Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Drift field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

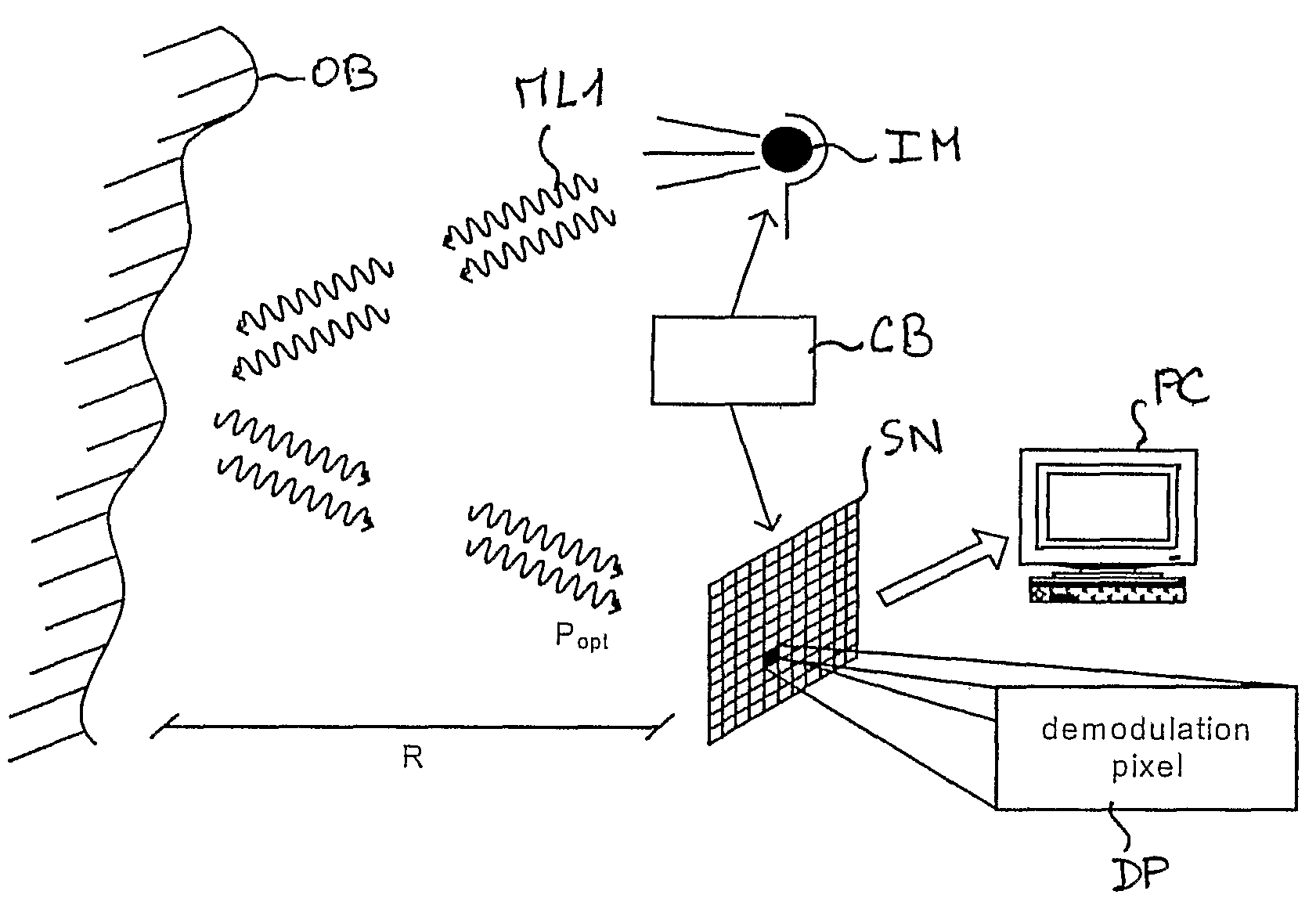

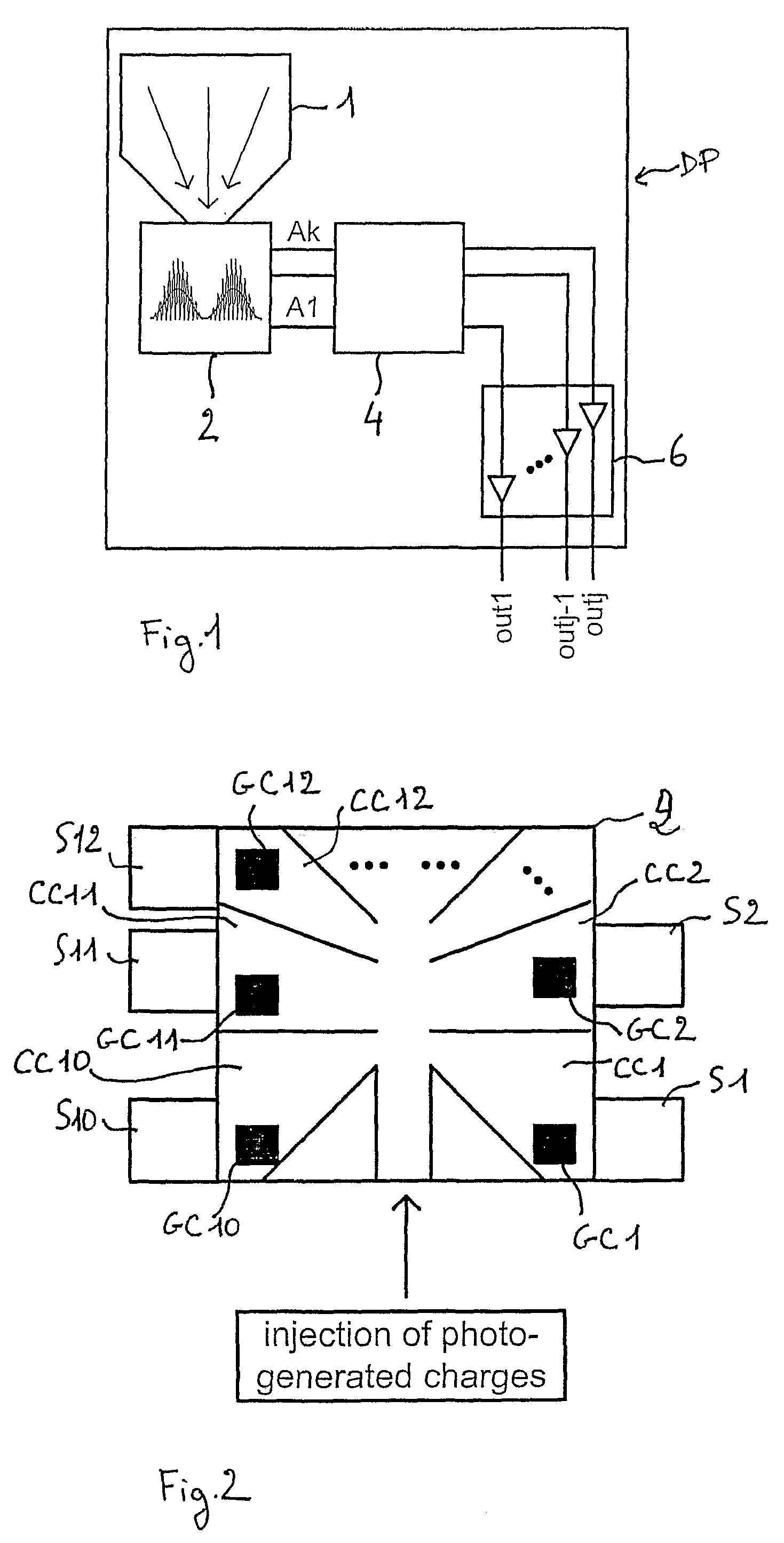

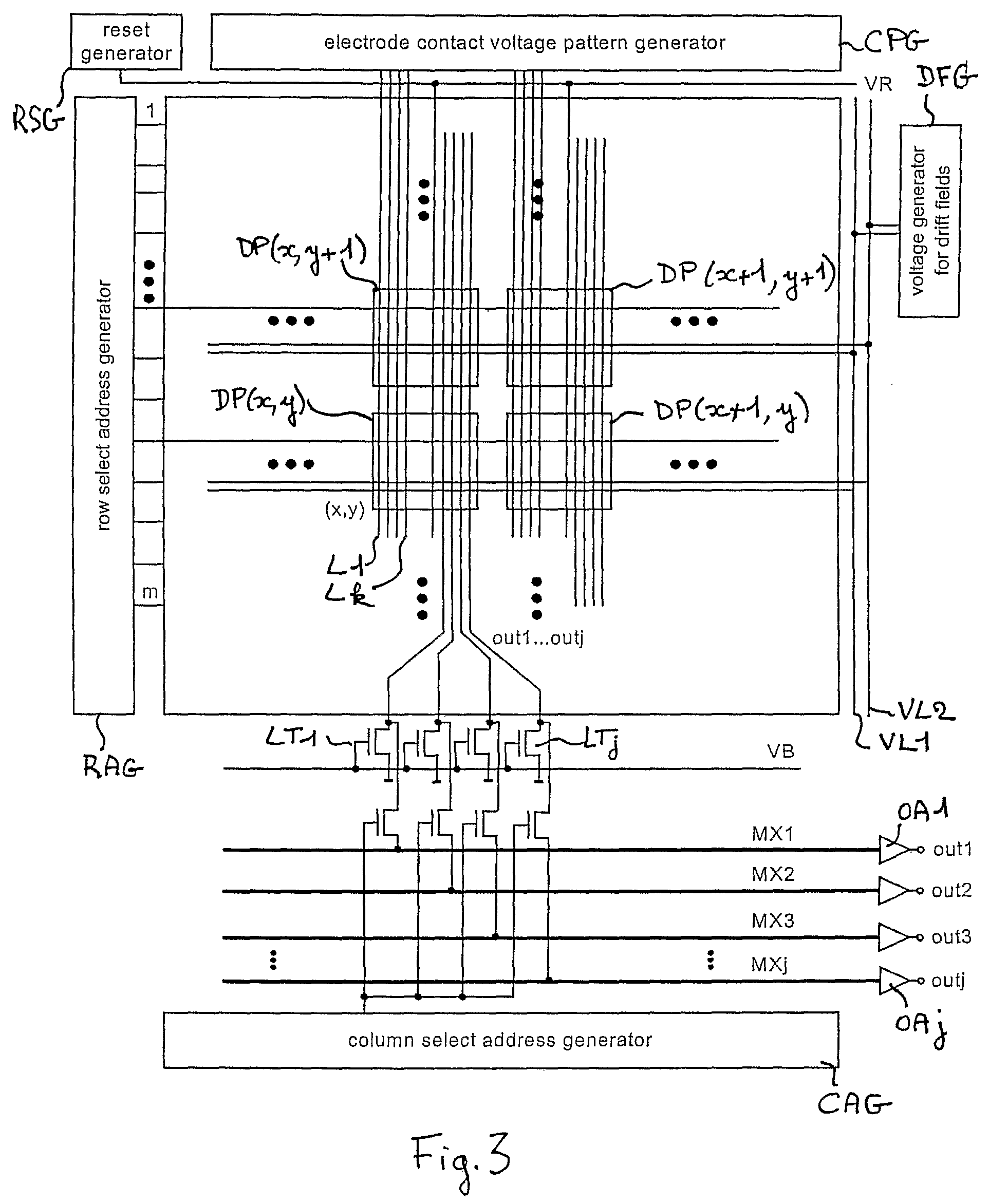

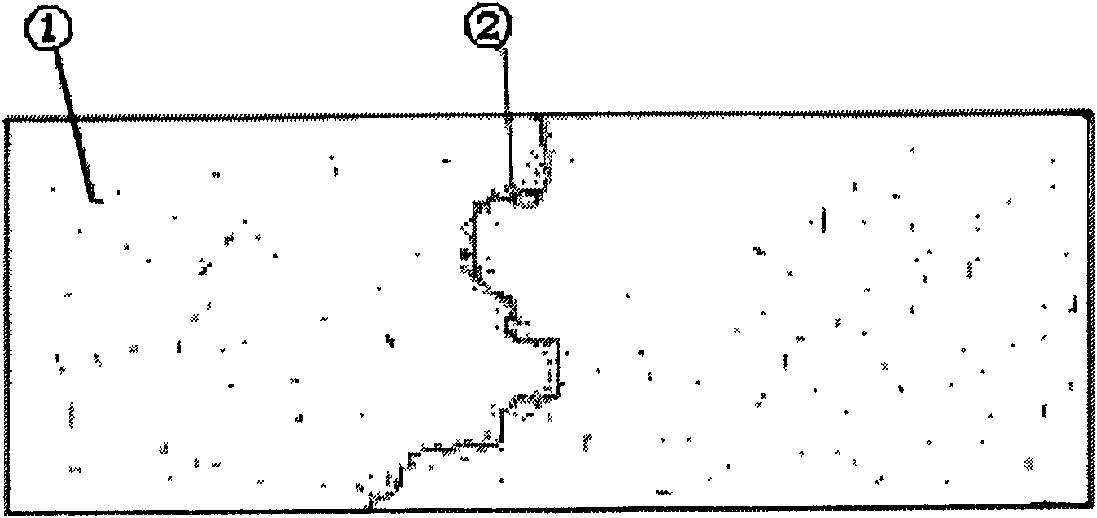

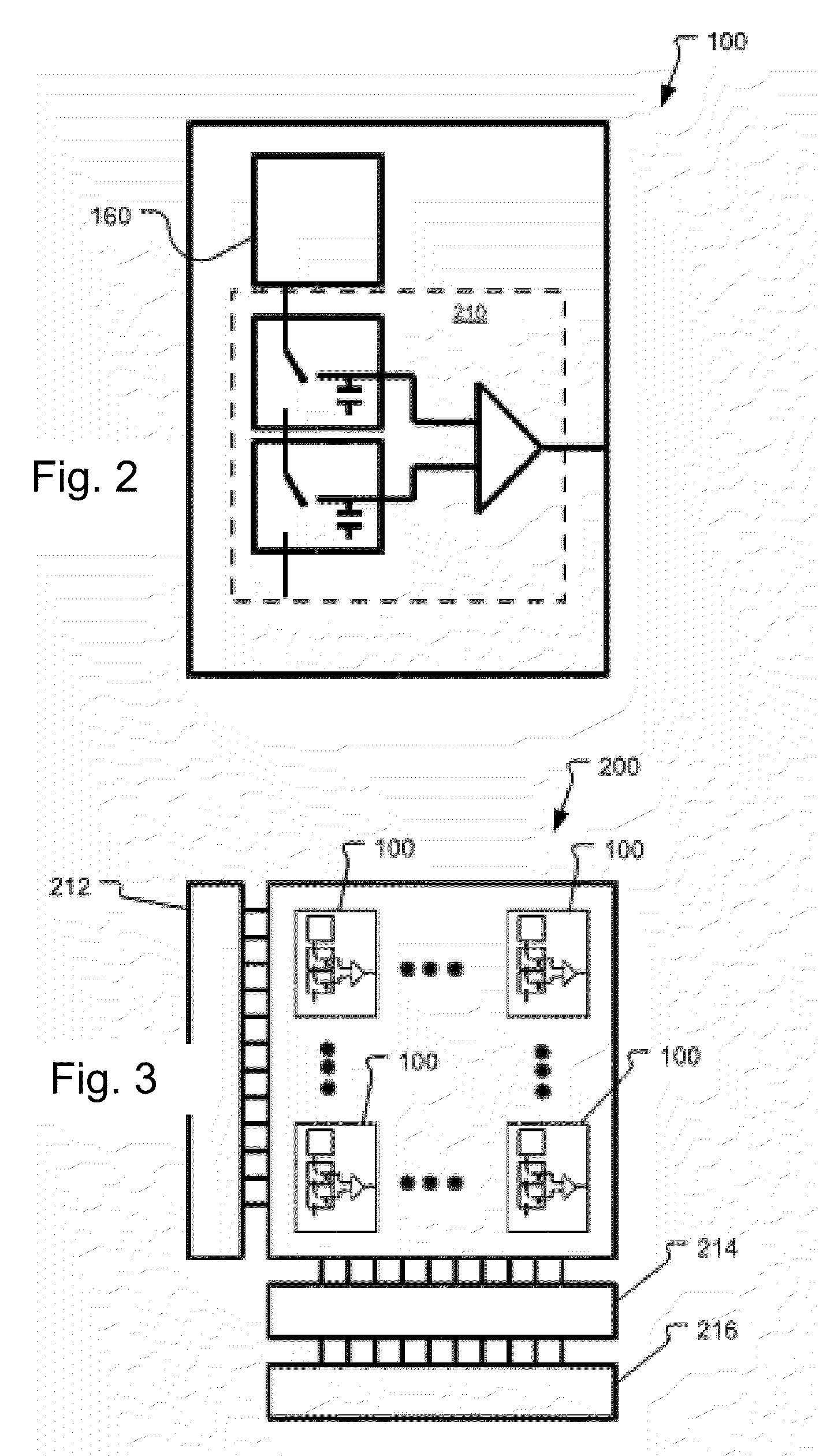

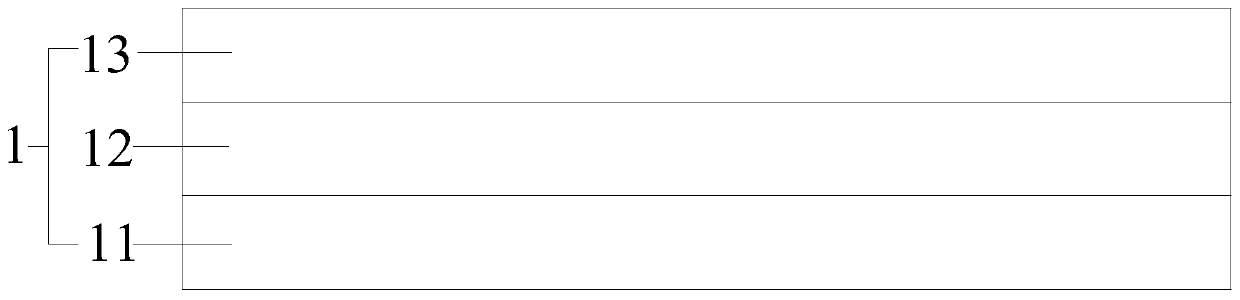

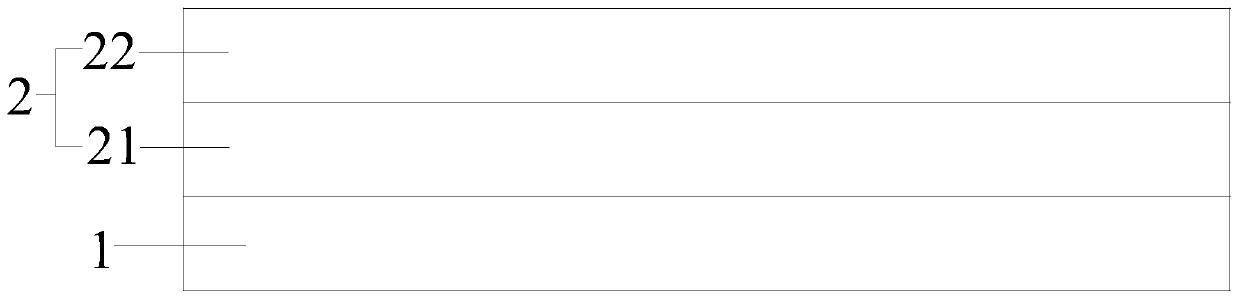

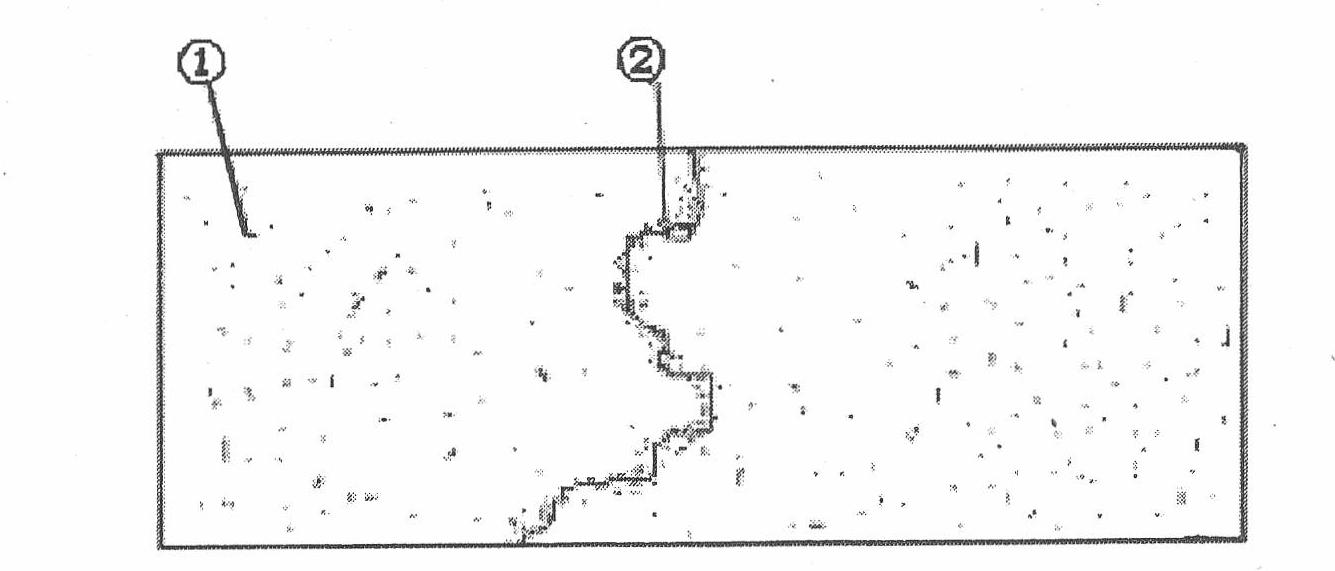

Device and method for the demodulation electromagnetic wave fields having separated detection and demodulation regions

ActiveUS7884310B2Increase speedFast shippingTelevision system detailsSolid-state devicesCharge currentWave field

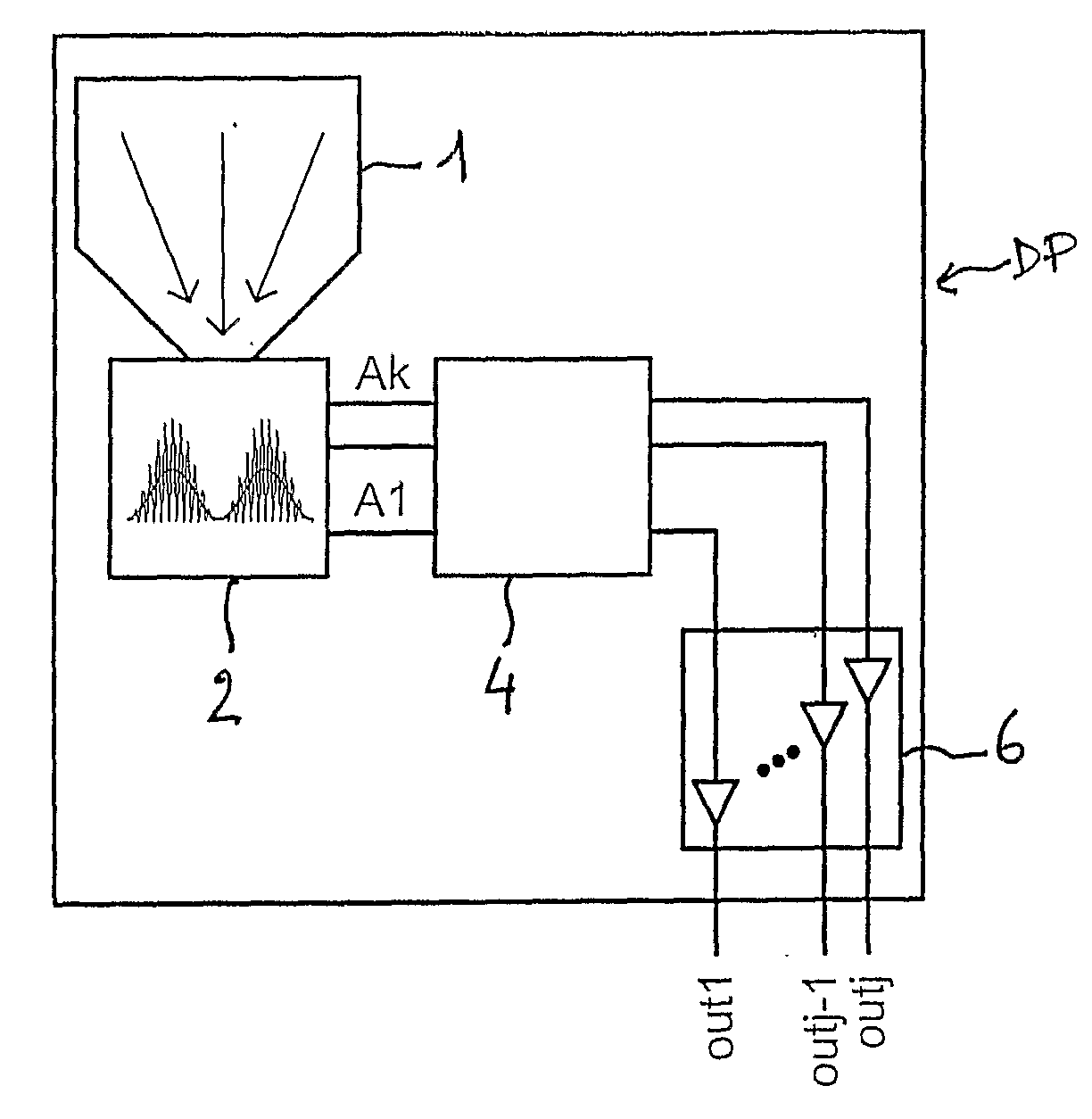

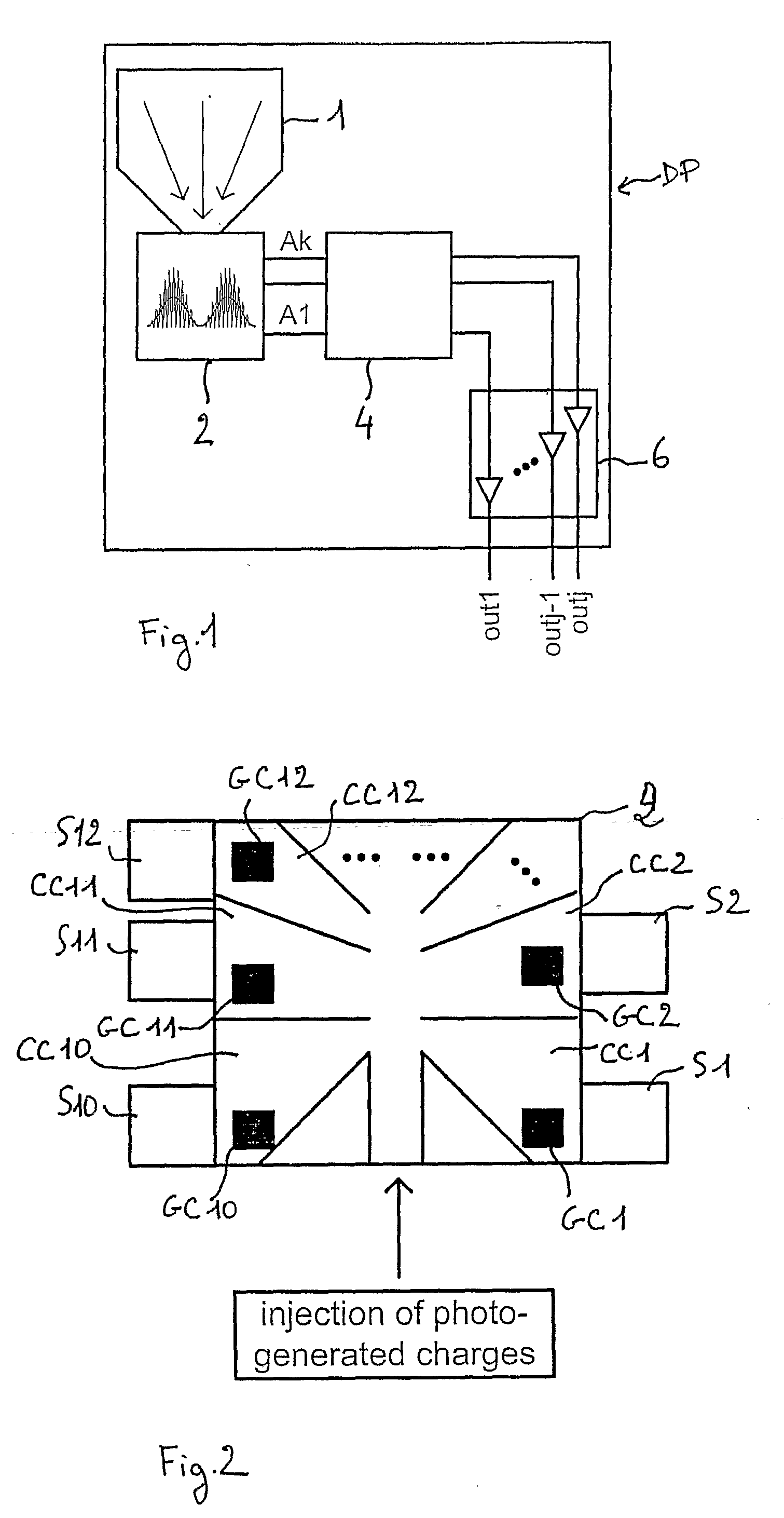

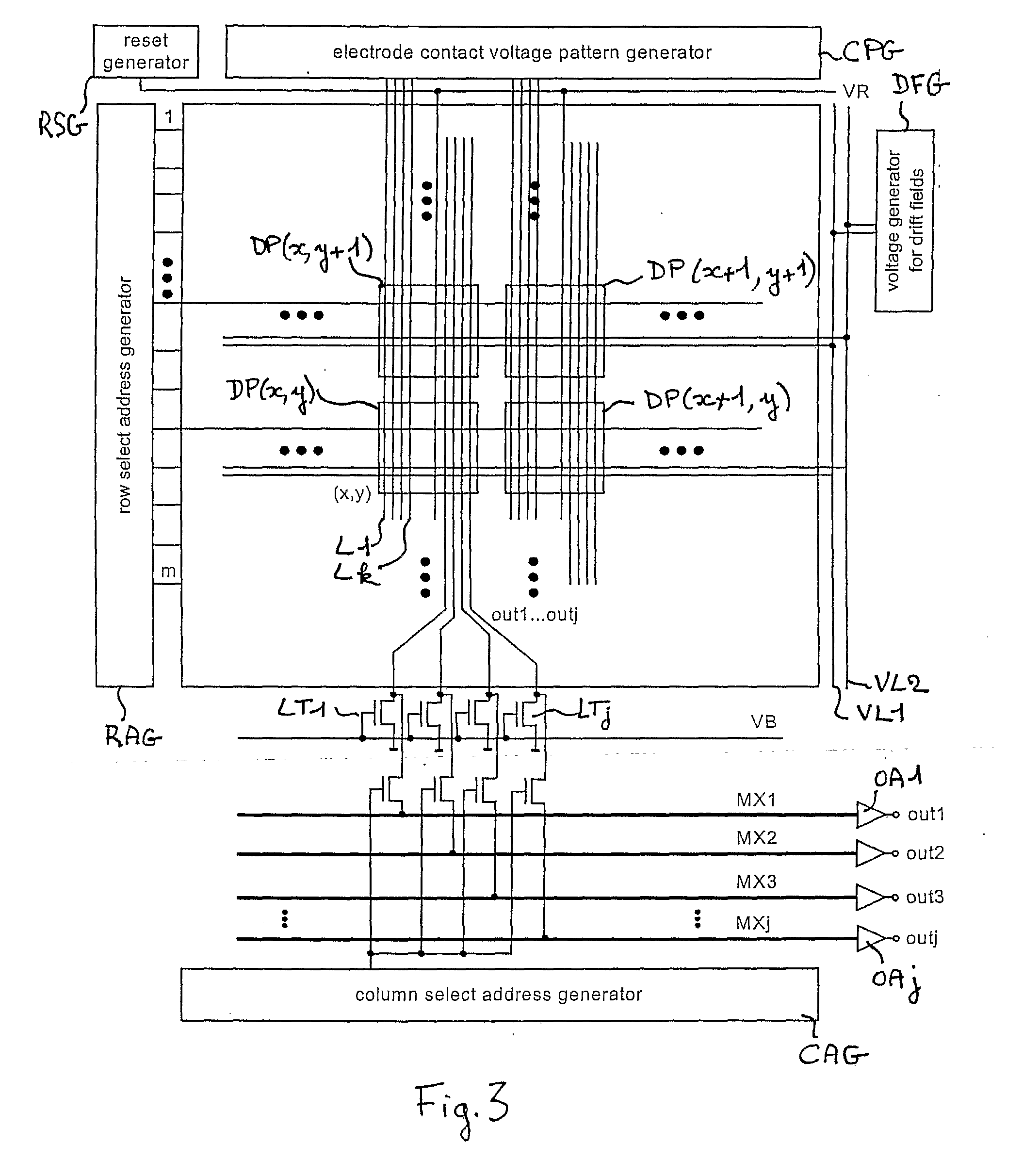

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

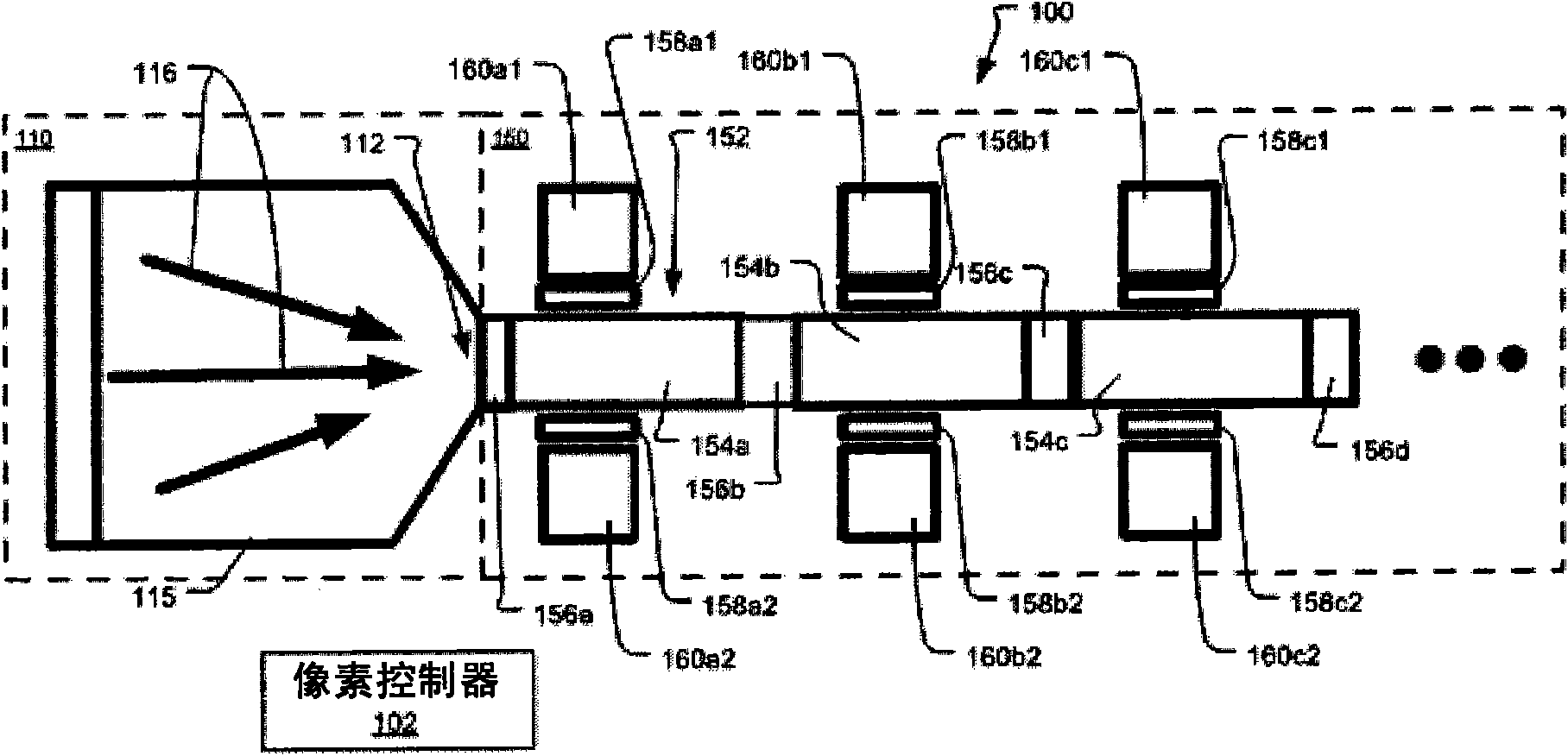

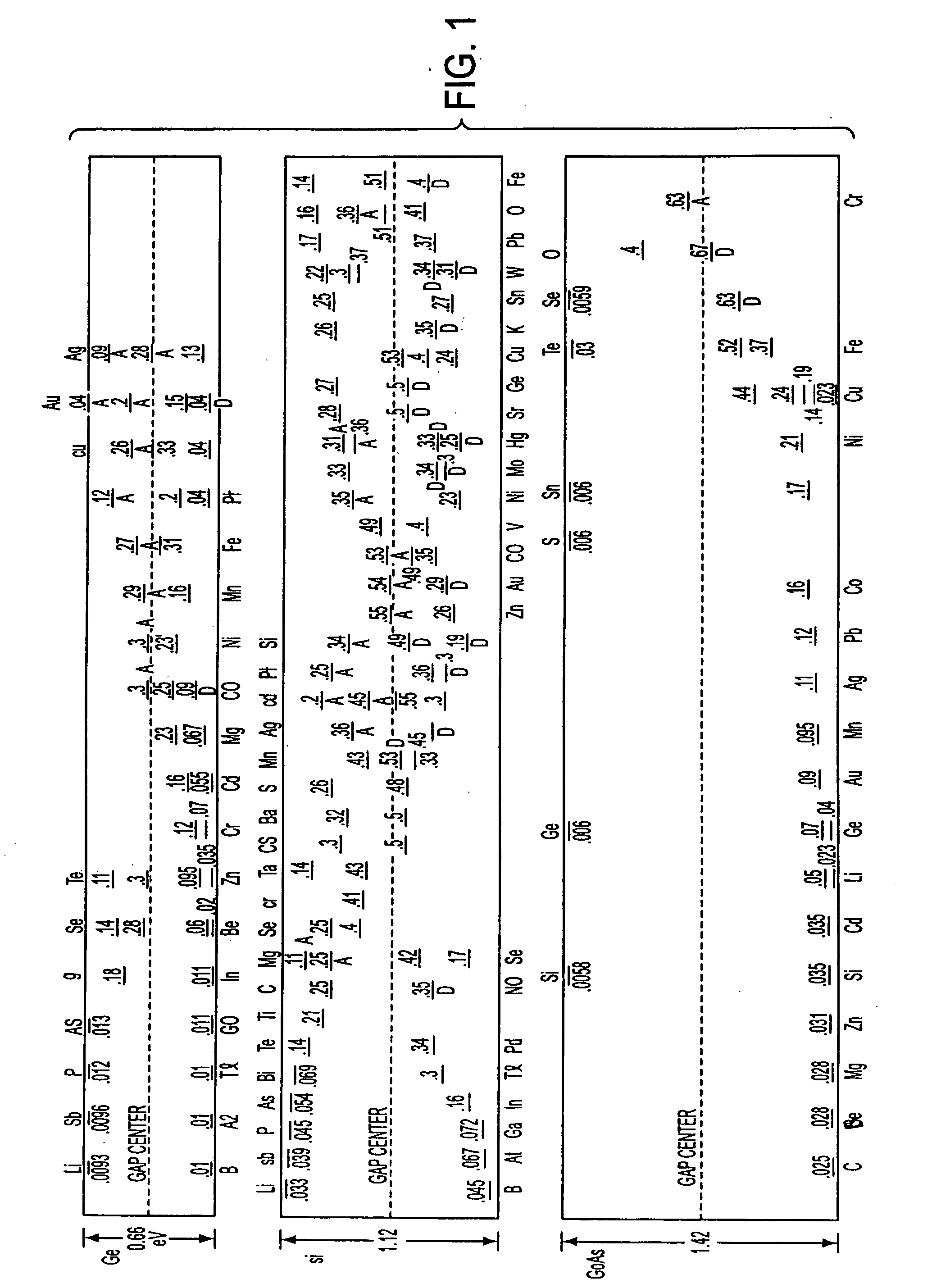

Drift Field Demodulation Pixel with Pinned Photo Diode

InactiveUS20090224139A1High rateReduce optical sensitivitySolid-state devicesMaterial analysis by optical meansSoi cmos technologyPhotodiode

A pixel based on a pinned-photodiode structure that creates a lateral electric drift field. The combination of the photodiode with adjacent CCD gates enables the utilization of the drift field device in applications such as 3-D imaging. Compared with recently used demodulation devices in CCD or CMOS technology, the new pinned-photodiode based drift field pixel has its advantages in its wide independence of the quantum efficiency on the optical wavelength, its high optical sensitivity, the opportunity of easily creating arbitrary potential distributions in the semiconductor, the straight-forward routing capabilities and the generation of perfectly linear potential distributions in the semiconductor.

