Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Overcome warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

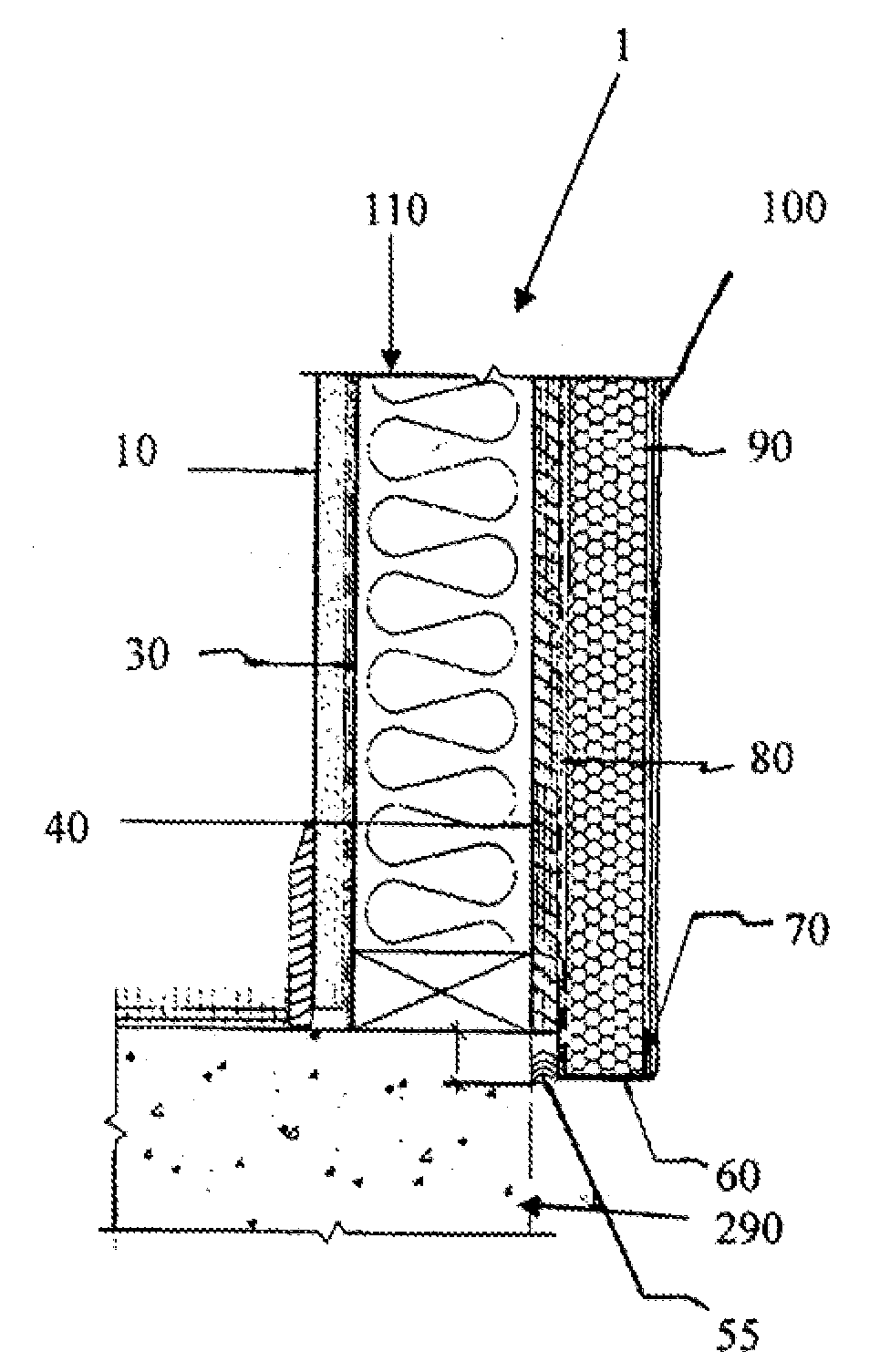

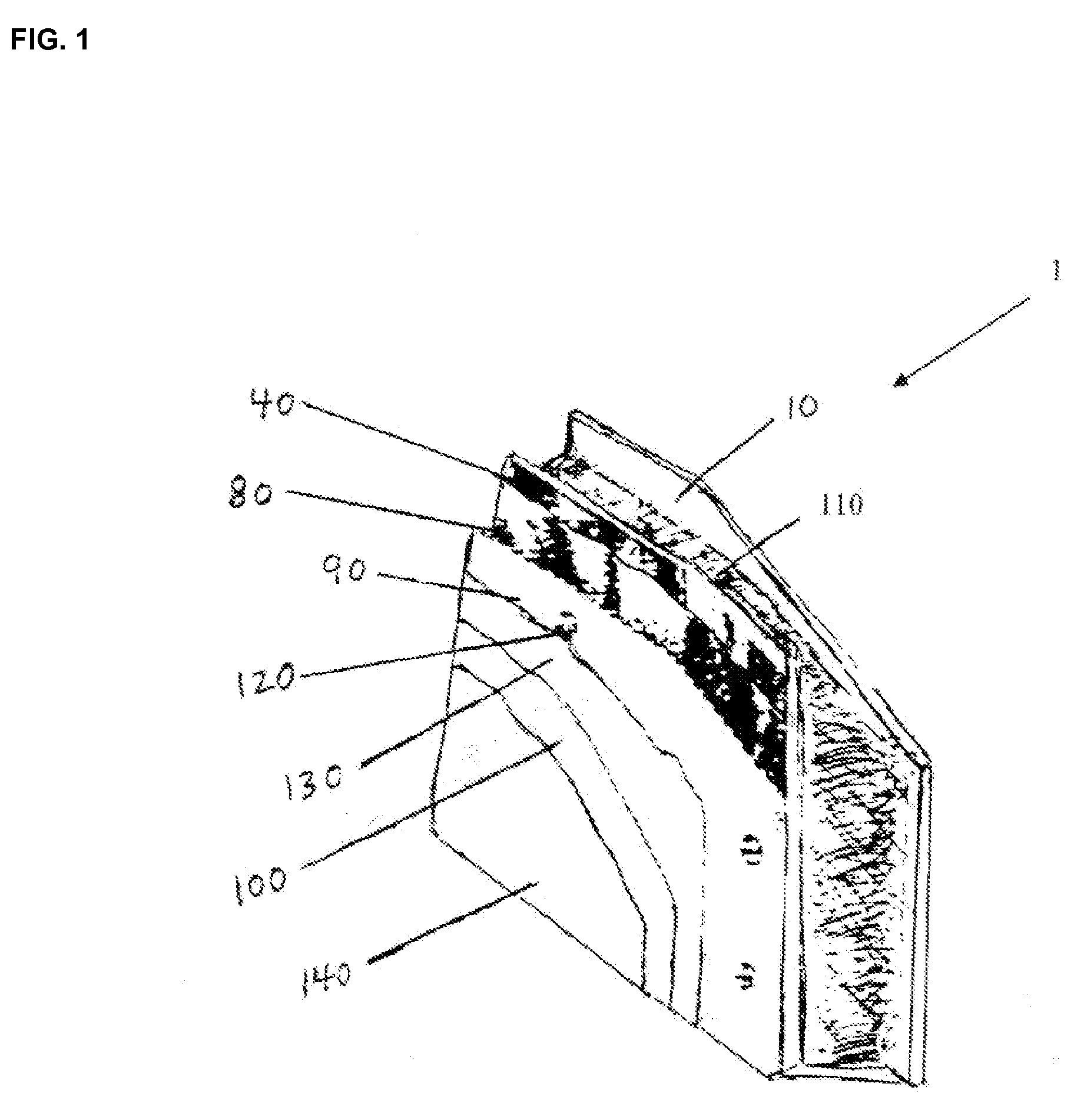

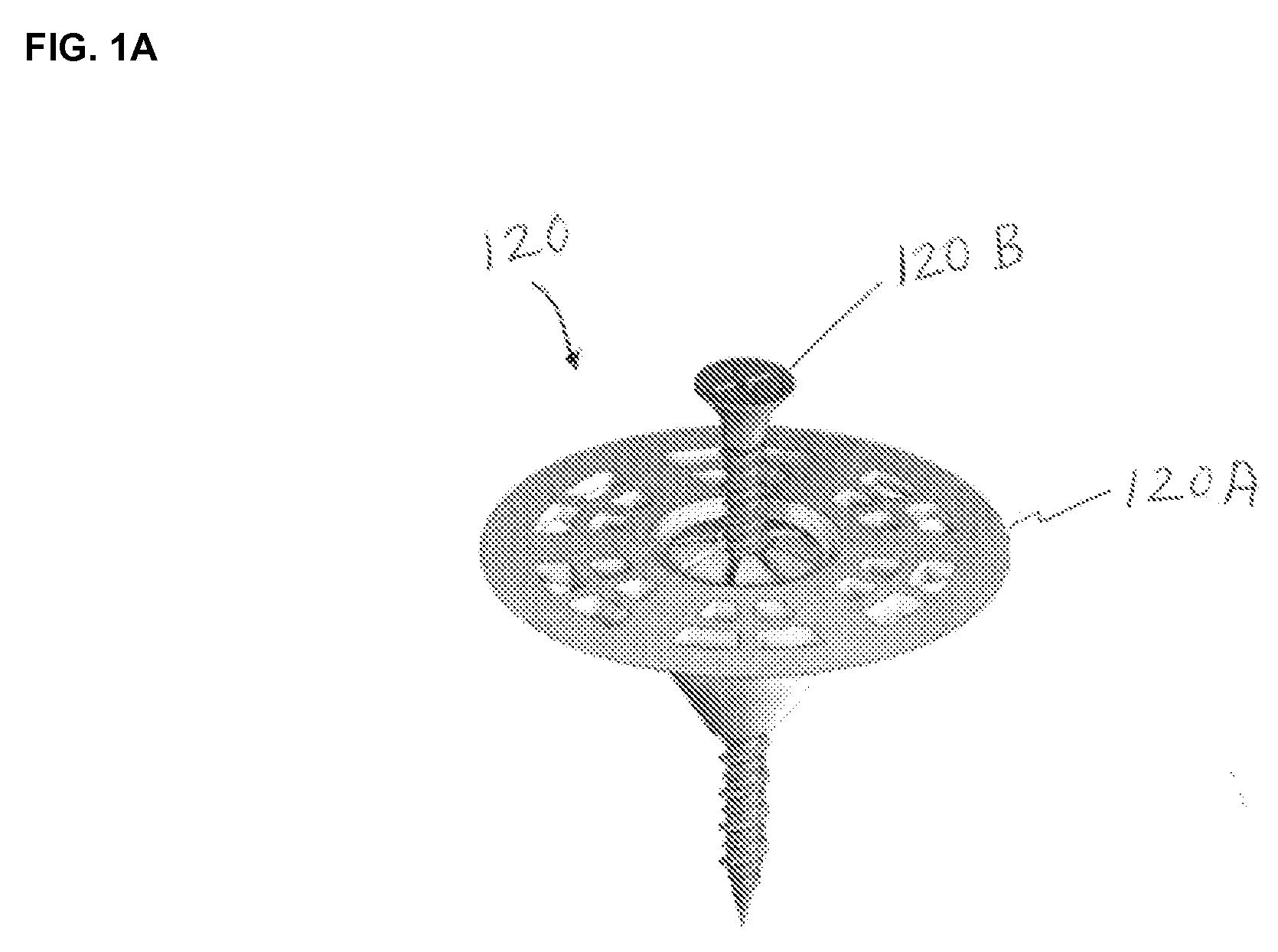

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

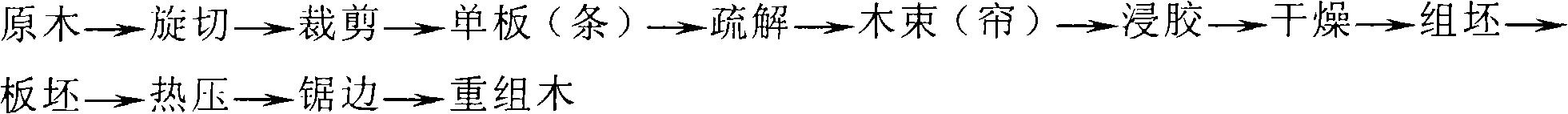

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

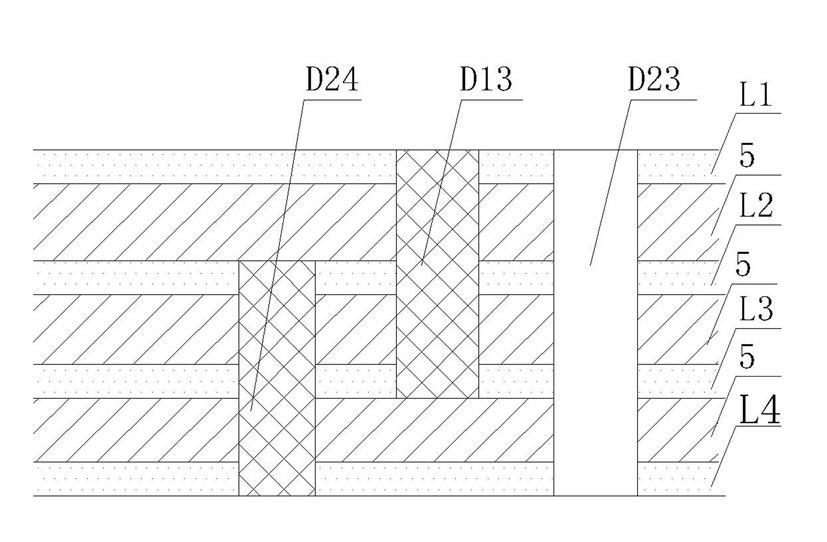

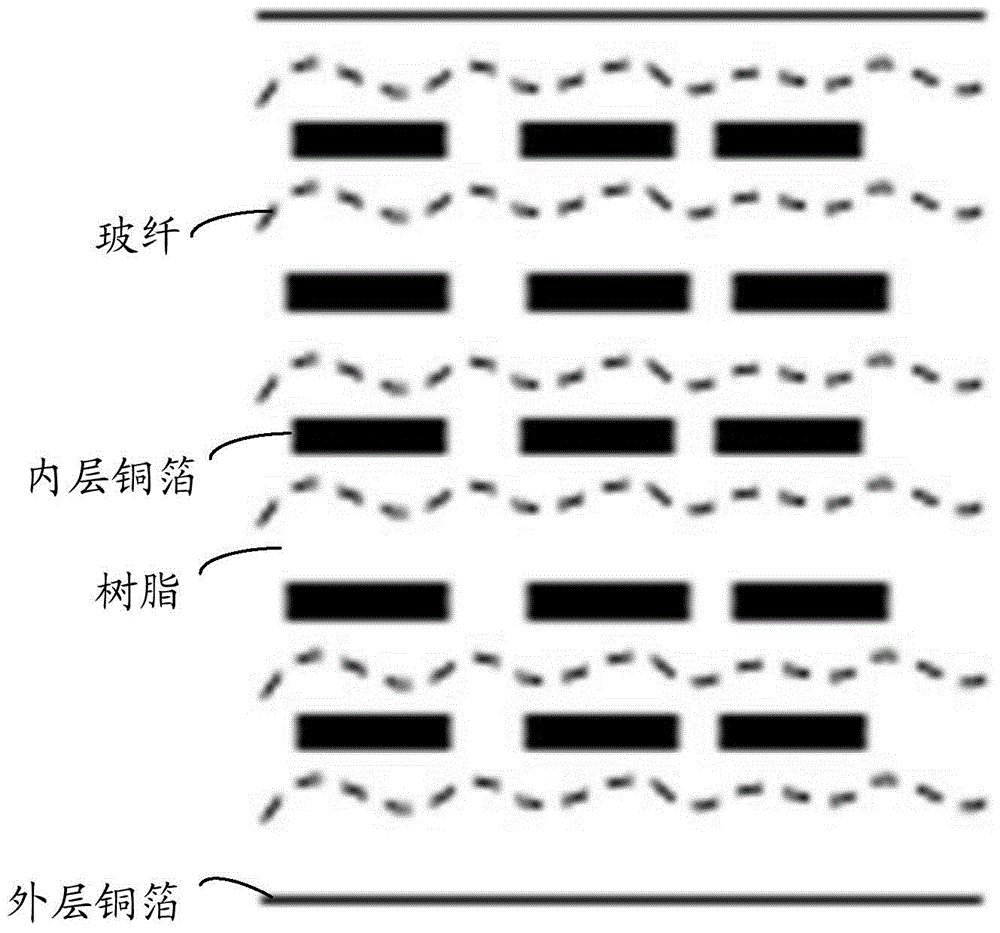

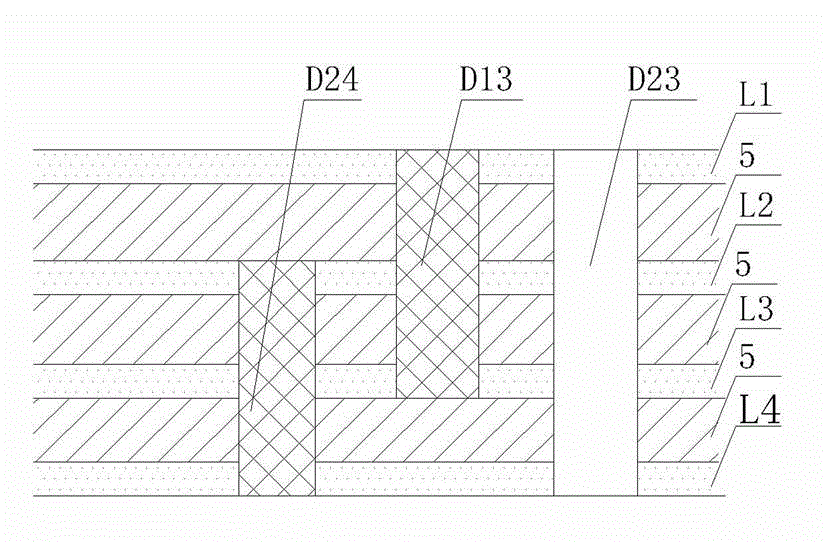

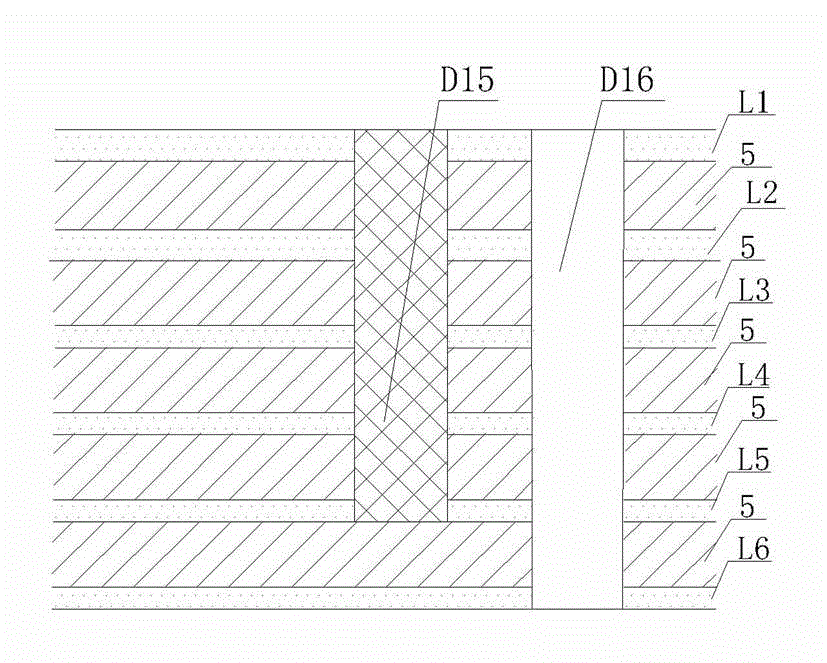

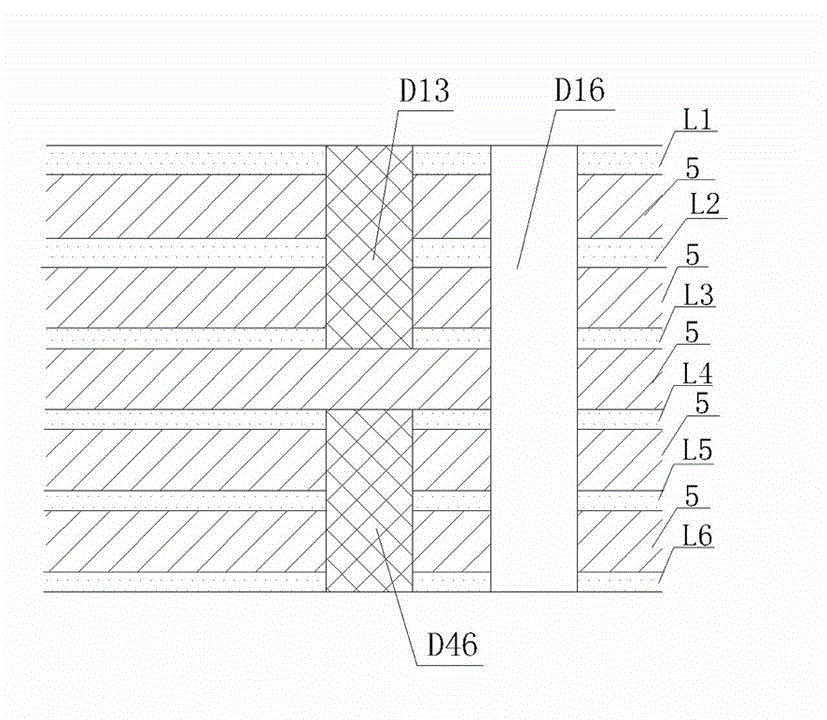

Method for processing blind buried hole on multilayer circuit board

ActiveCN102170759AOvercome warpingShort processPrinted element electric connection formationCopperElectroplating

The invention relates to a method for processing a blind buried hole on a multilayer circuit board, which belongs to the technical field of laser drilling. The technical key point of the invention comprises the following steps of: (1) confirming a position needing hole opening of the traditional mechanical blind buried hole circuit board; (2) processing a buried hole on an inner-layer plate of the position needing hole opening and electroplating again after filling resin into the buried hole for grinding to form a butting joint pad; and (3) drilling a laser blind hole on an upper-layer circuit board at at least one side of the processing buried hole and butting the laser blind hole with the pad formed electroplating on the mechanical buried hole to form a blind buried hole. Compared with the prior art, the invention has the advantages of shortening the process flow, thoroughly overcoming the phenomenon of board bending generated by asymmetric laminating structure design due to asymmetric hole layer distribution, solving the problem that a copper layer is relatively thicker and is adverse to the manufacture of a thin circuit because the traditional mechanical blind buried hole process outer layer is electroplated for many times, reducing the pressing frequency of board layers and the manufacture difficulty and improving the product quality.

