Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1320results about "Automatic/semiautomatic turning machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

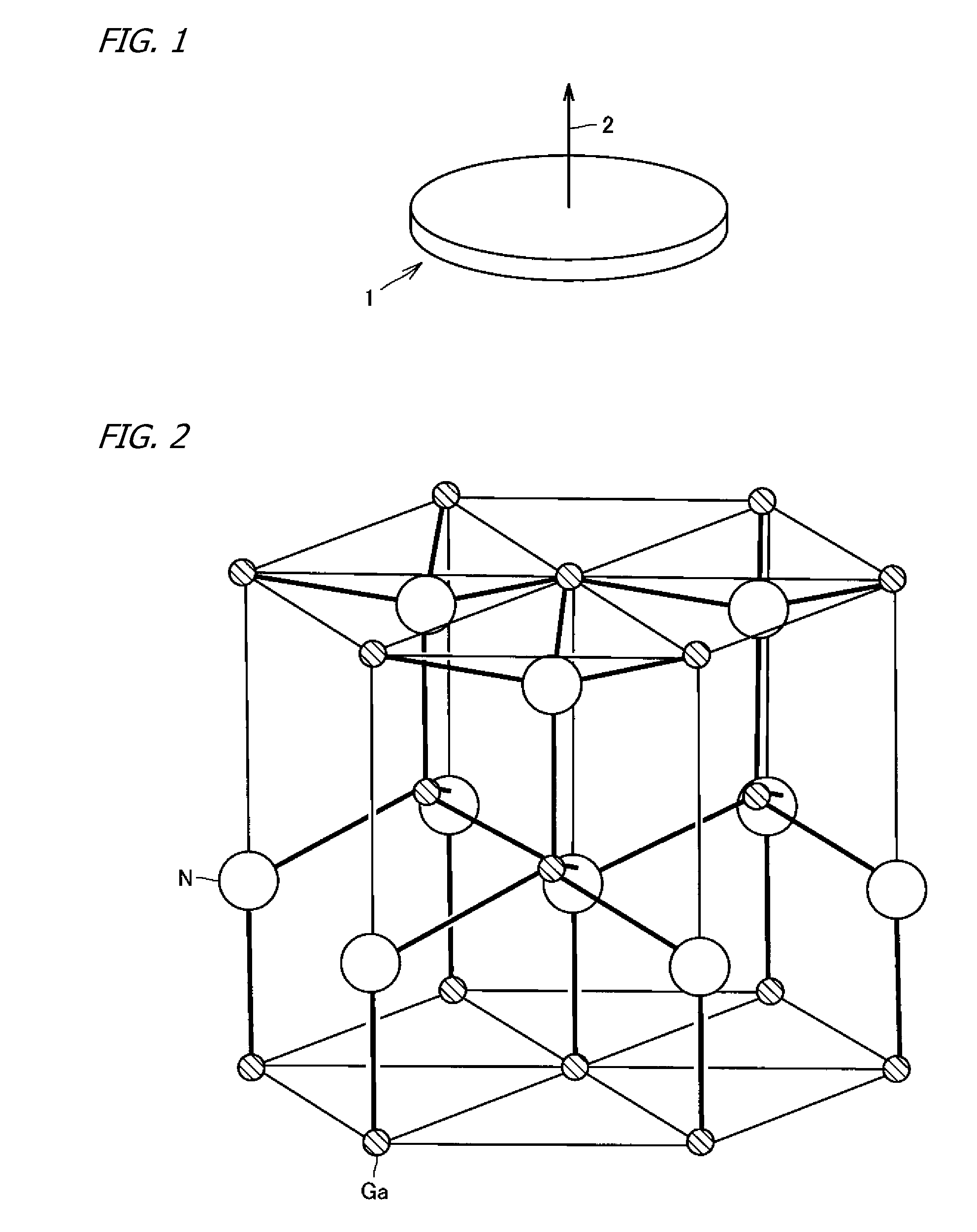

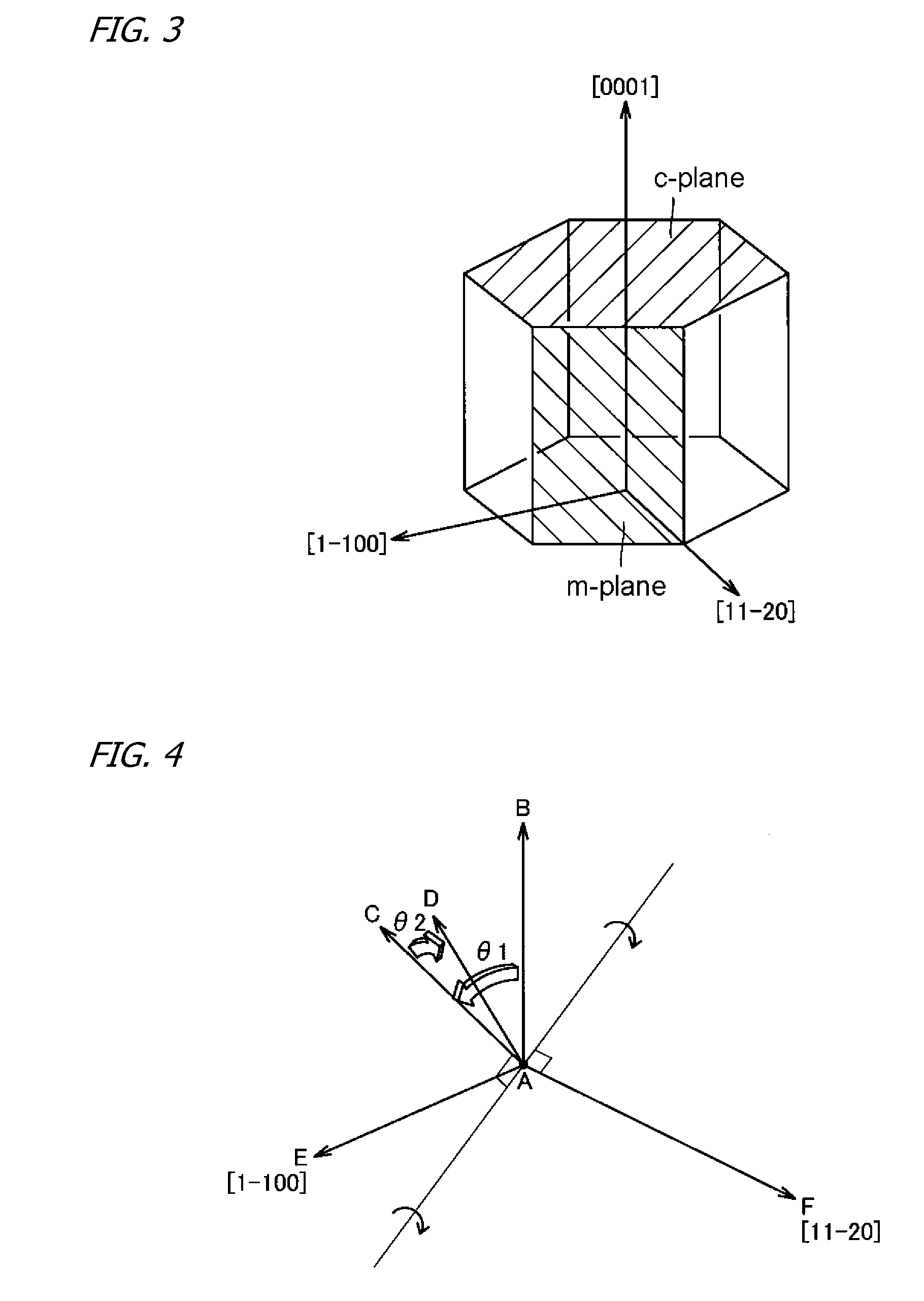

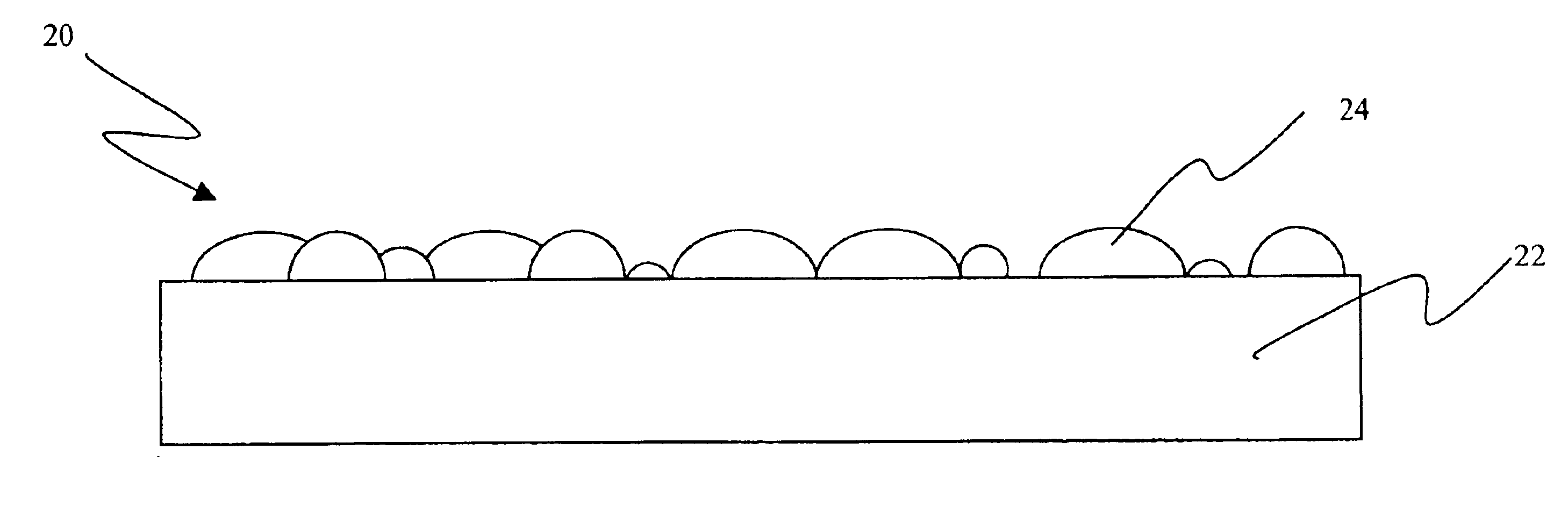

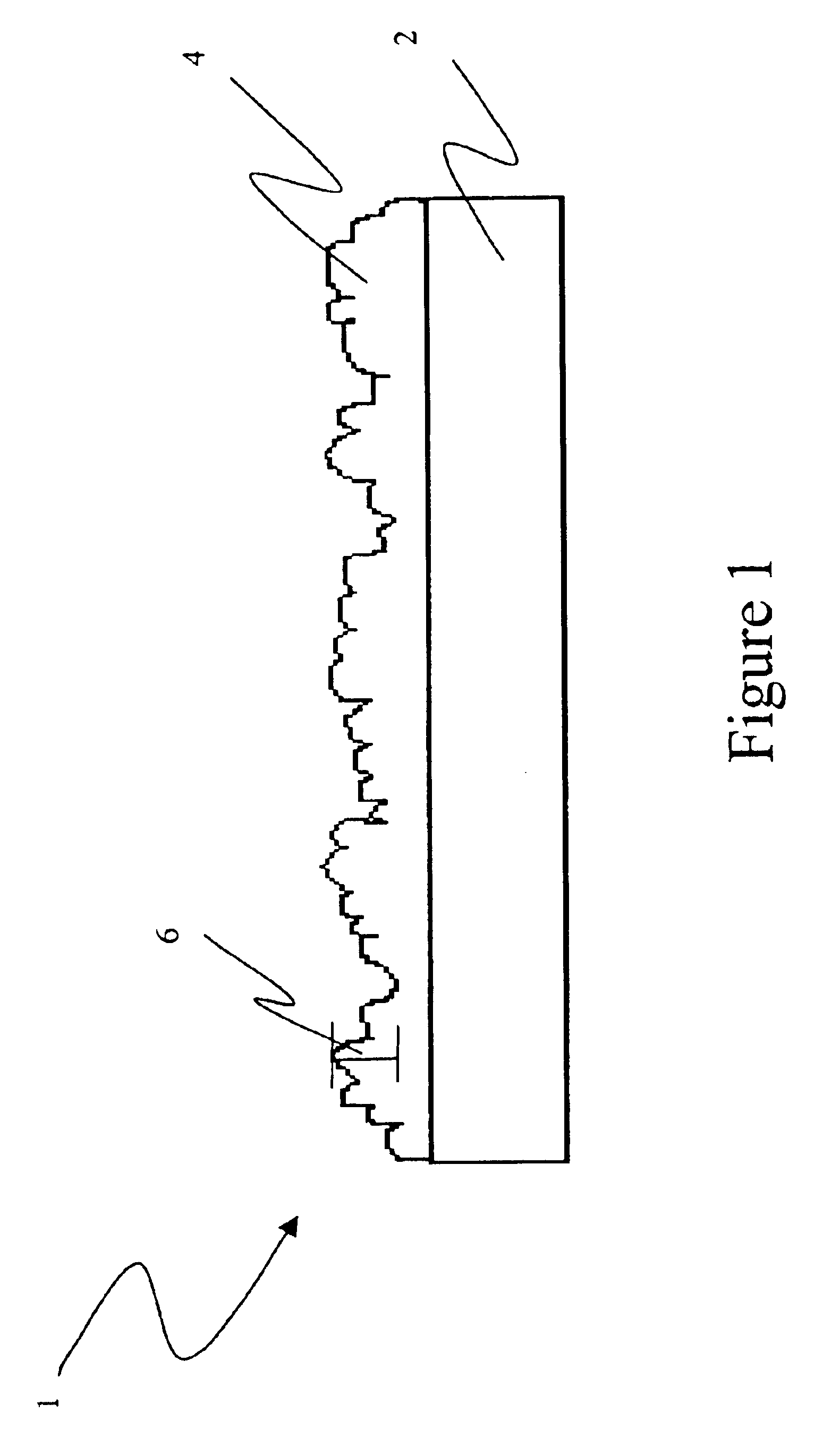

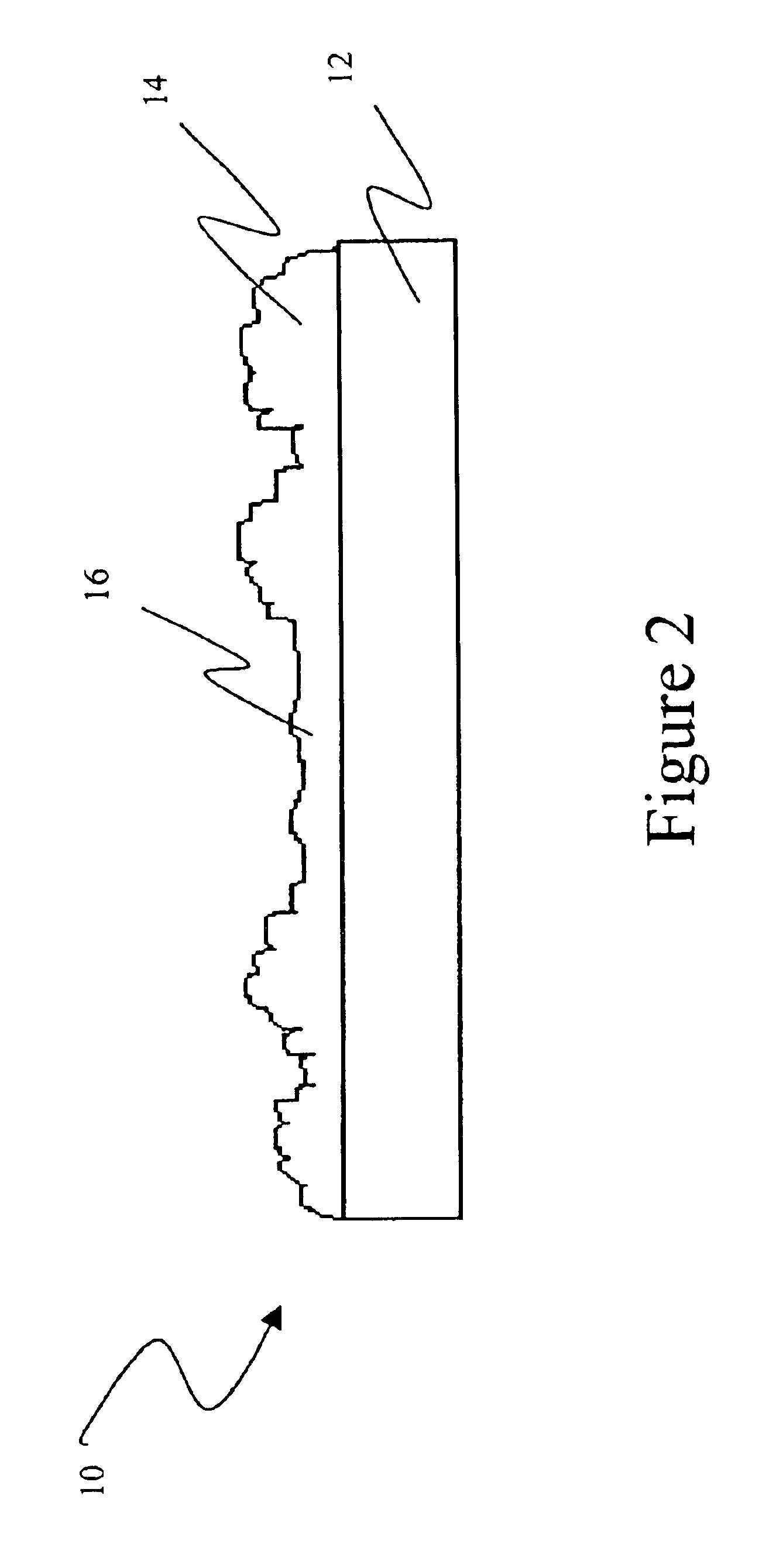

GaN Substrate, Substrate with an Epitaxial Layer, Semiconductor Device, and GaN Substrate Manufacturing Method

InactiveUS20080308815A1Control fluctuationsImprove emission efficiencyAutomatic/semiautomatic turning machinesPolycrystalline material growthDevice materialPlane orientation

Affords a GaN substrate from which enhanced-emission-efficiency light-emitting and like semiconductor devices can be produced, an epi-substrate in which an epitaxial layer has been formed on the GaN substrate principal surface, a semiconductor device, and a method of manufacturing the GaN substrate. The GaN substrate is a substrate having a principal surface with respect to whose normal vector the [0001] plane orientation is inclined in two different off-axis directions.

Owner:SUMITOMO ELECTRIC IND LTD

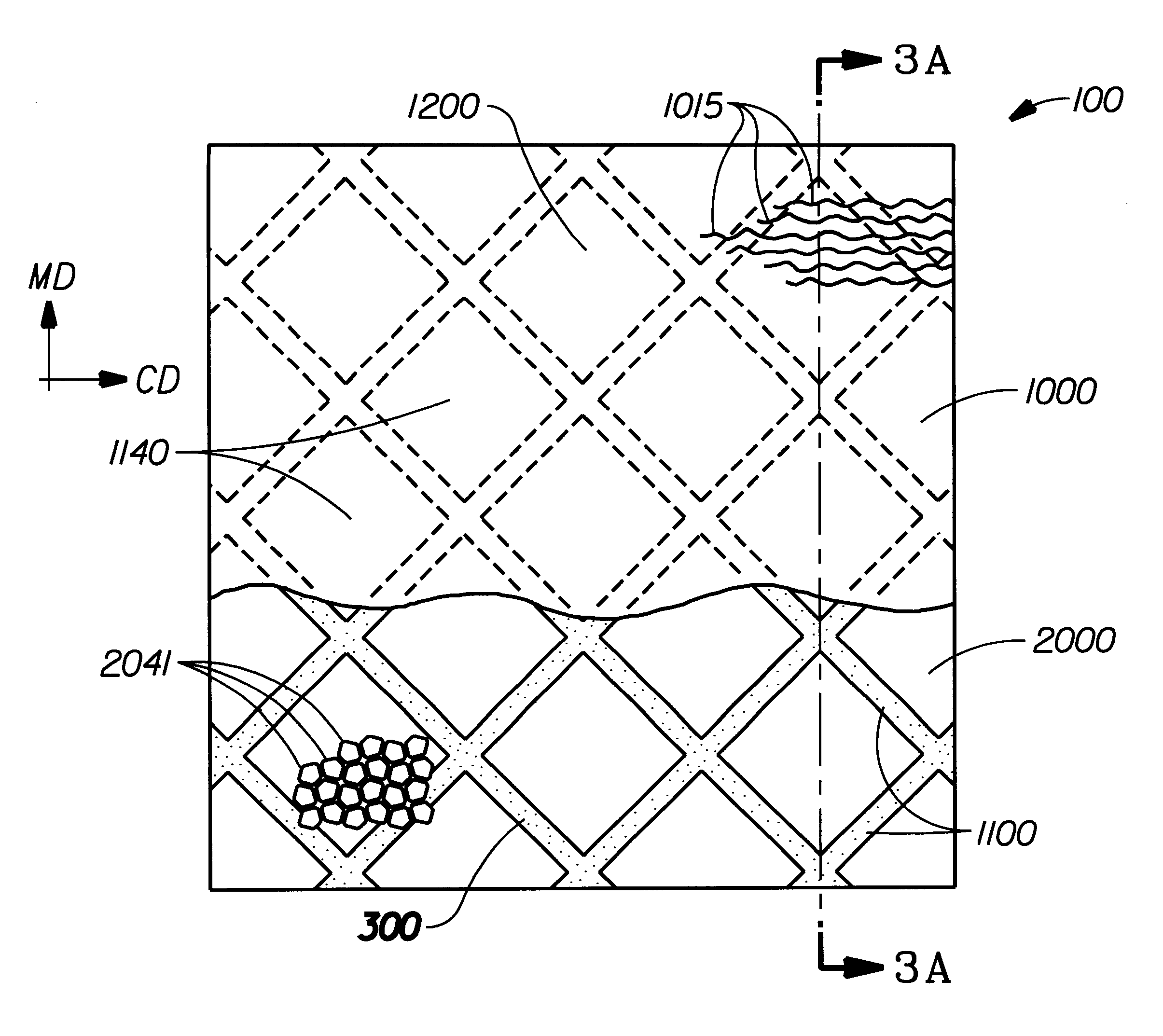

Laminate with integrated compact disk label and methods

A printable business laminate having an integrated compact disk label including methods of manufacture and use. The laminate has an integrated and printable compact disk label including a carrier lamina, a first adhesive lamina, a printable lamina adhesively secured to the carrier lamina by the first adhesive lamina, a first die cut through said carrier lamina substantially corresponding to the perimeter of a compact disk a second die cut through the printable lamina which may correspond to the hub or hole in a compact disk, and perforations through the printable lamina substantially corresponding to the perimeter of the compact disk.