Owner:HEPTAGON MICRO OPTICS

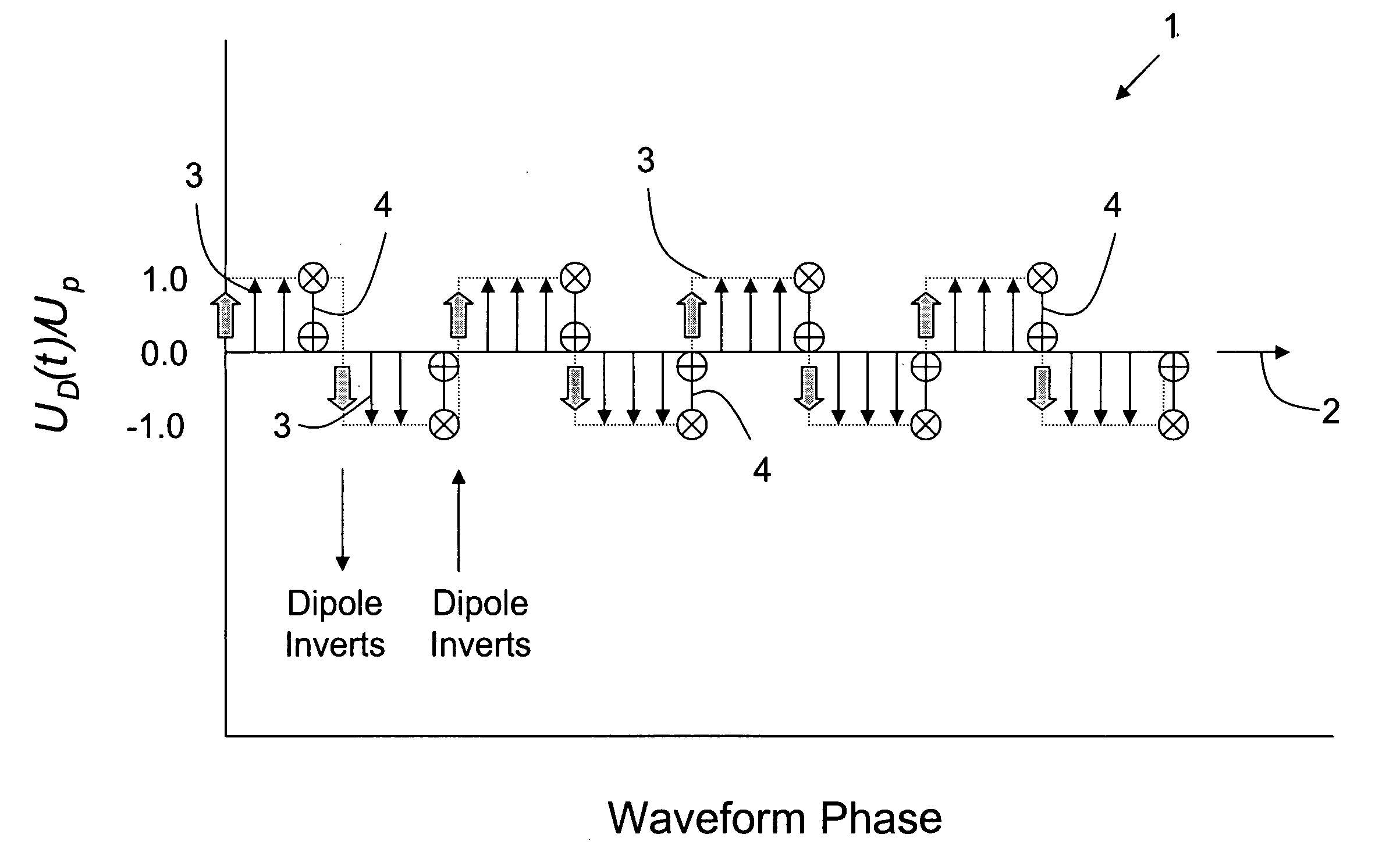

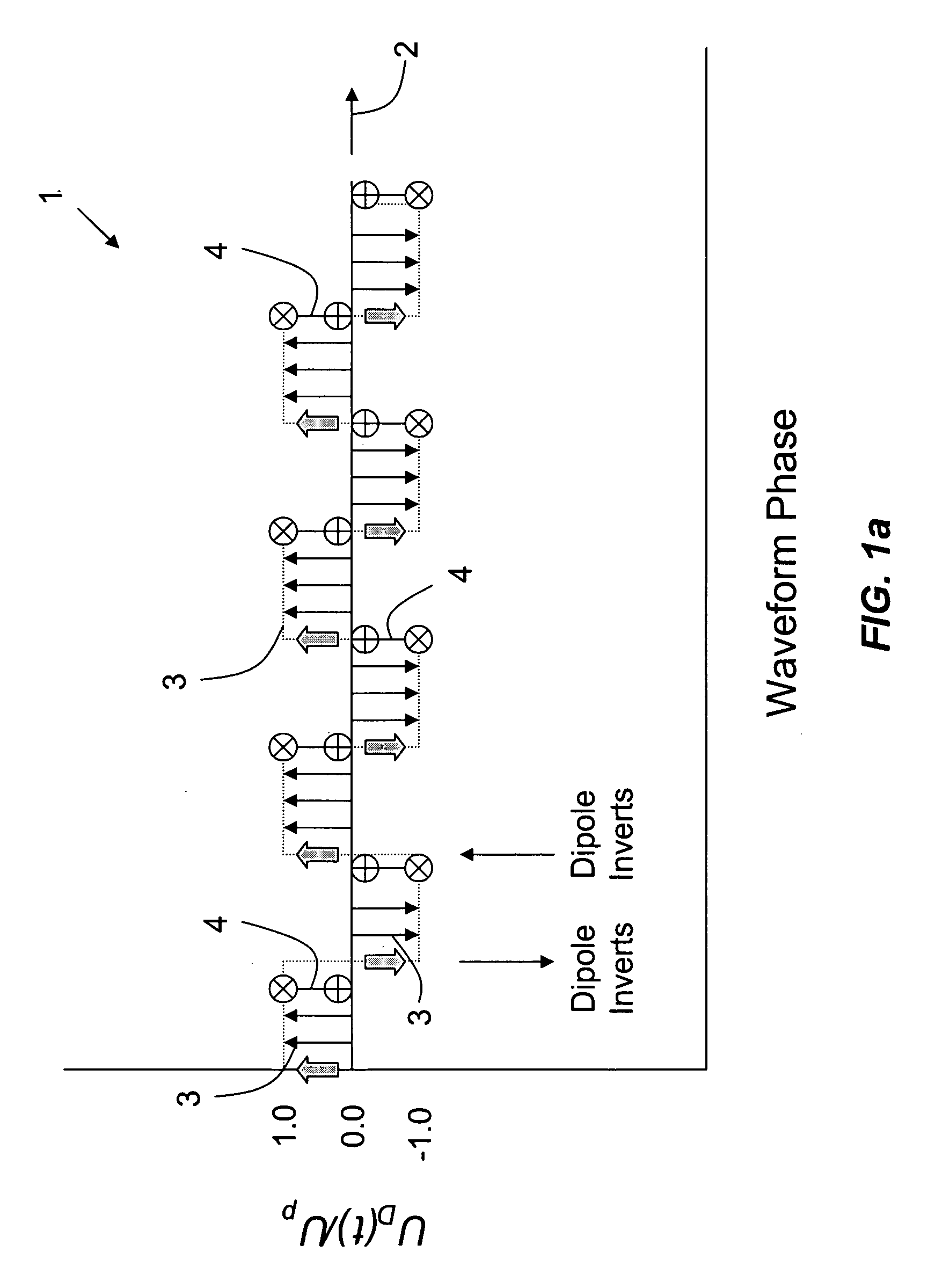

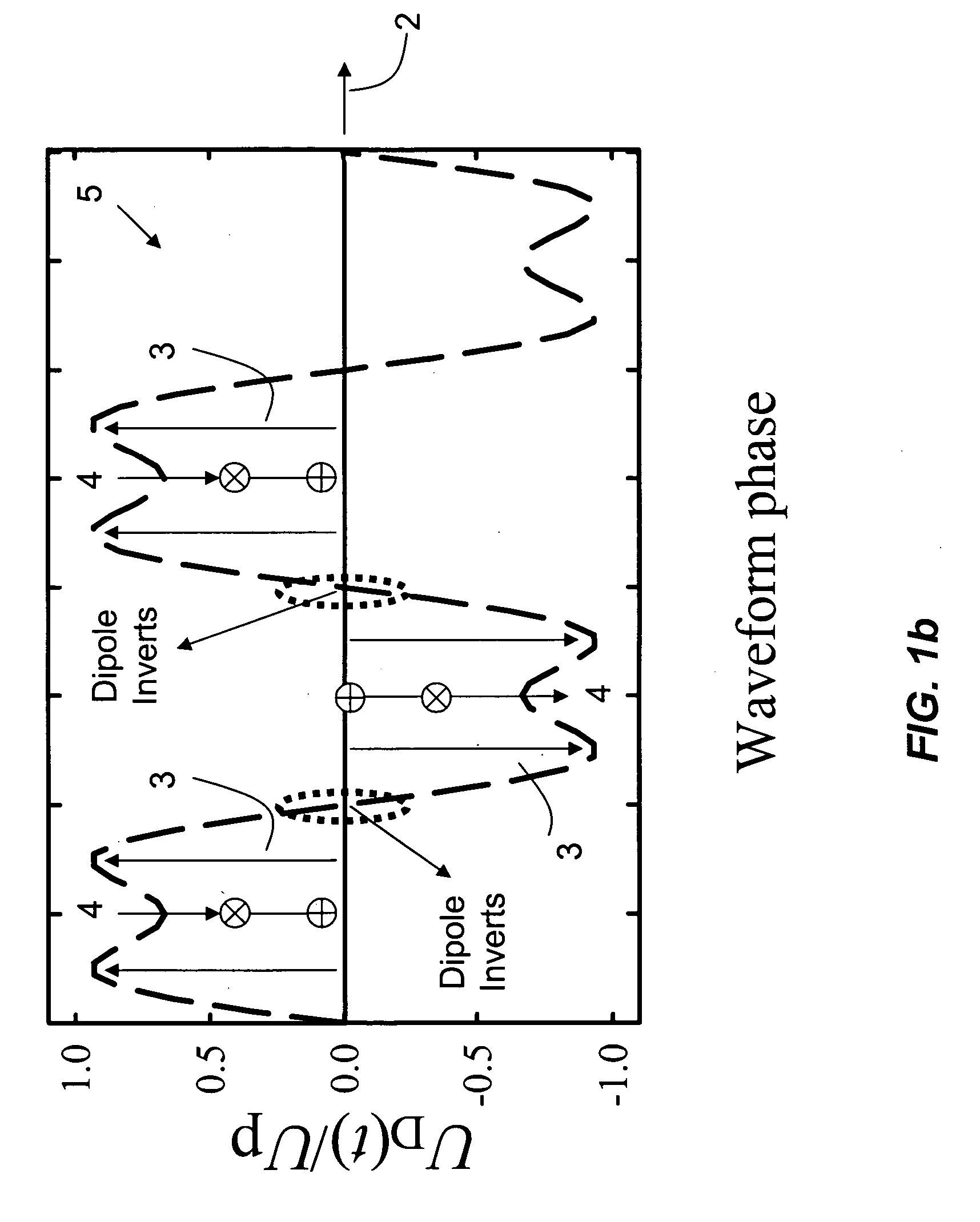

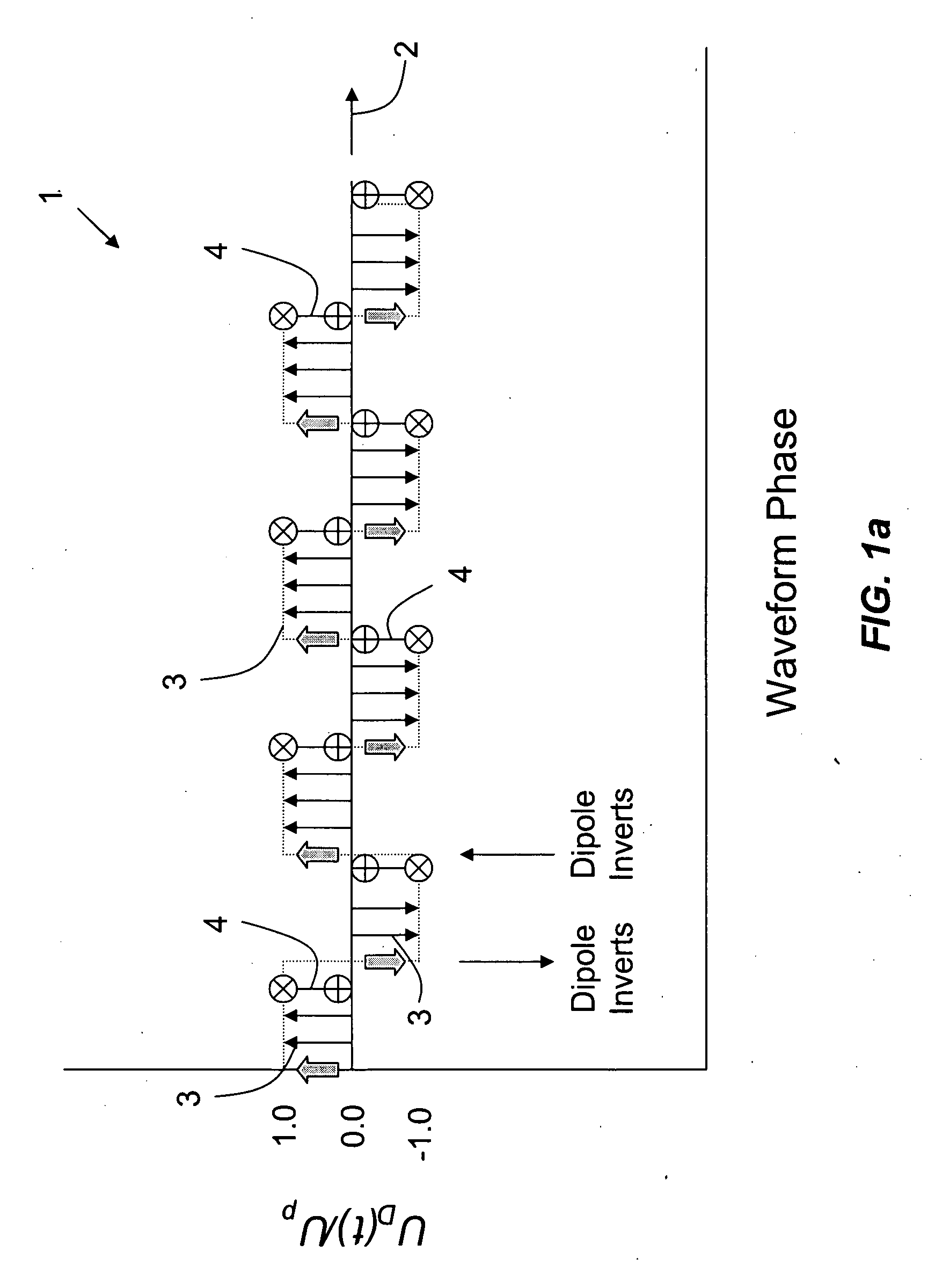

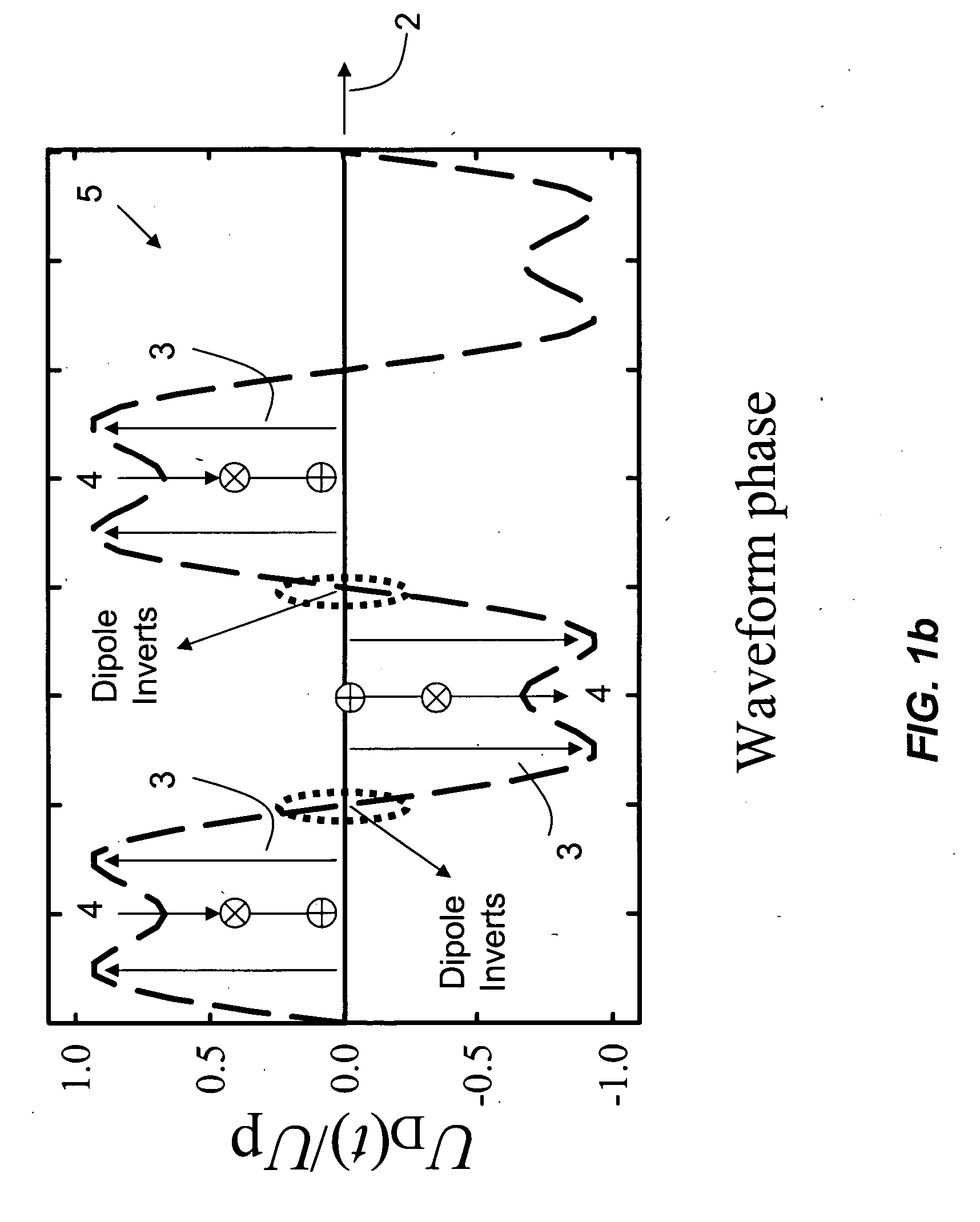

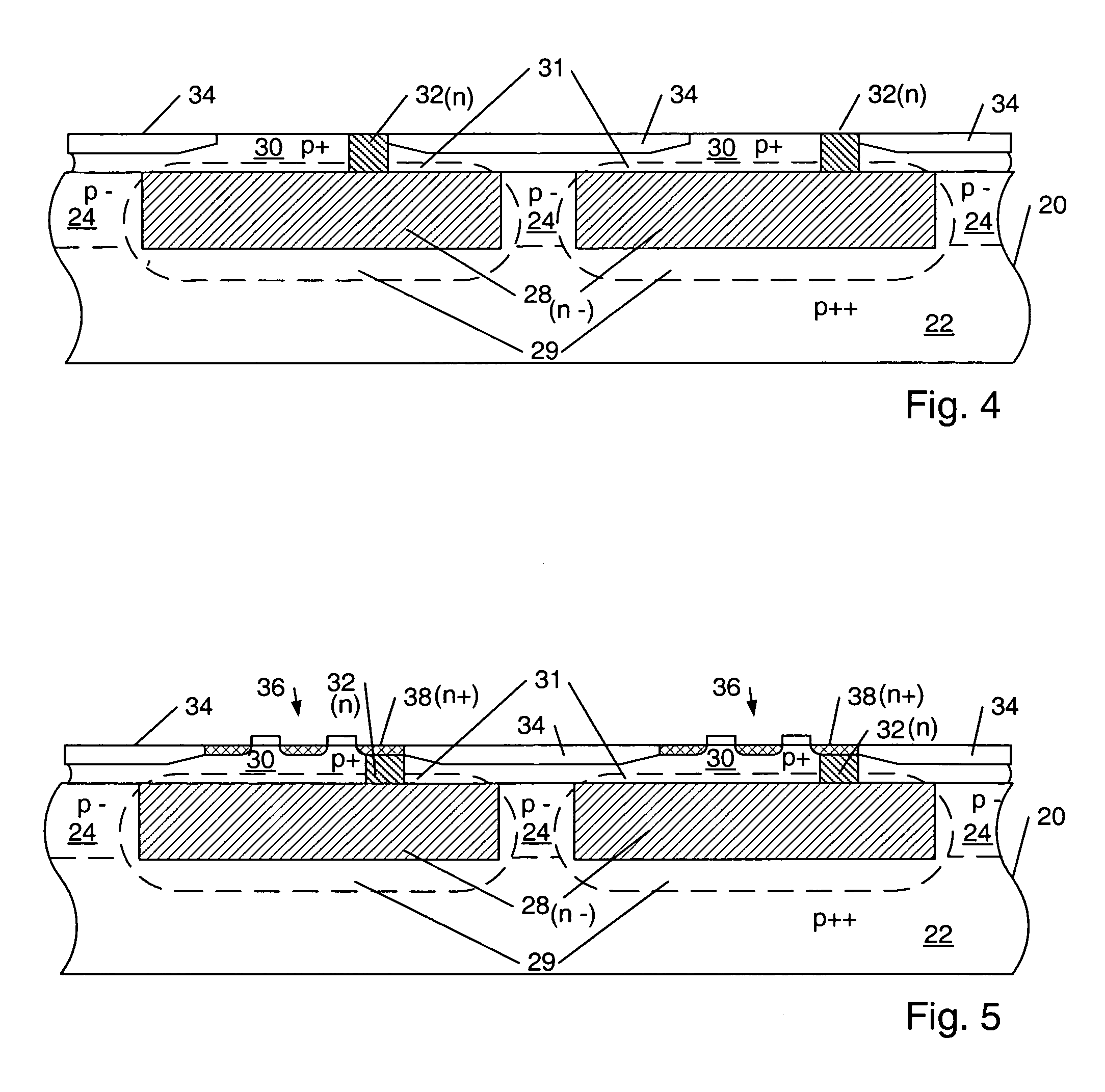

Method and apparatus for ion mobility spectrometry with alignment of dipole direction (IMS-ADD)

ActiveUS7170053B2Low ion lossesHigh sensitivityTime-of-flight spectrometersMaterial analysis by electric/magnetic meansDebyeFree rotation

Owner:BATTELLE MEMORIAL INST

Method and apparatus for ion mobility spectrometry with alignment of dipole direction (IMS-ADD)

ActiveUS20060219889A1Low ion lossesHigh sensitivityTime-of-flight spectrometersMaterial analysis by electric/magnetic meansDebyeFree rotation

Techniques and instrumentation are described for analyses of substances, including complex samples / mixtures that require separation prior to characterization of individual components. A method is disclosed for separation of ion mixtures and identification of ions, including protein and other macromolecular ions and their different structural isomers. Analyte ions are not free to rotate during the separation, but are substantially oriented with respect to the drift direction. Alignment is achieved by applying, at a particular angle to the drift field, a much stronger alternating electric field that “locks” the ion dipoles with moments exceeding a certain value. That value depends on the buffer gas composition, pressure, and temperature, but may be as low as ˜3 Debye under certain conditions. The presently disclosed method measures the direction-specific cross-sections that provide the structural information complementing that obtained from known methods, and, when coupled to those methods, increases the total peak capacity and specificity of gas-phase separations. Simultaneous 2-D separations by direction-specific cross sections along and orthogonally to the ion dipole direction are also possible.

Owner:BATTELLE MEMORIAL INST

Device and Method for the Demodulation Electromagnetic Wave Fields

ActiveUS20080239466A1Less susceptibleLess susceptibilityTelevision system detailsSolid-state devicesCharge currentWave field

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

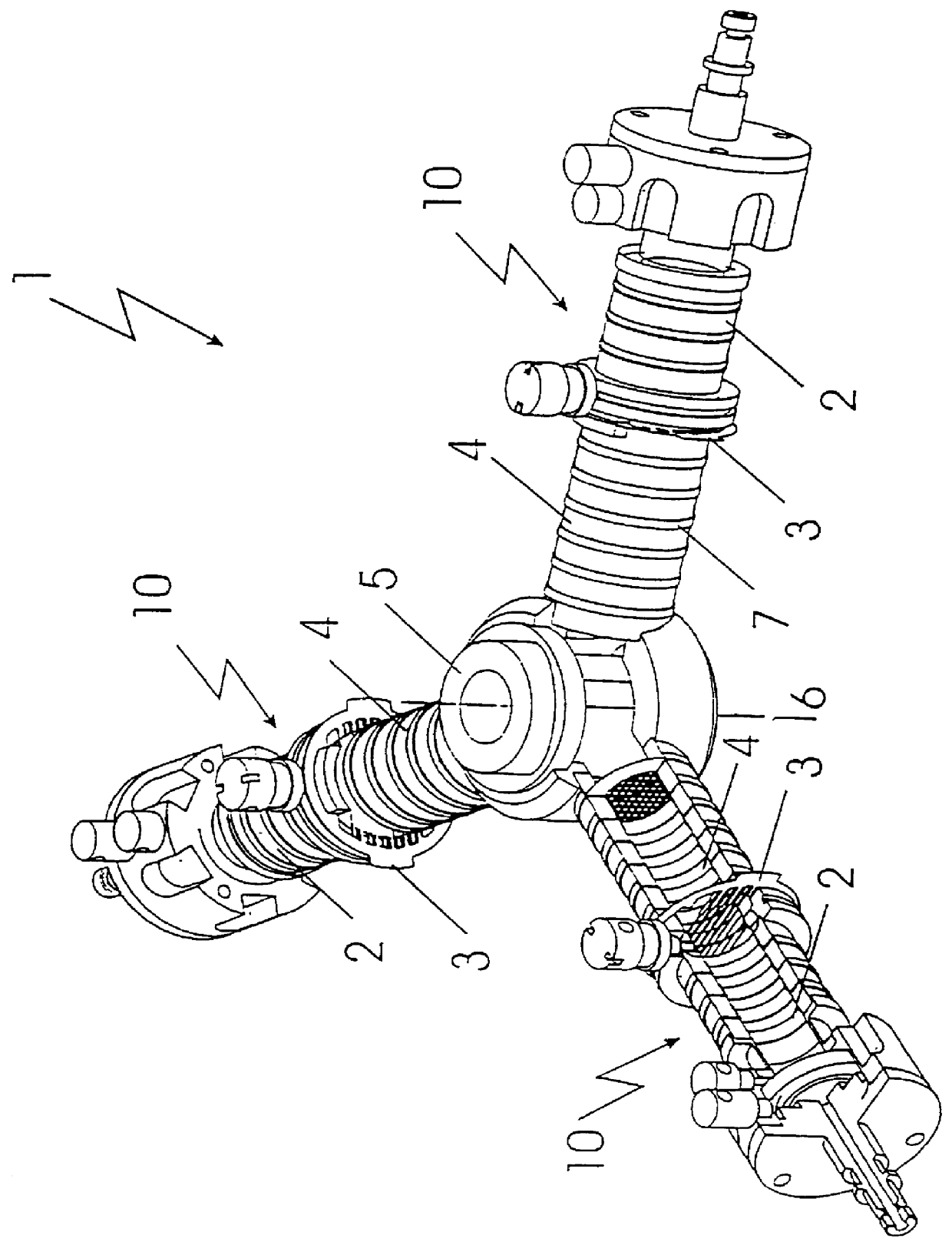

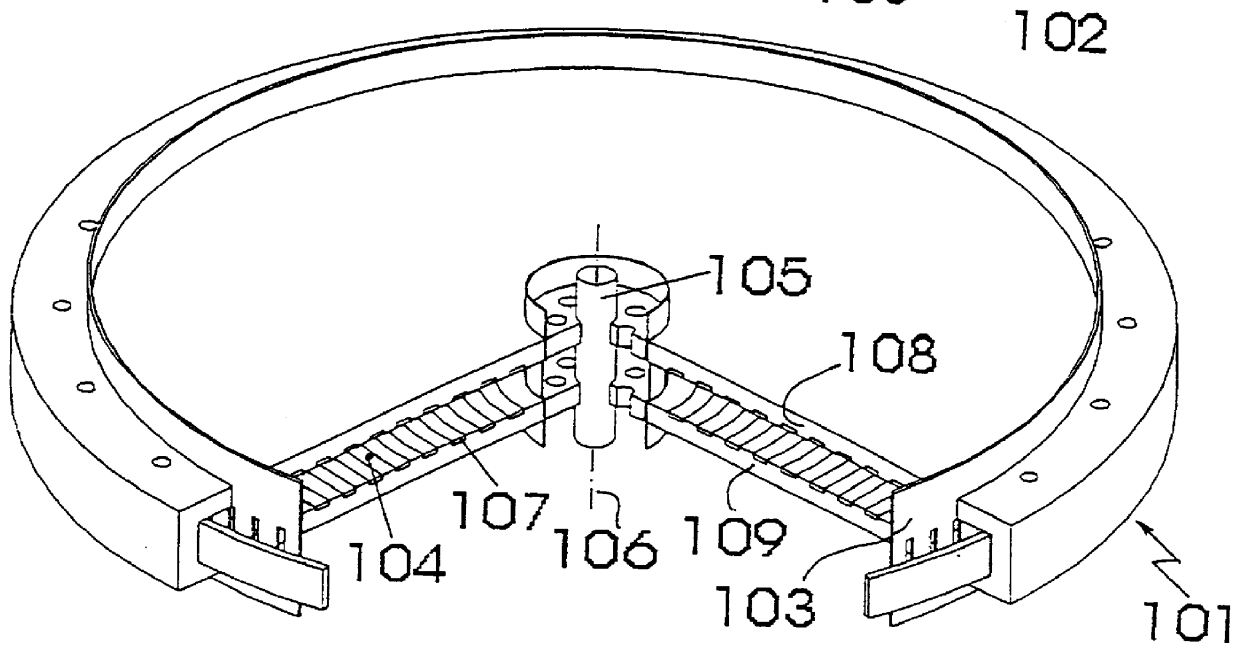

Ion mobility spectrometer in a centripetal arrangement

InactiveUS6100521AOptimize space utilizationEasy to manufactureTime-of-flight spectrometersMaterial analysis by electric/magnetic meansIon-mobility spectrometryDrift field

An ion mobility spectrometer (IMS) with electric drift fields directed at a central detector electrode. The IMS is rotationally symmetrical and has a disk shape.

Owner:BRUKER SAXONIA ANALYTIK

Field-shielded SOI-MOS structure free from floating body effect, and method of fabrication therefor

InactiveUS6933572B2Enhancing recombinationReduced recombination time constantTransistorSolid-state devicesFloating body effectElectrical conductor

A silicon-on-insulator structure provides an effective drift field for holes, and simultaneously enhanced recombination centers for holes and electrons. The structure includes a silicon substrate, an oxide insulation layer disposed above the silicon substrate, a silicon body layer disposed above the oxide insulation layer, and a field shield gate disposed above the silicon body layer. The field shield gate includes a conductor portion, and an alumina insulation layer disposed beneath the conductor portion. The oxide insulation layer and the silicon body layer each include at least one channel stop region, and at least one recombination center for the recombination of positive- and negative-charge carriers. The effective drift field and enhanced recombination centers facilitate the rapid recombination of the charge carriers, leading to a very small recombination time constant, which overcomes the floating body effect associated with conventional silicon-on-insulator structures.

