Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about "Geometric arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

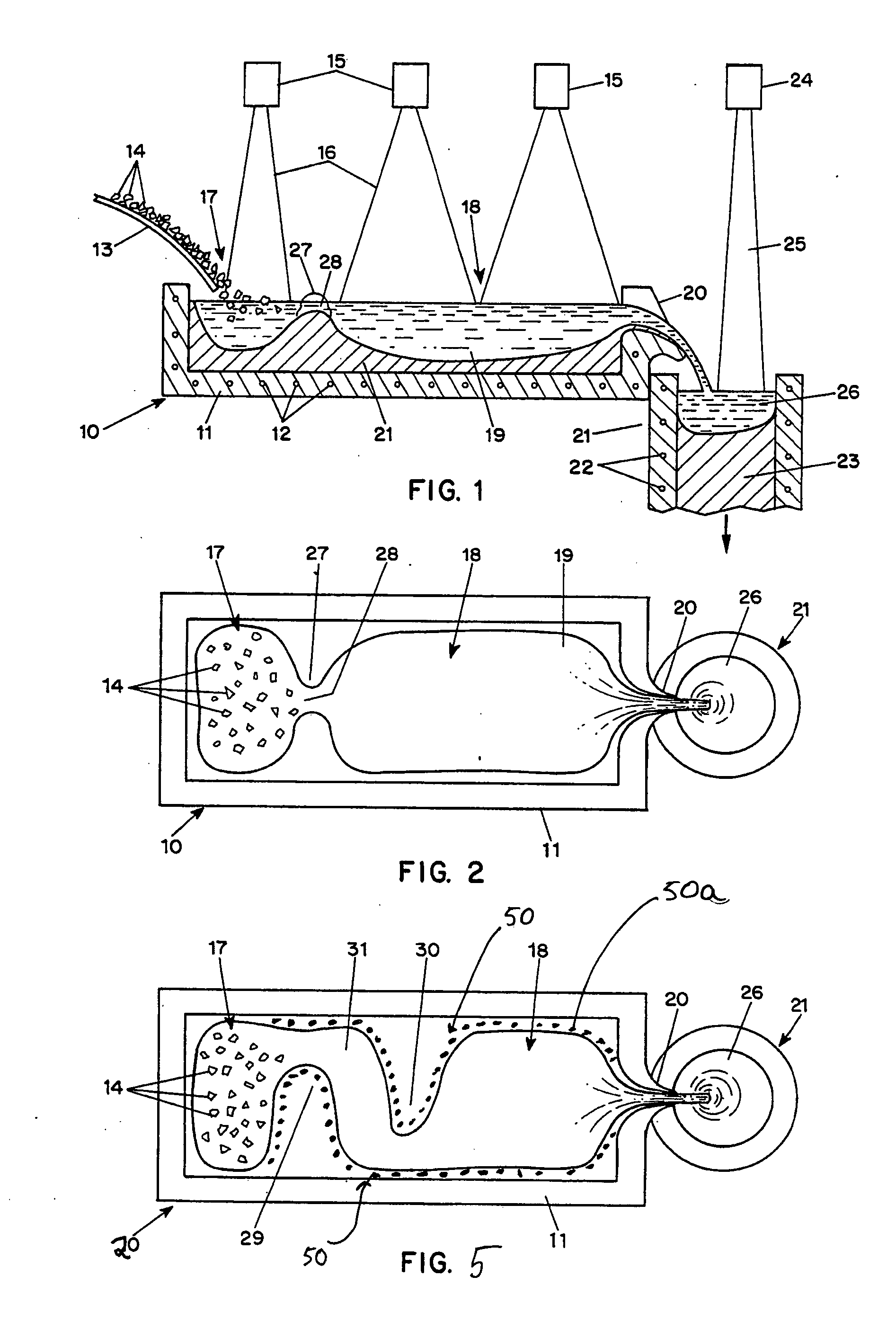

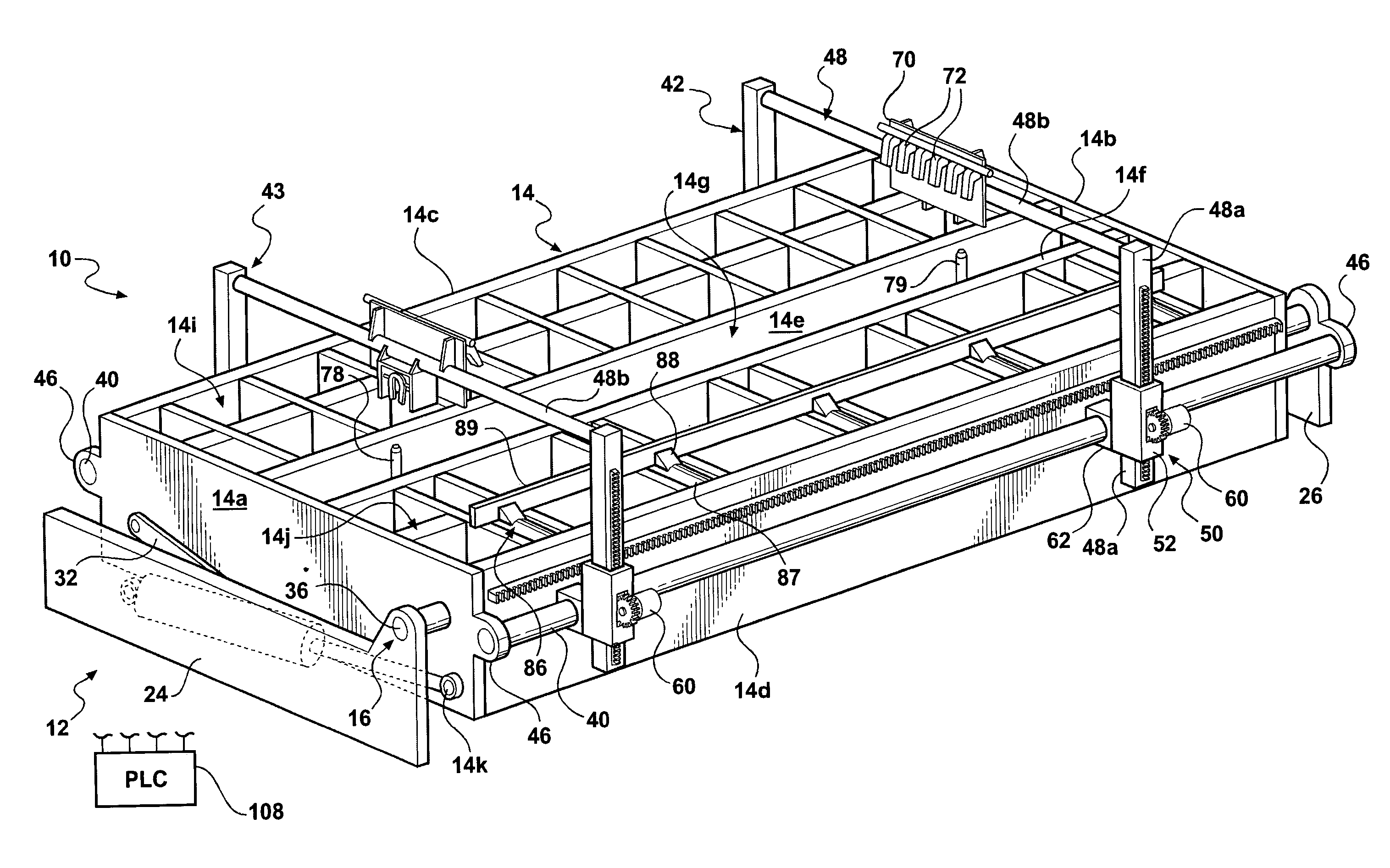

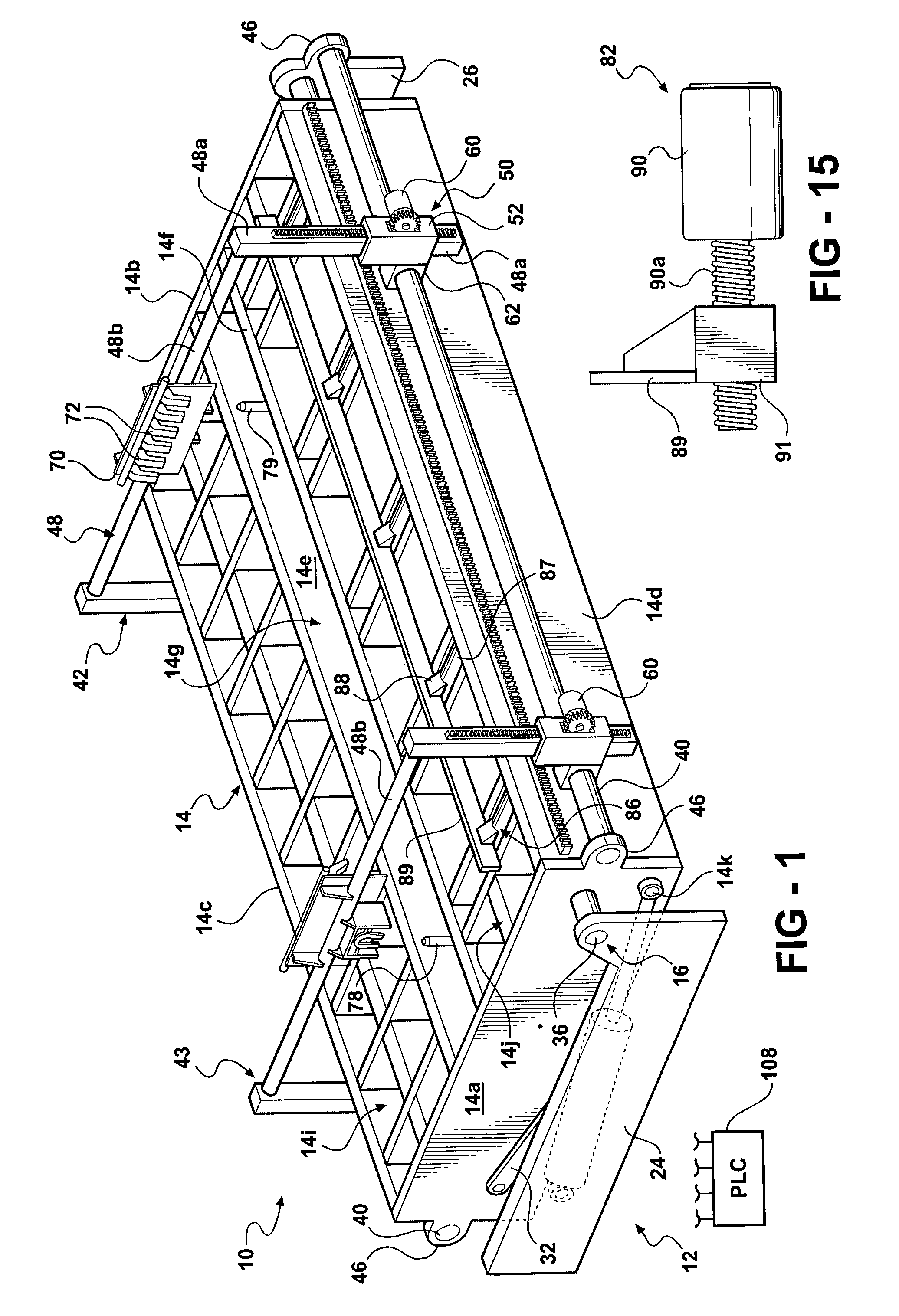

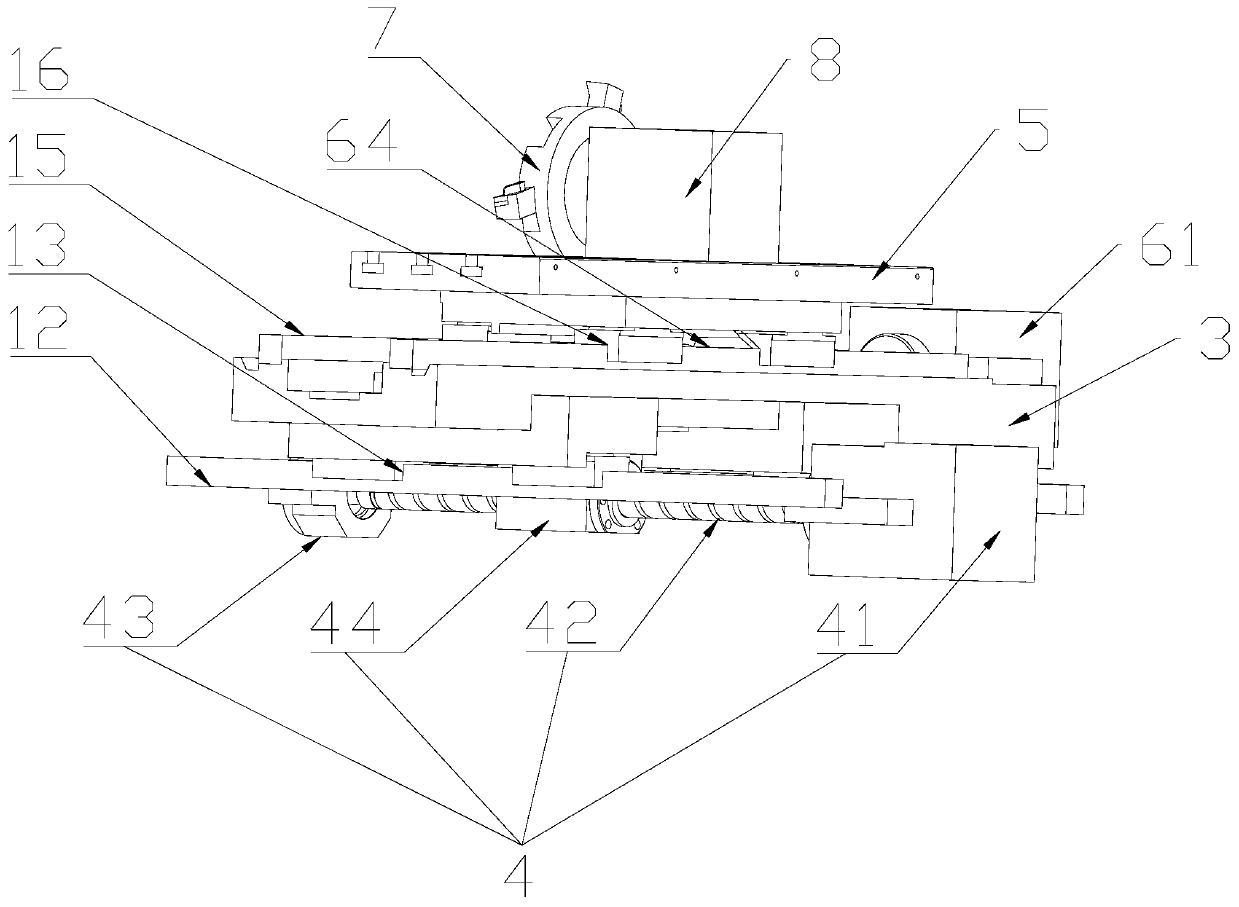

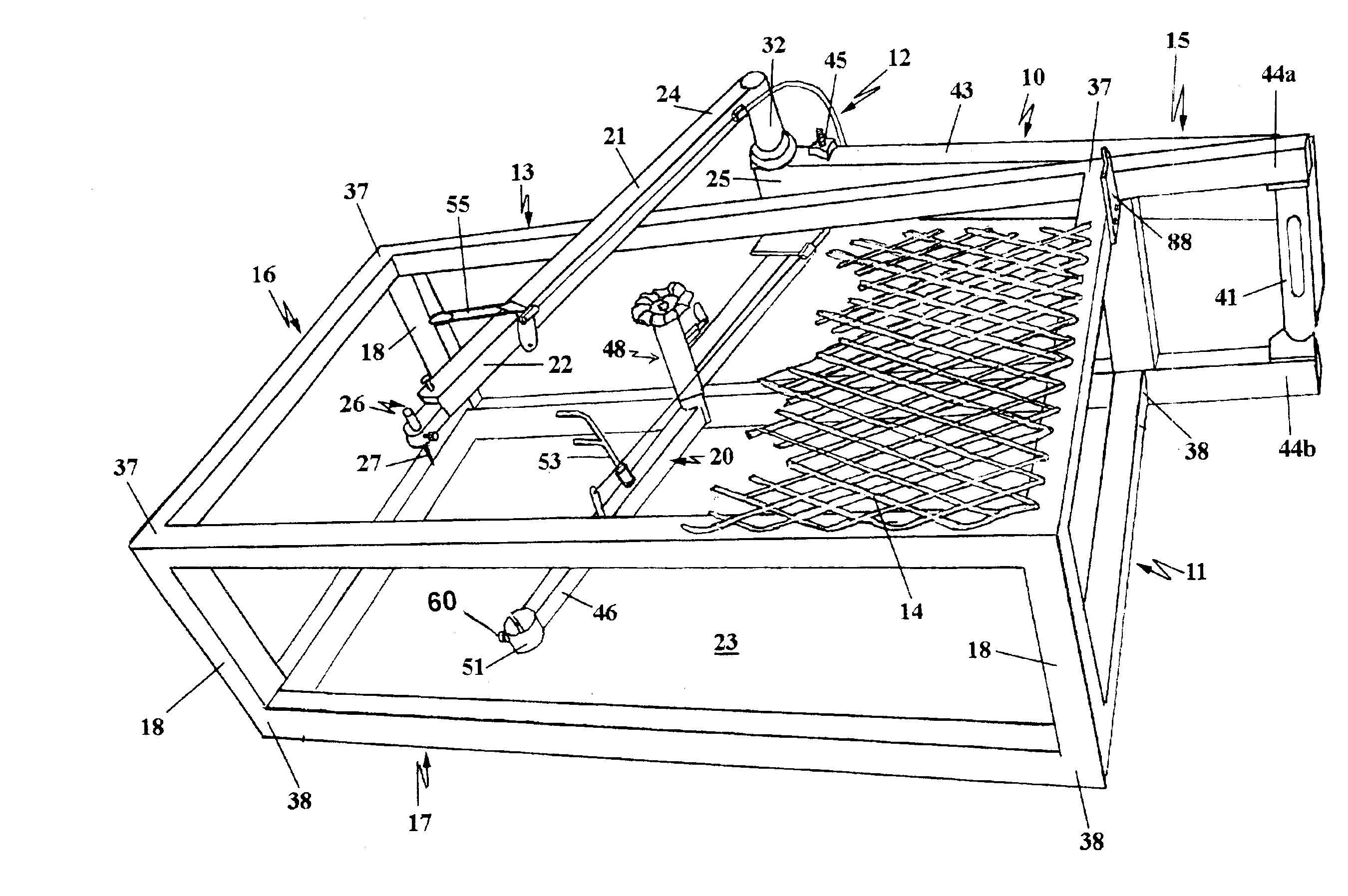

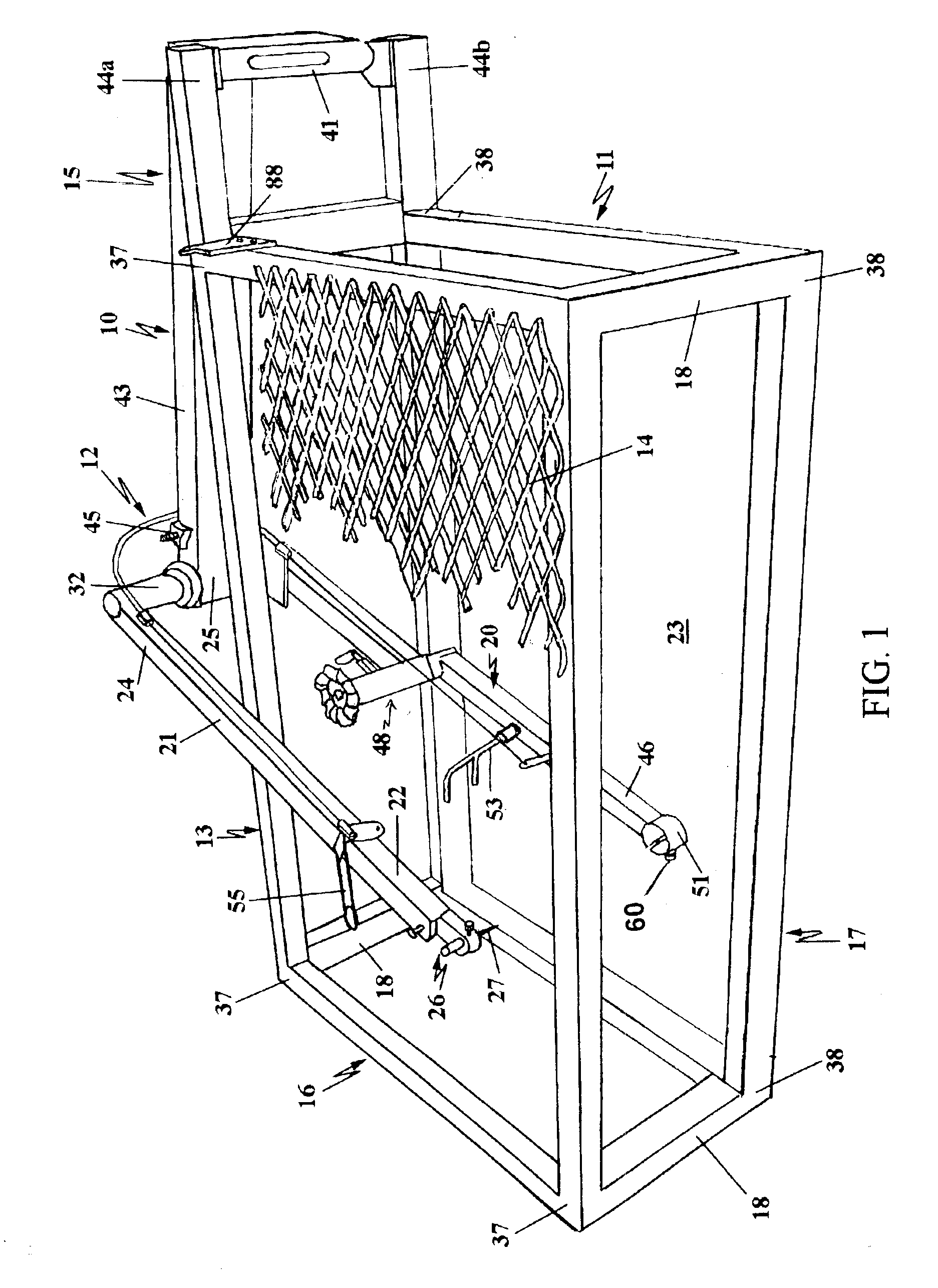

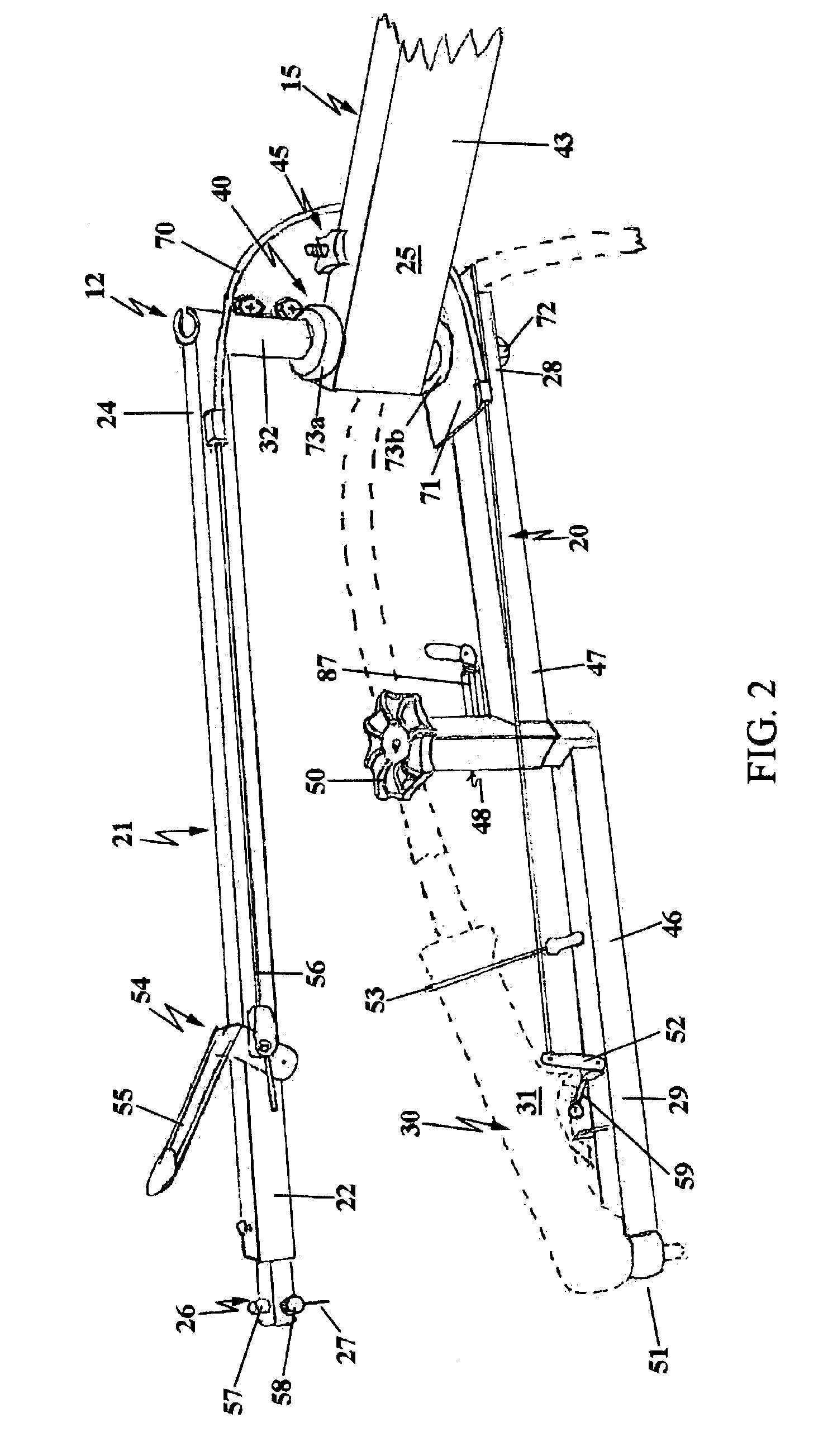

Method and apparatus for slitting steel slabs

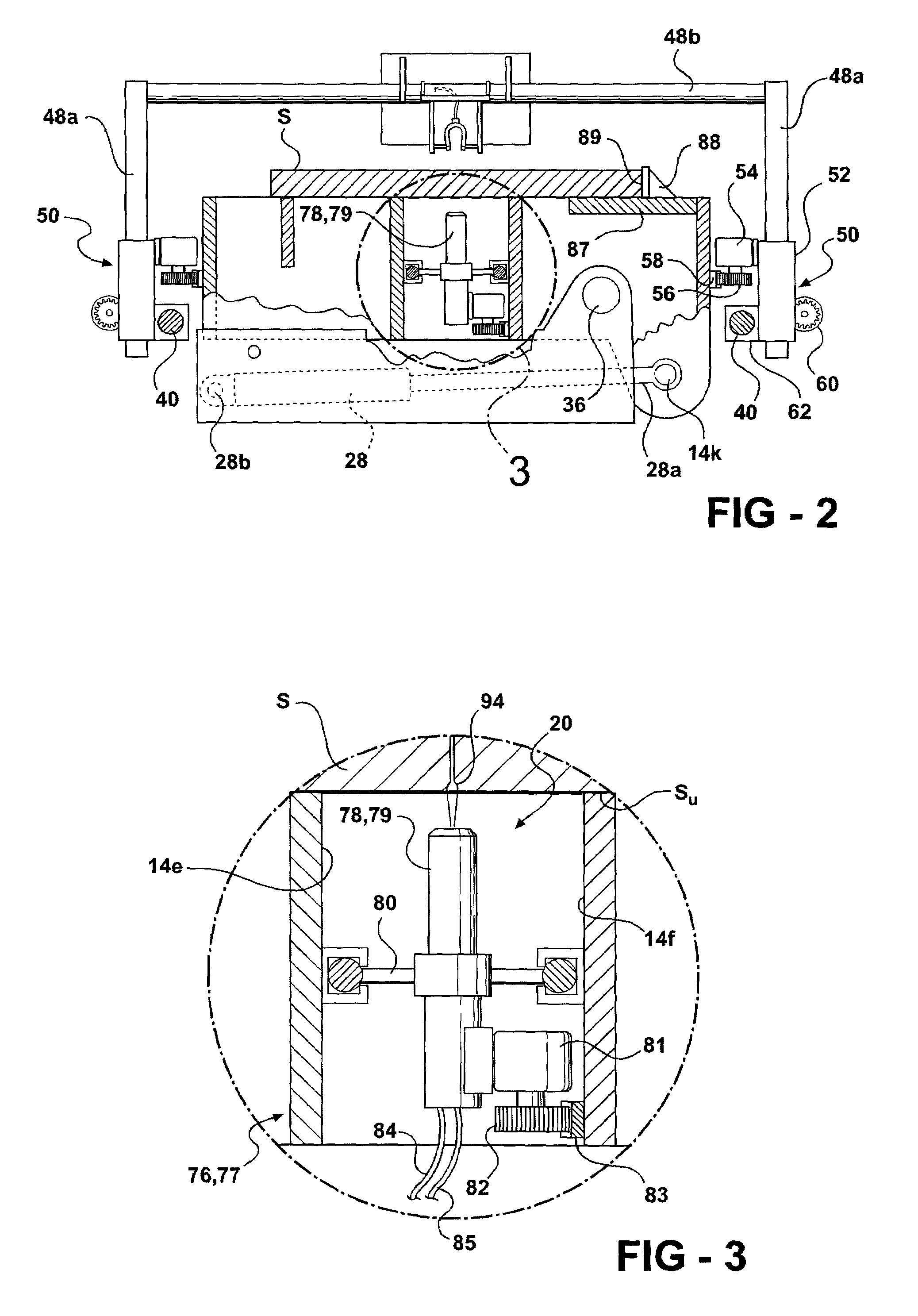

A cutting table assembly for oxy cutting comprising a cutting table having a slab loading face and mounted for pivotal movement between a loading position in which the loading face is generally horizontal and a cutting position in which the face is oblique, and a pair of torches mounted on the table. The loading face is constituted by a pair of loading subfaces separated by a slot and the torches are mounted in the slot below the loading face. The torches are positioned at opposite ends of the slot prior to the initiation of the cutting action and, upon the initiation of the cutting action, move toward each other and cut into opposite ends of the slab. A pair of gantries are mounted on the table and each carries a deburring device positioned in overlying opposition to a respective torch. Each gantry further includes a plurality of spaced downwardly directed nozzles which are supplied with compressed air to generate an air curtain.

