Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

930 results about "Workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Workmanship is a human attribute relating to knowledge and skill at performing a task. Workmanship is also a quality imparted to a product. The type of work may include the creation of handcrafts, art, writing, machinery and other products.

Property Scoring System & Method

A home rating and assessment system includes logic configured to identify, analyze and rate features of properties in accordance with customizable filters. By accounting for specific structural aspects of properties, including key structural features, their workmanship, condition, etc. more precise estimates can be calculated for rating / ranking homes relative to each other for particular industries.

Owner:REAL DATA GURU

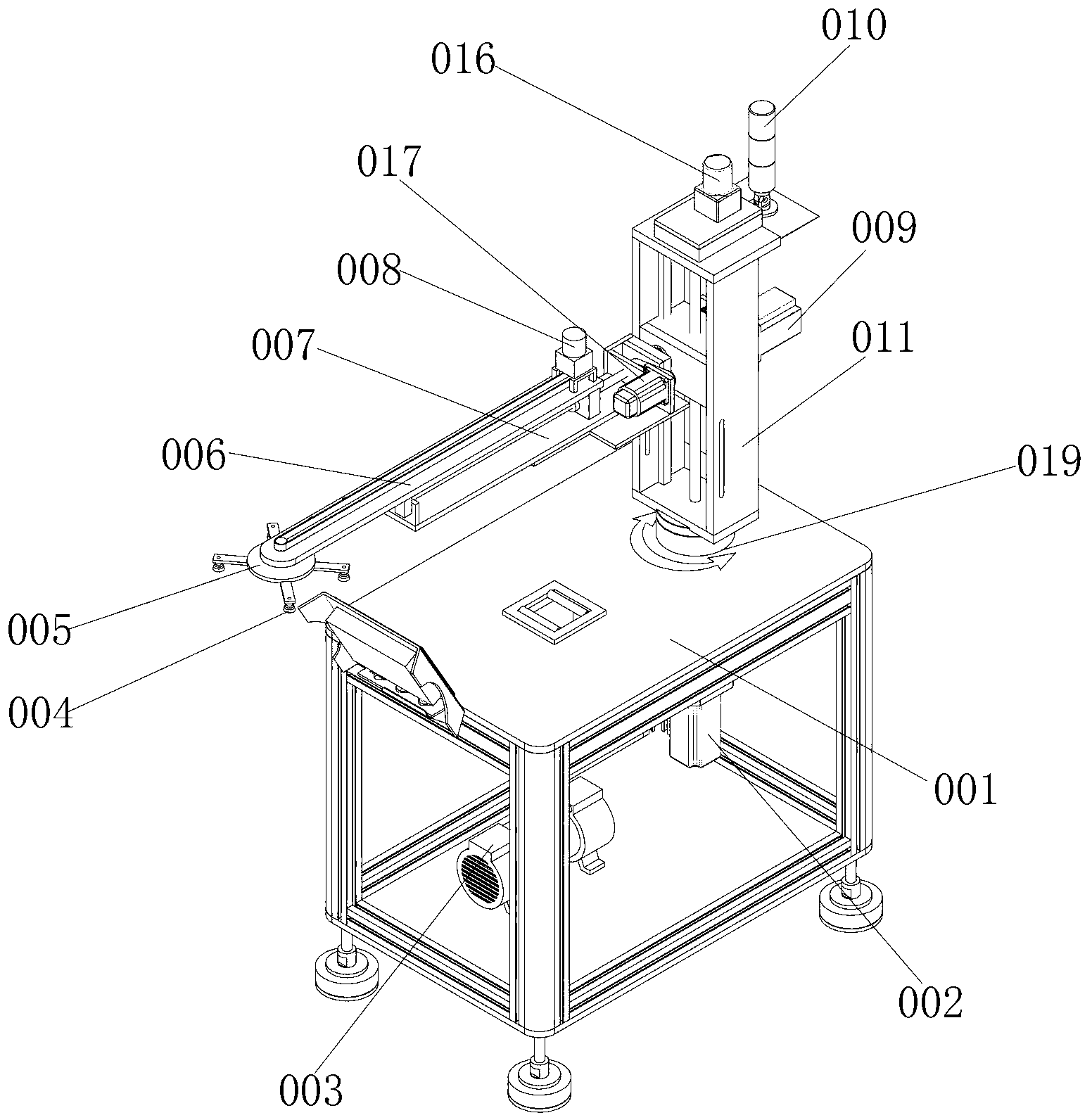

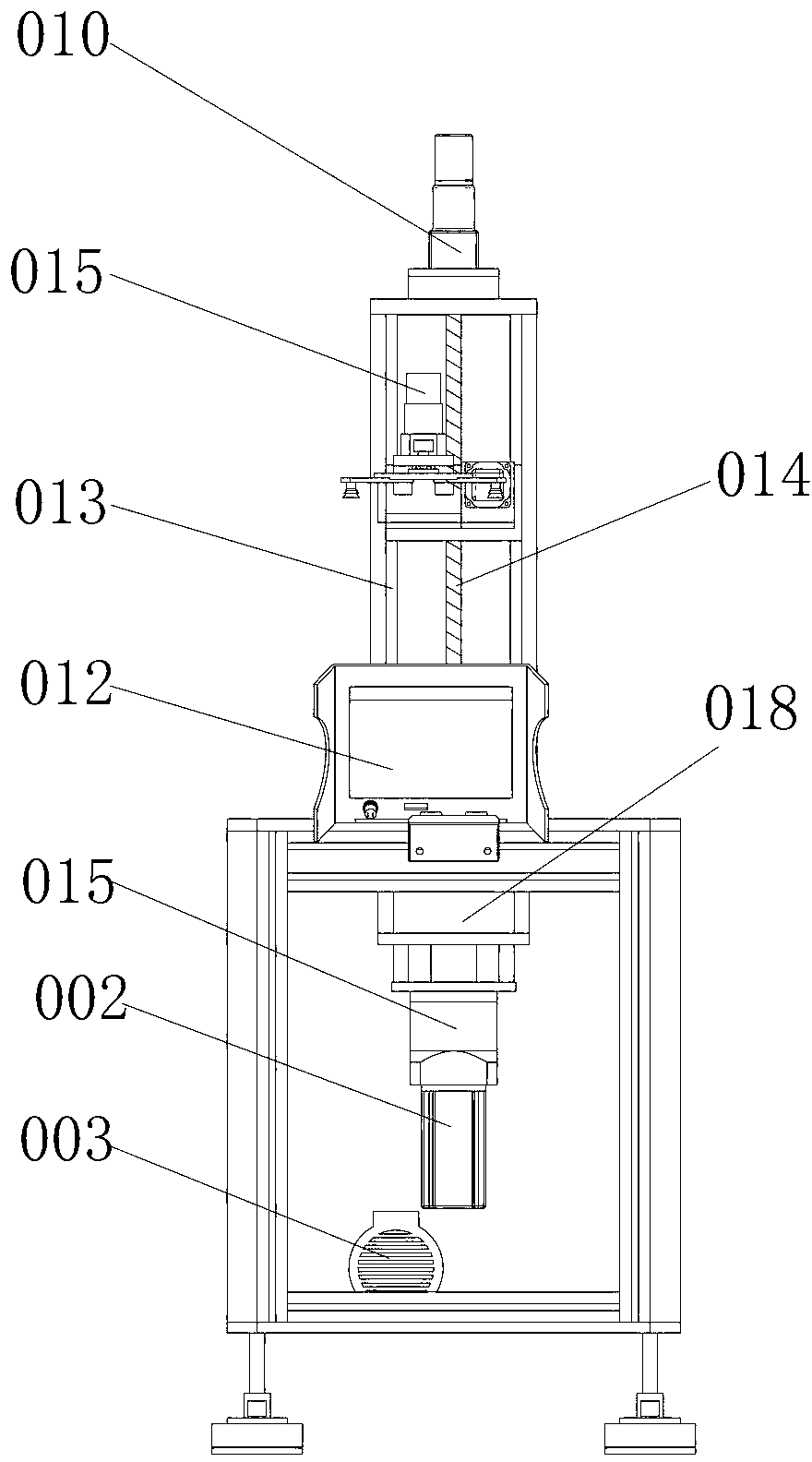

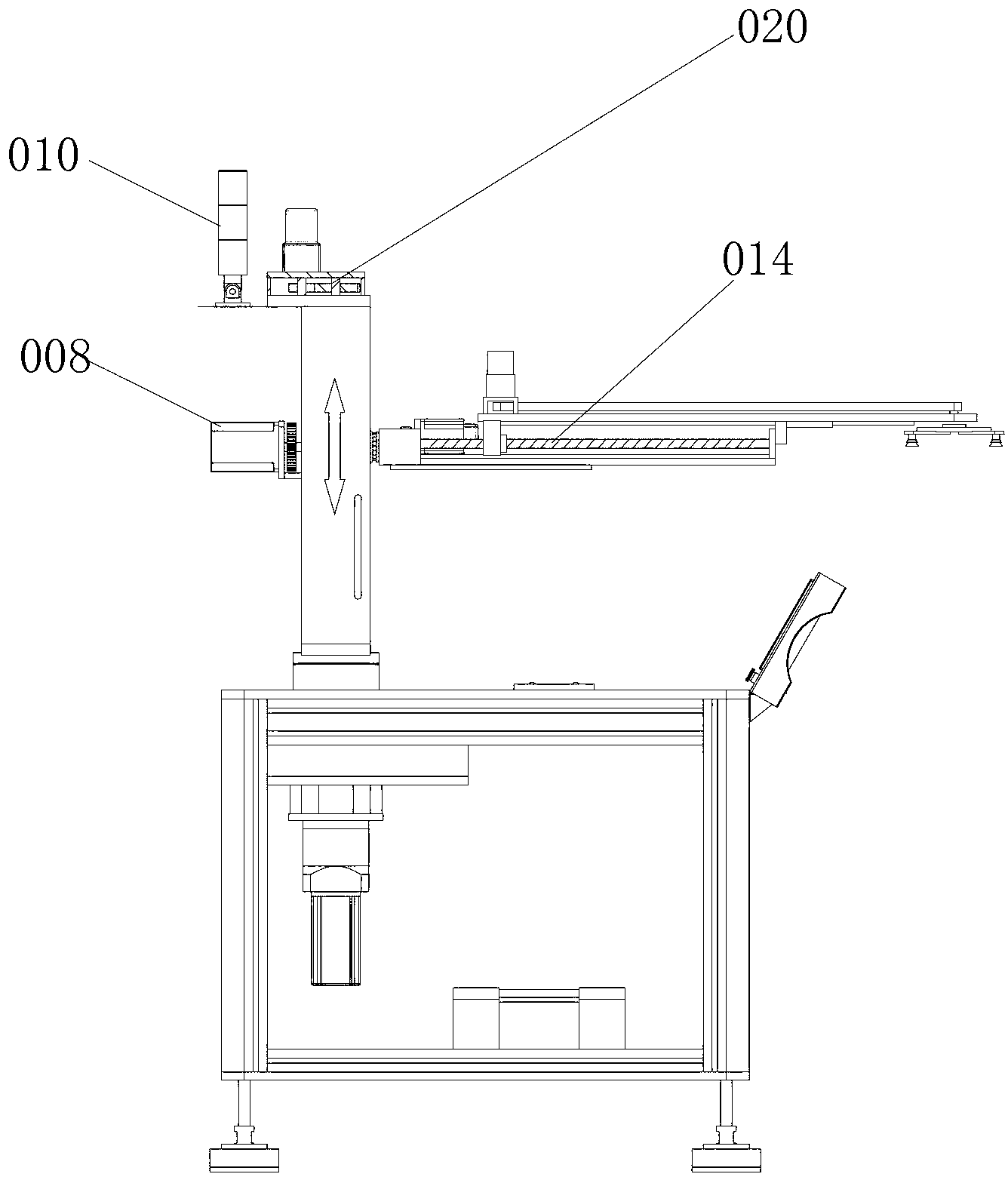

Workpiece stamping intelligent control process and intelligent control manipulator

InactiveCN103252770AImprove work efficiencyImprove securityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlMachining process

The invention discloses a workpiece stamping intelligent control process. The workpiece stamping intelligent control process controls automatically and satisfies all actions to be operated coherently to effectively improve working efficiency, no manual work is needed, safety is improved and cost is effectively saved. Product quality is guaranteed to enable products to meet market demands. The invention further provides an intelligent control manipulator implementing the process. Through an efficient, accurate, flexible, safe operation mode flexible in design, the intelligent control manipulator is convenient to operate, production efficiency is greatly improved, structural design is reasonable, design mode is flexible, effects are obvious, process persistence is high, raw materials are saved and energy consumption is quite low; a regulation and control type industrial control process satisfies different demands, the structural design enhances smoothness, swing precision is guaranteed, and machining process is guaranteed to be completed automatically, continuously and effectively; and conventional manual or semi-automatic machining modes are replaced, and resources are saved.

