Manufacturing method of superpositioning cutter handle adjusting gasket

A technology for adjusting shims and preparation methods, applied in positioning devices, manufacturing tools, clamping, etc., can solve the problems of long time for grinding shims, can only be used on designated machine tools and tool holders, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

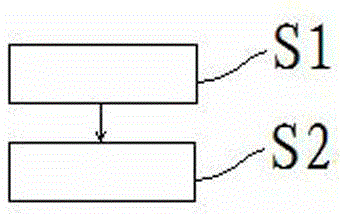

[0032] image 3 An exemplary embodiment of a logic flow of the method of the present invention is shown. Such as image 3 As shown, the preparation method of the over-positioning knife handle adjusting pad of the present invention comprises the steps:

[0033] Step S1, making a plurality of gaskets of corresponding thickness according to the design theoretical value of each thickness; and

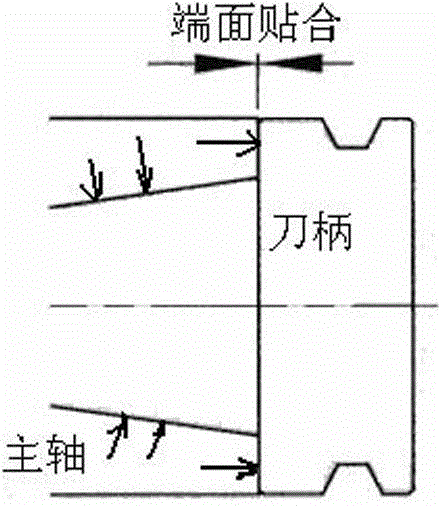

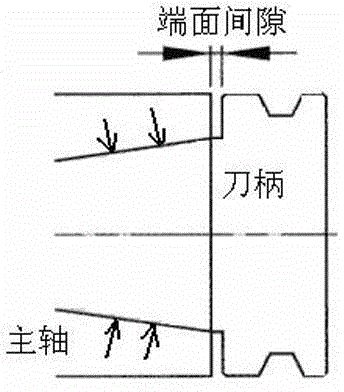

[0034] Step S2, based on the measured value of the gap between the end face of the over-positioned tool holder and the end face of the machine tool spindle, the required thickness value of the adjusting shim is determined, and the combined configuration of at least two shims among the plurality of shims ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com