Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262results about How to "Dip evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

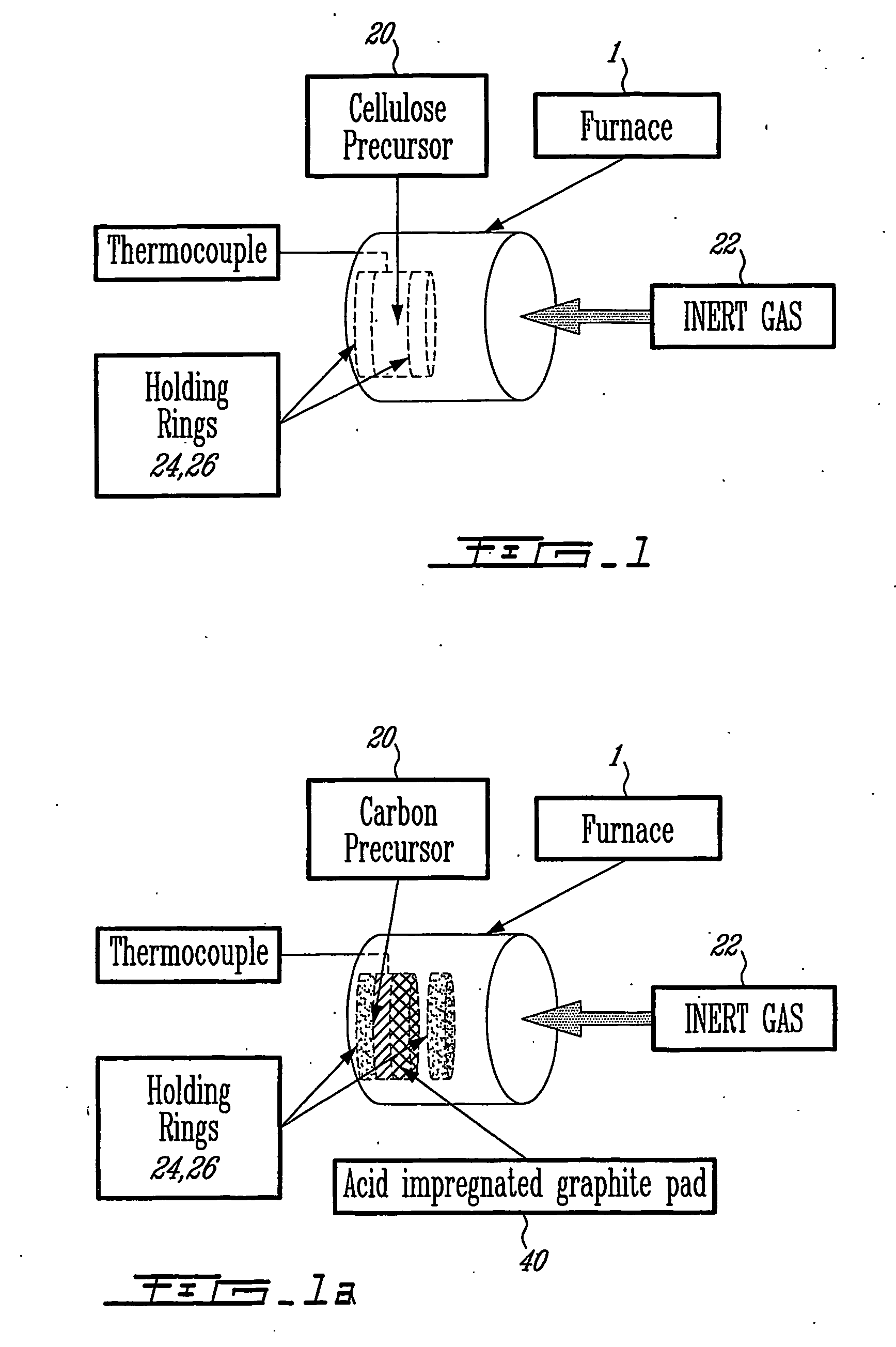

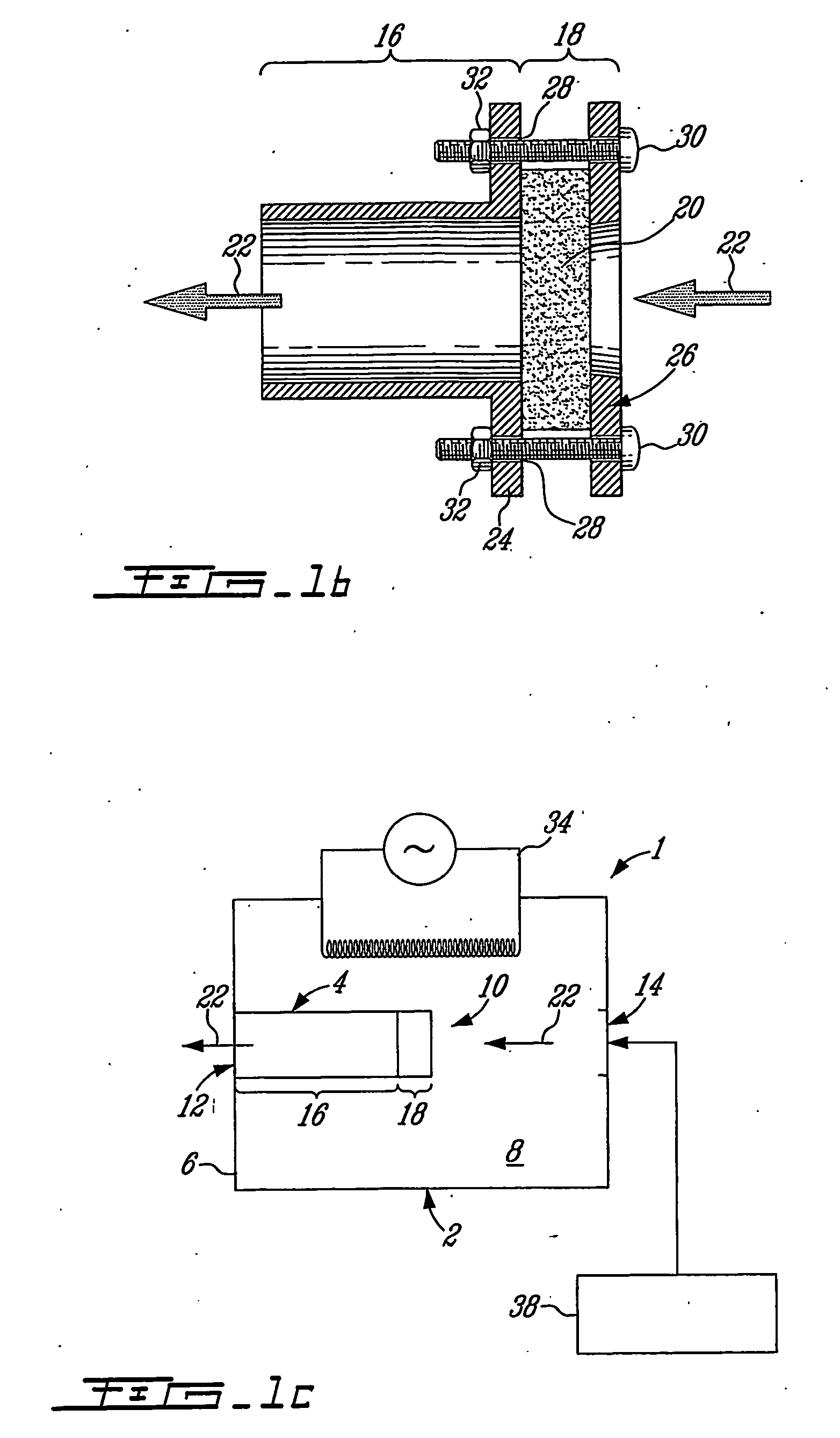

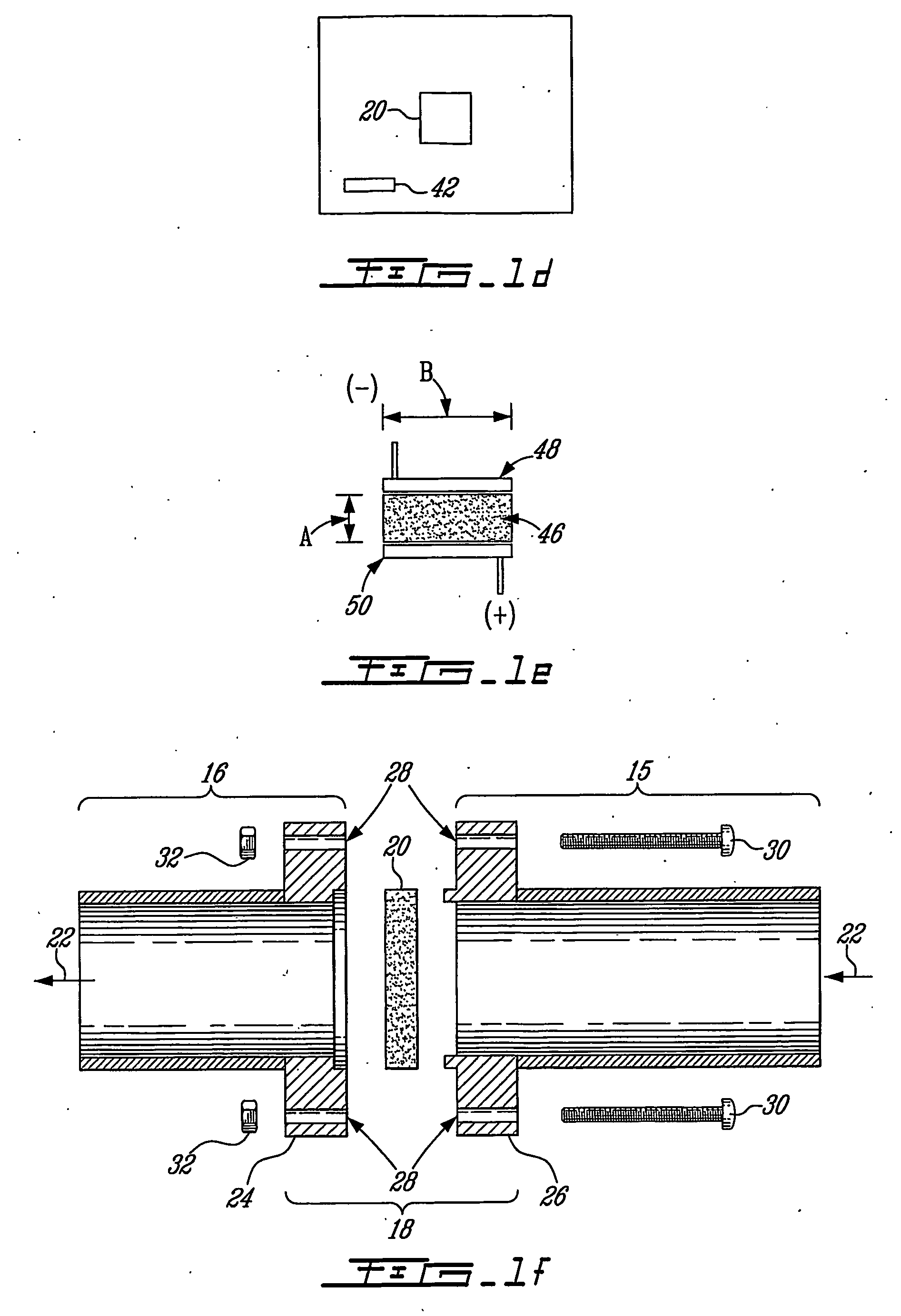

Process for the production of activated carbon

InactiveUS20070021300A1Prepare economicallyLower overall pressure dropCarbon compoundsOther chemical processesActivated carbonEnvironmental chemistry

The present invention relates processes for the preparation of activated carbon materials; the present invention also relates activated carbon materials and in particular to materials comprising activated carbon fibers such as for example fabric or fabric like materials of activated carbon fibers. These materials may be used as adsorbents to take up predetermined components from a fluid (e.g. undesirable organic compounds from air).

Owner:MCGILL UNIV +3

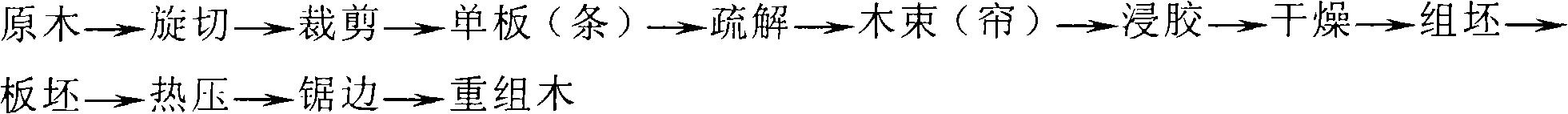

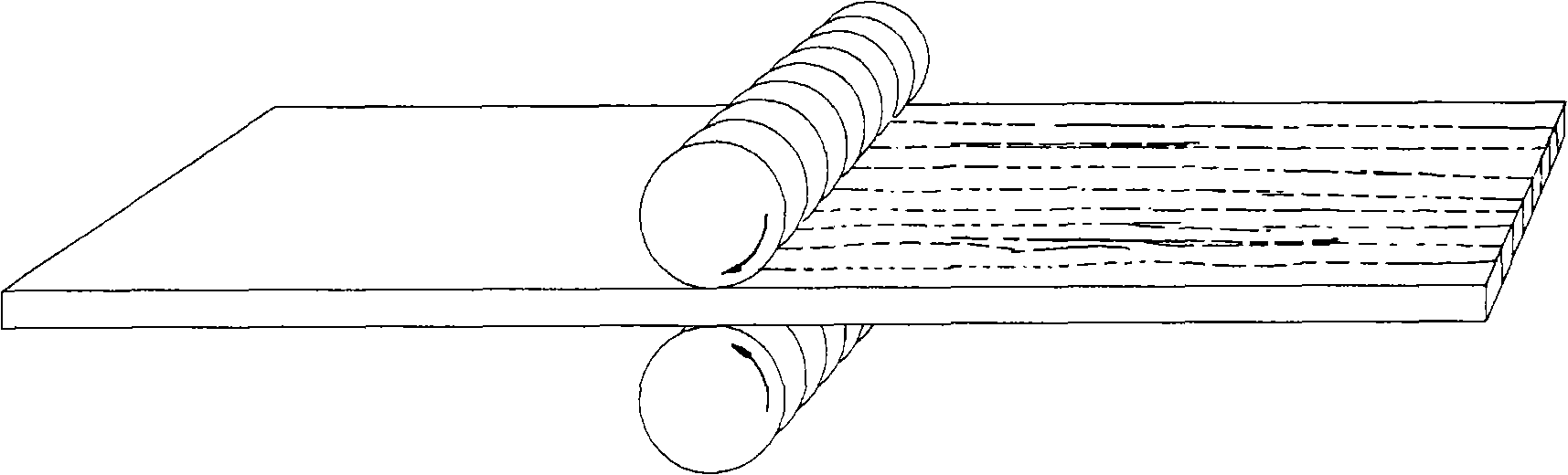

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Epoxy resin composition, prepreg, metal-clad laminate, printed wiring board and semiconductor device

InactiveUS20110083890A1Improve flame resistanceImprove heat resistanceMaterial nanotechnologySynthetic resin layered productsSilica nanoparticlesSilica particle

The present invention is to provide an epoxy resin composition uniformly containing a large amount of inorganic fillers, excellent in heat resistance and flame resistance, and having good impregnation into a base material, and a prepreg using the epoxy resin composition, having good tackiness, and being easy in handling. Furthermore, it is to provide a printed wiring board using a metal-clad laminate formed using the prepreg and / or the prepreg or the epoxy resin composition, capable of easily conducting an ENEPIG process, and a semiconductor device using the printed wiring board, excellent in performances. An epoxy resin composition comprises a solid epoxy resin, a silica nanoparticle having an average particle diameter of 1 nm or more and 100 nm or less, and a silica particle having an average particle diameter larger than that of the silica nanoparticle, in the range of 0.1 μm or more and 5.0 μm or less.