Owner:FOSHAN DINGFENG ROBOT

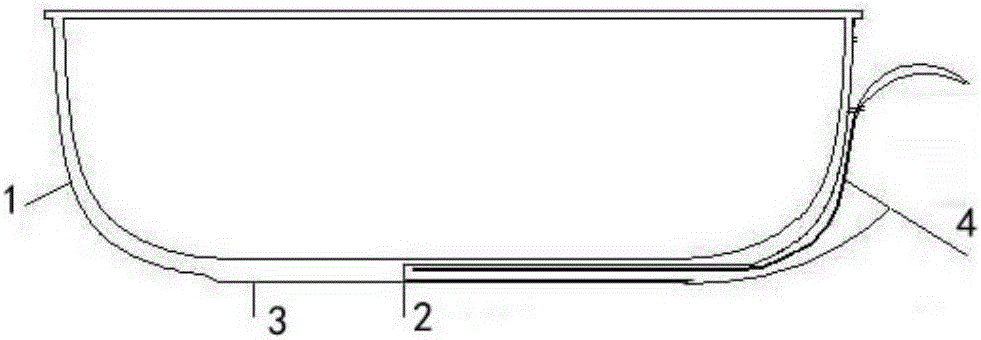

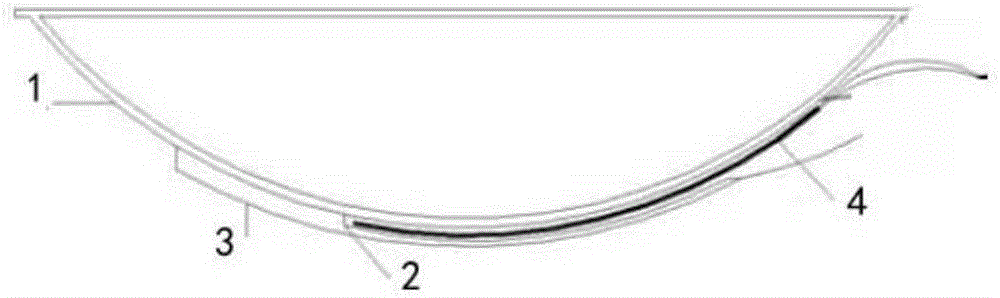

Pot with hidden temperature measurement structure

InactiveCN106419486AExpand the temperature measurement rangeHigh temperature range and high efficiencyCooking vessel constructionsEngineeringThermocouple

The invention relates to a pot with a hidden temperature measurement structure. The pot with the hidden temperature measurement structure comprises a pot body. The pot body is characterized in that an attached bottom is arranged on the bottom surface of the pot body, a thermocouple is provided with the connecting part of the pot body and the attached bottom, a detecting end of the thermocouple is hidden near the center position of the bottom surface of the pot body and in contact with the bottom surface of the pot body, so as to form a temperature measurement structure to directly detect the center position and the periphery of the pot body; the attached bottom is tightly united with the pot body, the detecting end of the thermocouple is inserted into a capillary steel tube and extends straightly into the bottom of the pot, a signal outputting end of the thermocouple is a real-time temperature outputting end of the pot body; a hidden temperature measurement structure is formed on the bottom surface of the pot body. According to the pot with a hidden temperature measurement structure, a temperature measurement structure capable of directly detecting the center position and the periphery of the pot body is formed, and the pot has the advantages of evenly distributed temperature measurement points, good concealing, and being solid and durable, safe in use, precise in temperature measurement, large in temperature measurement range, high in temperature measurement efficiency and simple in workmanship.

Owner:深圳酷平方科技有限公司

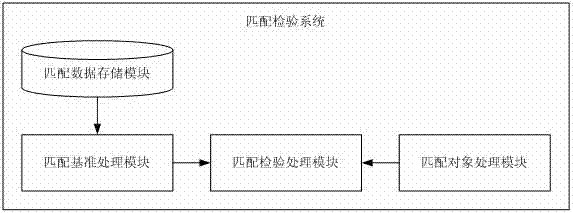

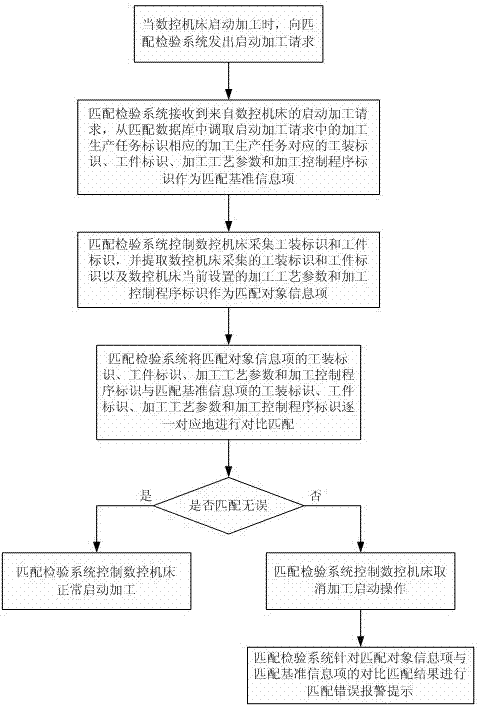

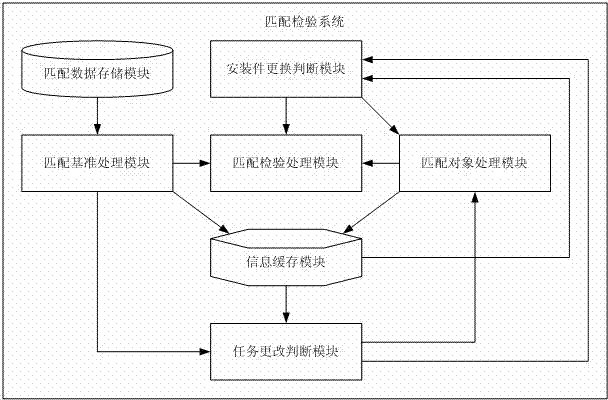

Tool and workpiece matching verification system and machining and controlling method of numerically-controlled machine tool

ActiveCN103286634AAvoid economic lossEnsure safetyCo-operative working arrangementsMeasurement/indication equipmentsNumerical controlMachine control

The invention provides a tool and workpiece matching verification system and a machining and controlling method of a numerically-controlled machine tool. When the numerically-controlled machine tool is started to perform machining, the numerically-controlled machine tool is not directly and normally started to be machined and directly and normally undergo machining and control operation, however, match verification is performed by the matching verification system through tools and workpieces used for machining of the numerically-controlled machine tool and machining technology parameters and machining control procedures set by the numerically-controlled machine tool. Whether the numerically-controlled machine tool can be started to perform machining or not is intervened and controlled by a matching verification result. Economic losses and machining accidents due to wrong installation of the tools and the workpieces or the fact that the machining technology parameters and the machining control procedures are not matched with required machining tasks are more efficiently eradicated in the process of machining of the numerically-controlled machine tool, and safety in machining of the numerically-controlled machine tool is ensured. Recording and storing of information of the matching verification result can be achieved, and basic data are provided for achieving information management of real-time monitoring, optimal scheduling of the machining tasks and the like of the information of machining and producing processes of the numerically-controlled machine tool by an enterprise.

Owner:CHONGQING UNIV

Workshop operation management method, system and server

The invention belongs to the technical field of production control, and provides a workshop operation management method, a workshop operation management system and a server. The method comprises the following steps of: determining a production plan list of a product to be produced, and generating a process command list and a plan feeding list; printing a process flow card according to the process command list, wherein the process flow card at least comprises two bar codes, respectively a bar code of the product to be produced and the bar code of each processing procedure; generating a dispatch list according to the process command list; transmitting the dispatch list to each personal terminal; receiving the start information and the completion information of each processing procedure transmitted by the personal terminal; and generating production process and cost accounting information according to the start information, the completion information and the processing batch quantity of each processing procedure. Therefore, the production management controlled by the bar codes on the process flow card is realized; the production process is managed and controlled effectively; the on-time delivery rate of orders is improved; quota material reception is realized; and simultaneously, the product quality is ensured.