Owner:MICRON TECH INC

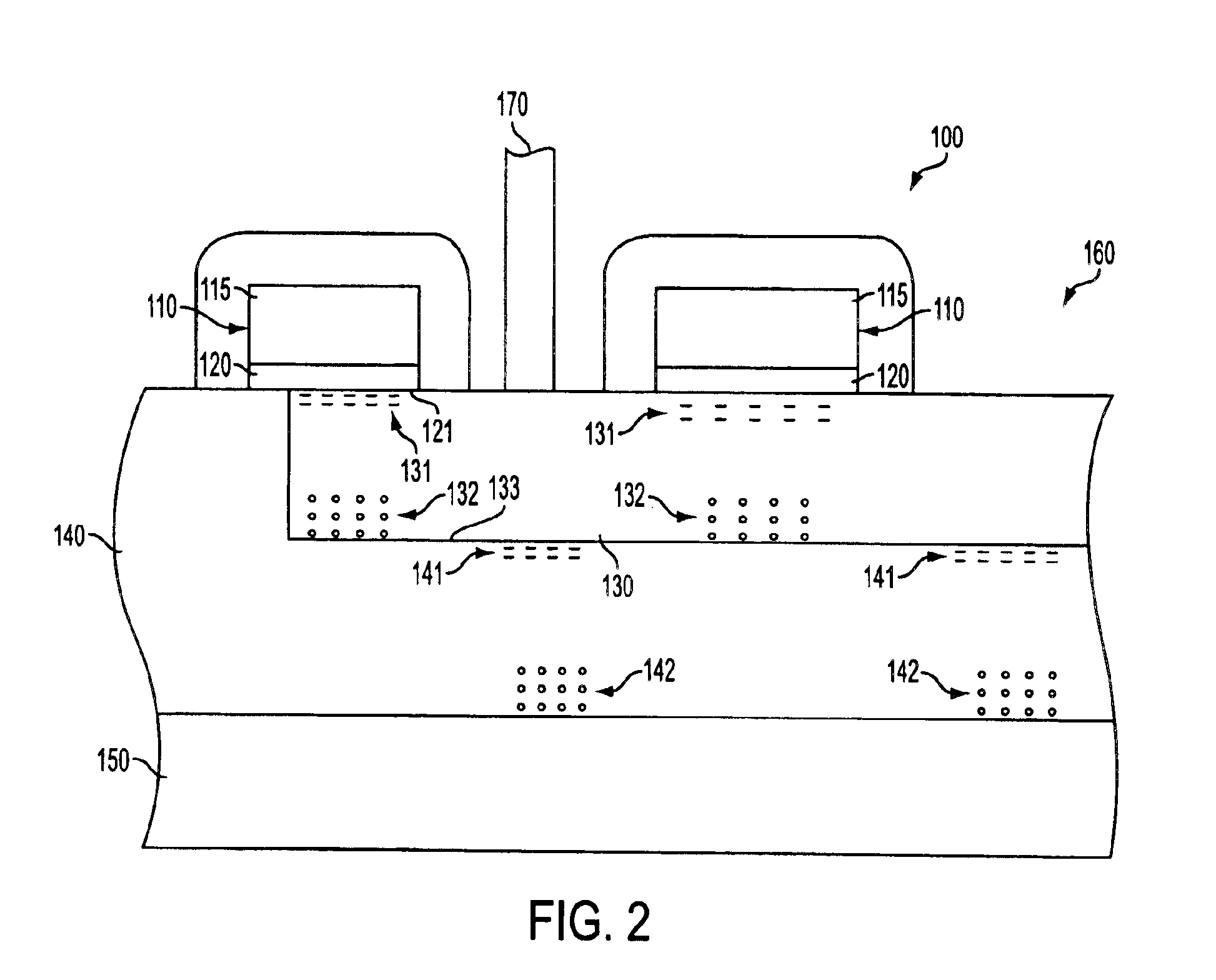

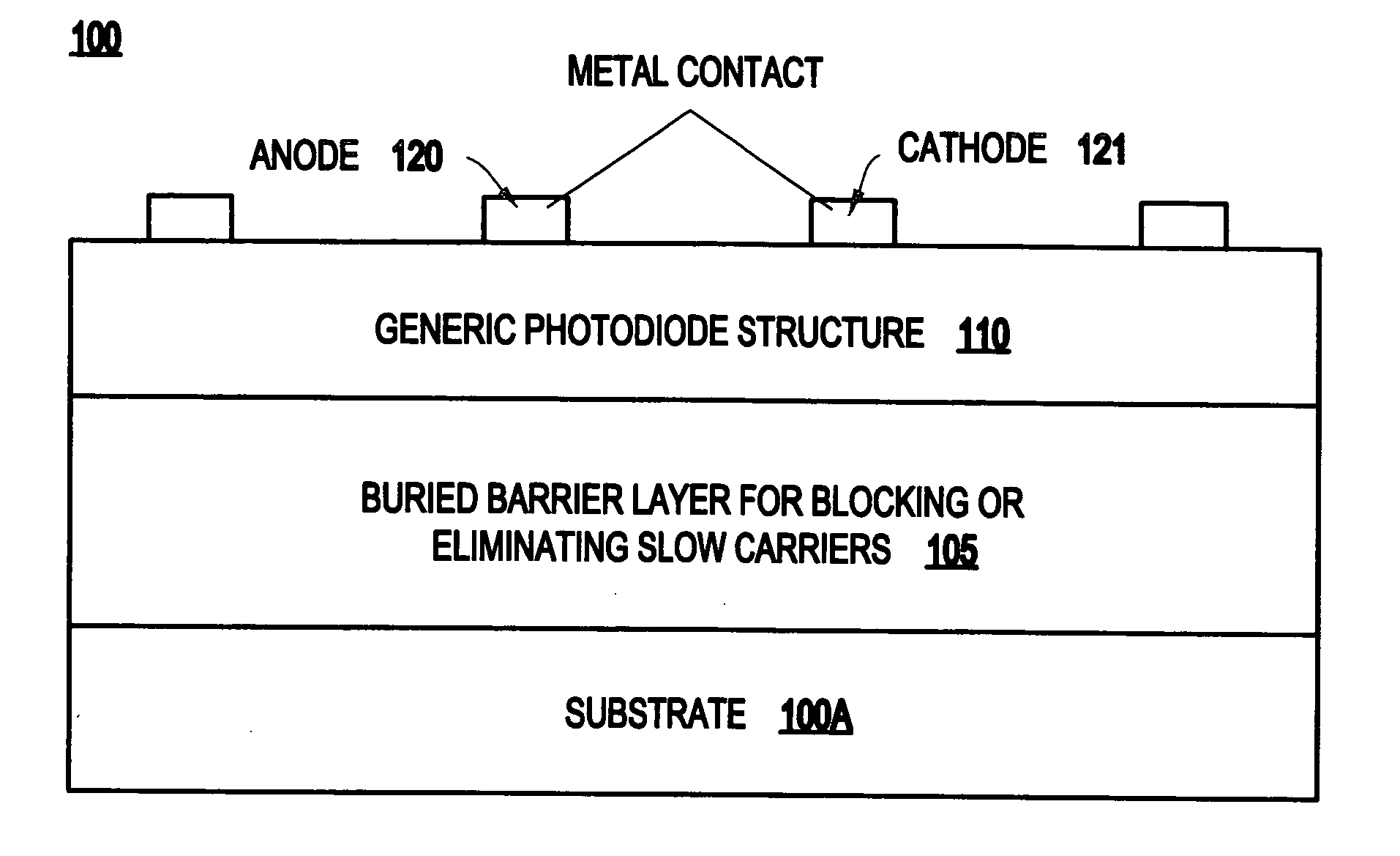

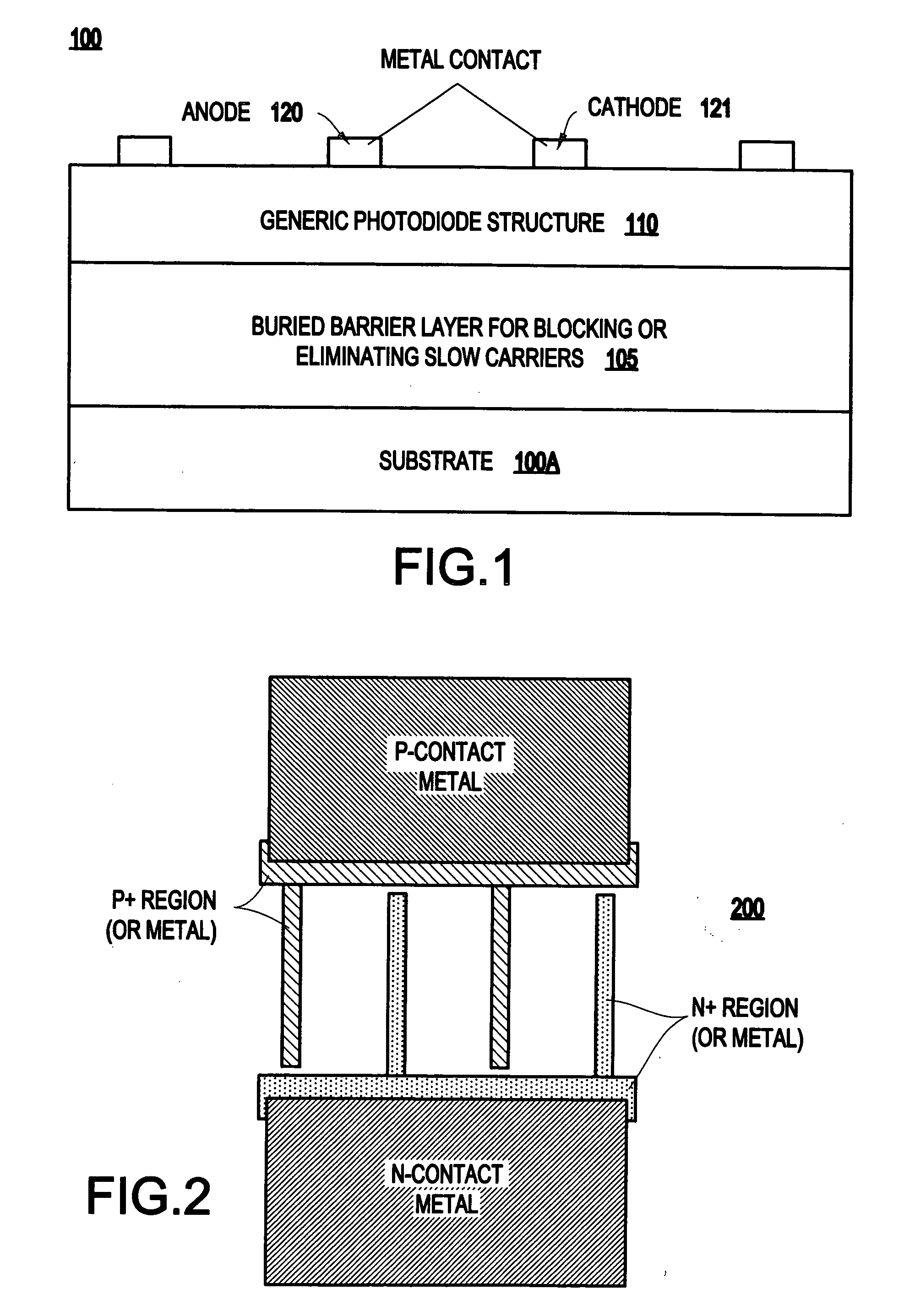

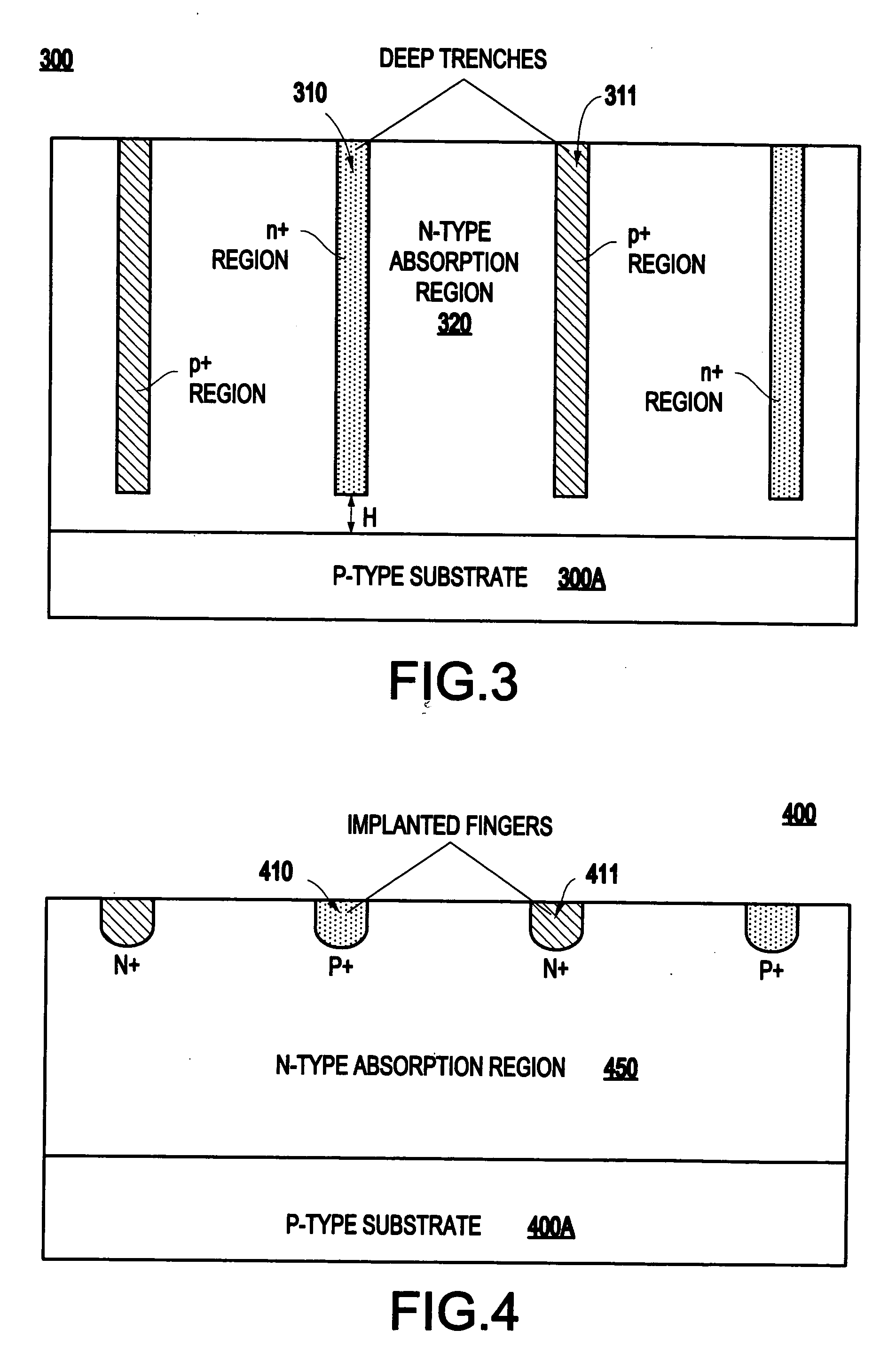

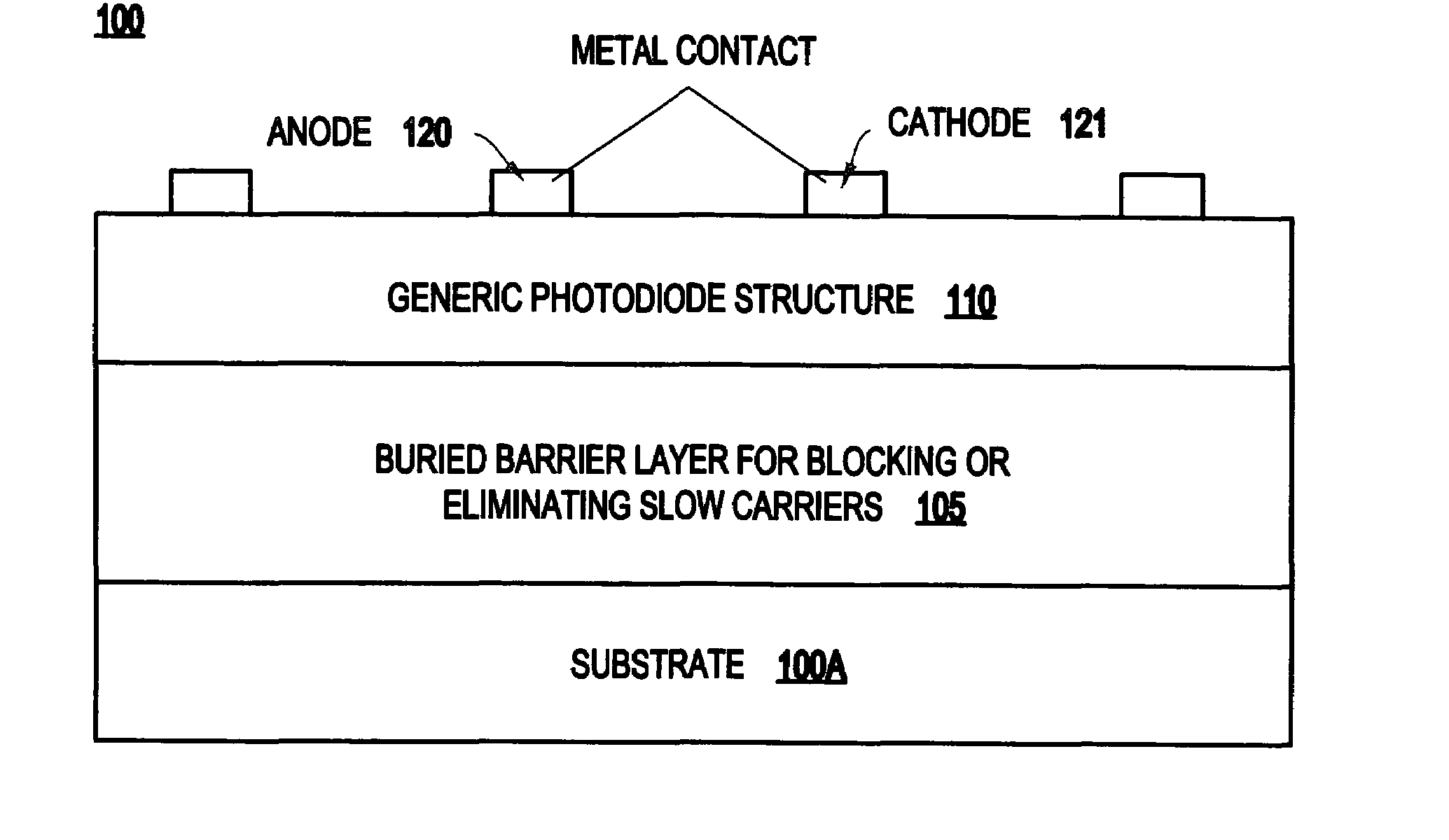

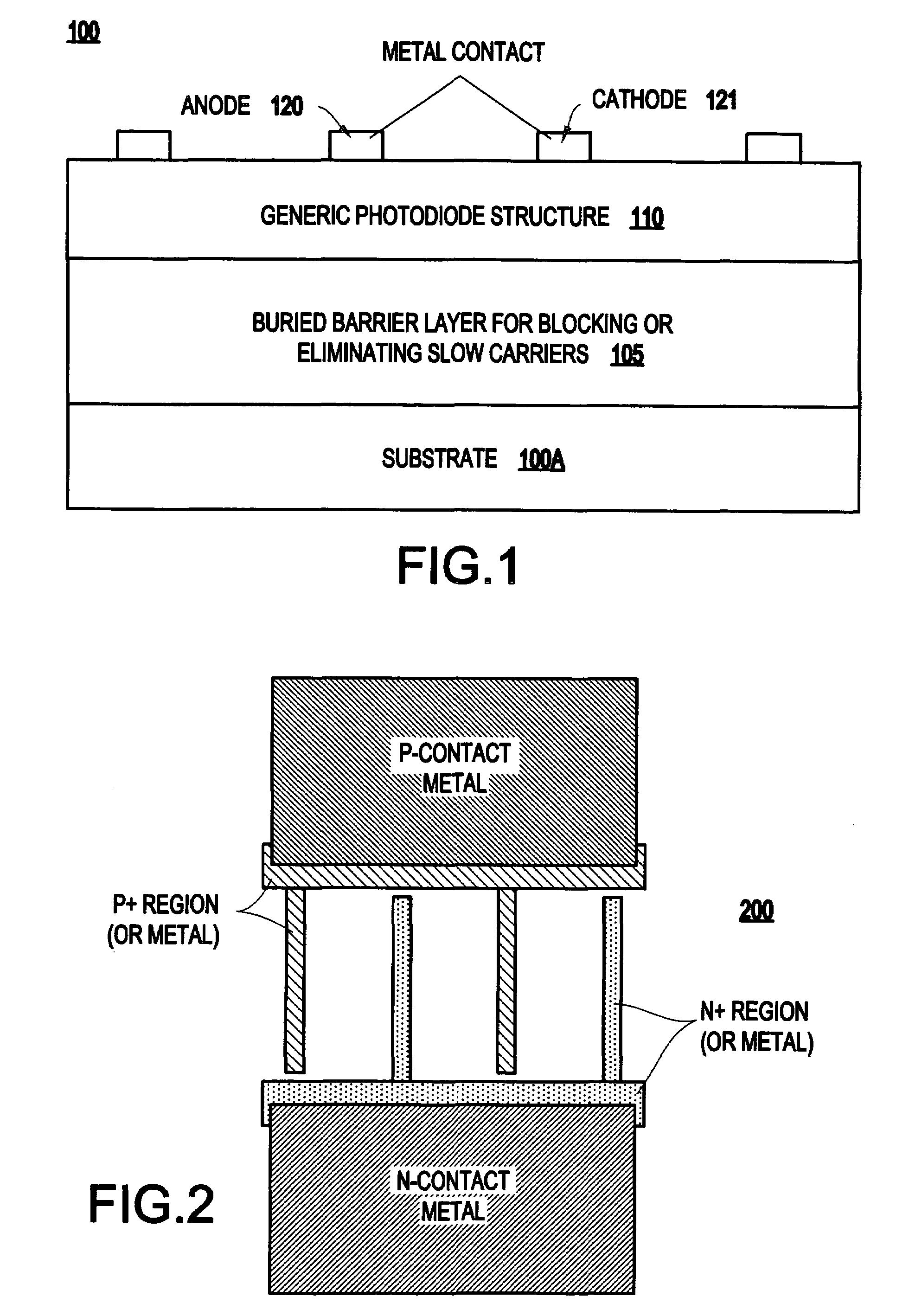

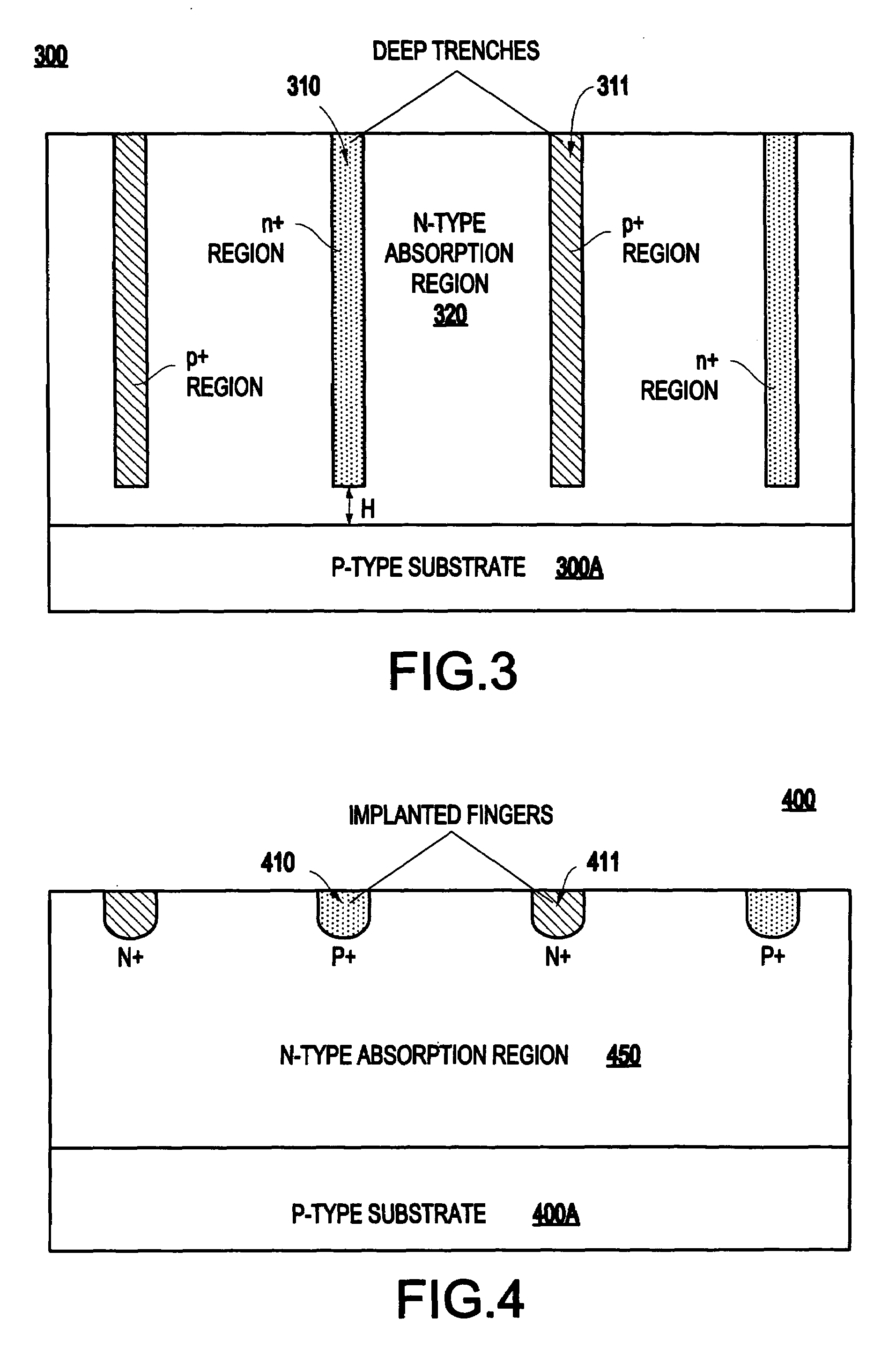

High speed photodiode with a barrier layer for blocking or eliminating slow photonic carriers and method for forming same

InactiveUS20040119093A1Television system detailsSolid-state devicesPhotovoltaic detectorsPhotodetector

A structure (and method for forming the structure) includes a photodetector, a substrate formed under the photodetector, and a barrier layer formed over the substrate. The buried barrier layer preferably includes a single or dual p-n junction, or a bubble layer for blocking or eliminating the slow photon-generated carriers in the region where the drift field is low.

