Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Realistic pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

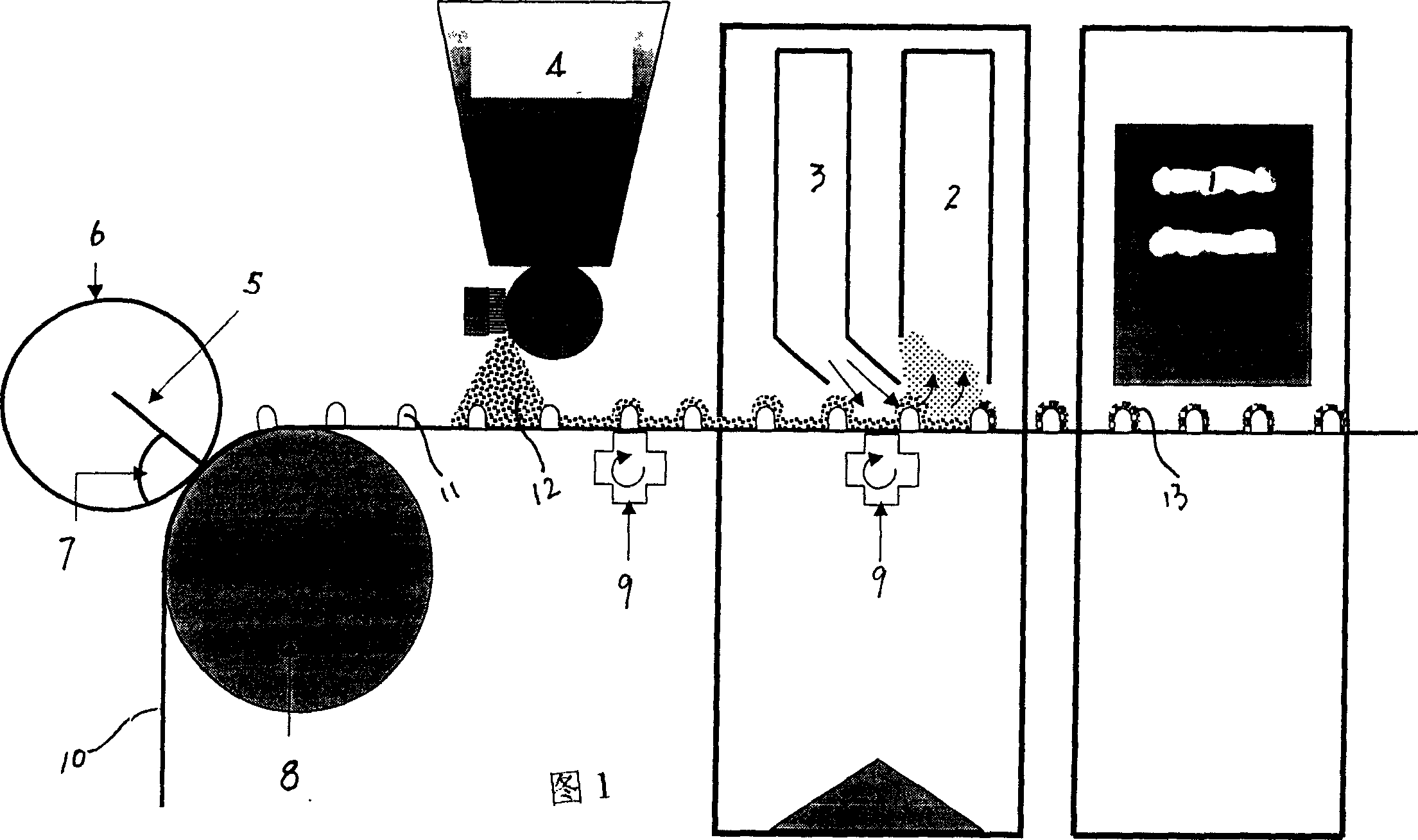

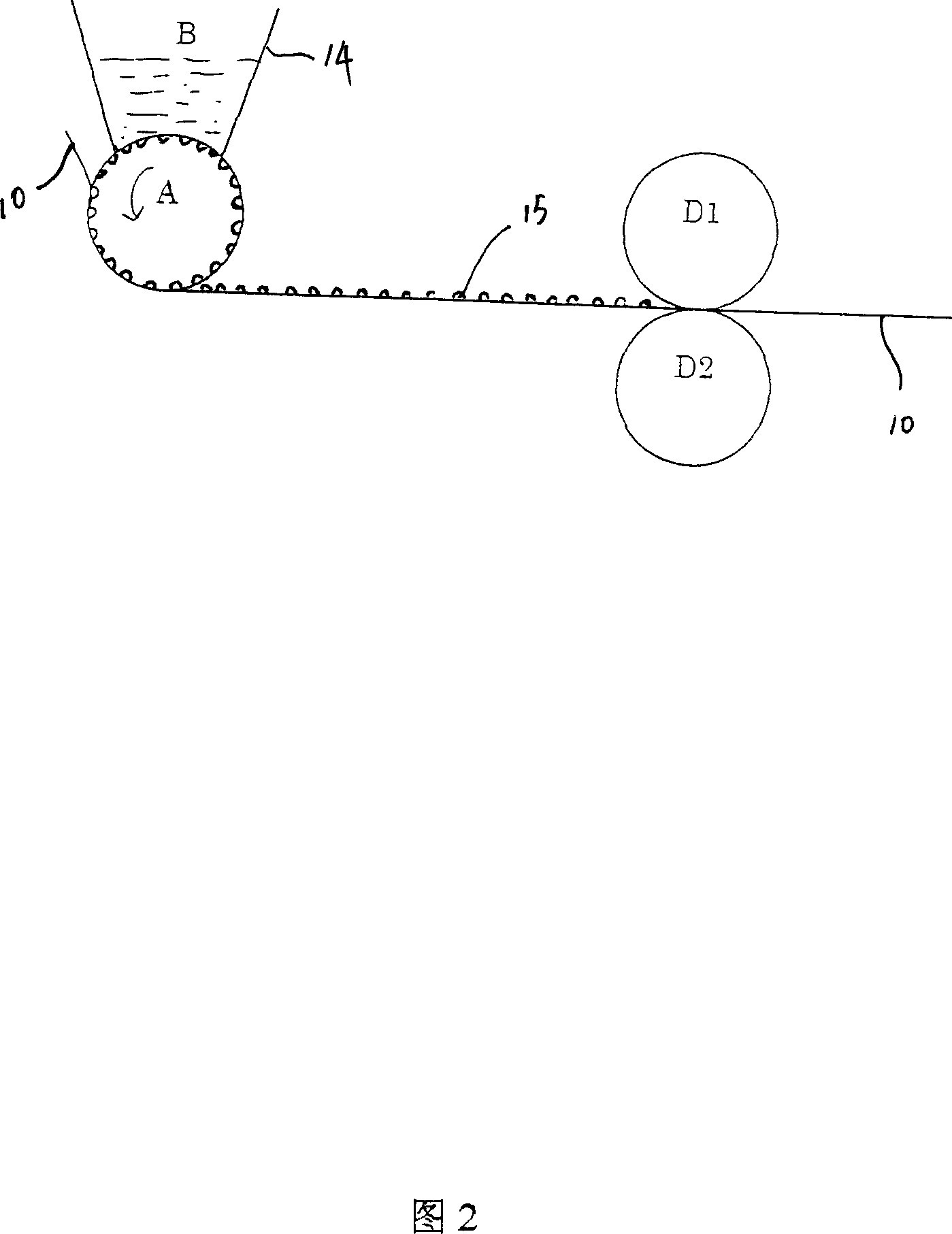

Printing adhesive liner cloth and its making process

InactiveCN101008155ARealistic patternStrong three-dimensional senseTransfer printing processTextile decorationSingle pointEngineering

The invention relates to a spinning adhesive liner and relative production, comprising that: preparing needed pattern on the treated base cloth via transfer or screen printing method; secondary treating and feeding it into special coating machine; to coat thermal-sensitive adhesive resin on the base cloth, with slurry point and single point, to obtain the target printed adhesive liner; using thermal rolling method to adhere the printed liner with face fabric to obtain clothes material.