Owner:BOMIN ELECTRONICS CO LTD +1

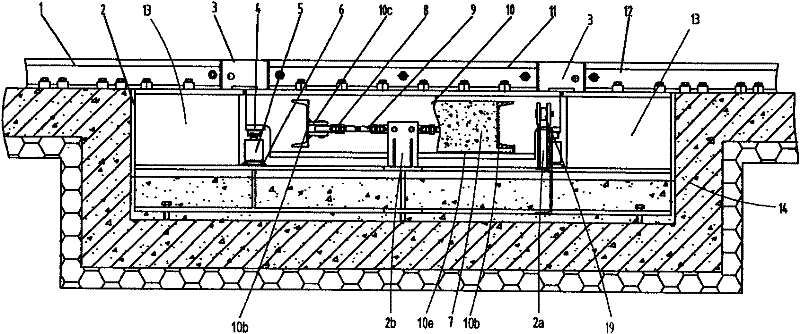

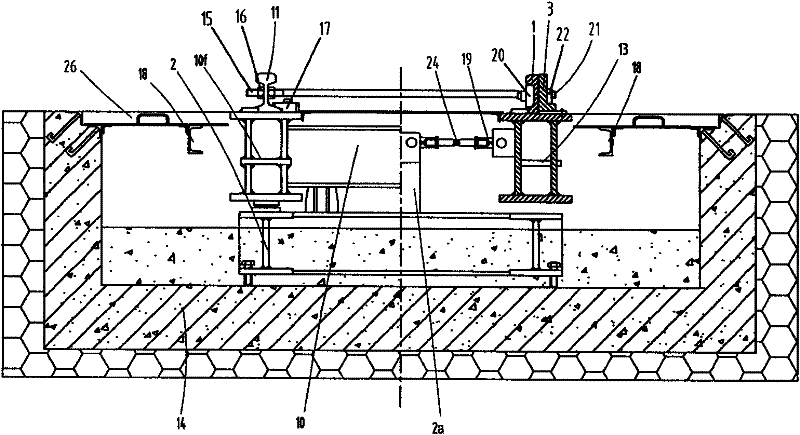

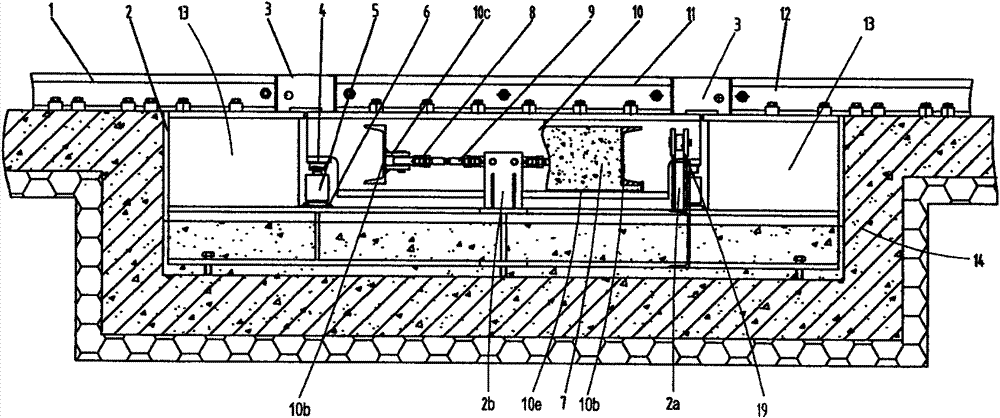

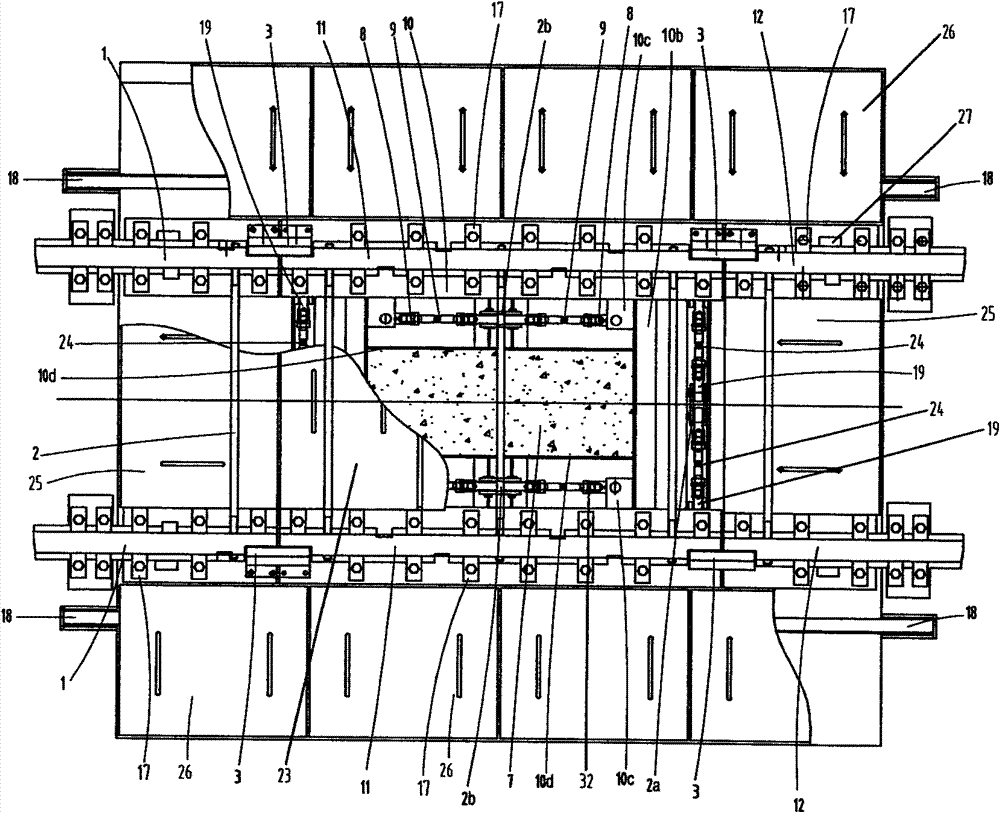

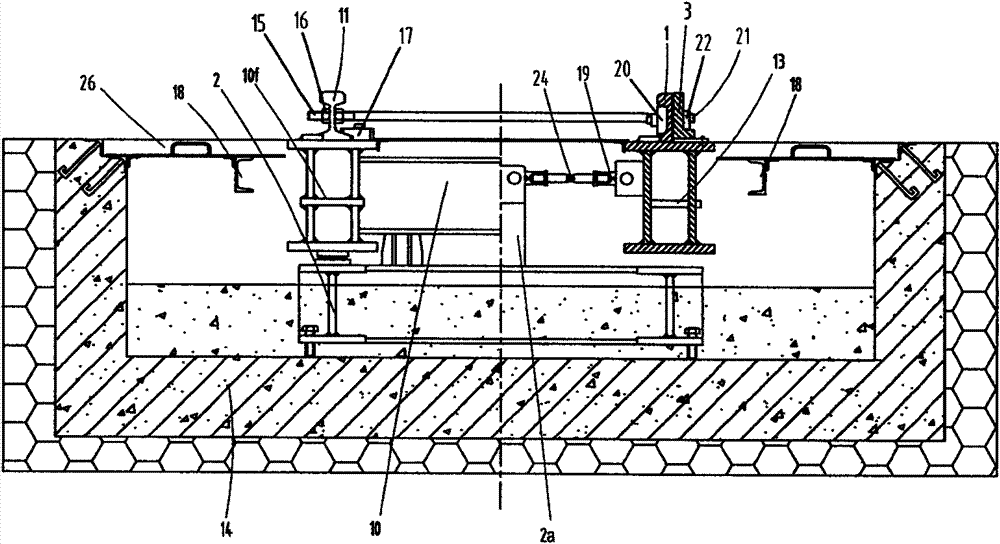

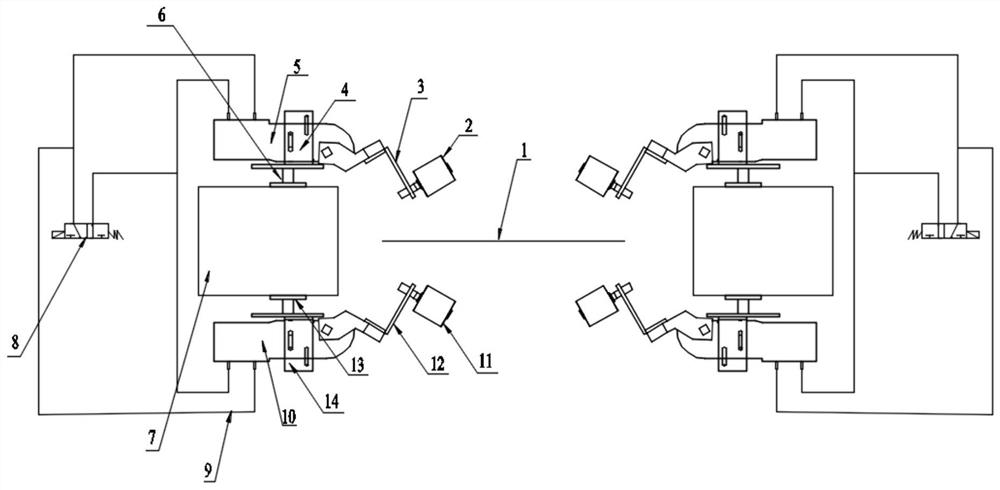

Integral dynamic rail weighbridge

ActiveCN102221395AImprove stabilityReduce distortionWeighing apparatus detailsSpecial purpose weighing apparatusUniversal jointUltimate tensile strength

The invention discloses an integral dynamic rail weighbridge, comprising a weighing body and a weighing bottom framework, wherein bottom ends of the weighing body are provided with a sensor respectively; the top surface of the weighing body is provided with two bearing rails which are arranged in parallel; joints between the bearing rail and a left approach rail and between the bearing rail and aright approach rail are connected with a transition device respectively; the top surfaces of the transition devices are consistent with those of the bearing rails, the left approach rail and the right approach rail; and one end of each transition device is arranged on one base of the approach rails, and the other end of each transition device extends to the weighing body. The integral structure is strong in matching performance, the sensors are used for detecting the weight, data channels and other advanced equipment are used for realizing transmission, treatment and other operations of data,electronic degree is high and operations are quick; the weighing bottom framework of the integral structure is configured and is integrally combined with a pit, the integral structure is simple and the bearing intensity is enough; a horizontal limited rod, a universal joint and other components in the weighing bottom framework performs self-limitation on four directions and eight positions of theweighing body directly, thus the integral design is reasonable; and the transition devices are configured, thus force points of wheels close to the inside of a weighing platform, thereby ensuring smooth transition and steady running.