Owner:SUMITOMO BAKELITE CO LTD

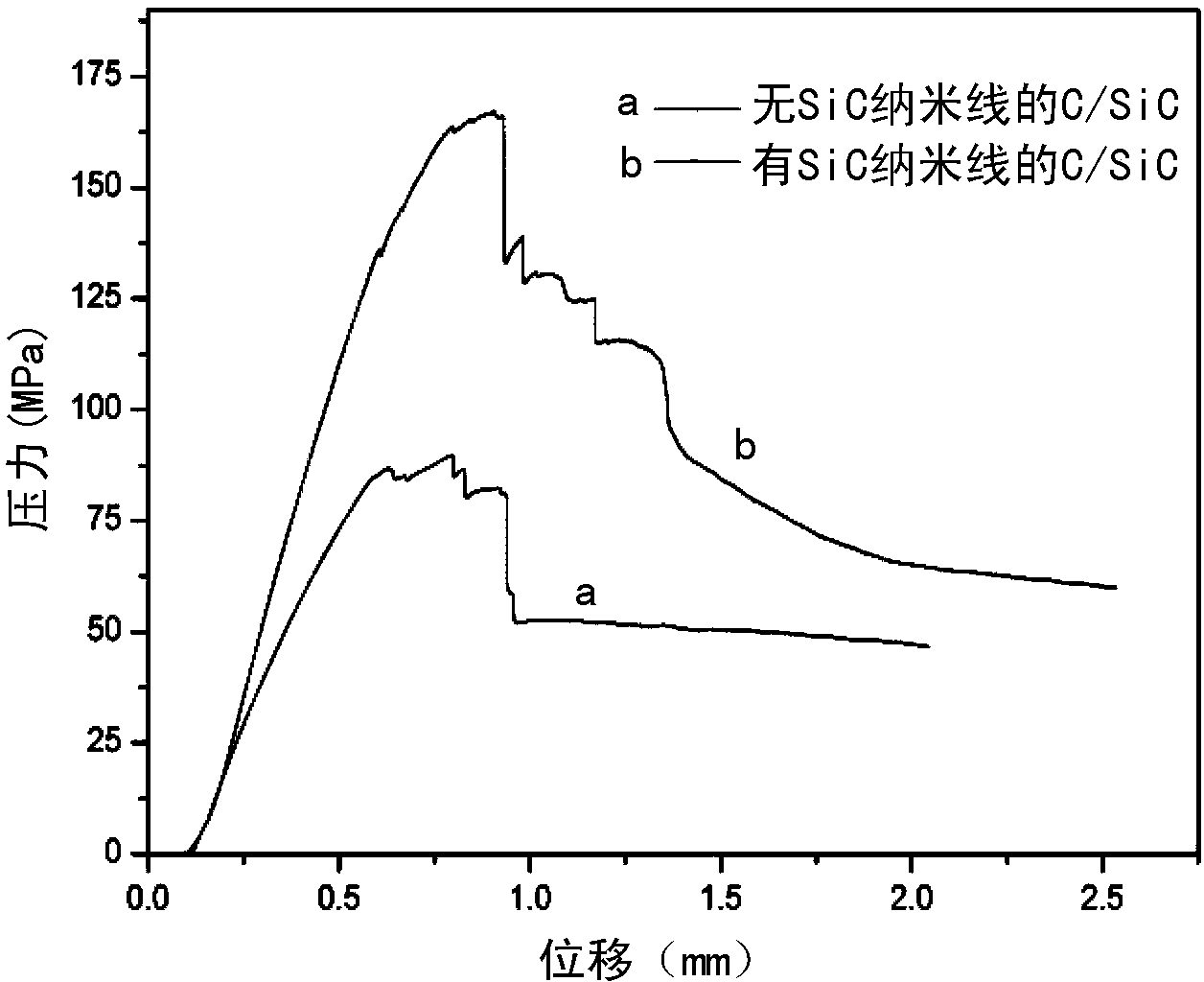

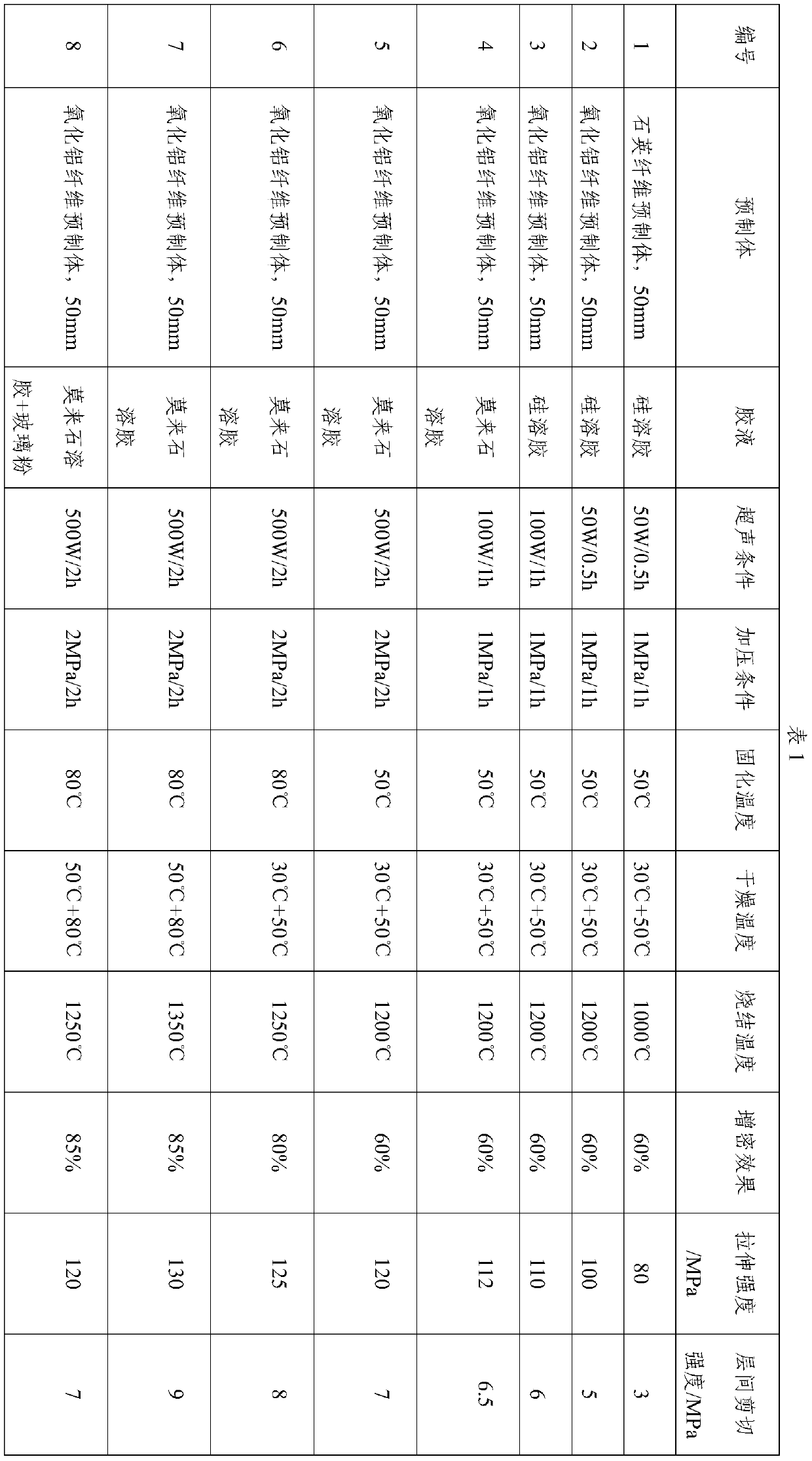

In-situ growth SiC nanowire enhanced C/SiC composite material and preparation method thereof

The invention relates to an in-situ growth SiC nanowire enhanced C / SiC composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing size, namely mixing and ball milling polycarbosilane, a catalyst and a solvent to prepare the size, wherein the catalyst is iron, nickel and / or ferrocene; (2) performing vacuum high pressure impregnation, namely immersing a C fiber preform in the size, keeping in a vacuum state for 0.1-1 hour, introducing high-pressure inert gases to 1-10MPa, and maintaining the pressure for 1-4 hours; (3) cross-linking and curing, namely performing cross-linking and curing on the impregnated C fiber preform in air for over 6 hours to prepare a preform; and (4) performing high-temperature pyrolysis, namely raising the temperature of the preform to be 1000-1300 DEG C at a temperature rise rate of 2-10 DEG C per minute in a protective atmosphere, keeping the temperature for 1-4 hours, and growing SiC nanowires in situ under the action of a metal catalyst in the polycarbosilane pyrolysis process, so that the in-situ growth SiC nanowire enhanced C / SiC composite material is prepared.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

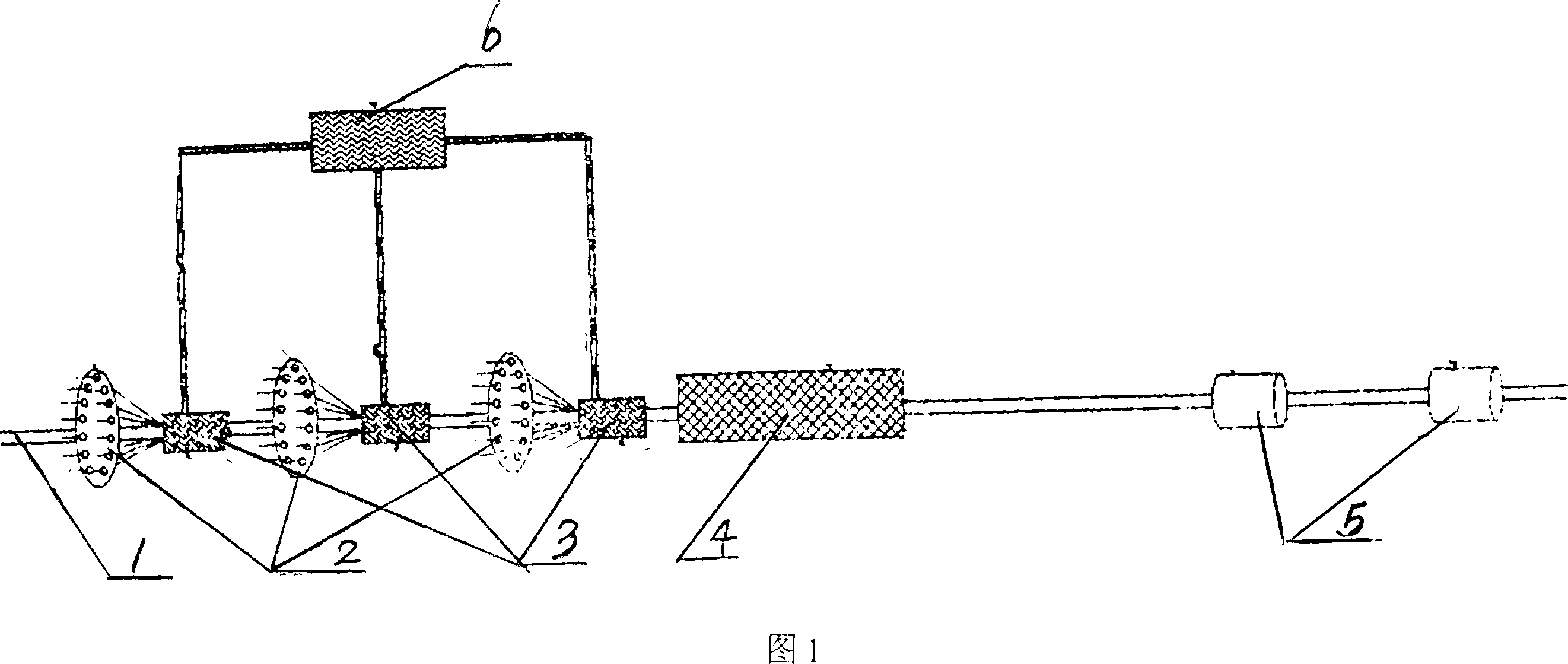

Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

InactiveCN101085551AWeave evenlyHigh precision of inner and outer diameterTubular articlesFiberMaterials science

The invention relates to the making of multi layer knitting structure on the wire pulling glass steel tube using several computers controlling the two dimensional horizontal knitter, using core mold, stretch mold, extractor synthesizing the glass steel tube, setting resin dipping slot at the back of each knitter, even direct core mold at both ends of the core mold that follows with the movement of the ring knitting layer in the direction from the first two dimensional horizontal knitter to the last knitter through the dipping slot to the stretch mold. The glass tube in and out radius has high precision, thickness of each knitting layer adjustable, even in each dipping and consistent in strength.

Owner:郝跟进

Paper-making-stage bamboo wood pulp plate denaturalization producing technique

ActiveCN101148836ADip evenlyFully impregnatedPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making bamboo pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making bamboo pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Epoxy resin composition, prepreg, metal-clad laminate, printed wiring board and semiconductor device

ActiveCN102040803AImprove heat resistanceImprove flame retardant performancePrinted circuit aspectsDomestic articlesSilica nanoparticlesEpoxy

An epoxy resin composition, a prepreg, a metal-clad laminate, a printed wiring board and a semiconductor device. The present invention is to provide an epoxy resin composition uniformly containing a large amount of inorganic fillers, excellent in heat resistance and flame resistance, and having good impregnation into a base material, and a prepreg using the epoxy resin composition, having good tackiness, and being easy in handling. Furthermore, it is to provide a printed wiring board using a metal-clad laminate formed using the prepreg and / or the prepreg or the epoxy resin composition, capable of easily conducting an ENEPIG process, and a semiconductor device using the printed wiring board, excellent in performances. An epoxy resin composition comprises a solid epoxy resin, a silica nanoparticle having an average particle diameter of 1 nm or more and 100 nm or less, and a silica particle having an average particle diameter larger than that of the silica nanoparticle, in the range of 0.1 [mu]m or more and 5.0 [mu]m or less.

Owner:SUMITOMO BAKELITE CO LTD

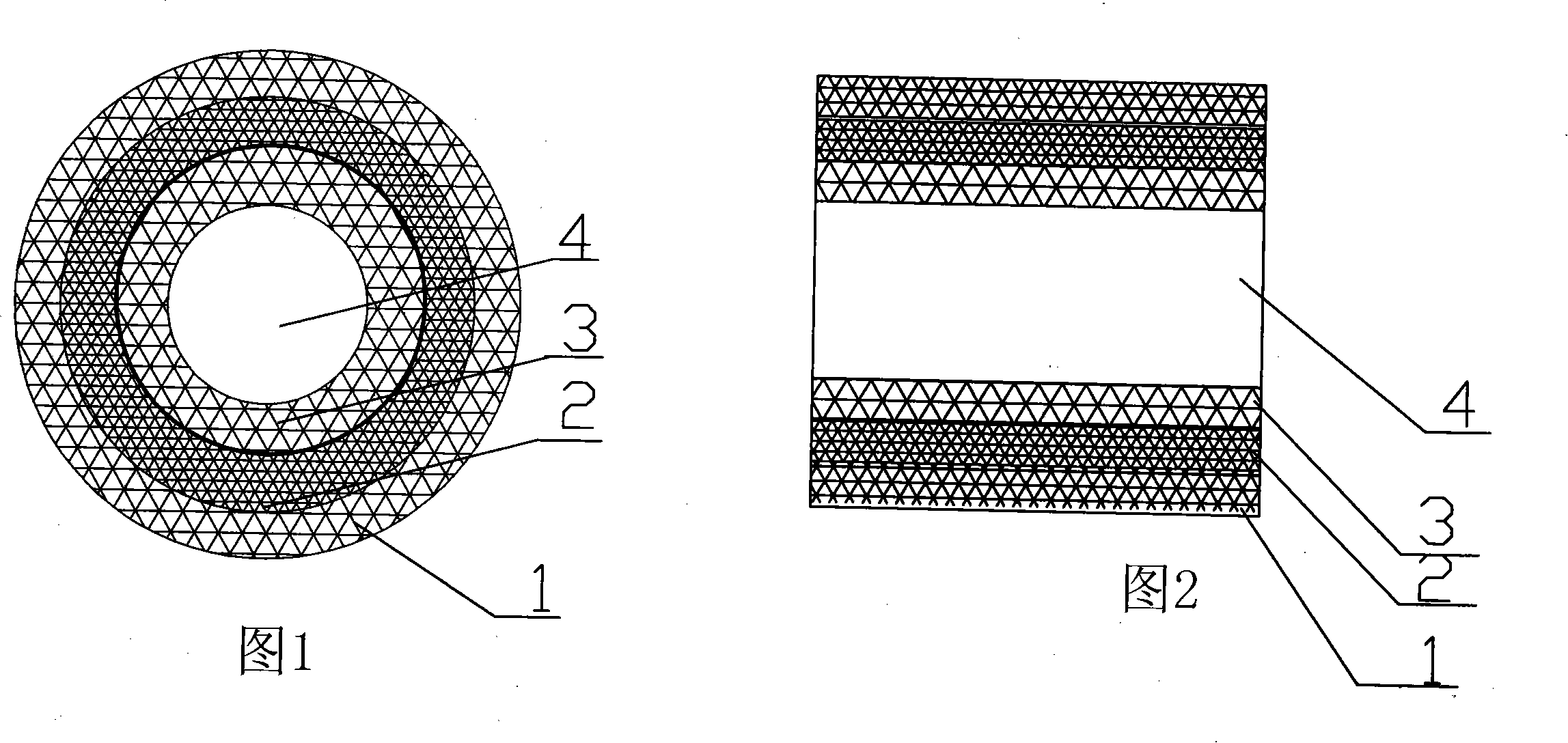

Fiberglass insulating tube with multi-layer ring shaped braiding structure

InactiveCN101119042AWeave evenlyHigh precision of inner and outer diameterWindings insulation materialWindings insulation shape/form/constructionUltimate tensile strengthManufacturing efficiency

The present invention discloses a glass steel insulating tube with the multi-layer round structure, which is compounded with the multi-layer glass steel insulating tube, each glass steel insulating tube of the compounded glass steel insulating tube is the glass steel insulating weaving tube which is weaved at the moving type core tube by the horizontal knitting machine, each layer of the lass steel insulating weaving tube is dipped by the bond before the compound; the compounded glass steel insulating tube is compound under the same straight core mould, and finally shape and solidified by a pulling mould; the glass steel insulating tube is formed by the 2 to 5 layers of the glass steel insulating weaving tube. Compared with prior compound tube, the intensity and the accuracy of the glass steel insulating tube are improved greatly, the thickness of the tube wall only differ from 1 to 2 threads, in particular to the application of the micro electromotor double insulating tubes make the manufacture efficiency of the micro electromotor improve, and the cost is reduced, and the production craftwork is simple.

