Rapid preparation method for C/SiC composite material

A composite material and fast technology, applied in the field of materials, can solve problems such as complex process, high cost, and long preparation cycle, and achieve the effects of reducing manufacturing cost, improving density, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

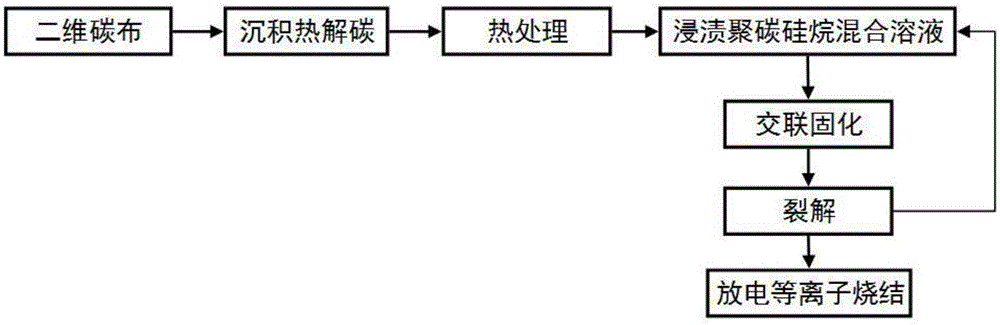

Image

Examples

Embodiment 1

[0029] Step 1: Depositing the interface layer: using a thin-layer carbon fiber prefabricated body with a thickness of less than 0.3 mm as a composite material reinforcement, and depositing a pyrolytic carbon (PyC) interface by chemical vapor infiltration. During pyrolysis, the precursor is propylene, methane, acetylene, ethylene or other hydrocarbons; the conditions are: argon is used as the dilution gas, the deposition temperature is 750-1100°C, and the time is 10-20h; and then at 1600-1800°C Heat treatment 0.5 ~ 2h;

[0030] Step 2: Solution preparation: weighing 0-20wt% aluminum oxide or earth metal oxide and 0-20wt% rare earth oxide as sintering aids, and mixing them with polycarbosilane (PCS). Use magnetic stirring for 4 ~ 20h until uniform.

[0031] Step 3: Matrix preparation: The thin-layer carbon fiber preform deposited on the PyC interface is immersed in the mixed solution for 1-10 hours, taken out, and then cross-linked and cured at 200-250°C for 2-3 hours under a p...

Embodiment 2

[0035] Step 1: Depositing the interface layer: using a thin-layer carbon fiber prefabricated body with a thickness of less than 0.3 mm as a composite material reinforcement, and depositing a pyrolytic carbon (PyC) interface by chemical vapor infiltration. During pyrolysis, the precursor is propylene, methane, acetylene, ethylene or other hydrocarbons; the conditions are: argon is used as the dilution gas, the deposition temperature is 750-1100°C, and the time is 10-20h; and then at 1600-1800°C Heat treatment 0.5 ~ 2h;

[0036] Step 2: Solution preparation: weighing 0-20wt% aluminum oxide or earth metal oxide and 0-20wt% rare earth oxide as sintering aids, and mixing them with polycarbosilane (PCS). Use magnetic stirring for 4 ~ 20h until uniform.

[0037] Step 3: Matrix preparation: The thin-layer carbon fiber preform deposited on the PyC interface is immersed in the mixed solution for 1-10 hours, taken out, and then cross-linked and cured at 200-250°C for 2-3 hours under a p...

Embodiment 3

[0041] Step 1: Depositing the interface layer: using a thin-layer carbon fiber prefabricated body with a thickness of less than 0.3 mm as a composite material reinforcement, and depositing a pyrolytic carbon (PyC) interface by chemical vapor infiltration. During pyrolysis, the precursor is propylene, methane, acetylene, ethylene or other hydrocarbons; the conditions are: argon is used as the dilution gas, the deposition temperature is 750-1100°C, and the time is 10-20h; and then at 1600-1800°C Heat treatment 0.5 ~ 2h;

[0042] Step 2: Solution preparation: weighing 0-20wt% aluminum oxide or earth metal oxide and 0-20wt% rare earth oxide as sintering aids, and mixing them with polycarbosilane (PCS). Use magnetic stirring for 4 ~ 20h until uniform.

[0043] Step 3: Matrix preparation: The thin-layer carbon fiber preform deposited on the PyC interface is immersed in the mixed solution for 1-10 hours, taken out, and then cross-linked and cured at 200-250°C for 2-3 hours under a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com