Owner:EDWARD C LEVY

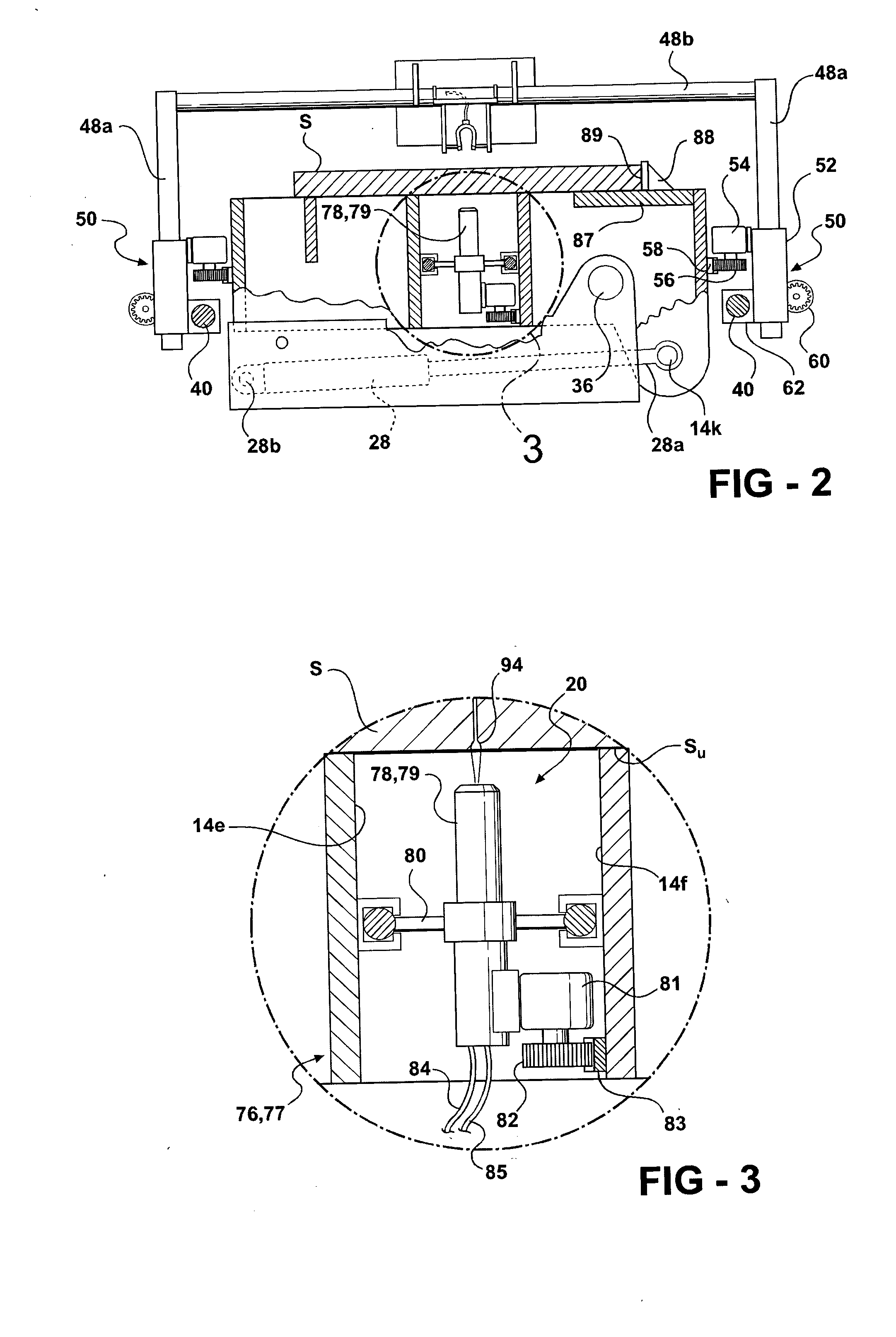

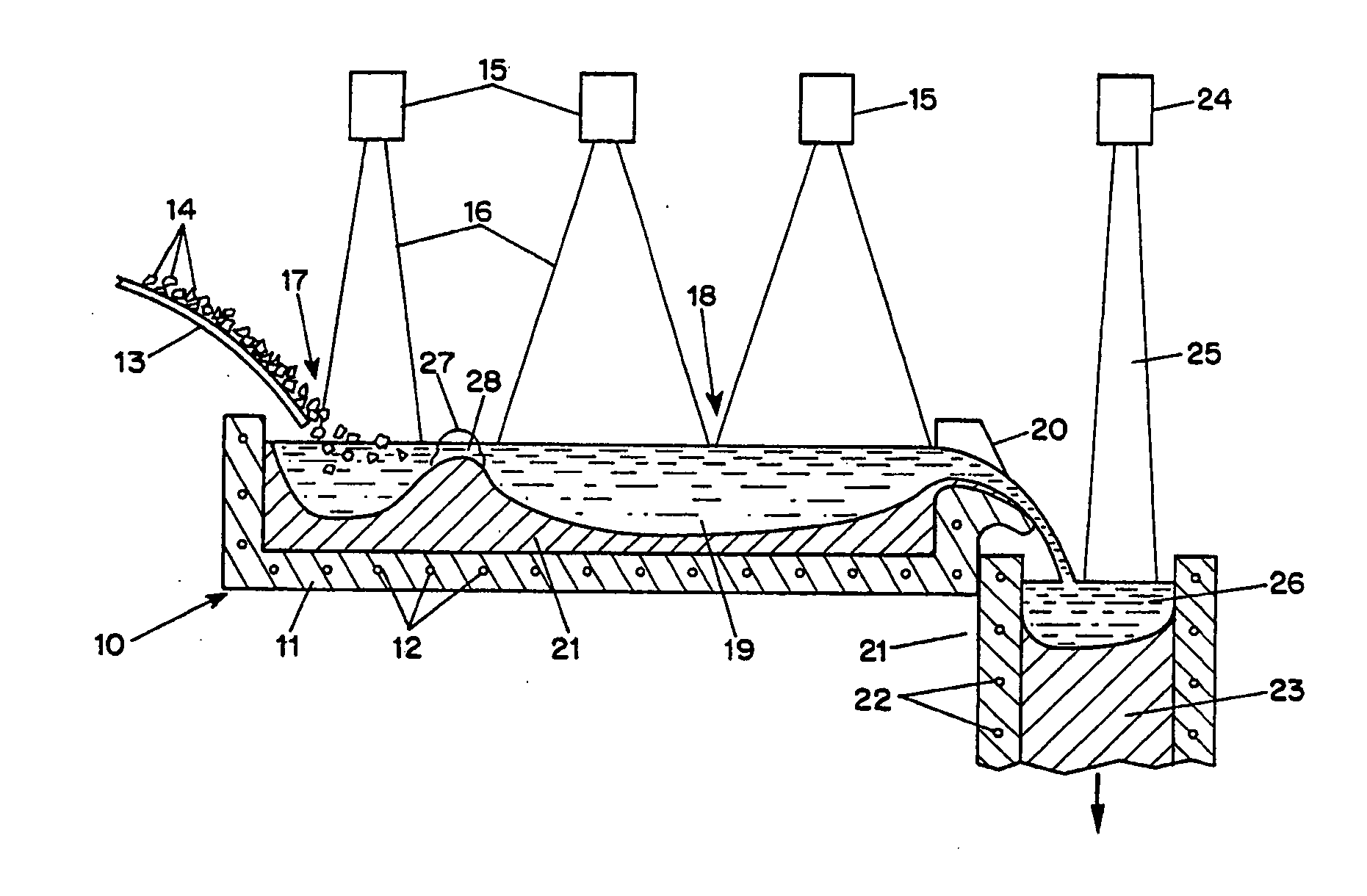

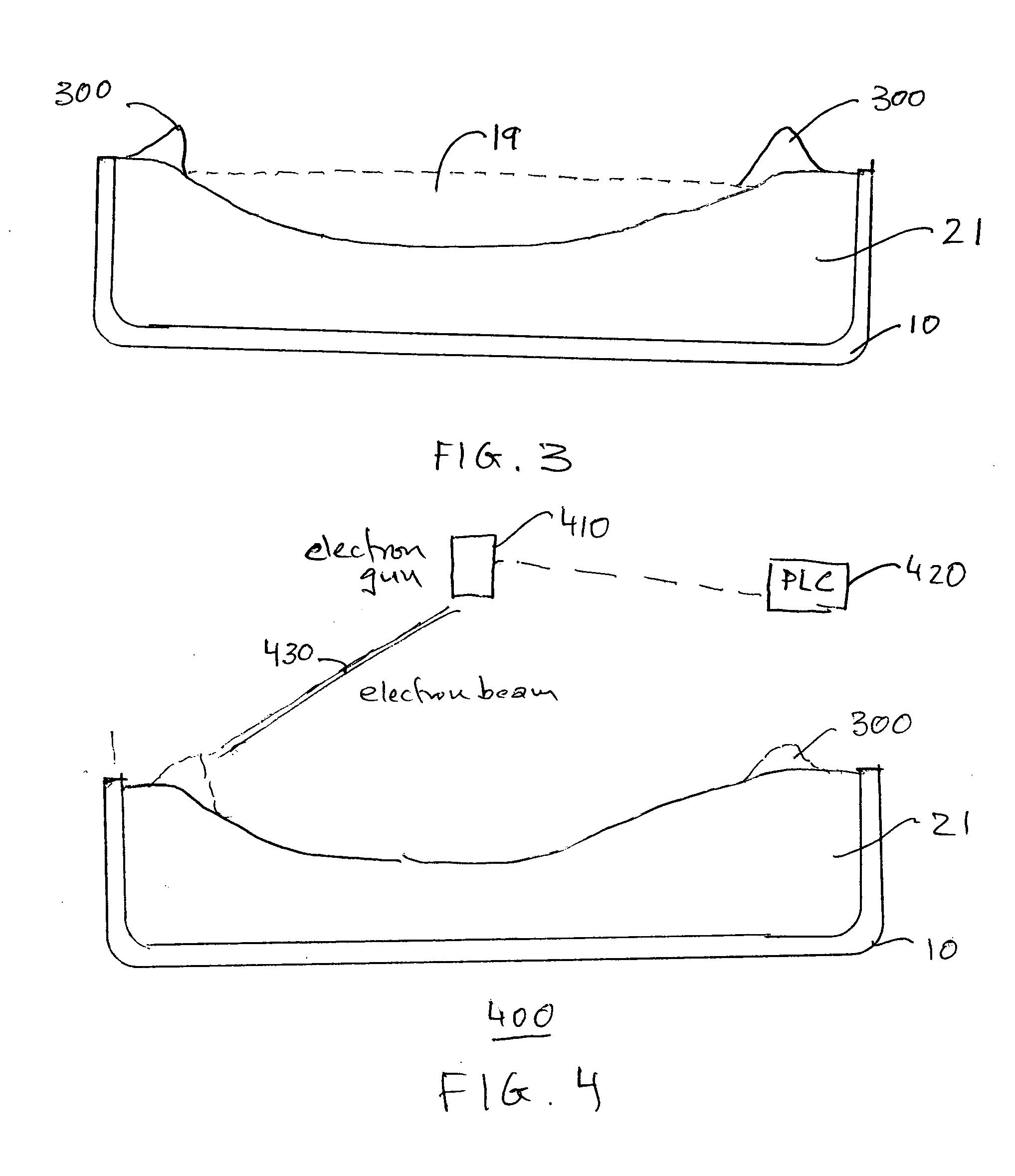

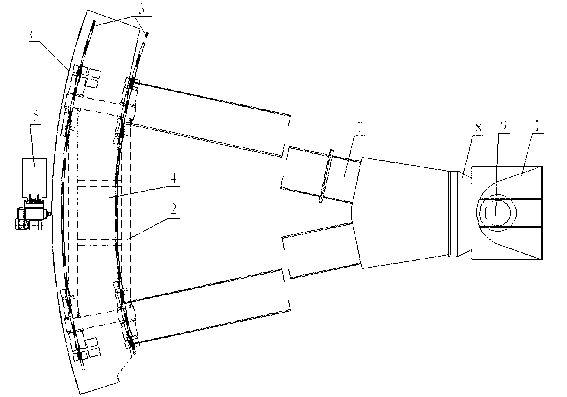

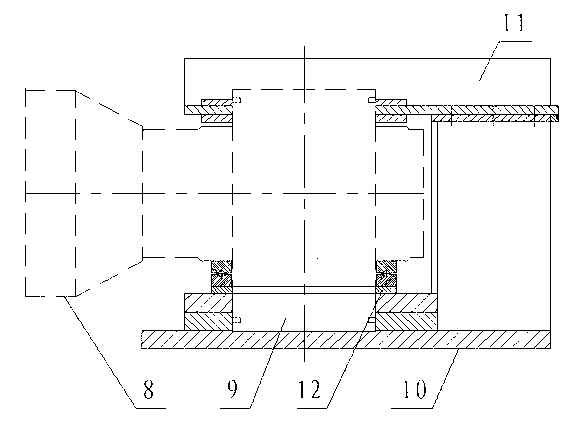

Method and apparatus for perimeter cleaning in cold hearth refining

InactiveUS20050173847A1Welding/cutting auxillary devicesGeometric arrangementsProgrammable logic controllerHearth

A cold hearth melting and refining arrangement for reactive or refractory metals utilizes an electron beam to automatically clean the perimeter of the pool of molten material in the hearth. A programmable logic controller is used to sweep the electron beam along at least a portion of the perimeter. The electron beam delivers energy to remelt or reevaporate volatile impurities that evaporate from the pool of molten material and redeposit on the perimeter.

Owner:BLACKBURN ALLAN E +1

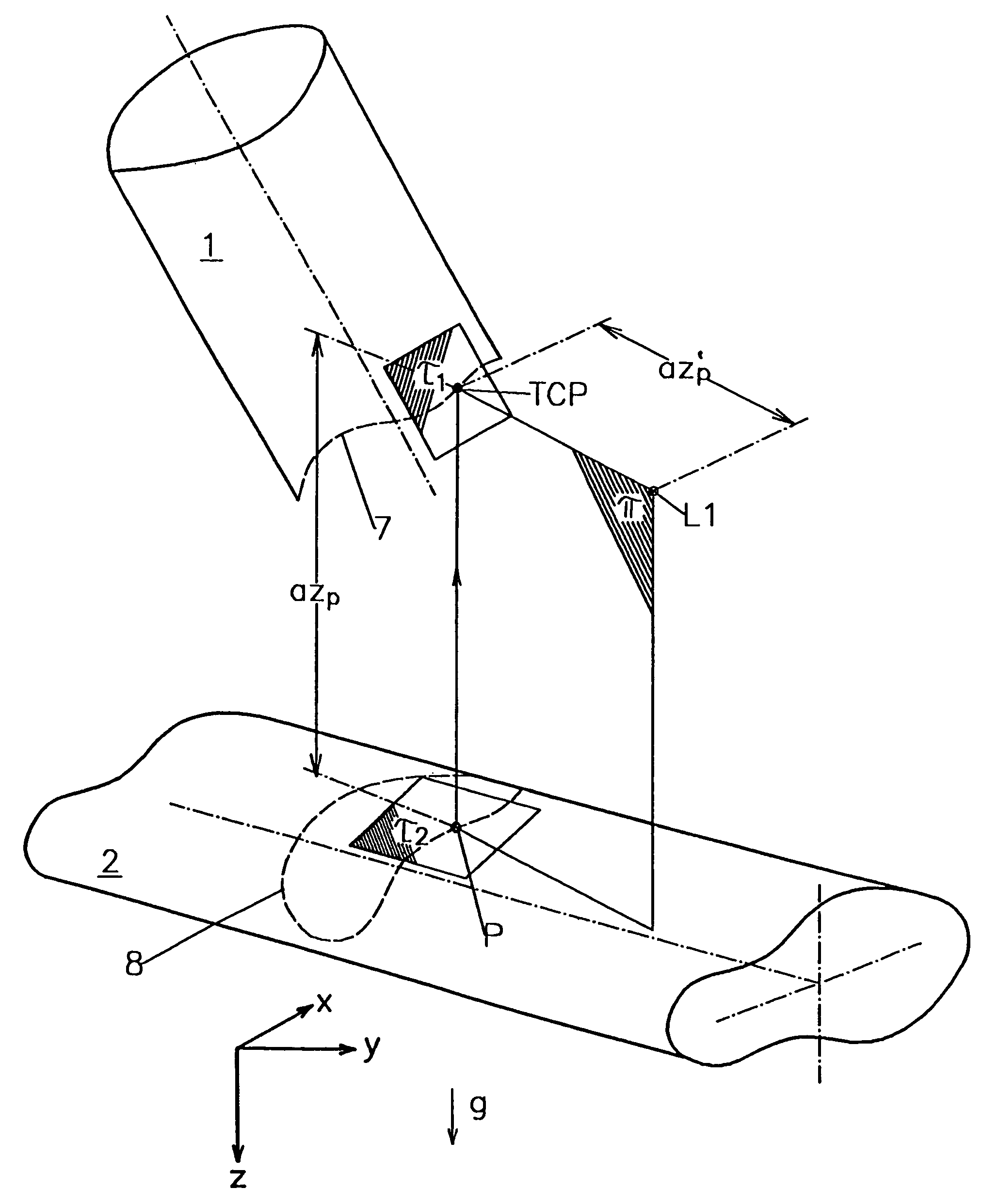

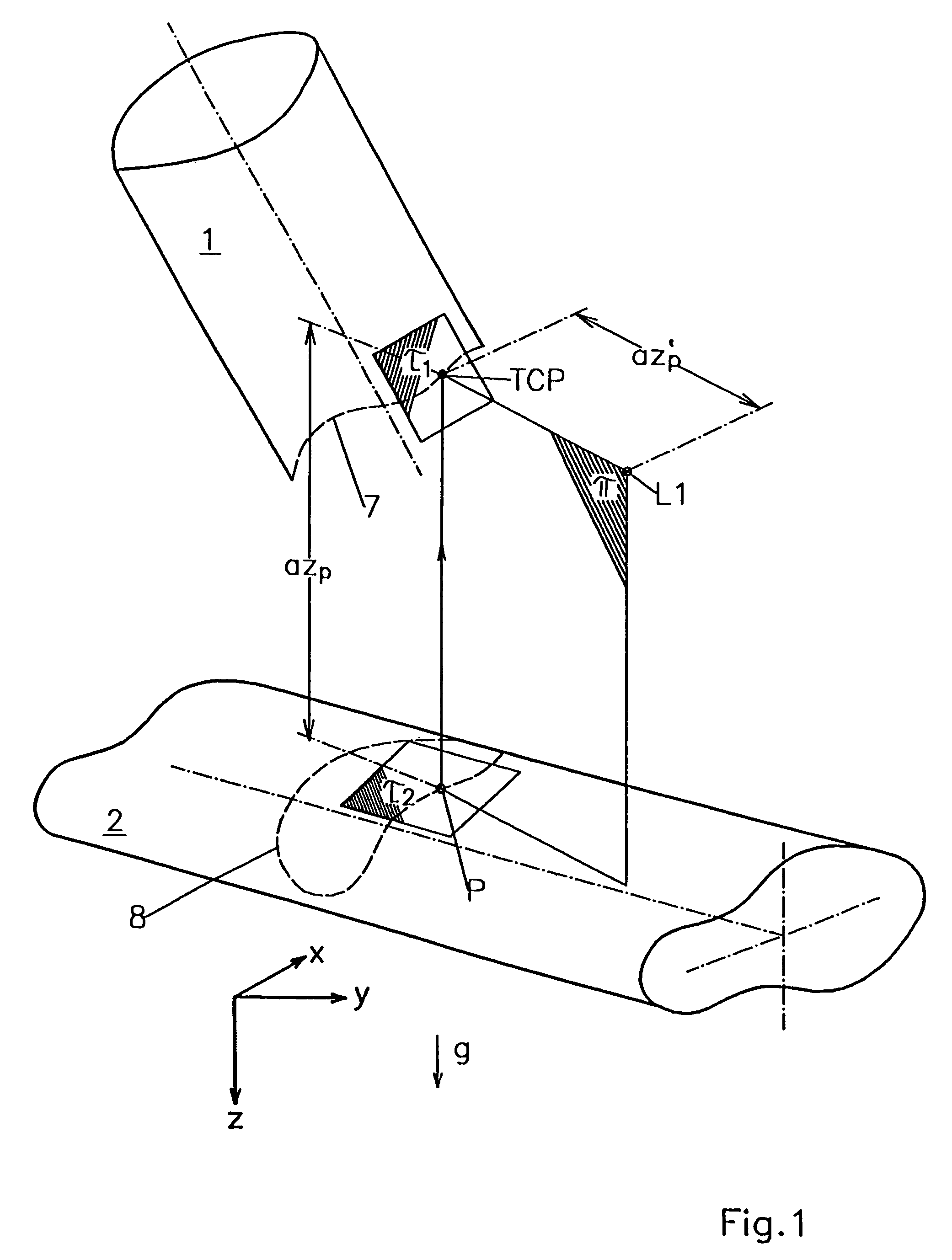

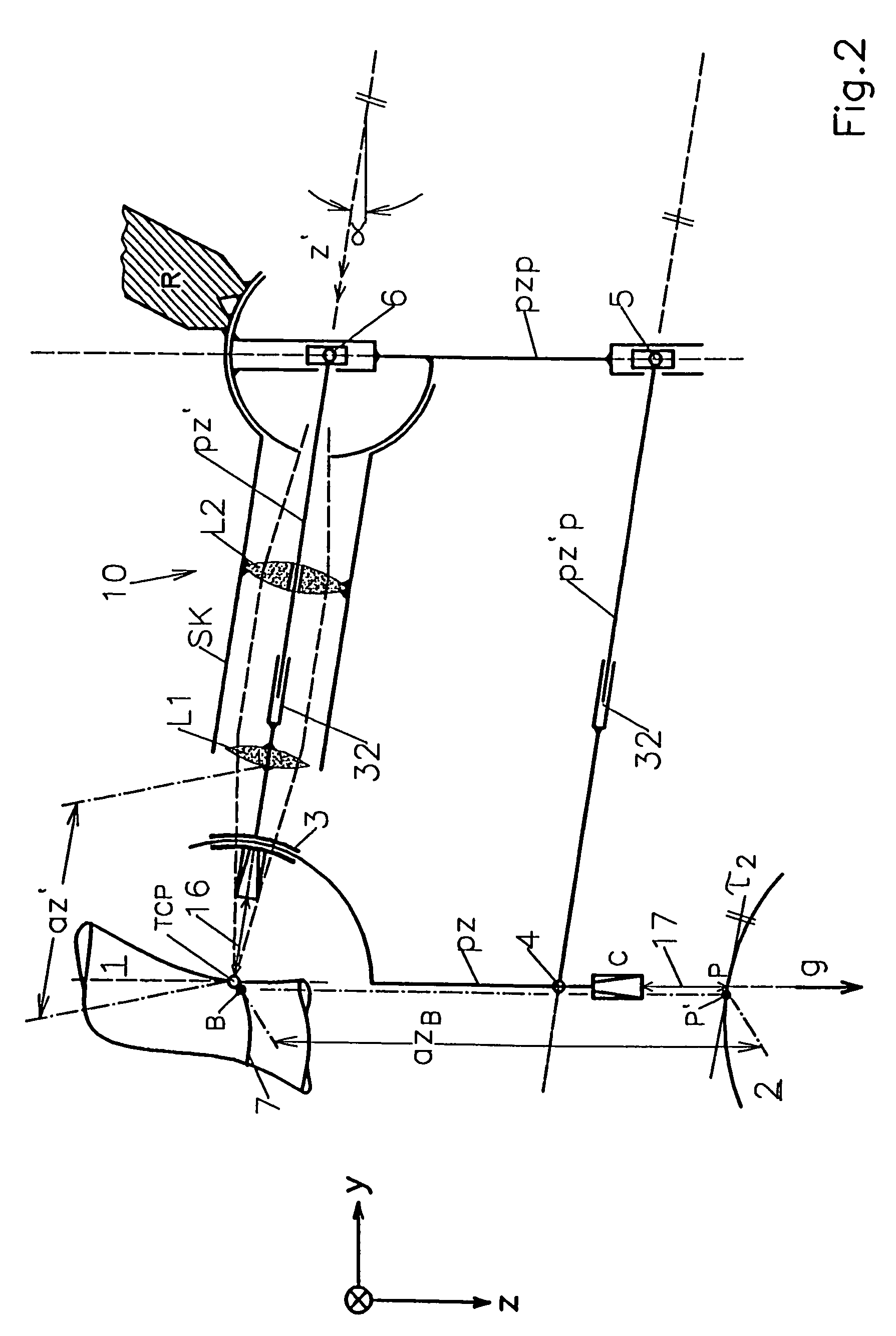

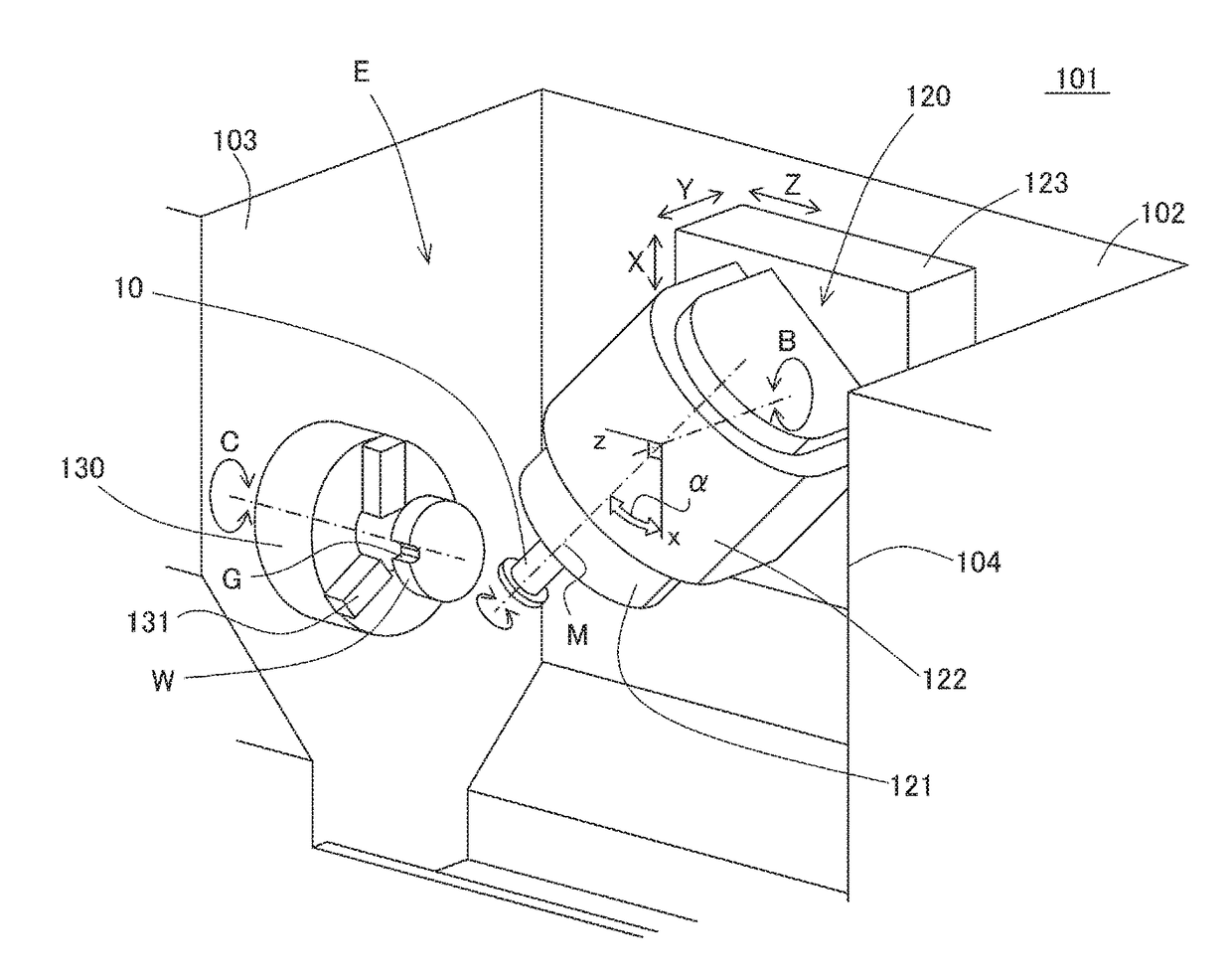

Method and device for the robot-controlled cutting of workpieces to be assembled by means of laser radiation

InactiveUS7248940B2High beam qualityMaximum precisionComputer controlSimulator controlEngineeringRobot control

In a method for robot-controlled cutting of workpieces to be joined by laser radiation, a first workpiece is arranged in vicinity of a second workpiece in a first position. A laser is focused onto the first workpiece. A contour of the first workpiece is cut with the laser beam; this contour is to be assembled and joined with the second workpiece. During cutting, a first spacing of a focal point of the laser beam from the second workpiece is repeatedly determined in a distance direction that is identically oriented during cutting and is adjusted to a direction of assembling the first and second workpieces. During cutting, a second spacing of a processing point of the laser beam from the second workpiece is maintained at a constant value.

Owner:THYSSEN LASER TECHN +1

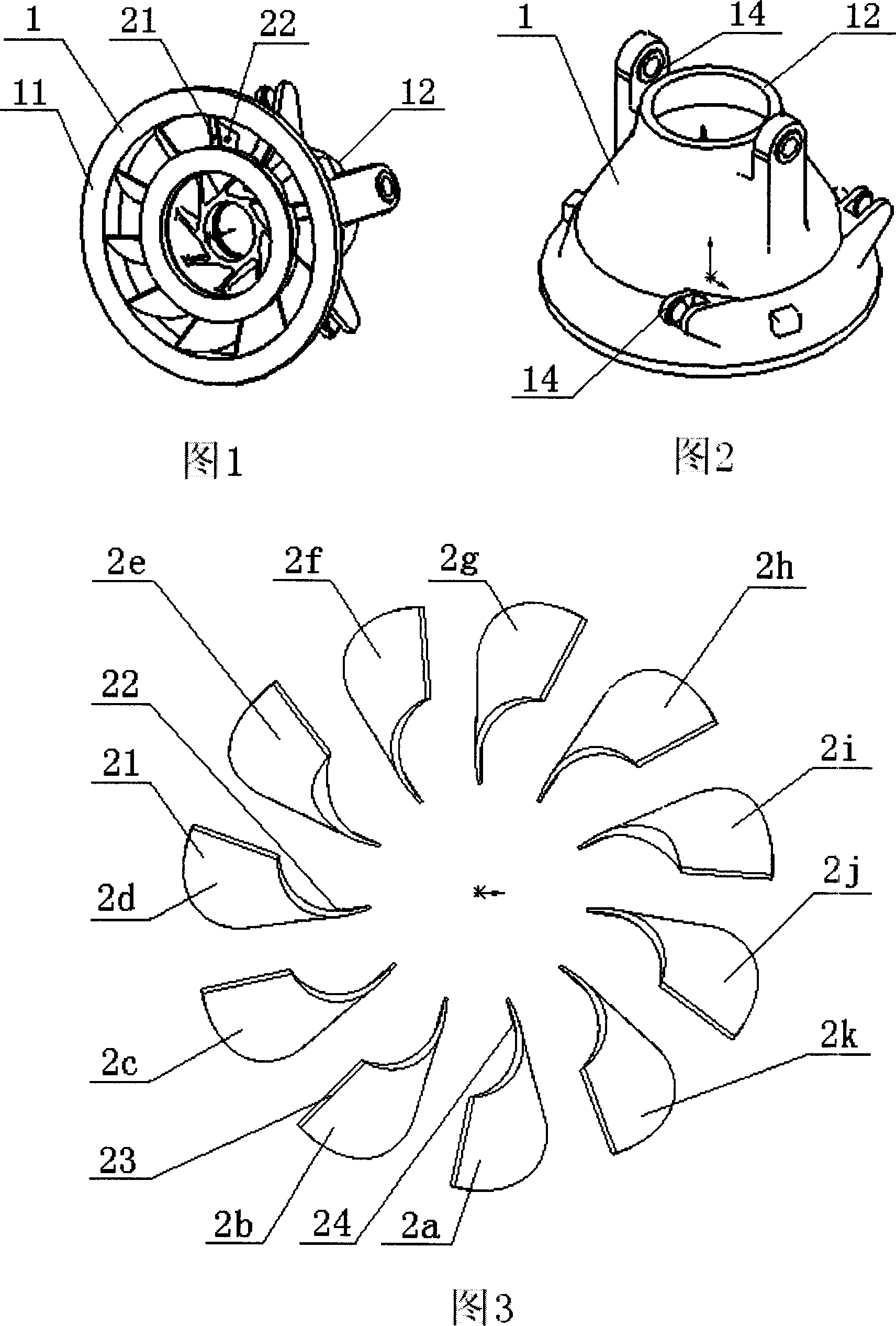

Water jet propelling device guide blade processing method

InactiveCN1962360AOvercome the problem that the line type is difficult to guaranteeImprove type value control abilityGeometric arrangementsPropulsive elementsInternational standardDouble phase

The invention relates to a method for processing the blades of injection propulsion unit, wherein it controls the process allowance of casting element, to improve the check and machine on each shaping surface of blade 2; it uses ultrasonic wave detector to detect the wall thickness of oil hole 25, improve the accuracy of curvature of blade 2 in double-phase stainless blade 1, and the control ability of blade 2; the processing accuracy of long lubricant hole of blade 2 is improved, to improve the process efficiency and accuracy of blades 1, 2. The invention's quality can reach international standard.