Owner:GLOBALFOUNDRIES US INC

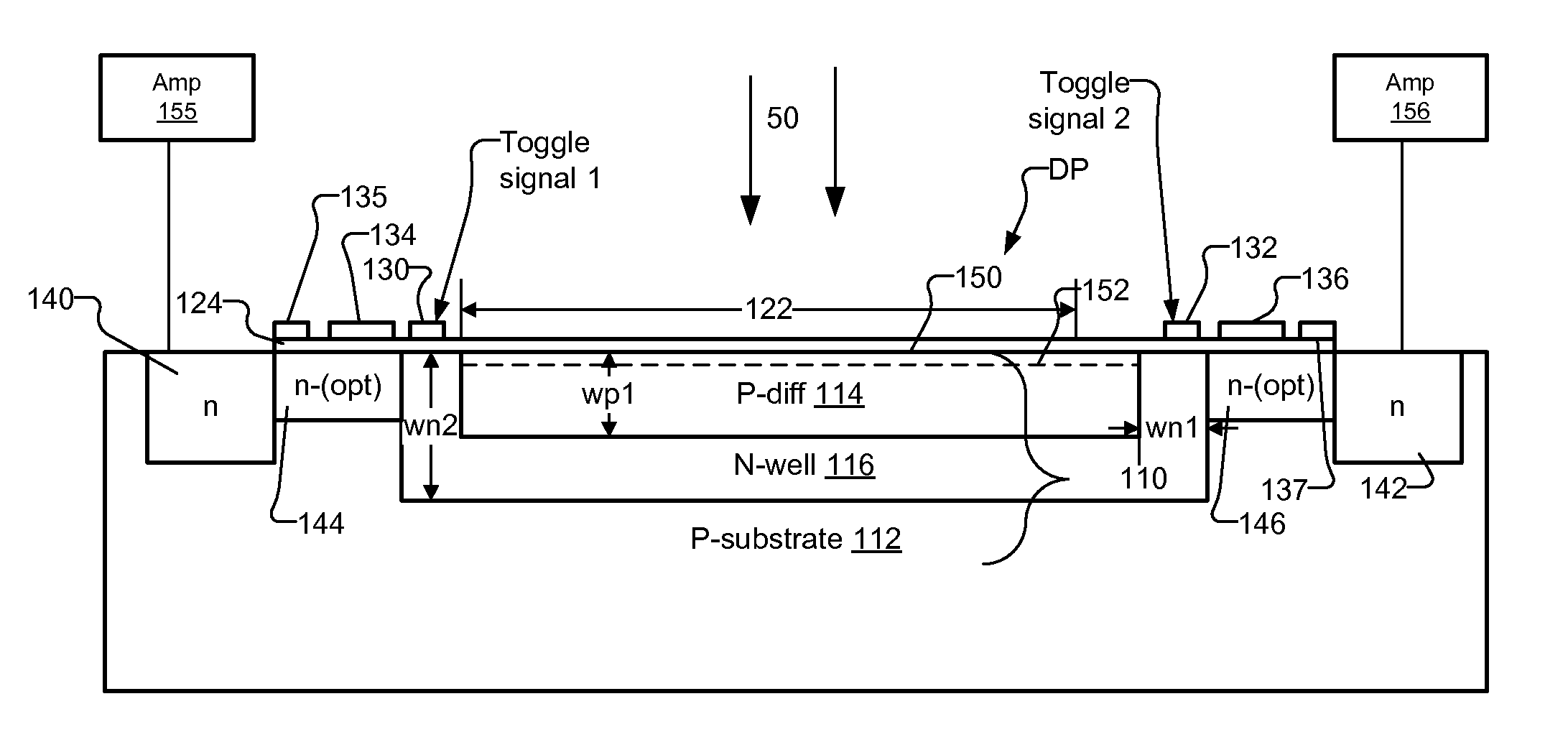

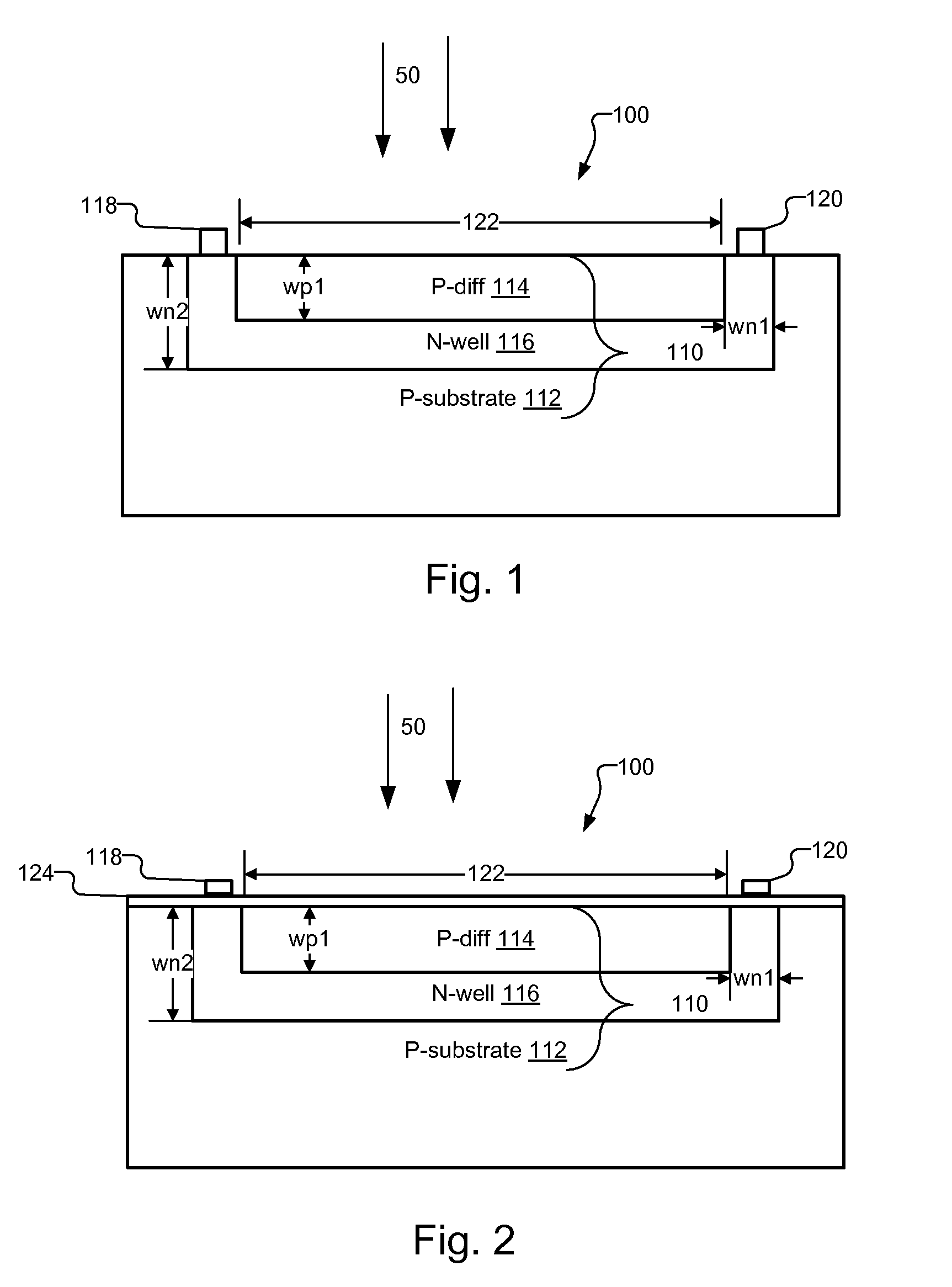

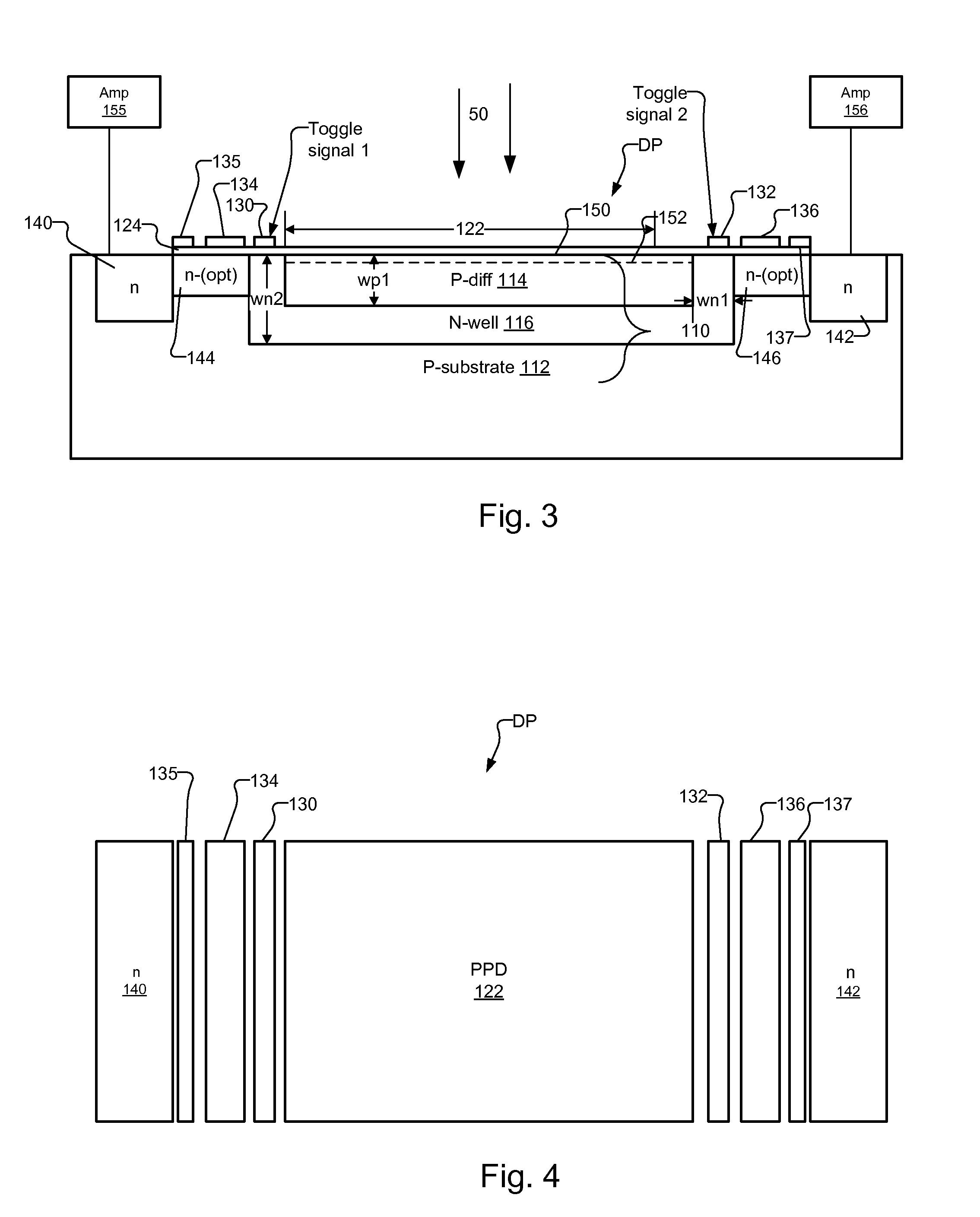

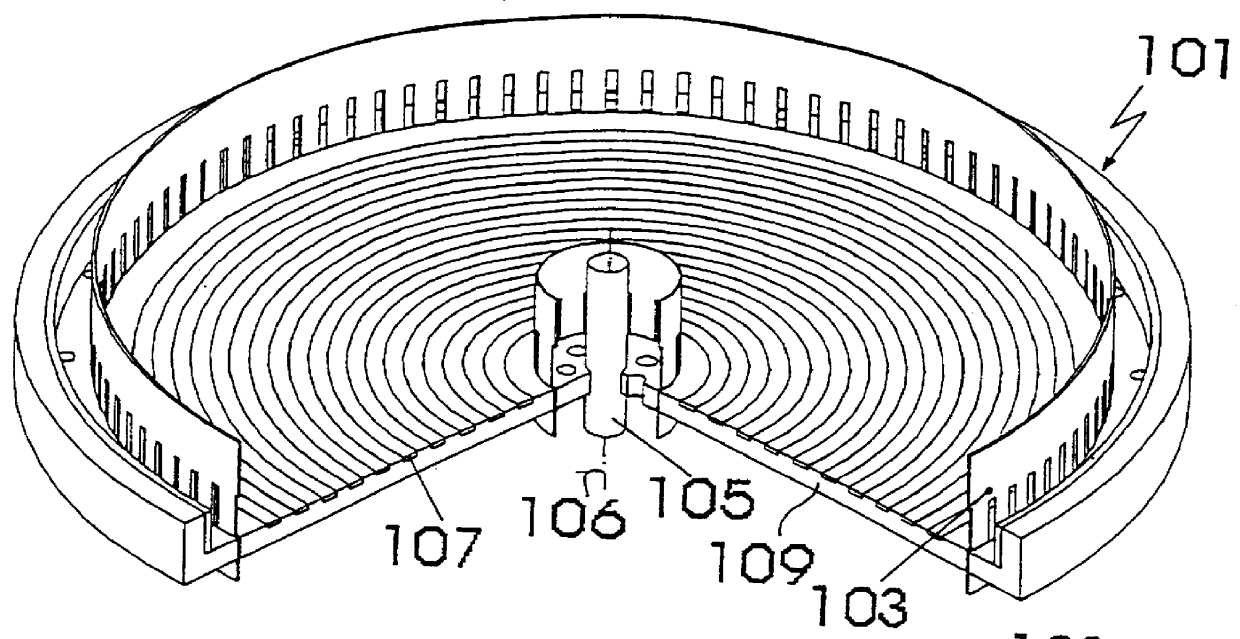

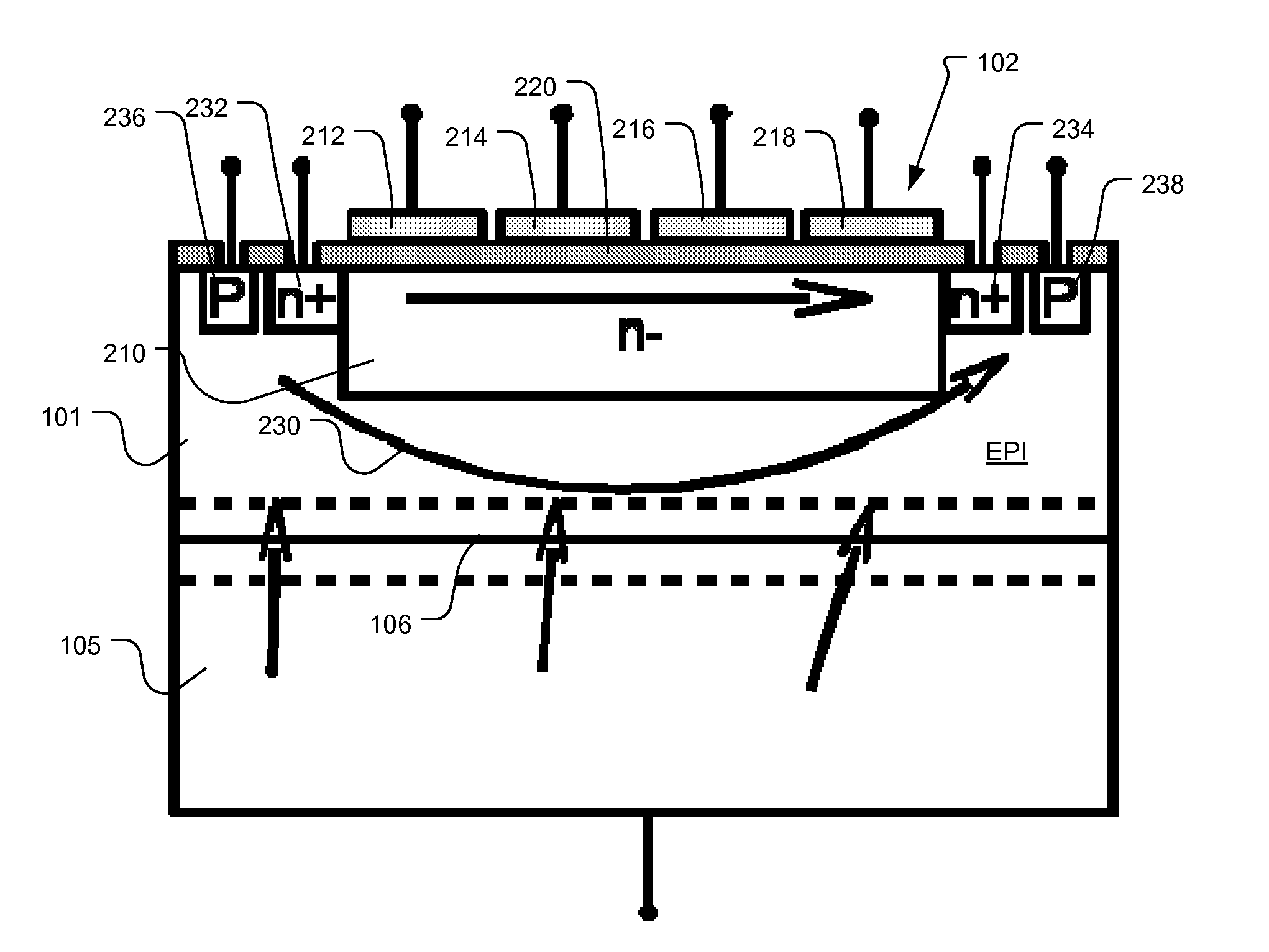

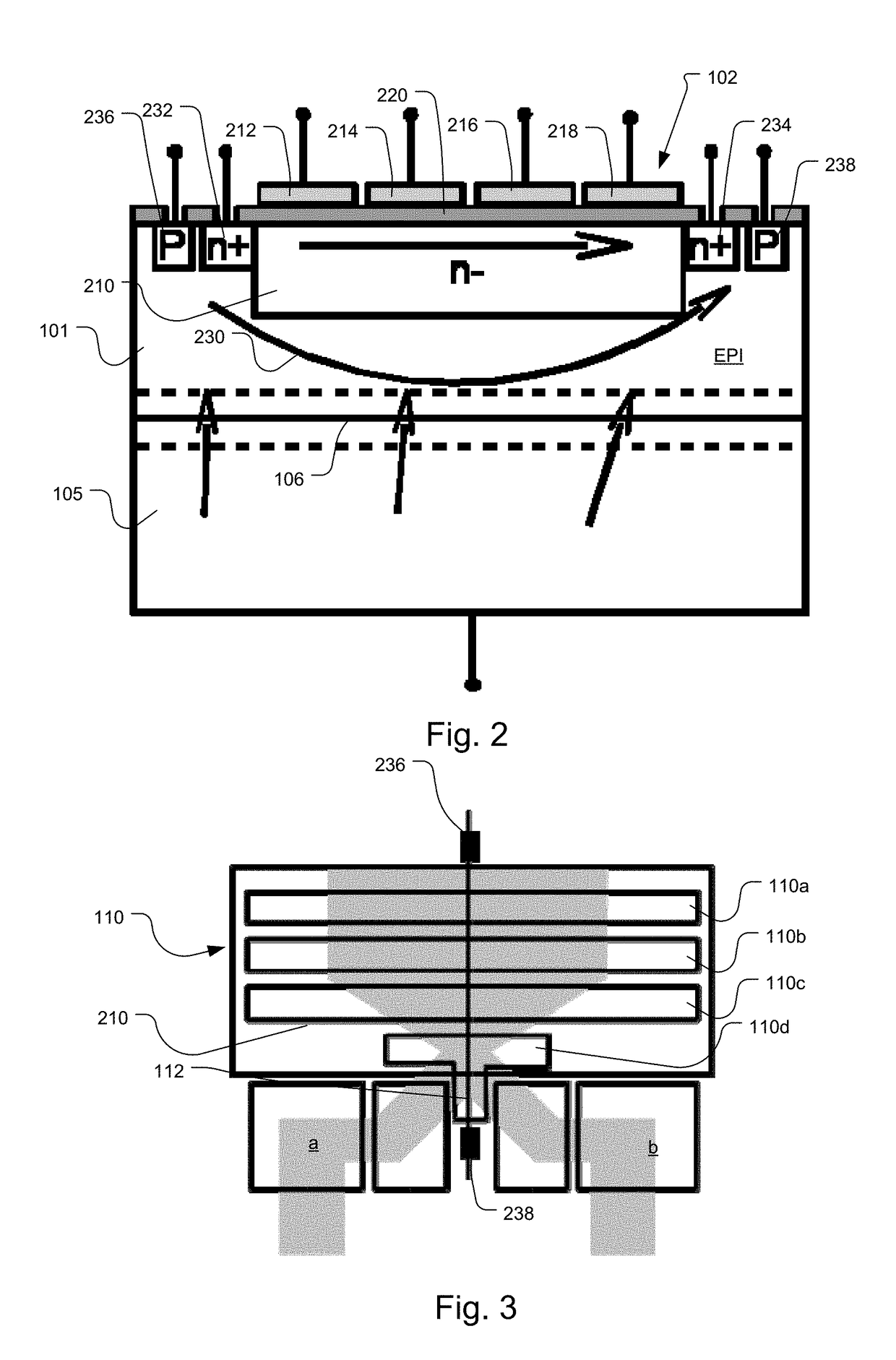

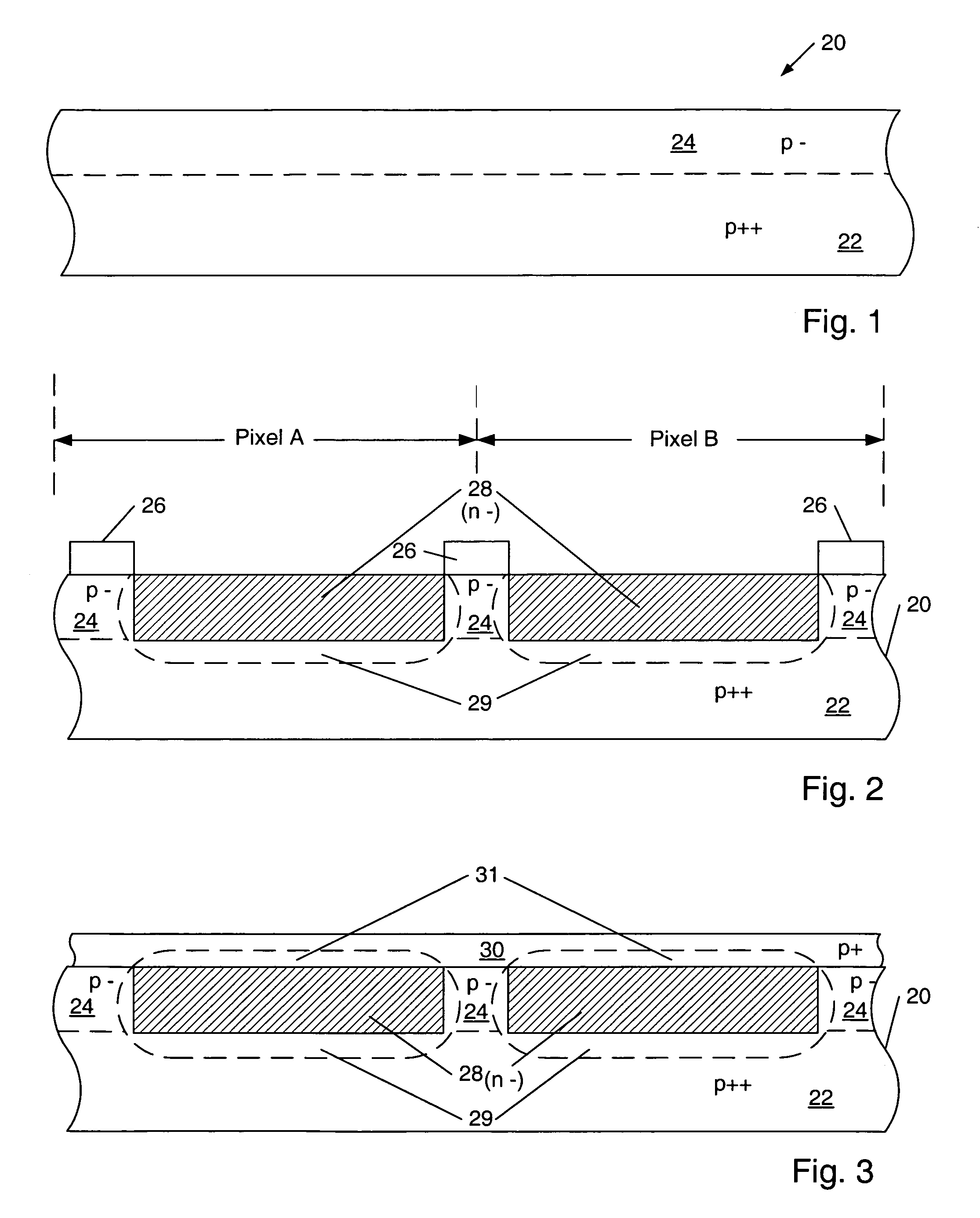

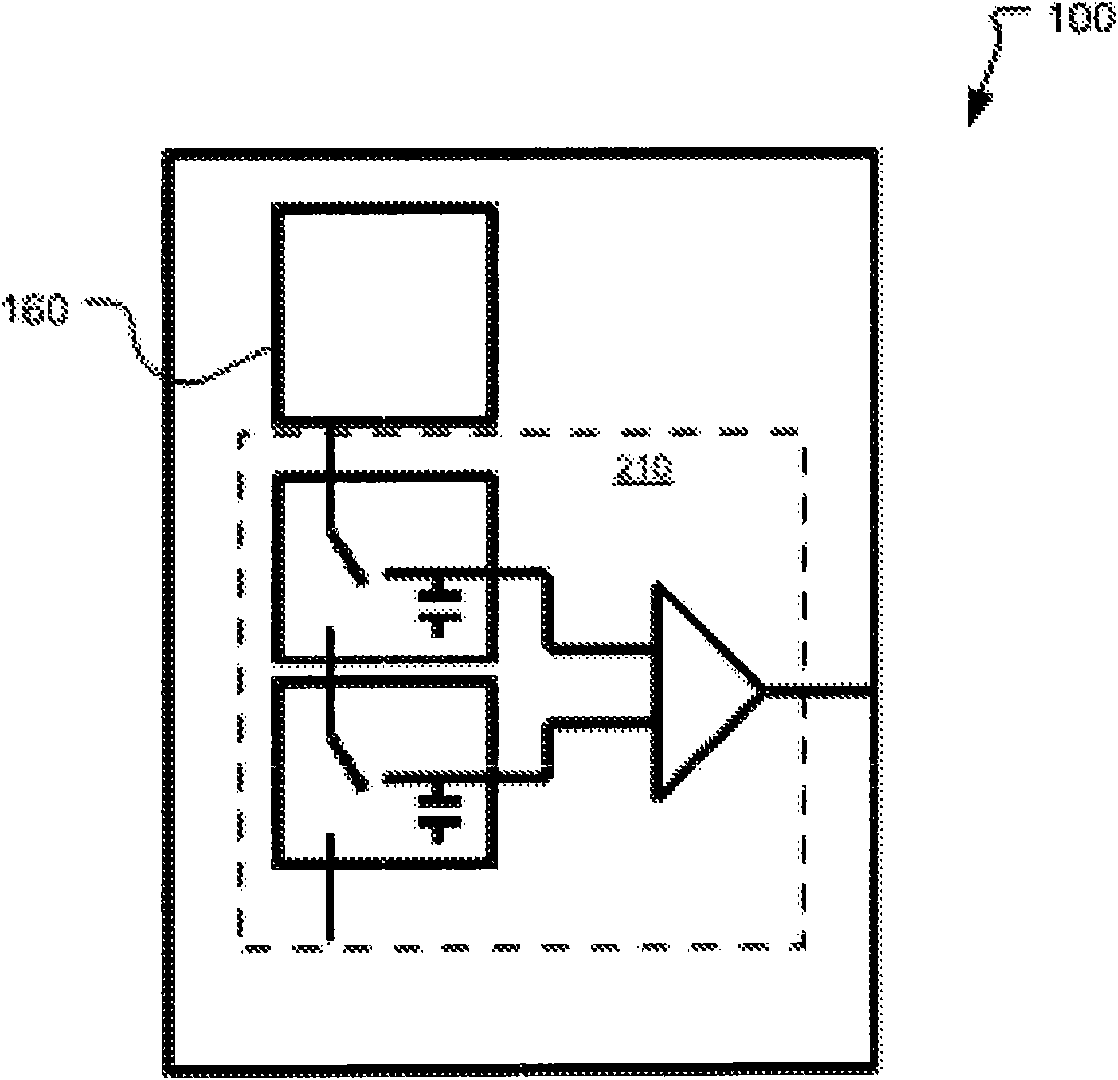

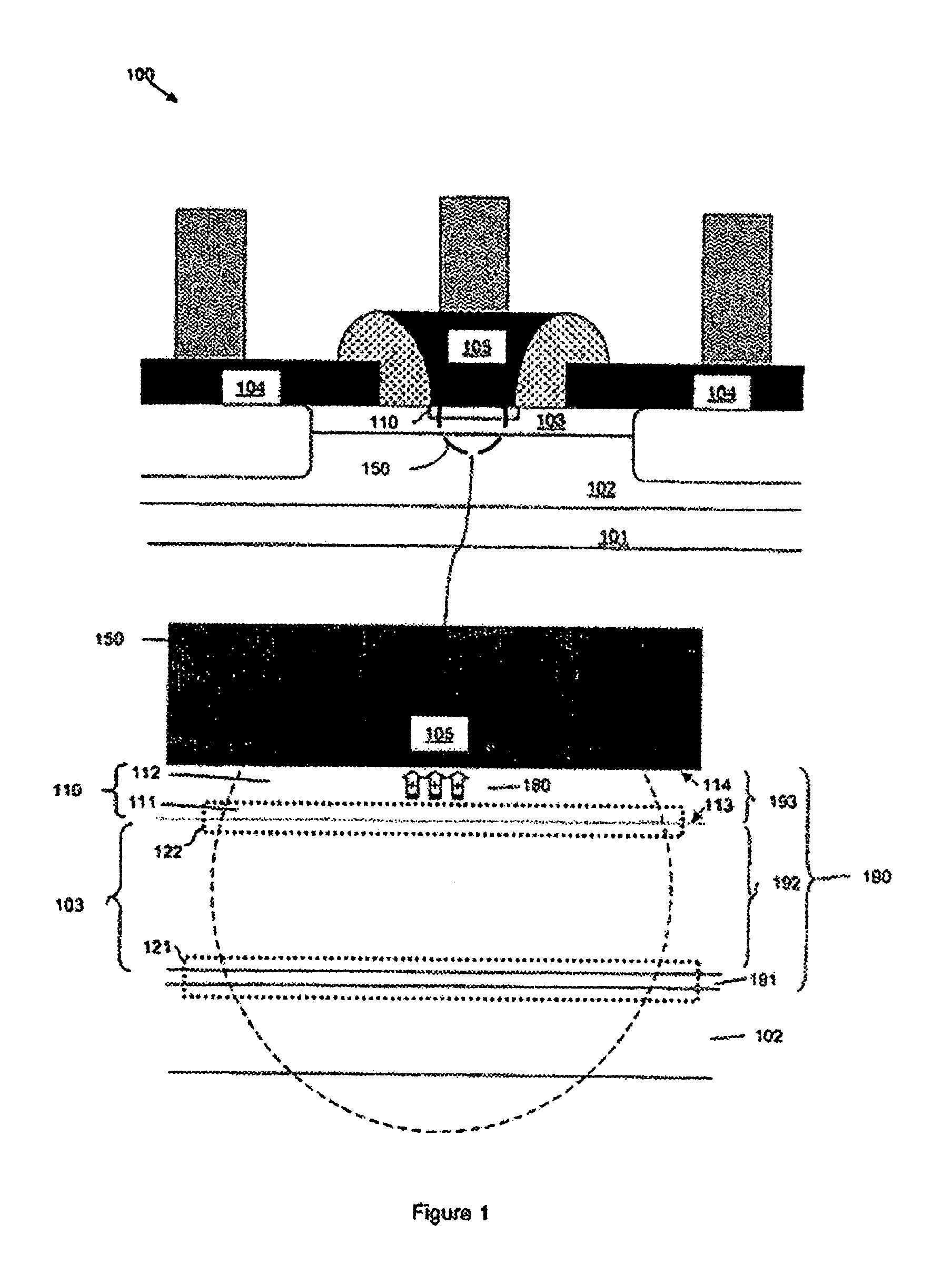

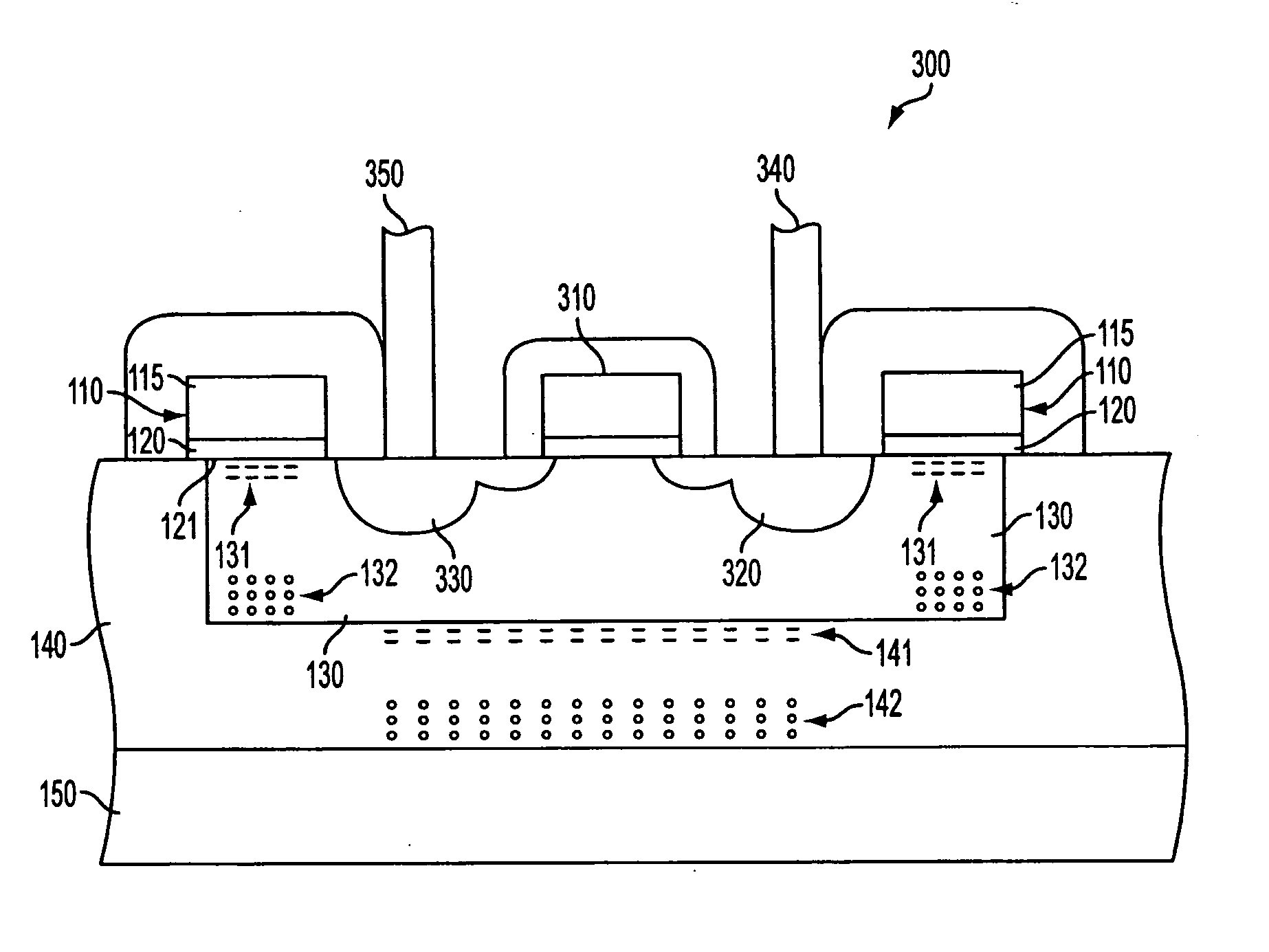

Demodulation Pixel Incorporating Majority Carrier Current, Buried Channel and High-Low Junction

A demodulation pixel improves the charge transport speed and sensitivity by exploiting two effects of charge transport in silicon in order to achieve the before-mentioned optimization. The first one is a transport method based on the CCD gate principle. However, this is not limited to CCD technology, but can be realized also in CMOS technology. The charge transport in a surface or even a buried channel close to the surface is highly efficient in terms of speed, sensitivity and low trapping noise. In addition, by activating a majority carrier current flowing through the substrate, another drift field is generated below the depleted CCD channel. This drift field is located deeply in the substrate, acting as an efficient separator for deeply photo-generated electron-hole pairs. Thus, another large amount of minority carriers is transported to the diffusion nodes at high speed and detected.

Owner:AMS SENSORS SINGAPORE PTE LTD

Phosphoric diffusion technology for metallurgical-grade polysilicon solar cells

ActiveCN101587918AReduce the effectImprove life expectancyFinal product manufactureSemiconductor devicesSolar cellImpurity

The invention relates to diffusion technology for manufacturing solar cells, in particular to phosphoric diffusion technology for metallurgical-grade polysilicon solar cells. The technology comprises the following steps: firstly, performing high temperature grain boundary gettering, wherein high temperature is used to make impurity atoms released at the prior settling position and simultaneously diffused and move to the position of a grain boundary defect to settle to form a clean area near the grain boundary; secondly, performing medium-low temperature phosphoric deposition, wherein diffusion deposition of fresh phosphorus is performed for a short time at a medium low diffusion temperature to finish surface low concentration phosphorus deposition to prepare for long time high temperature drive-in in a next step; thirdly, performing diffusion passivation of high temperature deep grain boundary, wherein high temperature long time phosphoric source drive-in is performed to form deep PN junction at the position of the grain boundary so as to make phosphor generate phosphoric gettering and passivation of phosphoric drift field at the position of the grain boundary; and finally, performing the diffusion again for adjusting to a needed sheet resistance value. The technology greatly reduces the composite of minority carrier originally happening in the position of the grain boundary by utilizing the properties of the diffusion of impurities in the polycrystalline silicon; and after the process is finished, the minority carrier lifetime of a silicon chip is improved compared with that of a silicon clip produced by a normal process, which has an active effect on the final performance of the cells.