Owner:YUYAO TONGYONG METER

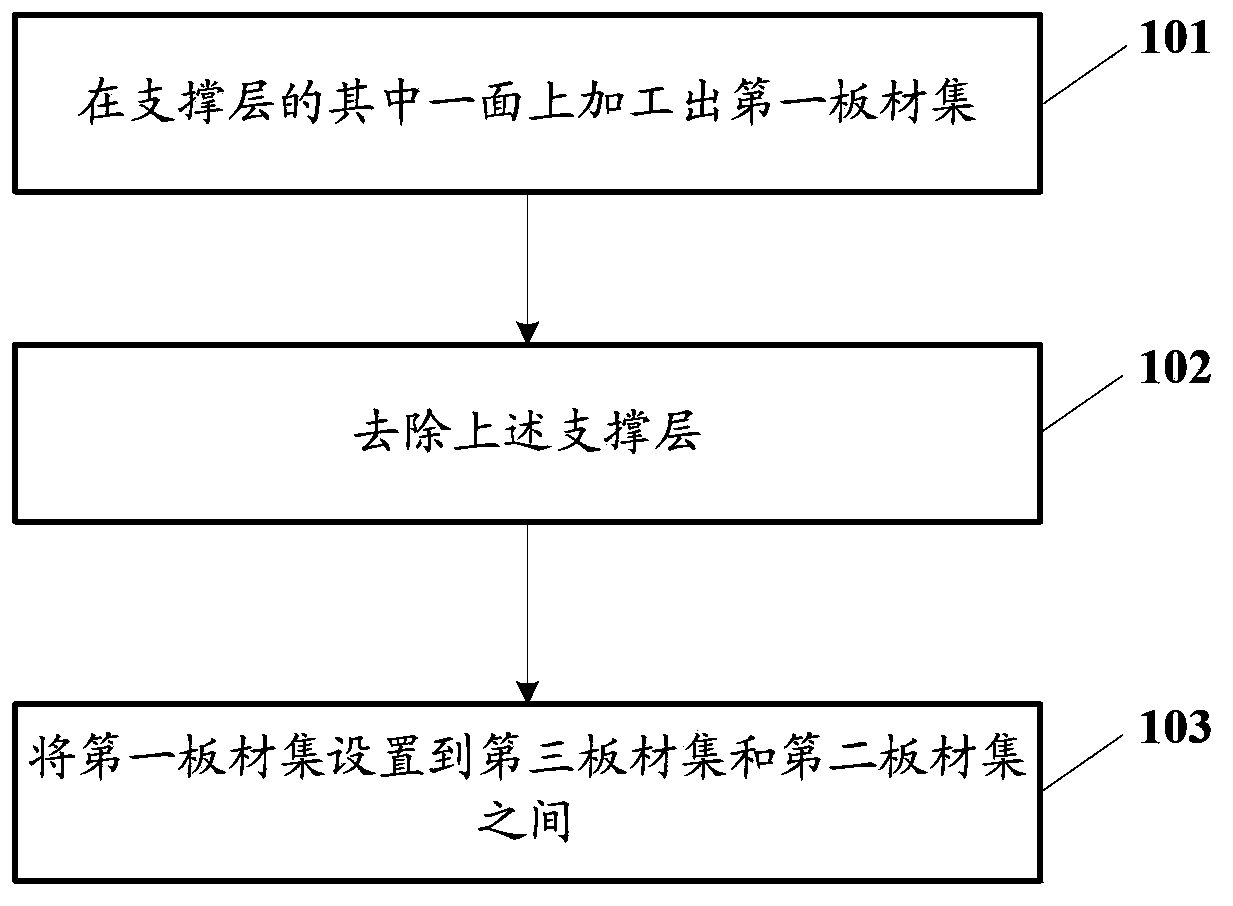

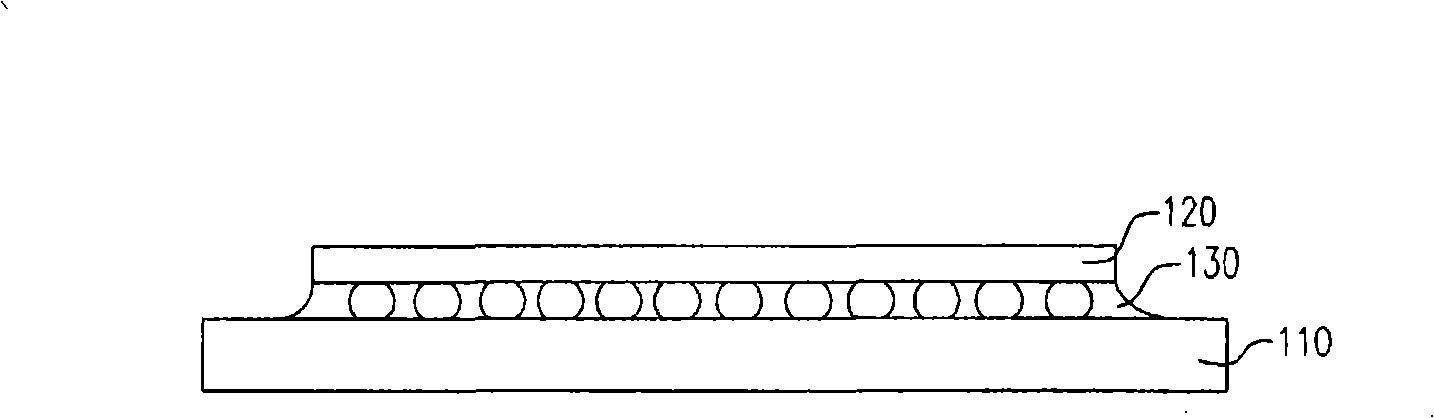

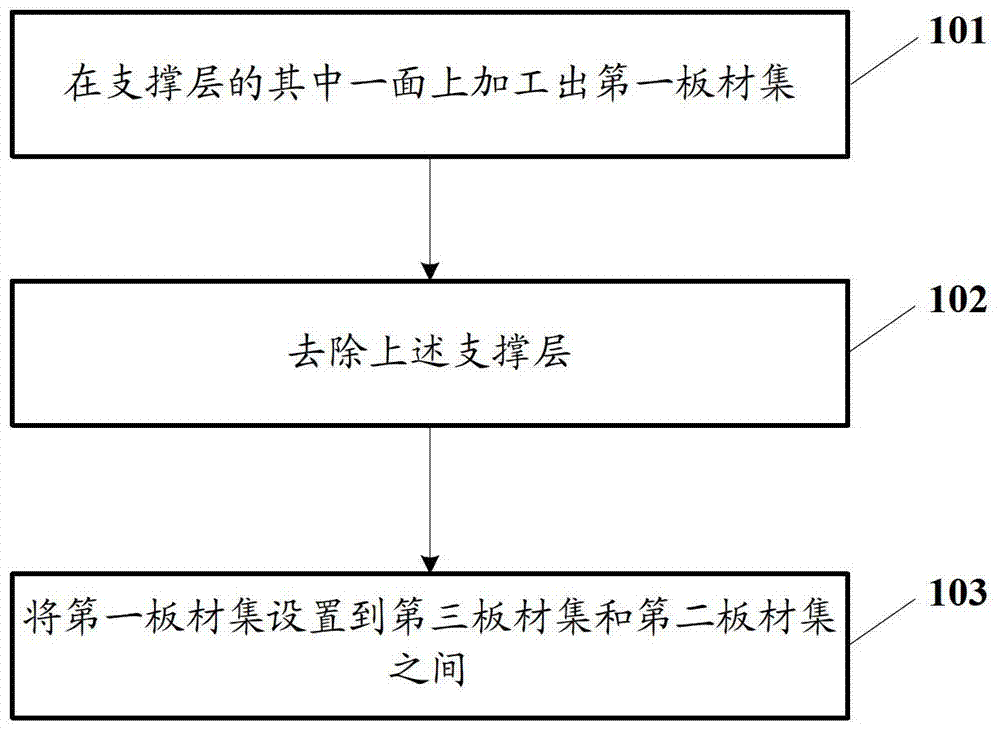

Coreless substrate processing method

ActiveCN104168726AOvercome warpage-prone problemsOvercome warpingMultilayer circuit manufacturePrinted element electric connection formationComputer science

An embodiment of the invention discloses a coreless substrate processing method which comprises the following steps: carrying out processing to form a first board set on one surface of a support layer; removing the support layer; and arranging the first board set between a third board set and a second board set. The technical scheme provided in the embodiment of the invention helps to improve production efficiency and qualified rate of the products.

Owner:SHENNAN CIRCUITS

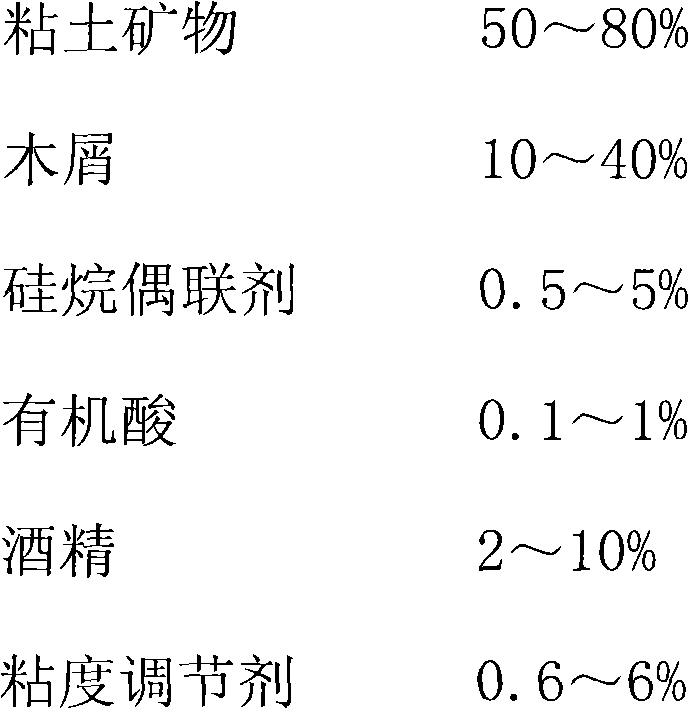

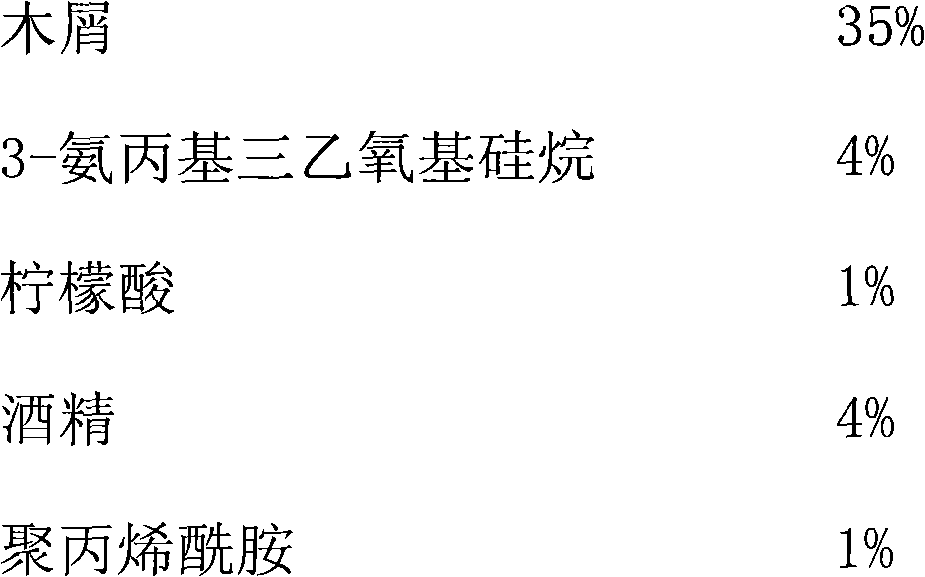

Filler special for glue mixing of plywood and preparation process of filler

InactiveCN102558892AIncrease solids contentHigh viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesOrganic acidAlcohol

The invention discloses a filler special for glue mixing of a plywood, comprising the following components: a clay mineral, sawdust, a silane coupling agent, an organic acid, alcohol and a viscosity regulator; a preparation process of the filler comprises the steps of: firstly, respectively grinding the clay mineral and the sawdust into powder and proportionally mixing the clay mineral and the sawdust in a mixer to form mixed powder; secondly, proportionally placing the silane coupling agent, the organic acid and the alcohol in a container and stirring by a stirrer to form mixed liquor; thirdly, slowly pouring the mixed liquor prepared in the last step into the mixed powder, starting the mixer at the same time and then warming to carry out full reaction between the mixed liquor and the mixed powder; and fourthly, adding the viscosity regulator in the reacted mixed powder and stirring well. The filler for glue mixing of plywood has the characteristics of low cost, strong viscosity and good economic benefit.

