Device assisting ordinary gear hobbing machine in machining arc-shaped gear

A technology of arc gears and gear hobbing machines, used in gear tooth manufacturing devices, gear cutting machines, components with teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

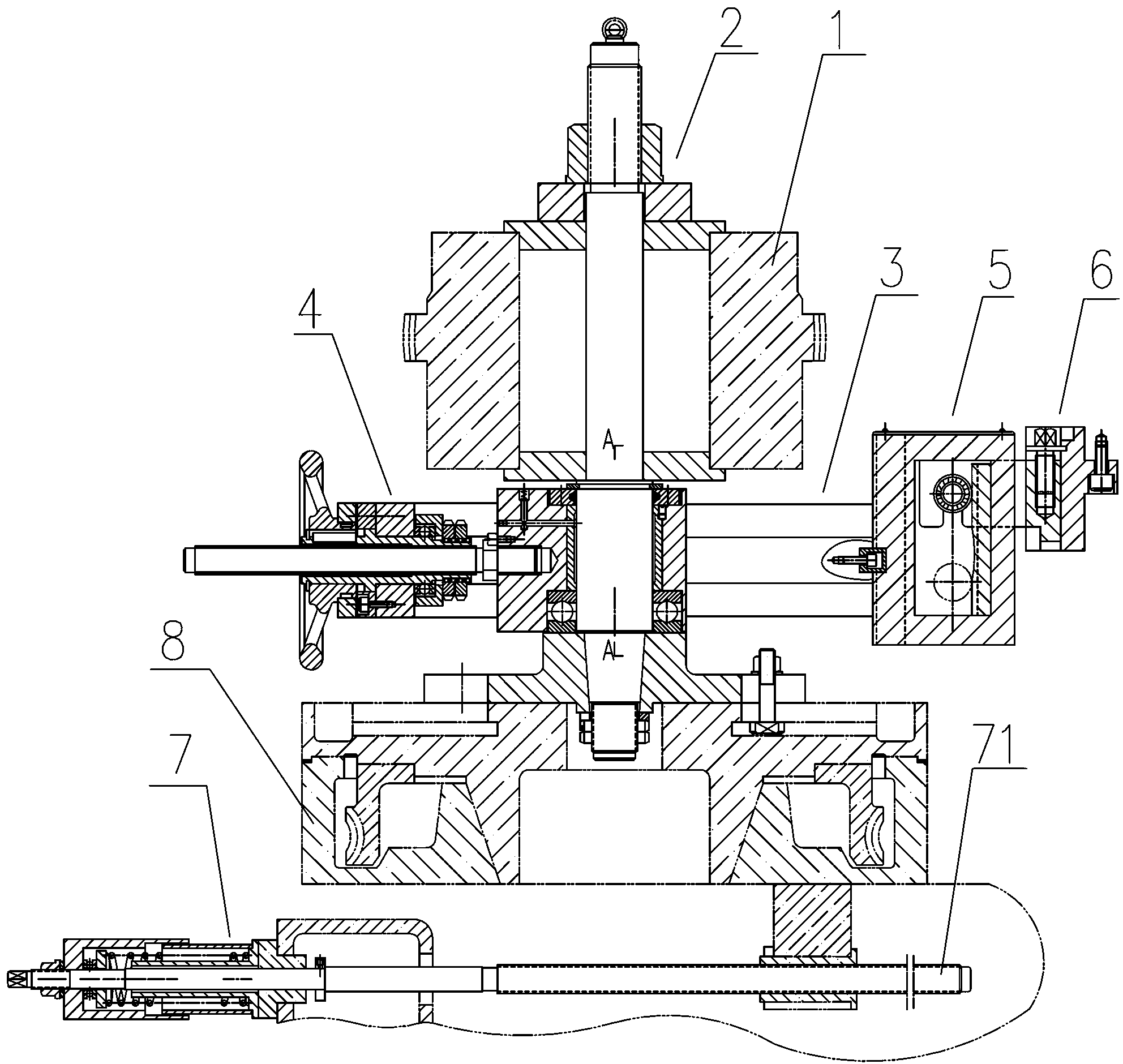