Owner:ANHUI KING LAN INFORMATION TECH

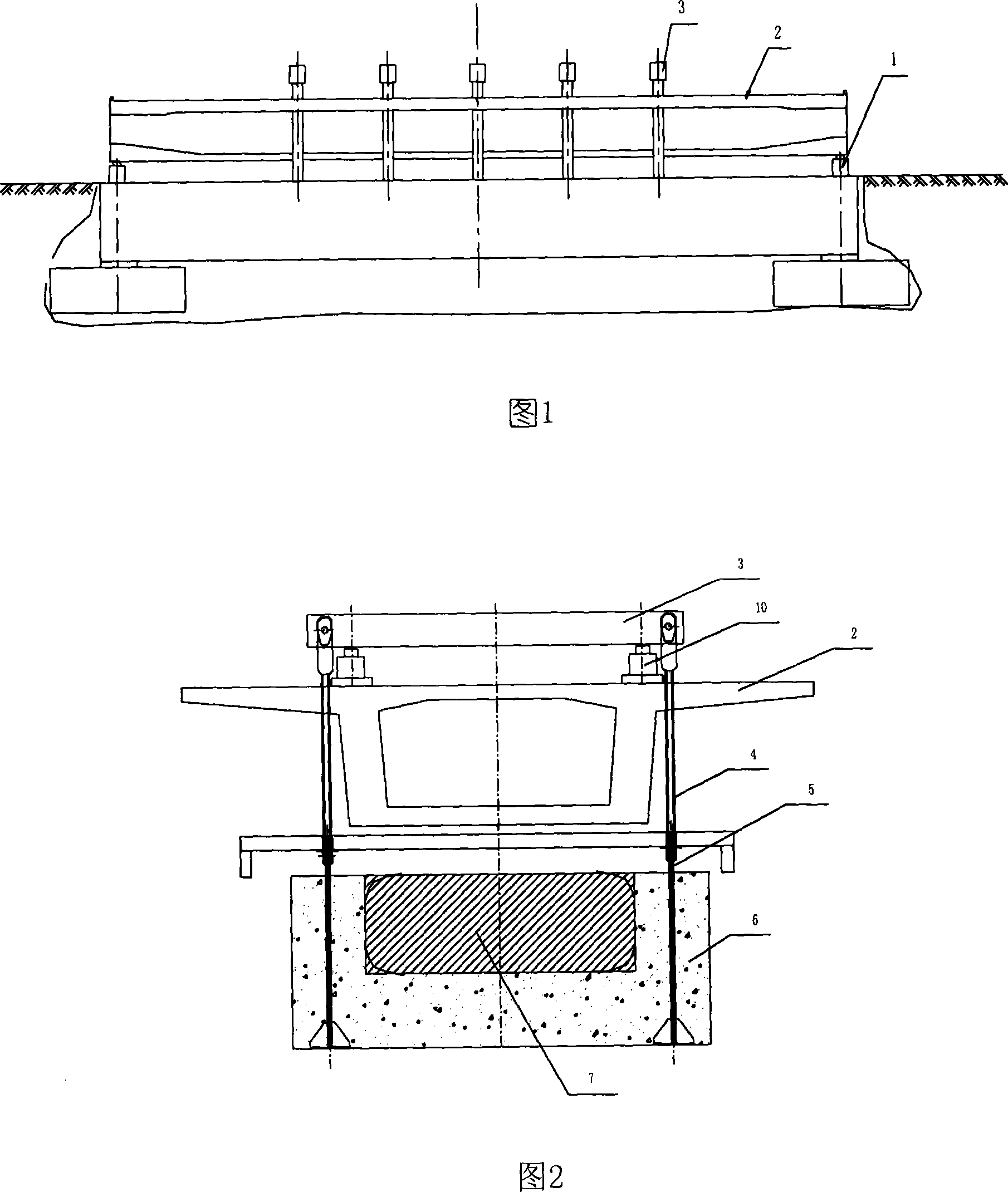

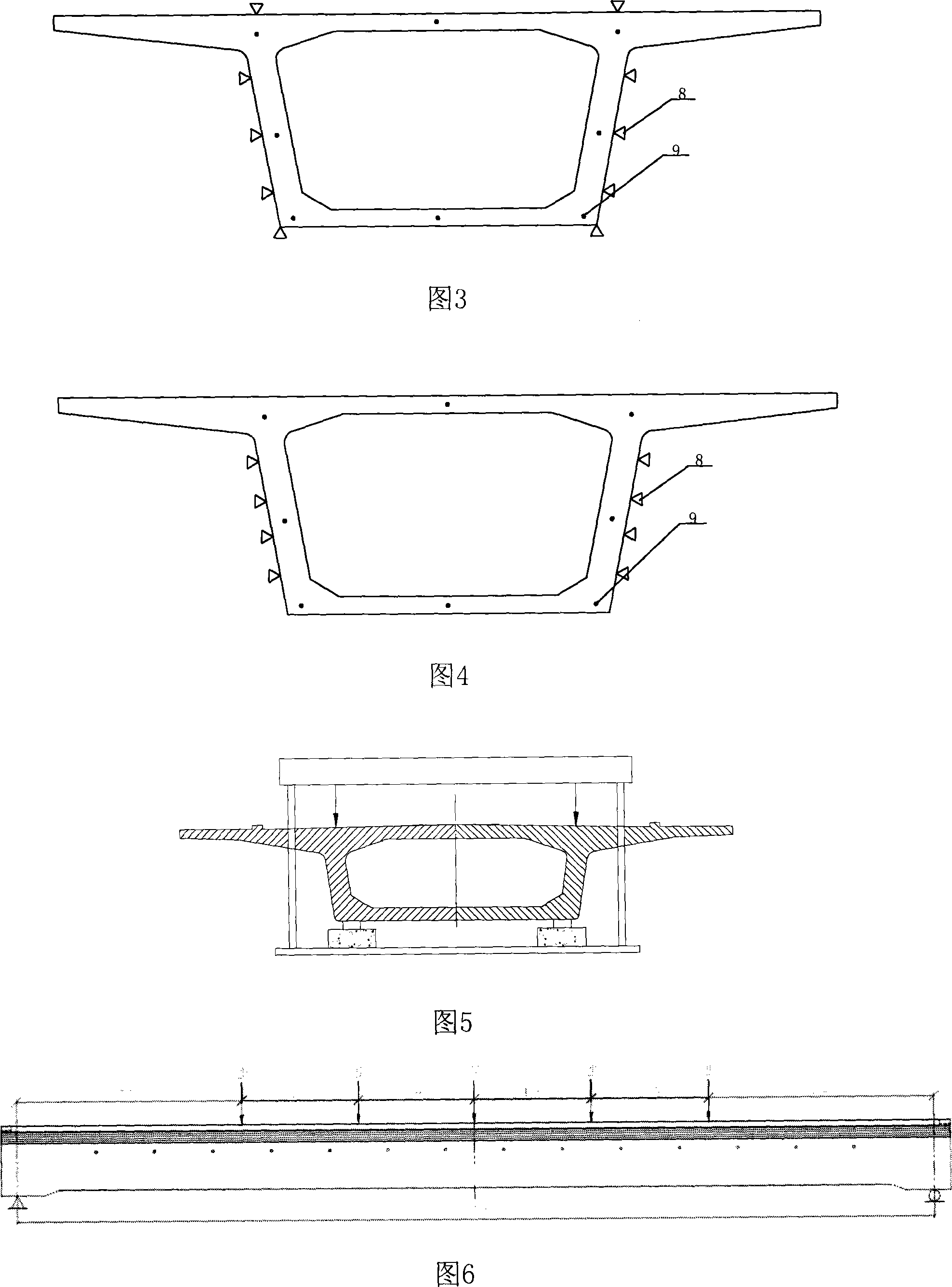

32m/900t prestressed concrete pretension box beam static loading test method

ActiveCN101101249AVerify crack resistanceAuthentication strengthFoundation testingMaterial strength using tensile/compressive forcesTest beamPre stress

The invention discloses a test procedure of 32m / 900t pre stress pre open box girder concrete box, it includes building testing counter, laying test beam body, fixing balance weight and setting test equipment, and doing load test of three circulation by ordering step by step, and dong crack test for the 32m / 900t pre open box girder effectively, splitting test and breaking test, dong experiment for the design of 32m pre open box girder, construct artwork, workmanship and the anti split and intensive properties of box girder.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

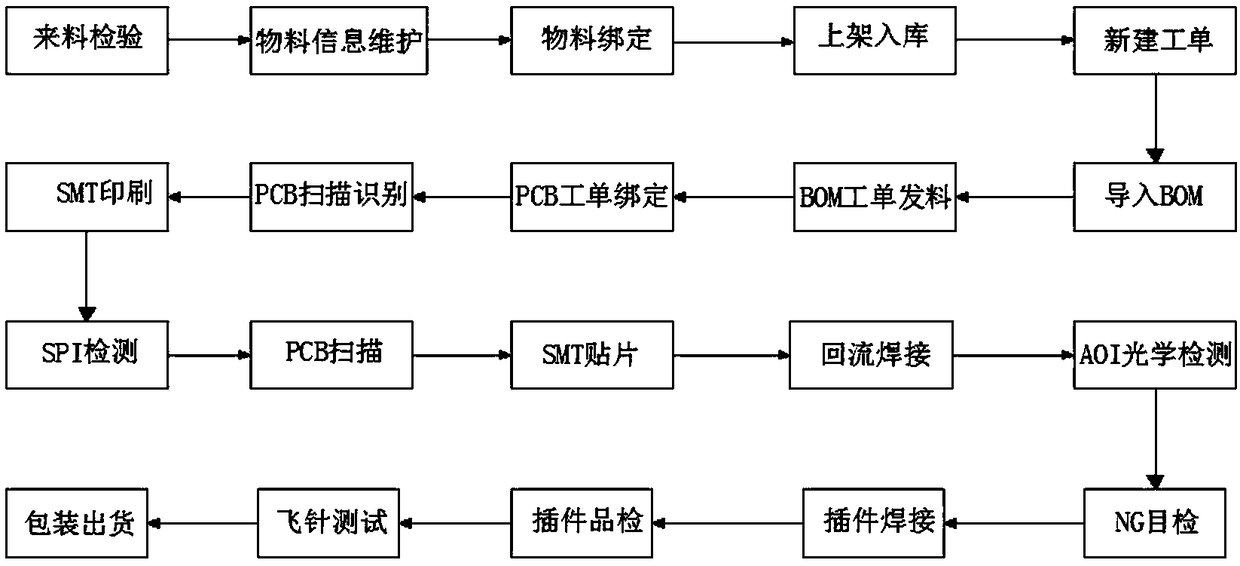

Intelligent SMT production error-proof tracing method and process

InactiveCN108811365AImprove satisfaction rateGuaranteed traceabilityPrinted circuit assemblingElectrical componentsFunctional testingVisual inspection

The invention discloses an intelligent SMT production error-proof tracing method and process, which comprises the following steps: incoming material inspection, material information maintenance, material binding, putaway and warehousing, work order filling, BOM introduction, material issuance according to BOM work order, PCB work order binding, PCB scanning identification, SMT printing, SPI detection, PCB scanning, SMT patching, reflow soldering, AOI optical inspection, NG visual inspection, insert welding, insert quality inspection, flying probe testing, packaging and shipping. The tracing method and process use the intelligent manufacturing production method on the basis of the conventional production process method to ensure the traceability of the product. After the production of the product, the flying probe test is added to perform the functional test to inspect the product reliability, so that the qualified rate is controlled from the source, the ex factory qualified rate is greatly improved, the customer satisfaction rate is improved, the repair rate is reduced correspondingly, and costs are reduced.

Owner:上海安理创科技有限公司

Process and device for manufacturing workpieces with non-circular inner or outer contours as well as eccentrically positioned round boreholes and/or journals

The invention pertains to a special process and devices for the production preferably by machining of workpieces with non-circular outer and inner contours such as squares, hexagons, ellipses, polygons and the like, or eccentric circular bores and / or tappets. In the claimed process, the workpiece is rotated at constant angular velocity while a tool (e.g. the blade of a lathe tool) set eccentrically in relation to the workpieces if moved without rotating about is own axis at controllable speed in a circular path, workpiece and tool being moved towards one another in cycles with the appropriate advance. This ensures that apart from a small cuttings volume far each advance, very narrow tolerances can be set.

Owner:IPROTEC MASCHEN UND EDELSTAHLPROD GMBH

X-ray detecting method for printed circuit board defect

InactiveCN1987437AImprove test coverageReduce preparation timeMaterial analysis by transmitting radiationContactless circuit testingRecognition algorithmX-ray

The intelligent analysis method, the intelligent system, and method for controlling position of X light source are in use for checking products of print circuit board (PCB). Defect recognition algorithm raises accuracy of recognition, and lowers erroneous judgment of false defect. Through user's main threaded, threaded of background operator, and monitoring threaded of serial port, the disclosed intelligent system at PC end, as well as PLC communication and control multithreading implements coordinational synchronization between PC intelligent system and PLC. Since penetrability of X ray, percentage of coverage for detecting defective workmanship of PCB by system is raised greatly.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