Owner:CHUZHOU YONGHE SERICITE

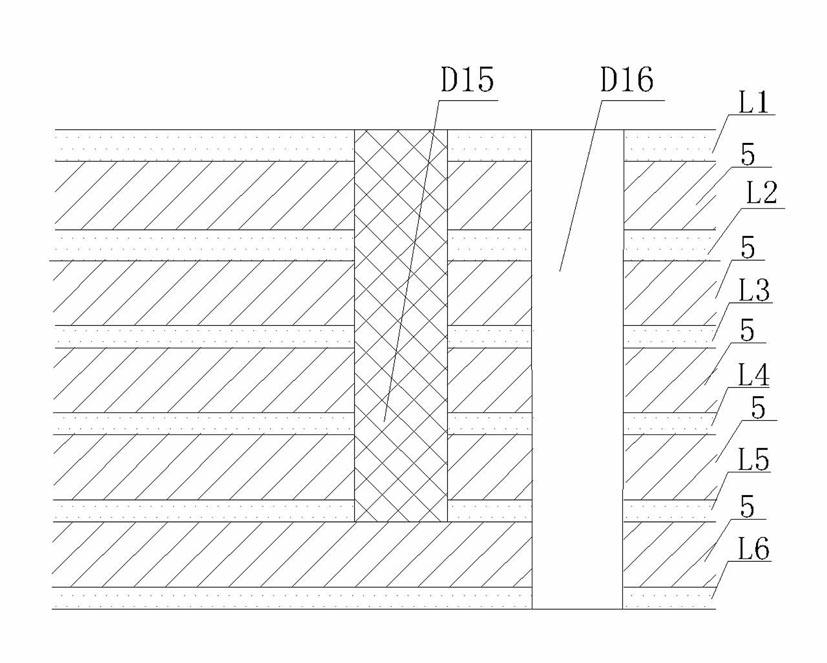

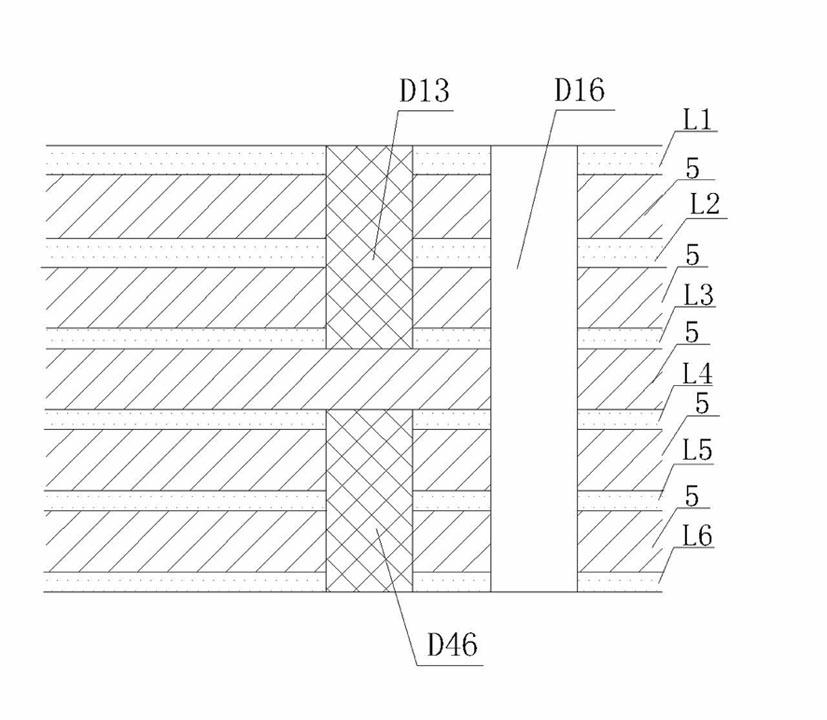

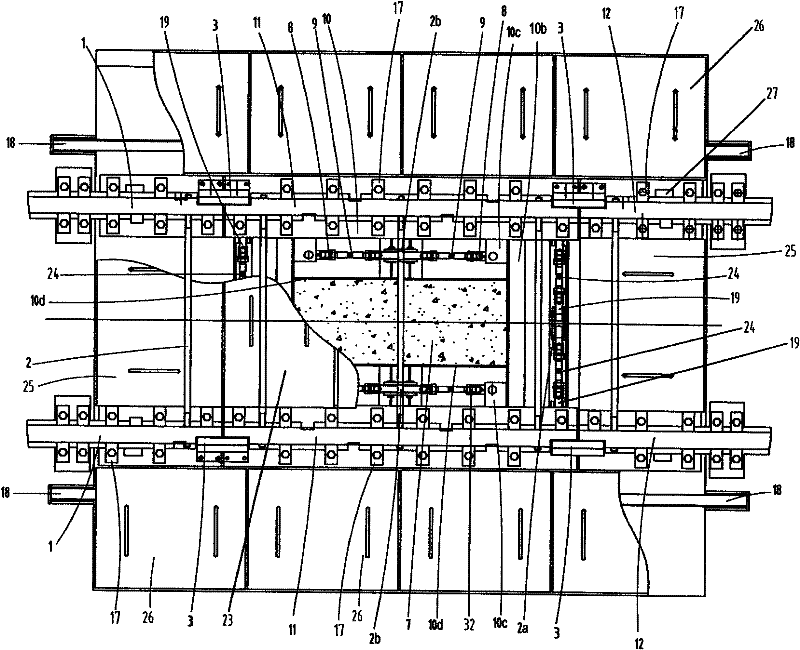

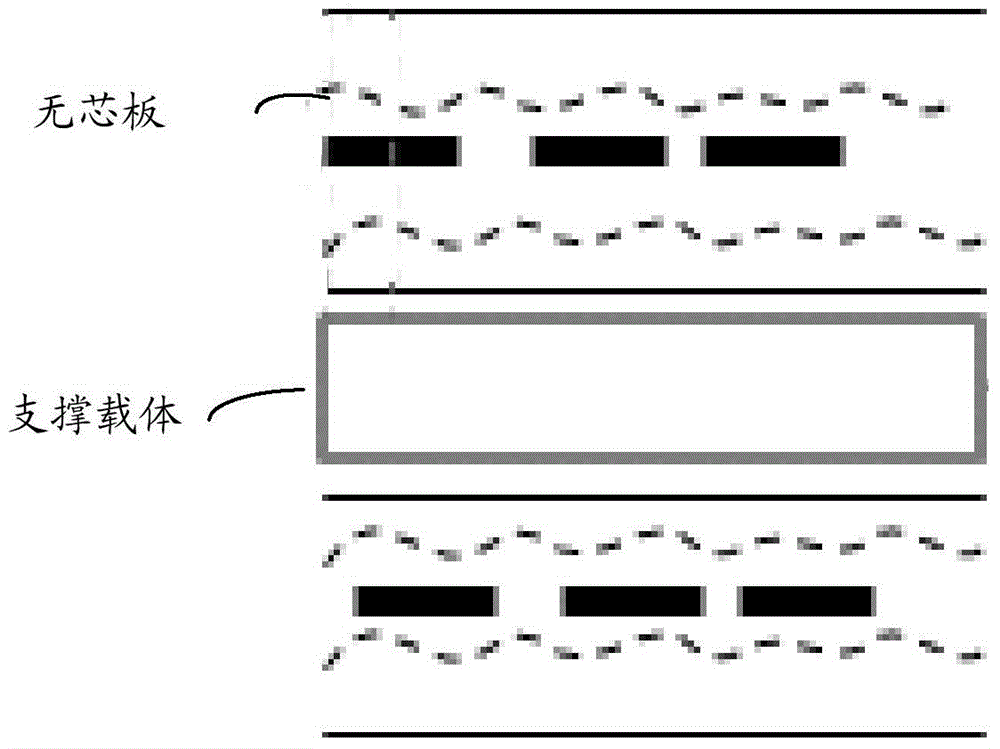

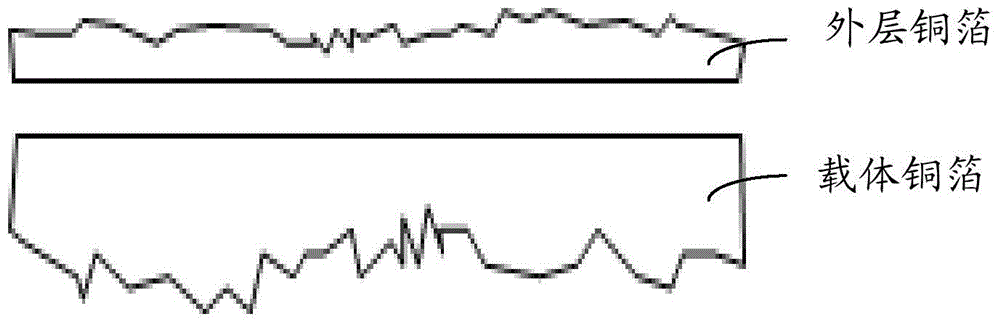

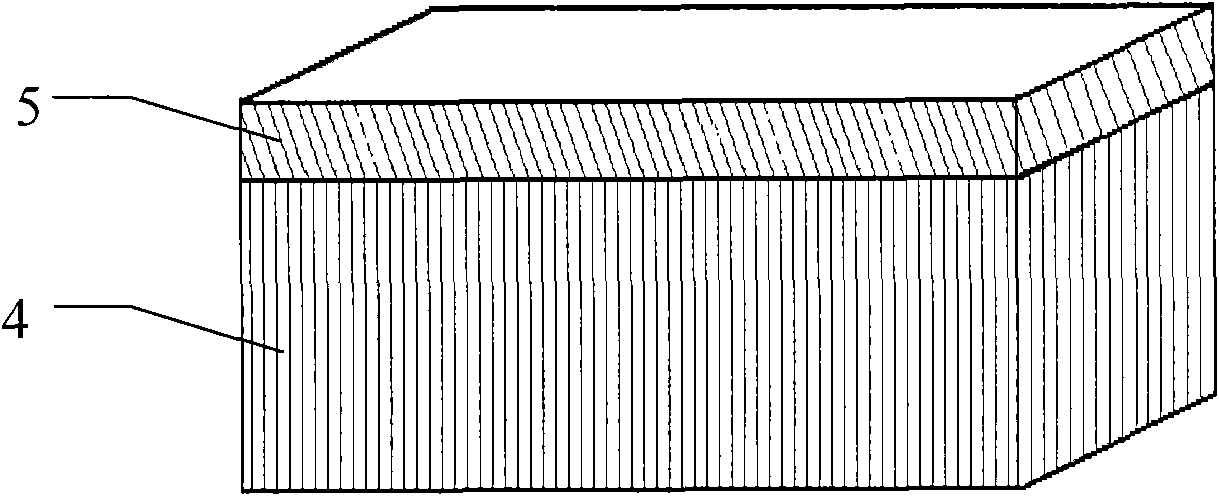

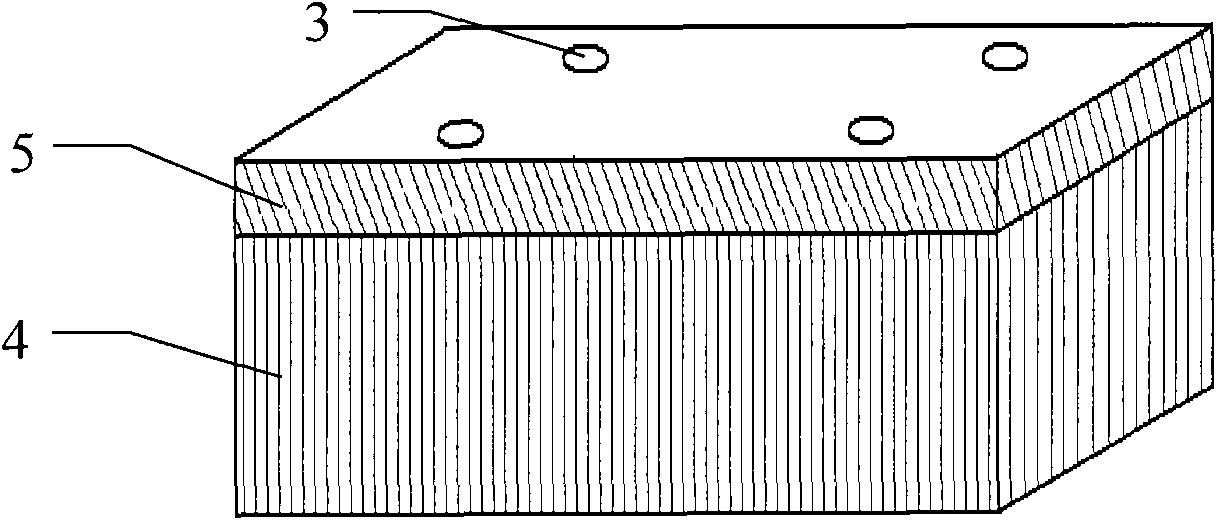

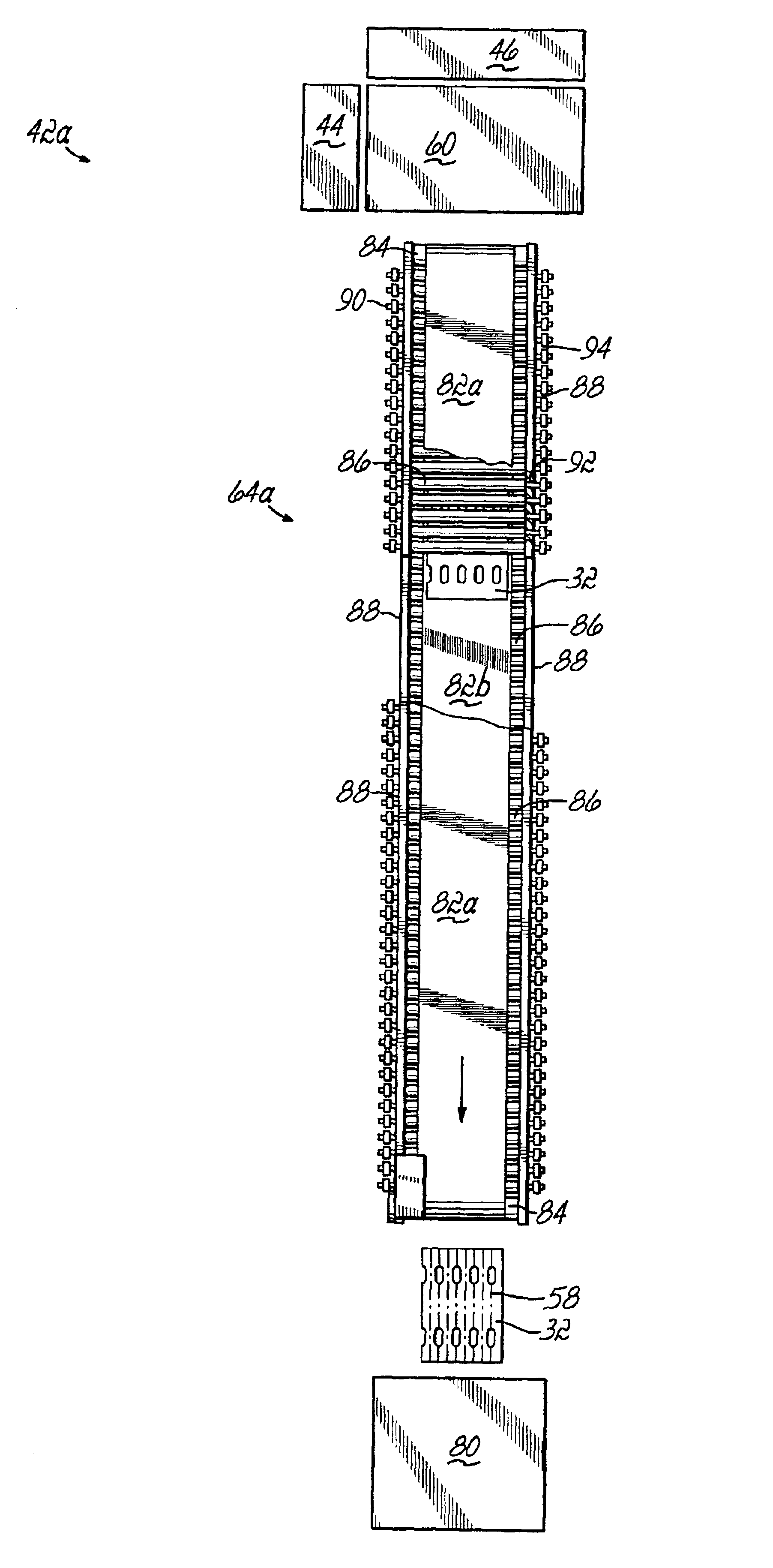

Core-less board manufacturing component, core-less board and manufacturing method for core-less board

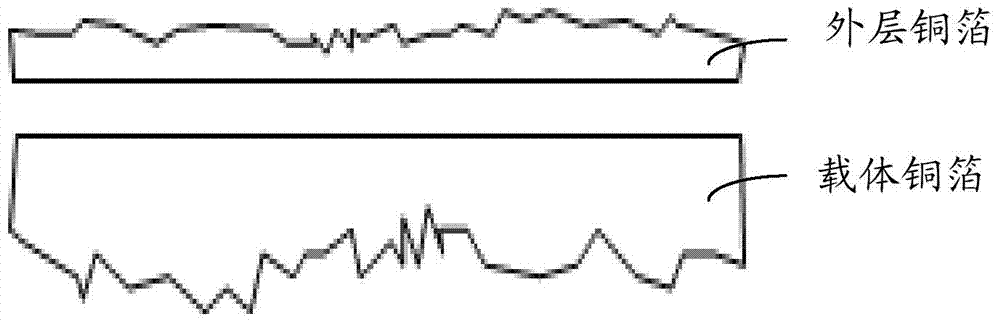

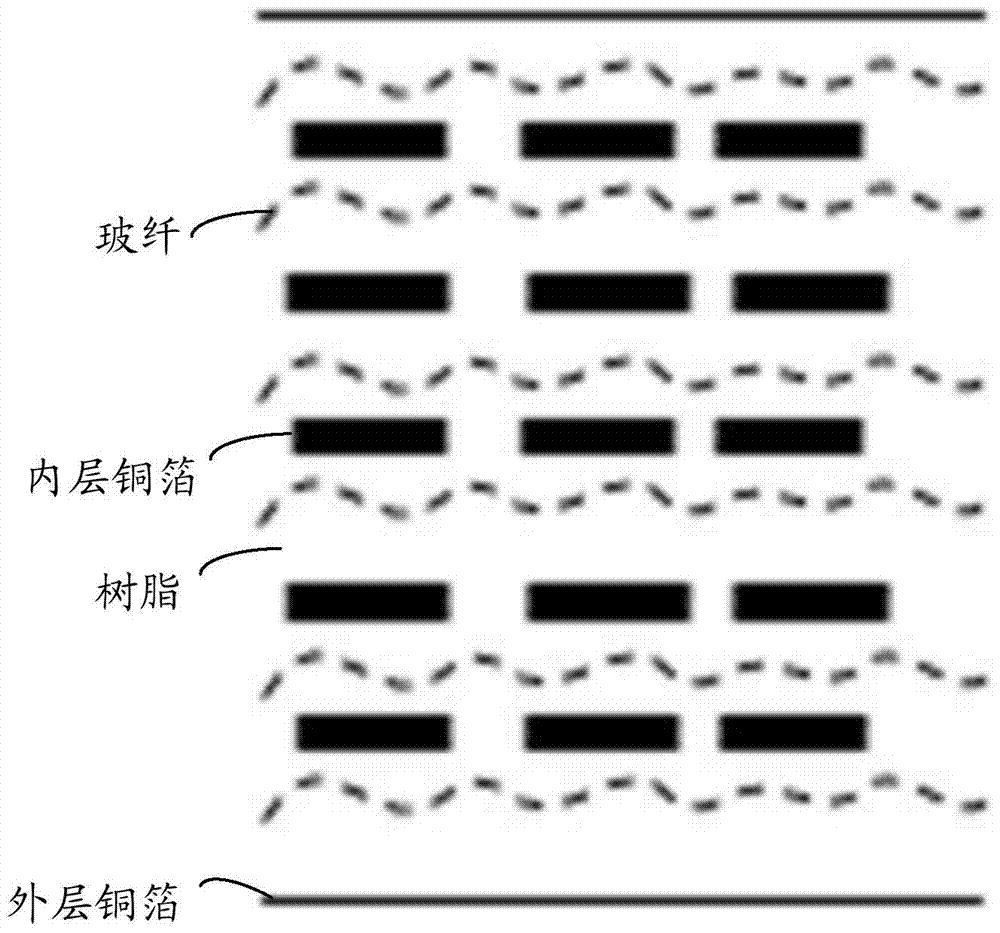

ActiveCN104540339AOvercome warpingImprove yield rateSemiconductor/solid-state device manufacturingMultilayer circuit manufactureCopper foilOuter coil

A core-less board manufacturing component comprises a supporting carrier and core-less boards arranged on the two sides of the supporting carrier. The core-less boards comprise inner prepregs, outer prepregs, inner copper foil layers and outer copper foil layers. The inner prepregs are arranged on the two sides of the inner copper foil layers. The outer prepregs are arranged on the outermost inner copper foil layers, and the outer coil foil layers are arranged on the outer prepregs. Gaps are formed in frames of the inner copper foil layers. According to the core-less board manufacturing component, the core-less board and a manufacturing method for the core-less board, the supporting carrier is arranged ingeniously, the warping problem of the core-less boards can be overcome effectively, and the yield of the core-less boards is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

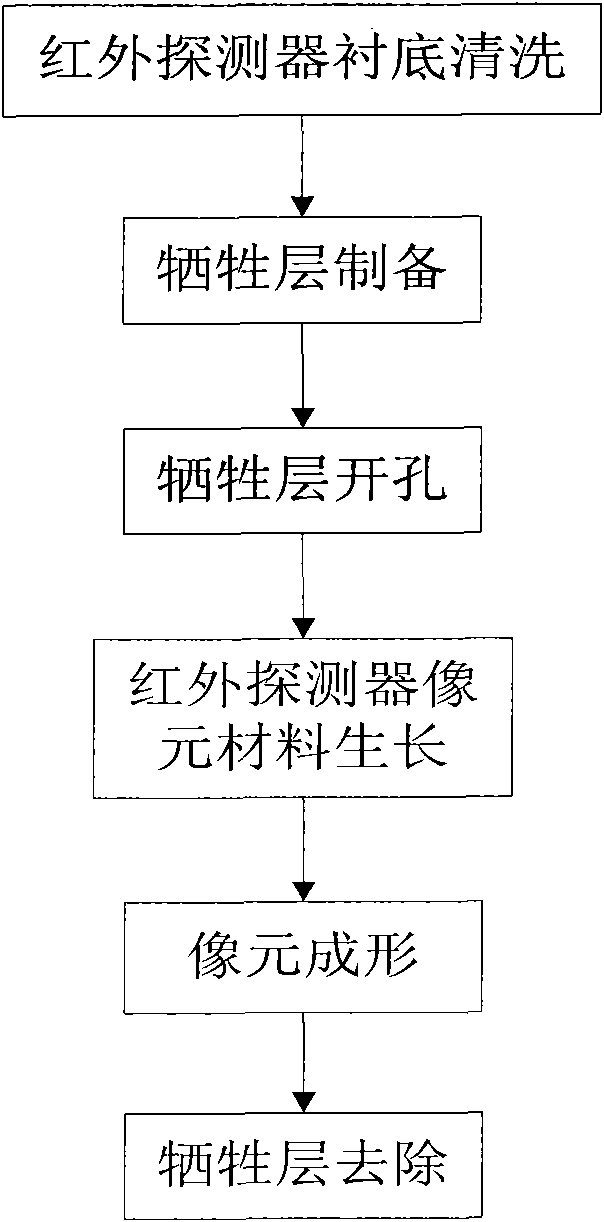

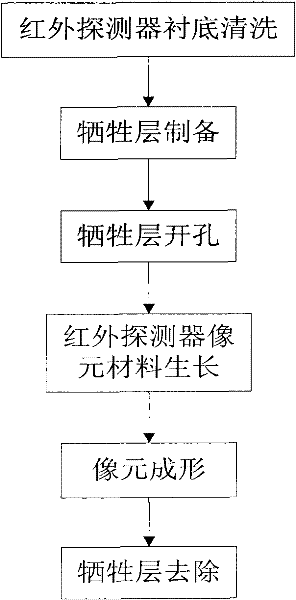

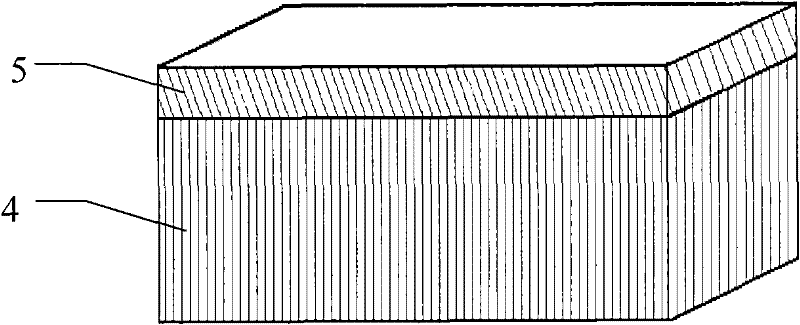

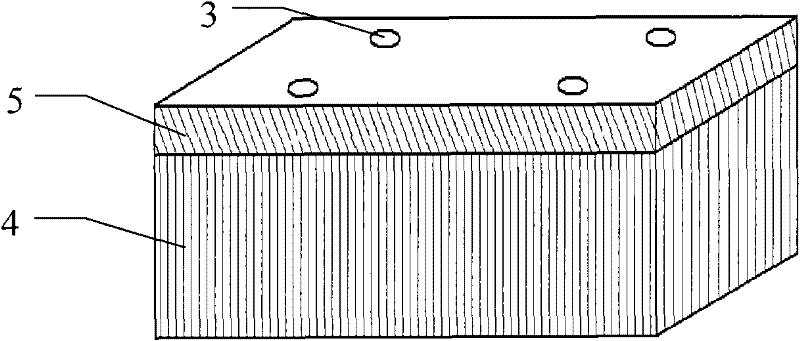

Thermal isolation structure of infrared detector and preparation method thereof

InactiveCN101603861AOvercome warpingImprove stabilityDecorative surface effectsPyrometry using electric radation detectorsThermal isolationSmall hole

The invention discloses a thermal isolation structure of an infrared detector and a preparation method thereof. The method erodes a sacrificial layer material by a wet method, utilizes traverse etching effect of corrosive liquid, has quick reaction, and does not need opening multiple holes in the center of an image element to help removing the sacrificial layer material, so the process method is simple, can effectively relieve the problem of deformation of the image element after the removal of the sacrificial layer due to stress, and ensures the smooth surface of the infrared detector. In the thermal isolation structure, the edge of the rectangular image element is evenly provided with support posts, better stability and support effect are achieved, and the defects of warp and falling off of the surface of the detector caused by stress mismatch in the prior thermal isolation structure are overcome.