Owner:NITTOBO CHINA CO LTD

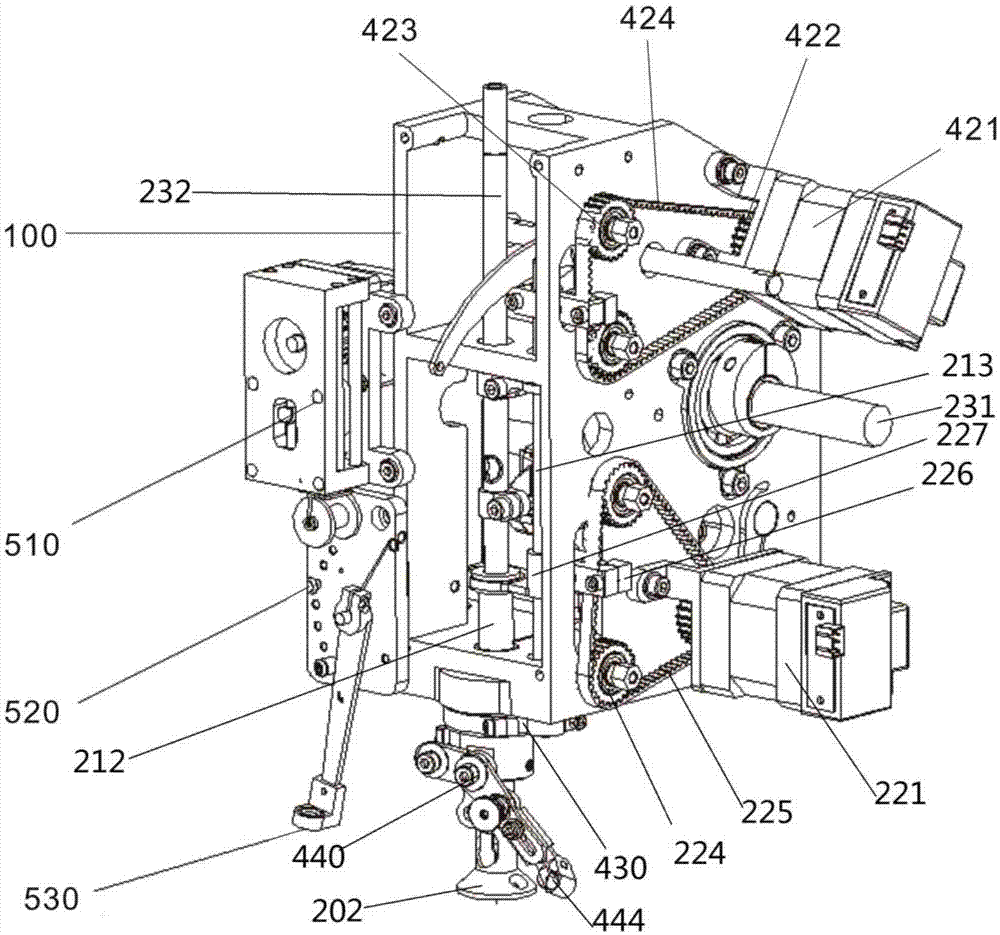

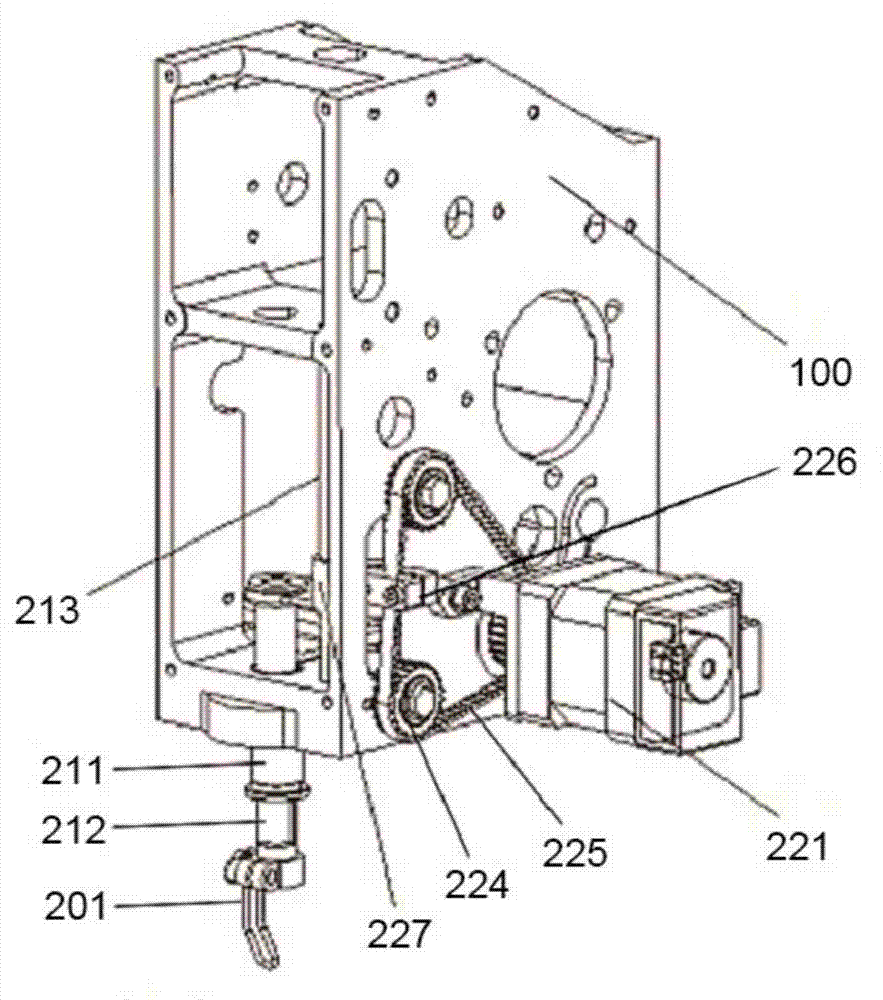

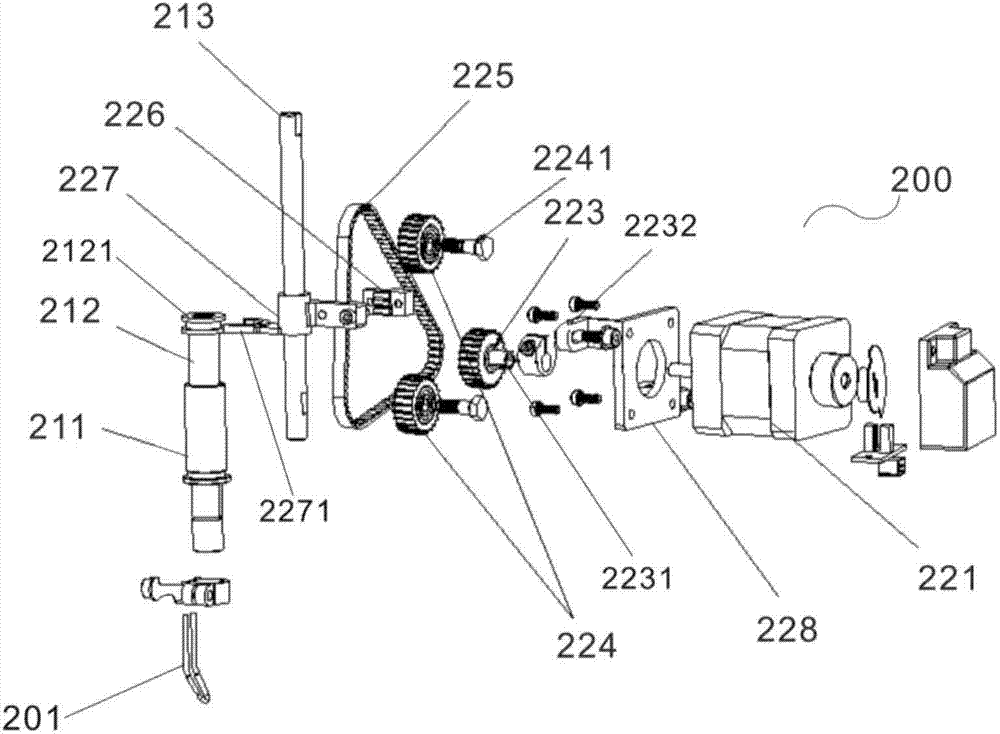

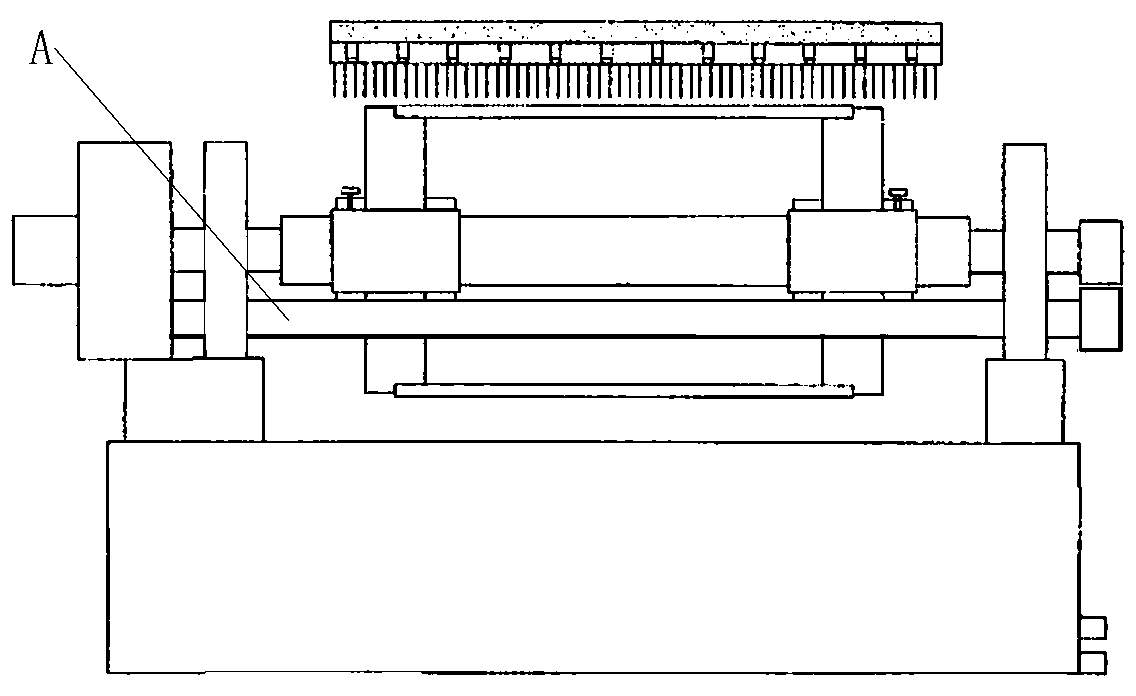

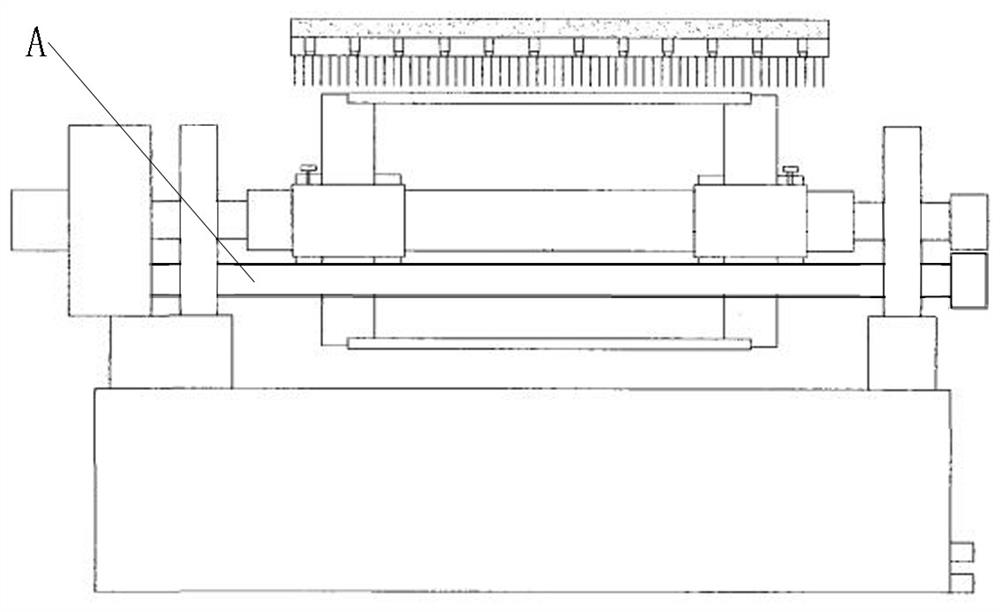

Independent taping embroidery device and embroidery machine comprising same

The invention provides an independent taping embroidery device and an embroidery machine comprising same. The independent taping embroidery device comprises an enclosure, a pressure foot mechanism arranged on the enclosure, an embroidery trajectory tracking mechanism, a cording embroidery mechanism and a needle bar driving mechanism, wherein the pressure foot mechanism comprises a pressure foot, a pressure foot transmission component and a pressure foot driving component; the embroidery trajectory tracking mechanism comprises a trajectory tracking driving component and a trajectory tracking transmission component, and the cording embroidery mechanism comprises a sliding bar, a cording embroidery driving component, a lifting ring component and a pendulum plate component, wherein the needle bar driving mechanism drives a needle bar to move up and down by a spindle of the embroidery machine, and the pressure foot mechanism, the embroidery trajectory tracking mechanism and the cording embroidery mechanism are respectively driven by stepping motors which are installed at corresponding positions on the enclosure and drive corresponding synchronous belts. Compared with the prior art, the invention can realize automatic switching of various working modes, and has the obvious advantages and positive effects such as simple and compact structure, convenience in installation and maintenance, more functions and wide application.

Owner:WENZHOU OULUOHUA INDAL

A woven back-cloth plastering carpet and method for manufacturing the same

InactiveCN1729899AFlat surfaceRealistic patternTufting apparatusLayered productsEngineeringBack-stripping

The invention relates to a woven back stripping carpet and its manufacturing method, comprising following steps: combing the spinning; beating the spinning and combining into section; weaving; printing decoration; filtering; fixing color; water washing; drying; scalding and cutting; and gluing the back stripping. In addition, the invention also relates to a carpet produced by said method, which has the advantages of flat surface of carpet, reality of pattern, non-fading, burliness, stability of fluff, and the neatness of the border while the bottom of carpet is antiskid and permeable to air.

Owner:刘福利 +1

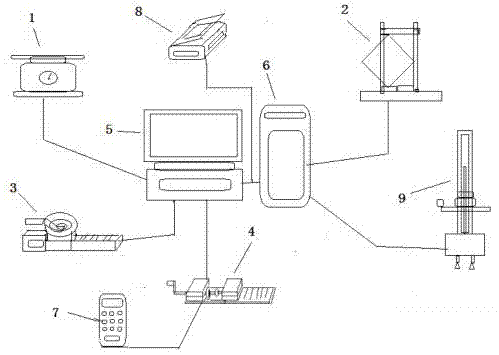

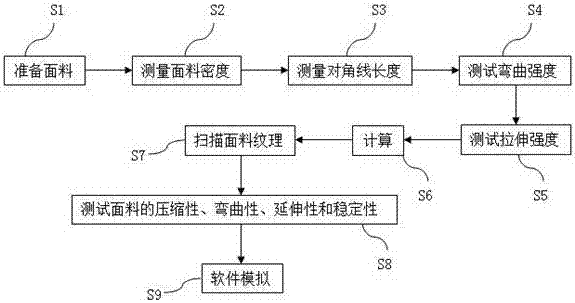

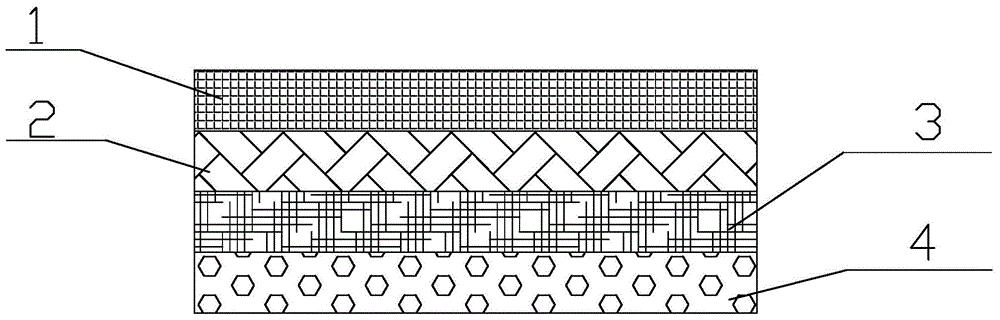

Simulation system for physical properties and digital attributes of textile fabric and measurement method

PendingCN106909763AEnhanced fabric simulationThe calculation process is simpleTextile testingDesign optimisation/simulationMeasurement deviceComputerized system

The invention discloses a simulation system for physical properties and digital attributes of a textile fabric and a measurement method. The simulation system comprises a computer system, fabric simulation software, a fabric physical property measurement device and a fabric scanning system, wherein the fabric simulation software is arranged in the computer system; the fabric physical property measurement device and the fabric scanning system are connected with the computer system separately; the computer system is provided with a data output port; and various physical data during fabric measurement and data during fabric scanning are subjected to operation work through the computer system. The real visual effect of the physical attributes of the garment fabric can be quickly and virtually shown, the technical problems of distortion and deficiency of various physical attributes of the garment fabric simulated by three-dimensional garment simulation software in the market at present are successfully solved, and the realistic design effects of various dresses, work clothes, underwear, three-dimensional embroideries and the like can be shown.

Owner:广西大海服装科技有限公司

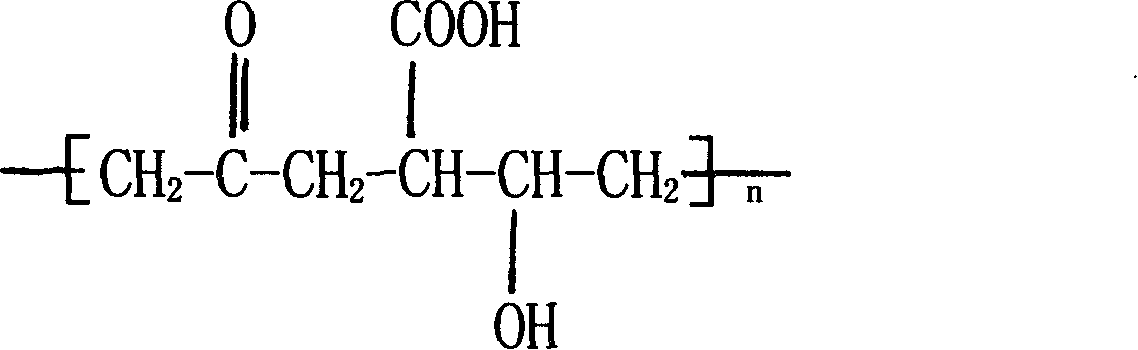

Silk printed fabric and preparation method thereof

ActiveCN108660815ARealistic patternEasy to operateTransfer printing processDyeing processPre treatmentWater soluble

The invention relates to a preparation method of a silk printed fabric. The preparation method comprises the following steps of applying a macromolecular modifier to the surface of paper, and treatingat the temperature of 60 DEG C, so as to obtain the transfer printing paper, wherein the weight increasing amount of the paper is 10 to 20g / m<2>, and the macromolecular modifier is prepared from thefollowing components in percentage by mass: 0.5 to 5% of water-soluble hot melt glue, 2 to 12% of thickener, 0.5 to 3% of acid and alkaline agent, 2 to 8% of moisture absorber, and the balance of water; performing ink jetting and printing onto the transfer printing paper by active dye ink or acid dye ink, and drying, so as to obtain the transfer printing paper jetted with ink; soaking and rollingthe silk fabric, wherein the liquid entrapping rate of the fabric is 80 to 90%; laminating the transfer printing paper jetted with ink and the pretreated silk fabric in a hot press way, steaming by vapor, and washing by water, so as to obtain the silk printed fabric, wherein the permeation hot press temperature is 100 to 160 DEG C, and the hot press pressure is 3 to 6MPa. The preparation method has the advantages that the technology is simple and environmentally friendly; the color depth value of the prepared silk printed fabric is 4 to 7, the permeation rate of dye is 90% to 111%, and the color fixation rate is 79 to 90%.

Owner:SUZHOU UNIV

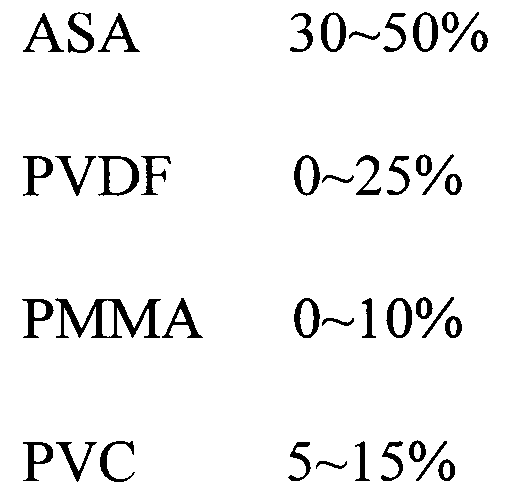

Weather-resistant decorative film and preparation method thereof

InactiveCN106496906AGood chemical resistanceGood weather resistanceFlat articlesPolymer scienceWeather resistance

The invention relates to a weather-resistant decorative film and a preparation method thereof. The weather-resistant decorative film comprises one or more of ASA, PVDF, PMMA and PVC and all the components are distributed in layers. The preparation method of the weather-resistant decorative film comprises raw material drying, extrusion, rolling, curtain coating, calendering, film blowing, edge cutting and winding. Compared with the existing decorative film, the weather-resistant decorative film is prepared from ASA and PVDF\PMMA\PVC through co-extrusion, rolling, curtain coating and film blowing so that a production cost is reduced. The weather-resistant decorative film is not easy to layer and has realistic patterns, scratch resistance and good weather resistance.