Owner:郝跟进

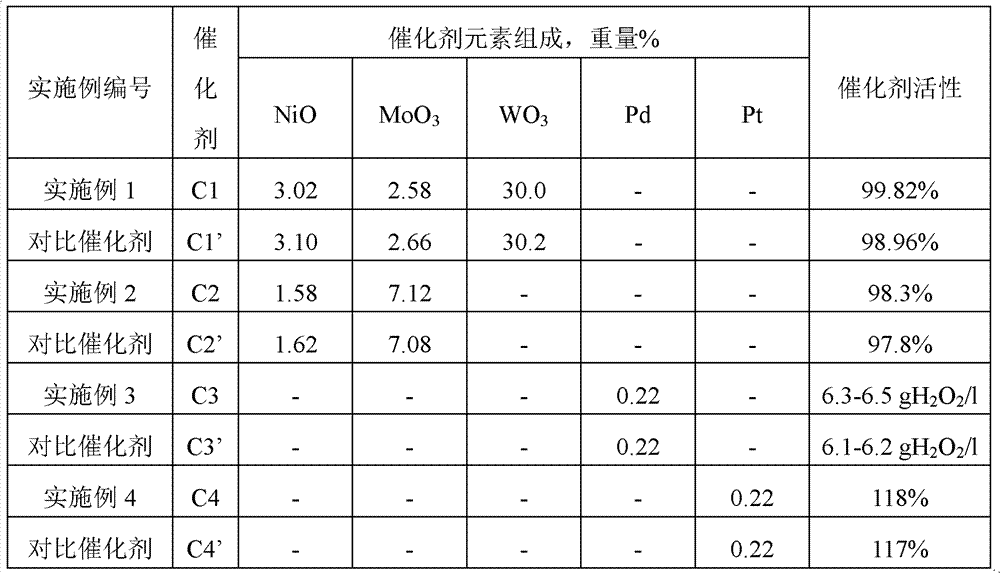

Acetylene-hydrochlorinated low-content gold compound catalyst

ActiveCN103191760ADip evenlyImprove conversion ratePhysical/chemical process catalystsPreparation by halogen halide additionAcetyleneAlkali metal

The invention discloses an acetylene-hydrochlorinated low-content gold compound catalyst, particularly a nonmerculic catalyst which is suitable for synthesis of chloroethylene through an acetylene hydrochlorination reaction. The catalyst comprises carrier active carbon, a main catalysis element and auxiliary elements A and B, wherein the content of the carrier active carbon is 10,000 parts, the main catalysis element is thiosulfate of gold with the content of 1-120 parts, the auxiliary element A is thiosulfate of silver with the content of 50-1,000 parts, the auxiliary element B is alkali metal compound and a mixture of the alkali metal compounds with the content of 50-1,000 parts. According to the acetylene-hydrochlorinated low-content gold compound catalyst disclosed by the invention, the content of gold in the prepared gold compound catalyst is low; the cost of noble metal catalyst is remarkably reduced; the prepared gold compound catalyst is a good-activity, strong-stability and high-selectivity novel nonmerculic catalyst; and the acetylene-hydrochlorinated low-content gold compound catalyst has the advantages of simple production process, short production period and environment-friendliness.

Owner:XINJIANG TIANYE GRP +1

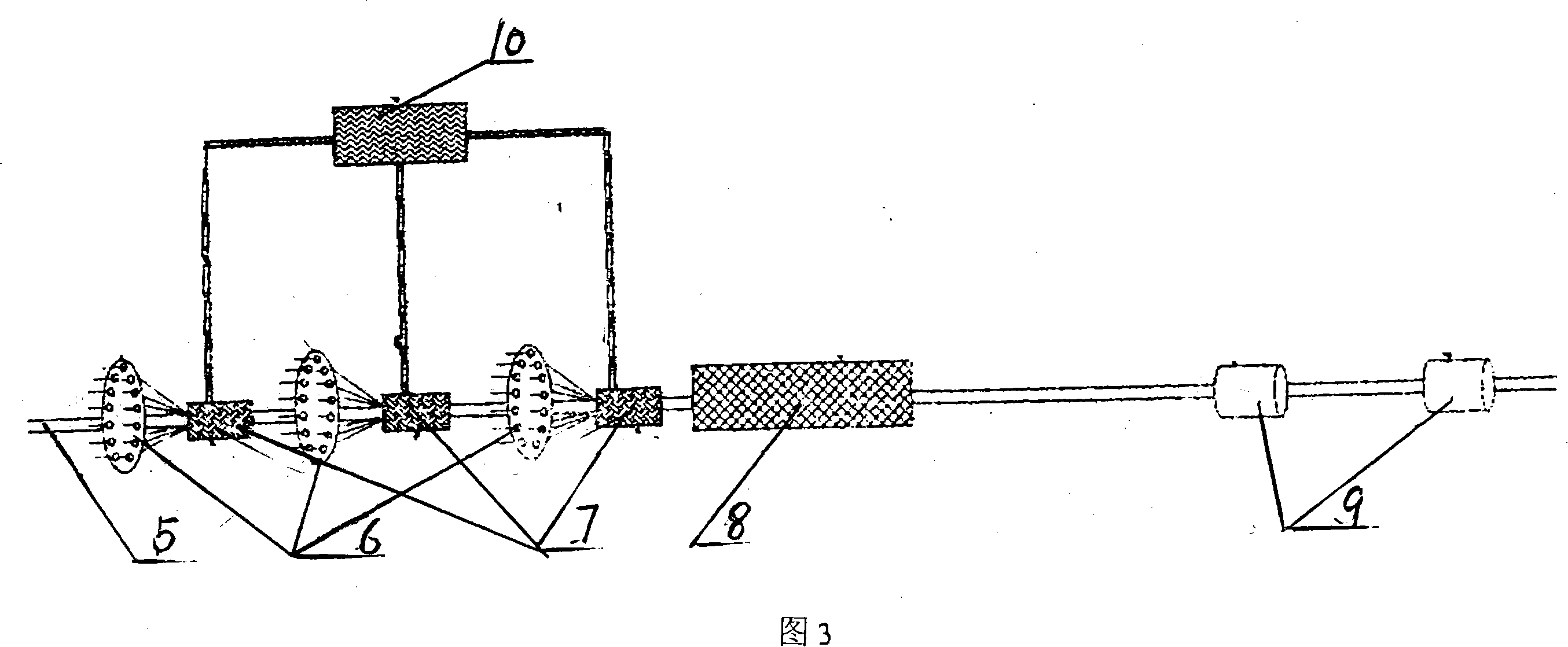

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

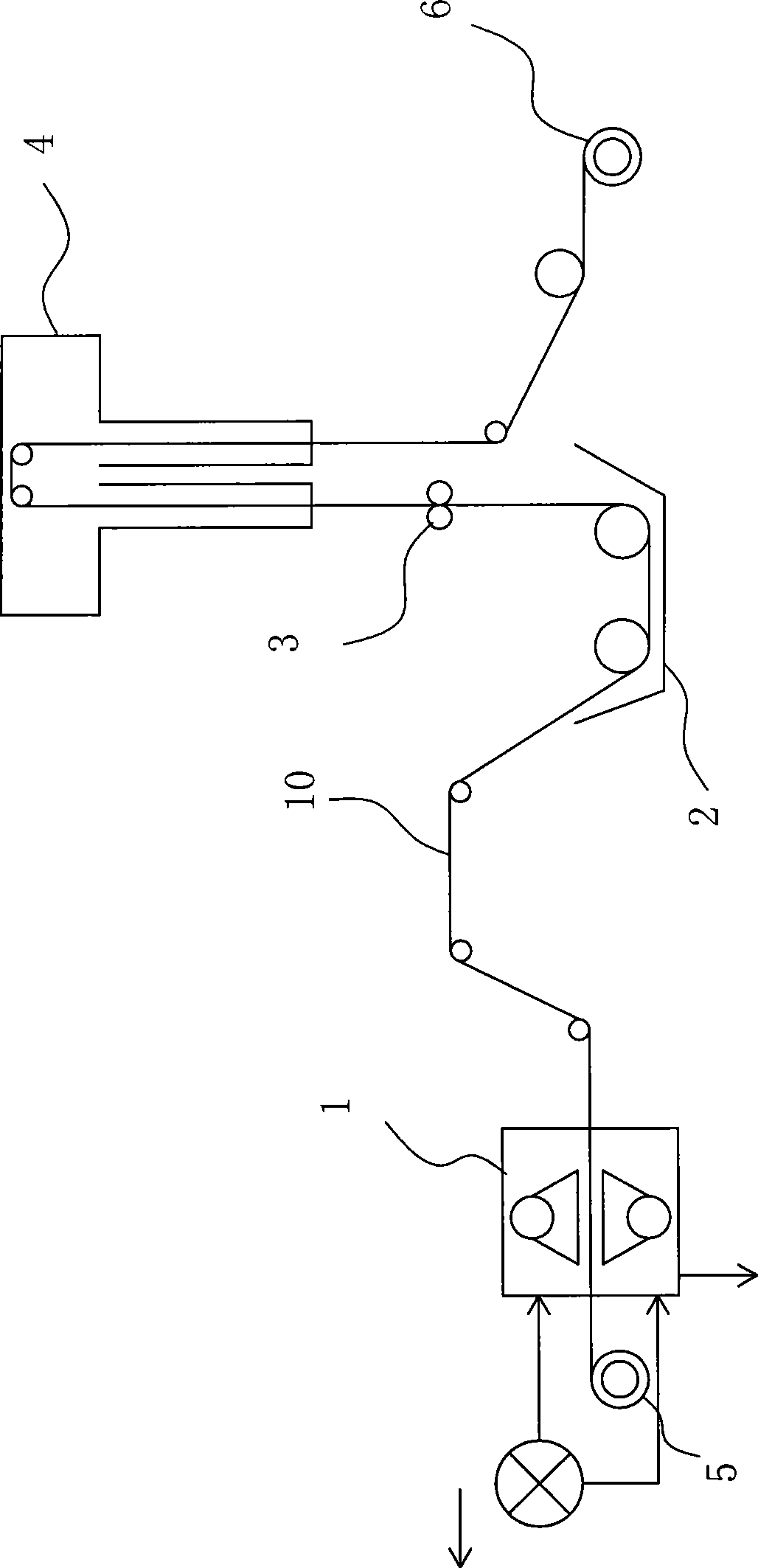

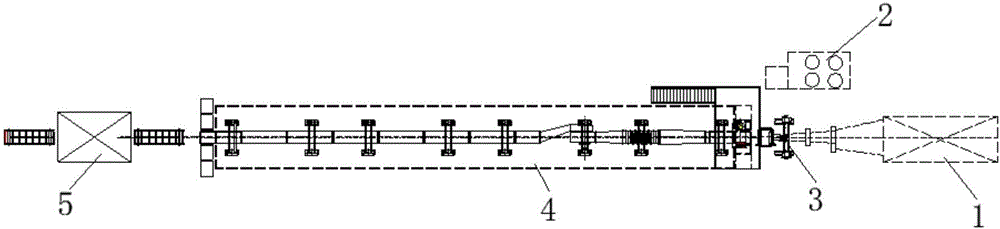

Method for producing semi-curing piece and device thereof

The invention discloses a method for manufacturing prepregs. The method comprises the process steps of putting an uncoiled glass-fiber-fabric substrate into a glue groove, impregnating the substrate with glue solution, controlling the content of the glue solution through a metering roll, heating and drying the glue solution through an oven. The method is characterized in that the substrate is impregnated with the glue solution and then is sprayed and smeared with glue; the glue solution is sprayed onto the glass-fiber-fabric substrate through high-pressure nozzles; and the spray pressure is between 1 and 10 km / cm<2>. A device for manufacturing prepregs comprises an uncoiling device, a main impregnation device, the metering roll, a heating-drying device and a coiling device, and is characterized in that the device also comprises a spray chamber positioned behind the uncoiling device, and a high-pressure pump, a horizontal shifting mechanism, an upper spray rod and a lower spray rod arranged in parallel, as well as a plurality of high-pressure nozzles which are uniformly distributed on the upper and lower spray rods respectively are arranged in the spray chamber. The method completes the process of spraying and smearing glue through the high-pressure nozzles in the spray chamber, utilizes high pressure to split the glass-fiber-fabric substrate, enables the glue solution to enter spaces among fibers, realizes the complete and uniform infiltration of the glue solution, and reduces the quantity of bubbles.

Owner:SHENGYI TECH SUZHOU

Manufacture of FRP composites

InactiveUS20060216490A1Low costImprove performanceNon-woven fabricsThin material handlingPolymer chemistry

Owner:HONDA MOTOR CO LTD

Absorbent for purifying sulfur-containing foul waste gas and preparation method thereof

ActiveCN1768924AEasy to useImprove adsorption capacityOther chemical processesDispersed particle separationActivated carbonSorbent

The invention relates to an absorbent for purifying sulfur-containing effluvium waste gas and it's preparing method. The invention uses active carbon as carrier, and has 0.1-30% additive components which comprise at least one of Li, K, Na, Cu, Ca, Ba and Mg, while they are distributed on the surfaces of pore passages of said active carbon carrier. The inventive absorbent loads additive components via high-temperature dipping method. The invention can overcome the defections of present absorbent with lower sulfur content and worse regeneration. The inventive method can significantly improve the utilization of effective pore passage of carrier to improve the property of absorbent. And said invention can apply the treatment of sulfur-containing effluvium waste gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paper-making-stage wood pulp plate denaturalization producing technique

ActiveCN101148835AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making wood pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-8 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Paper-making-stage broad-leaved wood pulp plate denaturalization producing technique

ActiveCN101148834AReduce manufacturing costReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHardwoodViscose fiber

The present invention provides denaturating production process of paper-making hardwood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making hardwood wood pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5.5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