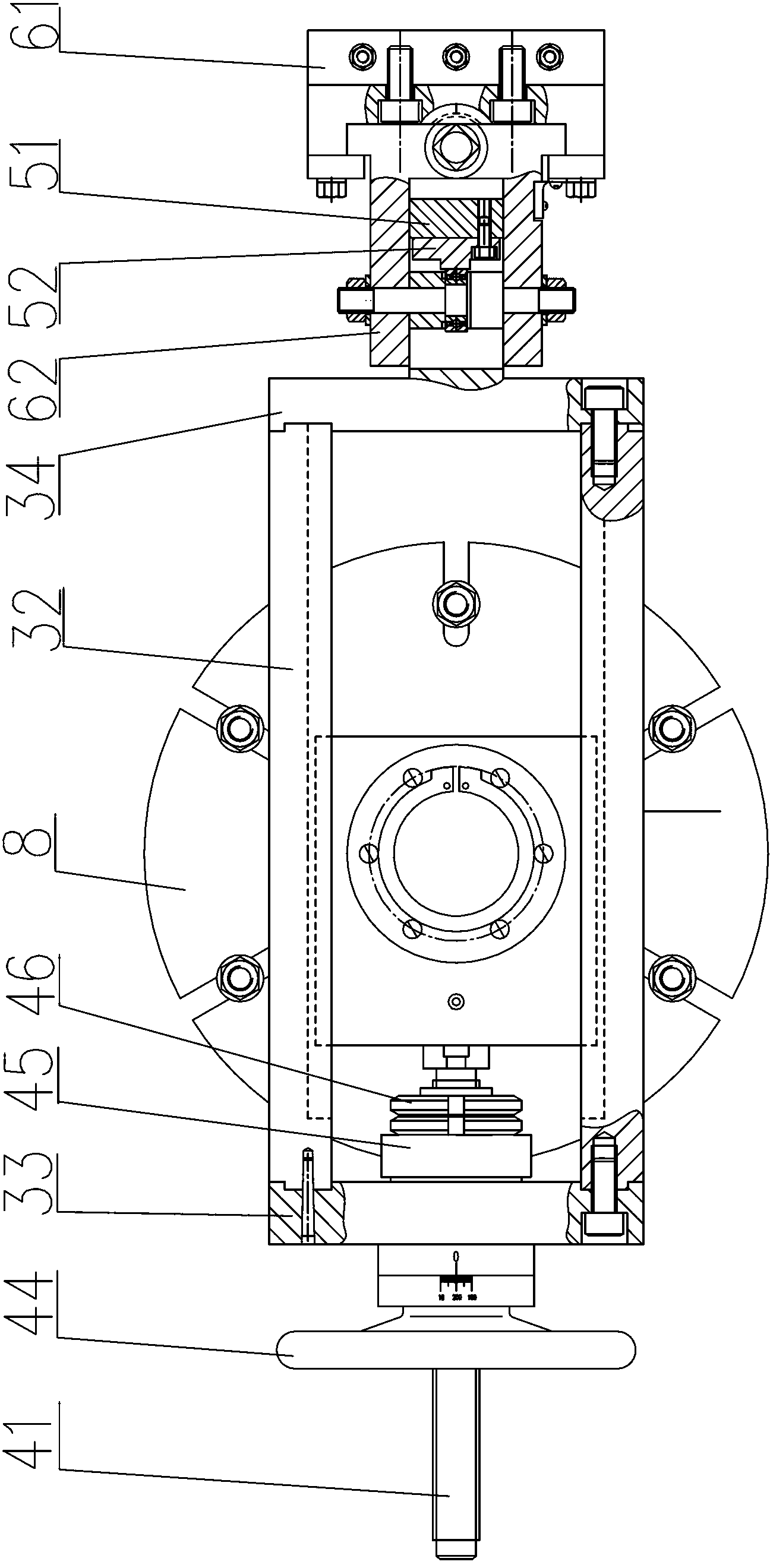

[0020] Such as figure 1 and 2 The shown device for processing arc gears with a gear hobbing machine includes a gear positioning device 2, a track device 3, a handwheel adjusting device 4, a profiling device 5, a roller device 6 and a tensioning device 7.