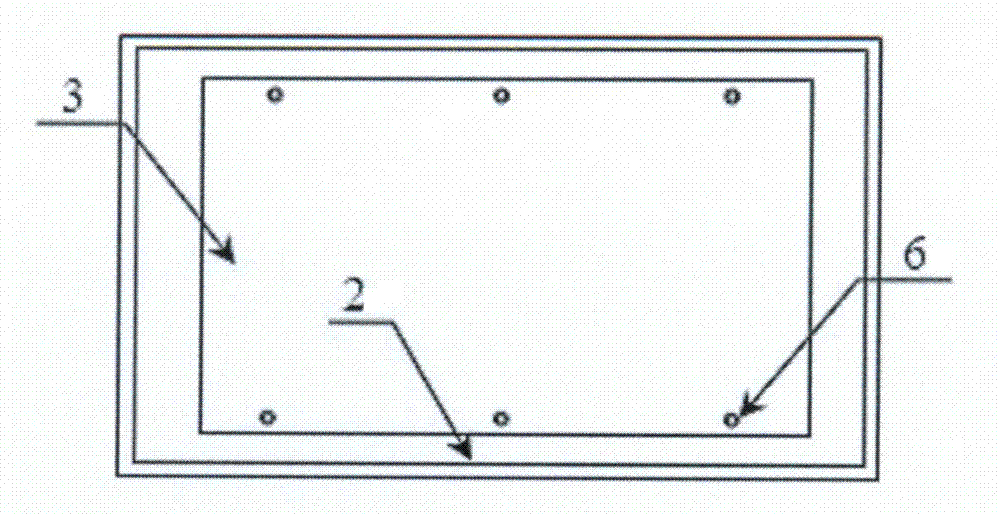

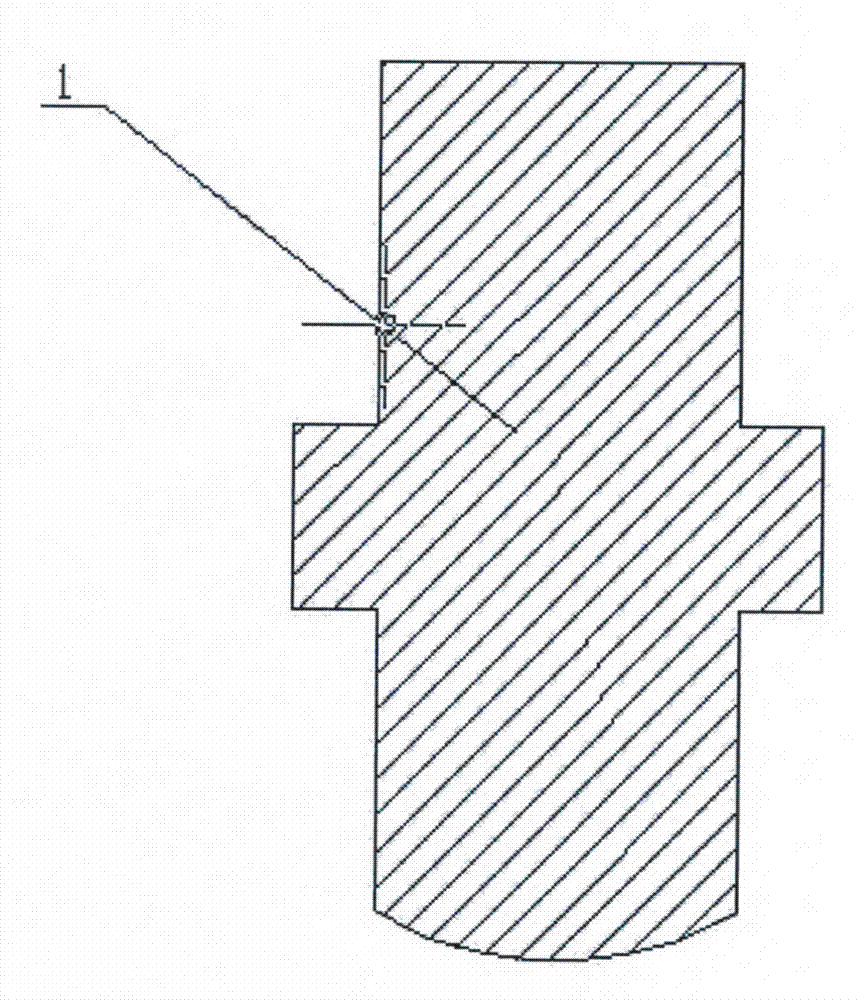

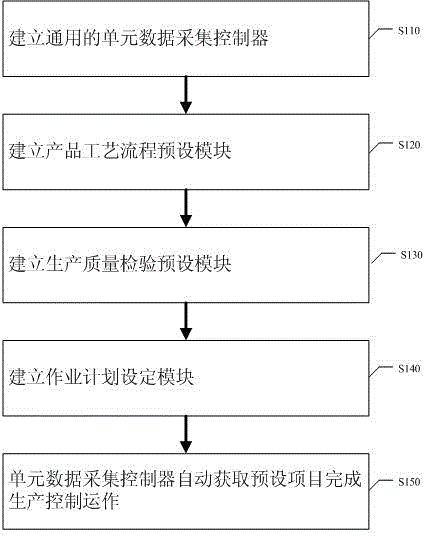

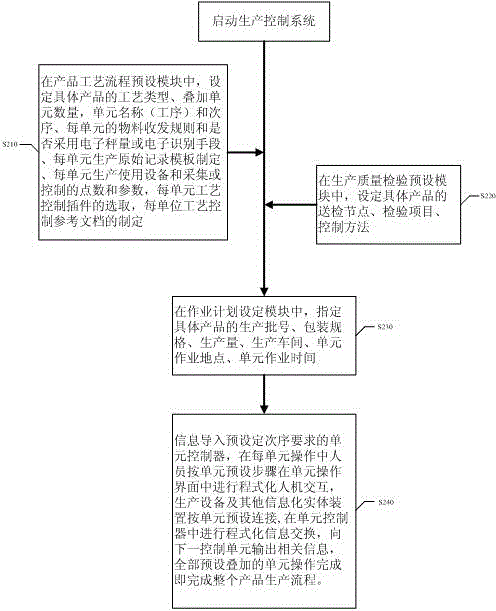

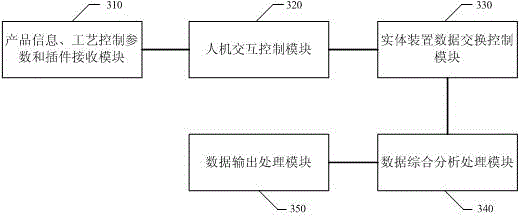

Realization method for general type production and manufacturing unit and control system thereof

ActiveCN104407576AImprove developmentSolve operational problemsTotal factory controlProgramme total factory controlWork planControl system

The invention relates to a realization method for a general type production and manufacturing unit control system. Different technical control processes of product production and manufacturing are decomposed into multiple independent production process computer input and output operation control units which are then substituted by one general virtual control device. The realization method comprises the following steps that one general virtual control device is established; a product technical process preset module is established; a production quality inspection preset module; a work plan setting module is established; and corresponding unit operation performed in a unit data acquisition controller according to a set sequence requirement is performed, stylized information exchange is performed, the related information is outputted to the next control unit and all the preset superimposed unit operation is completed so that the whole product production process is completed. Computer process control difficulty of manufacturing industry intermittence type and discrete type production is mainly solved by the method and the system so that system applicability and work efficiency are enhanced and product technical cost is reduced.

Owner:SHANGHAI YINDAO INFORMATION TECH

Metal component automatic positioning method and terminal device

ActiveCN108364311ARealize high-precision lossless positioningHigh precisionImage enhancementImage analysisNon destructiveEdge extraction

The invention is applicable to the technical field of visual positioning, and provides a metal component automatic positioning method and a terminal device. The automatic positioning method comprisesthe steps that an image of a metal component is acquired, and is binarized to acquire a binarized image; edge extraction is carried out on the binarized image to acquire an edge image; polygon fittingis carried out on the edge image, and the barycentric coordinate of the polygon is acquired according to the fitted polygon; and the center coordinate of the barycenter of all polygons and the slopeof a line fitted by the barycentric coordinates of all polygons are calculated according to the barycentric coordinate. According to the invention, some workpieces with high processing precision and fine workmanship are prevented from the risk of being scratched by a positioning device, and accurate and non-destructive positioning of processed workpieces is realized.

Owner:深圳市亿图视觉自动化技术有限公司

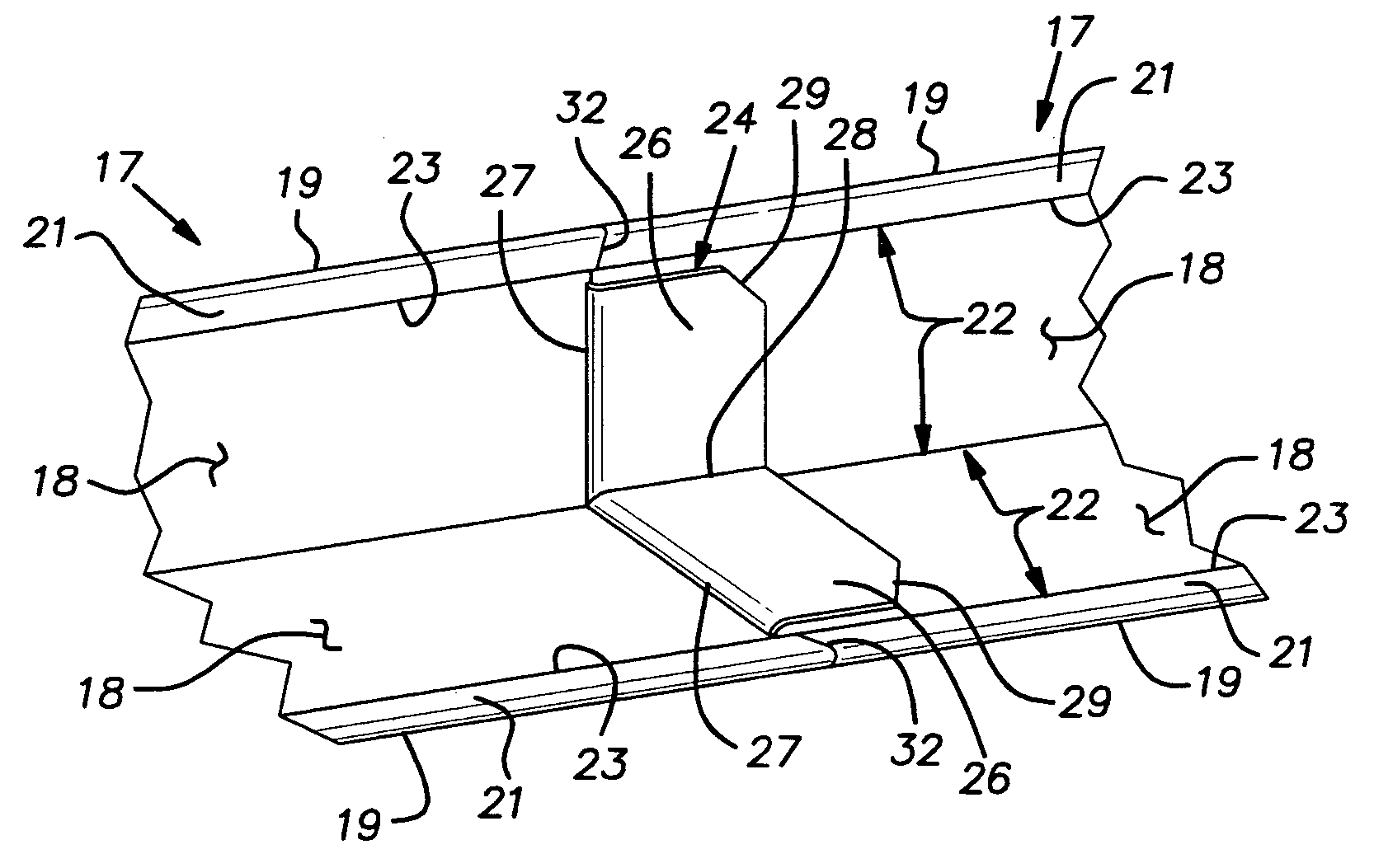

Perimeter angle trim

A wall molding for suspended ceiling systems has a self-aligning feature adapted to locate one end of a piece being installed on the end of a previously installed piece so that an installation of high quality workmanship is quickly obtained. The self-aligning feature is in the form of a tongue extending longitudinally beyond a faux end and adapted to nest in the previously installed piece. The tongue fits within the spaces between hems on the longitudinal edges of legs of a right angle cross-section and the opposed legs so that the tongue is laterally restrained in the planes of the legs and is longitudinally restrained by abutting end edges.

Owner:USG INTERIORS LLC

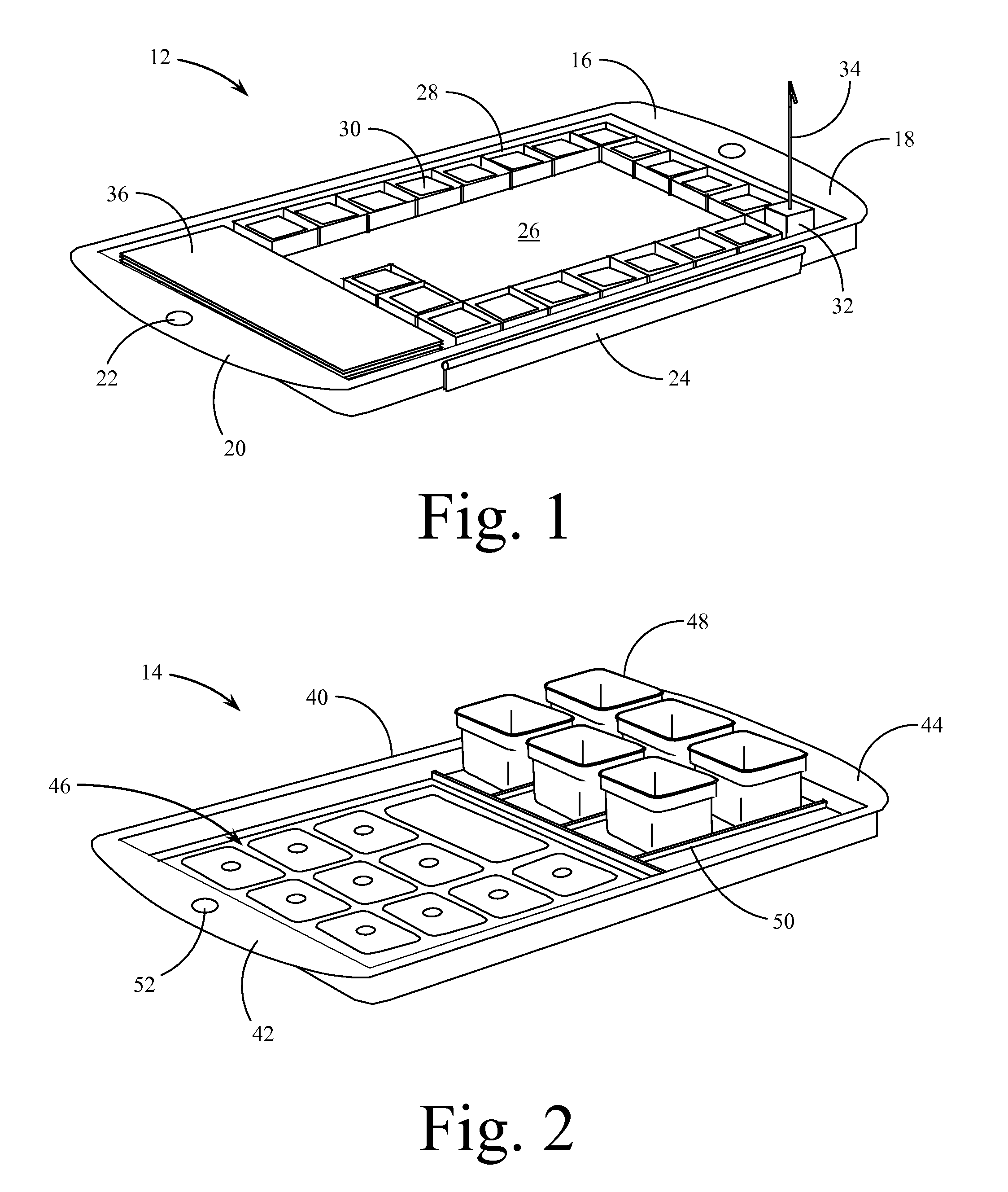

Paint and Craft Palettes and Case

InactiveUS20140284225A1Easy to usePlace safeLiquid surface applicatorsContainer/bottle contructionStatic clingAdhesive