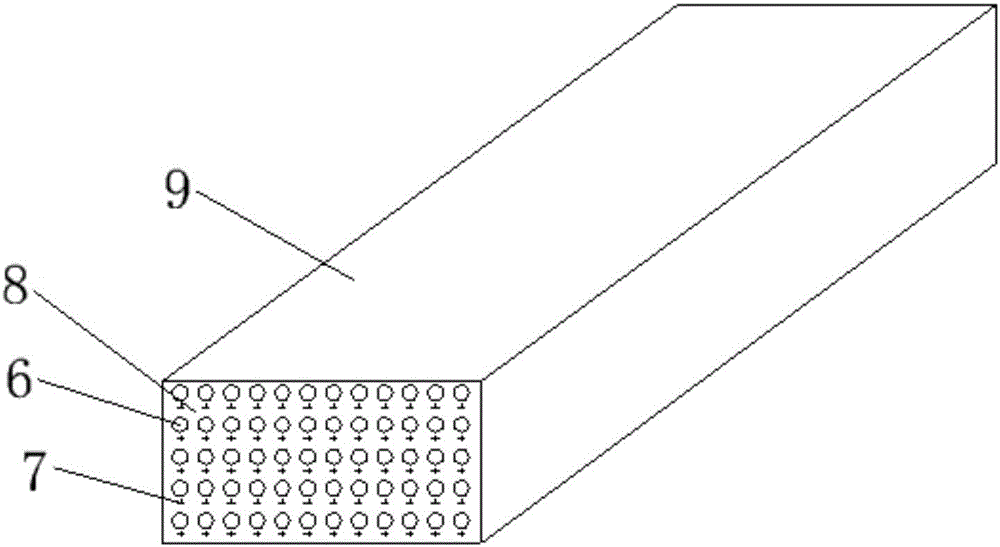

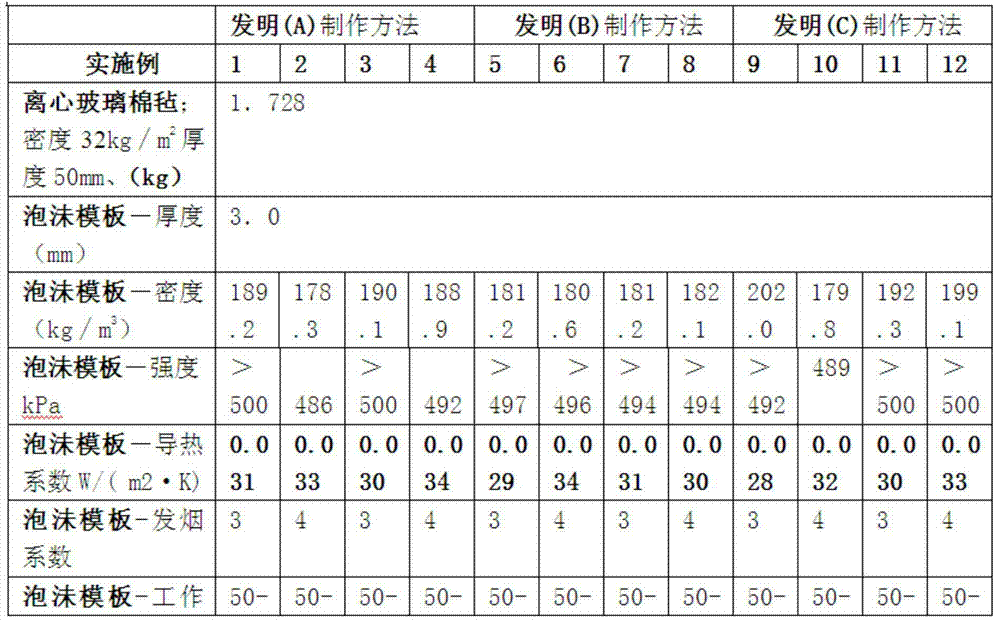

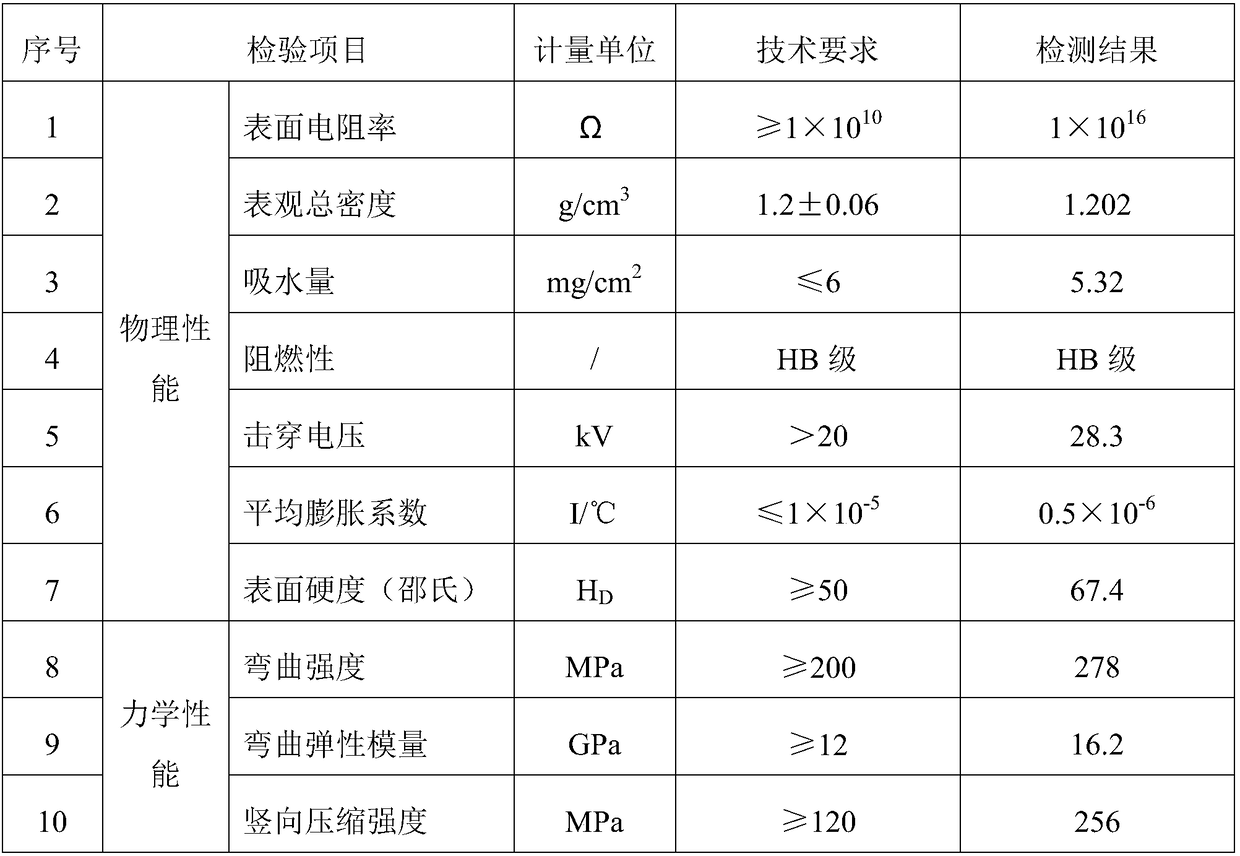

Fiber-reinforced rigid polyurethane foam synthesis sleeper with high fiber content and manufacturing method of sleeper

The invention relates to a fiber-reinforced rigid polyurethane foam synthesis sleeper with the high fiber content and a manufacturing method of the sleeper. The sleeper is formed by bonding multiple fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content through a bonding agent, an anti-corrosive paint film is arranged on the outer surface of the sleeper, and the fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content use polyurethane resin and reinforced fibers as base materials. Various technological measures such as mixed type polyether polyol with the low hydroxyl value and the low functionality degree and a coupling agent are adopted, the problem that the polyurethane resin and the reinforced fibers are not sufficiently impregnated is solved, so that the content of the reinforced fibers is increased, a fiber-reinforced rigid polyurethane foam material product with the density higher than 840 kg / m<3> and the content of the reinforced fibers larger than 60% can be manufactured, the technological blank of the fiber-reinforced rigid polyurethane foam synthesis boards is filled up, the standards and the performance of the product of the boards are diverse, and the requirements for different technical indexes are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

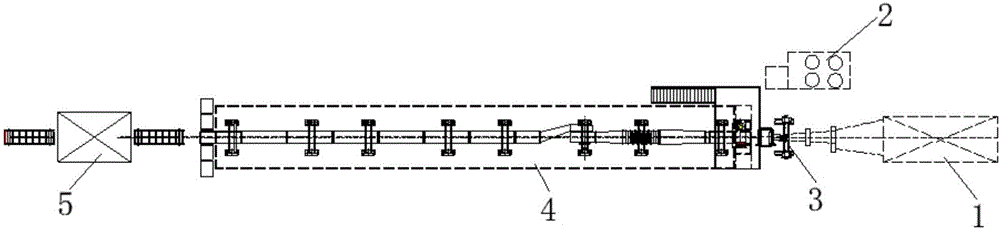

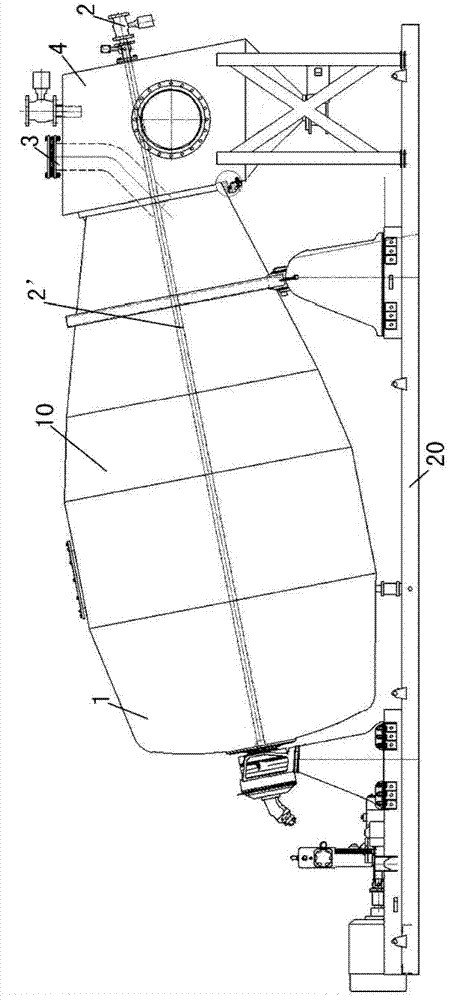

Fiberglass pultrusion grille continuous production line

The invention relates to a fiberglass pultrusion grille continuous production line which is characterized by comprising a rack, a core mould propulsion mechanism, automatic yarn laying mechanisms, a resin mixture injection mechanism, a heating solidification mechanism, a core mould demoulding mechanism, a grille cutting mechanism and a grille mould composed of fixed mould bodies and a plurality of moving core mould bodies; and the fixed mould bodies of the grille mould comprises a reinforcing fiber imbedding section fixed mould body, a resin mixture injection section fixed mould body and a heat solidification section fixed mould body which can be all matched with the moving core mould bodies in a core mould moving guide channel correspondingly to form a closed grille-shaped mold cavity. The fiberglass pultrusion grille continuous production line has the advantages that pultrusion manufacturing is conducted in a tunnel-type fixed mould cavity; the situations that each grille rib can allow more fibers to be placed in, steeping of matrix resin is more uniform and consistent, and materials are in the process state needed by pultrusion at the time of solidification and forming are guaranteed correspondingly, and accordingly continuous pultrusion production of fiber reinforced plastic is achieved finally.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