Owner:SUZHOU LUORUIKA NEW MATERIAL TECH CO LTD

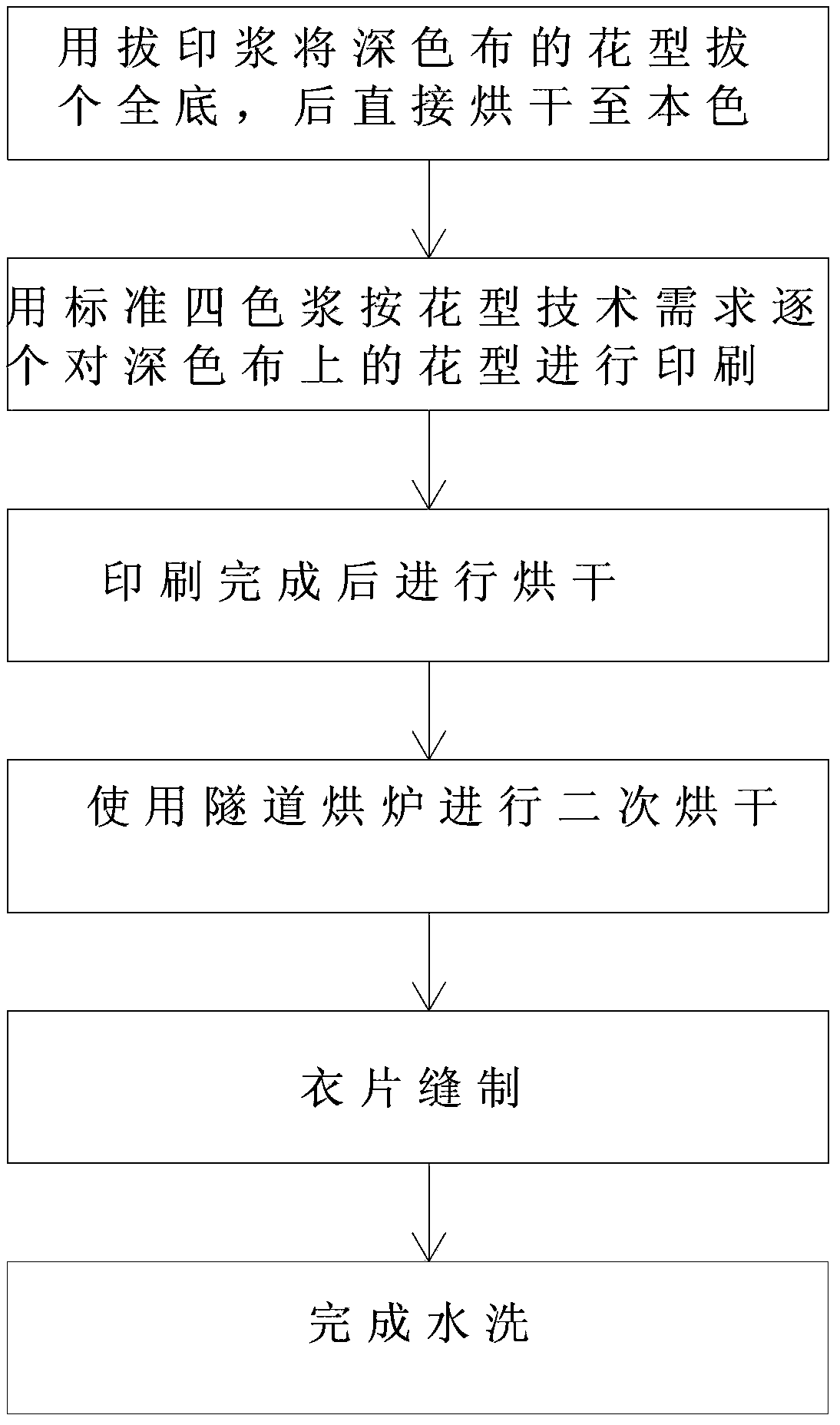

A four-color printing method for dark-color fabric of garments

A four-color printing method for dark-color fabric of garments is disclosed. The method includes following steps of: subjecting the dark-color fabric to complete discharge printing of flower patterns to be printed by using a discharge printing agent; directly drying by using a printing table drying oven until the natural color occurs; printing the flower patterns one by one through using standard four-color paste according to technical needs; drying after printing is finished; performing secondary drying by a tunnel stove; sewing garment pieces, and washing with water. The garments produced by the method are life-like, fine, soft in hand feeling, comfort in body feeling, and largely broadened in market. The method is simple and convenient in operation and is suitable for quantity production. Operability of the method is reflected in that: quality of printing can be seen clearly in a printing process (while quality of printing in direct discharge printing cannot be seen), quality deviation can be corrected in real time during quantity production, and the garments after sewing and water washing are very soft in hand feeling.

Owner:TIANJIN RUITONG GARMENT

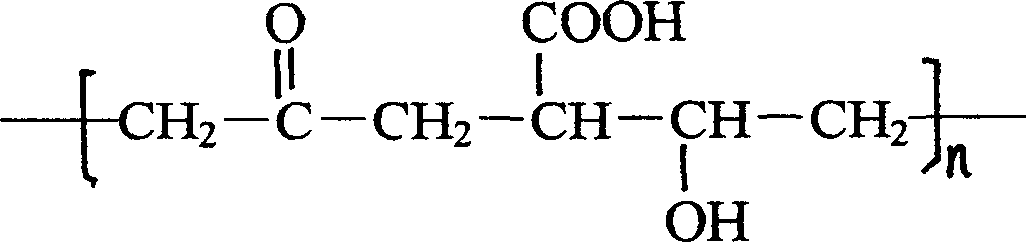

Reactive-dye wet-transfer printing technology of pure-cotton fabric

InactiveCN104562811ARealistic patternImprove the artistic effectTransfer printing processDyeing processSodium silicateChemistry

The invention discloses a reactive-dye wet-transfer printing technology of pure-cotton fabric. The reactive-dye wet-transfer printing technology adopts the technical process as follows: conducting alkali rolling on the fabric, rolling and transferring, piling and performing color fixing, and washing and drying; a formula of an alkali solution is as follows: 15g / L of a caustic soda solution and 31g / L of sodium silicate solution; transfer printing conditions are as follows: the alkali rolling liquid rate is 70-80% and the transfer printing pressure is 0.2-0.4MPa; printing of transfer printing paper adopts the technical process as follows: concocting a color paste, printing transfer paper and airing; a formula of the color paste is as follows: 0.5-3.0% of reactive dye, 3-15% of urea, 25-40% of modified starchRX60+ emulsified paste and the balance of water. Transfer printing adopts a method of printing the transfer printing paper, is rich and colorful and multi-layered in pattern, convenient and free in pattern design and strong in expressive ability, can print the pattern with vivid pattern shape and strong artistry, is simple in equipment and convenient in management, and can reduce pollution to the environment.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

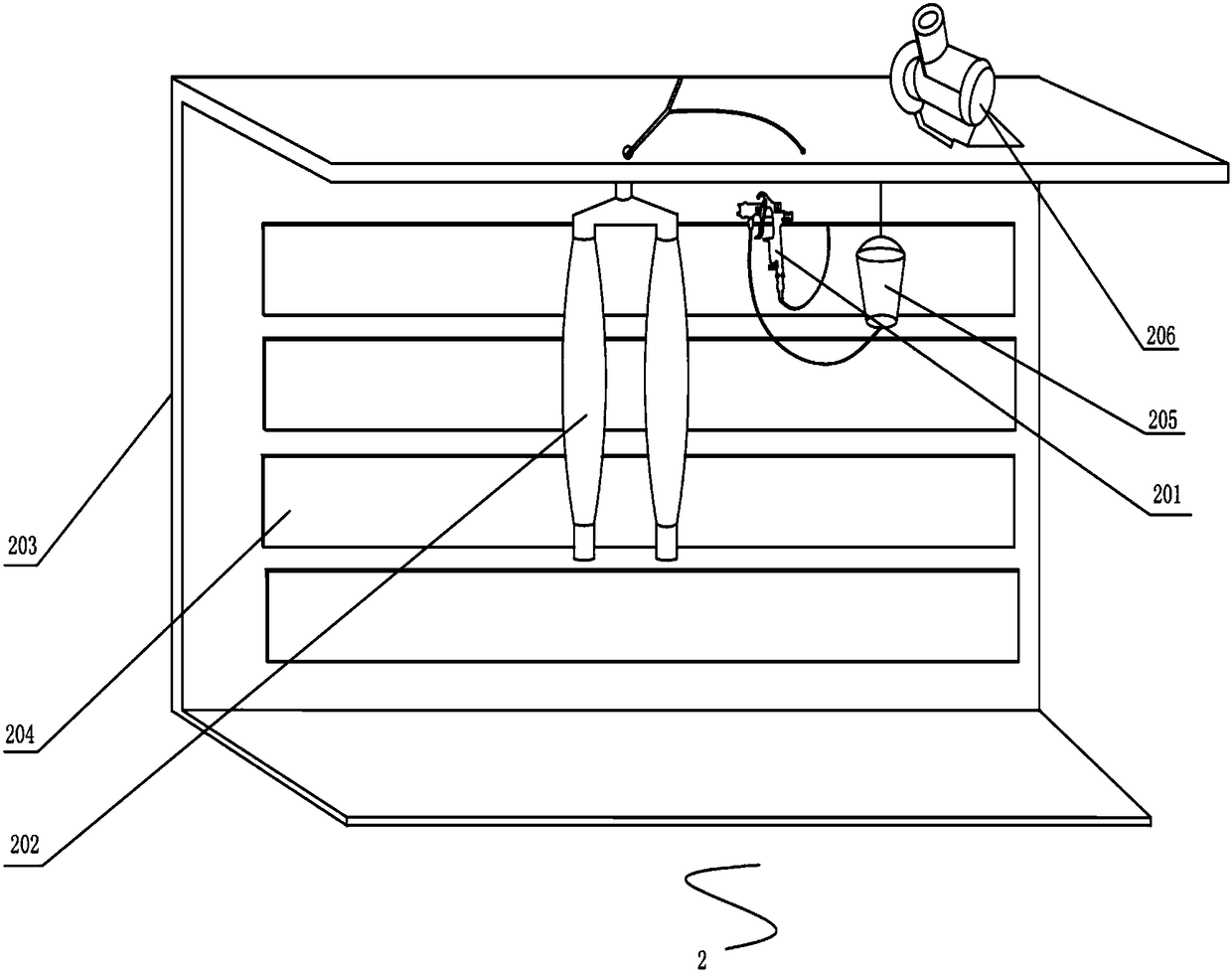

Jeans frosting apparatus and method

The invention discloses a jeans frosting apparatus, comprising a polishing device and a spraying device. The polishing device comprises a trouser-shaped soft bag, a control pedal and an electric grinder; the spraying device comprises a spray gun and another trouser-shaped soft bag; the spray gun is connected with potassium permanganate and high-pressure gas. Jeans polishing includes a grinding step and a spraying step; the grinding step includes inflating the trouser-shaped soft bag to expand jeans; primarily grinding the front and back of thighs and shanks of the jeans with the electric grinder, and holding an abrasive paper drum by hand to grind small parts so as to finish grinding; the spraying step includes placing the jeans on the trouser-shaped soft bag of the spraying device, inflating the trouser-shaped soft bag, spraying potassium permanganate to the proper parts of the front and back of the jeans with the spray gun, soaking in a soaking liquid, neutralizing the potassium permanganate, dewatering the soaked jeans, and drying to obtain jeans which are of great layering impression and have naturally changing color.