A paint palette with tray and accessory components having releasable bonding surfaces such as magnets and metallic layers, layers of sticky adhesive, static cling elements, or layers of other types of chemical or mechanical bonding surfaces. The palette components include paint pans, mix / wash pans, note stands, dividers, water container, and laminated value charts, all with bonding surfaces that adhere to and may be repositioned on the tray components. The paint pans and mix / wash pans are preferably stackable, of varying size and depth, some with slanted opening for ease of access to paint, and at least one rough exterior wall for labeling. A second embodiment uses multiple paint palettes in a modular system for use with mixed media. The palettes may be repositioned and held in place by magnets on the palette sides. The palettes are stackable and may be stored and transported in an adjustable carrying case.

Owner:DAVIS SHERRY

Bauxite-based nanometer composite oxide ceramic bond A1203-MgO-C unfired product and preparation method thereof

The invention relates to an A1203-MgO-C unfired product with carbon wrapped by nano Al2O3-MgO film and a preparation method thereof. The product uses natural high alumina bauxite (AlOOH) and sintered periclase (MgO) as initial raw material and employs method of sol-gel technology, which comprises following steps, putting superfine high alumina bauxite, carbon dust, water and additive into high speed impact mixer, carrying out coating process so as to let the materials have strong impact and mix with each other to form high density composite sol suspension liquid of carbon and aluminium hydroxide, therefore Al(OH)3 is mightily adsorbed on the surface of carbon, then realizing workmanship of coating powdered carbon by aluminium hydroxide. During the wet-milled process of mixture, the magnesium oxide powder and the mixture water in the matrix powder have hydration reaction to produce magnesium hydroxide sol, and the magnesium hydroxide sol and the aluminium hydroxide sol have situ synthesis reaction to produce nanostructured matrix of carbon-aluminium spinel to prepare A1203-MgO-C unfired product of the invention.

Owner:高树森

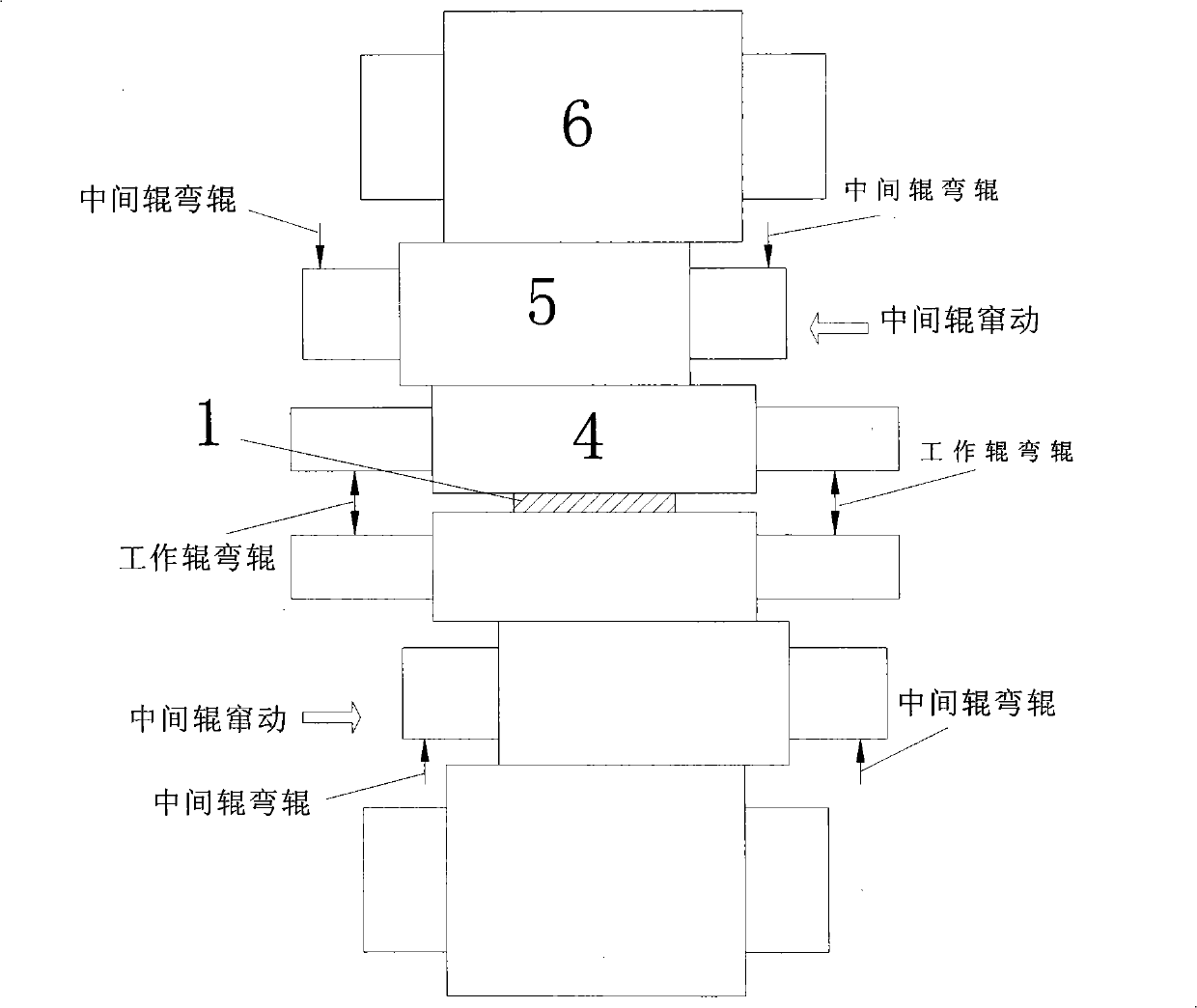

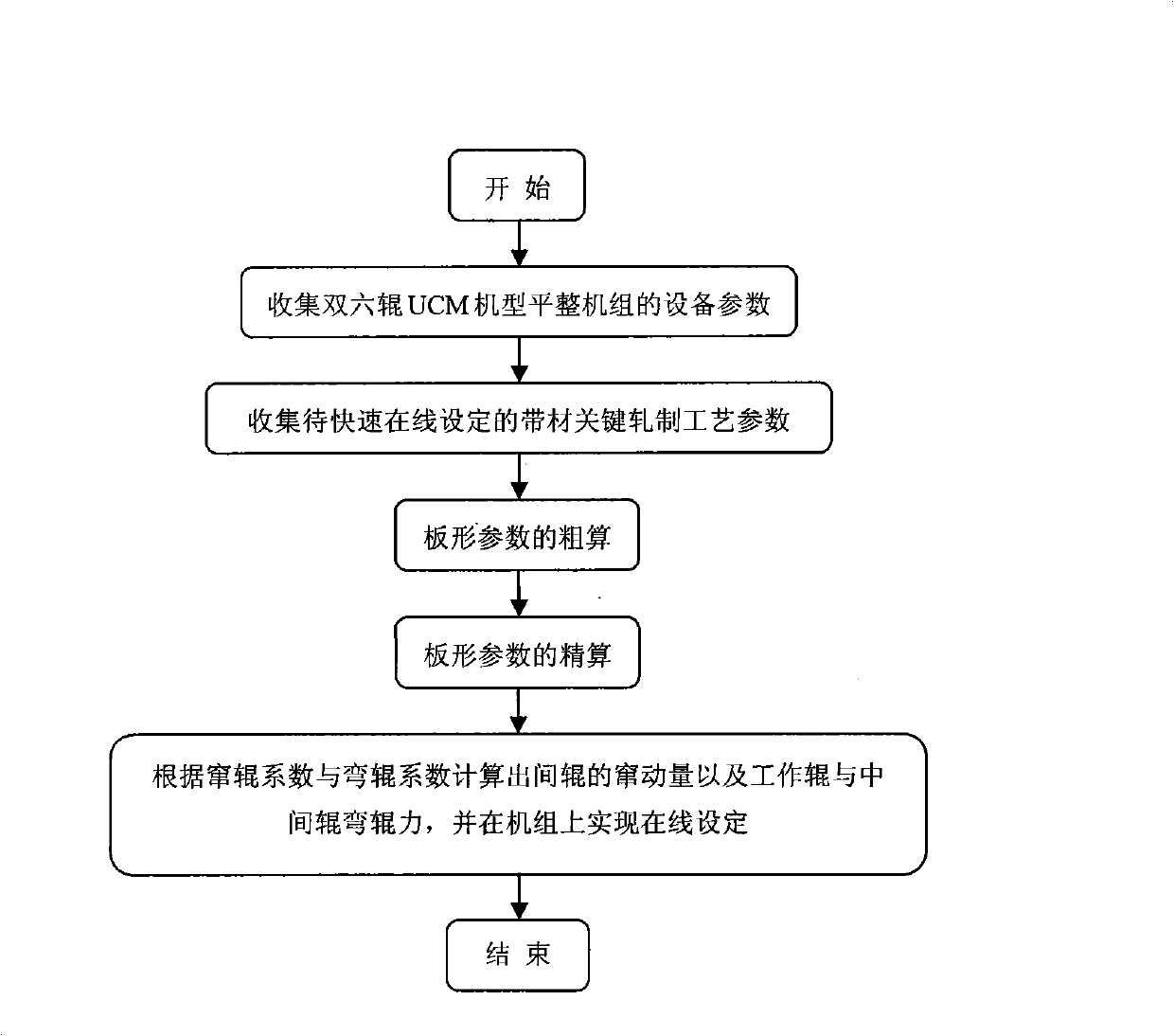

On-line method for setting mechanism model-based plate parameter of double UCM temper milling machine group

InactiveCN101301659AGuaranteed service lifeMeet precision requirementsNumerical controlProfile control deviceWork rollBending force

The invention discloses a plate-shape parameter online setting method for a dual-UCM temper mill on the basis of mechanism models. The method of the invention is characterized in that: a. the equipment parameters of the dual six-roll UCM type temper mill are collected; b. the key rolling process parameters of the strip to be quickly online set are collected; c. the plate-shape parameters are roughly calculated; d. the plate-shaped parameters are finely calculated; f. the shrinkage movement of the middle rolls of the frame 1model and frame 2model of the temper mill, and the roll bending force of a work roll and a middle roll are calculated correspondingly to the roll shifting coefficient and the roll bending coefficient; furthermore, the online setting of the parameters are realized on the temper mill. When the comprehensive control method provided by the invention is adopted, the plate-shape parameter setting technique on the basis of the mechanism models can be applied online, and can meet the precision requirement on engineering, as well as can effectively ensure the plate-shape quality of the finished product, the service life of the roller, and the service life of the bent roll cylinder, thus bringing obviously economical benefits for the enterprises. The method of the invention is simple and clear and suitable for online application.