Owner:TRINA SOLAR CO LTD

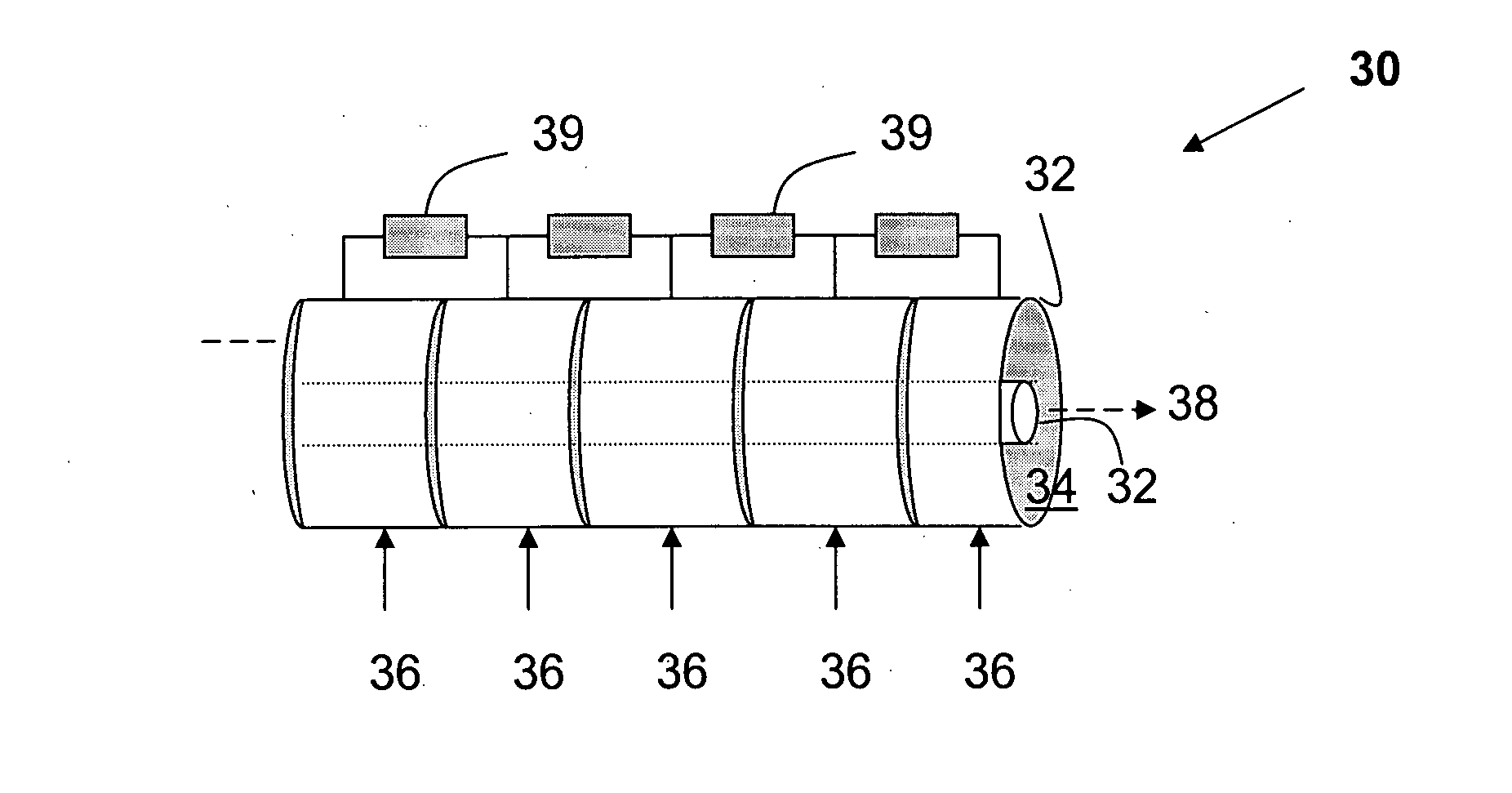

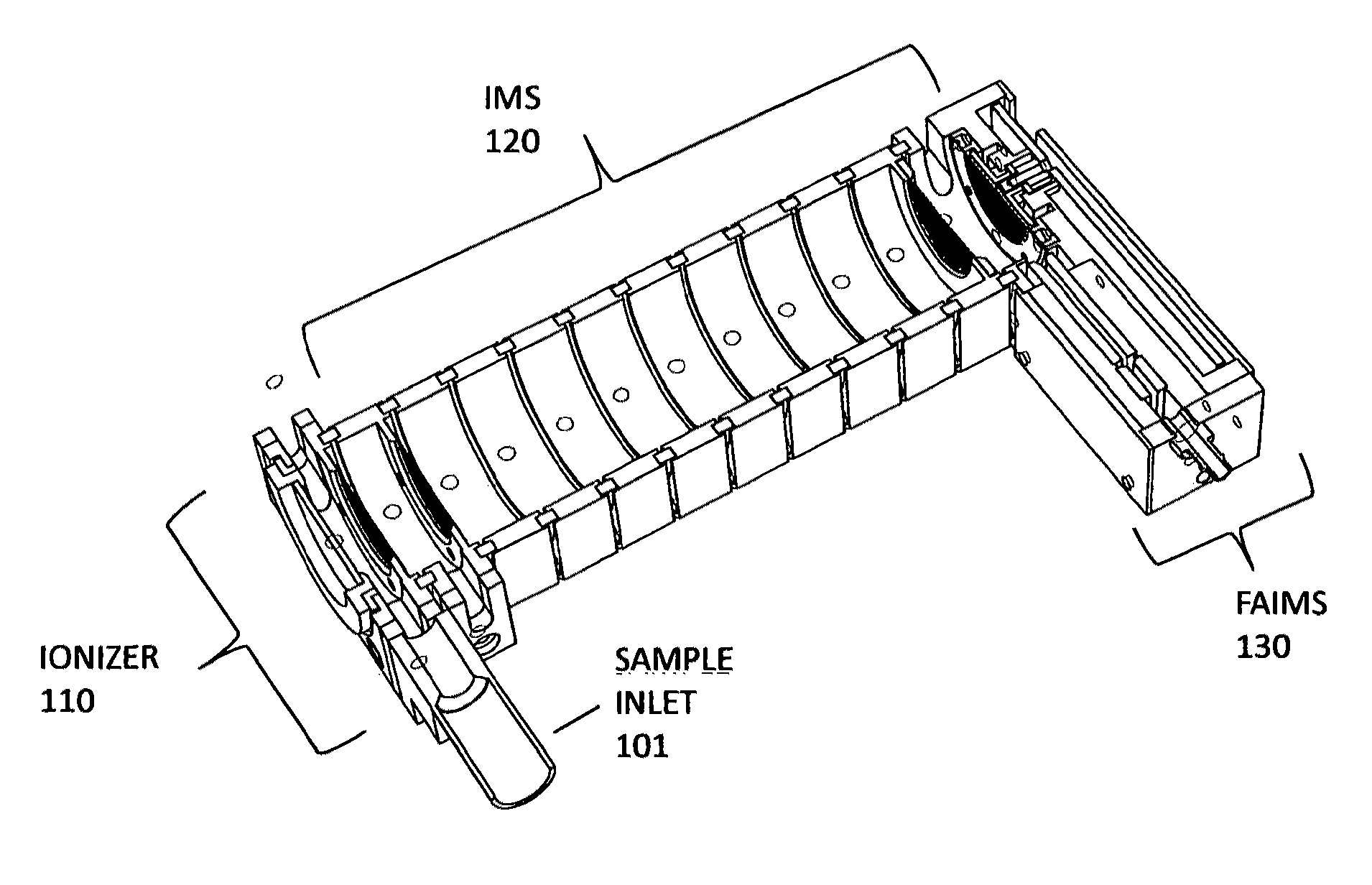

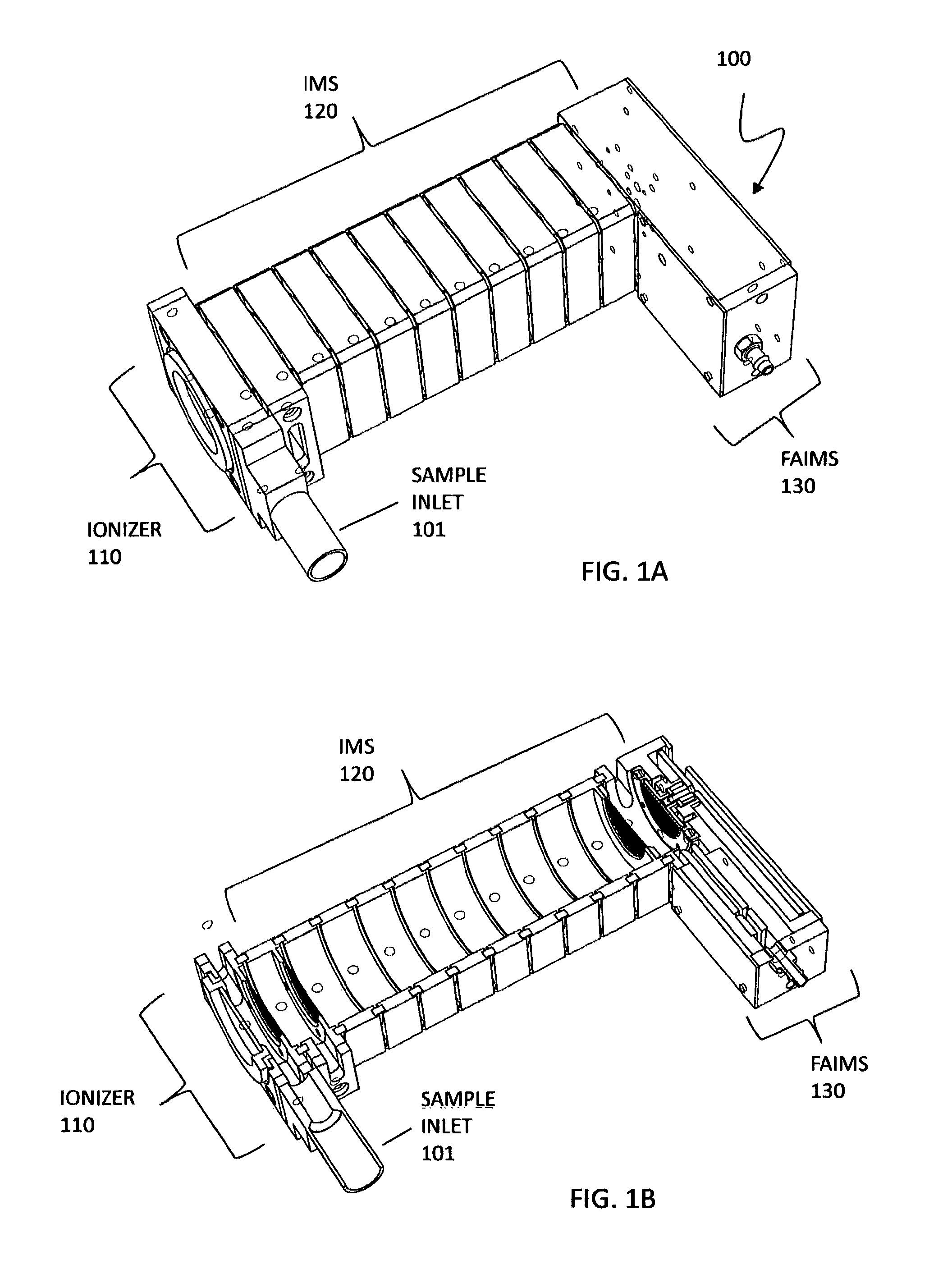

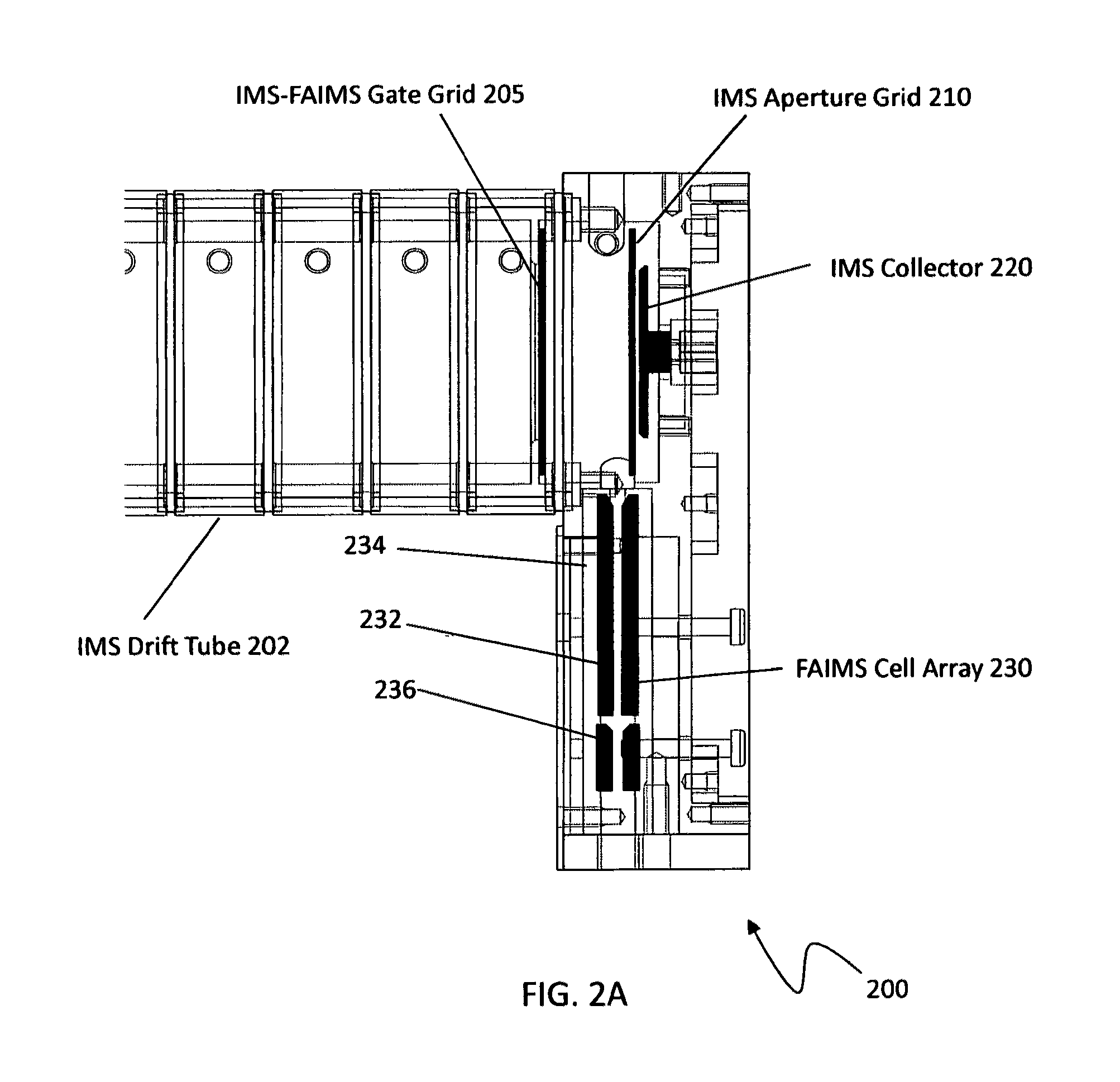

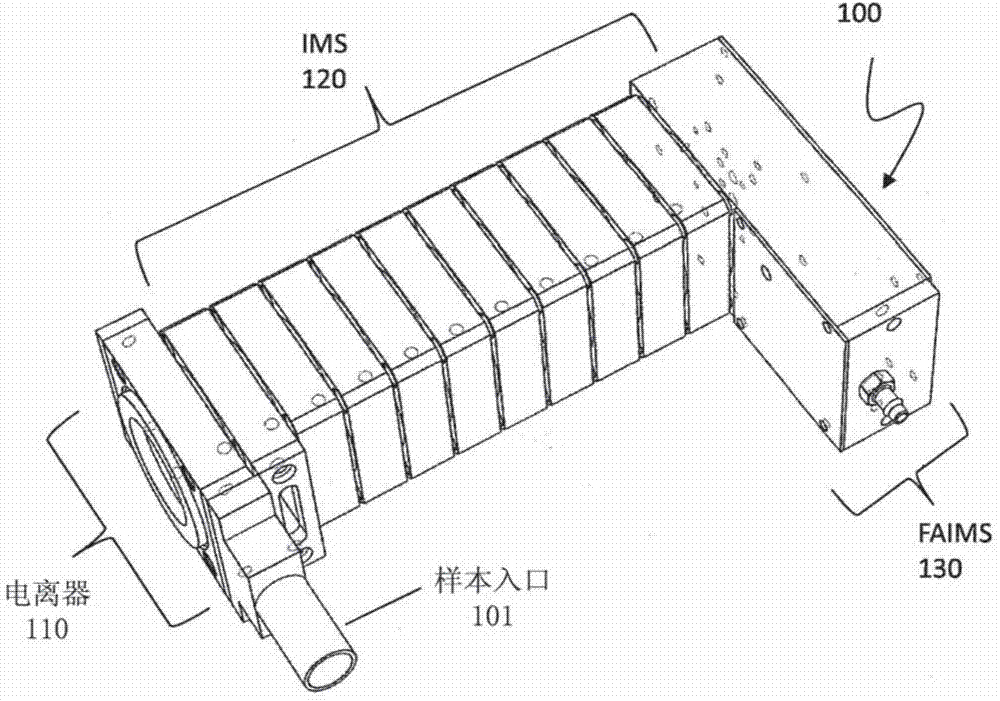

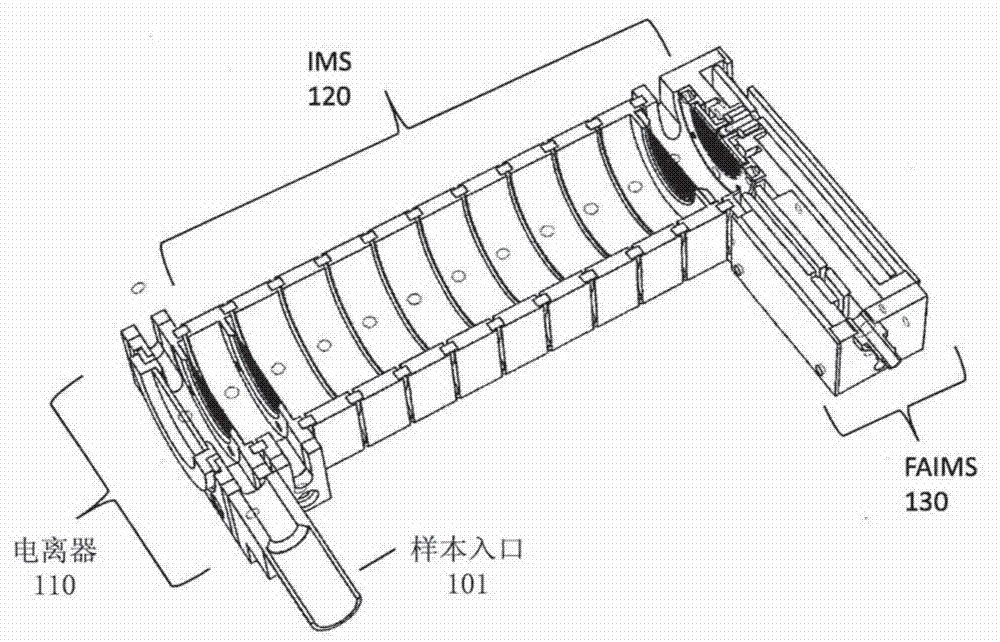

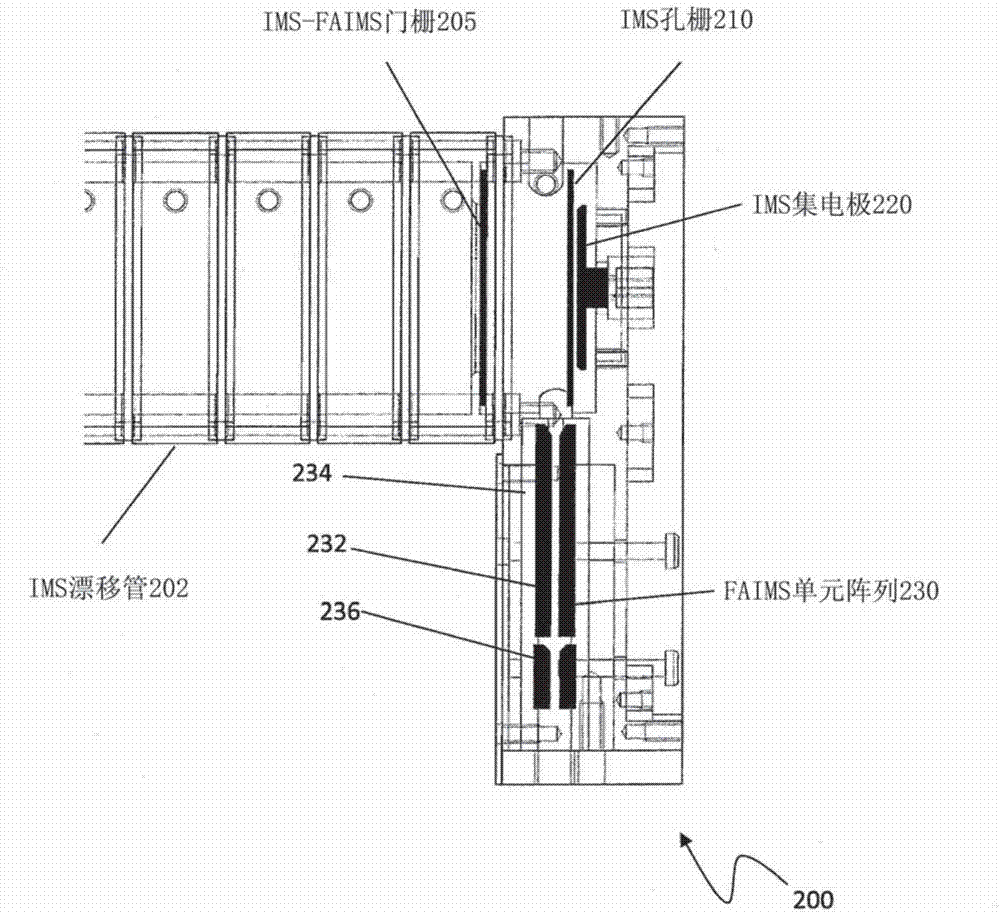

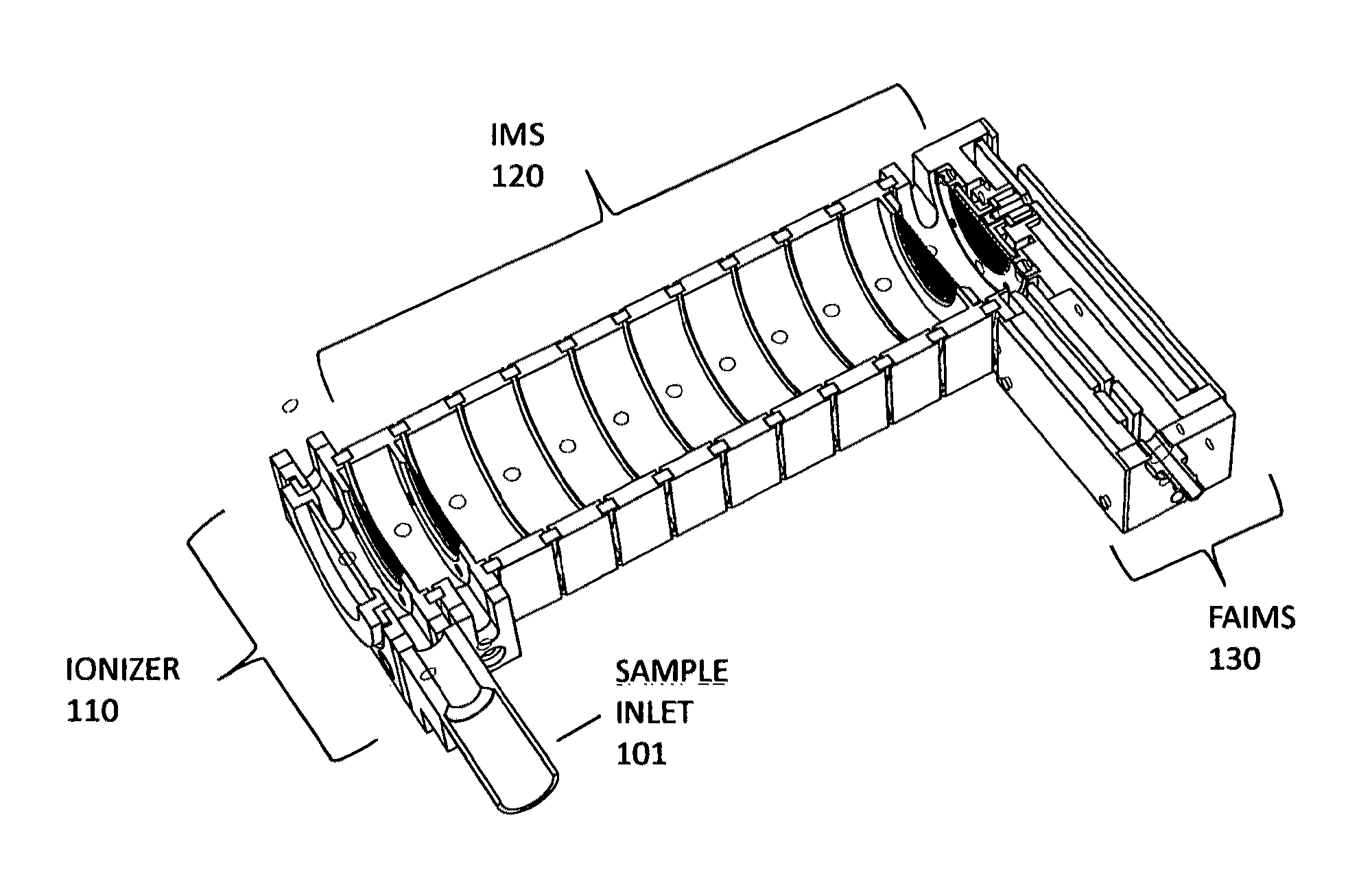

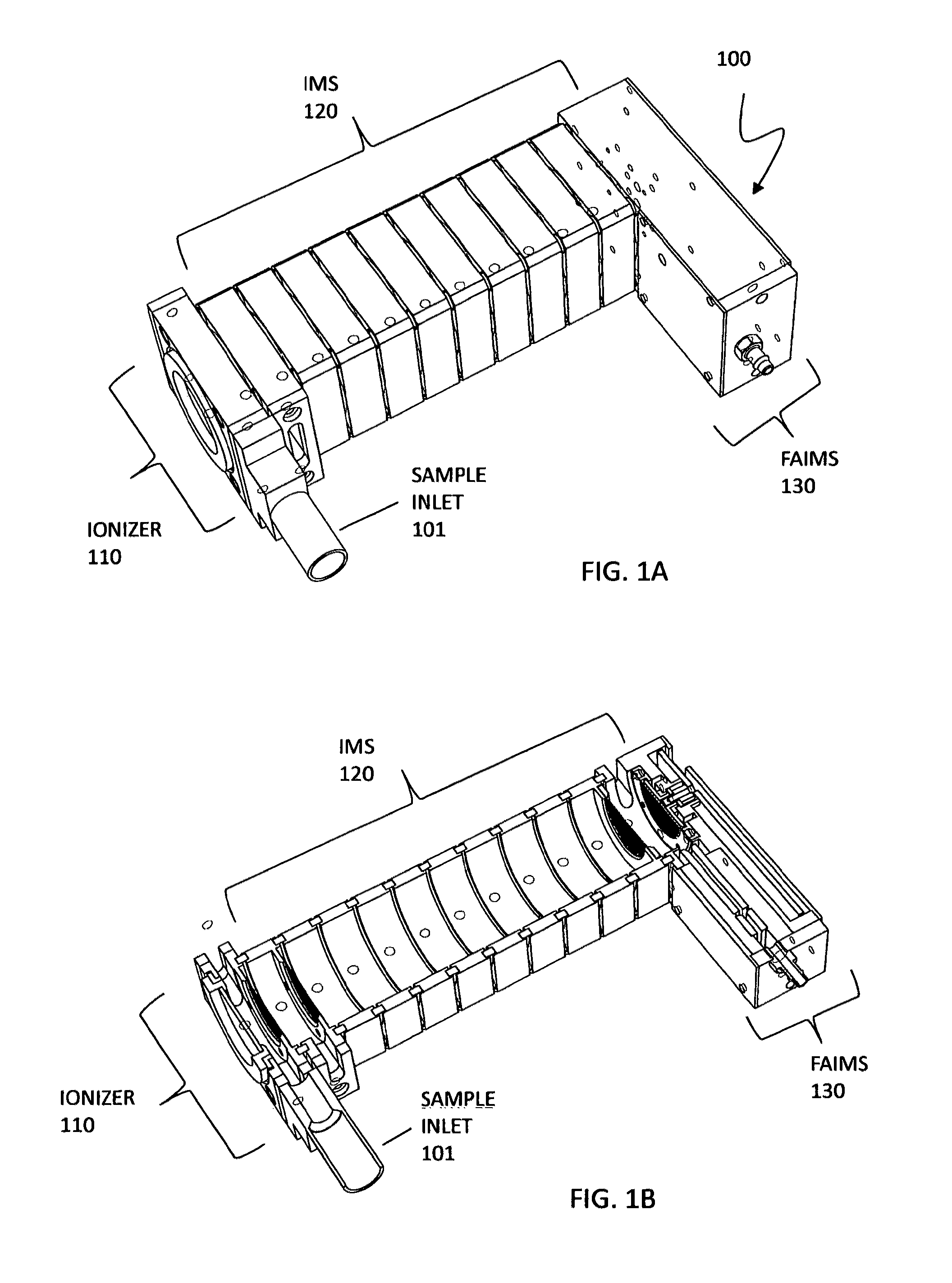

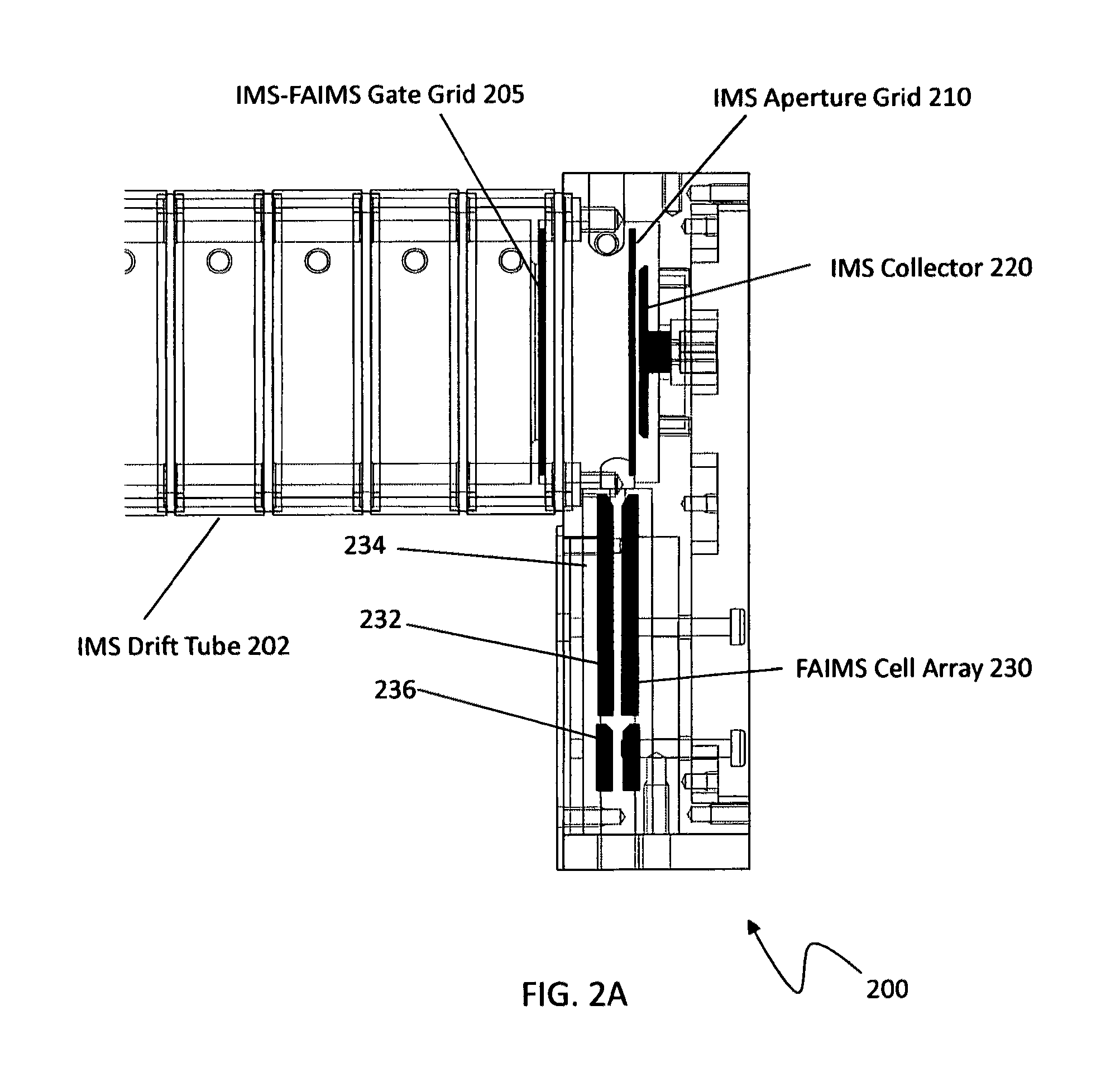

Ion mobility spectrometer device with embedded faims

ActiveUS20120326020A1Change in velocitySamples introduction/extractionMaterial analysis by electric/magnetic meansNon symmetricLow voltage

A tandem instrument using a variable frequency pulsed ionization source and two separation techniques, low (IMS) and high (FAIMS) field mobility is provided. The analytical stage features a field driven FAIMS cell embedded on-axis within the IMS drift tube. The FAIMS cell includes two parallel grids of approximately the same diameter as the IMS rings and can be placed anywhere along the drift tube and biased according to their location in the voltage divider ladder to create the same IMS field. The spacing between the grids constitutes the analytical gap where ions are subject, in addition to the drift field, to the asymmetric dispersive field of the FAIMS. The oscillatory motion performed during the high and low voltages of the asymmetric waveform separates the ions according to the difference in their mobilities.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