Owner:STRATA TAC

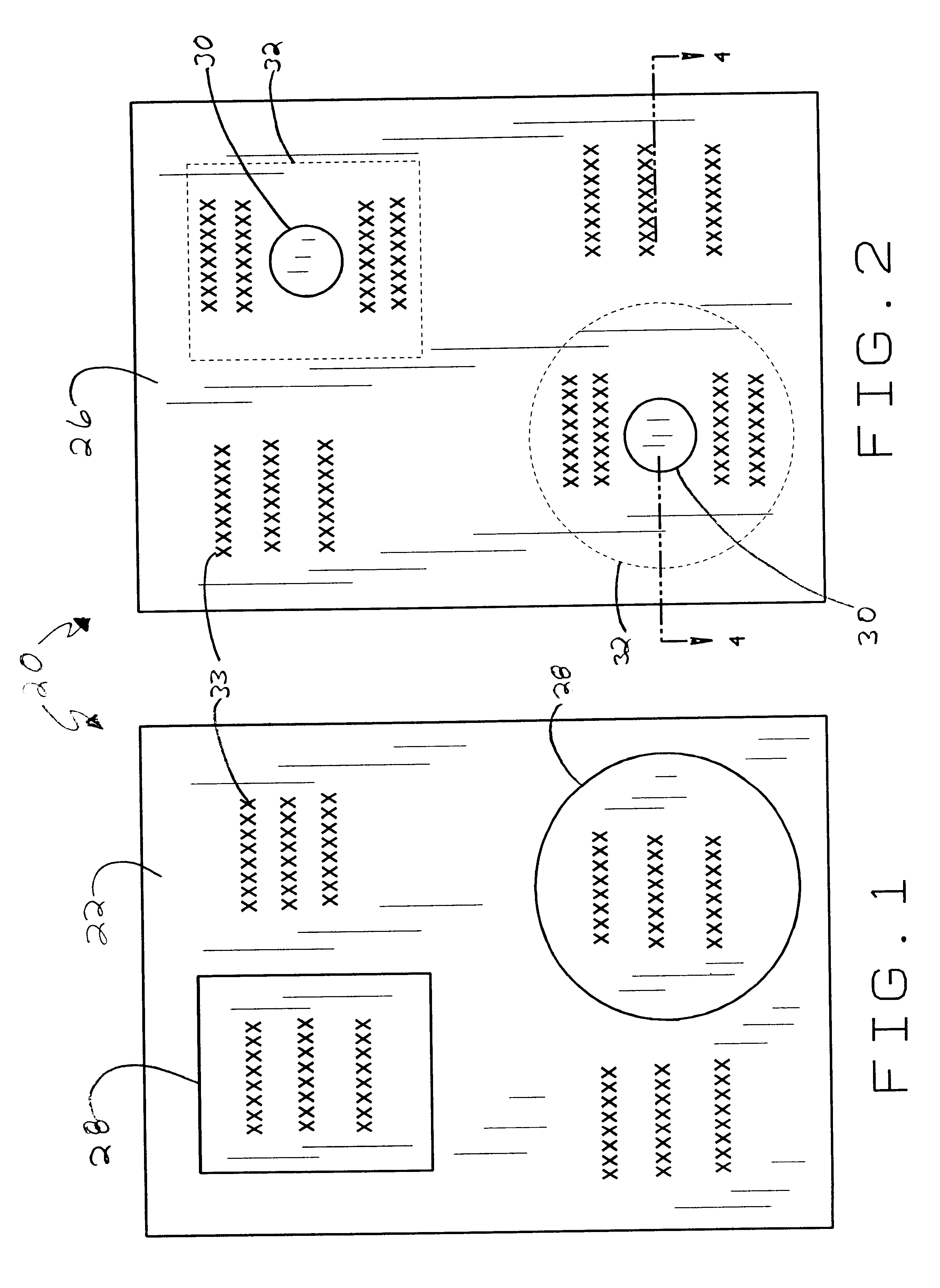

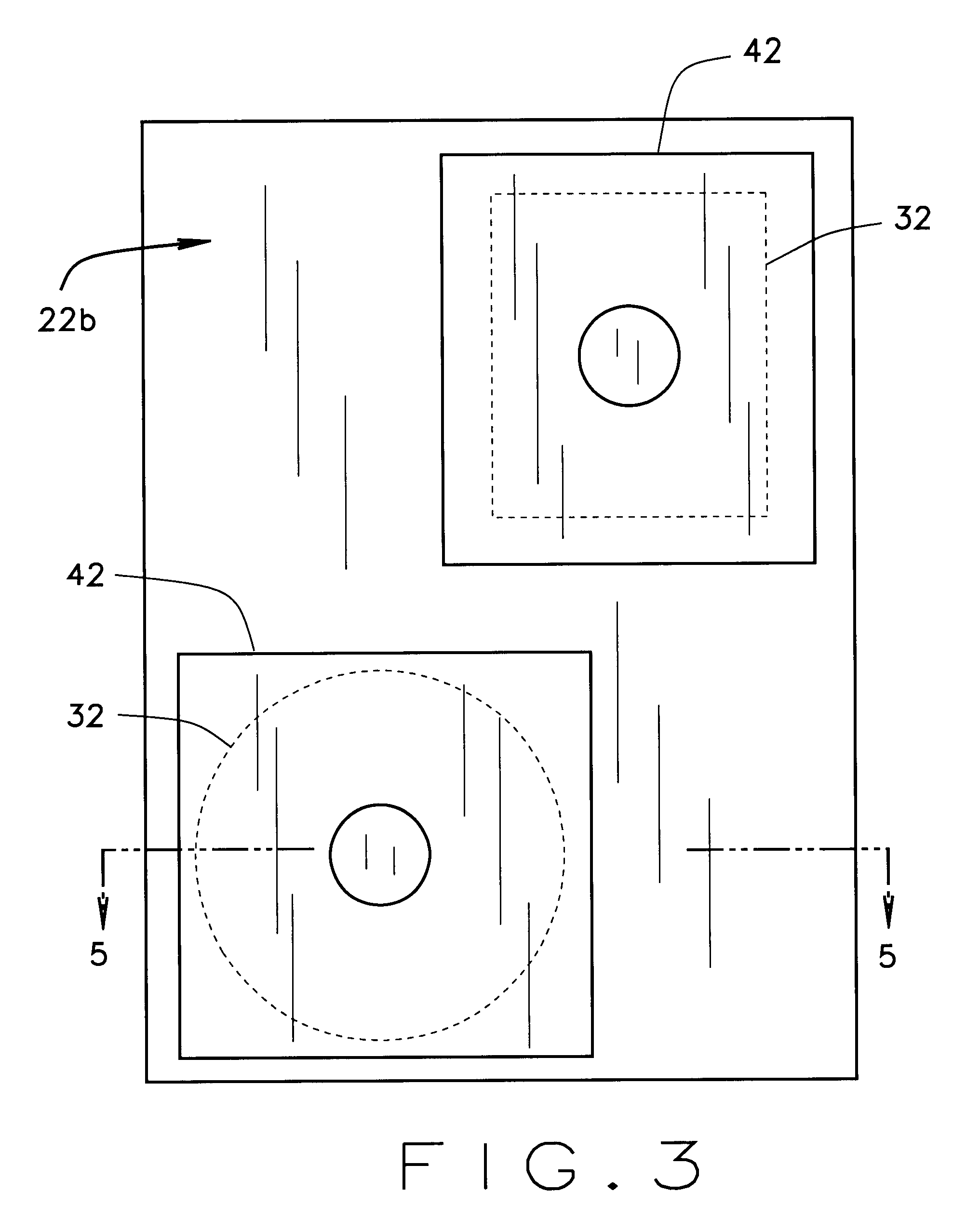

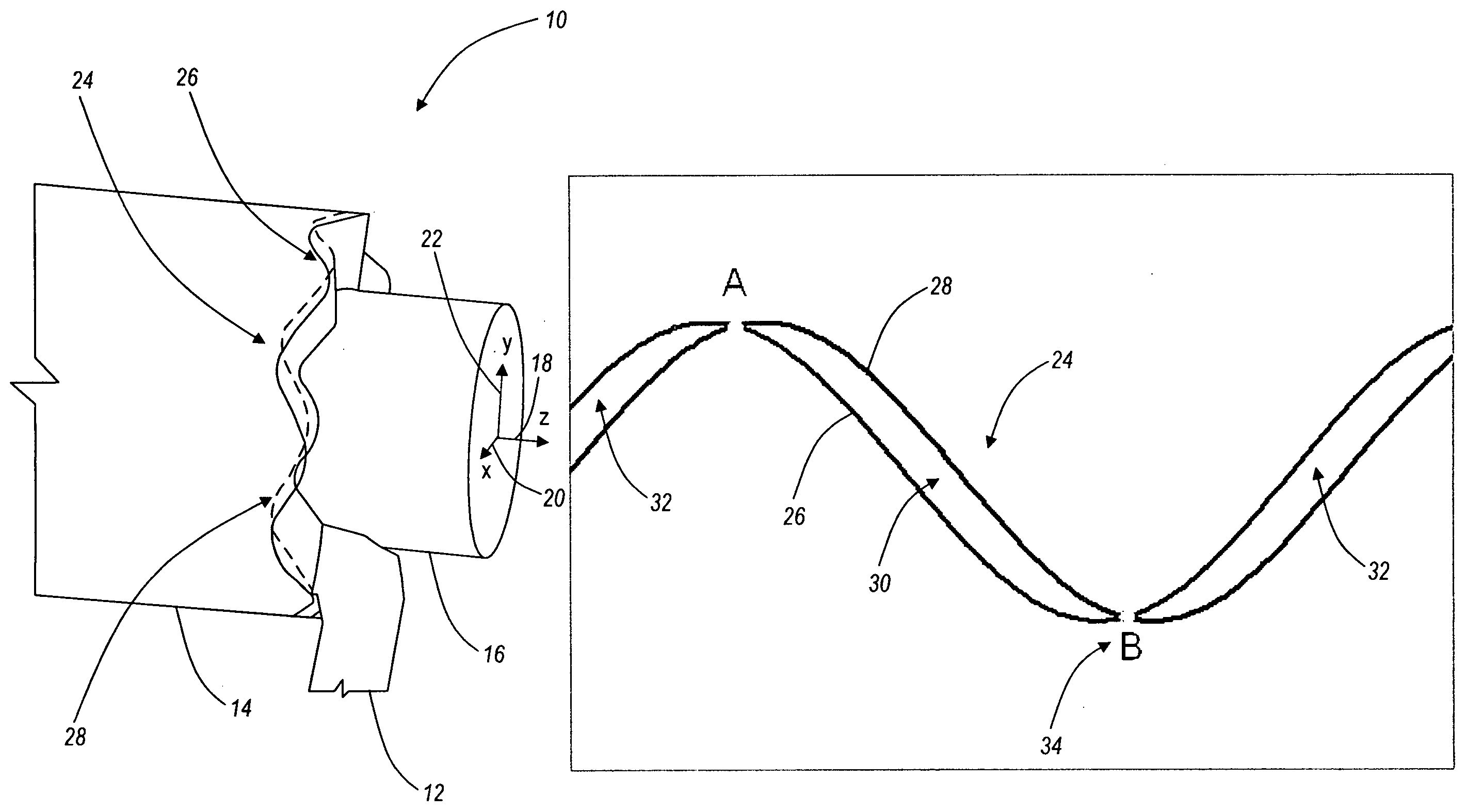

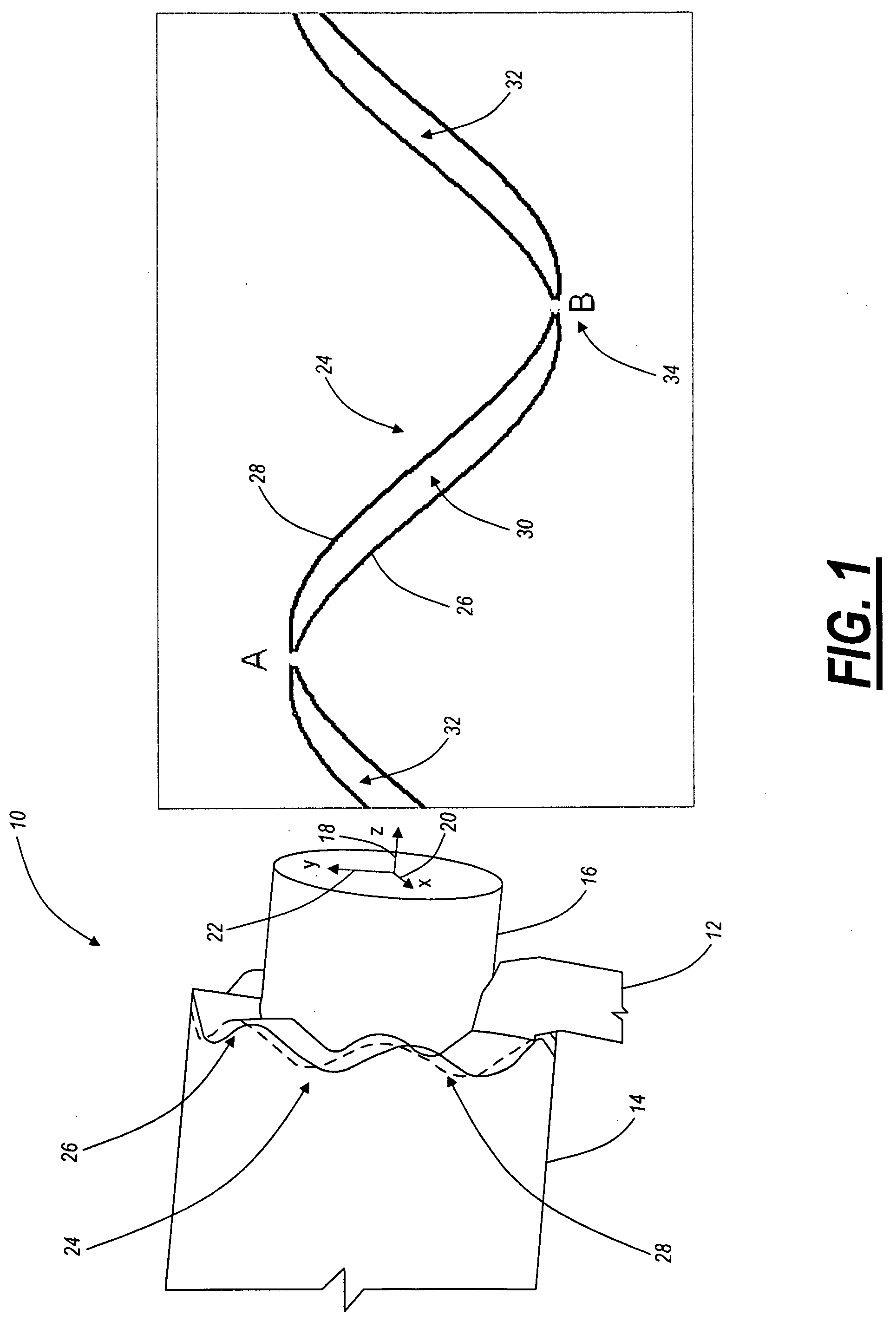

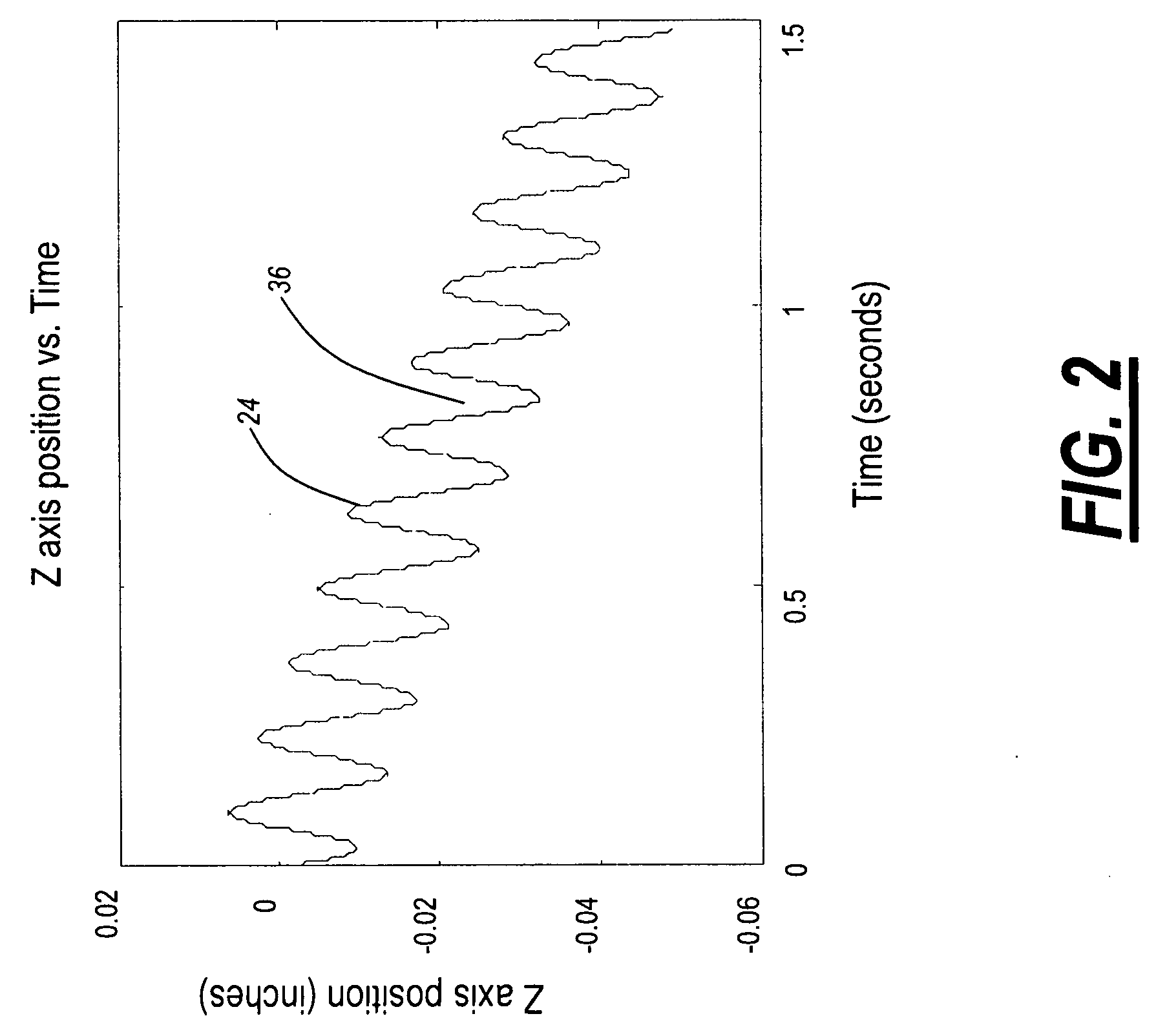

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

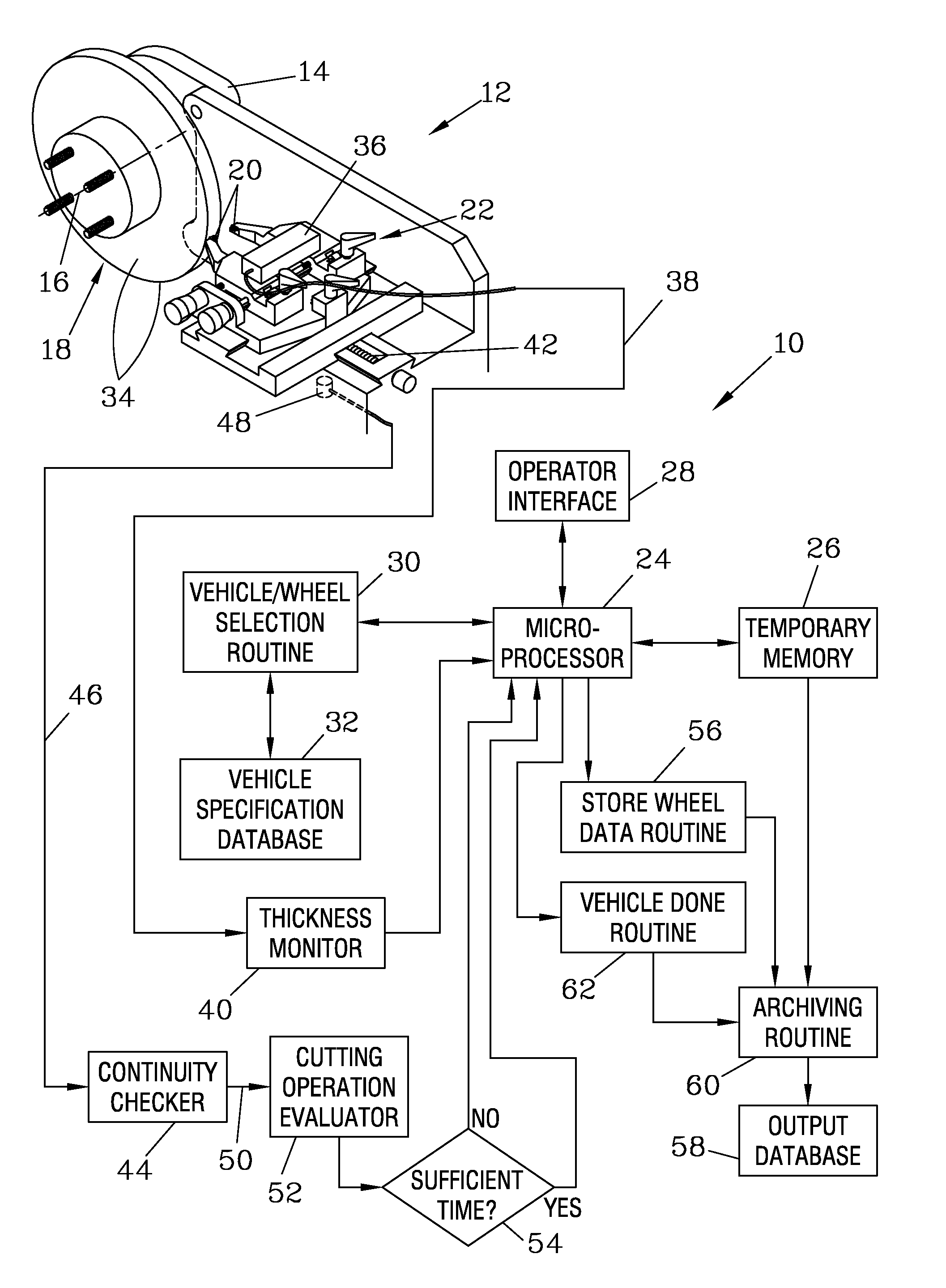

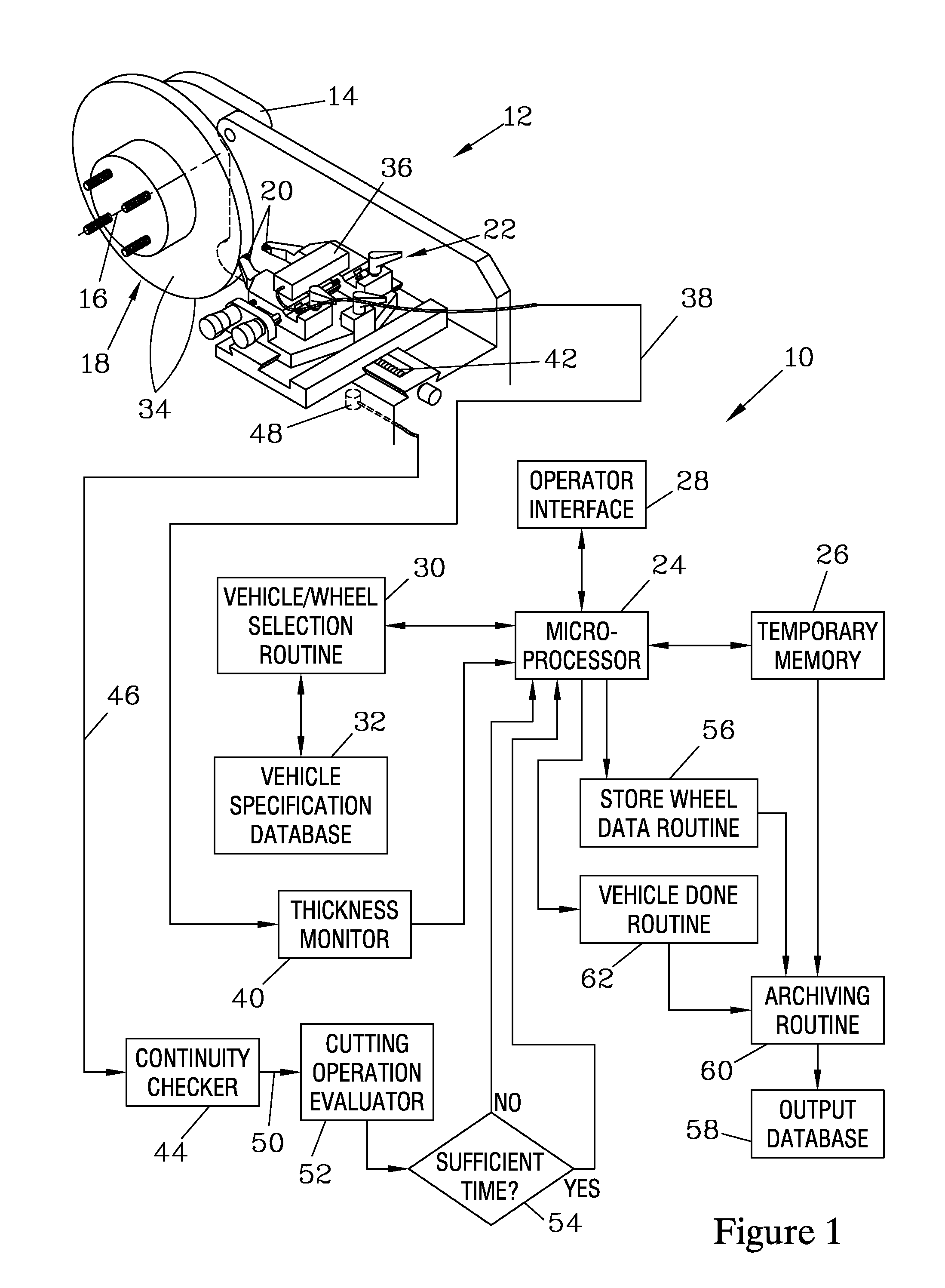

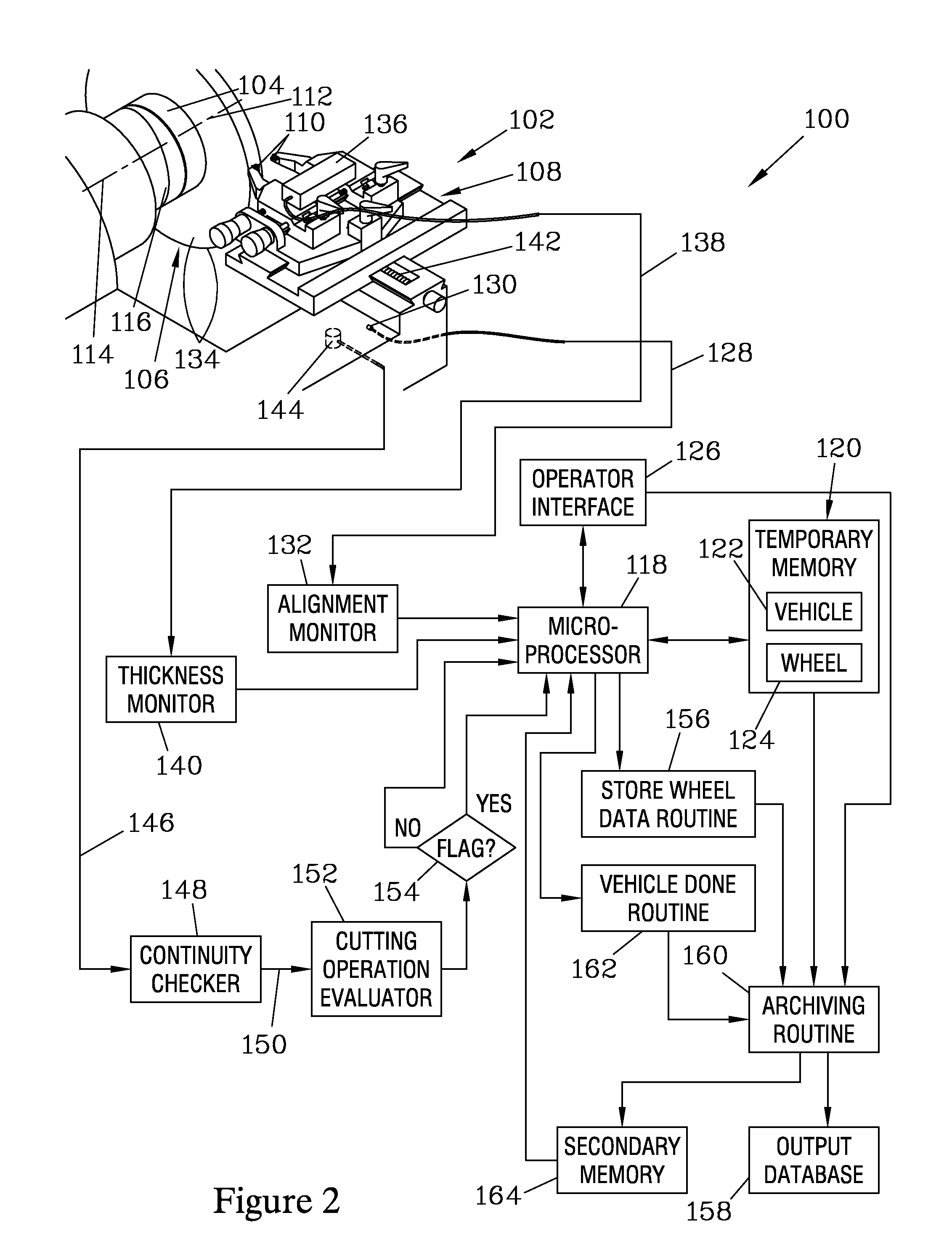

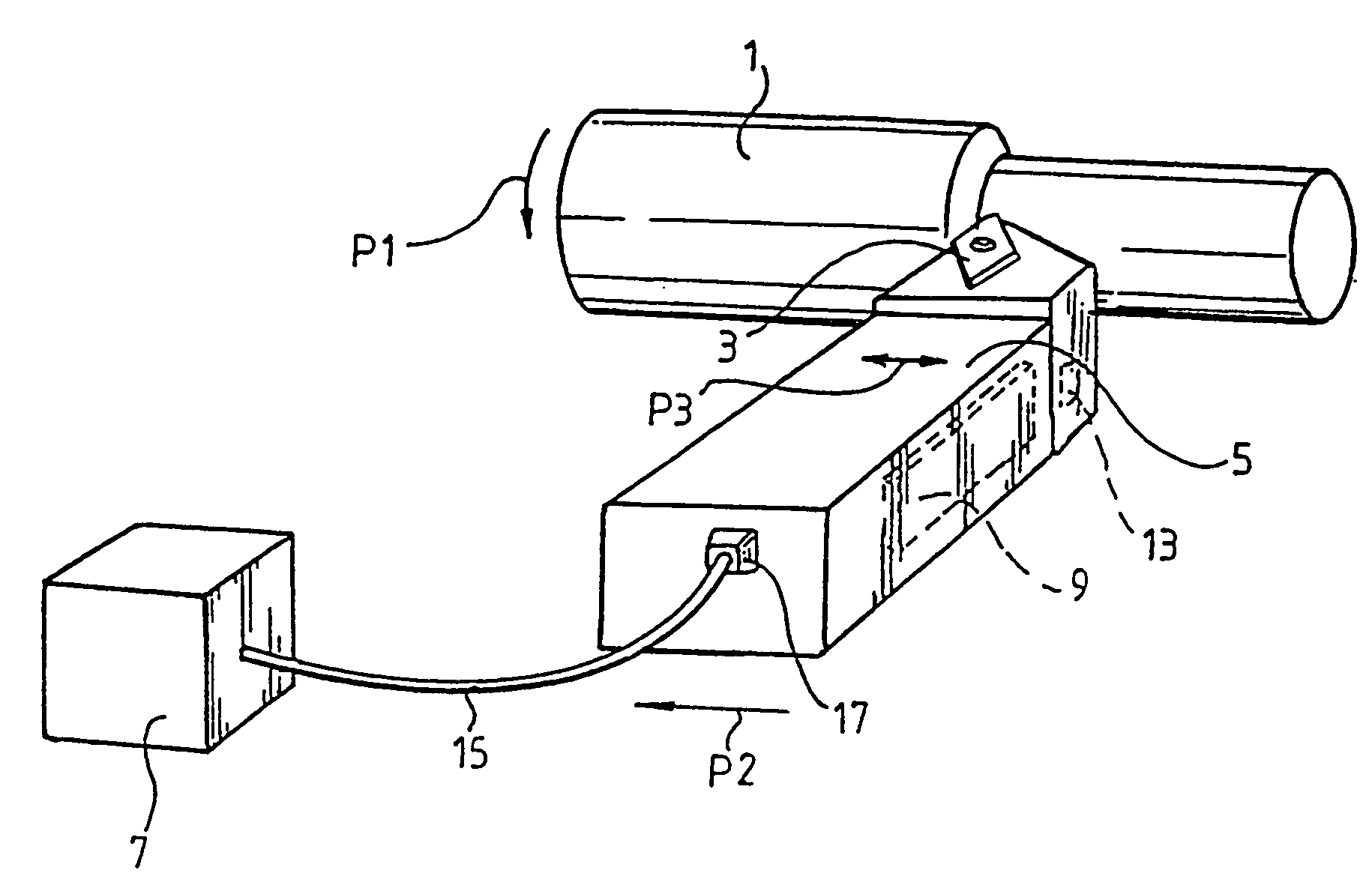

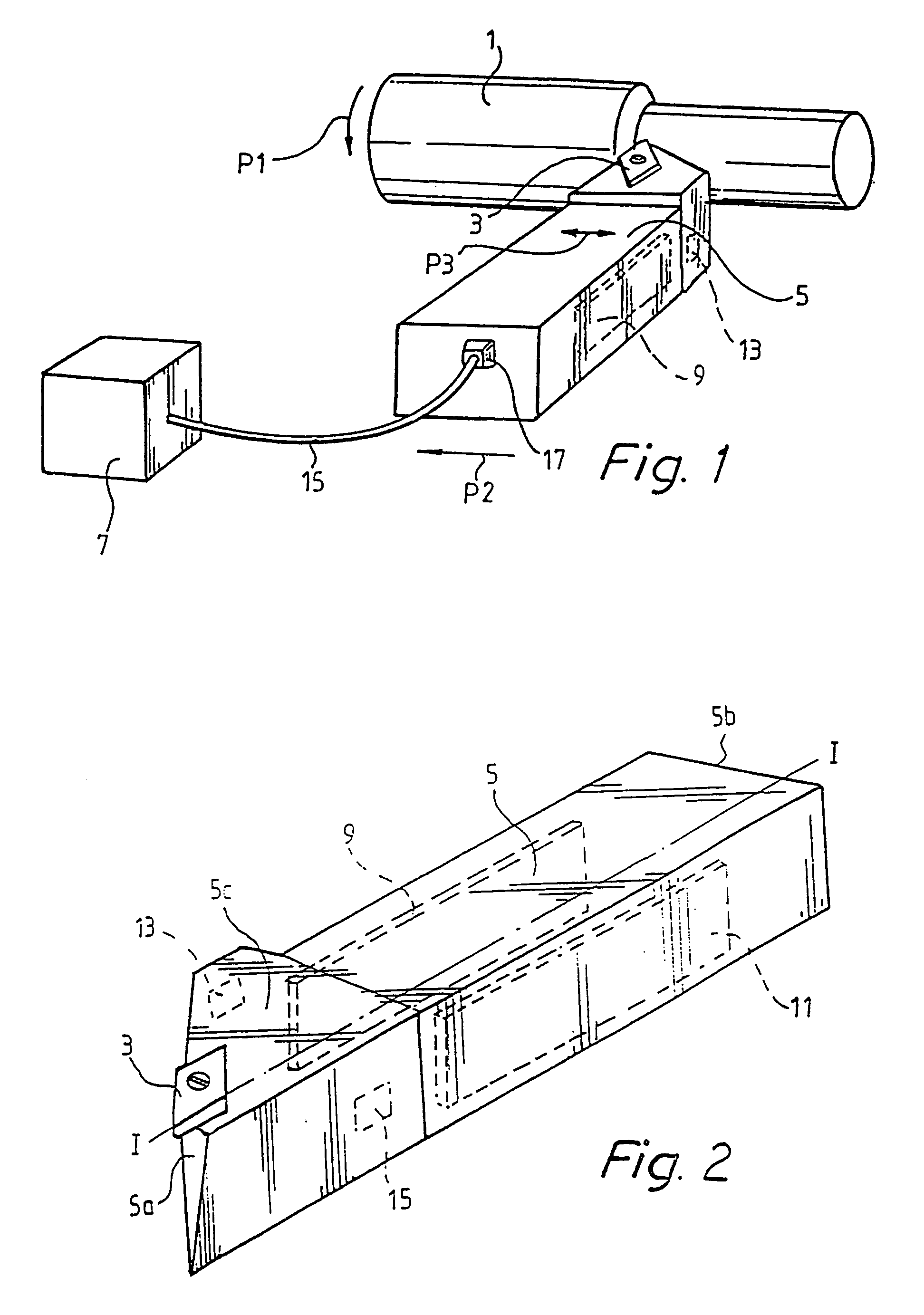

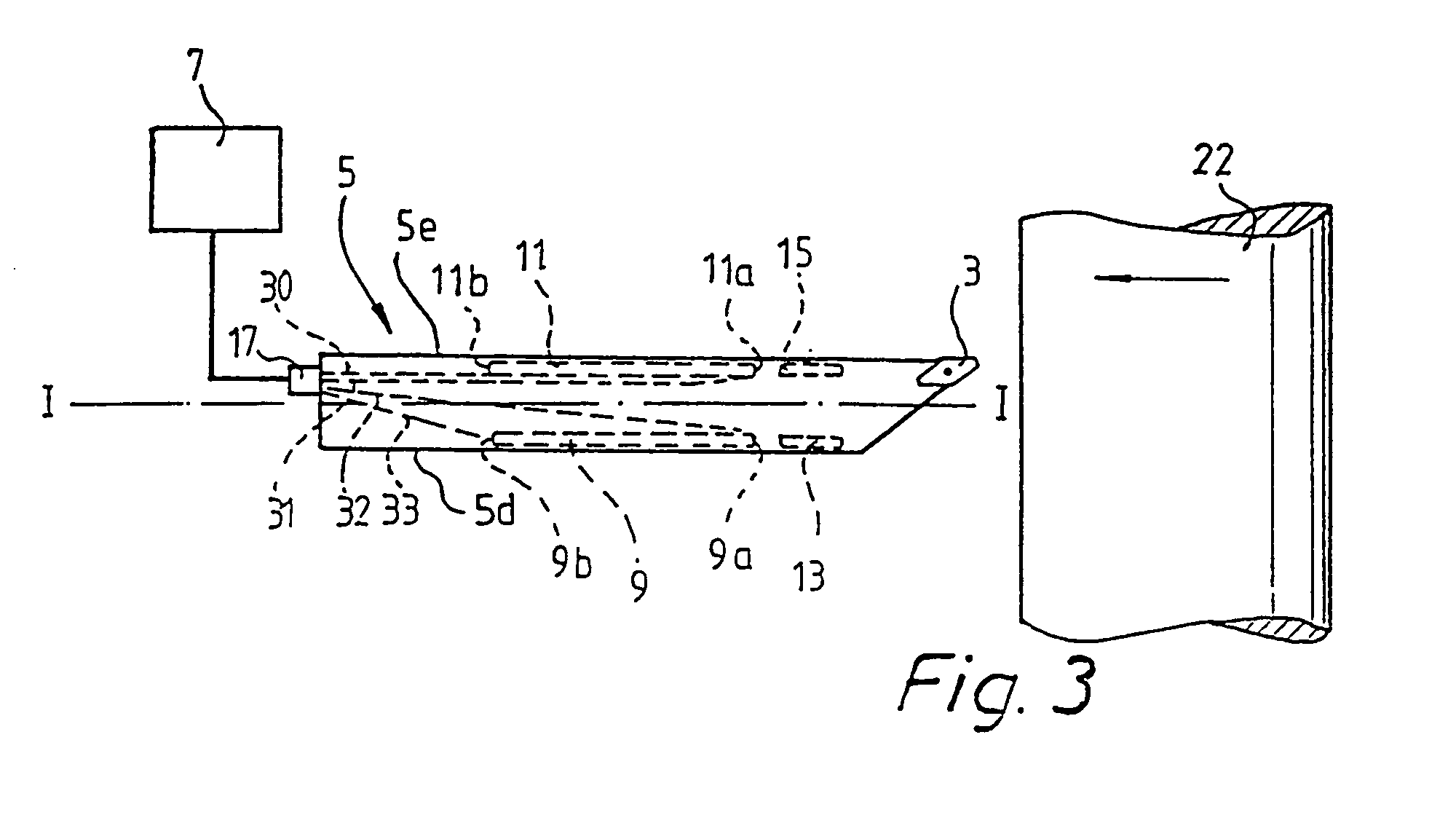

Reporting system for on-vehicle brake lathe

ActiveUS8245609B1Easy to operateEfficient executionProgramme controlAutomatic/semiautomatic turning machinesAutomotive engineeringVehicle brake

A reporting system, employing a microprocessor, tracks the operation of an on-vehicle brake lathe and provides records of the resurfacing operations performed by the lathe. Identification of the vehicle and wheel position of a brake disk to be resurfaced are inputted using an operator interface, and stored in a temporary memory. When tool bits of the lathe are positioned to set a depth of cut, a thickness monitor indicates the resulting thickness for the brake disk, which is compared to a minimum thickness specification for the inputted vehicle and wheel position to determine whether the disk can be resurfaced to meet the specification. If so, a cutting operation evaluator monitors a continuity checker that is responsive to contact of the tool bits and the disk to determine when the resurfacing operation is complete, at which time the collected data can be reported.

Owner:BONITA IP

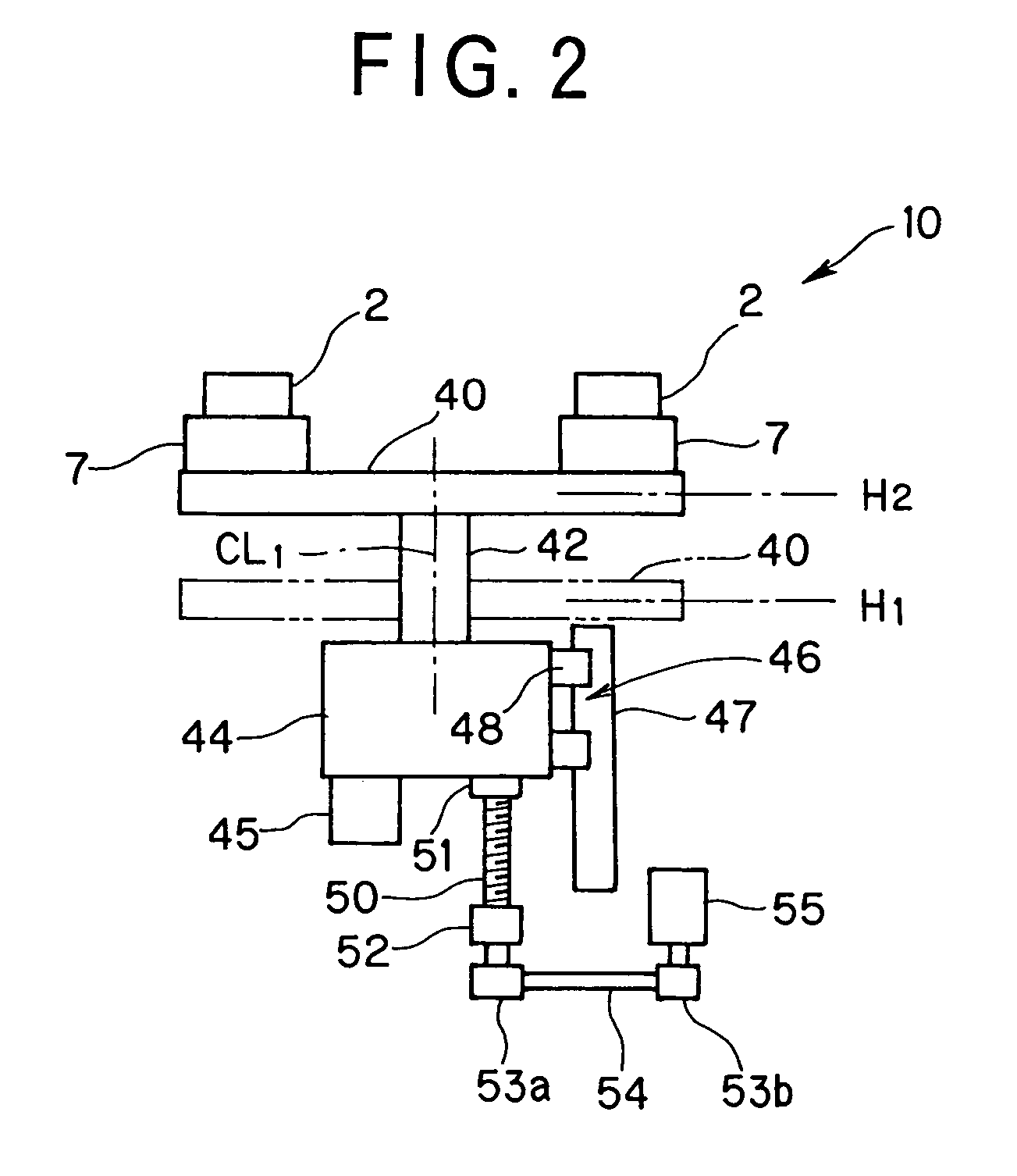

Method and device for controlling a turning operation

InactiveUS6925915B1Improve surface smoothnessLathesAutomatic/semiautomatic turning machinesControl systemActuator

A device increases the surface smoothness of a turned surface. The device comprising a control system with a control unit and an actuator connectible to the control unit and connectible with a tool holder. The actuator in adapted to impart a vibrating motion in the lateral direction to the tool holder. A method will also increase the surface smoothness of a turned surface, comprising the step of controlling the vibrations of the tool holder during turning. The method also comprises the step of imparting a vibrating motion in the lateral direction to the tool holder. Moreover, a turning lathe and a turning tool holder which like the device are designed to generate vibrating motion in the lateral direction.