Owner:中电科技集团红外工程技术有限公司

Stack type chip packaging structure and method for preparing stack encapsulation structure

ActiveCN101303985AImprove reliabilityOvercome warpingSolid-state devicesSemiconductor/solid-state device manufacturingColloidElectrical and Electronics engineering

The invention relates to a manufacturing method for a stacked chip encapsulation structure, which comprises the following steps: firstly, a substrate, a first chip and a second chip are provided; wherein, one surface of the second chip is equipped with a plurality of projections; secondly, the second chip is fixed on one side of the first chip; thirdly, the second chip and the first chip are inversely arranged on the substrate; chip inversion joint technology is used for electrically connecting the second chip with the substrate through the projections; fourthly, the first chip is electrically connected with the substrate; finally, an encapsulation colloid is formed on the substrate for coating the first chip, the second chip and the projections.

Owner:ADVANCED SEMICON ENG INC

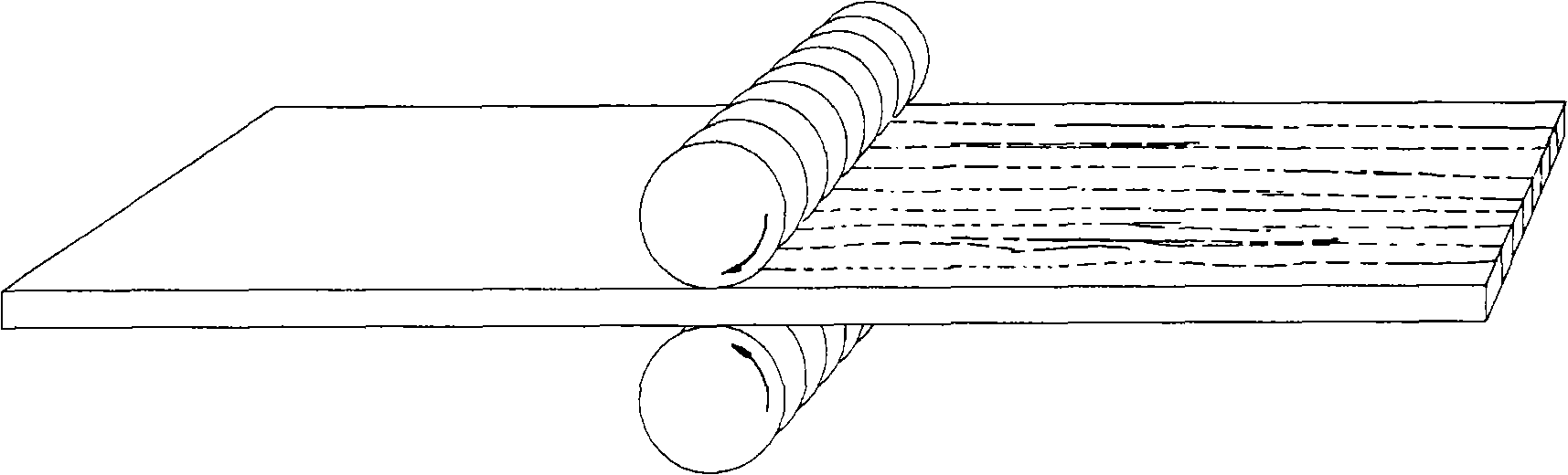

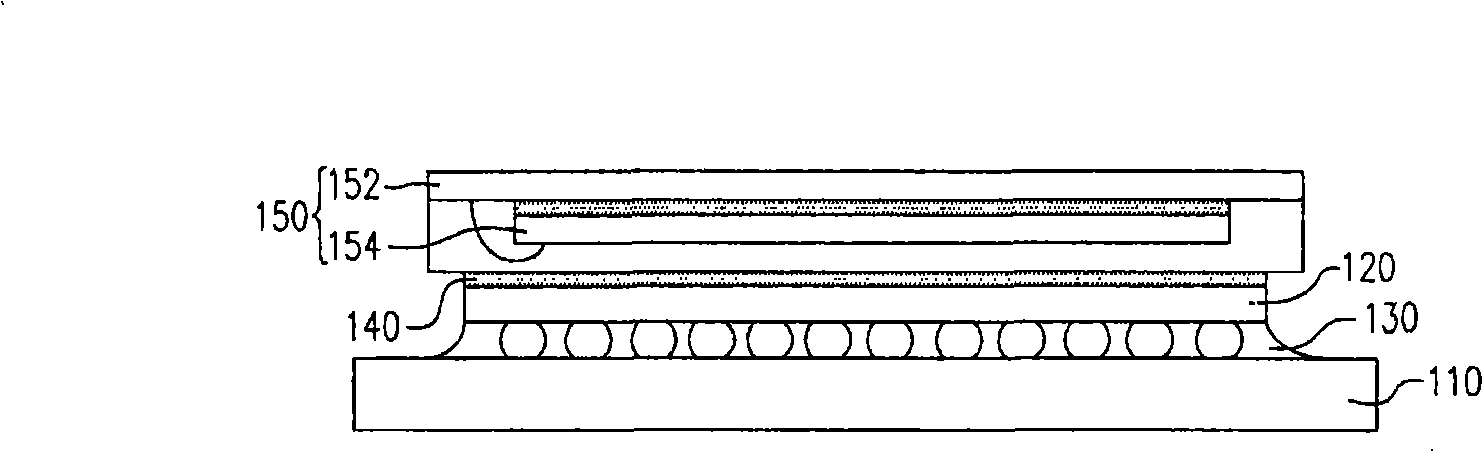

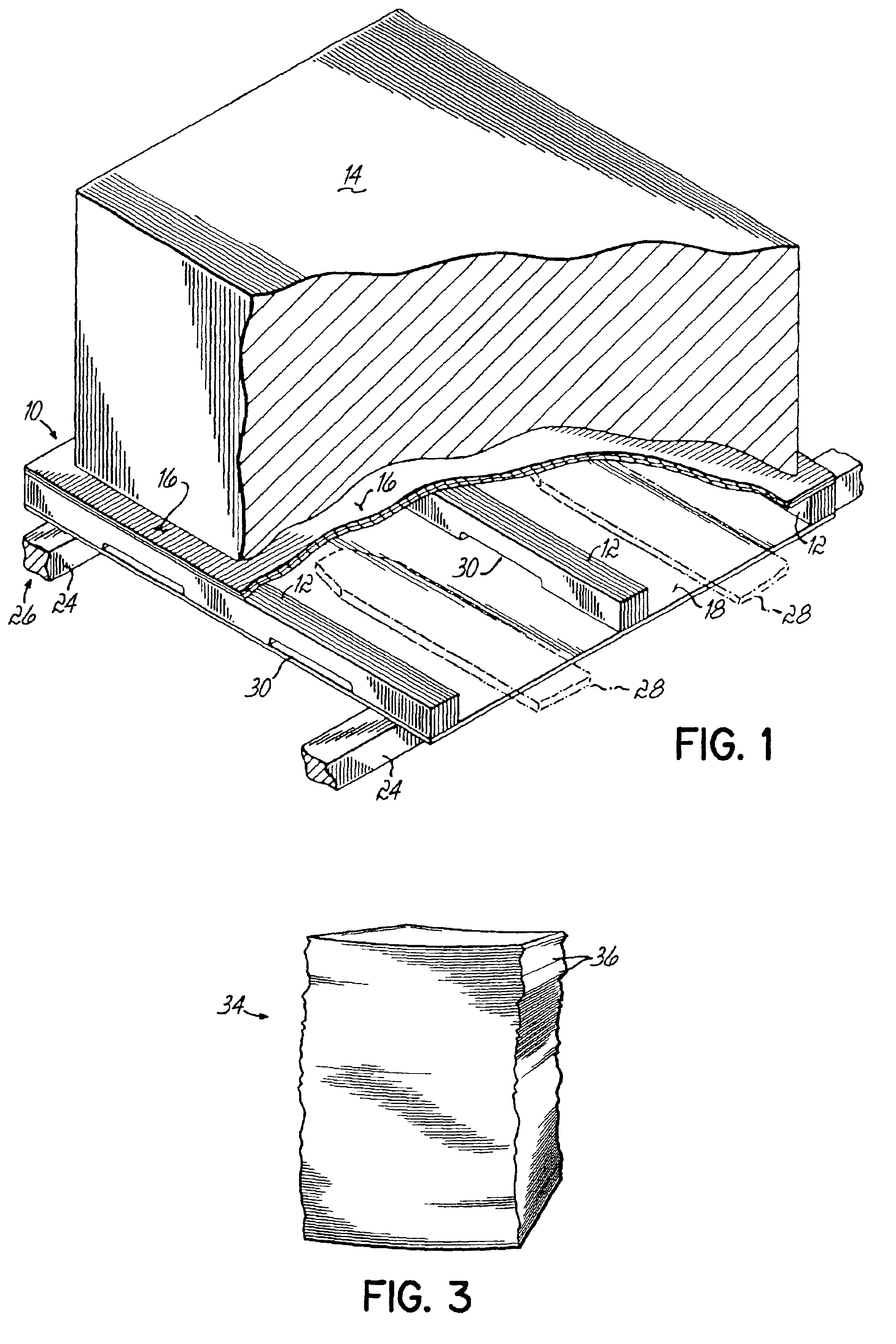

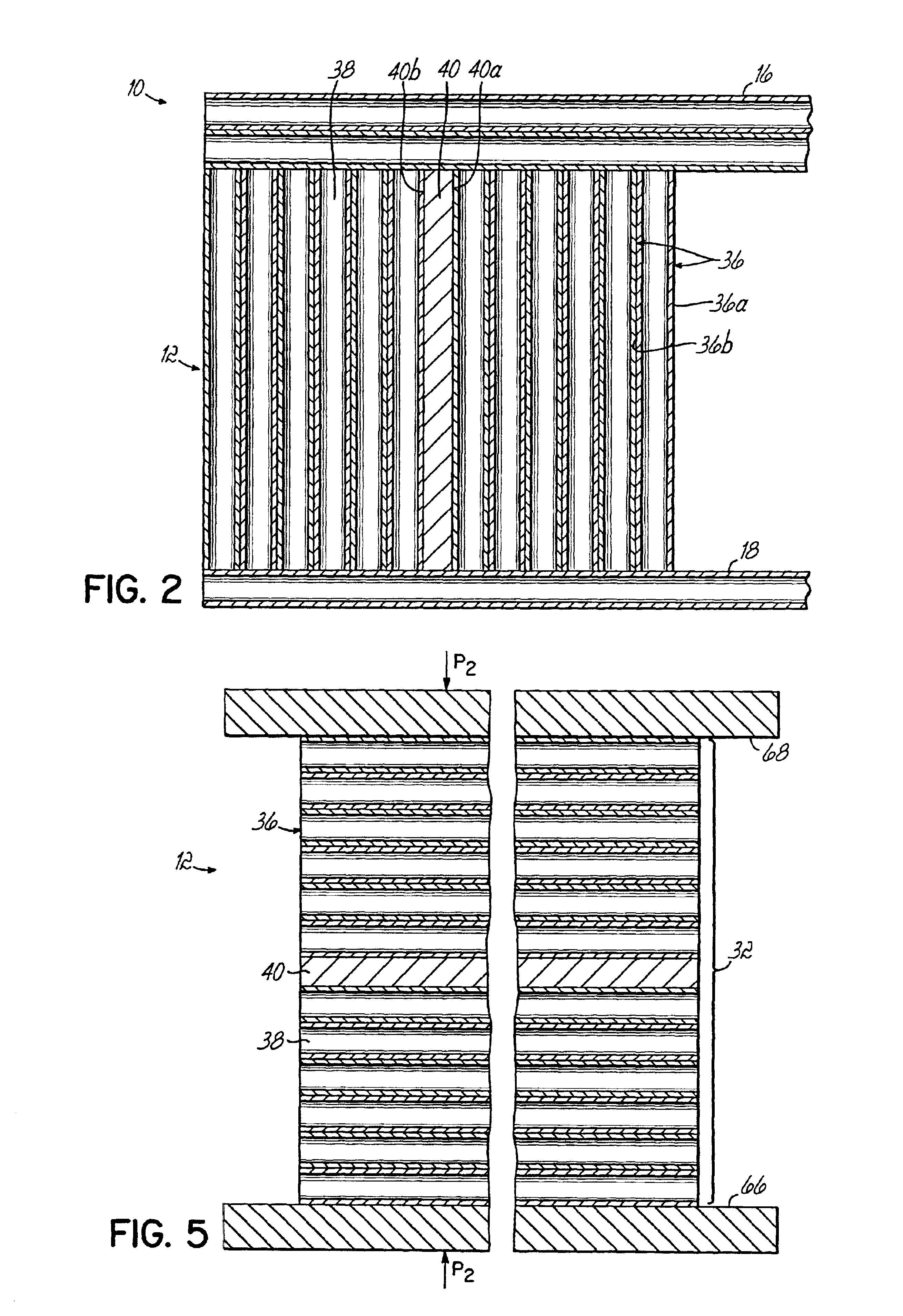

Method and associated system for manufacturing reinforced paperboard pallet runners

InactiveUS6899039B2Minimizing wayAvoid delaminationPaper/cardboard articlesRigid containersFlutePaperboard

A pallet includes a number of runners which may be sandwiched between upper and lower face sheets of corrugated paperboard. Each runner is comprised of multiple layers of corrugated paperboard with the flutes of the corrugations oriented vertically to provide compression strength to the runners and the associated pallet. Each runner also may include at least one reinforcing insert most preferably of hardboard to provide beam strength to the runner and a band to avoid failure without a prior indication. Moreover, the system and method for manufacturing the runners with reinforcing inserts overcomes problems of delaminating and separation of the adhesively bonded layers of the runner.

Owner:PERAZZO JOHN R

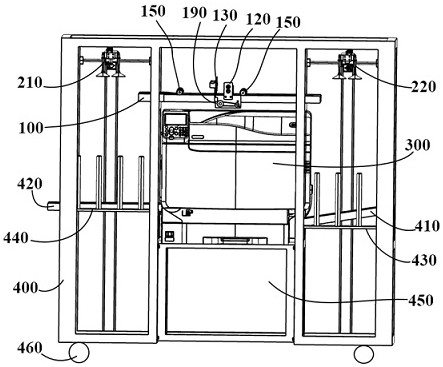

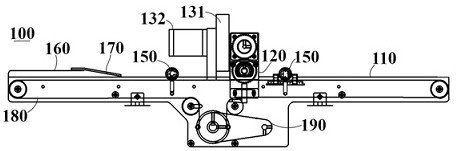

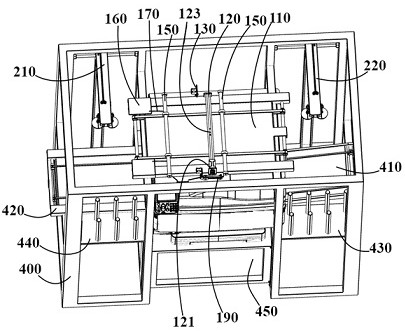

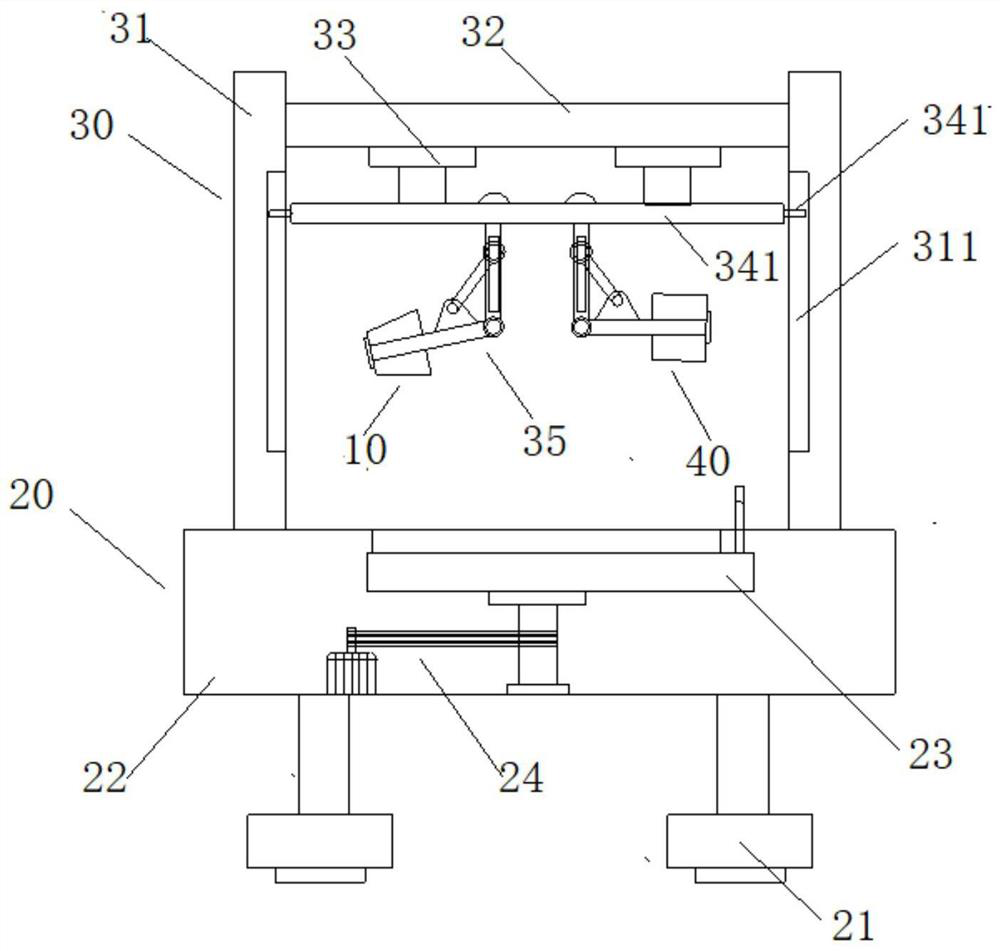

Printing device

PendingCN113386473AAvoid Paper Jam ProblemsRealize printingTypewritersOther printing apparatusComputer printingMechanical engineering

Owner:南京企顺自动化设备有限公司

PP film and solid wood board coating technology

The invention discloses a PP film and solid wood board coating technology. The PP film and solid wood board coating technology comprises the following steps that solid wood unit boards are prepared; moisture content is controlled; the moisture content of the prepared solid wood unit boards is controlled; an adhesive is applied to the solid wood unit boards, wherein the surfaces and peripheries ofthe solid wood unit boards are coated with the adhesive; PP film is prepared; the solid wood unit boards are coated with the with the PP film, wherein the solid wood unit boards coated with the adhesive are coated with the PP film, and sealing treatment is performed; assembly is performed, wherein the solid wood unit boards coated with the PP film are flatly laid between the two solid wood unit boards for assembly, one solid wood unit board coated with the PP film is laid between every two solid wood unit boards, the assembly layer number is N, and the number of the solid wood unit boards coated with the PP film is N-1; hot-pressing is performed, wherein hot-pressing is executed after assembly is completed; cold-pressing is performed, wherein boards are transferred into a cold-pressing machine within 2-3 minutes for cold-pressing after hot-pressing is completed. The PP film and solid wood board coating technology is somewhat improved based on solid wood boards, overcomes the shortcomings of possible arching, warping or deformation of the solid wood boards and has better stability.