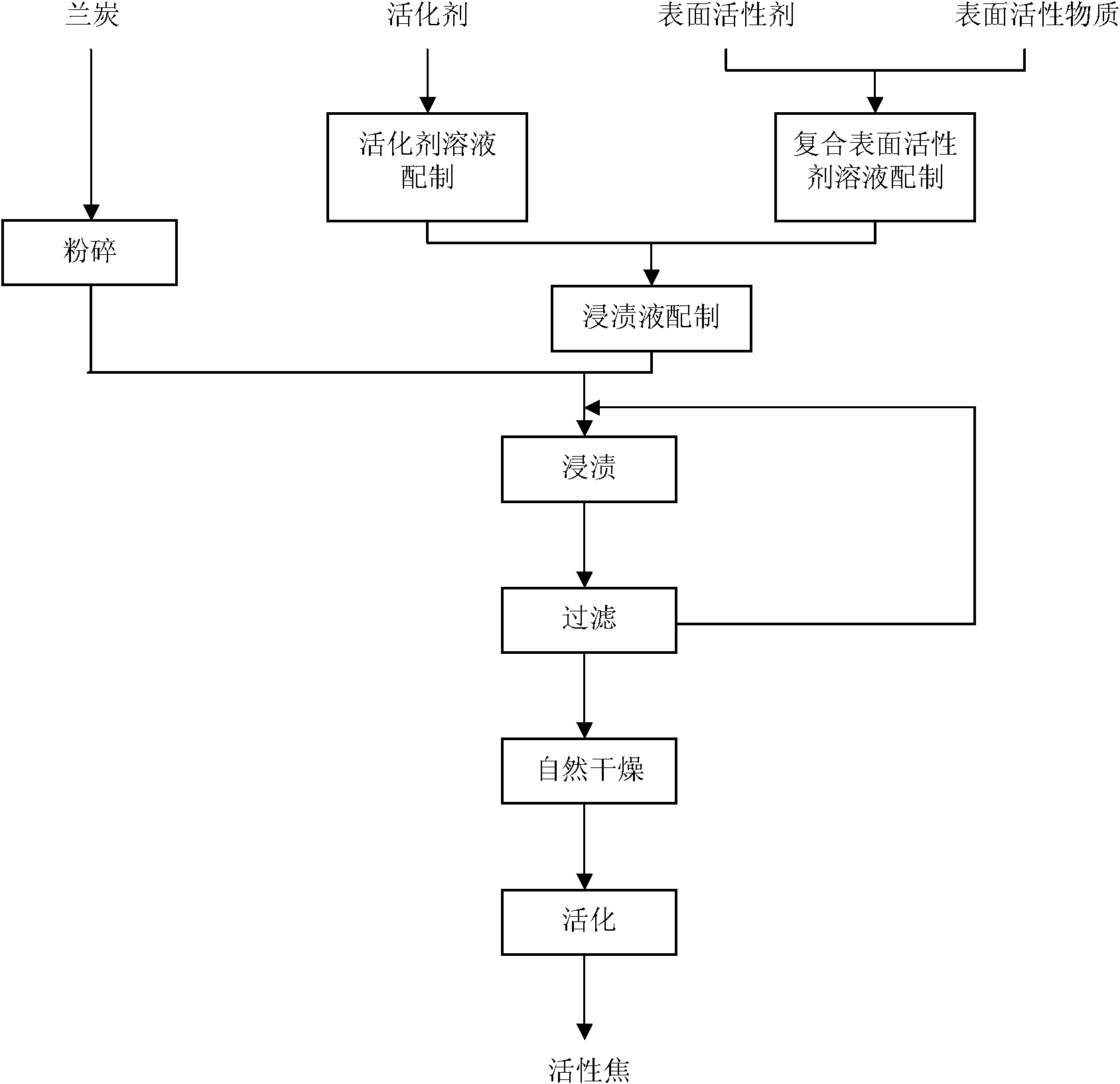

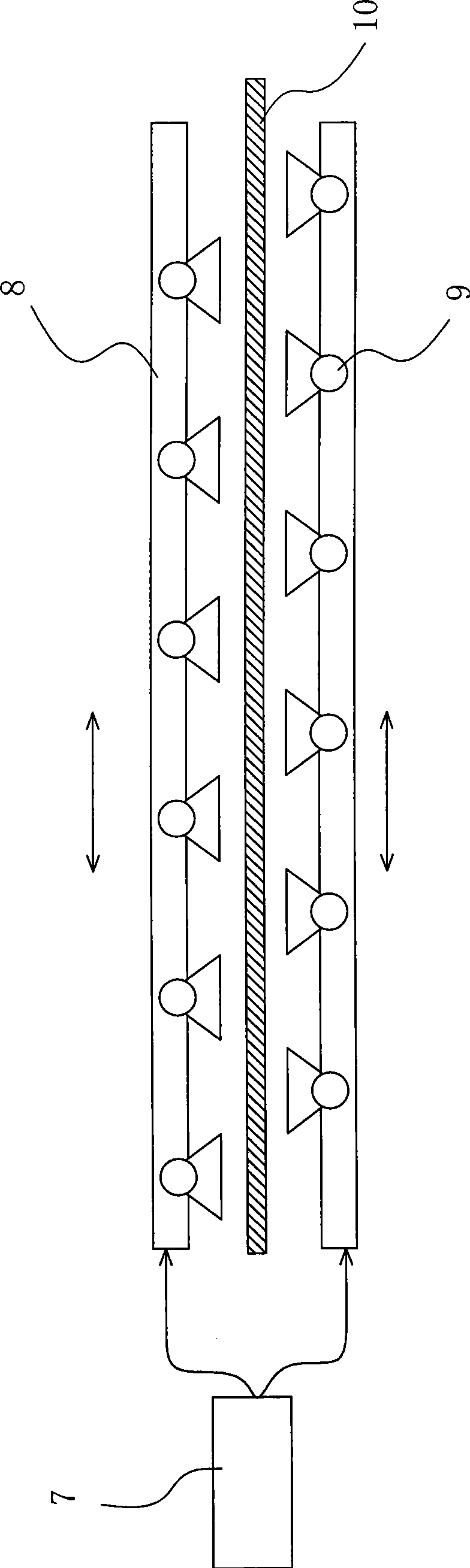

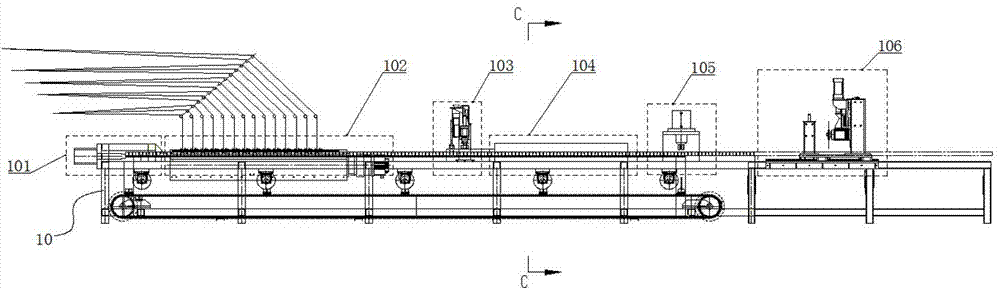

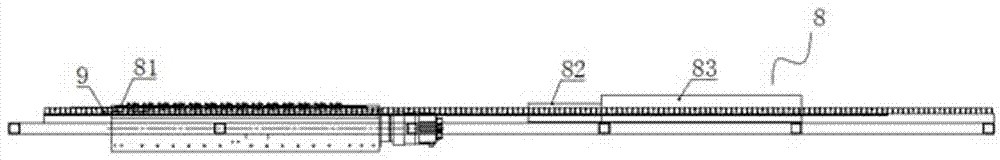

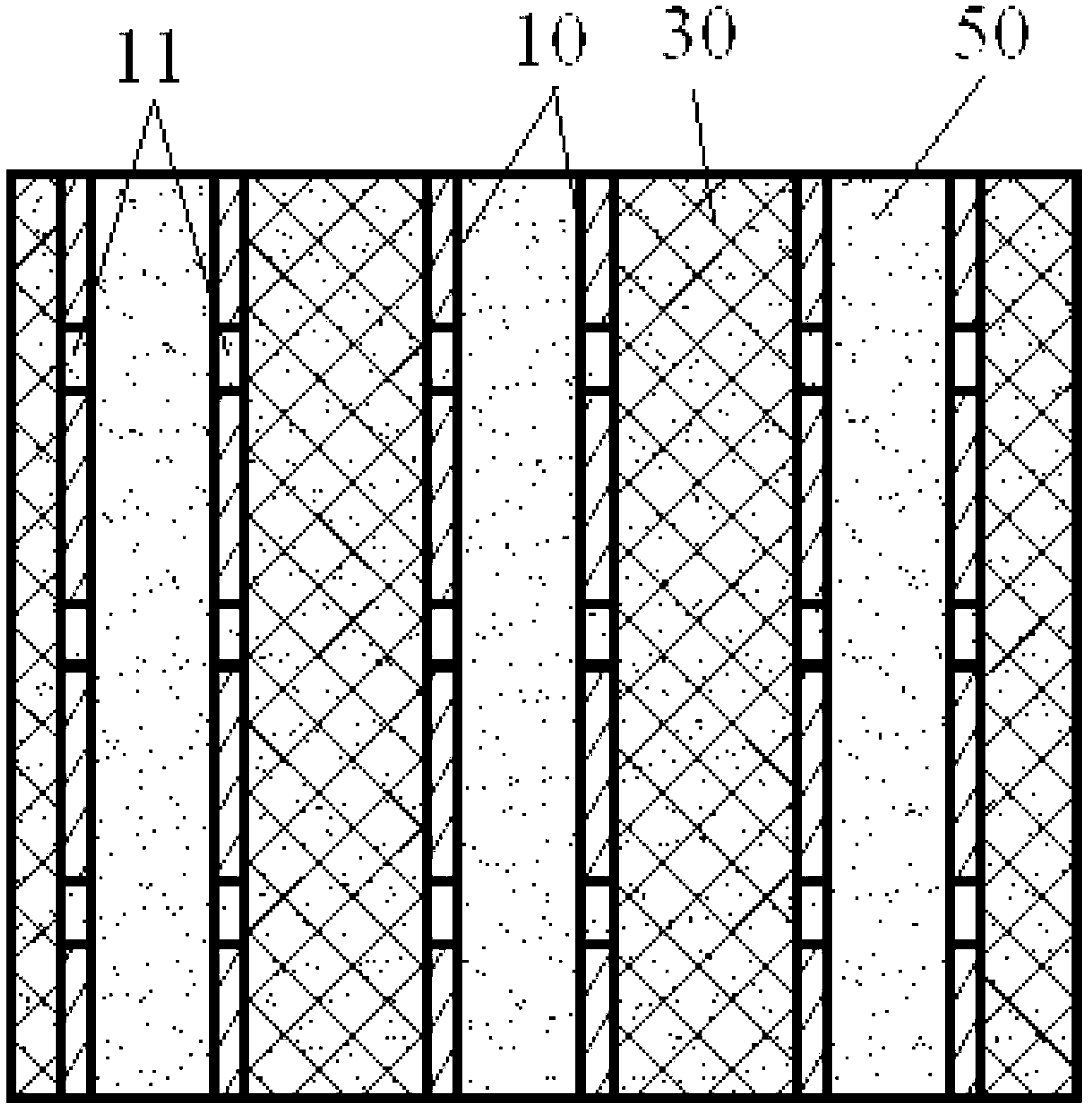

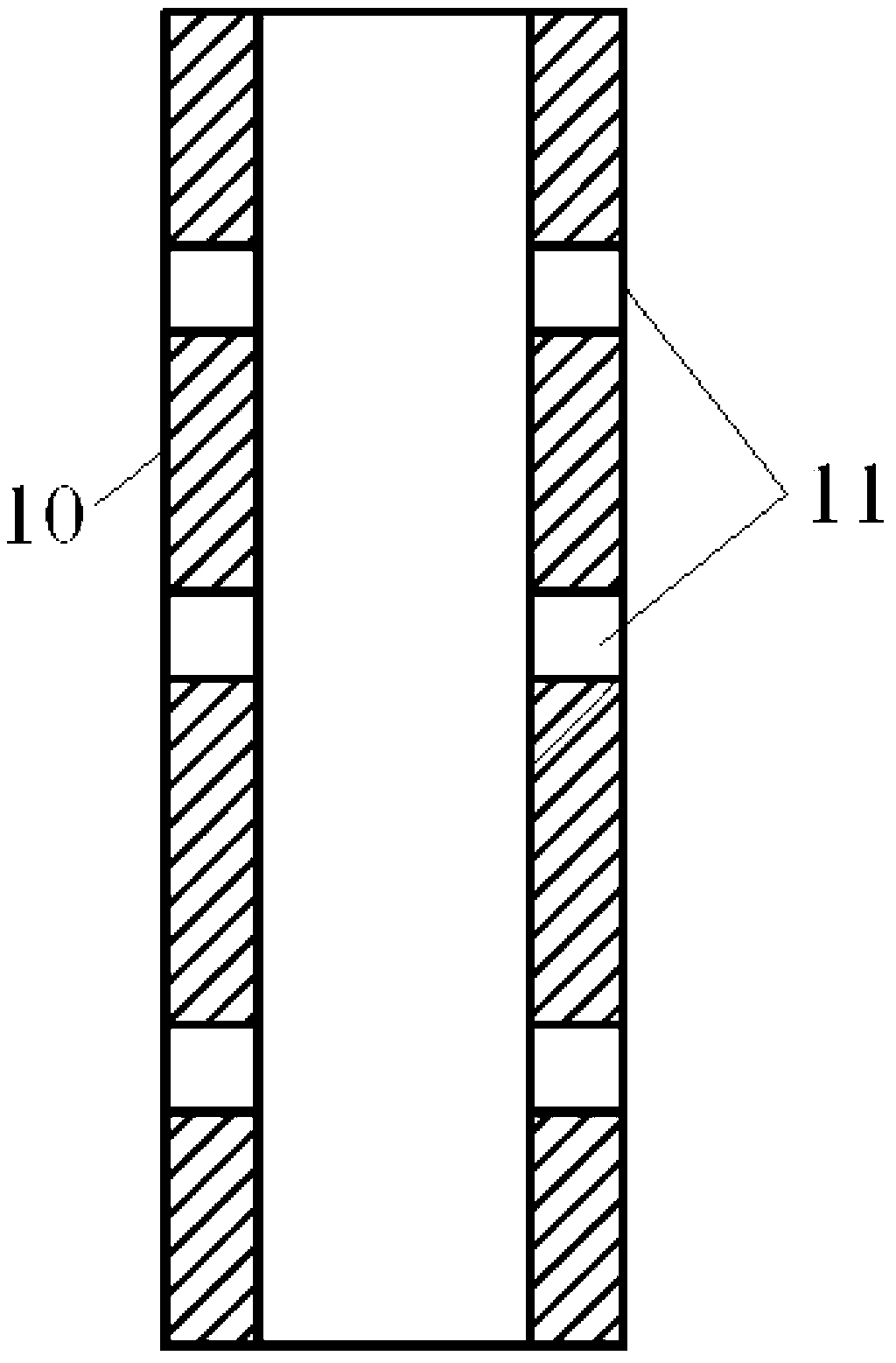

Fixed bed catalyst preparation method and fixed bed catalyst

ActiveCN103084183AReduce breakage rateImprove impregnation effectMetal/metal-oxides/metal-hydroxide catalystsAutomatic controlSpiral blade

The invention discloses a fixed bed catalyst preparation method and a fixed bed catalyst. The method comprises that a molded carrier contacts a metal compound solution in an impregnation machine, and the molded carrier after contacting is dried and calcined, wherein the impregnation machine comprises an obliquely-arranged roller (10), the roller (10) comprises a rotatable cylinder (1) and a spray device (2), the inner wall of the cylinder (1) is provided with a spiral blade, and the spray device (2) is fixedly arranged and extends into the internal space of the cylinder (1). According to the method, a molded carrier is conveyed into the cylinder (1), and a metal compound solution is sprayed on the molded carrier with the spray device (2). With the method, the fixed bed catalyst with characteristics of good impregnation uniformity and low impregnation breaking rate can be obtained, automatic catalyst impregnation control can be achieved, production cost can be reduced, and requirements of large-scale industrial production can be met.

Owner:CHINA PETROLEUM & CHEM CORP

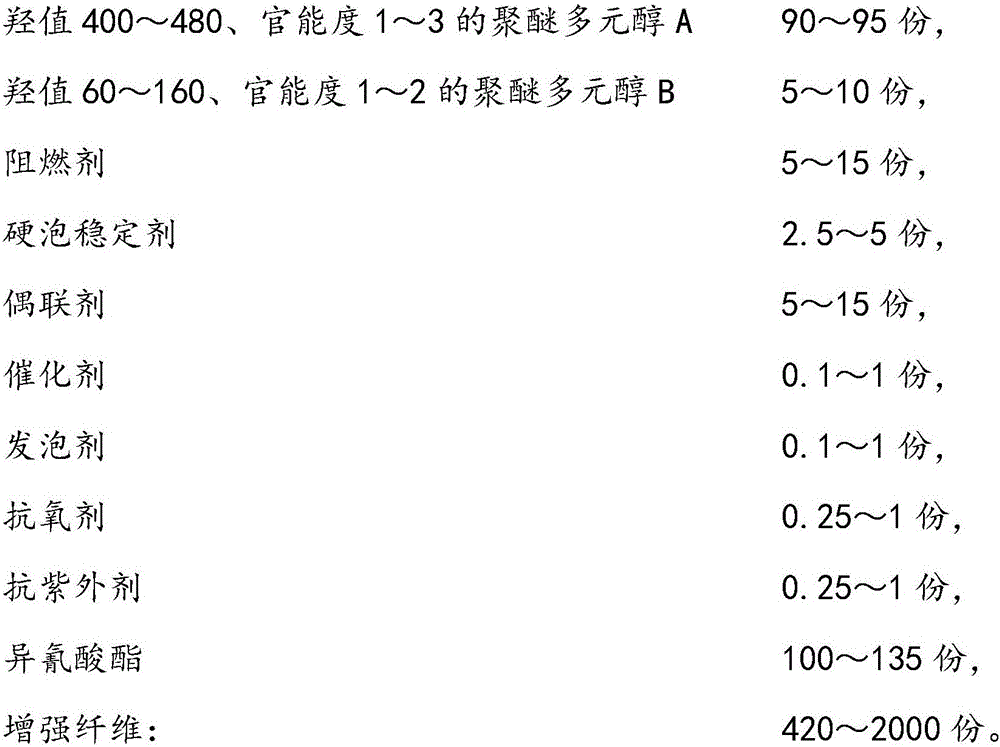

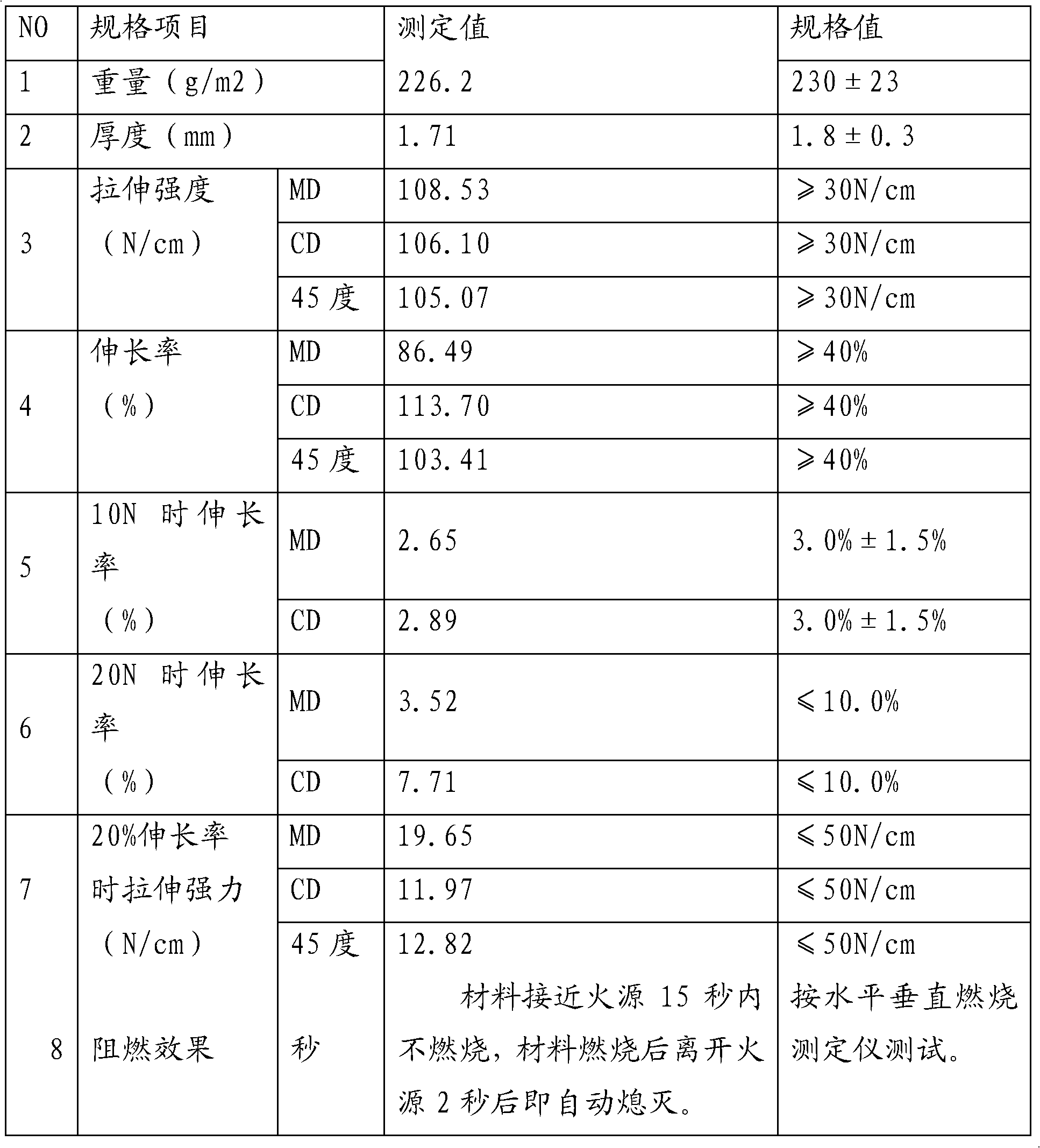

High-fiber-content fiber-reinforced rigid polyurethane foam composite board and manufacturing method thereof

ActiveCN106349446ASolve the problem of insufficient impregnationIncreased reinforcing fiber contentFoaming agentAntioxidant

The invention relates to a high-fiber-content fiber-reinforced rigid polyurethane foam composite board and a manufacturing method thereof; the high-fiber-content fiber-reinforced rigid polyurethane foam composite board is made from polyurethane resin and reinforcing fibers as base materials, as well as hybrid polyether polyol, a flame retardant, a rigid foam stabilizer, a coupling agent, a catalyst, a foaming agent, an antioxidant, an ultraviolet screening agent, an isocyanate, and reinforcing fibers, wherein the content of the reinforcing fibers is greater than 60%; by means of various techniques such as using low-hydroxyl value low-functionality hybrid polyether polyol and using the coupling agent, the problem that polyurethane resin is insufficiently steeped to reinforcing fibers is solved, the content of the reinforcing fibers is increased, a fiber-reinforced rigid polyurethane foam article higher than 840 kg / m<3> in density and higher than 60% in reinforcing fiber content can be manufactured, the technical blank of fiber-reinforced rigid polyurethane foam composite boards is filled, product specifications and properties are diversified, and the different technical index requirements are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Manufacturing method for impregnated wood and preparation method for impregnating resin

ActiveCN104526804AReduce polarityReduce acidityWood treatment detailsPretreatment apparatusMechanical propertyPolyresin

The invention provides a manufacturing method for impregnated wood and a preparation method for impregnating resin. The manufacturing method for the impregnated wood comprises the steps of primary drying, impregnating, secondary drying and hot and wet treatment. The mechanical property, the formaldehyde emission and the size stability of the impregnated wood manufactured through the method are obviously improved, and the impregnated wood can meet the using requirements of furniture and decoration such as cabinets, chests and doors and windows and wood floors. The preparation method for the impregnating resin comprises the steps of feeding, reacting and discharging, raw materials needed for preparing the resin are simple and easy to store, and under the condition that the water content of the wood is low, the resin can evenly impregnate the wood.

Owner:GUANGZHOU HOLIKE CREATIVE HOME FURNISHING

Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

ActiveCN101851863AImprove spinnabilityAvoid it happening againFibre typesNeedling machinesFoam rubberEngineering

The invention belongs to automotive non-woven textiles, in particular to an environmentally friendly differential fiber non-woven automotive interior trim material and a preparation method thereof. The preparation method comprises the following steps of: preparing needle-punched grey cloth through feeding fibers, roughly opening, mixing fibers, fine opening, carding the fibers into a net, crosswise spreading the net and needling by using environmentally friendly colored flame retardant terylene short fibers as a raw material; and then carrying out foam gum dipping in flame retardant polyacrylate foaming rubber latex to obtain the differential fiber non-woven automotive interior trim material, wherein the adhesion quantity of the rubber latex is controlled to be 12-18g / m<2>. The environmentally friendly differential fiber non-woven automotive interior trim material has good property, high quality, environmental protection and high safety; and the preparation method provided by the invention has low energy consumption, no pollution and low cost.

Owner:福建福能南纺卫生材料有限公司

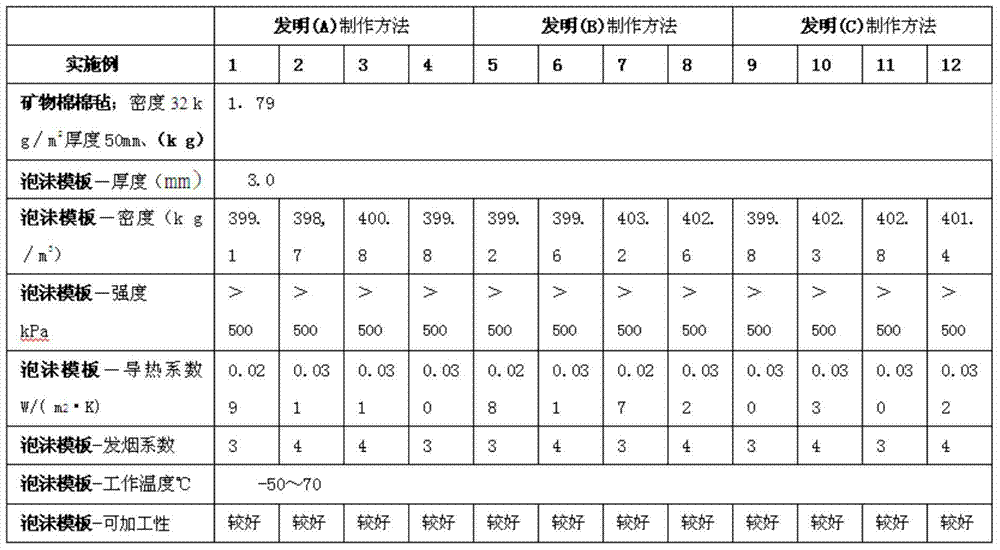

Enhanced foam stay-in-place building concrete template and manufacturing method thereof

ActiveCN104744886AFully impregnatedDip evenlyForming/stuttering elementsSustainable buildingsThermal insulationSurface-active agents

The invention relates to an enhanced foam stay-in-place building concrete template and a manufacturing method thereof. The enhanced foam stay-in-place building concrete template is an enhanced hard phenolic aldehyde foam template which is foamed and formed by taking phenolic resin and a glass wool or mineral wool blanket as the basic materials under the action of various additives including a glass wool or mineral wool fibre surface treatment agent, a foaming agent, a surface active agent, a curing agent, a modifying agent and a penetrating agent uniformly blended into the phenolic resin in advance. The enhanced foam stay-in-place building concrete template has a micro-porous structure of independent bubbles having uniformity, compactness and high closed pore rate; furthermore, because of the enhancement effect due to the fact that the micro-porous structure is bond to glass wool or mineral wool fibre in foam compactly and uniformly, the foam template not only has the excellent characteristics of phenolic aldehyde foam, such as fire resistance and heat insulation property, but also has higher compressive strength and impact resistance; therefore, the strength requirements of the building template can be satisfied; the construction processes of dismantling a poured concrete template and installing a thermal insulation layer in the construction process are avoided; the construction period and the cost are effectively saved; and the environment-friendly purposes of saving energy and reducing emission are achieved.