Owner:WUHAN MARINE MACHINERY PLANT

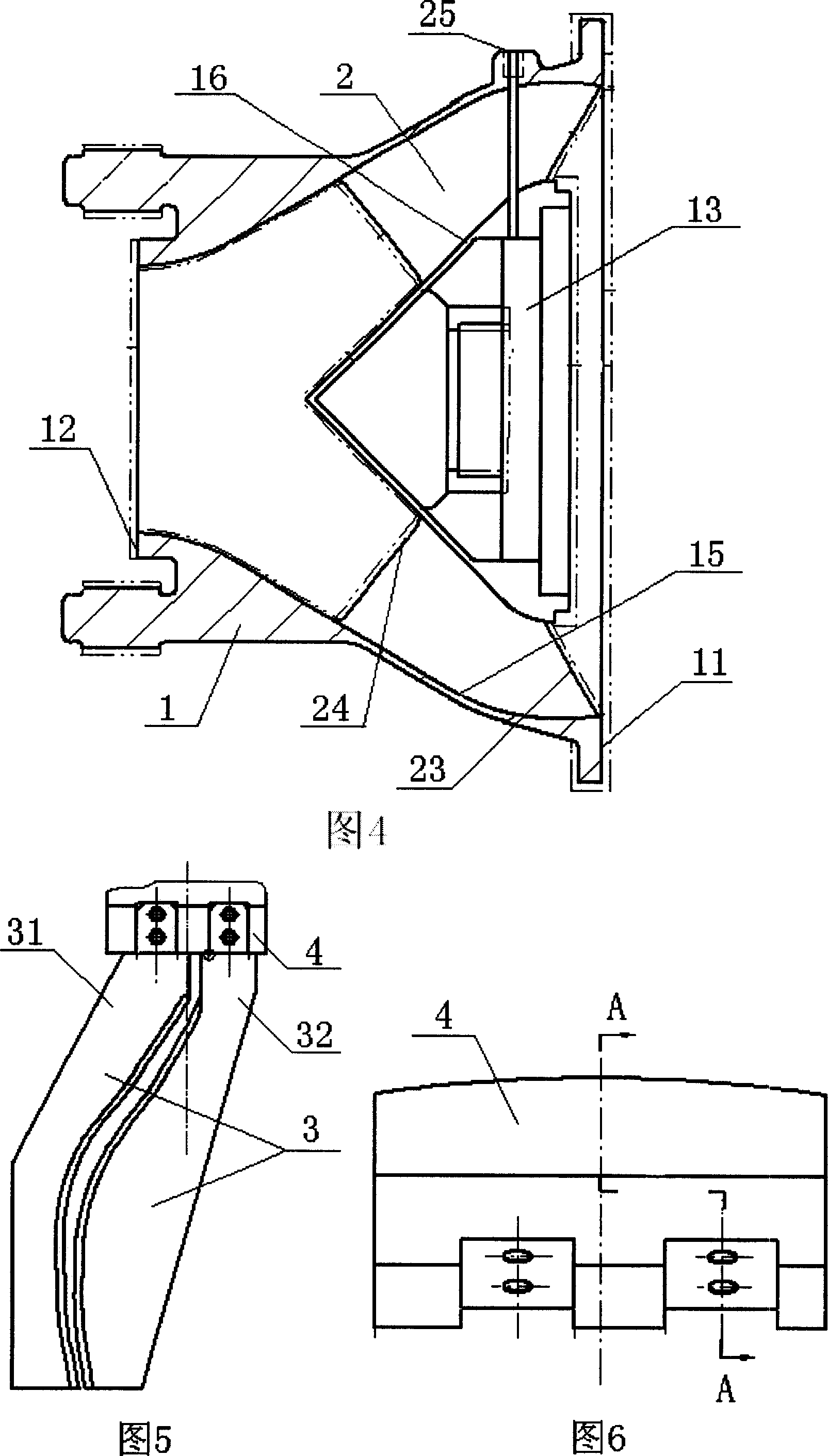

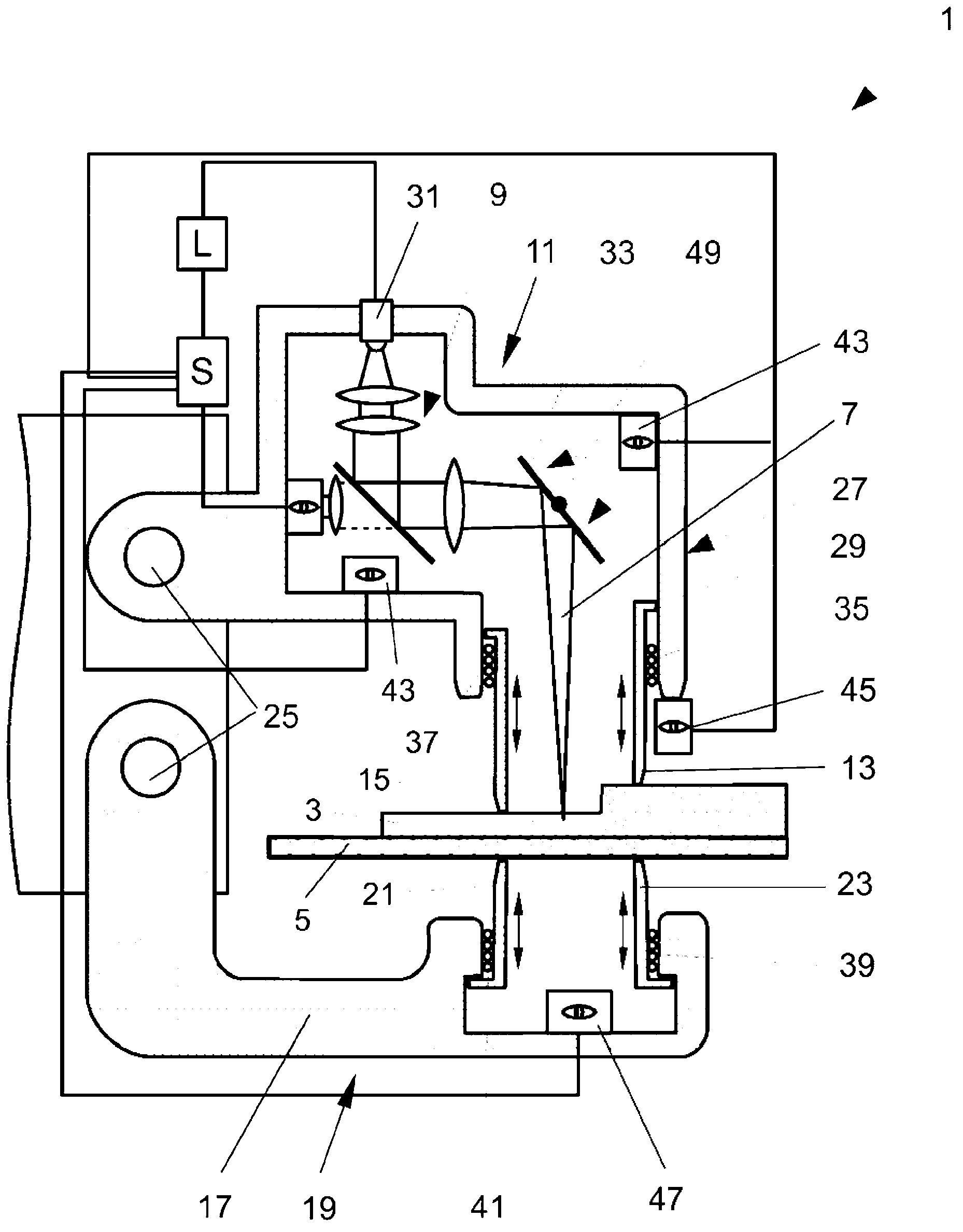

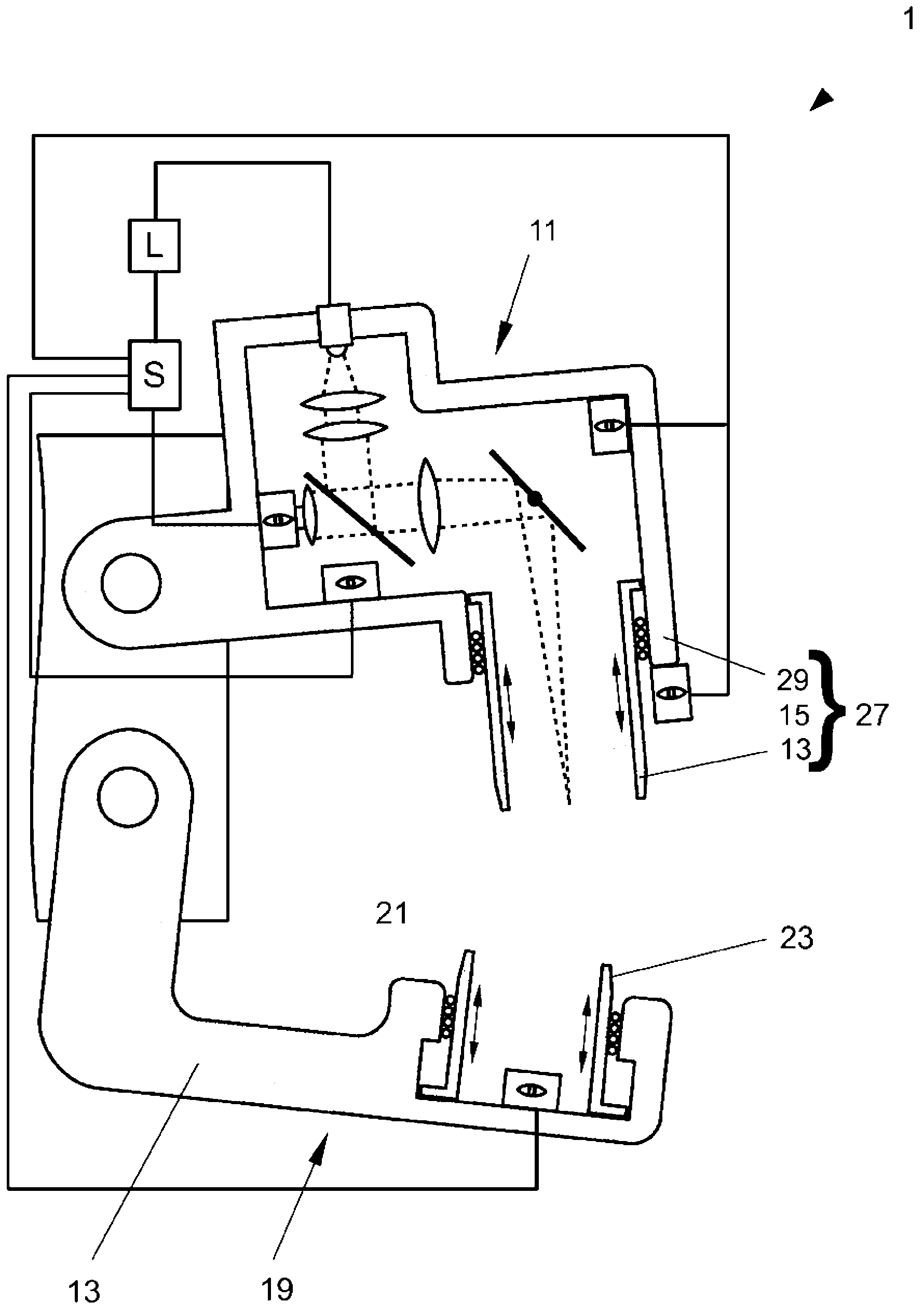

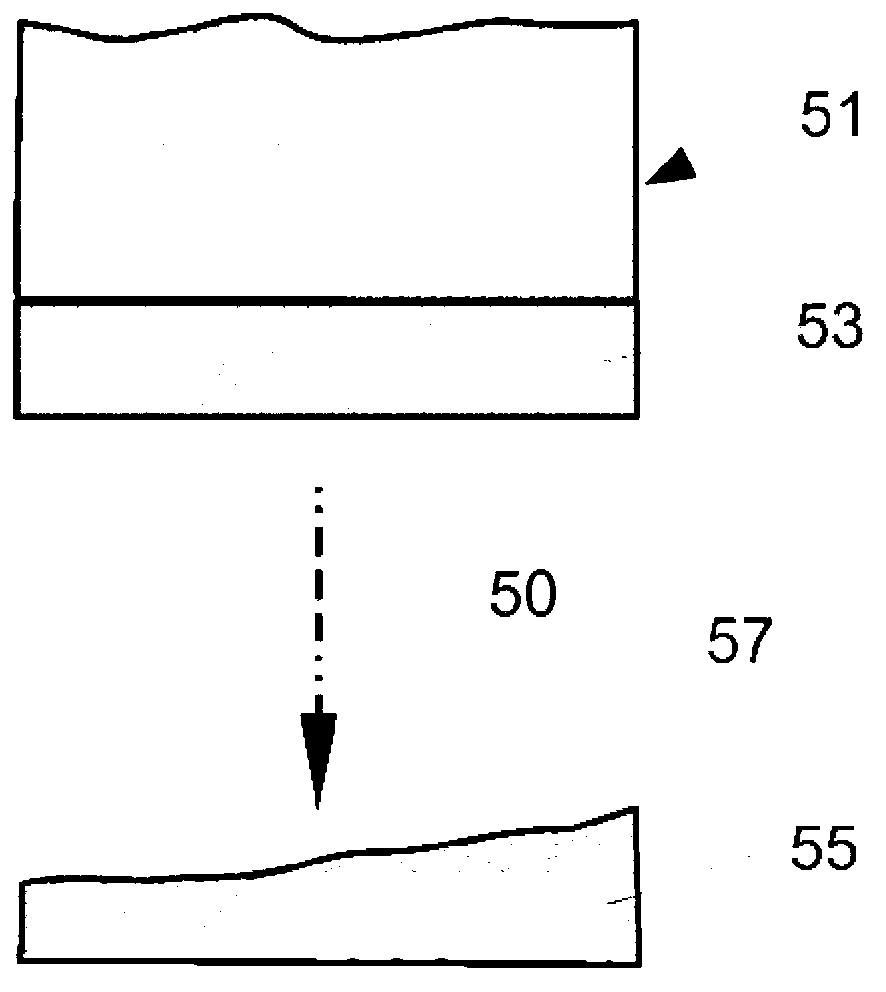

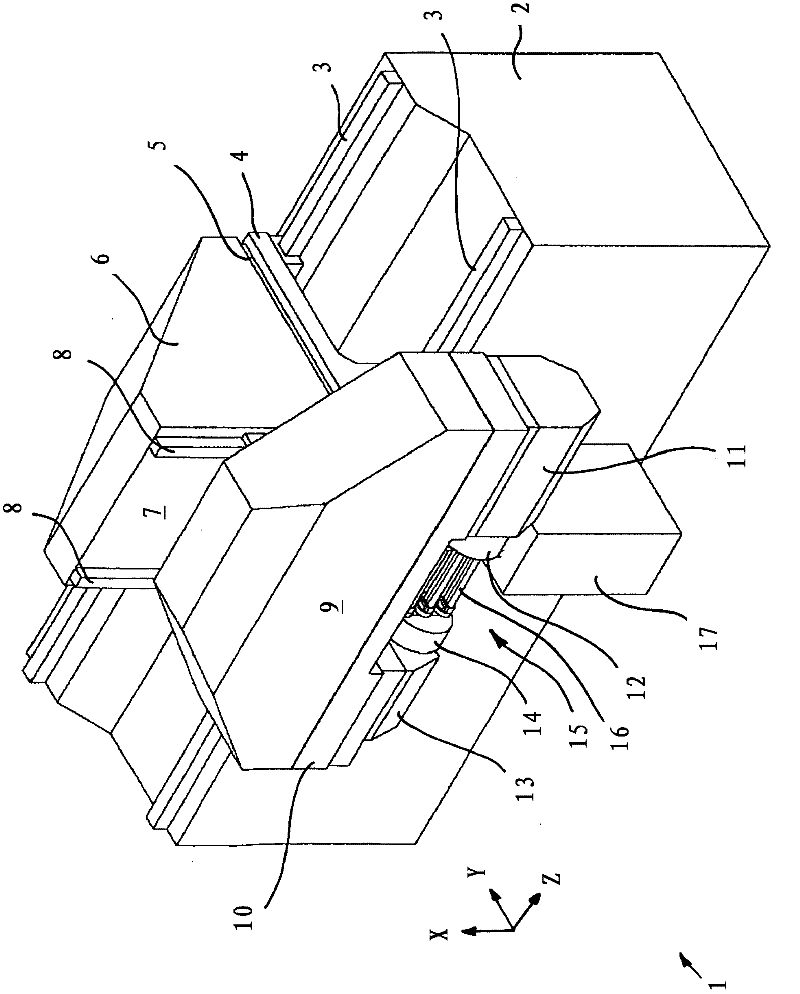

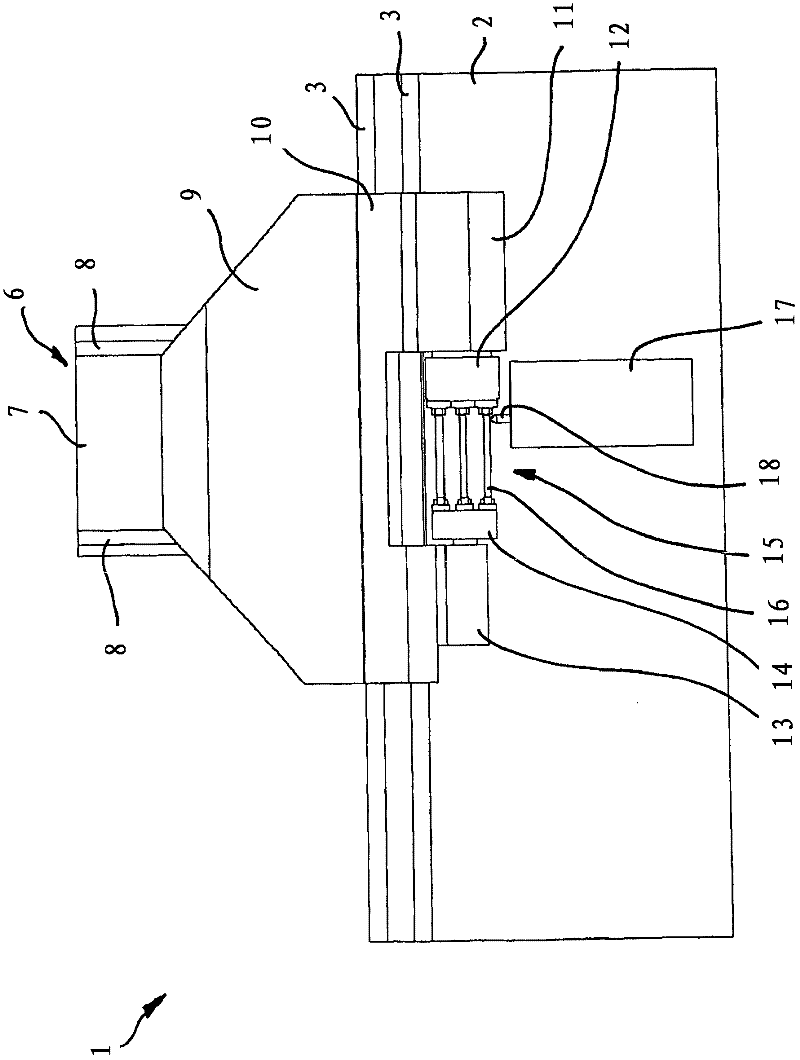

Device and method for joining workpieces by means of a laser beam and movable pressing element

InactiveCN103221174AWelding/cutting auxillary devicesGeometric arrangementsDegrees of freedomLaser beams

The invention relates to a method and a device (1) for joining workpieces (3, 5) by means of a laser beam (7), the device (1) comprising: a scanning optical system (9) for guiding the laser beam (7); a pressing element (13, 15, 21, 33), which is pressed onto at least one of the workpieces (3, 5) in a pressing direction in order to fix the workpieces (3, 5) during the joining process; and a housing (11), which encloses the scanning optical system (9) and the laser beam (7) extending from the scanning optical system (9) to the workpieces (3, 5). The pressing element (13, 15, 21, 23) forms part of the housing (11) and is movable relative to the remainder of the housing (11) with at least one degree of freedom.

Owner:SCANSONIC MI

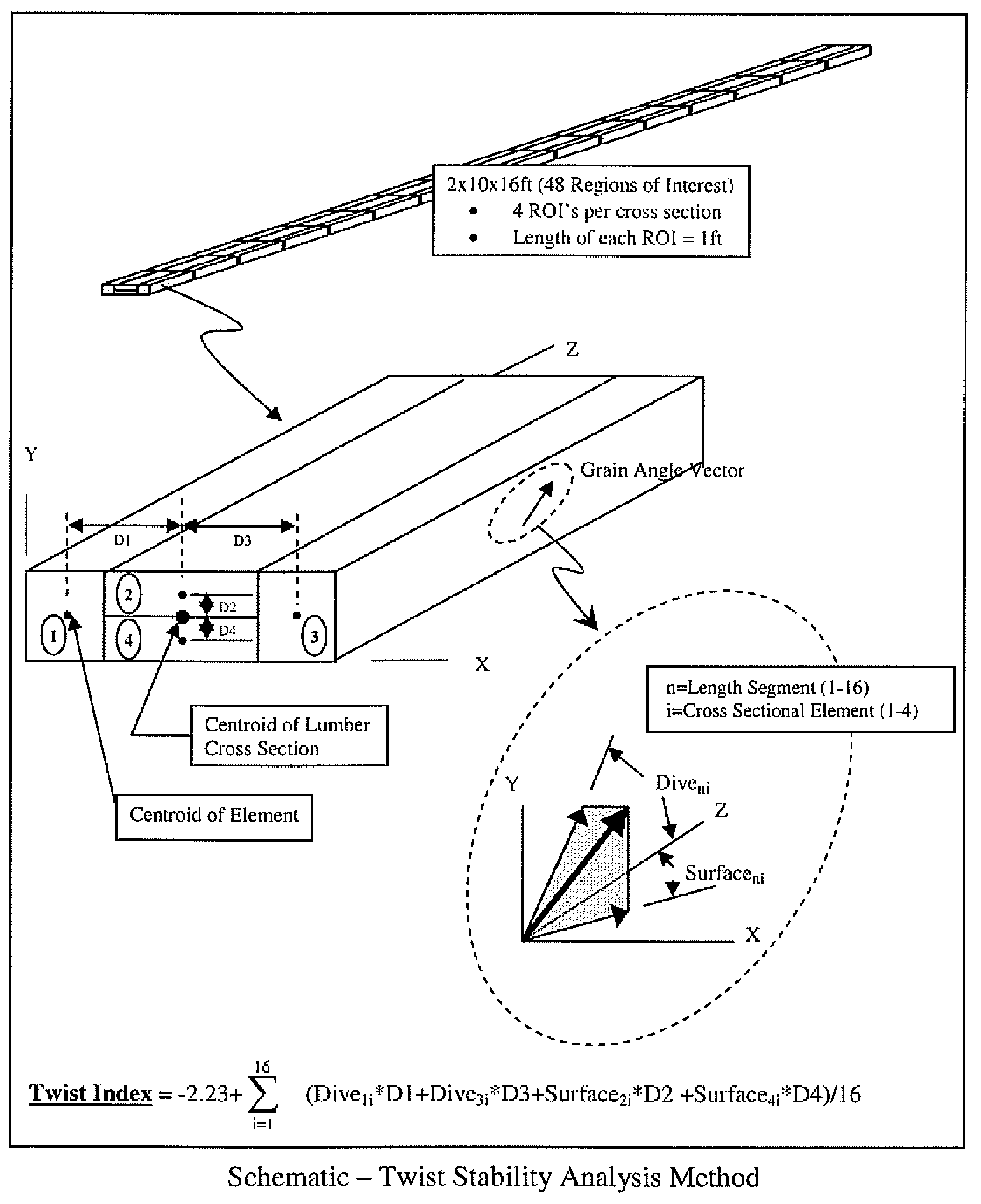

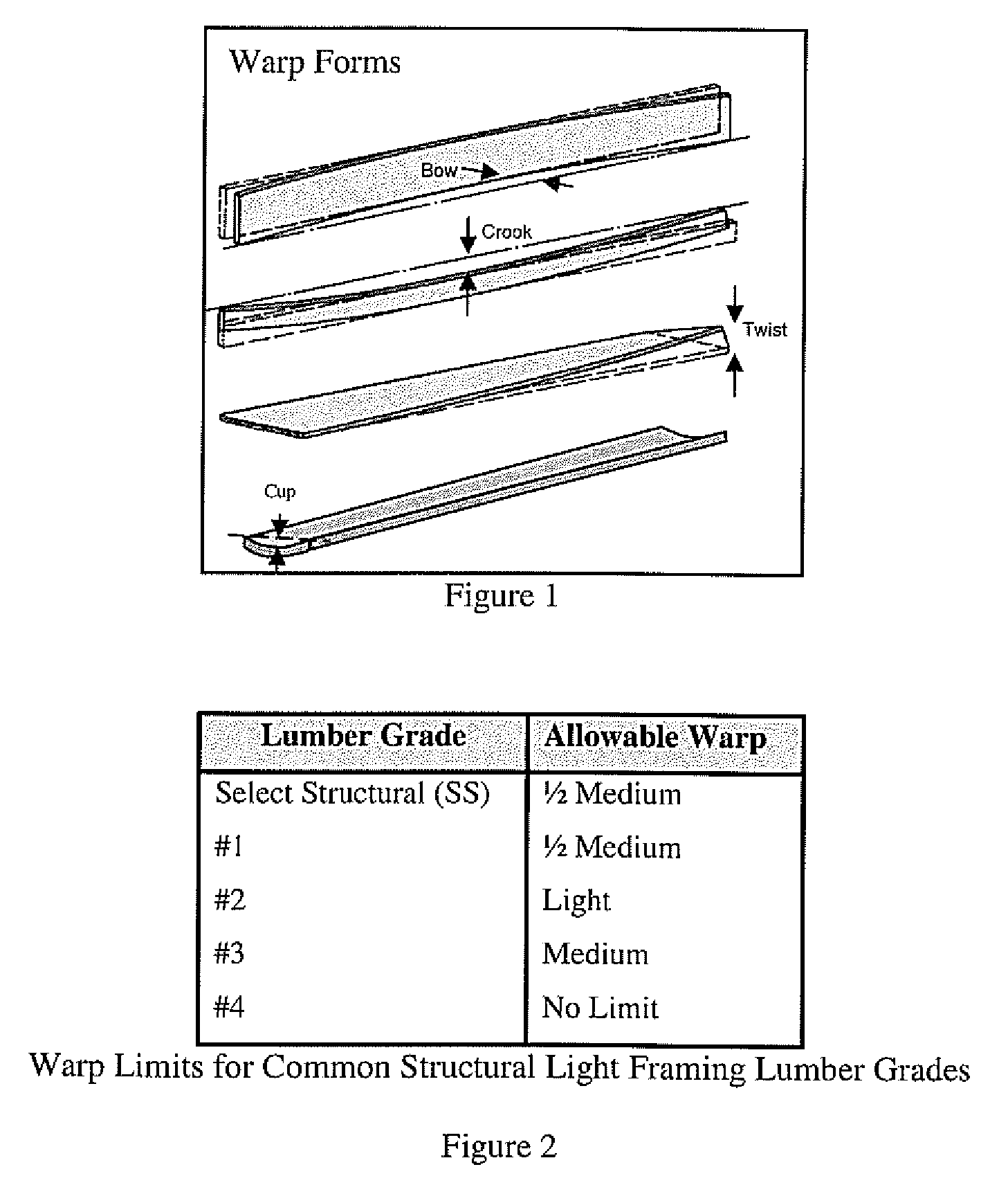

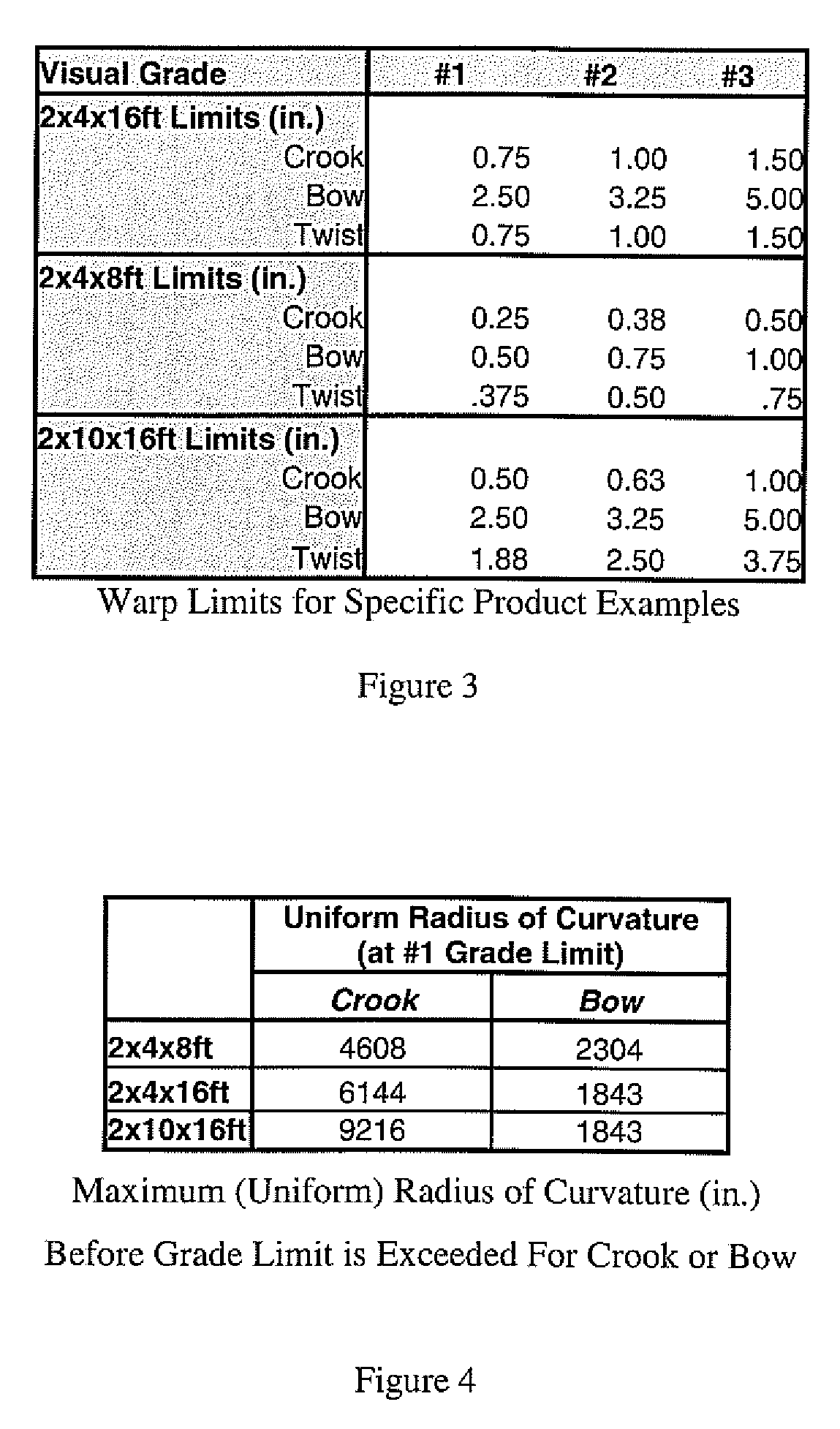

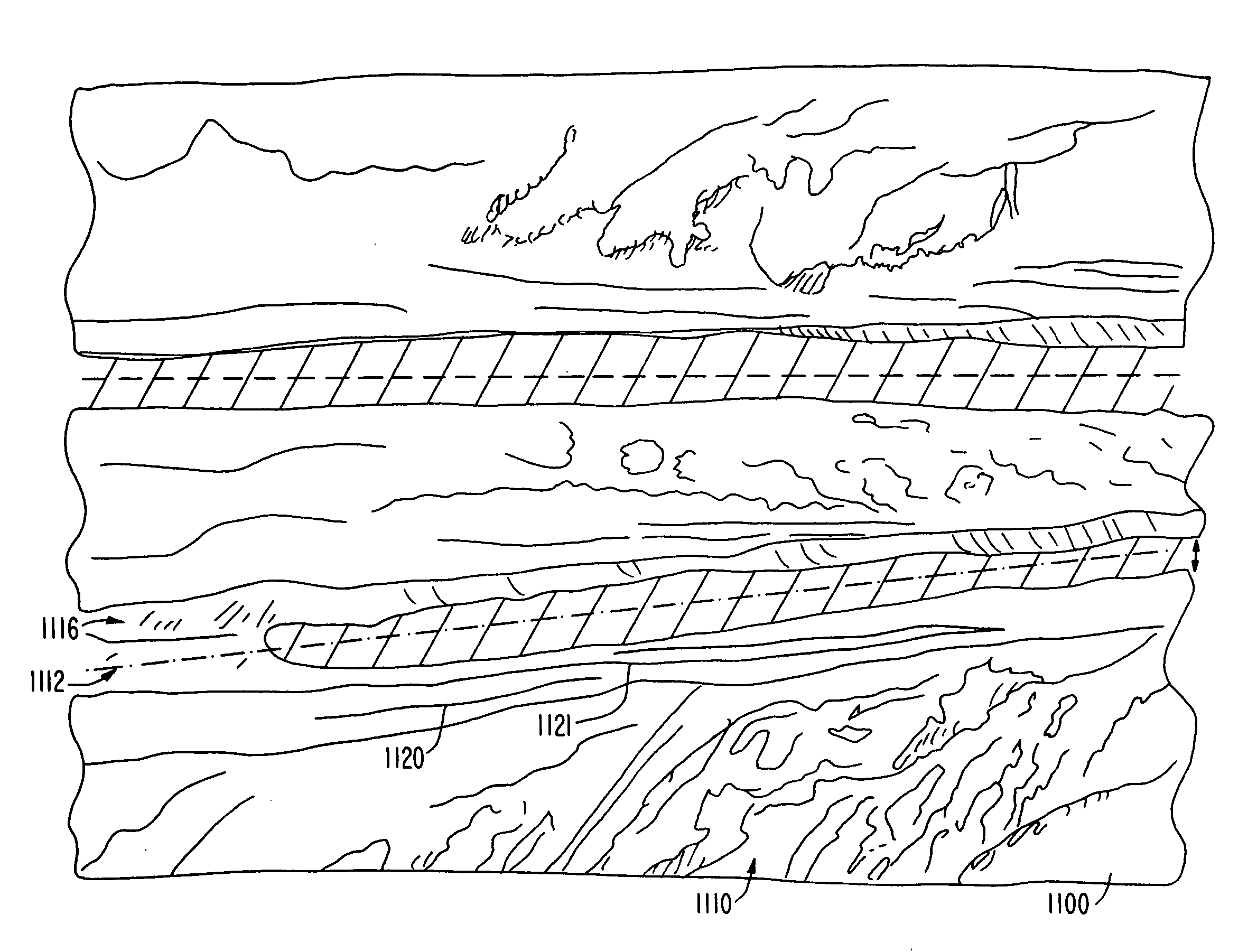

Warp Stable Wood Product And Methods For Detecting The Same

InactiveUS20080283151A1Automatic control devicesAnalysing solids using sonic/ultrasonic/infrasonic wavesChemical compositionPulp and paper industry

A warp stable wood product and methods for detecting the same are provided. The wood product may be sorted based on its morphology, microstructure, macrostructure, and / or chemical composition properties being substantially symmetric relative to at least one or more cross-sectional centroids of the wood product, thereby imparting warp stability.

Owner:WEYERHAEUSER NR CO

Process for rolling taper pipe thread on thin-wall metal pipe fitting

InactiveCN1962117ASimple structureEasy to operateThread cutting machinesGeometric arrangementsHigh volume manufacturingPipe fitting

The invention relates to a method for rolling taper tube screw on thin-wall metal tube, wherein it is characterized in that: based on present rolling machine, it uses spindle and expanding sheath to fix the metal tube, then rolling. The invention inserts spindle in / out the expanding sheath to form compress / unload device to meet the support and unload demand of metal tube. The invention has simple structure and easy operation.