Owner:STAFFANSBODA CIE

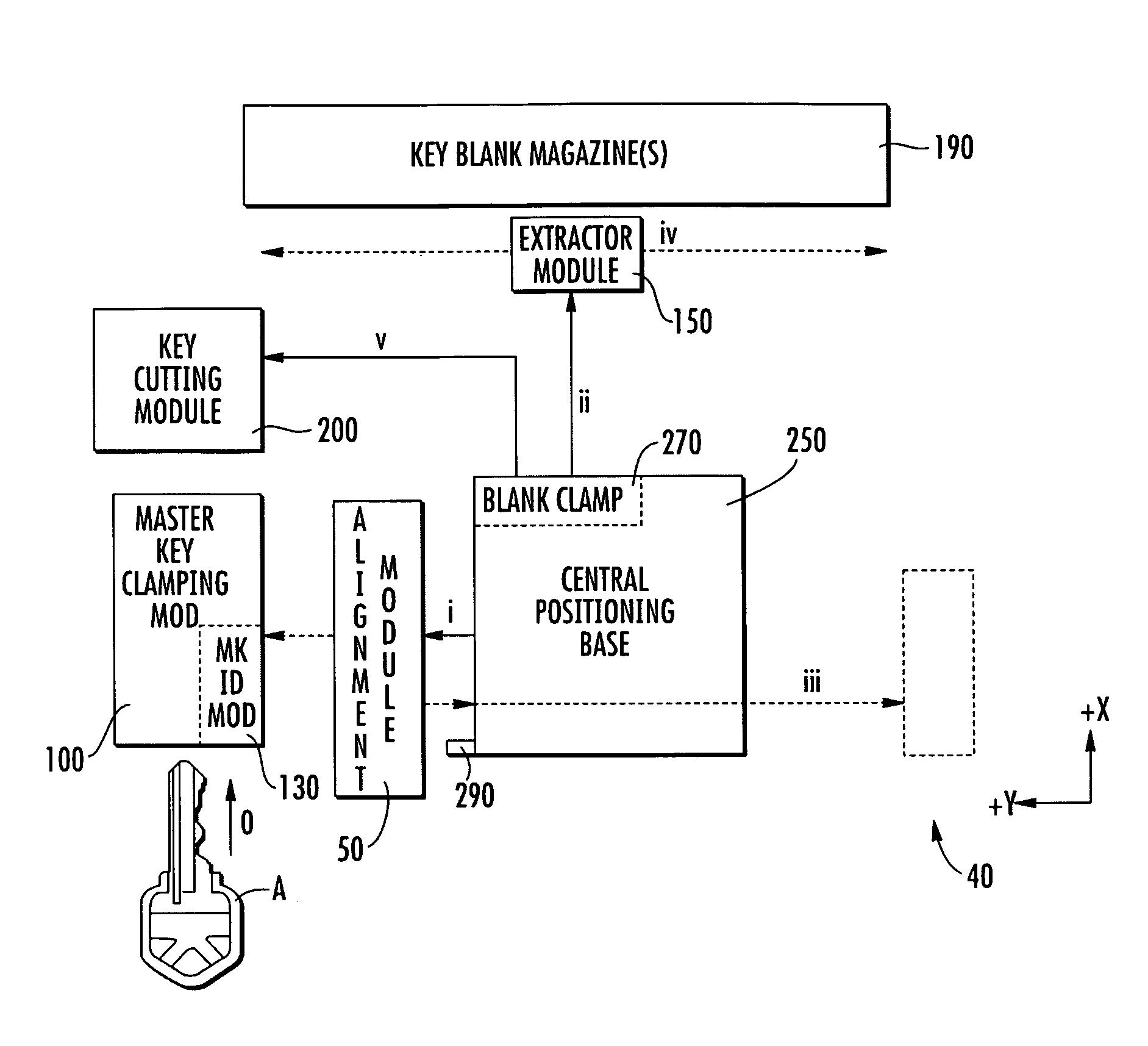

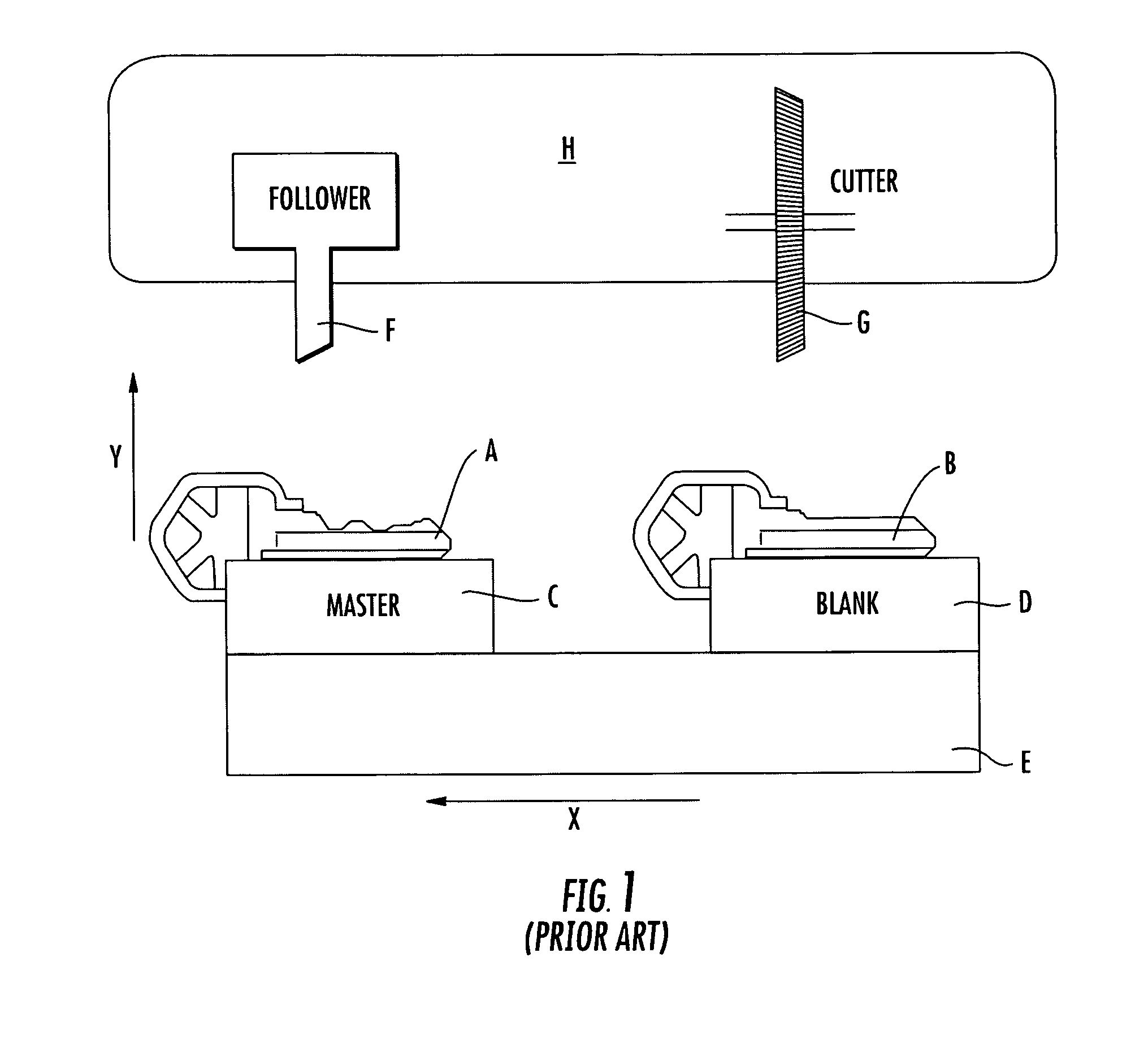

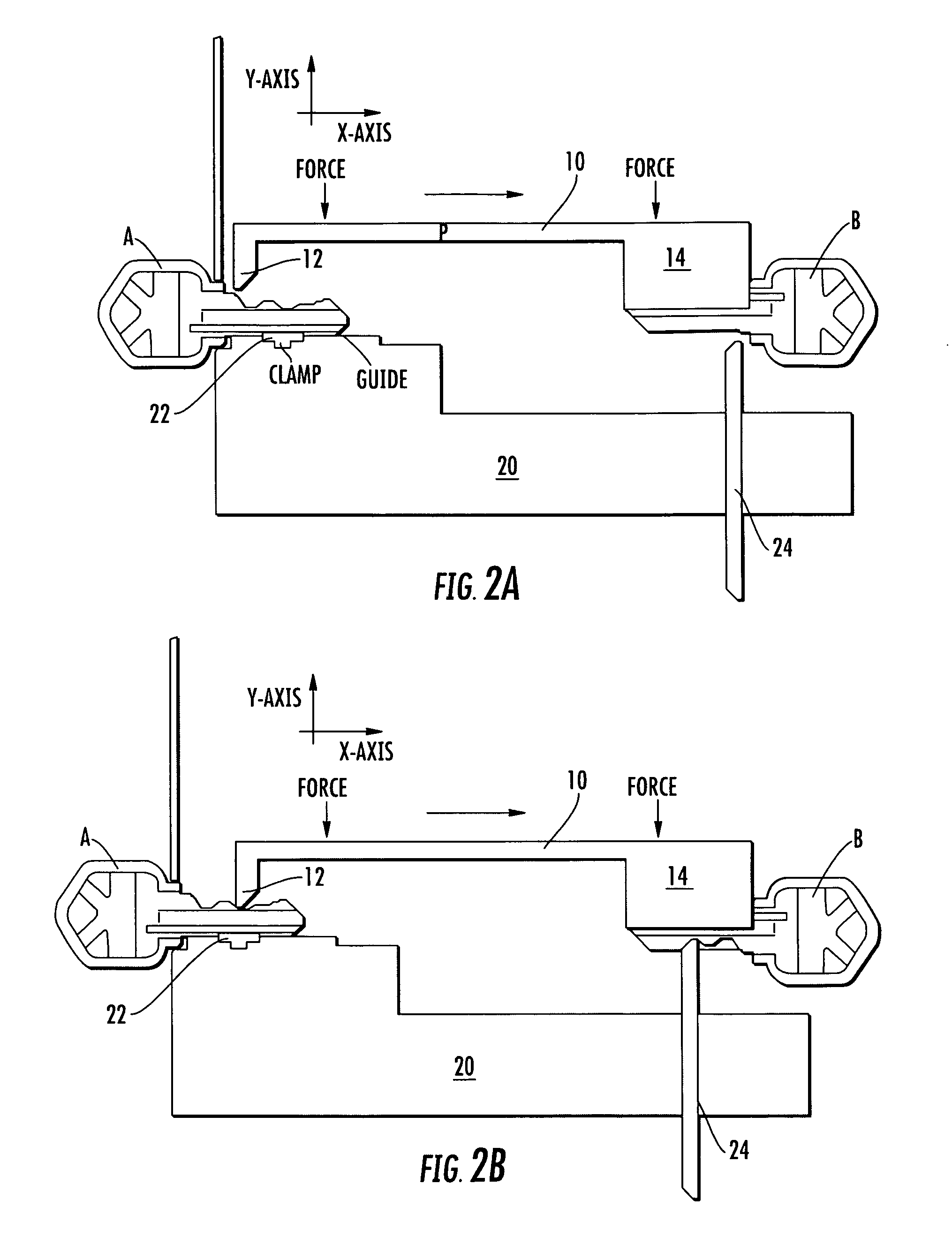

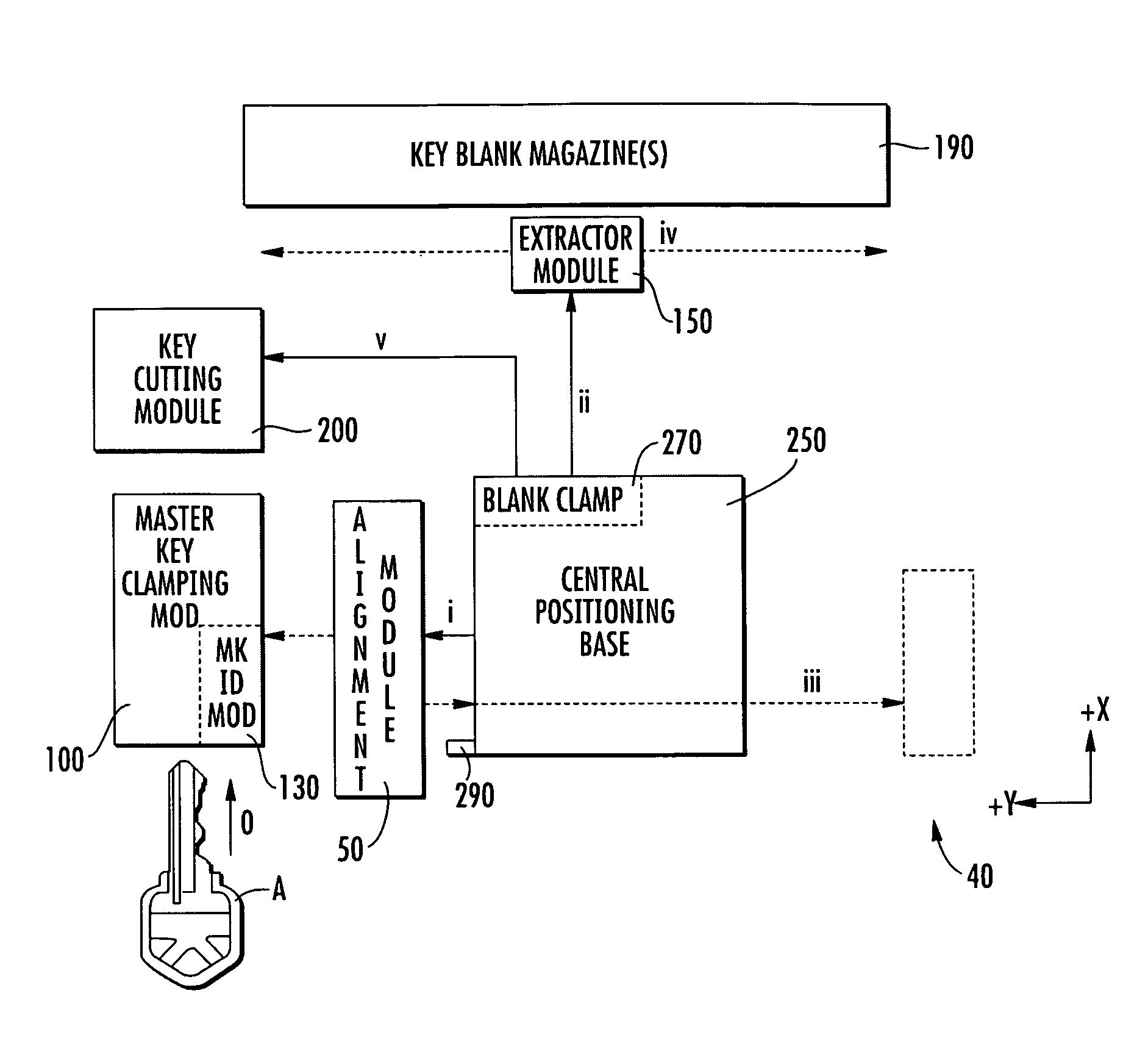

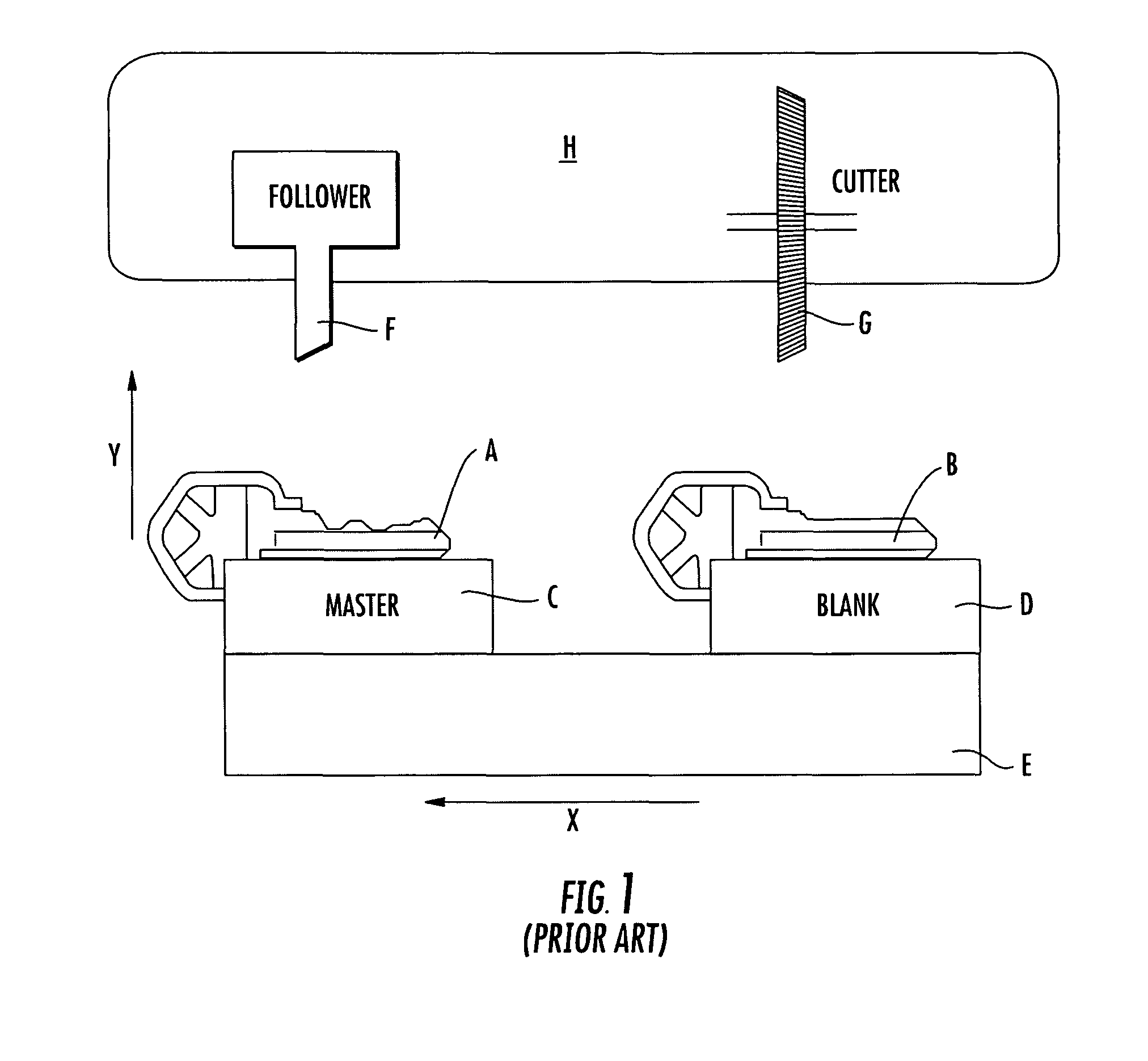

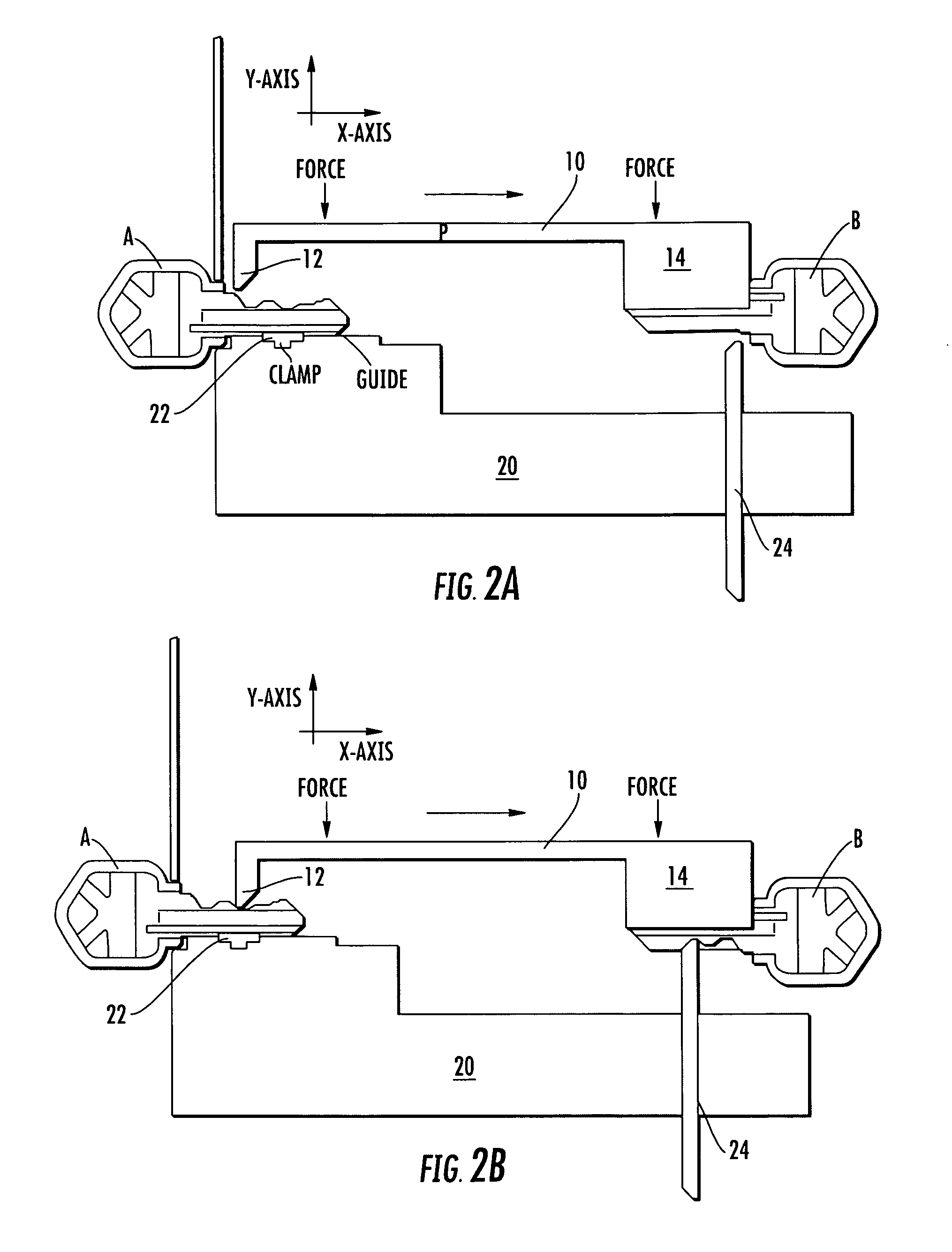

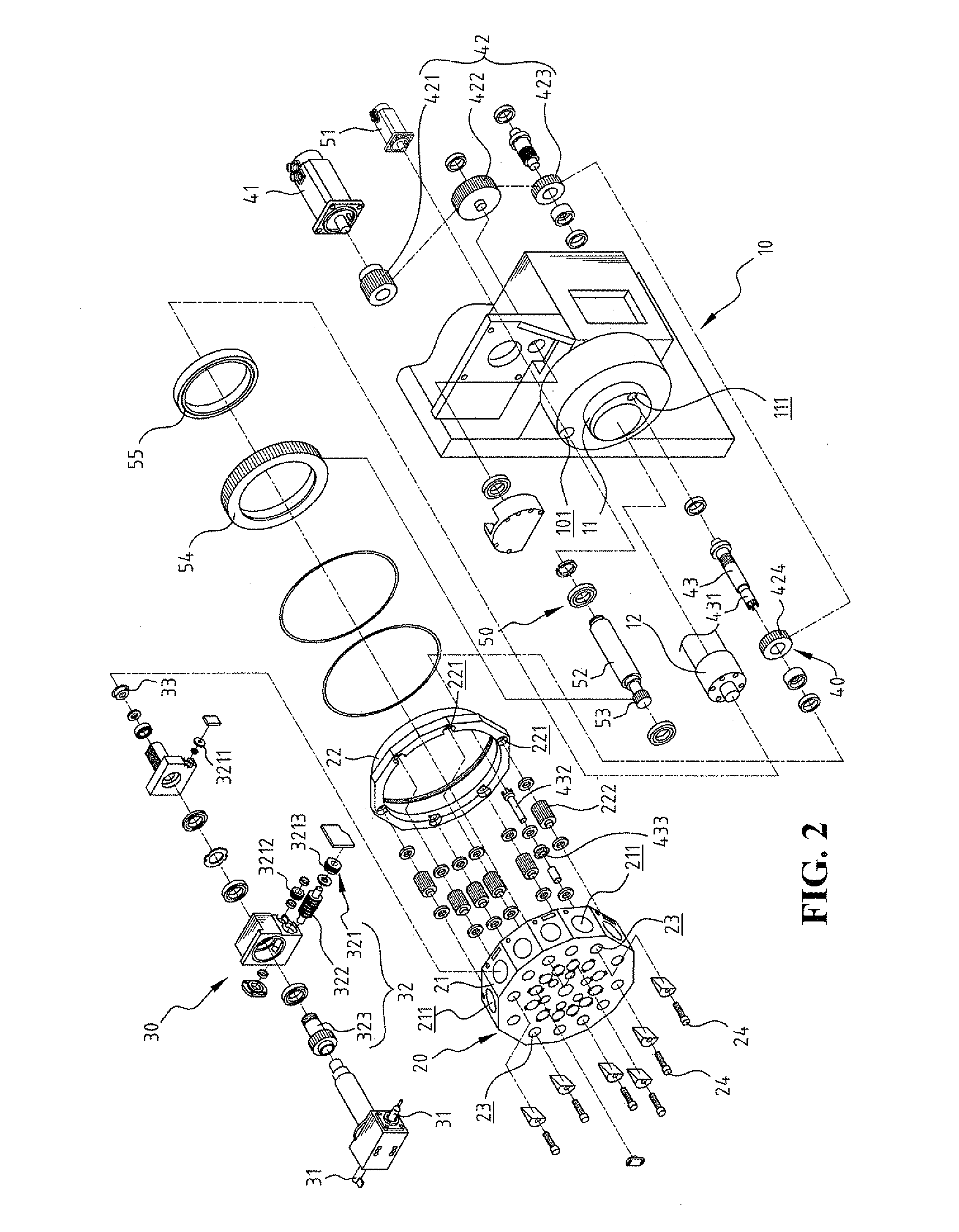

Fully automatic key duplicating machine with automatic key model identification system

ActiveUS20080145163A1Reduce the required powerIncrease powerAutomatic/semiautomatic turning machinesMeasurement devicesComputer moduleMaster key

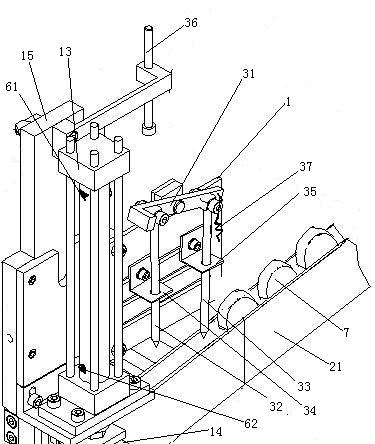

A fully automatic key duplicating machine. A master key alignment module is movably disposed into and out of proximity with a master key clamping module, the master key being aligned by the alignment module within the master key clamping module. A master key identification module is disposed in fixed relation to the master key clamping module and identifies a type of key secured in the master key clamping module. A central positioning base is provided automatically movable into and out of engagement with the key cutting module and optionally the alignment module, adapted to move the master key alignment module into proximity with the master key clamping module and adapted to secure a key blank to be cut at the key cutting module in accordance with the tooth pattern of a clamped master key.

Owner:THE HILLMAN GRP INC

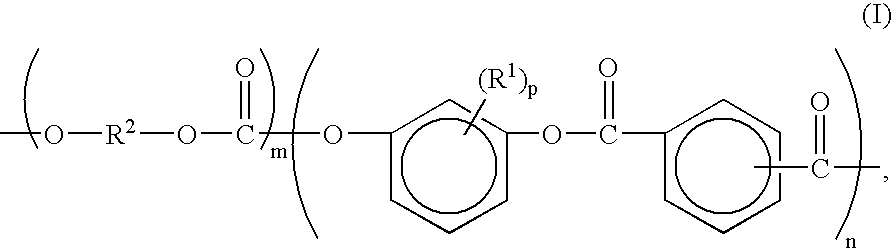

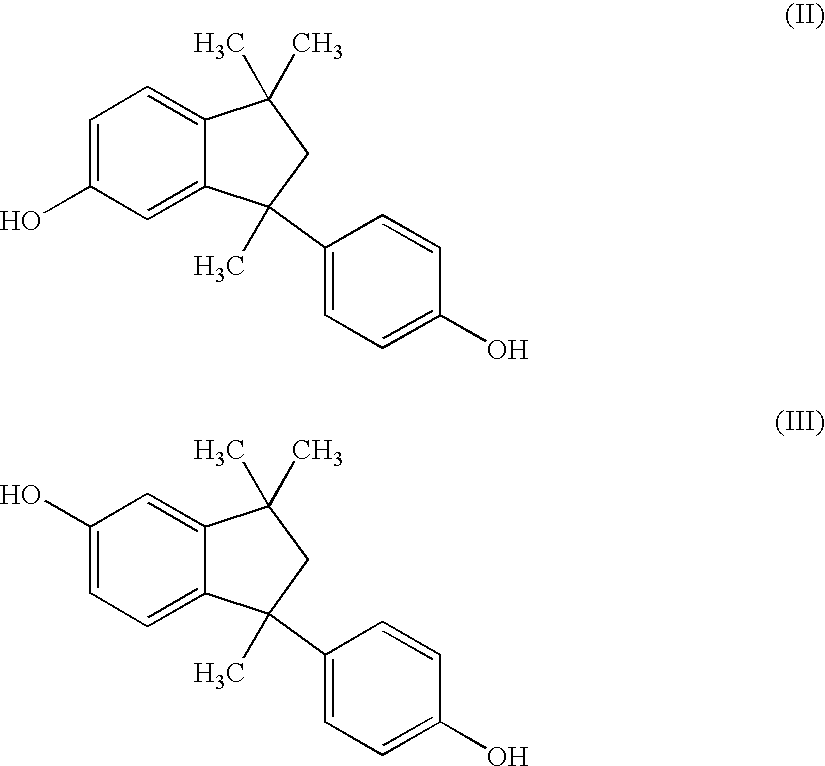

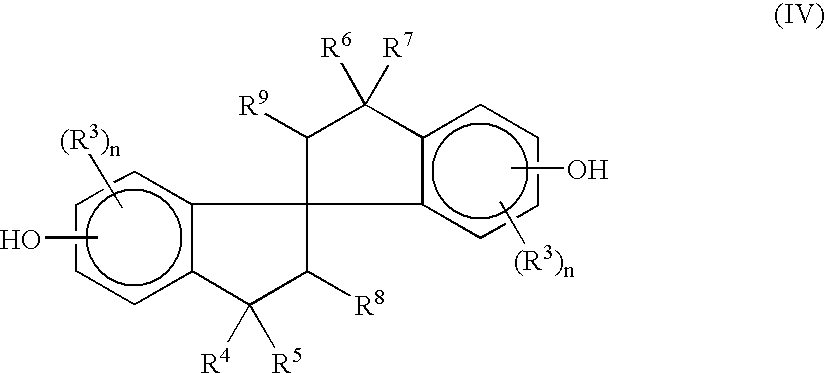

Weatherable multilayer articles and method for their preparation

InactiveUS20040028907A1Improve adhesionAvoid insufficient thicknessAutomatic/semiautomatic turning machinesPolyureas/polyurethane adhesivesPolymer scienceDicarboxylic acid

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyurethane, and (iv) a substrate layer, wherein the coating layer is in contiguous superposed contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