Owner:宁波与翼新材料科技有限公司

Paper-making-stage high viscosity wood pulp plate denaturalization producing technique

ActiveCN101148832AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscosity

The present invention provides denaturating production process of paper-making high viscosity wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making high viscosity wood pulp sheet in a paging device, alkali dipping in 8-18 % concentration alkali solution in a dip vat to form 2.5-4.5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

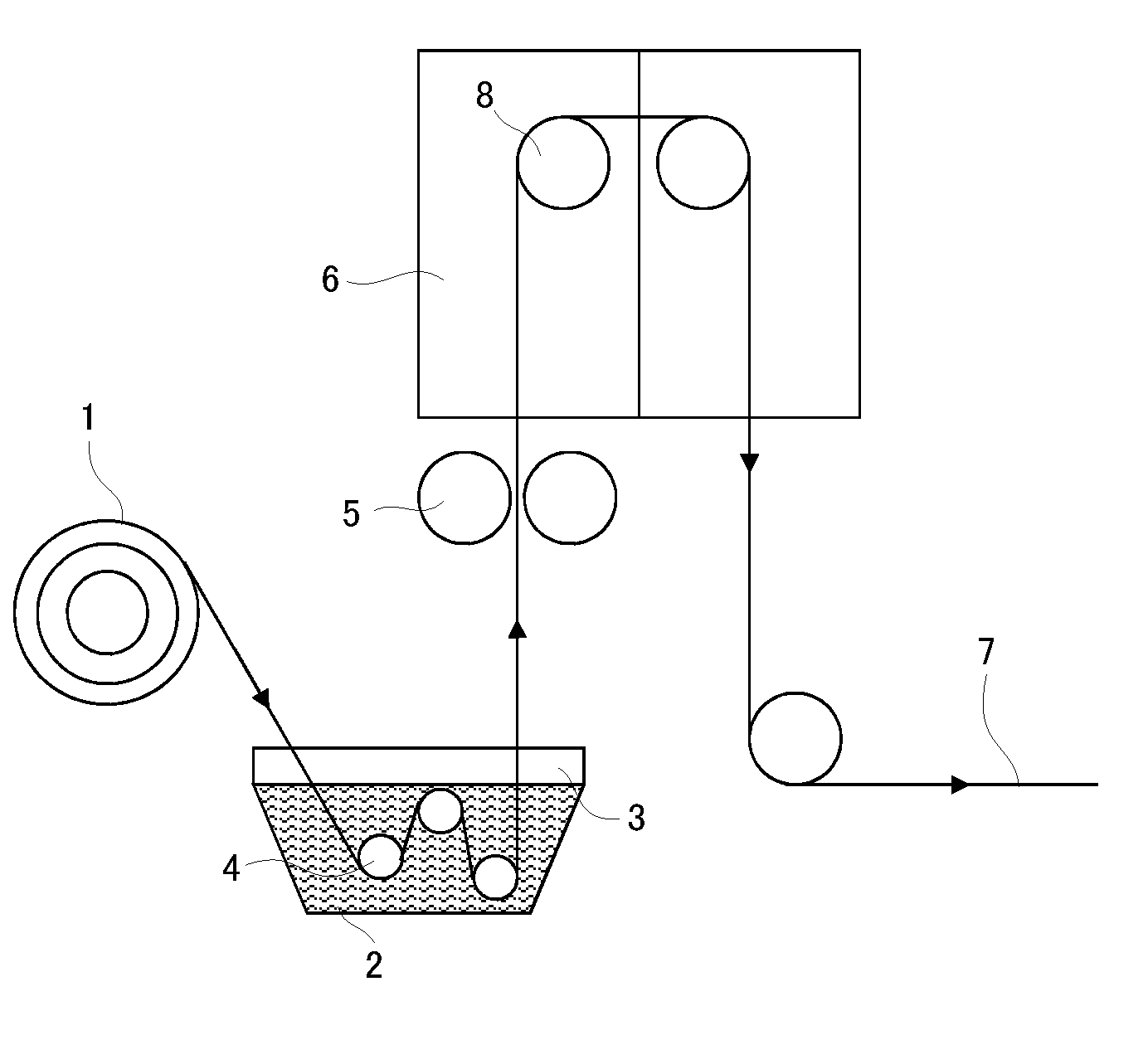

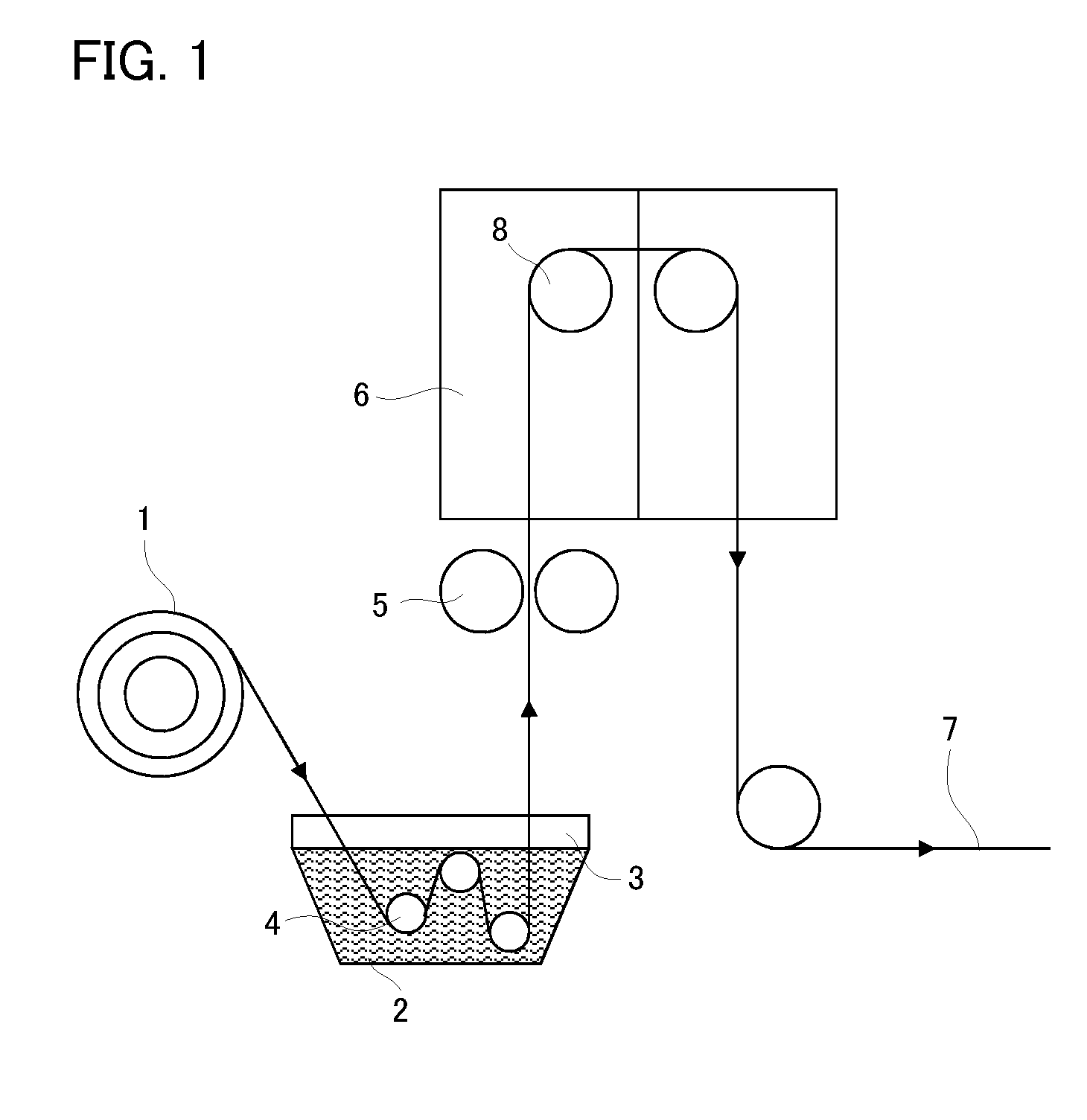

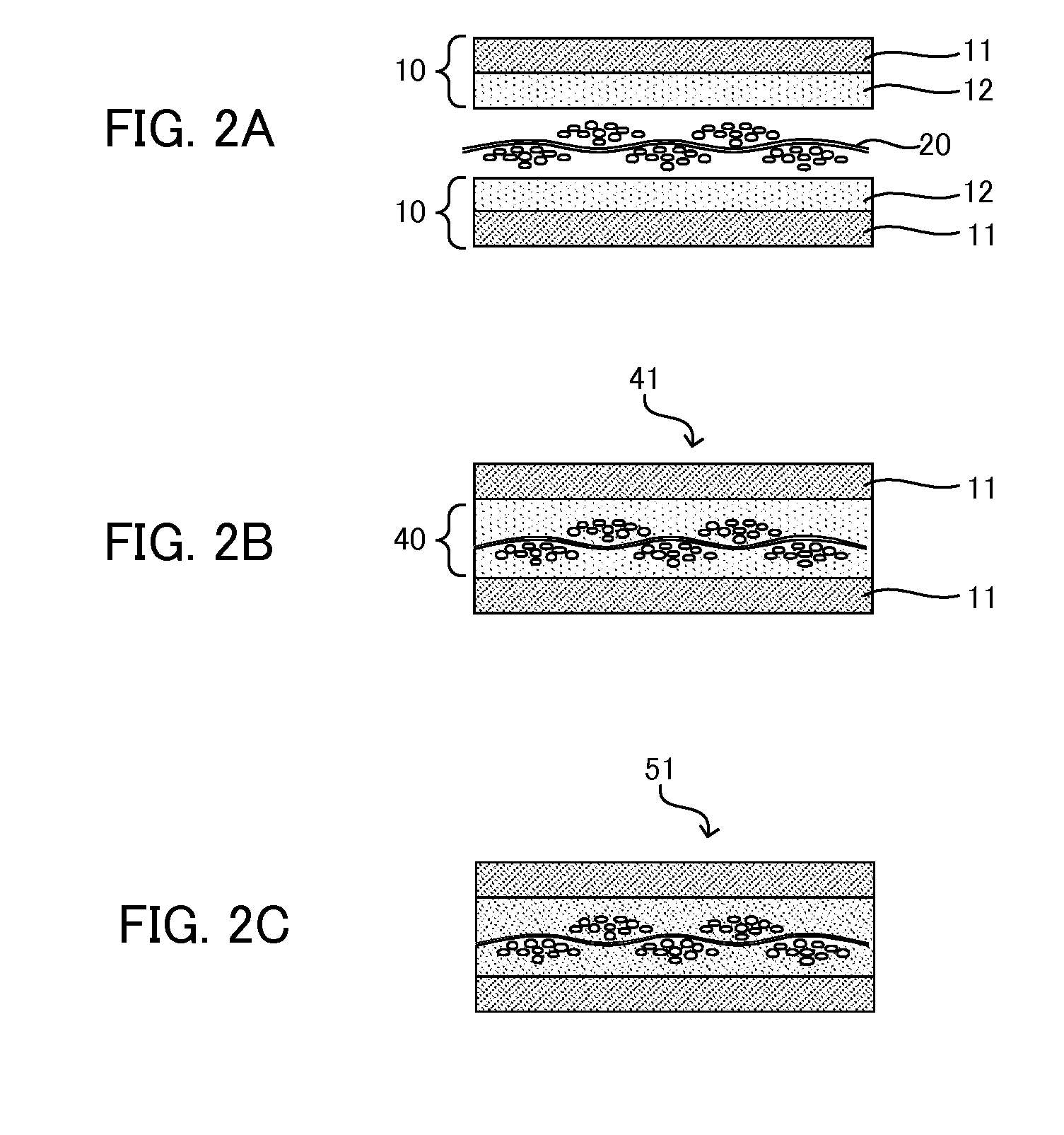

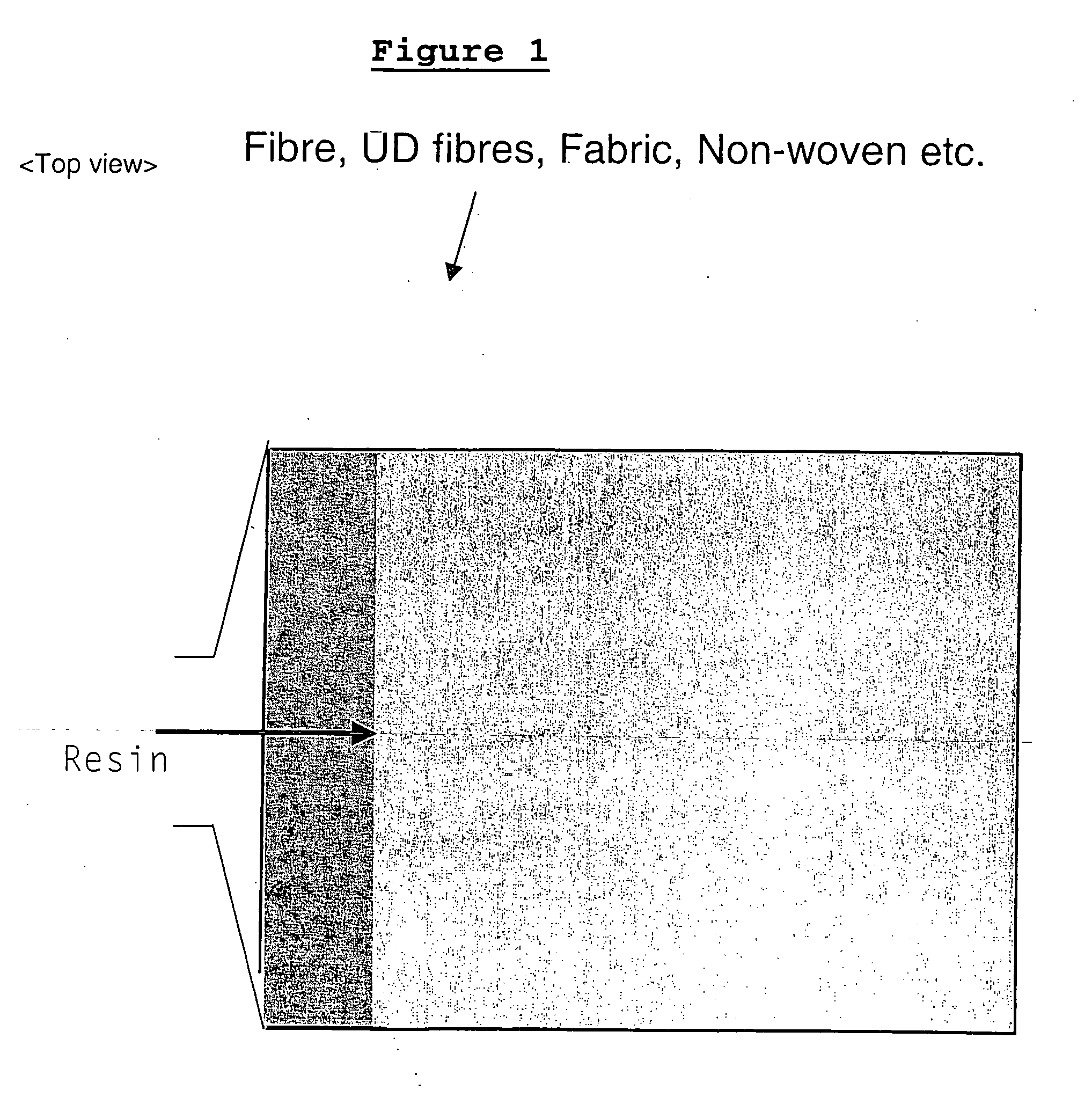

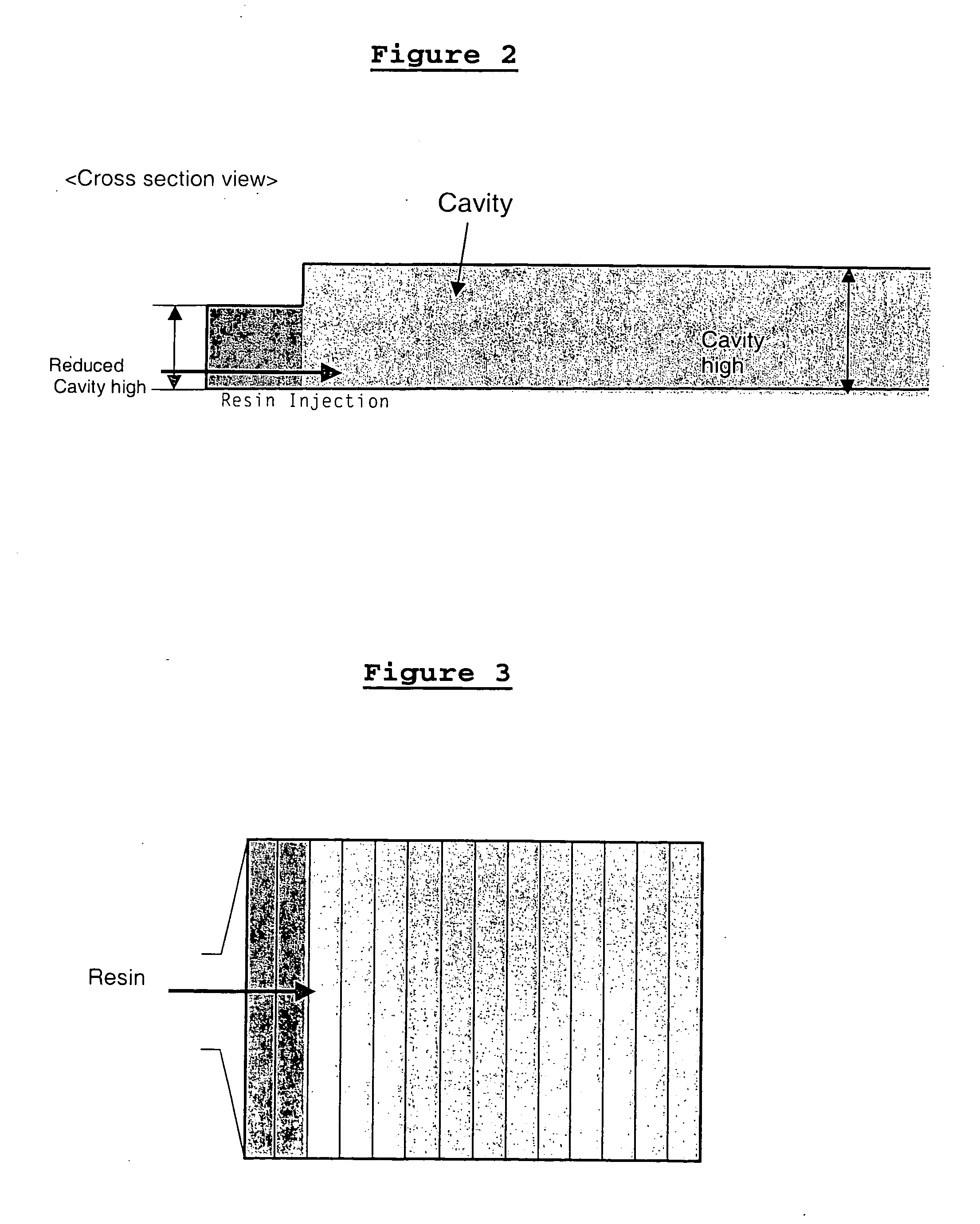

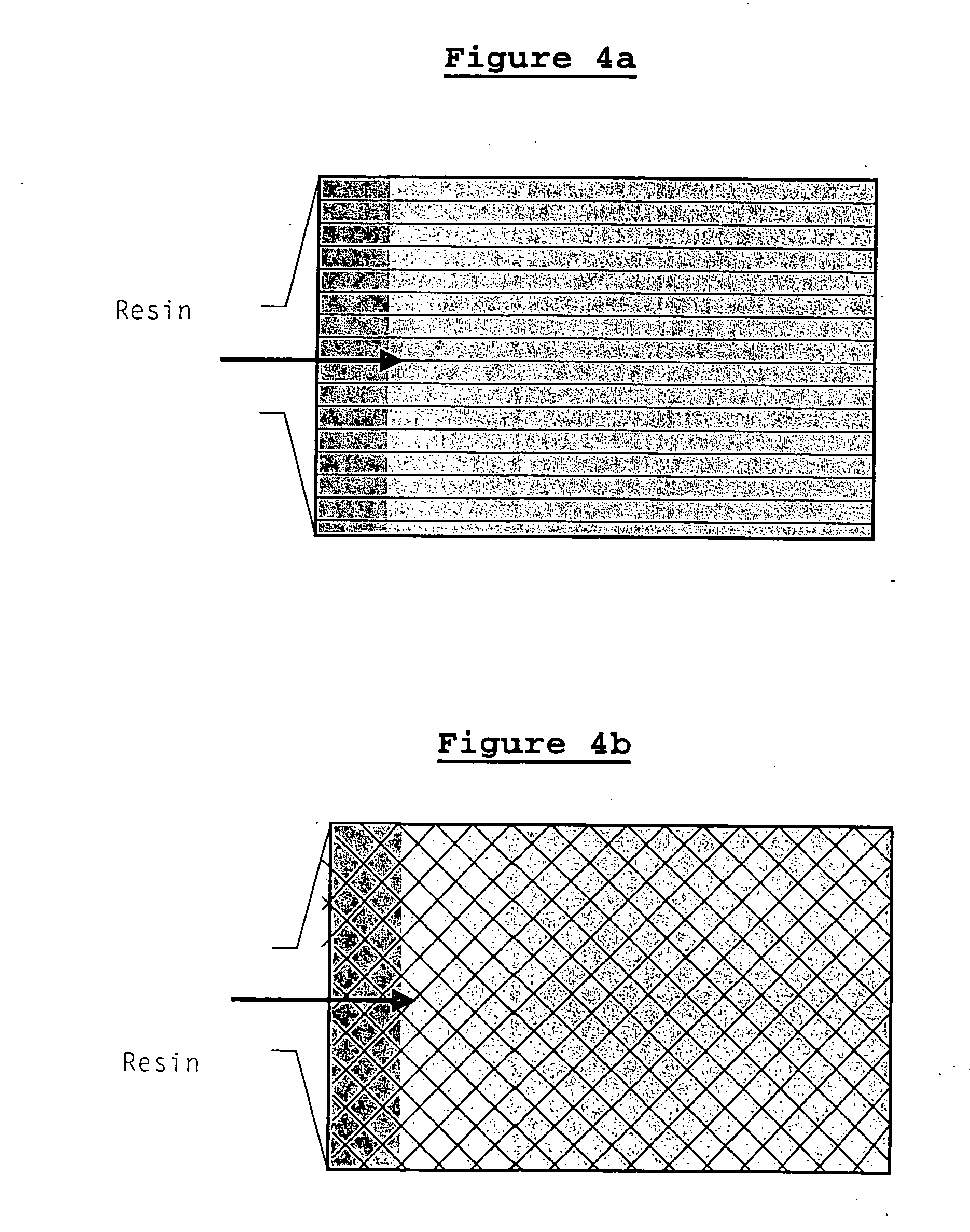

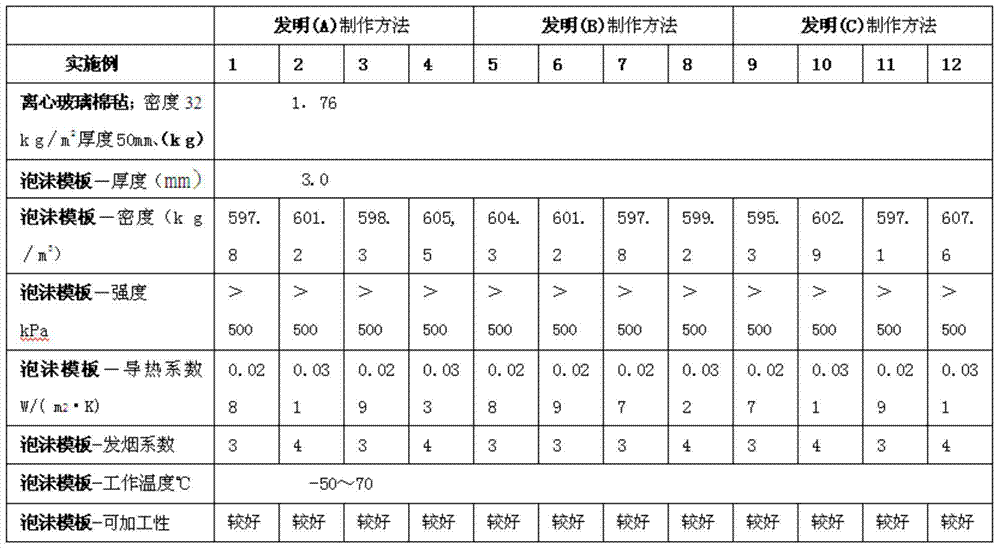

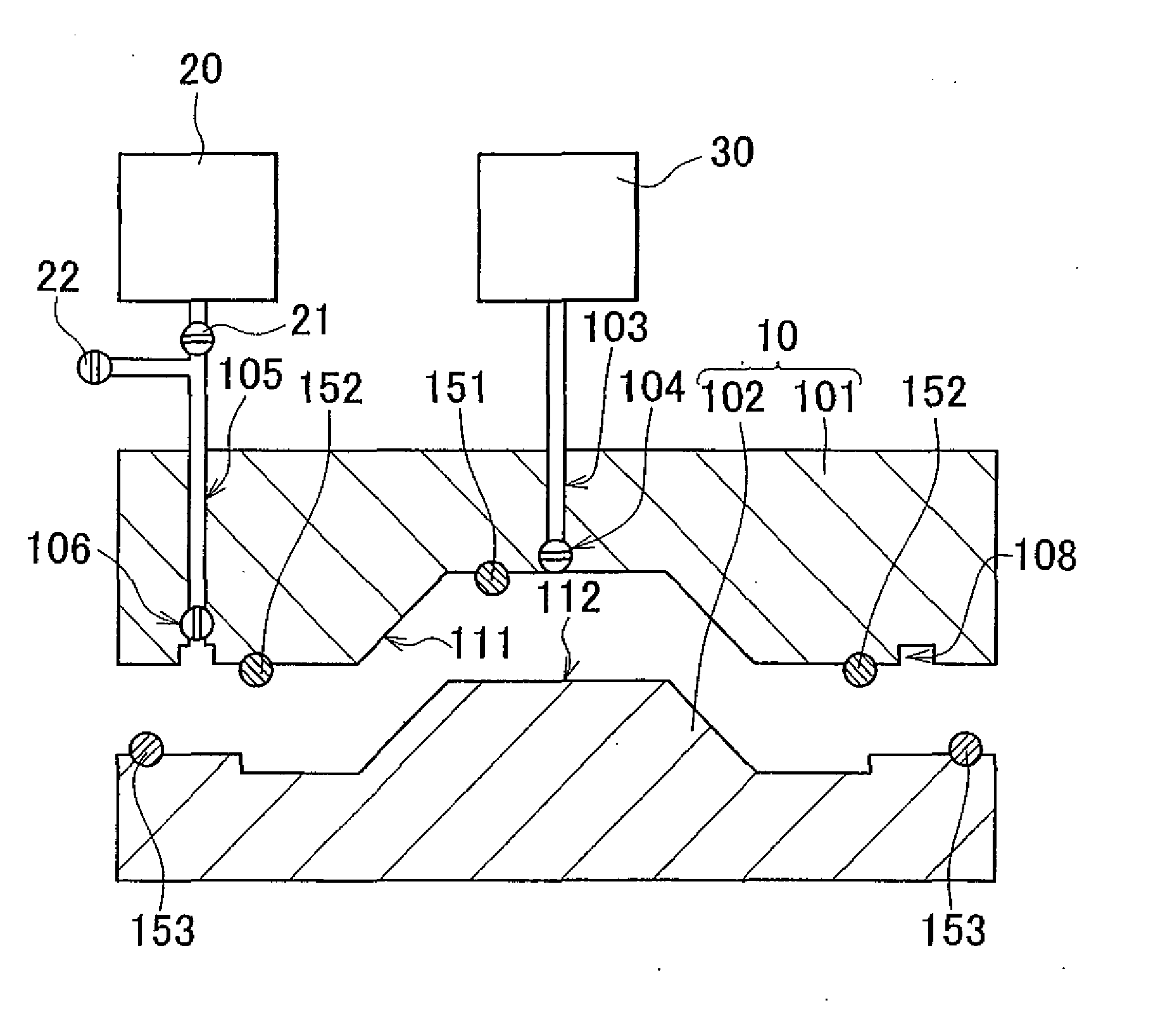

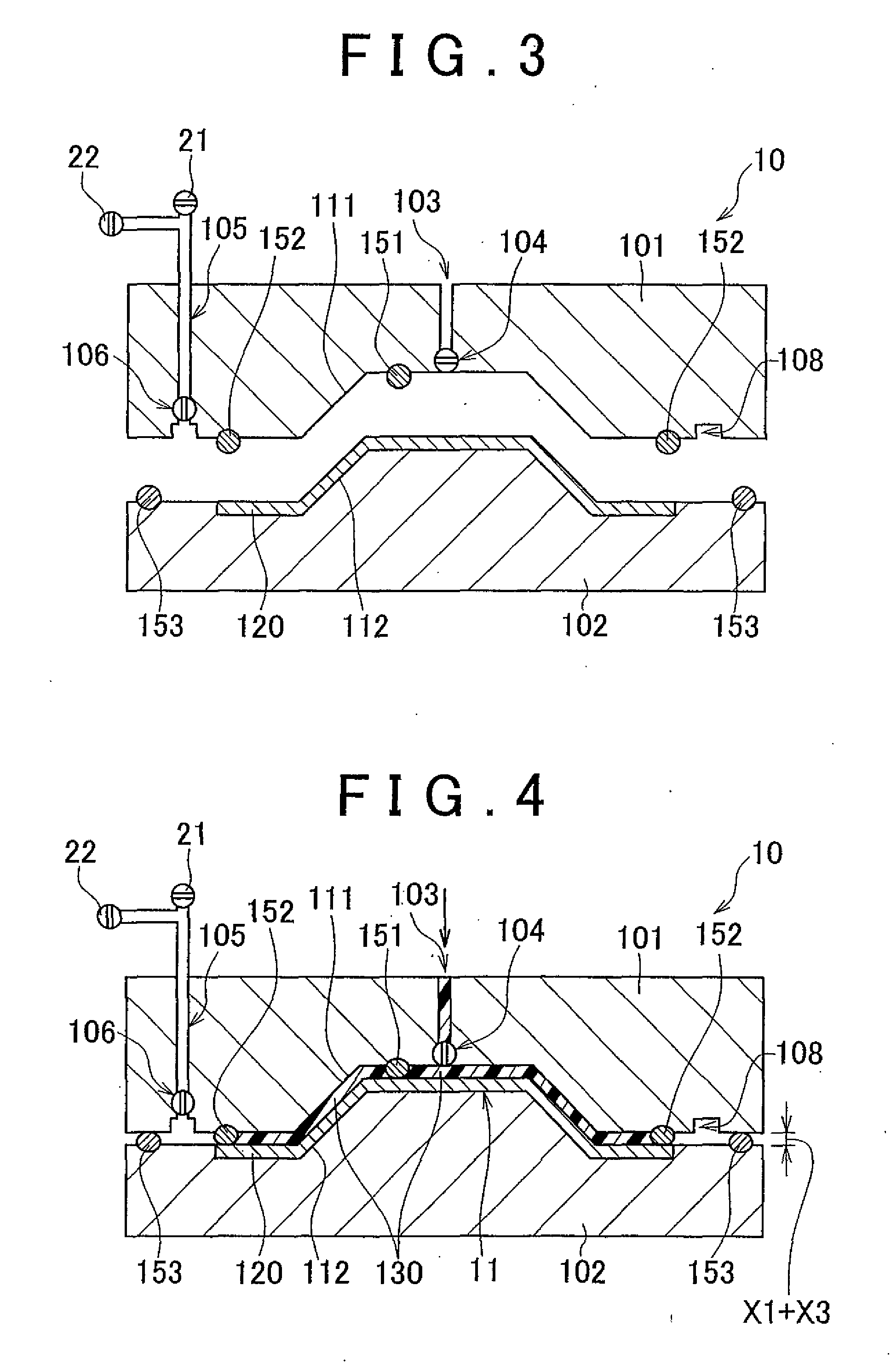

Fiber reinforced resin, manufacturing method for fiber reinforced resin, and manufacturing system for fiber reinforced resin

ActiveUS20120141765A1High strength and dimensional accuracySuppresses unevenness in qualitySynthetic resin layered productsLaminationFiber reinforcementManufacturing systems

A first process in which a fiber reinforced base is placed in a cavity of a molding die and then resin is injected into the cavity of the molding die in a state where the molding die is opened by a sum of a distance X1 and a distance at the time of completion of molding; a second process in which the molding die is closed to a state where the molding die is opened by a sum of a distance X2 and the distance at the time of completion of molding while resin in the cavity is being drained; and a third process in which the drain of the resin from the cavity is stopped and then the molding die is closed to the distance at the time of completion of molding while a die clamping pressure is maintained at a predetermined value to cure the resin, are carried out sequentially.

