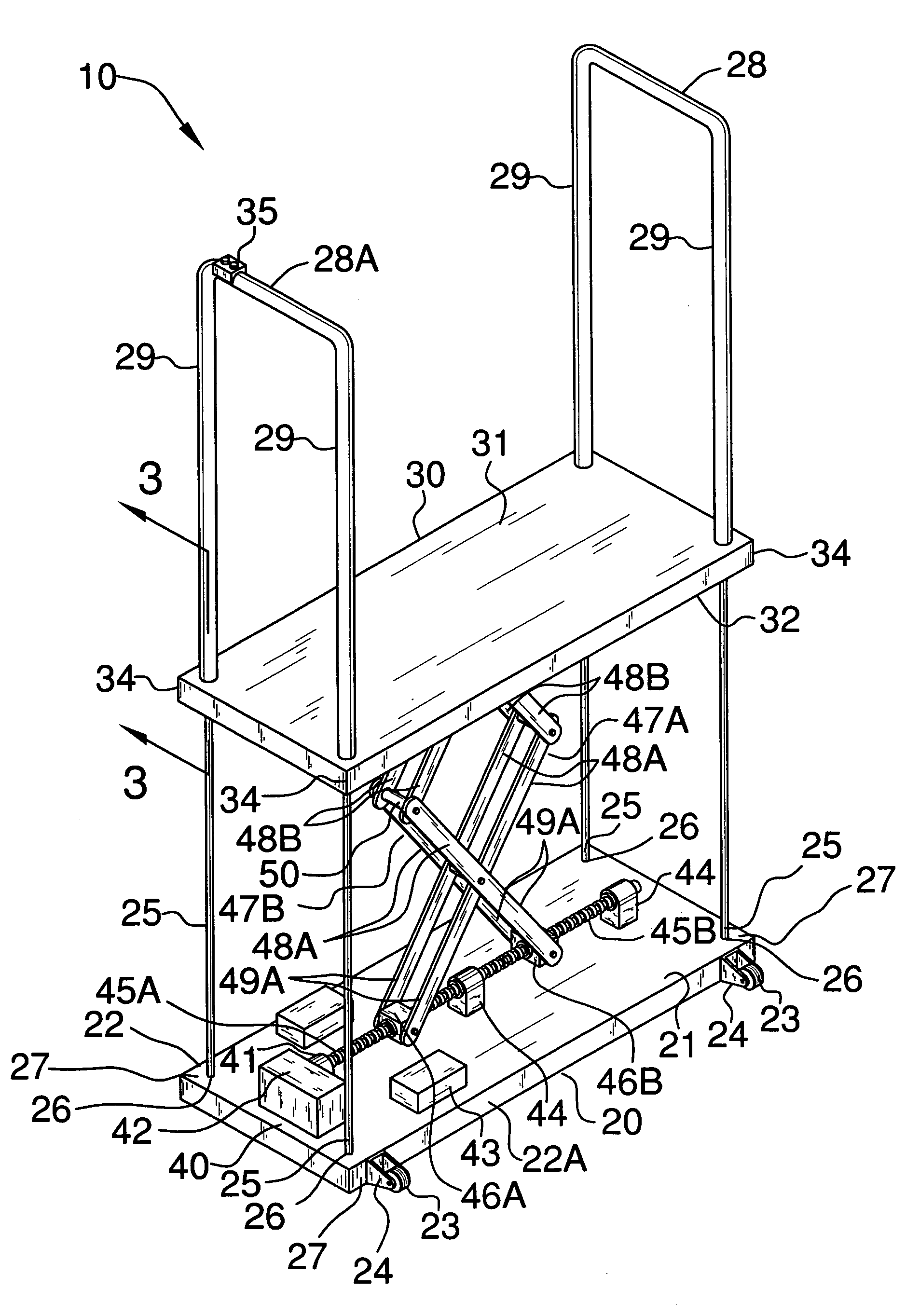

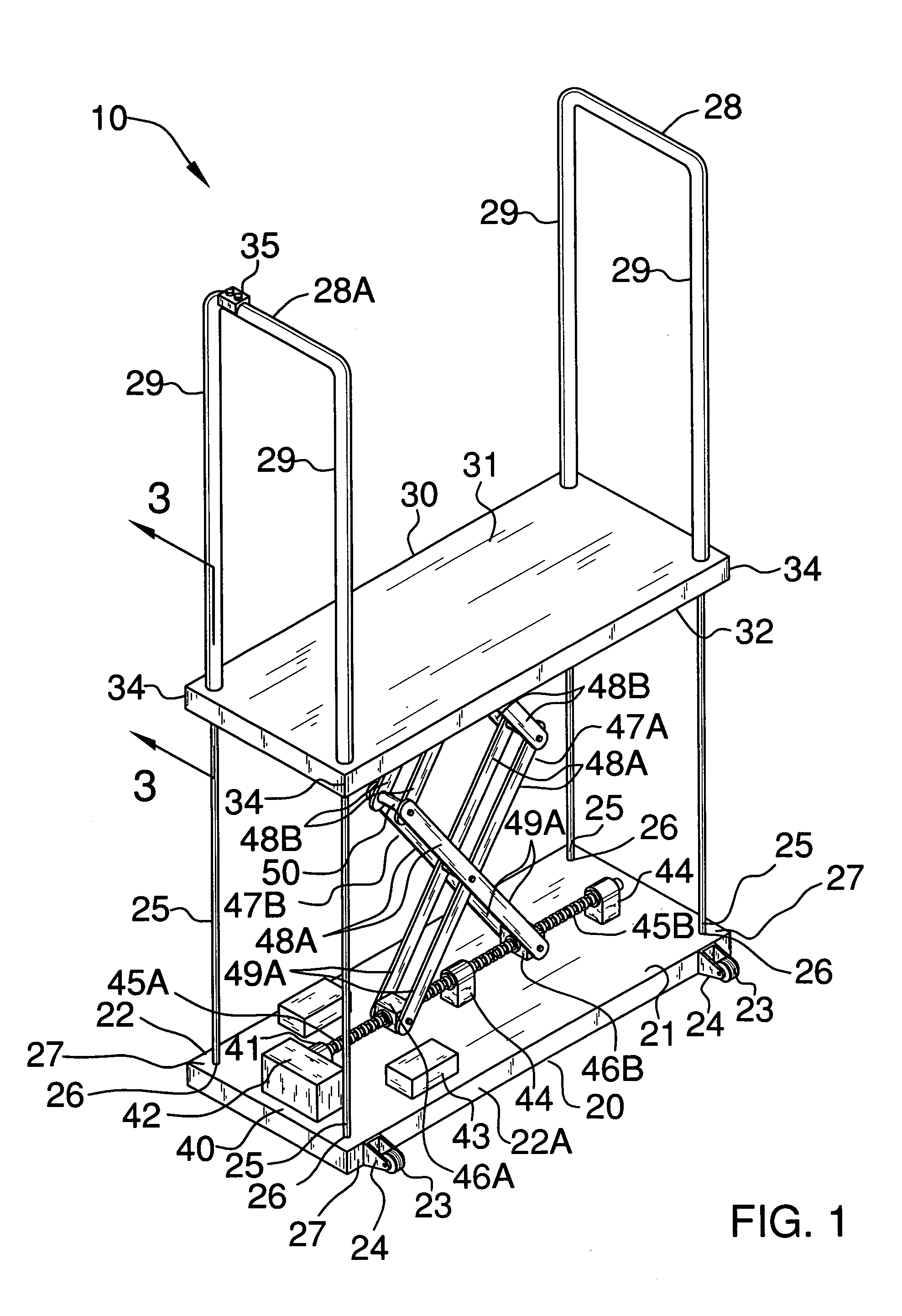

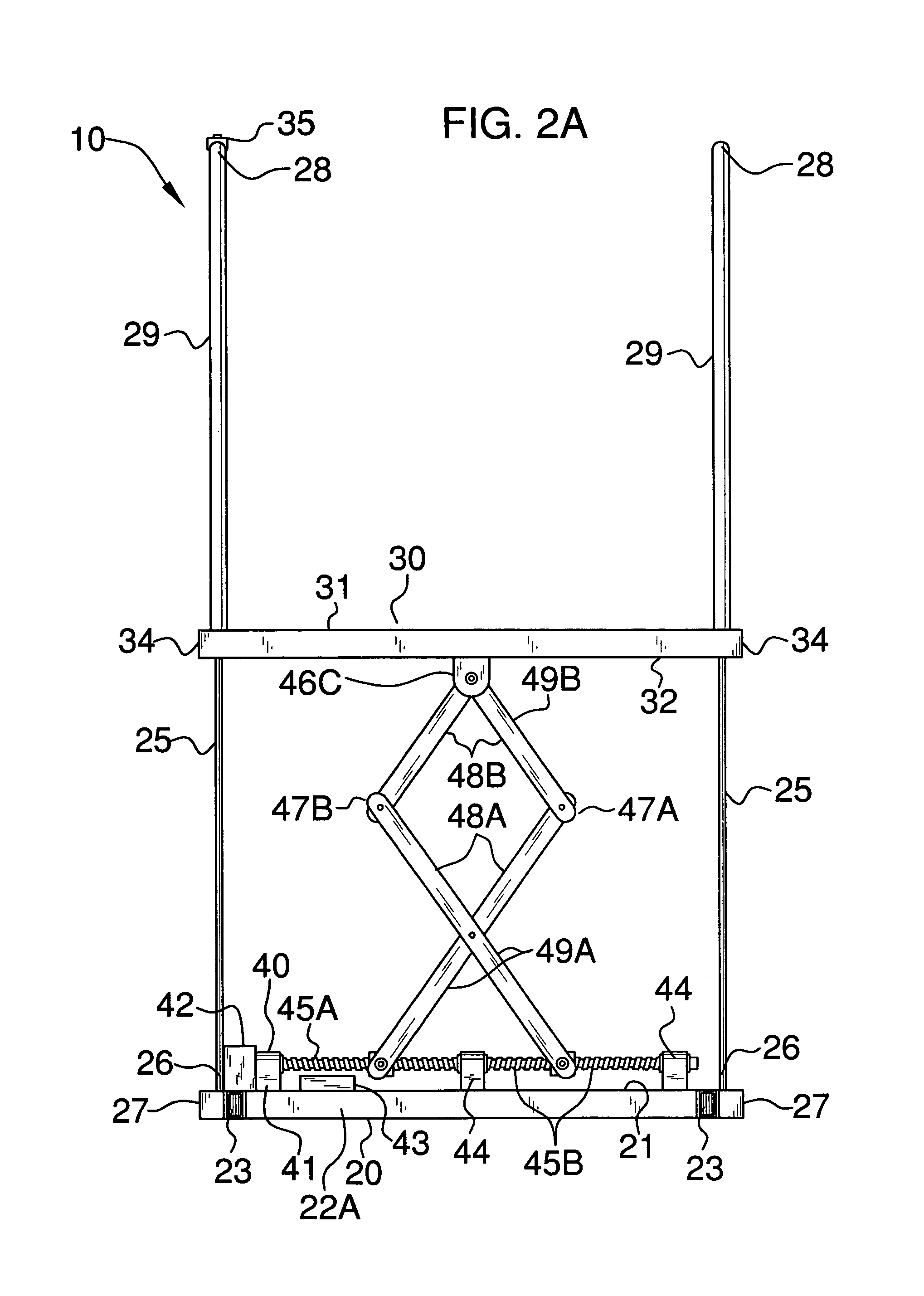

Portable scissor-lift-assembly

InactiveUS7093691B1Fast shippingRaised and loweredScaffold connectionsFoldable tablesEngineeringMechanical engineering

A lift assembly includes a first platform provided with a top surface, a pair of opposed sides, and wheels and brackets connected to one of the sides for rotating the assembly. A plurality of rectilinear support shafts have opposed end portions conjoined to the platform and extending upwardly therefrom, and are spaced at opposed corners of the platform. Inverted U-shape guide rails are telescopically engageable along a length of the support shafts and have a pair of rectilinear regions slidably positionable about the support shafts. A second platform is provided with top and bottom surfaces, and apertures formed at opposed corners thereof that are vertically registered with the support shafts. A lifting mechanism is included for vertically biasing the second platform and the guide rails along the support shafts. The lifting mechanism is connected to the top surface of the first platform and the bottom surface of the second platform.

Owner:VAUGHAN BARRY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com