Owner:广州市创兴服装集团有限公司

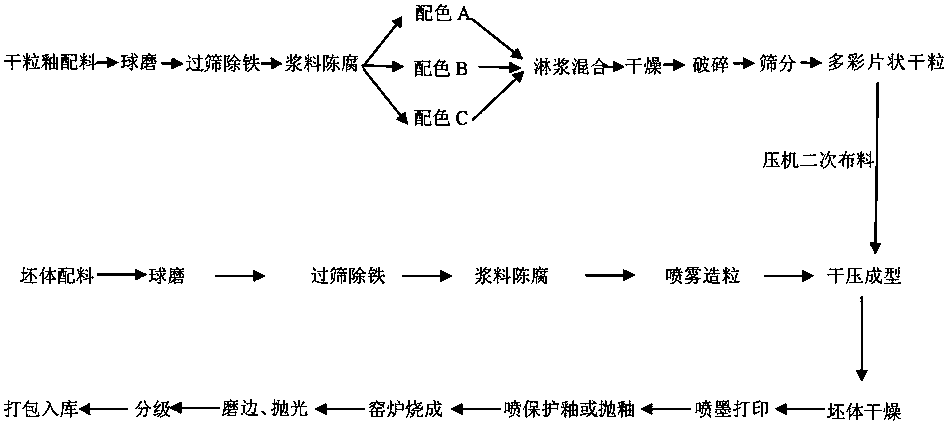

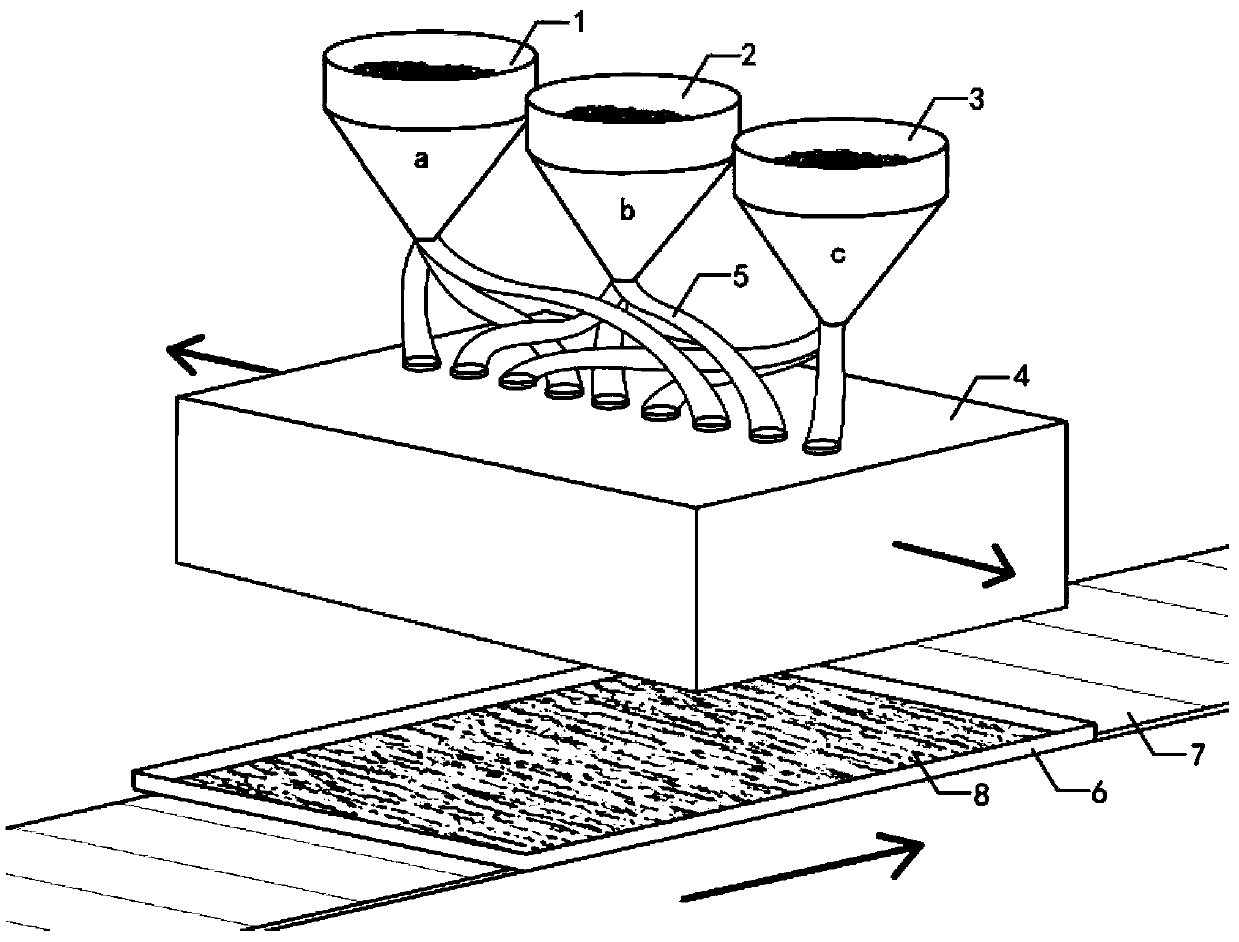

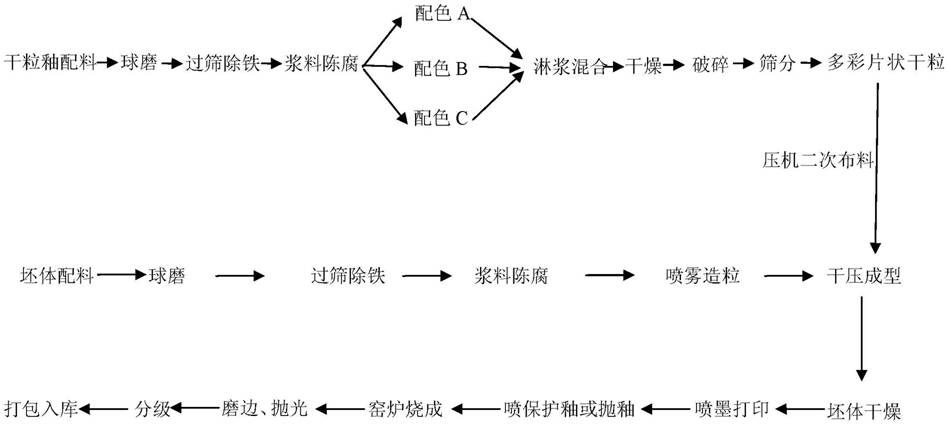

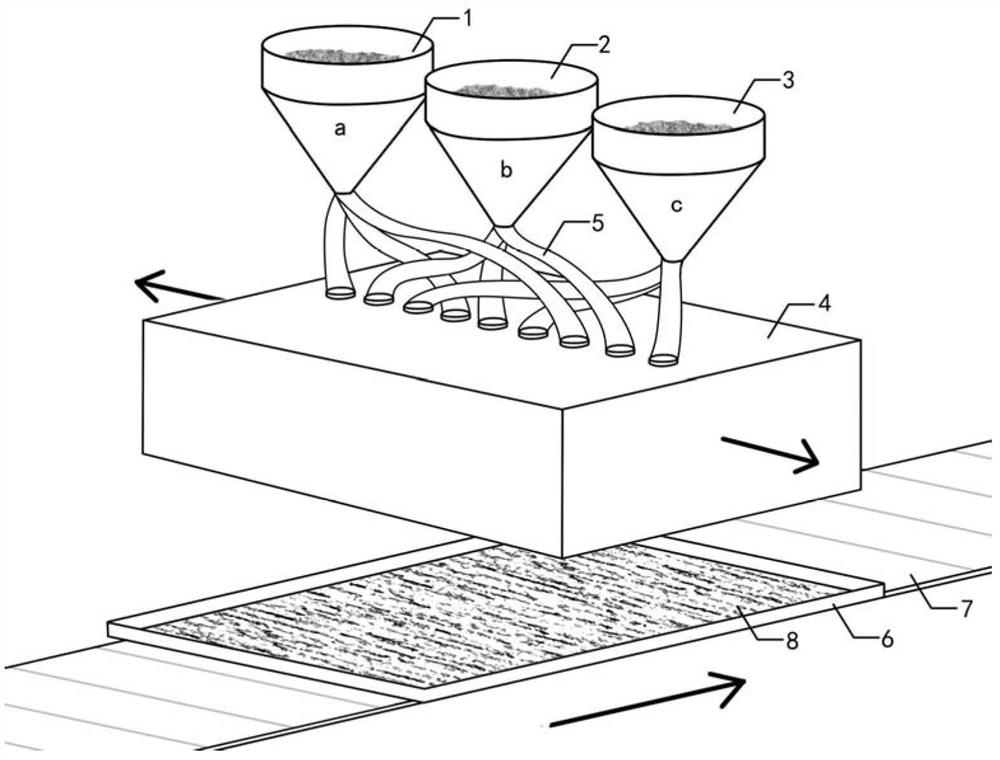

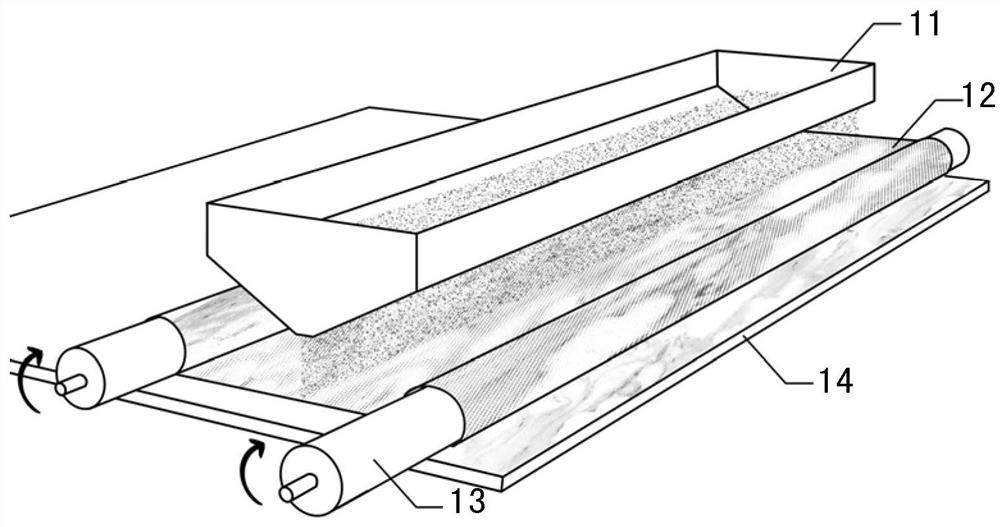

Colorful flake dry grain glaze and flake dry grain glaze cloth imitation stone brick, and production methods thereof

The invention relates to a colorful flake dry grain glaze and a flake dry grain glaze cloth imitation stone brick, and production methods thereof. The production method of the colorful flake dry grainglaze comprises the following steps: mixing glaze slips having different colors to form a colorful glaze slip, spraying the colorful glaze slip in a tray, drying the colorful glaze slip to obtain a colorful slurry layer, and breaking and sieving the colorful slurry layer to obtain the colorful flake dry grain glaze. The colorful flake dry grain glaze can be obtained through the simple method, andthe colorful flake dry grain glaze can be used in the production of ceramic bricks to obtain the imitation stone material product having accurate pattern, plentiful layers, natural texture, strong stereo perception and strong granular sensation.

Owner:MONALISA GRP CO LTD

Method for printing patterns on inorganic board through heat transfer

ActiveCN105034670AWith environmental protection functionWith fire protection functionDecorative surface effectsInfraredMaterial resources

The invention relates to a method for printing patterns on an inorganic board through heat transfer. The method includes the following steps that the board is coated with a heat transfer printing primer after being subjected to sanding and dust removing; then, infrared levelling and drying are conducted, so that uniform and smooth coating of the primer is achieved, and the primer is in a semi-dry state; and after a heat transfer film is thermo-printed on the surface of the treated board, a base layer of the heat transfer film is removed. The method has the beneficial effect that the film heat transfer printing technology and the UV photocuring technology are integrated with the inorganic board. The method can be directly applied to the inorganic board without the need of treating a base material through multiple procedures. In addition, the addition quantity of chemical coatings is reduced. According to the method, the technical procedure is simple and clear, and operation is easy. The method has the advantages that production efficiency is high, the printing technology is exquisite, product losses are small, and adhesive force is high. Investment of manpower and material resources is reduced.