Owner:TOYOTA JIDOSHA KK

Composite part and forming method thereof

The invention provides a composite part and a forming method thereof. The forming method comprises the following steps of: arranging a plurality of support framework pieces according to the shape of the composite part; arranging woven fibers among the external surfaces of the support framework pieces to form a preform of which the shape is matched with that of the composite part; and impregnating a pouring substrate into the manufactured preform, and curing to integrally form the composite part. According to the composite part and the forming method thereof, the whole preform of which the shape is matched with that of the composite part to be processed is formed by weaving the support framework pieces and the woven fibers and subjected to impregnation forming, so that the defects of interlaminar deformation, misplacement and the like are overcome, the interlaminar shear strength, compressive strength and bending strength of a composite are increased, the whole density, rigidity and reliability of the composite part are improved, and the requirements of main bearing structures in aerospace, national defense and military industry and the like are met.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

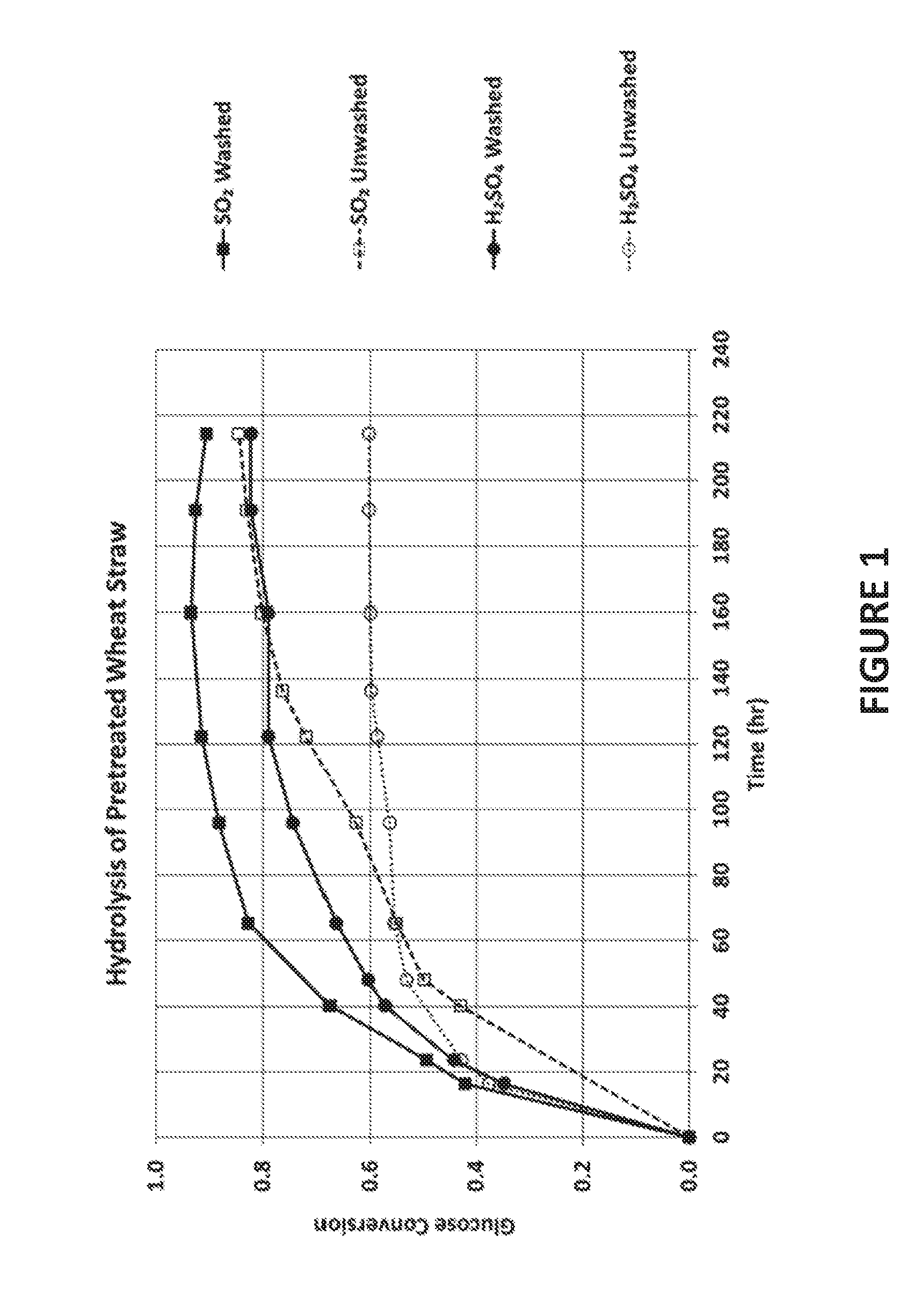

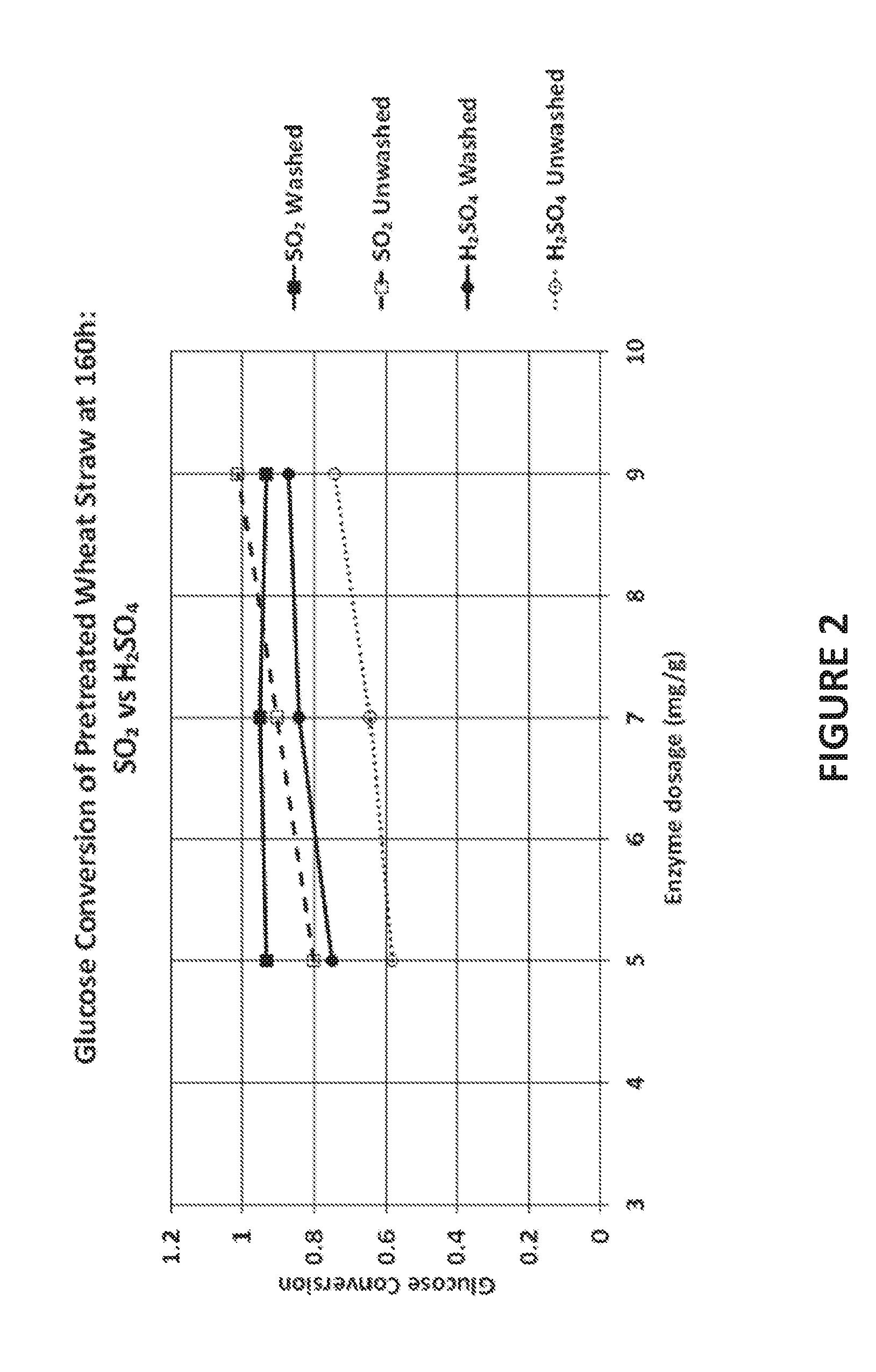

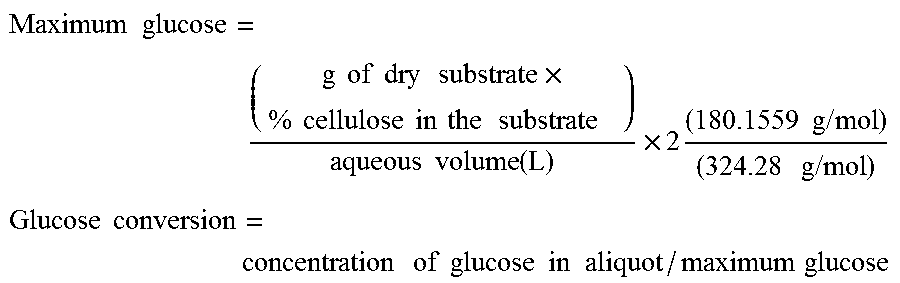

Process comprising sulfur dioxide and/or sulfurous acid pretreatment and enzymatic hydrolysis

ActiveUS9574212B2Reduce performanceEfficient use ofPretreatment with water/steamBioreactor/fermenter combinationsEnzymatic hydrolysisCellulase

The disclosure provides a process for producing a fermentation product from a lignocellulosic feedstock. The process describes soaking a lignocellulosic feedstock in an aqueous solution to produce a soaked feedstock. The soaked feedstock is at least partially dewatered and the at least partially dewatered feedstock is subjected to pretreating in the presence of sulfur dioxide, sulfurous acid or a combination thereof to produce a pretreated feedstock composition. The pretreated feedstock composition is fed to an enzymatic hydrolysis in which the concentration of dissolved solids fed to the enzymatic hydrolysis is at least 50% (w / w) of the concentration of dissolved solids in the pretreated feedstock composition. The cellulose in the pretreated feedstock composition is hydrolyzed with cellulase enzymes in the presence of the dissolved solids to produce glucose. The glucose is fermented to produce the fermentation product.

Owner:IOGEN CORPORATION

Fiber-reinforced ceramic matrix composite material, preparation method and application thereof

The invention relates to a fiber-reinforced ceramic matrix composite material, a preparation method and application thereof. The preparation method includes: (1) a step of preparation of a glue solution for impregnating a fiber preform; (2) a step of vacuum impregnation; (3) a step of curing; (4) a step of drying and sintering, and (5) a step of densification. Between the step (2) and the step (3), the method also includes the steps of: (i) carrying out ultrasonic vibration on a system containing the fiber preform and the glue solution for impregnation at the end of vacuum impregnation; and (ii) introducing compressed gas into the environment where the system is located at the end of ultrasonic vibration for pressurization, making the pressure of the environment where the system is locatedreach 1-4MPa, and keeping the maintaining time at 1-24h. The preparation method provided by the invention can prepare the fiber-reinforced ceramic matrix composite material which has thickness of 50mm or more and still has high density, excellent tensile strength and interlaminar shear strength.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Modified papermaking grade wood pulp production process

InactiveCN102277759ADip evenlyMeet production requirementsPulp bleachingPulping with inorganic basesCellulosePapermaking

The invention discloses a production process of modified paper-making grade wood pulp, which comprises the following steps: (1) preparing materials, feeding paper-making grade wood pulp boards into a hydraulic pulper, dispersing and dispersing through alkali spraying and agitator, After being sent to the press for extrusion and dehydration, it is sent to steaming balls; (2) cooking, the impregnated slurry enters steaming balls for cooking, and caustic soda is added; (3) chlorination, the cooked slurry is chlorinated, and added Hydrochloric acid, liquid chlorine, caustic soda; (4) bleaching, the chlorinated slurry is sent to the bleaching tank for bleaching; (5) acid treatment, adding hydrochloric acid for acid treatment, spraying into the bleaching tank, and papermaking , Packaged as wood pulp. The invention uses a hydraulic pulper to fully decompose and disperse the slurry, so that the impregnation of the wood fiber and the lye is more uniform, and the uniformity of cooking is greatly improved. Through the cooking process, the content of non-cellulose impurities can be reduced, and the degree of polymerization of cotton fibers can be reduced. Through the chlorination process, part of the colored impurities can be removed, and the content of methyl cellulose can be increased accordingly. Through the bleaching process, the whiteness of cellulose can be improved, and the polymerization can be continuously reduced to remove impurities. Through acid treatment, ash and iron can be removed, and the reaction performance can be improved. The modified papermaking grade wood pulp produced by the invention can meet the index requirement of dissolving wood pulp and meet the production requirement of viscose fiber.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

Method for preparing mesoporous activated carbon fibers

InactiveCN104264285APromote gasificationPromote formationFibre treatmentFibre chemical featuresFiberActivated carbon

The invention relates to a method for preparing mesoporous activated carbon fibers, belonging to the technical field of preparation methods of activated carbon fibers, and mainly solving the technical problems of difficulty in continuous spinning, non-uniform pore distribution of the product, complex production process, high requirement on equipment performance, high production cost and large industrial difficulty existing in a conventional method for preparing mesoporous activated carbon fibers. With the adoption of the technical scheme, the method for preparing mesoporous activated carbon fibers comprises the following steps: preparing an impregnant, impregnating, performing extrusion-suction, curing, carbonizing and activating and pickling. The method disclosed by the invention has the advantages of capability of performing continuous spinning, uniform pore distribution of the product, simple production process, low requirement on equipment performance, low production cost and simplicity in industrialization.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

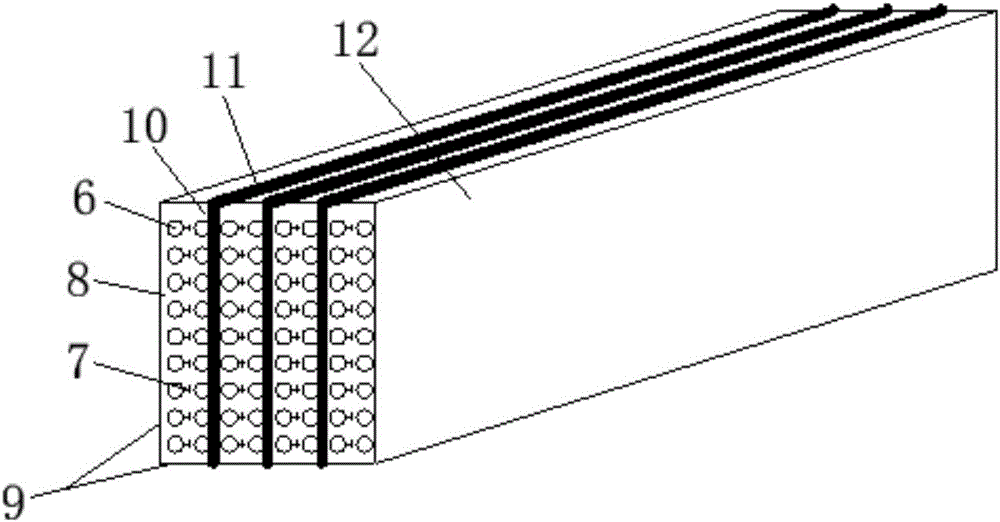

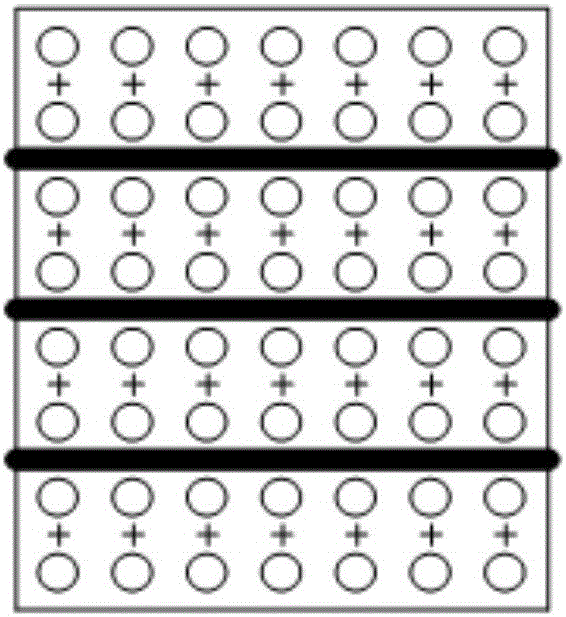

Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

The invention discloses a fiber-reinforced polyurethane foamed and synthesized sleeper and a preparation method thereof. The sleeper comprises a body formed by polyurethane resin in a one-time lamination manner, wherein multiple layers of composite felts with a transverse reinforcing effect are transversely arranged in the body, and a fiber yarn layer with a longitudinal reinforcing effect penetrates into the polyurethane resin between two adjacent composite felts; the fiber yarn layer and the composite felts account for 65%-75% of the total weight of the sleeper; the polyurethane resin accounts for 25%-35% of the total weight of the sleeper, and the density of the sleeper is 0.6g / cm<3>-1.6g / cm<3>; and the sleeper is prepared through combination of a double-steel belt laminating machine and a multilayer synchronous glue injection primary formation. According to the fiber-reinforced polyurethane foamed and synthesized sleeper, gum dipping is relatively adequate and uniform, so that thetransverse strength of the sleeper is enhanced, and the cracking phenomenon of a product during punching and indenting can be avoided; and the production process is simple, the equipment input is reduced, the production cost is lowered, and the production efficiency is improved.

Owner:铁科腾跃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com