Owner:YANSHAN UNIV +1

Workpiece hammering reinforcing device during metal additive manufacturing and application method thereof

PendingCN107297504AReduce residual stressImprove fatigue lifeAdditive manufacturing apparatusDimensional precisionData processing

The invention discloses a workpiece hammering reinforcing device during metal additive manufacturing and an application method thereof. The device comprise a hammering reinforcing device body, a linear motion part, a motion regulating part, a locking part, a hammering executing part, a hammering regulating support, a data processing and measuring control unit and a base and is characterized in that workpiece follow-up hammering reinforcing operation during the metal additive manufacturing is achieved by using the linear motion part and control flow based on process and working condition data. The workpiece hammering reinforcing device and the application method thereof have the advantages that the optimized process control flow is provided, a forming process can be favorably improved on the basis of an existing additive manufacturing system, and workpiece quality can be increased; the structure homogeneity of a formed part is increased, mechanical performance is improved while plasticity is enhanced, crack generation is inhibited, the fatigue life of the formed part is prolonged, the flatness of the surface of a formed layer is improved, and the dimensional precision of the formed part is increased effectively.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

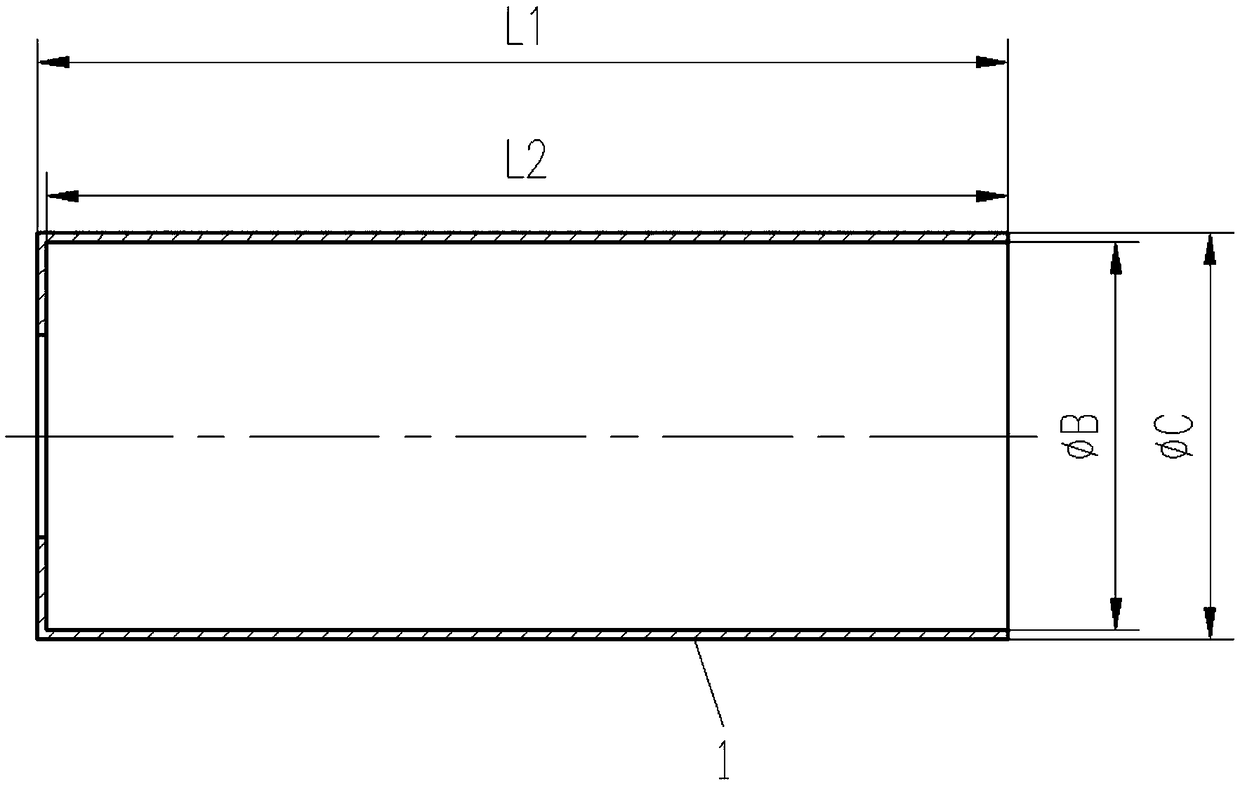

Machining method of high-precision deep and long hole thin-walled sleeve part

The invention provides a machining method of a high-precision deep and long hole thin-walled sleeve part. The machining method comprises the following steps that a rod is clamped and subjected to rough-machining forming, the machining allowance is reserved, and a process chuck is reserved; a roughly-machined workpiece is subjected to thermal treatment aging; and the process chuck of the workpieceis clamped by a lathe, finish machining of the workpiece is completed during primary clamping machining according to a workpiece drawing, and finish machining is divided into the following working steps that a core shaft, a lining and a screw are manufactured; the process chuck is clamped on the lathe, the core shaft is crammed into roughly-machined inner holes of the workpiece, and an outer circle of the part is machined to the required dimension; the screw is screwed into a core shaft threaded hole, and the core shaft is taken out of the workpiece; the lining sleeves the machined outer circle of the workpiece, the outer end face of the workpiece is machined, and the large and small inner holes and the bottom face are bored; tool setting is conducted from the bottom face, the outer end face of the workpiece is machined, and the length dimension L2 of the workpiece is ensured; and the workpiece is cut off, and the total length L1 of the workpiece is ensured. According to the machiningmethod of the high-precision deep and long hole thin-walled sleeve part, the rigidity of the part is improved, machining deformation of the part is reduced, vibration during thin-walled part machiningis reduced, and the machining quality and surface roughness are improved.

Owner:临沂产业研究院有限公司

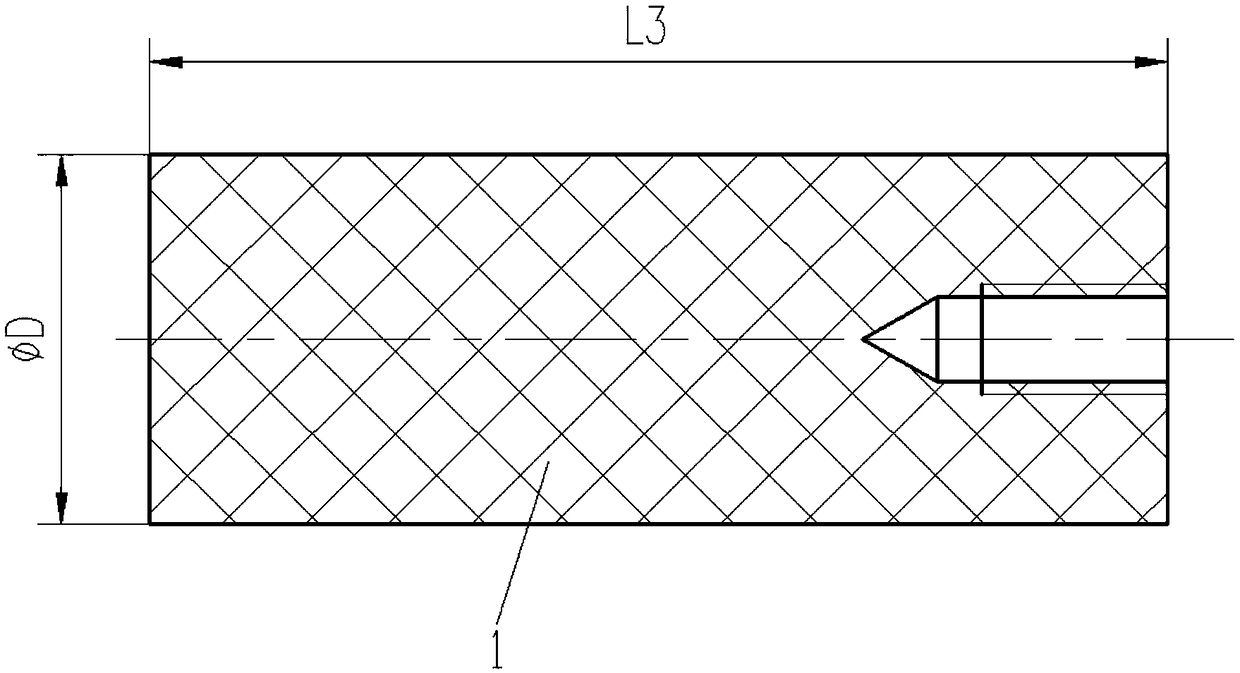

Manufacturing method for tool for machining heat treatment deformation circular-disc blade

The invention discloses a manufacturing method for a tool for machining a heat treatment deformation circular-disc blade. The manufacturing method comprises machining of a tool main body and machining of a tool accessory and comprises the following steps: (1) preparing tool main body raw materials; (2) annealing a forged blank; (3) initially machining the forged blank into a tool main body; (4) carrying out heat treatment on the tool main body; (5) deeply machining the tool main body; (6) detecting the tool main body; (7) preparing tool accessory raw materials; (8) annealing a forged blank ofthe tool accessory; (9) turning of the forged blank of the tool accessory; and (10) tightening the tool main body and the tool accessory together by using a bolt for combined use. According to the invention, through reasonable ingredient composition and a heat treatment process corresponding to the ingredient, a deformation-free effect of the tool is achieved; and during fixing the circular-disc blade, a deformation layer of the circular-disc blade can be rapidly eliminated, so that the machining accuracy of the circular-disc blade is improved and the qualified rate of products is increased.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Process for machining positioning gasket

The invention discloses a process for machining a positioning gasket. The process comprises the following steps of: 1, performing finish turning, namely performing the finish turning on an excircle and an inner hole of a raw material until the sizes of the excircle and the inner hole reach design sizes; 2, performing heat treatment; 3, performing wire cutting; 4, grinding, namely clamping a workpiece by using a double-sided grinding fixture, grinding the plane of the workpiece until the size of the workpiece reaches the design size, and keeping depth of parallelism, planeness and surface roughness; 5, performing finish-milling, namely milling positioning holes in the workpiece according to the requirement of a drawing; 6, performing aging, namely keeping the workpiece in a drying oven at the temperature of 140 DEG C for 12 hours; 7, polishing, namely polishing the surface of a part by using a magnetic force polishing machine without bumping and scratching, and demagnetizing the part by using a demagnetizing machine; and 8, packaging for warehousing. Due to the adoption of the process, the positioning gasket can be machined quickly and efficiently and is high in accuracy, the utilization rate of materials is high, cost is saved, and machining efficiency is improved.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

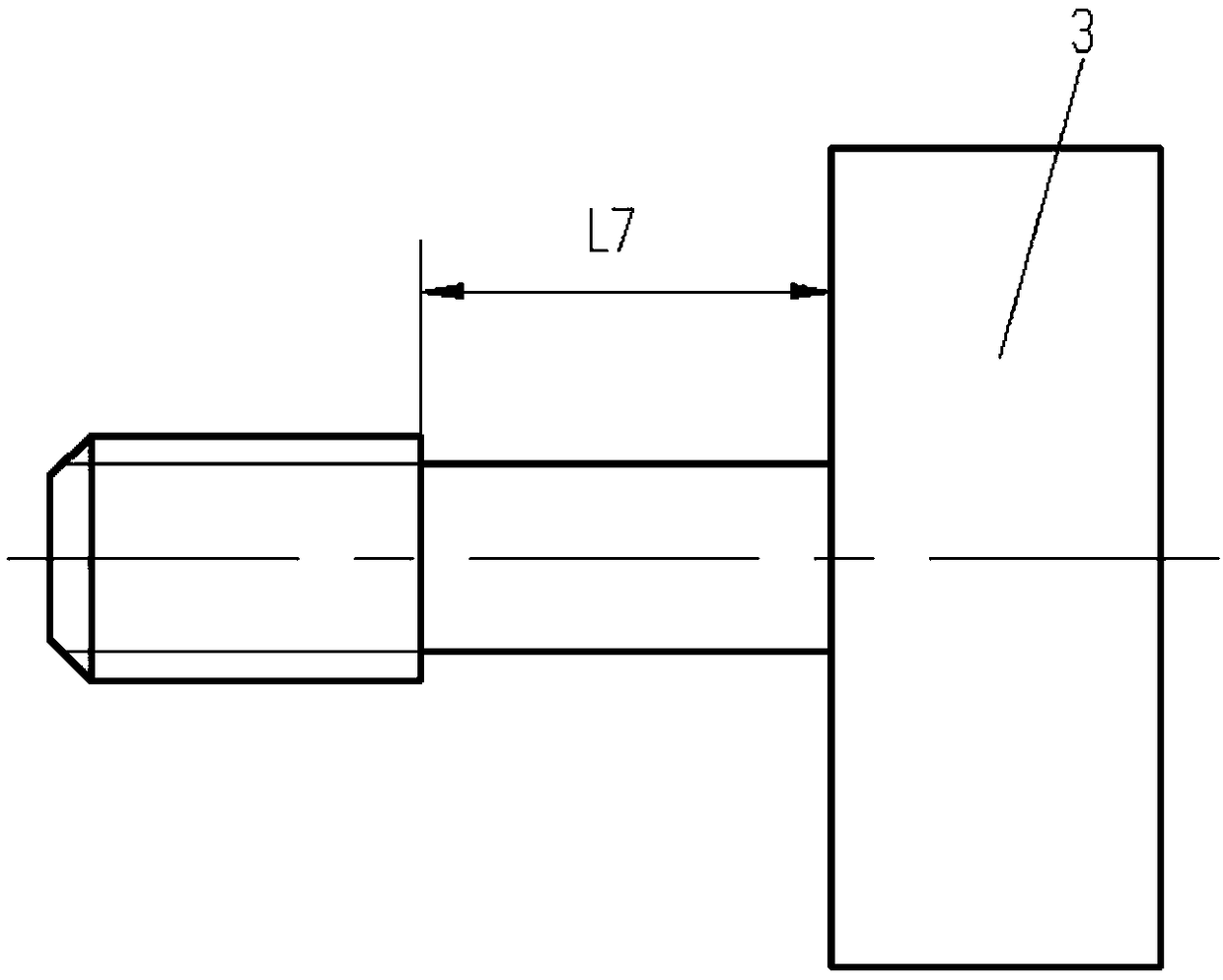

Nine-station machine tool for surface milling and drilling of taper sleeves and process of nine-station machine tool