Owner:李淑珍

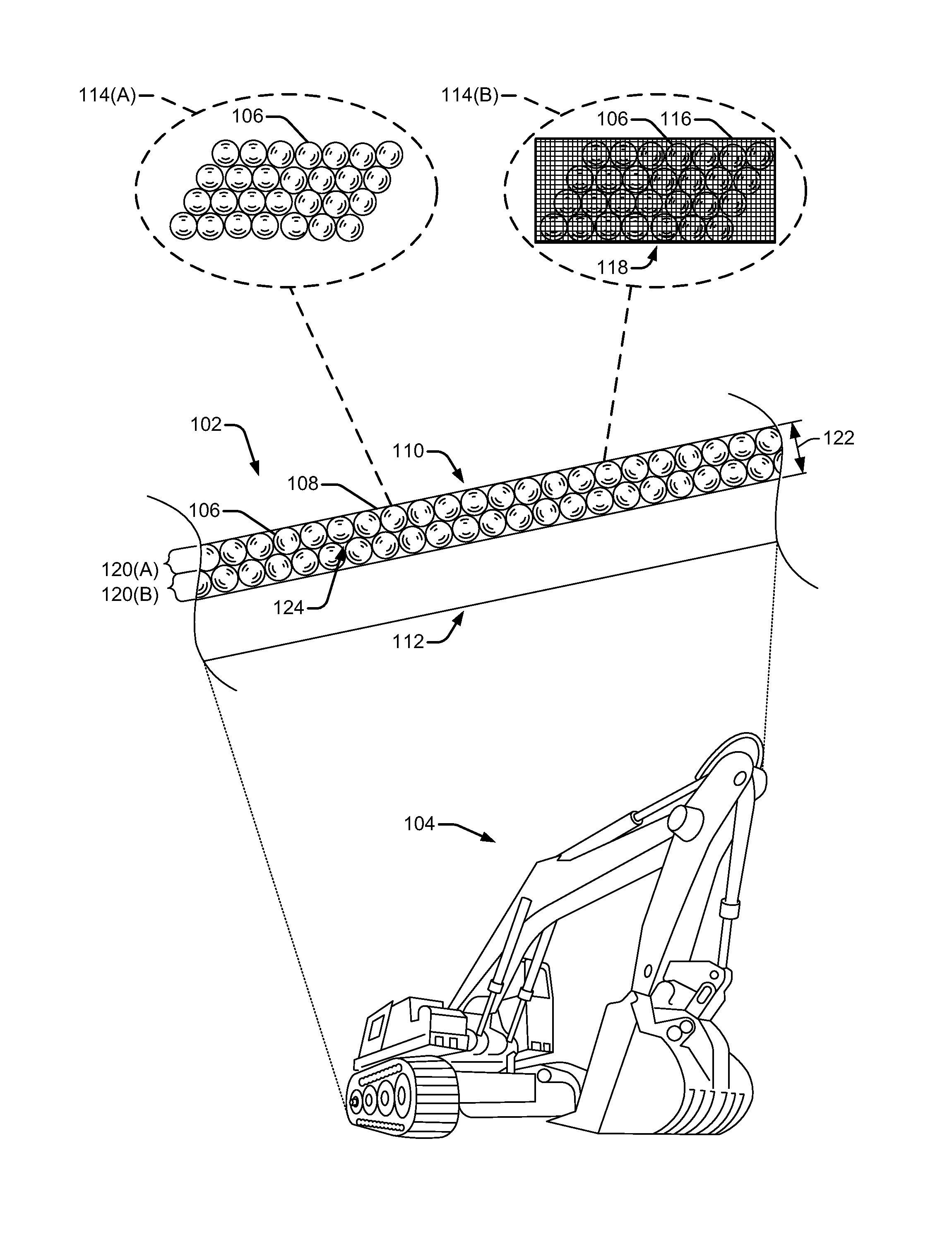

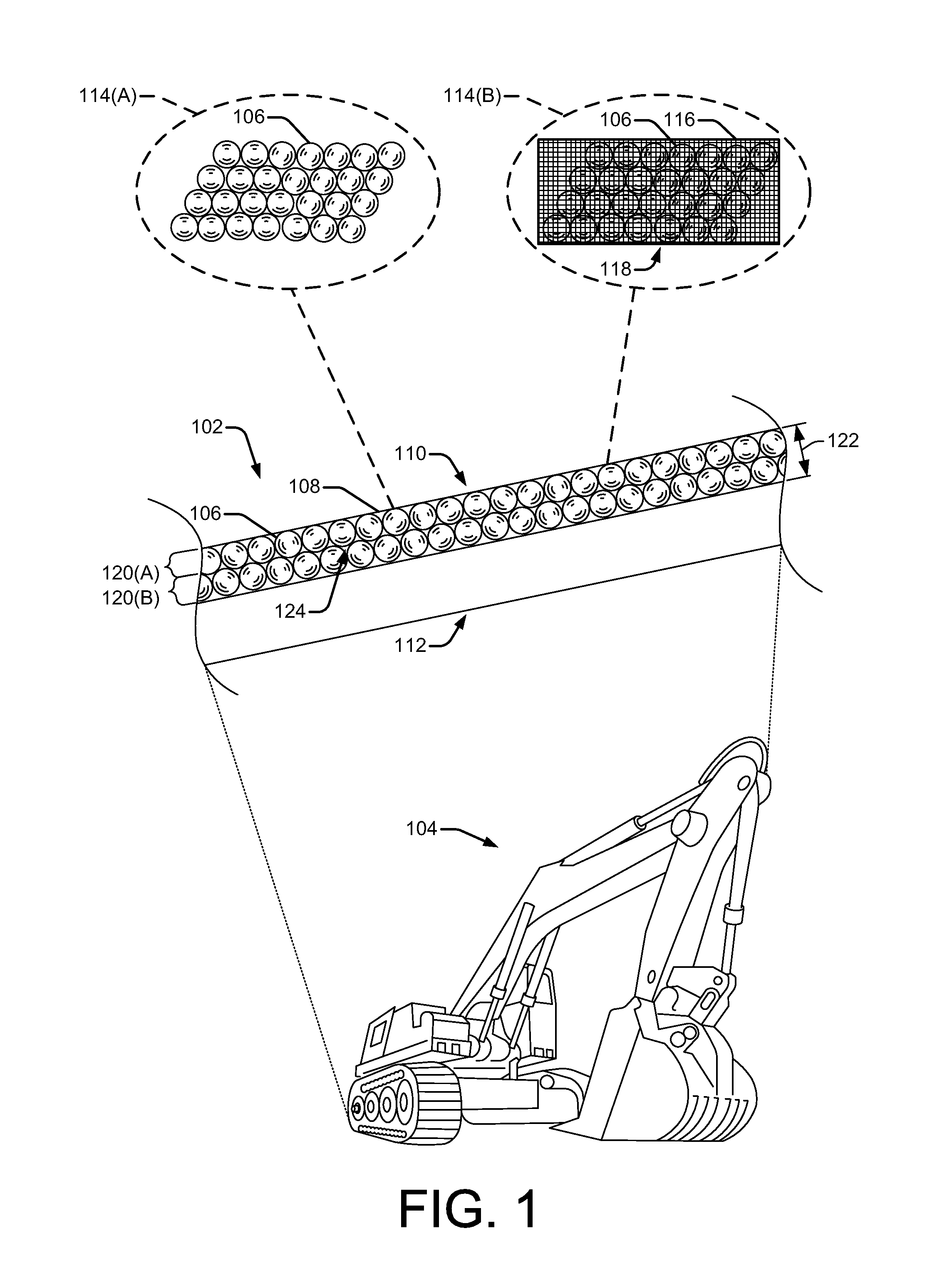

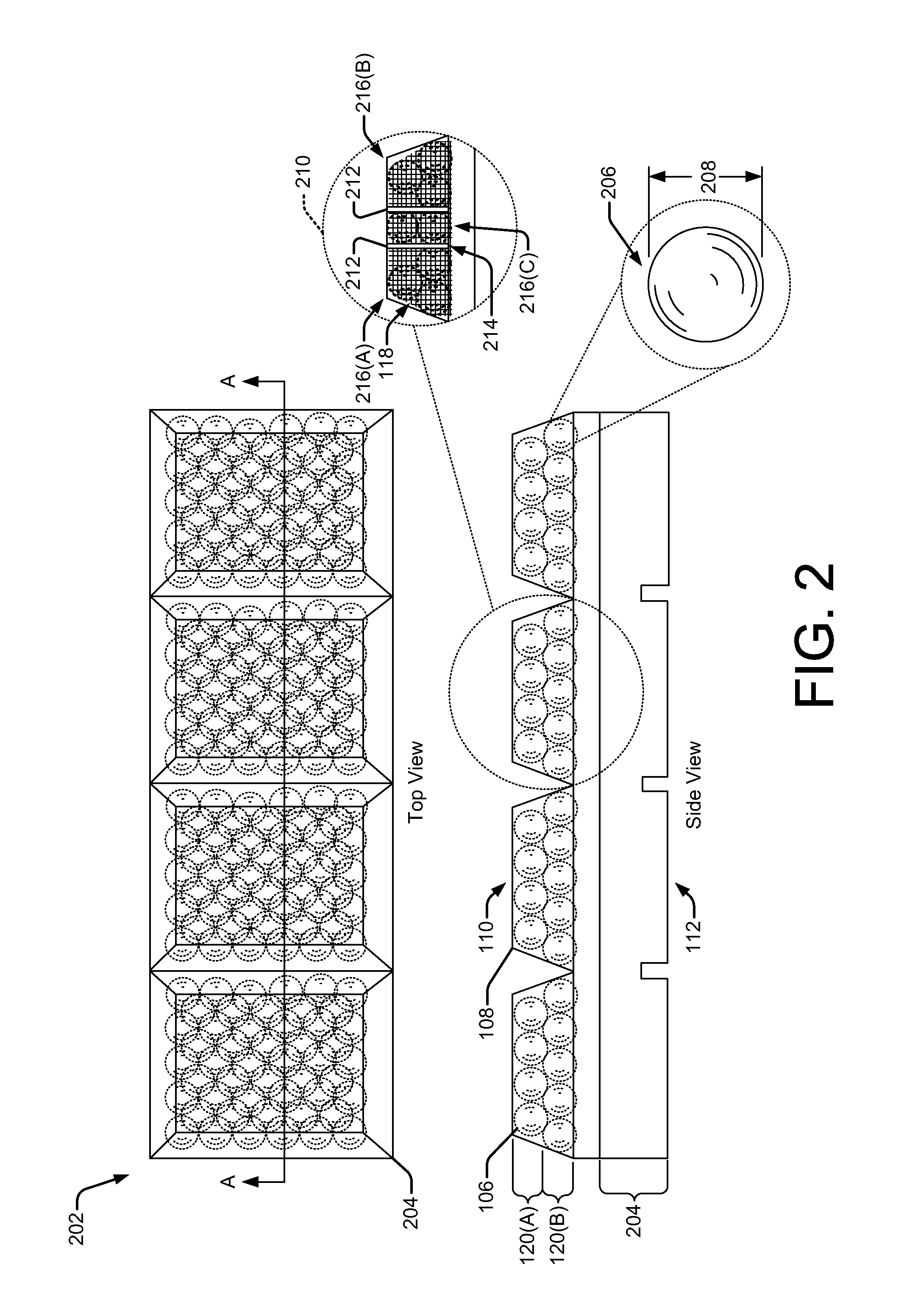

Encapsulated preformed shapes

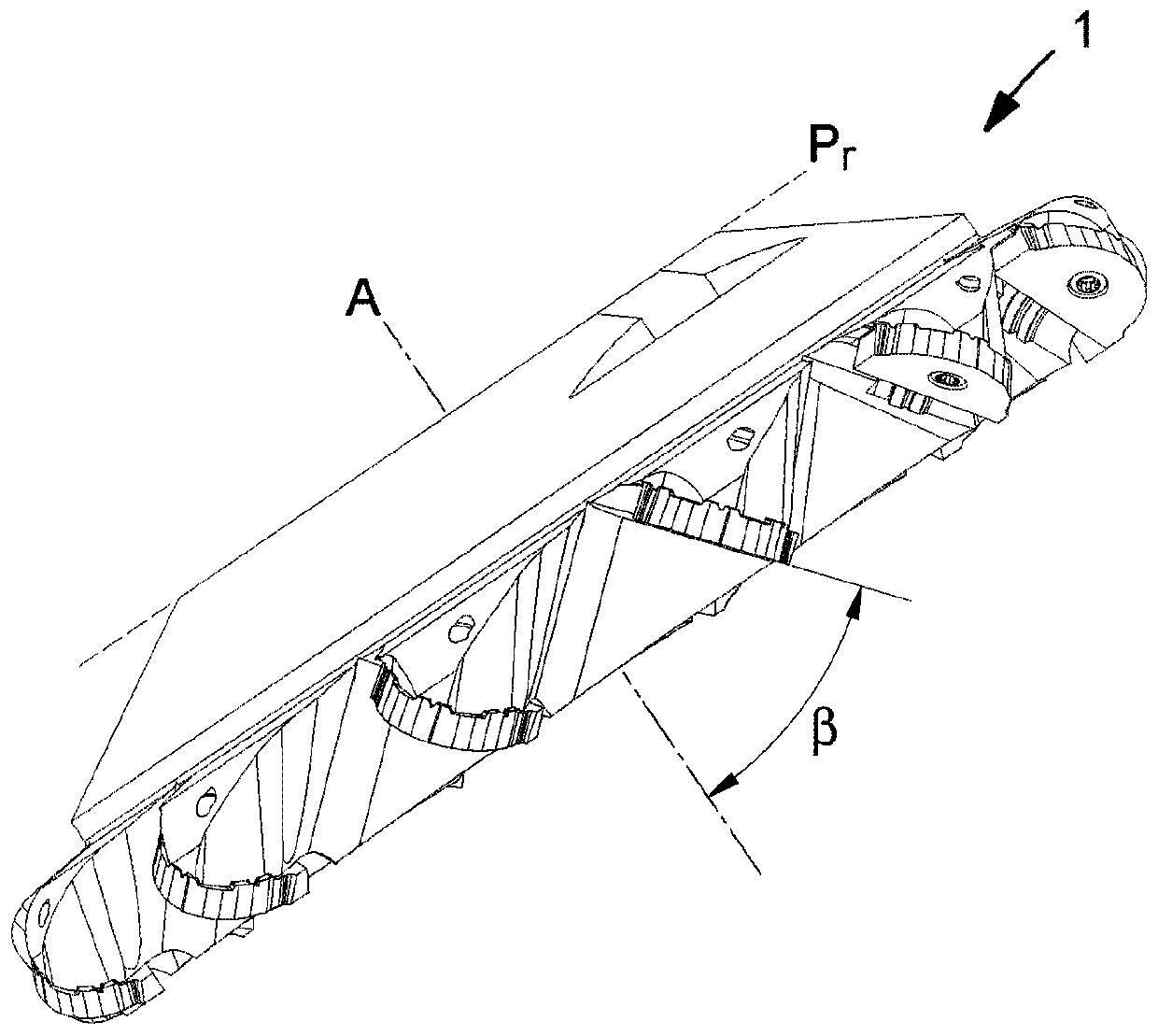

ActiveUS8795828B2Easy to handleEasy manipulationEnvelopes/bags making machineryGeometric arrangementsMetal alloySub region

Composite wear parts including encapsulated preformed ceramic shapes are disclosed. Preformed ceramic shapes are embedded in a metal alloy to protect the base metal from abrasion. The preformed ceramic shapes may have a uniform, preformed geometry that provides for packing the preformed ceramic shapes together in a uniform way. The preformed ceramic shapes may be positioned at a location in the composite wear part exposed to an abrasion without using a binding agent. The preformed ceramic shapes may also be contained in a porous container. A truss structure may be integrated in the preformed ceramic shapes to compartmentalize the preformed ceramic shapes into multiple isolated sub regions to stiffen the composite wear parts.

Owner:SPOKANE INDS

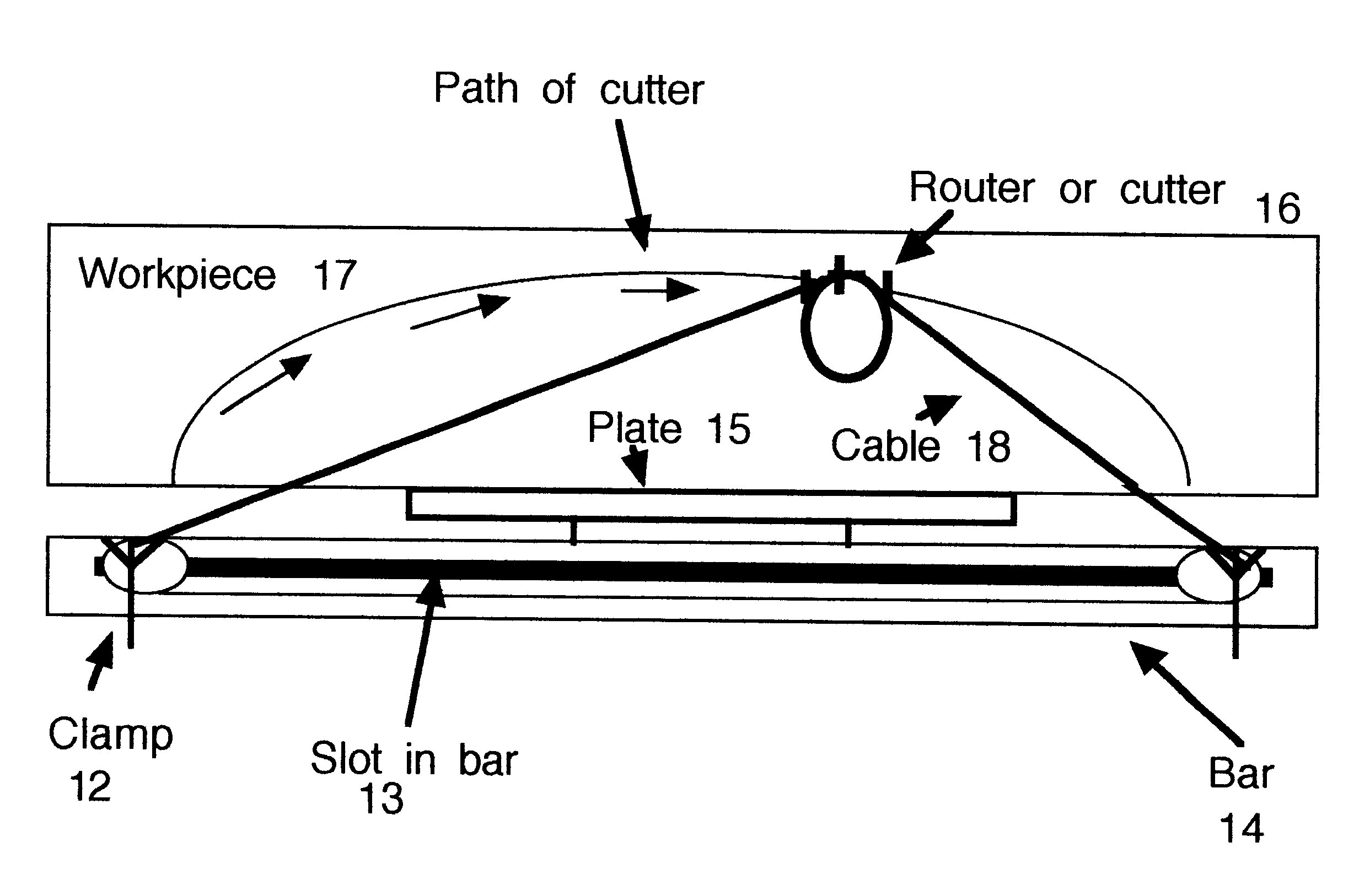

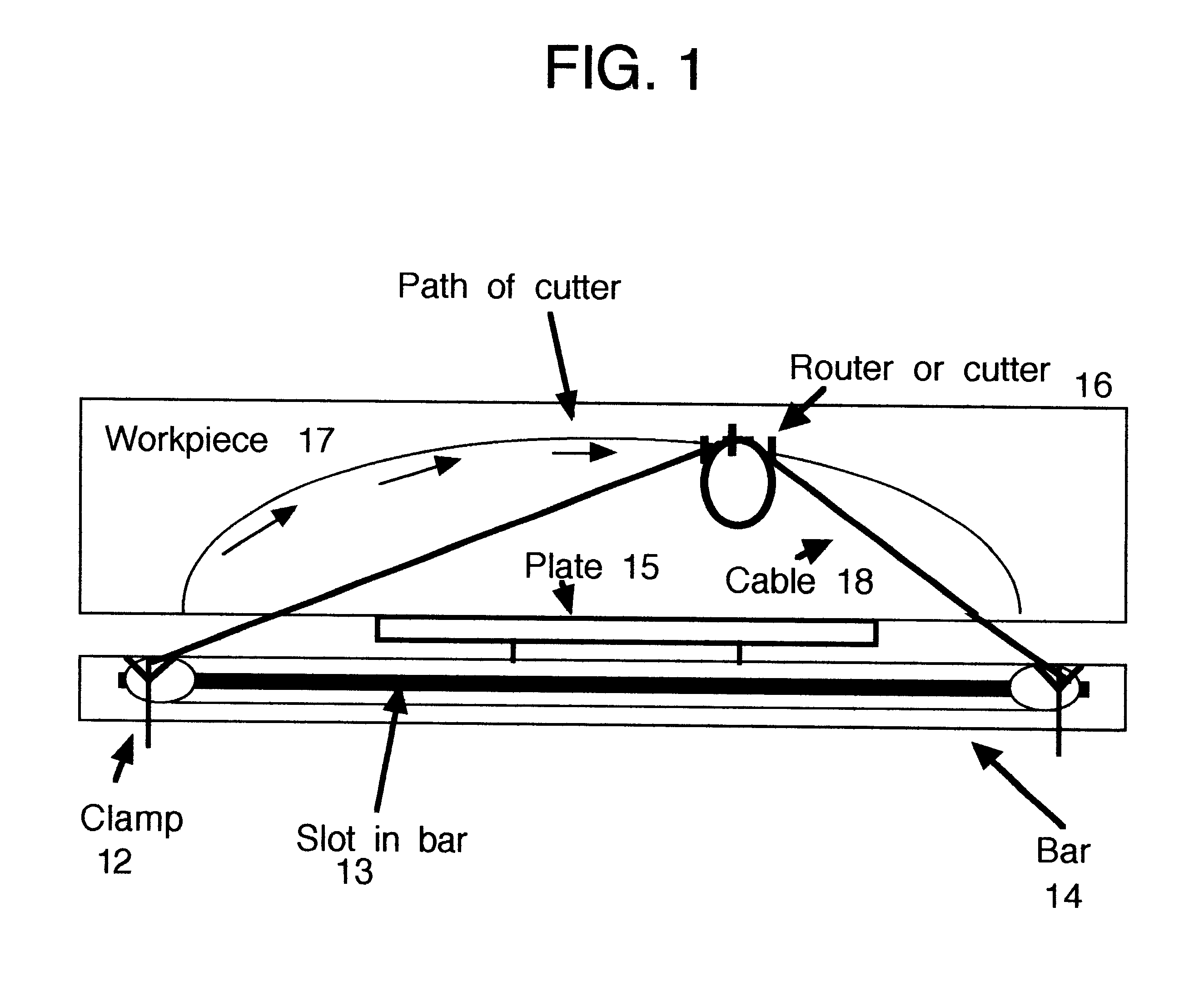

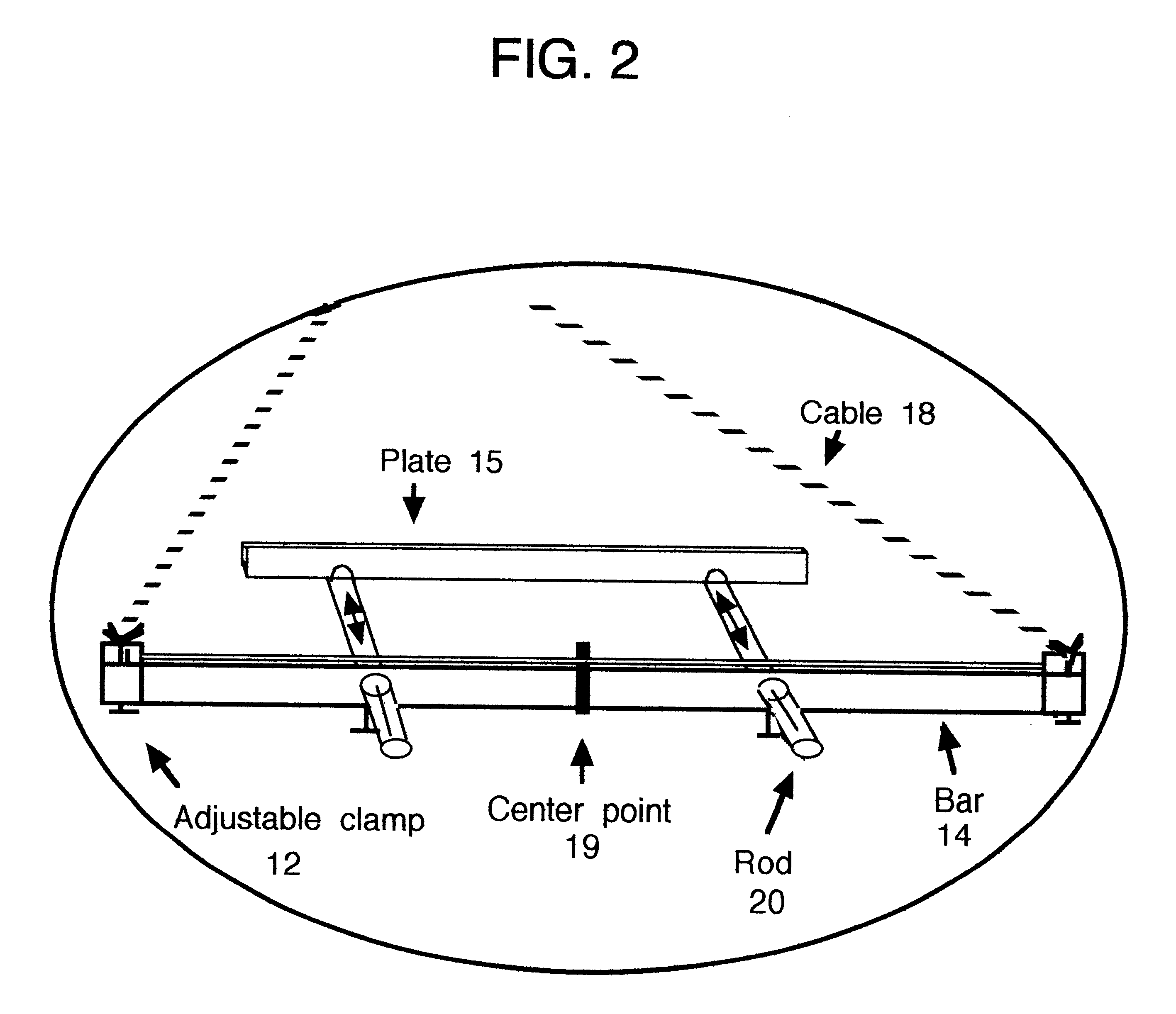

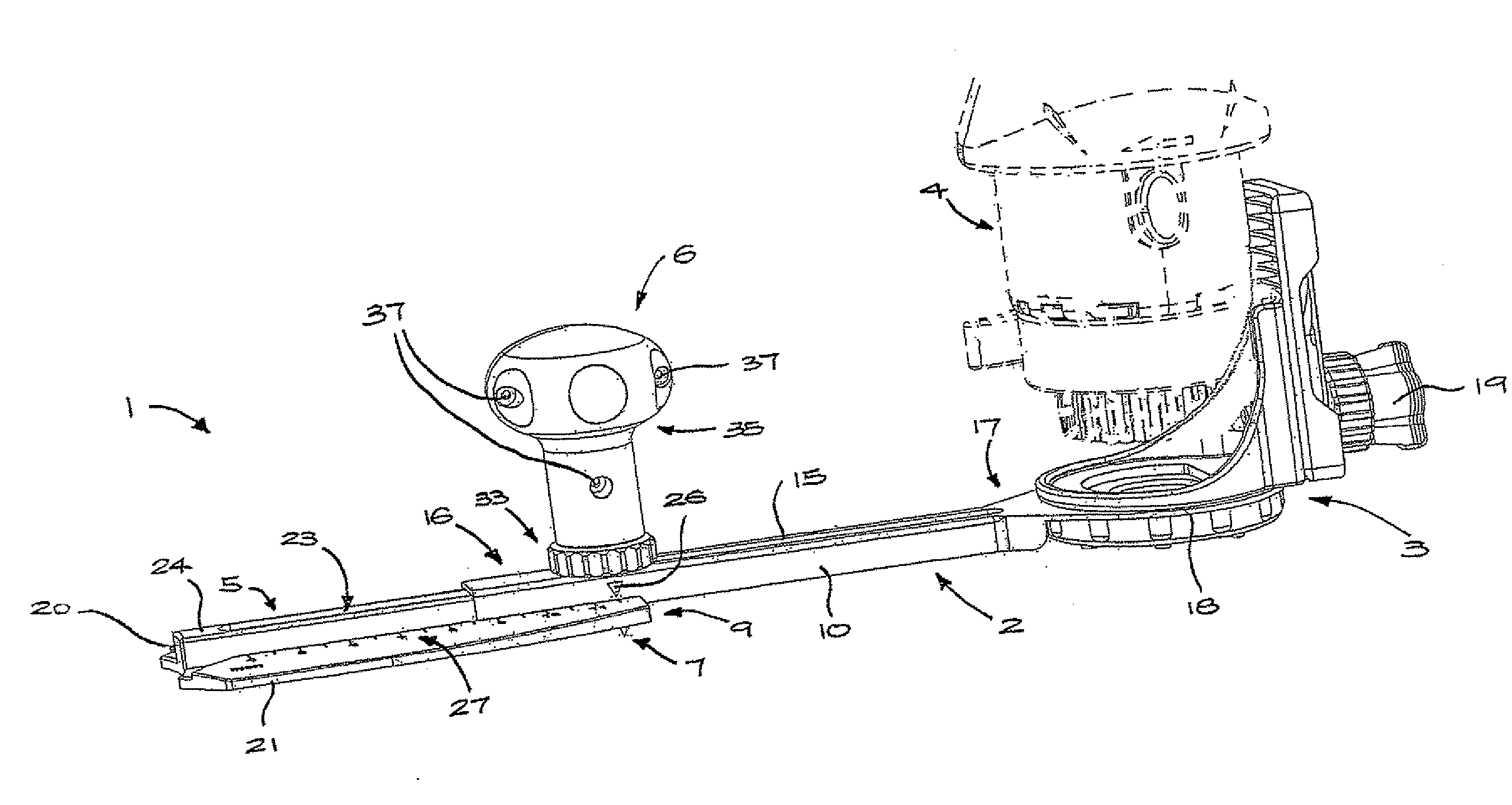

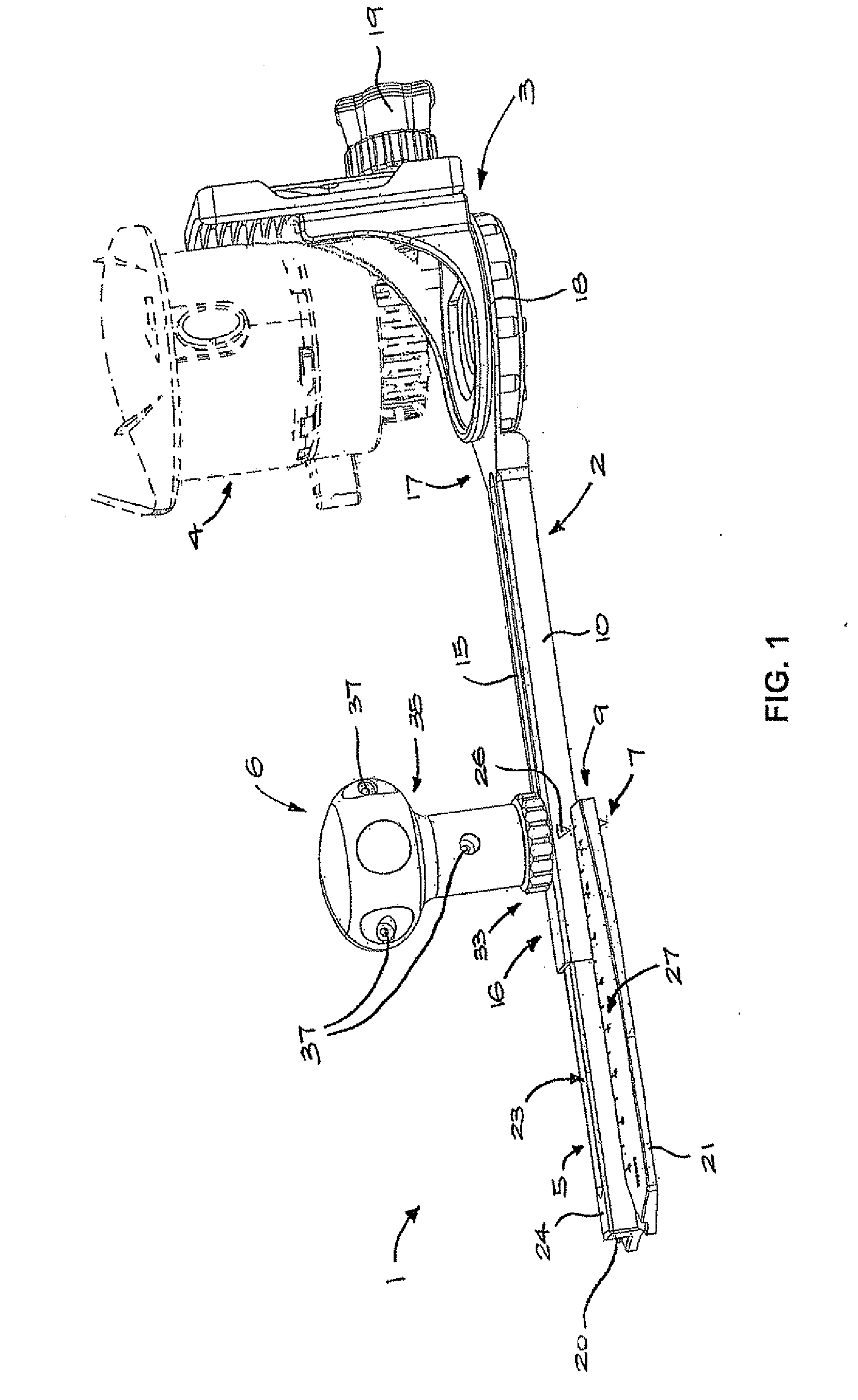

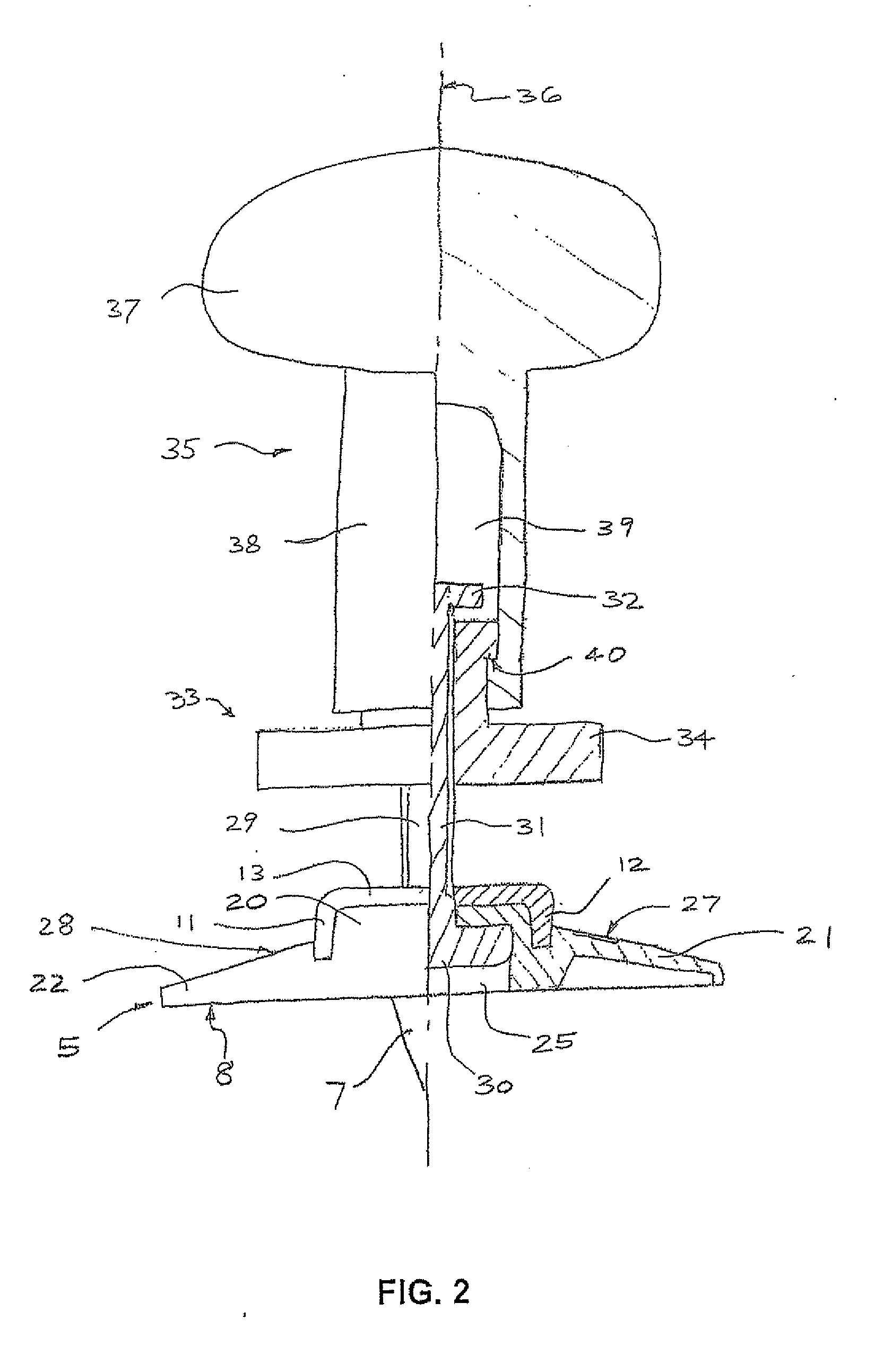

Arch cutting jig apparatus

InactiveUS6378580B1Multi-purpose machinesNon-circular curve drawing instrumentsEngineeringElectric cables

A jig apparatus that allows one to cut arches in a work piece quickly and efficiently. It is comprised of a bar that has sliding adjustable clamps that secure a cable which go around pulleys on a router or other cutting device that when the cable is pulled taut, creates a path for the router or other cutting device to follow while it cuts thus cutting an arch into the work piece. Prior to this apparatus one would have to cut this arch with a template which had been previously tooled. This jig apparatus creates a template and cut all in one step.