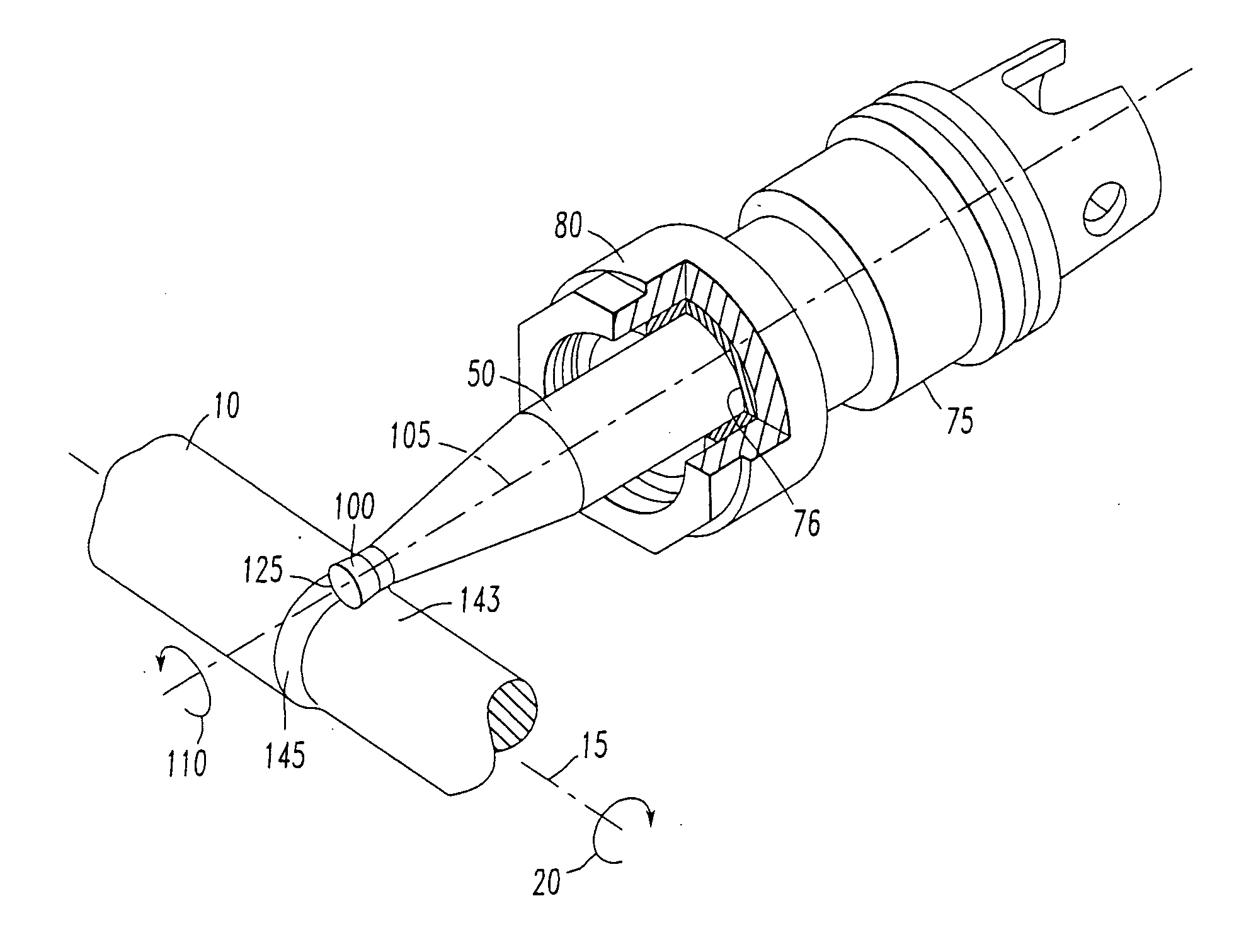

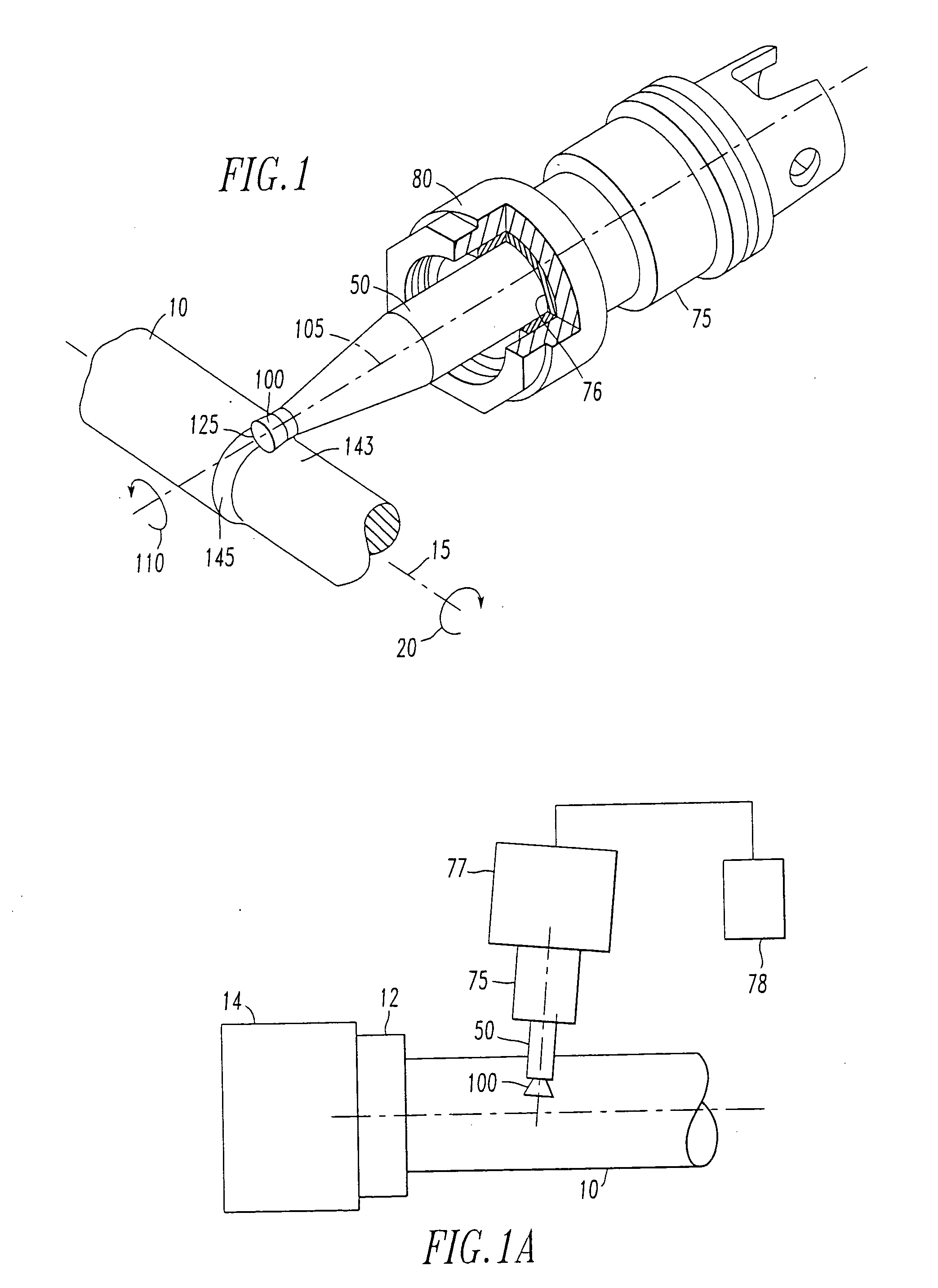

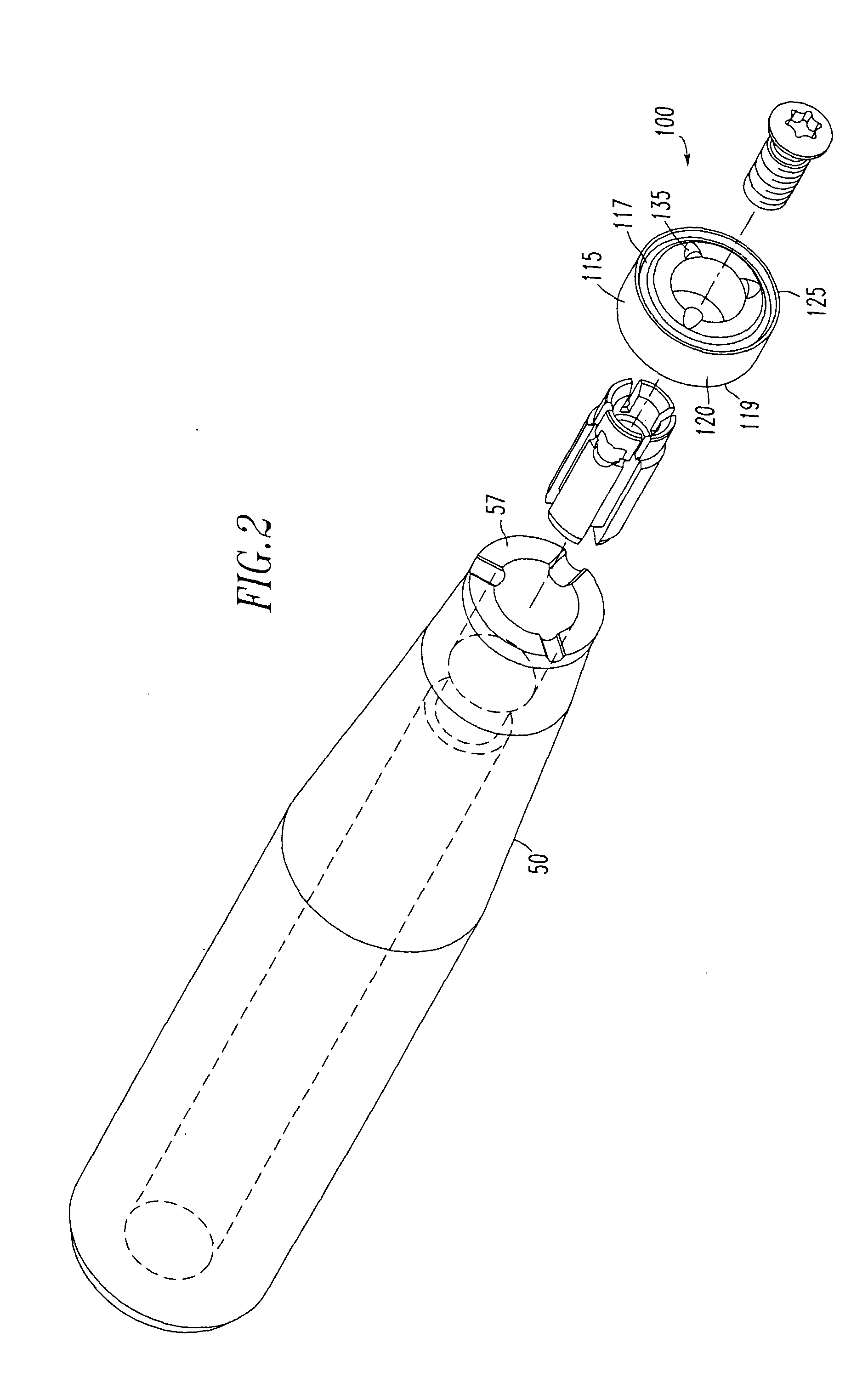

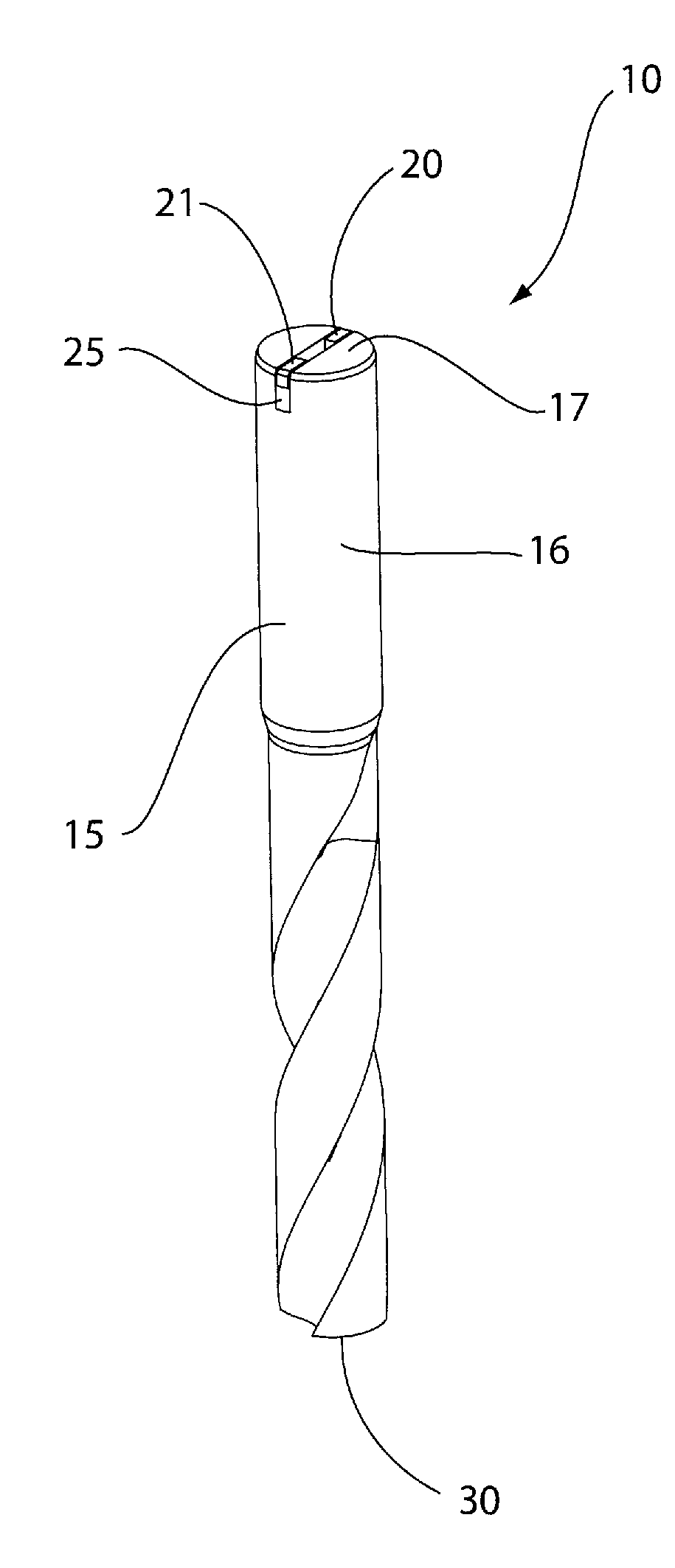

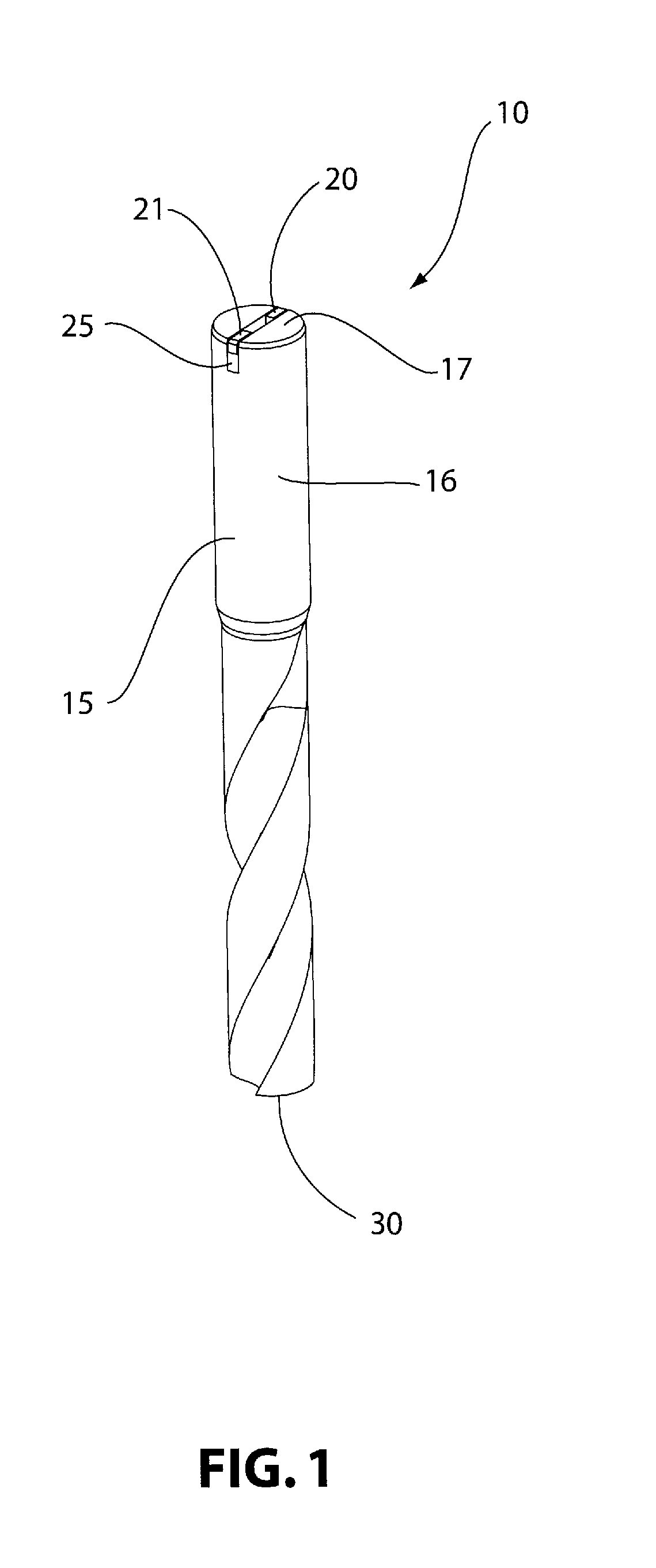

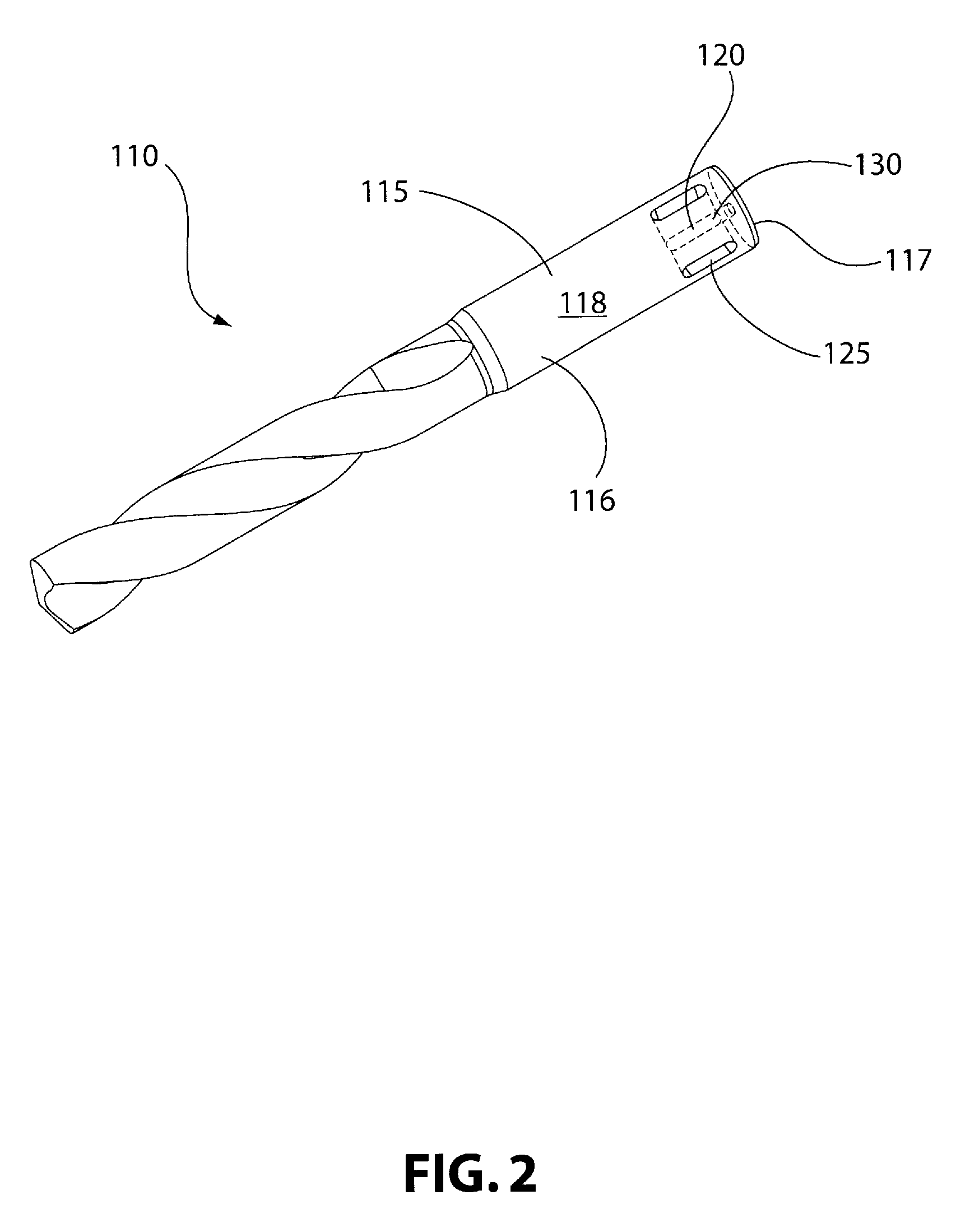

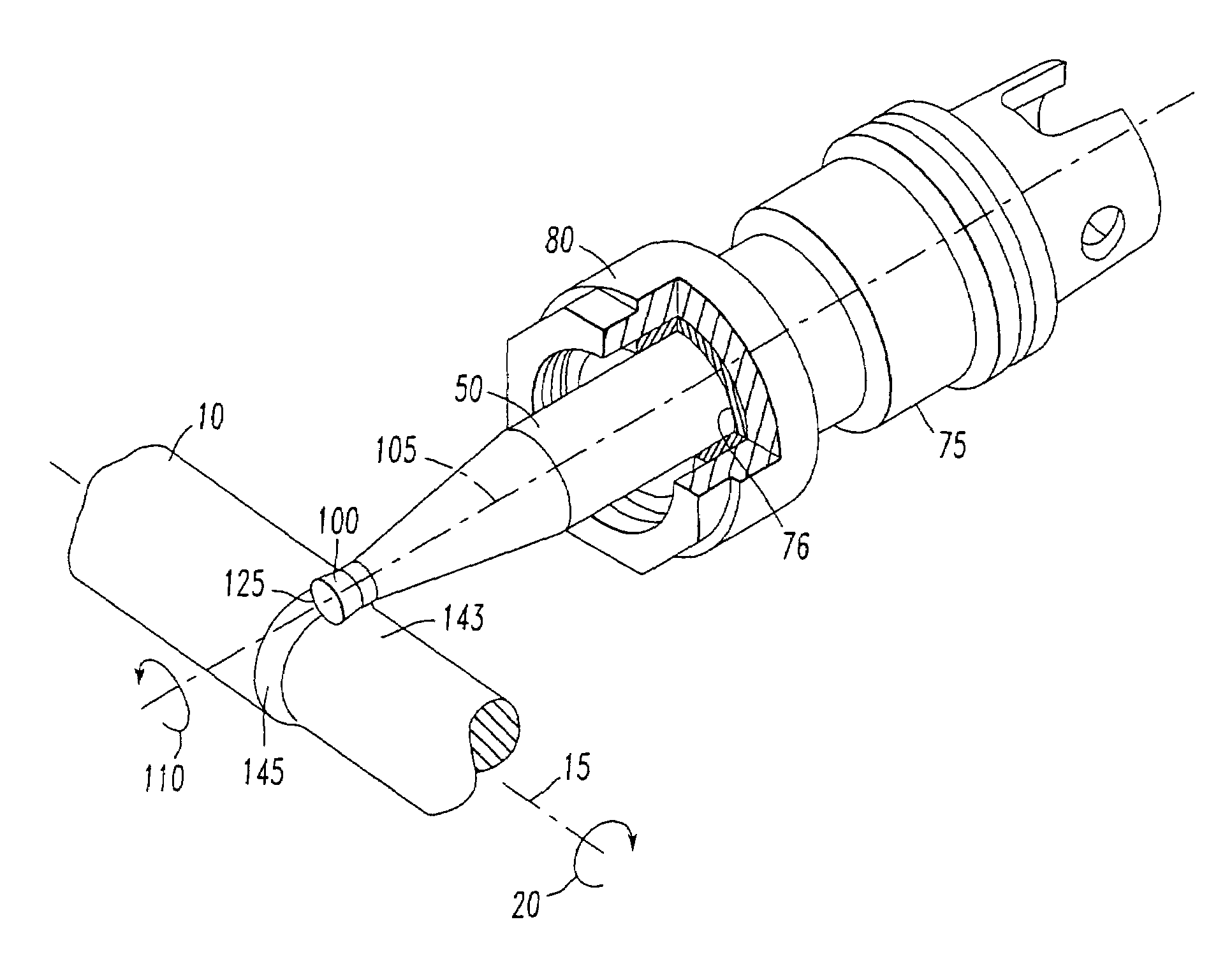

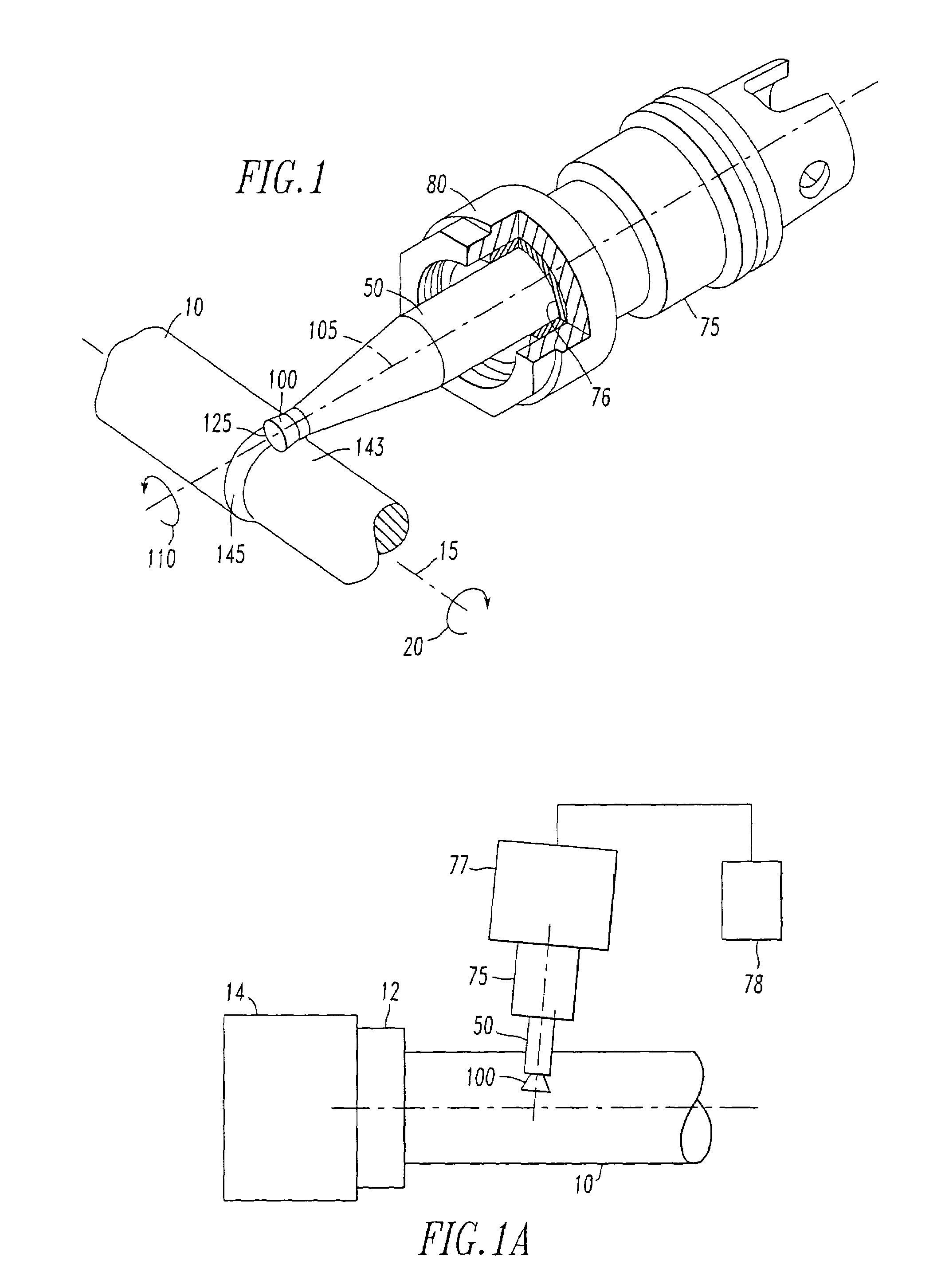

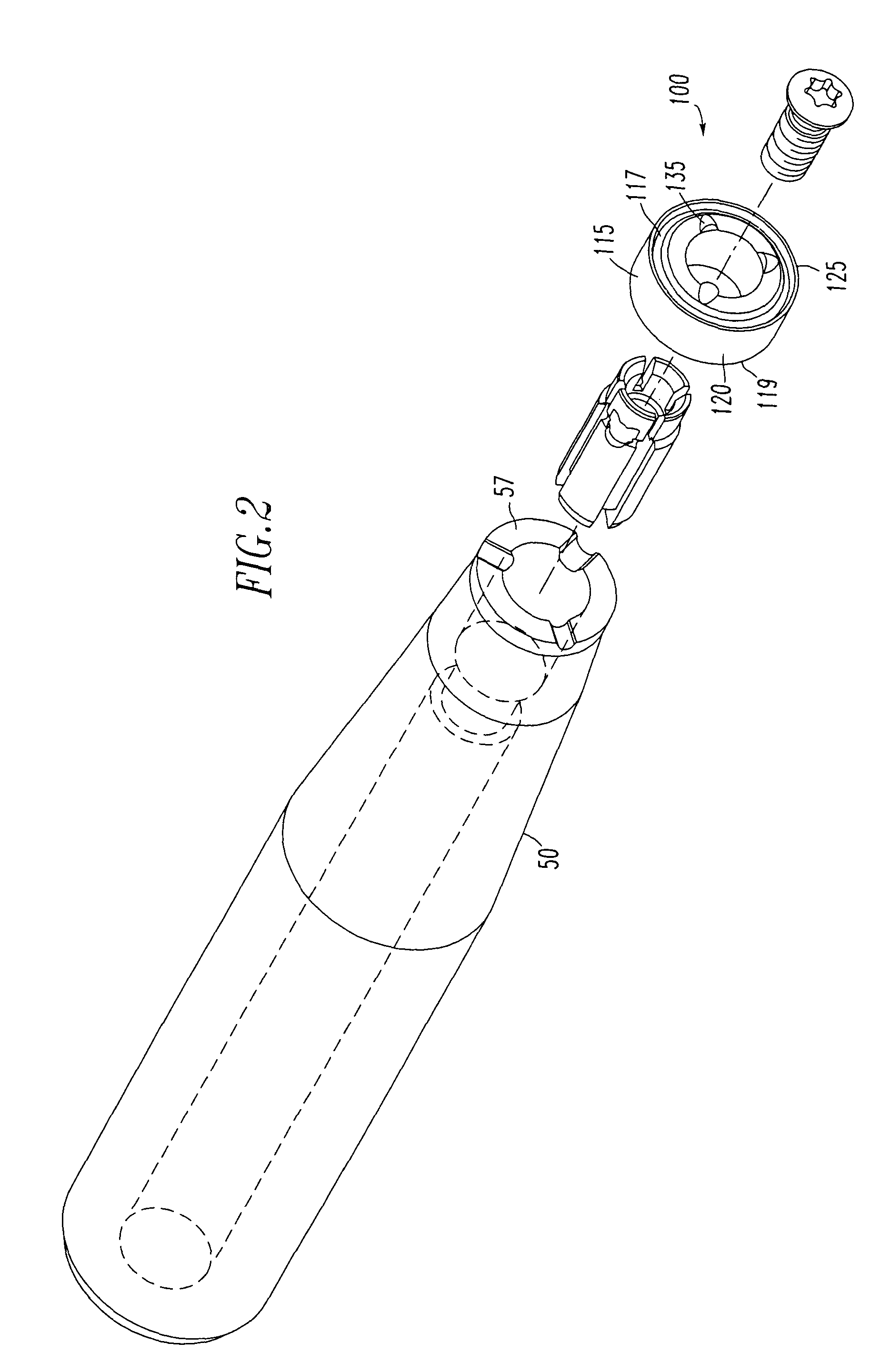

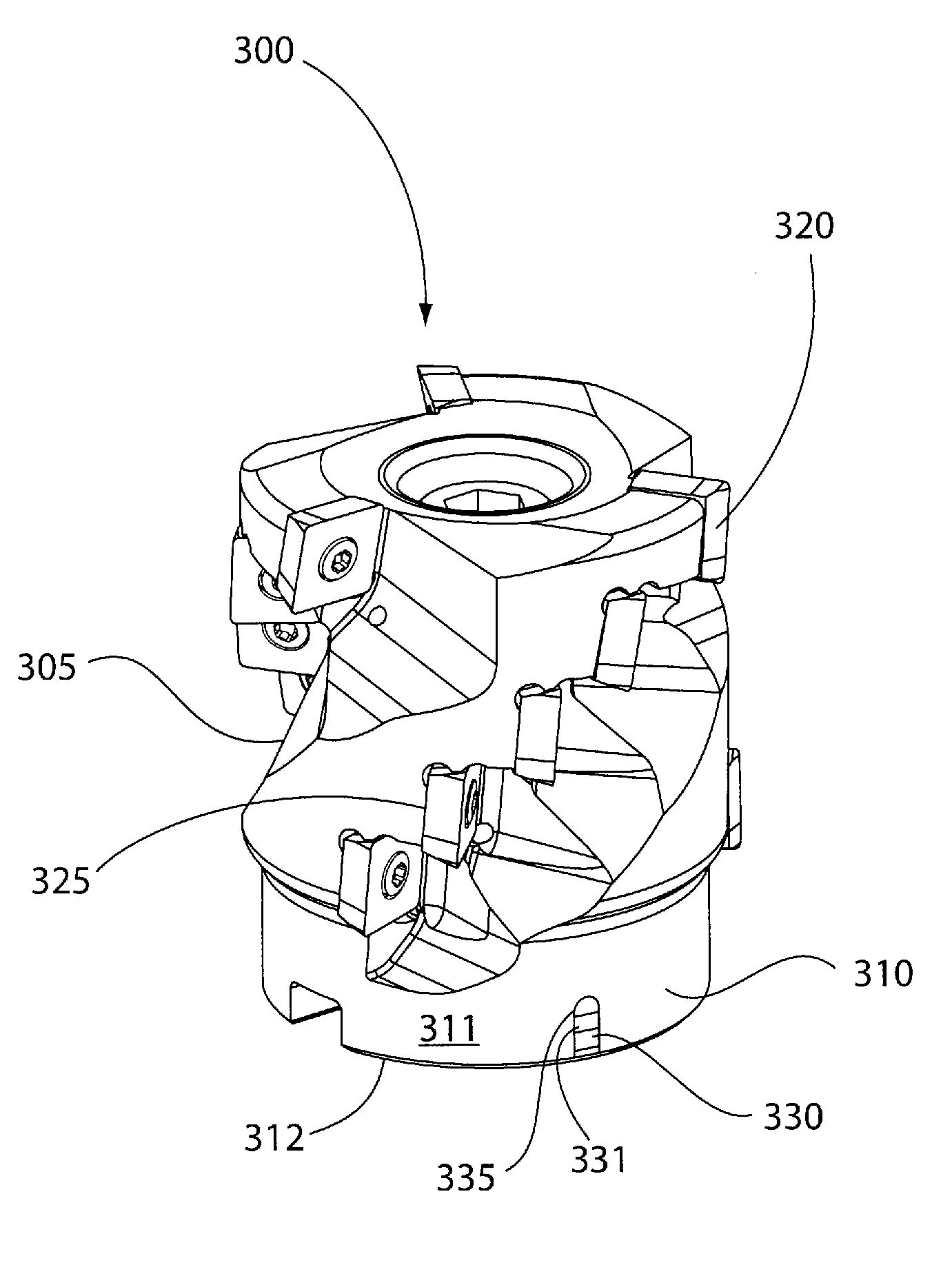

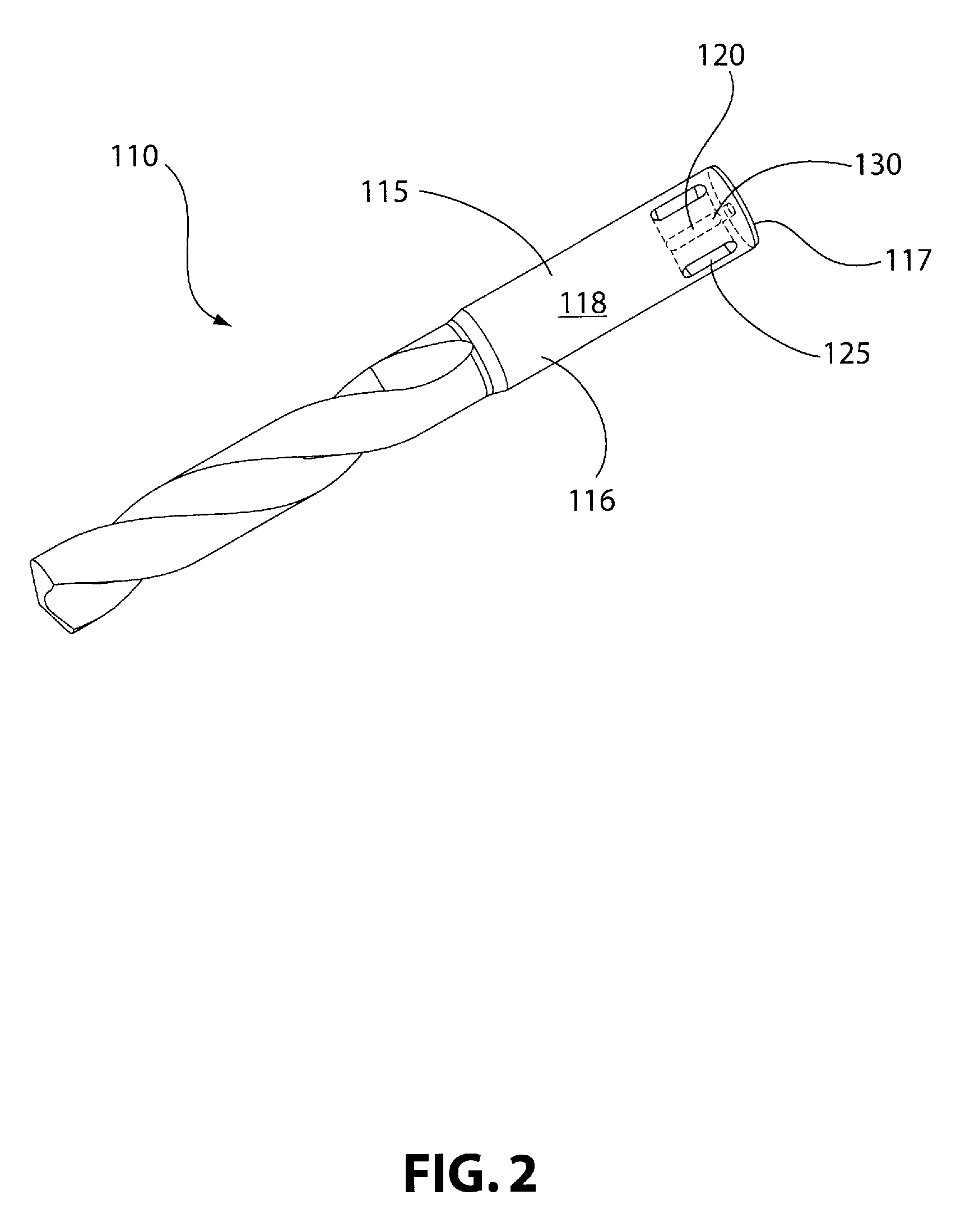

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

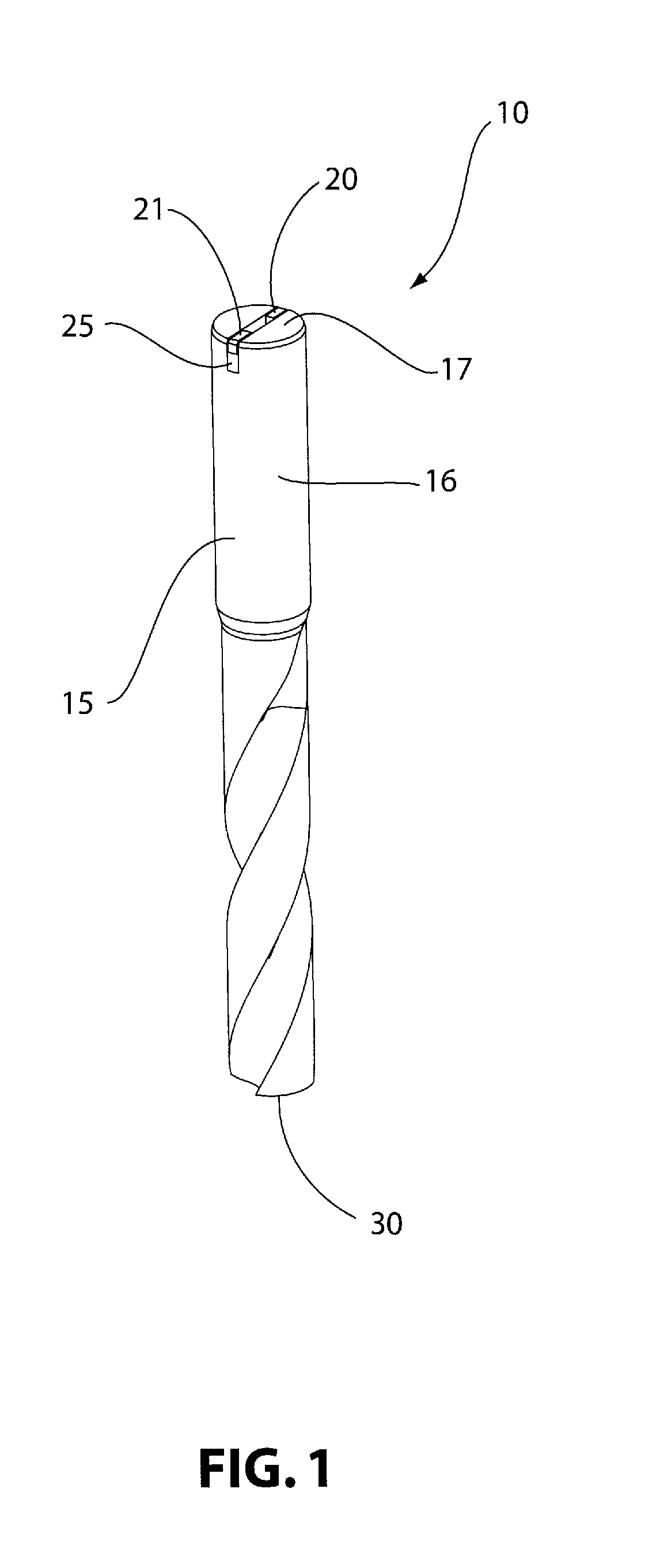

Cutting tool with integrated circuit chip

ActiveUS20090175694A1Programme controlAutomatic/semiautomatic turning machinesMilling cutterMachine tool

A system manages a machine tool operation. The system includes a cutting tool, which includes a tool body; an integrated circuit chip securely mounted within the tool body and capable of being read and written upon; and a read / write device for communicating with the integrated circuit chip. The integrated circuit chip is an RFID chip. The tool body may be a mounting chuck, adapter, twist drill, thread tap, indexable drill, milling cutter or a square shank lathe tool.