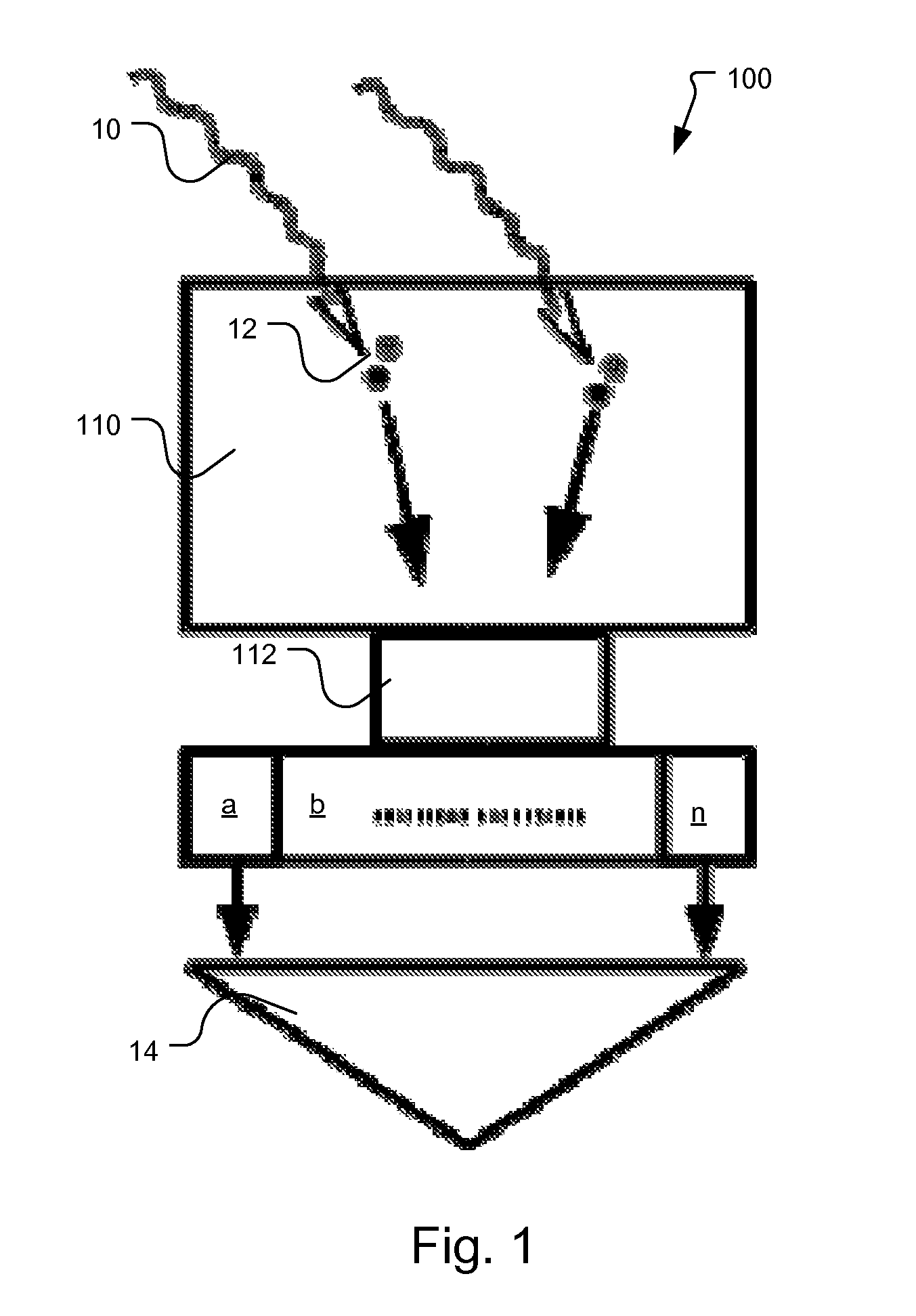

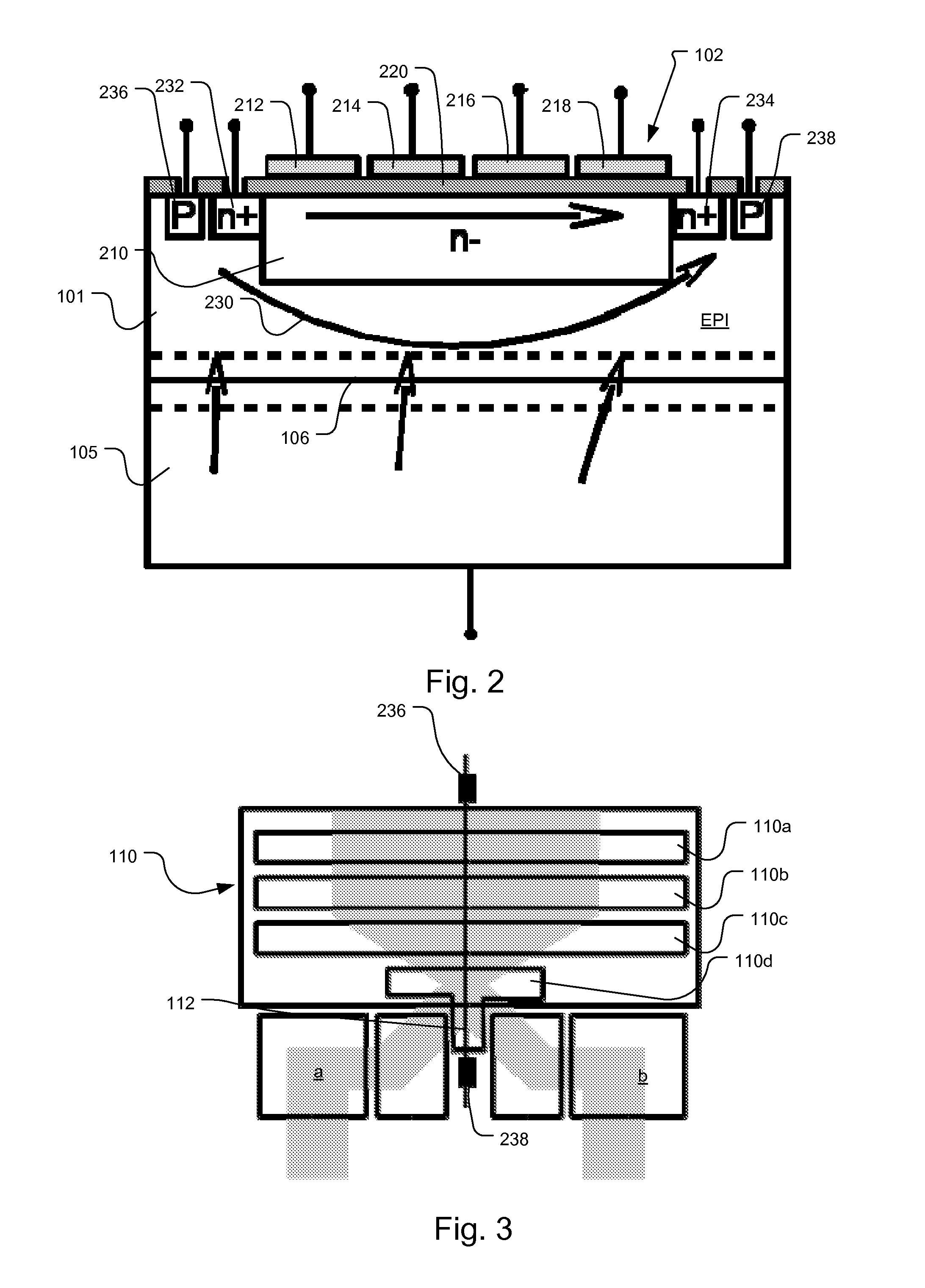

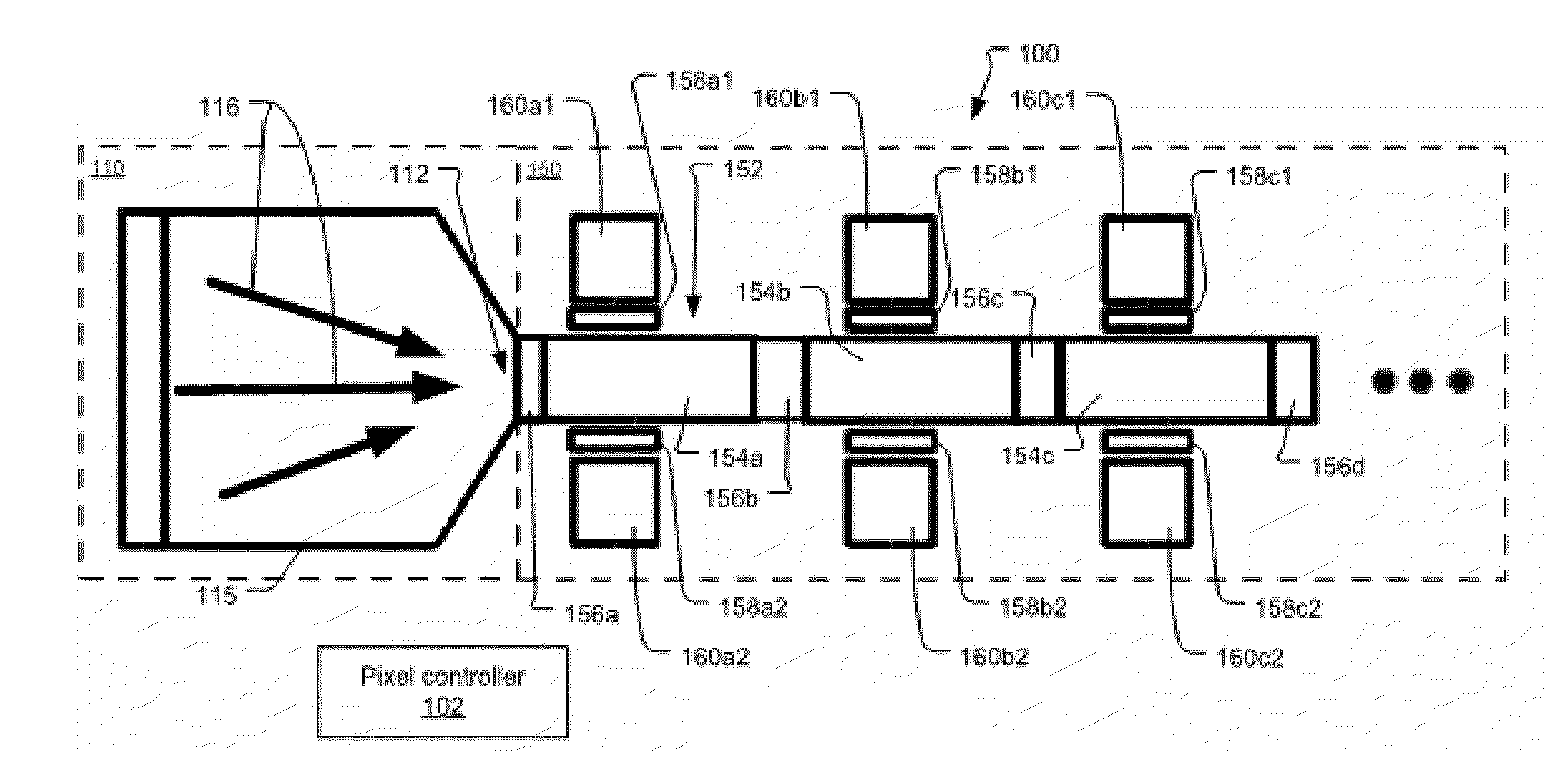

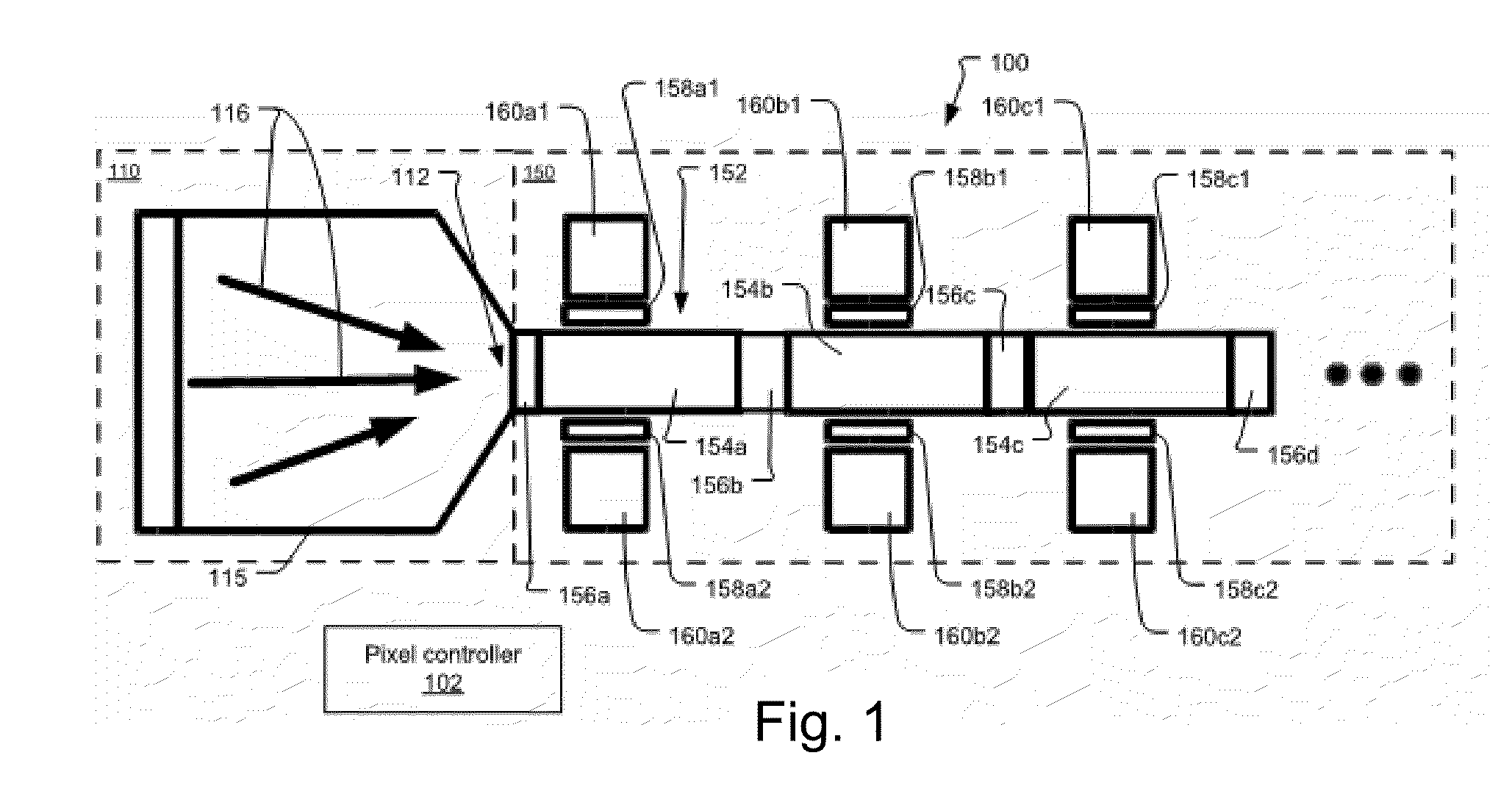

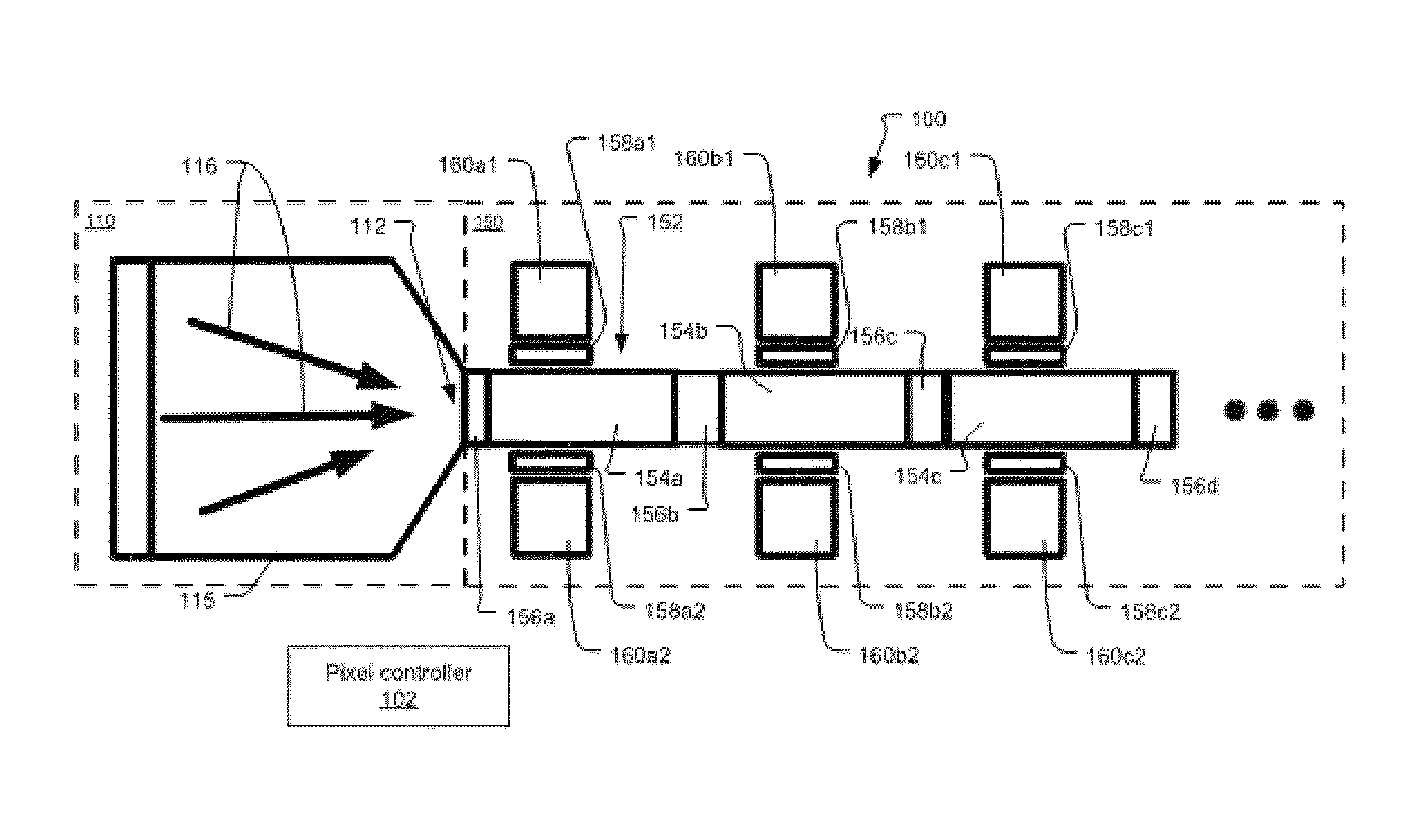

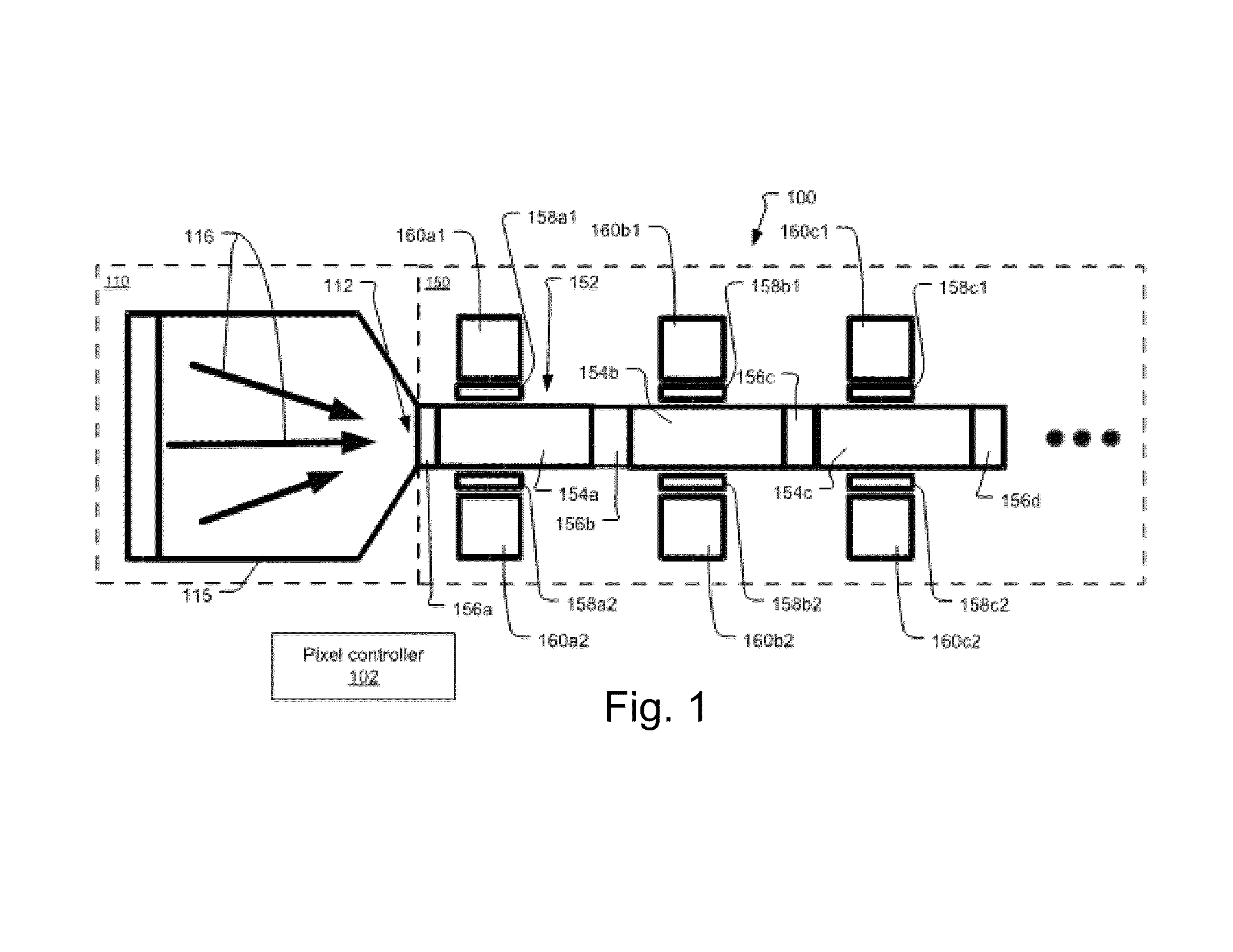

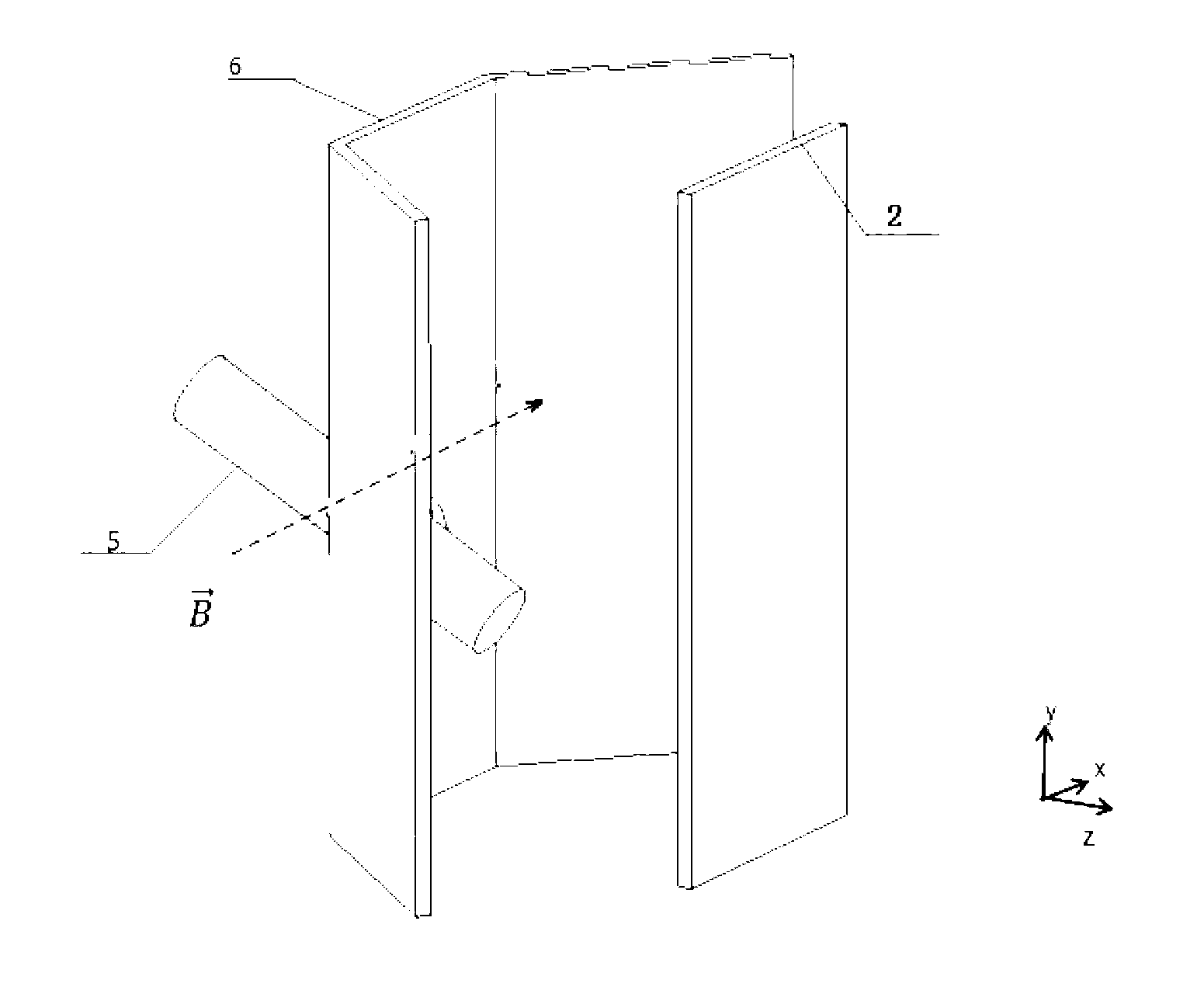

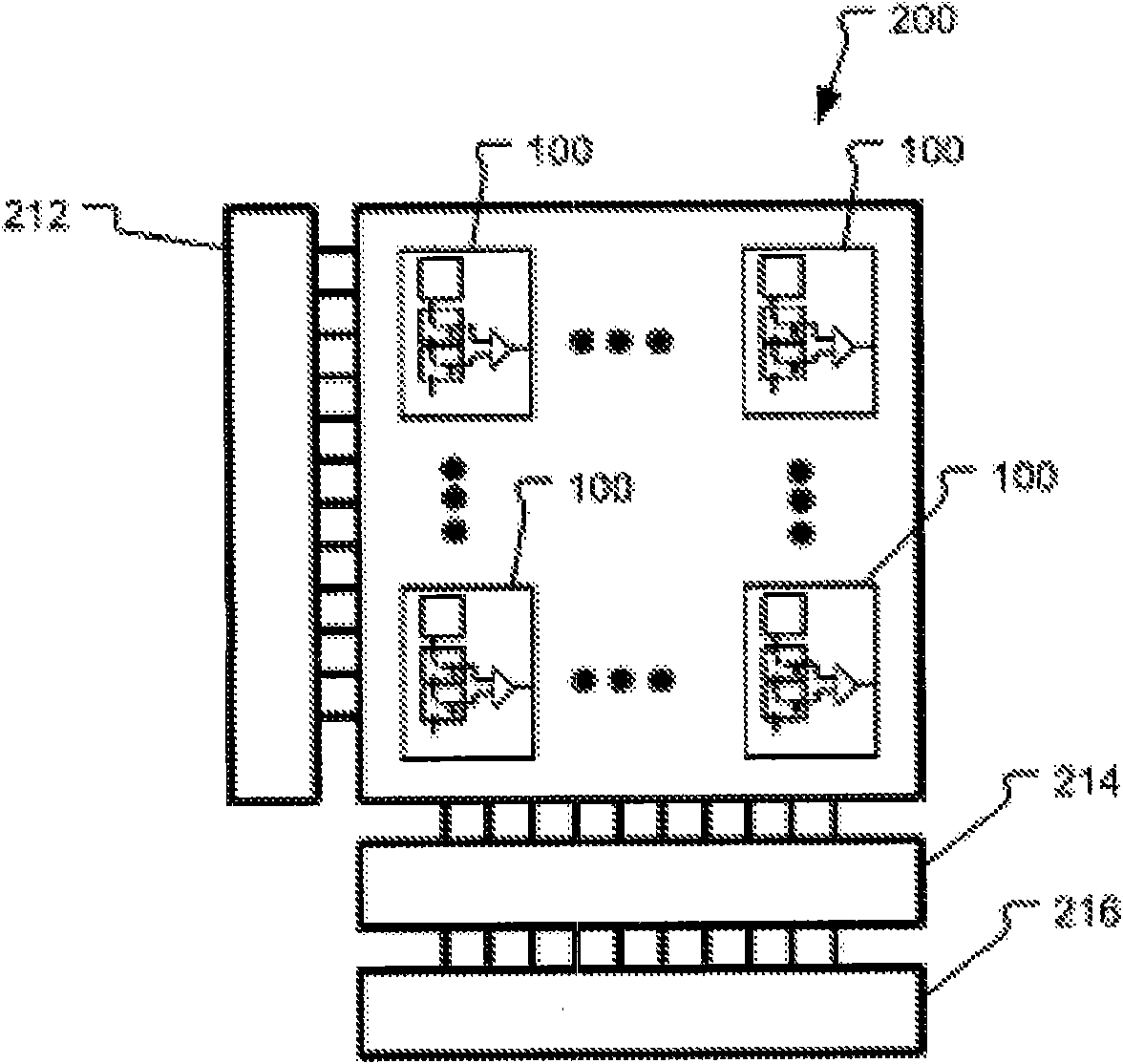

Demodulation Pixel with Daisy Chain Charge Storage Sites and Method of Operation Therefor

ActiveUS20100053405A1Mismatch problemReduce mismatchTelevision system detailsWave based measurement systemsEngineeringSignal-to-quantization-noise ratio

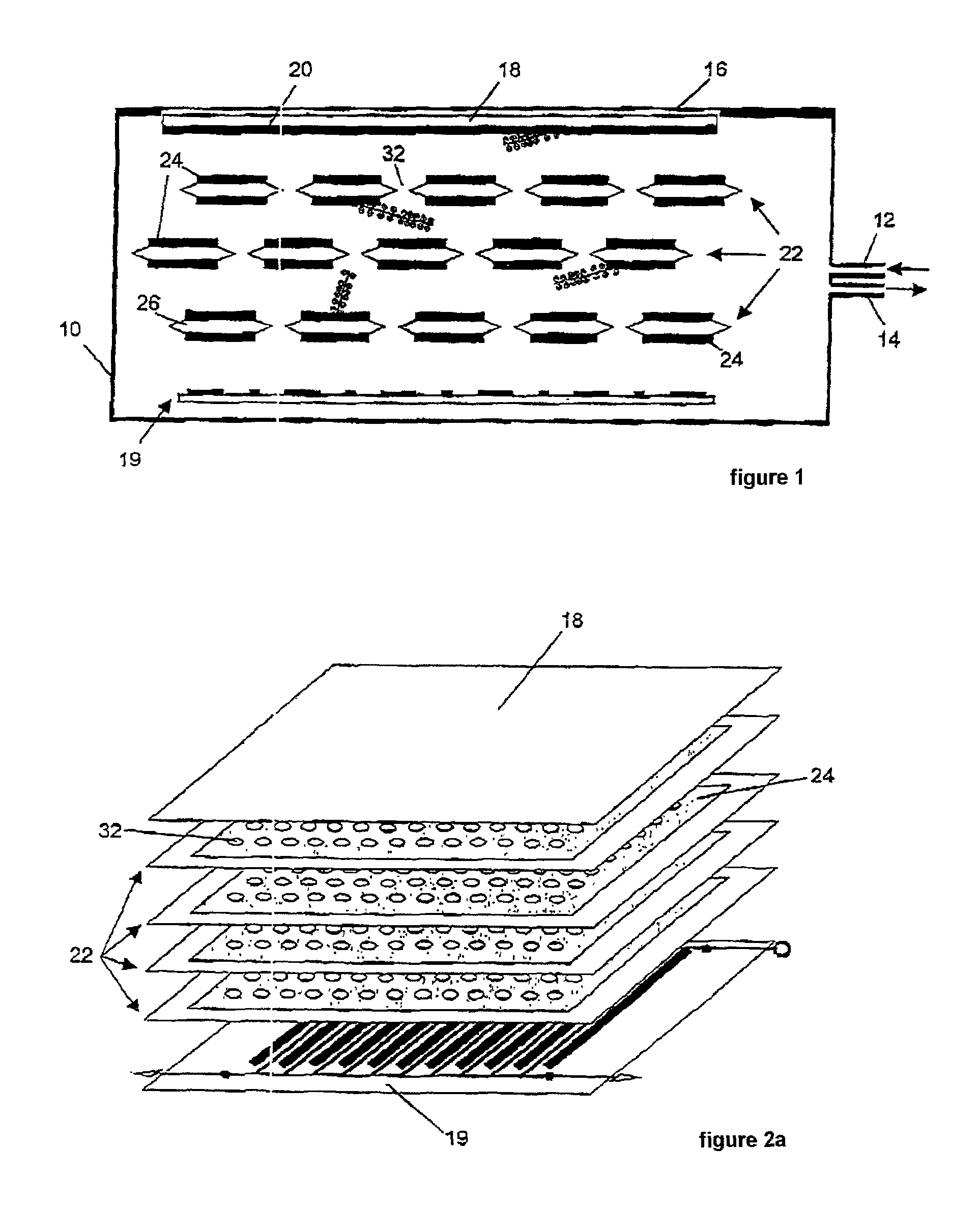

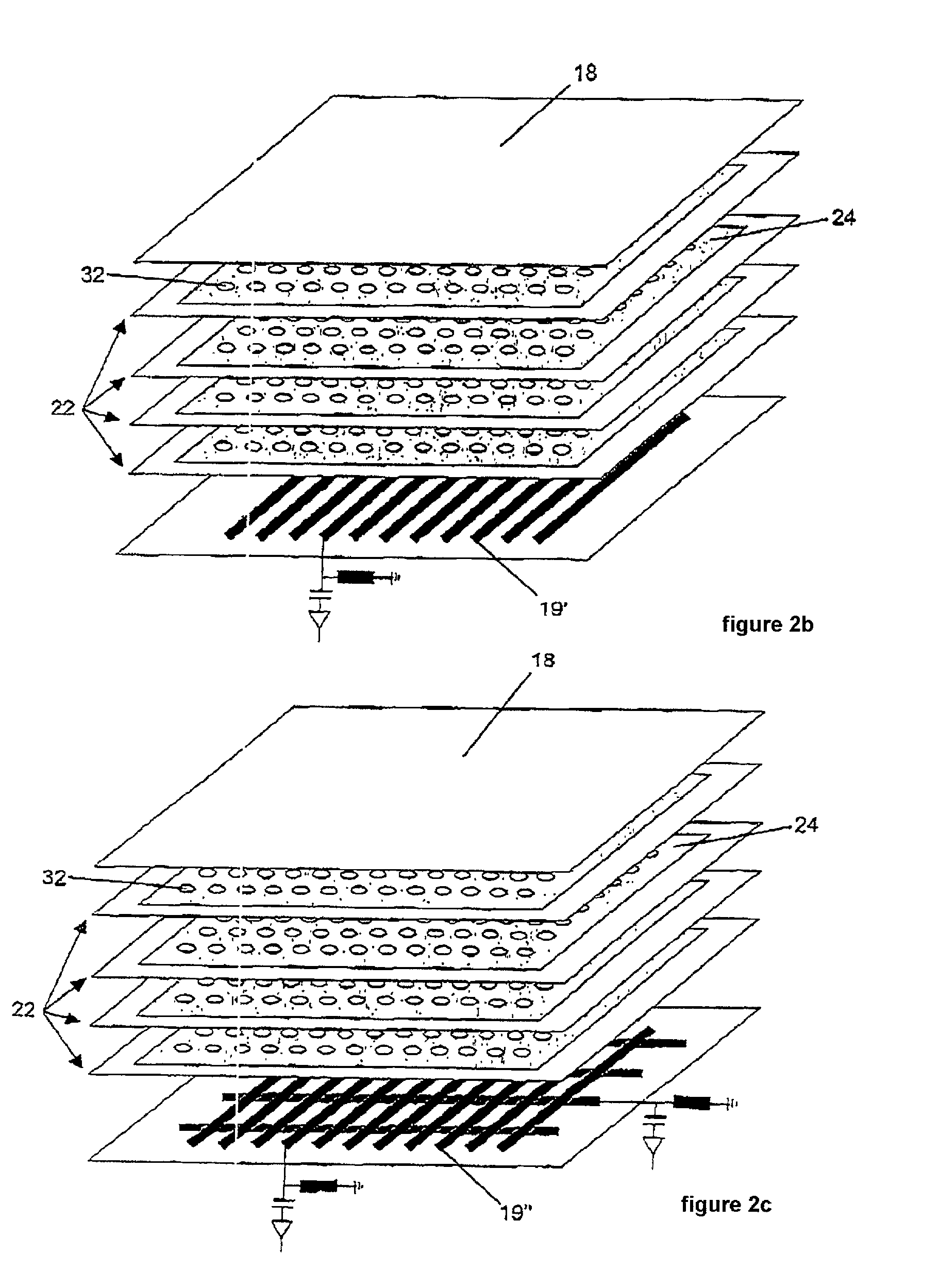

A demodulation pixel architecture allows for demodulating an incoming modulated electromagnetic wave, normally visible or infrared light. It is based on a charge coupled device (CCD) line connected to a drift field structure. The drift field is exposed to the incoming light. It collects the generated charge and forces it to move to the pick-up point. At this pick-up point, the CCD element samples the charge for a given time and then shifts the charge packets further on in the daisy chain. After a certain amount of shifts, the multiple charge packets are stored in so-called integration gates, in a preferred embodiment. The number of integration gates gives the number of simultaneously available taps. When the cycle is repeated several times, the charge is accumulated in the integration gates and thus the signal-to-noise ratio increases. The architecture is flexible in the number of taps. A dump node can be attached to the CCD line for dumping charge with the same speed as the samples are taken. Different implementations are described herein, which allow for smaller design or faster speed. The pixel structure can be exploited for e.g. 3D time-of-flight imaging. Both heterodyne and homodyne measurements are possible. Due to the highly-efficient charge transport enabled by static drift fields in the photo-sensitive region and small-sized gates in the CCD chain, high frequency bandwidth from just a few Hertz (Hz) up to greater GHz is supported. Thus, the pixel allows for highly-accurate optical distance measurements. Another possible application of this pixel architecture is fluorescence lifetime imaging microscopy (FLIM), where short laser pulses for triggering the fluorescence have to be suppressed.

Owner:AMS SENSORS SINGAPORE PTE LTD

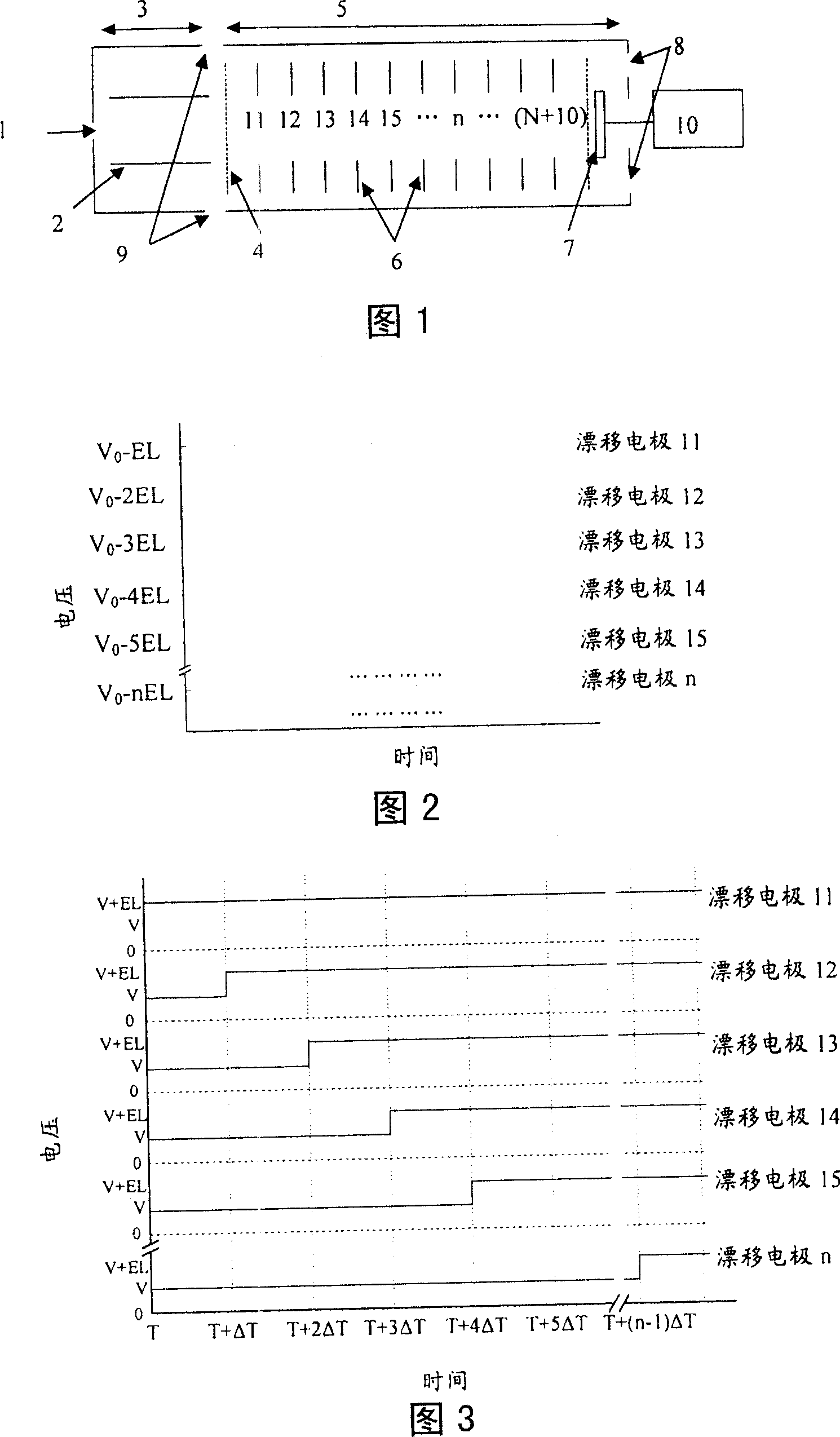

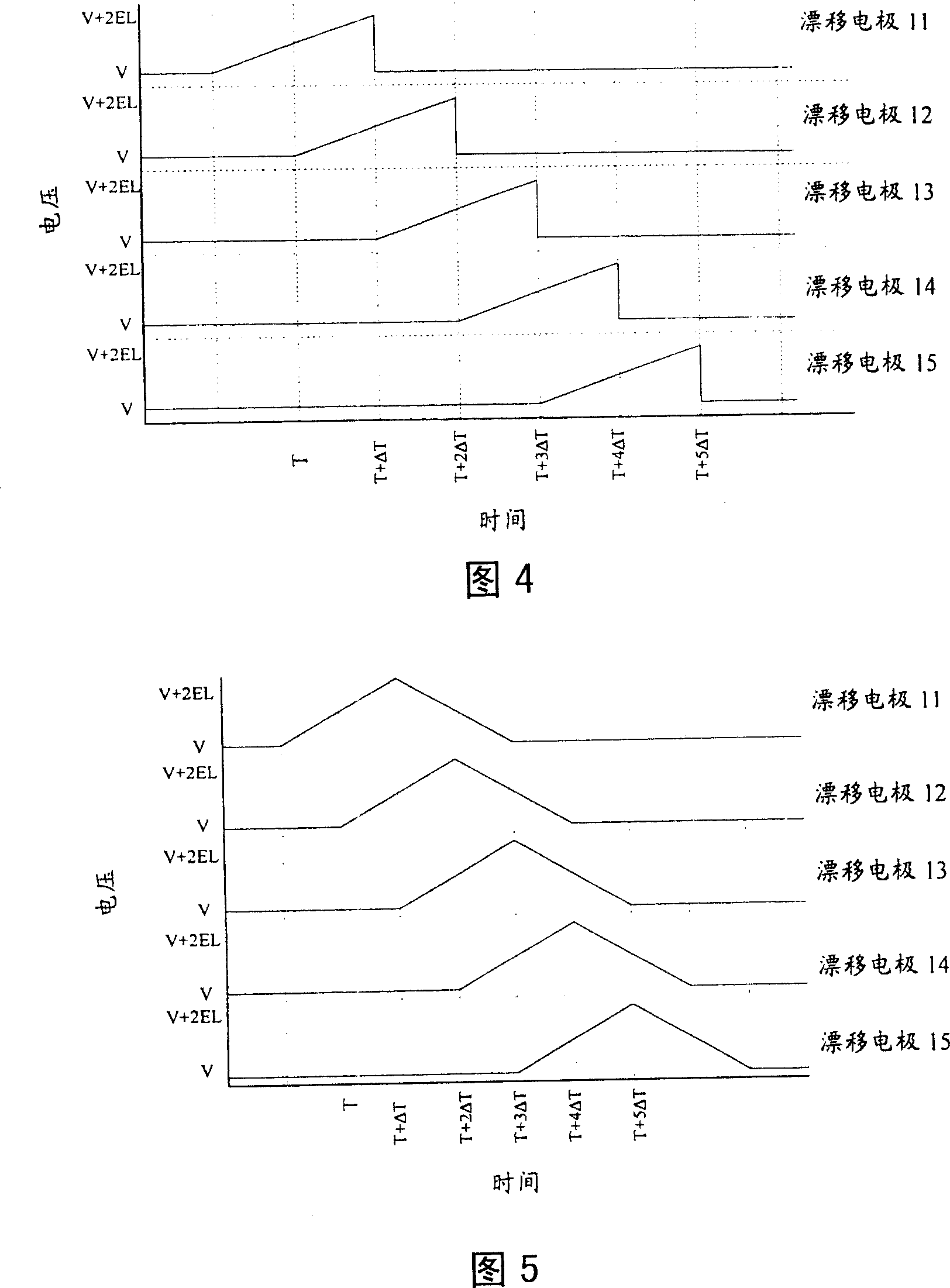

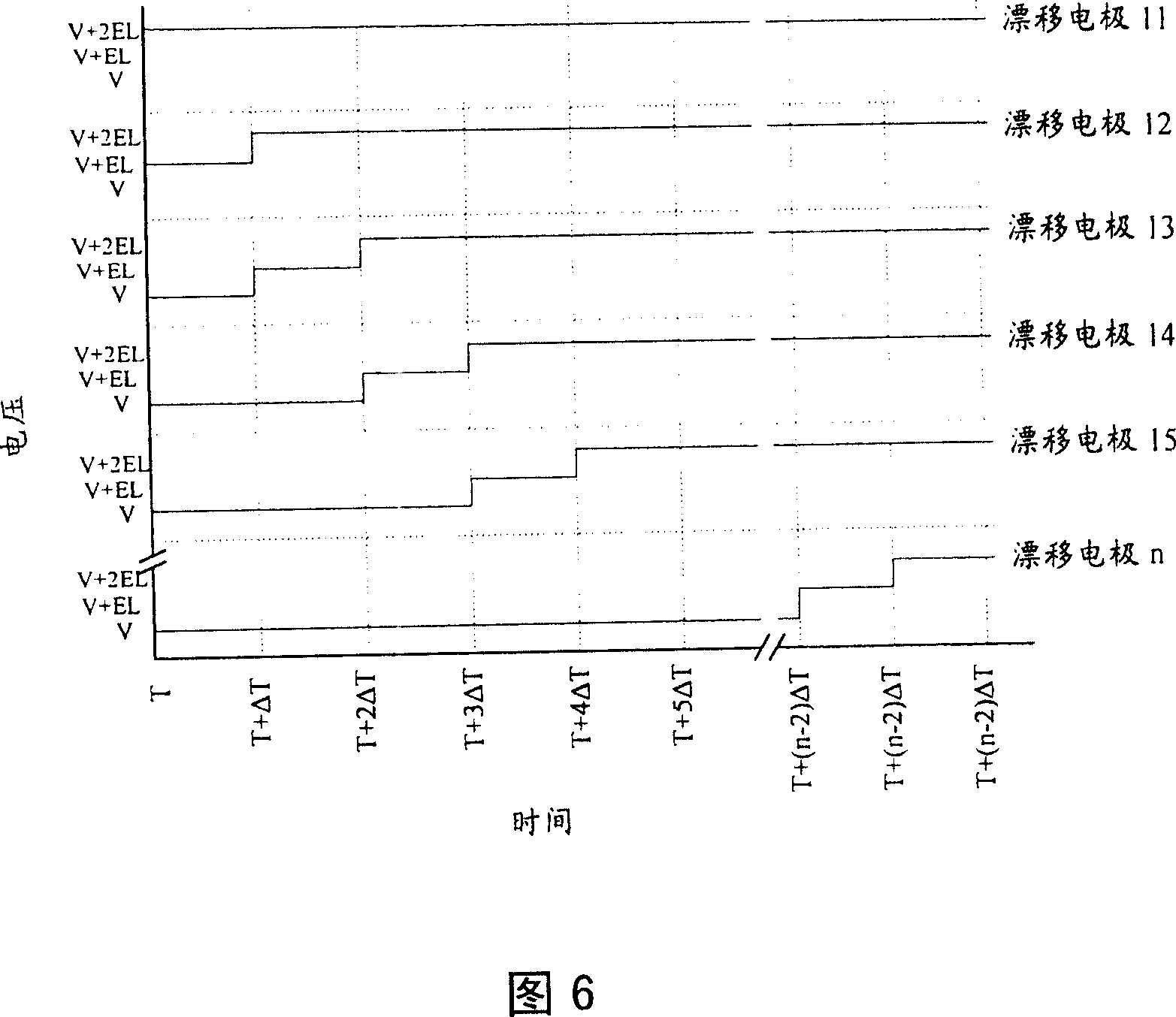

Transient drift field method in use for drift tube of ionic mobility spectrometer

InactiveCN101093211AEasy to integrateParticle separator tubesMaterial analysis by electric/magnetic meansDrift tubeUltimate tensile strength

A method of using transient electric field to make shift electric field for shift tube of IMB includes utilizing transient electric field as shift electric field in shift tube of IMB, shifting all ion groups to region between shift electrode of m +1 and m +2 and m +3 at certain time slot, separately exerting proper voltages on three said shift electrodes at shift tube to satisfy certain conditions and forming transient electric field with strength E at region between three said electrodes at shift tube.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

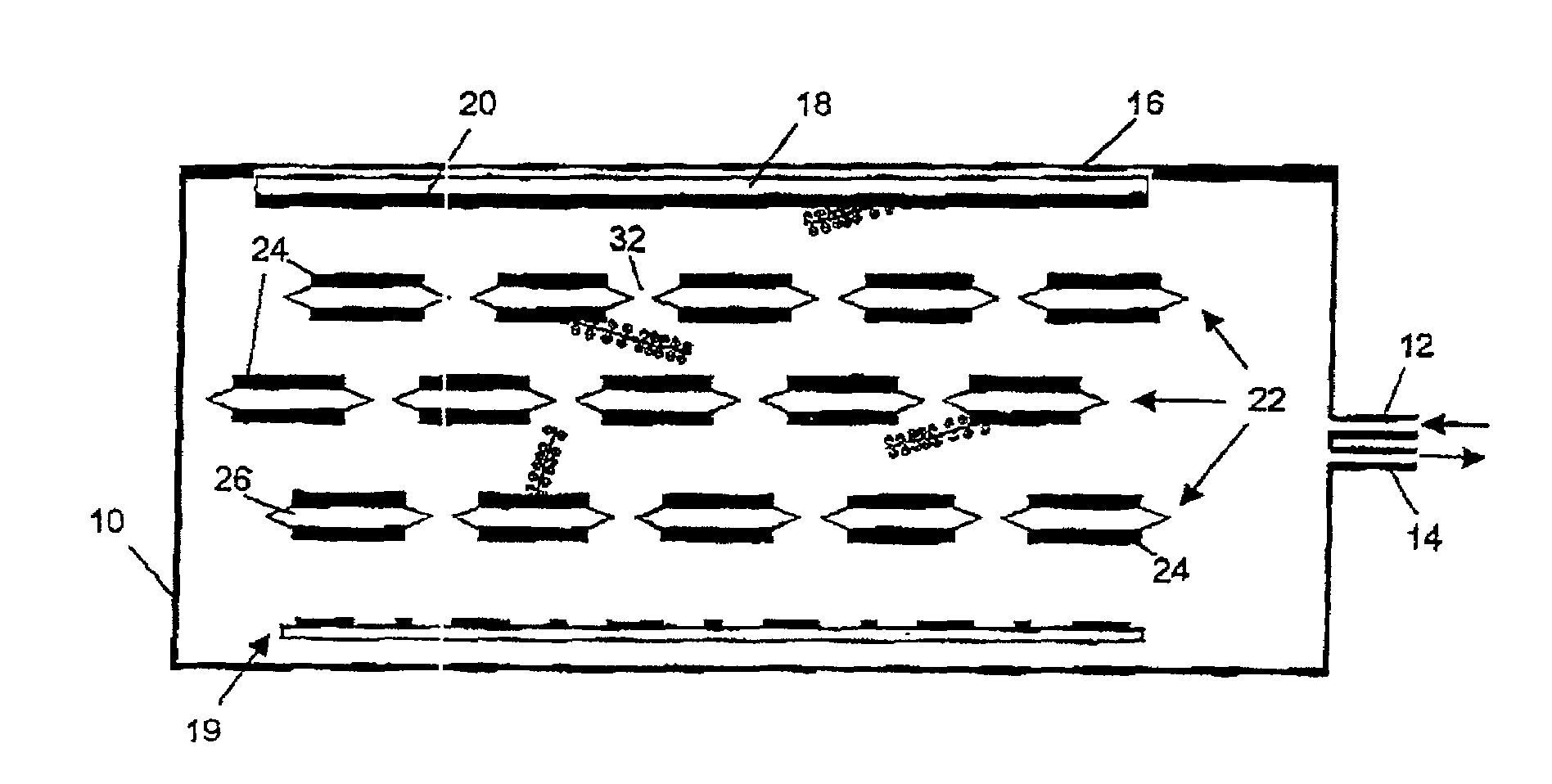

Detector

InactiveUS7635849B2High detection sensitivityEfficient and rapid diversionElectric discharge tubesMaterial analysis by optical meansDrift fieldAtomic physics

The invention relates to a detector for detecting electrically neutral particles. The detector has a housing (10) filled with a counting gas. A converter (22) in the housing (10) generates conversion products as a result of the absorption of the neutral particles. The conversion products generate electrically charged particles in the counting gas, and a readout device (19) detects the electrically charged particles. A device (18) generates an electrical drift field for the electrically charged particles in a region of the volume of the counting gas so that at least some of the electrically charged particles drift toward the readout device (19). The converter device (22) is of charge-transparent design and being arranged in the detector housing (10) so that the drift field passes through at least part of this device.

Owner:UNIVERSITY OF HEIDELBERG

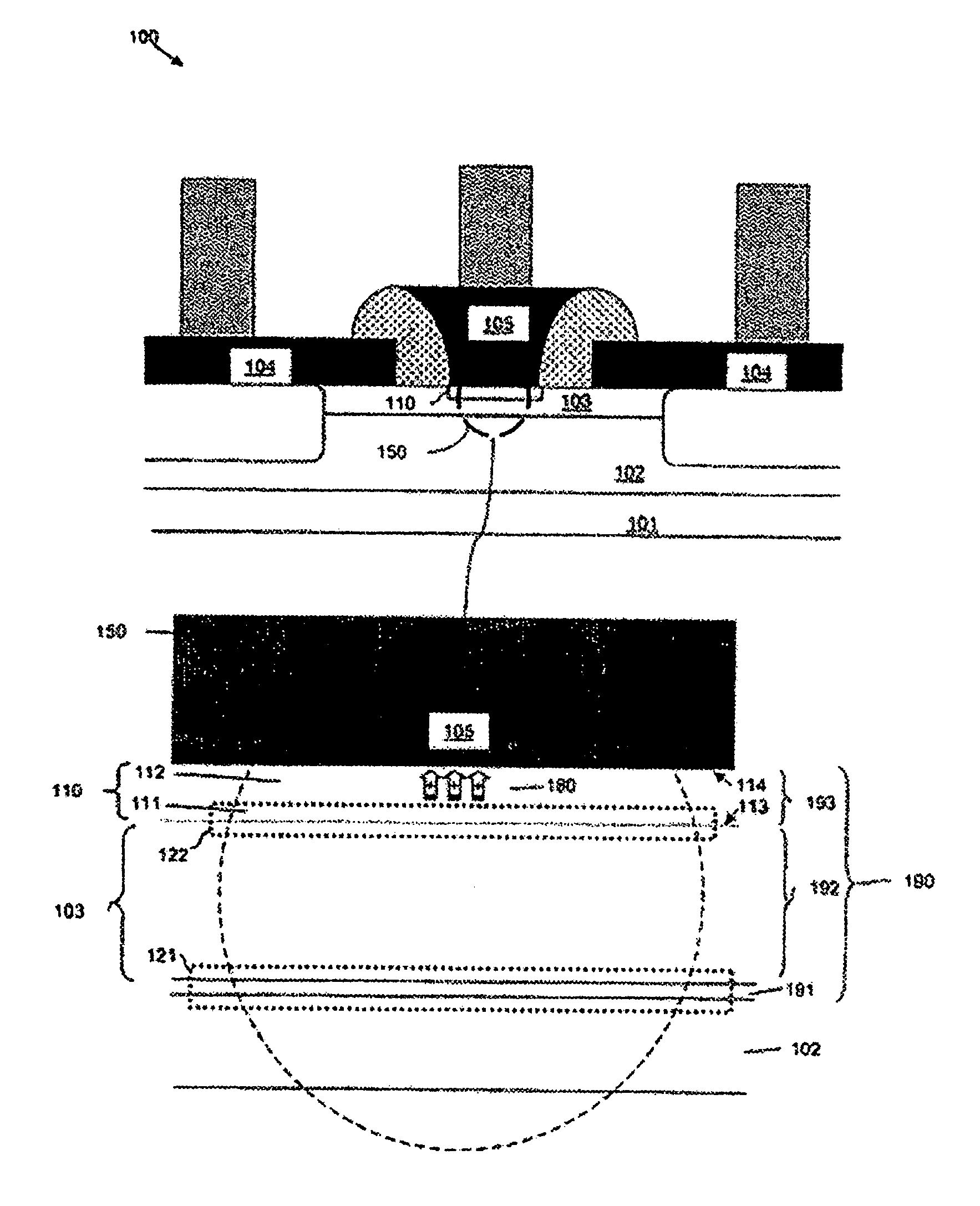

Demodulation pixel incorporating majority carrier current, buried channel and high-low junction

ActiveUS9698196B2Easy to transportSolid-state devicesRadiation controlled devicesTrappingSoi cmos technology

A demodulation pixel improves the charge transport speed and sensitivity by exploiting two effects of charge transport in silicon in order to achieve the before-mentioned optimization. The first one is a transport method based on the CCD gate principle. However, this is not limited to CCD technology, but can be realized also in CMOS technology. The charge transport in a surface or even a buried channel close to the surface is highly efficient in terms of speed, sensitivity and low trapping noise. In addition, by activating a majority carrier current flowing through the substrate, another drift field is generated below the depleted CCD channel. This drift field is located deeply in the substrate, acting as an efficient separator for deeply photo-generated electron-hole pairs. Thus, another large amount of minority carriers is transported to the diffusion nodes at high speed and detected.

Owner:AMS SENSORS SINGAPORE PTE LTD

Demodulation pixel with daisy chain charge storage sites and method of operation therefor

ActiveUS8760549B2Reduce mismatchMismatch between samples is strongly reducedTelevision system detailsWave based measurement systemsEngineeringHertz

A demodulation pixel architecture allows for demodulating an incoming modulated electromagnetic wave, normally visible or infrared light. It is based on a charge coupled device (CCD) line connected to a drift field structure. The drift field is exposed to the incoming light. It collects the generated charge and forces it to move to the pick-up point. At this pick-up point, the CCD element samples the charge for a given time and then shifts the charge packets further on in the daisy chain. After a certain amount of shifts, the multiple charge packets are stored in so-called integration gates, in a preferred embodiment. The number of integration gates gives the number of simultaneously available taps. When the cycle is repeated several times, the charge is accumulated in the integration gates and thus the signal-to-noise ratio increases. The architecture is flexible in the number of taps. A dump node can be attached to the CCD line for dumping charge with the same speed as the samples are taken. Different implementations are described herein, which allow for smaller design or faster speed. The pixel structure can be exploited for e.g. 3D time-of-flight imaging. Both heterodyne and homodyne measurements are possible. Due to the highly-efficient charge transport enabled by static drift fields in the photo-sensitive region and small-sized gates in the CCD chain, high frequency bandwidth from just a few Hertz (Hz) up to greater GHz is supported. Thus, the pixel allows for highly-accurate optical distance measurements. Another possible application of this pixel architecture is fluorescence lifetime imaging microscopy (FLIM), where short laser pulses for triggering the fluorescence have to be suppressed.