Owner:LOVETT PETER

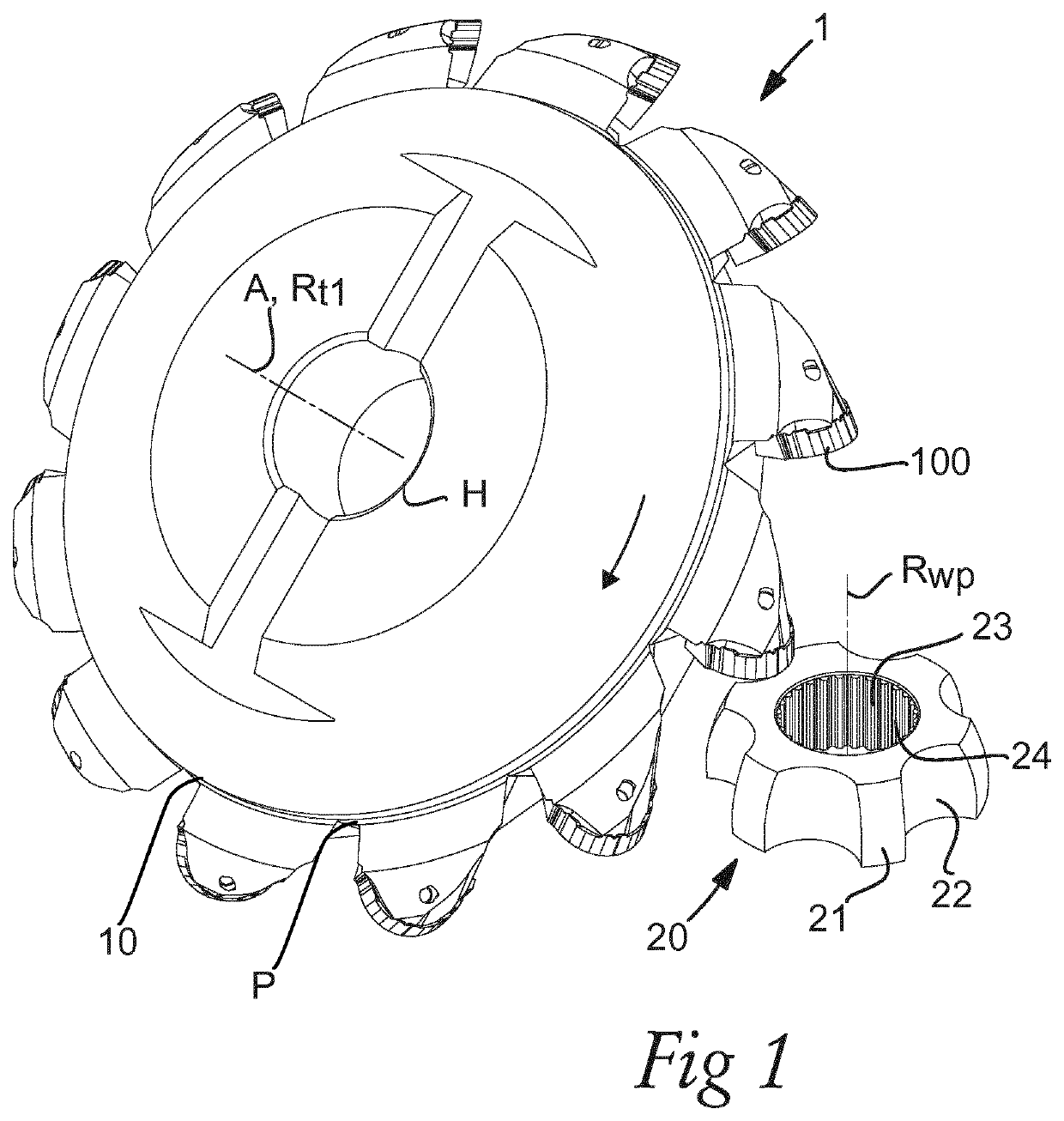

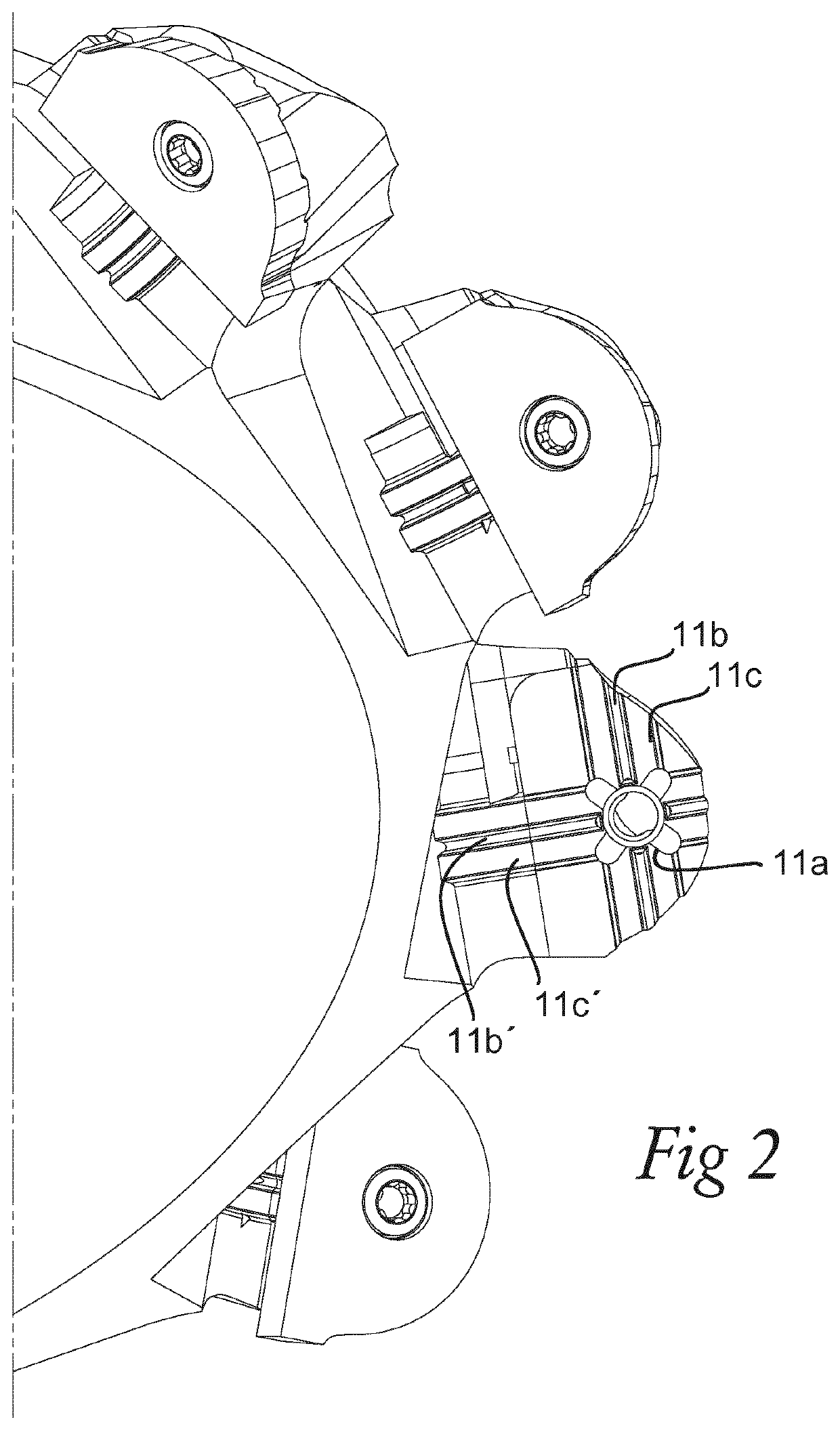

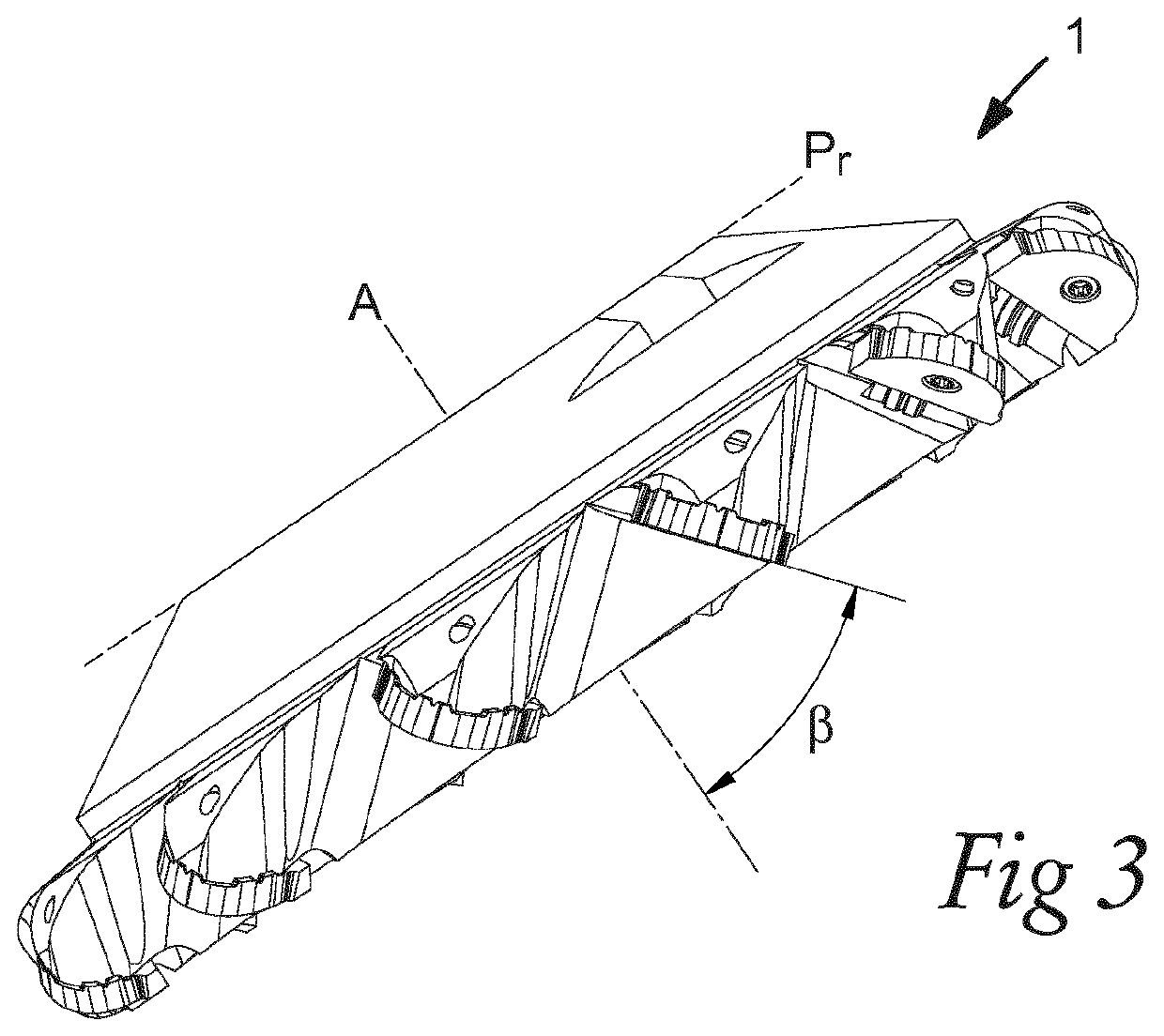

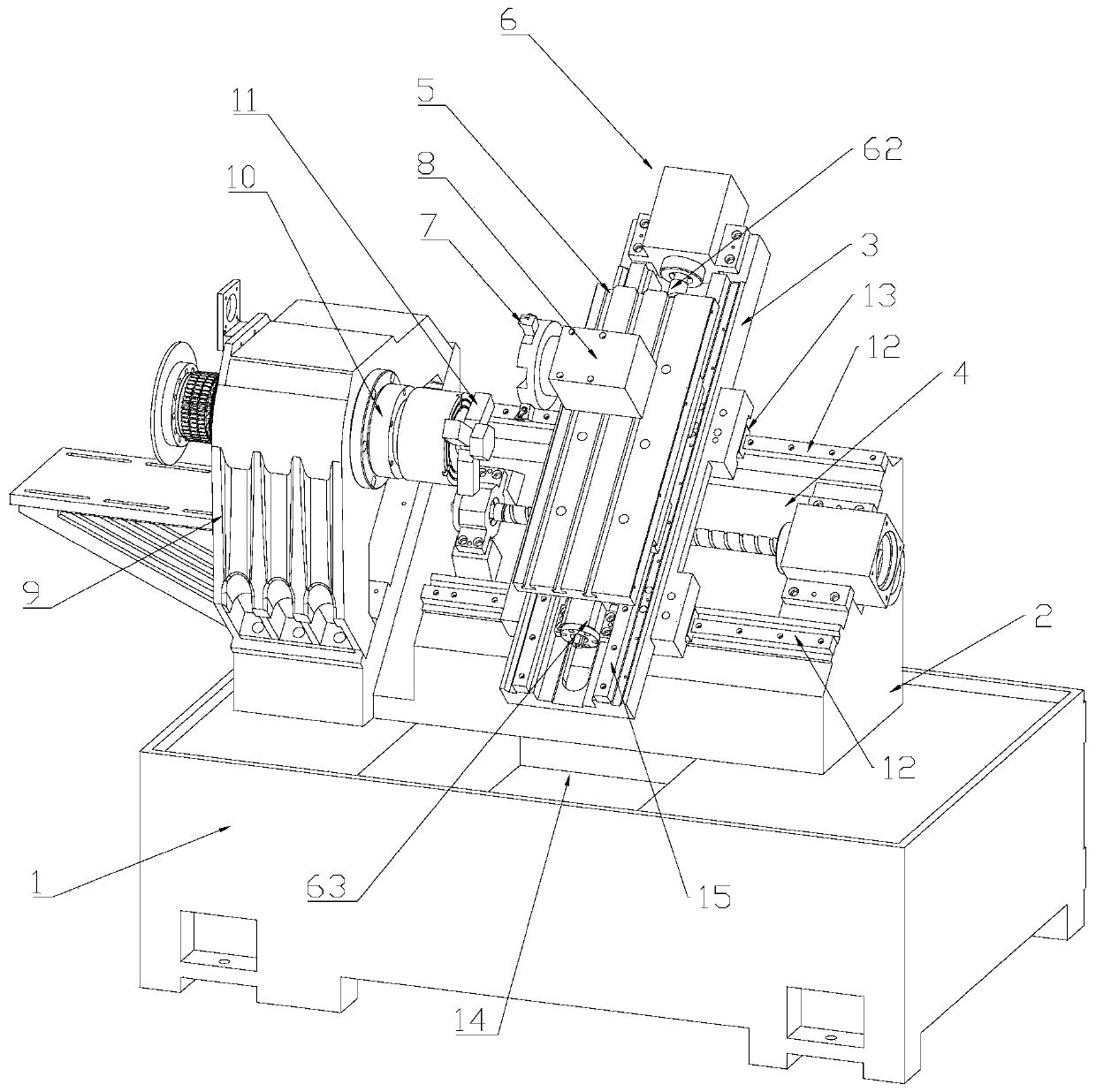

Method for machining of ball tracks of inner races of constant velocity joints

InactiveUS20190366455A1Reduce processing timeAdditional machiningMilling cuttersShearing machinesRotation velocityEngineering

A method for machining of ball tracks of an inner race of a constant velocity joint includes the step of providing a power skiving tool having a plurality of cutting members and a first axis of rotation and providing a work piece having an outer envelope surface extending along an axis of rotation. The first axis of rotation of the power skiving tool is arranged at a first distance from the axis of rotation of the work piece and oriented at a first angle. A first rotational speed to the power skiving tool and a second rotational speed to the work piece and a relative movement between the work piece and the power skiving tool, is applied such that the cutting members engage the outer envelope surface to machine the ball tracks. A cutting insert and a power skiving cutting tool are also provided.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

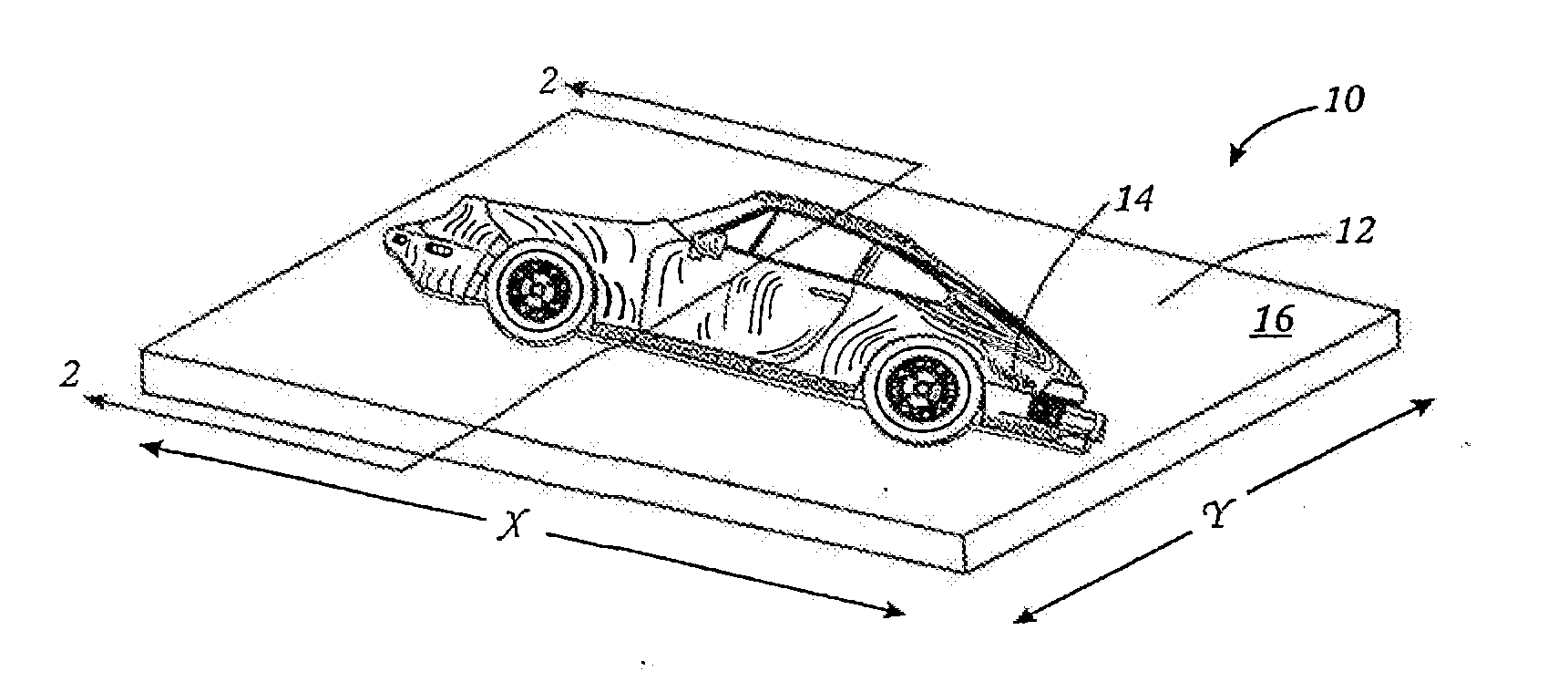

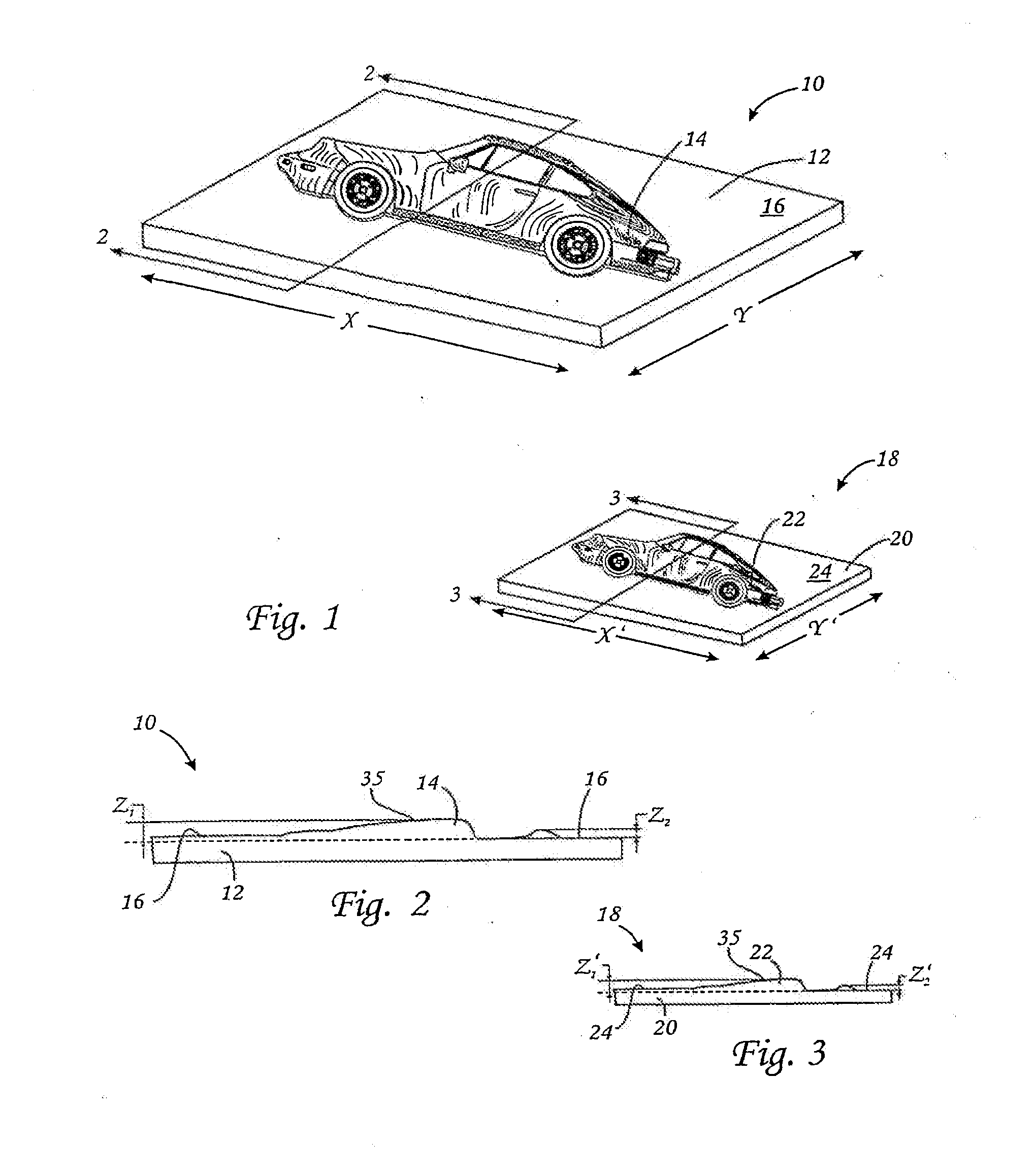

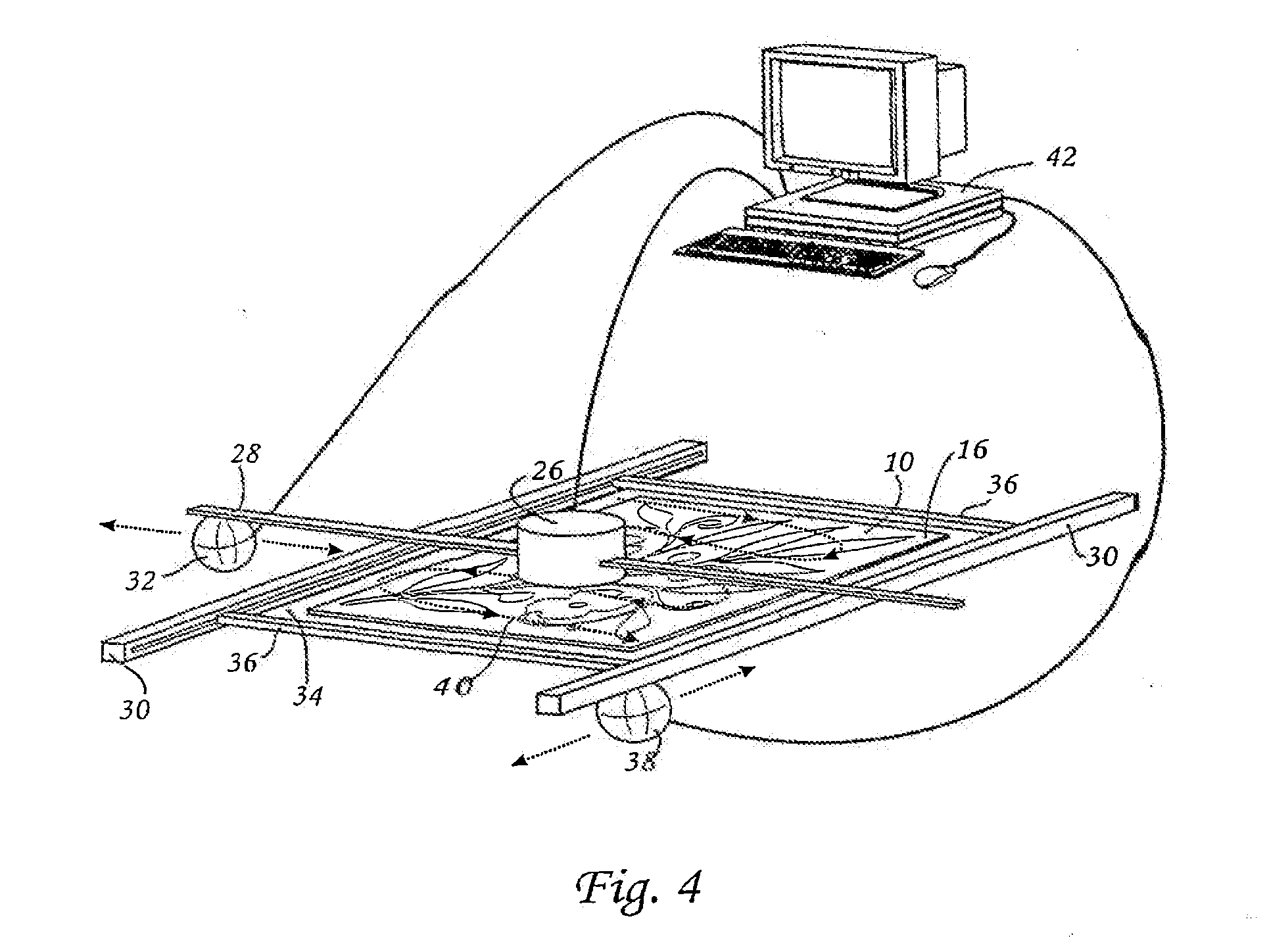

Method for the automated production of three-dimensional objects and textured substrates from two-dimensional or three-dimensional objects

InactiveUS20120215340A1Reduce stiffnessDecorative surface effectsThree-dimensional effectsComputer interpretationBrush stroke

Owner:CONRAD WAYNE ERNEST

Hobble turning method and preferred applications for said method

InactiveUS7513913B2Reduce manufacturing costEasy transferLathesTurning machine accessoriesArtificial hip jointsEngineering

Owner:HOERMANSDOERFER GERD

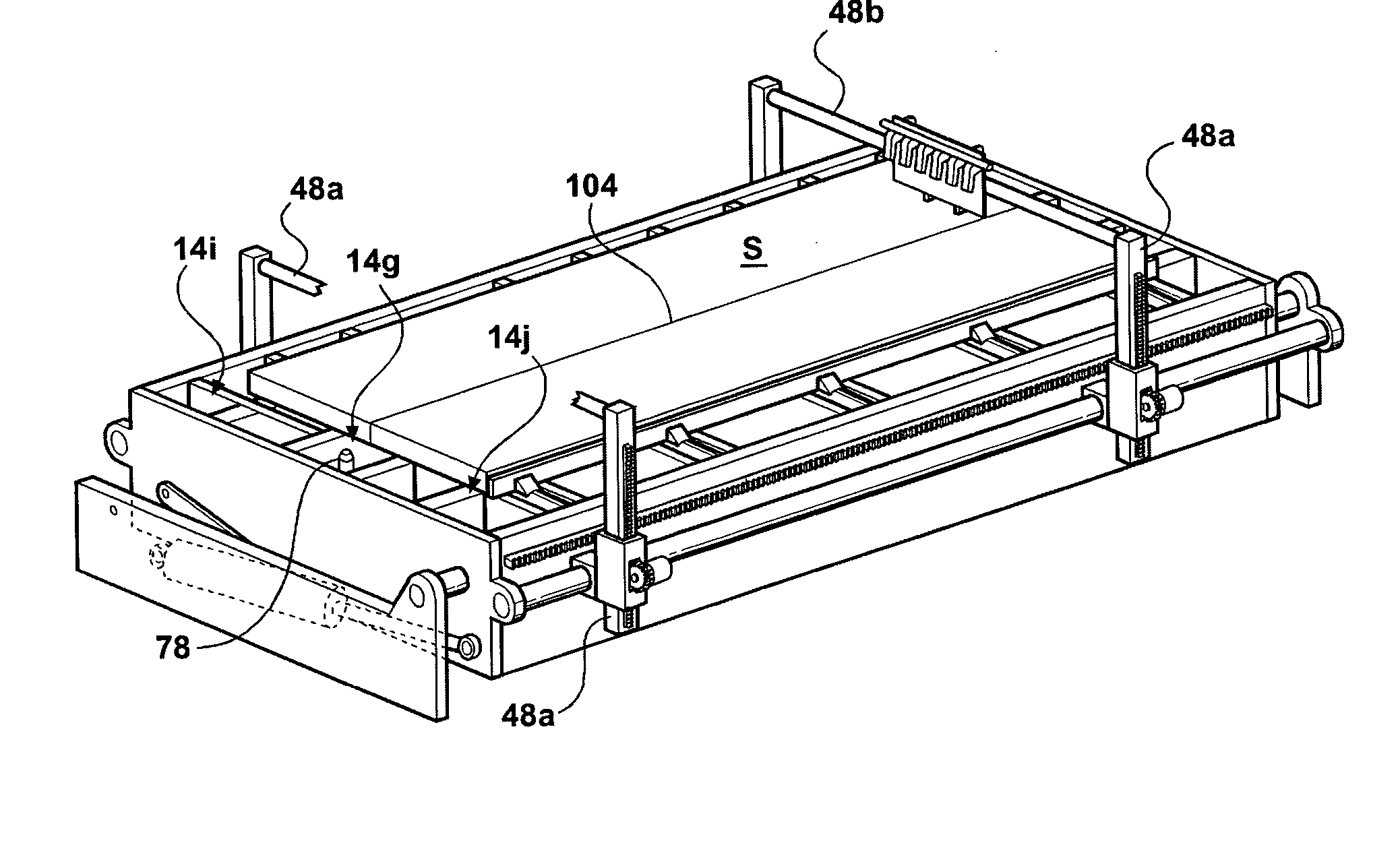

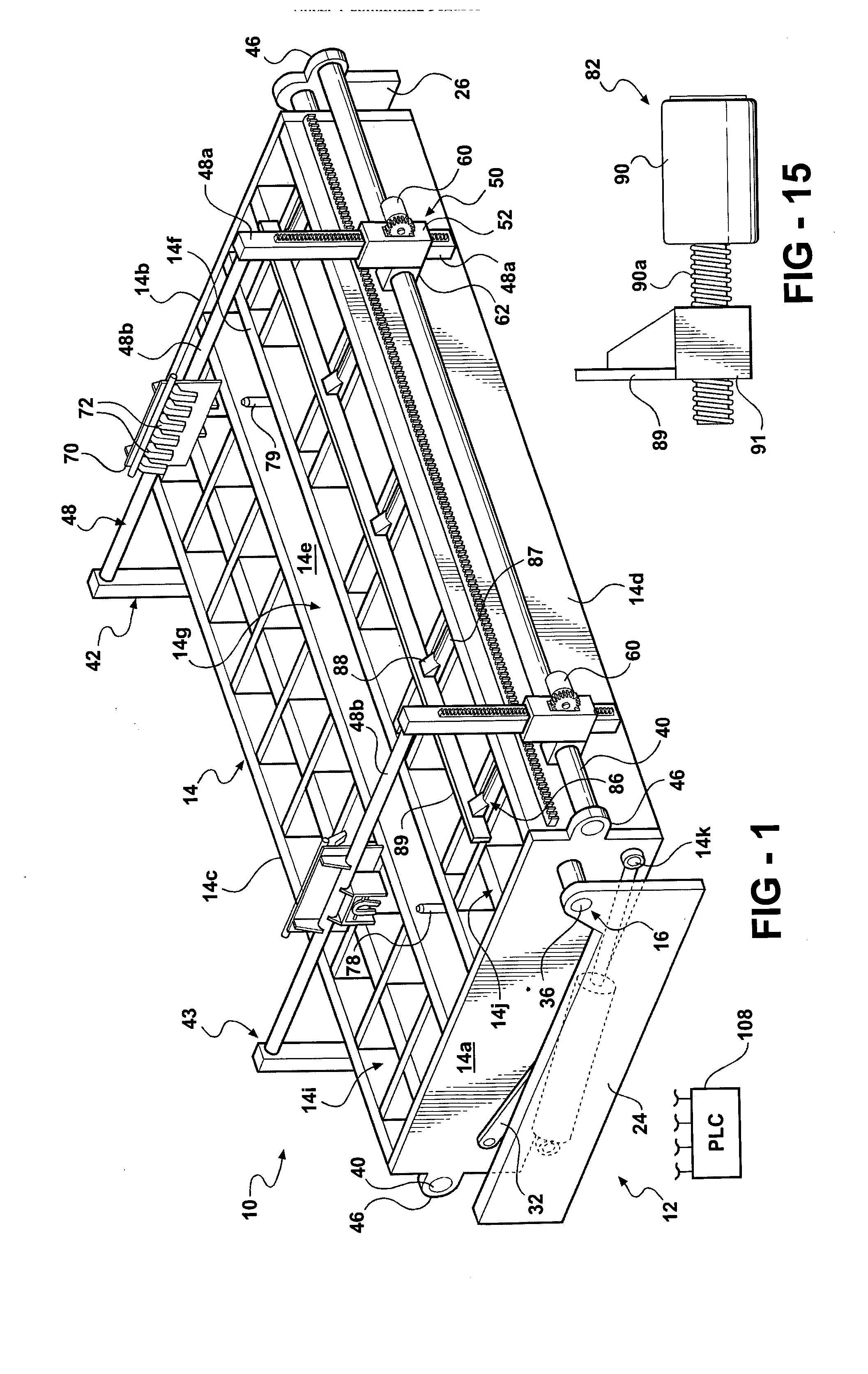

Method and apparatus for slitting steel slabs

A cutting table assembly for oxy cutting comprising a cutting table having a slab loading face and mounted for pivotal movement between a loading position in which the loading face is generally horizontal and a cutting position in which the face is oblique, and a pair of torches mounted on the table. The loading face is constituted by a pair of loading subfaces separated by a slot and the torches are mounted in the slot below the loading face. The torches are positioned at opposite ends of the slot prior to the initiation of the cutting action and, upon the initiation of the cutting action, move toward each other and cut into opposite ends of the slab. A pair of gantries are mounted on the table and each carries a deburring device positioned in overlying opposition to a respective torch. Each gantry further includes a plurality of spaced downwardly directed nozzles which are supplied with compressed air to generate an air curtain.