Owner:绿新(无锡)装饰新材料有限公司

Method for processing blind buried hole on multilayer circuit board

ActiveCN102170759BOvercome warpingShort processPrinted element electric connection formationCopperElectroplating

The invention relates to a method for processing a blind buried hole on a multilayer circuit board, which belongs to the technical field of laser drilling. The technical key point of the invention comprises the following steps of: (1) confirming a position needing hole opening of the traditional mechanical blind buried hole circuit board; (2) processing a buried hole on an inner-layer plate of the position needing hole opening and electroplating again after filling resin into the buried hole for grinding to form a butting joint pad; and (3) drilling a laser blind hole on an upper-layer circuit board at at least one side of the processing buried hole and butting the laser blind hole with the pad formed electroplating on the mechanical buried hole to form a blind buried hole. Compared with the prior art, the invention has the advantages of shortening the process flow, thoroughly overcoming the phenomenon of board bending generated by asymmetric laminating structure design due to asymmetric hole layer distribution, solving the problem that a copper layer is relatively thicker and is adverse to the manufacture of a thin circuit because the traditional mechanical blind buried hole process outer layer is electroplated for many times, reducing the pressing frequency of board layers and the manufacture difficulty and improving the product quality.

Owner:BOMIN ELECTRONICS CO LTD +1

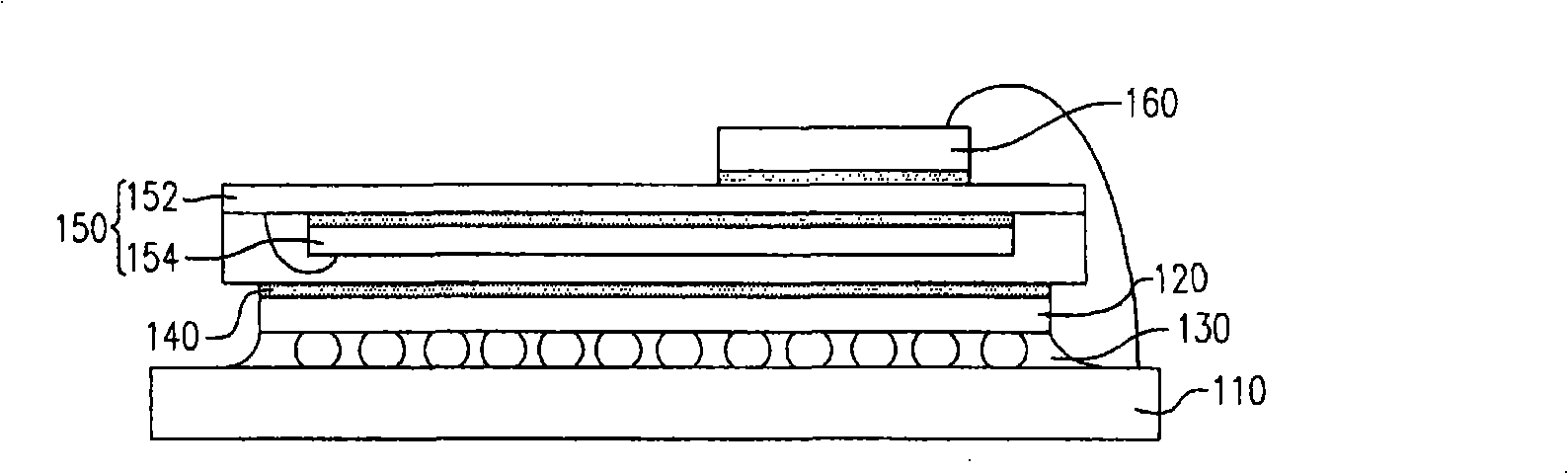

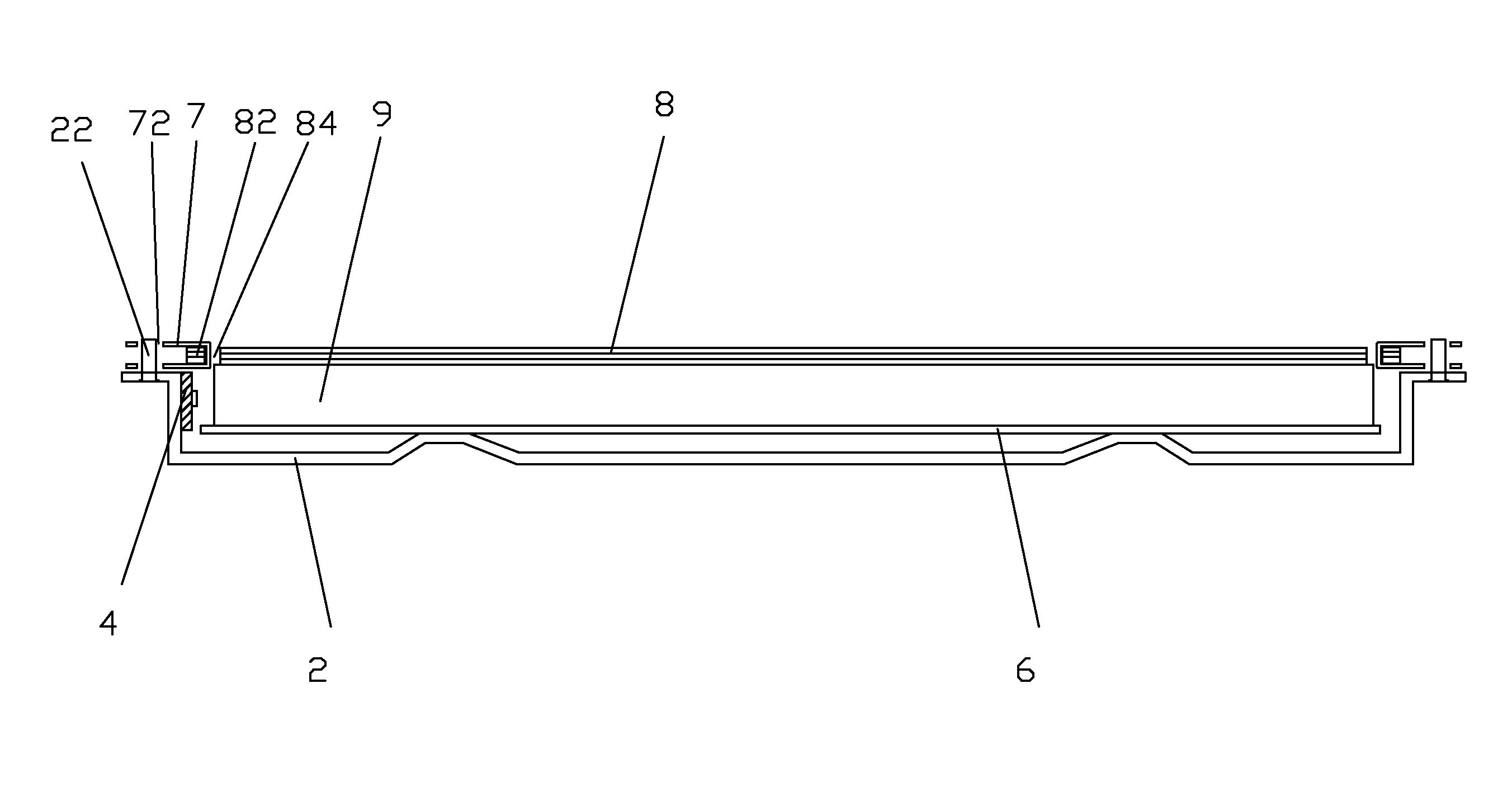

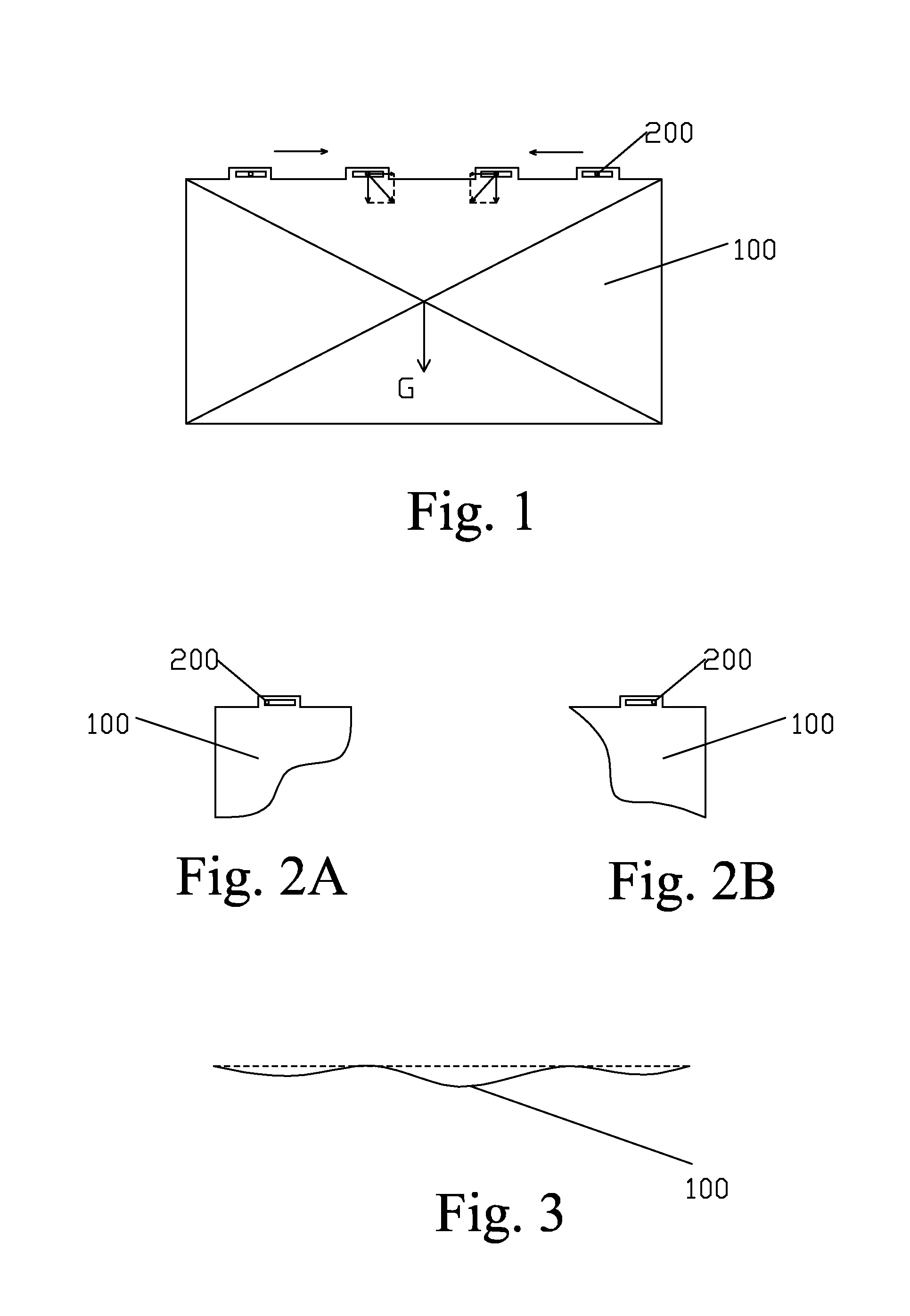

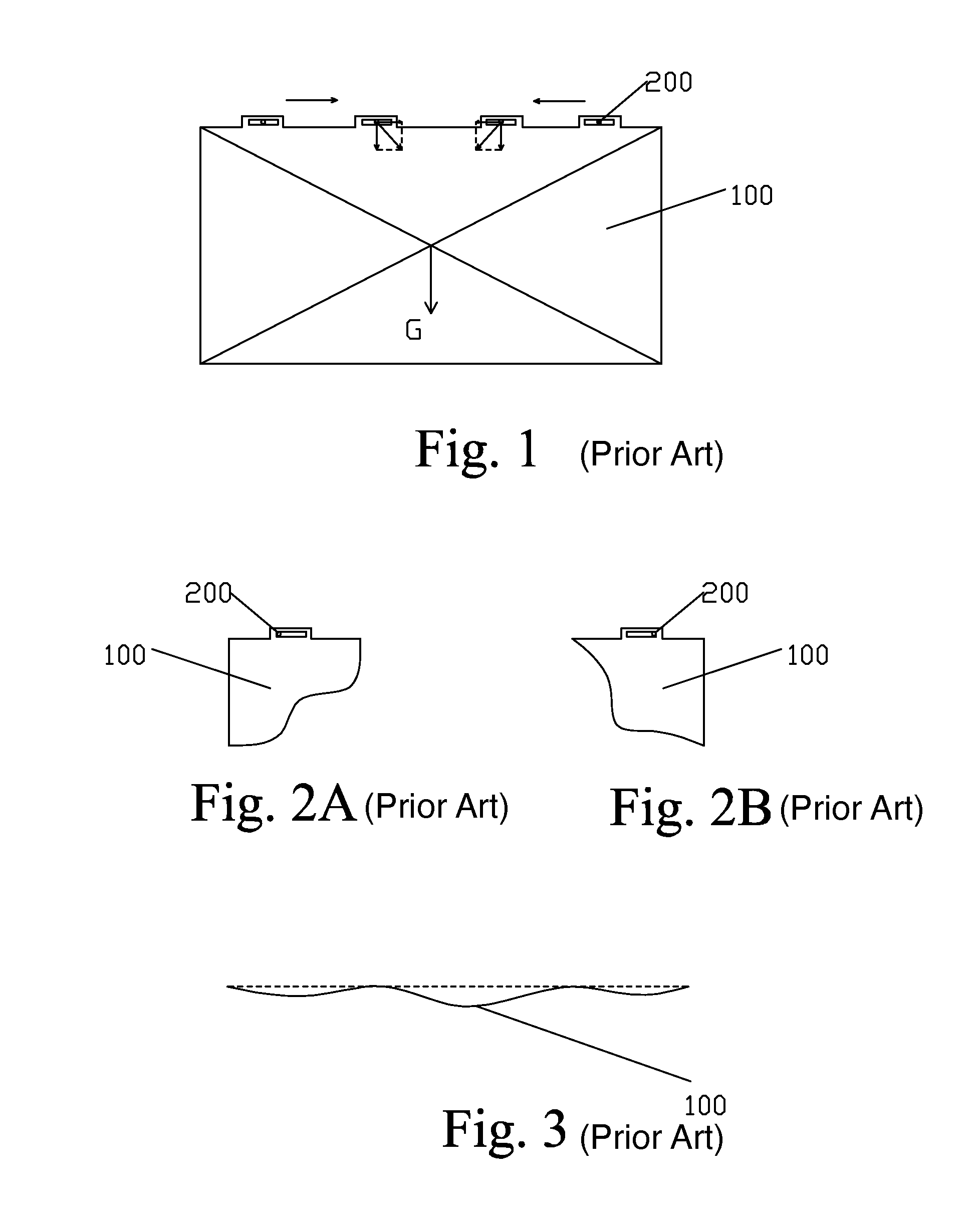

Backlight module

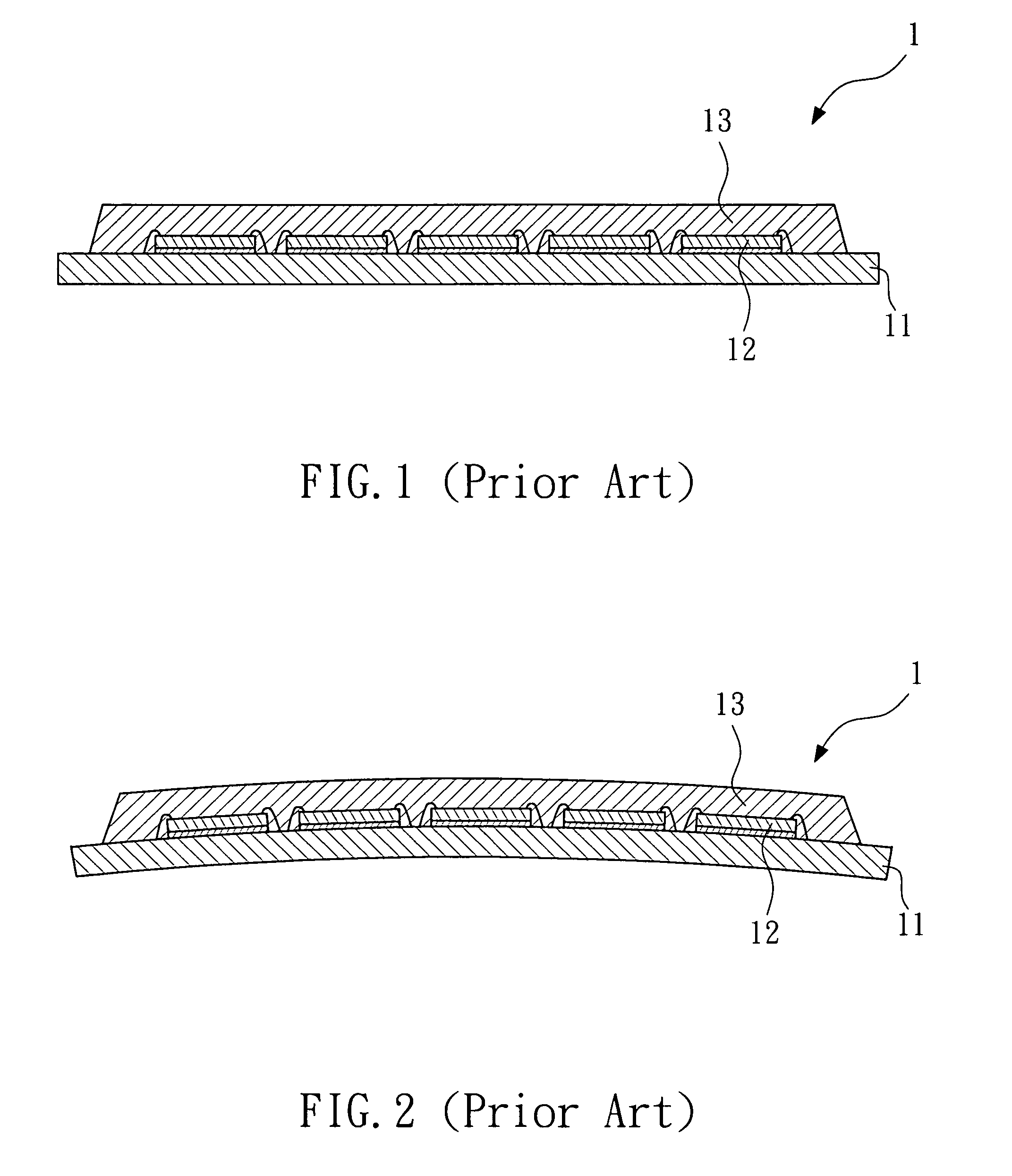

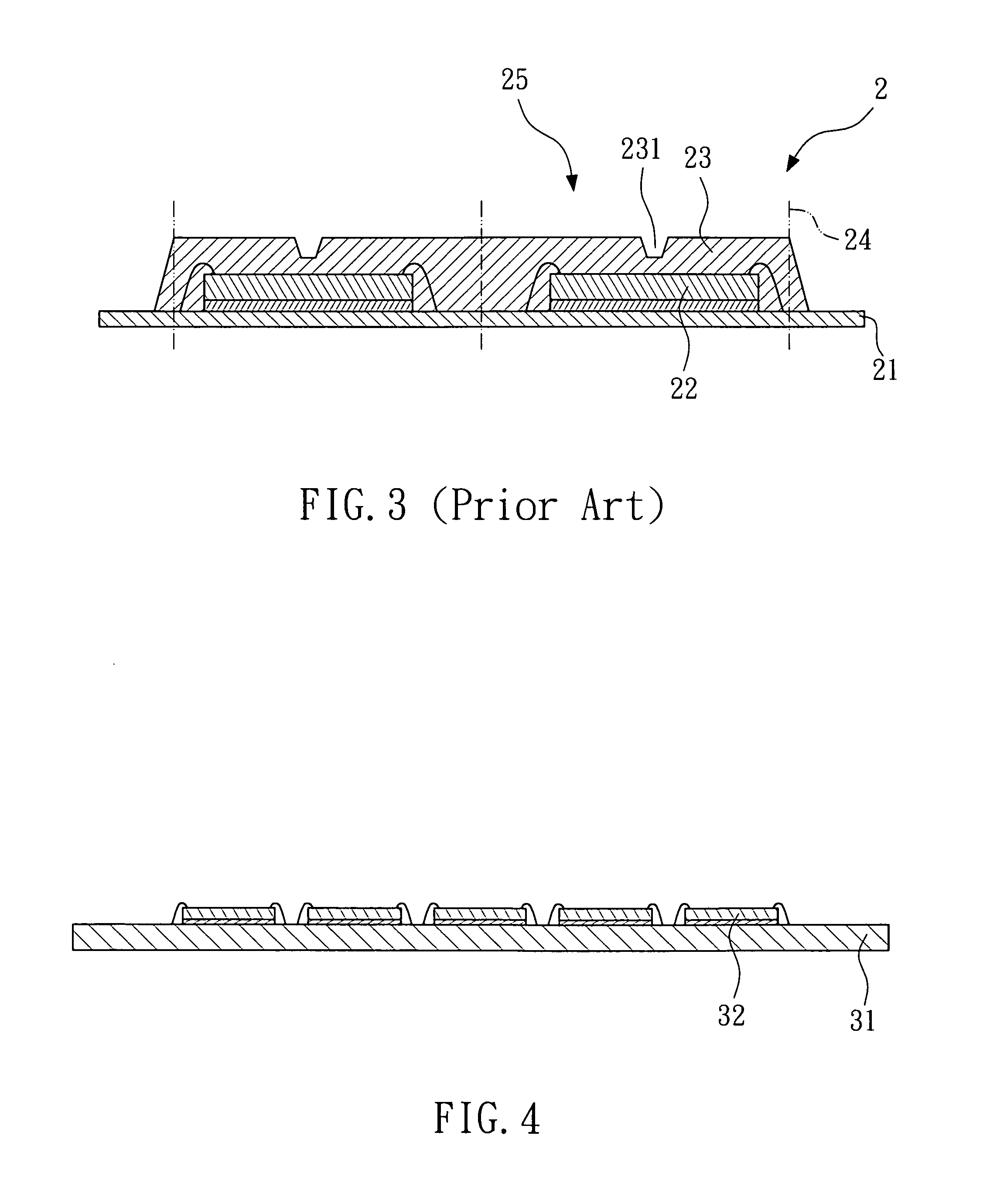

InactiveUS20140218963A1Additional warpingImprove image qualityMechanical apparatusPlanar/plate-like light guidesLight guideEngineering

The present invention provides a backlight module, which includes: a backplane, a backlight source arranged inside the backplane, a light guide plate arranged inside the backplane to correspond to the backlight source, a reflector plate disposed on a bottom of the light guide plate, an optic film disposed on a top of the light guide plate, and elastic members mounted to the backplane. The optic film has a top edge forming suspension sections and two first sidewalls respectively at left and right sides and each forming lugs. The suspension sections form first through holes. The lugs form second through holes. The backplane forms suspending pegs corresponding to the first through holes. The first through holes are mounted on the suspending pegs and the elastic members securely hold the second through holes and are mounted to the backplane so as to fix the optic films on the light guide plate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Jade enamel paint

InactiveCN106497285ABright colorRealistic patternFireproof paintsAnti-corrosive paintsSodium BentoniteLacquer