Owner:KENNAMETAL INC

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

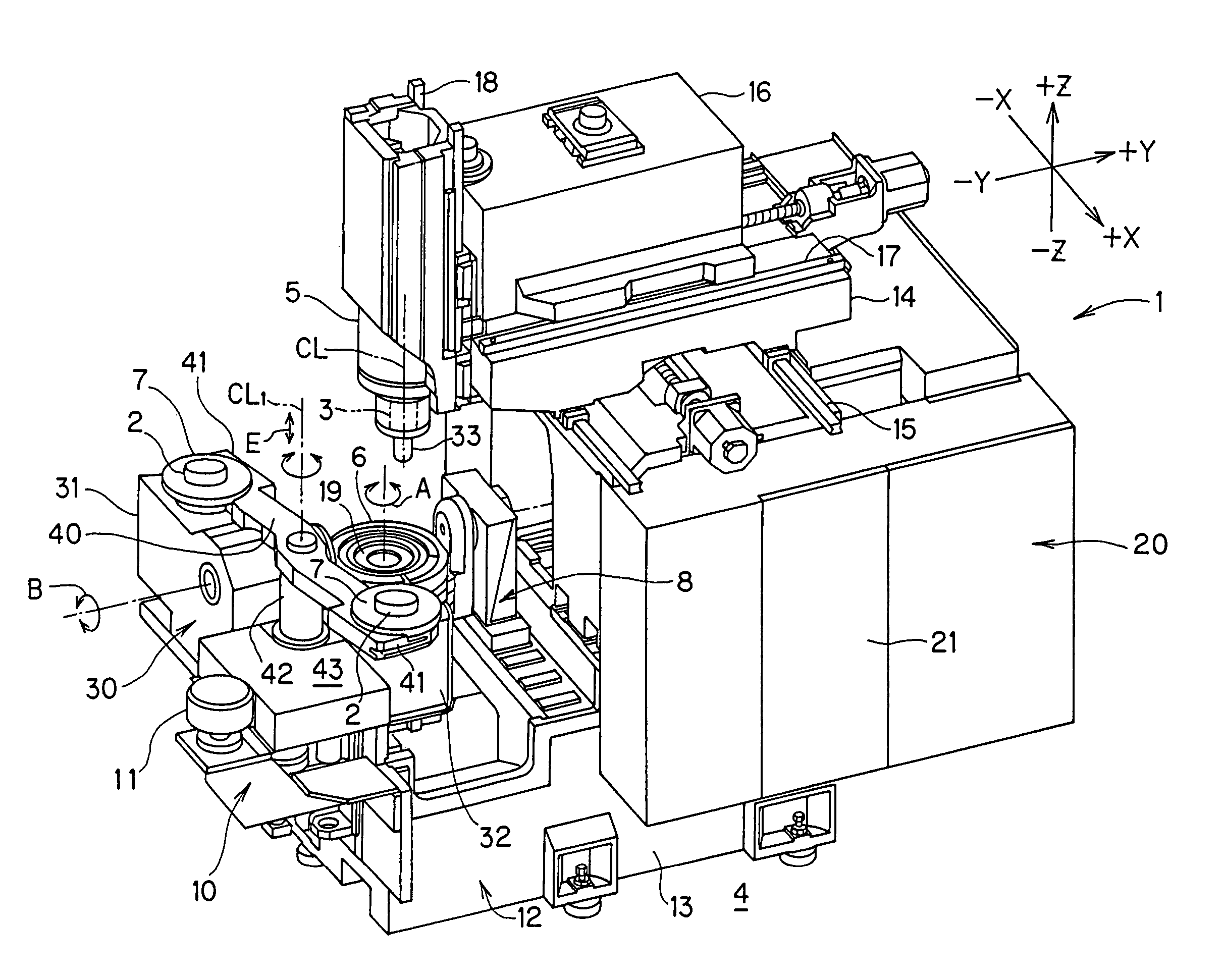

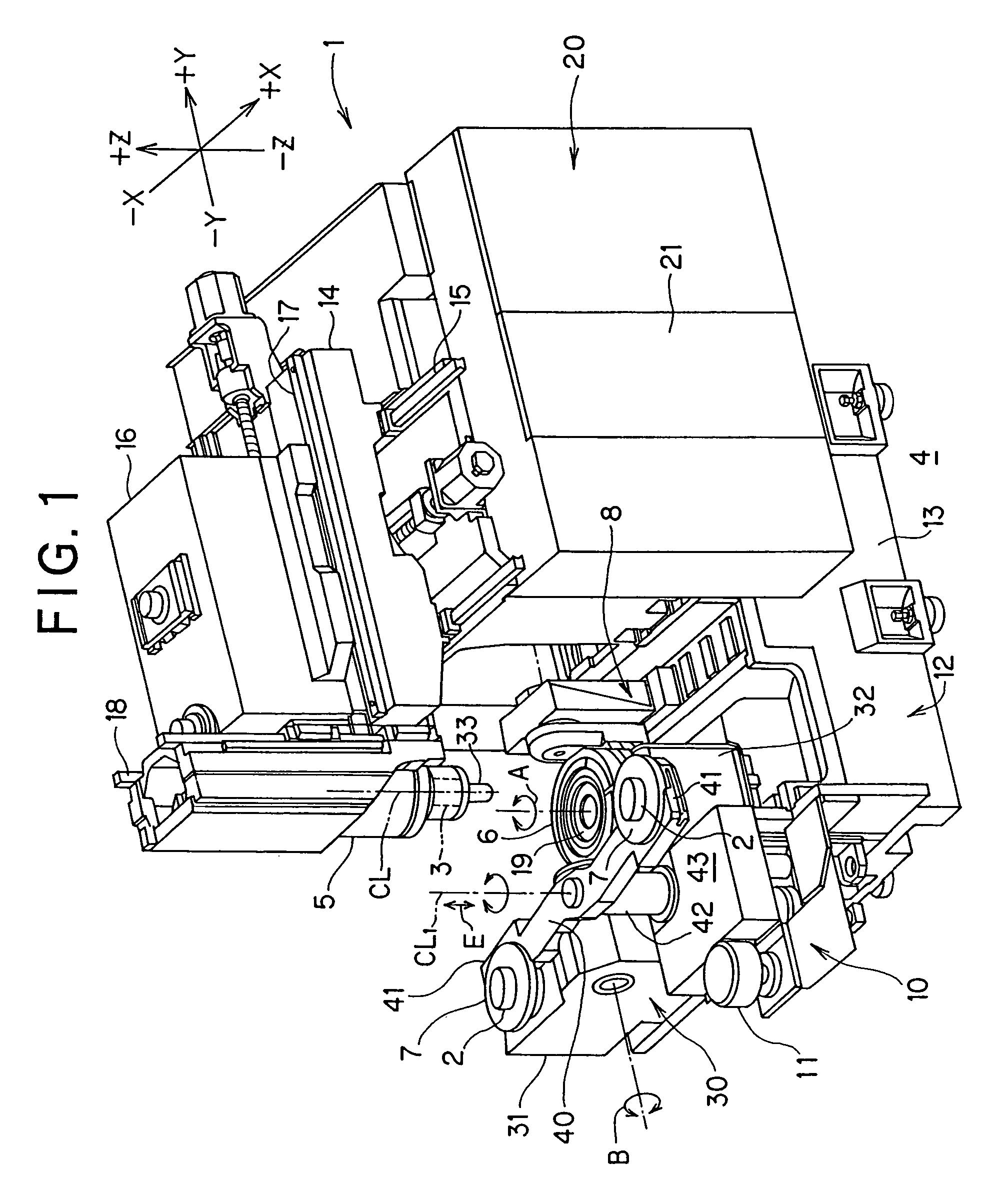

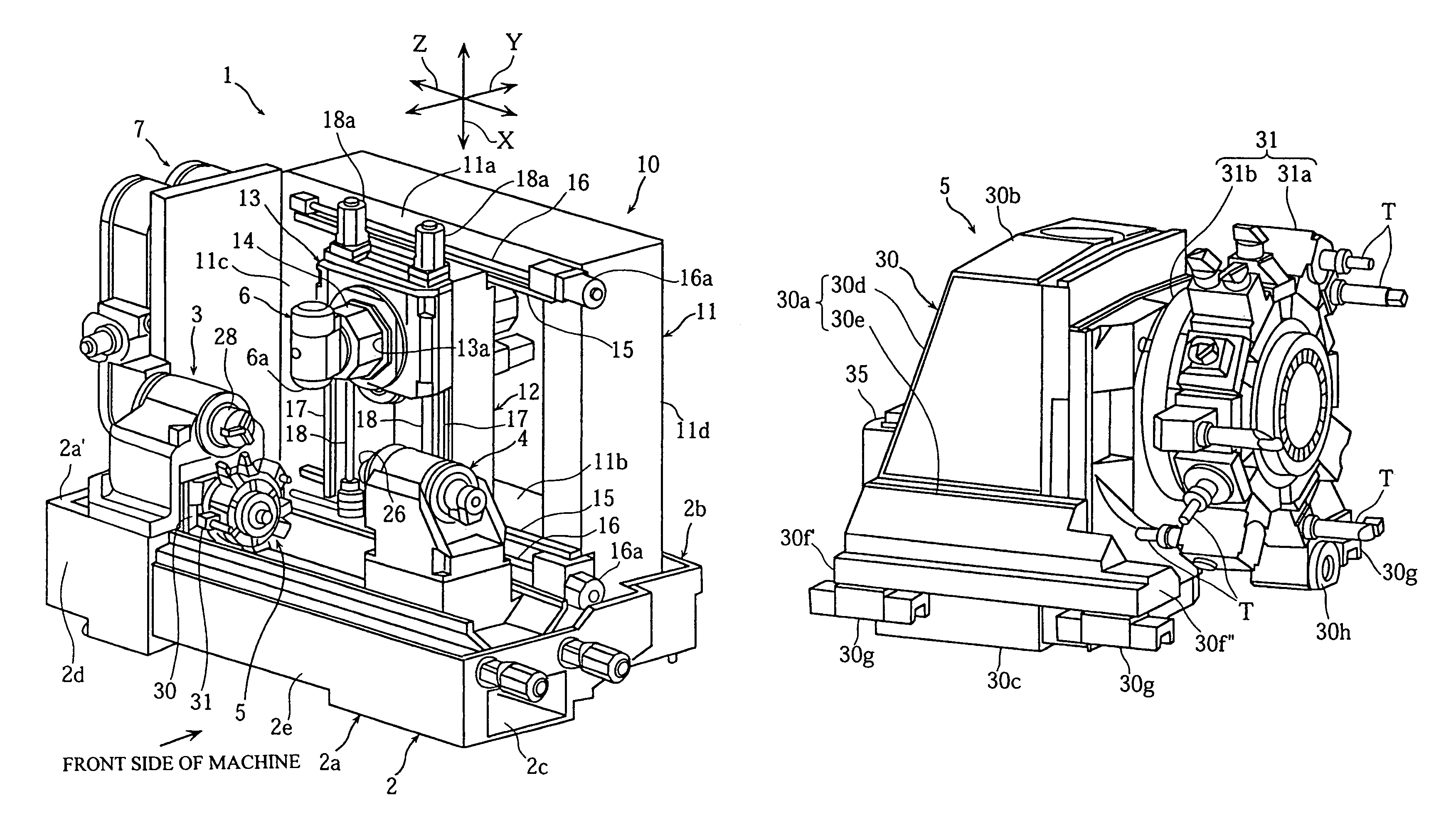

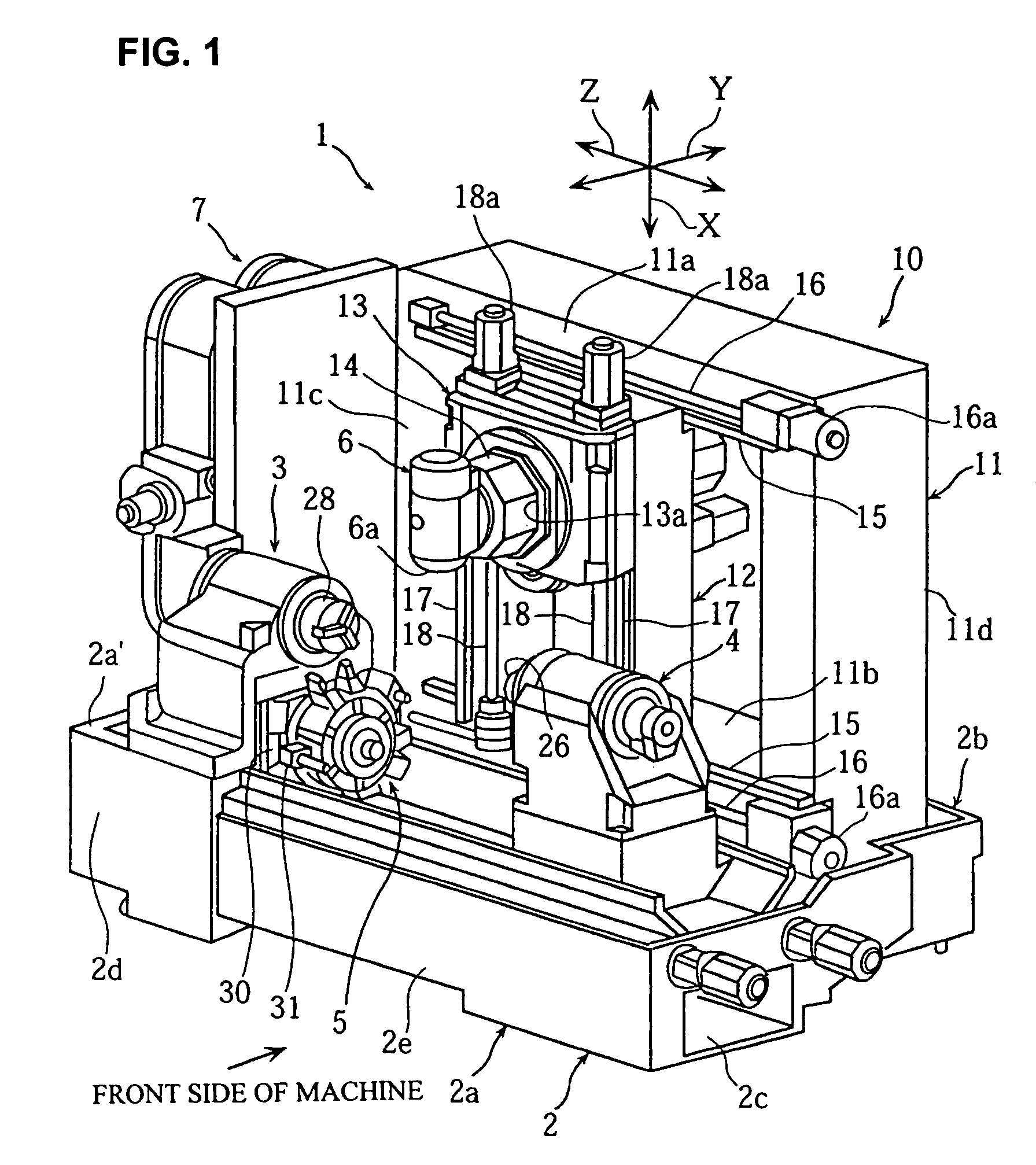

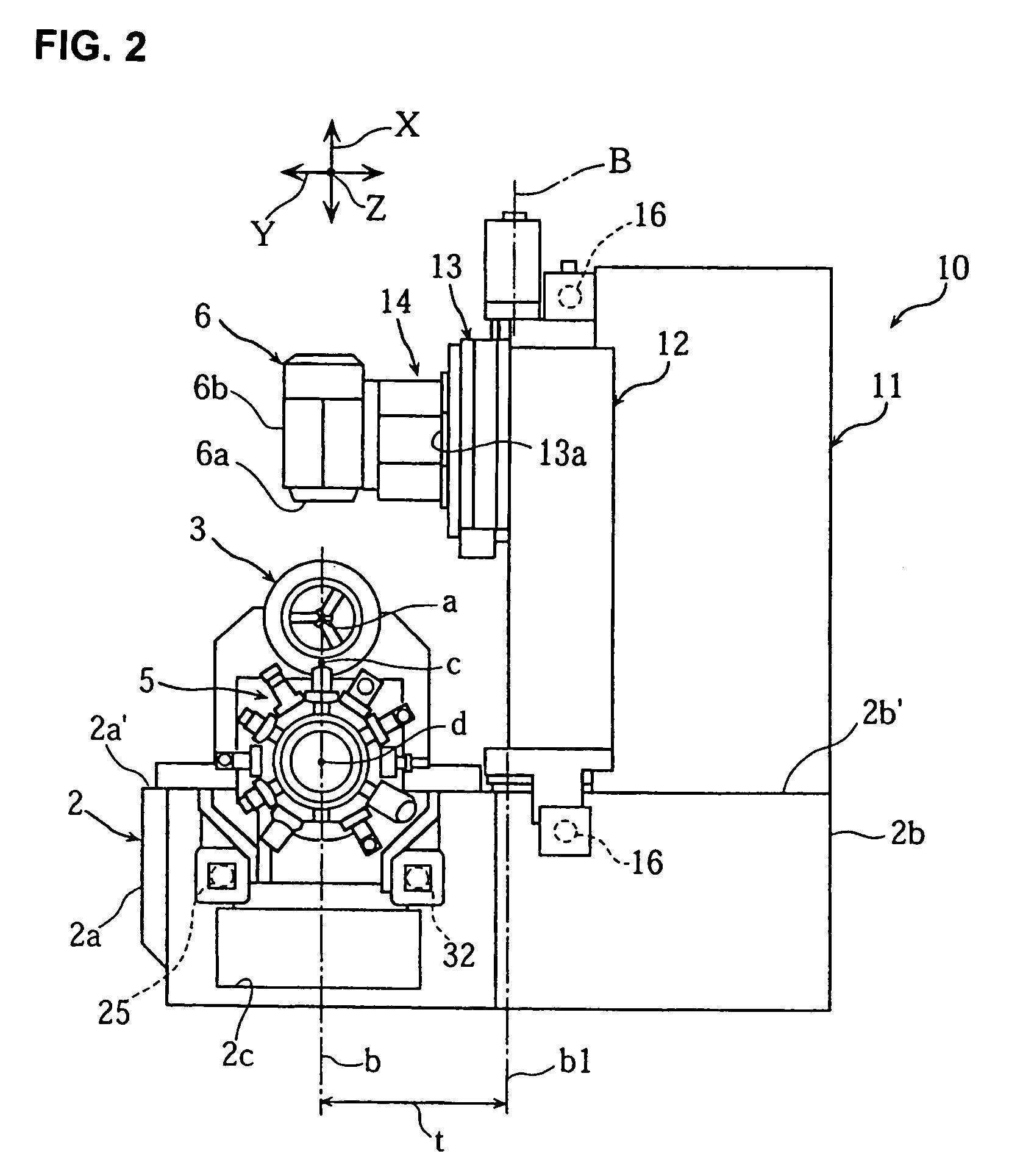

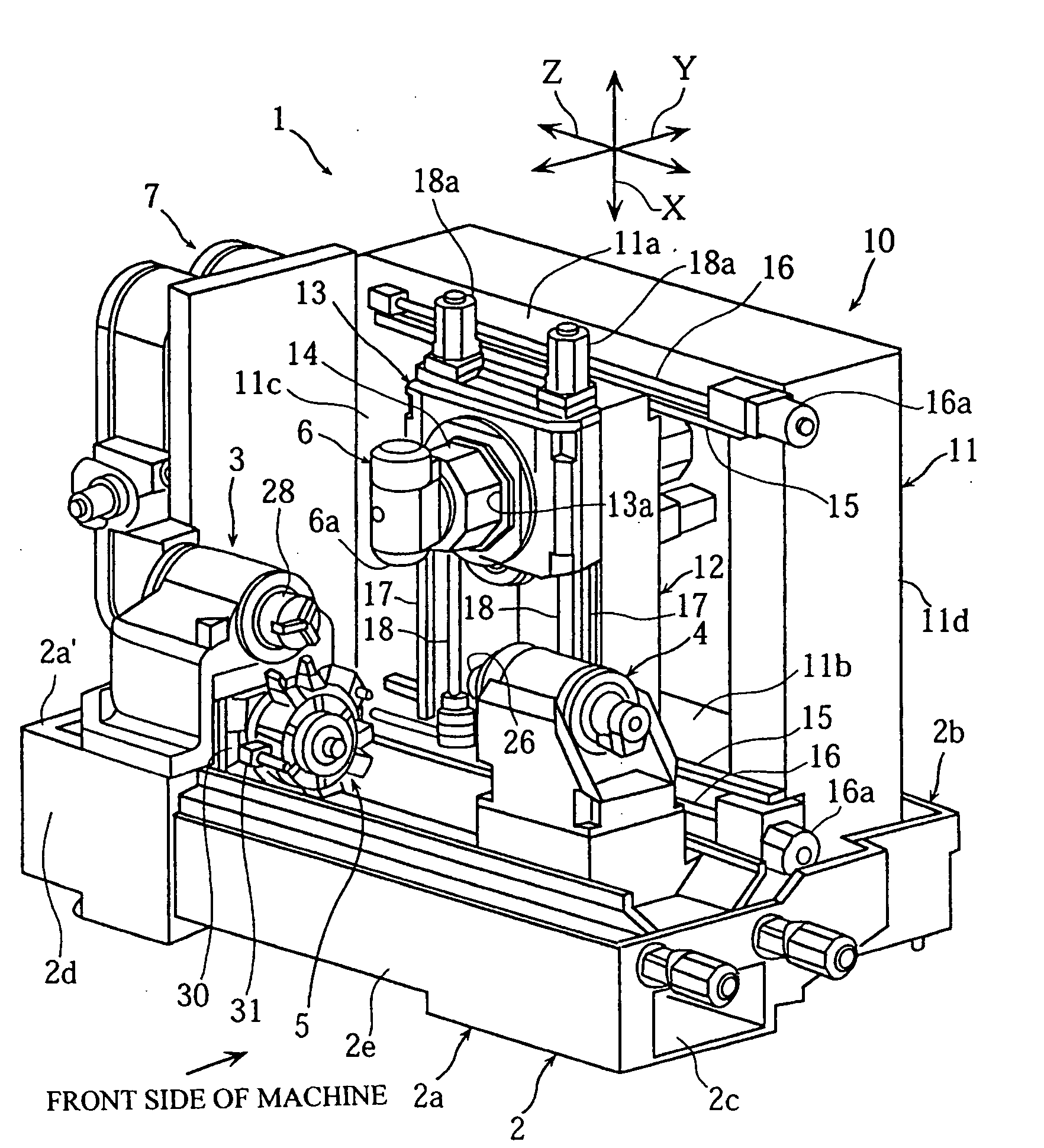

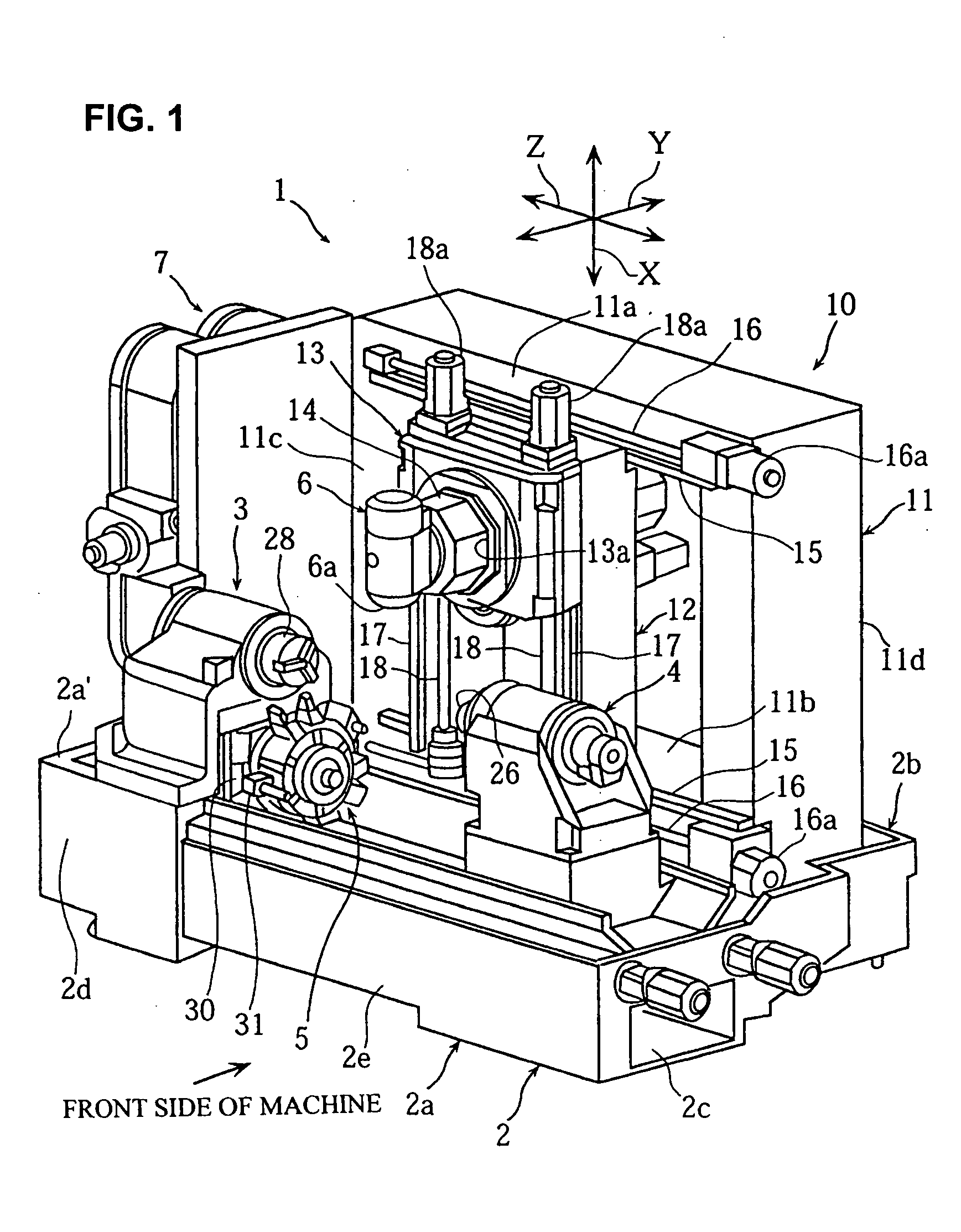

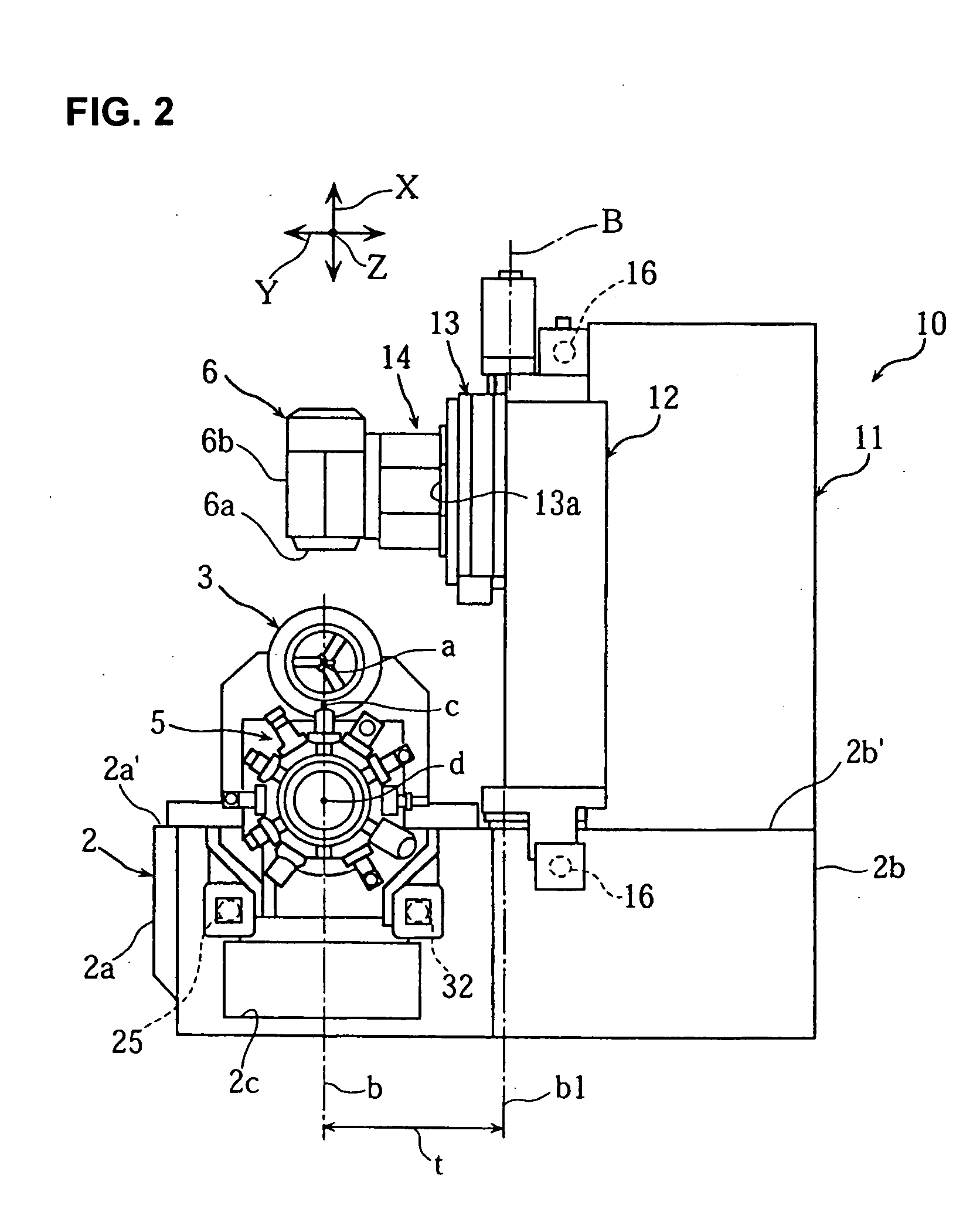

Machine tool and pallet changer for machine tool

InactiveUS7013544B2No longer be changedSimple and compact structureLathesAutomatic/semiautomatic turning machinesTransverse axisMachine tool

An APC is provided in a five-axis controlling vertical machining center. A spindle head is movable in three mutually transverse axes directions to a workpiece. A table disposed below swings to be positioned and is directed upwardly and indexed. A pallet setup base is provided outside a machining area. A pallet change arm has pallet grip portions for gripping and releasing the pallets. The arm makes a swivel motion and makes an ascending and descending motion. Thus, the pallet is transferred between the table and the pallet setup base and is received and discharged to the table and the pallet setup base.

Owner:MORI SEIKI HITECH

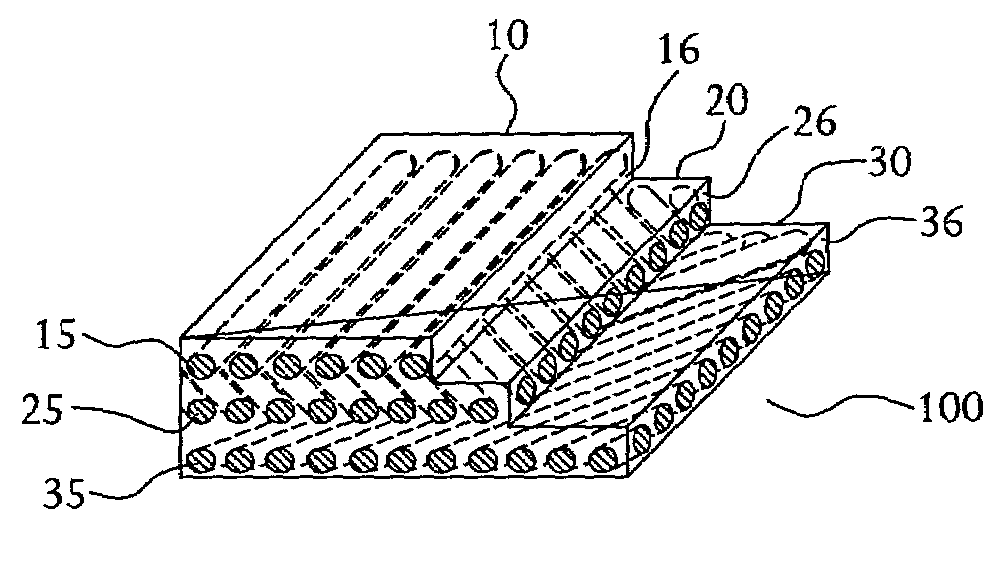

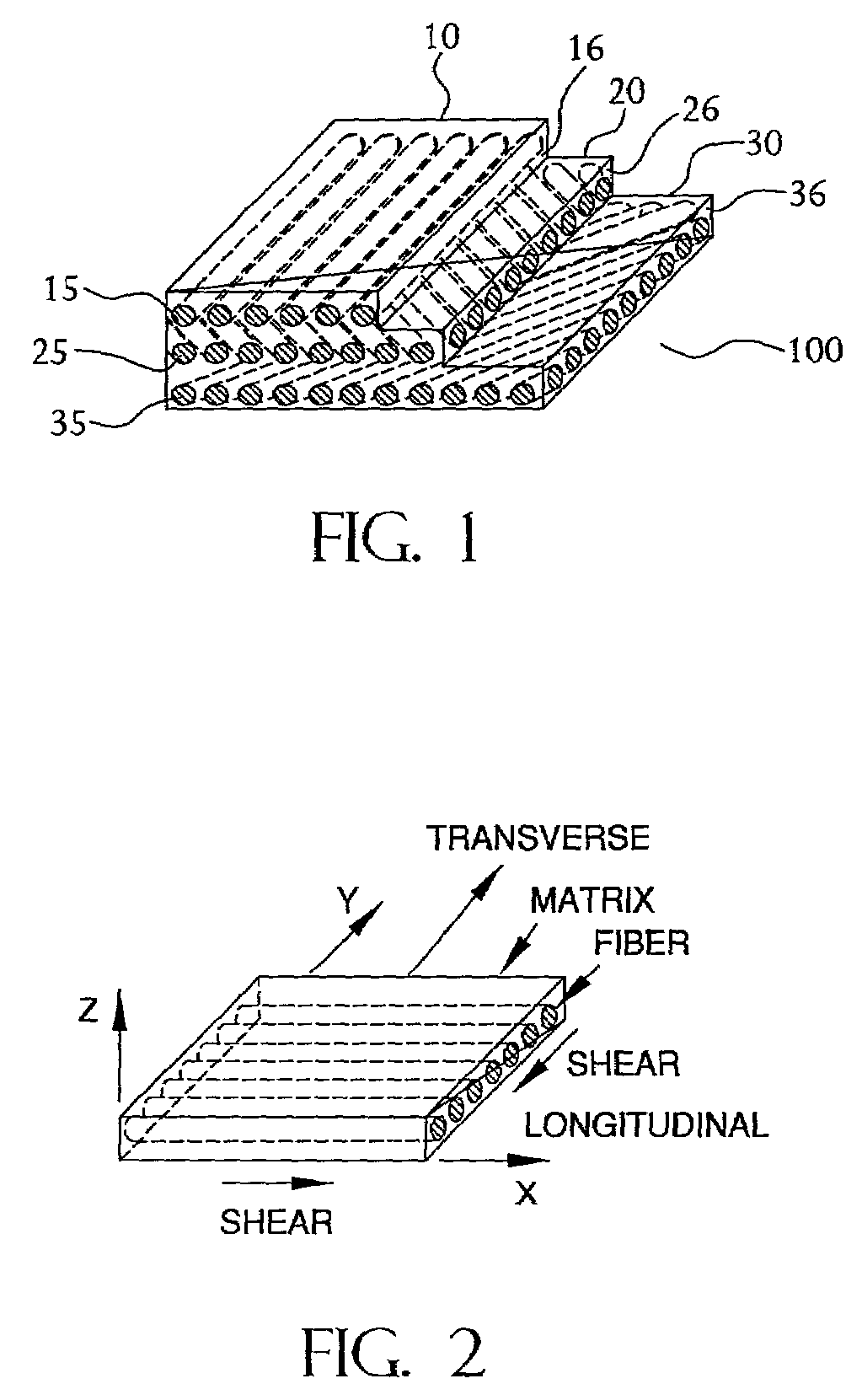

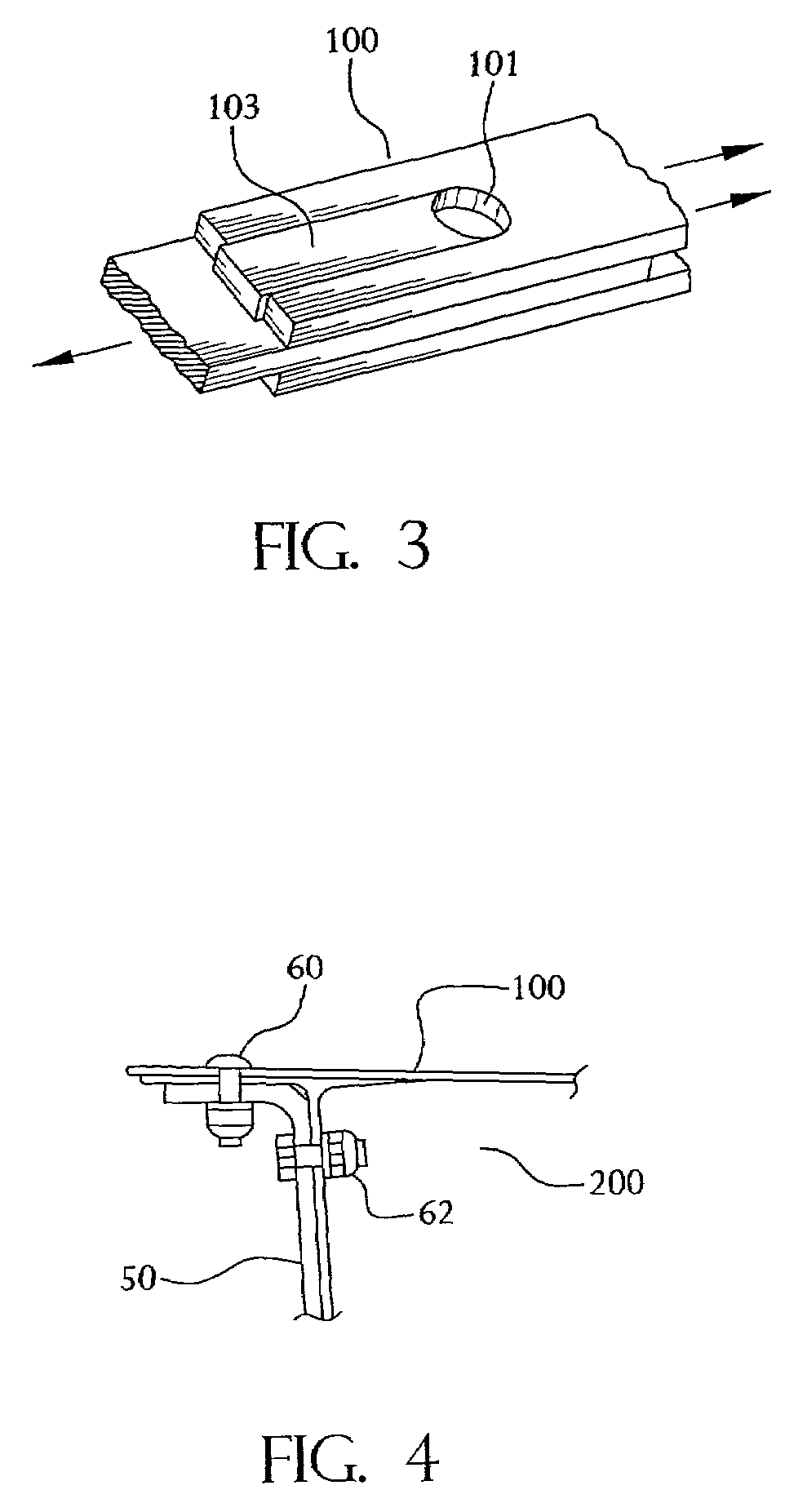

Energy absorbent laminate

InactiveUS7087296B2Tensile modulusImprove toughnessAutomatic/semiautomatic turning machinesSynthetic resin layered productsFiberFlexural modulus