Owner:EDWARD C LEVY

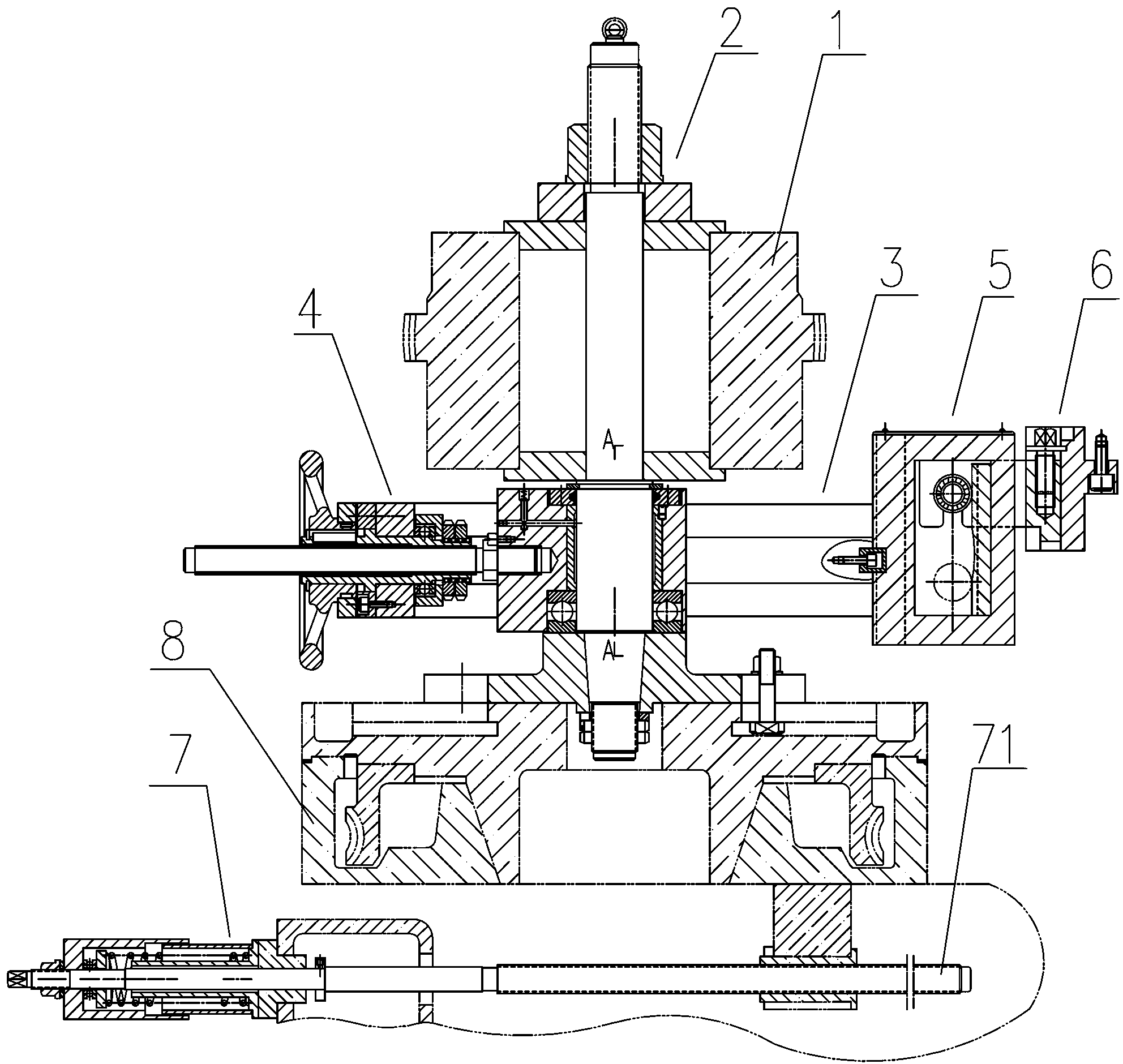

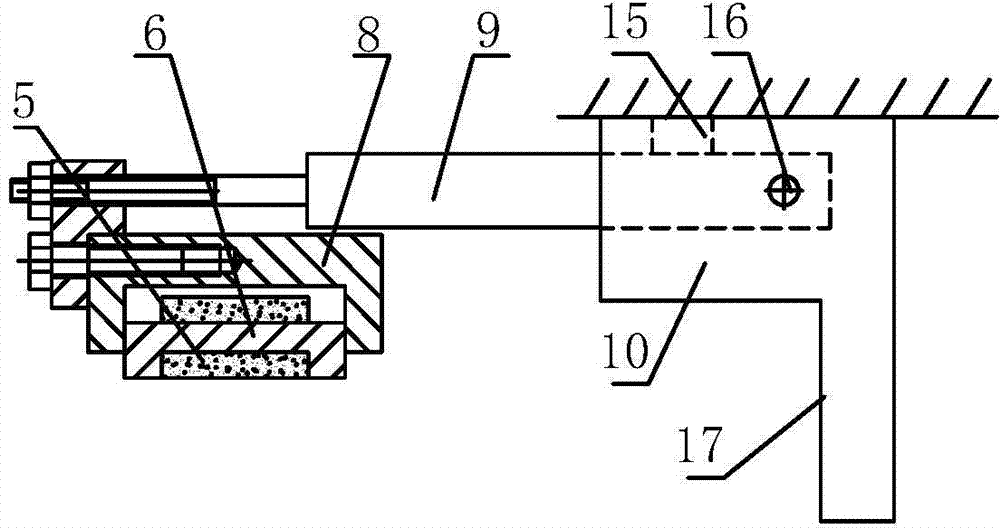

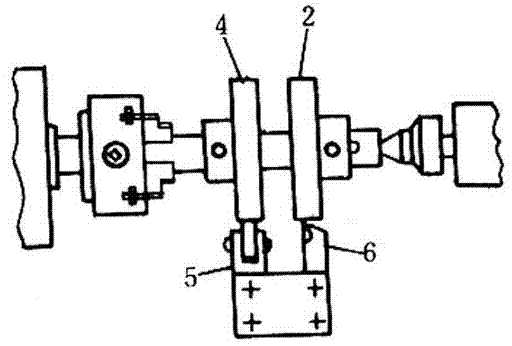

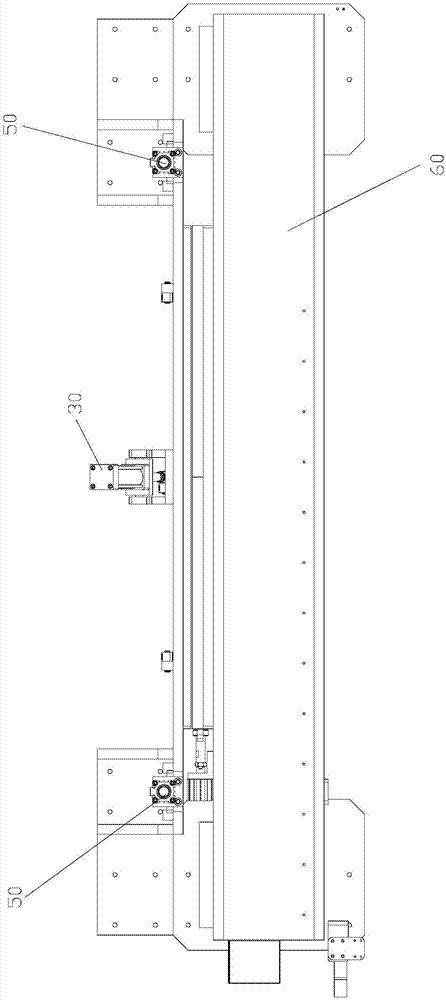

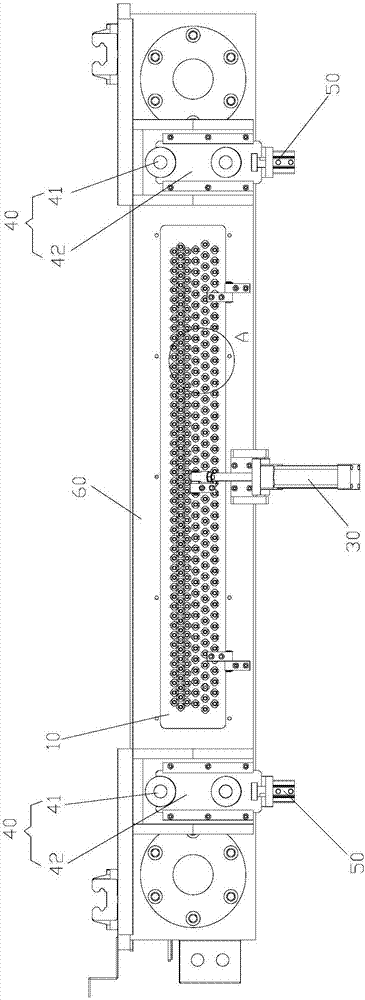

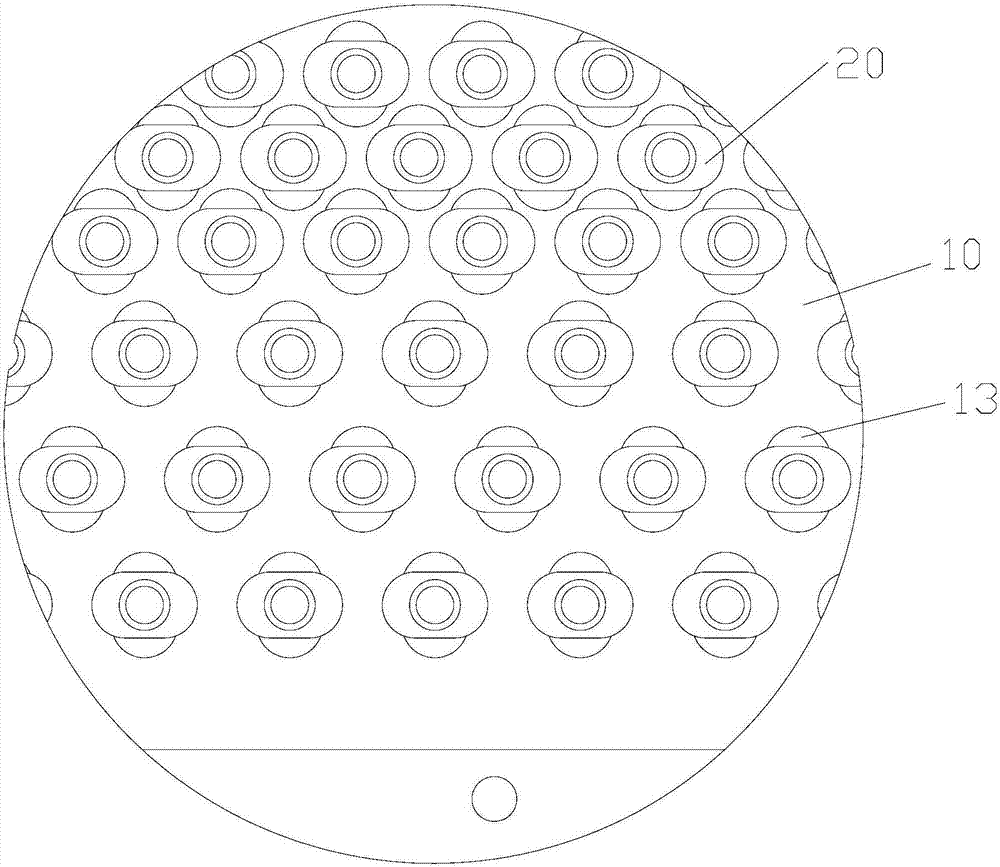

Device assisting ordinary gear hobbing machine in machining arc-shaped gear

The invention relates to a fixture assisting an ordinary gear hobbing machine in machining an arc-shaped gear. The fixture assisting the ordinary gear hobbing machine in machining the arc-shaped gear comprises a positioning device, a rail device, a hand wheel adjusting device, a profiling device, an idler wheel device and a tension device, wherein the positioning device fixes a gear blank on a working platform of the gear hobbing machine, the rail device is embedded in the positioning device, the hand wheel adjusting device is simultaneously and fixedly connected with one side, away from an idler wheel, of the positioning device and one side, away from the idler wheel, of the rail device, the hand wheel adjusting device can control the rail device to slide back and forth along the connecting line of the center of a gear and the center of a hob, the profiling device is fixedly connected with one side, close to the hob, of the rail device, the idler wheel device is fixedly connected with a knife rest of the hob and can move in the axial direction of the gear along with the knife rest of the hob, and the tension device is connected with the working platform of the gear hobbing machine in a threaded mode. The tension device always pulls and presses the profiling device on the idler wheel device, and a section of working surface which is in the axial direction of the gear and completely in line with a gear bus is arranged on one face, making contact with the idler wheel device, of the profiling device so that the gear can move in the radial direction of the gear relative to the hob.

Owner:SINOSTEEL HENGYANG MACHINERY

Arc-cutting guide for a portable powered hand tool

InactiveUS20090038460A1Accurate measurementEffective and efficient in operational useMilling machinesGeometric arrangementsMechanical engineeringEngineering

A swing arm has a fixture at one end for mounting a hand tool, and a longitudinally-extending channel including a slot. An elongate slider member is engaged in the channel, and includes a point offset longitudinally from center of the slider member for engagement with a workpiece to define a center about which the swing arm is rotated. A fastener having a head and threaded shank is retained in a recess such that the shank extends through the slot. A threaded knob is engaged with the shank for clamping the slider member in position, and a handle connected to and captively retained with the knob is free to rotate about a handle axis.

Owner:CHOON NANG ELECTRICAL APPLIANC

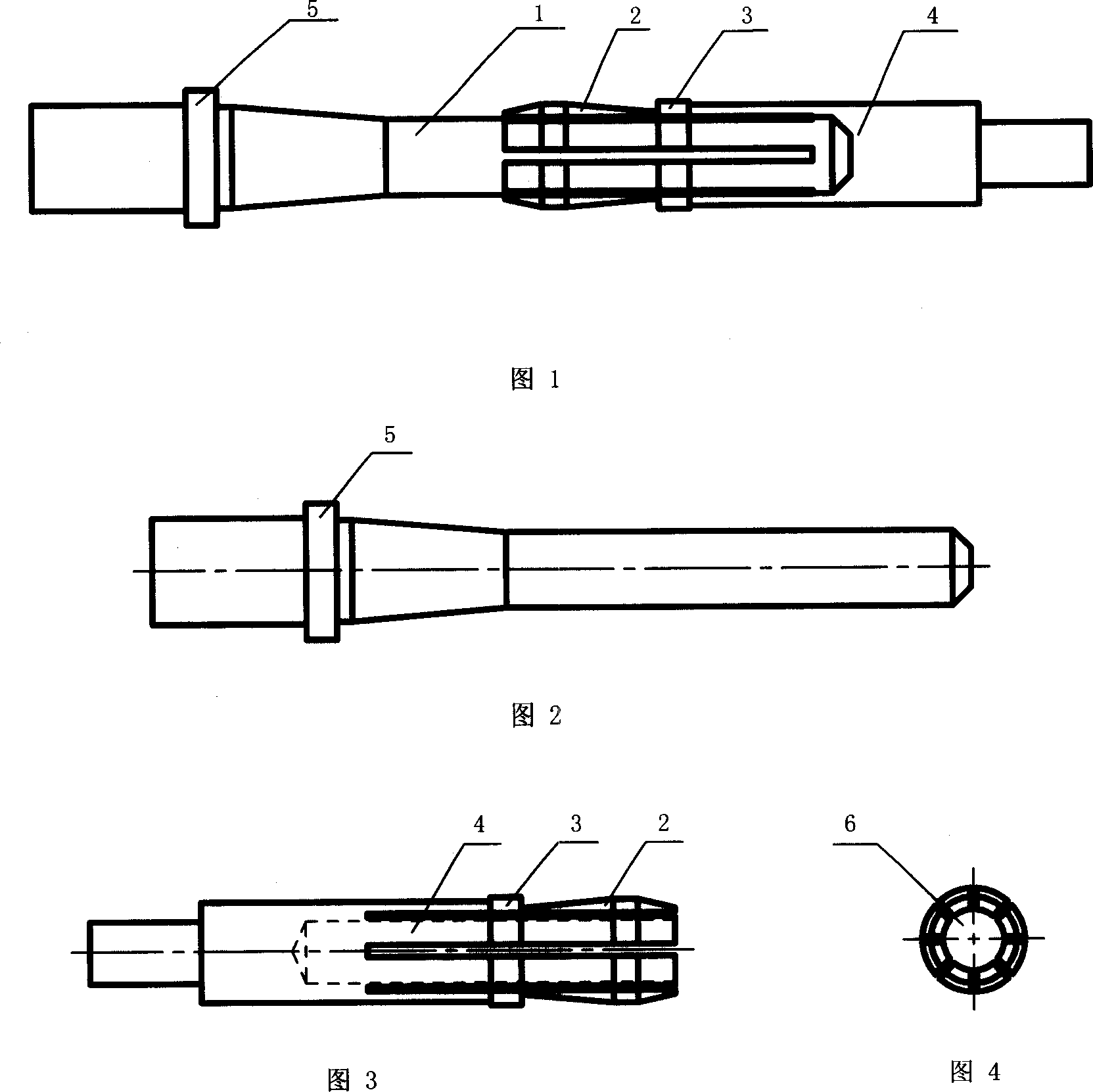

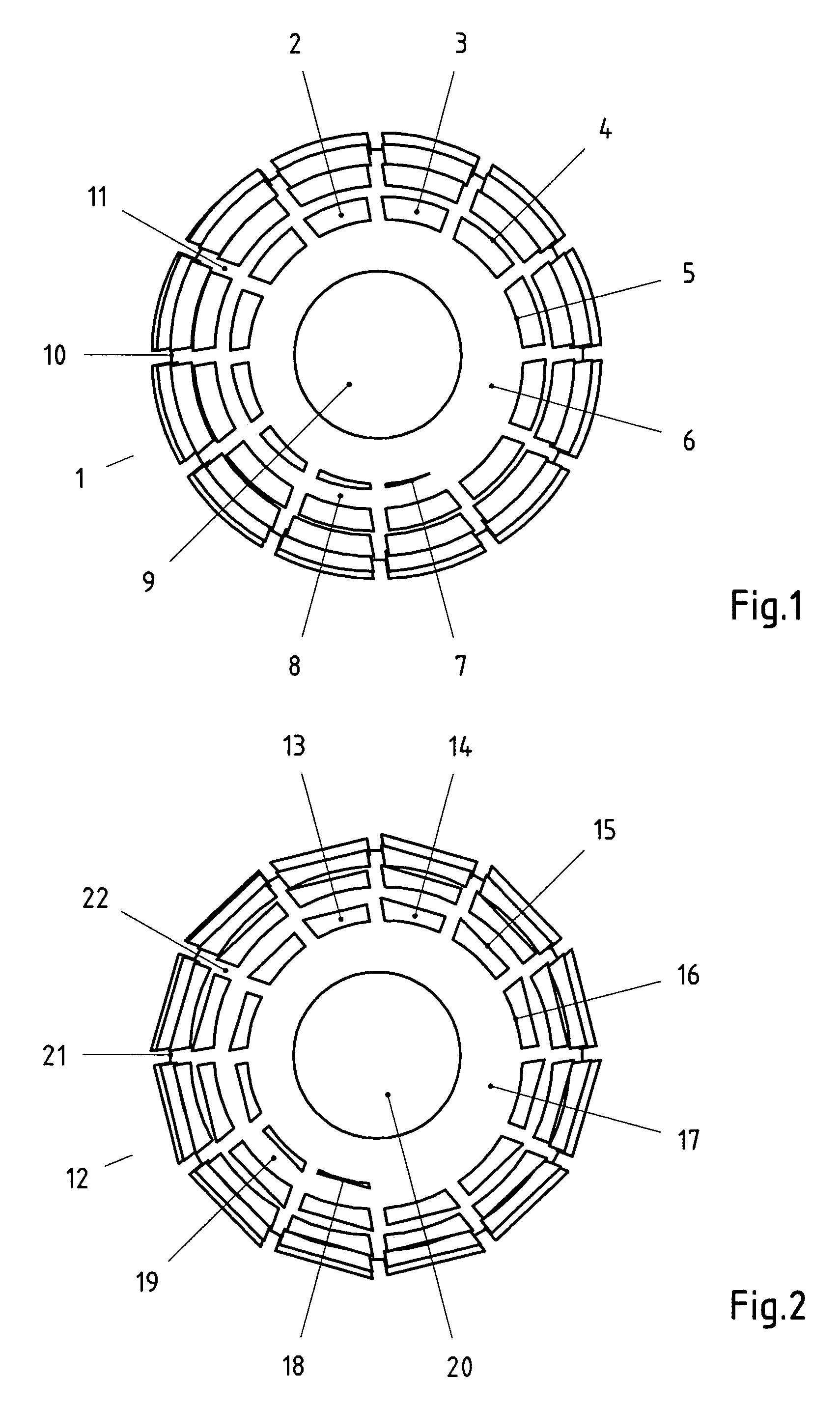

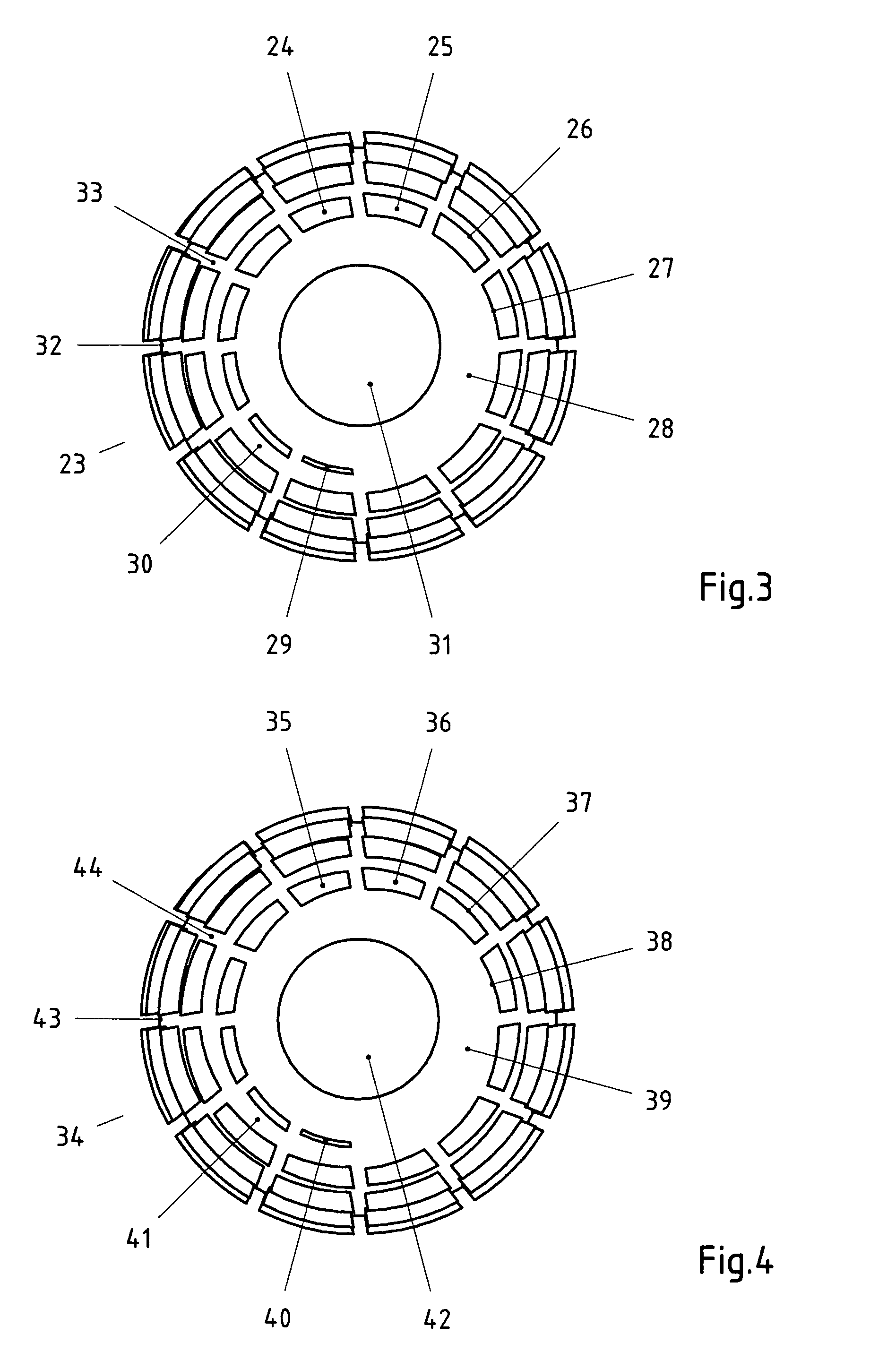

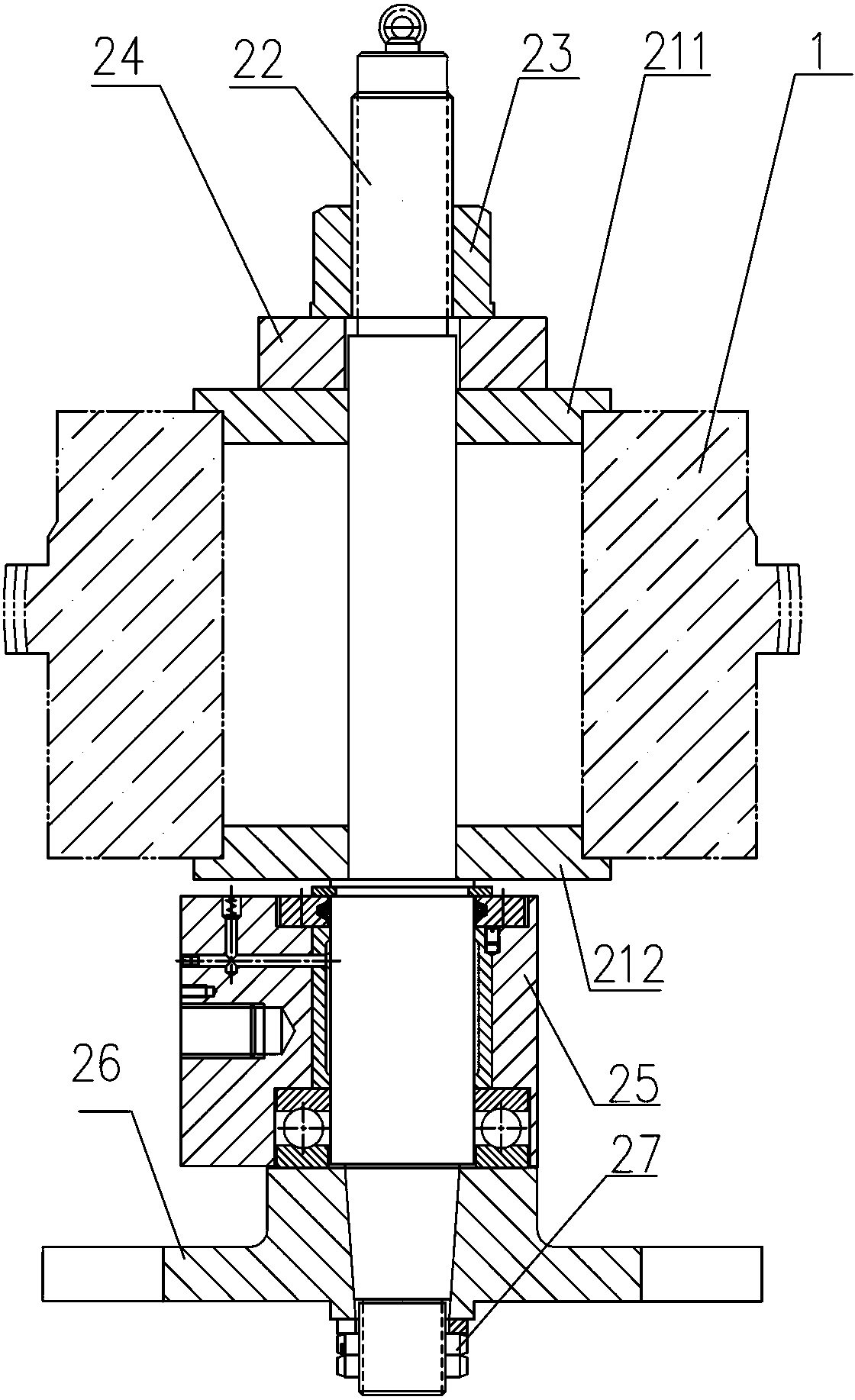

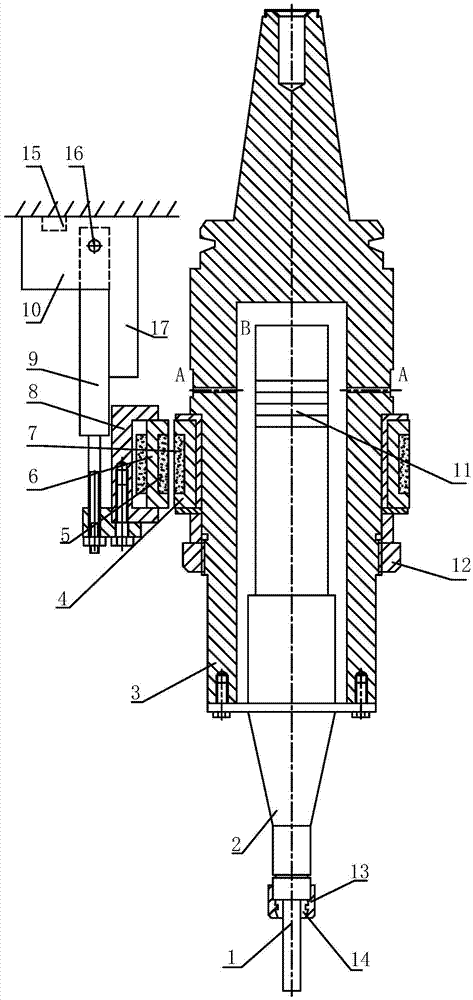

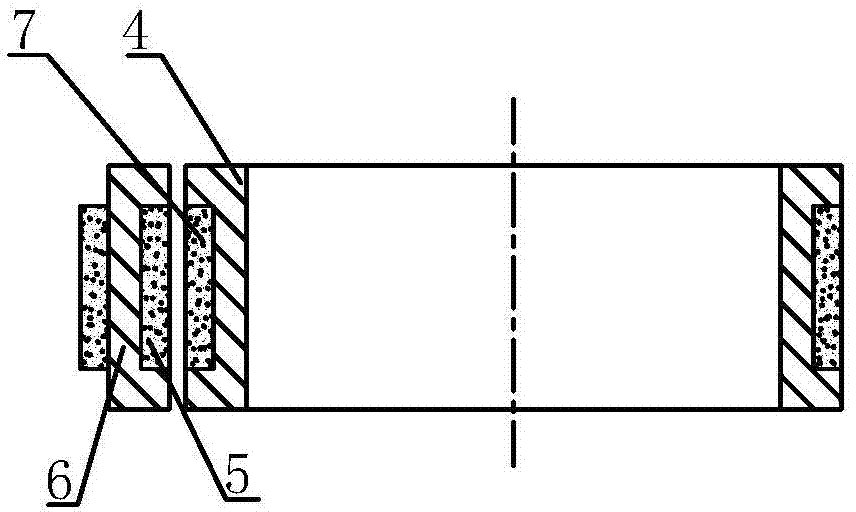

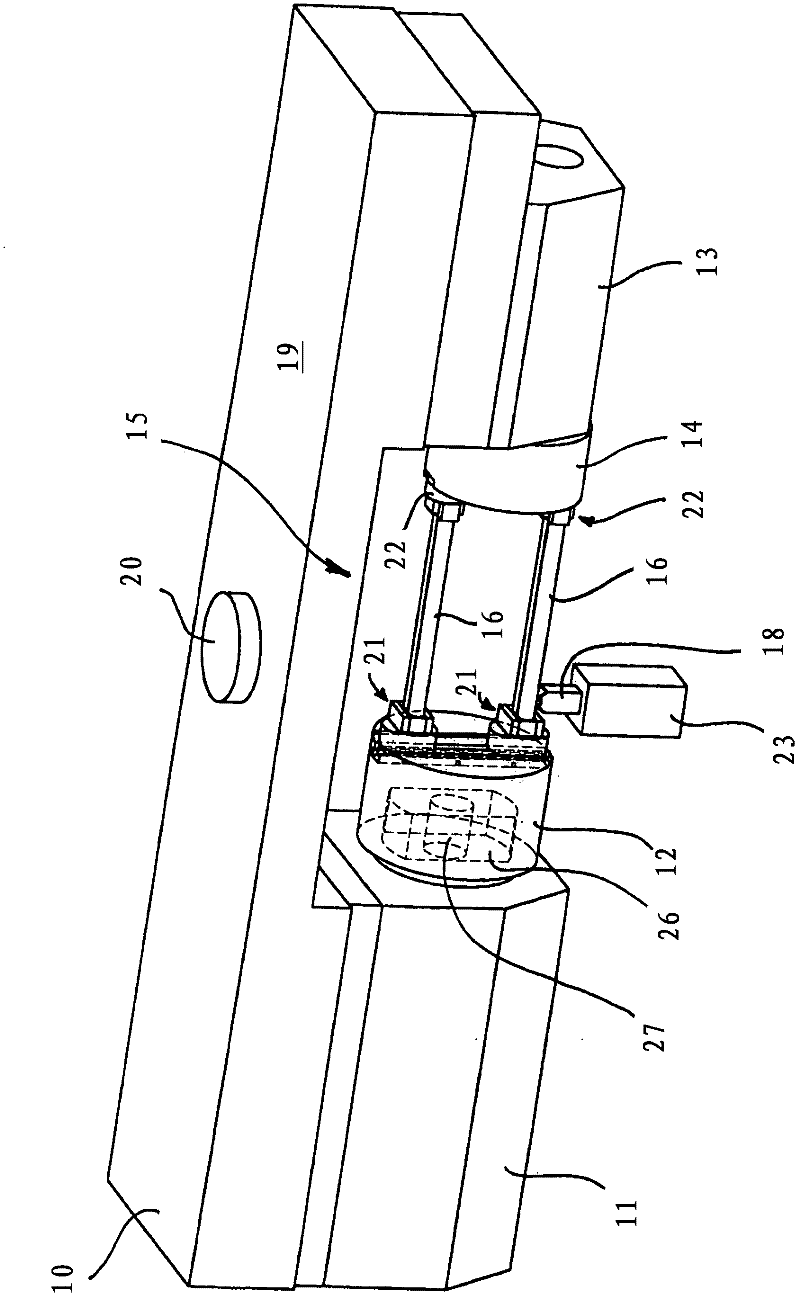

Locally induced attached rotary ultrasonic head based on machine tool

InactiveCN104842203AReduce in quantityReduce lossGeometric arrangementsPositioning apparatusUltrasonic machiningUltrasonic vibration

The invention discloses a locally induced attached rotary ultrasonic head based on a machine tool. The locally induced attached rotary ultrasonic head based on the machine tool comprises a hilt, wherein the hilt is connected with an ultrasonic vibration working device; a non-contact type current collecting ring sleeves the hilt; the rotary axis of the ultrasonic vibration working device, the rotary axis of the hilt and the rotary axis of the current collecting ring are positioned on the same straight line; the non-contact type current collecting ring comprises a main side magnetic core and a secondary side magnetic core; the main side magnetic core consists of an arc-shaped or rectangular permeability magnetic material; the secondary side magnetic core consists of an annular permeability magnetic material; the main side magnetic core and the secondary side magnetic core are coaxial; coils are respectively wound on the main side magnetic core and the secondary side magnetic core; the main side magnetic core is connected with a body of the machine tool through a connecting device; and the secondary side magnetic core sleeves the hilt fixedly. The structure of the attached rotary ultrasonic head is simplified, abrasion and energy loss of parts in a rotary ultrasonic machining process are reduced, and the working reliability of the locally induced attached rotary ultrasonic head is improved. Owing to transmission of locally induced non-contact energy, knives are changed simply, and change of the knives can be controlled automatically.