Owner:AMS SENSORS SINGAPORE PTE LTD

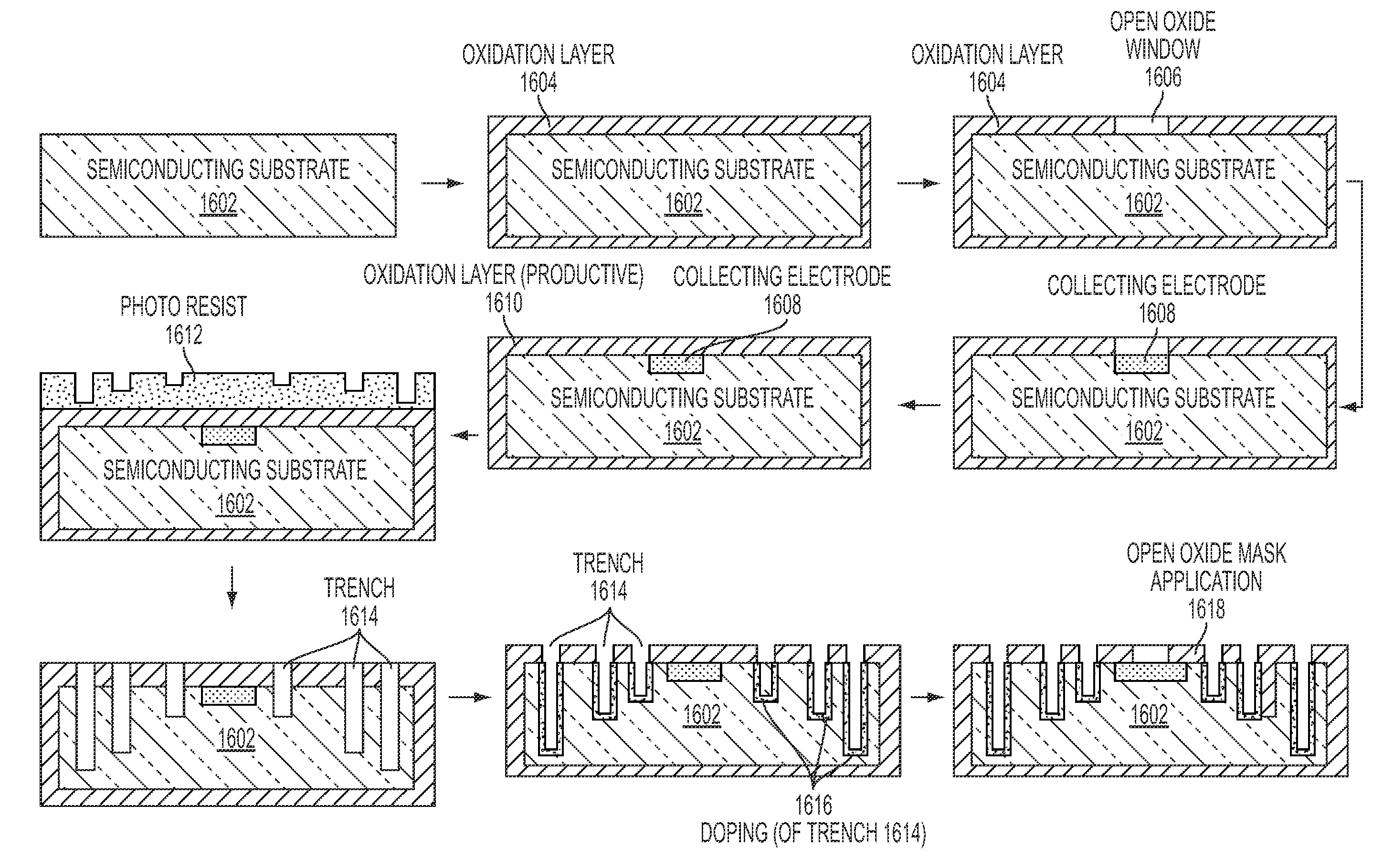

Methods and systems of thick semiconductor drift detector fabrication

InactiveUS7968959B2Better “X-ray stopping power”Quality improvementFinal product manufactureSolid-state devicesLithographic artistCharge carrier

Gray-tone lithography technology is used in combination with a reactive plasma etching operation in the fabrication method and system of a thick semiconductor drift detector. The thick semiconductor drift detector is based on a trench array, where the trenches in the trench array penetrate the bulk with different depths. These trenches form an electrode. By applying different electric potentials to the trenches in the trench array, the silicon between neighboring trenches fully depletes. Furthermore, the applied potentials cause a drifting field for generated charge carriers, which are directed towards a collecting electrode.

Owner:US GOVT AS REPRESENTED BY THE SEC OF THE NAVY OFFICE OF NAVAL RES NRL CODE OOCCIP

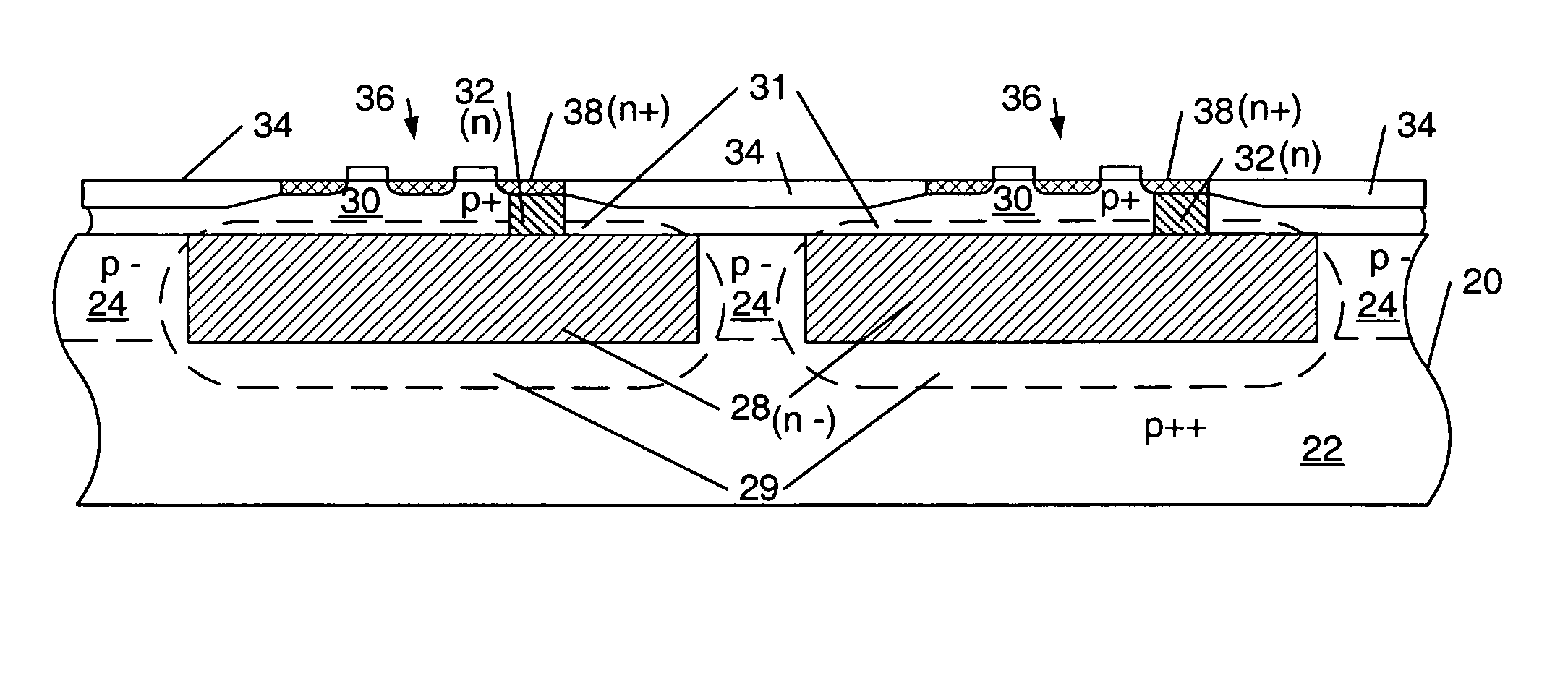

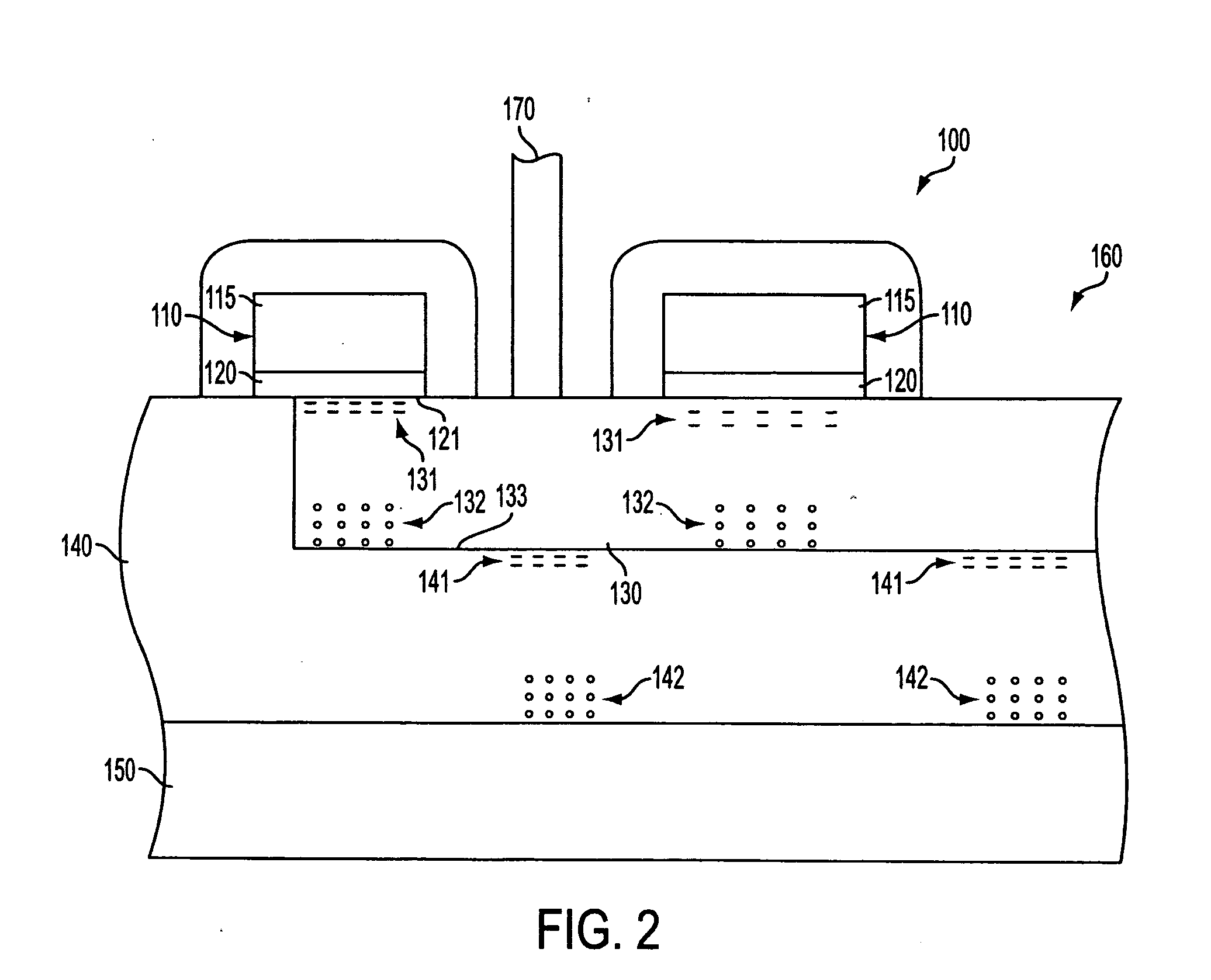

Photodiode having a buried well region

A photodiode pixel sensor is provided having a buried region of opposite conductivity type than a semiconductor substrate in which the sensor is formed. The photodiode pixel sensor further includes a well region arranged upon and in contact with an upper surface of the buried region and a collection-junction extending into the well region. The well region and collection-junction are of the same conductivity type as the buried region and include greater net concentrations of dopants than the buried region and the well region, respectively. Such a configuration creates a drift field to channel (i.e., funnel) charge to the collection-junction. In some cases, the collection-junction may be a drain region of a transistor spaced above the buried region. An imaging device is also provided which includes at least two adjacent photodiode pixel sensors each including the aforementioned architecture isolated from each other by a distance less than approximately 2.0 microns.

Owner:NVIDIA CORP

Electro beam ejection restraint method and device under strong magnetic field

InactiveCN102708931AEasy to implementDoes not affect magnetic field configurationNuclear energy generationThermonuclear fusion reactorReciprocating motionDrift field

The invention discloses an electro beam ejection restraint method and device under a strong magnetic field. The method comprises the following steps: an electric field is additionally arranged in a magnetic field and forms a potential trap configuration along the direction of the magnetic field, a drifting field is formed in a direction vertical to the magnetic field, and in the potential trap, an electro beam does reciprocating movement along the direction of a magnetic line under the action of electric field force component, and traverses the magnetic line at drifting speed of the electric field in direction vertical to the magnetic line. The device comprises a cathode plate, an anode plate, a cathode, and a first and second trap pole plate. In the method, through restraint of the potential trap, the electron beam is restrained effectively in a direction parallel to the magnetic field and traverses the magnetic field at the drifting speed of the electric field. For the device, after the cathode generates the electro beam, the electron beam is well restrained in a direction parallel to the magnetic field and traverses the magnetic without drift along the magnetic line and influence on the original magnetic field configuration, so that the ejection efficiency is high, and the process is simply and feasibly realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Demodulation pixel with daisy chain charge storage sites and method of operation therefor

A demodulation pixel architecture allows for demodulating an incoming modulated electromagnetic wave, normally visible or infrared light. It is based on a charge coupled device (CCD) line connected to a drift field structure. The drift field is exposed to the incoming light. It collects the generated charge and forces it to move to the pick-up point. At this pick-up point, the CCD element samples the charge for a given time and then shifts the charge packets further on in the daisy chain. After a certain amount of shifts, the multiple charge packets are stored in so-called integration gates, in a preferred embodiment. The number of integration gates gives the number of simultaneously available taps. When the cycle is repeated several times, the charge is accumulated in the integration gates and thus the signal-to-noise ratio increases. The architecture is flexible in the number of taps. A dump node can be attached to the CCD line for dumping charge with the same speed as the samples are taken. Different implementations are described herein, which allow for smaller design or faster speed. The pixel structure can be exploited for e.g. 3D time-of-flight imaging. Both heterodyne and homodyne measurements are possible. Due to the highly-efficient charge transport enabled by static drift fields in the photo-sensitive region and small-sized gates in the CCD chain, high frequency bandwidth from just a few Hertz (Hz) up to greater GHz is supported. Thus, the pixel allows for highly-accurate optical distance measurements. Another possible application of this pixel architecture is fluorescence lifetime imaging microscopy (FLIM), where short laser pulses for triggering the fluorescence have to be suppressed.

Owner:HEPTAGON MICRO OPTICS

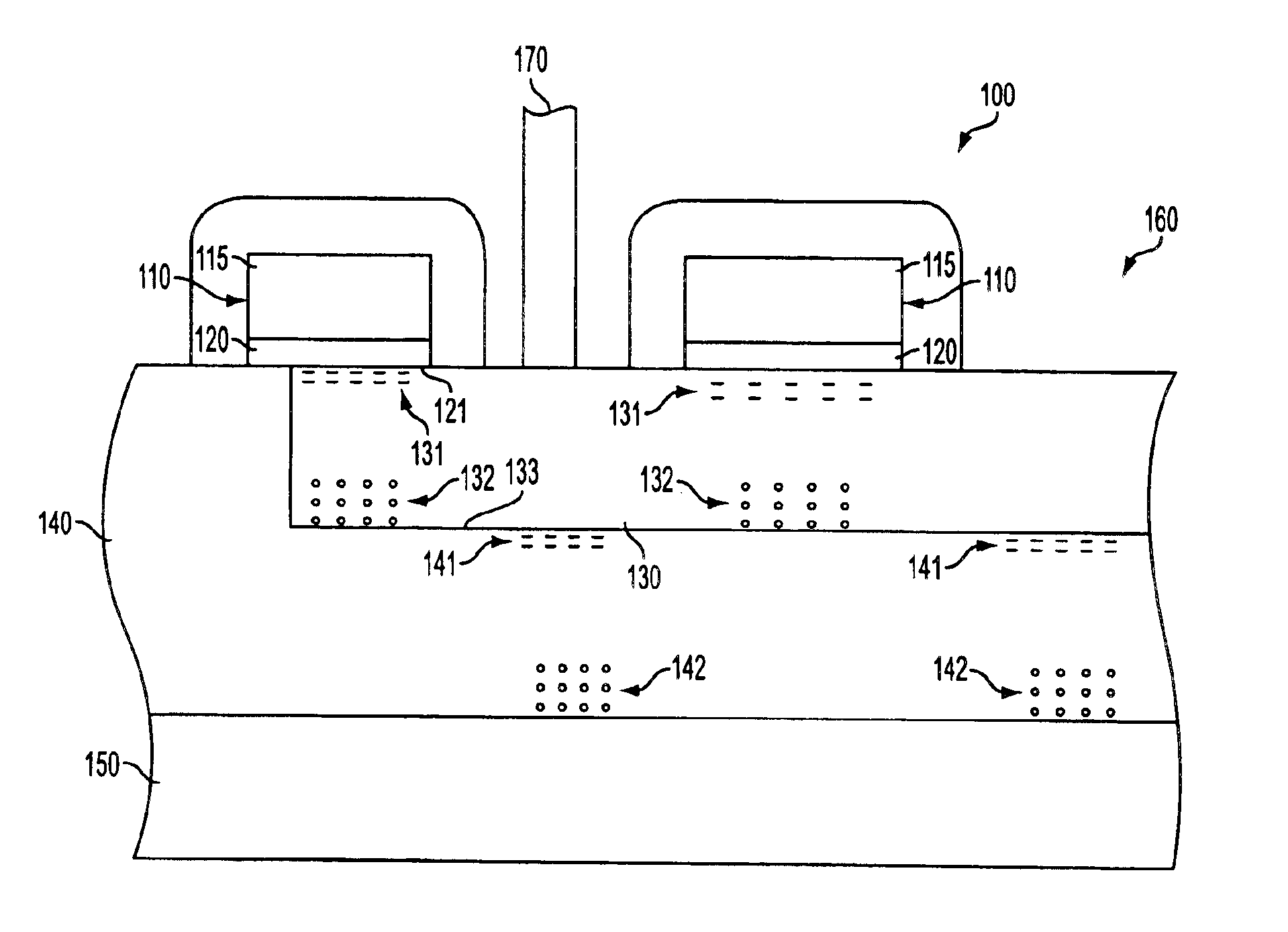

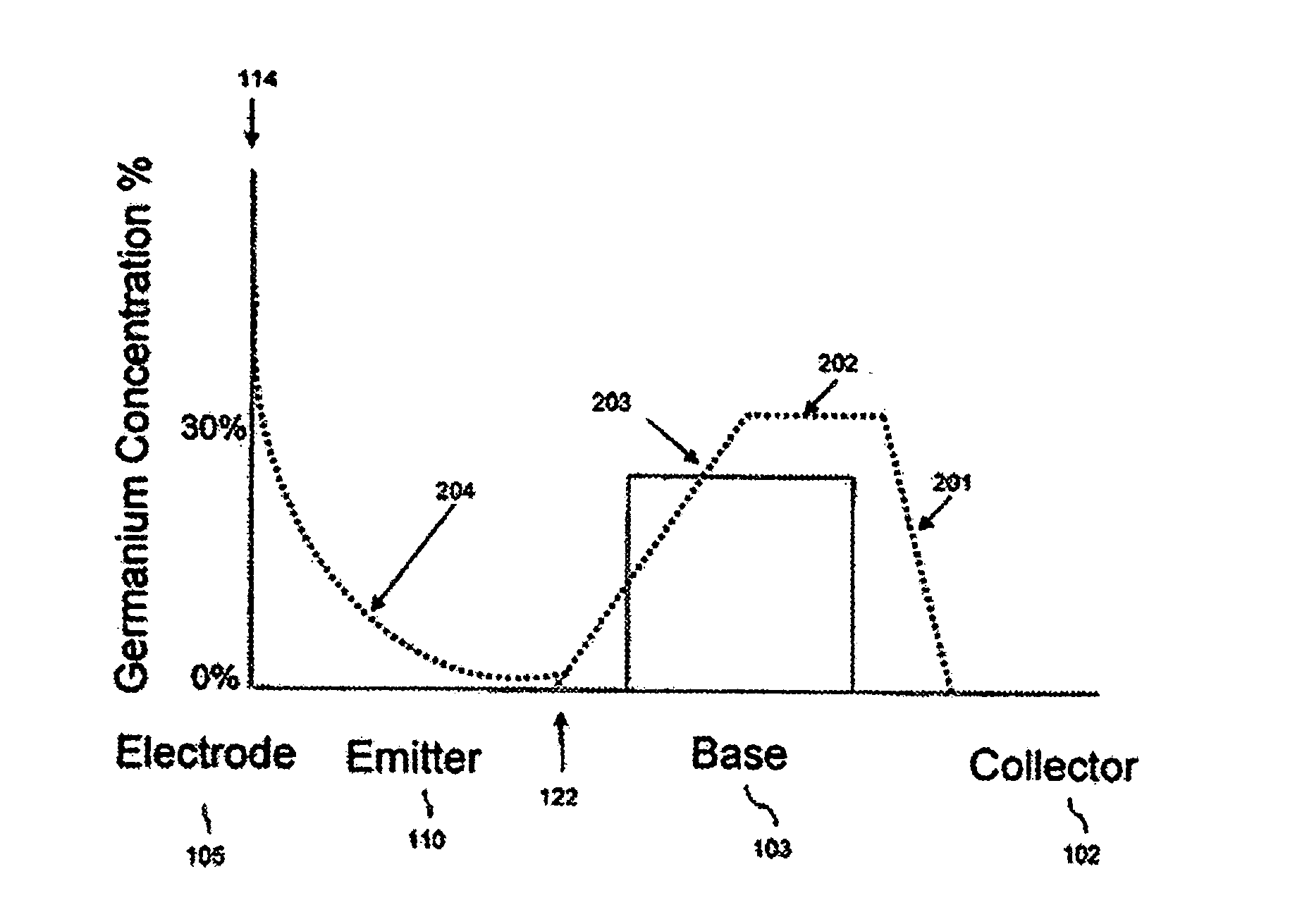

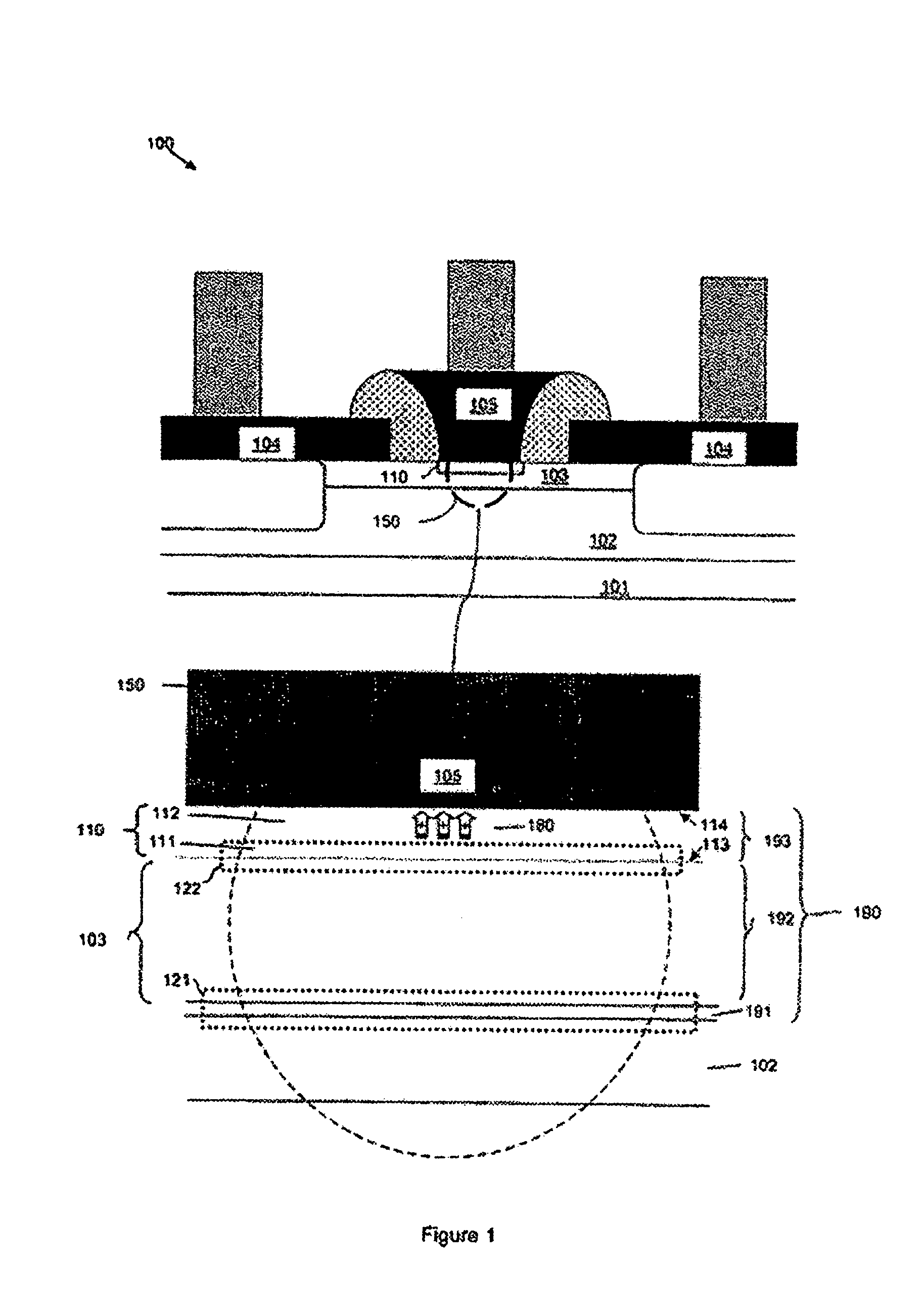

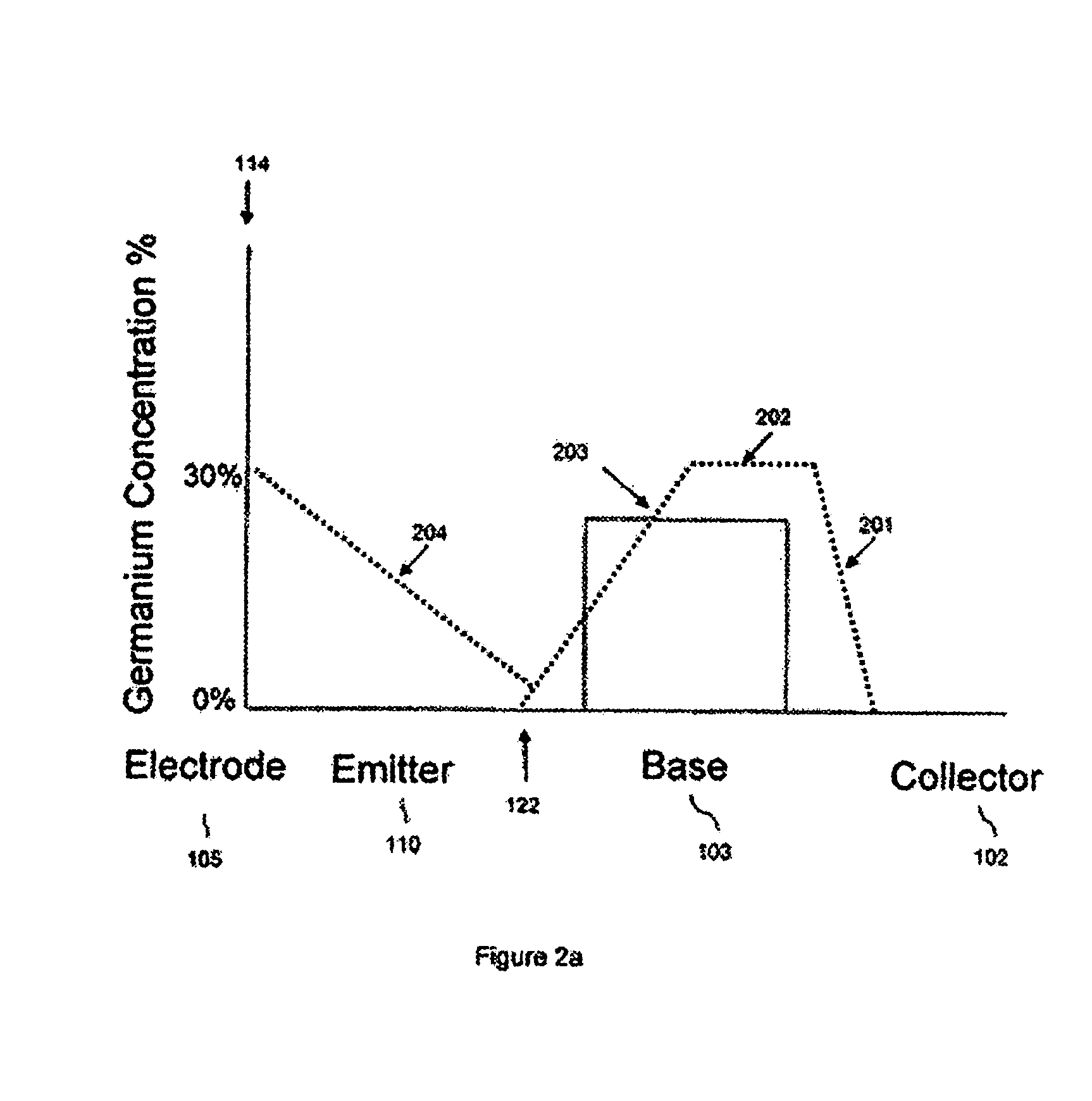

Silicon germanium emitter

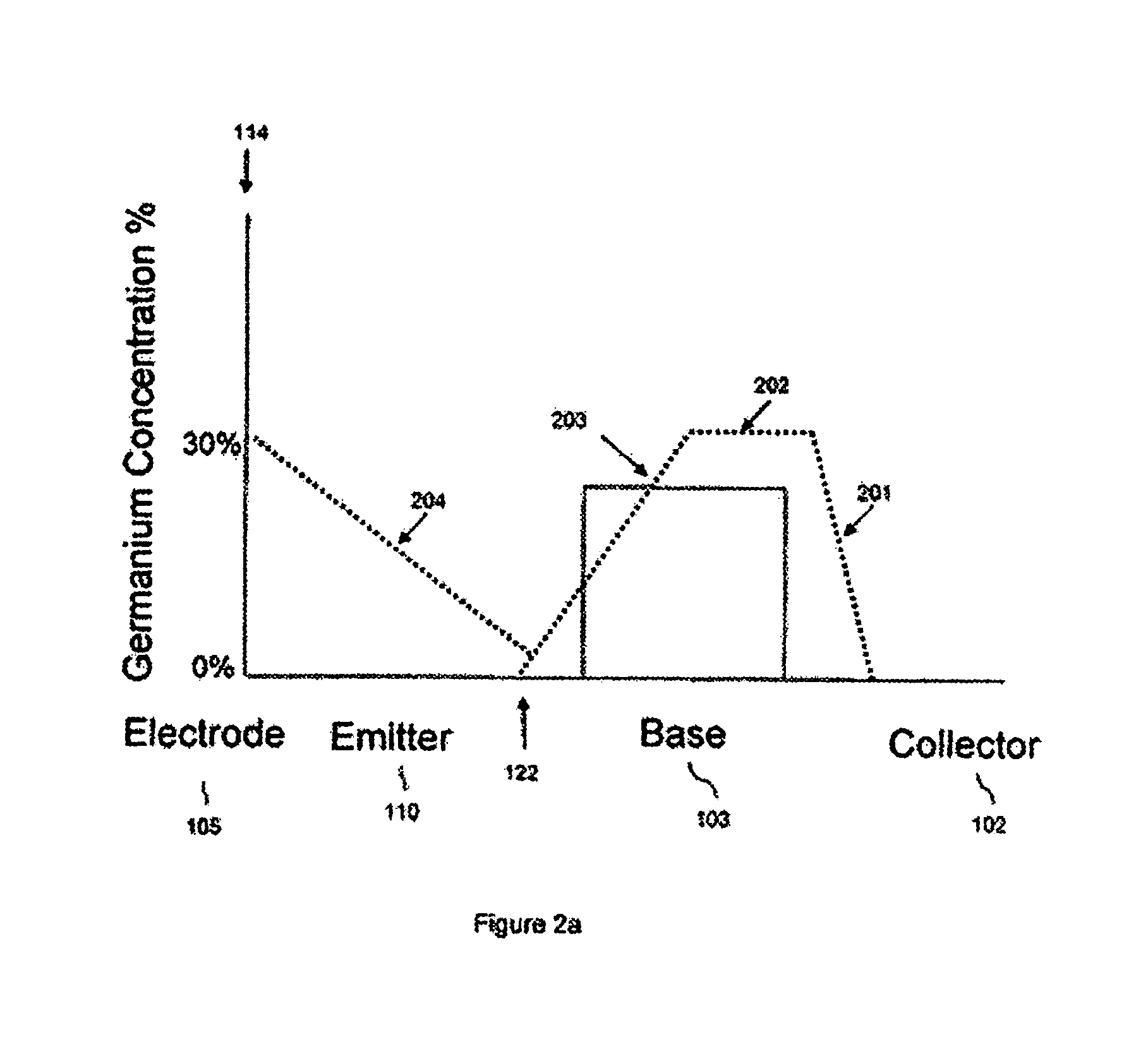

ActiveUS7294869B2Reduce latencyRaise the cutoff frequencySemiconductor/solid-state device manufacturingSemiconductor devicesBandgap gradingDelayed time

Disclosed are an improved hetero-junction bipolar transistor (HBT) structure and a method of forming the structure that incorporates a silicon-germanium emitter layer with a graded germanium profile. The graded germanium concentration creates a quasi-drift field in the neutral region of the emitter layer. This quasi-drift field induces valence bandgap grading within the emitter layer so as to accelerate movement of holes from the base layer through the emitter layer. Accelerated movement of the holes from the base layer through the emitter layer reduces emitter delay time and thereby, increases the cut-off frequency (fT) and the maximum oscillation frequency (fMAX) of the resultant HBT.

Owner:TAIWAN SEMICON MFG CO LTD

Ion mobility spectrometer device with embedded faims cells

InactiveCN103688163AStability-of-path spectrometersMaterial analysis by electric/magnetic meansConfocalLow voltage

Owner:IMPLANT SCI

Silicon germanium emitter

ActiveUS20070235762A1Reduce latencyRaise the cutoff frequencySemiconductor/solid-state device manufacturingSemiconductor devicesBandgap gradingDelayed time

Disclosed are an improved hetero-junction bipolar transistor (HBT) structure and a method of forming the structure that incorporates a silicon-germanium emitter layer with a graded germanium profile. The graded germanium concentration creates a quasi-drift field in the neutral region of the emitter layer. This quasi-drift field induces valence bandgap grading within the emitter layer so as to accelerate movement of holes from the base layer through the emitter layer. Accelerated movement of the holes from the base layer through the emitter layer reduces emitter delay time and thereby, increases the cut-off frequency (fT) and the maximum oscillation frequency (fMAX) of the resultant HBT.