The invention relates to building paint applied to interior walls, in particular to jade enamel paint. The jade enamel paint comprises water, hydroxyethyl cellulose, dispersing agent, glycol, light calcium carbonate, sodium bentonite, ground calcium carbonate, talcum powder, wollastonite, silicone-acrylate emulsion, coalescing agent, hydroxypropyl methyl cellulose, pH value regulating agent, defoamer and thickener. The jade enamel paint has the advantages of high breathability, water resistance, scrubbing resistance, high adhesion strength, non-existence of powdering, peeling and bulging, relative flame resistance effect, simplicity and convenience in construction, optional matching of various patterns, variety in texture selection and the like.

Owner:赵永福

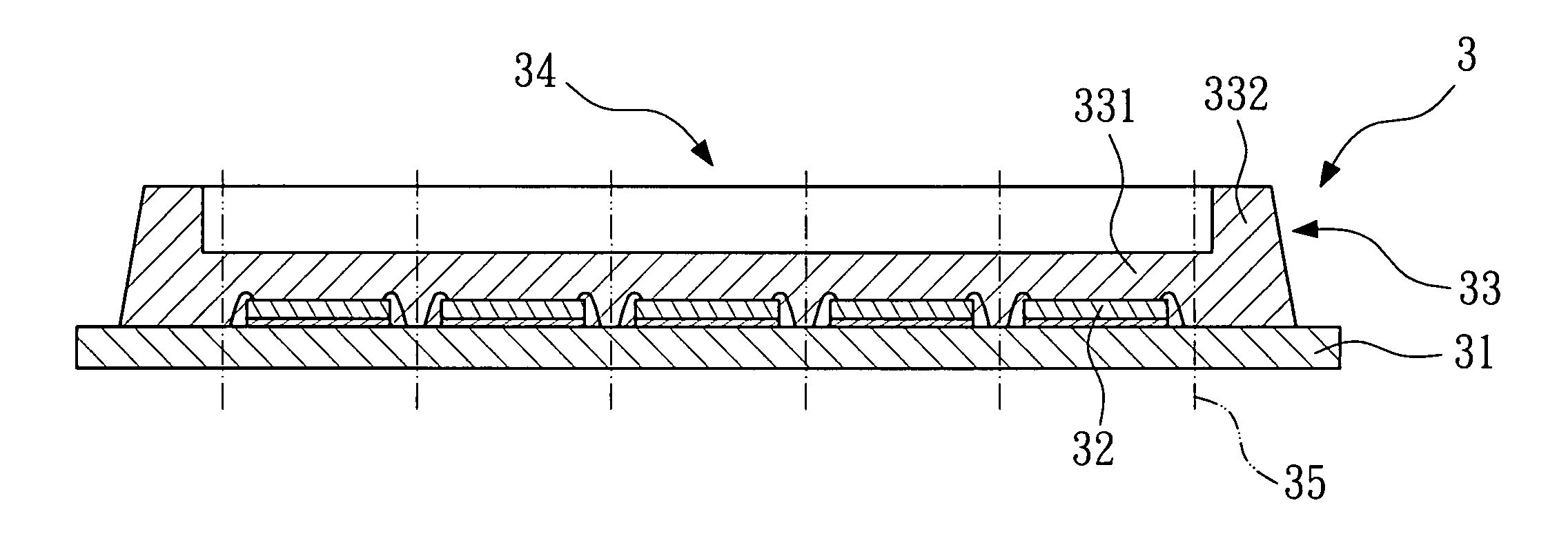

Semi-finished package and method for making a package

ActiveUS7927924B2Improve rigidityWarpage of the semi-finished packageSemiconductor/solid-state device detailsSolid-state devicesWork in processThermal expansion

The present invention relates to a semi-finished package and a method for making a package. The semi-finished package includes a carrier and at least one molding compound. The molding compound is disposed on a surface of the carrier, and has a body and a plurality of outer protrusions. The outer protrusions are disposed at the periphery of the body, and the height of the outer protrusions is greater than that of the body. Thus, by utilizing the outer protrusions, the rigidity of the semi-finished package is increased, so as to overcome the warpage of the semi-finished package caused by different coefficients of thermal expansion of the molding compound and the carrier. Therefore, the yield rate of the package unit is increased.

Owner:ADVANCED SEMICON ENG INC

Integral dynamic rail weighbridge

ActiveCN102221395BImprove stabilityReduce distortionWeighing apparatus detailsSpecial purpose weighing apparatusUniversal jointEngineering

Owner:YUYAO TONGYONG METER

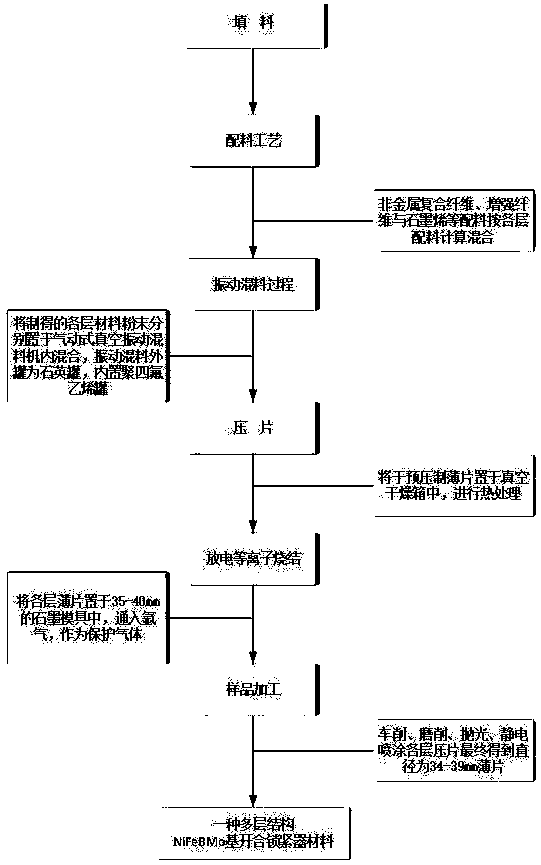

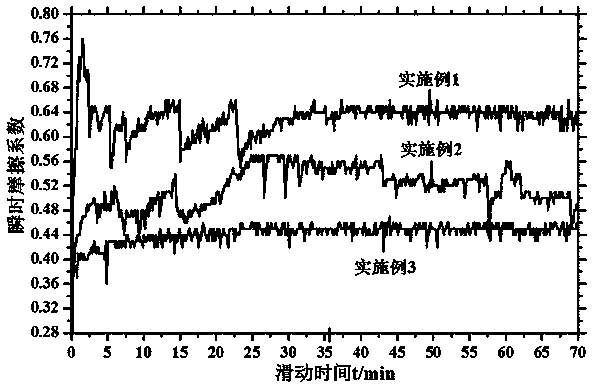

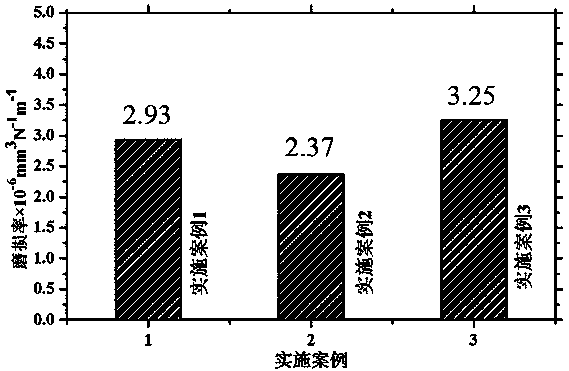

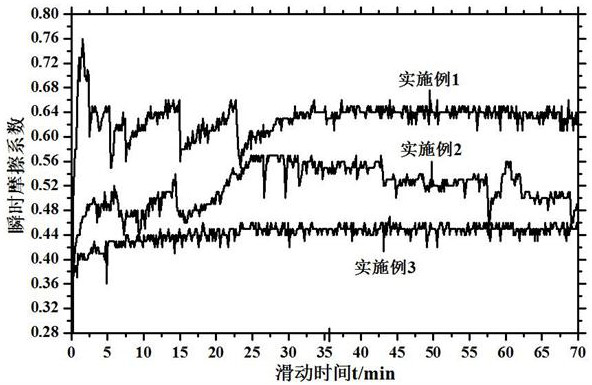

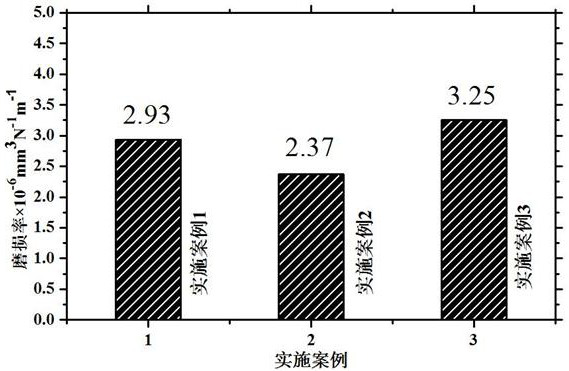

Preparation method of NiFeBMo-based opening and closing locker multilayer composite structure material

ActiveCN110747412AEasy to prepareThe preparation process is easy to controlFirming agentComposite structure

The invention discloses a preparation method of a NiFeBMo-based opening and closing locker multilayer composite structure material. The NiFeBMo-based opening and closing locker multilayer composite structure material is prepared from NiFeBMo matrix alloy, an anti-wear agent, a heat conduction agent, a reinforcing agent and a curing agent as raw materials through the steps of structural design andcomponent calculation of all layers, matching preparation, vibration mixing, dry hot-press molding, curing heat treatment, overlaying sintering and machining of all layers. The NiFeBMo-based opening and closing locker multilayer composite structure material has the advantages that all layers are different in component and thickness, and the component difference is large; the material shows the gradient distribution trend, the relative use amount of the material is reduced, and the friction and wear performance of the material is remarkably enhanced. Meanwhile, the preparation method is simple,the preparation technology is easy to control, efficiency is high, technological parameters are stable, operation is easy to control, all layers of structures of a prepared opening and closing lockercan be freely divided and repaired, the mechanical performance is stable, and the service life is long.

