Device and method for joining workpieces by means of a laser beam and movable pressing element

A laser beam and laser welding technology, applied in auxiliary devices, laser welding equipment, transportation and packaging, etc., can solve problems such as unbearable acceleration, feed speed limitation, and not involving the shape or structure of the workpiece to be processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

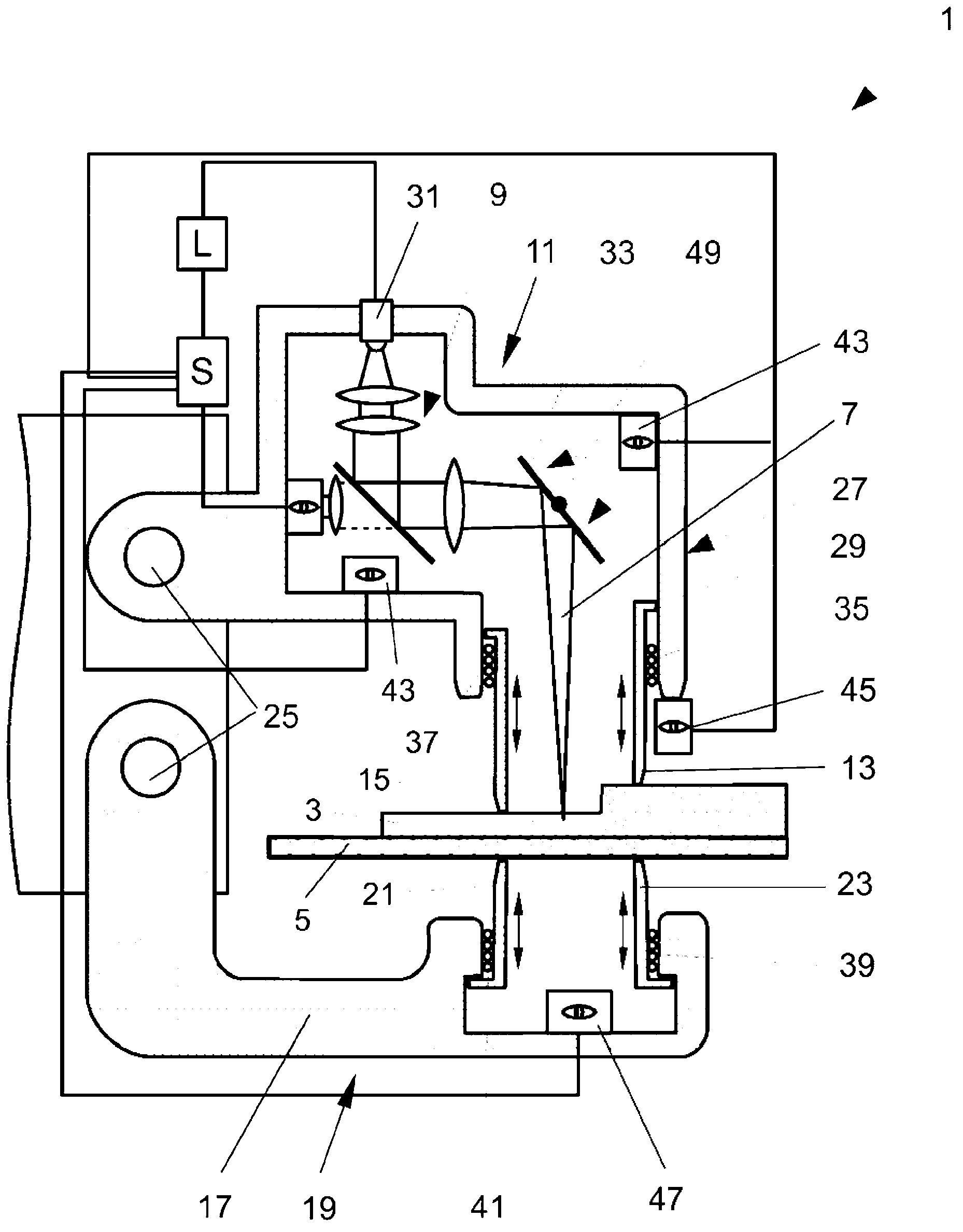

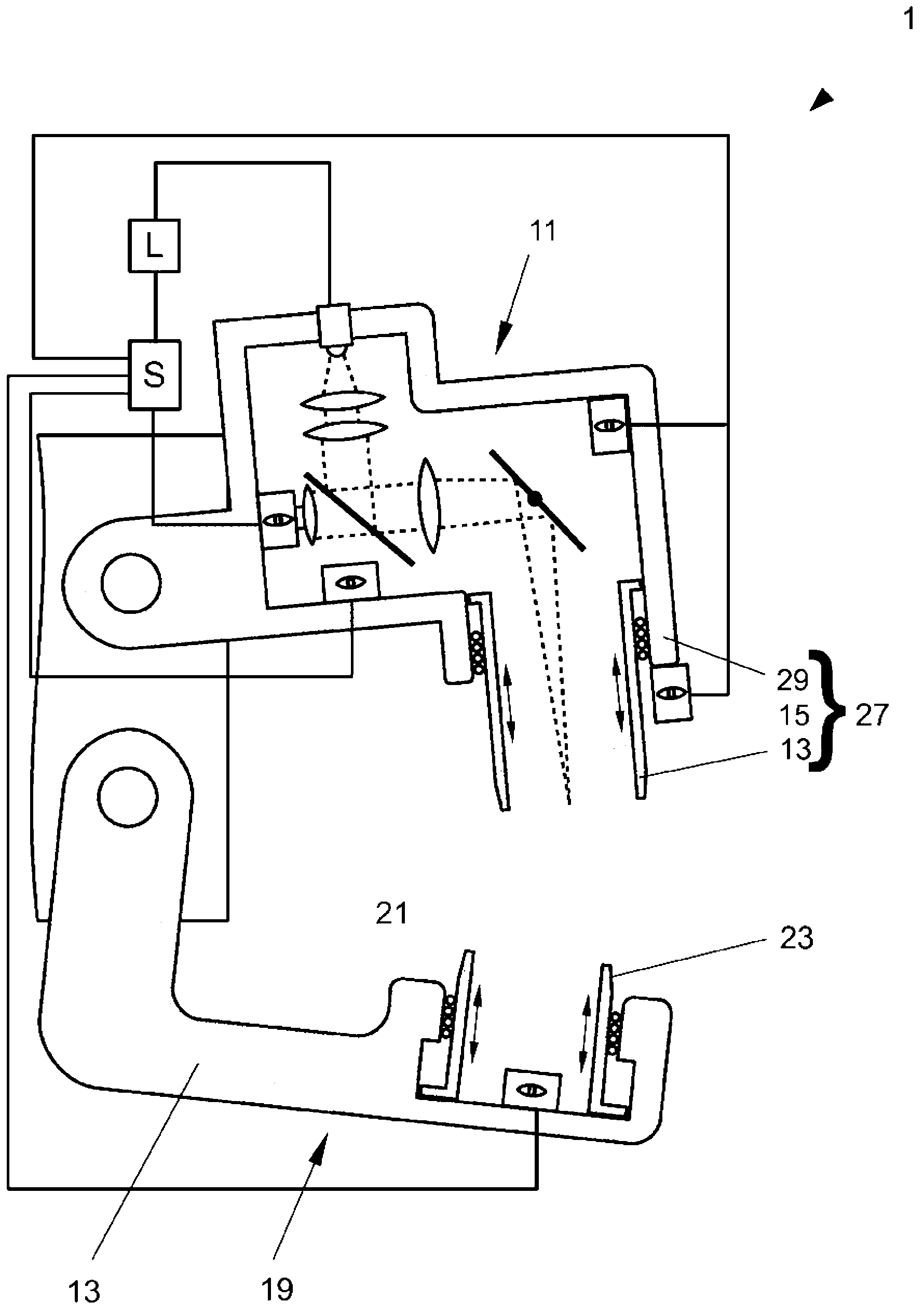

[0085] With the help of Figures 1 to 9 The illustrated embodiments illustrate the invention, wherein identical or similar features are indicated by the same reference symbols.

[0086] figure 1In one embodiment of the invention, a laser welding device 1 embodied as a welding torch 1 is joining two workpieces 3 , 5 by means of a laser beam 7 , wherein the laser beam 7 is guided and positioned by means of an optical scanner 9 . The welding torch 1 has two upper pressure elements 13 , 15 arranged on the upper arm 11 of the welding torch 1 , and two lower pressure elements 21 , 23 arranged on the bracket 17 of the lower arm 19 of the welding torch 1 . The arms 11 , 19 are rotatably connected to the guide unit 25 and press the workpieces 3 , 5 to be joined—here the metal plates 3 , 5 —together by means of the pressing elements 13 , 15 , 21 , 23 . The upper arm 11 forms a housing 27 which encloses the optical scanner 9 and the laser beam 7 extending from the optical scanner 9 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com