Owner:TIANJIN UNIV

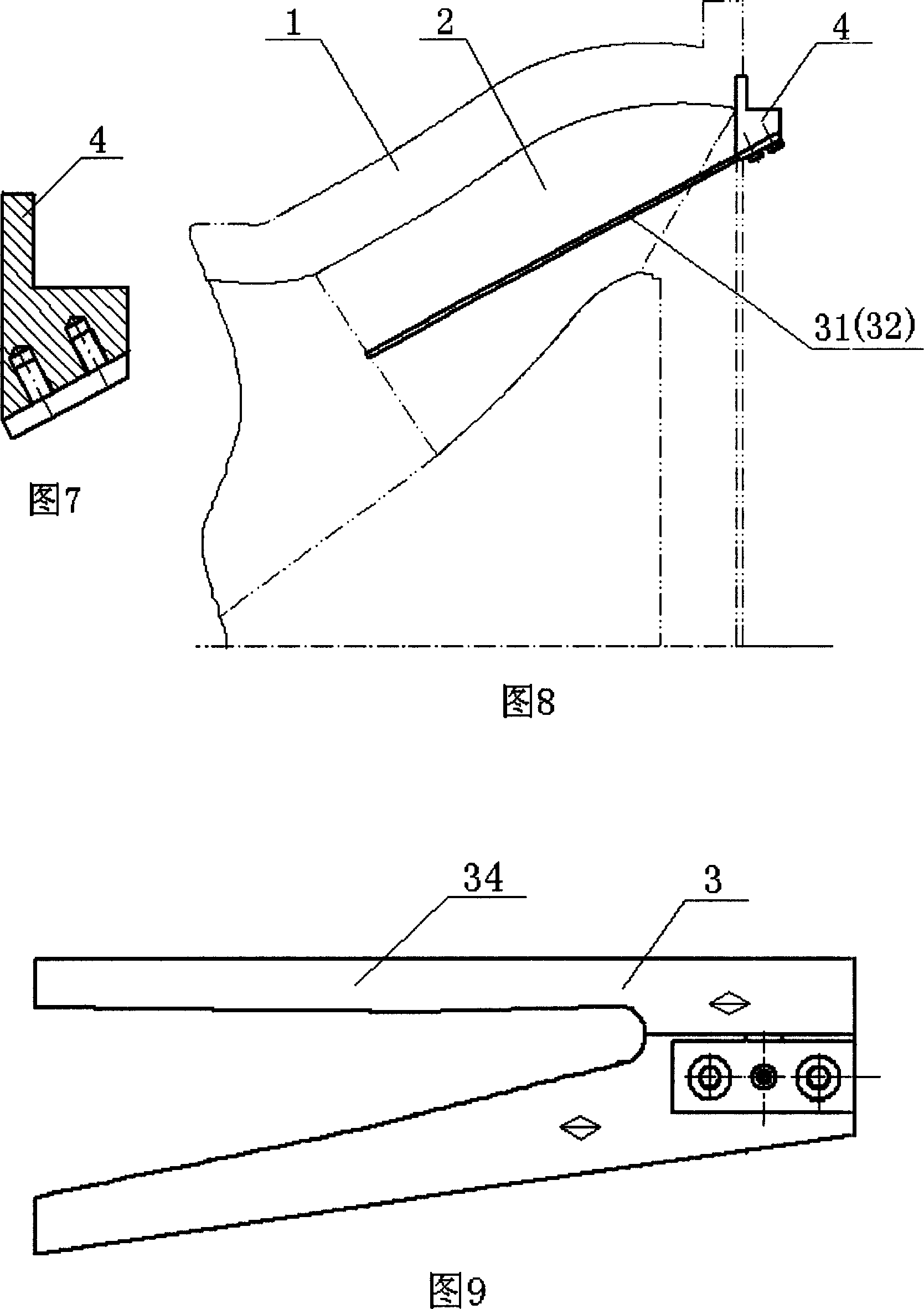

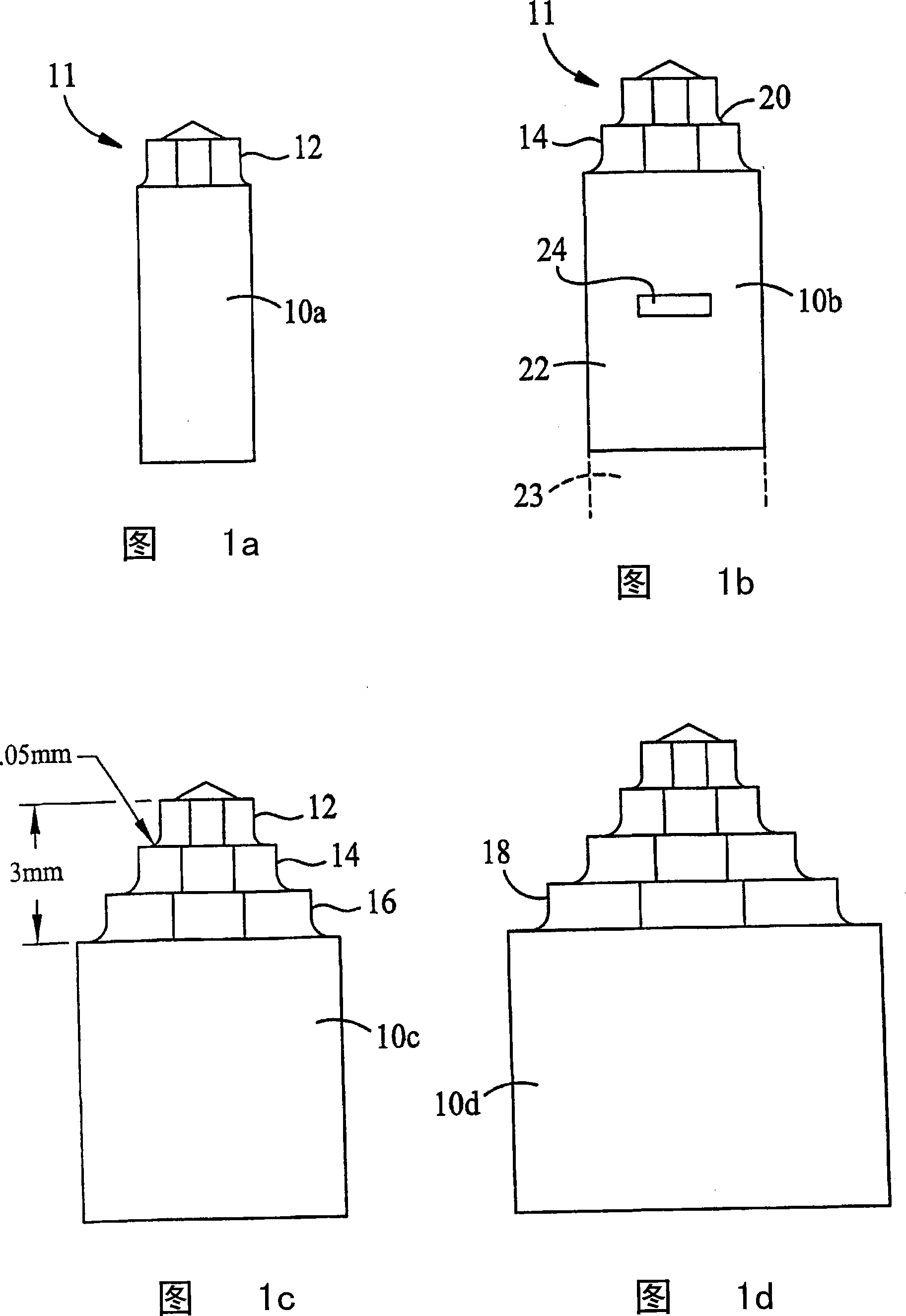

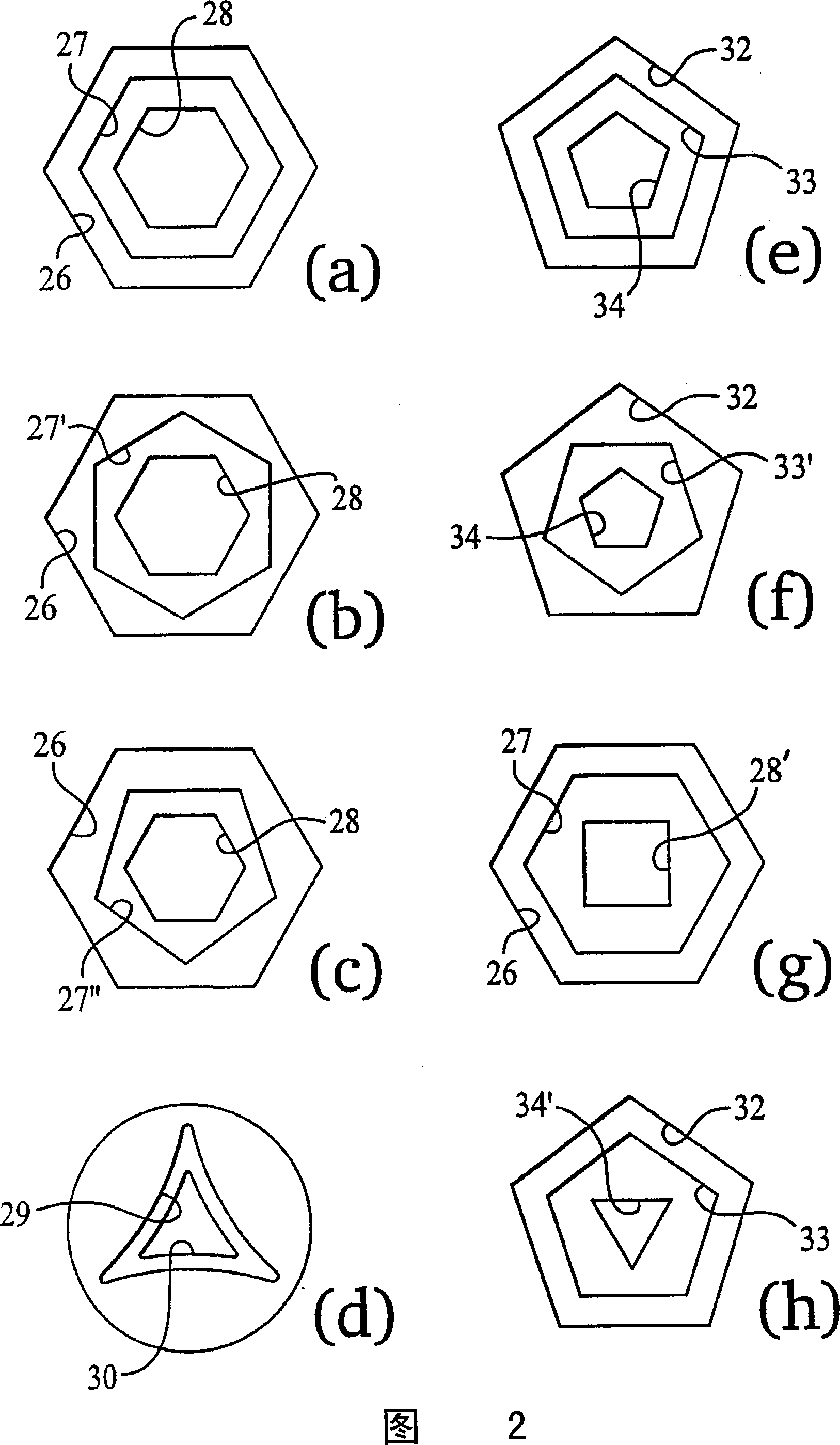

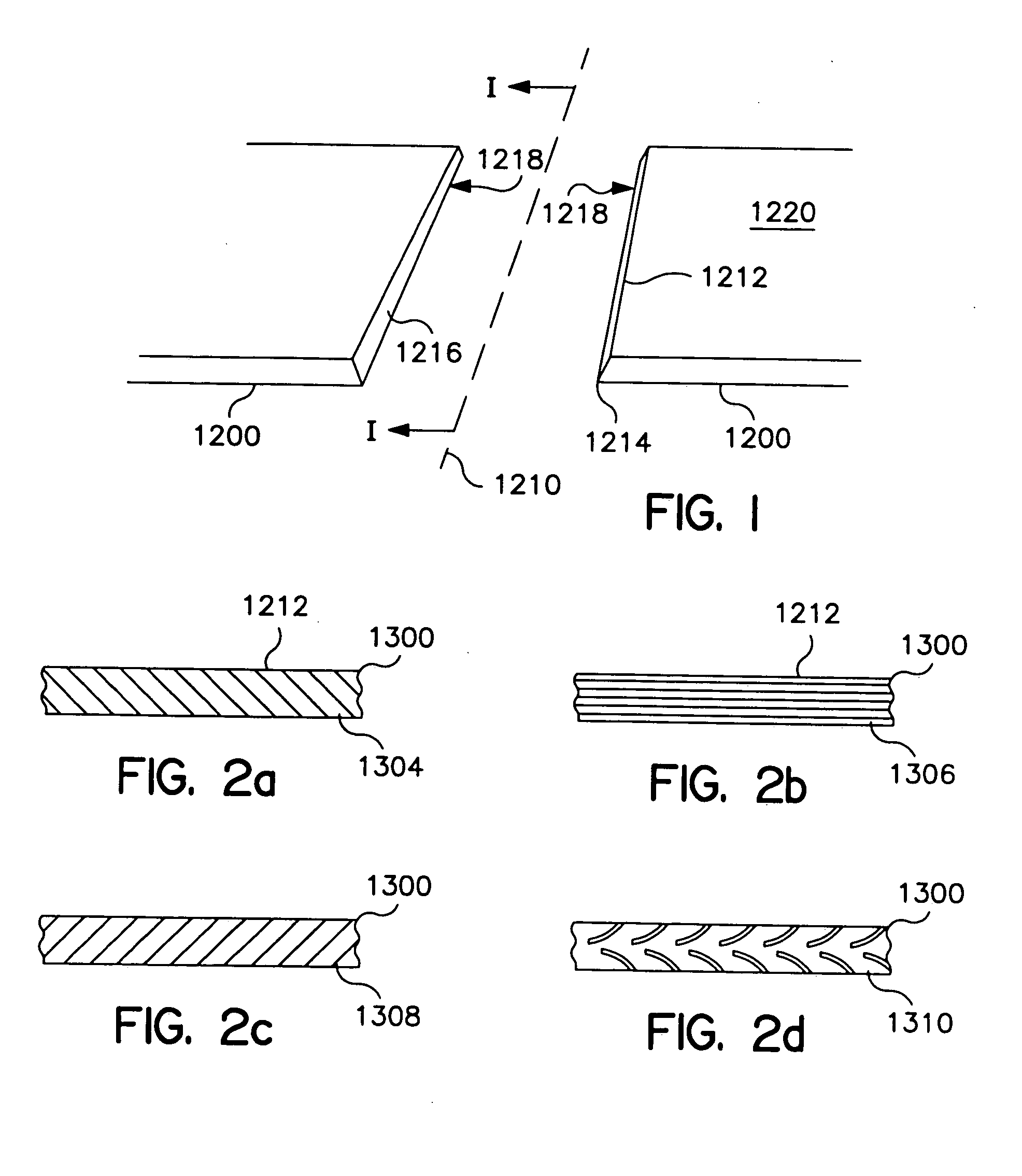

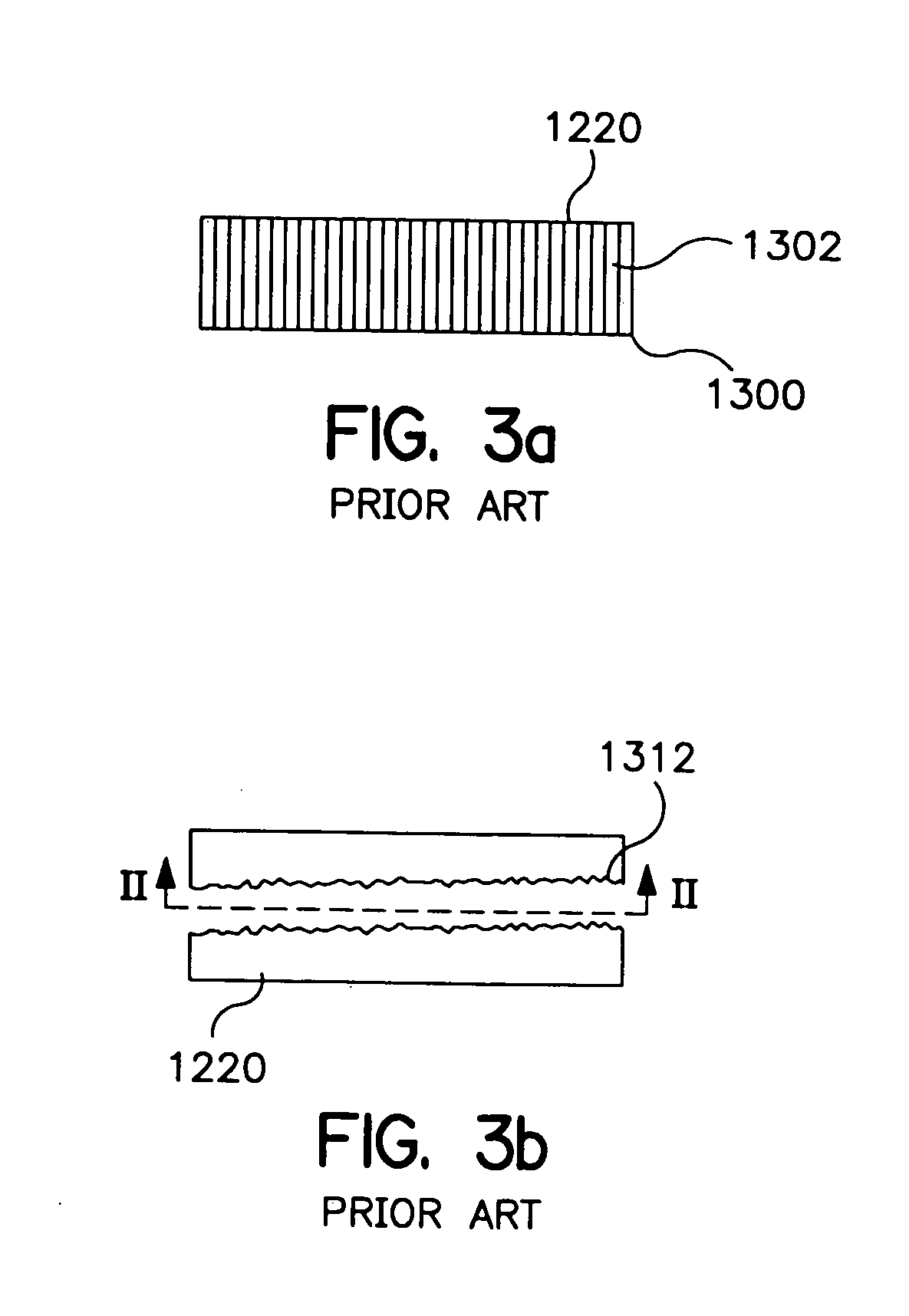

A method for manufacturing cold forming punch pin of screw head with multi-layer groove

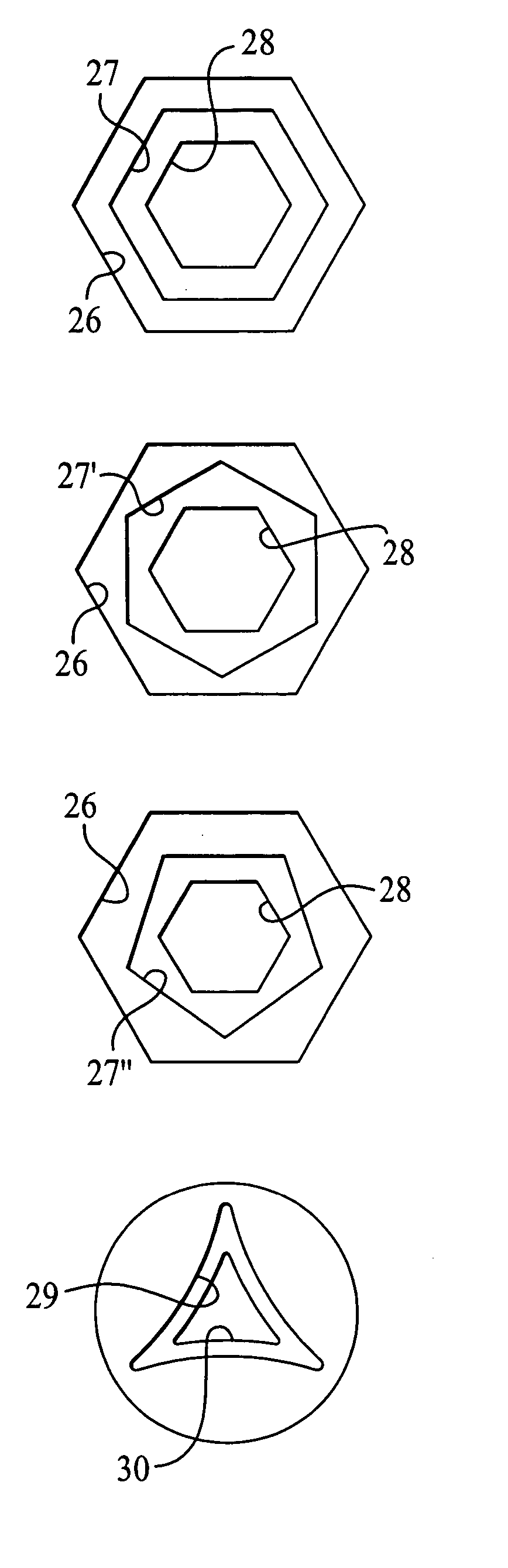

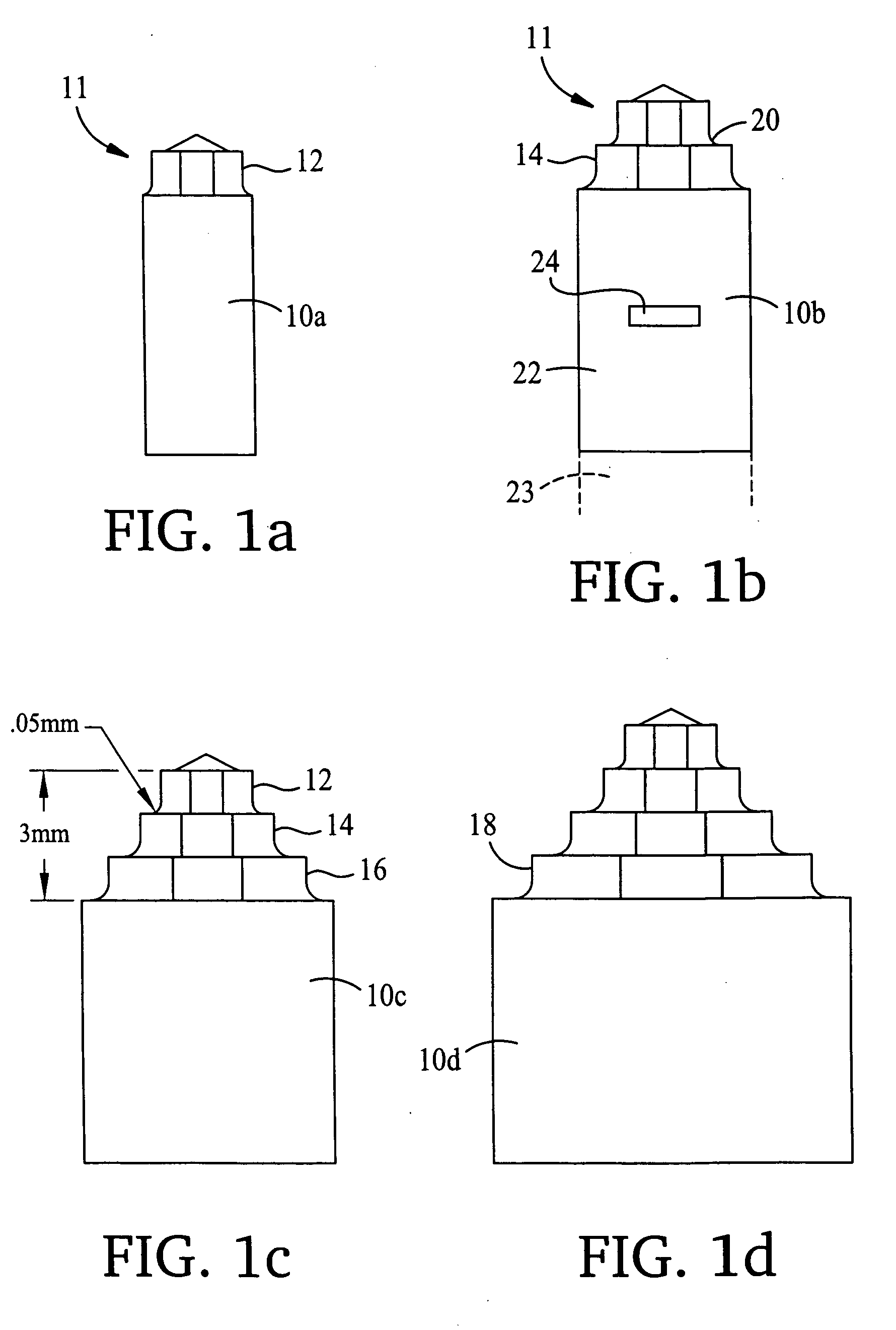

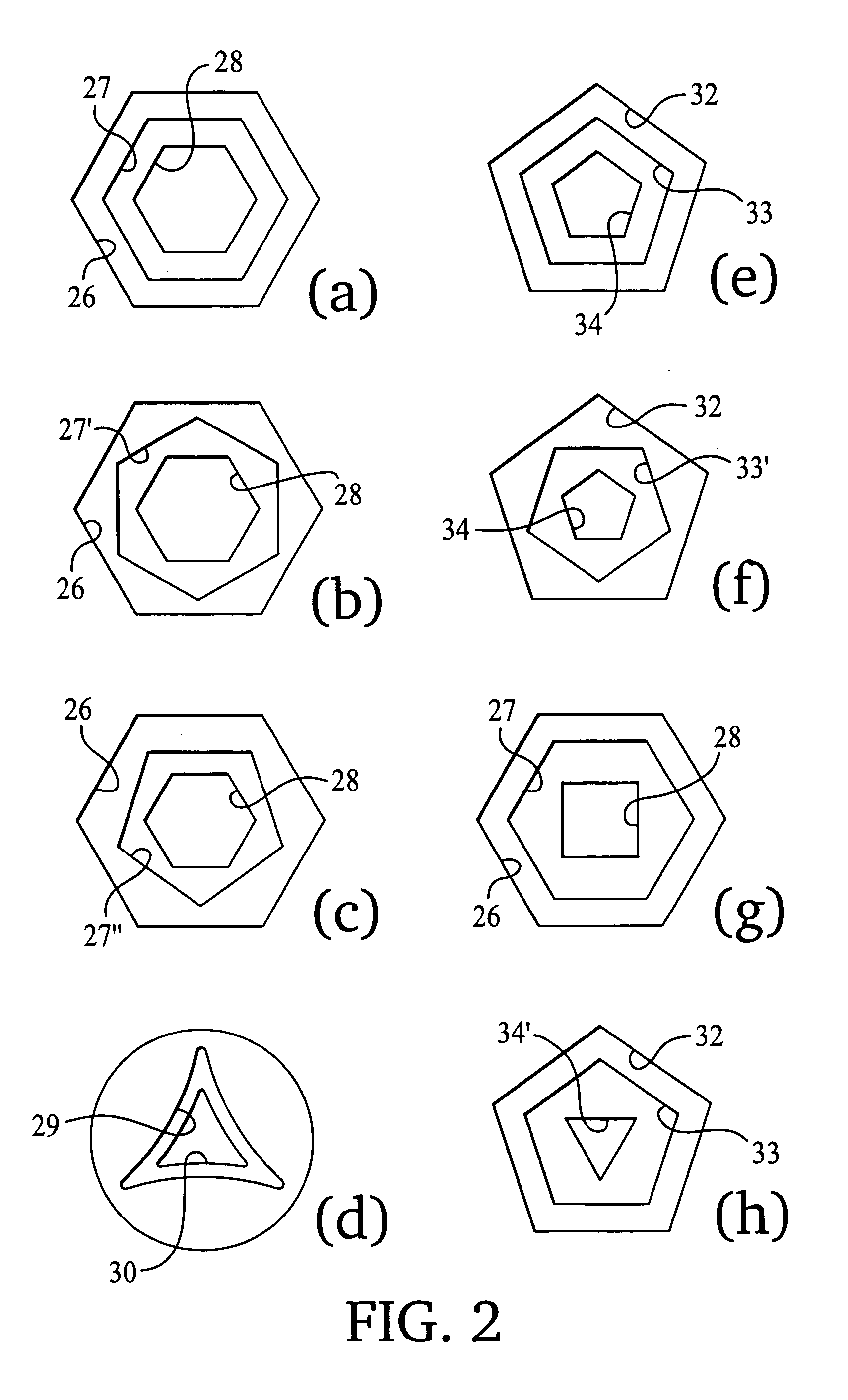

The screw has two or three non-circular super-imposed recesses. The depth of each recess is less than 1.2 mm and there is a less than 1 DEG of draw in each recess. The screw head recess is formed using a punch (10) in a cold-heading process. The punch is formed in a profilating CNC machine, cutting the profiles (12,14,16) of the punch to a tolerance of better than +-0.025 mm. A method of manufacture of a cold-forming punch for such a screw comprises providing a profilating head as one of the tools on a turret mounted adjacent the chuck in the CNC machine. The profilating head has several cutting elements, each being adjustable with respect to one another: axially, radially and angularly.

Owner:UNISCREW

Screw head formation

InactiveUS20050158148A1Considerable and patienceTrend downCutting toolsMilling cuttersNumerical controlEngineering

The screw has two or three non-circular super-imposed recesses. The depth of each recess is less than 1.2 mm and there is a less than 1° of draw in each recess. The screw head recess is formed using a punch (10) in a cold-heading process. The punch is formed in a profilating CNC machine, cutting the profiles (12, 14, 16) of the punch to a tolerance of better than ±0.025 mm. A method of manufacture of a cold-forming punch for such a screw comprises providing a profilating head as one of the tools on a turret mounted adjacent the chuck in the CNC machine. The profilating head has several cutting elements, each being adjustable with respect to one another: axially, radially and angularly.

Owner:UNI SCREW A UK CORP

Device for turning eccentric circle by profiling

InactiveCN104708021AGuaranteed fixed effectQuality assuranceGeometric arrangementsCopying process control systemsEngineeringTailstock

The invention discloses a device for turning an eccentric circle by profiling. The device comprises a lathe and a profiling (4), and is characterized in that the profiling is detachably in fixed connection to a chuck of the lathe, wherein a roller (5) of a tool post of the lathe is matched with the outer edge of the profiling; when a workpiece (2) is machined, the roller of the tool post of the lathe is bonded with the outer edge of the profiling, one end of the workpiece is bonded with the profiling, and the other end of the workpiece is bonded with a tail base tip of the lathe to guarantee the machining fixation of the workpiece; and the surface of the workpiece is turned by a turning tool (6) of the lathe after the fixation of the workpiece, so that the outer edge of the workpiece can be turned to have the same shape with the profiling, the machining precision is improved, and the product quality is guaranteed.

Owner:铜陵市永生机电制造有限责任公司

Accelerated steel cutting methods and machines for implementing such methods

InactiveUS20060208398A1Improved and inexpensiveImprove degradation rateWelding/cutting auxillary devicesGeometric arrangementsMetallurgyAcute angle

A method for cutting steel includes heating a portion of the steel until it is molten, positioning a cutting torch to have a high angle of incidence relative to the molten steel, and blasting hgih pressure oxygen at the molten metal. The blast of high pressure oxygen further heats the molten metal and blows the molten metal away from the steel to create a cutting trench. The cutting torch is then moved generally parallel to the cutting method includes a cutting torch that emits a high pressure combustible gas and a high pressure combustion enhancing gas. The torch directs the high pressure gases at the steel so that the gases hit the steel at an acute angle of attack. An automated device propels the torch in the general direction of the desired cut. The resultant cut metal product has at least one edge with a grain pattern that is not perpendicular to the direction of cut.