Owner:SAINT GOBAIN TECHN FABRICS CANADA +1

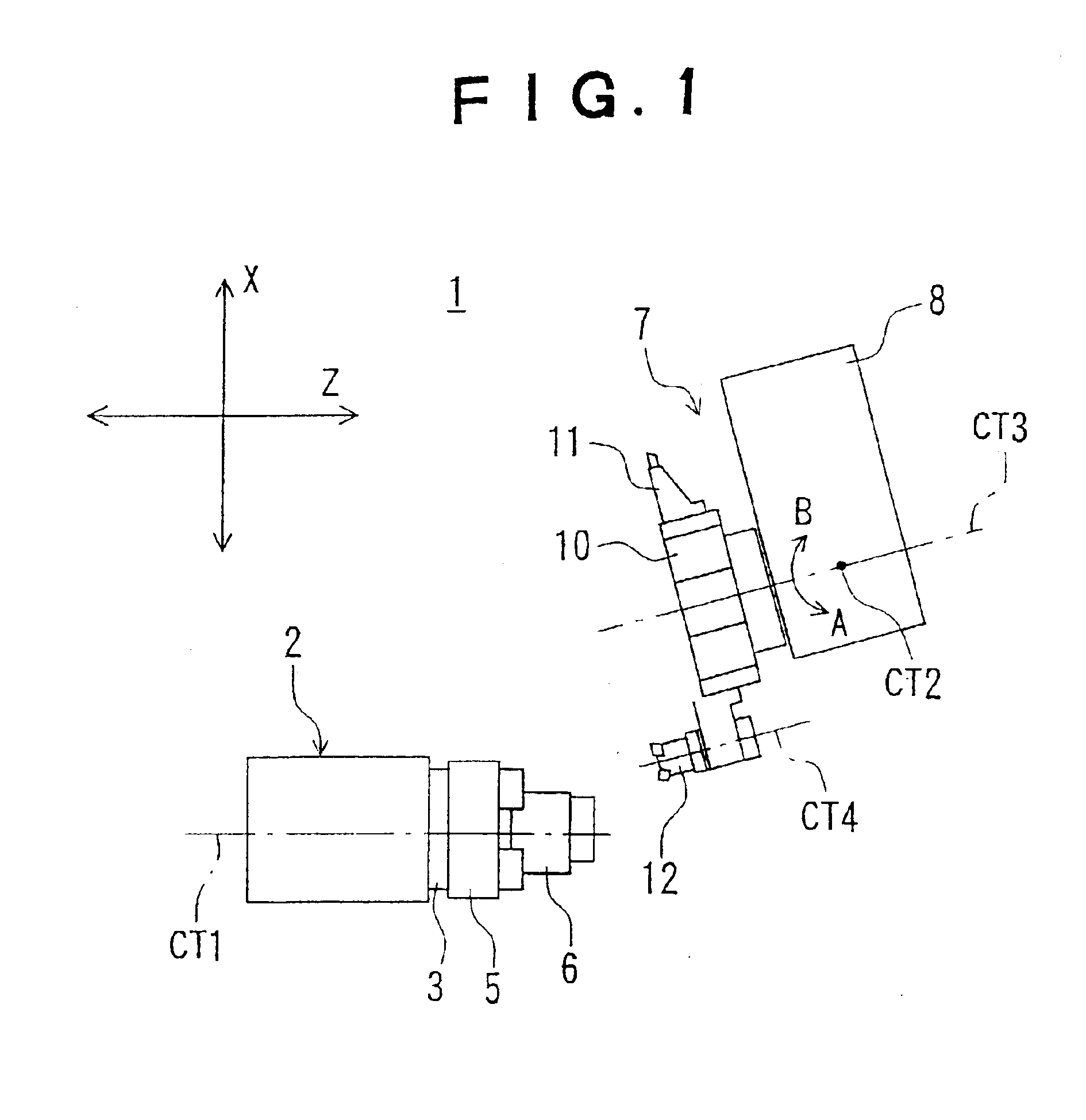

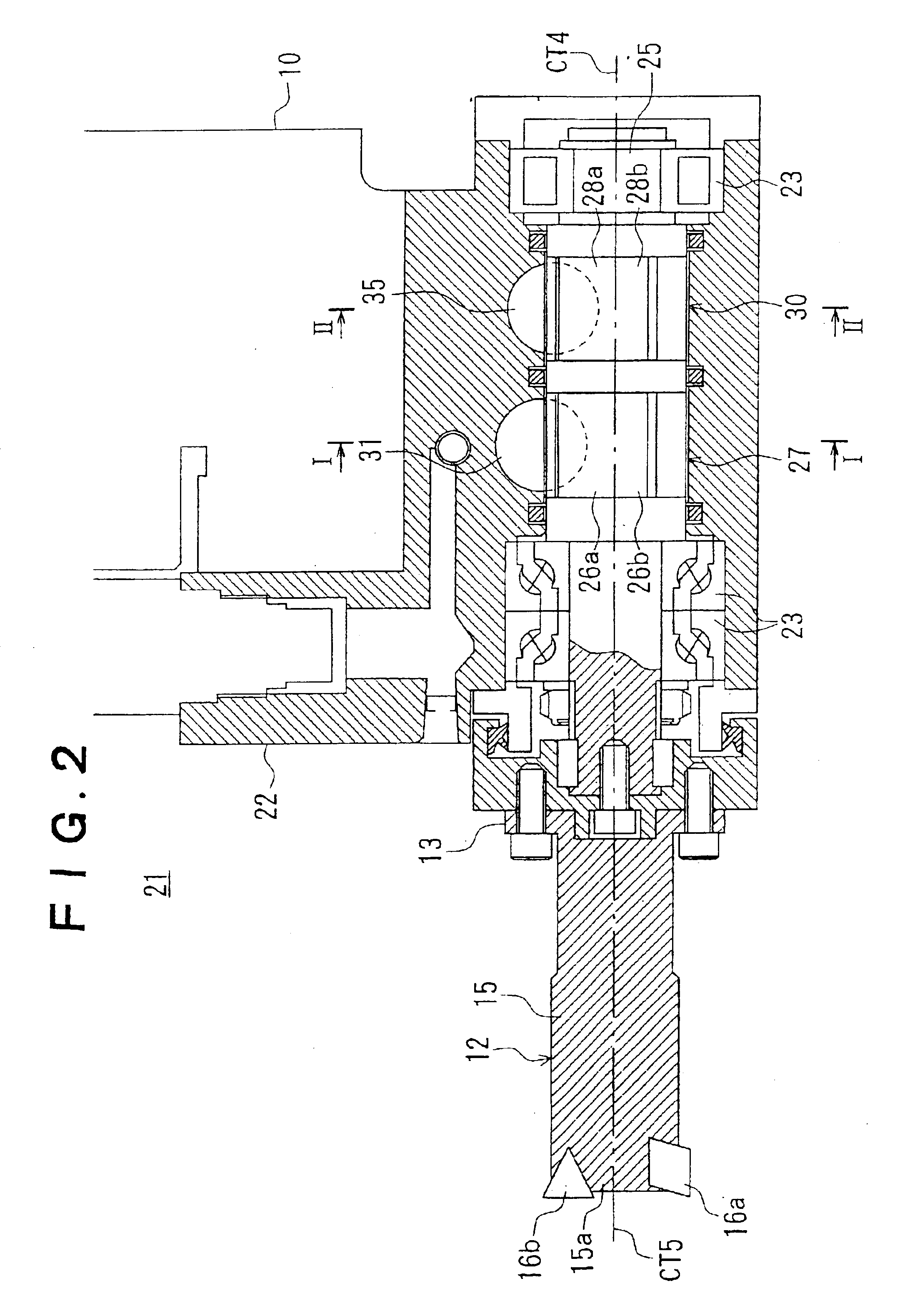

Control apparatus for cutting machine, cutting machine and cutting method

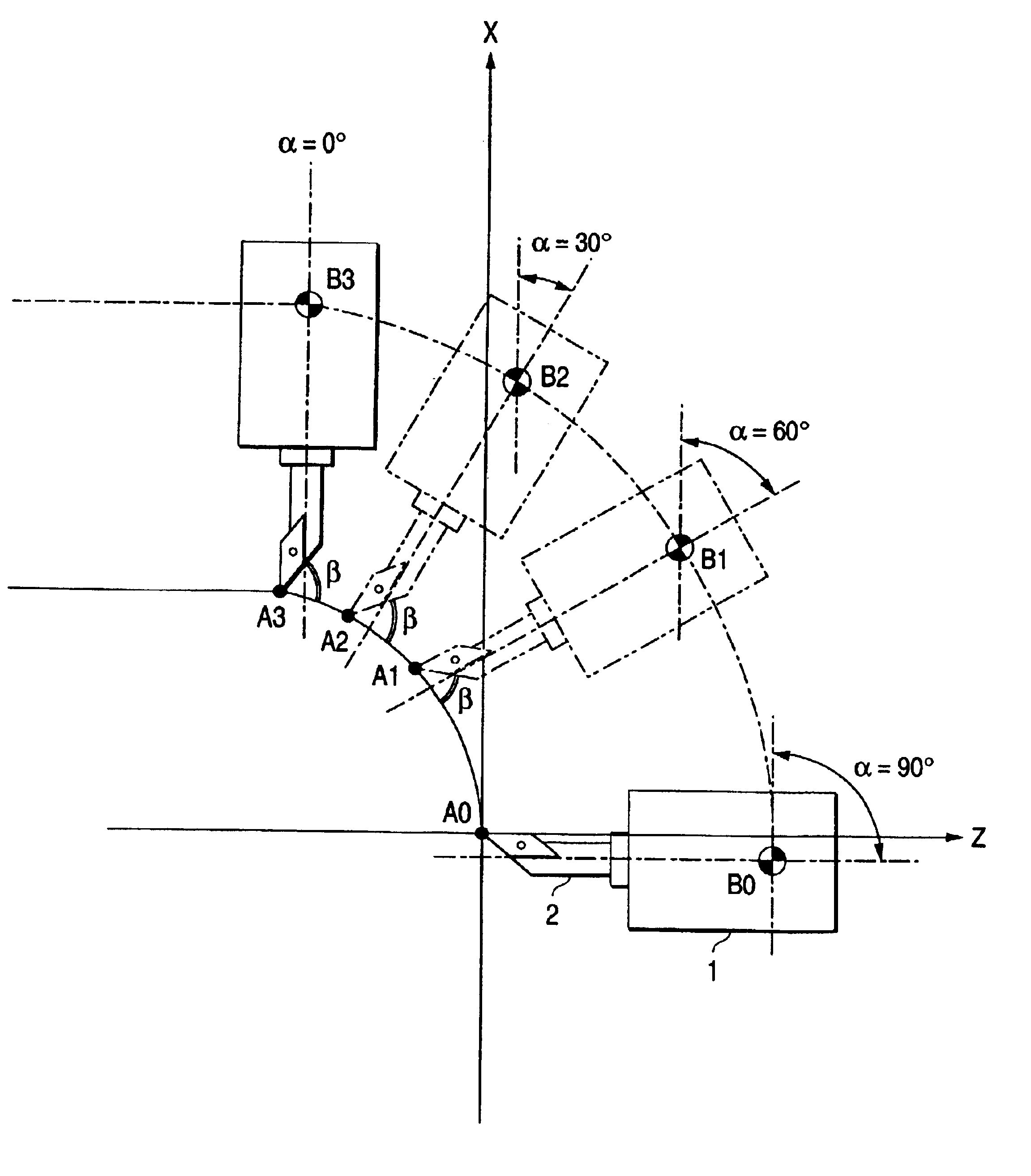

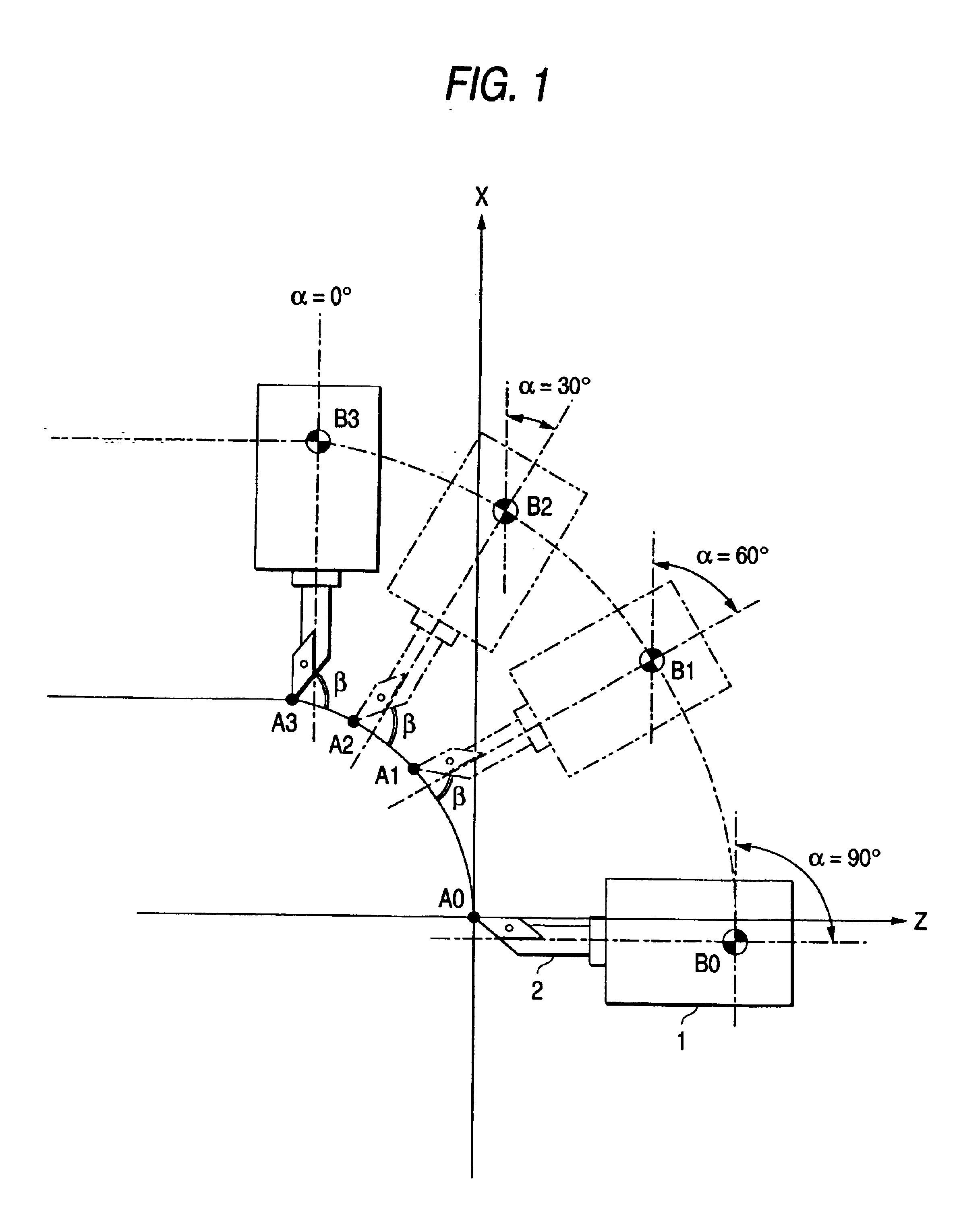

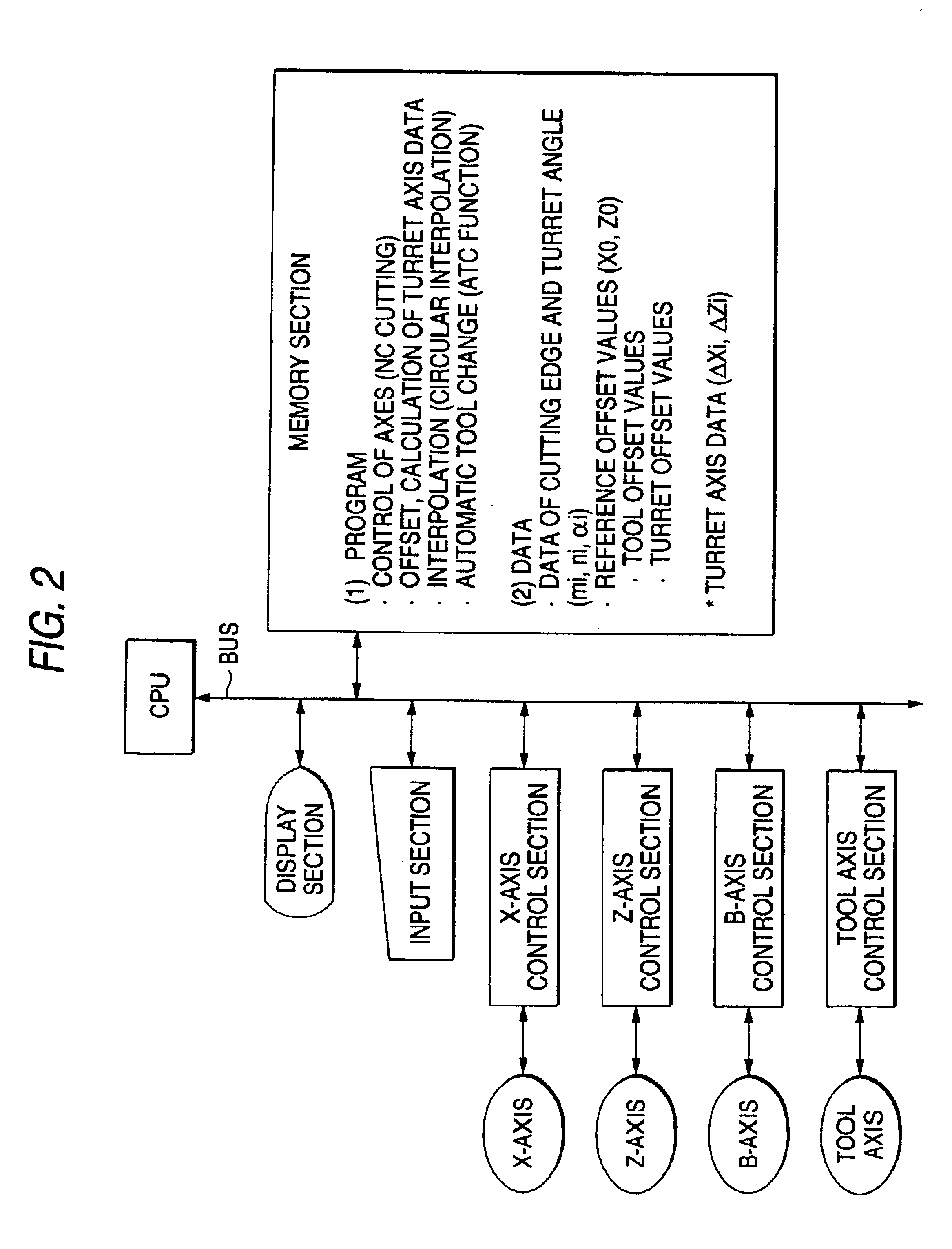

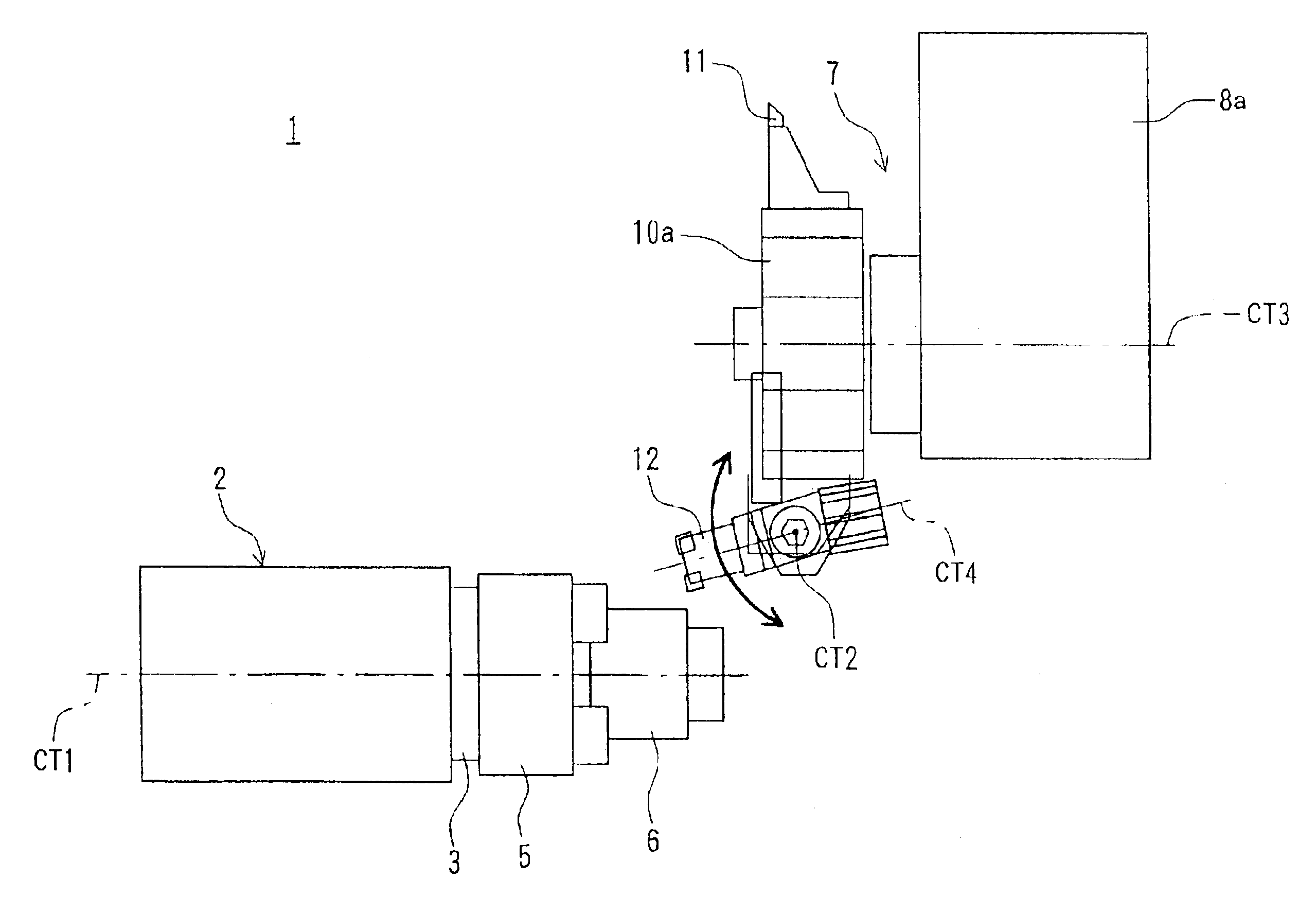

InactiveUS6842664B2Easy to calculateEasy to performLathesProgramme controlNumerical controlEngineering

This invention relates to a control apparatus for numerical control in a cutting machine having a turret which can be rotated to arbitrary positions, and characterized by including means for obtaining turret axis data (ΔX, ΔZ) from reference offset values (X0, Z0) corresponding to a length from a cutting edge to a turret axis B, turret angle data α, and cutting edge data (m, n), and moving the turret on the basis of these turret axis data (ΔX, ΔZ) to perform a cutting.

Owner:DMG MORI SEIKI CO LTD

Tool holder for turret lathe

InactiveUS6865789B2Improve machine efficiencyAvoid long exchangesAutomatic/semiautomatic turning machinesPrecision positioning equipmentRotation functionEngineering

A tool holder for attaching a complex tool having a plurality of kinds of cutting edges to a turret, has a base portion attachably and detachably formed at the turret. The base portion has a rotatable tool spindle attachably and detachably installing the complex tool thereon. The tool spindle is provided with indexing means for indexably rotating the tool spindle at an indexed position corresponding to each cutting edge of the complex tool. And, clamping means for clamping the tool spindle at a predetermined indexed position is provided. Indexing rotational function and clamping function owned by the tool holder makes the use of the complex tool in the lathe possible.

Owner:YAMAZAKI MAZAK KK

Cutting tool with integrated circuit chip

Owner:KENNAMETAL INC

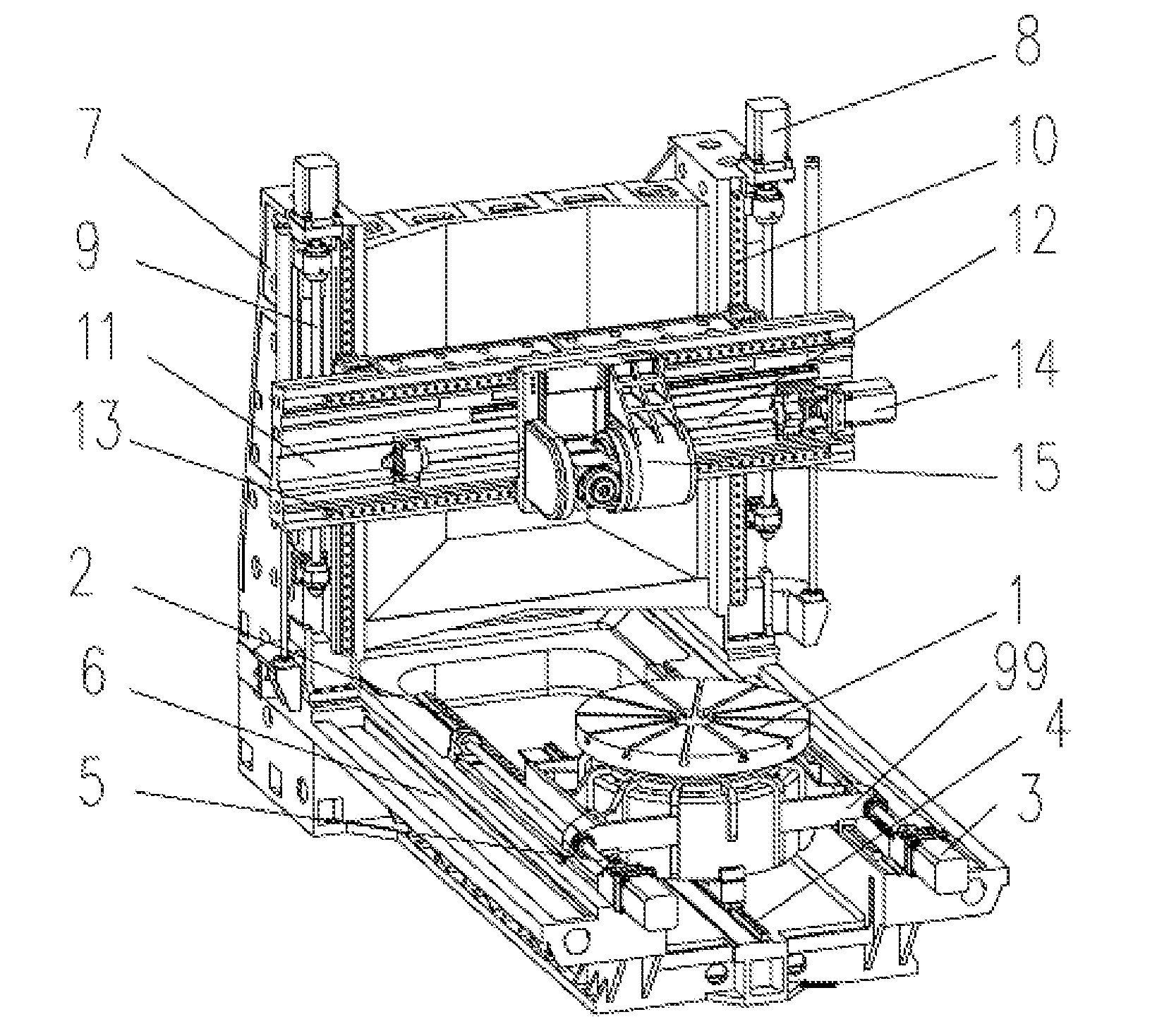

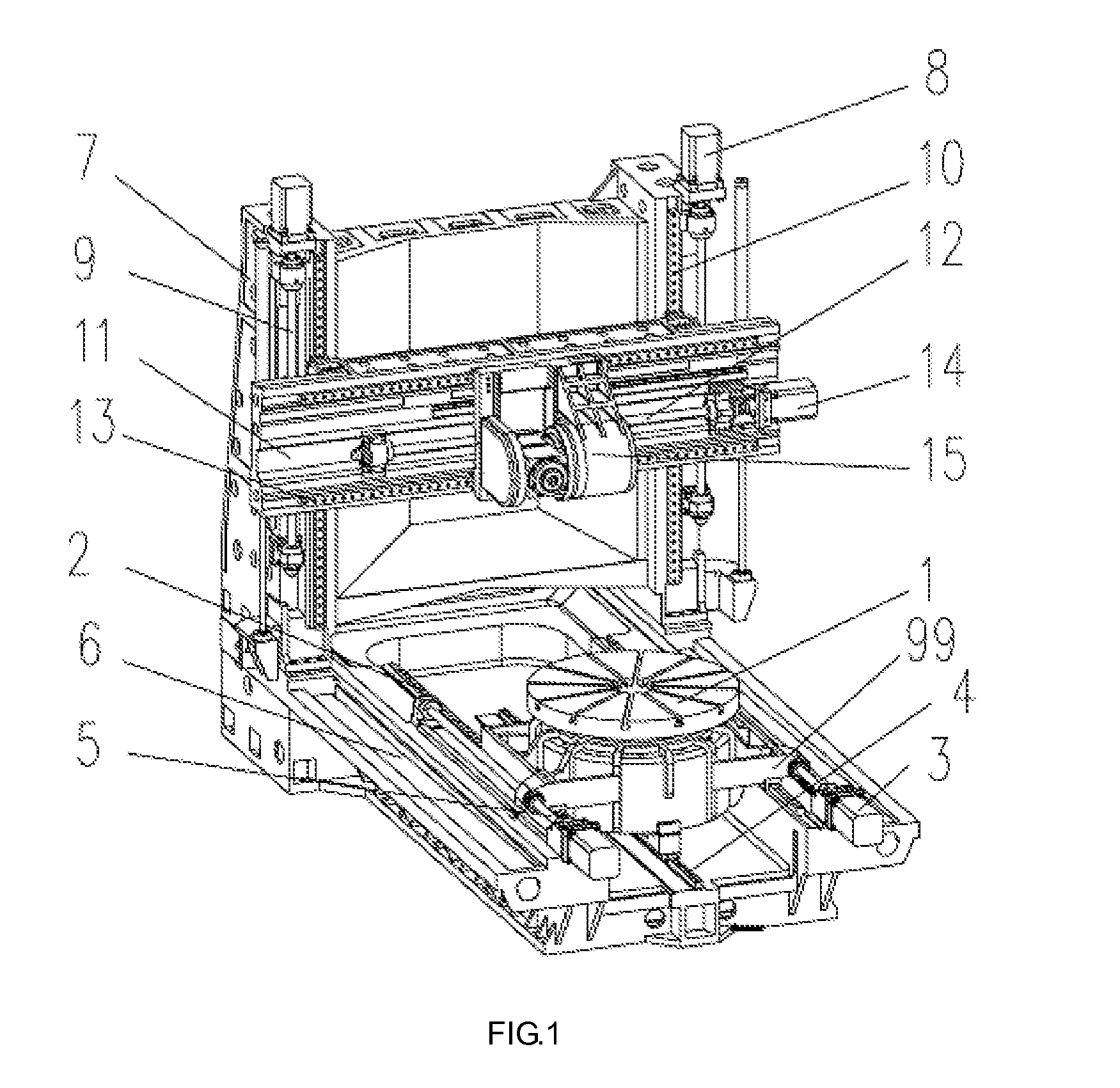

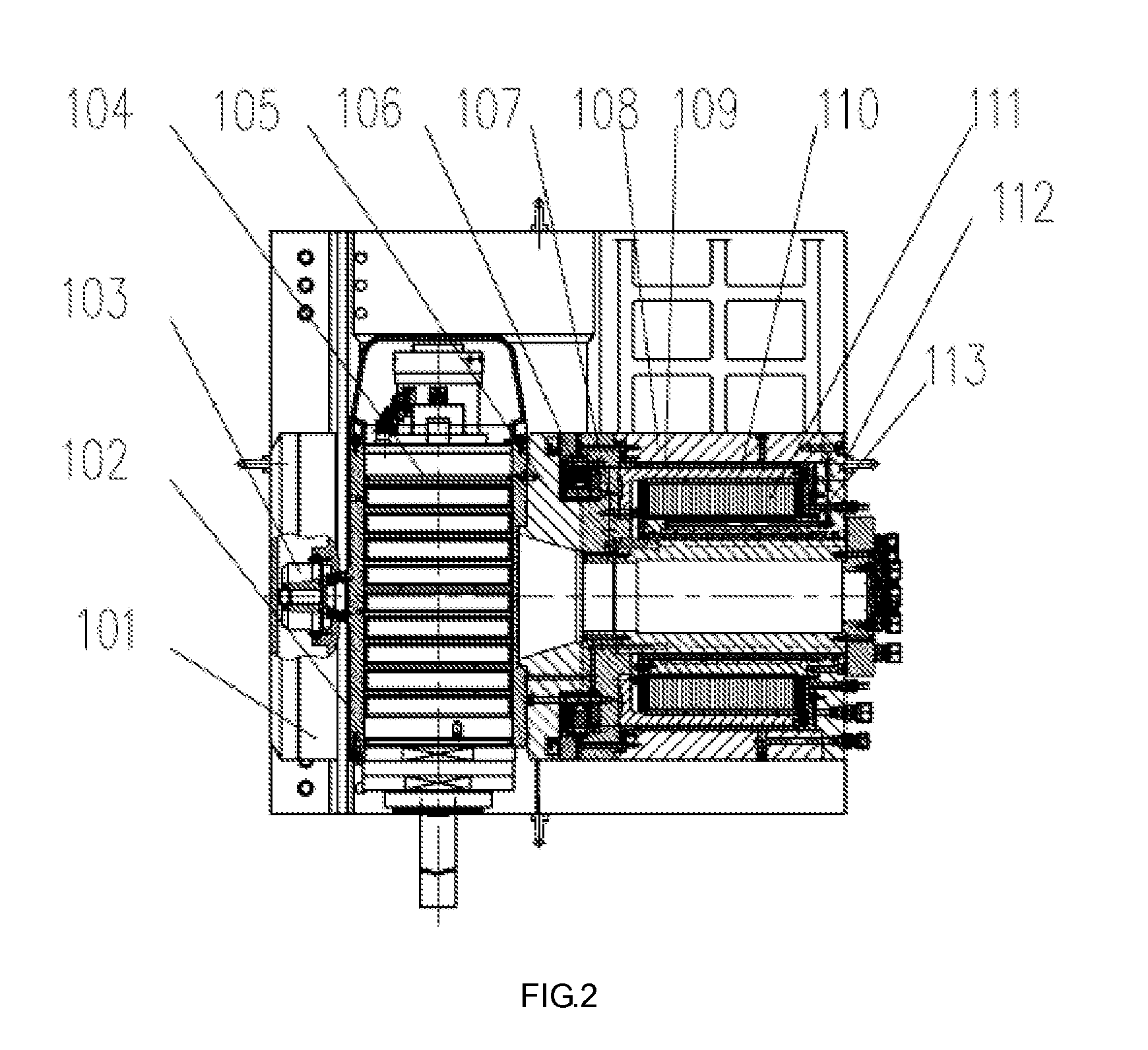

Vertical turning-milling complex machining center

ActiveUS20120210551A1Avoid vibrationDeformation MinimizationLathesAutomatic/semiautomatic turning machinesReciprocating motionTorque motor

A vertical turning-milling complex machining center comprises a horizontally-arranged bed body (6) and a vertically-arranged column (7). The bed body (6) is provided with an X-axis lateral supporting linear track (2) and an X-axis guide screw (5). The bed body (6) is also provided with a uniaxial rotating table (1) which can reciprocate and is driven directly by a first external rotor torque motor. The column (7) is vertically provided with a Z-axis lateral supporting linear track (10), a Z-axis guide screw (9) and a crossbeam (11) that reciprocates up and down. The crossbeam (11) is provided with a transverse Y-axis linear track (13), a Y-axis guide screw (12) and a single-pendulum milling head seat frame that can reciprocate along the Y-axis guide screw (12). The single-pendulum milling head is driven directly by a second external rotor torque motor. The vertical turning-milling complex machining center uses direct-drive technology applied to a B-axis and a C-axis, the motor torque is greatly increased and functional parts can stably operate, therefore the integral rigidity and stability of the machining center are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

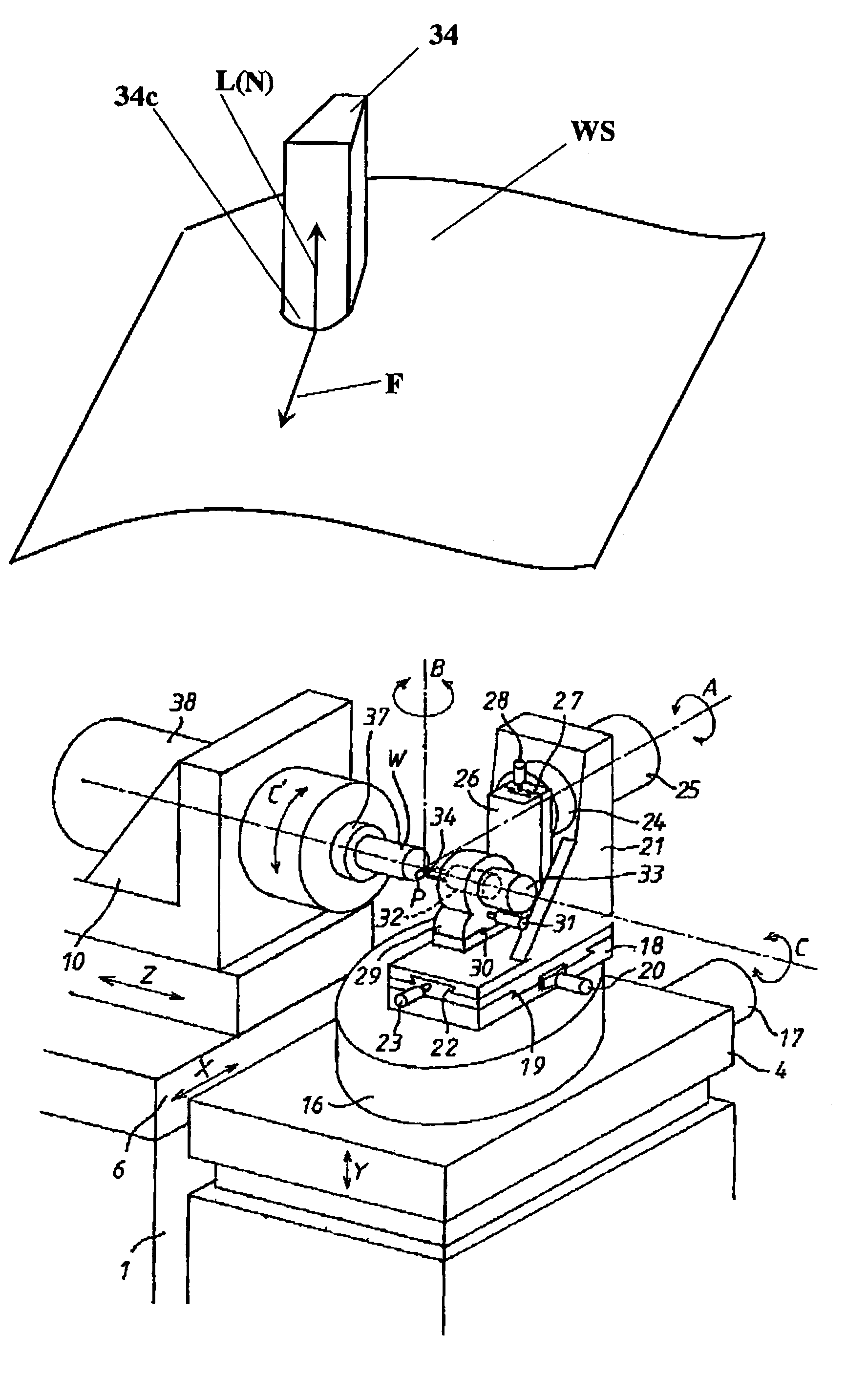

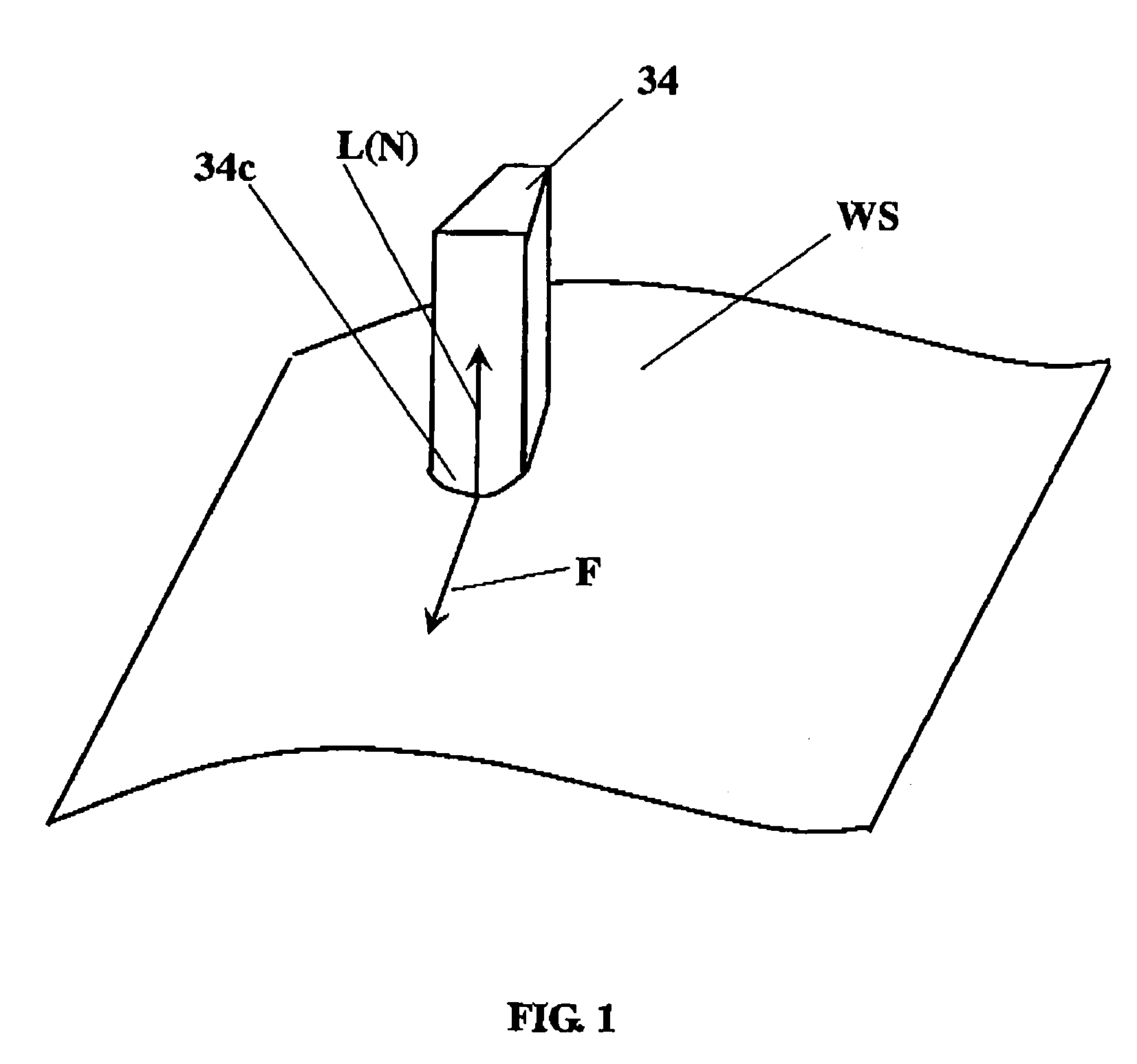

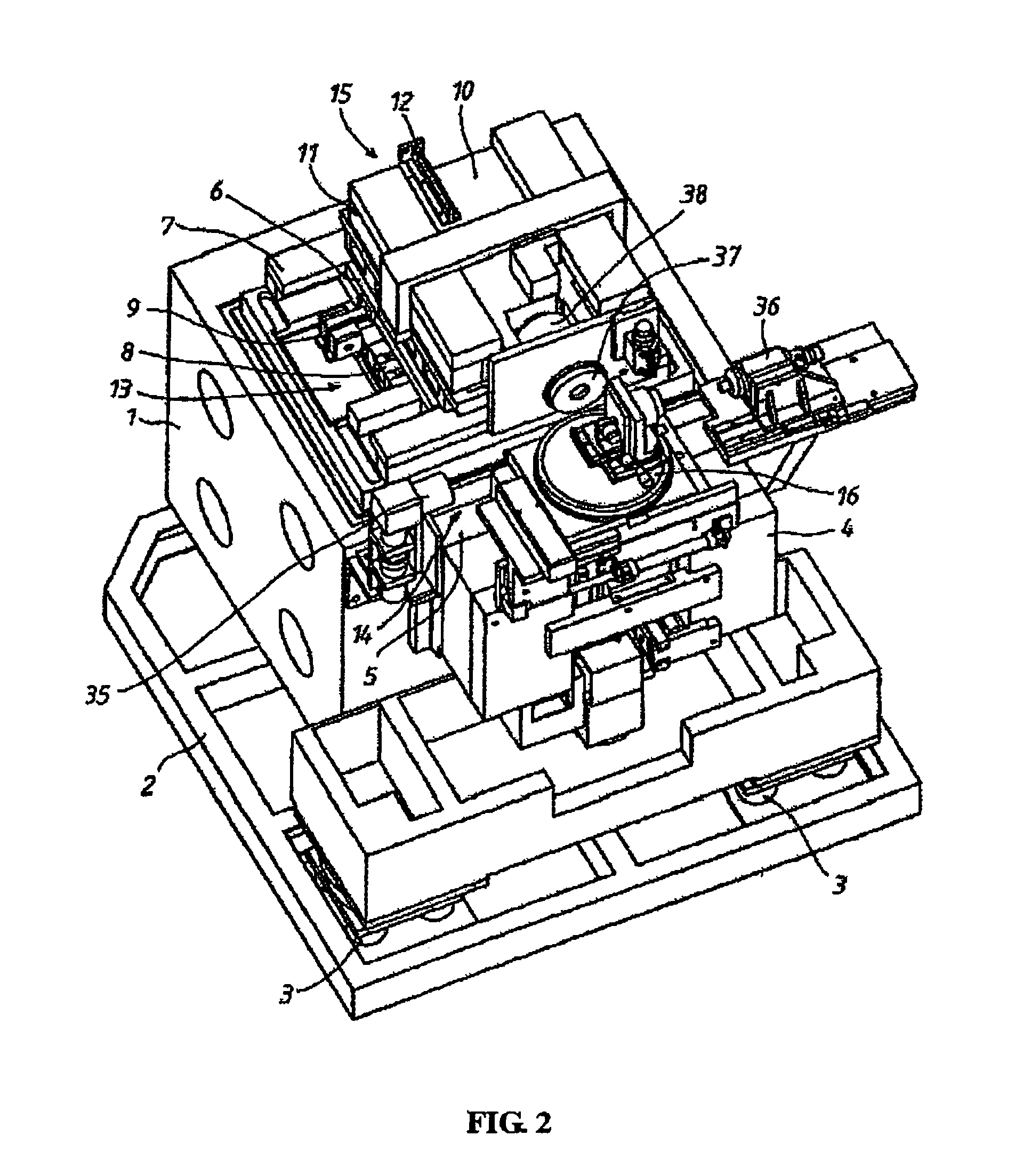

Hale-machining method and apparatus

InactiveUS7089836B2Easy to prepareHigh geometric accuracyLathesAutomatic/semiautomatic turning machinesRotary stageRotational axis

It is one object of a hale-machining method and apparatus thereof according to the present invention to achieve an easy preparation of an NC machining program and perform a high geometrical accuracy in the predetermined three-dimensional free curved surface.A haling tool 34 is set on a tool holder 32 in such a manner that a cutting point P of the haling tool 34 is substantially coincided with an intersection of a first rotating axis B, a second rotating axis A and a third rotating axis C. A rotary table 16 and a rotary base 24 are rotated in such a manner that a tool axis direction of said haling tool is substantially coincided with a normal direction of said machined surface. A tool holder 32 is rotated in such a manner that a front rake surface of the haling tool 34 is substantially directed in perpendicular to a feeding direction of said haling tool 34. A workpiece table holding a workpiece and the tool holder are relatively moved along a machined surface of said workpiece in three perpendicular axes including an axis parallel to said first rotating axis.