ActiveCN106271633AIncrease productivityIncrease productionOther manufacturing equipments/toolsRough surfaceEngineering

The invention discloses a nine-station machine tool for surface milling and drilling of taper sleeves. The nine-station machine tool comprises a machine body (1) and an oil-pressure toothed-type cutting platform (2). The oil-pressure toothed-type cutting platform (2) is rotationally mounted at the top of the machine body (1). Nine blank jigs (3) are arranged on the outer edge of the oil-pressure toothed-type cutting platform (2) evenly. A rough surface milling unit (4), a rough boring unit (5), a semi-fine boring unit (6), a fine surface milling unit (7), a fine boring unit (8), a drilling unit (9), a chamfering unit (10) and a tapping unit (11) are sequentially arranged at the top of the machine body (1) clockwise by taking the oil-pressure toothed-type cutting platform (2) as the circle center. The nine-station machine tool has the advantages of high processing accuracy, high automation degree, improved taper sleeve production efficiency, lowered labor intensity of workers and increased taper sleeve yield.

Owner:四川德恩精工科技股份有限公司

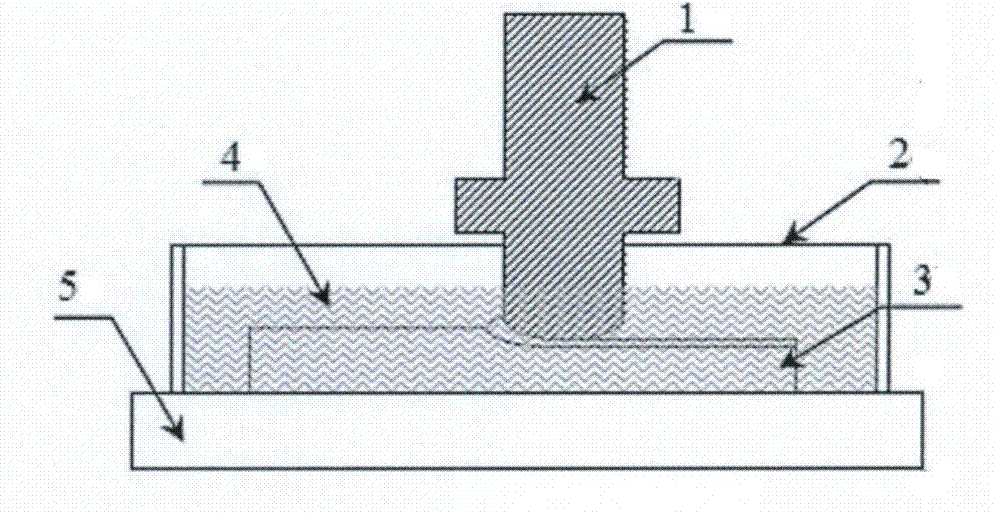

Workmanship of indoor microscopic oil displacement model

The invention relates to workmanship of a microscopic oil displacement model used in oilfield chemistry and acid fracturing laboratories to simulate a medium-low permeable oil deposit so as to study the oil displacement process. The invention adopts the technical scheme that the workmanship includes the steps: polishing, washing and blow-drying a glass substrate and then roasting the glass substrate on a glue baking plate; spin coating a layer of tackifier on the glass substrate and then baking on the glue baking plate, so as to form a nano-film; spin coating a layer of photoresist, and baking on the glue baking plate; converting an oil deposit picture into a black and white picture, importing the picture into photoetching software, exposing the glass substrate and then developing in developing liquid, washing, blow-drying, and baking on the glue baking plate; sealing the unexposed part of the glass substrate through paraffin wax, rusting in corrosive liquid, washing, then boiling in sulfuric acid and hydrogen peroxide, washing and blow-drying; tightly pressing the glass substrate to a mica sheet ,and sintering in a muffle furnace; and finally, grinding an access passageway, and putting capillary tubes into the access passageway to make a microscopic oil displacement model for studying the oil displacement process.

Owner:SOUTHWEST PETROLEUM UNIV

Machining process for annular thin-wall part and tool thereof

InactiveCN105710392AReduce stressReduce distortionAutomatic/semiautomatic turning machinesPositioning apparatusMachined surfaceMachining process

The invention discloses a machining process for an annular thin-wall part and a tool thereof. According to the machining process for the annular thin-wall part and the tool thereof, multiple times of half finish turning and finish turning are adopted, stress ageing is combined, and the influence of material stress and machined surface stress on the product dimensional precision is gradually reduced; innovative thinking is applied to the design of a tool clamp, rough turning and finish turning are conducted on an inner hole in a mode that an outer circle is positioned and an end surface is clamped, thus, the product clamping and positioning precision is high, and stress strain is gradually released; and the outer circle is subjected to rough turning and finish turning and a hollow-out groove is subjected to finish milling in the mode that inner holes of the two ends of expansion rings are clamped and positioned, so that the product positioning precision is high, and clamping is firm. By means of the machining process for the annular thin-wall part and the tool thereof, the labor intensity of workers is relieved, the production cost is reduced, the labor productivity is improved, using is safe, and the product quality is improved.

Owner:SUZHOU DOUSON VALVE CO LTD

Method for manufacturing purple mud pottery

The invention discloses a method for manufacturing purple mud pottery. The method comprises the following steps: selecting drying and crushing kaolin, red porcelain clay and yellow clay, adding water into the mixture, adding screened river sand to prepare mud, molding, drying in the shade, patching, manually manufacturing a mouth, a kettle handle and the like, assembling the mouth, the kettle handle and the like with a kettle body, polishing, performing press polish, drawing, sculpturing, carving, drying in the shade at low temperature, drying at medium temperature, drying at high temperature, firing in a kiln, discharging from the kiln to obtain a finished product. Because the raw material formula is improved, the large-scale kaolin and river sand are added on the basis of the original yellow clay and red porcelain clay, the density of the pottery products is improved, particularly the firing temperature is increased, the problems that the sintering hardness and the density can not be meet during low-temperature firing are solved, the problem that high-temperature firing water seepage can not be realized is solved, and the pottery is bright in color, ideal in air permeability and exquisite in workmanship and is a brand new pottery product.

Owner:SUILING TAOYUAN POTTERY CULTURE & ARTS DEV CO LTD

Virtual rolling simulation method of hot tandem rolling strip steel

InactiveCN101221417AImprove working environmentReduced commissioning timeSimulator controlInput controlStrip steel

The invention relates to the hot rolling strip steel rolling technology, in particular to the virtual simulation of hot continuous rolling strip steel rolling process, and discloses a hot continuous rolling strip steel virtual rolling simulation system which solves the problems during strip steel rolling including equipment problem, defective workmanship, system logic loophole and model precision by means of simulation technique. The hot continuous rolling strip steel virtual rolling simulation method comprises the following steps that: simulation equipment and a simulation input control strategy triggering system used during hot continuous rolling are set up; operating condition is input to the simulation equipment by the simulation input control strategy triggering system; the simulation equipment operates to obtain equipment data and basic automation level data; the equipment data and basic automation level data are converted and transmitted to real equipment, equipment after virtual execution conversion and the basic automation level data; moreover, execution results are monitored. The invention has the advantages that: the invention substantially reduces on-site maintenance and debugging time and greatly improves control quality and precision; moreover, the invention provides a visualized communication platform between designers and end users.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Production process full-period intelligent workshop system based on digital twinning technology and solving method

ActiveCN113110328AGuaranteed connectivityEasy to optimize and improveTotal factory controlProgramme total factory controlFull life cycleFeedback control

The invention discloses a production process full-period intelligent workshop system based on a digital twinning technology and a solving method. The system comprises a design planning module and a virtual-real synchronization module. The design planning module is used for building virtual components required by the digital twin of the automatic workshop in the virtual component design module, carrying out process design according to actual production requirements, arranging an automatic production line, and verifying a production line planning effect and a control program. The virtual-real synchronization module builds a real production line after verification, collects the operation data of the real production line, transmits the operation data to the data management and storage module, completes the synchronization between the real production line data and the digital twin data, and displays the virtual-real synchronization condition and the operation data, and finally guides the actual production by using the data processing result of the digital twin. The system and method run through the full life cycle of the production line, and production accidents and economic losses caused by design defects can be avoided; the simulation credibility is improved; and feedback control is performed on a real production line, so that major safety accidents and property loss can be effectively avoided.

Owner:DALIAN YAMING AUTOMOTIVE PARTS +1

Forging and heat treatment process of shell forge piece

ActiveCN109622836AImprove inner qualityImprove mechanical propertiesMetal-working apparatusFurnace typesIngotForge

The invention relates to a forging and heat treatment process of a shell forge piece. The forging and heat treatment process of the shell forge piece comprises the following steps that 1, raw materials are smelted; 2, forging heating is carried out; 3, forging is carried out, and the forging process comprises two heating numbers; 4, heat treatment is carried out, specifically, (1) normalizing treatment is carried out after forging; (2) mechanical roughening is carried out on the forge piece; and (3) tempering is carried out; and 5, mechanical finishing is carried out on the forge piece. According to the forging and heat treatment process of the shell forge piece, the inner quality of the forge piece is improved by improving steel ingot components and texture and the forging process, grainsare refined, the whole mechanical performance is improved, and the non-uniformity is eliminated. According to the technical scheme, the service life of products is greatly prolonged by the produced forge piece, and the service life of the products can reach at least ten years.

Owner:无锡继平新材料科技有限公司

System and technology for producing heat preservation and decoration integrated plate

The invention relates to a system and technology for producing heat preservation and decoration integrated plate. The system is simple in structure, convenient to operate, high in mechanization degree, high in continuous production capacity and high in automation degree; automatic production is carried out in the overall processes of feeding materials, processing the materials and obtaining finished products; equipment production lines are planed uniformly; the full-automatic production from the step of feeding the materials to the step of obtaining the finished products is achieved through four transfer machines; in addition, the operation rate of equipment is high, the quality of the manufactured products is stable, defective products caused by manual misoperation are reduced, raw materials of an enterprises are saved, and benefits are brought to the enterprise; the system is used in combination with different workpieces, all the workpieces are improved creatively, and the system is suitable for production on a large scale; the production technology is simple, technological parameters which are required finally can be directly obtained as long as the products go through the equipment at a time, the overall process is mechanized, the automation degree is high, the technological process is smooth and closely linked, resources are saved, the efficiency of the finished products is improved, and excellent social benefits and economic benefits are achieved.