Owner:南通柯益诺智能科技有限公司

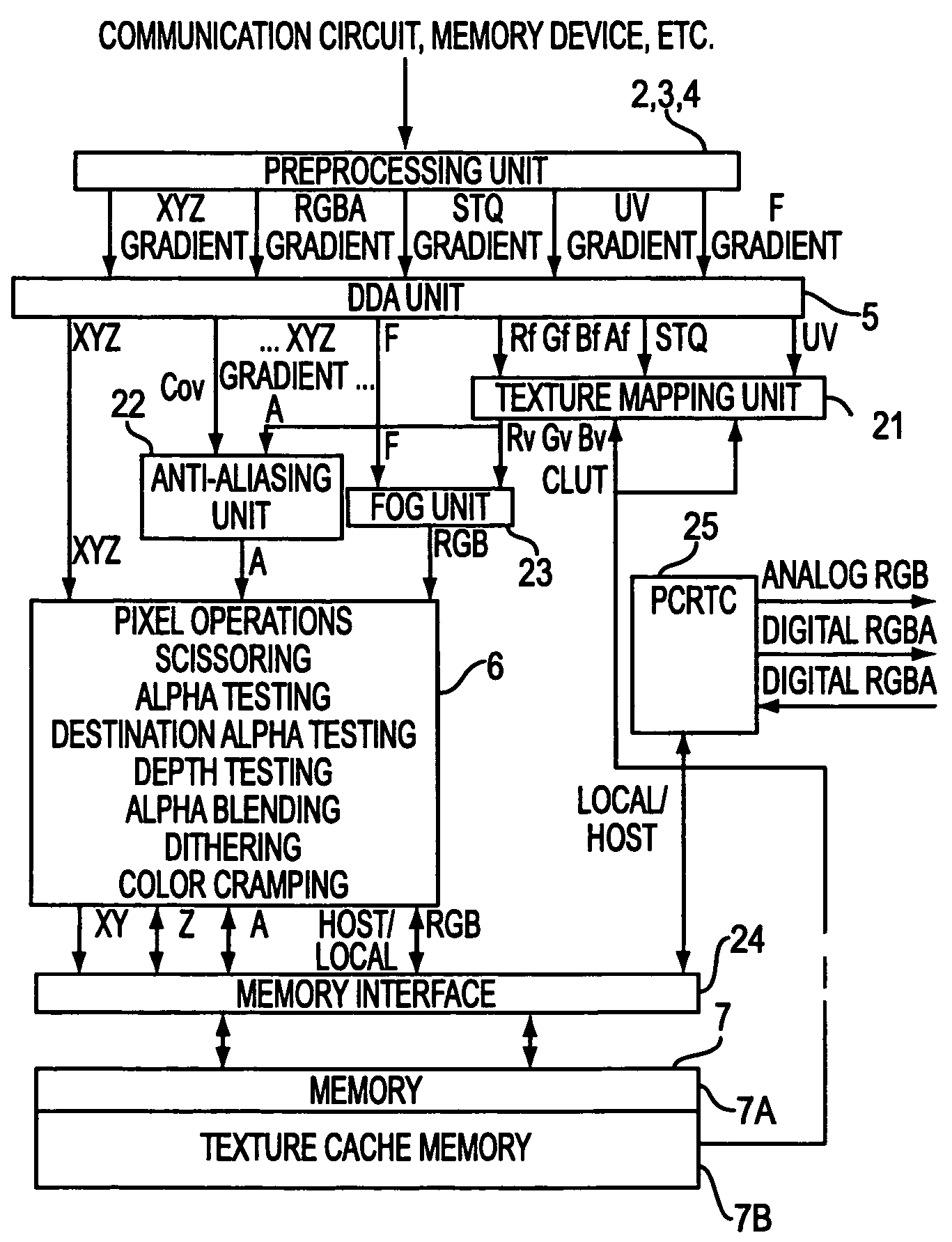

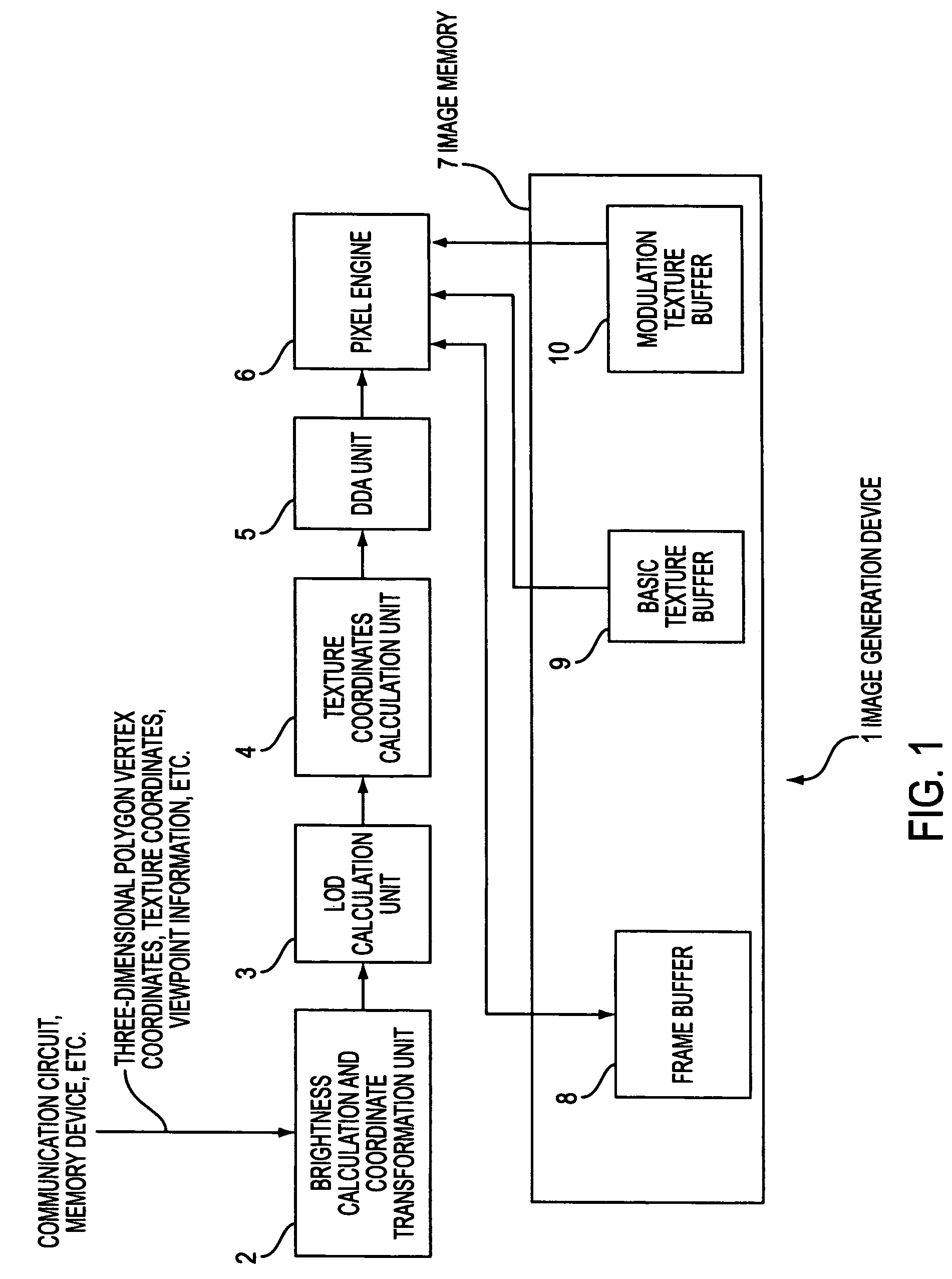

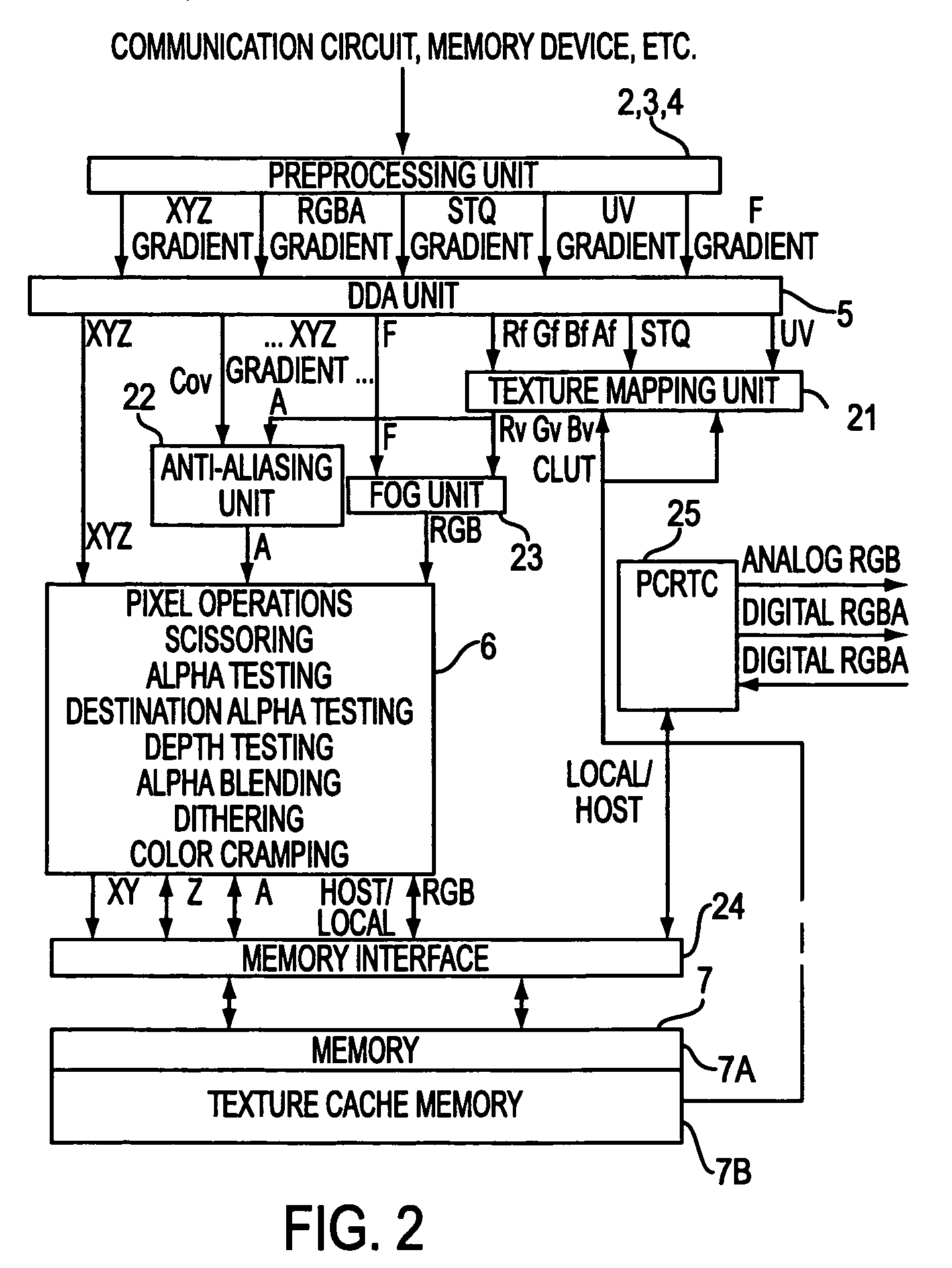

Image generation method and image generation device

InactiveUS7239325B2Realistic patternIndoor games2D-image generationComputer graphics (images)Image generation

It is an object of the present invention to generate more realistic pattern by mapping a texture to a three-dimensional polygon. An image generation device has image memory, in which are stored basic textures to be mapped to generate overall patterns on polygons by mapping and modulation textures with which amplitude modulation is applied to the patterns generated by mapping of the basic textures, and a pixel engine which, by amplitude modulation mapping of modulation textures, performs amplitude modulation processing on the patterns generated by mapping of basic textures.

Owner:SONY COMPUTER ENTERTAINMENT INC

Embedded surface ornament and its making process

InactiveCN1810525AFully reflect the textureCombined bonding is firmDecorative surface effectsSpecial ornamental structuresMaterials scienceOrnaments

Owner:王吉祥

Semi-color weaving and dyeing process of silk and cotton interwoven jacquard fabric

InactiveCN106638037AShorten production timeGuaranteed strongDyeing processWoven fabricsYarnPulp and paper industry

The invention provides a semi-color weaving and dyeing process of a silk and cotton interwoven jacquard fabric and belongs to the technical field of silk and cotton interwoven fabric dyeing. The semi-color weaving and dyeing process is characterized by the process steps that cotton fiber cone yarns are dyed, wherein starting is performed for operation, 0.5%owf-5%wf of mixed dual-active-group reactive dyes containing monochlorotriazine and vinylsulfsulfate in an axillary cylinder is firstly dissolved with water and fully stirred, and an additive is added; then, heating and mixing are performed; fixation, cold water washing, acid pickling, soaping, hot water washing and cold water washing are performed, then the mixture is taken out of the cylinder, and centrifugal dewatering and drying are performed; cotton fiber and raw silk are woven; warp silk dyeing is performed. 2.7-3.4 g / L of neutralization acid is added to cold water after washing, the operation is executed for three times, and down rolling is performed. The alkaline agent usage amount is decreased, and it is ensured that the strength in silk fiber dyeing process is not affected. Dyes in the dyeing process only produce covalence reaction with real silk and do not produce reaction with cotton yarns and fiber, the real silk can be dyed with any color, cotton fiber is almost not affected, and the silk and cotton interwoven jacquard fabric can be dyed to have any color in a color atlas.

Owner:ZIBO DARANFANG SILK GRP

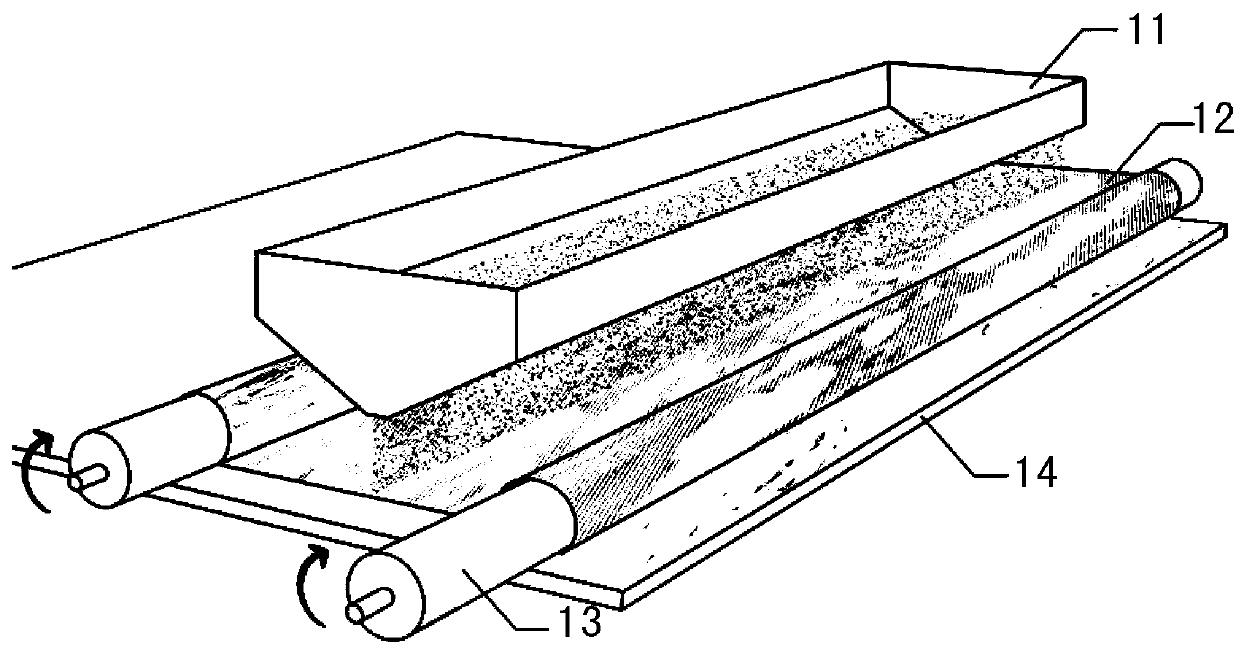

Method of making vehicle vibration damping bag composite material

InactiveCN1542307AExpand the scope ofSimple processSpringsResilient suspensionsProduct processingWork in process

The manufacture process of composite vibration absorbing bag material for vehicles includes the steps of first mixing adhesive for adhering facing film layer and non-woven fabric base; subsequent adhering the facing film layer onto non-woven fabric base via unwinding non-woven fabric, scraping and painting adhesive with 85-mesh netted grain roller to the surface of the non-woven fabric, gelatinizing, curing, adhering facing film layer to the non-woven fabric, cooling and winding; painting acrylic acid processing agent, cooling and winding; and final unwinding, passing through tension balancer, cooling, instantaneously hot knurling, re-cooling and winding as the product.

Owner:上海益鑫塑料制品厂

Jade enamel paint

InactiveCN106497285ABright colorRealistic patternFireproof paintsAnti-corrosive paintsSodium BentoniteLacquer

The invention relates to building paint applied to interior walls, in particular to jade enamel paint. The jade enamel paint comprises water, hydroxyethyl cellulose, dispersing agent, glycol, light calcium carbonate, sodium bentonite, ground calcium carbonate, talcum powder, wollastonite, silicone-acrylate emulsion, coalescing agent, hydroxypropyl methyl cellulose, pH value regulating agent, defoamer and thickener. The jade enamel paint has the advantages of high breathability, water resistance, scrubbing resistance, high adhesion strength, non-existence of powdering, peeling and bulging, relative flame resistance effect, simplicity and convenience in construction, optional matching of various patterns, variety in texture selection and the like.

Owner:赵永福

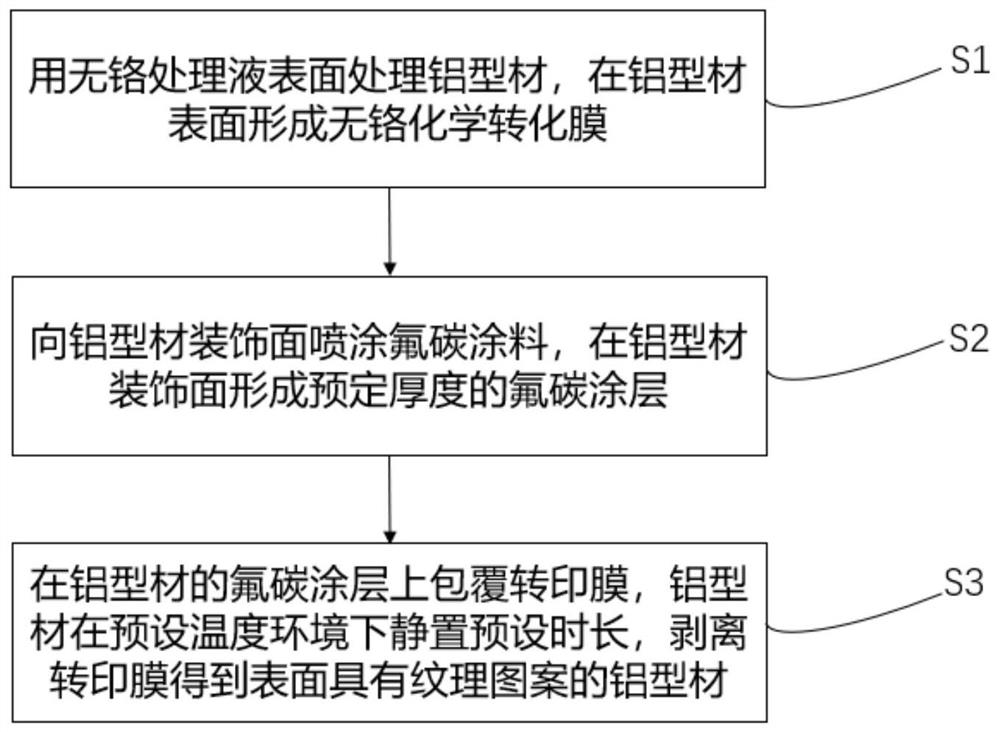

Aluminum profile with textured patterns on surface and processing technology of aluminum profile with textured patterns on surface

InactiveCN112403863AUnnecessary generationWon't happenDuplicating/marking methodsPretreated surfacesChromium freeWeather resistance

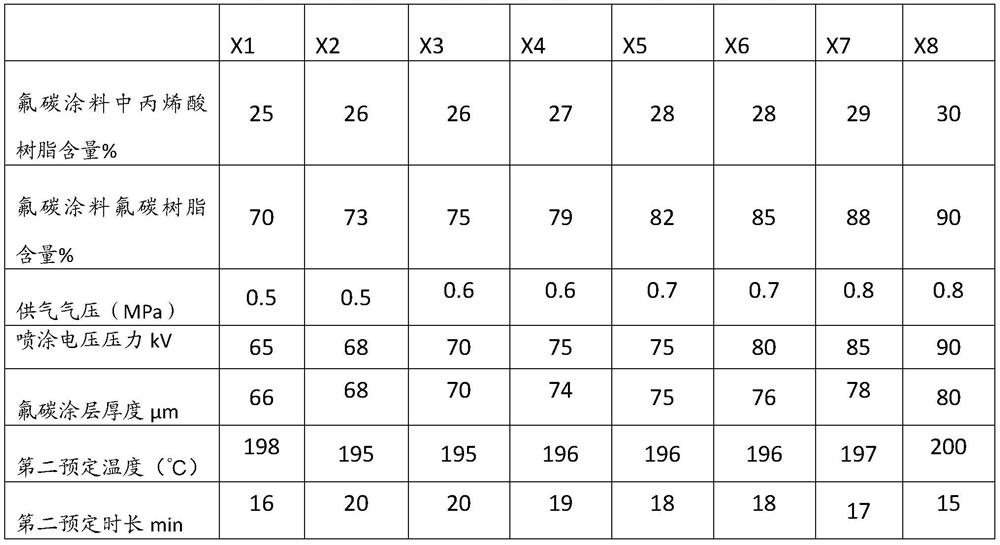

The invention discloses an aluminum profile with texture patterns on the surface and a machining process of an aluminum profile with the textured patterns on the surface. The machining process comprises the following steps that (1) a aluminum profile is subjected to surface treatment through chromium-free treatment liquid, and a chromium-free chemical conversion coating is formed on the surface ofthe aluminum profile; (2) a fluorocarbon coating is sprayed on an aluminum profile decorative surface to form a fluorocarbon coating with a preset thickness on the aluminum profile decorative surface; and (3) the fluorocarbon coating of the aluminum profile is coated with a transfer printing film, vacuumizing is conducted on the space between the transfer printing film and the fluorocarbon coating, the aluminum profile is allowed to be left to stand for a preset duration in a preset temperature environment, and the transfer printing film is stripped to obtain the aluminum profile with texturepatterns on the surface, wherein the fluorocarbon coating is prepared from the following components of, in percentage by mass, 70%-90% of fluorocarbon resin and 25%-30% of acrylic resin. According tothe aluminum profile with the texture patterns on the surface and the machining process of the aluminum profile with the textured patterns on the surface, the fluorocarbon coating selected in the invention improves the comprehensive performances of weather resistance, stability and the like of a product, maintains the optimal bottom color, prolongs the service life of the product, and does not generate VOC gas in a machining process.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

Production process of elastic burnt-out imitated-silk crepe fabrics

InactiveCN107385639ASimplify processing stepsEasy to implementTextile decorationWoven fabricsEngineeringBurning out

The invention discloses a production process of elastic burnt-out imitated-silk crepe fabrics, and belongs to the field of spinning. The production process includes the steps of weaving, dyeing, burnt-out printing, setting and preshrinking. The blending of rayon and real silk is used as warp, the blending of rayon, real silk and spandex is used as weft yarn, and the warp and the weft yarn are interweaved to obtain the crepe fabrics. The production process of elastic burnt-out imitated-silk crepe fabrics has the advantages of being simple in process, low in cost and convenient to achieve, and made products solve the problems that silk fabrics are easy to produce static electricity and has poor hygroscopicity. The blending of rayon, real silk and spandex has a realistic effect of imitated silk fabrics and meanwhile greatly improves the types and stereoscopic impression of the imitated silk fabrics.