Owner:TOYODA MASCH WORKS LTD

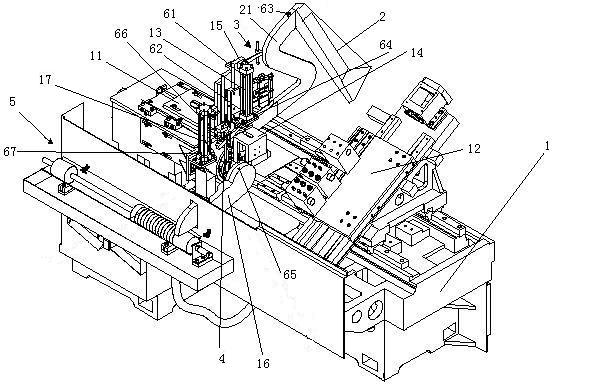

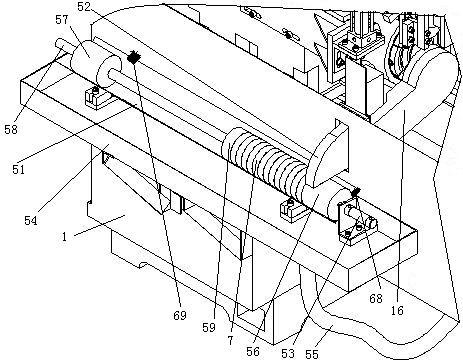

Fully automatic key duplicating machine with automatic key model identification system

ActiveUS8287215B2Reduce the required powerIncrease powerAutomatic/semiautomatic turning machinesMeasurement devicesEngineeringMaster key

A fully automatic key duplicating machine. A master key alignment module is movably disposed into and out of proximity with a master key clamping module, the master key being aligned by the alignment module within the master key clamping module. A master key identification module is disposed in fixed relation to the master key clamping module and identifies a type of key secured in the master key clamping module. A central positioning base is provided automatically movable into and out of engagement with the key cutting module and optionally the alignment module, adapted to move the master key alignment module into proximity with the master key clamping module and adapted to secure a key blank to be cut at the key cutting module in accordance with the tooth pattern of a clamped master key.

Owner:THE HILLMAN GRP INC

Machine for automatically processing bearing outer ring

InactiveCN102205425AReduce impactGood overall cutting performanceAutomatic/semiautomatic turning machinesMaterial distributionAutomation

The invention relates to a machine for automatically processing a bearing outer ring. The machine for automatically processing a bearing outer ring comprises a machine frame, an automatic elevator, a main shaft, a main motor for driving the main shaft, a chuck mechanism, a cutter block, a control device, a material feeding seat, a material ejection air cylinder for driving the material feeding seat, a material conveying oil cylinder for driving the material feeding seat and the material ejection air cylinder, a material loading channel, a stacking mechanism, a movable material unloading channel, and a material receiving air cylinder which drives the material unloading channel; a material distribution mechanism is arranged at the joint of the material loading channel and the material feeding seat; one end of the material loading channel which is butted with the material feeding seat is lower that the other end of the material loading channel; and one end of the material unloading channel which is butted with the chuck mechanism is higher than the other end of the material unloading channel. The invention provides the machine for automatically processing the bearing outer ring; in the machine, the processes from material loading to product stacking are all automated, and the machine has high processing efficiency; and the problems of low automation degree and processing efficiency during processing of the conventional bearing outer ring are solved.

Owner:ZHEJIANG KAIDA MACHINE TOOL

Increased contrast overhead projection films

InactiveUS6848795B2Increase contrastGood colorAutomatic/semiautomatic turning machinesLayered productsSheet filmPolymer

Disclosed is a projection media comprising a transparent polymer layer with random light diffusing elements and having a Tg of less than 75° C.

Owner:ROHM & HAAS DENMARK FINANCE

Machine Tool

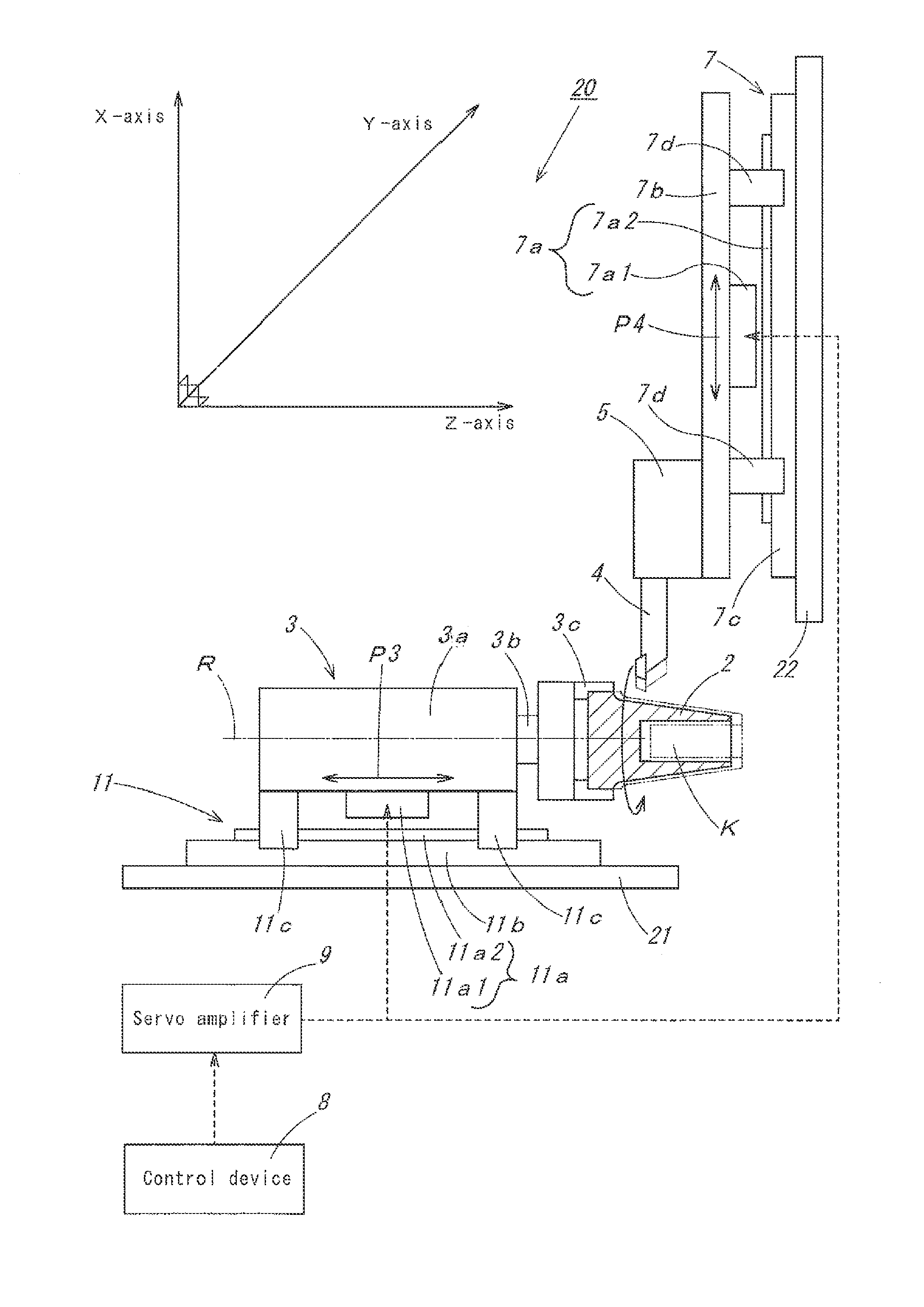

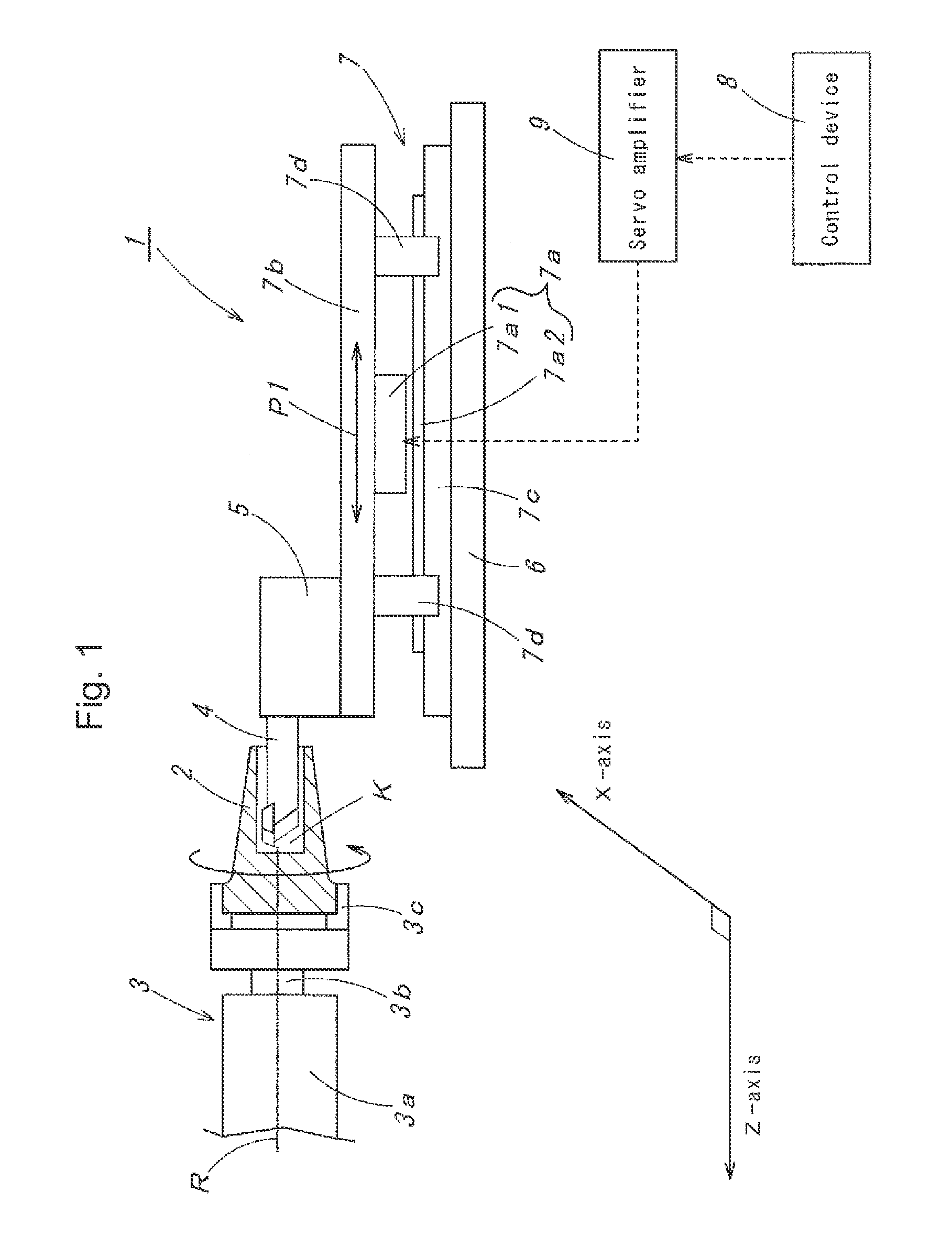

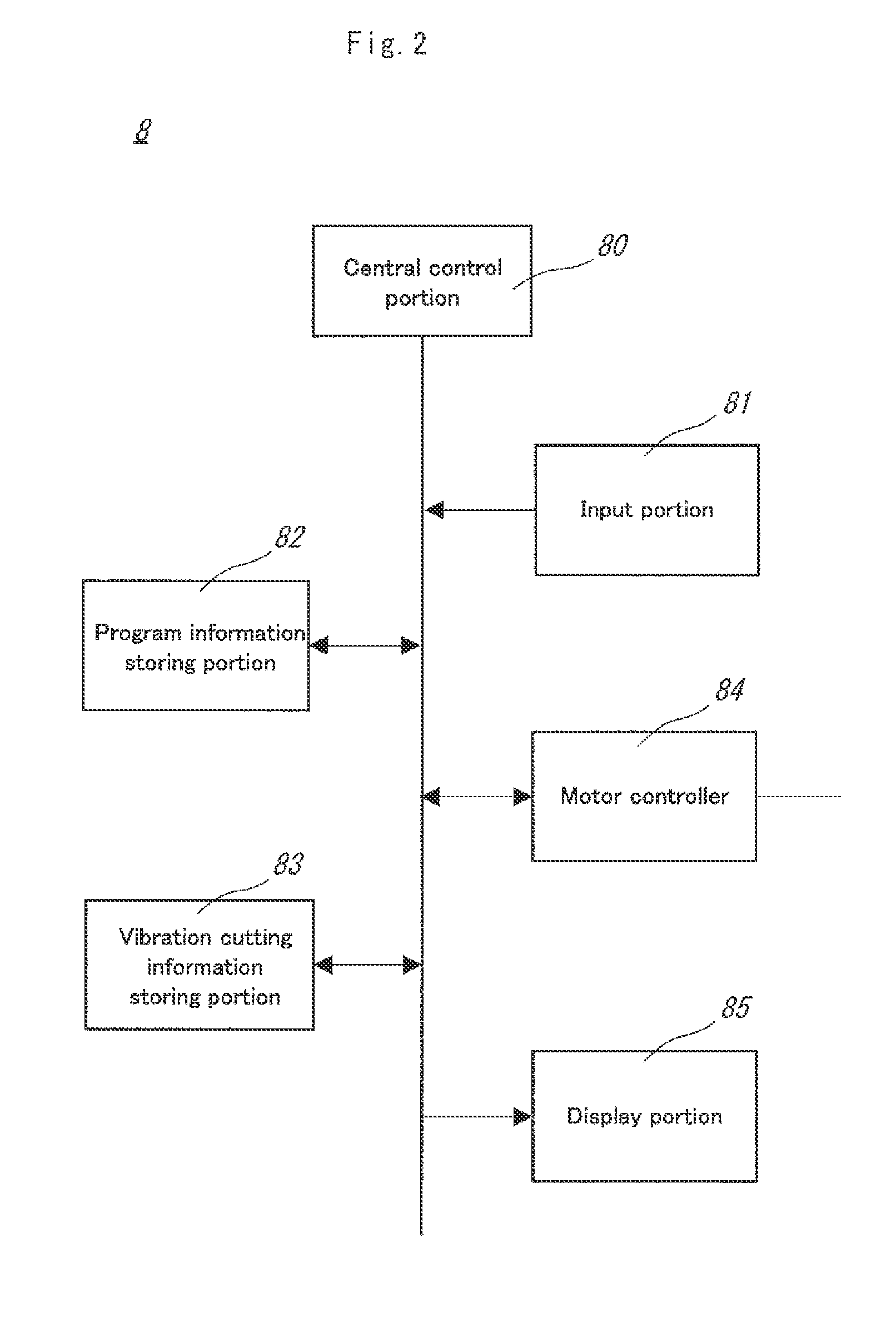

ActiveUS20140102268A1Improve vibrationReduce vibrationProgramme controlLathesMachine toolTool holder

A machine tool for machining a workpiece is provided with a cutting tool holder for holding a cutting tool and a rotation mechanism for holding the workpiece. One or both of the cutting tool holder and the rotation mechanism are movable on multiple axes so that the cutting tool is movable relative to the workpiece in multiple axial directions. A control device is provided for controlling the movement of one or both of the cutting tool holder and the rotation mechanism to synchronously vibrate the workpiece and the cutting tool relative to each other at a low frequency in multiple axial directions.

Owner:CITIZEN WATCH CO LTD

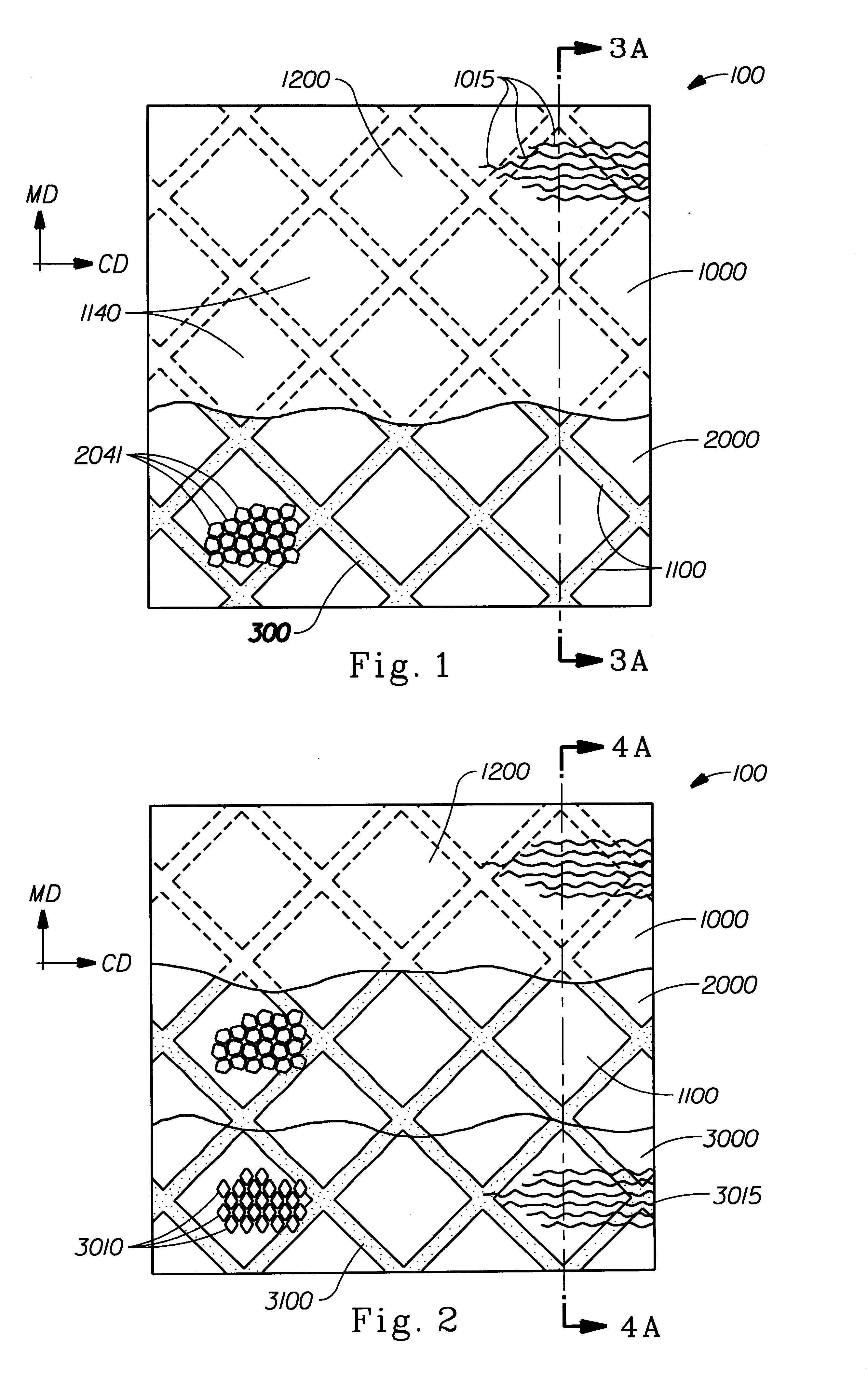

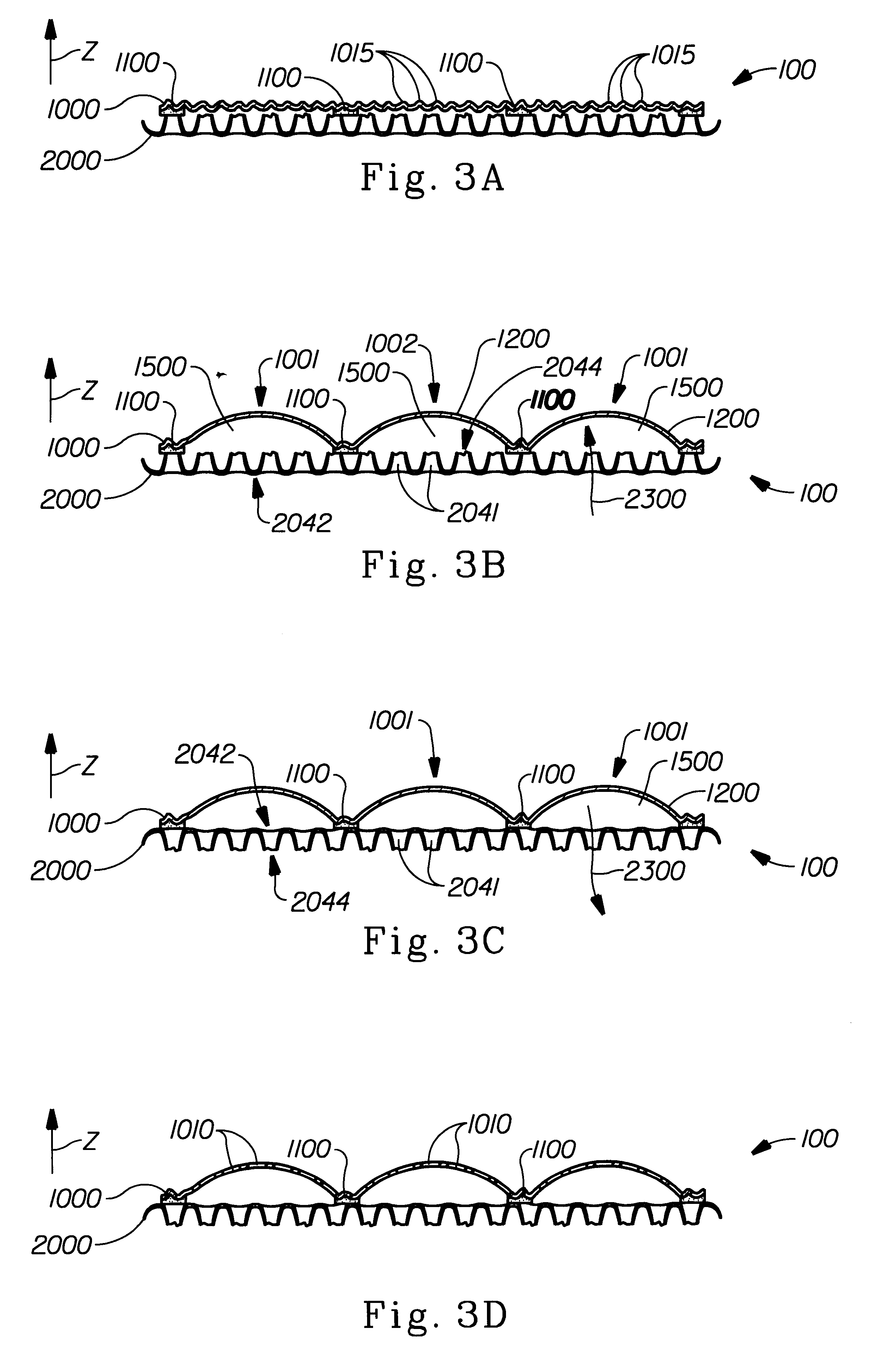

Multiple layer wipe

InactiveUS6270875B1Cosmetic preparationsAutomatic/semiautomatic turning machinesEngineeringCellulose fiber

A disposable wiping article is disclosed having at least a first layer and a second plastic film layer. The first layer has a wet extensibility greater than that of the second, layer. The first layer can be a dry creped web of cellulosic fibers, and the second layer can be an apertured, three dimensional plastic film. Selected portions of the first layer are bonded to the second layer to inhibit wet extension of the first layer in the plane of the first layer. In one embodiment, the wiping article comprises a third layer which can be a dry creped, apertured web of cellulosic fibers having a wet extensibility greater than that of the second layer. The second plastic film layer is disposed between the first layer and the third layer and inhibits wet extension of both the first and third layer when wetted.

Owner:THE PROCTER & GAMBLE COMPANY

Machine tool

InactiveUS7266871B2Improve support stiffnessImprove machining accuracyAutomatic/semiautomatic turning machinesTurning toolsEngineeringHeadstock

To provide a machine tool in which supporting stiffness of a tool post is increased, thereby enabling improvement in machining accuracy. When seen in a Z-axis direction, a tool post 5 includes: a supporting member 30 having a pair of left and right leg parts 30a, 30a and an upper beam part 30b coupling at least upper ends of the both leg parts 30a with each other; and a turret 31 to whose outer circumferential portion a plurality of tools are attached. The supporting member 30 is supported to be movable in a Z-axis direction between a first and a second spindle headstock 3, 4, and the turret 31 is supported to be movable in an X-axis direction by turret guide rails 33, 33 which are disposed on front faces of the left and right leg parts 30a, 30a.

Owner:DMG MORI CO LTD

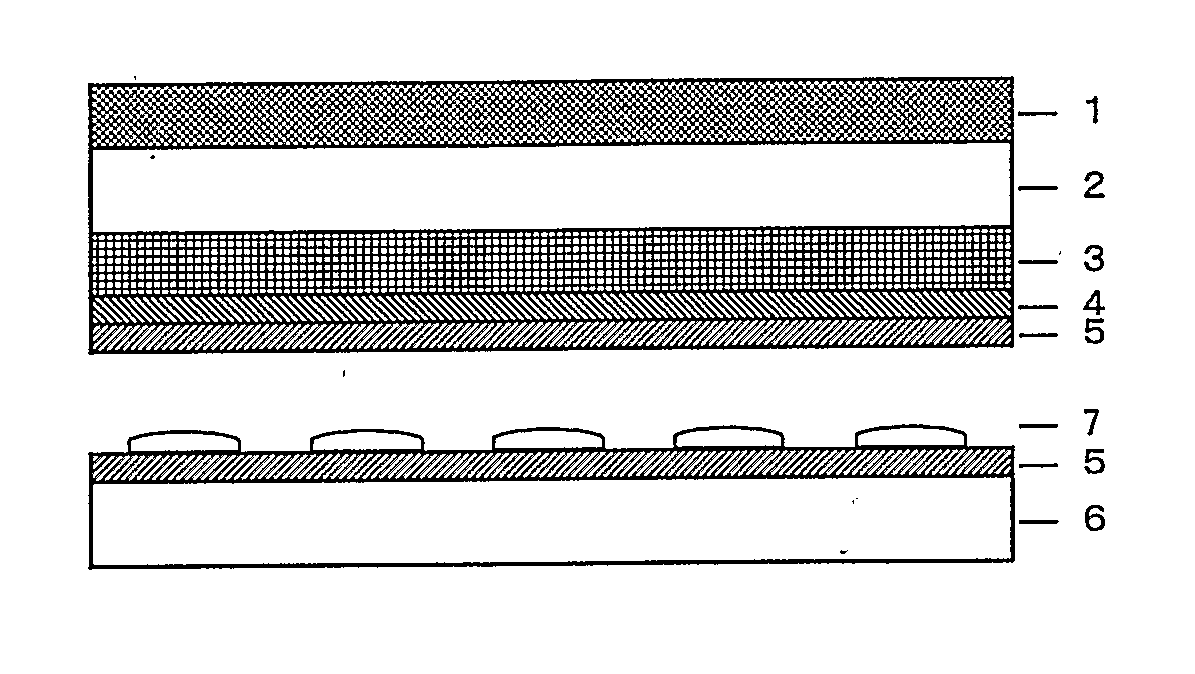

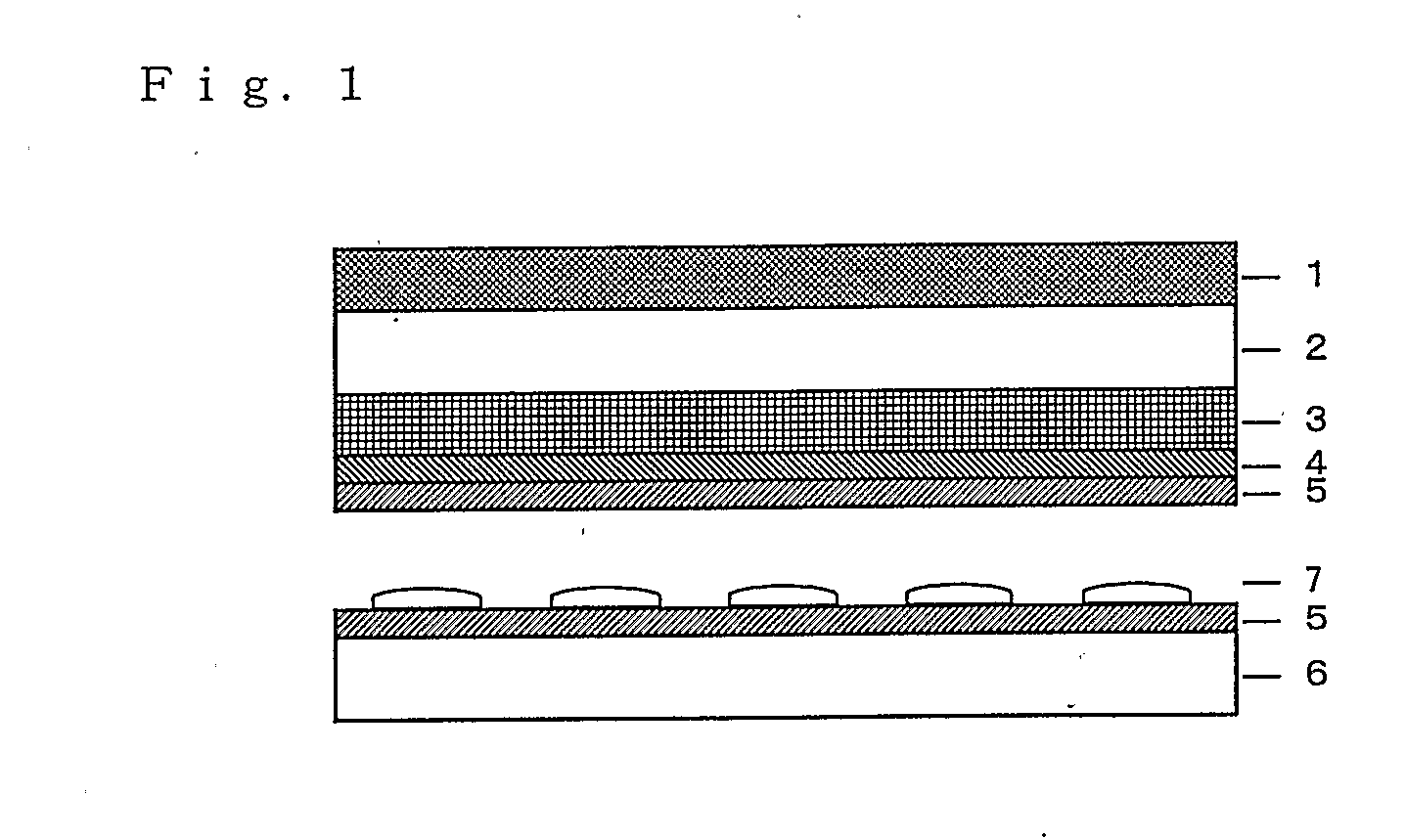

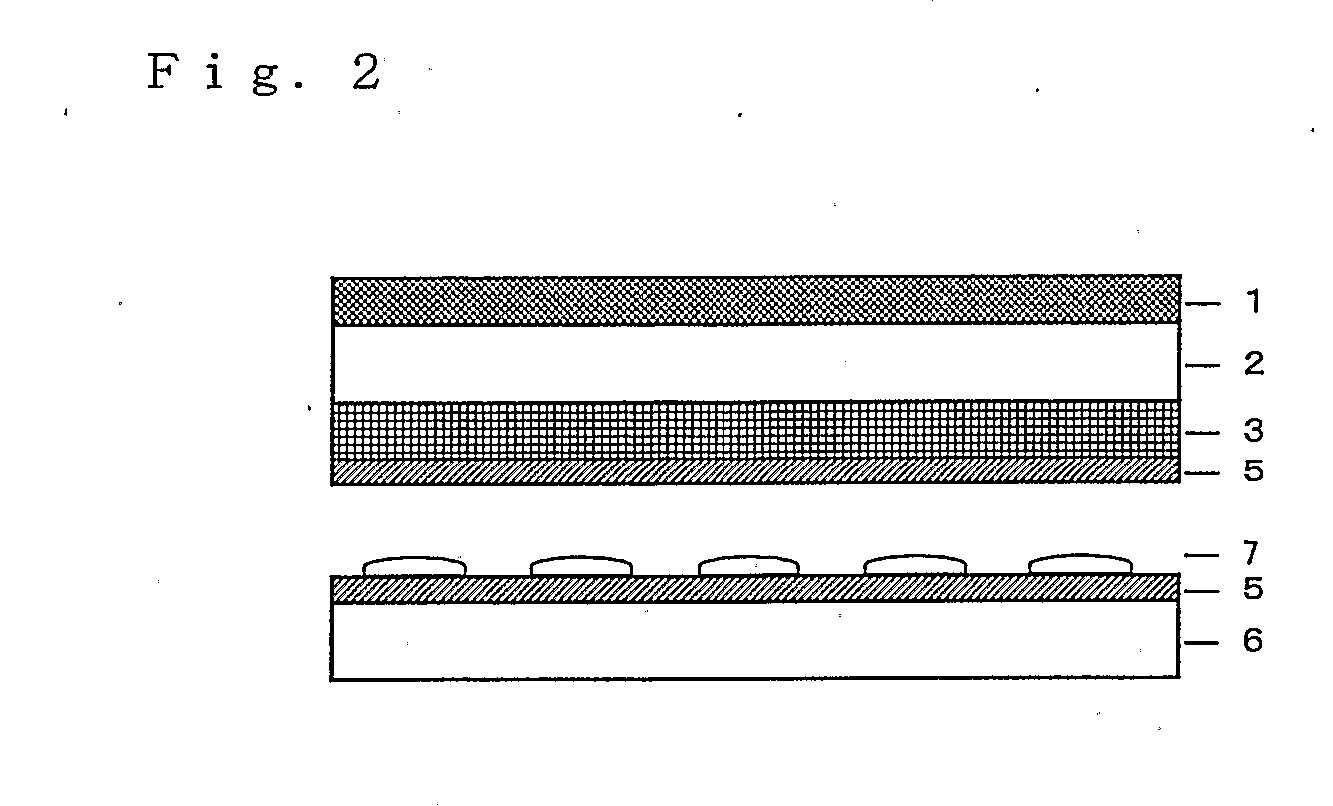

Transparent Conductive Laminated Body and Transparent Touch-Sensitive Panel

InactiveUS20070224412A1Add flexiblyAutomatic/semiautomatic turning machinesConductive layers on insulating-supportsOptoelectronicsPolymer

A transparent conductive laminated body (1) contains a polymer film having a metallic compound layer and a transparent conductive layer laminated sequentially on at least one surface thereof, (2) the metallic compound layer is in contact with the transparent conductive layer, and (3) the metallic compound layer has a thickness of 0.5 nm or more and less than 10.0 nm.

