Method for machining by lathing, and lathe

A processing device and turning technology, applied in turning equipment, positioning device, turning equipment, etc., can solve the problems of unsuitable and unsuitable turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

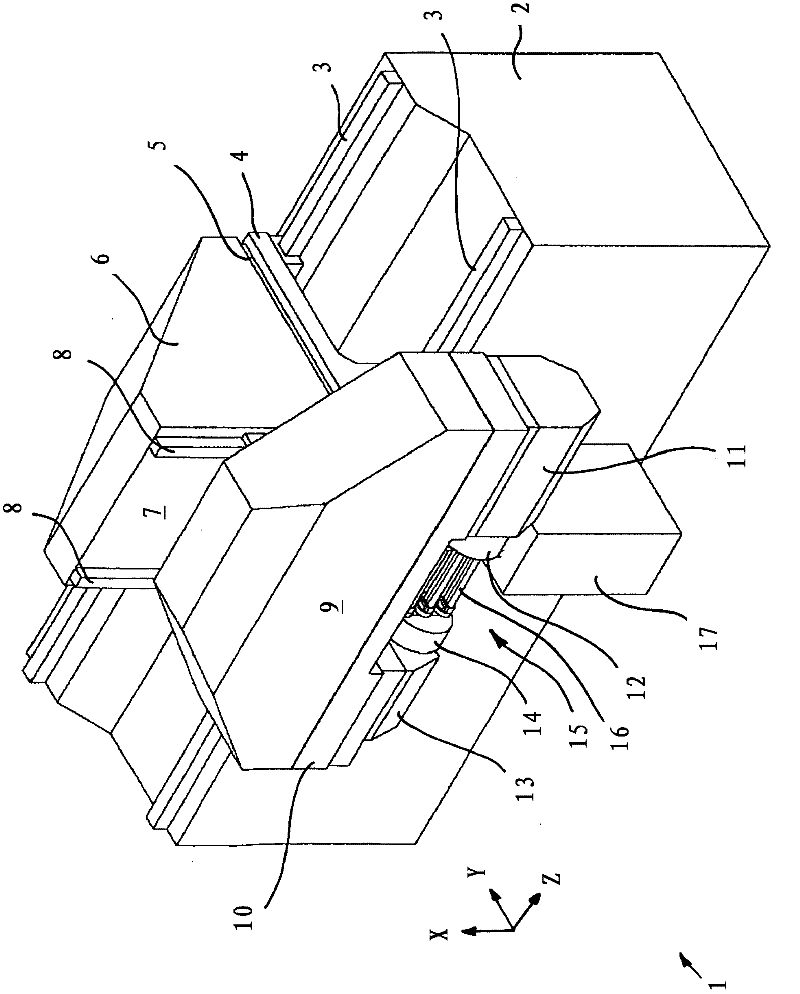

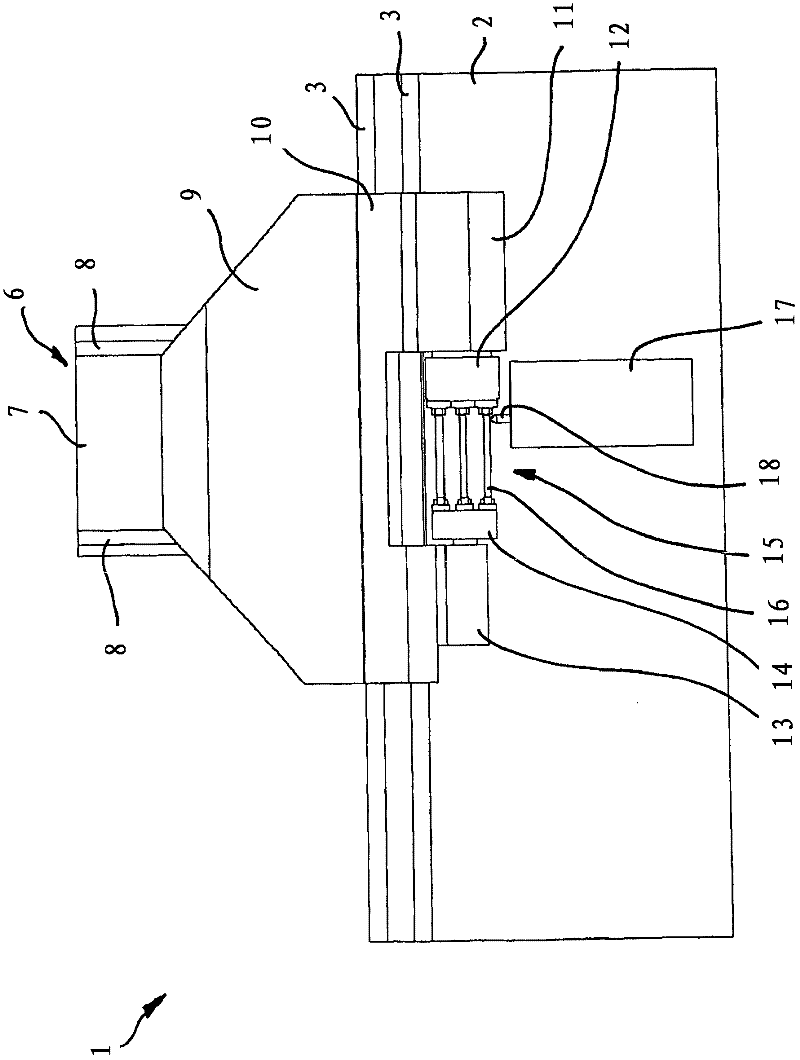

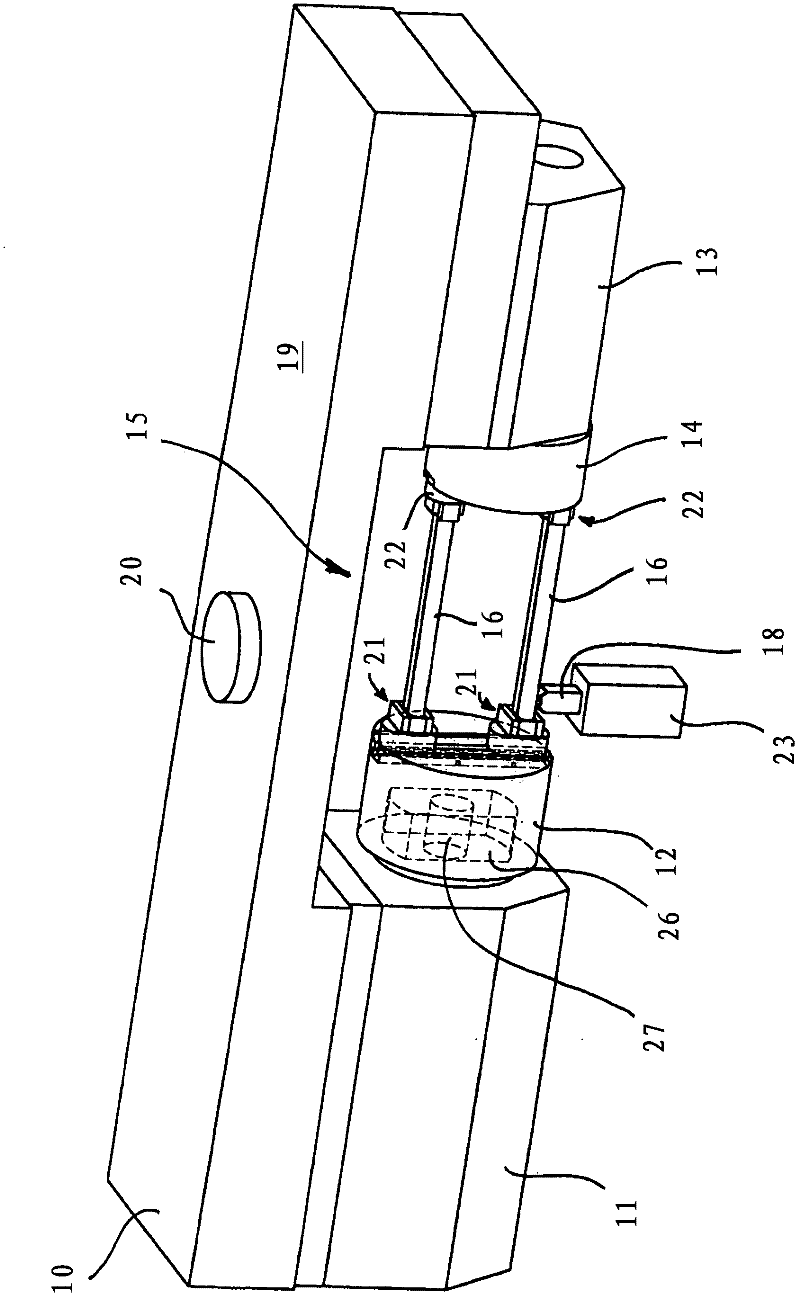

[0063] figure 1 A view from obliquely above is shown of the turning device, generally designated by the reference number 1 . figure 2 A view from the front of the turning device 1 is shown.

[0064] The turning device 1 has a bed 2 on which two horizontal linear guides 3 running in parallel are arranged. The sliding seat 4 is horizontally along the Z direction, that is, in figure 2 moves on the linear guide 3 in the plane of the drawing. The drives required for this are not otherwise shown.

[0065] Two further parallel-running and horizontally oriented linear guides 5 are arranged on the carriage 4 . exist figure 1 Only one linear guide 5 is visible. The linear guide 5 defines a movement path which is perpendicular to the movement path defined by the linear guide 3 .

[0066] A further slide 6 is arranged displaceably on the linear guide 5 , which can thus be moved along the linear guide 5 in the Y-direction by means of a drive not shown otherwise.

[0067] A furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com