Owner:绍兴水乡纺织科技有限公司

Novel textile dyeing technology

InactiveCN108930179AEmission reductionImprove protectionDyeing processVegetal fibresGlycerolEngineering

The invention relates to a novel textile dyeing technology. The technology includes performing unwinding on grey cloth on an unwinding machine; performing stitching on the unwound grey cloth; sendingthe grey cloth into dye vats to perform dyeing, adding 1-2 parts by weight of glycerol, 8-9 parts by weight of ethanol, 2-3 parts by weight of coconut oil fatty acid diethanolamide, 4-5 parts by weight of polyvinylpyrrolidone, 6-7 parts by weight of a natural plant pigment, 1-2 parts by weight of hydroxypropyl methyl cellulose, 2-3 parts by weight of imidazoline and 30-35 parts by weight of waterinto the dye vats before dying, and uniformly stirring the mixture, the soaking time of the grey cloth in the dye vats being 40 min; performing dehydration on the dyed cloth, putting the cloth in a pretreatment solution to perform reaction for 10 min, performing dehydration again, and widening and shaping the cloth on a scutching machine; performing printing through a calico printing machine; andperforming yardstick through a yardstick machine, and performing packing into finished products. The advantages of the technology are that the technology is simple in operation and environmentally friendly, sewage discharging can be reduced, and the protection on environments can be realized.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Polyester printed knitted fabric

The invention discloses a polyester printed knitted fabric. The fabric comprises a fabric layer and a printing layer; the printing layer is arranged on the fabric layer in a flat screen printing manner; the printing layer is composed of printing units distributed in a matrix mode; the fabric layer is provided with a loop structure formed by interweaving 11.1 tex polyester filament yarns and 20D spandex; the stitch length of the polyester filament yarn is 25 cm / 100 stitches, the stitch length of the spandex is 10.5 cm / 100 stitches, the gram weight of the knitted fabric is 130 g / m <2>, the polyester filament yarn is formed by twisting polyester monofilaments with X-shaped sections, the surfaces of the polyester monofilaments are covered with flame-retardant layers, and the flame-retardant layers contain phosphorus flame retardants. The polyester printed knitted fabric is bright in color, vivid in pattern and good in comfort and has a flame-retardant effect.

Owner:绍兴首典纺织有限公司

Colorful flaky dry granule glaze, flaky dry granule glaze cloth imitation stone brick and preparation method thereof

The invention relates to multi-color flake dry granule glaze, flake dry granule glaze cloth imitation stone brick and a preparation method thereof. The preparation method of the colorful flaky dry glaze comprises: mixing glaze slurries of different colors to form colorful glaze slurries, pouring them on a tray, and obtaining a colorful mud layer after drying, crushing the colorful flaky dry granules, and sieving to become colorful flaky dry glazes. grain glaze. The present invention can obtain multi-color flake dry granular glaze through a simple process, and the multi-color flake dry granular glaze can be used in the preparation of ceramic tiles, and can obtain imitation stone materials with realistic patterns, rich layers, natural texture, strong three-dimensional sense and grainy feeling product.

Owner:MONALISA GRP CO LTD

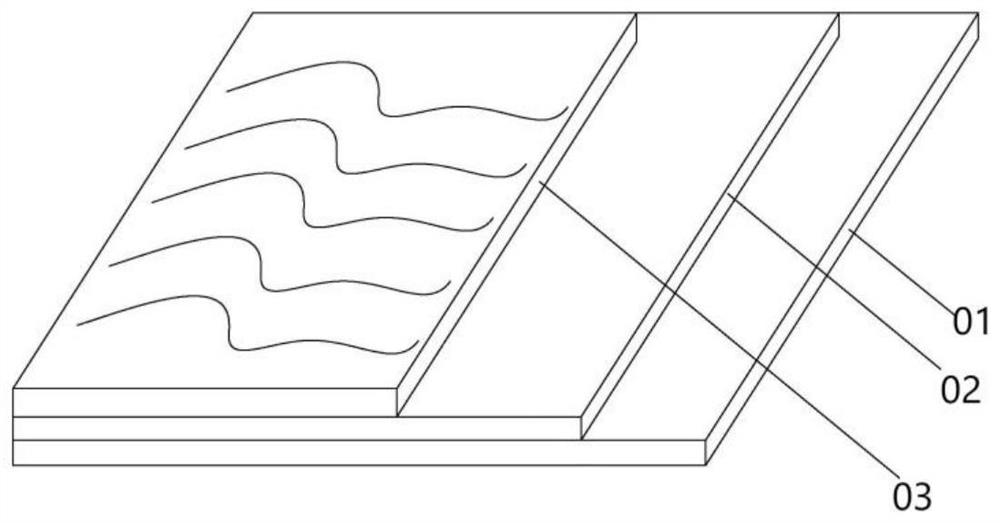

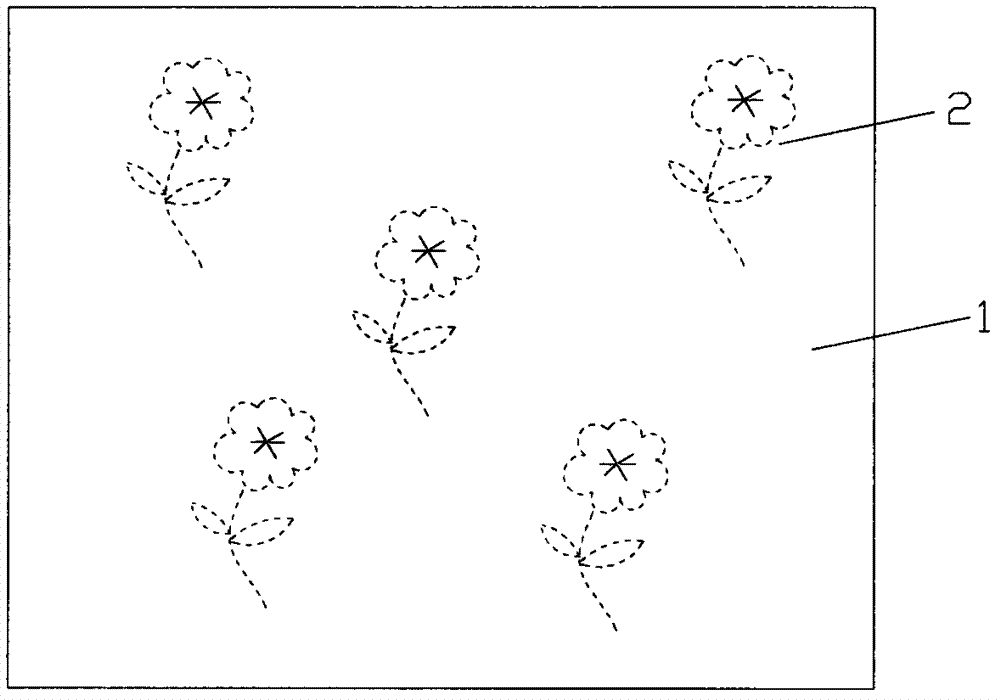

Mixed fabric by polyester fiber, cationic polyester fiber and wood pulp fiber

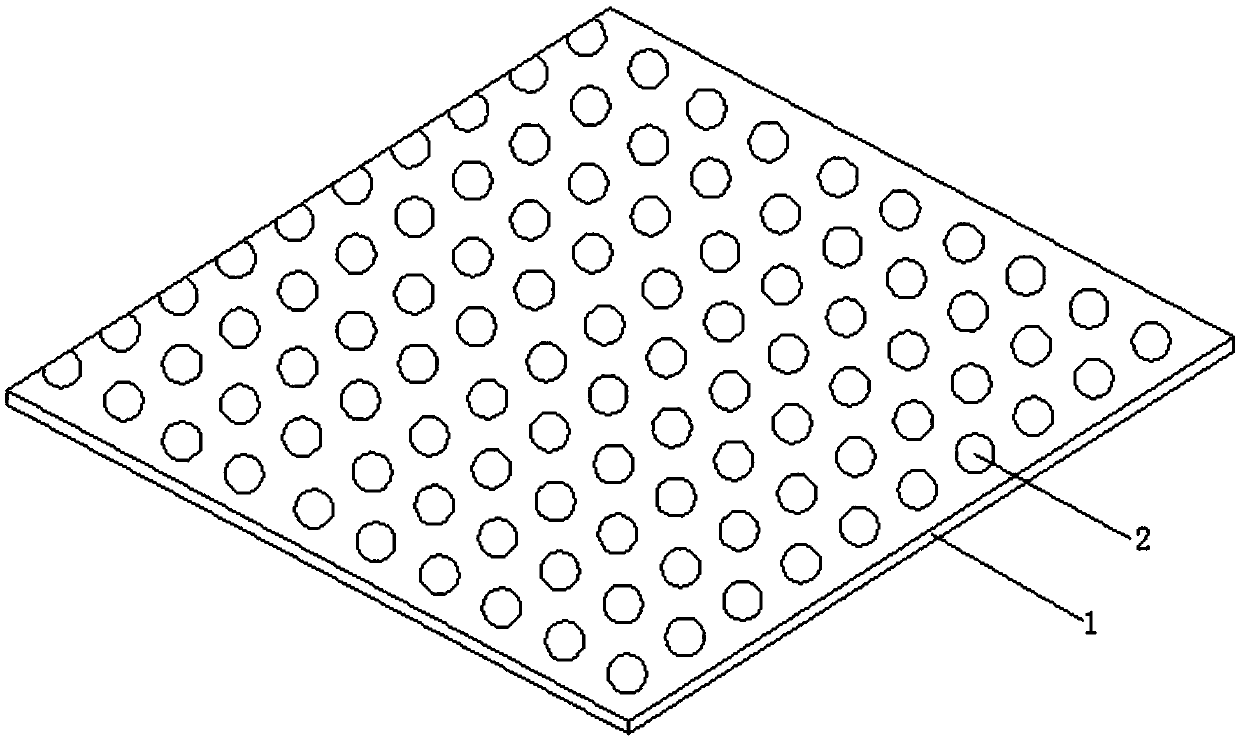

The invention relates to a mixed fabric of polyester fiber, cationic polyester fiber and wood pulp fiber. The burnt-out embroidery fabric includes a burnt-out fabric body (1). The burnt-out fabric body (1) is interwoven by warps and wefts, wherein the warps are polyester fiber, and the wefts are mixed fiber of wood pulp fiber and cationic polyester fiber. An embroidery layer (2) is locally arranged on the surface of the burnt-out fabric body (1). After the embroidery processing to the burnt-out fabric, patterns are more realistic to express the elegance of the burnt-out embroidery fabric. And the fabric is bright in colors, good in air and moisture permeability, fine in touch feeling, and strong in three-dimensional effect; and with a price lower than the price of real silk, the fabric of the invention is suitable for promotion in the home textile market.

Owner:李国平

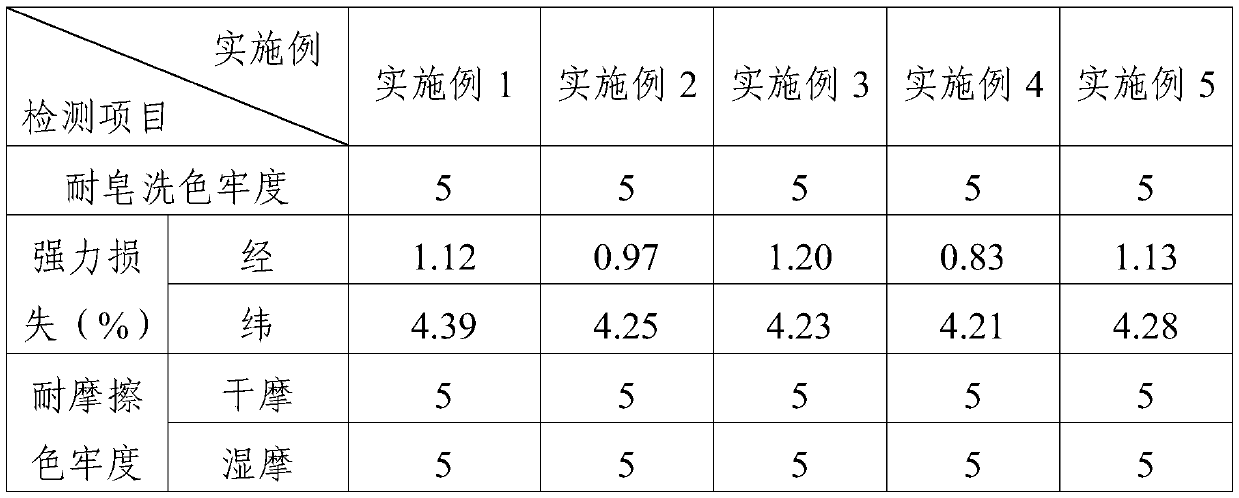

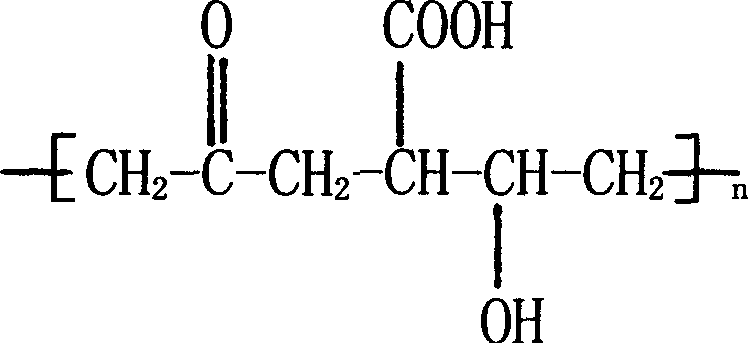

A wet transfer printing process of polyester-cotton blended fabric

ActiveCN107190538BHigh strengthImprove smoothnessDuplicating/marking methodsTransfer printing processFiberColour fastness

The invention provides a wetting transfer printing process of a polyester-cotton blended fabric and relates to the field of printing and dyeing. The wetting transfer printing process comprises the following steps: coating printing paper with a modifier, coating the printing paper with a separation agent, preparing transfer printing paper, carrying out transfer printing and press-rolling and carrying out color fixation to obtain a finished product. According to the wetting transfer printing process, the printing paper is modified and the strength, the smoothness and the moisture absorption property of the printing paper are greatly improved; in a subsequent transfer printing process, a transfer printing pattern has a vivid pattern, a fine figure, a clear layer and a strong stereoscopic impression; the separation agent can be used for reducing the adsorption effect of printing paper fibers on dyestuff and improving the printing coloring rate of the dyestuff and can also be used for improving the time of transfer-printing a figure pattern to the fabric; a common universal fabric alkali liquid padding procedure is replaced with a procedure of spraying alkali liquid to the fabric, so that the dosage of the alkali liquid is greatly reduced and the production cost and environment protection pressure are reduced; in a transfer printing process, transfer printing parameters are controlled and the fabric has high apparent color yield and color fastness; the brute force is also reduced in an acceptable range.