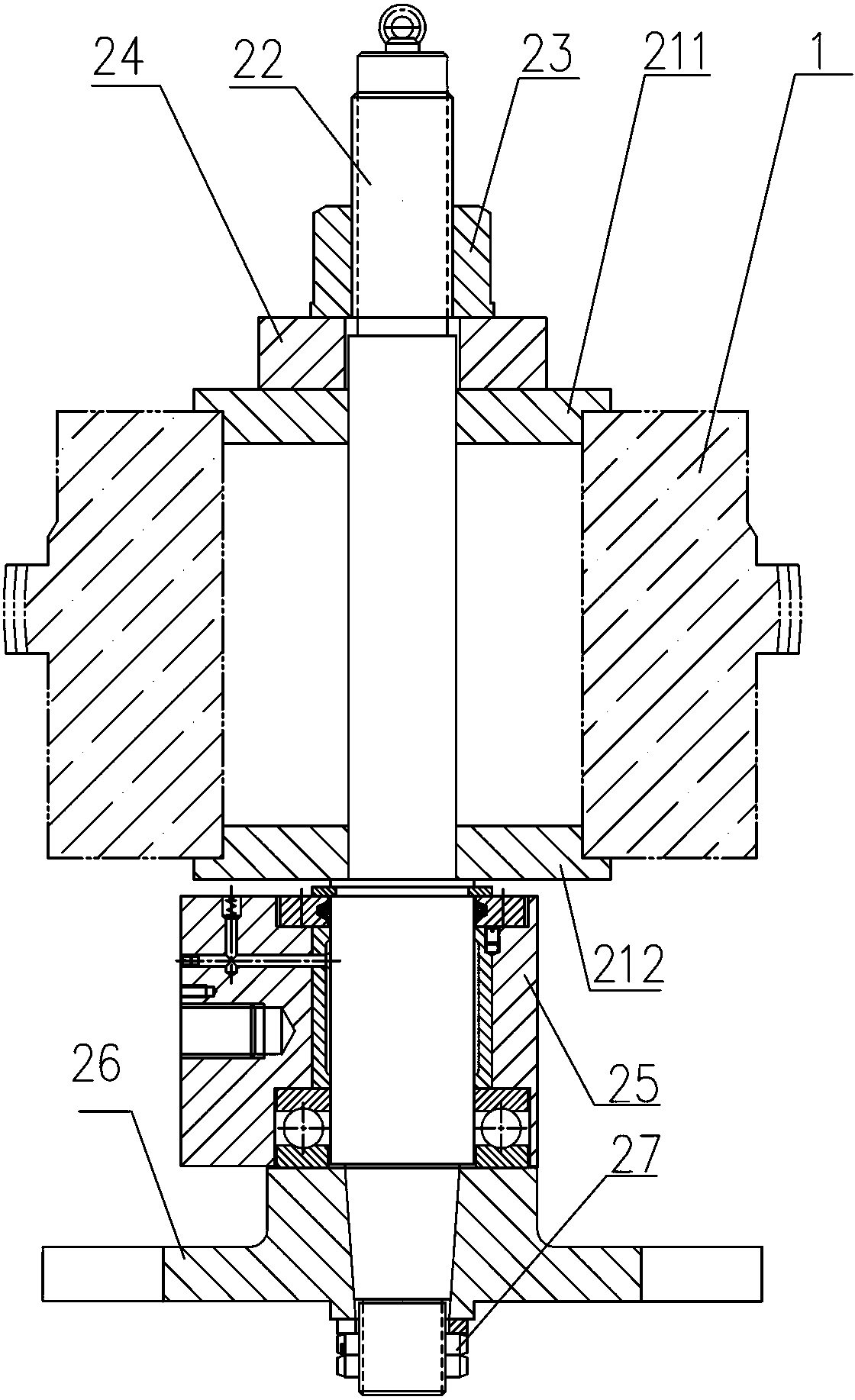

[0021] combine image 3 and Figure 4 As shown, the positioning device 2 is installed on the gear hobbing machine table 8, vertically opposite to the hob, and includes the first baffle plate 211 and the gear 1 close to the end surface of the gear hobbing machine table 8 side end surface respectively. The second baffle plate 212 passes through the positioning mandrel 22 of the first baffle plate 211 and the second baffle plate 212 . The positioning mandrel 22 is provided with a first stepped surface 221 , a second stepped surface 222 , a third stepped surface 223 and a fourth stepped surface 224 in sequence along the direction from the gear 1 to the gear hobbing machine table 8 . The outer diameter of the second stepped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com