Owner:TAIWAN SEMICON MFG CO LTD

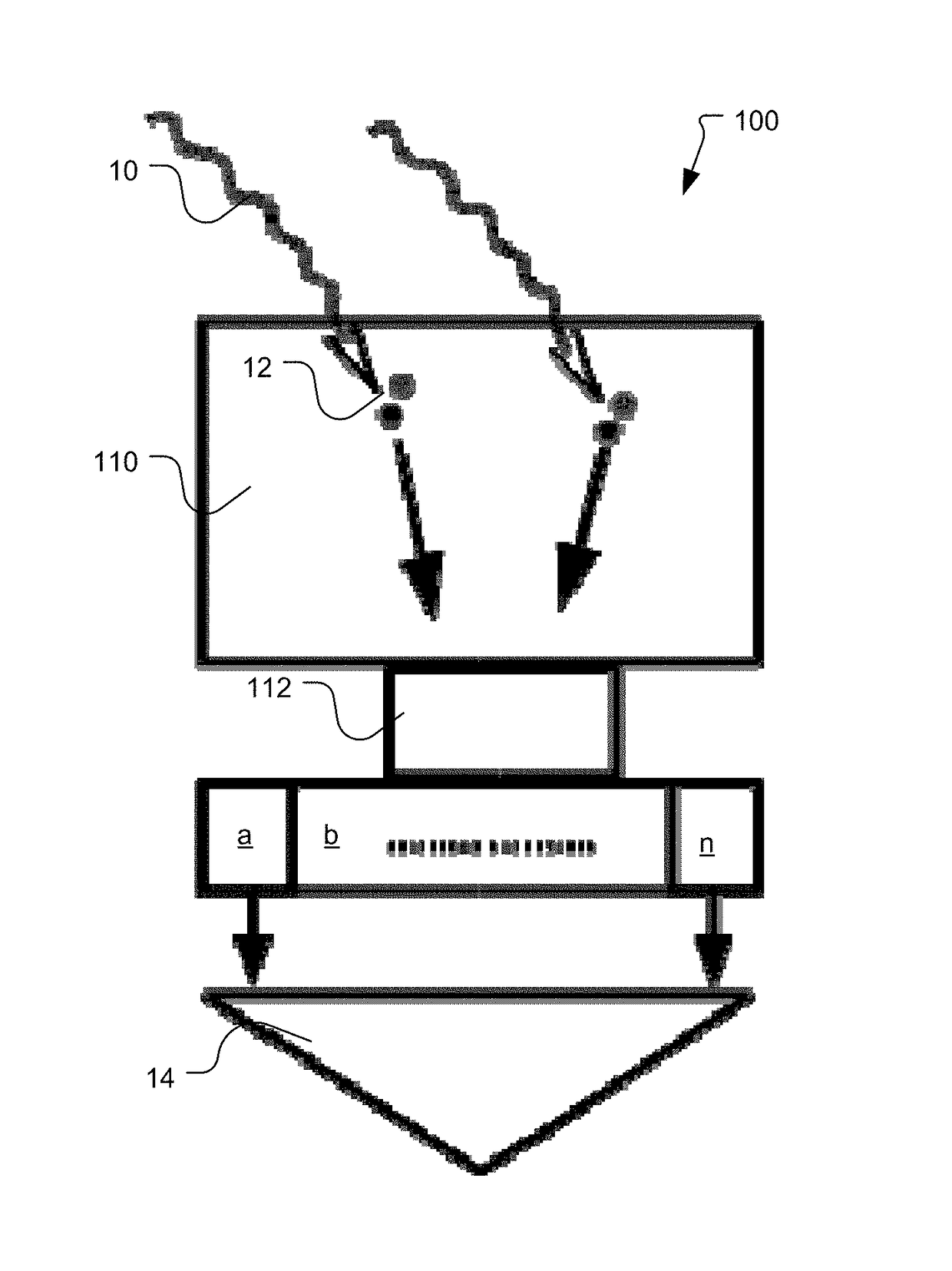

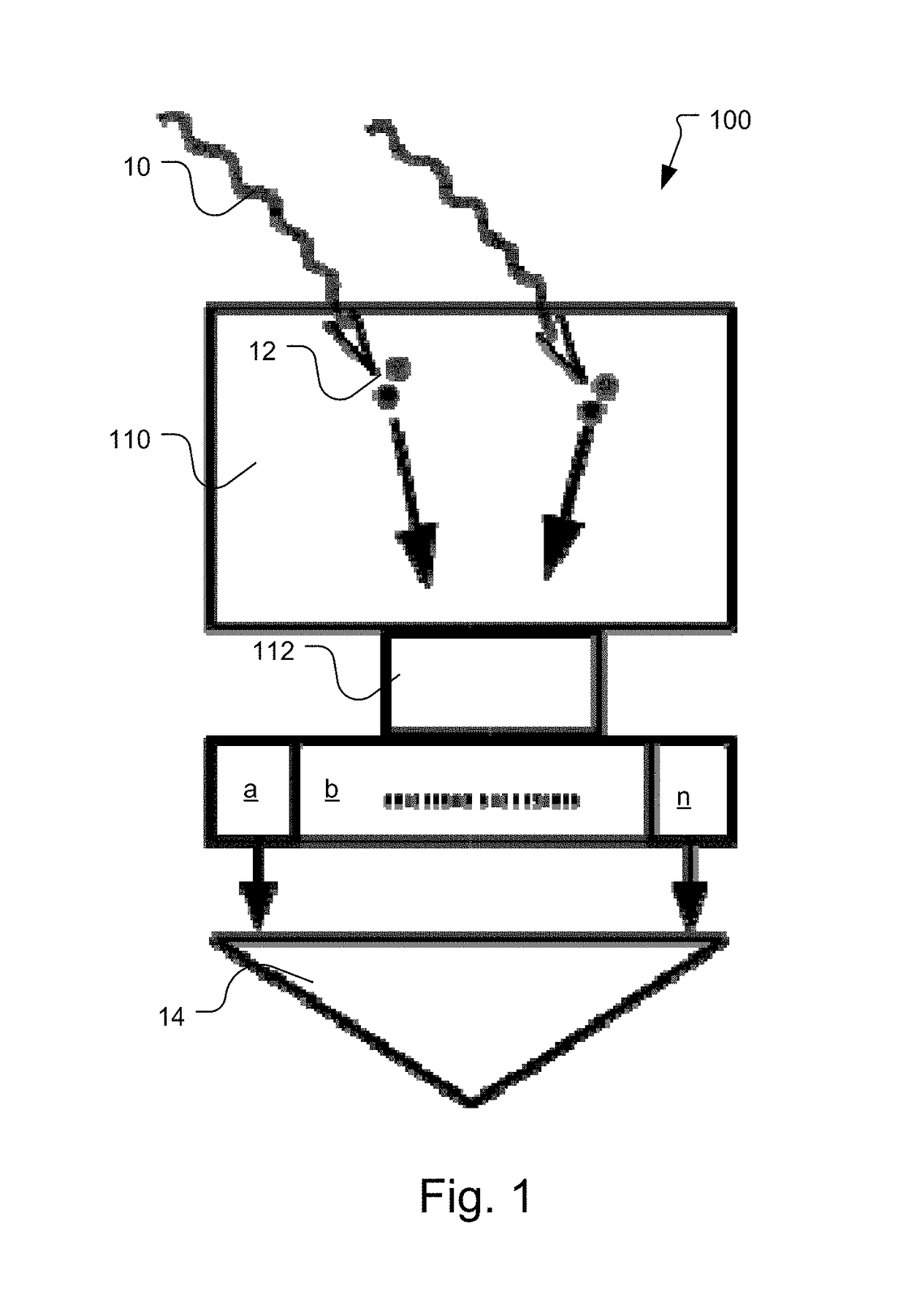

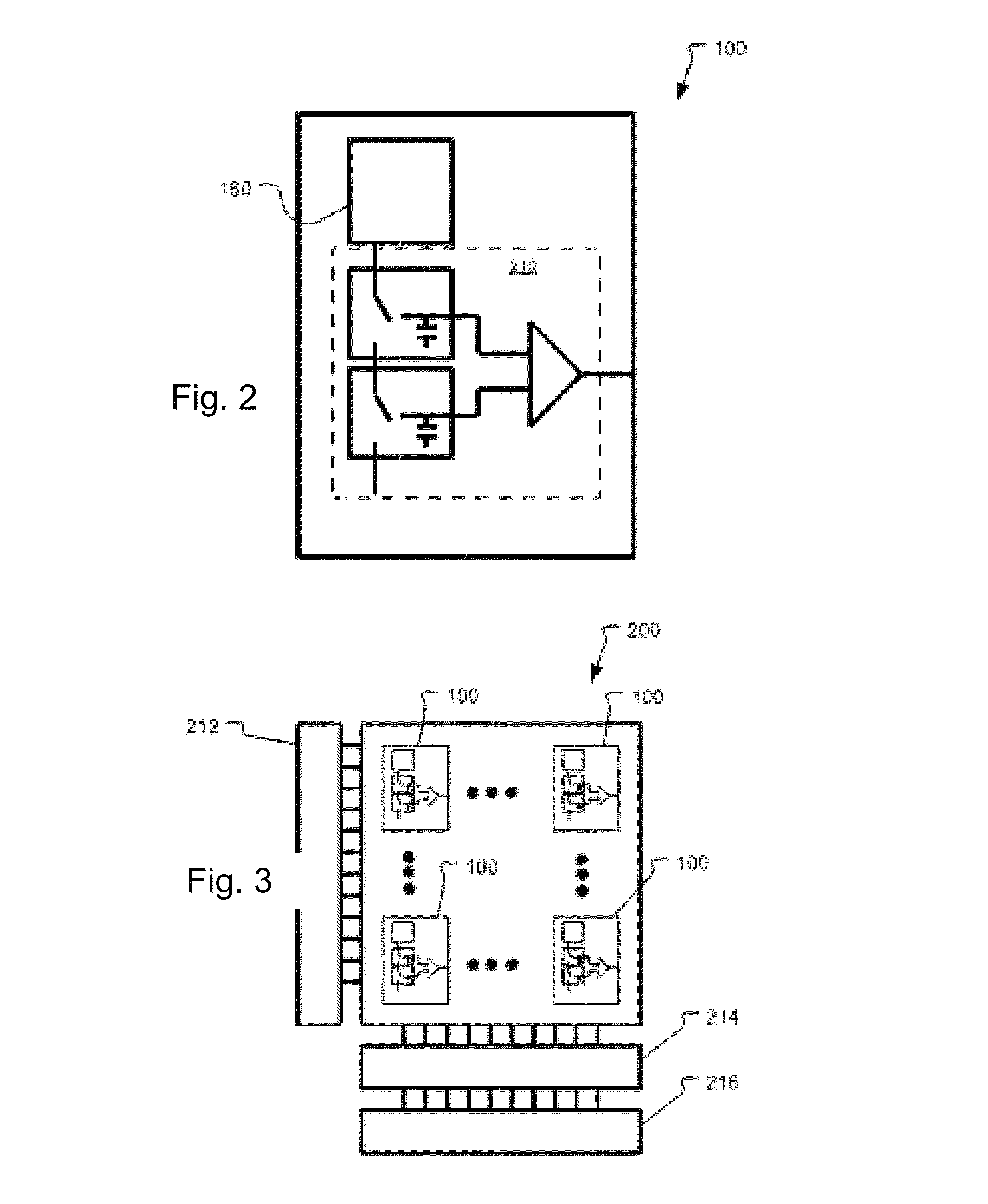

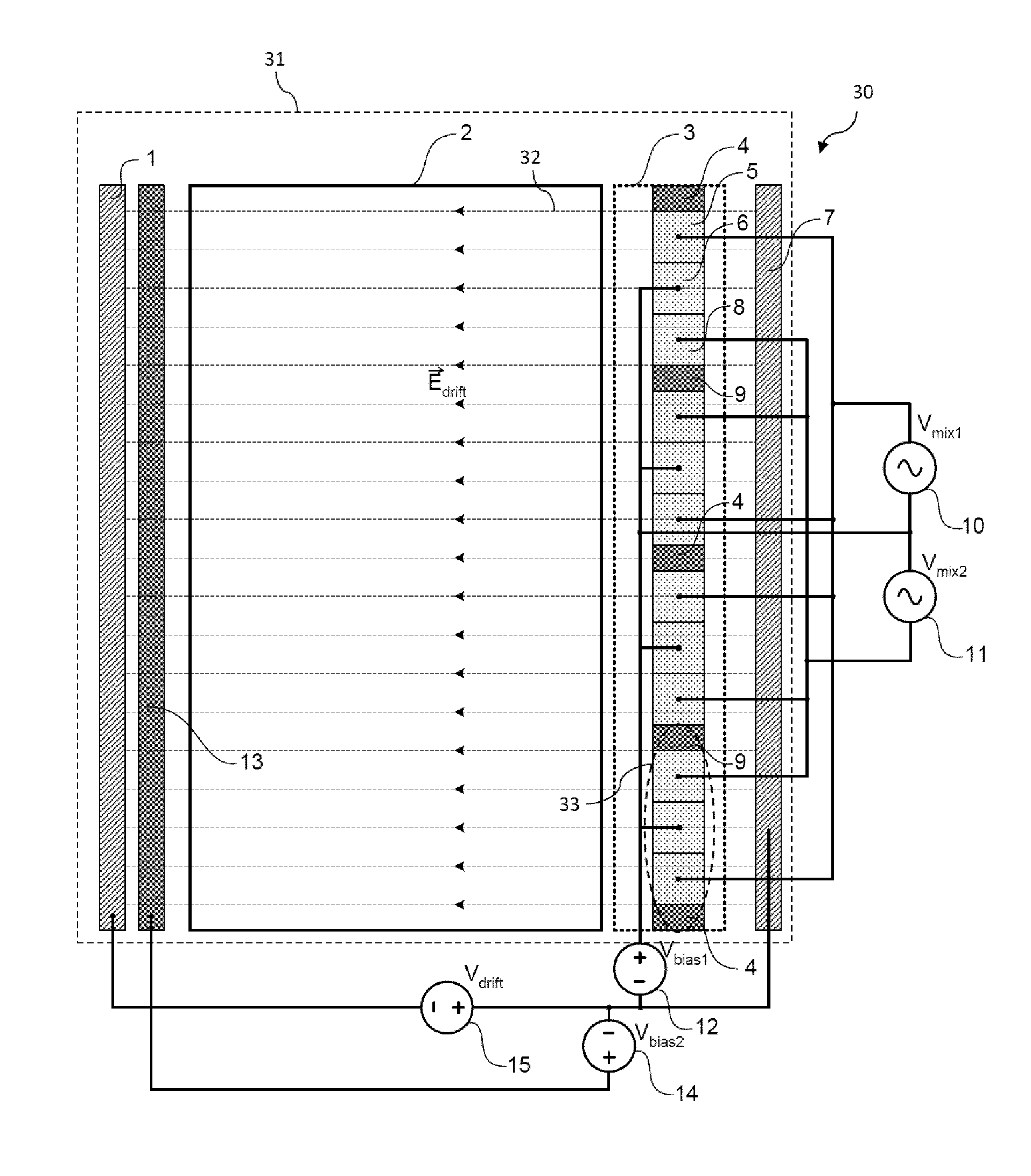

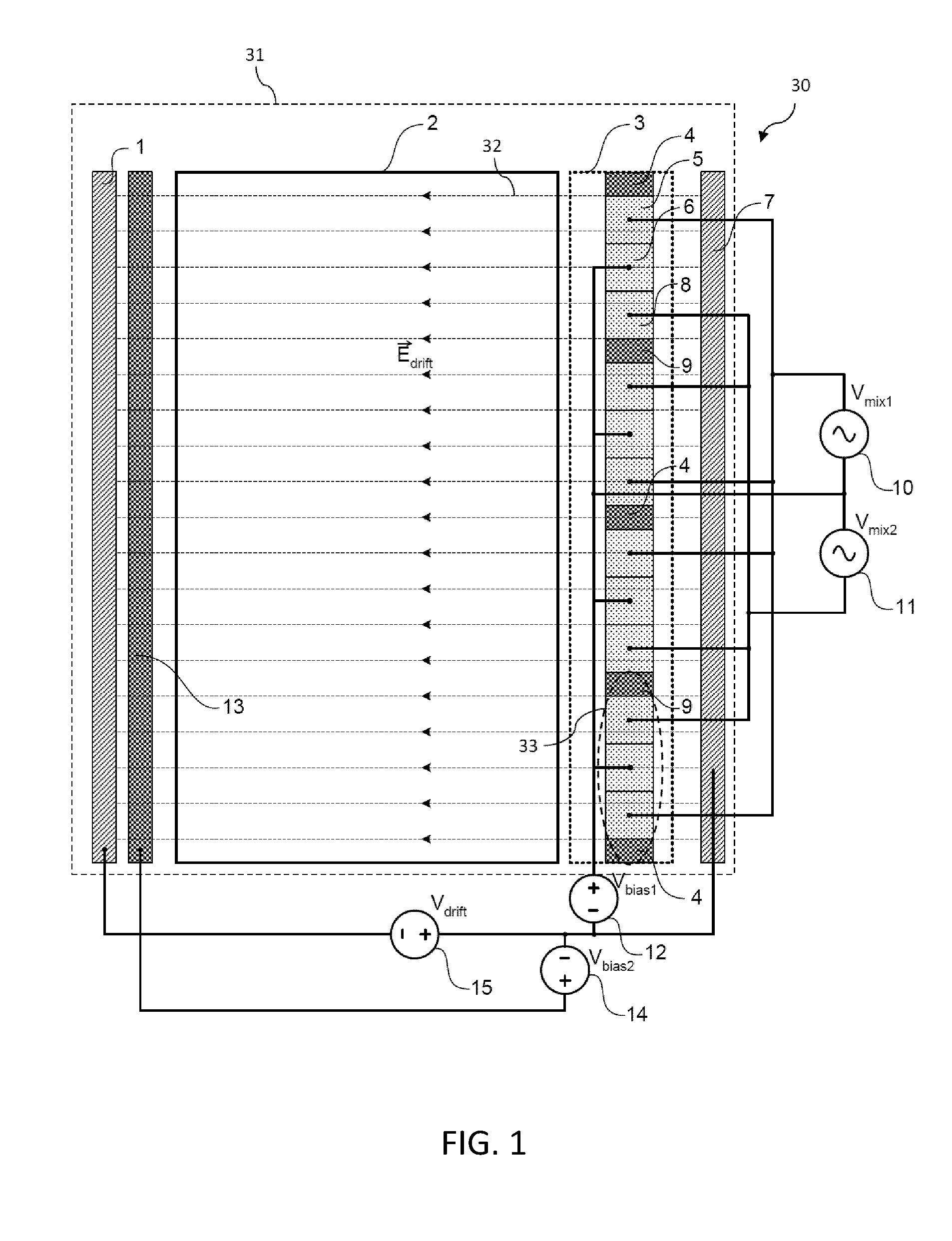

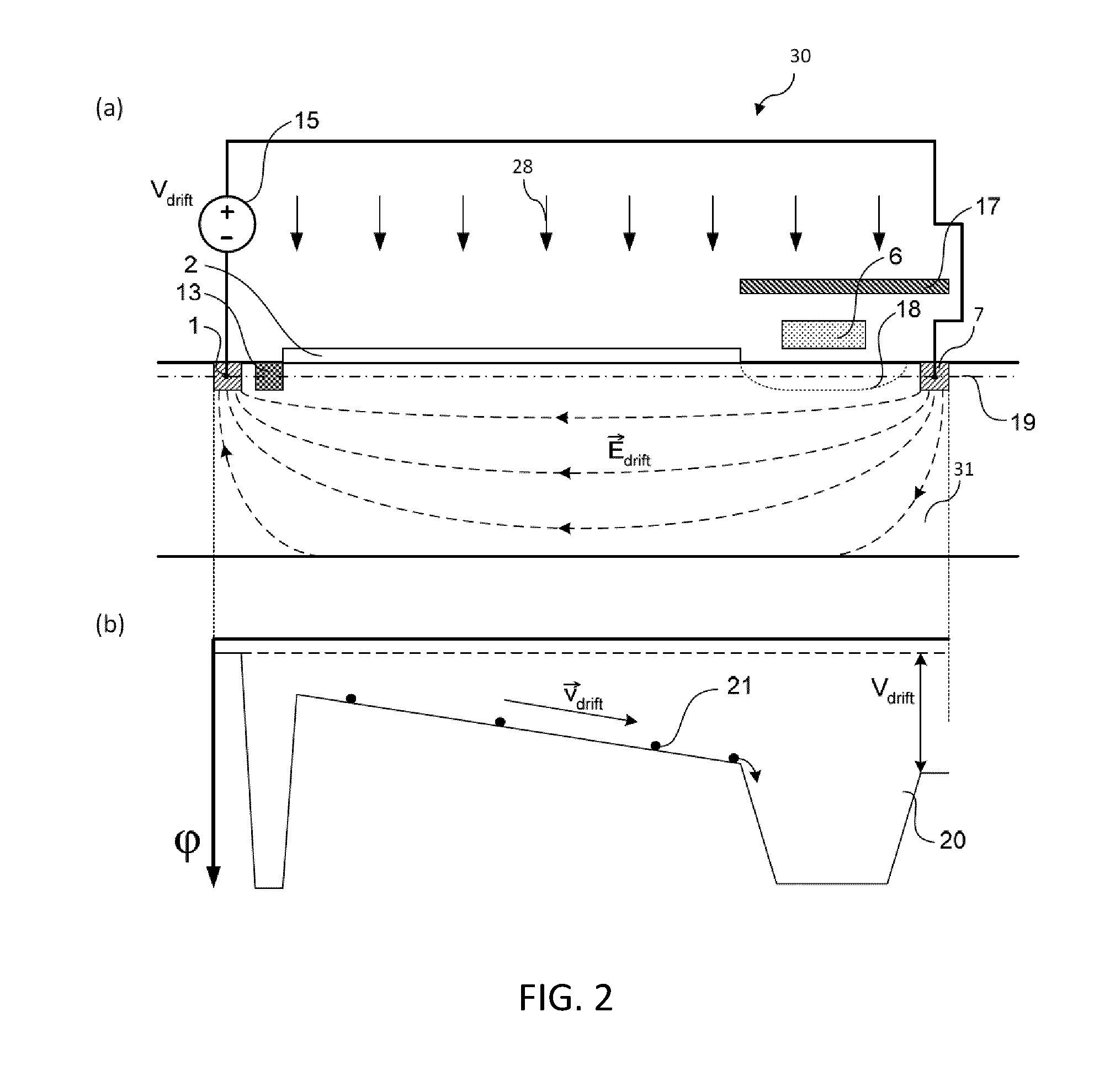

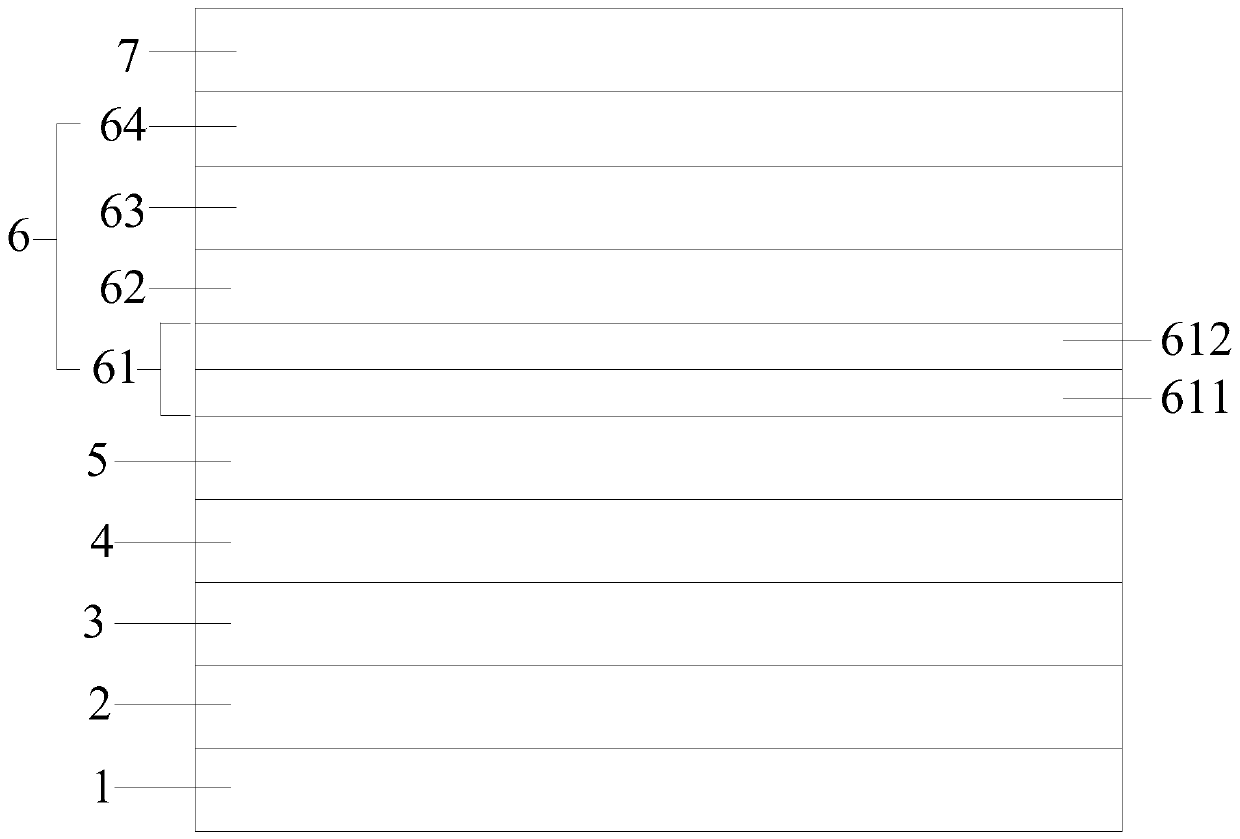

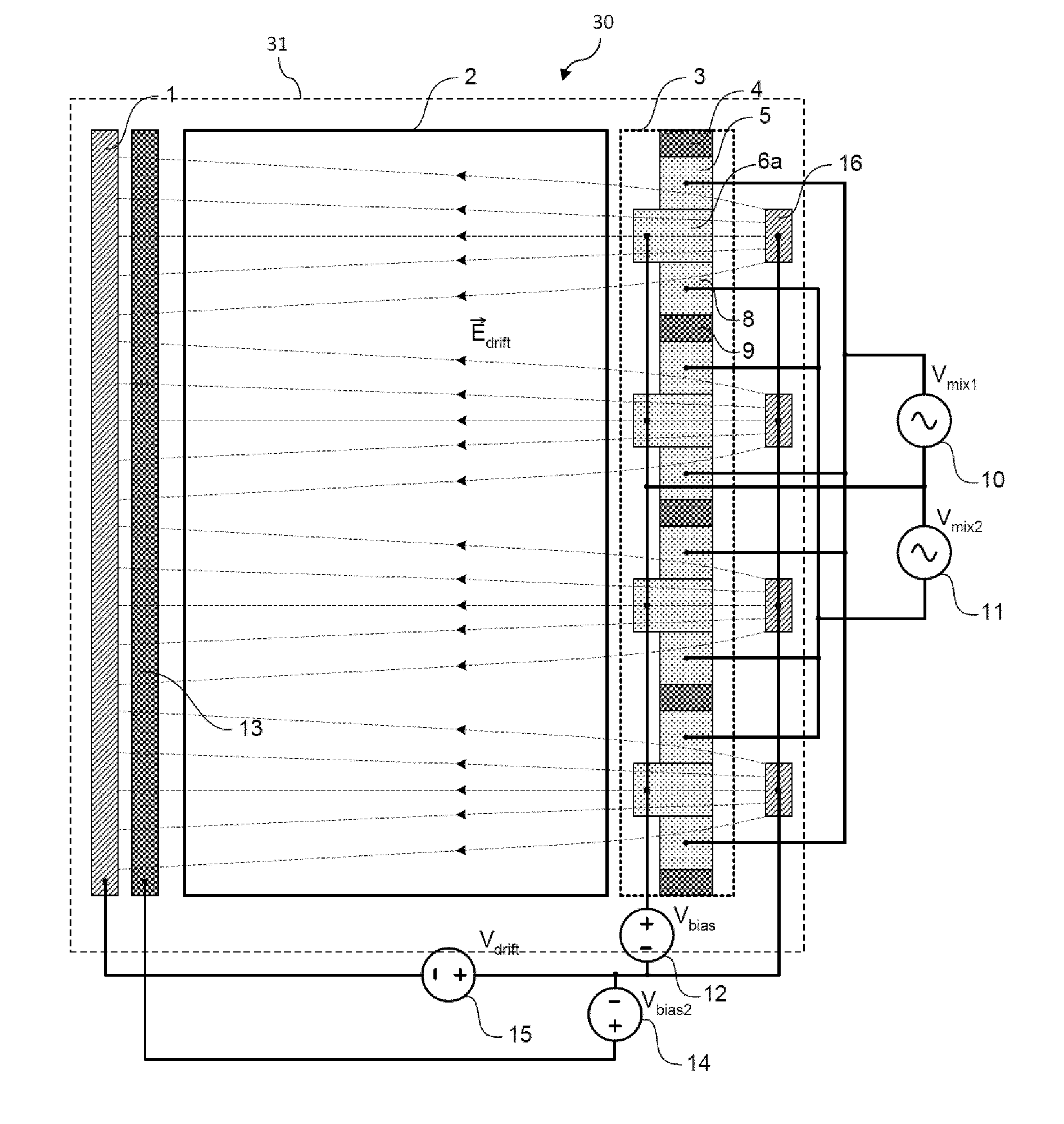

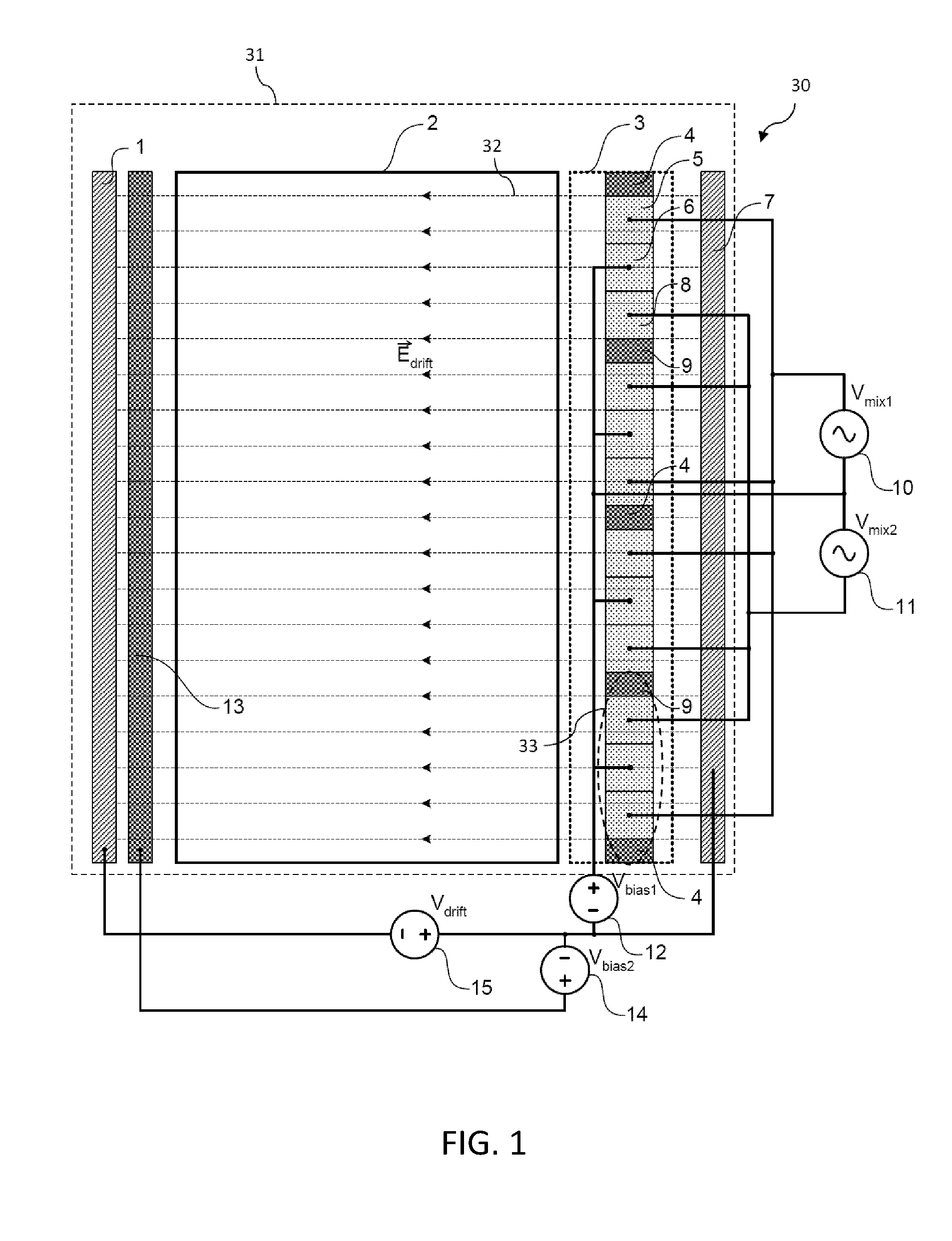

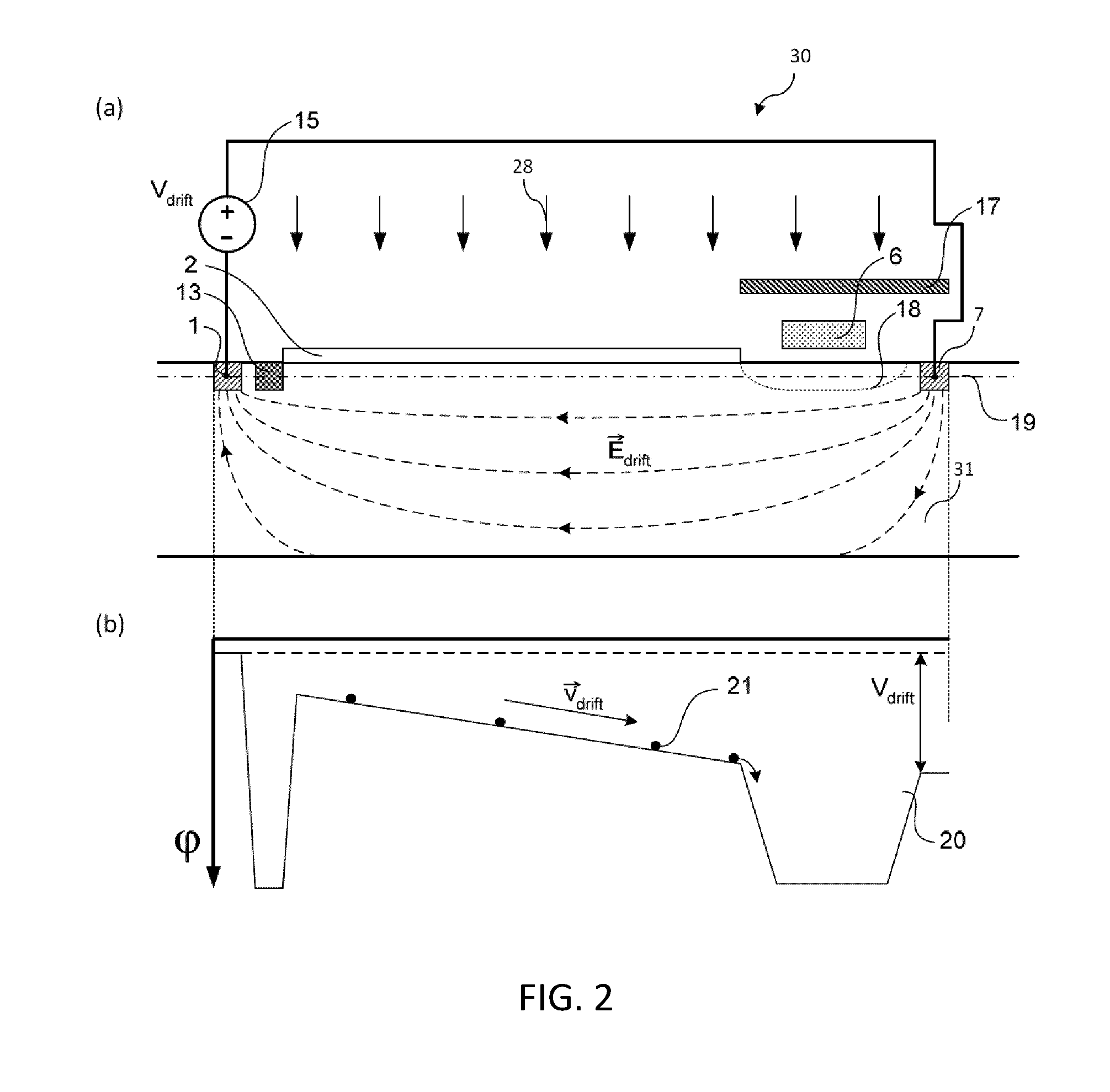

Method and system for demodulating signals

ActiveUS20130256546A1High sensitivityFast demodulationOptical measurementsSolid-state devicesPower flowRadiation field

A demodulation sensor (30) is described for detecting and demodulating a modulated radiation field impinging on a substrate (31). The sensor comprises the means (1,7,15) for generating, in the substrate, a static majority current assisted drift (Edrift) field, at least one gate structure (33) for collecting and accumulating minority carriers (21), the minority carriers generated in the substrate by the impinging radiation (28) field. The at least one gate structure comprises at least two regions (4,9,18) for the collection and accumulation of the minority carriers (21) and at least one gate (5,6,8) adapted for inducing a lateral electric drift field under the gate structure, the system thus being adapted for directing the minority carriers (21) towards one of the at least two regions (4,9) under influence of the static majority current assisted drift field and the lateral electric drift field induced by the at least one gate, and a means for reading out the accumulated minority carriers in that region.

Owner:MELEXIS TECH NV

High speed photodiode with a barrier layer for blocking or eliminating slow photonic carriers and method for forming same

A structure (and method for forming the structure) includes a photodetector, a substrate formed under the photodetector, and a barrier layer formed over the substrate. The buried barrier layer preferably includes a single or dual p-n junction, or a bubble layer for blocking or eliminating the slow photon-generated carriers in the region where the drift field is low.

Owner:GLOBALFOUNDRIES U S INC

Solar cell

InactiveCN111146305AEffective reflexImprove collection efficiencyPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The embodiment of the invention provides a solar cell. The solar cell comprises a bottom cell, a first tunneling junction layer, a back reflection layer, a middle cell, a second tunneling junction layer and a top cell, wherein the top cell comprises a top cell back field layer, a top cell base region, a top cell emitter region and a top cell window layer; the top cell back field layer comprises afirst back field layer and a second back field layer which are stacked. The band gaps of the first back field layer and the second back field layer are higher than the band gap of the top cell base region, so the reflection effect of photon-generated carriers is effectively exerted, the photon-generated carriers are transmitted to the top cell emitter region, and the collection efficiency of photon-generated carriers is improved. Moreover, the P-type doping concentration of the second back field layer is greater than the P-type doping concentration of the first back field layer and the top cell base region, so the resistivity of the top cell is effectively reduced, a drift field beneficial to photon-generated carrier collection is formed, the service life of minority carriers (namely electrons) can be prolonged, the short-circuit current density of the cell is further improved, and finally the conversion efficiency of the whole solar cell is improved.

Owner:YANGZHOU CHANGELIGHT

Field-shielded SOI-MOS structure free from floating body effects, and method of fabrication therefor

InactiveUS20050258490A1Enhancing recombinationGain is not constantTransistorSolid-state devicesElectrical conductorInsulation layer

A silicon-on-insulator structure provides an effective drift field for holes, and simultaneously enhanced recombination centers for holes and electrons. The structure includes a silicon substrate, an oxide insulation layer disposed above the silicon substrate, a silicon body layer disposed above the oxide insulation layer, and a field shield gate disposed above the silicon body layer. The field shield gate includes a conductor portion, and an alumina insulation layer disposed beneath the conductor portion. The oxide insulation layer and the silicon body layer each include at least one channel stop region, and at least one recombination center for the recombination of positive- and negative-charge carriers. The effective drift field and enhanced recombination centers facilitate the rapid recombination of the charge carriers, leading to a very small recombination time constant, which overcomes the floating body effect associated with conventional silicon-on-insulator structures.

Owner:MICRON TECH INC

Phosphoric diffusion technology for metallurgical-grade polysilicon solar cells

ActiveCN101587918BReduce the effectImprove life expectancyFinal product manufactureSemiconductor devicesSolar cellImpurity

The invention relates to diffusion technology for manufacturing solar cells, in particular to phosphoric diffusion technology for metallurgical-grade polysilicon solar cells. The technology comprises the following steps: firstly, performing high temperature grain boundary gettering, wherein high temperature is used to make impurity atoms released at the prior settling position and simultaneously diffused and move to the position of a grain boundary defect to settle to form a clean area near the grain boundary; secondly, performing medium-low temperature phosphoric deposition, wherein diffusion deposition of fresh phosphorus is performed for a short time at a medium low diffusion temperature to finish surface low concentration phosphorus deposition to prepare for long time high temperaturedrive-in in a next step; thirdly, performing diffusion passivation of high temperature deep grain boundary, wherein high temperature long time phosphoric source drive-in is performed to form deep PNjunction at the position of the grain boundary so as to make phosphor generate phosphoric gettering and passivation of phosphoric drift field at the position of the grain boundary; and finally, performing the diffusion again for adjusting to a needed sheet resistance value. The technology greatly reduces the composite of minority carrier originally happening in the position of the grain boundary by utilizing the properties of the diffusion of impurities in the polycrystalline silicon; and after the process is finished, the minority carrier lifetime of a silicon chip is improved compared with that of a silicon clip produced by a normal process, which has an active effect on the final performance of the cells.

Owner:TRINA SOLAR CO LTD

Method and system for demodulating signals

ActiveUS9151677B2Fast demodulationHigh sensitivityOptical measurementsSolid-state devicesElectricityRadiation field

A demodulation sensor (30) is described for detecting and demodulating a modulated radiation field impinging on a substrate (31). The sensor comprises the means (1,7,15) for generating, in the substrate, a static majority current assisted drift (Edrift) field, at least one gate structure (33) for collecting and accumulating minority carriers (21), the minority carriers generated in the substrate by the impinging radiation (28) field. The at least one gate structure comprises at least two regions (4,9,18) for the collection and accumulation of the minority carriers (21) and at least one gate (5,6,8) adapted for inducing a lateral electric drift field under the gate structure, the system thus being adapted for directing the minority carriers (21) towards one of the at least two regions (4,9) under influence of the static majority current assisted drift field and the lateral electric drift field induced by the at least one gate, and a means for reading out the accumulated minority carriers in that region.

Owner:MELEXIS TECH NV

Ion mobility spectrometer device with embedded faims

ActiveUS9395333B2Particle separator tubesMaterial analysis by electric/magnetic meansLow voltageDrift tube

A tandem instrument using a variable frequency pulsed ionization source and two separation techniques, low (IMS) and high (FAIMS) field mobility is provided. The analytical stage features a field driven FAIMS cell embedded on-axis within the IMS drift tube. The FAIMS cell includes two parallel grids of approximately the same diameter as the IMS rings and can be placed anywhere along the drift tube and biased according to their location in the voltage divider ladder to create the same IMS field. The spacing between the grids constitutes the analytical gap where ions are subject, in addition to the drift field, to the asymmetric dispersive field of the FAIMS. The oscillatory motion performed during the high and low voltages of the asymmetric waveform separates the ions according to the difference in their mobilities.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com