Owner:马鞍山市永运家纺有限公司

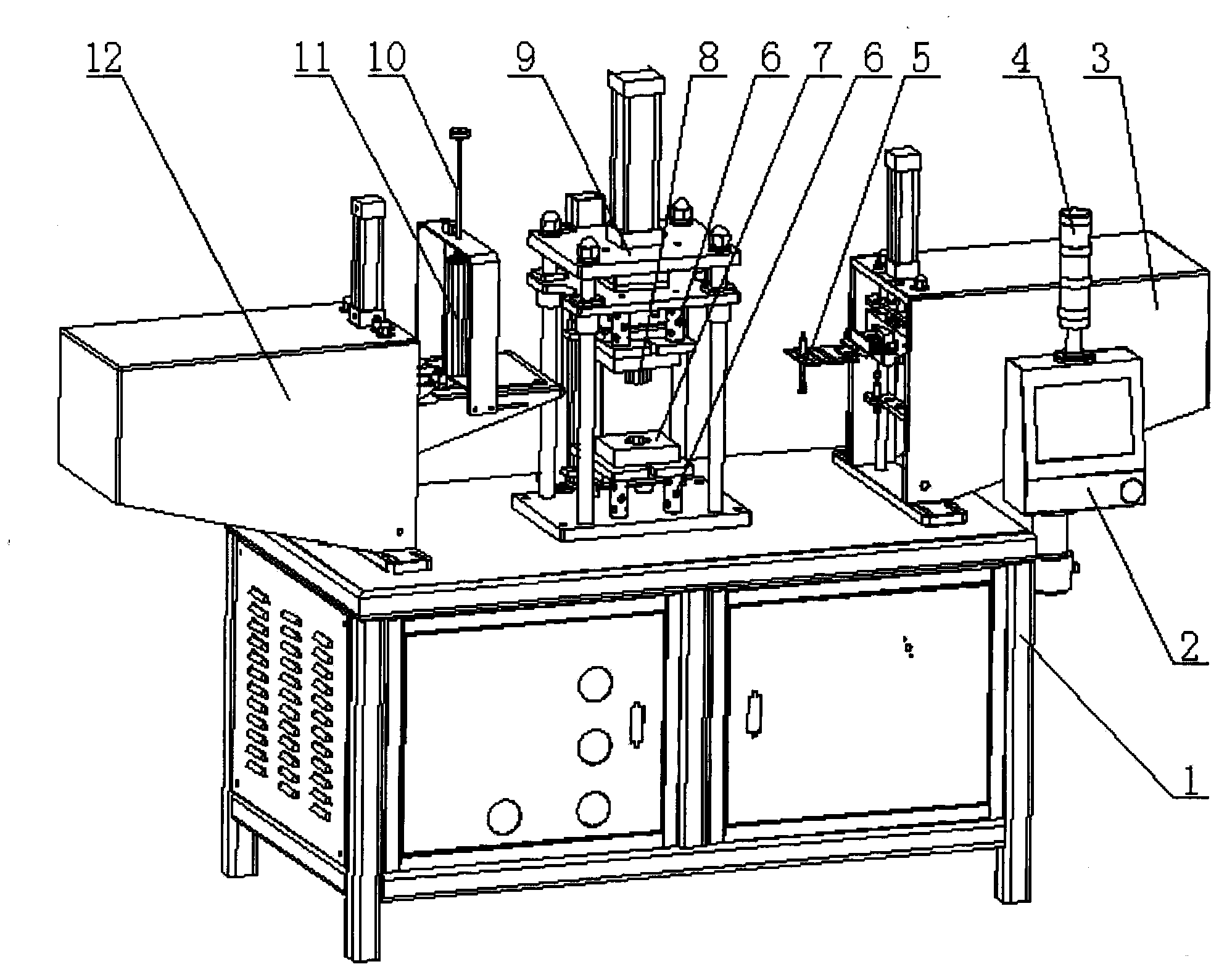

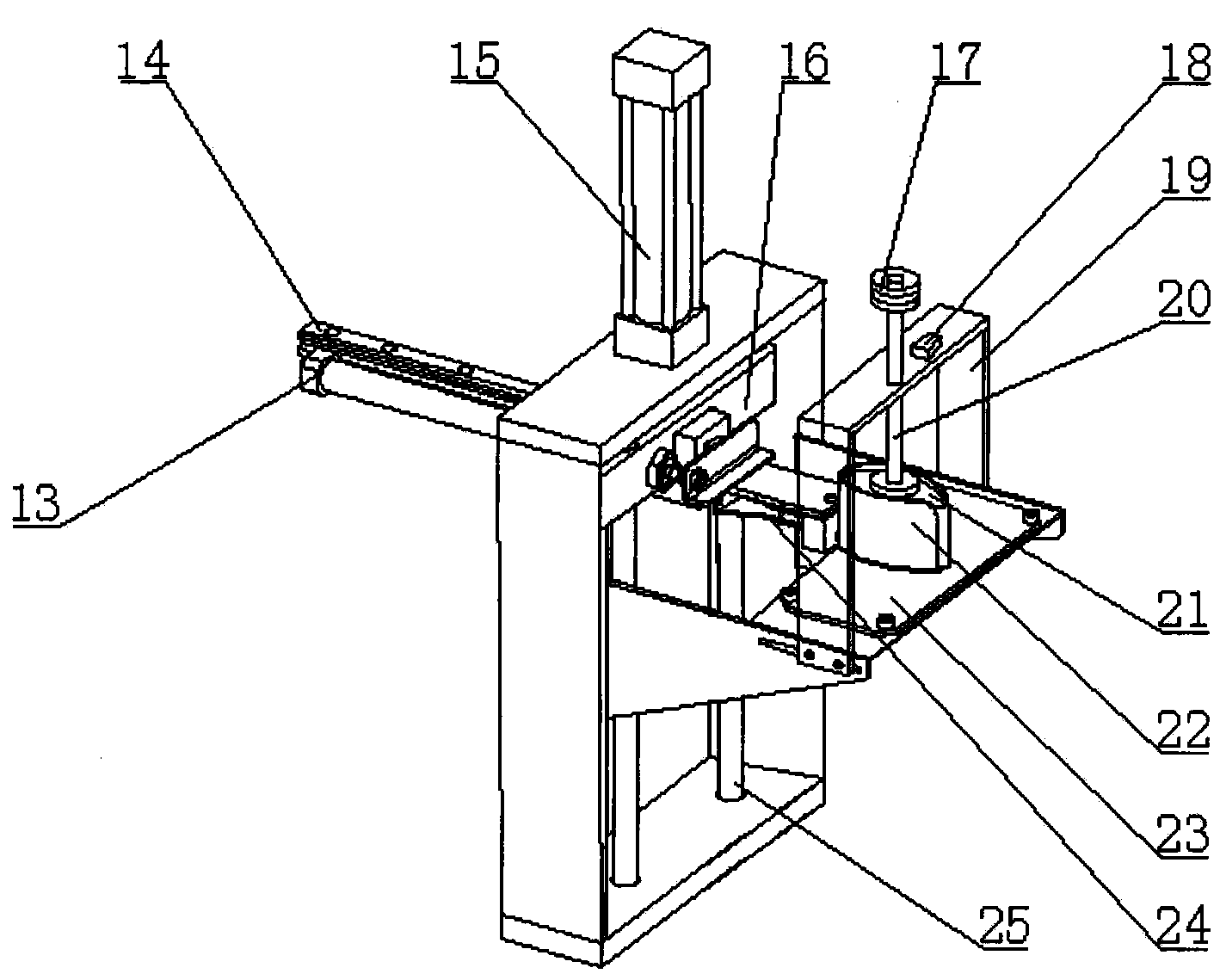

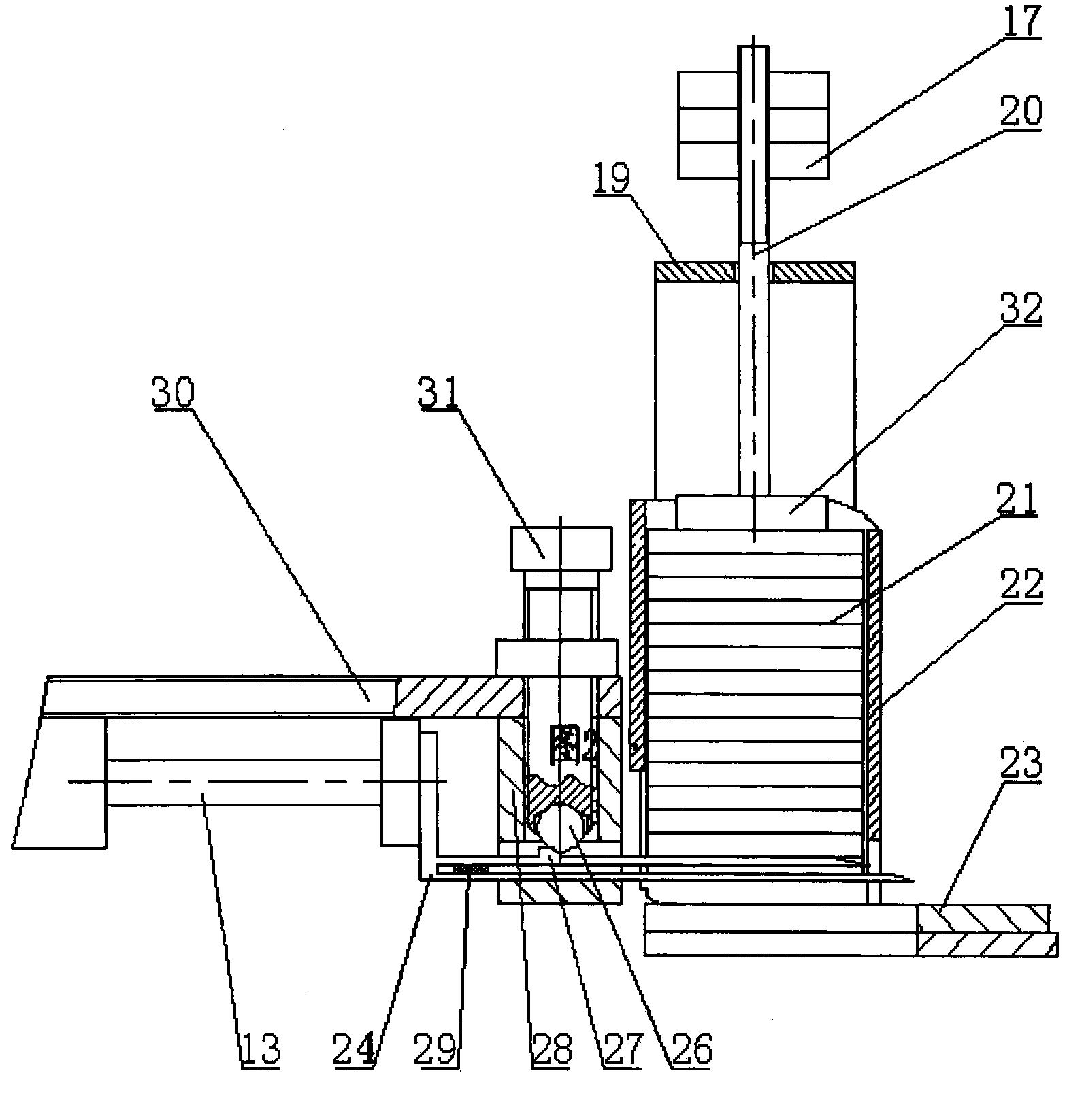

Artificial floral leaf setting machine

ActiveCN102499503BExactly fall intoImprove interchangeabilityArtificial flowers and garlandsEngineeringMechanical engineering

The invention discloses an artificial floral leaf setting machine which comprises a machine stand, a material sheet absorbing mechanism, a lower die, an upper die and a working press machine. The artificial floral leaf setting machine is characterized by also comprising a material sheet placing device for placing a plurality of material sheets, a material sheet clamping device for elastically clamping a material sheet nipper and heat insulating sleeves, wherein the upper die, the lower die and the working press machine are fixed on the machine stand, the material sheet absorbing mechanism, the material sheet placing device and the material sheet clamping device are arranged on both sides of the working press machine; the heat insulating sleeves are distributed on the upper plane of the upper die and the lower plane of the lower die, the heat insulating sleeves are provides with staggered heat radiating holes on cylinders along the radial direction, and the top faces and the bottom faces of the heat insulating sleeves are provided with crossed heat radiating slots. The setting machine has the characteristics of simple structure, good pressing quality, high production efficiency, wide applicability and the like.