Owner:HENAN DESHENG ENVIRONMENT ENERGY CONSERVATION TECH LIMITED

Double-driving shaft composite automatic finishing method for blisk

InactiveCN102107377AThorough processingImprove surface qualityEdge grinding machinesPolishing machinesRotational axisPolishing

The invention discloses a double-driving shaft composite automatic finishing method for a blisk. The method comprises the following steps of: machining by using special equipment with a rotary working table, wherein the equipment is provided with a fixed rotation axis; rotating a machined workpiece around the rotation axis relative to the rotary working table, wherein the rotation axis of the workpiece is parallel to the rotation axis of the rotary working table but is not coincident with the rotation axis of the rotary working table; revolving the machined workpiece around the rotation axis of the rotary working table during the rotation; and performing composite finishing operation on the machined workpiece by using a planar abrasive tool or / and a powdery or paste abrasive material under the motion condition. By the method, a completely new process is provided for improving the surface quality of a large-sized part with a complex shape and a high requirement on surface quality. A machining alternative method is found during the polishing of a large number of manually polished parts. The method has higher social value and economic value.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

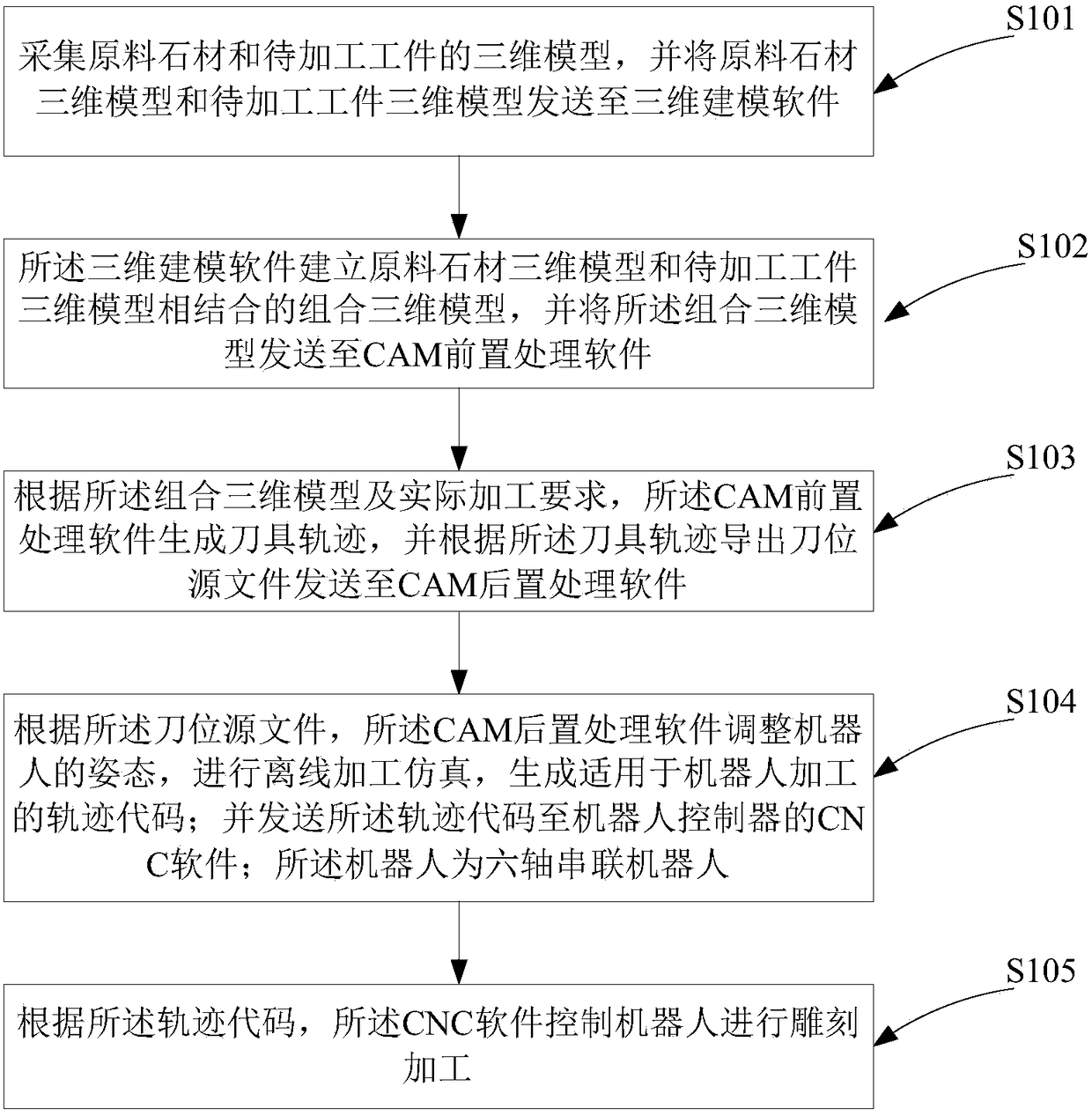

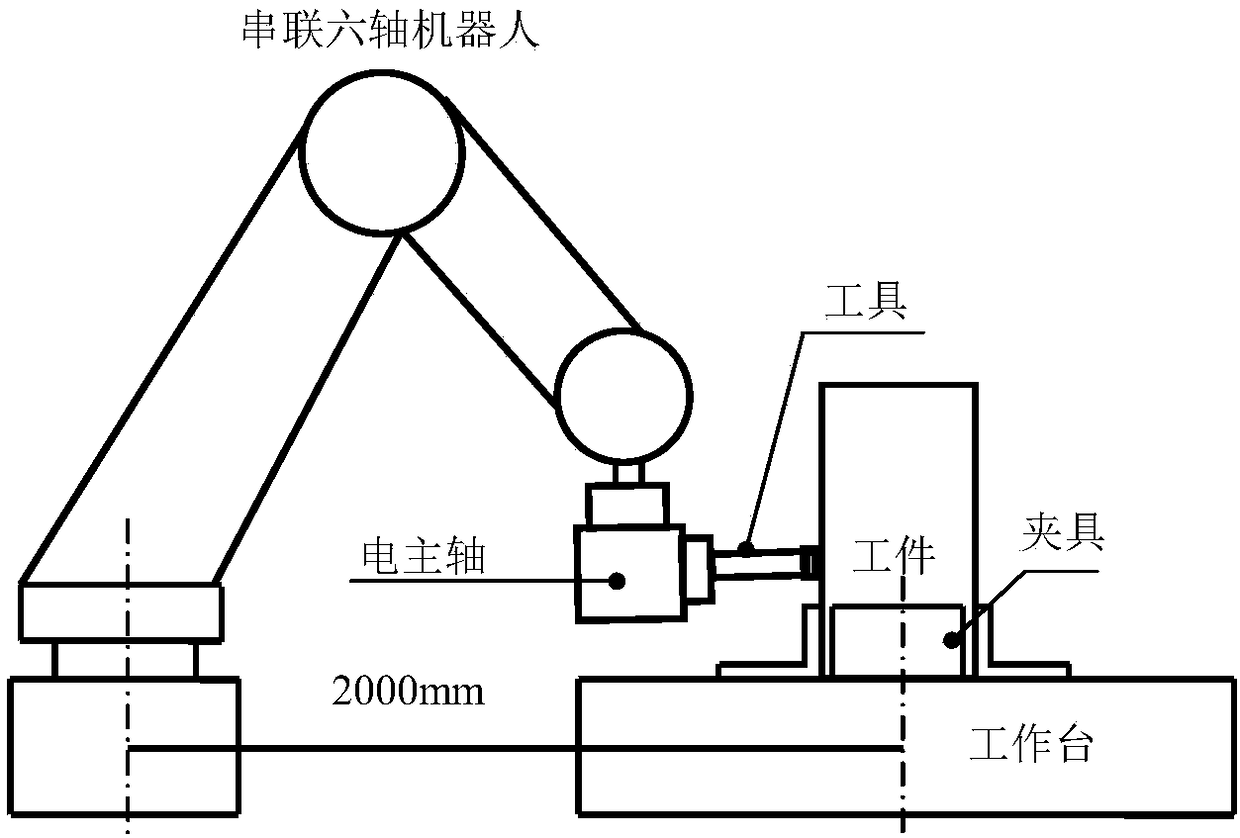

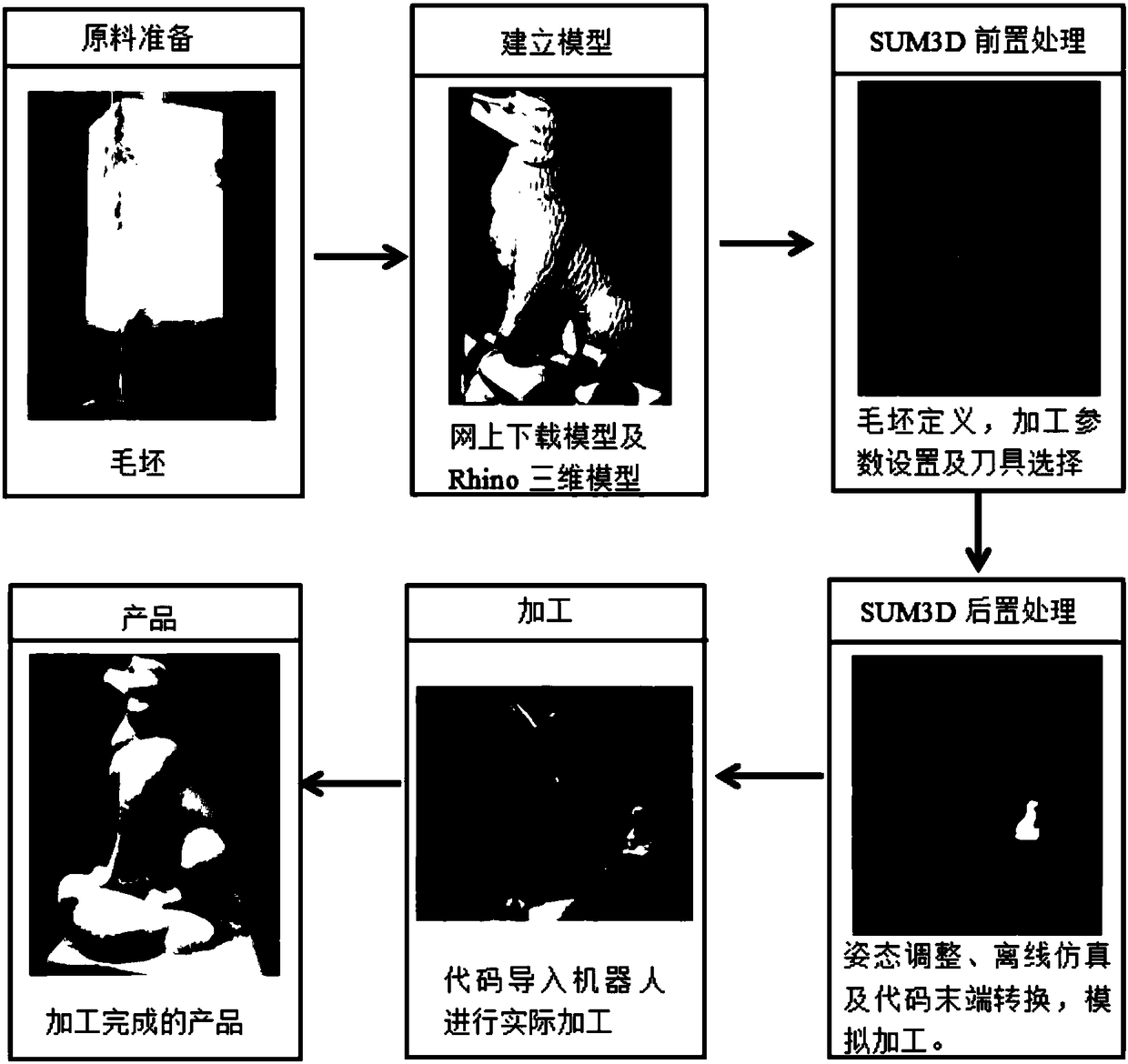

Method and system for robot carving machining for three-dimensional specially-shaped stone

ActiveCN108544880ARealize processingGuarantee processing qualityProgramme controlComputer controlStone carvingCam

The invention relates to a method and a system for robot carving machining for three-dimensional specially-shaped stone. A six-axis serial robot is utilized for cooperating with a rotatable workbench,carving machining for the three-dimensional specially-shaped stone is realized in combination with corresponding CAD, CAM and CNC software, and machining for a large carving can be realized, so thatthe machinable model range is greatly expanded; and many machining manners of saw cutting, rough machining, semi-finish machining and finish machining are combined in a machining process, and different tools and process parameters are selected in different machining processes, so that the machining efficiency is increased while the final machining quality is ensured, promotion and application fora fully-automatic stone carving technology are benefited, and the method and the system are of great significance to the development of the whole stone carving industry.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com