Owner:XINXIANG UNIV

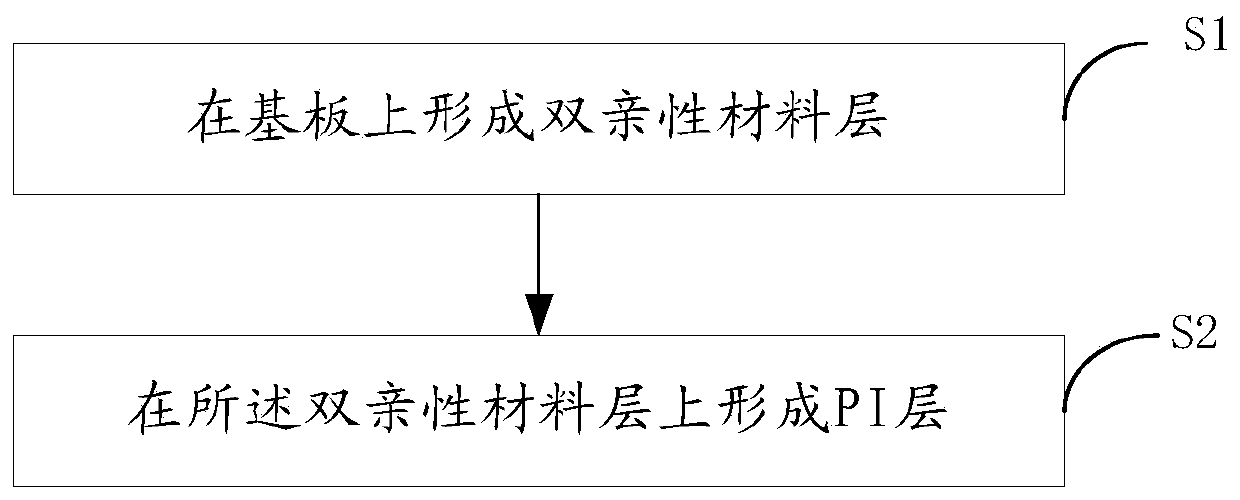

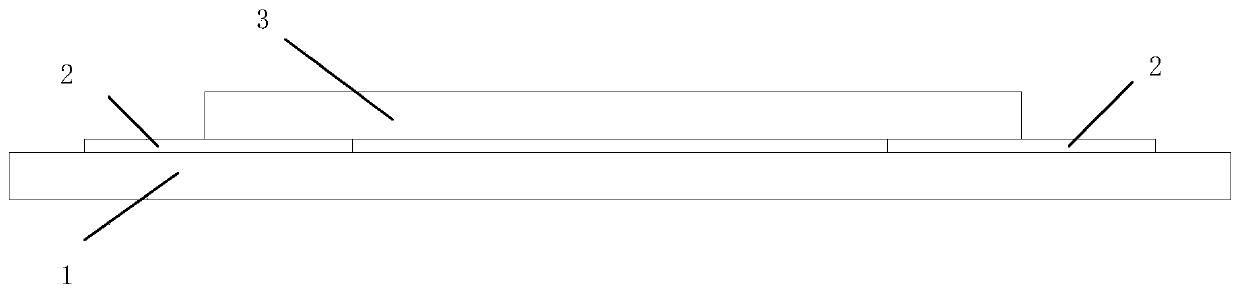

Method for stabilizing PI substrate to prevent warping and manufacturing method of display panel

ActiveCN110071231AGuaranteed manufacturing accuracyWon't hurtLiquid surface applicatorsSolid-state devicesAdhesion forceDissolution

The invention discloses a method for stabilizing a PI substrate to prevent warping and a manufacturing method of a display panel. The method for stabilizing the PI substrate to prevent warping comprises the steps of forming an amphiphilic material layer on the substrate; forming a PI layer on the amphiphilic material layer, wherein the amphiphilic material layer is at least located below the edgepart of the PI layer, and the curing temperature of the PI layer is higher than the critical dissolution temperature of the amphiphilic material layer. According to the scheme, due to the fact that the amphiphilic material layer is formed between the substrate and the PI layer, when the PI layer is heated to be solidified, and along with the temperature rise, the temperature is higher than the critical dissolution temperature of the amphiphilic material layer, an amphiphilic material in the amphiphilic material layer is lyophobic, so that the edge of the PI layer is contracted on the lyophobicamphiphilic material layer; a certain slip amount can be generated between the contracted part of the PI layer and the substrate, so that the problem that the contracted part of the PI layer pulls the substrate to be warped due to the existence of an adhesion force of the bonding strength between the PI layer and the substrate is solved; and under the condition that the substrate is not warped, the manufacturing precision of subsequent process devices can be ensured, and the damage to film forming equipment is avoided.

Owner:BOE TECH GRP CO LTD

Furniture edge sealant

InactiveCN102101989AOvercome warpingOvercome sheddingMonocarboxylic acid ester polymer adhesivesCellulose adhesivesCellulosePolymer science

The invention belongs to the technical field of adhesives, and in particular relates to a furniture edge sealant. The furniture edge sealant comprises the following raw materials in percentage by weight: 30 to 60 percent of wood glue powder, 15 to 40 percent of white latex and 10 to 40 percent of marine glue, wherein the wood glue powder is lignocelluloses; the marine glue is polymer cement-base marine glue; and the white latex is polyvinyl acetate white latex. The furniture edge sealant has high bonding strength, ageing resistance, certain flexibility and service life of 30 years, and can overcome the defects of warping and falling off of furniture edge bands due to wet expansion and dry shrinkage.

Owner:李角

Processing method of coreless substrate

ActiveCN104168726BOvercome warpage-prone problemsOvercome warpingMultilayer circuit manufacturePrinted element electric connection formationComputer science

An embodiment of the invention discloses a coreless substrate processing method which comprises the following steps: carrying out processing to form a first board set on one surface of a support layer; removing the support layer; and arranging the first board set between a third board set and a second board set. The technical scheme provided in the embodiment of the invention helps to improve production efficiency and qualified rate of the products.

Owner:SHENNAN CIRCUITS

A kind of preparation method of multi-layer composite structure material of nifebmo-based opening and closing locker

ActiveCN110747412BEasy to prepareThe preparation process is simple and controllableMetal layered productsFirming agentAlloy

Owner:XINXIANG UNIV

Thermal isolation structure of infrared detector and preparation method thereof

InactiveCN101603861BOvercome warpingImprove stabilityDecorative surface effectsChemical vapor deposition coatingThermal isolationEngineering

The invention discloses a thermal isolation structure of an infrared detector and a preparation method thereof. The method erodes a sacrificial layer material by a wet method, utilizes traverse etching effect of corrosive liquid, has quick reaction, and does not need opening multiple holes in the center of an image element to help removing the sacrificial layer material, so the process method is simple, can effectively relieve the problem of deformation of the image element after the removal of the sacrificial layer due to stress, and ensures the smooth surface of the infrared detector. In the thermal isolation structure, the edge of the rectangular image element is evenly provided with support posts, better stability and support effect are achieved, and the defects of warp and falling off of the surface of the detector caused by stress mismatch in the prior thermal isolation structure are overcome.

Owner:中电科技集团红外工程技术有限公司

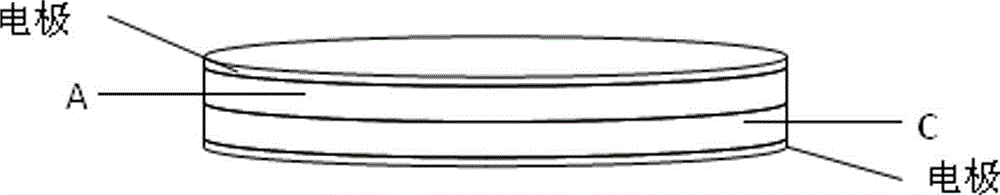

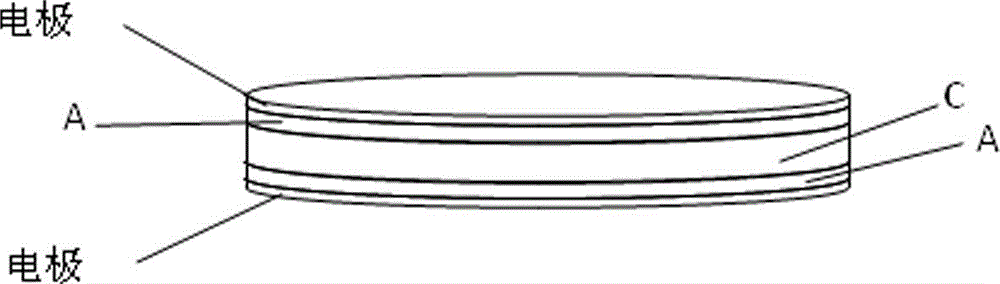

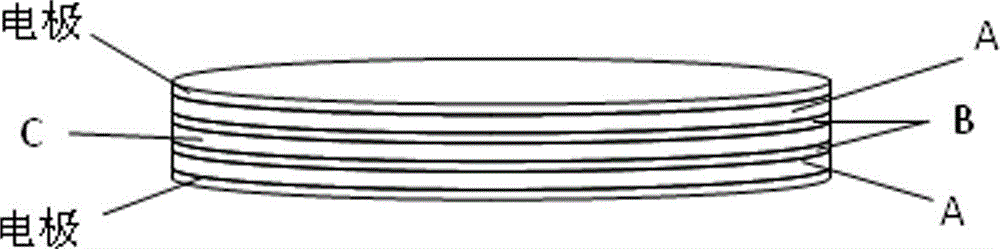

A temperature-stable heterogeneous multilayer dielectric ceramic capacitor and its preparation method

InactiveCN103208365BEasy to meet the requirements of X7ROvercome warpingFixed capacitor dielectricStacked capacitorsElectricityDopant

The invention provides temperature stable type heterogeneous laminated dielectric medium ceramic capacitors and a production method thereof. The production method comprises enabling barium strontium titanate to be main materials and the general formula to be as follows; adding modified dopant and combustion-supporting materials and dividing into three different main mediums, namely A, B and C, according to different proportions; performing lamination according to combination modes such as AC, ABC, ACA, CAC and ACBCA and laminating in an accumulating or mixing mode under the condition that the thickness of every layer is controlled to be small enough; and pressing, sintering and shearing electrodes to achieve the production of series and parallel heterogeneous laminated dielectric medium ceramic capacitors. Although the temperature stable type heterogeneous laminated dielectric medium ceramic capacitors are formed by the barium strontium titanate, lamination of multilayer with different proportions and different thicknesses is utilized and every layer is corresponding to different dielectric constants, dielectric losses and Curie temperatures, so that the requirements of a capacitor X7R can be met due to adjustment of different thicknesses or layers. At the same time, the electrodes are directly and externally arranged with no inner electrode, so that mismatching of sintering characteristics of an electrode layer and a dielectric layer is effectively overcome and the problems such as ceramic body layering and warping after co-firing caused by the mismatching are solved.

Owner:HUBEI UNIV

Backlight module

InactiveUS8960981B2Additional warpingImprove image qualityMechanical apparatusPlanar/plate-like light guidesLight guideEngineering

A backlight module includes: a backplane, a backlight source arranged inside the backplane, a light guide plate arranged inside the backplane to correspond to the backlight source, a reflector plate disposed on a bottom of the light guide plate, an optic film disposed on a top of the light guide plate, and elastic members mounted to the backplane. The optic film has a top edge forming suspension sections and two first sidewalls respectively at left and right sides and each forming lugs. The suspension sections form first through holes. The lugs form second through holes. The backplane forms suspending pegs corresponding to the first through holes. The first through holes are mounted on the suspending pegs and the elastic members securely hold the second through holes and are mounted to the backplane so as to fix the optic films on the light guide plate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Film processing device and method

The invention discloses a film processing device. The film processing device comprises a transverse pulling box and a transverse pulling unit, the transverse pulling unit comprises a transverse pulling pinch roll unit and a transverse pulling cutter unit which are arranged in the transverse pulling box, and the transverse pulling box comprises an N3 area, a first cooling area and a second cooling area which are sequentially arranged in the transverse pulling box in the traction direction of a film. The transverse pulling pinch roll unit comprises at least two sets of pinch roll groups. The at least two sets of pinch roll groups are separately arranged in the first cooling area and the second cooling area. Each set of pinch roller group is used for clamping the two sides of the film in the width direction. The transverse pulling cutter unit and the transverse pulling pinch roll unit are sequentially arranged in the traction direction of the film, and the transverse pulling cutter unit is arranged in the N3 area and used for cutting the edge of the film. The invention further discloses a film processing method, the film can be separated from the clamping of a chain clamp before entering the cooling areas, the longitudinal thermal shrinkage rate is improved, and the problem that the film is wrapped due to the fact that the film is beaten towards the middle under the action of no transverse tension is solved.

Owner:HEFEI LUCKY SCI & TECH IND

Adhesive for organic film of semiconductor components and its preparation method and application

ActiveCN105860921BOvercome warpingModerate rate of hydrolysisSemiconductor/solid-state device detailsSolid-state devicesOrganic filmAdhesive

The invention discloses adhesive used for a semiconductor component organic film. The adhesive comprises polyalkoxysilane with a coupling function and solvent, polyalkoxysilane has a silicon hydroxyl group, and the solvent is composed of 1-methoxy-2-propyl alcohol, 3-aminopropyl silanetriol and 2-methoxy-1-propyl alcohol; according to the adhesive used for the semiconductor component organic film, polyalkoxysilane having the adhesion function is fully hydrolyzed, little low polymer is generated during hydrolysis, the adhesive is good in adhesion effect when used for adhering to an organic base material and an inorganic base material, and a coating layer on the surface of the inorganic base material is prevented from warping or falling; the adhesive is particularly suitable for small-size electronic components with intensive and complex surface graphs.

Owner:昆山艾森世华光电材料有限公司

Coreless panel manufacturing component, coreless panel, and coreless panel manufacturing method

ActiveCN104540339BOvercome warpingImprove yield rateSemiconductor/solid-state device manufacturingMultilayer circuit manufactureCopper foilEngineering

Provided is a coreless plate fabricating member, comprising a supporting carrier and coreless plates disposed on both sides of the supporting carrier. The coreless plate comprises inner prepregs, outer prepregs, inner layer copper foils and outer layer copper foils; wherein the inner prepregs are disposed on both sides of the inner layer copper foils, the outer prepregs are disposed at the outermost layer of the inner layer copper foils, and the outer layer copper foils are provided at the outer prepregs; and gaps are opened on the frame of the inner layer copper foils. By using the coreless plate fabricating member, coreless plate and method for fabricating the coreless plate of the present application, the supporting carrier is ingeniously disposed, which can effectively overcome a problem of coreless plate warping, and improves the yield of the coreless plate production.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Horizontal rolling process and forming device for special-shaped ring piece

The invention relates to the field of ring piece machining equipment, in particular to a horizontal rolling process and forming device for a special-shaped ring piece. The horizontal rolling process comprises the following steps that a blank is heated to the forging temperature and subjected to punch forming; a formed ring piece blank is moved to a working platform to be fixed; two opposite grinding wheels and two opposite pressing wheels are used for rolling an obtained workpiece blank; and flashes and burrs are removed. The forming device comprises the grinding wheels pressed on the side edge of a ring piece to be formed, the pressing wheels pressed on the side edge of the other side of the ring piece to be formed and arranged opposite to the grinding wheels, an operation platform used for placing the ring piece to be formed and driving the ring piece to rotate, and a support arranged on the operation platform and rotationally connected with the grinding wheels. By means of the design scheme that the edge of the pressing wheel is rolled by the rolling wheel to be warped consistently, the edge warping problem of the ring piece is effectively solved, and the quality of a finally-formed product is effectively improved; the replacement frequency of the support or the grinding wheel or the pressing wheel is reduced through an adjustable installation frame, meanwhile, the time for adjusting the support is saved, and operation is easy.

Owner:常州和仕达机械装备制造有限公司

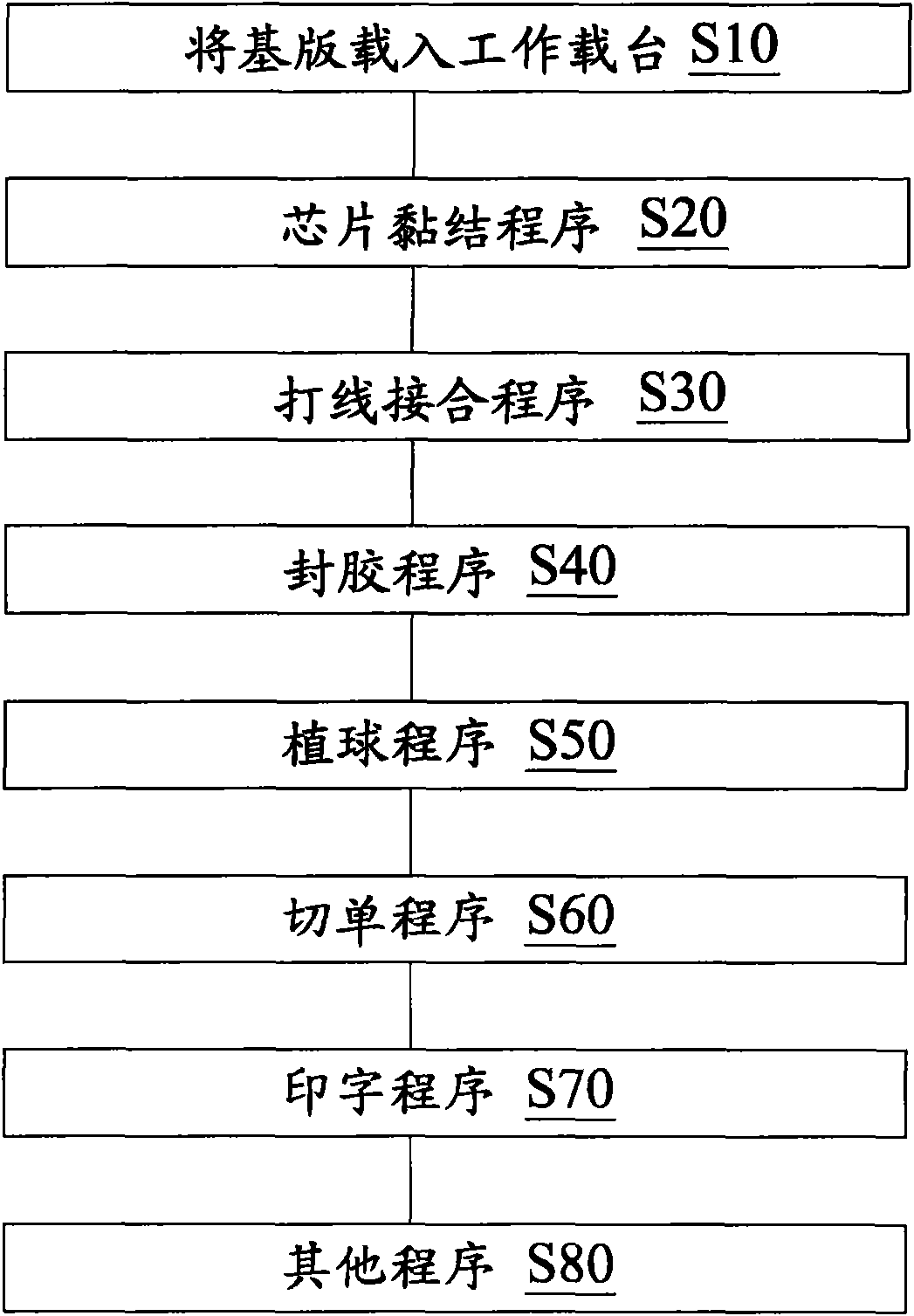

Electronic packaging method and device

InactiveCN101625959AIncrease productionLow costSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention discloses an electronic packaging method and an electronic packaging device. The method carries out each packaging program by loading a work loading platform to a whole substrate. A plurality of packaging devices are hung near the work loading platform and are moved to an operation position by a mechanical arm. Therefore, problems of warping and transferring of the substrate can be effectively solved. The electronic packaging method and the electronic packaging device can use the whole substrate to carry out the packaging operation and can simultaneously carry out the same or different packaging programs in different areas of the whole substrate so as to effectively increase the yield and reduce the cost.

Owner:POWERTECH TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com