Owner:PASULKA MATTHEW P

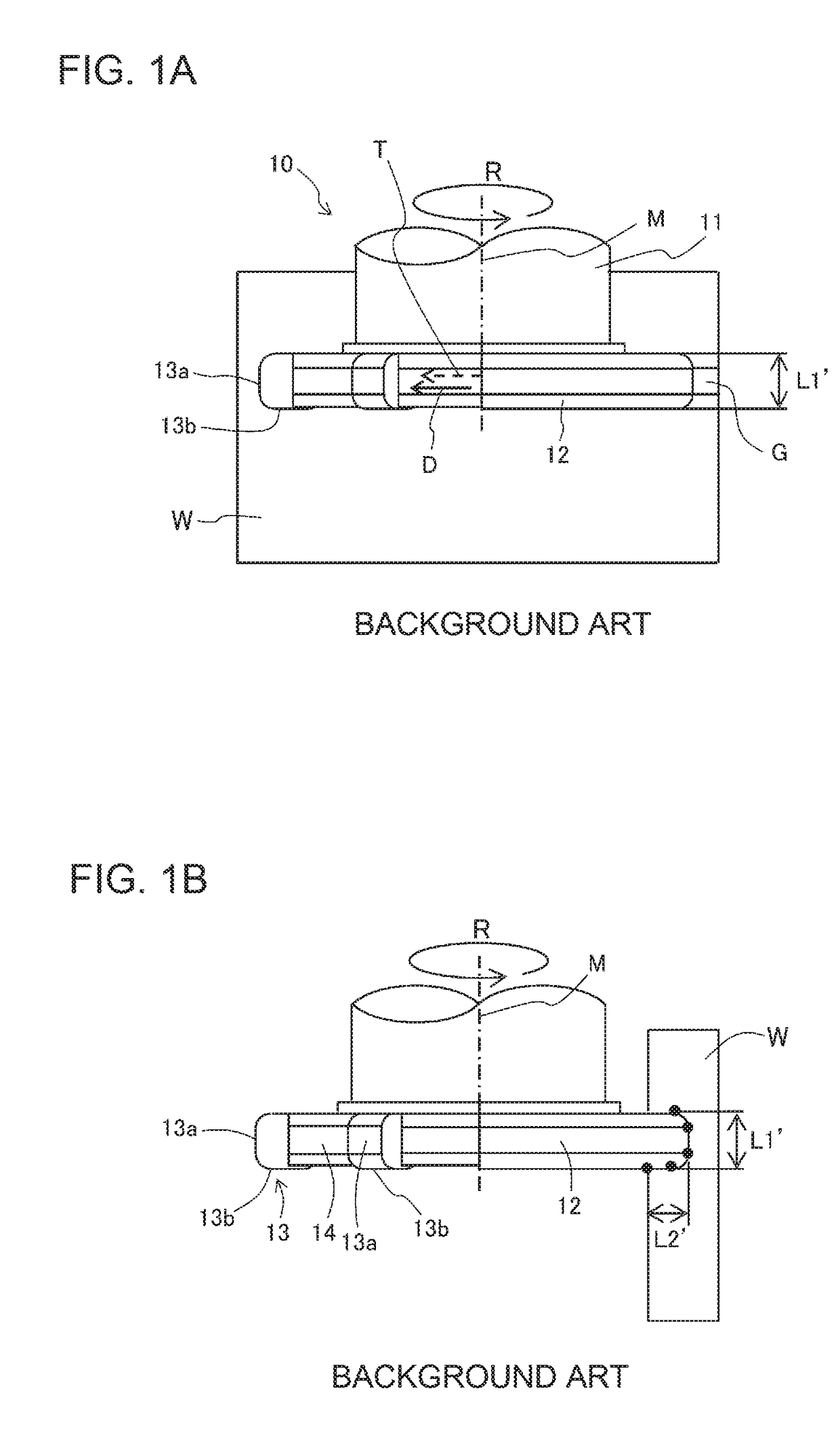

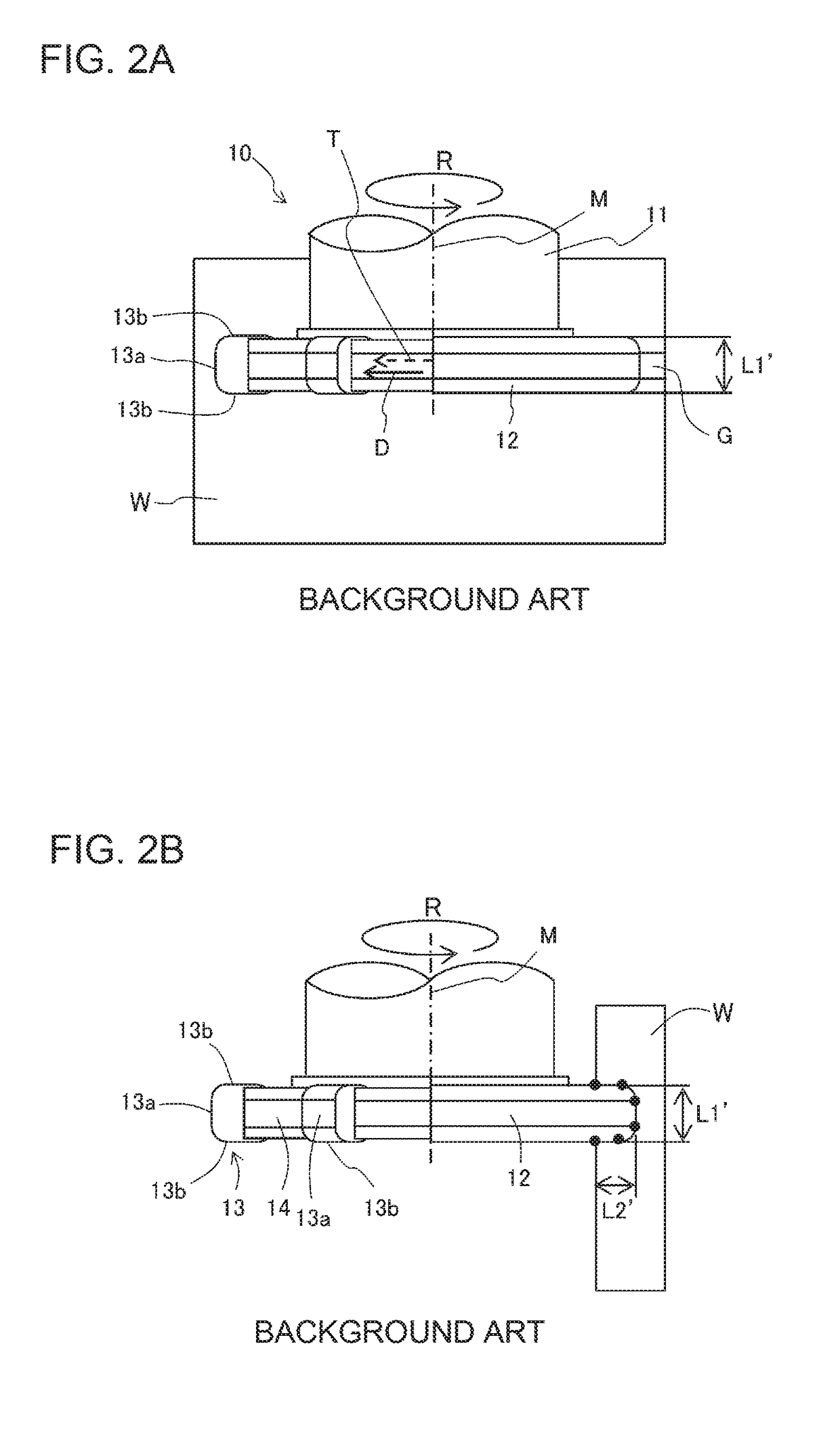

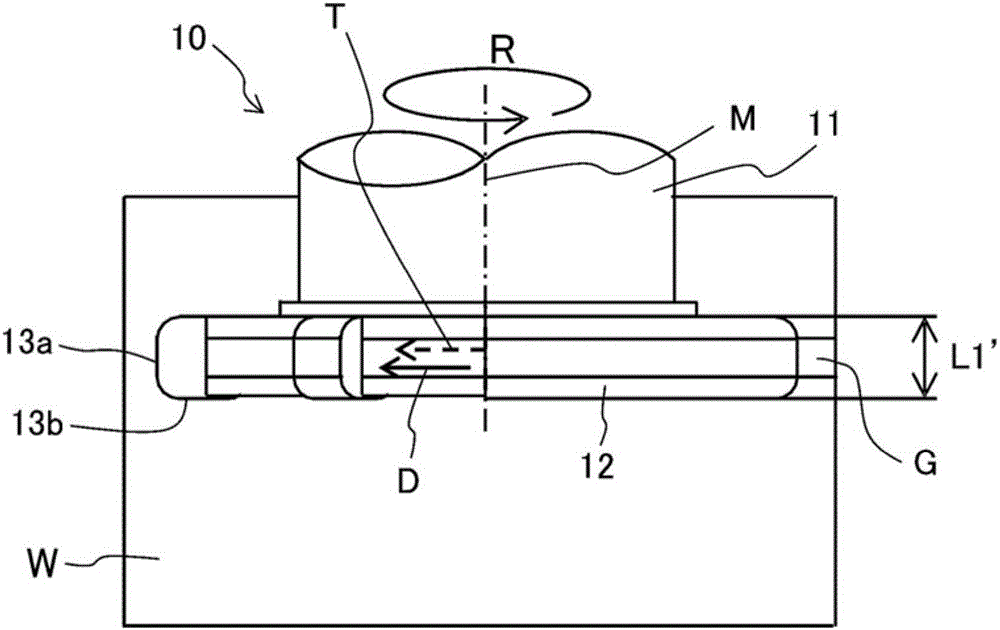

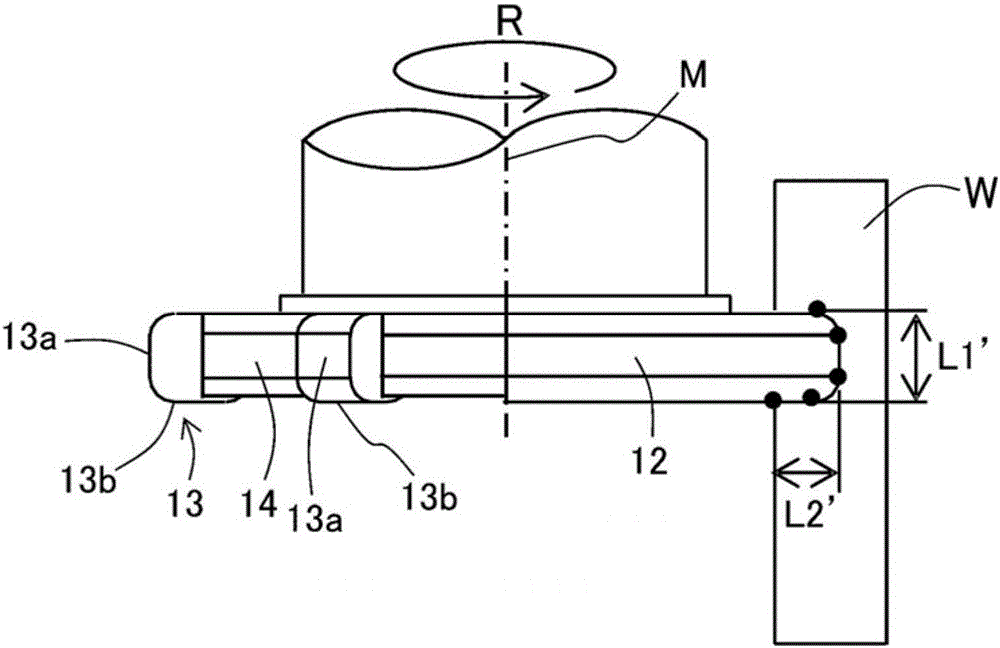

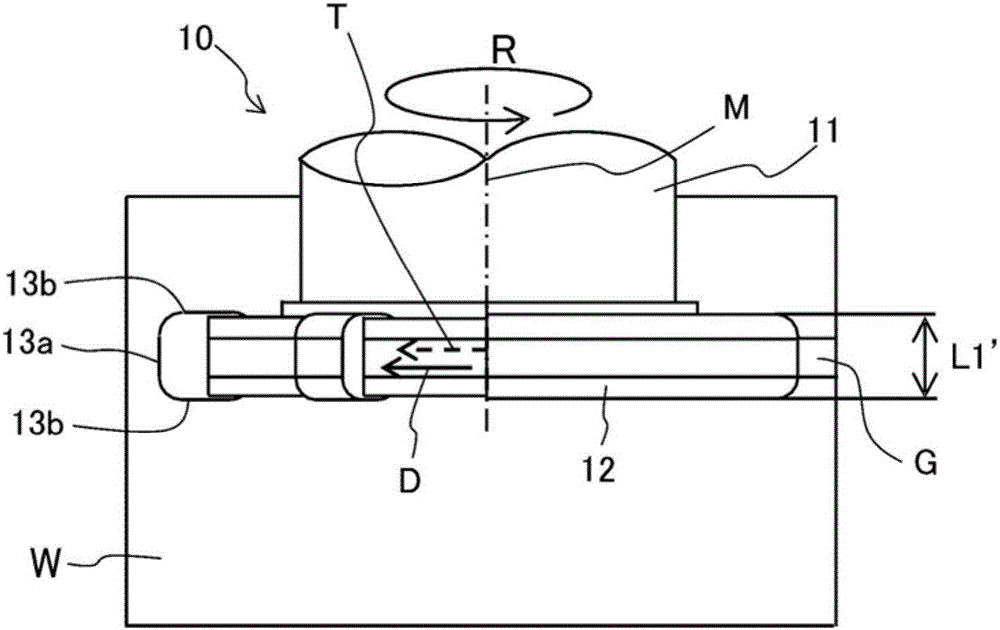

Method for machining workpiece and machine tool

A method for machining a workpiece, includes: rotating a rotary tool around a rotation axis, the rotary tool including at least one edge positioned on an outer periphery of the rotary tool around the rotation axis; relatively moving the rotary tool toward the workpiece in a first direction so that the at least one edge cuts the workpiece by a predetermined depth while the rotary tool is rotated around the rotation axis; and relatively moving the rotary tool with respect to the workpiece in a second direction that is substantially perpendicular to the first direction and that is inclined to a third direction substantially perpendicular to the rotation axis and the first direction.

Owner:YAMAZAKI MAZAK KK

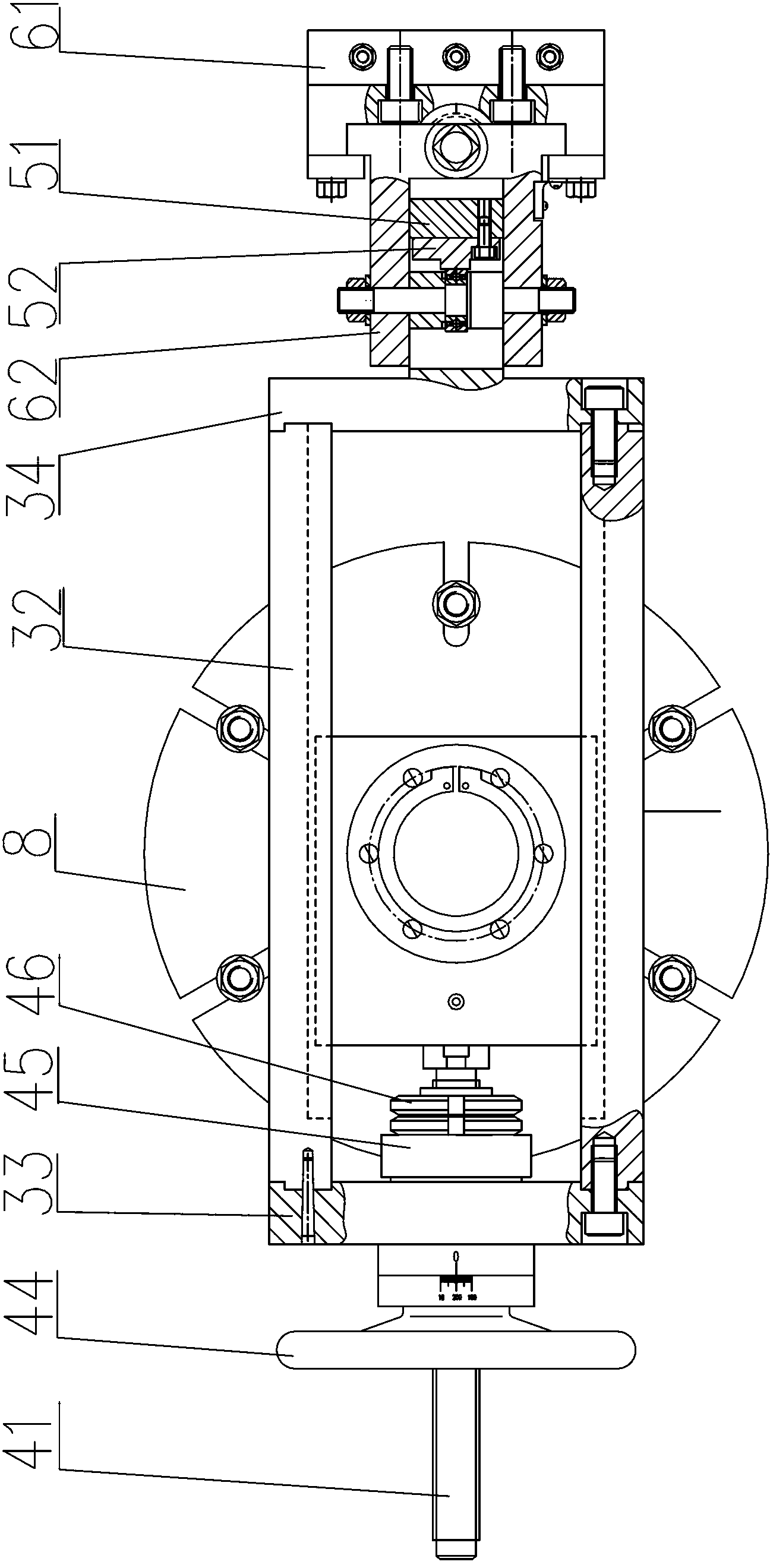

Numerical control square lathe

InactiveCN110449603AEasy to adjustAvoid scrappingGeometric arrangementsTurning machinesNumerical controlFixed frame

The invention discloses a numerical control square lathe and relates to the technical field of mechanical processing equipment. The numerical control square lathe comprises a lathe body, a fixed seat,a movable seat, a first movable mechanism, a fixed frame, a second movable mechanism, a fly cutter disc and a square power head, wherein the fixed seat is arranged in a right-angle trapezoid shape and is fixed on the top of the lathe body; the first movable mechanism is embedded in the inclined surface of the fixed seat; the fly cutter disc is fixed at the power output end of the square power head; the second movable mechanism is embedded in the upper surface of the movable seat so that the fixed frame can reciprocate vertically along the upper surface of the movable seat; the fly cutter disc, the square power head and the first movable mechanism are all parallel to the inclined surface; the left end of the fixed seat is also fixed with a connecting frame, a driving motor is fixed on theconnecting frame, and a chuck is fixed at the power output end of the driving motor. The lathe can turn a workpiece into any shape, is multifunctional and has high square surface accuracy.

Owner:广州和兴机电科技有限公司

Method for machining by lathing, and lathe

ActiveCN102481634AMultiple Turning ContoursShort processing timeLathesTurbinesRotational axisEngineering

The invention relates to a lathe (1), wherein the work piece (16) to be lathed with a tool (18) is clamped with the longitudinal axis of the work piece parallel to the rotational axis (29) of the rotating clamping device (15) such that the rotational axis (29) does not intersect the work piece (16), and that between two machining steps of the machining process by lathing, the position of the work piece (16) in the clamping device (15) is changed such that surface areas (30, 36) not previously machined are moved into the working area of the tool (18).

Owner:J G WEISSER SOHNE

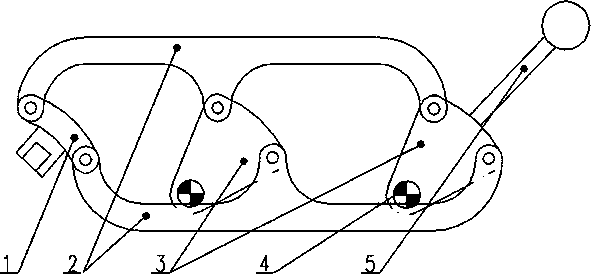

Cutter duplication apparatus

An apparatus for cutting a duplicate form includes:a) a rack portion including a frame, a screen supported on the frame, and an arm support extension extending from the frame; the frame including an upper, generally horizontally oriented upper frame portion, and at least two corner frame members extending; andb) a movable arm portion pivotally connected to the arm support extension; the arm portion including a movable torch support arm segment including a cutting torch support mechanism, and a movable stylus support arm segment including a stylus support mechanism; a first end of the torch support arm segment being extendible into a central area of the frame below the upper frame portion; a first end of the stylus support arm segment being extendible above the upper frame portion and above the torch arm support segment. Also included is a method for cutting a duplicate of a template form.

Owner:WAGNER JEFFERSON LOUIS

Mechanical device for generating circular motion trail

InactiveCN103433811ASimple structureSolve the generality problemGeometric arrangementsEngineeringCircular motion

The invention belongs to the technical field of machinery manufacture and particularly relates to a mechanical device for generating a circular motion trail. The mechanical device for generating the circular motion trail comprises two triangular plates and two supports, wherein the triangular plates are isosceles-triangular plates, and the two supports are arranged in parallel; the front ends of the two supports are connected through a connecting rod, and the rear ends of the two supports are connected through one isosceles-triangular plate. The device has the advantages of simple structure, low manufacturing cost and strong universality and adaptability.

Owner:JIGANG GRP

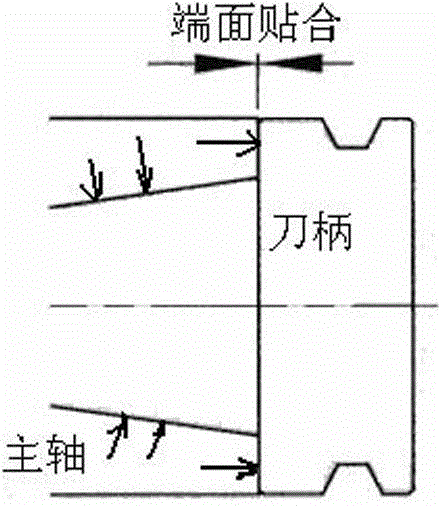

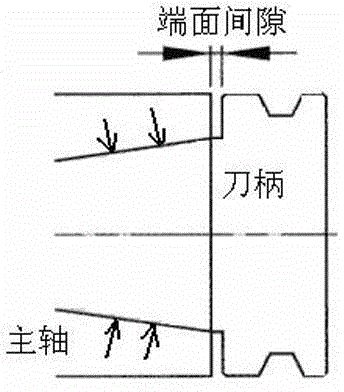

Manufacturing method of superpositioning cutter handle adjusting gasket

ActiveCN104827324AReduce demandEasy to manageGeometric arrangementsPositioning apparatusMachine toolDesign values

The invention discloses a manufacturing method of a superpositioning cutter handle adjusting gasket. The method comprises the following steps that firstly, a plurality of gasket bodies with the corresponding thicknesses are manufactured according to the theoretical thickness design values respectively; secondly, the needed thickness value of the adjusting gasket is determined according to the measurement value of the gap between the end face of a positioning cutter handle and the end face of a machine tool main shaft, and at least two of the gasket bodies obtained in the first step are combined to form the adjusting gasket with the needed thickness value. According to the method, multiple adjusting gaskets with different needed thicknesses can be manufactured through the limited number of gasket bodies, the manufacturing speed is high, the number of the needed gasket bodies is small, gasket management is facilitated, and cost is low.

Owner:DONGFANG TURBINE CO LTD

Processing device of lateral arc forming machine for large arc gate panel

InactiveCN103317173AControllable running forward speedEasy to controlGeometric arrangementsFeeding apparatusNumerical controlEngineering

The invention discloses a processing device of a lateral arc forming machine for a large arc gate panel, belonging to the technical field of arc gate body processing. The processing device comprises an arc track and a tool hinged seat, wherein a travelling trolley capable of placing an arc gate body is arranged on the arc track; a movable plane miller is arranged on the outer side of an outer arc of the arc track; a milling head cutter of the movable plane miller is vertical to the arc gate body; an arc gate supporting arm capable of being connected with the arc gate body is arranged on the inner side of an inner arc of the arc track; the arc gate supporting arm is hinged on the tool hinged seat; a hydraulic control system for driving the travelling trolley to run is arranged in the travelling trolley; the arc gate body can run along the arc track by taking the tool hinged seat as a center on the travelling trolley. According to the processing device, the technical problem that the large arc gate panel is processed in the absence of a numerical control boring and milling machine is solved and the safety risk of high-altitude operation of a vertical tool and the high input of the numerical control boring and milling machine can be avoided.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

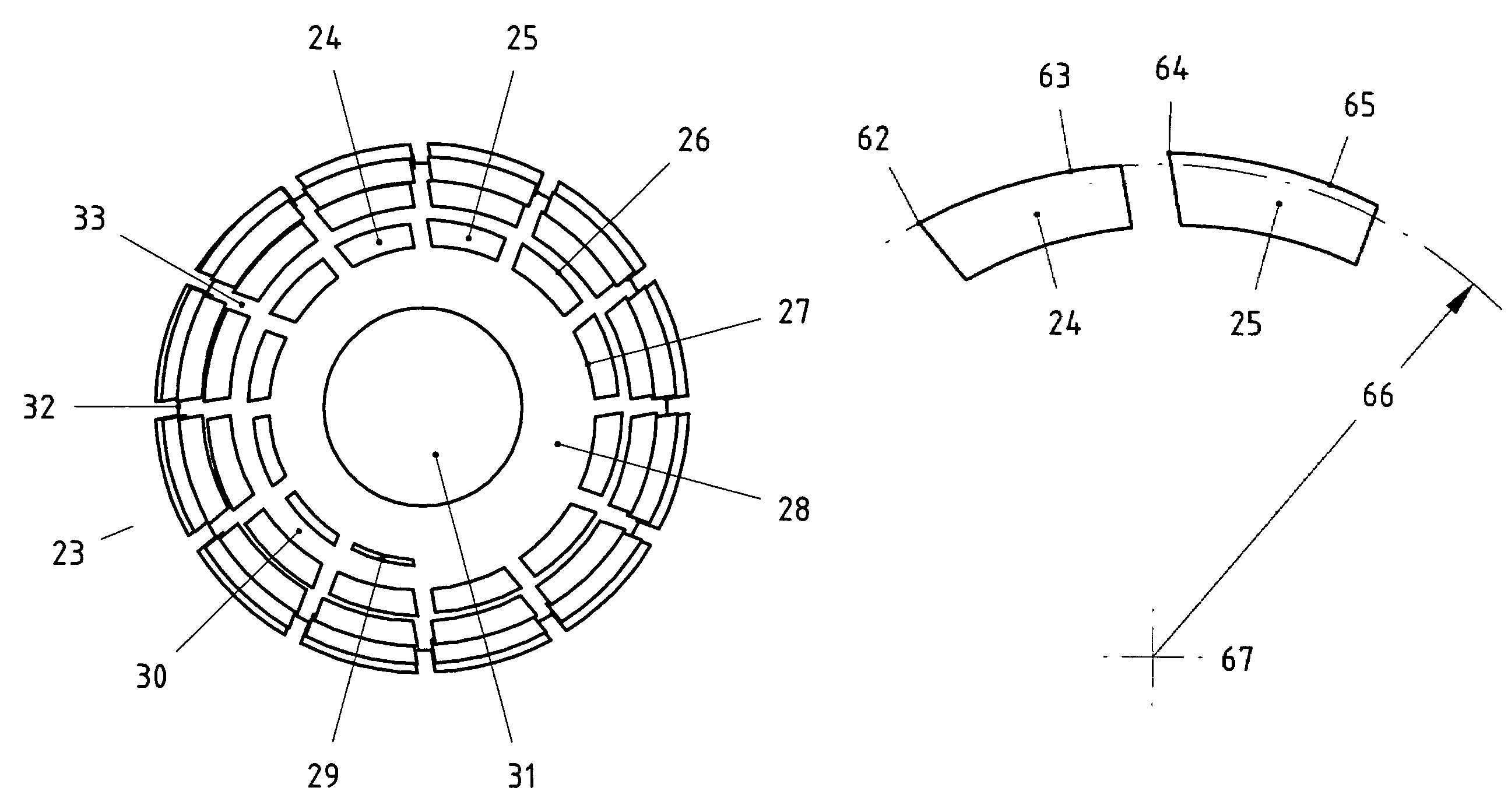

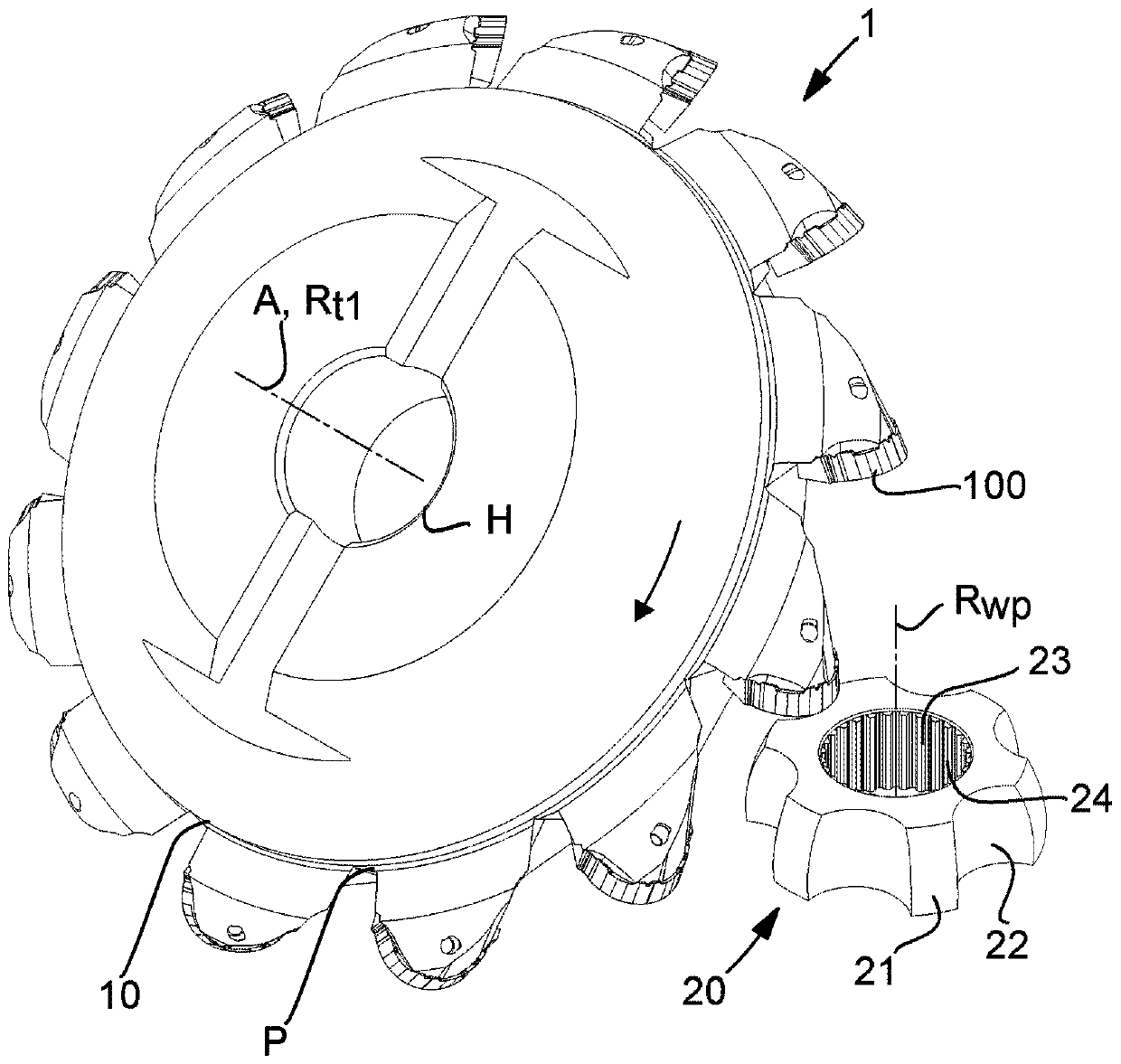

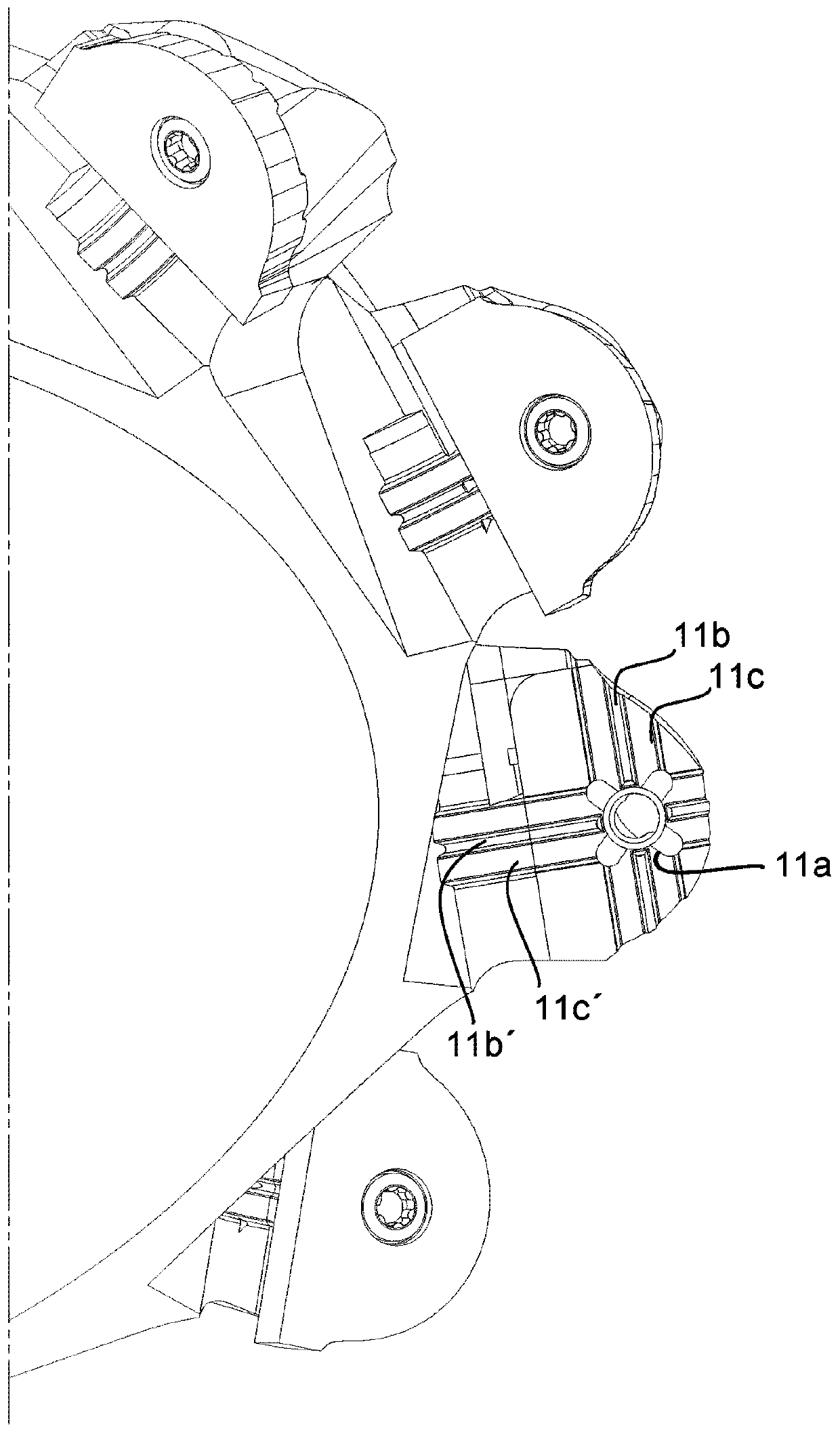

Method for machining of ball tracks of inner races of constant velocity joints

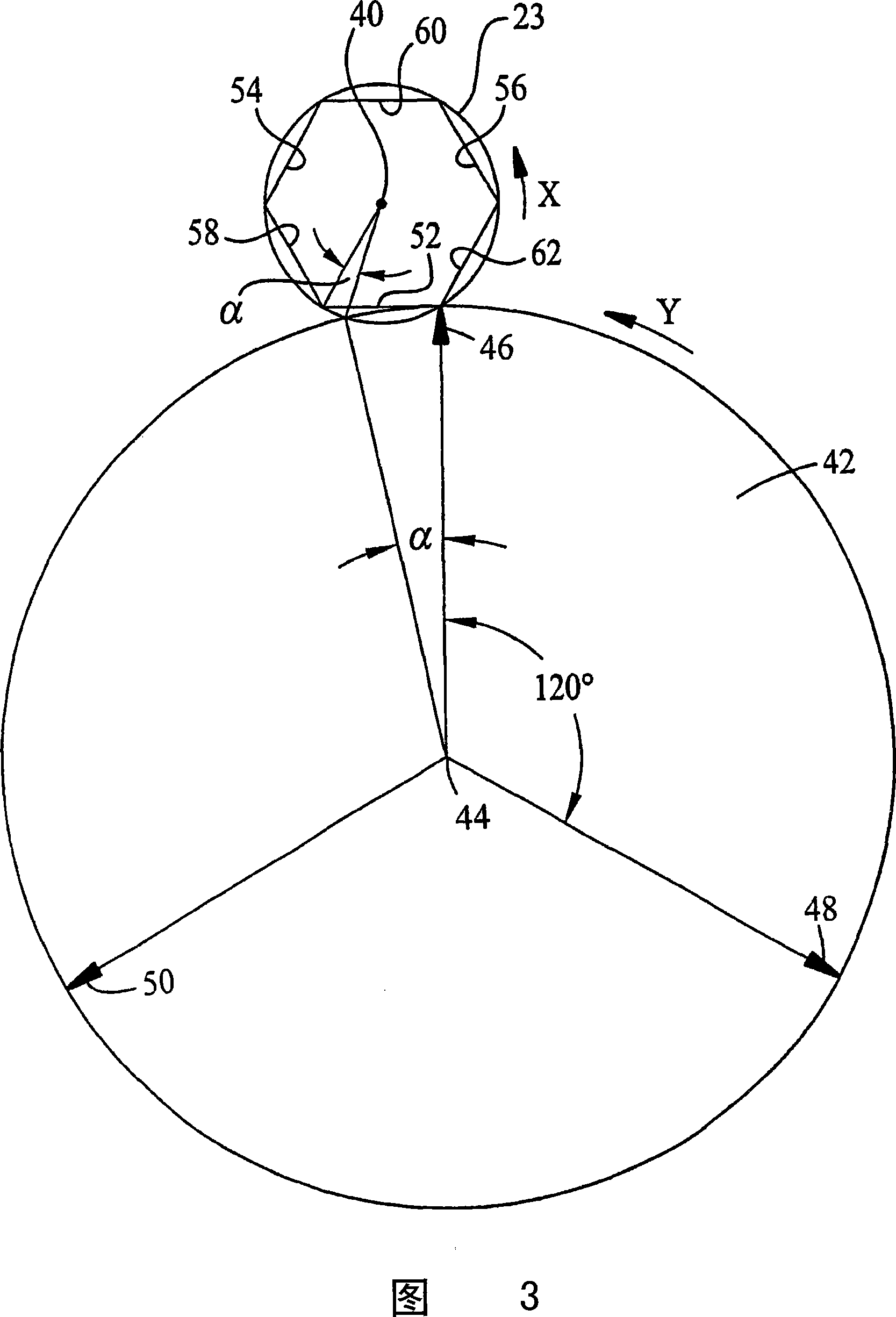

The present specification relates to a method for machining of ball tracks of an inner race of a constant velocity joint comprising the steps of providing a power skiving tool (1) having a plurality of cutting members and a first axis of rotation (Rt1), and a work piece (20) comprising an outer envelope surface (21) extending along an axis of rotation (Rwp), such that said first axis of rotation of said power skiving tool is arranged at a first distance from said axis of rotation of the work piece and oriented at a first angle (alpha) relative one another, applying a first rotational speed tosaid power skiving tool and a second rotational speed to said work piece and a relative movement between said work piece and said power skiving tool such that said cutting members engage said outer envelope surface to machine the ball tracks (22). The present specification also relates to a cutting insert and a power skiving cutting tool.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Groove machining method

ActiveCN106660143ASuppress tremorLarge machining allowanceGeometric arrangementsMilling machinesMachining

The invention discloses a groove machining method. The method for forming a groove with a specified width and depth in a workpiece using a rotating tool that is provided with a disc-shaped tool body and multiple cutting edges at equal intervals on the outer circumferential surface of said tool body, the method being characterized in that with the rotation direction at the point of contact between the outer circumferential surface of the rotating tool and the workpiece inclined by a specified angle with respect to the direction of groove machining movement, said rotating tool is rotated while the outer circumferential surface thereof cuts into the machining surface of said workpiece by a specified cutting depth, after which said rotating tool is moved relative to the workpiece in the direction of groove machining movement.

Owner:YAMAZAKI MAZAK KK

Expanding rod hanging-up mechanism and air conditioner machining device with same

ActiveCN106903556AAvoid taking down steps for stackingSave installation timeGeometric arrangementsStructural engineeringMechanical engineering

The invention provides an expanding rod hanging-up mechanism and an air conditioner machining device with the same. The expanding rod hanging-up mechanism comprises a hanging-up part. The hanging-up part is provided with a containing part for containing an expanding rod, the containing part is provided with a first placement position for allowing the expanding rod to penetrate in the first direction, and the containing part is provided with a second placement position for allowing the expanding rod to be rotated at the first placement position and then placed in the containing part. Due to the arrangement of the expanding rod hanging-up mechanism, after one end of the expanding rod not meeting a condenser or evaporator type penetrates the containing part of the hanging-up part in the first direction, the expanding rod is rotated in the circumferential direction of the expanding rod, and the expanding rod is located at the second containing position of the containing part, in other words, the expanding rod is hung on the hanging-up part through the containing part at the moment. By means of the arrangement, the step that expanding rods not meeting type requirements are taken down and stacked is avoided, the installation time of the expanding rod is effectively saved, and the machining efficiency of the air conditioner machining device is improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP TECH RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com