Owner:滕武超

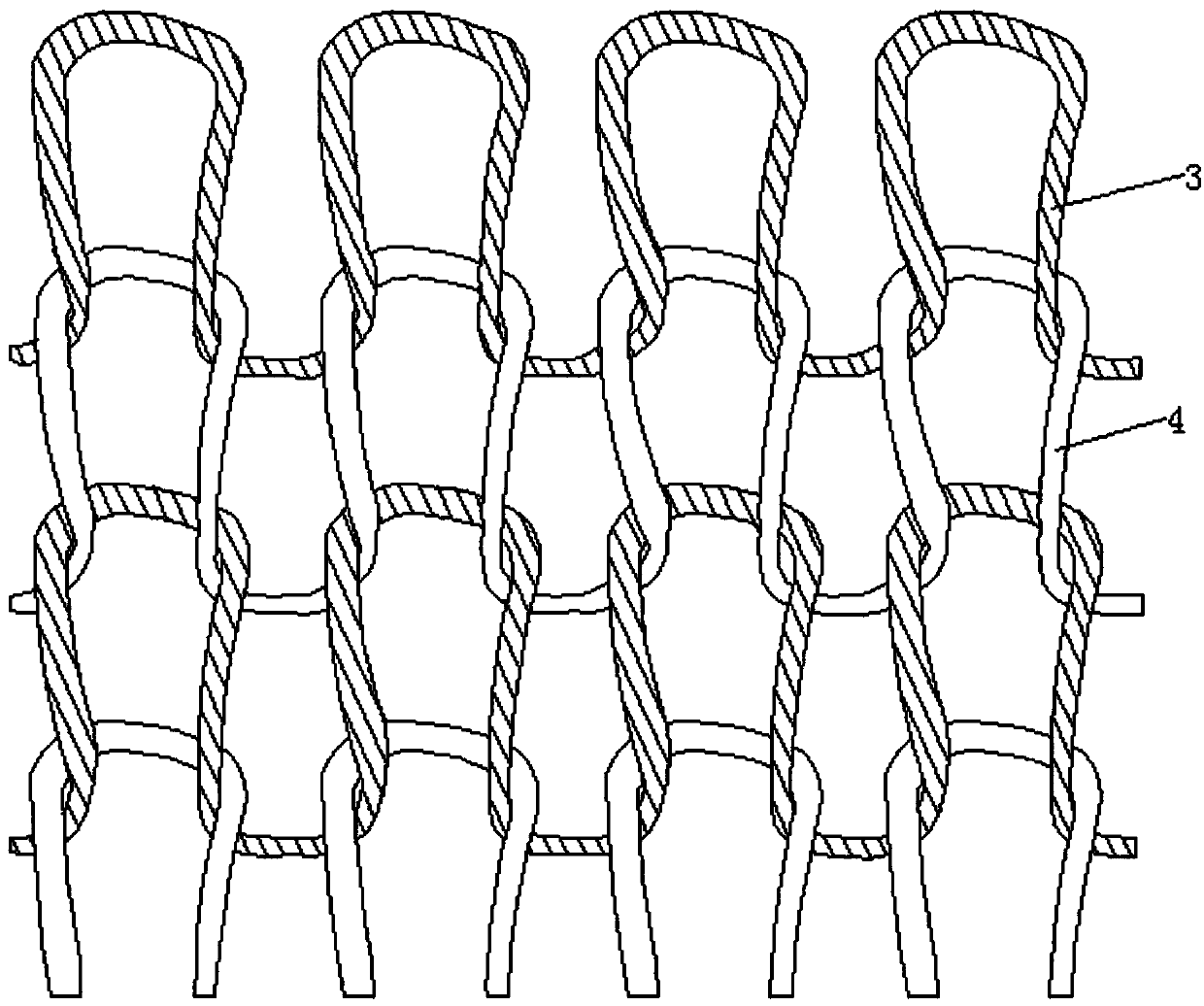

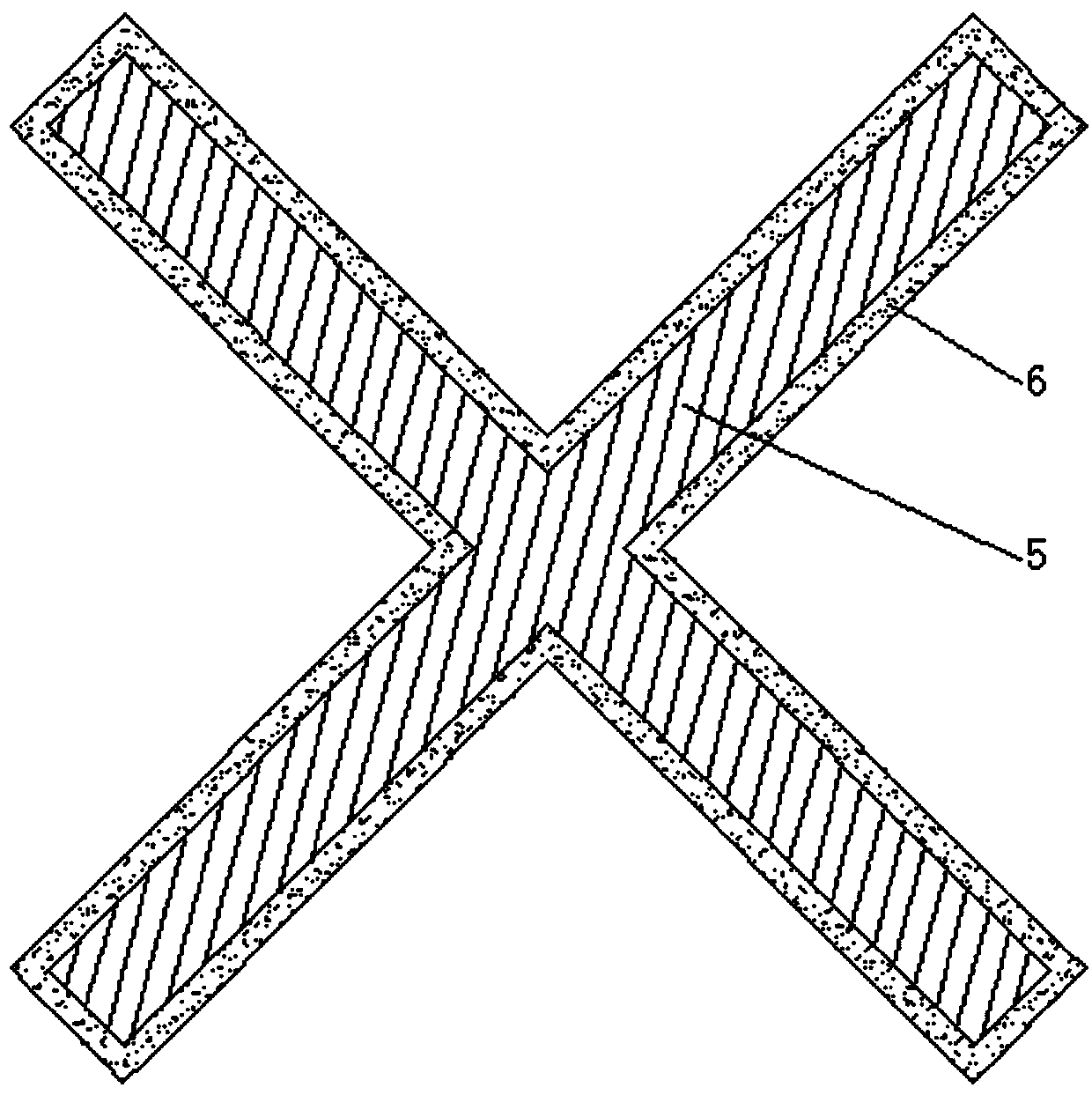

Wood pulp fiber/silk interweaved furnishing burnt-out fabric

InactiveCN102877239ARealistic patternSet off graceful and luxuriousWoven fabricsTextile decorationFiberEngineering

The invention relates to a burnt-out fabric which is widely used in fabrics for producing napkins, curtains, bedspread decorative fabrics, belonging to the field of textile fabrics. The burnt-out fabric disclosed herein comprises a fabric body (1), wherein the fabric body (1) is interweaved with warps and woofs, the warps are made from wood pulp fiber, the woofs are made from silk, and the partial surface of the fabric body (1) is provided with an embroidered layer (2). According to the invention, by embroidering the burnt-out fabric, the pattern is really true to life, and the beauty and luxury of the fabric are brought out; the color contrast is high, the air permeability and moisture penetrability are good, the hand feel is fine and smooth, the stereoscopic feeling is strong, the price of the fabric is lower than the price of silk, and the fabric is suitable for being applied in furnishing market.

Owner:朱浩炳

Circular screen copy-jeting wax and making method thereof

A wax for making screen plate by cylinder spraying is prepared from olefine oxide (10-20 pts. wt.), high-molecular hydrocarbon with 82.5 deg.C of melting point (40-55 pts.wt.), high-molecular hydrocarbon with 59-65 deg.C of melting point (20-30 pts.wt.), rosin pentaerythritol ester as adhesive (2-5 pts.wt.) and black pigment (3-5 pts.wt.). Its advantages are not blocking nozzle, clear mesh and lifelike pattern.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Treatment process of flexible plate for flexography gradient printing

ActiveCN110936701AImprove smoothnessHard dotsPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringNonwoven fabric

The invention discloses a treatment process of a flexible plate for flexography gradient printing and relates to the field of a printing plate. The process is characterized in that a base layer surface of a flexible plate is placed under a long-wave ultraviolet lamp in a plate burning machine for irradiation; according to a to-be-printed pattern shape, an embossment layer of the flexible board isplaced in an engraving machine for engraving, a black film is removed, and a to-be-printed pattern is obtained; the embossment layer of the flexible plate is placed under a short-wave ultraviolet lampof a plate burning machine for irradiation, so the to-be-printed pattern is partially hardened; the embossment layer of the flexible plate is cleaned through a plate cleaning machine, the flexible plate is tightly attached to a plate cleaning roller, the plate cleaning roller and a non-woven fabric roller rotate relatively, in the cleaning process, a black film on the embossment layer is melted at the high temperature and then converted into gas to exhaust, and residual resin is erased through non-woven fabric. The process is advantaged in that the cleaned flexible board is fixed, the embossment layer of the flexible board is irradiated by the long-wave ultraviolet lamp, the base surface layer is irradiated by the short-wave ultraviolet lamp, so the treated flexible board is finer, higherin hardness resistance and fine and smooth in pattern.

Owner:杭州全为包装印刷有限公司

Printing process for wallpaper

InactiveCN106364194ADelicate embossingFine workmanshipOther printing apparatusPrinting after-treatmentEngineeringComputer engineering

The invention discloses a printing process for wallpaper. The printing process comprises the following steps that (1) a rotary screen print plate and a form of intaglio printing are manufactured; (2) paste is prepared and the viscosity of water-based ink is adjusted; (3) the surface of a printing stock is smeared with the paste through the rotary screen print plate on rotary screen print equipment, so that required patterns are formed; (4) the printing stock with the patterns is fed into a drying oven to be dried; (5) The dried printing stock with the patterns is fed into intaglio printing equipment, and the area, with the patterns, of the printing stock is colored with the standby water-based ink through the form of intaglio printing; (6) the colored printing stock is fed into the drying oven to be dried; and (7) the dried printing stock is press-rolled through a compression roller to form a locally-embossed product. According to the printing process for the wallpaper, non-woven bottom paper is smeared with the specially-made paste to form the required patterns according to patterns on the rotary screen print plate, the locally-embossed product is formed through coloring by the form of intaglio printing, heating by the drying oven and press-rolling by the compression roller, the rich patterns are fine and smooth with fine workmanship and diverse colors, raw materials are guaranteed, and the printing process is safe and environmentally friendly.

Owner:ZHEJIANG VENECIA DECORATIVE MATERIAL

Flexible plate processing technology for gradient printing in flexo printing

ActiveCN110936701BImprove smoothnessHard dotsPhotomechanical exposure apparatusMicrolithography exposure apparatusNonwoven fabricMechanical engineering

Owner:杭州全为包装印刷有限公司

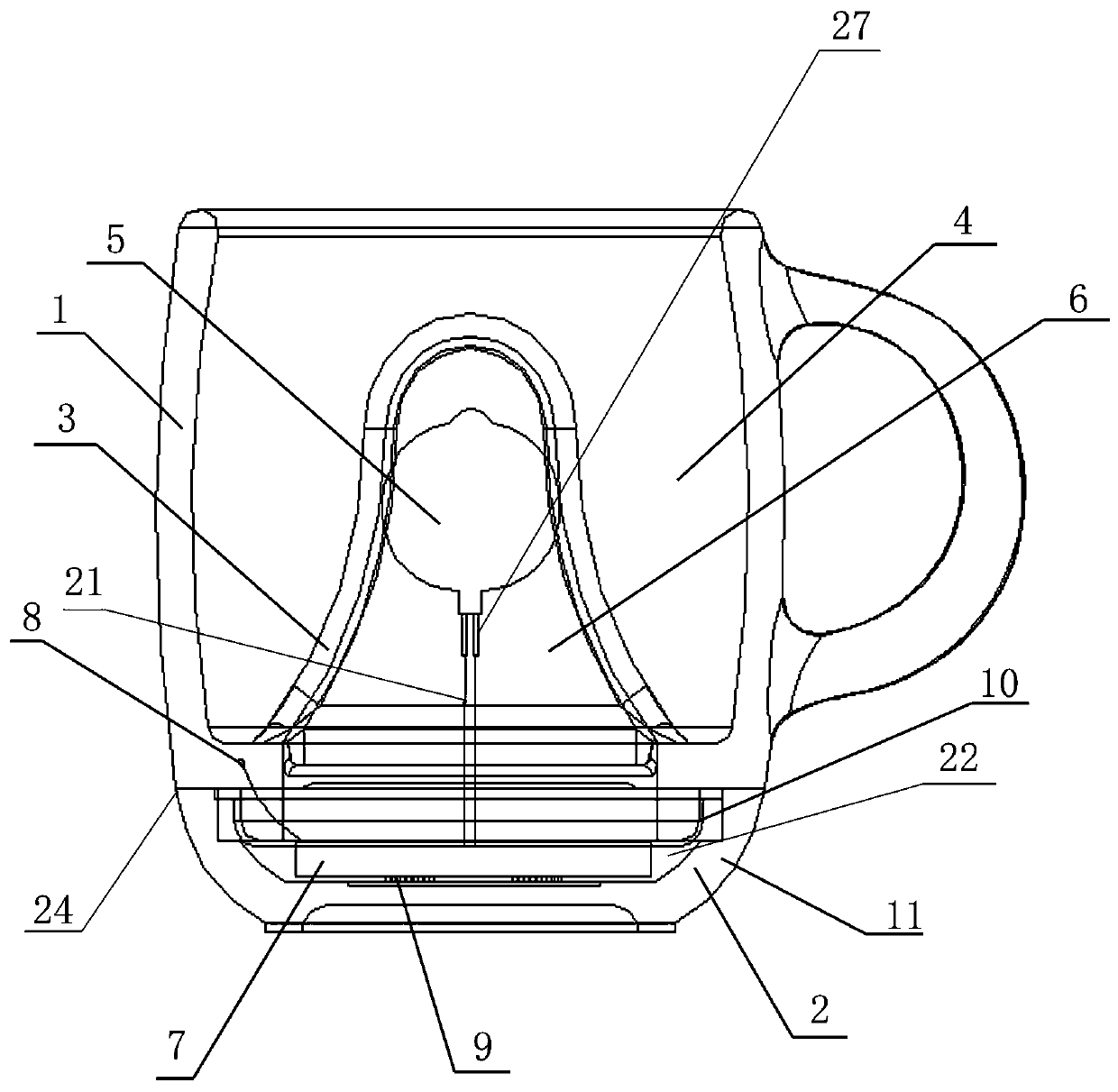

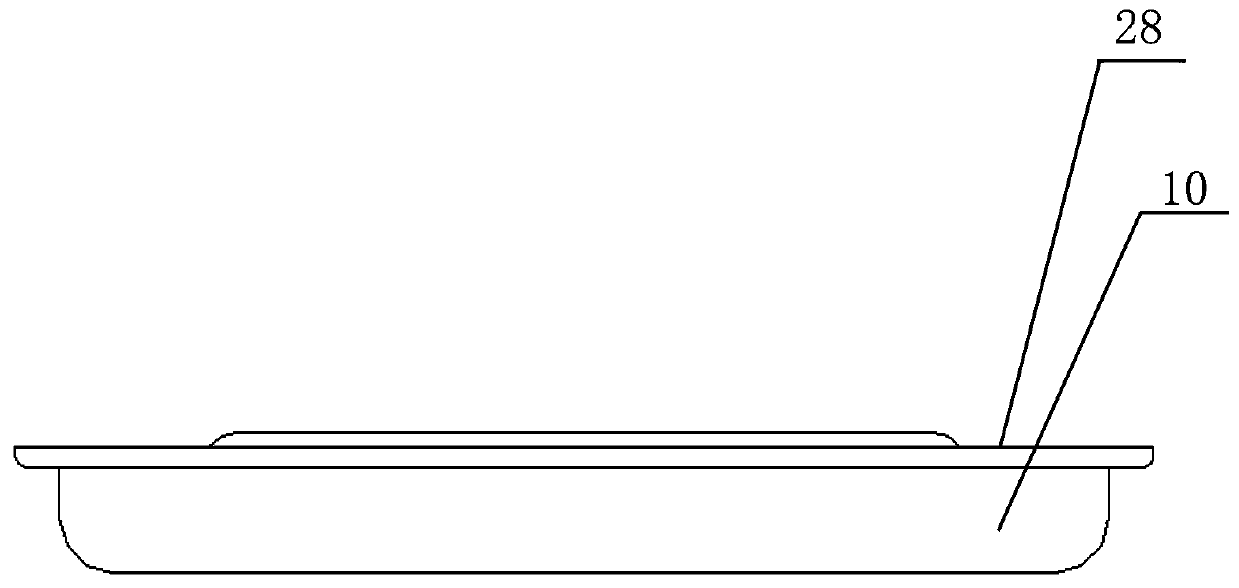

Water cup with COB (Chip On Board) packaged LED (Light Emitting Diode) modeling lamp sheet

PendingCN110226867AEasy to useRealistic patternLighting elementsDrinking vesselsOn boardLight-emitting diode

The invention discloses a water cup with a COB packaged LED modeling lamp sheet. A cup body (1) and a cup base (2) are separately arranged. The bottom surface of the cup body (1) protrudes upwards toform an interlayer (3). The interlayer (3) divides the interior of the cup body (1) into an outer cavity (4) for containing liquid and an inner cavity (6) for containing modeling lamp pieces. A COB packaged LED modeling lamp sheet (5) is placed in the inner cavity (6). A battery (7), a temperature sensing device (8) and a wireless charging receiving module (9) are arranged in the cup base (2). A binding post (27) at the bottom of the COB packaged LED modeling lamp piece (5) is connected with the battery (7). The input end of the temperature sensing device (8) is connected with the cup body (1). The output end of the temperature sensing device (8) is connected with the battery (7). The wireless charging receiving module (9) is connected with the battery (7), and the cup base (2) is connected with the bottom of the cup body (1) to form the water cup.

Owner:BRILLIANCE OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com