Owner:TEIJIN LTD

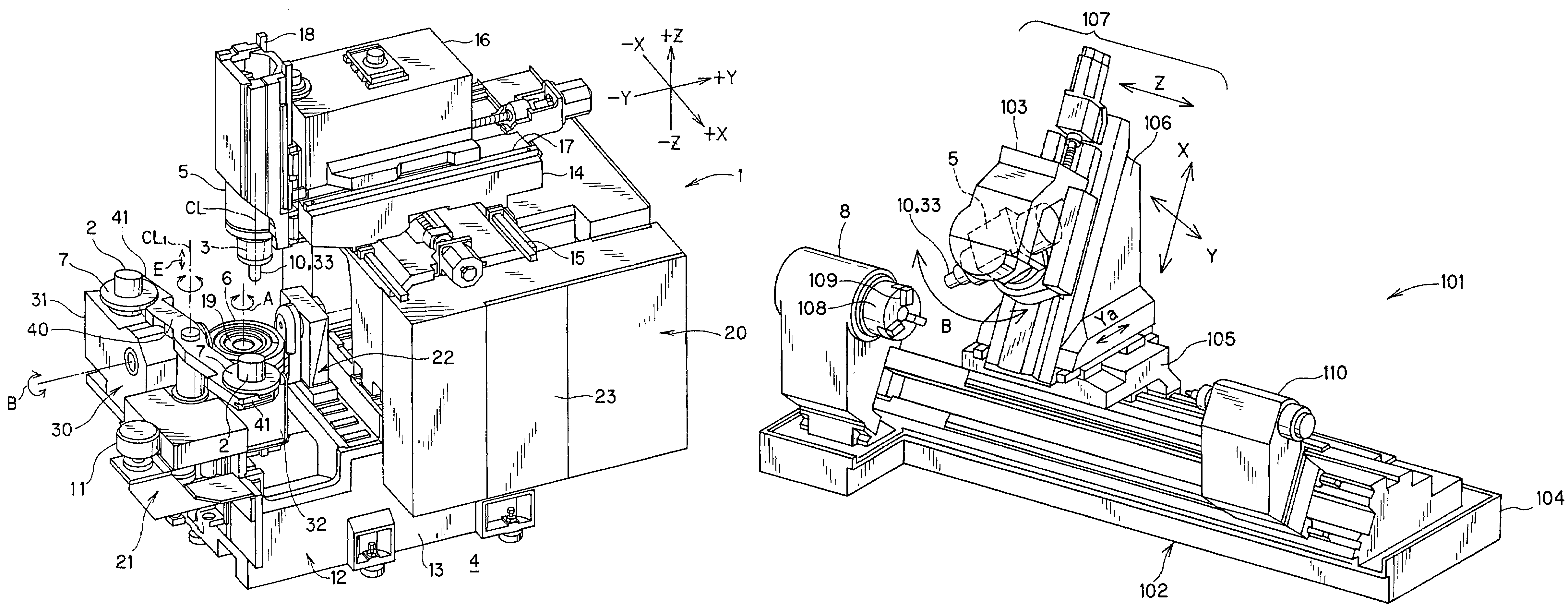

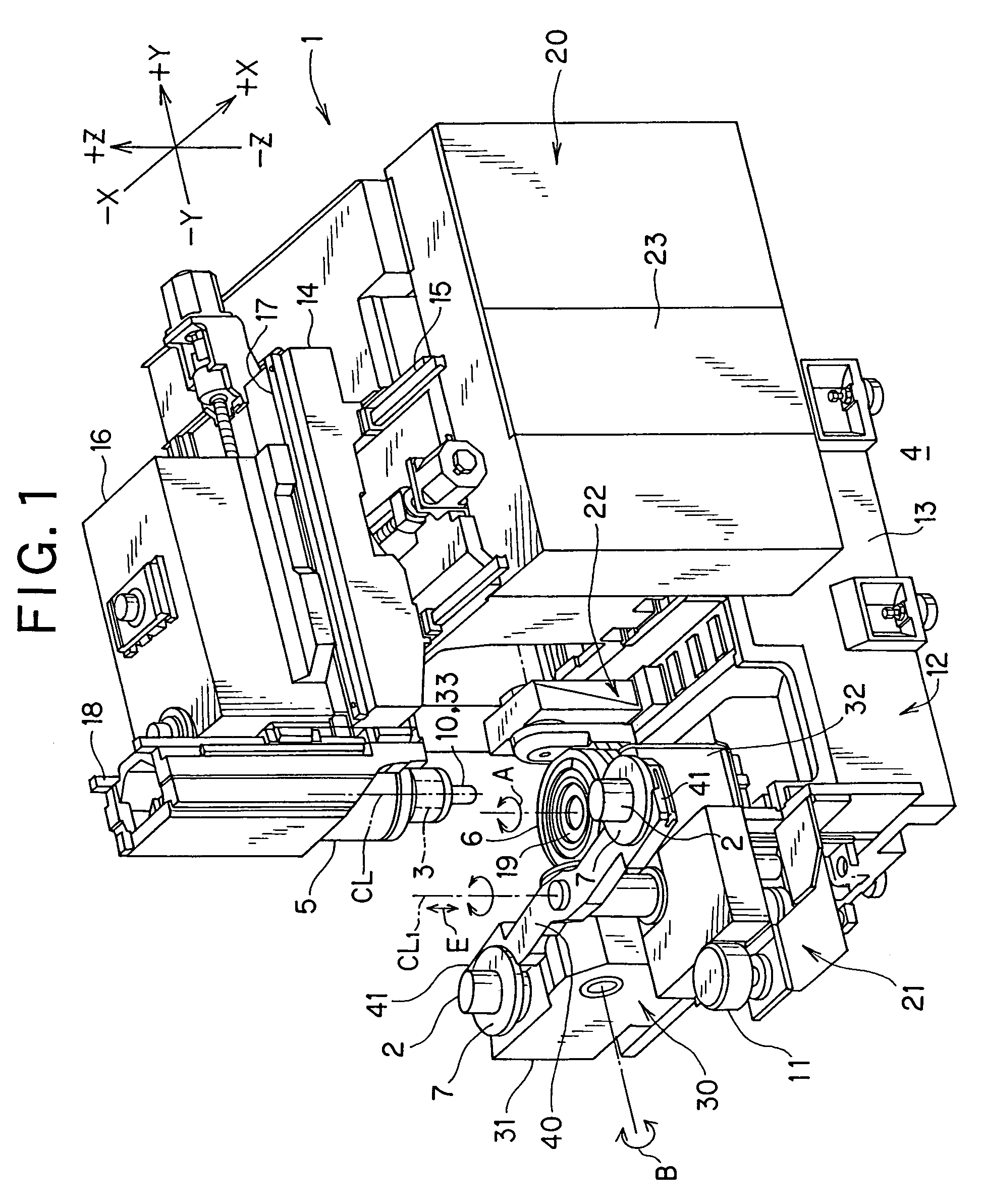

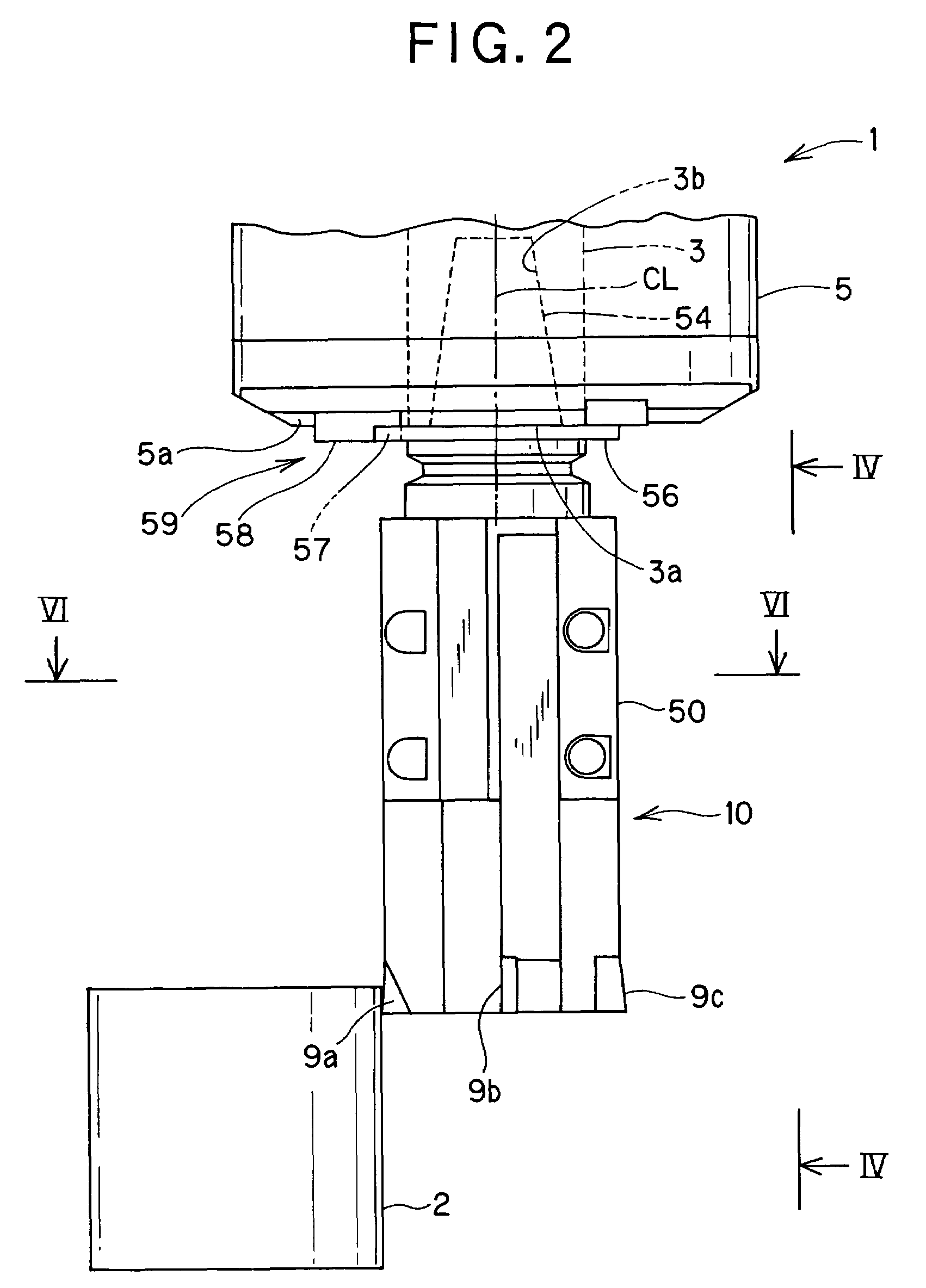

Multi-axis turning center and turning method

InactiveUS7506423B2Improve rigidityLathesAutomatic/semiautomatic turning machinesTransverse axisMulti axis

A multi-axis turning center has a spindle head, a spindle rotatably supported by the spindle head, and a table or a headstock for gripping and rotating a workpiece thereon. The table or the headstock is disposed in confronting relation to the spindle. The spindle head is relatively movable in the three mutually transverse axes directions to the workpiece gripped and rotated by the table or the headstock. A multi-point turning tool is mounted on the spindle and having a plurality of tips, for turning the workpiece gripped and supported by the table or the headstock. The spindle head is movable to translate the multi-point turning tool to one of positions around the workpiece, and the tips are selectively used depending on the one of the positions to turn the workpiece.

Owner:DMG MORI CO LTD

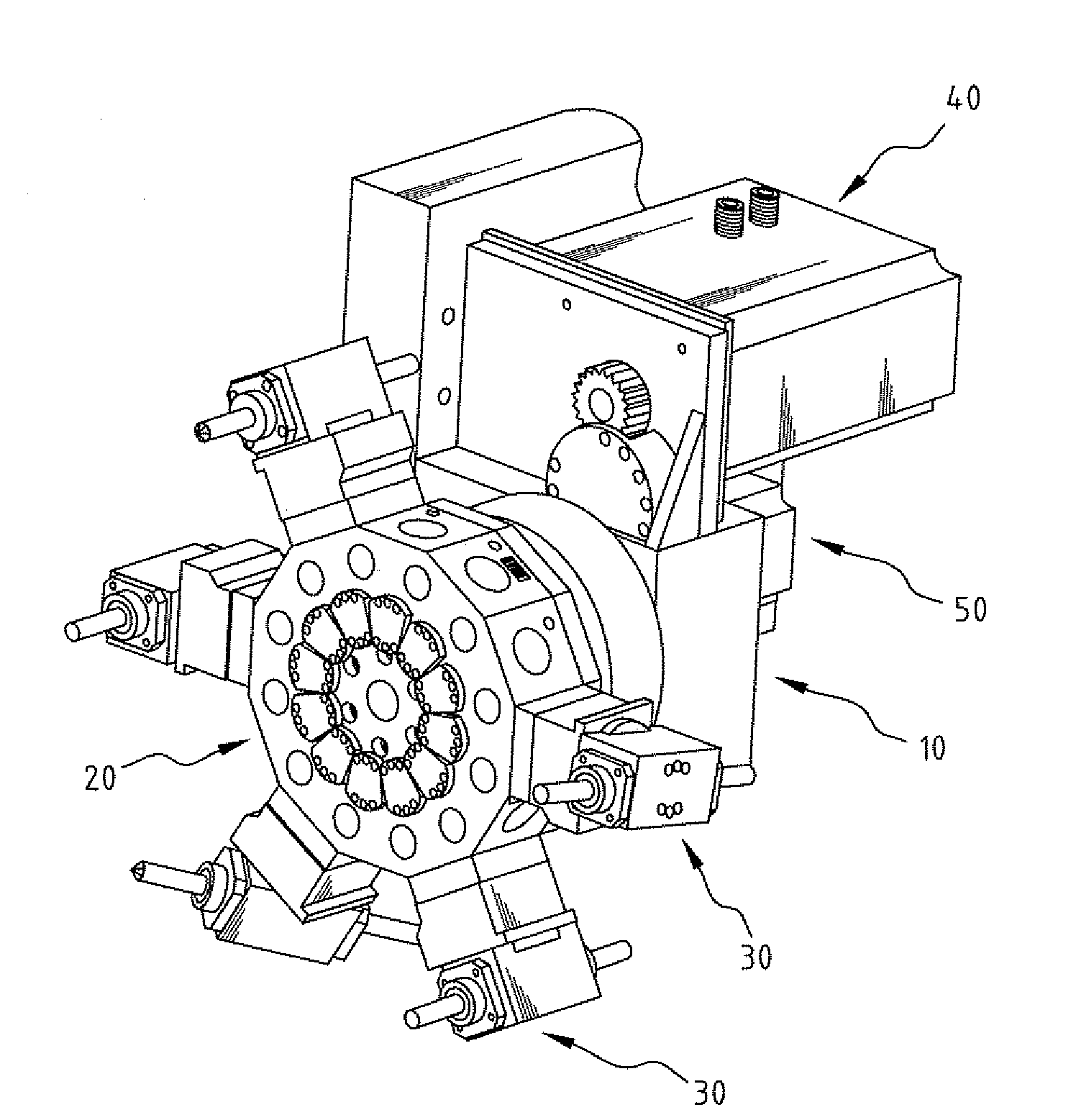

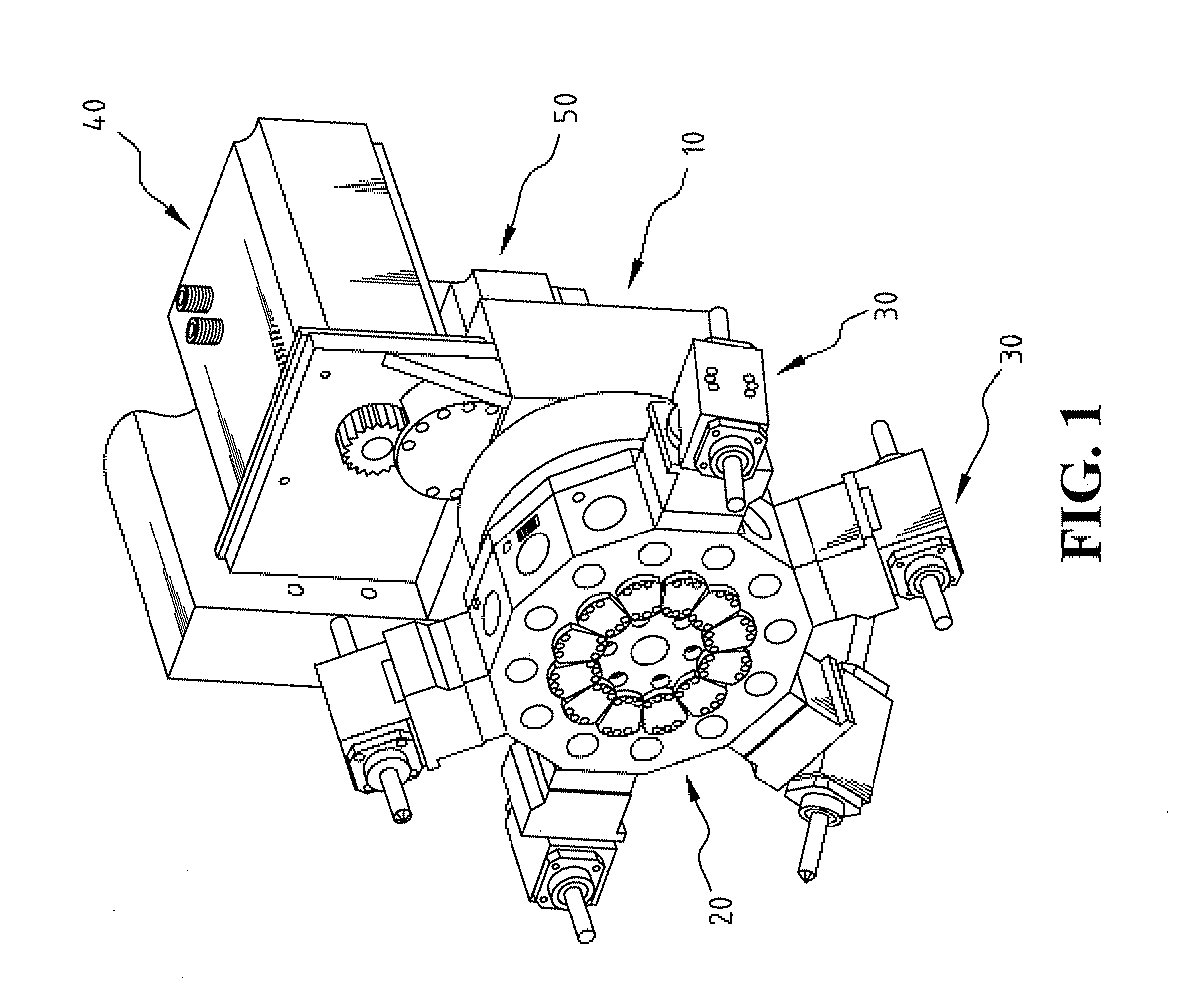

Rotational power servo toolpost

InactiveUS7395589B1Limited rangeWork lessAutomatic/semiautomatic turning machinesMachine tool componentsTurretTool holder

A rotational power servo toolpost includes a plurality of rotational tool holders, which can freely rotate 360 degrees, to cut a workpiece from various angles. The rotational power servo toolpost has a turret base, a turret, tool holders mounted on a side surface of the turret and having a variety of needed tools, a tool-holder-rotating device, and a tool-rotating device. When the tool holder with the needed tool rotates along with the turret to the preset area, a servo motor of the tool-holder-rotating device drives the related members to freely rotate the tool holder around 360 degrees according to the machining requirements. The tool-driving device then drives the tool, thereby cutting the workpiece from various angles.

Owner:KUO CHING HUI

Surface-coated cutting tool

ActiveUS20140193623A1Excellent effect of preventingImprove wear resistanceMilling cuttersVacuum evaporation coatingWear resistantCrystal structure

A surface-coated cutting tool according to the present invention is a surface-coated cutting tool including a base material and a coating film formed on the base material, wherein the coating film includes at least a wear-resistant layer and an adhesion-resistant layer, the wear-resistant layer has a multilayer structure in which an A layer of a nitride containing Ti and Al as well as a B layer of a nitride containing Al and Cr are alternately stacked, and has a cubic crystal structure, and the adhesion-resistant layer is located at an outermost surface of the coating film, is composed of a nitride expressed by (AlaCrbTi1-a-b)N (wherein a+b<0.99, b>0.01, and 0.2b+0.7<a), and has a wurtzite-type crystal structure.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Composite lathe

InactiveUS20060236514A1Reduce supportImprove machinabilityAutomatic/semiautomatic turning machinesTurning toolsEngineeringMachinability

To provide a composite lathe enabling the overlapping of movement areas without lowering supporting stiffness of a tool post, and thus realizing enhanced machinability. An XY supporting plane A by which a tool post 5 in is supported to be movable in an X-axis direction is set non-parallel to an XZ supporting plane B by which a third spindle 6 is supported to be movable in the X-axis direction, and an axis of the movement in the X-axis direction of the tool post 5 is set apart in a Y-axis direction from an axis of the movement in the X-axis direction of the third spindle 6.

Owner:DMG MORI CO LTD

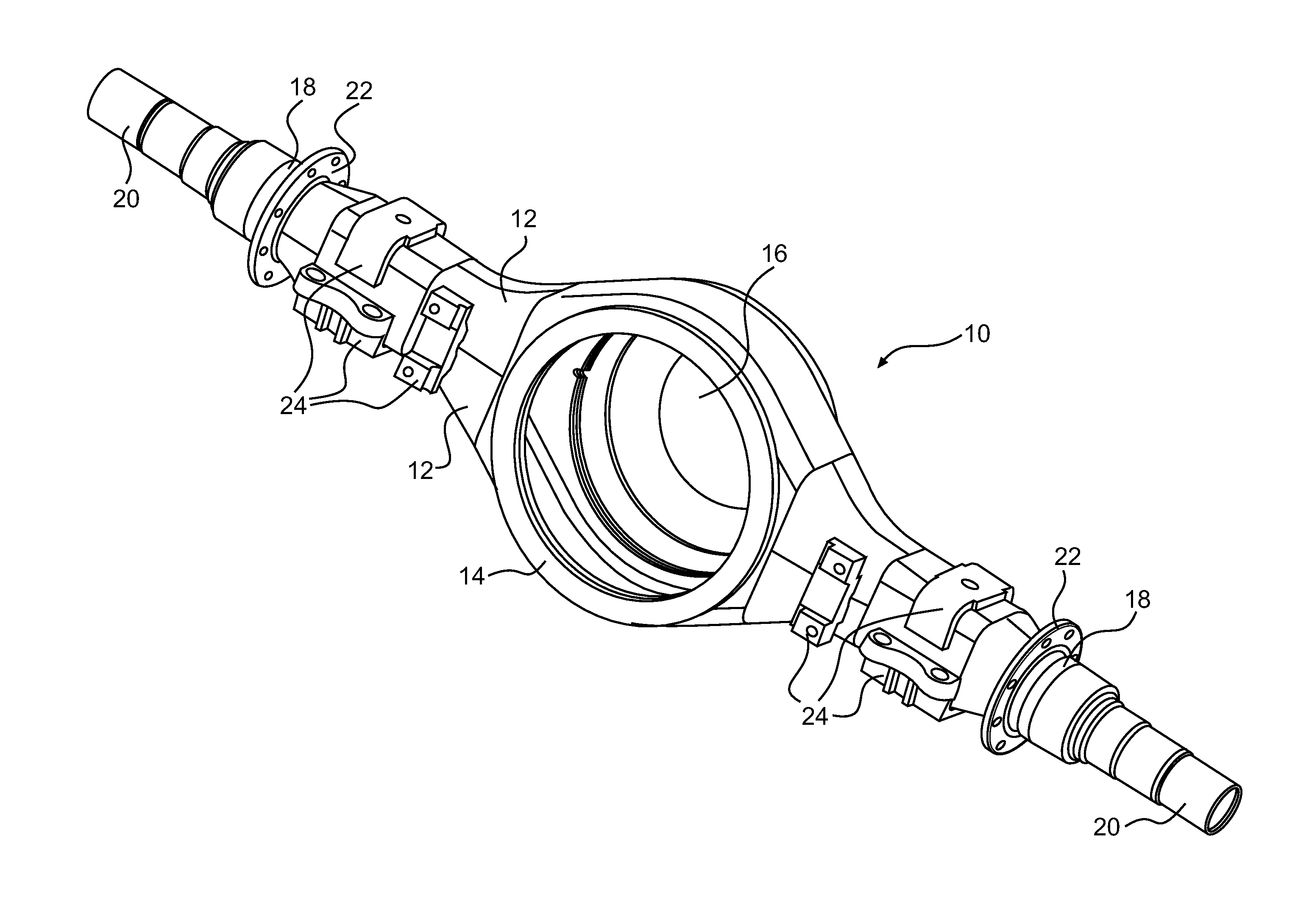

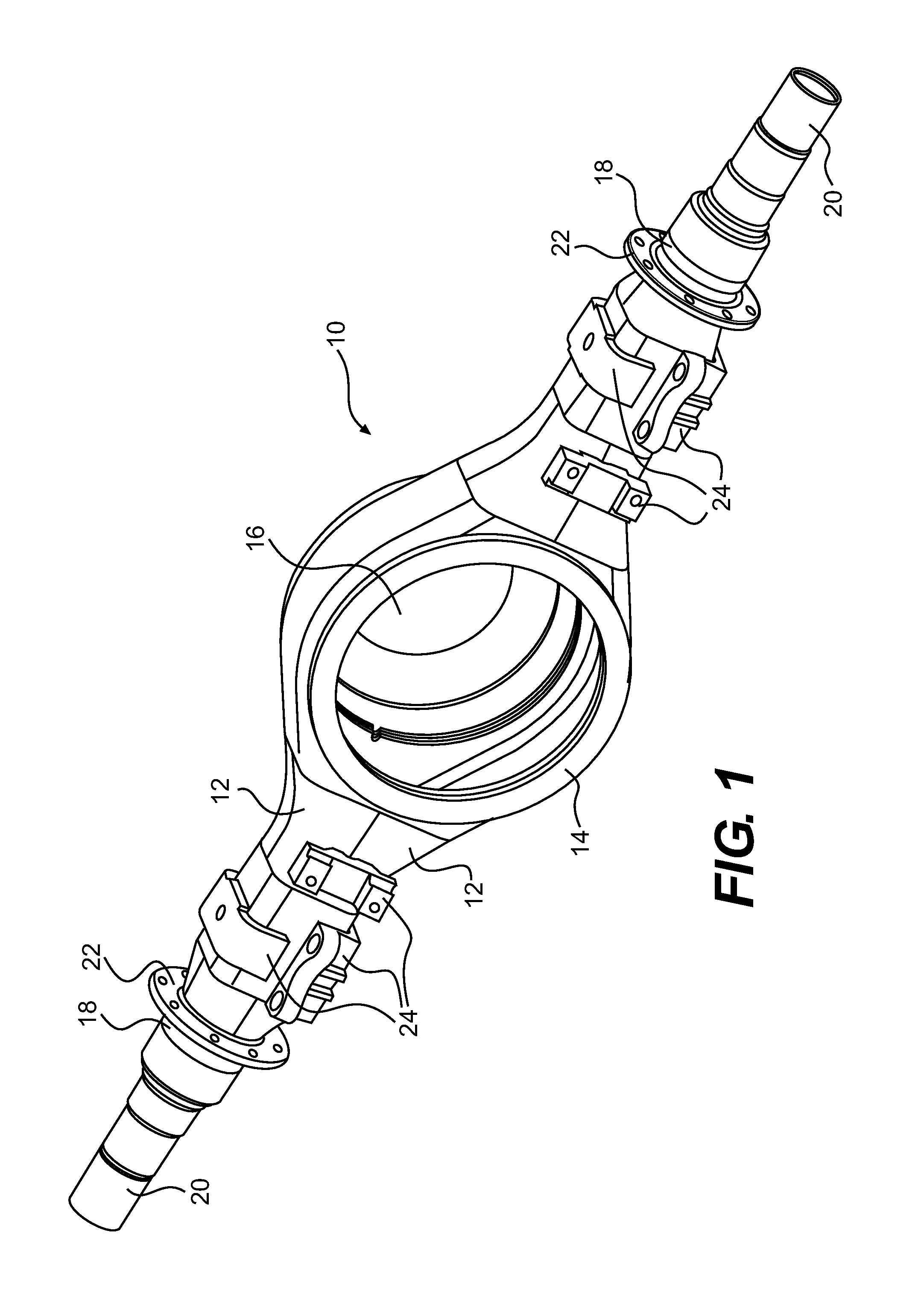

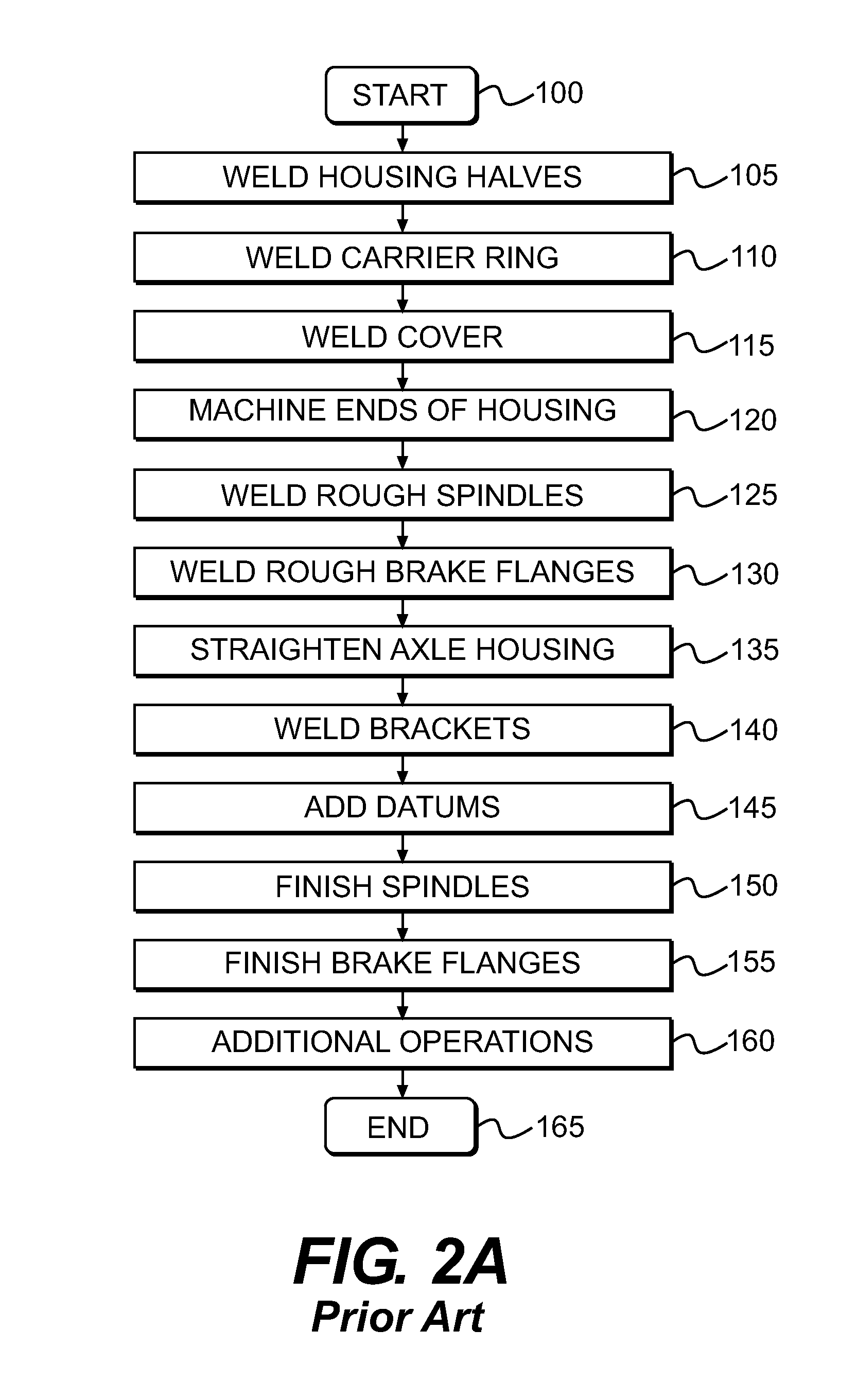

Method and apparatus for manufacturing an axle for a vehicle

ActiveUS20110265330A1Precise alignmentLow costAutomatic/semiautomatic turning machinesElectric heatingFlangeAutomotive engineering

A datum is created in an axle housing. A finished brake flange is welded to the axle housing with reference to the datum to make an axle sub-assembly. The axle sub-assembly is fixed to a first part of a machine. A finished spindle is supplied to a second part of the machine. The spindle is welded to the axle sub-assembly with reference to the datum. A dial indexing table is rotated to a first position. An axle is placed on the dial indexing table with its longitudinal axis oriented vertically. The dial indexing table is rotated to a second position, wherein the axle aligned with a CNC machine. A machining operation is performed on the axle with the CNC machine. The dial indexing table is rotated to a third position. The axle is removed from the dial indexing table. An axle and an apparatus for manufacturing an axle are described.

Owner:TRIMTOOL LTD

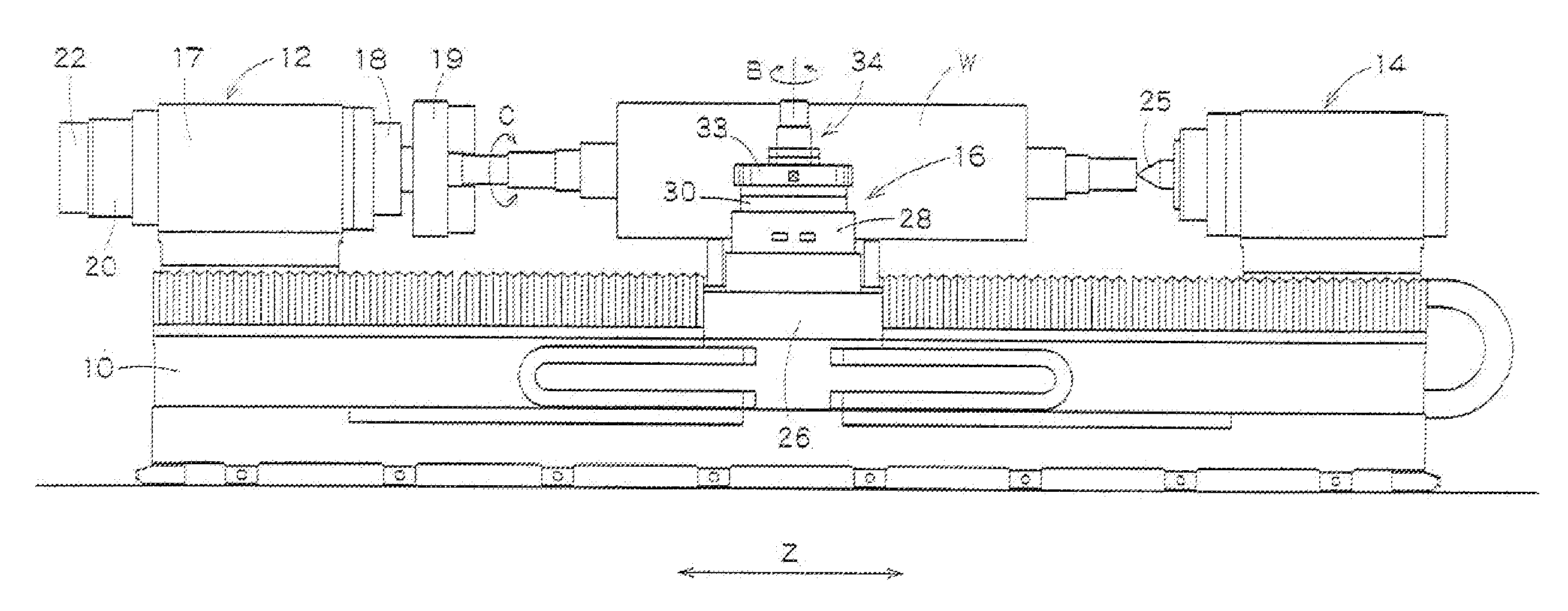

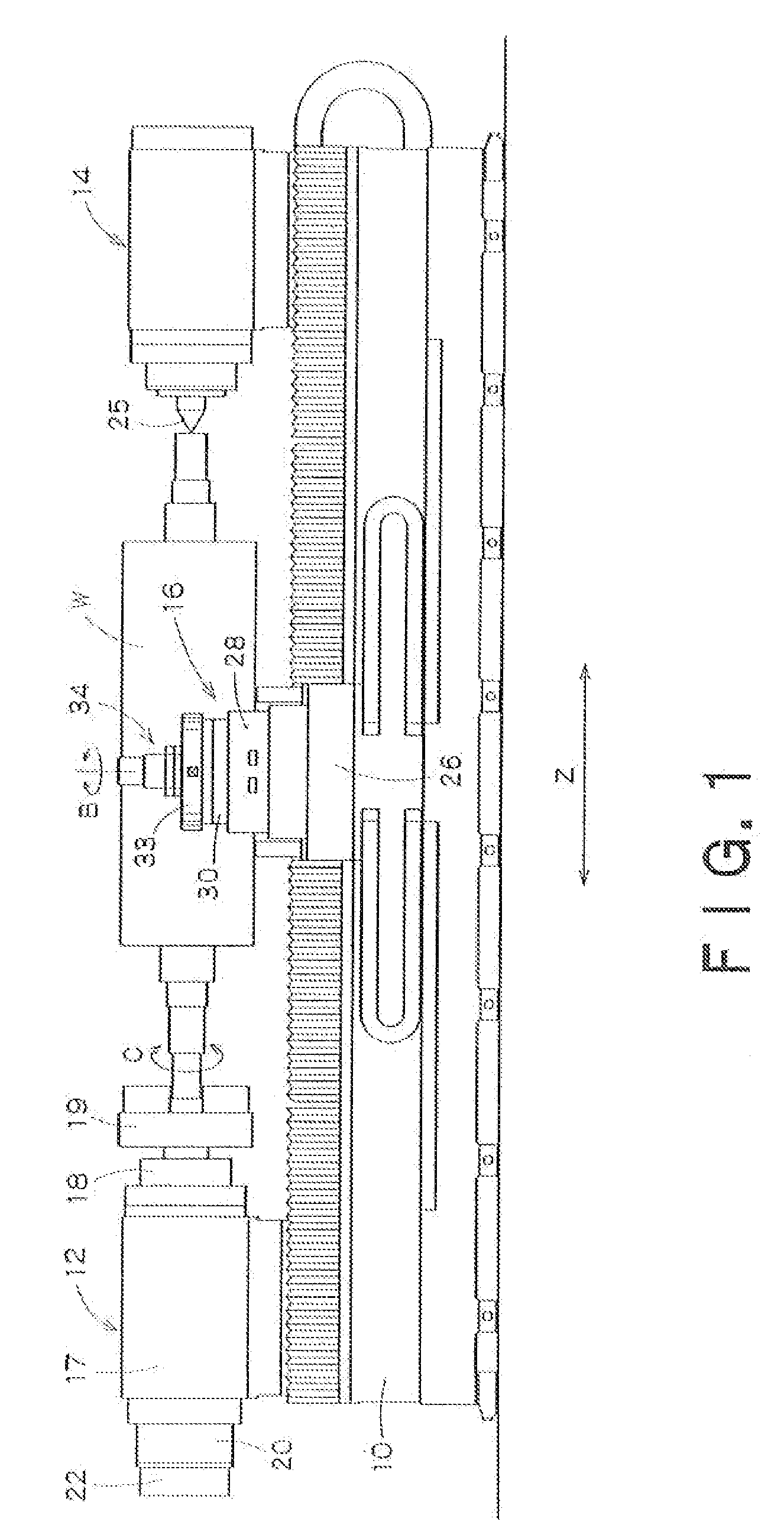

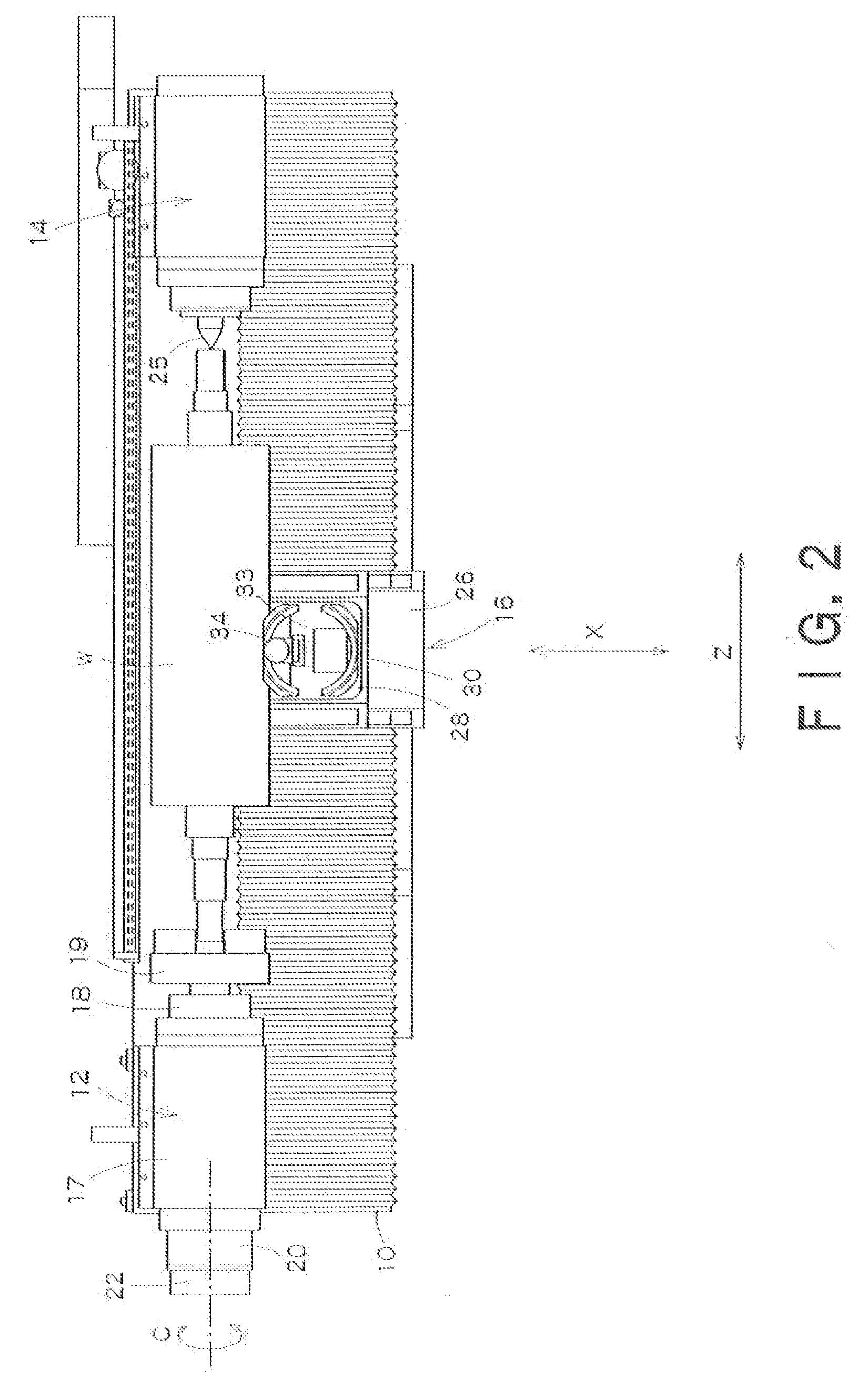

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com